Page 1

PRODUCT DATA &

SPECIFICATIONS

Bulletin K70-KDX-PDS-11

1064639

We are on the Internet

www.keepriterefrigeration.com

Type KDX

Direct Expansion

Coils

For Cooling & Dehumidifying

Refrigerants R22, R404A & R134a

KeepRite

Coil T ype (Direct Expansion)

Fin Series (70, 80, 100 or 120)

NOMENCLATURE

K DX 10 4 - 30 X 72 R-22

Refrigerant Type

(R-22 or R404A)

Nominal Tube Length

“W” Dimension

Rows Deep

Page 2

DIRECT EXPANSION COILS

TYPE KDX

SIZES AND MODELS FOR EVERY APPLICATION

Direct Expansion Type KDX Coils are engineered and

designed to deliver the maximum possible heat transfer

efficiency under all operating conditions. KeepRite coils

are manufactured using only the highest quality materials

and with the most modern manufacturing facilities

available. Each KeepRite Coil is inspected and tested

under rigid quality control standards to offer you the finest

quality Coil designed for long life and top performance.

A variety of fin selections make it possible to meet the

sensible and total requirements more accurately and

economically.

Select standard KeepRite Direct Expansion Coils

from any combination of the following:

1. Series70, 80, 100 and 12O Fin spacings.

2. From 2 through 10 rows deep

3. From 6" through 36" high face (3" increments).

4. From 6" through 120" nominal tube length.

5. Coils for R-22 and R-404A.

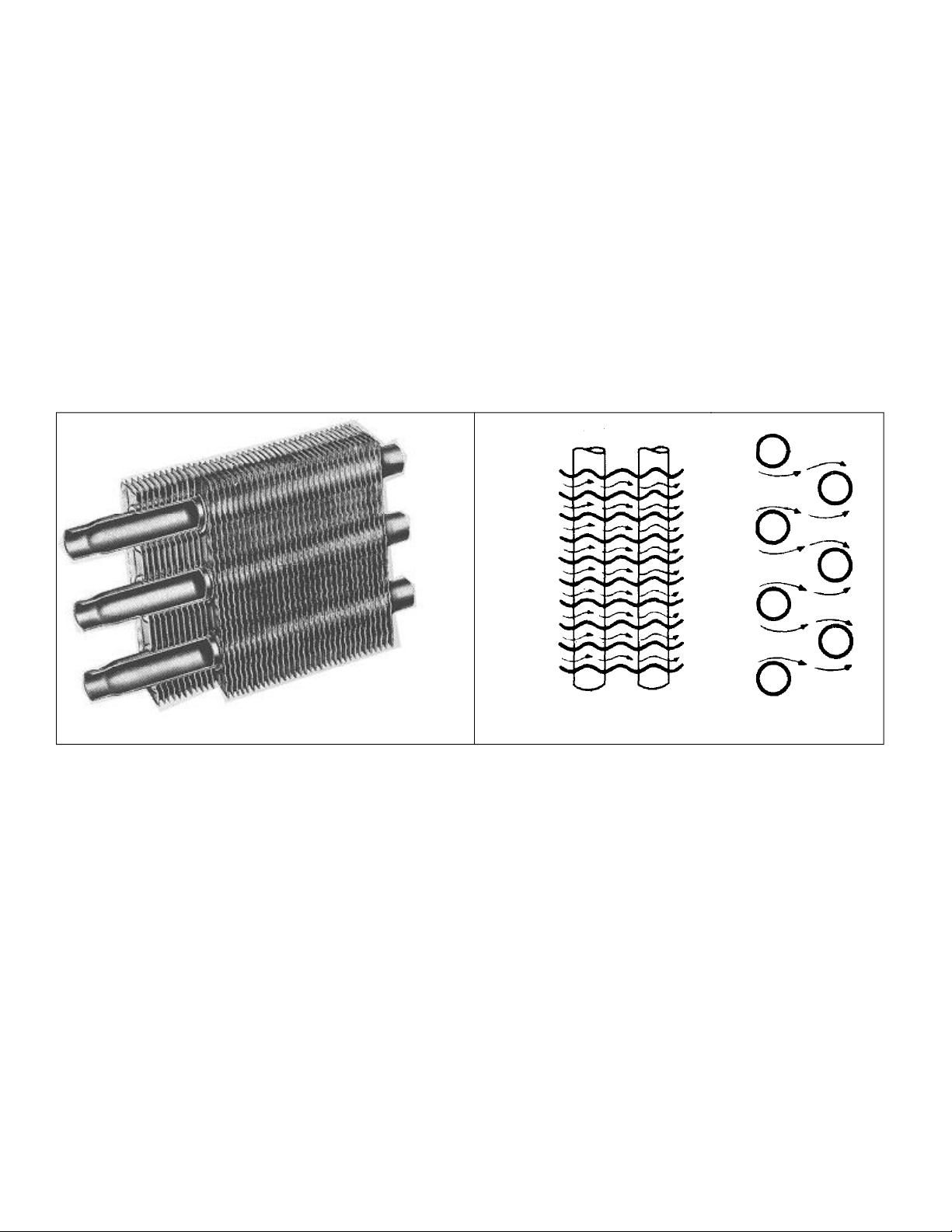

RIPPLE FIN CONSTRUCTION

All KeepRite Coils feature the Ripple Fin Coil

Construction to provide a more efficient transfer surface

of superior strength and durability. Rippled Aluminum

fins produce a rippled air flow pattern throughout the coil

creating the maximum air turbulence necessary for

efficient heat transfer. Copper tubing is mechanically

expanded into the Rippled Aluminum fins, making

positive, permanent metal to metal contact for durability

STAGGERED TUBE DESIGN

and peak efficiency. Wide, full fin collars drawn in the fin

stock not only provide accurate control of the fin spacing,

but also completely cover the tube for the greatest heat

transfer efficiency and coil protection.

Another important feature of KeepRite Coils is the

Staggered Tube design which offers an intimate and

prolonged contact of the air and cooling surface.

- 2 -

Page 3

TABLE OF CONTENTS

SIZES AND MODELS............................................................2

Coil nomenclature .............................................................. 2

FEATURES ...........................................................................3

COOL SPECIFICATIONS .....................................................4

GENERAL FORMULAS.........................................................4

COIL SELECTION

Wet bulb depression factor ............................................... 5

General considerations ..................................................... 5

Coil sizes, Table 1 ............................................................. 6

