Page 1

PRODUCT DATA

Bulletin K70-KHR-PDS-11

We are on the Internet

www.keepriterefrigeration.com

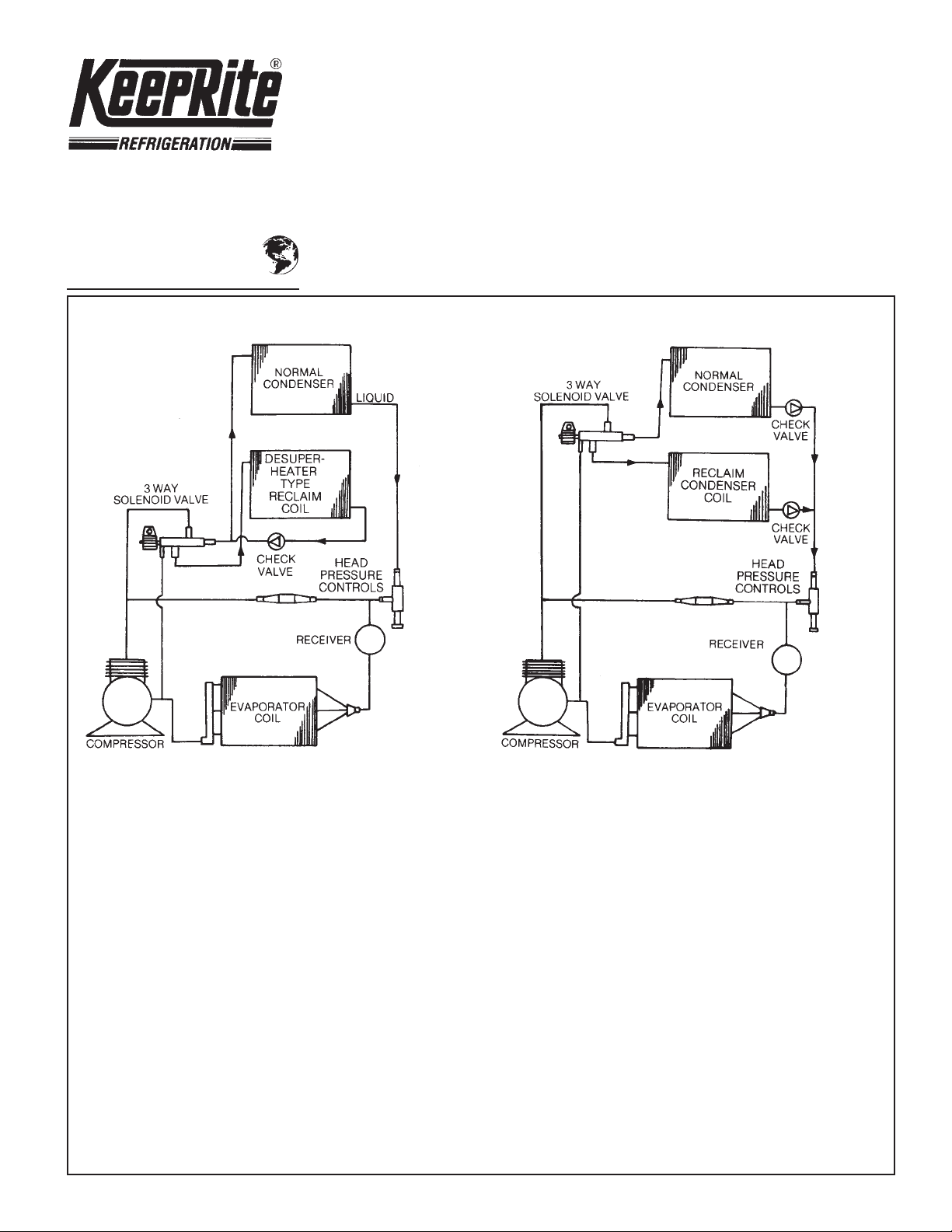

TYPICAL REFRIGERANT HEAT RECLAIM SYSTEMS

Heat Reclaim Coils

for Refrigeration

Systems

FIG.1 SERIES CONDENSER

General;There are basically two types of heat reclaim

coils used for refrigeration jobs:- 1. The heat reclaim coil

in series with an outside condenser. 2. The heat reclaim

coil in parallel with the outside condenser .

