Page 1

PRODUCT DATA &

INSTALLATION

Bulletin K50-KCC-PDI-10

1064435

We are on the Internet

www.keepriterefrigeration.com

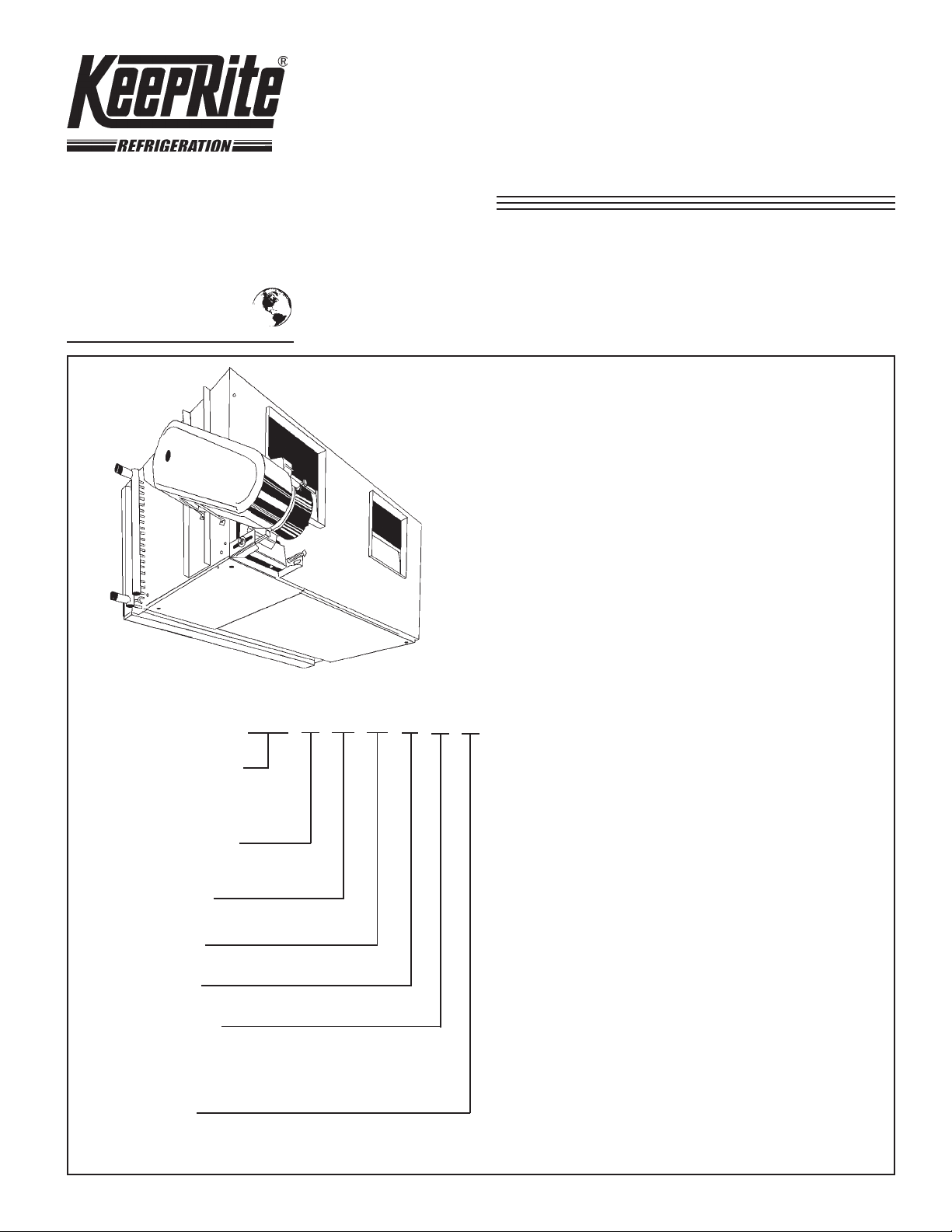

KCC Centrifugal

Fan Air Cooled

Condensers

Air Cooled Models from 103 Thru 164

Four to ninety Ton

• Galvanized steel, angular steel frame cabinet

construction

• Removable access panels

• Galvanized steel fan housings and wheels.

• 12” (305mm) diameter fan wheels keyed to fan

NOMENCLATURE

KCC 1 12 19 4 A D

CENTRIFUGAL F AN

AIR COOLED

CONDENSER

NUMBER OF FANS

1 OR 2

NOMINAL COIL

FACE AREA

FIN SPACING

ROW DEPTH

shaft

• Direct drive fan motors with inherent overload

protection.

• Weather protected motors with top end rain

shields and shaft moisture slingers.

• High efficiency rippled aluminum fin coils

• Adjustable motor bases and drives

CONTENTS

Nomenclature.........................................

Capacity Data.........................................

Fan Data..................................................

Selection Data........................................

Dimensional Data...................................

Installation Instructions.........................

PAGE

Cover

5,6

7,8

2

2

3

FIN THICKNESS

A = .0055

C = .0075

C = .009

FAN MOTOR

AND DRIVE

Design Specifications............................

Service Log.............................................

Project Information................................

