Page 1

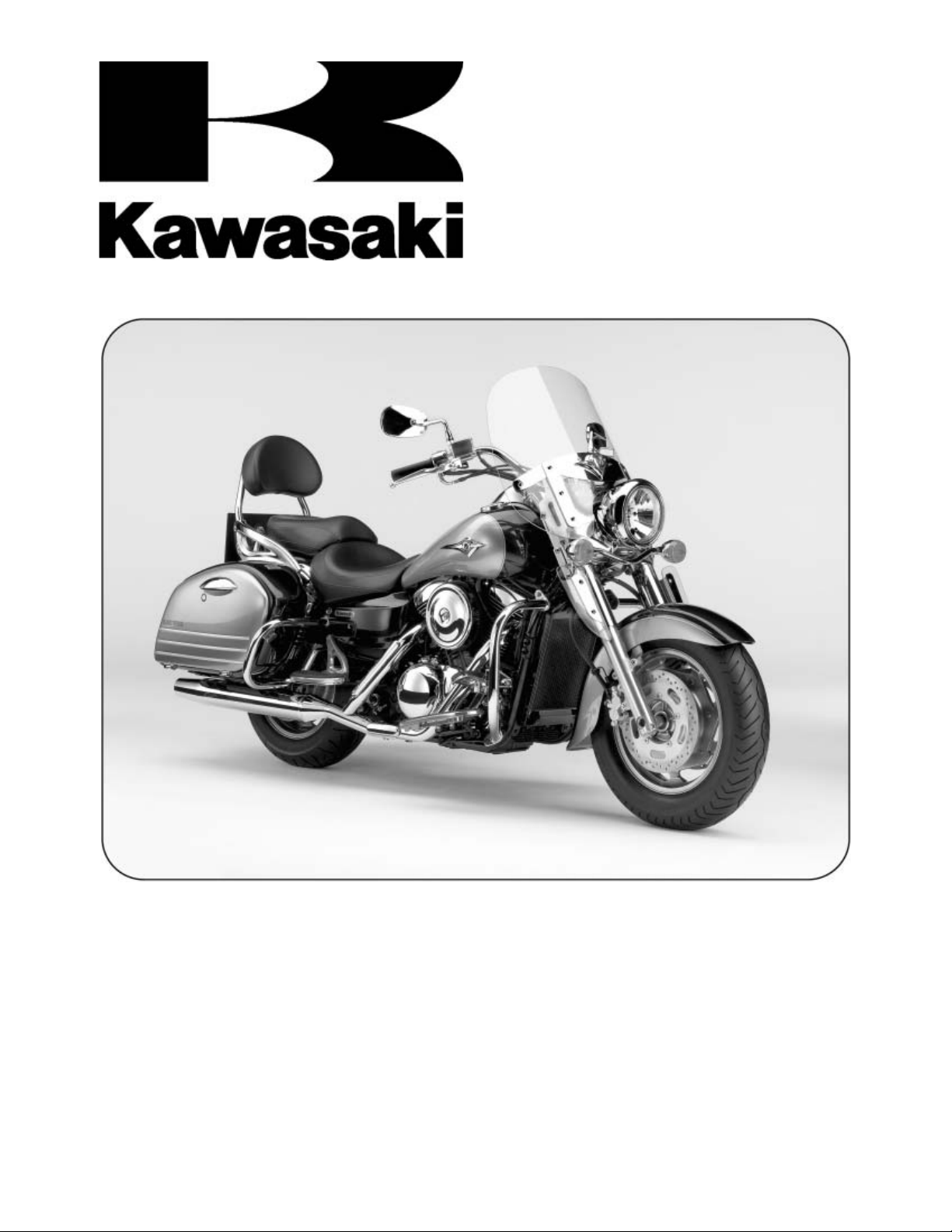

VULCAN 1600 NOMAD

VN1600 CLASSIC TOURER

Motorcycle

Assembly & Preparation

Manual

Page 2

Foreword

In order to ship Kawasaki vehicles as efficiently as possible, they are partially disassembled before crating. Since some of the most

commonly removed parts have a direct bearing on a vehicle’s reliability and safety, conscientious pre-sale assembly and preparation becomes extremely important. Good setup procedures can prevent needless warranty claims

and give customers a greater sense of confidence in Kawasaki and their Kawasaki Dealers.

This Assembly and Preparation Manual explains step by step procedures of the following

items for all Kawasaki motorcycles.

1. Uncrating

2. Assembly

3. Preparation

The selling dealer assumes sole responsibility for any unauthorized modifications prior to

sale. Refer to your Service Binder for any Service Bulletins specifying Factory Directed Modifications (Special Claims) which must be performed before the vehicle is ready for sale.

Whenever you see the following symbols

heed their instructions! Always follow safe

operating and maintenance practices.

WARNING

This warning symbol identifies special

instructions or procedures which, if not

correctly followed, could result in personal injury, or less of life.

CAUTION

This caution symbol identifies special

instructions or procedures which, if not

correctly followed, could result in damage to, or destruction of equipment.

NOTE

żThis note symbol indicates points of particular

interest for more efficient and convenient operation.

Kawasaki Heavy Industries, Ltd. accepts no

liability for any inaccuracies or omissions in this

publication, although every possible measure

has been taken to make it as complete and accurate as possible. All procedures and specifications subject to change without notice.

© 2004 Kawasaki Heavy Industries, Ltd. Nov. 2004 (K)

Page 3

Table of Contents

crating ......................................................................................

Un

Opening Crate ............................................................................. 3

Parts Check ................................................................................. 4

sembly ......................................................................................

As

Handlebar.................................................................................... 8

Throttle Grip and Right Switch Housing ...................................... 8

ront Brake Master Cylinder .......................................................

F

Left Switch Housing..................................................................... 9

Clutch Master Cylinder ................................................................ 10

iring Clamps .............................................................................10

W

Front Fender................................................................................ 11

Front Wheel Installation............................................................... 12

Front Brake Hose Grommets ...................................................... 14

Front and Rear Shift Pedals ........................................................ 14

Front Footboard (Left) ................................................................. 15

Front Guards (Left and Right) ..................................................... 15

Helmet Locks............................................................................... 16

Rear Guards (Left and Right) ...................................................... 16

Backrest Pad ............................................................................... 17

Horn............................................................................................. 17

Choke Knob................................................................................. 18

Rear View Mirrors (Left and Right) .............................................. 18

Windshield................................................................................... 19

License Plate Bracket.................................................................. 21

Rear Reflectors and License Plate Holder .................................. 21

Left Saddlebag ............................................................................ 22

Brake Disc Cleaning .................................................................... 24

Preparation ................................................................................... 24

Battery Service ............................................................................ 24

Front Brake Fluid ......................................................................... 30

Rear Brake Fluid ......................................................................... 31

Clutch Fluid ................................................................................. 32

Rear Shock Absorber .................................................................. 34

Tire Air Pressures........................................................................ 34

Fuel ............................................................................................. 34

Coolant ........................................................................................ 34

Engine Oil (4-stroke) ................................................................... 35

Final Gear Case Oil..................................................................... 36

Throttle Grip and Cable ............................................................... 37

Headlight Aim .............................................................................. 38

Idle Speed Adjustment ................................................................ 38

Rear Brake Light Switch.............................................................. 38

Fastener Check ........................................................................... 40

Standard Torque Table ................................................................ 42

Test Ride the Motorcycle ............................................................. 42

A & P Check List ......................................................................... 42

3

8

9

Page 4

Page 5

Uncrating

Opening Crate

Clear a space about 6 m (20 ft.) square to

•

give yo

Place the crate upright on its base.

•

Remove the cardboard cover.

•

Remov

•

parts box.

When you remove the crate bracket

from the motorcycle, be careful not to

drop any parts and bracket onto the

fuel tank and other components, and

not to scratch the fuel tank by the crate

bracket. This could damage the fuel

tank or components.

Unscrew the four bolts to remove the front

•

brake and clutch master cylinders.

Remove the two bracket bolts and the crate

•

bracket and discard them.

urself plenty of space to work.

e the handlebar, front wheel, and the

CAUTION

UNCRATI

A. Lower Bolts

B. Upper Bolts

C. Crate Bracket

Take out all the bolts and screws and remove

•

the top and sides of the crate.

NG 3

.Bolts

A

B. Bolt

C. Front Master Cylinder

D. Crate Bracket

E. Clutch Master Cylinder

Unscrew the two lower bolts, and then re-

•

move the two upper bolts and crate bracket.

Discard the bolts and bracket.

Page 6

4 UNCRAT

ING

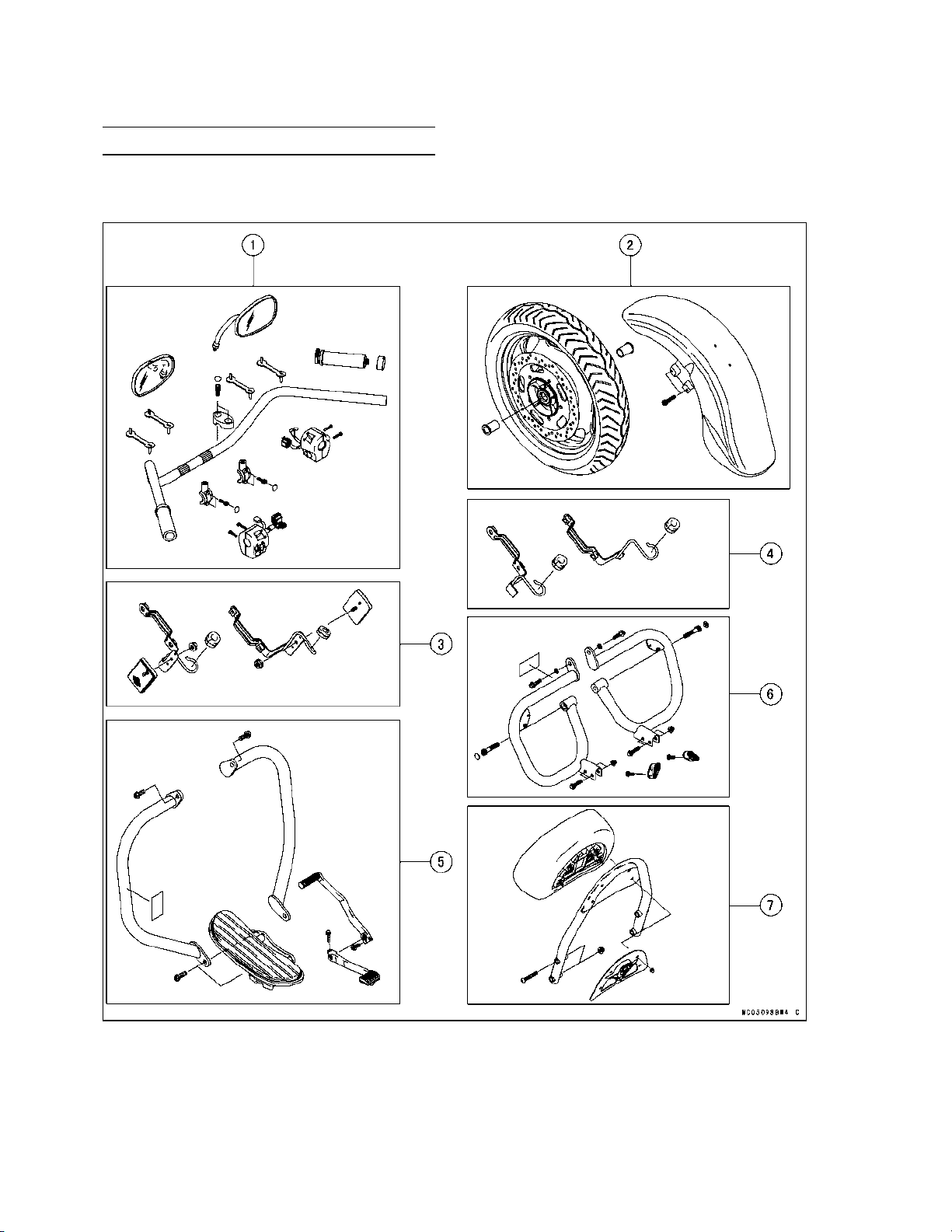

Parts Check

Open the parts box, and check the parts against the illustrations. There may be minor differences

•

between these illustrations and the actual vehicle parts. In the following charts under Remarks, D

= diameter in millimeters, L = length in millimeters, and T = Thickness in m illimeters.