Systern 1 Usually this type of coil is designed to recover

a maximum of 50% of the total heat of rejection, the

balance then being handled by the outside condenser.

Because the heat reclaim coil is in series with the

outside condenser , the refrigerant pressure drop through

the coil must be kept to a minimum. It is desirable to

feed as many face tubes on the coil as possible to

obtain this low pressure drop. Self-draining circuiting is

also desirable when using this arrangement. When used

in a series condensing system this type of heat reclaim

coil is referred to by KeepRite Refrigeration as a

“Desuperheater type coil”, although some condensing

may also take place. A typical series system is shown

in Fig 1.

FIG. 2 PARALLEL CONDENSERS

System 2 This type of system will require the heat reclaim

coil to handle 100% of the total heat of rejection. Coil will

perform as the main condenser when heat is required.

When there is no heat demand the total heat of rejection

will be directed to the outside unit. This application of heat

reclaim is known as a “Condenser type” and will be circuited

in the same manner as any condenser. A typical parallel

system is shown in Fig. 2. A parallel system may also

utilize less than 100% of Total Heat of Rejection, by

installing a by pass line to the main condenser .

GENERAL INFORMATION

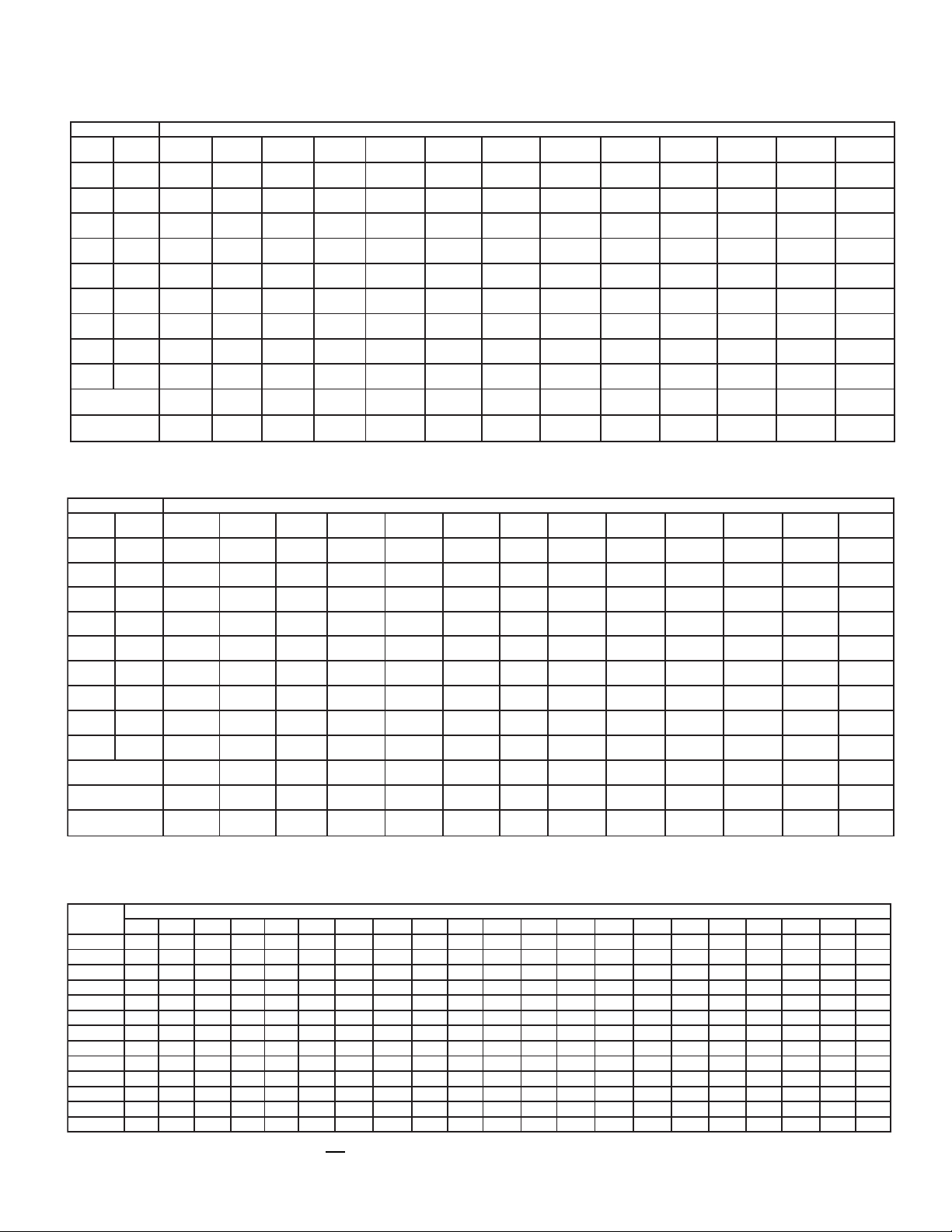

Tables 1 and 2 may be used to select the coil sizes

compatible with specific KeepRite air handling units.

