Page 1

PRODUCT DATA &

INSTALLATION

Bulletin K30-KTW-PDI-13

1070801

We are on the Internet

www.keepriterefrigeration.com

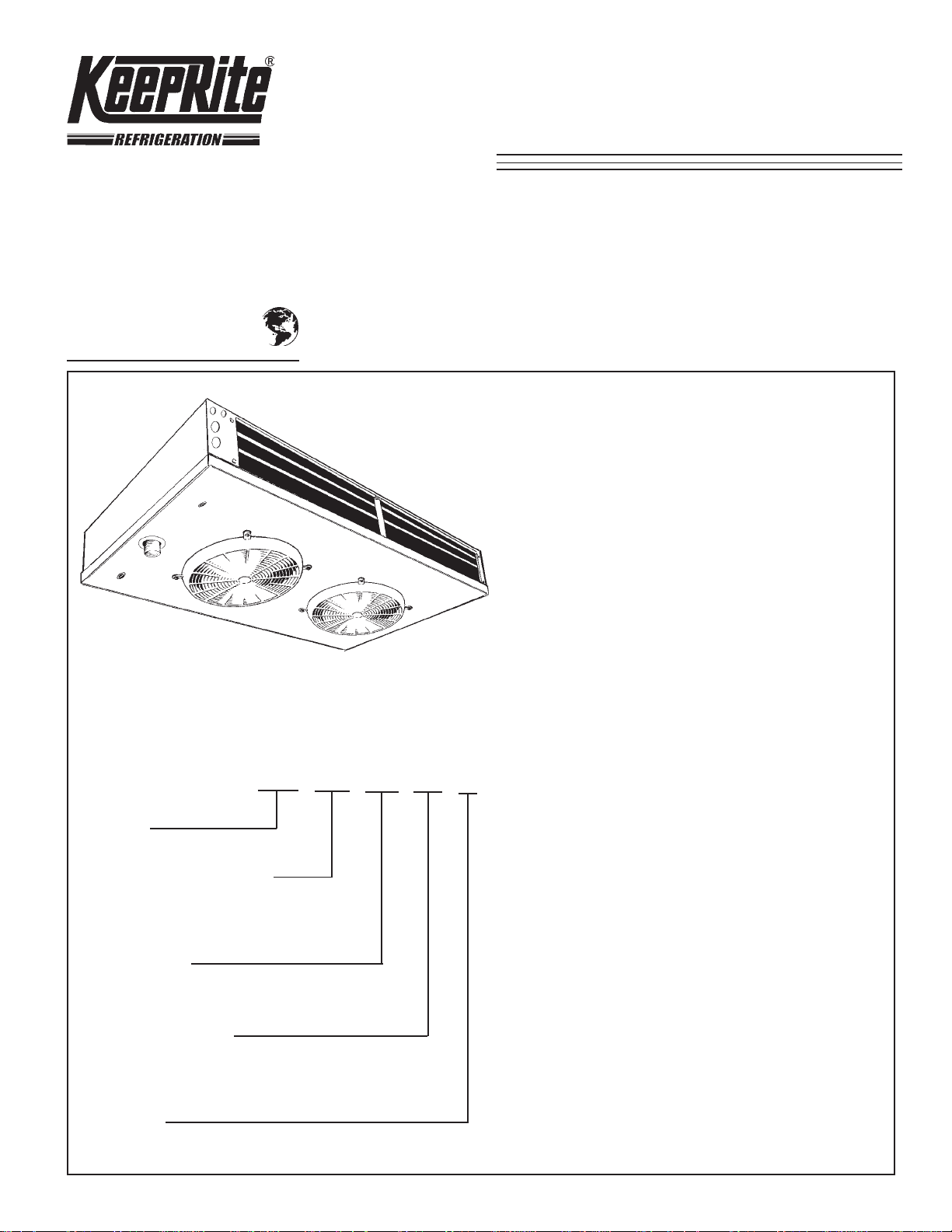

KTW Two-Way

Unit Coolers

High, Medium and Low Temperature

Applications -10°F (-23.3 °C) Room

and above

Air or Electric Defrost Models

Electrical Power:115/1/60,

208-230/1/60, 200-220/1/50

• Low height compact size maximizes useable

storage space

• Dual refrigeration coils and two-way air

distribution reduces air velocities to minimize

product dehydration.

NOMENCLATURE

KTW 009 AD - S1 A

KeepRite

Two-Way Unit Cooler

o

Nominal Capacity @ 10

9 = 900 Btuh

Air Defrost (AD) rated at 20 °F Evap. T emp.

Electric Defrost (ED) rated at -20°F Evap. T emp.

Type of Defrost

AD = Air Defrost

ED = Electric Defrost

Electrical Designation

S1 = 115/1/60

S2 = 208-230/1/60

S6 = 200-220/1/50

F TD

• Air enters through fan and discharges two ways

out of each coil side.

• NEW rugged heavy duty motor mount reduces

vibration and noise.

• Electric defrost models include factory installed

defrost termination and fan delay thermostat.

• NSF approved “flush to ceiling mount”

• Refrigerants R134a, R22 and R404A.

CONTENTS PAGE

General Specifications.......................

Wiring Diagrams..................................

Dimensional Data................................

TXV / Nozzle Selections.......................

Installation Instructions......................

Service Parts List................................

Service Log.........................................

