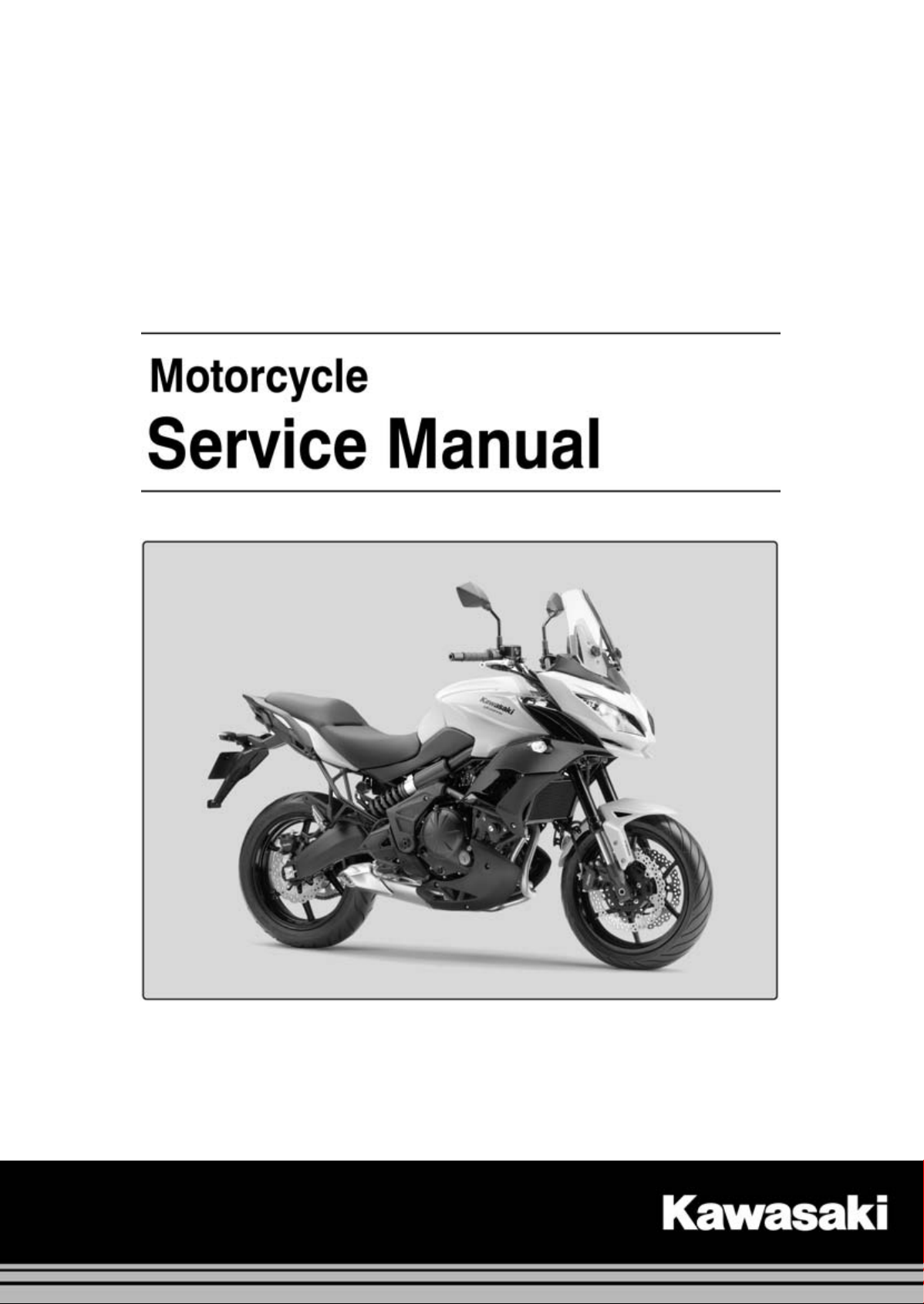

kawasaki versys 650 service manual

VERSYS 650

VERSYS 650 ABS

Quick Reference Guide

General Information 1 j

Periodic Maintenance 2 j

Fuel System (DFI) 3 j

Cooling System 4 j

Engine Top End 5 j

Clutch 6 j

Engine Lubrication System 7 j

Engine Removal/Installation 8 j

This quick reference guide will assist

you in locating a desired topic or procedure.

•Bend the pages back to match the

black tab of the desired chapter number with the black tab on the edge at

each table of contents page.

•Refer to the sectional table of contents

for the exact pages to locate the specific topic required.

Crankshaft/Transmission 9 j

Wheels/Tires 10 j

Final Drive 11 j

Brakes 12 j

Suspension 13 j

Steering 14 j

Frame 15 j

Electrical System 16 j

Appendix 17 j

VERSYS 650

VERSYS 650 ABS

Motorcycle

Service Manual

All rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise,

without the prior written permission of Quality Assurance Division/Motorcycle & Engine Company/Kawasaki

Heavy Industries, Ltd., Japan.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible

care has been taken to make it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation

to make such changes to products manufactured previously. See your Motorcycle dealer for the latest

information on product improvements incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time

of publication. Illustrations and photographs in this publication are intended for reference use only and may

not depict actual model component parts.

© 2014 Kawasaki Heavy Industries, Ltd. First Edition (3) : Sep. 26, 2014

LIST OF ABBREVIATIONS

A

ABDC after bottom dead cente

ABS antilock brake system km/h kilometers per hour

AC alternating current L liter(s)

Ah ampere hour LCD liquid crystal display

ATDC after top dead center LED light emitting diode

BBDC before bottom dead center lb pound(s)

BDC bottom dead center m meter(s)

BTDC before top dead center min minute(s)

°C degree(s) Celsius mmHg millimeters of mercury

cmHg centimeters of mercury mph miles per hour

CPU

cu in.

DC

DFI digital fuel injection PS horsepower

DOHC double overhead camshaft psi pound(s) per square inch

DOT department of transportation qt quart(s)

ECU electronic control unit r revolution

F farad(s) rpm revolution(s) per minute

°F degree(s) Fahrenheit s second(s)

ft foot, feet TDC top dead center

g gram(s) TIR total indicator reading

gal gallon(s) V volt(s)

h

HP

ampere(s) IC

r

central processing unit N

cubic inch(es)

direct current Pa

hour(s)

horsepower(s) Ω ohm(s)

in.

oz

W

integrated circuit

inch(es)

newton(s)

ounce(s)

pascal(s)

watt(s)

OUNTRY AND AREA CODES

C

AT Austria ID Indonesia

AU Australia MY Malaysia

AU LAMS Australia Leaner Approved Motorcycle

Scheme model

CA Canada

CAL California SEA-B2 Southeast Asia B2

CH Switzerland TH Thailand

CN China US United States

DE Germany

EUR Europe

PH Philippines

EA-B1

S

WVTA

(FULL H)

outheast Asia B1 (with Evaporative

S

Emission Control System)

WVTA Model with Honeycomb

Catalytic Converter (Full Power)

EMISSION CONTROL INFORMATION

To protect the environment in which we all live, Kawasaki has incorporated crankcase emission (1) and exhaust emission (2) control systems in compliance with applicable regulations of

the United States Environmental Protection Agency and California Air Resources Board. Additionally, Kawasaki has incorporated an evaporative emission control system (3) in compliance

with applicable regulations of the California Air Resources Board on vehicles sold in California

only.

1. Crankcase Emission Control System

This system eliminates the release of crankcase vapors into the atmosphere. Instead, the vapors

are routed through an oil separator to the intake side of the engine. While the engine is operating,

the vapors are drawn into combustion chamber, where they are burned along with the fuel and air

supplied by the fuel injection system.

2. Exhaust Emission Control System

This system reduces the amount of pollutants discharged into the atmosphere by the exhaust

of this motorcycle. The fuel, ignition, and exhaust systems of this motorcycle have been carefully

designed and constructed to ensure an efficient engine with low exhaust pollutant levels.

The exhaust system of this model motorcycle manufactured primarily for sale in California in-

cludes a catalytic converter system.

3. Evaporative Emission Control System

Vapors caused by fuel evaporation in the fuel system are not vented into the atmosphere. In-

stead, fuel vapors are routed into the running engine to be burned, or stored in a canister when

the engine is stopped.

The Clean Air Act, which is the Federal law covering motor vehicle pollution, contains what is

commonly referred to as the Act’s “tampering provisions”.

“Sec. 203(a) The following acts and the causing thereof are prohibited.

(3)(A) for any person to remove or render inoperative any device or element of design installed

on or in a motor vehicle or motor vehicle engine in compliance with regulations under this

title prior to its sale and delivery to the ultimate purchaser, or for any manufacturer or dealer

knowingly to remove or render inoperative any such device or element of design after such

sale and delivery to the ultimate purchaser.

(3)(B) for any person engaged in the business of repairing, servicing, selling, leasing, or trading

motor vehicles or motor vehicle engines, or who operates a fleet of motor vehicles knowingly to remove or render inoperative any device or element of design installed on or in a

motor vehicle or motor vehicle engine in compliance with regulations under this title following its sale and delivery to the ultimate purchaser...”

NOTE

The phrase “remo ve or render inoperative any device or element of design” has been generally

○

interpreted as follows.

1. Tampering does not include the temporary removal or rendering inoperative of devices or elements of design in order to perform maintenance.

2. Tampering could include.

a.Maladjustment of vehicle components such that the emission standards are ex-

ceeded.

b.Use of replacement p arts or accessories which adversely affect the performance

or durability of the motorcycle.

c.Addition of components or accessories that result in the vehicle exceeding the stan-

dards.

d.Permanently removing, disconnecting, or rendering inoperative any component or

element of design of the emission control systems.

WE RECOMMEND THAT ALL DEALERS OBSERVE THESE PROVISIONS OF FEDERAL

LAW, THE VIOLATION OF WHICH IS PUNISHABLE BY CIVIL PENALTIES NOT EXCEEDING

$10 000 PER VIOLATION.

TAMPERING WITH NOISE CONTROL SYSTEM PROHIBITED

Federal law prohibits the following acts or the causing thereof. (1) The removal or rendering

inoperative by any person other than for purposes of maintenance, repair, or replacement, of any

device or element of design incorporated into any new vehicle for the purpose of noise control

prior to its sale or delivery to the ultimate purchaser or while it is in use, or (2) the use of the

vehicle after such device or element of design has been removed or rendered inoperative by

any person.

Among those acts presumed to constitute tampering are the acts listed below.

Replacement of the original exhaust system or muffler with a component not in compliance

•

with Federal regulations.

Removal of the muffler(s) or any internal portion of the muffler(s).

•

Removal of the air box or air box cover.

•

Modifications to the muffler(s) or air intake system by cutting, drilling, or other means if such

•

modifications result in increased noise levels.

Foreword

This manual is designed primarily for use by

trained mechanics in a properly equipped shop.

However, it contains enough detail and basic information to make it useful to the owner who desires to perform his own basic maintenance and

repair work. A basic knowledge of mechanics,

the proper use of tools, and workshop procedures must be understood in order to carry out

maintenance and repair satisfactorily. Whenever the owner has insufficient experience or

doubts his ability to do the work, all adjustments, maintenance, and repair should be carried out only by qualified mechanics.

In order to perform the work efficiently and

to avoid costly mistakes, read the text, thoroughly familiarize yourself with the procedures

before starting work, and then do the work carefully in a clean area. Whenever special tools or

equipment are specified, do not use makeshift

tools or equipment. Precision measurements

can only be made if the proper instruments are

used, and the use of substitute tools may adversely affect safe operation.

For the duration of the warranty period,

we recommend that all repairs and scheduled

maintenance be performed in accordance with

this service manual. Any owner maintenance or

repair procedure not performed in accordance

with this manual may void the warranty.

To get the longest life out of your vehicle.

Follow the Periodic Maintenance Chart in the

•

Service Manual.

Be alert for problems and non-scheduled

•

maintenance.

Use proper tools and genuine Kawasaki Mo-

•

torcycle parts. Special tools, gauges, and

testers that are necessary when servicing

Kawasaki motorcycles are introduced by the

Service Manual. Genuine parts provided as

spare parts are listed in the Parts Catalog.

Follow the procedures in this manual care-

•

fully. Don’t take shortcuts.

Remember to keep complete records of main-

•

tenance and repair with dates and any new

parts installed.

How to Use This Manual

In this manual, the product is divided into

its major systems and these systems make up

the manual’s chapters. The Quick Reference

Guide shows you all of the product’s system

and assists in locating their chapters. Each

chapter in turn has its own comprehensive Table of Contents.

For example, if you want stick coil information,

use the Quick Reference Guide to locate the

Electrical System chapter. Then, use the Table

of Contents on the first page of the chapter to

find the Stick Coil section.

Whenever you see symbols, heed their instructions! Always follow safe operating and

maintenance practices.

DANGER

DANGER indicates a hazardous situa-

tion which, if not avoided, will result in

death or serious injury.

