Page 1

PRODUCT DATA &

INSTALLATION

Bulletin K60-KDF-PDI-10

1064436

We are on the Internet

www.keepriterefrigeration.com

KDF Direct Drive

Dry Type

Fluid Coolers

Air Cooled Models from 200 MBH

to 2,000 MBH

One to Six fan Units Glycol Selection Data

• Heavy gauge galvanized steel casing with zinc

plated nuts and bolts

• Die-formed legs

• High efficiency coils with rippled aluminum fins

hydraulically bonded to copper tubing.

NOMENCLATURE

KDF A 1 075 D 2 A T

KEEPRITE

DIRECT DRIVE

FLUID COOLER

GENERA TION

NUMBER OF FANS

PRODUCT OF ROW DEPTH

AND SQ. FT . OF F ACE AREA

EG. 5 ROW DEEP x 15.0

SQ. FT. = MODEL No. 075

ELECTRICAL DESIGNA TION

D = 208-230/1/60

F = 208-230/3/60

K = 460/3/60

L = 575/3/60

CONTROL OPTIONS

0 TO 6

CONNECTION OPTIONS

A TO D (BLANK SIGNIFIES NO FLANGES)

• Four-bladed heavy gauge rust resistant aluminum

fans with steel spider and hub.

• Direct drive fan motors with inherent overload

protection.

• Motors are weather protected by top end rain

shields and shaft moisture slingers.

CONTENTS PAGE

Nomenclature.........................................

Capacity Data.........................................

Selection Data Notes............................

Sample Selection..................................

Dimensional Data..................................

Installation Instructions........................

Design Specifications...........................

Service Log............................................

Project Information...............................

Cover

2

2

3, 4, 5

6

7, 8

Back

Back

Back

TEAC MOTOR

Page 2

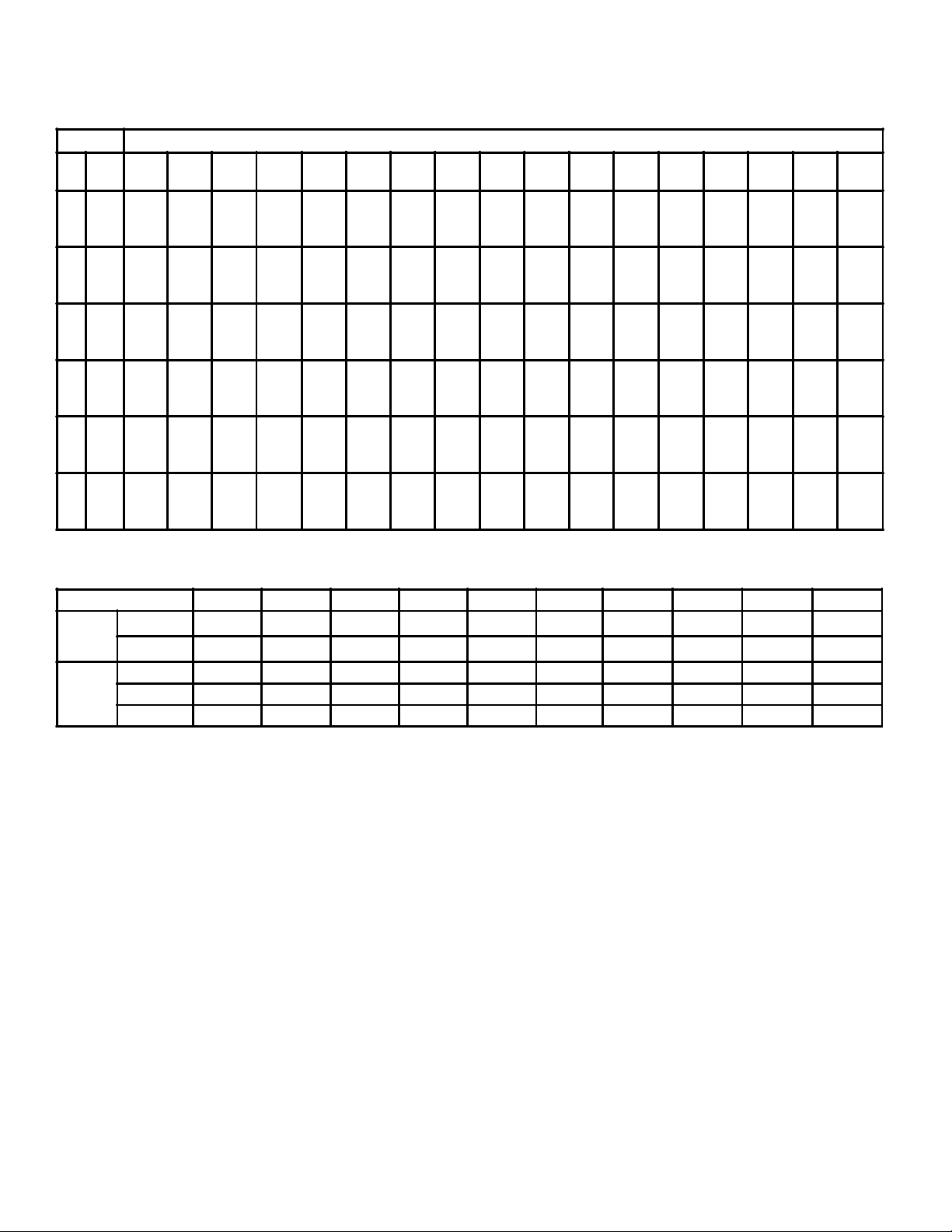

CAPACITY DATA

M.B.H. / SQ. FT. COIL FACE AREA

Table 1

Approach INITIAL TEMPERATURE DIFFERENCE (I.T.D.)

