Page 1

KaVo Scan eXam™ One

Digital Intraoral Imaging Plate System

User Manual

ENGLISH

209643 rev. 5

0.805.5080

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 2

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 3

Copyright Copyright © 2017 by, PaloDEx Group Oy.

All rights reserved.

Scan eXam™ is a common law trademark of

Kaltenbach & Voigt GmbH.

IDOT™ is common law trademark of PaloDEx Group

Oy.

All other trademarks are property of their

respective owners.

Documentation, trademark and the software are

copyrighted with all rights reserved. Under the

copyright laws the documentation may not be

copied, photocopied, reproduced, translated, or

reduced to any electronic medium or machine

readable form in whole or part, without the prior

written permission of PaloDex Group Oy.

This is the original approved English language

version.

The manufacturer reserves the right to make

changes in specification and features shown herein,

or discontinue the product described at any time

without notice or obligation. Contact your

representative for the most current information.

Manufacturer PaloDEx Group Oy

Nahkelantie 160

FI-04300 Tuusula

FINLAND

Tel. +358 10 270 2000

www.kavokerrgroup.com

For service, contact your local distributor.

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 4

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 5

Table of Contents

1 Introduction.................................................................................... 1

1.1 Unit with accessories................................................................... 1

1.2 System setup ............................................................................. 2

1.3 Controls and indicators ................................................................ 3

2 Basic use......................................................................................... 7

2.1 Preparing the imaging plates ........................................................ 9

2.2 Positioning and exposure ........................................................... 10

2.3 Processing the imaging plates..................................................... 12

3 Advanced use................................................................................ 15

3.1 Scan eXam™ One setup options.................................................. 15

3.1.1 Status............................................................................. 15

3.1.2 Image Scanning ............................................................... 16

3.1.3 Using the dental chart....................................................... 16

3.1.4 Resolution ....................................................................... 16

3.1.5 Image Processing - Noise Filtering ...................................... 16

3.1.6 Retrieve last image........................................................... 17

3.1.7 Scanner Unit Serial number ............................................... 17

3.2 Settings................................................................................... 17

3.3 Workflow ................................................................................. 18

3.3.1 Readout start................................................................... 18

3.3.2 Plate eject mode .............................................................. 20

3.4 Power options .......................................................................... 20

3.5 Occlusal 4C projection imaging (not included in delivery) ............... 21

4 Accessories introduction ............................................................... 23

4.1 Hygiene accessories .................................................................. 23

4.2 Imaging plates ......................................................................... 24

4.3 Imaging plate storage box ......................................................... 25

4.4 Holders ................................................................................... 25

4.5 Occlusal projection imaging with Occlusal 4C start-up kit and

accessories .............................................................................. 26

4.6 Microfiber cloth......................................................................... 26

4.7 Imaging plate care.................................................................... 26

4.8 Imaging plate cleaning .............................................................. 27

5 Introduction to imaging plate technique ....................................... 29

5.1 Imaging plate........................................................................... 29

5.2 Hygiene accessories .................................................................. 30

5.3 Processing ............................................................................... 31

5.4 Background radiation ................................................................ 32

5.5 Light ....................................................................................... 33

6 Installation of the imaging plate system....................................... 35

6.1 Positioning the unit ................................................................... 35

6.2 Connecting the unit to a network ................................................ 36

rev i

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 6

6.3 Install the Application software ................................................... 37

6.4 Accessing the unit from the software ........................................... 38

6.4.1 Direct connection method (uses the unit s/n) ....................... 38

6.4.2 IP method (using the unit static address) ............................ 39

6.4.3 EXPRESS Share................................................................ 39

6.5 Other devices........................................................................... 40

7 Troubleshooting............................................................................ 41

7.1 Error images ............................................................................ 41

7.1.1 Improper use of the hygiene accessories and imaging plates .. 41

7.1.2 Application errors ............................................................. 42

7.1.3 Imaging plate wearing ...................................................... 45

7.2 Error messages ........................................................................ 46

8 Other information ......................................................................... 47

8.1 Quality control.......................................................................... 47

8.2 Unit care ................................................................................. 47

8.3 Unit cleaning............................................................................ 47

8.4 Disinfecting the unit .................................................................. 48

8.5 Maintenance ............................................................................ 48

8.6 Repair ..................................................................................... 48

8.7 Disposal .................................................................................. 48

9 Technical specifications ................................................................ 49

9.1 Unit ........................................................................................ 49

9.2 System requirements and connections......................................... 51

9.3 Imaging plate specifications ....................................................... 52

9.4 Hygiene bag specifications ......................................................... 53

9.5 Electromagnetic Compatibility (EMC) tables .................................. 54

10 Symbols and labeling .................................................................... 58

10.1Symbols .................................................................................. 58

10.2Main label ................................................................................ 59

10.3Warnings and precautions .......................................................... 60

ii rev

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 7

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 8

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 9

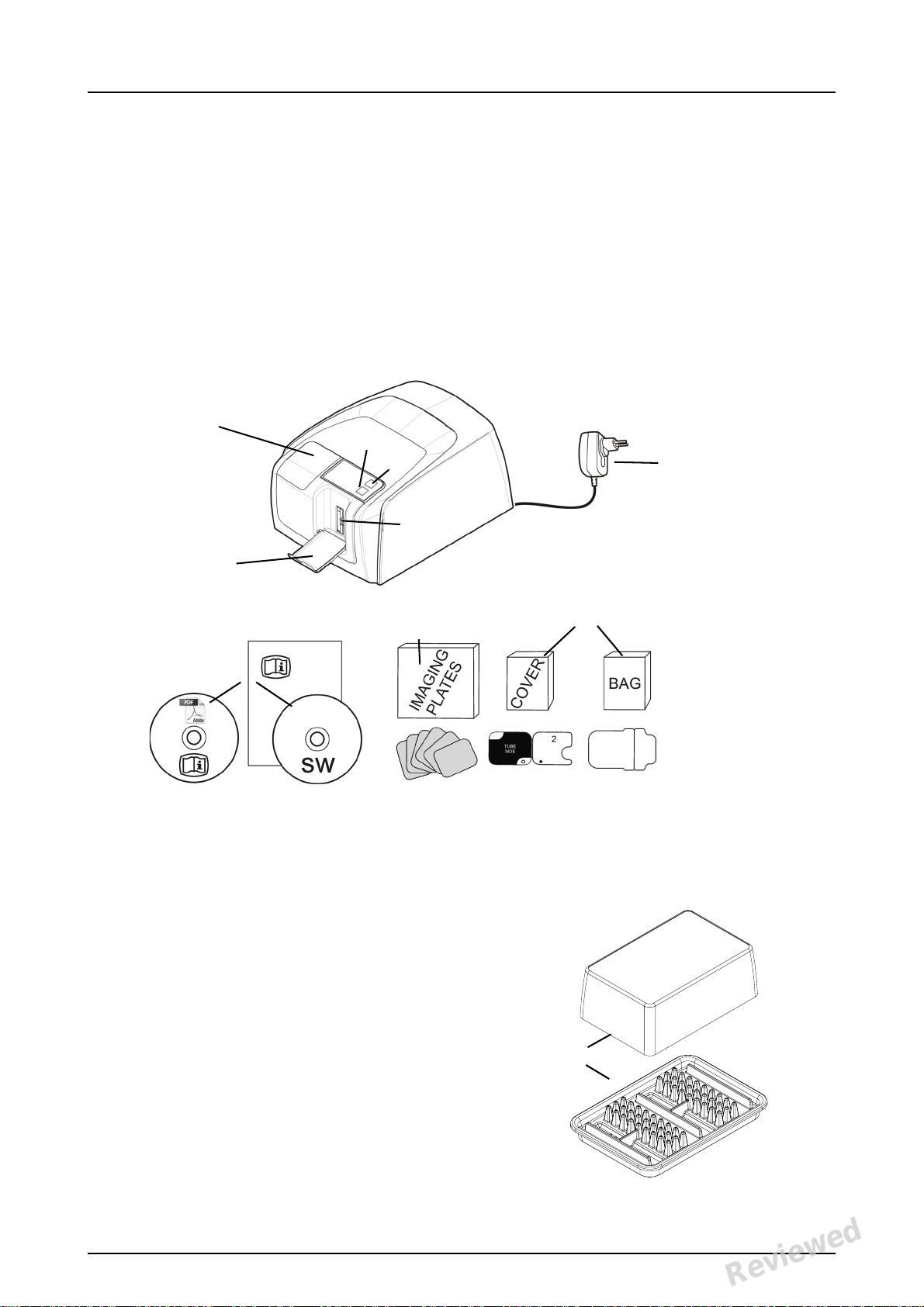

1Introduction

1. ON/OFF key

2. START key

3. Display

4. Imaging plate collector

5. Plate slot and plate carrier

6. Power supply

CAUTION:

Only use the power supply delivered with the unit or an approved

spare power supply supplied by

an authorized distributor (See

chapter Technical Specifications).

7. Documentation and

imaging application software

media

8. Hygiene accessories

9. Imaging plates

10. Imaging plate storage box

10

8

9

7

6

3

2

1

5

4

KaVo Scan eXam™ One system is intended to be

used by dentist and other qualified dental

professionals to process x-ray images exposed to

the imaging plates from the intraoral complex of

the skull.

