Page 1

SERVICE MANUAL

PORTABLE MINIDISC PLAYER

XM-PX50WT

UB Hong Kong

XM-PX50WT

Area Suffix

Contents

Safety Precautions

Important for laser products

Attention when

MD pick up is exchanged

Disassembly method

Adjustment method

Maintenance of laser pickup

Replacement of laser pickup

Description of major ICs

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

1-2

1-3

1-4

1-5

1-11

1-12

1-12

1-13~25

No.20902

Jan. 2001

Page 2

XM-PX50WT

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original design

unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of

the product should not be made. Any design alterations or additions will void the manufacturer`s

warranty and will further relieve the manufacture of responsibility for personal injury or property

damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded

by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special safety characteristics are identified in

the Parts List of Service Manual. Electrical components having such features are identified by

shading on the schematics and by ( ) on the Parts List in the Service Manual. The use of a

substitute replacement which does not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of Service Manual may create shock, fire, or other

hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the original lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

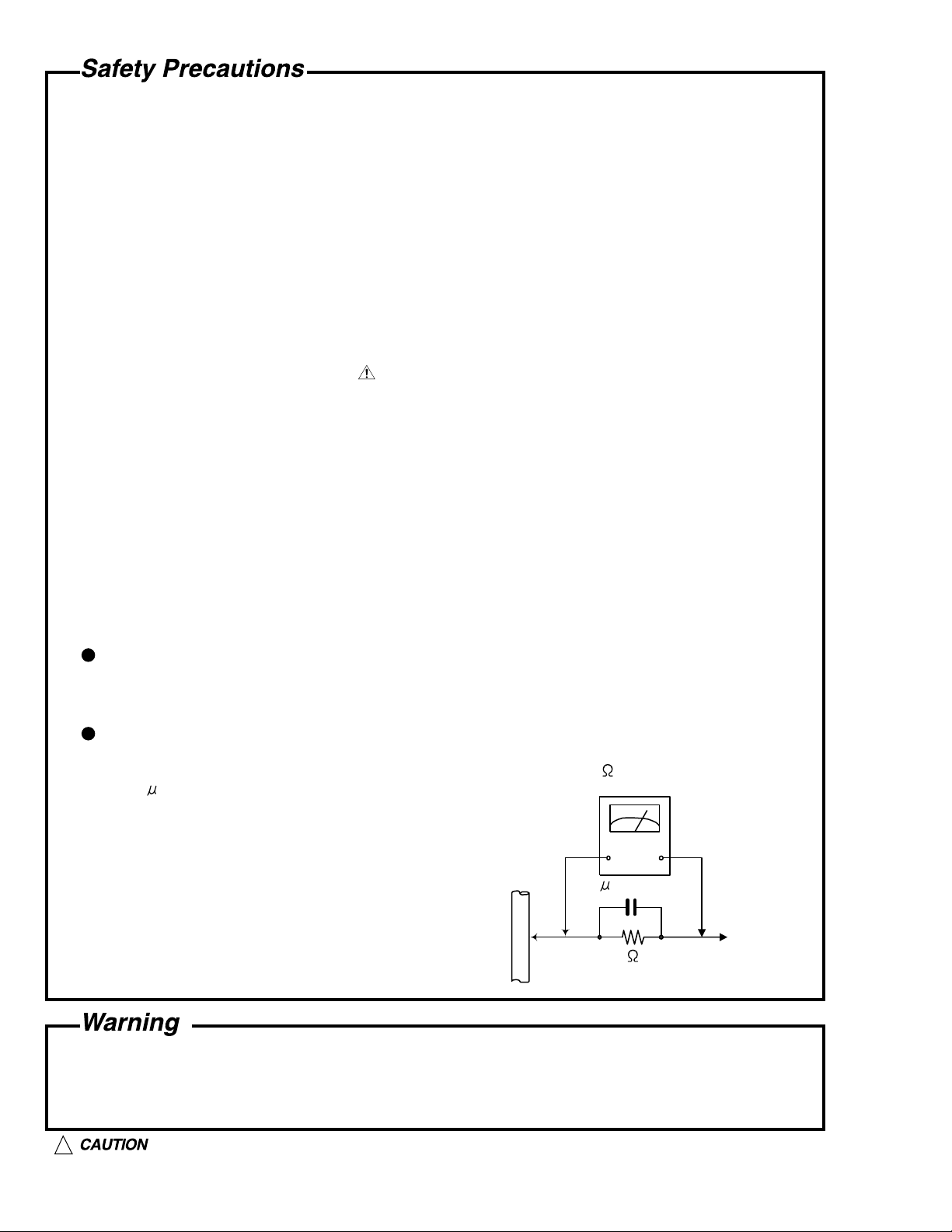

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts

of the product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control

shafts, etc.) to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure

the leakage current from each exposed metal parts of the cabinet , particularly any exposed

