Kawasaki PV48K SERIES, PV48KC1206 Maintenance Manual

PILOT VALVE

PV48K SERIES

OVERHAUL & MAINTENANCE MANUAL

KAWASAKI PRECISION MACHINERY OF AMERICA

5080 36

Grand Rapids, MI 49512

www.kawasakipmd.com

Date: July 2004

TH

Street S.E.

Copyright © Kawasaki Heavy Industries Ltd.

Overhaul & Maintenance Manual Pilot Valve PV48K

06/03

Preliminary Page i

COPYRIGHT

Copyright © Kawasaki Heavy Industries Ltd. 2000

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or

otherwise, without the prior permission of Kawasaki Heavy Industries Ltd.

Pilot Valve PV48K Overhaul & Maintenance Manual

06/03

Preliminary Page ii

Contents

Section Page

Safety .......................................................................................................................iii

1 Description and operation......................................................................................................1

1.1 General ......................................................................................................................1

1.2 Specifications.............................................................................................................1

1.3 Structure ....................................................................................................................2

1.4 Performance...............................................................................................................3

1.4.1 Basic performance.......................................................................................3

1.4.2 Performance of the main parts (see Figure 1) .............................................3

1.5 Operation ...................................................................................................................4

1.5.1 Control Handle Neutral (see Figure 3).........................................................4

1.5.2 Control Handle Tilted (see Figure 4)............................................................5

1.5.3 Control Handle Held (see Figure 5) .............................................................6

1.5.4 Control Handle Tilted Through a Wide Range.............................................7

2 Maintenance..........................................................................................................................7

2.1 Tools Equipment and Torque Settings....................................................................... 7

2.2 Adjustment Standards................................................................................................ 8

2.3 Disassembly............................................................................................................... 9

2.3.1 Preparations.................................................................................................9

2.3.2 Warnings and Cautions................................................................................9

2.3.3 Sequence of disassembly............................................................................9

2.4 Assembly..................................................................................................................17

2.4.1 Preparations...............................................................................................17

2.4.2 Sequence of Assembly ..............................................................................18

3 Troubleshooting, spares & tools..........................................................................................25

3.1 Troubleshooting .......................................................................................................25

3.2 Parts.........................................................................................................................26

