Page 1

PRODUCT DATA &

08/14/12

INSTALLATION

Bulletin K30-KTM-PDI-3

1087840

KTM Two-Way

Medium Prole

Unit Coolers

High, Medium and Low

Temperature

Applications -10°F (-23.3 °C) or

Above Box Temperature

Latest product updates and further information

at www.keepriterefrigeration.com

Air, Electric or Hot Gas

Defrost (Reverse Cycle)

CONTENTS

Nomenclature...................................................................................................................... 2

Features............................................................................................................................... 2

Page

Capacity Data (Imperial and Metric)................................................................................. 3

Electrical Data..................................................................................................................... 4 - 5

Wiring Diagrams.................................................................................................................. 6 - 9

Mechanical Data................................................................................................................. 10

Dimensional Data............................................................................................................... 11

Installation Clearances....................................................................................................... 12

TXV Selection..................................................................................................................... 13 - 15

Installation Instructions........................................................................................................ 16 - 17

Generic Service Parts List................................................................................................. 18

Warranty............................................................................................................................... 19

Project Information.............................................................................................................. 19

“As Built” Service Parts List............................................................................................... BACK

Page 2

Model Name

K30-KTM-PDI-3

- 2 -

08/14/12

K = KeepRite

NOMENCLATURE

K TM 2 9 5 M A - S1 A

Design Version

Product Name

TM = Two Way Medium Prole Unit Cooler

X 100 = Nominal Capacity

(10°F TD, 60Hz), Btu/H

Evap Temp Range

M = Medium Temp (10 - 45°F), 6 FPI.

L = Low Temp (-20 - 0°F), 6 FPI.

STANDARD FEATURES

• Heavy gauge textured aluminum cabinet

construction resists scratches/corrosion and

minimizes weight for shipment, installation and

service.

• Capacity up to 29,500 BTUH nominal.

• Dual refrigeration coils with two-way air

distribution reduces air velocities to minimize

product dehydration.

• Air enters through fan and discharges two

ways out of each coil side.

• Low height compact size useable storage

space.

Unit Electrical Designaton.

S1 = 115/1/60 (air defrost models only)

S2 = 208-230/1/60

S6 = 200-220/1/50

Defrost Type.

A = Air Defrost

E = Electric Defrost

G = Reverse Cycle w/ Electric Heater Pan

• Internally enhanced tube.

• Attractive and durable high - density

polyethylene fan guards.

• Standard PSC motors

• Hinged drain pan provides convenient access

for cleaning.

• Terminal board allows for easy electrical

connections.

• Reduced operating charge with 3/8” OD tubing

• Refrigerants R22, R404A, R507, R407C.

• Factory mounted solenoid valve, TXV and

Thermostat on air and electric defrost models.

• Fin material and special coatings.

OPTIONAL FEATURES

• Other options available - consult factory.

• ECM motors

Page 3

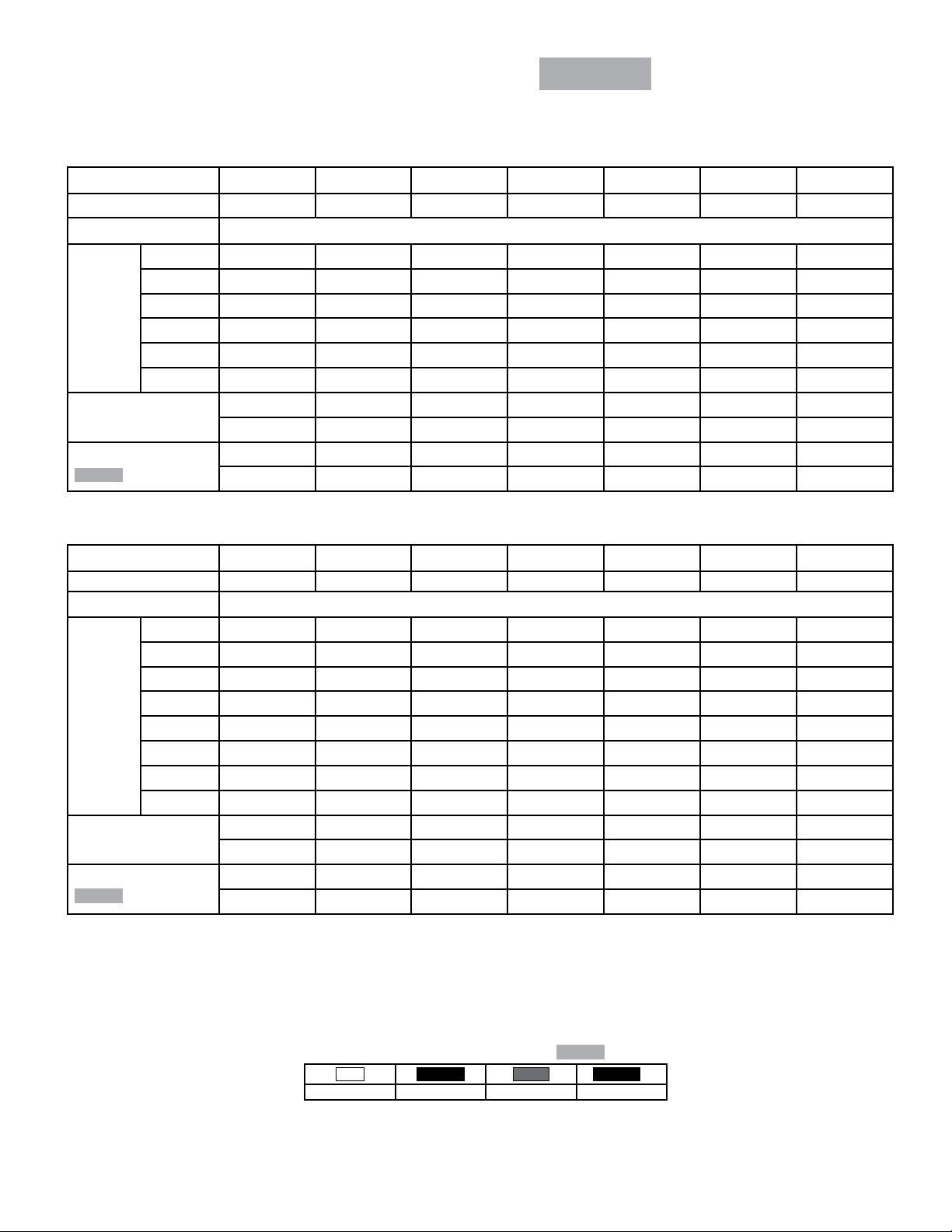

CAPACITY DATA

K30-KTM-PDI-3

- 3 -

08/14/12

KTM

R404A

60Hz

MEDIUM TEMPERATURE MODELS - CAPACITY

KTM115M KTM139M KTM172M KTM208M KTM236M KTM260M KTM295M

Number of Fans 2 2 3 3 4 4 5

Capacity BTUH (watts)

+ 20/25 11500 13900 17200 20800 23600 26000 29500

(-3.9/-6.7) (3370) (4074) (5041) (6096) (6916) (7620) (8646)

Evap

Temp

°F (°C)

Air Flow

CFM (L/s)

Refrigerant Charge*

R404A

15 11330 13690 16940 20490 23250 25610 29060

(-9.4) (3320) (4012) (4965) (6005) (6814) (7506) (8517)

10 11270 13620 16860 20380 23130 25480 28910

(-12.2) (3303) (3992) (4941) (5973) (6779) (7467) (8473)

2020 1900 3030 2850 3700 3780 4630

(953) (897) (1430) (1345) (1746) (1760) (2185)

2.1 2.8 3.1 4.2 4.2 5.2 5.2

Lbs (Kg)

(1.0) (1.3) (1.4) (1.9) (1.9) (2.4) (2.4)

LOW TEMPERATURE MODELS - CAPACITY

KTM105L KTM124L KTM153L KTM188L KTM210L KTM235L KTM265L

Number of Fans 2 2 3 3 4 4 5

Capacity BTUH (watts)

0 11240 13270 16370 20120 22470 25150 28360

(-17.8) (3294) (3889) (4798) (5897) (6585) (7371) (8311)

-10 10920 12900 15910 19550 21840 24440 27560

Evap

Temp

°F (°C)

Air Flow

CFM (L/s)

Refrigerant Charge*

R404A

*R404A @ +25 °F S.S.T. with coil 30% full of liquid

Capacities rated using R404A with 10° F (5.6°C) TD & 100°F (38°C) liquid temperature.

