JVC XVN-420-B Service manual

SERVICE MANUAL

DVD PLAYER

YD05720053

XV-N420B,XV-N422S

Area Suffix

EK ------------------------ U.K.

EU -------- Western Europe

EY -------- Northern Europe

EZ --------- Eastern Europe

ER ---- Russian Federation

STANDBY/ON

OPEN/

CLOSE

+

SLOW

DISPLAYON SCREEN

T

O

T

P

H

U

M

B

N

A

IL

L

ENTER

S

NEXTPREVIOUS

SELECT

CLEAR

123

456

789

0

SOUND

VFP

EFFECT

I/P

SUBTITLEANGLE

AUDIO

ZOOM

/

IS

T

E

T

U

P

®

VIDEO

M

E

N

U

M

E

N

U

CANCEL RETURN

TITLE/

GROUP DIMMER

SLIDE EFFECT

XV-N420BEKC,XV-N420BEUC,XV-N420BEYC,XV-N420BEZC,XV-N420BERC

XV-N422SEKC,XV-N422SEUC,XV-N422SEYC,XV-N422SEZC,XV-N422SERC

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.YD057

2005/3

SPECIFICATION

XV-N420B,XV-N422S forEK,EU,EY,EZ,ER

General

Readable discs DVD VIDEO, DVD-R (Video format), DVD-RW (Video format), SVCD, Video CD, Audio CD (CD-

DA),CD-R/RW (CD-DA, SVCD, Video CD, MP3/WMA format, JPEG, DivX)

Video format PAL, 625i/625p selectable

Other

Power requirements AC 230 V~, 50 Hz

Power consumption 11.0 W (POWER ON), 1.0 W (STANDBY mode)

Mass 1.5 kg

Dimensions (W × H × D) 435mm × 44mm × 203.5 mm

Video outputs

VIDEO OUT (pin jack) 1.0 Vp-p (75 Ω)

RGB Output 700 mVp-p (75 Ω)

Component (pin jacks) Y Output: 1.0 Vp-p (75 Ω)

Pb/Pr Output: 0.7Vp-p (75 Ω)

Horizontal resolution 500 lines or more

Audio outputs

ANALOG OUT (pin jack) 2.0 Vrms (10 kΩ)

DIGITAL OUT (COAXIAL) 0.5 Vp-p (75 Ω termination)

Audio characteristics

Frequency response CD (sampling frequency 44.1 kHz):2 Hz to 20 kHz

DVD (sampling frequency 48 kHz):2 Hz to 22 kHz

(4 Hz to 20 kHz for DTS and Dolby Digital bitstream signals)

DVD (sampling frequency 96 kHz):2 Hz to 44 kHz

Wow and flutter Unmeasurable (less than +- 0.002%)

Total harmonic distortion less than 0.009%

• Manufactured under license from Dolby Laboratories. “Dolby” and the double-D symbol are trademarks of Dolby Laboratories.

• “DTS” and “DTS Digital Out” are trademarks of Digital Theater Systems, Inc.

• “Official DivX Certified

TM

fied

technical requirements)” “DivX, DivX Certified, and associated logos are trademarks of DivXNetworks, Inc. and are used un-

der license.”

• This product incorporates copyright protection technology that is protected by U.S. patents and other intellectual property rights. Use

of this copyright protection technology must be authorized by Macrovision, and is intended for home and other limited viewing uses

only unless otherwise authorized by Macrovision. Reverse engineering or disassembly is prohibited.

• “CONSUMERS SHOULD NOTE THAT NOT ALL HIGH DEFINITION TELEVISION SETS ARE FULLY COMPATIBLE WITH THIS

PRODUCT AND MAY CAUSE ARTIFACTS TO BE DISPLAYED IN THE PICTURE. IN CASE OF 525 OR 625 PROGRESSIVE

SCAN PICTURE PROBLEMS, IT IS RECOMMENDED THAT THE USER SWITCH THE CONNECTION TO THE “STANDARD

DEFINITION” OUTPUT. IF THERE ARE QUESTIONS REGARDING OUR TV SET COMPATIBILITY WITH THIS MODEL 525p

AND 625p DVD PLAYER, PLEASE CONTACT OUR CUSTOMER SERVICE CENTER.”

TM

product” “Plays DivXR 5, DivXR 4, DivXR 3, and DivXR VOD video content (in compliance with DivX Certi-

1-2 (No.YD057)

1.9 Precautions for Service

1.9.1 Handling of Traverse Unit and Laser Pickup

(1) Do not touch any peripheral element of the pickup or the actuator.

(2) The traverse unit and the pickup are precision devices and therefore must not be subjected to strong shock.

(3) Do not use a tester to examine the laser diode. (The diode can easily be destroyed by the internal power supply of the tester.)

(4) To replace the traverse unit, pull out the metal short pin for protection from charging.

(5) When replacing the pickup, after mounting a new pickup, remove the solder on the short land which is provided at the center of

the flexible wire to open the circuit.

(6) Half-fixed resistors for laser power adjustment are adjusted in pairs at shipment to match the characteristics of the optical block.

Do not change the setting of these half-fixed resistors for laser power adjustment.

1.9.2 Destruction of Traverse Unit and Laser Pickup by Static Electricity

Laser diodes are easily destroyed by static electricity charged on clothingor the human body. Before repairing peripheral elements of

the traverse unit or pickup, be sure to take the following electrostatic protection:

(1) Wear an antistatic wrist wrap.

(2) With a conductive sheet or a steel plate on the workbench on which the traverse unit or the pick up is to be repaired, ground the

sheet or the plate.

(3) It solders to two short circuit sections on the substrate of a pick-up.

(4) After removing the flexible wire from the connector (CN101

(5) Short-circuit the laser diode by soldering the land which is provided at the center of the flexible wire for the pickup.

After completing the repair, remove the solder to open the circuit.

), short-circuit the flexible wire by the metal clip.

Pick-up

CN101Digital board

Short circuit

*Please refer to the disassembly method for details.

1-6 (No.YD057)

SECTION 3

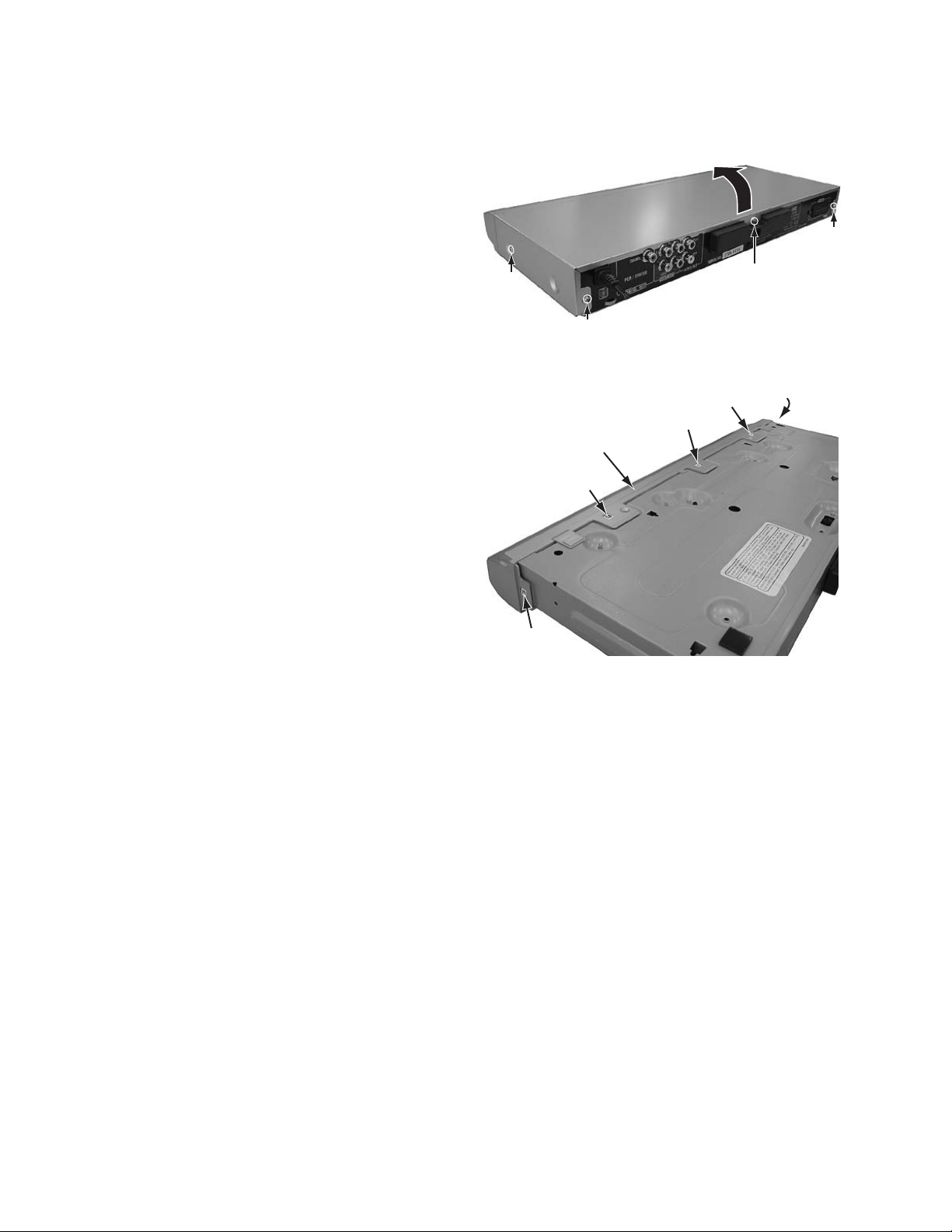

TOP COVER

DISASSEMBLY

3.1 Main body section

3.1.1 Removing the top cover (See Figure 1)

(1) Remove the two screws A attaching the top cover on both

sides of the main body.

(2) Remove the three screws B attaching the top cover on the

back of the main body.

(3) Raise the both sides and lower part of the rear of the top

cover, with opening them slightly in an outward direction.

And the top cover will be removed.

3.1.2 Removing the front panel assembly (See Figure 2)

• Prior to performing the following procedure, remove the top

cover.

• There is no need to remove the mechanism assembly.

(1) Hook a and b are removed respectively, and the front panel

assembly is removed.