3.2.1 Parts List....................................................................................................

27

Illustrations

Figure Page

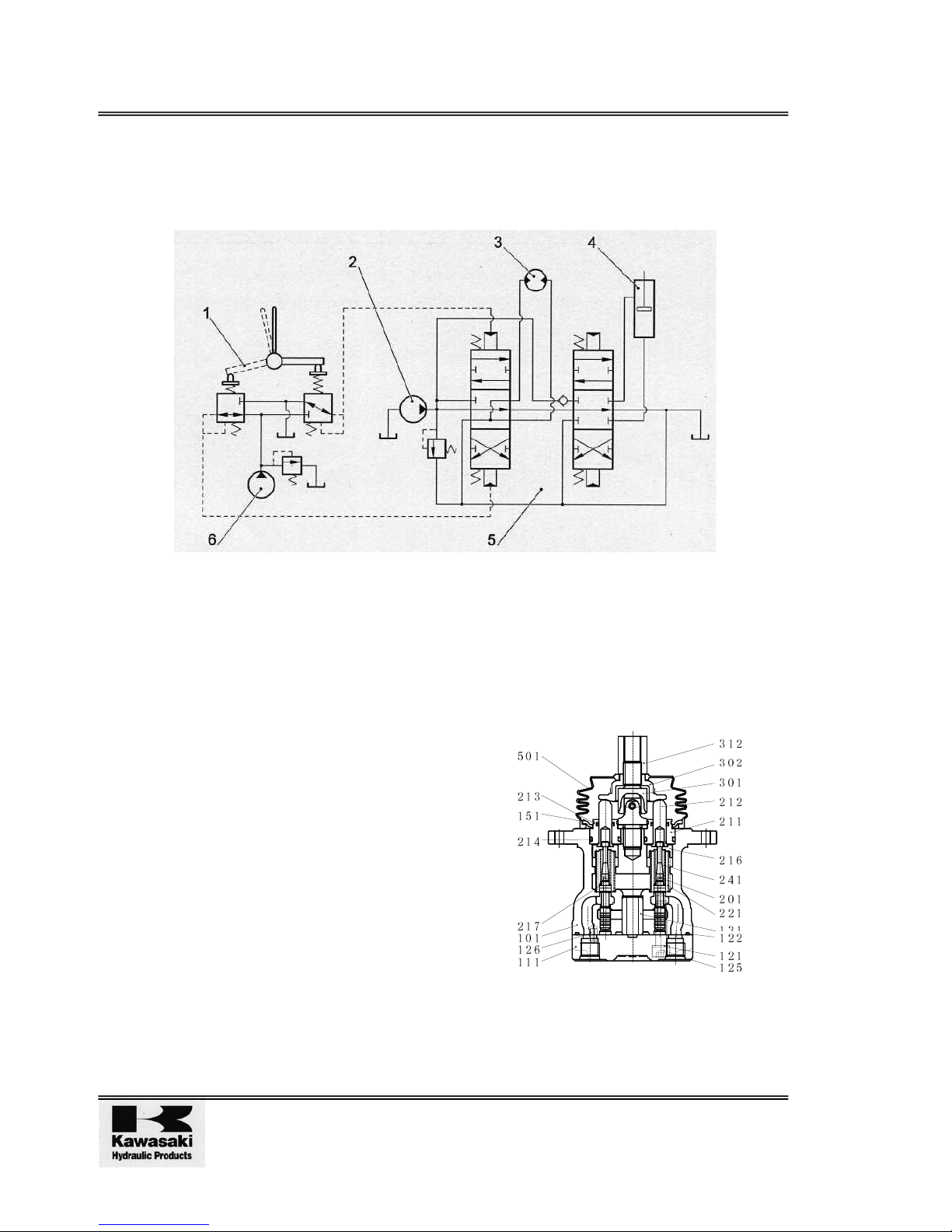

1. PV48K Valve – Cross Section 2

2. Hydraulic Circuit Plan (Typical) 4

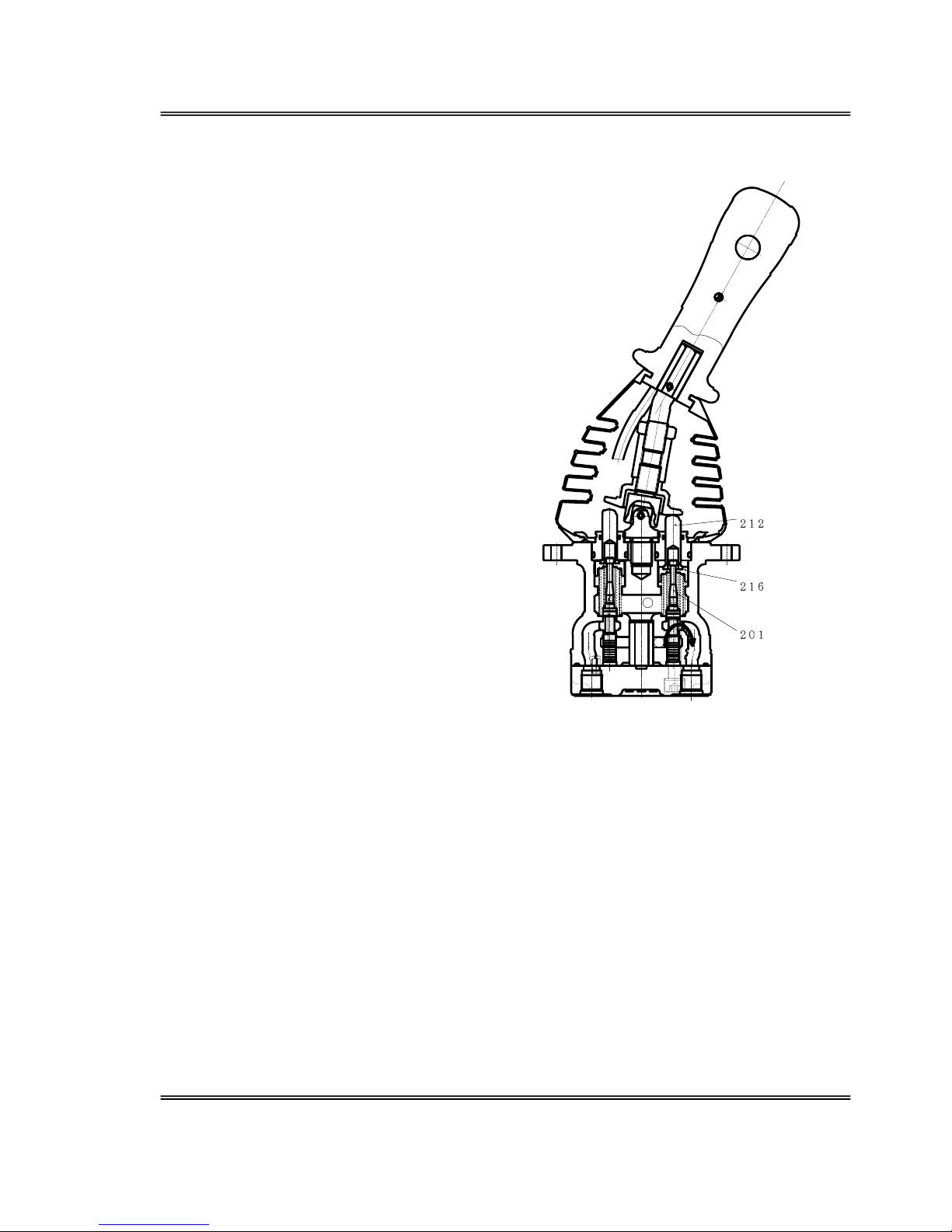

3. Control Handle in Neutral 4

4. Control Handle Tilted 5

5. Control Handle Held 6

6. Push rod Plug & Seals 20

7. Parts Breakdown 25

8 Exploded View 29

9. Special Jig 31

10. PV48K1THM & PV48KC1THM – Cross Section 32

Overhaul & Maintenance Manual Pilot Valve PV48K

06/03

Preliminary Page iii

SAFETY

Liability

Kawasaki Heavy Industries Ltd. guarantee the performance of this valve when supplied new.

Disassembly of the valve will invalidate any remaining warranty. Kawasaki Heavy Industries Ltd

. will not honour any warranty claim resulting from physical impact, mishandling or natural

disaster.

PERSONNEL

Before carrying out any procedures on this valve the safety section of this manual must be read

and understood. Work on the valve, piping and wiring must only be carried out by suitably

qualified personnel.

For safe operation, servicing and checking of this valve, make sure the contents of this manual

are fully understood. Keep this manual available for reference at all times.

These safety notes are intended to ensure that the valve is maintained and operated correctly

and that risks to personnel are minimised.

The instructions in this manual are intended to guide a trained and skilled maintainer to carry

out Overhaul and Maintenance of the valve. The procedures must be combined with current

good Engineering Practices and relevant local safety instructions.

WARNINGS, CAUTIONS AND NOTES

Throughout this manual attention is drawn to specific points as follows:

WARNING!

A WARNING ALERTS THE READER TO POTENTIAL HAZARDS. FAILURE

TO READ AND OBEY THE SAFETY INSTRUCTIONS MAY RESULT IN

SERIOUS INJURY TO PERSONNEL AND DAMAGE TO EQUIPMENT.

CAUTION! A caution alerts the reader to recommendations or instructions, non-

observance of which could cause damage to equipment.

