Page 1

1 High Temperature Application Guide

Fume Hood

Diagnostic Testing

A fume hood is a local ventilation device designed to

eliminate or minimize exposure to hazardous fumes,

dust or other airborne particulates. Basically, the fume

hood provides an area where a technician can safely

work with certain hazardous materials. The fume

hood is designed to contain and vent all dangerous

vapors and particulates away from the worker. A

typical fume hood will undergo quality testing by the

manufacturer, but it is also necessary to test the fume

hood in its installed state and to periodically make

sure the hood is performing correctly to limit human

exposure to airborne hazards. ASHRAE 110-1995 is the

current industry accepted standard for this testing

procedure.

The test is further broken down into different segments

some or all of which may be used to test a fume hood

depending on the setup and user requirements:

The rst, most basic, part of the test is a face velocity test

performed with the fume hood sash open at various

heights. This test involves using an anemometer to

measure the rate of airow in front of the fume hood

where a worker would be standing. The test involves

dividing the front of the hood into an imaginary grid

and then measuring at various equidistant points

along this grid to determine average velocity and

identify any points where excess air is escaping from

the fume hood.

Kanomax suggests using

our Climomaster 6541, with

its ±2% of reading accuracy

for this part of the test as it

can be programmed to

take 1 second readings,

for 20 readings per point.

This technique is taught

by NEBB fume hood

certication training. The

values from the 8 points

of (20) twenty, (1) one

second readings are then

Kanomax Climomaster

This is not only a time-saver, but eliminates the possibility

of an error occurring from manual calculations. The

lower cost Anemomaster Professional is also well

suited for this low velocity testing with an accuracy of

±3% of reading, however the values must be stored by

pressing the data store button for each value saved,

averaged automatically.

Copyright © 2013 by Kanomax USA, Inc.

Application Note

Fume Hoods are common in many

types of labs and industries

then automatically averaged using the calculation

feature. Both units use a small hot-wire sensor so they

are easy to position precisely at each point along the

grid.

Next is a smoke visualization test that is done in

conjunction with the face velocity test. This involves

introducing a visible smoke to the fume hood so that

the vapor can be observed. The fume hood fails the

test if visible vapor escapes the hood, but it also allows

a trained technician to identify if there are any eddies

or reversals in the air ow within the hood. An eddy

is an area where the air currents swirl around in one

place instead of owing properly and a reversal is a

localized area where the ow is going in the wrong

direction. An eddy or reversal is an indication that the

fume hood is not performing optimally as the ow is

being interrupted within the hood. Smoke sticks may

be used for test or a commercial fog machine such

as the one provided by Kanomax may be used to

generate large quantities of visible vapor.

Lastly we’ll talk about is the Tracer Gas Test. This

involves using a diffuser made to the specications

laid out in ASHRAE drawing 110-83M. The diffuser is

placed inside the fume hood and a tracer gas such as

sulphur hexauoride (SF6) is released at a controlled

rate of 4 liters per minute. SF6 is used because it has a

molar mass of 146.06 g mol−1 making it heavier than

ambient air. If the hood is operating correctly the

tracer gas will be removed by the ventilation system

of the hood. The test will be executed with the sash of

the hood in various positions to see if any gas escapes.

