Page 1

KLV Low Velocity

30/03/12

Evaporators

PRODUCT DATA &

INSTALLATION

Bulletin K30-KLV-PDI-22

1073480

Latest product updates and further information

at w w w . k e e pr it er e f r i g er at io n . c o m

KeepRite

Low Velocity Evaporators

NOMENCLATURE

KLV 150 ED - S2 B

Applications:

High Temperature

35 °F (2 °C) or Above Box Temperature and

Medium Temperature

28 °F to 34°F Box Temperature (-2 °C to 1 °C)

Defrost Types:

Air, Electric or Hot Gas Defrost

• Heavygaugetexturedaluminumcabinetconstruction

resistsscratches/corrosionandminimizesweightfor

shipment,installationandservice.

• High-efciencyPSCmotors.

• Speciallydesignedforquietoperation-idealfor

prep.rooms.

• Capacityupto37,000BTUHnominal.

• Dualrefrigerationcoilswithtwo-wayairdistribution

reducesairvelocitiestominimizeproductdehydration.

• Reducedoperatingchargewith3/8”ODtubing

• Spaciousendcompartmentallowsforeasy

componentinstallation.

• Attractiveanddurablehigh-densitypolypropylene

fanguards.

• Hingeddrainpanprovidesconvenientaccessfor

cleaning.

Terminalboardallowsforeasyelectricalconnections.

•

• RefrigerantsR22,R404A,R507,R134a,R407C.

• Options:-Factorymountedsolenoidvalve,TXVand

Thermostat.

-Finmaterialandspecialcoatings.

-EnergyEfcientECMotors

-Otheroptionsavailable-consultfactory.

Nominal Capacity @ 10

100=15000BTUH

Ratedat20oFEvap.Temp.

Type of Defrost

AD = Airdefrost

ED = ElectricDefrost

HE = 3PipeDefrost,ElectricHeatedDrainPan

RE = ReverseCycleDefrost,ElectricHeatedDrainPan

TE= ThermosaverDefrost,ElectricHeatedDrainPan

Electrical Designation

S1 = 115/1/60

S2 = 208-230/1/60

Unit Series

B=SecondGeneration

o

F TD150x

CONTENTS PAGE

Nomenclature.................................... Cover

Capacity Data ................................... 2

Electrical Data .................................. 3

Dimensional Data.............................. 4

Installation Clearances..................... 5

Wiring Diagrams............................... 6 - 10

TXV/ Distributor Nozzle Selection..... 11

Defrost Control Positions.................... 12

Installation Instructions...................... 13 - 15

Service Parts List............................... 15

Service Log....................................... 18

Warranty............................................ 19

Project Information............................ 19

“As Built” Service Parts List............... Back

Page 2

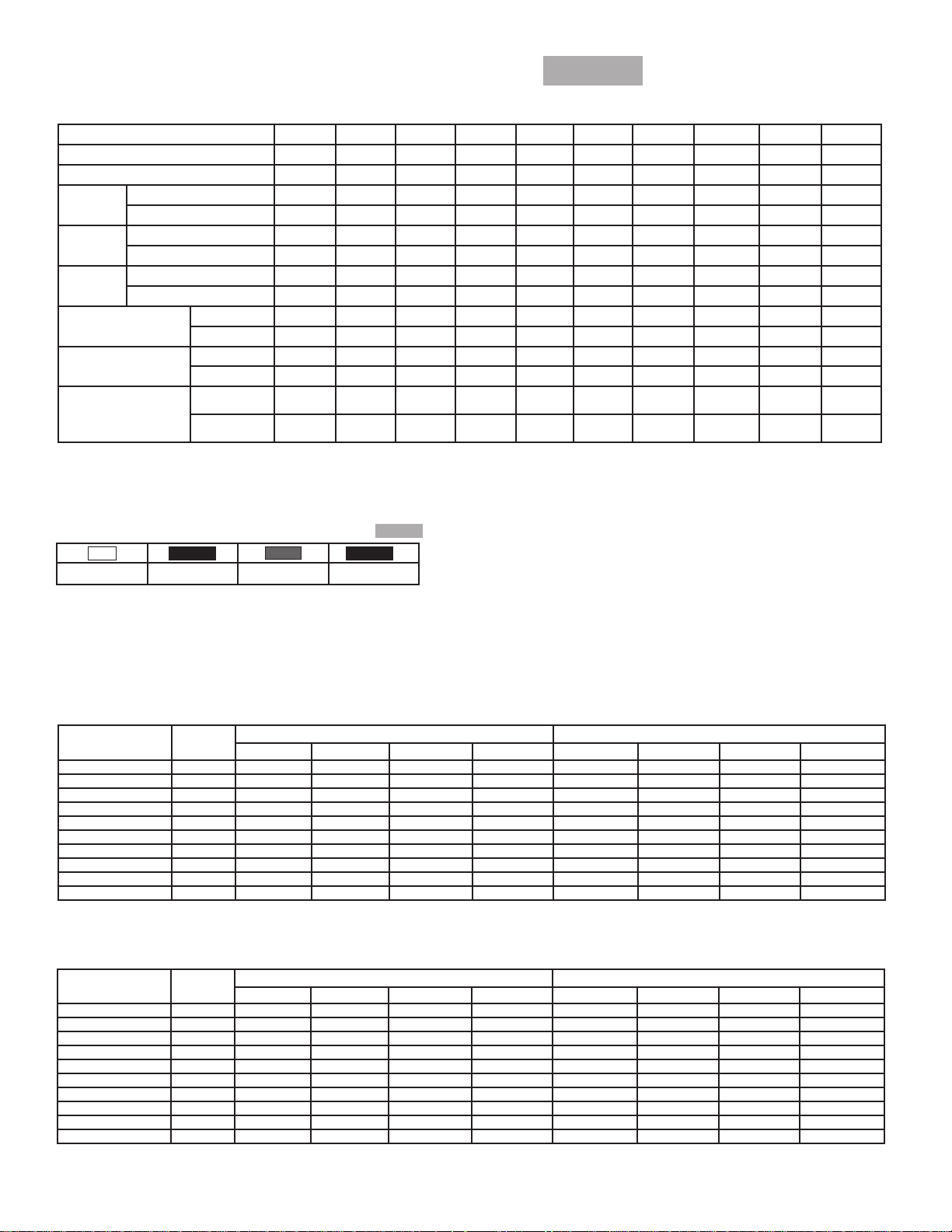

CAPACITY DATA -

K30-KLV-PDI-22

- 2 -

30/03/12

KLV

R404A

60Hz

ALL MODELS

High Temp. Model 060AD 090AD 120AD 150AD 180AD 220AD 270AD 300AD 340AD 370AD

Electric Defrost Model 060ED 090ED 120ED 150ED 180ED 220ED 270ED 300ED 340ED 370ED

Hot Gas Defrost Model

*Capacity

*Capacity

*Capacity

Air

Flow

Refrigerant

Charge **

Std. Unit Net

Weight

(w/o Refrigerant)

* Capacity rated with R404A @ +20°F(-6.6°C) S.S.T.