metal part having a return path to the chassis, to a known good earth ground. Any leakage

current must not exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms

per volt or more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by

a 0.15 F AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with the

AC voltmeter.

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Move the resistor connection to eachexposed metal

part, particularly any exposed metal part having a

return path to the chassis, and meausre the AC

voltage across the resistor. Now, reverse the plug in

the AC outlet and repeat each measurement. voltage

measured Any must not exceed 0.75 V AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Place this

probe on

each exposed

metal part.

This corresponds to 0.5 mA AC (r.m.s.).

Good earth ground

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

Page 3

Important for laser products

XM-PX50WT

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

VARNING : Osynlig laserstrålning är denna del är öppnad

och spårren är urkopplad. Betrakta ej strålen.

VARO : Avattaessa ja suojalukitus ohitettaessa olet

alttiina näkymättömälle lasersäteilylle.Älä katso

säteeseen.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

ADVARSEL : Usynlig laserstråling ved åbning , når

sikkerhedsafbrydere er ude af funktion. Undgå

udsættelse for stråling.

ADVARSEL : Usynlig laserstråling ved åpning,når

sikkerhetsbryteren er avslott. unngå utsettelse

for stråling.

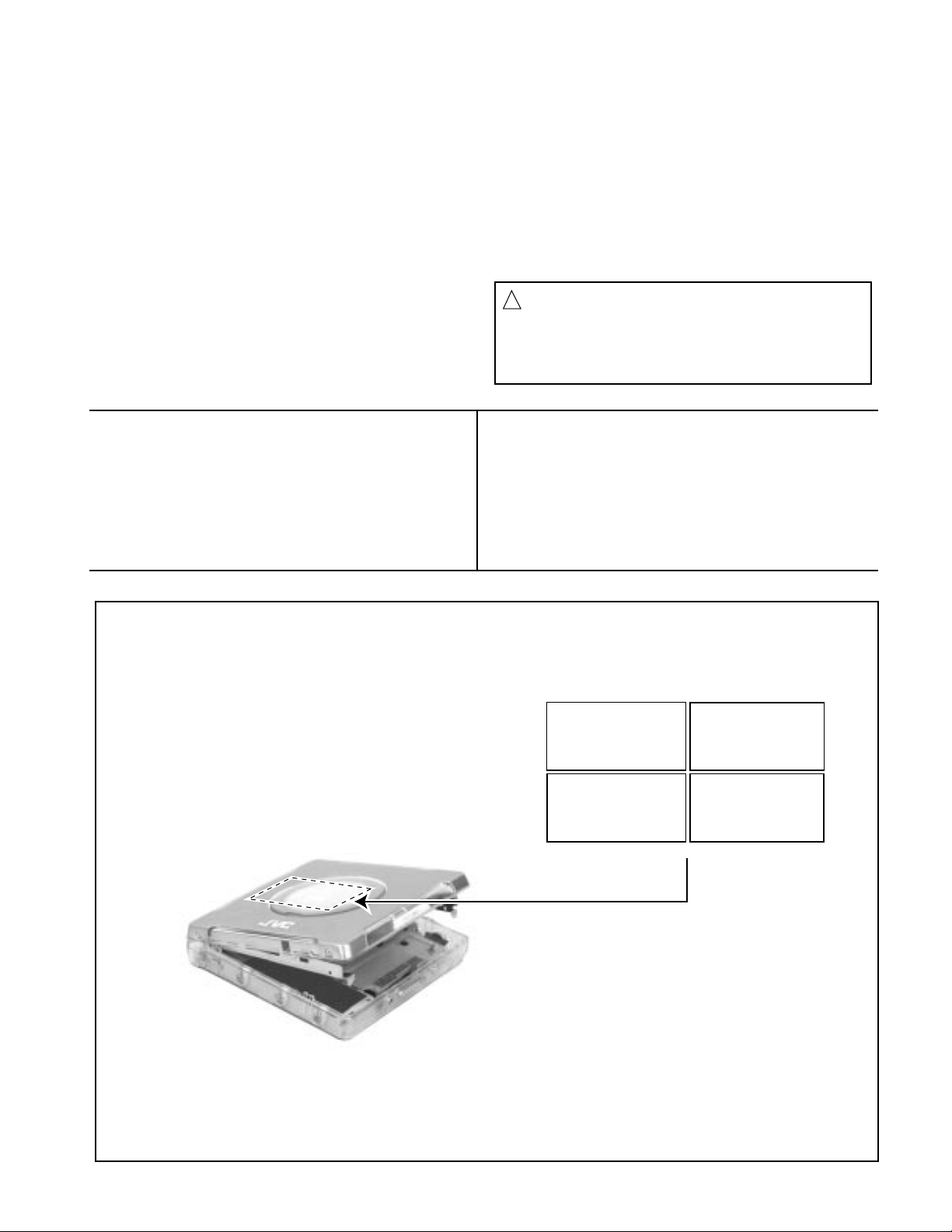

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

DANGER : Invisibie laser radiation

when open and interlock or

defeated.

AVOID DIRECT EXPOSURE TO

BEAM (e)

VARNING : Osynlig laserstrålning är

denna del är öppnad och spårren är

urkopplad. Betrakta ej strålen. (s)

VARO : Avattaessa ja suojalukitus

ohitettaessa olet alttiina

näkymättömälle lasersäteilylle.Älä

katso säteeseen. (d)

ADVARSEL :Usynlig laserstråling

ved åbning , når

sikkerhedsafbrydere er ude af

funktion. Undgå udsættelse for

stråling. (f)