T able 1 indicates the sizes and face areas of T ype HR

insert type coils as used in KLS and KHD units. Table 2

indicates the coil sizes and face areas of type KC coils

bolted to the KHF fan head.

Page 2

GENERAL INFORMATION (cont’d.)

It must be remembered that in models KLS 237 thru 164 air

handlers, two cooling coils are used. It is therefore possible

condensing system. T otal heat of rejection is 800,000

BTU/hr., 400,000 BTU/hr will be used for heat reclaim.

Condensing temperature is 1 10 °F , entering air is 65°F.

that the centre two tubes of a single H.R. heat reclaim coil

mounted against the two cooling coils may not receive the

full air flow. (See Bulletin AC4.7-SB1-2 Central Station Air

STEP 1. Coil size is 36" x 84-1/2" and air quantity

circulated is 10,600 C.F .M. (See Table 1).

Handlers).

Table 3 indicates the standard type of KC coil that may be

used for mounting in ductwork.

STEP 2. Determine the required coii performance in

BTU/hr. /C.F.M. from Total Load BTU/hr .

C.F.M.

HEAT RECLAIM SELECTION FORM

T o assist in the selection of heat reclaim coils, the KeepRite

Condenser Heat Reclaim Coil Selection Sheet may be used.

400,000

=

10,600

= 37.73 BTU/hr/C.F.M.

(See back cover.) For multiple compressor applications, the

BTU/Hour capacity for each unit may be tabulated.

Correction factors for T otal Heat of Rejection should be

applied from Chart 6. Actual tubes required to handle the

heat of rejection of each compressor may also be

calculated and listed. It should be noted when using 3 or 4

Row coils as Desuperheater type coils on a series system

that there will be one less tube in the face due to the free

drainage circuiting. A typical calculation is shown on

Page 7.

STEP 3. Temperature difference is 45°F. (Cond. Temp.

minus ent. air temp.). Refer to Chart 2. Using a 6 Row Coil,

10 F.P.l. at 500 F.P.M. note that the available capacity is

38.3 BTU/hr./C.F.M. This is close to the required capacity

and will be satisfactory .

STEP 4. Final T.D. will be as follows:

Performance Required (Step 2)

Performance Obtained (Step 3)

X 45°F .

= 37.73 X 45°F = 44.3°F, T.D.