Note: A note provides additional information, which should be given special attention.

Pilot Valve PV48K Overhaul & Maintenance Manual

06/03

Preliminary Page iv

OPERATION

During the Operation of the valve Observe the following:

1. Before operating machinery, clear all personnel and obstructions out of the zone of

operation.

2. If the machinery operates dangerously, the pressure source must be isolated

immediately.

3. If anything abnormal (i.e. abnormal noise or oil leaks) occurs, operation should be

stopped immediately and the problem dealt with.

4. Before the valve is run for the first time, confirm that the hydraulic circuits and electrical

wiring are correct and ensure that all fittings and connections are tight.

5. The valve must only be used within the specifications shown in the relevant data sheet.

6. Monitor the temperature of the valve during operation, if the temperature rises suddenly:

(a) Switch off the valve.

(b) Isolate the hydraulic and electrical supplies.

(c) Allow the valve to cool before touching.

(d) Investigate the sudden rise in temperature.

7. Use only the hydraulic oil specified in the relevant data sheet.

8. Make sure that all relevant filters specified in the data sheet are fitted and are in a clean

and operational condition.

HANDLING

Care should be taken with the following when handling the valve:

1. Wear protective clothing when appropriate.

2. Depending on the weight and operating configuration of the main machine, it may be

possible to trap fingers or strain the back.

3. Do not apply weight to, hit, drop or exert external force on the valve.

4. Wipe off any operating oil from the valve and/or floor.

Overhaul & Maintenance Manual Pilot Valve PV48K

06/03

Preliminary Page v

REMOV AL AND REPLACEMENT

Precautions for the removal and replacement of the valve:

Removal

Ensure that:

(a) Power to the machine is switched off.

(b) Electric motors, engines etc are at rest.

(c) Pressure inside hydraulic lines is zero.

(d) Residual pressure in the accumulator circuit is released. (i.e. Operate the valve's

lever several (at least ten) times).

Replacement

Ensure that:

(a) Attachment holes and surfaces are kept clean.

