Kärcher VNG4-30024B, VNG4-20024B, VNG4-20024A, VNG4-30024A, VNG4-20024H Operator's Manual

...

®

VNG/VLP

Hot Water - Electric Powered - Natural Gas or

LP Heated

Operator’ s Manual

Pressure Washer

MODELS:

VNG4-20024A

1.109-563.0

VNG4-20024B

1.109-564.0

VNG4-20024C

1.109-565.0

VNG4-20024H

1.109-568.0

VNG4-30024A

1.109-569.0

VNG4-30024B

1.109-570.0

VNG4-30024C

1.109-571.0

VNG6-30024B

1.109-575.0

VNG6-30024C

1.109-576.0

VNG8-30024B

1.109-579.0

VNG8-30024C

1.109-580.0

VNG8-30024H

1.109-582.0

VNG10-20024B

1.109-559.0

VNG10-20024C

1.109-560.0

VNG4-30024H

1.109-574.0

For the Landa Dealer nearest

you, consult our web page at

www.landa.com

8.913-939.0-AB 08/22/17

Machine Data Label

2 Landa VNG Operator’s Manual 8.913-939.0 - AB

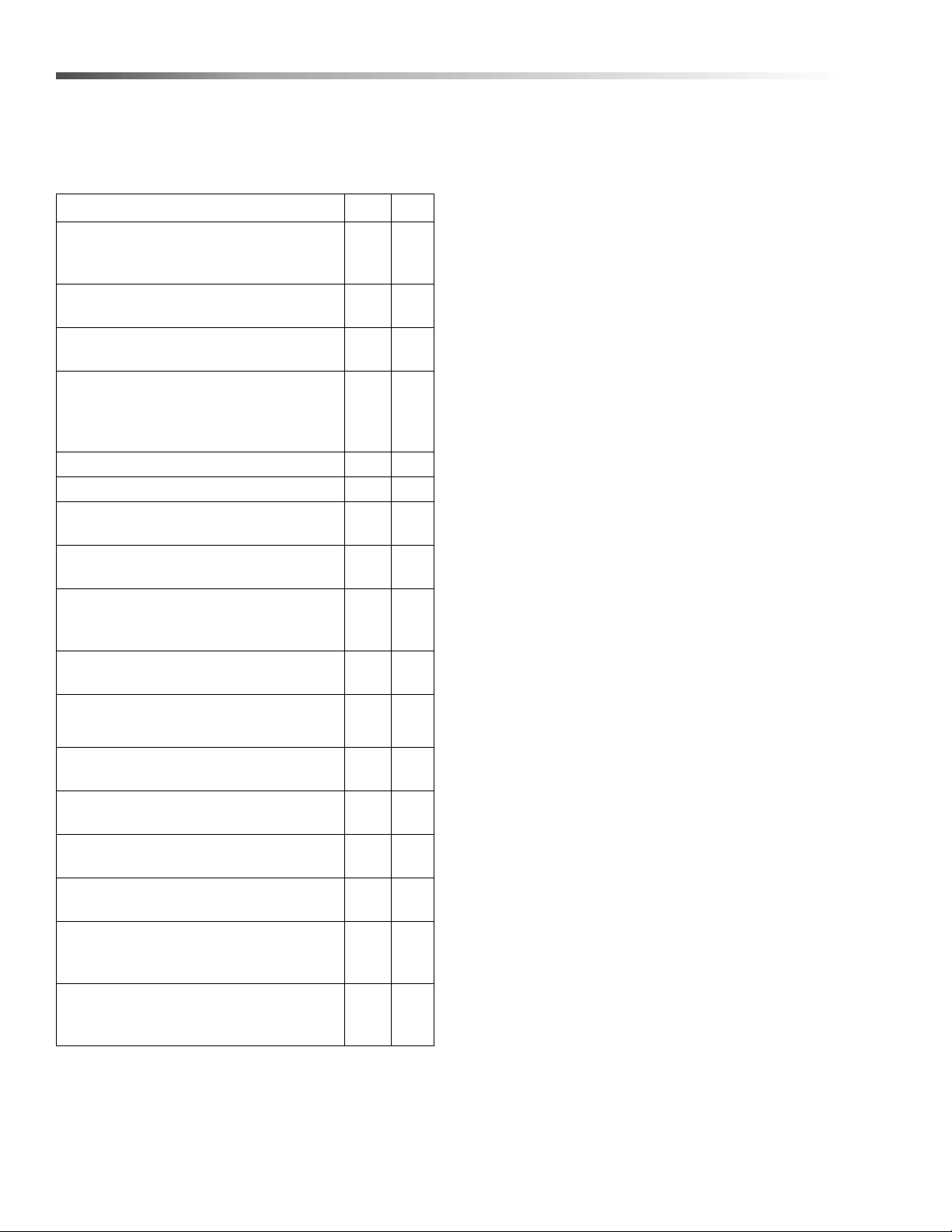

Table of Contents

Machine Data Label. . . . . . . . . . . . . . . . . . . . . . . . . .2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . .3

How To Use This Manual . . . . . . . . . . . . . . . . . . . . .4

Safety

Introduction & Safety Information . . . . . . . . . . . . . . .5

Important Safety Information. . . . . . . . . . . . . . . . . . .6

Propane Tank Safety Instructions. . . . . . . . . . . . . . .8

Operations

Component Identification . . . . . . . . . . . . . . . . . . . . .9

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Gas Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Union Connection . . . . . . . . . . . . . . . . . . . . . . . . . .10

Pipe Sizing Chart for Natural Gas. . . . . . . . . . . . . .12

LP-Gas (Liquid petroleum gas or propane). . . . . . .12

Filling the LP-Gas Container. . . . . . . . . . . . . . . . . .12

Propane Tank Disposal: . . . . . . . . . . . . . . . . . . . . .12

Combustion and Ventilation Air. . . . . . . . . . . . . . . .13

Water Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

High Pressure Connection . . . . . . . . . . . . . . . . . . .14

Inspection and Testing Gas Piping . . . . . . . . . . . . .14

Gas Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

For Your Safety Read Before Lighting . . . . . . . . . .15

Assembly Instructions. . . . . . . . . . . . . . . . . . . . . . .17

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . .18

Applying Detergent &

General Operating Techniques. . . . . . . . . . . . . .19

Thermal Pump Protection. . . . . . . . . . . . . . . . . . . .19

Rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Shutting Down And

Clean Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Spray Nozzles. . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Unloader Valves . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Winterizing Procedure. . . . . . . . . . . . . . . . . . . . . . .21

High Limit Hot Water Thermostat . . . . . . . . . . . . . .21

Pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Factory Set Parameters . . . . . . . . . . . . . . . . . . . . .26

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . .27

Oil Change Record . . . . . . . . . . . . . . . . . . . . . . . . .27

Troubleshooting - Burner . . . . . . . . . . . . . . . . . . . .28

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Parts

Landa - 4-2000, 4-3000 . . . . . . . . . . . . . . . . . . . . 36

Landa - 6-3000, 8-3000, 10-2000. . . . . . . . . . . . . 42

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Electrical Box VNG . . . . . . . . . . . . . . . . . . . . . . . . 52

Burner - VNG 6-3000, 8-3000, 10-2000 . . . . . . . . 56

Pump - VNG 4-2000, 4-3000, 6-3000. . . . . . . . . . 58

Pump - VNG 8-3000, 10-2000 . . . . . . . . . . . . . . . 60

Float Tank - VNGS . . . . . . . . . . . . . . . . . . . . . . . . 62

Float Tank - VNGL . . . . . . . . . . . . . . . . . . . . . . . . 63

Hose & Spray Gun . . . . . . . . . . . . . . . . . . . . . . . . 64

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Burner Specifications . . . . . . . . . . . . . . . . . . . . . . 70

Burner Basic Facts . . . . . . . . . . . . . . . . . . . . . . . . 71

Unloader - MG4000 w/ Microswitch . . . . . . . . . . . 72

VB8 Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Pump - LT.2 Series. . . . . . . . . . . . . . . . . . . . . . . . 78

Pump - LX.2 Series . . . . . . . . . . . . . . . . . . . . . . . 80

Maintenance

Heating Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

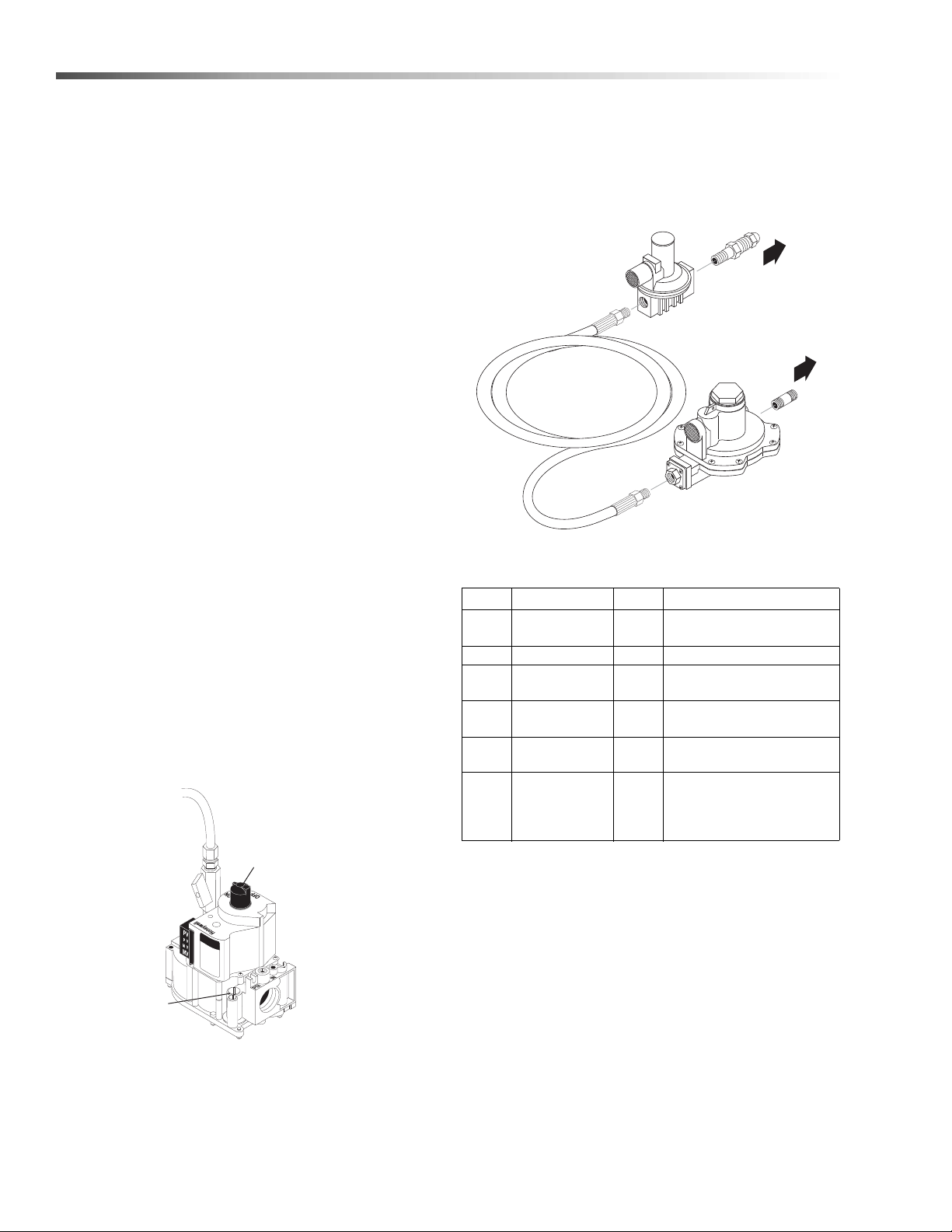

Gas Valve Regulator Adjustment . . . . . . . . . . . . . .22

Pressure Relief Valve . . . . . . . . . . . . . . . . . . . . . . .22

Propane Gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Gas Pressure Requirements. . . . . . . . . . . . . . . . . .23

Burner Features . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Care of Main Burner . . . . . . . . . . . . . . . . . . . . . . . .23

Smart Relay Instructions. . . . . . . . . . . . . . . . . . . . .24

Landa VNG Operator’s Manual 8.913-939.0 - AB

3

How To Use This Manual

Model:

Date of Purchase:

Serial Number:

Dealer:

Address:

Phone Number:

Sales Representative:

This manual contains the following sections:

• How to Use This Manual

•Safety

• Operations

• Maintenance

• Parts List

The HOW TO USE THIS MANUAL section will tell you

how to find important information for ordering correct

repair parts.