A x 2

TOP COVER

TOP COVER

B

Front panel

assembly

Hook b

Fig.1

Hook b

Hook b

B

B

Hook a

Hook a

Fig.2

1-8 (No.YD057)

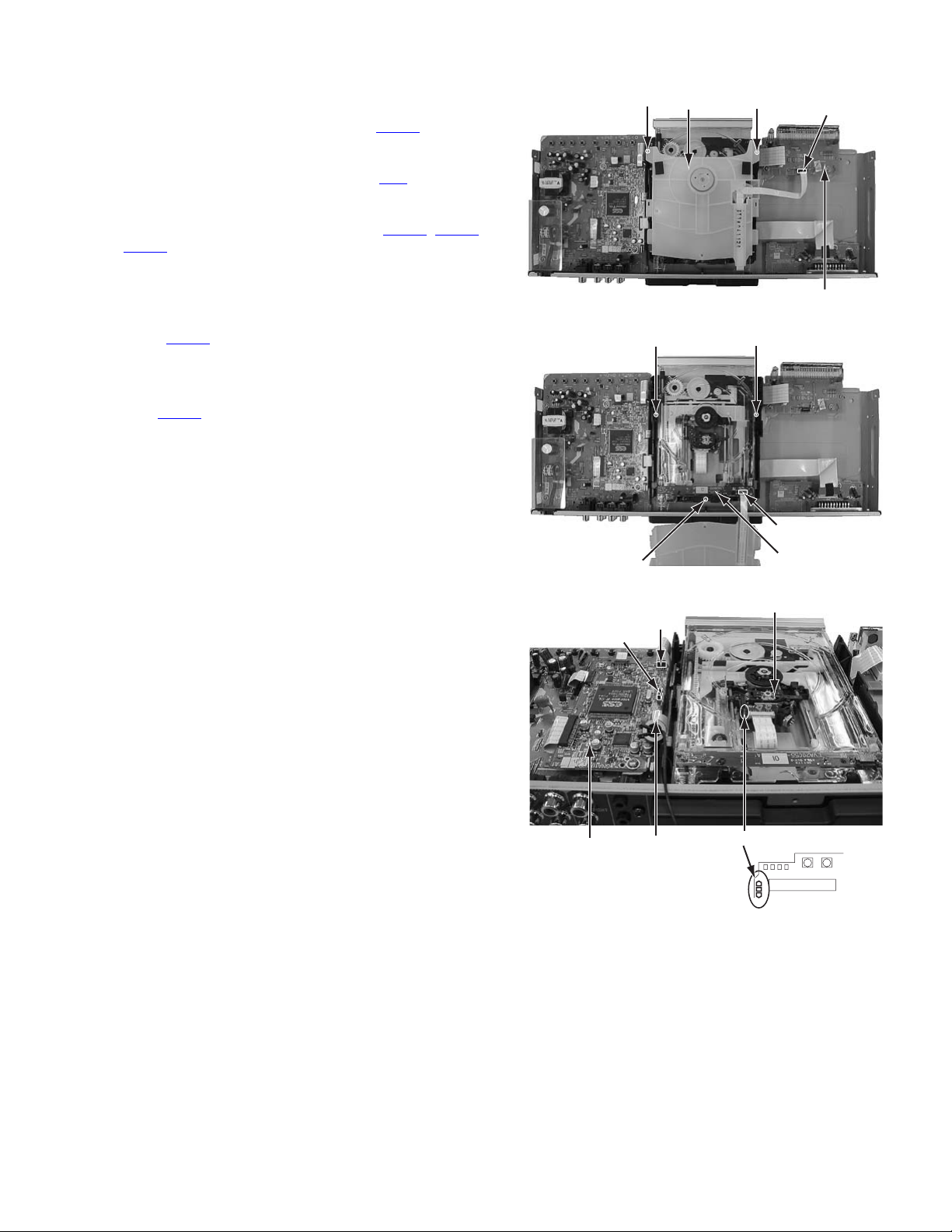

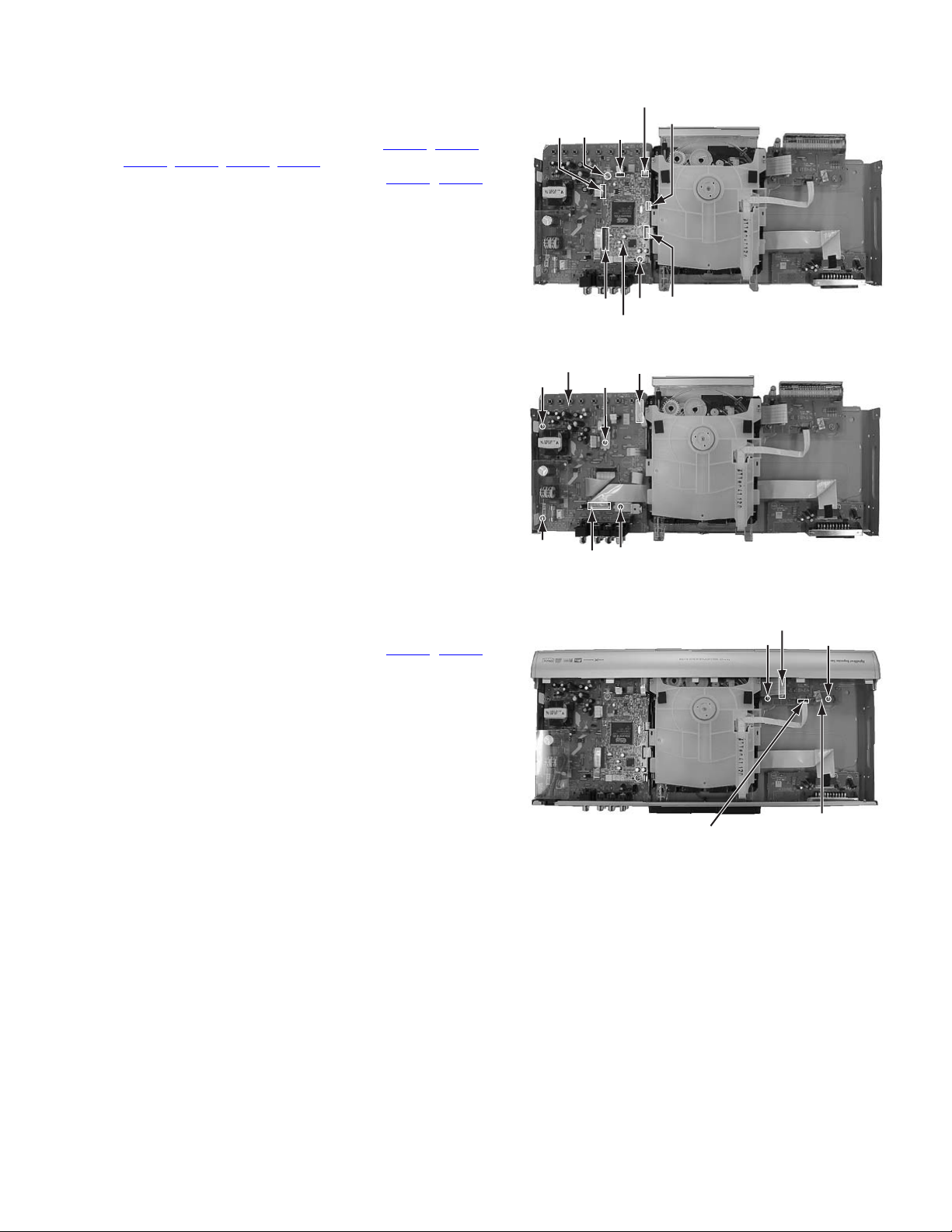

3.1.3 Removing the mechanism assembly (See Figure 3, Figure 4, Figure 5)

• Prior to performing the following procedure, remove the top

cover/front panel assembly.

(1) Disconnect the card wire from connector CN503

Display board.

(2) Remove the two screws D attaching the clamper base.

(3) Disconnect the card wire from connector CN4

board.

(4) It solders to two c sections on the pick-up unit.

(5) Disconnect the card wire from connector CN201

CN101 on the digital board.

ATTENTION:

Please extract the wire after short-circuited of two places

on the pick-up unit in part c with solder. Please remove

the solder two places of part c after connecting the wire

with CN101

CAUTION:

Be sure to solder the short land sections “c” on the pickup unit before disconnecting the card wire from connector CN101

If the card wire is disconnected without attaching solder,

the pick-up unit may be destroyed by static electricity.

(6) Remove the three screws E attaching the mechanism as-

sembly.

(7) Remove the mechanism assembly by lifting the front part

of the mechanism assembly.

when reassembling.

on the digital board.

on the FL

on the LED

, CN202,

CN201

D

Clamper base

E

E

CN202

Fig.3

Fig.4

D

CN503

FL Display board

E

CN4

LED board

Pick-up

CN101Digital board

Part c

Fig.5

(No.YD057)1-9

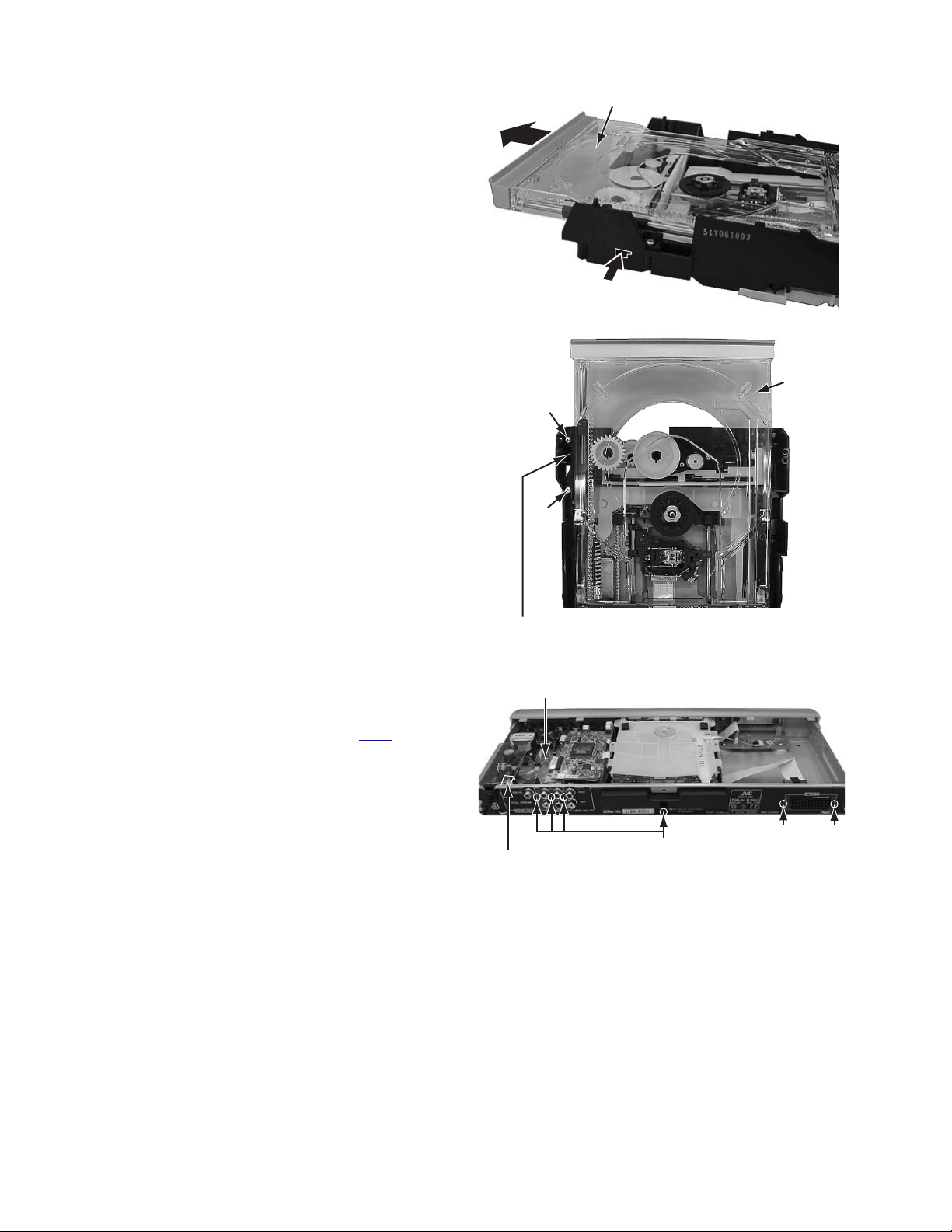

3.1.4 Removing the tray(See Figure 6, Figure 7)

• Prior to performing the following procedure, remove the mechanism assembly.

