Page 1

Instructions for use

KaVo Dig eXam 3520, 3530

Always be on the safe side.

Page 2

Sales:

KaVo Dental GmbH

Bismarckring 39

D-88400 Biberach

Tel. +49 7351 56-0

Fax +49 7351 56-1488

Manufacturer:

Kaltenbach & Voigt GmbH

Bismarckring 39

D-88400 Biberach

www.kavo.com

Page 3

Instructions for use KaVo Dig eXam 3520, 3530

Contents

Contents

Contents ...........................................................................................................................................................1

1 User notes .....................................................................................................................................................3

1.1 Intended users ......................................................................................................................................... 3

1.2 User guidelines ........................................................................................................................................ 4

1.2.1 Standard documentation ..................................................................................................................4

1.2.2 Abbreviations ...................................................................................................................................4

1.2.3 Symbols used ...................................................................................................................................5

1.2.4 Symbols on nameplates ................................................................................................................... 5

1.3 Service ..................................................................................................................................................... 6

1.4 Implied warranty ....................................................................................................................................... 7

1.5 Limitation of implied warranty ..................................................................................................................8

1.6 Transportation and storage ......................................................................................................................9

1.6.1 Transportation damage ....................................................................................................................9

1.6.2 Information on the packaging: Storage and transport ......................................................................9

2 Safety ..........................................................................................................................................................11

2.1 Explanation of safety symbols ...............................................................................................................11

2.1.1 Hazard warning symbol ..................................................................................................................11

2.1.2 Explanation of different levels of hazard ........................................................................................11

2.1.3 Structure .........................................................................................................................................11

2.2 Intended purpose ................................................................................................................................... 12

2.2.1 General ..........................................................................................................................................12

2.2.2 Product-specific ..............................................................................................................................12

2.3 Safety symbols ....................................................................................................................................... 14

2.4 Prerequisite for proper technical operation ............................................................................................ 16

2.4.1 Data backup ...................................................................................................................................16

2.4.2 Sensor handling .............................................................................................................................17

2.4.3 Standards for IT-components .........................................................................................................18

2.4.4 Standard conformity .......................................................................................................................18

3 Product description ...................................................................................................................................... 20

3.1 Entire system ......................................................................................................................................... 20

3.2 Where to affix the nameplates, power rating plates and caution labels .................................................21

3.2.1 Labeling ..........................................................................................................................................21

3.2.2 Symbols on identification labels .....................................................................................................23

3.3 Sensors ..................................................................................................................................................24

3.3.1 Installation sizes .............................................................................................................................24

3.3.2 KaVo Trigger ..................................................................................................................................25

3.3.3 Data connection via USB 2.0 .........................................................................................................25

3.3.4 Portability of KaVo Dig eXam ......................................................................................................... 26

3.3.5 Holder system for sensor ...............................................................................................................26

3.4 Integration in KaVo In eXam .................................................................................................................. 27

3.4.1 Attaching sensors to KaVo In eXam ..............................................................................................27

3.4.2 Internal USB connection in the scissor arm ...................................................................................28

3.5 Sensor holder ......................................................................................................................................... 29

3.5.1 Active Sensor holder ......................................................................................................................29

3.6 Status icon and sensor status on the PC ...............................................................................................31

1/60

Page 4

Instructions for use KaVo Dig eXam 3520, 3530

Contents

3.7 Technical Data ....................................................................................................................................... 33

3.7.1 KaVo Dig eXam Sensors and Interface .........................................................................................33

3.7.2 IT component requirements ...........................................................................................................33

3.7.3 Ambient conditions for KaVo Dig eXam sensors and interface [compliant with IEC601-1] ............34

3.7.4 Equipment classification .................................................................................................................34

3.7.5 Conformity with standards ..............................................................................................................34

3.7.6 Electrical connection ......................................................................................................................35

3.7.7 Dimensions, mass (original packaging) .........................................................................................35

3.7.8 Exposure times ..............................................................................................................................35

3.7.9 Information on electromagnetic compatibility .................................................................................36

3.8 Dig eXam inspection service (only available in Germany) .....................................................................39

4 Operation ..................................................................................................................................................... 40

4.1 Configuration of the Dig eXam driver software ...................................................................................... 40

4.1.1 Selection Information .....................................................................................................................40

4.1.2 Selection configuration ................................................................................................................... 41

4.1.3 Selection parameters .....................................................................................................................43

4.2 Taking a digital X-ray ............................................................................................................................. 44

4.2.1 Overview ........................................................................................................................................44

4.2.2 Activate programme and select patient .......................................................................................... 44

4.2.3 Prepare and position sensor ..........................................................................................................45

4.2.4 X-ray ...............................................................................................................................................47

4.2.5 Conclude X-ray procedure .............................................................................................................49

4.2.6 Create a diagnosis based on the radiograph .................................................................................49

5 Maintenance/safety inspections ..................................................................................................................50

5.1 Checks ................................................................................................................................................... 50

6 Preparation methods DIN EN ISO 17664 .................................................................................................... 51

6.1 Cleaning and disinfecting .......................................................................................................................51

6.1.1 Cleaning .........................................................................................................................................51

6.1.2 Disinfection .....................................................................................................................................51

7 Accessories and compatibility .....................................................................................................................53

7.1 eXam Family .......................................................................................................................................... 53

7.2 Compatibility ..........................................................................................................................................57

7.2.1 Non-KaVo X-ray machines .............................................................................................................57

7.2.2 IT components ...............................................................................................................................57

8 Troubleshooting ........................................................................................................................................... 58

8.1 Symptoms, causes and solution ............................................................................................................ 59

2/60

Page 5

Instructions for use KaVo Dig eXam 3520, 3530

1 User notes | 1.1 Intended users

1 User notes

1.1 Intended users

This document is intended for use by dentists and other practice or clinic employees

who are conversant with the taking, processing and archiving of computer-based

intraoral X-rays on the Microsoft® Windows operating system .

Prior to using the equipment, it assumed that users have been instructed in the use

of KaVo Dig eXam-Sensors in accordance with the stipulations of the country in

which they are practising, on the safe and proper use of X-ray radiation for the taking

of intraoral dental X-rays.

3/60

Page 6

Instructions for use KaVo Dig eXam 3520, 3530

1 User notes | 1.2 User guidelines

1.2 User guidelines

Requirement

Read these instructions before the initial startup to prevent misuse and damage.

This document has been translated from the German original.

Note

Microsoft and Windows are registered trademarks of Microsoft Corporation and its

registered subsidiaries.

VixWin PRO is a registered trademark of Gendex Dental Systems.

XCP-DS is a registered trademark of DENTSPLY RINN.

KaVo Dig eXam is a protected trademark of KaVo.

The utilisation of company logos or trademarks not named here does not indicate

that they are subject to unrestricted use. Every company logo or trademark men‐

tioned here is the sole property of the company mentioned. Brands, names and

prices are given for information purposes only.

1.2.1 Standard documentation

The product-related documentation consists of the following components. You can

order more of these from KaVo, if necessary:

▪ Customer documents

– User instructions

– Assembly instructions

▪ User instructions Software VixWin PRO.

1.2.2 Abbreviations

Abbrevia‐

tion

ALARA "As low as reasonably achievable": The guiding principle behind radiation protection during the

EMC Electromagnetic compatibility

UI User instructions

Hub A central point: a distribution device that makes available a number of USB interfaces.

IEC International Electrotechnical Commission

AI Assembly instructions

SQL "Structured Query Language": Standardised computer language for querying relational databases

SFC Safety checks

SW Software

STI Service Technician's instructions

USB Universal Serial Bus. Standardised means of connecting peripherals to personal computers.

Meaning

taking of X-rays, meaning that radiation doses for both workers and the public are typically kept

lower than their regulatory limits.

4/60

Page 7

Instructions for use KaVo Dig eXam 3520, 3530

1 User notes | 1.2 User guidelines

1.2.3 Symbols used

See the section Safety/Warning Symbol

Important information for users and technicians

Action request

1.2.4 Symbols on nameplates

Type BF application part [5333;IEC 417]

Consult user instructions

CE (Communauté Européenne) mark. Products bearing this mark conform

to the requirements of the pertinent EC directives (applicable European

standards).