Page 7

UNCRATI

NG 5

No. Part Name

1

Handlebar with Grip

Handlebar Clamp

Clamp Bolt, Socket

Plastic Plug, Clamp Bolt

Throttle Grip

Clamp, Master Cylinder

Clamp Bolt, Master Cylinder, Socket

Plastic Plug, Clamp Bolt

Plastic Clamp, Wiring and Hose

Screw, Switch Housing, LH & RH

Rear View Mirror, LH & RH

Qty

1

2

4 D = 10, L = 23

4 Large

1

2

4 D=6,L=20

4

Small

4 L = 88.5

4 D=5,L=25

2

2 Front Wheel 1

Axle Collar, LH & RH

2 L = 46.5

Front Fender with Brace 1

Socket Bolt, Front Fender

3

For US and CN Models

Brake Hose Clamp, LH & RH

Grommet, Brake Hose

Front Reflector, LH & RH

Flanged Nut, Reflector

4

For other than US and CN Models

Brake Hose Clamp, LH & RH

Grommet, Brake Hose

5

Front Left Footboard Assembly

4 D=8,L=35

2

2

2

2 D=5

2

2

1

Flanged Bolt, Front Footboard, LH 2 D = 10, L = 30

Front Guard, LH & RH

Flanged Bolt, Front Guard

Warning Label, Front Left Guard

Front Shift Pedal

Rear Shift Pedal

Flanged Bolt, Front and Rear Shift Pedals

6

Rear Guard, LH & RH

Flanged Bolt with Washer, Rear Guard, Upper

Socket Bolt, Rear Guard, Lower

Plastic Plug, Socket Bolt, Rear Guard

Flanged Bolt, Rear Guard

Cap Nut, Rear Guard

Helmet Lock 2

Screw with Non-permanent locking agent, Helmet Lock

Warning Label, Rear Left Guard

2

2 D = 10, L = 25

1

US and CN Models Only

1

1

2 D=8,L=25

2

2 D=8,L=30

2 D = 10, L = 50

2 Large

4 D=8,L=35

4 D=8

Located in the left side cover.

2 D=5,L=12

1

US and CN Models Only

7 Backrest Pad 1

Backrest Frame 1

Cover with Mark, Backrest

Cap Nut, Cover

1

4 D=6

Bolt, Backrest Frame 4 D=8,L=50

Nut, Backrest Frame 4 D=8

Remarks

Page 8

6 UNCRAT

ING

* : European Models Only

Page 9

UNCRATI

NG 7

No. Part Name

Qty

Remarks

8 Horn with Bracket 1

Flanged Bolt, Horn 1

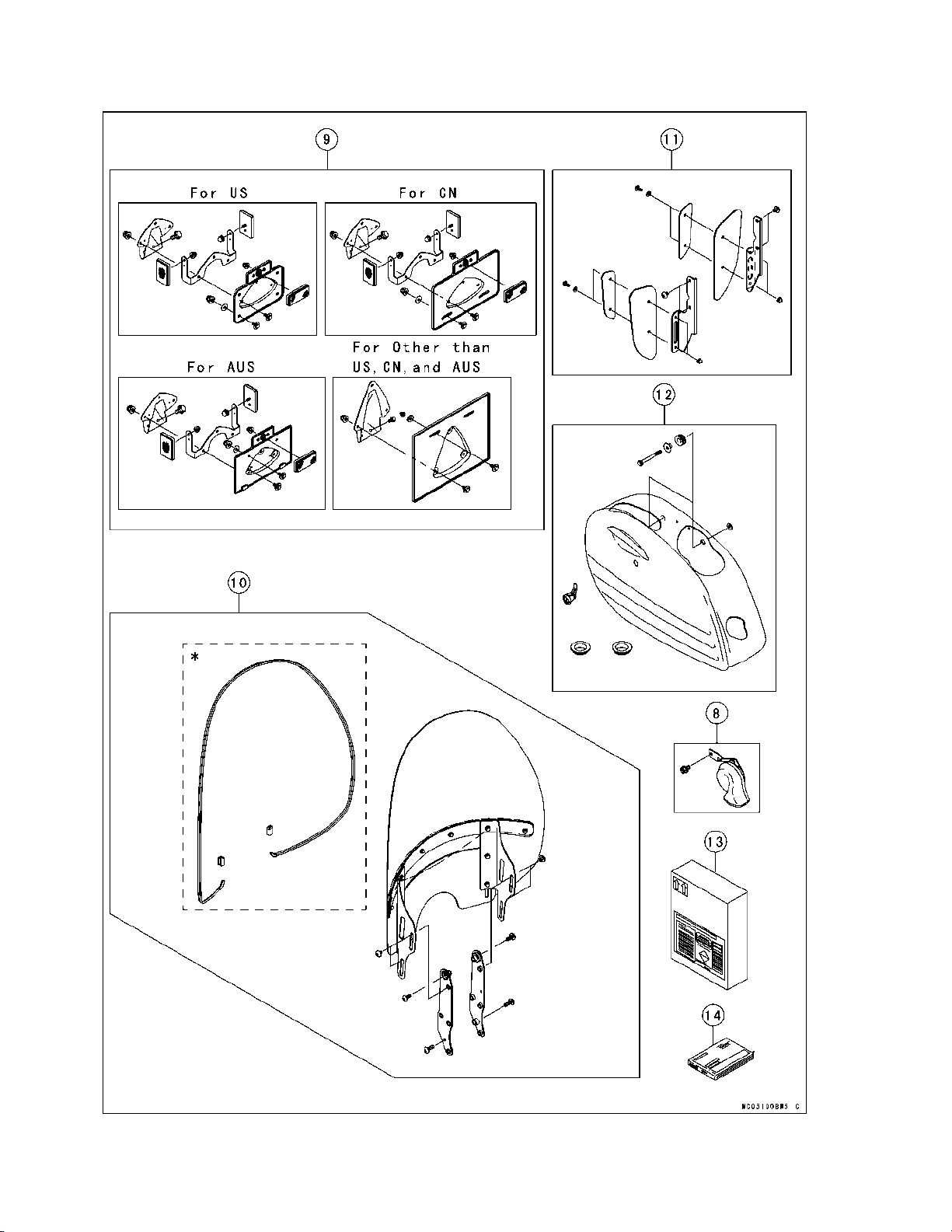

9 Licen

se Plate Bracket

1

Bolt, Bracket, License Plate 2 D=6,L=12

Bracket, Reflector

ector

Refl

1

(US)(CN)(AUS) only

(US)

(CN) only

3

Reflector 1 (AUS) only

Cap Nut, Reflector 3 D = 5, (US)(CN) only

Cap Nut, Reflector 1 D = 5, (AUS) only

Cap Nut, Black, License Plate

Cap Nut, Black, License Plate

Flat Washer, Black, Holder, License Plate 4

4

D = 6, (US) only

2

D = 6, (CN)(AUS)(EUR) only

6.5 × 20 × 1.6, (US) only

D=

Flat Washer, Black, Holder, License Plate 2 D = 6.5 × 20 × 1.6, (CN) (AUS)(EUR) only

Holder, License Plate 1

olt with Flat Washer

B

Bolt with Flat Washer 5

Cap Nut, Holder, License Plate

7 D = 6, L = 14 (US only)

D = 6, L = 14, (CN)(AUS)(EUR) only

3 D=6

10 Windshield Assembly with 1

Center Plate, Outer & Inner (2)

Damper, Center Plate, Outer & Inner (2)

Socket Bolt with Washer, Center Plate (4)

Cap Nut (10)

Vulcan Mark

D=6,L=20

D=6

(1) (US)(CN)(AUS) only

VN1600 Mark (1) (EUR) only

Outer Plate, LH & RH (2)

Inner Plate, LH & RH (2)

Outer Damper, Outer Plate, LH & RH (2)

Inner Damper, Inner Plate, LH & RH (2)

Socket Bolt with Washer, Outer & Inner Plate (6)

D=6,L=25

Sub-windshield (1)

Stay, Windshield, LH & RH (2)

Trim, Windshield 1 L = 1 900, (EUR) only

Clamp, Trim

Socket Bolt, Stay

Bracket, Windshield, LH & RH

2

(EUR) only

4 D=8,L=10

2

Socket Bolt, Bracket, Upper 2 D=8,L=20

Socket Bolt, Bracket, Lower 2 D=8,L=25

11 Outer Plate, Deflector, LH & RH 2

Deflector, LH & RH

Stay, LH & RH

Socket Bolt with Washer

2

2

4 D=6,L=16

Cap Nut 4 D=6

Socket Bolt, Stay 4 D=6,L=16

12 Saddlebag, LH 1

Lock, Saddlebag

1

Located in the left side cover.

Damper, Bottom 2 Large

Damper, Upper 2 D=12

Flanged Collar 2 D = 12, L = 13.1

Flanged Bolt, Saddlebag 2 D=8,L=75

Flat Washer, Saddlebag, Black 4 D = 8.5 × 20, T = 1.6

13

Battery Electrolyte, FTZ16-BS

14

Owner’s Manual

1

1

AUS:

Australian Model EUR: European Model

CN: CN Model US: United States Model

Page 10

8 ASSEMB

LY

Assembly

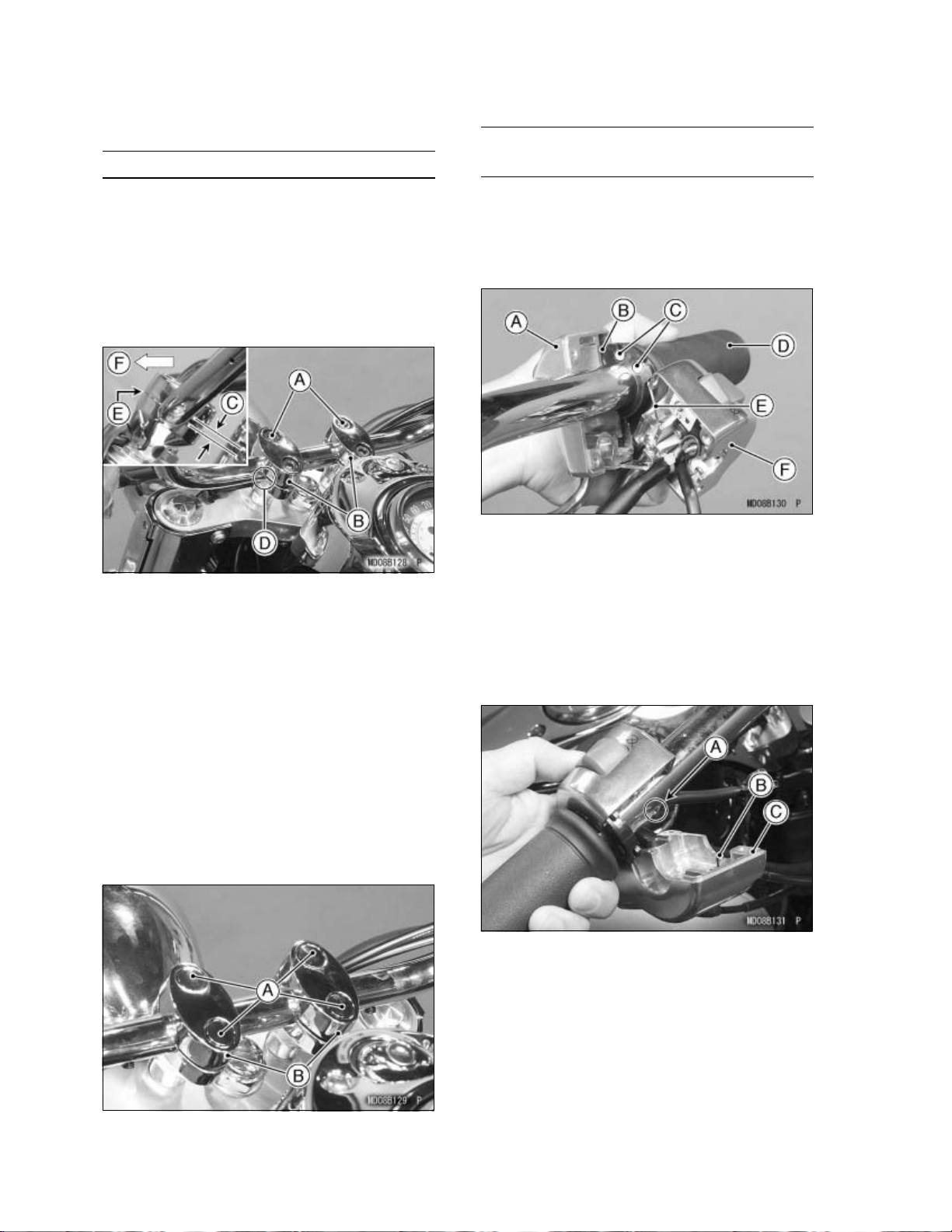

Handlebar

NOTE

żPosition the handlebar clamp on the handle-

bar with the slanted side facing rearward.

e handlebar to match its punched mark

Set th

•

to the rear portion of the lower clamp mating

face and install the upper clamps and bolts (D

=10,L

A. Front Bolts

B. Slanted Side

C.

D. Punched Mark

E. No Gap

. Forward

F

Handlebar Clamp Bolt Tightening

Tighten the front clamp bolts first, and then

•

the rear clamp bolts to the specified torque.

There will be a gap at the rear part of the

clamp after tightening.

Torque:

= 23).

Gap

34 N·m (3.5 kgf·m, 25 ft·lb)

Throttle Grip and Right Switch

Housing

Alignm

Apply a light coat of grease on the exposed

•

portion of the throttle inner cables.

Fit bot

•

socket in the throttle grip.

A. F

B. Throttle Cable (Accelerator)

C. Cable Tips: Apply Grease.

D. Throttle Grip

E. Throttle Cable (Decelerator)

F. Rear Half (Right Switch Housing)

Fit the two halves of the right switch housing

•

so that the pin on the front half fits into the

hole in the handlebar.

ent Pin Type

h throttle cable tips into the nearest

ront Half (Right Switch Housing)

Push the large plastic plugs (4) into the han-

•

dlebar clamp bolts.

A. Plastic Plugs

B. Handlebar Clamps

A. Hole

B. Pin

C. Front Half

Insert the two screws (D = 5, L = 25) and

•

tighten them.

Tighten the holder screw.

•

Check that the throttle grip moves smoothly

•

from full open to close, and the throttle closes

quickly and completely.

Page 11

A. Right Switch Housing

crews (L = 25)

B. S

C. Harness

D. Throttle Cable (Accelerator)

E. Throttle Cable (Decelerator)

F. Holder Screw

Front Brake Master Cylinder

Connect the right switch housing lead con-

•

nectors to the front brake light switch terminals on the front brake master cylinder.

Apply silicone grease or PBC grease to the

•

master cylinder clamp bolts.

Install the front master cylinder with its clamp

•

and the two socket bolts (D = 6, L = 20).

ASSEMBL

Push the small plastic plugs (2) into the mas-

•

ter cylinder clamp bolts.

A. Plastic Plugs

aster Cylinder

B. M

Left Switch Housing

Fit the two halves of the left switch housing

•

together so that the vertical parting line of the

front and rear halves align with the punched

mark on the handlebar.

Y9

A. Front Master Cylinder

B. Punched Mark

C. Clamp

D. Socket Bolts

E. Harness

F. Front Brake Light Switch

G. Connectors and Dust Covers

Position the master cylinder so that the gap

•

between the front and rear master cylinder

clamps aligns with the punched mark on the

handlebar.

Tighten the upper clamp bolt first and then the

•

lower bolt to the specified torque.

Torque:

8.8 N·m (0.90 kgf·m, 78 in·lb)

A. Punched Mark

B. Rear Half (Left Switch Housing)

C. Front Half

D. Screws (L = 25)

E. Harness

Insert the two screws (D = 5, L = 25) and

•

tighten them securely.

Page 12

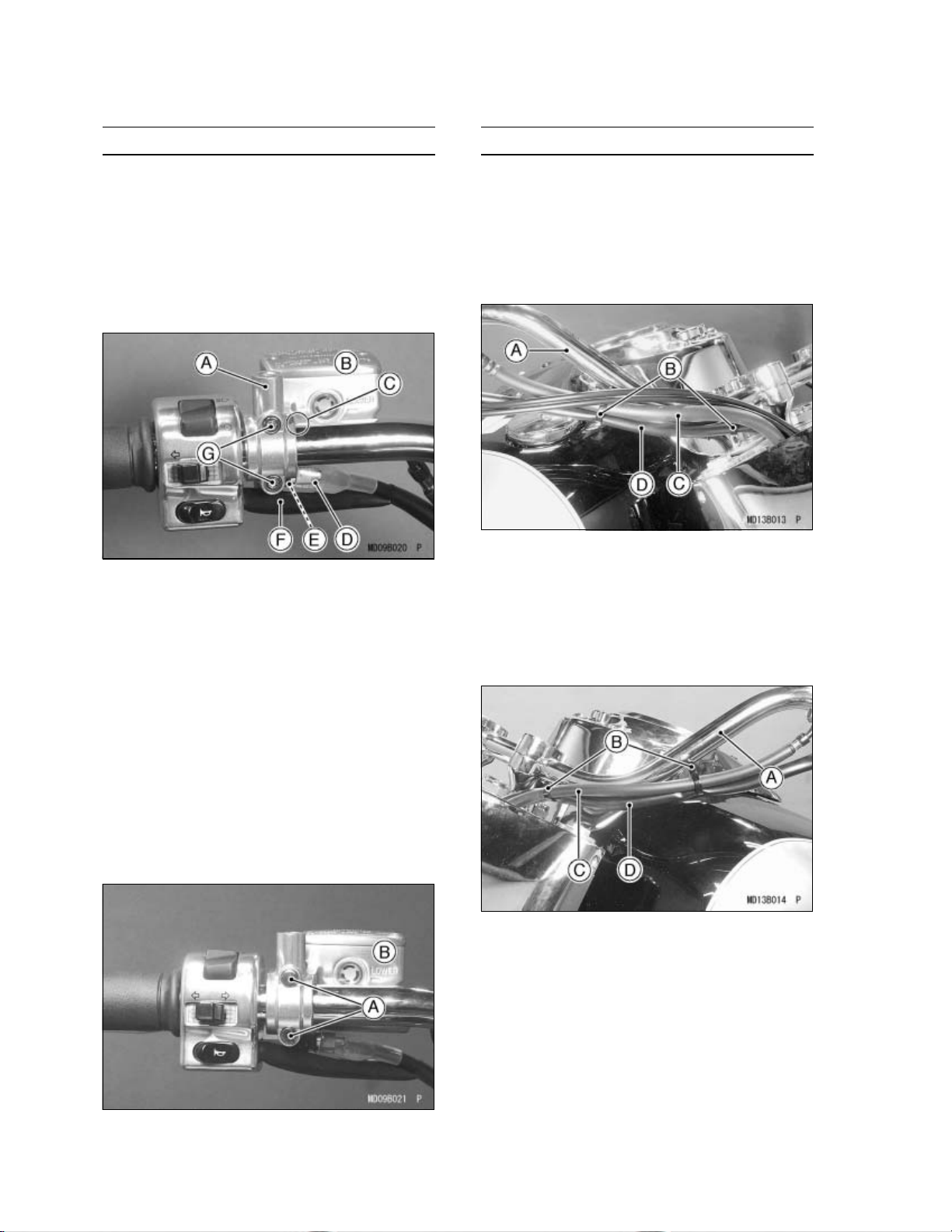

10 ASSEM

BLY

Clutch Master Cylinder

Apply silicone grease or PBC grease to the

•

master cylinder clamp bolts.

Install the clutch master cylinder with its

•

clamp and the two socket bolts (D = 6, L =

20).

Position the master cylinder so that the gap

•

between the front and rear master cylinder

clamps aligns with the punched mark on the

handlebar.

A. Clamp

B. Clutch Master Cylinder

C. Punched Mark

D. Connector and Dust Cover

E. Starter Lock-out Switch

F. Harness

G. Socket Bolts

Wiring Clamps

Fasten the front brake hose and the right

•

switch housing harness to the right side of

the handlebar with two plastic clamps.

NOTE

żThe plastic clamp at the inside fastens the

switch harness only.

right

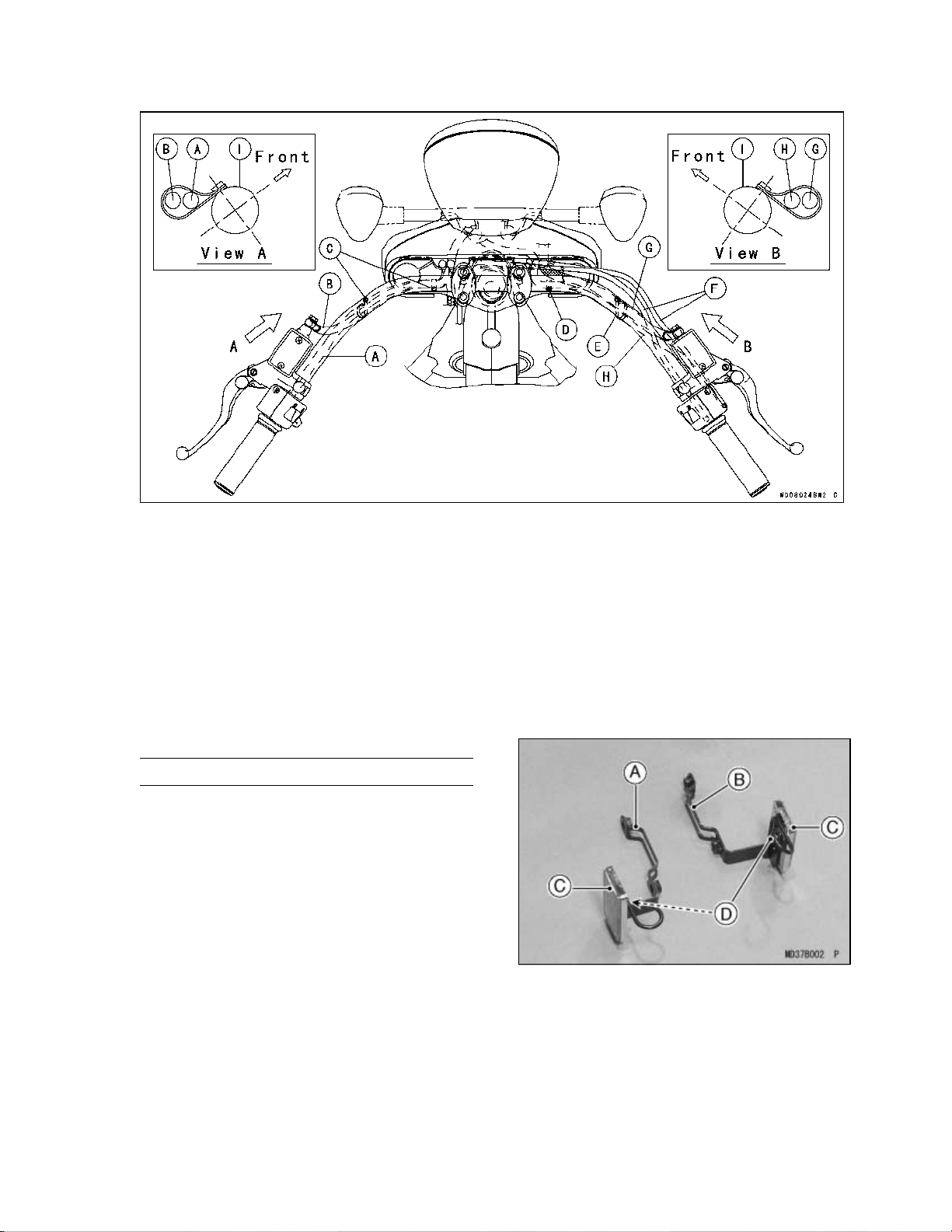

A. Handlebar (Right Side)

lastic Clamps

B. P

C. Front Brake Hose

D. Right Switch Harness

Fasten the clutch hose and the left switch

•

housing harness to the left side of the handlebar with two plastic clamps.