(1) Insert a kind of screwdriver in a hole located in the right

side of mechanism assembly, and push a lever until it can-

not be inserted any further.

(2) A tray is made to slide ahead.

(3) Remove the two screws F attaching the shaft guide.

Tr ay

Push

Fig.6

Tr ay

F

F

3.1.5 Removing the rear panel (See Figure 8 )

• Prior to performing the following procedure, remove the top

cover.

(1) Remove the six screws G attaching the rear panel.

(2) Disconnect the power cord from connector P901

main board

on the

Shaft guide

Main board

P901

Fig.7

G

Fig.8

G

G

1-10 (No.YD057)

3.1.6 Removing the digital board and main board. (See Figure 9 ,Figure 10)

• Prior to performing the following procedure, remove the top

cover/front panel assembly/rear panel.

(1) Remove the two screws H attaching the digital board.

(2) Disconnect the card wire from connector CN201

, CN301, CN302, CN303 on the digital board.

CN101

(3) Disconnect the card wire from connector CN903

on the main board.

(4) Remove the four screws I attaching the main board.

, CN202,

, CN904

CN301

H

CN202

CN201

CN303

3.1.7 Remove the FL Display board (See Figure 11)

• Prior to performing the following procedure, remove the top

cover.

(1) Disconnect the card wire from connector CN501

on the FL Display board.

(2) Remove the two screws J attaching the FL Dispiay board.

, CN503

CN302

Digital board

Main board

I

I

CN904

I

H

CN903

I

CN101

Fig.10

Fig.9

CN501

J

J

CN503

Fig.11

FL Display board

(No.YD057)1-11

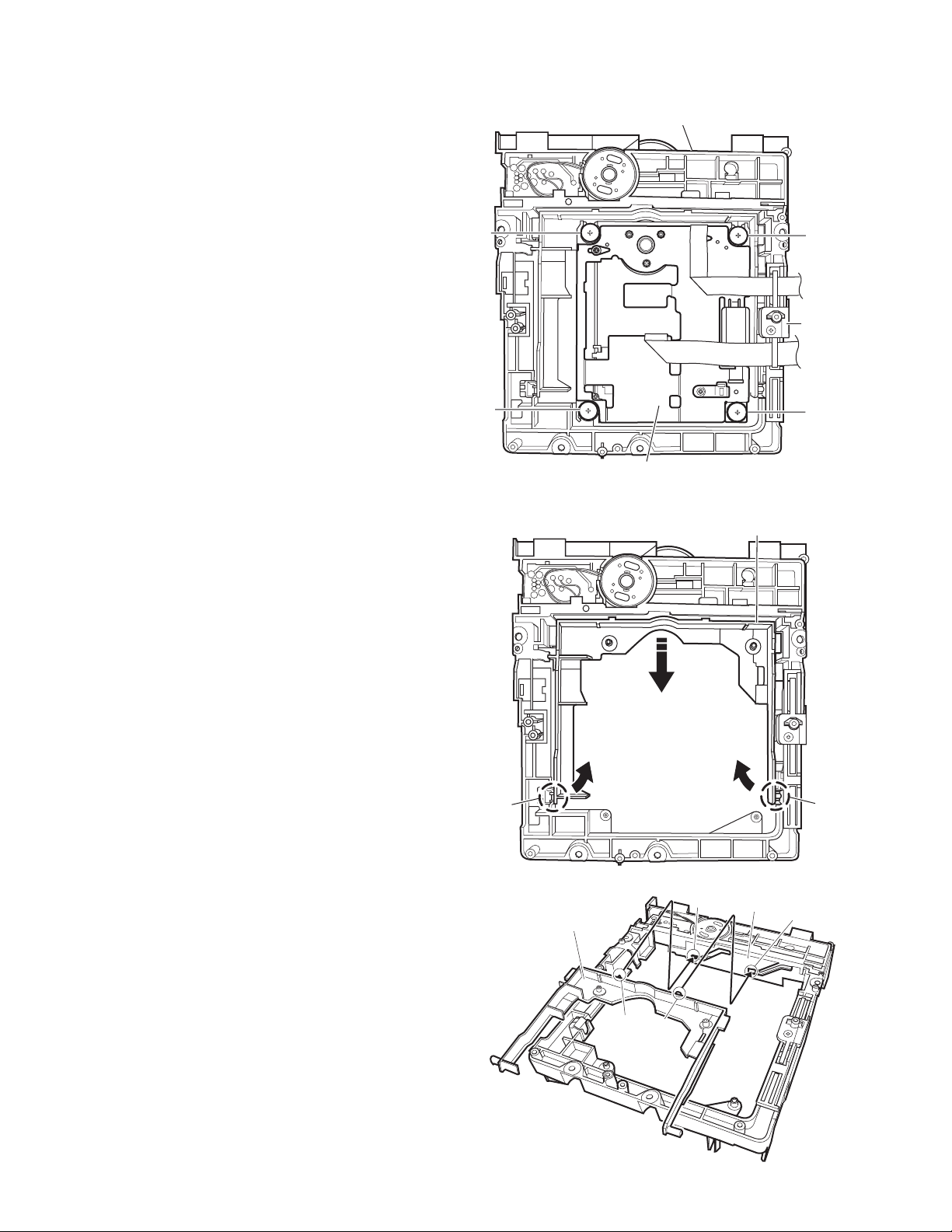

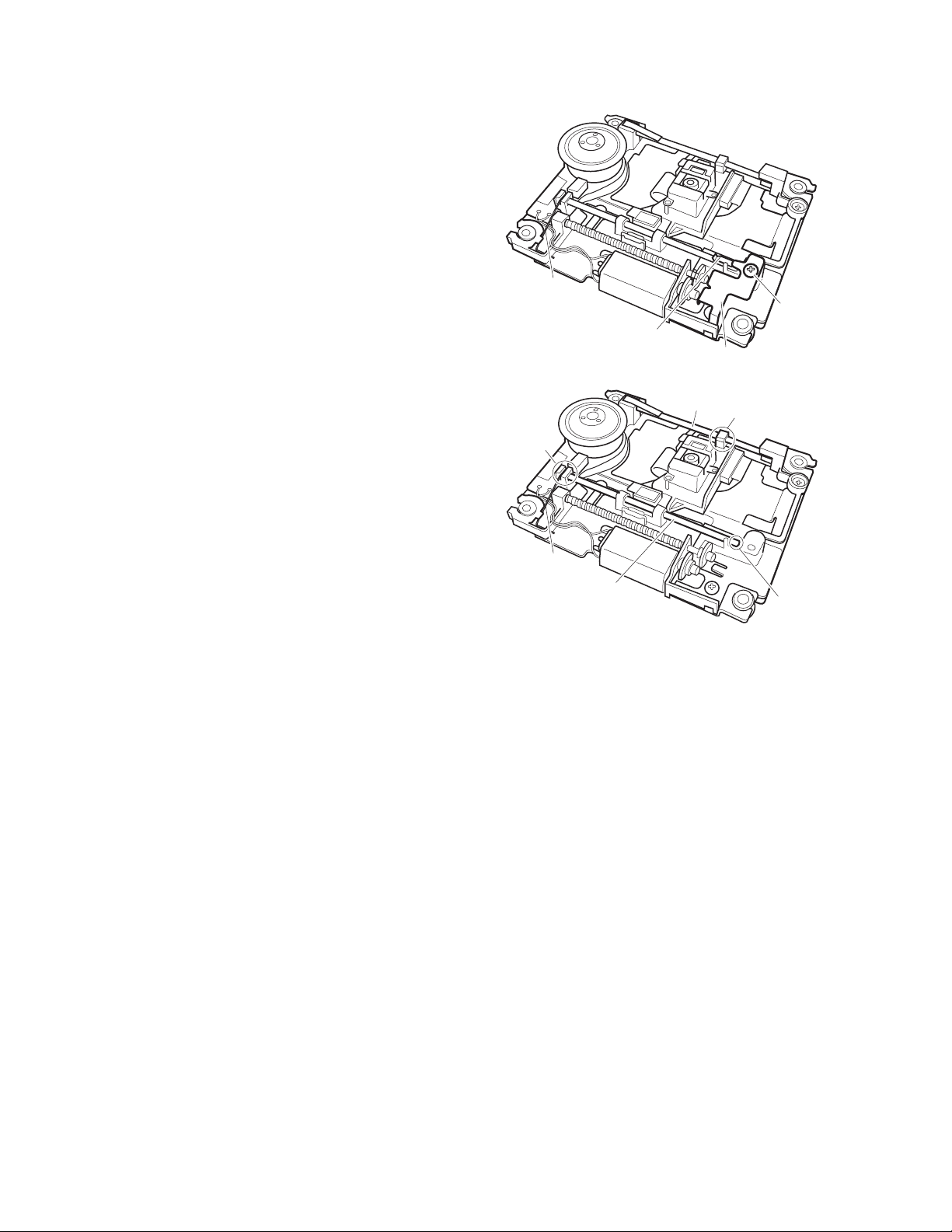

3.2 Loading mechanism assembly

A

Shaft

3.2.1 Removing the traverse mechanism assembly (See Figure 1)

(1) Reverse the loading mechanism assembly.

(2) A card wire is removed from a wire bracket.

(3) Remove the four screws A attaching the traverse mecha-

nism assembly. Remove the traverse mechanism assembly upward.

Loading mechanism assembly

A

wire

bracket

3.2.2 Removing the elevator (See Figure 2 and Figure 3)

• Prior to the following procedure, remove the traverse mechanism assembly.

(1) Remove the two arms of the elevator from the two parts a

by moving the arms in a direction of the arrow.

(2) Pull out the elevator in a rear direction.

Attaching the elevator:

Engage the two holes b to the two shafts on the front part of

the elevator. And then, attach the elevator.

