Page 1

SERVICE MANUAL

BLU-RAY DISC PLAYER

MB706<Rev.002>20097SERVICE MANUAL

XV-BP1J, XV-BP1C, XV-BP1B,

XV-BP1E, XV-BP1EN, XV-BP1EV,

XV-BP1EE, XV-BP1US,

XV-BP1UX, XV-BP1UJ

(Except J,C,UJ)

COPYRIGHT © 2009 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

COPYRIGHT © 2009 Victor Company of Japan, Limited

No.MB706<Rev.002>

2009/7

Page 2

SPECIFICATION

For Northern America

General

Power requirements AC 120 V~, 60 Hz

Power consumption 18W

Dimensions (W × H × D) Approx. 16.9 x 2.1 x 9.7 inches (430 x 54 x 245 mm) without foot

Net Weight (Approx.) 6.2 lbs (2.8 kg)

Operating temperature 41 °F to 95 °F (5 °C to 35 °C)

Operating humidity 5 % to 90 %

Outputs

VIDEO OUT 1.0 V (p-p), 75 Ω, sync negative, RCA jack × 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 Ω, sync negative, RCA jack × 1

(Pb)/(Pr) 0.7 V (p-p), 75 Ω, RCA jack × 2

HDMI OUT (video/audio) 19 pin (HDMI standard, Type A)

ANALOG AUDIO OUT 2.0 Vrms (1 kHz, 0 dB), 600 Ω, RCA jack (L, R) × 1

DIGITAL OUT (COAXIAL) 0.5 V (p-p), 75 Ω, RCA jack × 1

DIGITAL OUT (OPTICAL) 3 V (p-p), Optical jack × 1

System

Laser Semiconductor laser, wavelength: 405nm / 650 nm

Signal system Standard NTSC Color TV system

Frequency response 20 Hz to 20 kHz (48 kHz, 96 kHz, 192 kHz sampling)

Signal-to-noise ratio More than 100 dB (ANALOG OUT connectors only)

Harmonic distortion Less than 0.008%

Dynamic range More than 95 dB

LAN port Ethernet jack × 1, 10BASE-T/100BASE-TX

Design and specifications are subject to change without prior notice.

1-2 (No.MB706<Rev.002>)

Page 3

For Europe

General

Power requirements AC 220-240 V ~, 50/60 Hz

Power consumption 18W

Dimensions (W × H × D) Approx. 430 × 54 × 245 mm without foot

Net Weight (Approx.) 2.8 kg

Operating temperature 5 °C to 35 °C

Operating humidity 5 % to 90 %

Outputs

VIDEO OUT 1.0 V (p-p), 75 Ω, sync negative, RCA jack × 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 Ω, sync negative, RCA jack × 1

(Pb)/(Pr) 0.7 V (p-p), 75 Ω, RCA jack × 2

HDMI OUT (video/audio) 19 pin (HDMI standard, Type A)

ANALOGUE AUDIO OUT 2.0 Vrms (1 kHz, 0 dB), 600 Ω, RCA jack (L, R) × 1

DIGITAL OUT (COAXIAL) 0.5 V (p-p), 75 Ω, RCA jack × 1

DIGITAL OUT (OPTICAL) 3 V (p-p), Optical jack × 1

System

Laser Semiconductor laser, wavelength: 405nm / 650 nm

Signal system Standard PAL/NTSC Colour TV system

Frequency response 20 Hz to 20 kHz (48 kHz, 96 kHz, 192 kHz sampling)

Signal-to-noise ratio More than 100 dB (ANALOGUE OUT connectors only)

Harmonic distortion Less than 0.008%

Dynamic range More than 95 dB

LAN port Ethernet jack × 1, 10BASE-T/100BASE-TX

Bus power supply DC 5 V 500 mA

Design and specifications are subject to change without prior notice.

(No.MB706<Rev.002>)1-3

Page 4

For Asia

General

Power requirements AC 110-240 V ~, 50/60 Hz

Power consumption 18W

Dimensions (W × H × D) Approx. 430 × 54 × 245 mm without foot

Net Weight (Approx.) 2.8 kg

Operating temperature 5 °C to 35 °C

Operating humidity 5 % to 90 %

Outputs

VIDEO OUT 1.0 V (p-p), 75 Ω, sync negative, RCA jack × 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 Ω, sync negative, RCA jack × 1

(Pb)/(Pr) 0.7 V (p-p), 75 Ω, RCA jack × 2

HDMI OUT (video/audio) 19 pin (HDMI standard, Type A)

ANALOGUE AUDIO OUT 2.0 Vrms (1 kHz, 0 dB), 600 Ω, RCA jack (L, R) × 1

DIGITAL OUT (COAXIAL) 0.5 V (p-p), 75 Ω, RCA jack × 1

DIGITAL OUT (OPTICAL) 3 V (p-p), Optical jack × 1

System

Laser Semiconductor laser, wavelength: 405nm / 650 nm

Signal system Standard PAL/NTSC Colour TV system

Frequency response 20 Hz to 20 kHz (48 kHz, 96 kHz, 192 kHz sampling)

Signal-to-noise ratio More than 100 dB (ANALOGUE OUT connectors only)

Harmonic distortion Less than 0.008%

Dynamic range More than 95 dB

LAN port Ethernet jack × 1, 10BASE-T/100BASE-TX

Bus power supply DC 5 V 500 mA

Design and specifications are subject to change without prior notice.

1-4 (No.MB706<Rev.002>)

