Page 1

Operating instructions

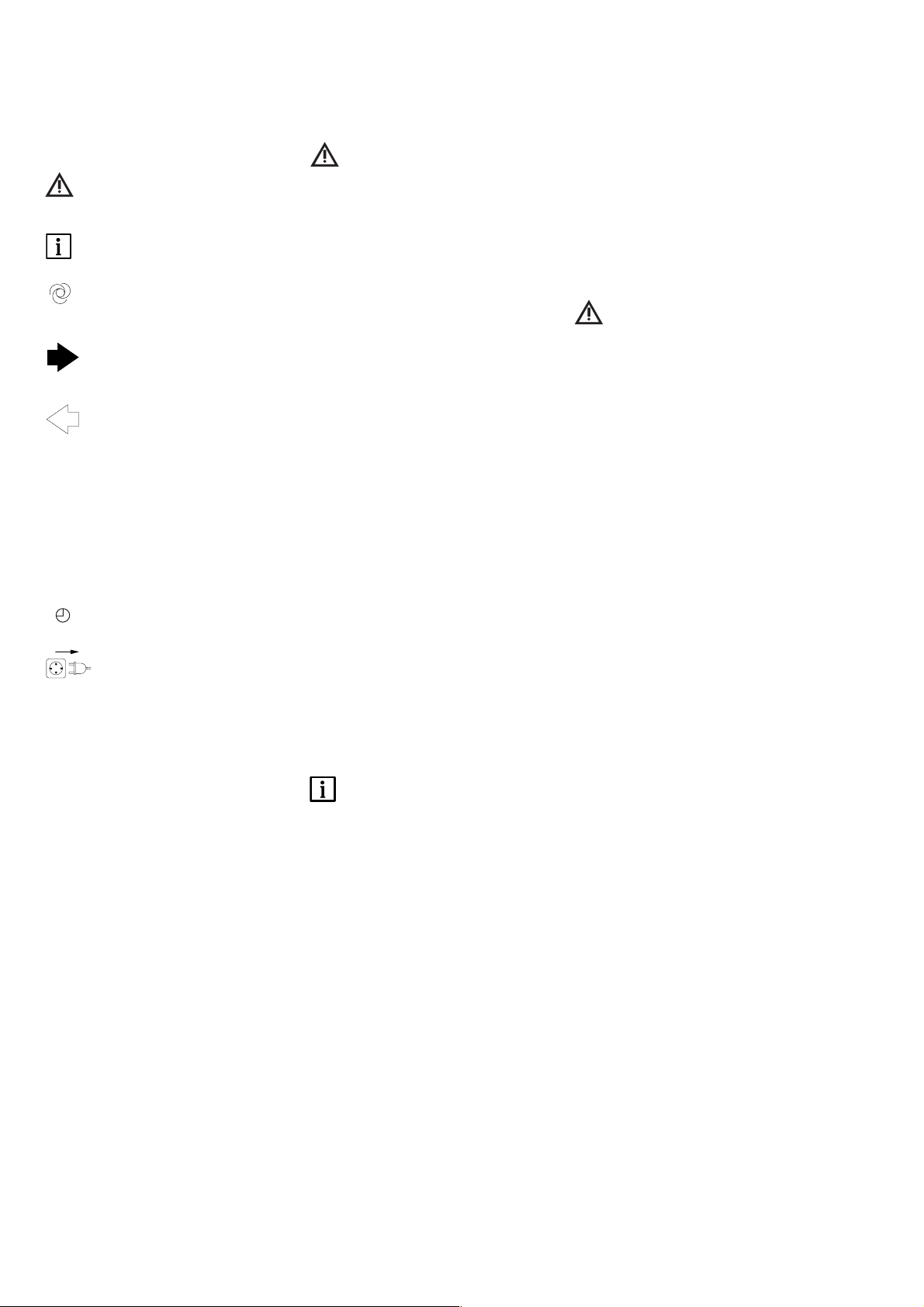

K- Control 4960, 4965, 4970.

Always on the safe side.

Page 2

Hersteller/manufacturer:

Kaltenbach & Voigt GmbH

Bismarckring 39

D-88400 Biberach

Vertrieb/distribution:

KaVo Dental GmbH

Bismarckring 39 D-88400 Biberach

Tel.: 0 73 51 / 56-0 • Fax: 0 73 51 / 56 -14 88

Page 3

A 1 User information ..............................................................................................................................................................2

A 1.1 Meaning of the pictograms ......................................................................................................................................2

A 1.2 Important information ..............................................................................................................................................2

A 1.3 Precautions ..............................................................................................................................................................2

A 1.4 Purpose and potential uses ......................................................................................................................................3

A 1.5 Technical data ..........................................................................................................................................................3

A 1.6 Combination Controller - handpiece ........................................................................................................................4

A 2 Scope of delivery/Accessories ......................................................................................................................................5

A 3 Electrical connection ......................................................................................................................................................5

A 4 Location ............................................................................................................................................................................6

A 5 Mounting and connection ..............................................................................................................................................7

A 5.1 Mounting 4960 ..........................................................................................................................................................7

A 5.2 Mounting 4965 / 4970 ..............................................................................................................................................8

A 5.3 Connection ..............................................................................................................................................................8

A 6 Controls and functional elements ..................................................................................................................................9

A 7 Preparations for commencing operation ....................................................................................................................10

A 8 Operation ........................................................................................................................................................................11

A 8.1 Starting K-Control knee control unit 4960 .............................................................................................................. 11

A 8.2 Starting K-Control Benchtop Control unit 4965. ....................................................................................................11

A 8.3 Starting a K-Control installation with the type 4970 Foot control unit. ..................................................................11

A 9 Operating faults ............................................................................................................................................................12

Guarantee conditions ......................................................................................................................................................14

Spare parts ......................................................................................................................................................................15

EC- Declaration of conformity ..........................................................................................................................................18

Drilling template ................................................................................................................................................................20

K- Control 4960, 4965, 4970.