A

Part a

A

Traverse mechanism assembly

Fig.1

Elevator

Part a

1-12 (No.YD057)

Elevator

Shaft

Fig.2

Fig.3

b

Slide cam

b

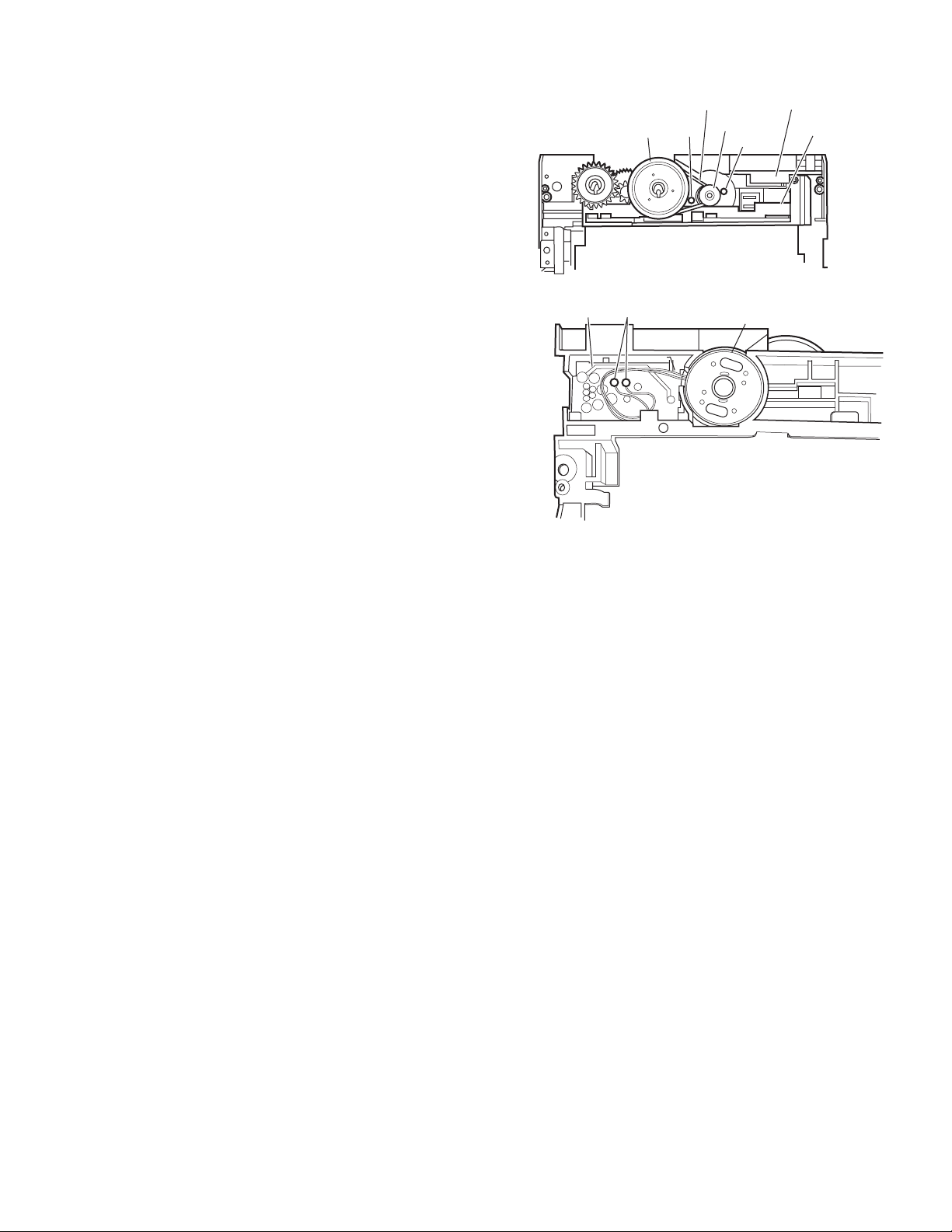

3.2.3 Removing the loading motor (See Figure 4 and Figure 5)

• Prior to the following procedure, remove the tray, the traverse

mechanism assembly, and the elevator.

(1) Remove the belt from the pulley.

(2) Remove two screws B attaching the loading motor.

(3) Remove two solders c on the switch board.

Pulley

Switch board Part

Belt

B

Fig.4

c

Loading base

Pulley

B

Loading motor

Slide cam

Fig.5

(No.YD057)1-13

3.3 Traverse mechanism assembly

3.3.1 Removing the pickup (See Figure 6, Figure 7)

• Prior to the following procedure, remove the traverse mechanism assembly.

(1) Remove one screw C attaching the plate.

(2) Remove the plate and the leaf spring.

(3) Lift d of the shaft 1, and pull out the shaft 1 from e.

(4) Remove f of the pickup from the shaft 2.

Attaching the pickup:

(1) Engage f of the pickup to the shaft 2.

(2) A spring is lifted and shaft 1 is inserted in the e, and at-

tach the shaft 1 to d.

(3) Attach the leaf spring, and then attach the plate. Fix the

leaf spring and the plate by using the screw C.

spring

C

Leaf spring

Plate

Fig.6

Part e

spring

Shaft 2

Part f

Shaft 1

Part d

Fig.7

1-14 (No.YD057)

SECTION 4

ADJUSTMENT

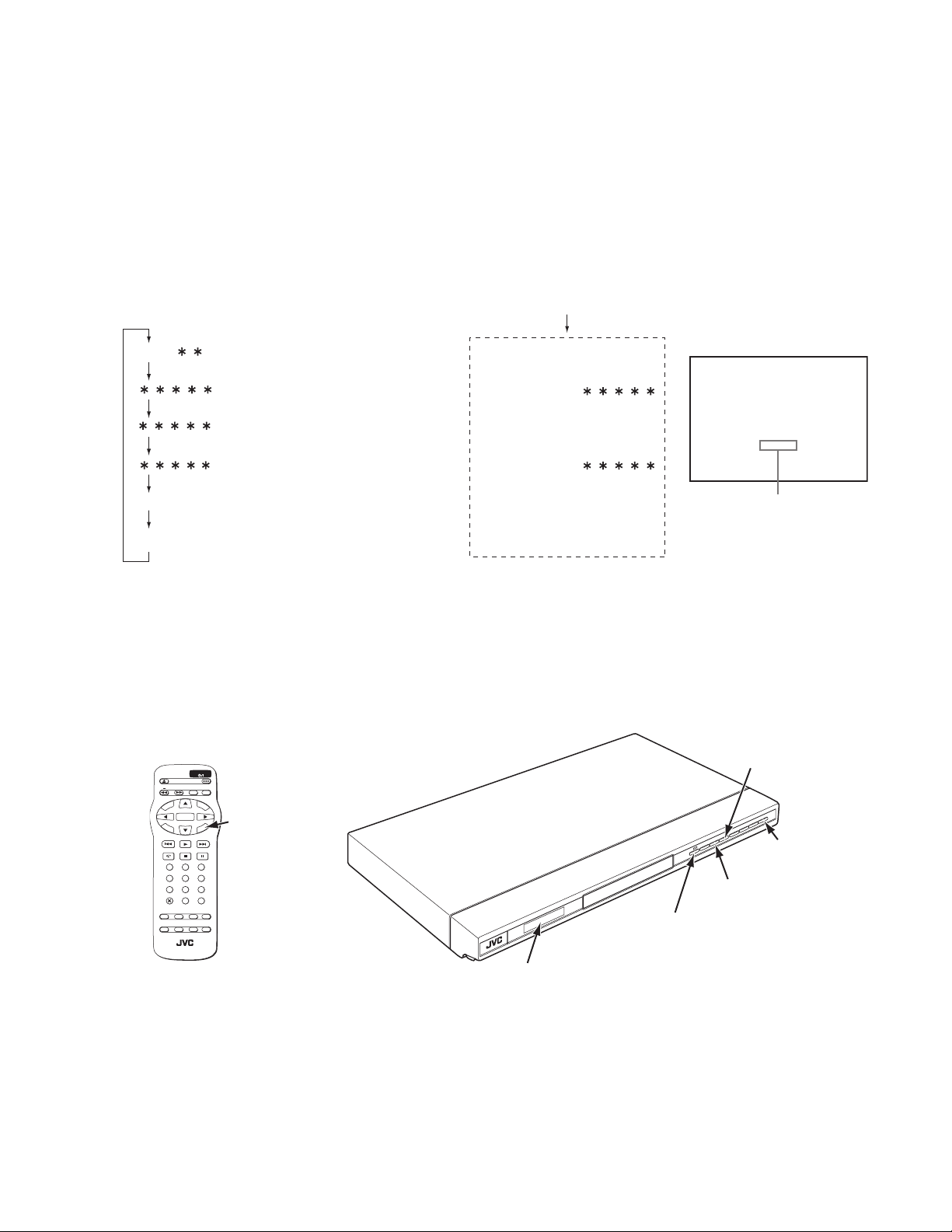

4.1 Test mode setting method

(1) Unplug the power plug.

(2) Insert power plug into outlet while pressing both "PLAY" key and "STOP" key of the main body.

(3) The FL display shows "N420 ∗∗ ", and the main body turns to test mode.

*The portion of "∗∗" changes with destinations.

(4) To release test mode, press "POWER" key of the main body.

NOTE:

Each pressing of "SET UP" key of the remote controller in test mode changes the mode as follows.

Message area of TV screen

N420 ---------------

-------------

-------------

-------------

Becomes test mode ----

Version of backend -----

Type of flash memory

Version of frontend -----

FL Display becomes all lighting

CHCK -------------------

Check mode --------------

TEST MODE

BE VERSION :

FE VERSION :

CHECK MODE

TV screen

TEST MODE

Message area

4.2 Initialization method

Please initialize according to the following procedures in the following case :

• Just after you upgrade the firmware

• After you confirm the symptoms that a customer points out. First initialize, and then confirm whether the symptoms are improved or

not.

• After servicing, before returning the main body to a customer. (Initialized main body should be returned to a customer.)

(1) Set the main body at test mode.

(2) Press "FWD SKIP" key of the main body.

(3) When indicate "P" on the FL display, initialization is completed.

PLAY key

STANDBY/ON

OPEN/

CLOSE

+

SLOW

DISPLAYON SCREEN

T

O

P

M

E

N

U

ENTER

M

E

N

U

SELECT

CLEAR

123

456

789

CANCEL RETURN

0

SOUND

TITLE/

VFP

EFFECT

GROUP DIMMER

I/P

SUBTITLEANGLE

AUDIO

SLIDE EFFECT

T

H

U

M

B

N

A

IL

/

L

IS

T

SET UP key

S

E

T

U

P

(switch of mode)

NEXTPREVIOUS

ZOOM

POWER key

(for test mode)

FWD SKIP key

(for initialize)

STOP key

(for test mode)

FL Display

(No.YD057)1-15

4.3 Upgrading of firmware

The latest firmware for upgrading is updated in "Digital Video Storage" page in JS-NET. At the time of service,compare the version of

the product and the latest version, and upgrade the old version into the latest version.

4.3.1 Distribution method

(1) Compressed file is distributed through JS-NET.

(2) Download the version of the destination of the model, and self-extract the file.

(3) "N420XXXX.rom" file is made.(The portion of “XXXX” may change with a model and destinations.)

(4) Write "N420XXXX.rom" file in the root of CD-R/RW. (Folders such as jvc_dvd are not necessary.)

4.3.2 Upgrade method

(1) Prepare upgrade disc with "N420XXXX.rom" file written in its root.

(2) Press "POWER" key of the main body to turn the main body on.

(3) Insert the upgrade disc.

(4) The contents of disc are read automatically and upgrade is started.

