KaVo ELECTROmatic M, ELECTROmatic C, ELECTROmatic PC, ELECTROmatic PM, ELECTROmatic TM Instructions For Use Manual

...Page 1

Instructions for use

ELECTROmatic M/C and PM/PC

Page 2

Distributed by:

KaVo Dental Technologies, LLC

11727 Fruehauf Drive

Charlotte, NC 28273 USA

Phone: 847 550 6800

Fax: 847 550 6825

Manufacturer:

Kaltenbach & Voigt GmbH

Bismarckring 39

88400 Biberach

Germany

www.kavo.com

Page 3

Instructions for use ELECTROmatic M/C and PM/PC

Table of contents

Table of contents

1 User notes........................................................................................................................... 6

1.1 User guidelines.............................................................................................................. 6

1.1.1 Abbreviations ..................................................................................................... 6

1.1.2 General marks and symbols................................................................................. 6

1.2 Target group................................................................................................................. 7

1.3 Service ......................................................................................................................... 7

1.3.1 Repair Service.................................................................................................... 7

1.4 Warranty terms and conditions........................................................................................ 8

1.5 Transportation and storage............................................................................................. 8

1.5.1 Damage in transit............................................................................................... 8

1.5.2 Information on the packaging: Storage and transport............................................. 9

1.6 Disposal........................................................................................................................ 10

1.7 Disposal of electronic and electrical devices ...................................................................... 11

2 Safety.................................................................................................................................. 12

2.1 Infection hazard ........................................................................................................... 12

2.2 Explosion hazard area.................................................................................................... 12

2.3 Technical condition......................................................................................................... 12

2.4 Ingress of liquids ........................................................................................................... 13

2.5 Accessories and combination with other equipment........................................................... 13

2.6 Qualification of personnel................................................................................................ 14

2.7 Service and repair.......................................................................................................... 14

2.8 Electromagnetic fields .................................................................................................... 14

3 Product description ............................................................................................................16

3.1 Purpose - proper use...................................................................................................... 16

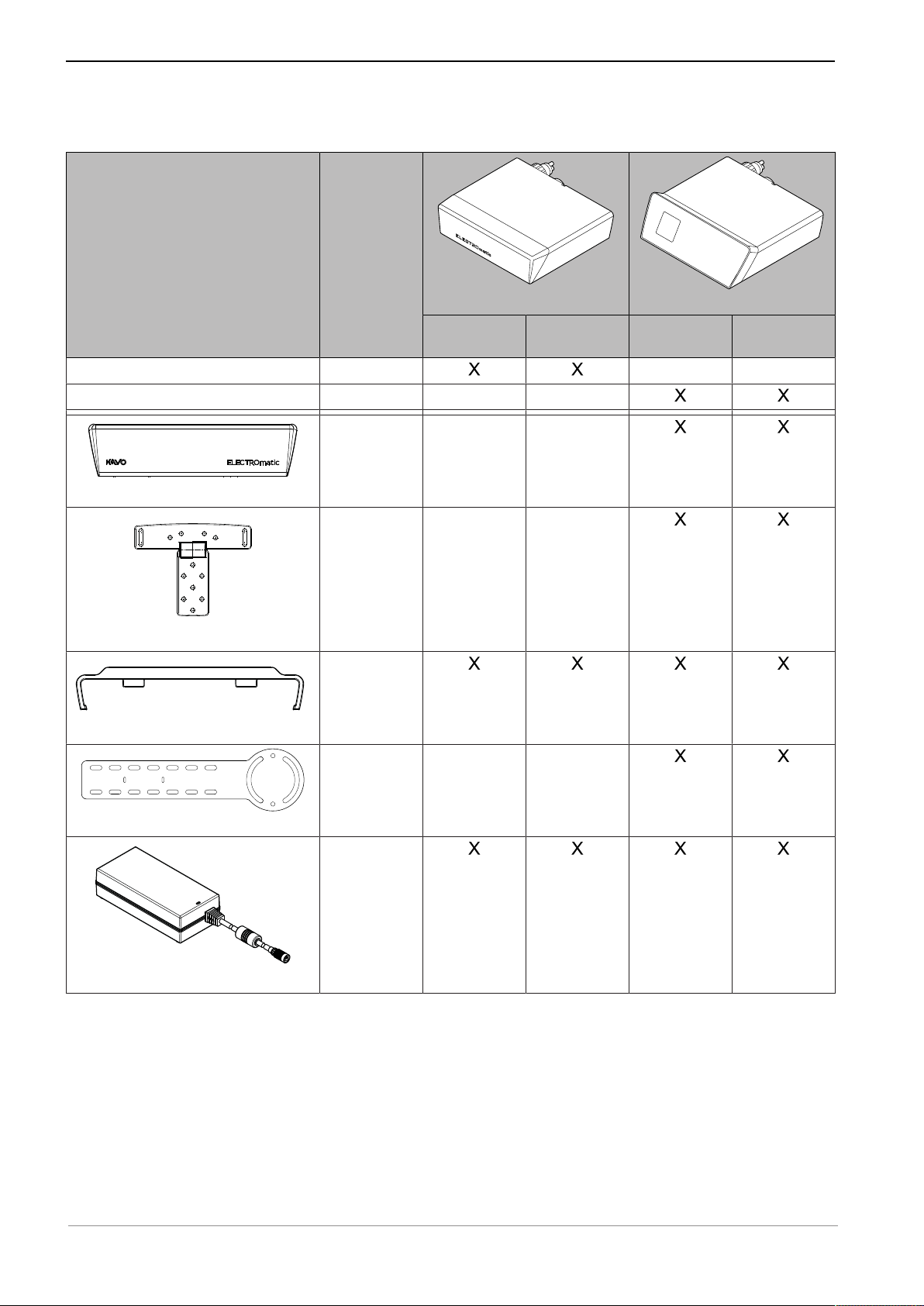

3.2 Scope of delivery........................................................................................................... 18

3.3 ELECTROmatic – Versions............................................................................................... 22

3.4 Motor hose.................................................................................................................... 22

3.5 Control panel (PM/PC only)............................................................................................. 23

3.6 Technical specifications of the ELECTROmatic ................................................................... 25

3.7 Symbols on product and rating plate................................................................................ 28

3.8 Power supply type 4882 ................................................................................................. 29

3.9 Technical data for the power supply type 4882 ................................................................. 29

3.10Symbols on the nameplate of the type 4882 power supply................................................. 30

4 Installation .........................................................................................................................32

4.1 Location........................................................................................................................ 32

4.2 Installation positions ...................................................................................................... 32

4.3 Preparing the installation................................................................................................ 34

4.4 Installation position 1: Mount below a holder.................................................................... 34

4.5 Installation position 2: Mount on the side of a holder......................................................... 36

4.6 Installation position 3: Mount on a holder or on the backside of a holder ............................. 38

4.7 Installation position 4: Mount control panel as remote control (PM/PC only)......................... 40

4.7.1 Disconnect the control panel from the control unit and install it on the mounting

bracket.............................................................................................................. 40

4.7.2 Mount control panel on a holder / on the backside of a holder ................................. 42

3 / 80

Page 4

Instructions for use ELECTROmatic M/C and PM/PC

Table of contents

4.7.3 Mount control panel on the side of a holder ........................................................... 43

4.7.4 Mount control panel to cabinet/wall ...................................................................... 46

4.8 Connect the ELECTROmatic ............................................................................................ 47

4.9 Check the installation ..................................................................................................... 47

5 Commissioning ................................................................................................................... 48

5.1 Connection.................................................................................................................... 48

5.1.1 Electrical operating conditions .............................................................................. 48

5.1.2 Connecting the ELECTROmatic............................................................................. 48

5.1.3 Connecting the motor.......................................................................................... 49

5.1.4 Connect the motor cord....................................................................................... 50

5.1.5 Connect the power supply .................................................................................. 50

5.2 Calibrating the foot control.............................................................................................. 51

5.3 Measure cooling air quantity at motor coupling ................................................................. 52

5.4 Making the device settings.............................................................................................. 52

6 Operation............................................................................................................................ 56

6.1 Switching the ELECTROmatic on/off................................................................................. 56

6.2 Start the motor ............................................................................................................. 57

6.3 Regulating the spray water............................................................................................. 57

6.4 Changing the speed setting............................................................................................. 58

6.5 Changing the direction of rotation.................................................................................... 58

6.6 Protection function SAFEdrive (PM/PC only)...................................................................... 58

6.6.1 Turning SAFEdrive on / off................................................................................... 59

6.6.2 Use with the SAFEdrive function........................................................................... 60

7 Decommissioning ............................................................................................................... 62

7.1 Disconnecting the electrical connection ............................................................................ 62

7.2 Disconnecting the ELECTROmatic from the treatment unit ................................................. 62

7.3 Unplugging the motor/COMFORTdrive.............................................................................. 62

8 Processing steps in accordance with DIN EN ISO 17664...................................................63

8.1 Cleaning ....................................................................................................................... 63

8.1.1 Preparation at the site of use ............................................................................... 63

8.1.2 Manual external cleaning..................................................................................... 63

8.1.3 Manual cleaning of the inside ............................................................................... 63

8.1.4 Mechanical cleaning of the exterior and interior...................................................... 64

8.2 Disinfection................................................................................................................... 64

8.2.1 Manual external disinfection................................................................................. 64

8.2.2 Manual disinfection of the interior......................................................................... 64

8.2.3 Mechanical disinfection of the exterior and interior ................................................. 65

8.3 Packaging..................................................................................................................... 65

8.4 Sterilization................................................................................................................... 65

8.5 Storage ........................................................................................................................ 65

8.6 Service, inspection and testing after processing ................................................................ 65

9 Maintenance .......................................................................................................................66

9.1 Changing the filter - water inlet....................................................................................... 66

9.2 Replacing the LED lamp of the KL 703 motor.................................................................... 67

9.3 Replacing the LED lamp of the COMFORTbase................................................................... 68

9.4 Replacing the motor hose............................................................................................... 68

4 / 80

Page 5

Instructions for use ELECTROmatic M/C and PM/PC

Table of contents

10Troubleshooting .................................................................................................................70

11Accessories and consumables............................................................................................73

12Information on electromagnetic compatibility...................................................................74

12.1Guidelines and manufacturer's declaration - electromagnetic emission ................................ 74

12.2Guidelines and manufacturer's statement - Electromagnetic immunity ................................ 74

12.3Guidelines and manufacturer's statement - Electromagnetic immunity ................................ 75

12.4Recommended safe distances between portable and mobile HF telecommunications

equipment and the ELECTROmatic................................................................................... 77

5 / 80

Page 6

Instructions for use ELECTROmatic M/C and PM/PC

1 User notes | 1.1 User guidelines

1 User notes

1.1 User guidelines

Requirement

Read these instructions prior to first startup to avoid misuse and prevent damage.