Connect the connector of the left switch hous-

•

ing to the starter lock-out switch on the master

cylinder.

Tighten the upper clamp bolt first and then the

•

lower bolt to the specified torque.

Torque: 11 N·m (1.1 kgf·m, 97 in·lb)

Push the small plastic plugs (2) into the clutch

•

master cylinder clamp bolts.

A. Plastic Plugs

B. Clutch Master Cylinder

A. Handlebar (Left Side)

B. Plastic Clamps

C. Clutch Hose

D. Left Switch Harness

Page 13

ASSEMBL

Y11

A. Left Switch Lead

B. Clutch Hose

C. Fasten the left switch lead and the clutch hose with two plastic clamps.

D. Fasten the right switch lead with the plastic clamp.

E. Fasten the right switch lead and the brake hose with the plastic clamp.

Throttle Cables

F.

G. Brake Hose

H. Right Switch Lead

Handlebar

I.

Front Fender

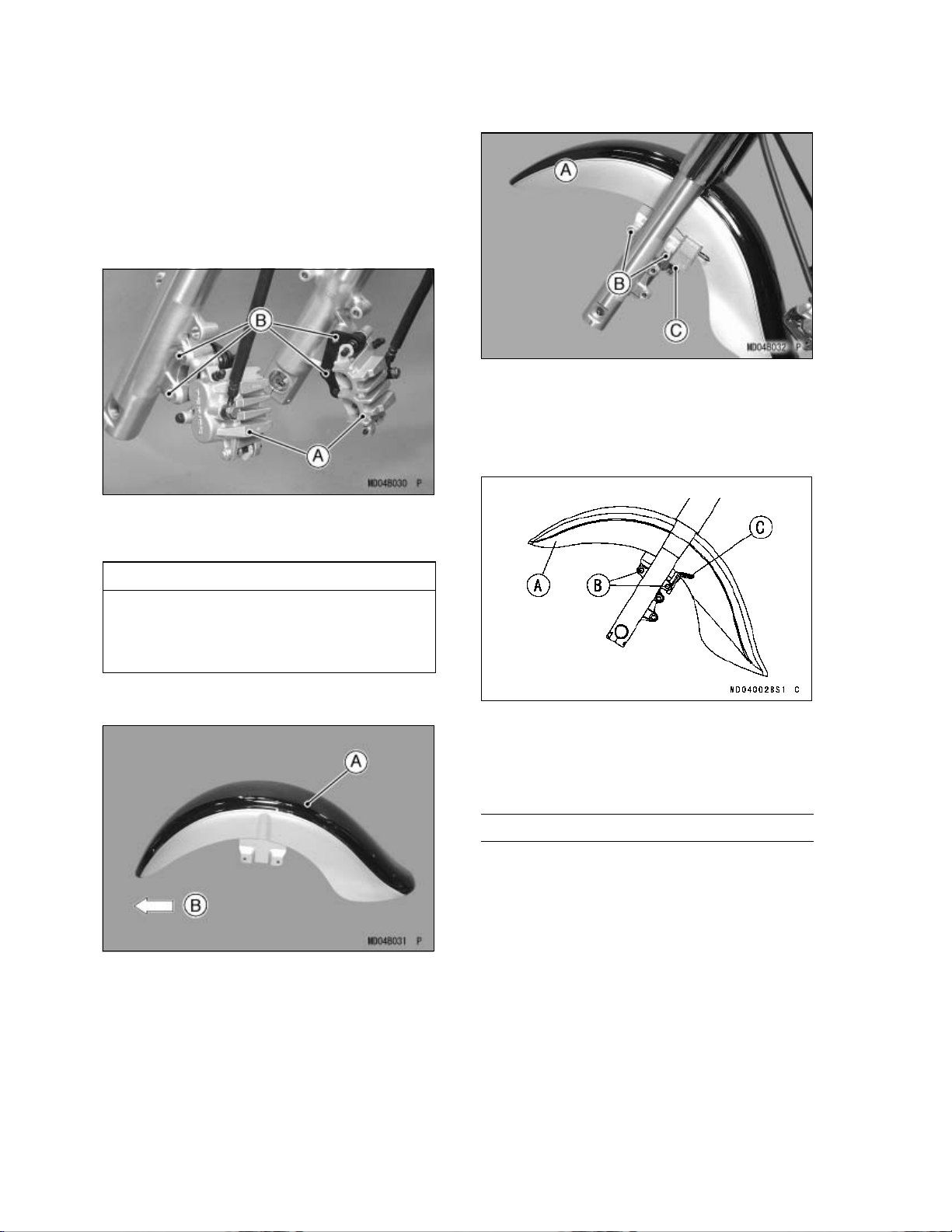

Front Reflectors (for US and CN Models

only)

Assemble the front left and right reflectors and

•

the brake hose clamps with the nut (D = 5) on

each.

A. Front Brake Hose Clamp (Left)

B. Front Brake Hose Clamp (Right)

C. Front Reflectors

D. Nuts

Page 14

12 ASSEM

BLY

Front Fender Installation

Lift the motorcycle off the crate base and sup-

•

port the motorcycle with a suitable stand or

jack.

Loosen the axle clamp bolts on the right fork

•

leg and remove the front axle.

Loosen the two flanged bolts (D = 10, L = 47)

•

to remove each front brake caliper.

A. Front Brake Calipers

B. Flanged Bolts (D = 10, L = 47)

US and CN Models

A. Front Fender

B. Bolts (D = 8, L = 35)

C. Brake Hose Clamp (Left)

Other than US and CN Models

CAUTION

Do not leave the calipers hanging by

the brake hoses. After removing the

calipers, secure them to the frame using

a suitable band.

Install the front fender with its more rounded

•

end facing forward.

A. Front Fender

B. Forward

Install the front fender on the fork legs, and in-

•

stall the front left and right brake hose clamps

on the inside of the fender with the four bolts

(D = 8, L = 35) and tighten them.

A. Front Fender

B. Bolts (D = 8, L = 35)

C. Brake Hose Clamp (Left)

Front Wheel Installation

Check the wheel rotation mark on the front

•

tire.

NOTE

żThe direction of the wheel rotation is shown

by an arrow on the front tire. Install the wheel

so that the rotation mark coincides with wheel

rotational direction.

Page 15

ASSEMBL

Y13

A. Front Tire

B. Arrow

C. Rotation

Fit the axle collars on both sides of the front

•

wheel hub. The collars are identical.

Put the front wheel assembly between the

•

fork legs.

Insert the front axle from the right side of the

•

wheel and push it completely through.

A. Front Axle

B. Collar (Right)

C. Axle Clamp Bolts (Right)

D. Collar (Left)

A. Pump the fork up and down.

B. Block

Tighten the axle clamp bolts on the right fork

•

leg to the specified torque.

Torque : 29 N·m (3.0 kgf·m, 21 ft·lb)

NOTE

żTighten the two front axle clamp bolts alter-

nately two times to ensure even tightening

torque.

Check the clearance between the right fork

•

leg and the axle collar with a thickness gauge.

There should be about 2.0 mm (0.08 in.) of

clearance. The clearance between 1.05 ~

3.19 mm (0.04 ~ 0.13 in.) is acceptable.

Tighten the front axle to the specified torque.

•

Torque : 108 N·m (11.0 kgf·m, 80 ft·lb)

Temporary install the front brake calipers.

•

Before tightening the axle clamp bolts on the

•

right fork leg, pump the front fork up and down

4 or 5 times to align the right front fork leg and

to seat the front axle. Do not pull the brake

lever when pumping the fork.

NOTE

żDo not apply the front brake during this

process to stop the motorcycle from rolling

forward. Put a block in front of the front wheel

to prevent movement.

A. Right Fork Leg

B. Front Axle

C. Axle Clamp Bolts

D. About 2.0 mm (0.08 in.)

E. Collar (Right)

If the clearance is out of this range, remove

•

the front wheel and check the axle, wheel hub

and other related parts for damage.

Tighten both front brake caliper mounting

•

bolts (D = 10, L = 47) to the specified torque.

Torque : 34 N·m (3.5 kgf·m, 25 ft·lb)

Page 16

14 ASSEM

BLY

Check the front brake.

•

A. Front Brake Caliper (Left)

lts (D = 10, L = 47)

B. Bo

WARNING

Do not attempt to ride the motorcycle until a full brake lever is obtained by pumping the brake lever until the pads are

against the disc. The brake will not function on the first application of the lever if

this is not done.

Other than US and CN Models

A. Front Brake Hose (Left)

B. Grommet

C. Brake Hose Clamp (Left)

Front and Rear Shift Pedals

NOTE

żInstall the front and rear shift pedals after the

“Clutch Fluid” section in the Preparation chapter.

Front Brake Hose Grommets

Fit the grommet onto each front left and right

•

brake hose, and install it in the clamp.

US and CN Models

A. Front Brake Hose (Left)

B. Grommet

C. Brake Hose Clamp (Left)

Install the front shift pedal on the shift shaft

•

aligning the punched marks on the pedal and

the shaft.

Install the pedal bolt (D = 8, L = 25) and

•

tighten it to the specified torque.

Torque : 30 N·m (3.1 kgf·m, 22 ft·lb)

Install the rear shift pedal with the bolt (D =

•

8, L = 25) in the same w ay as the front shift

pedal.

A. Front Shift Pedal

B.Bolt(D=8,L=25)

C. Align the Punched Marks.

D. Rear Shift Pedal

E. Shift Shaft

Page 17

Front Footboard (Left)

NOTE

żInstall the left footboard after the “Clutch Fluid”

n in the Preparation chapter.

sectio

Install the left footboard assembly on the

•

frame with one bolt (D = 10, L = 30) at the

rear and tighten it.

ASSEMBL

Install both front left and right guards on the

•

frame with the upper mounting bolts (D = 10,

L = 25), and on the front footboard brackets

with the lower mounting bolts (D = 10, L = 30).

A. Front Guard (Left)

B. Bolt (D = 10, L = 25)

C. Bolt (D = 10, L = 30)

D. Footboard Bracket

Y15

A. Front Footboard (Left)

olt (Rear)

B. B

NOTE

żThe bolt in front is for tightening the footboard

and the front guard together.

żTighten the front footboard mounting bolts af-

ter installing the front guards to the specified

torque.

Front Guards (Left and Right)

Front Guards Installation

Remove the front side mounting bolt from the

•

front right footboard.

Tighten the front footboard and the guard

•

mounting bolts to the specified torque.

