Kawasaki 840051 User Manual

COMPONENT

#840051

KAWASAKI™IS A TRADEMARK LICENSED BY KAWASAKI™

MOTORS CORP., U.S.A., WHICH DOES NOT MANUFACTURE OR

DISTRIBUTE THIS PRODUCT. CONSUMER INQUIRES SHOULD BE

DIRECTED TO:

©COPYRIGHT 2005 ALLTRADE TOOLS, LLC.

1431 VIA PLATA

LONG BEACH, CA 90810-1462 USA

840051 – 1/2" Corded Impact Wrench

1/2" IMPACT WRENCH KIT

INSTRUCTION MANUAL

THIS MANUAL CONTAINS IMPORTANT INFORMATION REGARDING SAFETY,OPERATION,MAINTENANCE AND STORAGE OF THIS

PRODUCT. BEFORE USE, READ CAREFULLY AND UNDERSTAND ALL CAUTIONS, WARNINGS, INSTRUCTIONS AND PRODUCT

LABELS. FAILURE TO DO SO COULD RESULT IN SERIOUS PERSONAL INJURY AND/OR PROPERTY DAMAGE.

IF YOU SHOULD HAVE ANY QUESTIONS OR EXPERIENCE A PROBLEM WITH YOUR ALLTRADE PRODUCT, DO NOT RETURN THIS

PRODUCT TO THE STORE. PLEASE CALL OUR CUSTOMER SERVICE DEPARTMENT AT 1-800-590-3723. BEFORE YOU CALL,

HAVE THE FOLLOWING INFORMATION AVAILABLE: MODEL No., DATE PURCHASED AND STORE LOCATION. AN ALLTRADE

REPRESENTATIVE CAN RESOLVE YOUR PROBLEM OVER THE PHONE. IF YOU WOULD LIKE TO MAKE A SUGGESTION OR

COMMENT,GIVE US A CALL OR EMAIL US AT: INFO@ALLTRADETOOLS.COM.YOUR FEEDBACK IS VITAL TO US.

FOR CUSTOMER SERVICE

POUR LE SERVICE APRÉS VENTE

OU DU CONSOMMATEUR

PARA EL SERVICIO

PARA EL CONSUMIDOR

1-800-590-3723

Printed in China

Imprimé dans la Chine French

Impreso en China Spanish

87-1904-60957

CONGRATULATIONS!

Thanks for choosing this product. At Alltrade, our aim is to provide you with quality

products at an affordable price, and we want you to be totally satisfied with your

product and our Customer Service. If any help and advice is needed, please

contact us at 1-800-590-3723. Properly cared for, this tool will give you many

years of satisfaction.

INTENDED USE

This tool is intended for consumer use only.

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

The safety instructions provided in this manual are not intended to cover all possible

conditions and practices that may occur when operating, maintaining and cleaning

power tools.

Always use common sense and pay particular attention to all the DANGER,

WARNING, CAUTION and NOTE statements of this manual.

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

!DANGER indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury.

!WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

!CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

TABLE OF CONTENTS

CONGRATULATIONS! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INTENDED USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SECTION ONE

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS . . . . . . . . . . . . 2-3

IMPORTANT SAFEGUARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

WORK AREA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ELECTRICAL SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PERSONAL SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

TOOL USE AND CARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY RULES FOR IMPACT WRENCHES . . . . . . . . . . . . . . . . . . . 6

SECTION TWO

SPECIFIC SAFETY RULES AND/OR SYMBOLS . . . . . . . . . . . . . . . . . . . 7

SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SECTION THREE

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

ROCKER SWITCH AND DIRECTION OF ROTATION . . . . . . . . . . . . 9

INSTALLING/REMOVING SOCKETS . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION FOUR

MAINTENANCE AND CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

OTHER CONSUMER DO-IT-YOURSELF (DIY) TOOLS . . . . . . . . . . . . . . 11

SECTION FIVE

3 YEAR LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-14

1 2

WORK AREA

Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

Do not abuse the cord. Never use the cord to carry the tool. Keep the cord

away from heat, oil, sharp edges, or moving parts. Replace damaged cords

immediately. Damaged cords may create a fire.

PERSONAL SAFETY

Stay alert, watch what you are doing, and use common sense when operating a

power tool. Do not use tool while tired or under the influence of drugs, alcohol

or medication. A moment of inattention while operating power tools may result in

serious personal injury.

Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair , clothing, and gloves away from moving parts.Loose clothes, jewelry or

long hair can be caught in moving parts.

Remove adjusting keys or wrenches before turning the power tool “ON”.

A wrench or a key that is left attached to a rotating part of the power tool may result

in personal injury.

Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the power tool in unexpected situations.

Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat or hearing protection must be used for appropriate conditions.

4

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

NOTE provides additional information that is useful

for proper use and maintenance of this tool. If a

NOTE is indicated make sure it is fully understood.

IMPORTANT SAFEGUARDS

People with electronic devices, such as pacemakers, should consult their

physician(s) before using this product. Operation of electrical equipment in

close proximity to a heart pacemaker could cause interference or failure of

the pacemaker.

WARNING: Some dust created by power sanding, sawing, grinding, drilling and

other construction activities contains chemicals known to the State of California

to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry products,

and arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type

of work. To reduce your exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such as dust masks that are

specially designed to filter out microscopic particles.

WARNING: Handling the power cord on this product may expose you to lead, a

chemical known to the State of California to cause cancer and birth defects or

other reproductive harm.

Wash hands after handling.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

3

SAFETY RULES FOR IMPACT WRENCHES

Use only impact sockets. Non-impact sockets may shatter or break causing

injury and/or damage.

Ensure fastener and/or system will withstand the level of torque generated

by the tool. Excessive torque may cause breakage and possible personal injury.

Always wear safety goggles or eye protection when using this tool. Use a dust

mask or respirator for applications which generate dust.

Do not grasp the tool or place your hands too close to the spinning anvil. Your

hand may be lacerated or may cause injury.

Secure the material being worked on. Never hold it in your hand or across your

legs. Unstable support can cause loss of control and injury.

Position yourself to avoid being caught between the tool or side handle and walls

or posts. Should the socket or bit become bound in the work, the reaction torque

of the tool could crush your hand or leg.

Check to see that keys and adjusting wrenches are removed from the Impact

Wrench before switching the tool “ON”. Keys or wrenches can fly away at high

velocity striking you or a bystander.

When using the Impact Wrench, always maintain a firm grip on the tool with both

hands.

Keep the handle of the Impact Wrench dry, clean, and free from oil and grease.

Do not run the Impact Wrench while carrying it at your side. A spinning socket or

bit could become entangled with clothing and injury may result.

Disconnect the plug from the power supply and place the switch in the locked or

“OFF” position before making any assembly adjustments, changing accessories,

performing any inspection, maintenance or cleaning procedures. Such preventive

safety measures reduce the risk of starting the tool accidentally.

Do not use the Impact Wrench if it has been damaged, left outdoors in the rain,

snow, wet or damp environments, or immersed in liquid.

Maintain labels and nameplates on the Impact Wrench. These carry important

information. If unreadable or missing, contact Alltrade for a replacement.

6

TOOL USE AND CARE

Use clamps or other practical ways to secure and support the workpiece to a

stable platform. Holding the work by hand or against your body is unstable and

may lead to loss of control.

Do not force tool. Use the correct tool for your application. The correct tool will

do the job better and safer at the rate for which it is designed.

Do not use the tool if the power switch does not turn it “ON” or “OFF”. A tool that

cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the power cord plug from the power source before making any

adjustments, changing accessories or storing the tool. Such preventive safety

measures reduce the risk of starting the tool accidentally.

Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools with a sharp cutting edge are less likely to bind and are easier to control.

Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tool’s operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained tools.

Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may create a risk of injury when used

on another tool.

SERVICE

Tool service must be performed only by qualified repair personnel. Ser vice or

maintenance by unqualified personnel may result in a risk of injury.

When servicing a tool, use only identical replacement parts. Follow instructions

in the Maintenance section of this manual. Use of unauthorized parts or failure to

follow Maintenance Instructions may create a risk of shock or injury.