WARNING

WARNING indicates a hazardous situa-

tion which, if not avoided, could result

in death or serious injury.

NOTICE

NOTICE is used to address practices not

related to personal injury.

This manual contains four more symbols

which will help you distinguish different types

of information.

NOTE

NOTE indicates information that may help

○

or g uide you in the operation or service of

the vehicle.

Indicates a procedural step or work to be

•

done.

Indicates a procedural sub-step or how to do

○

the work of the procedural step it follows. It

also precedes the text of a NOTE.

Indicates a conditional step or what action to

take based on the results of the test or inspec-

tion in the procedural step or sub-step it fol-

lows.

In most chapters an exploded v iew illustration

of the system components follows the Table of

Contents. In these illustrations you will find the

instructions indicating which parts require specified tightening torque, oil, grease or a locking

agent during assembly.

GENERAL INFORMATION 1-1

General Information

Table of Contents

Before Servicing ..................................................................................................................... 1-2

Model Identification................................................................................................................. 1-7

General Specifications............................................................................................................ 1-9

Unit Conversion Table ............................................................................................................ 1-12

1

1-2 GENERAL INFORMATION

Before Servicing

Before starting to perform an inspection service or carry out a disassembly and reassembly operation on a motorcycle, read the precautions given below. To facilitate actual operations, notes, illustrations, photographs, cautions, and detailed descriptions have been included in each chapter wherever

necessary. This section explains the items that require particular attention during the removal and

reinstallation or disassembly and reassembly of general parts.

Especially note the following.

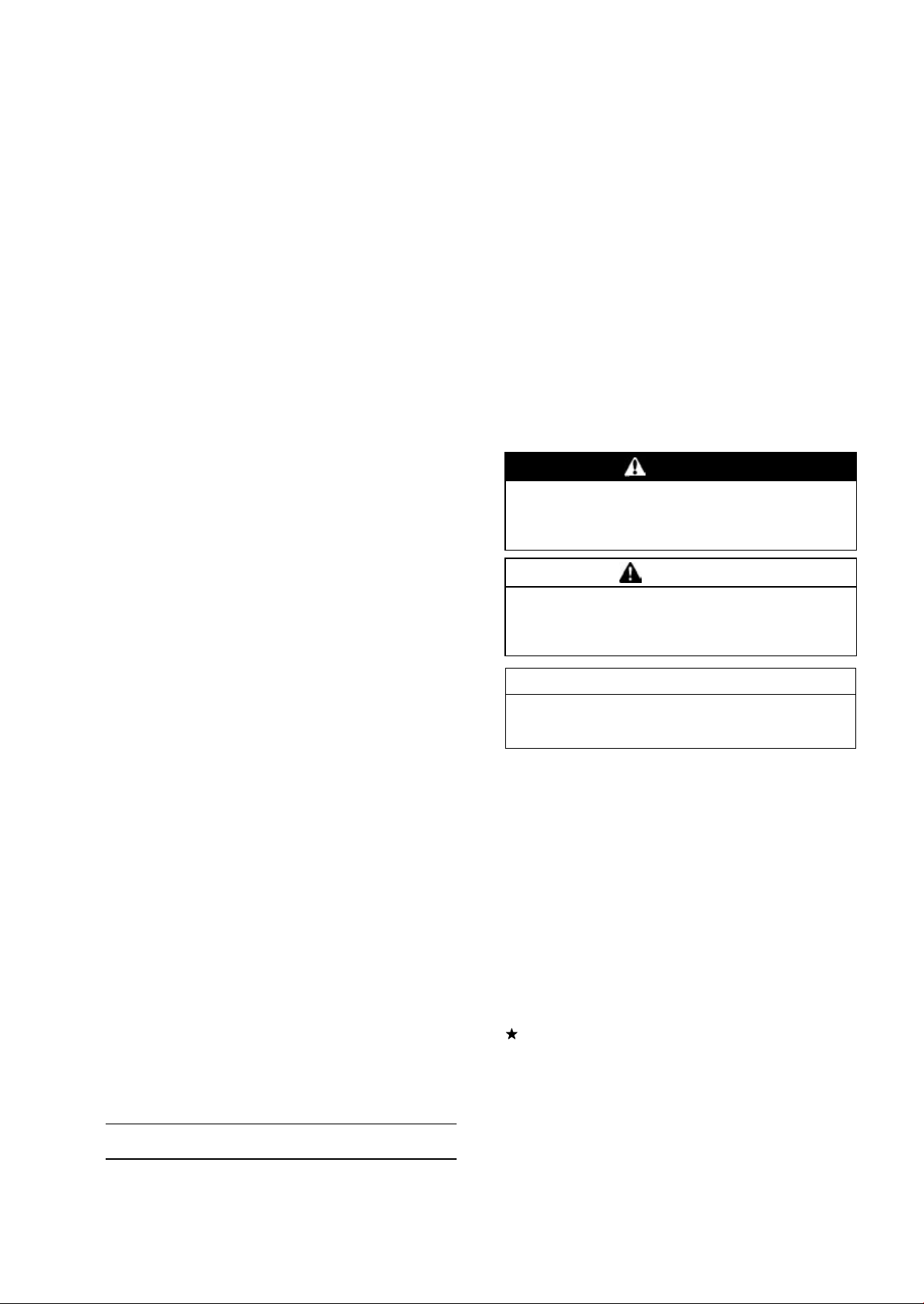

Battery Ground

Before completing any service on the motorcycle, disconnect the battery cables from the battery to prevent the engine from accidentally turning over. Disconnect the ground

cable (–) first and then the positive (+). When completed

with the service, first connect the positive (+) cable to the

positive (+) terminal of the battery then the negative (–) cable to the negative terminal.

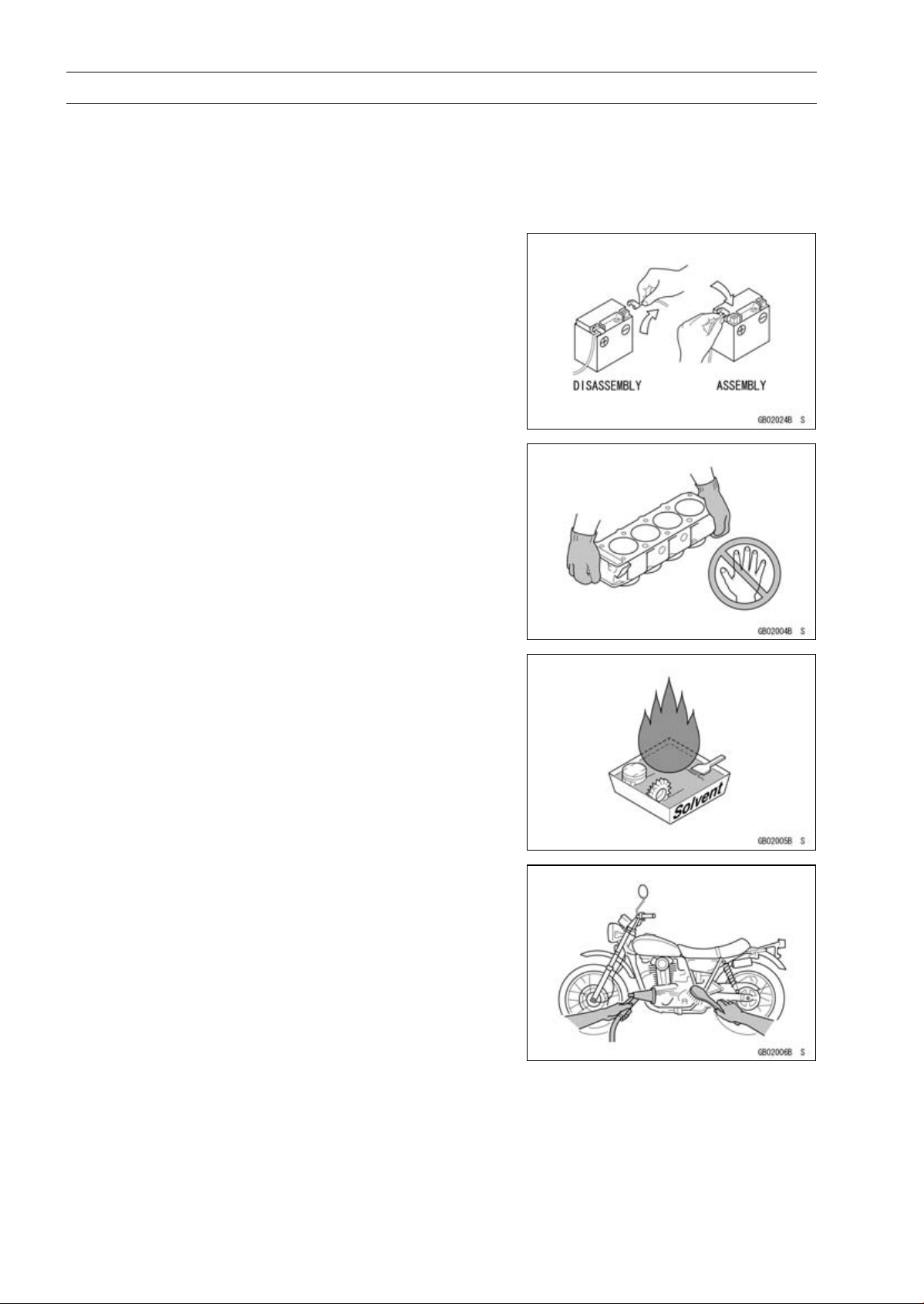

Edges of Parts

Lift large or heavy parts wearing gloves to prevent injury

from possible sharp edges on the parts.

Solvent

Use a high flash-point solvent when cleaning parts. High

flash-point solvent should be used according to directions

of the solvent manufacturer.

Cleaning Vehicle before Disassembly

Clean the vehicle thoroughly before disassembly. Dirt or

other foreign materials entering into sealed areas during vehicle disassembly can cause excessive wear and decrease

performance of the vehicle.

Before Servicing

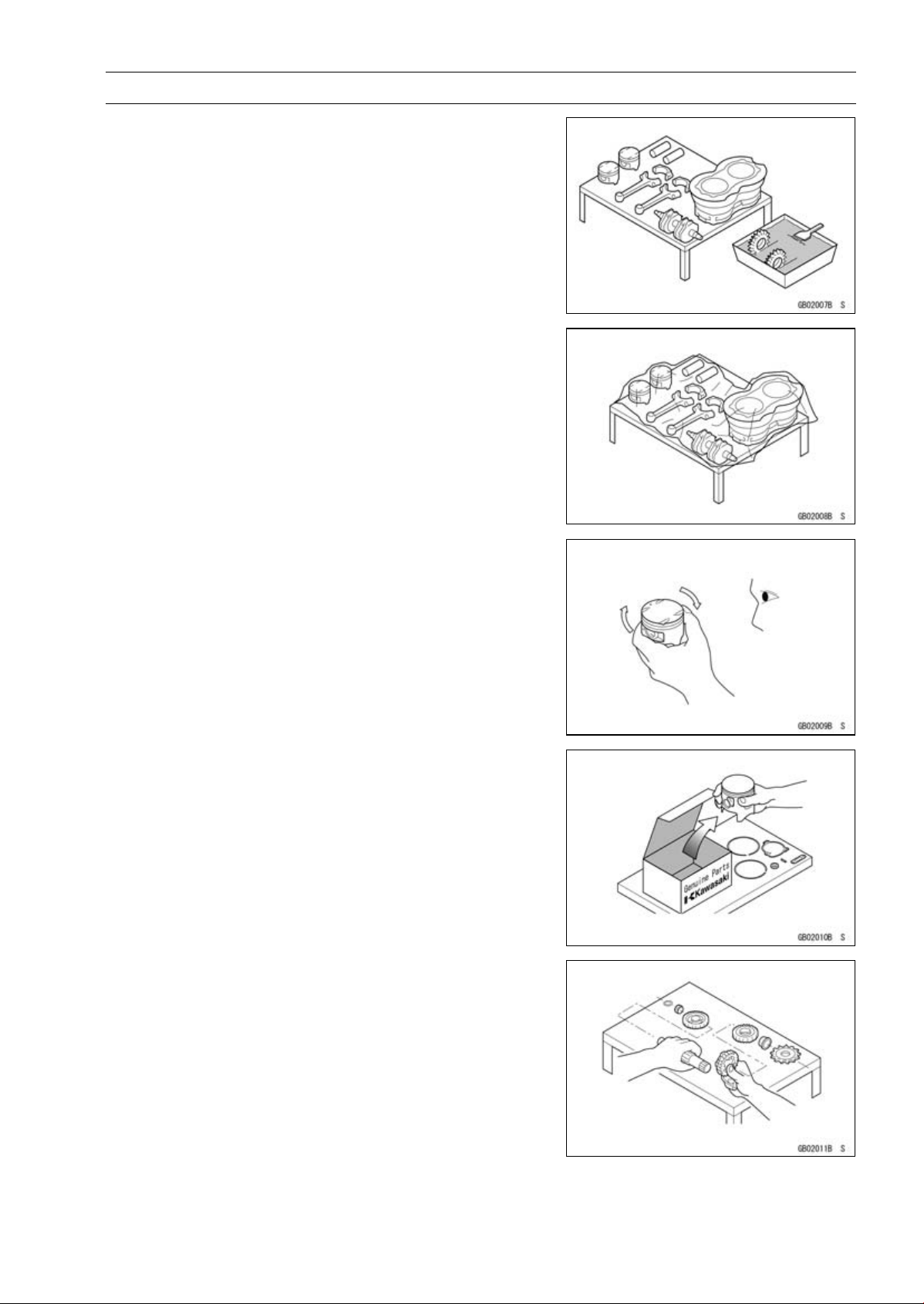

Arrangement and Cleaning of Removed Parts

Disassembled parts are easy to confuse. Arrange the

parts according to the order the parts were disassembled

and clean the parts in order prior to assembly.