1.1 Unit with accessories

1 Introduction

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

KaVo Scan eXam One 1

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

D510414, 5

Reviewed

Page 10

1 Introduction

1

2

3

4

5

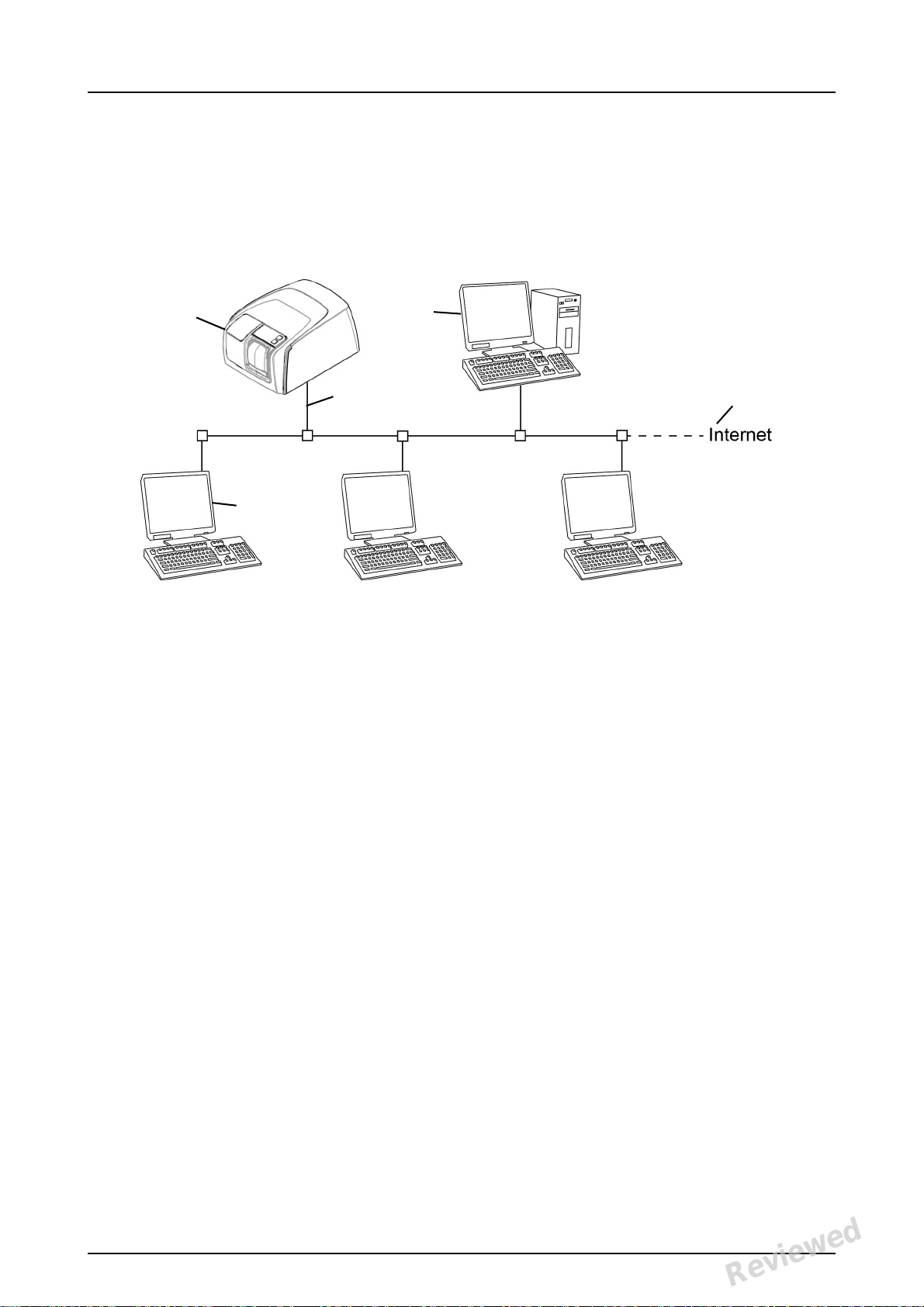

1.2 System setup

An example of a typical system set up in a local

area network (LAN).

1. Scan eXam™ One unit

2. Ethernet cable

3. Workstation (WS) computer (not included) contains

- patient data, images and a license server

4. Internet connection (optional, recommended)

5. Optional workstation (WS) computers (not included)

For more options and details of installing and

setting up the Scan eXam™ One system see

chapters 6 Installation of the imaging plate system

and 9 Technical specifications.

2 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 11

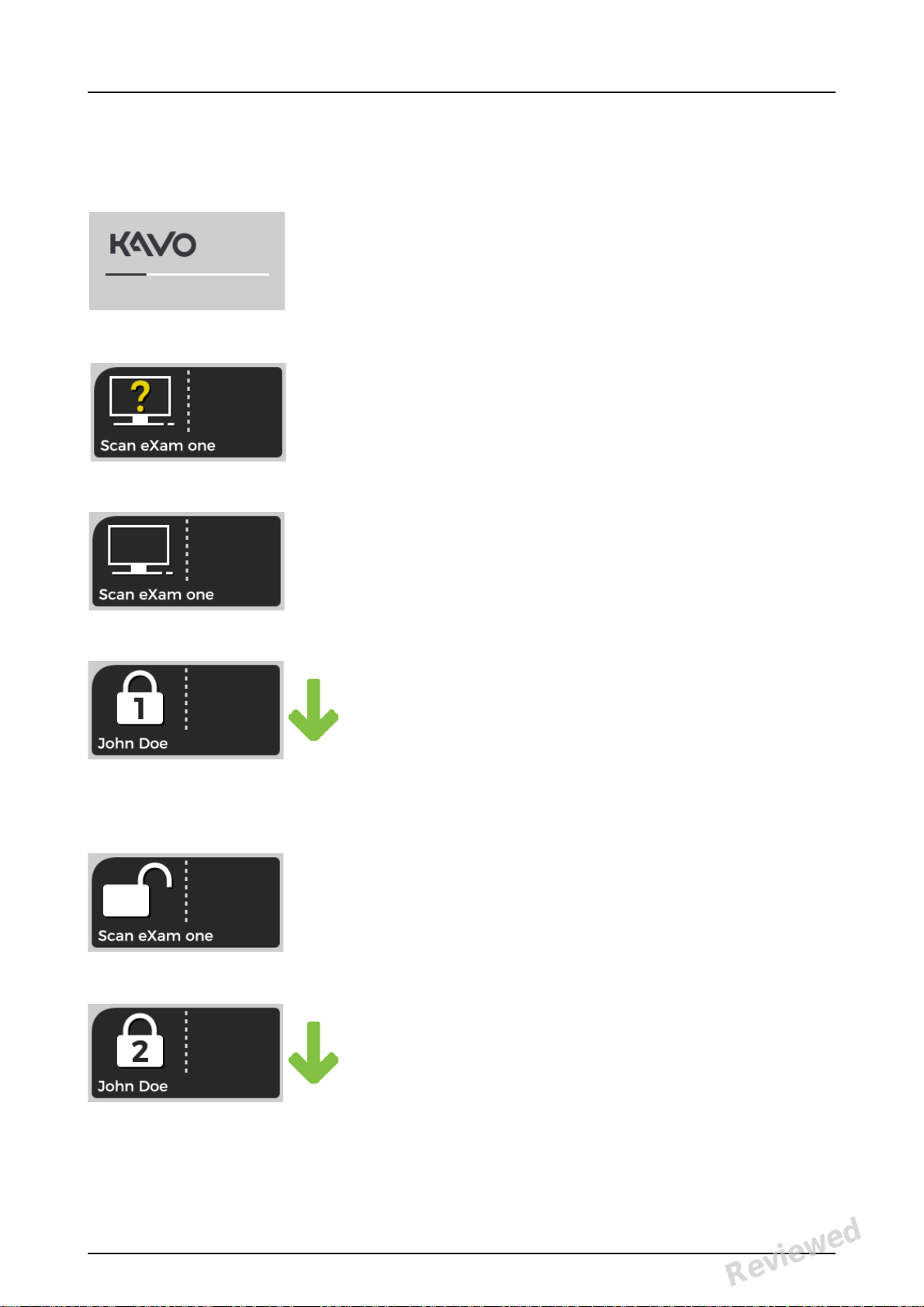

1.3 Controls and indicators

4

1

2

3

Control panel layout

1. ON/OFF key

2. START key

3. Plate feeding indicator

4. Status display

1 Introduction

ON/OFF key

• Press ON/OFF key to turn the unit on.

• Press and hold for 3 seconds to turn the unit

off.

• They key has a light when the unit is on.

• The light is softly blinking when the unit is in

a stand by mode.

• Press the ON/OFF key or the START key to

wake the unit.

START key

• Use the start key to wake the unit from the

stand by mode or

• to start processing in the manual mode or to

cancel (skip) the 2nd plate in the Occlusal 4C

mode.

• to access startup screen-information (IP, se-

rial number) when the scanner is not reserved by any user.

KaVo Scan eXam One 3

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 12

1 Introduction

Display and plate feeding indicators

Startup

During startup the unit serial number, IP address

and other information will appear on the unit display.

Waiting dental imaging software

Software not open, not ready or waiting for user

action.

Unit name is displayed.

Software active

Unit has a connection to a software. Unit not in

use.

Express Share reservation

The unit has been reserved using Express Share.

The workstation identifier is shown in the padlock. The name of the current patient is shown.

The green plate feeding indicator is showing

readiness for plate insert.

Express Share ready

Unit has a connection to a software using Express Share.

The unit is not reserved by any workstation in the

system.

Unit is activated

The unit is activated for image processing. The

name of the current patient is shown.

The green plate feeding indicator is showing

readiness for plate insert.

4 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 13

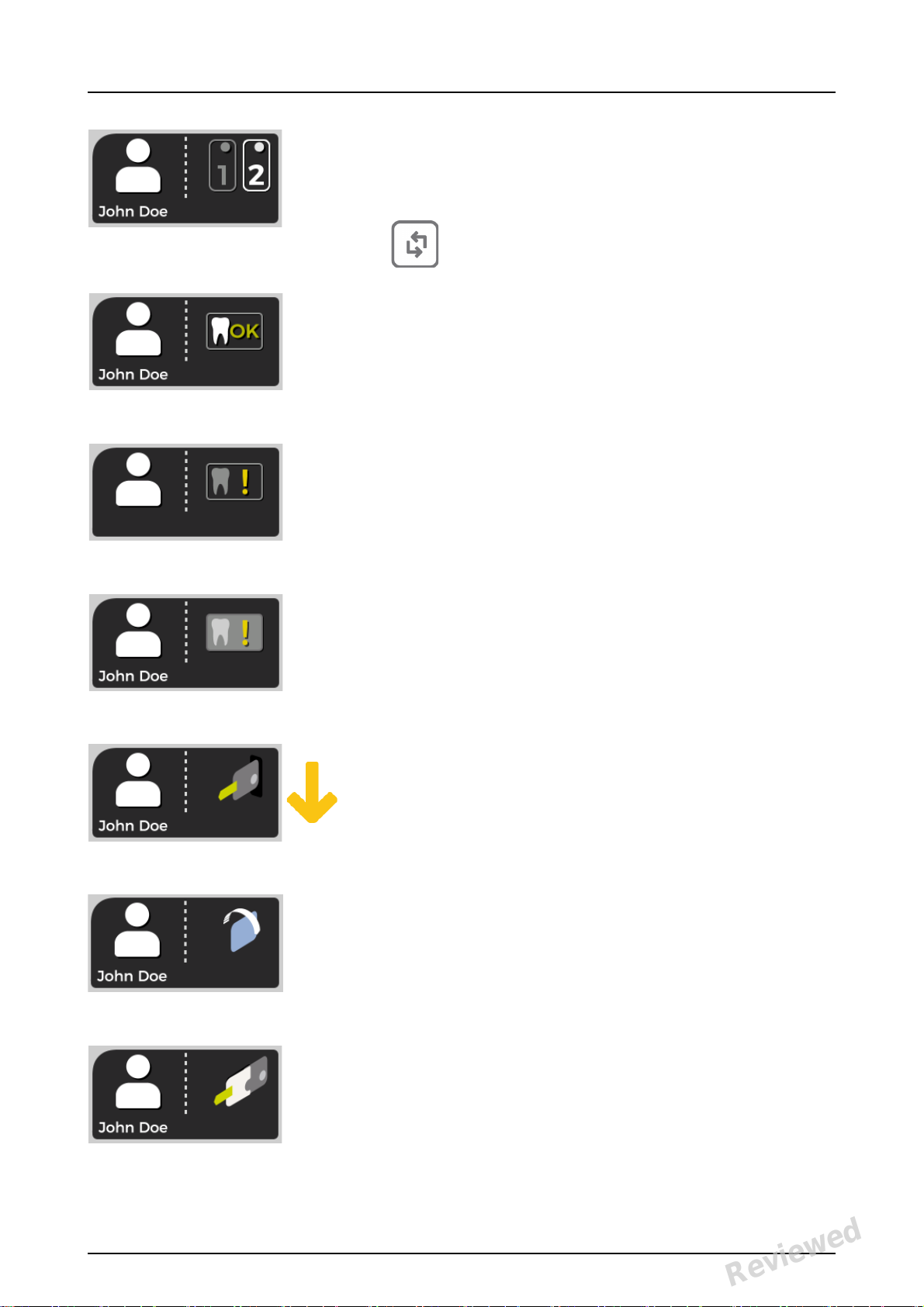

1 Introduction

Insert 2nd plate

Insert the second plate of the Occlusal 4C format.