DEHUMIDIFYING COIL SELECTION

Example problem No. 1 ..................................................... 7

Example problem No. 2 ..................................................... 8

Example problem No. 3 ..................................................... 9

TOTAL HEAT, Table 2.........................................................10

CONVERSION FACTORS - AIR VOLUME

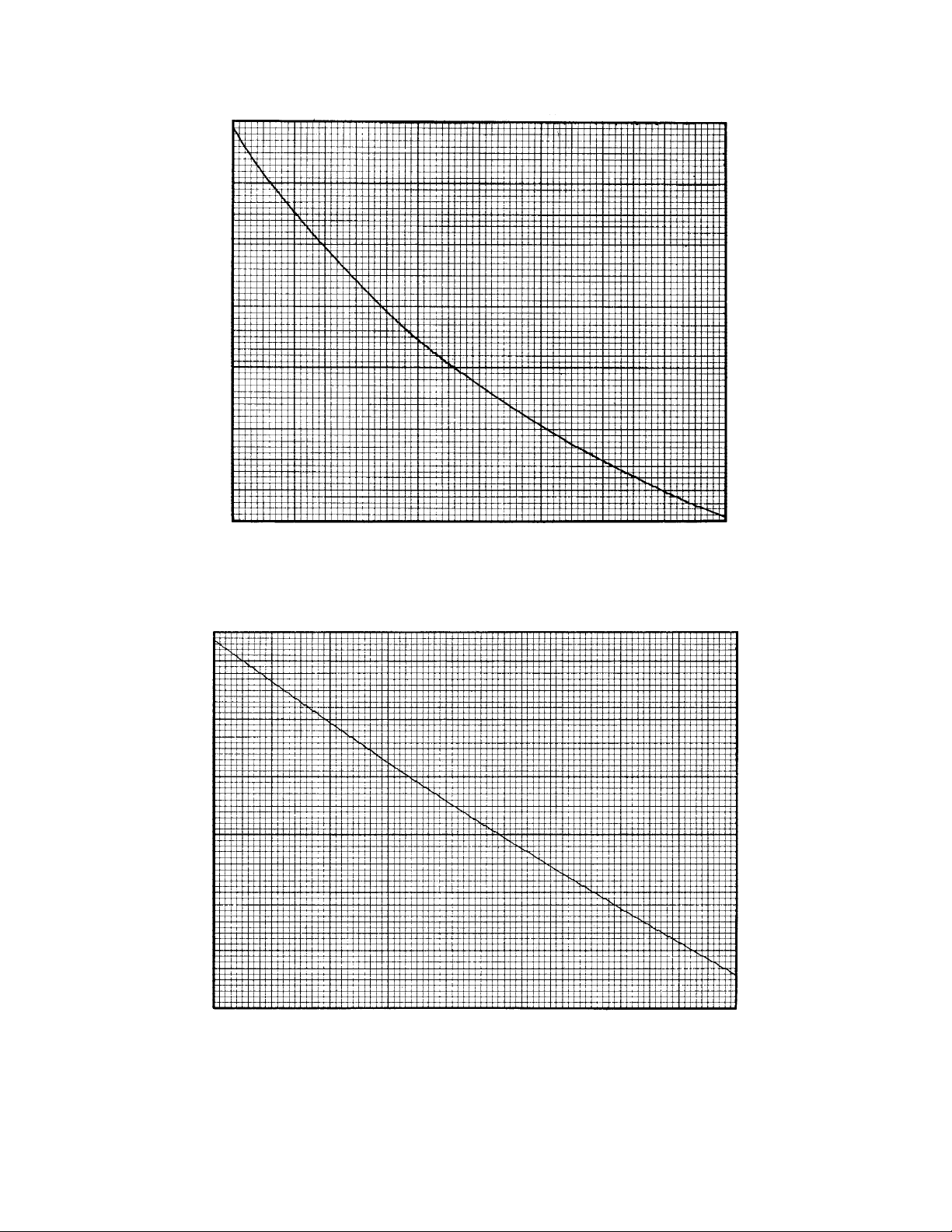

Temperature, Figure 1....................................................11

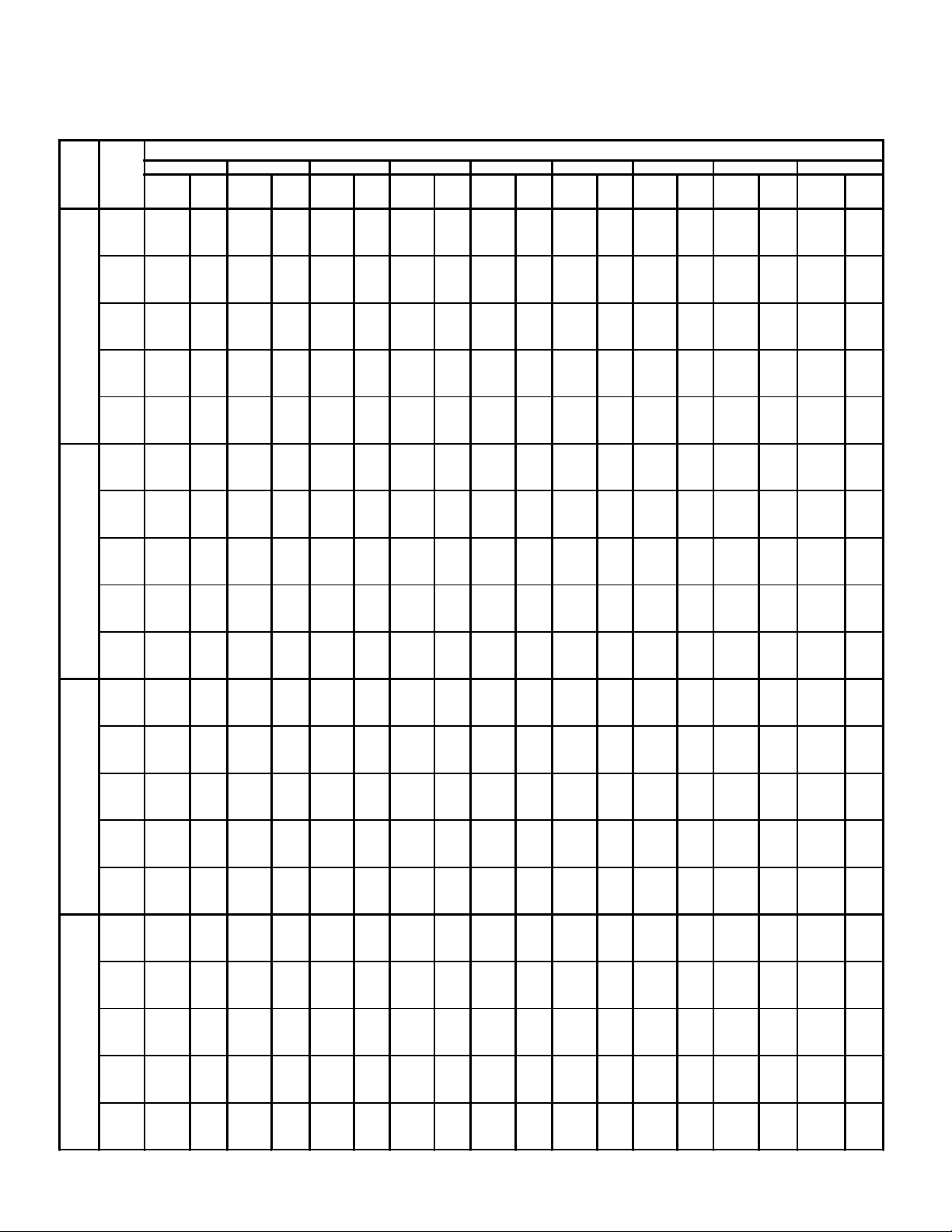

Altitude, Figure 2.............................................................11

DIRECT EXPANSION COIL RATINGS

For R-12, Table 3...................................................12 to 20

For R-22, Table 4...................................................21 to 29

DEHUMIDIFYING COIL

Basic rating curves for R-12, Figure 3............................30

Velocity and row correction factors for R-12, Figure 4...30

Fin series total capacity correction factors, Table 5.......30

Basic rating curves for R-22, Figure 5............................31

Velocity and row correction factors for R-22, Figure 6...31

Fin series total capacity correction factors, Table 6.......31

Wet bulb depression factors, Figure 7...........................32

SENSIBLE COOLING COIL SELECTION

Example problem No. 4...................................................33

SENSIBLE COOLING COIL

Basic rating curves for R-12, Figure 8............................34

Velocity and row correction factors for R-12, Figure 9...34

Fin series sensible total capacity correction factors,

Table 7..........................................................................34

Basic rating curves for R-22, Figure 10..........................35

Velocity and row correction factors for R-22, Figure 11..35

Fin series sensible capacity correction factors, Table 8.35

COIL AIR FRICTION

Dry coils, Figure 12.........................................................36

Air friction factor..............................................................36

Air friction. correction factors, Table 9.............................36

CAPACITY REDUCTION APPLICATIONS ........................36

COIL DIMENSIONS..............................................................37

TYPICAL SPECIFICATION..................................................38

“TYPE KDX COIL” OFFERS THESE

FEATURES

STAGGERED TUBES

Experience and KeepRite tests prove conclusively that

staggered tubes produce at least 5% higher capacity than

parallel tubes.

RIPPLED FINS

Experience and KeepRite tests prove conclusively that

KeepRite fins which ripple through fin depth produce a

minimum of 5% higher performance than flat plate fins.

HIGHER HEAT TRANSFER RATE

New KeepRite combination of staggered tubes and modified

rippled fins, produces the necessary turbulence to interrupt the

insulating boundary layer film, while retaining the intimate and

prolonged contact between air and the heat exchanger surface.

NON FERROUS HEADERS

Heavy wall seamless copper headers and copper tubes

eliminate leaks which could occur from unequal expansion rates

of dissimilar materials as well as from the possibility of galvanic

corrosion. Natural resistance of copper to corrosion means longer

coil life.

FLOW CIRCUITING

All coils are counterflow circuited and equipped with pressure

type distributors to insure equal distribution of refrigerant to each

circuit. Sufficient circuits are provided to insure equal,

distribution of refrigerant to each circuit. Circuiting for facecontrol and row-control is also available.

FULL FIN COLLARS

Wide, smooth die-formed fin collars provide accurate fin spacing

and completely cover the coil tube for maximum contact area

and highest heat transfer.

FULL FACE HEIGHT-Without Air By-Pass

POSITIVE PERMANENT TUBE FIN BOND

Mechanical pressure expansion of the tube into the fin provides

a positive and permanent metal to metal contact for durability

and peak performance.

UNMATCHED VARIETY OF STANDARD COILS

Provides practically unlimited flexibility in selection of coils to

more accurately meet load requirements.

- 3 -

Page 4

COIL SPECIFICATIONS

PRIMARY SURFACE

5/8" round seamless copper tubes are mechanically

expanded, offering positive, permanent, metal to metal

contact for efficient heat transfer.

SECONDARY SURFACE

Rippled, plate type aluminum fins create the maximum air

turbulence necessary to obtain efficient transfer of heat.

Wide, full, fin collars, smoothly drawn completely cover the

tubes increasing the contact area.

OPERATING CONDITIONS

Complete core rated at 200 psig working pressure.

CIRCUITING

Each Direct Expansion Coil is circuited for low pressure

drop with sufficient vapor velocity to insure maximum heat

transfer. All circuits are of equal length and all carry equal

loads.

CASING

Die formed heavy gauge casings are formed from

Continuous Galvanized Steel. Three eighths inch bolt

holes on 3” centers are provided in mounting frames.

TESTS

Complete Coil assembly is tested at 315 psig air under

warm water. Dehydrated by heating and circulating hot

dry air (-40°F, dew-point) throughout the coil and then

sealed.

SPECIAL REFRIGERANTS

For use with special refrigerants consult the factory.

SPECIAL PURPOSE COILS

Protective coatings, special materials, and fin spacings

to meet your individual needs are available for industrial

and process applications

BRAZING

All Core joints are made with copper brazing alloys.

RETURN BENDS

5/8” O.D. round seamless copper tubing.

HEADER END CAPS

Heavy gauge copper.

LIQUID DISTRIBUTORS

Pressure type brass distributors with accurately spaced

drilled outlets are furnished and mounted on each coil to

insure equal distribution of refrigerant to all circuits.

Expansion valve may be field installed and coil can be

mounted in any position.

CONNECTIONS

Male Sweat type. Liquid connections are brass and

suction connections are copper.

CERTIFIED DRAWINGS WILL BE FURNISHED ON REQUEST

GENERAL FORMULAS

1. TOTAL BTUH

Total Btuh = 4.5 X (total heat ent air total heat lvg air)

Where: 4.5 = (density std air) X (min

.075 = density std air in lbs/cu ft

60 = min/ hr

2. SENSIBLE BTUH

Sensible Btuh = 1.09 X cfm X (ent air dry bulb - lvg air

dry bulb)

Where: 1.09 = (sp ht air at 70 F) X (min/hr) X

(density std air)

.24 = sp ht air at 70 F

60 = min/hr

.075 = density std air in lbs/cu ft

3. LEAVIND AIR DRY BULB TEMPERATURE

a. Lvg air dry bulb = ent air dry bulb -

1.09 X cfm

b. Lvg air dry bulb = lvg air wet bulb + (wet bulb depression

factor) X (initial wet bulb depression)

sensible Btuh

4. FACE AREA SQ. FT.

5. FACE VELOCITY F.P.M.

6 . SENSIBLE TOTAL RATIO

7. TONS PER SQUARE FOOT OF FACE AREA

8. INITIAL WET BULB DEPRESSION

Initial wet bulb depression = (ent air dry bulb) (ent air wet bulb)

cfm

FA =

face velocity (fpm)

cfm

FV =

face area (sq ft)

S/T ratio =

total Btuh

Tons/sq ft =

sensible Btuh

total Btuh

face area (sq ft) X 12,000

- 4 -

Page 5

COIL SELECTION

WET BULB DEPRESSION FACTOR

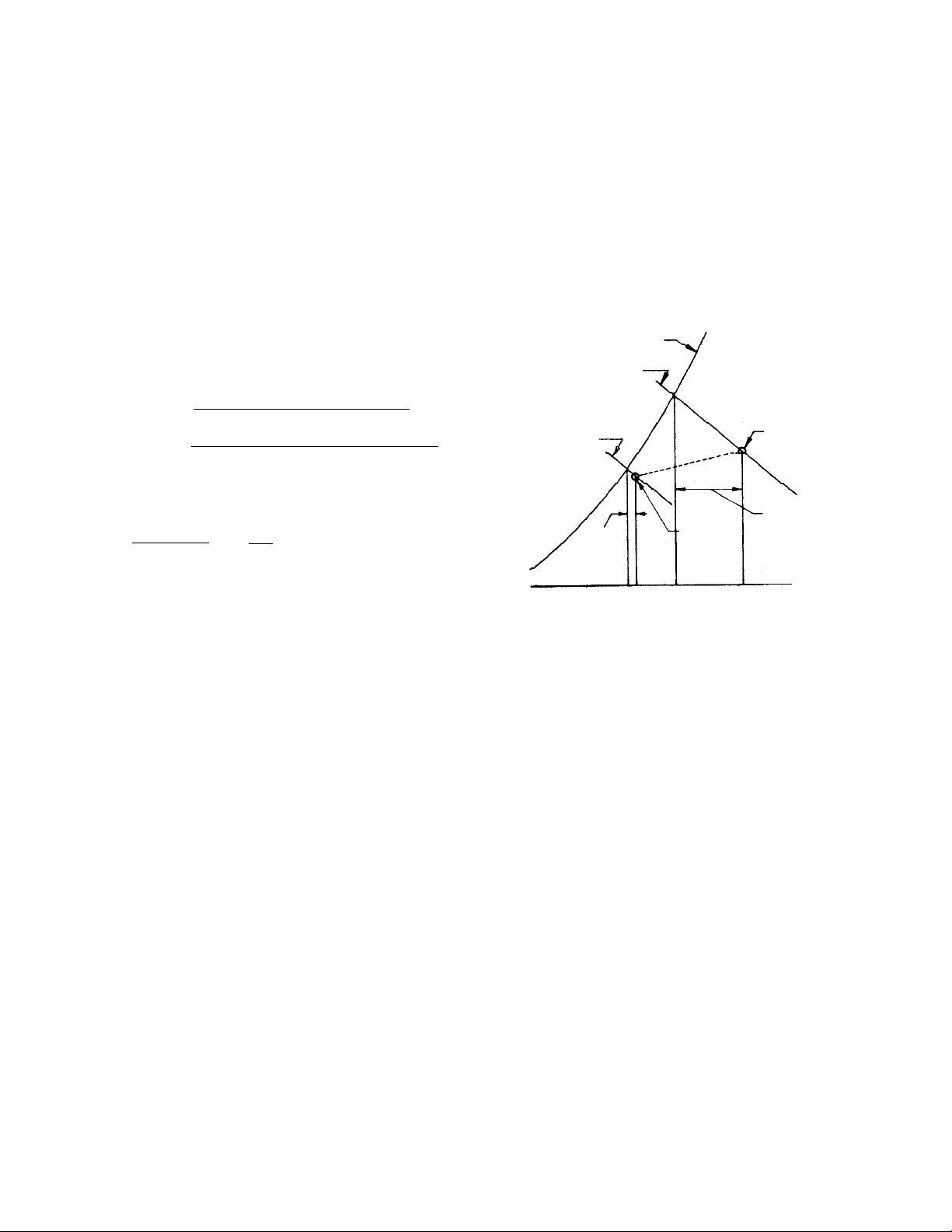

Since both sensible and latent heat transfer, are

occurring simultaneously between the surface of a

dehumidifying coil and the air passing over it, some coil

performance factor which establishes the relationship

between these two modes of heat transfer is required.