CSA label

SN: Serial number

REF: Material number (for sensor size IMat. no. 1.003.4498, for sensor size

IIMat. no. 1.003.4499)

Type: device type (for sensor size I 3520, for sensor size II 3530)

For information about proper disposal, see intended purpose

5/60

Page 8

Instructions for use KaVo Dig eXam 3520, 3530

1 User notes | 1.3 Service

1.3 Service

Service hotline:

+ 49 (0) 7351 56-2900

Service.Roentgen@kavo.com

Please indicate the version number of the program.

Additional information can be obtained at: www.kavo.com

For North America

KaVo Dental

KaVo Technologies / Gendex Imaging

019 West Oakton Street

Des Plaines, IL 60018-1884

USA

+1 (847) 640-48 00

6/60

Page 9

Instructions for use KaVo Dig eXam 3520, 3530

1 User notes | 1.4 Implied warranty

1.4 Implied warranty

The KaVo end-user customer guarantee for the product named in the completion

certificate guarantees that the product functions correctly and that there are no faults

in the material or workmanship for a duration of 12 months following the purchase

date, according to the following conditions:

Following a reasonable complaint relating to defects or short delivery, KaVo will

provide a replacement or perform repairs. KaVo reserves the right to perform re‐

pairs.

Claims of any other nature, damages in particular, are excluded. In case of default

and gross negligence or intent, the latter only applies if there are no compelling legal

provisions opposing it.

KaVo shall not be liable for defects and their consequences, which occur as a result

of normal normal wear and tear, or of improper cleaning and maintenance, nonobservance of the operating, maintenance or connection regulations; calcination or

corrosion; a contaminated air or water supply; or chemical or electrical effects, which

are non-standard or not permitted according to company regulations.

As a general rule, this guarantee does not apply to lamps, glassware, rubber parts

or the colour durability of synthetic materials.

KaVo shall not be liable for defects or their consequences if they are likely to be a

direct result of actions or modifications by a customer or third party.

Any claims arising from this guarantee can only be lodged if the completion certifi‐

cate (carbon copy) has been sent in to KaVo and the operator/user is able to produce

the original.

7/60

Page 10

Instructions for use KaVo Dig eXam 3520, 3530

1 User notes | 1.5 Limitation of implied warranty

1.5 Limitation of implied warranty

KaVo shall assume responsibility for the safety, reliability and performance of all

KaVo system components provided that:

▪ Assembly, upgrades, new settings, modifications or repairs are all carried out

by Service Technicians, who have been trained by KaVo, or by KaVo authorised

dealer personnel

▪ The IT components provided by the operator correspond to the technical hard‐

ware and software requirements included in these user instructions.

▪ The system has been installed and operated in accordance with the User in‐

structions and Assembly instructions.

▪ All servicing is performed in full compliance with DIN VDE-075-1.

▪ In Germany, the location in whichKaVo Dig eXam is installed, must comply with

the regulationsDIN VDE 0100-710: 2002-11 and VDE 0100-560:1995 in its de‐

sign. In other countries, the corresponding national regulations must be respec‐

ted.

▪ The VixWin PRO software has been installed in accordance with the VixWin Pro

user instructions

8/60

Page 11

Instructions for use KaVo Dig eXam 3520, 3530

1 User notes | 1.6 Transportation and storage

1.6 Transportation and storage

1.6.1 Transportation damage

Outside of Germany

Note

KaVo is not liable for damage arising from transportation.

Immediately inspect the delivery after receipt!

If external damage to the packaging is visible upon delivery, follow the procedure

below:

1. The recipient must record the loss or damage in the notice of delivery. The re‐

cipient and employee of the transportation firm must sign the notice of delivery.

The recipient can only assert damages against the transportation company ba‐

sed on these records.

2. Leave the product and packaging unchanged.

3. Do not use the product.

If the product is damaged and there is no discernable damage to the packaging

upon delivery, proceed as follows:

1. Report the damage immediately or at least 7 days after the delivery to the deli‐

very company .

2. Leave the product and packaging unchanged.

3. Do not use a damaged product.

Note

If the recipient does not follow one of the above instructions, the damage will be

held to have occurred after the delivery (according to . CMR law , section 5, Art.

30).

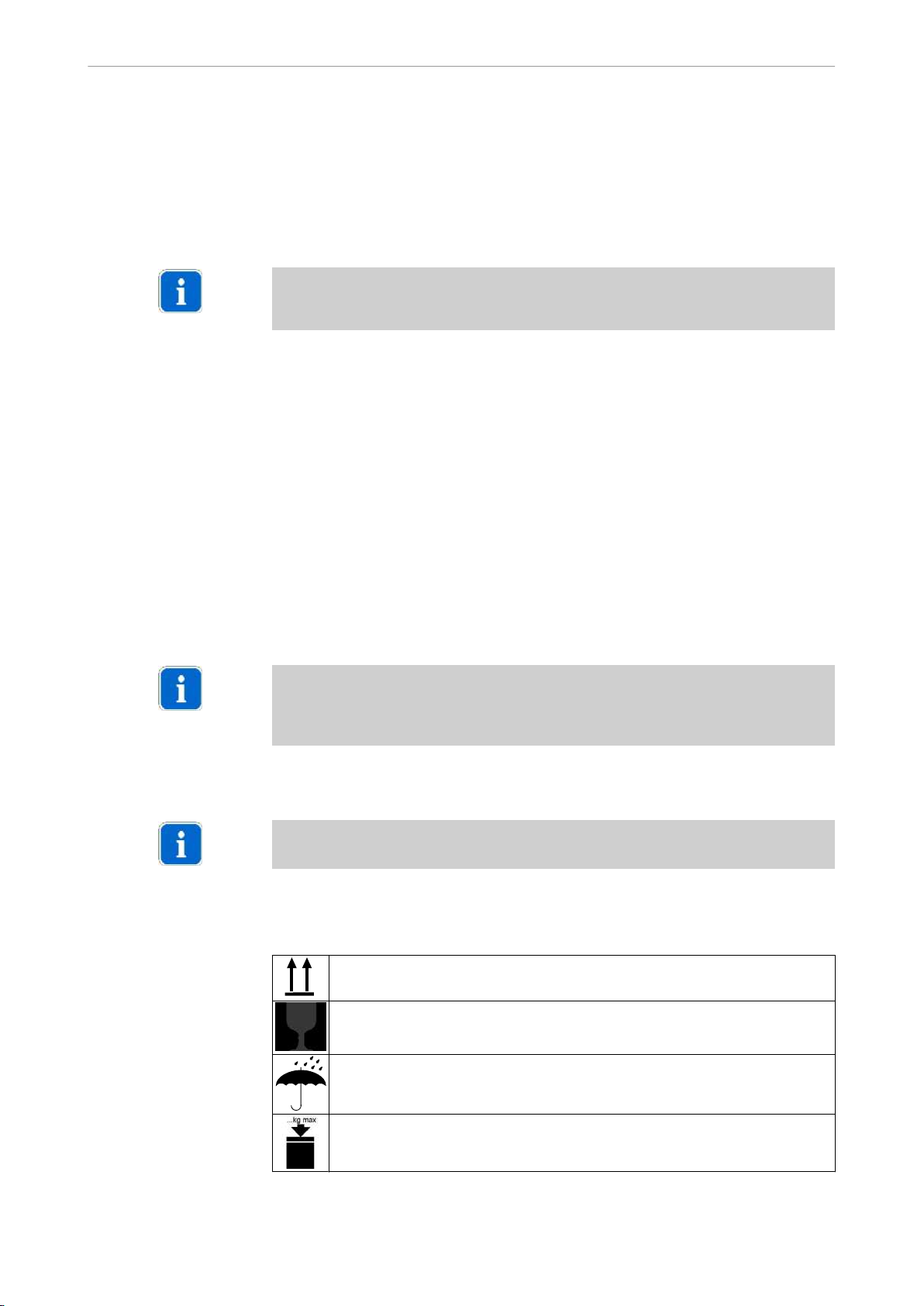

1.6.2 Information on the packaging: Storage and transport

Note

Keep the packaging for returning the product for service or repairs .