38.3

SELECTING A TYPICAL HR HEA T RECLAIM COIL

Given: An insert type heat reclaim coil is to be used in a

KeepRite KLS222 air handler. Coil will be operating with an

air face velocity of 500 F .P.M., and is used on a series type

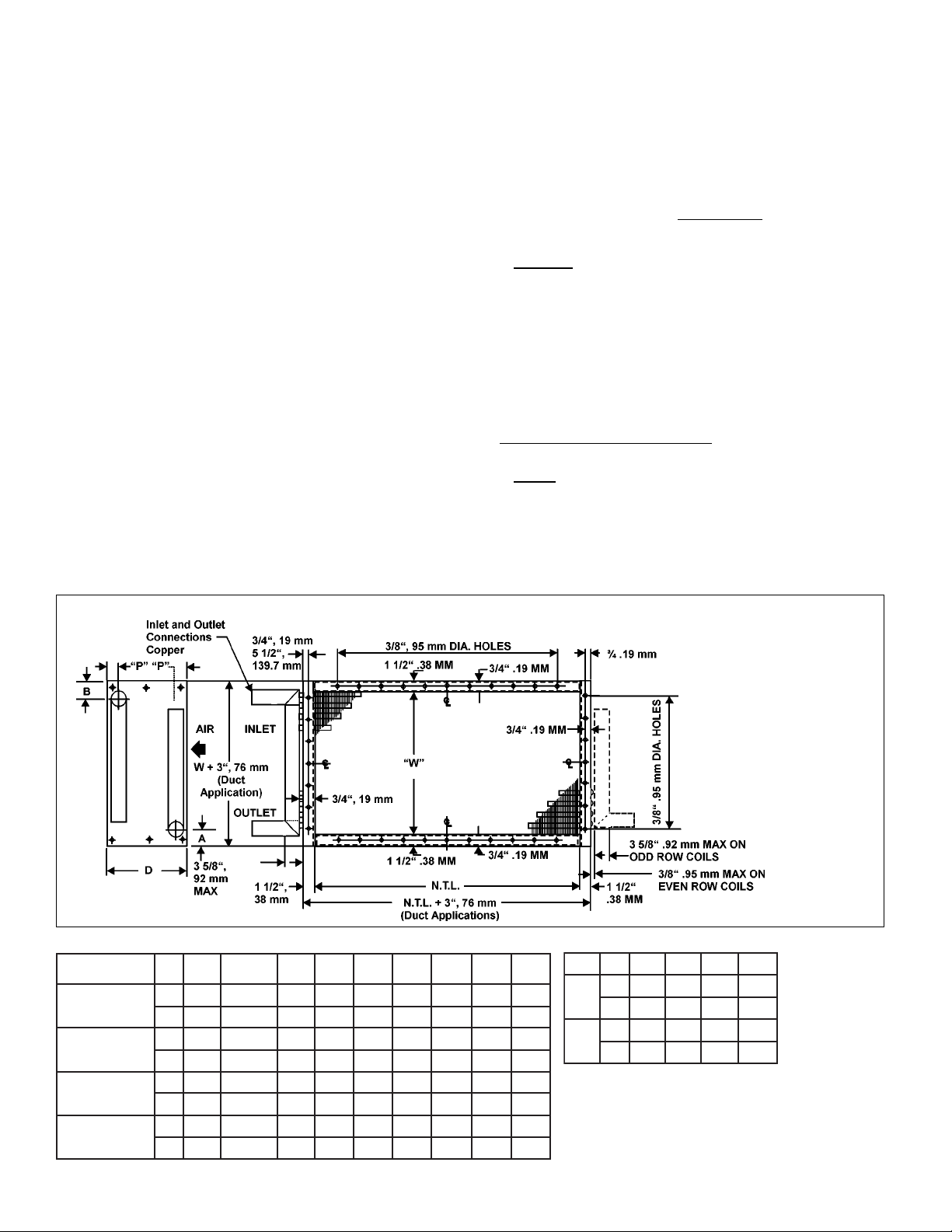

INFORMA TION SHOWN BELOW IS FOR GENERAL ARRANGEMENT AND DIMENSIONAL PURPOSES ONL Y

STEP 5. Coil selection is 1 - H R heat reclaim coil

10 F .P.I., 6 rows - 36" X 84 12” for use in a KeepRite

KLS 222 Air handling unit. Unit air volume 10,600 C.F.M.

Coil to be desuperheater type with 24 tubes fed.

Multiple Circuit Connection Sizes* and header Dimensions

TAEHLATOTTAEHLATOT

TAEHLATOTTAEHLATOT

TAEHLATOT

SNOT

SAGTOHSAGTOH

SAGTOHSAGTOH

SAGTOH

.S.D.O,TELNI.S.D.O,TELNI

.S.D.O,TELNI.S.D.O,TELNI

.S.D.O,TELNI

DIUQILDIUQIL

DIUQILDIUQIL

DIUQIL

.S.D.O,TELTUO.S.D.O,TELTUO

.S.D.O,TELTUO.S.D.O,TELTUO

.S.D.O,TELTUO

REDAEHREDAEH

REDAEHREDAEH

REDAEH

"A".MID"A".MID

"A".MID"A".MID

"A".MID

REDAEHREDAEH

REDAEHREDAEH

REDAEH

"B".MID"B".MID

"B".MID"B".MID

"B".MID

9-39-3

9-39-321-2/1921-2/19

9-3

mm75.8229.4329.4372.1479.3579.3576.6676.6673.97

sni8/118/318/318/518/128/128/528/528/13

mm22.2222.2275.8275.8229.4372.1472.1479.3579.35

sni8/78/78/118/118/318/518/518/128/12

mm26.7426.7426.7426.7426.7426.7426.7483.2583.25

sni8/718/718/718/718/718/718/7161/1261/12

mm26.7426.7426.7426.7483.2583.2537.8537.8580.56

sni8/718/718/718/7161/1261/1261/5261/5261/92

21-2/1921-2/1961-3161-31

21-2/19

61-3161-3122-7122-71

61-31

22-7122-7143-3243-32

22-71

43-3243-3224-5324-53

43-32

24-5324-5325-3425-34

24-53

25-3425-3486-3586-35

25-34

- 2 -

86-3586-3577-9677-96

86-35

NOTE:

1. Coil shown is for

Duct Application.

