Kawasaki KZ-ZX-GPZ-500-550 1979-1985 Service Manual

KZ500/550 & 2x550 1979-1985

SERVICE REPAIR MAINTENANCE

Chapter One

General Information

Chapter Two

Troubleshooting

Chapter Three

Periodic Maintenance, Lubrication and Tune-up

Chapter Four

Engine

Chapter Five

Clutch

Chapter Six

Transmission

Chapter Seven

Fuel and Exhaust

Chapter Eight

Electrical Systems

Chapter Nine

Wheels, Tires and Brakes

Chapter Ten

1982

and Later Service lnformation

Wiring Diagrams

Chassis

Supplement

Index

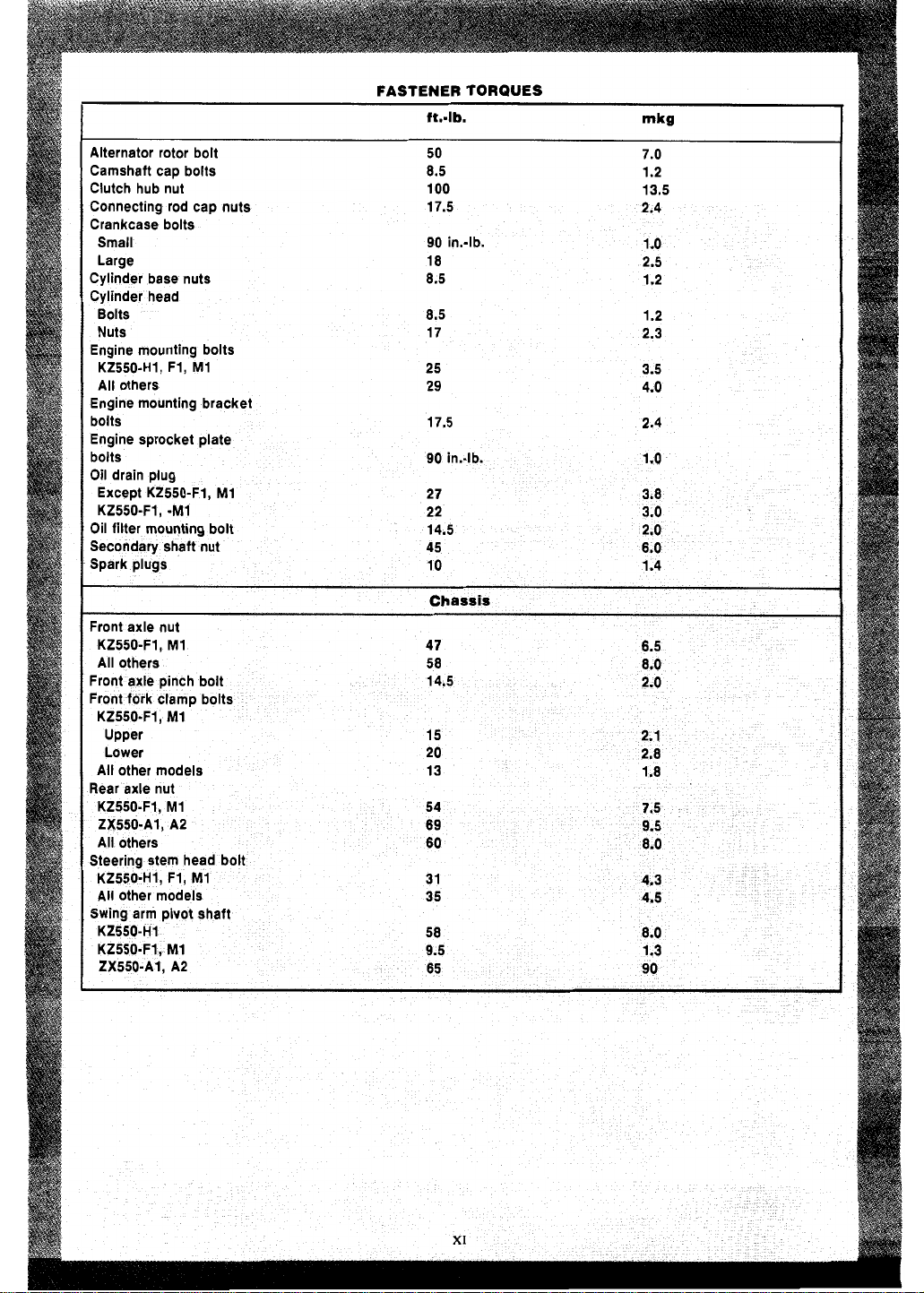

CONTENTS

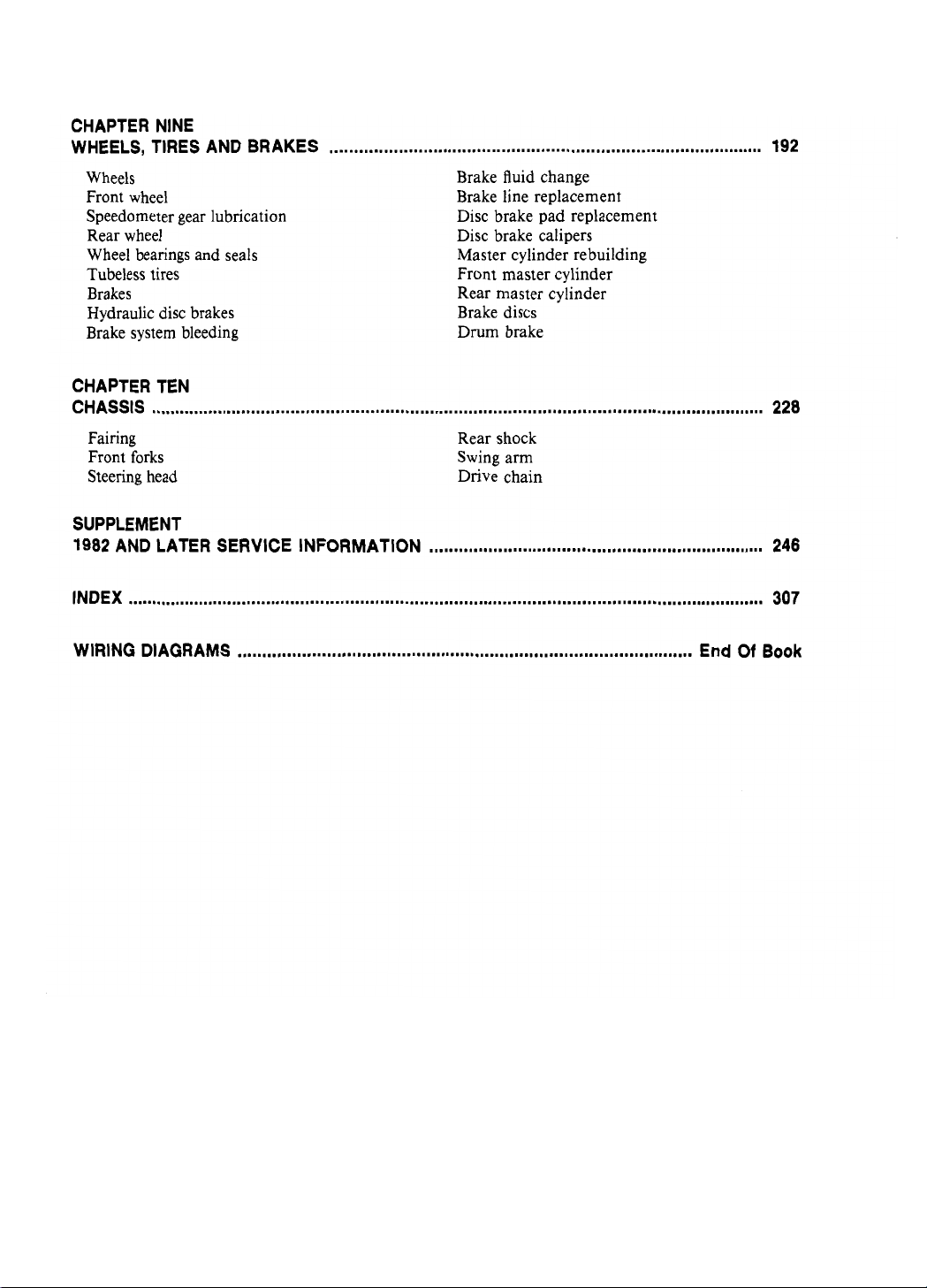

QUICK REFERENCE DATA

CHAPTER ONE

GENERAL INFORMATION

Manual organization

Service hints

Safety first

Expendable supplies

CHAPTER TWO

TROUBLESHOOTING

Starting difficulties

Poor performance

Clutch and transmission

Drive train

Chassis

Brakes

CHAPTERTHREE

LUBRICATION, MAINTENANCE AND TUNE-UP

Battery

Engine oil and filter

General lubrication

Clutch adjustment

Drive chain

Swing arm

Steering

Front forks

Rear shock absorbers

Tires

Wheel bearing lubrication

Disc brake

Drum brake

Engine tune-up

...............................................................................................

.....................................................................................................

.............................................................................................................

XI

1

Shop tools

Emergency tool kits

Troubleshooting and tune-up

equipment

9

Electrical system

Charging system

Lighting

Fuses

Wiring

.................................................................

Air filter

Nuts, bolts and fasteners

Fuel system

Spark plugs

Air suction valves (U.S. models)

Valve clearance

Contact breaker points

Ignition timing

(Contact point ignition)

Ignition timing

(Transistorized ignition)

Carburetor

Cylinder compression

Storage

33

CHAPTER FOUR

ENGINE 70

Tools

Engine design

Break-in

Servicing engine in frame

Cam chain and tensioner

Valve cover

Camshaft

Cylinder head

CHAPTER FIVE

CLUTCH

CHAPTER SIX

TRANSMlSSlON

.................................................................................................................................

Oil cooler

Removal/installation

Oil filter bypass valve

Oil pump

Crankcase

Secondary shaft and starter clutch

Crankshaft and connecting rods

Cam chain inspection

Valves and guides

Cylinder block

Pistons and rings

............................................................................................................................

Operation

Clutch release mechanism

....................

Sprocket cover

Neutral switch

Engine sprocket

Shift linkage

..

.......................................................................................

Primary chain inspection

Crankcase assembly

124

Clutch

133

Shift detent

Transmission

Shift drum and forks

Transmission gears

CHAPTERSEVEN

FUEL AND EXHAUST SYSTEMS

Carburetor operation

Carburetor troubleshooting

Rejetting

Carburetor tuning

Carburetor service

Fuel level inspection

Idle mixture adjustment

(Non-U.S. models)

CHAPTER EIGHT

ELECTRICAL

Wiring diagrams

Fuses

Battery

Ignition system

Contact breaker points and

condenser service

Spark plugs

Ignition advance mechanism

Ignition coil

Pickup coils

(Transistorized ignition)

SYSTEM

......................................................................................................

...................................................................................

Fast idle adjustment

Crankcase breather

Air suction system

(U.S. models)

Fuel tank

Fuel tap

Fuel level sending unit

Exhaust system

Alternator stator

Alternator rotor

Starting system

Starter motor

Starter clutch

Starter solenoid

Lighting system

Turn signal cancelling system

Fuel level sensor

Fuel gauge

Horn

148

169

CHAPTER NINE

WHEELS, TIRES AND BRAKES

Wheels

Front wheel

Speedometer gear lubrication

Rear wheel

Wheel bearings and seals

Tubeless tires

Brakes

Hydraulic disc brakes

Brake system bleeding

CHAPTERTEN

CHASSIS

Fairing

Front forks

Steering head

SUPPLEMENT

1982 AND LATER SERVICE INFORMATION

............................................................................................................................

...................

.............

Brake fluid change

Brake line replacement

Disc brake pad replacement

Disc brake calipers

Master cylinder rebuilding

Front master cylinder

Rear master cylinder

Brake discs

Drum brake

Rear shock

Swing arm

Drive chain

...........................................

..............................................................

192

228

246

INDEX

WIRING DIAGRAMS

......................................................................................................................

...................

..

.............................................................

