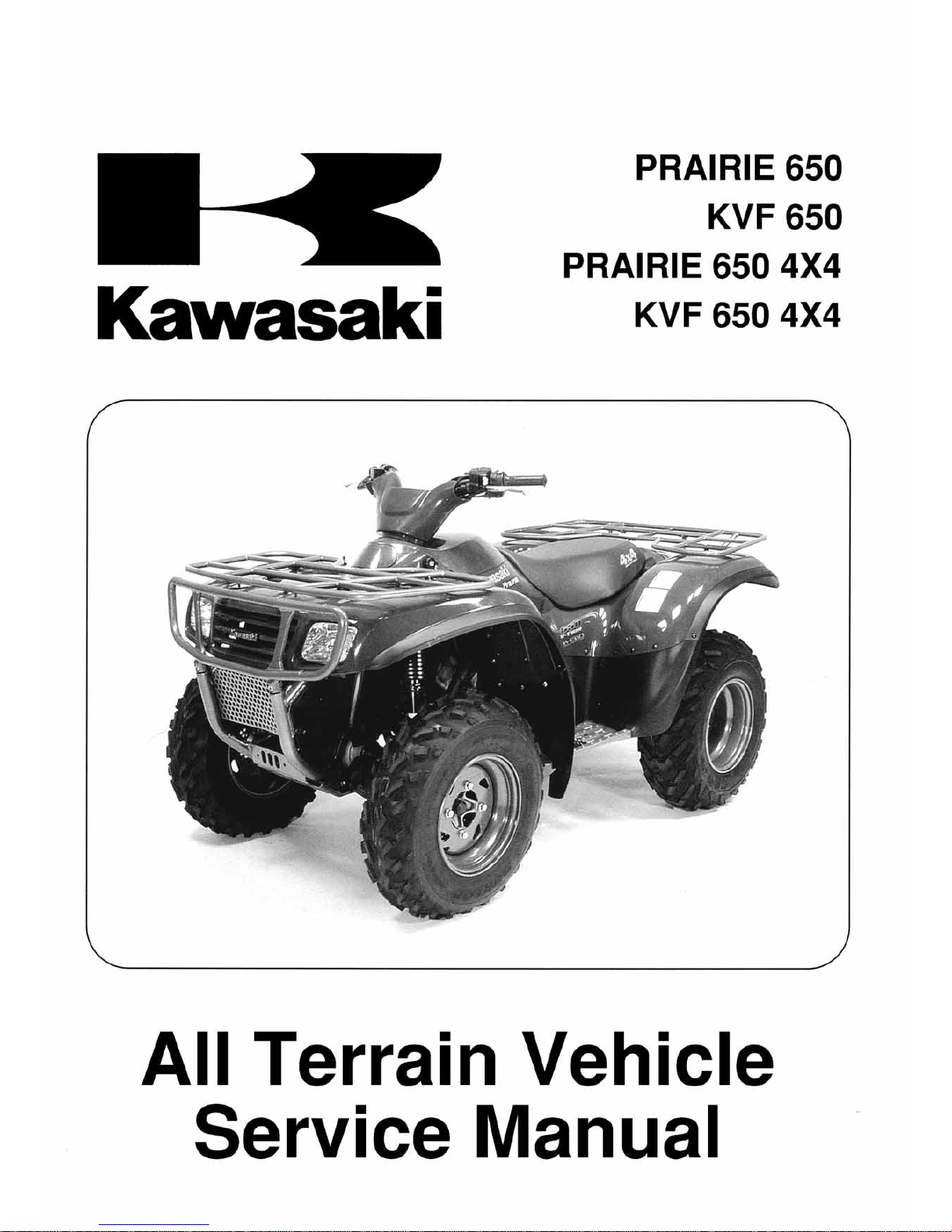

Kawasaki PRAIRIE 650, PRAIRIE 650 4X4 Service Manual

PRAIRIE 650

KVF 650

PRAIRIE 650 4X4

KVF 650 4X4

All Terrain Vehicle

Service Manual

All rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted in any

form or by any means, electronic mechanical photocopying, recording or otherwise, without the prior written permission of

Quality Assurance Department/Consumer Products & Machinery Company/Kawasaki Heavy Industries, Ltd., Japan.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible care has been

taken to make it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation to make

such changes to products manufactured previously. See your dealer for the latest information on product improvements

incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time of publication.

Illustrations and photographs in this publication are intended for reference use only and may not depict actual model

component parts.

© 2002 Kawasaki Heavy Industries. Ltd. 3rd Edition (1) : Jun. 21, 2002 (K)

LIST OF ABBREVIATIONS

A ampere(s) lb pounds(s)

ABDC after bottom dead center m meter(s)

AC alternating current min minute(s)

ATDC after top dead center N newton(s)

BBDC before bottom dead center Pa pascal(s)

BDC bottom dead center PS horsepower

BTDC before top dead center psi pound(s) per square inch

C degree(s) Celcius r revolution

DC direct current rpm revolution(s) per minute

F farad(s) TDC top dead center

F degree(s) Fahrenheit TIR total indicator reading

ft foot, feet V volt(s)

g gram(s) W watt(s)

h hour(s)

ohm(s)

L liter(s)

Read OWNER’S MANUAL before operating.

EMISSION CONTROL INFORMATION

To protect the environment in which we all live, Kawasaki has incor porated crankcase emission (1) and exhaust emission

(2) control systems in compliance with applicable regulations of the California Air Resources Board.

1. Crankcase Emission Control System

A sealed-type crankcase emission control system is used to eliminate blow-by gases. The blow-by

gases are led to the breather chamber through the crankcase. Then, it is led to the air cleaner.

Oil is separated from the gases while passing through the inside of the breather chamber from the

crankcase, and then returned back to the bottom of crankcase.

2. Exhaust Emission Control System

The exhaust emission control system applied to this engine family is engine modifications that consist

of a modified carburetor and an ignition system having optimum ignition timing characteristics.

The carburetor has been calibrated to provide lean air/fuel mixture characteristics and optimum fuel

economy with a suitable air cleaner and exhaust system.

A maintenance free ignition system provides the most favorable ignition timing and helps maintain a

thorough combustion process within the engine which contributes to a reduction of exhaust pollutants

entering the atomosphere.

The Clean Air Act, which is the Federal law covering motor vehicle pollution, contains what is commonly referred to as

the Act’s "tampering provisions."

"Sec. 203(a) The following acts and the causing thereof are prohibited...

(3)(A) for any person to remove or render inoperative any device or element of design installed on or

in a motor vehicle or motor vehicle engine in compliance with regulations under this title prior to

its sale and delivery to the ultimate purchaser, or for any manufacturer or dealer knowingly to

remove or render inoperative any such device or element of design after such sale and delivery

to the ultimate purchaser.

(3)(B) for any person engaged in the business of repairing, servicing, selling, leasing, or trading motor

vehicles or motor vehicle engines, or who operates a fleet of motor vehicles knowingly to remove

or render inoperative any device or element of design installed on or in a motor vehicle or motor

vehicle engine in compliance with regulations under this title following its sale and delivery to the

ultimate purchaser..."

NOTE

The phrase "remove or render inoperative any device or element of design" has been generally

interpreted as follows:

1.Tampering does not include the temporary removal or rendering inoperative of devices or

elements of design in order to perform maintenance.

2.Tampering could include:

a.Maladjustment of vehicle components such that the emission standards are exceeded.

b.Use of replacement parts or accessories which adversely affect the performance or

durability of the vehicle.

c. Addition of components or accessories that result in the vehicle exceeding the standards.

d.Permanently removing, disconnecting, or rendering inoperative any component or element

of design of the emission control systems.

WE RECOMMEND THAT ALL DEALERS OBSERVE THESE PROVISIONS OF FEDERAL LAW, THE VIOLATION OF

WHICH IS PUNISHABLE BY CIVIL PENALTIES NOT EXCEEDING $10,000 PER VIOLATION.

PLEASE DO NOT TAMPER WITH NOISE CONTROL SYSTEM

(US MODEL only)

To minimize the noise emissions from this product, Kawasaki has equipped it with effective intake and exhaust silencing

systems. They are designed to give optimum performance while maintaining a low noise level. Please do not remove

these systems, or alter them in any which results in an increase in noise level.

Foreword

This manual is designed primarily for use by trained

mechanics in a properly equipped shop. However, it

contains enough detail and basic information to make

it useful to the owner who desires to perform his own

basic maintenance and repair work. A basic knowledge

of mechanics, the proper use of tools, and workshop

procedures must be understood in order to carry out

maintenance and repair satisfactorily. Whenever the

owner has insufficient experience or doubts his ability to

do the work, all adjustments, maintenance, and repair

should be carried out only by qualified mechanics.

In order to perform the work efficiently and to avoid

costly mistakes, read the text, thoroughly familiarize

yourself with the procedures before starting work, and

then do the work carefully in a clean area. Whenever

special tools or equipment are specified, do not use

makeshift tools or equipment. Precision measurements

can only be made if the proper instruments are used,

and the use of substitute tools may adversely affect safe

operation.

For the duration of the warranty period, we recommend that all repairs and scheduled maintenance be

performed in accordance with this service manual. Any

owner maintenance or repair procedure not performed in

accordance with this manual may void the warranty.

To get the longest life out of your vehicle:

•

Follow the Periodic Maintenance Chart in the Service

Manual.

•

Be alert for problems and non-scheduled maintenance.

•

Use proper tools and genuine Kawasaki Vehicle parts.

Special tools, gauges, and testers that are necessary

when servicing Kawasaki vehicles are introduced by

the Special Tool Catalog or Manual. Genuine parts

provided as spare parts are listed in the Parts Catalog.

•

Follow the procedures in this manual carefully. Don’t

take shor tcuts.

•

Remember to keep complete records of maintenance

and repair with dates and any new parts installed.

How to Use This Manual

In preparing this manual, we divided the product into

its major systems. These systems became the manual’s

chapters. All information for a particular system from

adjustment through disassembly and inspection is located

in a single chapter.

The Quick Reference Guide shows you all of the

product’s system and assists in locating their chapters.

Each chapter in turn has its own comprehensive Table of

Contents.

The Periodic Maintenance Chart is located in the

General Information chapter. The chart gives a time

schedule for required maintenance operations.

If you want spark plug information, for example, go to

the Periodic Maintenance Chart first. The chart tells you

how frequently to clean and gap the plug. Next, use the

Quick Reference Guide to locate the Electrical System

chapter. Then, use the Table of Contents on the first page

of the chapter to find the Spark Plug section.

Whenever you see these WARNING and CAUTION

symbols, heed their instructions! Always follow safe

operating and maintenance practices.

This warning symbol identifies special instruc-

tions or procedures which, if not correctly fol-

lowed, could result in personal injury, or loss of

life.

CAUTION

This caution symbol identifies special instruc-

tions or procedures which, if not strictly ob-

served, could result in damage to or destruction

of equipment.

This manual contains four more symbols (in addition to

WARNING and CAUTION) which will help you distinguish

different types of information.

NOTE

This note symbol indicates points of particular interest for more efficient and convenient operation.

•

Indicates a procedural step or work to be done.

Indicates a procedural sub-step or how to do the work

of the procedural step it follows. It also precedes the

text of a NOTE.

Indicates a conditional step or what action to take based

on the results of the test or inspection in the procedural

step or sub-step it follows.

In most chapters an expIoded view illustration of the

system components follows the Table of Contents. In

these illustrations you will find the instructions indicating

which parts require specified tightening torque, oil, grease

or a locking agent during assembly.