1-3

Page 4

XM-PX50WT

Attention when MD pickup is exchanged

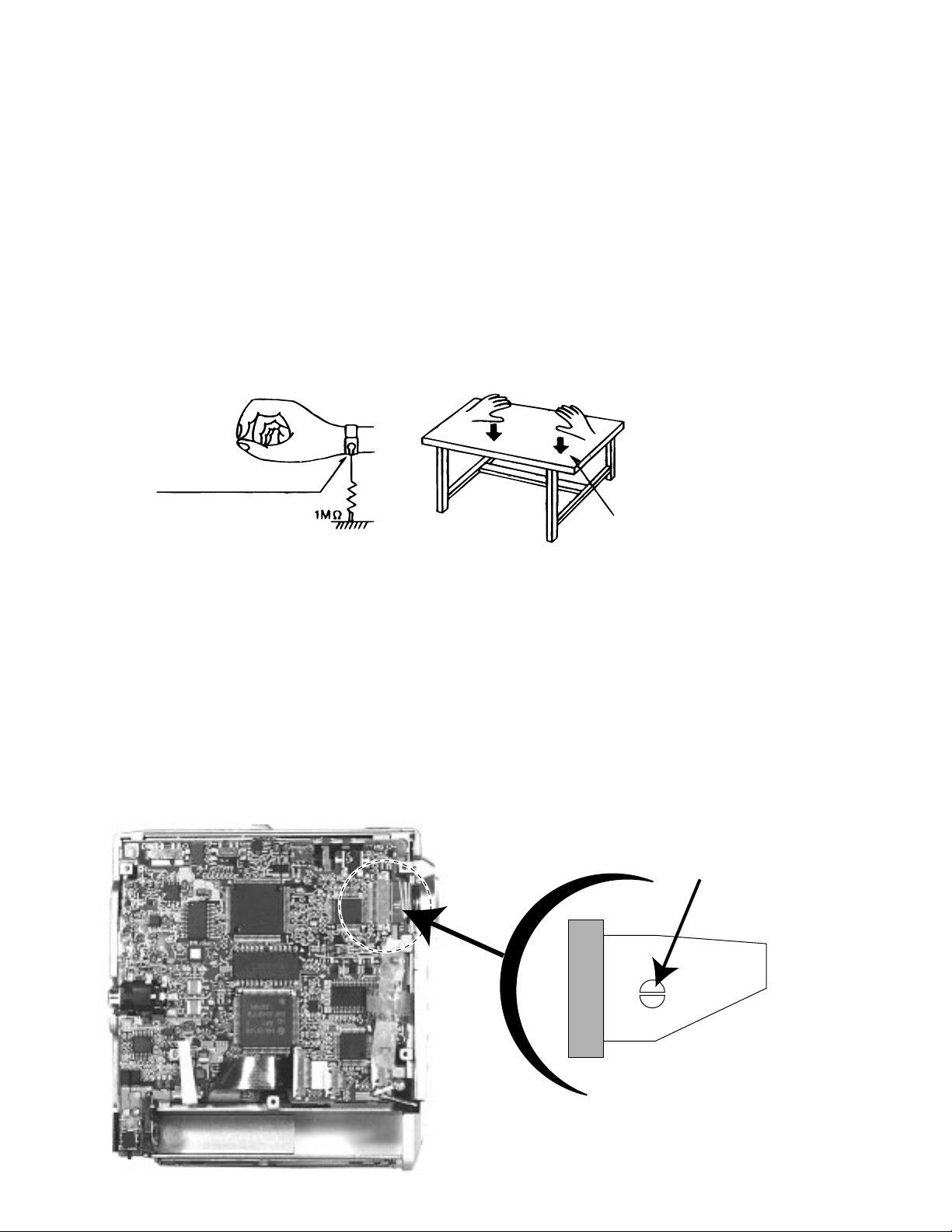

1. About the static electricity protection measures

The laser diode in the traverse unit (optical pick up) is easy to be destroyed by clothes and the human body

to the electrified static electricity.

Please note the explosion by static electricity when repairing.

2. About the earth processing for the electrostatic destruction prevention

In the equipment which uses an optical pick up (laser diode), an optical pick up is destroyed by the static

electricity of the work environment.

Please do the earth processing and work.

1) Earth of work stand

Please pull the conductive material (conductive sheet) or the iron plate to the depository

place of the traverse unit (optical pick up), and take the earth to ground.

2) Human body earth

Please use the anti-static wrist strap to exhaust the electrified static electricity to the human body.

anti-static wrist strap

Conductive material (conductive

sheet) or the iron plate

3. Handling the optical pick up

1) Please return according to a correct procedure based on short processing after exchanging

parts.

2) Do not use a tester to check the condition of the laser diode in the optical pick up .The tester 's internal

power source can easily destroy the laser diode.

4. Attention when unit is disassembled

Please refer to "Disassembling method" for how to detach .

1) Please be sure to solder before a flexible wire is removed from connector on a main printed

circuit board as shown.

if you removes without soldering.the MD picking up assembly might destroy

2) When installing , solder in the part of short round should be removed after a flexible wire is connected with

connector.