Page 5

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

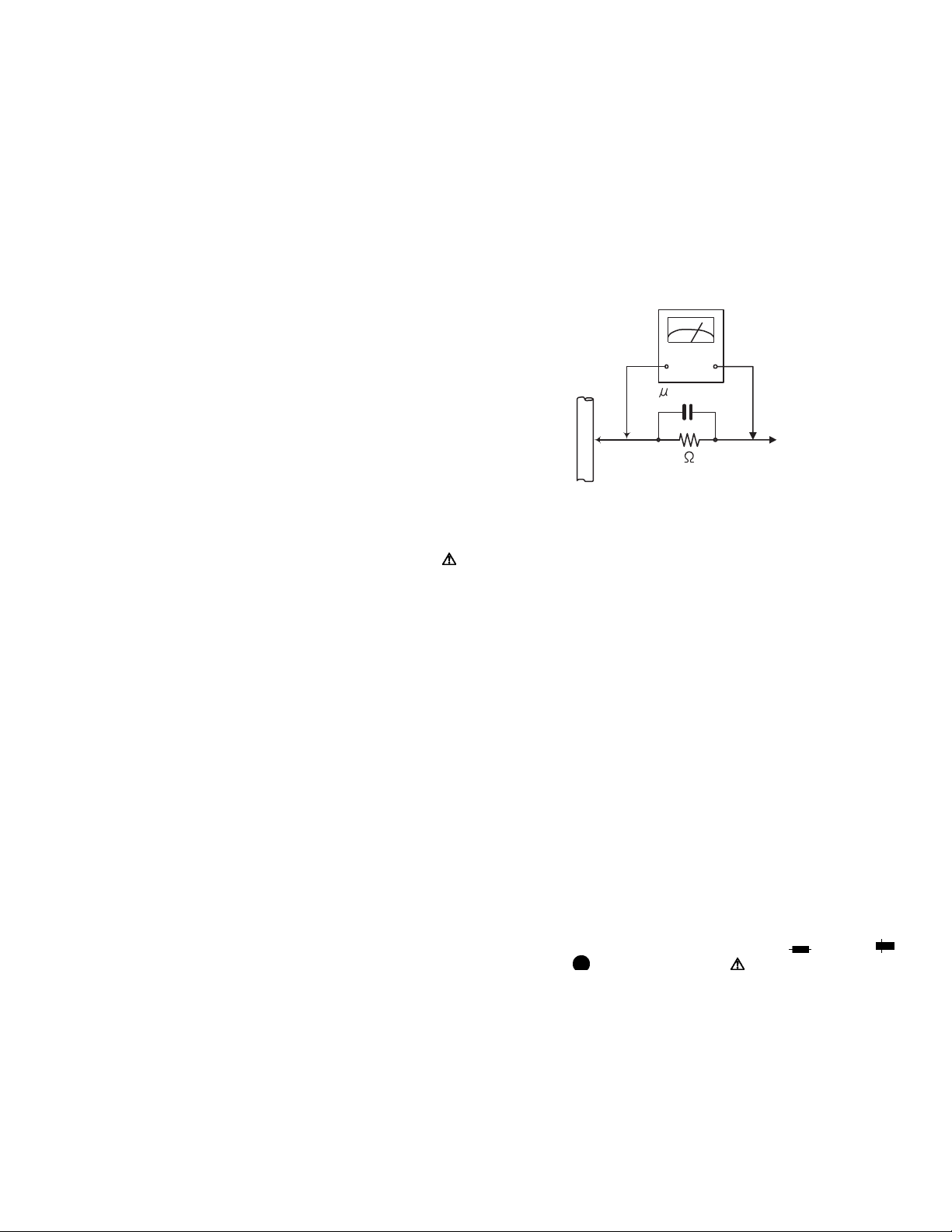

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

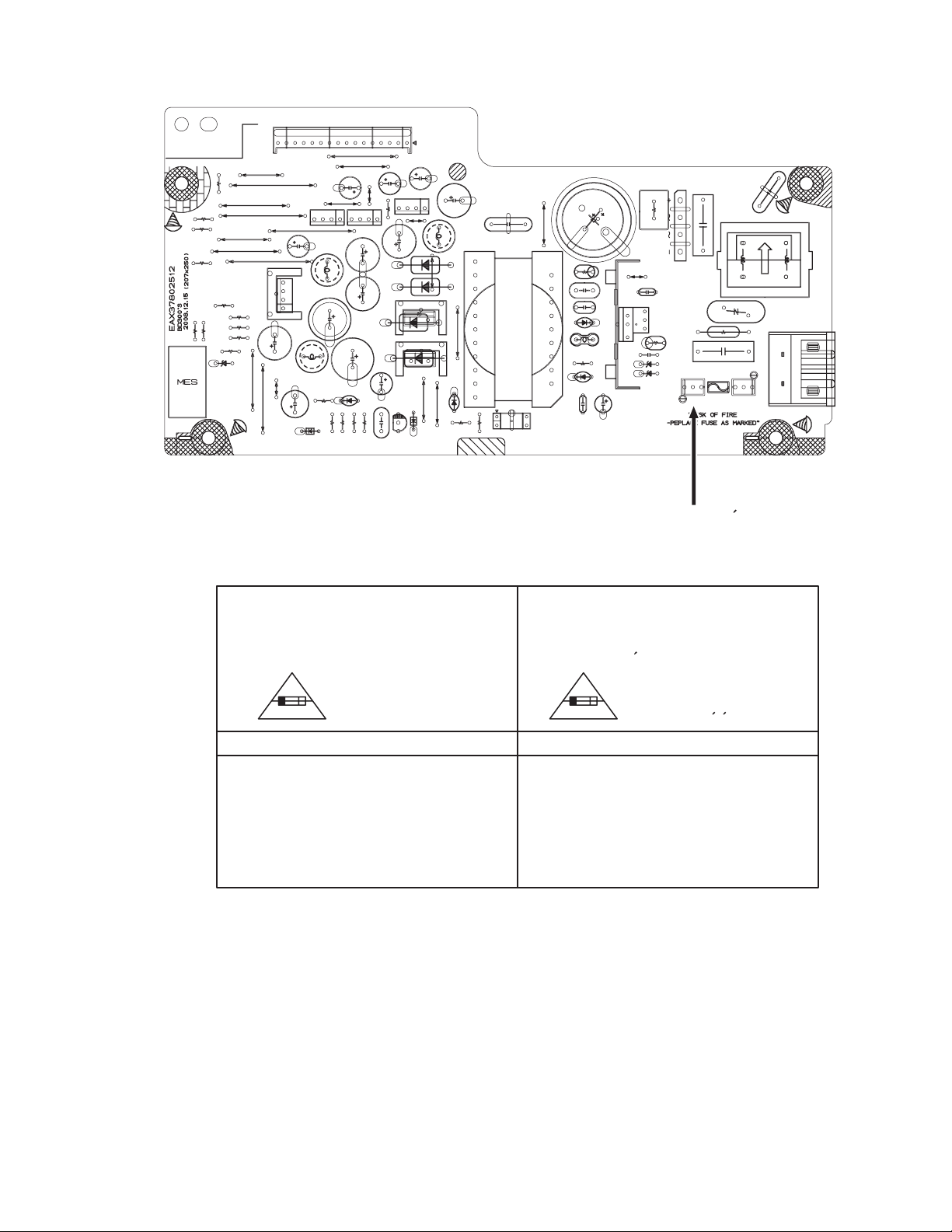

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB706<Rev.002>)1-5

Page 6

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

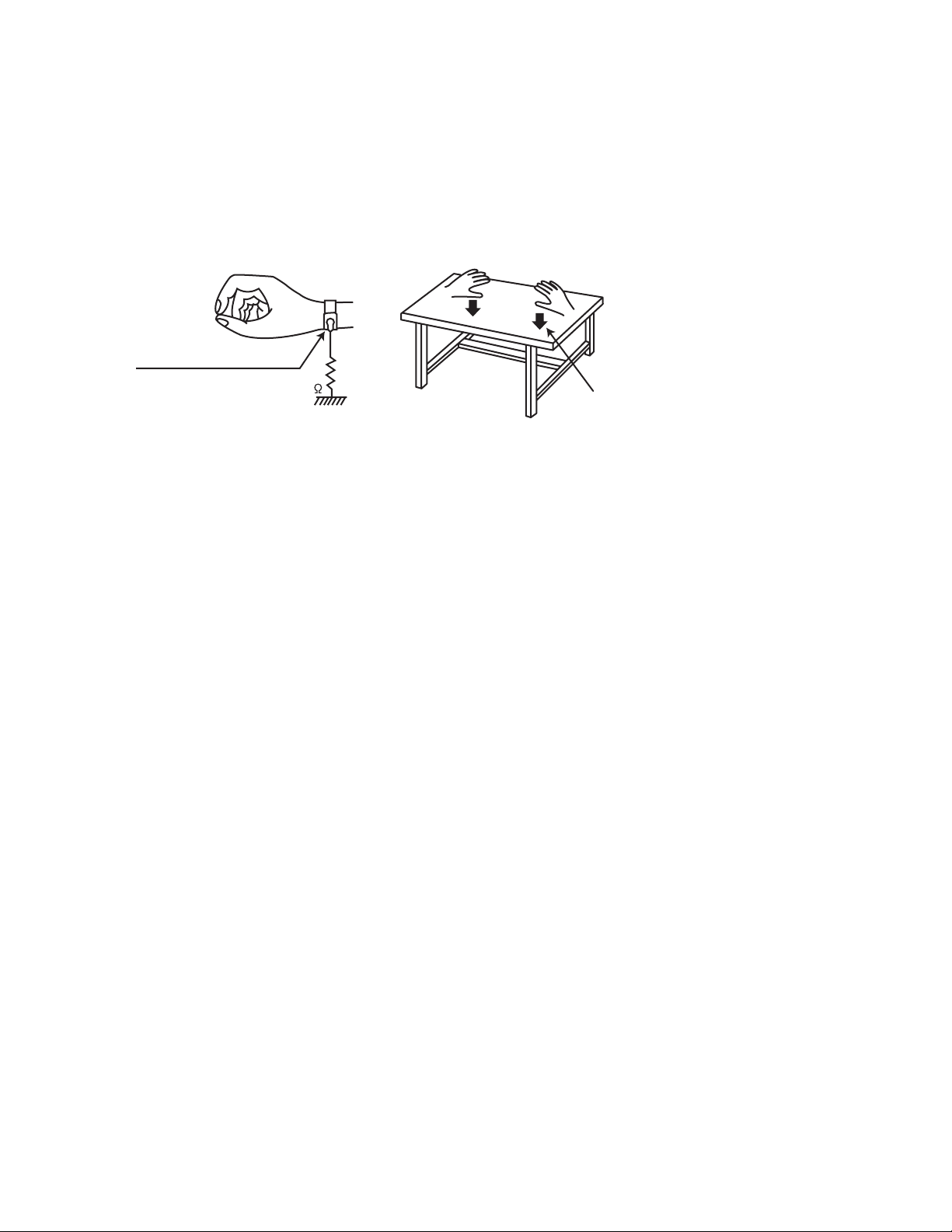

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1-6 (No.MB706<Rev.002>)

Page 7

1.6 Importance administering point on the safety

loader

W104

R145

8.P-CON

L127

7.5V

C122

R146

audio

6.GND

3.GND

2.3.3V

1.3.3V

5.12V

4.12V

C151

C154

IC153

78R33

J101

R153

IC151

78R12

C121

SB360

D133

D122

SB360

C125

D126

IC103

R143

C143

16.FD(+)

15.FD(-)

W119

W103

R157

W105

R154

R155

R156

R181

R191

W113

W107

W108

C152

W115

IC152

378R05

(278R05)

R131

R152

R151

C133

R150

R122

6.2B (2.7B)

ZD121

W109

W114

W110

C126

9.GND

14.-29VA

13.GND

12.5.3VA

11.5.3VA

10.GND

W117

W102

IC154

278R12

W106

C131

L123

C124

R121

D131

R144

P101

C153

C132

W116

L124

C123

D123

SB360

W182

D121

HER303

D132

W112

B5A60VI

D124

10A06

(B5A60VI)

D125

R141

W183

W111

D130

R142

C103

C111

W101

IC102

R105

D102

T101

C107

R101

R104

C105

C106

D101

BC101

C109

BD101

W118

C115

V101

IC101

R100

R109

C101

C104

33B

ZD101

10B

ZD103

FH102

C102

F101

T1.6AL 250V

C110

L102

PW101

FH101

fast blow type / type a fusion rapide

Full Fuse Replacement Marking

Graphic symbol mark

(This symbol means fast blow type fuse.)

should be read as follows ;

FUSE CAUTION

FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE

AND RATING OF FUSES ;

F901 : 3.5A 125V F901 : 3.5A 125V

Marquage Pour Le Remplacement

Complet De Fusible

Le symbole graphique (Ce symbole signifie

fusible de type a fusion rapide.)

^

doit etre interprete comme suit ;

PRECAUTIONS SUR LES FUSIBLES

POUR UNE PROTECTION CONTINUE CONTRE

DES RISQUES D'INCENDIE, REMPLACER

SEULEMENT PAR UN FUSIBLE DU MEME TYPE ;

(No.MB706<Rev.002>)1-7

Page 8

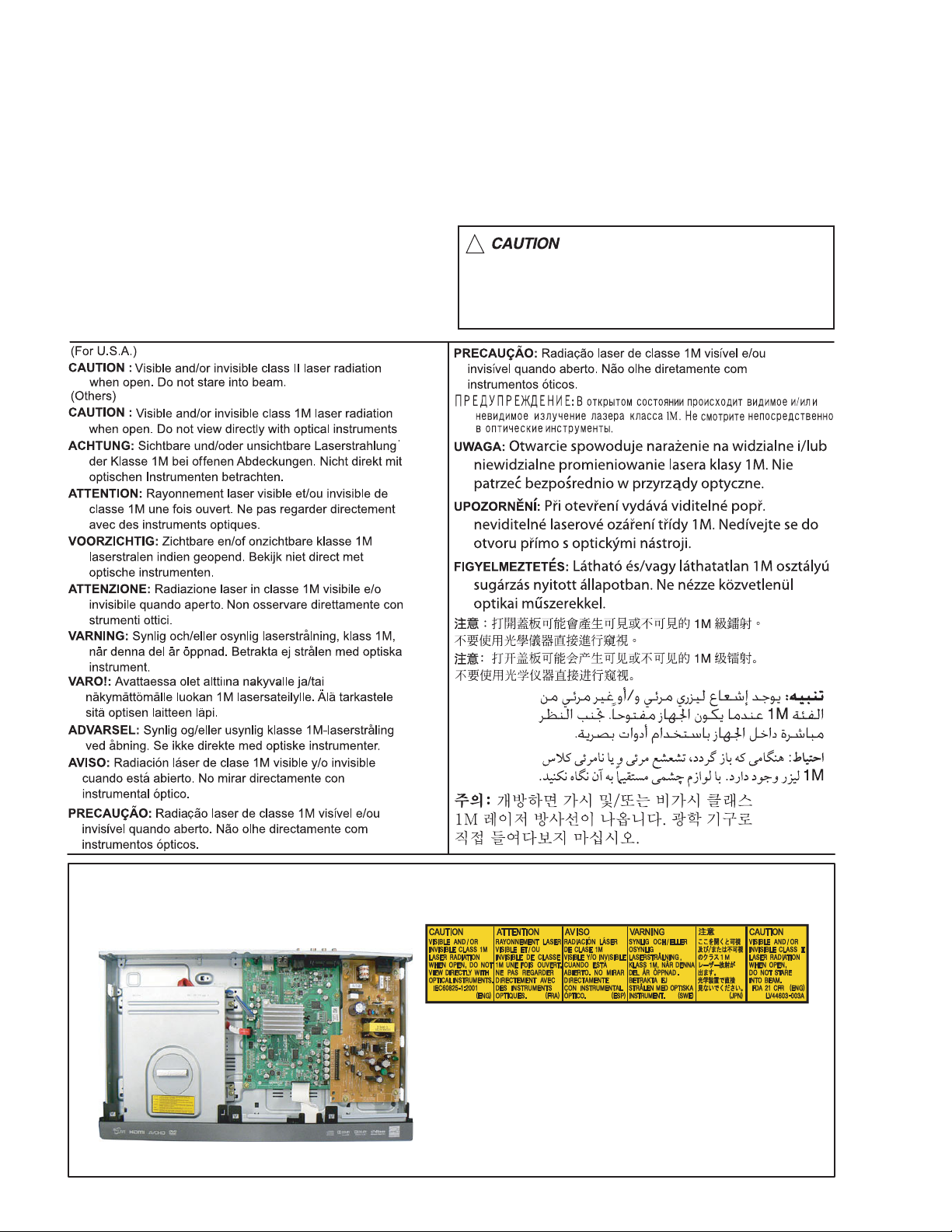

1.7 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

1-8 (No.MB706<Rev.002>)

Page 9

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.MB706<Rev.002>)1-9

Page 10

SECTION 3

DISASSEMBLY

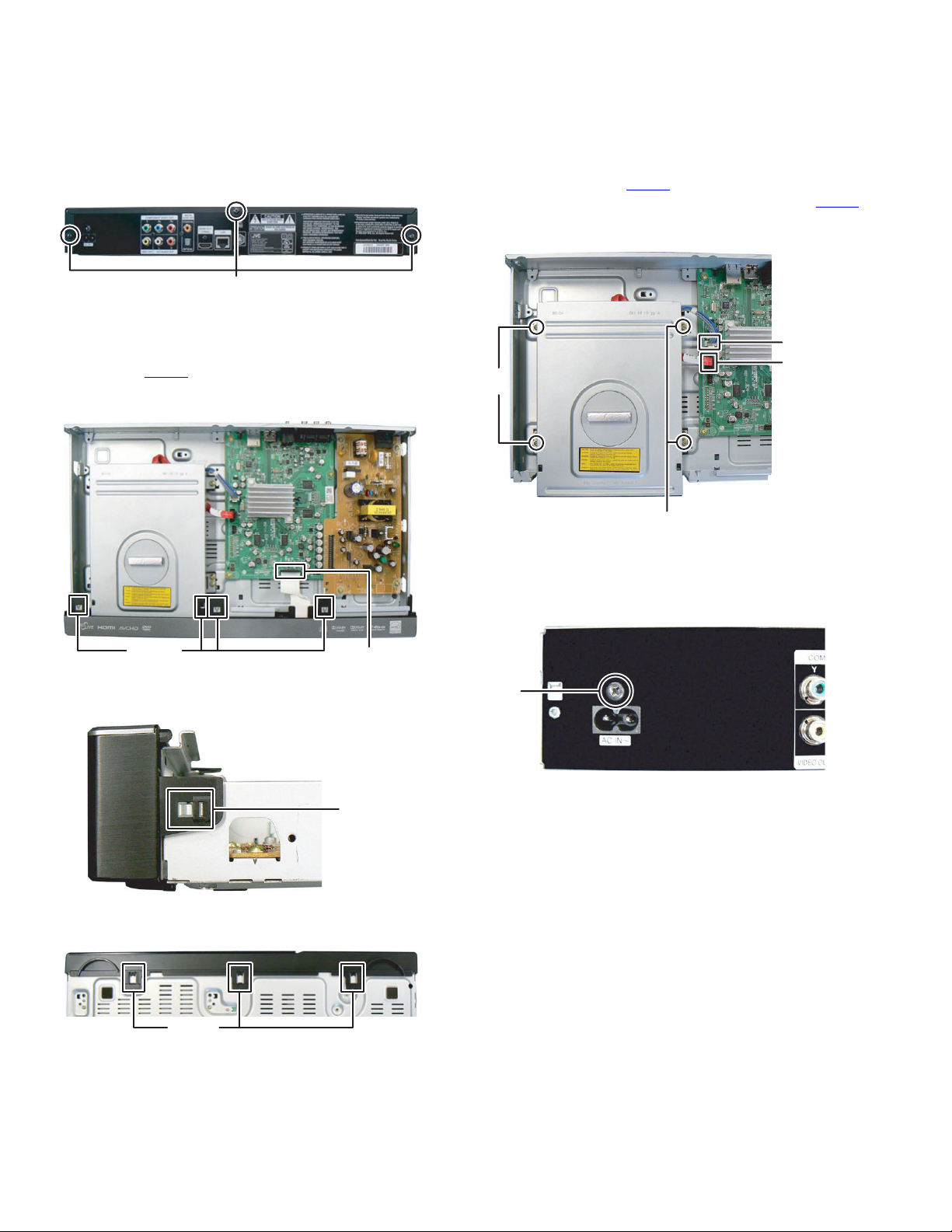

3.1 Main body

3.1.1 Removing the Top cover (See Fig.1)

(1) Remove the three screws A attaching the Top cover.