1

Page 4

K- Control 4960, 4965, 4970.

2

A 1.2 Important information

The instructions for use should be

read by the user before starting up the

unit for the first time, in order to avoid

incorrect operation and other damage. If

other language versions are required, please

request these from your responsible KaVo

agent. Duplication and distribution of the

instructions for use (IU) require KaVo's

prior consent.

All technical data, information and properties of the product described in the IU correspond to the state on going to press.

Modifications and improvements to the

product as a result of new technical developments are possible.

This does not imply any right to retrofitting

of existing units.

KaVo assumes no responsibility for damage

arising through:

• external influences (poor quality of the

media or inadequate installation)

• use of incorrect information

• improper use

• improperly performed repairs.

Repair and maintenance work - apart from

the activities described in these instructions

for use - may be performed only by qualified technical personnel.

In the event of modifications by third parties, the approvals become null and void.

KaVo recommends using only original

spare parts for operation and for repair.

Please note that the EC Directive on

waste electrical and electronic equipment applies to this product. Within Europe

therefore, this product must undergo special

disposal. For more detailed information

about this, please contact KaVo or your

specialist dental supplier.

A 1.3 Precautions

Safe operation and protection of the unit are

ensured only through proper use in accordance with the instructions for use and

using the tools approved for the purpose.

The following should also be observed:

• the work safety regulations,

• the accident prevention regulations.

!

Each time before switching on, check the

set speed.

! Observe the permissible maximum

speed and maximum pressure of the tools

(according to tool manufacturer's

instructions).

A 1.4 Purpose and potential uses

K-Control-installation is versatile and very

suitable for working on crowns and bridges.

A 1.5 Technical data

Dimensions and weight

K-Control Knee-Operated Control Unit

type 4960

Width: 95 mm

Depth: 280 mm

Height: 235 mm

Weight: approx.3 kg

K-Control Benchtop Control Unit

type 4965

Width: 95 mm

Depth: 280 mm

Height: 235 mm

Weight: approx. 3 kg

K-Control Foot Control Unit

type 4960

Width: 245 mm

Depth: 275 mm

Height: 125 mm

Weight: approx.3 kg

Rated voltage

Line voltage fluctuations < ± 10 %

Voltage range: 100 / 120 / 230 V

50 / 60 Hz

Rated power

K-Control units max.220 W

A 1 User information

A 1.1 Meaning of the pictograms

Situations where failure to follow the

instructions may lead to danger,

damage to material or operating faults.

Important information for operator

and engineer.

Automatic mode

Automatic sequence

Close, screw in,

fasten, etc.

Open, release, loosen

+ more, higher

- less, lower

∞ Continuous operation

Time, time sequence

Disconnect mains plug

I Device ON, turned on

O Device OFF, unplug from the power

supply

Page 5

K- Control 4960, 4965, 4970.

3

Speed range

Right-handed rotation:

1 000 - 35 000 min

-1

(K 5 Handpiece)

1 000 - 25 000 min

-1

(K 9 Handpiece)

1 000 - 40 000 min

-1

(K11 Handpiece)

1 000 - 40 000 min

-1

(K10 Handpiece)

1 000 - 50 000 min

-1

(K12 Handpiece)

5 000 - 60 000 min

-1

(SF-Handpiece)

1000 - 50 000 min

-1

(K-POWERgrip)

1000 - 50 000 min

-1

(K-ERGOgrip)

Left-handed rotation, limited to about 5,000

min

-1

Intermittent service 2 min / on

8 min / off

Pollution level 2

Overvoltage category ll

Amblent conditions:

Max. elevation 2000 m above sea level

• Permissible in inner rooms

• Permissible ambient temperature range

5 C - 40 C

• Permissible up to a max. relative humidity

of 80%

We reserve the right to make any alterations.

Transportation and storage conditions

Temperature range: -20 °C to +70°C

Relative humidity: 5% to 95% (noncondensing)

Air pressure: 700 hPa to 1060 hPa

Prior to start-up, very cold products

must be heated to a temperature of

20 ° to 25 °C. Avoid condensation.

Rating plate

Provides information on:

@ Manufacturer

2 Order number (REF number)

3 GS-Mark

4 For information about proper disposal,

see A1.2

5 CSA-Mark

6 Year of manufacture - Serial number

7 CE-Mark according to 89/336 EWG

8 VDE-Mark

9 Mode:

intermittent service: 2 min, 8 min pause

0 Unit type

@

4

2

6

0

5

7

8

3

9

x

a

m

l

o

r

t

n

o

c

K

l

ro

t

n

o

K

l

o

tr

n

co

0

3

x

a

m

n

n

i

m

/

0

0

0

1

x

c

0

3

x

a

m

n

n

i

m

/

0

0

0

1

x

0

3

/m

0

0

0

n

i

4620

4960

4965

4970

Page 6

K- Control 4960, 4965, 4970.

