Page 1

5.956–394 F 19695 10/95

Page 2

English 2000 GM

2

Page 3

2000 GM English

English

Please read these operating instructions before starting and strictly

observe the "Safety Instructions for High Pressure Cleaners"

(5.951-949).

Français

Veuillez lire attentivement la présente notice d´instructions avant la

mise en service et respecter en particulier les "Consignes de

sécurité pour nettoyeurs haute pression" (5.951-949).

Español

Page 4

Page 10

Página 16

Antes de poner en marcha el aparato deberá estudiar atentamente

las "Advertencias y observaciones relativas a la seguridad

para limpiadoras de alta presión" (5.951-949).

3

Page 4

English 2000 GM

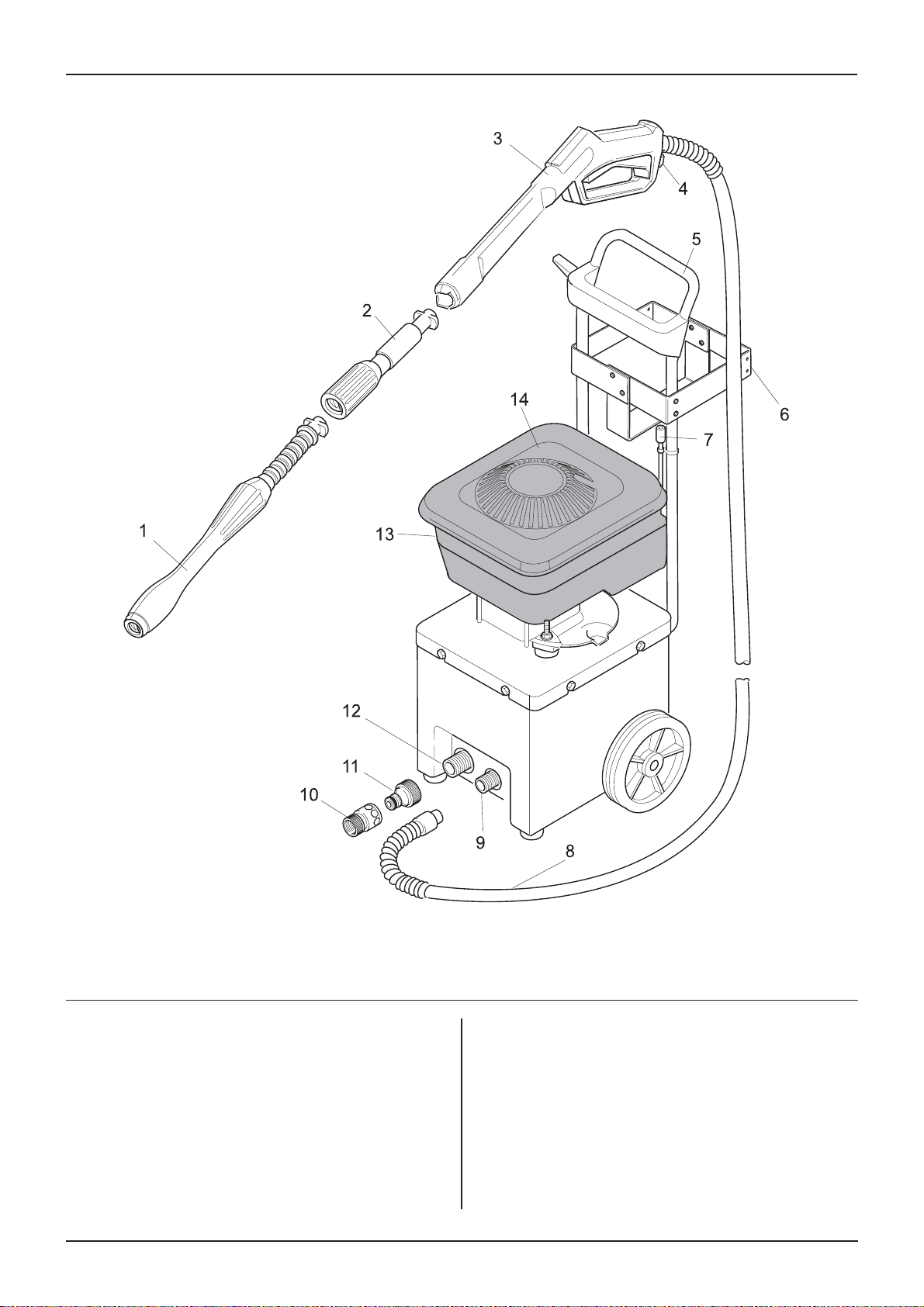

1 Spray lance with pressure regulator

2 Spray lance extension

3 Hand gun

4 Safety catch

5 Push handle

6 Basket for detergent reservoir

7 Detergent suction hose with filter

and metering ring

4

8 High-pressure hose

9 High-pressure outlet

10 Female coupling

11 Male coupling

12 Water inlet with strainer

13 Bracket

14 Engine

Page 5

2000 GM English

1. Unit Start-Up

CAUTION:

- FIRE HAZARD! Do not operate the high-pressure cleaner if fuel has been spilled. Instead,

move the machine to a different location and

avoid creating sparks of any kind.

- Do not store, spill or use engine fuels near

open flame or in the vicinity of devices featuring an open pilot flame, such as boilers, water

heaters, etc., or device that may create sparks

of any kind.