The symbols printed on the outside are for transportation and storage, and have the

following meaning:

Transport upright with the arrows pointing upwards

Fragile - protect against knocks

Keep dry

Maximum permitted stacking load

9/60

Page 12

Instructions for use KaVo Dig eXam 3520, 3530

1 User notes | 1.6 Transportation and storage

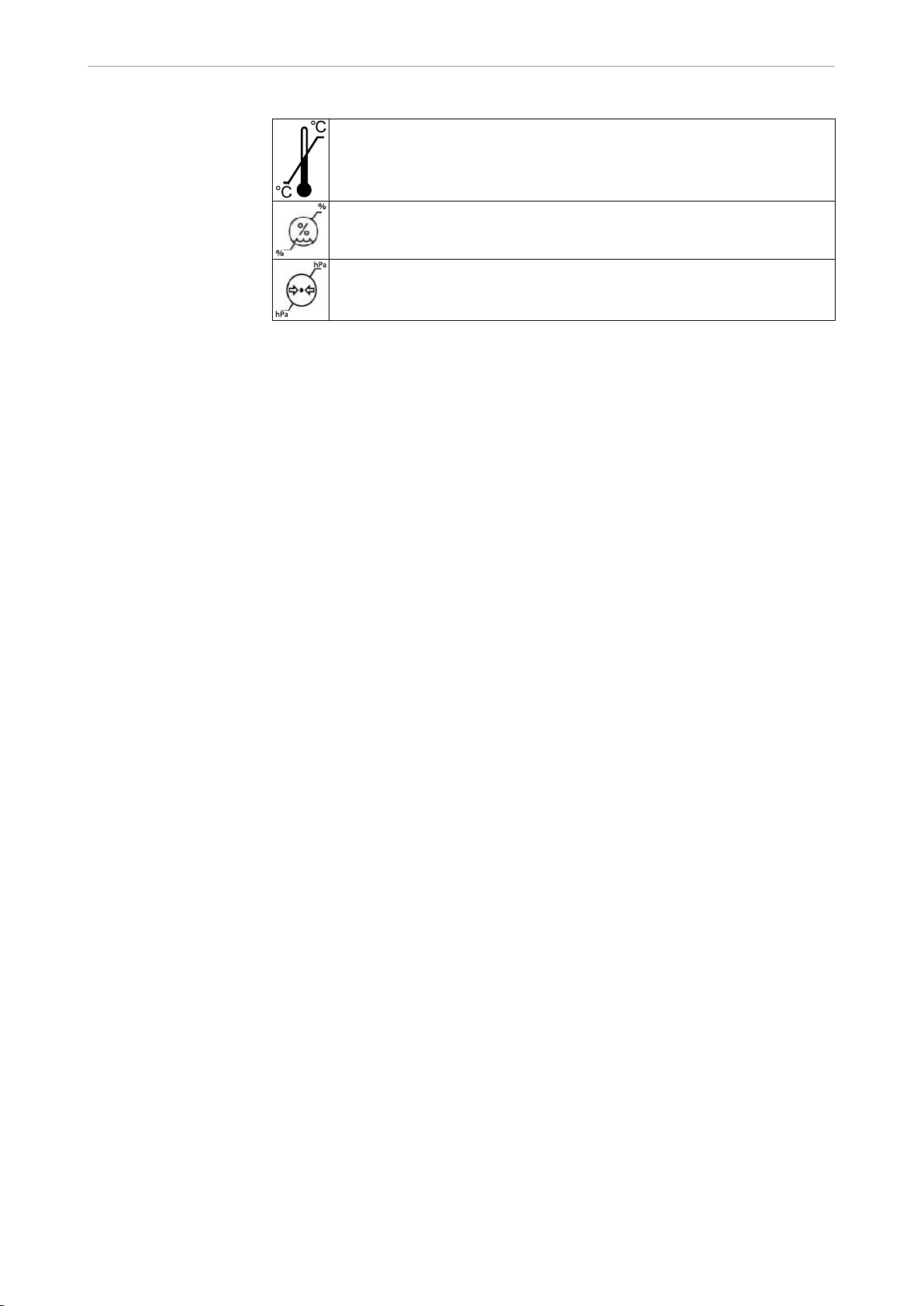

Temperature range

Humidity

Air pressure

10/60

Page 13

Instructions for use KaVo Dig eXam 3520, 3530

2 Safety | 2.1 Explanation of safety symbols

2 Safety

2.1 Explanation of safety symbols

2.1.1 Hazard warning symbol

Warning symbol

2.1.2 Explanation of different levels of hazard

Safety instructions with three hazard levels are used in this document for avoiding

personal and property damage.

CAUTION

indicates a hazardous situation that can lead to property damage or minor to mo‐

CAUTION

derate injury.

WARNING

DANGER

DANGER

WARNING

indicates a hazardous situation that can lead to serious injury or death.

DANGER

indicates a maximum hazardous situation that can directly cause serious injury or

death.

2.1.3 Structure

The introduction describes the type and source of the hazard.

This section describes the potential consequences of non-observance.

▶ The optional step contains necessary measures for avoiding hazards.

11/60

Page 14

Instructions for use KaVo Dig eXam 3520, 3530

2 Safety | 2.2 Intended purpose

2.2 Intended purpose

2.2.1 General

This KaVo product is intended only for use in the field of dentistry. It is impermissible

to use the product for a purpose for which it was not intended.

"Proper use" includes following all the instructions for use and ensuring that all in‐

spections and service tasks are performed.

Apply and meet the overarching guidelines and/or national laws, national regulati‐

ons and the rules of technology for medical devices applicable for startup and use

of the KaVo product for the intended purpose.

The user must ensure that that the device works properly and is in a satisfactory

condition before each use.

During use, national legal regulations must be observed, in particular:

▪ the applicable health and safety regulations.

▪ the applicable accident prevention regulations.

The user must observe the following:

▪ - only use properly operating equipment.

▪ protect himself or herself and third parties from danger.

▪ avoid contamination from the product.

The safety checks (SFC) must be performed on an annual basis.

Note

The product must be cleaned and serviced according to instructions if it is not to

be used for a long period.

Observe the corresponding country-specific regulations when finally shutting down

a KaVo product. Please direct all questions regarding the proper disposal of KaVo

products to the nearest KaVo branch.

2.2.2 Product-specific

Dig eXamtogether with VixWin PRO is intended for processing dental, intraoral Xrays.

The radiographs are displayed and archived using the software VixWin PRO.

Prior to using the equipment, users of the KaVo Dig eXam-Sensors must have un‐

dergone full instruction, in accordance with the stipulations of the country in which

they are practising, on the safe and proper use of X-ray radiation for the taking of

intraoral dental X-rays.

KaVo Dig eXam has electronic components in the Trigger and Sensor that are to

be disposed of in accordance with the relevant country specific regulations.

12/60

Page 15

Instructions for use KaVo Dig eXam 3520, 3530

2 Safety | 2.2 Intended purpose

Disposal of electronics

Note

According to the EC Directive 2002/96 concerning electrical and electronic used

devices, this product is subject to the cited directive and must be disposed accor‐

dingly within Europe.

Before disassembling and disposing of the product, it must be completely proces‐

sed (disinfected, sterilised) according to the section "Preparation methods".

Additional information can be obtained from KaVo (www.kavo.com) or your dental

supplier.

13/60

Page 16

Instructions for use KaVo Dig eXam 3520, 3530

2 Safety | 2.3 Safety symbols

2.3 Safety symbols

Ionising radiation

Overexposure to X-ray radiation.

CAUTION

CAUTION

CAUTION

▶ The handler can and must take measures, in accordance with country-specific

legal stipulations, to minimise their personal dose of radiation!

Risk of injury by using unsuitable electrical devices.

Increased risks within patient surroundings; e.g. sensing electrical current or re‐

ceiving electric shock through contact with parts

▶ Adhere to the requirements described within these user instructions

▶ Only use IT components that are fully compliant with the requirements descri‐

bed within these user instructions.

▶ If any of the system components are damaged, stop use immediately.

▶ Only use standard-compliant devices.

Injury caused by damaged sensors

Damaged sensors may cause personal injury.

▶ If sensors are damaged, stop using them.

▶ If the sensor wire is damaged, stop using it.

CAUTION

CAUTION

CAUTION

CAUTION

Ignition of ignitable mixtures due to electrical equipment in operation

Deflagration

▶ KaVo Dig eXam must not be operated when using ignitable mixtures.

Malfunctions from electromagnetic fields.

The product meets the applicable requirements regarding electromagnetic fields.

Given the complex interactions between equipment and cell phones, the product

may be influenced by a cell phone that is in use.

▶ Do not use cell phones in medical offices, hospitals, or laboratories.

▶ Turn off electronic devices such as computer storage media, hearing aids, etc.

during operation .

Risks from electromagnetic fields.

The functions of implanted systems (such as pacemakers) can be influenced by

electromagnetic fields.

▶ Ask patients before treatment.