2, 3

4 - 6

7, 8

9

10, 11

Back

Back

Unit Series

A = First Generation

Page 2

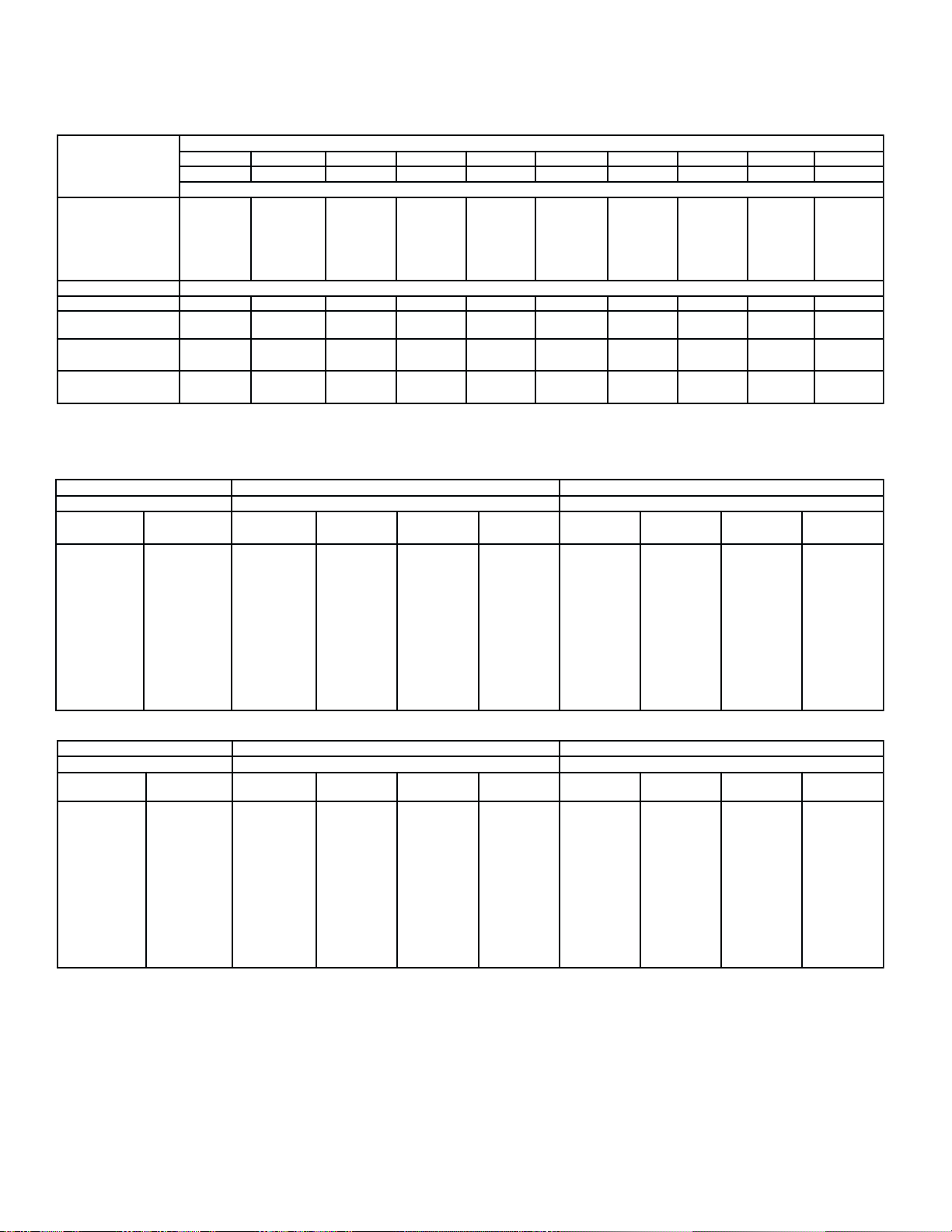

60Hz Capacity Data - BTUH

60Hz SPECIFICATIONS

pmeT.pavE

)C°(F°

)9.3-/7.6-(52+/02+

)2.21-(01+

)8.71-(0

)3.32-(01-

)9.82-(02-

)9.3-/7.6-(52+/02+503109810942540305730054057600090053105271

MFC03108173207204404482970824210061

BL.girfeR

GK*egrahC

.BLtinU

GKthgieW

078

358

728

297

047

4.0

2.0

3.5

* Coil at 30% full (liquid)