4

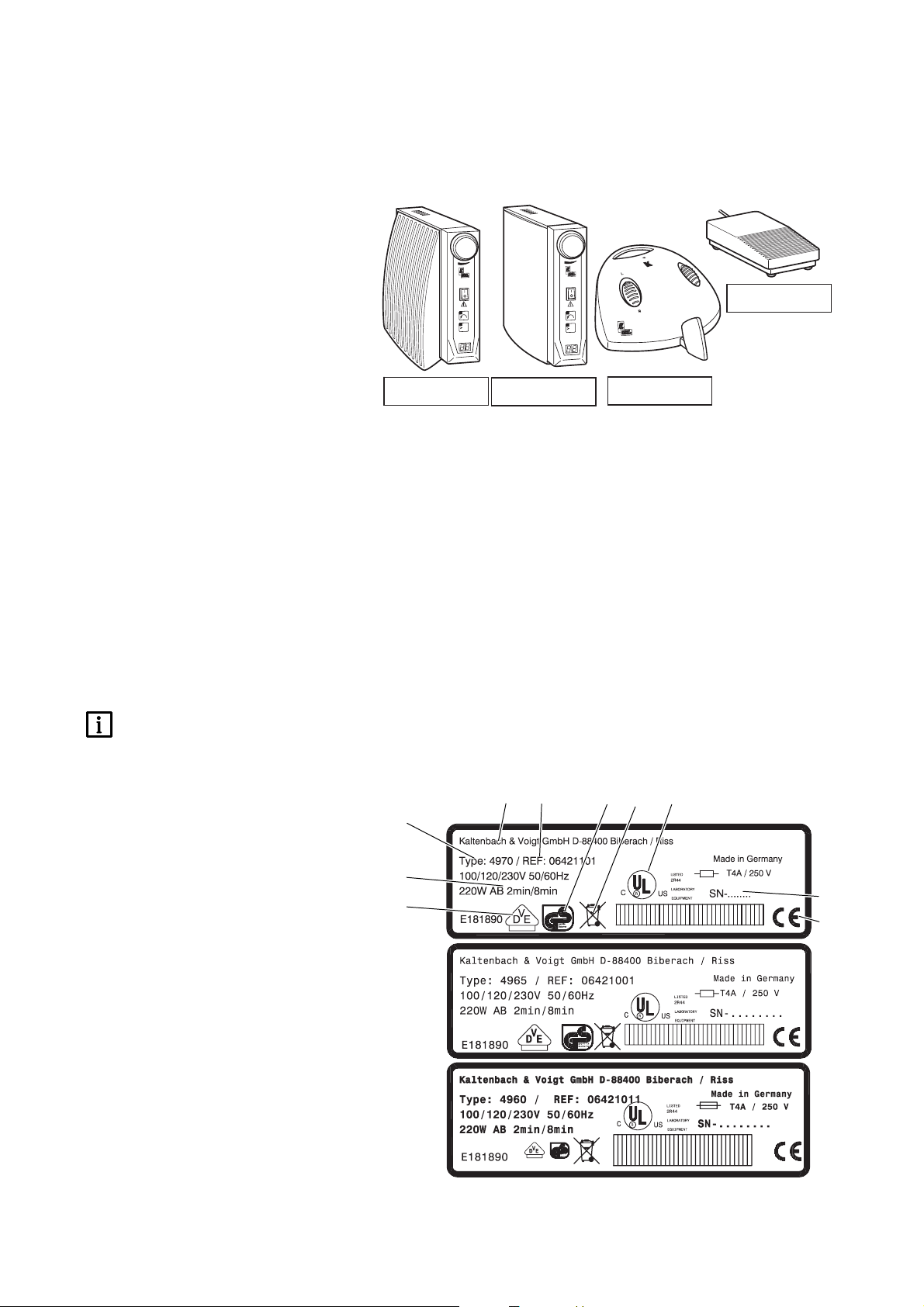

A 1.6 Combination Controller - handpiece

In the combination with K-Control control

units of types 4960, 4965 and 4970, the

following handpieces can be operated:

K 5 Handpiece 4910

K 9 Handpiece 950/955

K 9 Handpiece 4930

K 9 Compact motor 970

K 9 Cutter spindle 960

K 10 Handpiece 4950

(with Adapter 0.674.4721)

K 11 Handpiece 4990

K 12 Handpiece 4940

SF Handpiece 4005

(with supply cable 0.674.4921)

K-POWERgrip 4941

K-ERGOgrip 4944

The safty of the K-Control control

units with handpieces can be

guaranteed only with the handpiece/control

unit combinations approved by KaVo.

4960

4965

K

l

o

tr

n

o

K

l

o

r

t

n

o

c

0

3

x

a

m

n

n

i

m

/

0

0

0

1

x

max

l

o

r

t

n

o

c

in

/m

0

0

0

0

3

c

0

3

x

ma

n

x1000/min

4970

-POWERgrip K12 K5 K11 K9 SF K-ERGOgrip

Page 7

K- Control 4960, 4965, 4970.