Loss of data when taking x-rays

When the transmission of data from the KaVo Dig eXam sensor to the computer

does not meet the USB 2.0 standard, data may be lost when taking x-rays due to

the limited bandwidth of earlier USB versions.

▶ Each USB connection between the computer and sensor must completely meet

the USB 2.0 standard.

▶ Each port (computer or hub) to which the sensors are connected must offer the

full output of 500 mA specified fur USB.

▶ The operating system for the computer must support USB 2.0 in high-speed

mode. The most recent service pack by Microsoft must be installed.

▶ The protective conductor connections described in these instructions must be

installed.

14/60

Page 17

Instructions for use KaVo Dig eXam 3520, 3530

2 Safety | 2.3 Safety symbols

Monitor image interference preventing accurate diagnosis

The quality of the X-ray image displayed on screen is dependent both on the prac‐

CAUTION

tice or clinic's ambient conditions as well as the monitor settings.

▶ If you suspect interference on the image display, use test images to check

whether the problem lies with the monitor.

▶ Clean the screen on a regular basis.

▶ Make sure that you use correct screen settings only.

Note

When positioning the screen, keep it out of direct sunlight and prevent light reflec‐

ting off it to enable the medical data to be read properly.

15/60

Page 18

Instructions for use KaVo Dig eXam 3520, 3530

2 Safety | 2.4 Prerequisite for proper technical operation

2.4 Prerequisite for proper technical operation

Responsibility is assumed for the safety, reliability and performance of the compo‐

nent supplied by KaVo when:

▪ Installation, expansions, adjustments, changes or repairs is done by technicians

trained by KaVo or third parties authorised by KaVo for the Dig eXam, or by the

personnel of authorised distributors.

▪ The unit is operated according to the instructions for use and installation.

▪ The IT components supplied by the operator meet the technical requirements in

these instruction for use for hardware and software, and they are installed and

set up according to the descriptions of these components.

▪ KaVo Dig eXam is an electronic medical device, and is subject to the special

precautions necessary for EMC. KaVo Dig eXam may only be operated when it

has been installed according to the EMC instructions in the instructions for use

and installation.

▪ When setting up the unit, follow all the requirements of VDE 0751-1, "Repeated

tests and test before startup of electronic medical devices and systems - general

guidelines".

▪ In Germany ,the room in which the Dig eXam is installed must be designed ac‐

cording to the specifications DIN VDE 0100-710:2002-11 ad VDE

0100-560:1995. In other countries, follow the corresponding national specifica‐

tions.

CAUTION

Note

The installation and fitting of IT components for Dig eXam are the responsibility of

the practice or clinic.

Unauthorised accessories

Only original replacement parts and accessories should be used, to ensure that

there is no increase in the emissions and/or a reduction in the stability in terms of

the electromagnetic compatibility.

▶ Only use authorised or recommended spare parts and accessories.

See also: 3.7 Technical Data, Page 33

Observe the corresponding country-specific regulations when finally shutting down

a KaVo product. Please direct all questions regarding the proper disposal of KaVo

products to the nearest KaVo branch.

See also: Technical data in user instructions.

2.4.1 Data backup

It is the user's responsibility alone to back up data.

KaVo recommends daily back-up.

16/60

Page 19

Instructions for use KaVo Dig eXam 3520, 3530

2 Safety | 2.4 Prerequisite for proper technical operation

Data loss

Establish a data backup strategy.

CAUTION

▶ VixWin PROuses the file system supplied with the Microsoft operating system

for saving image data. Correspondingly, this data must also be included within

the backup strategy of your practice or clinic.

Note

The image data produced using KaVo Dig eXam replaces the conventional intraoral

radiographs taken on X-ray film and, as such, is subject to the same country-spe‐

cific requirements governing this; such as the mandatory length of time for storing

X-rays etc.

These country-specific stipulations and requirements may also include the recor‐

ding of dosage levels and information about the patient's indication.

The user should regularly make back-up copies If a hard disk in the PC fails, this

protects from data loss and increases the safety of the system data. Such a copy is

also termed a backup. It should not be confused with the export of data in which the

data remain in the PC.

Store backup copies in a safe place.

There are various backup options. You can choose between:

▪ A full backup, which always backs up every single piece of data on the hard drive

that needs backing up.

▪ An incremental backup, which only saves data that has been modified since the

last backup.

A full backup is a lengthy procedure and cannot be performed on a daily basis.

Therefore, practices nowadays usually decide to implement a hybrid of the two

backup options (full and incremental). whereby, at one point in time, the entire

quantity of stored data is backed up and, on later occasions, backups are run at

regular intervals for modified data only.

Please also note that a hard drive error may occur whilst a backup is being written.

For this reason, you should never overwrite the most recent backup copy.

Note

The computer expert or system administrator at your practice will have the most

up-to-date technical information as regards keeping and running backup copies.

2.4.2 Sensor handling

Precautionary instructions for handling the sensors

Never:

▪ Sterilise the sensors or subject them to high-pressure sterilisation (autoclave).

▪ Drop the sensors.

▪ Twist or tread on the sensor wires.

▪ Let patients bite on the sensor or its wire.

▪ Remove the sensors when in use or while the X-ray is being taken.

▪ Pull or bend the wire..

▪ Immerse the KaVo trigger in the cleaning bath.

17/60

Page 20

Instructions for use KaVo Dig eXam 3520, 3530

2 Safety | 2.4 Prerequisite for proper technical operation

Electrostatic discharge

▪ When the sensors are not in use, it is recommended that they be stored in the

storage containers provided.

▪ Never touch the USB connection contact points!

2.4.3 Standards for IT-components

The IT components used in conjunction with Dig eXam, in particular USB-connec‐

tion between Dig eXam and the PC must correspond with the details given in these

User instructions.

See also: 2.4.4 Standard conformity, Page 18

See also: 3.3.3 Data connection via USB 2.0, Page 25

2.4.4 Standard conformity

The KaVo Dig eXam Sensors and the KaVo Dig eXam Interface comply with the

following standards

▪ IEC 60601-1:1988 +A1:1991 + A2:1995 [For the USA UL 60601-1:2003. For

Canada CAN/CSA 22.2 N0.: 601-1]

▪ IEC 60601-1-2:2001

The KaVo Dig eXamdriver software conforms to standards:

▪ IEC 60601-1-4: 1996 + A1: 1999

Note

The delivered Vix Win Pro software also meets this standard.

KaVo Dig eXam and the IT components together make up a medical, electrical sys‐

tem.

The standards applicable to these IT components depend on their specific location

within the practice or clinic. In general, these IT components must comply with IEC

60950-1:2001.

The system that is formed by these IT components andKaVo Dig eXam when in‐

stalled in accordance with the assembly instructions for KaVo Dig eXam and meets

the requirements stipulated in this section, conforms to standard

- IEC 60601-1-1:2000

Rooms used for medical purposes

The room where KaVo Dig eXam Sensors are operated, must be designed in ac‐

cordance with regulationDIN VDE 0100-710:2002-11. In other countries, the corre‐

sponding national regulations must be respected.

18/60

Page 21

Instructions for use KaVo Dig eXam 3520, 3530

2 Safety | 2.4 Prerequisite for proper technical operation

patient environment

When the above-mentioned IT components are installed in the patient environment,

the requirements of basic specialist standard IEC 60601-1:1988 +A1:1991 +

A2:1995

defines the surroundings of the patient in accordance with IEC 60601-1-1:2000: „ ...

any volume whereby, intentionally or unintentionally, a connection may be created

between the PATIENT and parts of the SYSTEM or other persons who may come

into contact with parts of the SYSTEM. ... “

Medical system

The requirements of the applicable standards have been met if:

▪ The IT-components on the Dig eXam via USB are installed in the same room

and

▪ One of the following applies:

– The Dig eXam Sensor together with the Dig eXam Interface is connected

(integrated solution in In eXam or in connection with the active sensor holder

of Dig eXam). The IT device can be run in accordance with IEC 60950-1 if

arranged outside of the patient surroundings.

– The IT components are located within the patient environment: The device

on which the Dig eXam is connected directly, fulfills the standard IEC

60601-1.

– The IT components are located outside of the patient environment: The de‐

vice is on which the Dig eXamis directly connected, complies with the

standard IEC 60950-1 and has a second permanently connected equipo‐

tential bonding that complies with IEC 60601-1-1.