Requirement

If other languages are required, they can be requested from the responsible

KaVo branch. Prior approval from KaVo must be obtained before copying and

passing on the instructions for use.

1.1.1 Abbreviations

Abbreviation

IFU Instructions for use

CI Care instructions

Short

IfU

AI Assembly instructions

TI Technician's instructions

IEC International Electrotechnical Commission

RI Repair instructions

RK Retrofitting kit

AS Assembly set

CK Conversion kit

EP Enclosed parts

EMC Electromagnetic compatibility

PI Processing instructions

Explanation

Short instructions for use

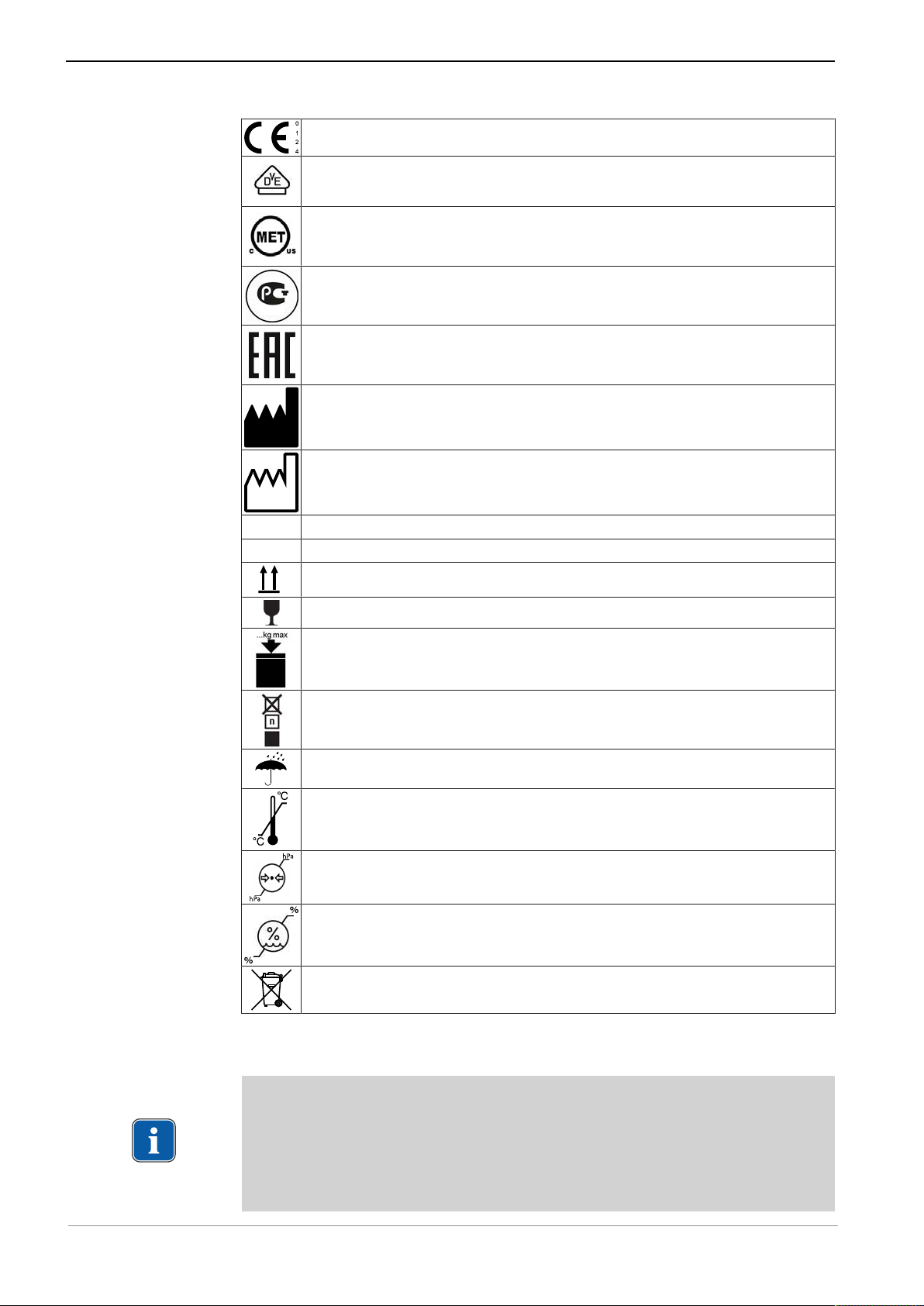

1.1.2 General marks and symbols

See section on Hazard levels

Important information for users and technicians

CE mark (European Community). A product bearing this mark meets

the requirements of the applicable EU directive.

Action required

Hazard levels

The warning and safety notes in this document must be observed to prevent

personal injury and property damage. The warning notes are designated as

shown below:

6 / 80

Page 7

Instructions for use ELECTROmatic M/C and PM/PC

1 User notes | 1.2 Target group

DANGER

In cases which – if not prevented – directly lead to death or severe injury.

WARNING

In cases which – if not prevented – can lead to death or severe injury.

CAUTION

In cases which – if not prevented – can lead to minor or moderate injury.

NOTICE

In cases which – if not prevented – can lead to property damage.

1.2 Target group

This document is for dentists, dental practice staff and service staff.

1.3 Service

Note

Send the product in for a service check every two years.

In this service check, the safety checks are performed according to IEC 62353 VDE 0751-1.

Please direct all questions regarding the product, service and maintenance to

the

KaVo Technical Service:

Toll-free: 1-888-ASK-KAVO (888-275-5286)

Email: techservice@kavokerr.com

Please refer to the serial number of the product in all inquiries!

1.3.1 Repair Service

For repairs, please contact KaVo Repair Service.

For scheduling or if you have any questions, please contact:

KaVo Repair Service

KaVo Dental Technologies, LLC

11727 Fruehauf Drive

Charlotte, NC 28273 USA

Toll-free Direct Customer Service: 1-888-ASK-KAVO (888-275-5286)

Email: techservice@kavokerr.com

www.kavo.com

7 / 80

Page 8

Instructions for use ELECTROmatic M/C and PM/PC

1 User notes | 1.4 Warranty terms and conditions

1.4 Warranty terms and conditions

Within the scope of the applicable KaVo delivery and payment conditions, KaVo

guarantees proper function, absence of defects in material and workmanship

for a period of 36 months from the date of purchase as confirmed by the salesperson.

In case of justified complaints, KaVo will honor its warranty with a free replacement or repair.

The warranty does not cover defects and their consequences that arose or may

have arisen due to natural wear, improper handling, cleaning or servicing, noncompliance with operating, maintenance or connection instructions, corrosion,

contaminated media supply or chemical or electrical influences deemed abnormal or impermissible in accordance with factory specifications.

The warranty does not usually cover lamps, light conductors made of glass and

glass fibers, glassware, rubber parts and the colorfastness of plastic parts.

The warranty shall be void if defects or their consequences may be related to

modifications of or changes to the product. Warranty claims can only be asserted when they are immediately reported to KaVo in writing.

This notification must be accompanied by a copy of the invoice or delivery note

on which the manufacturing number is clearly visible. In addition to the warranty, the statutory warranty claims of the purchaser also apply with a warranty period of 12 months.

Defects and the consequences of defects, in particular because of insufficient

servicing of the water filter, are not covered by the warranty.

1.5 Transportation and storage

1.5.1 Damage in transit

In Germany

If the packaging is visibly damaged on delivery, please proceed as follows:

1. The recipient of the package must record the loss or damage on the delivery

receipt. The recipient and the representative of the shipping company must

sign this delivery receipt.

2. Leave the product and packaging in the condition in which you received it.

3. Do not use the product.

4. Report the damage to the shipping company.

5. Report the damage to KaVo.

6. Consult with KaVo first, before returning a damaged product.

7. Send the signed delivery receipt to KaVo.

If the product is damaged but there was no discernable damage to the packaging on delivery, proceed as follows:

1. Report the damage to the shipping company immediately and no later than

7 days after delivery.

2. Report the damage to KaVo.

3. Leave the product and packaging in the condition in which you received it.

4. Do not use a damaged product.

8 / 80

Page 9

Instructions for use ELECTROmatic M/C and PM/PC

1 User notes | 1.5 Transportation and storage

Note

Failure on the part of the recipient to comply with any of the above-mentioned obligations will mean that the damage will be considered to have

arisen only after the time of delivery (in accordance with the General German

Freight Forwarders' Terms and Conditions, Art. 28).

Outside of Germany

Note

KaVo shall not be held liable for damage arising from transportation.

The shipment must be checked on arrival.

If the packaging is visibly damaged on delivery, please proceed as follows:

1. The recipient of the package must record the loss or damage on the delivery

receipt. The recipient and the representative of the shipping company must

sign this delivery receipt.

Without this evidence, the recipient will not be able to assert a claim for

damages against the shipping company.

2. Leave the product and packaging in the condition in which you received it.

3. Do not use the product.

If the product is damaged but there was no discernable damage to the packaging on delivery, proceed as follows:

1. Report any damage to the shipping company immediately and no later than

7 days after delivery.

2. Leave the product and packaging in the condition in which you received it.

3. Do not use a damaged product.

Note

If the recipient fails to comply with any of the above-mentioned obligations,

the damage will be considered to have arisen only after the time of delivery

(in accordance with CMR law, Chapter 5, Art. 30).

1.5.2 Information on the packaging: Storage and

transport

Note

Please keep the packaging in case you need to return the product for servicing or repair.

The symbols printed on the outside are for transportation and storage, and

have the following meaning:

Caution

Follow instructions for use

Please note the electronic instructions for use

HIBC Code

9 / 80

Page 10

Instructions for use ELECTROmatic M/C and PM/PC

1 User notes | 1.6 Disposal

CE mark (European Conformity mark)

VDE mark

MET mark

GOST R certification

EAC conformity mark (Eurasian Conformity = Eurasische Konformität)

Manufacturer

Date of manufacture: Year - Month - Day

SN Serial number

REF Catalog number

Transport upright with the arrows pointing upwards!

Fragile - protect against impact!

Permissible stacking load

Stacking limit by number

Protect from moisture!

Temperature range

Air pressure

Humidity

Do not dispose this product into the ordinary municipal waste or

garbage system

1.6 Disposal

Note

Any waste produced must be recycled or disposed of in strict compliance with

all applicable national regulations in a manner which is safe for both people

and the environment.

If you have any questions regarding proper disposal of the KaVo product,

please contact the KaVo branch.