End Of

307

Book

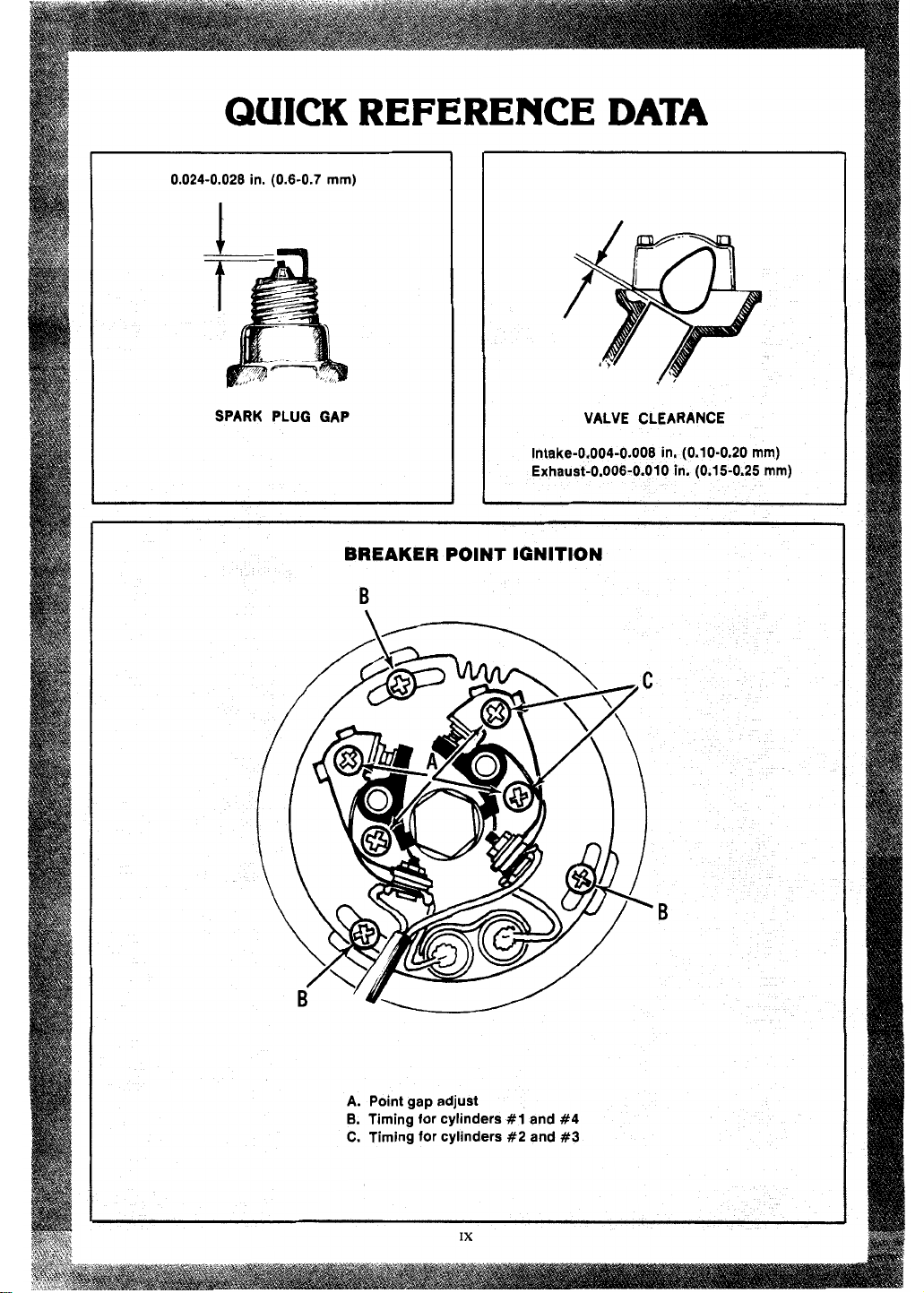

TIRES AND TIRE PRESSURE

ModellTire size Pressure

0.215 Ib.

(0.97.5

kg)

CYLINDER HEAD

TORQUE

SEQUENCE

@

load

Over 215 Ib.

(Over 97.5

kg)

KZ500-01, 02, KZ550-A1 (tube-type)

Front-3.25H-19 4PR

Rear-3.75-18 4PR

KZ500-03, KZ550-A2,B2,Dl (tubeless)

Front-3.25H-19 4PR

Rear-3.75H-18 4PR

KZ550-C1, C2 (tubeless)

Front-3.25s-19 4PR 25 psi (175 kPa) 25 psi (175 kPa)

Rear-130/90-16 67H PR

KZ550-HI (tubeless)

Front-3.25H-19 4PR

Rear-4.00-18 4PR

KZ550-F1, Ml (tubeless)

Front-100190-19 57s

Rear-130190.16 67s

ZX550-A1, A2 (tubeless)

Front-100190-18 56H

Rear-120180-18 62H

TUNE.UP SPECIFICATIONS

1979-1981; 1982-on US.

1982-on non-US.

Valve clearance (cold)

28 psi (200 kPa) 28 psi (200 kPa)

36 psi (245 kPa)

28 psi (200 kPa) 28 psi (200 kPa)

32 psi (225 kPa)

21 psi (150 kPa)

25 psi (175 kpa)

21 psi (147 kPa)

28 psi (196 kPa) 28 psi (196 kPa)

32 psi (225 kPa)

0.024-0.028 in. (0.6-0.7 mm)

NGK D8EA; ND X24ES-U

NGK D8ES; ND X24ESR-0

0.004-0.008 in. (0.10-0.20 mm)

0.006-0.010 in. (0.15-0.25 mm)

40 psi (280 kPa)

40 psi (280 kPa)

28 psi (200 kPa)

See tire data decal

25 psi (175 kPa)

28 psi (196 kPa)

36 psi (245 kPa)

1,150-1,250 rpm

All other models 1,000-1,100 rpm

X

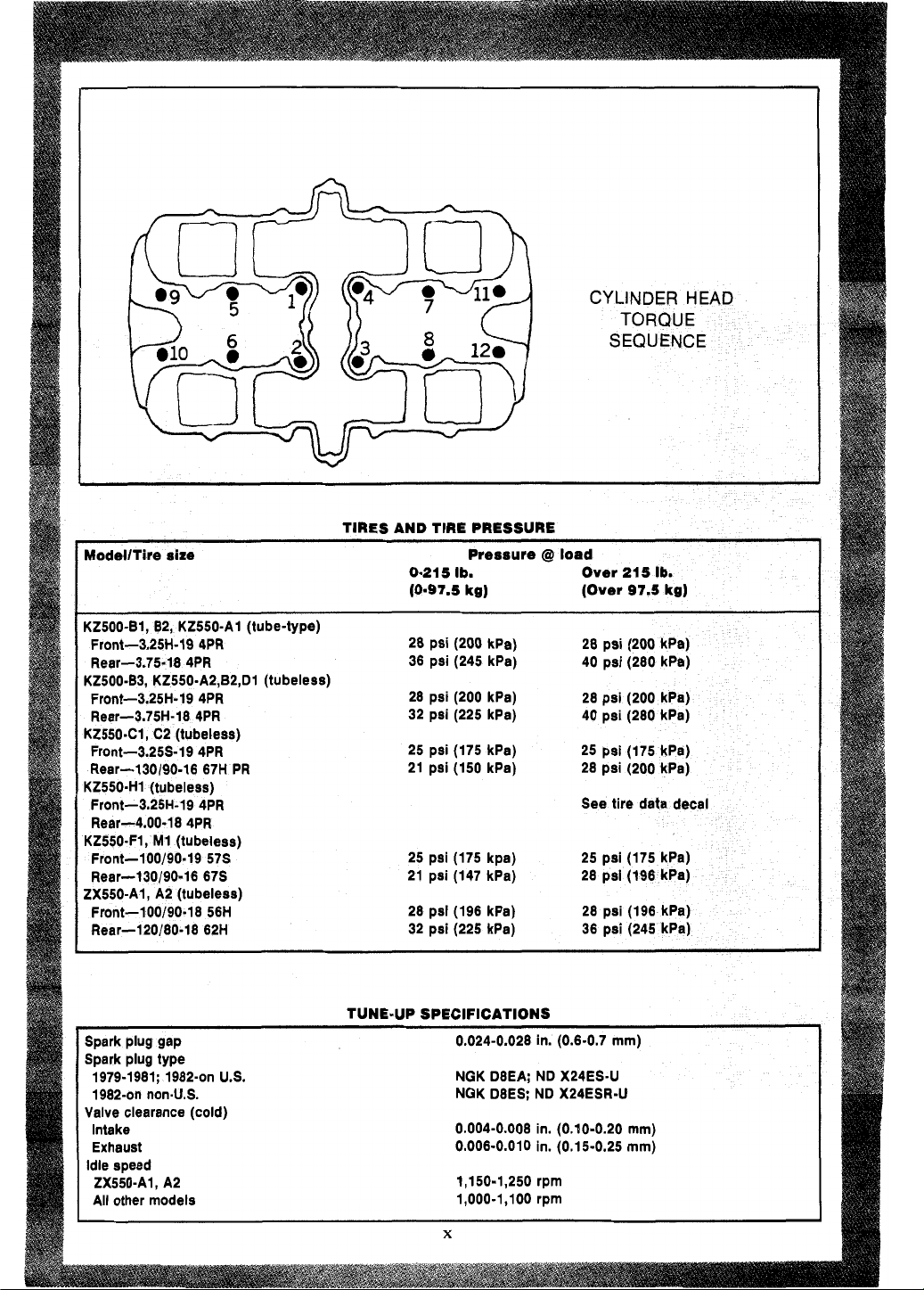

FASTENERTORQUES

ft..lb.

mkf4

Alternator rotor bolt

Camshaft cap bolts

Clutch hub nut

Connecting rod cap nuts

Crankcase bolts

Small

Large

Cylinder base nuts

Cylinder head

Bolts

Nuts

Engine mounting bolts

KZ550-HI, F1, MI

All others

Engine mounting bracket

bolts

Engine sprocket plate

bolts

Oil drain plug

Except KZ550-F1, MI

KZ550-F1, -M1

Oil filter mounting bolt

Secondary shaft nut

Spark plugs 10 1.4

Chassis

Front axle nut

KZ550-F1, MI 47 6.5

All others 58 8.0

Front axle pinch bolt 14.5 2.0

Front fork clamp bolts

KZ550-F1, MI

Upper

Lower

All other models

15 2.1

20 2.8

13 1.8

Rear axle nut

KZ550-F1, M1

2x550-At, A2

All others

54 7.5

69 9.5

60 8.0

Steering stem head bolt

KZ550bH1, F1, M1 31 4.3

All other models 35 4.5

Swing arm pivot shaft

KZ550-H1

KZ550-F1, M1

ZX550-A1, A2

58 8.0

9.5 1.3

65 90

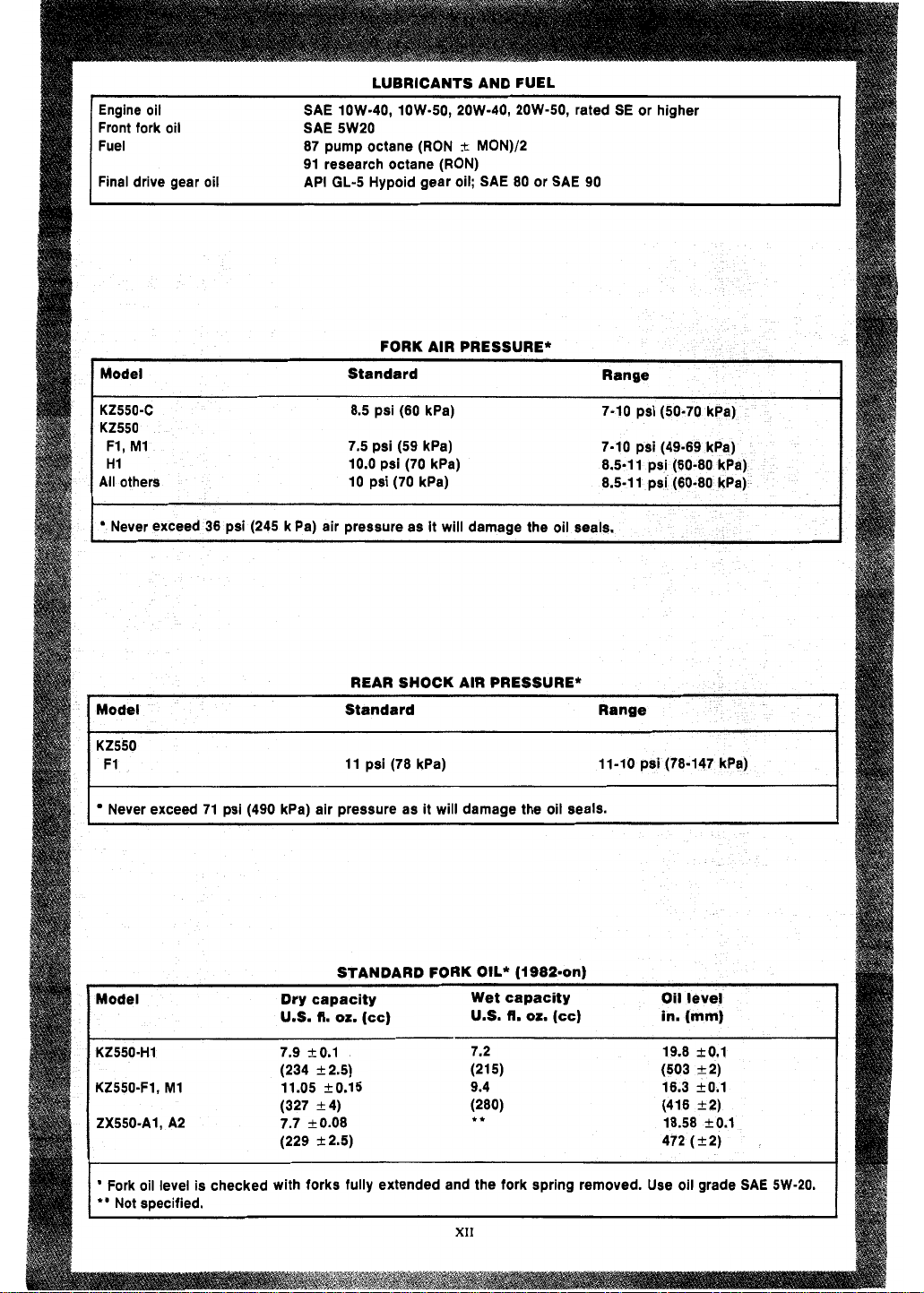

LUBRICANTS AND FUEL

Engine oil

SAE 10W-40, 1OW-50, 20W-40, 20W-50, rated SE or higher

Front fork oil SAE 5W20

Fuel

87 pump octane (RON

~t

MON)/2

91 research octane (RON)