(b) The correct bolts are used and tightened to the specified torque values.

(c) Seals are not damaged.

MAINTENANCE AND STORAGE

Precautions for the Maintenance and Storage of the valve:

Maintenance

Ensure that:

(a) No modifications to the product are made by the customer.

(b) Trained personnel carry out maintenance and Overhaul.

Storage

Ensure that:

(a) The ambient temperature and humidity levels are not extreme.

(b) The valve is protected from dust and corrosion.

(c) Provision is made to change the valve seals if the valve is stored for long periods.

Pilot Valve PV48K Overhaul & Maintenance Manual

06/03

Preliminary Page vi

Intentionally Blank

Overhaul & Maintenance Manual Pilot Valve PV48K

06/03

Page 1

1 DESCRIPTION AND OPERATION

1.1 General

The Pilot PV48K is a remote-control pilot valve with four reduction spools controlling secondary

pressure mounted in a single valve casing. Tilting the control handle controls the output

pressure.

1.2 Specifications

Primary pressure Maximum pressure 6.9Mpa{995psi}

Secondary pressure Maximum control pressure 0~4. 4Mpa{640psi}

Permissible back

pressure

Maximum 0.3Mpa{43psi}

Nominal flow 20L/min{5.3gal/min}

Control angles ±19o, ±25o (single)

Mass 1.9kg

Port size G-1/4(ISO 228/1)

9/16-18UNF(SAE 514)

Piping

A supply pipe approximately φ8mm internal diameter and

a maximum of 3 metres in length should be used to

achieve good responsiveness. The return oil should go

directly to the tank to avoid the effects of back-pressure.