Press Start to treat the first plate as a

single size 3 image.

Image processing complete

Exposure level OK.

Image processing complete

Image considered over exposed. Check exposure

settings.

Image processing complete

Image considered under exposed. Check exposure settings.

Remove plate

Remove the imaging plate from the plate carrier.

Rotate the plate

Rotate the imaging plate. Light blue side to the

left.

Remove cover

Remove the hygienic cover gently leaving the

imaging plate in the plate carrier.

KaVo Scan eXam One 5

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 14

1 Introduction

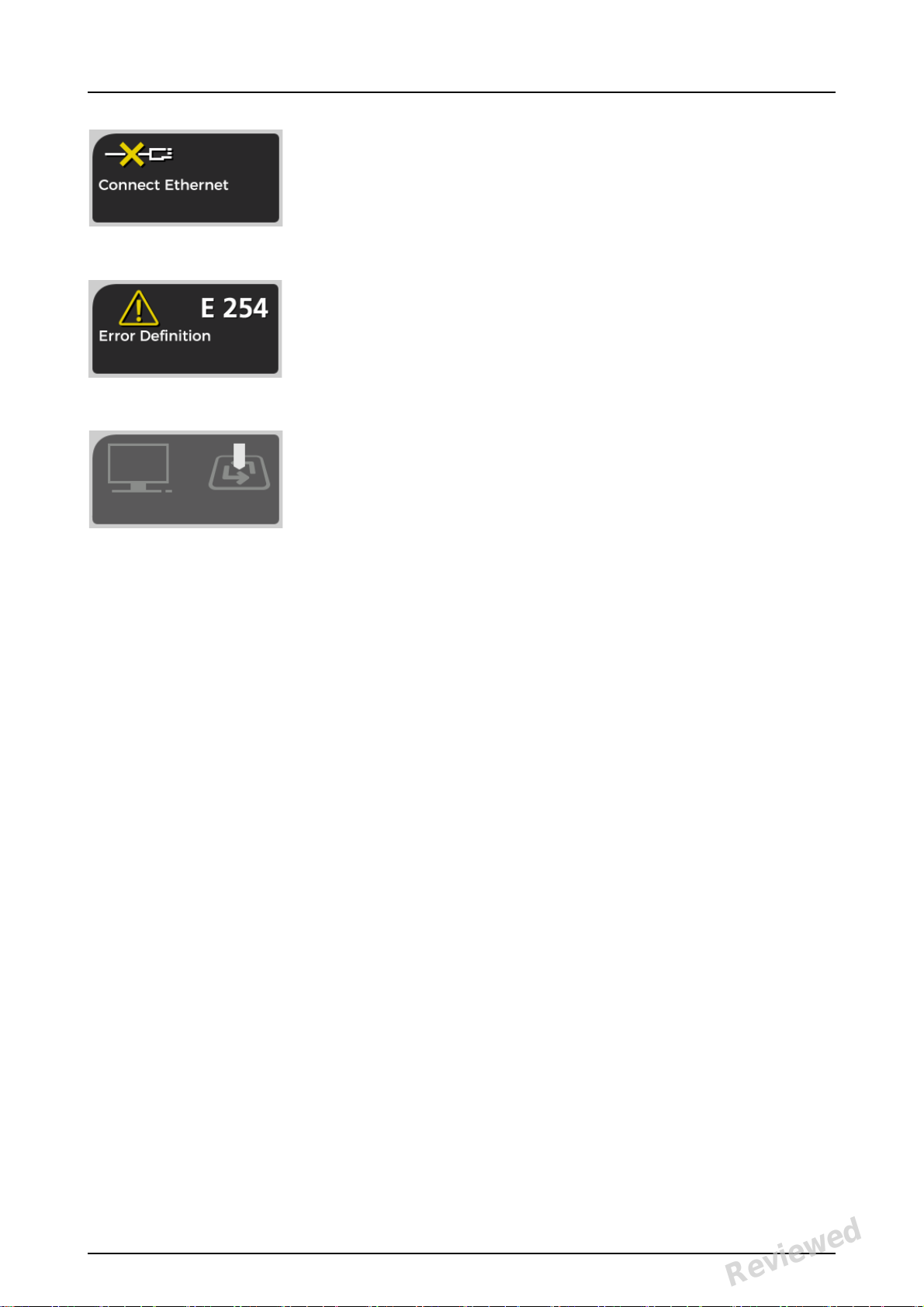

Unit disconnected

Missing ethernet connection. Check the connectors, cables and the network.

Error

Error ID and a short description is displayed.

Contact service.

Press START

Press the START button to wake the unit from a

standby mode.

6 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 15

2 Basic use

1

2

5

4

3

6

1

2

3

4

2 Basic use

Prepare imaging plates.

See chapter 2.1 for more information.

Activate the Scan eXam™ One from the imaging application.

Refer to the application software manual for

more information.

Position and take an exposure.

See chapter 2.2 for more information.

Process the imaging plate.

See chapter 2.4 for more information.

KaVo Scan eXam One 7

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 16

2 Basic use

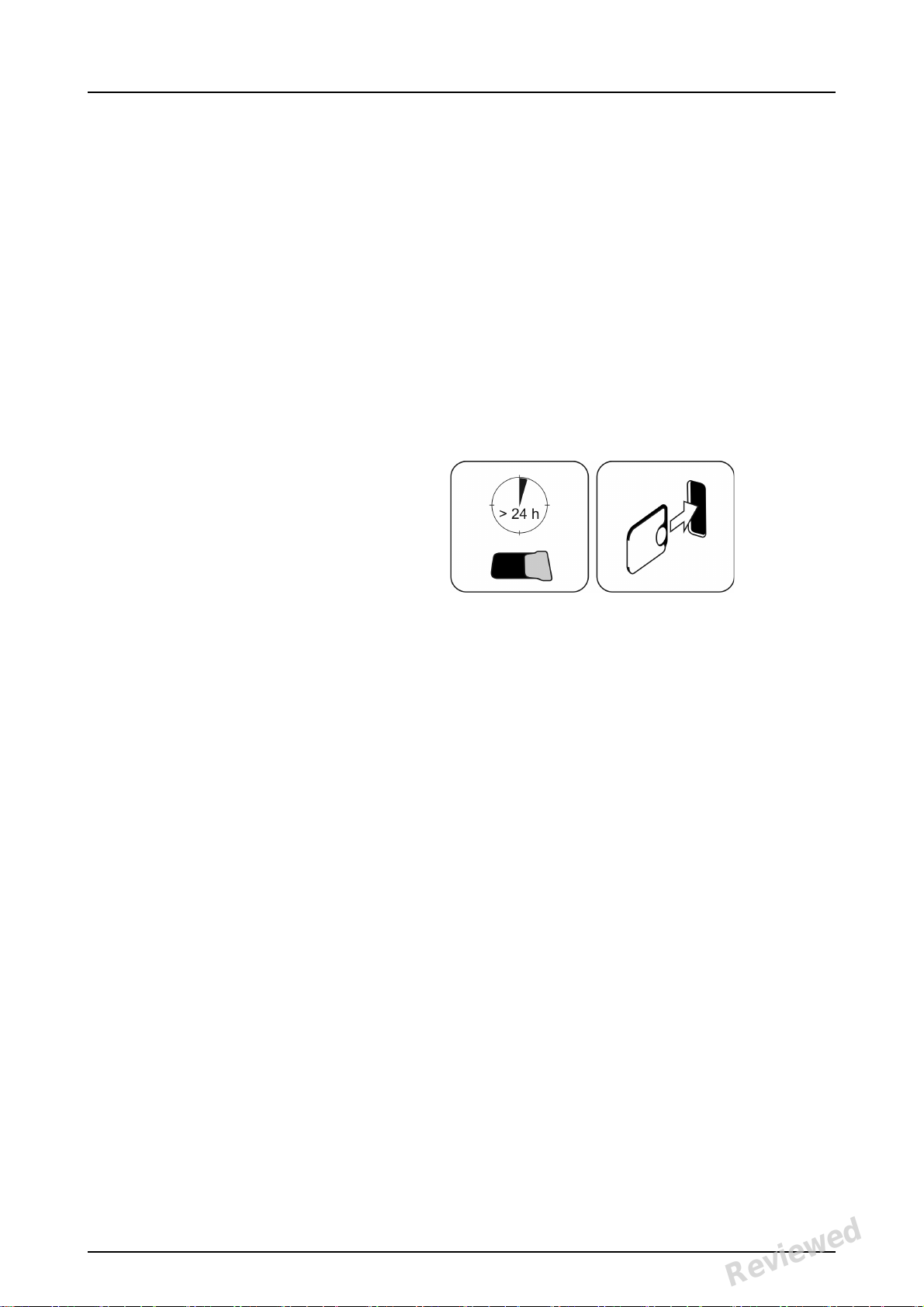

CAUTION! Process unexposed imaging plates to

erase potentially accumulated background radiation

when

• Taking new imaging plates into use.

• Imaging plates have been packaged and un-

used for more than 24 hours.

• Imaging plates have stored in dark (not ex-

posed to ambient light) susceptible for background radiation for more than 24 hours.

This will remove any potential fogging due to

collected natural background radiation.

