Page 1

PRODUCT DATA &

INSTALLATION

Bulletin K30-KLP-PDI-50-6

1087150-50

We are on the Internet

www.keepriterefrigeration.com

KLP

Low Profile

Unit Cooler

Air, Electric, Hot Gas

& Warm Fluid Defrost

Electrical Power:

200-220/1/50, 200-220/3/50, 380-400/1/50

CONTENTS

Page

Nomenclature........................................................................................................................ 2

Features & Options..............................................................................................................2

Capacity Data - S tandard Models (PSC Motors)............................................................. 3

Capacity Data - Models with Optional EC Motors ............................................................ 4

Electrical Data...................................................................................................................... 5 - 10

Wiring Diagrams.................................................................................................................. 11 - 20

Dimensional Data................................................................................................................21

Shipping Weights................................................................................................................22

Recommended Thermostatic Expansion Valve Selections............................................ 23 - 25

Installation Instructions........................................................................................................ . 26 - 28

Hot Gas Piping Schematics................................................................................................. 29 - 30

Glycol Fluid Cooler Data.................................................................................................... 31

Generic Service Parts List.................................................................................................... 32 - 33

Warranty....................................................................................................................... ............ 35

Project Information................................................................................................................ 35

“As Built” Service Parts List................................................................................................. 36

Page 2

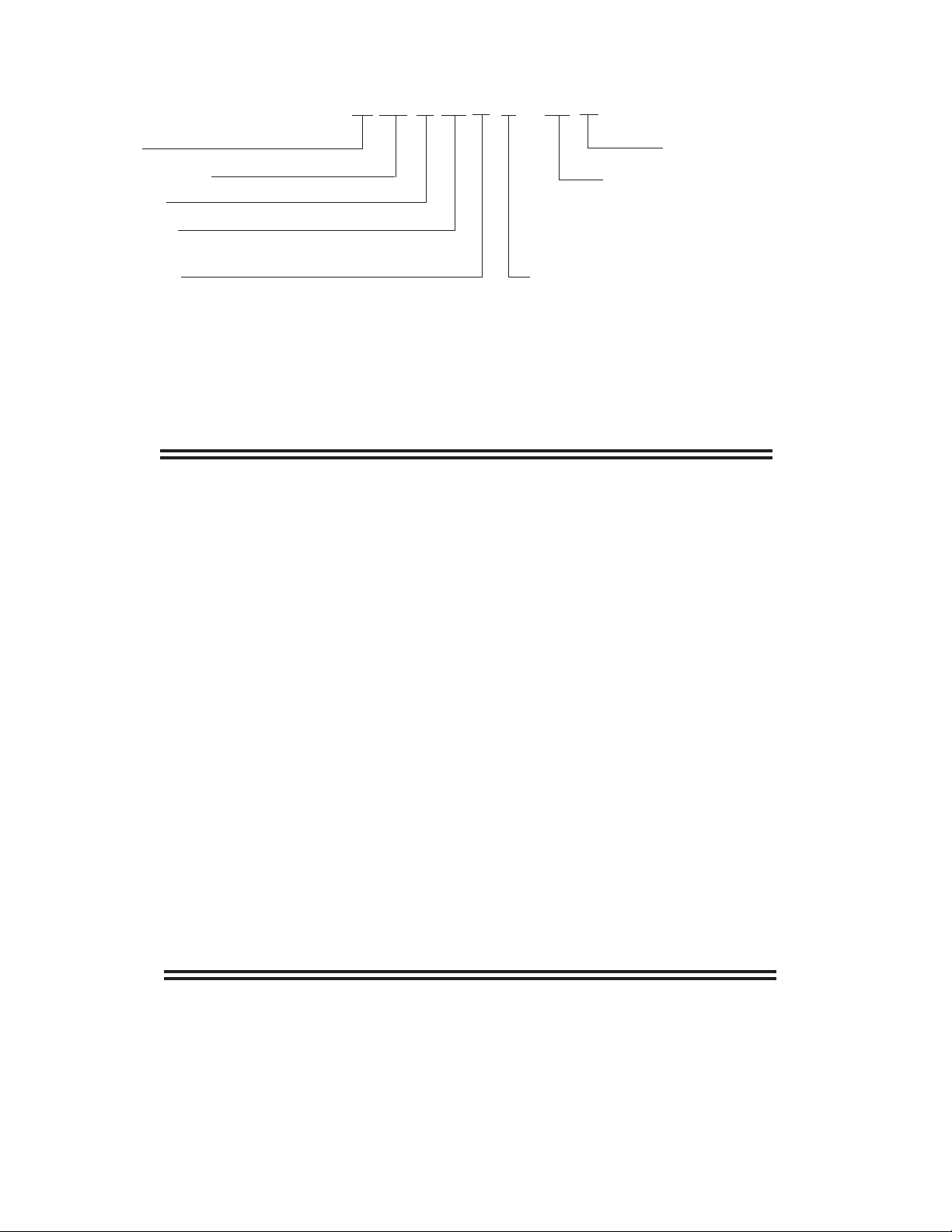

NOMENCLATURE

K LP 3 15 V E - T5 B

K = KeepRite

Low Profile Unit Cooler

Number of Fans

Nominal Capacity:

x 1000 @ 10°F TD, Btu/H, R404A

Application Range:

M = Medium to High Temp 6 FPI (10°F to 45°F (-12°C to 7°C) Evap Temp)

L = Low Temp 6 FPI (-40°F to 0°F(-40°C to -17°C) Evap Temp)

V = Low Temp 4 FPI (-40°F to 0°F (-40°C to -17°C) Evap Temp)

W = Fluid Air Cooler (with water or glycol)

STANDARD FEATURES

• Modern look

• High efficiency and high strength fan guard

Generation: B = 2

Voltage:

S6 = 200-220/1/50

S9 = 380-400/1/50

T7 = 200-220/3/50

Defrost*:

A = Air E = Electric

T = 3 Pipe Hot Gas w/ Electric Heater Pan

or Warm Fluid w/ Electric Heater Pan for Fluid Air Coolers

H = 3 Pipe Hot Gas w/ Hot Gas Loop Pan (optional)

G = Reverse Cycle w/ Electric Heater Pan

R = Reverse Cycle w/ Hot Gas Loop Pan (optional)

* T, H, G, R, available on 2 to 6 fan models only

nd

• PSC motors

• Proven motor/fan/motor mount design

• Front access

• Higher capacity

• Compact

• Internally enhanced tubing

• More uniform air flow

• Reverse cycle & 3 pipe hot gas available

• Convenient mounting brackets

• Ample electrical and header compartments

• Lower heater wattage

OPTIONAL FEATURES

• Liquid line solenoid valve wire harness factory

installed

• Schrader valve on suction header

• Positive slope, hinged drain pan

• Central drain connections (approximate)