5

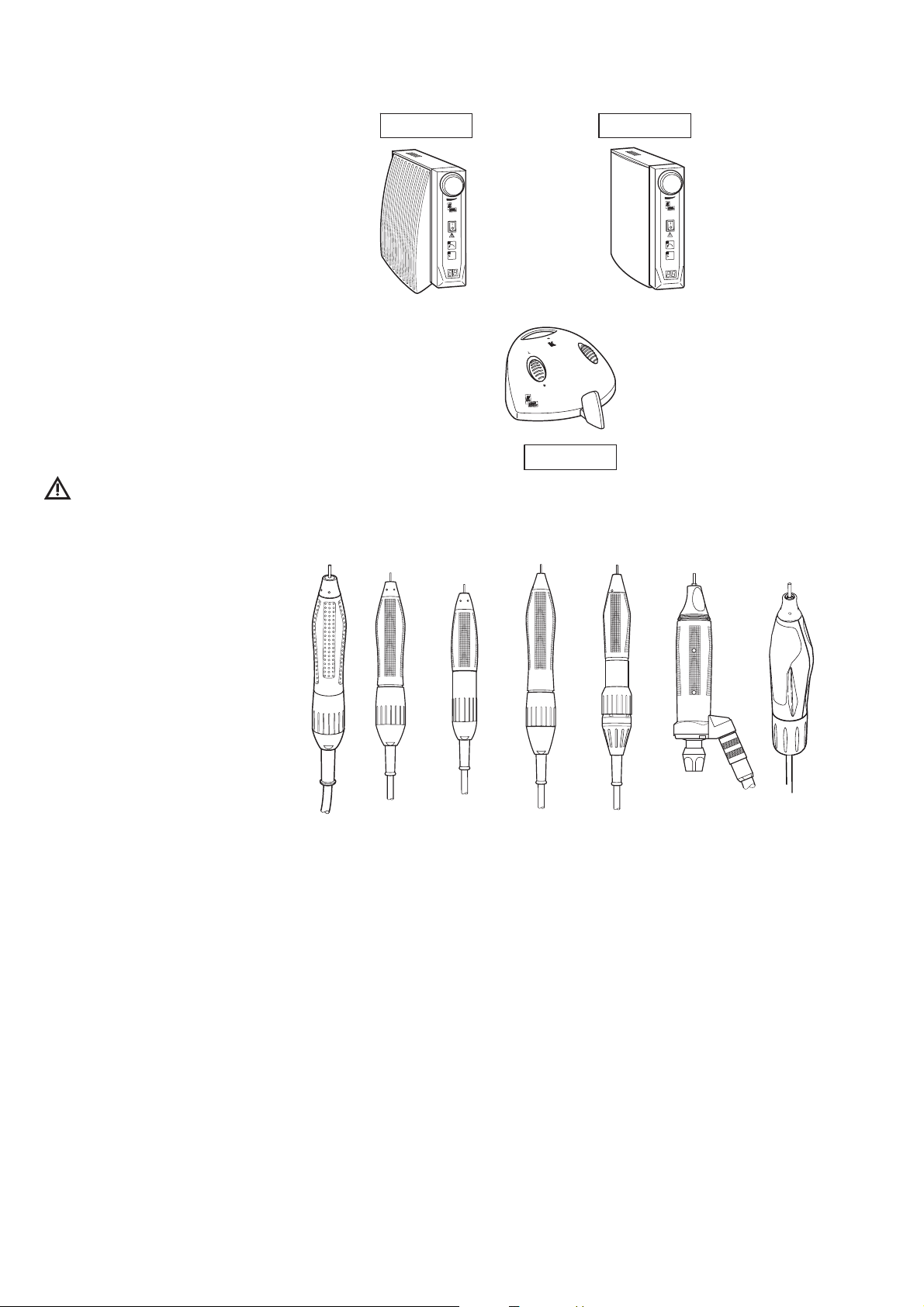

A 2 Scope of delivery/Accessories

K-Control Knee-operated control unit 4960

or

K-Control Benchtop, control unit 4965

optional

Foot switch 4620

Mat.-No. 0.223.2085

or

K-Control Foot control unit 4970

A 3 Electrical connection

Electrical connection

Check that the local mains voltage and

mains frequency conincide with the specifications on the rating plate and the fuse

holder @. Adapt if required.

Voltage adaptation to 100 V/120 V or

230 V.

By removing the fuse holder @, the sleeve

2 with contacts (including fuses) can be

removed. The adaptation is achieved by

appropriately rotating the sleeve ” until

the required voltage, 100 V/120 V or 230 V,

appears in the inspection window of fuse

holder @.

Connected load.

Nominal power max. 220 W.

Disconnection:

Use mains plug as disconnection.

@

2

3

0

1

2

0

1

0

0

4960

0

3

n

m

a

x

x

1

0

0

0

/

m

i

n

K

c

o

n

t

r

o

l

4965

4620

0

3

n

m

a

x

x10

0

0

/

m

i

n

K

co

n

tro

l

4970

c

o

n

t

r

o

l

3

0

0

0

0

/

m

i

n

m

a

x

”

@

Page 8

6

K- Control 4960, 4965, 4970.