5

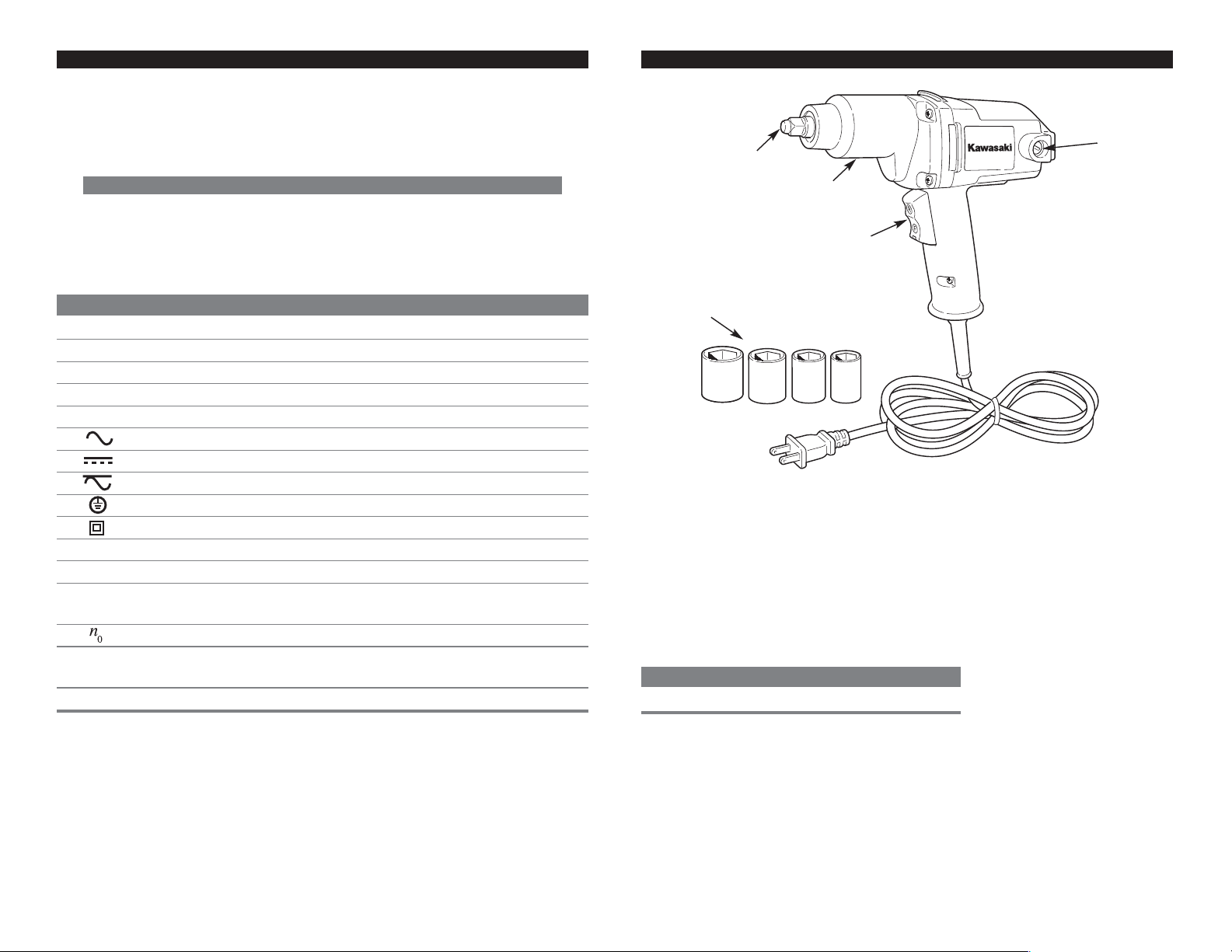

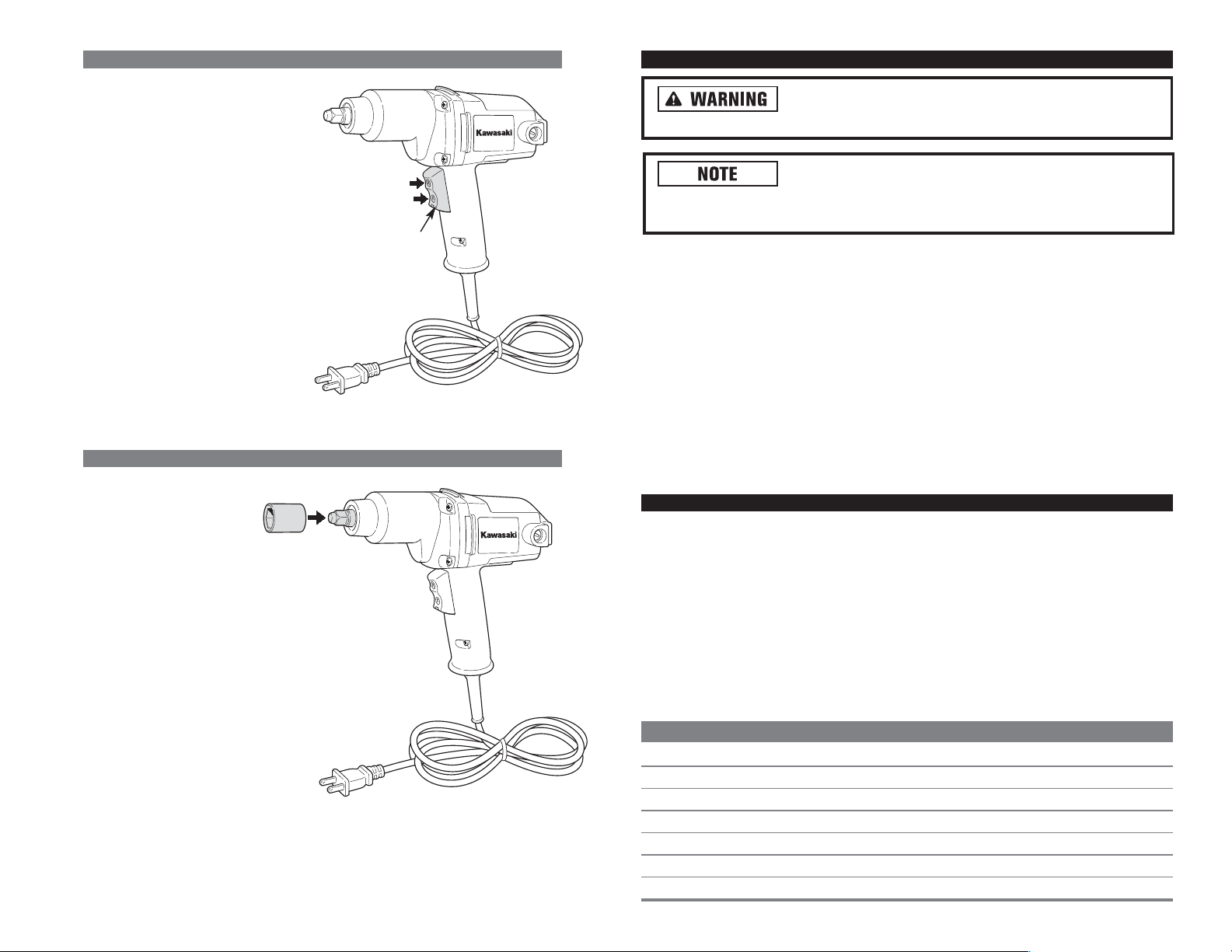

OPERATING INSTRUCTIONS

CONTROLS AND COMPONENTS:

1. Rocker Switch

2. Gear Enclosure

3. Brush Caps

4. Anvil

COMPONENT MODEL NUMBER

CARBON BRUSHES 690296

8

SPECIFIC SAFETY RULES AND/OR SYMBOLS

Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring. Contact with a “live” wire will also make

exposed metal parts of the tool “live” and shock the operator.

SYMBOLS

IMPORTANT: Some of the following symbols may be used on your tool. Please

study them and learn their meaning. Proper interpretation of these symbols will

allow you to operate the tool better and safer.

SYMBOL NAME EXPLANATION

V Volts Voltage (Potential)

A Amperes Current

Hz Hertz Frequency (Cycles per Second)

W Watt Power

Kg Kilograms Weight

Alternating Current Type of Current

Direct Current Type of Current

Alternating or Direct Current Type of Current

Earthing Terminal Grounding Terminal

Class II Construction Denotes Double Insulation

min Minutes Time

s Seconds Time

Diameter Size of Drill Bits,

Grinding Wheels, etc.

No load speed No-load Rotational Speed

.../min Revolutions per Minute Revolutions, Sur face Speed,

Strokes, etc. per Minute

1,2,3, … Ring Selector Settings Speed, Torque or Position Settings

7

1

2

4

5

3

ACCESSORIES:

5. Impact Sockets (4)

6. Carbon Brushes (2) (not shown)

ROCKER SWITCH AND DIRECTION OF ROTATION

• To rotate the Impact Wrench

in a clockwise direction, press

the lower portion of the

Rocker Switch.