For this purpose KeepRite employs the wet bulb

depression factor which has the general acceptance of

the finned tube coil industry.

The wet bulb depression factor is the ratio of the

leaving air to entering air wet bulb depressions and is

expressed as follows:

Wet Bulb Depression

Factor (WBDF) =

Entering Wet Bulb Depression

= Lvg. Air D.B. - Lvg. Air W.B. Temp.

Lvg. Air D.B. - Ent. Air W.B. Temp.

For the example illustrated below, the Wet Bulb

Depression Factor is:

WBDF =

61°F - 58°F 3

80°F - 67°F = 13

Leaving Wet - Bulb Depression

= .231

laboratory tests of each particular coil surface design. The

wet bulb depression factor does not apply to dry surface

cooling coils and is recommended for application only where

the sensible to total heat ratio is 0.9 or less. When the

sensible to total ratio is greater than 0.9, the fin surface is

essentially dry and the coil selection can be based on dry

surface to handle the total load.

Curves giving the wet bulb depression factor for

KeepRite Type KDX Coils are shown on page 33.

SATURATION CURVE

ENTERING

67°F WET BULB

TEMP.

LEAVING

58°F WET BULB

TEMP.

LEAVING

DEPRESSION

W.B.

AIR CONDITION

LEAVING COIL

AIR CONDITION

ENTERING COIL

ENTERING W.B.

DEPRESSION

Since the wet bulb depression factor describes a heat

transfer relationship on the fin side of a coil only, it varies

with the air side heat transfer performance, the amount

of heat transfer surface and with the air velocity.

The WB depression factor is determined by

GENERAL CONSIDERATIONS IN COIL SELECTION

The cooling process should always be plotted on a

psychrometric chart to be sure that the desired

psychrometric changes are feasible.

When selecting a coil it should be remembered that if the

required leaving wet bulb temperature is met, the total

load is satisfied and vice versa. Also, that when the,

required leaving Dry Bulb temperature is met, the

sensible load requirement is satisfied.

A coil must meet both the total load and the sensible

load requirement in order to achieve the conditions

desired in the space to be cooled. Normally the total

load capacity is checked first, however, the leaving dry

bulb should always be checked. When the sensible/

total ratio is low, the coil selection is normally controlled

by the total load even though the sensible cooling may

exceed the requirement. In some cases if the leaving

dry bulb temperature is too low, reheat may be required.

58 61 67 80

When the S/T ratio is high the coil selection is normally

controlled by the sensible cooling even though the total

load may exceed that required by an appreciable amount.

If the total capacity far exceeds the requirement, a recheck

on the refrigeration system balance should be made to be

sure sufficient system capacity is available.

MATCHING SENSIBLE-LATENT REQUIREMENTS - In

order to more accurately meet the sensible loads and the

total loads. The 70 and 80 fin series coils are

recommended for the lower S/T ratios, and the 100 and

120 fin series for the higher S/T ratios. For normal S/T

ratios fin series 80 and 100 are recommended.

When the refrigerant temperature is low and possible

frosting on the coil, surfaces may occur, fin series 70 is

recommended.

For selecting coils for sensible cooling only (dry coil) see

page 33.

- 5 -

Page 6

COIL SELECTION

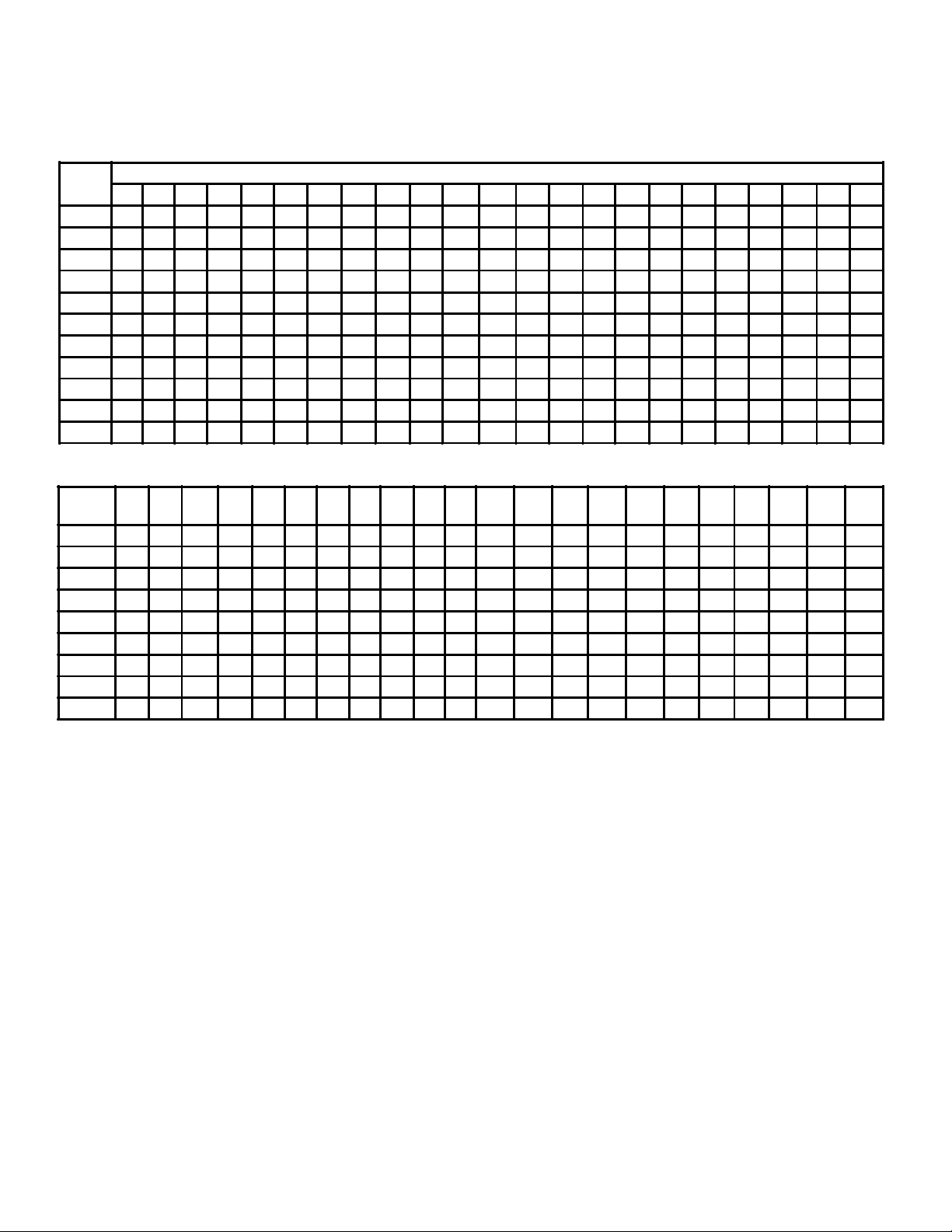

COIL SIZES

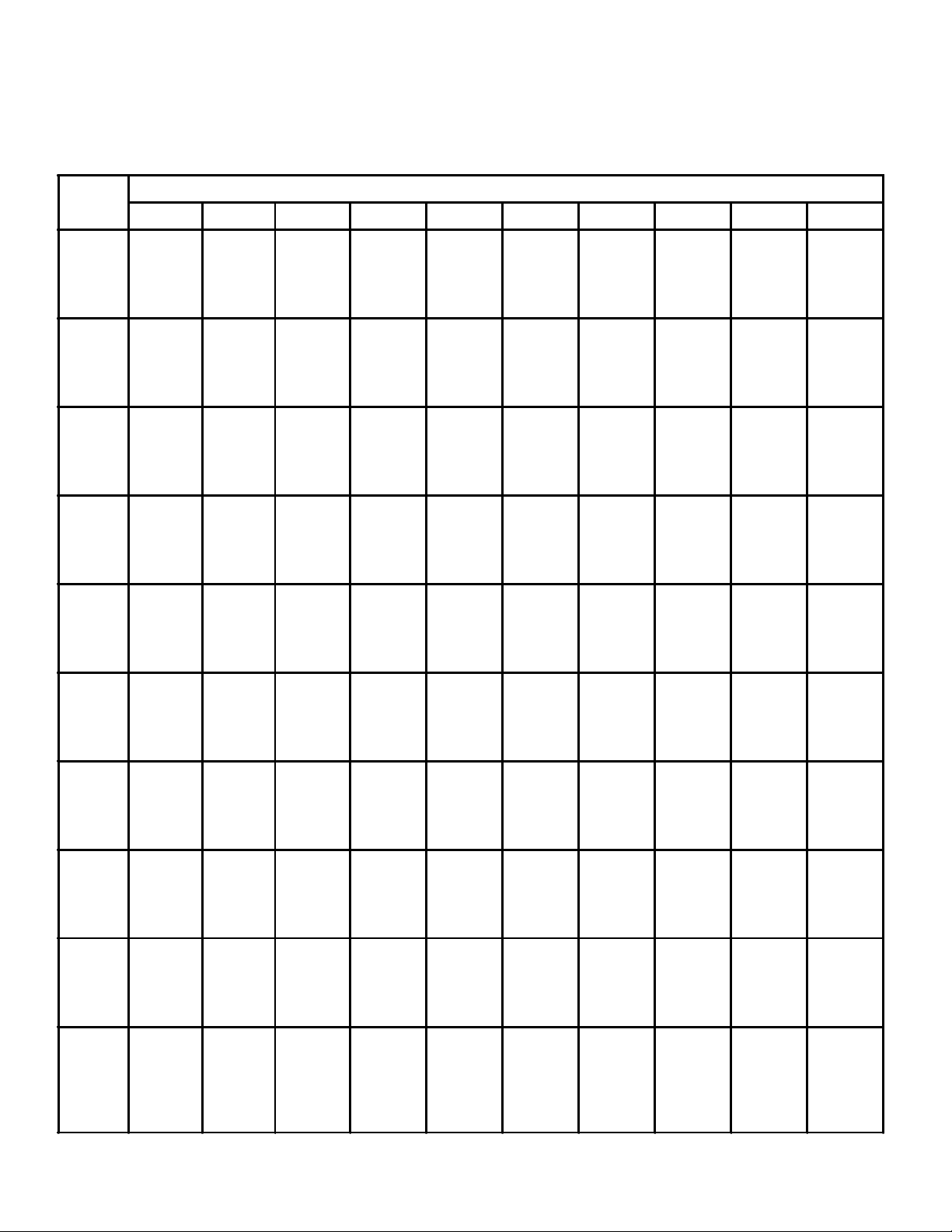

TABLE 1 - COIL SIZES - NOMINAL FACE AREA IN SQ. FT.