• Universal drain fitting

• Large 3/4" ID (3/4" MPT) drain hole

• Factory installed distributor nozzle

• 380-400/1/50 PSC motor only

• EC motors

• Hot gas loop pan with hot gas defrost models

• Factory installed expansion valve,

solenoid valve and room thermostat

• Wire fan guard

- 2 -

Page 3

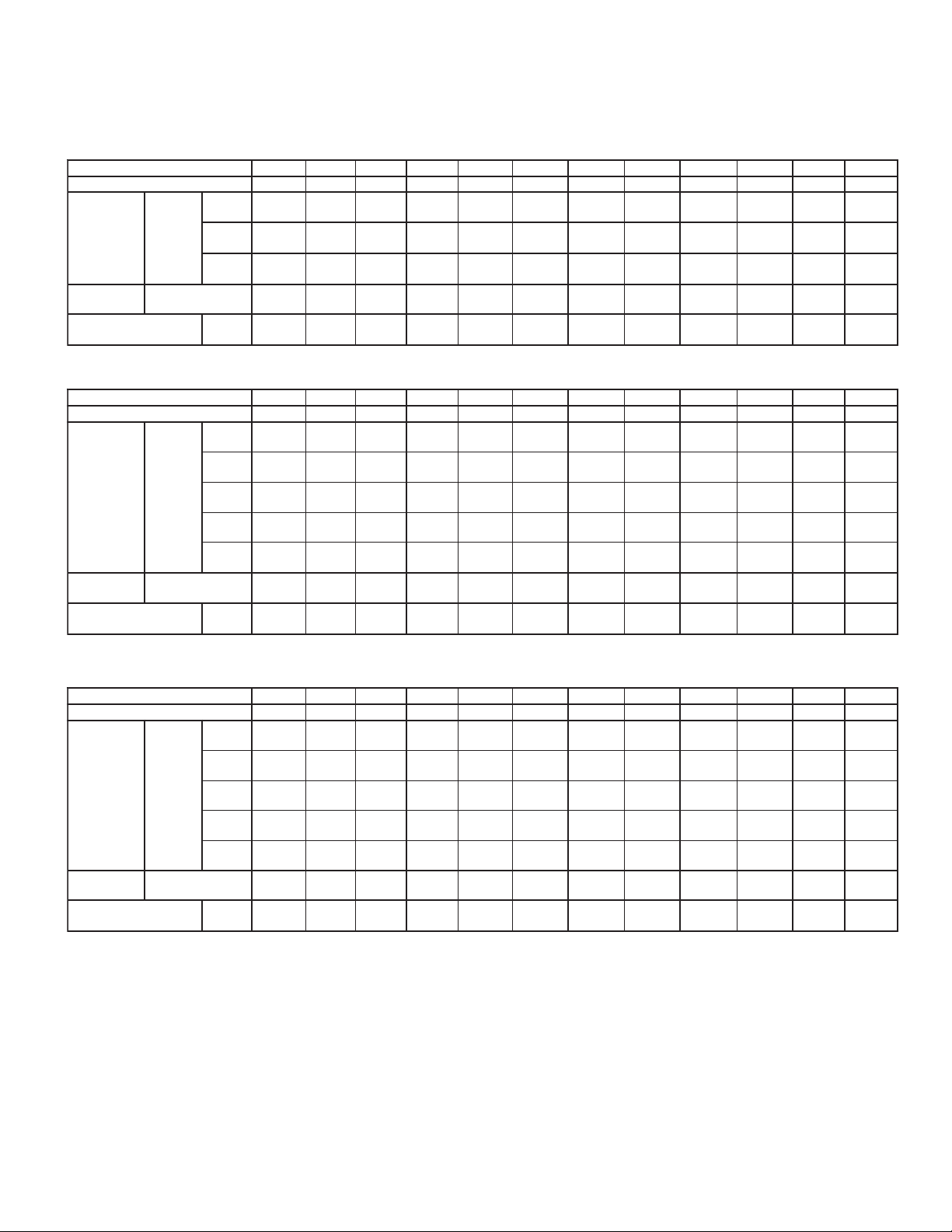

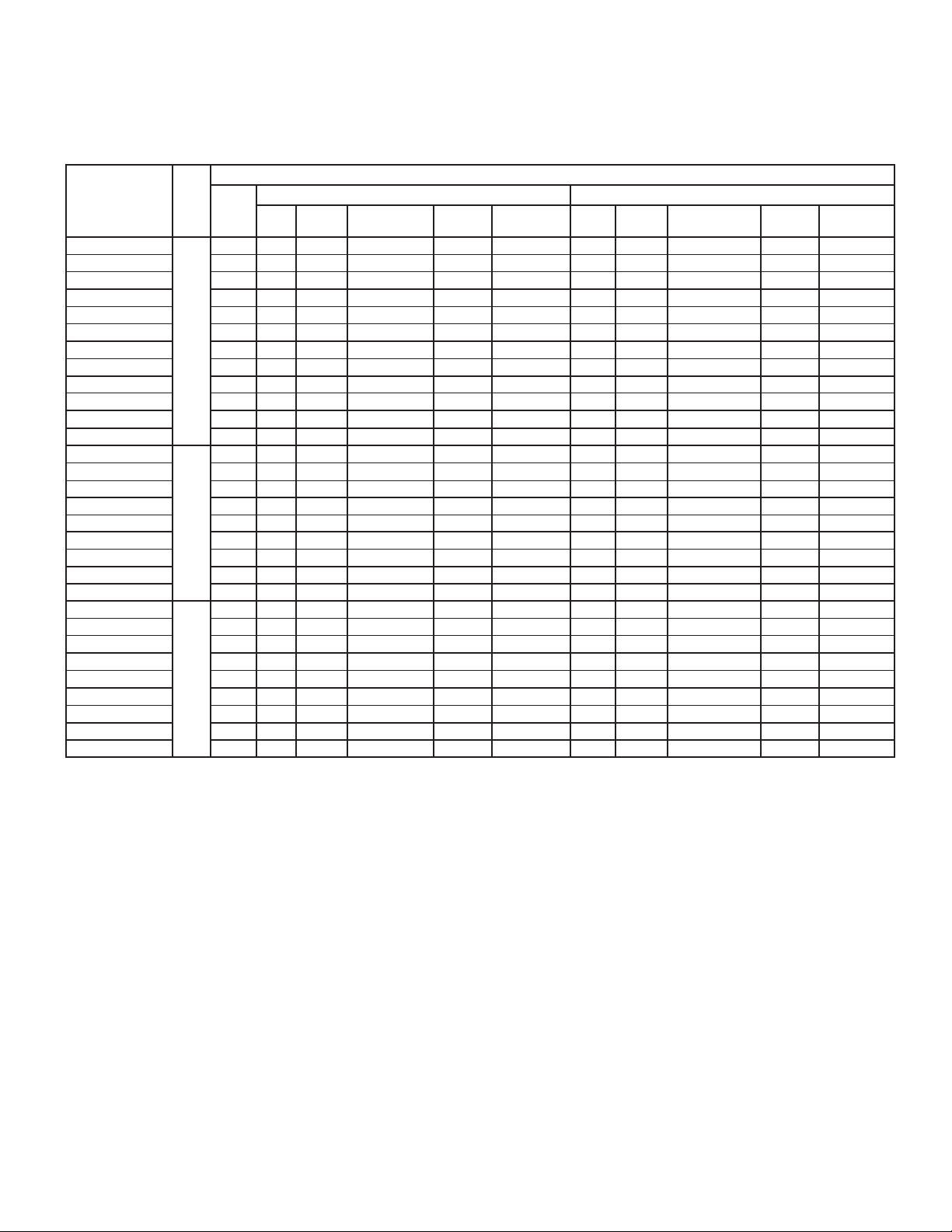

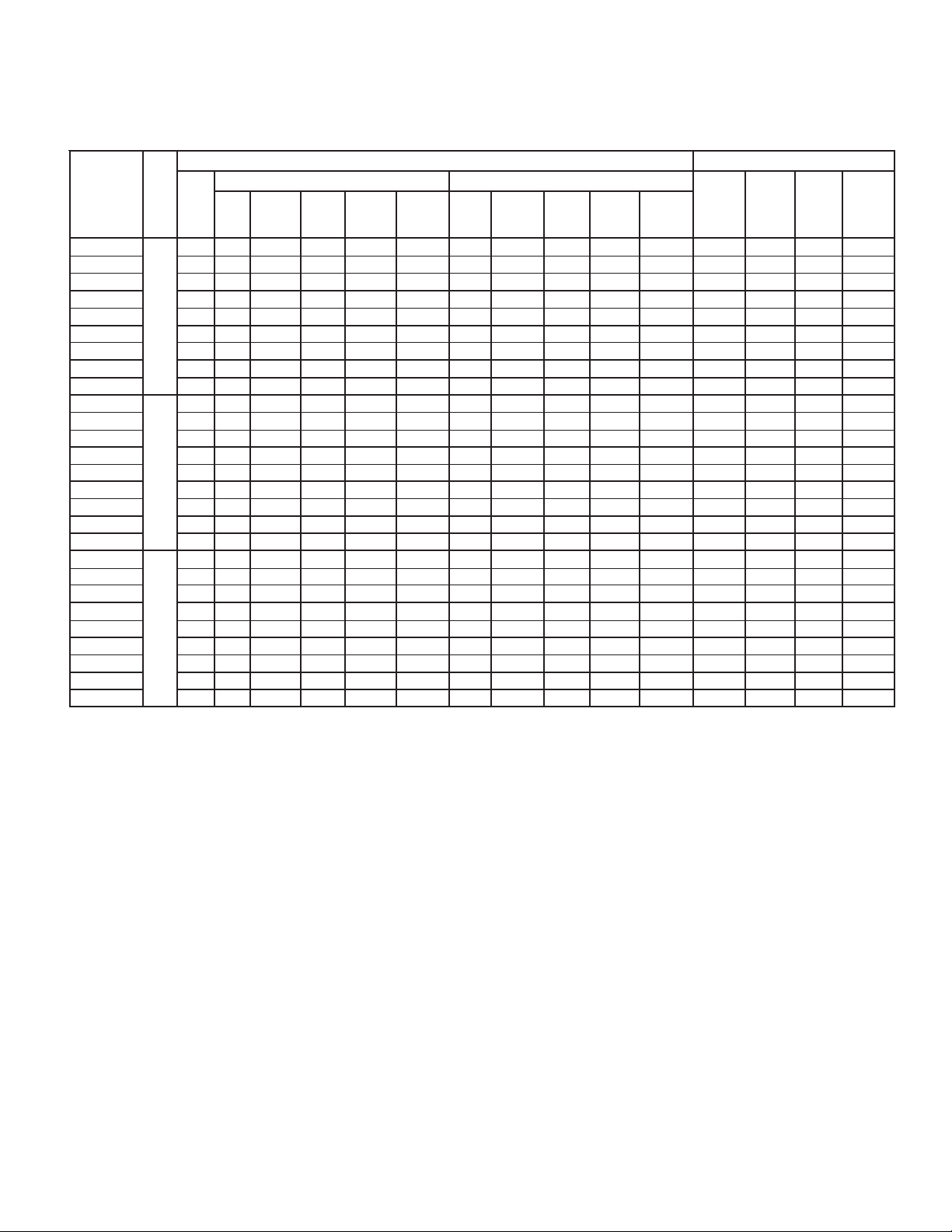

CAPACITY DATA

STANDARD MODELS (PSC MOTORS)

Medium Temperature Models - Capacity @ 6 F.P.I.

sledoM.pmeTmuideMM401M601M701M902M112M412M713M023M324M624M235M936

snaFfOrebmuN 111222334456

02

/52

)7-/4-(

51

)9-(

01

)21-(

BL .

( GK )

HUTB

( STTAW )

yticapaC

wolFriAMFC ( S/L )

)A404R(

pavE

.pmeT

°F )C°(

egrahCtnaregirfeR

Low Temperature Models - Capacity @ 6 F.P.I.

sledoM.pmeTwoLL401L501L601L702L902L112L413L713L914L224L725L136

snaFfOrebmuN 111222334456

0

(

)81-

01-

yticapaC

HUTB

)STTAW(

wolFriAMFC )S/L(

04R(

)A4

pavE

.pmeT

°F )C°(

egrahCtnaregirfeR

)32-(

02-

)92-(

03-

-(

)43

04-

)04-(

.BL

)GK(

0693

0293

0883

058

)004(

7.0

)3.0(

0163

0553

0843

0723

)069(

0003

)088(

058

)004(

7.0

)3.0(

0505

)0611(

0005

)9411(

0594

)7311(

087

)073(

0.1

)5.0(

0774

)0601(

0064

)0401(

0044

)0201(

0604

0563

087

)073(

0.1

)5.0(

0426

)0841(

)5641(

)1541(

)0041(

)0531(

)0921(

)0911(

)0701(

)0381(

0816

)1181(

216

0

)4971(

047

)053(

3.1

)6.0(

0955

)0461(

0945

)0161(

0235

)0651(

0494

)0541(

0454

)0331(

047

)053(

3.1

)6.0(

)0197

)0232(

0387

)5922(

0577

)1722(

0761

)097(

3.1

)6.0(

0037

)0412(

0607

)0702(

0976

)0991(

0726

)0481(

0965

)0761(

0761

097(

)

3.1

)6.0(

00101

)0792(

00001

)1392(

0099

)2092(

0951

)057(

9.1

)9.0(

0398

)0262(

0368

)0352(

0928

)0342(

0067

)0322(

0586

)0102(

0951

)057(

7.1

)8.0(

00921

)0773(

07721

)3473(

04621

)5073(

0051

)017(

5.2

)1.1(

00601

)0013(

00401

)0503(

00101

)0792(

0839

)0572(

0958

)0252(

0051

)017(

5.2

)1.1(

50Hz

00651

)0854(

04451

)5254(

09251

)1844(

0732

)0211(

8.2

)3.1(

00931

)0704(

00431

)0493(

00921

)0773(

00911

)0843(

00701

13(

)05

0732

)0211(

8.2

)3.1(

00481

)0935(

02281

)0435(

03081

)4825(

0522

)0601(

7.3

)7.1(

00661

)0884(

00261

)0474(

00651

)0854(

00441

)0324(

00131

)0583(

0522

)0601(

7.3

)7.1(

00112

0026(

)

09802

)3216(

08602

)1606(

0813

)0051(

7.3

)7.1(

00481

)0935(

00081

)0825(

00571

)0215(

00261

)0474(

00841

)0434(

0813

)0051(

7.3

)7.1(

00932

)0107(

06632

)4396(

02432

)4686(

0103

)0241(

9.4

)2.2(

00112

)0026(

00702

)0706(

00202

)0395(

00881

)0055(

00371

)0705(

0103

)0241(

9.4

)2.2(

00492

)0368(

01192

)2358(

01882

)4448(

0573

)0771(

1.6

)7.2(

00762

)0287(

00852

)0757(

00842

)0827(

00922

)0176(

00702

)0706(

0573

)0771(

1.6

)7.2(

00853

)01501(

04453

)78301(

08053

18201(

)

0944

)0212(

2.7

)3.3(

00613

)0729(

00203

)0788(

00582

)0638(

00162

)0667(

00332

)0286(

0944

)0212

2.

7

)3.3(

Low Temperature Models - Capacity @ 4 F.P.I.

sledoMIPF4.pmeTwoLV301V401V501V602V802V902V213V513V614V914V325V726

snaFfOrebmuN 111222334456

(

yticapaC

HUTB

)STTAW(

wolFriAMFC )S/L(

)A404R

°F )C°(

0

)81-(

01-

pavE

.pmeT

egrahCtnaregirfeR

)32-(

02-

)92-(

03-

)43-(

04-

)04-(

.BL

)GK(

0382

)038(

0082

)028(

0672

)018(

0952

)067(

0242

)017(

098

)024(

7.0

)3.0(

0993

0983

0973

0843

0713

)039(

058

)004(

0.1

)5.0(

0474

)0711(

0764

)0411(

0064

)0111(

0034

)0201(

0693

087

)073(

3.1

)6.0(

0716

)0931(

0406

)0731(

009

5

)0531(

0645

)0621(

0894

)0611(

0871

)048(

3.1

)6.0(

0757

)0181(

)0771(

)0371(

)0061(

)0641(

)0222(

0047

)0712(

0617

)0012(

0566

)0591(

0706

)0871(

0761

)097(

7.1

)8.0(

0388

)0952(

0378

)0652(

0658

)0152(

0897

)0432(

0737

)0612(

0951

)057(

5.2

)1.1(

00611

)0043(

00311

)0233(

00011

)0323(

00201

)0992(

0839

)0572(

0252

)0911(

8.2

)3.1(

00441

)0324(

00241

)0514(

00831

)0404(

00821

)0573(

0811

0

)0543(

0732

)0211(

7.3

)7.1(

Capacities rated using R404A with 10°F (5.6°C) TD & 100°F (38°C) liquid temperature.

Capacities at other TD within a range of 8 to 15 °F (4.4 to 8.3°C) are directly proportional to TD, or use formula:

Capacity = Rated capacity ÷ 10 x TD.

For capacities at TD outside of range 8 to 15 °F (4.4 to 8.3°C), or liquid temperature lower than 75°F (24°), consult factory .