8 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 17

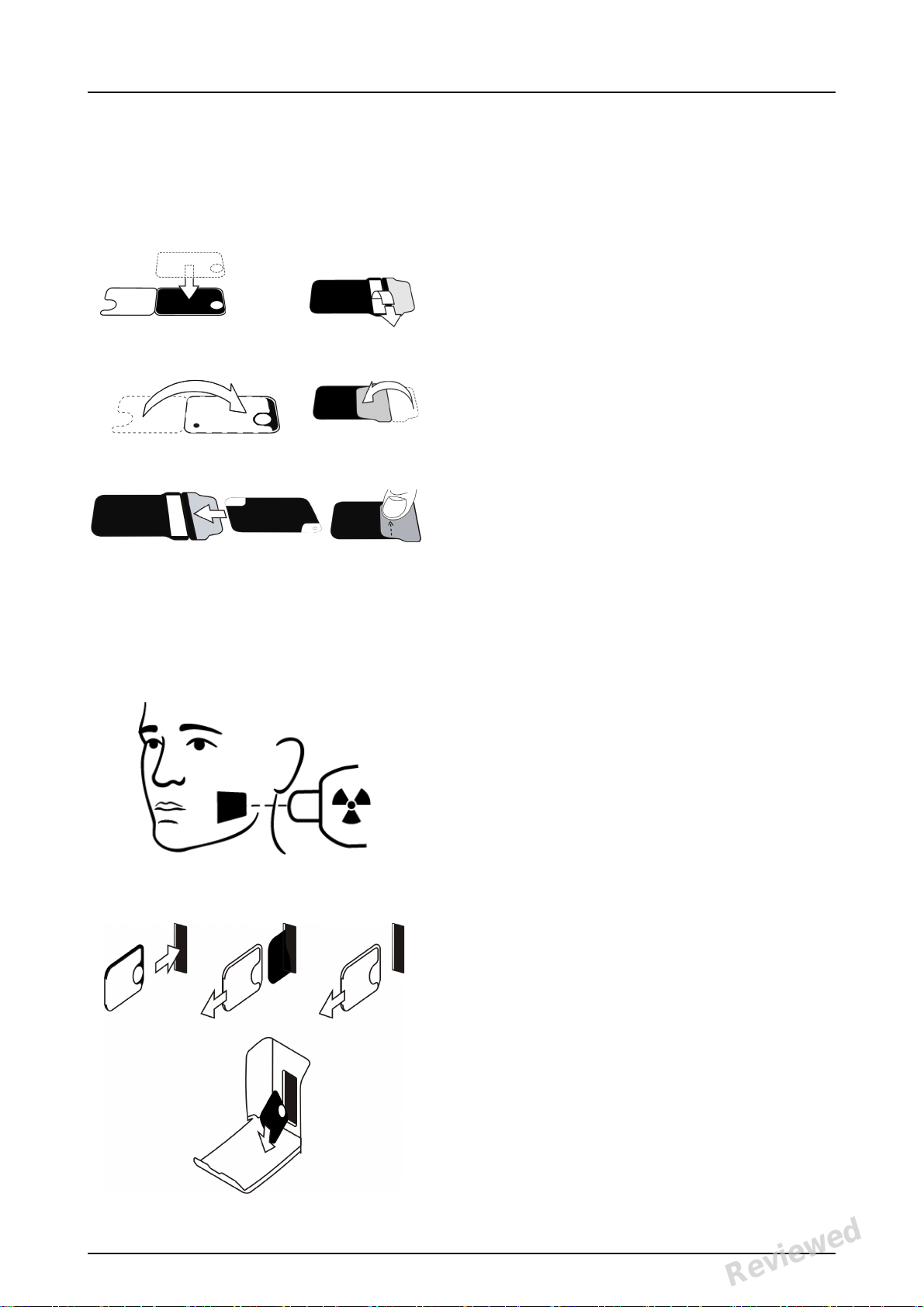

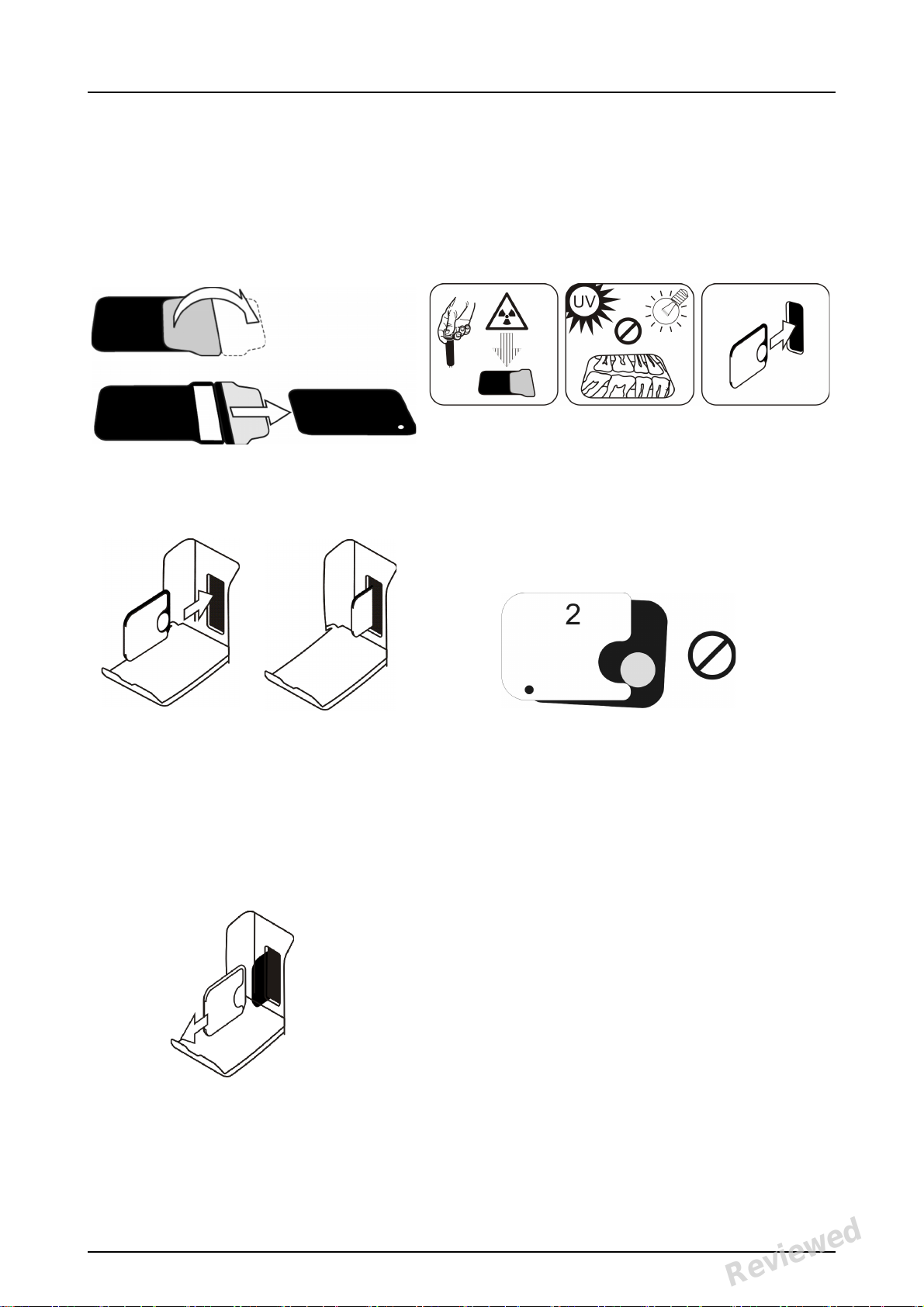

2.1 Preparing the imaging plates

Apply protective cover and package the plates into

the original hygiene bag.

Seal the bag properly.

Observe the orientation of the plates, cover and the

bag.

Active side of the imaging plate has a light blue

color.

2 Basic use

NOTICE! Keep the imaging plates packed max. 24

hours before using. Packaged plates accumulate

radiation from the background. Plates can be

erased by reading the plate.

KaVo Scan eXam One 9

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 18

2 Basic use

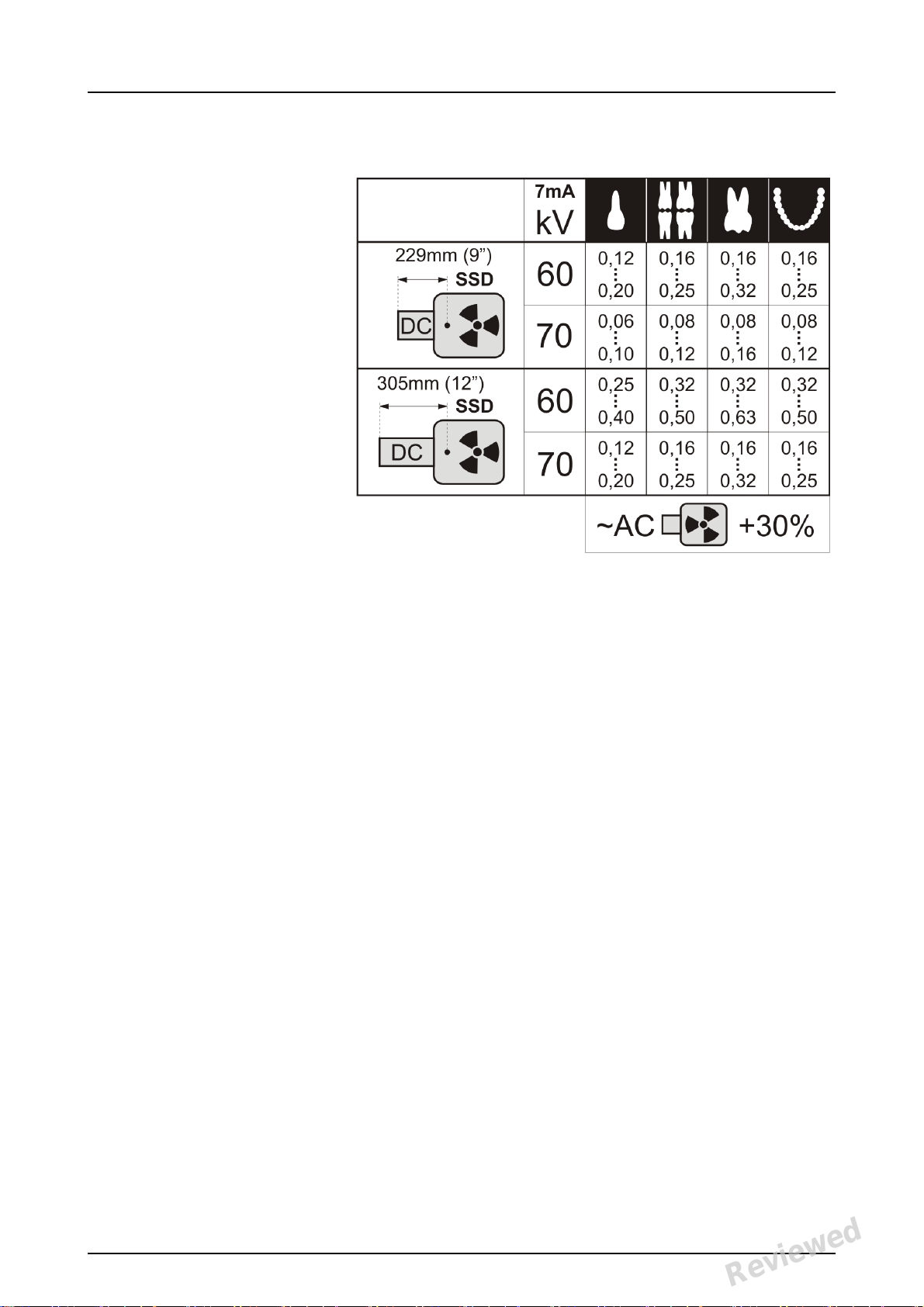

2.2 Positioning and exposure

Position the imaging plate according to the

anatomical area of interest. Holders (petitioners)

are recommended for the best positioning

accuracy. See the chapter 4.4 Holders, for more

information.

Apply X-ray according to the anatomical area of

interest and on the intraoral X-ray tube in use.

Find guidelines of exposure times in seconds for a

standard DC X-ray unit in the table below.

Correct exposure settings depend on the X-ray unit

type in use. For an AC-unit or for a low tube current

(i.e. portable X-ray) apply higher exposure times.

10 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 19

2 Basic use

Exposure factors close to F-speed film are often

appropriate.

KaVo Scan eXam One 11

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 20

2 Basic use

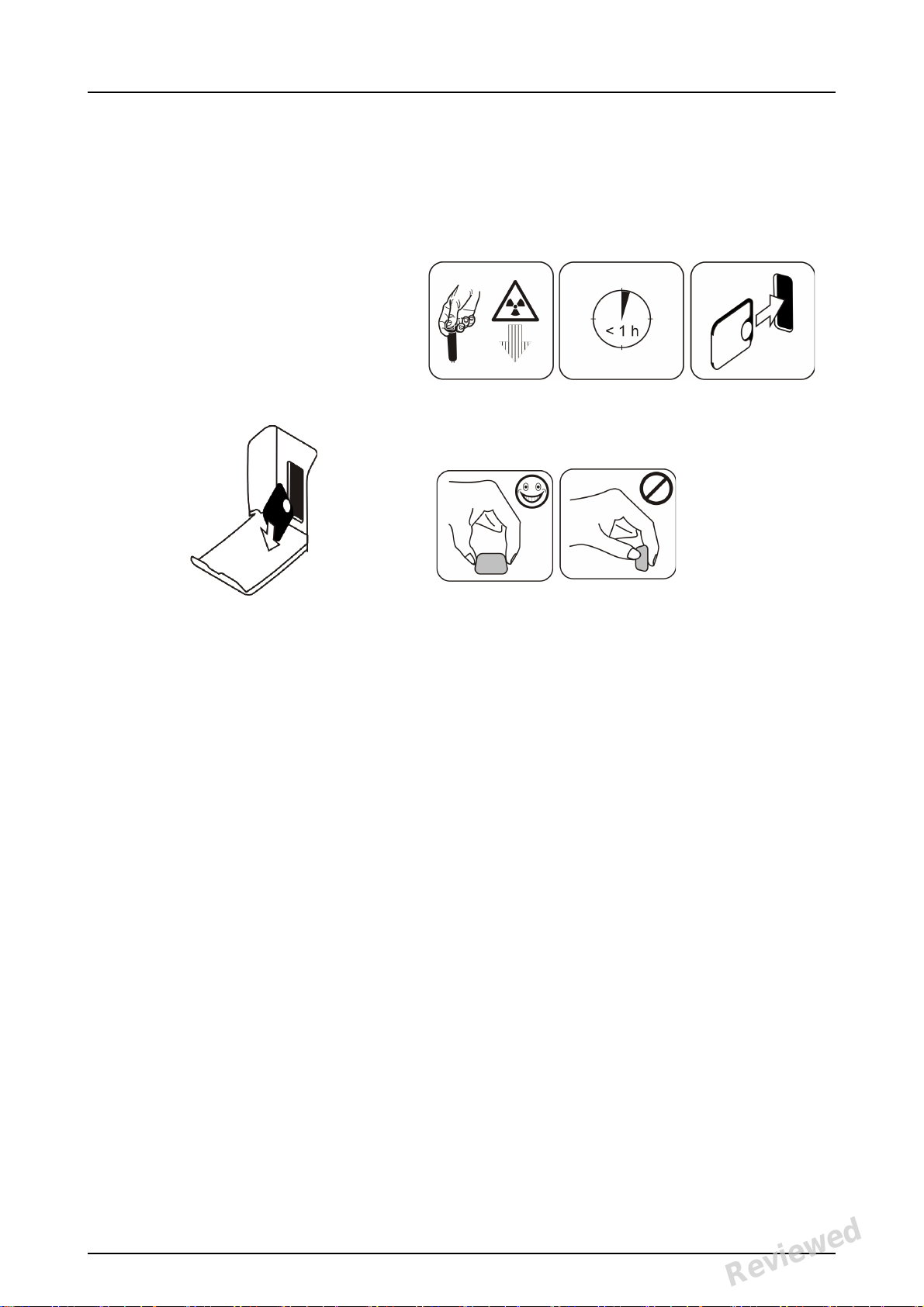

2.3 Processing the imaging plates

Unpack and process the imaging plates

immediately after unpacking.

NOTICE! Ambient light harms the image information when not protected by the protective cover.

Insert the imaging plate with the cover.

NOTICE! Do not partially slide the imaging

plate from the cover. You can place the

plate with cover and leave it to the plate carrier. Unit will not start the processing before

removing the cover.

Remove the cover.

12 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 21

2 Basic use

The image appears on the imaging application screen.

NOTICE! Process within one hour after exposure.

Processed imaging plate is ready to be

packed and exposed again.

KaVo Scan eXam One 13

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 22

2 Basic use

14 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 23

3Advanced use

3.1 Scan eXam™ One setup options

The Scan eXam™ One setup options allow you to

configure the Scan eXam™ One to the user’s

clinical preferences.

From the imaging application software you are

using select unit Setup/Scanner page (for more

instruction on how to access setup page review

application software manual).

3 Advanced use

3.1.1 Status

Shows the scanner type, firmware version and unit

serial number.

KaVo Scan eXam One 15

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 24

3 Advanced use

3.1.2 Image Scanning

If Show Image Preview and Dental Chart is selected

a preview image with a dental chart for tooth

numbering appears before the image is saved.

3.1.3 Using the dental chart

1. After an imaging plate has been processed a

window

2. opens that shows a preview image and a dental

chart.

Click the tooth / teeth on the chart that correspond to the tooth / teeth in the image. Tooth

numbers are assigned to the selected teeth.

The tools at the top of the window allow the image

to be manipulated.

3. Click OK to save the image and tooth numbers.

3.1.4 Resolution

Super gives a pixel size of 30 μm. This results in

images with better resolution, but may require

longer exposure time to compensate.High

(recommended default) gives a pixel size of 60 μm.

This results in images with less noise especially if

short exposure times are used.

3.1.5 Image Processing - Noise

Filtering

Noise filtering makes images smoother when they

are taken at short exposure times. There are two

options available: Classic mode offers traditional

noise filtering algorithms that has been applied to

all previous models of imaging plate systems.

The Progressive mode applies another algorithm

that reduces noise while efficiently retaining image

clarity. The progressive algorithm requires

appropriate exposure level for efficient

16 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 25

3 Advanced use

performance. Ensure that the exposure level

indicator is Ok.

3.1.6 Retrieve last image

If the last image processed is not transferred to the

PC because of a network, communication, PC or

software failure, the last image processed can be

retrieved.

NOTICE! The LAST processed image can only be

retrieved if the unit is left on. If the unit is switched

off the image is lost.

1. To retrieve the last processed image:

1. Correct the problem that caused the communication failure. When the connection between the

unit and the PC is re-established the last processed image is automatically transferred to the

PC.

2. PC: If the image is not automatically transferred

to the PC, select the Setup > Scanner page from

the imaging application software your are using.

3. PC: In the Last Image field, click Retrieve now

to retrieve the last processed image.

NOTICE! If required you can select different parameters (e.g. resolution, show image preview

etc.) for the image to be retrieved.

4. PC: Click OK to close the Setup window. The last

processed image is transferred to the PC.

3.1.7 Scanner Unit Serial number

Adds the unit serial number to all new images.

KaVo Scan eXam One 17

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 26

3 Advanced use

3.2 Settings

See chapter Installation for more information on

connecting the unit to a PC/LAN.

3.3 Workflow

From the imaging application software you are

using select unit Setup / Workflow page.

3.3.1 Readout start

Select Automatic if you want the unit to start

automatically image plate processing.The Start

after options all ow to select when the unit starts

image plate processing:

• After Plate insert: processing starts auto-

matically when it detects right way inserted

imaging plate in the plate carrier.

• After Cover removal: after the imaging plate

and protective cover have been inserted into

18 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 27

3 Advanced use

the plate carrier, processing starts automatically when the protective cover is removed.

The Start delay options allow the start delay time

to be selected.

• Short = approximately 0.2 seconds

• Medium = approximately 0.4 seconds (rec-

ommended default)

• Long = approximately 0.6 seconds

Select Manual if you want processing to start only

when the START key is pressed.

NOTICE! Processing starts even if the plate is:

• Wrong way round

•Not detected

• Not inserted at all

NOTICE! Unit turns off in manual mode if user is

pressing ON/ OFF key regardless of imaging plate

sensing in the plate carrier.

KaVo Scan eXam One 19

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 28

3 Advanced use

3.3.2 Plate eject mode

•The options are:Drop in plate collector:

the imaging plate is ejected into the plate

collector after the imaging plate has been

processed.

• Leave in plate carrier: the imaging plate

remains in the plate carrier after the imaging

plate has been processed.

The Leave in plate carrier option is recommended for users who want to handle the

imaging plates with more care and reduce

wear and tear on them. This option extends

service life of the imaging plates and allows

greater hygiene standards to be observed.

3.4 Power options

From the imaging application software you are

using select unit Setup / Power options page.

Standby after (seconds): Allows you to select

the period of time the unit remains unused before it

enters the standby mode (plate carrier is driven

20 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 29

3 Advanced use

inside the unit, door is closed and ON/OFF key dims

on and off). Press ON/OFF key to recover.

Beep when entering standby mode: Audible

signal is heard before the unit enters the standby

mode.

Shutdown after (minutes): Allows you to select

the period of time the unit remains in standby

mode before automatically switching itself off.

3.5 Occlusal 4C projection imaging (not included in delivery)

To change Occlusal 4C projection imaging settings

select from the imaging application software unit

Setup / Occlusal page.

Occlusal 4C projection image is formed from two

sequential size 3 plates. Image plates are

processed separately and then stitched together to

form a single Occlusal 4C projection image.

Following text shortly describe how Occlusal 4C

projection image is taken. For more information

refer to instructions supplied with the Occlusal 4C

kit.

1. Place two size 3 imaging plates into their corre-

sponding protective covers.

2. Slide the two size 3 imaging plates and protec-

KaVo Scan eXam One 21

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 30

3 Advanced use

tive covers into the Occlusal 4C bite protector.

3. Insert the Occlusal 4C bite protector and imag-

ing plates into the Occlusal 4C hygiene bag.

4. Seal the bag. Place the sealed Occlusal 4C hy-

giene bag into the patient’s mouth and take an

exposure.

5. Remove the sealed Occlusal 4C hygiene bag

from the patient’s mouth. Open it.

6. Remove each individual imaging plate from the

Occlusal 4C bite protector and process one at a

time.

7. Occlusal 4C image appear on the imaging

application software.

NOTICE! When you are in the Occlusal 4C mode it

is possible to temporarily override the mode and

process a single size 3 imaging plate. Insert the

size 3 imaging plate into the unit so that it can be

processed. When the insert second plate symbol

appears on the unit user interface press the start

key. This cancels the Occlusal 4C mode for this

operation and produce a single size 3 image.

Size 3 image mode from each size 3 plate allows

size 3 imaging plates to process as individual

imaging plates.

NOTICE! Due to Occlusal 4C projection imaging

geometry and imaging plate positioning, accurate

distance and angle measurements cannot be taken

from Occlusal 4C projection images.

22 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 31

4 Accessories introduction

Protective covers

Hygiene bags

4 Accessories introduction

NOTICE! USE ONLY GENUINE ACCESSORIES FROM

THE MANUFACTURER to ensure the optimal clinical

results, safe use of the system and long service life

for the imaging plates.

NOTICE! Never use hygiene accessories more than

once.

4.1 Hygiene accessories

KaVo Scan eXam One 23

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 32

4 Accessories introduction

4.2 Imaging plates

Compatible with all intraoral sizes equal to film: 0,

1, 2, 3 and Occlusal 4C, all with film-like usability.

IDOT™ imaging plates have individual

identification marking that appear on the images.

Standard (STD) imaging plates (optional)

have no identification mark on the sensitive side of

the plate.

24 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 33

4 Accessories introduction

4.3 Imaging plate storage box

Practical, dedicated storage box keeps imaging

plates clean and ready for use by protecting the

plates from:

• Dust (which will be visible in the image)

• Airborne contamination

• Fogging caused by background radiation

(which may decrease image quality)

• Ultraviolet radiation (which is harmful for the

imaging plates)

Base part of the storage box is autoclavable at 121

°C

(250 F) or 134 °C (272 F). The top cover cannot be

autoclaved.

4.4 Holders

It is recommended to use imaging plate holders to

ensure accurate patient positioning and

consistently good image quality. Problems caused

by manually positioning the imaging plate include:

• incorrect vertical alignment

• distortion

• cone cut off

• poor projection standardization

• inferior image quality

• contamination risk

Contact your distributor for more information on

imaging with plate holders.

KaVo Scan eXam One 25

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 34

4 Accessories introduction

4.5 Occlusal projection imaging with Occlusal 4C start-up kit and accessories

The complete image is produced automatically from

two size 3 imaging plates. The plates are shielded

from biting damage with a rigid bite protector. For

more information see instructions provided with the

Occlusal 4C kit and on chapter Advanced use.

4.6 Microfiber cloth

Imaging plate microfiber cloth is used for dry

cleaning of the imaging plates (comparable to

eyeglasses cleaning).

4.7 Imaging plate care

Sensitive surface,

handle with care

You can bend. Do not fold or

Touch the edges

only.

Do not scratch. Do not stab.

Use only original

accessories.

Single use only!

bend

excessively.

Do not touch the

sensitive surface.

26 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 35

4 Accessories introduction

Avoid moist and

water.

Allowed

temperature.

Avoid direct

sunlight and

UV radiation.

4.8 Imaging plate cleaning

Do not sink.

Avoid dust.

Not household

waste.

Use ONLY > 70%

Ethanol

Do not apply

Ethanol directly

on the plate.

Apply Ethanol on

lint free soft fabric.

KaVo Scan eXam One 27

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 36

4 Accessories introduction

Wipe the plate

gently.

Wipe dry or let dry

for 1 minute.

Pack the plate.

NOTICE! Pack the imaging plates in advance, but

no longer than 24 hours before the exposure.

28 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 37

5 Introduction to imaging plate technique

Sensitive side

1. Protective (topcoat)

layer

2. Photo-stimulable layer

3. Support material layer

(=back side, black)

5 Introduction to imaging plate

technique

5.1 Imaging plate

Imaging plate is a film-like thin, flexible and

wireless phosphorescent plate, which works as a

wireless receptor. Imaging plate is better than film

because:

• no need for film development chemicals and

darkroom.

• tolerates wider range of exposure values,

both overexposure and underexposure are

practically eliminated.

• All benefits of digital images.

Imaging plate sizes:

•0 child

• 1 small adult

•2 large adult

•3 bitewing

• 4C occlusion

The support base material is black plastic. On top of

the base material is blueish photo-stimulable layer

(does not contain any prosphor/phosphorus). On

top of the blueish material is a top coat protective

layer and the edges are closed with lacquer.

The phosphorescent side of the plate records and

stores the image. This side is sensitive and should

be protected against dust and dirt.

Visible light clears the image information from the

plate, so it must be protected from ambient light

between exposure and processing.

Even when packed properly, the image starts to

fade out slightly within time.

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

KaVo Scan eXam One 29

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

D510414, 5

Reviewed

Page 38

5 Introduction to imaging plate technique

5.2 Hygiene accessories

The imaging plate is protected with a protective cover and a hygiene bag before the exposure. Protective cover and hygiene bag are protecting the plate

from:

•Ambient light

• Contamination

•Mechanical wearing

•Moisture

NOTICE! USE ONLY GENUINE, ORIGINAL HYGIENE

ACCESSORIES AND IMAGING PLATES DESIGNED

FOR THIS SYSTEM AND SUPPLIED BY AUTHORIZED

DISTRIBUTOR. The manufacturer of this system

will not be held responsible for any problems

caused by using accessories from other

manufacturers. PROPER USE OF ORIGINAL

HYGIENE ACCESSORIES ENSURES THE BEST

IMAGE QUALITY AND MAXIMUM SERVICE LIFE OF

THE IMAGING PLATES.

The packed imaging plate is positioned with a

holder in the patient’s mouth. The exposure is

made as with film. The hygiene bag should be

disinfected after exposure and disposed off after

single use.

1. Imaging plate is inserted together with the protective cover all the way into the plate slot.

2. Magnet on the plate carrier grabs the imaging

plate.

3. Processing starts automatically after you remove the protective cover.

Dispose protective cover after single use.

30 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 39

5 Introduction to imaging plate technique

1.

2.

3.

KaVo Scan eXam One 31

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 40

5 Introduction to imaging plate technique

1.

2.

4.

5.3 Processing

1. Red laser light stimulates the sensitive surface

of the imaging plate.

2. Imaging plate glows blue light in relation to the

amount of X-ray information stored to the plate.

3. Glowing blue light is optically collected pixel by

pixel (line by line) and measured with extremely

sensitive photodetector.

4. Digital image is formed from the measured light

intensity variation.

After stimulating, imaging plate is exposed to

bright light, which clears the remaining image

information from the plate. The imaging plate is

dropped out of the unit.

X-ray exposures and processing are not aging the

imaging plate, so it is re-usable hundreds of times.

In practice, mechanical wearing limits the service

life of the plate.

32 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 41

5 Introduction to imaging plate technique

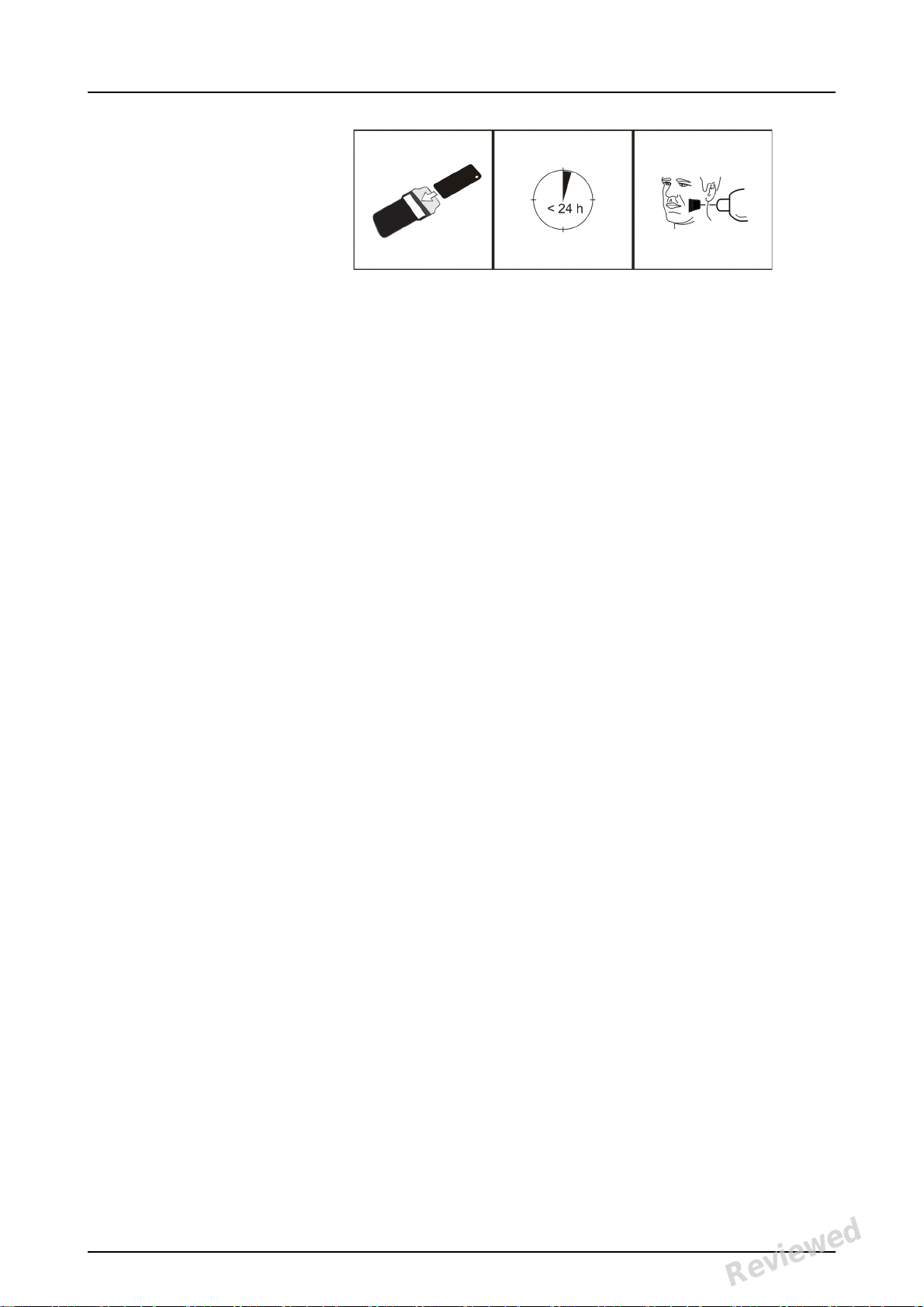

5.4 Background radiation

The user can pack imaging plates ready for use.

However, it is not recommended to store prepacked plates more than 24 hours.

NOTICE! Imaging plates react sensitively to

natural background radiation, which may cause

“fogging” and lack of contrast on the image.

The X-ray dose of single intraoral imaging is

approximately the same as the dose one person

gets from natural background radiation during one

day.

Imaging plates may gather radiation also during

transportation from the manufacturer. Therefore it

is recommended to perform initial erasing for the

new plates. This means that all imaging plates

should be processed once prior to use.

KaVo Scan eXam One 33

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 42

5 Introduction to imaging plate technique

5.5 Light

Ambient light is good when storing the imaging

plates:

it keeps the plates clean from background radiation

“fogging”.

NOTICE! Ambient light is harmful for the image

information on the plate between the exposure and

processing.

NOTICE! UV light is harmful for the imaging plates.

34 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 43

6 Installation of the imaging plate system

6 Installation of the imaging plate

system

Imaging plate system is formed of one or more PC

that connects the imaging plate scanner unit,

software, accessories and consumables.

Electronic equipment that does not fulfill medical

safety standards (office PC, network connecting

units etc.) must not be installed in the patient area.