- Keep flammable items and materials away

from the engine silencer (minimum distance: 2

meters).

- Do not operate the motor without the silencer,

and check and clean the latter on a regular

basis. Replace if necessary.

- Do not use the motor in woods, scrubs and

grasslands without having a spark catcher attached to the silencer.

- Except during engine tuning, do not operate

the engine with the air cleaner removed, or

without a suitable cover over the air intake.

- Do not make adjustments to governor springs,

governor linkages or other parts that may result in a higher engine RPM.

- BURN HAZARD! Do not touch hot silencers,

cylinders or cooling fins.

- ASPHYXIATION HAZARD! Exhaust fumes

are poisonous. Never operate the unit in enclosed rooms.

1.1 Unpacking the unit

l Should you notice any transport damage during

unpacking, notify your dealer immediately.

l Because you care about the environment, please

do not dispose of packaging components in regular domestic waste. Instead, take the items to a

collection point for recycling.

1.2 Attaching the accessories

l Mount the holding basket for the detergent (3 me-

tal hoops) to the push handle.

l Attach the push handle to the unit.

1.3 Engine

l Prior to using the unit, read the operating instruc-

tions supplied by the engine manufacturer, and

pay particular attention to the safety instructions.

l Fill the fuel tank with unleaded petrol. Do not use

a petrol/oil mixture for two-stroke engines.

l The engine is supplied without engine oil. A cer-

tain amount of engine oil is packaged with the

unit. Pour this engine oil into the oil filler hole on

the engine.

l Check the engine oil level. Do not start the engine

if the oil level has dropped below the „MIN“ level.

Top up oil if necessary.

1.4 Pump

l The pump is filled with oil. An oil change is not

required.

1.5 Water inlet

l See „Specifications“ for connection data.

1.Screw male coupling (11) onto the machine.

Do not overtighten.

2.Screw female coupling (10) onto male end of garden hose. Be sure the hose end is in good condition so a leak does not occur. Do not overtighten.

3. To connect, push female coupling onto male

coupling all the way until it clicks

twice to assure

full flow of water to the pump.

Caution: Failure to push female coupling on all the

way can damage the pump if allowed to run dry.

4.Turn on water supply: If leak occurs, retrace steps

1 to 3, making sure connections are tight and that

couplings are not reversed.

Caution: The male and female connection are

not the same thread size. Reversing the connections will damage the coupling and cause a water

leak preventing the pump from priming properly.

1.6 Suction feed operation

To draw water from an open reservoir, proceed as

follows:

l Remove the threaded coupling from the unit’s

water inlet, and directly connect a suction feed

hose with filter (order no. 4.440-238) to the water

inlet.

l Set the metering ring on the detergent suction

hose to zero.

l Without the high-pressure hose being attached,

operate the pump until a solid stream of water

exits at the high-pressure outlet.

l At this point, connect the high-pressure hose

again.

Note: Dirt in the feed water could lead to the appliance being damaged. To avoid this risk, we

recommend fitting a filter. A suitable filter with

3/4" connection (order no. 4.730-059).

1.7 Spray lance

l To attach the spray lance to the hand gun, insert

the spray lance into the bayonet coupling of the

hand gun. Overcoming the spring pressure, firmly

press the lance into the coupling and twist it a

quarter-turn until it locks into place.

If required, you can use the additional spray lance

extension.

5

Page 6

English 2000 GM

2. Operation

2.1 Operating with high pressure

l Start the engine while observing the engine

manufacturer’s operating instructions.

l Using the safety catch, unlock the handgun trig-

ger and pull the trigger.

l The working pressure can be variably adjusted by

turning the spray lance on the outside (+/-).

2.2 Operating with detergent

l Set the lowest working pressure with the spray -

lance. No detergent can be drawn in with a high

working pressure.

l Hang the detergent suction hose into the deter-

gent reservoir (not supplied with the unit).

l To protect the environment, we recommend to

use detergents sparingly. Observe the metering

and/or mixing instructions provided on the pakkaging labels of the detergent supply containers.

l By offering you an individualised range of cle-

aning and preserving agents, Kärcher guarantees

trouble-free operation of the unit. Request more

information or ask for our catalogue and/or individual information brochures on specific detergents.

2.3 Work interruptions

l To prevent damage caused by overheating wa-

ter, switch OFF the pump during work breaks that

are longer than 10 minutes.

2.4 Switching OFF the unit

l After operating the unit with water having a high

saline content (i.e., sea water), the unit should be

flushed for 2 – 3 minutes with tap water while the

handgun is open.

l Set the throttle to the STOP position.

l Close the water supply valve and unscrew the

water supply line from the water inlet of the unit.

l Actuate the handgun trigger until the unit is no

longer pressurised.

l Prevent inadvertent opening of the handgun trig-

ger by locking it with the safety catch.

Universal cleaner Profi RM 555 ASF

This cleaning agent may be used undiluted.

Universal cleaner Profi RM 555 ULTRA

Automotive cleaner Profi RM 555 ULTRA

House and garden cleaner Profi RM 565 ULTRA

Boat cleaner Profi RM 575 ULTRA

Before using, these cleaning agents must be diluted

with 9 parts of water (1:9).

Note:

Only cleaning agents approved by the equipment

manufacturer may be used. Unsuitable detergents

may damage the unit and the object being cleaned.

We recommend the following cleaning method:

Step 1: Pre-soaking the area to be cleaned.