A

Fig.1

3.1.2 Removing the Front panel (See Fig.2 to 4)

(1) Disconnect the card wire from Front panel connected to

connector CN202

(2) Disengage four hooks a engaged top side of the Front pan-

el. (See Fig.2)

of the Main board. (See Fig.2)

3.2 Removing the Blu-ray drive unit (See Fig.5)

(1) Disconnect the connector wire from Blu-ray drive unit con-

nected to connector CN801

(2) Disconnect the FFC cable connected to connector CN802

of the Main board.

(3) Remove the four screws B attaching the Blu-ray drive unit.

of the Main board.

CN801

CN802

B

B

Fig.5

3.3 Removing the SMPS board (See Fig.6, 7)

(1) Remove the one screw C attaching the AC jack. (See

Fig.6)

hook a

Fig.2

(3) Disengage two hooks b engaged both side of the Front

panel. (See Fig.3)

Fig.3

(4) Disengage three hooks c engaged bottom side of the Front

panel. (See Fig.4)

hook

c

Fig.4

CN202

hook b

C

Fig.6

1-10 (No.MB706<Rev.002>)

Page 11

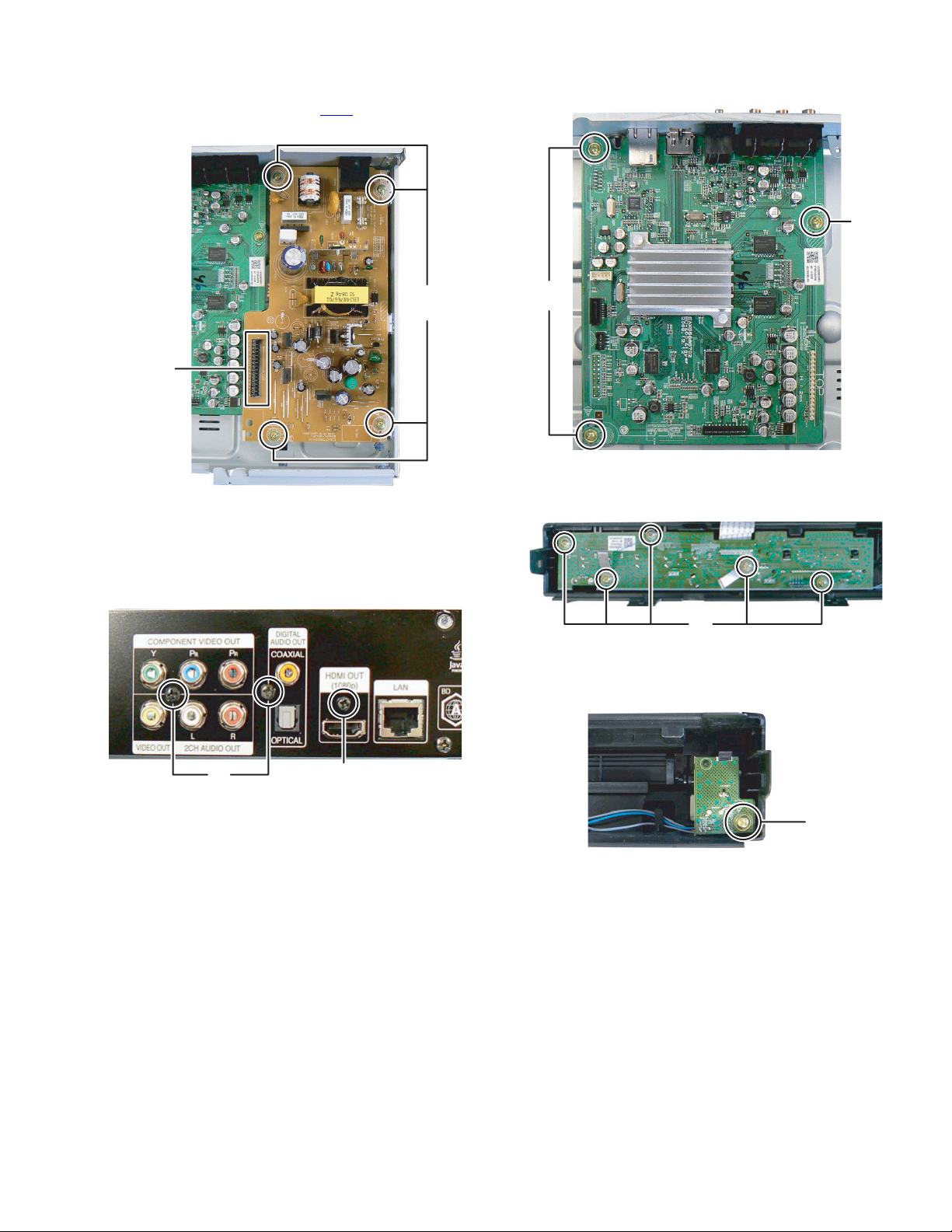

(2) Remove the four screws D attaching the SMPS board.

(See Fig.7)

(3) Disconnect the B-B connector P101

from Main board. (See Fig.7)

of the SMPS board

(3) Remove the three screws G attaching the Main board.

(See Fig.9)

G

D

P101

Fig.7

3.4 Removing the Main board (See Fig.8, 9)

(1) Remove the two screws E attaching the RCA jacks. (See

Fig.8)

(2) Remove the one screw F attaching the HDMI jack. (See

Fig.8)

G

Fig.9

3.5 Removing the Timer board (See Fig.10)

(1) Remove the five screws H attaching the Timer board.

H

Fig.10

3.6 Removing the Key board (See Fig.11)

(1) Remove the one screw J attaching the Key board.

EF

Fig.8

Fig.11

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

J

(No.MB706<Rev.002>)1-11

Page 12

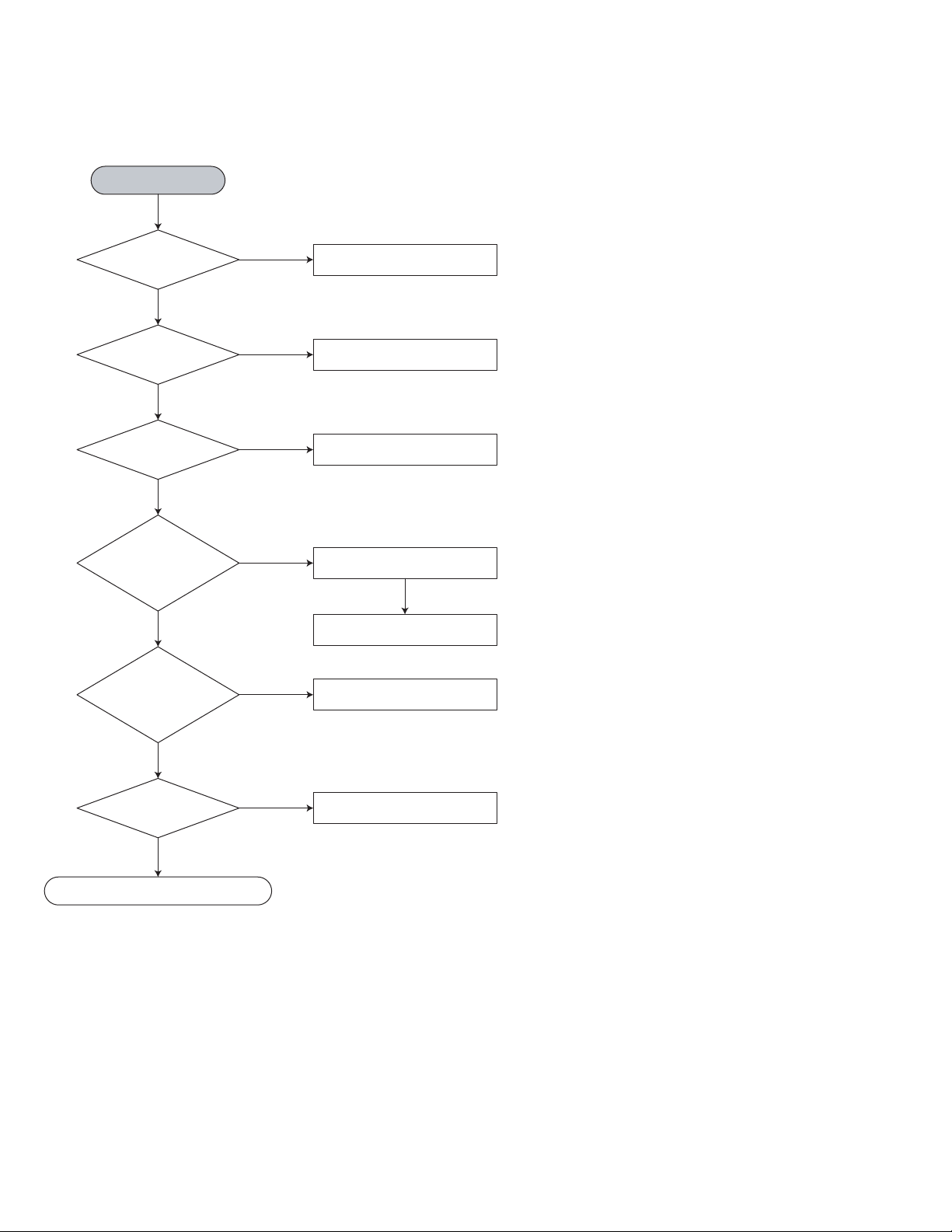

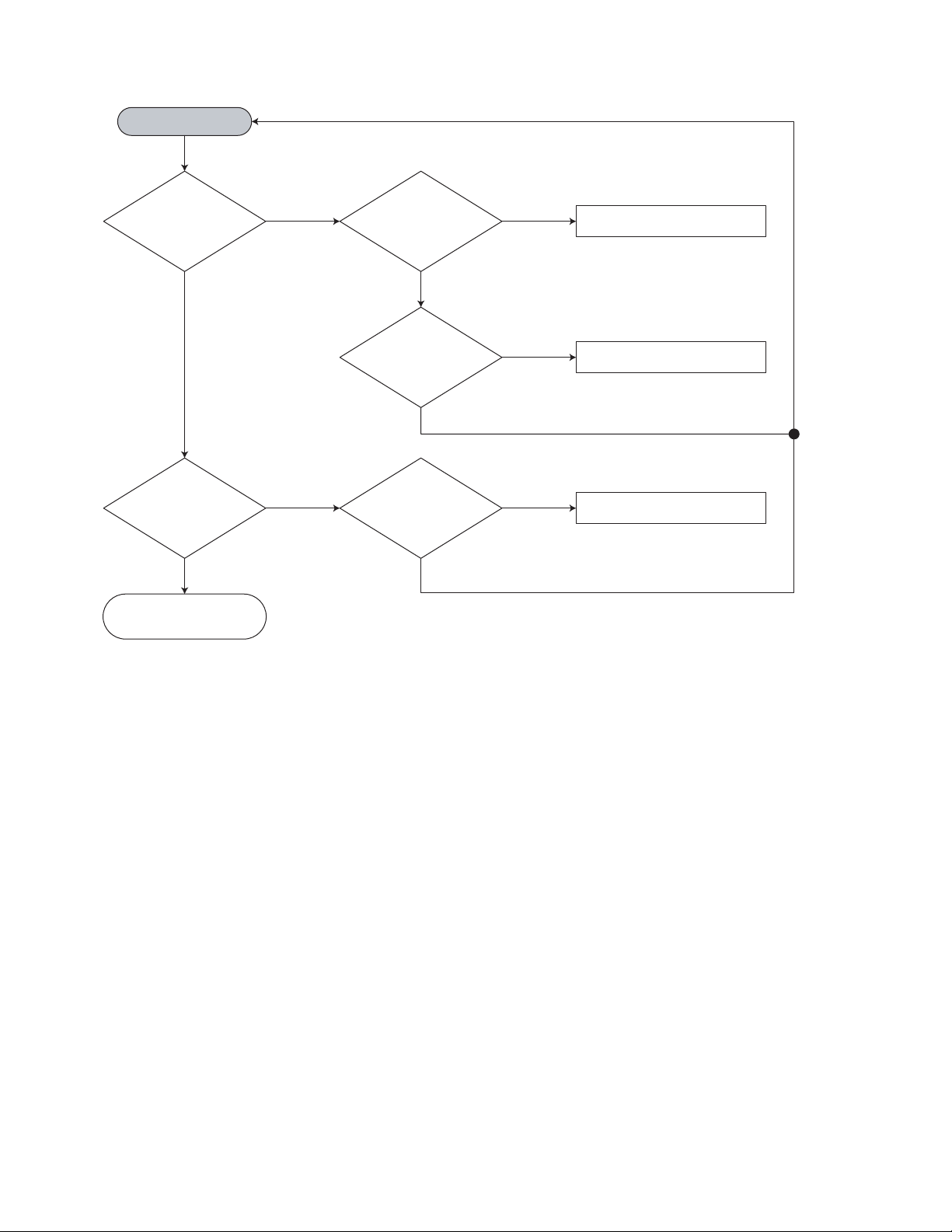

5.1 Power supply (SMPS)

No 5.3VA

SECTION 5

TROUBLESHOOTING

Is the

F101 normal?