Monitors

Note

The dental radiographs created byKaVo Dig eXam are examined and diagnosed

using the dental practice's own image representation device (monitor). There are

country-specific regulations in force governing (regular) check-ups of the greyscale

display for these image representation devices.

In Germany, at least one monitor at the dental practice must be tested for constancy

on a regular basis in accordance with DIN-V 6868-57:2001.

19/60

Page 22

Instructions for use KaVo Dig eXam 3520, 3530

HUB

HUB

HUB

HUB

< 5m

< 5m

1

1

2

3

3 Product description | 3.1 Entire system

3 Product description

3.1 Entire system

The entire KaVo Dig eXam consists of:

- the ① Dig eXam Sensors (comprising detector and trigger, the KaVo Dig eXamInterface (optional), the ② Dig eXam-Driver-Software

- the ③ VixWin PRO-Software

- IT-components

- accessories

KaVo Dig eXam and the VixWin PRO-Software together form a complete system

which can easily be used with non-KaVo X-ray machines.

Used in conjunction with KaVo In eXam and the Dig eXam interface, you have a

fully integrated X-ray system with extra functions.

Dig eXam has two additional software programs for customers in Germany:

1. A tool for supporting the required acceptance and constancy test in Germany.

2. A program for listing the existing images (x-ray folder)

20/60

Page 23

Instructions for use KaVo Dig eXam 3520, 3530

K

a

V

o Dig

e

X

am

1

A

C

B

5

3

2

4

X. XX X. XXX X

XXXXX X

Dig eXam Sensor Size 1

Kaltenbach & V oigt Gmb H

Bismarckring 39

D-88400 Biberach / Riss

!

3520 T ype :

Ref : 1.003.4498

SN :

Manufactored : Month, Y ea r

USB 2.0 max. 500 mA

6

3 Product description | 3.2 Where to affix the nameplates, power rating plates and caution labels

3.2 Where to affix the nameplates, power rating plates and caution

labels

3.2.1 Labeling

① Product name ⑥ Rating plate overview (on packaging)

② Consult user instructions (A) Dot to mark position. This is entered

③ Type BF application part (B) Sensor label (sensor I or sensor II)

④ KaVo Dig eXam sensor rating plate (C) USB symbol on connector

⑤ Label for KaVo Trigger/USB lead

automatically on the radiographs by

KaVo Dig eXam.

21/60

Page 24

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.2 Where to affix the nameplates, power rating plates and caution labels

Hardware driver for Vix-Win Mat. no. 1.002.8220

① Program version ③ Unambiguous ID

② ID and language edition

Installations CD Vix Win Pro. Mat. no. 1.002.4813

22/60

Page 25

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.2 Where to affix the nameplates, power rating plates and caution labels

3.2.2 Symbols on identification labels

Type BF application part [5333;IEC 417]

Consult user instructions

CE (Communauté Européenne) mark. Products bearing this mark conform

to the requirements of the pertinent EC directives (applicable European

standards).

CSA label

SN: Serial number

REF: Material number (for sensor size IMat. no. 1.003.4498, for sensor size

IIMat. no. 1.003.4499)

Type: device type (for sensor size I 3520, for sensor size II 3530)

For information about proper disposal, see intended purpose

23/60

Page 26

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.3 Sensors

3.3 Sensors

3.3.1 Installation sizes

Sensor I (left) and sensor II (right).

The receiver side is marked with a dot that is also shown on the digital X-ray.

24/60

Page 27

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.3 Sensors

3.3.2 KaVo Trigger

KaVo Trigger

The KaVo trigger connects the X-ray image detector to the computer system via a

USB 2.0 data path. This connection takes place in the X-ray device

KaVo In eXamsimply by inserting the interface in the X-ray head and in the

KaVo Dig eXamfitted in the machine.

When using the Dig eXam sensors with other X-ray machines it is possible to con‐

nect the KaVo Trigger to the so-called "active sensor holder" or alternatively to

connect it directly to the computer using the accessory cable supplied. In this case

a Dig eXAM sensor of one size can be exchanged with a sensor of another size by

changing the trigger.

Note

The accessory line is "Pull/Push“-Connection. It must not be twisted when pulled

out and plugged in.

when changing the Dig eXam Sensor from machine to machine or for another sensor

size, the detector can be laid down in the sensor holder fitted on the KaVo Trigger.

This sensor holder can be removed for cleaning the KaVo Trigger..

When the sensor holder is opened and the detector is removed, a button is acces‐

sible.

This button directly activates the system to take x-rays when the Dig eXam sensor

is not connected to the KaVo In eXam or is being operated in mixed-mode.

See also: 3.4.1 Attaching sensors to KaVo In eXam, Page 27

3.3.3 Data connection via USB 2.0

The sensor is connected to the machine via a USB 2.0 connection. The components

are physically connected to each other via simple plug-fit connections. Anchoring

the KaVo trigger into the device on the X-ray generator establishes the physical

connection between the machine and KaVo trigger or sensors. In accordance with

USB standards, the USB data connection may comprise up to four 5m sections.

Hubs that are compliant with USB 2.0 must be used to connect up the individual

sections

25/60

Page 28

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.3 Sensors

Every hub that is directly connected to a KaVo sensor, i.e. with

noKaVo Dig eXamInterface, must be capable of supplying the requisite current. As

a rule, this means that a transformer will need to be used (also for laptops if neces‐

sary).

The requirements listed in the chapter "Standard conformity" must be complied with.

See also: 2.4.4 Standard conformity, Page 18

Note

When using 5 metre long USB-cables the the USB-connection must plugged di‐

rectly into the so-called motherboard. Insertion in the USB ports that are within the

PC on further cables, is not permitted.

Note

Passive USB extension cords may not be used. The distances between two HUBs

may only be bridged with a cord 5 m or less.

3.3.4 Portability of KaVo Dig eXam

KaVo Dig eXam is can be transported from one location to another, in order to

enable operation of the sensors in different treatment rooms.

KaVo Dig eXam is thus excellently suited for a multi-user installation in dental clinics

or group practices.

The handy size provides optimum flexibility and offers you independence when

using the sensors on a day-to-day basis.

3.3.5 Holder system for sensor

The positions in which the sensor can be placed in the mouth are the same as those

for classic radiology when using X-ray film.

A colour-coded XCP-DS holding system is supplied as standard to assist in the

positioning of KaVo Dig eXam sensors for the parallel/right-angle technique.

This system includes the following:

▪ Blue holder for the anterior teeth

▪ Yellow holder for the molar area

▪ A red holder for bitewing radiographs

▪ A green holder for endodontic use

Note

The use of the retention system is shown on the poster that comes with the retention

system.

See also:

7 Accessories and compatibility, Page 53

26/60

Page 29

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.4 Integration in KaVo In eXam

3.4 Integration in KaVo In eXam

3.4.1 Attaching sensors to KaVo In eXam

KaVo Dig eXamSensors are specifically intended to be integrated with

theKaVo In eXam. In this case, the optional USB lead is separated from the KaVo

trigger and the KaVo trigger is inserted directly into the prepared opening at the head

of the X-ray machine. The detector itself is placed in its special holder on the KaVo

trigger, meaning that it is always on hand for use by the dentist.

Position of KaVo Sensors on the device

KaVo Dig eXam then enables the sensor to be removed without switching off the

machine, simply by pulling gently and placing in another room.

Storage in the RWT holder.

A Dig eXam sensor can be stored in the provided RWT holder on the In eXam.

The sensor must have hygienic protection and be inserted in the desired variation

of the RWT holding set.

27/60

Page 30

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.4 Integration in KaVo In eXam

The prepared RWT holder can be inserted with the guide rod into the provide clip

on the In eXam.

Note

KaVo recommends that this option only be used for temporary storage to prevent

damage from bumps, etc.

3.4.2 Internal USB connection in the scissor arm

If the KaVo trigger is operated in conjunction with a KaVo In eXam machine, it is

connected to the system via a plug-fit connection at the X-ray emitter. This establi‐

shes a USB connection to the machine or to KaVo Dig eXam, enabling the transfer

of data.

Technical background:

KaVo X-ray machines are equipped with an internal USB line that leads directly to

theKaVo Dig eXaminterface in the X-ray machine via the scissor arm.

28/60

Page 31

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.5 Sensor holder

3.5 Sensor holder

A sensor holder belongs to the Dig eXam.

It is fitted on the wall and is used for holding a sensor between treatments when the

Dig eXam-Sensor is not used together with the KaVo In eXam.

The sensor is held in the holder by a magnet.