Spay the detergent sparingly onto the area to be

cleaned and allow to soak for 1 – 4 minutes.

Step 2: Cleaning step

Using the high-pressure jet, flush the area clean.

l After using a detergent, the unit should be flushed

with clean water. To do this, hang the detergent

suction hose into a container filled with clean

water, and operate the pump for approximately

1 minute.

6

Page 7

2000 GM English

3. Care and Maintenance

3.1 Monthly or as required

l Clean the filter on the detergent suction hose.

l Clean the high-pressure nozzle.

Using a needle, remove possible blockages from

the nozzle orifice. Afterwards, flush with water

from the front.

l Clean the strainer in the water inlet. It can easily

be pulled out with a pair of pliers.

3.2 Precautions in freezing

temperatures

l A unit that has not been completely drained may

be damaged by water freezing inside the components. During the winter season, it is recommended to store the unit in a heated area. If this

is not feasible, the unit should be completely drained and flushed with antifreeze.

l Draining the unit

– Remove the water feed hose and high-pressu-

re hose from the unit.

– Allow the unit to operate for a maximum 1 mi-

nute until the pump and the lines have been

purged.

l Antifreeze

In the event that the unit is taken out of operation

for extended periods, flushing the unit with an

antifreeze is recommended. This practice also

achieves a certain degree of corrosion protection.

4. Troubleshooting

This chapter contains a few helpful hints which may

help you remedy small defects without requiring

further assistance. In all other cases please contact

the authorised customer service.

4.1 Unit does not run

l Perform the maintenance procedures on the en-

gine as outlined in the operating instructions issued by the engine manufacturer.

4.2 Unit does not reach operating

pressure

l Set the spray lance to the maximum working

pressure.

l Clean the water inlet strainer.

l Check the water supply volume.

4.3 Strong pressure fluctuations

l Clean the high-pressure nozzle. Remove dirt from

the nozzle hole with a needle and then rinse out

with water from the front.

4.4 Pump is leaking

l Three drops per minute are normal. In the event

that the exiting water volume is larger, contact the

authorised customer service.

4.5 No detergent is being drawn in

l Set the spray lance to the minimum working

pressure.

l Clean both the detergent suction hose and the

filter, and check the hose for leaks.

l Check all supply lines feeding the pump for pos-

sible leaks or blockage.

7

Page 8

English 2000 GM

5. General Information

5.1 Possible applications

– Use the unit for cleaning machines, vehicles,

buildings, tools, etc.

– For example, clean facades, terraces, and gar-

den implements, etc. with the high-pressure jet

only.

– For reasons of environmental protection, engines

may only be cleaned in locations equipped with

suitable oil separators.

– In the event that the unit is used at petrol stations

and in other hazardous areas, the appropriate

safety regulations must be observed.

– For the removal of stubborn dirt, we recommend

the use of the dirt blaster which is available as an

optional accessory.

6. Specifications

5.2 Safety devices

Safety Valve/Overflow valve

The safety valve also serves as the overflow valve.

When the hand gun is closed, the valve opens and

water is returned to the suction side of the pump.

5.3 Warranty

The applicable warranty conditions in different countries are issued by the respective national distributor

of products. During the warranty period, any malfunctions of the unit caused by a material or manufacturing defect will be repaired free of charge.

In the event of a warranty claim, please take the unit,

with proof of purchase, to your original dealer, or to

the nearest authorised customer service centre.

Engine Data (Honda GXV 140)

1 Cylinder, four-stroke

Nominal output at 3600 RPM................................................. 3.7 kW (5.0 HP)

Operating RPM ................................................................... 3150 r.p.m. (3150 U/min.)

Fuel tank capacity.................................................................. 0.4 gal (1,1 l)

Fuel type ............................................................................ petrol unleaded

Sound pressure level (45635)................................................. 87 dB (A)

Sound power level ................................................................ 100 dB (A)

Water connection

Supply temperature (max.) ................................................... 140 °F (60 °C)

Supply rate (min.) .................................................................. 2.6 g.p.m. (600 l/h)

Supply hose (Order no. 4.440-207)

- length (min.) ...................................................................... 25 ft (7,5 m)

- diameter (min.)................................................................. 3/4 "

Suction height from open tank

at a water temperature of 20 °C/68 °F.................................... 39 in (1 m)

Performance data

Operating pressure ............................................................. 2000 psi (138 bar)

Flow rate ................................................................................ 2.2 g.p.m. (500 l/h)

Detergent intake.................................................................... 0- 8 g.p.h. (0- 30 l/h)

Recoil force of handgun

at operating pressure (max.) .................................................. 22 N

Dimensions

Length ..................................................................................... 23 in (575 mm)

Width....................................................................................... 14 in (360 mm)

Height...................................................................................... 36 in (915 mm)

Weight without accessories .................................................... 59 lbs (27 kg)

8

Page 9

Page 10

Français 2000 GM

10

1 Lance à régulation de pression

2 Rallonge de lance

3 Poignée-pistolet

4 Cran de sécurité

5 Etrier

6 Support du réservoir de détergent

7 Flexible à détergent,

avec filtre et dosage

8 Flexible haute pression

9 Prise haute pression

10 Accouplement féminin

11 Accouplement mâle

12 Prise d’eau avec crible

13 Support de poignée-pistolet

14 Moteur

Page 11

2000 GM Français

1. Mise en service

ATTENTION:

– Ne pas faire fonctionner le nettoyeur haute pres-

sion si du carburant a été répandu. Transférer

l’appareil a un autre endroit et éviter toute formation d’étincelle.