Final drive gear oil

Model Standard

API GL-5 Hypoid gear oil; SAE 80 or SAE 90

FORK AIR PRESSURE*

Range

KZ550-C 8.5 psi (60 kPa) 7-10 psi (50-70 kPa)

KZ550

F1, MI 7.5 psi (59 kPa) 7-10 psi (49-69 kPa)

1

8.5-1

1

psi (60-80 kPa)

psi (60-80 kPa)

H1 10.0 psi (70 kPa) 8.5-1

All others

10 psi (70 kPa)

Never exceed 36 psi (245 k Pa) air pressure as it will damage the oil seals.

REAR SHOCK AIR PRESSURE*

Model Standard Range

KZ550

F1 11 psi (78 kPa) 11-10 psi (78-147 kPa)

Never exceed 71 psi (490 kPa) air pressure as it will damage the oil seals.

STANDARD FORK OIL* (1982-on)

Model Dry capacity Wet capacity Oil level

fl.

U.S.

fl.

oz. (cc)

U.S.

ox. (CC) in.

KZ550-HI 7.9 t 0.1 7.2 19.8

(mm)

+O.l

(234 k2.5) (215) (503 12)

KZ550-F1, MI 11.05 k0.15 9.4 16.3 +0.1

ZX550-A1, A2 7.7 k0.08

(327 +4) (280) (416 +2)

(229 22.5) 472

*.

18.58

tO.l

(

k

2)

Fork oil level is checked with forks fully extended and the fork spring removed. Use oil grade SAE 5W-20.

'

Not specified.

XI1

This detailed, comprehensive manual covers

Kawasaki

text gives complete information on maintenance,

repair and overhaul. Hundreds of photos and

drawings guide you through every step. The book

includes all you need to know to keep your bike

running right.

Chapters One through Ten contain general

information on all models and specific information on

1979-1 98 1 models. The Supplement at the end of the

book contains information on 1982 and later models

that differ from earlier years. Where repairs are

practical for the owner/mechanic, complete

procedures are given. Equally important, difficult jobs

are pointed out. Such operations are usually more

economically performed by a dealer or independent

garage.

A shop manual is a reference. You want to be able

to find information fast. As in all Clymer books, this

one is designed with this in mind. All chapters are

thumb tabbed. Important items are indexed at the

end of the book. All the most frequently used

specifications and capacities are summarized on the

Quick Reference

Keep the book handy. It will help you to better

understand your Kawasaki, lower repair and

maintenance costs and generally improve your

satisfaction with your bike.

KZ500/550

and

ZX550

pages at the beginning of the book.

models. The expert

CHAPTER

ONE

GENERAL INFORMATION

The troubleshooting, maintenance, tune-up,

and step-by-step repair procedures in this book

are written specifically for the owner and home

mechanic. The text is accompanied by helpful

photos and diagrams to make the job as clear

and correct as possible.

Troubleshooting, maintenance, tune-up, and

repair are not difficult if you know what to do

and what tools and equipment to use. Anyone

of average intelligence, with some mechanical

ability, and not afraid to get their hands dirty

can perform most of the procedures in this

book.

In some cases, a repair job may require tools

or skills not reasonably expected of the home

mechanic. These procedures are noted in each

it

chapter and

is recommended that you take

the job to your dealer, a competent mechanic,

or a machine shop.

MANUAL

ORGANIZATION

This chapter provides general information,

safety and service hints. Also included are lists

of recommended shop and emergency tools as

well as a brief description of troubleshooting

and tune-up equipment.

Chapter Two provides methods and sugges-

tions for quick and accurate diagnosis and

repair of problems. Troubleshooting pro-

cedures discuss typical symptoms and logical

methods to pinpoint the trouble.

Chapter Three explains all periodic lubrica-

tion and routine maintenance necessary to keep

your motorcycle running well. Chapter Three

also includes recommended tune-up pro-

cedures, eliminating the need to constantly con-

sult chapters on the various subassemblies.

Subsequent chapters cover specific systems

such as the engine, transmission, and electrical

system. Each of these chapters provides

disassembly, inspection, repair, and assembly

procedures in a simple step-by-step format. If a

it

repair is impractical for the home mechanic

is

indicated. In these cases it is usually faster and

less expensive to have the repairs made by a

dealer or competent repair shop. Essential

specifications are included in the appropriate

chapters.

When special tools are required to perform a

task included in this manual, the tools are

lustrated.

It

may be possible to borrow or rent

il-

these tools. The inventive mechanic may also be

able to find a suitable substitute in his tool box,

or to fabricate one.

NOTE,

The terms

CAUTION,

specific meanings in this manual. A

vides additional or explanatory information.

and

WARNING

NOTE

have

pro-

A

2

CHAPTER

ONE

CAUTION

is used to emphasize areas where

equipment damage could result if proper

precautions are not taken. A

WARNING

is used to

stress those areas where personal injury or

death could result from negligence, in addition

to possible mechanical damage.

SERVICE

HINTS

Time, effort, and frustration will be saved

and possible injury will be prevented if you

observe the following practices.

Most of the service procedures covered are

straightforward and can be performed by

anyone reasonably handy with tools. It is sug-

gested, however, that you consider your own

capabilities carefully before attempting any

operation involving major disassembly of the

engine.

Some operations, for example, require the

use of a press. It would be wiser to have these

performed by a shop equipped for such work,

rather than to try to do the job yourself with

makeshift equipment. Other procedures require

precision measurements. Unless you have the

skills and equipment required, it would be bet-

ter to have a qualified repair shop make the

measurements for you.

Repairs go much faster and easier if the parts

that will be worked on are clean before you

begin. There are special cleaners for washing

the engine and related parts. Brush or spray on

the cleaning solution, let stand, then rinse it

away with a garden hose. Clean all oily or

greasy parts with cleaning solvent as you

remove them.

WARNING

Never use gasoline as a cleaning agent.

It presents an extreme fire hazard. Be

sure to work in a well-ventilated area

when using cleaning solvent. Keep a fire

extinguisher, rated for gasoline fires,

handy in any case.

Much of the labor charge for repairs made by

dealers is for the removal and disassembly of

other parts to reach the defective unit. It is fre-

quently possible to perform the preliminary

operations yourself and then take the defective

unit in to the dealer for repair, at considerable

savings.

Once you have decided to tackle the job

yourself, make sure you locate the appropriate

section in this manual, and read it entirely.

Study the illustrations and text until you have a

good idea of what is involved in completing the

job satisfactorily. If special tools are required,

make arrangements to get them before you

start. Also, purchase any known defective parts

prior to starting on the procedure. It is

frustrating and time-consuming to get partially

into a job and then be unable to complete it.

Simple wiring checks can be easily made at

home, but knowledge of electronics is almost a

necessity for performing tests with complicated

electronic testing gear.

During disassembly of parts keep a few

general cautions in mind. Force is rarely needed

to get things apart. If parts are a tight fit, like a

bearing in a case, there is usually a tool de-

signed to separate them. Never use a

screwdriver to pry apart parts with machined

surfaces such as cylinder head or crankcase

halves. You will mar the surfaces and end up

with leaks.

Make diagrams wherever similar-appearing

parts are found. You may think you can

-

remember where everything came from

but

mistakes are costly. There is also the possibility

you may get sidetracked and not return to work

-

for days or even weeks

in which interval,

carefully laid out parts may have become

disturbed.

Tag all similar internal parts for location,

and mark all mating parts for position. Record

number and thickness of any shims as they are

removed. Small parts such as bolts can be iden-

tified by placing them in plastic sandwich bags

that are sealed and labeled with masking tape.

Wiring should be tagged with masking tape

and marked as each wire is removed. Again, do

not rely on memory alone.

Disconnect battery ground cable before

working near electrical connections and before

disconnecting wires. Never run the engine with

the battery disconnected; the alternator could

be seriously damaged.

Protect finished surfaces from physical

damage or corrosion. Keep gasoline and brake

fluid off painted surfaces.

GENERAL

INFORMATION

3

Frozen or very tight bolts and screws can

often be loosened by soaking with penetrating

oil like Liquid Wrench or

striking the bolt head a few times with a ham-

mer and punch (or screwdriver for screws).

Avoid heat unless absolutely necessary, since it

may melt, warp, or remove the temper from

many parts.

Avoid flames or sparks when working near a

charging battery or flammable liquids, such as

gasoline.

No parts, except those assembled with a press

fit, require unusual force during assembly. If a

part is hard to remove or install, find out why

before proceeding.

Cover all openings after removing parts to

keep dirt, small tools, etc., from falling in.

When assembling two parts, start all

fasteners, then tighten evenly.

Wiring connections and brake shoes, drums,

pads, and discs and contact surfaces in dry

clutches should be kept clean and free of grease

and oil.

When assembling parts, be sure all shims and

washers are replaced exactly as they came out.

Whenever a rotating part butts against a sta-

tionary part, look for a shim or washer. Use

new gaskets if there is any doubt about the con-

dition of old ones. Generally, you should apply

gasket cement to one mating surface only, so

the parts may be easily disassembled in the

future. A thin coat of oil on gaskets helps them

seal effectively.

Heavy grease can be used to hold small parts

in place if they tend to fall out during assembly.

However, keep grease and oil away from elec-

trical, clutch, and brake components.

High spots may be sanded off a piston with

sandpaper, but emery cloth and oil do a much

more professional job.

Carburetors are best cleaned by disas-

sembling them and soaking the parts in a com-

mercial carburetor cleaner. Never soak gaskets

and rubber parts in these cleaners. Never use

wire to clean out jets and air passages; they are

easily damaged. Use compressed air to blow out

the carburetor, but only if the float has been

removed first.

Take your time and do the job right. Do not

forget that a newly rebuilt engine must be

WD-40,

then sharply

broken in the same as a new one. Refer to your

owner's manual for the proper break-in pro-

cedures.

SAFETY FIRST

Professional mechanics can work for years

and never sustain a serious injury. If you

observe a few rules of common sense and

safety, you can enjoy many safe hours servicing

your motorcycle. You could hurt yourself or

damage the motorcycle if you ignore these

rules.

1.

Never use gasoline as a cleaning solvent.

2.

Never smoke or use a torch in the vicinity of

flammable liquids such as cleaning solvent in

open containers.

3.

Never smoke or use a torch in an area where

batteries are being charged. Highly explosive

hydrogen gas is formed during the charging

process.

4.

Use the proper sized wrenches to avoid

damage to nuts and injury to yourself.

5.

When loosening a tight or stuck nut, be

guided by what would happen if the wrench

should slip. Protect yourself accordingly.

6.

Keep your work area clean and uncluttered.

7.

Wear safety goggles during all operations in-

volving drilling, grinding, or use of a cold

chisel.

8.

Never use worn tools.

9.

Keep a fire extinguisher handy and be sure it

is rated for gasoline (Class

(Class

C)

fires.