"W" NOMINAL TUBE LENGTH - NTL - (INCHES)

INCHES 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60 63 66 69 72 75 78

6 .50 .62 .75 .87 1.00 1.13 1.25 1.38 1.50 1.63 1.75 1.88 2.0 2.1 2.2 2.4 2.5 2.6 2.7 2.9 3.0

9 .75 .94 1.12 1.31 1.50 1.69 1.87 2.06 2.25 2.44 2.62 2.81 3.0 3.2 3.4 3.6 3.7 3.9 4.1 4.3 4.5

12 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.0 4.3 4.5 4.8 5.0 5.3 5.5 5.8 6.0 6.3 6.5

15 1.56 1.87 2.19 2.50 2.81 3.12 3.44 3.75 4.06 4.37 4.68 5.0 5.3 5.6 5.9 6.2 6.6 6.9 7.2 7.5 7.8 8.1

18 2.25 2.62 3.00 3.37 3.75 4.12 4.50 4.87 5.25 5.62 6.0 6.4 6.7 7.1 7.5 7.9 8.2 8.6 9.0 9.4 9.7

21 3.06 3.50 3.94 4.37 4.82 5.25 5.69 6.12 6.56 7.0 7.4 7.9 8.3 8.7 9.2 9.6 10.1 10.5 10.9 11.4

24 4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50 8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 12.5 13.0

27 5.06 5.62 6.19 6.75 7.32 7.87 8.44 9.0 9.6 10.1 10.7 11.2 11.8 12.4 12.9 13.5 14.1 14.6

30 6.25 6.88 7.50 8.12 8.75 9.37 10.0 10.6 11.2 11.9 12.5 13.1 13.7 14.4 15.0 15.6 16.2

33 7.56 8.25 8.94 9.62 10.30 11.0 11.7 12.4 13.1 13.7 14.4 15.1 15.8 16.5 17.2 17.9

36 9.00 9.75 10.50 11.20 12.0 12.7 13.5 14.2 15.0 15.7 16.5 17.2 18.0 18.7 19.5

"W"

INCHES

Type KDX coils over 120” N.T.L. are considered special.

Consult Local KeepRite Refrigeration Sales Office for coils other than sizes shown above

81 84 87 90 93 96 99 102 105 108 111 114 117 120 123 126 129 132 135 138 141 144

12 6.8 7.0 7.3 7.5 7.8 8.0 8.3 8.5 8.8 9.0 9.3 9.5 9.8 10.0

15 8.4 8.7 9.1 9.4 9.7 10.0 10.3 10.6 10.9 11.2 11.6 11.9 12.2 12.5

18 10.1 10.5 10.9 11.2 11.6 12.0 12.4 12.7 13.1 13.5 13.9 14.2 14.6 15.0 15.4 15.8

21 11.8 12.2 12.7 13.1 13.6 14.0 14.4 14.9 15.3 15.7 16.2 16.6 17.1 17.5 17.9 18.4 18.8 19.3

24 13.5 14.0 14.5 15.0 15.5 16.0 16.5 17.0 17.5 18.0 18.5 19.0 19.5 20.0 20.5 21.0 21.5 22.0 22.5 23.0 23.5 24.0

27 15.2 15.7 16.3 16.9 17.4 18.0 18.6 19.1 19.7 20.2 20.8 21.4 21.9 22.5 23.1 23.6 24.2 24.8 25.3 25.9 26.4 27.0

30 16.9 17.5 18.1 18.7 19.3 20.0 20.6 21.2 21.9 22.5 23.1 23.7 24.4 25.0 25.6 26.2 26.9 27.5 28.1 28.8 29.4 30.0

33 18.6 19.2 19.7 20.6 21.3 22.0 22.7 23.4 24.0 24.7 25.4 26.1 26.8 27.5 28.2 28.9 29.6 30.2 30.9 31.6 32.3 33.0

36 20.2 21.0 21.8 22.5 23.2 24.0 24.7 25.5 26.2 27.0 27.7 28.5 29.2 30.0 30.7 31.5 32.2 33.0 33.7 34.5 35.2 36.0

- 6 -

Page 7

DEHUMIDIFYING COIL SELECTION

EXAMPLE PROBLEM NO. 1

(Showing Use of R-12 Direct Selection Table No. 3)

GIVEN:

Entering Air Dry Bulb.......................................................................................................94°F

Entering Air Wet Bulb.......................................................................................................74°F

CFM (Std Air)...............................................................................................................13,600

Total BTUH Required................................................................................................691,000

Sensible BTUH Required..........................................................................................454,000

Refrigerant Temperature.................................................................................................40°F

Refrigerant......................................................................................................................R-12

Maximum Face Velocity..........................................................................................510 FPM

Maximum Height of Coil-Over Casing....................................................................37 Inches

SOLUTION

1. SENSIBLE TOTAL RATIO

S/T ratio =

total Btuh 691,000

As the S/T ratio is below .90 the direct selection tables can be

used.

sensible Btuh 454,000

= .657 (Formula 6)

6. REQUIRED LEAVING DRY BULB TEMPERATURE

Req’d lvg dry bulb = ent dry bulb -

1.09 X cfrn

109 X 13,600

= 94 - 30.6 = 63.4 F (Formula 3a)

= 94 -

454,000

sensible Btuh

2. MINIMUM FACE AREA REQUIRED

cfm

FA =

face velocity 510

=

13,600

= 26.7 sq. ft. (Formula 4)

3. PHYSICAL SIZE

From Table 1, Page 6 select a coil that has a face area equal

to, or greater than 26.7 sq ft and not exceeding the 37”

overall height specified. (See Page 37 for casing

dimensions.)

For the example problem we have assumed that the correct

selection is a 33 X 117 coil with 26.8 sq ft of face area.

4. ACTUAL FACE VELOCITY

FV (actual) =

face area 26.8

In using the direct selection tables a face velocity of 500 fpm

can be used with negligible error. In critical cases

interpolation may be necessary.

cfm 13,600

= 508 fpm (Formula 5)

5. TONS PER SQUARE FOOT OF FACE AREA

REQUIRED

Tons/sq ft =

face area X 12,000 26.8 X 12,000

total Btuh

691,000

=

(Formula 7)

= 2.15

7. COIL SELECTION

Refer to the 40°F refrigerant temperature, 74°F entering air wet

bulb section of the R-12 direct selection table (Table 3, Page 17).

Enter this section at 500 fpm and proceed down to 2.17 tons/sq

ft. This meets the 2.15 tons/sq ft requirements. Reading to the

left, this is a model 104 coil. The leaving air wet bulb, immediately

to the right of the 2.17 tons/sq ft, is 59.6 F.

8. LEAVING AIR DRY BULB FOR 4 ROW 100 FIN

SERIES COIL

Lvg air dry bulb = Lvg air wet bulb + (wet bulb depression

factor) X (initial wet bulb depression)

(Formula 3b)

= 59.6 + (.09 X 20) = 59.6 +1.8° = 61.4° D.B.

Where: .09 = wet bulb depression factor for 100 fin series,

500 fpm and 4 rows deep (Fig. 7C Page 32)

20 = 94-74 = initial wet bulb depression (Formula 8)

The leaving air dry bulb is 61.4°F which meets 63.4°F calculated

in Step 6 and will satisfy the sensible cooling requirements.

The final selection is a “KDX104- 33 X 117” R-12 DX Coil.

9. ACTUAL CAPACITY OF COIL SELECTED

Total Btuh = (tons/sq ft) X (face area) X 12,000 (Formula 7)

= 2.17 X 26.8 X 12,000 = 697,000

Sensible Btuh = 1.09 X cfm X (ent air dry bulb lvg air dry bulb) (Formula 2)

= 1.09 X 13,600 X (94 - 61.4)

= 484,000

- 7 -

Page 8

DEHUMIDIFYING COIL SELECTION

EXAMPLE PROBLEM NO. 2

(Showing Use of R-22 Direct Selection Table No. 4)

GIVEN:

Entering Air Dry Bulb.......................................................................................................84 F

Entering Air Wet Bulb......................................................................................................68 F

CFM (Std Air).................................................................................................................3090

Leaving Air Dry Bulb.....................................................................................................54.0 F

Leaving Air Wet Bulb....................................................................................................53.7 F

Refrigerant Temperature.................................................................................................45 F

Refrigerant......................................................................................................................R-22

Maximum Face Velocity...........................................................................................550 FPM

1. TOTAL BTUH REQUIRED

Total Btuh = 4.5 X cfm X (total heat difference) (Formula 1)

Total heat ent air @ 68.0°F wet bulb = 32.42 Btu/lb

Total heat lvg air @ 53.7°F wet bulb = 22.44

Total heat difference = 9.98 Btu/lb

(Table 2, Page 10)

Total Btuh = 4.5 X 3090 X 9.98 = 138,800

2. SENSIBLE BTUH REQUIRED

Sensible Btuh = 1.09 X cfm X (ent air dry bulb - lvg air

dry bulb) (Formula 2)

= 1.09 X 3090 X (84 - 54)

= 1.09 X 3090 X 30 = 101,040

3. SENSIBLE TOTAL RATIO

S/T ratio =

total Btuh 138,800

As the S/T ratio is below .90 the direct selection tables can

be used

4. MINIMUM FACE AREA REQUIRED

FA =

face Velocity 500

5. PHYSICAL DIMENSION OF COIL FACE

From Table 1, Page 6 select a coil that has a face area

equal to, or greater than 5.62 sq ft.

For this example assume that the correct selection is an

18 X 45 coil with 5.62 sq ft of face area.

6. TONS PER SQUARE FOOT OF FACE AREA REQUIRED

Tons/sq ft =

face area X 12,000 5.62 X 12,000

sensible Btuh = 101,040

cfm = 3090

total Btuh = 138,800

= 2.06 (Formula 7)

= .728 (Formula 6)

= 5.62 sq ft (Formula 4)

- 8 -

7. PRELIMINARY COIL SELECTION

Refer to the 45°F refrigerant temperature, 68°F entering

air wet bulb section of the R-22 direct selection table

(Table 4. Page 28). Enter this section at 550 fpm and

proceed down to 2.06 tons/sq ft. This exactly meets the

load requirements. Reading to the left, this is a model 106

coil.

The leaving air wet bulb, immediately to the right of the

2.06 tons,/sq ft, is 53.7 F.

8. LEAVING AIR DRY BULB

Lvg air dry bulb = (Ivg air wet bulb) + (wet bulb

depression factor) X (initial wet bulb

depression)

= 53.7 + (.031 X 16) = 53.7 + 0.5

= 54.2 F (Formula 3b)

Where: .031 = wet bulb depression factor for 100 fin

series, 550 fpm and 6 rows deep

(Figure 7c, Page 32)

16 = 84 - 68 = initial wet bulb depression

(Formula 8)

Since the lvg air dry bulb is above the 54.0°F required, a

model 126 coil should be selected.