YES

Is BD101 normal? Replace BD101

YES

Is R101 normal? Replace R101

YES

Is VCC

(13~27V) supplied to

IC101 Pin4?

YES

Is there about

2.5V at the IC103

Pin1?

NO

NO

NO

NO

NO

Replace F101 (same fuse)

Is D102 normal?

YES

Check or replace the D102

Replace IC103

YES

Is the IC102

normal?

YES

Power Line or Main PCB is short

1-12 (No.MB706<Rev.002>)

NO

Replace IC102

Page 13

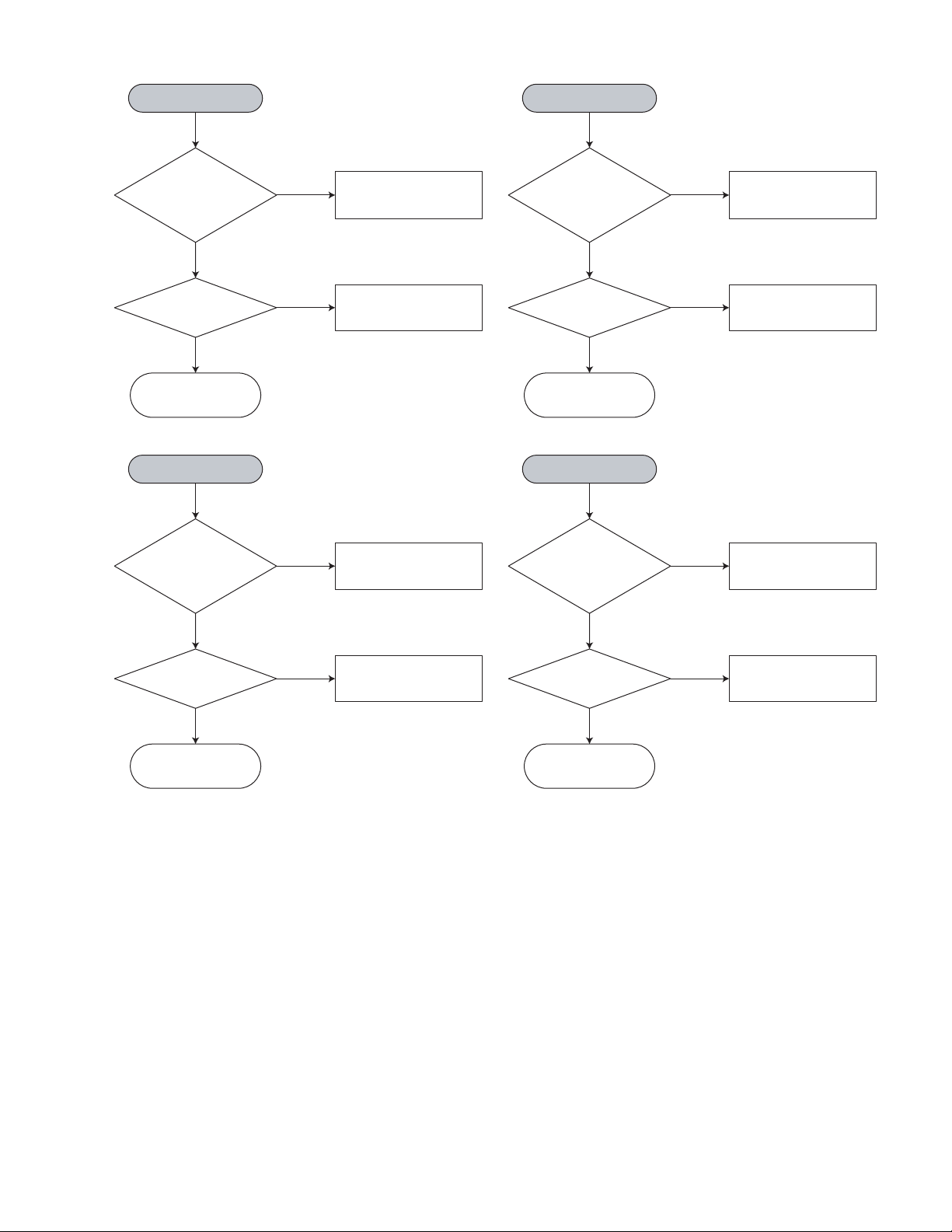

No 3.3VA

No 5VA

YES

Is the Vcc

(3.8V) supplied to

IC153 Pin1?

YES

Is the IC153

Pin4 "H"?

YES

Check or Replace

the IC153

No 12V_A

YES

Is the Vcc

(13.5V) supplied to

IC151 Pin1?

NO

NO

NO

Check or Replace

the D123

Check the DVD CTL

"H" signal from u-com

Check or Replace

the D121

YES

Is the Vcc

(5.5V) supplied to

D132 anode?

YES

Is the IC152

Pin4 "H"?

YES

Check or Replace

the IC152

No 12V_L

YES

Is the Vcc

(13.5V) supplied to

IC154 Pin1?

NO

NO

NO

Check or Replace

the D132

Check the DVD CTL

"H" signal from u-com

Check or Replace

the D121

YES

Is the IC151

Pin4 "H"?

YES

Check or Replace

the IC151

NO

Check the DVD CTL

"H" signal from u-com

YES

Is the IC154

Pin4 "H"?

YES

Check or Replace

the IC154

NO

Check the DVD CTL

"H" signal from u-com

(No.MB706<Rev.002>)1-13

Page 14

5.2 Power ON

POWER on

"HELLO

PLEASE WAIT"

Display on VFD

OK?

YES

"JVC LOGO"

display on monitor

OK?

YES

Normal TV

function OK

NO

NO

Front I/F

cable connection

OK?

YES

VFD power

cable connection

OK?

YES

Display

cable connection

OK?

YES

NO

NO

NO

Front I/F cable connect

VFD power cable connect

Proper display cable connect

1-14 (No.MB706<Rev.002>)

Page 15

5.3 SYSTEM PART

POWER on

"HELLO

PLEASE WAIT"

Display on VFD

OK?

YES

NO

CN501, Pin18:

+5.3VA, Pin3: -29VA,

Pin17: -27V, Pin13:

-24V?

YES

X501 10MHz

OK?

YES

R516

About 625kHz Serial

Clock OK?

YES

R523

About 500kHz

OK?

YES

DIG501 Change

NO

NO

NO

NO

Check SMPS

X501 Change

IC501 Change

IC502 Change

Timer board

"READING"

display on VFD

OK?

YES

System part OK

NO

CN701, Pin5:

12V, Pin7: 5V,

Pin2: 2.2V, Pin11:

5.3VA?

YES

CA207: 5.3VA

CA210: 1.2V

CA211: 5V

YES

X301: 27MHz

OK?

YES

X302: 25MHz

OK?

YES

Check IC301

NO

NO

NO

NO

Check SMPS

IC202, IC203, IC204 Change

X301 Change

X102 Change

Main board

(No.MB706<Rev.002>)1-15

Page 16

5.4 COMPONENT (Y,Pb,Pr) VIDEO OUT

Component video no display

L906 +3.3V

OK?

YES

C913, C914, C915

Signal OK?

YES

R923, R924, R925

Signal OK?

YES

JK904

Soldering OK?

YES

Component Video OK

NO

NO

NO

NO

Re-soldering

Re-soldering

Re-soldering

Re-soldering

5.5 CVBS VIDEO OUT

CVBS video no display

C910

Video signal input

OK?

YES

C913

Video signal output

OK?

YES

JK904

Soldering OK?

YES

Component Video OK

NO

NO

NO

IC301 Check

IC901 Check

Re-soldering

1-16 (No.MB706<Rev.002>)

Page 17

5.6 AUDIO (S/PDIF, OPTICAL)

No Audio

C917

Digital Audio

output OK?

YES

JK903 Red

Lighting OK?

YES

S/PDIF, OPTICAL

audio out OK

NO

NO

IC301 Check

JK903 (Pin2)

+5.0V OK?

JK903 Re-soldering

NO

IC204 Check

(No.MB706<Rev.002>)1-17

Page 18

5.7 AUDIO (ANALOG)

No Audio

IC603 (Pin8)

12V AUDIO

OK?

YES

Q905 (Pin2)

LOW?

YES

IC903

Pin 6, 7, 8, I2S

Output OK?

YES

IC903 Pin 14, 15

audio output before

Amp OK?

YES

NO

NO

NO

NO

CN201 (Pin4)

12V AUDIO

OK?

R947 Re-soldering

Q902 Re-soldering

IC301 Check

IC903 Check

NO

Check SMPS

CA907, CA908

audio output

OK?

YES

R949, R950

JK904 (Pin2, 5)

soldering OK?

YES

Audio Output OK

NO

NO

IC904 Check

Re-soldering

1-18 (No.MB706<Rev.002>)

Page 19

5.8 HDMI

No A/V

JK902

Soldering OK?

YES

JK902 Pin 18

VCC +5V OK?

YES

JK902 Pin 19

+2.0V < Voltage < +5.3V

OK?

YES

JK902 Pin 15, 16

(SCL, SDA)

OK?

YES

NO

NO

NO

NO

Re-soldering

L902

soldering OK?

IC204 Pin 4 Check

TV hot plug detect signal

check (from IC301)

Check HDMI Voltage

Level Shifter

NO

Re-soldering

HDMI out OK

(No.MB706<Rev.002>)1-19

Page 20

Victor Company of Japan, Limited

Audio/Video Systems Division 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB706<Rev.002>)

Printed in Japan

VSE

Page 21

SCHEMATIC DIAGRAMS

Blu-ray Disc Player

XV-BP1J,XV-BP1C,XV-BP1B,

XV-BP1E,XV-BP1EN,XV-BP1EV,

XV-BP1EE,XV-BP1US,XV-BP1UX,

XV-BP1UJ

DVD-ROM No.SML2009Q1

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Contents

Block diagrams

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2009 Victor Company of Japan, Limited.

(Except J,C,UJ)

2-1

2-2

2-11 to 12

No.MB706SCH<Rev.002>

2009/7

Page 22

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

Page 23

Block diagram

IC601

1.8V DCDC

IC701

1Gbit DDR2 SDRAM

IC702

1Gbit DDR2 SDRAM

512Gbit DDR2SDRAM

512Gbit DDR2SDRAM

IC703

IC704

27MHz 25MHz

SATA 1.1V DCDC

1.2V LDO

IC804

FAST ETHERNET

PHYCEIVER

IC301

2HD Decode

400MHz ARM11x2

200MHz Audio DSPx2

HDMI 1.3

Ethernet MAC

5V LDO

JK603

HDMI

JK901

Ethernet

Optical

coaxial

Debug

UART1

Front Panel

UART0

USB 2.0

IC801

Puer NAND

IC803

S_FLASH

IC903

Audio DAC

IC904

Dual Op Amp.