EXPENDABLE SUPPLIES

Certain expendable supplies are necessary.

These include grease, oil, gasket cement, wiping

rags, cleaning solvent, and distilled water.

Also, special locking compounds, silicone

lubricants, and engine and carburetor cleaners

may be useful. Cleaning solvent is available at

most service stations and distilled water for the

battery is available at supermarkets.

SHOP TOOLS

For complete servicing and repair you will

need an assortment of ordinary hand tools

(Figure

1).

B)

and electrical

4

CHAPTER

ONE

As a minimum, these include:

Combination wrenches

Sockets

Plastic mallet

Small hammer

Impact driver

Snap ring pliers

Gas pliers

Phillips screwdrivers

Slot (common) screwdrivers

Feeler gauges

Spark plug gauge

Spark plug wrench

Special tools required are shown in the

chapters covering the particular repair in which

they are used.

Engine tune-up and troubleshooting pro-

cedures require other special tools and equip-

ment. These are described in detail in the

following sections.

EMERGENCY TOOL

KITS

Highway

A

small emergency tool kit kept on the bike is

handy for road emergencies which otherwise

could leave you stranded. The tools and spares

Figure

2

listed below and shown in

handle most roadside repairs.

a. Motorcycle tool kit (original equipment)

b. Impact driver

c. Silver waterproof sealing tape (duct tape)

(3

d. Hosedamps

e. Silicone sealer

f. Lock

g. Flashlight

h. Tire patch kit

i. Tire irons

j.

k. Waterless hand cleaner

1.

'N'

Plastic pint bottle (for oil)

Rags for clean up

sizes)

Seal

will let you

Off-Road

A few simple tools and aids carried on the

motorcycle can mean the difference between

walking or riding back to camp or to where

Figure

repairs can be made. See

A

few essential spare parts carried in your

truck or van can prevent a day or weekend of

trail riding from being spoiled. See

3.

Figure

4.

GENERAL

INFORMATION

5

On

the Motorcycle

a. Motorcycle tool kit (original equipment)

b. Drive chain master link

c. Tow line

d. Spark plug

e. Spark plug wrench

f. Shifter lever

g.

Clutch/brake lever

h. Silver waterproof sealing tape (duct tape)

i.

Loctite Lock

In

the Truck

'N'

Seal

a. Control cables (throttle, clutch, brake)

b. Silicone sealer

c. Tire patch kit

d. Tire irons

e. Tire pump

f. Impact driver

g. Oil

WARNlNG

Tools and spares should be carried on

the tnotorcycle

a simple fall could result in serious in-

jury from a sharp tool.

-

not in clothing where

TROUBLESHOOTING AND

TUNE-UP EQUIPMENT

Voltmeter, Ohmmeter,

and

Ammeter

For testing the ignition or electrical system, a

good voltmeter is required. For motorcycle use,

an instrument covering 0-20 volts is satisfac-

tory. One which also has a 0-2 volt scale is

necessary for testing relays, points, or in-

dividual contacts where voltage drops are much

_+

X

smaller. Accuracy should be

volt.

An ohmmeter measures electrical resistance.

This instrument is useful for checking conti-

nuity (open and short circuits), and testing

fuses and lights.

The ammeter measures electrical current.

Ammeters for motorcycle use should cover 0-50

amperes and 0-250 amperes. These are useful

for checking battery charging and starting cur-

rent.

Several inexpensive vakl's (volt-ohm-milli-

ammeter) combine all three instruments into

one which fits easily in any tool box. See

ure

5.

However, the ammeter ranges are usually

Fig-

too small for motorcycle work.

Hydrometer

The hydrometer gives a useful indication of

battery condition and charge by measuring the

6

CHAPTER

ONE

specific gravity of the electrolyte in each cell.

See

Figure

6.

Complete details on use and inter-

pretation of readings are provided in the elec-

trical chapter.

Compression Tester

The compression tester measures the com-

pression pressure built up in each cylinder. The

results, when properly interpreted, can indicate

general cylinder, ring, and valve condition. See

Figure

7.

Extension lines are available for hard-

to-reach cylinders.

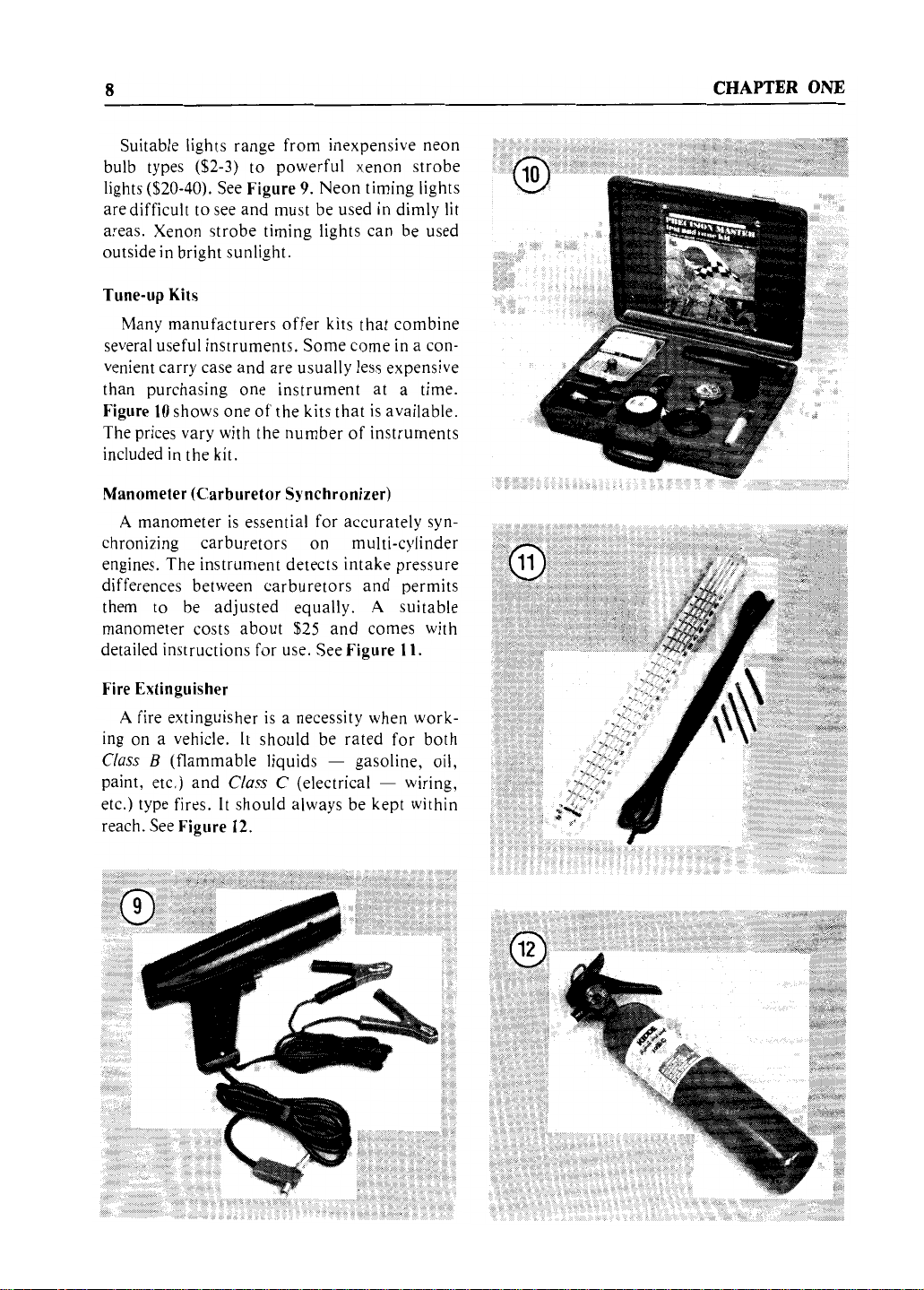

Dwell Meter (Contact Breaker

Point Ignition Only)

A

dwell meter measures the distance in

degrees of cam rotation that the breaker points

remain closed while the engine is running. Since

GENERAL INFORMATION

7

this angle is determined by breaker point gap,

dwell angle is an accurate indication of breaker

point gap.

Many tachometers intended for tuning and

testing incorporate a dwell meter as well. See

Figure

8.

Follow the manufacturer's instruc-

tions to measure dwell.

Tachometer

A

tachometer is necessary for tuning. See

Figure

8.

Ignition timing and carburetor ad-

justments must be performed at the specified

idle speed. The best instrument for this purpose

is one with a low range of 0-1,000 or 0-2,000

rpm for setting idle, and a high range of 0-4,000

or more for setting ignition timing at 3,000

rpm. Extended range (0-6,000 or 0-8,000 rpm)

instruments lack accuracy at lower speeds. The

instrument should be capable of detecting

25

changes of

NOTE:

not accurate enough for correct

justmen

Strobe

This instrument is necessary for tuning, as

rpm on the low range.

The motorcycle's tachometer is

I.

Timing Light

idle

ad-

it

permits very accurate ignition timing. The light

flashes at precisely the same instant that No.

1

cylinder fires, at which time the timing marks

on the engine should align. Refer to Chapter

Three for exact location of the timing marks for

your engine.

II

Suitable lights range from inexpensive neon

bulb types ($2-3) to powerful xenon strobe

Figure

9.

lights ($20-40). See

are difficult to see and must be used in dimly

areas. Xenon strobe timing lights can be used

outside in bright sunlight.

Tune-up Kits

Many manufacturers offer kits that combine

several useful instruments. Some come in a con-

venient carry case and are usually less expensive

than purchasing one instrument at a time.

Figure

10

shows one of the kits that is available.

The prices vary with the number of instruments

included in the kit.

Manometer (Carburetor Synchronizer)

A

manometer is essential for accurately syn-

chronizing carburetors on multi-cylinder

engines. The instrument detects intake pressure

differences between carburetors and permits

them to be adjusted equally.

manometer costs about $25 and comes with

detailed instructions for use. See

Neon timing lights

lit

A

suitable

Figure

11.

CHAPTER

ONE

Fire Extinguisher

A

fire extinguisher is a necessity when work-

ing on a vehicle. It should be rated for both

Class

B (flammable liquids - gasoline, oil,

paint, etc.) and

etc.) type fires.

reach. See

It

Figure

Class

C

(electrical - wiring,

should always be kept within

12.

CHAPTER

TWO

TROUBLESHOOTING

Troubleshooting motorcycle problems is

relatively simple. To be effective and efficient,

however, it must be done in a logical step-by-

it

step manner. If

may be wasted, good parts may be replaced un-

necessarily, and the true problem may never be

uncovered.

Always begin by defining the symptoms as

closely as possible. Then, analyze the symptoms

carefully so that you can make an intelligent

guess at the probable cause. Next, test the prob-

able cause and attempt to verify it; if it's not at

fault, analyze the symptoms once again, this

time eliminating the first probable cause. Con-

tinue on in this manner, a step at a time, until

the problem is solved.

At first, this approach may seem to be time

consuming, but you will soon discover that it's

not nearly so wasteful as a hit-or-miss method

that may never solve the problem. And just as

important, the methodical approach to

troubleshooting ensures that only those parts

that are defective will be replaced.