Storage of Remov ed Parts

After all the parts including subassembly parts have been

cleaned, store the parts in a clean area. Put a clean cloth

or plastic sheet over the parts to protect from any foreign

materials that may collect before re-assembly.

GENERAL INFORMATION 1-3

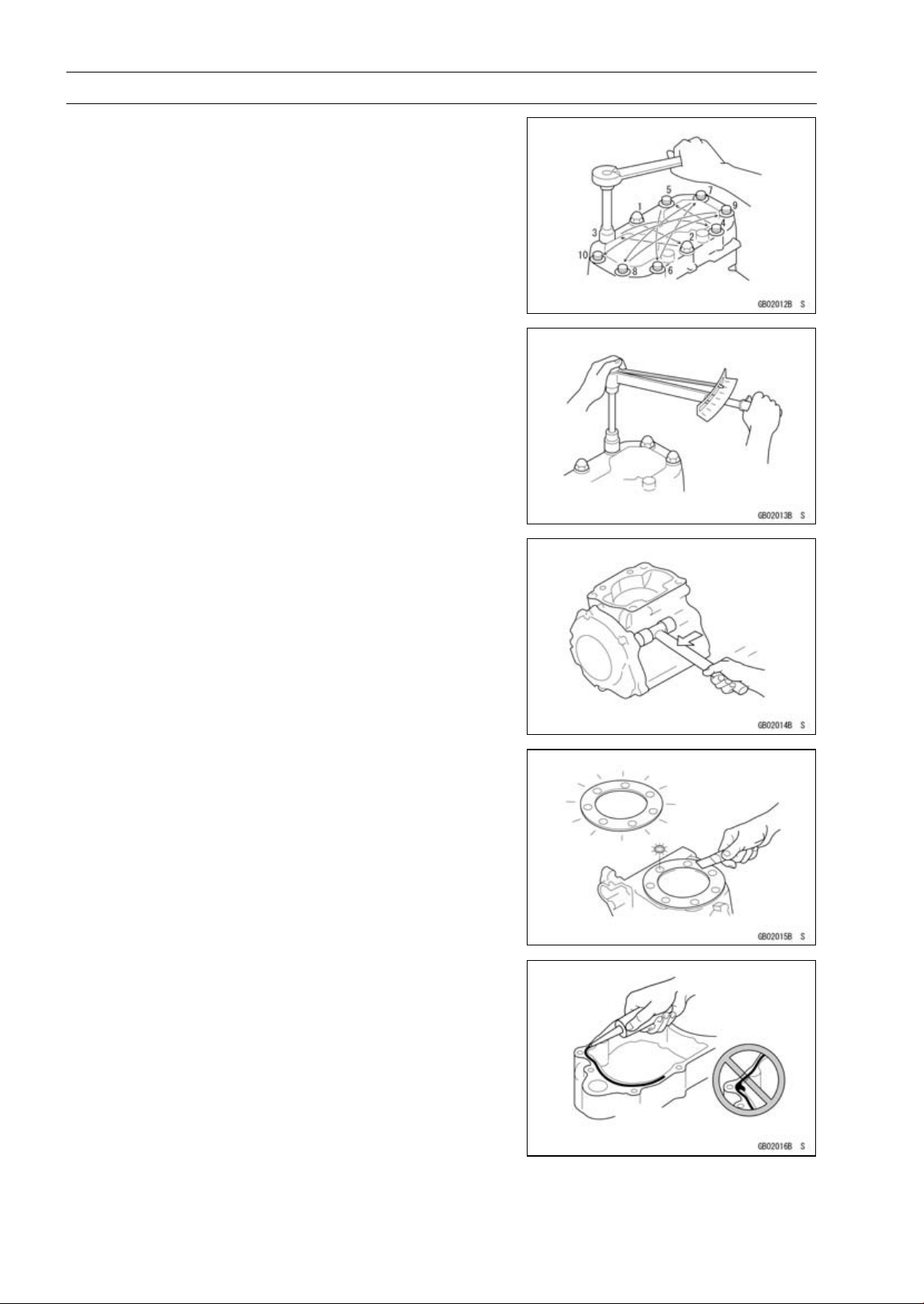

Inspection

Reuse of worn or damaged parts may lead to serious accident. Visually inspect removed parts for corrosion, discoloration, or other damage. Refer to the appropriate sections

of this manual for service limits on individual parts. Replace

the parts if any damage has been found or if the part is beyond its service limit.

Replacement Parts

Replacement parts must be KAWASAKI genuine or

recommended by KAWASAKI. Gaskets, O-rings, oil seals,

grease seals, circlips, cotter pins or self-locking nuts must

be replaced with new ones whenever disassembled.

Assembly Order

In most cases assembly order is the reverse of disassembly, however, if assembly order is provided in this Service

Manual, follow the procedures given.

1-4 GENERAL INFORMATION

Before Servicing

Tightening Sequence

Generally, when installing a part with several bolts, nuts,

or screws, start them all in their holes and tighten them to

a snug fit. Then tighten them according to the specified sequence to prevent case warpage or deformation which can

lead to malfunction. Conversely when loosening the bolts,

nuts, or screws, first loosen all of them by about a quarter turn and then remove them. If the specified tightening

sequence is not indicated, tighten the fasteners alternating

diagonally.

Tightening Torque

Incorrect torque applied to a bolt, nut, or screw may

lead to serious damage. Tighten fasteners to the specified

torque using a good quality torque wrench.

All of the tightening torque values are for use with dry,

solvent - cleaned threads unless otherwise indicated. If a

fastener which should have dry, clean threads gets contaminated with lubricant, etc., applying even the specified torque

could damage it.

Force

Use common sense during disassembly and assembly,

excessive force can cause expensive or hard to repair damage. When necessary, remove screws that have a non

-permanent locking agent applied using an impact driver.

Use a plastic-faced mallet whenever tapping is necessary.

Gasket, O-ring

Hardening, shrinkage, or damage of both gaskets and

O-rings after disassembly can reduce sealing performance.

Remove old gaskets and clean the sealing surfaces thoroughly so that no gasket material or other material remains.

Install the new gaskets and replace the used O-rings when

re-assembling.

Liquid Gasket, Non-permanent Locking Agent

For applications that require Liquid Gasket or a

Non-permanent Locking Agent, c lean the surfaces so

that no oil residue remains before applying liquid gasket or

non-permanent locking agent. Do not apply them excessively. Excessive application can clog oil passages and

cause serious damage.

Before Servicing

Press

For items such as bearings or oil seals that must be

pressed into place, apply small amount of oil to the contact area. Be sure to maintain proper alignment and use

smooth movements when installing.

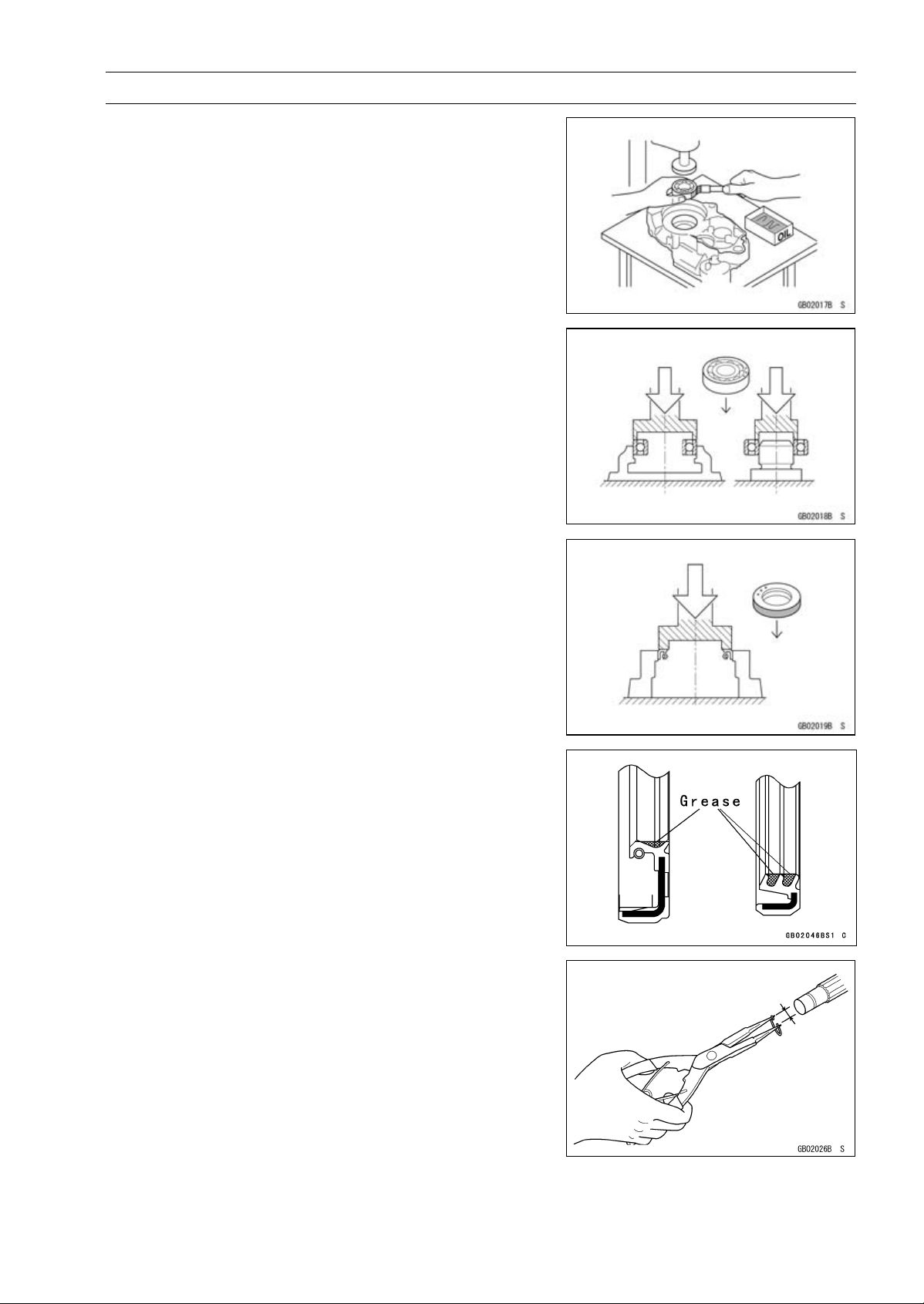

Ball Bearing and Needle Bearing

Do not remove pressed ball or needle unless removal is

absolutely necessary. Replace with new ones whenever

removed. Press bearings with the manufacturer and size

marks facing out. Press the bearing into place by putting

pressure on the correct bearing race as shown.

Pressing the incorrect race can cause pressure between

the i nner and outer race and result in bearing damage.

GENERAL INFORMATION 1-5

Oil Seal, Grease Seal

Do not remove pressed oil or grease seals unless removal

is necessary. Replace with new ones whenever removed.

Press new oil seals with manufacture and size marks facing

out. Make sure the seal is aligned properly when installing.

Apply specified grease to the lip of seal before installing

the seal.

Circlips, Cotter Pins

Replace the circlips or cotter pins that were removed with

new ones. Take care not to open the clip excessively when

installing to prevent deformation.