9

Back

Back

Page 2

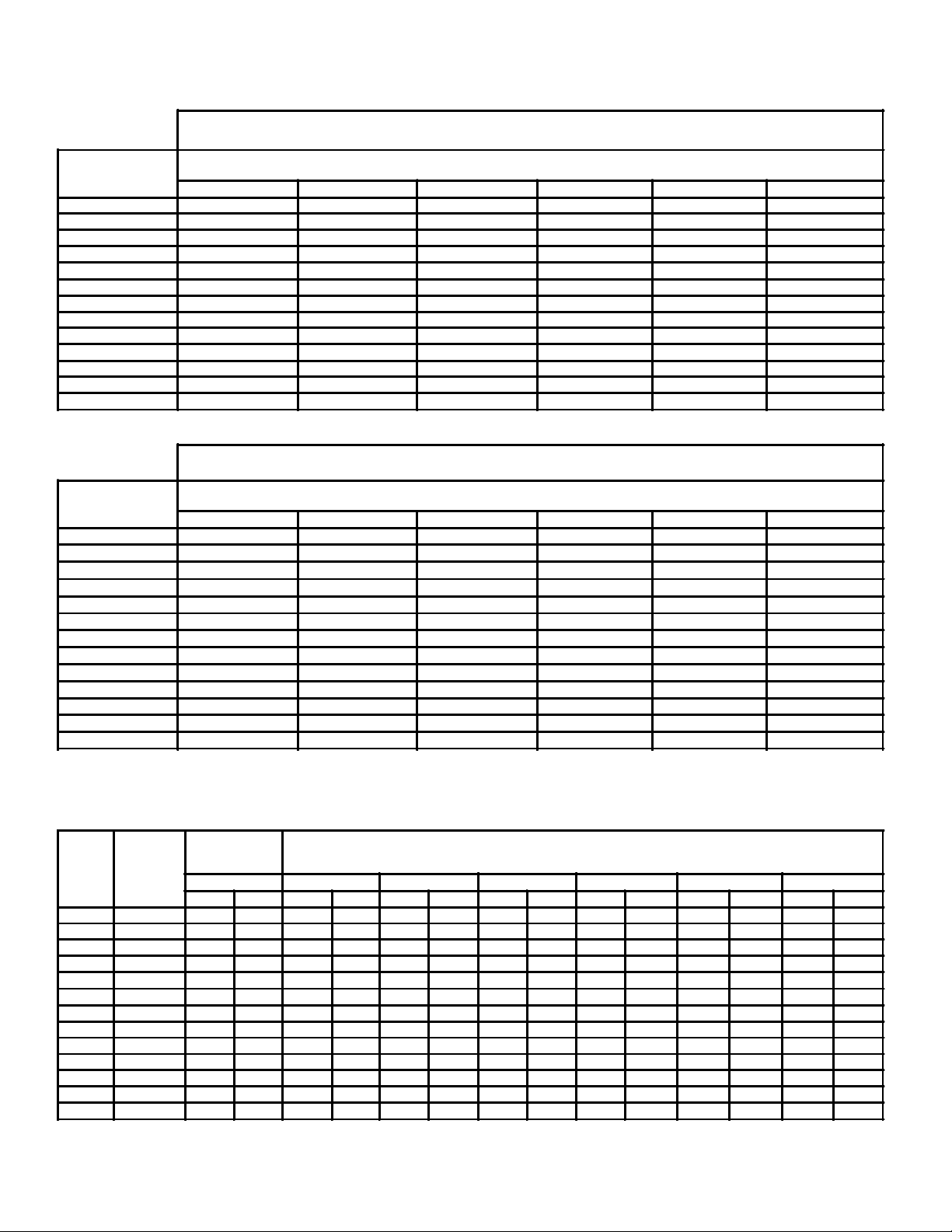

CAPACITY DATA

TABLE 2

KCC

MODEL NO.

103 1800 18000 27000 36000 45000 54000

104 2730 27300 41000 54600 68300 82000

106 3900 39000 58500 78000 97500 117000

108 5200 52000 78000 104000 130000 156000

111 6930 69300 104000 138600 173300 208000

214 8860 88600 133000 177300 221600 266000

217 10500 105000 157500 210000 262500 315000

222 13030 130300 195500 260600 325800 391000

228 16360 163600 245500 327300 409100 491000

237 21460 214600 321900 429200 536600 643800

141 25200 252000 378000 504000 630000 756000

150 28980 289800 434700 579600 724500 869400

164 36580 365800 548700 731600 914500 1097400

TABLE 2

KCC

MODEL NO.

103 1750 17500 26250 35000 43750 52500

104

106

108

111 6720 67900 100800 134400 168000 201600

214 8590 85900 128850 171800 214750 257700

217

222

228

237 20820 208200 312300 416400 520500 624600

141 24440 244400 366600 488800 611000 733200

150

164

R-22 TOTAL HEAT REJECTION (BTU/HR)

°F. (°C) TEMPERATURE DIFFERENCE = CONDENSING TEMPERATURE MINUS AMBIENT TEMPERATURE

1 (.6) 10 (6) 15 (8) 20 (11) 25 (14) 30 (17)

R-404A TOTAL HEAT REJECTION (BTU/HR)

°F. (°C) TEMPERATURE DIFFERENCE = CONDENSING TEMPERATURE MINUS AMBIENT TEMPERATURE

1 (.6) 10 (6) 15 (8) 20 (11) 25 (14) 30 (17)

2650 26500 39750 53000 66250 79500

3780 37800 56700 75600 94500 113400

5040 50400 75600 100800 126000 151200

10190 101900 152850 203800 254750 305700

12640 126400 189600 252800 316000 379200

15870 158700 238050 317400 396750 476100

28110 281100 421650 562200 702750 843300

35480 354800 532200 709600 887000 1064400

FAN DATA

TABLE 3

STANDARD

MODEL

NOMINAL

NO.