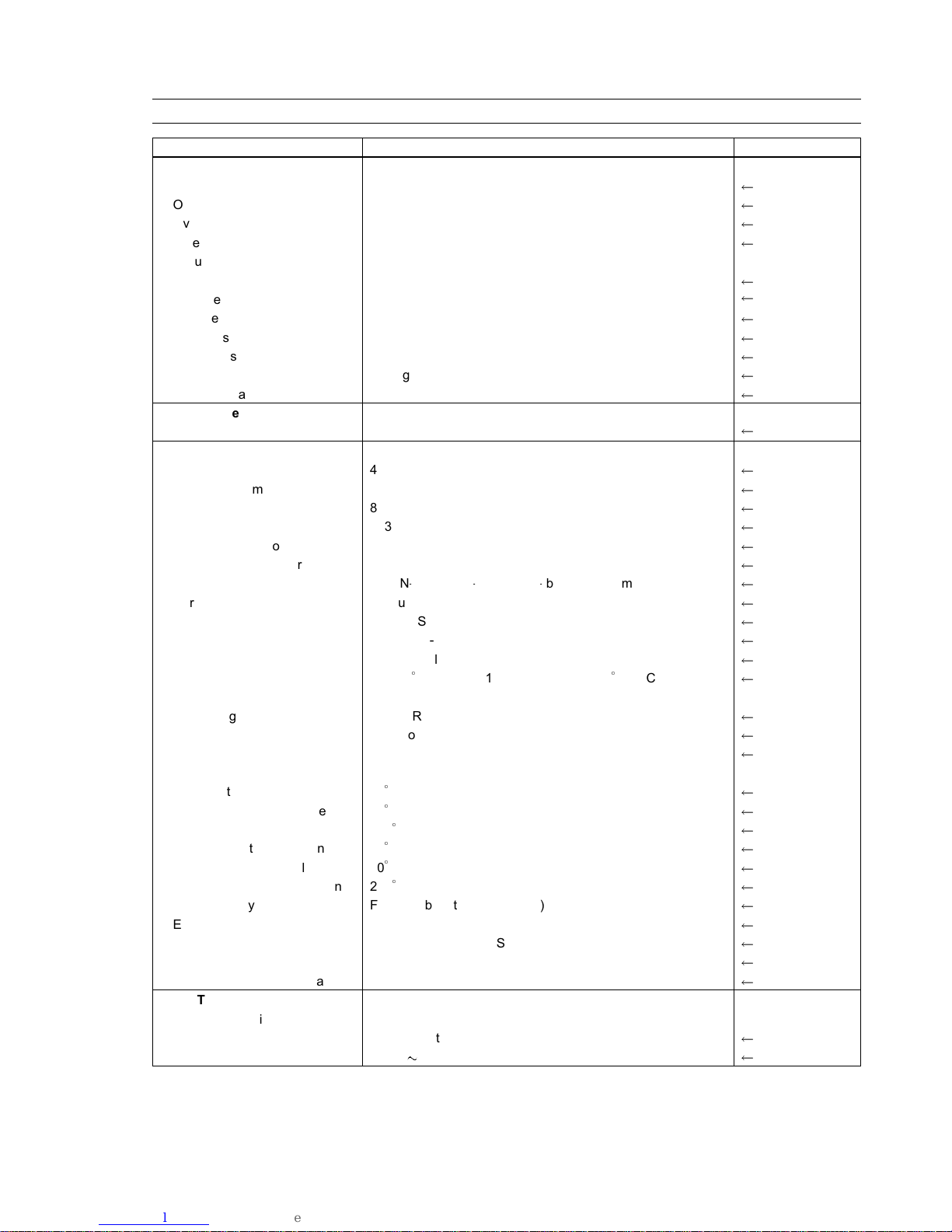

GENERAL INFORMATION 1-1

General Information

Table of Contents

1

Before Servicing................................................................................................................................................................1-2

Model Identification ........................................................................................................................................................... 1-4

General Specifications ...................................................................................................................................................... 1-7

Periodic Maintenance Chart..............................................................................................................................................1-9

Technical Information — Engine .....................................................................................................................................1-11

Technical Information — K-EBC System ........................................................................................................................ 1-12

Technical Information — Selectable 2WD/4WD ............................................................................................................. 1-19

Technical Information — Drive Belt Failure Detection System.......................................................................................1-24

Techinical Information — Variable Limited Slip Differential Control................................................................................1-26

Technical Information — Rear Brake..............................................................................................................................1-28

Torque and Locking Agent .............................................................................................................................................. 1-30

Special Tools and Sealant...............................................................................................................................................1-35

Cable, Wire, and Hose Routing ......................................................................................................................................1-42

1-2 GENERAL INFORMATION

Before Servicing

Before starting to perform an inspection service or carry out a disassembly and reassembly operation on a vehicle,

read the precautions given below. To facilitate actual operations, notes, illustrations, photographs, cautions, and detailed

descriptions have been included in each chapter wherever necessary. This section explains the items that require particular

attention during the removal and reinstallation or disassembly and reassembly of general parts.

Especially note the following:

(1) Dirt

Before removal and disassembly, clean the vehicle. Any dirt entering the engine will shorten the life of the vehicle.

For the same reason, before installing a new part, clean off any dust or metal filings.

(2) Battery Ground

Disconnect the ground (–) wire from the battery before performing any disassembly operations on the vehicle. This

prevents the engine from accidentally turning over while work is being carried out, sparks from being generated while

disconnecting the wires from electrical parts, as well as damage to the electrical parts themselves. For reinstallation,

first connect the positive wire to the positive (+) terminal of the battery

(3) Installation, Assembly

Generally, installation or assembly is the reverse of removal or disassembly. However, if installation or assembly

sequence is given in this Service Manual, follow it. Note parts locations and cable, wire, and hose routing during

removal or disassembly so they can be installed or assembled in the same way. It is preferable to mark and record

the locations and routing whenever possible.

(4) Tightening Sequence

When installing bolts, nuts, or screws for which a tightening sequence is given in this Service Manual, make sure

to follow the sequence. When installing a part with several bolts, nuts, or screws, start them all in their holes and

tighten them to a snug fit, thus ensuring that the part has been installed in its proper location. Then, tighten them

to the specified torque in the tightening sequence and method indicated. If tightening sequence instructions are not

given, tighten them evenly in a cross pattern. Conversely, to remove a part, first loosen all the bolts, nuts, or screws

that are retaining the part a 1/4–turn before removing them.

(5) Torque

When torque values are given in this Service Manual, use them. Either too little or too much torque may lead to

serious damage. Use a good quality, reliable torque wrench.

(6) Force

Common sense should dictate how much force is necessary in assembly and disassembly. If a part seems especially

difficult to remove or install, stop and examine what may be causing the problem. Whenever tapping is necessary, tap

lightly using a wooden or plastic-faced mallet. Use an impact driver for screws (particularly for the removing screws

held by non-permanent locking agent) in order to avoid damaging the screw heads.

(7) Edges

Watch for sharp edges, as they could cause injury through careless handling, especially during major engine

disassembly and assembly. Use a clean piece of thick cloth when lifting the engine or turning it over.

(8) High-Flash Point Solvent

A high-flash point solvent is recommended to reduce fire danger. A commercial solvent commonly available in North

America is standard solvent (generic name). Always follow manufacturer and container directions regarding the use

of any solvent.

(9) Gasket, O-Ring

Replace a gasket or an O-ring with a new part when disassembling. Remove any foreign matter from the mating

surface of the gasket or O-ring to ensure a perfectly smooth surface to prevent oil or compression leaks.

(10) Liquid Gasket, Locking Agent

Clean and prepare surfaces where liquid gasket or non-permanent locking agent will be used. Apply them sparingly.

Excessive amount may block engine oil passages and cause serious damage.

(11) Press

When using a press or driver to install a part such as a wheel bearing, apply a small amount of oil to the area

where the two parts come in contact to ensure a smooth fit.

(12) Ball Bearing and Needle Bearing

Do not remove a ball bearing or a needle bearing unless it is absolutely necessary. Replace any ball or needle

bearings that were removed with new ones. Install bearings with the manufacturer and size marks facing out, applying

pressure evenly with a suitable driver. Apply force only to the end of the race that contacts the press fit portion, and

press it evenly over the base component.

(13) Oil Seal and Grease Seal

Replace any oil or grease seals that were removed with new ones, as removal generally damages seals. Oil or

grease seals should be pressed into place using a suitable driver, applying a force uniformly to the end of seal until

the face of the seal is even with the end of the hole, unless instructed otherwise. When pressing in an oil or grease

seal which has manufacturer’s marks, press it in with the marks facing out.

GENERAL INFORMATION 1-3

Before Servicing

(14) Circlip, Retaining Ring, and Cotter Pin

When installing circlips and retaining rings, take care to compress or expand them only enough to install them and

no more. Install the circlip with its chamfered side facing load side as well.

Replace any circlips, retaining rings, and cotter pins that were removed with new ones, as removal weakens and

deforms them. If old ones are reused, they could become detached while the vehicle is driven, leading to a major

problem.

(15) Lubrication

Engine wear is generally at its maximum while the engine is warming up and before all the sliding surfaces have

an adequate lubricative film. During assembly, make sure to apply oil to any sliding surface or bearing that has been

cleaned. Old grease or dirty oil could have lost its lubricative quality and may contain foreign particles that act as

abrasives; therefore, make sure to wipe it off and apply fresh grease or oil. Some oils and greases in particular should

be used only in certain applications and may be harmful if used in an application for which they are not intended.

(16) Direction of Engine Rotation

To rotate the crankshaft manually, make sure to do so in the direction of positive rotation. Positive rotation is

counterclockwise as viewed from the left side of the engine. To carry out proper adjustment, it is furthermore necessary

to rotate the engine in the direction of positive rotation as well.

(17) Replacement Parts

When there is a replacement instruction, replace these parts with new ones every time they are removed.

Replacement parts will be damaged or lose their original function once they are removed. Therefore, always

replace these parts with new ones every time they are removed. Although the previously mentioned gasket, O-ring,

ball bearing, needle bearing, grease seal, oil seal, circlip, and cotter pin have not been so designated in their respective

text, they are replacement parts.

(18) Electrical Wires

All the electrical wires are either one-color or two-color. A two-color wire is identified first by the primary color and

then the stripe color. For example, a yellow wire with thin red stripes is referred to as a “yellow/red” wire; it would

be a “red/yellow” wire if the colors were reversed. Unless instructed otherwise, electrical wires must be connected to

wires of the same color.

Two-Color Electrical

(19) Inspection

When parts have been disassembled, visually inspect these parts for the following conditions or other damage. If

there is any doubt as to the condition of them, replace them with new ones.

Abrasion Crack Hardening Warp

Bent Dent Scratch Wear

Color change Deterioration Seizure

(20) Specifications

Specification terms are defined as follows:

"Standards" show dimensions or performances which brand-new parts or systems have.

"Service Limits" indicate the usable limits. If the measurement shows excessive wear or deteriorated performance,

replace the damaged parts.

(21) Instrument

Use a meter that has enough accuracy for an accurate measurement. Read the manufacture’s instructions thgoughly

before using the meter. Incorrect values may lead to improper adjustments.