** R404A @ +20°F(-6.6°C) S.S.T. with coil 30 % full of liquid.

‡

Refer to Hot Gas Defrost nomenclature and insert appropriate code

NOTE: Defrost heaters can be eld converted to operate on 208-230/3/60

BTUH @ 1°F T.D. 600 900 1200 1500 1800 2200 2700 3000 3400 3700

(WATTS @ 0.55°C T.D.) (175.7) (263.5) (351.4) (439.2) (527.1) (644.2) (790.6) (878.4) (995.6) (1083.4)

BTUH @ 10°F T.D. 6000 9000 12000 15000 18000 22000 27000 30000 34000 37000

(WATTS @5.55°C T.D.) (1756.9) (2635.3) (3513.7) (4392.2) (5270.6) (6441.8) (7905.9) (8784.3) (9955.6) (10834)

BTUH @ 15°F T.D. 9000 13500 18000 22500 27000 33000 40500 45000 51000 55500

(WATTS @8.33°C T.D.) (2635.3) (3952.9) (5270.6) (6588.2) (7905.9) (9662.7) (11858.8) (13176.5) (14933.3) (16251)

CFM 850 1120 1500 2000 2530 2785 3400 4000 4370 4840

(L/S) (401) (529) (708) (944) (1194) (1314) (1605) (1888)

LB. 2.4 4.0 5.9 6.6 7.2 9.2 9.0 10.8 13.8 13.8

(KG) (1.2) (2.0) (3.0) (3.3) (3.6) (4.6) (4.5) (5.5) (7.0) (7.0)

LB. 90 105 139 158 220 235 257 270 280 290

(KG) (41) (48) (63) (72) (100) (107) (117) (123) (127) (132)

60

‡

90

‡

120

‡

150

‡

180

‡

220

‡

270

‡

300

‡

340

(2062) (2284)

‡

370

‡

R407C

R404A

Values Multiplied By:

*

Correction Factors for Other Refrigerants Use

R22

0.95 0.90 1.00 0.90

* When using R407C, the factor above is to be used when matching to condensing units with Dew Point ratings. This factor will ensure that proper

system balancing will occur to compensate for glide to t the application. If the system is sized correctly, one may expect a slight increase in system

capacity, along with slightly higher saturated suction temperatures.

R134a

R507

ELECTRICAL DATA

Air Defrost Models - 115/1/60

Model

KLV 060AD 1 1.1 1.4 90 15 0.8 1.0 55 15

KLV 090AD 1 1.1 1.4 130 15 1.6 2.0 95 15

KLV 120AD 2 2.2 2.5 180 15 1.6 1.8 110 15

KLV 150AD 2 2.2 2.5 260 15 3.2 3.6 190 15

KLV 180AD 3 3.3 3.6 270 15 2.4 2.6 165 15

KLV 220AD 3 3.3 3.6 390 15 4.8 5.2 285 15

KLV 270AD 3 3.3 3.6 390 15 4.8 5.2 285 15

KLV 300AD 4 4.4 4.7 520 15 6.4 6.8 380 15

KLV 340AD 4 4.4 4.7 520 15 6.4 6.8 380 15

KLV 370AD 5 5.5 5.8 650 15 8.0 8.4 475 15

FLA = Full Load Amps MCA = Minimum Circuit Ampacity MOP = Maximum Over Current Protection

* Electrical wiring is to be sized in accordance with minimum circuit ampacity

No. of

Fans

FLA MCA* Watts MOP FLA MCA* Watts MOP

Air Defrost Models - 208-230/1/60

Model

KLV 060AD 1 0.5 0.6 90 15 0.5 0.6 55 15

KLV 090AD 1 0.5 0.6 130 15 1.0 1.3 95 15

KLV 120AD 2 1.0 1.1 180 15 1.0 1.1 110 15

KLV 150AD 2 1.0 1.1 260 15 2.0 2.3 190 15

KLV 180AD 3 1.5 1.6 270 15 1.5 1.6 165 15

KLV 220AD 3 1.5 1.6 390 15 3.0 3.3 285 15

KLV 270AD 3 1.5 1.6 390 15 3.0 3.3 285 15

KLV 300AD 4 2.0 2.1 520 15 4.0 4.3 380 15

KLV 340AD 4 2.0 2.1 520 15 4.0 4.3 380 15

KLV 370AD 5 2.5 2.6 650 15 5.0 5.3 475 15

FLA = Full Load Amps MCA = Minimum Circuit Ampacity MOP = Maximum Over Current Protection

* Electrical wiring is to be sized in accordance with minimum circuit ampacity

No. of

Fans

FLA MCA* Watts MOP FLA MCA* Watts MOP

Standard PSC Motor Optional EC Motor

Standard PSC Motor Optional EC Motor

Page 3

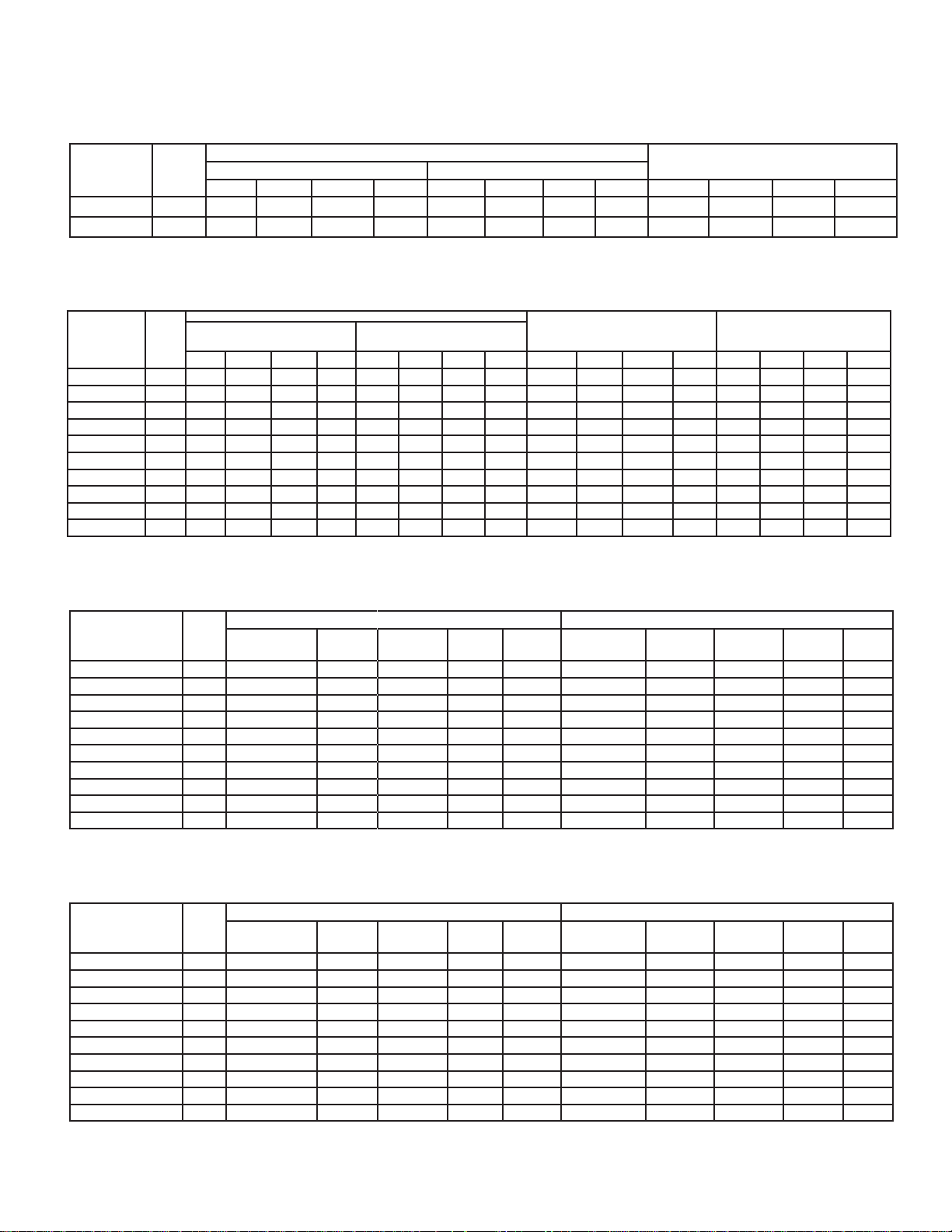

ELECTRICAL DATA

K30-KLV-PDI-22

- 3 -

30/03/12

KLV

Electric Defrost Models - 115/1/60

Model

KLV 060ED 1 1.1 1.4 90 15 0.8 1.0 55 15 1880 16.4 20.4 25

KLV 090ED 1 1.1 1.4 130 15 1.6 2.0 95 15 1880 16.4 20.4 25

FLA = Full Load Amps MCA = Minimum Circuit Ampacity MOP = Maximum Over Current Protection