Torque : 34 N·m (3.5 kgf·m, 25 ft·lb)

Label Installation (for US and CN Mod-

els o nly)

Wipe off any oil or grease from the application

•

area.

Peel the warning label off the backing sheet

•

and stick it on the center of the front left guard.

A. Front Guard (Left)

B. Label For US Models (56070-1285)

C. Label Top

D. Label For CN Models (56070-1180)

A. Front Footboard (Right)

B. Bolt

Page 18

16 ASSEM

BLY

Helmet Locks

Unlock the helmet lock with the key and fit

•

the small projection of the lock into the hole

in the bracket of each rear guard and fasten

it with the screw (D = 5, L = 12) having a

non-permanent locking agent.

Lock the helmet lock.

•

A. Bolts (D = 8, L = 75)

Join the rear left guard end and the left sad-

•

dlebag/muffler bracket with the bolts (D = 8, L

= 35)(2) and cap nuts (2) and tighten them.

Install the guard on the brackets with the up-

•

per bolt (D = 10, L = 30) and the lower socket

bolt (D = 10, L = 50) and tighten them.

A. Helmet Lock

B. Ignition Key

C. Projection

D. Screw

E. Rear Guard (Left)

Rear Guards (Left and Right)

Rear Guards Installation

Remove the right saddlebag.

•

Insert the ignition key into the lock and turn

•

the key counterclockwise and pull the knob

outward to open the lid.

A. Rear Guard (Left)

B. Bolts (D = 8, L = 35) and Cap Nuts

C. Bolt (D = 10, L = 30)

D. Socket Bolt (D = 10, L = 50)

Push the large plastic plug into the top of the

•

socket bolt.

A. Saddlebag (Right)

B. Ignition Key

C. Counterclockwise

D. Knob

Open the saddlebag lid and remove the bolts

•

(D = 8, L = 75) inside the saddlebag, and then

pull it up.

A. Plastic Plug

B. Rear Guard (Left)

Install the right guard in the same manner as

•

the left guard.

Page 19

ASSEMBL

Y17

Label Installation (for US and CN Mod-

els only)

Wipe off any oil or grease from the application

•

area.

Peel the warning label off the backing sheet

•

and stick it on the rear left guard.

A. Rear Guard (Left)

B. Label For US Models (56070-1285)

C. Label Top

D. 20 mm (0.8 in.)

E. Label For CN Models (56070-1180)

NOTE

żReinstall the right saddlebag after the “Rear

Brake Fluid” and “Rear Shock Absorber” sections in the Preparation chapter. When installing the right saddlebag, see “Left Saddlebag” section in the Assembly chapter.

Install the backrest between the brackets with

•

the flanged bolts (D = 8, L = 50)(4) and the cap

nuts (D = 8).

Tighten all the bolts and nuts securely.

•

ckrest

A. Ba

B.CapNuts(D=8)

C. Bolts (D = 8, L = 50)

Horn

Connect the horn lead connectors (BK, BK)

•

of the harness to the horn terminals at the left

side of the radiator.

Backrest Pad

Assemble the backrest pad, frame, and cover

•

with the cap nuts (D = 6)(4).

A. Backrest Pad

B. Cover

C. Cap Nut (D = 6)

D. Frame

A. Horn

B. Connectors (BK, BK)

C. Bracket

Install the horn with bracket to the frame with

•

the bolt (D = 8, L = 12) and tighten it.

Page 20

18 ASSEM

BLY

A. Horn

olt (D = 8, L = 12)

B. B

C. Bracket

Choke Knob

Loosen the locknut and fasten the choke knob

•

to the bracket with locknut.

A. Choke Knob

B. Locknut

C. Bracket

Rear View Mirrors (Left and Right)

A. Locknut

B. Rear View Mirror (Left)

Installation and adjustment of the right side

•

mirror is common with the left side. Follow

the procedure specified for the left side.

Turning Stay Type

Screw the mounting area of the left rear view

•

mirror into the holder all the way, and tighten

the lower hexagonal area securely.

A. Lower Hexagonal Area for Tightening

B. Upper Hexagonal Area (Adapter)

C. Rear View Mirror (Left)

Conventional Type (Single Nut)

Loosen the locknut completely.

•

Screw the rear view mirror in completely, and

•

then back it two turns out.

Turn the mirror stay to assure visibility to the

•

rear with the operator sitting on the motorcycle and tighten the locknut securely.

Adjust the rear view mirror by slightly moving

•

only the mirror portion of the assembly.

CAUTION

Do not force to tighten and/or loosen the

upper hexagonal area (adapter) with a

spanner or wrench. Disassembly of this

area is not possible. Non-permanent

locking agent is already applied to the

threads of this inner area. Forcible loosening may damage the adapter and/or

the turning mechanism of the stay.

Page 21

ASSEMBL

Y19

A. Lower Hexagonal Area for Tightening

B. Upper Hexagonal Area (Adapter)

C. Stay

D. Non-permanent Locking Agent applied.

Turn the stay to assure visibility to the rear

•

with the operator sitting on the motorcycle.

Adjust the rear view mirror by slightly moving

•

only the mirror portion of the assembly.

A. Stay

B. Mirror

A. Windshield Assembly

Remove the dummy bolts on the fork cover

•

and discard them.

A. Fork Cover

B. Dummy Bolts (Right Side)

Install the left and right mounting brackets on

•

the fork cover with the socket bolts (D = 8, L

= 20)(D = 8, L = 25).

Installation and adjustment of the right side

•

mirror is common with the left side. Follow

the procedure specified for the left side.

Windshield

CAUTION

Be sure not to damage the surface of the

windshield when installing or handling.

A. Mounting Bracket (Right)

B. Socket Bolt (D = 8, L = 20)

C. Socket Bolt (D = 8, L = 25)

Install the windshield assembly on the mount-

•

ing brackets with the socket bolts (D = 8, L =

10)(4).

Set the windshield all the way down and

•

tighten the bolts securely.

Page 22

20 ASSEM

A. Windshield Assembly

B. Socket Bolts (D = 8, L = 10)

BLY

Install each deflector on the bracket with the

•

socket bolts (D = 8, L = 10)(2) for each side

and tighten them.

Trim Installation [EUR Models Only]

Fit the windshield trim onto the edge of the

•

windshield starting from each lower edge.

Fix the trim ends with the clamps (2).

•

A. Trim

B. Clamps

Deflectors (Left and Right) Installation

Assemble the left and right stays, deflectors,

•

and outer plates with the socket bolts (D = 6,

L = 16)(4) and cap nuts (D = 6)(4).

A. Deflector (Right)

B. Socket Bolts (D = 8, L = 10)

Windshield Height Adjustment

The windshield can be adjusted 50 mm (2 in.)

in height to suit the rider’s preference.

Loosen both the upper and lower bolts on

•

each lower side of the windshield and move

it up or down.

Align both the left and right windshield stays.

•

Tighten the bolts securely.

•

A. Stay (Left)

B. Deflector

C. Outer Plate

D. Socket Bolts (D = 6, L = 16)

E. Stay (Right)

F. Ca p N u t s

A. Windshield

B. Bolts

C. Positioning Marks

Sub-windshield Adjustment

Loosen the windshield bolts on the left and

•

right vertical outer plates and move the sub

-windshield up or down. The distance should

be 10 mm (0.04 in.) between the lower edge

of the sub-windshield and the headlight body.

Tighten the windshield bolts.

•

Page 23

ASSEMBL

Y21

A. Bolts

B. Sub-windshield

License Plate Bracket

License Plate Bracket Installation

Install the license plate bracket onto the rear

•

fender with the bolts (D = 6, L = 12)(2).

A. Rear Fender

B. License Plate Bracket

C. Bolts (D = 6, L = 12)

Rear Reflectors and License Plate

Holder

US and CN Models only

Assemble the rear reflectors, bracket, and li-

•

cense plate holder with the cap nut (D = 5) on

each.

A. Reflectors

B. Reflector Bracket

icense Plate Holder

C. L

D.CapNuts(D=5)

Install the license plate holder and the rear

•

reflector bracket on the license plate bracket

with the bolts (D = 6, L = 14)(3) and plated

cap nuts (3) and tighten them. The remaining

fasteners are used for the license plate.

A. License Plate Holder

B. Reflector Bracket

C. Bolt (D = 6, L = 14)

D. Cap Nut

E. License Plate Bracket

F. For US Models

G. For CN Models

AUS Models only

Install the rear reflector on the license plate

•

holder with the cap nut (D = 5) and tighten it.

Page 24

22 ASSEM

BLY

A. Reflector

B. License Plate Holder

ap Nut (D = 5)

C. C

Install the license plate holder on the license

•

plate bracket with the bolts (D = 6, L = 14)(3)

and plated cap nuts (3) and tighten them. The

remaining fasteners are used for the license

plate.

A. License Plate Holder

B. Bolt (D = 6, L = 14)

C. Cap Nut

D. License Plate Bracket

Other than US, CN, and AUS Models

only

Install the license plate holder on the license

•

plate bracket with the bolts (D = 6, L = 14)(3)

and plated cap nuts (3) and tighten them. The

remaining fasteners are used for the license

plate.

A. License Plate Holder

B.Bolt(D=6,L=14)

ap Nut

C. C

D. License Plate Bracket

Left Saddlebag

NOTE

żInstall the saddlebags after the “Final Gear

Case Oil”, “Rear Brake Fluid”, and “Rear

Shock Absorber” sections in the Preparation

chapter.

Left Saddlebag Lid Lock Installation

NOTE

żAfter the saddlebag is installed, you can install

the left saddlebag lid lock.

Inspect the saddlebags for damage.

•

Insert the ignition key into the lock, and turn

•

the key counterclockwise to the unlocked position (hook faces left).

With the locked-position mark on the lock fac-

•

ing up (toward the handle), insert the hook

of the lock, then the lock into the hole in the

left saddlebag lid, and push it straight ahead

so that the projections on the lock fit into the

notches

Page 25

A. Lock

B. Left Saddlebag

ocked-position Mark

C. L

D. Projections

E. Notches

ASSEMBL

Open the saddlebag lid, and insert the upper

•

dampers (2) into the holes in the saddlebag.

Push the flanged collars (2) into the damper.

•

A. Upper Damper

B. Collars

Y23

NOTE

żPush the lid lock all the way into the hole in

the lid so that the projection ends are inserted

into it.

A. Lock

Turn the key clockwise and counterclockwise,

•

to check the saddlebag lid lock operation.

Left Saddlebag Dampers Installation

Insert the large dampers (2) so that the

•

grooves fit into the holes in the lower brackets of the left saddlebag/muffler bracket.

Left Saddlebag Installation

NOTE

żOnly use the flat washers (T = 1.6 mm) (4)

to adjust the clearance [1.0 mm (0.04 in.) or

more] between the saddlebag upper dampers

and the bracket, as needed.

While aligning the protrusions on the bottom

•

of the saddlebag with the holes in the lower

bracket, engage the hook on the back of the

saddlebag with the upper bracket, then push

it down.

A. Saddlebag

B. Protrusion

C. Hook

D. Upper Bracket

A. Dampers

Page 26

24 PREPA

RATION

Measure the clearances between both the

•

front and rear upper dampers and the upper mounting bracket with the saddlebag

lightly pushed by hand against the mounting

bracket.

If the clearance is 1.0 mm (0.04 in.) or more

•

at the front and/or rear, adjust it. Insert one or

two flat washer(s) between the upper damper

and the mounting bracket until it is less than

1.0 mm (0.04 in.) at the front and/or rear.

A. Saddlebag

B. Top Stay

C. Upper Bracket

D. Upper Dampers

. Clearance

E

F. Flat Washer

G. Bolts

After the saddlebag is installed, open and

•

close the lid several times, and check for

smooth movement of the lid handle and lid

lock operation. If they operate improperly,

remove the bolts and readjust the clearance.