(5) TV screen 1/28,2/28... if the count-up is displayed and it becomes 28/28, it will be displayed on FL display as "DONE", and up-

grade will be completed.

(6) When upgrade finishes, the main body changes from the POWER ON mode to STANDBY mode.

(7) Press the "OPEN/CLOSE" key, and open the tray to eject the disc.

(8) Set the main body at test mode, and perform initialization. Then, confirm the version of the firmware.

1-16 (No.YD057)

4.4 Confirm method of operation

Please confirm the operation of the undermentioned item after doing the repair and the upgrade of the firmware.

Initialize Refer to the initialization method.

Muting working The noise must not be had to the performance beginning when you push "PLAY" button or

at ON/STANDBY.

FL Display The mark and the logo, etc. displayed by each operation must be displayed correctly.

FL Display should light correctly without any unevenness.

All Function button All function buttons should worked correctly with moderate click feeling.

Open and close movement of tray When press OPEN/CLOSE button the tray should move smoothly without any noise.

Remote controller unit working Check the correctly operation in use of remote controller unit.

Reading of TOC Be not long in the malfunction.

Search Both forward-searches and backward-searches should be able to be done.Do not stop be

searching or after the search.

Skip Both forward-skip and backward-skip should be able to be done.Do not stop be after the skip.

Playback Do not find abnormality etc. of tone quality and the picture quality.

Most outside TITLE playback check Play VT-501 TITLE 59 CHAPTER 1 , check normal playback.

(No.YD057)1-17

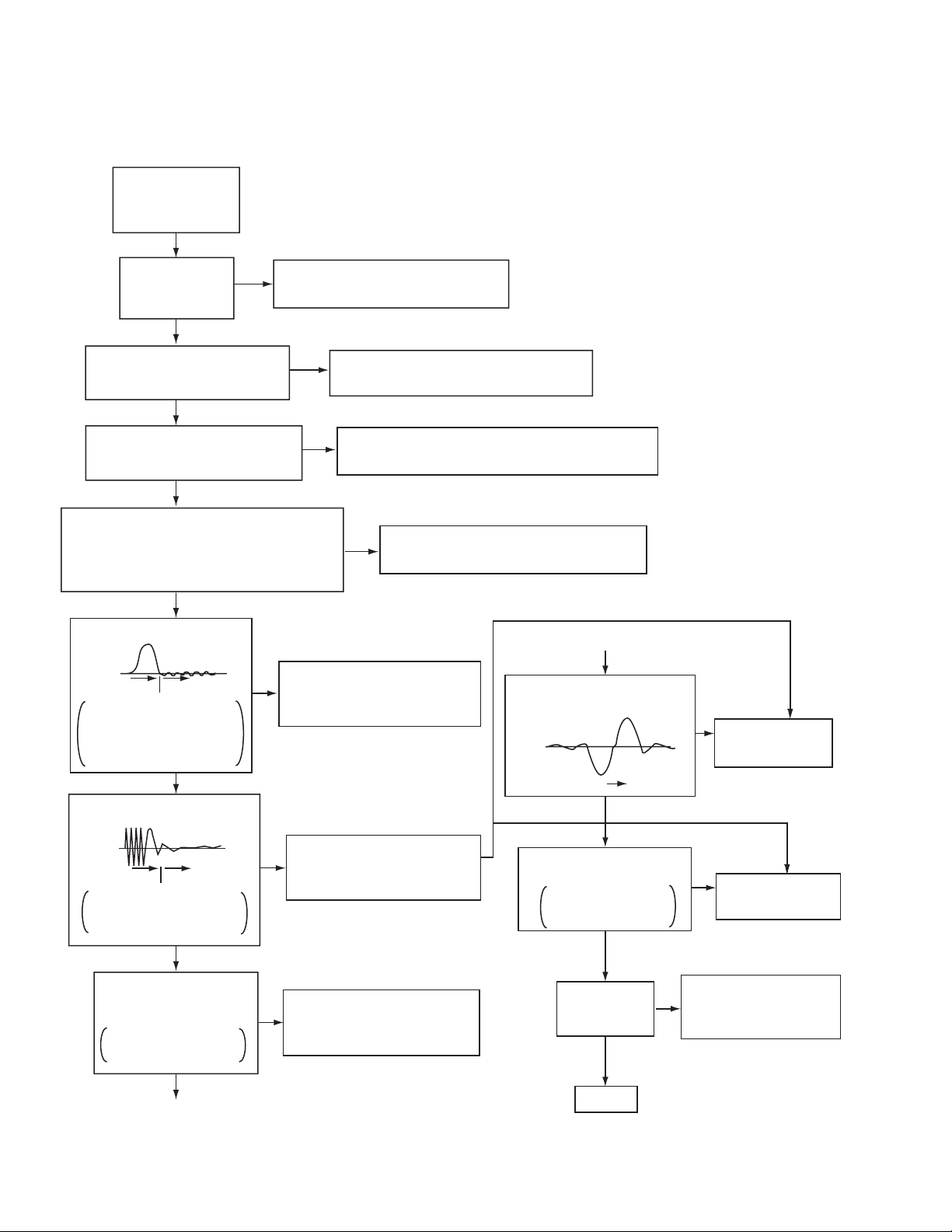

5.1 Servo volume

Press OPEN

/CLOSE key

SECTION 5

TROUBLESHOOTING

Is tray

operation

Confirmation of tray drive circuit

N

and circuit in surrounding

correct?

Y

Is the traverse moving

along the innermost

N

perimeter for SW detection?

Y

"NO DISC" message appears

Y

immediately after vertical

movement of the pick-up lens

N

The state that DISC does not rotate continues for

several seconds, and becomes NO DISC or an

error display afterwards.

The rotation of DISC becomes high-speed and

abnormal, and becomes NO DISC or an error

display afterwards.

N

Is focus retraction OK?

FE

OFF

Even when it retracts

correctly, if it is out of focus

and makes repeated retries

with a clicking sound, it is

in error.

ON

See "(4) Focus ON error"

N

in "Check points for

individual errors"

Y

Is tracking retraction OK?

See "(3) Traverse movement error"

in "Check points for individual errors"

See "(2) Disk detection, distinction error"

in "Check points for individual errors"

Y

See "(1) Spindle startup error"

in "Check points for individual errors"

Is the inter-layer jump OK?

FE

LO LI

A

Two layers of DVD only.

N

(8) Inter-layer

jump error

Y

TE

OFF

If TE waveform reappears

or fails to converge after the

TE retraction, it is in error.

Is the spindle servo

locked correctly?

Is the RF OUT waveform

locked correctly?

1-18 (No.YD057)

ON

A

See "(5) Tracking ON error"

N

in "Check points for

individual errors"

Has the disc information

been collected?

Stop will result

N

(7) Address read

error

Y

Y

Check (9),(10),(11), and

See "(6) Spindle CLV error"

N

in "Check points for

individual errors"

Is playback

possible?

Y

N

(12) items in "Check points

for individual errors"

Y

OK !

Fig.1

5.2 Check points for each error

5.2.1 Spindle start error

(1) Defective spindle motor

• Are there several ohms resistance between each pin of CN201

(The power supply is turned off and measured.)

(2) Defective spindle motor driver (IC201

• Has motor drive voltage of a sine wave or a rectangular wave gone out to each terminal(UOUT,VOUT,WOUT)

of CN201

• Is FG pulse output from the terminal of IC201"41"(FG) according to the rotation of the motor?

(3) Has the control signal come from the microcomputer?

• Is it "H" while the terminal of IC201

• Is the control signal input to the terminal of IC201"25"(SPDRV)?

• Is the SVREF voltage input to the terminal of IC201

(4) Is the FG signal input to the servo IC?

• Is FG pulse input to the terminal of IC301

5.2.2 Disc Detection, Distinction error (no disc, no RFENV)

• Laser is defective.

• Front End Processor is defective (IC101

• APC circuit is defective. --- Q101, Q102.

• Pattern is defective. --- Lines for CN101

• IC101 --- For signal from IC101 to IC301, is signal output from IC101 "40" (FE)?

5.2.3 Traverse movement NG

(1) Defective traverse driver

• Has the voltage come between terminal of CN201

(2) Defective BTL driver (IC201)

• Has the motor drive voltage gone out to IC201"11" or "14"?

(3) Has the control signal come from the microcomputer?

• TRSDRV Is the signal input? (IC301

(4) TRVSW is the signal input to microcomputer? (IC301 "177")

5.2.4 Focus ON NG

• Is FE output ? --- Pattern, IC101

• Is FODRV signal sent ? (R275) --- Pattern, IC301 "160"

• Is driving voltage sent ?IC101 "3", "4" --- If NG, pattern, driver, mechanical unit .

• Mechanical unit is defective.

5.2.5 Tracking ON NG

• When the tracking loop cannot be drawn in, TE shape of waves does not settle.

• Mechanical unit is defective.

Because the self adjustment cannot be normally adjusted, the thing which cannot be normally drawn in is thought.

• Periphery of driver (IC201

Relative component or IC it self is defective.

• Microcomputer (IC301

When improperly adjusted due to defective IC.

"2,3,4" and IC201"19,18,17"?

)

)

)

"48"(MUTE1) is operating?

"26"(VREF)?

"175"(FGIN) according to the rotation of the motor?

).

- All patterns which relate to pick-up and patterns between IC101

"7" and "8" ?

"161")

"2-3","3-4","2-4"?

(No.YD057)1-19

5.2.6 Spindle CLV NG

• IC101

• Does not the input or the output of driver's spindle signal do the grip?

• Has the tracking been turned on?

• Spindle motor or driver is defective.

• Additionally, "IC101

5.2.7 Address read NG

• Besides, the undermentioned cause is thought though specific of the cause is difficult because various factors are thought.

5.2.8 Between layers jump NG (double-layer disc only)

• Mechanism defective

• Defect of driver's IC(IC201

• Defect of microcomputer(IC301

5.2.9 Neither picture nor sound is output

5.2.10 Picture is distorted or abnormal sound occurs at intervals of several seconds.

• Is the feed operation normal?

• Are not there caught of the feeding mechanism etc?

5.2.11 Others

• The image is sometimes blocked, and the image stops.

• The image is blocked when going to outer though it is normal in surroundings in the disk and the stopping symptom increases.

There is a possibility with bad jitter value for such a symptom.

5.2.12 CD During normal playback operation

-- "55"(DIN), "54(DIP).

and IC301" and "Mechanism is defective(jitter)", etc. are thought.

Mechanism is defective. (jitter)

IC301

The disc is dirty or the wound has adhered.

)

)

(1) It is not possible search

• Has the tracking been turned on?

• To "(5.2.5) Tracking ON NG" in "Check points for each error" when the tracking is not normal.

• Is the feed operation normal?

To "(5.2.3) traverse movement NG" in "Check points for each error" when it is not normal.Are not there caught of the feeding

mechanism etc?

(1) Is TOC reading normal?

• Displays total time for CD-DA.

• Shifts to double-speed mode for V-CD

(2) Is playback afterwards possible?

(3) When can not do a normal playback

• --:-- is displayed during FL search.