* Electrical wiring is to be sized in accordance with minimum circuit ampacity

No. of

Fans

Standard PSC Motor Optional EC Motor

FLA MCA* Watts MOP FLA MCA* Watts MOP Watts FLA MCA* MOP

Fan Motors

Electric Defrost Models - 208-230/1/60

Fan Motors - 208-230/1/60

Model

KLV 060ED 1 0.5 0.6 90 15 0.5 0.6 55 15 1880 8.2 10.2 15 1880 4.9 6.1 15

KLV 090ED 1 0.5 0.6 130 15 1.0 1.3 95 15 1880 8.2 10.2 15 1880 4.9 6.1 15

KLV 120ED 2 1.0 1.1 180 15 1.0 1.1 110 15 3180 13.8 17.3 20 3180 8.5 10.6 15

KLV 150ED 2 1.0 1.1 260 15 2.0 2.3 190 15 3180 13.8 17.3 20 3180 8.5 10.6 15

KLV 180ED 3 1.5 1.6 270 15 1.5 1.6 165 15 4540 19.7 24.7 25 4540 12.1 15.1 20

KLV 220ED 3 1.5 1.6 390 15 3.0 3.3 285 15 4540 19.7 24.7 25 4540 12.1 15.1

KLV 270ED 3 1.5 1.6 390 15 3.0 3.3 285 15 4540 19.7 24.7 25 4540 12.1 15.1 20

KLV 300ED 4 2.0 2.1 520 15 4.0 4.3 380 15 4540 19.7 24.7 25 4540 12.1 15.1 20

KLV 340ED 4 2.0 2.1 520 15 4.0 4.3 380 15 5580 24.3 30.3 35 5580 14.9 18.6 20

KLV 370ED 5 2.5 2.6 650 15 5.0 5.3 475 15 5580 24.3 30.3 35 5580 14.9 18.6 20

FLA = Full Load Amps MCA = Minimum Circuit Ampacity MOP = Maximum Over Current Protection

* Electrical wiring is to be sized in accordance with minimum circuit ampacity

No. of

Fans

Standard PSC Motor Optional EC Motor

FLA MCA* Watts MOP FLA MCA* Watts MOP Watts FLA MCA* MOP Watts FLA MCA* MOP

Defrost Heaters -

208/230/1/60

Defrost Heaters

converted to operate on 208-

60Hz

Defrost Heaters eld

230/3/60

20

Hot Gas Defrost Models - 115/1/60

Model

KLV 060 HE/RE 1 580 5.0 1.1 6.3 15 580 5.0 0.8 6.6 15

KLV 090 HE/RE 1 580 5.0 1.1 6.3 15 580 5.0 1.6 6.6 15

KLV 120 HE/RE 2 580 5.0 2.2 6.3 15 580 5.0 1.6 6.6 15

KLV 150 HE/RE 2 580 5.0 2.2 6.3 15 580 5.0 3.2 6.6 15

KLV 180 HE/RE 3 820 7.1 3.3 8.9 15 820 7.1 2.4 9.4 15

KLV 220 HE/RE 3 820 7.1 3.3 8.9 15 820 7.1 4.8 9.4 15

KLV 270 HE/RE 3 820 7.1 3.3 8.9 15 820 7.1 4.8 9.4 15

KLV 300 HE/RE 4 820 7.1 4.4 8.9 15 820 7.1 6.4 9.4 15

KLV 340 HE/RE 4 1020 8.9 4.4 11.1 15 1020 8.9 6.4 11.6 15

KLV 370 HE/RE 5 1020 8.9 5.5 11.1 15 1020 8.9 8 11.6 15

FLA = Full Load Amps MCA = Minimum Circuit Ampacity MOP = Maximum Over Current Protection

* Electrical wiring is to be sized in accordance with minimum circuit ampacity

No. of

Fans

Drain Pan

Heater Watts

Standard PSC Motor Optional EC Motor

Heater

Amps

Fan Motor

FLA

MCA* MOP

Drain Pan

Heater Watts

Heater

Amps

Fan Motor

FLA

MCA* MOP

Hot Gas Defrost Models - 208-230/1/60

Model

KLV 060 HE/RE 1 580 2.5 0.5 3.2 15 580 2.5 0.5 2.9 15

KLV 090 HE/RE 1 580 2.5 0.5 3.2 15 580 2.5 1.0 2.9 15

KLV 120 HE/RE 2 580 2.5 1.0 3.2 15 580 2.5 1.0 2.9 15

KLV 150 HE/RE 2 580 2.5 1.0 3.2 15 580 2.5 2.0 2.9 15

KLV 180 HE/RE 3 820 3.6 1.5 4.5 15 820 3.6 1.5 4.1 15

KLV 220 HE/RE 3 820 3.6 1.5 4.5 15 820 3.6 3.0 4.1 15

KLV 270 HE/RE 3 820 3.6 1.5 4.5 15 820 3.6 3.0 4.1 15

KLV 300 HE/RE 4 820 3.6 2.0 4.5 15 820 3.6 4.0 4.1 15

KLV 340 HE/RE 4 1020 4.4 2.0 5.5 15 1020 4.4 4.0 5.1 15

KLV 370 HE/RE 5 1020 4.4 2.5 5.5 15 1020 4.4 5.0 5.1 15

FLA = Full Load Amps MCA = Minimum Circuit Ampacity MOP = Maximum Over Current Protection

