A0041200303

XV-N50BK,XV-N55SL

SERVICE MANUAL

DVD VIDEO PLAYER

XV-N50BK,XV-N55SL

TV DVD

STANDBY/ON

OPEN/

TV DVD

CLOSE

TV1 TV2 TV3

213

TV4 TV5 TV6

546

TV7 TV8 TV9

879

TV-/-- TV0 MUTING

010 +10

TITLE/

GROUP

U

N

E

CH

M

+

P

O

T

VOL VOL+

ENTER

C

CH

H

O

I

C

E

SELECTCLEAR

-

SLOW

3D

PHONIC

SUB TITLE

ANGLE

AUDIO

REPEAT

DIMMER

TV/VIDEO

CANCELRETURN

N

O

NEXTPREVIOUS

SLOW+

PROGRESSIVE

Area Suffix (XV-N50BK)

J -------------------------- U.S.A.

C --------------------- Canada

Area Suffix (XV-N55SL)

J -------------------------- U.S.A.

C --------------------- Canada

B -------------------------- U.K.

E ------ Continental Europe

EN ------- Northern Europe

EV --------- Eastern Europe

EE ---- Russian Federation

UF ---------------------- China

M

E

N

U

N

E

E

R

C

S

VFPZOOM

SCAN

AMP

VOL

TABLE OF CONTENTS

1 Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 Disassembly method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

3 Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

4 Description of major ICs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.A0041

2003/04

XV-N50BK,XV-N55SL

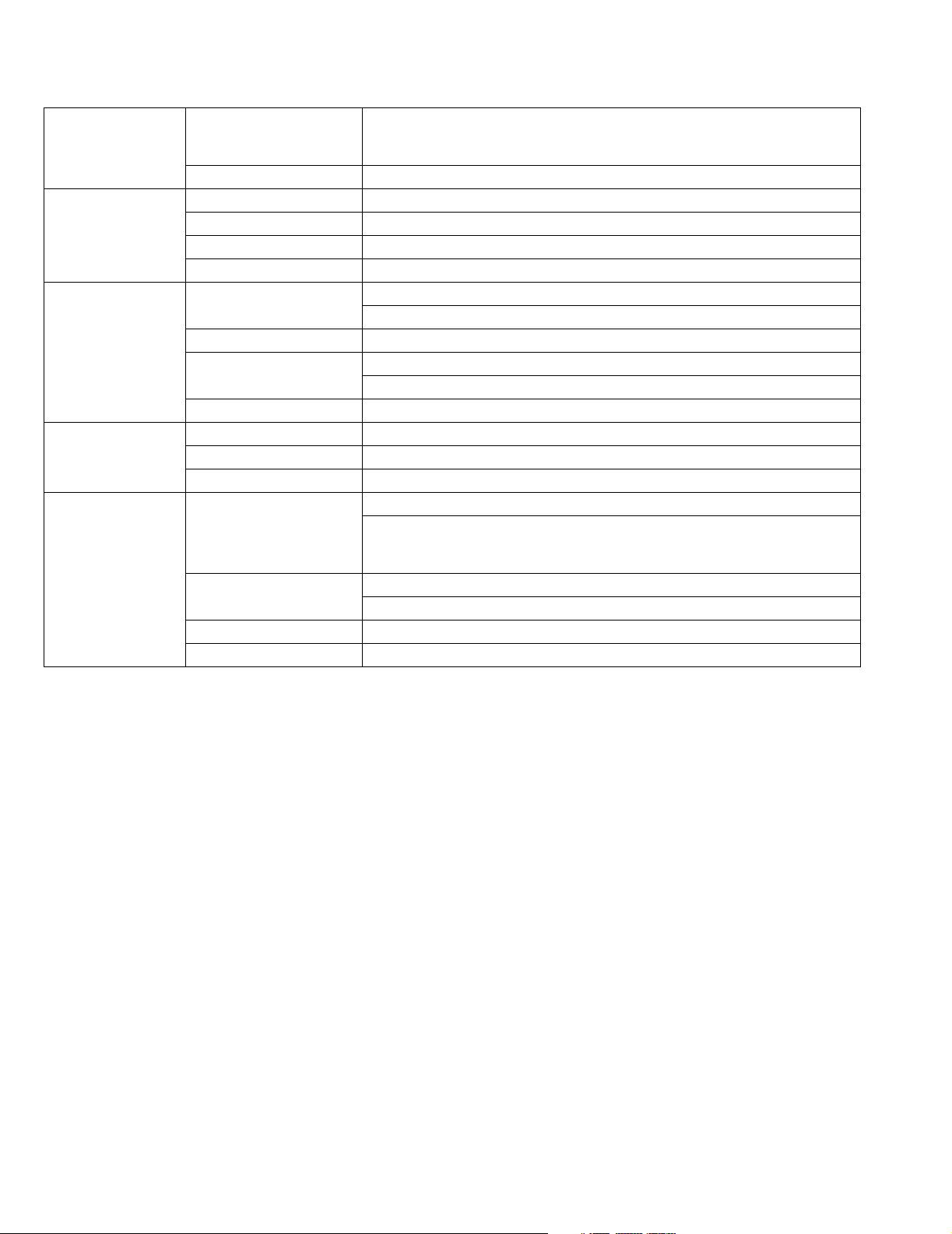

SPECIFICATION

General Readable discs DVD VIDEO, DVD-R (Video format), DVDRW(Video format),

+RW (Video format),SVCD, Video CD, Audio CD (CD-DA),MP3/WMAformat,

JPEG, CD-R/RW(CDDA,SVCD,Video CD, MP3/WMA format, JPEG)

Video format NTSC, 480i (Interlaced scan) / 480p(Progressive scan) selectable

Other Power requirements AC 120 V, 60 Hz

Power consumption 11 W (POWER ON), 0.7 W (STANDBYmode)

Mass 2.1 kg (4.7 lbs)

Dimensions (W xH x D) 435 mm x 45 mm x 270.5 mm (17-3/16 inch x 2-13/16 inch x 10-11/16 inch)

Video outputs COMPONENT (pin jacks) Y Output: 1.0 Vp-p (75 ohm)

PB/PR Output: 0.7 Vp-p (75 ohm)

VIDEO OUT (pin jack) 1.0 Vp-p (75 ohm)

S-VIDEO OUT (S jack) Y Output: 1.0 Vp-p (75 ohm)

C Output: 286 mVp-p (75 ohm)

Horizontal resolution 500 lines or more

Audio outputs ANALOG OUT (pin jack) 2.0 Vrms (10 kohm)

DIGITAL OUT (COAXIAL) 0.5 Vp-p (75 ohm termination)

DIGITAL OUT (OPTICAL) -21 dBm to -15 dBm (peak)

Audio characteristics Frequency response CD (sampling frequency 44.1 kHz):2 Hz to 20 kHz

DVD (sampling frequency 48 kHz):2 Hz to 22 kHz(4 Hz to 20 kHz for DTS and

Dolby Digital bitstream signals)

DVD (sampling frequency 96 kHz)2 Hz to 44 kHz

Dynamic range 16 bit: More than 98 dB

20/24 bit: More than 100 dB

Wow and flutter Unmeasurable (less than + 0.002%)

Total harmonic distortion less than 0.006%

• Specifications and appearance are subject to change without prior notice.

• Manufactured under license from Dolby Laboratories. “Dolby” and the double-D symbol are trademark of Dolby Laboratories.

• Manufactured under license from Digital Theater Systems, Inc. “DTS” and “DTS Digital Surround” are registered trademarks of

Digital Theater Systems, Inc.

1-2 (No.A0041)

SECTION 1

Important Safety Precautions

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes.

For continued protection, no changes should be made to the

original design unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special safety

characteristics are identified in the Parts List of Service Manual. Electrical components having such features are identified by shading on the schematics and by ( ) on the

Parts List in the Service Manual. The use of a substitute replacement which does not have the same safety characteristics as the recommended replacement parts shown in the

Parts List of Service Manual may create shock, fire, or other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

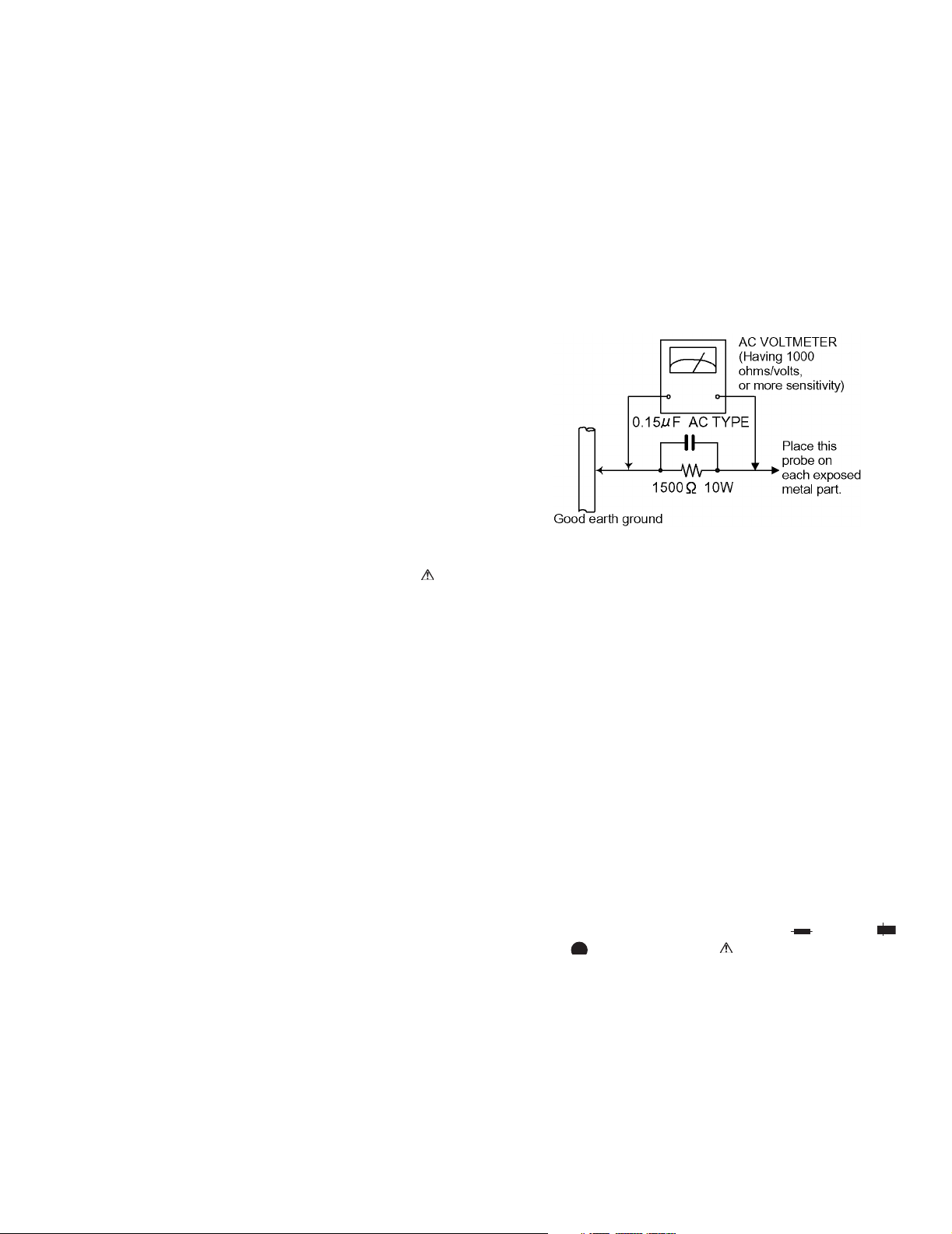

(5) Leakage shock hazard testing)

After reassembling the product, always perform an isolation

check on the exposed metal parts of the product (antenna

terminals, knobs, metal cabinet, screw heads, headphone

jack, control shafts, etc.) to be sure the product is safe to

operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC

voltmeter having, 1,000 ohms per volt or more sensitivity in

the following manner. Connect a 1,500 ohm 10W resistor

paralleled by a 0.15 µF AC-type capacitor between an

XV-N50BK,XV-N55SL

exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and measure the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75

V AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

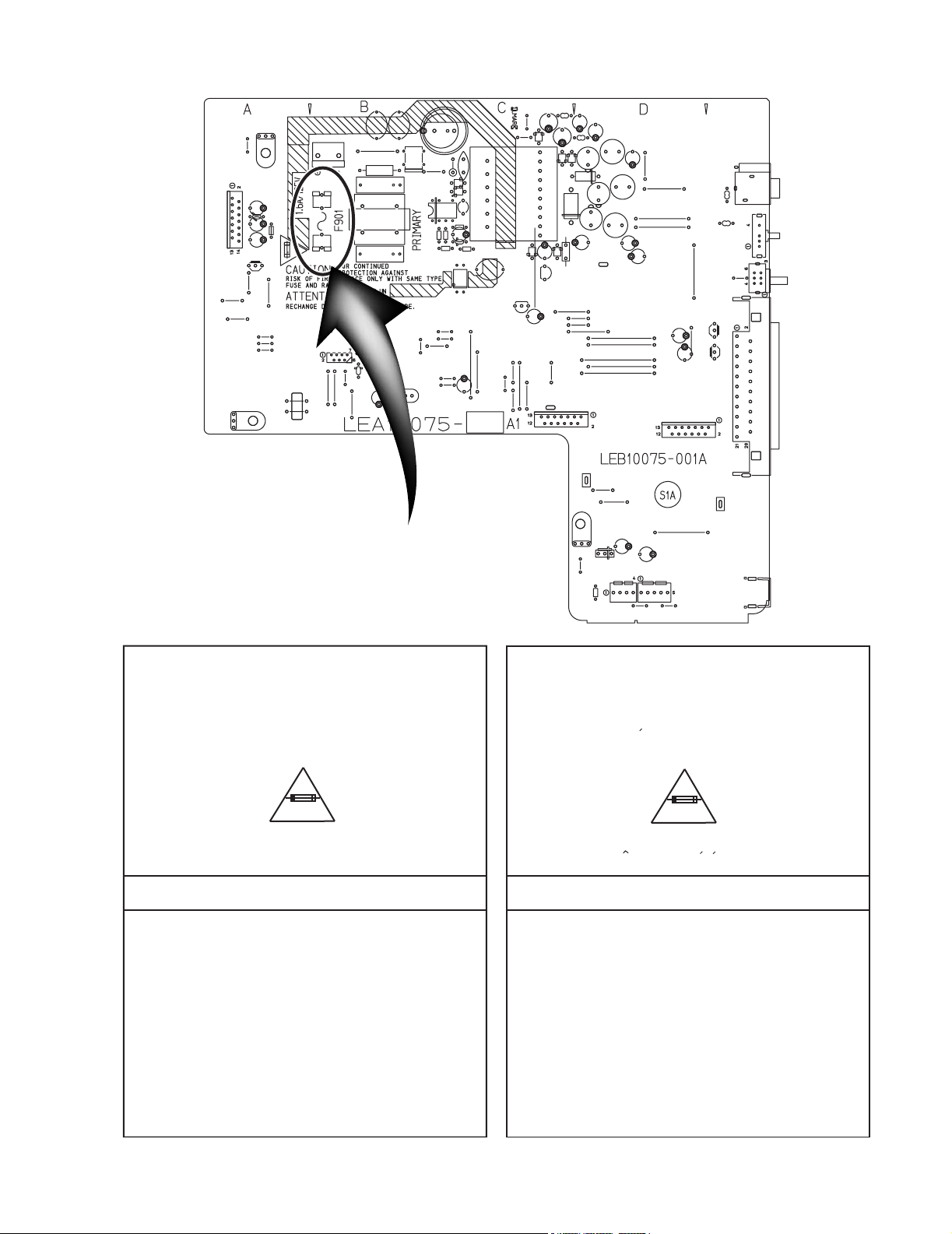

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical for

safety.