Parts may be ordered from authorized dealers. When

placing an order for parts, the machine model and

machine serial number are important. Refer to the

MACHINE DATA box which is filled out during the

installation of your machine. The MACHINE DATA box

is located on the inside of the front cover of this manual.

The model and serial number of your machine is

located on the back of the machine.

The SAFETY section contains important information

regarding hazardous or unsafe practices of the

machine. Levels of hazards are identified that could

result in product damage, personal injury, or severe

injury resulting in death.

The OPERAT IONS section is to familiarize the operator

with the operation and function of the machine.

The MAINTENANCE section contains preventive maintenance to keep the machine and its components in

good working condition. They are listed in this general

order:

• Spray Nozzles

• Unloader Valves

• Winterizing Procedure

• High Limit Hot Water Thermostat

• Pumps

•Heating Coil

• Gas Valve Regulator Adjustment

• Propane Gas

• Burner Features

• Smart Relay Instructions

• Preventative Maintenance

• Oil Change Record

• Troubleshooting - Burner

• Troubleshooting

The PARTS LIST section contains assembled parts

illustrations and corresponding parts list. The parts lists

include a number of columns of information:

4

• REF – column refers to the reference number

on the parts illustration.

• PART NO. – column lists the part number for

the part.

• QTY – column lists the quantity of the part used

in that area of the machine.

• DESCRIPTION – column is a brief description

of the part.

• NOTES – column for information not noted by

the other columns.

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement parts

numbers needed for ordering future parts.

NOTE: The manual part number is located on the

lower right corner of the front cover.

Landa VNG Operator’s Manual 8.913-939.0 - AB

Introduction & Safety Information

Thank you for purchasing this Pressure Washer. We

reserve the right to make changes at any time

without incurring any obligation.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this pressure washer . Warning in formation

should be emphasized and understood. If the operator

is not fluent in English, the manufacturer’s instructions

and warnings shall be read to and discussed with the

operator in the operator’s native language by the

purchaser/owner, making sure that the operator

comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

The operator must know how to stop the machine

quickly and understand the operation of all controls.

Never permit anyone to operate the engine without

proper instructions.

Safety

SAVE THESE INSTRUCTIONS

This manual should be considered a permanent par t of

the machine and should remain with it if machine is

resold.

When ordering parts, please specify model and

serial number. Use only identical replacement parts.

This machine is to be used only by trained operators.

Landa VNG Operator’s Manual 8.913-939.0 - AB

5

Safety

WARNING

READ OPERATOR’S

MANUAL THOROUGHLY

PRIOR TO USE.

OPERATIONS

SAFETY

MAINTENANCE

KEEP WATER

SPRAY AWAY FROM

ELECTRICAL WIRING.

WARNING

WARNING

RISK OF EXPLOSION:

IF GAS SMELL

PRESENT TURN OFF

SUPPLY

WARNING

USE PROTECTIVE

EYE WEAR

AND CLOTHING

WHEN OPERATING

THIS EQUIPMENT.

CAUTION

HOT DISCHARGE FLUID:

DO NOT TOUCH OR

DIRECT DISCHARGE

STEAM AT PERSONS.

WARNING

RISK OF FIRE.

DO NOT ADD FUEL

WHEN OPERATING

MACHINE.

WARNING

RISK OF INJURY.

HOT SURFACES

CAN CAUSE BURNS

Important Safety Information

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result, causing

property damage, personal injury or loss of life.

WARNING: To reduce the risk of

injury, read operating instructions carefully before using.

1. Read the owner's manual thoroughly. Failure to follow instructions and warnings could cause

malfunction of the machine and

result in death, serious bodily

injury and/or property damage.

2. Know how to stop the machine and bleed pressure

quickly. Be thoroughly familiar with the controls.

3. Stay alert — watch what you are doing.

4. Use only your hand to push in or turn the gas

control knob. Never use a tool. If the knob will not

push in or turn by hand, don't try to repair it; call a

qualified service technician.

5. All installations must comply with local codes.

Contact your electrician, plumber, utility company

or the selling dealer for specific details. This

product should only be connected to a power

supply protected by a GFCI.

DANGER: Improper connection of the equipmentgrounding conductor can result in a risk of electrocution. Check with a qualified electrician or service

personnel if you are in doubt as to whether the

outlet is properly grounded. Do not modify the plug

provided with the product - if it will not fit the outlet,

have a proper outlet installed by a qualified electrician. Do not use any type of adapter with this

product.

WARNING: Keep wand, hose, and

water spray away from electric

wiring or fatal electric shock may

result.

6. To protect the operator from

electrical shock, the machine

must be electrically grounded. It

is the responsibility of the owner

to connect this machine to a

properly grounded power

supply. Do not spray water on or near electrical

components. Do not touch machine with wet hands

or while standing in water. Always disconnect

power before servicing.

WARNING: Flammable liquids can

create fumes which can ignite,

causing property damage or

severe injury.

WARNING: Risk of explosion —

Operate only where open flame or

torch is permitted. Do not spray

flammable liquids.

WARNING: Risk of fire — Do not

change propane tanks when the

product is operating or still hot.

WARNING: Use vapor fuel only.

7. Gas appliances shall be

installed only in locations where

combustible dusts and

flammable gases or vapors are

not present. Do not store or use

gasoline near this machine.

8. Keep operating area clear of all persons.

WARNING: In the event of a pilot outage, wait at

least five minutes to clear out any gas before

relighting.

WARNING: High pressure spray

can cause paint chips or other

particles to become airborne and

fly at high speeds. To avoid

personal injury, eye, hand an d foot

safety devices must be worn.

9. Wear properly rated eye protection such as safety goggles or

face shield while spraying.

(Safety glasses do not provide

full protection)

CAUTION: Hot discharge fluid. Do

not touch or direct discharge

stream at persons or animals.

WARNING: This machine produces

hot water and must have insulated

components attached to protect

the operator.

WARNING: Risk of injury. Hot

surfaces can cause burns. Use

only designated gripping areas of

spray gun and wand. Do not place

hands or feet on non-insulated

areas of the pressure washer.

6

Landa VNG Operator’s Manual 8.913-939.0 - AB

Safety

WARNING

TRIGGER GUN KICKS

BACK — HOLD WITH

BOTH HANDS

WARNING

RISK OF INJECTION

OR SEVERE INJURY

TO PERSONS. KEEP

CLEAR OF NOZZLE.

WARNING

PROCTECT FROM

FREEZING

WARNING

RISK OF INJURY

FROM FALLS WHEN

USING LADDER.

DANGER

RISK OF

ASPHYXIATION.

USE THIS PRODUCT

ONLY IN A WELL

VENTILATED AREA.

10. To reduce the risk of injury, close supervision is

necessary when a machine is used near children.

Do not allow children to operate the pressure

washer. This machine must be attended during

operation.

WARNING: Grip cleaning wand

securely with both hands before

starting. Failure to do this could

result in injury from a whipping wand.

11. Never make adjustments on

machine while in operation.

12. Be certain all quick coupler

fittings are secured before using

pressure washer

WARNING: High pressure

developed by these machines will

cause personal injury or

equipment damage. Keep clear of

nozzle. Use caution when operating. Do not direct discharge

stream at people or animals, or

severe injury or death will result.

WARNING: Be extremely careful

when using a ladder, scaffolding

or any other relatively unstable

location. The cleaning area

should have adequate slopes

17. Do not overreach or stand on

unstable support. Keep good

footing and balance at all times.

18. Do not operate this machine

when fatigued or under the

influence of alcohol, prescription medications, or

drugs.

19. Follow the maintenance instructions specified in

the manual.

WARNING: Use vapor fuel only.

20. The LP models are designed to run on vapor

propane fuel. Do not use liquid fuel. Have a

qualified serviceman install and service your equipment.

21. Never expose a spark or flame where there may be

unburned gas present.

WARNING: Protect machine

from freezing.

13. To keep machine in best

operating conditions, it is

important you protect machine

from freezing. Failure to

protect machine from freezing

could cause malfunction of the

machine and result in death,

serious bodily injury, and/or

property damage. Follow storage instructions

specified in this manual.

DANGER: Risk of asphyxiation.

Use this product only in a well

ventilated area.

14. Avoid installing machines in

small areas or near exhaust

fans. Adequate oxygen is

needed for combustion or

dangerous carbon monoxide

will result.

22. Install this machine about 2 feet from wall to

provide adequate ventilation and servicing space.

This equipment incorporates parts such as snap

switches or similar parts that tend to produce arcs

or sparks. Therefore, when located in a garage, it

should be in a room or enclosure provided for the

purpose or should be installed 18" (457mm) or

more above the floor.

WARNING: To reduce the risk of electric shock,

disconnect all electrical connections and shut-off

gas valve before servicing.

23. Install this machine on non combustible flooring.

24. Do not allow acids, caustic or abrasive fluids to

pass through the pump.

25. Never run pump dry or leave spray gun closed

longer than 3 minutes.

15. Manufacturer will not be liable for any changes

made to our standard machines or any components not purchased from us.

16. The best insurance against an accident is precaution and knowledge of the machine.

Landa VNG Operator’s Manual 8.913-939.0 - AB

7

Safety

WARNING

DO NOT SPRAY

MACHINE OR ANY

PEOPLE, ANIMALS OR

ELECTRICAL PARTS.