IC901

3ch SDTV

Video amp

IC902

3ch HDTV

Video amp

JK904

Audio L/R

CVBS

YPbPr

2-1

Page 24

Standard schematic diagrams

r

SMPS CIRCUIT DIAGRAM

BD101

GBL206

100nF /250VA

L102

25mH

100nF/250VA

4

C102

1

2

1

3

2

4

4

3

R100

1.5M/0.5W

C101

V101

PW101

1

2

BR

BL

(BK)

(WH)

2

2

1

2

1

3

FH02

FH01

F 10 1

T1.6AL /250V

R101

2.7/2W

1

C103

100u/450V

1

D

STR-W6251

S/OCP FM GND

3

R109

0.33 /2W

C110

1000pF/250AV

C111

1000pF/250VA

BEAD

BC101

IC101

7

C115

4

VCC

5

4.7nF

R104

56K/2W

D101

1N17

6

FB

1.5nF

C107

C106

UZ-10BSB

UZ-33BSB

ZD103

C105

0.01u/630V

68pF/1KV

D102

RL104F

C109

47nF/50V

ZD101

R105

39

HOT

T101EER3530

2

3

4

5

6

7

8

9

10

100nF

C104

CIRCUIT

FD (+)

22

21

FD (-)

-29VA

20

19

GND

18

5. 3VA

GND

17

16

5.5VA(LOADER)

13VA(LODER, AUDIO)

15

14

GND

3. 8VA 1A

13

12

GND

IC102

LTV-817B

4

3

D126

RL104F

D125

RL104F

D122

SB360

10A60V

D124

D133

SB360

B5A60V1

D132

D121

UF5402(HER303)

D123

SB360

1

2

IMPORTANT SAFETY

WHEN SERVICING THIS CHASSIS, UNDER NO

CIRCUMSTANCES SHOULD THE ORIGINAL

DESIGN BE MODIFIED OR ALTERED WITHOUT

PERMISSION FROM THE JVC. ALL COMPONENTS

SHOULD BE REPLACED ONLY WITH TYPES

IDENTICAL TO THOSE IN THE ORIGINAL CIRCUIT

SPECIAL COMPONENTS ARE SHADED ON THE

R121

0.2

C126

220uF/16V

R131

82K

C125

47uF/ 50V

C133

L123

22uH

L127

22uH

22uH

L124

D130

1SS133

1000uF/ 10V

D131

1SS133

3.3K

R145

0.01

OPTION

R141

220

R142

2.2K

IC103

KA431AZ

C143

0.1u

C124

2200uF/ 16V

(105DEG)

C122

2200uF/ 16V

(105DEG)

C121

1000uF/ 25V

(105DEG)

C123

2200uF/ 10V

(105DEG)

R143

1K

R144

4.7K

0.01

R146

820

SCHEMATIC FOR EASY IDENTIFICATION. THIS

CIRCUIT DIAGRAM MAY OCCASIONALLY DIFFER

FROM THE ACTUAL CIRCUIT USED. THIS WAY,

IMPLEMENT ATION OF THE LATEST SAFETY

AND PERFORMANCE IMPROVEMENT CHANGES

INTO THE SET IS NOT DELAYED UNTIL THE NEW

SERVICE LITERATURE IS PRINTED.

R181

15

R191

15

ZD121

UZ-6.2B

R122

100K

R150

1.2K

C131

470uF/ 25V

C132

1000uF/ 10V

R151

1.2K

R152

OPTION with Heatsink

OPEN

1

1

1

278R12

1

4

IC152

378R05

3

4

IC154

3

4

IC151

78R12

3

4

IC153

78R33

3

2

2

J101

2

2

2

1

R156

4.7K

C152

100uF/16V

R154

4.7K

C154

100uF/16V

R155

4.7K

C151

100uF/16V

R153

4.7K

C153

100uF/16V

NOTE:

1. Shaded

( )

psrts are critical for safety. Replace only

with specified part number

2. Voltages are DC-measured with a digital voltmete

during Play mode.

9

4

FD(+)

FD(-)

-29VA

GND

5.3VA

5.3VA

GND

GND

P_CON

5V LODER

GND

12V LOADER

12V AUDIO

GND

3.3V

3.3V

P101

R157

10K

16

15

14

13

12

11

10

8

7

6

5

3

2

1

NOTES)

Symbol denotes AC ground.

Symbol denotes DC chassis ground.

Warning

NOTES)

Parts that are shaded are critical

With respect to risk of fire or

electrical shock.

120V

110 240V

2-2

C103

150uF/250V

100uF/450V

BD300

BD400

L102

04150ST

145E

(145L)

(145G)

D132

5A60VI

(H/S)

D133

D124

D122

10A60

X

(H/S)

SB360

X

X

SB360

IC152

C122

378B05

2200uF

X

(H/S)

1000uF

278R05

IC151

78R12

ZD121

J101

X

6.2B

2.7B

0

X

Page 25

POWER/TIMER/USB CIRCUIT DIAGRAM

1uF

0.1uF

0.1uF

0.1uF

C201

C202

C203

C204

FROM SMPS

CN201

3.3V

3.3V

GND

12V_AUDIO

12V_LOADER

GND

5V_LOADER

P_CON

GND

GND

5.3VA

5.3VA

GND

-29VA

FD-

FD+

FRONT TIMER I/F

GND

USB_P

USB_N

GND

PWR_CTRL_5.3VA

5.3VA

FD-

GND

RXO

TXO

FD+

GND

CEC

INST_OPEN

PWR_CTRL

D3

D2

D1

RESET#

A_MUTE

-29VA

5V

5V

CN202

1

2

3

4

5

6

7

8

9

10

11

12

13

GND

14

15

16

C217

0.1uF

TP219

23

TP218

22

TP217

21

20

TP216

19

TP215

18

TP214

17

16

TP213

15

TP212

14

TP211

13

12

TP210

11

TP209

10

TP208

9

TP207

8

TP206

7

TP205

6

TP204

5

TP203

4

TP202

3

TP201

2

1

GND

C255

FD+

C218

0.1uF

GND

R214 0

R215 0

C244

2pF

FD-

FD+

R219

R299 2.2K

-29VA

HB_102(2)

10uF(2012)

5:14

PWR_CTRL

FD-

GND GND

C245

2pF

C254

(N.C)

0

L205

C219

0.1uF

V201

5.3VA

NC

C252

C251

C253

-29VA

5V

NC

V202

(N.C)

(N.C)

(N.C)

1uF

C205

0.1uF

C206

+

GND

12V_AUDIO

0.1uF

0.1uF

C207

C208

GND

1uF

C209

1uF

C213

1uF

0.1uF

0.1uF

C220

C221

C222

USB_P

USB_N

PWR_CTRL_5.3VA

T_RX

T_TX

HDMI_CEC

A_MUTE

PWR_CTRL

INST_OPEN

D2_CTL2

D2_CTL3

RESET

D2_CTL1

CA201

330uF/16V

+

CA202

330uF/16V

0.1uF

0.1uF

C210

C211

0.1uF

C214

0.1uF

C223

3.3V

12V_LOADER

0.1uF

CA203

330uF/16V

C212

GND

5V_LOADER

0.1uF

0.1uF

++

CA204

330uF/16V

C215

C216

GND

5.3VA

+

+

CA206

330uF/16V

CA205

330uF/16V

GND

*USB Design & Layout Guide*

1.USB Data DP/DN must be routed as100ohm differential pairs.

2.Match Trace length of DP/DN

3.Trace spacing is same as trace width.

4.Route differential pairs above gnd plane and gnd plane are not split under differential pairs.

5.Avoid via aspossible as you can.

6.Trace spacing between DP/DN and other traces must be more than 5 times of DP/DN trace width.

7.Consider current upto 500mA.

8.Consider abrupt USB power short.

9.USB RREF resistor (R114) must be place close to BCM7440.

T_RX

T_TX

RESET

R202

10(2012)

C224

0.1u(2012)

GND

3.3V

D

S

G

Q202

N.C(2SK3018-T106)

3.3V

D

S

G

Q203

2SK3018-T106

R223

N.C(10K)

D202

N.C(RB501V-40)

D

22

R225

Q201

N.C(2SK3018-T106)

C225

R220 150

G

0.1u(2012)

R228

N.C(10K)

N.C(150)

10K

R229

3.3V5.3VA

S

R221

R218

150

IC201

G5627

1

VCC

2

REF

3

GND

4

PGND

FB

MAX. : 3A (max:2.4A)

TEMP. RANGE : -40~85

TIMER CIRCUIT

TIMER_RX

C249

120pF

GND

TIMER_TX

C248

120pF

GND

RESET CIRCUIT

R224

N.C(10K)

R226

6.2K

10K

R227

GND

HB_102(2)

VIN

LX

EN

L201

GND

5.3VA

8

7

6

5

RESET#

C226

10uF(2012)

C227

10uF(2012)

R204

2K

N.C

R203

GND

GND

C228

20K_1%(2012)

OPEN

R207

3.3V

100UF/6.3V

PWR_CTRL_5.3VA

L202

10uH

R206

GND

CA209

5V

1.1V

C229

C230

10uF(2012)

10uF(2012)

R205

7.5K_1%

GND GND

*Msut be placed Inductor L202

390(2012)

*Must be placed sama plane as L202

IC203

TJ3965S-1.2V-3L

VIN

OUT

GND

1 2 3

C240

0.1uF

GND

IC205

VIN

GND

1 2 3

GND

+

GND

C246

NC

GND GND

C241

0.1uF

OUT

C247

0.1uF

CA207

100uF/16V

5.3VA

+

GND

HH_102(2)

PWR_CTRL_5.3VA

1.2V

CA210

220UF/6.3V

2.5V

GND

C231

22uF

1

L204

2

3

4

C232

0.1uF

GND

100K

R209

GND

+

CA212

100UF/16V

GND

OPTION (EFUSE CIRCUIT)

[5.6VA TO 1.8V]

AOZ1021 (max 3A@1.8V. max : 2A)

IC202

AOZ1021

PGND

VIN

AGND

FB

C234

102

C233

OPEN

C235

OPEN

5.3VA

PWR_CTRL

C243

0.1uF

1 2 34 5

8

LX

7

LX

6

EN

5

COMP

R210

15K

IC204

TJ3965RS-5.0V-5L

EN

VIN

GND

GND

VOUT

BZX84-C6V8

C237

C238

10uF(2012)

C236

GND

OPEN

GND

+

10uF(2012)

5V

CA211

220UF/16V

L203

10uH

R212

27K_1%

R217

1.5K_1%

R211

20K_1%

*Msut be placed Inductor L203

*Must be placed sama plane as L203

SENSE

R231

N.C(6.2K_1%)

R232

N.C(390)

R230

0(20K_1%)

ZD201

C242

0.1uF

C239

1.8V

N.C(0.1UF)

BD370

R230 : 0 ohm

R231.2 : N.C

BD360

R230 : 20K ohm_1%

R231 : 6.2K ohm_1%

R232 : 390 ohm

2-3

Page 26

MPEG4-1 CIRCUIT DIAGRAM

3.3V

HB2012_1000

HB2012_1000

HB2012_1000

HB2012_1000

HB2012_1000

HB2012_1000

HB2012_1000

HB2012_1000

HB2012_1000

HB2012_1000

HB2012_1000

HB2012_1000

HB2012_1000

HB2012_1000

1.2V

L301

L302

L303

L304

L305

L306

L307

L308

L309

L310

L311

C391

GND

C390

RESET#

L312

L313

L314

RTC OPTION

3.3V

4.7uF

C302

4.7uF

C303

4.7uF

C304

4.7uF

4.7uF

C306

4.7uF

C307

4.7uF

C308

4.7uF

C309

4.7uF

C310

4.7uF

C311

4.7uF

15pF

15pF

C312

4.7uF

C313

4.7uF

C314

4.7uF

L315

HB2012_1000

C330

0.1uF

GND

C301

C305

TP301

TP302

TP303

TP304

X301

27MHZ

GND

C317

0.1uF

C318

0.1uF

C319

0.1uF

C320

0.1uF

0.1uF

0.1uF

C323

0.1uF

0.1uF

C325

0.1uF

C326

0.1uF

C327

0.1uF

C328

0.1uF

C315

0.1uF

C316

0.1uF

C321

C322

C324

C329

0.1uF

100K

R334

R301

R303

R304

R305

R308

R309

C331

C332

R310

1.5K_(1%)