When replacing them, be sure to use the parts of the same type

and rating as specified by the manufacturer. (Except the JC version)

(No.A0041)1-3

XV-N50BK,XV-N55SL

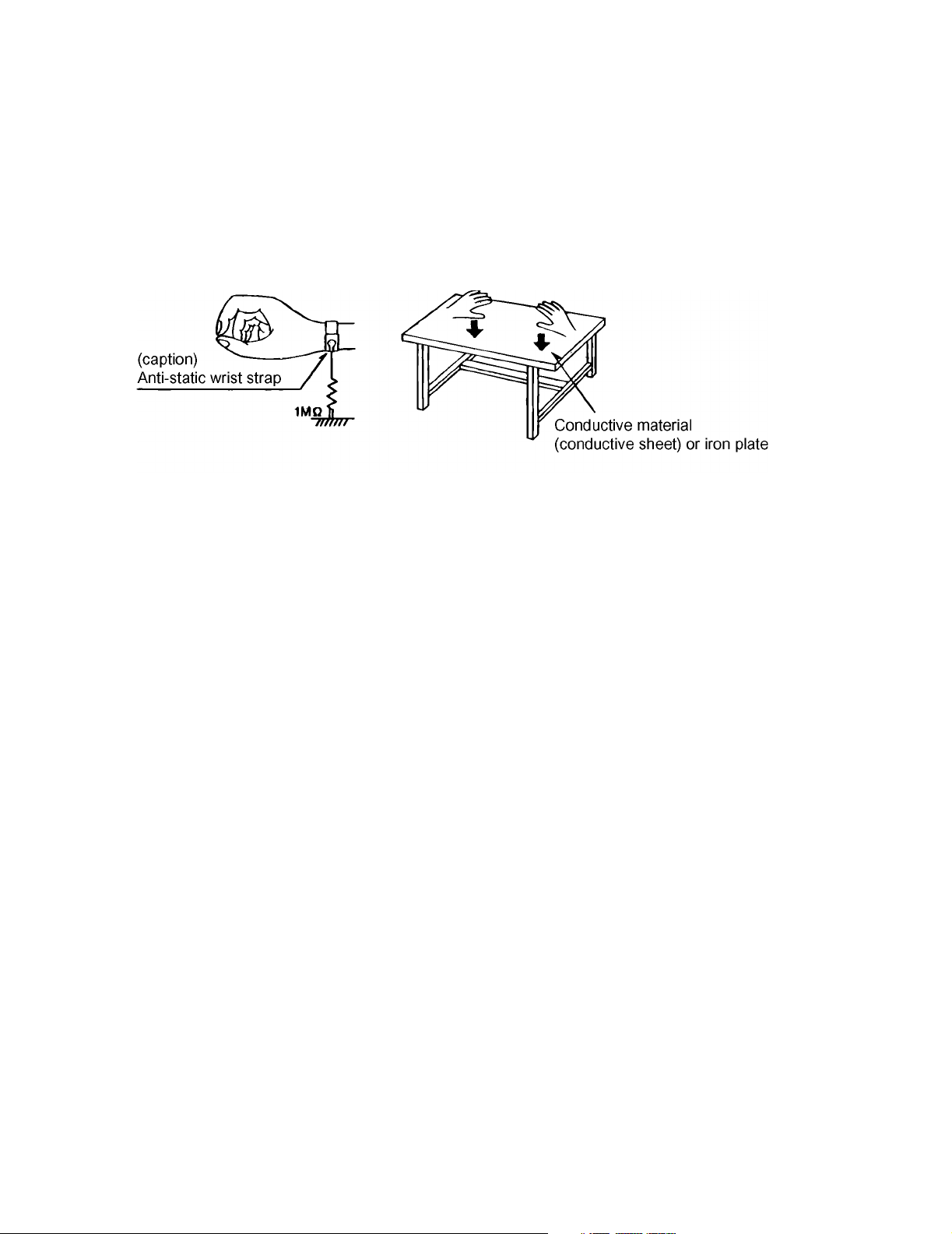

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long

a time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1-4 (No.A0041)

1.7 Importance admistering point on the safety

B4

EP951

C951

D960

CN901

C808

C802

Q951

B110

B202

B111

B112

B16

B17

B18

EP952 EP952 EP952 EP952 EP952 EP952 EP952 EP952 EP952 EP952 EP952

P901

R951

B129

B128

C904 C905

B402

R910

C918

FC901 FC902

L901

C902

B205

B303

B304

B13

B105

P704

B302

B14

D701

B15

C706

B204

XV-N50BK,XV-N55SL

L953

C963

B19

D956

B6

C908

C907

R901

B104

D901

D903

D902

IC901

C913

R912

C914

R913

R906

D904

R915

R903

PC901

B8

B9

B109

B12

B803

B10

B401

B11

X701

C701

D951

C906

C950

CP951

IC952

C970

B102

B7

B206

B501

B103

C965

C966

L954

C964

D954

D957

D955

C958

D953

C952

T901

C953

R954

D952

B301

B107

B101

B403

B106

CN904

C988

L955

C967

B207

B404

L952

L951

C955

B601

B603

C959

B801

B802

B901

B804

B902

C762

C761

CN651

J702

L709

L710

S902

B604

B3

S901

Q754

B201

Q753

J603

Full Fuse Replacement Marking

Graphic symbol mark

(This symbol means fast blow type fuse.)

should be read as follows ;

FUSE CAUTION

WC802

B108

B203

EP953

C957

Q953

C973

B55

CN902 CN903

R966

B2

B1

WC801

B602

EP910

Marquage Pour Le Remplacement

Complet De Fusible

Le symbole graphique (Ce symbole signifie

fusible de type a fusion rapide.)

doit etre interprete comme suit ;

PRECAUTIONS SUR LES FUSIBLES

FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE

AND RATING OF FUSES ;

F901 : 1.6 A / 125 V F901 : 1.6 A / 125 V

POUR UNE PROTECTION CONTINUE CONTRE

DES RISQUES D'INCENDIE, REMPLACER

SEULEMENT PAR UN FUSIBLE DU MEME TYPE ;

(No.A0041)1-5

XV-N50BK,XV-N55SL

1.8 Important for laser products

(1) CLASS 1 LASER PRODUCT

(2) DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

(3) CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace the

complete Laser Unit if it malfunctions.

(4) CAUTION : The compact disc player uses invisible laser

radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are de feated.

It is dangerous to defeat the safety switches.

(5) CAUTION : If safety switches malfunction, the laser is able

to function.

(6) CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

Please use enough caution not to see the beam directly

or touch it in case of an adjustment or operation check.

VARNING

Osynlig laserstrålning är denna del är öppnad och spårren är

urkopplad. Betrakta ej strålen.

VARO

Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle lasersäteilylle. Älä katso säteeseen.

ADVARSEL

Usynlig laserstråling ved åbning, når sikkerhedsafbrydere er

ude af funktion. Undgå udsasttelse for stråling.

ADVARSEL

Usynlig laserstråling ved åpning, når sikkerhetsbryteren er avslott. unngå utsettelse for stråling.

REPRODUCTION AND POSITION OF LABEL and PRINT

WARNING LABEL and PRINT

C

A

U

T

I

O

r

a

N

d

:

ia

t

In

io

v

n

i

n

is

t

e

i

w

b

r

l

lo

h

e

e

c

n

k

A

f

V

a

o

il

O

p

e

I

e

d

D

n

o

D

T

r

d

IR

O

e

E

B

f

e

C

E

a

T

A

t

e

E

M

d

.

.

X

P

O

S

U

R

E

(

e

)

The inside of a chassis base

la

s

e

r

a

V

n

d

A

R

N

I

N

s

G

t

r

å

:

ln

O

in

s

g

öp

y

n

n

p

li

ä

n

g

r

a

d

d

la

o

u

e

s

r

n

k

e

n

o

c

r

a

-

p

h

p

s

d

l

a

s

e

t

l

d

r

p

A

å

.

är

ä

B

D

le

r

V

r

n

e

.

A

n

R

e

tr

s

S

t

ä

a

E

r

r

ålin

k

L

t

:

a

U

g

s

s

ik

y

e

v

n

k

j

e

lig

e

d

r

h

e

la

å

a

(

d

s)

b

s

f

s

e

n

a

f

r

in

u

f

-

b

n

g

r

k

,

y

t

te

d

io

e

ls

n

n

V

re

år

e

.

A

f

R

U

o

e

r

O

r

n

s

d

:

u

tr

g

ja

d

å

A

å

e

lu

lin

u

v

a

k

g

t

itu

d

t

a

s

e

æt

s

a

o

s

lt

s

t

a

iin

h

it

ja

a

e

n

tt

(

la

d

s

a

s

u

)

e

e

o

s

r

-

s

s

ä

a

äte

k

s

y

ät

m

o

il

le

y

e

ä

ll

e

t

t

e

t

s

ö

.

e

m

e

n

ä

Ä

.

ll

l

ä

e

k

a

t

s

o

(

f

)

1-6 (No.A0041)

XV-N50BK,XV-N55SL

1.9 Precautions for Service

1.9.1 Handling of Traverse Unit and Laser Pickup

(1) Do not touch any peripheral element of the pickup or the actuator.

(2) The traverse unit and the pickup are precision devices and therefore must not be subjected to strong shock.

(3) Do not use a tester to examine the laser diode. (The diode can easily be destroyed by the internal power supply of the tester.)

(4) To replace the traverse unit, pull out the metal short pin for protection from charging.

(5) When replacing the pickup, after mounting a new pickup, remove the solder on the short land which is provided at the center of

the flexible wire to open the circuit.

(6) Half-fixed resistors for laser power adjustment are adjusted in pairs at shipment to match the characteristics of the optical block.

Do not change the setting of these half-fixed resistors for laser power adjustment.

1.9.2 Destruction of Traverse Unit and Laser Pickup by Static Electricity

Laser diodes are easily destroyed by static electricity charged on clothing

or the human body. Before repairing peripheral elements of the traverse unit or pickup, be sure to take the following electrostatic

protection:

(1) Wear an antistatic wrist wrap.

(2) With a conductive sheet or a steel plate on the workbench on which the traverse unit or the pick up is to be repaired, ground the

sheet or the plate.

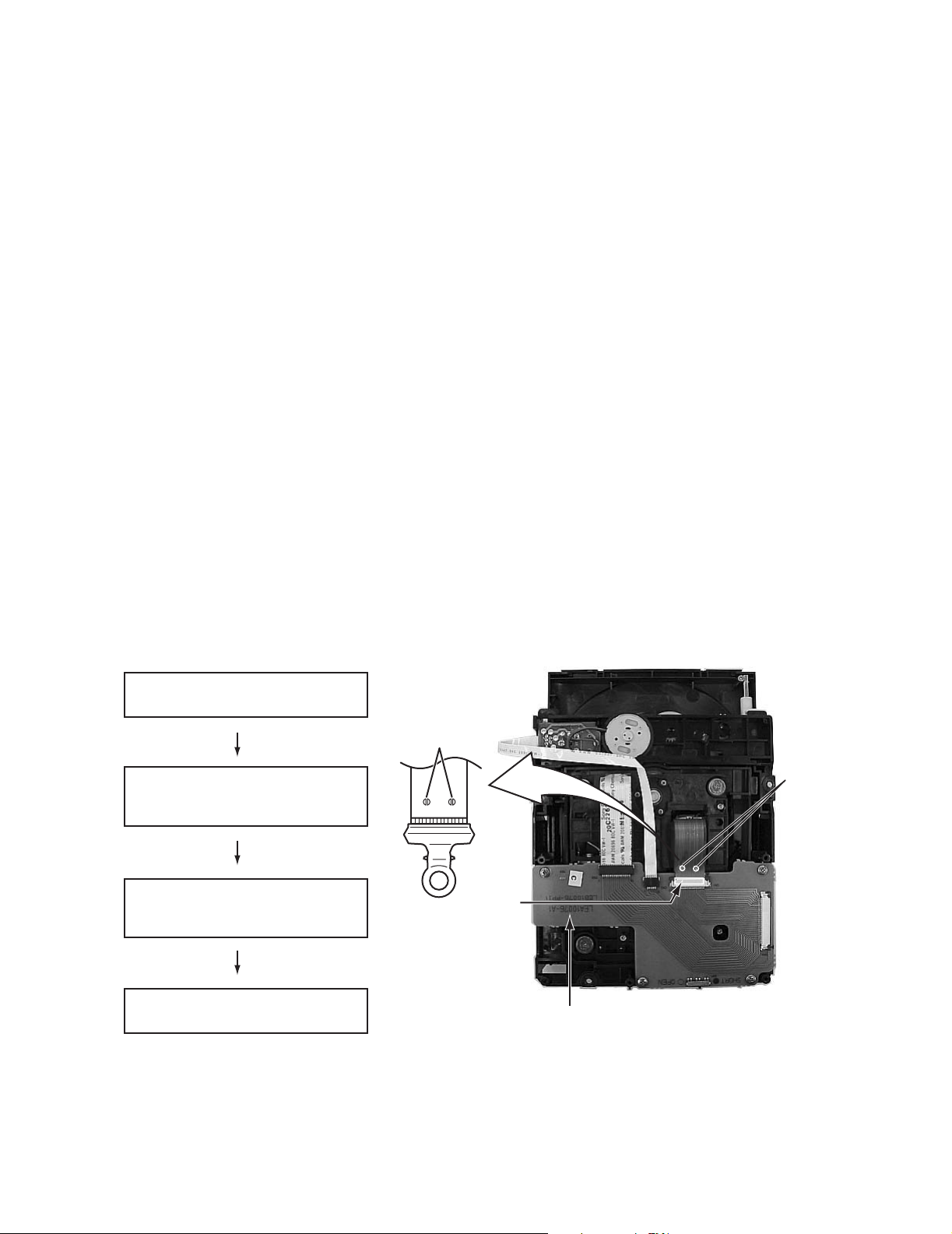

(3) Please be sure to make the switch of a relay board into the "SHORT" side before drawing out a wire from the connector CN101

on a servo control board,

when taking out a mechanism assembly from a main body.