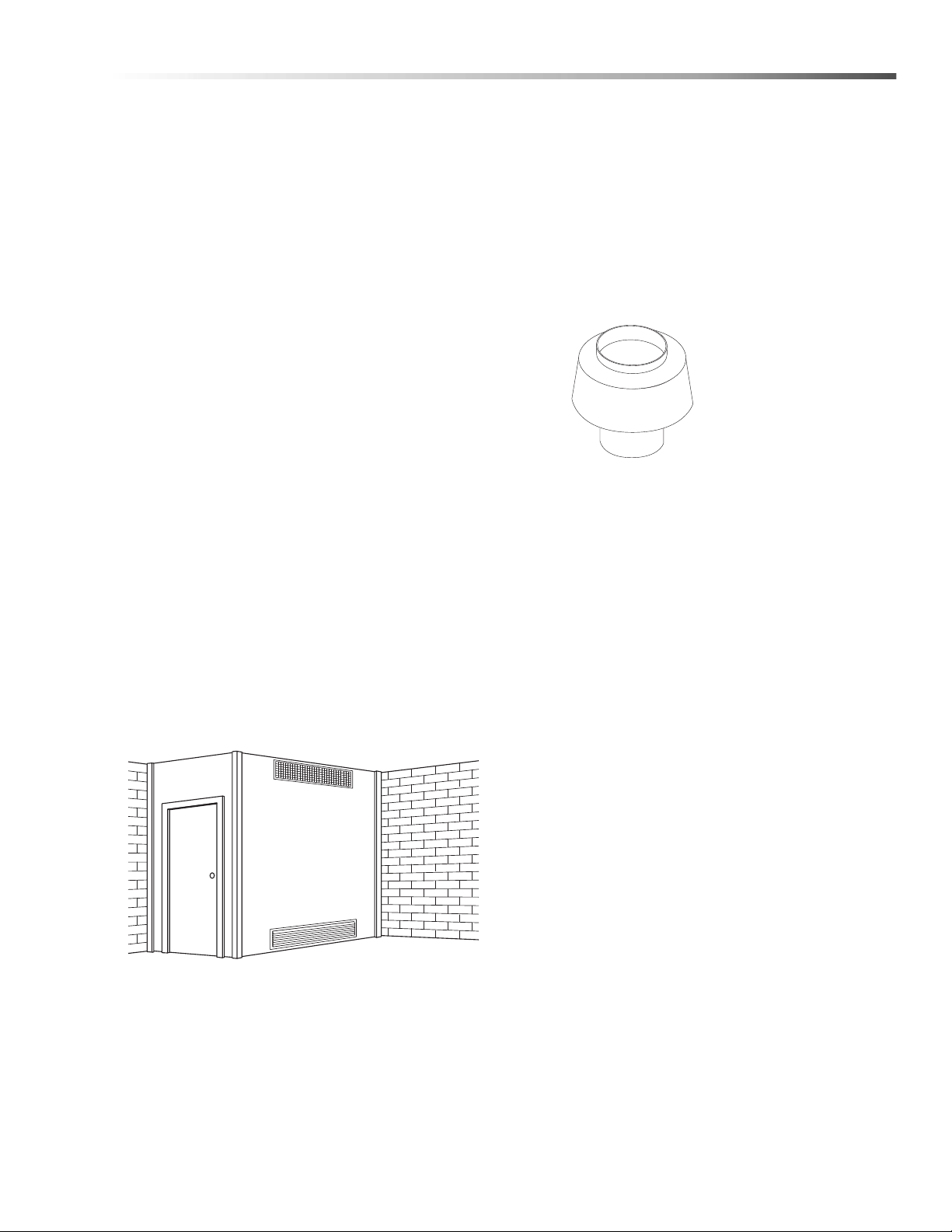

26. Exhaust gases should not be vented into a wall, a

ceiling or a concealed space of a building. A draft

diverter must be installed to prevent down draft and

to allow cooling of exhaust temperatures. Down

draft diverters shall be

installed in the vents and located at a distance from

the pressure washer stack to achieve maximum

draft of 36" minimum. Exhaust gases that exceed

470°F (243°C) are not suitable for connection to

Type B gas vents.

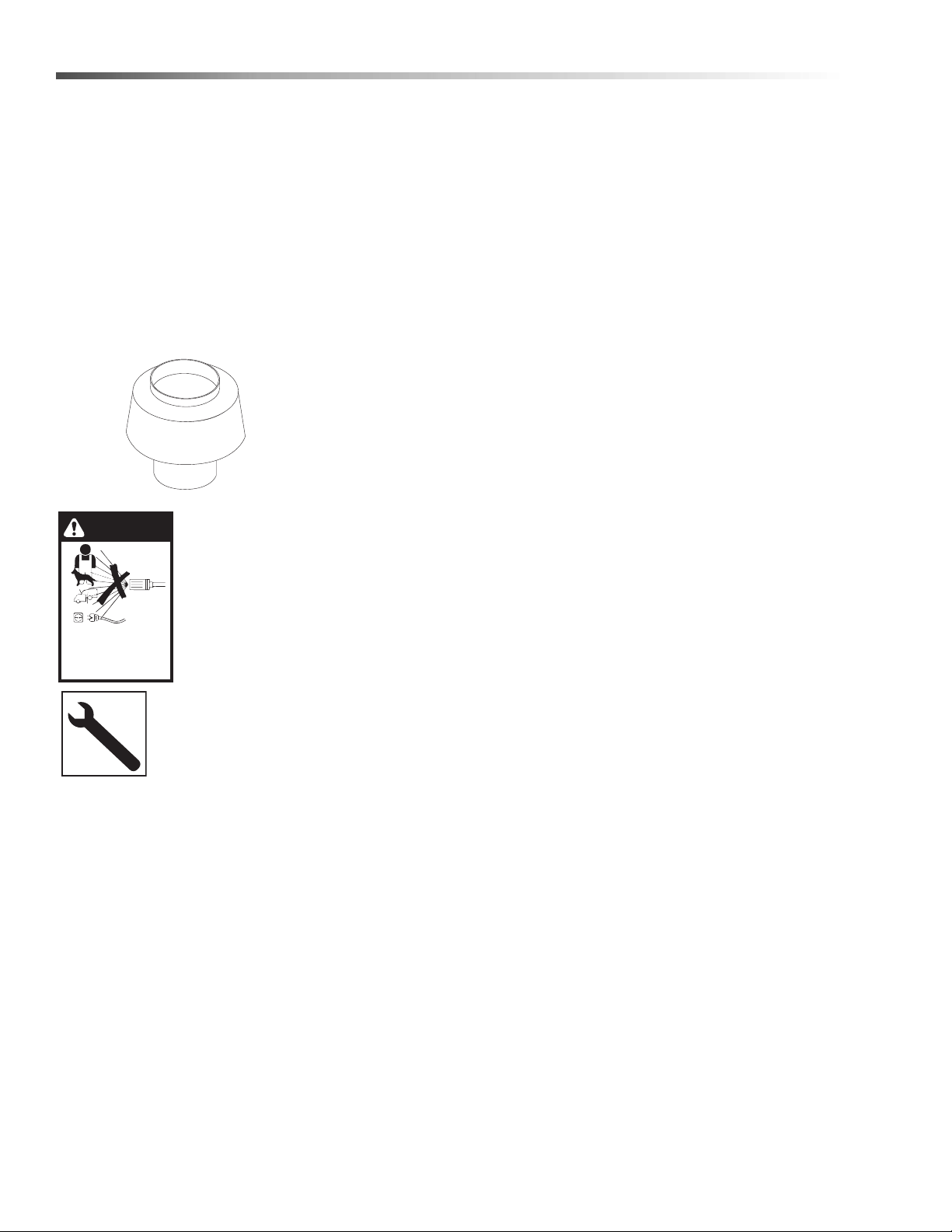

Example of Down Draft Diverter for Gas Fired

Machines

WARNING: Do not spray machine

or any people, animals, or electrical parts.

Follow the maintenance instructions

specified in the manual.

Propane Tank Safety Instructions

CAUTION: Only qualified persons should fill your

LP-gas containers.

1. Never allow your LP-gas container to be filled

above the maximum safe level as indicated by a

scale or the fixed liquid level gauge (outage). Do

not use the visible gauge for filling.

2. Do not use a wrench or pliers to close the service

valve or fixed liquid level gauge. These valves are

designed to be closed leak-tight by hand or screwdriver as appropriate. If wrenches are necessary to

stop a leak, the valve needs repair or replacement.

3. When tightening the POL Nut (left hand thread) on

the service valve, draw it up snug with a proper

wrench. This is a machined male brass fitting

which seats securely against a female seat in the

POL valve – no pipe dope is necessary. Acme/

Type 1 valves have righ t handed threads which are

secure when hand tight, and on the Quick Disconnect/Type 2 Valves, the male connection is

inserted into the female connection on the cylinder

valve. (No wrenches required for both the Acme

and the Quick Disconnect.)

4. When using container, slowly open service valve

all the way. Listen to the regulator. A continuous

hiss may indicate a leak or an open valve on an

appliance.

5. Check all tank and the line connections periodically

to be sure they are tight. When testing for leaks,

use approved leak detector solution – not matches.

6. Make certain your container is properly fastened in

place.

7. Turn container with open part of conta iner guard

towards frame. This protects valves and regulator

against flying rocks and mud. Transport container

in the proper position in which it is used, with the

valves closed and POL Plugs inserted for POL

Valves or Dust Caps for Acme Valves. Secure the

tank against falling or rolling.

8. Check for leaks after connecting. Apply approved

leak detector solution to connection, turn off all

burners and pilots, and open service valve. Leaks

will be detected by the growth of the bubbles. If

bubbles grow, tighten or repair the connection as

needed. Repeat leak test until problem is

corrected.

9. LP-gas is normally non-corrosive – you need not

worry about the inside of your container. However,

the outside should be kept free from rust by a

periodic coat of paint in a light reflective color. It is

very important to inspect and maintain the bottom

and foot ring on the container.

10. Do not store LP-gas containers indoors or in

enclosed areas. Do not expose LP-gas container

to heat. Always store with service valve closed and

plugged as required.

11. Do not attempt to repair any containers, container

valves, regulator or appliances by yourself. Use

only trained certified LP-gas service personnel to

perform repairs.

8

Landa VNG Operator’s Manual 8.913-939.0 - AB

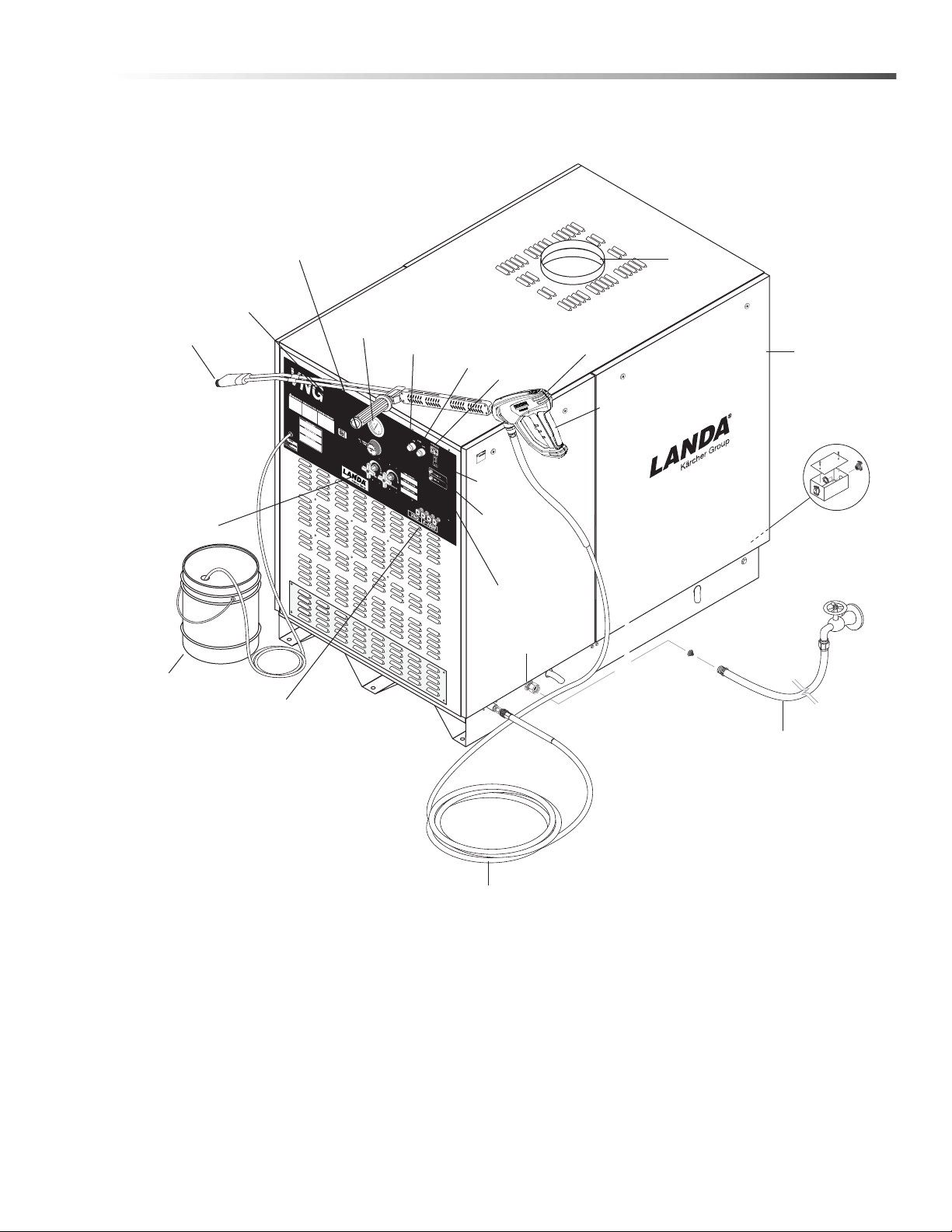

Component Identification

Side Panel

Spray Gun

Draft

Diverter

High Pressure

Nozzle & Coupler

Water Supply Hose

(Not Included)

High Pressure Hose

Variable Pressure

Control Handle

Trigger

Voltage

Light

Pump Light

Pressure

Gauge

Adjustable

Thermostat

Water

Supply

Inlet

Pump

Switch

High

Pressure

Nozzles

Detergent

Bucket

(not included)

Detergent

Valve

Stop

Switch

Hour

Meter

Burner

Switch

Incoming

Power

Electrical Box

Operations

Landa VNG Operator’s Manual 8.913-939.0 - AB

9

Operations

Manual

Shut-Off

Valve

1/8" NPT Plugged Pressure Gauge

Port Location

Union

Drop

Floor Level

Installation

Place machine in a convenient location providing

ample support, drainage and room for maintenance.

