Page 1

ORTHOPANTOMOGRAPH™ OP 3D

Service manual

ENGLISH

215241 rev. 4

0.805.4918

Page 2

Page 3

Contents

1 Disclaimer................................................................... 6

2 Introduction................................................................ 7

2.1 ORTHOPANTOMOGRAPH™ OP 3D............................................................. 7

2.2 Intended use......................................................................................... 7

2.3 Abbreviations......................................................................................... 7

2.4 Disposal and recycling............................................................................ 8

2.5 Associated documentation....................................................................... 8

3 Safety..........................................................................9

3.1 Service precautions and warnings.............................................................9

3.1.1 Signal words...............................................................................9

3.1.2 General servicing precautions........................................................9

3.1.3 Electrical safety........................................................................... 9

3.1.4 Electrostatic discharge................................................................10

3.1.5 Device modifications during service..............................................10

3.1.6 Radiation safety.........................................................................10

3.1.7 Symbols that may appear on the device or its parts....................... 11

4 Device description.....................................................13

4.1 Mechanical description...........................................................................13

4.1.1 Main parts................................................................................ 13

4.1.2 Device movements.....................................................................14

4.1.3 Device covers............................................................................14

4.1.4 Status indicator light.................................................................. 15

4.1.5 Device labels.............................................................................16

4.1.6 Emergency stop switch...............................................................16

4.2 Device software....................................................................................17

4.2.1 Firmware overview.....................................................................17

4.2.2 Firmware update....................................................................... 17

4.3 Electrical description............................................................................. 19

4.3.1 Circuit board locations................................................................19

4.3.2 Circuit boards overview.............................................................. 19

4.3.3 Position control..........................................................................20

4.3.4 Exposure logic........................................................................... 20

4.3.5 Power supply.............................................................................20

4.3.6 Fuses....................................................................................... 21

4.4 User Interfaces.....................................................................................22

4.4.1 Graphical User Interface (GUI).................................................... 22

4.4.2 Positioning panel....................................................................... 33

4.5 Circuit boards.......................................................................................34

4.5.1 i2000 image capture board......................................................... 34

4.5.2 i3000 Main control board............................................................ 37

4.5.3 i4000 power supply board.......................................................... 40

4.5.4 i4100 back panel board.............................................................. 42

4.5.5 i6000 user interface board..........................................................42

4.5.6 i8000 LED indicator board.......................................................... 42

4.5.7 i9000 chin rest sensor board.......................................................44

ORTHOPANTOMOGRAPH™ OP 3D 3

Page 4

5 Diagrams...................................................................45

5.1 Wiring diagram.....................................................................................45

5.2 Fusing diagram.....................................................................................47

5.3 Emergency stop....................................................................................47

5.4 Mains voltage distribution...................................................................... 47

5.5 Power distribution +24Vdc..................................................................... 48

5.6 Ethernet communication........................................................................ 48

5.7 CAN communication.............................................................................. 48

5.8 i2C self diagnosis communication........................................................... 49

5.9 Rotation movement...............................................................................49

5.10 Linear movement................................................................................ 50

5.11 Pivot movement..................................................................................50

5.12 Z movement...................................................................................... 51

5.13 Collimator movements......................................................................... 51

5.14 Positioning lights.................................................................................52

5.15 Imaging chain 3D............................................................................... 52

5.16 Exposure control 1..............................................................................53

5.17 Exposure control 2..............................................................................53

5.18 Exposure warning light........................................................................ 54

5.19 Device control panel............................................................................54

5.20 Chin rest detection..............................................................................55

6 Maintenance..............................................................56

6.1 Annual maintenance..............................................................................56

6.1.1 Cleanliness of the device............................................................ 56

6.1.2 Condition of the cables...............................................................56

6.1.3 Device movements and functionality............................................ 57

6.1.4 Exposure indicator functionality................................................... 58

6.1.5 Changing the fuses.................................................................... 59

6.1.6 Monitor calibration..................................................................... 59

6.2 Calibrations.......................................................................................... 60

6.2.1 When to calibrate the device....................................................... 60

7 Troubleshooting........................................................ 62

7.1 Initial actions....................................................................................... 62

7.1.1 Error codes............................................................................... 62

7.1.2 Acknowledging errors................................................................. 62

7.1.3 Image transfer.......................................................................... 62

7.2 List of error codes................................................................................ 63

8 Part replacement instructions................................. 100

8.1 Before replacing parts......................................................................... 100

8.2 Removing the covers........................................................................... 100

8.2.1 Disconnecting power supply...................................................... 100

8.2.2 Removing upper shelf covers.....................................................100

8.2.3 Removing the carriage covers....................................................102

8.2.4 Removing the rotating unit covers..............................................107

8.2.5 Removing the lower shelf covers................................................111

8.3 Replacing parts................................................................................... 113

8.3.1 Disconnecting and connecting the cables.....................................113

8.3.2 Replacing the PAN/3D sensor.................................................... 113

8.3.3 Replacing the horizontal lasers.................................................. 116

8.3.4 Replacing the i4000 power supply board..................................... 120

8.3.5 Replacing the carriage cable set.................................................122

4 ORTHOPANTOMOGRAPH™ OP 3D

Page 5

8.3.6 Replacing the main cable set..................................................... 125

8.3.7 Replacing the i2000 image capture board....................................128

8.3.8 Replacing the i3000 main control board...................................... 129

8.3.9 Replacing the tube head........................................................... 130

8.3.10 Replacing the lower shelf upper cover assembly......................... 134

8.3.11 Replacing the collimator.......................................................... 137

8.3.12 Removing the upper shelf plate................................................140

8.3.13 Replacing the linear and pivot movement and motor................... 140

8.3.14 Replacing the speaker with cable............................................. 145

8.3.15 Replacing the firmware card.................................................... 146

8.3.16 Replacing the emergency stop switch with cable......................... 147

8.3.17 Replacing the i8000 LED indicator board................................... 147

8.3.18 Replacing the i4100 back panel board.......................................148

8.3.19 Replacing the mains switch..................................................... 149

8.3.20 Replacing the pivot and linear movement sensors....................... 150

8.3.21 Replacing the linear movement sensor wiper..............................152

8.4 After service work...............................................................................152

8.5 Safety tests for maintenance................................................................153

8.5.1 Introduction............................................................................ 153

8.5.2 Warnings and precautions......................................................... 153

8.5.3 Measurement equipment...........................................................153

8.5.4 Protective earth resistance test..................................................153

8.5.5 Measuring protective earth........................................................154

ORTHOPANTOMOGRAPH™ OP 3D 5

Page 6

1 Disclaimer

1 Disclaimer

ORTHOPANTOMOGRAPH™ OP 3D Service manual, 215241 r4.

Copyright © 2017 by PaloDEx Group Oy. All rights reserved.

ORTHOPANTOMOGRAPH™, OP™, ORTHOselect™, QUICKcompose™, SMARTview™,

ORTHOfocus™ and Low Dose Technology™ are either registered trademarks or

trademarks of KaVo Kerr Group Finland in the United States and/or other countries.

KaVo™ is either registered trademark or trademark of Kaltenbach & Voigt GmbH in the

United States and/or other countries.

All other trademarks are property of their respective owners.

Documentation, trademark and the software are copyrighted with all rights reserved.

Under the copyright laws the documentation may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form

in whole or part, without the prior written permission of PaloDEx Group Oy.

The original language of this manual is English, code 215241 rev 2. In a case of

interpretation disagreement the English text is applied.

PaloDEx Group Oy reserves the right to make changes in specification and features

shown herein, or discontinue the product described at any time without notice or

obligation. Contact your PaloDEx Group Oy representative for the most current

information.

The manufacturer has no liability for consequential damage, personal injury, loss,

damage or expense directly or indirectly caused by the use of the product. No agent,

distributor or other party is authorized to give warranty or other liability on behalf of the

manufacturer with respect to its products.

Manufacturer:

PaloDEx Group Oy

Nahkelantie 160

FI-04300 Tuusula

FINLAND

Tel. +358 10 270 2000

www.kavokerrgroup.com

6 ORTHOPANTOMOGRAPH™ OP 3D

Page 7

2 Introduction

2 Introduction

2.1 ORTHOPANTOMOGRAPH™ OP 3D

The ORTHOPANTOMOGRAPH™ OP 3D (later called device) is a dental X-ray device

producing high quality digital images of dentition, TM-joints and skull. To take images,

you need a suitable workstation connected to the device and a dental imaging software

to capture and manage the images.

The ORTHOPANTOMOGRAPH™ OP 3D can be used for the following procedures:

Panoramic Imaging

• Standard Panoramic

• Segmented Panoramic

• Pediatric Panoramic

• Bitewing

• TMJ, lateral projection

3D CBCT Imaging

Volume Height x Diameter (H x D)

• 5 x 5 cm; implant and other single tooth imaging

• 6 x 9 cm; single jaw imaging

• 9 x 11 cm; whole dental area imaging (both jaws)

• 9 x 14 cm (optional); both jaws including TMJ

• FOV position and height fine-tuning is possible according to scout images

CAUTION! USA only: Federal law restricts this device to sale by or on the order

of a dentist or other qualified professional.

2.2 Intended use

ORTHOPANTOMOGRAPH™ OP 3D is an X-ray device that is configured to take panoramic

and 3D images of the cranio-maxillofacial complex for use in diagnostic support.

ORTHOPANTOMOGRAPH™ OP 3D must only be used and operated by dentist and other

qualified professionals.

2.3 Abbreviations

PCBA Printed Circuit Board Assembly

THA Tube Head Assembly

GUI Graphical User Interface

EMI Electromagnetic Interference

ESD Electrostatic Discharge

DUT Device Under Test

ORTHOPANTOMOGRAPH™ OP 3D 7

Page 8

2 Introduction

2.4 Disposal and recycling

The device and its components are lead-free, including its radiation protection

components. The device meets the RoHS Directive 2011/65/EU, WITHOUT any

exemptions mentioned in Annex IV.

At least the following parts of the device should be re-cycled according to local and

national regulations regarding disposal of non-environmentally friendly materials:

• Tubehead (oil)

• All electronic circuits and electronic boards

• Plastic parts

2.5 Associated documentation

• ORTHOPANTOMOGRAPH™ OP 3D User and Installation Manual

• Dental imaging software documentation

• ORTHOPANTOMOGRAPH™ OP 3D Sparepart Catalogue.

8 ORTHOPANTOMOGRAPH™ OP 3D

Page 9

3 Safety

3 Safety

3.1 Service precautions and warnings

3.1.1 Signal words

The following signal words and labels are used in this document:

WARNING! Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION! Indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE! Highlights suggestions which will result in enhanced installation,

reliability, or operation. Not used for safety related hazards.

3.1.2 General servicing precautions

CAUTION! Only trained and qualified service persons authorized by the

manufacturer of the device are allowed to service the device.

• Use only the original spare parts that are provided by the manufacturer when you

repair the device or replace any parts in it.

• Before you attempt to service the device make sure that you know how to operate it.

Read the ORTHOPANTHOMOGRAPH OP 3D User and Installation Manual.

• Attach the covers before you hand over the device after service.

• Ensure the electrical safety of the device by inspecting the proper grounding of user

touchable metallic parts before handing the device to the user.

• Clean the device from dust.

• Attach and tighten all screws that have been removed or loosened during service

work.

• Check the tightness of the screws in the device, especially in the carriage and the wall

mount.

• For connection requirements and safety, see the Connection requirements section in

the User manual.

• Read and understand the warnings and precautions listed in the following sections of

this service manual and in the User and Installation manual.

3.1.3 Electrical safety

• Disconnect the device from the main power supply before repairing or replacing any

mechnical parts, circuit boards or installing accessories.

• Disconnect the device from the main power supply before removing the covers.

• Disconnect the device from the main power supply before replacing circuit boards or

other electrical components.

• The circuit boards and electrical components of the device can contain capacitors with

high voltages. Wait ten (10) minutes, after disconnecting the device from the power

supply, before handling the board or component.

• If you have to leave the device unattended during service or maintenance, disconnect

the device from main power supply to protect people, who may touch the device, from

electric shock.

• The device must only be used in areas that are provided with a protective earth

connection to ensure an equipotential ground connection.

• Assemble the device according to the instructions in User and Installation manual,

always use the correct materials and original spare parts.

ORTHOPANTOMOGRAPH™ OP 3D 9

Page 10

3 Safety

Do not compromise:

• EMI enclosures and tightness of cases and screw contacts

• Gaskets

• Cable shields and their grounding to the chassis

• Electromagnetic immunity by incorrect cabling.

3.1.4 Electrostatic discharge

Electrostatic Discharge (ESD) can damage or destroy electronic components.

When you service the device take precautions to avoid electrostatic charge to build up

and discharge (ESD). Follow the local and national recommendations for the prevention

of ESD. If no recommendations are available, follow the guidelines below:

• Leave all new or replacement circuit boards and electrical parts in their protective

packaging until the boards are needed.