20°F

25°F

30°F

35°F

40°F

45°F

50°F

55°F

60°F

65°F

11.6

14.1

15.7

17.2

18.4

19.4

20.3

21.2

21.9

23.2

70°F

(39°C)

12.3

15.0

16.6

18.3

19.4

20.5

21.5

22.4

23.2

23.9

24.5

25.0

(42°C)

°F °C

5

10

15

20

11

25

14

30

17

35

19

40

22

45

25

50

28

55

30

60

33

65

36

70

39

75

42

80

44

85

47

90

50

(11°C)

(14°C)

(17°C)

(19°C)

(22°C)

(25°C)

(28°C)

(30°C)

(33°C)

(36°C)

3

4.9

5.7

6.6

7.5

8.1

8.8

9.5

10.2

10.9

6

6.1

7.0

8.0

8.9

9.9

10.8

11.7

12.5

13.3

8

8.0

9.1

10.0

9.9 11.0

11.7

11.2

12.1

13.0

13.7

12.1

13.1

13.1

14.1

14.0

15.0

14.8

16.0

15.5 16.7

17.5

14.0

15.1

16.2

17.2

17.9

18.7

19.3

14.9

16.2

17.4

18.4

19.2

20.0

20.6

21.2 22.5

75°F

80°F

(44°C)

13.1

13.9

15.7

16.4

17.5

18.5

19.1

20.0

20.4

21.4

21.5

22.7

22.6

23.7

23.5

24.6

24.3

25.4

25.0

26.2

25.7

27.0

26.2

27.5

27.0 28.1

28.7

85°F

(47°C)

14.5

17.2

19.3

20.8

22.9

23.5

24.7

25.6

26.5

27.3

28.1

28.7

29.4

30.0

30.7

90°F

95°F

(50°C)

(53°C)

15.2

18.1

20.2

21.8

23.3

24.5

25.6

26.6

27.6

28.5

29.3

30.0

30.7

31.4

32.0

32.6 33.9

15.9

18.8

20.9

22.6

24.1

25.4

26.6

27.7

28.6

29.5

30.4

31.1

31.8

32.5

33.2

34.6

100°F

(55°C)

16.7

19.6

21.7

23.5

25.0

26.4

27.5

28.5

29.5

30.5

31.4

32.3

33.0

33.7

34.4

35.1

35.8

36.5

COIL FACE AREA

Table 1A

Model KDF 1052 1060 2100 2120 3152 3180 4200 4240 6300 6360

Coil

Face

Area

Fan

Data

Data shown covers 10 models. 10 additional models available. Consult your local KeepRite Refrigeration Sales Office.

1. Temperature Limitations

2. Elevation Adjustment

3. Ratings

Sq. Ft. 12.5 15.0 25.0 30.0 37.5 45.0 50.0 60.0 75.0 90.0

2

m

1.16 1.39 2.32 2.79 3.48 4.18 4.65 5.57 6.97 9.36

No. 1 1 2 2 3 3 4 4 6 6

Total CFM 7050 7380 14100 14760 21150 22140 28200 29520 42300 44280

Total m3/s 3.33 3.48 6.65 6.97 9.98 10.45 13.31 13.93 19.96 20.9

KeepRite fluid coolers are suitable for leaving air

temperatures up to a maximum of 130°F (54°C).

Fluid temperature up to an average of 150°F (66°C)

selection programme is available. Interpolation of

capacities shown in Table 1 is permitted. Do not

extrapolate.

may be used at ambient temperatures up to 90°F

(32°C). Entering fluid conditions should however not

exceed 200°F (93°C).

4. Fluid Velocities

Fluid velocities are adjusted in accordance with the

average temperature and the glycol mixtures used.

Where a selected unit has a coil face area larger or

Capacities are suitable for elevations up to 2000 ft.

Above 2000 ft. and up to 3000 ft. elevation, unit

capacities shown in Table 1 must be corrected by

.90 before selecting unit.

smaller than the actual size required, the basic

fluid velocity must be adjusted (see example).

5. Low Flow Rates

Where flow rate is low (approx. 1 0 USGPM or

lower), standard circuiting may not provide the

necessary tube velocity. Contact Head Office for

Ratings are based on a standard heat transfer rate

special circuiting.

and fluid velocity is varied to suit. Ratings and

selections will be conservative. For additional fluid

cooler models and more detailed analysis and

selections, the KeepRite fluid cooler computer

6. KeepRite selection sheets are available for

assisting in the selection and recording of data.