Location

The location should protect machine from damaging

environmental conditions, such as wind, rain and

freezing.

1. The machine should be run on a level surface

where it is not readily influenced by outside

sources such as strong winds, freezing temperatures, rain, etc. The machine should be located

considering accessibility for the replacing of

components and the refilling of detergents, adjustments and maintenance. Normal precautions

should be taken by the operator of the machine to

prevent excess moisture from reaching the

machine.

2. It is recommended that a partition be made

between the wash area and machine to prevent

direct spray from the spray gun from coming in

contact with the machine. Excess moisture

reaching the power unit or electrical controls will

reduce the machine’s life and may cause electrical

shorts.

Electrical

The machine, when installed, must be electrically

grounded in accordance to local codes. Check for

proper power supply using a volt meter; check the

serial plate for the correct requirements.

Gas Piping

This machine shall be rigidly connected to the gas

piping outlet and equipped with external manual shutoff valves adjacent to such machine. All gas piping shall

be approved and installed in accordance with the

Uniform Mechanical Code.

Install a gas union in the gas line adjacent to and

upstream from the control manifold and downstream

from the manual main shut-off valve. A 1/8" NPT

plugged tapping accessible for test gauge connection

shall be installed immediately upstream of the gas

supply connection for the purpose of determining the

gas supply pressure to the burner, and to prevent

damage to gas valve.

If a manual gas shut off valve is not in the gas supply

line within six feet of the machine and in an accessible

location, one shall be installed.

Union Location

3. During installation of the machine, beware of

poorly ventilated locations or areas where exhaust

fans may cause an insufficient supply of oxygen.

Sufficient combustion can only be obtained when

there is a sufficient supply of oxygen available for

the amount of fuel being burned. If it is necessary

to install a machine in a poorly ventilated area,

outside fresh air may have to be piped to the

burner and a fan installed to bring the air into the

area.

4. Do not locate near any combustible material. Keep

all flammable material at least 20 feet away.

Allow enough space for servicing the machine.

Local code will require certain distances from

floor and walls. (Two feet away should be adequate).

WARNING: Av oid small areas or near exhaust fa ns.

Gas Codes

Confer with local gas company and with proper

municipal officials regarding any specific code or regulations governing the installation. The installation must

conform to local codes (NFPA 54).

Union Connection

The following pipe sizes are just recommendations.

Always consult a local plumber and venting contra ct or

for local codes and regulations during installation.

10

Landa VNG Operator’s Manual 8.913-939.0 - AB

Operations

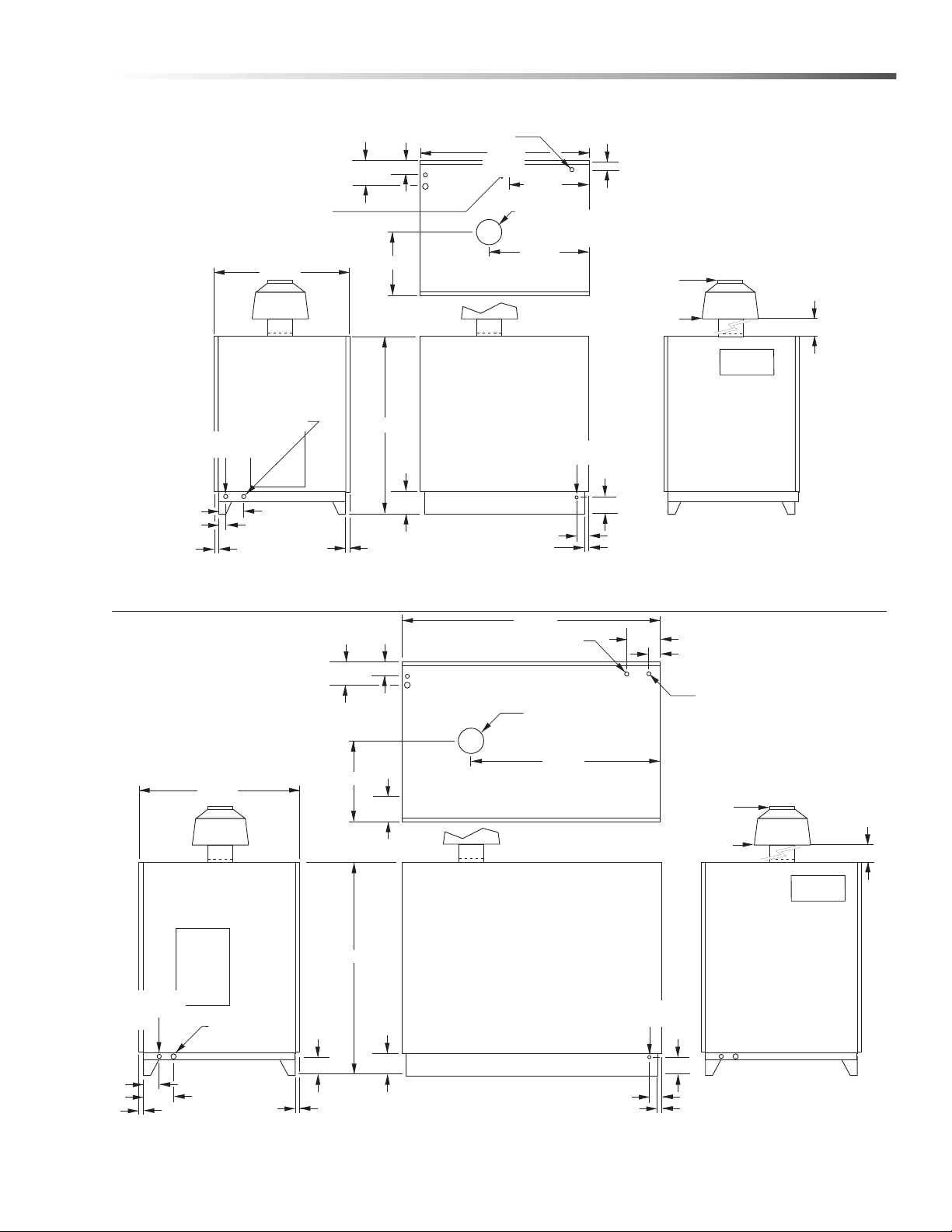

12.00"

2.00"

High Pressure

Out 3/8"

HP Nipple

12.00" Dia.

25.00" Dia.

Control

Panel

Detergent In

5.00"

1.00"

2.00"

1.50"

1.50"

8.75"

5.75"

5.00"

6.00”

57.00"

Gas In

1” NPT-M

Elect. In

3/4 NPT

42.63"

5.75"

21.21"

8.75"

5.00"

Water In 3/4" GHF

69.13"

Electric

Gas

Exhaust Gases

12" Dia.

44.13"

VNG6-3000, 8-3000, 10-2000

18.25"

3.25"

10.00” Dia.

19.50” Dia.

Control

Panel

Detergent In

5.00"

1.00"

2.00"

1.50"

1.50"

2.00"

5.25"

6.00"

47.50"

Gas In

1" NPT-M

Elect. In

3/4 NPT

36.00"

High Pressure Out

3/8" HP Nipple

36.00" Mininum

36.00" Mininum

5.25"

3.50"

Water In 3/4” GHF

Electric

Gas

32.25"

45.00"

Exhaust Gases

10” Dia.

14.50"

VNG4-2000, 4-3000, 4-4000

Landa VNG Operator’s Manual 8.913-939.0 - AB

11

Operations

Length of

Pipe (ft.)

Iron Pipe Size

3/4" 1" 1 -1/4" 1- 1/2" 2"

10 360 680 1400 2100 3950

20 250 465 950 1460 2750

30 200 375 770 1180 2200

40 170 320 660 990 1900

50 151 285 580 900 1680

60 138 260 530 810 1520

70 125 240 490 750 1400

80 118 220 460 690 1300

90 110 205 430 650 1220

100 103 195 400 620 1150

150 84 160 325 500 950

200 72 135 280 430 800

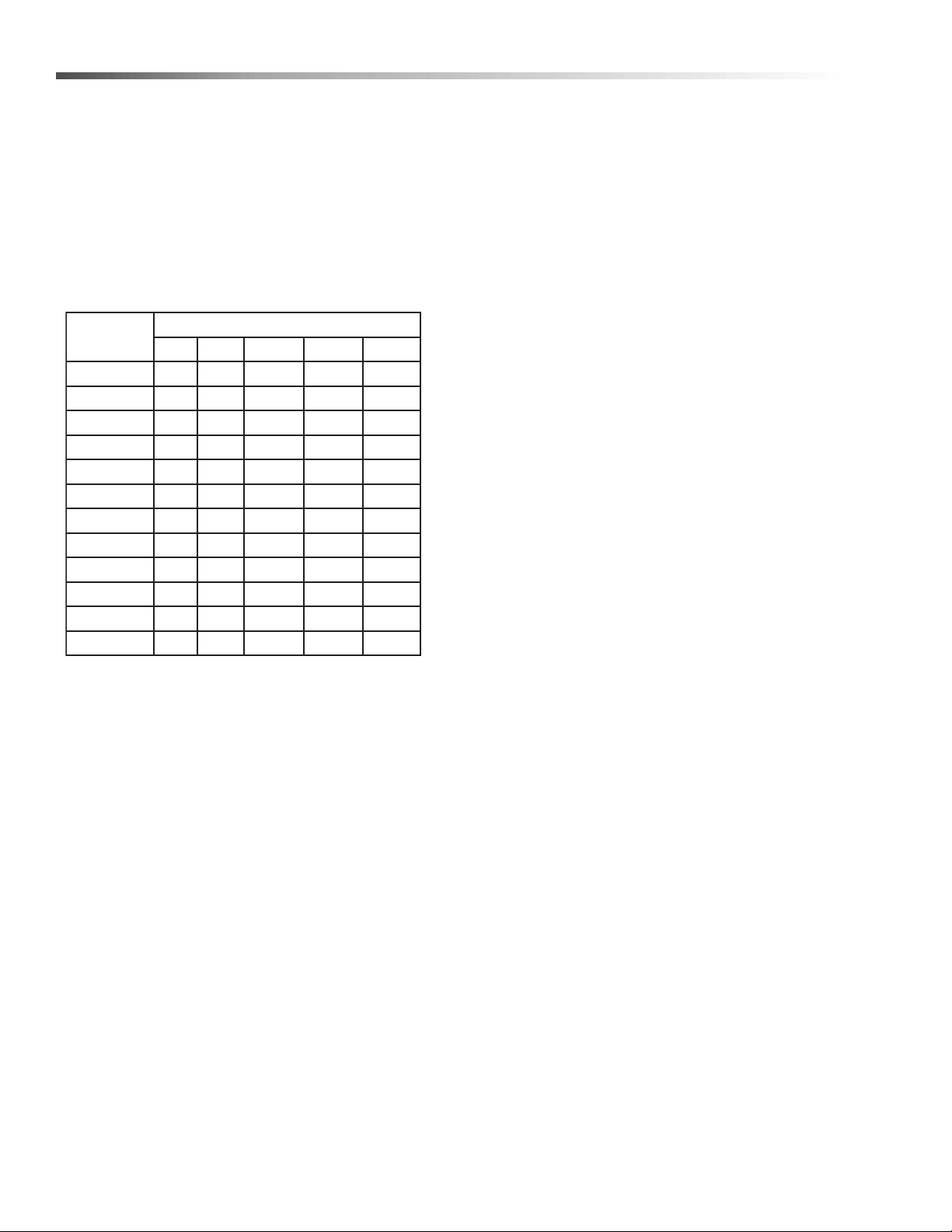

Pipe Sizing Chart for Natural Gas

The following chart is based on gas pressure in the

range 0-0.5 psi, specific gravity of 0.6 and pressure

loss of 0.5" W.C. Numbers are for straight schedule 40

pipe; fittings further reduce capacity. For example, in 1"

size, an elbow is equivalent to about 2.6 feet of pipe

and a tee is equivalent to about 5.2 feet of pipe.