Install the right saddlebag in the same man-

•

ner as the left saddlebag.

Brake Disc Cleaning

Clean the front and rear brake discs using

•

ss solvent.

oille

WARNING

If not removed, the anticorrosive treat-

applied to the brake disc surface

ment

will interfere with brake action, and an

unsafe riding condition could result.

If the clearance is less than 1.0 mm (0.04

•

in.) at the front and/or rear, the flat washer

is unnecessary.

Open the saddlebag lid and install the flanged

•

bolts (D = 8, L = 75)(2), (through the flat

washer(s) if necessary) and tighten them securely.

A. Left Saddlebag

B. Bolts (D = 8, L = 75)

Preparation

Battery Service

The battery used in this motorcycle is a sealed

type and never needs to be refilled. Follow the

procedure for activating a new battery to ensure

the best possible battery performance.

Activating the battery requires two steps, filling the battery with electrolyte, and charging.

Read the electrolyte safety label and the following procedures carefully before battery activation.

CAUTION

Incorrect Battery Activation will reduce

attery performance and service life. Be

b

sure to strictly follow the Battery Service

instructions in this Manual.

Make sure to use the electrolyte packed in the

•

crate with the unit.

Make sure that the model name of the elec-

•

trolyte container matches the model name of

the battery. These names must be the same.

Page 27

BatteryModelNamefor

VN1600–D1: FTZ16–BS

A. Model Name of the Electrolyte

B. Model Name of the Battery

CAUTION

Sealed battery electrolyte has a h igher

concentration of sulfuric acid. Each

container contains the proper amount

of electrolyte for its specific battery.

Insufficient or incorrect electrolyte will

reduce battery performance and service

life. Electrolyte over capacity can lead

to battery cracking or leaking and result

in corrosion damage to the vehicle.

PREPARA

A. Rider’s Seat

olt (D = 6, L = 14)

B. B

Remove the screw (D = 6, L = 14) and pull

•

the right side cover outward to clear the projections.

TION 25

Riders Seat Removal

Remove the bolt (D = 6, L = 14) and pull the

•

passenger’s seat rearward.

A. Bolt (D = 6, L = 14)

B. Passenger’s Seat

Remove the bolt (D = 6, L = 14) and pull the

•

rider’s seat rearward.

A. Right Side Cover

B. Screw (D = 6, L = 14)

C. Projections

Unfasten the wiring clamp.

•

Remove the two battery holder nuts, and dis-

•

connect the white 1 P (Pin), 2 P, and the 3 P

connectors.

Disconnect the 6 P connector and remove

•

the black diagnosis 4 P connector from the

holder, and then unfasten the plastic clamp

on the bottom of the battery holder while lifting the holder.

Page 28

26 PREPA

A. Wiring Clamp

B. 1

C. 2 P Connector

D. 3 P Connector

attery Holder Nuts

E. B

F. Battery Holder

G. Battery

. 6 P Connector (Rear Harness)

H

I. 4 P Connector (Diagnosis)

J. Plastic Clamp

. 15 A Fuse Holder

K

L. Harness (Fuel Pump)

M. Harness (Fuel Gauge)

RATION

P Connector (Negative Lead)

Battery Activation

g the Battery with Electrolyte

Fillin

CAUTION

Do not remove the aluminum sealing

sheet [A] from the filler ports [B] until

just prior to use. Be sure to use the dedicated electrolyte container for correct

electrolyte volume.

Place the battery on a level surface.

•

Check to see that the sealing sheet [A] has no

•

ing, tears, or holes in it.

peel

Remove the sealing sheet [A].

•

NOTE

żThe battery is vacuum sealed. If the sealing

sheet has leaked air into the battery, it may

require a longer initial charge.

Remove the 15 A fuse holder from the battery

•

holder, then remove the battery holder.

A. Battery Holder

B. 15 A Fuse Holder

C. Projection

D. Screwdriver

Take the battery out of the battery case.

•

Clean the terminals.

•

Battery Specifications

Make Furukawa

Battery Type FTZ16-BS

Battery Capacity 12 V 18 Ah

Electrolyte Capacity 0.82 L

Battery/Electrolyte Set P/No. 26012-1371

Remove the electrolyte container from the

•

vinyl bag.

Detach the strip of caps [A] from the container

•

and set aside, these will be used later to seal

the battery.

NOTE

o not pierce or otherwise open the sealed

żD

cells [B] of the electrolyte container. Do not

attempt to separate individual cells.

Page 29

PREPARA

TION 27

Place the electrolyte container upside down

•

with the six sealed cells into the filler ports

of the battery. Hold the container level, push

down to break the seals of all six cells. You

will see air bubbles rising into each cell as the

ports fill.

NOTE

żDo not tilt the electrolyte container.

Check the electrolyte flow.

•

If no air bubbles [A] are coming up from the

•

ller ports, or if the container cells have not

fi

emptied completely, tap the container [B] a

few times.

NOTE

żCharging the battery immediately after filling

can sho

at least 60 minutes after filling.

Initial Charge

Place

•

ports.

A. Strip

Newly activated sealed batteries require an

•

initial charge.

Standard Charge

If using a recommended battery charger, fol-

•

low the charger’s instructions for newly activated sealed battery.

Kawasaki-recommended chargers:

rten service life. Let the battery sit for

the strip of caps loosely over the filler

1.8 A × 5 a 10 hours

Optimate III

Yuasa 1.5 Amp Automatic Charger

Battery Mate 150–9

Keep the container in place for 20 minutes or

•

more. Don’t remove the container from the

battery until it’s empty, the battery requires all

the electrolyte from the container for proper

operation.

CAUTION

Removal of the container before it is

completely empty can shorten the service life of the battery. Do not remove

the electrolyte container until it is completely empty and 20 minutes have

elapsed.

Gently remove the container from the battery.

•

Let the battery sit for 60 minutes prior to

•

charging to allow the electrolyte to permeate

into the plates for optimum performance.

If the above chargers are not available, use

•

equivalent one.

NOTE

żCharging rates will vary depending on how

long the battery has been stored, temperature, and the type of charger used. Let battery

sit 60 minutes after initial charge, then check

voltage using a voltmeter. If it is not at least

12.6 volts, repeat charging cycle.

After charging is completed, press down

•

firmly with both hands to seat the strip of

caps [A] into the battery (don’t pound or hammer). When properly installed, the strip of

caps will be level with the top of the battery.

Page 30

28 PREPA

RATION

CAUTION

Once the strip of caps [A] is installed

onto the battery, never remove the caps,

nor add water or electrolyte to the battery.

NOTE

żTo ensure maximum battery life and customer

satisfaction, it is recommended the battery be

d tested at three times its amp-hour rating

loa

for 15 seconds.

Re-check voltage and if less than 12.6 volts

peat the charging cycle and load test. If still

re

below 12.6 volts the battery is defective.

Battery Installation

rn the ignition switch OFF.

Tu

•

Place the battery into the battery case.

•

A. Negative Cable (–)

B. Positive Cable (+)

C. Battery Holder

D. Plastic Clamp

E. Battery

F. 15 A Fuse Holder

G. Run the positive cable (+) through

the guide in the right side of the

battery case.

Pull the battery positive cable (+) downward

•

and through the guide in the right side of the

battery case, and then route t he cable as

shown.

Reinstall the 15 A fuse holder and the battery

•

holder, and then install the black diagnosis 4

P connector on the holder and connect the 6

P connector, and fasten the harness with the

plastic clamp.

Pull the Positive Cable (+) downward.

A.

B. Positive Cable (+)

C. Battery

4 P Connector (Diagnosis)

D.

E. 6 P Connector (Rear Harness)

F. 15 A Fuse Holder

. Wiring Clamp

G

H. 3 P Connector

I. 2 P Connector

J. 1 P Connector (Negative Lead)

K. Negative Cable (–)

Connect the 1 P, 2 P, and 3 P connectors,

•

and fasten the harness of the 2 P and 3 P

connectors with the wiring clamp.

First connect the red capped positive cable

•

(+) to the positive terminal, and then connect

the negative cable (–) to the negative terminal.

Put a light coat of grease on the terminals to

•

prevent corrosion.

Cover the (+) terminal with its protective cap,

•

and install the battery holder nuts and tighten

them.

NOTE

żInstall the right side cover after the “Coolant”

section in the Preparation chapter.

Page 31

PREPARA

TION 29

Viewed from Right

A. Positive Terminal (+)

B. Battery

C. Positive Cable (+)

D. ECU Relay

E. Negative Cable (–)

Viewed from Top

Rider’s Seat Installation

Insert the projection at the front of the rider’s

•

seat into the receptacle on the frame.

A. Projection

B. Receptacle

Install the bolt (D = 6, L = 14) and tighten it.

•

A. Negative Cable (–)

B. Run the Positive Cable (+) through

the Guide in the Battery Case.

C. Positive Cable (+)

D. Battery

E. 4 P Connector (Diagnosis)

F. 6 P Connector (Rear Harness)

G. Plastic Clamp

H. 15 A Fuse Holder

I. ECU Connector

J.3Connectors(1P,2P,3P)

A. Rider’s Seat

B. Bolt (D = 6, L = 14)

Insert the projection at the front of the passen-

•

ger’s seat into the receptacle on the frame.

A. Receptacle

B. Projection

Install the bolt (D = 6, L = 14) and tighten it.

•

Page 32

30 PREPA

RATION

A. Bolt (D = 6, L = 14)

assenger’s Seat

B. P

Front Brake Fluid

Front Brake Fluid Level Inspection

With the front brake fluid reservoir held hori-

•

zontal, check that the fluid level is above the

lower level line.

A. Front Brake Fluid Reservoir

B. Lower Level Line

If the f luid level in the reservoir is lower than

•

the lower level line, check for fluid leaks in the

front brake lines and fill the reservoir.

Loosen the screws to remove the front brake

•

fluid reservoir cap and diaphragm.

Fill the reservoir to the upper level line with

•

DOT4 brake fluid. Inside the front brake

reservoir is a stepped line showing the upper

level line.

A. Front Brake Fluid Reservoir

B. Upper Level Line

WARNING

Never reuse old b rake fluid.

Do not use fluid from a container that

has been left unsealed or that has been

open for a long time.

Do not mix two types of fluid for use in

the brakes. This lowers the brake fluid

boiling point and could reduce brake effectiveness. It may also cause the rubber brake parts to deteriorate.

Don’t leave the reservoir cap off for any

length of time to prevent moisture contamination of the fluid.

Don’t add or change brake fluid in the

rain or during conditions of blowing dust

or debris.

CAUTION

Brake fluid quickly ruins painted surfaces. Wipe up any spilled fluid immediately.

Operate the brake lever several times.

•

If it feels spongy, there might be air in the

•

brake line.

If necessary, bleed the air in the front brake

•

lines.

Also check for fluid leakage around the fit-

•

tings.

Front Brake Line Air Bleeding

Remove the reservoir cap and diaphragm,

•

and check that there is plenty of fluid in the

reservoir.

NOTE

żThe fluid level must be checked several times,

during the bleeding operation and replenished

as necessary. If the fluid in the reservoir runs

completely out any time during bleeding, the

bleeding operation must be repeated from the

beginning since air will have entered the line.

Page 33

Attach a clear plastic hose to the bleed valve

•

on each front brake caliper and run the other

end of the hose into a container.

With the reservoir cap off, slowly pump the

•

brake lever several times until no air bubbles

can be seen rising up through the fluid from

the holes at the bottom of the reservoir. This

bleeds the air from the brake master cylinder

end of the line.

Pump the brake lever a few times until it

•

becomes hard and then, holding the lever

squeezed, quickly open (turn counterclockwise) and close the bleed valve. Then release

the lever. Repeat this operation until no more

air can be seen coming out into the plastic

hose.