10 / 80

Page 11

Instructions for use ELECTROmatic M/C and PM/PC

1 User notes | 1.7 Disposal of electronic and electrical devices

1.7 Disposal of electronic and electrical devices

Note

In accordance with EC directive 2012/19 concerning waste electrical and

electronic equipment, this product is subject to the cited directive and must

be disposed of accordingly within Europe.

For more information, please visit www.kavo.com or contact your specialized

dental supplier.

For final disposal:

In Germany

To return an electrical device, you need to proceed as follows:

1. On the homepage www.enretec.de of enretec GmbH, you can download a

form for a disposal order under the menu item, eom. Download the disposal

order or complete it as an online order.

2. Enter the corresponding information to complete the order, and submit it as

an online order or by fax +49 (0)3304 3919 590 to enretec GmbH.

The following contact options are also available for questions and for initiating a disposal order:

Telefon: +49 (0) 3304 3919 500

Email: eom@enretec.de and

Postal address: enretec GmbH, Geschäftsbereich eomRECYCLING®

Kanalstraße 17

D-16727 Velten

3. A unit that is not permanently installed will be picked up at the office.

A permanently installed unit will be picked up at the curb at your address on

the agreed date.

The owner or user of the device will have to bear the cost of disassembly,

transportation and packaging.

International

For country-specific information on disposal, contact your dental supplier.

11 / 80

Page 12

Instructions for use ELECTROmatic M/C and PM/PC

2 Safety | 2.1 Infection hazard

2 Safety

The instructions for use are a component of the product and must be read carefully prior to use and be accessible at all times.

The device may only be used in accordance with the intended use, any other

type of use is not permitted.

2.1 Infection hazard

Patients, users or third parties can be infected by contaminated medical devices.

▶ Take suitable personal protective measures.

▶ Follow the instructions for use of the components.

▶ Before initial startup and after each use, process the product and acces-

sories appropriately.

▶ Carry out the processing as described in the instructions for use. The proce-

dure has been validated by the manufacturer.

▶ If you deviate from this procedure, it is essential to make sure that the pro-

cessing is effective.

▶ Process the product and accessories appropriately before disposal.

2.2 Explosion hazard area

Electrical sparks in the product can lead to explosion or fire.

▶ Do not use product in explosion hazard areas.

▶ Do not operate the product in an oxygen-enriched atmosphere.

▶ Do not use the product in the vicinity of flammable gases.

2.3 Technical condition

A damaged device or components can injure patients, users and third parties. A

damaged power cable or missing protective conductor can lead to electrical

shock.

▶ Use the device and components only if there is no damage on the outside.

▶ Check the power cable before use.

▶ Connect only to sockets with a protective contact that meet the respective

national regulations.

▶ Check the proper working order and proper condition of product and acces-

sories before each use.

▶ Have parts with sites of breakage or surface changes checked by the Ser-

vice.

▶ Safety checks may only be performed by trained service personnel.

▶ Perform a test run with the handpiece before each use.

▶ If any of the following defects on the product or accessories occurs, stop

working and have the service personnel carry out repair work:

▪ Malfunctions

▪ Damage

▪ Irregular running noise

▪ Excessive vibration

12 / 80

Page 13

Instructions for use ELECTROmatic M/C and PM/PC

2 Safety | 2.4 Ingress of liquids

▪ Overheating

▪ Dental bur or diamond is not firmly locked in the handpiece

Careless setup/installation of the product or accessories can cause injury to patients, users and third parties. Power supplies and/or cords/hoses on the floor

can cause slipping or tripping.

▶ Power supply and cord/hoses need to be set-up/routed appropriately such

that they are not on the floor.

Note

The SAFEdrive function is a monitoring function for detection of defective

high-speed handpieces. Defective high-speed handpieces can heat up

strongly during use due to additional friction, especially in the head region,

and possibly cause burn injuries. KaVo recommends to activate the

SAFEdrive function during treatments inside the oral cavity in order to reduce

the risk of burn injuries caused by defective high-speed handpieces.

2.4 Ingress of liquids

Use of the product in moist or electrically conductive environments can lead to

electrical shock and injury to patients, users and third parties.

▶ Use the product in dry environments exclusively.

▶ Use the product only in environments that are not electrically conductive.

▶ Protect openings of the product from any ingress of liquids.

▶ Do not place the product in a trough-like container.

▶ If any liquid is detected on the device, disconnect the power cable from the

supply mains right away and do not touch the product.

▶ Make sure that the surface of the product is absolutely dry before plugging

the power cable back into the socket.

▶ After interventions on and repairs of the device and before re-use, have the

service personnel perform a safety check on the device.

2.5 Accessories and combination with other equipment

Use of un-authorized accessories on the device or un-authorized modifications

to the device can lead to injury.

▶ Only use accessories that have been approved for combination with the

product by the manufacturer.

▶ Only use accessories that are equipped with standardized interfaces.

▶ Do not make any modifications to the device unless these have been ap-

proved by the manufacturer of the product.

Improper use of handpieces can cause injuries.

You need to comply with the following guidelines to ensure the safe use of the

electrically-driven handpieces:

▶ Comply with the instructions for use of the respective handpiece.

▶ Check the speed setting each time you turn on the device.

▶ Comply with the permissible maximum speed and maximum contact pres-

sure of the tools as specified by the tool manufacturer.

▶ Comply with the servicing instructions for handpieces as specified in the re-

spective instructions for use.

13 / 80

Page 14

Instructions for use ELECTROmatic M/C and PM/PC

2 Safety | 2.6 Qualification of personnel

▶ Never press the push-button during operation of the device.

▶ Never use the push-button to lift the cheek or tongue.

Improper use of tools, e.g. wrong drill lengths and files, can cause injuries.

▶ Comply with manufacturer's instructions (mode of operation, speed, torque

levels, torsion resistance, etc.), and use the files according to their intended

use.

2.6 Qualification of personnel

Application of the product by users lacking appropriate medical training can injure the patient, the user or third parties.

▶ Make sure that the user has read and comprehends the instructions for use.

▶ Only employ the device if the user has the appropriate medical training.

▶ Comply with national and regional regulations.

The bluish LED light of the motors can damage the cornea or lens of the eye.

▶ Do not gaze into the lamp when it is in operation.

▶ Use adequate shielding for eye protection.

2.7 Service and repair

Servicing work that is described in the "Servicing" chapter of the present Instructions for Use can be performed by the operator/user.

Repairs and safety checks may only be performed by trained service personnel.

The following persons are authorized to do this:

▪ Service technicians of KaVo branches after the appropriate product training

▪ Service technicians of KaVo authorized dealers after the appropriate product

training

▪ Independent service technicians after the appropriate product training

Comply with the following items during all servicing work:

▶ Have the service and testing tasks carried out in accordance with the autho-

rized personal.

▶ After interventions on and repairs of the device and before re-use, have the

service personnel perform a safety check on the device.

▶ The device should be serviced, cleaned, and stored in a dry location, and

should be disconnected from the power system, according to instructions, if

it is not to be used for extended periods.

Note

KaVo provides wiring diagrams, component lists, descriptions, calibration instructions or other information on request to support the service personnel

during repair work.

2.8 Electromagnetic fields

Electromagnetic fields might interfere with the functions of implanted systems

(such as cardiac pacemakers).

14 / 80

Page 15

Instructions for use ELECTROmatic M/C and PM/PC

2 Safety | 2.8 Electromagnetic fields

Medical electrical devices are subject to special precautions regarding electromagnetic compatibility and must be installed and operated in accordance with

the tables of electromagnetic compatibility.

See also:

2 12 Information on electromagnetic compatibility, Page 74

High-frequency communications devices may interfere with medical electrical

devices.

▶ Ask patients if they have a cardiac pacemaker or other system implanted

before you start the treatment.

▶ Comply with the tables of electromagnetic compatibility during installation

and commissioning.

▶ If the device needs to be used in the immediate vicinity of other equipment,

monitor the device or system for malfunctions.

15 / 80

Page 16

Instructions for use ELECTROmatic M/C and PM/PC

3 Product description | 3.1 Purpose - proper use

3 Product description

The ELECTROmatic dental control unit is a stand-alone system for operating

electric driven handpieces. An external power supply provides electric power to

the unit. The 4-hole tubing connected to the unit supplies chip / cooling air, water and pressure signal. The electrical low-voltage motor is connected to the

KaVo-specific tubing of the ELECTROmatic. The converted pneumatic output

signal (electrical energy) from a dental treatment center drives the motor to

operate an electric driven dental handpiece. The speed of the electric handpiece

is controlled by air pressure of the dental treatment center. The control unit is

positioned close to a treatment unit at the location preferred by the dentist. The

ELECTROmatic system consists of a base unit with a motor hose, an electrical

motor, a transformer, and a power cord.

The following versions of the product can be ordered:

▪ ELECTROmatic M

▪ ELECTROmatic C

▪ ELECTROmatic PM

▪ ELECTROmatic PC

See also:

2 3.2 Scope of delivery, Page 18

Only the ELECTROmatic PM/PC version of the product is depicted in the following. The descriptions apply to all versions of the ELECTROmatic M/C and

ELECTROmatic PM/PC product, unless explicitly stated otherwise.

3.1 Purpose - proper use

Indications for use:

The ELECTROmatic is intended to convert pneumatic output from a dental

treatment center to electrical energy to drive the COMFORTdrive motor handpiece and the INTRA LUX KL 703 LED motor for operation of electrically-driven

dental handpieces. This device is intended for use by a trained professional in

the field of general dental medicine.

CAUTION

US Federal law restricts this device to sale by or on the order of a

healthcare professional / dentist.

For dental use only.

Proper Use:

The overarching guidelines and/or national laws, national regulations and the

rules of technology applicable to medical devices for startup and use of the

KaVo product for the intended indications for use must be applied and followed.

Definition (purpose) Explanation

Primary function Dental treatment for preparations and

endodontics

16 / 80

Page 17

Instructions for use ELECTROmatic M/C and PM/PC

3 Product description | 3.1 Purpose - proper use

Definition (purpose) Explanation

Use For dental treatment of humans

Tooth crown and root

Specification of the primary function Network-dependent add-on devise for

the dentist unit

Duration of use Approximately 30 to 40 minutes with

individual interruptions

KaVo shall not be responsible for damage caused by:

▪ External influences, poor media quality or faulty installation.

▪ The use of incorrect information.

▪ Repair work carried out incorrectly.