Maximum capacity of pipe in cubic feet/hr of natural

gas (Multiply values by 1000 to get nominal BTU/hr

capacity.

ported, installed and used in the proper position. Do not

transport, install or use a vertical cylinder in a horizontal

or upside down position. Proper care must be taken to

position a horizontal container in the correct position for

vapor withdrawal. Liquid LP-gas could enter the

system designed for vapor only, possibly creating a

hazardous condition.

Always use a POL plug installed on a POL valve or a

dust cap on an ACME/Type 1 valve when transporting

or storing disconnected containers (full or empty).

Check for leaks after connecting. Apply approved leak

detector solution to connection, turn off all burners and

pilots and open service valve. Leaks will be detected by

the growth of bubbles. If bubbles grow , tighten or repair

the connection as needed. Repeat leak test until

problem is corrected.

Check all tank and the line connections periodically to

be sure they are tight. When testing for leaks, use

approved leak detector solution — not matches.

Improved Regulation: The second stage regulator

receives a relatively uniform pressure from the first

stage regulator. This helps the second stage regulator

to maintain appliance pressure at a nearly constant 11"

W.C.

LP-Gas (Liquid petroleum gas or propane)

LP-gas is gas compressed into liquid form for easy

transportation and storage. It is also known as propane

or bottle gas. (Propane tanks are not supplied with this

equipment.)

LP-gas is flammable, is always contained under

pressure and the liquid can freeze skin. Therefore, in

the interest of safety, it is important to understand the

basic facts about LP-gas and LP-gas containers.

Federal DOT (Department of Transportation) regulations require periodic inspections and re-qualifications

of cylinders. DO NOT USE damaged or rusted

containers.

DO NOT store LP-gas containers indoors or in

enclosed areas. Do not expose LP-gas container to

heat. Always store with service valve closed and

plugged as required.

CAUTION: Use LP-gas containers in proper

position.

Most LP-gas pressure washer heaters are designed to

operate on LP-gas vapor only. Therefore, all LP-gas

containers designed for vapor service must be trans-

12

Filling the LP-Gas Container

Only qualified persons should fill your LP-gas

containers.

CAUTION: Overfilling is hazardous!

DO NOT allow your LP-gas container to be overfilled.

Stop filling when liquid appears at the fixed level gauge.

Bleed off excess propane in a safe area. Most LP-gas

containers are equipped with a fixed liquid level gauge

which contacts the liquid level at 80% of container

capacity, allowing 20% for expansion. LP-gas

containers not equipped with a fixed liquid level gau ge

can only be filled by weight.

In cold climates, in order to keep vaporization of LP-gas

at the highest level, keep the fuel levels above 50%.

Propane Tank Disposal:

Propane tanks present a real danger in the waste

stream, so it is essential to properly dispose of old

tanks so they do not injure you or sanitation workers.

The best way to dispose of unused pro pane tanks is by

calling a propane company to pick it up. Propane tanks

are not picked up by garbage collectors, and improper

disposal is illegal in some areas. If a propane tank is

unfit for service, one should contact a propane

company.

Landa VNG Operator’s Manual 8.913-939.0 - AB

Operations

Draft Diverter

Required

8.717-728.0 8"

9.801-040.0 10"

8.717-730.0 12"

Illustration showing air openings necessary

to supply air for combustion when installed

Combustion and Ventilation Air

Properly sized vents are vital for the safe and efficient

operation of a pressure washer installed in a confin e d

space. When combustion and ventilation air are

supplied from inside the building, each opening must

have an area of one square inch for every 1,000 BTUH

input. When combustion air is supplied from the

outside, each opening must have an area of one

square inch for every 2,000 BTUH for horizontal ducts

and one square inch for every 4,000 BTUH for vertical

ducts (refer to NFPA 54).

The purpose of venting a gas pressure washer is to

completely remove all products of combustion and to

vent gasses to the outside air without condensation in

the vent or spillage at the draft hood (except in cases of

downdraft or poor stack conditions). To assure correct

venting, use a strong, gas-tight insulated pipe with a

cross section equal to that of the flue collar or draft

hood outlet and of sufficient vertical height.

During vent installation, avoid sharp turns, long horizontal runs and improper pitches. Maintain proper

support of vent connectors and joints, observe clearances from all combustibles and top the vent outlet with

an approved cap.

Type “B”, due to its temperature rating, can only be

used with natural draft pressure washers. A “B” vent is

designed for exhaust temperatures not to exceed

470°F (245°C).

All venting installations must conform to local codes. In

the absence of local codes, refer to “National Fuel Gas

Code” NFPA 54 and be constr ucted of materials

approved by the Uniform Building Code.

Sampling Port and Rain Cap. An adapter can be

installed between the collar and stack to adjust the

diameter from 10” to 8” or 12” to 10”.

Size the stack according to the following (see also

applicable local and national standards regarding

installation of gas-fired appliances):

• 3.5 to 4.4 gpm 10” Collar 8” Stack

• 4.5 to 5.5 gpm 10” Collar 10” Stack

• 6.3 gpm 12” Collar 10” Stack

• 8 – 10 gpm 12” Collar 12” Stack

Draft Diverter/Hood The draft required to vent

combustion gases is created by the heat inside the

pressure washer coil. A draft diverter helps improve

draft into the stack without pulling more air through the

combustion box and decreasing combustion ef ficiency.

The draft diverter can also help prevent back drafting

that can inhibit combustion. The draft diverter should be

installed a minimum of 36” above the flue collar.

Power Vent (Draft Inducer) If this machine is going to

be installed on a 90° or extended exhaust vent run

length which may restrict air flow it is recommended

that a contractor install a power vent. When a

contractor has found it impossible to vent straight

through the roof power venting is recommended to

help eliminate exhaust restriction of this natural draft

machine. This draft inducer (power vent) must be

installed by a licensed contractor who can calculate

size, operation connections and associated dampeners. Since we are a manufacturer and not a licensed

contractor and as such we are unable to make recommendations for suitable make and model of power

vents and compliance with local building codes.

in an enclosed room.

The pressure washer includes a collar that will mate

with standard HVAC ducting. The user will be responsible for installation of an exhaust stack. The exhaust

stack should include a Draft Diverter/Inducer, Damper,

Landa VNG Operator’s Manual 8.913-939.0 - AB

Damper An exhaust stack can reduce thermal efficiency by drawing in too much combustion air . This can

be controlled by adding a damper just below the draft

diverter. 8.753-473.0 - 8" Damper, 8.753-474.0 -10"

Damper, 8.753-418.0 - 12" Damper.

NOTE: Closing the damper can create high levels of

CO in the exhaust. Adjustments to the damper should

only be performed by a trained technician using a flue

gas analyzer. If an analyzer is not used the damper

should be set in the fully open position.

13

Operations

Sampling Port A port for sampling flue gases and

measuring the flue gas temperatur e sho u ld be placed

18” above the flue collar. The port should be covered

when sampling is not being performed. The size of the

port should be only slightly larger than the probe for the

flue gas analyzer.

Rain Cap A rain cap should be installed on top of the

stack to prevent rain water, leaves and debris from

entering the stack. Your installer may also recommend

specialty caps for high wind areas or cold weather

zones to help prevent back drafting. 8.717-731.0 - 10"

Raincap, 8.717-732.0 - 12" Raincap

Vents penetrating ceilings or walls should be doublewall approved appliance vents and should be one to

two inches from combustibles. Vents passing through

enclosed spaces and vents exposed to the weather

should also be the double-wall type. Sometimes vents

have to be built of such great length that they come

apart at their joints under their own weight. These

should be screwed together at the joints with sheet

metal screws, usually three per joint. If the inspector

indicates that the vent is too close to combustibles, it

may be necessary to chisel away some of the combustible or route the vent pipe around the combustible. The

cross-sectional area of any flue shall not be less that

the cross-sectional area of the flue vent connection

outlet of machine.

Water Source

The water source for the machine should be supplied

by a 5/8" I.D. garden hose with a city water pressure of

not less than 30 PSI. If the water supply is inadequate,

or if the garden hose is kinked, the machine will run

very rough and the burner will not fire.

High Pressure Connection

Connect the high pressure hose by pulling the coupler

collar back and then inserting it onto the discharge

nipple. Secure it by pushing the collar forward.

Attach the wand into the spray gun using teflon tape on

the pipe threads to avoid leaks.

Inspection and Testing Gas Piping

The building structure should not be weakened by

installing the gas piping. The piping should not be

supported by other piping, but should be firmly

supported with gas hooks, straps, bands or hangers.

Butt or lap welded pipe should not be run through or in

an air duct or clothes chute.

Before turning gas under pressure into piping, all

openings from which gas can escape should be closed.

Immediately after turning on gas, the system should be

checked for leaks. This can be done by watching the 1/

2 cubic foot test dial for 5 minutes for any movement or

by soaping each pipe connection and watching for

bubbles. If a leak is found, make the necessary repairs

and repeat the above test.

Defective pipes or fittings should be replaced and not

repaired. Never use a flame or fire in any for m to locate

gas leaks — use a soap solution.

After the piping and meter have been checked

completely , purge the system of air. DO NOT bleed the

air inside an enclosed room.

During pressure testing of the system at test pressures

in excess of 1/2 PSIG, the pressure washer and its individual shut-off valve must be disconnected from gas

supply piping system or damage to the gas valve will

occur.

Gas Pressure

The ideal incoming gas pressure is 11 w.c.i (water

column inches). Minimum is 9 w.c.i., maximum is 14

w.c.i. or 1/2 PSIG. The correct operating manifold

pressure for natural gas is 3.5 w.c.i. The operating

manifold pressure for propane gas is 10 w.c.i. By

adjusting the gas valve pressure regulator be tw ee n 3

and 4 w.c.i. a side range can be achieved for natural

gas.

If the desired input rating cannot be obtained within the

above manifold pressure adjusting range, then the next

size larger or smaller burner orifice should be used.

The gas pressure coming out of the regulator and going

to the burner ring has been factory set for elevations of

0 to 2000 ft. Altitudes greater than 2000 ft will require

adjustments to the gas manifold pressures. Consult

your local service dealer for high altitude adjustments.