Capacities at other TD within a range of 8 to 15°F (4.4 to 8.3°C) are directly proportional to TD, or use formula”

CAPACITY = (RATED CAPACITY / 10) x TD

(-23.3) (3200) (3781) (4663) (5730) (6401) (7163) (8077)

-15 10710 12650 15610 19180 21420 23970 27030

(-26.1) (3139) (3707) (4575) (5621) (6278) (7025) (7922)

-20 10500 12400 15300 18800 21000 23500 26500

(-28.9) (3077) (3634) (4484) (5510) (6154) (6887) (7766)

2020 1900 3030 2850 3700 3780 4630

(953) (897) (1430) (1345) (1746) (1760) (2185)

2.1 2.8 3.1 4.2 4.2 5.2 5.2

Lbs (Kg)

(1.0) (1.3) (1.4) (1.9) (1.9) (2.4) (2.4)

‡ When using R407C, the factor above is to be used when matching to condensing units with Dew Point ratings. This factor will ensure that proper

system balancing will occur to compensate for glide to t the application. If the system is sized correctly, one may expect a slight increase in system

capacity, along with slightly higher saturated suction temperatures.

Correction Factors for Other Refrigerants Use

R22

0.95 0.90 1.00 0.90

R134a

R507

R404A

Values Multiplied By:

R407C

‡

Page 4

KTM

K30-KTM-PDI-3

- 4 -

08/14/12

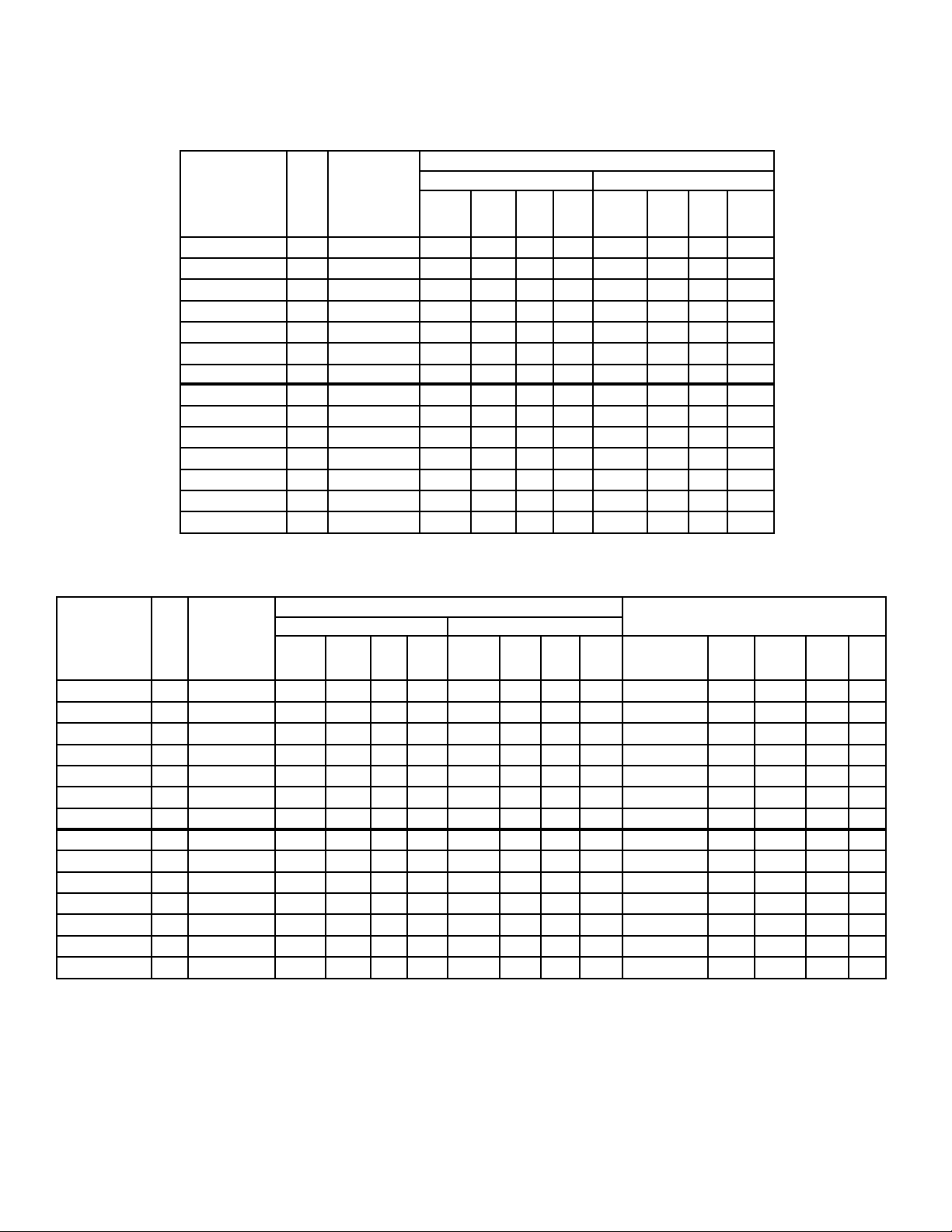

ELECTRICAL DATA

AIR DEFROST

FAN MOTOR(S)

MODEL

KTM115MA-S1 2 115/1/60 2.2 2.5 200 15 3 3.4 104 15

KTM139MA-S1 2 115/1/60 2.2 2.5 200 15 3 3.4 104 15

KTM172MA-S1 3 115/1/60 3.3 3.6 300 15 4.5 4.9 156 15

KTM208MA-S1 3 115/1/60 3.3 3.6 300 15 4.5 4.9 156 15

KTM236MA-S1 4 115/1/60 4.4 4.7 400 15 6 6.4 208 15

KTM260MA-S1 4 115/1/60 4.4 4.7 400 15 6 6.4 208 15

KTM295MA-S1 5 115/1/60 5.5 5.8 500 15 7.5 7.9 260 15

KTM115MA-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15

KTM139MA-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15

KTM172MA-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15

KTM208MA-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15

KTM236MA-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15

KTM260MA-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15

KTM295MA-S2 5 208-230/1/60 2.5 2.6 500 15 5.0 5.3 260 15

No.

of

FANS

POWER

SUPPLY

PSC-Standard ECM-Optional

TOTAL

MOTOR

FLA

M.C.A. Watts M.O.P

TOTAL

MOTOR

FLA

M.C.A. Watts M.O.P

60Hz

ELECTRIC DEFROST

FAN MOTOR(S)

MODEL

KTM115ME-S1 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15 208-230/1/60 2600 11.3 14.1 15

KTM139ME-S1 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15 208-230/1/60 2600 11.3 14.1 15

KTM172ME-S1 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15 208-230/1/60 3720 16.2 20.3 25

KTM208ME-S1 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15 208-230/1/60 3720 16.2 20.3 25

KTM236ME-S1 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15 208-230/1/60 3720 16.2 20.3 25

KTM260ME-S1 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15 208-230/1/60 4560 19.8 24.8 25

KTM295ME-S1 5 208-230/1/60 2.5 2.6 500 15 5.0 5.3 260 15 208-230/1/60 4560 19.8 24.8 25

KTM105LE-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15 208-230/1/60 2600 11.3 14.1 15

KTM124LE-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15 208-230/1/60 2600 11.3 14.1 15

KTM153LE-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15 208-230/1/60 3720 16.2 20.3 25

KTM188LE-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15 208-230/1/60 3720 16.2 20.3 25

KTM210LE-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15 208-230/1/60 3720 16.2 20.3 25

KTM235LE-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15 208-230/1/60 4560 19.8 24.8 25

KTM265LE-S2 5 208-230/1/60 2.5 2.6 500 15 5.0 5.3 260 15 208-230/1/60 4560 19.8 24.8 25

No.