▪ If the 2-year service check have not been done

17 / 80

Page 18

Instructions for use ELECTROmatic M/C and PM/PC

3 Product description | 3.2 Scope of delivery

3.2 Scope of delivery

Figure Catalog

number

Control unit 1.011.1800

Control unit 1.011.1900

1.011.8054

Cover panel

1.011.7165

Mounting bracket

1.011.7168

Insert holder

1.011.8106

ELECTROmatic M/C

ELECTROmatic M

ELECTROmatic C

ELECTROmatic PM/PC

ELECTROmatic PM

ELECTROmatic PC

Mounting plate

Power supply type 4882

1.005.0120

18 / 80

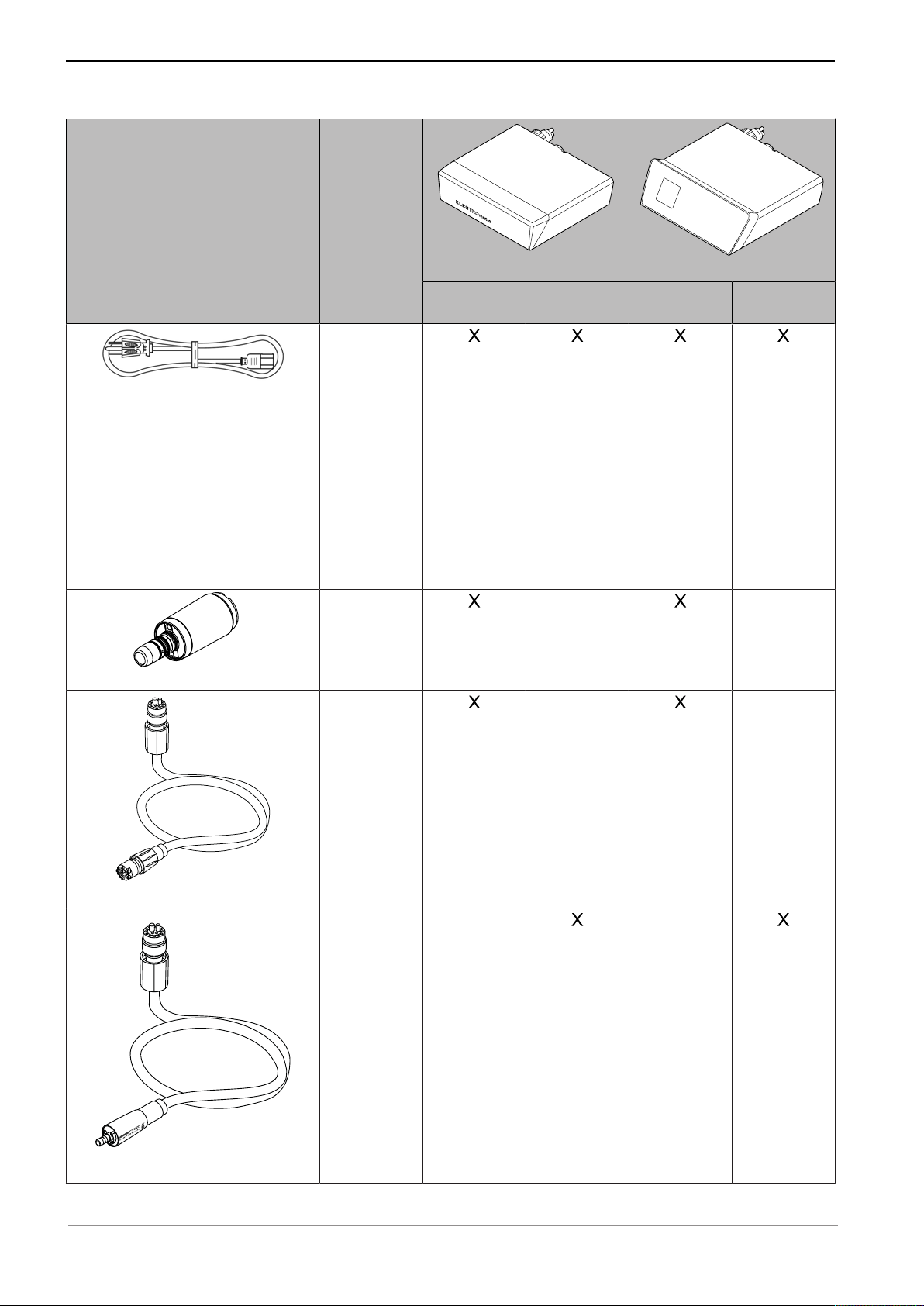

Page 19

Figure Catalog

number

Instructions for use ELECTROmatic M/C and PM/PC

3 Product description | 3.2 Scope of delivery

Power cable (country-specific)

INTRA LUX Motor KL 703 LED

1.002.6861

US

0.223.4142

EU

0.692.6901

UK

0.692.6851

AU

1.013.2293

BR

1.004.3850

CN

0.692.6881

CH

1.007.0150

KL Motor

hose 1750

1.011.7200

or

KL Motor

hose 2200

1.011.5668

ELECTROmatic M/C

ELECTROmatic M

ELECTROmatic C

ELECTROmatic PM/PC

ELECTROmatic PM

ELECTROmatic PC

KL Motor hose 1750/2200

COMFORTbase 1750/2200

COMFORTbase 1750

1.011.7335

or

COMFORTbase 2200

1.011.7076

19 / 80

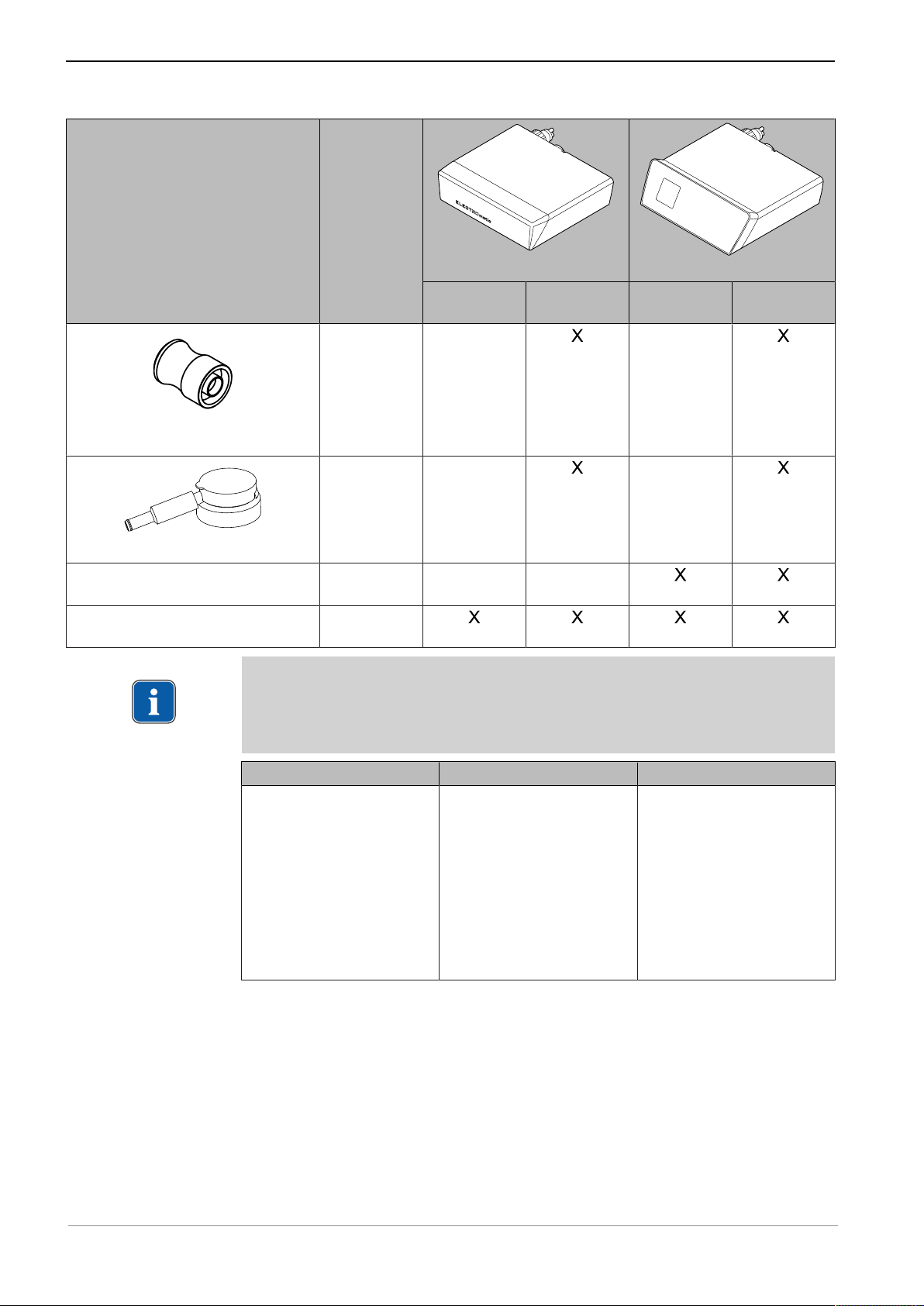

Page 20

Instructions for use ELECTROmatic M/C and PM/PC

3 Product description | 3.2 Scope of delivery

Figure Catalog

number

Germ reduction attachment for COMFORTdrive

Spray head for COMFORTdrive

Short instructions for use

ELECTROmatic PM/PC

Assembly instructions

ELECTROmatic

Note

Use exclusively the power cables and mains plugs approved in the specific

country. Use exclusively the power cables and mains plugs with the electrical

nominal data as listed in the following table.