In Canada, certification for installation at altitudes over

4500 feet above sea level is the jurisdiction of local

authorities. You should not readjust the burner ring gas

pressure. If you replace your gas valve, you will need to

adjust the new valve. Refer to your machine’s specifi-

cation plate for the correct pressure setting. Follow the

installation and adjustment instructions provided with

your replacement valve.

NOTE: Air for combustion and ventilation along with

exhaust flue sizing must conform to methods outlin ed in

current American Standard (ANSI-Z223.1) National

Fuel Gas Code or National Standard of Canada CSA-

149.1 and CSA-149.2 “Installation Code for Gas

Burning Appliances”.

14

Landa VNG Operator’s Manual 8.913-939.0 - AB

Operations

WARNING

READ OPERATOR’S

MANUAL THOROUGHLY

PRIOR TO USE.

OPERATIONS

SAFETY

MAINTENANCE

Start Up

WARNING: Read and follow

instructions carefully when

installing or servicing machine.

Failure to do so may result in

damage to property or personal

injury.

1. Installation or servicing of gas

appliances and controls must

only be performed by qualified

personnel. After installation or

servicing, test the manual valve, operating valves,

pressure regulation, and automatic shut-off valve

for proper operation.

2. Install in a suitable dry location. Machine must be

located in an area properly protected from weather.

3. Shut off gas and electricity before starting installation or service. Turn back on to test or operate.

4. DO NOT connect machine before pressure testing

the gas piping. Damage to gas valve may result.

(9" - 14" W.C.P. or 1/2 PSIG)

5. DO NOT insert any object other than suitable pipe

or tubing in the inlet or outlet of the gas valve.

Internal damage may occur and result in a

hazardous condition.

6. DO NOT short the gas valve terminals.

7. DO NOT grip gas valve body with a pipe wrench or

vise. Damage may result causing gas leak

Use inlet or outlet bosses or a special body wrench.

8. DO NOT allow any flame to impinge on the

regulator vent tubing if supplied. It may clog and

cause gas valve malfunction.

age.

For Your Safety Read Before Lighting

WARNING

If you do not follow these instructions exactly, a fire or

explosion may result, causing property damage,

personal injury or loss of life.

A. This appliance has a pilot which must be lighted by

hand. When lighting the pilot, follow these instructions

exactly.

B. BEFORE LIGHTING smell all around the appliance

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

"FOR YOUR SAFETY

"WHAT TO DO IF YOU SMELL GAS"

• Do not try to light any appliance.

• Do not touch any electrical switch, do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your supplier, call the fire

dept.

C. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will not push

in or turn by hand, don't try to repair it; call a qualified

service technician. Forced or attempted repair may

result in a fire or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

9. DO NOT use the gas cock to adjust gas flow.

10. If main burner fails to shut off, turn off gas supply.

11. Keep all combustible materials away from gas

appliances. DO NOT allow lint or dust to collect in

burner area.

12. Dials must only be operated by hand. Never use

pliers, wrenches or other tools to turn dials.

13. Leak test with a soap solution after installation or

service with the main burner on. Coat pipe and

tubing joints, gaskets, etc.

Landa VNG Operator’s Manual 8.913-939.0 - AB

15

Operations

Check List Before Starting

CAUTION! If “NO” has been checked on any of the

following sixteen questions, do not operate this

machine.

YES NO

Has gas supply been inspected by an

authorized contractor to meet local

codes?

Is machine protected from downdraft and

excessive wind?

Is machine shielded from moisture or

water spray?

Is the voltage correct and are the circuit

breaker and supply cord adequate

according to specifications and serial

plate notation?

Is the machine electrically grounded?

Is there ample water supply?

Have all flammable liquids or gases been

removed from installation location?

Is there adequate gas supply for the BTU

rating of the burner?

"Is incoming gas supply pressure

between 6" - 14" water column inches or

1/2 PSIG?"

Has the proper gas regulator been

installed for pressure and volume?

Have you installed the optional LP

gas regulator assembly 9.802-633.0?

Is the machine properly vented to

allow adequate air flow?

Are the propane tanks large enough,

according to rating to prevent freezing?

Have gas lines been checked for gas

leaks?

Have gas lines been checked with local

codes?

Have all operators using this machine

been instructed properly and have they

read the manual?

Has the machine been installed

according to operator's manual

instructions?

16

Landa VNG Operator’s Manual 8.913-939.0 - AB

Assembly Instructions

Safety

Switch

Spray

Gun

High Pressure

Hose

Pump

Discharge

Fitting

High

Pressure

Hose

Cold

Water

Source

Garden

Hose

98015100-8

Pump

Water Inlet

Garden

Hose

Pressure

Nozzle

Wand

Coupler

Coupler

Collar

Operations

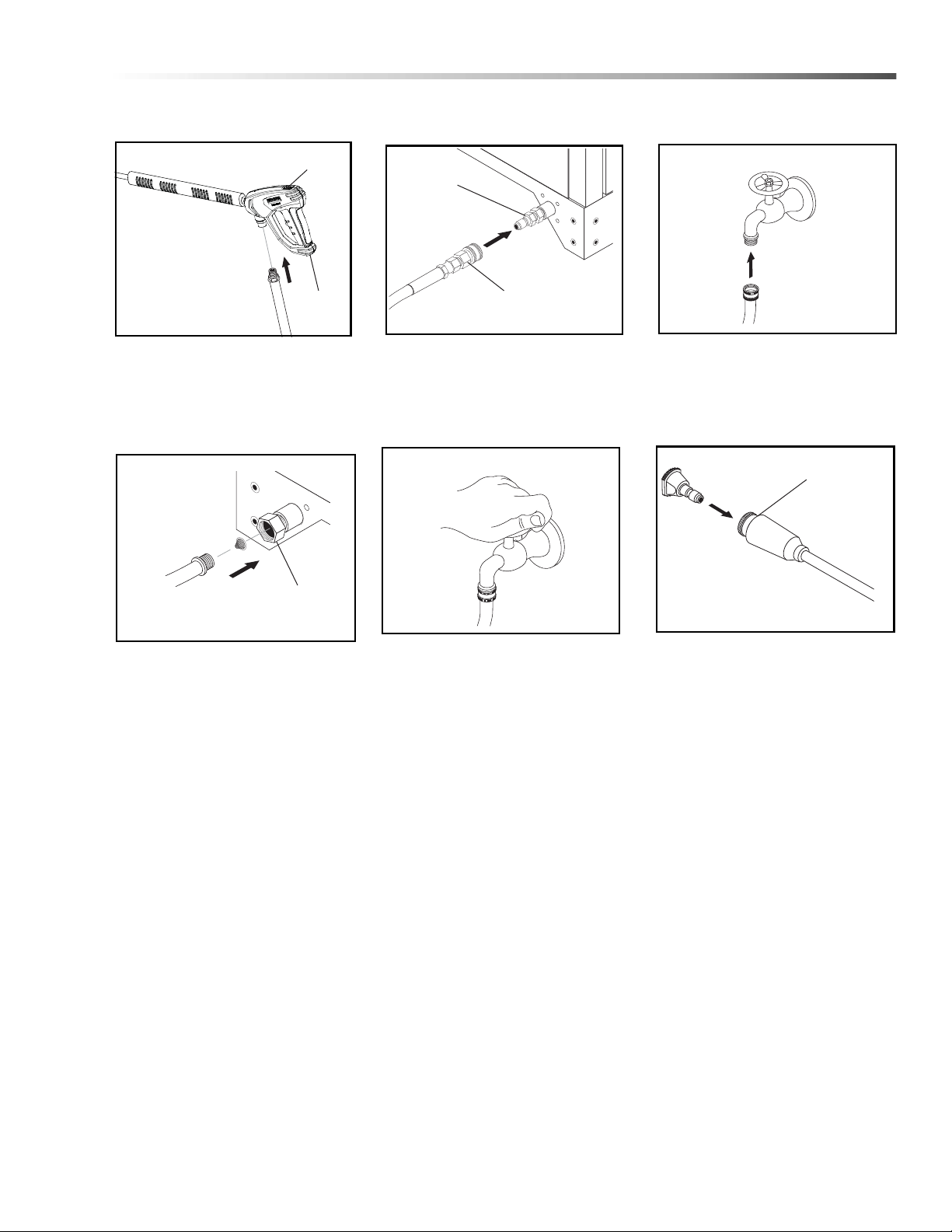

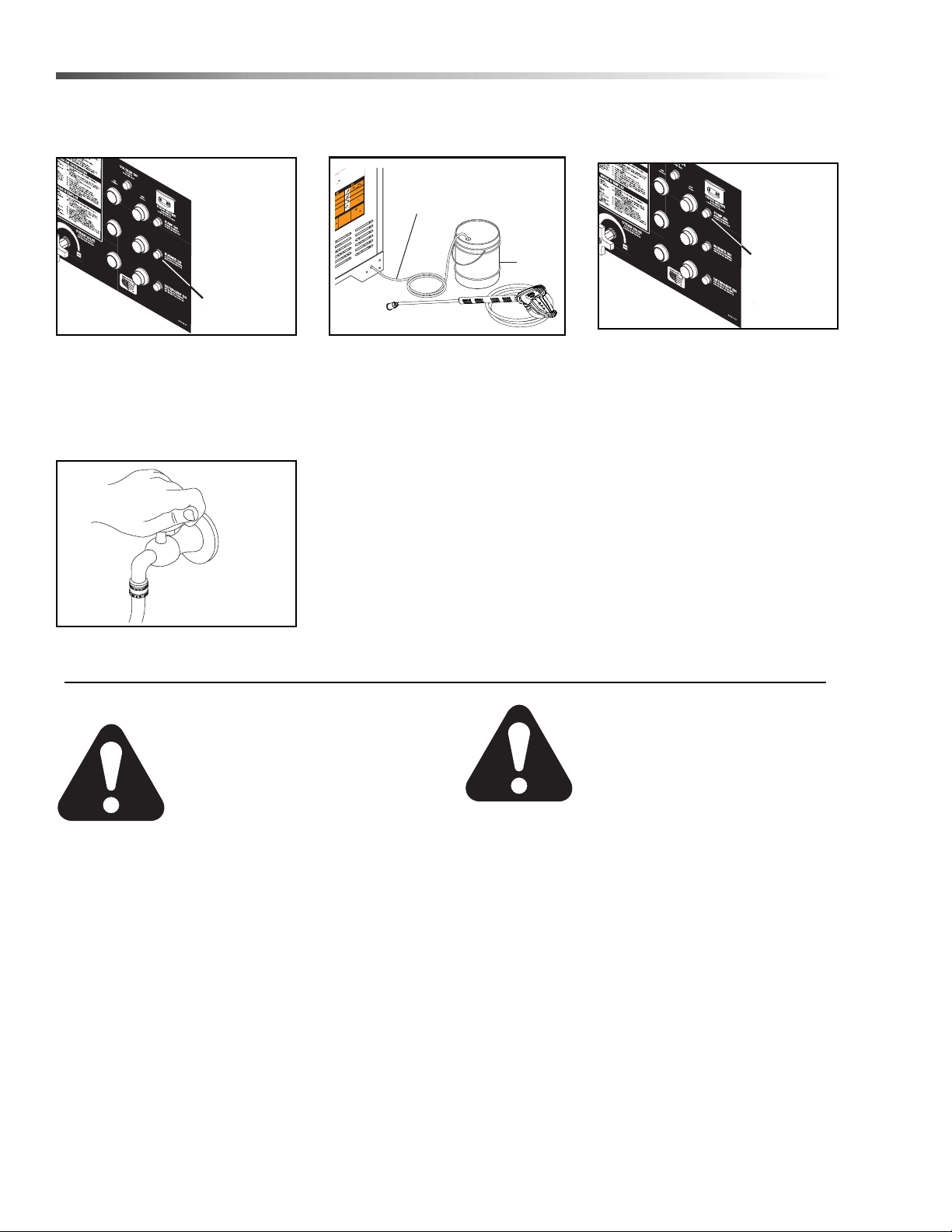

STEP 1: Attach the high pressure

hose to the spray gun using teflon

tape on hose threads. Move safety

latch into locked position to prevent

spray gun trigger from activating.

STEP 4: Connect the garden hose

to pump water inlet. Inspect inlets.

CAUTION: Do not run the pump

without water or pump damage

will result.

STEP 2: Connect the high pressure

hose to the discharge fitting. Push

coupler collar forward until secure.

STEP 5: Before installing nozzle,

turn on the water supply and run

machine allowing water to run from

the end of the wand until clear . T urn

off machine. Check for water leaks

and tighten as needed.

STEP 3: Connect garden hose to

the cold water source.

STEP 6: Pull the spring-loaded

collar of the wand coupler back to

insert pressure nozzle. Release the

coupler collar and push the nozzle

until the collar clicks. Pull the

nozzle to make sure it is seated

properly.

Landa VNG Operator’s Manual 8.913-939.0 - AB

17

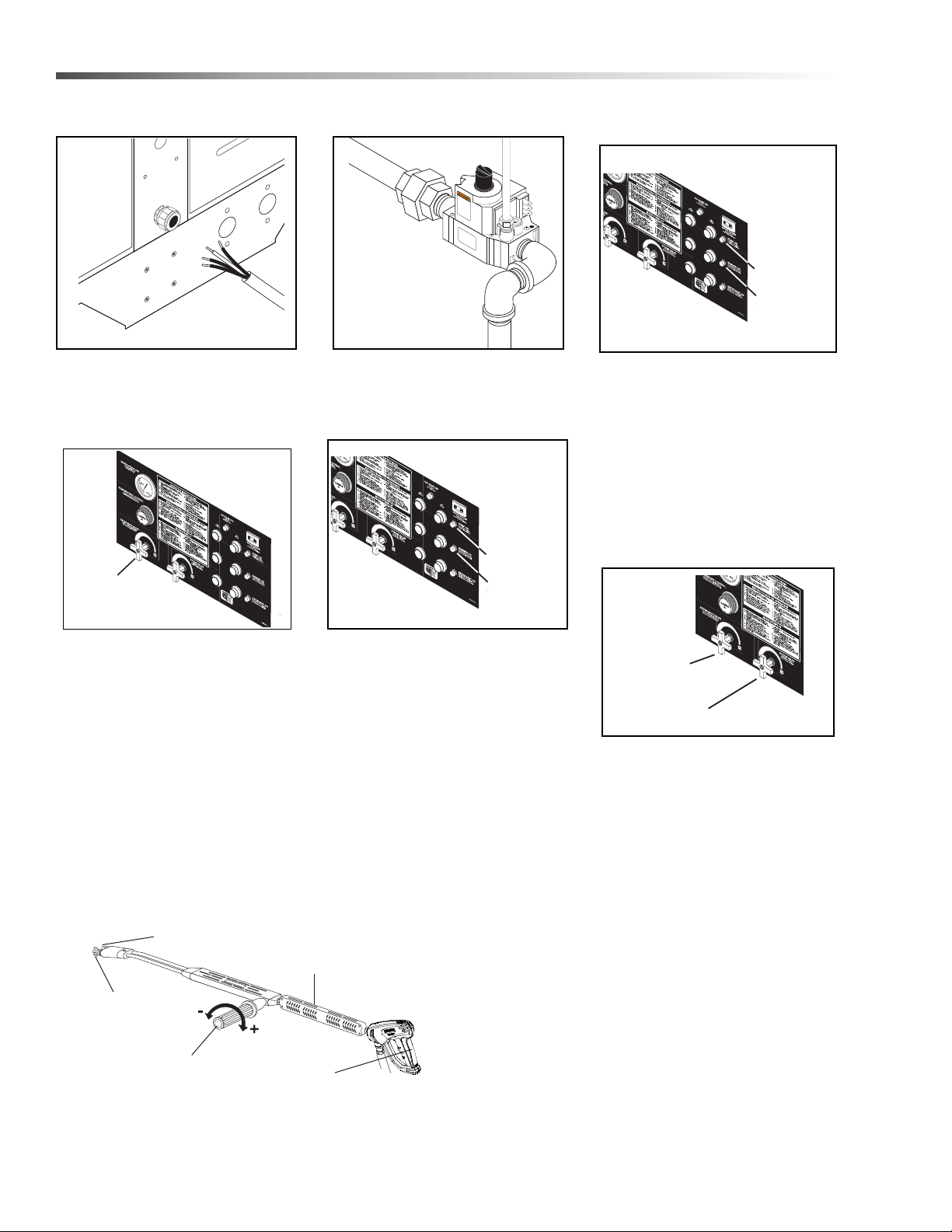

Operations

Detergent

Valve

Burner Switch

Pump Switch

Burner Switch

Pump Switch

Steam Valve

Detergent Valve

Variable Pressure

Control Handle

Trigger

Variable Pressure

Wand (VP)

High

Pressure

Nozzle

Brass Soap

Nozzle

Operating Instructions

ON

OFF

STEP 1: Have an electrician

connect power supply into electrical box according to information

shown on the serial plate.

STEP 4: To apply detergent open

the detergent valve counterclockwise making sure that the

detergent pick-up tube is in the

detergent solution and not sucking

air. With optional remotes, the

detergent switch needs to be

turned to the OFF position before

turning to the ON position to

activate the detergent solenoid.

STEP 2: Turn on main gas supply

and depress and turn control knob

to the ‘ON’ position.

STEP 5: To Stop: Turn the burner

switch off and place the detergent

pick-up tube into fresh water . Op en

the detergent valve and trigger

spray gun allowing detergent lines

to be flushed and the burner to

cool. Otherwise, coil damage will

result. After water has cooled, turn

pump switch to OFF position. If the

machine is going to be off for an

extended period of time, put the

manual valve on the gas valve into

the OFF position.

STEP 3: Push pump ‘ON’ switch, or

turn to pump position and pull the

trigger on the spray gun allowing

cold water to flow. To activate the

gas control valve for hot water,

push the burner switch to the ‘ON’

position and pull the trigger on the

spray gun.When steam is needed,

turn the steam knob counterclockwise. Then turn the temperature

adjustment knob to 275°F.

STEP 6: Close the steam knob and

detergent valve by turning

clockwise and settling the temperature control knob between 200°225°F.

NOTE: Do not allow acids,

caustic or abrasive fluids to pass

through the pump.

18

NOTE: Never run pump dry or

leave spray gun closed longer

than 3 minutes.

NOTE: Selection of high or low pressure is

accompanied by turning the handle. High

pressure nozzle must be inserted at end of wand

to obtain hight pressure. To apply soap read

operator’s manual.

Landa VNG Operator’s Manual 8.913-939.0 - AB

Operations

Detergent

Valve

WARNING

Applying Detergent &

General Operating Techniques

WARNING: Some detergents may

be harmful if inhaled or ingested,

causing severe nausea, fainting or

poisoning. The harmful elements

may cause property damage or

severe injury.

STEP 1: Use detergent designed

specifically for pressure washers.

Household detergents could damage

the pump. Prepare detergent solution

as required by the manufacturer. Fill a

container with pressure washer detergent. Place the filter end of detergent

suction tube into the detergent

container.

STEP 2: Open detergent valve counterclockwise until

you obtain desired mixture. Detergent will mix with the

high pressure water stream.

Thermal Pump Protection

If you run the engine for 3-5 minutes witho u t pres s ing

the trigger on the spray gun, circulating water in the

pump can reach high temperatures. When the water

reaches this temperature, the pump protector engages

and cools the pump by discharging the warm water

onto the ground. This thermal device prevents internal

damage to the pump.

Cleaning Tips

Pre-rinse cleaning surface with fresh water. Place

detergent suction tube directly into cleaning solution

and apply to surface. For best results, limit your work

area to sections approximately 6 feet square and

always apply detergent from bottom to top. Allow

detergent to remain on surface 1-3 minutes. Do not

allow detergent to dry on surface. If surface appears to

be drying, simply wet down surface with fresh water. If

needed, use brush to remove stubborn dirt. Rinse at

high pressure from top to bottom in an even sweeping

motion keeping the spray nozzle approximately 1 foot

from cleaning surface. Use overlapping strokes as you

clean and rinse any surface. For best surface cleaning

action spray at a slight angle.

STEP 3: With the motor running,

pull trigger to operate machine.

Liquid detergent is drawn into the

machine and mixed with water.

Apply detergent to work area. Do

not allow detergent to dry on

surface.

IMPORTANT: You must flush the detergent from

your pressure washer after each use by p lacing the

suction tube into a bucket of clean water, then run

the pressure washer for 2 minutes.

Recommendations:

• Before cleaning any surface, an inconspicuous

area should be cleaned to test spray pattern

and distance for maximum cleaning results.

• If painted surfaces are peeling or chipping, use

extreme caution as pressure washer may

remove the loose paint from the surface.

• Keep the spray nozzle a safe distance from the

surface you plan to clean. High pressure wash

a small area, then check the surface for

damage. If no damage is found, continue to

pressure washing.

CAUTION - Never use:

• Bleach, chlorine products and othe r co rro siv e

chemicals

• Liquids containing solvents (i.e., paint thinner,

gasoline, oils)

• Tri-sodium phosphate products

• Ammonia products

• Acid-based products

These chemicals will harm the machine and will

damage the surface being cleaned.

NOTE: If you remove detergent siphon tube from

container or allow container to empty, it will cause low

pressure by sucking air, which will damage the pump.

Landa VNG Operator’s Manual 8.913-939.0 - AB

Rinsing

Turn detergent valve clockwise to close. Operate

pressure washer and allow a few seconds for the

detergent to clear.

19

Operations

Burner Switch

Pump Switch

T

e

s

t

r

e

s

a

nd

o

ut

-

on.

g

h

t

a

CI

O

L

E

A

E

L

M

A

N

U

A

L DE

O

P

E

R

A

C

IÓN

AN

TES

DE

U

S

A

R

S

E

.

L

A O

P

ER

A

C

IN

A

D

EC

U

A

D

A

P

U

ED

E

O

C

A

S

IONA

R

L

E

S

IO

N

E

S

PE

R

S

O

N

A

L

ES

O

DA

Ñ

O

S

A

L

A

S

PR

OP

I

ED

A

D

E

S

.

N

E

.

Y

O

R

M

e

t

2

.

C

o

n

n

ct

e

m

ise

à

l

a

te

r

e

à

l’

aid

e

de

s

proc

é

d

u

d

i

s

jo

n

c

t

eu

r

.

L

e

d

is

j

o

nc

t

e

u

s

a

t

io

n

.

3.

F

i

xe

z

l

e

t

u

y

a

u

à

ha

u

te

pr

e

ss

i

on,

l

p

i

de

s

o

r

ti

e

.

4

.

C

o

n

ne

c

te

z

l

e

t

uya

u

à

e

a

u

e

t

f

ai

t

es

c

o

u

le

r

l’

e

u

5

.

T

e

n

e

z

l

e

t

u

b

e

r

igid

e

f

e

r

m

em

e

n

t

.

M

e

t

t

e

z

l’

i

n

t

e

r

r

u

p

t

ur

po

s

it

i

o

n

“

O

N

”

.

6.

T

ou

rn

e

z

l

e

bo

u

t

o

n

d

u ro

b

i

n

et

d

e

g

a

z

en

p

o

s

i

ti

o

n

“

O

N

”

.

La

ei

l

s

’

a

ll

u

m

e

a

u

t

o

m

a

ti

q

u

e

me

nt

l

o

rs

q

ue

l

’i

n

t

e

r

r

up

t

e

u

r

d

u

b

r

û

l

e

u

r

e

s

t

m

is

s

u

r

WARNIN

G

P

R

E

CA

U

C

IO

N

/

A

VE

R

TI

S

S

E

M

E

N

T

S

K

A

L

E

N

E

B

Y

O

N

G

P

ROT

E

J

A

S

E

LO

S

O

JO

S

CU

-

A

N

D

O

se

o

p

e

r

e

e

st

e

e

q

u

i

p

o

.

DE

S

L

U

N

ETT

E

S

DE

S

E

C

U

R

I

T

E

D

O

I

V

EN

T

E

T

R

E

P

O

R

T

E

ES

l

o

r

s

q

u

e

vo

u

s

o

pe

r

ez

c

e

t

a

p

p

a

re

i

l

.

e

d

e

v

e

c

t

.

u

s

r

e

s

.

u

R

I

S

QUE

D

E

F

E

U

O

U

D

’

E

X

P

LO

S

IO

N

R

IE

S

GO

D

E

IN

CEND

I

O

O

E

XPLOS

IÓ

N

O

SION

c

o

m

bu

s

t

i

bl

e

n

c

e

ar

e

a

f

o

r

s

e

s

o

m

e

g

a

s

I

f

y

o

u

s

m

el

l

tr

u

c

t

i

on

s

.

I

f

d

e

p

a

r

tm

e

n

t

.

c

g

r

e

p

ai

r

m

a

y

n

o

b

t

o

O

F

F

b

e

e

n

u

n

de

r

n

Detergent

Tube

Fresh

Water

Shutting Down And

Clean Up

.

r

v

e

a

e

e

1.

A

R

z

E

e

gl

é

r

t

e

”

ad

N

o

DE OP

I

d

O

“

o

C

S

F

.

m

ur

)

E

G

s

O

y

(

r

de

N

a

D

u

o

r

a

i

r

A

r

le

O

r

e

ic

û

i

G

I

e

r

n

a

i

i

A

t

T

b

e

C

P

a

a

u

se

r

A

r

a

d

C

o

(

e

d

r

d

de

i

n

u

F”

a

s

.

o

rd

F

te

ct

o

e

p

RU

t

p

e

O

g

-

Pé

n

“

y

T

u

n

r

r

e

e

o

i

o

ya

n

r

.

e

c

d

o

ó

s

e

t

m

t

r

i

t

ue

e

ci

e

l

NS

n

t

d

e

i

ia

I

mac

le

u

nt

l’

e

n

c

o

,

o

c

en

e

t

z

i

i

s

v

e

posi

ini

l

l

r

r

e

e

ro

r

r

t

t

e

e

e

t

z

r

o

o

r

la

u

d

p

e

u

C

n

s

e

r

t

i

ac

m

b

o

a

en

nce

r

,

m

or

m

lo

e

e

s

é

u

n

o

e

.

3

p

t

lad

e

t

d

p

”

m

ó

r

I

i

o

p

n

ea

à

n

o

’

m

c

m

d

C

o

a

l

i

t

FF

u

i

e

2

a

c

s

F

p

r

d

co

t

t

O

a

a

o

u

e

“

G

.

f

t

.

a

r

l

on

.

f

i

r

a

z

r

e

e

p

an

a

í

me

u

c

e

e

u

à l

El

t

a

d

t

N”

g

c

l

a

m

c

s

t

.

n

n

la

n

h

a)

è

I

l

i

O

n

o

a

e

i

t

A

r

i

e

“

c

t

r

v

ur

s

g

s

e

en

p

i

s

r

i

ar

t

t

y

e

ener

ND

:

.

l

o

lo

u

.

v

b

er

u

e

s

a

”

t

ptor

û

.

e

o

a

e

b

s

m

r

F

y

osi

u

u

v

a

de

r

hu

P

CE

e

g

nt

r

o

b

’

dé

d

a

m

d

r

l

e

a

i

a

e

e

d

.

N

ll

isp

n

e

OF

h

y

e

g

n

o

7

t

ol

l

t

“

(s

E

d

bo

t

r

du

t

o

er

”

o

(

n

la

t

r

i

s

e

z

I

r

t

u

cie

e

t

o

le

a

N

s

u

s)

uent

l

e

u

a

c

e

n

pi

.

f

é

h

s

s

N”

r

é

v

O

e

n

l

e

i

el

c

,

qu

d

t

“

e

b

t

va

O

e

re

g

se

la

e

n

o

p

e

a

e

di

l

é

e

n

“

l

p

p

s

n

b

ó

u

s

e

i

l

o

Ac

r d

ó

n

y

t

I

n

e

i

s

e

di

m

a

s

z

rr

o

i

ó

l

C

.

c

n

e.

e

u

t

i

è

n

a

o

i

e

or

e

e

r

o

r

8

ec

s

t

e

r

p

.

e

u

s

p

d

ic

p

s

hi

fr

P

n

u

n

p

u

1

ir

g

o

i

a

c

u

o

s

e

a

o

Ap

l

l’

u

a

p

os

rr

r

a

o

d

a

m

t

C

.

d

se

p

e

l

a

do.

C

a

e

e

m

e

gla

r

l

9

é

i

a

.

ez

a

de

d

e

a

u

.

t

o

l

s

in

a

2

n

t

u

r

u

l

q

e

p

A

o

l int

c

e

n

r

u

l

q

r

e

z

ob

e

t

e

d

r

e

o

e

e

our r

z

e

b

t

s

a

o

c

sus

i

p

e

M

.

s

e

p

o

.

d

n

a

u

s

in

i

a

l

u

i

v

B

a

or

r

et

q

gas

d

uer

nd

l

a

m

a

a

e

p

a

g

a

o

lo

L

u

e

u

t

ter

e

em

n

o

s

ad

eb

q

.

s

s

d

u

i

a

in

c

C

cu

C

e

e

a

q

p

l’

ru

l

m

e

.

l

d

ps

p

u

d

z

e

a

ba

e

l

l

a

v

a

l

m

e

l

l

i

e

d

r

t

ent

r

e

á

u

r

era

t

e

.

tu

et

v

r

o

u

.

nez

t

pr

a

am

u

)

g

a

va

M

r

au

l

n

p

c

g

i

n

a

e

O

l

t

u

’e

io

e

a

l

r

p

t

á

D.

D

se

r

c

z

m

m

.

.

A

l d

A

m

A

e

e

a

o

o

a

te

t

nte

r

l

p

t

se

).

i

z

.

t

3.

n

AG

l

a

e

n

E

e

l

ie

e

P

e

t

ou

e

i

o

u

p

r

DO

s

c

A

a

C

I

c

e

q

(

e

o

m

U

u

i

o

D

”

n

l

.

g

a

t

erá au

q

r

F

F

de

o

N

e

a

o

—

ta

a

l

l

F

u

E

C

nd

s

f

p

la

o

te

.

l

n

N

C

.

o

i

l

)

“O

e

s

ce

c

j

4

N

,

m

O

n

e

er

e

u

IO

n

to

i

r

co

a

e

p

D

ó

c

u

(E

S

S

e

e

a

i

d

t

A

n

o

”

a

c

d

gu

.

i

l

l

i

r

e

a

5

N

G

se

e

on

m

c

l

o

os

A

d

O

PLO

t

ue

e

o

e

“

p

No

P

t

o

3

q

X

s

r

l

.

s

pr

i

.

ó

a

o

a

a

E

(A

l

u

t

j

r

y

e

p

os

”

ol

2

ue

r

a

n

E

d

F

r

C

g

á

El

se

e

len

te

y

ti

i

D

o

F

l

.

r

.

a

n

t

i

n

)

p

t

c

6

s

e

O

e

“O

O

U

do

a

e

g

.

njua

e

r

G

ermi

a

DO)

s

n

D

a

e

d

I

e

e

p

S

ó

gu

e

t

—

i

y

u

m

D

:

a

d

E

e

ucto

n

em

i

n

e

I

e

N

N

d

a

u

u

e

t

ar

d

R

st

i

l d

E

A

i

q

e

q

O

u

n

osic

n

i

ro

p

I

e

l

s

s

e

p

C

p

rg

l

S

el

g

a

7.

e

l

N

a

r

lim

d

la

O

d

e

c

E

e

de

r

ma

nd

t

(

L

r

o

a

e

e

l

es

en

e

P

l

s

e

s

d

ión

X

i

a

n

o

upt

r

s

a

do

E

b

r

u

i

o

e

’

Enci

r

n

y

r

i

u

l

m

p

e

pués de

ù

D

.

p

t

u

q

o

a

ue el d

n

s

i

8

l

o

v

b

g

E

in

a

e

o

l

s

áq

a

t

s

D

a

r

i

l

el

e

p

m

a

t

a

o

.

QU

i

r

a

9

a

a

p

v

S

.

A

l

d

i

g

.

de

n

n

í

r

er

al

A

RI

t

e

on

o

p

ue

Ne

.

n

t

.

P

q

x

ra

a

e

e

O

u

a

.

up

p

s

e

i

j

r

r

p

a

gu

S

.

B

e

e

a

m

E

er

a

N

s

r

t

OF

D

T

l

e

n

O

i

.

de

I

p

e

l

s

C

istol

EN

o

e

S

e

a

SK

I

ed.

r

í

p

I

t

t

.

L

fr

re

s

a

it

n

i

R

l

a

ga

á

LO

e

n

z

n

en

i

m

CA

s

P

n

p

r

o

ne

m

a

a

X

e

l

P

l

S

o

u

p

.

E

E

e

e

a

I

s

t

l

r

l

esio

D

s

n

i

C

e

e

I

y

e

Pr

h

y

F

h

o

—

re

l

m

.

l

a

c

w

R

i

es

r

a

r

E

i

S

er

l

E

t

i

p

at

r

P

C

g

s

to

so

DE

l

t

U

pa

s

.

e

or

t

o

S

F

se

s

d

e

AU

n

e

H

tol

o

t l

C

s

n

— U

i

das

s.

D

p

S

d

la

i

s

me

E

e

i

u

e

é

T

a

C

l

iq

n

u

l

A

e

ig

F

s

HO

R

E

r

po

S

—

e

N

s

SU

h

Y

U

e

c

as

l

R

A

u

CO

o

n

s d

U

C

E

T

o

e

.

J

c

s

N

lé

f

N

o

a

o

I

ce

y

s

g

UEV

l

i

ES

n

F

CA

s

n

n

T

a

e

M

la

O

R

o

t

S

t

e

s

E

r

e

e

E

AN

S

a

SE

s

C

SK

N

-

So

I

A

E

U

g

A

L

R

n

B

.

IO

—

F

i

RE

.

-

s

O

E

C

p

R

d

n

—

T

A

T

i

D

A

p

n

i

S

ÓN

E

IS

r

I

R

a

O

SU

L

ER

ma

P

g

S

E

w

P

P

O

I

x

RN

E

P

d

.

A

T

u

d

O

U

R

s

U

e

L

S

e

O

n

I

P

Q

n

R

B

d

a

no

P

g

i

E

O

R

A

AL

a

à

n

s

E

L

E

U

U

r

m

P

i

u

e

T

E

E

N

n

K

E

g

s

L

d

S

T

I

e

A

T

o

C

y

T

.

E

A

E

d

N

M

IGN

.

A

-

S

O

R

ra

R

E

E

O

-

L

B

A

O

E

—

p

M

P

s

P

E

D

PA

E

S

ÓN

A

RS

ER

SO

S

e

P

O

A

A

’

L

s.

c

R

CI

S

L

A

E

L

n

ICA

O

CK

OP

A

U

L

I

a

T

F

E

S

USA

I

PE

R

c