For insert in, or

bolting to a KeepRite

AH Unit, unit size

must be specified.

2. Header location

subject to verification

for specific orders.

Dimension data

WORWOR

WORWOR22222333334444466666

WOR

77-9677-96

77-96

.MID.MID

.MID.MID

.MID

mm0.7214.2515.0917.662

DDDDD

sni56 2/172/101

.MID.MID

.MID.MID

.MID

mm26.7472.1413.348.05

PPPPP

sni8/718/514/312

NOTE: HEADERS MAY.EXTEND BEYOND DIMENSION “D”

* When used as Desuperheter, inlet and outlet connections will

be the same size and based on Hot Gas sizing. Every face

tube is fed on Desuperheater applications.

* For circuit loading less than 3 tons on R502 and R22, and less

than 1.7 tons on R12, no headers will be supplied. Hot gas inlet

and outlet will be 1/2” (13 mm) O.D.

Page 3

FULL-FACE AREA HEAT RECLAIM COILS INSERTED IN KEEPRITE REFRIGERATION

CENTRAL STATION KLS & KHD AIR HANDLERS

Table 1 SIZE AND FACE AREA TYPE HR

SEBUTECAFSEBUTECAF

6&26&2

6&26&2

6&2

WOR

010101010199999

21212121211111111111

41414141413131313131

02020202029191919191

42424242423232323232

23232323231313131313

63636363635353535353

44444444443434343434

65656565655555555555

SEBUTECAFSEBUTECAF EZISRELDNAHRIAEZISRELDNAHRIA

SEBUTECAF

4*&34*&3

4*&34*&3

4*&3

301301

301301401401

WOR

TA.M.F.CTA.M.F.C

TA.M.F.CTA.M.F.C

TA.M.F.C

.M.P.F005

TA.M.F.CTA.M.F.C

TA.M.F.CTA.M.F.C

TA.M.F.C

.M.P.F006

301

0511057105720073003505860048006,01054,31059,71002,02056,42004,13

083100120033044406360228080,01027,21041,61045,12042,42085,92086,73

401401601601

401

2/112x51

.tf.qs3.2

601601801801

601

2/172x81

.tf.qs5.3

801801111111

801

2/173x12

.tf.qs5.5

111111412412

111

2/153x03

.tf.qs4.7

2/105x03

.tf.qs6.01

412412712712

412

2/156x33

.tf.qs7.31

712712222222

712

2/108x03

EZISRELDNAHRIAEZISRELDNAHRIA

EZISRELDNAHRIA

222222822822

222

.tf.qs8.61

822822732732

822

2/148x63

tf.qs2.12

732732141141

732

2/1701x63

.tf.qs9.62

141141051051

141

2/1701x84

.tf.qs9.53

051051461461

051

2/1701x45

.tf.qs4.04

461461

461

2/1701x66

.tf.qs3.94

HEAT RECLAIM COILS BOLTED DIRECTLY TO KHF FAN HEADS

Table 2 SIZE AND FACE AREA TYPE KC

SEBUTECAFSEBUTECAF

SEBUTECAFSEBUTECAF EZISRELDNAHRIAEZISRELDNAHRIA

6&26&2

6&26&2

6&2

WOR

21212121211111111111

41414141413131313131

61616161615151515151

22222222221212121212

62626262625252525252

43434343433333333333

04040404049393939393

64646464645454545454

85858585857575757575

SEBUTECAF

4*&34*&3

4*&34*&3

4*&3

WOR

005@.M.F.C005@.M.F.C

005@.M.F.C005@.M.F.C

005@.M.F.C

.M.P.F

006@.M.F.C006@.M.F.C

006@.M.F.C006@.M.F.C

006@.M.F.C

.M.P.F

007@.M.F.C007@.M.F.C

007@.M.F.C007@.M.F.C

007@.M.F.C

.M.P.F

301301

301301401401

301

578152620573000505660548000,01054,21007,51005,02051,42008,72000,53

401401601601

401

03x81

.tf.qs57.3

