JVC XV-N512S Service Manual

SERVICE MANUAL

DVD AUDIO/VIDEO PLAYER

YD028

XV-N512S

B -------------------------- U.K.

E ------ Continental Europe

EN ------- Northern Europe

EV --------- Eastern Europe

EE ---- Russian Federation

UJ ------------ U.S.A. Militaly

UW ----- Brazil,Mexico,Peru

US ---------------- Singapore

Turkey,South Africa,Egypt

UG UX ------------- Saudi Arabia

UP ---------------------- Korea

UF ---------------------- China

UT --------------------- Taiwan

UB --------------- Hong Kong

A --------------------- Australia

TV DVD

STANDBY/ON

OPEN

TV DVD

/CLOSE

TV1 TV2 TV3

1

2

TV4 TV5 TV6

4

5

TV7 TV8 TV9

7

8

TV-/-- TV0 MUTING

010 +10

TITLE

/GROUP

U

N

E

CH+

M

P

O

T

VOL VOL+

ENTER

S

E

T

CH

U

P

SELECTCLEAR

-

SLOW

3D PHONIC

SUB TITLE

ANGLE

AUDIO

fs/Rate

REPEAT

DIMMER

TV/VIDEO

CANCELRETURN PAGE

N

O

NEXTPREVIOUS

SLOW+

PROGRESSIVE

3

6

9

M

E

N

U

N

E

E

R

C

S

VFPZOOM

SCAN

AMP

VOL

Except ver.B,E,EN,EV,EE Except ver.UJ

Except ver.

B,E,EN,EV,EE,UJ

Area Suffix

XV-N512SBC, XV-N512SEC, XV-N512SENC, XV-N512SEVC, XV-N512SEEC, XV-N512SUJC,

XV-N512SUWC, XV-N512SUSC, XV-N512SUGC, XV-N512SUXC, XV-N512SUPC, XV-N512SUFC,

XV-N512SUTC, XV-N512SUBC, XV-N512SAC,

This service manual is a service manual of a model in which destination is added to

the issued service manual XV-N510B, XV-N512S (issue number: YD016 2004/8).

This service manual consists of only "Parts List," "Standard Schematic Diagrams,"

"Printed Circuit Boards," "Block Diagram," and "Instruction Book." Regarding

service information other than these sections, refer to the service manual

XV-N510B, XV-N512S (issue number: YD016 2004/8).

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

COPYRIGHT © 2004 Victor Company of Japan, Limited

No.YD028

2004/9

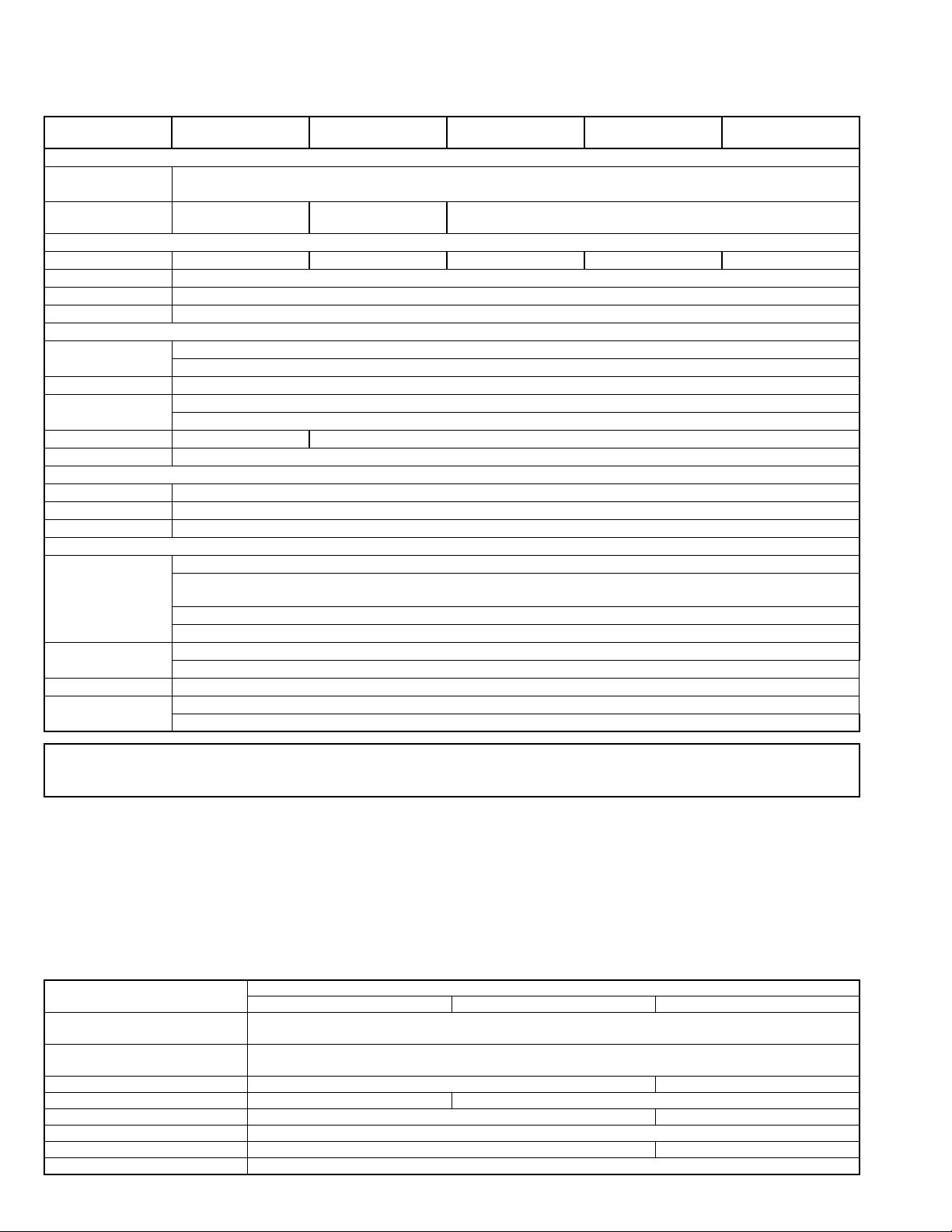

SPECIFICATION

XV-N512S for

B,E,EN,EV,EE

Readable discs

Video format

Power requirements AC 230 V~, 50 Hz AC 120 V~, 60 Hz

Power consumption

Mass

Dimensions (W × H × D)

COMPONENT

(pin jacks)

VIDEO OUT (pin jack)

S-VIDEO OUT

(S jack)

RGB output 700 mVp-p (75 Ω)

Horizontal resolution

ANALOG OUT (pin jack)

DIGITAL OUT (COAXIAL)

DIGITAL OUT (OPTICAL)

Frequency response

Dynamic range

Wow and flutter

Total harmonic distortion

DVD AUDIO, DVD VIDEO, DVD-R (Video format), DVD-RW (Video format/VR format), DVD-RAM (VR format), SVCD, Video

CD, Audio CD (CD-DA), CD-R/RW (CD-DA, SVCD, Video CD, MP3/WMA format, JPEG)

PAL, Interlaced scan/Pro-

gressive scan selectable

13 W (POWER ON), 2.0 W (STANDBY mode)

1.9 k g

435 mm × 44 mm × 258.6 mm

Y Output: 1.0 Vp-p (75 Ω)

PB/PR Output: 0.7 Vp-p (75 Ω)

1.0 Vp-p (75 Ω)

Y Output: 1.0 Vp-p (75 Ω)

C Output: 286 mVp-p (75 Ω)

500 lines or more

2.0 Vrms (10 kΩ)

0.5 Vp-p (75 Ω termination)

-21 dBm to -15 dBm (peak)

CD (sampling frequency 44.1 kHz):2 Hz to 20 kHz

DVD (sampling frequency 48 kHz):2 Hz to 22 kHz

(4 Hz to 20 kHz for DTS and Dolby Digital bitstream signals)

DVD (sampling frequency 96 kHz):2 Hz to 44 kHz

DVD (sampling frequency 192 kHz/176.4 kHz):2 Hz to 88 kHz

16 bit: More than 98 dB

20 bit/24 bit: More than 106 dB

Unmeasurable (less than +- 0.002%)

16 bit: less than 0.006%

20 bit/24 bit: less than 0.005%

XV-N512S for UJ

REMOTE, 480i (Interlaced scan)/

480p (Progressive scan) selectable

-

Audio characteristics

XV-N512S for

US,UB,UG,UX,UW,UF,UT

General

REMOTE, 525i/625i (Interlaced scan)/525p/625p (Progressive scan) selectable

Other

AC 110 V-240V~, 50Hz/60 Hz

Video outputs

Audio outputs

XV-N512S for A XV-N512S for UP

AC240V~,50Hz

AC 220 V~, 60 Hz

* Notes for PX model (Check the specification indication on the rear panel.)

Power requirements AC 110 V to 240 V~ , 50 Hz/60 Hz

Power consumption 13 W (POWER ON), 2.0 W(STANDBY mode)

• Manufactured under license from Dolby Laboratories. “Dolby,” “MLP Lossless,” and the double-D symbol are trademarks of Dolby Laboratories.

• “DTS” and “DTS Digital Surround” are registered trademarks of Digital Theater Systems, Inc.

• This product incorporates copyright protection technology that is protected by U.S. patents and other intellectual property rights. Use of this copyright

protection technology must be authorized by Macrovision, and is intended for home and other limited viewing uses only unless otherwise authorized

by Macrovision. Reverse engineering or disassembly is prohibited.

• “CONSUMERS SHOULD NOTE THAT NOT ALL HIGH DEFINITION TELEVISION SETS ARE FULLY COMPATIBLE WITH THIS PRODUCT AND

MAY CAUSE ARTIFACTS TO BE DISPLAYED IN THE PICTURE. IN CASE OF 525 OR 625 PROGRESSIVE SCAN PICTURE PROBLEMS, IT IS

RECOMMENDED THAT THE USER SWITCH THE CONNECTION TO THE “STANDARD DEFINITION” OUTPUT.

IF THERE ARE QUESTIONS REGARDING OUR TV SET COMPATIBILITY WITH THIS MODEL 525p AND 625p DVD PLAYER, PLEASE CONTACT OUR CUSTOMER SERVICE CENTER.”

Digital output signal chart

Disc type

DVD with 48/44.1 kHz, 16/20/24 bit

linear PCM DVD AUDIO with MLP

DVD with 192/176.4/96/88.2 kHz, 16/22/24

bit linear PCM DVD AUDIO with MLP

DVD with DTS 48 kHz, 16 bit, stereo linear PCM DTS bitstream

DVD with Dolby Digital 48 kHz, 16 bit, stereo linear PCM Dolby Digital bitstream

DVD with MPEG Multichannel 48 kHz, 16 bit, stereo linear PCM MPEG bitstream

SVCD/Video CD/Audio CD 44.1 kHz, 16 bit, stereo linear PCM

Audio CD with DTS 44.1 kHz, 16 bit, stereo linear PCM DTS bitstream

CD-R/RW with MP3/WMA Linear PCM

PCM ONLY DOLBY DIGITAL/PCM STREAM/PCM

48/44.1 kHz, 16/20/24 bit, stereo linear PCM

48/44.1 kHz, 16/20/24 bit, stereo linear PCM (Down sampling)

Output

1-2 (No.YD028)

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

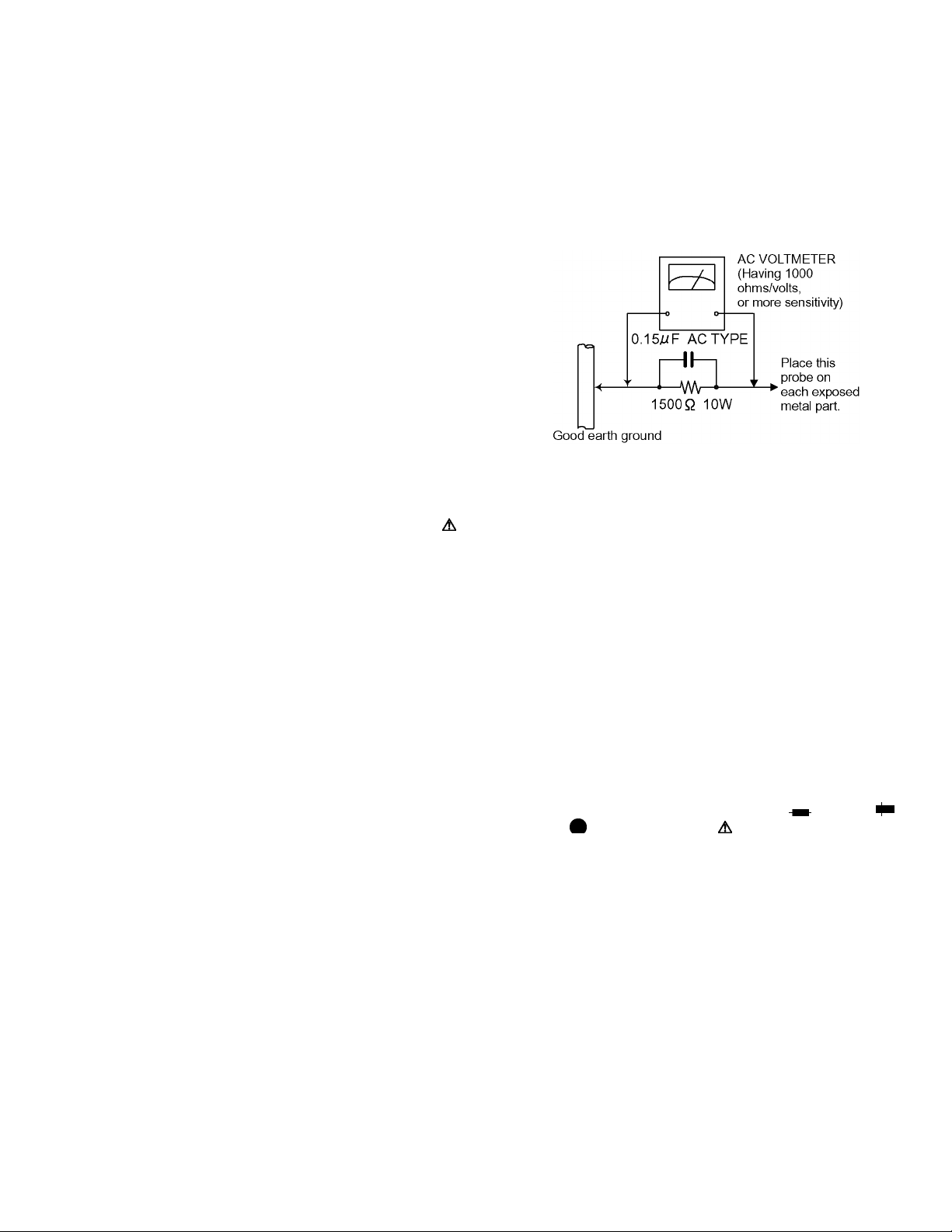

(5) Leakage shock hazard testing)

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000 ohms per volt or more sensitivity in the following manner. Connect a 1,500 ohm 10W

resistor paralleled by a 0.15 F AC-type capacitor between an exposed metal part and a known good earth

ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical for

safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer. (Except

the JC version)

(No.YD028)1-3

Loading...

Loading...