According to [It is not possible to search ] for DVD(9), check the feed and tracking systems.

• No sound is output although the time is displayed.(CA-DA)

DAC, etc, other than servo.

• The passage of time is not stable, or picture is abnormal.(V-CD)

• The wound of the disc and dirt are confirmed.

1-20 (No.YD057)

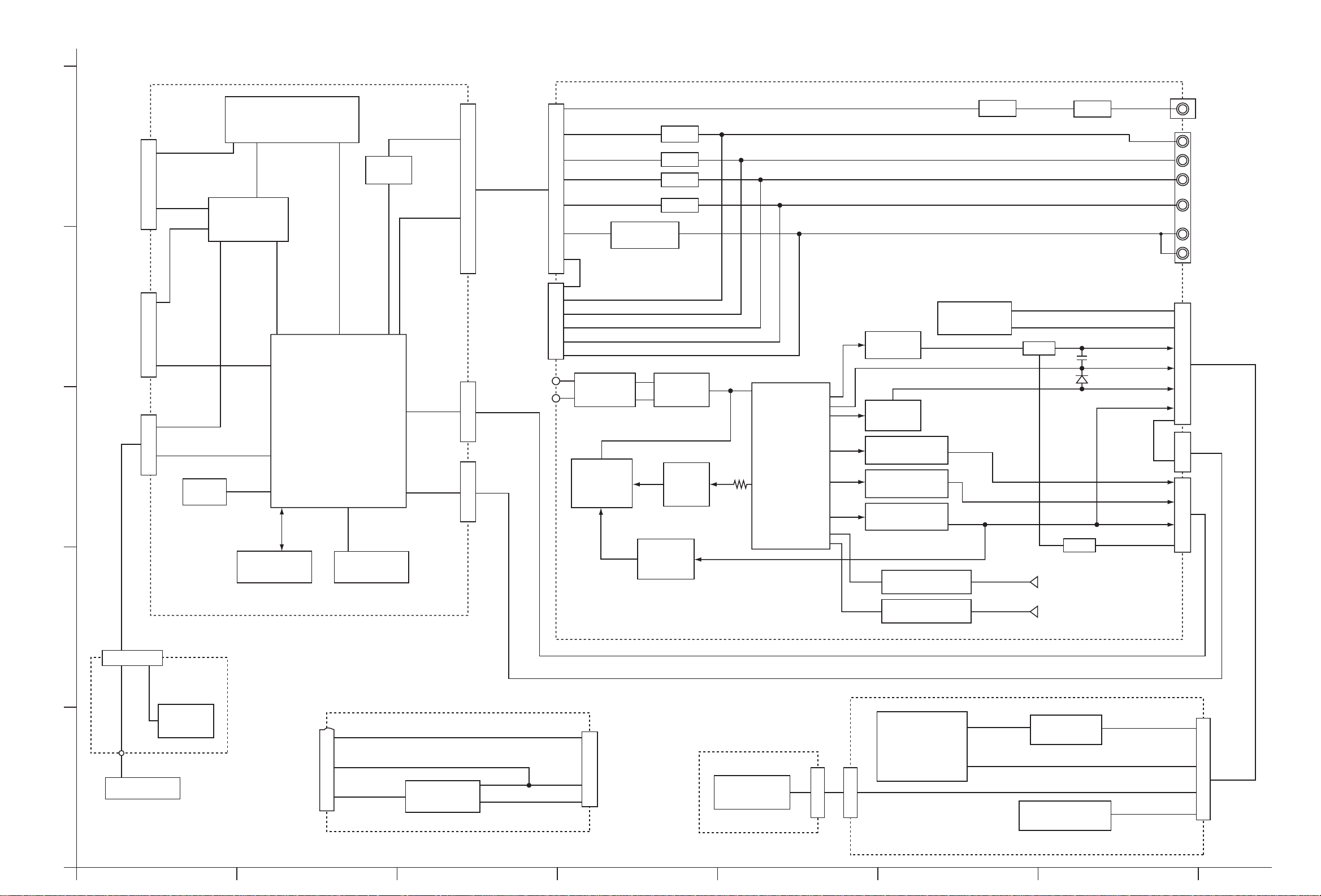

Block diagram

5

4

Spindle motor

3

2

FROM

Pick-up

Unit

FROM

assembly

A B C D E F RF

CN101

CDPD DVDPD

T+ TF+ F-

WOUT

VOUT

UOUT

COM

FM+

FM-

CN201 CN202

TRVSW

CLOSESW OPENSW

LM+

LM-

X301

FEP

(Front end processor)

IC101

SVREF

4CH Driver

IC201

FODRV

TRDRV

TRSDRV

OPEN

FG SPDRV

RPBC

AMPSTBY

(

Super optical disc controller

VID_XO

VID_XI

64M SDRAM

IC302

DFCT

BSUM

FE CE

MINTR

SCLK

S DATA

SDEN

INB IN

TE

SODC

and

AV Decoder

IC301

LA0 to LA20

LWRL LOE

LCS3 LD0 to LD7

Flash ROM

AOUTL+ AOUTR+

2CH DAC

IC403

)

IC303

SPDIF

AOUTLAOUTRYOUT

Cb/Pb

Cr/Pr

C/Cv/Y

S1(FUNCTION)

BLANKING

RGB(VIDEOSW)