60Hz Electrical Data

zH06-1-v511

rebmuNledoMWTK)s(rotoMnaFsretaeHtsorfeD

tsorfeDriAcirtcelE

A1S-DA900

A1S-DA310

A1S-DA710

A1S-DA020

A1S-DA520

A1S-DA030

A1S-DA540

A1S-DA060

A1S-DA090

A1S-DA511

A1S-DE800

A1S-DE110

A1S-DE510

A1S-DE810

A1S-DE220

A1S-DE620

A1S-DE930

A1S-DE150

A1S-DE770

A1S-DE890

)tsorfeDcirtcelE(DE)tsorfeDriA(DArebmuNledoMWTK

DA900DA310DA710DA020DA520DA030DA540DA060DA090DA511

DE800DE110DE510DE810DE220DE620DE930DE150DE770DE890

0621

5321

7911

7411

1701

5.0

6.11

2.0

6.21

7.5

ytitnauQ

)aePH52/1(

1

1

1

1

1

1

2

2

3

4

0661

7261

7751

1151

1141

7.0

3.0

7.31

2.6

latoT

ALF

2.1

2.1

2.1

2.1

2.1

2.1

4.2

4.2

6.3

8.4

0302

9891

9291

7481

6271

8.0

4.0

7.41

7.6

ACM

)spmA(

5.1

5.1

5.1

5.1

5.1

5.1

7.2

7.2

9.3

1.5

0052

0542

5732

5722

5212

9.0

4.0

9.81

6.8

sledoMtsorfeDcirtcelEdnatsorfeDriA sledoMtsorfeDcirtcelE

POM

)spmA(

51

51

51

51

51

51

51

51

51

51

DT)C°6.5(F°01@yticapaC

0003

0492

0582

0372

0552

2.1

5.0

0.02

1.9

0054

0144

5724

5904

5283

DT)C°4.8(F°51@yticapaC

4.1

6.0

8.73

2.71

latoT

sttaW

602

035

035

035

057

057

0011

0451

0722

0172

0006

0885

0075

0645

0015

3.2

0.1

9.93

1.81

latoT

spmA

8.1

6.4

6.4

6.4

5.6

5.6

6.9

4.31

7.91

6.32

0009

0288

0558

0918

0567

4.3

5.1

9.95

2.72

ACM

)spmA(

2.2

8.5

8.5

8.5

2.8

2.8

0.21

8.61

6.42

5.92

00511

07211

52901

56401

5779

0.4

8.1

8.97

3.63

POM

)spmA(

51

51

51

51

51

51

51

02

52

03

zH06-1-v032/802

rebmuNledoMWTK)s(rotoMnaFsretaeHtsorfeD

tsorfeDriAcirtcelE

A2S-DA900

A2S-DA310

A2S-DA710

A2S-DA020

A2S-DA520

A2S-DA030

A2S-DA540

A2S-DA060

A2S-DA090

A2S-DA511

A2S-DE800

A2S-DE110

A2S-DE510

A2S-DE810

A2S-DE220

A2S-DE620

A2S-DE930

A2S-DE150

A2S-DE770

A2S-DE890

MCA = Minimum Circuit Ampacity

MOP = Maximum Overcurrent Protection

sledoMtsorfeDcirtcelEdnatsorfeDriA sledoMtsorfeDcirtcelE

ytitnauQ

)aePH52/1(

1

1

1

1

1

1

2

2

3

4

latoT

ALF

7.0

7.0

7.0

7.0

7.0

7.0

4.1

4.1

1.2

8.2

ACM

)spmA(

9.0

9.0

9.0

9.0

9.0

9.0

6.1

6.1

3.2

0.3

POM

)spmA(

51

51

51

51

51

51