R302

R307

TP362

TP316

TP370

TP309

TP310

TP312

TP313

TP314

TP315

0/NC

4.7uF

0.1uF

0.1uF

C333

R313

TP359

TP317

TP318

TP360

TP361

10K

10K

22

22

22

R342

0

0/NC

2.2K

GND

L316

HB2012_1000

0.1uF

C334

GND

A_MCLK

A_BCK

A_LRCK

A_DATA2_R

A_DATA4

ASPDIF

AMUTE

EFVDDQ_CTL

PR

PB

Y

CVBS_I

NAND_CEN2

1.2V

HB2012_1000

4.7uF

C335

GND

TXC+

TXC-

TX0+

TX0-

TX1+

TX1-

TX2+

TX2-

HPD

H_SDA

H_SCL

1k_1%

GND

SACD OPTION

1.1V

0.1uF

0.1uF

0.1uF

CA302

470UF/6.3V

1.1V

CA306

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

CA303

470UF/6.3V

K11

K12

K15

K16

L10

L11

L13

L14

L16

L17

M10

M17

N11

N16

P11

P16

R10

R17

T10

T11

T13

T14

T16

T17

U11

U12

U15

U16

AA5

AB4

AB5

AC3

AC4

AD2

AD3

AE2

220uF/6.3V

D8

E20

E21

E9

F4

G5

Y5

AC5

AD6

AA4

AB3

0.1uF

C351

CA301

L326

CA304

220uF/6.3V

33UF/6.3V

C375

C376

C377

C378

C379

C380

C381

C382

C383

GND

R311

10K

R312

3.3V

TP321

TP322

TP323

TP324

TP325

TP326

TP327

TP328

TP329

TP330

TP331

TP332

TP333

TP334

TP335

TP336

TP337

TP338

TP339

TP340

TP341

TP342

TP343

TP344

TP345

10K

B23

SFCS

A23

SFCK

C22

SFDI

D21

SFDO

B22

SFCS2

A25

NFCEN

A26

NFREN

A24

NFWEN

C24

NFRBN

B24

NFALE

C23

NFCLE

D22

NFD0

B25

NFD1

B26

NFD2

D23

NFD3

E22

NFD4

C25

NFD5

C26

NFD6

D24

NFD7

E4

PMCD1N

D3

PMD7

D2

PMA7

D1

PMA4

E3

PMCE1N

E1

PMVS1N

E2

PMOEN

F3

PMWRN

F2

PMWEN

G3

PMRDY

G2

PMVS2N

G1

PMWAITN

H1

PMREGN

F5

PMA6

G4

PMCE2N

H5

PMRDN

H3

PMRST

H4

PMBVD2

H2

PMBVD1

A2

SD2CLK

A1

SD2CMD

B2

SD2D0

B1

SD2D1

C2

SD2D2

C1

SD2D3

AA2

UATXD

Y3

UARXD

AA1

TDO

AC1

TRST#

AB2

TDI

AA3

TMS

Y4

TCK

AB1

RTCK

GND

SF_CS

SF_CK

SF_DI

SF_DO

TIMER_TX

NF_CEN

NF_REN

NF_WEN

NF_EBN

NF_ALE

NF_CLE

NF_D0

NF_D1

NF_D2

NF_D3

NF_D4

NF_D5

NF_D6

NF_D7

3.3V

L317

C394

0.1uF

S

D

GND

G

Si2302ADS N Ch

5V

N.C(0.1uF)

Q301

C395

UATXD

UARXD

TTDO

TTRST#

TTDI

TTMS

TTCK

TRTCK

RESET OPTION'

IC301

MT8520

AVDD12_STX1

AVDD12_SRX1

AVSS12_ST1

AVSS12_ST1

SRXP_1

SRXN_1

STXN_1

STXP_1

AVDD12_SRX2

AVDD12_STX2

AVSS12_ST2

AVSS12_ST2

SRXP_2

SRXN_2

STXN_2

STXP_2

AVDD33_ST

AVDD12_ST

AVDD33_XTAL25M

AVSS33_XTAL25M

XTAL25M0

XTAL25MI

SVCTST

RREF

VSTB

VD ATA

VCLK

LCDRD

1.2V

L319

0.1uF

C341

TP352

TP353

TP354

12.1K(1%)

HB2012_1000

L320

HB2012_1000

C339

0.1uF

GND

SATA_RX+

SATA_RX-

SATA_TXSATA_TX+

1.2V

HB2012_1000

L321

HB2012_1000

L322

3.3V

HB2012_1000

HB2012_1000

C346

0.1uF

GND

HB2012_1000

C374

X302

25MHZ

C373

3.3V

R347

4.7K

20pF

20pF

1.2V

3.3V

CA308

220uF/6.3V

3.3V

HB2012_1000

GND

EFPWRQ33

RESER_P

EFPWQ

C343

2.2uF

L323

L324

L325

C348

2.2uF

R317

100K

GND

TP363

TP364

TP365

TP366

K3

J3

C338

0.1uF

J4

K4

J1

J2

K1

K2

L3

M3

0.1uF

L4

C340

M5

TP346

L1

L2

TP347

TP348

M1

TP349

M2

C342

0.1uF

N5

M4

C345

C344

0.1uF

2.2uF

N2

P3

C347

0.1uF

GND

R316

10

P1

P2

N3

R318

N4

AE4

AD5

AE5

AF5

AF2

IR

C353

C352

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

DVCC3I0-2

DVCC3I0-3

DVCC3I0-3

DVCC3I0-2

DVCC3I0-2

DVCC3I0-2

DVCC3I0-1

DVCC3I0-1

DVCC3I0-1

EFPWRQ-U

EFPWRQ-T

C354

0.1uF

C355

0.1uF

C356

0.01uF

C357

0.01uF

C358

0.1uF

C359

0.01uF

0.01uF

C360

C361

IC301

MT8520

0.1uF

C362

0.01uF

C363

0.1uF

C364

0.1uF

C365

0.1uF

0.01uF

0.01uF

C368

C367

C366

ETMDIO

ETMDC

ETTXEN

ETTXER

ETTXCLK

ETTXD0

ETTXD1

ETTXD2

ETTXD3

ETRXCLK

ETRXD0

ETRXD1

ETRXD2

ETRXD3

ETRXDV

ETRXER

ETCOL

ETCRS

AVDD33_USB

AVSS33_USB

AVDD12_USB

AVSS12_USB

USB_XTALO

USB_XTALI

USB_DPO

USB_DMO

USB_DP1

USB_DM1

USB_VRT

GPI00

GPI01

GPI02

GPI03

GPI010

GPI011

GPI014

SCL

SDA

C369

0.1uF

0.1uF

C370

AE3

AD4

AF3

AF4

AE1

AF1

G20

AC2

AD1

0.1uF

0.01uF

0.1uF

C392

C393

C371

GND

B7

E8

A3

D7

D5

B4

A4

C4

B3

E6

B5

A5

E7

D6

C5

C6

C3

B6

V4

U5

U4

T5

V1

V2

U2

U3

W2

W1

V3

C384

0.1uF

ETMDIO

ETMDC

ETTXEN

TP355

ETTXCLK

ETTXD0

ETTXD1

ETTXD2

ETTXD3

ETRXCLK

ETRXD0

ETRXD1

ETRXD2

ETRXD3

ETRXDV

ETRXER

ETCOL

ETCRS

L327

C385

4.7uF

L328

C386

C387

0.1uF

4.7uF

GND

TP375

TP376

USB_P

USB_N

TP356

TP357

5.1K(1%)

R320

TP371

TP374

TP373

TP368

TP369

33

R321

33

R322

HB2012_1000

HB2012_1000

GND

ML

TIMER_RX

SCL_MC

SCL_MD

3.3V

1.2V

IC301

MT8520

B17

AVDD33_APLL

E16

AVSS33_APLL

A18

AVDD33_VDPLL

D17

AVSS33_VDPLL

B18

AVDD33_ARMPLL

E17

AVSS33_ARMPLL

C18

AVDD33_VDACR

E18

AVSS33_VDACR

D18

AVDD33_VDACY

D19

AVSS33_VDACY

C17

AVDD33_SYSPLL2

D16

AVSS33_SYSPLL2

C19

AVDD33_VDACBG

D20

AVSS33_VDACBG

AC26

AVDD33_DMPLL

AC25

AVSS33_DMPLL

D14

AVDD12_SYSPLL

E14

AVSS12_SYSPLL

A17

AVDD33_XTAL

C15

AVSS33_XTAL

AB24

AVDD33_DMXTAL

AA23

AVSS33_DMXTAL

AB25

DMXTALI

AB26

DMXTAL0

B16

XTALI

A16

XTAL0

C16

TXP

D15

TXN

W5

RESET#

R3

AVDD33_SACD

P4

AVSS33_

R4

T4

R5

P5

W4

V5

W3

Y1

Y2

A22

GND

SACD

AVDD12_ADCD

AVSS12_ADCD

AVDD12_ADC

AVSS12_ADC

AVDD10_RTC

AVSS_RTC

RTCRBIAS

XI_RTC

XO_RTC

DACVREF

AOSDATA0

AOSDATA1

AOSDATA2

AOSDATA3

AOSDATA4

AOSDATA5

AVDD10_HDMI

AVDD33_HDMI

AVDD33_HDMI

AVSS_HDMI

AVSS_HDMI

AVSS_HDMI

NS_CKIN_33

AOMCLK

AOBCK

AOLRCK

SPDIF

MCIN

AMUTE

IOR

IOB

IOG

IOX

IOC

IOY

FS

PWM0

CLK_P

CLK_M

CHO_P

CHO_M

CH1_P

CH1_M

CH2_P

CH2_M

HTPLG

CEC

HDMISD

HDMISCK

EXT_CAP

EXT_RES

NS_TSTP

NS_TSTN

NS_RFIP

NS_RFIN

A10

B10

D10

E10

B19

B20

A20

C20

A21

B21

C21

E19

C12

C13

C14

C11

D12

D13

A14

B14

A13

B13

A12

B12

A11

B11

E12

D11

C10

E11

A15

B15

C9

B9

B8

A8

D9

C8

A7

C7

T3

T1

T2

R2

R1

4.7uF

C372

2

GND

VCC

GND

OUT

IC302

R348

N.C(10K)

1

3

R346

CA307

22uF/6.3V(N.C)

GND

N.C(0)

RESET#

2-4

Page 27

MPEG4-2 CIRCUIT DIAGRAM

1.8V

DDR2_VREF

0.1uF

0.1uF

C629

C630

GND

R601

75(1%)

R602

75(1%)

R605

R603

R608

R606

;3:B4

DDR2_A_RA[0-13]

0

0

0

0

DDR2_A_DQ[0-31]

1.8V

1uF

220uF/6.3V

220uF/6.3V

CA601

GND

DDR2_VREF

220uF/6.3V

N.C (220uF/6.3V)

CA604

CA603

DDR2_0V9

C623

0.1uF

CA605

C601

CA606

0.1uF

0.1uF

C603

C602

C624

220uF/6.3V

0.1uF

0.1uF

C604

0.1uF

C605

CA607

220uF/6.3V

GND

0.1uF

C606

1

2

3

4

0.1uF

C607

0.1uF

C608

NC

GND

VSENSE

VREF

0.1uF

C609

IC601

G2995P1X

0.1uF

C610

0.1uF

C611

VTT

PVIN

AVIN

VDDQ

0.1uF

C612

3.3V

0.1uF

C613

8

7

6

5

0.1uF

C614

R615

N.0(0)

R616

0.1uF

C615

0.1uF

C616

0

CA608

220uF/6.3V

GND

0.1uF

C617

0.1uF

C618

0.1uF

C625

0.1uF

C619

0.1uF

C631

0.1uF

C620

0.1uF

C621

C632

0.1uF

C622

0.1uF

DDR2 SDRAM LAYOUT GUIDE

1) a. DQS pairs will eventually have length matching rule to their respective byte lane data

b. CK pairs will eventually have length matching rule to address lines

2) The decaps and VREF resistors and caps should be laid out near the associated balls.For 7440 they should be

backside in the depopulated ring. VREF is the most senstive net ( in terms of isolation ) to route.

3) use top and bottom layers only.

4) Lay out escape plan per attached sketch

5) Complete the layout of the wires in the following order. Keeping signals on their layer as much as possible:

CK pairs

DQS diff pairs

DQ and DM

remaining signals

6) Signals can be freely substituted within the follwing groups: [RS] if this is done, the schematic should be updated to mach

DQ[7:0] DQ[15:8] DQ[23:16] DQ[31:24]

7) Diff pairs should be routed together 4 mil etch 4 mil spacing

8) Signals should be routed 4 mil etch 4 mil space min, 8 mil spacing mostly.

9) Keep data lines separate from address lines, to avoid x-talk between the two

10) Prepare wire length report and schedule a review

11) LENGTH RULE: Data bits DDA2_n_DATA[31:0] <=1.5

12) Keep decoupling caps on back side out from beneath backing plate.

13) Route clocks as differential pairs - Match differential impedance

60 ohm to plane.