1-6 GENERAL INFORMATION

Before Servicing

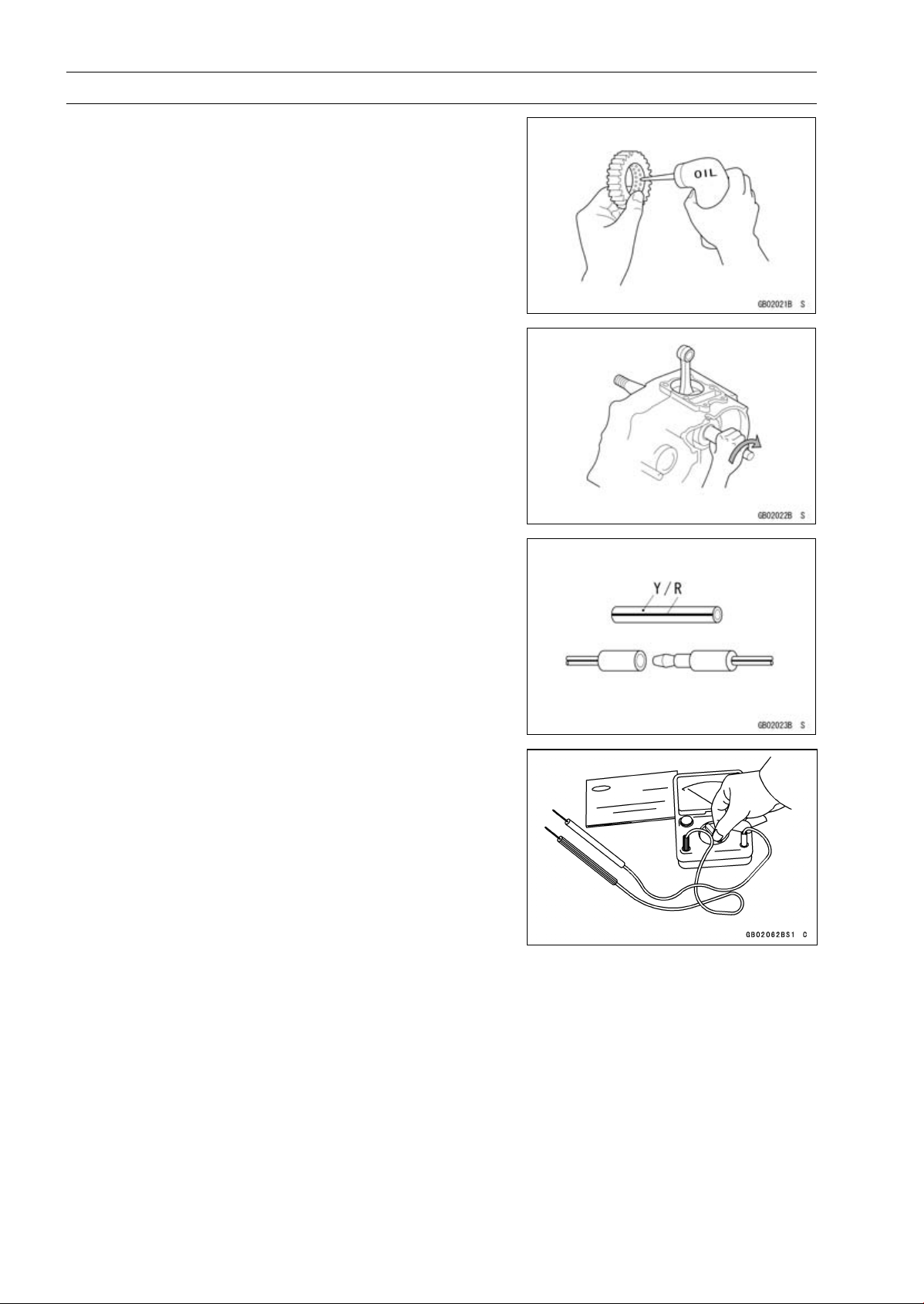

Lubrication

It is important to lubricate rotating or sliding parts during

assembly to minimize wear during initial operation. Lubrication points are called out throughout this manual, apply

the specific oil or grease as specified.

Direction of Engine Rotation

When rotating the crankshaft by hand, the free play

amount of rotating direction will affect the adjustment. Rotate the crankshaft to positive direction (clockwise viewed

from output side).

Electrical Wires

A two-color wire is identified first by the primary color and

then the stripe color. Unless instructed otherwise, electrical

wires must be connected to those of the same color.

Instrument

Use a meter that has enough accuracy for an accurate

measurement. Read the manufacture’s instructions thoroughly before using the meter. Incorrect values may lead

to improper adjustments.

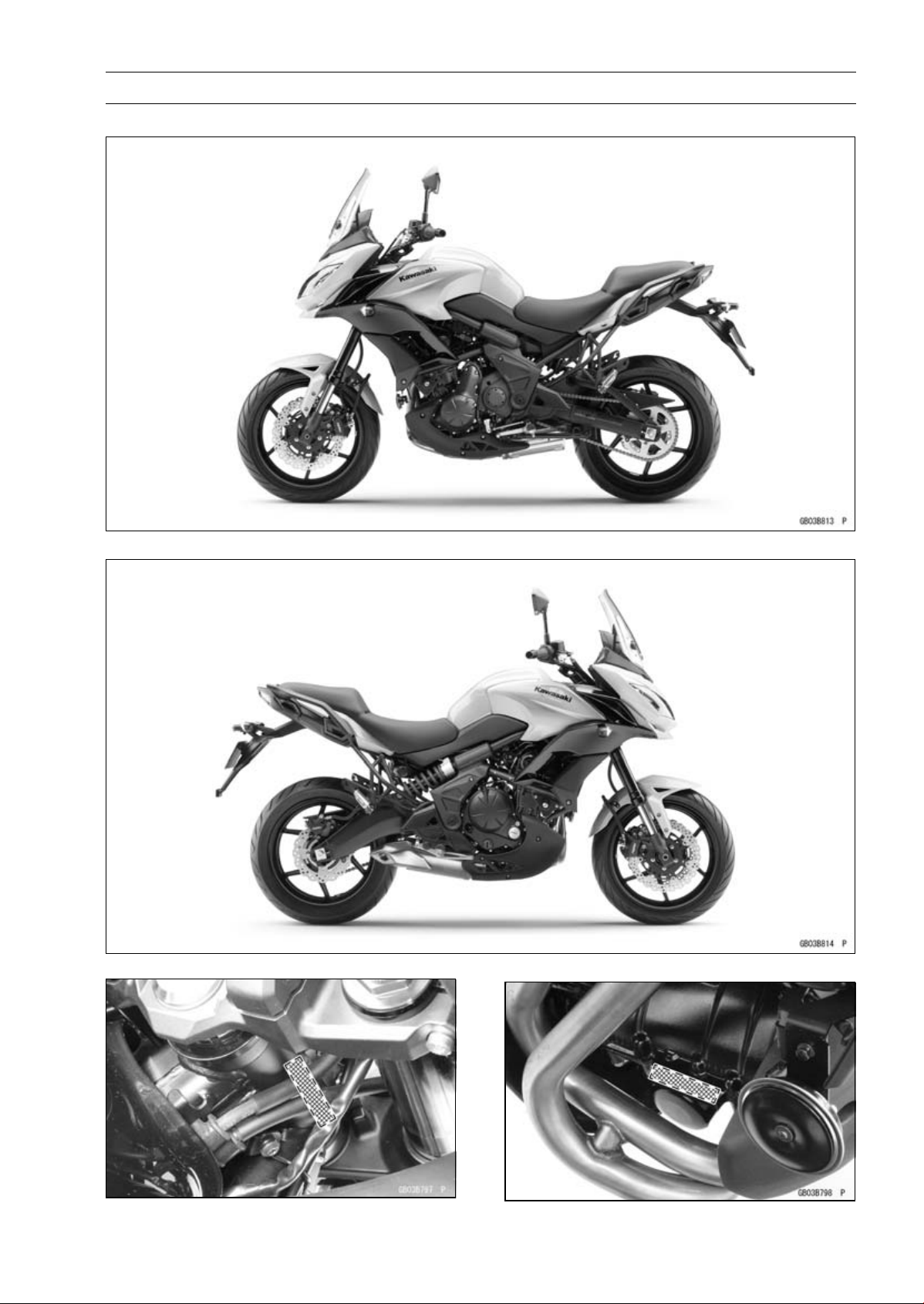

Model Identification

KLE650EF Left Side View

GENERAL INFORMATION 1-7

KLE650EF Right Side View

Frame Number Engine Number

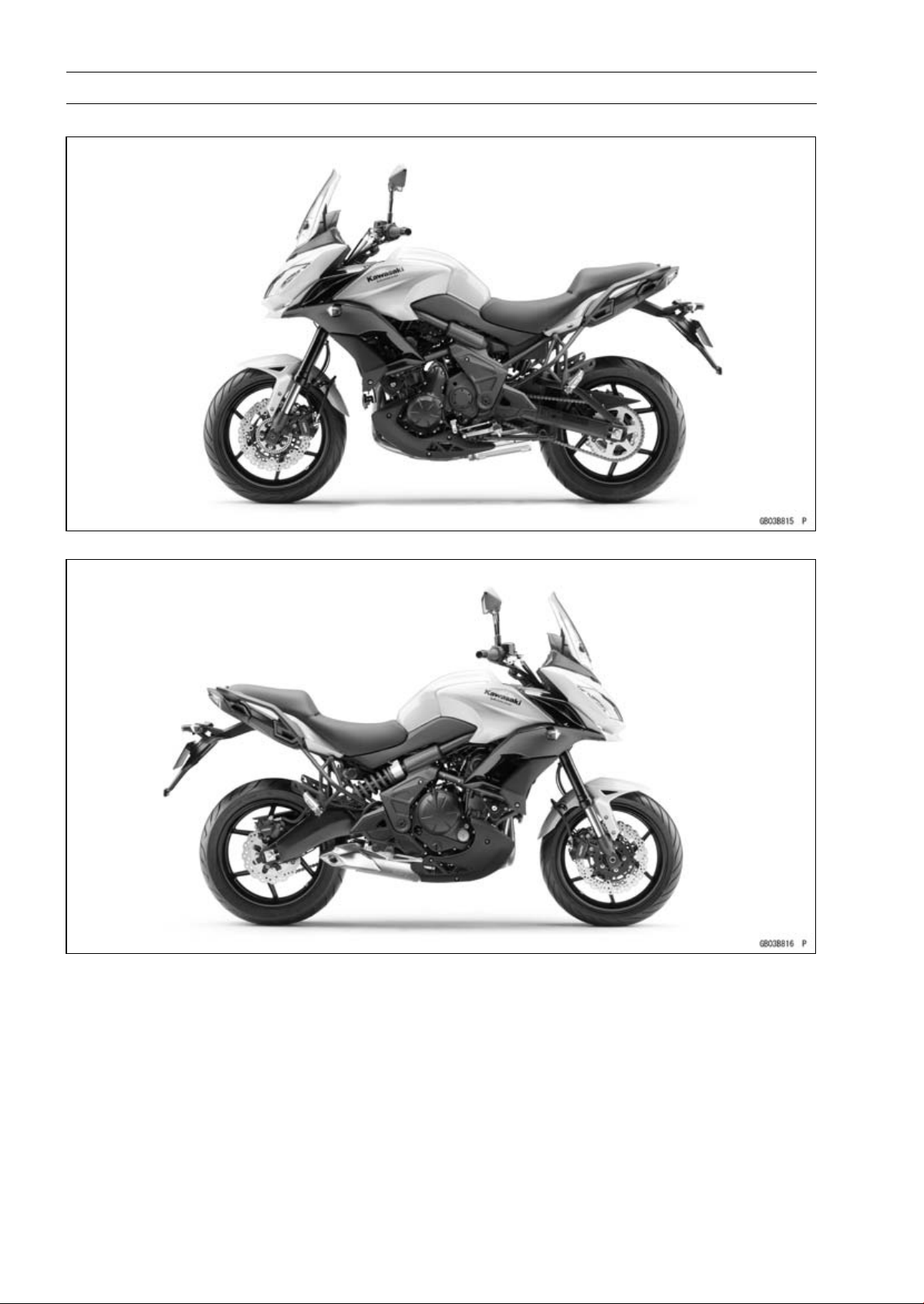

1-8 GENERAL INFORMATION

Model Identification

KLE650FF Left Side View

KLE650FF Right Side View

GENERAL INFORMATION 1-9

General Specifications

Items KLE650EF/FF

Dimensions

Overall Length 2 165 mm (85.24 in.)

Overall Width 840 mm (33.07 in.)

Overall Height/High Position 1 400 mm (55.12 in.)/1 450 mm (57.09 in.)

Wheel Base 1 415 mm (55.71 in.)

Ground Clearance 170 mm (6.69 in.)

Seat Height 840 mm (33.1 in.)

Curb Mass:

KLE650E

KLE650F

Front:

KLE650E 108 kg (238 lb)

KLE650F 109 kg (240 lb)

Rear:

KLE650E 106 kg (234 lb)

KLE650F 107 kg (236 lb)

Fuel Tank Capacity 21 L (5.5 US gal)

Performance

Minimum Turning Radius 2.7 m (8.9 ft.)

Engine

Type 4-stroke, DOHC, 2-cylinder

Cooling System Liquid-cooled

Bore and Stroke 83.0 × 60.0 mm (3.27 × 2.36 in.)

Displacement 649 cm3(39.6 cu in.)