0513005400060897041,01000,21049,41048,81006,42089,82063,33000,24

601601801801

601

63x12

.tf.qs52.5

801801111111

801

54x42

.tf.qs5.7

44x33

00070139038,11000,41034,71089,12007,82018,33029,83000,94

111111412412

111

.tf.qs0.01

85x33

412412712712

412

.tf.qs3.31

712712222222

712

47x33

88x33

.tf.qs9.61

* Use the Face Tubes shown for “Desuperheater Type” coils only.

For “Condenser Type” coils, 3 & 4 Row Face tubes will be the same as 2 & 6 Row Coils.

EZISRELDNAHRIAEZISRELDNAHRIA

EZISRELDNAHRIA

222222822822

222

.tf.qs02

29x93

822822732732

822

.tf.qs9.42

611x93

732732141141

732

.tf.qs4.13

611x15

141141051051

141

.tf.qs0.14

611x06

051051461461

051

.tf.qs3.84

461461

461

611x96

.tf.qs6.55

2/1701x48

.tf.qs8.26

611x78

.tf.qs0.07

Table 3 DUCT HEAT RECLAIM COILS SIZE AND FACE AREA TYPE KC

"W""W"

"W""W" )SEHCNI(-LTN-HTGNELEBUTLANIMON)SEHCNI(-LTN-HTGNELEBUTLANIMON

"W"

SEHCNISEHCNI

SEHCNISEHCNI21212121215151515151818181818112121212124242424242030303030363636363632424242424848484848445454545450606060606666666666627272727278787878787484848484809090909096969696969201201

SEHCNI

66666

99999

2121212121

5151515151

8181818181

1212121212

4242424242

7272727272

0303030303

3333333333

6363636363

9393939393

2424242424

Face Tubes in Condenser Type Duct Coils = (

05.26.57.78.00.152.105.157.10.22.25.27.20.3

57.49.21.113.105.178.152.226.20.34.37.31.45.4

00.152.105.157.100.205.200.305.30.45.40.55.50.65.60.75.70.85.80.95.90.01

65.178.191.205.221.357.373.40.56.52.69.65.71.87.84.90.016.012.119.115.21

52.226.200.357.305.452.50.67.65.72.80.97.95.012.110.217.215.312.410.51

60.305.373.452.521.60.79.77.86.95.014.112.211.310.419.417.516.615.71

00.400.500.600.70.80.90.010.110.210.310.410.510.610.710.810.910.02

3

26.557.678.70.91.012.114.215.316.417.519.610.811.912.024.125.22

52.605.757.80.012.115.217.310.512.615.717.810.022.125.227.320.52

52.826.90.114.217.311.515.619.712.916.020.224.327.421.625.72

00.905.010.215.310.515.610.815.910.125.220.425.520.725.820.03

73.110.316.412.619.715.911.027.224.420.626.722.929.035.23

52.210.417.515.712.910.127.225.422.620.827.925.132.330.53

‘w’

x 2) 3 & 4 Row Desuperheater Type Coils have one Face Tube less than Condenser Coils.

- 3 -

)SEHCNI(-LTN-HTGNELEBUTLANIMON)SEHCNI(-LTN-HTGNELEBUTLANIMON

)SEHCNI(-LTN-HTGNELEBUTLANIMON

201201801801

201

801801411411

801

411411021021

411

021021

021

Page 4

HEAT RECLAIM COIL PERFORMANCE 1/2” O.D. TUBE

CHART 1

HEAT RECLAIM COIL PERFORMANCE 1/2” O.D. TUBE

CHART 2

- 4 -

40

30

20

BTU/H - C.F.M.

40

30

BTU/H - C.F.M.

20

10

300 400 500 600 700 800

FACE VELOCITY, F .P.M. FACE VELOCITY, F .P.M.

10

300 400 500 600 700 800

Page 5

HEAT RECLAIM COIL PERFORMANCE 1/2” O.D. TUBE

CHART 3

50

HEAT RECLAIM COIL PERFORMANCE 1/2” O.D. TUBE

CHART 4

60

- 5 -

40

30

20

BTU/H - C.F.M.