* Electrical wiring is to be sized in accordance with minimum circuit ampacity

No. of

Fans

Drain Pan

Heater Watts

Standard PSC Motor Optional EC Motor

Heater

Amps

Fan Motor

FLA

MCA* MOP

Drain Pan

Heater Watts

Heater

Amps

Fan Motor

FLA

MCA* MOP

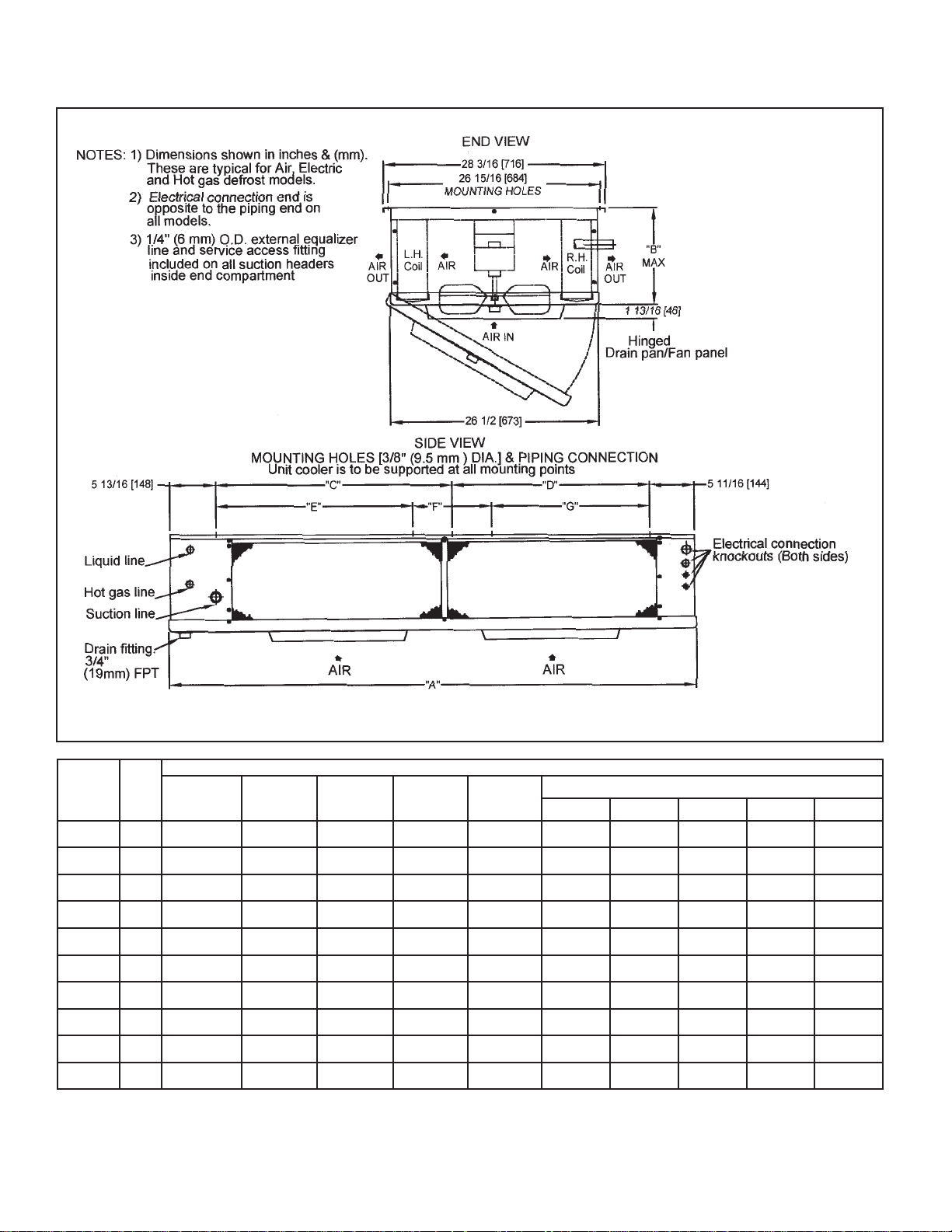

Page 4

KLV

K30-KLV-PDI-22

- 4 -

30/03/12

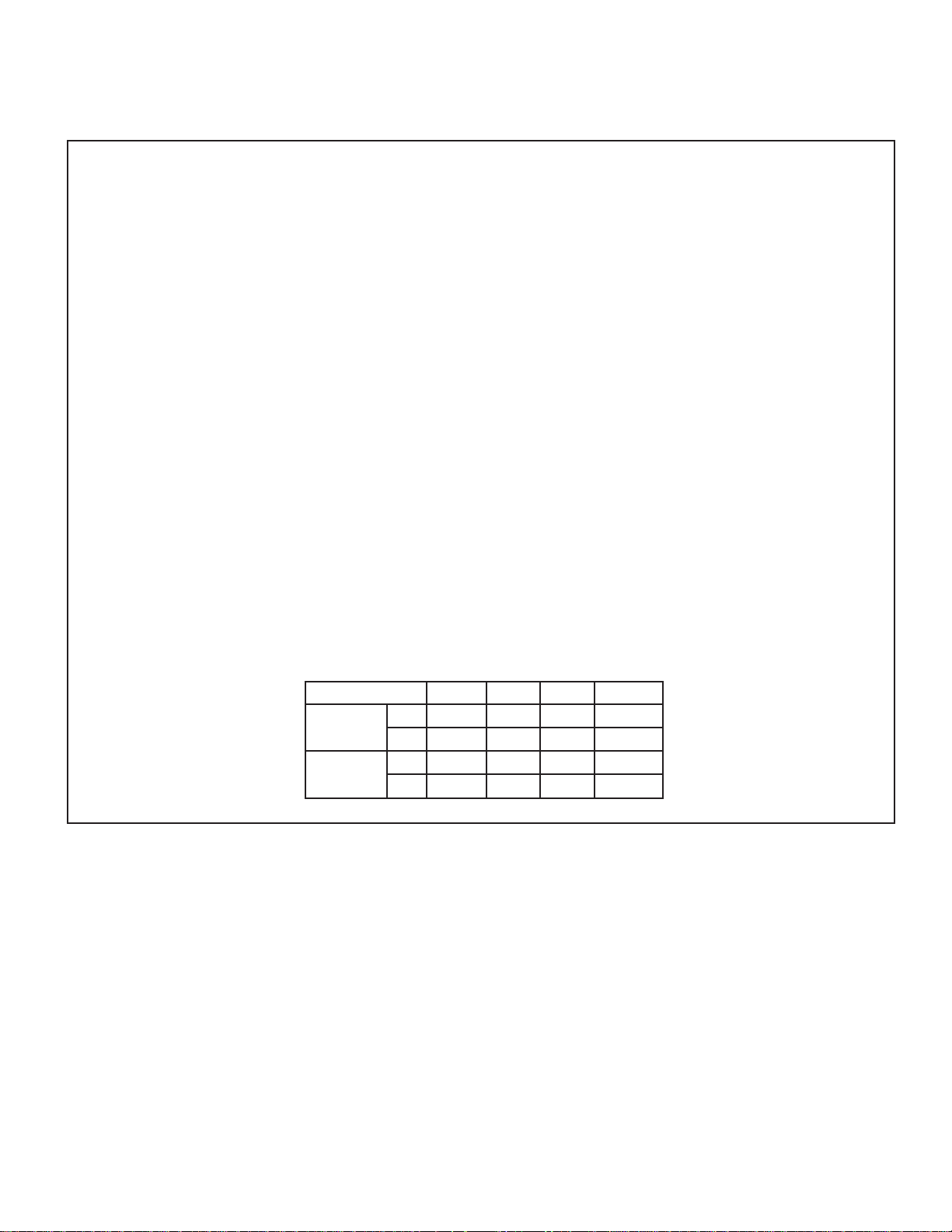

DIMENSIONAL DATA - Inches (mm)

60Hz

MODEL

* Reducer supplied to accomodate 1/2” or 7/8” TXV outlet connection.

No. of

Fans

060 1 5/8 (16) 1/2 (13) 1/2 (13)

090 1 7/8 (22) 1/2 (13) 1/2 (13)

120 2 7/8 (22) 1/2 (13) 1/2 (13)

150 2 1 1/8 (29) 1/2 (13) 1/2 (13)

180 3 1 1/8 (29) 1/2 (13) 1/2 (13)

220 3 1 1/8 (29) 1/2 (13) 1/2 (13)

270 3 1 1/8 (29) * 7/8 (22) 5/8 (16)

300 4 1 1/8 (29) * 7/8 (22) 5/8 (16)

340 4 1 3/8 (35) * 7/8 (22) 5/8 (16)

370 5 1 3/8 (35) * 7/8 (22) 5/8 (16)

Suction

Connection

(OD)

Distributor

Inlet

(OD)

Hot Gas

Side Conn.