1-4 GENERAL INFORMATION

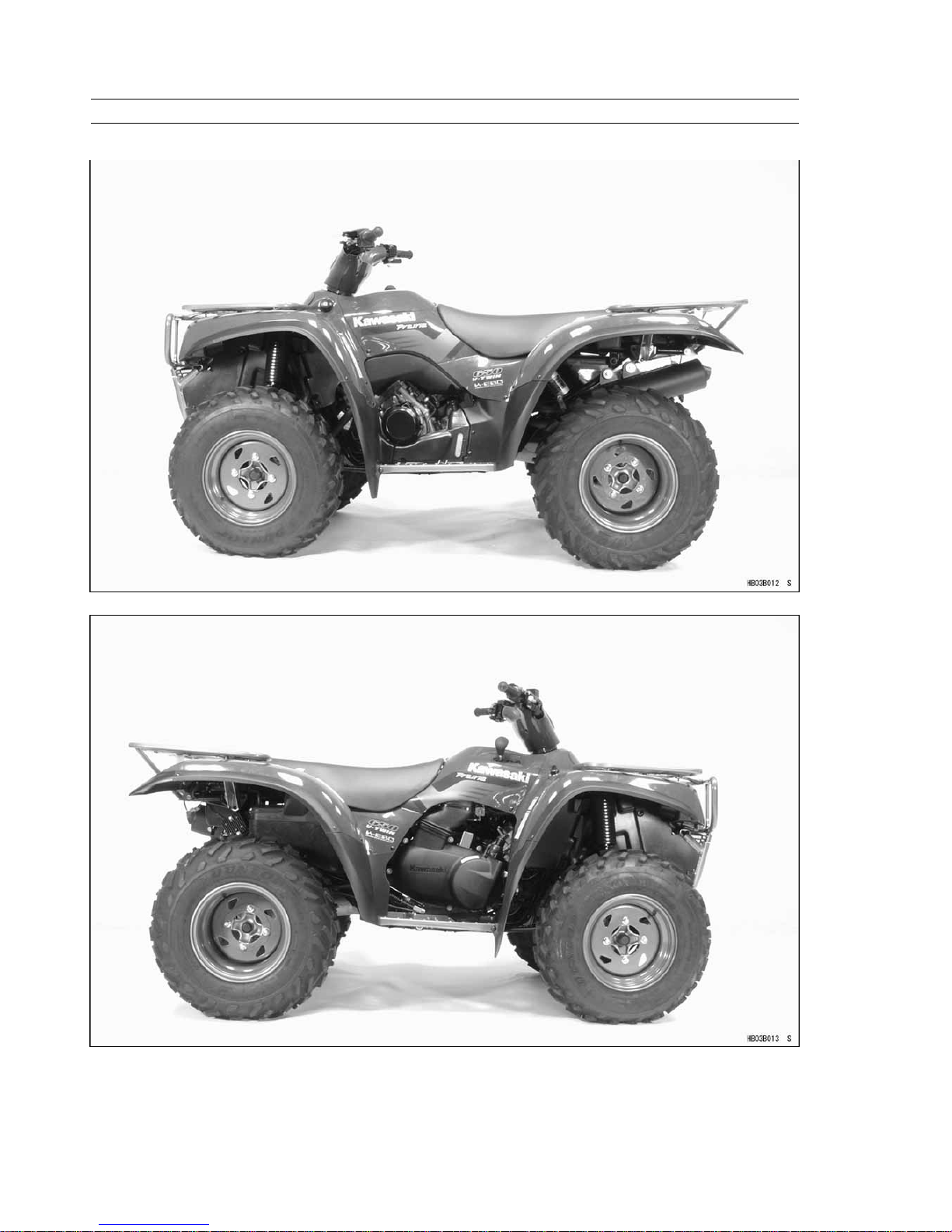

Model Identification

KVF650–A1

GENERAL INFORMATION 1-5

Model Identification

KVF650–A2

1-6 GENERAL INFORMATION

Model Identification

KVF650–B1, B2

GENERAL INFORMATION 1-7

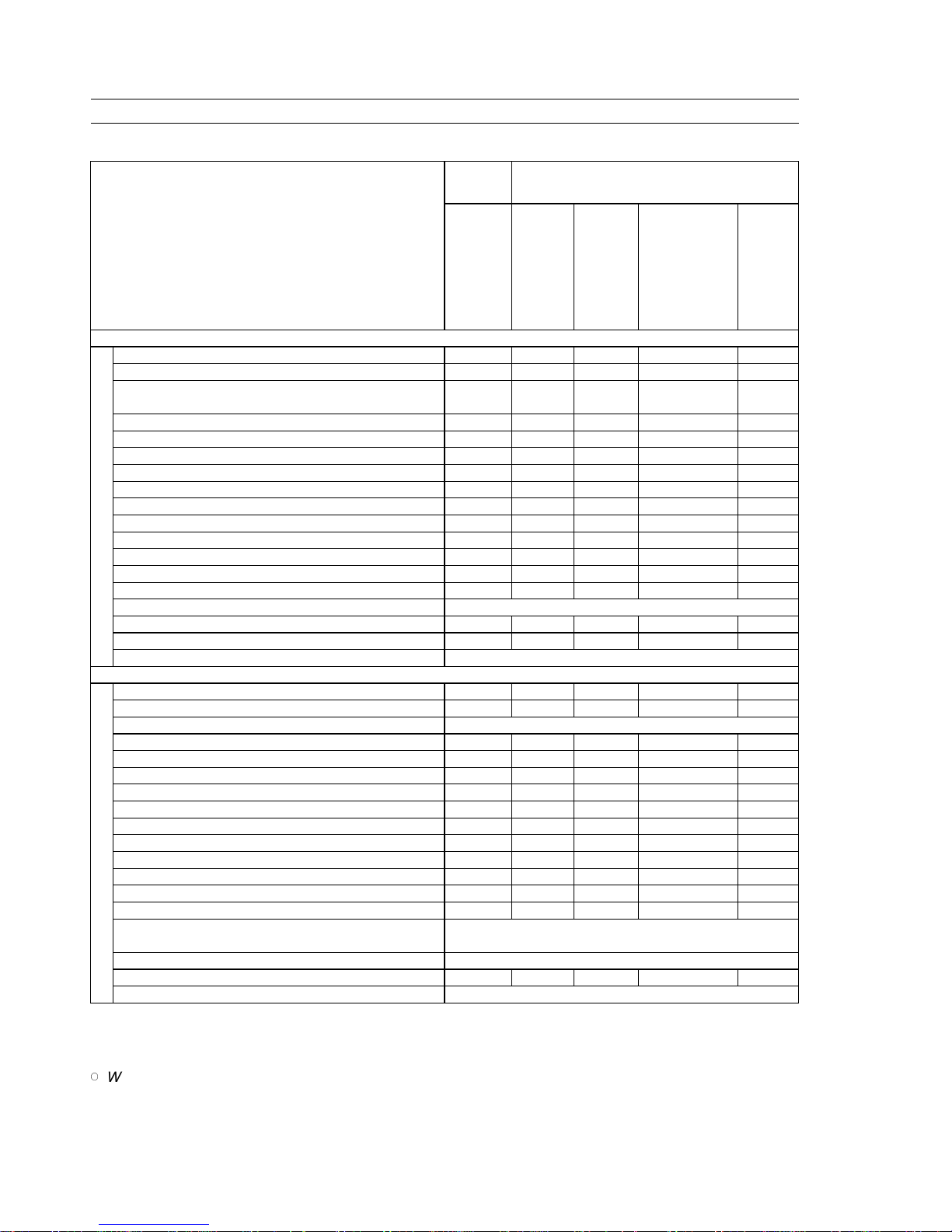

General Specifications

Items KVF650-A1, B1 KVF650-A2, B2

Dimensions:

Overall length 2 155 mm (84.84 in.)

Overall width 1 170 mm (46.06 in.)

Overall height 1 150 mm (45.28 in.)

Wheelbase 1 295 mm (50.98 in.)

Ground clearance:

Rear final gear case 193 mm (7.60 in.)

Center of frame 240 mm (9.45 in.)

Seat height 855 mm (33.66 in.)

Dry mass 274 kg (604 lb)

Curb mass: Front 155 kg (342 lb)

Rear 138 kg (304 lb)

Fuel tank capacity 17 L (4.5 US gal)

Performance:

Minimum turning radius 3.1 m (10.17 ft)

Engine:

Type 4-stroke, SOHC, V2-cylinders

Cooling system Liquid-cooled

Bore and stroke 80.0 x 63.0 mm (3.15 x 2.48 in.)

Displacement 633 mL (38.6 cu in.)

Compression ratio 9.9:1

Maximum horsepower 30.9 kW (42 PS) @6 500 r/min (rpm), (US) Maximum torque 52.1 N1m (5.3 kgf1m, 38.33 ft1lb) @4 000 r/min (rpm)

Carburetion system Carburetor, Keihin CVKR-D32

Starting system Electric Starter & Recoil Starter

Ignition system Digital DC-CDI

Timing advance Electronically advanced

Ignition timing From 5BTDC @1 100 r/min (rpm) to 28BTDC

@5 000 r/min (rpm)

Spark plug NGK CR7E, DENSO U22ESR-N

Cylinder numbering method Front to rear, 1-2

Firing order 1-2

Valve timing:

Inlet Open 30BTDC

Close 34ABDC

Duration 244

Exhaust: Open 54BBDC

Close 10ATDC

Duration 244

Lubrication system Forced lubrication (wet sump)

Engine oil: Grade API SF or SG class

API SH or SJ with JASO MA class

Viscosity

SAE10W-40

Capacity 2.05 L (2.17 US qt)

Drive Train:

Primary reduction system:

Type Belt converter

Reduction ratio 3.122 0.635

1-8 GENERAL INFORMATION

General Specifications

Items

KVF650-A1, B1 KVF650-A2, B2

Transmission:

Type 2-speed plus reverse

Gear ratios:

Forward: High 3.098 (30/26 x 29/18 x 20/12)

Low 4.833 (36/20 x 29/18 x 20/12)

Reverse: 4.028 (16/12 x 18/16 x 29/18 x 20/12)

Final drive system:

Type Shaft, 2WD/4WD

Reduction ratio 4.375 (35/8)

Overall drive ratio

Forward: High 42.32 8.61

Low 66.02 13.43

Reverse: 55.01 11.19

Front final gear case oil: Grade API SF or SG class

API SH or SJ with JASO MA class

Viscosity

SAE10W-40

Capacity 0.43 L (0.45 US qt)

Rear final gear case oil: Type MOBIL Fluid 424

MOBIL Fluid 424 or

CITGO TRANSGARD

TRACTOR

HYDRAULIC FLUID

Capacity 0.9 L (0.95 US qt)

Frame:

Type Double tubular

Caster (rake angle) 3.5

Camber 0@1 G

King pin angle 15.5

Trail 15 mm (0.59 in.)

Tread Front 914 mm (35.98 in.)

Rear 910 mm (35.83 in.)

Front tire: Type Tubeless

Size AT25 x 8 – 12

Rear tire: Type Tubeless

Size AT25 x 10 – 12

Suspension:

Front Type

MacPherson strut

Wheel travel 170 mm (6.69 in.)

Rear Type Swingarm

Wheel travel 184 mm (7.24 in.)

Brake: Front Disc (Hydraulic) x 2

Rear Enclosed Wet Multi-Plate

Electrical Equipment:

Battery 12 V 12 Ah

Headlight: Type Semi-sealed beam

Bulb 12 V 45/45 W x 2

Tail/brake light Bulb 12 V 8/27 W 12 V 5/21 W

Alternator: Type Three - phase AC

Rated output 25 A, 14 V @6 000 r/min (rpm)

Specifications are subject to change without notice, and may not apply to every country.

US: U.S.A. Model

GENERAL INFORMATION 1-9

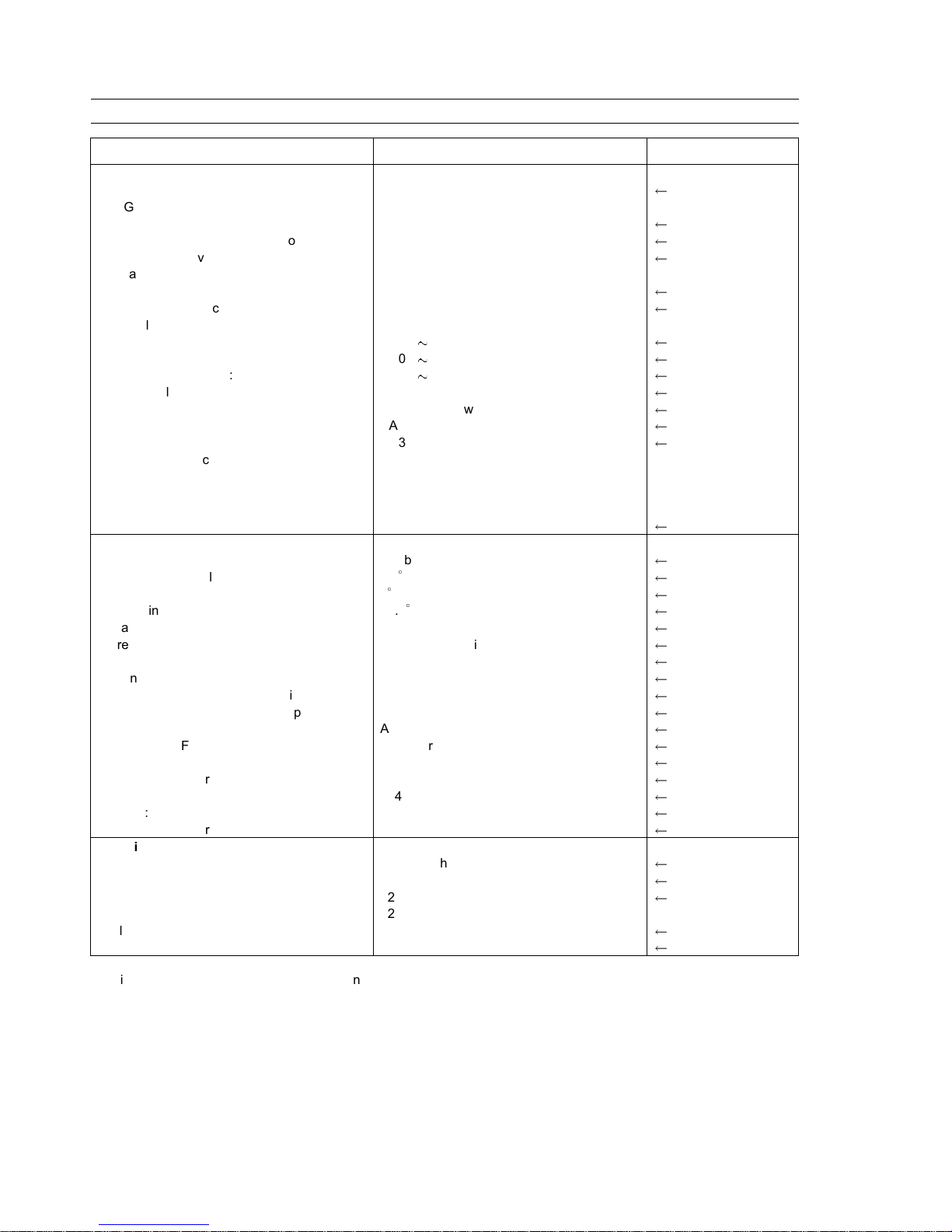

Periodic Maintenance Chart

The scheduled maintenance must be done in accordance with this chart to keep the vehicle in good running condition.