• Before handling circuit boards and electrical parts make sure that any static electricity

charge that has built up in your body is discharged.

• When examining and checking circuit boards use an antistatic wrist wrap which is

connected to a ground point through a 1 Mohm current limiting cable. Also use a cable

to connect the device to the same ground potential as the wrist wrap.

• When handling circuit boards hold them by their edges and do not touch any

components or connectors.

• If an antistatic mat is used, connect the wrist wrap to the mat and the mat to the

ground potential.

• To make sure that the wrist wrap is in good condition, check and wash it frequently.

3.1.5 Device modifications during service

CAUTION! Only authorized service technicians are allowed to service,

install and replace parts of the device.

CAUTION! Only approved spareparts supplied by the manufacturer are allowed

to be used.

CAUTION! Make sure that any modifications done to the device do not degrade

the EMC performance of the device.

• Never make unauthorized changes or modifications to the device or its parts.

• Never dismantle or remanufacture any part of the tube head assembly or beam

limiting device.

• Never adjust any part of the beam limiting device unless under the direction of the

manufacturer.

• Ensure that the EMC performance of the device is not degraded when the device is

upgraded, serviced and repaired.

NOTICE! Ensure that the EMC performance is not degraded thoughout the whole

service life of the device.

3.1.6 Radiation safety

CAUTION! When you take test exposures, take adequate precautions to protect

youself from radiation. Stand behind a suitable radiation shield that is positioned

at least two meters from the device.

10 ORTHOPANTOMOGRAPH™ OP 3D

Page 11

3 Safety

Before you use or service the device familiarize yourself with local and national radiation

safety standards and requirements relating to dental x-ray equipment.

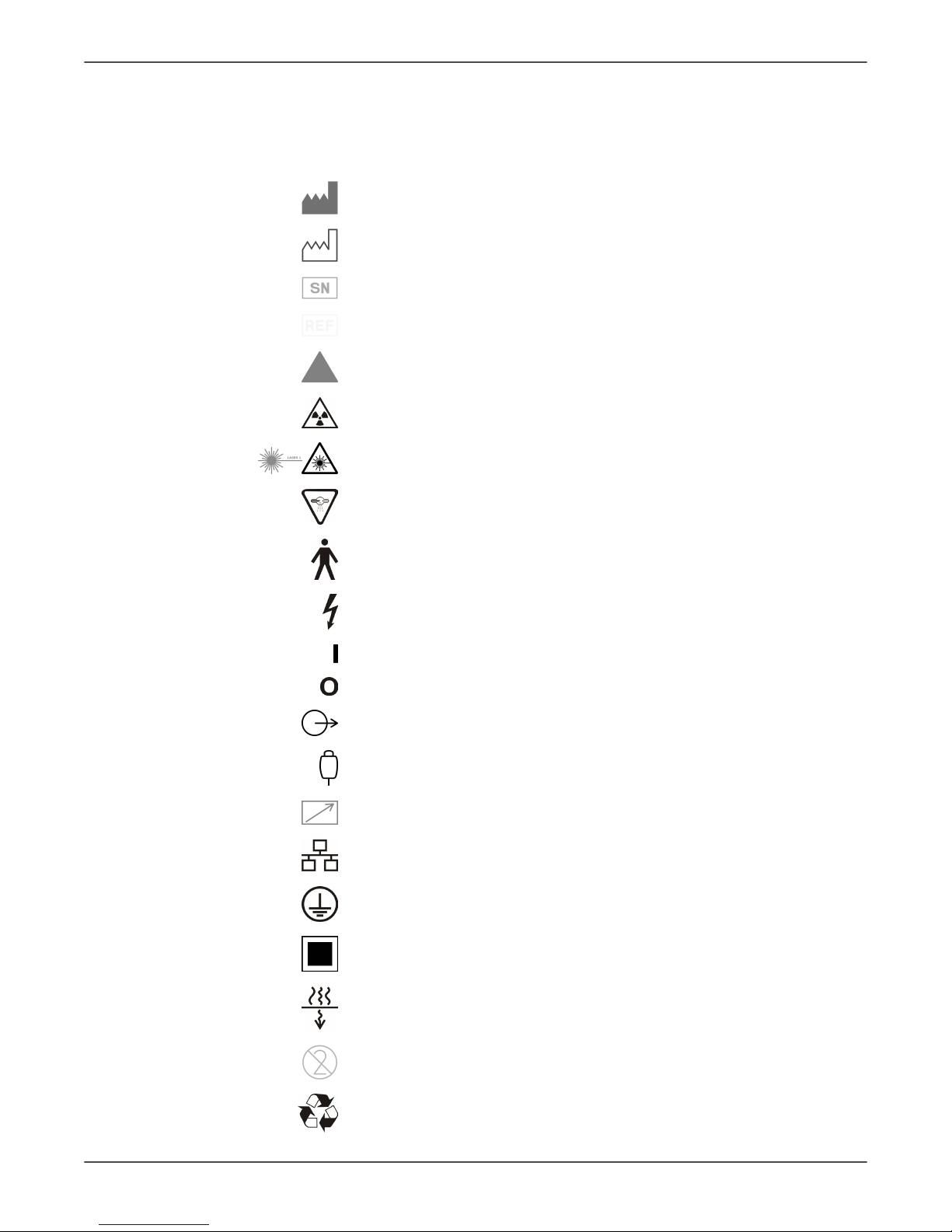

3.1.7 Symbols that may appear on the device or its parts

Manufacturer

Date of manufacture

Serial number

Catalog or model number

Caution

Radiation warning

Laser warning

Radiation emitting device

Type B Applied part

Dangerous voltage

On or enabled

Off or disabled

External warning light

Exposure switch

Remote exposure switch

Ethernet

Protective earth (ground)

Focal spot

Total X-ray filtration

Do not reuse

Recyclable

ORTHOPANTOMOGRAPH™ OP 3D 11

Page 12

3 Safety

Operating instructions

Refer to operating instructions for more information. The

operating instructions can be supplied electronically or in

paper format.

Caution: Federal law restricts this device to sale by or on the

order of a licensed healthcare practitioner.

This symbol indicates that the waste of electrical and

electronic equipment must not be disposed as unsorted

municipal waste and must be collected separately. Please

contact an authorized representative of the manufacturer

for information concerning the decommissioning of your

equipment.

CE (0537) symbol

NRTL Mark

Conforms to AAMI ES60601-1:2006. Certified to CSA.

Fragile, Handle with Care (Packaging)

This way up (Packaging)

Keep dry (Packaging)

Maximum number of boxes that can be stacked on the

bottom box (Packaging)

12 ORTHOPANTOMOGRAPH™ OP 3D

Page 13

4 Device description

4 Device description

4.1 Mechanical description

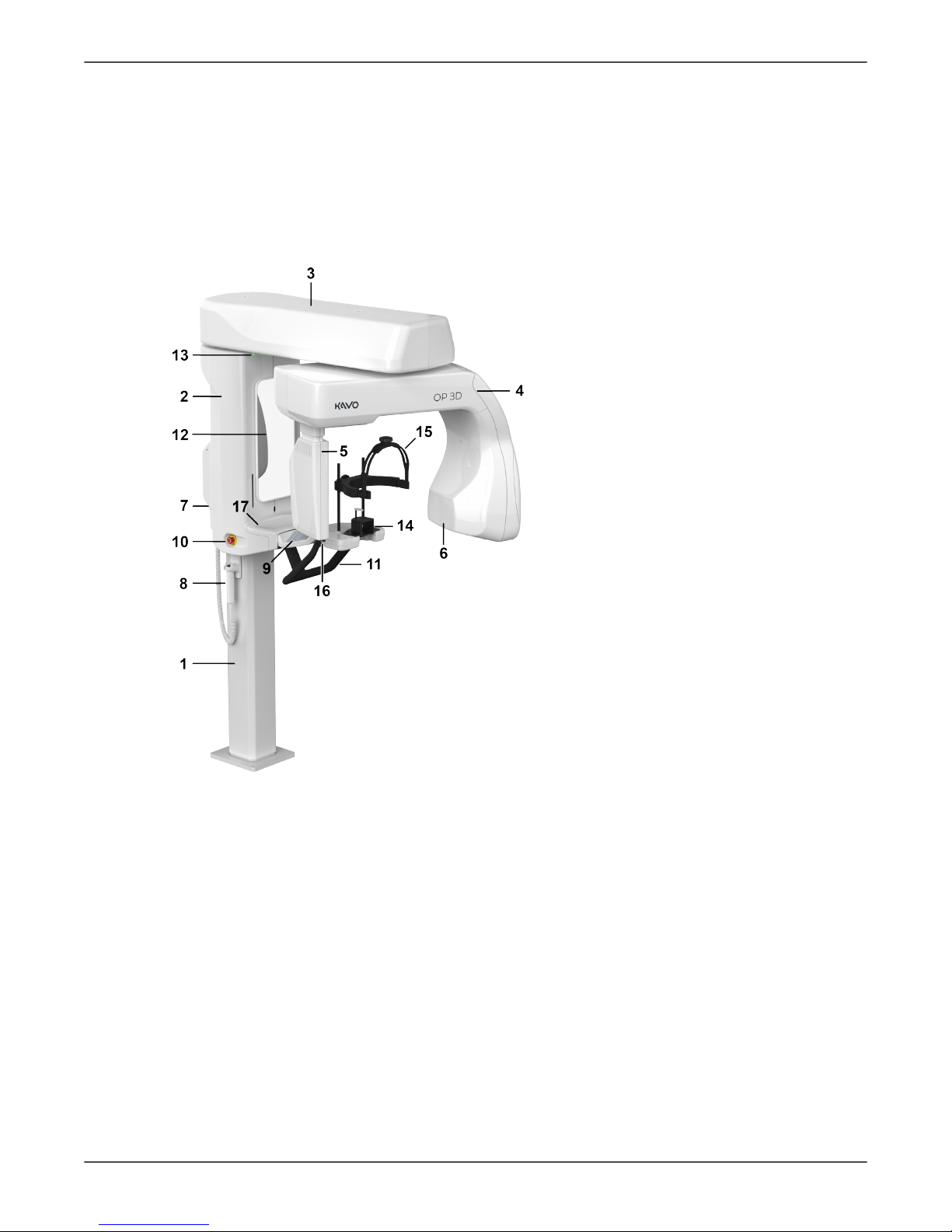

4.1.1 Main parts

1. Column

2. Carriage

3. Upper shelf

4. Rotating unit

5. Sensor

6. Tubehead

7. Power switch (Back of

the device)