120 ohm on pair

DDR2_D_CLK0

R604

100_1%

DDR2_D_CLK0#

DDR2_D_CLK1

R607

100_1%

DDR2_D_CLK1#

DDR2_A_0DT

0.1uF

C633

1.8V

CA609

330uF/6.3V

IC301

MT8520

V21

BDQ0

W23

BDQ1

AA25

BDQ2

W22

BDQ3

Y22

BDQ4

Y24

BDQ5

W21

BDQ6

U20

BDQ7

T23

BDQ8

U25

BDQ9

T22

BDQ10

U22

B

DQ11

V25

B

DQ12

U26

B

DQ13

T21

B

DQ14

U24

B

DQ15

K21

B

DQ16

K23

B

DQ17

K22

B

DQ18

K24

B

DQ19

J25

B

DQ20

J21

B

DQ21

H24

B

DQ22

J23

B

DQ23

G22

B

DQ24

H22

B

DQ25

G21

B

DQ26

E26

BDQ27

F25

BDQ28

F23

BDQ29

E25

BDQ30

E24

B

DQ31

W24

D4

DVSS

E5

DVSS

E23

DVSS

F21

DVSS

F22

DVSS

F24

DVSS

K10

DVSS

K13

DVSS

K14

DVSS

K17

DVSS

L12

DVSS

L15

DVSS

L21

DVSS

L23

DVSS

M11

DVSS

M12

DVSS

M13

DVSS

M14

DVSS

M15

DVSS

M16

DVSS

M22

DVSS

M24

DVSS

N10

DVSS

N12

DVSS

N13

DVSS

N14

DVSS

N15

DVSS

N17

DVSS

P10

DVSS

P12

DVSS

P13

DVSS

P14

DVSS

P15

DVSS

P17

DVSS

R11

DVSS

R12

DVSS

R13

DVSS

R14

DVSS

R15

DVSS

R16

DVSS

T12

DVSS

T15

DVSS

U10

DVSS

U13

DVSS

U14

DVSS

U17

DVSS

DVSS

U23

DVSS

V22

DVSS

V24

DVSS

AA11

DVSS

AA17

DVSS

AA21

DVSS

AB6

DVSS

AB12

DVSS

AB18

DVSS

AB22

DVSS

AC6

DVSS

AC11

DVSS

AC17

DVSS

AC23

DVSS

AD12

DVSS

AD18

DVSS

AD24

DVSS

GND

BDQM0

BDQM1

BDQM2

BDQM3

B

DQS0

B

DQSB0

BDQS1

BDQSB1

BDQS2

BDQSB2

B

DQS3

BDQSB3

B

BA0

B

BA1

BBA2

B

CAS#

B

CKE

BRAS#

BRCS#

BRWE#

BRA0

BRA1

BRA2

BRA3

BRA4

BRA5

BRA6

BRA7

BRA8

BRA9

BRA10

BRA11

BRA12

BRA13

B

RCLK

B

RCLKB

B

RCLK1

B

RCLKB1

B

0DT

VDD_BRVREF

V23

G26

G23

Y25

Y26

W26

W25

H25

H26

G25

G24

L24

M23

L25

P20

K25

T24

R23

K26

P26

N26

P22

L26

R25

M25

M24

M21

P25

N23

N25

N21

N22

P24

T25

T26

D25

D26

R21

L22

DDR2_B_DQ[0]

DDR2_B_DQ[1]

DDR2_B_DQ[2]

DDR2_B_DQ[3]

DDR2_B_DQ[4]

DDR2_B_DQ[5]

DDR2_B_DQ[6]

DDR2_B_DQ[7]

DDR2_B_DQ[8]

DDR2_B_DQ[9]

DDR2_B_DQ[10]

DDR2_B_DQ[11]

DDR2_B_DQ[12]

DDR2_B_DQ[13]

DDR2_B_DQ[14]

DDR2_B_DQ[15]

DDR2_B_DQ[16]

DDR2_B_DQ[17]

DDR2_B_DQ[18]

DDR2_B_DQ[19]

DDR2_B_DQ[20]

DDR2_B_DQ[21]

DDR2_B_DQ[22]

DDR2_B_DQ[23]

DDR2_B_DQ[24]

DDR2_B_DQ[25]

DDR2_B_DQ[26]

DDR2_BDQ[27]

DDR2_B_DQ[28]

DDR2_B_DQ[29]

DDR2_B_DQ[30]

DDR2_B_DQ[31]

DDR2_B_DQM[0]

DDR2_B_DQM[1]

DDR2_B_DQM[2]

DDR2_B_DQM[3]

DDR2_B_DQS0

DDR2_B_DQS0#

DDR2_B_DQS1

DDR2_B_DQS1#

DDR2_B_DQS2

DDR2_B_DQS2#

DDR2_B_DQS3

DDR2_B_DQS3#

DDR2_B_BA[0]

DDR2_B_BA[1]

DDR2_B_BA[2]

DDR2_B_CAS#

DDR2_B_CKE

DDR2_B_RAS#

DDR2_B_CS#

DDR2_B_WE#

DDR2_B_RA[0]

DDR2_B_RA[1]

DDR2_B_RA[2]

DDR2_B_RA[3]

DDR2_B_RA[4]

DDR2_B_RA[5]

DDR2_B_RA[6]

DDR2_B_RA[7]

DDR2_B_RA[8]

DDR2_B_RA[9]

DDR2_B_RA[10]

DDR2_B_RA[11]

DDR2_B_RA[12]

DDR2_B_RA[13]

DDR2_B_CLK0

B

_CLK0#

DDR2_

B

DDR2_

B

DDR2_

DDR2_B_0DT

DDR2_

VREF

0.1uF

C628

GND

IC301

MT8520

H21

VCC18I0

H23

VCC18I0

J22

VCC18I0

J24

VCC18I0

P21

VCC18I0

P23

VCC18I0

R22

VCC18I0

R24

VCC18I0

Y21

VCC18I0

Y23

VCC18I0

AA8

VCC18I0

AA14

VCC18I0

AA20

VCC18I0

AA22

VCC18I0

AA24

VCC18I0

AB9

VCC18I0

AB15

VCC18I0

AB21

VCC18I0

AB23

VCC18I0

AC8

VCC18I0

AC14

VCC18I0

AC20

VCC18I0

AC22

VCC18I0

AC24

VCC18I0

AD9

VCC18I0

AD15

VCC18I0

AD21

VCC18I0

AD23

VCC18I0

AD25

VCC18I0

AE24

VCC18I0

AE25

VCC18I0

AE26

VCC18I0

AF25

VCC18I0

AA16

VDD_ARVREF

AB16

VDD_ARVREF

1.8V

AF24

REXTUP

AD26

REXTDN

GND

ARCLKB1

ADQ0

ADQ1

ADQ2

ADQ3

ADQ4

ADQ5

ADQ6

ADQ7

ADQ8

ADQ9

ADQ10

ADQ11

ADQ12

ADQ13

ADQ14

ADQ15

ADQ16

ADQ17

ADQ18

ADQ19

ADQ20

ADQ21

ADQ22

ADQ23

ADQ24

ADQ25

ADQ26

ADQ27

ADQ28

ADQ29

ADQ30

ADQ31

ADQM0

ADQM1

ADQM2

ADQM3

ADQS0

ADQSB0

ADQS1

ADQSB1

ADQS2

ADQSB2

ADQS3

ADQSB3

ABA0

ABA1

ABA2

ARAS#

ACAS#

ACKE

ARCS#

ARWE#

ARA0

ARA1

ARA2

ARA3

ARA4

ARA5

ARA6

ARA7

ARA8

ARA9

ARA10

ARA11

ARA12

ARA13

ARCLK

ARCLKB

ARCLK1

A0DT

AC7

AB8

AD7

AB7

AA7

AA9

Y8

AE6

AF10

AB11

AA10

AE9

AD8

AE10

AC10

AD10

AE17

AE18

AC18

AF17

AB17

AA18

AD17

AD19

AD22

AB20

AF22

AD20

AB19

AE22

AC21

AE21

AC9

AB10

AC19

AA19

AE7

AF7

AF8

AE8

AE19

AF19

AF20

AE20

AE16

AD16

AC15

AC12

AE12

AC16

Y11

AA15

AC13

AA13

AB13

AF16

AA12

AE15

AF13

AE14

AD13

AD14

AB14

AF14

Y14

AE13

AE11

AF11

AE23

AF23

AD11

DDR2_A_DQ[0]

DDR2_A_DQ[1]

DDR2_A_DQ[2]

DDR2_A_DQ[3]

DDR2_A_DQ[4]

DDR2_A_DQ[5]

DDR2_A_DQ[6]

DDR2_A_DQ[7]

DDR2_A_DQ[8]

DDR2_A_DQ[9]

DDR2_A_DQ[10]

DDR2_A_DQ[11]

DDR2_A_DQ[12]

DDR2_A_DQ[13]

DDR2_A_DQ[14]

DDR2_A_DQ[15]

DDR2_A_DQ[16]

DDR2_A_DQ[17]

DDR2_A_DQ[18]

DDR2_A_DQ[19]

DDR2_A_DQ[20]

DDR2_A_DQ[21]

DDR2_A_DQ[22]

DDR2_A_DQ[23]

DDR2_A_DQ[24]

DDR2_A_DQ[25]

DDR2_A_DQ[26]

DDR2_A_DQ[27]

DDR2_A_DQ[28]

DDR2_A_DQ[29]

DDR2_A_DQ[30]

DDR2_A_DQ[31]

DDR2_A_DQM[0]

DDR2_A_DQM[1]

DDR2_A_DQM[2]

DDR2_A_DQM[3]

DDR2_A_DQS0

DDR2_A_DQS0#

DDR2_A_DQS1

DDR2_A_DQS1#

DDR2_A_DQS2

DDR2_A_DQS2#

DDR2_A_DQS3

DDR2_A_DQS3#

DDR2_A_BA[0]

DDR2_A_BA[1]

DDR2_A_BA[2]

DDR2_A_RAS#

DDR2_A_CAS#

DDR2_A_CKE

DDR2_A_CS#

DDR2_A_WE#

DDR2_A_RA[0]

DDR2_A_RA[1]

DDR2_A_RA[2]

DDR2_A_RA[3]

DDR2_A_RA[4]

DDR2_A_RA[5]

DDR2_A_RA[6]

DDR2_A_RA[7]

DDR2_A_RA[8]

DDR2_A_RA[9]

DDR2_A_RA[10]

DDR2_A_RA[11]

DDR2_A_RA[12]

DDR2_A_RA[13]

DDR2_A_CLK0

DDR2_A_CLK0#

DDR2_A_CLK1

DDR2_A_CLK1#

_CLK1

_CLK1#

R611

R609

R614

R612

;3:B4

0

100_1%

0

0

100_1%

0

DDR2_A_DQ[0-31]

DDR2_B_RA[0-13]

R610

R613

DDR2_D_CLK2

D

_CLK2#

DDR2_

DDR2_D_CLK3

DDR2_D_CLK3#

2-5

Page 28

KEY CIRCUIT DIAGRAM

2

SW401

LED401

1

2

3

PN401

STBY_LED

PWR_KEY

DGND

Power

1

GND

GND

2-6

Page 29

TIMER CIRCUIT DIAGRAM

RESET

5.3VA

CN502

USB_VCC

USB_D-

USB_D+

GND

GND

GND

5V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

GND

USB

1

2

3

4

5

6

GND

C514

0.1uF

GND

CN501

5V

5V

-29VA

D1

RESET

D3

D2

INST_OPEN

PWR_CTRL

A_MUTE

HDMI_CEC

GND

FD+

Timer Tx

Timer Rx

GND

FD-

5.3VA

PWR_CTRL _5.3V

GND

USB_N

USB_P

GND

R568

R563

5.3VA

FLASH D/L

TXD

VDD

CLK

GND

PVX01

1

5.3VA

R551

0(N.C)

-29VA

CEC

FD+

TX0

RX0

FD-

1K

D1

D3

D2

X2

X1

C527

100nF(N.C)

GND

GND

BZX84-C6V8

X2

X1

GND

5.3VA

ZD504

BZX84-C6V8

100nF

ZD501

R554

C524

R503

0

100nF

C501

GND

10K

CE502

22uF/16V

C525

1uF

F/W HW Option

BD400 GND

BD300 Open

C504

C503

100nF

100nF

5.3VA

R552

330

GND

IC504

KTA7042AT

3

GND

C505

18pF

X501

10MHz

C506

18pF

OUT

R539

1

VCC

RESET#

INST_OPEN

PWR_CTRL

A_MUTE

P_CON_5.3V

4

1

R507

1M

2

3

2

GND

0

0

GND

GND

10

11

C502

12

1uF

13

14

GND

IC506

2SC5344Y

C

ZD503

BZX84-C3V6

15

16

B

GND

JIG502

JIG501

GND

64

63

PAL

1

NC

NT/PAL OPT

2

Self program Mode

3

NC

4

NC

5

NC

6

RESET

7

XT2(32.768Khz)

8

XT1(32.768Khz)

9

DownLoad(10K Pulldown)

X2(10.0Mhz)

X1(10.0Mhz)

REGC

VSS

EVSS

VDD

EVDD

IIC_CLK

17

18

3.3VA

E

C532

1uF

GND

RESET

2

3

4

JIG503

X2

RESET#

62

61

OPTION_RTN1

HOST_RESET_L

HOST_ENA_L(H)