1.006.5370

1.005.3154

1.012.9291

1.013.0312

ELECTROmatic M/C

ELECTROmatic M

ELECTROmatic C

ELECTROmatic PM/PC

ELECTROmatic PM

ELECTROmatic PC

Power cable Mains plug IEC coupler

▪ 3 x 18 AWG

▪ 60 oC / 140 oF

▪ 300 V

▪ black

▪ Style SJT

▪ Plug Hospital Grade

▪ NEMA 5 - 15

▪ Norm UL 498, CSA

▪ EN 60320 / C13

▪ 10 A

▪ 250 VAC

▪ black or transparent

C22.2 no 42

▪ black or transparent

▪ Marking ZJCZ.E41542

oder ZJCZ+CSA oder

ELBZ2/8

The installation set is part of the scope of delivery of all versions and consists of

the following parts:

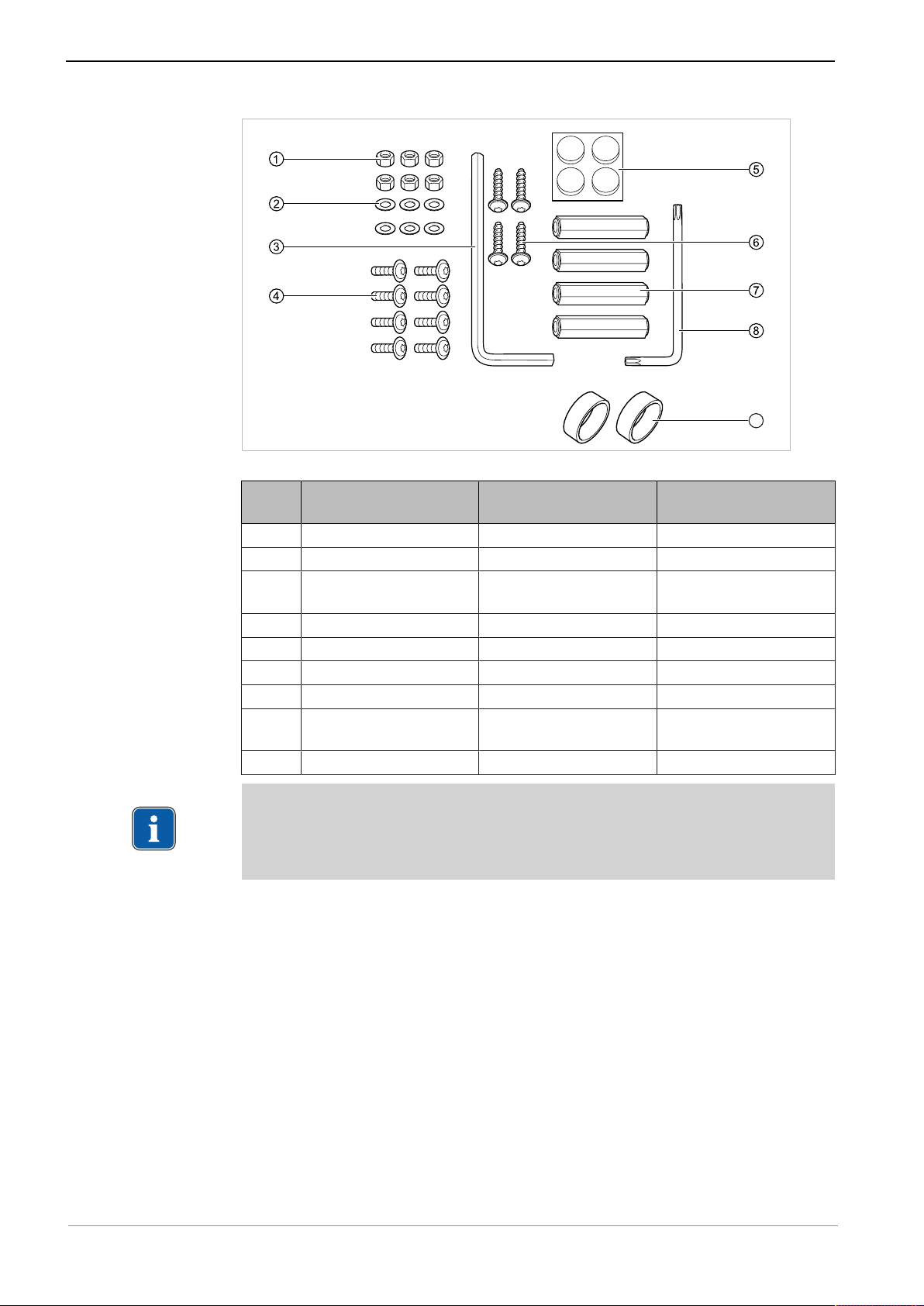

20 / 80

Page 21

Instructions for use ELECTROmatic M/C and PM/PC

9

3 Product description | 3.2 Scope of delivery

ELECTROmatic installation set (Mat. no. 1.012.1883)

Pos.

Mat. No. Description Number

no.

① 0.251.5804 Hexagonal nuts M4 6

② 0.242.4012 Washers 6

③ 1.004.1568 Offset screwdriver

1

SW5

④ 1.012.0213 Screws M4x12 8

⑤ 0.220.0441 Pad 4

⑥ 1.012.0184 Screws 4x14 4

⑦ 1.012.1999 Spacer bolt, 35 mm 4

⑧ 1.012.1853 Offset screwdriver Torx

1

T20

⑨ 1.007.9736 Filter insert 2

Note

The pads enclosed in the installation set can be attached to the underside of

the device, if needed. The purpose of the pads is to prevent the device from

slipping.

See also:

2 4.6 Installation position 3: Mount on a holder or on the backside of a holder,

Page 38

21 / 80

Page 22

Instructions for use ELECTROmatic M/C and PM/PC

ELECTROmatic M/CELECTROmatic PM/PC

2

1

3

2

1

3

4

5

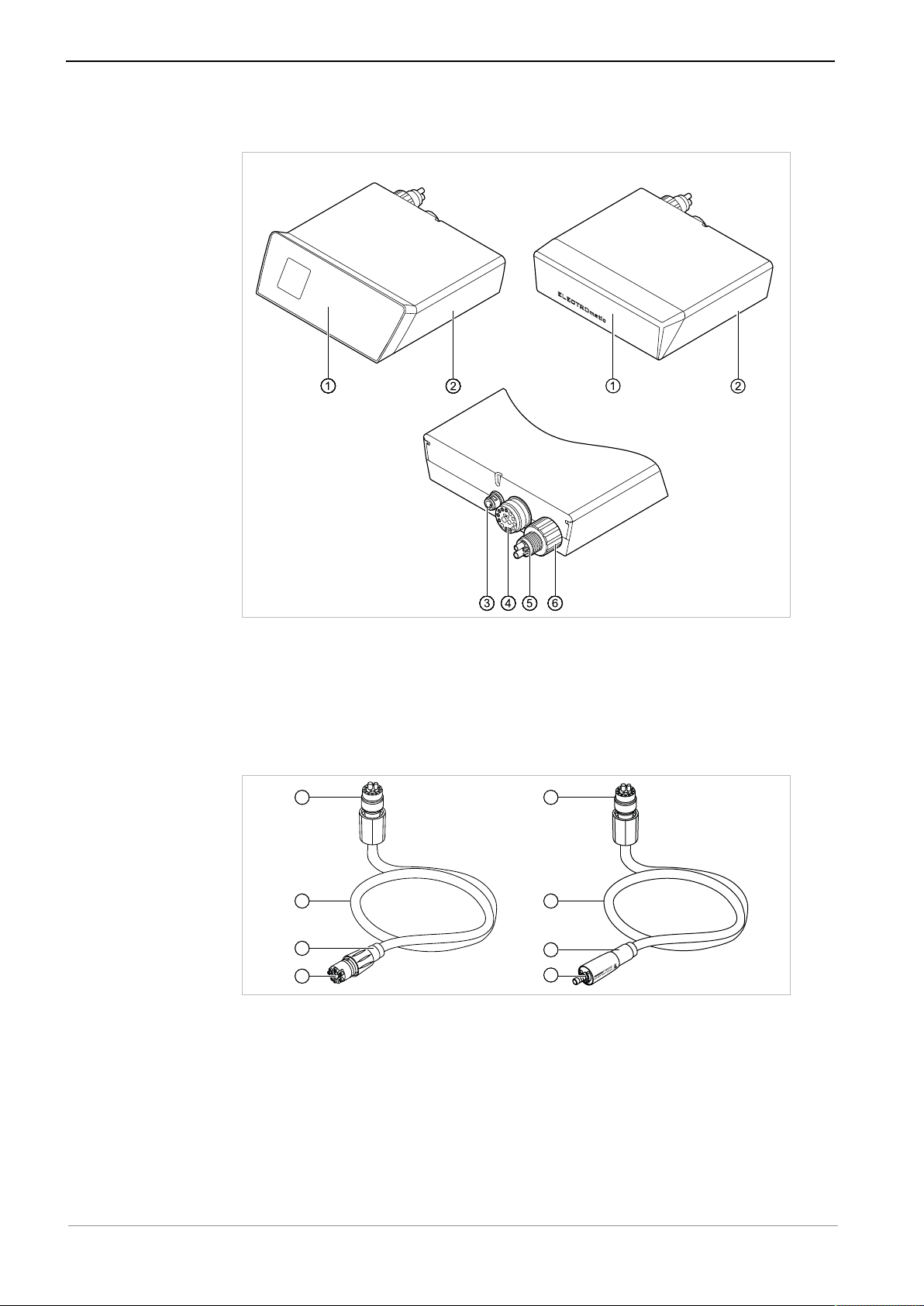

3 Product description | 3.3 ELECTROmatic – Versions

3.3 ELECTROmatic – Versions

ELECTROmatic Front and rear of the device

① Control panel/cover panel ④ Motor hose connector

② Control unit ⑤ 4-hole standard connection

③ Power supply connector ⑥ Water filter, replaceable

3.4 Motor hose

KL motor hose/COMFORTbase

① Connector for ELECTROmatic ④ Connector for motor

② KL motor hose 1750/2200 /

COMFORTbase 1750/2200

③ Spray regulation

⑤ Connector for COMFORTdrive

22 / 80

Page 23

Instructions for use ELECTROmatic M/C and PM/PC

5

4

3

2

1

3

2

1

5

4

3 Product description | 3.5 Control panel (PM/PC only)

3.5 Control panel (PM/PC only)

Note

The ELECTROmatic M/C versions of the product have no control panel. An

LED on the rear of the device flashes when the ELECTROmatic M/C is ready

for use.

Control panel ELECTROmatic PM/PC

Display information ELECTROmatic PM/PC

Display information example 1

① Speed memory 1 ④ Speed factor and unit

② SAFEdrive active = yellow ⑤ Speed

③ Clockwise rotation = green

Display information example 2

① Speed memory 2 ④ Speed factor and unit

② SAFEdrive inactive = grey ⑤ Speed

③ Counterclockwise rotation = red

23 / 80

Page 24

Instructions for use ELECTROmatic M/C and PM/PC

4

3

2

1

3

2

1

4

3 Product description | 3.5 Control panel (PM/PC only)

If the speed display is set to "analog", the speed is displayed in analog manner

when the motor is running. When the motor is at rest, the maximum set speed

is shown digitally and the display switches to analog only when the foot control

is pressed, i.e. when the motor is started up.

Display information example 3

① Speed memory 3 ③ Clockwise rotation = green

② SAFEdrive inactive = grey ④ Analog speed display (approxi-

mately 50% of set maximum

speed)

Display information example 4

① No speed memory selected ③ Counterclockwise rotation = red

② SAFEdrive active = yellow ④ Analog speed display (100% of set

maximum speed)

Function of the operating keys of the ELECTROmatic

PM/PC

Key Function

▶ Press both the plus and minus key for 2 seconds

to start the "Settings" menu.