STBY

REMO

FLDIN

CLK

STB

CN302

CN301

CN303

TO CN702

SHEET 3

AC IN

CN905

AOUTL+/AOUTR+/-

CN904

PbOUT

PrOUT

C/Cv/Y

BLANKING

FUNCTION

VIDEOSW

Line filter

L901

Switching

regulator

IC901

Y

OP.Amplifier

IC701

FEED BACK

PC901

L706

L730

L709

L701

Y/G

Pb/B

Pr/R

Cv/Y

LCH RCH

AC-DC

D903

AC-DC

D906

C909

Power

transformer

T901

AC-DC

D951,C950

AC-DC

D952,C982

AC-DC

D955,C954,L952

AC-DC

D954,C955,L953

AC-DC

D953,C983,L951

AC-DC

D956,L954,C957,C985

AC-DC

D957,L955,C956,C966

SPDIF

Operation switch

S501 to S508

IC704

-12V

+12V

Q951

Q952

L707

SG1 to SG4

AUDIOL/R

K1,K2

-VDISP

B3.3V

REMO

FLDIN

CLK

STB

B5.7V

M9V

B3.3V

STBY

F+

F-

Pb

J602

Coaxial digital

output

J601

Y

Component

Pr

video output

Composite

video output

Analog

audio output

CN901CN902CN903

CN1

Tray switch

S1

Scart terminal

1

Loading motor

A

LCH RCH Pr/R Pb/B FUNCTION BLANKING

Y/G

CN702

TO CN904

SHEET 2

Tray illumination

2-1 2-2

D1 D2

CN4

CN503

J702

G

2IN-1OUT SW

Y/COMPOSITE

IC703

Cv/Y VIDEOSW

BCD EFG

FL Display driver

IC501

GR1 to GR7

SG1 to SG9

K1 K2 SG1 to SG4 -VDISP STB FLDIN CLK

FL Display

DI501

Remote controller

IC502

F+ F-

CN501

REMO

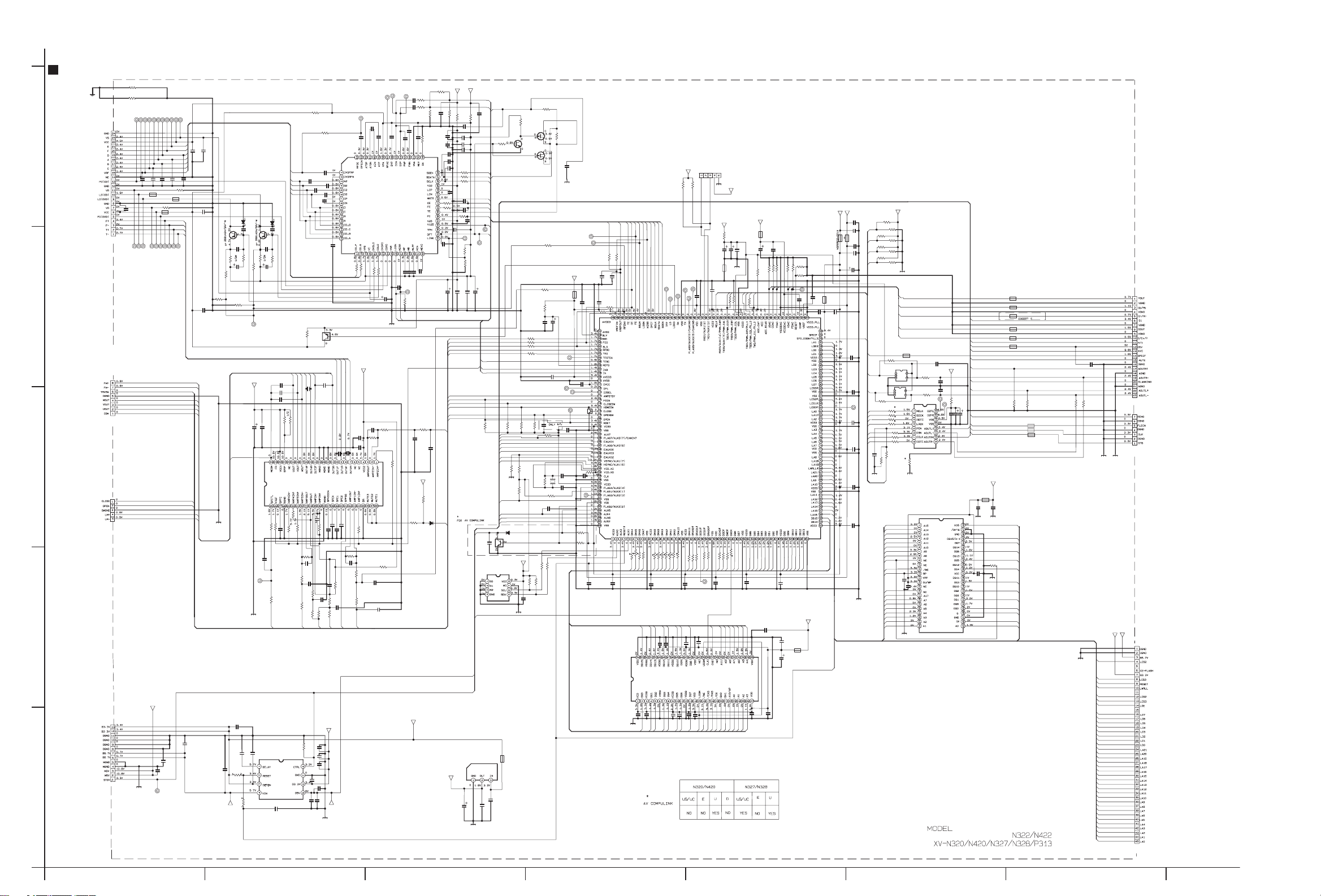

Standard schematic diagrams

Servo control section

5

To pick-up

unit

4

To Spindle motor

assembly

3

TO CN1

SHEET 4

2

TO CN901

SHEET 2

1

QGF1044F1-13X

CN101

QGF0536C1-24W

CN201

QGF1007C2-08X

CN202

QGF1007C2-05X

CN301

R145

0

R146

0

TP1

TP3

TP4

TP5

TP6

TP11

TP7

TP8

TP9

TP2

C132

K102

C131

470p

TP14

TP15

MGND

TP10

E

F

D

C102

C101

0.1

0.1

A

B

C

RF

C136

C135

C133

C134

NI

NI

NI

NI

NI

TP16

100

R102

0

0

K103

R101

100

NQR0022-005X

K101

TP18

TP19

M9V

C422

TP94

C103

0.1

F+

FT+

T-

TP20

TP21

TP22

TP23

TP24

C108

NI

FM+

FMTRVSW

WOUT

VOUT

UOUT

COM

CLOSESW

OPENSW

LM+

LM-

C380

0.1

C423

0.1

0.1

R103

NI

DGND

C961

1.0

Q101

2SB1424/R/-W

C104

10

R106

33K

R105

R104

10K

COM

C381

0.1

R361

4.7K

B5.7V

D102

NI

C137

1000P

2SB1424/R/-W

NI

R109

0

R107

33K

C106

47/6.31047/6.3

R108

TP93

M9V

NI

C263

TP100

MGND

C373

C375

0.1

0.01

1K

R365

Q102

NI

C105

R110

C107

C260

C261

C262

0.1

C217

0

R257

0.015

C290

R208

SPDRV

MM1688BHBE-X

C374

0.01

0

R259

10K

IC961

RF

A

B

C

D

D103

NI

C138

1000P

VOUT

UOUT

0.022

0.022

0.022

2.2

0.47

R251

R252

10K

R209

0

10K

R221

0.1

R291

C256

R213

R278

680P

R124

WOUT

6.8K

10K

C211

0.022

R214

NI

R216

R215

TRSDRV

R319

C971

1.0

C109

LM+

C275

8.2K

0

C111

C277

NI

NI

NI

R125

C110

NI

LM-

LA6502-X

NI

680P

IC201

C943

D5V

D3.3V

TP48

TP49

TP47

NI

TP150

R142

0

C140

680P

680P

680P

C112

C113

100P

C141

680P

R118

Q103

RT1P141C-X

F+

T+

T-

F-

FM-

FM+

C203

NI

C202

C201

NI

NI

C210

1

0.01

0.015

0.47

0.015

6.8K

C257

C259

R225

C258

C251

R207

C206

2200P

C207

10K

R212

C209

18K

C208

NI

R211

NI

NI

0

R276

R210

OPEN

FG

RPBC

D3.3V

0.1

C914

0.1

C913

0.1

C912

1

C915

0.1

0.1

D5V

C916

DGND

C264

NI

R205

R275

100

F

C204

0.1

R220

47K

NI

FODRV

RFO

DIN

DIP

RFDC

C114

4700P

R117

100

E

B5.7V

C205

15K

5.1K

22K

0.1

C115

0.1

0.1

0.1

0.1

C117

C118

C116

IC101

ES6602

1K

8200P

1K

R116

R115

C183

NI

C173

47/6.3

R112

MIRR

LDONJ

DGND

R204

120P

22K

R206

30K

15K

R219

R217

4.7K

C273

560P

C274

560P

R126

NI

R174

C181

0

0.1

R175

C182

0.1

0

4.7K

R127

R128

C965

0.1

C152

0.01

0.1

12K

C119

C153

C120

R111

0.1

C146

33P

33P

33P

R137

R138

NI

3.3K

3.3K

C143

NI

160P

C127

8200P

0.22

C130

C129

C128

TP50

4.7K

R273

3.3K

B3.3V

47/4

C126

R271

TRDRV

36K

560P

C272

560P

C271

B5.7V

10K

R274

D271

AMPSTBY

MA111-X

B1.8V

4.7K

R113

C149

C147

C148

C121

C122

0.1/16

C125

SPDRV

FODRV

TRSDRV

RPBC

TRDRV

AMPSTBY

FG

CLOSESW

TRVSW

OPENSW

OPEN

C401

47/4

1

1000P

R134

33

33

33

0.047

NI

1000P

R139

0.1

TP132

R140

R141

D5V

STBY

1

R114

C154

0.1

C155

0.1

C156

0.1

R135

R136

C145

C144

C180

1000P

TP131

4.7K

4.7K

0.1/16

47/6.3

C124

C123

SVREF

LM1117MP1.8-X

DGND

TP151

SDEN

SDATA

MINTR

SVREF

AVC

C371

STBY

IC401

INB

IN

TE

C978

0.1

R130

5.1K

2SD1623/ST/-X

TEBC

SCLK

CE

FE

BSUM

DFCT

TEBC

INB

IN

20K

R391

R255

CLK

MUTE

DCOTI

DCLK

DACCS

DACDENA

S1

RGB

R364

DGND

BLANKING

REMO

STB

FLDIN

D301

MA111-X

330P

Q301

UN2214-X

IC304

NI

DGND

K401

NQR0502-001X

C405

C402

0.1/16

0.1/16

3.3K

R132

5.1K

R131

Q131

R302

NI

R355

Q132

0

0

0

0

4.7K

R395

NAX0770-001X

NI

R357

NI

R356

SCL

SDA

NI

R133

CN310

D3.3V

1000P

C151

DGND

CE

TE

FE

BSUM

SDEN

SDATA

MIRR

SVREF

SCLK

MINTR

TP310

R313

R321

NI

R301

0.1

C319

C385

C310

4.7K

100K

R312

1000P

TP311

0

B3.3V

K321

NQR0502-001X

4.7K

47/4

C320

TP301

0.1

C336

TP302

TP303

TP153

KRC107S-X

0.1

R320

C337

0.1

C322

C324

12P

NI

X301

C323

12P

R384

NI

C321

R378

NI

R379

NI

NI

R358

NI

R316

R308

C317

C357

1

0.1

0.1

0.1

C318

R317

C351

R318

0

NI

0.1

Q302

R311

33

TP312

C353

C358

470P

0.1/16

DFCT

LDONJ

39K

TP304

TP306

TP305

100

100

R350

MA4

DGND

100

100

R348

R349

MA5

C306

100

100

100

100

100

100

R341

R347

R345

R342

R344

R346

R343

MA7

MA3

MA9

MA2

MA6

MA8

MA1

MA0

C325

0.1

DB15

DB14

DB13

DB12

DB11

NI

470p

C361

C304

NI

C368

C367

470p

470p

DB4

DB0

DB1

DB2

DB3

NI

D5V

DGND

NI

R393

R394

NI

D3.3V

NI

R315

33

R333

/DOE

C333

/RAS2

MA9

NI

NI

R396

AOUTR

33

R332

/WE

MA8

MA10

K331

C339

C331

100/4

0.1

AGND

NI

R322

TBCK

LRCLK

0

R314

1K

TSD0

TSD1

R398

0

AOUTL

360

R331

DB2

DB3

DB4

DB5

DB6

DQM

DB7

C328

0.1

C363

0.1

MA4

MA7

MA6

MA5

C365

470p

MA0

MA1

MA2

MA3

TP307

100

R340

MA10

C326

DB10

DB9

C362

K4S641632H-UC75

NI

C307

DB5

DB6

D3.3V

C330

NI

K311

TP98

C334

0.1

TP97

0.1

MCLK

C335

IC301

ES6802

33

33

100

33

33

33

R338

R337

R336

R335

R339

R334

/CAS

/CS0

/RAS0

/RAS2

MA11

/RAS1

C327

0.1

TP309

0.1

DB8

MA11

/DOE

C305

NI

470p

IC302

C366

NI

C308

470p

DQM

/WE

/CAS

/RAS0

/CS0

/RAS1

DB7

Refer to the "E" in a table

NQR0251-001X

C340

0.1

82

68

82

R330

R327

R326

Cr/Pr

YOUT

Cb/Pb

DB1

DB0

C344

47/4

NI

C309

DB8

C329

0.1

C364

0.1

82

68

R307

4.7K

R360

R328

R329

390

TP346

COUT

C/Cv/Y

DB12

DB11

DB10

DB9

K306

NQR0502-001X

B1.8VB3.3V

C342

0.1