• To rotate the Impact Wrench

in a counter-clockwise

direction, press the upper

portion of the Rocker Switch.

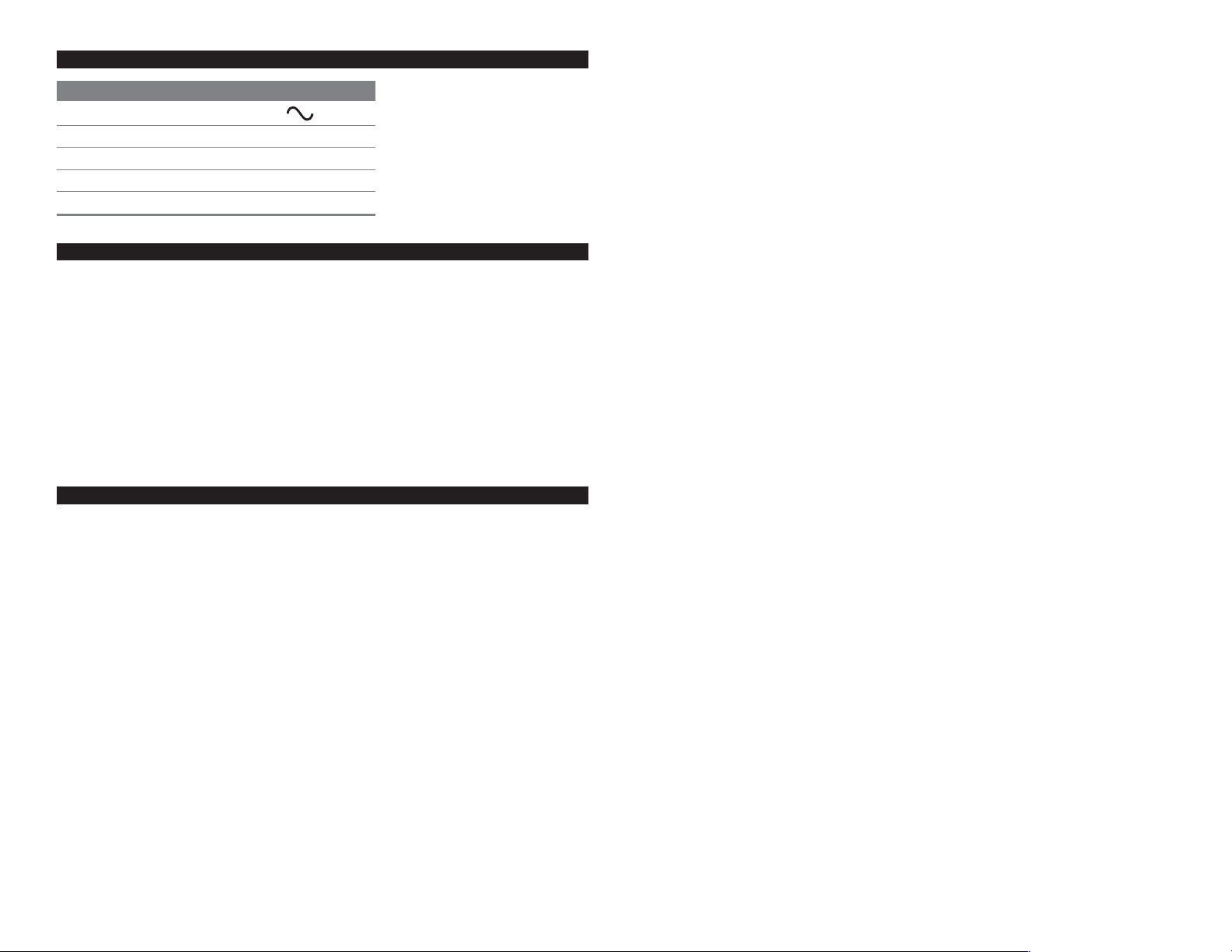

INSTALLING / REMOVING SOCKET

When installing a socket,

align the holes in the side

of the socket with the dent

pin. Press the socket on until

the dent pin engages in the hole.

To remove a socket, depress

the dent pin through the hole

using a small pointed object, and

pull the socket off.

When removing the socket or bit

from the tool, avoid contact with

skin and use proper protective

gloves when grasping the socket,

bit or accessory. Accessories may

be hot after prolonged use.