FANS

of

POWER

SUPPLY

PSC-Standard ECM-Optional

TOTAL

MOTOR

FLA

M.C.A. Watts M.O.P

TOTAL

MOTOR

FLA

M.C.A. Watts M.O.P

POWER

SUPPLY

DEFROST HEATERS

TOTAL

WATTS

TOTAL

MOTOR

FLA

M.C.A. M.O.P

Page 5

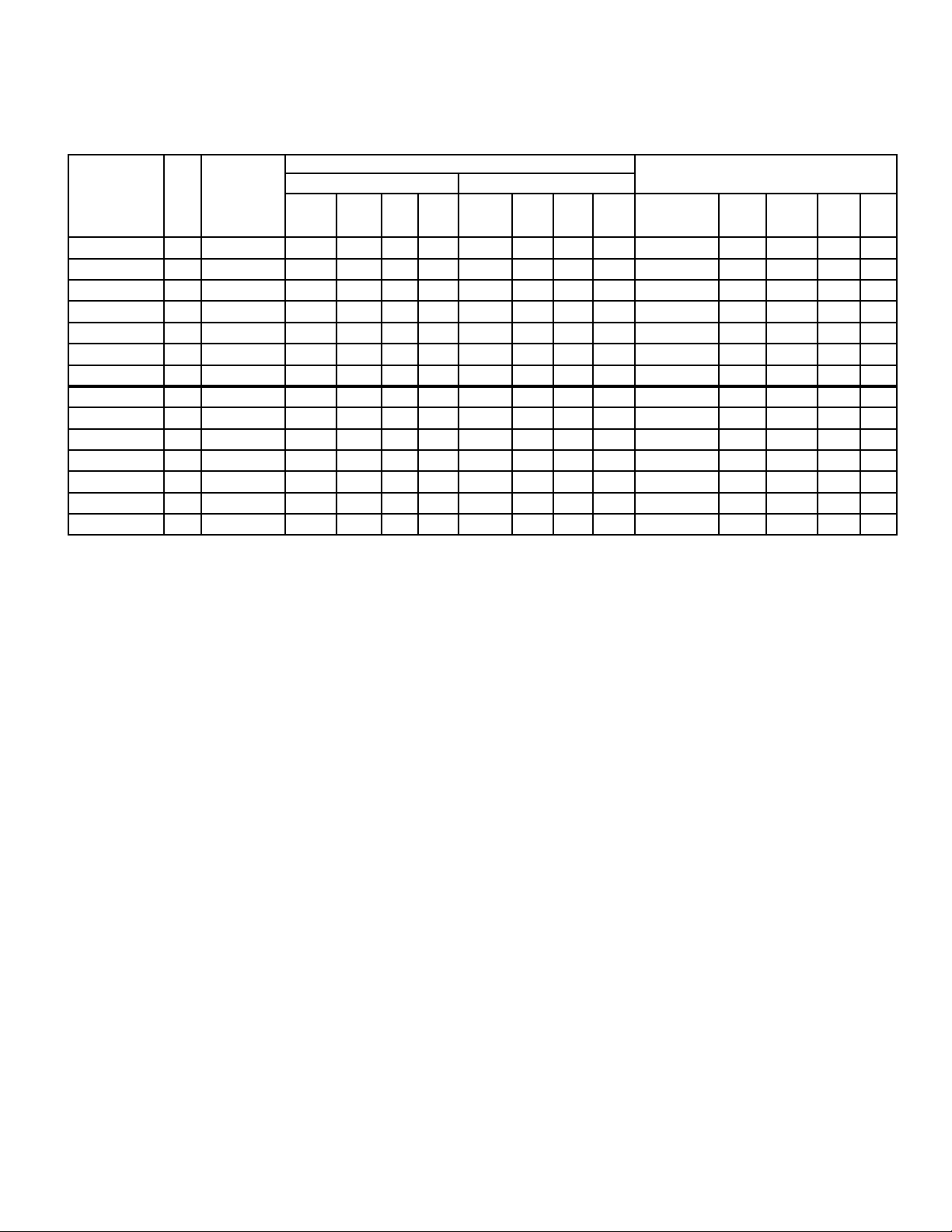

ELECTRICAL DATA

K30-KTM-PDI-3

- 5 -

08/14/12

KTM

HOT GAS DEFROST

FAN MOTOR(S)

MODEL

KTM115MG-S1 2 115/1/60 2.2 2.5 200 15 3.0 3.4 104 15 115/1/60 1300 11.3 14.1 15

KTM139MG-S1 2 115/1/60 2.2 2.5 200 15 3.0 3.4 104 15 115/1/60 1300 11.3 14.1 15

KTM172MG-S1 3 115/1/60 3.3 3.6 300 15 4.5 4.9 156 15 115/1/60 1860 16.2 20.3 25

KTM208MG-S1 3 115/1/60 3.3 3.6 300 15 4.5 4.9 156 15 115/1/60 1860 16.2 20.3 25

KTM236MG-S1 4 115/1/60 4.4 4.7 400 15 6.0 6.4 208 15 115/1/60 1860 16.2 20.3 25

KTM260MG-S1 4 115/1/60 4.4 4.7 400 15 6.0 6.4 208 15 115/1/60 2280 19.8 24.8 25

KTM295MG-S1 5 115/1/60 5.5 5.8 500 15 7.5 7.9 260 15 115/1/60 2280 19.8 24.8 25

KTM115MG-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15 208-230/1/60 1300 5.7 7.1 15

KTM139MG-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15 208-230/1/60 1300 5.7 7.1 15

KTM172MG-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15 208-230/1/60 1860 8.1 10.1 15

KTM208MG-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15 208-230/1/60 1860 8.1 10.1 15

KTM236MG-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15 208-230/1/60 1860 8.1 10.1 15

KTM260MG-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15 208-230/1/60 2280 9.9 12.4 15

KTM295MG-S2 5 208-230/1/60 2.5 2.6 500 15 5.0 5.3 260 15 208-230/1/60 2280 9.9 12.4 15

No.