The troubleshooting procedures in this

chapter analyze typical symptoms and show

logical methods for isolating and correcting

trouble. They are not, however, the only

methods; there may be several approaches to a

given problem, but all good troubleshooting

methods have one thing in common

logical, systematic approach.

is not, a great deal of time

-

a

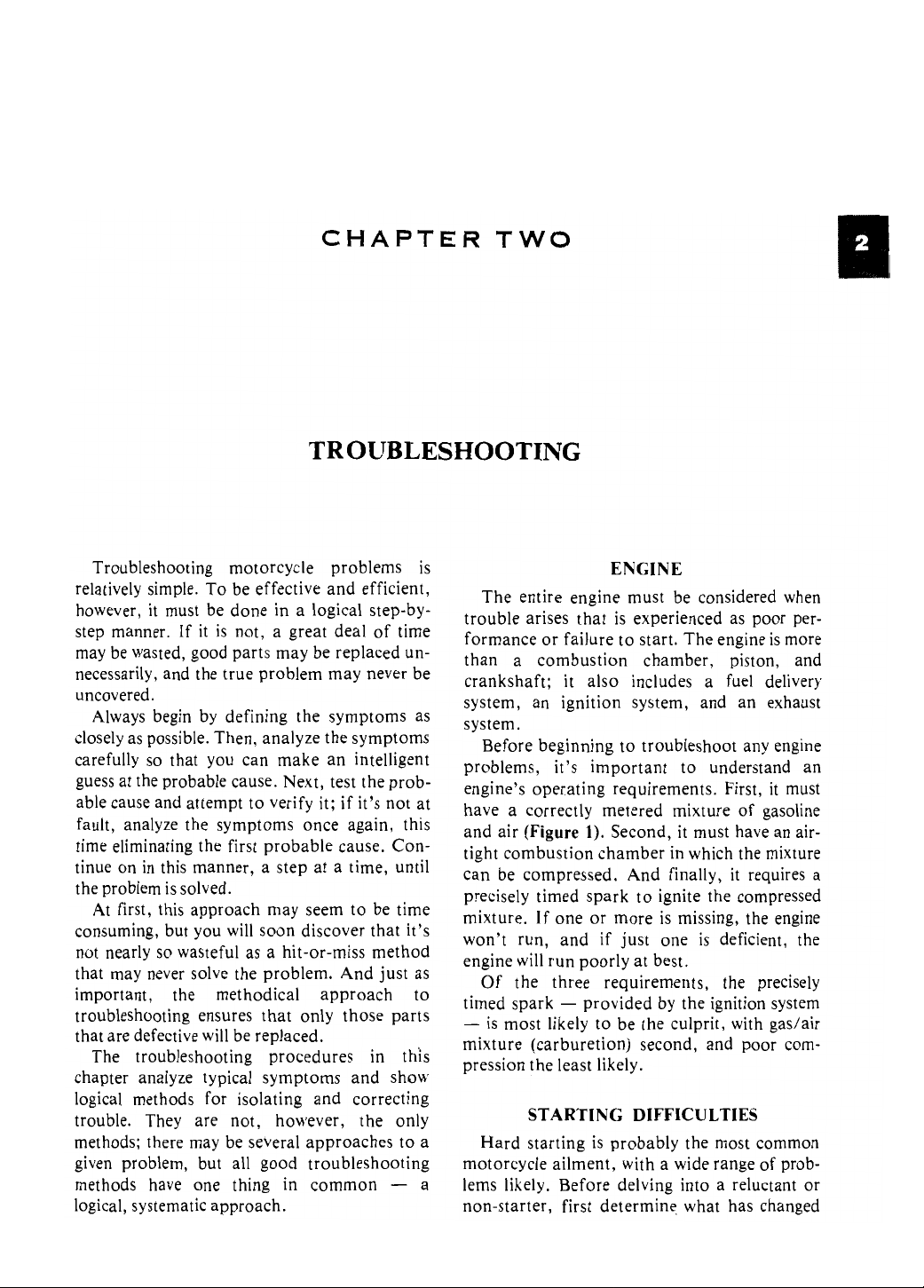

ENGINE

The entire engine must be considered when

trouble arises that is experienced as poor per-

formance or failure to start. The engine is more

than a combustion chamber, piston, and

crankshaft; it also includes a fuel delivery

system, an ignition system, and an exhaust

system.

Before beginning to troubleshoot any engine

problems, it's important to understand an

it

engine's operating requirements. First,

have a correctly metered mixture of gasoline

1).

and air (Figure

tight combustion chamber in which the mixture

can be compressed. And finally, it requires a

precisely timed spark to ignite the compressed

mixture. If one or more is missing, the engine

won't run, and if just one is deficient, the

engine will run poorly at best.

Of the three requirements, the precisely

timed spark

-

is most likely to be the culprit, with gadair

mixture (carburetion) second, and poor com-

pression the least likely.

STARTING DIFFICULTIES

Hard starting is probably the most common

motorcycle ailment, with a wide range of prob-

lems likely. Before delving into a reluctant or

non-starter, first determine, what has changed

Second, it must have an air-

-

provided by the ignition system

must

10

4-STROKE OPERATING PRINCIPLES

CHAPTER

TWO

TROUBLESHOOTING

11

since the motorcycle last started easily. For in-

stance, was the weather dry then and is it wet

now? Has the motorcycle been sitting in the

garage for a long time? Has it been ridden

many miles since it was last fueled?

Has starting become increasingly more dif-

ficult? This alone could indicate a number of

things that may be wrong but is usually

associated with normal wear of ignition and

engine components.

While it's not always possible to diagnose

trouble simply from a change of conditions,

this information can be helpful and at some

future time may uncover a recurring problem.

Fuel Delivery

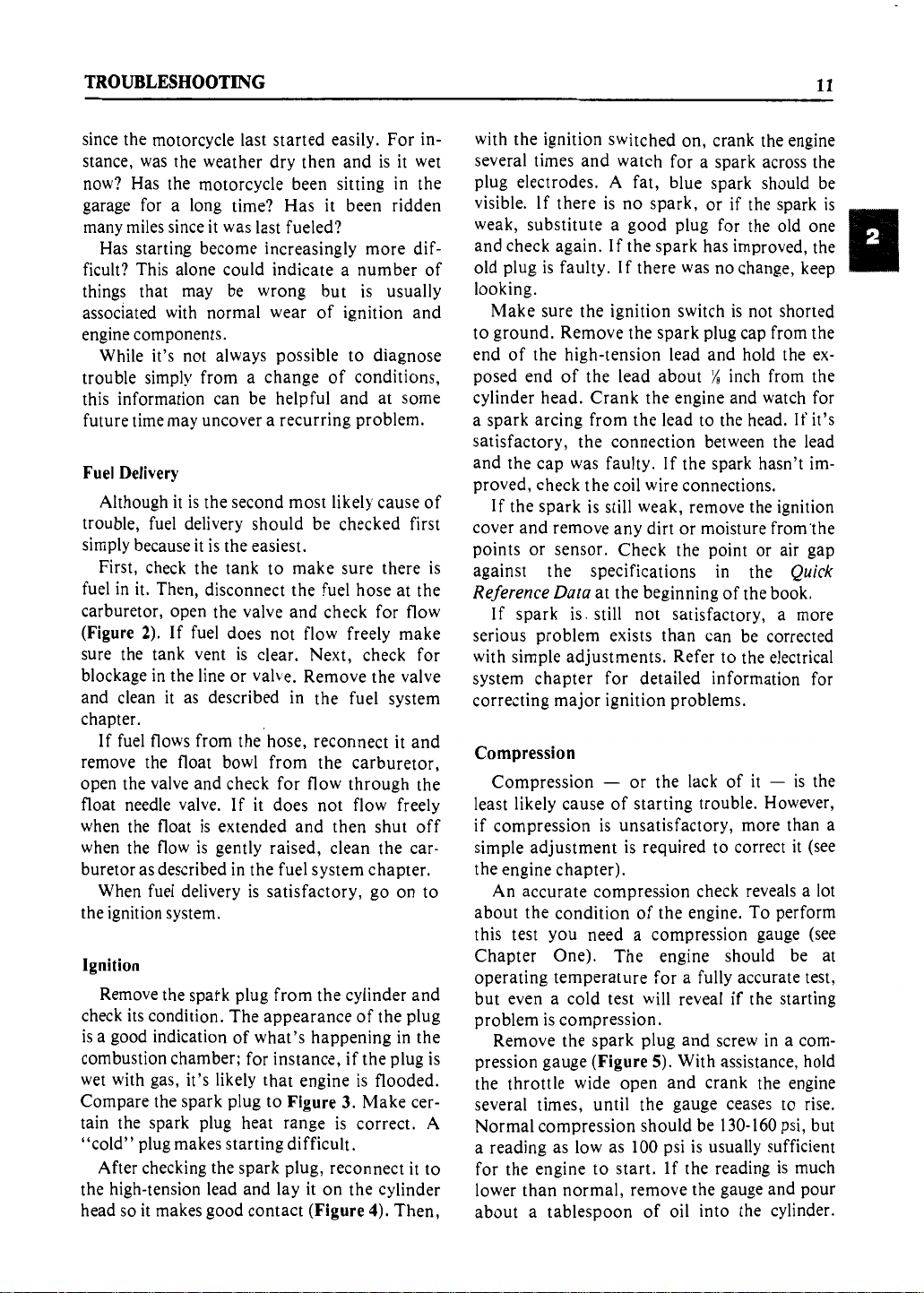

Although it is the second most likely cause of

trouble, fuel delivery should be checked first

simply because it is the easiest.

First, check the tank to make sure there is

fuel in it. Then, disconnect the fuel hose at the

carburetor, open the valve and check for flow

(Figure

2).

If fuel does not flow freely make

sure the tank vent is clear. Next, check for

blockage in the line or valve. Remove the valve

and clean it as described in the fuel system

chapter.

If fuel flows from the'hose, reconnect it and

remove the float bowl from the carburetor,

open the valve and check for flow through the

float needle valve. If it does not flow freely

when the float is extended and then shut off

when the flow is gently raised, clean the car-

buretor as described in the fuel system chapter.

When fuel delivery is satisfactory, go on to

the ignition system.

Ignition

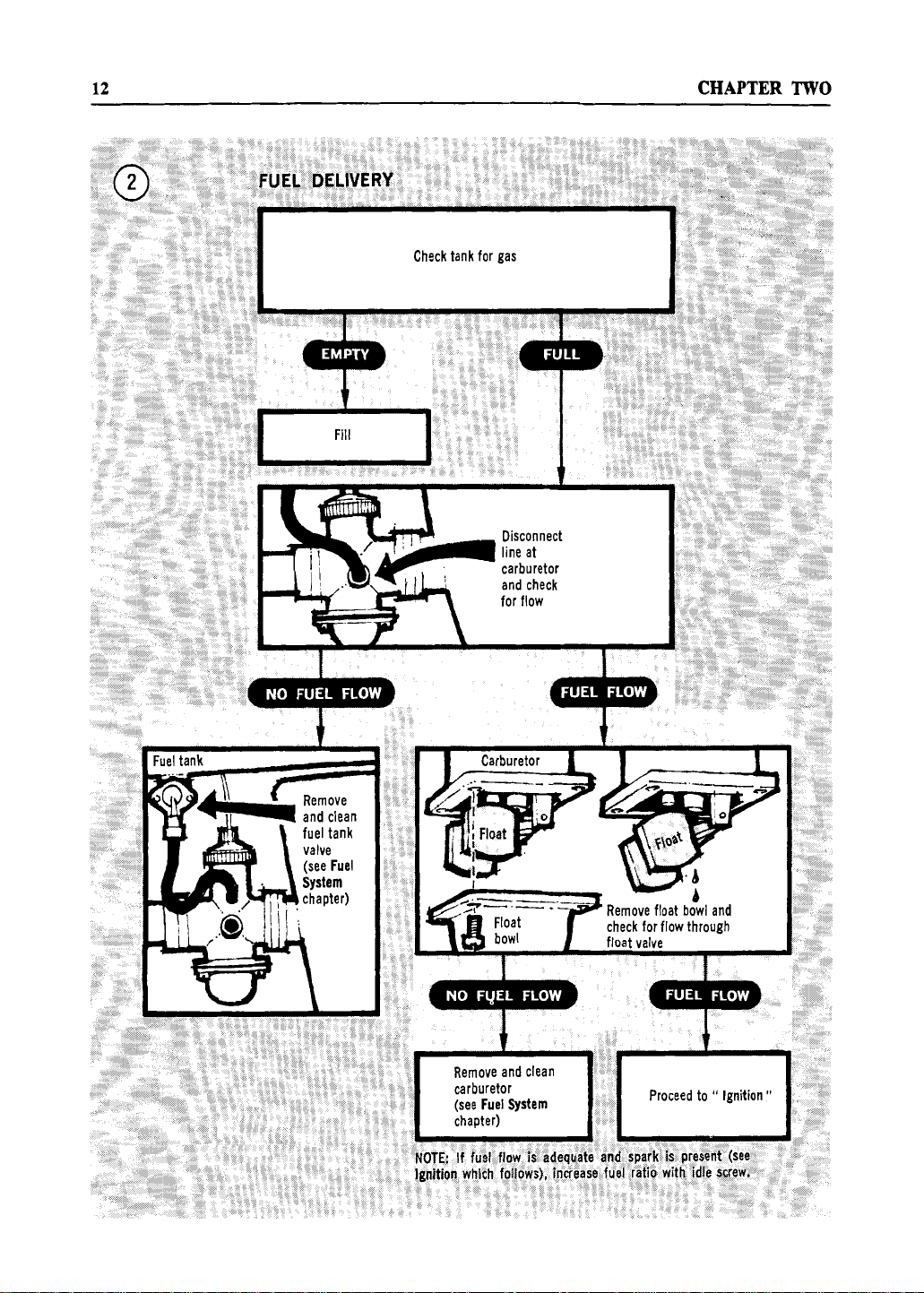

Remove the spark plug from the cylinder and

check its condition. The appearance of the plug

is a good indication of what's happening in the

combustion chamber; for instance, if the plug is

wet with gas, it's likely that engine is flooded.