The initial maintenance is vitally important and must not be neglected.

KVF650–A1, B1

FREQUENCY First Ser-

vice

Regular Service

OPERATION

After 10

hrs. or

100 km

(60 mi.)

of use

Every 10

days or

200 km

(120 mi.)

of use

Every 30

days or

600 km

(360 mi.)

of use

Every 90

days or

1700 km

(1100

mi.) of

use

Every

year of

use

ENGINE

Converter drive belt wear – check *

•

Converter drive belt deflection - check *

•

Drive belt failure detection system function – check*

•

Engine brake control (K-EBC) lever – check*

•

Air cleaner – service*

• •

Throttle lever play – check*

• •

Valve clearance – check*

•

Fuel system cleanliness – check*

• •

Engine oil – change *

• •

Oil filter – replace*

• •

Spark plug – clean and gap

• •

Spark arrester – clean

•

Radiator – clean*

• •

Radiator hoses, and connections – check*

•

Coolant – change* 2 years

Coolant filter of carburetor – clean

•

Fuel hoses, connections – check

•

Fuel hose – replace 4 years

CHASSIS

Joint boots – check*

• •

Rear brake pedal and lever adjustment – check*

• •

Rear brake plates – change* every 10 000 km (6 000 mi.)

Cable adjustment*

• •

Bolts and nuts – tighten

• •

Front brake pad wear – check*

• •

Brake light switch – check*

• •

Steering – check

• •

Differential control lever play– check

• •

Tire wear – check*

•

Front and rear finial gear case oil – change

• •

General lubrication*

•

Front brake fluid level – check

• •

Front brake fluid – change

•

Brake master cylinder piston assembly and dust

seal – replace

2 years

Caliper piston seal and dust seal – replace 2 years

Brake hoses, connections– check

•

Brake hose – replace 4 years

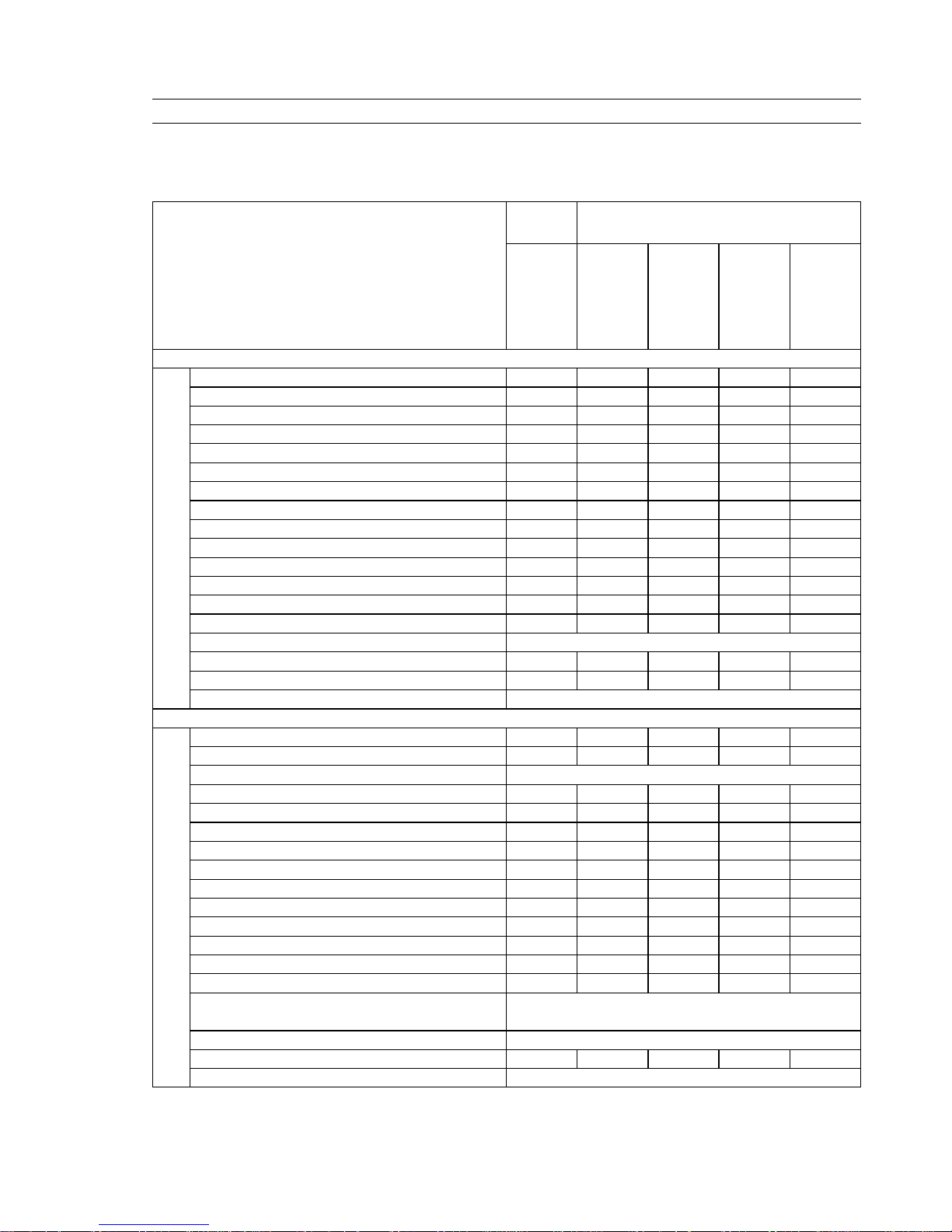

1-10 GENERAL INFORMATION

Periodic Maintenance Chart

KVF650–A2, B2

FREQUENCY

First

Service

Regular Service

OPERATION

After 10

hrs. or

100 km

(60 mi.)

of use

Every

10 days

or 200

km (120

mi.) of

use

Every

30 days

or 600

km (360

mi.) of

use

Every 90 days of

vehicle use,1700

km (1100 mi.) or

when belt indica-

tor light comes on

(100 hours)

whichever comes

first

Every

year of

use

ENGINE

Converter drive belt wear – check *

•

Converter drive belt deflection - check *

•

Drive belt failure detection system function – check*

•

(Note)

Engine brake control (K-EBC) lever – check*

•

Air cleaner – service*

• •

Throttle lever play – check*

• •

Valve clearance – check*

•

Fuel system cleanliness – check*

• •

Engine oil – change *

• •

Oil filter – replace*

• •

Spark plug – clean and gap

• •

Spark arrester – clean

•

Radiator – clean*

• •

Radiator hoses, and connections – check*

•

Coolant – change* 2 years

Coolant filter of carburetor – clean

•

Fuel hoses, connections – check

•

Fuel hose – replace 4 years

CHASSIS

Joint boots – check*

• •

Rear brake pedal and lever adjustment – check*

• •

Rear brake plates – change* every 10 000 km (6 000 mi.)

Cable adjustment*

• •

Bolts and nuts – tighten

• •

Front brake pad wear – check*

• •

Brake light switch – check*

• •

Steering – check

• •

Differential control lever play– check

• •

Tire wear – check*

•

Front and rear finial gear case oil – change

• •

General lubrication*

•

Front brake fluid level – check

• •

Front brake fluid – change

•

Brake master cylinder piston assembly and dust seal

– replace

2 years

Caliper piston seal and dust seal – replace 2 years

Brake hoses, connections– check

•

Brake hose – replace 4 years

*: Service more frequently when operated in mud, dust, or other harsh riding conditions.

•

: Clean, adjust, lubricate, torque, or replace parts as necessary.

NOTE

When the drive belt failure detection system is activated, return the vehile immediately to an authorized

Kawasaki dealer for drive belt inspection and adjustment or replacement.

GENERAL INFORMATION 1-11

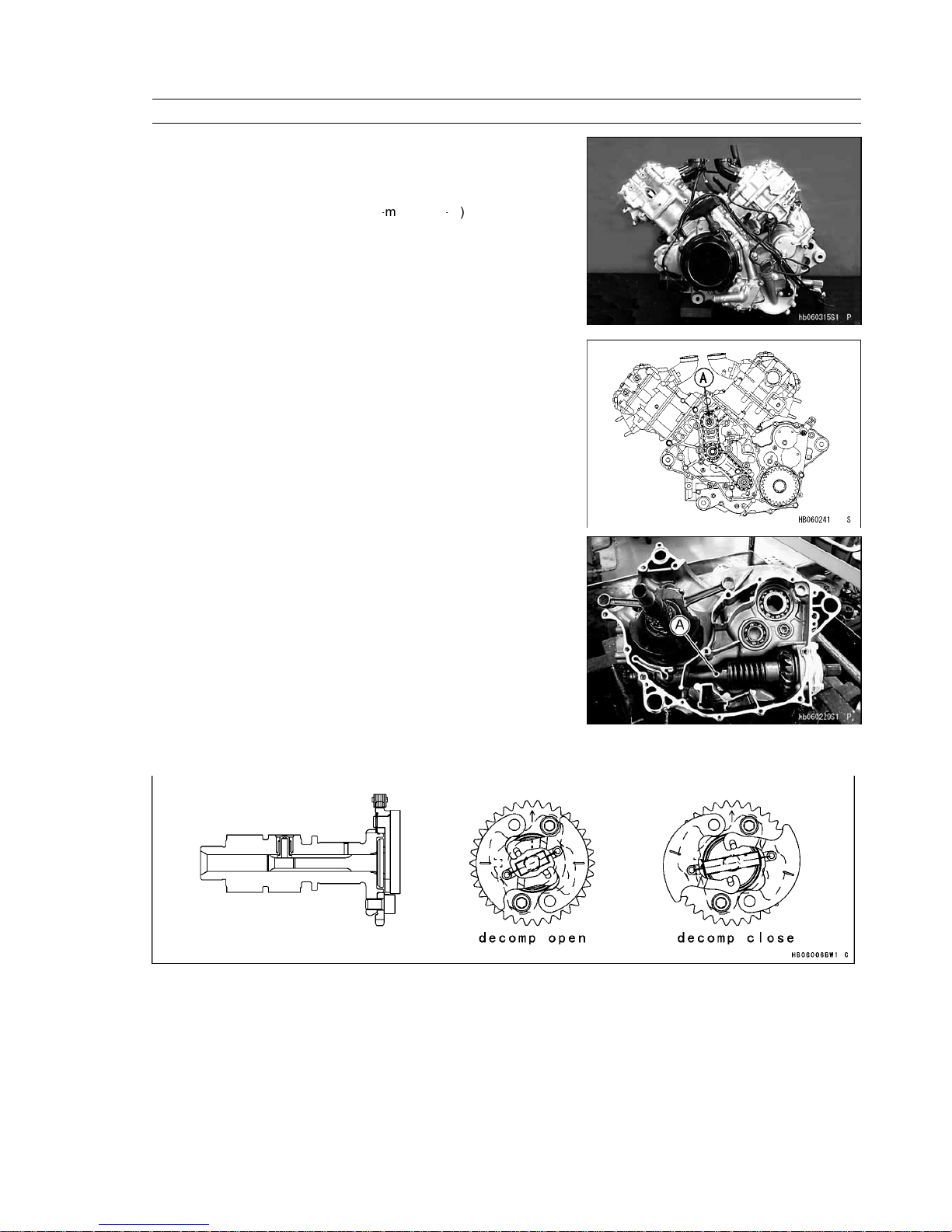

Technical Information — Engine

Engine Main Specification

1. Newly designed, liquid-cooled, 633 cm

3

SOHC, 4–valve V-twin

engine produces 30.9 kW (42 PS)/6,500 rpm.

2. Over square bore and stroke of 80.0 mm x 63.0 mm contributes

to a high torque output of 52.1 N

1

m (5.3 kgf1m)/4,000 rpm and a

flat, user-friendly torque curve.

3. Off-setting the cylinders by 90-degree results in perfect primary

balance, for low vibration levels and comfortable riding.

4. Concave piston crown improves combustion efficiency.

5. Large, 30 mm intake and 26 mm exhaust valves are set at a

narrow 19-degree intake and 21-degree exhaust for a compact,

high-efficiency combustion chamber.

6. Dual, CVKR-D32 downdraft carburetors deliver smooth throttle

response and efficient fuel consumption.