IIC_DATA

NC

20

19

R567

0

C526

1uF

CEC

RXD

FLMD0

6

5

7

JIG505

JIG504

JIG506

58

60

59

HOST_CLK_IN

HOST_DATA_IN

HOST_DATA_OUT

IC501

uPD78F0535GK

- PIN 10- 11 : 9.8304MHz

CEC_TX

CEC_RX

NC

NC

23

22

21

5.3VA

R509

100K

D501

RB501V-40

D

G

IC505

2SK3018-T106

PORT

8

JIG507

TX0

GND

57

55

56

NC

DIG_LINK_TV_H

A_MUTE

NC

24

26

25

A_MUTE

3.3VA

S

R555

RX0

ZD502

BZX84-C6V8

54

53

52

NC

NC

NC

INSTANT_OPEN

3.3V POWER_CTL_H

DIMMER_RESET

28

29

27

0

R560

INST_OPEN

P_CON_5.3V

PWR_CTRL

27K

R553

D502

RB501V-40

C528

0

1500pF(N.C)

GND

Tx Rx Level Shifter

C530

100pF

GND

KEY_RTN_0

100

R524

49

50

51

NC

NC

KEY_RTN1

48

KEY_RTNO

AVSS

47

AVRE F

46

FLD_CLK

45

FLD_DATA_IN

44

FLD_DATA_OUT

FLD_ENA_L

REMOCON_IN

NC

32

31

43

42

41

40

NC

39

NC

38

37

D3

36

D2

35

D1

34

NC

33

NC

NC

10K

10K

R540

R541

GND

GND

D2

D1

D3

FLASH_DOWNLOAD

FLASH_DOWNLOAD

PWR_CTL_H

NC

30

CEC

R543

100

R547

100

R548

100

C531

100pF

GND

GND

5.3VA

5.3VA

GND

GND

5.3VA

GND

GND

R542

10K

R544

7.5K

R549

10K

R550

7.5K

C511

1uF

R545

10K

R546

7.5K

R558

10K

R517

10K

R536

5.3VA

1K

R512

100

5.3VA

5.3VA

R535

DIG501

HNS-06SC41

FD+ option

4G

2G

6G

5G

3G

NC

P1

F+

F+

2

R537

1

22

22

R538

C521

100nF

GND

GND

Q501

RC501

3

GND

2

VCC

1

OUT

RCU

Receiver

R513

330

CE503

47uF/16V

GND

C3205

R516

1K

R515

1K

R514

1K

5.3VA

L502

HB-1M2012-102JT

C517

10nF

GND

R564

33K

Q502

C

KRA103S

B

E

PWR_CTRL

FLD_DATA_OUT

BD_LED_CTRL

HD_LED_CTRL

GND

FLD_CLK

FLD_ENA_L

R565

0

C533

0.1uF

FD-

PO1

PO2

PO3

PO4

PO5

PO6

PO7

PO8

PO9

FD+

KEY_RTN_0

C529

0.1uF

CE501

R559

22uF/16V

10K

GND

GND

C510

GND

100nF

1K

P4

P5

P2

P3

10

8

7

9

6

5

P05

P04

P06

P03

P02

P01

VSS

12

VDD

13

SG1/KS1

14

SG2/KS2

15

SG3/KS3

16

SG4/KS4

17

SG5/KS5

18

SG6/KS6

19

SG7/KS7

20

SG8/KS8

21

SG9/KS9

22

SUB_KEY

P6

11

P07

K2

SG10/KS10

P10

P7

12

P08

11

K1

SG11/KS11

23

P11

P8

P9

14

13

P10

P09

FLD_CLK

FLD_ENA_L

10

9

CLK

STB

IC502

PT6315

SG12/KS12

SG13/KS13

24

25

13

P12

P

P10

15

P11

FLD_DATA_OUT

8

DIN

SG14/KS14

26

14

P

P11

16

P12

7

DOUT

SG15/KS15

27

15

P

P12

P13

6

OSC

SG24/GR5

SG23/GR6

SG22/GR7

SG21/GR8

SG20/GR9

SG16/KS16

28

KEY

2

SW501

Play/Pause

1

GND

R525

680

R526

820

2

SW502

Power ON/OFF

1

2

SW503

OPEN/CLOSE

1

R527

1.2K

1G

P13

P14

P15

23

24

21

17

18

20

19

G01

P14

P15

2

4

1

3

5

LED2

LED1

LED3

LED4

VSS

VDD

GR1

GR2

GR3

GR4

VEE

SG18/GR11

SG19/GR10

SG17/GR12

29

31

32

33

30

-29VA

22

G02

G03

HD_LED_CTRL

25

G05

G04

R523

56K

44

43

42

41

40

39

38

37

36

35

34

BD_LED_CTRL

26

G06

SUB_KEY

F-

30

29

C520

100nF

GND

FD-

GND

5.3VA

L503

HB-1M2012-102JT

CE504

47uF/16V

C519

22nF

F-

GO1

GO2

GO3

GO4

GO5

GO6

GND

From I/O_BRD to LED_BRD

CN503

1

SUB_KEY

2

GND

BD_LED_CTRL

3

HD_LED_CTRL

5V

GND

4

5

5V

SMD 5PIN 1MM

2-7

Page 30

DDR2-SDRAM CIRCUIT DIAGRAM

1.8V

1.8V

3:C5:B4

1uF

220uF/6.3V

0.1uF

0.1uF

C743

C742

C741

CA703

GND

1.8V

A1

VDD

F1

VDD

J9

VDD

M9

VDD

R1

VDD

A9

C1

C3

C7

C9

F9

G1

G3

G7

G9

J1

J2

K9

0DT

R9

R1

D9

D1

D3

D7

C2

DQ9

C8

DQ

8

F9

DQ

7

F1

DQ

6

H9

DQ

5

H1

DQ

4

H3

DQ

3

H7

DQ

2

G2

DQ

1

G8

DQ

0

B7

A8

F7

F8

A2

NC

F2

NC

DDR2_B_DQS1

DDR2_B_DQS1#

DDR2_B_DQS0

DDR2_B_DQS0#

0.1uF

0.1uF

0.1uF

0.1uF

C747

C746

C744

C745

Place as close as possible

in VDDL pin

DDR2_VREF

N.C

C757

GND

DDR2_B_ODT

0.1uF

C748

0.1uF

C749

0.1uF

C740

0.1uF

C751

0.1uF

C752

0.1uF

0.1uF

C753

C754

DDR2_B_DQ[15]

DDR2_B_DQ[14]

DDR2_B_DQ[13]

DDR2_B_DQ[12]

DDR2_B_DQ[11]

DDR2_B_DQ[10]

DDR2_B_DQ[9]

DDR2_B_DQ[8]

DDR2_B_DQ[7]

DDR2_B_DQ[3]

DDR2_B_DQ[5]

DDR2_B_DQ[6]

DDR2_B_DQ[1]

DDR2_B_DQ[2]

DDR2_B_DQ[4]

DDR2_B_DQ[0]

C755

0.1uF

C756

0.1uF

;3:B4

DDR2_B_DQ[0-31]

DDR2_A_RA[0-13]

DDR2_A_RA[13]

DDR2_A_RA[12]

DDR2_A_RA[11]

DDR2_A_RA[10]

DDR2_A_RA[9]

DDR2_A_RA[8]

DDR2_A_RA[7]

DDR2_A_RA[6]

DDR2_A_RA[5]

DDR2_A_RA[4]

DDR2_A_RA[3]

DDR2_A_RA[2]

DDR2_A_RA[1]

DDR2_A_RA[0]

DDR2_A_BA[2]

DDR2_A_BA[1]

DDR2_A_BA[0]

DDR2_D_CLK0

DDR2_D_CLK0#

DDR2_A_CKE

DDR2_A_CS#

DDR2_A_RAS#

DDR2_A_CAS#

DDR2_A_WE#

DDR2_A_DQM[1]

DDR2_A_DQM[0]

1uF

R7

NC[A15]

R3

NC[A14]

R8

A13

R2

A12

P7

A11

M2

A10/AP

P3

A9

P8

A8

P2

A7

N7

A6

N3

A5

N8

A4

N2

A3

M7

A2

M3

A1

M8

A0

L1

BA2/NC

L3

BA1

L2

BA0

J8

CK

K8

nCK

K2

CKE

L8

nCS

K7

nRAS

L7

nCAS

K3

nWE

B3

UDM

F3

LDM

A3

VSS

E3

VSS

J3

VSS

N1

VSS

P9

VSS

A7

VSSQ

B2

VSSQ

B8

VSSQ

D2

VSSQ

D8

VSSQ

F2

VSSQ

F8

VSSQ

H2

VSSQ

H8

VSSQ

E7

VSSQ

J7

VSSDL

IC701

HYB18TC1G160C2F-2.5(6-6-6)

VDD

VDD

VDD

VDD

VDD

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDL

VREF

0DT

DQ15

DQ14

DQ13

DQ12

DQ11

DQ10

DQ9

DQ

DQ

DQ

DQ

DQ

DQ

DQ

DQ

DQ

UDQS

nUDQS

LQDS

nLQDS

220uF/6.3V

0.1uF

0.1uF

C701

C703

C702

CA701

GND

1.8V

A1

F1

J9

M9

R1

A9

C1

C3

C7

C9

F9

G1

G3

G7

G9

J1

J2

K9

R9

R1

D9

D1

D3

D7

C2

C8

8

F9

7

F1

6

H9

5

H1

4

H3

3

H7

2

G2

1

G8

0

B7

A8

F7

F8

A2

NC

F2

NC

DDR2_A_DQS1

DDR2_A_DQS1#

DDR2_A_DQS0

DDR2_A_DQS0#

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

C708

C707

C709

C706

C704

C705

Place as close as possible

in VDDL pin

Place C717,c737,C757,C799

on each VREF ball as close as possible

DDR2_VREF

C717

N.C

DDR2_A_ODT

GND

GND

0.1uF

C710

0.1uF

C711

0.1uF

C712

0.1uF

C713

0.1uF

0.1uF

0.1uF

C716

C714

C715

DDR2_A_DQ[15]

DDR2_A_DQ[14]

DDR2_A_DQ[13]

DDR2_A_DQ[12]

DDR2_A_DQ[9]

DDR2_A_DQ[10]

DDR2_A_DQ[11]

DDR2_A_DQ[8]

DDR2_A_DQ[2]

DDR2_A_DQ[6]

DDR2_A_DQ[5]

DDR2_A_DQ[3]

DDR2_A_DQ[1]

DDR2_A_DQ[7]

DDR2_A_DQ[4]

DDR2_A_DQ[0]

;3:G6

DDR2_A_DQ[0-31]

DDR2_B_RA[0-13]

DDR2_B_RA[13]

DDR2_B_RA[12]

DDR2_B_RA[11]

DDR2_B_RA[10]

DDR2_B_RA[9]

DDR2_B_RA[8]

DDR2_B_RA[7]

DDR2_B_RA[6]

DDR2_B_RA[5]

DDR2_B_RA[4]

DDR2_B_RA[3]

DDR2_B_RA[2]

DDR2_B_RA[1]

DDR2_B_RA[0]

DDR2_B_BA[2]

DDR2_B_BA[1]

DDR2_B_RA[0]

DDR2_D_CLK2

DDR2_B_CLK2#

DDR2_B_CKE

DDR2_B_CS#

DDR2_B_RAS#

DDR2_B_CAS#

DDR2_B_WE#

DDR2_B_DQM[1]

DDR2_B_DQM[0]

IC703

HYB18TC512160B2F-2.5(6-6-6)

R7

NC

R3

NC

R8

NC

R2

A12

P7

A11

M2

A10/AP

P3

A9

P8

A8

P2

A7

N7

A6

N3

A5

N8

A4

N2

A3

M7

A2

M3

A1

M8

A0

L1

NC

L3

BA1

L2

BA0

J8

CK

K8

CK

K2

CKE

L8

CS

K7

RAS

L7

CAS

K3

WE

B3

UDM

F3

LDM

A3

VSS

E3

VSS

J3

VSS

N1

VSS

P9

VSS

A7

VSSQ

B2

VSSQ

B8

VSSQ

D2

VSSQ

D8

VSSQ

F2

VSSQ

F8

VSSQ

H2

VSSQ

H8

VSSQ

E7

VSSQ

J7

VSSDL

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDL

VREF

DQ15

DQ14

DQ13

DQ12

DQ11

DQ10

UDQS

UDQS

LQDS

LQDS

GND

1.8V

1.8V

1uF

220uF/6.3V

0.1uF

1uF

220uF/6.3V

0.1uF

0.1uF

C721

C723

C722

VDD

VDD

VDD

VDD

VDD

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