(OD)

DIMENSIONAL DATA - INCHES (mm)

A B

66 7/8

(1699)

66 7/8

(1699)

66 7/8

(1699)

66 7/8

(1699)

92 7/8

(2359)

92 7/8

(2359)

92 7/8

(2359)

92 7/8

(2359)

112 7/8

(2867)

112 7/8

(2867)

8 11/16

(221)

9 9/16

(252)

12 7/16

(316)

14 15/16

(378)

14 15/16

(378)

14 15/16

(378)

17 7/16

(443)

17 7/16

(443)

17 7/16

(443)

17 7/16

(443)

Mounting Holes

C D E F G

27 1/2

(699)

27 1/2

(699)

27 1/2

(699)

27 1/2

(699)

40 1/2

(1029)

40 1/2

(1029)

40 1/2

(1029)

40 1/2

(1029)

- -

- -

27 1/2

(699)

27 1/2

(699)

27 1/2

(699)

27 1/2

(699)

40 1/2

(1029)

40 1/2

(1029)

40 1/2

(1029)

40 1/2

(1029)

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

40 1/2

(1029)

40 1/2

(1029)

20

(508)

20

(508)

40 1/2

(1029)

40 1/2

(1029)

Page 5

KLV

K30-KLV-PDI-22

- 5 -

30/03/12

RECOMMENDED

60Hz

INSTALLATION CLEARANCES

DIMENSION A B C D

Minimum

Maximum

ft. 2 2 6 3

(cm.) (61) (61) (183) (92)

ft. - 7 40 20

(cm.) - (210) (1200) (600)

Page 6

KLV

K30-KLV-PDI-22

- 6 -

30/03/12

WIRING DIAGRAM

60Hz

Air Defrost - All Voltages

AIR DEFROST

TYPICAL WIRING:

WITH DEFROST TIME CLOCK

DEFROST CLOCK

PARAGON # 8145

OR EQUIVALENT

TM

3

1 2

4 X

PUMP DOWN

N

SWITCH

(IF USED)

NAMEPLATE FOR ELECTRICAL

SPACE

THERMOSTAT

NOTE #4

FOR MULTIPLE EVAPORATORS AND OTHER

ALTERNATIVE WIRING, SEE INSTALLATION MANUAL

REFER TO EVAPORATOR

REQUIREMENTS

L2(N)

L1

GND

FUSE OR

CIRCUIT

BREAKER

NOTE #3

SOLENOID VALVE

OMIT

FUSE

IF (N)

LIQUID LINE

NOTE #4

WITHOUT DEFROST TIME CLOCK

REFER TO EVAPORATOR

NAMEPLATE FOR ELECTRICAL

REQUIREMENTS

L2(N)

L1

GND

FUSE OR

CIRCUIT

BREAKER

NOTE #3

OMIT

FUSE

IF (N)

SPACE

THERMOSTAT

NOTE #4

LIQUID LINE

SOLENOID VALVE

NOTE #4

4

F

TERMINAL BOARD

GND.

RIBBED

FAN

MTR

PLAIN

FAN

MTR

FAN

MTR

FAN

MTR

NOTES

1). USE COPPER CONDUCTORS ONLY

2). USE 75°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

EVAPORATOR FAN MOTORS AND DEFROST

HEATERS MUST NOT EXCEED MAXIMUM

VALUE SHOWN ON EVAPORATOR NAMEPLATE.

4). MAY BE FACTORY INSTALLED-MOUNTED

AND WIRED ON EVAPORATOR

(PRE-ASSEMBLED MODELS)

EVAPORATOR

FAN MOTOR

POWER PLUGS

REFER TO EVAPORATOR

FAN

DATA PLATE FOR

MTR

MOTOR QUANTITY

4

F

TERMINAL BOARD

GND.

TERMINALS

DH -DRAIN PAN HEATER

-COMP0NENT TERMINAL - MARKED

-COMPONENT TERMINAL - UNMARKED

( IDENTIFIABLE BY LOCATION )

-COMPONENT TERMINAL - UNMARKED

( UNIDENTIFIABLE )

-TERMINAL BLOCK TERMINAL

-WIRE SPLICE

CONDUCTORS/WIRING

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

PLAIN

RIBBED

FAN

FAN

MTR

FACTORY WIRING

WIRING BY OTHERS

OPTIONAL FACTORY OR

BY OTHERS

FAN FAN

MTR

MTR

FAN

MTR

EVAPORATOR

FAN MOTOR

POWER PLUGS

REFER TO EVAPORATOR

DATA PLATE FOR

MTR

MOTOR QUANTITY

REV A

11/05/01

1073979

Page 7

KLV

K30-KLV-PDI-22

- 7 -

30/03/12

DEFROST CLOCK

PARAGON # 8145

OR EQUIVALENT

3

1 2

TERMINAL

BOARD

GND.

WIRING DIAGRAM

Electric Defrost - Single Evaporator

ELECTRIC DEFROST

EVAPORATOR WITH DEFROST HEATER CONTACTOR

TYPICAL WIRING:

TM

4NX

4

RIBBED

FAN

MTR

F

PLAIN

PUMP DOWN

(IF USED)

X

RD

DEFROST TERMINATION

(CLOSES AT 55°F)

(OPENS AT 35°F)

FAN

MTR

FUSE OR

CIRCUIT

BREAKER

NOTE #3

COMPR CONTACTOR

AUXILLARY

(DEFR. HTR. LOCKOUT)

SWITCH

OR JUMPER

FAN

MTR

SPACE

THERMOSTAT

NOTE #4

ORANGE

3

JUMPER

RD

FAN

MTR

FOR MULTIPLE EVAPORATORS AND OTHER

ALTERNATIVE WIRING, SEE INSTALLATION MANUAL

REFER TO EVAPORATOR

NAMEPLATE FOR ELECTRICAL

L3

L3

T3

N

RD

NOTE #6

DEFROST

HEATER

CONTACTOR

TO H3

GND

FUSE OR

CIRCUIT

BREAKER

NOTE #3

LIQUID LINE

SOLENOID VALVE

NOTE #4

"Y"

H1

BK

R.H. COIL

BOTTOM

BK

BK

L.H. COIL

BOTTOM

BK

R.H.COIL

TOP

BK

FAN MOTOR

POWER PLUGS

REFER TO EVAPORATOR

DATA PLATE FOR

FAN

MOTOR QUANTITY

MTR

C

H2

L.H.

DRAIN PAN

YL

DRAIN PAN

BK

YL

L.H.COIL

TOP

BK

EVAPORATOR

L1

ORANGE

JUMPER

YL

R.H.

L2

L2

L1

T2

T1

H3

YL

BK

FOR THREE PHASE

NOTE #6

H1

DRAIN PAN

YL

BK

BK

H2

YL

L.H.

DRAIN PAN

YL

L.H.COIL

TOP

BK

NOTE #5

R.H.

BK

R.H. COIL

BOTTOM

BK

L.H. COIL

BOTTOM

BK

R.H.COIL

TOP

HEATER LOADS MUST NOT

EXEED CONTACT RATING.

FOR THREE PHASE HEATER

OPERATION (FIELD CONVERSION)

A. REMOVE ORANGE JUMPER

BETWEEN TERMINALS

H3

AND

H2

B. RECONNECT L.H. BOTTOM

HEATER WIRE (SHOWN AS "Y")

H1

FROM

TO

60Hz

"Y"

H3H2

BK

YL

BK

NOTES

1). USE COPPER CONDUCTORS ONLY

2). USE 75°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

EVAPORATOR FAN MOTORS AND DEFROST

HEATERS MUST NOT EXCEED MAXIMUM

VALUE SHOWN ON EVAPORATOR NAMEPLATE.

4). MAY BE FACTORY INSTALLED-MOUNTED

AND WIRED ON EVAPORATOR

(PRE-ASSEMBLED MODELS)

ON MULTIPLE PRE-ASSEMBLED EVAPORATORS

WIRE SECOND EVAPORATOR SOLENOID IN

PARALLEL WITH FIRST ONE. ONLY USE ONE

THERMOSTAT.