PREPARA

A. Rear Brake Fluid Reservoir

B. Cover

C. Upper Level Line

ower Level Line

D. L

If the fluid level in the reservoir is lower than

•

the lower level line, check for fluid leaks in the

brake line, and fill the reservoir.

Loosen the bolt to remove the cover from the

•

reservoir.

Remove the reservoir cap and diaphragm,

•

and fill the reservoir to the upper level line with

DOT4 brake fluid.

TION 31

A. Hold the brake lever applied.

B. Quickly open and close the bleed

alve.

v

C. Release the brake lever.

Repeat the previous step one more time for

•

the other front disc brake.

When air bleeding is finished, check that the

•

fluid level is between the upper and lower

level lines.

Install the diaphragm and reservoir cap.

•

Tighten the bleed valve(s) to the specified

•

torque.

Torque: 7.8 N·m (0.80 kgf·m, 69 in·lb)

Apply the brake forcefully for a few seconds,

•

and check for fluid leakage around the fittings.

Rear Brake Fluid

Rear Brake Fluid Level Inspection

With the rear brake fluid reservoir held hor-

•

izontal, check that the fluid level is between

the upper and lower level lines.

CAUTION

Brake fluid quickly ruins painted surfaces. Wipe up any spilled fluid immediately.

NOTE

żFirst, tighten the rear brake fluid reservoir cap

clockwise by hand until slight resistance is felt

indicating that the cap seated on the reservoir body, then tighten the cap an additional

1/6 turn while holding the brake fluid reservoir

body.

A. Reservoir

B. Cap

C. Clockwise

D. 1/6 turn

Page 34

32 PREPA

RATION

Operate the brake lever several times.

•

If it feels spongy, there might be air in the

•

brake line.

If necessary, bleed the air in the rear brake

•

line.

Also check for fluid leakage around the fit-

•

tings.

Rear B

•

rake Line Air Bleeding

Remove the rear brake reservoir cap and diaphragm, and check that there is plenty of

d in the reservoir.

flui

NOTE

żThe fluid level must be checked several times,

during the bleeding operation and replenished

as necessary. If the fluid in the reservoir runs

completely out any time during bleeding, the

bleeding operation must be repeated from the

beginning since air will have entered the line.

ach a clear plastic hose to the bleed valve

Att

•

on the rear brake caliper and run the other

end of the hose into a container.

th the reservoir cap off, slowly pump the

Wi

•

brake pedal several times until no air bubbles can be seen rising up through the fluid

om the holes at the bottom of the reservoir.

fr

This bleeds the air from the rear brake master

cylinder end of the line.

ump the brake pedal a few times until it

P

•

becomes hard and then, holding the pedal

pushed down, quickly open (turn counter-

lockwise) and close the bleed valve. Then

c

release the pedal. Repeat this operation until

no more air can be seen coming out into the

plastic hose.

When air bleeding is finished, check that the

•

fluid level is between the upper and lower

level lines.

Tighten the bleed valve(s) to the specified

•

torque.

Torque: 7.8 N·m (0.80 kgf·m, 69 in·lb)

Install the diaphragm and reservoir cap.

•

NOTE

żFirst, tighten the rear brake fluid reservoir cap

clockwise by hand until slight resistance is felt

indicating that the cap seated on the reservoir body, then tighten the cap an additional

1/6 turn while holding the brake fluid reservoir

body.

Apply the brake forcefully for a few seconds,

•

and check for fluid leakage around the fittings.

Install the cover with the bolt.

•

Clutch Fluid

Clutch Fluid Level Inspection

With the clutch reservoir held horizontal,

•

check that the fluid level is above the lower

level line.

A. Hold the brake pedal applied.

B. Quickly open and close the bleed

valve.

C. Release the brake pedal.

A. Clutch Fluid Reservoir

B. Lower Level Line

If the fluid level in the reservoir is lower than

•

the lower level line, check for fluid leaks in the

clutch line and fill the reservoir.

NOTE

żSince the clutch fluid is the same as the brake

fluid, refer to the “Front or Rear Brake Fluid”

section for further details.

Loosen the screws to remove the clutch fluid

•

reservoir cap and diaphragm.

Fill the reservoir to the upper level line with

•

DOT4 clutch fluid. Inside the clutch reservoir

is a stepped line showing the upper level line.

Page 35

A. Clutch Fluid Reservoir

B. Upper Level Line

Operate the clutch lever several times.

•

If it feels spongy, there might be air in the line.

•

If necessary, bleed the air in the lines.

•

Also check for fluid leakage around the fit-

•

tings.

Clutch Line Air Bleeding

Loosen the mounting bolts to remove the al-

•

ternator outer cover.

PREPARA

Attach a clear plastic hose to the bleed valve

•

on the clutch slave cylinder and run the other

end of the hose into a container.

With the reservoir cap off, slowly pump the

•

clutch lever several times until no air bubbles

can be seen rising up through the fluid from

the holes at the bottom of the reservoir. This

bleeds the air from the clutch master cylinder

end of the line.

Pump the clutch lever a few times until it

•

becomes hard and then, holding the lever

squeezed, quickly open (turn counterclockwise) and close the bleed valve.

Then release the lever. Repeat this operation

until no more air can be seen coming out into

the plastic hose.

TION 33

A. Alternator Outer Cover

B. Socket Bolts and Washers

Remove the reservoir cap and diaphragm,

•

and check that there is plenty of fluid in the

reservoir.

NOTE

żThe fluid level must be checked several times

during the bleeding operation and replenished

as necessary. If the fluid in the reservoir runs

completely out any time during bleeding, the

bleeding operation must be repeated from the

beginning since air will have entered the line.

A. Hold the clutch lever applied.

B. Quickly open and close the bleed

valve.

C. Release the clutch lever.

When air bleeding is finished, check that the

•

fluid level is between the upper and lower

level lines.

Install the diaphragm and reservoir cap.

•

Tighten the bleed valve to the specified

•

torque.

Torque: 7.8 N·m (0.80 kgf·m, 69 in·lb)

Apply the clutch forcefully for a few seconds,

•

and check for fluid leakage around the fittings.

Apply a soap and water solution or rubber

•

lubricant to the body of the alternator cover

bolts for easy installation.

Reinstall the alternator outer cover with the

•

bolts and washers and tighten the bolts to the

specified torque.

Torque:

Reinstall the front and rear shift pedals. See

•

“Shift Pedal” section in the Assembly chapter.

Reinstall the left footboard assembly. See

•

“Front Footboard (Left)” section in the Assembly chapter.

6.9 N·m (0.70 kgf·m, 61 in·lb)

Page 36

34 PREPA

RATION

Rear Shock Absorber

Air Pre

STD Air pressure: Atmospheric

ssure Adjustment

Rebound Damping Force Adjustment

Check the position of the rebound damping

•

force adjuster at the upper end of each rear

shock absorber. It has four positions. The

numbers on the adjuster show the setting position.

STD Rebound Damping Force:

No. 2 position

A. Air Valve

B. Rebound Damping Force Adjuster

C. Number

Turn the rebound damping force adjuster to

•

the No. 2 position.

Tire Air Pressures

To prevent flat-spotting during shipment, the

•

tires are over-inflated before crating. Adjust

the pressures to the specified values in the

front and rear, and make sure to tighten the

caps securely.

Tire Air Pressure [when cold]:

Front:

Rear:

225 kPa (2.25 kgf/cm², 32 psi)

280 kPa (2.80 kgf/cm², 40 psi)

A. Tire Air Pressure Gauge

Fuel

WARNING

Fill the tank in a well-ventilated area, and

take ample care that there are no sparks

or open flames anywhere near the work

area.

Open the fuel tank cap, and check for debris

•

in the fuel tank.

Fill the fuel tank with one gallon or four liters

•

of unleaded gasoline. Use a gasoline with a

minimum Antiknock Index rating according to

the recommendation of your country. Refer to

the following table.

The antiknock index is an average of the Research Octane Number (RON) and the Motor

Octane Number (MON), as shown in the table.

Octane Rating Method

Antiknock

Index

Research Octane Number

Close the fuel tank cap, and check for any

•

leaks.

(RON + MON)

2

(RON)

Minimum

Rating

90

95

Coolant

Coolant Level Inspection

Situate the motorcycle so that it is perpendic-

•

ular to the ground.

Check the coolant level through the coolant

•

level gauge. The coolant level should be between the F (Full) and L (Low) marks.

NOTE

żCheck the level when the engine is cold (room

or atmospheric temperature).

Page 37

PREPARA

NOTE

TION 35

żA permanent type of antifreeze is installed in

the coo

ored green and contains ethylene glycol. It is

mixed at 50 % and has the freezing point of –

35°C (

Engine Oil (4-stroke)

Engine Oil Level Inspection

ling system when shipped. It is col-

– 31°F).

Full) Mark

A. F (

B. L (Low) Mark

C. Right Side Cover

Coolant Filling

If the amount of coolant is insufficient, remove

•

the right side cover, pull open the cap from the

reserve tank and add coolant through the filler

opening to the F (Full) mark.

A. Cap

B. F (Full) Mark

C. L (Low) Mark

Install the cap.

•

To install the right side cover, insert the pro-

•

jections into the grommets.

Tighten the screw.

•

NOTE

żThis vehicle’s engine is filled with 10W-40 oil

he factory. DO NOT DRAIN and refill

from t

the crankcase before u se. Check oil level and

drain plug tightness.

Engine Oil Drain Plug Torque:

20 N·m (2.0 kgf·m, 14 ft·lb)

A. Oil Drain Plug

Park the vehicle on level ground.

•

Before starting the engine, check that the en-

•

gine has oil.

Check that the engine has oil through the oil

•

level sight gauge in the lower right side of the

engine.

CAUTION

If the engine is run without oil, it will be

severely damaged.

A. Right Side Cover

B. Projections

C. Grommets

Start the engine and run it for several minutes

•

at idle speed. Stop the engine, then wait several minutes until the oil settles.

With the motorcycle held level, check the en-

•

gine oil level through the oil level sight gauge.

The oil level should come up between the

H (High) and L (Low) level lines next to the

gauge.

Page 38

36 PREPA

RATION

Final Gear Case Oil

A. Oil Filler Cap

il Level Sight Gauge

B. O

C. H (High) Level Line

D. L (Low) Level Line

If the oil level is too high, remove the excess

•

oil through the oil filler opening, using a syringe or some other suitable device.

If the oil level is too low, add oil to reach the

•

correct level. Use the same type of oil that is

already in the engine.

When replacing the cap, be sure the O-ring is

•

in place, and tighten the cap.

Recommended Engine Oil

Type :

Viscosity:

Capacity: 2.9 L (3.1 US qt)

Although 10W-40 engine oil is the recommended oil for most conditions, the oil viscosity

may need to be changed to accommodate

atmospheric conditions in your riding area.

API SE, SF or SG

APISHorSJwithJASOMA

SAE 10W-40

[when filter is not removed]

3.1 L (3.3 US qt)

[when filter is removed]

Final G

Have a helper hold the motorcycle vertical on

•

level ground.

Remove

•

Check the oil level. If it is low, add oil as

•

necessary. The oil level should come to the

botto

motorcycle held vertical on level ground.

A. Bottom Thread

B. Filler Cap

If the oil level is too low, add the specified oil.

•

If the oil level is too high, remove the excess

•

oil, using a syringe or some other suitable

device.

ear Case Oil Level Inspection

the filler cap.

m thread of the filler opening with the

WARNING

Be careful that no oil gets on the tire, rim,

and brake disc. Clean off any oil that

inadvertently gets on them with oilless

solvent.

CAUTION

Be careful not to allow any dirt or foreign

materials to enter the gear case.

NOTE

żUse the same type of oil that is already in the

final gear case.