9. RESELECTION - DETERMINE CAPACITY OF A MODEL

126 COIL

Return to Table 4, Page 28. The tons/ /sq ft for a model

126 coil is 2.16 and the leaving air wet bulb is 52.9°F.

Both exceed the requirements.

Determine the leaving air dry bulb as follows:

Lvg air dry bulb = 52.9 + (0.25 X 16) = 52.9 + .4 = 53.3°F

Where: .025 = wet bulb depression factor for 120 fin

series, 550 fpm and 6 rows deep

(Figure 7d, Page 32)

This is below the required 54.0°F.

Therefore, the final selection is a KDX 126 - 18"X 45"

R-22 DX Coil.

Page 9

DEHUMIDIFYING COIL SELECTION

EXAMPLE PROBLEM NO. 3

(Showing Use of the Basic Rating Curves-Pages 24 and 25)

GIVEN:

Entering Air Dry Bulb.......................................................................................................60°F

Entering Air Wet Bulb......................................................................................................58°F

CFM (Std Air)..................................................................................................................2000

Total BTUH Required..................................................................................................64,250

Sensible BTUH Required............................................................................................31,000

Refrigerant Temperature.................................................................................................36°F

Refrigerant......................................................................................................................R-22

Maximum Face Velocity...........................................................................................450 FPM

1 . SENSIBLE TOTAL RATIO

S/T ratio =

total Btuh 64,250

As S/T ratio is below .90 the basic rating curves on page

31 can be used.

2. MINIMUM FACE AREA REQUIRED

FA =

face velocity 450

3. PHYSICAL SIZE

From Table 1, Page 6 select a coil that has a face area

equal to, or greater than 4.45 sq ft.

For this example assume that the correct selection is an

18 X 36 coil with 4.5 sq ft of face area. This is close

enough to 4.45 sq ft to use 450 fpm.

4. TONS PER SQUARE FOOT REQUIRED

Tons/sq ft =

face area X 12,000 4.5 X 12,000

(Formula 7)

5. BASE RATING

Turn to the R-22 Base Rating Curves (Figure 5, Page 25).

The base rating for 58 F entering air wet bulb and 36°F

refrigerant temperature is 1.19 tons/sq ft.

6. VELOCITY AND ROW CORRECTION FACTOR

REQUIRED

In view of the low S/T ratio a series 70 coil will be

checked.

VR correction factor =

= 1.19

1.19 X .93

Where: .93 = fin correction factor for 70 fin series (Table 6,

sensible Btuh

cfm

=

total Btuh

Page 31)

31,000

=

2000

= 4.45 sq ft (Formula 4)

tons/sq ft

(base rating) X (fin correction factor)

= .482 (Formula 6)

64,250

=

= 1.075

= 1.19

8. ACTUAL TOTAL BTUH OF 5 ROW 70 FIN SERIES COIL

Total Btuh = 12,000 X (base rating) X (face area) X (VR

corr fact.) X (fin series corr fact.)

= 12,000 X 1.19 X 4.5 X 1.088 X .93 = 65,020

This meets the total load requirements.

9. LEAVING AIR WET BULB FOR 5 ROW 70 FIN SERIE COIL

Total Btuh = 4.5 X cfm X (total heat difference) (Formula 1)

Total heat difference =

Total heat ent air @ 58°F wet bulb = 25.12 Btu/lb

Total heat difference = 7.22

Total heat lvg air = 17.90 Btu/lb

Lvg air wet bulb = 45.5°F

10. LEAVING AIR DRY BULB FOR 5 ROW 70 FIN SERIES

COIL

Lvg air dry bulb = (Lvg air wet bulb) + (wet bulb depression

factor) X (initial wet bulb depression)

(Formula 3b)

= 45.5 + (.079 X 2) = 45.5 + .2 = 45.7

Where: .079 = wet bulb depression factor for 70 fin series,

450 fpm and 5 rows deep (Fig. 7a, Page 32)

2 = 60-58 = initial wet bulb depression (Formula 8)

11. SENSIBLE BTUH OF 5 ROW 70 FIN SERIES COIL

Sensible Bruh = 1.09 X cfm X (ent air dry bulb-lvg air dry

bulb) (Formula 2)

= 1.09 X 2000 X (60-45.7)

= 1.09 X 2000 X 14.3 = 31,174

total Btuh = 65,020

4.5 X cfm 4.5 X 2000

(Table 2, Page 10)

= 7.22 Btu/lb

7. ROWS DEEP REQUIRED

Turn to the R-22 Velocity and Row Correction Factor

Curves (Figure 6, Page 31). At the required 1.075 velocity

and row correction factor and 450 fpm, a 5 row 70 fin series

coil will be required. This coil has an actual velocity and

row correction factor of 1.088.

12. FINAL COIL SELECTION

The final coil selected is a KDX75-18"X36" R-22 DX Coil

A KDX124-18"X36" Coil would also meet requirements;

however, it exceeds the total load and the sensible load by

a wide margin.

- 9 -

Page 10

TOTAL HEAT

TABLE 2 - BTU CONTENT OF 1 LB. OF DRY AIR WITH WATER VAPOR REQUIRED

FOR COMPLETE SATURATION†

(Standard Atmospheric Pressure 29.921” HG.)

WET

BULB

°F. *

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

.0 .1 .2 .3 .4 .5 .6 .7 .8 .9

13.01

13.44

13.87

14.32

14.77

15.23

15.70

16.17

16.66

17.15

17.65

18.16

18.68

19.21

19.75

20.30

20.86

21.44

22.02

22.61

23.22

23.84

24.48

25.12

25.78

26.46

27.15

27.85

28.57

29.31

30.06

30.83

31.62

32.42

33.25

34.09

34.95

35.83

36.74

37.66

38.61

39.57

40.57

41.58

42.62

43.69

44.78

45.90

47.04

48.22

49.43

13.05

13.48

13.92

14.36

14.82

15.28

15.74

16.22

16.71

17.20

17.70

18.21

18.73

19.26

19.81

20.36

20.92

21.49

22.08

22.68

23.28

23.90

24.54

25.19

25.85

26.53

27.22

27.92

28.64

29.38

30.14

30.91

31.70

32.50

33.33

34.18

35.04

35.92

36.83

37.75

38.71

39.67

40.67

41.68

42.73

43.80

44.89

46.01

47.16

48.34

49.55

13.09

13.52

13.96

14.41

14.86

15.32

15.79

16.27

16.75

17.25

17.75

18.26

18.79

19.32

19.86

20.41

20.98

21.55

22.14

22.74

23.34

23.97

24.61

25.25

25.92

26.60

27.29

27.99

28.72

29.46

30.21

30.99

31.78

32.59

33.42

34.26

35.13

36.01

36.92

37.85

38.80

39.77

40.77

41.79

42.83

43.91

45.00

46.13

47.28

48.46

49.68

13.14

13.57

14.01

14.45

14.91

15.37

15.84

16.32

16.80

17.30

17.80

18.32

18.84

19.37

19.92

20.47

21.03

21.61

22.20

22.80

23.41

24.03

24.67

25.32

25.98

26.67

27.36

28.07

28.79

29.53

30.29

31.07

31.86

32.67

33.50

34.35

35.21

36.10

37.02

37.94

38.90

39.87

40.87

41.89

42.94

44.02

45.12

46.24

47.39

48.58

49.80

TENTHS OF DEGREES

13.18

13.61

14.05

14.50

14.95

15.42

15.89

16.37

16.85

17.35

17.85

18.37

18.89

19.43

19.97

20.52

21.09

21.67

22.26

22.86

23.47

24.10

24.74

25.38

26.05

26.74

27.43

28.14

28.87

29.61

30.37

31.15

31.94

32.75

33.59

34.43

35.30

36.19

37.11

38.04

39.00

39.98

40.97

42.00

43.05

44.13

45.23

46.36

47.51

48.70

49.92

13.22

13.66

14.10

14.54

15.00

15.46

15.93

16.41

16.90

17.40

17.91

18.42

18.95

19.48

20.03

20.58

21.15

21.73

22.32

22.92

23.53

24.16

24.80

25.45

26.12

26.80

27.50

28.21

28.94

29.68

30.44

31.22

32.02

32.83

33.67

34.52

35.39

36.28

37.20

38.13

39.09

40.07

41.07

42.10

43.15

44.23

45.34

46.47

47.63

48.82

50.04

13.27

13.70

14.14

14.59

15.05

15.51

15.98

16.46

16.95

17.45

17.96

18.47

19.00

19.53

20.08

20.64

21.21

21.79

22.38

22.98

23.59

24.22

24.86

25.52

26.19

26.87

27.57

28.28

29.01

29.76

30.52

31.30

32.10

32.92

33.75

34.61

35.48

36.38

37.29

38.23

39.19

40.17

41.18

42.20

43.26

44.34

45.45

46.58

47.75

48.95

50.17

13.31

13.74

14.19

14.63

15.09

15.56

16.03

16.51

17.00

17.50

18.01

18.52

19.05

19.59

20.14

20.69

21.26

21.84

22.44

23.04

23.65

24.29

24.93

25.58

26.26

26.94

27.64

28.35

29.09

29.83

30.60

31.38

32.18

33.00

33.84

34.69

35.57

36.47

37.38

38.32

39.28

40.27

41.28

42.31

43.37

44.45

45.56

46.70

47.87

49.07

50.29

13.35

13.79

14.23

14.68

15.14

15.60

16.08

16.56

17.05

17.55

18.06

18.58

19.10

19.64

20.19

20.75

21.32

21.90

22.50

23.10

23.72

24.35

24.99

25.65

26.32

27.01

27.71

28.43

29.16

29.91

30.68

31.46

32.26

33.08

33.92

34.79

35.65

36.56

37.48

38.42

39.38

40.37

41.38

42.41

43.48

44.56

45.68

46.81

47.98

49.19

50.41

13.39

13.83

14.27

14.73

15.18

15.65

16.12

16.61

17.10

17.60

18.11

18.63

19.16

19.70

20.25

20.81

21.38

21.96

22.56

23.16

23.78

24.42

25.06

25.71

26.39

27.08

27.78

28.50

29.24

29.98

30.75

31.54

32.34

33.17

34.00

34.86

35.74

36.65

37.57

38.51

39.47

40.47

41.48

42.52

43.58

44.67

45.79

46.93

48.10

49.31

50.54

* Use wet bulb temperature only in determining total heat † Compiled from data in ASHRAE Guide.

- 10 -

Page 11

CONVERSION OF AIR VOLUME TO STANDARD AIR

FIGURE 1 - TEMPERATURE CONVERSION FACTOR

1.30

1.25

)

1

TEMPERATURE CONVERSION FACTOR (F

1.20

1.15

1.10

1.05

1.00

0.95

0.90

0.85

0.80

0.75

0.70

0.65

-50 -25 0 25 50 75 100 125 150 175 200 225 250 275 300 325

350

TEMPERATURE °F

1.30

1.25

1.20

1.15

1.10

1.05

1.00

0.95

0.90

0.85

0.80

0.75

0.70

0.65

When the specified air volume (CFM) is given at any temperature other than 70 °F or at any altitude other than sea level, these charts should be

used for correction before using the following capacity and friction tables (which are based on CFM @ standard air conditions).