51

51

51

51

latoT

sttaW

602

035

035

035

057

057

0011

0451

0722

0172

latoT

spmA

9.0

3.2

3.2

3.2

3.3

3.3

8.4

7.6

9.9

8.11

ACM

)spmA(

1.1

9.2

9.2

9.2

1.4

1.4

0.6

4.8

4.21

8.41

POM

)spmA(

51

51

51

51

51

51

51

51

51

51

- 2-

Page 3

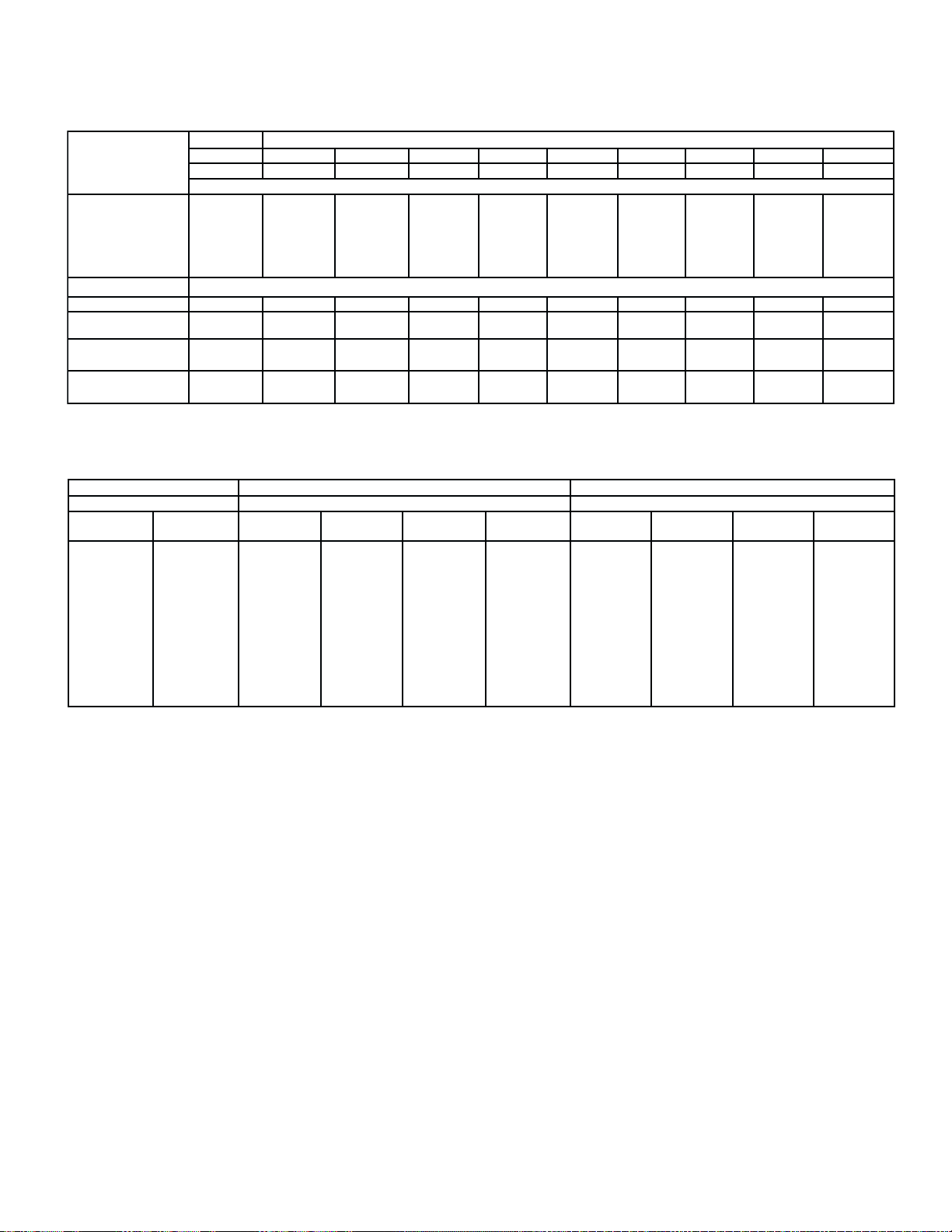

50Hz Capacity Data - BTUH

50Hz SPECIFICATIONS

pmeT.pavE

)C°(F°

)9.3-/7.6-(52+/02+

)2.21-(01+

)8.71-(0

)3.32-(01-

)9.82-(02-

)9.3-/7.6-(52+/02+102193711922108205430414012608280242107851

MFC80194179142256356307707613018231

BL.girfeR

GK*egrahC

.BLtinU

GKthgieW

DA900DA310DA710DA020DA520DA030DA540DA060DA090DA511

DE800DE110DE510DE810DE220DE620DE930DE150DE770DE890

008

487

067

827

086

4.0

2.0

6.11

3.5

50Hz Electrical Data

zH05-1-v022/002

rebmuNledoMWTK)s(rotoMnaFsretaeHtsorfeD

tsorfedriAcirtcelE

A6S-DA900

A6S-DA310

A6S-DA710

A6S-DA020

A6S-DA520

A6S-DA030

A6S-DA540

A6S-DA060

A6S-DA090

A6S-DA511

MCA = Minimum Circuit Ampacity

MOP = Maximum Overcurrent Protection

A6S-DE800

A6S-DE110

A6S-DE510

A6S-DE810

A6S-DE220

A6S-DE620

A6S-DE930

A6S-DE150

A6S-DE770

A6S-DE890

)tsorfeDcirtcelE(DE)tsorfeDriA(DArebmuNledoMWTK

DT)C°6.5(F°01@yticapaC

9511

6311

1011

5501

589

5.0

2.0

6.21

7.5

ytitnauQ

)aePH52/1(

1

1

1

1

1

1

2

2

3

4

7251

7941

1541

0931

8921

7.0

3.0

7.31

2.6

latoT

ALF

7.0

7.0

7.0

7.0

7.0

7.0

4.1

4.1

1.2

8.2

8681

0381

4771

0071

7851

8.0

4.0

7.41

7.6

ACM

)spmA(

9.0

9.0

9.0

9.0

9.0

9.0

6.1

6.1

3.2

0.3

0032

4522

5812

3902

5591

9.0

4.0

9.81

6.8

sledoMtsorfeDcirtcelEdnatsorfeDriA sledoMtsorfeDcirtcelE

POM

51

51

51

51

51

51

51

51

51

51

0672

5072

2262

2152

6432

2.1

5.0

0.02

1.9

)spmA(

0414

7504

3393

7673

9153

DT)C°4.8(F°51@yticapaC

4.1

6.0

8.73

2.71

latoT

sttaW

881

584

584

584

686

686

7001

9041

7702

0842

0255

0145

4425

3205

2964

3.2

0.1

9.93

1.81

latoT

spmA

9.0

2.2

2.2

2.2

1.3

1.3

6.4

4.6

4.9

3.11

0828

4118

6687

5357

8307

4.3

5.1

9.95

2.72

ACM

)spmA(

1.1

8.2

8.2

8.2

9.3

9.3

7.5

0.8

8.11

1.41

08501

86301

15001

8269

3998

0.4

8.1