1

00251

)0744(

00051

)0934(

00741

)0134(

00731

)0204(

00621

)0963(

0733

)0951(

7.3

)7.1(

0008

)0825(

00771

)0025(

00571

)0215(

00461

)008

4(

00151

)0244(

0813

)0051(

9.4

)2.2(

00222

)0256(

00712

)0636(

00112

)0026(

00691

)0475(

00971

)0625(

0893

)0881(

1.6

)7.2(

.3(

00762

)0487(

00852

)0757(

00842

)0827(

00922

)0176(

00702

)0706(

0774

)0522(

2.7

)3

- 3 -

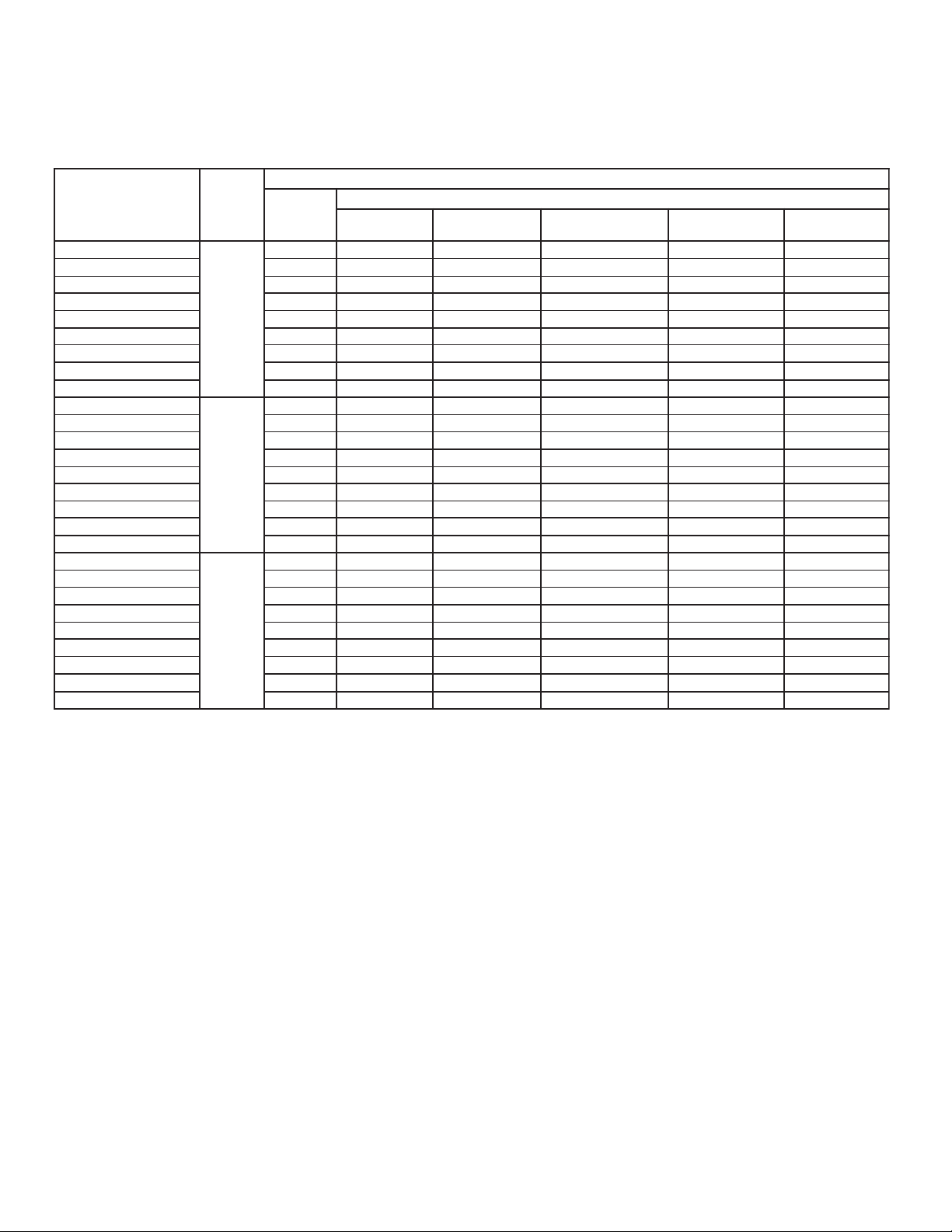

Page 4

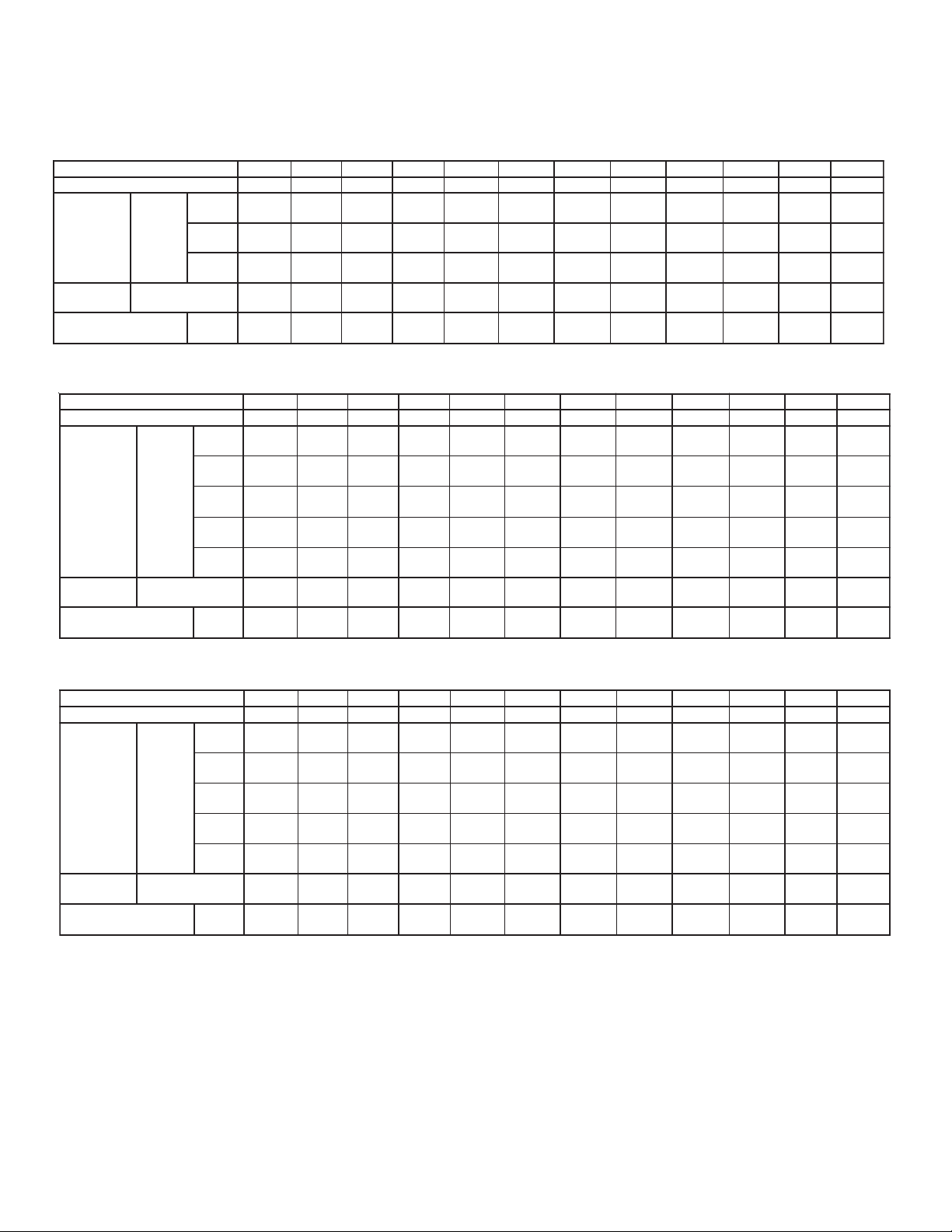

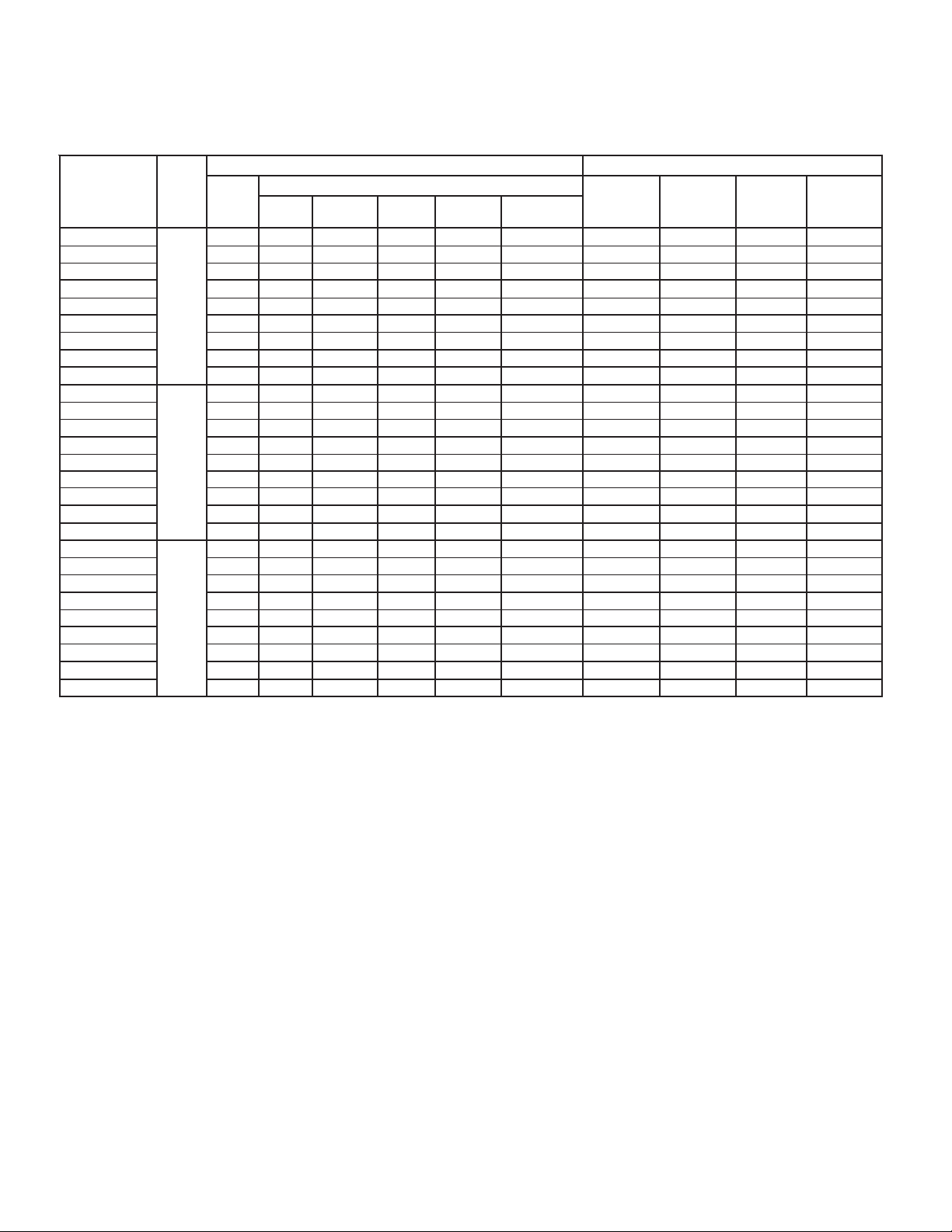

CAPACITY DATA

MODELS WITH EC MOTORS

Medium Temperature Models - Capacity @ 6 F.P.I.

sledoM.pmeTmuideMM401M601M701M902M112M412M713M023M324M624M235M936

snaFfOrebmuN 111222334456

/52

02

yticapaC

HUTB

)STTAW(

wolFriAMFC ( )S/L

)A404R(

F° )C°(

pavE

egrahCtnaregirfeR

51

.pmeT

)9-(

01

)21-(

.BL

)GK(

Low Temperature Models - Capacity @ 6 F.P.I.

sledoM.pmeTwoLL401L501L601L702L902L112L413L713L914L224L725L136

snaFfOrebmuN 111222334456

0

(

01-

yticapaC

HUTB

)STTAW(

wolFriAMFC ( )S/L

eR

)A404R(

F° )C°(

pavE

.pmeT

egrahCtnaregirf

02-

03-

3-(

04-

.BL

)GK(

0034

)7-/4-(

)81)32-(

)92-(

)4

)04-(

)0621(

0624

)9421(

0124

)4321(

0101

)074(

7.0

)3.0(

0393

0783

0083

0553

0723

0101

7.0

0055

0545

0935

059

)054(

0.1

)5.0(

)0511(

)0311(

)0111(

)0401(

)069(

059

)084(

0.1

)3.0(

0086

)0161(

0376

)7951(

66

06

)0851(

009

)034(

3.1

)6.0(

0025

)0251(

0205

)0741(

0084

)0141(

0144

)0921(

0893

)0711(

009

)054(

3.1

)5.0(

0068

)0991(

)2791(

)2591(

0906

0695

0085

0835

0294

)034(

)6.0(

)0252(

0158

)4942(

0348

)1742(

0202

)059(

3.1

)6.0(

0397

)0871(

0967

)0571(

047

0

)0071(

0286

)0851(

0816

)0441(

202

0

)059(

3.1

)6.0(

00011

)0223(

09801

)2913(

08701

)9513(

0191

)009(

9.1

(

)9.0

0279

)0232(

0049

)0522(

0009

)0712(

0828

)0002(

0747

)0181(

0191

)009(

7.1

)8.0(

00041

)0014(

06831

2604(

)

02731

)1204(

0081

)058(

5.2

)1.1(

)0582(

)0572(

)0462(

)0342(

)0912(

00511

)0733(

00311

)0133(

00011

)0223(

00201

)0992(

0439

)0472(

0081

)058(

5.2

)1.1(

50Hz

00071

)0894(

03861

)3394(

06661

)3884(

0682

)0531(

8.2

)3.1(

00151

00641

00041

00921

00711

0682

8.2

)3.1(

00002

)0685(

00891

)3085(

00691

)4475(

0072

)0721(

7.3

)7.1(

)0244(

)0824(

)0014(

)0873(

)0343(

)0531(

00181

)0035(

00671

)0615(

00071

)0894(

00751

)0064(

00341

)0914(

0072

)0721(

7.3

)7.1(

00032

476(

)0

07722

)4766(

04522

)6066(

0183

(

)0081

7.3

)7.1(

00002

)0685(

00691

)0475(

00091

)0755(

00671

)0615(

00161

)0274(

0183

)0081(

7.3

)7.1(

00062

)0167(

04752

)4457(

08452

)8647(

0063

)0071(

9.4

)2.2(

00032

00522

00022

0040

2

00881

0063

9.4

)2.2(

00023

)0739(

08613

)5829(

06313

)1919(

0054

)0212(

1.6

)7.2(

)0476(

)0956(

)0446(

)0895(

)0155(

0054

)0071(

1.6

)7.2(

00093

)00411(

01683

)61311(

02283

)20211(

0045

)0552(

2.7

)3.3(

00092

)0948(

00182

)0328(

00072

)0197(

00942

)0927(

00522

)0956(

)0212(

00443

)00101(

00923

)0469(

00013

)0809(

00482

)0238(

00352

)0147(

0045

)0552(

2.7

)3.3(

Low Temperature Models - Capacity @ 4 F.P.I.

sledoMIPF4.pmeTwoLV301V401V501V602V802V902V213V513V614V914V325V726

snaFfOrebmuN 111222334456

0703

)009(

0403

)098(

0003

)088(

0282

)038(

0262

)077(

0701

)015(

7.0

)3.0(

yticapaC

HUTB

)STTAW(

wolFriAMFC ( )S/L

A404R(

)

F° )C°(

0

)81-(

01-

pavE

.pmeT

egrahCtnaregirfeR

)32-(

02-

)92-(

03-

)43-(

04-

)04-(

.BL

)GK(

Capacities rated using R404A with 10°F (5.6°C) TD & 100°F (38°C) liquid temperature.

Capacities at other TD within a range of 8 to 15 °F (4.4 to 8.3°C) are directly proportional to TD, or use formula:

For capacities at TD outside of range 8 to 15 °F (4.4 to 8.3°C), or liquid temperature lower than 75°F (24°), consult factory .

0434

0324

0014

0973

0643

0101

)084(

0.1

)5.0(

0715

)0721(

0015

)0421(

0005

)0021(

0664

)0111(

0134

)0101(

059

)054(

3.1

)6.0(

0276

)0151(

0756

)0941(

6

004

)0741(

0395

)0731(

0345

)0621(

0412

0101(

3.1

)6.0(

0428

)0791(

)0291(

)0881(

)0471(

)0951(

)

)0142(

0408

)0632(

0087

)0922(

0227

)0212(

0956

)0391(

0202

)059(

7.1

)8.0(

0169

)0282(

0849

)0872(

0039

)0272(

0868

)0452(

0208

)0532(

0191

)009(

5.2

)1.1(

Capacity = Rated capacity ÷ 10 x TD.

00621

)0963(

00321

)0063(

00021

)0253(

00111

)0523(

00201

(

)0992

0303

)0341(

8.2

)3.1(

00751

)0064(

00451

)0154(

00051

)0934(

00931

)0704(

00821

)0573(

0682

)0531(

7.3

)7.1(

00661

)0684(

00361

)0774(

00061

)0964(

00941

)0634(

00731

)0104(

0404

)0191(

7.3

)7.1(

0069

1

)0475(

00391

)0565(

00091

)0755(

00871

5(

)012

00461

)0084(

0183

)0081(

9.4

)2.2(

00242

)0907(

00632

)0196(

00032

)0476(

00312

)0426(

00591

)0175(

0774

)0522(

1.6

)7.2(

00192

)0258(

00182

)0328(

00072

)0197(

00942

)0927(

00522

)0956(

0275

)0072(

2.7

)3.3(

- 4 -

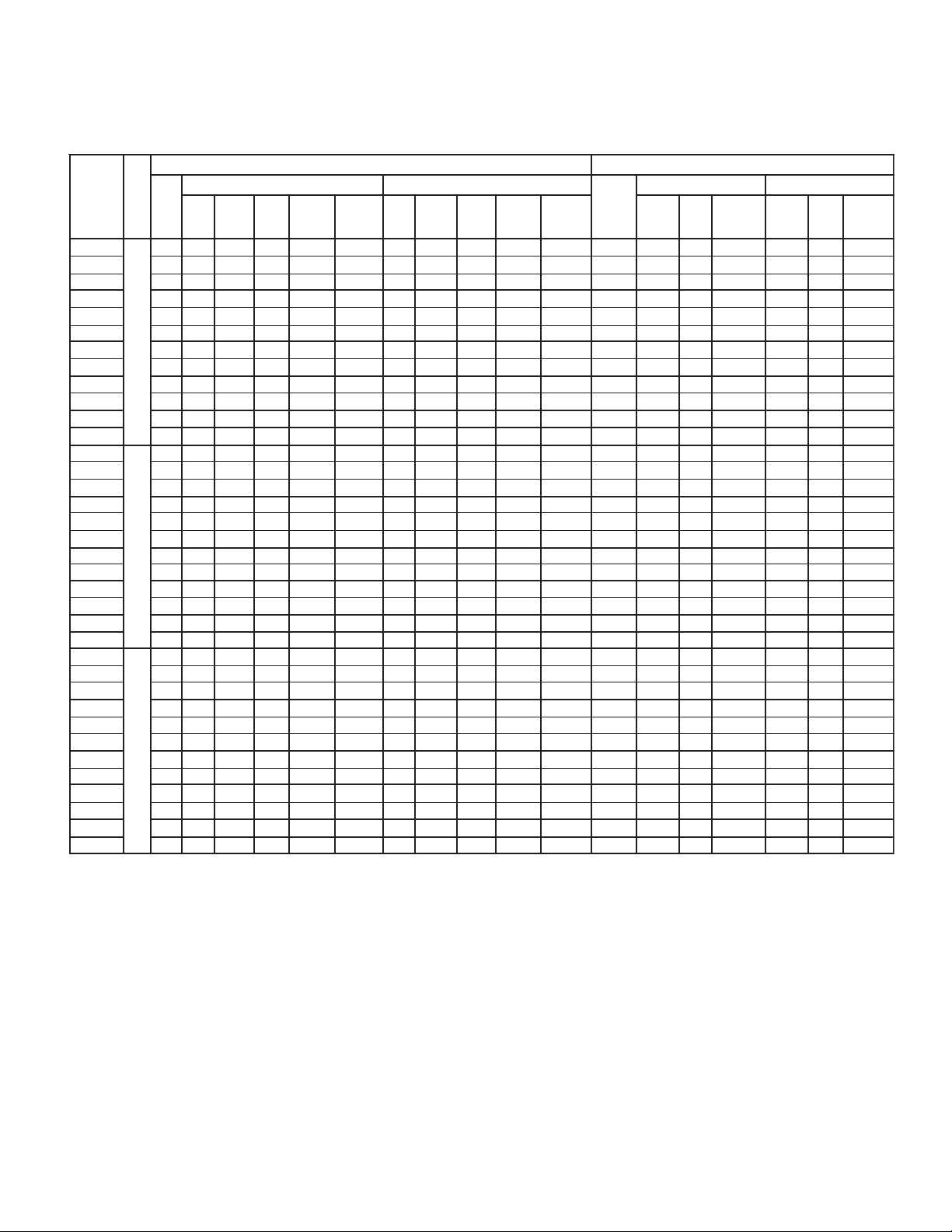

Page 5

ELECTRICAL DATA - 200-220/1/50

AIR DEFROST &

50Hz

HOT GAS DEFROST WITH HOT GAS LOOP PAN MODELS

SROTOMNAF

SROTOMCSPSROTOMCE

.CRIC.NIM

)A(YTICAPMA

STTAW

425151/18.10.208151

ESUF.XAM

PH

)SPMA(

14.26.204251

ALF

14.102151

14.102151

NIM

LATOT

.CRIC.