Contact your local KeepRite Sales Office for

copies.

- 2 -

Page 3

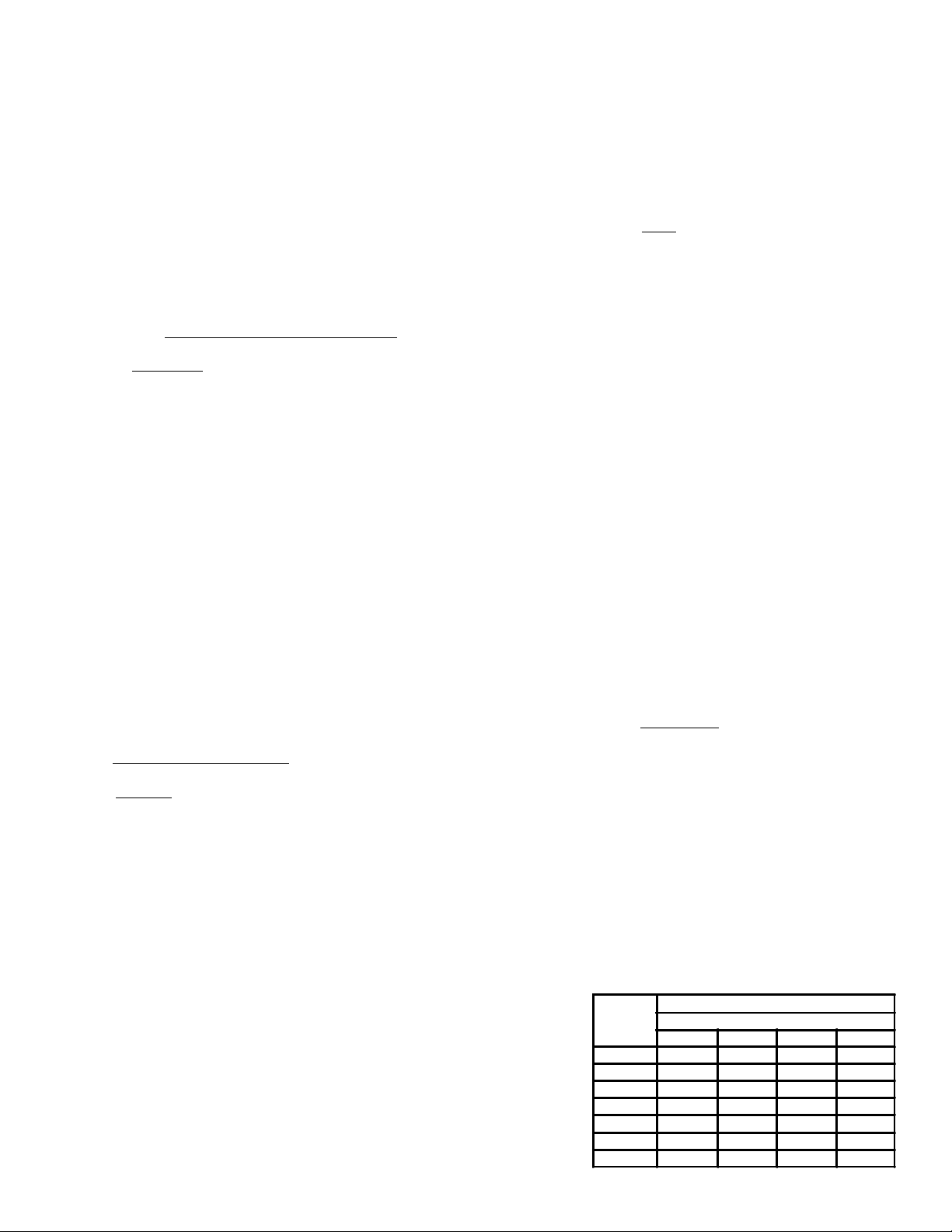

SAMPLE SELECTION

Example

Required:

A computer room application requires a KDF fluid cooler

to handle a load of 50 USGPM of 50% Ethylene Glycol.

(By wt.) from 115°F (46°C) to 105°F (40°C) at 95°F

(35°C) Ambient. Unit located at sea level.

Selection Method

(1) Find the Total BTU/hr. Requirements (Q)

BTU/hr. = USGPM x fluid T.D. x Factor “N” (Table 2)

= 50 x 10 x 434

= 217,000 BTU/hr. (63 kw)

(2) Find minimum CFM required

CFM =

=

1.09 x 35

1.09 x (130°F - Amb. Temp. °F.)

217,000

(3) Find initial temperature difference and approach

I.T.D.: = Ent, fluid temperature minus entering

ambient air temperature

= 115° - 95°F

= 20°F(11°C)

Approach: = Leaving fluid temperature minus

entering ambient temperature

= 105° - 95°F

= 10°F (6°C)

(4) Find MBH Capacity per sq. foot of fluid cooler

surface

For an ITD of 20°F (11°C) and an approach of 10°F

(6°C) read from Table 1 a unit capacity of 6.1MBH/

sq. ft. of coil surface area. As this application is at

sea level no correction is necessary.

(5) Determine total area of coil surface required

Coil surface, sq. ft.

= Total BTU/hr. (Q) (Step 1)

MBH/sq. ft. (Step 4) x 1000

217,000

=

6100

= 35.6 sq. ft.

(6) Select Unit

From Table 1A select a unit size having a coil

face area equal to or larger than 35.6 sq. ft. A

Model 3152 has a face area of 37.5 sq. ft. This

selection would be suitable.

(Q) BTU/hr

= 5688 CFM

(NOTE. When unit selected has a face area larger or

smaller than that required in step (5), basic fluid

velocity should be adjusted using velocity correction

factor from Table 4.

For this example, the required coil face area is

35.6 sq. ft. (5 above). Actual coil face area is 37.5 sq. ft.

Ratio oversize =

35.6

37.5

= 1.05

From Table 4 the velocity correction factor is .95.

This is applied to the basic velocity to obtain th required

minimum velocity:

.95 x 3.1 = 2.9 ft./sec.

(9) Circulting requirements

Refer to Chart 1 at 50 G.P.M., Type.30 circuiting will

provide a velocity of 2.83 ft./sec. This is close to the

required minimum velocity of 2.9 ft./sec. and may be

used. (See note 2 Chart 1 for minimum velocity range).

(10) Determining Fluid Pressure Drop

Knowing the circuiting to be used, the fluid pressure

drop can be determined as follows:

(a) Find the Total Equivalent Length of tube circuit

from Table 5. For a model KDF 3152, using type

30 circuiting, the T.E.L. is 51 feet.

(b) From Table 6, note the pressure drop under 50%

solution at 2.9 ft./sec. as 060 P.S. 1. per foot of

equivalent length.

(c) Total pressure drop, P.S.I. = Pressure drop per

foot (b) multiplied by 51 feet T.E.L. (a) plus

standard allowance of 2 P.S. I. for headers:

.060 x 51 = 3.06 P. S. I.

Headers = 2.00 P. S. I.

5.06 P. S. 1.

Apply temperature correction factor from Table 7

= .9 7 x 5.06 = 4.90 P. S. I.

(11) Final Selection

1 - KeepRite KDF fluid cooler model 3152 using type 30

circuiting, having a fluid pressure drop of 4.90 P.S.I.

connections will be same end (Table 5).

Headers and connection sizes will be 2 1/8" O.D.

(Table 8).

(7) Check air quantity

A Model 3152 is rated at 21150 CFM. This

exceeds the minimum of 5688 CFM (step 2) and

is satisfactory. (See Table 1A for CFM

capacities).

(8) Determine minimum fluid velocity required

From Table 3 for a 50% glycol solution at an

average temperature of 110°F (43°C), the

required basic velocity is 3.1 ft./second.

- 3 -

“N” FACTORS

Table 2

AVE. FACTOR "N"

FLUID % GLYCOL SOLUTION

TEMP. 30% 40% 50% 60%

50 466 437 420 394

70 467 442 426 400

100 469 446 432 408

120 470 448 436 411

130 470 450 438 414

140 470 452 439 416

150 470 452 440 418

Page 4

250

200

Chart 1

TUBE CIRCUITING

BASIC

FLUID VELOCITY

Table 3

AV.

FLUID

TEMP°

50 2.9 3.7 4.6 5.8

70 2.5 3.1 3.9 5.0

100 2.0 2.6 3.2 4.2

110 2.0 2.5 3.1 4.0

120 2.0 2.4 3.0 3.8

130 2.0 2.3 2.8 3.6

140 2.0 2.2 2.7 3.4

150 2.0 2.0 2.6 3.3

GLYCOL

SOLUTION %

30 40 50 60

150

100

U.S. GALLONS / MINUTE

50

1 2 3 4 5 6

NOTES: 1. For more accurate readings use the following formula

Fluid VEL Ft./sec. =

2. When selecting circuiting, the velocity obtained can be lower than the desired velocity by not

more than 5%. A greater difference will require an alternate circuit type to be selected.

Velocities higher than the desired velocity are acceptable.

GPM x 1.70

Circuit Type

COIL AREA

RATIO

.85 1.30

.90 1.20

.95 1.10

1.00 1.00

1.10 .90

1.20 .80

1.30 and

over

* When VEL correction factor is

applied to basic fluid velocity

maximum velocity should not

exceed 6 ft./sec. Minimum should

not exceed 2 ft./sec.

VEL.* CORR.

FACTOR

.70

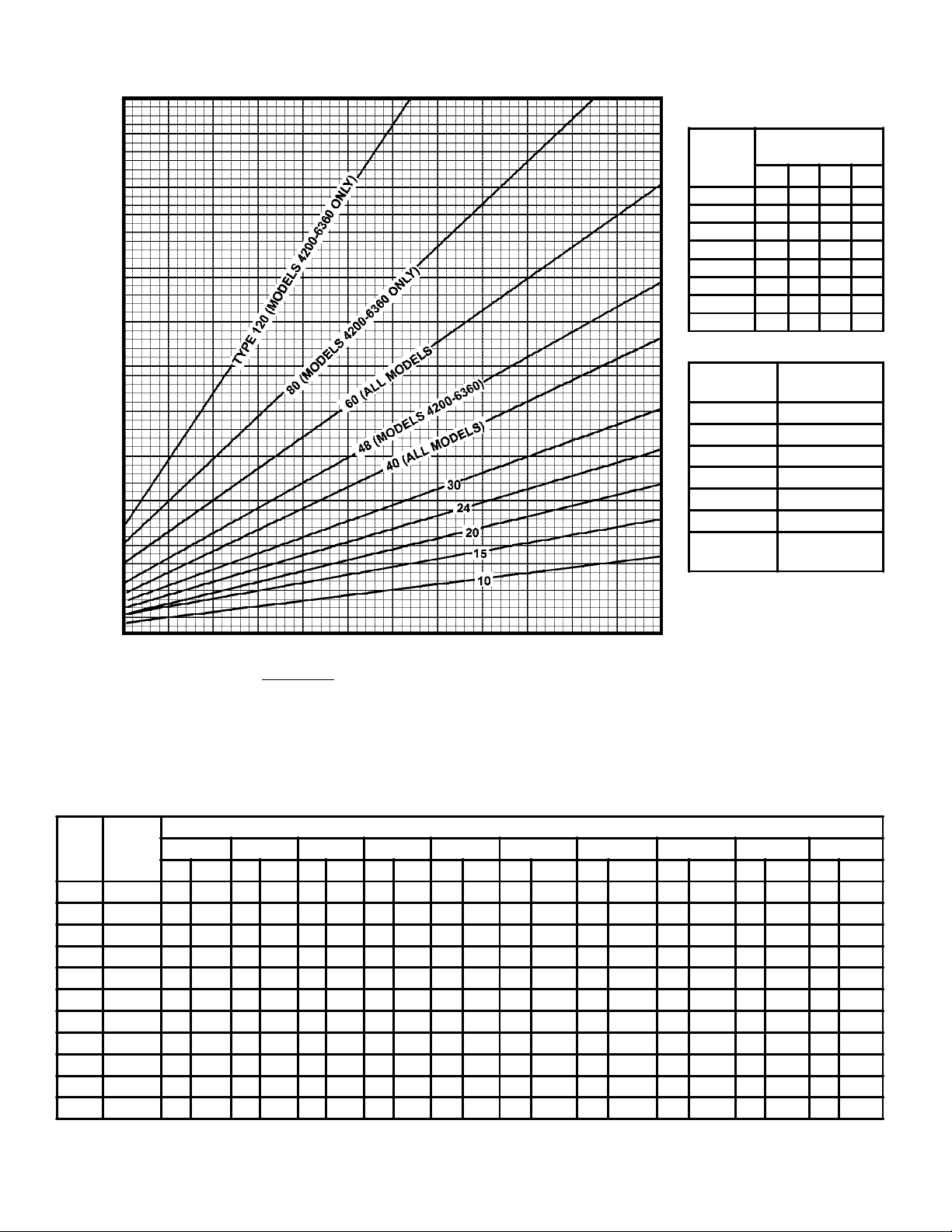

LENGTH OF TUBE CIRCUIT

Table 5

Table 4

Circuit

† 1052-3180 - Opposite End 4200-6360 - Same End

Header

Location

120 SE NA NA NA NA NA NA NA NA NA NA NA NA 20 6.10 23 7.02 27 8.24 31 9.46

80 OE NA NA NA NA NA NA NA NA NA NA NA NA 29 8.85 33 10.07 39 11.90 44 13.42

60 SE 14 4.27 15 4.58 20 6.10 23 7.02 27 8.24 31 9.46 38 11.59 42 12.81 51 15.56 58 17.69

48 OE NA NA NA NA NA NA NA NA NA NA NA NA 46 14.03 52 15.86 63 19.22 72 21.96

40 † 19 5.80 21 6.41 29 8.85 33 10.07 39 11.90 44 13.42 55 16.78 62 18.91 75 22.88 86 26.23

30 SE 24 7.32 27 8.24 38 11.59 42 12.81 51 15.56 58 17.69 72 21.96 82 25.01 99 30.20 113 34.47

24 † 30 9.15 33 10.07 46 14.03 52 15.86 63 19.22 72 21.96 90 27.45 101 30.81 123 37.52 141 43.01

20 SE 37 11.29 39 11.90 55 16.78 62 18.91 75 22.88 86 26.23 107 32.64 121 36.91 147 44.84 168 51.24

15 SE 46 14.03 50 15.25 72 21.96 82 25.01 99 30.20 113 34.47 142 43.31 160 48.80 195 59.48 223 68.02

10 SE 67 20.44 74 22.57 107 32.64 121 36.91 147 44.84 168 51.24 211 64.36 239 72.90 291 88.76 333 101.57

5 SE 131 39.95 145 44.23 211 64.36 239 72.90 291 88.76 333 101.57 419 127.80 475 144.88 579 176.60 663 202.22

1052 1060 2100 2120 3152 3180 4200 4240 6300 6360

FT. M FT. M FT. M FT. M FT. M FT. M FT. M FT. M FT. M FT. M

EQUIVILANT LENGTH OF TUBE CIRCUIT

- 4 -

Page 5

TUBE PRESSURE LOSS**

Table 6

FLUID PRESS. LOSS PSI/FT. T.E.L.

VEL. F/S 30% 40% 50% 60%

2.0 .028 .029 .032 .034

2.2 .036 .050 .041 .044

2.5 .042 .044 .048 .051

2.7 .048 .050 .055 .059

3.0 .055 .058 .063 .067

3.2 .064 .069 .074 .079

3.5 .072 .077 .083 .089

3.7 .080 .085 .092 .098

4.0 .090 .097 .104 .111

4.2 .100 .107 .115 .123

4.5 .110 .117 .126 .135

4.7 .122 .130 .140 .150

5.0

5.2 .164 .175 .189 .202

5.5 .183 .195 .210 .225

5.7

6.0 .231 .247 .266 .285

.140 .149 .161 .172

.207 .221 .238 .255

Where to Use Direct Drive Fluid Coolers

COMPUTER COOLING SECONDARY

HEAT EXCHANGERS

The KeepRite direct drive cooler is suitable for use with

computer room process cooling units. (See Fig. 1).

PRESSURE DROP TEMPERATURE

CORRECTION FACTORS

Table 7

GLYCOL AVG. FLUID TEMP. °F.

SOLUTION 50 70 100 110 120 130 140 150

30% 1.25 1.00 .87 .84 .82 .79 .77 .74

40% 1.27 1.10 .93 .90 .87 .84 .82 .79

50% 1.30 1.20 1.00 .97 .94 .90 .88 .85

60% 1.40 1.25 1.09 1.05 1.01 .97 .94 .90

** Based on Ave. Fluid Temp of 100°FD. Apply correction factor from

table 7.

Particularly suitable for applications where long runs of

refrigerant piping to an air cooled condenser are not practical.

Eliminates the maintenance required with cooling towers and

problems of winter operation. Piping can be easily installed

and low ambient control can be obtained by using water

regulating valves. Can be easily connected to city water for

emergency use.

REMOTE RADIATORS FOR DIESEL AND GAS ENGINES

A remote radiator is usually required with the larger style of

diesel or gas engine. The KeepRite K.D.F. direct drive cooler is

suitable for this type of application. Designed to give the

customer trouble free operation, the multiple fan arrangement

reduces the possibility of down time. Units are completely

pre-assembled and require only piping and electrical

connections. Flexible circuiting permits low fluid pressure

drop characteristics. (See Figure 2.)

INDUSTRIAL WATER COOLING*

The problem of water conservation and pollution has become

critical in recent years. The “Once-only” use of water for

industrial cooling purposes has been wasteful and often

unnecessary. By using a KeepRite dry type cooler, water for

industrial cooling applications can be cooled to within 10°F

(6°C) of the ambient dry bulb temperature. The water is

continuously recirculated and remains in a closed system so

reducing the corrosion problem normally encountered in non

recirculated systems. (See Fig. 3)

Considerable savings can be affected by using a KeepRite dry

type cooler. Many industries have reduced water

consumption by millions of gallons and reduced

maintenance costs to a fraction of that experienced prior to

using a closed recircuiation system.

*For water cooling consult your local KeepRite sales office.

- 5 -

Page 6

DIMENSIONS DATA

NOTE: Headers can be located at either end of unit.

Whether both supply and return headers are located same end or opposite end depends on coil rows and circuiting used.

KDF

MODEL

No.

1039

1052

1060

1075

2075

2100

2120

2150

3114

3152

3180

3225

4150

4200

4240

4300

6225

6300

6360

6450

A B C D

Inches mm Inches mm Inches mm Inches mm Pounds kg

43

1092

43

50

50

83 1/8

83 1/8

97 1/8

97 1/8

123 1/4

123 1/4

144 1/4

144 1/4

83 1/8

83 1/8

97 1/8

97 1/8

123 1/4

123 1/4

144 1/4

144 1/4

1092

1270

1270

2111

2111

2467

2467

3131

3131

3664

3664

2111

2111

2467

2467

3131

3131

3664

3664

48 1/8

48 1/8

48 1/8

48 1/8

48 1/8

48 1/8

48 1/8

48 1/8

48 1/8

48 1/8

48 1/8

48 1/8

93 1/8

93 1/8

93 1/8

93 1/8

93 1/8

93 1/8

93 1/8

93 1/8

1222

1222

1222

1222

1222

1222

1222

1222

1222

1222

1222

1222

2365

2365

2365

2365

2365

2365

2365

2365

36

36

43

43

76 1/8

76 1/8

90 1/8

90 1/8

116 1/4

116 1/4

137 1/4

137 1/4

76 1/8

76 1/8

90 1/8

90 1/8

116 1/4

116 1/4

137 1/4

137 1/4

914

914

1092

1092

1934

1934

2289

2289

2953

2953

3483

3483

1934

1934

2289

2289

2953

2953

3483

3483

41 1/8

41 1/8

41 1/8

41 1/8

41 1/8

41 1/8

41 1/8

41 1/8

41 1/8

41 1/8

41 1/8

41 1/8

86 1/8

86 1/8

86 1/8

86 1/8

86 1/8

86 1/8

86 1/8

86 1/8

INTERNAL VOLUME

U.S. *

GALLONS

WATER

1045

1045

1045

1045

1045

1045

1045

1045

1045

1045

1045

1045

2188

2188

2188

2188

2188

2188

2188

2188

3 1/2

4 1/2

5 1/2

6 1/2

6

8

10

12

9

12

14 1/2

18

12 1/2

16 1/2

19 1/2

24

18

24

29

36

LITRES* No.

109.8

136.3

13.3

17.0

20.8

24.6

22.7

30.3

37.9

45.4

34.0

45.4

54.9

68.1

47.3

62.3

73.8

91.0

68.1

91.0

NUMBER

OF FACE

TUBE

ROWS

30

30

30

30

30

30

30

30

30

30

30

30

60

60

60

60

60

60

60

60

FAN DATA

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

6

6

6

6

TOTAL

CFM

7370

7050

7380

7150

14740

14100

14760

14300

22110

21150

22140

21450

29480

28200

29520

28600

44220

42300

44280

42900

TOTAL

M3/S

3.48

3.33

3.48

3.37

6.96

6.65

6.97

6.75

10.43

9.98

10.45

10.12

13.91

13.31

13.93

13.5

20.87

19.96

20.9

20.25

SHIPPING

WEIGHT

320

355

390

430

580

645

725

800

870

965

1080

1200

1075

1200

1340

1500

1600

1850

2000

2200

145

161

177

195

263

293

329

363

395

438

490

544

488

544

608

680

726

839

907

998

* Headers not included. Motors are available for 208-230/1/60 - 1 HP, 208-230/3/60 - 1 1/3 HP, 575/3/60 - 1 1/4 HP.

Contact KeepRite Refrigeration for special requirements NOTE: Metric figures are approximate to avoid excessive decimals.

OPTIONAL FACTORY SUPPLIED FLANGES

SIZE

(mm)

3"

(76.2)

4"

(101.6)

5"

(127.0)

6"

(152.4)

FITTING

Flanged

Flanged

Flanged

Flanged

FLANGE

DIA. (mm)

7 1/2"

(190.5)6"(152.4)

9"

(228.6)

10"

(254.0)

11"

(279.4)

BOLT

CIRCLE

(mm)

7 1/2"

(190.5)

8 1/2"

(215.9)

9 1/2"

(241.3)

HOLES

(mm)

4-3/4"

(19.05)

8-3/4"

(19.05)

8-7/8"

(22.2)

8-7/8"

(22.2)

OPTIONAL FLANGED CONNECTIONS

BOLT HOLE LOCATION

(150 lbs. working shock pressure)

- 6 -

Page 7

FIG 1

INSPECTION

INSTALLATION INSTRUCTIONS

LOCATION

In selecting a location for the cooler, consideration

should be given to the following:

(a) Loading capacity of the floor or roof.

(b) Distance to suitable electrical supply.

(c) Adequate air circulation.

(d) Accessibility for maintenance.

(e) Local building codes.

(f) Adjacent buildings relative to noise levels.

(g) Wishes of the purchaser.

When all of the above points have been considered

and a specific location chosen, it is advisable to

obtain written approval of this location from the

building and/or cooling unit owner. This may be the

means of avoiding disagreement and expense at a

later date.

GENERAL CHECK-UP BEFORE STARTING

(1) Check the electrical characteristics of all

components to be sure they agree with the power

supply.

(2) Check fans for correct rotation on 3 phase units.

Air is drawn through the cooler core. To change

direction of rotation reverse any two (2) connecting

leads.

A thorough inspection of the cooler and all component

parts should be made immediately on delivery and any

camage in transit or any missing parts must be reported

at once to the carrier, As consignee, you must make any

claim for damage or losses. Damaged or missing parts

discovered at the outset can prevent later costly delays

and unnecessary expense. Electrical characteristics of

all motors should also be checked to ensure that they are

as ordered.

WARNING

ADEQUATE PRECAUTIONS MUST BE TAKEN, AFTER

FIELD LEAK TESTING, TO INSURE REMOVAL OF

WATER IN TUBES. KEEPRITE RECOMMEND THAT

A GLYCOL SOLUTION BE USED TO FLUSH THE

COMPLETE COIL. FAILURE TO TAKE PRECAUTIONS

CAN RESULT IN FROZEN TUBES SHOULD UNIT BE

SUBJECTED TO LOW AMBIENT CONDITIONS

BEFORE BEING PLACED IN OPERATION.

HANDLING AND PLACING

Air Cooled Fluid Coolers are by necessity large and heavy

pieces of mechanical equipment and must be handled as

such. A fully qualified and properly equipped crew with

necessary tackle and rigging should be engaged to locate

the unit in position.

Lifting brackets have been provided at the corners for

attaching lifting slings. Spreader bars or a similar device

must be used when lifting so that the lifting force will be

applied vertically on the lifting brackets. (See Fig. 1).

Important:

Units with solid state speed control option are for

use with 208-230/1/60 service only.

SERVICE INSTRUCTION

Casing

Since the Fluid Cooler is normally installed outdoors, in

the elements, the casing is fabricated from heavy gauge

continuous process galvanized sheet steel for maximum

rust and corrosion protection.

Motors

Motors are split capacitor type and are permanently

lubricated.

Coil

The coil should be checked periodically for cleanliness

and for leaks. It is important that the coil be kept clean

and free from any type of air blockage. The coil may be

washed down with a hose when dirty. Power must be

disconnected for this operation.

HEADER SIZING

Table 8

G.P.M.

0 - 10

11 - 20

21 - 30

31 - 50

51 - 80

81 - 150

151 - 250

251 - 400

400 - 700

Header Size

O.D.

1 1/8 (29mm)

1 3/8 (35mm)

1 5/8 (41mm)

2 1/8 (54mm)

2 5/8 (67mm)

3 1/8 (79mm)

4 1/8 (105mm)

5 1/8 (130mm)

6 1/8 (156mm)

Connections

Available

PLAIN

or

MPT

PLAIN

or

FLANGED

- 7 -

Page 8

PIPING INSTALLATION

1. All piping must comply with local codes. Care

should be taken to correctly size the piping to

ensure minimum pumping costs.

2. Sufficient valves and unions should be provided to

permit easy removal of equipment for repair or

replacement.

3. All piping should be leak tested after installation.

4. Where city water is required for make-up, local

plumbing codes should be observed. A pressure

reducing valve should not be used in glycol

systems. Installation of same would dilute the

mixture in the case of a leak.

5. Piping system must be complete with an

expansion tank, purge valve, relief valve and fill

point for glycol. Vent valves should be provided at

system high points for air removal. See fig. 2 for

typical glycol system piping.

CIRCULATING PUMP

Mechanical seal type circulating pumps are generally

used for glycol systems. Pump must be selected for

friction loss through the cooler, piping and heat source.

In a closed system no allowance is required for vertical

lift.

Parallel pumps are recommended for standby operation

where pump failure may interfere with a critical process.

One pump on a parallel system may also carry the load

under certain conditions thus contributing to power

economy.

GLYCOL DESIGN

Usually a glycol solution is used in fluid cooler

applications. The common range of mixtures will be 30%

to 50% in water. Glycol mixtures have a higher density

than water , but a lower specific heat. This will result in an

increased flow rate over water by approx. 15% - 20%.

Where a fluid cooler is used with an existing water cooled

condenser, a decrease in condenser capacity will result.

Condenser manufacturers should be consulted to obtain

recommended flow rates.

MAINTAINING THE SYSTEM

As the system is the closed type with a compression

tank, little or no corrosion will take place as the initial

oxygen is absorbed. No fresh oxygen is introduced unless

the system requires re-filling due to leaks or repairs.

Maintenance of the system will therefore be confined to

the pumps and valves. Manufacturers data should be

consulted for the maintenance of these items.

Figure 2

TYPICAL FLUID COOLER PIPING SYSTEM

- 8 -

Page 9

- 9 -

Page 10

- 10 -

Page 11

- 11 -

Page 12

DESIGN SPECIFICA TIONS

03/15/2007

CASING

Heavy gauge galvanized steel with zinc plated nuts and

bolts. All KeepRite Fluid Coolers are mounted on heavy

die-formed legs.

COILS

The KeepRite Direct Drive Fluid Cooler is equipped with

high-efficiency heat transfer surface. Surface consists of

rippled aluminum fins hydraulically bonded to copper

tubing. Coils are leak tested to 300 p.s.i. under water.

Flanged connections available if required.

SERVICE LOG

ETADSTNEMMOC

FANS

Four-bladed, constructed from heavy gauge, rustresistant aluminum with steel spider and hub. Zinc

plated for added weather protection.

MOTORS

Direct drive fan motors with permanently lubricated ball

bearings. Motors are complete with inherent overload

protection. Motors are weather protected by top end rain

shields and shaft moisture slingers. Contactors available if required. Motors are all wired to an electrical box

on end of unit.

PROJECT INFORMA TION

metsyS

rebmuNledoM pU-tratSfoetaD

rebmuNlaireS rotcartnoCecivreS

tnaregirfeRenohP

ylppuSlacirtcelExaF

NA TIONAL REFRIGERA TION &

AIR CONDITIONING CANADA CORP.

CANADA

159 ROY BL VD., BRANTFORD, ONT ARIO, CANADA N3R 7K1

PHONE: 1-800-463-9517 (519)751-0444 FAX (519)753-1140

USA

985 WHEELER WA Y, LANGHORNE, P A. 19047 USA

PHONE:1-888-KEEPUS1 OR 1-888-533-7871

Due to National Refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice.

Loading...

Loading...