103 2000

104 3150 810 1.16 870 1.25 930 1.37 1007 1.49 1075 1.57 1136 1.66 1195 1.98

106 4500 910 1.76 948 1.89 996 2.06 1045 2.25 1096 2.44 1148 2.65 1202 2.87

108 6000 680 2.00 716 2.15 765 2.42 813 2.71 863 3.02 911 3.33 960 3.66

111 8000

214 10000

217 12000

222 15000

228 19000 505 6.15 533 6.79 573 7.68 613 8.61 653 9.60 691 10.62 729 11.68

237 23000 447 7.22 473 7.88 511 8.97 547 10.10 584 11.27 619 12.47 653 13.70

141 29000 338 10.55 355 11.73 370 13.14 397 14.53 420 15.92 442 17.28 463 18.68

150 34000 285 11.17 301 12.39 326 1.398 350 15.57 372 17.20 393 18.85 413 20.55

164 42000

C.F.M.

6 ROW COIL

ONLY

.55 .75 1.00 1.25 1.50 1.75 2.00

R.P.M. B.H.P. R.P.M. B.H.P. R.P.M. B.H.P. R.P.M. B.H.P. R.P.M. B.H.P. R.P.M. B.H.P. R.P.M. B.H.P.

1077 0.65 1167 0.72 1272 0.81 1371 0.91 1465 1.01 1555 1.12 1644 1.23

658 3.05 691 3.28 727 3.60 767 3.95 808 4.35 850 4.78 894 5.23

800 3.63 842 3.98 900 4.40 956 4.84 1012 5.30 1066 5.77 1120 6.27

706 4.15 744 4.54 795 5.05 846 5.59 897 6.15 948 6.74 998 7.36

655 5.42 689 5.89 734 6.53 780 7.20 825 7.91 869 8.64 913 9.40

263 14.58 279 16.03 300 18.12 321 20.18 340 22.20 363 24.24 376 26.27

TOTAL STATIC PRESSURE (Includes Coil, Ductwork etc.)

- 2 -

Page 3

SELECTION DATA

The selection of an air cooled condenser is based on the

heat rejection capacity at the condenser rather than net

refrigeration effect at the evaporator because the refrigerant gas absorbs additional energy in the

compressor. This additional energy, the heat of

compression, varies appreciably with the operating

conditions of the system and with compressor design,

whether open or suction cooled hermetic type.

Some compressor manufacturers publish heat rejection

figures as part of their compressor ratings. Since heat

rejection varies with compressor design, it is

recommended that the compressor manufacturer’s data

be used whenever available in selecting an air cooled

condenser.

HEAT REJECTION FACTORS

CONDENSER LOAD = COMPRESSOR CAPACITY X FACTOR

OPEN COMPRESSORS

TABLE NO. 4

EVAPORATOR

TEMP

°F. °C.

-30

-20

-10

10

20

30

40

50

-34

-29

-23

0

-18

-12

-7

-1

4

10

* Outside of normal limits for single stage compressor application.

For two stage application use formulas above.

CONDENSING TEMPERATURE °F. (°C.)

90

(32)

1.37

1.33

1.28

1.24

1.21

1.17

1.14

1.12

1.09

100

(38)

1.42

1.37

1.32

1.28

1.24

1.20

1.17

1.15

1.12

110

(43)

1.47

1.42

1.37

1.32

1.28

1.24

1.20

1.17

1.14

120

(49)

*

1.47

1.42

1.37

1.32

1.28

1.24

1.20

1.17

130

(54)

*

*

1.47

1.41

1.36

1.32

1.27

1.23

1.20

140

(60)

1.47

1.42

1.37

1.32

1.28

1.24

*

*

*

If thecompressor manufacturer does not publish heat

rejection ratings, factors from Table Nos. 4 and 5 may be

used to estimate total heat rejection-THR.

For systems outside the normal limits of single stage

compressor application, (such as compound or cascade

refrigeration systems) the following formulas may be

used to arrive at the heat rejection requirements for

selection of the condenser:

Open Compressors

THR = Compressor Capacity (Btuh) + 2545 x Bhp

Suction Cooled Hermetic Compressors

THR = Compressor Capacity (Btuh) + 3413 x KW

SUCTION COOLED HERMETIC COMPRESSORS

TABLE NO. 5

EVAPORATOR

TEMP

°F. °C. 90 (32)

-30

-20

-10

10

20

30

40

50

-34

-29

-23

0

-18

-12

-7

-1

4

10

* Outside of normal limits for single stage compressor application.

For two stage application use formulas above.

CONDENSING TEMPERATURE °F. (°C.)

1.57

1.49

1.42

1.36

1.31

1.26

1.22

1.18

1.14

100

(38)

1.62

1.53

1.46

1.40

1.34

1.29

1.25

1.21

1.17

110

(43)

1.68

1.58

1.50

1.44

1.38

1.33

1.28

1.24

1.20

120

(49)

*

1.65

1.57

1.50

1.43

1.37

1.32

1.27

1.23

130

(54)

1.64

1.56

1.49

1.43

1.37

1.31

1.26

140

(60)

*

*

*

*

*

1.62

1.55

1.49

1.42

1.35

1.29

SELECTION EXAMPLE

GIVEN:

Compressor Capacity 350,000 Btuh

Evaporator Temperature 40°F.

Refrigerant R-22

Ambient Air 95°F.

Maximum Condensing Temperature 120°F.

Suction Cooled Hermetic Compressor

PROCEDURE:

(1) Assuming the compressor manufacturer’s heat

rerejection data is not available, determine the

heat rejection factors for the specified conditions

from Table No. 5 above (1.27).

(2) Multiply the compressor capacity by the heat

rejection factor to estimate the required

condenser capacity.

(3) Since R-22 is specified, select the proper

condenser from Table No. 1 based on the

specified difference between condensing

refrigerant and the ambient air (T.D.).