MAINTENANCE AND CLEANING

Always UNPLUG the Impact Wrench from power source

before attempting cleaning or maintenance.

This Impact Wrench is lubricated before it leaves the

factory. This lubrication should last for the life of the tool. No further

lubrication is required.

Use only mild soap and a damp cloth to clean the tool. Never let any liquid get

inside the casing. Never immerse any part of the tool in a liquid. Always keep the

ventilation openings clear.

Brushes will wear with use and should be inspected periodically by qualified

personnel. Unscrew the plastic caps on the sides of the motor housings to inspect

the spring and brush assembly. If the brushes are worn down to the line closest to

the spring, replace them immediately.

Regularly clean the ventilation slots in your tool and charger using only a soft

brush or dry cloth.

Never open the Impact Wrench case. Do not attempt to repair the Impact Wrench

yourself. Opening this tool will void your warranty.

ACCESSORIES

Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may become hazardous when used on

another tool.

Always attach grounded (3-prong) extension cords to grounded (3-hole) outlets.

If you must use an extension cord, be sure that the gauge is large enough to carry

the amount of current necessary for your power tool. If not, your tool may experi-

ence a loss of power, excessive voltage drop or overheating. The smaller the gauge

number, the heavier the cord (see table below).

RECOMMENDED SIZES OF EXTENSION CORDS 120 VOLT AC 60 HZ TOOLS

TOOL CURRENT RATING CONDUCTOR SIZE IN A.W.G

AMPERE 10FT. 25FT. 50FT. 100FT.

3-6 18 18 18 18

6-8 18 18 18 16

8-10 18 18 18 14

10-12 16 16 14 14

12-16 14 12 12 16-20 12 12 12 -

9

ROCKER

SWITCH

CLOCKWISE

COUNTER-CLOCKWISE

component thereof is modified or altered. This warranty does not apply to any

other product and/or component thereof manufactured or distributed by Alltrade,

and does not apply to products and/or components thereof designed, manufactured

and/or assembled by others, for which Alltrade makes no warranties whatsoever.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON

THE FACE HEREOF.

Warranty Performance

By purchasing the product, purchaser expressly acknowledges and agrees that their

sole and exclusive remedy under this warranty shall be strictly limited to the repair

or replacement of any covered nonconforming items or parts thereof provided that

any such nonconforming item and/or part is promptly returned to Alltrade’s facility

postage pre-paid and insured (address: ALLTRADE Warranty Claims & Repair,

1431 Via Plata, Long Beach, CA 90810, Attn: Customer Service #310-522-9008)

within the applicable warranty period, with a written request by purchaser that

Alltrade repair and/or replace the nonconforming item and/or part. We recommend

that you keep the original product packaging in the event you need to ship the unit.

We suggest the package be insured against loss or in transit damage. When

sending your product include your name, address, phone number, dated proof

of purchase (or copy), and a statement about the nature of problem. Warranty

coverage is conditioned upon purchaser furnishing Alltrade with adequate written

proof that they are the original purchaser and of the original purchase date. Parts

returned, freight prepaid and insured, to Alltrade’s facility (see above address) will

be inspected and, at Alltrade’s option, repaired and/or replaced free of charge if

found to be defective and subject to warranty. Alltrade retains the sole discretion

to determine whether any item or part is nonconforming and, if so, whether the

item and/or part will be repaired and/or replaced. If the unit is repaired, new or

reconditioned replacement parts may be used. If Alltrade chooses to replace

the product, it may replace it with a new or reconditioned one of the same or

comparable design. The repaired or replaced unit will be warranted under the terms

of the remainder of the warranty period. Typically, a defective product that is

returned within the first 30 days after the purchase date will be replaced; for items

returned after the first 30 days and within the warranty period, covered defective

parts not subject to normal wear and tear or other exclusions will be repaired or

replaced, at Alltrade’s option. During the warranty period, Alltrade will be responsible for the return shipping charges. Alltrade’s repair and/or replacement of any nonconforming item and/or part thereof shall constitute fulfillment of all

obligations to the purchaser. Alltrade shall not be responsible or liable for any

expense, including freight charges, or repairs made outside Alltrade’s facility, unless

expressly agreed to by Alltrade in writing. Under no circumstances shall Alltrade

bear any responsibility for loss of the unit, loss of time or rental, inconvenience,

commercial loss or consequential damages.