)A(YTICAPMA

STTAW

L702†6SL902†6SL112†6SL413†6SL713†6SL914†6SL224†6SL725†6SL136†6SV602†6SV802†6SV902†6SV213†6SV513†6SV614†6SV914†6SV325†6SV726†6S-

LEDOMIPF

*6S-AM401

*6S-AM601

*6S-AM701

6S-#M902

6S-#M112

6S-#M412

6S-#M713

6S-#M023

6S-#M324

6S-#M624

6S-#M235

6S-#M936

.YTQ

PH

151/15.06.0085151/16.057.00651

151/15.06.0085151/16.057.00651

151/15.06.0085151/16.057.00651

251/10.11.10615151/12.14.102151

251/10.11.10615151/12.14.102151

251/10.11.10615151/12.

6

351/15.16.10425151/18.10.208151

351/15.16.10425151/18.10.208151

451/10.21.20235151/14.26.204251

451/10.21.20235151/14.26.204251

551/15.26.20045151/10.32.300351

651/10.31.30845151/16.38.306351

251/10.11.10615151/12.

251/10.11.10615151/12.14.102151

251/10.11.10615151/12.14.102151

351/15.16.10425151/18.10.208151

351/15.16.10

6

451/10.21.20235151/14.26.204251

451/10.21.20235151/14.26.204251

551/15.26.20045151/10.32.300351

1/10.31.30845151/16.38.306351

65

251/10.11.10615151/12.14.102151

251/10.11.10615151/12.14.102151

251/10.11.10615151/12.14.10215

351/15.16.10425151/18.10.208151

4

351/15.16.10425151/18.10.208151

451/10.21.20235151/14.26.204251

451/10.21.20235151/

551/15.26.20045151/10.32.300351

651/10.31.30845151/16.38.306351

ALF

LATOT

sliatedroferutalcnemoNotrefeR.RroH,A=#

lnosledomnaf6ot2noelbaliavaRroH=*

y

sliatedroferutalcnemoNotrefeR.RroH=†

ESUF.XAM

)SPMA(

1

-5 -

Page 6

ELECTRICAL DATA - 380-400/1/50

AIR DEFROST &

50Hz

HOT GAS DEFROST WITH HOT GAS LOOP PAN MODELS

SROTOMNAF

LEDOMIPF

9S-#M902

#M112

9S-

9S-#M412

9S-#M713

9S-#M023

9S-#M324

9S-#M624

9S-#M235

9S-#M936

L702†9SL902†9SL112†9S-

413†9S-

L

L713†9SL914†9SL224†9SL725†9SL136†9SV602†9SV802†9SV902†9SV213†9SV513†9SV614†9SV914†9SV325†9SV726†9S-

.YTQ

251/18.09.006151

251/18.09.006151

251/18.09.006151

351/12.13.104251

6

6

4

naf6ot2noelbaliavaRroH=*

351/12.13.104251

451/16.17.102351

45

551/10.21.200451

651/14.25.208451

251/18.09.006151

251/18.09.006151

251/18.09.006151

351/12.13.104251

351/12.13.104251

451/16.17.102351

451/16.17.102351

551/10.21.200451

651/14.25.208451

251/18.09.006151

251/18.09.006151

251/18.09.006151

351/12.13.104251

351/12.13.104251

451/16.17.102

451/16.17.102351

551/10.21.200451

651/14.25.208451

sliatedroferutalcnemoNotrefeR.RroH,A=#

ylnosledom

sliatedroferutalcnemoNotrefeR.RroH=†

PH

1/16.17.102351

ALF

LATOT

SROTOMCSP

.CRIC.NIM

)A(YTICAPMA

STTAW

351

ESUF.XAM

)SPMA(

-6 -

Page 7

LEDOMIPF

*-EM401

*-EM601

*-EM701

*-EM902

*-EM112

*-EM412

*-EM713

*-EM023

*-EM324

*-EM624

*-EM235

*-EM936

*-EL401

*-EL501

*-EL601

*-EL702

*-EL902

*-EL112

*-EL413

*-EL713

*-EL914

*-EL224

*-EL725

*-EL136

*-EV301

*-EV401

*-EV501

*-EV602

*-EV802

*-EV902

*-EV213

*-EV513

*-EV614

*-EV914

*-EV325

*-EV726

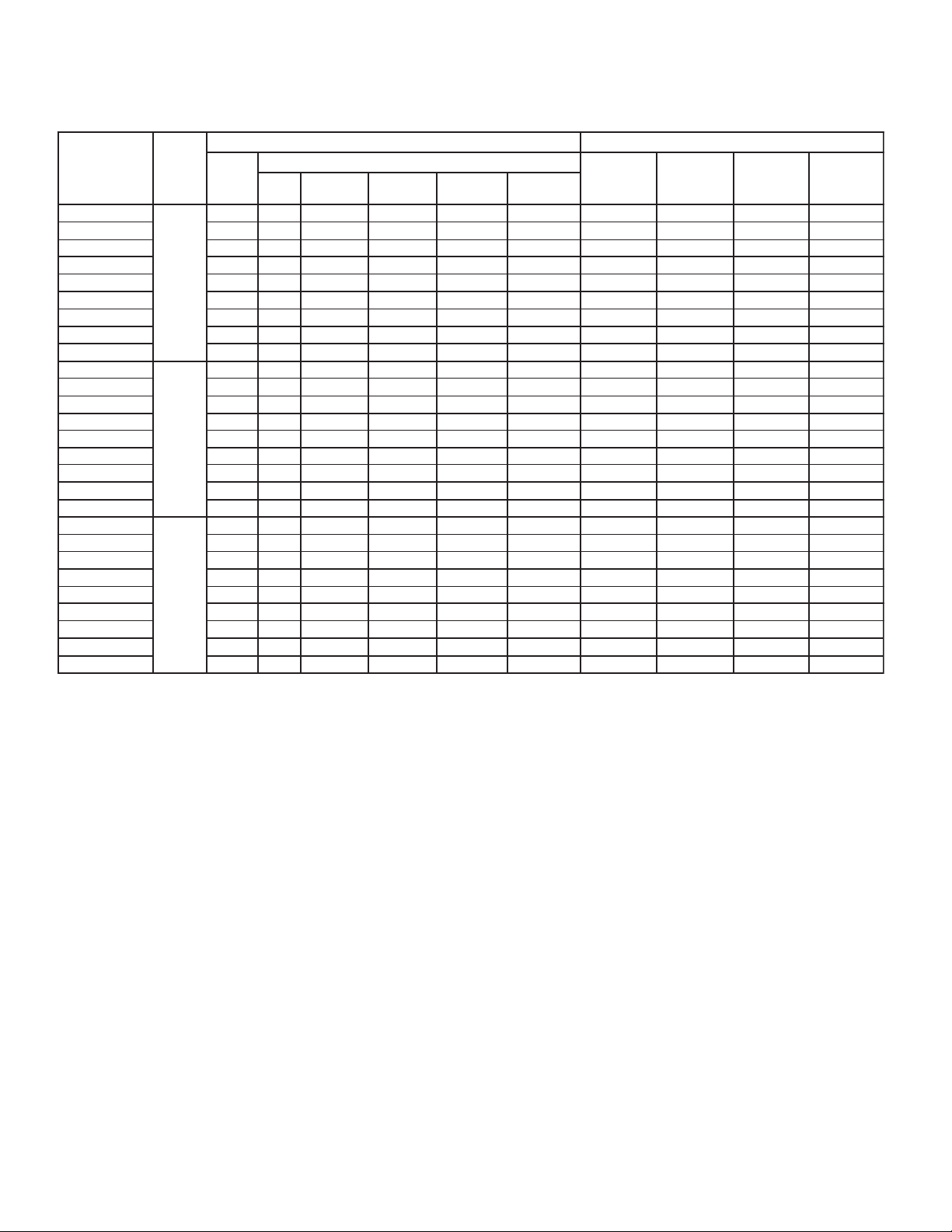

ELECTRICAL DATA -

200-220/1/50 & 200-220/3/50

50Hz

ELECTRIC DEFROST MODELS

SROTOMNAF SRETAEHTSORFED

SROTOMCSPSROTOMCE

.YTQ

151/15.06.0085151/16.057.006510794.45.5519.26.351

151/15.06.0085151/16.057.006510794.45.5519.26.351

151/15.06

251/10.11.10615151/12.14.10215103719.78.9511.54.651

251/10.11.10615151/12.14.10215103719.78.

251/10.11.10615151/12.14.10215103719.78.9511.54.651

6

351/15.16.10425151/18.10.20815100524.112.41513.72.951

351/

15.16.10425151/18.10.20815100524.112.41513.72.951

451/10.21.20235151/14.26.20425106238.415.81025.99.1151

451/10.21.20235151/14.26.

551/15.26.20045151/10.32.30035103043.819.22527.117.4151

651/10.31.30845151/16.38.30635109748.122.7

151/15.06.0085151/16.057.006510794.45.5519.26.351

151/15.06.0085151/16.057.006510794.45.5519.26.351

151/15.06

251/10.11.10615151/12.14.10215103719.78.9511.54.651

251/10.11.10615151/12.14.10215103719.78.

251/10.11.10615151/12.14.10215103719.78.9511.54.651

6

351/15.16.10425151/18.10.20815100524.112.41513.72.951

351/

15.16.10425151/18.10.20815100524.112.41513.72.951

451/10.21.20235151/14.26.20425106238.415.81025.99.1151

451/10.21.20235151/14.26.

551/15.26.20045151/10.32.30035103043.819.22527.117.4151

651/10.31.30845151/16.38.30635109748.122.7

151/15.06.0085151/16.057.006510794.45.5519.26.351

151/15.06.0085151/16.057.006510794.45.5519.26.351

151/15.06

251/10.11.10615151/12.14.10215103719.78.9511.54.651

251/10.11.10615151/12.14.10215103719.78.

251/10.11.10615151/12.14.10215103719.78.9511.54.651

4

351/15.16.10425151/18.10.20815100524.112.41513.72.951

351/

15.16.10425151/18.10.20815100524.112.41513.72.951

451/10.21.20235151/14.26.20425106238.415.81025.99.1151

451/10.21.20235151/14.26.

551/15.26.20045151/10.32.30035103043.819.22527.117.4151

651/10.31.30845151/16.38.30635109748.122.7

ALF

ACM

PH

LATOT

TAW

)A(

.0085151/16.057.006510794.45.5519.26.351

.0085151/16.057.006510794.45.5519.26.351

.0085151/16.057.006510794.45.5519.26.351

sliatedroferutalcnemoNotrefeR.7Tro6S=*

.XAM

ESUF

ST

)SPMA(

ALF

PH

ACM

LATOT

)A(

20425106238.415.81025.99.1151

20425106238.415.81025.99.1151

20425106238.415.81025.99.1151

STTAW

.XAM

ESUF

LATOT

LATOT

STTAW

)SPMA(

SPMA

05/1/022-00205/3/022-002

ACM

)A(

9511.54.651

2030.415.7102

9511.54.651

2030.415.7102

9511.54.651

2030.415.7102

.XAM

ESUF

LATOT

SPMA

)SPMA(

ACM

)A(

.XAM

ESUF

)SPMA(

- 7 -

Page 8

EM713

L914

EV325

LEDOMIPF

9S-EM902

9S-EM112

9S-EM412

9S9S-EM023

9S-EM324

9S-EM624

9S-EM235

9S-EM936

9S-EL702

9S-EL902

9S-EL112

9S-EL413

9S-EL713

9S-E

9S-EL224

9S-EL725

9S-EL136

9S-EV602

9S-EV802

9S-EV902

9S-EV213

9S-EV513

9S-EV614

9S-EV914

9S9S-EV726

ELECTRICAL DATA - 380-400/1/50

ELECTRIC DEFROST MODELS

SROTOMNAF SRETAEHTSORFED

SROTOMCSP

.YTQ

PH

251/18.09.00615103713.44.551

251/18.09.00615103713.44.551

251/18.09.00615103713.44.551

351/12.13.10425100523.68.751

6

6

4

351/12.13.10425100523.68.751

451/16.17.10235106232.82.0151

451/16.17.10235106232

551/12 1.20045103041.016.2151

651/14.25.20845109740.210.5151

251/18.09.00615103713.44.551

18.09.00615103713.44.551

251/

251/18.09.00615103713.44.551

351/12.13.10425100523.68.751

351/12.13.10425100523.68.751

451/16.17.10235106232.82.0151

451/16.17.10235106232.82.0151

551/12 1.20045103041.016.2151

651/14.25.20845109740

251/18.09.00615103713.44.551

251/18.09.00615103713.44.551

251/18.09.00615103713.44.551

351/12

351/12.13.10425100523.68.751

451/16.17.10235106232.82.0151

451/16.17.10235106232.82.0151

551/12 1.20045103041.016.2151

651/14.25.20845109740.210.5151

ALF

LATOT

.13.10425100523.68.751

ACM

)A(

AW

STT

ESUF.XAM

)SPMA(

LATOT

STTAW

LATOT

SPMA

.82.0151

.210.5151

50Hz

ACM

)A(

ESUF.XAM

)SPMA(

- 8 -

Page 9

ELECTRICAL DATA - 200-220/1/50

HOT GAS DEFROST

50Hz

WITH DRAIN PAN HEATER MODELS

SROTOMNAF SRETAEHNAPNIARD

LEDOMIPF

6S-^M902

112

6S-^M

6S-^M412

6S-^M713

6S-^M023

6

6S-^M324

6S-^M624

6S-^M235

6S-^M936

6S-^L702

6S-^L902

6S-^L112

6S-^L413

6S-^L713

6

6S-^L914

224

6S-^L

6S-^L725

6S-^L136

6S-^V602

6S-^V802

6S-^V902

6S-^V213

6S-^V513

4

6S-^V614

6S-^V914

6S-^V325

6S-^V726

.YTQ

PH

251/10.11.10615151/12.14.1021515737.11.251

251/10.11.10615151/12.14.1021515737.11.251

251/10.11.10615151/12.14.1021515737.11.251

351/15.16.10425151/18.10.2081512153.29.