Compression Ratio 10.8:1

Maximum Horsepower

Maximum Torque 64 N·m (6.5 kgf·m, 47 ft·lb) @7 000 r/min (rpm)

Fuel System FI (Fuel injection) KEIHIN TTK38 × 2

Fuel Type: Unleaded gasoline

Minimum Octane Rating:

Research Octane

number (RON)

Antiknock Index (RON +

MON)/2

Starting System Electric Starter

Ignition System Battery and coil (transistorized)

Timing Advance Electronically advanced (IC igniter in ECU)

214 kg (472 lb)

216 kg (476 lb)

51 kW (69 PS) @8 500 r/min (rpm)

(EUR) 51.0 kW (69 PS) @8 500 r/min (rpm)

(AU-LAMS) 39 kW (53 PS) @7 800 r/min (rpm)

(CN) 48 kW (65 PS) @8 000 r/min (rpm)

(CA, CAL, US) – – –

(EUR) 64.0 N·m (6.5 kgf·m, 48 ft·lb) @7 000 r/min (rpm)

(AU-LAMS) 57 N·m (5.8 kgf·m, 42 ft·lb) @3 800 r/min (rpm)

(CN) 61 N·m (6.2 kgf·m, 45 ft·lb) @7 000 r/min (rpm)

(CA, CAL, US) – – –

91

87

1-10 GENERAL INFORMATION

General Specifications

Items KLE650EF/FF

Ignition Timing From 10° BTDC @1 300 r/min (rpm) to 56° BTDC @5 200 r/min

(rpm)

Spark Plug NGK CR9EIA-9

Cylinder Numbering Method Left to right, 1-2

Firing Order 1-2

Valve Timing:

Intake:

Open 26° BTDC

Close 54° ABDC

Duration 260°

Exhaust:

Open 47° BBDC

Close 25° ATDC

Duration

Lubrication System Forced lubrication (semi-dry sump)

Engine Oil:

Grade API SG, SH, SJ, SL or SM with JASO MA, MA1 or MA2

Viscosity SAE 10W-40

Capacity 2.3L(2.4USqt)

Drive Train

Primary Reduction System:

Type Gear

Reduction Ratio 2.095 (88/42)

Clutch Type Wet multi disc

Transmission:

Type

Gear Ratios:

1st 2.438 (39/16)

2nd 1.714 (36/21)

3rd 1.333 (32/24)

4th 1.111 (30/27)

5th 0.966 (28/29)

6th 0.852 (23/27)

Final Drive System:

Type Chain drive

Reduction Ratio

Overall Drive Ratio 5.473 @Top gear

Frame

Type Tubular, diamond

Caster (Rake Angle) 25°

Trail 108 mm (4.25 in.)

252°

6-speed, const

3.067 (46/15)

ant mesh, return shift

General Specifications

Items KLE650EF/FF

Front Tire:

Type Tubeless

Size 120/70ZR 17M/C (58W)

Rim Size J17M/C × MT3.50

Rear Tire:

Type Tubeless

Size 160/60ZR 17M/C (69W)

Rim Size J17M/C × MT4.50

Front Suspension:

Type Telescopic fork (upside-down)

Wheel Travel 150 mm (5.91 in.)

Rear Suspension:

Type Swingarm

Wheel Travel

Brake Type:

Front Dual discs

Rear Single disc

Electrical Equipment

Battery 12V10Ah(10HR)

Headlight:

High Beam 12 V 55 W × 2

Low Beam 12 V 55 W

Brake/Tail Light LED

Alternator:

Type Three-phase AC

Maximum Output 14 V – 24 A @5 000 r/min (rpm)

145 mm (5.71 in.)

GENERAL INFORMATION 1-11

Specifications are subject to change without notice, and may not apply to every country.

1-12 GENERAL INFORMATION

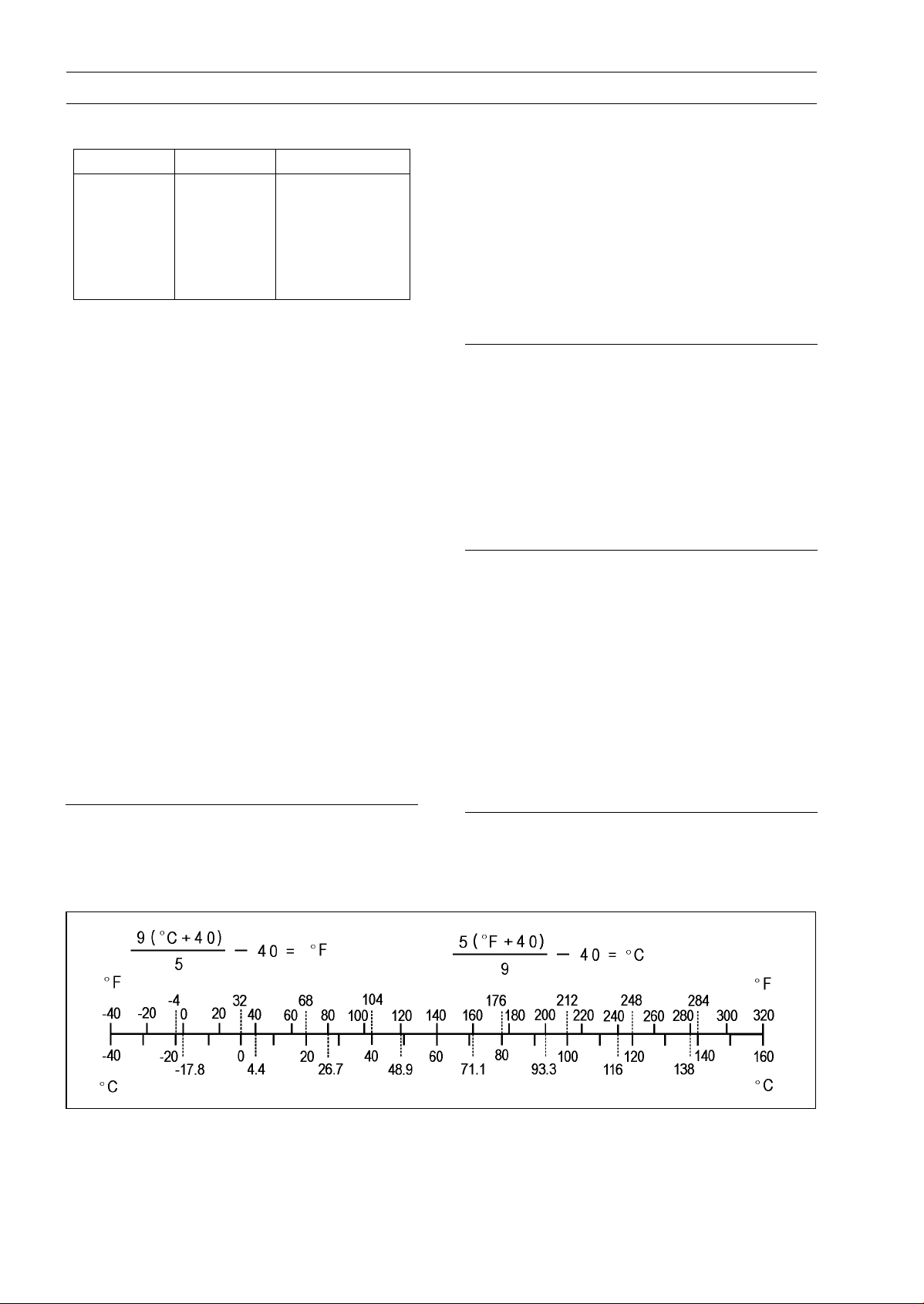

Unit Conversion Table

Prefixes for Units:

Prefix Symbol Power

mega M × 1 000 000

kilo k × 1 000

centi c ×0.01

milli m × 0.001

micro µ × 0.000001

Units of Mass:

kg × 2.205 = lb

g × 0.03527 = oz

Units of Volume:

L × 0.2642 = gal (US)

L × 0.2200 = gal (IMP)

L×1.057=

L × 0.8799 =

L × 2.113 = pint (US)

L × 1.816 = pint (IMP)

mL × 0.03381 = oz (US)

mL × 0.02816 = oz (IMP)

mL × 0.06102 = cu in.

qt (US)

qt (IMP)

Units of Length:

km × 0.6214 = mile

m × 3.281 = ft

mm × 0.03937 = in.

Units of Torque:

N·m × 0.1020 = kgf·m

N·m × 0.7376 = ft·lb

N·m × 8.851 = in·lb

kgf·m × 9.807 = N·m

kgf·m × 7.233 = ft·lb

kgf·m × 86.80 = in·lb

Units of Pressure:

kPa × 0.01020 = kgf/cm²

kPa × 0.1450 = psi

kPa × 0.7501 = cmHg

kgf/cm² × 98.07 = kPa

kgf/cm² × 14.22 = psi

cmHg × 1.333 = kPa

Units of Speed:

km/h

× 0.6214 = mph

Units of Force:

N × 0.1020 = kg

N × 0.2248 = lb

kg × 9.807 = N

kg × 2.205 = lb

Units of Temperature:

Units of Power:

kW × 1.360 = PS

kW × 1.341 = HP

PS

PS × 0.9863 = HP

× 0.7355 = kW

PERIODIC MAINTENANCE 2-1

Periodic Maintenance

Table of Contents

Periodic Maintenance Chart ................................................................................................... 2-3

Torque and Locking Agent...................................................................................................... 2-5

Specifications ......................................................................................................................... 2-11

Special Tools .......................................................................................................................... 2-13

Periodic Maintenance Procedures.......................................................................................... 2-14

Fuel System (DFI)................................................................................................................ 2-14

Air Cleaner Element Replacement.................................................................................... 2-14

Idle Speed Inspection ....................................................................................................... 2-15

Idle Speed Adjustment...................................................................................................... 2-15

Throttle Control System Inspection................................................................................... 2-15

Engine Vacuum Synchronization Inspection..................................................................... 2-16

Fuel System Inspection..................................................................................................... 2-19

Fuel Hose Replacement ................................................................................................... 2-20

Evaporative Emission Control System Inspection (CAL, SEA-B1, TH and CN Models)... 2-22

Cooling System.................................................................................................................... 2-22

Coolant Level Inspection................................................................................................... 2-22

Cooling System Inspection ............................................................................................... 2-23

Coolant Change ................................................................................................................ 2-23

Water Hose and O-ring Replacement ............................................................................... 2-25

Engine Top End ................................................................................................................... 2-25

Valve Clearance Inspection .............................................................................................. 2-25

Valve Clearance Adjustment............................................................................................. 2-27

Air Suction System Damage Inspection............................................................................ 2-31

Clutch................................................................................................................................... 2-32

Clutch Operation Inspection ............................................................................................. 2-32

Engine Lubrication System .................................................................................................. 2-33

Engine Oil Change............................................................................................................ 2-33

Oil Filter Replacement ...................................................................................................... 2-34

Wheels/Tires........................................................................................................................ 2-35

Air Pressure Inspection..................................................................................................... 2-35

Wheels and Tires Inspection............................................................................................. 2-35

Wheel Bearing Damage Inspection .................................................................................. 2-36

Final Drive............................................................................................................................ 2-37

Drive Chain Lubrication Condition Inspection ................................................................... 2-37

Drive Chain Slack Inspection ............................................................................................ 2-37

Drive Chain Slack Adjustment .......................................................................................... 2-38

Wheel Alignment Inspection ............................................................................................. 2-39

Drive Chain Wear Inspection ............................................................................................ 2-39

Chain Guide Wear Inspection ........................................................................................... 2-40

Brakes.................................................................................................................................. 2-40

Brake System Inspection .................................................................................................. 2-40

Brake Operation Inspection .............................................................................................. 2-41

Brake Fluid Level Inspection............................................................................................. 2-41

Brake Fluid Change .......................................................................................................... 2-42

Brake Hose and Pipe Replacement .................................................................................. 2-44

Master Cylinder Rubber Parts Replacement .................................................................... 2-48

Caliper Rubber Parts Replacement .................................................................................. 2-49

Brake Pad Wear Inspection .............................................................................................. 2-52

Brake Light Switch Operation Inspection .......................................................................... 2-53

Suspension.......................................................................................................................... 2-53

2

2-2 PERIODIC MAINTENANCE

Suspension System Inspection......................................................................................... 2-53

Steering ............................................................................................................................... 2-54

Steering Play Inspection ................................................................................................... 2-54

Steering Play Adjustment.................................................................................................. 2-55

Steering Stem Bearing Lubrication ................................................................................... 2-56

Electrical System ................................................................................................................. 2-57

Lights and Switches Operation Inspection........................................................................ 2-57

Headlight Aiming Inspection ............................................................................................. 2-59

Side Stand Switch Operation Inspection........................................................................... 2-60

Engine Stop Switch Operation Inspection......................................................................... 2-61

Spark Plug Replacement .................................................................................................. 2-62

Others.................................................................................................................................. 2-62

Chassis Parts Lubrication ................................................................................................ 2-62