7. An intermediate sprocket is used between the crank and cams for

more compact engine design.

[A] Intermediate Shaft

8. The propeller shaft is built into the crankcase for a compact, low

mass drive train. The capacity of cam-damper is increased.

[A] Propeller Shaft

9. The KVF650A,B comes equipped with both an electric starter and a recoil starter. Together with KACR (Kawasaki

Automatic Compression Release), starting is quick and easy. The deviation of operating degree and lift is improved.

1-12 GENERAL INFORMATION

Technical Information — K-EBC System

1. Outline

This vehicle is equipped with the K-EBC (Kawasaki Engine Brake Control) system. It can assist the operator when

descending hills by supplementing the wheel brake systems with additional braking force that is produced by the engine.

When descending hills, the K-EBC system alone may not supply enough braking force. The operator should apply the

brakes to keep the speed safe for the type of terrain, visibility, operating conditions, and operator’s experience. The K-EBC

system is applied automatically under certain conditions when the throttle is released.

This system detects the ATV’s speed and running direction electrically, and when the conditions are met, a electric

actuator presses the torque converter drive pulley resulting in connecting the drive pulley with the driven pulley through

the belt and then generating braking force by the engine.

The K-EBC is a supplemental braking system when the speed is comparatively low (about 3 km/h — 20 km/h) and does

not function in reverse.

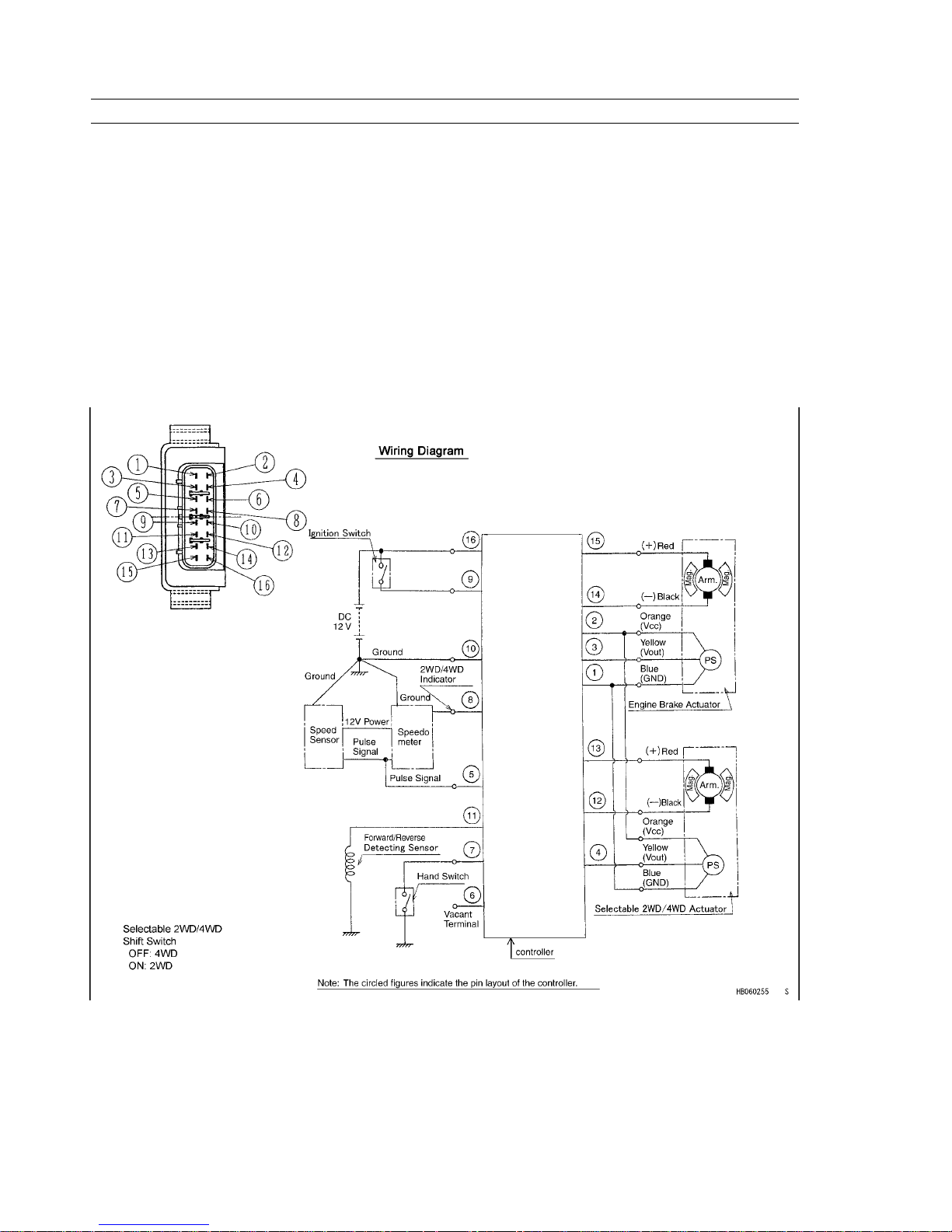

2. Wiring Diagram

The entire system is shown in the wiring diagram. The system is powered by a 12 Volt battery. Always keep the battery

connected even when the battery is discharged and operator needs to start engine. The engine can be started with the

recoil starter with the battery disconnected. However, the controller will not operate correctly.

GENERAL INFORMATION 1-13

Technical Information — K-EBC System

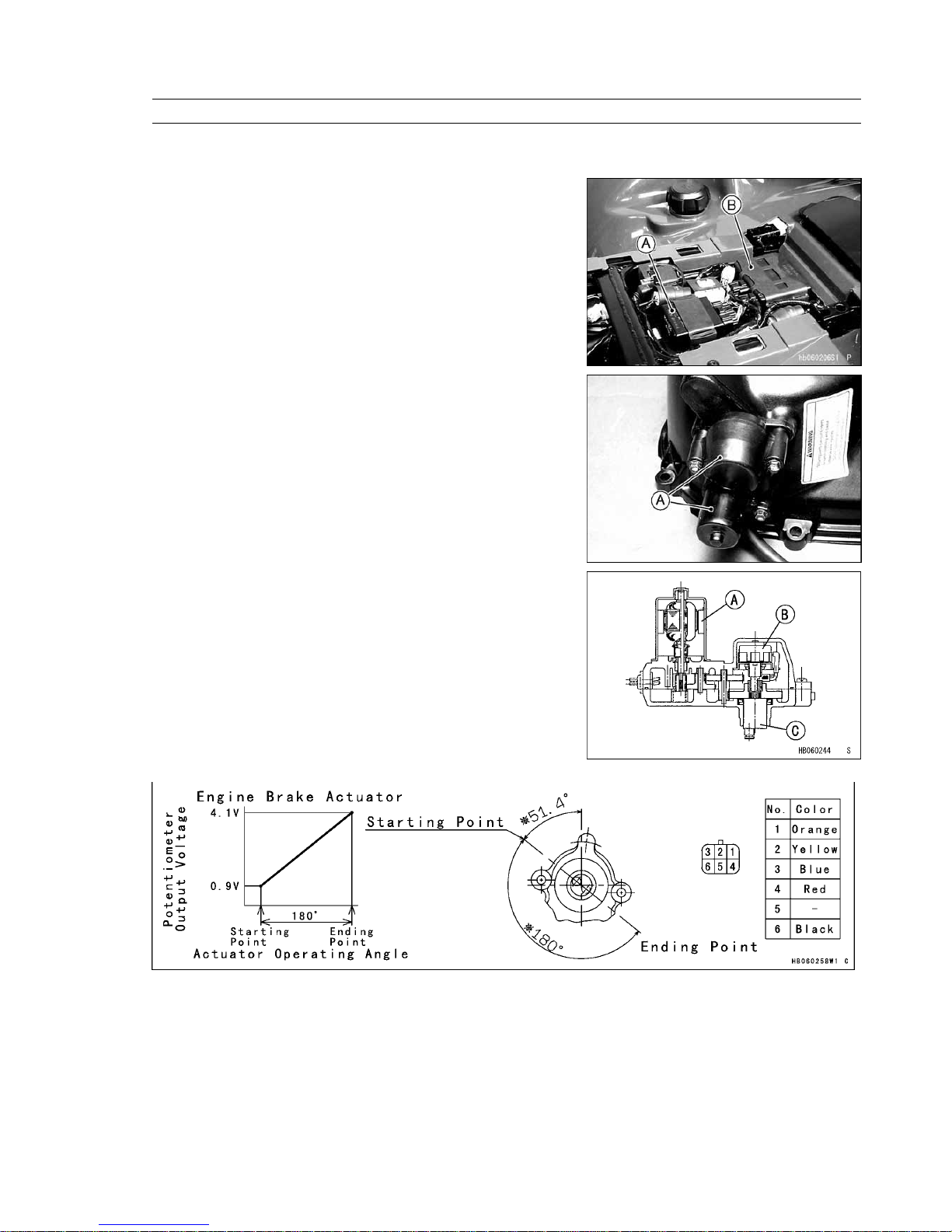

3. Component Parts

This system consists of a controller, actuator, lever assembly, forward/reverse detecting sensor, and a speed sensor.

1) Controller

The controller is located under the seat and controls the engine brake

and selectable 2WD/4WD actuators.

[A] Controller

[B] Igniter

2) Engine Brake Actuator

The engine brake actuator is installed on the converter cover. It

consists of a DC motor, reduction gears, and potentiometer.

[A] Engine Brake Actuator

[A] DC Motor

[B] Potentiometer

[C] Output Shaft

Engine Brake Actuator

1-14 GENERAL INFORMATION

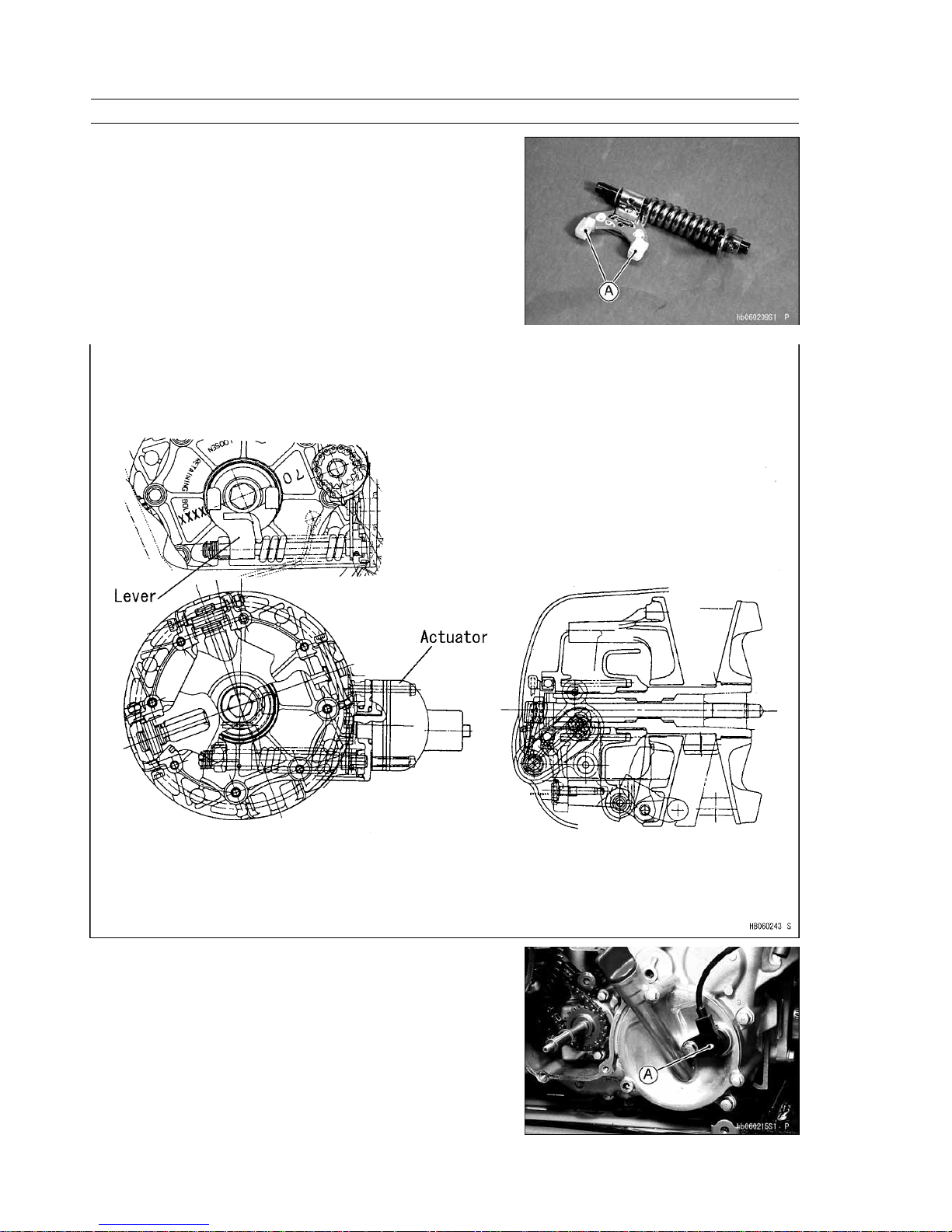

Technical Information — K-EBC System

3) Lever Assembly

The lever assembly is installed in the converter cover. This transmits

the actuator’s force to the drive pulley.

