Page 1

JUH Heat Reclaim

Unit Heaters

For Refrigeration Systems

Bulletin K90-JUH-PDI-10

1064634

We are on the Internet

www.keepriterefrigeration.com

Electrical Power: 115/1/60, 208-230/1/60,

208-230/3/60, 460/3/60,

575/3/60

CONTENTS PAGE

Nomenclature.........................................

Features..................................................

System Design.......................................

Circuit Arrangement..............................

Specifications.........................................

Dimensional Data...................................

Cover

2

2

3

3

Back

• Designed for Supermarkets, Convenience

Stores, Restaurants, Refrigerated warehouses,

arenas/curling rinks and institutions.

• Reclaims waste heat for use in shipping/

receiving areas, storage, preparation and work

areas.

• Heavy gauge all aluminum cabinet with plated

and non-ferrous corrosion resistant fasteners

throughout.

• Cleanable, durable textured aluminum

cabinet.

• Thermally protected and permanently

lubricated fan motor for long life and

dependability .

• Compact size maximizes usable storage

space.

• Stainless steel and nylon hardware

eliminates rusting and stripping of fasteners.

• Corrosion resistant white polycarbonate fan

guard.

Page 2

JUH HEAT RECLAIM UNIT HEATERS

FEATURES

CABINET - Heavy gauge all aluminum construction for long

life and minimum weight. Plated and non-ferrous corrosion

resistant fasteners used throughout. Electrical connection

box and all refrigerant connections on outside of cabinet.

COIL - Heat reclaim coil fabricated from 5/8” (16mm) O.D.

copper tube mechanically expanded to provide a secure bond

with rippled aluminum plate fins for optimum heat transfer.

Coil circuited for minimum pressure drop and drainability to

prevent logging of oil and liquid refrigerant. Coil assembly

leak tested at 300 psig. dehydrated and sealed.

NUMBER OF COIL CIRCUITS - Standard models are supplied

with two equal circuits. Other arrangements of two or three

circuits are available.

FANS - Aluminum fans. Die formed venturi fan discharge

provides quiet, efficient operation with maximum air throw.

MOTORS - Permanently lubricated. totally enclosed motors

feature thermal protection and current overload sensors for

maximum life and dependability. Direct drive arrangement

eases service and allows operation of the unit in case of

partial motor failure. Available for 575/3/60, 460/3/60,

208/3/60, 208-230/1/60 or 115/1/60 entering electrical service.

FAN GUARD/MOTOR MOUNTS - Heavy gauge steel wire fan

guard/motor mounts are zinc plated for corrosion protection.

WIRING - Moisture and fungus resistant wiring harness. All

electrical connections at one location.

INSTALLATION FEATURES - “Z” bar mounting brackets with

mounting holes on 8” (203mm) centers allows installation

to varied joist centers or ceilling panel lengths. External

electrical connection box and refrigeration connections

simplify installation.