Solder short

1-4

Page 5

XM-PX50WT

Disassembly method

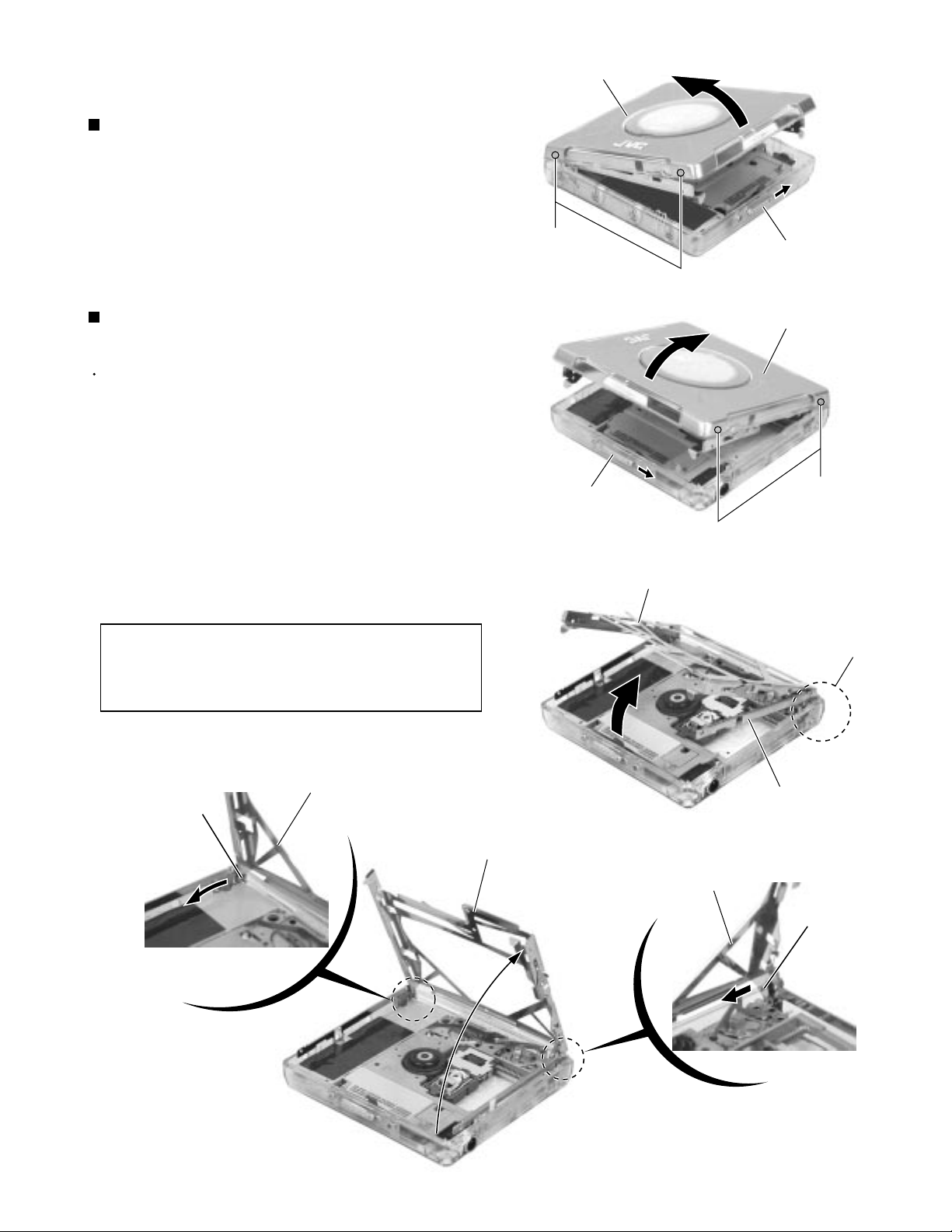

Removing the MD door assembly

(See Fig.1 and 2)

1.

Shift the door lever to open the door.

2.

Remove the four screws A and detach the MD

assembly from the main body.

Removing the holder assembly

(See Fig.3 and 4)

Prior to performing the following procedure, remove

the MD door assembly.

1.

Turn the Holder assembly as shown in Fig.3.

2.

Pull the side arm (L) marked a and

Open the Holder assembly as

shown in Fig.4.

remove outward.

door

MD door assembly

A

Door lever

Door lever

Fig.1

MD door assembly

A

3.

Move the “U-shaped” notch marked b in the direction

of the arrow and release it from the shaft.

4.

Move the part c inward and pull out the Holder

assembly from the shaft.

ATTENTION:

”U-shaped” notch

When reassembling, first reattach the

part c to the shaft of the Chassis

assembly. And next, fit the “U-shaped”

notch to the shaft.

assembly

Holder

Part b

Holder

assembly

Holder

Fig.2

assembly

Fig.3

Holder

Part a

Side arm (L)