The definition of the patient area is 1,5 m in

horizontal distance and 2.5 m in vertical distance to

the patient. The Scan eXam™ One meets safety

requirements of a medical electrical unit and it can

be installed also in the patient area.

6.1 Positioning the unit

Position the unit on a stable flat surface so that any

potential vibrations do not degrade the image

quality. The unit must not be positioned so that it is

touching other equipment. It must not be placed on

top of or under other equipment.

Do not position the unit in direct sunlight or near

bright light. Sunlight or bright light must not be

allowed to shine directly on the unit door into which

the imaging plates are inserted.

Typical location for a scanner unit in a shared use

by multiple operators is somewhere in a common

space for all users having an easy access to.

KaVo Scan eXam One 35

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 44

6 Installation of the imaging plate system

If the X-ray images are being captured and images

scanned in a single location only (X-ray room or

single user environments) it is most convenient to

place the scanner unit near to the X-ray.

NOTICE! Always position the unit so that you can

easily detach the power supply (PSU) from supply

mains.

6.2 Connecting the unit to a network

The unit can be connected directly to a single PC or

several PC using a wired local area network (LAN).

It is recommended to use a LAN in all installations.

Also any workstation used for managing an image

capture should be connected to a wired LAN.

It is recommended to have an internet connection

from the LAN. This makes registering potential

software license easier.

36 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 45

6 Installation of the imaging plate system

Connect the Ethernet cable from the unit to the

local area networking unit (router/switch). Consult

a computer network specialist to build up a local

area network if needed.

The unit can obtain an IP address automatically

(DHCP) or it can be set manually (static IP).

The unit will show its IP number during the boot up

sequence when powered on.

6.3 Install the Application software

The imaging plate system is delivered with an

software required to operate the system. In a

functional system there are two main parts: a

server for storing the patient data and images and

client software for operating the system and the

units. Both parts can be on the same computer but

there must be only one computer acting as

database server in a network. If the imaging plate

system is operated and images are viewed from

multiple PC in a network install only the client

software on the remaining other PC. The PC that is

acting as a server must be powered at any times

the system is used on any of the PC.

In addition there can be a license server in the local

area network to manage software licenses for

multiple PC.

KaVo Scan eXam One 37

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 46

6 Installation of the imaging plate system

Turn the unit on by pressing the power ON/OFF

button before installing the software.

Insert the software installation media (DVD) and

launch the software installer if it does not start

automatically.

Read the software installation manual. Follow the

instructions of the installation wizard to complete

the software installation. Refer the software

installation manual for details.

6.4 Accessing the unit from the software

In order to operate the scanner unit from a PC the

software needs to access the desired scanner unit

in the network. There can be multiple scanners in

one network. When using multiple scanners each

unit can be assigned a unique call name by the user

to separate the scanners in the network. By default

the name of the scanner unit is “Scan eXam™

One”.

There are multiple ways of configuring the

connection between the scanner unit and the

operators software. The automatic connection is

based on automatically detecting the scanner in the

network. This is a preferred method.

6.4.1 Direct connection method (uses

the unit s/n)

NOTICE! It may not be possible to connect the unit

to the PC using the direct connection method if

another device is al ready connected to the PC

using direct connection. If the direct connection

field is not active (greyed out) or the system does

not work correctly after the unit has been

connected, reconnect the unit using the imaging

plate connection method.

1. After positioning the unit connect it to the PC(s)

in the local area network using the Ethernet cable (not included in delivery).

2. Switch the unit on. The imaging application soft-

ware symbol appears in the unit user interface.

This indicates that the unit is not communicating

with the PC(s)

in the network.

38 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 47

6 Installation of the imaging plate system

3. PC: Install the imaging application software to

be used

in the PC(s).

4. PC: Open the imaging application software and

select the scanner setup window.

5. PC: From the scanner setup window select the

Settings tab to open the Scanner Connection

page.

6. PC: Select Direct Connection.

Key the serial number of the unit into the Scanner

serial number field. The serial number of the unit

appears on the type label on the back of the unit.

Make sure that the Computer network connection

that provides the LAN network connection is

selected.

6.4.2 IP method (using the unit static

address)

If your system does not allow the direct connection

method to be used to connect the PC(s), connection

can be done using an IP address.

1. Follow steps 1 to 5 from the previous section,

Direct connection method (uses the unit s/n).

2. PC: From the Settings tab select IP based and

then select the Enable changing IP address box.

Obtain an IP address for the unit from your network administrator and key it into the IP field in

the Scanner IP address area.

NOTICE! The PC and the unit must be in the

same subnet when setting the IP address of the

unit.

3. PC + Unit: Press and hold down the Start key

on the unit and then click Send to Scanner on

the settings window. You hear a beep which indicates that the PC is now sending the IP address the unit.

4. PC: Click OK to connect the PC to the unit.

5. Now connect the other PCs in the network to the

KaVo Scan eXam One 39

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 48

6 Installation of the imaging plate system

unit. Just enter the IP address into the IP field

and then click OK to connect the PC to the unit

(it is not necessary to hold down the Start key

and click Send to Scanner with the other PCs

once the unit has already got an IP address).

6.4.3 EXPRESS Share

1. PC: If the unit is to be used with several PCs se-

lect the Use Multiconnect check box and select a

unique Workstation identifier number (between

1 and 4), for the PC being configured, from the

drop down list. Addition workstation information, for example, user name, location etc, can

be entered into the field next to the work

station identifier number.

NOTICE! If only one PC is connected to the unit

do not select the Use Multiconnect check box.

The Scanner Autorelease timeout is the length

of time that the unit remains reserved and unused by a PC before the PC automatically released the unit so that it can be used by another

PC in the system (the scanner can be reserved

in advance from another PC). The default setting

is 40 seconds. This can be changed by keying in

a new value.

2. Click OK to connect the PC to the unit.

3.

NOTICE! An automatic technique automatically

locates the unit within the local area network

and connect the PC.

4. Repeat the above process for all the other PCs in

the network. Make sure that you give each PC a

different Workstation identifier.

5. Check the installation by starting image capture

using the imaging application software. If the

Use Multiconnect was selected the Workstation

identifier of the PC (1 - 4) being used appears on

the unit user interface.

40 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 49

6 Installation of the imaging plate system

6.5 Other devices

DO NOT connect any other devices to the unit or

the PC connected to the unit that are:

• not part of the supplied system

• not supplied by the manufacturer of the unit

• not recommended by the manufacturer of

the unit.

The PC connected to the unit should not be used in

the patient environment. The minimum horizontal

distance between the patient and the PC is 1.5 m

(4.5 ft). The minimum vertical distance between

the patient and the PC is 2.5 m (6.5 ft).

KaVo Scan eXam One 41

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 50

6 Installation of the imaging plate system

42 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 51

7Troubleshooting

7.1 Error images

7.1.1 Improper use of the hygiene accessories and imaging plates

Decreased contrast, shadows or shading,

ghost images…

Shows a “ghost image” (having shape of the plate

or other object). Plate not properly shielded from

light between exposure and process. Part of the

image erased by ambient light.

• Protective cover misused or not used at all.

• Hygiene bag not sealed properly.

• Improper, non-genuine hygiene accessories use.

7 Troubleshooting

• Improper storing of the imaging plates or

excessively high X-ray dose used.

• Imaging plate has been exposed to ultraviolet (UV) radiation.

• Imaging plate has collected background

radiation because:

- Plate has been stored near X-ray unit

- Plate has been stored in the bag or in

dark too long

• Use dedicated imaging plate storage box

to avoid these.

• Alternatively, perform initial erasing for

the plate(s) if they have been stored in

dark and/or near X-ray unit.

KaVo Scan eXam One 41

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 52

7 Troubleshooting

7.1.2 Application errors

Improper x-ray settings used

Too dark image. Some areas showing uniform

“black”. Decreased diagnostic value.

• Too long exposure time/too high X-ray

dose.

Too light, noisy image with decreased diagnostic

value. Showing only part of the image.

Showing wrong size of the image (Image smaller

than imaging plate).

• Too short exposure time / Too low X-ray

dose.

42 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 53

7 Troubleshooting

Ghost images, shadows

• Imaging plate has been exposed twice

without processing in

between.

• More than one image exposed to the same

plate.

• Imaging plate has not been erased properly after processing.

• Unit erasing leds are monitored during

normal operation. If leds are defected, application SW shows warning.

Circular shape on the image

Imaging plate has been exposed from the wrong

side, which shows the phantom of the metal disc

on the rear side of the plate.

KaVo Scan eXam One 43

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 54

7 Troubleshooting

Cone cut

X-ray beam has exposed only part of the imaging

plate surface. Image may show on different

(smaller) size than the imaging plate used.

• Check exposure procedure.

• Use of proper holder avoids this.

Unsharp or blurred images, motion artefact

Patient or X-ray cone has moved during the exposure.

• Check exposure procedure.

• Check the stability of your intraoral X-ray

unit.

• Use proper holders.

• Too long exposure time may have been

used.

Use shorter exposure time (increase kV if

necessary to compensate effect of shorter

exposure time).

Geometry distortion

Improper patient positioning.

• Use proper holders to avoid this.

NOTICE! Never do accurate measurements on intraoral images unless having known size of reference object in the imaging plane.

44 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 55

7 Troubleshooting

7.1.3 Imaging plate wearing

White or grey dots, spots or stains in images

• Dust or stains on the imaging plates.

•Any extra particle on top of the active sensitive surface of the plate is visible on the

image.

- Clean the plate(s).

- Replace if cleaning does not help.

- Pay attention on handling, storing and

mai nte nan ce. Ens ure that only the genuine

hygiene accessories are used.

Wearing of the imaging plate

Scratches

- Clean the plate(s).

- Replace if cleaning does not help.

- Pay attention on handling, storing and

mai nte nan ce. Ens ure that only the genuine

hygiene accessories are used.

Spots, dots (white or gray) or any visible pattern.

• Most probably caused by wearing of the

imaging plate.

• Can be caused by moisture or improper

cleaning.

- Clean the plate(s), ONLY >70% ETHANOL

MUST BE USED.

- Replace if cleaning does not help.

- Pay attention on handling, storing and

mai nte nan ce. Ens ure that only the genuine

hygiene accessories are used.

KaVo Scan eXam One 45

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 56

7 Troubleshooting

7.2 Error messages

In unit user interface the wrench symbol and error

number indicates the error.

Number Description

1 K100 error

(CPU / main controller error)

2 PMT error (imaging plate infor-

mation cannot be read due to

photo detector not working)

3 Laser error (imaging plate infor-

mation cannot be read due to

laser not working)

4 Resonator error (imaging plate

information cannot be read due

mirror not moving properly)

12 K200 board not connected prop-

erly (laser detection, erasing &

movement control)

13 K300 board not connected prop-

erly (imaging plate sensing /

detection)

23 K200 error (erase LED, linear

movement detection sensor or

laser synchronization error)

24 Plate carrier movement error

34 Plate sensor error (imaging

plate cannot be detected)

123 Door movement error (position

of the door not detected or

movement is blocked)

124 Safety cover error (light cover

inside the unit is not in its place

/ not detected)

234 K400 control panel error (con-

1234 Other, see driver status window

Turn power off and on to see if the unit recovers. If

not, please contact local dealer or distributor.