– Ne pas ranger, renverser ou utiliser de carburant

à proximité de flammes nues et d’appareils tels

que fours, chaudières, chauffe-eau, comportant

une veilleuse ou générateurs d’étincelles.

– Eloigner du silencieux tous objets et matériaux

facilement inflammables (distance minimum: 2

mètres).

– Ne pas faire marcher le moteur sans son pot

d’échappement et contrôler et nettoyer ce dernier

régulièrement ou le changer si nécessaire.

– Ne pas faire marcher le moteur sur terrain boisé,

buissonneux ou à hautes herbes, sauf si le pot

d’échappement est équipé d’un dispositif pareétincelles.

– Sauf pour les opérations de réglage, ne pas faire

marcher le moteur sans son filtre à air ou sans

capot au-dessus du manchon d’aspiration.

– Ne pas modifier les réglages des ressorts régula-

teurs, des tringleries régulatrices ou d’autres

pièces car ceci risquerait de hausser la vitesse du

moteur.

– Ne pas toucher les pots d’échappement, cylindres

ou ailettes de refroidissement lorsqu’ils sont

chauds. Risque de brûlure.

– Il est interdit de faire marcher l’appareil dans des

locaux fermés. RISQUE D’INTOXICATION.

1.1 Déballer l’appareil

• Si lors du déballage vous constatez des dégâts

dûs au transport, veuillez en informer votre transporteur par lettre recommandée avec accusé de

réception dans les 3 jours.

• Remplissez le réservoir de carburant avec de

l’essence sans plomb. N’utilisez en aucun cas de

l’essence deux-temps.

• Le moteur est livré sans son plein d’huile. Pour

cette raison, versez dans le carter moteur, par

l’orifice de remplissage, le contenu du bidon

d’huile compris dans les fournitures.

• Contrôlez le niveau d’huile du moteur. Ne mettez

pas l’appareil en service si le niveau d’huile est

descendu en-dessous du repère „MIN“. Rajoutez

de l’huile si nécessaire.

1.4 Pompe

• La pompe est livrée avec un plein d’huile. Un

changement d’huile n’est pas nécessaire.

1.5 Prise d’eau

• Valeurs de branchement: voir les données tech-

niques.

• Vissez le raccord de flexible sur la prise d’eau de

l’appareil.

• Reliez un flexible d’alimentation en eau (non

compris dans les fournitures) à l’appareil et à la

conduite d’eau domestique.

1.6 Mode Aspiration

Si vous aspirez de l’eau depuis un réservoir découvert, respectez les consignes suivantes:

– Dévissez la pièce-raccord de la prise d’eau de

l’appareil puis branchez directement un flexible

d’aspiration avec filtre (n° de réf. 4.440-238) directement contre l’appareil.

– Sur le flexible d’aspiration de détergent, réglez la

bague de dosage sur zéro.

– Laissez la pompe marcher sans flexible haute

pression jusqu’à ce que l’eau sorte sans bulles

par la sortie haute pression.

– Ensuite, rebranchez le flexible haute pression.

• Après le déballage, ne jetez pas l’emballage tout

simplement à la poubelle. Rapportez les éléments

constitutifs de l’emballage à un point de collecte

approprié en vue de leur recyclage.

1.2 Monter les accessoires

• Montez le support du réservoir de détergent

(3 étriers en tôle) contre le guidon.

• Montez le guidon contre l’appareil.

1.3 Moteur

• Avant de mettre l’appareil en service, veuillez lire

la notice d’instructions publiée par le fabricant du

moteur et respectez tout particulièrement les consignes de sécurité.

Remarque: Les impuretés éventuellement présentes dans l’eau d’alimentation peuvent endommager l’appareil. Pour empêcher cela, nous recommandons l’emploi d’un filtre à eau à raccord

3/4".

1.7 Lance

• Enfoncez la lance dans la fermeture à bayonnette

du pistolet (il faut ce faisant vaincre la résistance

du ressort). Tournez ensuite la lance de 90° pour

qu’elle encoche.

Si nécessaire, vous pouvez utiliser la rallonge de

lance.

11

Page 12

Français 2000 GM

2. Commande

2.1 Service haute pression

• Faites démarrer le moteur en respectant la notice

d’instructions publiée par le fabricant du moteur.

• Déverrouillez le cran d’arrêt de la gâchette du

pistolet puis enfoncez la gâchette.

• La pression de travail est réglable en continu: il

suffit de tourner l’extérieur de la lance (+/-).

2.2 Service avec des détergents

• Régler la lance sur la pression de service

minimum. Le détergent ne peut pas être aspiré à

haute pression.

• Accrochez le flexible de détergent dans le réservoir de détergent (non compris dans les fournitures).

• Pour ménager l’environnement, nous recommandons d’utiliser le détergent parcimonieusement.

Respectez les recommandations de dosage portées sur les étiquettes des bidons de détergent.

• Nous vous proposons une gamme personnalisée

de détergents et de produits d’entretien et vous

garantissons des travaux sans incident. Demandez conseil ou réclamez notre catalogue ou les

fiches d’information sur les détergents.

Nous vous recommandons la méthode de nettoyage suivante:

1ère étape: décoller les souillures

Pulvériser le détergent parcimonieusemnt puis le

laisser agir pendant 1 à 4 minutes.