8.97

3.63

POM

)spmA(

51

51

51

51

51

51

51

51

51

51

- 3 -

Page 4

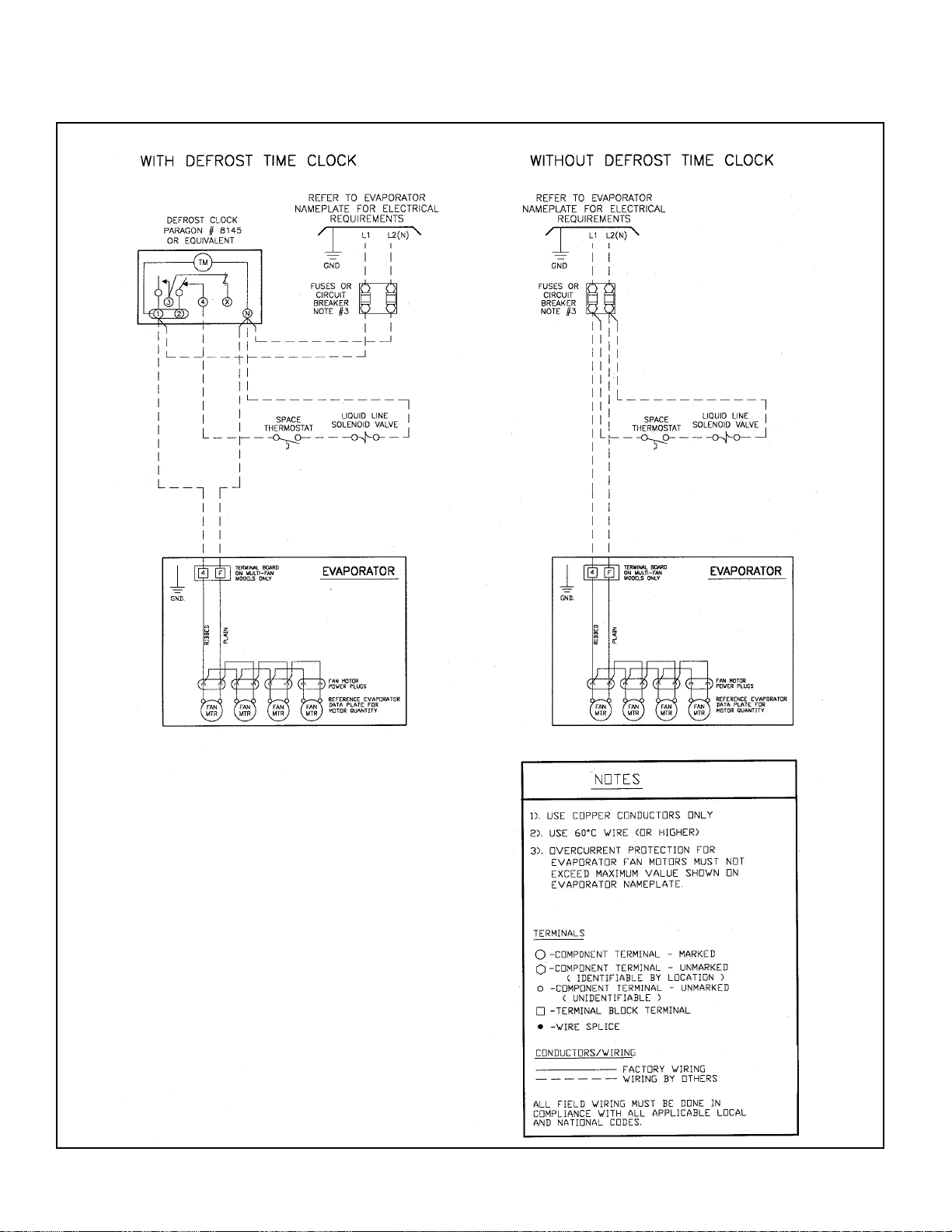

WIRING DIAGRAMS

AIR DEFROST - All Voltages

- 4 -

Page 5

WIRING DIAGRAMS

ELECTRIC DEFROST - 115V

- 5 -

Page 6

WIRING DIAGRAMS

ELECTRIC DEFROST - 230V

- 6 -

Page 7

DIMENSIONAL DATA

SINGLE FAN MODELS

3”

(76 mm)

1-3/8”

(35 mm)

B

AIR

OUT

Defrost Control

E

CONNECTION END VIEW SIDE VIEW

AIR IN

A

7/8 (22 mm) dia.

knockouts

2 connection end

AIR

OUT

1/2 (12 mm) dia. O.D.

9/16 (14 mm) dia.

knockouts

2 each side

7/8 (22 mm) dia.

knockouts

2 each side

aluminum drain

C

BOTTOM VIEW

Splice box.

Electric defrost models

NOTE: Dimensional views shown

with electric defrost heaters

splice box and defrost control

mounted.

4 Mounting holes

7/32 (6 mm) dia.

* TXV conn.

1/2” flare

Suction

3/8” O.D.

D

9/16”

(14 mm)

DE/DA:LEDOM

800/900WTK

110/310WTK

510/710WTK

810/020WTK

220/520WTK

620/030WTK

* TXV Connection on KTW 026 ED only is 1/2” O.D.S.

ABCDE

)MM(SEHCNI-ATADLANOISNEMID

)974(8/781)411(2/14)953(8/141)154(4/371)842(4/39

)974(8/781)411(2/14)953(8/141)154(4/371)842(4/39

)974(8/781)041(2/15)953(8/141)154(4/371)842(4/39

)974(8/781)041(2/15)953(8/141)154(4/371)842(4/39

)555(8/712)041(2/15)684(8/191)725(4/302)573(4/341

)555(8/712)041(2/15)684(8/191)725(4/302)573(4/341

- 7 -

Page 8

DIMENSIONAL DATA

MULTIPLE FAN MODELS

DE/DA:LEDOMsnaFfo.oN

930/540WTK

150/060WTK

770/090WTK

890/511WTK

)MM(SEHCNI-ATADLANOISNEMID

.nnoCnoitcuSCDEF

2)31(.DO"2/1)6801(4/324)302("8@seloh4)591(61/117)872(61/5101

2)61(.DO"8/5)6801(4/324)302("8@seloh4)591(61/117)872(61/5101

3)61(.DO"8/5)1151(2/195)302("8@seloh6)302(8)192(61/711

4)22(.DO"8/7)9571(4/196)302("8@seloh8)711(8/54)912(8/58

- 8 -

Page 9

TXV / NOZZLE SELECTIONS - 60Hz

All models require the use of a TXV (thermostatic expansion valve). These should be mounted within the cabinet at the flare

nut connection or distributor stub (all 026 ED and higher models ). An internally equalized TXV can be used on any of the

single fan AD models and 022 ED and smaller electric defrost models. All other models must use an externally equalized