5). THESE HEATERS NOT USED ON _LV060ED

AND _LV090ED MODELS

TERMINALS

-COMP0NENT TERMINAL - MARKED

-COMPONENT TERMINAL - UNMARKED

( IDENTIFIABLE BY LOCATION )

-COMPONENT TERMINAL - UNMARKED

( UNIDENTIFIABLE )

-TERMINAL BLOCK TERMINAL

-WIRE SPLICE

CONDUCTORS/WIRING

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

FACTORY WIRING

WIRING BY OTHERS

OPTIONAL FACTORY

OR BY OTHERS

REV B

11/05/01

1073978

Page 8

KLV

K30-KLV-PDI-22

- 8 -

30/03/12

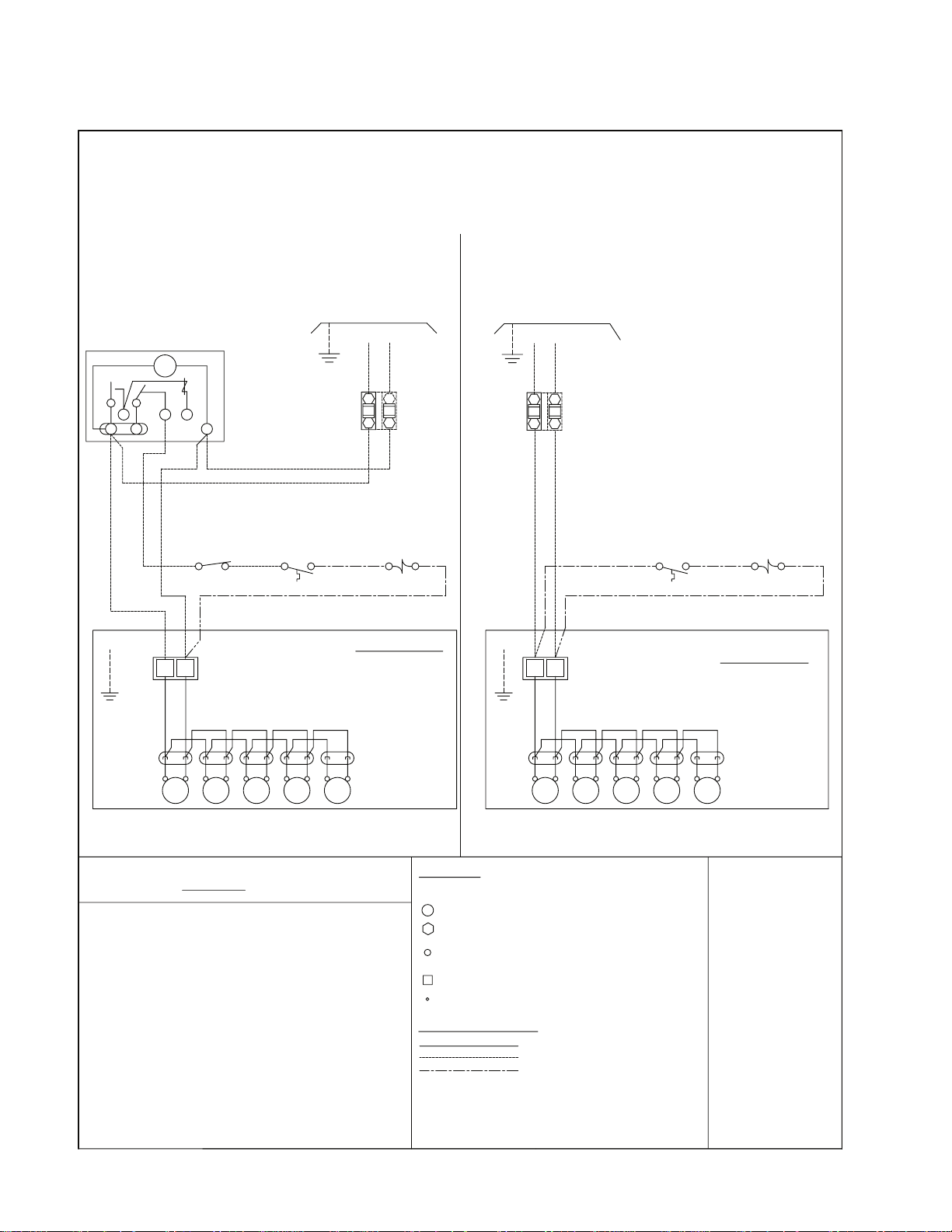

WIRING DIAGRAM

Electric Defrost - Multiple Evaporators

FOR ALL MODELS USING DEFROST HEATER CONTACTOR

60Hz

Page 9

KLV

K30-KLV-PDI-22

- 9 -

30/03/12

WIRING DIAGRAM

Electric Defrost - (For optional use on models 060ED

and 090ED operating on 208-230/1/60)

ELECTRIC DEFROST

EVAPORATOR WITHOUT DEFROST HEATER CONTACTOR

USING MAX 15A HEATER OVERCURRENT PROTECTION

TYPICAL WIRING:

FOR MULTIPLE EVAPORATORS AND OTHER

ALTERNATIVE WIRING, SEE INSTALLATION MANUAL

60Hz

DEFROST CLOCK

PARAGON # 8145

OR EQUIVALENT

TM

4

231

4

F

GND.

PLAIN

RIBBED

X

N

PUMP DOWN

SWITCH

(IF USED)

X

RD

DEFROST TERMINATION

(CLOSES AT 55°F)

(OPENS AT 35°F)

RD

NAMEPLATE FOR ELECTRICAL

SPACE

THERMOSTAT

NOTE #4

ORANGE JUMPER

ORANGE

JUMPER

H1

3

REFER TO EVAPORATOR

REQUIREMENTS

L2(N)

L1

GND

FUSE OR

CIRCUIT

BREAKER

NOTE #3

LIQUID LINE

SOLENOID VALVE

NOTE #4

H2

R.H.

COIL

BK

BK

BK

L.H.

COIL

YL

BK

OR

JMPR

DRAIN

YL

L.H.

PAN

R.H.

DRAIN

PAN

MAX 15A

OR

H3

N

JMPR

YL

YL

NOTES

1). USE COPPER CONDUCTORS ONLY

2). USE 75°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

EVAPORATOR FAN MOTORS AND DEFROST

HEATERS MUST NOT EXCEED MAXIMUM

VALUE SHOWN ON EVAPORATOR NAMEPLATE.

4). MAY BE FACTORY INSTALLED-MOUNTED

AND WIRED ON EVAPORATOR

(PRE-ASSEMBLED MODELS)

ON MULTIPLE PRE-ASSEMBLED EVAPORATORS

WIRE SECOND EVAPORATOR SOLENOID IN

PARALLEL WITH FIRST ONE. ONLY USE ONE

THERMOSTAT.

FAN

MTR

MTR MTR

FANFAN

MTR

RD

FAN MOTOR

POWER PLUGS

REFER TO EVAPORATOR

DATA PLATE FOR

FAN

FAN

MTR

MOTOR QUANTITY

EVAPORATOR

TERMINALS

-COMP0NENT TERMINAL - MARKED

-COMPONENT TERMINAL - UNMARKED

( IDENTIFIABLE BY LOCATION )

-COMPONENT TERMINAL - UNMARKED

( UNIDENTIFIABLE )

-TERMINAL BLOCK TERMINAL

-WIRE SPLICE

CONDUCTORS/WIRING

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

FACTORY WIRING

WIRING BY OTHERS

OPTIONAL FACTORY

OR BY OTHERS

1074180

REV-A

Page 10

KLV

K30-KLV-PDI-22

- 10 -

30/03/12

WIRING DIAGRAM

60Hz

Hot Gas Defrost - All Voltages

REVERSE CYCLE AND 3-PIPE HOT GAS DEFROST

Page 11

KLV

K30-KLV-PDI-22

- 11 -

30/03/12

THERMOSTATIC EXPANSION VALVE

60Hz

SELECTION - SPORLAN

MODEL NO. TD °F TD (°C)

060

090

120

180

270

340

370

SELECTIONS BASED ON 100°F(37.7°C) LIQUID

10 (5.6)

15 (8.3)

10 (5.6)