2ème étape: enlever les souillures

Avec le jet haute pression, chasser les souillures

décollées.

• Bien rincer les circuits de l’appareil après un travail ayant fait appel à un détergent. Pour ce faire,

accrocher le flexible d’aspiration de détergent

dans un réservoir d’eau claire puis laisser marcher la pompe pendant environ 1 minute.

2.3 Interruption du service

• Lors de pause prolongées (plus de 10 minutes),

arrêter la pompe afin qu’elle ne soit pas endommagée par une surchauffe de l’eau.

2.4 Eteindre l’appareil

• Après un travail à l’aide d’eau salée (eau de mer),

rincer l’appareil pendant au moins 2-3 minutes à

l’eau douce, gâchette de la poignée-pistolet

enfoncée.

Détergent universel Profi RM 555 ASF

Ce détergent est utilisable sans avoir à le diluer.

Détergent universel Profi RM 555 ULTRA

Détergent pour voitures Profi RM 565 ULTRA

Détergent pour la maison

et le jardin Profi RM 570 ULTRA

Détergent pour bateaux Profi RM 575 ULTRA

Ces détergents devront être dilués avant utilisation

(1 part de détergent, 9 parts d’eau).

Remarque:

N’utiliser que des détergents reconnus aptes par le

fabricant de l’appareil. Des détergents inappropriés

peuvent endommager l’appareil ou l’objet à nettoyer.

• Réglez la manette des gaz sur „STOP“.

• Fermez l’arrivée d’eau puis dévissez le flexible

d’arrivée d’eau de l’appareil.

• Appuyez sur la gâchette jusqu’à ce que l’appareil

soit hors pression.

• Pour empêcher toute pulvérisation involontaire,

bloquez la gâchette du pistolet à l’aide du cran

d’arrêt.

12

Page 13

2000 GM Français

3. Entretien et nettoyage

3.1 Chaque mois ou suivant besoins

• Nettoyez le filtre du flexible à détergent.

• Nettoyer la buse haute pression.

A l’aide d’une aiguille, retirez les souillures obstruant l’alésage de la buse. Rincez ensuite à l’eau

en faisant rentrer celle-ci par l’avant de la buse.

• Nettoyez le crible situé dans la prise d’eau.

Le crible s’enlève facilement à l’aide d’une pince

plate.

3.2 Protection antigel

• Le gel peut détruire l’appareil s’il contient encore

de l’eau. Pendant l’hivernage, le mieux est encore de ranger l’appareil dans un local chauffé. Nous

recommandons sinon de vidanger l’appareil ou

de le rincer avec de l’antigel.

• Vidange de l’appareil

– De l’appareil, dévissez le flexible d’arrivée

d’eau et le flexible haute pression.

– Laissez marcher l’appareil pendant 1 minute

maximum, temps nécessaire à la pompe et aux

conduites pour se vider.

• Antigel

Avant des pauses de service prolongées, nous

recommandons de pomper de l’antigel dans

l’appareil. Ceci le protège relativement bien de la

corrosion.

4. Dérangements et remèdes

Dans ce chapitre nous vous conseillons comment

remédier vous-même aux petits dérangements.

Dans tous les autres cas, veuillez vous adresser au

service après-vente (SAV) agréé.

4.1 L’appareil ne marche pas

• Effectuez les travaux d’entretien du moteur con-

formément aux indications figurant dans la notice

d’instructions publiée par le fabricant du moteur.

4.2 L’appareil ne monte pas en pression

• Régler la lance sur la pression de travail

maximale.

• Nettoyez le crible situé dans la prise d’eau.

• Vérifiez le débit de l’eau d’alimentation.

• Vérifiez si toutes les conduites d’alimentation ar-

rivant à la pompe sont étanches ou obstruées.

4.3 Fortes variations de pression

• Nettoyer la buse haute pression. A l’aide d’une

aiguille, retirer les impuretés obstruant le trou de

la buse. La rincer ensuite par devant.

4.4 Pompe non étanche

• Une fuite de 3 gouttes par minute est admissible.

Si le gouttage augmente, confiez la réparation au

SAV agréé.

4.5 Pas d’aspiration de détergent

• Régler la lance sur la pression de travail minimum.

• Nettoyez le flexible d’aspiration de détergent avec

filtre et vérifiez son étanchéité.

13

Page 14

Français 2000 GM

5. Consignes générales

5.1 Destination

– Utilisez l’appareil pour nettoyer les machines,

véhicules, bâtiments, outils, etc.

– Nettoyez par ex. les façades, terrasses, appareils

de jardin uniquement au jet haute pression et sans

détergent.

– Les nettoyages de moteurs ne pourront être ef-

fectués qu’aux endroits équipés d’un séparateur

d’huile correspondant (protection de l’environnement).

– Si l’appareil est mis en oeuvre dans des stations-

service ou dans d’autres zones dangereuses, il

faut respecter la réglementation de sécurité correspondante.

– En présence de souillures rebelles, nous recom-

mandons d’utiliser la fraise à souillures (accessoire spécial).

5.2 Dispositifs de sécurité

Vanne de sécurité/Vanne de surpression

La vanne de sécurité sert en même temps de vanne

de surpression.

Lorsque vous relâchez la gâchette de la poignéepistolet, cette vanne s’ouvre et l’eau retourne du

côté aspiration de la pompe.