FIGURE 2 - ALTITUDE CONVERSION FACTOR

1.025

1.000

0.975

)

2

0.950

0.925

0.900

0.875

0.850

0.825

0.800

0.775

TEMPERATURE CONVERSION FACTOR (F

0.750

0.725

0.700

-500 0 500 1500 2500 3500 4500 5500 6500 7500 8500

ALTITUDE (FEET ABOVE SEA LEVEL)

1.025

1.000

0.975

0.950

0.925

0.900

0.875

0.850

0.825

0.800

0.775

0.750

0.725

0.700

Example: To convert 15,900 CFM of air at 94 °F and at 3,000

ft. altitude to standard conditions:

CFM of Std. Air

= CFM of specified Air x F1 x F

2

= 15,900 X 955 X .896 = 13,600

Where: F1 = Temperature conversion factor from Fig. 1.

F2 = Altitude conversion factor from Fig. 2.

- 11 -

Page 12

DIRECT EXPANSION COIL RATINGS

FOR REFRIGERANT R-12 - 35°35°

TABLE 3 8°F SUPER HEAT

ENT.

WET

BULB

°F

65

66

67

68

COIL

MODEL

73

83

103

123

74

84

104

124

75

85

105

125

76

86

106

126

78

88

108

128

73

83

103

123

74

84

104

124

75

85

105

125

76

86

106

126

78

88

108

128

73

83

103

123

74

84

104

124

75

85

105

125

76

86

106

126

78

88

108

128

73

83

103

123

74

84

104

124

75

85

105

125

76

86

106

126

78

88

108

128

400 425 450 475 500 525 550 575 600

TONS

LVG.

TONS

LVG.

TONS

PER

SQ. FT.

1.08

1.16

1.24

1.29

1.33

1.43

1.52

1.59

1.53

1.64

1.75

1.82

1.68

1.81

1.93

2.01

1.93

2.08

2.22

2.31

1.13

1.22

1.30

1.35

1.39

1.49

1.59

1.65

1.59

1.71

1.82

1.90

1.76

1.89

2.01

2.10

2.02

2.17

2.31

2.41

1.18

1.27

1.35

1.41

1.45

1.56

1.66

1.73

1.66

1.79

1.91

1.99

1.83

1.97

2.10

2.19

2.11

2.27

2.42

2.52

1.24

1.33

1.42

1.48

1.51

1.62

1.73

1.80

1.73

1.86

1.98

2.06

1.92

2.06

2.19

2.29

2.19

2.36

2.51

2.62

WET

BULB

54.4

53.5

52.6

52.0

51.6

50.4

49.3

48.5

49.2

47.8

46.4

45.5

47.3

45.7

44.1

43.0

44.1

42.0

40.1

38.8

55.1

54.1

53.2

52.7

52.2

51.1

49.8

49.1

49.9

48.4

47.0

46.0

47.8

46.1

44.6

43.4

44.4

42.4

40.4

39.0

55.9

54.9

54.0

53.3

52.9

51.6

50.5

49.6

50.5

48.9

47.4

46.4

48.4

46.6

44.9

43.7

44.8

42.7

40.6

39.1

56.5

55.5

54.6

53.9

53.6

52.3

51.0

50.2

51.0

49.5

48.0

47.0

48.8

47.0

45.3

44.0

45.3

43.1

41.0

39.4

PER

SQ. FT.

1.12

1.20

1.28

1.33

1.37

1.47

1.57

1.63

1.57

1.69

1.80

1.88

1.75

1.88

2.00

2.09

2.02

2.17

2.31

2.41

1.16

1.25

1.33

1.39

1.43

1.54

1.64

1.71

1.65

1.77

1.89

1.96

1.82

1.96

2.09

2.18

2.10

2.20

2.41

2.51

1.22

1.31

1.40

1.45

1.49

1.60

1.70

1.78

1.72

1.85

1.97

2.05

1.91

2.05

2.18

2.28

2.19

2.36

2.51

2.62

1.26

1.36

1.45

1.51

1.55

1.67

1.78

1.85

1.79

1.93

2.06

2.14

1.99

2.14

2.28

2.38

2.30

2.47

2.63

2.74

WET

BULB

54.7

53.8

53.0

52.5

52.0

51.0

49.8

49.1

49.8

48.5

47.2

46.2

47.7

46.2

44.7

43.6

44.5

42.6

40.7

39.4

55.5

54.6

53.8

53.1

52.7

51.5

49.5

48.6

50.3

48.9

47.5

46.7

48.4

46.7

45.1

44.0

45.0

43.0

41.0

39.7

56.2

55.3

54.4

53.8

53.4

52.2

51.2

50.3

50.9

49.5

48.1

47.1

48.8

47.1

45.6

44.3

45.4

43.3

41.4

39.9

57.1

56.1

55.2

54.5

54.1

52.9

51.7

50.9

51.6

50.0

48.5

47.6

49.3

47.6

45.6

44.7

45.6

43.5

41.5

40.0

PER

SQ. FT.

1.14

1.23

1.31

1.37

1.41

1.52

1.62

1.69

1.63

1.75

1.86

1.94

1.81

1.95

2.08

2.16

2.09

2.25

2.40

2.50

1.19

1.28

1.36

1.42

1.48

1.59

1.69

1.76

1.70

1.83

1.95

2.03

1.89

2.03

2.16

2.25

2.19

2.36

2.51

2.62

1.25

1.34

1.43

1.49

1.54

1.66

1.77

1.84

1.78

1.91

2.03

2.12

1.97

2.12

2.26

2.35

2.29

2.46

2.62

2.73

1.30

1.40

1.49

1.55

1.61

1.73

1.84

1.92

1.86

2.00

2.13

2.22

2.06

2.21

2.35

2.45

2.39

2.57

2.74

2.85

LVG.

WET

BULB

55.1

54.2

53.5

52.9

52.5

51.3

50.3

49.3

50.2

48.9

47.7

46.8

48.2

46.7

45.2

44.2

45.0

43.1

41.3

40.0

55.9

55.0

54.3

53.7

53.1

51.9

50.9

50.2

50.8

49.4

48.1

47.2

48.8

47.2

45.7

44.7

45.4

43.5

41.6

40.2

56.6

55.7

54.9

54.3

53.8

52.6

51.5

50.7

51.4

50.0

48.7

47.7

49.4

47.7

46.1

45.1

45.8

43.8

41.8

40.5

57.4

56.4

55.6

55.0

54.4

53.3

52.1

51.3

51.9

50.5

49.1

48.1

49.8

48.2

46.6

45.5

46.2

44.1

42.0

40.6

COIL FACE VELOCITY - FPM

TONS

LVG.

WET

BULB

55.4

54.6

53.9

53.3

52.8

51.8

50.8

50.1

50.6

49.3

48.0

47.2

48.7

47.2

45.8

44.9

45.3

43.5

41.8

40.5

56.1

55.3

54.5

53.9

53.5

52.4

51.4

50.7

51.1

49.8

48.6

47.7

49.2

47.7

46.2

45.2

45.7

43.9

42.0

40.7

57.0

56.1

55.3

54.8

54.2

53.1

52.0

51.3

51.8

50.5

49.1

48.2

49.8

48.2

46.7

45.6

46.2

44.2

42.2

41.0

57.7

56.9

56.1

55.4

54.9

53.8

52.6

52.0

52.4

51.0

49.7

48.6

50.3

48.6

47.1

46.0

46.8

44.7

42.7

41.3

TONS

PER

SQ. FT.

1.20

1.29

1.37

1.43

1.49

1.60

1.70

1.78

1.73

1.86

1.98

2.06

1.93

2.08

2.22

2.31

2.26

2.43

2.59

2.70

1.26

1.35

1.44

1.50

1.55

1.67

1.78

1.85

1.80

1.94

2.07

2.15

2.02

2.17

2.31

2.41

2.36

2.54

2.71

2.82

1.31

1.41

1.50

1.57

1.62

1.74

1.85

1.93

1.89

2.03

2.16

2.25

2.11

2.27

2.42

2.52

2.46

2.65

2.82

2.94

1.37

1.47

1.57

1.63

1.69

1.82

1.94

2.02

1.97

2.12

2.26

2.35

2.19

2.36

2.51

2.62

2.57

2.76

2.94

3.06

PER

SQ. FT.

1.17

1.26

1.34

1.40

1.45

1.56

1.66

1.73

1.68

1.81

1.93

2.01

1.87

2.01

2.14

2.23

2.18

2.34

2.49

2.60

1.23

1.32

1.41

1.47

1.52

1.63

1.74

1.81

1.76

1.89

2.01

2.10

1.95

2.10

2.24

2.33

2.28

2.45

2.61

2.72

1.27

1.37

1.46

1.52

1.58

1.70

1.81

1.89

1.83

1.97

2.10

2.19

2.04

2.19

2.33

2.43

2.38

2.56

2.73

2.84

1.33

1.43

1.52

1.59

1.65

1.77

1.89

1.96

1.92

2.06

2.19

2.29

2.13

2.29

2.44

2.54

2.47

2.66

2.83

2.95

LVG.

WET

BULB

55.7

54.9

54.2

53.7

53.2

52.2

51.2

50.5

50.9

49.7

48.5

47.7

49.0

47.5

46.1

45.2

45.7

43.9

42.2

40.9

56.4

55.8

54.9

54.4

53.9

52.8

51.8

51.2

51.6

50.3

49.1

48.3

49.6

48.1

46.7

45.6

46.2

44.3

42.4

41.2

57.2

56.4

55.7

55.0

54.6

53.5

52.5

51.8

52.2

50.9

49.6

48.8

50.1

48.6

47.1

46.0

46.7

44.7

42.8

41.5

58.0

57.2

56.3

55.8

55.3

54.1

53.1

52.4

52.8

51.4

50.1

49.2

50.8

49.1

47.7

46.6

47.1

45.1

43.2

41.8

TONS

PER

SQ. FT.

1.23

1.32

1.41

1.47

1.53

1.64

1.75

1.82

1.78

1.91

2.03

2.12

1.99

2.14

2.28

2.38

2.33

2.50

2.66

2.78

1.28

1.38

1.47

1.53

1.59

1.71

1.82

1.90

1.86

2.00

2.13

2.22

2.04

2.24

2.39

2.49

2.44

2.62

2.79

2.91

1.34

1.44

1.53

1.60

1.66

1.78

1.90

1.98

1.94

2.09

2.23

2.32

2.18

2.34

2.49

2.60

2.54

2.73

2.91

3.03

1.40

1.50

1.60

1.67

1.73

1.86

1.98

2.06

2.03

2.18

2.32

2.42

2.27

2.44

2.60

2.71

2.65

2.85

3.02

3.15

LVG.

WET

BULB

56.0

55.2

54.5

54.0

53.4

52.5

51.5

50.9

51.3

50.1

49.0

48.2

49.4

48.0

46.6

45.6

46.1

44.4

42.8

41.5

56.8

56.0

55.2

54.7

54.2

53.2

52.3

51.5

51.9

50.7

49.5

48.6

49.9

48.4

47.0

46.0

46.5

44.7

43.0

41.7

57.5

56.7

56.0

55.4

54.9

53.9

52.9

52.2

52.6

51.2

50.0

49.2

50.4

49.0

47.5

46.5

47.1

45.2

43.4

42.1

58.3

57.5

56.7

56.2

55.7

54.6

53.6

52.9

53.1

51.8

50.6

49.7

51.1

49.5

47.9

47.0

47.5

45.6

43.9

42.5

TONS

PER

SQ. FT.