And please be sure to make a switch into the "OPEN" side after connecting a wire to CN101, when it mounts a mechanism as-

sembly in a main body.

(4) After removing the flexible wire from the connector (CN1), short-circuit the flexible wire by the metal clip.

(5) Short-circuit the laser diode by soldering the land which is provided at the center of the flexible wire for the pickup.

After completing the repair, remove the solder to open the circuit.

The procedure for protecting a pickup

The switch on a relay board is

changed from "OPEN" to "SHORT."

Short circuit

A wire is extracted from the

connector CN101 on a servo control

board.

It solders to the short circuit part on a

flexible wire, and it is made to shortcircuit.

A flexible wire is extracted from the

connector CN1 on a relay board.

In case you assemble, please do all work conversely.

Short circuit

CN1

Relay board

(No.A0041)1-7

XV-N50BK,XV-N55SL

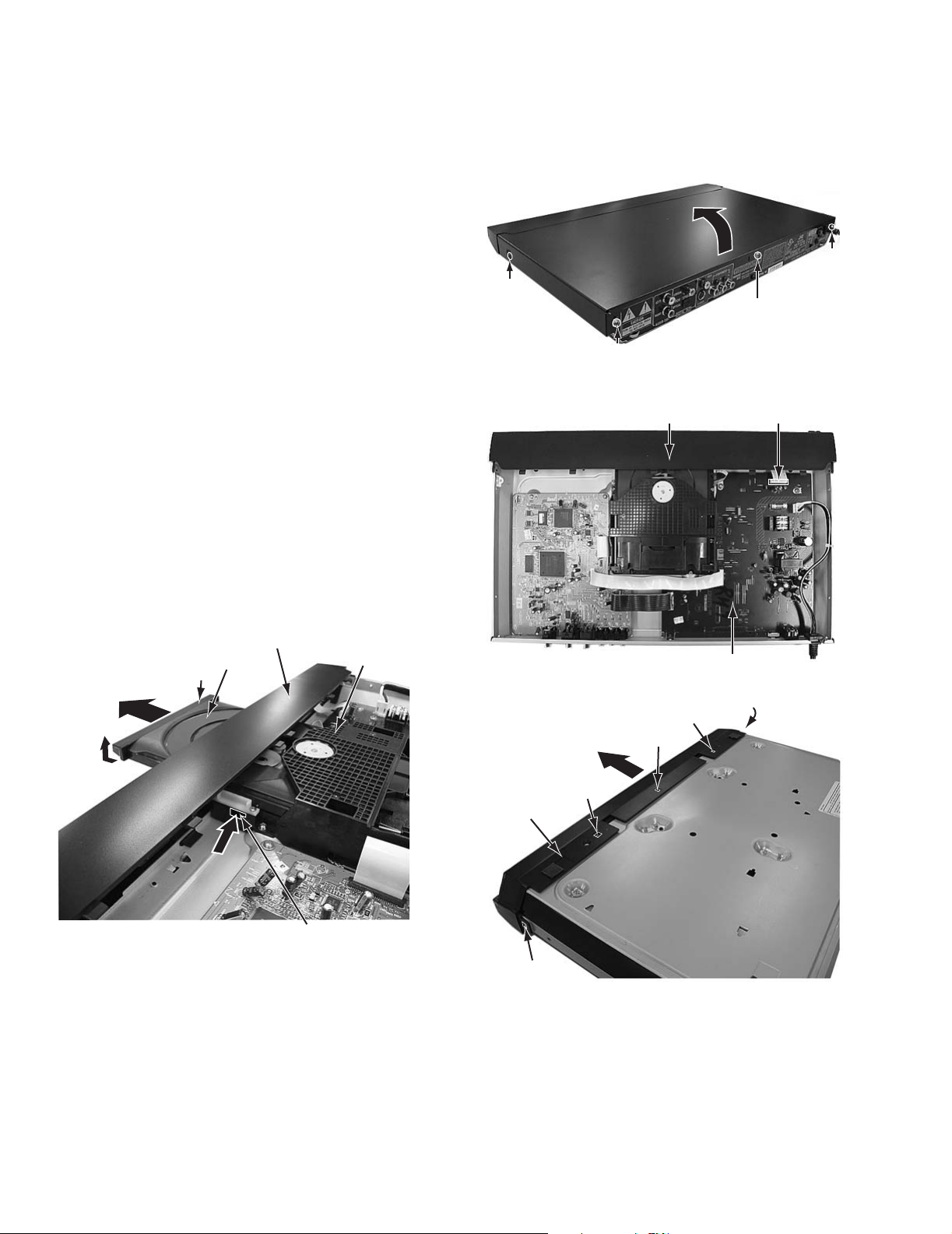

TOP COVER

Push

SECTION 2

Disassembly method

2.1 Main body section

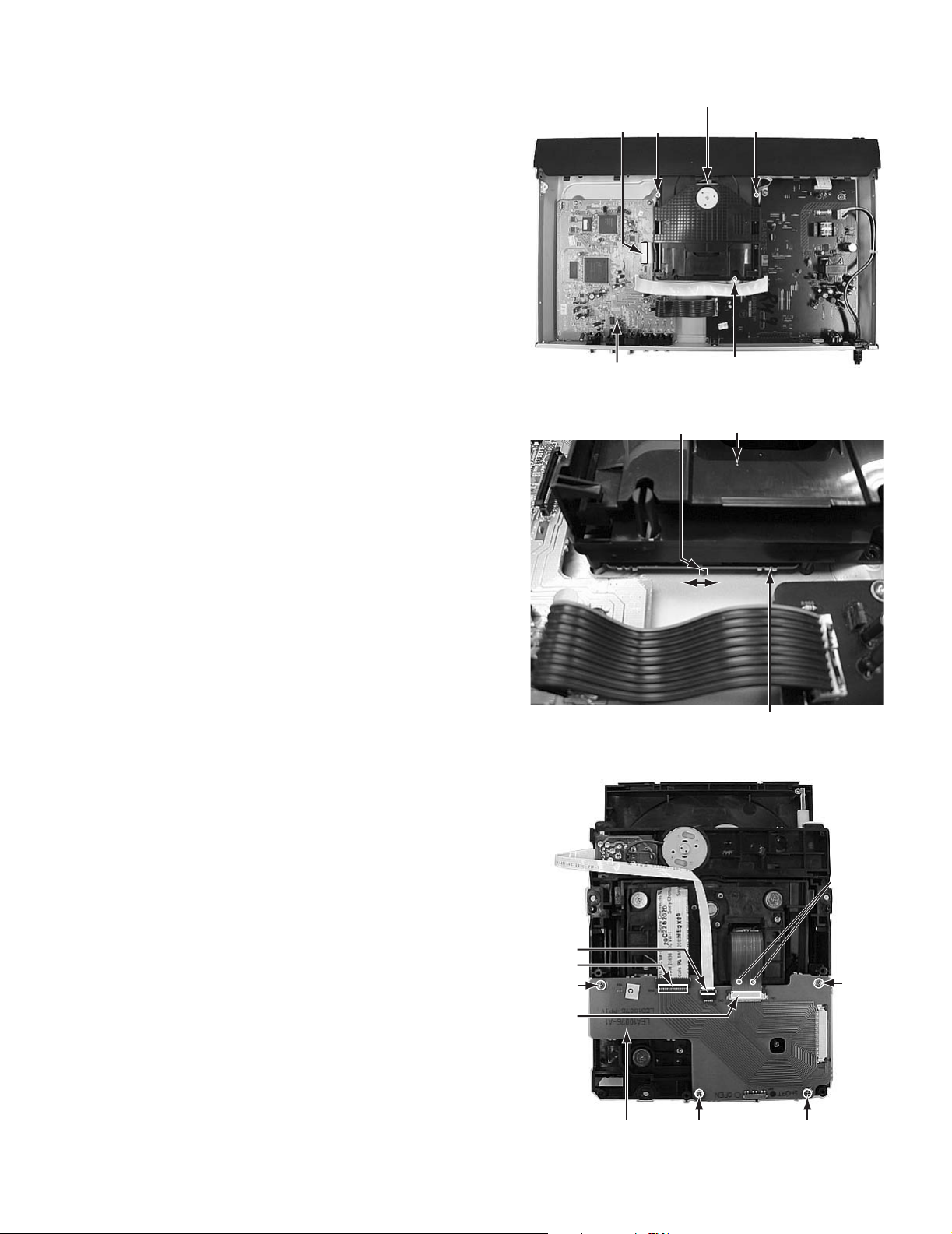

2.1.1 Removing the top cover (See Figure 1)

(1) Remove the two screws A attaching the top cover on both

sides of the main body.

(2) Remove the three screws B attaching the top cover on the

back of the main body.

(3) Raise the both sides and lower part of the rear of the top

cover, with opening them slightly in an outward direction.

And the top cover will be removed.

2.1.2 Removing the front panel assembly (See Figure 2, Figure 3, Figure 4)

• Prior to performing the following procedure, remove the top

cover.

• There is no need to remove the mechanism assembly.

(1) Insert a kind of screwdriver in a hole located in the right

side of mechanism assembly, and push a lever until it cannot be inserted any further.

(2) And then, a tray will come out. Remove the tray in an upper

direction, with slightly opening the lower part of fitting in an

outward direction.

(3) Disconnect the card wire from connector CN901 on the

power supply board.

(4) Hook a and b are removed respectively, and the front panel

assembly is removed.

Front panel assembly

Fitting

Tr ay

Mechanism assembly

A x 2

TOP COVER

TOP COVER

B

Fig.1

Front panel assembly

Power supply board

Fig.3

Hook b

Hook b

B

B

CN901

Hook a

1-8 (No.A0041)

Push

Fig.2

Hole and lever

Front panel

assembly

Hook a

Hook b

Fig.4

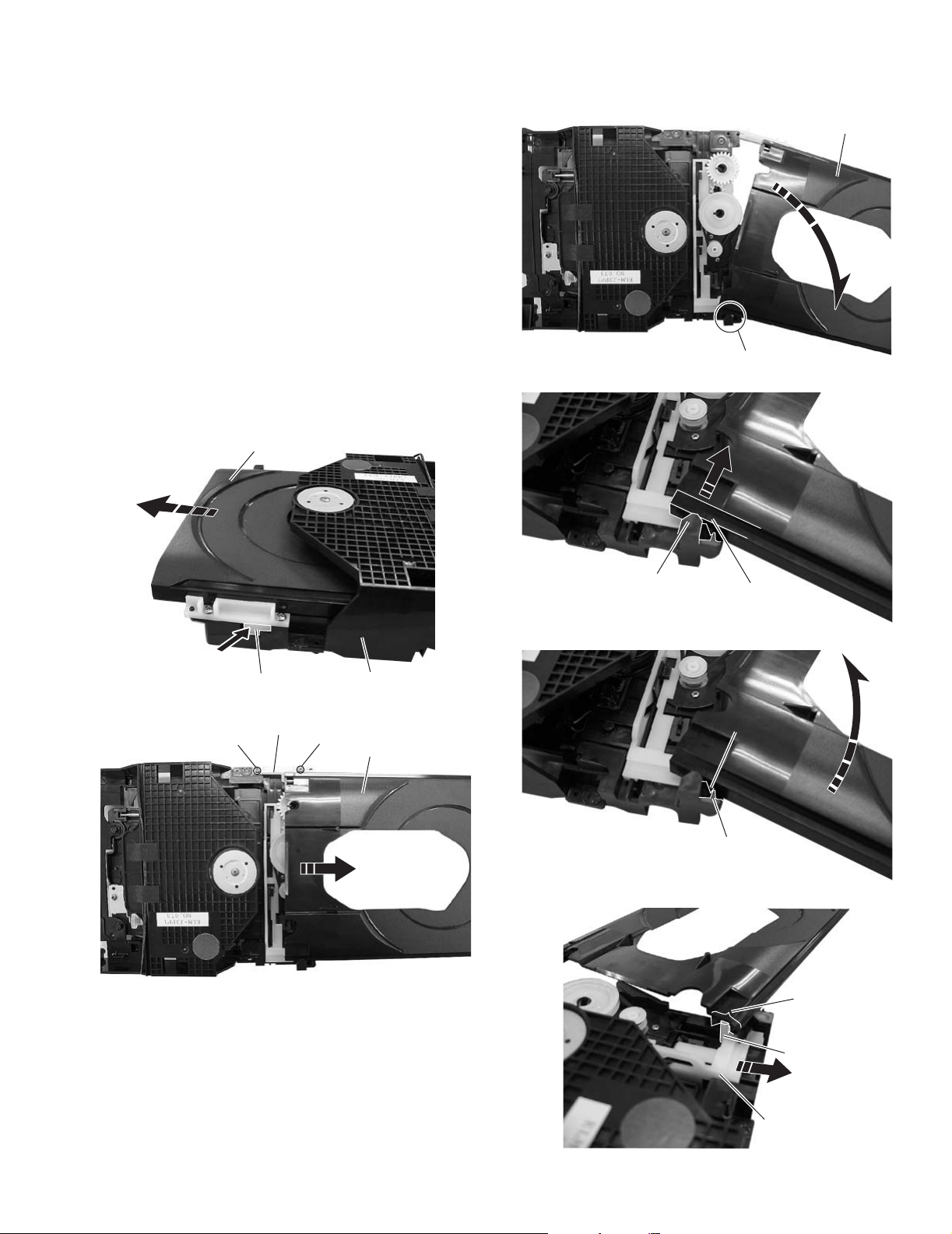

2.1.3 Removing the mechanism assembly (See Figure 2, Figure 5, Figure 6)

OPENSHORT

• Prior to performing the following procedure, remove the top

cover.

• There is no need to remove the front panel assembly.

(1) Insert a kind of screwdriver in a hole located in the right

side of mechanism assembly, and push a lever until it cannot be inserted any further. (See Figure 2)

(2) And then, a tray will come out. Remove the tray in an upper

direction, with slightly opening the lower part of fitting in an

outward direction. (See Figure 2)

(3) Remove the three screws C attaching the mechanism as-

sembly.

(4) The switch on a relay board is made into the “SHORT” side.

(5) Disconnect the card wire from connector CN101 on the

servo control and signal output terminal board.

(6) Remove the mechanism assembly by lifting the rear part of

the mechanism assembly.

ATTENTION:

Please be sure to make the switch on a relay board into a

Servo control and signal

output terminal board

“SHORT” side before disconnect a card wire from the connector CN101 on servo control and signal output terminal board.

Moreover, please be sure to make a switch into the “OPEN”

side after inserting a card wire in a connector CN101 at the

time of an assembly.

There is a possiblity of destroying the laser diode of a pick-up

unit with static electricity.

Mechanism assembly

CN101

C

Switch

XV-N50BK,XV-N55SL

C

C

Fig.5

Mechanism assembly

2.1.4 Removing the relay board (See Figure 7)

• Prior to performing the following procedure, remove the mechanism assembly.

(1) Remove the four screws D attaching the relay board.

(2) Disconnect the card wire from connector CN2,CN3 on the

relay board respectively.

(3) Disconnect the flexible wire from connector CN1 on the re-

lay board from pick-up unit.

ATTENTION:

At this time, please extract the wire after short-circuited

of two places on the wire in part c with solder. Please remove the solder two places of part c after connecting the

wire with CN1 when reassembling.

There is a possibility of destroying the laser diode of a

pick-up unit with static electricity.

CN2

CN3

CN1

SHORT OPEN

OPEN

Relay board

Fig.6

Part c

D

D

Relay board

DD

Fig.7

(No.A0041)1-9

XV-N50BK,XV-N55SL

2.1.5 Removing the rear panel (See Figure 8, Figure 9)

• Prior to performing the following procedure, remove the top

cover.

(1) Remove the eight screws E attaching the rear panel.

(2) Disconnect the power cord from connector P901 on the

power supply board

(3) Remove tie band.

CN101

CN502

Servo control and signal

output terminal board

2.1.6 Removing the servo control and signal output terminal board. (See Figure 9)

• Prior to performing the following procedure, remove the top

cover/rear panel.

(1) Remove the two screws F attaching the servo control and

signal output terminal board.

(2) Disconnect the card wire from connector CN101,CN502 on

the servo control and signal output terminal board.

(3) Disconnect the flat wire from connector CN902,CN903 on

the power supply board.

Rear panel

E E

F F

CN902,CN903

E

Fig.8

Fig.9

G CN901

Power supply board

G

G

P901

2.1.7 Removing the power supply board. (See Figure 9)

• Prior to performing the following procedure, remove the top

cover/rear panel.

(1) Remove the three screws G attaching the power supply

board.

(2) Disconnect the wire from connector CN901,CN902,

CN903,CN904 on the power supply board.

(3) Disconnect the socket wire from socket P901 on the power

supply board.

1-10 (No.A0041)

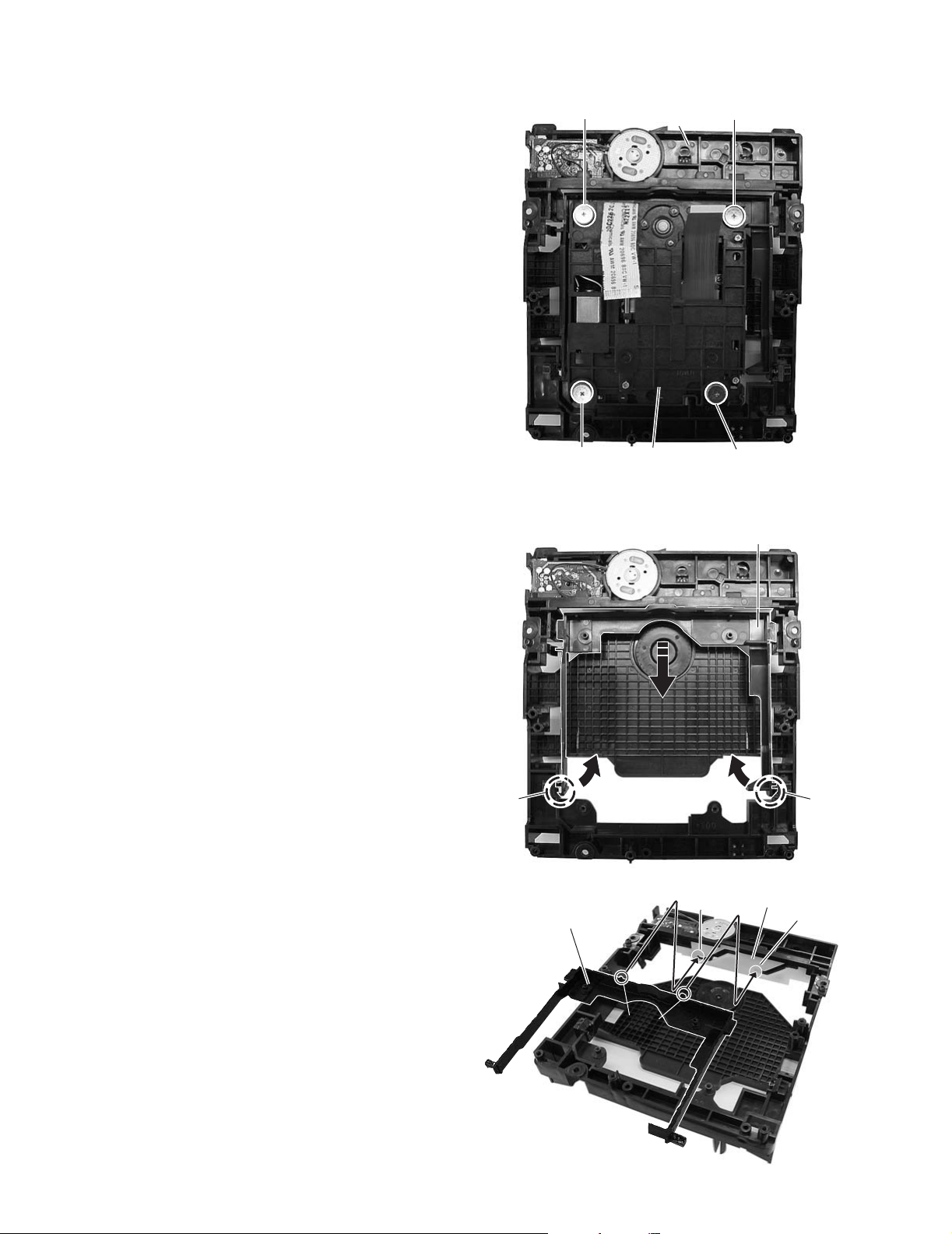

2.2 Loading mechanism assembly

Projection of the tray

2.2.1 Removing the tray (See Figure 1, Figure 2, Figure 3, Figure 4, Figure 5, Figure 6)

(1) Push a of the slide cam on the hole in the right side of the

loading base by using a driver until it stops. (See Figure 1.)

(2) The tray comes out. Pull the tray in a front direction until it

stops.

(3) Remove the two screws A attaching the slide bracket. (See

Figure 2.)

(4) Tilt the tray in a direction of the arrow around the point in

the left rear part of the tray. (See Figure 3.)

(5) The rail of the tray is removed from b of the loading base.

Then, remove the tray upward. (See Figure 4.)

Attaching the tray:

Engage c of the loading base to the projection of the tray while

tilting the tray to the left. Turn the tray in a direction of the arrow, and attach the slide bracket. (See Figure 5.)

Note:

Prior to the procedure above, move the slide cam in a direction

of the arrow so that d of the slide cam can be inserted in e of

the tray. (See Figure 6.)

Tray

XV-N50BK,XV-N55SL

Tray

The point in the left rear part

Fig.3

Push

Slide cam part a

Slide bracket

A

Fig.1

Fig.2

Loading base

A

Tray

Loading base part b

Projection of the tray

Projection of the tray

Loading base part c

Rail of the tray

Fig.4

Fig.5

Part e

Part d

Slide cam

Fig.6

(No.A0041)1-11

XV-N50BK,XV-N55SL

f

Shaft

2.2.2 Removing the traverse mechanism assembly (See Figure 7)

Reverse the loading mechanism assembly. Remove the four

screws B attaching the traverse mechanism assembly. Remove

the traverse mechanism assembly upward.

Loading mechanism

B

assembly

B

2.2.3 Removing the elevator (See Figure 8 and Figure 9)

• Prior to the following procedure, remove the traverse mechanism assembly.

(1) Remove the two arms of the elevator from the two parts f

by moving the arms in a direction of the arrow.

(2) Pull out the elevator in a rear direction.

Attaching the elevator:

Engage the two holes g to the two shafts on the front part of

the elevator. And then, attach the elevator.

Part f

Elevator

Traverse mechanism

B

assembly

Fig.7

Fig.8

g

B

Elevator

Part

Slide cam

g

1-12 (No.A0041)

Shaft

Shaft

Fig.9

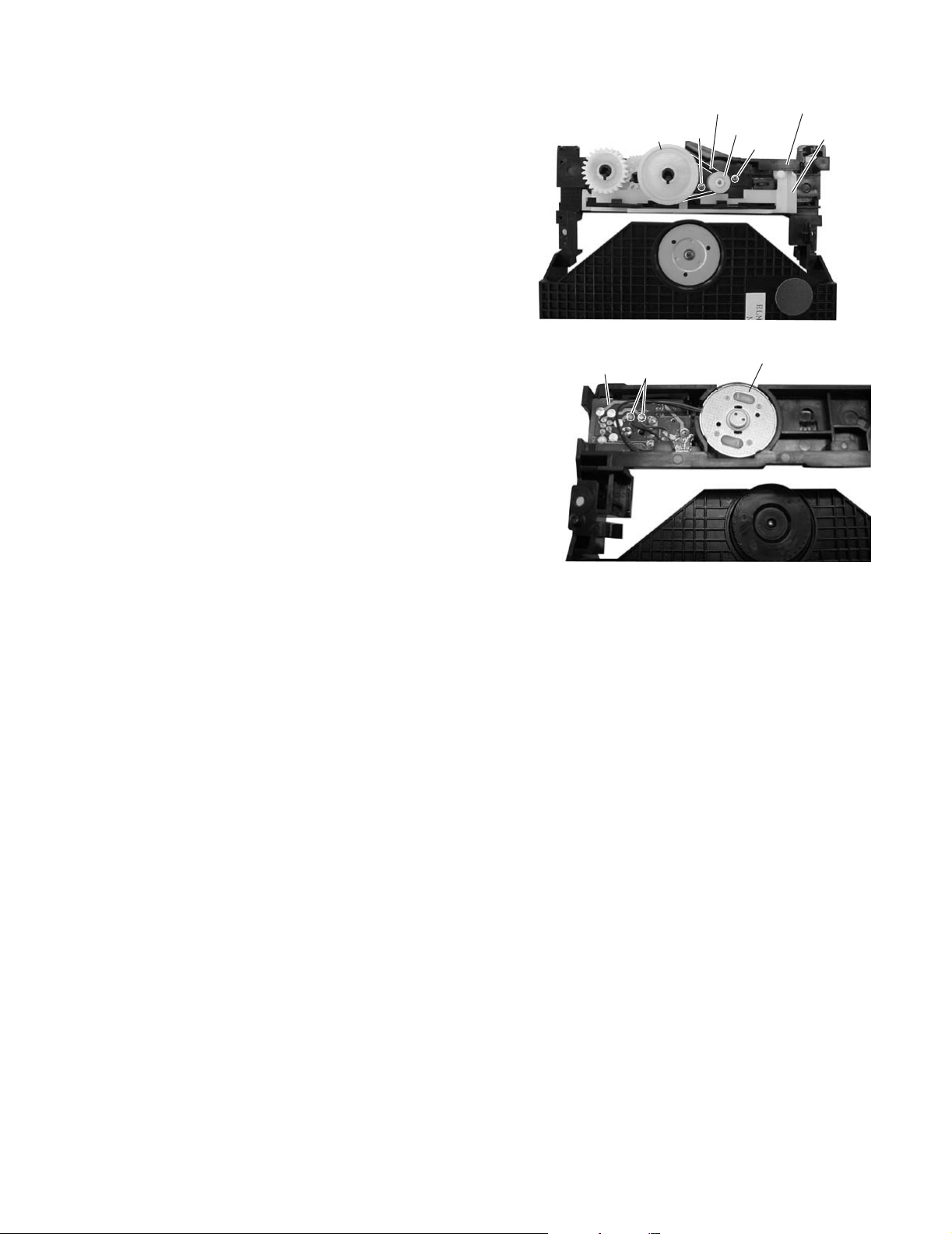

2.2.4 Removing the loading motor (See Figure 10 and Figure 11)

• Prior to the following procedure, remove the tray, the traverse

mechanism assembly, and the elevator.

(1) Remove the belt from the pulley.

(2) Remove two screws C attaching the loading motor.

(3) Remove two solders h on the switch board.

Switch board

Pulley

Part h

Belt

C

Fig.10

Loading base

Pulley

C

Loading motor

XV-N50BK,XV-N55SL

Slide cam

Fig.11

(No.A0041)1-13

XV-N50BK,XV-N55SL

2.3 Traverse mechanism assembly

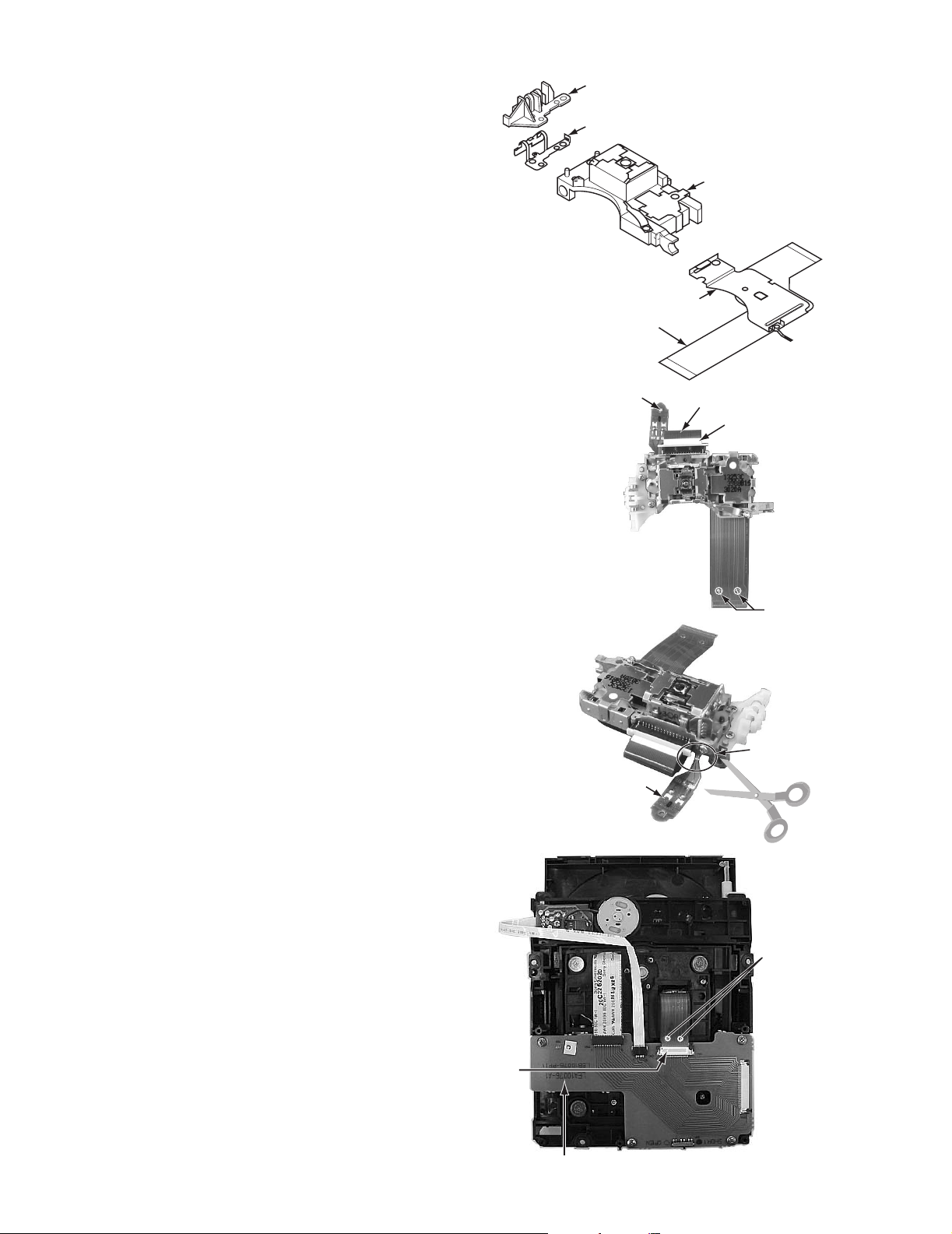

2.3.1 Removing the pickup (See Figure 12, Figure 13, and Figure 14)

• Prior to the following procedure, remove the traverse mechanism assembly.

(1) Remove one screw D attaching the plate.

(2) Remove the plate and the leaf spring.

(3) Lift i of the shaft 1, and pull out the shaft 1 from j.

(4) Remove k of the pickup from the shaft 2.

Attaching the pickup:

(1) Engage k of the pickup to the shaft 2.

Note:

As Figure 14 shows, the spring must come under the

shaft 2.

(2) Insert the shaft 1 in j, and attach the shaft 1 to i.

(3) Attach the leaf spring, and then attach the plate. Fix the

leaf spring and the plate by using the screw D.

Pick-up

Plate

D

Leaf spring

Fig.12

Part j

Shaft 1

Part k

Part i

Shaft 2

Fig.13

Spring

Shaft 2

Fig.14

1-14 (No.A0041)

XV-N50BK,XV-N55SL

SECTION 3

Adjustment

3.1 Test mode setting method

(1) Unplug the power plug.

(2) Insert power plug into outlet while pressing both "PLAY" key and "STOP" key of the main body.

(3) The FL display shows " 0", and the main body turns to test mode. " " means the destination, and "0" means parameter adjust-

ment status.

(4) To release test mode, press "POWER" key of the main body.

NOTE:

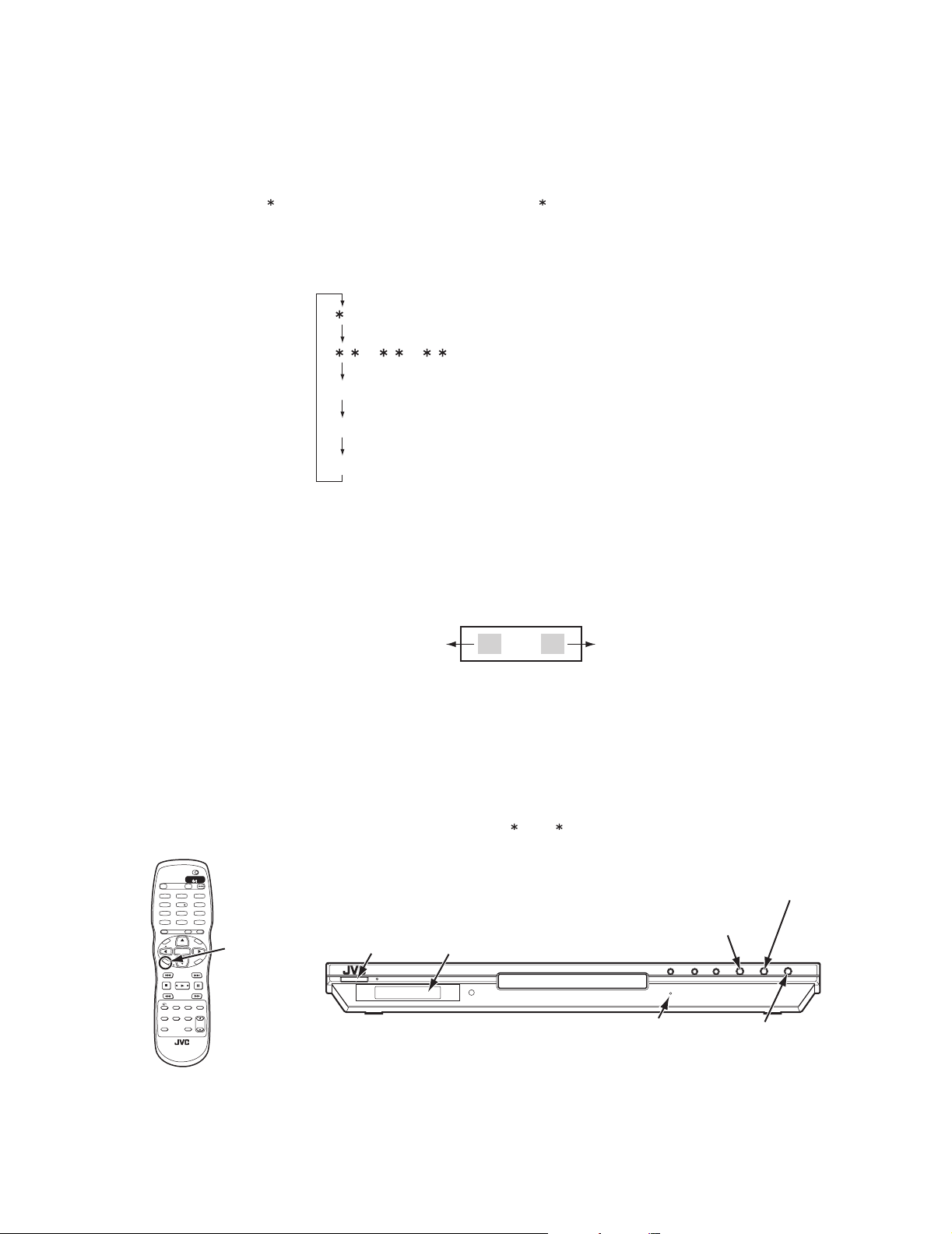

Each pressing of "CHOICE" key of the remote controller in test mode changes the mode as follows.

0 ------------------------------

_ _ -------------

Becames test mode

Version of firmware

FL Display becames all lighting

CHECK -------------------------

EXPERT -----------------------

3.2 Method of displaying version of firmware

(1) Set the main body at test mode.

(2) Press "CHOICE" key of the remote controller once. Then, version number and alphabetical letter of the system controller and

the back end are displayed in the FL display as follows:

Check mode

Not used

FL Display (Example)

System controller

04_02_17

3.3 Initialization method

Please initialize according to the following procedures in the following case:

• Just after you upgrade the firmware.

• After you confirm the symptoms that a customer points out. First Initialize, and then confirm whether the symptoms are improved or

not.

• After servicing, before returning the main body to a customer. (Initialized main body should be returned to a customer.)

(1) Set the main body at test mode.

(2) Press "PAUSE" key of the main body.

(3) When initialization is completed, the FL display changes from " 0" to " 00" and a progressive indicator lights up.

(The left "0" of "00" is not always "0". It shows parameter adjustment status.)

TV DVD

STANDBY/ON

OPEN/

TV DVD

CLOSE

TV1 TV2 TV3

213

TV4 TV5 TV6

546

TV7 TV8 TV9

879

TV-/-- TV0 MUTING

010 +10

TITLE/

TV/VIDEO

GROUP

CANCELRETURN

U

M

N

E

E

CH

N

M

U

+

P

O

T

VOL VOL+

ENTER

C

CH

H

O

I

C

E

SELECTCLEAR

-

SLOW

3D

PHONIC

SUB TITLE

ANGLE

AUDIO

REPEAT

DIMMER

CHOICE key

N

E

E

R

C

S

(switch of mode)

N

O

NEXTPREVIOUS

SLOW+

VFPZOOM

PROGRESSIVE

SCAN

AMP

VOL

POWER key

FL Display

Back end

(for test mode)

Progressive indicator

(for initialize)

PLAY key

(for test mode)

STOP key

PAUSE key

(for initialize)

(No.A0041)1-15

XV-N50BK,XV-N55SL

3.4 All-initialization method

Please perform all-initialization according to the following procedures in the following case:

• Just after you exchange the pick-up.

• Just after you exchange the spindle motor.

• Just after you exchange the traverse mechanism base.

NOTE:

Please perform all-initialization when you exchange the parts above and also when you remove the parts above.

• Just after the flap adjustment of the pick-up guide shaft

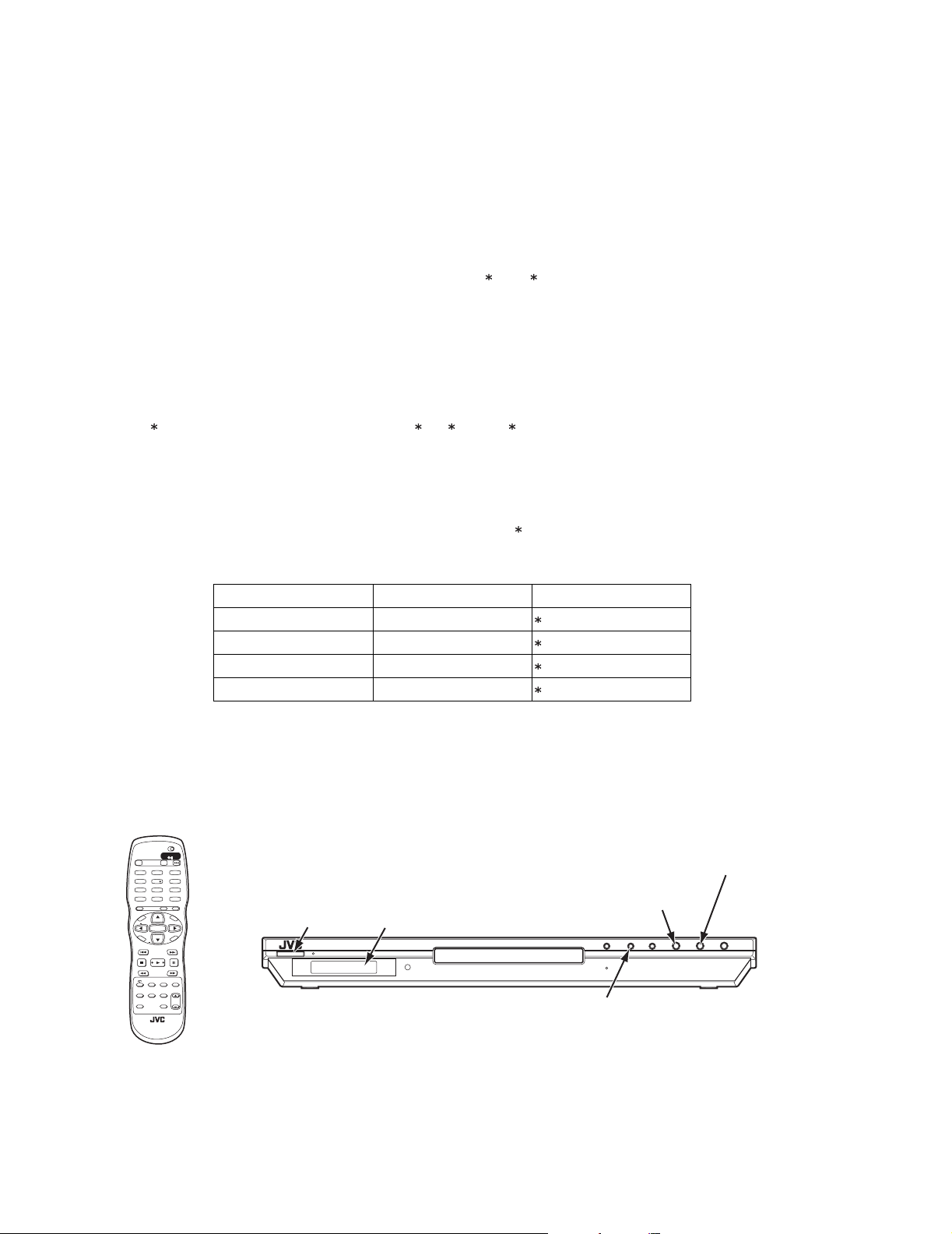

(1) Set the main body at test mode.

(2) Press and hold "BACKWARD SKIP" key of the main body for more than 2 seconds.

(3) When all-initialization is completed, the FL display changes from " 0" to " 33".

NOTE:

After all-initialization, be sure to perform optimization adjustment of Front End parameter.

3.5 Optimization adjustment of Front End parameter

Adjustment to optimize Front End parameter must be performed in each mechanism assembly of this model for high-speed starting.

Please perform optimization according to the following procedures just after all-initialization is completed and when FL display shows

anything except " 0" (For example when FL display shows " 1", " 2", and " 3") at test mode.

(1) Press "POWER" key of the main body to turn the main body on (not to set the main body at test mode).

(2) Insert the test disc VT-501 or commercial dual-layer DVD software.

(3) Remove the disc when the FL display changes from "READ" to disc information.

(4) Perform the same procedures as in (2) and (3) above by using the test disc CTS-1000 or commercial CD-DA software.

(5) Set the main body at test mode, and check that the FL display shows " 0".

NOTE:

Status of this adjustment can be judged by the number displayed at test mode as follows:

DVD adjustment CD adjustment FL display at test mode

Adjusted Adjusted 0

Not adjusted Adjusted 1

Adjusted Not adjusted 2

Not adjusted Not adjusted 3

NOTE:

As for a disc used for adjustment,

• Disc should be mounted. ("Mounting" means to display "READ" after the disc is inserted and then display the disc information.) Disc need not be played.

• If you do not have test disc either VT-501 (DVD) or CTS-1000 (CD-DA), use a commercial disc (for DVD, dual-layer software) after seeing and checking that the disc is neither curved nor foreseen that it may shake at the time of playback.

If you use a disc with bad features, starting time may be slow or disc may not be read.

TV DVD

STANDBY/ON

OPEN/

TV DVD

CLOSE

TV1 TV2 TV3

213

TV4 TV5 TV6

546

TV7 TV8 TV9

879

TV-/-- TV0 MUTING

010 +10

TITLE/

GROUP

U

N

E

CH

M

+

P

O

T

VOL VOL+

ENTER

C

CH

H

O

I

C

E

SELECTCLEAR

-

SLOW

3D

PHONIC

SUB TITLE

ANGLE

AUDIO

REPEAT

DIMMER

TV/VIDEO

N

O

NEXTPREVIOUS

SLOW+

PROGRESSIVE

CANCELRETURN

M

E

N

U

N

E

E

R

C

S

VFPZOOM

SCAN

AMP

VOL

POWER key

FL Display

BACKWARD SKIP key

(for test mode)

(for All initialize : It pushes 2 seconds or more.)

STOP key

PLAY key

(for test mode)

1-16 (No.A0041)

XV-N50BK,XV-N55SL

3.6 Display of current value of laser

(1) Set the main body at test mode.

(2) Press "CHOICE" key of the remote controller three times. Then, FL display is displayed "CHECK".

(3) The laser current value can be switched between the value of CD and that of DVD by pressing the following key of the remote

controller.

FL Display (Example)

00002530

The number shown in the FL display shows mA of current value of laser.

The first two numbers ("25" in "2530") shows current value of laser at the time of adjustment after the latest all-initialization, 25mA

in this example.

The last two numbers ("30" in "2530") shows the present current value of laser, 30mA in this example.

The first two numbers ("25" in "2530") usually shows current value of laser at the time of shipment, so you can see how the product has been deteriorated by comparing the first two numbers ("25" in "2530") and the last two numbers ("30" in "2530").

CD:

The laser current value of 49 mA or less is normal.

The laser current value of over 50 mA is not normal. Laser diode of the pickup has been deteriorated.

DVD:

The laser current value of 64 mA or less is normal.

The laser current value of over 65 mA is not normal. Laser diode of the pickup has been deteriorated.

Remote controller "4" key --- Laser of CD

Remote controller "5" key --- Laser of DVD

To return to test mode, press "STOP" key of the main body.

3.7 Flap adjustment of the pick-up guide shaft

Please perform flap adjustment of the pick-up guide shaft in the following case:

• Just after you exchange the pick-up.

• Just after you exchange the spindle motor.

• Just after you exchange the traverse mechanism base.

NOTE:

Please perform flap adjustment of the pick-up guide shaft when you exchange the parts above and also when you remove the

parts above.

• When the reading accuracy of the signal is bad (There is a block noise in the screen, Screen stops in the outer circumference of a

disc, etc.)

1 key (automatic adjustment)

5 key (laser of DVD)

TV DVD

STANDBY/ON

OPEN/

TV DVD

CLOSE

TV1 TV2 TV3

213

TV4 TV5 TV6

546

TV7 TV8 TV9

879

TV-/-- TV0 MUTING

010 +10

TITLE/

GROUP

U

N

E

CH

M

+

P

O

T

VOL VOL+

ENTER

C

CH

H

O

I

C

E

SELECTCLEAR

-

SLOW

3D

PHONIC

SUB TITLE

ANGLE

AUDIO

REPEAT

DIMMER

6 key

(display of jitter value)

TV/VIDEO

CANCELRETURN

M

E

N

U

4 key (laser of CD)

N

E

E

R

C

S

N

O

NEXTPREVIOUS

SLOW+

VFPZOOM

CHOICE key

PROGRESSIVE

SCAN

(switch of mode)

AMP

VOL

POWER key

(for test mode and jitter value)

STOP key

(for test mode)

FL Display

PLAY key

(No.A0041)1-17

XV-N50BK,XV-N55SL

S

OPEN SHORT

a

b

c

3.7.1 Tool for adjustment

*Stud: One set (four studs), Part number: JIGXVS40 (Note: One of the four studs is not used here.)

3.7.2 Preparation for adjustment

(1) See the disassembly procedure, and remove the Mechanism assembly from the main body.

(2) Remove the relay board attached to the mechanism assembly.

(If you disconnect the wires connected to the Relay board, connect them again.)

(3) Attach the three studs to the Mechanism assembly.

(4) Put the Mechanism assembly in the center of the main body, and connect the 50 pin wire from the connector CN4 on the

Relay board to the connector CN101 on the Servo control & signal output terminal board.

Stud

Stud

Mechanism

assembly

Mechanism assembly

CN4

CN101

Relay board

tud

CN4

Relay board

Servo contro &

signal output

terminal board

OPEN SHORT

OPEN SHORT

Switch

3.7.3 Adjustment

(1) Set the unit to test mode.

(2) Press the "CHOICE" key of the remote controller three times, and the FL display is displayed "CHECK".

(3) Insert a test disc (VT-501), and press the numeric key "1" of the remote controller for automatic adjustment.

(4) After a few seconds, press the numeric key "6" of the remote controller. Then, the FL display displays a jitter value.

(5) Turn the adjustment screws on the underside of the traverse mechanism with phillips screw driver until the maximum jitter value

is displayed on the FL display. (In this model, a bigger jitter value means a better result.)

NOTE:

During operation, the switch on the Relay board should be switched to "OPEN".

Reference values to judge whether the jitter is allowable or not are displayed, instead of actual jitter values.

1-18 (No.A0041)

Screw

Screw

Screw

POINT:

Turn the adjustment screws a and b to the same angle in the

right direction. And turn the adjustment screws a and b to the

same angle in the left direction. Then, turn the screws a and b

in either the right or the left direction to increase the number of

jitter. Don't turn the adjustment screw c.

XV-N50BK,XV-N55SL

A

3.8 Upgrading of firmware

The latest firmware for upgrading is updated in "Optical disc CSG" page in JS-net.

At the time of service, compare the version of the product and the latest version, and upgrade the old version into the latest version.

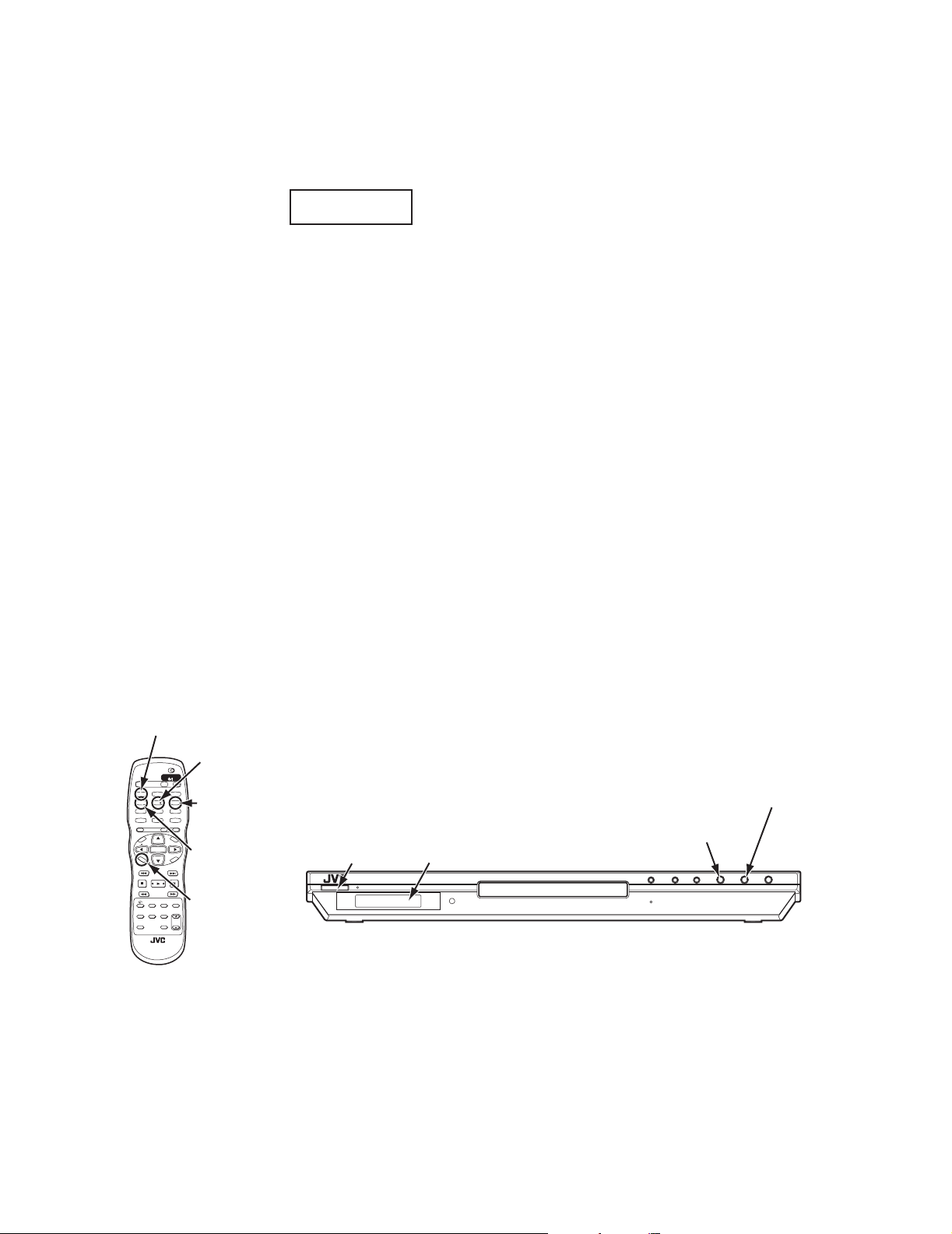

(1) Press "POWER" key of the main body to turn the main body on

(2) Insert the upgrade disc.

(3) When FL display of the main body changes from "READ" to "UP", press "cursor UP" key ( ) of the remote controller.

(4) The entire screen becomes blue, and upgrading starts.

(5) The tray opens automatically. Remove the upgrade disc.

(6) The screen returns to the normal screen. Then, press "POWER" key of the main body. When the stand-by indicator is lighted,

upgrading is completed.

(7) Set the main body at test mode, and perform initialization. Then, confirm the version of the firmware.

Firmware upgrade Disc ... press UP

fter inserting the up-grade disc

TV DVD

STANDBY/ON

OPEN/

TV DVD

CLOSE

TV1 TV2 TV3

TV4 TV5 TV6

TV7 TV8 TV9

TV-/-- TV0 MUTING

U

N

E

CH

M

+

P

O

T

VOL VOL+

ENTER

C

CH

H

O

I

C

E

SELECTCLEAR

-

SLOW

3D

PHONIC

SUB TITLE

ANGLE

REPEAT

UP key

213

(for firmware upgrade)

546

879

010 +10

TITLE/

TV/VIDEO

GROUP

CANCELRETURN

M

E

N

U

CHOICE key

N

E

E

R

C

S

N

(switch of mode)

O

NEXTPREVIOUS

SLOW+

VFPZOOM

PROGRESSIVE

SCAN

AUDIO

AMP

VOL

DIMMER

POWER key

Upgrade application initializing...

While upgrading (blue screen)

FL Display

OPEN/CLOSE key

Progressive indicator

(for initialize)

NO DISC

When up-grade is completed

PLAY key

(for test mode)

STOP key

(for test mode)

PAUSE key

(for initialize)

(No.A0041)1-19

XV-N50BK,XV-N55SL

3.9 Attention when pick-up is exchanged

(1) Flexible wire, pick-up spring, switch actuator, and lead

spring are removed from an old pick-up (broken the one).

Guide:

Flexible wire, pick-up spring and switch actuator,lead

spring are removed without each decomposing while assembled.

(2) The above-mentioned parts are installed in a new pick-up

(non-defective article).

(3) A flexible wire is inserted in the connector which has taken

side with the pick-up, and solder is put up to short land part

"a" two places on a flexible wire.

(4) The electrostatic breakdown protection circuit attached to

the pick-up is cut.

ATTENTION:

Please cut the electrostatic breakdown protection

circuit attached to the pick-up after solder is put up

to two places on a flexible wire short land part "a" of

the insertion of a flexible wire this time in the connector without fail.

The procedure might be mistaken and if solder has

not surely adhered to two places on a flexible wire

short land part "a", the laser diode in the pick-up be

destroyed again.

(5) The pick-up is installed in the traverse mechanism.

(6) A flexible wire is connected with connector CN101 on the

servo control board by installing the traverse mechanism in

the loading mechanism.

(7) Solder in two places on a flexible wire in part "a" is re-

moved.

Switch actuator

Lead spring

Pick-up spring

Flexible wire

Electrostatic breakdown

protection circuit

Pick-up

Flexible wire

Connector

Short land

part "a"

ATTENTION :

Please remove solder in two places in part "a" after

connecting a flexible wire with connector CN1 on the

relayl board without fail this time.

When the procedure is mistaken, the laser diode in

the pick-up might be destroyed.

Please remove solder in two places in part "a" surely.

Cutting part

Electrostatic breakdown

protection circuit

Short land

part "a"

CN1

1-20 (No.A0041)

Relay board

XV-N50BK,XV-N55SL

3.10 Confirm method of operation

Please confirm the operation of the undermentioned item after doing the repair and the upgrade of the firmware.

Initialize Refer to the initialization method.

All-initialize Refer to the All-initialization method.

Parameter adjustment status Set the main body at test mode, and check that the FL display shows " 0".

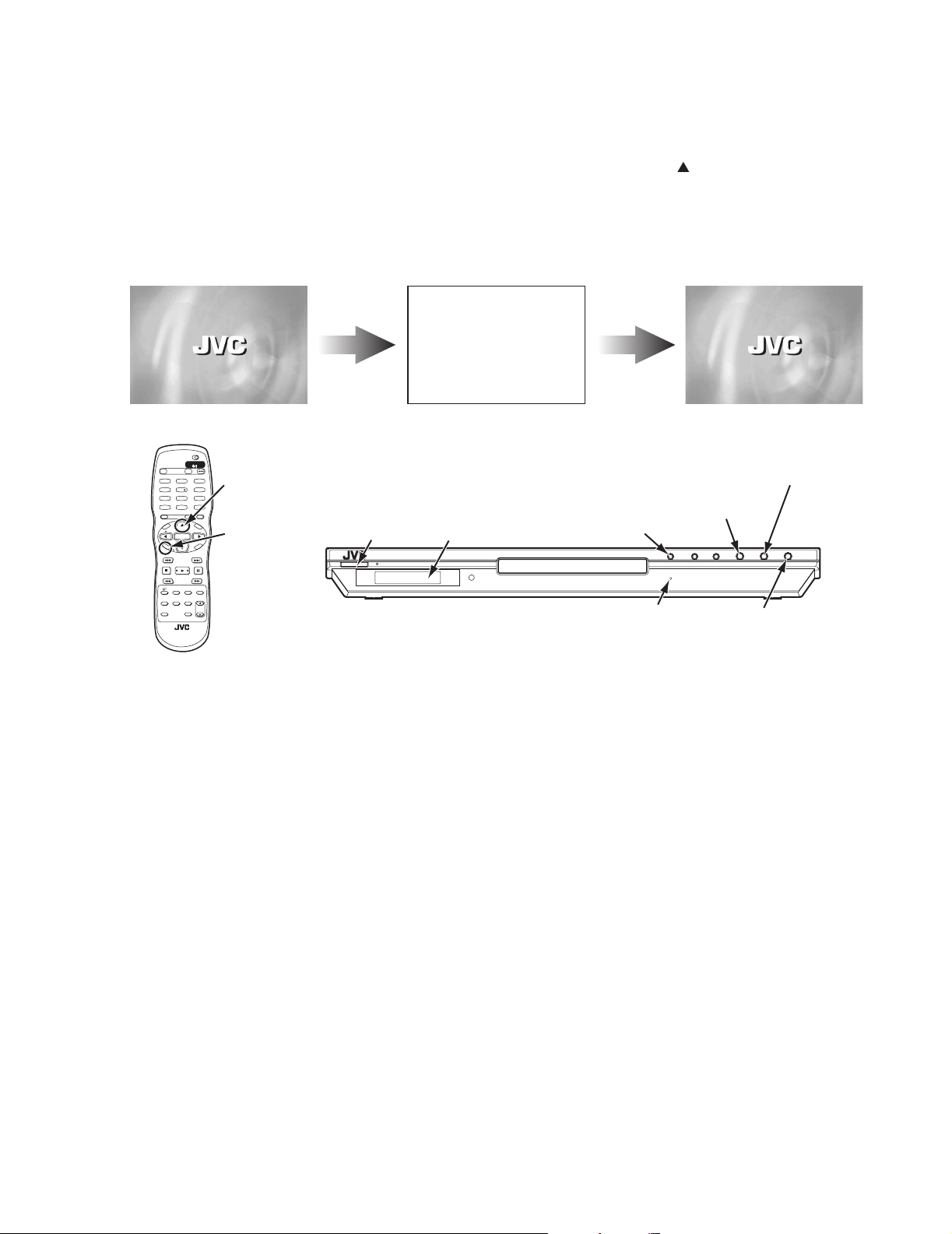

Opening picture check (Power ON) It should be display "JVC"

Muting working The noise must not be had to the performance beginning when you push "PLAY" button or

at ON/STANDBY.

FL Display The mark and the logo, etc. displayed by each operation must be displayed correctly.

FL Display should light correctly without any unevenness.

All Function button All function buttons should worked correctly with moderate click feeling.

Open and close movement of tray When press OPEN/CLOSE button the tray should move smoothly without any noise.

Remote controller unit working Check the correctly operation in use of remote controller unit.

Reading of TOC Be not long in the malfunction.

Search Both forward-searches and backward-searches should be able to be done.

Do not stop be searching or after the search.

Skip Both forward-skip and backward-skip should be able to be done.

Do not stop be after the skip.

Playback Do not find abnormality etc. of tone quality and the picture quality.

Most outside TITLE playback check Play VT-501 TITLE 59 CHAPTER 1 , check normal playback.

(No.A0041)1-21

XV-N50BK,XV-N55SL

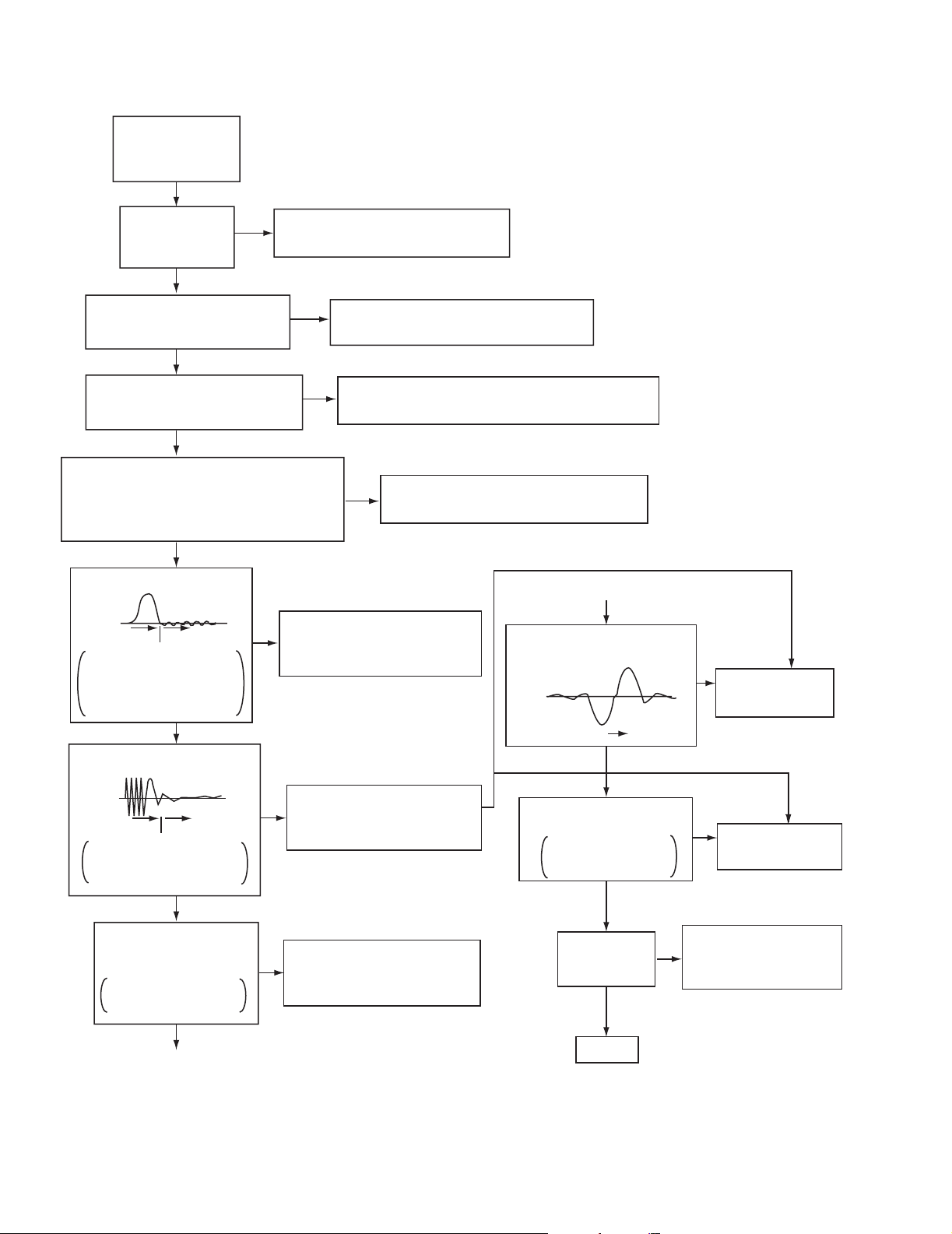

3.11Troubleshooting

3.11.1 Servo volume

Press OPEN

/CLOSE key

Is tray

operation

Confirmation of tray drive circuit

N

and circuit in surrounding

correct?

Y

Is the traverse moving

along the innermost

N

perimeter for SW detection?

Y

"NO DISC" message appears

Y

immediately after vertical

movement of the pick-up lens

N

The state that DISC does not rotate continues for

several seconds, and becomes NO DISC or an

error display afterwards.

The rotation of DISC becomes high-speed and

abnormal, and becomes NO DISC or an error

display afterwards.

N

Is focus retraction OK?

FE

OFF

Even when it retracts

correctly, if it is out of focus

and makes repeated retries

with a clicking sound, it is

in error.

ON

See "(4) Focus ON error"

N

in "Check points for

individual errors"

Y

Is tracking retraction OK?

See "(3) Traverse movement error"

in "Check points for individual errors"

See "(2) Disk detection, distinction error"

in "Check points for individual errors"

Y

See "(1) Spindle startup error"

in "Check points for individual errors"

Is the inter-layer jump OK?

FE

LO LI

A

Two layers of DVD only.

N

(8) Inter-layer

jump error

Y

TE

OFF

If TE waveform reappears

or fails to converge after the

TE retraction, it is in error.

Is the spindle servo

locked correctly?

Is the RF OUT waveform

locked correctly?

1-22 (No.A0041)

A

ON

See "(5) Tracking ON error"

N

in "Check points for

individual errors"

Has the disc information

been collected?

Stop will result

N

(7) Address read

error

Y

Y

Check (9),(10),(11), and

See "(6) Spindle CLV error"

N

in "Check points for

individual errors"

Is playback

possible?

Y

N

(12) items in "Check points

for individual errors"

Y

OK !

Fig.1

3.12Check points for each error

3.12.1 Spindle start error

(1) Defective spindle motor

• Are there several ohms resistance between each pin of CN101 "5-6","6-7","5-7"?

(The power supply is turned off and measured.)

• Is the sign wave of about 100mVp-p in the voltage had from each terminal?

[ CN101"9"(H1+),"10"(H1-),"11"(H2+),"12"(H2-),"13"(H3+),"14"(H3-) ]

(2) Defective spindle motor driver (IC251)

• Has motor drive voltage of a sine wave or a rectangular wave gone out to each terminal(SM1~3)

of CN101"5,6,7" and IC251"2,4,7"?

• Is FG pulse output from the terminal of IC251"24"(FG) according to the rotation of the motor?

• Is it "L(about 0.9V)" while terminal of IC251"15"(VH) is rotating the motor?

(3) Has the control signal come from servo IC or the microcomputer?

• Is it "L" while the terminal of IC251"18"(SBRK) is operating?

Is it "H" while the terminal of IC251"23"(/SPMUTE) is operating?

• Is the control signal input to the terminal of IC251"22"(EC)?

(changes from VHALF voltage while the motor is working.)

• Is the VHALF voltage input to the terminal of IC251"21"(ECR)?

(4) Is the FG signal input to the servo IC?

• Is FG pulse input to the terminal of IC301"69"(FG) according to the rotation of the motor?

XV-N50BK,XV-N55SL

3.12.2 Disc Detection, Distinction error (no disc, no RFENV)

• Laser is defective.

• Front End Processor is defective (IC101).

• APC circuit is defective. --- Q101,Q102.

• Pattern is defective. --- Lines for CN101 - All patterns which relate to pick-up and patterns between IC101

• IC101 --- For signal from IC101 to IC301, is signal output from IC101 "21" (ASOUT) and IC101 "36"(RFENV) and IC101 "20"

(FEOUT)?

3.12.3 Traverse movement NG

(1) Defective traverse driver

• Has the voltage come between terminal of CN101 "49" and "50" ?

(2) Defective BTL driver (IC201)

• Has the motor drive voltage gone out to IC201"17" or "18"?

(3) Has the control signal come from servo IC or the microcomputer?

• Is it "H" while the terminal of IC201"9"(STBY1) ?

• TRSDRV Is the signal input? (IC301 "67")

(4) TRVSW is the signal input from microcomputer? (IC301 "56")

3.12.4 Focus ON NG

• Is FE output ? --- Pattern, IC101

• Is FODRV signal sent ? (R209) --- Pattern, IC301 "115"

• Is driving voltage sent ?

• IC201 "13", "14" --- If NG, pattern, driver, mechanical unit .

• Mechanical unit is defective.

3.12.5 Tracking ON NG

• When the tracking loop cannot be drawn in, TE shape of waves does not settle.

• Mechanical unit is defective.

Because the self adjustment cannot be normally adjusted, the thing which cannot be normally drawn in is thought.

• Periphery of driver (IC201)

Constant or IC it self is defective.

• Servo IC (IC301)

When improperly adjusted due to defective IC.

(No.A0041)1-23

XV-N50BK,XV-N55SL

3.12.6 Spindle CLV NG

• IC101 -- "27"(ARF-), "26(ARF+).

• Does not the input or the output of driver's spindle signal do the grip?

• Has the tracking been turned on?

• Spindle motor and driver is defective.

• Additionally, "IC101 and IC301" and "Mechanism is defective(jitter)", etc. are thought.

3.12.7 Address read NG

• Besides, the undermentioned cause is thought though specific of the cause is difficult because various factors are thought.

Mechanism is defective. (jitter)

IC301

The disc is dirty or the wound has adhered.

3.12.8 Between layers jump NG (double-layer disc only)

Mechanism defective

Defect of driver's IC(IC201)

Defect of servo control IC(IC301)

3.12.9 Neither picture nor sound is output

(1) It is not possible search

• Has the tracking been turned on?

• To "(5) Tracking ON NG" in "Check points for each error" when the tracking is not normal.

• Is the feed operation normal?

To "(3) traverse movement NG" in "Check points for each error" when it is not normal.

Are not there caught of the feeding mechanism etc?

3.12.10 Picture is distorted or abnormal sound occurs at intervals of several seconds.

Is the feed operation normal?

Are not there caught of the feeding mechanism etc?

3.12.11 Others

• The image is sometimes blocked, and the image stops.

• The image is blocked when going to outer though it is normal in suroundings in the disk and the stopping sympton increases.

There is a possibility with bad jitter value for such a symptom.

3.12.12 CD During normal playback operation

(1) Is TOC reading normal?

• Displays total time for CD-DA.

• Shifts to double-speed mode for V-CD

(2) Is playback afterwards possible?

(3) When can not do a normal playback

• --:-- is displayed during FL search.

According to [It is not possible to search ] for DVD(9), check the feed and tracking systems.

• No sound is output although the time is displayed.(CA-DA)

DAC, etc, other than servo.

• The passage of time is not stable, or picture is abnormal.(V-CD)

• The wound of the disc and dirt are confirmed.

1-24 (No.A0041)

SECTION 4

Description of major ICs

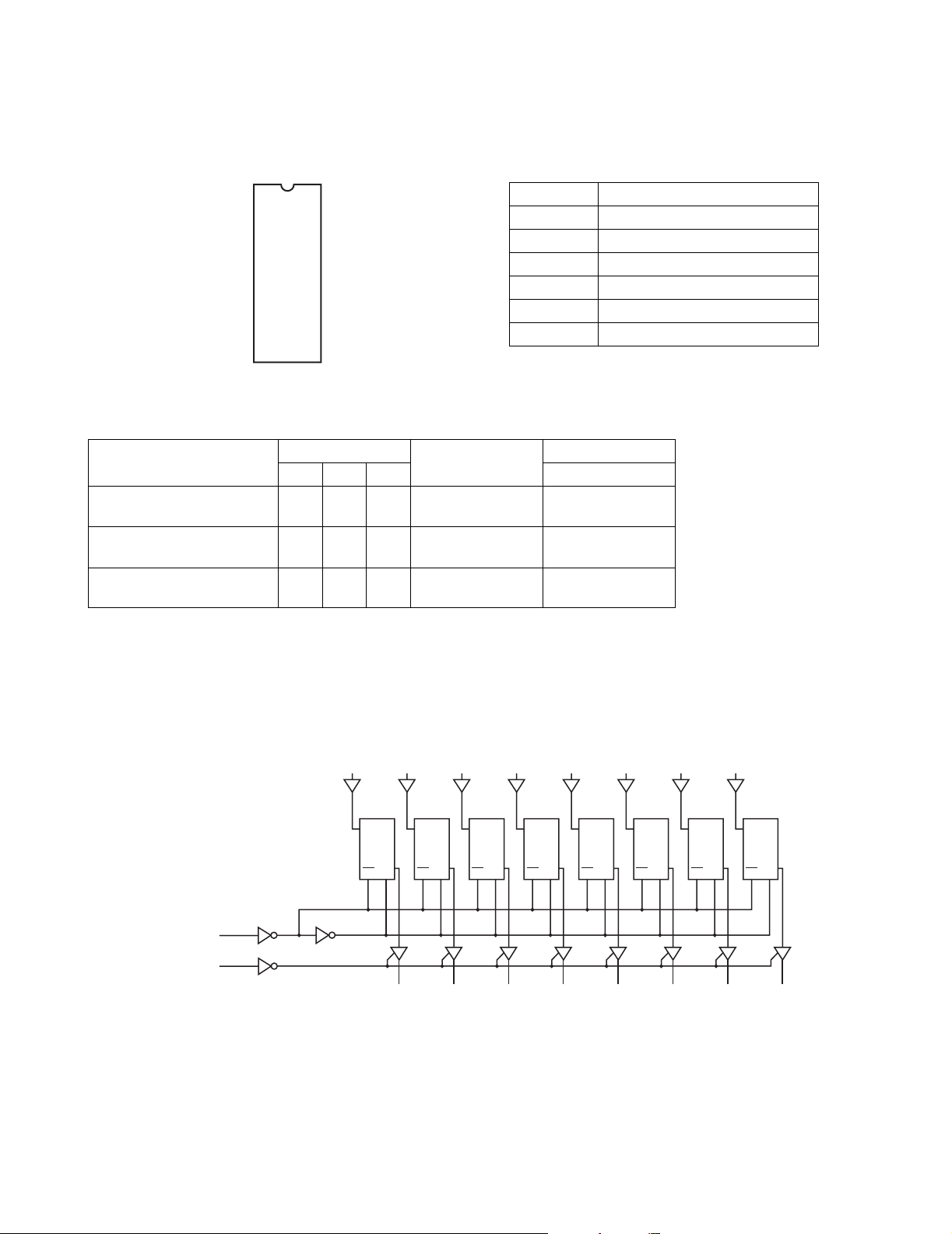

4.1 74LVC373APW-X (IC512, IC513) : Octal D-type transparet latch

• Pin Layout • Pin function

OE

Q0

D0

D1

Q1

Q2

D2

D3

Q3

GND

• Truth table

Operating modes

Enable and read register

(trasparant mode)

Latch and read register L

Latch register and

disable outputs

20

1

2

3

4

5

6

7

8

9

10

19

18

17

16

15

14

13

12

11

VCC

Q7

D7

D6

Q6

Q5

D5

D4

Q4

LE

(TOP VIEW)

Inputs

OE LE Dn Q0 to Q7

L

H

L

H

L

L

L

H

L

H

L

L

H

l

h

l

h

Internal latches

L

H

L

H

L

H

Symbol Description

D0-D7 Data Inputs

LE Latch enable Input (active-high)

OE Output enable Input (active-low)

Q0-Q7 Data outputs

GND Connect to ground

Vcc Power supply

XV-N50BK,XV-N55SL

Outputs

L

H

H

H

Z

Z

H=HIGH Voltage Level

h=HIGH Voltage level one setup time prior to the HIGH-to-LOW LE transition

L=LOW Vlotage Level

l=LOW Voltage level one setup time prior to the HIGH-to-LOW LE transition

X=Don't care

Z=High Impedance OFF-state

• Block Diagram

LE

OE

D0

3

11

1

D1

4

D

Q

LE

2

Q0

D2

7

D

Q

LE

5

Q1

D3

8

D

LE

D

Q

6

Q2

LE

D4

13

Q

9

Q3

D5

14

D

Q

LE

12

Q4

D6

17

D

Q

LE

15

Q5

D7

18

D

LE

Q

16

Q6

D

Q

LELE LE LE LE LE LE LE LE

19

Q7

(No.A0041)1-25

XV-N50BK,XV-N55SL

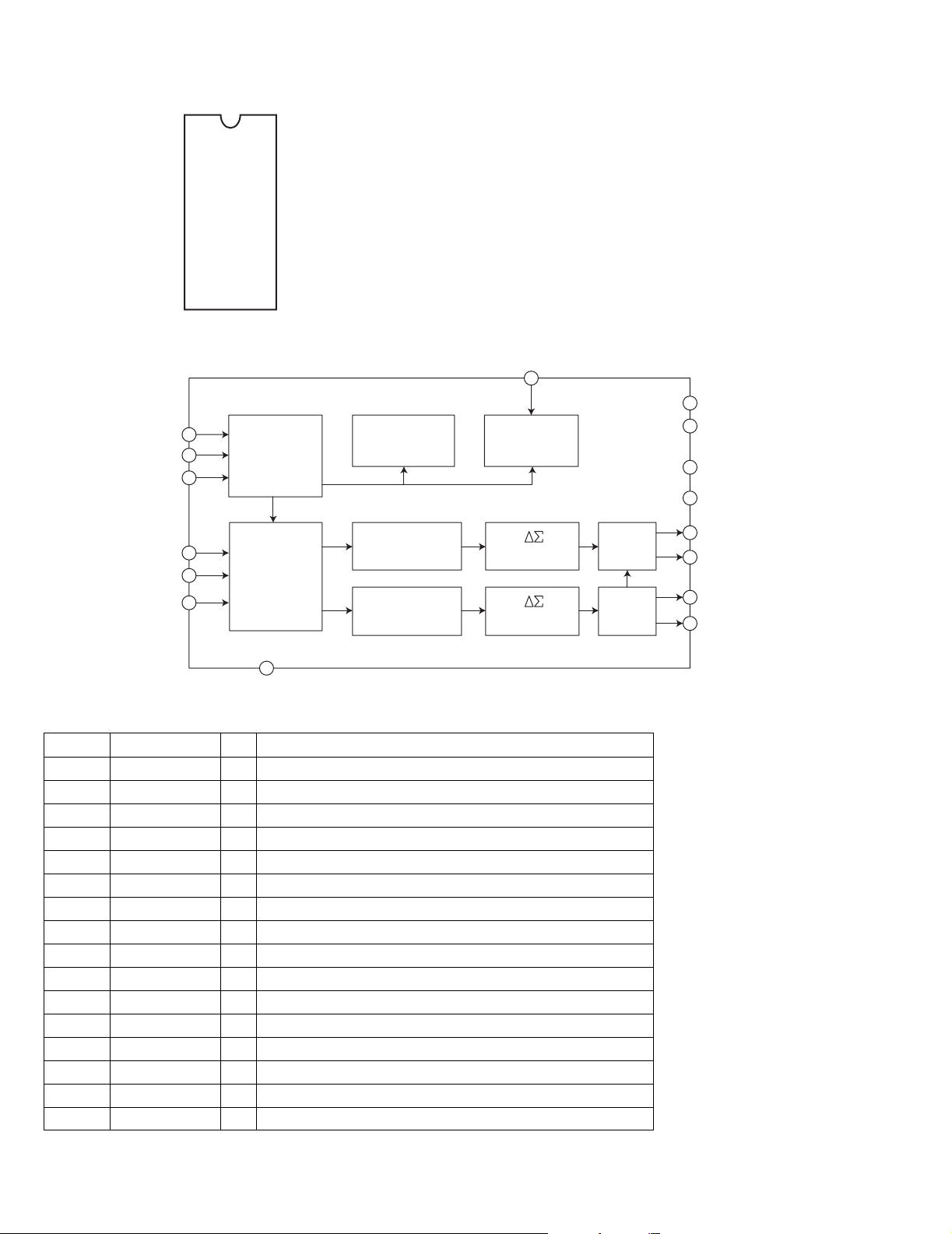

4.2 AK4381VT-X (IC402) : 2ch DAC

• Pin layout

• Block diagram

MCLK

BICK

SDTI

LRCK

PDN

CSN

CCLK

CDTI

CSN

CCLK

CDTI

LRCK

BICK

SDTI

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

DZFL

DZFR

VDD

VSS

AOUTL+

AOUTLAOUTR+

AOUTR-

MCLK

VDD

VSS

DZFL

uP

Interface

De-emphasis

Control

Clock

Divider

DZFR

AOUTL+

AOUTL-

Audio

8X

Interpolator

Modulator

SCF

Data

Interface

8X

Interpolator

Modulator

SCF

AOUTR+

AOUTR-

PDN

• Pin functions

Pin No. Symbol I/O Description

1 MCLK I Master clock input terminal

2 BICK I Audio serial data clock terminal

3 SDTI I Audio serial data input terminal

4 LRCK I L/R Clock terminal

5 PDN I Power down mode terminal

6 CSN I Chip select

7 CCLK I Control data input terminal

8 CDTI I Control data input terminal

9 AOUTR- O Rch negative analog output terminal

10 AOUTR+ O Rch positive analog output terminal

11 AOUTL- O Lch negative analog output terminal

12 AOUTL+ O Lch positive analog output terminal

13 VSS - Connect to ground

14 VDD - Power supply terminal

15 DZFR O Rch data zero input detection terminal

16 DZFL O Lch data zero input detection terminal

1-26 (No.A0041)

4.3 AN8708FHK(IC101):Frontend processor

•Pin layout

48 37

XV-N50BK,XV-N55SL

1

12

36

25

13 24

• Pin function

Pin No. Symbol I/O Description

1 GND1 - Connect to ground

2 LPC1 I Laser input terminal (DVD)

3 LPC01 O Laser drive output terminal (DVD)

4 LPC2 I Laser input terminal (CD)

5 LPC02 O Laser drive output terminal (CD)

6 FBAL I Focus balance control terminal

7 TBAL I Tracking balance control terminal

8 POFLT O Track detection filter terminal

9 SEN I SEN (Serial data input terminal)

10 SCK I SCK (Serial data input terminal)

11 STDI I/O STDI (Serial data input/output terminal)

12 VRE18 - RF Standard voltage filter

13 TE O Tracking error signal output terminal

14 VSS - Connect to ground

15 OFTR O OFTR output

16 BDO O BDO output

17 VDD - Power supply terminal 3 (3.3V)

18 RSCL - Source terminal of standard current

19 GND2 - Connect to ground

20 FE O Focus error signal output terminal

21 FS O Focus addition signal output terminal

22 VHALF O VHALF Voltage output terminal

23 MIRSL O MIRROR Slow envelope detection terminal

24 BDOSL O BDO Slow envelope detection terminal

25 VCC2 - Power supply terminal 2 (3.3V)

26 FLTOP O Filter amplifier positive output terminal

27 FLTON O Filter amplifier negative output terminal

28 SAG O SAG Cancel detention terminal

29 DCAGC O FLT-DC Cut filter terminal

30 AGCG O AGC Amp.gain control terminal

31 TESTSG I TEST signal input terminal

32 RFINP I RF signal positive input terminal

33 RFINN I RF signal negative input terminal

34 DCRF O Filter terminal for RF all addition AMP.DC cut

35 PEAK O Peak envelope detection filter terminal

36 RFENV O RF Envelope output terminal

37 VCC1 - Power supply terminal 2 (5V)

38,39 VIN5,6 I Internal four division (CD) RF input terminal 1,2

40,41 VIN7,8 I External two division (DVD) RF input terminal 1,2

42 VREF - VREF Voltage output terminal

43~46 VIN1~4 I Internal four division (DVD) RF input terminal 1~4

47,48 VIN9,10 I Three beam sub (CD) input terminal 1,2

(No.A0041)1-27

Loading...

Loading...