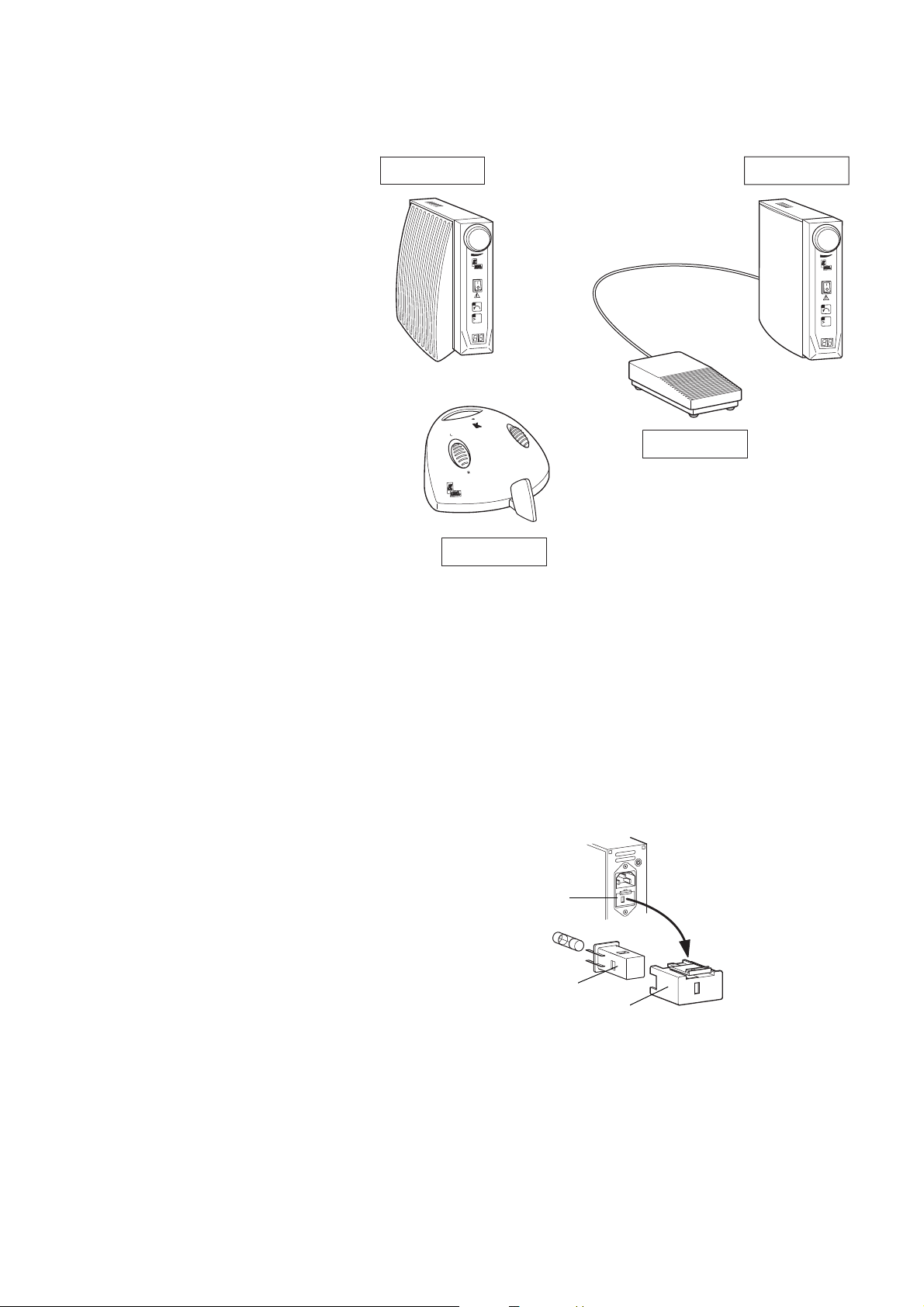

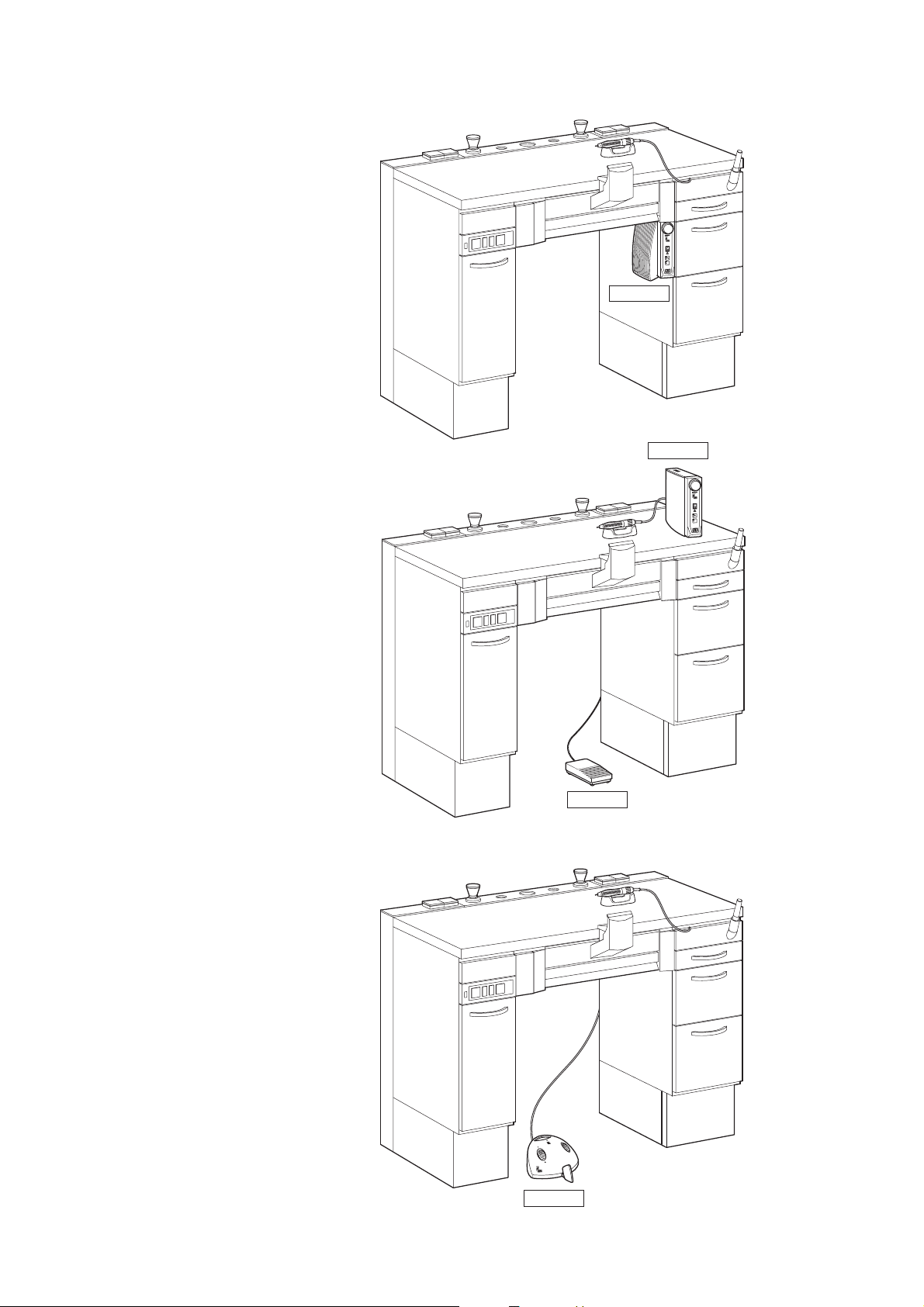

A 4 Location

The K-Control Knee control unit, type

4960, is made to be attached to the side of

a storage cabinet (A 5.1).

The K-Control Benchtop control unit, type

4965, is made to be set on a workbench

and connected underbench with Foot

switch type 4620 (A 5.2).

The K-Control Foot control unit, type

4970, can be set unsecured on the floor (A

5.2).

4960

0

3

n

m

a

x

x

1

0

0

0

/

m

i

n

K

c

o

n

t

r

o

l

4965

0

3

n

m

a

x

x

1

0

0

0

/

m

i

n

K

c

o

n

t

r

o

l

4620

4970

c

o

n

t

r

o

l

3

0

0

0

0

/

m

i

n

m

a

x

Page 9

7

K- Control 4960, 4965, 4970.

A 5 Mounting and connection

A 5.1 Mounting 4960

The K-Control Knee control unit, type

4960, is made to be fastened to the side of

a storage cabinet on a suspenslon

rail 1 (drilling template see page 20).

Fix in place at the front with screws

and insert mains plug into a grounded mains socket which is easy to reach.

(Similarly if using an extension line)

Demounting

page 20

12mm

Ø2,3

Ø3,5

l

tro

n

o

c

K

1

0

3

x

a

m

n

n

i

m

/

0

0

0

1

x

l

tro

n

o

c

K

0

3

x

a

m

n

n

i

m

/

0

0

0

1

x

Page 10

K- Control 4960, 4965, 4970.

8

A 5.2 Mounting 4965 / 4970

Set K-Control Benchtop control unit, type

4965 on a workbench