Page 2

2 Fume Hood Testing Application Guide

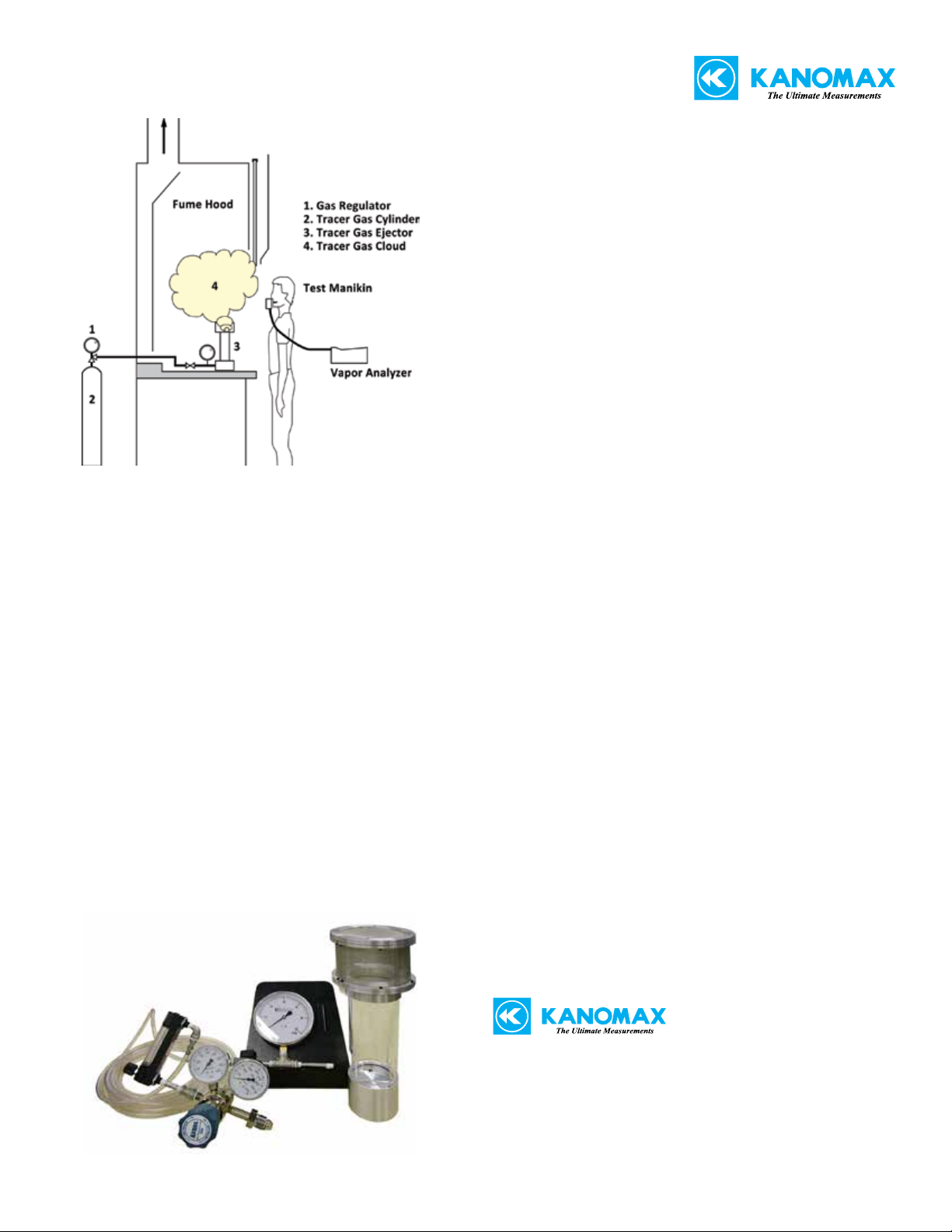

Setup Diagram for the Tracer Gas Test

During this test a manikin designed to simulate

an average person is placed in front of the fume

hood during testing and a vapor analyzer is used to

check for the tracer gas near the manikin’s face.

The purpose of the manikin is two-fold. First, if any

signicant amounts of tracer gas are detected near

the manikin’s face it means the hood is not working

properly as a person working at the hood would be

inhaling the fumes. Second, the manikin simulates

the space and disruption to the room’s airow that a

worker would cause if they were present at the hood.

Kanomax provides all the components for tracer

gas testing except the actual tracer gas itself. Our

dif-kit is made of durable and reliable stainless steel

components to the specications of drawing 110-

83M. Our test-manikin includes an adjustable stand

so you can easily position it at the correct height for

the ASHRAE 110 test. We also offer a vapor analyzer

calibrated to detect SF6.

Note: There has been some concern about using

SF6 for the test as it is a known greenhouse gas and

there is considerable concern about its effects on

the environment. For now it is still the accepted

standard, but there has been some discussion about

using nitrous oxide N2O or heptauoropropane C3HF7

(more commonly known by its trade names FE-227

FM-200). The dif-kit and vapor analyzer provided by

Kanomax are both able to be adapted to use and

detect these alternative gases respectively.

Kanomax offers fume hood testing equipment to

cover all parts of ASHRAE 110. The entire kit may be

purchased together or just the parts you require for

your specic testing may be bought separately. Our

experienced team is active in the industry and we’ll be

ready with whatever future requirements or changes

are announced. Wherever possible we try and design

our products so they can be upgraded to meet future

requirements rather than needing to be replaced.

We don’t think you should have to buy another meter

or test-kit if your existing one can be modied to meet

changing requirements for a fraction of the cost.

About Kanomax USA, Inc.

Kanomax has delivered the best measurement solutions in its products and services that adapt precision

measurement technology for uids and particles.

Kanomax product lines include anemometers, particle counters, dust monitors, and IAQ monitors. Kanomax is contributing to technological innovation and

quality improvement for the processes of quality management, environment management, and technology development in the areas of environment, health

, and energy, which are essential to sustain human

well-being, as well as in other industrial areas including automobile, aerospace, semiconductor, electronics manufacture, heavy industry, steel, shipbuilding,

pharmaceutical, biotechnology, food-processing,

medical, construction, and civil engineering.

Kanomax Dif-Kit for Fume Hood Testing

Copyright © 2013 by Kanomax USA, Inc.

Kanomax USA, Inc.

P.O. Box 372

219 US Hwy 206, Andover, NJ 07821 USA

TEL: 800-247-8887 (USA) * 973-786-6386

FAX: 973-786-7586

E-mail: info@kanomax-usa.com

URL: www.kanomax-usa.com

Loading...

Loading...