[A] Contact Surface

4) Forward/Reverse Detecting Sensor

The sensor is installed on the engine and uses the principle of

electromagnetic induction. The sensor generates AC voltage according

to the speed of the rotor. The output waveforms vary in accordance

with the shape of the rotor teeth. The controller detects the running

direction from the waveforms.

[A] Forward/Reverse Detecting Sensor

GENERAL INFORMATION 1-15

Technical Information — K-EBC System

[A] Magnet

[B] Pole

[C] Coil

[A] Rotor Tooth

5) Speed Sensor

The sensor is installed on the engine and generates pulses according

to the gap difference between the sensor and the rotating gear. The

controller calculates the vehicle’s speed by counting the pulse sent from

the speed sensor.

[A] Speed Sensor

1-16 GENERAL INFORMATION

Technical Information — K-EBC System

Description of Actuator Controller Operation

1. Outline

The actuator controller has a microprocessor that detects the vehicle speed, the state of the selectable 2WD/4WD shift

switch, ignition switch, and the forward/reverse movement of the vehicle in order to control the engine brake and selectable

2WD/4WD actuators.

2. Engine Brake Actuator Controls

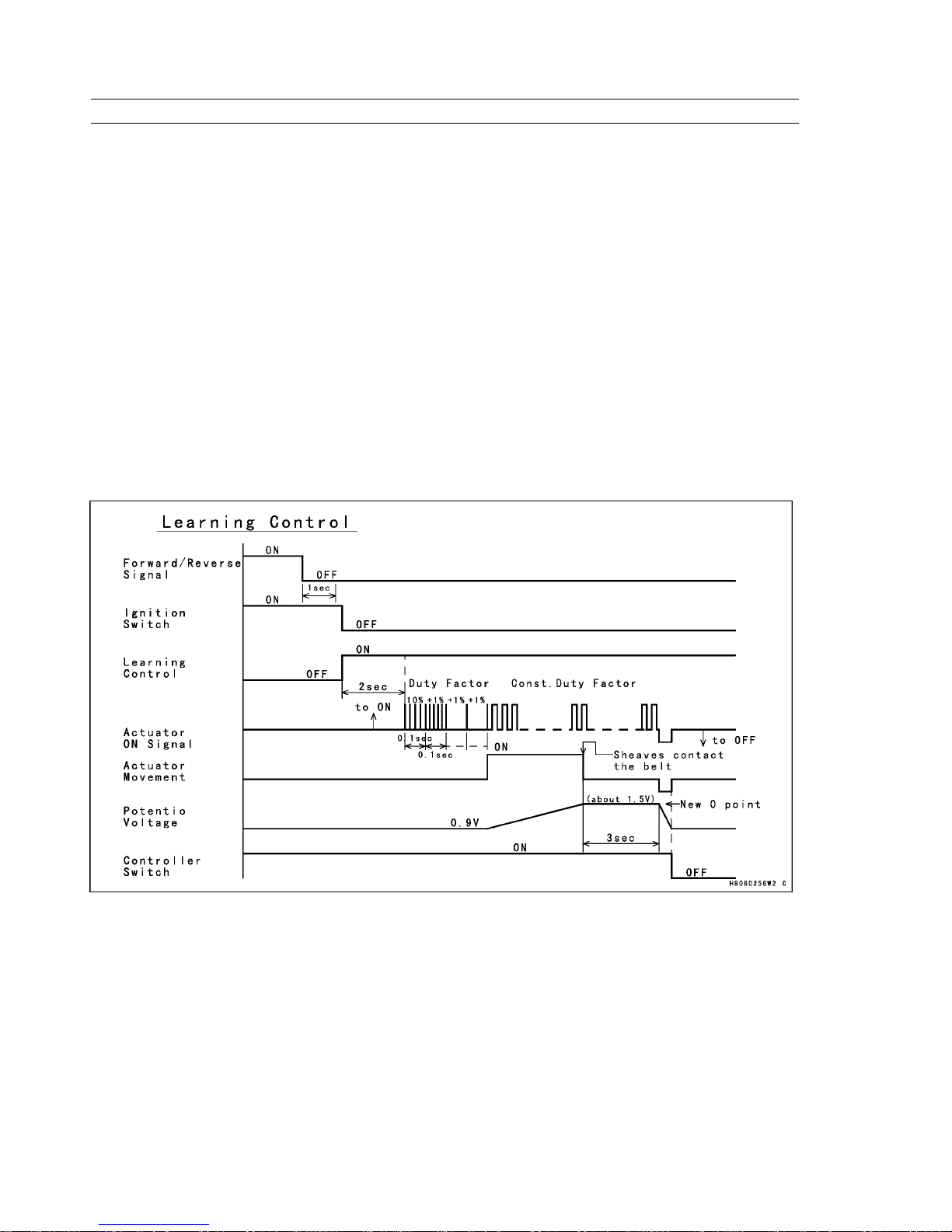

2–1 Learning Control

After the signal from the forward/reverse detecting sensor stops and 1 second elapses, turning the ignition switch OFF

causes the learning control to start.

After the ignition switch is turned OFF and a prescribed length of time elapses, current is applied to the actuator at a

prescribed duty factor in order to move the actuator towards engine brake ON position.

After the application of the current, if the actuator does not move within a prescribed length of time, the duty factor

increases in an attempt to move the actuator. This process is repeated until the actuator moves.

Once the actuator starts moving, the actuator continues to move at that duty factor.

The lever moves the drive pulley’s movable sheave until it contacts the belt. After contact with the belt, the actuator

cannot move any further because of the small duty cycle, and no more play in the system.

After the actuator stops moving, and a prescribed length of time elapses, the voltage (0 point = datum point) of the

potentiometer that is installed in the actuator is recorded on the EEPROM. The actuator returns to the engine brake OFF

position and the power to the controller turns OFF by the power ON/OFF circuit.

Learning Control

GENERAL INFORMATION 1-17

Technical Information — K-EBC System

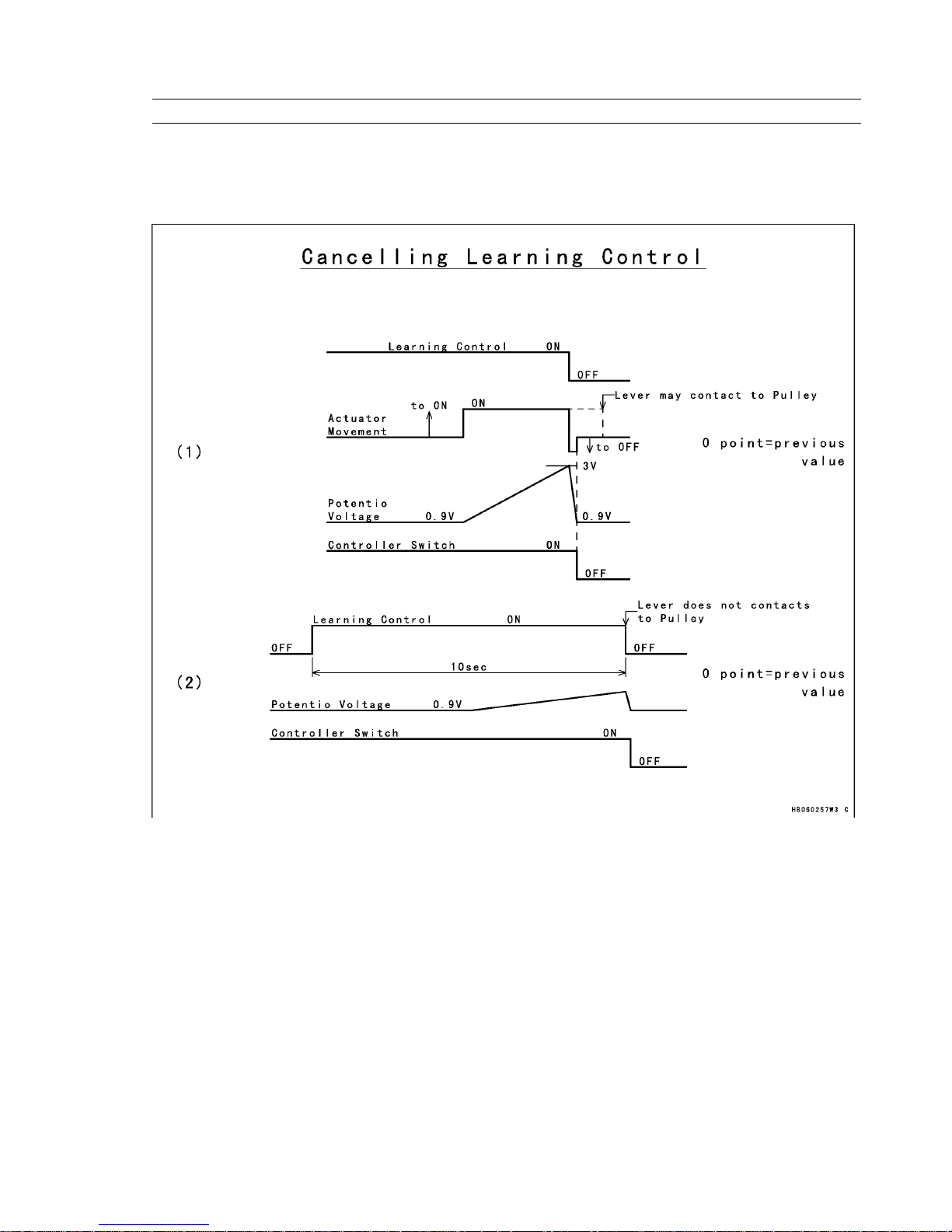

In case the Learning Control has failed, the previously learned value is used for the 0-point position of the actuator.

1) When the voltage of the potentiometer that is installed in the actuator exceeds a prescribed voltage.

2) When the learning control has not finished within 10 seconds.

Canceling Learning Control

1-18 GENERAL INFORMATION

Technical Information — K-EBC System

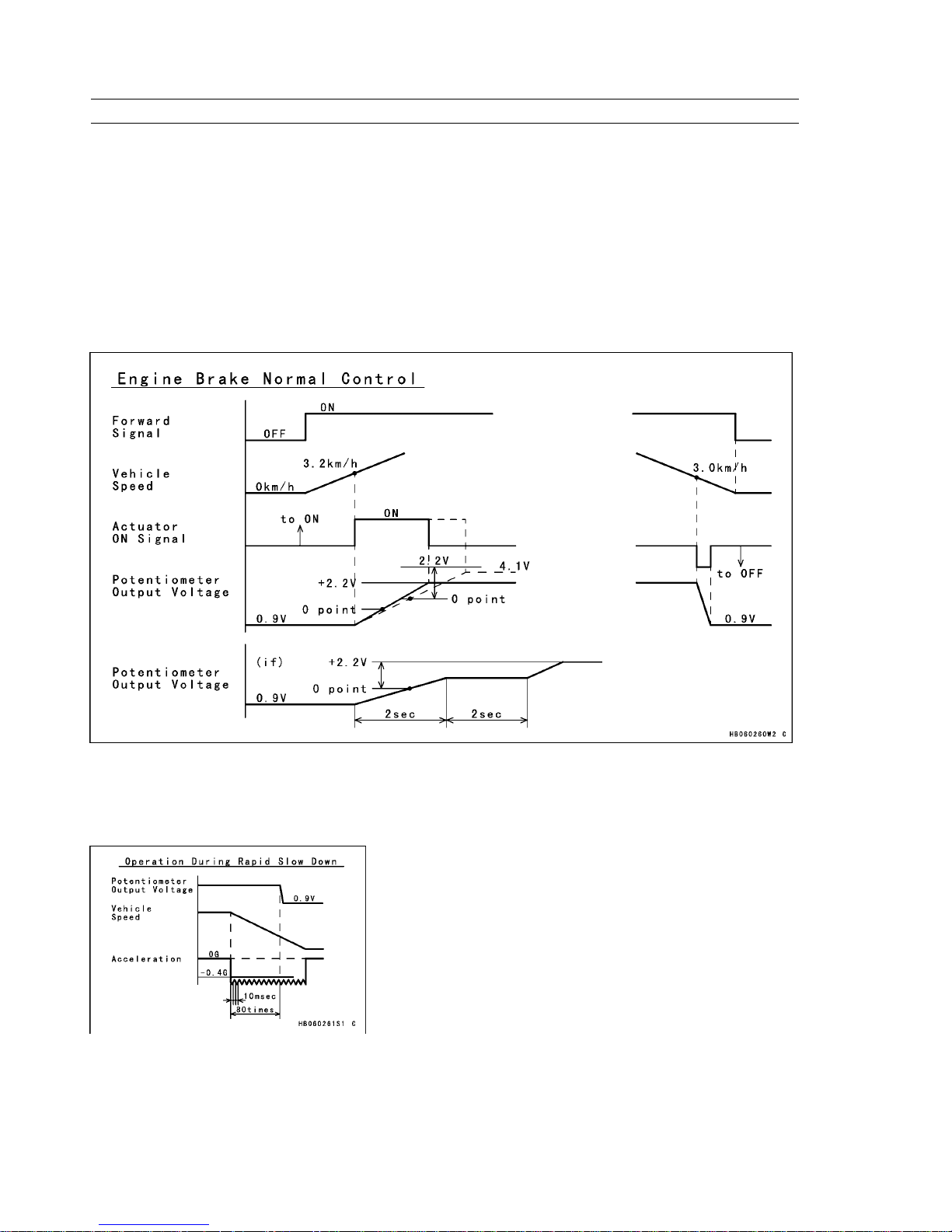

2–2 Normal Control

After forward movement is detected from the forward/reverse detecting sensor:

1) If the vehicle speed is higher than the prescribed value, the actuator moves towards engine brake ON position.

2) If the vehicle speed is less than the prescribed value, the actuator moves towards engine brake OFF position.

The maximum movement of the actuator ranges between the starting position and the ending position. The actuator

moves from the learned 0-point position to a position to which a prescribed voltage has been added.

However, if the sum of the learned value and the prescribed voltage exceeds the voltage of the ending position, the

actuator stops at the ending position.

During actuator operation, if the target value is not attained even if the actuator is moved longer than a prescribed

length of time, the controller stops the actuator temporarily. After a prescribed length of time, the controller resumes the

movement of the actuator. This process is repeated until the actuator attains the target value.

Engine Brake Normal Control

2–3 Operation During Rapid Slow Down

This control works to avoid the engine stopping when the vehicle speeds down rapidly.

When the actuator is in the engine brake ON position, if the deceleration of the vehicle is greater than a prescribed rate

and is detected within an interval time of 10 milliseconds, the actuator returns to engine brake OFF position.

Operation During Rapid Slow Down

GENERAL INFORMATION 1-19

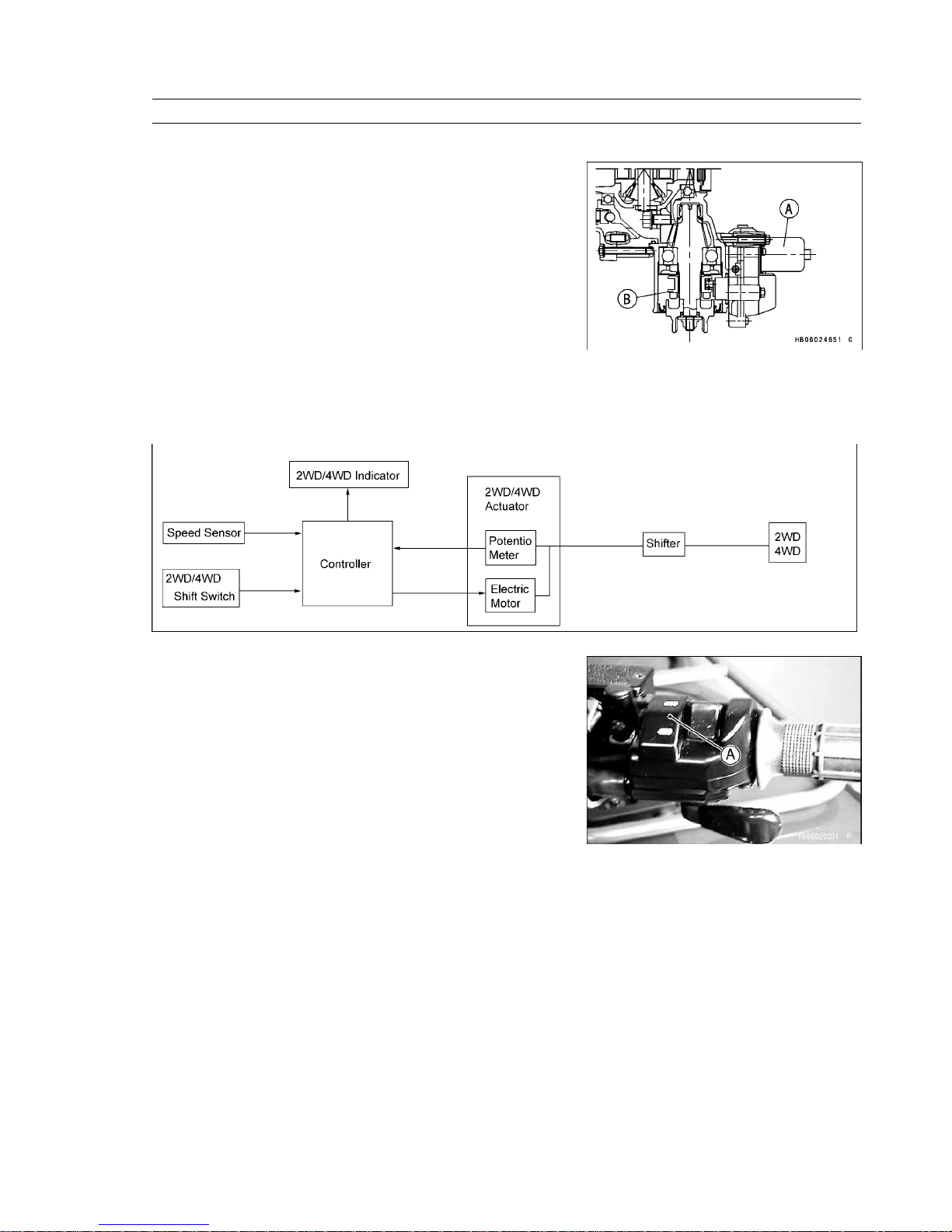

Technical Information — Selectable 2WD/4WD

1. Feature

Selectable 2WD/4WD system allows easy changing between 2WD

and 4WD drive systems to suit changing terrain and applications.

[A] 2WD/4WD Actuator

[B] Shifter

2. System Outline and Component Parts

This system consists of a 2WD/4WD shift switch, speed sensor, 2WD/4WD actuator, controller, and indicator for 2WD/

4WD.

See the wiring diagram in the K-EBC chapter.

(1) 2WD/4WD Shift Switch

The 2WD/4WD shift switch is installed on the right side of the

handlebar. This switch should be used when the vehicle is stopped.

(2) Speed Sensor

The sensor is installed on the right rear of the engine. It generates

pulses according to the gap difference between the sensor and the

rotating gear.

1-20 GENERAL INFORMATION

Technical Information — Selectable 2WD/4WD

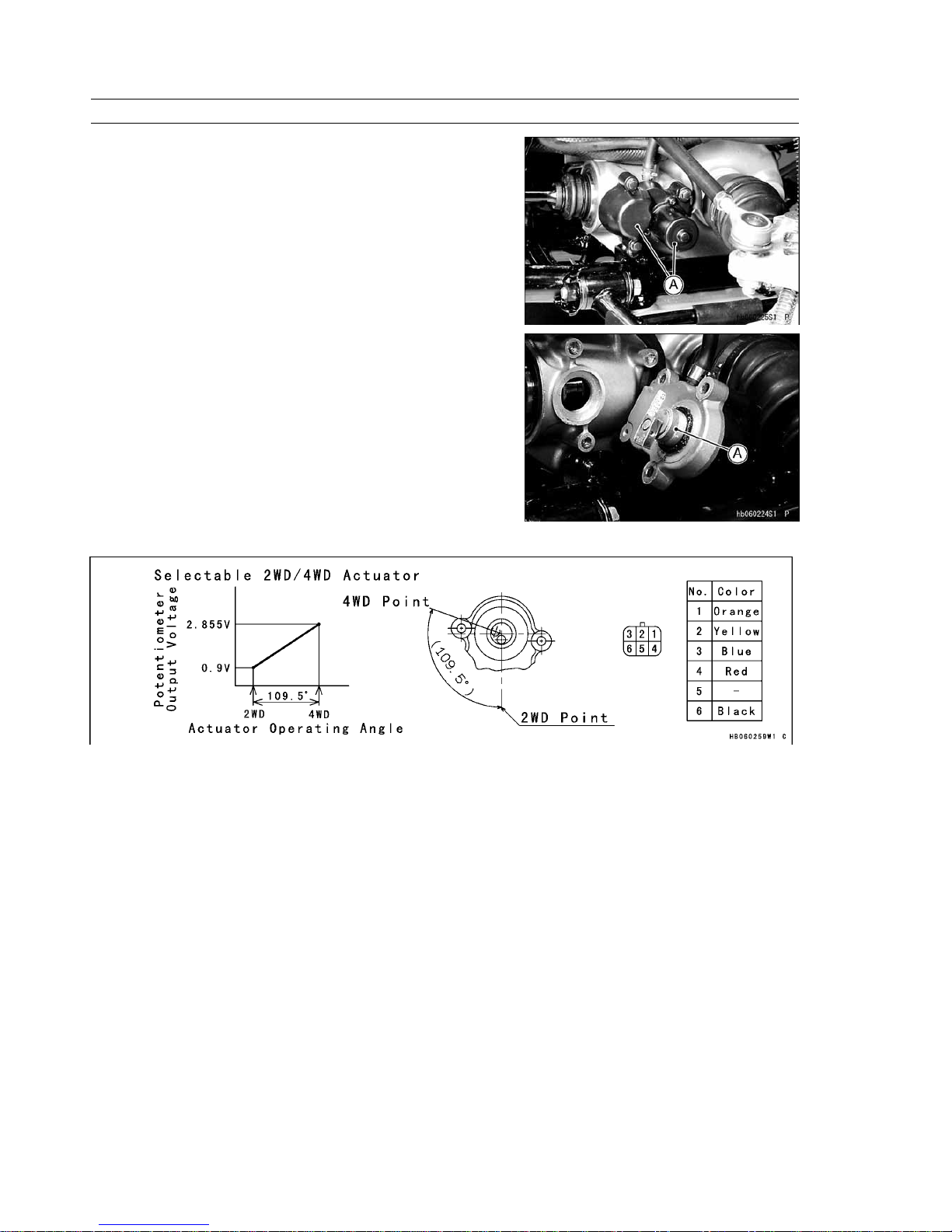

(3) 2WD/4WD Actuator

The actuator is installed on the front gear case. It consists of a DC

motor, reduction gears, and potentiometer.

[A] 2WD/4WD Actuator

[A] Output Shaft of Actuator

This figure shows the operation of the actuator.

(4) Controller

Refer to the K-EBC chapter.