351/15.16.10425151/18.10.2081512153.29.251

451/10.21.20235151/14.26.2042519560.37.351

451/10.21.20235151/14.26.204

551/15.26.20045151/10.32.3003510187.36.451

651/10.31.30845151/16.38.3063510493.43.551

251/10.11.1061515

251/10.11.10615151/12.14.1021515737.11.251

251/10.11.10615151/12.14.1021515737.11.251

351/15

351/15.16.10425151/18.10.2081512153.29.251

451/10.21.20235151/14.26.2042519560.37.351

451/10.21.20235151/14.26.2042519560.37.351

551/15.26.20045151/10.32.3003510187.36.451

651/10.31.30845151/16.38.3063510493.43.

251/10.11.10615151/12.14.1021515737.11.251

251/10.11.10615151/12.14.1021515737.11.251

251/10.11.10615151/12.14.10

351/15.16.10425151/18.10.2081512153.29.251

351/15.16.10425151/18.10.2081512153.29.251

451/10.21.2023515

451/10.21.20235151/14.26.2042519560.37.351

551/15.26.20045151/10.32.3003510187.36.451

651/10

CM

ALF

LATOT

.16.10425151/18.10.2081512153.29.251

.31.30845151/16.38.3063510493.43.551

SROTOMCSPSROTOMCE

A

)A(

sliatedroferutalcnemoNotrefeR.GroT=^

STTAW

.XAM

ESUF

)SPMA(

PH

1/12.14.1021515737.11.251

1/14.26.2042519560.37.351

ALF

ACM

LATOT

)A(

STTAW

2519560.37.351

21515737.11.251

.XAM

ESUF

)SPMA(

LATOT

STTAW

LATOT

SPMA

ACM

)A(

251

551

.XAM

ESUF

)SPMA(

- 9 -

Page 10

713

LEDOMIPF

9S-^M902

9S-^M112

9S-^M412

9S-^M

9S-^M023

9S-^M324

9S-^M624

-^M235

9S

9S-^M936

9S-^L702

9S-^L902

9S-^L112

9S-^L413

9S-^L713

9S-^L914

9S-^L224

9S-^L725

9S-^L136

9S-^V602

9S-^V802

9S-^V902

9S-^V213

9S-^V513

9S-^V614

9S-^V914

9S-^V325

9S-^V726

ELECTRICAL DATA - 380-400/1/50

HOT GAS DEFROST

50Hz

WITH DRAIN PAN HEATER MODELS

SROTOMNAF SRETAEHNAPNIARD

SROTOMCSP

.YTQ

PH

251/18.09.0061515739.02.151

251/18.09.0061515739.02.151

251/18.09.0061515739.02.151

351/12.13.1042512153.16.151

6

6

4

351/12.13.1042512153.16.151

451/16.17.1023519566.11.251

451/16.17.1023519566.11.251

551/121.2004510180.25.251

651/14.25.2084510494.29.251

251/18.09.0061515739.02.151

251/18.09.0061515739.02.151

251/18.09.0061515739.02.151

351/12.13.1042512153.16.151

351/12.13.1042512153.16.151

451/16.17.1023519566.11

451/16.17.1023519566.11.251

551/121.2004510180.25.251

651/14.25.2084510494.29.251

251/18.09.0061515739

251/18.09.0061515739.02.151

251/18.09.0061515739.02.151

351/12.13.1042512153.16.151

351/12.13.10425

451/16.17.1023519566.11.251

451/16.17.1023519566.11.251

551/121.2004510180.25.251

651/14.25.208

ALF

LATOT

sliatedroferutalcnemoNotrefeR.GroT=^

ACM

)A(

TAW

ST

4510494.29.251

ESUF.XAM

)SPMA(

12153.16.151

LATOT

STTAW

LATOT

SPMA

.02.151

ACM

)A(

.251

ESUF.XAM

)SPMA(

- 10 -

Page 11

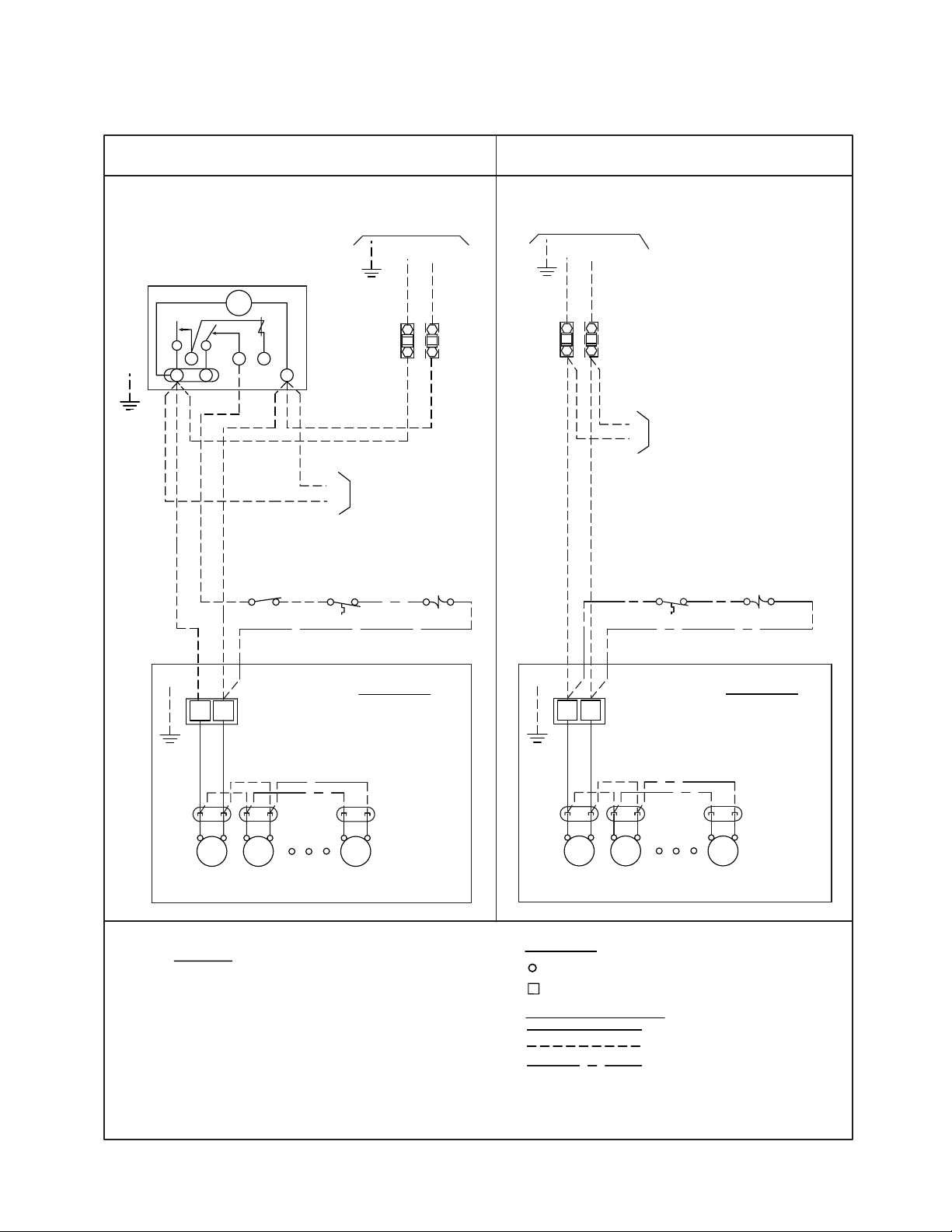

WIRING DIAGRAM - 200-220/1/50

AIR DEFROST MODELS

GND

WITH DEFROST TIME CLOCK

DEFROST CLOCK

PARAGON # 8145

OR EQUIVALENT

TM

3

1

2

4X

PUMP DOWN

SWITCH

(IF USED)

N

THERMOSTAT

SPACE

NOTE #4

REFER TO EVAPORATOR

NAMEPLATE FOR ELECTRICAL

REQUIREMENTS

L2(N)

L1

GND

FUSE OR

CIRCUIT

BREAKER

NOTE #3

OMIT 2ND

FUSE

IF(N)

TO MULTIPLE EVAPS

F

4

(IF APPLIC)

LIQUID LINE

SOLENOID VALVE

NOTE #4

WITHOUT DEFROST TIME CLOCK

REFER TO EVAPORATOR

NAMEPLATE FOR ELECTRICAL

REQUIREMENTS

L2(N)

L1

GND

FUSE OR

CIRCUIT

BREAKER

NOTE #3

OMIT

2ND FUSE

IF(N)

F

4

THERMOSTAT

TO MULTIPLE

EVAPORATORS (IF APPLIC)

SPACE

NOTE #4

SOLENOID VALVE

LIQUID LINE

NOTE #4

4

F

TERMINAL BOARD

GND.

FAN

MTR

FAN

MTR

NOTES

1). USE COPPER CONDUCTORS ONLY

2). USE 75°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

EVAPORATOR FAN MOTORS AND DEFROST

HEATERS MUST NOT EXCEED MAXIMUM

VALUE SHOWN ON EVAPORATOR NAMEPLATE.

4). MAY BE FACTORY INSTALLED-MOUNTED AND

WIRED ON EVAPORATOR .

1-LP AIR 09/06

EVAPORATOR

FAN MOTOR

POWER

PLUGS

REFER TO

EVAPORATOR

FAN

MTR

DATA PLATE

FOR MOTOR

QUANTITY

N.C.

N.C.

EVAPORATOR

4

F

TERMINAL BOARD

GND.

FAN MOTOR

POWER

PLUGS

REFER TO

FAN

MTR

FAN

MTR

EVAPORATOR

FAN

MTR

DATA PLATE

FOR MOTOR

QUANTITY

TERMINALS

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

CONDUCTORS/WIRING

FACTOR Y WIRI NG

WIRING BY OTHERS

OPTIONAL FACTORY OR

BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

- 1 1 -

Page 12

WIRING DIAGRAM - 380-400/1/50

AIR DEFROST MODELS

460-1-60 Hz

380/400-1-50Hz

L1

GND

WITH DEFROST TIME CLOCK

FUSE OR

CIRCUIT

BREAKER

NOTE #3

OMIT 2ND

FUSE

IF(N)

GND

TO MULTIPLE

SPACE

NOTE #4

CONTROL VOLTAGE

GND

L2

3

1

2

DEFROST CLOCK

PARAGON # 8145

OR EQUIVALENT

TM

4X

N

M2

M1

PUMP DOWN

SWITCH

(IF USED)

EVAPORATORS (IF APPLIC)

THERMOSTAT

L2(N)

L1

LIQUID LINE

SOLENOID VALVE

NOTE #4

N.C.

WITHOUT DEFROST TIME CLOCK

460-1-60 Hz

380/400-1-50Hz

L2

L1

GND

CONTROL VOLTAGE

GND

FUSE OR

CIRCUIT

BREAKER

NOTE #3

M2

M1

TO MULTIPLE

EVAPORATORS (IF APPLIC)

SPACE

THERMOSTAT

NOTE #4

L2(N)

L1

LIQUID LINE

SOLENOID VALVE

NOTE #4

N.C.

OMIT

2ND FUSE

IF(N)

EVAPORATOR

M1

M2

TERMINAL BOARD

GND.

FAN

FAN

MTR

MTR

NOTES

1). USE COPPER CONDUCTORS ONLY

2). USE 75°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

EVAPORATOR FAN MOTORS AND DEFROST

HEATERS MUST NOT EXCEED MAXIMUM

VALUE SHOWN ON EVAPORATOR NAMEPLATE.

4). MAY BE FACTORY INSTALLED-MOUNTED AND

WIRED ON EVAPORATOR .

6-LP 460 AIR 09/06

FAN MOTOR

POWER

PLUGS

REFER TO

EVAPORATOR

FAN

MTR

DATA PLATE

FOR MOTOR

QUANTITY

EVAPORATOR

M1

4

N

M2

TERMINAL BOARD

GND.

4

N

FAN MOTOR

POWER

PLUGS

REFER TO

FAN

MTR

FAN

MTR

EVAPORATOR

FAN

MTR

DATA PLATE

FOR MOTOR

QUANTITY

TERMINALS

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

CONDUCTORS/WIRING

FACTORY WIRING

WIRING BY OTHERS

OPTIONAL FACTORY OR

BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

- 12 -

Page 13

WIRING DIAGRAM - 200-220/1/50

ELECTRIC DEFROST MODELS

SINGLE EVAPORATOR 12A MAX. HEATERS

FOR ALL MODELS WITHOUT DEFROST HEATER CONTACTOR

USING MAXIMUM 15A HEATER OVERCURRENT PROTECTION

REFER TO EVAPORATOR

DEFROST CLOCK

PARAGON # 8145

OR EQUIVALENT

TM

3

4X

21

NAMEPLATE FOR ELECTRICAL

REQUIREMENTS

GND

FUSE OR

CIRCUIT

BREAKER

N

COMPR INTERLOCK

(IF USED)

L2L1

15A

GND.

SPACE

THERMOSTAT

NOTE #4

PUMP DOWN

SWITCH

(IF USED)

4

FAN

MTR

1

F

BK

X

BN

DT

FD

DEFROST TERMINATION

& FAN DELAY

CONTROL

(10.0A MAX.)

DT-DEFROST TERM

FD-FAN DELAY

FAN

MTR

2

C

RD

FAN

MTR

N

WH

6

N.C.

LIQUID LINE

SOL VALVE

NOTE #4

3

1

YL

HEATER

LIMIT

SWITCH

(10.0A MAX.)

FAN MO TOR

POWER PLUGS

REFER TO

EVAPORATOR

DATA PLATE FOR

MOTOR QUANTITY

ORANGE JUMPER

H1

DEFROST HEATERS

EVAPORATOR

EVAP FIELD MODIFICATION

SEE NOTE:

2

H2

MUST BE MADE

1

RELOCATE WHITE WIRE FROM

N TO H1 AS SHOWN

2

INSTALL ORANGE JUMPER

(SUPPLIED LOOSE)

FROM H2 TO N

H3

WARNING

NOTES

1). USE COPPER CONDUCTORS ONLY

2). USE 75°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

4.) MAY BE FACTORY INSTALLED-MOUNTED

AND WIRED ON EVAPORATOR

2-LP ED 12/07

- 13 -

TERMINALS

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

CONDUCTORS/WIRING

FACTORY WIRING

WIRING BY OTHERS

OPTIONAL FACTORY

OR BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

Page 14

WIRING DIAGRAM - 200-220/1/50

ELECTRIC DEFROST MODELS

SINGLE EVAPORATOR

FOR ALL MODELS USING DEFROST HEATER CONTACTOR

DEFROST CLOCK

PARAGON # 8145

OR EQUIVALENT

TM

3

4X

21

N

COMPR INTERLOCK

PUMP DOWN

SWITCH

(IF USED)

FUSE OR

CIRCUIT

BREAKER

NOTE #3

(IF USED)

SPACE

THERMOSTAT

NOTE #4

REFER TO EVAPORATOR NAMEPLATE

FOR ELECTRICAL REQUIREMENTS

L2L1

GND

L1

C

T1

N.C.

LIQUID LINE

SOL VALVE

NOTE #4

L2

T2

FUSE OR

CIRCUIT

BREAKER

NOTE #3

DEFROST HEATER

CONTACTOR

4

F

GND.

FAN

MTR

NOTES

1). USE COPPER CONDUCTORS ONLY

2). USE 75°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

4.) MAY BE FACTORY INSTALLED-MOUNTED

AND WIRED ON EVAPORATOR

3-LP ED CONTACTOR SINGLE 12/07

X

BN

DT

BK

FD

DEFROST TERMINATION

& FAN DELAY

CONTROL

(10.0A MAX.)

DT-DEFROST TERM

FD-FAN DELAY

FAN

MTR MTR

RD

C

N

WH

(10.0A MAX.)

HEATER

LIMIT

SWITCH

FAN

621

3

H1

YL

FAN MOTOR

POWER PLUGS

REFER TO

EVAPORATOR

DATA PLATE FOR

MOTOR QUANTITY

H2

H3

DEFROST HEATERS

EVAPORATOR

TERMINALS

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

CONDUCTORS/WIRING

FACTORY WIRING

WIRING BY OTHERS

OPTIONAL FACTORY

OR BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

- 14 -

Page 15

WIRING DIAGRAM - 200-220/3/50

ELECTRIC DEFROST MODELS

SINGLE EVAPORATOR

FOR ALL MODELS USING 3 PHASE DEFROST HEATER CONTACTOR

DEFROST CLOCK

PARAGON # 8145

OR EQUIVALENT

TM

3

4X

21

N

COMPR INTERLOCK

PUMP DOWN

SWITCH

(IF USED)

FUSE OR

CIRCUIT

BREAKER

NOTE #3

(IF USED)

SPACE

THERMOSTAT

NOTE #4

REFER TO EVAPORATOR NAMEPLATE

FOR ELECTRICAL REQUIREMENTS

GND

L1

C

T1

N.C.

LIQUID LINE

SOL VALVE

NOTE #4

L3

L2L1

L2

L3

T2

T3

FUSE OR

CIRCUIT

BREAKER

NOTE #3

DEFROST HEATER

CONTACTOR

GND.

4

FAN

MTR

X

F

BN

DT

BK

FD

DEFROST TERMINATION

& FAN DELAY

CONTROL

(10.0A MAX.)

DT-DEFROST TERM

FD-FAN DELAY

FAN

MTR

12 6

NOTES

1). USE COPPER CONDUCTORS ONLY

2). USE 75°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

4.) MAY BE FACTORY INSTALLED-MOUNTED

AND WIRED ON EVAPORATOR

3A-LP ED 3ph.CONTACTOR SINGLE 12/07

N

RD

C

3

WH

HEATER

LIMIT

SWITCH

(10.0A MAX.)

FAN

MTR

H1

YL

FAN MOTOR

POWER PLUGS

REFER TO

EVAPORATOR

DATA PLATE FOR

MOTOR QUANTITY

DEFROST HEATERS

EVAPORATOR

H2 H3

TERMINALS

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

CONDUCTORS/WIRING

FACTORY WIRING

WIRING BY OTHERS

OPTIONAL FACTORY

OR BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

- 15 -

Page 16

WIRING DIAGRAM - 380-400/1/50

ELECTRIC DEFROST MODELS

SINGLE EVAPORATOR

FOR ALL 460V MODELS USING DEFROST HEATER AND FAN CONTACTORS

DEFROST CLOCK

PARAGON # 8145

OR EQUIVALENT

TM

FUSE OR

CIRCUIT

3

4X

21

EVAP FAN

L2

L1

T1

T2

CONTACTOR

C

N

PUMP DOWN

(IF USED)

BREAKER

NOTE #3

COMPR INTERLOCK

(IF USED)

SPACE

THERMOSTAT

SWITCH

REFER TO EVAPORATOR NAMEPLATE

FOR ELECTRICAL REQUIREMENTS

L1

L2(N)

GND

NOTE #4

LIQUID LINE

SOL VALVE

NOTE #4

GND

C

N.C.

L2L1

L2

L1

T2

T1

FUSE OR

CIRCUIT

BREAKER

NOTE #3

DEFROST HEATER

CONTACTOR

M2

M1

GND.

MTR

NOTES

1). USE COPPER CONDUCTORS ONLY

2). USE 75°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

4.) MAY BE FACTORY INSTALLED-MOUNTED

AND WIRED ON EVAPORATOR

7-LP ED CONTACTOR SINGLE 12/07

H1 H2

COIL DEFROST HEATERS

FANFAN

MTR

X

3

FAN

MTR

4

FAN M OTOR

POWER PLUGS

REFER TO

EVAPORTOR

DATA PLATE FOR

MOTOR QUANTITY

F

BN

DT

BK

FD

DEFROST TERMINATION

& FAN DELAY

CONTROL

(10.0A MAX.)

DT-DEFROST TERM

FD-FAN DELAY

YL

HEATER

LIMIT

SWITCH

(10.0A MAX.)

EVAPORATOR

N

C

RD

WH

TERMINALS

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

CONDUCTORS/WIRING

FACTORY WIRING

WIRING BY OTHERS

OPTIONAL FACTORY

OR BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

- 16 -

Page 17

WIRING DIAGRAM - 200-220/1/50

ELECTRIC DEFROST MODELS

MULTIPLE EVAPORATORS

FOR ALL MODELS USING DEFROST HEATER CONTACTOR

GND.

DEFROST CLOCK

PARAGON # 8145

OR EQUIVALENT

TM

3

4X

21

4

F

X

BN

BK

DEFROST TERMINATION

& FAN DELAY

(10.0A MAX.)

DT-DEFROST TERM

FD-FAN DELAY

DT

FD

CONTROL

N

COMPR INTERLOCK

PUMP DOWN

SWITCH

(IF USED)

C

RD

REFER TO EVAPORATOR NAMEPLATE

FOR ELECTRICAL REQUIREMENTS

GND

FUSE OR

CIRCUIT

BREAKER

NOTE #3

C

(IF USED)

N.C.

LIQUID LINE

SPACE

NOTE #4

3

YL

SOL VALVE

NOTE #4

H1N

DEFROST HEATERS

THERMOSTAT

WH

HEATER

LIMIT

SWITCH

(10.0A MAX.)

L2

L1

FUSE OR

CIRCUIT

BREAKER

NOTE #3

DEFROST HEATER

L2

L1

CONTACTOR

T2

T1

WARNING

FUSE OR

CIRCUIT

BREAKER

NOTE #3

H2

GND.

4

F

X

BN

2

BK

DEFROST TERMINATION

DT-DEFROST TERM

FD-FAN DELAY

DT

FD

& FAN DELAY

CONTROL

(10.0A MAX.)

1

C

RD

WH

HEATER

LIMIT

SWITCH

(10.0A MAX.)

* Remove & Insulate

EVAP#2 FIELD MODIFICATION

MUST BE MADE

SEE NOTE:

1

RELOCATE WHITE WIRE FROM

N AS SHOWN

2

REMOVE AND INSULATE

AS SHOWN

3

H1NH2

YL

DEFROST HEATERS

FAN M OTO R

POWER PLUGS

REFER TO

FANFAN

MTR

MTR

FAN

MTR

EVAPORATOR

DATA PLATE FOR

MOTOR QUANTITY

PRIMARY

EVAPORATOR

* Fan delay not used on second evap / use fan contactor if total fan amps exceeds 10A

NOTES

1). USE COPPER CONDUCTORS ONLY

2). USE 75°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

4.) MAY BE FACTORY INSTALLED-MOUNTED

AND WIRED ON EVAPORATOR

4-LP ED CONTACTOR MULTI 12/07

- 17 -

FAN M OTO R

POWER PLUGS

REFER TO

FAN

MTR

MTR

FANFAN

MTR

EVAPORATOR

DATA PLATE FOR

MOTOR QUANTITY

TERMINALS

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

CONDUCTORS/WIRING

FACTORY WIRING

WIRING BY OTHERS

OPTIONAL FACTORY

OR BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

SECONDARY

EVAPORATOR

Page 18

WIRING DIAGRAM - 380-400/1/50

ELECTRIC DEFROST MODELS

MULTIPLE EVAPORATORS

FOR ALL 460V MODELS USING DEFROST HEATER AND FAN CONTACTORS

REFER TO EVAPORATOR NAMEPLATE

DEFROST CLOCK

PARAGON # 8145

OR EQUIVALENT

TM

3

4X

21

EVAP FAN

L2

L1

C

CONTACTOR

T2

T1

N

PUMP DOWN

FOR ELECTRICAL REQUIREMENTS

L1

GND

FUSE OR

CIRCUIT

BREAKER

NOTE #3

COMPR INTERLOCK

(IF USED)

SPACE

THERMOSTAT

NOTE #4

LIQUID LINE

SWITCH

(IF USED)

SOL VALVE

L2(N)

N.C.

NOTE #4

GND

L2

L1

FUSE OR

CIRCUIT

BREAKER

NOTE #3

DEFROST HEATER

CONTACTOR

L2

L1

C

T2

T1

FUSE OR

CIRCUIT

BREAKER

NOTE #3

WARNING

EVAP#2 FIELD MODIFI-

CATION MUST BE MADE

1

RELOCATE WHITE WIRE FROM

N AS SHOWN

FAN

MTR

4

FAN MO TOR

POWER PLUGS

REFER TO

EVAPORATOR

DATA PLATE FOR

MOTOR QUANTITY

GND.

M2

M1

MTR

H1 H2

DEFROST HEATERS

FANFAN

MTR

NOTES

1). USE COPPER CONDUCTORS ONLY

2). USE 75°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

4.) MAY BE FACTORY INSTALLED-MOUNTED

AND WIRED ON EVAPORATOR

8-LP 460v ED CONTACTOR MULTI 09/06

3

F

X

BN

DT

BK

FD

DEFROST TERMINATION

& FAN DELAY

CONTROL

(10.0A MAX.)

DT-DEFROST TERM

FD-FAN DELAY

YL

HEATER

SWITCH

(10.0A MAX.)

PRIMARY

EVAPORATOR

LIMIT

MTR

FAN

*

4

3

DEFROST TERMINATION

FAN MO TOR

POWER PLUGS

REFER TO

EVAPORATOR

DATA PLATE FOR

MOTOR QUANTITY

F

X

BN

DT

BK

FD

& FAN DELAY

CONTROL

(10.0A MAX.)

DT-DEFROST TERM

FD-FAN DELAY

YL

(10.0A MAX.)

SECONDARY

EVAPORATOR

M2

GND.

M1

FAN

MTR

N

C

RD

WH

H1 H2

DEFROST HEATERS

FAN

MTR

* Note: Fan Delay not used on second evap

HEATER

LIMIT

SWITCH

N

C

1

RD

WH

TERMINALS

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

CONDUCTORS/WIRING

FACTORY WIRING

WIRING BY OTHERS

OPTIONAL FACTORY

OR BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

- 18 -

Page 19

WIRING DIAGRAM - 200-220/1/50

HOT GAS DEFROST MODELS

USING MAXIMUM 15A HEATER OVERCURRENT PROTECTION

REFER TO EVAPORATOR

NAMEPLATE FOR ELECTRICAL

REQUIREMENTS

FUSE OR

CIRCUIT

BREAKER

REFER TO SPECIFIC SYSTEM

WIRING DIAGRAM (BY OTHERS)

FOR FIELD CONTROL WIRING

GND

L2(N)

L1

15A

FAN MOTOR / HEATER WIRING

4

GND.

MTR

X

F

BK

**DEFROST TERMINATION

FANFAN

MTR

*FAN HEATER

RD

CONTROL

CONTROL

C

FAN

MTR

BN

RD

RD

FAN MOTOR

POWER PLUGS

REFER TO

EVAPORATOR

DATA PLATE FOR

MOTOR QUANTITY

NOTES

1). USE COPPER CONDUCTORS ONLY

2). USE 75°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

4.) MAY BE FACTORY INSTALLED-MOUNTED

AND WIRED ON EVAPORATOR

5-LP HG 08/06

H1

N

DRAIN PAN HEATER

(IF APPLICABLE)

EVAPORATOR

H2

*FAN HEATER

CONTROL

ON REVERSE CYCLE LOCATED AT SUCTION LINE.

ON THREE-PIPE LOCATED AT DISTRIBUTOR SIDE PORT.

NOTE: DURING THE HOT GAS DEFROST CYCLE

THE FAN/HEATER CONTROL DE-ENERGIZES THE

EVAPORATOR FANS AND ENERGIZES THE

DRAIN PAN HEATER.

(ANYTIME THE TEMPERATURE OF THE INCOMING

REFRIGERANT GAS IS ABOVE 50° F).

**DEFROST TERMINATION

CONTROL

OPTIONAL FACTORY WIRED OR BY OTHERS

LOCATED ON TUBE END SHEET

THE CONTROL CLOSES WHEN REACHES 55` F (20 F DIFF)

TERMINALS

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

CONDUCTORS/WIRING

FACTORY WIRING

WIRING BY OTHERS

OPTIONAL FACTORY

OR BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

- 19 -

Page 20

WIRING DIAGRAM - 380-400/1/50

HOT GAS DEFROST MODELS

USING MAXIMUM 15A HEATER OVERCURRENT PROTECTION

REFER TO EVAPORATOR

NAMEPLATE FOR ELECTRICAL

REQUIREMENTS

FUSE OR

CIRCUIT

BREAKER

GND

L2

L1

15A

FAN MOTOR / HEATER WIRING

GND.

EVAP FAN

L2

L1

T1

BN

T2

C

FAN

MTR

CONTACTOR

RD

RD

FAN MOTOR

POWER PLUGS

REFER TO

EVAPORATOR

DATA PLATE FOR

MOTOR QUANTITY

C

DRAIN PAN HEATER

(IF APPLICABLE)

EVAPORATOR

C

M2

M1

MTR

F

FANFA N

MTR

3H1H2N

X

BK

*FAN HEATER

CONTROL

RD

**DEFROST TERMINATION

CONTROL

L2

L1

T2

T1

DEFROST HEATER

CONTACTOR

REFER TO SPECIFIC SYSTEM WIRING DIAGRAM

(BY OTHERS) FOR FIELD CONTROL WIRING

*FAN HEATER

CONTROL

ON REVERSE CYCLE LOCATED AT SUCTION LINE.

ON THREE-PIPE LOCATED AT DISTRIBUTOR SIDE PORT.

NOTE: DURING THE HOT GAS DEFROST CYCLE

THE FAN/HEATER CONTROL DE-ENERGIZES THE

EVAPORATOR FANS AND ENERGIZES THE

DRAIN PAN HEATER.

(ANYTIME THE TEMPERATURE OF THE INCOMING

REFRIGERANT GAS IS ABOVE 50° F).

**DEFROST TERMINATION

CONTROL

OPTIONAL FACTORY WIRED OR BY OTHERS

LOCATED ON TUBE END SHEET.

THE CONTROL CLOSES WHEN REACHES 55` F (20 F DIFF)

NOTES

1). USE COPPER CONDUCTORS ONLY

2). USE 90°C WIRE (OR HIGHER)

3). OVERCURRENT PROTECTION FOR

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

4.) MAY BE FACTORY INSTALLED-MOUNTED

AND WIRED ON EVAPORATOR

9-LP 460 HG 05/06

- 20 -

TERMINALS

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

CONDUCTORS/WIRING

FACTORY WIRING

WIRING BY OTHERS

OPTIONAL FACTORY

OR BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

Page 21

DIMENSIONAL DATA

15 7/8

[403]

[341]

13 7/16

LEDOM

^M401

^M601

^M701

#M902

#M112

#M412

#M713

#M0

#M324

#M624

#M235

#M936

^L401

^L501

^L601

#L702

#L902

#L112

#L413

#L713

#L914

#L2

#L725

#L136

^V301

^V401

^V501

#V602

#

#V902

#V213

#V513

#V614

#V914

#V325

#V726

3

[76]

11 7/8 3 1/8

6 1/2

[165]

MTG SLOTS

FO.ON

SNAF

14/103

14/103

14

24/164

24/164

24/164

34/126

34/126

44/187

44/187

54/149

64/1011

14/103

14/103

14/103

24/164

24/164

24/164

34/126

34/126

44/187

44/187

54/149

64/101

14/103

14/103

14/103

24/164

24/164

24/164

34/126

34/126

44/187

44/187

54/149

64/1011

1 3/8

[35]

12

[305] [302] [79]

MINIMUM

23

24

V802

.438 SLOTS IN

MOUNTING BRACKETS

AIR THROW

APPROX 35'

IN OPEN

SPACE

3/4 MPT / 3/4 FLARE

DRAIN CONNECTION

REFRIGERATION

CONNECTIONS.

SUCTION & LIQUID.

[341]

13 7/16

[102]

TYP

MTG SLOTS

C

AB C

NI

mm(

/103

1(

1

NI

)

)867(

)867(

)867(

)5711(

)5711(

)5711(

)1851(

)1851(

)8891(

)8891(

)4932(

)0082(

)867(

)867(

)867(

)5711(

)571

)5711(

)1851(

)1851(

)8891(

)8891(

)4932(

)0082(

)867(

)867(

)867(

)5711(

)5711(

)5711(

)1851(

)1851(

)8891(

)8891(

)4932(

)0082(

4/171

4/171

4/171

4/133

4/133

4/133

4/194

4/194

8/523

8/523

8/523

8/584

4/171

4/171

4/171

4/133

4/133

4/133

4/194

4/194

8/523

8/523

8/523

8/584

4/171

4/171

834(

4/171

4/133

4/133

4/133

4/19

4

4/194

8/523

8/523

8/523

8/584

NI

)mm(

)834(

)834(

)834(

)548(

)548(

)548(

)928(

)928(

)928(

5321(

)834(

)834(

)834(

)548(

)548(

)548(

)928(

)928(

)928(

)834(

)

)834(

)548(

)548(

)548(

)928(

)928(

)928(

A/N

A/N

A/N

A/N

A/N

A/N

A/N

)1521(

A/N

)1521(

8/523

8/523

8/584

)

8/584

A/N

A/N

A/N

A/N

A/N

A/N

A/N

)1521(

A/N

)1521(

8/523

8/523

8/584

)5321(

8/584

A/N

A/N

A/N

A/N

A/N

A/N

A/N

)1521(

A/N

)1521(

8/523

8/523

8/584

)5321(

8/584

elbaliavaRroG,H,T.EroA=^.Rro,G,H,T,E,A=#

[165]

4

A

B

6 1/26 1/2

[165]

ELECTRICAL

CONNECTIONS.

1, 2 AND 3 FAN

MODELS.

(TOP VIEW)

A

B

4, 5 AND 6 FAN

MODELS.

(TOP VIEW)

NOITCUS

)mm(

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

)928(

)928(

)5321(

)5321(

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

)928(

)928(

)5321(

)5321(

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

)928(

)928(

)5321(

)5321(

NOITCENNOC

TAEWS)DI(

8/52/12/1A/N

8/52/12/1A/N

8/52/12/1A/N

8/72/12/18/5

8/72/12/18/5

8/72/12/18/5

8/72/12/18/7

8/72/12/18/7

8/112/12/18/7

8/112/12/18/7

8/312/12/18/11

8/318/78/58/11

8/52/12/1A/N

8/52

8/52/12/1A/N

8/72/12/18/5

8/72/12/18/5

8/72/12/18/5

8/72/12/18/7

8/112/12/18/7

8/112/12/18/7

8/118/78/58/7

8/318/78/58/11

8/318/78/58/11

8/52/12/1A/N

8/52/12/1A/N

8/52/12/1A/N

8/72/12/18/5

8/72/12/18/5

8/72/12/18/5

8/72/12/18/7

8/112/12/18/7

8/112/12/18/7

8/118/78/58/7

8/318/78/58

8/318/78/58/11

ROTUBIRTSID

TELNI

EZIS

SAGTOH

ROTUBIRTSID

TROPEDIS

/12/1A/N

sliatedroferutalcnemoNotrefeRylnosledomnaf6ot2ni

NAPNIARD

POOL

/11

- 21 -

Page 22

SHIPPING WEIGHTS

Air Defrost and Hot Gas Defrost with Drain Pan Heater Models

REBMUNLEDOM

AM401A/NA/NA/NA/NA/NA/NAW401

AM601A/NA/NA/NA/NA/NA/NAW601

AM701A/NA/NA/NA/NA/NA

AM902TM902GM902GL702TL702GV602TV602AW902

AM112TM112GM112GL902TL902GV802TV802AW112

AM412TM412GM4

AM713TM713GM713GL413TL413GV213TV213AW713

AM023TM023GM023GL713TL713GV513TV513AW023

AM324TM324GM324GL914TL914GV614TV614AW324

AM624TM624GM624GL224TL224GV914TV914AW624

AM235TM235GM235GL7

AM936TM936GM936GL136TL136GV726TV726AW936

12GL112TL112GV902TV902AW412

Electric Defrost Models

EM401EL401EV301EW401

EM601EL501EV401EW601

EM701EL601EV501EW701

EM902EL702EV602EW902

EM112EL902EV802EW112

EM412EL112EV902EW412

EM713EL413EV213EW713

EM023EL71

EM324EL914EV614EW324

EM624EL224EV914EW624

EM235EL725EV325EW235

EM936EL136EV726EW

3EV513EW023

25TL725GV325TV325AW235

REBMUNLEDOM

/NAW701

936

.BL

54

74

94

07

47

87

101

701)84(

711

531

361

291

.BL

94

15

35

67

08

48

901

511)25(

721

541

671

702

THGIEWGNIPPIHS

)gk(

)02(

)12(

)22(

)23(

)33(

)53(

)64(

)35(

)16(

)47(

)78(

THGIEWGNIPPIHS

)gk(

)22(

)32(

)42(

)43(

)63(

)83(

)94(

)85(

)66(

)08(

)49(

Hot Gas Defrost with Drain Pan Loop Models

REBMUNLEDOM

HM902RM902HL702RL702HV602RV602

HM112RM112HL902RL902HV802RV802

HM412RM4

HM713RM713HL413RL413HV213RV213

HM023RM023HL713RL713HV513RV513

HM324RM324HL914RL

HM624RM624HL224RL224HV914RV914

HM235RM235HL725RL725HV325RV325

HM936RM936HL136RL136HV7

12HL112RL112HV902RV902

914HV614RV614

26RV726

-22 -

.BL

78

19

59

421

031)95(

541

361

891

332

THGIEWGNIPPIHS

)gk(

)93(

)14(

)34(

)65(

)66(

)47(

)09(

)601(

Page 23

RECOMMENDED THERMAL EXPANSION VALVE SELECTIONS

MEDIUM TEMPERATURE MODELS

DANFOSS

LEDOM

M401

M601

M701

M902

M112

M412

M713

M023

M324

M624

M235

M936

YROTCAF

DELLATSNI

ELZZON

A/NN-4-A404R-EAUTN-3-22R-EAUTN-3-a431R-EAUT

2/1-LN-4-A

2/1-LN-5-A404R-EAUTN-4-22R-EAUTN-5-a431R-EAUT

4/3-LN-6-A404R-EAUTN

1-LN-6-A404R-EAUTN-5-22R-EAUTN-6-a431R-EAUT

1-LN-7-A404R-EAUTN-6-22R-EAUTN-7

2/11-LN-8-A404R-EAUTN-7-22R-EAUTN-8-a431R-EAUT

2/11-LN-8-A404R-EAUTN-7-22R-EAUTN-8-a431R2-LN-8-A404R-EAUTN-8-22R-EAUTN-8-a431R-EAUT

2-LN-9-A404R-EAUTN-8-22R-EAUTN-9-a431R-EAUT

2/12-

LN-1CT-A404R-EACTN-8-22R-EAUTN-9-a431R-EAUT

3-GN-2CT-A404R-EACTN-9-22R-EAUTN-2CT-a431R-EACT

/A404R

705R

404R-EAUTN-4-22R-EAUTN-4-a431R-EAUT

22Ra431R

-4-22R-EAUTN-6-a431R-EAUT

ALCO

LEDOM

M401

M601

M701

M902

M112

M412

M713

M023

M324

M624

M235

M936

YROTCAF

DELLATSNI

ELZZON

A/NCS4/1CSEFHCH2/1CSEFHCM2/1CSEFH

2/1-LCS2/1CSEFHCH2/1C

2/1-LCS2/1CSEFHCH2/1CSEFHCM4/3CSEFH

4/3-LCS1CSEFHCH1CSEFHCM4/3CSEFH

1-LCS1CSEFHCH1CSEF

1-LCS4/1-1CSEFHCH2/1-1CSEFHCM1CSEFH

2/11-LCS2/1-1CSEFHCH2/1-1CSEFHCM2/1-1CSEFH

2/11-LCS2/1

2-LCS2CSEFHCH2CSEFHCM4/3-1CSEFH

2-LCS2CSEFHCH2/1-2CSEFHCM2/1-2CSEFH

2/12

-LCS2/1-3CSEFHCH2/1-2CSEFHCM2/1-2CSEFH

3-GCS2/1-3CSEFHCH3CSEFHCM4CSEFH

Above selections based on:

1) 100°F (38°C) vapor free liquid entering expansion valve

2) 110°F (43°C) Condensing temperature

3) 8 -12°F (4.4 -6.7°C) evaporator TD

/A404R

705R

-1CSEFHCH2CSEFHCM4/3-1CSEFH

22Ra431R

SEFHCM4/3CSEFH

HCM1CSEFH

SPORLAN*

LEDOM

M401

M601

M701

M902

M112

-a431R-EAUT

EAUT

M412

M713

M023

M324

M624

M235

M936

YROTCAF

DELLATSNI

ELZZON

A/NC-4/1-ESGEC-3/1-EVGEC-4/1-EJGE

2/1-LC-2/1-ESGEC-2/1

2/1-LC-2/1-ESGEC-4/3-EVGEC-2/1-EJGE

4/3-LC-1-ESGEC-4/3-EVGEC-1-EJGE

1-LC-1-ESGEC-1-EV

1-LC-2/1-1-ESGEC-2/1-1-EVGEC-1-EJGE

2/11-LC-2/1-1-ESGEC-2/1-1-EVGEC-2/1-1-EJGE

2/11-LC-22-LC-2-ESGEC-2-EVGEC-2/1-1-EJGE

2-LC-2-ESGEC-2-EVGEC-2-EJGE

2/12-LC-3-ES

3-GC-4-ESSC-3-EVGEC-3-EJGE

/A404R

*705R

ESGEC-2/1-1-EVGEC-2/1-1-EJGE

SC-3-EVGEC-2/1-2-EJGE

22Ra431R

-EVGEC-2/1-EJGE

GEC-1-EJGE

ELZZON

.

oNECIFIRO

2/1070.

4/3680.

15990.

2/1-1021.

26041.

2/1-2751.

3271.

4991.

5112.

6242.

8662.

01182.

lliwevlavnoisnapxenalropSrofedoctnaregirfer,705RroF*

"EPGE"semoceb"ESGE":.e.i."S"fodaetsni"P"eb

tonsielzzontcerrocfI

reporpeht,elbaliava

ebnacezisecifiro

gnisudleifehtnidellird

trahcgniwollofeht

LLIRD

EZIS

.NI

- 23 -

Page 24

RECOMMENDED THERMAL EXPANSION VALVE SELECTIONS

LOW TEMPERATURE R404A/R507 MODELS

DANFOSS

LEDOM

L401

L501

L601

L702

L902

L112

L413

L713

L914

L2

24

L725

L136

V301

V401

V501

V602

V802

V902

V213

V513

V614

V914

V325

V726

YROTCAF

2/1-LN-4-A404R-EAUTMN-5-A404R-EAUTMN-5-A404R-EAUTMN-6-A404R-EAUTMN-6-A404R-EAUT

4/3-LN-5-A404R1-LN-6-A404R-EAUTMN-6-A404R-EAUTMN-6-A40

1-LN-6-A404R-EAUTMN-7-A404R-EAUTMN-7-A404R-EAUTMN-7-A404R-EAUTMN-8-

2/1-1N-7-A404R-EAUTMN-7-A404R-EAUTMN-8-A404R-EAUTMN-8-A404R-EAUTMN-8-A404R-EAUT

2-LN-7-A40

2-LN-8-A404R-EAUTMN-8-A404R-EAUTMN-93-LN-9-A404R-EAUTMN-9-A404R-EAUTMN-9-A404R-EAUTMN-1CT-A404R-EAC

3-LN-9-A404R-EAUTMN-9-A404R-EAUTMN-1CT-A404R-EACTMN-1CT-A404R-EACTMN-1CT-A404R-EACT

4-GN-9-A404R-EAUTMN-1CT-A404R-EACTMN-1CT-A404R-EACTMN-1CT-A404R-EACTMN-2CT-A404R-EACT

4-GN-1CT-A404R-E

5-GN-2CT-A404R-EACTMN-2CT-A404R-

2/1-LN-4-A404R-EAUTMN-4-A404R-EAUTMN-4-A404R-EAU

4/3-LN-5-A404R-EAUTMN-5-A404R-EAUTMN-5-A404R-EAUTMN-6-A404R-EAUTMN-6-A404

1-LN-5-A404R-EAUTMN-6-A404R-EAUTMN-6-A404R-EAUTMN-6-A404R-EAUTMN-7-A404R-EAUT

1-LN-6-A404R-EAU

2/11-LN-6-A404R-EAUTMN-7-A404R-EAUTMN-7-A40

2-LN-7-A404R-EAUTMN-7-A404R-EAUTMN-8-A404R-EAUTMN-8-A404R-EAUTMN-82-LN-8-A404R-EAUTMN-8-A404R-EAUTMN-8-A404R-EAUTMN-9-A404R-EAUTMN-9-A404R-EAUT