Condition of Bolts, Nuts and Fasteners Tightness Inspection .......................................... 2-63

PERIODIC MAINTENANCE 2-3

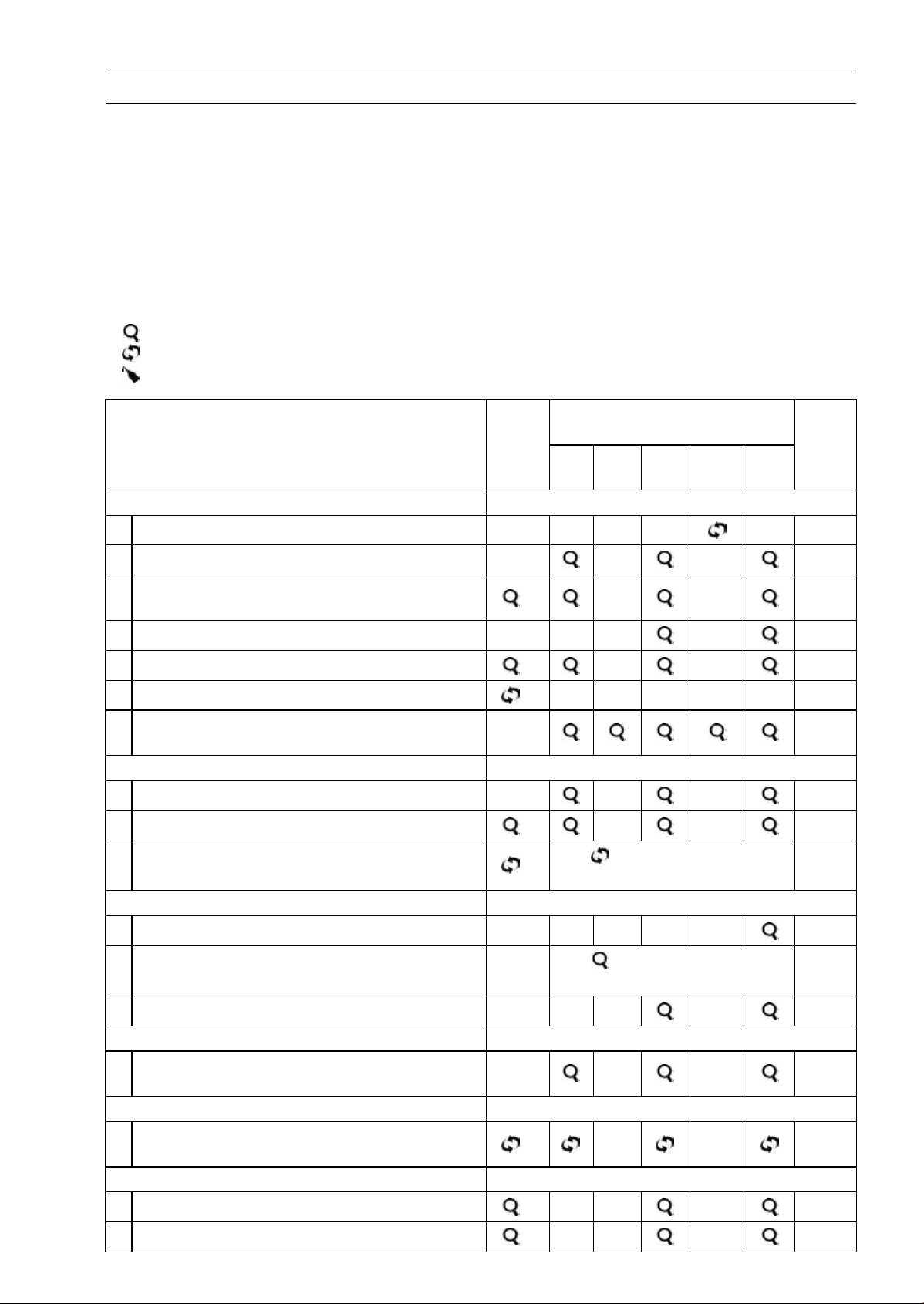

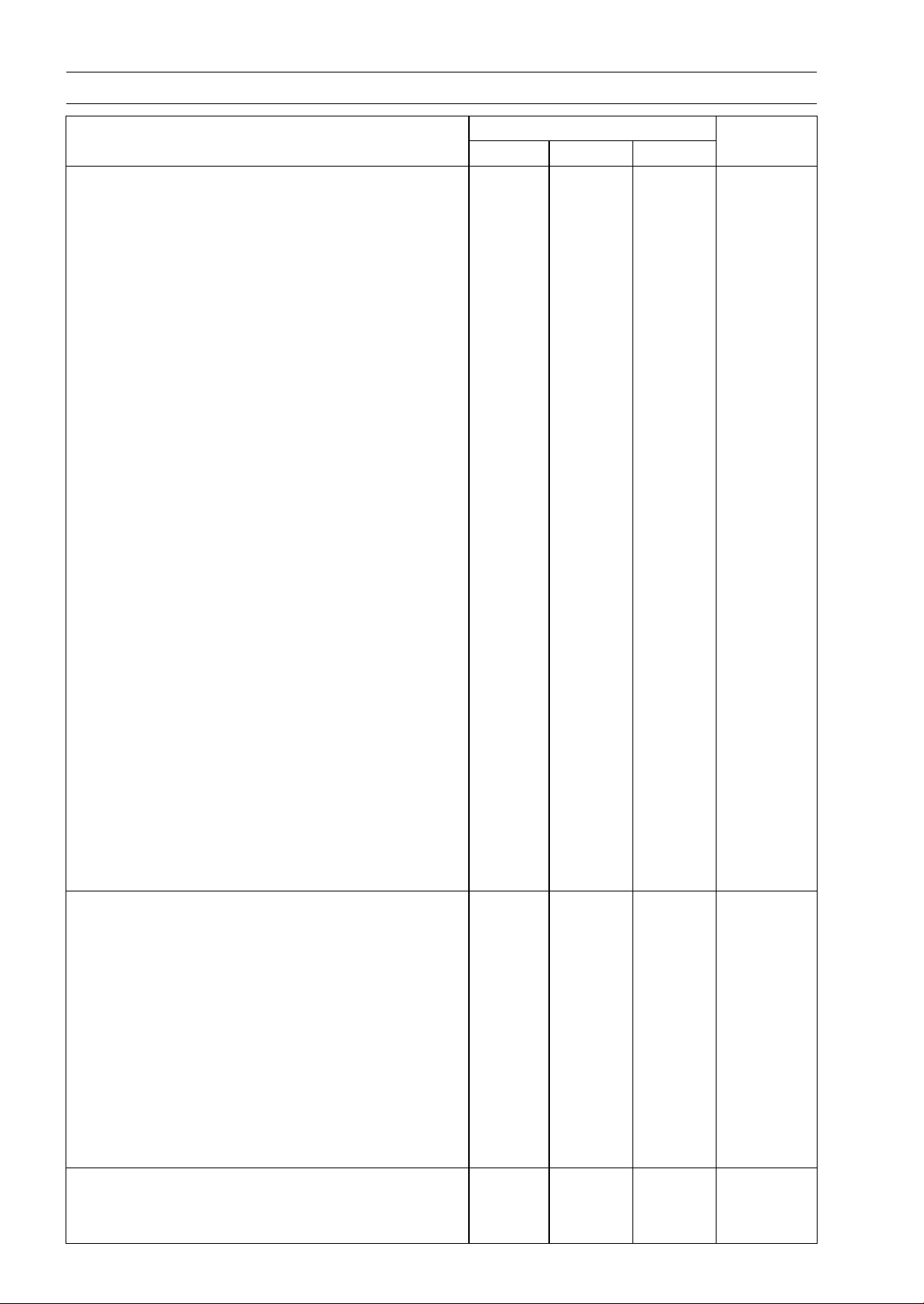

Periodic Maintenance Chart

The scheduled maintenance must be done in accordance with this chart to keep the motorcycle in

good running condition.The initial maintenance is vitally important and must not be neglected.

Periodic Inspection

*A: Service at number of years shown or indicated odometer reading intervals, whichever comes

first.

*B: For higher odometer readings, repeat at the frequency interval established here.

*C: Service more frequently when operating in severe conditions: dusty, wet, muddy, high speed,

or frequent starting/stopping.

: Emission Related Item

○

: Inspection

: Change or Replace

: Lubrication

Odometer Reading (*B)

year

(*A)

Items

Fuel System

×1000km(×1000mile)

1

(0.6)6(3.8)12(7.6)18(11.4)24(15.2)

See

Page

Air cleaner element (*C) 2-14

○

Idle speed 2-15

○

Throttle control system (play, smooth return,

○

no drag)

Engine vacuum synchronization 2-16

○

Fuel system

Fuel hose

Evaporative emission control system (CAL,

○

SEA-B1, TH and CN Models)

Cooling System

Coolant level 2-22

Cooling system

Coolant, water hoses and O-rings

Engine Top End

Valve clearance (US and CA Models) 2-25

○

Valve clearance (Other than US and CA

Models)

:1

:1

:5

:1

:3

: every 36 000 km

(22 500 mile)

: every 42 000 km

(26 250 mile)

2-15

2-19

2-20

2-22

2-23

2-23,

2-25

2-25

Air suction system 2-31

○

Clutch

Clutch operation (play, engagement,

disengagement)

Engine Lubrication System

Engine oil and oil filter (*C)