5.3 Garantie

Dans chaque pays, les conditions de garantie en

vigueur sont celles publiées par notre société de

distribution autorisée. Si pendant la durée de la

garantie votre machine présente des vices de matière ou de fabrication, la réparation est gratuite.

En cas de garantie, veuillez vous adresser à votre

revendeur ou à votre bureau du service après-vente

le plus proche de chez vous. Prière de toujours retourner l’appareil avec les accessoires, la carte de

garantie et la preuve d’achat.

6. Données techniques

Performances du moteur (Honda GXV 140)

1 cylindre, 4 temps

Puissance nominale à 3600 t/min.......................................... 3,7 kW (5,0 HP)

Vitesse de service............................................................... 3150 U/min (3150 r.p.m.)

Contenance du réservoir ....................................................... 1,1 l (0,4 gal)

Carburant .......................................................................Essence sans plomb

Niveau de pression acoustique (DIN 45 635)......................... 87 dB (A)

Niveau de puissance sonore ................................................ 100 dB (A)

Branchement de l’eau

Température d’arrivée (maxi.) ................................................ 60 °C (140 °F)

Débit d’arrivée (maxi.)........................................................... 600 l/h (2.6 g.p.m.)

Flexible d’arrivée (n° de réf. 4.440-207)

- Longueur (minµi.)............................................................. 7,5 m (25 ft)

- Diamètre (mini.) ............................................................... 3/4 "

Hauteur d’aspiration depuis un

réservoir ouvert, eau à 20°C/68°F ............................................ 1 m (39 in)

Performances

Pression de travail ................................................................ 138 bars (2000 psi)

Débit de refoulement ............................................................ 500 l/h (2,2 g.p.m.)

Aspiration de détergent..................................................... 0 – 30 l/h (0–8 g.p.h.)

Force de recul à la poignée pistolet,

développée par la pression de travail..................................... 22 N

Dimensions

Longueur............................................................................... 575 mm (23 in)

Largeur.................................................................................. 360 mm (14 in)

Hauteur ................................................................................. 915 mm (36 in)

Poids sans les accessoires..................................................... 27 kg (59 lbs)

14

Page 15

Page 16

Español 2000 GM

16

1 Lanza con regulación de la presión

2 Prolongación de lanza

3 Pistola

4 Seguro contra accionamiento

involuntario de la pistola

5 Asa

6 Soporte para el depósito del detergente

7 Manguera del detergente con filtro y

dosificación

8 Manguera de alta presión

9 Conexión (salida) de alta presión

10 Acoplamiento

11 Acoplamiento

12 Toma de agua con filtro

13 Soporte de alojamiento de la pistola

14 Motor

Page 17

2000 GM Español

1. Puesta en marcha

ATTENTIÓN:

-No trabajar con la limpiadora de alta presión en

caso de haberse derramado combustible

(gasolina). Retirar la máquina del lugar. ¡Evitar

cualquier formación de chispas hasta que no se

haya evaporado el combustible!

-No guardar, derramar ni manipular el combustible

cerca de fuentes de fuego abierto o de aparatos

tales como estufas, calderas, calentadores de

agua, etc. que posean llama de encendido o

puedan originar chispas.

-Mantener alejados (distancia mínima 2 m) los

objetos o materiales fácilmente inflamables del

colector de escape.

- No operar el motor sin silenciador. Revisar

regularmente el estado del silenciador. Verificarlo,

limpiarlo o sustituirlo por uno nuevo en caso

necesario.

- No trabajar con el aparato en áreas o zonas

recubiertas de bosque, matorrales o hierba si no

se ha equipado el tubo de escape del aparato con

un parachispas.

-No hacer funcionar el motor sin el filtro de aire o sin

la tapa sobre la boca de aspiración, con excepción

de los trabajos de ajuste.

-No efectuar reajustes ni modificaciones en los

muelles de ajuste, varillajes del regulador u otras

piezas o elmentos susceptibles de elevar el número

de revoluciones del motor. En caso de unos

regímenes de revoluciones excesivamente

elevados, el motor puede sufrir graves desperfectos.

1.1 Desembalar el aparato

• Si al desembalar el aparato comprobara Vd. al-

gún daño o desperfecto en el mismo atribuible al

transporte, rogamos se dirija inmediatamente al

Distribuidor en donde adquirió su aparato.

• No tire el embalaje del aparato y sus elementos al

cubo de basura. Entréguelo en los Puntos o Centros Oficiales de recogida para su reciclaje o recuperación

1.2 Montar los accesorios

• Montar el soporte para el depósito del detergente

(3 estribos de chapa) sobre el asa del aparato.

• Montar el asa en el aparato.

1.3 Motor

• Antes de poner en marcha el aparato deberán

leerse las instrucciones de servicio del fabricante

de los motores y observarse asimismo los consejos y advertencias de seguridad.

• Llenar el depósito del combustible con gasolina

sin plomo. No utilizar en ningún caso mezcla para

motores de dos tiempos.

• El motor se suministra con el depósito de aceite

vacío. Rellenar el aceite que se suministra con el

aparato en la boca de llenado del motor.

• Verificar el nivel del aceite del motor. No poner el

aparato en marcha en caso que el nivel del aceite se

encontrara por debajo de la marca de mínimo nivel

de llenado.

1.4 Bomba

• La bomba está llena de aceite. No es necesario

cambiar el aceite.

-No tocar los silenciadores, cilindros o aletas de

refrigeración que estuvieran calientes. ¡Peligro de

quemaduras!