50

BTU/H - C.F.M.

40

30

10

300 400 500 600 700 800

FACE VELOCITY, F .P.M. FACE VELOCITY, F .P.M.

20

300 400 500 600 700 800

Page 6

HEAT RECLAIM COIL PERFORMANCE 1/2” O.D. TUBE

CHART 5

60

50

BTU/H - C.F.M.

HEAT REJECTION FACTORS SUCTION COOLED

SEMI-HERMATIC COMPRESSORS

CHART 6

- 6 -

40

30

20

300 400 500 600 700

FACE VELOCITY, F .P.M.

CONDENSING TEMPERATURE °F.

Page 7

CHART 7

h/UTB.rh/UTB

h/UTB

h/UTB.rh/UTB

INCHES OF WATER

FACE VELOCITY F.P.M.

COIL AIR SIDE PRESSURE LOSS

.90

.80

.70

.60

.50

.40

NOTE: For Multi Circuit Applications Enter

Columns (1) through (6). Then enter total under (7) and

follow items (8) through (17).

Customer

Coil Air Handler Size Coil

Type: H.R. Insert and Type

K.C. Bolt-On Condenser

K.C. Duct Coil size

Total C.F.M.

(1) (2) (3) (4) (5) (6) (15) (16) (17)

.pmoC.pmoC

.pmoC.pmoC

.pmoC

.oN

1111102+02+

2222201+01+

3333353+53+

4444402-02-

5555502-02-

6666602-02-

† For desuperheater type coil BTU/hr, for

Heat Reclaim will be a percentage of

compressor heat.

(8) Coil Face Velocity =

(9) Coil Performance req’d. =

C.F.M.

John Doe

21,540

Ent. Air temp.

.tcuS.tcuS

.tcuS.tcuS

.tcuS

.F.pmeT

02+02+2121212121000,06000,06

02+

01+01+2121212121005,73005,73

01+

53+53+2121212121000,55000,55

53+

02-02-205205

02-

02-02-205205

02-

02-02-205205

02-

.30

CONDENSER HEAT RECLAIM COIL SELECTION

Project

.feR.feR

.feR.feR

.feR

epyT

205205000,03000,03

205

205205005,73005,73

205

205205000,53000,53

205

Total Heat reclaim (7)

.25

.20

48

.rh/UTB.rh/UTB

.rh/UTB.rh/UTB

.rh/UTB

yticapaC

000,06000,0633.133.1

000,06

005,73005,7343.143.1

005,73

000,55000,5562.162.1

000,55

000,03000,0395.195.1

000,03

005,73005,7395.195.1

005,73

000,53000,5395.195.1

000,53

600

F.P.M.

.15

LS 237

107 1/2

x

65

°F Design T.D.

=

.10

.09

.08

.07

.06

.05

.04

For single circuit applications enter total load under (7) and

then follow items (8) through (13).

Food Store

rotcaFrotcaF

rotcaFrotcaF

rotcaF

33.133.1008,97008,97

33.1

43.143.1521,25521,25

43.1

62.162.1003,96003,96

62.1

95.195.1007,74007,74

95.1

95.195.1526,95526,95

95.1

95.195.1056,55056,55

95.1

=mialceR)7(taeHlatoT=mialceR)7(taeHlatoT

=mialceR)7(taeHlatoT=mialceR)7(taeHlatoT

=mialceR)7(taeHlatoT

Date

Application: Desuperheater

)6trahC(

.r

.r

.r

taeH

mialceR

008,97008,97217,11217,11

008,97

521,25521,25217,11217,11

521,25

003,96003,96217,11217,11

003,96

007,74007,74217,11217,11

007,74

526,95526,95217,11217,11

526,95

056,55056,55217,11217,11

056,55

002,463002,463

002,463002,463

002,463

364,200

21,540

Face Area

.rh/UTB.rh/UTB

.rh/UTB.rh/UTB

.rh/UTB

217,11217,1118.618.6

217,11

217,11217,1154.454.4

217,11

217,11217,1129.529.5

217,11

217,11217,1170.470.4

217,11

217,11217,1190.590.5

217,11

217,11217,1157.457.4

217,11

16.9

=

BTUhr/C.F.M.

45

ebuTecaFreP

.035

.03

35.9

sq. ft.