C370

0.1

K304

K303

C341

0.1

C369

470P

C379

C376

C377

0.1

K305

0.1

NQR0502-001X

C332

C343

0.1/16

470P

SPDIF

LA1

LOE

LD0

C311

LD1

0.1

LD2

LD3

LD4

LD5

LD6

LD7

C312

LCS3

0.1

LCS2

TP308

LA0

LA17

C313

LA2

0.1

LA3

LA4

LA5

LA6

C314

LA7

0.1

LA8

LA18

LA19

LWRLL

LA21

LA20

LA9

C315

LA10

0.1

LA11

LA12

LA13

LA14

LA15

LA16

DB15

C349

DB14

0.1/16

DB13

DGND

B3.3V

RESET

B3.3V

R399

NI

R371

AOUTL

1K

R372

NI

R373

TSD1

1K

R374

NI

R375

TSD0

1K

R376

NI

R377

SPDIF

1K

DGND

NI

DGND

SPDIF

AOUTR

AOUTL

MCLK

TBCK

TSD0

LRCLK

R403

DACCS

DCLK

DCOTI

C421

470P

R423

R404

NI

R413

R414

R415

R417

R418

R419

3.3K

DACDENA

LA16

LWRLL

R412

R420

100

LA15

LA14

LA13

LA12

LA11

LA10

LA9

LA20

RESET

LA19

LA18

LA8

LA7

LA6

LA5

LA4

LA3

LA2

YOUT

Cb/Pb

Cr/Pr

COUT

C/Cv/Y

NQR0251-001X

K333

NI

C406

IC406

NI

NI

R362

IC407

470

470

470

470p

C407

NI

C408

NI

R363

TP56

IC403

AK4385ET-X

470

33

33

33

0

R406

DGND

C391

C392

DGND

IC303

NI

0.1

D5V

NI

NI

R402

TP55

10

0.1

C417

C440

AOUTL+

AOUTR+

MBM29LV160TE70

220/6.3

C418

220/6.3

S1

RGB

D5V

AVC

MUTE

AOUTR+

BLANKING

AOUTL+

REMO

FLDIN

CLK

STB

K307

C350

0.1

DGND

C352

0.1

NQR0360-002X

K371

NQR0251-001X

K372

NQR0360-002X

K373

NQR0251-001X

K374

K375

NQR0251-001X

NQR0251-001X

K332

TO CN905

SHEET 2

0.1

C382

R353

R352

R351

NI

NI

NQR0251-001X

K376

K377

NQR0251-001X

NQR0251-001X

K378

B3.3V

0

C355

NI

DGND

LA17

LA0

LD7

LD6

LD5

NI

R367

LD4

LD3

DGND

LD2

LD1

LD0

LOE

LCS3

LA1

0

DGND

R354

0

CN302

QGF1016F2-23W

TO CN502 or CN902

SHEET 2

CN303

QGF1044F1-07X

AGND

DGND

B3.3V

B5.7V

LCS2

LCS3

RESET

LWRLL

LCS2

LCS3

LOE

LD7

LD6

LD5

LD4

LD3

LD2

LD1

LD0

LA21

LA20

LA19

LA18

LA17

LA16

LA15

LA14

LA13

LA12

LA11

LA10

LA9

LA8

LA7

LA6

LA5

LA4

LA3

LA2

LA1

LA0

Not use

gns10031001a1_rev0

CN404

NI

SHEET 1

Q130

2SK3019-X

2SK3019-X

R303

R304

R305

4.7K

4.7K

R392

0

NI

R366

NI

R383

B3.3V

NI

C372

A

BCDEFG

2-3 2-4

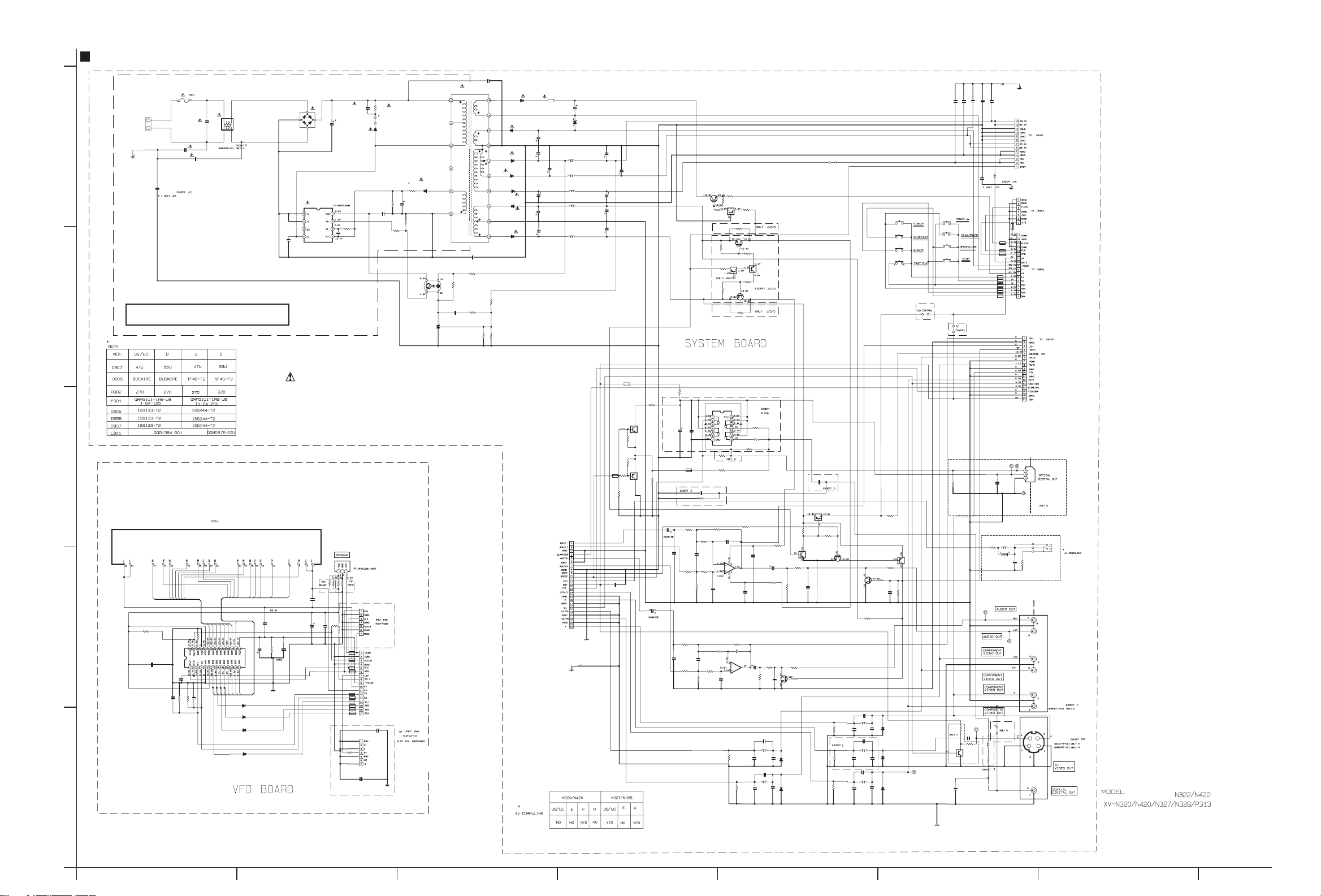

Power supply and AV output terminal section

!

FC901

QNG0019-001Z

P901

QGA7901C1-02

5

C980

NQR0129-002X

C903

100P

FC902

QNG0019-001Z

!

!

!

C904

NI

C901

0.082

QQR1384-001

!

D903

!

L901

DI106

C907

47/200

!

IC901

MIP2C40MP

R903

C911

390K

C908

22P

0.0022

4

DANGEROUS VOLTAGE

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

Refer to the "E" in a table

3

QLF0158-001

0

0

NI

NI

R514

R512

R515

SG9

SG6

SG8

SG4

SG3

SG2

SG5

GR6

GR7

GR4

GR3

GR5

GR1

GR2

2

R502

10K

C502

0.1

C509

4700p

R503

C504

PT6315-S

NI

2.2k

R510

C510

4700p

2.2k

R504

SG7

GR1

SG9

GR6

GR7

GR3

GR5

GR2

GR4

100K

IC501

SG6

SG1

SG4

SG5

SG7

SG8

SG2

SG3

D504

1SS133-T2

D505

1SS133-T2

D506

1SS133-T2

D507

1SS133-T2

SG1

C511

0.1

100/6.3

C508

R508

C505

0.022/50

NI

22K

DGND

1

R513

C515

0.1

C507

C506

R509

0.1

0

K511

NQR0251-001X

K512

K513

K514

K515

K516

K517

K518

K519

K520

R910

56

!

C906

1000P

IC502

QAL0552-001

CN502

QGF1036C1-07

0

0

0

0

0

0

0

0

0

CN501

QGF1208C1-17

CN503

QGF1036C1-07

C501

0

!

R901

68K

D905

!

D902

1F4G-T2

R904

18K

C910

0.1

R905

R906

18K

TO CN903

SHEET 2

C503

0

!

R902

D906

1SS133-T2

220

C909

39/35

10K

PC901

PS2581AL1/QW/

IC902

TL432/A/-T

TO CN303

SHEET 1

TO CN4

SHEET 4

C902

NI

!

T901

QQS0328-001

C905

2200P

R953

100

R954

1.5k

C967

R955

1k

1

R956

220K

!

!

D951

1F4G-T2

!

1F4G-T2

!

D953

SB240-F26

!

D955

PS154R-F83

D954

1F4G-T2

D956

1SS133-T2

1SS133-T2

R957

5.6K

R958

3.3K

R950

ICP-N10-T

C950

100/6.3

D960

D952

C982

39/35

C983

470/10

!

C955

330/16

!

82/16

!

82/16

D957

MTZJ3.6B-T2

C958

L951

QQR1633-001

C954

470/10

QQR1633-001

QQR1633-001

C957

C956

100/6.3

C959

100/16

100/10

Q951

2SC3576-JVC-T

R961

10K

Q952

RT1P441C-X

R969

10K

R983

1.5k

R935

10K

R963

R932

10k

Q961

KRA104S-X

DGND

4.7

R911

0

R912

0

R934

1.5K

Q960

2SC3928A/Q/-X

R962

4.7K

KRC102S-X

R981

4.7K

Q963

2SA1530A/Q/-X

Q962

C964

C985

47/25

C966

47/25

L952

L953

L954

100U

L955

100U

CP950

BUSWIRE

S502

QSW0651-001Z

S503

QSW0651-001Z

S504

QSW0651-001Z

S505

QSW0651-001Z

S501

QSW0651-001Z

S508

QSW0651-001Z

S507

QSW0651-001Z

S506

QSW0651-001Z

C920

C919

0NI

C918

NI

C991

C917

0

NI

C990

L970

NQR0129-002X

K502

K503

K505

K506

K507

K508

K509

K510

EP901

NI

QGF1040C1-13

10U

K501

0

0

0

0

0

0

CN901

CN902

K504

QGF1040C1-07

NQR0251-001X

0

0

0

CN903

QGF1208C1-17

TO CN301

SHEET 1

TO CN303

SHEET 1

TO CN501

SHEET 2

TO CN702

CN904

QGF1201C3-17

TP704

TP705

R965

100

J703

GP1FA553TZ

QNS0221-001

J901

SHEET 3

J601

QNN0668-001

J602

QNN0698-001

TO CN302

SHEET 1

CN905

QGF1040F1-23

EP902

NI

DGND

K701

C727

NI

R779

NI

K703

NQR0251-001X

R781

NI

NI

R777

NI

R778

R780

NI

NI

0

R788

Q712

NI

Q711

NI

R789

R771

NI

C730

C729

100/6.3

NI

C755

NI

C790

NI

C756

NI

R718

3.9K

C777

NI

R737

3.9K

Y

C

C/Cv/Y

PrOUT

PbOUT

IC704

SN74AHCT08NS-X

0.1

K702

NI

C741

150P

R741

82

R704

R701

3.9K

R705

200

C701

IC701

0.0033

RC4558D-X

R735

R734

200

3.9K

C731

4.7K

R736

470P

R753

200

C709

IC701

0.0033

RC4558D-X

R738

200

4.7k

R739

R772

620

R773

620

R756

NI

R775

NI

R774

NI

R703

47K

4.7K

C702

470P

R723

4.7k

C711

470P

C710

470P

NI

R758

R757

NI

0.1/16

C745

R706

100

C952

0.1/16

C706

22/25

R709

100

C953

C712

R725

560

22/25

C713

R724

27K

0.0022

2SC3928A/QR/-X

C748

47P

L709

2.2U

C744

C746

220P

330P

47P

C771

L730

2.2U

C753

220P

330P

R712

Q705

D701

MA111-X

D702

MA111-X

C742

0.1

Q760

RT1P44QC-X

10K

R713

R710

100K

Q701

RT1N44HC-X

R711

560

C707

27K

0.0022

R726

100

R727

10k

Q702

2SC3928A/QR/-X

C751

NI

R752

150P

NI

R728

NI

R729

C715

330P

C717

330P

C752

L706

1U

C714

L702

220P

C718

L701

2.2U

Q703

2SC3928A/QR/-X

R717

47K

27P

C740

100P

47P

2.2U

C716

47P

C719

220P

Q704

RT1P141C-X

R715

10k

C708

0.0015

D703

MA111-X

D704

MA111-X

D705

MA111-X

R790

1K

R714

100

27K

R716

TP604

100K

R754

4.7K

R733

C720

0.1/16

R732

Q706

KRC102S-X

C743

NI

TP603

8.2K

C725

100

R964

NQR0251-001X

TP702

1U

L707

10

R776

TP703

0.1

NI

L960

K901

C989

100p

TP701

DGND

Refer to the "E" in a table

gns10031001a2_rev0

SHEET 2

A

BCD EFG

2-5 2-6

Loading...

Loading...