1.25

1.34

1.43

1.49

1.55

1.67

1.78

1.85

1.82

1.96

2.09

2.18

2.05

2.20

2.34

2.44

2.40

2.58

2.75

2.86

1.30

1.40

1.49

1.55

1.63

1.75

1.86

1.94

1.91

2.05

2.18

2.28

2.14

2.30

2.45

2.55

2.51

2.70

2.88

3.00

1.37

1.47

1.57

1.63

1.70

1.83

1.95

2.03

1.99

2.14

2.28

2.38

2.23

2.40

2.56

2.66

2.62

2.82

3.00

3.13

1.42

1.53

1.63

1.70

1.78

1.91

2.03

2.12

2.07

2.23

2.37

2.48

2.33

2.50

2.66

2.78

2.73

2.94

3.13

3.26

LVG.

WET

BULB

56.3

55.5

54.8

54.4

53.9

52.9

52.0

51.4

51.7

50.5

49.3

48.5

49.7

48.3

47.1

46.1

46.5

44.8

43.1

42.0

57.1

56.3

55.6

55.2

54.5

53.4

52.6

52.0

52.2

51.0

49.9

49.0

50.3

48.9

47.5

46.6

47.0

45.2

43.4

42.2

57.8

57.0

56.3

55.8

55.3

54.2

53.2

52.6

52.9

51.7

50.5

49.6

50.9

49.4

48.0

47.1

47.4

45.6

43.9

42.6

58.6

57.8

57.1

56.5

55.9

54.9

53.9

53.2

53.6

52.3

51.1

50.2

51.5

50.0

48.6

47.5

47.9

46.0

44.2

42.9

TONS

PER

SQ. FT.

1.27

1.37

1.46

1.52

1.59

1.71

1.82

1.90

1.86

2.00

2.14

2.23

2.09

2.25

2.40

2.50

2.46

2.65

2.82

2.94

1.33

1.43

1.52

1.59

1.66

1.79

1.91

1.99

1.94

2.09

2.23

2.32

2.19

2.35

2.50

2.61

2.58

2.77

2.95

3.07

1.40

1.50

1.60

1.67

1.73

1.86

1.98

2.06

2.03

2.18

2.32

2.42

2.29

2.46

2.62

2.73

2.70

2.90

3.09

3.22

1.45

1.56

1.66

1.73

1.80

1.94

2.07

2.15

2.12

2.28

2.43

2.53

2.38

2.56

2.73

2.84

2.81

3.02

3.22

3.35

LVG.

WET

BULB

56.5

55.8

55.1

54.7

54.1

53.2

52.3

51.7

52.0

50.8

49.7

48.9

50.1

48.8

47.5

46.6

46.9

45.2

43.7

42.5

57.3

56.6

55.9

55.4

54.9

53.8

52.9

52.3

52.7

51.5

50.3

49.6

50.7

49.3

48.1

47.1

47.3

45.6

44.0

42.9

58.0

57.3

56.6

56.1

55.6

54.6

53.7

53.1

53.3

52.1

51.0

50.2

51.2

49.8

48.5

47.5

47.9

46.0

44.3

43.1

58.9

58.1

57.4

56.9

56.4

55.3

54.3

53.7

54.0

52.7

51.5

50.7

51.9

50.4

49.0

48.1

48.3

46.5

44.7

43.5

SQ. FT.

TONS

PER

1.30

1.40

1.49

1.55

1.62

1.74

1.85

1.93

1.90

2.04

2.17

2.26

2.14

2.30

2.45

2.55

2.53

2.72

2.90

3.02

1.36

1.46

1.55

1.62

1.69

1.82

1.94

2.02

1.99

2.14

2.28

2.38

2.23

2.40

2.56

2.66

2.64

2.84

3.02

3.15

1.41

1.52

1.62

1.69

1.77

1.90

2.02

2.11

2.06

2.22

2.36

2.46

2.33

2.51

2.67

2.79

2.76

2.97

3.16

3.30

1.48

1.59

1.69

1.76

1.84

1.98

2.11

2.20

2.17

2.33

2.48

2.59

2.44

2.62

2.79

2.91

2.88

3.10

3.30

3.44

LVG.

WET

BULB

56.7

56.0

55.3

54.9

54.4

53.5

52.7

52.1

52.3

51.3

50.2

49.5

50.4

49.2

47.9

47.1

47.3

45.6

44.0

43.0

57.5

56.8

56.2

55.7

55.2

54.2

53.3

52.7

53.0

51.8

50.7

49.9

51.1

49.7

48.4

47.6

47.8

46.1

44.5

43.4

58.4

57.6

56.9

56.6

55.9

54.9

54.0

53.4

53.7

52.5

51.5

50.7

51.7

50.3

49.0

48.0

48.3

46.5

44.9

43.6

59.1

58.3

57.7

57.2

56.6

55.6

54.7

54.0

54.3

53.1

51.9

51.1

52.2

50.8

49.5

48.5

48.8

46.9

45.2

44.0

- 12 -

Page 13

DIRECT EXPANSION COIL RATINGS

FOR REFRIGERANT R-12 - 35°35°

TABLE 3 8°F SUPER HEAT

ENT.

WET

BULB

°F

69

70

71

COIL

MODEL

73

83

103

123

74

84

104

124

75

85

105

125

76

86

106

126

78

88

108

128

73

83

103

123

74

84

104

124

75

85

105

125

76

86

106

126

78

88

108

128

73

83

103

123

74

84

104

124

75

85

105

125

76

86

106

126

78

88

108

128

400 425 450 475 500 525 550 575 600

TONS

LVG.

TONS

LVG.

TONS

PER

SQ. FT.

1.28

1.38

1.47

1.53

1.57

1.69

1.80

1.88

1.80

1.94

2.07

2.14

1.99

2.14

2.28

2.38

2.30

2.47

2.63

2.74

1.34

1.44

1.53

1.60

1.64

1.76

1.87

1.95

1.88

2.02

2.15

2.24

2.07

2.23

2.37

2.48

2.39

2.57

2.74

2.85

1.40

1.50

1.60

1.67

1.70

1.83

1.95

2.03

1.96

2.11

2.25

2.34

2.16

2.32

2.47

2.58

2.48

2.67

2.84

2.96

WET

BULB

57.4

56.3

55.4

54.7

54.3

52.9

51.7

50.7

51.7

50.0

48.4

47.6

49.4

47.6

45.8

44.5

45.5

43.3

41.0

39.5

58.1

57.0

56.1

55.2

54.9

53.6

52.3

51.4

52.2

50.6

49.0

47.9

50.0

48.0

46.2

44.8

46.0

43.6

41.3

39.7

58.7

57.7

56.7

56.0

55.6

54.2

52.9

52.0

52.8

50.9

49.4

48.3

50.4

48.5

46.6

45.2

46.5

44.0

41.6

40.0

PER

SQ. FT.

1.32

1.42

1.51

1.58

1.62

1.74

1.85

1.93

1.87

2.01

2.14

2.23

2.07

2.23

2.37

2.48

2.39

2.57

2.74

2.85

1.38

1.48

1.58

1.64

1.69

1.82

1.94

2.02

1.95

2.10

2.24

2.33

2.16

2.32

2.47

2.58

2.49

2.68

2.85

2.97

1.43

1.54

1.64

1.71

1.76

1.89

2.01

2.10

2.03

2.18

2.32

2.42

2.25

2.42

2.58

2.69

2.59

2.79

2.97

3.10

WET

BULB

57.8

56.8

55.8

55.2

54.8

53.5

52.4

51.5

52.1

50.6

49.1

48.1

49.1

48.1

46.4

45.1

46.1

43.9

41.8

40.3

58.5

57.5

56.5

55.9

55.4

54.1

52.8

52.0

52.7

51.1

49.5

48.5

50.4

48.6

46.8

45.5

46.6

44.2

42.1

40.5

59.3

58.2

57.3

56.6

56.1

54.8

53.5

52.6

53.3

51.7

50.2

49.0

50.9

49.0

47.2

45.8

47.0

44.6

42.3

40.6

SQ. FT.

PER

1.36

1.46

1.55

1.62

1.67

1.80

1.92

2.00

1.93

2.08

2.22

2.31

2.15

2.31

2.46

2.56

2.49

2.68

2.85

2.97

1.41

1.52

1.62

1.69

1.75

1.88

2.00

2.09

2.02

2.17

2.31

2.41

2.24

2.41

2.57

2.68

2.59

2.79

2.97

3.10

1.47

1.58

1.68

1.75

1.81

1.95

2.08

2.16

2.10

2.26

2.41

2.51

2.33

2.50

2.66

2.78

2.70

2.90

3.09

3.22

LVG.

WET

BULB

51.8

57.2

56.3

55.7

55.2

53.9

52.8

51.9

52.6

51.1

49.6

48.7

50.4

48.6

47.0

45.8

46.6

44.4

42.4

40.9

58.9

57.9

57.0

56.4

55.8

54.5

53.4

52.5

53.2

51.6

50.2

49.1

50.9

49.1

47.3

46.1

47.1

44.8

42.7

41.0

59.7

58.7

57.8

57.2

56.6

55.3

54.0

53.2

53.8

52.2

50.7

49.6

51.5

49.7

48.0

46.6

47.5

45.2

43.0

41.4

COIL FACE VELOCITY - FPM

TONS

LVG.

WET

BULB

58.5

57.6

56.8

56.2

55.6

54.4

53.3

52.5

53.0

51.5

50.2

49.1

50.9

49.1

47.5

46.4

47.1

45.0

42.9

41.4

54.2

58.3

57.5

56.8

56.3

55.0

53.8

53.1

53.7

52.2

50.9

49.8

51.4

49.6

48.0

46.8

47.6

45.4

43.3

41.8

60.0

59.1

58.2

57.6

57.0

55.8

54.6

53.8

54.3

52.8

51.3

50.2

52.0

50.2

48.5

47.3

48.0

45.8

43.6

42.1

TONS

PER

SQ. FT.

1.42

1.53

1.63

1.70

1.77

1.90

2.02

2.11

2.06

2.21

2.35

2.45

2.30

2.47

2.63

2.74

2.68

2.88

3.07

3.20

1.49

1.60

1.70

1.78

1.84

1.98

2.11

2.20

2.14

2.30

2.45

2.55

2.39

2.57

2.74

2.85

2.79

3.00

3.20

3.33

1.54

1.66

1.77

1.84

1.92

2.06

2.19

2.29

2.22

2.39

2.55

2.65

2.48

2.67

2.84

2.96

2.90

3.12

3.32

3.46

PER

SQ. FT.

1.39

1.49

1.59

1.65

1.72

1.85

1.97

2.05

2.00

2.15

2.29

2.39

2.22

2.39

2.55

2.65

2.59

2.78

2.96

3.09

1.45

1.56

1.66

1.73

1.79

1.93

2.06

2.14

2.07

2.23

2.37

2.48

2.32

2.49

2.65

2.76

2.69

2.89

3.08

3.21

1.51

1.62

1.73

1.80

1.86

2.00

2.13

2.22

2.17

2.33

2.48

2.59

2.41

2.59

2.76

2.87

2.80

3.01

3.21

3.34

LVG.