12

SPECIFICATIONS

SPECIFICATIONS

Voltage 120V 60 Hz

Rated Current 7.0A

No-Load Speed 2100/min

Impacts Per Minute 2700

Maximum Torque 220 ft.lbs.

OTHER CONSUMER DO-IT-YOURSELF (DIY) TOOLS

Alltrade offers a full range of Kawasaki™ tools that make DIY jobs easy. If you would

like further information on the following products, please contact Alltrade Customer

Service Department at 1-800-590-3723.

Cordless Drills/Screwdrivers

Impact Wrenches

Sanders

Jigsaws

Circular Saws

Angle Grinders

3 YEAR LIMITED WARRANTY

Express and Exclusive Limited Warranty to Original Retail Buyer

Alltrade Tools LLC (hereinafter "Alltrade") expressly warrants to the original retail

purchaser of the accompanying KAWASAKI(tm) power tool and no one else all

parts of the product (except those parts referred to below which are specifically

excluded from such warranty (see Exclusions)) to be free from defects in materials

and workmanship for a period of three years from original date of purchase, except

that such warranty with regard to the battery shall be for a period of two years from

original date of purchase, unless the tool is used for commercial or rental

purposes.

SPECIAL WARRANTY NOTE FOR COMMERCIAL OR RENTAL USE: The above

warranty for this Kawasaki(tm) power tool, including the battery, shall be effective

for only 90 days from the original date of purchase if this tool is used for any

COMMERCIAL OR RENTAL PURPOSE.

The date of purchase shall be the date of shipment to the original purchaser, or the

date the original purchaser took possession, custody or control of the product,

whichever occurred first. This warranty shall be null and void if the product or any

11

Reciprocating Saws

Routers

Rotary Tools

Corded and Cordless Multi-Purpose Tools

Wide Range of Accessories and more

WARRANTY IS MADE WITH REGARD TO THIS PRODUCT. ALL EXPRESS AND/OR

IMPLIED WARRANTIES, GUARANTIES AND/OR REPRESENT ATIONS BY ALLTRADE

AND/OR ITS REPRESENTATIVE(S) REGARDING THE DESIGN, MANUFACTURE,

PURCHASE, USE AND/OR OPERATION OF THE PRODUCT OR ANY COMPONENT

THEREOF SOLD HEREUNDER, REGARDLESS OF WHETHER ANY SUCH WARRANTY,

GUARANTY AND/OR REPRESENTATION, WRITTEN OR ORAL, ARISES BY

OPERATION OF LAW AND/OR EQUITY AND/OR BY ANY ACT OR OMISSION OF

ALLTRADE AND/OR ITS REPRESENTATIVE(S), OR THE PURCHASER, INCLUDING

BUT NOT LIMITED TO THE IMPLIED WARRANTY OF MERCHANTABILITY AND THE

WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY EXPRESSLY

EXCLUDED AND DISCLAIMED BY ALLTRADE AND/OR ITS REPRESENTATIVES.

PURCHASER KNOWINGLY AND WILLINGLY WAIVES ANY AND ALL SUCH

WARRANTIES AND RIGHTS, CLAIMS AND/OR CAUSES OF ACTION ARISING

THEREFROM OR BASED THEREON. PURCHASER’S SOLE AND EXCLUSIVE

REMEDY IS AS STATED ABOVE.

Limitation Of Liability

IN NO EVENT SHALL ALL TRADE AND/OR ITS REPRESENTATIVE(S) BE LIABLE FOR

INDIRECT, INCIDENTAL, SPECIAL AND/OR CONSEQUENTIAL DAMAGES OF ANY

KIND ARISING OUT OF OR RELATED TO, DIRECTLY OR INDIRECTLY, ANY BREACH

OF ANY PROVISION OF ANY AGREEMENT BETWEEN ALLTRADE AND/OR ITS

REPRESENTATIVE(S) AND PURCHASER, ANY WARRANTY HEREUNDER,

AND/OR THE EXISTENCE, DESIGN, MANUFACTURE, PURCHASE, USE AND/OR

OPERATION OF ANY ITEM(S) SOLD HEREUNDER EVEN IF ALLTRADE AND/OR ITS

REPRESENTATIVE(S) HAS BEEN ADVISED OF THE POSSIBILITY OF ANY SUCH

DAMAGES. IN NO EVENT, WHETHER AS A RESULT OF A BREACH OF CONTRACT,

WARRANTY, TORT (INCLUDING NEGLIGENCE) OR OTHERWISE, SHALL

ALLTRADE’S AND/OR ITS REPRESENTATIVE(S)’ LIABILITY EXCEED THE PRICE OF

THE PRODUCT. ANY AND ALL LIABILITY CONNECTED WITH THE USE OF

THIS PRODUCT SHALL TERMINATE UPON THE EXPIRATION OF THE WARRANTY

PERIODS SPECIFIED ABOVE.