The sensor holder can be taken off the KaVo Trigger in this case and laid in the

sensor tray.

3.5.1 Active Sensor holder

With the optionally obtainable Dig eXam interface Mat. no. 1.003.2363 the distance

to the PC or hub can be increased to a max. 5 m line length from the USB 2.0, for

example to place the IT components outside of the patient's environment.

The interface in this case is mounted covered by the plastic part of the sensor holder,

and the accessory line to the KaVo trigger is tightly connected to the arising active

sensor holder.

29/60

Page 32

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.5 Sensor holder

In addition, it is possible in this case to run the line under the wall surface from the

sensor cover to the IT component.

30/60

Page 33

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.6 Status icon and sensor status on the PC

3.6 Status icon and sensor status on the PC

Two icons are visible in the Windows system area (cut-out in the so-called taskbar

next to the system clock)

The blue -Icon displays that the software interfaces between Dig eXam-Hard‐

ware and VixWin-Software is loaded.

The colour of the -Icon shows the availability of the Dig eXam-Systems connected.

Note

Other icons can be displayed dependent on the set up of the X-ray system. These

icons refer to further KaVo or Gendex equipment and are described in the relevant

documentation.

Note

This area of the Windows desktop in which the status icons are show is a part of

the so-called windows taskbar. Windows should be configured so that the status

icons are always visible when taking an X-ray. The configuration of the taskbar is

described in Windows Help.

The following is a list of all the possible statuses and their icons

31/60

Page 34

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.6 Status icon and sensor status on the PC

When the icon is green, the electronics, sensor and connections are operating cor‐

rectly.

The sensor is ready to detect the x-rays.

When the icon is YELLOW, the electronics, sensor and connections are operating

correctly.

The sensor is waiting for the exposure to be activated.

Note

If you are using a system that is not connected to KaVo In eXam, the KaVo trigger

must be used to activate the process and must be pressed before the X-ray is taken.

If you are using a system that is connected to KaVo In eXam, activation occurs

automatically once you start taking the X-ray.

The icon in RED status: Dig eXam is not connected to the PC and/or not ready to

take an X-ray.

32/60

Page 35

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.7 Technical Data

3.7 Technical Data

3.7.1 KaVo Dig eXam Sensors and Interface

Data connection USB 2.0

Pixel size 18,5 µm / theoretical resolution 27 LP/

Pixel binning 1 x 1

System resolution typ. 18 LP/mm / min 16 LP/mm [at

Active surface sensor size (3520) 30 x 22 mm

Active surface sensor size II(3530) 36 x 27 mm

kV range 60-70 kV

3.7.2 IT component requirements

mm

200µGy, 60kV] > 50 µGy

2

2

Compliance with standards when instal‐

IEC 60601-1:1988 +A1:1991 +A2:1995

ling IT components in patient surroun‐

dings

Compliance with standards when instal‐

IEC 60950-1:2001

ling IT components outside of patient

surroundings and using the Dig eXam

interface to connect the sensor.

Compliance with standards when instal‐

ling IT components outside of patient

IEC 60950-1: 2001 and a second pro‐

tective conductor connection

surroundings and connecting sensor di‐

rectly without using the Dig eXam inter‐

face.

Data interface for sensors USB 2.0, 500 mA, High Speed

Data interface for Dig eXam Interface

100 mA

USB 2.0

(self-powered mode)

Data interface for Dig eXam Interface

500 mA

USB 2.0

(bus-powered mode)

Operating system Windows 2000 or Windows 2003 with

most up-to-date service pack, Windows

XP with most up-to-date service pack

Labelling European CE marking

Connection of IT components to mains

supply

Use of portable multiple sockets is pro‐

hibited.

Note

Further information in theuser instructions VixWin PRO.

33/60

Page 36

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.7 Technical Data

3.7.3 Ambient conditions for KaVo Dig eXam sensors and interface

[compliant with IEC601-1]

Operation

Air humidity Condensation is not permitted to form on

Air pressure between 700 hPa and 1060 hPa

Ambient temperature 10° to 40° Centigrade

Storage and transport

Air humidity relative Air humidity between 10% and

Air pressure between 700 hPa and 1060 hPa

Unpacked 5° to 70° centigrade

In original packaging -20° to 70° centigrade (short term up to

the machine; relative atmospheric humi‐

dity 30-75%

95% (TBC uwezel)

2h: -40° C to 85° centigrade)

3.7.4 Equipment classification

KaVo Dig eXam Sensors

▪ Class I

– in accordance with EC Directive 93/42/EEC of June 14, 1993

▪ Application part type BF (IEC 601-1)

– Not protected from the penetration of water [IP20].

– Not suitable for sterilisation.

– Suitable for wipe or surface disinfection using the cleansers described in the

instructions for use.

– Not suitable for operation in environments with combustible mixtures.

KaVo active sensor holder

▪ Not protected from the penetration of water [IP20].

▪ Not suitable for sterilisation.

▪ Suitable for wipe or surface disinfection using the cleansers described in the

instructions for use.

▪ Not suitable for operation in environments with combustible mixtures.

3.7.5 Conformity with standards

See also: 2.4.4 Standard conformity, Page 18

34/60

Page 37

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.7 Technical Data

3.7.6 Electrical connection

KaVo Dig eXam Sensors

DC voltage 5V [supply via USB 2.0]

Max. power 500 mA

Data connection USB 2.0

KaVo active sensor holder

DC voltage 12V ±10 %

Max. current 600 mA

Data connection USB 2.0 interface

Compliance with

power supply standards

Length of feeder < 20 m

Must comply with IEC 60950-1:2001

Note

In Europe, the manufacturer's CE marking on the power supply unit confirms that

relevant power supply standards have been complied with.

3.7.7 Dimensions, mass (original packaging)

Size of packaging approx. 300 x 330 x 220 mm³

Weight < 5 kg

3.7.8 Exposure times

KaVo Dig eXam sensors in conjunction with KaVo In eXam

Preset dose level of 5 (60 kV is recommended) in digital mode.

Note

This recommended dosage is based on thresholds which are applicable for the

Federal Republic of Germany and may need to be adjusted in accordance with

relevant country-specific regulations and/or individual diagnostic circumstances.

See also: User instructions KaVo In eXam.

KaVo Dig eXam sensors in conjunction with non-KaVo intraoral X-ray

equipment

The dose must be preselected according to applicable national regulations (ALARA

principle). The sensor can be operated over a wide dose range corresponding to

ISO film speed class F-20% up to speed class D.

35/60

Page 38

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.7 Technical Data

KaVo recommends that the sensors be operated at 60kV

3.7.9 Information on electromagnetic compatibility

Guidelines and manufacturer's declaration - electromagnetic emissi‐

ons

In eXam is intended for use in an environment as stipulated below. The customer

or user of In eXam should ensure that it is operated in an environment of this type.

Emissions measurements Conformity Electromagnetic environment - gui‐

de

HF-emissions in accordance within

CISPR 11

HF-emissions in accordance with

CISPR 11

Emissions of harmonic oscillations

in accordance with IEC61000-3-2

Emissions of voltage fluctuations /

flicker in accordance with

IEC61000-3-3

Group 1 Dig eXam uses HF energy solely for

its internal functions. Its HF radiati‐

on is therefore very low, and it is

unlikely that nearby devices will be

subject to interference.

Class B Dig eXam is suitable for use in all

devices, including those used in do‐

mestic environments and similar

which are connected directly to a

public supply grid which also sup‐

plies buildings which are used for

residence purposes.

Class A Dig eXam is suitable for use in all

devices, including those used in do‐

mestic environments and similar

which are connected directly to a

public supply grid which also sup‐

plies buildings which are used for

residence purposes.

Compliant Dig eXam is suitable for use in all

devices, including those used in do‐

mestic environments and similar

which are connected directly to a

public supply grid which also sup‐

plies buildings which are used for

residence purposes.

Stability tests IEC 60601 - Test level Compliance level Electromagnetic environment - gui‐

de

Discharge of static

electricity in accor‐

dance with IEC

61000-4-2

Rapid transient electri‐

cal disturbances / burst

in accordance with IEC

61000-4-4

Surges in accordance

with IEC 61000-4-5

+/- 6 kV Contact di‐

scharge

+/- 8 kV Air discharge

+/- 2 kV +/- 2 kV for

mains cables +/- 1 kV

for input and output ca‐

bles

+/- 1 kV Normal mode

voltage

+/- 2 kV Common mode

voltage

+/- 6 kV Contact di‐

scharge

+/- 8 kV Air discharge

+/- 2 kV for mains ca‐

bles

+/- 1 kV for input and

output cables

+/- 1 kV Common mode

voltage

+/- 2 kV Common mode

voltage

36/60

Floors should be made of wood or

concrete or be covered with cera‐

mic tiles If the floor is covered with

a synthetic material, the relative air

humidity must be at least 30 %.