assembly

Part c Shaft

Fig.4

Part c

1-5

Page 6

XM-PX50WT

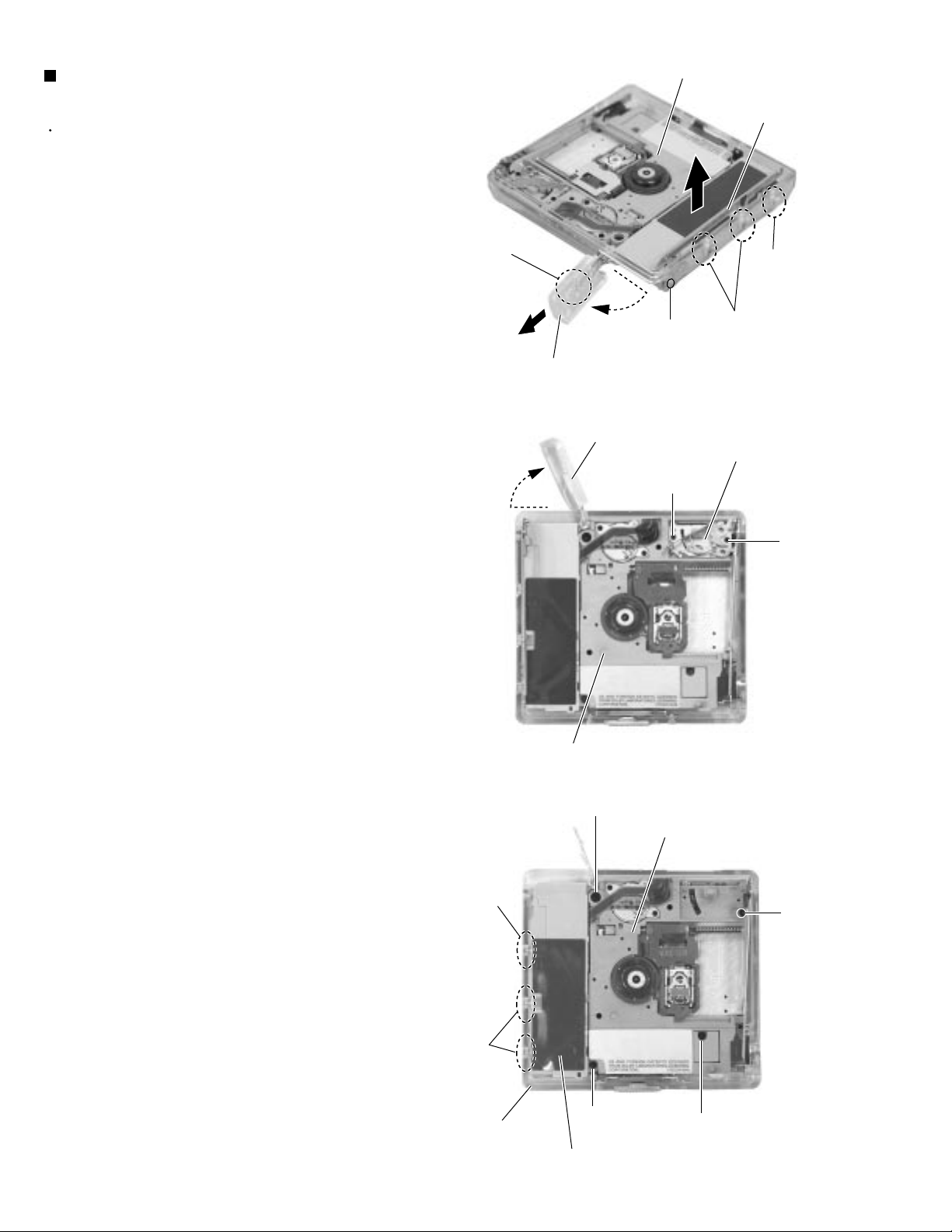

Removing the chassis assembly

(See Fig.5 to 7)

Prior to performing the following procedure, remove

the MD door assembly and the holder assembly.

1.

Open the battery lid. Release the tab d and pull out

the battery lid.

2.

Remove the screw B and pull out the side arm (R)

upward.

3.

Remove the two screws C and pull out the eject unit.

4.

Remove the screw D, E, F and G attaching the

chassis assembly respectively.

5.

Disengage the three joints e of the bottom case and

the battery holder. Remove the chassis assembly

and the jack cover at once.

Tab d

Chassis assembly

Side arm (R)