15 (8.3)

10 (5.6)

15 (8.3)

10 (5.6)

15 (8.3)

10 (5.6)

15 (8.3)

10 (5.6)

15 (8.3)

10 (5.6)

15 (8.3)

10 (5.6)

15 (8.3)

10 (5.6)

15 (8.3)

10 (5.6)

15 (8.3)

R22

EGVE-3/4-C EGSE-1/2-C

EGVE-1-C EGSE-1-C EGPE-1-C

EGVE-1 1/2-C EGSE-1 1/2-C EGPE-1 1/2-C150

EGVE-2-C

EGVE-3-C

SVE-4-C SSE-4-C SPE-4-C

R404A R507

EGPE-1/2-C

EGPE-1-C

EGSE-2-C EGPE-2-C220

SSE-3-C SPE-3-C300

DISTRIBUTOR NOZZLE SELECTION

STANDARD NOZZLES FACTORY INSTALLED FOR ALL MODELS

T.D. 8 °F TO 12 °F (4.4 °C to 6.6 °C)

EVAP. TEMP. RANGE 18 °F TO 40 °F (-7.7 °C TO 4.4 °C)

REFRIGERANT R22, R-404A, R507, R407C

060 L-3/4

090 L- 1

120, 150 L-1 1/2

180 L- 2

220 L-2 1/2

270 G- 2 1/2

300 G- 3

340, 370 G-4

SELECTIONS BASED ON 100 °F(37.7 °C) LIQUID

Page 12

KLV

K30-KLV-PDI-22

- 12 -

30/03/12

DEFROST CONTROL POSITIONS

60Hz

FAN/HEATER CONTROL

AND DEFROST TERMINATION CONTROL POSITION

HOT GAS DEFROST (REVERSE CYCLE)

HOT GAS DEFROST (3-PIPE OR BYPASS)

Page 13

KLV

K30-KLV-PDI-22

- 13 -

30/03/12

INSTALLATION INSTRUCTIONS

60Hz

INSTALLATION

The installation and start-up of LV Evaporators should only be

performed by qualied refrigeration mechanics.

This equipment should be installed in accordance with all applicable codes, ordinances and local by-laws.

INSPECTION

Inspect all equipment before unpacking for visible signs of

damage or loss. Check shipping list against material received to

ensure shipment is complete.

IMPORTANT: Remember, you, the consignee, must make any

claim necessary against the transportation company. Shipping

damage or missing parts, when discovered at the outset, will

prevent later unnecessary and costly delays.

If damage or loss during transport is evident, make claim to

carrier, as this will be their responsibility, not the

manufacturer’s.

Should carton be damaged, but damage to equipment is not

obvious, a claim should be led for “concealed damage” with the

carrier.

IMPORTANT: The electrical characteristics of the unit should

be checked at this time to make sure they correspond to those

ordered and to electrical power available at the job site.

LOCATION

The unit location in the room should be selected to ensure

uniform air distribution throughout the entire space to be

refrigerated. Be sure that the unit does not draw air in, or

blow directly out, through an opened door and that the

product does not obstruct the free circulation of air. Allow a

minimum of 24” clearance at each end. LV Evaporators draw

air through the fans and discharge air through both coils.

Consideration should be given to the coil location in order

to minimize the piping run length to the condensing unit and

oor drain.

EXPANSION VALVE (TXV) SELECTION

All units require the use of an externally equalized

expansion valve. (A 1/4” (6 mm) O.D. equalizer line has been

provided on the coil) TX valves should not be selected strictly

by their nominal ton rating. (This rating is based at a specic

pressure differential and entering liquid

temperature). Since applications will differ it is suggested the

following selection procedure be followed.

1. Determine actual unit cooler BTUH or KW (thermal).

The nominal rating is based at 10 °F T.D. (5 .5°C)

(Room Temp. minus Evap. Temp.). Note that a higher /

lower operating T.D.will increase / decrease this capacity

rating by their direct ratio.

Save all shipping papers, tags and instruction sheets for

reference by installer and owner.

APPLICATION

LV Unit Coolers are designed for use with R22, R404A, R134a,

R407C or R507 refrigerants. At room temperatures above 34°F

(1.1 C) (and evaporating temps no lower than 24 °F (-4.4°C))

positive coil defrosting (Electric or Hot Gas) is not required. (The

air owing through the coil will accomplish the defrost). At room

temperatures of 34°F (1.1°C) and below, positive defrosting is

required (either Electric (ED) or Hot Gas (HE, RE, TE) in model

nomenclature). These models require the use of (1) Time Clock

or equivalent (to initiate and terminate the defrost cycle), and (2)

Defrost Termination Control (to prevent unnecessary prolonged

heating and steaming of the coil once all the ice and frost has

melted), (3) Hot Gas models also utilize a Fan/Heater drain pan

control.

The coil must not be exposed to any abnormal atmospheric or

acidic environments. This may result in corrosion to the cabinet

and possible coil failure (leaks). (Consult manufacturer for

optional baked on phenolic protective coatings).

2. Determine the pressure drop across the valve by

subtracting the suction (evaporating) pressure from the

high side liquid pressure. Note: Also subtract the

distributor pressure loss (use approx. 25 psig (1.1 bar)

for R134a and 35 psig (2.4 bar) for R22, R404A, R507).

3. Estimate entering liquid temperature. Temperatures

lower than 100 °F (37.7 °C) increase valve capacity

ratings. Refer to valve manufacturer’s specs for details.

4. Select valve from the valve manufacturer selection charts

for the appropriate refrigerant, evaporating temp and

pressure drop.

5. After following the manufacturer’s installation instructions

and after the room has reached the desired temperature

the valve superheat should be checked. This will conrm

that the evaporator is operating properly and performing

to maximum efciency. The superheat should be around

5 (2.7°C) to 8 °F (4.4°C) for a 10 to 12 °F (5.5 to 6.6°C)

T.D. Too high or low a super heat will result in

unsatisfactory system performance and possible

compressor problems.

NOZZLE INSTALLATION

All LV Evaporators have nozzles installed at factory. For nozzle selection refer to selection table. In case it is

required to install the nozzle at some point in the future, the

nozzle retainer clip (in distributor) must be removed before

inserting nozzle. Re-install clip ensuring nozzle is properly in

place.

Page 14

KLV

K30-KLV-PDI-22

- 14 -

30/03/12

INSTALLATION INSTRUCTIONS (cont’d)

60Hz

MOUNTING

Refer to dimensional drawing for recommended mounting arrangements. Formed mounting channels are provided for ush

mounting to the ceiling. Ensure adequate clearance (at least

24” (600 mm)) is provided at each end (to enable access to the

electrical and refrig. compartments).

Ensure that the ceiling is level since the drain pan has

been sloped for drainage during the defrost cycle.

DRAIN LINE

The drain line should be run from the drain connection, sloping

at least 1/4” (6 mm) per foot. A trap in a warm area outside the

room will allow proper draining through the tubing. Connection

should be made to proper drainage facilities that comply with

local regulations.

To prevent freeze-up when the temperature of the refrigerated

space is 35

along its run inside the cold room. The heated drain line should

be insulated. It is recommended that the heater be energized

at all times. A heat input of 20 watts per foot in a 28°F (-2.2°C)

room, is satisfactory. Drain line heaters are not required for

constant room temperature above 35°F (1.6°C).

Ensure that the drain line has sufcient slope for proper

drainage (prevention of ice build up/blockage in pan).

o

F (1.7 °C) or lower, the drain line should be heated

PIPING

Refrigerant line sizes are important and may not be the same

size as the coil connections. Consult “Recommended refrigerant line sizes” charts in any standard reference book for proper

line sizing.