Pilot Valve PV48K Overhaul & Maintenance Manual

Issue 1 09/00

Page 2

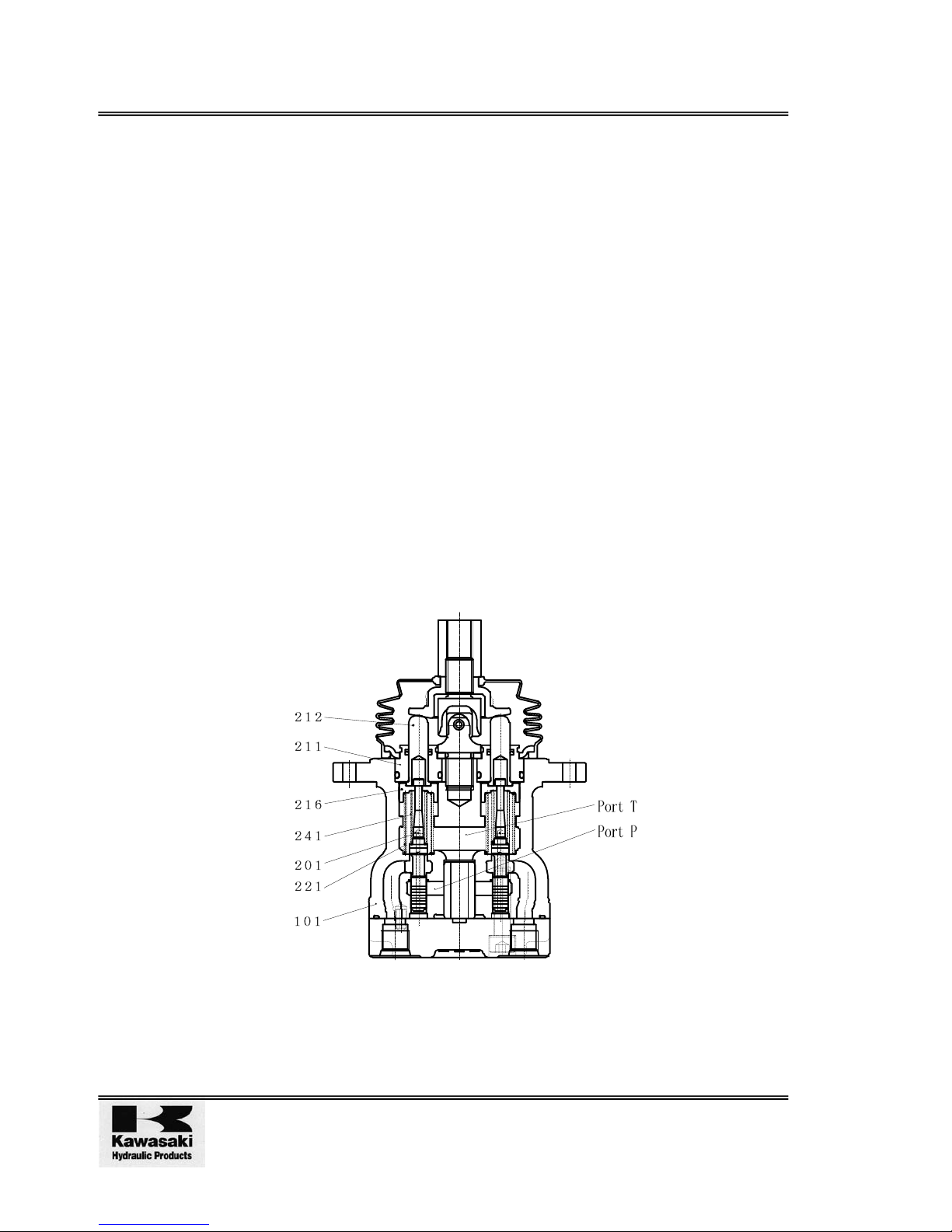

1.3 Structure

The structure of the pilot valve is as shown in the assembly cross-section (see Figure 1). There

is a vertical axial hole in the casing and the reduction valves are inserted into this.

Each reduction valve comprises:

1. Spool (201)

2. Secondary pressure setting spring (241)

3. Return spring (221)

4. Spring seating (216)

5. Push rod (212)

6. Plug (211)

The secondary pressure setting spring (241) is set such that the secondary pressure is

calculated as 5~10kgf/cm2 (depending on the model). Spool (201) is pushed onto the push rod

(212) by return spring (221).

Tilting the control handle pushes down push rod (212), the spring seat (216) also moves down

and the setting of the secondary pressure setting spring (241) is changed.

Port P, oil inlet (primary pressure) and port T outlet (tank) are in the casing (101).

Por t s 2, 4 Por t s 1, 3

Figure 1 PV48K Valve - Cross-Section

Overhaul & Maintenance Manual Pilot Valve PV48K

06/03

Page 3

1.4 Performance

1.4.1 Basic performance

The pilot valve controls the stroke and direction of the control valve spools. This is achieved by

the output pressure of the pilot valve acting on the tip of the control valve spool.

To achieve satisfactory performance, the pilot valve comprises the following elements:

1. An inlet port (P) for oil fed from the hydraulic pump.

2. Multiple output ports (1,2,3 and 4) to allow pressure from the inlet port to act on the

spool tips of the control valve.

3. A tank port (T) to control the output pressure.

4. A spool to connect the output port to the inlet port or tank port.

5. A mechanical assembly, which contains a spring which acts on the spool and controls

the output pressure.

1.4.2 Performance of the main parts (see Figure 1)

The spool (201) operates to take the supply oil pressure from the hydraulic pump. This

switches the oil channel so that the port P oil pressure is directed to the output ports 1,2,3,4 or

to port T. The secondary pressure setting spring (241) determines the output pressure that acts

on the spool (201).

The push-rod (212), which changes the strain of the secondary pressure setting spring (241), is

inserted so that it can move smoothly into the plug (211).

The return spring (221) acts to return the push-rod (212) towards zero displacement without

reference to the output pressure acting on the spring seating (216) and casing (101). This acts

to ensure the return to neutral of the spool (201) and also acts as a resistance spring to provide

the operator with an appropriate operating "feel".

Pilot Valve PV48K Overhaul & Maintenance Manual

Issue 1 09/00

Page 4

1.5 Operation

The operation of the pilot valve is described in the hydraulic circuit plan (see Figure 2) and

operation explanatory figures (see Figures 3, 4 and 5). Figure 2 shows a typical example of the

use of the pilot valve.

KEY:

1 Pilot valve 2 Main pump 3 Hydraulic motor

4 Hydraulic cylinder 5 Control valve 6 Pilot pump

Figure 2 Hydraulic Circuit Plan (Typical)

1.5.1 Control Handle Neutral (see Figure 3)

The force of the secondary pressure setting

spring (241) (which determines the output

pressure of the pilot valve) does not act on the

spool (201).

Spool (201) is pressed upward by the return

spring (221)

Spring seating 1 (216) and output ports (2,4)

and port T are open.

The output pressure is the same as the tank

pressure.

Figure 3 Control Handle in Neutral

Overhaul & Maintenance Manual Pilot Valve PV48K

06/03

Page 5

1.5.2 Control Handle Tilted (see Figure 4)

The push-rod moves, (spring seat (216)),

spool (201) moves downward, port P and ports

(2, 4) are open and the oil fed from the pilot

pump flows to ports (2,4) and generates

pressure.

Figure 4 Control Handle Tilted

T

P

Loading...

Loading...