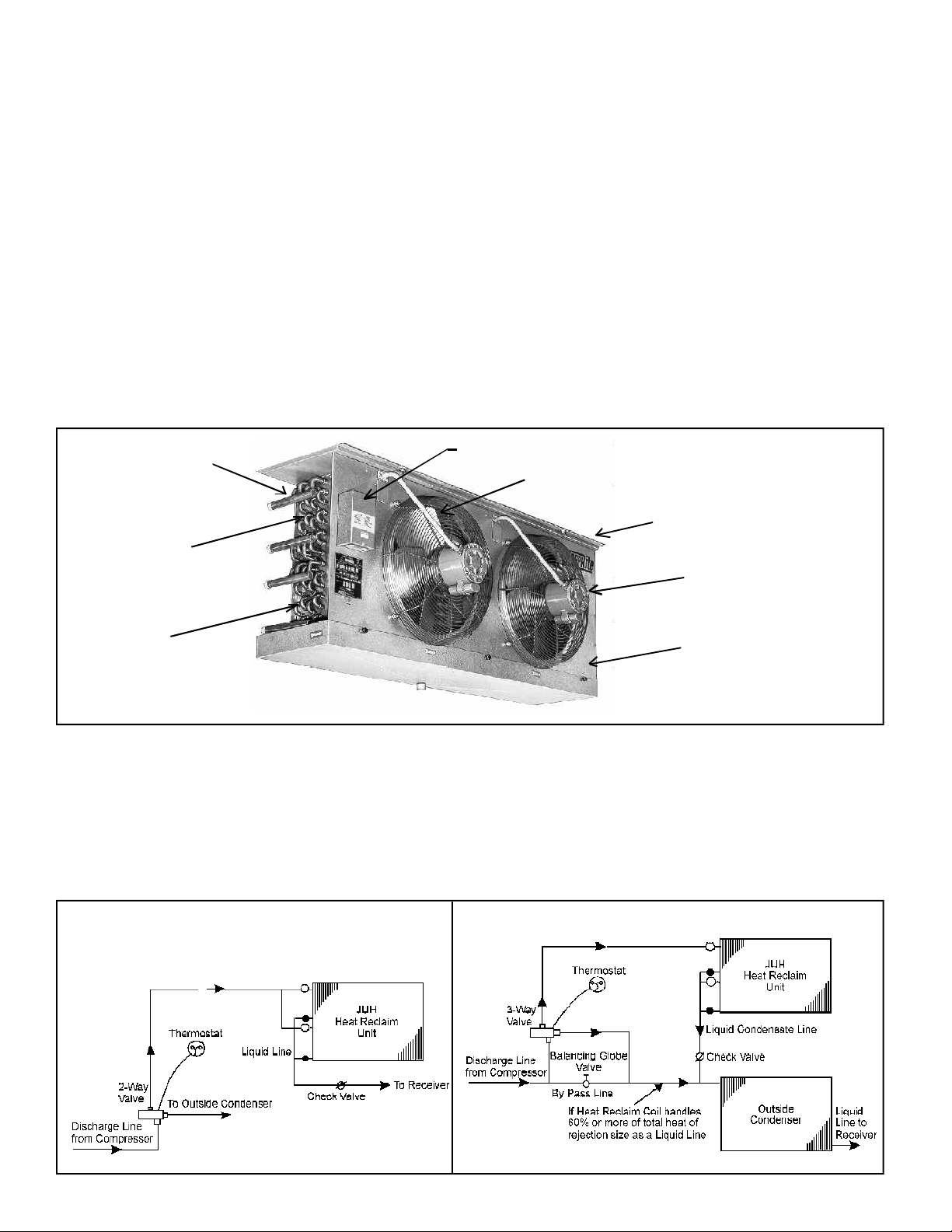

EXTERNAL ALL COPPER

REFRIGERANT

CONNECTIONS

FREE DRAINING COIL,

CIRCUITED FOR

MINIMUM

PRESSURE DROP

HIGH EFFICIENCY

COPPER TUBE,

ALUMINUM FIN

HEAT RECLAIM COIL

SYSTEM DESIGN

JUH Heat reclaim units may be used in series or parallel with

an outside condenser.

Parallel piping is used when the heat reclaim system is to

recover 100% of the system total heat of rejection. A three-way

valve in the discharge line directs the refrigerant flow either to

the outside condenser or to the heat reclaim unit. See Fig. 1

Figure 1 - JUH Heat Reclaim Unit piping arrangement when

total heat of rejection does not exceed capacity of heat

reclaim unit.

EXTERNAL ELECTRICAL CONNECTION BOX

HEAVY DUTY, CORROSION RESISTANT FAN GUARDS

“Z” BAR MOUNTING BRACKETS

DIRECT DRIVE

1100 RPM FAN MOTORS

HEAVY GAUGE, TEXTURED

ALUMINUM CABINET

ASSEMBLED WITH

CORROSION RESISTANT

FASTENERS

Series piping is used when the amount of heat to be

recovered is less than the total heat of rejection. A three-way

valve controls refrigerant flow. A by-pass arrangement with a

balancing globe valve, is used to prevent excressive

refrigerant pressure drop in the heat reclaim unit. See Fig, 2.