24 / 80

Page 25

Instructions for use ELECTROmatic M/C and PM/PC

3 Product description | 3.6 Technical specifications of the ELECTROmatic

Key Function

▶ Press the Plus key to increase a value.

▶ Press the Minus key to decrease a value.

Key is assigned doubly:

▶ Press the key to switch between clockwise and

counterclockwise rotation.

Requirement

"Settings" menu is active:

▶ Press key to select a parameter.

Key is assigned doubly:

▶ Press key to select speed memory 1.

See also:

2 6.4 Changing the speed setting, Page 58

Requirement

"Settings" menu is active:

▶ Press key to select a parameter.

▶ Press key to select speed memory 2.

See also:

2 6.4 Changing the speed setting, Page 58

▶ Press key to select speed memory 3.

See also:

2 6.4 Changing the speed setting, Page 58

3.6 Technical specifications of the ELECTROmatic

Dimensions of the package

Length 472 mm / 18.58"

Width 190 mm / 7.48"

Height 113 mm / 4.45"

Dimensions and weight of the control unit

Device version

M/C 143/5.63 118/4.65 36/1.42 331/11.68

PM/PC 145/5.71 132/5.2 44/1.73 381/13.44

Width in

mm/inch

Depth in

mm/inch

Height in

mm/inch

Weight in g/

ounces

Requirements

Protection class IP 30

25 / 80

Page 26

Instructions for use ELECTROmatic M/C and PM/PC

3 Product description | 3.6 Technical specifications of the ELECTROmatic

Ambient conditions

Permissible installation sites Indoor use

Permissible ambient temperature

range

Maximum relative humidity 80 % at 31 oC / 88 oF

Maximum relative humidity linearly decreasing 50 % at 40 o /

Pollution degree 2

Permissible up to 3,000 m / 9843 feet altitude

Air pressure 700 to 1060 hPa

+10oC to +35oC / 50oF to 95oF

104 oF

Transportation and storage conditions

Permissible ambient temperature

range

Permissible up to a maximum humidity of

Air pressure 700 to 1060 hPa

-20oC to +50oC / -4oF to +122oF

5 to 90 % non-condensing

Mode: intermittent operation

Operating time 0.5 minutes

Pause time 9 minutes

▶ Do not exceed the threshold load of the motor of 0.5 minutes operating

time / 9 minutes pause.

Note

In practical application, pulse loads lasting seconds or pause times lasting

seconds or minutes are realistic, usually without reaching the maximally possible motor current. This corresponds to the common working procedure of

dentists.

Note

If a handpiece is defective, the treatment time might be less than 30 seconds

due to the SAFEdrive function (automatic motor shut-off).

See also:

2 6.6 Protection function SAFEdrive (PM/PC only), Page 58

26 / 80

Page 27

3 Product description | 3.6 Technical specifications of the ELECTROmatic

Media options

Instructions for use ELECTROmatic M/C and PM/PC

Water quality according to DIN EN

Tap water

7494-2

Water hardness 8.4 to 12 °dH

pH 7.2 to 7.8

System pressure 1.8 to 5 bar / 26 to 72.5 psi

Spray air 1.0 to 2.5 bar / 14.5 to 36.2 psi

Spray water 0.8 to 2.0 bar / 11.6 to 29 psi

Cooling air exit at the motor coupling 6 to 9 Nl/min

Air filter 50 micrograms

Customer-provided water filtering 80 µm

Ideal settings at the dental unit

System pressure 3 bar / 43.5 psi

Spray air pressure

Spray water pressure

1)

pressure measured at the motor coupling using a pressure gauge Mat. no.

1.003.1050.

1)

1)

1 bar / 14.5 psi

0.8 bar / 11.6 psi

Speed

Speed range of the Motor KL 703 100 - 40,000 min-1 (rpm)

Speed range of the

20,000 - 200,000 min-1 (rpm)

COMFORTdrive 200 XDR

Motor torque

Maximum torque of the

Motor KL 703

Torque of the Motor KL 703 minimum

Maximum torque

COMFORTdrive 200 XDR

3 Ncm

0.15 Ncm

0.4 Ncm

Electrical ratings

Input voltage 36 V DC

Power 120 W

27 / 80

Page 28

Instructions for use ELECTROmatic M/C and PM/PC

3 Product description | 3.7 Symbols on product and rating plate

Motor cords

Cable lengths,

depends on ordered version|

1.75 m / 2.20 m (69" / 87")

3.7 Symbols on product and rating plate

The rating plates are affixed to the underside of the unit.

Accompanying documents

Please note the instructions for use

Please note the instructions for use

Please note the electronic instructions for use

HIBC Code

Certification

CE mark (Communauté Européenne)

VDE mark

MET mark

GOST R certification

EAC conformity mark (Eurasian Conformity = Eurasische Konformität)

Product characteristics

Manufacturer

Type Device type

Serial number

Catalog number

Type B applied part

28 / 80

Page 29

Instructions for use ELECTROmatic M/C and PM/PC

3 Product description | 3.8 Power supply type 4882

Supply voltage

Operating mode: continuous operation with intermittent load

Protection class II

Do not dispose of with household waste

3.8 Power supply type 4882

① Mains connection ③ Connecting cord

② Standby LED display

3.9 Technical data for the power supply type 4882

Note

The connection of the power supply must comply with the country-specific

regulations and requirements for medical devices.

Dimensions and weight

Width 160 mm/6.3 "

Height 44 mm/1.7 "

Depth 76 mm/3 "

Weight 0.78 kg /27.51 ounces

Length of connection cable 4.5 m / 177"

29 / 80

Page 30

Instructions for use ELECTROmatic M/C and PM/PC

3 Product description | 3.10 Symbols on the nameplate of the type 4882 power supply

Electrical ratings

Supply voltage 100 to 240 V AC, 47 to 63 Hz

Output voltage 36 V DC

Power 120 W

Current 3.34 A

Overvoltage category II

Mains voltage fluctuations ± 10 %

Requirements

Protection class I

Protection class IP 40

Environmental conditions

Permissible installation sites Indoor use

Permissible ambient temperature

range

Relative humidity 10 to 95% RH non-condensing

Pollution degree 2

Permissible up to 3,000 m / 9843 feet altitude

Air pressure 700 to 1060 hPa

0oC to +40oC / 32oF to 104oF

Transportation and storage conditions

Ambient temperature -20 ℃ to +80 ℃ / -4 oF to 176 oF

Relative humidity 10 to 95% RH non-condensing

Air pressure 700 hPa to 1060 hPa

3.10 Symbols on the nameplate of the type 4882 power supply

The rating plate is located on the underside of the device.

Certification

TÜV Rheinland mark

UL mark for components for USA/Canada

CE mark

30 / 80

Page 31

Instructions for use ELECTROmatic M/C and PM/PC

3 Product description | 3.10 Symbols on the nameplate of the type 4882 power supply

Product characteristics

Manufacturer

Type Device type

Catalog number

IN-

Input data: voltage, frequency, current

PUT:

Output data: power, voltage, current

OUTPUT:

S/N: Serial number

Manufacturing date

WEEK

:

Do not dispose of with household waste

31 / 80

Page 32

Instructions for use ELECTROmatic M/C and PM/PC

4 Installation | 4.1 Location

4 Installation

4.1 Location

Damage to the dentist element.

Installations involving an intervention on the dental unit might damage components, which can interfere with the safe function and cause injury.

▶ Have installations involving an intervention on the dental unit performed by

trained expert personnel only.

▶ Have the treatment center subjected to a safety check after installation.

Power supply and cords/hoses are on the floor.

Slipping and tripping.

▶ Power supply and cord/hoses need to be set-up/routed appropriately such

that they are not on the floor.

CAUTION

CAUTION

Note

To completely disconnect the device from the mains, the mains plug must be

pulled. For this reason, the unit must be set-up appropriately such that the

mains plug and the electrical outlet are easily accessible.

Note

Mind the electrical cord of the power supply! Route all cords appropriately

such that they do not get squashed, clamped or have a chair rolling over

them.

Note

Use the power supply in dry environments exclusively. Make sure that the

power supply is protected from the ingress of liquids.

▶ Place the product in an easily accessible place and visible for diagnostic pur-

poses.

4.2 Installation positions

There is a wide range of installation options for the ELECTROmatic. This overview makes no claim of being comprehensive. If possible, the installation

should be done without modification of the dentist element and/or existing attachment options on the dentist element should be utilized.

The 4 basic installation positions on holders are described in the following:

▪ Installation position 1: Below a holder

▪ Installation position 2: On the side of a holder

▪ Installation position 3: On a holder or on the backside of a holder

▪ Installation position 4: Mount control panel as remote control

32 / 80

Page 33

Instructions for use ELECTROmatic M/C and PM/PC

4 Installation | 4.2 Installation positions

Below a holder with insert

holder

Install control panel on

holder as remote control

On the side of a holder On a holder

Install control panel on

cabinet/wall as remote

control

Optional: Install control panel as remote control (PM/PC

only)

All installation positions afford the opportunity to install the ELECTROmatic in

two separate parts: The control panel as a remote control and the control unit

in two different installation positions.

For this purpose, the control panel must be disconnected from the control unit.

See also:

2 4.7.1 Disconnect the control panel from the control unit and install it on the

mounting bracket, Page 40

The control panel is connected to the control unit by a standard telephone cable

of 80 cm in length.

33 / 80

Page 34

Instructions for use ELECTROmatic M/C and PM/PC

9

4 Installation | 4.3 Preparing the installation

4.3 Preparing the installation

Insert holder

Mounting plate

Mounting bracket

Cover panel

ELECTROmatic installation set (Mat. no. 1.012.1883)

▶ Keep the installation set handy.

▶ For the parts from the scope of delivery required for each installation, see

list in the respective installation chapter.

▶ If needed, keep a suitable tool for shortening the mounting plate handy.

Note

If a larger gap needs to be bridged for installation, larger spacer bolts ⑦ from

commercial electronics supplies can be used.

▶ Connect the motor hose to the ELECTROmatic.

▶ Connect motor to motor hose.

See also:

2 5.1.3 Connecting the motor, Page 49

▶ Check to make sure that the motor is seated firmly in the holder of the

treatment unit.

4.4 Installation position 1: Mount below a holder

Below a holder with insert holder

34 / 80

Page 35

Instructions for use ELECTROmatic M/C and PM/PC

1

4

4

4

8

1

4

4 Installation | 4.4 Installation position 1: Mount below a holder

CAUTION

Damage to the dentist element.