Set K-Control Foot control unit, type 4970,

on the floor under a workbench.

Fix in place at the front with screw

and insert mains plug into a

grounded mains socket which is easy to

reach. (Similarly if using an extension line)

A 5.3 Connection

Plug in Handpiece and foot switch and

screw finger tight.

Plug in Handpiece and screw finger tight.

control

4965

K

l

tro

n

o

c

0

3

x

a

m

n

n

i

m

/

0

0

0

1

x

x

a

m

n

i

m

/

0

0

0

0

3

4970

4965

4960

4970

Page 11

K- Control 4960, 4965, 4970.

9

A 6 Controls and functional elements

1 Digital speed and malfunction indicator

2 Speed limitation preselector

3 Direction switch (counterclockwise

running limited to max. 5000 min-1)

4 Mains switch "0"/"1"

5 Knee switch

6 Speed preselector (continuous)

7 Suspension rail

8 Fuse holder with voltage adjustment

9 Motor sockets (4-pole)

¯ Starter socket (5-pole)

(Foot switch)

» Foot switch Type 4620

w Foot lever

‰ Control cable jack (connection to the

dust extractor)

0

3

n

m

ax

x

10

0

0

/

m

i

n

K

co

n

tro

l

0

3

n

m

ax

x1

0

0

0

/

m

i

n

K

c

o

n

tro

l

c

o

n

t

r

o

l

3

0

0

0

0

/

m

i

n

m

a

x

#

»

„

@

”

#

£

fi

Ì

\

|

·

¯

@

”

#

£

Ì

@

”

|

·

‰

Page 12

10

A 7 Preparations for commencing

operation

On K-Control control units 4960 and 4965,

push mains switch £ to the "0" OFF position.