Compare the spark plug to Figure

3.

Make cer-

tain the spark plug heat range is correct. A

"cold" plug makes starting difficult.

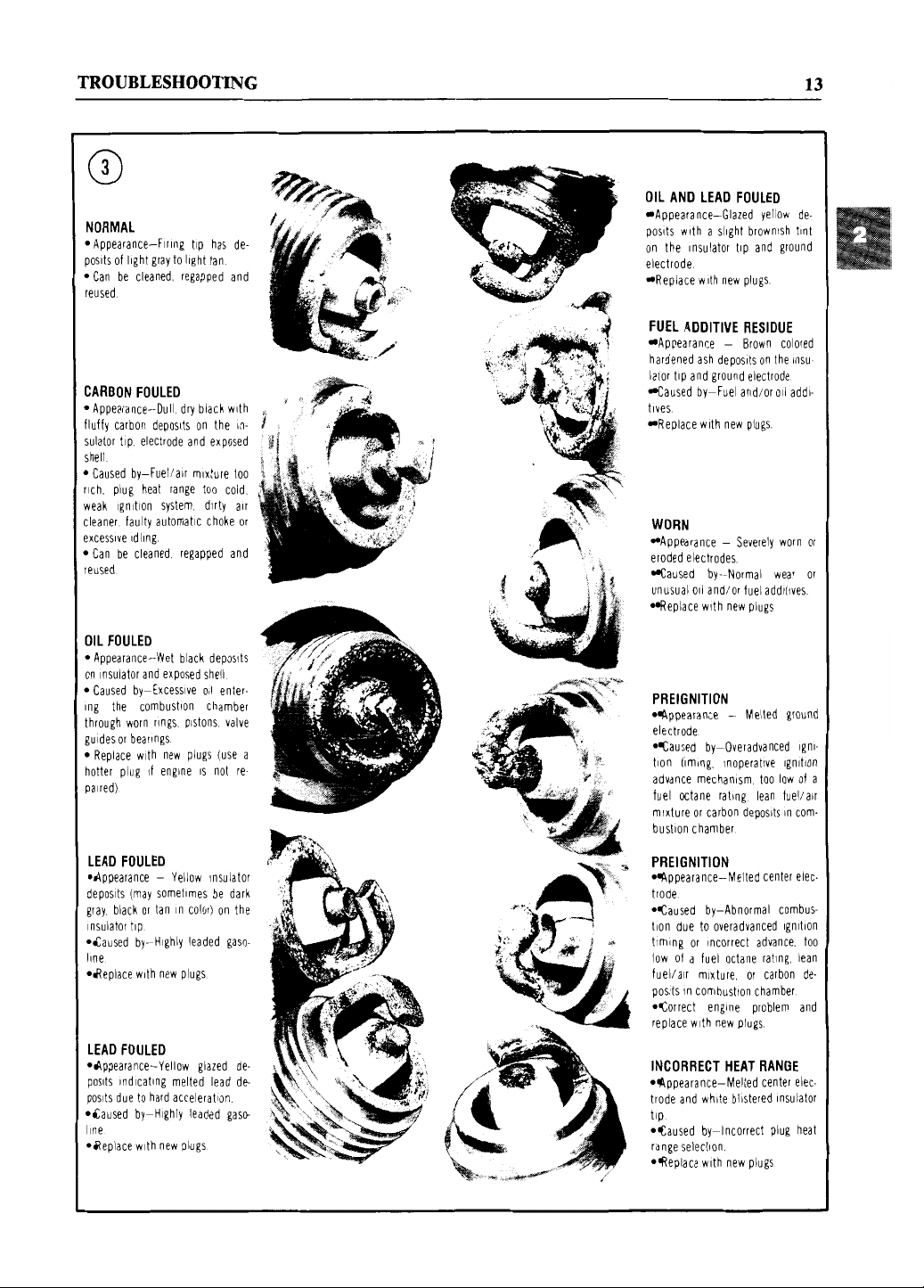

After checking the spark plug, reconnect it to

the high-tension lead and lay it on the cylinder

head so it makes good contact (Figure

4).

Then,

with the ignition switched on, crank the engine

several times and watch for a spark across the

plug electrodes. A fat, blue spark should be

visible. If there is no spark, or if the spark is

weak, substitute a good plug for the old one

and check again. If the spark has improved, the

old plug is faulty. If there was no change, keep

looking.

Make sure the ignition switch is not shorted

to ground. Remove the spark plug cap from the

end of the high-tension lead and hold the ex-

)/8

posed end of the lead about

inch from the

cylinder head. Crank the engine and watch for

a spark arcing from the lead to the head. If it's

satisfactory, the connection between the lead

and the cap was faulty. If the spark hasn't im-

proved, check the coil wire connections.

If the spark is still weak, remove the ignition

cover and remove any dirt or moisture from'the

points or sensor. Check the point or air gap

against the specifications in the

Data

Reference

at the beginning of the book.

Quick

If spark is. still not satisfactory, a more

serious problem exists than can be corrected

with simple adjustments. Refer to the electrical

system chapter for detailed information for

correcting major ignition problems.

Compression

Compression

-

or the lack of it - is the

least likely cause of starting trouble. However,

if compression is unsatisfactory, more than a

simple adjustment is required to correct it (see

the engine chapter).

An accurate compression check reveals a lot

about the condition of the engine. To perform

this test you need a compression gauge (see

Chapter One). The engine should be at

operating temperature for a fully accurate test,

if

but even a cold test will reveal

the starting

problem is compression.

Remove the spark plug and screw in a com-

pression gauge (Figure

5).

With assistance, hold

the throttle wide open and crank the engine

several times, until the gauge ceases to rise.

Normal compression should be

a reading as low as

100

psi is usually sufficient

130-160

psi, but

for the engine to start. If the reading is much

lower than normal, remove the gauge and pour

about a tablespoon of oil into the cylinder.

12

CHAPTER

'IWO

TROUBLESHOOTING

13

w

lORMAL

Appearance-Firing tip has de-

ios~ts of light gray to light tan

Can be cleaned, regapped and

eused

:ARBON FOULED

Appearance-Dull dry black w~th

luffy carbon depos~ts on the in

ulator tip electrode and exposed

hell

Caused by-Fuellair m~xture too

ch plug heat range too cold

teak ignition system dirty air

leaner faulty automatic choke or

xcesslve Idling

Can be cleaned regapped and

eused

31L FOULED

Appearance-Wet black depos~ts

In insulator and exposed shell

Caused by-Excessive oil enter-

ng the combust~on chamber

hrough worn rlngs pistons valve

gdes or bear~ngs

1

Replace with new plugs (use a

latter plug if engine 18 not re

)aired)

OIL AND LEAD FOULED

Appearance-Glazed yellow de

pos~ts w~th a sl~ght brown~sh tint

on the insulator tip and ground

electrode

Replace with new plugs

FUEL ADDITIVE RESIDUE

Appearance - Brown colored

hardened ash deposits on the insu

lator t~p and ground electrode

Caused by-Fuel andlor oil addi-

t~ves

Replace w~th new plugs

WORN

Appearance - Severely worn or

eroded electrodes

Caused by-Normal wear or

unusual 011 andlor fuel add~tives

Replace w~th new plugs

PREIGNITION

Appearance - Melted ground

electrode

Caused by-Overadvanced ignl

tion timing inoperative ignhtion

advance mechanism too low of a

fuel octane rating lean fuellair

m~xture or carbon deposits in com-

bustion chamber

LEAD FOULED

Appearance - Yellow mulator

deposits (may sometimes be dark

gray black or tan in color) on the

insulator t~p

Caused by-Highly leaded gaso-

lhne

Replace with new plugs

LEAD FOULED

Appearance-Yellow glazed de-

pos~ts indcat~ng melted lead de-

posits due to hard acceleration

Caused by-Highly leaded gas@

line

Replace with new plugs

PREIGNITION

Appearance-Melted center elec.

trade

Caused by-Abnormal combus-

tion due to overadvanced ignit~on

tim~ng or ~ncorrect advance too

low of a fuel octane rating lean

fuellair mixture or carbon de-

posits In combustion chamber

Correct engine problem and

replace with new plugs

INCORRECT HEAT RANGE

Appearance-Melted center elec-

trode and white blistered ~nsulator

tip

Caused by-Incorrect plug heat

range select~on

Replace w~th new plugs

14

CHAPTER

TWO

IGNITION:

Turn switches on. Remove spark plug

and check for spark outside cyiinder

Refer to engine chepter

for

correction

Refer

to

electrical chapter for correction

t

TROUBLESHOOTING

15

Crank the engine several times to distribute the

it

oil and test the compression once again. If

is

now significantly higher, the rings and bore are

worn. If the compression did not change, the

valves are not seating correctly. Adjust the

valves and check again. If the compression is

still low, refer to the engine chapter.

NOTE:

developing problem. The condition

causing it should be corrected as soon as

possible.

Low compression indicates

a

POOR PERFORMANCE

Poor engine performance can be caused by

any of a number of things related to carbure-

tion, ignition, and the condition of the sliding

and rotating components in the engine. In addi-

tion, components such as brakes, clutch, and

transmission can cause problems that seem to

be related to engine performance, even when

the engine is in top running condition.

Poor Idling

Idling that is erratic, too high, or too low is

most often caused by incorrect adjustment of

the carburetor idle circuit. Also, a dirty air

filter or an obstructed fuel tank vent can affect

idle speed. Incorrect ignition timing or worn or

faulty ignition components are also good

possibilities.

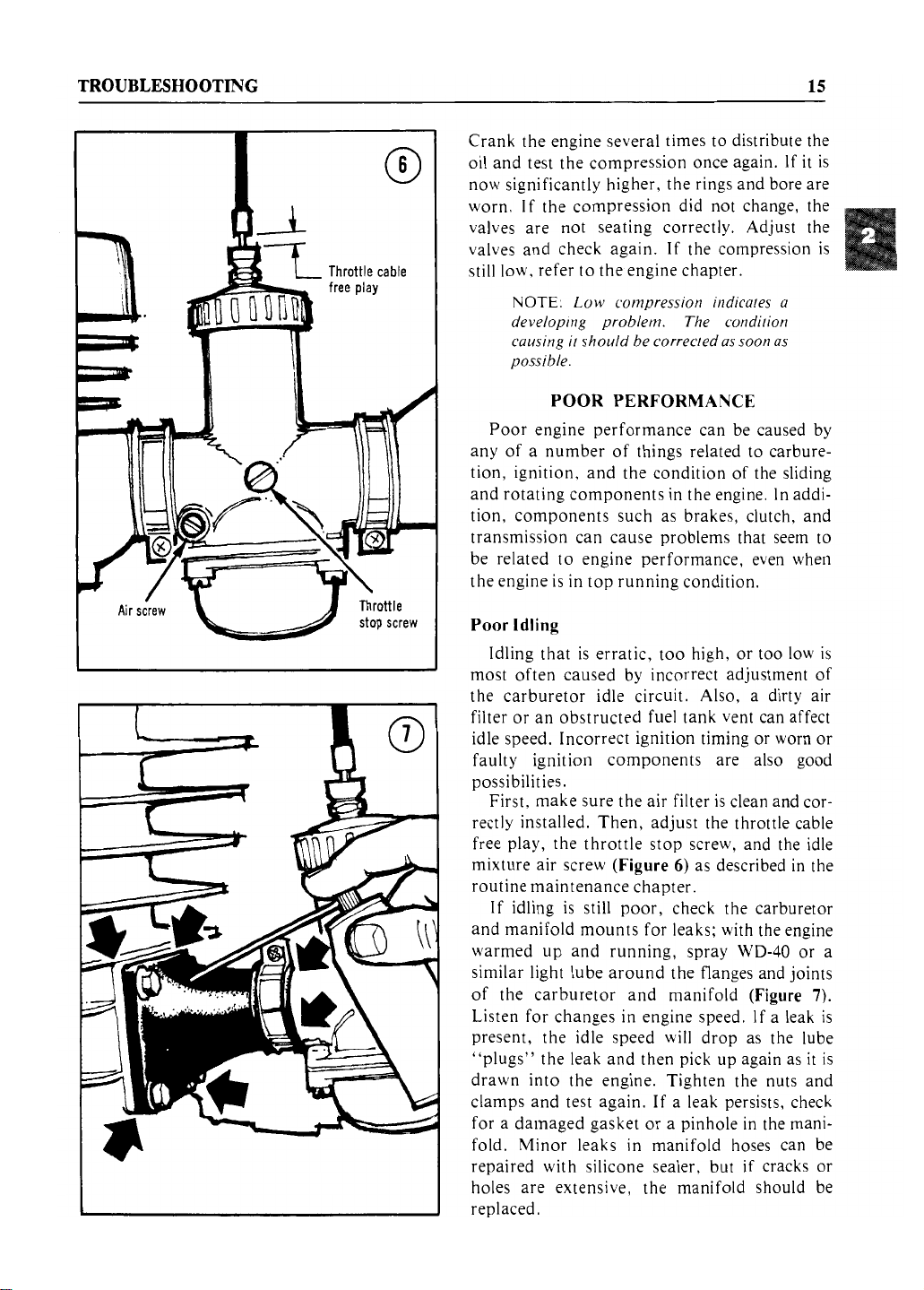

First, make sure the air filter is clean and cor-

rectly installed. Then, adjust the throttle cable

free play, the throttle stop screw, and the idle

mixture air screw

(Figure

6)

as described in the

routine maintenance chapter.