8. Exposure switch

9. Positioning panel

10. Emergency stop switch

11. Patient handles

12. Mirror

13. Status indicator light

14. Chin rest

15. Head support

16. Head support locking

lever

17. Lower shelf tray

ORTHOPANTOMOGRAPH™ OP 3D 13

Page 14

4 Device description

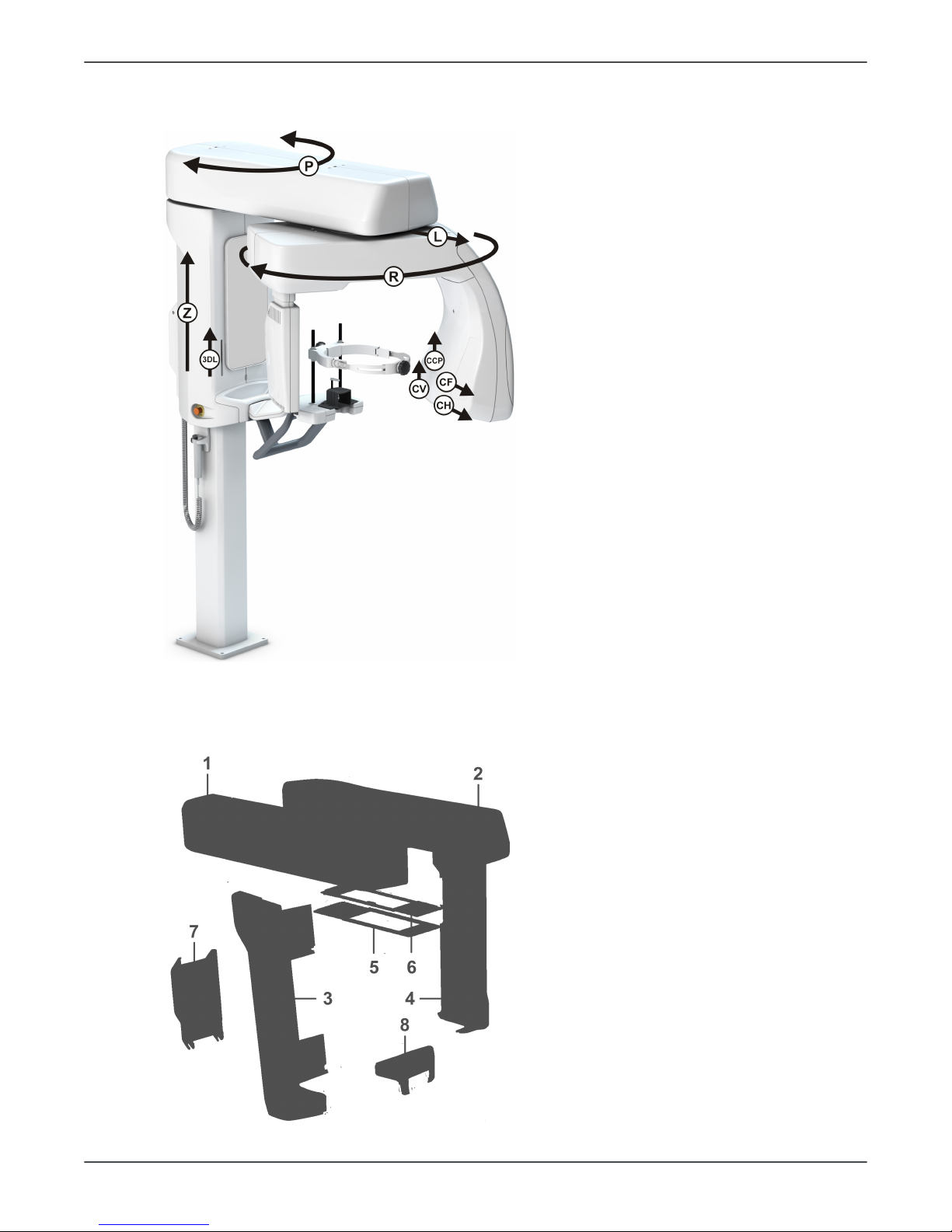

4.1.2 Device movements

Z - Column UP/DOWN movement

P - Pivot movement of the upper

shelf

L - Linear movement of the

rotating unit

R - Rotating movement of the

rotating unit

CV - Vertical movement of the

collimator plate

CH - Horizontal movement of the

collimator plate

CF - Collimator filter movement

3DL - 3D Horizontal and PAN FH

Laser movement

CCP - Child collimator plate

movement (Panoramic only)

4.1.3 Device covers

Carriage covers

1 Upper shelf cover left

2 Upper shelf cover right

3 Carriage side cover left

4 Carriage side cover right

5 Finger shield plate 1

6 Finger shield plate 2

7 Back panel cover

8 Lower shelf tray

14 ORTHOPANTOMOGRAPH™ OP 3D

Page 15

4 Device description

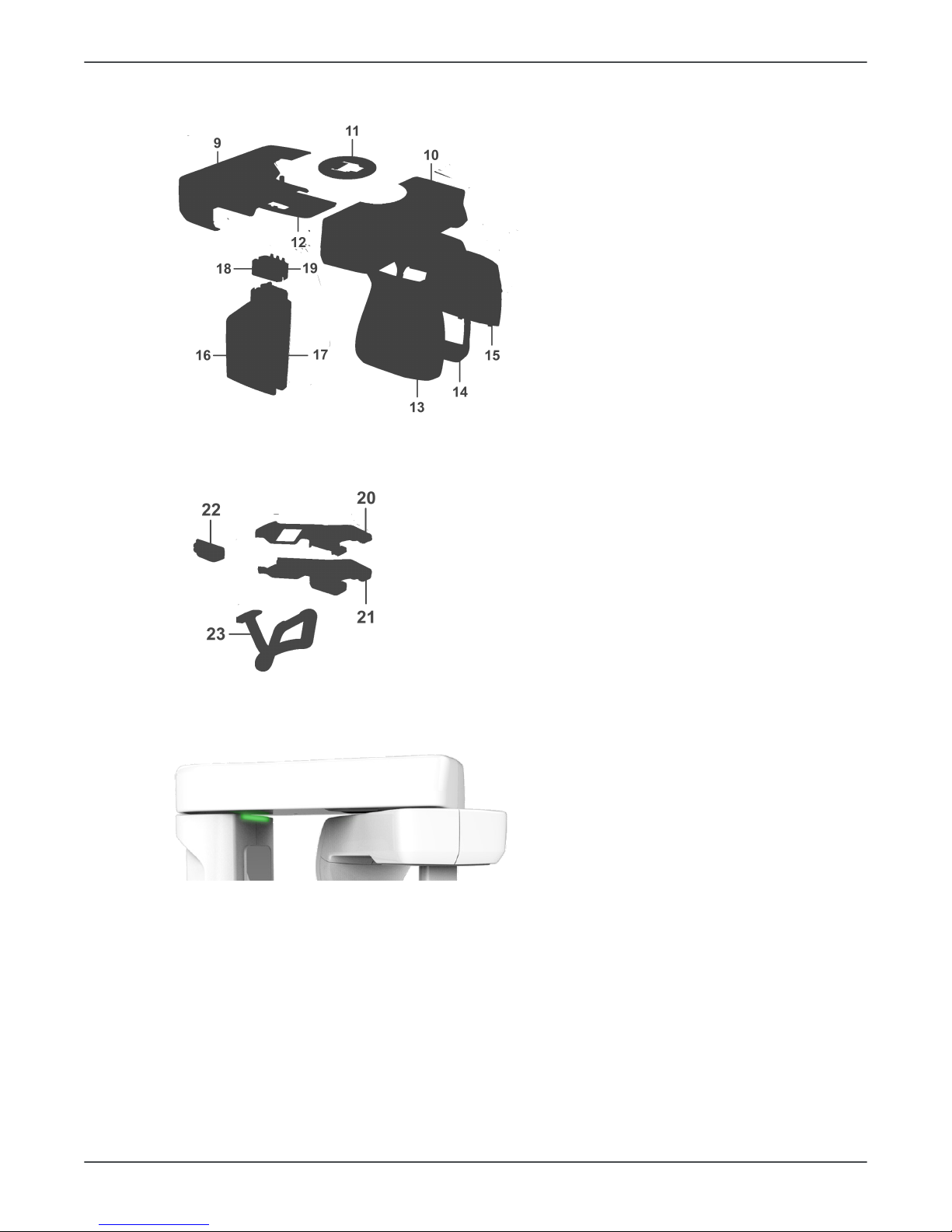

Rotating unit covers

9 Rotator back cover

10 Rotator front cover

11 Rotator finger protection

upper

12 Rotator finger protection

lower

13 Tube head front cover

14 Tube head back cover

15 Tube head plate

16 3D sensor back cover

17 3D sensor front cover

18 Outer sensor collar cover

19 Inner sensor collar cover

Lower shelf covers

20 Lower shelf cover set with

control panel

21 Lower shelf bottom cover set

22 Layer laser cover assembly

23 Patient handle

4.1.4 Status indicator light

Device status indicator light, located on the top of the carriage, illuminates according the

device status:

• YELLOW: Device is radiating.

• BLUE: Device is in error state or pending user action. Check the GUI for details.

• BLUE (blinking): Press HOME button or no EHT connection.

• GREEN: Device is ready for imaging.

• GRAY: Power down mode. Device is not ready for imaging, follow the instructions on

the status message bar

ORTHOPANTOMOGRAPH™ OP 3D 15

Page 16

4 Device description

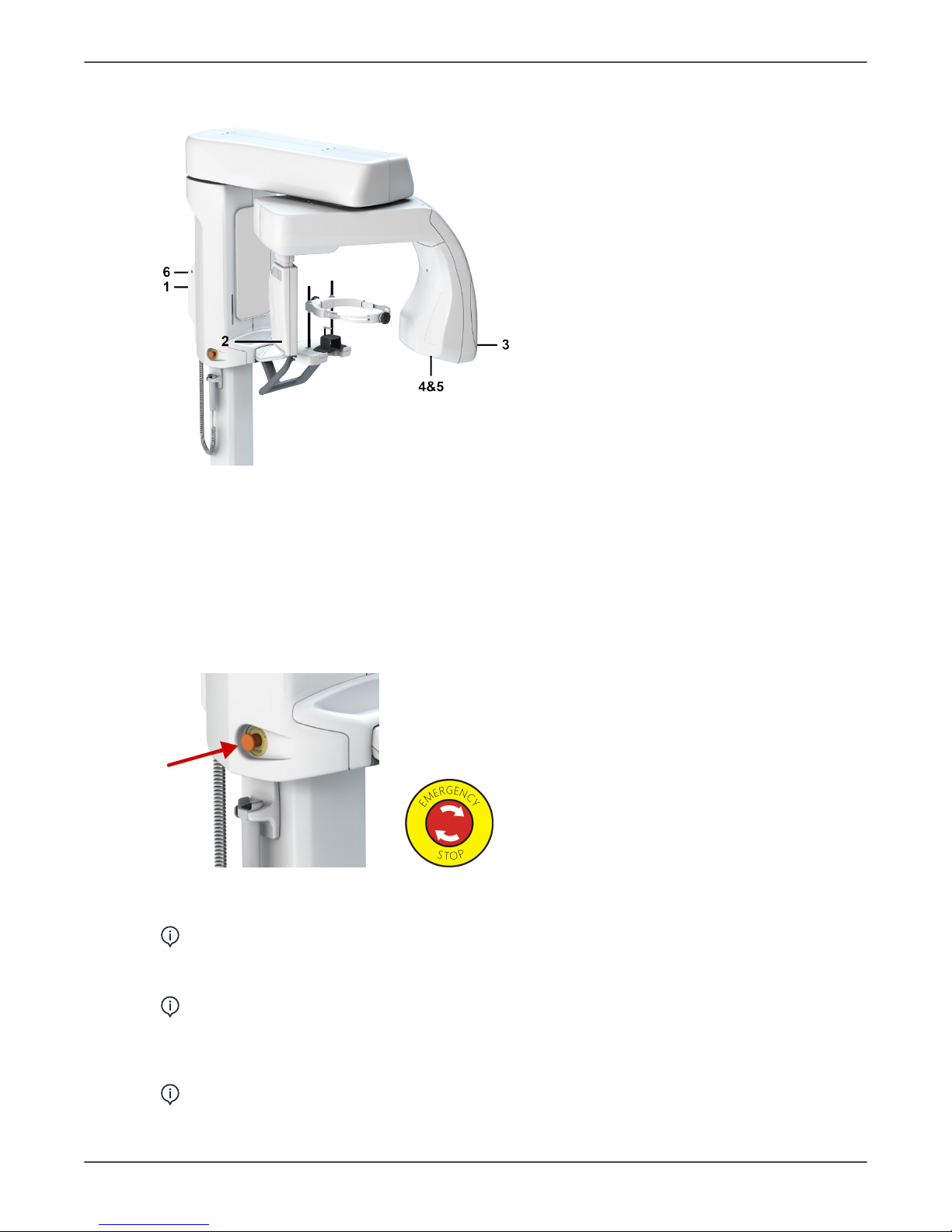

4.1.5 Device labels

1. Type label

2. Sensor label

3. THA label

4. Collimator label

5. Filtration label

6. Warning label

4.1.6 Emergency stop switch

An emergency stop switch is located on the left side of the carriage.

Pressing the emergency stop switch immediately terminates the imaging and all device

movements and resets all circuit boards.

NOTICE! An interrupted imaging process cannot be resumed. A new image needs

to be taken.

To release the emergency stop switch, rotate it clockwise.

NOTICE! Make sure that the emergency stop switch is not pressed down when

you start the imaging process.

The Graphical User Interface (GUI) has indication if the emergency stop is active and the

device status indication lights are blue.

NOTICE! Activating the emergency stop causes the device to restart.

16 ORTHOPANTOMOGRAPH™ OP 3D

Page 17

4 Device description

4.2 Device software

4.2.1 Firmware overview

Firmware description

The device firmware (FW) consists of board and processor component specific binary

files, that are loaded on various system board locations.

NOTICE! The device Firmware versions can be found under the System info on

the Settings menu on the GUI.

The device components communicate via CAN buses and other interfaces.

The FW system is split into four main areas:

1. Real time operations

2. Image data capturing

3. General functions

4. GUI client

The main control functions are located in different parts of the system:

• PCBA i4000: Controls generator, tube head, column

• PCBA i3000: Controls pivot and linear movement

• PCBA i2000: Controls image capturing hardware, rotating unit movement

Non-time critical tasks are handled by the main application controlling the overall

operations. The main application includes, for example:

• graphical user interface

• interfaces to modality SW

• device data storage

• device reservation.

The device has a remote Graphical User Interface (GUI) which is interfaced over

Ethernet. The i3000 board includes a SD-card for the permanent storage of data.

4.2.2 Firmware update

The firmware update can be performed through the device GUI. See chapter Settings

menu.

NOTICE! You can update the firmware only in the Service menu.