Wheels and Tires

Tire air pressure

Wheels and tires

:1

:1

:1

2-32

2-33,

2-34

2-35

2-35

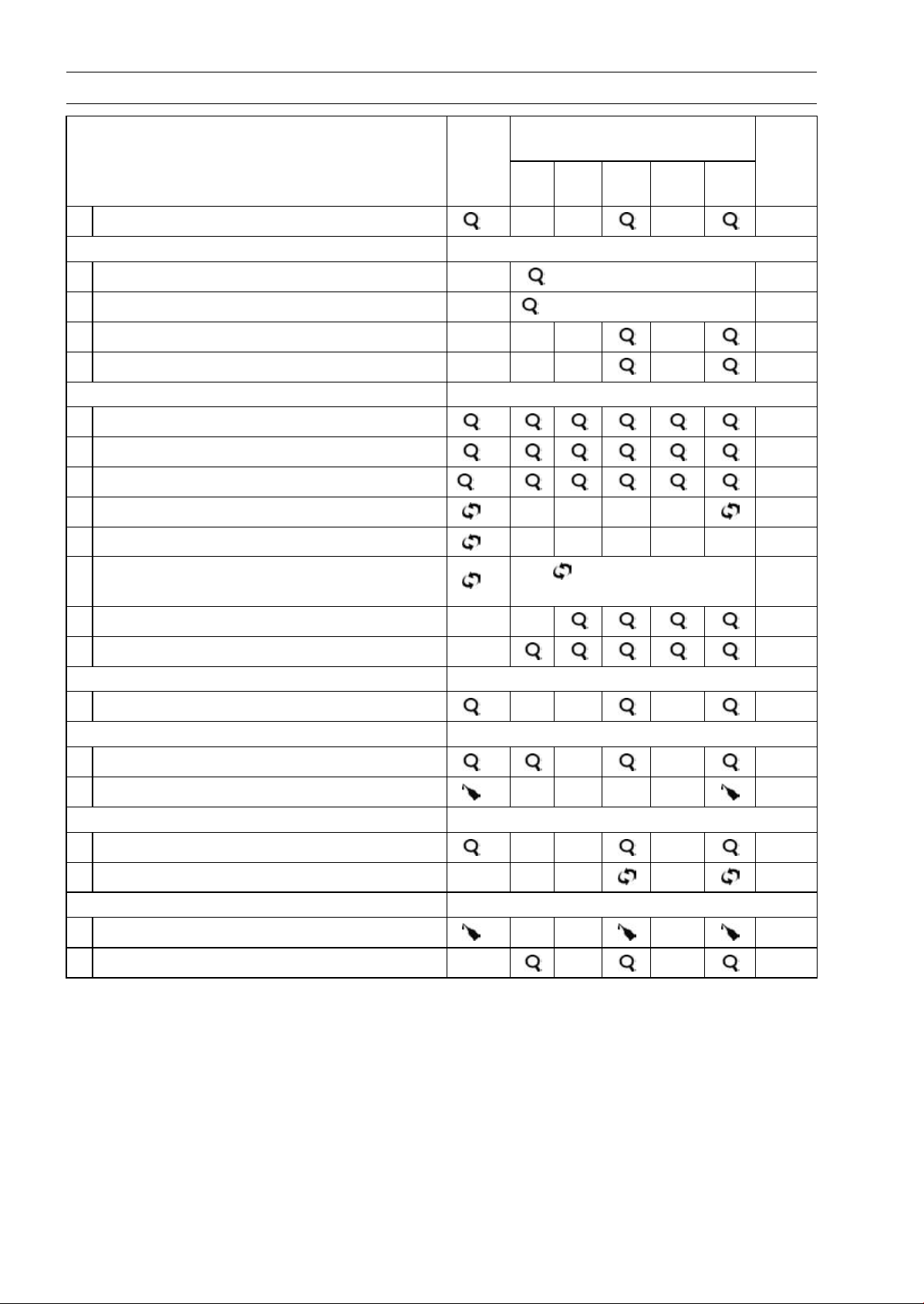

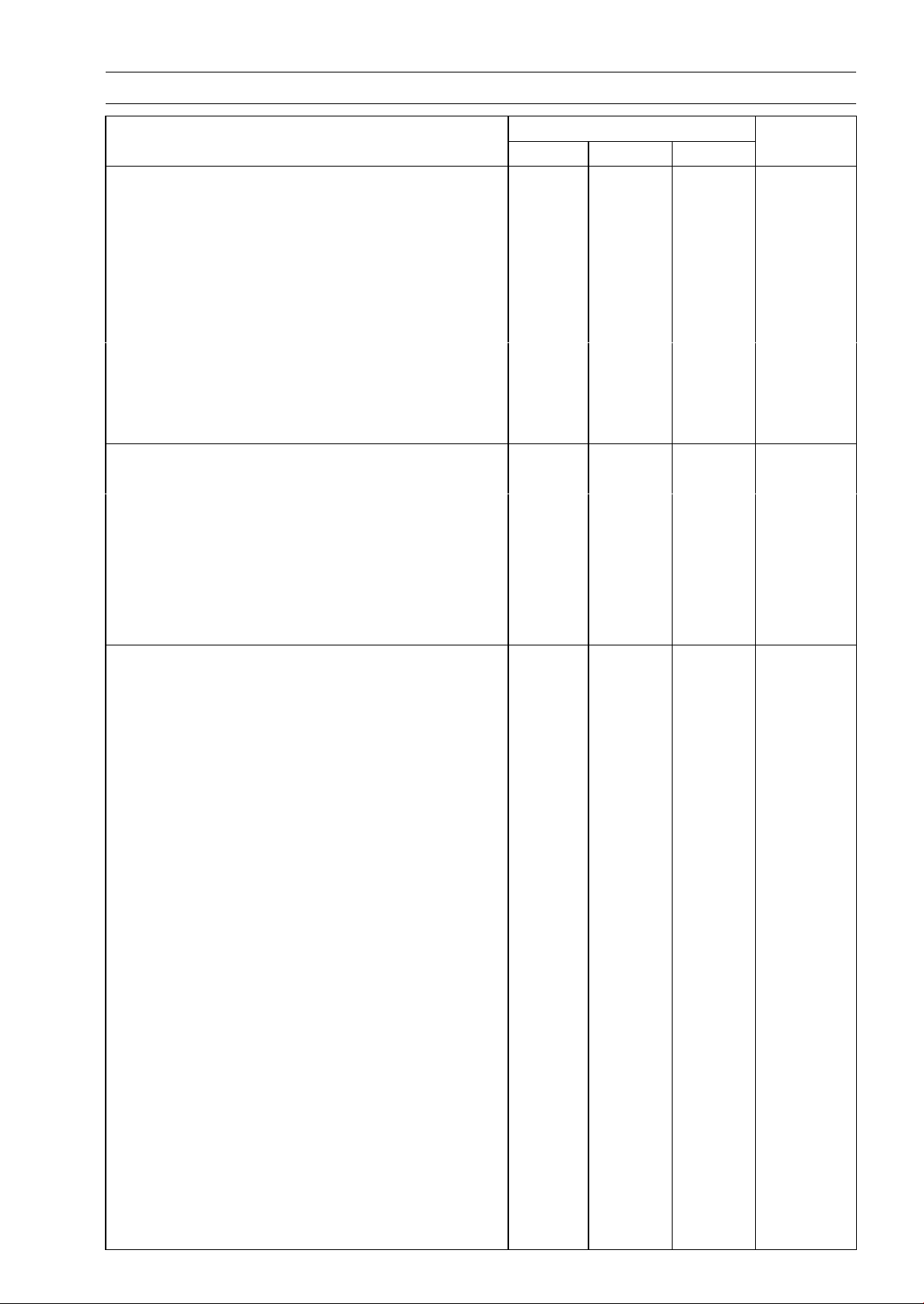

2-4 PERIODIC MAINTENANCE

Periodic Maintenance Chart

Items

year

(*A)

Odometer Reading (*B)

× 1 000 km (× 1 000 mile)

1

(0.6)6(3.8)12(7.6)18(11.4)24(15.2)

See

Page

Wheel bearing damage

Final Drive

Drive chain lubrication condition (*C)

Drivechainslack(*C)

Drive chain wear (*C)

Drive chain guide wear 2-40

Brakes

Brake system

Brake operation (effectiveness, play, no drag)

Brake fluid level

Brake fluid (front and rear)

Brake hoses

Rubber parts of brake master cylinder and

caliper

Brake pad wear (*C) 2-51

Brake light switch operation 2-52

:1

:1

:1

:0.5

:2

:4

:4

: every 600 km (400 mile)

: every 1 000 km (600 mile)

: every 48 000 km

(30 000 mile)

2-36

2-37

2-37

2-39

2-40

2-41

2-41

2-42

2-44

2-47,

2-48

Suspension

Suspension system

Steering

Steering play

Steering stem bearings

Electrical System

Electrical system

Spark plugs

○

Others

Chassis parts

Condition of bolts, nuts and fasteners

:1

:1

:2

:1

:1

2-52

2-53

2-55

2-56

2-61

2-61

2-62

PERIODIC MAINTENANCE 2-5

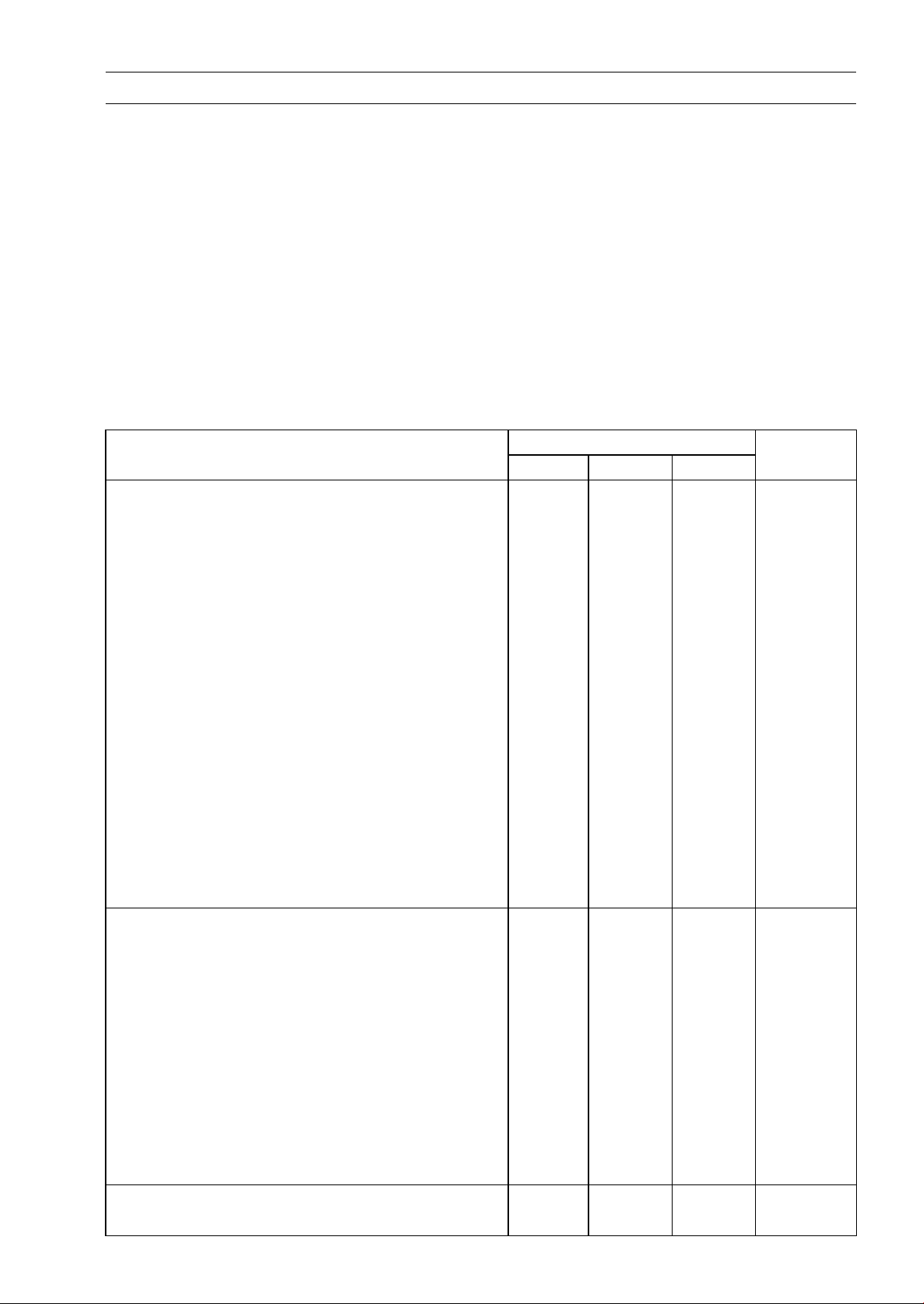

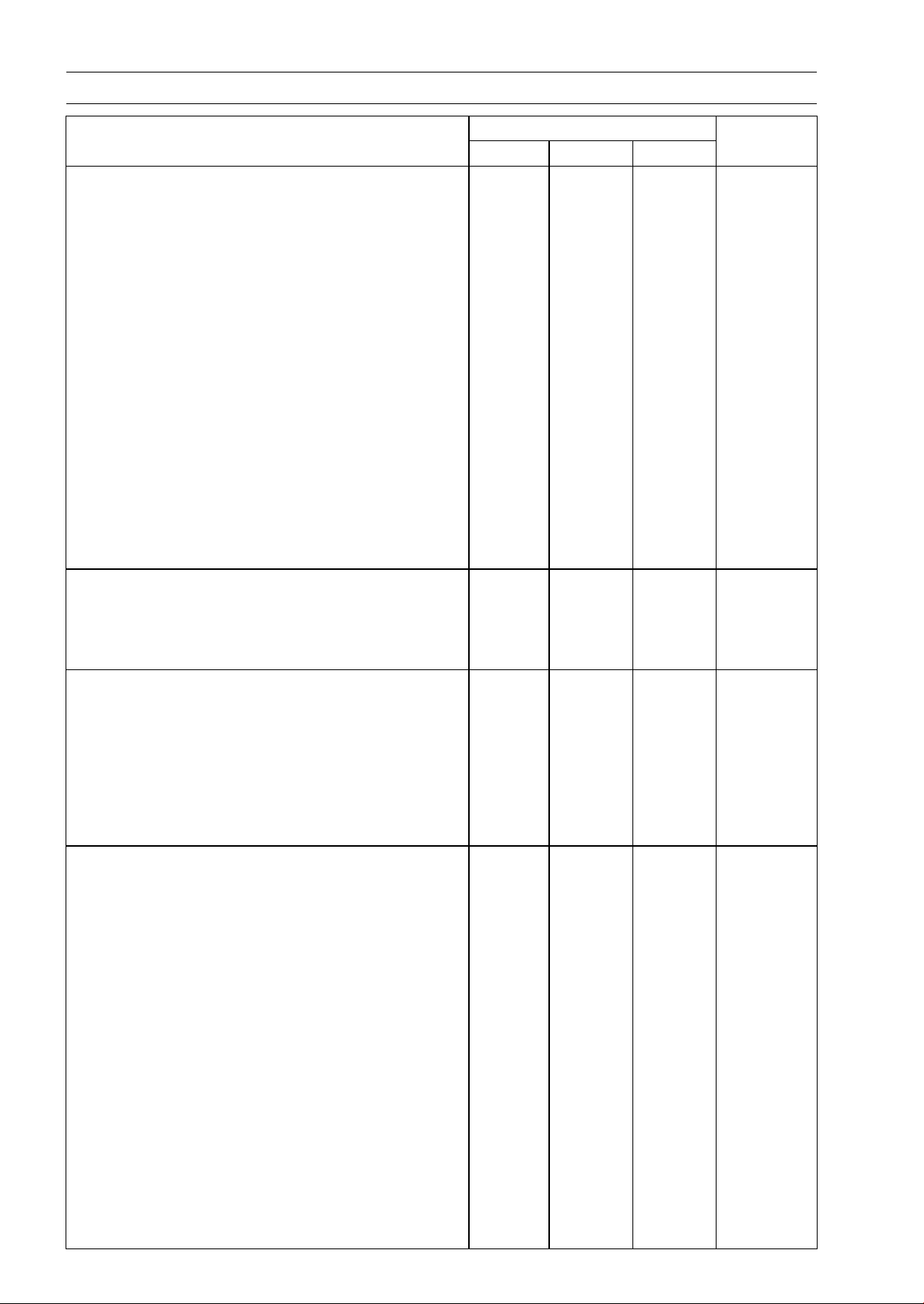

Torque and Locking Agent

The following tables list the tightening torque for the major fasteners requiring use of a

non-permanent locking agent or silicone sealant etc. All of the values are for use with dry solvent cleaned threads unless otherwise indicated.