°F.

sebuTecaFsebuTecaF

sebuTecaFsebuTecaF

sebuTecaF

.d’qeR

18.618.677777

18.6

54.454.455555

54.4

29.529.566666

29.5

70.470.444444

70.4

90.590.555555

90.5

57.457.455555

57.4

=)81(ecafnisebuTlatoT=)81(ecafnisebuTlatoT

=)81(ecafnisebuTlatoT=)81(ecafnisebuTlatoT

=)81(ecafnisebuTlatoT

.025

desU

2323232323

200 250 300 400 500 600 700 800 1000

.02

sebuTecaFsebuTecaF

sebuTecaFsebuTecaF

sebuTecaF

TYPICAL REFRIGERATION HEAT RECLAIM CALCULATION

(10) Select from performance Charts at

design T.D. coil nearest to (9) above = Rows:

(11) Max. capacity of Coil = BTUhr/C.F.M. (10) X C.F.M.

=

(12) Actual operating T.D.

(13) Determine No. of Face Tubes in coil (Tables 1 or 2) =

(14) Determine Capacity per face tube =

Now complete columns 16 & 17

Final coil selection Rows 2 F.P.I. 10 48 Ins. X 107 1/2 Ins.

Air side Pressure drop = .15 Inches of Water (Chart 7)

= Performance req’d. (9)

=

17.4 X 21,540 = 374,796 BTU/hr

Performance from (10)

16.9

17.4

Max. Capacity BTU hr. (11)

=

374,796

No. of face tubes (13)

2

X 45 °F = 43.7 T.D.

=

32

F.P.I.

X Design T.D.

10

11,712 BTU/hr

(Enter Under 15)

=

17.4

BTUhr/C.F.M.

32

Tubes (Enter in 18 above)

- 7 -

Page 8

CONDENSER HEA T RECLAIM COIL SELECTION

US

C

03/17/07

NOTE: For Multi Circuit Applications Enter

Columns (1) through (6). Then enter total under (7) and

follow items (8) through (17).

Suct.

Project

Ent. Air temp. °F Design T.D.

Ref.

Type

BTU/hr.

Capacity

Customer

Coil Air Handler Size Coil

Type: H.R. Insert and Type

K.C. Bolt-On Condenser

K.C. Duct Coil size

Total C.F.M.

(1) (2) (3) (4) (5) (6) (15) (16) (17)

Comp.

No.

Tem p . °F.

x

Factor

(Ch art 6 )

For single circuit applications enter total load under (7) and

then follow items (8) through (13).

Date

Application: Desuperheater

Face Area

BTU/hr.

Heat

Reclaim

BTU/hr.

Per Face

Tube

sq. ft.

°F.

Face Tubes

Req'd.

Face Tubes

Used

† For desuperheater type coil BTU/hr, for

Heat Reclaim will be a percentage of

compressor heat.

(8) Coil Face Velocity =

(9) Coil Performance req’d. =

(10) Select from performance Charts at

design T.D. coil nearest to (9) above = Rows:

(11) Max. capacity of Coil = BTUhr/C.F.M. (10) X C.F.M.

= X = BTU/hr

(12) Actual operating T.D.

Performance from (10)

(13) Determine No. of Face Tubes in coil (Tables 1 or 2) =

(14) Determine Capacity per face tube =

C.F.M.

Now complete columns 16 & 17

Final coil selection Rows F.P.I. Ins. X Ins.

Air side Pressure drop = Inches of Water (Chart 7)

Total Heat (7) Reclaim = Total Tubes in face (18) =

= Performance req’d. (9)

=

F.P.M.

Total Heat reclaim (7)

X

=

F.P.I.

X Design T.D.

= BTUhr/C.F.M.

= BTUhr/C.F.M.

°F = T.D.

Tubes (Enter in 18 above)

Max. Capacity BTU hr. (11)

No. of face tubes (13)

= =

BTU/hr

(Enter Under 15)

NA TIONAL REFRIGERA TION &

AIR CONDITIONING CANADA CORP.

CANADA

159 ROY BL VD., BRANTFORD, ONT ARIO, CANADA N3R 7K1

PHONE: 1-800-463-9517 (519)751-0444 FAX (519)753-1140

Due to National Refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice.

USA

985 WHEELER WA Y, LANGHORNE, PA. 19047 USA

PHONE:1-888-KEEPUS1 OR 1-888-533-7871

Loading...

Loading...