Installations involving an intervention on the dental unit might damage components, which can interfere with the safe function and cause injury.

▶ Have installations involving an intervention on the dental unit performed by

trained expert personnel only.

▶ Have the treatment center subjected to a safety check after installation.

▶ Use the insert holder as a template for the screw positions on the underside

of the holder. If possible, use existing screws or perforations as screw positions.

Installation variant a)

The following parts from the scope of delivery and the installation set are required:

▪ 1x Insert holder

▪ 4x Screws M4x12 ④ with self-locking nuts ①

▪ 4x Washers ②

▶ Use 4 screws ④ and 4 washers ② to screw the insert holder to the holder

and fasten it using the 4 nuts ①.

Installation variant b)

The following parts from the scope of delivery and the installation set are required:

▪ 1x Insert holder

▪ 8x Screws M4x12 ④

▪ 4x Spacer bolts, 35 mm ⑦

▶ Use 8 screws to mount the spacer bolts ⑦ or larger commercial spacer bolts

(electronics supplies) between the insert holder and the lower edge of the

holder to increase the distance between the holder and the insert holder, if

applicable.

35 / 80

Page 36

Instructions for use ELECTROmatic M/C and PM/PC

4

4

4

1

4 Installation | 4.5 Installation position 2: Mount on the side of a holder

Installation variant c)

The following parts from the scope of delivery and the installation set are required:

▪ 1x Insert holder

▪ 4x Screws M4x12 ④ with self-locking nuts ①

▪ 4x Washers ②

▪ 1x Mounting plate

▶ To increase the distance between the holder and the insert holder, if appli-

cable, chamfer the mounting plate twice (U-shape) and use it for a spacer.

▶ Make sure that the insert holder is firmly seated.

▶ Slide the control unit of the ELECTROmatic into the insert holder.

4.5 Installation position 2: Mount on the side of a holder

CAUTION

Damage to the dentist element.

Installations involving an intervention on the dental unit might damage components, which can interfere with the safe function and cause injury.

▶ Have installations involving an intervention on the dental unit performed by

trained expert personnel only.

▶ Have the treatment center subjected to a safety check after installation.

The following parts from the scope of delivery and the installation set are required:

▪ 1x Mounting plate

▪ 4x Screws M4x12 ④ with self-locking nuts ①

36 / 80

Page 37

Instructions for use ELECTROmatic M/C and PM/PC

4 Installation | 4.5 Installation position 2: Mount on the side of a holder

▪ 4x Washers ②

▪ 2x Plastic screws ⑥ for fastening to the mounting plate

▶ Shorten the mounting plate with a suitable tool, if needed.

▶ Select the position of the mounting plate. If possible, use existing screws or

perforations as screw positions.

▶ Screw the ELECTROmatic to the round side of the mounting plate using 2

plastic screws ⑥ tightening the screws only lightly.

▶ Use the 4 screws ④ and 4 washers ② to screw the mounting plate to the

holder and secure it with the 4 nuts ①.

▶ Align the ELECTROmatic in its final ergonomic position and screw it to the

mounting plate such as to be hand-tightened.

37 / 80

Page 38

Instructions for use ELECTROmatic M/C and PM/PC

4 Installation | 4.6 Installation position 3: Mount on a holder or on the backside of a holder

4.6 Installation position 3: Mount on a holder or on the backside of a holder

On a holder

CAUTION

Damage to the dentist element.

Installations involving an intervention on the dental unit might damage components, which can interfere with the safe function and cause injury.

▶ Have installations involving an intervention on the dental unit performed by

trained expert personnel only.

▶ Have the treatment center subjected to a safety check after installation.

▶ Use the control unit as a template for the screw positions on a holder or on

the backside of a holder. If possible, use existing screws or perforations as

screw positions.

Installation variant a)

The following parts from the scope of delivery and the installation set are required:

▪ 1x Mounting bracket

▪ 2x Screws M4x12 ④ with self-locking nuts ①

▪ 2x Washers ②

▪ 2x Plastic screws

▶ Use 2 plastic screws to screw the mounting bracket to the control panel.

▶ Fold the mounting bracket and fasten it to the holder using 2 screws, 2

washers and 2 self-locking nuts.

38 / 80

Page 39

Instructions for use ELECTROmatic M/C and PM/PC

2

4 Installation | 4.6 Installation position 3: Mount on a holder or on the backside of a holder

Installation variant b)

The following parts from the scope of delivery and the installation set are required:

▪ 2x Screws

▶ Use screws to screw the control unit directly to the holder.

Installation variant c)

The following parts are needed:

▪ Double-sided adhesive tape

▶ Stick pads in the 4 recesses on the underside of the device and then set up

the control unit.

ð The pads keep the control unit from slipping.

39 / 80

Page 40

Instructions for use ELECTROmatic M/C and PM/PC

4 Installation | 4.7 Installation position 4: Mount control panel as remote control (PM/PC only)

4.7 Installation position 4: Mount control panel as remote control (PM/PC only)

4.7.1 Disconnect the control panel from the control unit and install it on the mounting bracket

▶ To detach the control panel from the control unit, unscrew 2 screws on the

underside of the device.

▶ Pull the control panel off the control unit.

▶ Break out one of the 4 cable feed-throughs on the inside of the cover panel.

▶ Guide the connecting cable of the control unit through this opening to the

control panel.

▶ Hold the cover panel to the position of the control panel and tighten the 2

screws on the underside of the device again.

40 / 80

Page 41

Instructions for use ELECTROmatic M/C and PM/PC

4 Installation | 4.7 Installation position 4: Mount control panel as remote control (PM/PC only)

▶ If required, break out the cable feed-through on the control panel.

▶ Guide the connecting cable of the control unit through this opening to the

control panel.

▶ Use 2 plastic screws to screw the control panel to the mounting bracket

such as to be hand-tightened.

▶ Define the position for the control unit and check the length of the standard

telephone cable.

▶ Mount the control unit.

See also:

2 4.4 Installation position 1: Mount below a holder, Page 34

The following chapters describe the installation of the control panel at the different installation positions.

41 / 80

Page 42

Instructions for use ELECTROmatic M/C and PM/PC

4 Installation | 4.7 Installation position 4: Mount control panel as remote control (PM/PC only)

4.7.2 Mount control panel on a holder / on the backside of a holder

CAUTION

Damage to the dentist element.

Installations involving an intervention on the dental unit might damage components, which can interfere with the safe function and cause injury.

▶ Have installations involving an intervention on the dental unit performed by

trained expert personnel only.

▶ Have the treatment center subjected to a safety check after installation.

The following parts from the scope of delivery and the installation set are required:

▪ 1x Insert holder

▪ 1x Mounting bracket

▪ 1x Cover panel

▪ 4x + 2x Screws M4x12 ④ with self-locking nuts ①

▪ 4x + 2x Washers ②

▪ Optional: 4x Spacer bolts, 35 mm ⑦

▪ Optional: 1x Mounting plate

▪ 2x Plastic screws ⑥

▶ Define the position of the control panel on the holder or on the rear of the

holder and draw a hole pattern for attachment. If possible, use existing

screws or perforations as screw positions.

▶ Drill the holes.

▶ Screw the mounting bracket with control panel to the holder or to the rear

of the holder using the 2 screws ④, washers ② and nuts ①.

42 / 80

Page 43

Instructions for use ELECTROmatic M/C and PM/PC

4 Installation | 4.7 Installation position 4: Mount control panel as remote control (PM/PC only)

▶ Mount the control unit.

See also:

2 4.4 Install below the dentist element, a holder or a cabinet, Page 34

4.7.3 Mount control panel on the side of a holder

CAUTION

Damage to the dentist element.

Installations involving an intervention on the dental unit might damage components, which can interfere with the safe function and cause injury.

▶ Have installations involving an intervention on the dental unit performed by

trained expert personnel only.

▶ Have the treatment center subjected to a safety check after installation.

Installation variant a)

The following parts from the scope of delivery and the installation set are required:

▪ 1x Mounting plate

▪ 1x Mounting bracket

▪ 1x Cover panel

▪ 4x Screws M4x12 ④ with self-locking nuts ①

▪ 4x Washers ②

▪ 2x Plastic screws ⑥ for fastening to the mounting plate

▶ Shorten the mounting plate with a suitable tool, if needed.

▶ Select the position of the mounting plate. If possible, use existing screws or

perforations as screw positions.

43 / 80

Page 44

Instructions for use ELECTROmatic M/C and PM/PC

4 Installation | 4.7 Installation position 4: Mount control panel as remote control (PM/PC only)

▶ Mark the attachment points and drill the holes on the holder.

▶ Screw the mounting bracket with control panel to the round side of the

mounting plate using the plastic screws ⑥ tightening the screws only

lightly.

▶ Use the 4 screws ④ and the washers ② to screw the mounting plate to the

holder and secure it with the nuts ①.

▶ Align the ELECTROmatic in its final ergonomic position and screw it down

such as to be hand-tightened.

Installation variant b)

The following parts from the scope of delivery and the installation set are required:

▪ 1x Mounting bracket

▪ 1x Cover panel

▪ 2x Screws M4x12 ④ with self-locking nuts ①

▪ 2x Washers ②

▶ Mark the attachment points and drill the holes.

▶ Use the 2 screws ④ and washers ② to screw the mounting bracket with

control panel to the holder in upright orientation and secure it with the nuts

①.

▶ Align the ELECTROmatic in its final ergonomic position and screw it down

such as to be hand-tightened.

44 / 80

Page 45

Instructions for use ELECTROmatic M/C and PM/PC

4 Installation | 4.7 Installation position 4: Mount control panel as remote control (PM/PC only)

Installation variant c)

The following parts from the scope of delivery and the installation set are required:

▪ 1x Mounting bracket

▪ 1x Cover panel

▪ 2x Screws M4x12 ④ with self-locking nuts ①

▪ 2x Washers ②

▪ 2x Plastic screws ⑥, for fastening to the mounting bracket

▶ Use a suitable tool to shorten the mounting bracket to the size of the con-

trol panel.

▶ Use 2 plastic screws to screw the control panel to the mounting bracket

such as to be hand-tightened.

▶ Mark the attachment points and drill the holes.

▶ Use the 2 screws ④ and the washers ② to screw the mounting bracket with

control panel to the holder and secure it with the nuts ①.

▶ Align the ELECTROmatic in its final ergonomic position and screw it down

such as to be hand-tightened.

45 / 80

Page 46

Instructions for use ELECTROmatic M/C and PM/PC

4 Installation | 4.7 Installation position 4: Mount control panel as remote control (PM/PC only)

▶ Mount the control unit.