Switch the K-Control Foot control unit,

type 4970, to "0" OFF by letting back the

foot lever. Set sliding switch 2 or button

2 for speed limitation to “max. 30,000

min

-1

“.

Set direction switch # to “clockwise“

(yellow LED does not light up) or “R“.

For “counterclockwise“, the handpiece

speed is limited to about 5000 min

-1

.

Do not operate or lay down your

Motorhandpiece, unless an instrument or the test pin is clamped in the

chuck. When the chuck is open, Handpiece

is locked, and inadvertent use will cause

the K-Control control unit to switch to

malfunction. Malfunction indicator

1

lights up or begins to flash.

K- Control 4960, 4965, 4970.

0

3

n

m

a

x

x1

0

0

0

/

m

i

n

K

c

o

n

tro

l

0

3

n

m

a

x

x

1

0

0

0

/m

i

n

K

c

o

n

tr

o

l

c

o

n

t

r

o

l

3

0

0

0

0

/

m

i

n

m

a

x

#

@

”

@

”

#

£

£

#

”

@

Page 13

11

K- Control 4960, 4965, 4970.

A 8 Operation

Check set speed each time before

switching on.

Regulations for prevention of accidents are

to be observed!

When preselecting a speed over 30,000 min

-1

,

button

2

should be pressed (yellow LED

lights up). This additional “enabling“

serves for consciously registering the high

speed and the resultant possible danger

when using tools which may be unsuitable.

A 8.1 Starting K-Control knee control unit 4960

Preselect desired maximum speed on speed

limiter 2.

When the knee switch plate is pressed in

the direction of the arrow the speed can be

continuously regulated from 1000 min

-1

to

the preselected maximum speed.

A 8.2 Starting K-Control Benchtop

Control unit 4965.

Preselect desired maximum speed on speed

limiter 2.

Start your Handpiece at the preselected

speed by depressing Foot switch 4620 q.

A 8.3 Starting a K-Control installation with the type 4970 Foot control

unit.

By pressing the foot control lever in the

direction of the arrow, the speed of the

Handpiece can be regulated (enabled by

sliding switch 2).

Allowing the foot lever | to return under

spring pressure all the way back, stops the

Handpiece.

»

Ì

”

”

”

|

4960

K

l

o

r

nt

o

c

0

3

x

a

m

n

n

i

m

/

0

0

0

1

x

K

l

o

r

t

on

c

0

3

x

a

m

n

n

i

/m

0

0

0

1

x

4620

4965

K

l

o

r

t

n

o

c

0

3

x

a

m

n

n

i

m

/

0

0

0

1

x

K

trol

con

0

3

x

a

m

n

n

i

m

/

x1000

4970

ax

m

l

o

r

t

n

o

c

n

i

30000/m

x

a

m

l

o

r

t

n

o

c

n

i

m

/

0

0

0

0

3

Page 14

12

K- Control 4960, 4965, 4970.

A 9 Operating faults

Repairs and servicing work on the

electrical part of this equipment must

only be undertaken by experts or by persons trained in our factory who are aware

of the safety regulations. Disconnect the

mains plug from the power supply, resp.

switch off the disconnecting switch before

carrying out any maintenance work.

In K-Control knee and table-top con-

trol units, error messages are shown

visually on the display

1

. In the KControl foot control unit, error messages

are indicated by flashing of the malfunction

LED

2

(e.g. error message No. 7 = 7 x

flashes, etc.).

C • Main processor not running

R • Repair or replace motor electronics

C • Overloading of motor, motor current

above 4 A for 7 sec

R • Reduce motor load or stop and re-start

with foot switch.

C • Handpiece blocked for more than 3

seconds

R • Eliminate blocking, stop and restart

C • No handpiece connected (also open

circuit K9, K10)

R • Connect handpiece and restart

C • No handpiece connected (also open

circuit K5, K11, K12, SF)

R • Connect handpiece and restart

C • Handpiece speed too high for longer

than 2 seconds, a phase of the

handpichas been interrupted or

electronics are faulty.

R • Repair handpiece or control unit

F = Fault C = Cause R = Rectificatio

F • Error display: F 6

F • Error display: F 4

F • Error display: F 3

F • Error display: F 2

F • Error display: F 1

F • Error display: F 0

4620

4965

0

3

n

m

ax

x

10

0

0

/

m

i

n

K

co

n

t

r

o

l

0

3

n

m

a

x

x

1

0

0

0

/m

i

n

K

c

o

n

tr

o

l

4960

c

o

n

t

r

o

l

3

0

0

0

0

/

m

i

n

m

a

x

4970

K12 K5 K11 K9 SF

@

@

”

Page 15

K- Control 4960, 4965, 4970.

13

C • Open circuit in speed potentiometer

R • Replace speed potentiometer with

cable

C • Magnets (Knee switch, Foot lever)

inserted twisted

R • Insert magnets correct

C • Fault in hall-effect element

R • For 3 seconds after switching the device

on, a self -diagnosis program is automatically activated.