- El aparato no deberá funcionar en espacios o recintos

cerrados. ¡PELIGRO DE INTOXICACION!

1.5 Circuito de alimentación de agua

• Observar los valores de conexión que se descri-

ben en las características técnicas del aparato.

• Montar el acoplamiento para la manguera en la

toma (entrada) del aparato.

• Empalmar una manguera para la alimentación de

agua (no está incluida en el equipo de serie) al aparato y a la conexión (grifo) de agua de la red.

1.6 Servicio de aspiración

En caso de aspirar agua desde recipientes abiertos,

deberán observarse estrictamente las instrucciones

y normas de la empresa abastecedora de agua de

la zona.

- Retirar el racor de acoplamiento de la toma de

agua del aparato y acoplar directamente al aparato una manguera de aspiración con filtro (Nº de

pedido 4.440-238).

- Ajustar el anillo de dosificación en la manguera

de aspiración del detergente a la posición «0».

- Hacer funcionar la bomba, sin acoplar la manguera de alta presión, hasta que el agua salga sin

burbujas de aire en la salida de alta presión del

aparato.

- Empalmar la manguera de alta presión al aparato.

Advertencia: La suciedad disuelta en el agua de

alimentación puede dañar el aparato. Con objeto de

evitar esta situación, aconsejamos emplear un filtro

para el agua, acoplamiento 3/4".

1.7 Lanza con regulación de la presión

• Encajar la lanza, haciendo presión contra la fuer-

za del muelle, en el acoplamiento de bayoneta de

la pistola y girarla en un ángulo de 90°, hasta que

enclave.

17

Page 18

Español 2000 GM

2. Manejo del aparato

2.1 Servicio de alta presión

• Poner en marcha el motor según las instruccio-

nes de servicio facilitadas por el fabricante del

motor.

• Desbloquear la pistola a través del seguro contra

accionamiento involuntario y oprimir la palanca

de accionamiento de la pistola.

• La presión de trabajo se puede ajustar de modo

continuo, girando la lanza hacia el exterior (+/-).

2.2 Pulverización del detergente

• Ajustar la lanza a baja presión de trabajo. Con alta

presión no se puede aspirar detergente.

• Introducir la manguera de aspiración del detergente en el depósito del detergente (no incluido

en el equipo de serie de la limpiadora).

• En interés de la protección del medio ambiente,

recomendamos hacer un uso muy moderado de

los detergentes.

• Disponemos de una amplia gama individual de

detergentes y agentes conservantes, por lo que

podemos garantizar el funcionamiento seguro y

correcto de su aparato. No dude en consultarnos

o solicite nuestro catálogo general o las hojas

informativas específicas sobre detergentes.

Detergente universal Profi RM 555 ULTRA

Detergente específico

para turismos Profi RM 565 ULTRA

Detergente específico

para el hogar y jardín Profi RM 570 ULTRA

Detergente específico

para embarcaciones Profi RM 575 ULTRA

Estos detergentes tienen que ser diluidos en agua

en la proporción de 1:9

(1 parte de detergente, 9 partes de agua).

Advertencia:

Sólo deberán utilizarse aquellos detergentes

recomendados u homologados por el Fabricante.

Unos detergentes inapropiados pueden causar

daños en el aparato y en el objeto a limpiar.

Método de limpieza aconsejado:

Primer paso: Separar la suciedad

Pulverizar el detergente en cantidad mdoerada

sobre la superficie u objeto a limpiar y dejar que

actúe durante 1 a 4 minutos.

Segundo paso: Eliminar la suciedad

Eliminar la suciedad separada con el chorro de

agua de alta presión.

• Una vez finalizados los trabajos con un detergente deberá enjuagarse el aparato con agua limpia.

Para ello se introduce la manguera de aspiración

del detergente en un recipiente con agua limpia,

haciendo funcionar la bomba durante 1 minuto

aproximadamente.

2.3 Interrupción del funcionamiento

del aparato

• En caso de estar el aparato inactivo durante unos

períodos de prolongados (más de 10 minutos),

deberá desconectarse la bomba a fin de evitar

daños por el sobrecalentamiento del agua.

2.4 Desconexión del aparato

• Tras haber trabajado con agua salada (del mar),

enjuagar la limpiadora con agua de red (limpia),

con la palanca de accionamiento de la pistola

oprimida, durante un período mínimo de 2-3 minutos.

• Colocar la palanca del acelerador en la posición

de parada «STOP».

• Cerrar la alimentación de agua (grifo) y desempalmar la manguera de alimentación de agua del

aparato.

• Oprimir la palanca de accionamiento de la pistola

hasta que el aparato quede totalmente sin presión.

• Conectar el seguro contra accionamiento involuntario de la pistola.

18

Page 19

2000 GM Español

3. Trabajos de cuidado y mantenimiento

3.1 Mensualmente o según necesidad

• Limpiar el filtro en la manguera de aspiración del

detergente.

• Limpiar la boquilla de alta presión.

Eliminar las obstrucciones en la boquilla con ayuda de una aguja. Enjuagarla con agua limpia de

dentro hacia afuera.

• Limpiar el filtro en la toma de agua del aparato. El

filtro se extrae con ayuda de unos alicates de boca

plana.