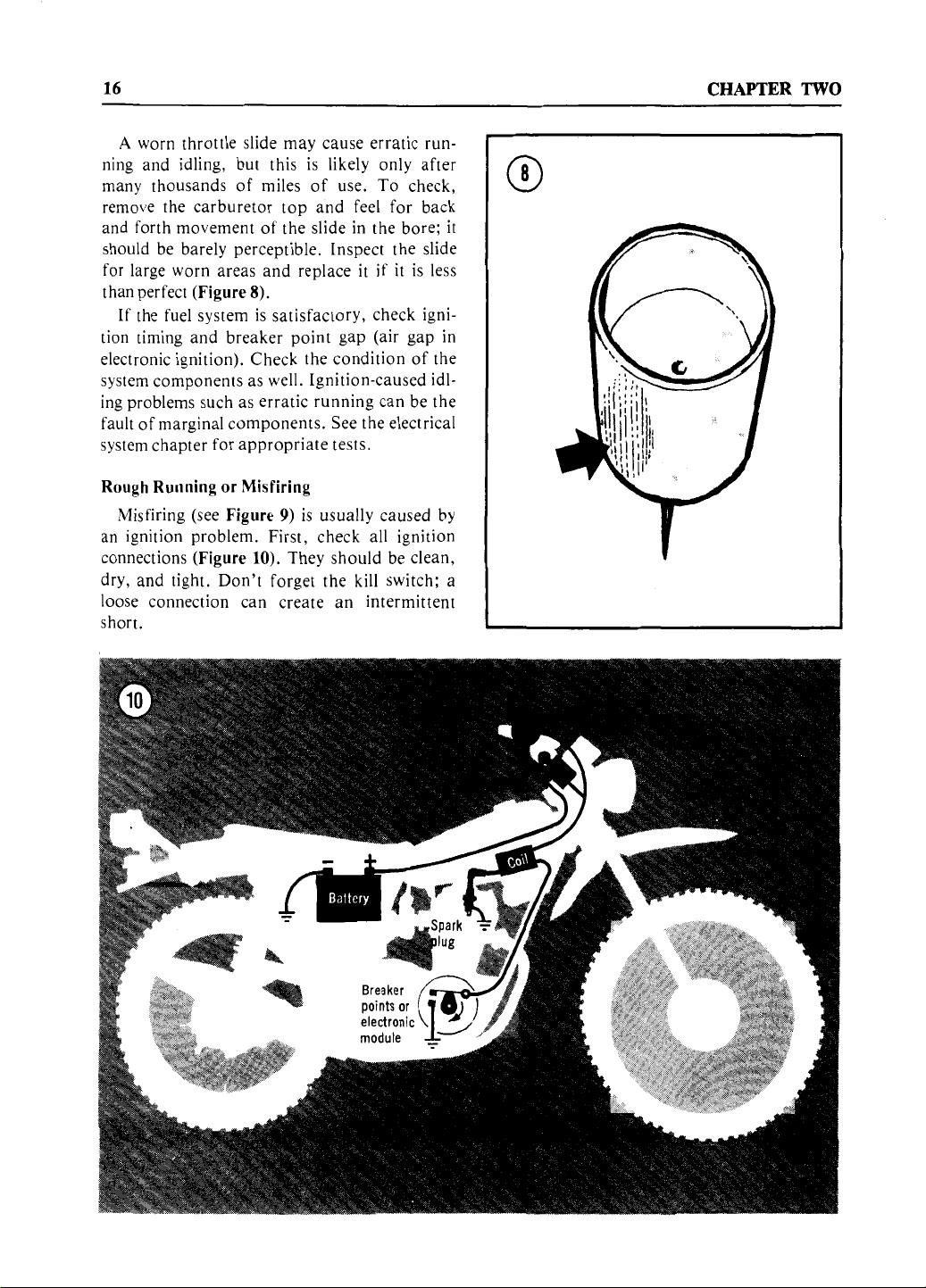

If idling is still poor, check the carburetor

and manifold mounts for leaks; with the engine

warmed up and running, spray

WD-40

or a

similar light lube around the flanges and joints

of the carburetor and manifold

(Figure

7).

Listen for changes in engine speed. If a leak is

present, the idle speed will drop as the lube

it

"plugs" the leak and then pick up again as

is

drawn into the engine. Tighten the nuts and

clamps and test again. If a leak persists, check

for a damaged gasket or a pinhole in the mani-

fold. Minor leaks in manifold hoses can be

repaired with silicone sealer, but if cracks or

holes are extensive, the manifold should be

replaced.

16

A

worn throttle slide may cause erratic run-

ning and idling, but this is likely only after

many thousands of miles of use. To check,

remove the carburetor top and feel for back

and forth movement of the slide in the bore; it

should be barely perceptible. Inspect the slide

for large worn areas and replace it if it is less

than perfect

(Figure

8).

If the fuel system is satisfactory, check igni-

tion timing and breaker point gap (air gap in

electronic ignition). Check the condition of the

system components as well. Ignition-caused idl-

ing problems such as erratic running can be the

fault of marginal components. See the electrical

system chapter for appropriate tests.

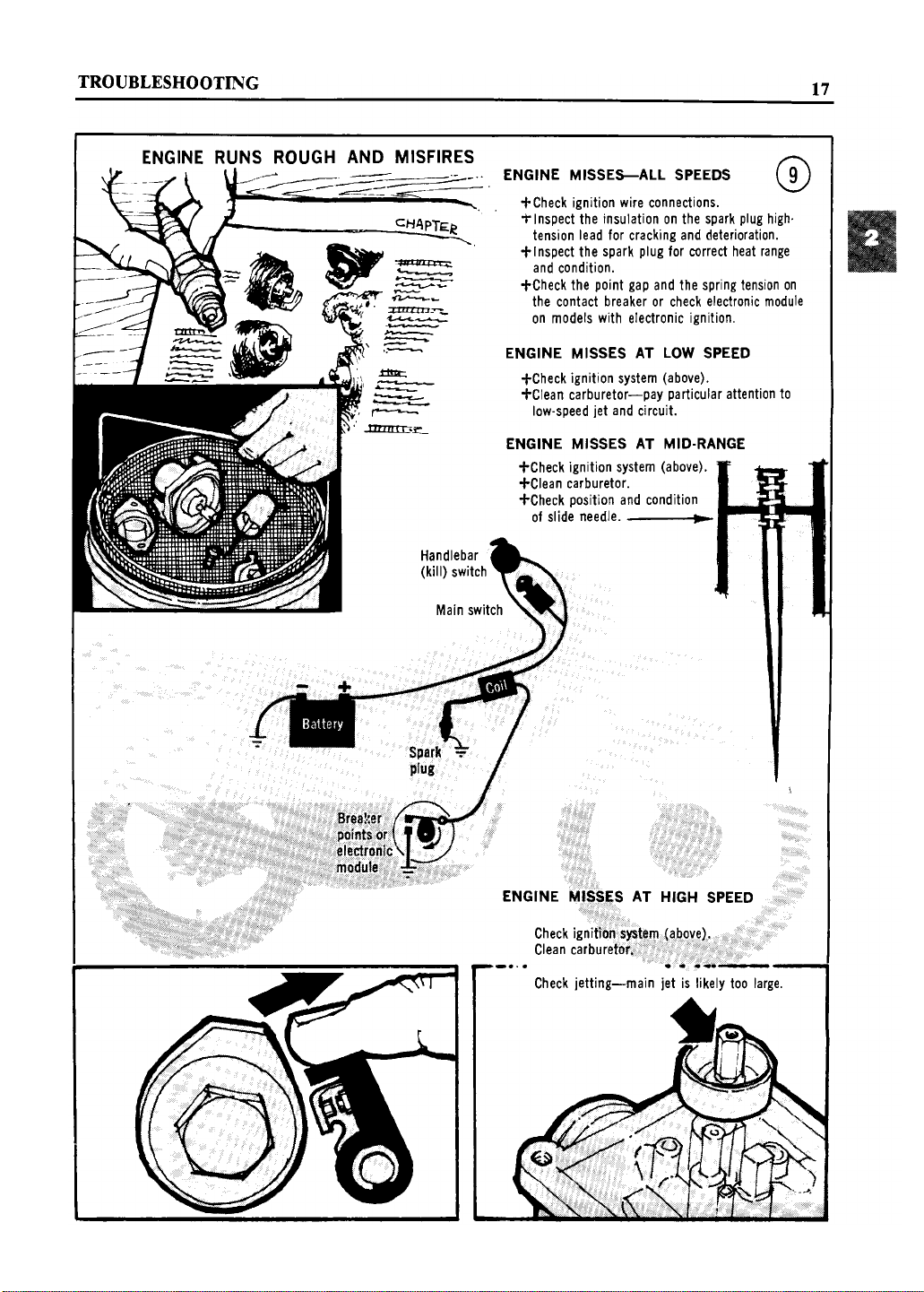

Rough Running or Misfiring

Misfiring (see

Figure

9)

is usually caused by

an ignition problem. First, check all ignition

connections

(Figure

10).

They should be clean,

dry, and tight. Don't forget the kill switch; a

loose connection can create an intermittent

short.

CHAPTER

TWO

TROUBLESHOOTING

17

ENGINE RUNS ROUGH

AND

MISFIRES

Handlebar

(kill) switch

Main switch

ENGINE MISSESALL SPEEDS

f

Check ignition wire connections.

+Inspect the insulation on the spark plug high.

tension lead for cracking and deterioration.

+Inspect the spark plug for correct heat range

and condition.

+Check the point gap and the spring tension on

the contact breaker or check electronic module

on models with electronic ignition.

ENGINE MISSES AT LOW SPEED

+Check ignition system (above).

+Clean carburetor-pay particular attention to

low-speed jet and circuit.

ENGINE MISSES AT MID-RANGE

+Check ign~t~on system (above).

+Clean carburetor.

+

Check pos~tion and cond~tion

of slide needle.