TXV. (a 1/4 “ OD equalizing tube is provided). All models using a distributor require a nozzle. Air Defrost models have the

nozzle already FACTORY installed. Electric defrost models 026ED and larger have TWO distributor nozzles SHIPPED

LOOSE and the correct selection must be made and installed prior to mounting the TXV. Refer to the following charts for

nozzle / TXV selections.

NOZZLE SELECTIONS

Air Defrost Nozzles (already factory installed)

For all applications and refrigerants

ledoMelzzoN

DA5402/1-L

DA0604/3-L

DA0901-L

DA5112/11-L

SPORLAN TXV SELECTIONS

Air Defrost (35 °F and up Room Temperatures)

ledoM

DA900078

DA3100621

DA7100661

DA0200302

DA5200052

DA0300003

DA5400054

DA0600006

DA0900009

DA51100511

Note: Based on 100 °F Liquid Temperature

hutBa431R/21R22R205R/A404RhutBa431R/21R22R205R/A404R

DTF°01 DTF°51

C8/1-JGC5/1-VGC8/1-SG

C8/1-JGC5/1-VGC8/1-SG

C8/1-JGC5/1-VGC8/1-SG

C8/1-JGC5/1-VGC8/1-SG

C4/1-JGC5/1-VGC4/1-SG

C4/1-JGC5/1-VGC4/1-SG

C2/1-EJGEC2/1-EVGEC2/1-ESGE

C2/1-EJGEC4/3-EVGEC2/1-ESGE

C1-EJGEC1-EVGEC1-ESGE

C1-EJGEC1-EVGEC1-ESGE

R22 Electric Defrost (34 °F and below Room Temperatures) 10 °F TD

/ledoMDE800DE110DE510DE810DE220

.pmeTpavEhutB#evlaVhutB#evlaVhutB#evlaVhutB#evlaVhutB#evlaV

F°52+/02+078

F°01+358

F°0728

F°01-297

F°02-047

/ledoMDE620DE930DE150DE770DE890

.pmeTpavEhutB#evlaVhutB#evlaVhutB#evlaVhutB#evlaVhutB#evlaV

F°52+/02+0003

F°01+0492

F°00582

F°01-0372

F°02-0552

Note: Based on 95 °F Liquid Temperature for -20 °F / -10 °F Evap. Temps. and 100 °F Liquid for 0 to +25 °F Evap. Temps.

CV5/1-VG

CV5/1-VG

CV5/1-VG

ZV5/1-VG

ZV5/1-VG

CV5/1-EVGE

CV5/1-EVGE

CV3/1-EVGE

ZV3/1-EVGE

ZV3/1-EVGE

0621

5321

7911

7411

1701

0054

0144

5724

5904

5283

CV5/1-VG

CV5/1-VG

CV5/1-VG

ZV5/1-VG

ZV5/1-VG

CV3/1-EVGE

CV3/1-EVGE

CV3/1-EVGE

ZV2/1-EVGE

ZV2/1-EVGE

R404A Electric Defrost (34 °F and below Room Temperatures) 10 °F TD

/ledoMDE800DE110DE510DE810DE220

.pmeTpavEhutB#evlaVhutB#evlaVhutB#evlaVhutB#evlaVhutB#evlaV

F°52+/02+078

F°01+358

F°0728

F°01-297

F°02-047

/ledoMDE620DE930DE150DE770DE890

.pmeTpavEhutB#evlaVhutB#evlaVhutB#evlaVhutB#evlaVhutB#evlaV

F°52+/02+0003

F°01+0492

F°00582

F°01-0372

F°02-0552

Note: Based on 95 °F Liquid Temperature for -20 °F / -10 °F Evap. Temps. and 100 °F Liquid for 0 to +25 °F Evap. Temps.

CS8/1-SG

CS8/1-SG

CS8/1-SG

ZS8/1-SG

ZS8/1-SG

CS6/1-ESGE

CS6/1-ESGE

CS6/1-ESGE

ZS6/1-ESGE

ZS6/1-ESGE

0621

5321

7911

7411

1701

0054

0144

5724

5904

5283

CS8/1-SG

CS8/1-SG

CS8/1-SG

ZS8/1-SG

ZS8/1-SG

CS4/1-ESGE

CS4/1-ESGE

CS4/1-ESGE

ZS4/1-ESGE

ZS2/1-ESGE

Electric Defrost Nozzles (for field installation)

For -20°F to +25 °F Evap. Temps., 8-12°F TD

ledoM

DE620

DE930

DE150

DE770

DE890

* Use L-1/16 if lower than 9°F T.D.