46 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

trol panel button defected /

stuck)

D510414, 5

Reviewed

Page 57

8 Other information

8.1 Quality control

To ensure maximum system performance

1. Observe “Exposure level” indication on the application SW to see that the x-ray settings are

optimal.

2. Perform self quality control regularly according

instructions provided with quality control test

set SP00267

(Intra digi QC IEC phantom w. instructions).

8.2 Unit care

WARNING:

Switch the unit off and disconnect it from the main

power supply before cleaning or disinfecting the

unit. Do not allow liquids to enter the unit.

8 Other information

8.3 Unit cleaning

To clean the unit use a non abrasive cloth

moistened with:

• cool or lukewarm water

•soapy water

• mild detergent

• isopropyl alcohol

• or ethanol (ethyl alcohol) 70 - 96%

• CaviCide, CaviWipes by Metrex

• FD322 by Dürr Dental

• Easydes by Kiilto

After cleaning wipe the unit with a non abrasive

cloth moistened with water. Never use solvents or

abrasive cleaners to clean the unit. Never use

unfamiliar or untested cleaning agents. If you are

not sure what the cleaning agent contains, DO NOT

use it.

If you use a spray cleaning agent DO NOT spray it

directly into the unit door.

KaVo Scan eXam One 47

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 58

8 Other information

8.4 Disinfecting the unit

CAUTION:

Wear gloves and other protective clothing when

disinfecting the unit.

Wipe the unit with a cloth dampened with a suitable

disinfectant solution such as ethanol 96%. Never

use abrasive, corrosive or solvent disinfectants. All

surfaces must be dried before the unit is used.

WARNING:

Do not use any disinfecting sprays as the vapor

could ignite and cause injury.

Disinfecting techniques for both the unit and the

room where the unit is used must comply with all

local and national regulations and laws concerning

such equipment and its location.

8.5 Maintenance

The unit does not require any maintenance.

8.6 Repair

The unit does not require any maintenance. If the

unit is damaged or malfunctions in any way it must

only be repaired by service personnel authorized by

the manufacturer of the unit.

8.7 Disposal

At the end of the useful working life of the unit and/

or its accessories make sure that you follow

national and local regulations regarding the

disposal of the unit, its accessories, parts and

materials. The unit includes some or all of the

following parts that are made of or include

materials that are non-environmentally friendly or

hazardous:

• electronic circuit boards

• electronic components

• imaging plates

48 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 59

9 Technical specifications

9 Technical specifications

9.1 Unit

Product name

Model

Product type

Intended use

Manufacturer

Quality system

KaVo Scan eXam™ One

eXam6

Intraoral digital imaging plate system

System is intended to be used only by dentist

and other qualified dental professionals to

process x-ray images exposed to the imaging

plates from the intraoral complex of the skull.

USA only

Federal law restricts this unit to sale by or on

the order of a dentist or other qualified professional.

PaloDEx Group Oy, Nahkelantie 160 (P.O.

Box 64)

FI-04300 Tuusula, FINLAND

In accordance with ISO13485 and ISO9001

standard

Environmental management

system

Conformity to standards

eXam6 Classification

IEC60601-1

In accordance with ISO14001

standard

IEC 60601-1: 1988 and A1+A2

IEC 60601-1-1: 2000

IEC 60601-1-4: 1996 and A1

IEC 60601-1-2: 2001

IEC 60601-1: 2005

EN 60825-1: 2007

UL 60601-1: 2003

CAN/CSA –C22.2 No. 601-1-M90 and S1+A2

/

DHHS 21 CFR Chapter I,

Subchapter J at the date of manufacture.

In conformity with the provisions of Council

Directive 93/ 42/EEC as amended by the Directive 2007/47/EC concerning medical devices.

- Class 2 equipment

- No applied part

- Continuous operation

- IPX0 (enclosed equipment without protection against ingress of liquids

KaVo Scan eXam One 49

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 60

9 Technical specifications

Laser Safety Classification

Dimensions (H x W x D)

Weight

Power supply unit (PSU)

Operating voltage

Operating current

Power consumption

Pixel size (selectable)

Bit depth

Theoretical resolution

CLASS 1 LASER PRODUCT,

EN 60825-1 :2007

168 mm x 233 mm x 328 mm

(6.6 x 9.2 x 12.9 inches)

3,7 kg (8.2 lb)

CINCON TR30RAM240

FRIWO FW7362M/24

PHIHONG PSAM30R-240

24 VDC (External PSU:

100 – 240 VAC, 50/60 Hz)

Less than 1.25 A

Less than 30VA

30 μm (Super resolution) /

60 μm (High resolution)

16-bit

16,7 lp/mm

Firmware version

Interface connection

Plastic materials

Operating environment

Storage / transportation

environment

Other

1.0 or higher

Connection type RJ-45

Unshielded CAT 6 Ethernet cable

Used materials are phthalate free containing

< 0.1% w/w of DEHP and is not

manufactured from raw materials containing

or derived from Bisphenol A (BPA).

+10°C - +40°C, 30 – 90 RH%,

700 – 1060 mbar

-10°C – +50°C, 0 – 90 RH%,

500 – 1080 mbar

Integrated Kensington security slot for

securing unit with Microsaver series locks.

50 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 61

9 Technical specifications

9.2 System requirements and connections

Minimum requirements for the PC/laptop, network adapter and network

switch

PC / laptop network switch

Network connection settings

Use

Class I or Class II according IEC 60950

10/100Mbs LAN

UDP/IP protocol traffic allowed

Traffic to UDP port 10000 allowed (unit UDP

port)

UDP broadcast traffic allowed

CAT6 Ethernet cable

DHCP server is recommended but not necessary

Use antivirus software.

Use firewall.

When LAN configuration is changed or devices are added/removed, it may affect existing

devices in the LAN. Therefore keep in mind

that correct operation of the imaging system

needs to be checked after changes are

made.

When adding new devices to LAN, make sure

they all have unique IP address, otherwise

they may cause communication problems

with existing LAN devices. Place unit and PC

with imaging application software to same

subnet in LAN.

NOTICE! Image is not transferred from unit to PC imaging application software in

case of connection lost during image processing. Image is stored in unit memory

until it has been transferred to PC. Unit cannot be turned off in that case. When

network is operational again, image is automatically transferred to imaging

application software. Do not disconnect unit PSU adapter before network is

operational and image has been transferred to imaging application software.

For more details of the hardware requirements running the imaging application

software please refer to the user manual of it.

KaVo Scan eXam One 51

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 62

9 Technical specifications

9.3 Imaging plate specifications

Imaging plates

Plate size Size 0 Size 1 Size 2 Size 3 Size 4C

Dimensions (mm) 22 x 31 24 x 40 31 x 41 27 x 54 48 x 54

nominal

Image size (pixels)*734 x

1034

Image size (MB) * 1.44 2.03 2.69 3.09 5.49

Environmental

conditions

Storage

and

transportation

Use +10°C …+40 °C / max 80% RH / NO UV radiation

-10°C … +40 °C / max 80% RH / NO UV radiation

800 x

1334

1034 x

1368

900 x

1800

1600 x

1800

nominal

nominal

Material Layer of small photo-stimulable particles (that exhibit the

phenomenom of phosphorescence) uniformly coated on

a support plastic material. Shielded with a protective top

coat layer on the sensitive surface and encapsulated with

lacquer around the edges. Imaging plates do not not include phosphorous / phosphorus (P).

Use

The typical service life for an imaging plate is several

hundreds of cycles provided that the imaging plate is

handled with care and according to the supplied instructions. The use of genuine hygiene accessories (protective

covers and hygiene bags) will extend the service life of

the imaging plates.

Disposal Imaging plates are industrial waste and must be dis-

posed of in accordance with local and national regulations concerning the disposal of such material. Never use

damaged imaging plates.

* High resolution mode image sizes are

approximately half of the values in the table.

52 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 63

9 Technical specifications

9.4 Hygiene bag specifications

Hygiene bags

Material Latex-free, food-grade polyethylene

Biocompatibil-

ity conformity

to

standard

Packaging Supplied in boxes

Use For the best performance it is recommended the hygiene bags

Disposal Observe relevant national requirements.

Not having irritative, toxic or injurious effects on biological

system in

accordance with ISO 10993-1 and ISO 10993-5.

are used within two years from the date of manufacture. The

date of manufacture is printed on the bottom of the box containing the hygiene bags (DDMMYYXX). Extended storage time

or exceeding the specified storage conditions may compromise

the performance of the adhesive tape and/or the plastic material from which the hygiene bags are made of.

KaVo Scan eXam One 53

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 64

9 Technical specifications

9.5 Electromagnetic Compatibility (EMC) tables

NOTICE! Medical electrical equipment needs

special precautions regarding EMC and needs to be

installed according to EMC information.

NOTICE! Mobile RF communications equipment

can effect medical electrical equipment

Guidance and manufacturer’s declaration - electromagnetic emissions

The eXam6 is intended for use in the electromagnetic environment specified

below. The customer or the user of the eXam6 should assure that it is used in

such an environment.

Emissions

Test

RF emissions

CISPR 11E

RF emissions

CISPR 11

Harmonic

emissions

IEC 61000-3-2

Voltage

fluctuations/

flicker

emissions

IEC 61000-3-3

Compliance Electromagnetic environment - guidance

Group 1 The eXam6 uses RF energy only for its

internal function. Therefore, its RF emissions

are very low and are not likely to cause any

interference in nearby electronic equipment.

Class B The eXam6 is suitable for use in all establish-

ments, including domestic establishments

Not

applicable

and those directly connected to the public

low-voltage power supply network that supplies buildings used for domestic purposes.

Complies

54 KaVo Scan eXam One

Reviewed: Jalkanen Joni 2017-02-13 16:00

Approved:

See PDM system to determine the status of this document. Printed out: 2017-03-17 10:35:17

Copyright © by PaloDEx Group Oy. All rights reserved.

D510414, 5

Reviewed

Page 65

9 Technical specifications

Guidance and manufacturer’s declaration – electromagnetic immunity

The eXam6 is intended for use in the electromagnetic environment specified

below. The customer or the user of the eXam6 should assure that it is used in

such an environment.

Immunity

Test

Electrostatic

discharge

(ESD) IEC

61000-4-2

Electrical fast

transients/

bursts

IEC 610004-4

Surge

IEC 610004-5

Voltage dips,

short interruptions and

voltage variations on

power supply

lines

IEC 610004-11

IEC 60601

Test Level

± 6 kV contact

± 8 kV air

± 2 kV for

power supply

lines

± 1 kV for

input/output

lines

± 1 kV differential mode

line to line

< 5% U

T

(> 95% dip in

UT) for 0.5 cy-

cle

40% U

T

(60% dip in

)

U

T

for 5 cycles

70% U

T

(30% dip in

UT)

for 25 cycles

Compliance

Level

± 6 kV contact

± 8 kV air

± 2 kV for

power supply

lines

± 1 kV for

input/output

lines

± 1 kV differential mode

< 5% U

T

(> 95% dip in

UT) for 0.5 cy-

cle

40% U

T

(60% dip in

)

U

T