The quality of the supply voltage

should be equivalent to that of a ty‐

pical business or hospital environ‐

ment.

The quality of the supply voltage

should be equivalent to that of a ty‐

pical business or hospital environ‐

ment.

Page 39

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.7 Technical Data

Stability tests IEC 60601 - Test level Compliance level Electromagnetic environment - gui‐

de

Voltage drops, shortli‐

ved interruptions und

fluctuations in the sup‐

ply voltage in accor‐

dance with IEC

61000-4-11

< 5 % UT (> 95 % drop

in UT) for 1/2 period)

40 % UT (60 % drop in

UT) for 5 periods,

70 % UT (30 % drop in

UT) for 25 periods,

< 5 % UT (> 95 % drop

in UT) for 1/2 periods

< 5 % UT (> 95 % drop

in UT) for 1/2 period)

40 % UT (60 % drop in

UT) for 5 periods,

70 % UT (30 % drop in

UT) for 25 periods,

< 5 % UT (> 95 % drop

in UT) for 1/2 period)

The quality of the supply voltage

should be equivalent to that of a ty‐

pical business or hospital environ‐

ment. When the user of Dig eXam

demands continuing function of the

device even when the power supply

is interrupted, it is recommended

that Dig eXam be powered via an

uninterruptible power supply or a

battery.

Magnetic field at the

supply frequency

(50/60 Hz) in accor‐

dance with IEC

3 A/m 3 A/m Magnetic fields at the mains fre‐

quency should correspond to the

typical values found in business

and hospital environments.

61000-4-8

Guidelines and manufacturer's declaration - electromagnetic stability

Dig eXam is intended for use in the electromagnetic environment stipulated below.

The customer or user of In eXam should ensure that it is operated in an environment

of this type.

Stability tests IEC 60601 - test level Compliance level Electromagnetic environment - gui‐

de

Directed HF disturban‐

ces in accordance with

IEC 61000-4-6

Directed HF disturban‐

ces in accordance with

IEC 61000-4-3

3 V

eff

150 kHz to 80 MHz

3 V/m

80 MHz to 2.5 GHz

3 V

3 V/m

Portable and mobile radio equip‐

ment should not be used near to In

eXam or its cables, as the recom‐

mended safe distance has been

calculated in accordance with the

equation applicable for the trans‐

mitting frequency.

Recommended safe distance :

P

d = 1,2 *

up to 800 MHz

d = 2,3 * P for 800 MHz to 2.5 GHz

where PA is the power rating of the

transmitter in watts (WA) according

to information from the manufactu‐

rer of the transmitter, and d is the

recommended safe distance in me‐

tes (m).

The field intensity of stationary ra‐

dio transmitters should, at all fre‐

quencies according to local investi‐

gations,a be lower than the

compliance levelB.

Near to devices bearing the symbol

, interference is possible.

Comment:

The higher frequency range is applicable at 80 MHz und 800 MHz.

37/60

Page 40

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.7 Technical Data

a

The field intensity of stationary transmitters such as the base stations of radio

telephones and mobile land radio devices, amateur radio stations, AM and FM

broadcasting services or television transmitters cannot, in theory, be determined

precisely in advance. To determine the electromagnetic environment in respect of

stationary transmitters, a study of the location should be considered.

If the measured field intensity at the location in which Dig eXam is being used ex‐

ceeds the compliance level above, care should be taken with Dig eXam to ensure

that it is functioning in accordance with regulations. If unusual performance features

are noted, additional measures may be required, such as changing the alignment

or moving In eXam somewhere else.

b

The field intensity should be less than 3 V/m over the frequency range 150 kHz to

80 MHz.

Recommended safe distances between portable and mobile telecom‐

munications equipment and Dig eXam

Dig eXam is intended for use in an electromagnetic environment in which HF dis‐

turbances are checked The customer or user of In eXam can help to prevent

electromagnetic disturbances by complying with the minimum distance between

portable and mobile HF telecommunications equipment (transmitters) and In eXam,

depending on the output power of the communication device, as stipulated below.

The table shows the necessary safe distance, as a function of the transmission

frequency, in m:

Rated power of the trans‐

mitter in W

150 kHz to 80 MHz

D=1.2 *

P

80 MHz to 800 MHz

D=1.2 *

P

800 MHz to 2.5 GHz

D= 2.3 *

0.01 0.12 0.12 0.23

0.1 0.38 0.38 0.73

1 1.2 1.2 2.3

10 3.8 3.8 7.3

100 12 12 23

For transmitters for which the rated power is not shown in the table above, the dis‐

tance can be determined using the equation belonging to the relevant column, where

P is the rated power of the transmitter in watts (W) according to information from

the manufacturer of the transmitter.

Note

These guidelines may not be applicable in all situations The propagation of elect‐

romagnetic waves is affected by absorption and reflection due to buildings, objects

and people.

P

38/60

Page 41

Instructions for use KaVo Dig eXam 3520, 3530

3 Product description | 3.8 Dig eXam inspection service (only available in Germany)

3.8 Dig eXam inspection service (only available in Germany)

The function and calibration of connected devices, such as the monitor and X-ray

generator can be inspected and/or reconfigured via a separate service application

(KaVo Dig eXam inspection service).

39/60

Page 42

Instructions for use KaVo Dig eXam 3520, 3530

4 Operation | 4.1 Configuration of the Dig eXam driver software

4 Operation

4.1 Configuration of the Dig eXam driver software

▶ Left click on the X-ray Icon, to open the configuration dialogue.

The configuration dialogue covers three areas that are activated via the selection

tab:

▪ Information ("Information“)

▪ Configuration ("Configure“)

▪ Parameters ("Treatments“)

4.1.1 Selection Information

This dialog shows the software version of the interface between Dig eXam and Vix‐

Win in the top part.

The status of the connected sensors is shown in the middle area. When the Dig

eXam interface is activated in the Configure dialog, the status of the interface is also

shown. By clicking the Update button, this information can be reentered by the

Windows operating system.

When the Dig eXam Interface is not used, click the button "Prepare Acquisition" in

the bottom area (instead of using the button on the KaVo trigger) or in mixed mode

to prepare the device for taking an x-ray.

Note

The button is only displayed in the "Use In eXam" mode when "Mixed mode" is also

active.

40/60

Page 43

Instructions for use KaVo Dig eXam 3520, 3530

4 Operation | 4.1 Configuration of the Dig eXam driver software

4.1.2 Selection configuration

The upper part of the dialogue makes it possible to set the X-ray parameters that

are transferred automatically to VixWin.

The system events (e.g. "Sensor covered", "In eXam switched off") to be displayed

by the operating system in their own windows can be set in the bottom area of the

dialogue window.

Note

These data are used by the separate X-ray folder support program.

Without In eXam

By selecting the mode "Custom“ means that the user can specify standard values

for tube voltage (kV), the tube current (mA) and the exposure time (ms). These

parameters are added to every X-ray produced using Dig eXam and can be dis‐

played later in the VixWin-Software and if necessary adjusted to the parameters

selected for the individual X-ray image.

Using In eXam

When using In eXam the exposure time of the current X-ray image is automatically

recognised by the system and added to the X-ray image taken using Dig eXam. The

possible standard values can be preset for the values for the tube voltage (kV) and

the tube current (mA), in order to add these to the X-ray image as well. All three

parameters can be displayed in VixWin later and if necessary adjusted to the para‐

meters selected for the individual X-ray image.

41/60

Page 44

Instructions for use KaVo Dig eXam 3520, 3530

4 Operation | 4.1 Configuration of the Dig eXam driver software

Dig eXam as the exclusive image receptor

▶ -Deactivate the "Mixed mode" button.

Each time In eXam is triggered, a sensor image is taken.

Dig eXam alternating with other image receptors

Requirement

Each time before a sensor image is taken with Dig eXam, the system must assume

a ready state by pressing the trigger button or the button "Prepare for exposure" to

obtain a sensor image.

▶ Activate the "Mixed mode" button.