Limitations on Warranty Disclaimers

Some states do not allow limitations on how long an implied warranty lasts

and some states do not allow the exclusion or limitation of the incidental or

consequential damages, so part or all of the above limitations or exclusions may not

apply to you. This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

If your product is not covered by this warranty, please call our Customer Service

Department at 1-310-522-9008 or toll free at 1-800-590-3723 for general repair

information and charges.

14

Exclusions

This warranty does not cover parts damaged due to normal wear, abnormal

conditions, misapplication, misuse, abuse, accidents, operation at other than

recommended pressures or temperatures, improper storage or freight damage.

Parts damaged or worn by operation in dusty environments are not warranted.

Failure to follow recommended operating and maintenance procedures also

voids warranty.

This limited warranty does not apply to accessory items such as drill bits,

screwdriving bits, circular saw blades, jigsaw blades, grinding wheels, sanding

sheets and other related items.

DAMAGE TO THE PRODUCT RESULTING FROM TAMPERING, ACCIDENT, ABUSE,

NEGLIGENCE, FAILURE TO FOLLOW INSTRUCTIONS, UNAUTHORIZED REPAIRS

OR ALTERATIONS, DAMAGE WHILE IN TRANSIT TO OUR SERVICE FACILITY,

USE OF UNAPPROVED OR IMPROPER ATTACHMENTS OR ACCESSORIES,

COMMERCIAL AND RENTAL APPLICATIONS OR OTHER CAUSES UNRELATED TO

PROBLEMS WITH MATERIAL OR WORKMANSHIP ARE NOT COVERED BY THIS

WARRANTY.

Alltrade will not be liable for the following: labor charges, loss or damage resulting

from improper operation, maintenance or repairs made by other persons;

pre-delivery services such as assembly, oil or lubricants, and adjustment;

maintenance services that are normally required to maintain the product.

The use of other than genuine Alltrade Repair Parts will void warranty.

Warranty Disclaimers

EXCLUSION AND DISCLAIMER OF ALL OTHER EXPRESS WARRANTIES,

GUARANTIES AND/OR REPRESENTATIONS. EXCEPT FOR THE LIMITED WARRANTY

PROVIDED ABOVE, ALL OTHER EXPRESS WARRANTIES, GUARANTIES AND/OR

REPRESENTATIONS BY ALLTRADE AND/OR ITS REPRESENTATIVE(S) REGARDING

THE DESIGN, MANUFACTURE, PURCHASE, USE AND/OR OPERATION OF THE

PRODUCT OR ANY COMPONENT THEREOF SOLD HEREUNDER, REGARDLESS OF

WHETHER ANY SUCH WARRANTY, GUARANTY AND/OR REPRESENTATION,

WRITTEN OR ORAL, ARISES BY OPERATION OF LAW AND/OR EQUITY AND/OR BY

ANY ACT OR OMISSION OF ALLTRADE AND/OR ITS REPRESENTATIVE(S), OR THE

BUYER, ARE HEREBY EXPRESSLY EXCLUDED AND DISCLAIMED BY ALLTRADE

AND/OR ITS REPRESENTATIVES. PURCHASER KNOWINGLY AND WILLINGLY

WAIVES ANY AND ALL SUCH WARRANTIES AND RIGHTS, CLAIMS AND/OR

CAUSES OF ACTION ARISING THEREFROM OR BASED THEREON. PURCHASER’S

SOLE AND EXCLUSIVE REMEDY IS AS STATED ABOVE.

EXCLUSION AND DISCLAIMER OF ALL IMPLIED WARRANTIES, INCLUDING THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. NO WARRANTY, ORAL OR WRITTEN, OTHER THAN THE ABOVE

13

Loading...

Loading...