FANS

of

POWER

SUPPLY

PSC-Standard ECM-Optional

TOTAL

MOTOR

FLA

M.C.A. Watts M.O.P

TOTAL

MOTOR

FLA

M.C.A. Watts M.O.P

DRAIN PAN HEATERS

POWER

SUPPLY

TOTAL

WATTS

60Hz

TOTAL

MOTOR

FLA

M.C.A. M.O.P

Page 6

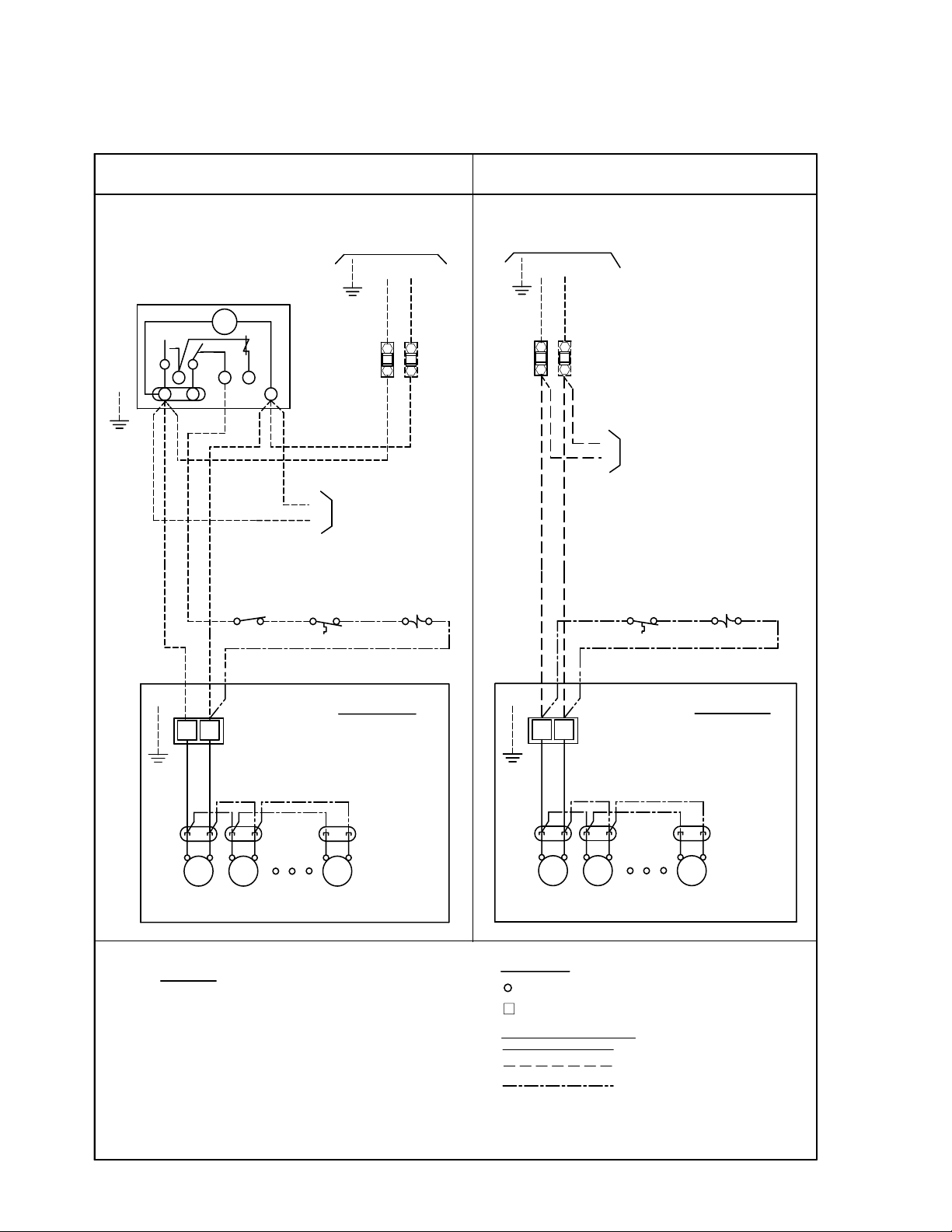

1-TM AD 03/08

TERMINAL BOARD

PUMP DOWN

WIRED ON EVAPORATOR .

2). USE 90°C WIRE (OR HIGHER)

EVAPORATOR FAN MOTORS AND DEFROST

HEATERS MUST NOT EXCEED MAXIMUM

VALUE SHOWN ON EVAPORATOR NAMEPLATE.

1). USE COPPER CONDUCTORS ONLY

3). OVERCURRENT PROTECTION FOR

4). MAY BE FACTORY INSTALLED-MOUNTED AND

NOTES

MTR

FAN

MTR

FAN

4

GND.

F

(IF USED)

SWITCH

CONDUCTORS/WIRING

FACTORY WIRING

WIRING BY OTHERS

BY OTHERS

OPTIONAL FACTORY OR

COMPLIANCE WITH ALL APPLICABLE LOCAL

ALL FIELD WIRING MUST BE DONE IN

AND NATIONAL CODES.

TERMINAL BOARD

NOTE #4

SPACE

THERMOSTAT

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

FAN MOTOR

POWER

PLUGS

REFER TO

EVAPORATOR

DATA PLATE

FOR MOTOR

QUANTITY

MTR

FAN

TERMINALS

MTR

FAN

MTR

FAN

SOLENOID VALVE

EVAPORATOR

NOTE #4

SPACE

THERMOSTAT

N.C.

NOTE #4

LIQUID LINE

4

GND.

F

FAN MOTOR

POWER

PLUGS

REFER TO

EVAPORATOR

DATA PLATE

FOR MOTOR

QUANTITY

MTR

FAN

EVAPORATOR

N.C.

NOTE #4

LIQUID LINE

SOLENOID VALVE

WITH DEFROST TIME CLOCK

GND

132

4NX

TM

OR EQUIVALENT

DEFROST CLOCK

PARAGON # 8145

EVAPORATORS (IF APPLIC)

NAMEPLATE FOR ELECTRICAL

REFER TO EVAPORATOR

WITHOUT DEFROST TIME CLOCK

GND

IF(N)

TO MULTIPLE EVAPS

F

4

(IF APPLIC)

OMIT 2ND

BREAKER

NOTE #3

FUSE OR

FUSE

CIRCUIT

4

F

BREAKER

NOTE #3

CIRCUIT

FUSE OR

NAMEPLATE FOR ELECTRICAL

REFER TO EVAPORATOR

REQUIREMENTS

L2(N)

L1

REQUIREMENTS

GND

L1

L2(N)

TO MULTIPLE

IF(N)

2ND FUSE

OMIT

KTM

K30-KTM-PDI-3

- 6 -

08/14/12

WIRING DIAGRAM

AIR DEFROST - ALL VOLTAGES

60Hz

Page 7

2-TM ED 03/08

FOR ALL MODELS USING DEFROST HEATER CONTACTOR

1

GND.

2). USE 75°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

1). USE COPPER CONDUCTORS ONLY

AND WIRED ON EVAPORATOR

EVAPORATOR FAN MOTORS AND

EVAPORATOR NAMEPLATE.

MAXIMUM VALUE SHOWN ON

4.) MAY BE FACTORY INSTALLED-MOUNTED

DEFROST HEATERS MUST NOT EXCEED

NOTES

JUMPER

ORANGE

TERMINAL BOARD

POWER PLUGS

EVAPORATOR

MOTOR QUANTITY

DATA PLATE FOR

DT-DEFROST TERM

FD-FAN DELAY

FANFAN

MTRMTR

FAN MOTOR

MTR

FAN

REFER TO

DEFROST TERMINATION

GND.

BK

4

BN

F

X

C

CONTROL

(10.0A MAX.)

& FAN DELAY

FD

RD

DT

N

3

EVAPORATOR

H1

H2 H3

FOR ALL MODELS WITHOUT DEFROST HEATER CONTACTOR

USING MAXIMUM 15A HEATER OVERCURRENT PROTECTION

N

21

LIQUID LINE

SOL VALVE

NOTE #4

N.C.

NOTE #4

PUMP DOWN

(IF USED)

SWITCH

(IF USED)

THERMOSTAT

SPACE

COMPR INTERLOCK

REFER TO EVAPORATOR

NAMEPLATE FOR ELECTRICAL

3

4X

TM

OR EQUIVALENT

DEFROST CLOCK

PARAGON # 8145

FUSE OR

GND

BREAKER

CIRCUIT

15A

REQUIREMENTS

L1

N

-TERMINAL BLOCK TERMINAL

COMPLIANCE WITH ALL APPLICABLE LOCAL

ALL FIELD WIRING MUST BE DONE IN

OR BY OTHERS

WIRING BY OTHERS

OPTIONAL FACTORY

FACTORY WIRING

AND NATIONAL CODES.

CONDUCTORS/WIRING

-COMPONENT TERMINAL

TERMINALS

MOTOR QUANTITY

DATA PLATE FOR

(10.0A MAX.)

DT-DEFROST TERM

FAN

MTR

FAN

MTR

FD-FAN DELAY

FAN MOTOR

MTR

FAN

EVAPORATOR

REFER TO

POWER PLUGS

DEFROST TERMINATION

& FAN DELAY

BK

CONTROL

FD

4

F

DT

BN

X

C

TERMINAL BOARD

RD

N

JUMPER

3

ORANGE

EVAPORATOR

H1

H3

H2

NOTE #4

N.C.

SWITCH

(IF USED)

PUMP DOWN

NOTE #4

SOL VALVE

LIQUID LINE

COMPR INTERLOCK

(IF USED)

THERMOSTAT

SPACE

DEFROST HEATER

T2

T1

C

L1

L2

CONTACTOR

NAMEPLATE FOR ELECTRICAL

GND

(IF APPLIC.)