WET

BULB

58.8

57.9

57.1

56.5

56.0

54.8

53.8

53.0

53.4

52.0

50.7

49.8

51.2

49.6

48.0

46.9

47.5

45.5

43.5

42.0

59.5

58.7

57.8

57.2

56.7

55.5

54.4

53.6

54.1

52.7

51.3

50.3

51.8

50.1

48.5

47.4

48.0

45.9

43.7

42.3

60.4

59.5

38.6

58.0

57.4

56.2

55.1

54.2

54.8

53.3

51.9

50.9

52.5

50.7

49.1

47.9

48.5

46.3

44.2

42.7

TONS

PER

SQ. FT.

1.45

1.56

1.66

1.73

1.80

1.94

2.07

2.15

2.11

2.27

2.42

2.52

2.36

2.54

2.71

2.82

2.76

2.97

3.16

3.30

1.52

1.63

1.74

1.81

1.88

2.02

2.15

2.24

2.20

2.37

2.52

2.63

2.46

2.65

2.82

2.94

2.88

3.10

3.30

3.44

1.58

1.70

1.81

1.89

1.95

2.10

2.24

2.33

2.29

2.46

2.62

2.73

2.57

2.76

2.94

3.06

2.99

3.22

3.43

3.57

LVG.

WET

BULB

59.2

58.3

57.5

57.0

56.4

55.3

54.2

53.5

53.9

52.5

51.2

50.3

51.7

50.1

48.5

47.5

48.0

46.0

44.1

42.7

59.9

59.0

58.2

57.7

57.1

56.0

54.9

54.2

54.5

53.0

51.8

50.8

52.3

50.6

49.1

47.9

48.5

46.3

44.4

42.9

60.7

59.8

59.0

58.4

58.9

56.7

55.6

54.8

55.2

53.7

52.4

51.4

52.7

51.1

49.5

48.4

49.0

46.8

44.8

43.3

TONS

PER

SQ. FT.

1.48

1.59

1.69

1.76

1.85

1.99

2.12

2.21

2.16

2.32

2.47

2.58

2.43

2.61

2.78

2.90

2.85

3.06

3.26

3.40

1.54

1.66

1.77

1.84

1.93

2.07

2.20

2.30

2.25

2.42

2.58

2.69

2.53

2.72

2.90

3.02

2.97

3.19

3.40

3.54

1.61

1.73

1.84

1.92

2.00

2.15

2.29

2.39

2.34

2.52

2.68

2.80

2.63

2.83

3.01

3.14

3.09

3.32

3.54

3.69

LVG.

WET

BULB

59.4

58.6

57.9

57.4

56.7

55.6

54.6

53.9

54.3

53.0

51.7

50.8

52.1

50.5

49.0

48.0

48.4

46.5

44.6

43.2

60.2

59.4

58.6

58.1

57.4

56.3

55.3

54.5

54.9

53.6

52.3

51.3

52.7

51.1

49.5

48.4

48.9

46.9

44.9

43.6

61.0

60.1

59.4

58.8

58.2

57.1

56.0

55.2

55.6

54.2

52.9

51.9

53.3

51.6

50.1

49.0

49.4

47.3

45.3

43.8

TONS

PER

SQ. FT.

1.52

1.63

1.74

1.81

1.89

2.03

2.16

2.25

2.20

2.37

2.52

2.63

2.48

2.67

2.84

2.96

2.93

3.15

3.35

3.50

1.58

1.70

1.81

1.89

1.96

2.11

2.25

2.34

2.30

2.47

2.63

2.74

2.59

2.78

2.96

3.09

3.05

3.28

3.49

3.64

1.65

1.77

1.89

1.96

2.05

2.20

2.34

2.44

2.41

2.57

2.76

2.87

2.70

2.90

3.09

3.22

3.17

3.41

3.63

3.79

LVG.

WET

BULB

59.6

58.9

58.1

57.6

57.0

56.0

55.0

54.3

54.7

53.4

52.2

51.3

52.5

51.0

49.6

48.6

48.8

46.9

45.1

43.1

60.4

59.6

58.9

58.3

57.8

56.7

55.7

55.2

55.3

54.0

52.8

51.9

53.1-

51.6

50.1

49.0

49.3

47.4

46.0

44.1

61.2

60.4

59.6

59.1

58.5

57.4

56.4

55.7

55.9

54.7

53.2

52.3

53.7

52.1

50.6

49.5

49.9

47.9

45.9

44.4

TONS

PER

SQ. FT.

1.54

1.66

1.77

1.84

1.93

2.07

2.20

2.30

2.26

2.43

2.59

2.70

2.54

2.73

2.91

3.03

3.00

3.23

3.44

3.59

1.61

1.73

1.84

1.92

2.00

2.15

2.29

2.39

2.35

2.53

2.69

2.81

2.64

2.84

3.02

3.15

3.12

3.36

3.58

3.73

1.67

1.80

1.92

2.00

2.08

2.24

2.39

2.49

2.45

2.63

2.80

2.92

2.75

2.96

3.15

3.29

3.26

3.50

3.73

3.89

LVG.

WET

BULB

59.9

59.1

58.4

57.9

57.3

56.3

55.4

54.7

55.0

53.7

52.5

51.7

52.9

51.4

50.0

49.1

49.3

47.4

45.6

44.3

60.7

59.9

59.2

58.7

58.1

57.1

56.1

55.4

55.7

54.4

53.2

52.3

53.6

52.1

50.7

49.6

49.9

47.9

46.0

44.7

61.5

60.7

59.9

59.4

58.9

57.8

56.8

56.1

56.3

55.1

53.8

52.9

54.2

52.6

51.2

50.0

50.3

48.3

46.4

45.0

- 13 -

Page 14

DIRECT EXPANSION COIL RATINGS

FOR REFRIGERANT R-12 - 35°35°

TABLE 3 8°F SUPER HEAT

ENT.

WET

BULB

°F

72

73

74

COIL

MODEL

73

83

103

123

74

84

104

124

75

85

105

125

76

86

106

126

78

88

108

128

73

83

103

123

74

84

104

124

75

85

105

125

76

86

106

126

78

88

108

128

73

83

103

123

74

84

104

124

75

85

105

125

76

86

106

126

78

88

108

128

400 425 450 475 500 525 550 575 600

TONS

LVG.

TONS

LVG.

TONS

PER

SQ. FT.

1.45

1.56

1.66

1.73

1.78

1.91

2.03

2.12

2.04

2.19

2.33

2.43

2.25

2.42

2.58

2.69

2.59

2.78

2.96

3.09

1.51

1.62

1.73

1.80

1.84

1.98

2.11

2.20

2.12

2.28

2.43

2.53

2.33

2.51

2.67

2.79

2.69

2.89

3.08

3.21

1.56

1.68

1.79

1.86

1.92

2.06

2.19

2.29

2.20

2.37

2.52

2.63

2.43

2.61

2.78

2.90

2.79

3.00

3.20

3.33

WET

BULB

59.6

58.5

57.4

56.7

56.2

54.8

53.5

52.4

53.3

51.6

50.0

48.8

50.9

48.9

46.9

45.5

46.8

44.3

41.8

40.0

60.3

59.2

58.1

57.4

57.0

55.5

54.1

53.1

54.0

52.2

50.4

49.2

51.6

49.5

47.5

46.0

47.2

44.6

42.1

40.2

61.2

60.0

58.9

58.2

57.2

56.1

54.7

53.2

54.6

52.7

51.0

49.7

52.0

49.9

47.8

46.3

47.7

45.0

42.3

40.5

PER

SQ. FT.

1.49

1.60

1.70

1.78

1.83

1.97

2.10

2.19

2.11

2.27

2.42

2.52

2.33

2.51

2.67

2.79

2.70

2.90

3.09

3.22

1.55

1.67

1.78

1.85

1.91

2.05

2.18

2.28

2.19

2.36

2.51

2.62

2.43

2.61

2.78

2.90

2.80

3.01

3.21

3.34

1.61

1.73

1.84

1.92

1.97

2.12

2.26

2.35

2.28

2.45

2.61

2.72

2.52

2.71

2.89

3.01

2.91

3.13

33.3

3.47

WET

BULB

60.0

59.0

58.1

57.3

56.8

55.4

54.1

53.1

53.9

52.3

50.6

49.5

51.6

49.6

47.8

46.3

47.4

45.0

42.6

40.8

60.8

59.7

58.7

58.0

57.4

56.1

54.7

53.7

54.6

52.8

51.2

50.0

52.1

50.1

48.2

46.7

47.9

45.4

42.9

41.3

61.6

60.5

59.5

58.7

58.3

56.8

55.4

54.5

55.2

53.4

51.7

50.5

52.7

50.6

48.6

47.2

48.3

45.7

43.2

41.4

SQ. FT.

PER

1.53

1.65

1.76

1.83

1.89

2.03

2.16

2.25

2.19

2.35

2.50

2.61

2.42

2.60

2.77

2.89

2.81

3.02

3.22

3.35

1.59

1.71

1.82

1.90

1.96

2.11

2.25

2.34

2.27

2.44

2.60

2.71

2.52

2.71

2.89

3.01

2.92

3.14

3.34

3.49

1.66

1.78

1.90

1.99

2.04

2.19

2.33

2.43

2.36

2.54

2.71

2.82

2.61

2.81

2.99

3.12

3.03

3.26

3.47

3.62

LVG.

WET

BULB

60.4

59.4

58.4

57.8

57.2

55.9

54.5

53.8

54.4

52.8

51.3

50.1

52.0

50.2

48.4

47.0

47.9

45.5

43.2

41.6

61.2

60.2

59.3

58.5

58.0

56.6

55.3

54.4

55.1

53.4

51.8

50.7

52.6

50.7

48.7

47.4

48.4

45.9

43.6

41.8

62.0

60.9

59.9

59.2

58.7

57.3

56.0

55.1

55.7

54.0

52.3

51.1

53.3

51.3

49.3

47.9

48.9

46.3

43.9

42.1

COIL FACE VELOCITY - FPM

TONS

LVG.

WET

BULB

60.6

59.9

59.0

58.4

57.7

56.4

55.2

54.3

55.0

53.4

51.8

50.8

52.6

50.8

49.0

47.7

48.5

46.2

44.0

42.4

61.6

60.7

59.8

59.1

58.4

57.1

55.9

55.0

55.6

54.0

52.4

51.3

53.2

51.3

49.5

48.1

49.0

46.5

44.2

42.5

62.4

61.4

60.4

59.8

59.2

57.9

56.5

55.7

56.3

54.6

53.1

51.9

53.7

51.8

49.9

48.6

49.5

47.0

44.6

42.9

TONS

PER

SQ. FT.

1.61

1.73

1.84

1.92

1.99

2.14

2.28

2.38

2.32

2.49

2.65

2.76

2.59

2.78

2.96

3.09

3.02

3.25

3.46

3.61

1.67

1.80

1.92

2.00

2.06

2.22

2.36

2.46

2.41

2.59

2.76

2.87

2.69

2.89

3.08

3.21

3.14

3.38

3.60

3.75

1.74

1.87

1.99

2.08

2.15

2.31

2.46

2.56

2.50

2.69

2.86

2.99

2.79

3.00

3.20

3.33

3.26

3.51

3.74

3.90

PER

SQ. FT.

1.56

1.68

1.79

1.86

1.94

2.09

2.23

2.32

2.25

2.42

2.58

2.69