Page 39

When replacing the filler cap, be sure the O

•

-ring is in place, and install the cap.

Final G

Type :

Viscosity: SAE 90 [above 5°C (41°F)]

Capacity: 0.2 L (0.21 US qt)

Final Gear Case Oil Drain Plu g Torque:

ear Case Oil

API “GL-5”

Hypoid gear oil

SAE 80 [below 5°C (41°F)]

8.8 N·m (0.90 kgf·m, 78 in·lb)

PREPARA

A. Throttle Grip

~ 3 mm (0.08 ~ 0.12 in.)

B. 2

Run the engine at idle speed, and turn the

•

handlebar all the way to the right and left to

ensure that the idle speed does not change.

If the idle speed increases, check the throttle

grip free play.

TION 37

A. Oil Drain Plug

Reinstall the saddlebags. See “Left Saddle-

•

bag” section in the Assembly chapter.

Throttle Grip and Cable

Throttle Grip Free Play Inspection

Inspect the throttle grip free play. If the free

•

play is incorrect, adjust the throttle cables.

Throttle Grip Free Play:

2~3mm(0.08~0.12in.)

Check that the throttle grip moves smoothly

•

from full open to close, and the throttle closes

quickly and completely in all steering positions by the return spring. If the throttle grip

does not return properly, check the throttle cable routing, grip free play, and for possible cable damage. Then lubricate the throttle cables.

WARNING

Operation with an improperly adjusted,

incorrectly routed, or damaged cable

could result in an unsafe riding condition.

Throttle Grip Free Play Adjustment

Loosen both locknuts of the throttle cables

•

and turn both adjusters in completely to give

the throttle grip plenty of play.

Turn out the decelerator cable adjuster until

•

there is no play when the throttle grip is completely closed. Tighten the locknut.

A. Accelerator Cable

B. Decelerator Cable

C. Locknuts

D. Adjusters

Turn out the accelerator cable adjuster un-

•

til the specified amount of play is obtained.

Tighten the locknut.

Page 40

38 PREPA

RATION

Headlight Aim

The headlight beam is adjustable both horizontally and vertically. Headlight aim must be

correctly adjusted for safe riding as well as oncoming drivers. In most areas it is illegal to ride

with an improperly adjusted headlight.

Horizontal Adjustment

Turn th

•

headlight rim in or out until the beam points

straight ahead.

e horizontal adjusting screw on the

A. Idle Adjusting Screw

Open and close the throttle grip a few times

•

to make sure that the idle speed does not

change.

With the engine idling, turn the handlebar to

•

each side. If handlebar movement changes

the idle speed, check the throttle cable routing

and free play.

A. Horizontal Adjusting Screw

B. Vertical Adjusting Screw

Vertical Adjustment

Turn the vertical adjusting screw on the head-

•

light rim in or out to adjust the headlight vertically.

NOTE

żOn high beam, the brightest point should be

slightly below horizontal with the motorcycle

on its wheels and the rider seated. Adjust

the headlight to the proper angle according to

local regulation.

Idle Speed Adjustment

Start the engine and warm it up thoroughly.

•

Adjust the idle speed to 900 ~ 1 000 r/min

•

(rpm) by turning the idle adjusting screw.

Idle Speed: 900 ~ 1 000 r/min (rpm)

WARNING

Operation with improperly routed, or

damaged throttle cables could result in

an unsafe riding condition.

Check for any exhaust leaks and correct if

•

necessary.

Rear Brake Light Switch

Rear Brake Light Switch Adjustment

Turn on the ignition switch. The brake light

•

should illuminate when the brake pedal is depressed about 10 mm (0.4 in.)

A. Brake Pedal

B. 10 mm (0.4 in.)

If it does not, turn the adjusting nut at the rear

•

brake light switch as required.

Page 41

A. Rear Brake Light Switch

B. Adjusting Nut

C. Lights sooner.

D. Lights later.

CAUTION

To avoid damaging the electrical connections inside the switch, be sure that

the switch body does not turn during adjustment.

PREPARA

TION 39

Page 42

40 PREPA

RATION

Fastener Check

The torque values listed are for assembly and

•

preparation items only, see the appropriate

Service Manual for a more comprehensive

list. Check tightness of all fasteners that are

in the table before retail delivery. Also check

to see that each cotter pin or circlip is in place.

Page 43

PREPARA

TION 41

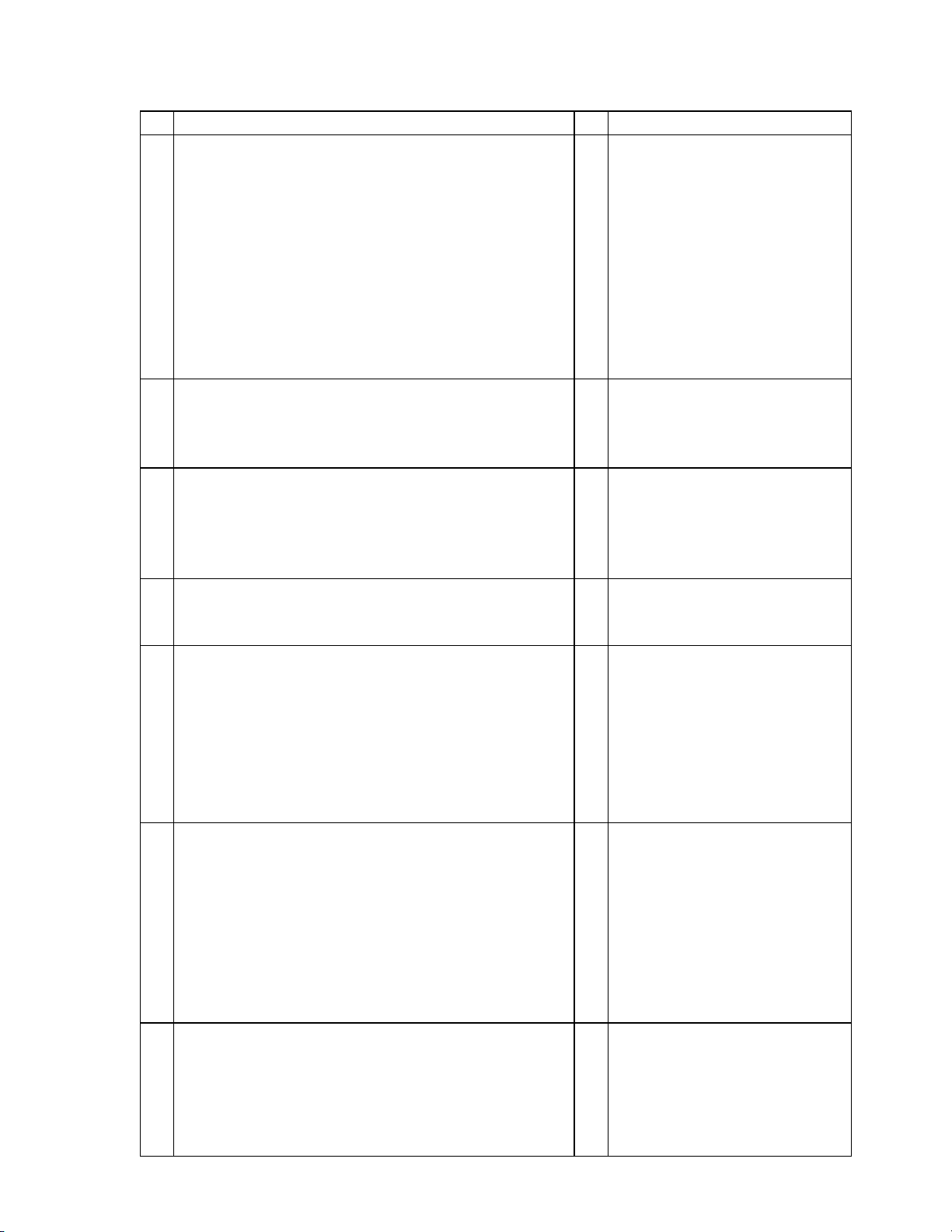

No. Fastener

N·m kgf·m ft·lb

Torque

Remarks

Steering

1 Handlebar clamp bolts 34 3.5 25

2 Steering stem head nut 88 9.0 65

Brake

3 Front master cylinder clamp bolts 8.8 0.90 78 in·lb S

4 Front caliper mounting bolts (Left and Right) 34 3.5 25

5 Front brake bleed valves (Left and Right) 7.8 0.80 69 in·lb

6 Rear master cylinder mounting bolts 25 2.5 18

7 Rear caliper mounting bolts 34 3.5 25

8 Rear brake bleed valves 7.8 0.80 69 in·lb

Wheel

9 Front axle shaft 108 11.0 80

10 Front axle clamp bolts (Right) 29 3.0 21 AL

Suspe

Other

nsion

Rear shock absorber mounting nuts (Left and

11

Right)(Uper and Lower)

s

12

Front footboard bracket bolts (Left and Right)

34 3.5 25

34 3.5 25

13 Rear footboard bracket bolts (Left and Right) 25 2.5 18

14 Clutch master cylinder clamp bolts 11 1.1 97 in·lb

Engine

Engine Oil Drain Plugs:

15 Engi

ne oil drain plug

20 2.0 15

16 Final gear case drain plug 8.8 0.90 78 in·lb

Cotter P in or Circlip

17 Rear axle nut cotter pin – – –

18 Rear master cylinder cotter pin – – –

19 Front footboard pin circlips (Left and Right) – – –

20 Rear footboard pin circlips (Left and Right) – – –

AL: Tighten the two clamp bolts alternately two times to ensure even tightening torque.

S: Tighten the upper clamp bolt first, and then the lower clamp bolt.

Page 44

42 PREPA

RATION

Standard Torque Table

This table relating tightening torque to thread

diameter, lists the basic torque for bolts and

nuts. Use this table for only the bolts and nuts

which do not require a specific torque value.

All of the values are for use with dry solvent

-cleaned threads.

General Fasteners:

Threads Torque

dia. mm N·m

5 3.4~4.9 0.35~0.50

6 5.9~7.8 0.60~0.80

8 14~19 1.4~1.9 10.0~13.5

10 25~34 2.6~3.5 19.0~25

12 44~61 4.5~6.2 33~45

14 73~98 7.4~10.0 54~72

16 115~155 11.5~16.0 83~115

18 165~225 17.0~23.0 125~165

20 225~325 23~33 165~240

kgf·m ft·lb

30 ~ 43

in·lb

52 ~ 69

in·lb

Test Ride the Motorcycle

Complete the test ride checklist.

•

Control

Cables:

Steering: Action is free from

Suspension: Check operation front and

Engine: Electric starter works

Transmission

and Clutch:

Brakes: Adequate, smooth stopping

Speedometer: Check operation

Electrical System:

Headlight - check high and low beams.

Taillight - check operation.

Brake Light - check operation

Turn Signal Lights - check operation.

Horn - check operation

Instrument Lights and Indicator Lights -

Check operation.

Engine Stop Switch Works:

Starter Interlock Switch Works:

No Unusual Noises:

No Fuel, Oil, Brake Fluid, Clutch Fluid,

or Coolant Leaks:

PREPARATION COMPLETE.

Throttle control cables must

work without binding in any

steering position.

to-lock.

lock-

rear.

properly and engine starts

promptly. Good throttle

ponse and return.

res

Smooth operation.

power, No drag.

WARNING

New tires are slippery and may cause

loss of control and injury. A break-in period of 160 km (100 miles) is necessary

to establish normal tire traction.

During break-in, avoid sudden and maximum braking and acceleration, and hard

cornering.

A & P Check List

CompletetheA&PCheckList.

•

Page 45

Page 46

MODEL APPLICATION

Year Model Name

2005 VN1600–D1

VULCAN 1600 NOMAD

VN1600 CLASSIC TOURER

Part No. 99931-1445-01

Loading...

Loading...