2/12-LN-8-A4

2/12-LN-8-A404R-EAUTMN-9-A404R-EA

3-GN-9-A404R-EAUTMN-9-A404R-EAUTMN-1CT-A404R-EACTMN-1CT

4-GN-9-A404R-EAUTMN-1CT-A404R-EACTMN-1CT-A404R-EACTMN-2CT-A404R-EACTMN-2CT5-GN-1CT-A404R-EACTMN-2CT-A404R-EACTMN-2CT-A404R-EACTMN-2CT-A404R-EACTMN-3CT-A404R-EACT

F°0 )C°81-( .PAVEF°01- )C°32-( .PAVEF°02- )C°92-( .PAVEF°03- )C°43-( .PAVEF°04- )C°04-(

ELZZONDELLATSNI

EAUTMN-6-A404R-EAUTMN-6-A404R-EAUTMN-6-A404R-EAUTMN-6-A404R-EAUT

4R-EAUTMN-7-A404R-EAUTMN-7-A404R-EAUT

4R-EAUTMN-8-A404R-EAUTMN-8-A404R-EAUTMN-8-A404R-EAUTMN-9-A404R-EAUT

A404R-EAUTMN-9-A404R-EAUTMN-9-A404R-EAUT

TMN-1CT-A404R-EACT

ACTMN-2CT-A404R-EACTMN-2CT-A404R-EACTMN-2CT-A404R-EACTMN-3CT-A404R-EACT

EACTMN-3CT-A404R-EACTMN-3CT-A404R-EACTMN-3CT-A404R-EACT

TMN-5-A404R-EAUTMN-5-A404R-EAUT

TMN-6-A404R-EAUTMN-7-A404R-EAUTMN-7-A404R-EAUTMN-7-A404R-EAUT

4R-EAUTMN-8-A404R-EAUTMN-8-A404R-EAUT

04R-EAUTMN-9-A404R-EAUTMN-9-A404R-EAUTMN-9-A404R-EAUTMN-1CT-A404R-EACT

UTMN-9-A404R-EAUTMN-9-A404R-EAUTMN-1CT-A404R-EACT

-A404R-EACTMN-1CT-A404R-EACT

.PAVE

A404R-EAUT

R-EAUT

A404R-EAUT

A404R-EACT

SPORLAN*

LEDOM

L401

L501

L601

L702

L902

L112

L413

L713

L914

L224

L725

L136

V301

V401

V501

V602

V802

V902

V213

V513

V614

V914

V325

V726

YROTCAF

2/1-LC-4/1-ESGEPZ-4/1-ESGEPZ-2/1-ESGEPZ-2/1-ESGEPZ-2/1-ESGE

4/3-LC-2/1-ESGEPZ-2/1-ESGEPZ-2/1-ESGEP

1-LC-2/1-ESGEPZ-2/1-ESGEPZ-2/1-ESGEPZ-2/1-ESGEPZ-2/1-ESGE

1-LC-2/1-ESGEPZ-2/1-ESG

2/1-1C-1-ESGEPZ-1-ESGEPZ-1-ESGEPZ-1-ESGEPZ-1-ESGE

2-LC-1-ESGEPZ-1-ESGEPZ-1-ES

2-LC-2/1-1-ESGEPZ-2/1-1-ESGEPZ-2/1-1-ESGEPZ-2/1-1-ESGEPZ-2/1-1-ESGE

3-LC-2/1-1-ESG

3-LC-2-ESGEPZ-2-ESGEPZ-2-ESGEPZ-2-ESGEPZ-2-ESGE

4-GC-2-ESGEP

4-GC-3-ESSPZ-3-ESSPZ-3-ESSPZ-3-ESSPZ-4-ESS

5-GC-4-ESSPZ-4-ESSPZ-4-ESSPZ-4

2/1-LC-6/1-ESGEPZ-6/1-ESGEPZ-4/1-ESGEPZ-4/1-ESGEPZ-4/1-ESGE

4/3-LC-4/1-ESGEPZ-4/1-ESGEPZ-2/

1-LC-2/1-ESGEPZ-2/1-ESGEPZ-2/1-ESGEPZ-2/1-ESGEPZ-2/1-ESGE

1-LC-2/1-ESGEPZ-2

2/11-LC-2/1-ESGEPZ-2/1-ESGEPZ-1-ESGEPZ-1-ESGEPZ-1-ESGE

2-LC-1-E

2-LC-1-ESGEPZ-1-ESGEPZ-1-ESGEPZ-1-ESGEPZ-2/1-1-ESGE

2/12-LC-2/1-1

2/12-LC-2/1-1-ESGEPZ-2/1-1-ESGEPZ-2/1-1-ESGEPZ-2

3-GC-2/1-1-ESGEPZ-2/1-1-ESGEPZ-2-ESGEPZ-2-ESGEPZ-2-ESGE

4-GC-2-ESGEPZ-2-ESGEPZ-3-ESSPZ

5-GC-3-ESSPZ-3-ESSPZ-3-ESSPZ-3-ESSPZ-4-ESS

Above selections based on:

1) 100°F (38°C) vapor free liquid entering expansion valve

2) 110°F (43°C) Condensing temperature

3) 8 -12°F (4.4 -6.7°C) evaporator TD

F°0 )C°81-( .PAVEF°01- )C°32-( .PAVEF°02- )C°92-( .PAVEF°03- )C°43-( .PAVEF°04- )C°04-(

ELZZONDELLATSNI

EPZ-2/1-1-ESGEPZ-2/1-1-ESGEPZ-2-ESGEPZ-2-ESGE

SGEPZ-1-ESGEPZ-1-ESGEPZ-1-ESGEPZ-1-ESGE

-ESGEPZ-2/1-1-ESGEPZ-2/1-1-ESGEPZ-2/1-1-ESGEPZ-2/1-1-ESGE

.PAVE

Z-2/1-ESGEPZ-2/1-ESGE

EPZ-1-ESGEPZ-1-ESGEPZ-1-ESGE

GEPZ-1-ESGEPZ-1-ESGE

Z-2-ESGEPZ-2-ESGEPZ-3-ESSPZ-3-ESS

-ESSPZ-4-ESS

1-ESGEPZ-2/1-ESGEPZ-2/1-ESGE

/1-ESGEPZ-2/1-ESGEPZ-2/1-ESGEPZ-2/1-ESGE

/1-1-ESGEPZ-2-ESGE

-3-ESSPZ-3-ESS

"EPGE"semoceb"ESGE":.e.i."S"fodaetsni"P"eblliwevlavnoisnapxenalropSrofedoctnaregirfer,705RroF*

- 24 -

Page 25

RECOMMENDED THERMAL EXPANSION VALVE SELECTIONS

LOW TEMPERATURE R404A/R507 MODELS

ALCO

LEDOM

L401

L501

L601

L702

L902

L112

L413

L713

L914

L224

L725

L136

V301

V401

V501

V602

V802

V902

V213

V513

V614

V914

V325

V726

YROTCAF

2/1-LCS4/1CSEFH54WS2/1CSEFH54WS2/1CSEFH54WS2/1CSEFH54WS2/1CSEFH

4/3-LCS2/1CSEFH54WS2/1CSEFH54WS2/

1-LCS2/1CSEFH54WS2/1CSEFH54WS1CSEFH54WS1CSEFH54WS1CSEFH

1-LCS1CSEFH54WS1CSE

2/1-1CS1CSEFH54WS1CSEFH54WS4/1-1CSEFH54WS4/1-1CSEFH54WS2/1-1CSEFH

2-LCS1CSEFH54WS4/1-1CSEFH54WS2/1-1CSEFH54WS2/1-1CSEFH54WS2CSEFH

2-LCS4/1-1CSEFH54WS2/1-1CSEFH54WS2CSEFH54WS

3-LCS2/1-1CSEFH54WS2CSEFH54WS2CSEFH54WS2CSEFH54WS2/1-3CSEFH

3-LCS2/1-1CSEFH54WS2CSEFH54

4-GCS2CSEFH54WS2CSEFH54WS2/1-3CSEFH54WS2/1-3CSEFH54WS2/1-3CSEFH

4

-GCS2/1-3CSEFH54WS2/1-3CSEFH54WS2/1-3CSEFH54WS2/1-3CSEFH54WS5CSEFH

5-GCS2/1-3CSEFH54WS2/1-3CSEFH54WS2/1-3C

2/1-LCS4/1CSEFH54WS4/1CSEFH54WS4/1CSEFH54WS2/1CSEFH54WS2/1CSEFH

4/3-LCS4/1CSEF

1-LCS2/1CSEFH54WS2/1CSEFH54WS2/1CSEFH54WS1CSEFH54WS1CSEFH

1-LCS2/1CSEFH54WS2/1CSEFH54WS1CSEFH54WS1CSEFH54WS4/1-1CSEFH

2/11-LCS1CSEFH54WS1CSEFH54WS1CSEFH54WS4/1-1

2-LCS1CSEFH54WS1CSEFH54WS4/1-1CSEFH54WS4/1-1CSEFH54WS2/1-1CSEFH

2-LCS4/1-1CSEFH54WS

2/12-LCS4/1-1CSEFH54WS2/1-1CSEFH54WS2CSEFH54WS2CSEFH54WS2

2/12-LCS2/1-1CSEFH54WS2/1-1CSEFH54WS2CSEFH54WS2CSEFH54WS2/1-3CSEFH

3-GCS2/1-1CSEFH54WS2CSEFH54WS2

4-GCS2CSEFH54WS2/1-3CSEFH54WS2/1-3CSEFH54WS2/1-3CSEFH54WS2/1-3CSEFH

5-GCS2/1-3CSEFH54WS2/1-3CSEFH54WS2/1-3CSEFH54WS2/1-3CSEFH54WS5CSEFH

Above selections based on:

1) 100°F (38°C) vapor free liquid entering expansion valve

2) 110°F (43°C) Condensing temperature

3) 8 -12°F (4.4 -6.7°C) evaporator TD

F°0 )C°81-( .PAVEF°01- )C°32-( .PAVEF°02- )C°92-( .PAVEF°03- )C°43-( .PAVEF°04- )C°04-(

ELZZONDELLATSNI

H54WS2/1CSEFH54WS2/1CSEFH54WS2/1CSEFH54WS2/1CSEFH

(cont’d)

.PAVE

1CSEFH54WS2/1CSEFH54WS1CSEFH

FH54WS1CSEFH54WS1CSEFH54WS4/1-1CSEFH

2CSEFH54WS2CSEFH

WS2CSEFH54WS2/1-3CSEFH54WS2/1-3CSEFH

SEFH54WS5CSEFH54WS5CSEFH

CSEFH54WS4/1-1CSEFH

4/1-1CSEFH54WS2/1-1CSEFH54WS2/1-1CSEFH54WS2CSEFH

CSEFH

CSEFH54WS2/1-3CSEFH54WS2/1-3CSEFH

- 25 -

Page 26

INSTALLATION INSTRUCTIONS

INSTALLATION

The installation and start-up of Unit Coolers should only

be performed by qualified refrigeration mechanics.

This equipment should be installed in accordance with all

applicable codes, ordinances and local by-laws.

INSPECTION

Inspect all equipment before unpacking for visible signs of

damage or loss. Check shipping list against material

received to ensure shipment is complete.

IMPORTANT: Remember, you, the consignee, must make

any claim necessary against the transportation company .

Shipping damage or missing parts, when discovered at

the outset, will prevent later unnecessary and costly

delays.

If damage or loss during transport is evident, make

claim to carrier, as this will be their responsibility,

not the manufacturer’s.

Should carton be damaged, but damage to equipment is

not obvious, a claim should be filed for “concealed

damage” with the carrier.

IMPORTANT: The electrical characteristics of the unit

should be checked at this time to make sure they

correspond to those ordered and to electrical power

available at the job site.

Save all shipping papers, tags and instruction sheets for

reference by installer and owner .

APPLICATION

LP unit coolers are designed for walker-in cooler and

freezer applications used with refrigerant R22 or R404A.

For room temperatures above 35°F (2 °C) AND evaporating

temperatures above 26°F (-3 °C), positive defrosting

means (with electric or hot gas) may not be required,

otherwise, electric defrost or hot gas defrost models

should be used. Electric defrost models come with defrost

termination and fan delay as standard to control the

defrost cycle termination and fan delay , while defrost

initiation means (e.g. defrost timer) is not included.

The coil must not be exposed to any abnormal

atmospheric or acidic environments. This may result in

corrosion to the cabinet and possible coil failure (leaks).

(Consult manufacturer for optional baked on phenolic

protective coatings).

LOCATION

The unit location in the room should be selected to ensure

uniform air distribution throughout the entire space to be

refrigerated. Be sure that the product does not obstruct

the free circulation of air. Allow a minimum of 24” clearance at each end. Do not locate evaporators over doors.

Consideration should be given to the coil location in order

to minimize the piping run length to the

condensing unit and floor drain.

EXPANSION VALVE (TXV) SELECTION

All units require the use of an externally equalized

expansion valve. (A 1/4” (6 mm) O.D. equalizer line has

been provided on the coil) TX valves should not be

selected strictly by their nominal ton rating. (This rating

is based at a specific pressure differential and entering

liquid temperature). Since applications will differ it is

suggested the following selection procedure be followed.

1.Determine actual unit cooler capacity.

The nominal rating is based at 10OF T .D. (5 .6°C)

(Entering Air T emp. minus Evap. T emp.), R404A

refrigerant. For R22, use the rated capacity x 0.95.

For medium temperature R134a, use the rated

capacity x 0.90. Note that a higher / lower operating

T.D.will increase / decrease this capacity rating by

their direct ratio within a range of 8 to 12°F (4 .4 to

6.7°C) T .D.

2.Determine the pressure drop across the valve by

subtracting the evaporating pressure and distributor

pressure drop from the high side liquid pressure.

The distributor pressure drop is typically in the range

of 20 to 35 psig (1.4 to 2.4 bar) depending on the type

of refrigerant and operating conditions.

3.Estimate entering liquid temperature. T emperatures

lower than 100

ratings. Refer to valve manufacturer’s specs for

details.

4.Select valve from the valve manufacturer selection

charts for the appropriate refrigerant, evaporating temp

and pressure drop.

For best performance, the outlet of the expansion valve

should be installed directly to the distributor body . If this

is not possible, a straight tube up to 12 inches may be

used for the connection.

Locate the expansion valve bulb on a horizontal length

of suction line preferably 3 to 6 inches from the suction

header. Locate the bulb at 4 or 8 clock position and

insulate with a waterproof type of insulation. Clamp the

bulb to ensure 100% contact of the bulb with the

suction line.

Ensure appropriate nozzle has been installed in the