Check valves prevent refrigerant back flow to the coil not in

use.

Figure 2 - JUH Heat Reclaim Unit piping arrangement when

total heat of rejection exceeds capacity of heat reclaim unit.

Page 3

JUH HEAT RECLAIM UNIT HEATERS

CIRCUITING ARRANGEMENT

Each JUH Heat Reclaim Unit has a total of 16 “face tubes”. Five (5) different circuiting arrangements are

available, consisting of various combinations of 4, 6, 8, 10 and 12 tube circuits, totalling 16 tubes.

(1) 2 - 8 face tube circuits (standard models)

(2) 1 - 6 face tube circuit and 1 - 10 face tube circuit

(3) 1 - 4 face tube circuit and 1 - 12 face tube circuit

(4) 1 - 4 face tube circuits and 2 - 6 face tube circuits

(5) 2 - 4 face tube circuits and 1 - 8 face tube circuit

No other combinations are avilable.

JUH MODEL JUH2-23 JUH2-30 JUH3-35 JUH3-45

(1)

4

FACE TUBE

CIRCUIT

6

FACE TUBE

CIRCUIT

8

FACE TUBE

CIRCUIT

10

FACE TUBE

CIRCUIT

12

FACE TUBE

CIRCUIT

4 FACE TUBE

CIRCUIT

6 FACE TUBE

CIRCUIT

8 FACE TUBE

CIRCUIT

10 FACE TUBE

CIRCUIT

12 FACE TUBE

CIRCUIT

HEAT RECLAIM CAPACITY PER CIRCUIT - MBH (kW) R-22

20°F (11°C) T.D.

30°F (17°C) T.D.

40°F (22°C) T.D.

50°F (28°C) T.D.

20°F (11°C) T.D.

30°F (17°C) T.D.

40°F (22°C) T.D.

50°F (28°C) T.D.

20°F (11°C) T.D.

30°F (17°C) T.D.

40°F (22°C) T.D.

50°F (28°C) T.D.

20°F (11°C) T.D.

30°F (17°C) T.D.

40°F (22°C) T.D.

50°F (28°C) T.D.

20°F (11°C) T.D.

30°F (17°C) T.D.

40°F (22°C) T.D.

50°F (28°C) T.D.

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

14.3 (4.2) 17.8 (5.2) 21.4 (6.3) 26.6 (7.8)

21.5 (6.3) 26.7 (7.8) 32.1 (9.4) 39.8 (11.7)

28.6 (8.4) 35.5 (10.4) 42.8 (12.5) 53.1 (15.6)

35.8 (10.5) 44.4 (13.0) 53.5 (15.7) 66.4 (19.4)

21.5 (6.3) 26.6 (7.8) 32.1 (9.4) 39.8 (11.7)

32.2 (9.4) 40.0 (11.7) 48.2 (14.1) 59.7 (17.5)

42.9 (12.6) 53.3 (15.6) 64.1 (18.8) 79.6 (23.3)

53.7 (15.7) 66.6 (19.5) 80.2 (23.5) 99.5 (29.1)

26.8 (8.4) 35.5 (10.4) 42.8 (12.5) 53.1 (15.6)

42.9 (12.6) 53.3 (15.6) 64.2 (18.8) 79.6 (23.3)

57.2 (16.8) 71.0 (20.8) 85.5 (25.0) 106.1 (31.1)

71.6 (21.0) 88.8 (26.0) 106.9 (31.3) 132.7 (38.9)

35.8 (10.5) 44.4 (13.0) 53.5 (15.7) 66.4 (19.4)

53.6 (15.7) 66.6 (19.5) 80.3 (23.5) 99.5 (29.1)

71.5 (20.9) 88.8 (26.0) 106.9 (31.3) 132.6 (38.8)

89.5 (26.2) 111.0 (32.5) 133.6 (39.1) 165.9 (48.6)

42.9 (12.6) 53.3 (15.6) 64.2 (18.8) 79.7 (23.3)