Refrigerant piping and control system should be designed to

prevent possible liquid slugging (from oil or refrigerant) of the

compressors on start-up after the defrost cycle. On Hot Gas

Defrost Systems the suction accumulator should be at least 2.5

times the coils operating charge.

See Dimensional data for line locations. For Reverse Cycle

and Hot Gas models and 3-Pipe - see g. 2 & 3 respectively on

page 12 for typical unit piping. These models include a check

valve (unmounted) packaged along with the nozzle in the

refrig. connection compartment end panel.

WIRING

Wire system in accordance with governing standards and local

codes. See data and wiring diagrams on pages 6 to 10 for wiring arrangement. Electrical wiring is to be sized in accordance

with minimum circuit ampacity rating (MCA).

For ease of identifying the proper wiring terminal, unit wiring is

color coded and terminal block connections are identied.

SYSTEM CHECK

Before Start-Up:

1. All wiring should be in accordance with local codes.

2. Refrigerant lines should be properly sized.

3. Off cycle defrost and electric defrost systems preferably

must include a liqud line solenoid valve and suction

accumulator.

4. Thorough evacuation and, dehydration has been

performed.

5. The suction, discharge, and receiver service valves must

be open.

6. The system preferably must include a liquid line drier

moisture indicator and suction lter.

7. Pour enough water into the drain pan to allow a good check

on drainage and seal the trap.

After Start-Up:

1. Check the oil level to be sure the oil charge is correct.

2. On initial start up the fans do not start until coil temperature

is pulled down to approximately 35 °F (1.7 °C) on the hot

gas coil. Also, it is normal for the fans to cycle a few times

until the room temperature is pulled down.

3. Fan/Heater control and defrost termination control is

factory installed for reverse cycle defrost operation. Refer

to Fig. 1 on page 12.

4. If coil is to be used for 3-pipe (bypass) Hot Gas Defrost,

Fan/Heater must be moved from suction line to hot gas

inlet line and the defrost termination control moved to the

suction line. Refer to Fig. 1 on page 12.

5. In general, evaporators running with a TD of 10 °F should

have a superheat reading of 5° to 8 °F (2.7 °C to 4.4 °C).

For evaporators with a higher TD, the superheat should be

8° to 12°F (4.4 °C to 6.6 °C).

6. Heavy moisture loads are usually encountered when

starting the system for the rst time. This will cause a rapid

build-up of frost on the unit cooler. During the initial pull

down, we suggest that the frost build-up be watched and

defrosted manually as required. This may be done by

rotating the inner dial on the timer until the pin in the outer

dial is directly opposite the timer pointer. (Paragon 8145-

20 Timer by others).

7. Observe that the system goes through at least one

complete DEFROST CYCLE.

MAINTENANCE

The unit should be periodically inspected for any dirt or

build-up on the n surface and cleaned if necessary with a soft

whisk or brush. Also ensure coils inner and outer drain pans

do not have any ice build-up from improper defrost operation.

When replacing heater elements rst remove heater retainer

brackets and heater clips.

Page 15

SERVICE PARTS LIST

K30-KLV-PDI-22

- 15 -

30/03/12

KLV

Motors Models Part Number

100V-115V PSC, 1/15HP All 1073403

200V-230V PSC,1/15HP All 1073405

100V-115V ECM 060, 120, 180 1086913

100V-115V ECM 090, 150, 220, 270, 300, 340, 370 1086912

200V-230V ECM 060, 120, 180 1086915

200V-230V ECM 090, 150, 220, 270, 300, 340, 370 1086914

Heaters

Coil Face Heater, 115V, 650W 060, 090, 120, 150 1070854-003

Coil Face Heater, 115V, 930W 180, 220, 270, 300 1070854-002

Coil Face Heater, 115V, 1140W 340, 370 1070854-001

Drain Pan Heater, 115V, 290W 060, 090, 120, 150 1070854-006

Drain Pan Heater, 115V, 410W 180, 220, 270, 300 1070854-005

Drain Pan Heater, 115V, 510W 340, 370 1070854-004

Fan Blades

14” 35° 5 Blades 090, 270, 340 1073414

14” 32° 5 Blades 150, 220, 300, 370 1073415

14” 22° 5 Blades 060, 120, 180 1073416

Fan/Heater Control Hot Gas Defrost Models (RE & HE) 1073640

Defrost Termination All 1071280

Fan Guard All 1073456

60Hz

Page 16

KLV

K30-KLV-PDI-22

- 16 -

30/03/12

NOTES

60Hz

Page 17

KLV

K30-KLV-PDI-22

- 17 -

30/03/12

NOTES

60Hz

Page 18

KLV

K30-KLV-PDI-22

- 18 -

30/03/12

DATE COMMENTS

SERVICE LOG

60Hz

Page 19

FINISHED GOODS WARRANTY

K30-KLV-PDI-22

- 19 -

30/03/12

The terms and conditions as described below in the General Warranty Policy cover all products

manufactured by National Refrigeration.

GENERAL WARRANTY POLICY

Subject to the terms and conditions hereof, the Company warrants all Products, including Service

Parts, manufactured by the Company to be free of defects in material or workmanship, under normal use and application for a period of one (1) year from the original date of installation, or eighteen

(18) months from the date of shipment from the Company, whichever occurs rst. Any replacement

part(s) so supplied will be warranted for the balance of the product’s original warranty. The part(s) to

be replaced must be made available in exchange for the replacement part(s) and reasonable proof

of the original installation date of the product must be presented in order to establish the effective

date of the warranty, failing which, the effective date will be based upon the date of manufacture plus

thirty (30) days. Any labour, material, refrigerant, transportation, freight or other charges incurred in

connection with the performance of this warranty will be the responsibility of the owner at the current rates and prices then in effect. This warranty may be transferred to a subsequent owner of the

product.

THIS WARRANTY DOES NOT COVER

(a) Damages caused by accident, abuse, negligence, misuse, riot, re, ood, or Acts of God (b) damages

caused by operating the product in a corrosive atmosphere (c) damages caused by any unauthorized

alteration or repair of the system affecting the product’s reliability or performance (d) damages caused

by improper matching or application of the product or the product’s components (e) damages caused by

failing to provide routine and proper maintenance or service to the product (f) expenses incurred for the

erecting, disconnecting, or dismantling the product (g) parts used in connection with normal maintenance,

such as lters or belts (h) products no longer at the site of the original installation (i) products installed

or operated other than in accordance with the printed instructions, with the local installation or building

codes and with good trade practices (j) products lost or stolen.

No one is authorized to change this WARRANTY or to create for or on behalf of the Company any

other obligation or liability in connection with the Product(s). There is no other representation, warranty

or condition in any respect, expressed or implied, made by or binding upon the Company other than

the above or as provided by provincial or state law and which cannot be limited or excluded by such

law, nor will we be liable in any way for incidental, consequential, or special damages however caused.

The provisions of this additional written warranty are in addition to and not a modication of or subtraction

from the statutory warranties and other rights and remedies provided by Federal, Provincial or State laws.

PROJECT INFORMATION

Sy stem

Mo del N umber Date of S tart- Up

Se rial Numbe r Servi ce Co ntrac tor

Re frige rant Pho ne

El ectri cal S upply Fa x

Page 20

“AS BUILT” SERVICE PARTS LIST

30/03/12

Service Parts List

Label

To Be Attached

HERE

NATIONAL REFRIGERATION &

AIR CONDITIONING CANADA CORP.

CANADA

159 ROY BLVD., BRANTFORD, ONTARIO, CANADA N3R 7K1

PHONE: 1-800-463-9517 (519)751-0444 FAX (519)753-1140

Due to National Refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice.

USA

985 WHEELER WAY, LANGHORNE, PA. 19047 USA

PHONE: 1-888-KEEPUS1 OR 1-888-533-7871

Loading...

Loading...