42/60

Page 45

Instructions for use KaVo Dig eXam 3520, 3530

4 Operation | 4.1 Configuration of the Dig eXam driver software

4.1.3 Selection parameters

This dialogue enables the setting of the details that are used for displaying the Xray image taken.

Note

It is recommended that the parameters are not altered without consulting the tech‐

nician and or KaVo Customer Services.

43/60

Page 46

Instructions for use KaVo Dig eXam 3520, 3530

4 Operation | 4.2 Taking a digital X-ray

4.2 Taking a digital X-ray

4.2.1 Overview

Taking an X-ray using KaVo Dig eXam together with VixWin PRO takes place in a

few steps that are explained in detail in the following:

▪ Start the program or toggle to it if already open

▪ Select patient

▪ Prepare and position sensor

▪ Take X-ray

▪ Form diagnosis from image

▪ Accept X-ray

4.2.2 Activate programme and select patient

▶ Click the VixWin Pro-Software icon.

44/60

Page 47

Instructions for use KaVo Dig eXam 3520, 3530

4 Operation | 4.2 Taking a digital X-ray

or

▶ Activate the program from the start menu

or

▶ Call up VixWin Pro via the interface administration software used in the practice /

clinic.

VixWin PRO is active.

▶ Select patient.

See also: User instructionsVixWin PRO.

Note

It is possible, as an alternative to the procedure described here, to take the X-ray

first and then after taking the X-ray to allocate the X-ray to the patient.

CAUTION

4.2.3 Prepare and position sensor

Hygiene is a key issue during the preparation and taking of X-rays and must be

considered alongside the issue of radiation protection.

Hygiene

To avoid health risks,KaVo sensors must be placed in a disposable hygienic pro‐

tective cover before each use. So called hygienic covers are placed over the sensor

before each treatment to guarantee the optimum levels of hygiene.

▶ Cover sensor with hygienic covers.

▶ Use a new disposable hygienic sensor cover for every patient.

Risk of infection

Contaminated sensors can transmit infections.

▶ Your practice should have a set of hygiene procedures which must be adhered

to.

▶ Disinfect sensors after contamination.

▶ Disinfect the used parts of the right-angle holder ( XCP-DS) after contamination.

▶ Always use hygienic covers Mat. no. 1.003.2690.

45/60

Page 48

Instructions for use KaVo Dig eXam 3520, 3530

4 Operation | 4.2 Taking a digital X-ray

Prepare the sensor with the hygiene sheet

See also: 6.1 Cleaning and disinfecting, Page 51

Right-angle holder set

Avoidable exposure to radiation.

Increased exposure to radiation through not using a radiation field limitation facility

CAUTION

during the right-angle technique.

▶ Always use a right-angle holder and radiation field limitation facility unless there

is a contra-indication in a particular case.

The XCP DS holding system is supplied with an operating instruction poster. For

further explanations on X-raying techniques, please see related textbooks.

See also:

Pasler, Friedrich A.: Zahnärztliche Radiologie (Dental Radiology), Thieme, 4th edi‐

tion 2003, ISBN 3136046048

Whaites, Eric: Essentials of Dental Radiography and Radiology (Dental Series),

Churchill Livingstone 1996, ISBN 0443053499

Position KaVo Dig eXam

TheKaVo Dig eXamdetector is positioned at the X-ray tube head during use of

theKaVo In eXam so that it is always in close proximity to the patient's head.

Place the sensor

If you are usingKaVo Dig eXam with X-ray sources from other manufacturers, the

patient should either be given the KaVo trigger to hold or have it placed on their

chest.

46/60

Page 49

Instructions for use KaVo Dig eXam 3520, 3530

4 Operation | 4.2 Taking a digital X-ray

Faults as a result of disruption to the USB line.

Breaking the connection between the KaVo trigger and USB line during use can

CAUTION

CAUTION

lead to faults.

▶ During use, never disconnect the KaVo trigger from the USB line!

Faults as a result of patient action.

If patients are unsupervised during the X-ray procedure, they may do something

that results in a fault or disruption.

▶ Ensure that patients are never left unsupervised during the X-ray procedure.

4.2.4 X-ray

▶ Position the X-ray source in accordance with the X-ray machine's operating in‐

structions for the type of X-ray you are about to take.

X-ray radiation danger

Increased exposure to radiation for patient and/or operator.

CAUTION

▶ Adhere to the X-ray machine operating instructions and country-specific regu‐

lations governing patient protection.

▶ Adhere to the X-ray machine operating instructions and country-specific regu‐

lations governing operator protection by keeping a safe distance or using a

screen.

Activate sensors (use eXam with other image receptors)

Requirement

When using third-party x-ray equipment or when the mixed mode setting is activa‐

ted to support the alternating use of other image receptors, activate the status

"Ready to take x-rays".

▶ Press the KaVo trigger button.

KaVo Trigger

or

47/60

Page 50

Instructions for use KaVo Dig eXam 3520, 3530

4 Operation | 4.2 Taking a digital X-ray

▶ Select button "Repair Acquisition“ in the information area of the Dig eXam-driver

software.

Note

This step is not necessary for KaVo In eXam with activatedKaVo Dig eXam Inter‐

face. KaVo Dig eXamis always ready to take an X-ray if the sensor is inserted on

account of its permanent connection to the interface.

Visual inspection

Visual inspection

Before you take the X-ray, have a quick look to make sure that

▪ The green icon is showing in the Windows System area

▪ The patient has not moved at all

▪ When using Dig eXam without In eXam-connection the ready dialogue is visible.

Sensor is activated (operation without In eXam connection)

48/60

Page 51

Instructions for use KaVo Dig eXam 3520, 3530

4 Operation | 4.2 Taking a digital X-ray

Image lost during the taking of X-rays.

The X-ray will not take if the driver is not active.

CAUTION

▶ Before taking an X-ray, make sure the software is ready.

▶ Take X-ray.

4.2.5 Conclude X-ray procedure

After you have finished taking the X-ray

▪ Detach the holding system and sensor

▪ Remove hygienic cover

▪ Restore used holder

▪ Restore contaminated sensor

▪ When using non-KaVo X-ray sources, store the sensor in a safe place

4.2.6 Create a diagnosis based on the radiograph

See also: User instructions VixWin Pro.

49/60

Page 52

Instructions for use KaVo Dig eXam 3520, 3530

5 Maintenance/safety inspections | 5.1 Checks

5 Maintenance/safety inspections

5.1 Checks

The following checks must be made at the times specified

▪ Monthly: Check the data backup function is running smoothly.

▪ Annually: Perform a visual inspection of connection leads, wires and casing to

check for damage.

50/60

Page 53

Instructions for use KaVo Dig eXam 3520, 3530

6 Preparation methods DIN EN ISO 17664 | 6.1 Cleaning and disinfecting

6 Preparation methods DIN EN ISO 17664

Damage resulting from improper equipment preparation

Improper cleaning and disinfection can lead to damage to the KaVo Dig eXam.

CAUTION

▶ Adhere closely to the instructions provided in this section.

▶ Use the correct substances and procedures for the job at hand.

6.1 Cleaning and disinfecting

Note

KaVo Dig eXam does not include any parts requiring sterilisation as part of their

intended use.

The sensor holder can be removed from the KaVo trigger for cleaning and disin‐

fection.

Note

The detector including the connecting line should be provided with a hygiene sheet

to prevent direct contamination by the detector during use.

The sensors used within intraoral dentistry are highly sophisticated electronic devi‐

ces. And as such should be handled with extreme care.

▪ Before you begin cleaning and disinfecting, detach the sensors from the USB

connection.

▪ Do not exert pressure on the sensors during the cleaning and disinfection pro‐

cedure; in particular, do not pull or bend their wires.

▪ Do not entangle the KaVo trigger and USB line when connecting or disconnec‐

ting.

▪ Do not allow moisture to penetrate the KaVo trigger and USB line plug-fit con‐

nections and the line's USB connector.

6.1.1 Cleaning

All external surfaces of the KaVo Dig eXam can be wiped with a soft cloth impreg‐

nated with a mild cleaning fluid.

The sensor holders and separate parts of the right-angle holder set can also be

machine-cleaned.

6.1.2 Disinfection

Disinfect contaminated parts of KaVo Dig eXam after use.

Wipe disinfection with disinfecting agents containing alcohol

All external surfaces of the KaVo Dig eXam can be wiped with a soft cloth impreg‐

nated with a mild cleaning fluid.

The following disinfectant is permitted: