Page 1

Operating Instructions

WATERCLEAN 600 LP / MP

BTA 5.960-505.0

ETL 5.970-054.0 (LP 400V)

5.970-055.0 (MP 400V)

5.970-156.0 (LP 230V)

5.970-157.0 (MP 230V)

A 2011201

Page 2

Version 06/05

WTC 600 LP / MP

18

5

6 7

19

4

3

8

9

10

11

12

13

20

14

15

2

16

17

1

2

Page 3

WTC 600 LP / MP

y

Version 06/05

Safety Notes

Contents

1 Safety Notes ...........................................3

2 Intended Use..........................................3

3 Maintenance and Care ...........................4

3.1 Starting Operation ..................................4

3.1.1 Admission-pressure Unit ........................4

3.1.2 Filling the Metering Stations ...................4

3.1.3 Switching On the Equipment ..................5

3.1.4 Operating Indicators ...............................5

3.2 During Operation ....................................5

3.2.1 Control and Corrective Action Intervals..5

3.2.2 Sand and Activated Carbon Filter ..........6

3.2.3 Bleeding the Metering Pump ..................6

3.2.4 Replacing the Fine Filter ........................7

3.2.5 Fine Adjustment of the Operating Pressu-

res ...............................................................7

3.2.6 Mixing the Chemicals .............................8

3.3 Switching Off the Equipment ..................9

4 Consumption Materials...........................9

5 Malfunctions .........................................10

6 Technical Data .....................................11

7 EU Declaration of Conformit

...............12

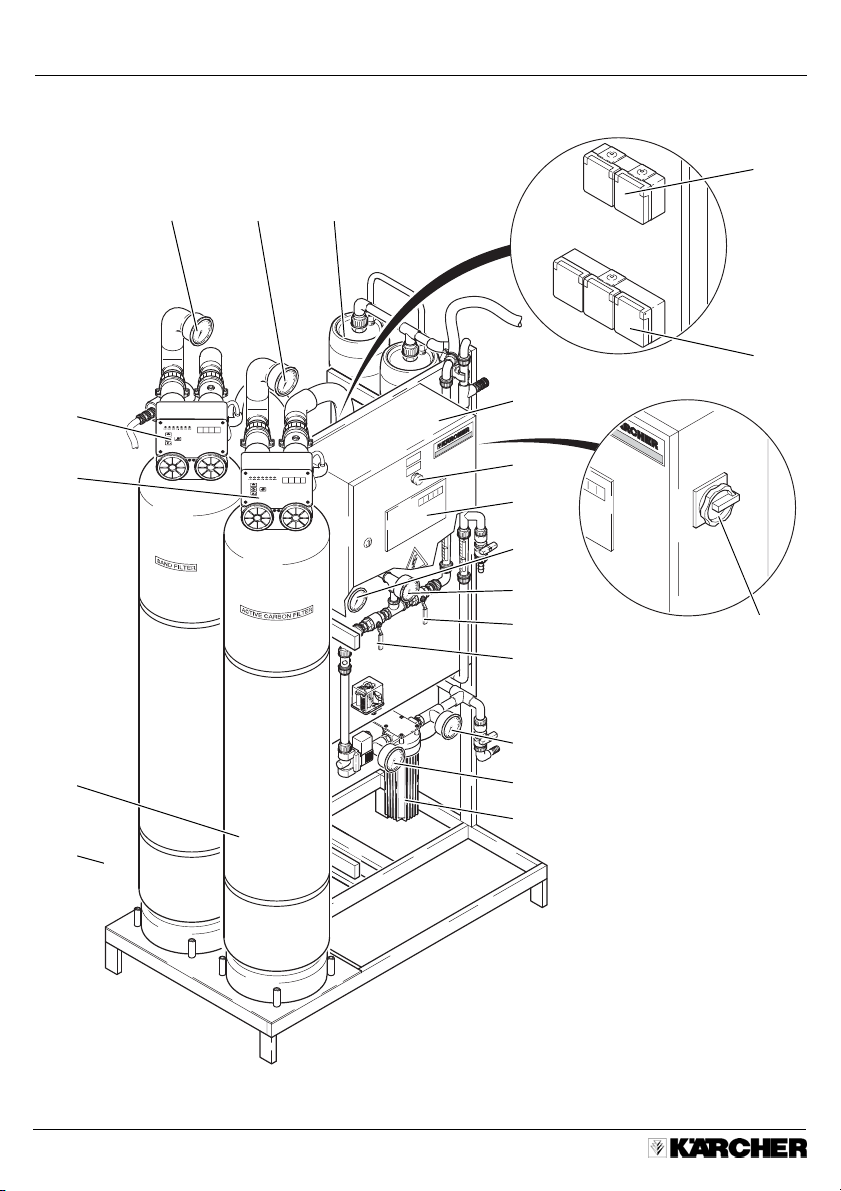

Equipment Components

1 Sand filter

2 Activated carbon filter

3 Control, activated carbon filter

4 Control, sand filter

5 Manometer, sand filter supply pressure

6 Manometer, activated carbon filter supply

pressure

7 RO filter unit

8 Switch box

9 Operating mode switch

10 Control panel

11 Manometer, pump pressure

12 Manometer, concentrate pressure

13 Concentrate control valve

14 Pressure control valve

15 Manometer, fine filter supply pressure

16 Manometer, fine filter output pressure

17 Fine filter unit

18 Power outlets, sand and activated carbon

filter

19 Power outlets (3x) for metering stations

20 Main switch

1 Safety Notes

Safe operation of the equipment is

possible only when the operating instructions and safety notes are read

completely, and the instructions contained therein are strictly followed.

Drinking Water

❑ Drinking water quality is ensured only when the

equipment is controlled within the scheduled

periods. Observe the given control intervals.

❑ Have the drinking water quality checked in reg-

ular intervals; the valid drinking water regulations are to be observed.

Chemicals

❑ Wear acid-resistant protective clothing (gog-

gles and gloves).

❑ Store chemicals cool and dry, however, not

below 5 °C.

❑ Keep chemicals at locations not accessible for

children.

❑ Ensure good room ventilation and provide a

washing facility.

❑ Have eye wash bottle readily available.

Electrical Equipment

❑ Work on the electrical equipment is to be car-

ried out only by skilled persons for electrical

work.

❑ Never touch damaged or cut through mains

cables; pull the mains plug immediately, as

required.

❑ Never operate the equipment with a damaged

cable.

2 Intended Use

The equipment is used for conditioning of surface

water, well water and river water.

Depending on the untreated water quality,

the modular set-up enables secure separation

of turbid materials, water hardeners, salts and

bacteria/ virus.

3

Page 4

Maintenance and Care

3 Maintenance and Care

The equipment may be put into operation only when set-up, installed and prepared for operation by an authorized KÄRCHER specialist dealer.

Version 06/05

WTC 600 LP / MP

3.1 Starting Operation

Before starting operation:

• Make sure that the equipment is connected to

the untreated water source and the respective

transporting gear, e. g., admission-pressure

unit.

• Ensure the unrestricted flow of the drinking water

into a tank or a suitable device on the user side.

The drinking water must be able to run

off without counterpressure. The height

difference must not exceed 3 m.

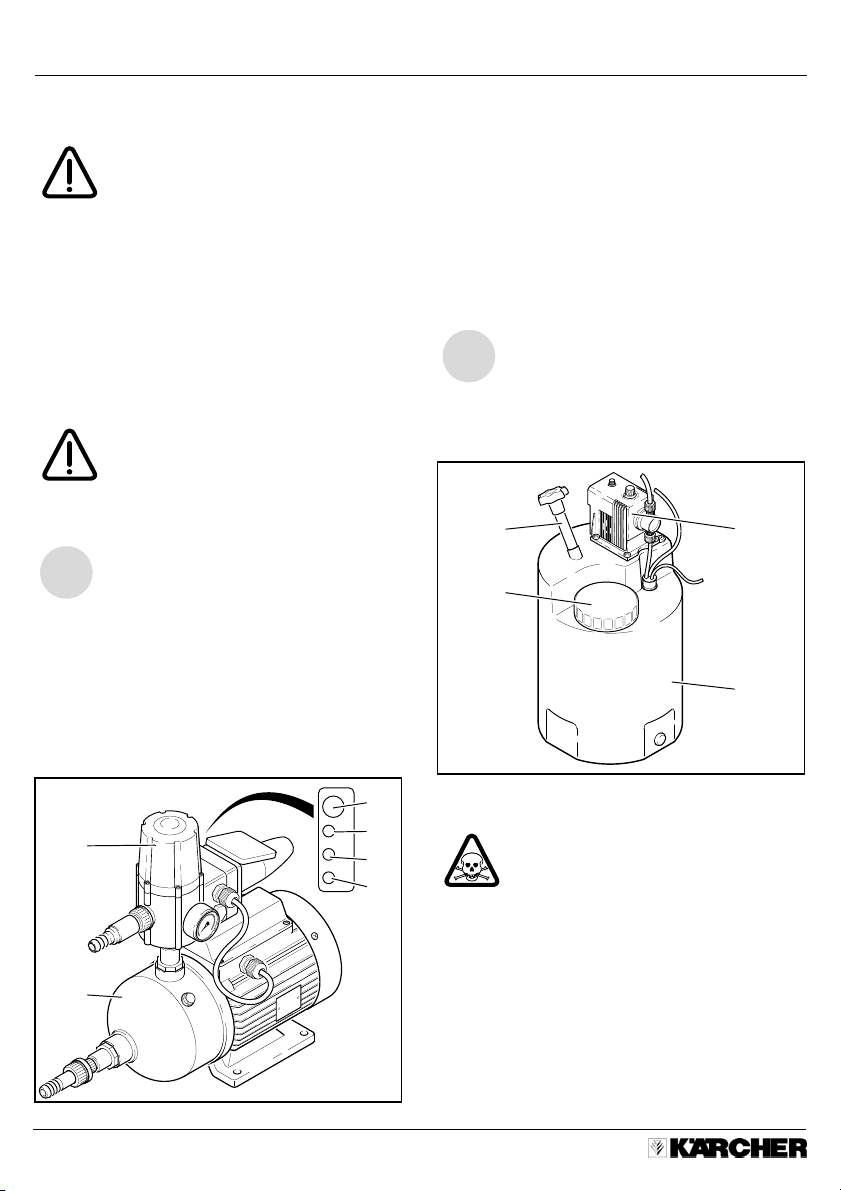

3.1.1 Admission-pressure Unit

In case an admission-pressure unit

is necessary, it will be installed by a

i

Kärcher service technician.

The admission-pressure unit consists of a

pump (21) and a control device (22). The operating condition of the pump is indicated with three

indicator lights:

• Green (24): Ready for operation

• Yellow (25): Pump delivering

• Red (26): Malfunction or water low

23

22

21

24

25

26

• The reset button (23) starts the pump after failure

3.1.2 Filling the Metering Stations

If the system is equipped with one or

more metering stations, it must be en-

i

sured that these are correctly filled and

connected.

• Put on protective clothing.

• Open the lid (27) of the metering station (30).

28 29

27

30

• Fill the respective chemical into the metering

station according to Section 3.2.6.

The metering stations must not be

mixed up or mistaken, meaning filled

with the wrong chemical.

• Add the corresponding amount of chlorine-free

drinking water.

• Shut the lid of the metering station.

• Pull the mixing rod (28) out of the metering

station to the stop and push back in again.

Repeat this procedure for approx. 5 minutes

until the chemical is completely mixed.

4

Page 5

WTC 600 LP / MP

If the metering container was completely empty, the metering pump (29)

may have possibly drawn in air. In this

case, bleed the air from the pump as

described in Section 3.2.3.

Version 06/05

3.1.3 Switching On the Equipment

• Check if the pumps of the metering station,

sand and activated carbon filter are connected

to the respective power outlets (18 / 19) at the

switch box (8).

• Check if the operating mode switch (9) is in the

correct position “Automatic” or “Hand”.

In the “Automatic” operating mode, the

system is controlled via an external float

i

switch in the drinking water tank.

In the “Hand” operating mode, the system is switched on and off manually via

the main switch.

• Switch the main switch (20) to the “I” position;

the system starts the drinking water production.

3.1.4 Operating Indicators

Display of the controls (3/ 4) of the sand and activated carbon filters:

• Display of the time

• LED line: Display of the weekday

Maintenance and Care

Control of the RO system:

The following is alternately indicated on the

two-line display of the control panel (10) of the RO

system:

• Equipment/model No. and operating condition,

• Drinking water temperature and drinking water

conductance value,

• Operating hours (_ _ _ _ _h _ _min).

5

Page 6

Maintenance and Care

Version 06/05

WTC 600 LP / MP

3.2 During Operation

Drinking water quality is ensured only when the following control intervals are met. In case

deviations from the desired condition can not be eliminated through the measures mentioned,

the drinking water production must be stopped and the Kärcher Service must be notified.

3.2.1 Control and Corrective Action Intervals

d…daily, w…weekly, m… monthly

Interval Check/Activity Target/ Purpose In Case of Deviation

d Level, metering container Sufficient amount/ filling Fill up; mixing chemi-

Air bubbles in metering line No air bubbles Bleed metering pump,

Flow of drinking water

based on the operational start-up value

Drinking water conductance value

based on the operational start-up value

Pressure difference between pump

and concentrate pressure

Hour meter for sand und activated

carbon filter

*

Reduction of the drinking water

flow up to 10 %

Increase of the drinking water

conductance value up to 10 %

15 % maximum above start-up

difference

Backwashing has occurred

within the past 24 h

Pressure difference, fine filter ≥ 0,8 bar Replace fine filter,

Visual inspection of the equipment No leakage Kärcher Service

w Fill out operating log

m Clean and flush the metering

container

Visually check the untreated water

No damages/leaks detectable Kärcher Service

pump

Float switch in the drinking water

tank

No operational malfunctions

detectable

cals,

see Section 3.2.6

see Section 3.2.3

Fine adjustment,

see Section 3.2.5 (1)

Fine adjustment,

see Section 3.2.5 (2)

See Section 3.2.5 (3)

Kärcher Service

Kärcher Service

see Section 3.2.4

Kärcher Service

* for switching over the indication, see Section 3.2.2

3.2.2 Sand and Activated Carbon Filter

During operation, the sand and activated carbon

filter control indicates the actual time. To change

the indication:

• Press button (32) for approx. 5 s; the display

(31) indicates the time of the regeneration.

• Press button (32) briefly; the display indicates

the number of regenerations.

6

• Press the ADVANCE key button briefly; the

display indicates the number of days and hours

since the last regeneration.

Page 7

WTC 600 LP / MP

Version 06/05

Maintenance and Care

• After a while the indication moves back to the

current time.

31

32

3.2.3 Bleeding the Metering Pump

The metering pump must be bled when the pump

has drawn in air (e. g., because the metering container is completely empty).

• The system stops; the “Motor/hard water“ malfunction indication is shown in the display.

This malfunction indication is shown independent of which metering container

i

is empty.

• Fill the empty metering container and mix the

chemicals according to Section 3.2.6.

33

• Screw in the bleeding screw again.

production / pr oduction

produccion / produzione

fault / default

error / guasto

disinfection / nettoyage

desinfeccion / disinfezione

reject / rejet

evacuation / evacuatione

regeneration / regeneration

regeneracion / rigenerazione

tank full / stockage plein

deposito lleno / serbatoto pieno

RO 1000

36

ESC

• On the control panel, acknowledge the malfunction indication with the RETURN key button (36); the system starts.

3.2.4 Replacing the Fine Filter

Check the pressure difference at manometers (15)

and (16). Replace the filter insert when over 0.8 bar:

• Switch off the equipment at the main switch (20).

• Stop the untreated water supply.

15

16

37

38

34

35

• Unscrew the bleeding screw (34) by one turn.

• Press the MANUAL pushbutton (33) until the

medium flows without bubbles through the

bleeding line (35) back into the container.

39

40

41

• Place a bucket under the untreated water drain

cock (37) and open the cock.

• Wait until no more water emerges out of the

cock, then shut the cock again.

• Attach the filter wrench (41) to the filter bowl

(40) and screw off the filter bowl.

The filter bowl is still filled with water.

i

• Remove the filter insert (38) from the filter bowl

and replace with a new one.

7

Page 8

Maintenance and Care

Version 06/05

WTC 600 LP / MP

• Before screwing on the filter bowl, check the

sealing ring (39) for damage.

• Screw on the filter bowl and tighten with the filter wrench.

• Open the untreated water supply again and

start the system with the main switch.

3.2.5 Fine Adjustment of the Operating

Pressures

In case of alterations to the system

adjustments, the following values must

not be exceeded under any circumstances:

• Pump pressure, max. 21 bar (MP) or

14 bar (LP)

• Drinking water amount, max. 650 l/h

• The concentrate amount must not exceed the operational start-up value

The system reacts somewhat timedelayed to alterations of the regulation

i

valves. Therefore carry out the adjustment at the pressure control valve (14)

and at the concentrate control valve

(13) only in small steps, and wait until

checking the respective effect.

(1) Flow of drinking water has decreased

from _____ to _____ l/h

Read off the amount of drinking water at the flow

meter (42) and compare with the value taken

when starting operation (see operational start-up

record).

If the flow of drinking water has decreased to _____ l/h , the following fine

adjustment is to be carried out.

If the fine adjustment does not lead to

an increase in the drinking water flow,

the Kärcher Service must be contacted.

• Slowly shut the pressure control valve (14) in

clockwise direction until the desired amount is

almost reached at the flow meter (42).

• Slowly shut the concentrate control valve (13)

in clockwise direction until the respective set

value is reached on both flow meters for concentrate (43) and drinking water (42).

Notice: The quantity of concentrate will increase. This is correct.

• Carry out a readjustment on both valve levers,

if required.

10

42

11

43

13

12

14

(2) Conducting capacity of the drinking

water has increased from _____

to _____ µS/cm

Small increases of the drinking water

conducting capacity do not influence

i

the drinking water quality.

On the display of the control panel (10), read the

current drinking water conductance value and

compare with the value taken when starting operation (see operational start-up record).

If the drinking water conductance value

has increased to _____ µS/cm, the following fine adjustment is to be carried out.

If the fine adjustment does not lead to a

decrease of the drinking water conductance value, the Kärcher Service

must be contacted.

• Open the concentrate control valve (13) in counterclockwise direction in small steps until the conductance capacity has reached the set value.

• Shut the pressure control valve (14) in clockwise direction in small steps until the drinking

water amount in the viewing glass (42) has

reached the set value.

8

Page 9

WTC 600 LP / MP

Version 06/05

Maintenance and Care

Notice: The amount of concentrate will increase. This is correct.

Observe the maximum pressure of 21 bar

(MP) or 14 bar (LP) at the manometer (11)!

• Repeat the adjustment steps, if required. The

original drinking water amount may possibly

not quite be reached.

• Compare the differential pressure with the

(3) The difference between pump and

concentrate pressure has increased

by more than _____ bar

• Read the values at the manometer for the

pump pressure (11) and for the concentrate

3.2.6 Mixing the Chemicals

When working with chemicals, always wear protective clothing.

Values for the metering of the various chemicals result from the untreated water analysis and

the system capacity.

i

Upon starting operation, the Kärcher service technician enters the required metering amounts

for your equipment into the following metering table.

(1) Metering Table

Metering

Container

Prechlorination

Pre-flocculation Ferrifloc 6.294-703.0

Anti Scalant RM 5000 hardness stabilizer 6.290-991.0

Post

chlorination

Chemical Item No.

*

RM 852 sterilization agent

Chlorinated lime

RM 852 sterilization agent

Chlorinated lime

*

*

6.291-772.0

6.291-505.0

*

6.291-772.0

6.291-505.0

pressure (12), and determine the differential

pressure.

value taken when starting operation (see operational start-up record).

If the differential pressure has increased by more than _____ bar, then

the RO filter membrane is clogged.

Readjustment is no longer possible.

Stop the drinking water production and

notify the Kärcher Service.

Metered Amount of the Chemical [ml] per

10 l Metering Solution

* These chemicals can each be used alternatively

9

Page 10

Consumption Materials

Version 06/05

WTC 600 LP / MP

(2) Metered Addition

For mixing of the chemical, only unchlorinated drinking water may be

used.

This water is taken from the drinking

water sampling valve (44).

44

The metered addition is carried out dependent of

the level in the metering container.

Completely emptied metering container:

• Fill 10 l of drinking water into the metering container.

• With a measuring cup, measure the 7.5 -fold

amount mentioned in the “10 Liter Water” column of the respective chemical and fill into the

container.

• Fill the container with drinking water to the “75

l” mark and mix according to Section 3.1.2.

Partially emptied metering container:

• Read off the level of the fluid with help of the

scale at the metering container, e. g., 35 l.

• Determine the quantity to be refilled by subtracting the read level from the 75 l.

Example: 75 l - 35 l = 40 l.

• Determine the required amount of the respective chemical from the metering table.

Example: 4 x the amount for 10 l water.

• Measure the determined amount of the respective chemical and fill into the container.

• Refill amount of water to the “75 l” mark and

mix in accordance with Section 3.1.2.

3.3 Switching Off the Equipment

If the equipment is not operated for

periods exceeding 14 days, it must be

preserved by the Kärcher Service.

Otherwise permanent damage must be

expected.

• Switch the main switch (20) to the “O” position;

the equipment stops the drinking water production.

Never switch off the equipment overnight! Otherwise the automatic cleaning of the pre-filter is not carried

through. Danger of damage to the

equipment is given!

4 Consumption Materials

Product Item No.

RM 852 sterilization agent 24 kg 6.291-772.0

Chlorinated lime 6 x 870 g 6.291-505.0

RM 5000 hardness stabilizer 23 kg 6.290-991.0

RM 5001 flocculation agent 10 l 6.294-703.0

RM 5001 flocculation agent 60 l 6.294-716.0

Filter element 5µ 6.414-466.0

10

Page 11

WTC 600 LP / MP

Version 06/05

Malfunctions

5 Malfunctions

Malfunctions of the RO system are signaled with LEDs at the control panel (10) and indicated at the

display.

In case of a malfunction, the system is generally switched off and the drinking water production

is interrupted.

i

If the malfunction can not be corrected, stop the drinking water production and notify the

Kärcher Service.

Designation/ Indication Possible Cause Corrective Action

LED fault Metering container empty

Sensor signal missing

regeneration Flushing of the pre-filter is active Not required, as the system

tank full Drinking water tank full

Switch defective

Display CV exceeded Conductance value of the

drinking water too high

Hard water Metering container empty Fill metering container and

Pressure malfunction Pressure of untreated water

too low

Fill metering container and acknowledge malfunction afterwards

Kärcher Service

switches on again automatically

Not required, as the system

switches on again automatically

Check switch;

if required, Kärcher Service

Kärcher Service

acknowledge malfunction afterwards

Check untreated water supply

• Installation on building side

• Admission-pressure pump

• Hoses for untreated water

Malfunctions on the admission-pressure unit are indicated with the red LED (26) on the control unit of

the admission-pressure unit.