To update the firmware, do the following:

1. Download the firmware distribution package.

NOTICE! The package is named in format OP3D-FW_x_x_x_216403D519721-y.zip where the x_x_x indicates the firmware version.

2. Unzip the firmware distribution package to the hard drive of the workstation

connected to the device.

3. Ensure that the workstation software and drivers are up to date so that they meet

the requirement of the firmware release.

4. Update SW and drivers, if needed.

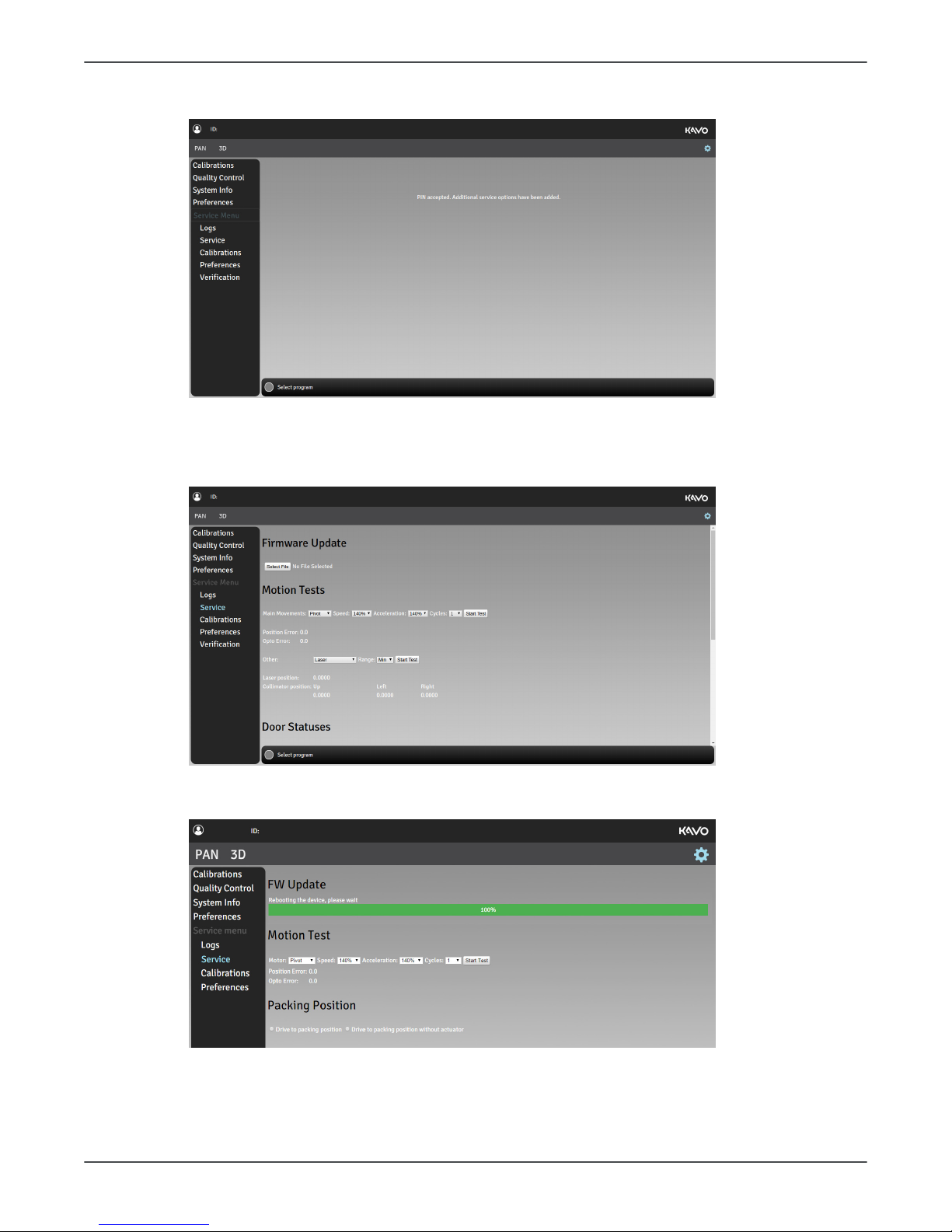

5. Browse to Settings> Service menu.

ORTHOPANTOMOGRAPH™ OP 3D 17

Page 18

4 Device description

6. Enter PIN code 1917 to access the Service menu.

7. Browse to Service> FW Update.

8. Click Select File and browse to the location to the firmware file to be loaded, for

example C:\temp\OP_3D_EMBEDDED_SOFTWARE_Rx_y_z_abcd.tar.gz. Select the

update file.

9. Click Start Update.

10. Wait for the update to finish.

11. Close the GUI to disconnect the device from the imaging software.

12. Re-connect the device by using the imaging software to finalize the update.

13. Perform all the device calibrations in accordance to the calibrations procedure, refer

to Complete device calibration chapter of the OP 3D User and Installation manual.

18 ORTHOPANTOMOGRAPH™ OP 3D

Page 19

4 Device description

4.3 Electrical description

4.3.1 Circuit board locations

1. i4000 Power Supply

board

2. i2000 Image Capture

Board

3. i3000 Main Control

Board

4. i4100 Back panel

board

5. i5000 Cascade board

(in the Tubehead

assembly)

6. i6000 User interface

board

7. i7000 Tubehead

interface board (in the

Tubehead assembly)

8. i8000 LED indicator

board

9. i9000 Chin rest

sensor board

4.3.2 Circuit boards overview

The OP 3D HW structure is based on three main electrical boards. Each board

implements certain control functions, such as exposure control and motion control, and

they interact with each other through the communication buses.

The main boards are:

i2000 Image Capture Board

i3000 Main Control Board

i4000 Power Supply board

The device also contains seven smaller boards:

i4100 Back panel board

i5000 Cascade board (part of the tube head)

i6000 User interface board

i7000 Tubehead interface board (part of the tube head)

i8000 LED indicator board

i9000 Chin rest sensor board

ORTHOPANTOMOGRAPH™ OP 3D 19

Page 20

4 Device description

For further information on the boards, see the relevant sections in this document.

4.3.3 Position control

Positioning of the device is done by stepper- and DC-motors, using feedback from

optical, resistive and Hall sensors. The control chain per actuator is described below.

Upper shelf linear and pivot movement, rotator movement

The movement is driven by a stepper motor. A resistive sensor determines the

approximate position of the actuator. A number of exact positions is determine by

matching the approximate position with feedback from an optical sensor changing state

at regular intervals. Positioning between these points is based on by counting steps fed

to the stepper motor.

Lasers and collimator movement

The movement is driven by a stepper motor. An optical sensor is used to determine the

Home position. Driving to wanted position is done by first finding the Home position, and

then counting steps fed to the stepper motor.

Z-movement

The movement is driven by a DC motor. An optical sensor is used to determine the Home

position. The Z-position is determined by using the home position as reference and

counting pulses generated by a Hall sensor connected to the motor.

Imaging chain overview / Image data transfer

Image capturing is handled by the i2000 Image Capture Board. This board is responsible

for both triggering the sensor and capturing image data. The data is stored in the i2000

Image Capture Board until transferred through the I3000 board to the image capturing

workstation.

4.3.4 Exposure logic

Exposure logic is solely controlled by i4000 board. The i4000 board includes power

supply, inverter and filament power supply that are responsible for supplying the X-ray

tube head.

Filament pre-heat

Prior the high voltage generation at the tube head the filament is pre-heated. The preheating process is controlled and monitored by the i4000 board.

Exposure

After the filament pre-heat, the exposure is enabled. Exposure is monitored by the i4000

board by utilizing the KVFB and MAFB signals and comparing them against the selected

reference signals.

Backup timer

The exposure timing is controlled by the firmware. In the event of malfunction there

is an added safety timer implemented in hardware, which will cut the exposure in case

EXPENA-signal is active too long.

4.3.5 Power supply

The mains power supply comes from the wall socket through the back panel to the i4100

board. For further information, see i4100 back panel board en la página 42. See also

Power distribution +24Vdc en la página 48.

Mains power configuration

Detach the indicated screw on the back panel cover and lift it off to access the device

back panel.

20 ORTHOPANTOMOGRAPH™ OP 3D

Page 21

4 Device description

Refer to User and Installation manual, chapter Mains power configuration for detailed

instructions.

NOTICE! In i4100 back panel board there is a switch (SW1) that is used for

changing, for example, from permanent to plug connection. Refer to User and

Installation manua, chapter Mains power configuration.

4.3.6 Fuses

The allowed main fuse types are listed in the table below. See also Fusing diagram.

Table 1: Main fuses

Location Ref Value Type

i4100

220-240Vac

(6.3x32mm)

Littelfuse 215 (Time-Lag) 10A

Cooper Bussman (Time Delay)

S505H-10-R

Back panel

F1 & F2

100-120Vac

(6.3x32mm)

Littelfuse 326 (SlowBlow) 15A

Cooper Bussman (Time Delay)

MDA-15

External warning light

fuse (i4100)

F3 Cooper Bussmann (Time Delay)

S506-2-R

For fuses in circuit boards, see:

i2000 image capture board

i3000 Main control board

i4000 power supply board

ORTHOPANTOMOGRAPH™ OP 3D 21

Page 22

4 Device description

4.4 User Interfaces

4.4.1 Graphical User Interface (GUI)

GUI Overview

1. Selected patient name and Patient Identification (ID).

2. Selection of imaging modality, PAN or 3D.

3. Imaging program settings.

4. Main view area. Shows a dental chart for the selected modality and previews of the

taken images.

5. Status message bar shows the device status and provides messages and instructions

to the user. Click on the bar to show messages if there are more than the ones

shown.

6. Imaging parameters. Imaging parameters, kV (PAN only) and mA, can be manually

adjusted according to the patient size and skull anatomy using the - & + icons.

7. Sample image of the selected Panoramic program or 3D FOV size and location

illustration.

8. Scan time and DAP display. Shows the duration of X-ray radiation and the dose

production with the selected imaging program and parameters.

9. Device settings. Opens a menu which is used to access the device settings, quality

control and calibration programs and to show the device information, like serial

number and software versions.

22 ORTHOPANTOMOGRAPH™ OP 3D

Page 23

4 Device description

IMAGING PROGRAM SETTINGS:

Test mode

Indicates if Test mode is active.

Press Test mode icon to disable/enable device radiation production.

This mode can be used for example to demonstrate the device

movements.

You can also use the positioning panel to activate the Test mode.

Patient size

Indicates the currently selected patient size preset.

Press the Patient size selection icon to open a list of patient sizes;

Small, Medium & Large.

Press on the listed patient size icon to activate it.

Selecting a patient size, according to the scanned patient, adjusts

the kV and mA to preset levels.

NOTICE! Patient size presets can be adjusted from settings

menu.

End Study

Press End Study icon to finalize the imaging procedure and return to

the main view.

STATUS MESSAGE BAR:

Device status indicator

Status message bar shows the device status with a colored Device

status indicator.

Refer to Status indicator light for more information.