REFER TO EVAPORATOR

FUSE OR

BREAKER

NOTE #3

CIRCUIT

3

2

X4

TM

N

DEFROST CLOCK

OR EQUIVALENT

PARAGON # 8145

REQUIREMENTS

FUSE OR

NOTE #3

BREAKER

CIRCUIT

L1

N

DEFROST HEATERS

L.H. COIL

BK

BK

BOTTOM

BOTTOM

BK

R.H. COIL

BK

BK

DEFROST HEATERS

BK

BOTTOM

L.H. COIL

BK

BOTTOM

R.H. COIL

BK

KTM

K30-KTM-PDI-3

- 7 -

08/14/12

WIRING DIAGRAM

ELECTRIC DEFROST -

230V (SINGLE EVAPORATOR)

60Hz

Page 8

* Fan delay not used on second evap / use fan contactor if total fan amps exceeds 10A

4.) MAY BE FACTORY INSTALLED-MOUNTED

FAN MOTOR

POWER PLUGS

REFER TO

EVAPORATOR

MOTOR QUANTITY

DATA PLATE FOR

3-TM ED CONTACTOR MULTI 03/08

3). OVERCURRENT PROTECTION FOR

1). USE COPPER CONDUCTORS ONLY

DEFROST HEATERS MUST NOT EXCEED

EVAPORATOR FAN MOTORS AND

AND WIRED ON EVAPORATOR

EVAPORATOR NAMEPLATE.

MAXIMUM VALUE SHOWN ON

2). USE 90°C WIRE (OR HIGHER)

NOTES

MTR

FANFAN

MTR MTR

FAN

DT-DEFROST TERM

FD-FAN DELAY

& FAN DELAY

(10.0A MAX.)

DEFROST TERMINATION

BK

GND.

4

BN

F

X

CONTROL

FD

RD

DT

C

N

COMPLIANCE WITH ALL APPLICABLE LOCAL

ALL FIELD WIRING MUST BE DONE IN

WIRING BY OTHERS

FACTORY WIRING

OPTIONAL FACTORY

AND NATIONAL CODES.

TERMINALS

CONDUCTORS/WIRING

OR BY OTHERS

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

SECONDARY

EVAPORATOR

* Remove & Insulate

EVAPORATOR

FAN

MTR

PRIMARY

MTR

FANFAN

MTR

DATA PLATE FOR

MOTOR QUANTITY

REFER TO

EVAPORATOR

FD-FAN DELAY

DT-DEFROST TERM

POWER PLUGS

FAN MOTOR

H1

H2

GND.

4

F

N

BK

& FAN DELAY

CONTROL

(10.0A MAX.)

DEFROST TERMINATION

FD

RD

BN

DT

X

C

H1 H2

FUSE OR

NOTE #3

BREAKER

CIRCUIT

(IF USED)

SPACE

NOTE #4

THERMOSTAT

FOR ALL MODELS USING DEFROST HEATER CONTACTOR

COMPR INTERLOCK

REFER TO EVAPORATOR

PUMP DOWN

(IF USED)

SWITCH

DEFROST CLOCK

PARAGON # 8145

OR EQUIVALENT

3

12

X4

N

TM

DEFROST HEATER

LIQUID LINE

SOL VALVE

NOTE #4

N.C.

NOTE #3

BREAKER

CIRCUIT

FUSE OR

T1

L1

C

CONTACTOR

T2

L2

REQUIREMENTS

L1

GND

FUSE OR

CIRCUIT

NOTE #3

BREAKER

L2

NAMEPLATE FOR ELECTRICAL

DEFROST HEATERS

L.H. COIL

BK

BOTTOM

BK

R.H. COIL

BOTTOM

BK

BK

DEFROST HEATERS

BK

BOTTOM

L.H. COIL

BK

BK

BK

BOTTOM

R.H. COIL

KTM

K30-KTM-PDI-3

- 8 -

08/14/12

WIRING DIAGRAM

ELECTRIC DEFROST -

230V (MULTI EVAPORATOR)

60Hz

Page 9

CONTROL

**DEFROST TERMINATION

4.) MAY BE FACTORY INSTALLED-MOUNTED

AND WIRED ON EVAPORATOR

4-TM HG 03/08

2). USE 90°C WIRE (OR HIGHER)

EVAPORATOR NAMEPLATE.

MAXIMUM VALUE SHOWN ON

3). OVERCURRENT PROTECTION FOR

1). USE COPPER CONDUCTORS ONLY

DEFROST HEATERS MUST NOT EXCEED

EVAPORATOR FAN MOTORS AND

NOTES

MTR

FANFAN

MTR

BK

GND.

4

F

X

OR BY OTHERS

COMPLIANCE WITH ALL APPLICABLE LOCAL

ALL FIELD WIRING MUST BE DONE IN

WIRING BY OTHERS

FACTORY WIRING

OPTIONAL FACTORY

AND NATIONAL CODES.

THE CONTROL CLOSES WHEN REACHES 55` F (20 F DIFF)

OPTIONAL FACTORY WIRED OR BY OTHERS

ON REVERSE CYCLE LOCATED AT SUCTION LINE.

(ANYTIME THE TEMPERATURE OF THE INCOMING

EVAPORATOR FANS AND ENERGIZES THE

THE FAN/HEATER CONTROL DE-ENERGIZES THE

NOTE: DURING THE HOT GAS DEFROST CYCLE

EVAPORATOR

FAN MOTOR

POWER PLUGS

REFER TO

EVAPORATOR

MOTOR QUANTITY

DATA PLATE FOR

MTR

FAN

CONDUCTORS/WIRING

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

TERMINALS

LOCATED ON TUBE END SHEET

**DEFROST TERMINATION

CONTROL

RD

DRAIN PAN HEATER

RD

RD

*FAN HEATER

CONTROL

C

BN

N

H1

REFRIGERANT GAS IS ABOVE 50° F).

DRAIN PAN HEATER.

CONTROL

*FAN HEATER

REFER TO SPECIFIC SYSTEM

WIRING DIAGRAM (BY OTHERS)

FOR FIELD CONTROL WIRING

USING MAXIMUM 15A HEATER OVERCURRENT PROTECTION

15A

FUSE OR

FAN MOTOR / HEATER WIRING

BREAKER

CIRCUIT

NAMEPLATE FOR ELECTRICAL

L2(N)

REFER TO EVAPORATOR

GND

L1

REQUIREMENTS

BK

BK

H2

KTM

K30-KTM-PDI-3

- 9 -

08/14/12

WIRING DIAGRAM

REVERSE CYCLE DEFROST - 230V

60Hz

Page 10

KTM

K30-KTM-PDI-3

- 10 -

08/14/12

MECHANICAL DATA

60Hz

TUBE CONNECTIONS

MODEL

KTM115M 7/8 22 1/2 13 1/2 13 110 50

KTM139M 7/8 22 1/2 13 1/2 13 116 53

KTM172M 7/8 22 1/2 13 1/2 13 150 68

KTM208M 1 1/8 29 1/2 13 1/2 13 157 71

KTM236M 1 1/8 29 1/2 13 1/2 13 164 74

KTM260M 1 1/8 29 7/8 22 5/8 16 191 87

KTM295M 1 1/8 29 7/8 22 5/8 16 198 90

KTM105L 7/8 22 1/2 13 1/2 13 110 50

KTM124L 1 1/8 29 1/2 13 1/2 13 116 53

KTM153L 1 1/8 29 1/2 13 1/2 13 150 68

KTM188L 1 1/8 29 7/8 22 5/8 16 157 71

KTM210L 1 1/8 29 7/8 22 5/8 16 164 74

KTM235L 1 3/8 35 7/8 22 5/8 16 191 87

KTM265L 1 3/8 35 7/8 22 5/8 16 198 90

SUCTION (OD) DISTRIBUTOR INLET HOT GAS SIDE (OD)

Inches mm Inches mm Inches mm Lbs. Kgs

APPROX. SHIPPING WEIGHT

Page 11

KTM

on all suction headers inside

"C"

"D"

3). 1/4" O.D. external equalizer line

Drain fitting.