GENERAL INFORMATION 1-21

Technical Information — Selectable 2WD/4WD

2. Selectable 2WD/4WD Actuator Control

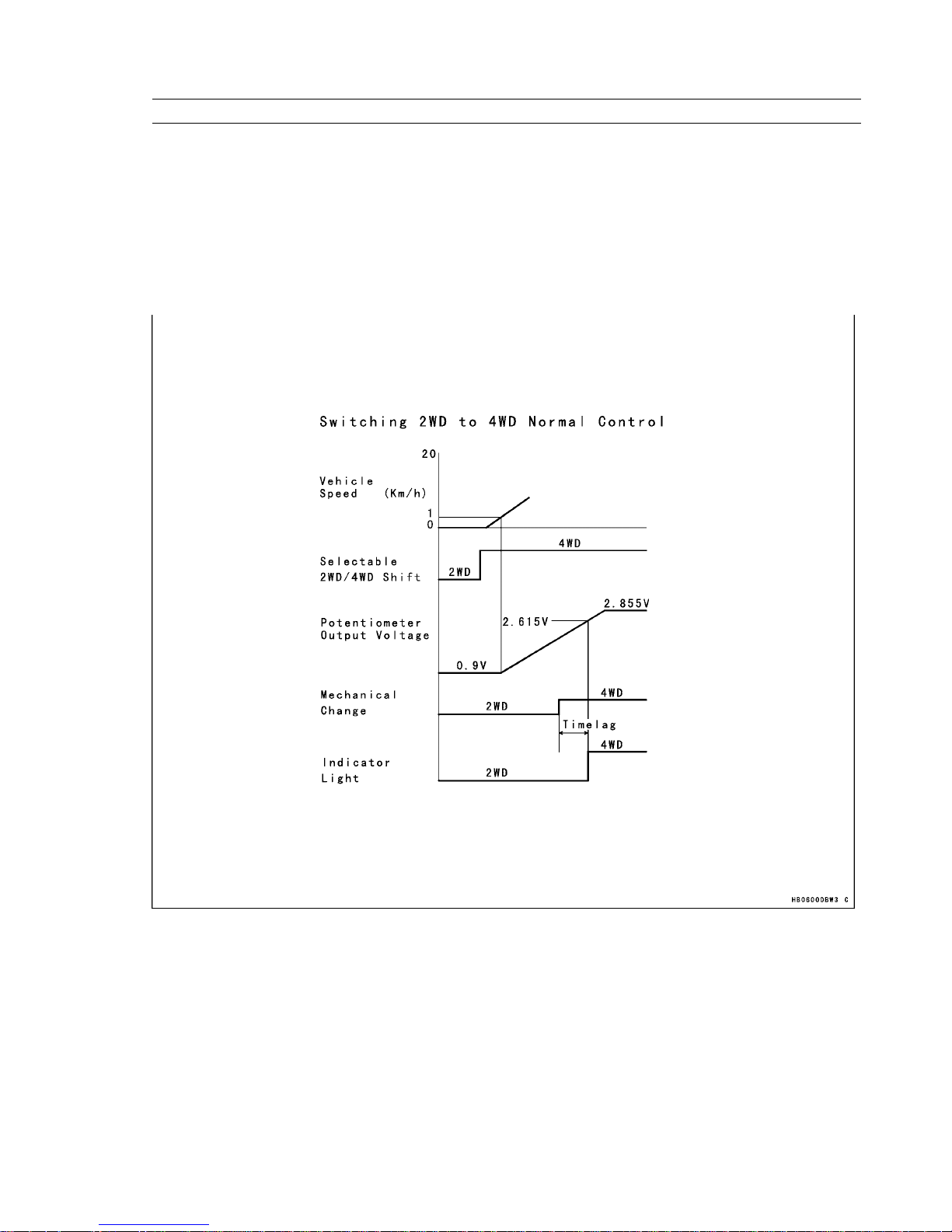

2–1 Switching 2WD to 4WD Control

1) Normal Control

This control operates only if the vehicle speed is within the range of 1 km/h and 20 km/h, and the selectable 2WD/4WD

shift switch is in 4WD.

The movement range of the actuator is between the starting position for 2WD, and the ending position for 4WD.

During actuator operation, at the time the potentiometer voltage becomes greater than a prescribed voltage, the indicator

light on the multifunction meter changes from 2WD to 4WD.

Selectable 2WD/4WD Normal Control

1-22 GENERAL INFORMATION

Technical Information — Selectable 2WD/4WD

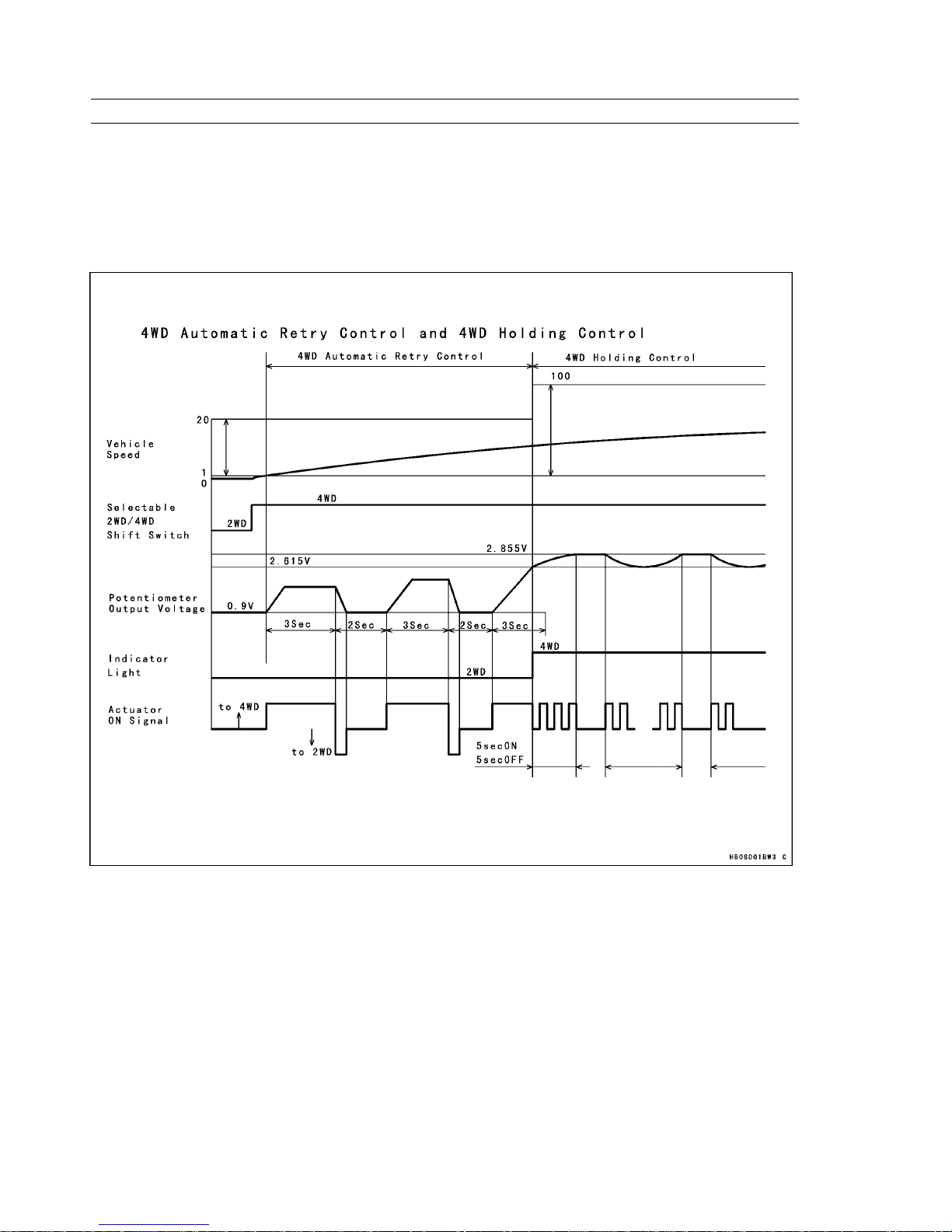

2) 4WD Automatic Retry Control

During actuator operation, if the actual value does not reach the indicator light switching voltage even after the actuator

moves longer than a prescribed length of time, the actuator returns temporarily in the 2WD direction. After a prescribed

length of time elapses, the actuator moves again in the 4WD direction. This process is repeated until the actuator reaches

the indicator light switching voltage.

This control applies to vehicle speeds that range between 1 km/h and 20 km/h.

4WD Automatic Retry Control

GENERAL INFORMATION 1-23

Technical Information — Selectable 2WD/4WD

3) 4WD Holding Control

During the implementation of "4WD Automatic Retry Control", control transfers to "4WD Holding Control" at the time the

potentiometer voltage becomes greater than the indicator light switching voltage and the actuator movement is less than

the ending position.

If the actuator is pushed back toward the 2WD direction, this control moves the actuator in the 4WD direction in order

to return it to the final position. The interval times of the actuator movement consist of ON time toward 4WD and OFF

times, which are repeated until the potentiometer voltage reaches the final position.

This control applies to vehicle speeds that range between 1 km/h and 100 km/h. The control ends when the potentiometer

voltage reaches the ending position voltage.

When the vehicle speed is above 20 km/h, control continues even if the selectable 2WD/4WD shift switch is switched

to 2WD. When the vehicle speed is between 1 km/h to 20 km/h, this control stops and transfers to 2WD control.

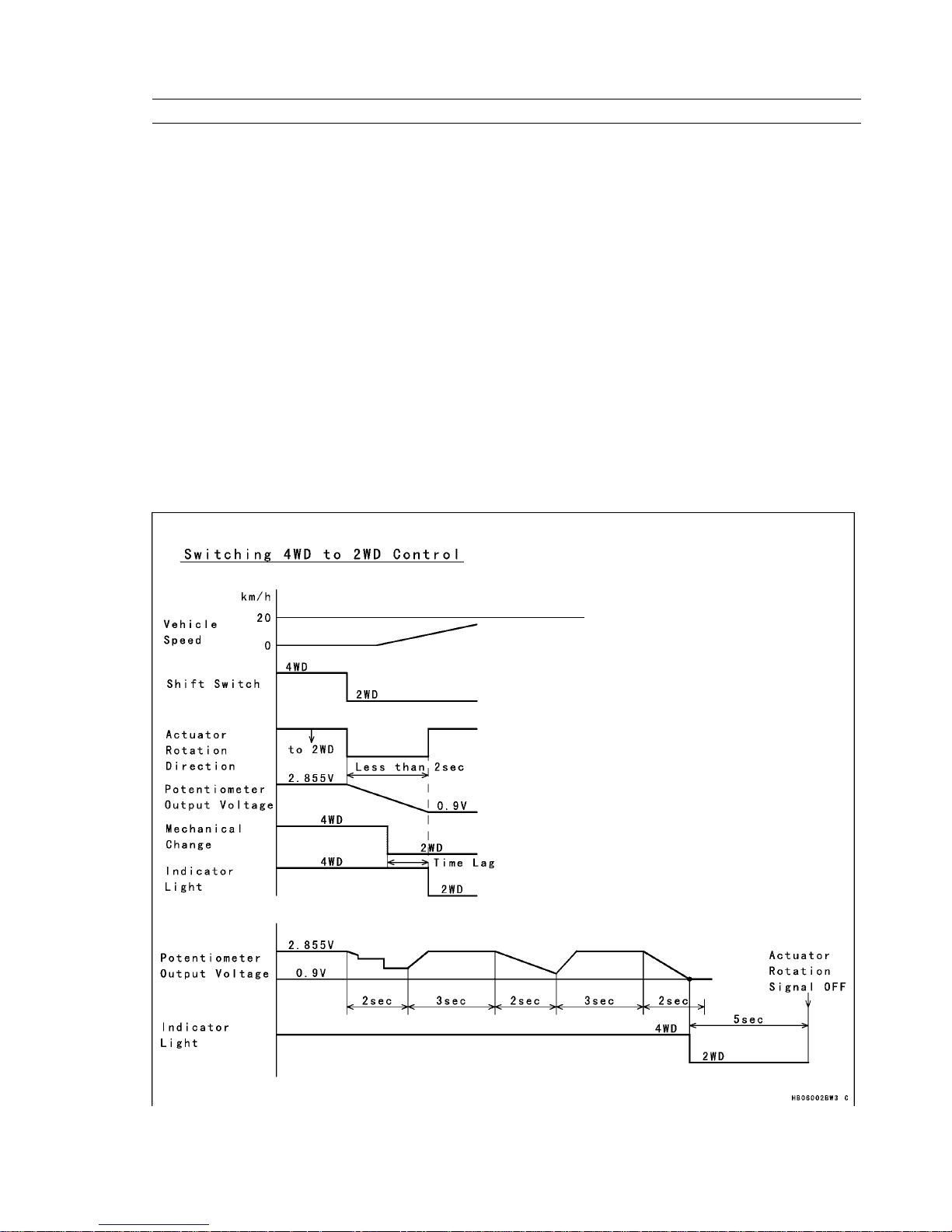

2–2 Switching 4WD to 2WD Control

This control is in effect only when the vehicle speed is between 0 km/h and 20 km/h, and the selectable 2WD/4WD shift

switch is in 2WD.

The movement range of the actuator is between the starting position for 4WD, and the ending position for 2WD.

During actuator operation, at the time the potentiometer output voltage is ending position voltage, the indicator light on

the multifunction meter changes from 4WD to 2WD.

During actuator operation, if the potentiometer output voltage does not reach the ending position voltage even after the

actuator moves longer than a prescribed length of time, the actuator returns temporarily in the 4WD direction, and moves

again in the 2WD direction. This process is repeated until the actuator reaches 2WD position.

Switching 4WD to 2WD Control

Loading...

Loading...