64.4 (18.9) 80.0 (23.4) 96.3 (28.2) 119.4 (35.0)

85.8 (25.1) 106.5 (31.2) 128.3 (37.6) 159.2 (46.6)

107.4 (31.5) 133.2 (39.0) 160.4 (47.0) 199.1 (58.3)

CONNECTION SIZES - O.D.S. - IN. (MM)

INLET 1 1/8 (28.5) 1 1/8 (28.5) 1 1/8 (28.5) 1 1/8 (28.5)

OUTLET 1 1/8 (28.5) 1 1/8 (28.5) 1 1/8 (28.5) 1 1/8 (28.5)

INLET 1 1/8 (28.5) 1 1/8 (28.5) 1 1/8 (28.5) 1 1/8 (28.5)

OUTLET 1 1/8 (28.5) 1 1/8 (28.5) 1 1/8 (28.5) 1 1/8 (28.5)

INLET 1 1/8 (28.5) 1 1/8 (28.5) 1 1/8 (28.5) 1 3/8 (35.0)

OUTLET 1 1/8 (28.5) 1 1/8 (28.5) 1 1/8 (28.5) 1 3/8 (35.0)

INLET 1 1/8 (28.5) 1 1/8 (28.5) 1 3/8 (35.0) 1 3/8 (35.0)

OUTLET 1 1/8 (28.5) 1 1/8 (28.5) 1 3/8 (35.0) 1 3/8 (35.0)

INLET 1 1/8 (28.5) 1 3/8 (35.0) 1 3/8 (35.0) 1 5/8 (41.0)

OUTLET 1 1/8 (28.5) 1 3/8 (35.0) 1 3/8 (35.0) 1 5/8 (41.0)

NOTES: • For R12 use R22 ratings x .95. For R502, use R22 ratings x 0.98

• TD = Condensing temperature minus entering air temperature

Page 4

LEDOMHUJ32-2HUJ03-2HUJ53-3HUJ54-3HUJ

03/15/2007

llarevO

htgneL

edistuO

seloHregnaH

oC

riAMFC

NOTE: For R12 use R22 charge x 1.11

noitcenn

).S.D.O(seziS

dradnatS

ledoM

pihS

gnip

emuloV

gnippihS

thgieW

srotoMnaF

)MPR0011(

latoT

ALF

tnaregirfeR

rePegrahC

ebuTecaF

)1(

205-R,22-R

wolFS/L

A-

B-

telnI

teltuO

W&.ytQ

06/3/575

4

06/3/06

06/1/511

lamroN

lortimiL

DIMENSIONAL DATA

ATADLANOISNEMID

.nI

mm

.nI

mm

.nI

mm

.nI

mm

.tF.uC

m.uC

.tF.uC

m.uC

PH&.ytQ

06/3/032/802

06/1/032/802

.bl

gk

.bl

gk

4/1464/1464/1094/109

2361236129222922

65650808

2241224123022302

8/118/118/118/31

5.825.825.8253

8/118/118/118/31

5.825.825.8253

3.343.347.857.85

22.122.166.166.1

932972033793

801721051081

ATADLACIRTCELE

4/1-24/1-24/1-34/1-3

681-2681-2681-3681-3

29.029.083.183.1

40.140.165.165.1

08.208.202.402.4

08.208.202.402.4

06.506.504.804.8

ATADNOITACILPPA

8.96.413.415.12

44.426.694.657.9

3.564.791.593.341

6.922.441.340.96

0005008400570027

632562204535933

0

NA TIONAL REFRIGERA TION &

AIR CONDITIONING CANADA CORP.

CANADA

159 ROY BL VD., BRANTFORD, ONT ARIO, CANADA N3R 7K1

PHONE: 1-800-463-9517 (519)751-0444 FAX (519)753-1140

Due to National Refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice.

USA

985 WHEELER WA Y, LANGHORNE, P A. 19047 USA

PHONE:1-888-KEEPUS1 OR 1-888-533-7871

Loading...

Loading...