7/8 (22 mm)

hole & knockout

Suction line

6-1/4

and service access fitting included

all models.

Air defrost, Electric, and

NOTES: 1). Dimensions shown are typical for

opposite to the piping end on

2). Electrical connection end is

"B"

MAX

AIR

AIR

"C"

"D"

SIDE VIEW

Unit cooler is to be supported at all mounting points

MOUNTING HOLES (3/8" DIA.) & PIPING CONNECTION

"E"

26 1/2

AIR

OUT

Coil

AIR

AIR IN

AIR

Coil

3-3/8

7/8 (22 mm)

knockouts

3 each side

Hinged

Drain pan/Fan panel

OUT

AIR

26 15/16

MOUNTING HOLES

28 3/16

END VIEW

"A"

1 13/16

L.H.

R.H.

end compartment

3/4" FPT

Hot Gas defrost

K30-KTM-PDI-3

- 11 -

08/14/12

DIMENSIONAL DATA

Inches (mm)

60Hz

DIMENSIONS

MODEL

NUMBER

NO.FANS

KTM115M 2 67 1/2 1715 8 11/16 221 27 1/2 699 - - - -

KTM139M 2 67 1/2 1715 8 11/16 221 27 1/2 699 - - - -

KTM172M 3 93 1/2 2375 8 11/16 221 40 1/2 1029 - - - -

KTM208M 3 93 1/2 2375 8 11/16 221 40 1/2 1029 - - - -

KTM236M 4 93 1/2 2375 8 11/16 221 40 1/2 1029 - - - -

KTM260M 4 113 1/2 2883 8 11/16 221 - - 40 1/2 1029 20 508

KTM295M 5 113 1/2 2883 8 11/16 221 - - 40 1/2 1029 20 508

KTM105L 2 67 1/2 1715 8 11/16 221 27 1/2 699 - - - -

KTM124L 2 67 1/2 1715 8 11/16 221 27 1/2 699 - - - -

KTM153L 3 93 1/2 2375 8 11/16 221 40 1/2 1029 - - - -

KTM188L 3 93 1/2 2375 8 11/16 221 40 1/2 1029 - - - -

KTM210L 4 93 1/2 2375 8 11/16 221 40 1/2 1029 - - - -

KTM235L 4 113 1/2 2883 8 11/16 221 - - 40 1/2 1029 20 508

KTM265L 5 113 1/2 2883 8 11/16 221 - - 40 1/2 1029 20 508

* Reducer supplied to accomodate 1/2” or 7/8” TXV outlet connection.

A B C D E

in mm in mm in mm in mm in mm

Page 12

KTM

A

B

WALL

WALL

CEILING

D

C

A

A

D

TOP VIEW

TOP VIEW

SIDE VIEW

SIDE VIEW

K30-KTM-PDI-3

- 12 -

08/14/12

RECOMENDED INSTALLATION

CLEARANCES

60Hz

DIMENSION A B C D

MINIMUM

Maximum

ft. 2 2 6 3

cm. 61 61 183 92

ft. - 7 40 20

cm. - 210 1200 600

Page 13

KTM

K30-KTM-PDI-3

- 13 -

08/14/12

NOZZLE SELECTIONS

60Hz

Nozzle Selections (Factory installed)

For all applications and refrigerants

Model Nozzle

KTM115M L-1

KTM139M L-1 1/2

KTM172M L-1 1/2

KTM208M L-2

KTM236M L-2

KTM260M G-2 1/2

KTM295M G-3

MEDIUM TEMP - EXPANSION VALVE SELECTION

SPORLAN

MODEL TD

KTM115M

KTM139M

KTM172M

KTM208M

KTM236M

KTM260M

KTM295M

CAPACITY @

25°F SST

10 11,500 EGSE-1-C EGVE-1-C

15 17,250 EGSE-1-1/2-C EGVE-1-1/2-C

10 13,900 EGSE-1-C EGVE-1-C

15 20,850 EGSE-2-C EGVE-2-C

10 17,200 EGSE-1-1/2-C EGCE-1-1/2-C

15 25,800 SSE-3-C EGVE-3-C

10 20,800 EGSE-1-1/2-C EGCE-1-1/2-C

15 31,200 SSE-3-C EGVE-3-C

10 23,600 EGSE-2-C EGVE-2-C

15 35,400 SSE-3-C EGVE-3-C

10 26,000 EGSE-2-C EGVE-2-C

15 39,000 SSE-4-C EGVE-3-C

10 29,500 SSE-3-C EGVE-3-C

15 44,250 SSE-4-C SVE-4-C

* For medium temp. R-507, refrigerant designation changes

from ‘S’ to ‘P’.

R404A

R507

*

R22

R407C

Model Nozzle

KTM105L L-1 1/2

KTM124L L-2

KTM153L L-2

KTM188L G-2 1/2

KTM210L G-3

KTM235L E-3

KTM265L E-4

DANFOSS

MODEL TD

KTM115M

KTM139M

KTM172M

KTM208M

KTM236M

KTM260M

KTM295M

CAPACITY @

25°F SST

10 11,500 TUAE-R404A-6-N TUAE-R22-6-N

15 17,250 TUAE-R404A-8 TUAE-R22-7-N

10 13,900 TUAE-R404A-7-N TUAE-R22-6-N

15 20,850 TUAE-R404A-8-N TUAE-R22-7-N

10 17,200 TUAE-R404A-7-N TUAE-R22-7-N

15 25,800 TUAE-R404A-9-N TUAE-R22-8-N

10 20,800 TUAE-R404A-8-N TUAE-R22-7-N

15 31,200 TUAE-R404A-9-N TUAE-R22-8-N

10 23,600 TUAE-R404A-8-N TUAE-R22-8-N

15 35,400 TCAE-R404A-1-N TUAE-R22-9-N

10 26,000 TUAE-R404A-9-N TUAE-R22-8-N

15 39,000 TCAE-R404A-2-N TUAE-R22-9-N

10 29,500 TUAE-R404A-9-N TUAE-R22-8-N

15 44,250 TCAE-R404A-2-N TUAE-R22-9-N

R404A

R507

R22

R407C

ALCO

MODEL TD

KTM208M

KTM236M

KTM260M

KTM295M

CAPACITY @

25°F SST

10 20,800 HFESC - 1-1/2 - SC HFESC - 2 - HC

15 31,200 HFESC- 3-1/2 - SC HFESC - 3- HC

10 23,600 HFESC - 2 - SC HFESC - 2 - HC

15 35,400 HFESC- 3-1/2 - SC HFESC - 3 - HC

10 26,000 HFESC - 2 - SC HFESC - 2-1/2 - HC

15 39,000 HFESC- 3-1/2 - SC HFESC - 3 - HC

10 29,500 HFESC - 2 - SC HFESC - 2-1/2 - HC

15 44,250 HFESC- 3-1/2 - SC HFESC - 3 - HC

ALL TXV Selections based on 90-100°F liquid.

R404A

R507

R22

R407C

Page 14

KTM

K30-KTM-PDI-3

- 14 -

08/14/12

LOW TEMP

EXPANSION VALVE SELECTION

60Hz

SPORLAN -

Model 0°F Evap -10°F Evap -20°F Evap

KTM105L EGSE-1-C EGSE-1-ZP EGSE-1-ZP

KTM124L EGSE-1-C EGSE-1-ZP EGSE-1-ZP

KTM153L EGSE-1-1/2-C EGSE-1-1/2-ZP EGSE-1-1/2-ZP

KTM188L EGSE-1-1/2-C EGSE-2-ZP EGSE-2-ZP

KTM210L EGSE-2-C EGSE-2-ZP EGSE-2-ZP

KTM235L EGSE-2-C EGSE-2-ZP SSE-3-ZP

KTM265L SSE-3-C SSE-3-ZP SSE-3-ZP

For low temp. R-507, refrigerant designation changes from ‘SE’ to ‘PE’.