Indication Possible Cause Corrective Action

Red LED lights Untreated water supply

disconnected

Check and reestablish the untreated

water supply.

After correcting the malfunction,

press the “Reset” pushbutton (23).

11

Page 12

Technical Data

Version 06/05

WTC 600 LP / MP

6 Technical Data

Parameter WTC 600 LP WTC 600 MP

Ambient temperature +1 °C – +50 °C

Storage temperature (upon delivery) to –10 °C

Humidity <100 % r.F.

Supply voltage 3*400 V 50 Hz

1*230 V 50 Hz

Pre-filter controls: prim./ sec. 230 V/12 V 50 Hz

Metering pumps 220 – 240 V 50 –60Hz

Electrical protection 16 A

Connected load 2.2kW 2.2 kW

Effective power consumtion 1.5 kW 2.2 kW

Minimum temperature of untreated water +5 °C

Maximum temperature of untreated water +35 °C

Reference temperature +15 °C

pH-value of untreated water 6 – 9.5

pH-value cleaning agent for cleaning the equipment 3 – 11

System intake pressure 2 – 6 bar

Capacity range 15000 l/day (±15 %)

Maximum drinking water supply 650 l/h

Dimensions: H x W x D

WTC 600 LP/MP 1800 x 660 x 720 mm

WTC 600 LP/MP - A 1800 x 1120 x 720 mm

WTC 600 LP/MP - AM 1800 x 1120 x 720 mm

Weight, in delivery condition

WTC 600 LP/MP 135 kg

WTC 600 LP/MP - A 155 kg

WTC 600 LP/MP - AM 175 kg

Designed for untreated water based on a

maximum salt content of 2000 ppm 5000 ppm

*

*

* depending on supply by the customer

12

Page 13

WTC 600 LP / MP

Version 06/05

EU Declaration of Conformity

7 EU Declaration of Conformity

We hereby declare that the equipment described below conforms to the relevant fundamental safety and

health requirements of the appropriate EU Directive, both in its basic design and construction as well as

in the version marketed by us.

This declaration will cease to be valid if any modifications are made to the machine without our express

approval.

Product: Water treatment plant

Model: 1.024-xxx

Relevant EU Directives: EU - Machinery Directive (98/37/EU)

EU - Low-Voltage Equipment Directive (73/23/EEC)

amended by 93/68/EEC

EU - Directive on Electromagnetic Compatibility (89/336/EEC)

amended by 91/263/EEC, 92/31/EEC, 93/68/EEC

Harmonized standards applied: DIN EN ISO 14971

DIN EN 50178

DIN EN 60 204 – 1

DIN EN 55 011 : 1998

DIN EN 55 014 – 1 : 2000 + A1: 2001 + A2 : 2002

DIN EN 55 014 – 2 : 1997 + A1: 2001

DIN EN 61 000 – 3 – 2 : 2000

DIN EN 61 000 – 3 – 3 : 1995 + A1: 2001

National standards applied: DIN 1988

Winnenden

Appropriate internal measures have been taken to ensure that series-production units conform at all times to the requirements of current

EU Directives and relevant standards.

The signatories are empowered to represent and act on behalf of the company management.

Alfred Kärcher Kommanditgesellschaft. Sitz Winnenden. Registergericht: Waiblingen, HRA 169.

Persönlich haftende Gesellschafterin: Kärcher Reinigungstechnik GmbH. Sitz Winnenden, 2404 Registergericht Waiblingen, HRB

Geschäftsführer: Dr. Bernhard Graf, Hartmut Jenner, Georg Metz

5.957-716

06/05

13

Loading...

Loading...