See also:

2 4.4 Installation position 1: Mount below a holder, Page 34

4.7.4 Mount control panel to cabinet/wall

Installation on a cabinet/wall

CAUTION

Damage to the dentist element.

Installations involving an intervention on the dental unit might damage components, which can interfere with the safe function and cause injury.

▶ Have installations involving an intervention on the dental unit performed by

trained expert personnel only.

▶ Have the treatment center subjected to a safety check after installation.

The following parts from the scope of delivery and the installation set are required:

▪ 1x Insert holder

▪ 1x Mounting bracket

▪ 1x Cover panel

46 / 80

Page 47

Instructions for use ELECTROmatic M/C and PM/PC

4 Installation | 4.8 Connect the ELECTROmatic

▪ 4x + 2x Screws M4x12 ④ with self-locking nuts ①

▪ 4x + 2x Washers ②

▪ Optional: 4x Spacer bolts, 35 mm ⑦

▪ Optional: 1x Mounting plate

▪ 2x Plastic screws ⑥

▶ Open the cabinet.

▶ Define the position of the control panel in the cabinet or on the wall and

draw a hole pattern for attachment. If possible, use existing screws or perforations as screw positions.

▶ Installation in a cabinet: Use 2 plastic screws to screw the control panel to

the cabinet.

▶ Installation on the wall: Use 2 screws ④ and washers ② to screw the

mounting bracket with control panel to the wall and secure it with the nuts

①.

▶ Mount the control unit.

See also:

2 4.4 Installation position 1: Mount below a holder, Page 34

4.8 Connect the ELECTROmatic

See also:

2 5.1.2 Connect the ELECTROmatic, Page 48

2 5.1.5 Connect the power supply, Page 50

4.9 Check the installation

▶ Check if the fastening is secure.

▶ Perform the startup.

See also:

2 5 Startup, Page 48

47 / 80

Page 48

Instructions for use ELECTROmatic M/C and PM/PC

5 Commissioning | 5.1 Connection

5 Commissioning

Note

The ELECTROmatic may be operated exclusively with the

INTRA LUX KL703 LED motor (Mat. no. 1.007.0150), the COMFORTdrive

motorized contra-angle handpiece and the type 4882 power supply.

5.1 Connection

5.1.1 Electrical operating conditions

Property damage due to incorrect pressures.

Property damage to motor or handpiece.

▶ Set the pressures according to the technical specifications.

Property damage due to bad media.

Property damage to motor or handpiece.

▶ Make sure that the compressed air is dry and free of dirt and oil according

to EN ISO 7494-2.

▶ Make sure that the pH of the water is between 7.2 and 7.8.

NOTICE

NOTICE

Note

If the water is hard (above 12 °dH), a water softening device based on an

ion-exchange procedure must be fitted.

Insufficient water hardness (below 8.4 °dH) can promote the growth of algae.

Note

If necessary, insert a filter, water trap or air dryer.

Air and water requirements according to DIN EN 7494-2

The compressed air must be free of oil, dirt, and contamination. If needed:

▪ Use a compressor with a dry air system.

▪ Include an upstream air filter (on the compressor), if applicable.

▪ Blow out the lines before connecting them.

5.1.2 Connecting the ELECTROmatic

NOTICE

Property damage due to soiled water lines.

Property damage to the product.

▶ Make sure that the water filter does not get clogged by soiled water.

▶ For this purpose, rinse the turbine hose for at least 1 minute before con-

necting its free end to the product in order to remove any soiled water from

the lines.

48 / 80

Page 49

Instructions for use ELECTROmatic M/C and PM/PC

5 Commissioning | 5.1 Connection

Note

The ELECTROmatic has an automatic spray air and spray water shut-off. The

automatic spray air and spray water shut-off prevents the following:

- Dripping of spray water after the motor is stopped

- Continuous exit of water/air through leaky treatment centers

▶ Connect the 4-hole, 5-hole or 6-hole turbine hose of the treatment unit to

the filter of the ELECTROmatic.

or

▶ If the turbine hose of the treatment unit has a 2-hole or 3-hole connector,

replace the turbine hose with a 4-hole, 5-hole or 6-hole turbine hose or use

a commercial adapter available from specialized dealers.

See also:

2 11 Accessories and consumables, Page 73

5.1.3 Connecting the motor

▶ Slightly wet the O-rings on the connection hose with KAVOspray.

▶ Connect the motor to the supply hose and twist.

ð The correct attachment position is attained automatically.

▶ Screw tight the hose-side union nut proceeding in the direction of the ar-

row.

49 / 80

Page 50

Instructions for use ELECTROmatic M/C and PM/PC

5 Commissioning | 5.1 Connection

5.1.4 Connect the motor cord

▶ Plug the motor hose onto the motor hose connector on the rear of the

ELECTROmatic device and screw it tight.

▶ Set the spray regulation on the hose to maximum amount of water.

See also:

2 6.3 Regulating the spray water, Page 57

5.1.5 Connect the power supply

CAUTION

Power supply and cords/hoses are on the floor.

Slipping and tripping.

▶ Power supply and cord/hoses need to be set-up/routed appropriately such

that they are not on the floor.

NOTICE

Property damage from non-approved power supply.

Property damage to the product.

▶ Operate the product with the type 4882 power supply (Mat. no.

1.005.0120) exclusively.

Note

The connection of the power supply must comply with the country-specific

regulations and requirements for medical devices.

Note

The power supply automatically adjusts to the available mains voltage.

Note

Grounding reliability can only be achieved when the equipment is connected

to an equivalent receptacle marked "Hospital Only" or "Hospital Grade".

Note

The protective earth conductor is used as functional earthing (FE) rather than

as protective earthing (PE).

Note

Use the power supply in dry environments exclusively. Make sure that the

power supply is protected from the ingress of liquids.

50 / 80

Page 51

Instructions for use ELECTROmatic M/C and PM/PC

5 Commissioning | 5.2 Calibrating the foot control

▶ Connect the type 4882 power supply to the socket of the ELECTROmatic.

▶ Connect the power cable first to the power supply and then to the supply

mains socket.

▶ Route the cables appropriately such that there is no kinking and, if possible

and permitted by the treatment unit, in the support arm.

▶ Affix the cord with cord ties and/or cord tape.

5.2 Calibrating the foot control

▶ Press the foot control down once as far as it will go (maximum pressure) in

order to calibrate the foot control.

ð This starts up the motor and the system calibrates automatically to the ex-

isting system pressure.

Automatic calibration of the foot control

The calibration is performed automatically during the first startup, when the

foot control is pressed for the first time.

Once the calibration of the foot control has been done once, the calibration to

the maximum system pressure takes place automatically in the background

during operation (automatic calibration).

Minor pressure fluctuations are balanced automatically in this process.

51 / 80

Page 52

Instructions for use ELECTROmatic M/C and PM/PC

5 Commissioning | 5.3 Measure cooling air quantity at motor coupling

5.3 Measure cooling air quantity at motor coupling

▶ Place the airflow measuring tube ① (Mat. no. 0.411.4441) on the motor.

▶ Press the foot control to start the motor.

▶ Adapt the system pressure of the treatment unit appropriately such that the

cooling airflow is 6 to 9 Nl/min (upper edge of sphere ②).

▶ Comply with the system pressure limits from the technical specifications for

media.

See also:

2 3.6 Technical specifications of the ELECTROmatic, Page 25

5.4 Making the device settings

▶ Press both the plus and minus key for 2 seconds to start the "Settings"

menu.

52 / 80

Page 53

Instructions for use ELECTROmatic M/C and PM/PC

5 Commissioning | 5.4 Making the device settings

▶ Press the arrow keys to select the various parameters.

▶ Press the Plus key to increase a value.

or

▶ Press the Minus key to decrease a value.

ð The settings are always saved instantaneously.

▶ Press both the plus key and the minus key for 2 seconds to exit from the

"Settings" menu.

The following device settings can be changed according to need and/or displayed when the device is being put into service.

Display information Setting

Displays the software versions.

Turning SAFEdrive on / off.

See also:

2 6.6 Protection function SAFEdrive (PM/PC only),

Page 58

The LUX brightness can be adjusted between 0 and

4. "0" means that the LUX light is switched off.

53 / 80

Page 54

Instructions for use ELECTROmatic M/C and PM/PC

5 Commissioning | 5.4 Making the device settings

Display information Setting

The LUX afterglow time of the straight or contra-angle handpiece can be adjusted between 0 and 9 seconds. "0" means that the LUX light does not afterglow.

The volume of the key tone can be adjusted between 1 and 3.

You can select from 3 different kinds of key tones.

Pressure display in psi and bar for checking the input

pressure of the turbine hose.

Alignment of display.

The display can be aligned accordingly depending on

its installation position.

54 / 80

Page 55

Display information Setting

Select from digital and analog speed display.

Reset the device to factory settings.

Restores the condition of the device at the time of

delivery.

Press the "Plus" key 2x to reset the device to factory

settings.

Instructions for use ELECTROmatic M/C and PM/PC

5 Commissioning | 5.4 Making the device settings

55 / 80

Page 56

Instructions for use ELECTROmatic M/C and PM/PC

6 Operation | 6.1 Switching the ELECTROmatic on/off

6 Operation

Growth of germs.

Infections.

▶ Before treating a patient, let the spray air and spray water exit for at least

20 seconds.

▶ Before the first start-up and after downtimes (weekends, holidays, vaca-

tions, etc.), the air and water lines must be purged and/or rinsed.

▶ The germ reduction of the ELECTROmatic must be carried out via the treat-

ment unit.

See also:

2 8 Processing steps in accordance with DIN EN ISO 17664, Page 63

Incorrectly set parameters.

Property damage from incorrect input values.

▶ Check all input values on the display before use.

CAUTION

NOTICE

NOTICE

Contaminated or moist compressed air at the compressed air connection.

Premature wear.

▶ Supply dry, clean and uncontaminated compressed air in accordance with

ISO 7494-2 only.

Note

Please note the transmission/reduction ratio of the attachment handpieces as

these have an impact on the displayed speed of the clamped tool.

6.1 Switching the ELECTROmatic on/off

The unit is ready for operation as soon as it is connected.

▶ To switch the product on, connect the device to the power circuit.

ð An LED on the rear of the ELECTROmatic M/C flashes.

ð The treatment parameters are displayed on the display of the

ELECTROmatic PM/PC:

▶ To switch the device off, unplug the unit from the mains.

ð The LED on the rear of the ELECTROmatic M/C is off.

56 / 80

Page 57

Instructions for use ELECTROmatic M/C and PM/PC

1

3

2

6 Operation | 6.2 Start the motor

Note

The power consumption on idling is so low that the device does not need to

be disconnected.

6.2 Start the motor