*

DANFOSS -

Model 0°F Evap -10°F Evap -20°F Evap

KTM105L TUAE-R404A-7-N TUAE-R404A-8-NM TUAE-R404A-8-NM

KTM124L TUAE-R404A-7-N TUAE-R404A-8-NM TUAE-R404A-8-NM

KTM153L TUAE-R404A-8-N TUAE-R404A-8-NM TUAE-R404A-9-NM

R404A

R404A

R507

R507

KTM188L TUAE-R404A-9-N TUAE-R404A-9-NM TCAE-R404A-1-NM

KTM210L TUAE-R404A-9-N TUAE-R404A-9-NM TCAE-R404A-1-NM

KTM235L TUAE-R404A-9-N TCAE-R404A-1-NM TCAE-R404A-1-NM

KTM265L TCAE-R404A-1-N TCAE-R404A-1-NM TCAE-R404A-2-NM

ALCO -

Model 0°F Evap -10°F Evap -20°F Evap

KTM105L HFESC - 1 - SC HFESC - 1-1/4 - SW45 HFESC - 1-1/4 - SW45

KTM124L HFESC - 1 - SC HFESC - 1-1/4 - SW45 HFESC - 1-1/2 - SW45

KTM153L HFESC - 1-1/4 - SC HFESC - 1-1/2 - SW45 HFESC - 2 - SW45

KTM188L HFESC - 1-1/2 - SC HFESC - 2 - SW45 HFESC - 2 - SW45

KTM210L HFESC - 1-1/2 - SC HFESC - 2 - SW45 HFESC - 2 - SW45

KTM235L HFESC - 2 - SC HFESC - 2 - SW45 HFESC - 3-1/2 - SW45

KTM265L HFESC - 2 - SC HFESC - 3-1/2 - SW45 HFESC - 3-1/2 - SW45

* For low temp. R-507, refrigerant designation changes from ‘SC’ to ‘PC’.

R404A

R507

Page 15

REVERSE CYCLE DEFROST

ELECTRIC DRAIN PAN HEATER

EVAPORATOR COIL

G

OPT1

FACTORY PIPING

CHECK VALVE SHIPPED LOOSE

CHECK

VALVE

DISTRIBUTOR

TXV

REVERSE CYCLE DEFROST

HOT GAS

ENTERING

ELECTRIC DRAIN PAN HEATER

STD-G

FACTORY PIPING

LEAVING

HOT GAS

WITH CHECK VALVE LOOSE

EVAPORATOR COIL

DISTRIBUTOR

CHECK

VALVE

ENTERING

HOT GAS

WITH DRAIN PAN HEATERWITH DRAIN PAN HEATER

WITH TXV FACTORY INSTALLED

HOT GAS

LEAVING

KTM

K30-KTM-PDI-3

- 15 -

08/14/12

FAN/HEATER CONTROL AND DEFROST

TERMINATION CONTROL POSITION

60Hz

HOT GAS DEFROST (REVERSE CYCLE)

Page 16

KTM

K30-KTM-PDI-3

- 16 -

08/14/12

INSTALLATION INSTRUCTIONS

60Hz

INSTALLATION

The installation and start-up of Two-Way Unit Coolers should only

be performed by qualied refrigeration mechanics.

This equipment should be installed in accordance with all applica-

ble codes, ordinances and local by-laws.

INSPECTION

Inspect all equipment before unpacking for visible signs of dam-

age or loss. Check shipping list against material received to

ensure shipment is complete.

IMPORTANT: Remember, you, the consignee, must make any

claim necessary against the transportation company. Shipping

damage or missing parts, when discovered at the outset, will prevent later unnecessary and costly delays.

If damage or loss during transport is evident, make claim to

carrier, as this will be their responsibility, not the

manufacturer’s.

Should carton be damaged, but damage to equipment is not

obvious, a claim should be led for “concealed damage” with the

carrier.

IMPORTANT: The electrical characteristics of the unit should

be checked at this time to make sure they correspond to those

ordered and to electrical power available at the job site.

Save all shipping papers, tags and instruction sheets for

reference by installer and owner.

APPLICATION

Two-Way Unit Coolers are designed for use in coolers and freez-

ers such as reach in boxes, walk-in rooms and any other cooler

applications where a low velocity, uniform air ow is required. The

compact and low height unit provides maximum useable product

storage space.

At room temperatures above 34

peratures no lower than 27

coil will accomplish the defrost (Air Defrost).

At room temperatures 34

frosting is required ( Electric defrost) . These will require the use

of :

1. Time Clock (to initiate and terminate the defrost cycle ),

2. Defrost termination thermostat (to prevent unnecessary

prolonged heating and steaming of the coil once all the frost

and ice has melted). And if a freezer,

3. Fan delay thermostat (to prevent evaporator fans starting up

right away and blowing water on to the fan blades, guards

and oor).

This evaporator coil must not be exposed to any abnormal environments (acidic or caustic) that can result in coil corrosion and

leaks. Consult factory for optional baked on phenolic protective

coatings. These unit coolers are for use primarily on R134a, R22

and R404A refrigerants and their approved alternatives / replacements.

o

F (1.1 oC) and evaporating tem-

o

F (-2.8 oC) the air owing through the

o

F and below ( to -10 oF) positive de-

LOCATION

The unit location in the room should be selected to ensure

uniform air distribution throughout the entire space to be

refrigerated. Be sure that the unit does not draw air in, or

blow directly out, through an opened door and that the product

does not obstruct the free circulation of air. Allow a minimum

of 24” clearance at each end. Two-Way Unit Coolers draw air

through the fans and discharge air through both coils.

Consideration should be given to the coil location in order to

minimize the piping run length to the condensing unit and oor

drain.

EXPANSION VALVE (TXV) SELECTION

All units require the use of an externally equalized

expansion valve. (A 1/4” (6 mm) O.D. equalizer line has been

provided on the coil) TX valves should not be selected strictly

by their nominal ton rating. (This rating is based at a specic

pressure differential and entering liquid temperature). Since

applications will differ it is suggested the following selection

procedure be followed.

1. Determine actual unit cooler BTUH or KW (thermal).

The nominal rating is based at 10

(Room Temp. minus Evap. Temp.). Note that a higher /

lower operating T.D.will increase / decrease this capacity

rating by their direct ratio.

2. Determine the pressure drop across the valve by

subtracting the suction (evaporating) pressure from the

high side liquid pressure. Note: Also subtract the

distributor pressure loss (use approx. 25 psig (1.1 bar)

for R134a and 35 psig (2.4 bar) for R22, R404A, R507).

3. Estimate entering liquid temperature. Temperatures

lower than 100

ratings. Refer to valve manufacturer’s specs for details.

4. Select valve from the valve manufacturer selection charts

for the appropriate refrigerant, evaporating temp and

pressure drop.

5. After following the manufacturer’s installation instructions

and after the room has reached the desired temperature

the valve superheat should be checked. This will conrm

that the evaporator is operating properly and performing

to maximum efciency. The superheat should be

around 5 (2.7°C) to 8

(5.5 to 6.6°C) T.D. Too high or low a super heat will result

in unsatisfactory system performance and possible

compressor problems.

°

F (37.7 °C) increase valve capacity

O

F (4.4°C) for a 10 to 12 OF

O

F T.D. (5 .5°C)

NOZZLE INSTALLATION

All Two-Way unit coolers have nozzles installed at factory. For

nozzle selection refer to selection table. In case it is required to

install the nozzle at some point in the future, the nozzle retainer

clip (in distributor) must be removed before inserting nozzle.

Re-install clip ensuring nozzle is properly in place.

Page 17

KTM

K30-KTM-PDI-3

- 17 -

08/14/12

INSTALLATION INSTRUCTIONS (cont’d)

60Hz

MOUNTING

Refer to dimensional drawing for recommended mounting ar-

rangements. Formed mounting channels are provided for ush

mounting to the ceiling. Ensure adequate clearance (at least

24” (600 mm)) is provided at each end (to enable access to the

electrical and refrig. compartments).

Ensure that the ceiling is level since the drain pan has

been sloped for drainage during the defrost cycle.