SELECTION:

Using the heat rejection factor from Table No. 5 above,

the required condenser capacity is:

1.27 x 350.000 = 444,000 Btuh

From Table No. 1 for the specified T.D. of 25°F the proper

selection is the Model KCC 237 with a capacity of

536,600 Btuh. In this instance the condenser is slightly

oversized and the condenser will balance the

compressor heat rejection at less than the maximum

condensing temperature of 120°F.

- 3 -

Page 4

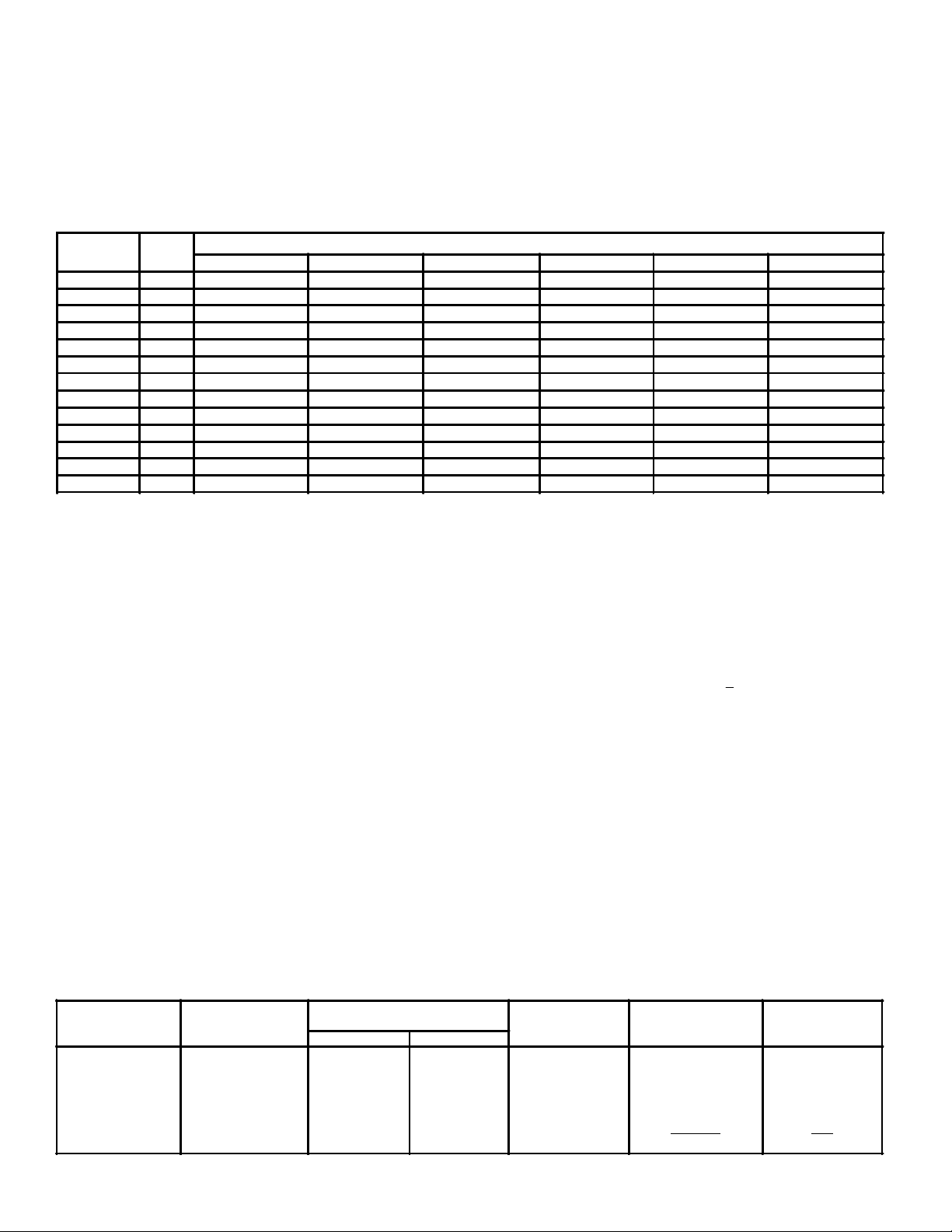

MULTIPLE COMPRESSOR APPLICATIONS

Multi-section units are available for applications where

more than one compressor is used either on the same

system or separate systems. Usually, this

arrangement will result in lower installation costs as

opposed to using separate units.

Coils for multi-section condensers are factory circuited

and divided into the proper number of sections, each sized

to meet the specified capacity. Each circuit is supplied

with a hot gas inlet and liquid outlet connection and

tagged for identification. The fan on a multi-section unit

should remain operative as long as a condensing requirement exists in any section of the coil.

TABLE 6 HEAT REJECTION CAPACITY PER FACE TUBE (BTU / HR) - R12

KCC

MODEL NO.

103 12 150 1502 2252 3003 3754 4505

104 14 194 1943 2914 3885 4856 5828

106 16 245 2447 3670 4893 6116 7340

108

111

214 22 402 4022 6032 8043 10054 12065

217 22 477 4767 7151 9534 11918 14301

222

228

237

141 40 630 6300 9450 12600 15750 18900

150 46 630 6300 94.50 12600 15750 18900

164

For R-404A ratings, multiply above capacities by 0.97.

FACE

TUBES

22 236 2363 3544 4725 5906 7088

22 315 3150 4725 6300 7875 9450

26 500 4998 7479 9996 12495 14994

26 630 6300 9450 12600 15750 18900

34 630 6300 9450 12600 15750 18900

58 626 6258 9387 12516 15646 18774

SELECTION EXAMPLE

°F. (°C) TEMPERATURE DIFFERENCE = CONDENSING TEMPERATURE MINUS AMBIENT TEMPERATURE

1 (.6) 10 (6) 15 (8) 20 (11) 25 (14) 30 (17)

GIVEN:

Six hermetic compressors with capacities and

evaporator temperatures (tabulated below).

Refrigerant R-22

Ambient Air Temperature 100°F.

Maximum Condensing Temperature 120°F.

PROCEDURE:

1. Tabulate the compressor capacities, evaporator

temperatures and heat rejection factors for each

compressor. (See Sample Tabulation, below.)

2. Determine the required heat rejection capacity for

each compressor.

3. Total the sectional heat rejection capacities for the

six compressors.

SELECTION:

Based on the total heat rejection capacity for the six

compressors of 186,160 Btuh, it can be seen from

Table No. 1 that the smallest unit which will meet this

requirement is the Model KCC217 with 210,000 Btuh

SAMPLE TABULATION

COMPRESSOR

NO.

1

2

3

4

5

6

COMPRESSOR

CAPACITY (BTUH)

13500

10000

36000

11000

31000

25000

EVAPORATOR

TEMPERATURE

°F. °C.

+20

-15

+15

+20

-10

+20

at 20 °F. T.D. Table No. 6 lists the heat rejection

capacity per “face tube” at various T.D.’s.

At 20 °F. T.D., the KCC 217 has a capacity of 9534 Btuh

per “face tube”. To determine the required number of face

tubes for each section, divide the required sectional

capacity by the capacity per “face tube”. For example,

compressor No. 1 requires 18,000 : 9534 = 2 “face tubes”.

Section No. 1 should be eircuited with 2 “face tubes” for

Compressor No. 1. Following this same procedure will

determine the size of each section for the remaining

compressors.

The sample tabulation shows the results of this selection

and indicates that 22 “face tubes” are required when

using the Model KCC 217. Since the Model KCC 217

has 22 “face tubes” available, the selection has been

satisfied. If the total required number of “face tubes”

exceeds the number of “face tubes” available as listed in

Table No. 6 it will be necessary to permit a slightly higher

condensing temperature than planned for one or two of

the sections. A second alternative would be to select the

next larger size condenser.

REQUIRED

CONDENSER

CAPACITY (BTUH)

18000

17440

51400

15070

50000

_34250_

186160

NUMBER OF

FACE TUBES

-7

-23

-9

-7

-23

-7

HEAT REJECTION

FACTOR

1.37

1.57

1.40

1.37

1.57

1.37

REQUIRED

2

2

6

2

6

_4_

22

- 4 -

Page 5

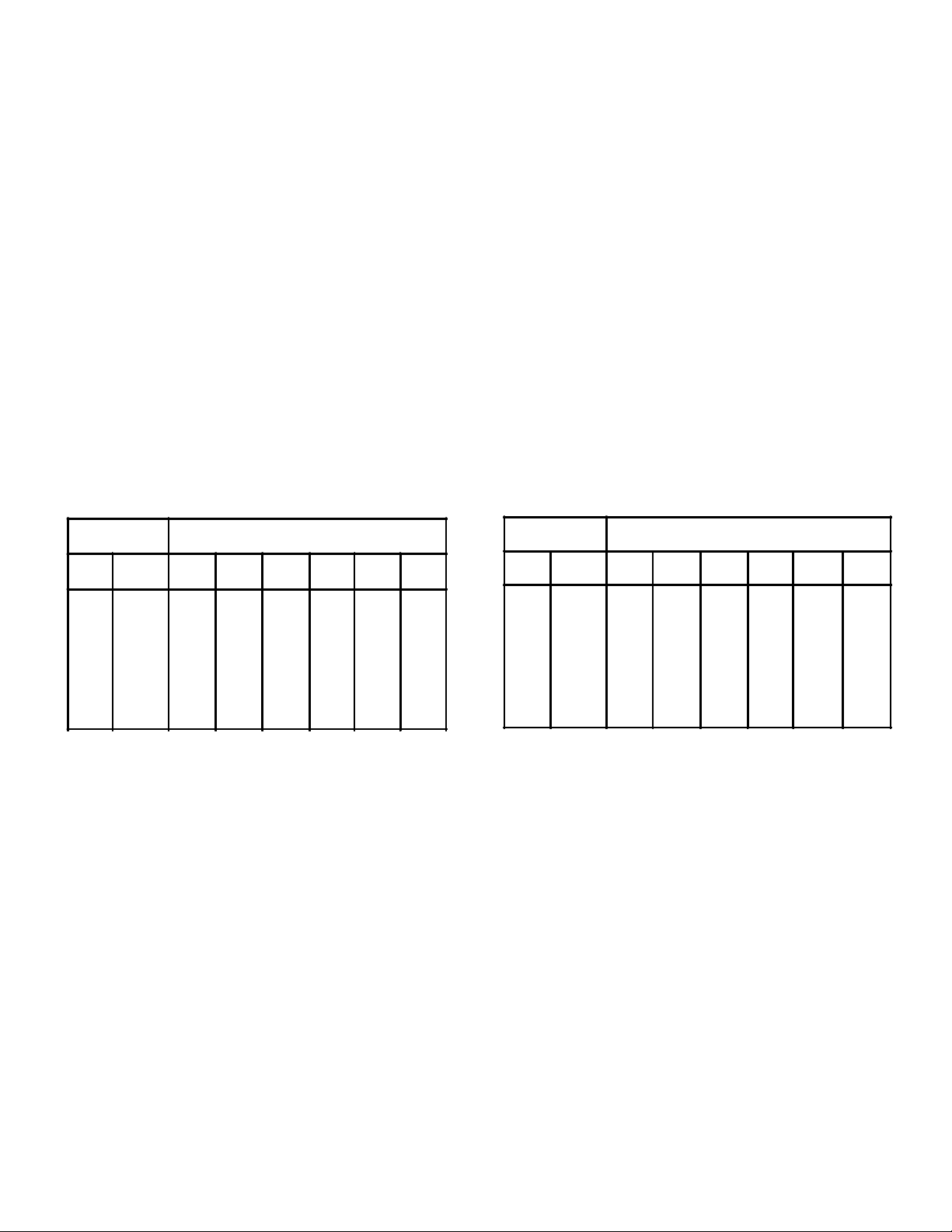

MODELS KCC103 THRU KCC223

MODELS KCC237 THRU KCC164

DIMENSIONAL DATA

DIMENSIONS - GENERAL DATA

MODEL

No.

KCC

103

104

106

108

111

214

217

222

228

237

141

150

164

A B D G H J K M N P R S T U V

ins. 34 22 3/4 21 3/4 11 3/4 10 1/4 6 1/2 11 1/8 16 1/8 - 28 1/2 1 1/2 - 15 18 30

mm

864 578 553 299 260 165 283 410 - 724 38 - 381 457 762

ins.

40 25 3/4 24 3/4 12 1/4 13 1/2 6 1/2 13 7/8 19 1/8 - 34 1/2 1 1/2 - 15 21 36

mm

1016 654 629 311 343 165 352 486 - 876 38 - 381 533 914

ins. 50 29 28 17 1/4 15 7/8 6 1/2 16 3/8 22 3/8 - 44 1/2 1 1/2 - 16 24 45

mm 1270 737 711 438 403 165 416 568 - 1130 38 - 406 610 1143

ins. 48 37 3/4 36 3/4 21 1/8 19 3/8 8 13 3/8 31 1/8 - 42 1/2 1 1/2 - 18 33 44

mm 1219 959 934 537 492 203 340 791 - 1080 38 - 457 838 1118

ins. 63 37 3/4 36 3/4 23 1/4 21 5/8 8 19 7/8 31 1/8 - 57 1/2 1 1/2 - 18 33 58

mm 1600 959 934 591 549 203 505 791 - 1461 38 - 457 838 1473

ins. 78 37 3/4 36 3/4 19 17 7/8 8 10 31 1/8 - 72 1/2 1 1/2 20 21 33 74

mm 1981 959 934 483 454 203 254 791 - 1842 38 508 533 838 1880

ins. 93 37 3/4 36 3/4 21 1/8 19 3/8 8 12 3/4 31 1/8 - 87 1/2 1 1/2 25 3/8 21 33 88

mm 2362 959 934 537 492 203 324 791 - 2223 38 645 533 838 2235

ins. 97 44 3/4 43 3/4 23 1/4 21 5/8 9 12 5/8 38 1/8 - 91 1/2 2 25 1/4 21 39 92

mm 2464 1137 1111 591 549 229 321 968 - 2324 51 641 533 991 2337

ins. 120 44 3/4 43 3/4 28 1/4 26 1/2 9 15 7/8 38 1/8 - 114 1/2 2 31 3/4 23 39 116

mm

3048 1137 1111 718 673 229 403 968 - 2908 51 807 584 991 2946

ins.

122 1/8 57 3/8 45 5/8 31 1/2 28 3/4 11 1/2 15 1/8 39 1/2 11 3/4 117 7/8 2 29 25 51 116

mm 3102 1457 1159 800 730 292 384 1003 299 2994 51 737 635 1295 2946

ins. 122 1/8 65 5/8 59 1/8 46 3/8 43 1/4 11 1/2 37 7/8 53 6 1/2 117 7/8 1 3/4 - 25 60 116

mm 3102 1667 1502 1178 1099 292 962 1346 165 2994 45 - 635 1524 2946

ins. 122 1/8 75 3/8 66 5/8 51 1/2 47 1/4 11 1/2 35 3/8 60 1/2 8 3/4 117 7/8 2 - 25 69 116

mm 3102 1915 1692 1308 1200 292 899 1537 222 2994 51 - 635 1753 2946

ins. 122 1/8 93 3/8 72 5/8 56 3/4 52 3/8 11 1/2 32 5/8 66 1/2 20 3/4 117 7/8 2 - 25 87 116

mm

3102 2372 1845 1442 1330 292 829 1689 527 2994 51 - 635 2210 2946

* For R502 multiply charge in lbs. by 0.93 and for R500 by 0.88. For winter charge, multiply by 6.65.

** For filter section dimensions refer to page 7.

- 5 -

REFRIGERANT*

No. of

FACE

TUBES

12 3.31 1.50 2.98 1.35 343 156

14 4.50 2.04 4.05 1.84 431 196

16 5.85 2.66 5.27 2.39 600 272

22 7.88 3.58 7.09 3.22 806 366

22 10.28 4.67 9.25 4.20 996 452

22 13.02 5.91 11.72 5.32 1171 531

22 14.20 6.45 12.90 5.86 1393 632

26 17.46 7.93 15.86 7.20 1714 778

26 21.55 9.78 19.59 8.89 2163 981

34 28.72 13.04 26.10 11.85 3420 1551

40 34.29 15.57 31.15 14.14 3500 1588

46 41.28 18.74 38.05 17.27 4500 2041

58 53.31 24.20 47.98 21.78 5900 2676

CHARGE

6 ROW COIL

R-12 R-22

Lbs. kg. Lbs. kg

SHIPPING

WEIGHT

Lbs. kg

Page 6

MULTIPLE CIRCUIT CONNECTION SIZES

NET TONS 0 - 7 1/2 † 8-10 11-13 14-18 19-28 29-35 36-43 44-57 58-64 65-72 73 & up

HOT GAS

INLET

LIQUID

OUTLET

ins. 1 1/8 1 3/8 1 3/8 1 5/8 2 1/8 2 1/8 2 5/8 2 5/8 3 1/8 3 1/8 3 5/8

mm 29 35 35 41 54 54 67 67 79 79 92

ins. 7/8 7/8 1 1/8 1 1/8 1 3/8 1 5/8 1 5/8 2 1/8 2 1/8 2 5/8 2 5/8

mm 22 22 29 29 35 41 41 54 54 67 67

FAN DISCHARGE ARRANGEMENTS MOTOR & ACCESS PANEL LOCATIONS

(Viewed from Drive End)

NOTE: Models 237 thru 164 only available with CU and CCU discharge arrangement when furnished with a special “square” fan cabinet.

Not available with motor location or access location on bottom.

FILTER SECTIONS

FILTER SECTIONS

UNIT

SIZE

103 34 864 21 5/8 549 28 1/2 724 16 1/2 419 30 5/8 778 17 5/8 448

104

106

108

111 63 1600 36 5/8 930 57 1/2 1461 20 1/2 521 59 5/8 1514 32 1/2 826 118 54

214 78 1981 36 5/8 930 72 1/2 1842 25 1/2 648 74 5/8 1895 32 1/2 826 26 660 74 5/8 1895 33 1/4 845 26 660 140 64 305 138

217 93 2362 36 5/8 930 87 1/2 2223 25 1/2 648 89 5/8 2276 32 1/2 826 26 660 89 5/8 2276 33 1/4 845 26 660 161 73 348 158

222 97 2464 43 5/8 1108 91 1/2 2324 16 1/2 419 93 5/8 2378 40 1/8 1019 23 584 93 5/8 2378 40 1/4 1022 23 584 189 86 377 171

228

237

141

150 119 3/8 3032 73 1/8 1857 117 7/8 2994 20 1/2 521 116 5/8 2962 70 1/8 1781 25 1/2 648 115 1/8 2934 69 3/4 1772 25 1/2 648 342 155 776 352

164 119 3/8 3032 91 1/8 2314 117 7/8 2994 20 1/2 521 116 5/8 2962 85 1/4 2165 27 1/8 689 115 1/8 2934 87 3/4 2229 27 1/8 689 416 189 903 410

A B P

T U V T U V Y Flat Angular

ins mm ins mm ins mm ins mm ins mm ins mm ins mm ins mm ins mm ins mm lb kg lb kg

40 1016 24 5/8 626 34 1/2 876 20 1/2 521 36 5/8 930 20 508 49 22

50 1270 27 7/8 708 44 1/2 1130 16 1/2 419 45 5/8 1184 23 1/8 587 62 28

48 1219 36 5/8 930 42 1/2 1080 25 1/2 648 44 5/8 1133 32 1/2 826 86 39

120 3048 43 5/8 1108 114 1/2 2908 20 1/2 521 116 5/8 2962 40 1/8 1019 23 584 116 5/8 2962 40 1/4 1022 23 584 232 105 449 204

119 3/8 3032 55 1/8 1400 117 7/8 2994 20 1/2 521 116 5/8 2962 50 1/8 1273 25 1/2 648 115 1/8 2934 51 3/4 1314 22 1/4 565 278 126 675 283

119 3/8 3032 63 3/8 1610 117 7/8 2994 20 1/2 521 116 5/8 2962 60 1/8 1527 21 1/8 536 115 1/8 2934 60 1524 21 1/8 536 303 137 656 298

FLAT ANGULAR

NA NA NA NA NA NA NA NA

SHIPPING

WEIGHTS

39 18

NA NA

- 6 -

Page 7

IMPORTAN THE FOLLOWING KEEPRITE REFRIGERATION CENTRIFUGAL FAN UNITS MUST BE

GENERAL

INSTALLATION INSTRUCTIONS

PLATFORM OR FLOOR MOUNTED

CONDENSERS KCC237, KCC141, KCC150, KCC164

Unit should be carefully checked for damage when

received. Visible or concealed damage should be

reported immediately to the carrier and a claim

filed.

All KCC Centrifugal condensers are inspected

thoroughly before shipment. However, fans and

shaft should be inspected before installation to

insure that misalignment has not happened in

shipment or handling. For long and trouble free

life, the units should have proper care and

maintenance.

Units should be located so that enough space is left

around the unit for lubrication, belt adjustment and

coil removal if necessary.

For units with free air intake and discharge, care

should be taken to insure that there are no

obstructions that will interfere with the air flow.

DRIVE INSTALLATION

Smaller motors are usually shipped mounted on the

unit. Larger motors will be shipped separately.

When motors are shipped separately the mounting

procedure should be as follows:

(a) Bolt motor to the motor base on the unit.

(b) If not already mounted, install fan motor

sheaves.

(c) Align sheaves with straight edge to insure true

running belts.

(d) Adjust motor mount for proper belt tension.

(e) Attach belt guard to end panel of blower

section.

MOUNTING UNITS

Smaller models may be floor mounted or ceiling

hung. Larger models may be floor mounted only.

When hoisting units, a spreader bar should be

used to prevent damage to the casing. Units are

equipped with 518 “ (16 mm) N.C. tapped hanger

nuts or 3/4 “ (19 mm) anchor holes for floor

mounting.

DUCTWORK

Where ductwork is to be used with units,

connection to unit should be

made with flexible canvas sleeves.