5031

0981

0942

5403

0573

0054

0576

0009

00531

05271

0661

7261

7751

1151

1141

0006

0885

0075

0645

0015

0661

7261

7751

1151

1141

0006

0885

0075

0645

0015

CV5/1-VG

CV5/1-VG

CV5/1-VG

ZV5/1-VG

ZV5/1-VG

CV2/1-EVGE

CV2/1-EVGE

CV2/1-EVGE

ZV4/3-EVGE

ZV4/3-EVGE

CS8/1-SG

CS8/1-SG

CS8/1-SG

ZS8/1-SG

ZS8/1-SG

CS2/1-ESGE

CS2/1-ESGE

CS2/1-ESGE

ZS2/1-ESGE

ZS2/1-ESGE

22RA404R

*4/1-L

3/1-L

2/1-L

4/3-L

1-L

0302

9891

9291

7481

6271

0009

0288

0558

0918

0567

0302

9891

9291

7481

6271

0009

0288

0558

0918

0567

elzzoN

C8/1-JGC5/1-VGC8/1-SG

C4/1-JGC5/1-VGC8/1-SG

C4/1-JGC5/1-VGC8/1-SG

C4/1-JGC5/1-VGC4/1-SG

C4/1-JGC3/1-VGC4/1-SG

C2/1-JGC3/1-VGC4/1-SG

2/1-EJGEC4/3-EVGEC2/1-ESGE

C1-EJGEC1-EVGEC1-ESGE

C1-EJGEC2/11-EVGEC1-ESGE

C2/11-EJGEC2/11-EVGEC2/11-ESGE

CV5/1-VG

CV5/1-VG

CV5/1-VG

ZV5/1-VG

ZV5/1-VG

CV4/3-EVGE

CV4/3-EVGE

CV4/3-EVGE

ZV4/3-EVGE

ZV4/3-EVGE

CS8/1-SG

CS8/1-SG

CS8/1-SG

ZS8/1-SG

ZS8/1-SG

CS2/1-ESGE

CS2/1-ESGE

CS2/1-ESGE

ZS2/1-ESGE

ZS1-ESGE

- 9 -

3/1-L

2/1-L

4/3-L

1-L

2/11-L

0052

0542

5732

5722

5212

00511

07211

52901

56401

5779

0052

0542

5732

5722

5212

00511

07211

52901

56401

5779

CV5/1-VG

CV5/1-VG

CV5/1-VG

ZV5/1-VG

ZV5/1-VG

ZV1-EVGE

ZV1-EVGE

ZV1-EVGE

CS8/1-SG

CS8/1-SG

CS8/1-SG

ZS8/1-SG

ZS8/1-SG

CS1-ESGE

CS1-ESGE

CS1-ESGE

ZS1-ESGE

ZS1-ESGE

CV4/3-EVGE

CV4/3-EVGE

Page 10

INSTALLATION INSTRUCTIONS

INSPECTION

Careful inspection of all parts when received for loss

or damage in transit is very important - Remember,

you, the consignee, must make any claim necessary

against the transportation company. Shipping

damage or missing parts, when discovered at the

outset, will prevent later unnecessary and costly

delays.

Electrical characteristics should also be checked at

this time to ensure that they are as ordered.

APPLICATION

Two-Way Unit Coolers are designed for use in

coolers and freezers such as reach in boxes, display

cases, back bars, walk-in rooms and any other

cooler applications where a low velocity, uniform air

flow is required. The compact and low height unit

provides maximum useable product storage space.

o

At room temperatures above 34

evaporating temperatures no lower than 27

o

C) the air flowing through the coil will accomplish

F (1.1 oC) and

o

F (-2.8

the defrost (Air Defrost).

o

At room temperatures 34

F and below ( to -10 oF)

positive defrosting is required ( Electric defrost) .

These will require the use of :

1. Time Clock (to initiate and terminate the defrost

cycle ),

2. Defrost termination thermostat (to prevent

unnecessary prolonged heating and steaming of the

coil once all the frost and ice has melted). And if a

freezer,

3. Fan delay thermostat (to prevent evaporator fans

starting up right away and blowing water on to the

fan blades, guards and floor).

This evaporator coil must not be exposed to any

abnormal environments (acidic or caustic) that can

result in coil corrosion and leaks. Consult factory for

optional baked on phenolic protective coatings.

These unit coolers are for use primarily on R134a,

R22 and R404A refrigerants and their approved

alternatives / replacements.

INSTALLATION

The installation and start up of Unit Coolers should

only be performed by qualified refrigeration

mechanics. This equipment should be installed in

accordance with all applicable codes, ordinances,

and local by-laws.

LOCATION

The Unit Cooler is designed to be mounted to the

ceiling of the box or cabinet. Refrigeration piping and

electrical connections are routed to the rear sides

(through the knock-outs). The unit must be mounted

to a level ceiling to ensure complete drainage from

the condensate pan to the drain fitting. Refer to the

dimensional drawings for the drain fitting and

mounting location details.

On freezer applications it is important that warm,

humid infiltrated air is not drawn directly towards

the unit cooler. Keeping the unit cooler away from

the door, using strip curtains, and using door

switches to lock out and de-energize the liquid solenoid valve are all effective methods to minimize

any unnecessary frost build -up of the fan guard.

(Air enters the fan and discharges out each side of

the coil ).

TXV (thermostatic expansion valve)

SELECTION

For normal operating conditions refer to the TXV

selection chart on P. 9. When selecting valves

ensure they are sized to meet the capacity at the

actual evaporating temperature, liquid temperature

and operating TD of the system . All these conditions

can greatly affect the size and selection. Consult

the factory or valve manufacturer for assistance. All

models that use a distributor (larger models) must

use a nozzle. Smaller models do not have

distributors or nozzles.