3.2 Protección contra heladas

• Los aparatos que no hayan sido vaciados com-

pletamente de agua o por cuyo interior no se haya

hecho circular una solución de agente anticongelante, pueden sufrir daños a consecuencia de las

bajas temperaturas. Por eso aconsejamos guardar el aparato durante la estación invernal en una

nave o espacio protegido contra las bajas temperaturas (provisto de calefacción).

• Vaciado del aparato

– Desempalmar las mangueras de alimentación

de agua y de alta presión del aparato.

– Hacer funcionar el aparato durante 1 minuto como

máximo, hasta haber evacuado completamente

el agua de la bomba y las tuberías.

• Adición de anticongelante

Para largos períodos de inactividad del aparato,

aconsejamos la aplicación de agente anticongelante, dado que de este modo también se logra

una cierta protección contra la corrosión.

4. Localización de averías

En el prsente capítulo queremos facilitarle una serie

de consejos que le permitirán subsanar por sí mismo

perturbaciones y averías de menor importancia. En

caso de averías de mayor envergadura deberá

avisarse al Servicio Postventa Oficial.

4.1 El aparato no se pone en marcha

• Revisarlo y efectuar los trabajos de mantenimien-

to tal y como se explica en las instrucciones de

servicio del fabricante del motor.

4.2 El aparato no coge presión

• Ajustar la máxima presión de trabajo en la lanza.

• Limpiar el filtro en la toma de agua del aparato.

• Verificar el caudal de alimentación de agua.

• Verificar la estanqueidad de las tuberías de ali-

mentación hacia la bomba. Verificar asimismo si

presentan obstrucciones.

4.3 En el aparato se producen fuertes

oscilaciones en la presión

• Limpiar la boquilla de alta presión. Eliminar con

ayuda de una aguja las obstrucciones que pudieran existir en la boquilla y enjuagarla con agua (de

dentro hacia afuera).

4.4 Inestanqueidades en la bomba

• Unas fugas del orden de 3 gotas por minuto son

admisibles. En caso de registrarse unas fugas

mayores, avisar al Servicio Postventa Oficial.

4.5 No se produce aspiración

de detergente

• Ajustar la lanza a la mínima presión de trabajo.

• Limpiar la manguera de aspiración del detergente

con filtro. Verificar su estanqueidad.

19

Page 20

Español 2000 GM

5. Advertencias y consejos de carácter general

5.1 Aplicación del aparato

– El aparato ha sido diseñado para la limpieza de

máquinas, vehículos, edificios, herramientas, etc.

– Limpiar fachadas y exteriores de edificios, terra-

zas, aparatos de jardinería, etc. sin detergentes,

sólo con el chorro de alta presión.

– Por razones de protección medioambiental, la lim-

pieza de motores sólo puede efectuarse en aquellos puntos y zonas que estén dotadas del correspondiente separador de aceite.

– En caso de emplear el aparato en gasolineras y

estaciones de servicio, o en zonas de peligro,

habrá que observar las correspondientes normas

de seguridad.

– Para la eliminación de suciedad particularmente

resistente y fuertemente adherida, aconsejamos

utilizar nuestra boquilla rotativa con ‘efecto fresadora’.

5.2 Dispositivos de seguridad

Válvula de seguridad/Válvula de derivación

La válvula de seguridad es al mismo tiempo una

válvula de derivación. Al dejar de oprimir la palanca

de accionamiento de la pistola, la válvula abre y el

agua vuelve a las válvulas de aspiración de la

bomba.

5.3 Garantía

En cada país rigen las condiciones de garantía

establecidas por las correspondientes Sociedades

Distribuidoras. Las perturbaciones y averías de su

aparato serán subsanadas de modo gratuito en la

medida en que las causas de las mismas sean

debidas a defectos de material o de fabricación.

En un caso de garantía rogamos se dirija, con el

aparato y los accesorios, así como el comprobante

de compra del mismo, al Distribuidor en donde

adquirió el aparato o a la Delegación Oficial del

Servicio Postventa más próxima.

6. Características Técnicas

Potencia y rendimientos del motor (Honda GXV 140)

monocilíndrico, de gasolina, cuatro tiempos

Potencia nominal a 3.600 r.p.m. ................................................... 3,7 kW

Número de revoluciones de servicio del motor.......................... 3150 r.p.m.

Capacidad del depósito de combustible .......................................0,4 gal

Combustible ......................................................................... gasolina sin plomo

Nivel sonoro según norma DIN 45635........................................... 87 dB (A)

Nivel de potencia acústica ........................................................... 100 dB (A)

Conexión a la red de agua

Máx. temperatura del agua de alimentación................................140 °F

Caudal de alimentación ................................................................ 2,6 g.p.m.

Manguera de alimentación (Nº de pedido 4.440-207)

- Longitud (mín.)............................................................................ 25 ft

- Diámetro (mín.)..........................................................................3/4 "

Altura de aspiración del agua desde un recipiente

abierto a una temperatura de 20°C ............................................... 39 in

Potencia y rendimientos

Presión de trabajo......................................................................2000 psi

Caudal...........................................................................................2,2 g.p.m.

Aspiración de detergente ........................................................... 0 – 8 g.p.h.

Fuerza de retroceso a

máxima presión de trabajo............................................................. 22 N

Medidas del aparato

Longitud ......................................................................................... 23 in

Altura.............................................................................................. 14 in

Altura.............................................................................................. 36 in

Peso sin accesorios ....................................................................... 59 lbs

20

Page 21

Loading...

Loading...