DRAIN LINE

The drain line should be run from the drain connection, sloping

at least 1/4” (6 mm) per foot. A trap in a warm area outside the

room will allow proper draining through the tubing. Connection

should be made to proper drainage facilities that comply with

local regulations.

To prevent freeze-up when the temperature of the refrigerated

space is 35

along its run inside the cold room. The heated drain line should

be insulated. It is recommended that the heater be energized

at all times. A heat input of 20 watts per foot in a 28°F (-2.2°C)

room, is satisfactory. Drain line heaters are not required for

constant room temperature above 35°F (1.6°C).

Ensure that the drain line has sufcient slope for proper

drainage (prevention of ice build up/blockage in pan).

o

F (1.7 °C) or lower, the drain line should be heated

PIPING

Refrigerant line sizes are important and may not be the same

size as the coil connections. Consult “Recommended refriger-

ant line sizes” charts in any standard reference book for proper

line sizing.

Refrigerant piping and control system should be designed to

prevent possible liquid slugging (from oil or refrigerant) of the

compressors on start-up after the defrost cycle. On Hot Gas

Defrost Systems the suction accumulator should be at least 2.5

times the coils operating charge.

See Dimensional data for line locations. Reverse Cycle mod-

els include a check valve (unmounted) packaged along with

the nozzle in the refrig. connection compartment end panel.

WIRING

Wire system in accordance with governing standards and local

codes. See data and wiring diagrams on pages 7 to 12 for wir-

ing arrangement. Electrical wiring is to be sized in accordance

with minimum circuit ampacity rating (MCA).

For ease of identifying the proper wiring terminal, unit wiring is

color coded and terminal block connections are identied.

SYSTEM CHECK

Before Start-Up:

1. All wiring should be in accordance with local codes.

2. Refrigerant lines should be properly sized.

3. Off cycle defrost and electric defrost systems preferably

must include a liqud line solenoid valve and suction

accumulator.

4. Thorough evacuation and, dehydration has been

performed.

5. The suction, discharge, and receiver service valves must

be open.

6. The system preferably must include a liquid line drier

moisture indicator and suction lter.

7. Pour enough water into the drain pan to allow a good check

on drainage and seal the trap.

After Start-Up:

1. Check the oil level to be sure the oil charge is correct.

2. On initial start up the fans do not start until coil

temperature is pulled down to approximately 35 °F (1.7 °C)

on the hot gas coil. Also, it is normal for the fans to cycle a

few times until the room temperature is pulled down.

3. Fan/Heater control and defrost termination control is

factory installed for reverse cycle defrost operation.

4. In general, evaporators running with a TD of 10 °F should

have a superheat reading of 5° to 8 °F (2.7 °C to 4.4 °C).

For evaporators with a higher TD, the superheat should be

8° to 12°F (4.4 °C to 6.6 °C).

5. Heavy moisture loads are usually encountered when

starting the system for the rst time. This will cause a rapid

build-up of frost on the unit cooler. During the initial pull

down, we suggest that the frost build-up be watched and

defrosted manually as required. This may be done by

rotating the inner dial on the timer until the pin in the outer

dial is directly opposite the timer pointer. (Paragon 8145-

20 Timer by others).

6. Observe that the system goes through at least one

complete DEFROST CYCLE.

MAINTENANCE

The unit should be periodically inspected for any dirt or

build-up on the n surface and cleaned if necessary with a soft

whisk or brush. Also ensure coils inner and outer drain pans

do not have any ice build-up from improper defrost operation.

When replacing heater elements rst remove heater retainer

brackets and heater clips.

Page 18

GENERIC SERVICE PARTS LIST

K30-KTM-PDI-3

- 18 -

08/14/12

KTM

MODEL NUMBER PSC Motor EC Motor

MEDIUM

TEMP

KTM 115M KTM 105L 1073403 1073405 1087600 1091176 1091 177 1087600 1073456 1073642 1070854-003

KTM 139M KTM 124L 1073403 1073405 1087600 1091176 1091 177 1087600 1073456 1073642 1070854-003

KTM 172M KTM 153L 1073403 1073405 1087600 1091176 1091 177 1087600 1073456 1073643 1070854-002

KTM 208M KTM 188L 1073403 1073405 1087600 1091176 1091 177 1087600 1073456 1073643 1070854-002

KTM 236M KTM 210L 1073403 1073405 1087600 1091176 1091 177 1087600 1073456 1043315 1070854-002

KTM 260M KTM 235L 1073403 1073405 1087600 1091176 1091 177 1087600 1073456 1073644 1070854-001

KTM 295M KTM 265L 1073403 1073405 1087600 1091176 1091 177 1087600 1073456 1043316 1070854-001

Terminal Board - 1048825

Fan Delay / Defrost Terminaltion Control - 1071280 ( electric defrost models only)

Fan Delay / Heater Control - 1073640 (hot gas models only)

LOW

TEMP

Motor

115V

Motor

230V

Fan

Blade

Motor

115V

Motor

230V

Fan

Blade

Fan

Guard

60Hz

Wire

Harness

* Drain Pan

Heater

(if appl)

Page 19

Finished Goods Warranty

K30-KTM-PDI-3

- 19 -

08/14/12

The terms and conditions as described below in the General Warranty Policy cover all products

manufactured by National Refrigeration.

GeneraL Warranty PoLiCy

Subject to the terms and conditions hereof, the Company warrants all Products, including Service

Parts, manufactured by the Company to be free of defects in material or workmanship, under nor-

mal use and application for a period of one (1) year from the original date of installation, or eighteen

(18) months from the date of shipment from the Company, whichever occurs rst. Any replacement

part(s) so supplied will be warranted for the balance of the product’s original warranty. The part(s) to

be replaced must be made available in exchange for the replacement part(s) and reasonable proof

of the original installation date of the product must be presented in order to establish the effective

date of the warranty, failing which, the effective date will be based upon the date of manufacture plus

thirty (30) days. Any labour, material, refrigerant, transportation, freight or other charges incurred in

connection with the performance of this warranty will be the responsibility of the owner at the cur-

rent rates and prices then in effect. This warranty may be transferred to a subsequent owner of the

product.

this Warranty does not CoVer

(a) Damages caused by accident, abuse, negligence, misuse, riot, re, ood, or Acts of God (b) damages

caused by operating the product in a corrosive atmosphere (c) damages caused by any unauthorized

alteration or repair of the system affecting the product’s reliability or performance (d) damages caused

by improper matching or application of the product or the product’s components (e) damages caused by

failing to provide routine and proper maintenance or service to the product (f) expenses incurred for the

erecting, disconnecting, or dismantling the product (g) parts used in connection with normal maintenance,

such as lters or belts (h) products no longer at the site of the original installation (i) products installed

or operated other than in accordance with the printed instructions, with the local installation or building

codes and with good trade practices (j) products lost or stolen.

No one is authorized to change this WARRANTY or to create for or on behalf of the Company any

other obligation or liability in connection with the Product(s). There is no other representation, warranty

or condition in any respect, expressed or implied, made by or binding upon the Company other than

the above or as provided by provincial or state law and which cannot be limited or excluded by such

law, nor will we be liable in any way for incidental, consequential, or special damages however caused.

The provisions of this additional written warranty are in addition to and not a modication of or subtraction

from the statutory warranties and other rights and remedies provided by Federal, Provincial or State laws.

PROJECT INFORMATION

System

Model Number Date of Start-Up

Serial Number Service Contractor

Refrigerant Phone

Electrical Supply Fax

Page 20

“AS BUILT” SERVICE PARTS LIST

08/14/12

Service Parts List

Label

To Be Attached

HERE

NATIONAL REFRIGERATION &

AIR CONDITIONING CANADA CORP.

CANADA

159 ROY BLVD., BRANTFORD, ONTARIO, CANADA N3R 7K1

PHONE: 1-800-463-9517 (519)751-0444 FAX (519)753-1140

Due to National Refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice.

USA

985 WHEELER WAY, LANGHORNE, PA. 19047 USA

PHONE: 1-888-KEEPUS1 OR 1-888-533-7871

Loading...

Loading...