ORTHOPANTOMOGRAPH™ OP 3D 23

Page 24

4 Device description

Settings menu

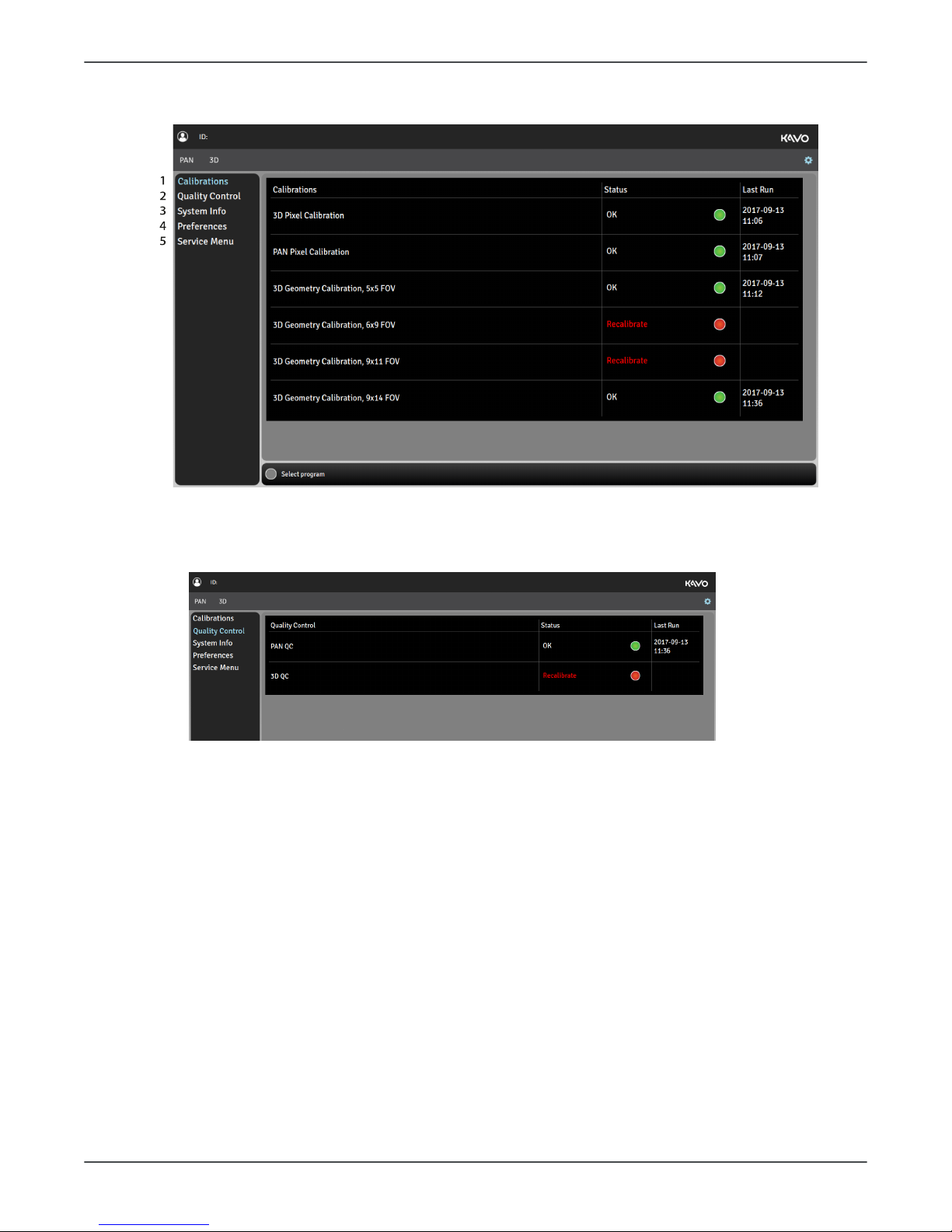

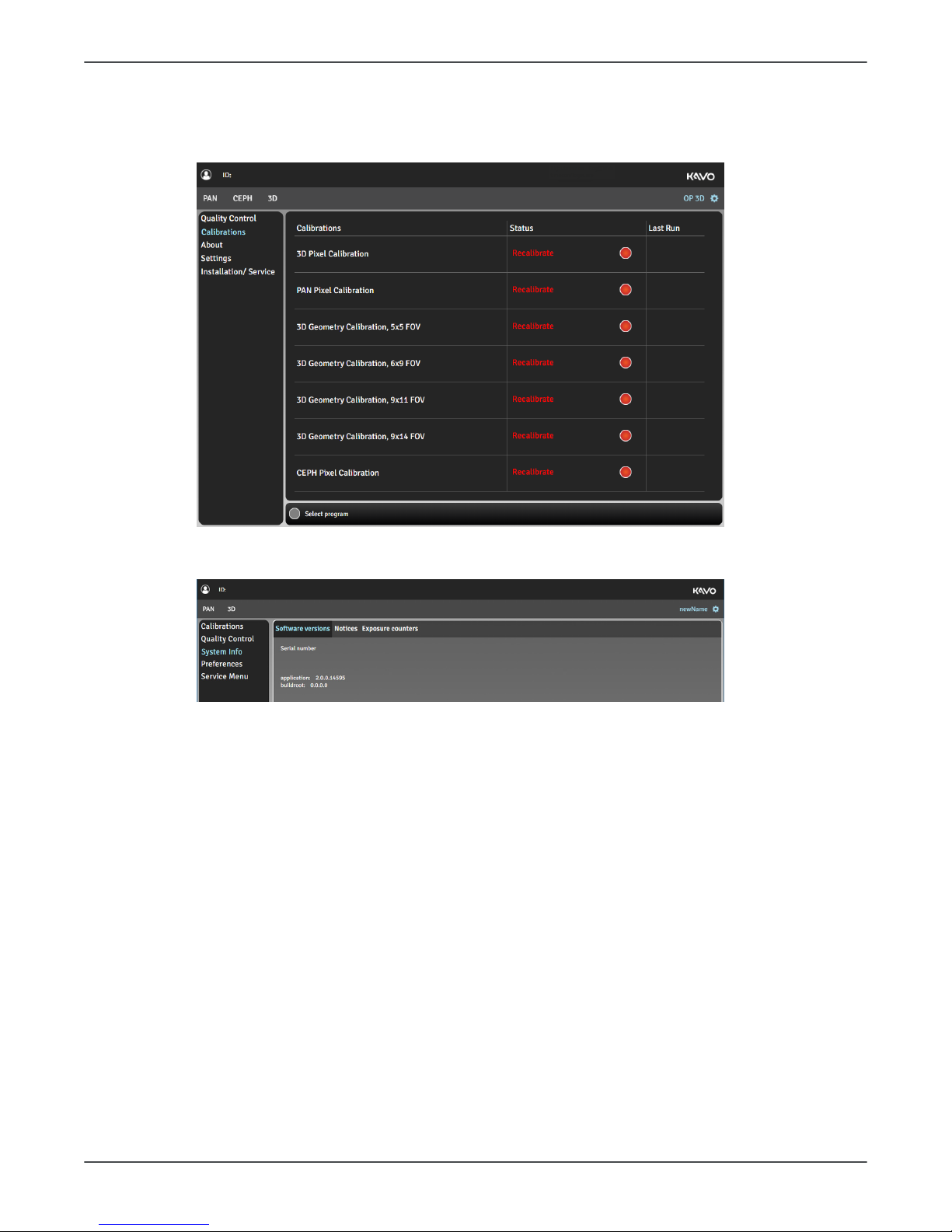

1. QUALITY CONTROL

Shows a list of Quality Control (QC) programs, their completion status and last

completion date.

24 ORTHOPANTOMOGRAPH™ OP 3D

Page 25

4 Device description

2. CALIBRATIONS

Shows a list of user performable device calibrations, their completion status and last

completion date. The calibrations are performed through this menu.

3. SYSTEM INFO

Software

versions

Show the device serial number and firmware versions.

Notices Legal information and terms and conditions for use.

Exposure

counters

Show amount of exposures taken with the device.

ORTHOPANTOMOGRAPH™ OP 3D 25

Page 26

4 Device description

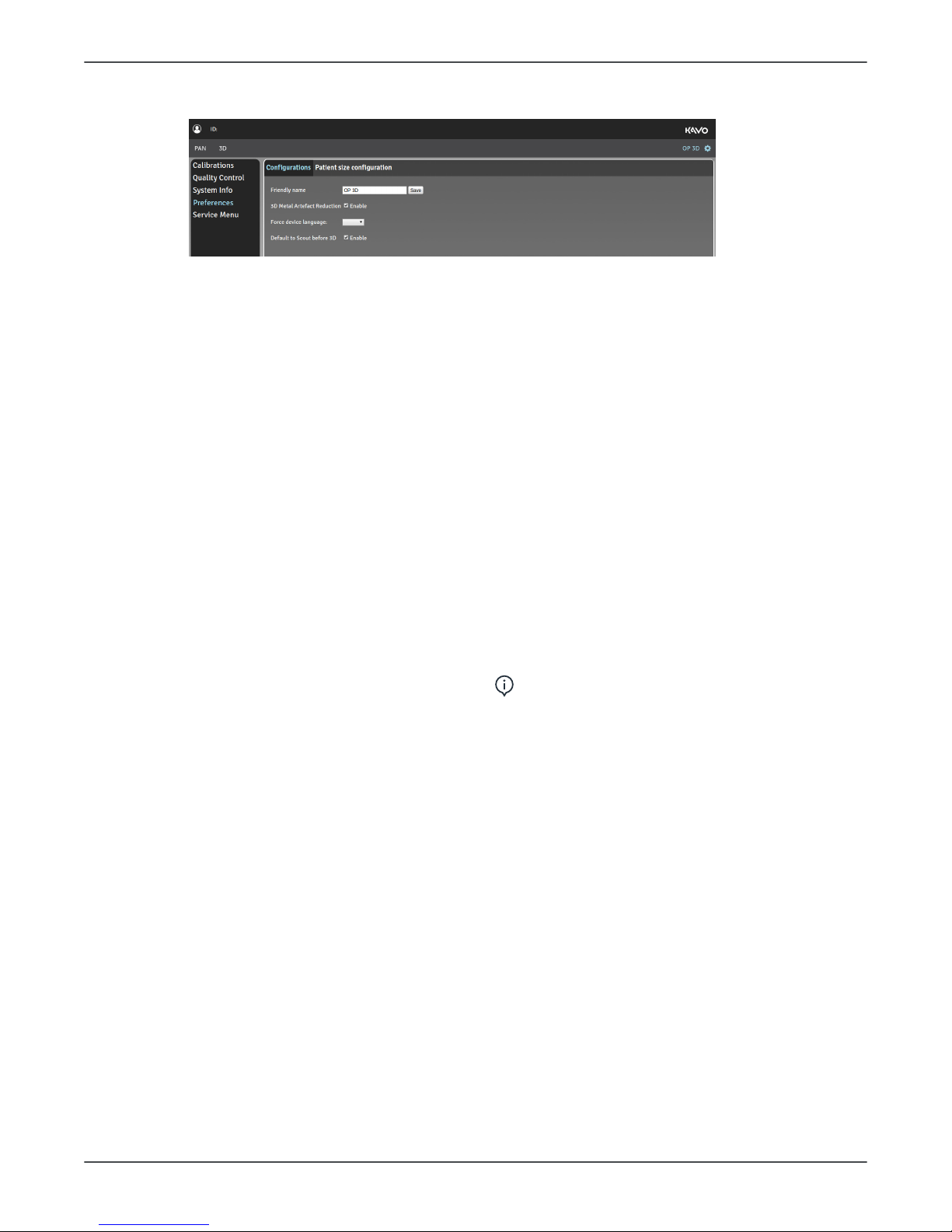

4. PREFERENCES

Friendly name Set a name for the device, which is shown

next to the settings icon and on the

imaging software.

3D Metal Artefact

Reduction

Enable or disable MAR, Metal Artefact

Reduction. MAR is used to reduce

the effect of metals and other dense

radiopaque objects on the 3D image.

It is recommended to keep MAR activated.

Force device

language

Change the language of the GUI if needed.

It is recommended not to force the

language of the GUI but change the

language profile of the workstation.

Configurations

Default to Scout

before 3D

Enable or disable automatic Scout image

activation when a 3D imaging modality is

selected.

It is recommended to have the Scout

image taking enabled.

NOTICE! If the selection is set to

"disabled", a Scout image mode can

still be activated manually in the 3D

imaging program selection view.

26 ORTHOPANTOMOGRAPH™ OP 3D

Page 27

4 Device description

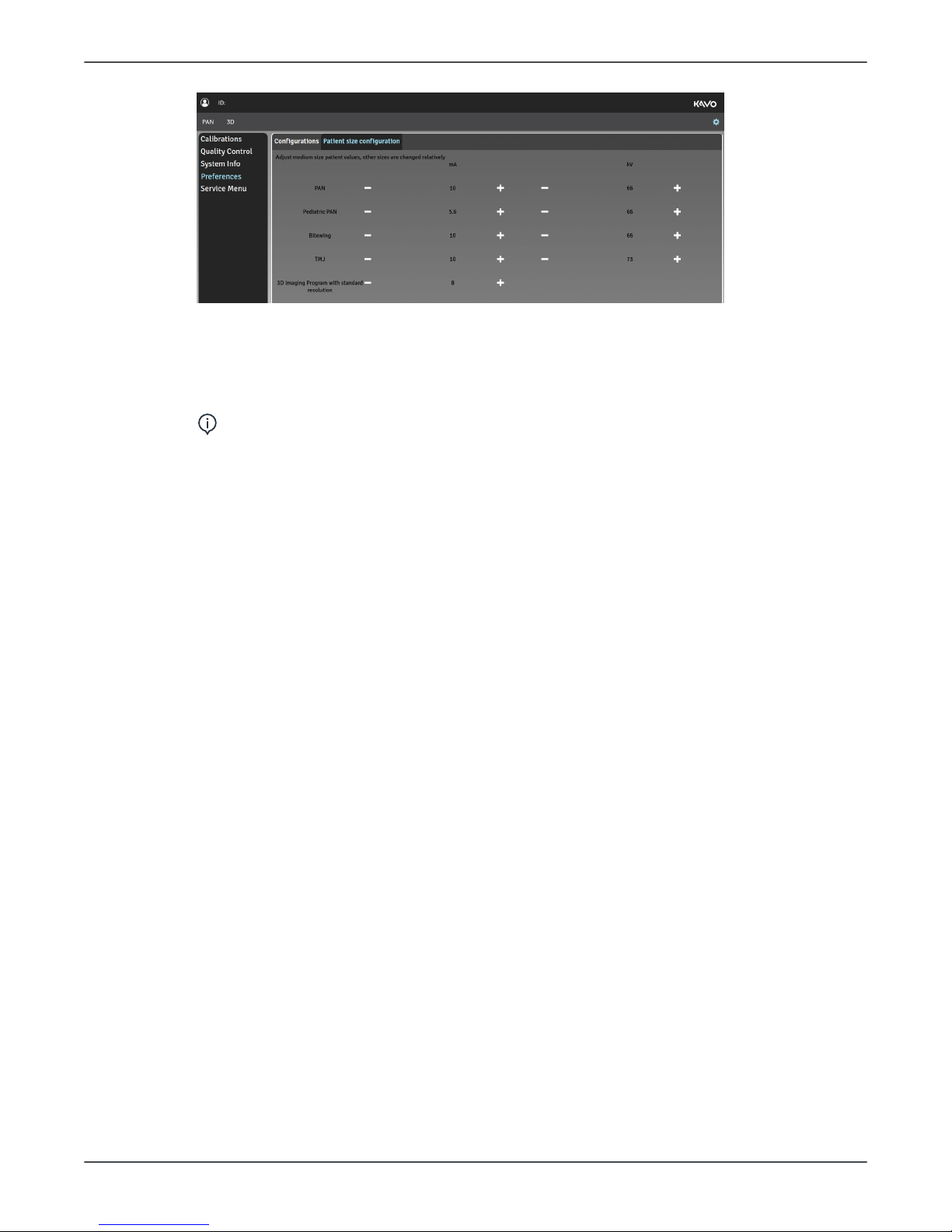

Patient size

configuration

Adjust the default mA and kV values for imaging programs.

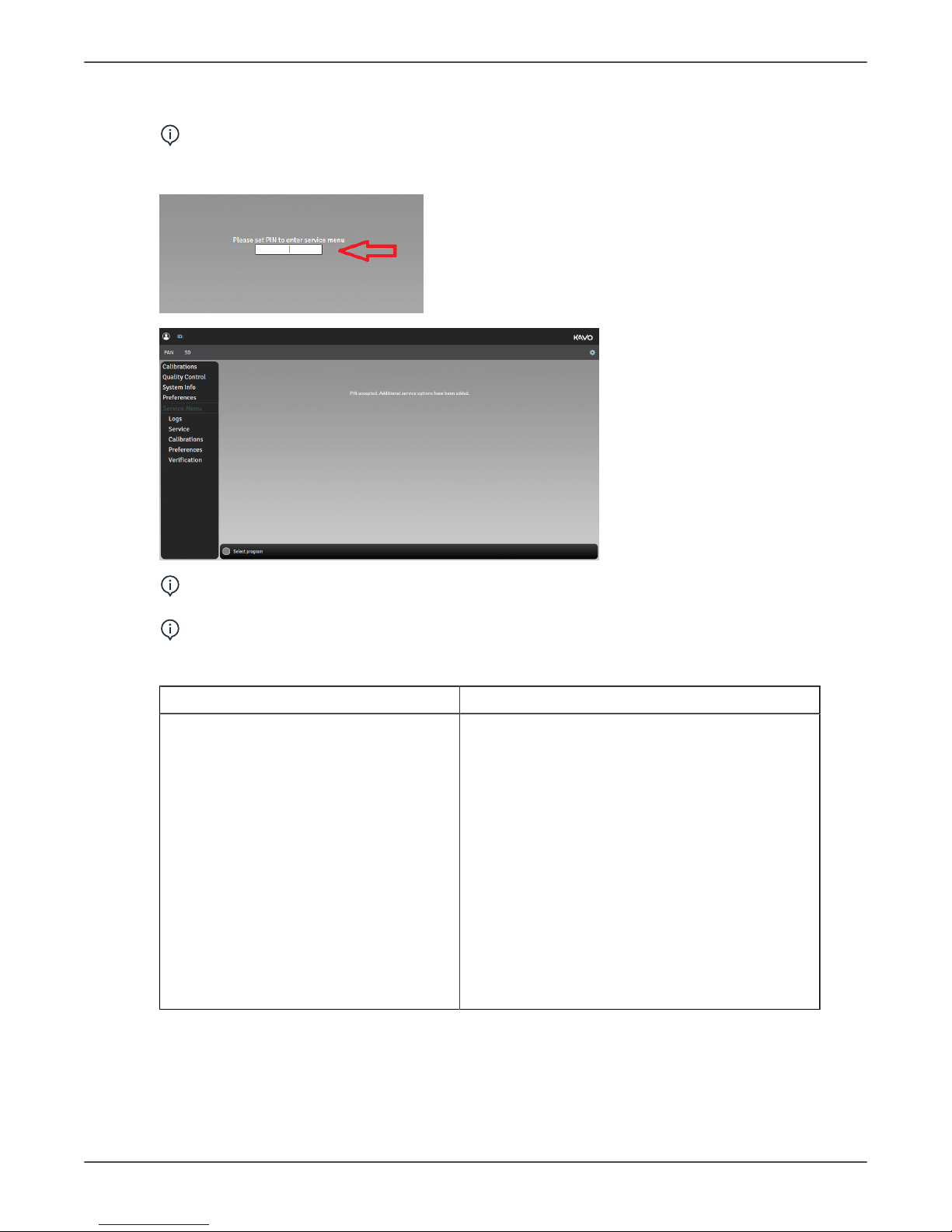

5. SERVICE MENU

NOTICE! This menu is intended for authorized service personnel only.

The Service menu can be accessed only with a PIN code.

The Service menu contains:

• Device settings

• Calibrations for installation and service of the device

• Optional imaging programs activation

• Demonstration mode activation for exhibition use

• Verification programs for radiation related testing

ORTHOPANTOMOGRAPH™ OP 3D 27

Page 28

4 Device description

Service menu

NOTICE! The Service menu is intended only for authorized service men for

service use.

To access the Service menu from the Settings, input PIN code 1917 to the field:

NOTICE! PIN code 0612 is intended for installation only and contents of the

Service menu is limited. See the table below.

NOTICE! As a user of the OP 3D Service manual, you have a full access to the

Service menu.

In the Service menu you can:

PIN 1917 PIN 0612

• Access the device logs and errors

(Logs)

• Update the device sofware

(Service)

• Drive the device to packing position

(Service)

• Perform motion tests(Service)

• Perform device calibrations

(Calibrations)

• View and modify configuration

preferences, for example: Define

calibration intervals, enter license

keys, select country (Preferences)

• Perform PAN and 3D tests

(Verification).

• Drive the device to packing position

(Service)

• Perform device calibrations (Calibrations)

• View and modify configuration preferences,

for example: Define calibration intervals,

enter license keys, select country

(Preferences)

• View and modify patient size configurations

(Preferences)

• Demo mode (Preferences)

• Perform PAN and 3D tests (Verification)

28 ORTHOPANTOMOGRAPH™ OP 3D

Page 29

4 Device description

Service

In the Service menu you can:

• update the device firmware

• perform accelerated motion test for different main movents

• test the door and mirror door switch status change

• drive the device to packing position

• test the 3D sensor connectivity

• test the functionality of internal communication buses

• check the statuses of the internal power supplies.

For more information on how to update the device firmware, see chapter Firmware

update.

Motion tests are used for testing the individual movements of the device. To perform a

motion test to the following:

• Select the main movement (PIVOT, ROTATION, LINEAR) or other movement (LASER,

UPPER COLLIMATOR, LEFT COLLIMATOR, RIGHT COLLIMATOR)

• For main movements, select the number of movements for the test.

• For other movements, select the range of movement (min/max). Change the range

between tests when you test the same movement.

• Press the exposure button to perform the movement.

• Verify the selected movement visually.

Internal communication bus test results and power supply status results are provided in

the system logs. After you have executed the test, check the results from Logs menu by

clicking log/messages.

Logs

In the Logs menu you can access device logs and error messages.

To dowload logs or error messages to the workstation, select the logs/error messages

and click Download.

ORTHOPANTOMOGRAPH™ OP 3D 29

Page 30

4 Device description

Calibrations

In the Calibrations menu you can select the device calibrations that you want to

perform.

For information on how to perform the calibrations, see User and Installation manual.

Preferences

In the Preferences> Configurations you can:

• enter a friendly name (for the device)

• select the desired intervals for User calibrations, Service calibrations, PAN QC, 3D QC

• enter licence keys

• change the device language

• enable the default Scout before 3D

• select the country

• enable the Door switch

• enable the Demo mode

• specify the DAP calibration factor.

30 ORTHOPANTOMOGRAPH™ OP 3D

Page 31

4 Device description

Refer to User and Installation manual, chapter Device configuration for instructions on

setting and using the Preferences menu items.

In the Preferences > Patient Size Configuration you can:

• adjust the medium size patient values

Verification

The device offers Panoramic and 3D verification test programs with the device

movements disabled. These programs can be used for radiation related measurements.

A separate radiation measuring device/equipment is required for taking the radiation

measurements.

1. Go to Settings menudevice settings.

2. Select Service menu and enter PIN code 1917.

3. Select Verification menu that appears under the Service menu.

4.

ORTHOPANTOMOGRAPH™ OP 3D 31

Page 32

4 Device description

5. Select the PAN testing tab for Panoramic verification test or 3D testing tab for 3D

verification test.

6. Adjust the verification test settings:

PAN testing

• Select the mA and kV values for the test program using the + and - buttons.

7. Attach the measuring device in front of the sensor cover. The detector of the

measuring device must be positioned to the area where the X-ray beam hits. The

center of this area is located approximately 2,5 cm from the left side of the detector

opening.

NOTICE! The X-ray beam must fully hit the detector of the measuring device.

NOTICE! You may use a fluorescent screen to pinpoint the beam location

more accurately.

NOTICE! When using the PAN testing program, the X-Ray beam is adjusted

wider (over 2 cm) than in normal imaging programs to allow easier positioning

of the measurement device.

8. Protect yourself from radiation.

9. Press and hold down the exposure button to start the test program.

10. When the exposure warning stops and the program end tone is played, the program

is complete.

11. Review the measurement data. The measured kV shouldn't differ more than 5kV

from the set value.

32 ORTHOPANTOMOGRAPH™ OP 3D

Page 33

4 Device description

12. If the verification fails, ensure the alignment of the measurement device and redo

the test program. If the problem persists, contact service.

13. Adjust the verification test settings:

3D testing

• Select the length of the radiation pulse, 5ms (LDT/standard), 10ms (Standard

resolution) or Constant (High/ENDO resolution).

• Select the mA value for the test program using the + and - buttons.

14. Perform the 3D testing.

4.4.2 Positioning panel

1. Carriage up/down slider. The carriage can be driven up and down by sliding a finger

on the carriage up/down slider. The speed of the carriage movement depends on the

distance the finger is moved.

2. Test mode button. Disables radiation production of the device. You can also use the

GUI to activate the Test mode.

3. Patient positioning lights button. Turns the patient positioning lights on/off.

4. HOME button. Drives the rotating unit to HOME (Patient-In) and scan start positions.

5. Exposure indicator (YELLOW). Illuminates when the device is radiating.

6. Status indicator (BLUE). Illuminates when the device is in Error state. The error

details are shown on the GUI.

7. Ready indicator (GREEN). Illuminates when the device is ready for imaging.

NOTICE! If carriage up/down slider backlight is not illuminated, the carriage up/

down slider is in safe mode and cannot be used. Wait until the light comes back on

or wipe the panel clean if it is dirty.

ORTHOPANTOMOGRAPH™ OP 3D 33

Page 34

4 Device description

4.5 Circuit boards

4.5.1 i2000 image capture board

The i2000 image capture board is located on top of the rotating unit, see Locations of

circuit boards.

The i2000 board handles image capturing function of the OP 3D X-ray imaging system.

The main functions of the i2000 board are listed below.

• Image capturing from both the 3D and the PAN sensor

• Image storing to the image memory

• Image transmission to the modality workstation.

• Driving the

• spinning of the rotation unit

• collimator plates.

• Providing voltage for the sensors.

34 ORTHOPANTOMOGRAPH™ OP 3D

Page 35

4 Device description

Table 2: Indicators

LED # Color Default

state

Function Notes

H1 Green ON Configuration done

H2 Green ON Ethernet Link

H3 Green ON FPGA init done

H4 Green Blinking Ethernet RX/TX activity

H5 Green ON P1V35 PG OFF when device is

in the sleep mode

H6 Red OFF FPGA PIO LED5

H7 Green OFF PAN_P5V_D_3D ON when 3D

imaging mode

selected and device

is reserved.

H8 Green OFF PAN_P5V_A_CEPH ON when 3D

imaging mode

selected and device

is reserved and.

H9 Green OFF Panel supply P12/P6V PG ON when the device

is reserved

H10 Green OFF PAN_P12V ON when 3D

imaging mode

selected and device

is reserved.

H11 Green ON P24V Board input voltage

H12 Red OFF FPGA FW_ERR ON when error state

H13 Red OFF FPGA CORE_ERR ON when error state

H14 Green Blinking FPGA PIO LED1

FPGA PIO LED0-2

forms a group of

running lights.

Fast blinking (1s

round time) when

FPGA boots up.

Slow blinking

(8s round time)

when FPGA fully

operational.

H15 Green ON P3V3 PG OFF when device is

in the sleep mode.

H16 Red OFF FPGA PIO LED4

H17 Green ON P5V PG OFF when device is

in the sleep mode

H18 Green Blinking FPGA PIO LED2 See H14

H19 Green OFF FPGA PIO LED3

H20 Green Blinking FPGA PIO LED0 See H14

ORTHOPANTOMOGRAPH™ OP 3D 35

Page 36

4 Device description

LED # Color Default

state

Function Notes

H21 Red OFF Motor driver POR on ON when a motor

malfunction

detected

H22 Green ON DDR_VTT OFF when device is

in the sleep mode

H23 Green Blinking MCU STAT0 MCU SW controlled

LED

H24 Green ON NSTATUS

H25 Red OFF FPGA RESET

H26 Green OFF CPAN_P12V ON when PAN

imaging mode

selected.

H27 Red OFF MCU STAT1 SW controlled LED

H28 Green ON P24V_MOTOR +24Vdc power input

for motors.

H29 Green OFF PAN_P5V_D_CEPH ON when

PANimaging mode

selected.

H30 Green OFF PAN_P5V_A_3D ON when PAN

imaging mode

selected.

36 ORTHOPANTOMOGRAPH™ OP 3D

Page 37

4 Device description

i2000 fuses

Location Ref Value Type Replaceable

i2000 F1 FUSE slow 4A

250Vac 5x20 mm

Cooper Bussmann

S506-4-R

Yes

i2000 F2 FUSE slow 6.3A

250Vac 5x20mm

Cooper Bussmann

S506-6.3-R

Yes

i2000 F3 Resettable Fuse

PPTC 16V, 0.25A,

Itrip 0.5A

Cooper Bussmann

PTS120616V025

No

Replacing the i2000 image board

To replace the board, follow the instructions given in chapter Replacing the i2000 image

capture board.

4.5.2 i3000 Main control board

The i3000 main control board is located on top of the upper shelf. See figure Locations of

circuit boards.

The i3000 board is the main controller of the OP 3D X-ray imaging system. The main

features of i3000 board are listed below.

Functionality

The main functions of the i3000 Main control board are:

• Main control of the system

• Linear and pivot motion drive and position sensing

• Exposure control

• Image data streaming between i2000 and MWS

• Audio output

• User interfaces

• Remote GUI through LAN

• I4000 and i2000 firmware & FPGA updates.

ORTHOPANTOMOGRAPH™ OP 3D 37

Page 38

4 Device description

Indicators

LED # Color Default state Function Notes

H1 Green ON VAUX33 power on

H2 Green ON MWS Ethernet link

H3 Green ON i2000 Ethernet link

H4 Green ON/blink MWS Ethernet RX/TX

activity

H5 Green OFF Motor in reset (POR)

H6 Green ON

+24V supply connected to

board and

FUSE ok

H8 Green ON/blink MPU STAT0 SW controlled LED

H9 Green ON P3V7 power on

H10 Green ON/blink i2000 Ethernet RX/TX

activity

H11 Green ON

+24V supply connected to

board and

FUSE ok

H12 Green ON Photo interrupter power on

H13 Green OFF Motor in reset (POR)

H14 Green ON/blink MCU STAT0 SW controlled LED

H15 Green ON P3V3 power on

H16 Green OFF Board main reset active

(power up)

H17 Green ON P5V power on

H18 Red OFF MPU STAT1 SW controlled LED

H19 Red OFF Peripheral reset active Control reset

H20 Green ON P1V8 power on

H21 Green ON VMMC power on

H22 Green ON DDR VTT ok

H23 Red OFF MCU STAT1 SW controlled LED

38 ORTHOPANTOMOGRAPH™ OP 3D

Page 39

4 Device description

i3000 fuses

Location Ref Value Type Replaceable

i3000 F1 6,3AT/250Vac Cooper Bussmann

S506-6.3-R

Yes

i3000 F2 4A 250Vac slow (5x20mm) Cooper

Bussmann S506-4-R

Yes

i3000 F3 1,1A/6V Resetable PTC#fuse No

i3000 F4 1,1A/6V Resetable PTC#fuse No

i3000 F5 0,25A/16V Resetable PPTC#fuse No

i3000 F6 2A/6V Resetable PTC#fuse No

i3000 F7 0,25A/16V Resetable PPTC#fuse No

i3000 F8 0,25A/16V Resetable PPTC#fuse No

Replacing the i3000 circuit board

To replace the board, follow the instructions given in chapter Replacing the i3000 main

control board.

ORTHOPANTOMOGRAPH™ OP 3D 39

Page 40

4 Device description

4.5.3 i4000 power supply board

The i4000 power supply board is located on the carriage. See figure Locations of circuit

boards.

The i4000 board is one of three control boards of the OP 3D X-ray imaging system. The

main features of the i4000 power supply board are listed below.

Functionality

• Generate all main supplies to OP 3D

• UI control

• Z motor control and position sensing

• Laser motor control and position sensing

• Chin rest sensor interface

• Patient positioning lights control

• Scan motor control and positioning

• Filament control

• HV control

Indicators

LED # Color Default state Function

H1 Green ON +3V3HV is on

H2 Green ON #15V is on

H3 Green ON +20V Triac is on

H4 Green ON +17V is on

H5 Green ON HV395 is on

H6 Green ON PFC power is on

H7 Green ON P15V is on

H8 Green OFF Preheat is on

H9 Green ON P3V3 is on

H10 Green ON P5V is on

H11 Green ON +24V is on

H12 Red OFF Tubefail error

H13 Green ON +20V DCDC

H14 Yellow OFF Exposure on

H15 Yellow OFF Power detected

LA100 ON Mains voltage on

40 ORTHOPANTOMOGRAPH™ OP 3D

Page 41

4 Device description

i4000 fuses

Location Ref Value Type Replaceable

i4000 F1 FF8A/500Vac (6,3x32mm) Siba

70-125-40 8A

Yes

i4000 F2 2A/6V

Resetable PPTC

fuse Littelfuse

0805L200SLTHYR

No

i4000 F3 8AT/250Vac (5x20mm) Cooper

Bussmann S506-8-R

Yes

i4000 F4,

F6-9

0.5A/6V Resetable PTC#

fuse Bourns MFPSMF050X

No

i4000 F5 0.25A/16V Resetable PPTC#fuse No

i4000 F10 0.5A/6V Resetable PTC#fuse No

i4000 F11,

F12

2A/250Vac (TE5) Littelfuse

39212000440

No

Replacing the i4000 circuit board

To replace the board, follow the instructions given in chapter Replacing the i4000 power

supply board.

ORTHOPANTOMOGRAPH™ OP 3D 41

Page 42

4 Device description

4.5.4 i4100 back panel board

The i4100 back panel board is located on the backside of the carriage. See Locations

of circuit boards. The board has a mains input connector and mains fuses. It also has

several connectors to external features.

The main features of the i4100 back panel board are listed below.

Functionality

• Mains fuses

• Switch of permanent or non-permanent mains installation:

• When the non-permanent installation is made, both L (live) and N (neutral) fuses

must be used. Switch SW1 must be set to 2F position.

• When the permanent installation is made, only L (live) fuse must be used. Switch

SW1 must be set to 1F position.

• Mains switch is connected to this board

• Exposure switch connector

• Remote exposure switch connector

• Door switch connector

• External warning light connector

Table 3: Indicators

LED # Color Default state Function Notes

H1 Green ON Green led

controlled by

FW.

Replacing the i4100 circuit board

To replace the board, follow the instructions given in chapter Replacing the i4100 back

panel board.

i4100 fuses

See chapter Fuses.

4.5.5 i6000 user interface board

The i6000 user interface board is located on the lower shelf. See figure Locations of

circuit boards.

The i6000 user interface board contains no parts that can be serviced. The board comes

as a part of the lower shelf assembly.

Replacing the i6000 circuit board

To replace the i6000 board you need to replace the lower shelf upper cover assembly,

see chapter Replacing the lower shelf upper cover assembly.

Test points

J3 GND test clip

4.5.6 i8000 LED indicator board

The i8000 LED indicator board is located between the carriage and the upper shelf. See

figure Locations of circuit boards.

Functionality

42 ORTHOPANTOMOGRAPH™ OP 3D

Page 43

4 Device description

The i8000 board generates exposure warning, ready and error status indications. The

status is indicated with colored LEDs.

Indicators

Refer to Status indicator light for the indicators.

Replacing the i8000 circuit board

For instructions on how to replace the i8000 LED indicator board, see chapter Replacing

the i8000 LED indicator board.

ORTHOPANTOMOGRAPH™ OP 3D 43

Page 44

4 Device description

4.5.7 i9000 chin rest sensor board

The i9000 chin rest sensor board is located in the lower shelf. See figure Locations of

circuit boards.

Functionality

The i9000 board senses the chin rest positions and calibration phantoms with three HALL

sensors.

Indicators

Replacing the i9000 board

For instructions on how to replace the i9000 chin rest sensor board, see chapter

Replacing the i9000 chin rest sensor with lasers.

Fuses

None.

Test points

None.

44 ORTHOPANTOMOGRAPH™ OP 3D

Page 45

5 Diagrams

5 Diagrams

5.1 Wiring diagram

ORTHOPANTOMOGRAPH™ OP 3D 45

Page 46

5 Diagrams

ROTATING UNITTHA

PAN3D

i7000 TUBEHEAD

INTERFACE BOARD

i2000 IMAGE

CAPTURE BOARD

J2013 J2017

J2005

J7005

J7003

J7001

J7000 J7002

SELF

DIAGNOSTICS

i5000 CASCADE BOARD

J5001J5005

J5003 J5002

TUBE

J1036

COL RIGHT

BORDER

2PH

J1035

COL LEFT

BORDER

2PH

J1034

COL UPPER

BORDER

2PH

J1031

J1032

J1033

CRB HOME

CLB HOME

CUB HOME

J2003

J1028

J1029

LIMIT 3D

LIMIT PAN/CEPH

J1014

DETECTOR

SWAP (D)

2PH

J2012

J2015

J2007

J2015

J2007

J2003 J2001J2002

J1012

ROTATING

2PH

ROT. HOME

J1027 J1013

ABS.

ANGLE

J2000 J2011 J2004J2010

J0601

J0100

J0101

J0300

J0301

J0200

J0201

J0400

J0401

J0500

J0501

SENSOR ASSEMBLY

J1107

J1106

1

2

3

4

5

6

7

46 ORTHOPANTOMOGRAPH™ OP 3D

Page 47

5 Diagrams

5.2 Fusing diagram

i4100 BACK PANEL BOARD

i4000 POWER SUPPLY i2000 IMAGE CAPTURE

i3000 MAIN CONTROL

PFC DC/DC

GENERATOR

STAND-BY

SUPPLY

SUPPLY

SWITCH

F1

F2

SW1

F12

F11

F1

F1

F2

F3

F6

Motors

Logic

Motors

Motors

Logic

L

N

MAINS INLET

5.3 Emergency stop

i4000

10

J1011

J4002

Emergency stop button

11

3

6

1

3

3

1

5.4 Mains voltage distribution

i4100 i4000

MAINS SWITCH

4 2 1 3

L

LIVE

NEUTRAL

PROTECTIVE EARTH

MAINS CORD

J4107

2

1

F1

F2

J4018

L N

N

SW1

J4106

1A 2A 2 1

J4001

2

1

ORTHOPANTOMOGRAPH™ OP 3D 47

Page 48

5 Diagrams

5.5 Power distribution +24Vdc

13

2 5

P24V

P24V_MOT

i2000

P24V_MOT ON

P24V ON

24V

P24V_MOT

P24V

P24V ON P24V MOTOR ON

24V

i4000

P24V ON

P24V P24V

J4016

J4019

i4100

i3000

F1

F2

F1

F2

24V

J4101

THA

J1005

J7000

24V

8

13

8

J4013

24V power supply

2 5

1

2

J4020

1

2

13

8

13

8

1

2

J3002

J3003

1

2

J2000

5.6 Ethernet communication

i2000 i3000

Back panel

J1002

J2011

J3007

J3006

Link

OK

Link

OK

Link

OK

LAN

or

MWS

5.7 CAN communication

2

i2000

i3000

i4000

J2010

J3009

J4009

1

2

1

2

1

2

1

48 ORTHOPANTOMOGRAPH™ OP 3D

Page 49

5 Diagrams

5.8 i2C self diagnosis communication

i2000

i3000

3

1

2

4

3

J3008

J2004

+5Vdc

i4000

4

+24Vdc

J4019

i7000

THA

PAN

+5V ON

2

1

+5Vdc

3

J3001

+5Vdc

4

2

1

3

1

2

4

J4006

+5Vdc

2 6 12 5

10

2

9

5

J7000

+5Vdc

5.9 Rotation movement

i2000

J2001

J2010

J2002

CAN BUS

FROM

i3000

J1013

J1027

ROT. ABS.