Letters used in the “Remarks” column mean:

AL: Tighten the two clamp bolts alternately two times to ensure even tightening torque.

G: Apply grease.

L: Apply a non-permanent locking agent.

LG: Apply liquid gasket.

Lh: Left-hand Threads

MO: Apply molybdenum disulfide oil solution.

(mixture of the engine oil and molybdenum disulfide grease in a weight ratio 10:1)

R: Replacement Parts

S: Follow the specified tightening sequence.

Si: Apply silicone grease.

Fastener

Fuel System (DFI)

Spark Plugs

Water Temperature Sensor

Crankshaft Sensor Bolts 6.0 0.61 53 in·lb

Intake Air Temperature Sensor Screw 1.2 0.12 11 in·l b

Air Cleaner Housing Assembly Screws 1.2 0.12 11 i n ·lb

Air Cleaner Element Screw 1.2 0.12 11 i n ·lb

Vehicle-down Sensor Mounting Bolls

Air Cleaner Housing Clamp Bolt

Speed Sensor Bolt 7.8 0.80 69 in·lb L

Oxygen Sensor 25 2.5 18

Switch Housing Screws 3.5 0.36 31 in·lb

Fuel Pump Bolts 9.8 1.0 87 in·lb L, S

Throttle Valve Assy Clamp Mounting Screw

Delivery Pipe Assy Mounting Screws

Canister Bracket Bolts 9.8 1.0 87 in·lb

Purge Valve Mounting Nut 7.0 0.71 62 in·lb

Cooling System

Radiator Mounting Bolt 7.9 0.81 70 in·lb

Coolant Reserve Tank Bolts

Radiator Fan Assembly Mounting Bolts 8.4 0.86 74 in·lb

Water Hose Clamp Screws 3.0 0.31 27 in·lb

Thermostat Housing Bolts 12 1.2 106 in·lb

Water Temperature Sensor 12 1.2 106 in·lb

Water Pump Cover Bolts, L = 30 mm (1.2 in.) 12 1.2 106 in·lb

Water Pump Cover Bolts, L = 40 mm (1.6 in.)

Coolant Drain Bolt

Water Pump Impeller Bolt 9.8 1.0 87 in·lb

Engine Top End

Air Suction Valve Cover Bolts 9.8 1.0 87 in·lb

N·m kgf·m ft·lb

15 1.5 11

12 1.2 106 in·lb

6.9 0.70 61 in·lb

2.0 0.20 18 in·lb

2.1 0.21 19 in·lb

3.4 0.35 30 in·lb

7.9 0.81 70 in·lb

12 1.2 106 in·lb

12 1.2 106 in·lb

Torque

Remarks

2-6 PERIODIC MAINTENANCE

Torque and Locking Agent

Fastener

Cylinder Head Cover Bolts 9.8 1.0 87 in·lb

Bracket Mounting Bolts 6.9 0.70 61 in·lb

Clamp Mounting Bolt 9.8 1.0 87 in·lb

Camshaft Sprocket Bolts 15 1.5 11 L

Camshaft Cap Bolts 12 1.2 106 in·lb S

Cylinder Head Plugs

Rear Camshaft Chain Guide Bolts 20 2.0 15 L

Throttle Body Assy Holder Clamp Bolts 2.0 0.20 18 in·lb

Throttle Body Assy Holder Bolts 12 1.2 106 in·lb

Camshaft Chain Tensioner Cap Bolt 20 2.0 15

Camshaft Chain Tensioner Mounting Bolts 9.8 1.0 87 in·lb

Cylinder Head Bolts (M10), L = 158 mm (6.2 in.),

First

Cylinder Head Bolts (M10), L = 158 mm (6.2 in.),

Final

Cylinder Head Bolts (M10), L = 176 mm (6.9 in.),

First

Cylinder Head Bolts (M10), L = 176 mm (6.9 in.),

Final

Cylinder Head Bolts (M10), L = 80 mm (3.1 in.),

First

Cylinder Head Bolts (M10), L = 80 mm (3.1 in.),

Final

Cylinder Head Bolts (M6) 12 1.2 106 in·lb S

Cylinder Bolt (M8) 27.5 2.80 20.3 MO, S

Cylinder Bolts (M6) 12 1.2 106 in·lb S

Cylinder Nut

Muffler Body Mounting Bolt 20 2.0 15

Muffler Body Mounting Nut 20 2.0 15

Exhaust Pipe Holder Nuts 17 1.7 13

Clutch

Clutch Lever Holder Clamp Bolts 7.8 0.80 69 in·lb S

Clutch Cable Holder Bolts 9.8 1.0 87 in·lb L

Clutch Cover Bolts 9.8 1.0 87 in·lb S

Timing Inspection Cap 3.9 0.40 35 in·lb

Timing Rotor Bolt Cap

Clutch Spring Bolts 9.8 1.0 87 in·lb

Clutch Hub Nut 200 20.4 148 R

Oil Pump Sprocket Bolt 12 1.2 106 in·lb L, Lh

Oil Pump Chain Guide Bolt, L = 12 m m (0.47 in.) 12 1.2 106 in·lb L

Oil Pump Chain Guide Bolt, L = 11 mm (0.43 in.) 12 1.2 106 in·lb

Engine Lubrication System

Oil Filter 17.5 1.78 12.9 G, R

Oil Filter Pipe 25 2.5 18 L

N·m kgf·m ft·lb

19.6 2.00 14.5 L

25 2.5 18 MO, S

55.9 5.70 41.2 MO, S

25 2.5 18 MO, S

55.9 5.70 41.2 MO, S

25 2.5 18 MO, S

55.9 5.70 41.2

49 5.0 36

4.9 0.50 43 in·lb

Torque

Remarks

MO, S

MO, S

Torque and Locking Agent

PERIODIC MAINTENANCE 2-7

Fastener

Oil Pressure Switch

Oil Pressure Relief Valve 15 1.5 11 L

Oil Pipe Retaining Plate Bolt 9.8 1.0 87 in·lb L

Oil Passage Plug (PT3/8) 20 2.0 15 L

Oil Pump Sprocket Bolt 12 1.2 106 in·lb L, Lh

Oil Pump Chain Guide Bolt, L = 12 mm (0.47 in.)

Oil Pump Chain Guide Bolt, L = 11 mm (0.43 in.)

Oil Pump Cover Bolts 9.8 1.0 87 in·lb L

Oil Strainer Holder Bolts 9.8 1.0 87 in·lb L

Oil Pan Bolts 12 1.2 106 in·lb S

Engine Oil Drain Bolt 30 3.1 22

Engine Removal/Installation

Engine Bracket Bolts 25 2.5 18

Front Engine Mounting Bolt, L = 110 mm (4.33 in.) 44 4.5 32 S

Front Engine Mounting Bolt, L = 150 mm (5.90 in.) 44 4.5 32 S

Upper Engine Mounting Nut 44 4.5 32 S

Lower Engine Mounting Nut 44 4.5 32 S

Adjusting Collar Locknut

Adjusting Collar

Crankshaft/Transmission

Connecting Rod Big End Nuts see Text – – MO

Side Oil Plate Bolts 9.8 1.0 87 in·lb L

Oil Pipe Bolts 9.8 1.0 87 in·lb L

Middle Oil Plate Bolts

Oil Passage Plug (M6)

Oil Passage Plug (PT3/8) 20 2.0 15 L

Breather Plate Bolts 9.8 1.0 87 in·lb L

Shift Shaft Return Spring Pin

Bottom Oil Plate Bolts 9.8 1.0 87 in·lb L

Crankcase Bolts (M8, Front), L = 60 mm (2.4 in.) 27.5 2.80 20.3 MO, S

Crankcase Bolts (M8), L = 73 mm (2.9 in.) 25.5 2.60 18.8 MO, S

Crankcase Bolts (M9), L = 113 mm (4.45 in.) 44.1 4.50 32.5 MO, S

Crankcase Bolts (M8), L = 110 mm (4.3 in.)

Crankcase Bolt (M8, Rear), L = 60 mm (2.4 in.)

CrankcaseBolts(M6)L=45mm(1.8in.) 19.6 2.00 14.5 S

CrankcaseBolts(M6)L=38mm(1.5in.) 19.6 2.00 14.5 S

Crankcase Bolt (M8), L = 50 mm (2.0 in.) 27.5 2.80 20.3 S

Crankcase Bolt (M6) L = 32 mm (1.3 in.) 19.6 2.00 14.5 S

Crankcase Bolts (M9), L = 83 mm (3.3 in.)

Upper Crankcase Bolt (M8), L = 120 mm (4.72 in.)

Upper Crankcase Bolts (M8), L = 110 mm (4.33 in.) 27.5 2.80 20.3 S

Transmission Case Bolts, L = 30 mm (1.2 in.) 20 2.0 15 S

Transmission Case Bolts, L = 26 mm (1.0 in.) 20 2.0 15 S

N·m

15 1.5 11

12 1.2 106 in·lb L

12 1.2 106 in·lb

49 5.0 36

9.8 1.0 87 in·lb

9.8 1.0 87 in·lb L

3.5 0.36 31 in·lb

29 3.0 21 L

27.5 2.80 20.3

27.5 2.80 20.3

44.1 4.50 32.5

27.5 2.80 20.3

Torque

Remarks

kgf·m ft·lb

MO, S

LG

S

S

S

S

2-8 PERIODIC MAINTENANCE

Torque and Locking Agent

Fastener

Gear Positioning Lever Bolt 12 1.2 106 in·lb L

Transmission Case Oil Nozzle 2.9 0.30 26 in·lb L

Neutral Switch Holder Screw

Shift Drum Cam Holder Bolt 12 1.2 106 in·lb L

Shift Drum Bearing H older Screws 4.9 0.50 43 in·lb L

Shift Rod Retaining Plate Bolt 9.8 1.0 87 in·lb L

Drive Shaft Bearing Holder Screw 4.9 0.50 43 in·lb L

Race Holder Screw 4.9 0.50 43 in·lb L

Shift Shaft Cover Bolts, L = 45 mm (1.8 in.)

Shift Shaft Cover Bolt, L = 30 mm (1.2 in.) 9.8 1.0 87 in·lb L, S

Neutral Switch 15 1.5 11

Shift Shaft Cover Bolts, L = 30 mm (1.2 in.) 12 1.2 106 in·lb S

Shift Shaft Cover Bolt, L = 40 mm (1.6 in.) 12 1.2 106 in·lb S

Shift Shaft Cover Screw 4.9 0.50 43 in·lb L, S

Shift Lever Bolt

Shift Lever Tie-rod Locknuts 9.8 1.0 87 in·lb Lh (1)

Wheels/Tires

Front Axle Clamp Bolts 34 3.5 25

Front Axle 108 11 . 0 79.7

Rear Axle Nut 108 11 . 0 79.7

Final Drive

Engine Sprocket Cover Bolts 9.8 1.0 87 in·lb

Speed Sensor Bolt 7.8 0.80 69 in·lb L

Speed Sensor Bracket Bolts

Engine Sprocket Nut 165 16.8 122 MO

Rear Sprocket Nuts 59 6.0 44 R

Rear Axle Nut 108 11 . 0 79.7

Brakes

Front Brake Fluid Reservoir Cap Screws 1.5 0.15 13 in·lb

Brake Lever Pivot Bolt 1.0 0.10 8.9 in·lb

Brake Lever Pivot Bolt Locknut 5.9 0.60 52 in·lb

Brake Hose Banjo Bolts 25 2.5 18

Front Master Cylinder Clamp Bolts 11 1.1 97 in·lb S

Front Brake Light Switch Screw 1.2 0.12 11 i n ·lb

Front Caliper Mounting Bolts 25 2.5 18

Front Caliper Holder Shafts

Bleed Valves 7.8 0.80 69 in·lb

Front Brake Pad Pins 17 1.7 13

Front Brake Disc Mounting Bolts 27 2.8 20 L

Rear Master Cylinder Mounting Bolts 25 2.5 18

Brake Pedal Bolt 8.8 0.90 78 in·lb

Rear Master Cylinder Push Rod Locknut

Rear Caliper Holder Pin Bolt 27 2.8 20 Si

N·m kgf·m ft·lb

4.9 0.50 43 in·lb L

9.8 1.0 87 in·lb

12 1.2 106 in·lb

9.8 1.0 87 in·lb

22 2.2 16

17 1.7 13

Torque

Remarks

L, Si

L, S

Si

Loading...

Loading...