MAINTENANCE BEFORE START UP

(a) Check tightness of all bearing, sheave and

fan wheel set screws.

(b) If fan wheel set screws are loose, check to

insure that Wheel is not rubbing in housing.

(c) Leak-lest system to make sure that all joints

are tight.

(d) Ball bearings are pre-lubricated and require

no further lubrication at start-up.

(e) Rotate shaft by hand to make sure it runs

freely.

(f) Check fan and motor for correct rotation. If

running the wrong direction, reverse phases

at motor. Re-check rotation.

(g) Check drive alignment and belt tension.

- 7 -

Page 8

AFTER FIRST 48 HOURS

1. Check all previous points under ”Before

Start-Up”.

2. Belts will have stretched. Re-check tension

and adjust motor where necessary.

PERIODIC SERVICE & MAINTENANCE

(a) Check all moving parts for wear every 6

months.

(b) Check bearing collar set screws for

tightness every 6 months.

(c) Check belt tension and adjust if necessary.

MOTOR BEARINGS

All ball bearings are pre-lubricated and do not

require any additional grease at time of

installation. However, periodic cleaning out and

renewal of grease is necessary. Please note

extreme care must be taken to insure that foreign

matter does not enter the bearing. It is also

important to avoid over greasing. Only a high

grade clean mineral grease should be used.

Specific greasing instructions should be in

accordance with the motor manufacturer’s

recommendations. Melting point of grease should

not be under 150°C (302°F).

FAN BEARINGS

panel in cabinet. Units are equipped with extended

lube lines and will have grease fittings for internal

bearings on drive end panel of blower section.

Apply grease when bearings are running, adding

slowly until a slight bleeding of grease from the

seals is noted. Access door should be removed so

that internal bearing may be viewed when greasing.

DO NOT OVER LUBRICATE

The lubrication interval varies with the period of

operation and temperature of the ambient air. The

following interval is recommended:

Temperature Range Time Interval

60 - 80°F (1 6 - 26°C) 2 years

81 - 100°F (27 - 37°C) 1 1/2 years

101 -120°F (38 - 49°C) 1 year

For units which have been in operation for several

years or where some bearing wear has occurred

through adverse operating conditions, lubrication

may be required as frequently as every 2 months.

ARMVAC 781 available from Standard Oil

Company or Imperial Oil Company is the

recommended lubricant for fan shaft bearings.

Lubricant will be satisfactory down to -40°F (-40°C)

ambient temperature.

All ball bearings are pre-lubricated and do not

require any additional lubrication at time of

installation. However, periodic cleaning out and

renewal of grease is necessary.

Internal bearings are accessible through access

REPLACEMENT PARTS

When replacement parts are required, furnish

factory with Unit Model No. and Serial No. as

shown on drive end of unit.

- 8 -

Page 9

DESIGN SPECIFICATIONS

TYPE KCC CENTRIFUGAL FAN AIR COOLED CONDENSERS

CASING

Furnish and install where shown on the drawings,

Centrifugal Fan Air Cooled Condenser(s) by

KeepRite or approved equal. Sizes and

performance shall be as indicated in the unit

schedule. Cabinets shall be of sectionalized

construction, and all sheet metal parts, including

accessories, shall be of continuous galvanized

sheet steel. Cabinet shall be angular steel frame

construction with casing panels easily removable

for access to the interior of the unit.

FANS

Fans shall be designed for class 1 operation. Fan

ratings shall be based on fan tests conducted in

accordance with AMCA Code No. 210. Fan

housings and wheels shall be continuous

galvanized steel. Fan wheels over 12 “ (305mm)

diameter shall be keyed to the fan shaft. The fan

shaft shall be solid high carbon steel, fully sized

throughout.

The maximum rate of fan RPM shall be well below

the first critical fan shaft speed.

BEARINGS

Bearings shall be self-aligning, grease lubricated,

ball type. All bearings shall be sized with a

minimum service factor of four. Extended

lubrication lines with zerk type fittings shall be

provided and permanently lubricated bearings will

not be allowed.

COILS

Coils shall be constructed of rippled aluminum fins

hydraulically bonded to copper tubing for

permanent metal-to-metal contact and maximum

heat transfer efficiency. Fins shall be die-formed

with wide smooth collars to completely cover the

tubing for optimum corrosion resistance. Coils

shall be factory leak tested at 300 psi,

dehydrated, sealed and braced to seamless

copper headers. Any number of coil circuits shall

be available provided the total does not exceed

the number of tubes in the coil face. Coils shall

be provided with sweat-type connections and

shall be circuited for proper refrigerant drainage.

DRIVE

Units shall be provided with adjustable motor

bases and adjustable drives so as to permit 10%

adjustment in fan speed in either direction.

Factory supplied and mounted motor electrical

characteristics: 208, 230 or 575/3/60.

- 9 -

Page 10

- 10 -

Page 11

- 11 -

Page 12

SERVICE LOG

07/04/2007

ETADSTNEMMOC

PROJECT INFORMA TION

metsyS

rebmuNledoM pU-tratSfoetaD

rebmuNlaireS rotcartnoCecivreS

tnaregirfeRenohP

ylppuSlacirtcelExaF

NA TIONAL REFRIGERA TION &

AIR CONDITIONING CANADA CORP.

CANADA

159 ROY BL VD., BRANTFORD, ONT ARIO, CANADA N3R 7K1

PHONE: 1-800-463-9517 (519)751-0444 FAX (519)753-1140

Due to National Refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice.

USA

985 WHEELER WA Y, LANGHORNE, P A. 19047 USA

PHONE:1-888-KEEPUS1 OR 1-888-533-7871

Loading...

Loading...