Electric defrost models 026ED and higher require

a nozzle to be selected and field installed before

mounting the TXV. Refer to P.9 for details. Air defrost

models 045AD and higher already have the nozzle

factory installed.

- 10 -

Page 11

INSTALLATION INSTRUCTIONS

The TXV superheat setting should NOT be initially

adjusted . After the room has reached or is close to

the required operating temperature the TXV superheat should then be checked and only adjusted if

necessary. Refer to Section on SYSTEM CHECK.

To avoid overheating the valve or distributor

wrap a wet cloth around the valve diaphragm

and body.

MOUNTING

Mounting brackets with 7/32 - 5/16” diameter holes

are provided for flush mounting to the ceiling. For

details refer to the dimensional data on P.7 and 8.

Ensure the evaporator is located correctly with the

air flowing in the two desired directions.

Avoid discharging the air directly on to glass doors

or door openings.

After mounting the coil check the slope of the drain

pan with a level. If the ceiling is not level the drain

pan slope may not be correct which can result in

defrosting (ice-up) problems.

DRAIN LINE

The drain line should be run from the drain

connection, sloping at least 4" vertical drop

for every foot of horizontal distance . A trap outside

the room will allow proper draining throughout the

line. Connection should be made to proper drainage

facilities that comply with local codes and

regulations.

In freezers, to prevent drain line freeze up problems,

the line must be heated and insulated. A heat input

o

of 20 W per foot in a 0

o

a -20

F room is usually satisfactory. Once the line

F room and 30 W per foot in

has been completed , double check the slope in the

drain pan to ensure proper drainage (prevention of

ice build-up on pan).

PIPING

Refrigerant line sizes are important and are not

necessarily the same size as the connections at the

condensing unit or evaporator. If in doubt refer to a

recognized source. (Manufacturer’s Engineering

Manual, Ashrae Manuals, etc.)

WIRING

Wire system in accordance with local codes and

regulations. A 36" cord is provided for single fan air

defrost models (AD) .Multiple fans have a junction

terminal box for conduit connections.

See electrical data and wiring diagrams on P. 2 - 6.

When Fan delay thermostats are installed the fans

may not start up until the coil temperature

o

reaches approximately 26

F . On initial start up it

may be necessary to bypass (jumper) this control

temporarily until the coil is cold enough.

SYSTEM CHECK

Before Start Up:

1. Ensure wiring is in accordance with codes.

2. Refrigerant lines are properly sized and routed.

3. Thorough leak check, evacuation and

dehydration has been performed.

4. Drain line has been checked for free flow.

After Start Up:

1. Fan has been checked for correct air flow and no

obstructions.

2. Expansion valve superheat has been checked for

proper operation. (Superheat of the coil should

o

be around 5 to 6

MAINTENANCE

The unit should be periodically inspected for any dirt

or build up on the fin surface and cleaned if

necessary with a soft whisk or brush.

The fan motor is permanently lubricated and should

not require service.

F for a 10 oF TD.)

-11 -

Page 12

SERVICE P ARTS LIST

06/29/07

REBMUNLEDOMROTOMNAF

RIACIRTCELE06/1/51106/1/032-802)ylnosledomDE(

DA90

0WTKDE800WTK

DA310WTKDE110WTK

DA710WTKDE510WTK

DA020WTKDE810WT

DA520WTKDE220WTK

DA030WTKDE620WTK

DA540WTKDE930WTK

DA060WTKDE150WTK

DA090WTKDE770WTK

DA511WTKDE890WTK

DcirtcelE 0600701

* All heaters are rated at 115V - either wired in series (for 230V) or parallel (for 115V)

K

29596013959601100-07834013923401100-8640701100-8683401

29596013959601200-07834013923

29596013959601300-07834013923401100-1689601100-8683401

29596013959601400-07834013923401100-1689601100-8683401

29596013959601500-07834014923401200-1689

29596013959601500-07834014923401200-1689601100-9683401

2959601395

29596013959601500-07834014923401300-1689601100-0100

29596013959601600-07834014923401400-1689601100-1100701

29596013959601600-078

-draoBlanimreT)pudna540(tsorfeDriA 5288401

-draoBlanimreT)pudna930(tsorfe

9601500-07834014923401200-8640701100-0100701

-lortnoCnoitanimreTtsorfeD/yaleDnaFtsorfeDcirtcelE 5273401

SERVICE LOG

ETADSTNEMMOC

EDALBNAFDRAUGNAF

401100-1689601100-8683401

601100-9683401

34014923401500-1689601100-2100701

*SRETAEHTSORFED

NAPNIARD

701

PROJECT INFORMA TION

metsyS

rebmuNledoM pU-tratSfoetaD

rebmuNlaireS rotcartnoCecivreS

tnaregirfeRenohP

ylppuSlacirtcelExaF

NA TIONAL REFRIGERA TION &

AIR CONDITIONING CANADA CORP.

CANADA

159 ROY BL VD., BRANTFORD, ONT ARIO, CANADA N3R 7K1

PHONE: 1-800-463-9517 (519)751-0444 FAX (519)753-1140

Due to National Refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice.

USA

985 WHEELER WA Y, LANGHORNE, P A. 19047 USA

PHONE:1-888-KEEPUS1 OR 1-888-533-7871

Loading...

Loading...