R • Repair control unit

C • Short-circuit in D.C. chopper transistor

R • Remedy: Repair control unit

C • Measuring device for motor voltage is

faulty

R • Repair control unit

C • Cooling attachment too hot (>90°)

R • Repair control unit

C • Temperature sensor on cooling

R • Repair control unit (short-circuit)

C • Data loss in EEPROM

R • Repair or recalibration of the

control unit

F = Fault C = Cause R = Rectification

F• Error display: F 19

F• Error display: F 18

F • Error display: F 17

F • Error display: F 14

F • Error display: F 13

F • Error display: F 11

F • Error display: F 10

F • Error display: F 9

4620

4965

0

3

n

m

ax

x

10

0

0

/

m

i

n

K

co

n

t

r

ol

0

3

n

m

a

x

x

1

0

0

0

/

m

i

n

K

co

n

t

r

o

l

4960

c

o

n

t

r

o

l

3

0

0

0

0

/

m

i

n

m

ax

4970

K12 K5 K11 K9 SF

Page 16

K- Control 4960, 4965, 4970.

14

Guarantee provisions

For the product cited in the transfer protocol, KaVo warrantees the end customer that the product will function properly, have no material

or manufacturing flaws for 12 months from the date of purchase under the following conditions:

In the case of valid complaints due to defects or a short delivery, KaVo will make good its warranty by replacing the product free of cost or

repairing it according to your wishes. All other claims of any kind are excluded, especially claims for damages.

In case of delayed performance, gross negligence or criminal intent, this shall apply only if there are no compelling legal regulations to the

contrary. KaVo is not liable for defects and their consequences that arise from natural wear, improper cleaning or servicing, the nonobservance of instructions for use, servicing or connection, scale formation or corrosion, impurities in the air and water supply,

or chemical or electrical influences that are unusual or impermissible according to the manufacturer's specifications.

The warranty does not generally extend to lamps, glassware, rubber parts and the colour fastness of plastic parts.

No liability is assumed when defects or their consequences can arise from manipulations or changes to the product by the customer or a

third party.

Claims from this warranty can only be asserted when the transfer protocol (copy) belonging to the product has been sent to KaVo, and the

original can be presented by the operator or user.

Page 17

15

K- Control 4960, 4965, 4970.

4960

2

3

0

1

2

0

1

0

0

0

3

n

m

a

x

x

1

0

0

0

/

m

i

n

K

c

o

n

t

r

o

l

0.642.0561

0.642.0252

0.221.9116

0.642.0272

0.245.5015

0.200.6529

0.200.6528

0.260.9677

0.642.0282

0.692.9051

0.223.2735

0.642.0661

0.692.9031

0.692.9041

0.692.9021

0.696.0221

AT 1.002.6852

0.642.0561

0.696.0311

0.201.7065

0.221.4909

0.242.4012

0.260.8505

0.224.2498

0.223.4142 DE

0.692.6881 CH

0.692.6891 USA/JP

0.692.6901 GB

0.692.6851 AUS

0.223.0050

0.223.2801

F 6,3A 250V

Page 18

16

K- Control 4960, 4965, 4970.

4965

0.245.5015

0.223.0050

0.223.2735

0.642.0561

0.642.0661

0.200.6529

0.200.6528

0.642.0272

0.617.0511

0.692.9051

0.617.0460 1,8 m

0.617.0410 1,0 m

0.224.7001

F 6,3A 250V

0.223.2801

0.223.2085

0.223.2111

0.692.9021

0.220.0423

0.696.0221

AT 1.002.6852

0.642.0561

0.223.4142 DE

0.692.6881 CH

0.692.6891 USA/JP

0.692.6901 GB

0.692.6851 AUS

0.692.9031

0.692.9041

0.221.4909

0.224.2498

0.696.0311

0.242.4012

0.260.8505

0.201.7065

Page 19

17

K- Control 4960, 4965, 4970.

4970

0.642.0572

0.642.0572

0.221.9110

n

i

m

/

0

0

0

0

3

0.642.0582

0.642.0641

0.642.0582

0.223.2059

F 6,3A 250V

0.223.2801

0.221.4909

0.220.0443

0.223.0050

0.251.4545

0.641.7642

0.223.2735 T 4.0A

0.642.0661

0.696.0221

AT 1.002.6852

0.223.4101 DE

0.223.4110 CH

0.223.4127 USA/JP

0.691.8101 GB

0.691.8091 AUS

0.201.7127

0.258.6010

0.221.9116

4x 0.260.9654

0.642.0562

Page 20

18

K- Control 4960, 4965, 4970.

Page 21

19

K- Control 4960, 4965, 4970.

Page 22

20

K- Control 4960, 4965, 4970.

156,5 mm

53 mm MASTERspace

51mm FLEXspace

Ø2,3 mmØ2,3 mm

90 mm MASTERspace

93 mm FLEXspace

Drilling template

Page 23

Page 24

1.000.4575

"

Fk

"

11/07

"

en

"

01.26

KaVo Dental GmbH. D-88400 Biberach/Riss

Telefon +49 7351 56-0 Fax +49 7351 56-1488

Internet: www.kavo.com

Loading...

Loading...