.-+

0

-

AT HIGH SPEED

18

CHAPTER

TWO

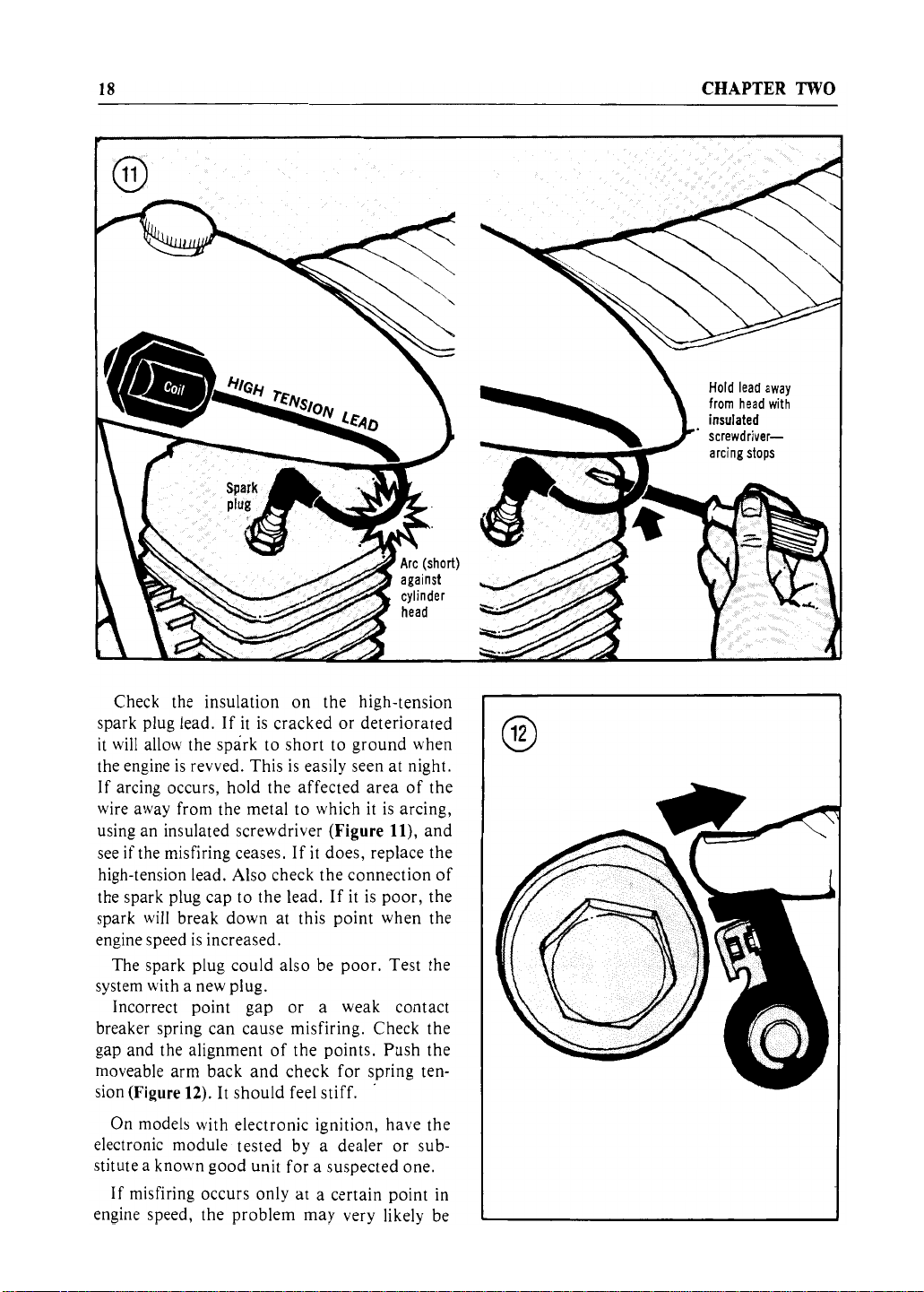

Check the insulation on the high-tension

spark plug lead. If it is cracked or deteriorated

it

will allow the spark to short to ground when

the engine is revved. This is easily seen at night.

If arcing occurs, hold the affected area of the

wire away from the metal to which it is arcing,

using an insulated screwdriver

(Figure

ll),

and

see if the misfiring ceases. If it does, replace the

high-tension lead. Also check the connection of

the spark plug cap to the lead. If it is poor, the

spark will break down at this point when the

engine speed is increased.

The spark plug could also be poor. Test the

system with a new plug.

Incorrect point gap or a weak contact

breaker spring can cause misfiring. Check the

gap and the alignment of the points. Push the

moveable arm back and check for spring ten-

sion

(Figure

12).

It should feel stiff.

'

On models with electronic ignition, have the

electronic module tested by a dealer or sub-

stitute a known good unit for a suspected one.

If misfiring occurs only at a certain point in

engine speed, the problem may very likely be

TROUBLESHOOTING

19

IDLE/ LOW-SPEED

:

-

-

Needle

jet

\I

MID-RANGE

20

LOSS

OF

POWER

Handlebar (kill) switch

Gradual

V

Check ignition and carburetion and tune

engine if necessary.

Check compression. If compression rises

following wet test, ring and cylinder wear is

indicated. If compression remains low during

wet test, valve and seat wear are indicated.

Check brake adjustment and condition; they

may be dragging.

CHAPTER

TWO

Main switch

W

Sudden

Check wheel bearings for dirt, dryness, and

wear that may create drag.

module

Check compression (above). If power

sudden, damage

valves and seats are more likely than wear.

Check the ignition system for a failed

component, poor contact, or change in timing

or point gap. Check electronic module on

electronic ignition.

Check the fuel system for an obstruction.

to

rings, piston, and bore or

loss

is

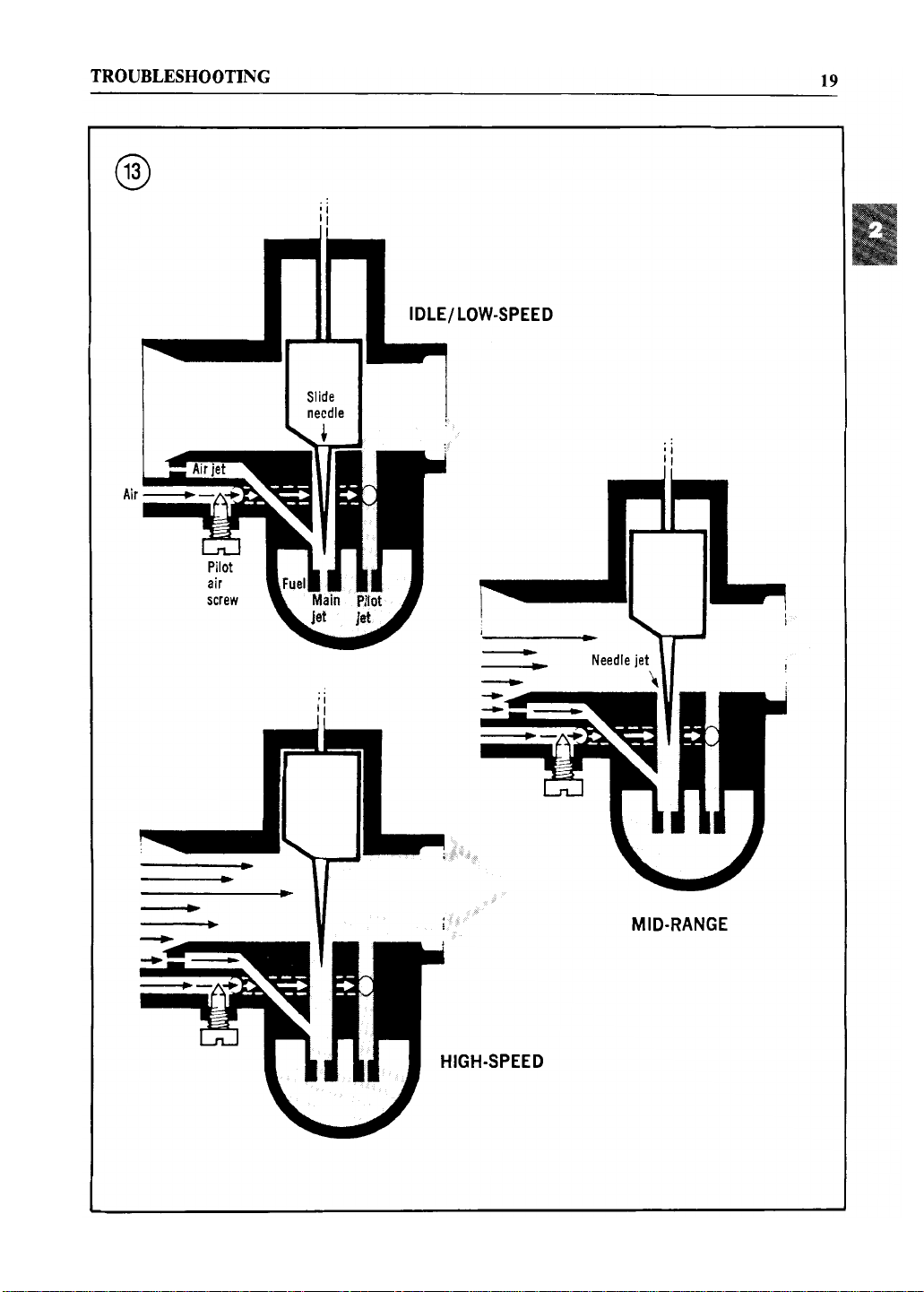

carburetion. Poor performance at idle is

described earlier. Misfiring at low speed (just

above idle) can be caused by a dirty low-speed

circuit or jet

(Figure

13).

Poor midrange per-

formance is attributable to a worn or incor-

rectly adjusted needle and needle jet. Misfiring

at high speed (if not ignition related) is usually

caused by a too-large main jet which causes the

engine to run rich. Any of these carburetor-

related conditions can be corrected by first

it

cleaning the carburetor and then adjusting

as

described in the tune-up and maintenance

chapter.

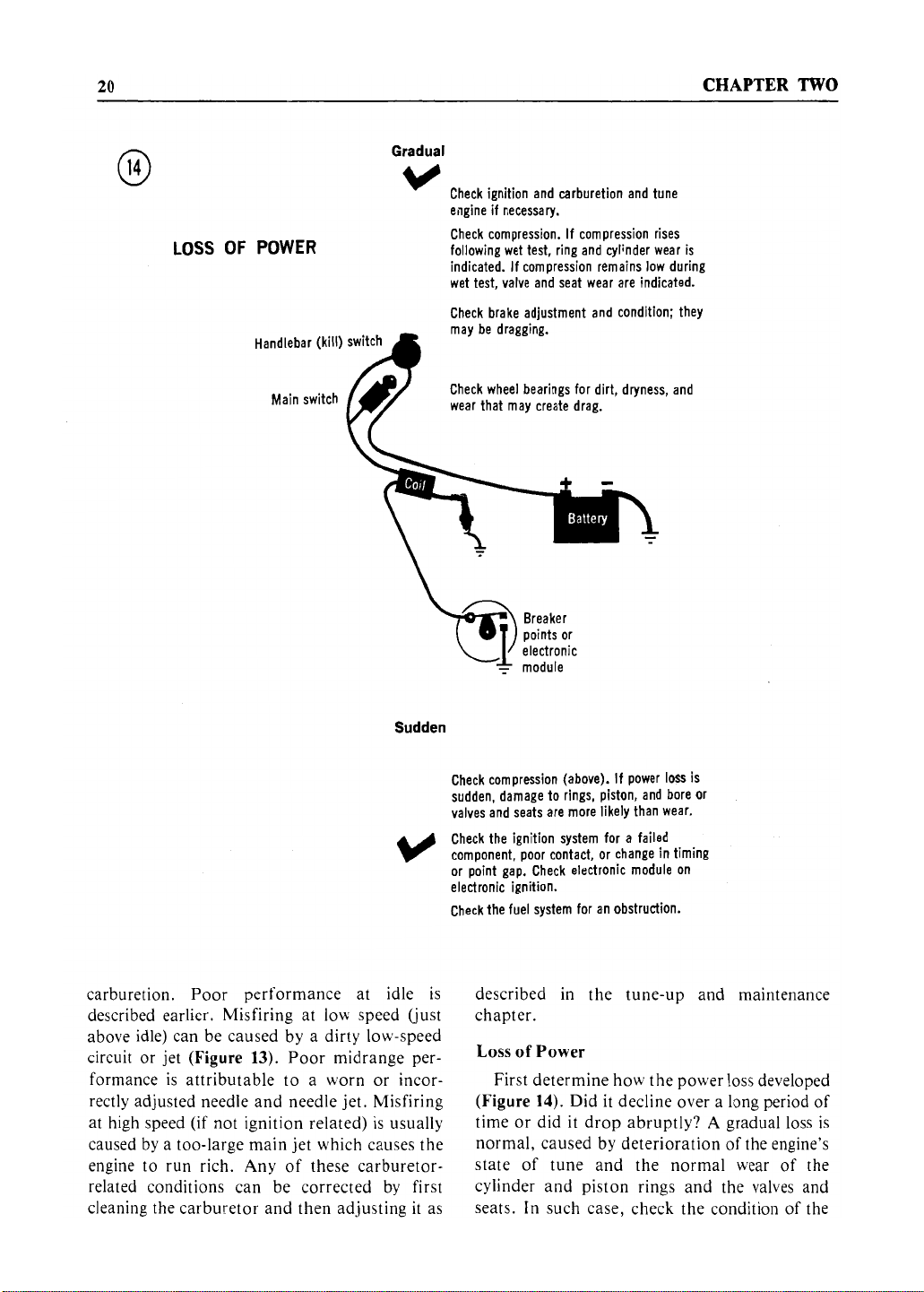

Loss of

Power

First determine how the power loss developed

(Figure

14).

Did it decline over a long period of

time or did it drop abruptly? A gradual loss is

normal, caused by deterioration of the engine's

state of tune and the normal wear of the

cylinder and piston rings and the valves and

seats. In such case, check the condition of the

Loading...

Loading...