ROT. HOME

J1012

M

2ph Step

MOTOR

ERROR

ORTHOPANTOMOGRAPH™ OP 3D 49

Page 50

5 Diagrams

5.10 Linear movement

i3000

J3004

J

J3010

J3011

CAN BUS

FROM

i4000

J1017

J1025

LINEAR ABS.

LINEAR HOME

J1015

M

2ph Step

5.11 Pivot movement

i3000

J3005

J

J3010

J3011

CAN BUS

FROM

i4000

J1018

J1026

PIVOT ABS.

PIVOT HOME

J1016

M

2ph Step

50 ORTHOPANTOMOGRAPH™ OP 3D

Page 51

5 Diagrams

5.12 Z movement

UI PANEL

+

i6000

i4000

Z-ACTUATOR

CAN BUS

From i3000

E

J1037

Z-HOME

J6001

J4007

J4009

J4002

M

DC

TACOMETER

J1011

J1039

5.13 Collimator movements

ORTHOPANTOMOGRAPH™ OP 3D 51

Page 52

5 Diagrams

5.14 Positioning lights

i4000

J4018

J4009

J4010

J4003

LASER LIFT

J1022

J1008

J1009

J1003

J1010

3D FOV

HEIGHT

POSTERIOR

ANTERIOR

SHARP

LAYER

MID

SAGITTAL

LASER HOME

M

2ph Step

CAN BUS

FROM

i3000

5.15 Imaging chain 3D

1

2

4

3

1

2

3D X-ray

sensor

J601

3

4

7

8

J101

i2000

J0301

J2015

J3007

IMG.MEM

i3000

J2013

J2013

J3006

Status

J1002

Back

panel

J2013- 3:GND (trigger)

- 4: Ext.trigger

- 7: +12Vdc

- 8: GND (PWR)

H10

+12V OK

IMG.DATA

LVDS

LAN

LAN

52 ORTHOPANTOMOGRAPH™ OP 3D

Page 53

5 Diagrams

5.16 Exposure control 1

i4000

THA PAN

i7000

THA CEPH

i7000

1

J4019 J7000

J7002

J1004

J1005

J4016

J7000

J4005

J4004

J7002

2

3

4

5

8

12

9

1

2

3

4

5

7

11

8

1

2

1

2

1

2

3

4

5

7

11

8

1

2

1

2

3

4

5

7

11

8

1

2

1

2

3

4

5

7

11

8

1

2

5.17 Exposure control 2

i4100

i4000

2

P5V

P3V3

J4103

J4014

J4102

J4102

Door switch

1

2

1

2

1

8

7

Remote exposure

button

Remote exposure

button

Exposure button

J4101

2

1

6

3

8

7

2

1

6

3

8

7

J4013

ORTHOPANTOMOGRAPH™ OP 3D 53

Page 54

5 Diagrams

5.18 Exposure warning light

3

5 6

5

6

Remote controller

Exposure

warning

J4104/

J4102

1

J4105

External

warning

lamp

i4100

i4000

J4101

J4013

J4007

J6001

i6000

Exposure

warning

Error

Ready

J8000

i8000

Exposure

warning

Error

Ready

J4022

7

8

12

13

3

7

8

12

13

1

2

8

9

6

10

1

2

8

9

6

10

1

2

3

4

5

6

1

2

3

4

5

6

2

F3

5.19 Device control panel

i6000

J6001

i4000

J4007

J4009

CAN

BUS

FROM

i3000

Positioning

panel

54 ORTHOPANTOMOGRAPH™ OP 3D

Page 55

5 Diagrams

5.20 Chin rest detection

1

HAL-C

HAL-B

HAL-A

J4009

i4000

CAN

BUS

FROM

i3000

J9001

i9000

4

3

7

6

10

2

1

3

4

5

6

ORTHOPANTOMOGRAPH™ OP 3D 55

Page 56

6 Maintenance

6 Maintenance

The maintenance and calibration procedure intervals described here are minimum

requirements and can be made more frequent and stringent to comply with local

regulations regarding the use and maintenance of dental X-ray devices.

6.1 Annual maintenance

Annual maintenance procedures must be performed annually to ensure that the

performance and functionality of the device remains consistent. Annual maintenance

consists of visual inspections, functional tests and calibrations.

Carry out the following inspections during the annual maintenance:

• Check that all fixing screws are tight.

• Check that all covers and mechanical parts are correctly secured and have not come

loose.

• Check that the protective earth is connected.

• Check that no oil is leaking from the tube head.

Perform the following maintenance procedures:

• Confirm the cleanliness of the device. See chapter Cleanliness of the device.

• Check the condition of external cables. See chapter Condition of the cables.

• Check device movements and common device functionality. See chapter Device

movements and functionality.

• Check that the exposure warning indicators work correctly. See chapter Exposure

indicator functionality.

• Perform all calibrations and QC programs described in the User and Installation

Manual.

NOTICE! Compare the QC program results to the previous reference images

and if no noticeable image quality degradation is apparent, save the images as

new reference images and inform the user of their location.

6.1.1 Cleanliness of the device

The device has to be cleaned regularly as instructed in the User and Installation Manual.

NOTICE! Switch the device off before cleaning it.

Use a soft cloth dampened with a mild detergent to clean the:

• Device covers and outer surfaces in general

• Patient positioning mirror

• Positioning panel

Check, that any vents in the covers are not blocked with dust and that no dust has

accumulated inside the device. Clean the vents and remove the covers to remove the

dust inside the device if necessary.

6.1.2 Condition of the cables

1. Visually check that the power supply cord is in good condition and not damaged in

any way.

2. Visually check that the exposure button cable is in good condition and not damaged

in any way.

56 ORTHOPANTOMOGRAPH™ OP 3D

Page 57

6 Maintenance

3. Visually check that the Ethernet cable is in good condition and not damaged in any

way.

4. Visually check that the Remote exposure switch cable, Remote warning light cable

and door switch cable, if installed, are in good condition and not damaged in any

way.

5. Check that all of the cable connectors are properly attached and are routed through

the strain relief.

6. Replace the damaged cables if necessary.

6.1.3 Device movements and functionality

1. Power the device on from the power switch.

2. Power the workstation on and launch the imaging software to access the device GUI.

3. Select 3D modality and the largest FOV size available.

4. Set the device into Test mode.

5. Press and hold the exposure switch down.

6. Check the smoothness of the rotation and pivot movements. Monitor the device

operation and observe for any excessive noises or evident vibrations of the device

during its rotation and pivot movements. Also make sure that the rotation and pivot

movements are continuous until the end of exposure.

NOTICE! If the exposure switch is released, the device movements should

stop.

7. Press the HOME button to drive the device back to Home position.

8. Monitor the device operation and observe for any excessive noises or evident

vibrations of the device during its rotation movement.

9. Drive the device Up/Down using the positioning panel.

10. Monitor the device during up and down movement and observe for any excessive

noises or non-smoothness of the movement.

NOTICE! Check that the upward movement stops at the set Z-movement

limit.

ORTHOPANTOMOGRAPH™ OP 3D 57

Page 58

6 Maintenance

11. Select Pan and 3D imaging modalities from the device GUI and press the Patient

positioning lights button. Check that the correct lights are lit according to the

selected modality. For more information on the positioning lights, see the User and

Installation Manual.

12. Press the emergency stop switch.

13. Check that the device GUI indicates that the emergency stop switch has been

pressed.

NOTICE! The device restarts after the emergency stop has been pressed.

14. Make sure that the device cannot be driven up/down, rotated by pressing the HOME

button and that an exposure cannot be taken while the emergency stop switch is

activated.

15. Release the emergency stop switch by rotating it clockwise.

16. Check that the GUI indication disappears and that the movements work normally

again.

17. Switch the device off from the power switch.

18. Check that the device and all of its parts are isolated from mains and all device

functions are disabled.

6.1.4 Exposure indicator functionality

NOTICE! This check can be also done while performing the QC programs.

1. Power the device on.

2. Power the workstation on and launch the imaging software to access the device GUI.

3. Open or create a patient on the imaging software for the annual maintenance.

4. Prepare the device for Panoramic imaging and disable the Test mode.

NOTICE! Select the lowest imaging parameters available.

5. Protect yourself from radiation.

6. Press and hold the exposure button down.

58 ORTHOPANTOMOGRAPH™ OP 3D

Page 59

6 Maintenance

7. When the exposure starts, check that all exposure warning indicators are working:

• Exposure warning indicator on the GUI

• Yellow exposure indicator light on the Positioning panel

• Yellow exposure indicator light on the Status indicator light on top of the carriage.

• Audible exposure warning signal

• Remote exposure switch (if in use)

• Warning light (if in use)

8. When the exposure ends, check that the indicator lights go out, exposure warning

signal stops and a program end tone is played.

9. Check that the taken image transfers to the imaging workstation.

6.1.5 Changing the fuses

Main fuses are located at the rear of the carriage, under the back panel cover. To reach

the fuses, remove the cover first.

NOTICE! See chapter Fuses for details on the correct fuses.

To release a fuse cap, push it inwards and rotate counterclockwise with a flat head

screwdriver.

Remove the fuse from the socket and replace it with a new one. Install the fuse by

pushing the fuse cap in and rotating it clockwise with a screwdriver.

The 10A and 15A fuses are physically of different sizes and have their own fuse caps. If

you need to change the fuse rating, also the fuse cap needs to be changed. The fuses

are supplied with the corresponding fuse caps.

6.1.6 Monitor calibration

It is recommended to calibrate or check a test image with the primarily used workstation

monitor. Refer to the monitor/software manuals for information on how to do this.

ORTHOPANTOMOGRAPH™ OP 3D 59

Page 60

6 Maintenance

If you are using the Display Calibration Kit purchaceable from PaloDEx Group Oy, refer to

the Display Calibration Kit Instructions.

6.2 Calibrations

6.2.1 When to calibrate the device

The device must be calibrated and, if necessary, adjusted at regular intervals in

accordance with the national regulations regarding the use, maintenance and service of

dental X-ray devices.

The device must be re-calibrated completely at least once a year, by a service

technician according to ORTHOPANTOMOGRAPH™ OP 3D User and Installation manual.

The last calibration date for each program is listed in the calibration menu.

The device must be calibrated after the first installation or when parts are replaced:

QC images have to be taken always after calibration.

NOTICE! Refer to the OP 3D User and installation manual for the complete

calibration instructions.

60 ORTHOPANTOMOGRAPH™ OP 3D

Page 61

6 Maintenance

Table 4: Calibration matrix

i2000i3000 i4000 i3000

SD

card

CollimatorTube

head3DPanel

Pivot

and

linear

sensors

Lasers Any

part

in the

imaging

chain

Device

Movement

Calibration

X X X X

ZMovement

Limits

X X

X-ray

generator

Calibration

X X

3D Pixel

Calibration

X X X X

Device

Geometry

Calibration

X X X X

Collimator

Calibration

X X X X

PAN Pixel

Calibration

X X X X

3D

Geometry

Calibration,

5x5 FOV

X X X X

3D

Geometry

Calibration,

6x11 and

9x11 FOV

X X X X

3D

Geometry

Calibration,

9x14 FOV

X X X X

Pan QC X X X X X X X X X

3D QC X X X X X X X X X

Lasers

alignment

X

ORTHOPANTOMOGRAPH™ OP 3D 61

Page 62

7 Troubleshooting

7 Troubleshooting

Problem Possible cause Solution

Taken image is not

transferred to the modality

workstation.

Local network connection

is disrupted, which causes

loss of data.

The device stores the latest

image until a confirmation

of a succesfull transfer to

the workstation has been

received. Re-establish the

local network connection

and the image data is

transferred automatically.

Do not power the device off

or the image will be erased.

Device cannot be driven

upwards or downwards.

1. Up/down slider is on

safe mode.

2. Mechanical safety

device on the driving

motor has activated.

3. Positioning panel not

working.

1. Clean the positioning

panel and wait for the

safe mode to clear out.

2. Contact service.

No connection to the device.

1. The device is not

powered on.

2. Problem with the local

area network (LAN).

3. Check the device

configuration.

1. Power the device on.

2. Check the Ethernet

cable connections on

the workstation and the

device.

3. Restart the device and

the workstation.