Joint e

Joints e

B

Battery lid

Fig.5

Battery lid

Eject unit

C

Joint e

C

Chassis assembly

Fig.6

D

Chassis assembly

G

1-6

Joints e

Bottom case

E

Battery holder

F

Fig.7

Page 7

XM-PX50WT

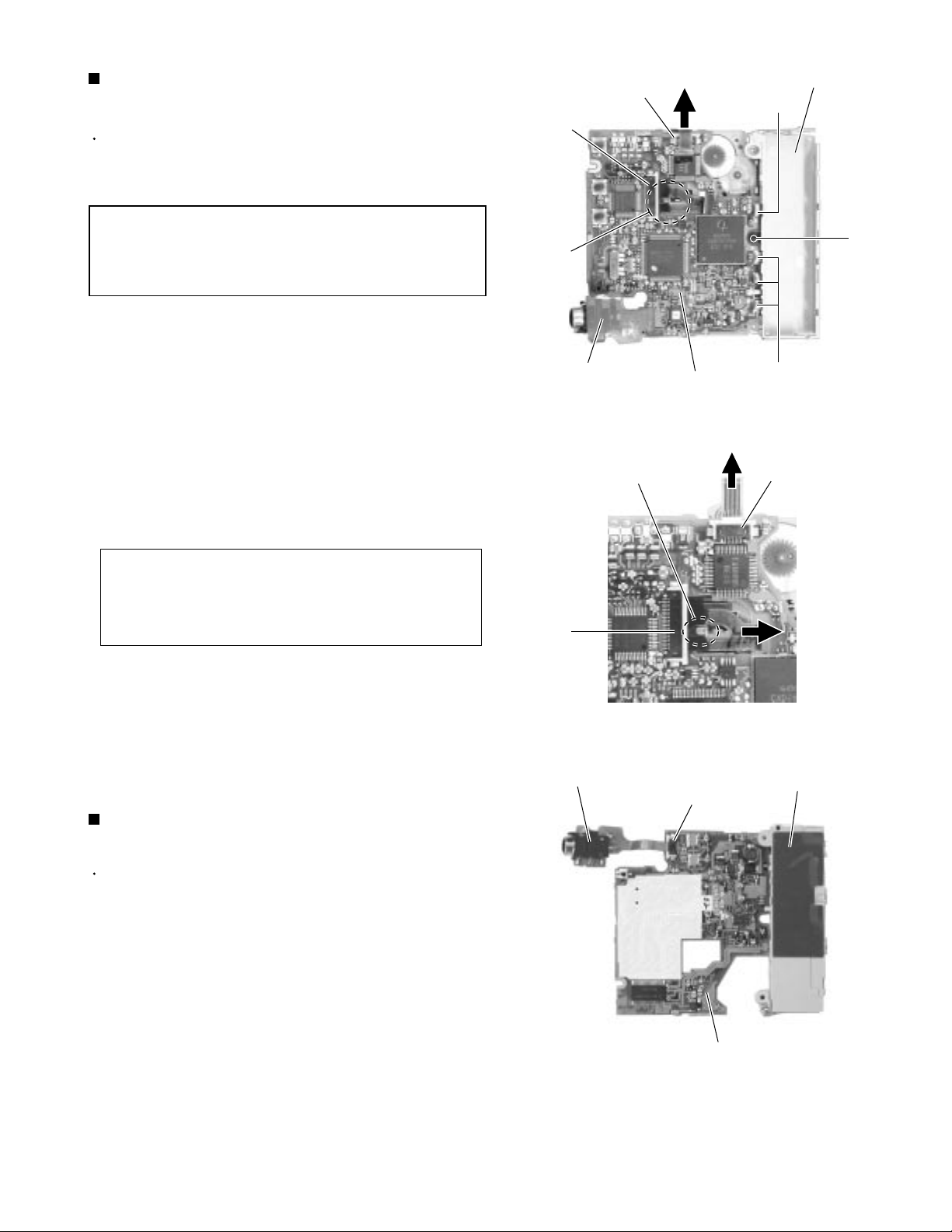

Removing the main board and the

battery holder (See Fig.8 and 9)

Prior to performing the following procedures, remove

the MD door assembly, the holder assembly and the

chassis assembly.

ATTENTION:

1.

Solder the short circuit round of the flexible wire on

the main board.

Disconnect the flexible wires from connector CN301

and CN401 on the main board.

Remove the one screw H attaching the main board.

Remove the main board with the battery holder .

Unsolder the four soldered parts f retaining the main

board and the battery holder.

Before disconnecting the flexible wire

extending from the pickup, make sure to

solder the short circuit round to prevent

damage to the pickup.

CN401

CN301

Short circuit

round

Headphone jack assembly

Short circuit round

Main board

Fig.8

Battery holder

Soldering f

H

Soldering f

CN401

ATTENTION:

When reassembling, connect the

flexible wire extending from the pickup

to the connector on the main board

and unsolder the short circuit round.

Removing the headphone jack assembly

(See Fig.10)

Prior to performing the following procedures, remove

the MD door assembly, the holder assembly, chassis

assembly and the main board.

1.

Disconnect the flexible wire extending from the

headphone jack from connector CN601 on the main

board.

CN301

Headphone jack assembly

Fig.9

Battery holder

CN601

Main board

Fig.10

1-7

Page 8

XM-PX50WT

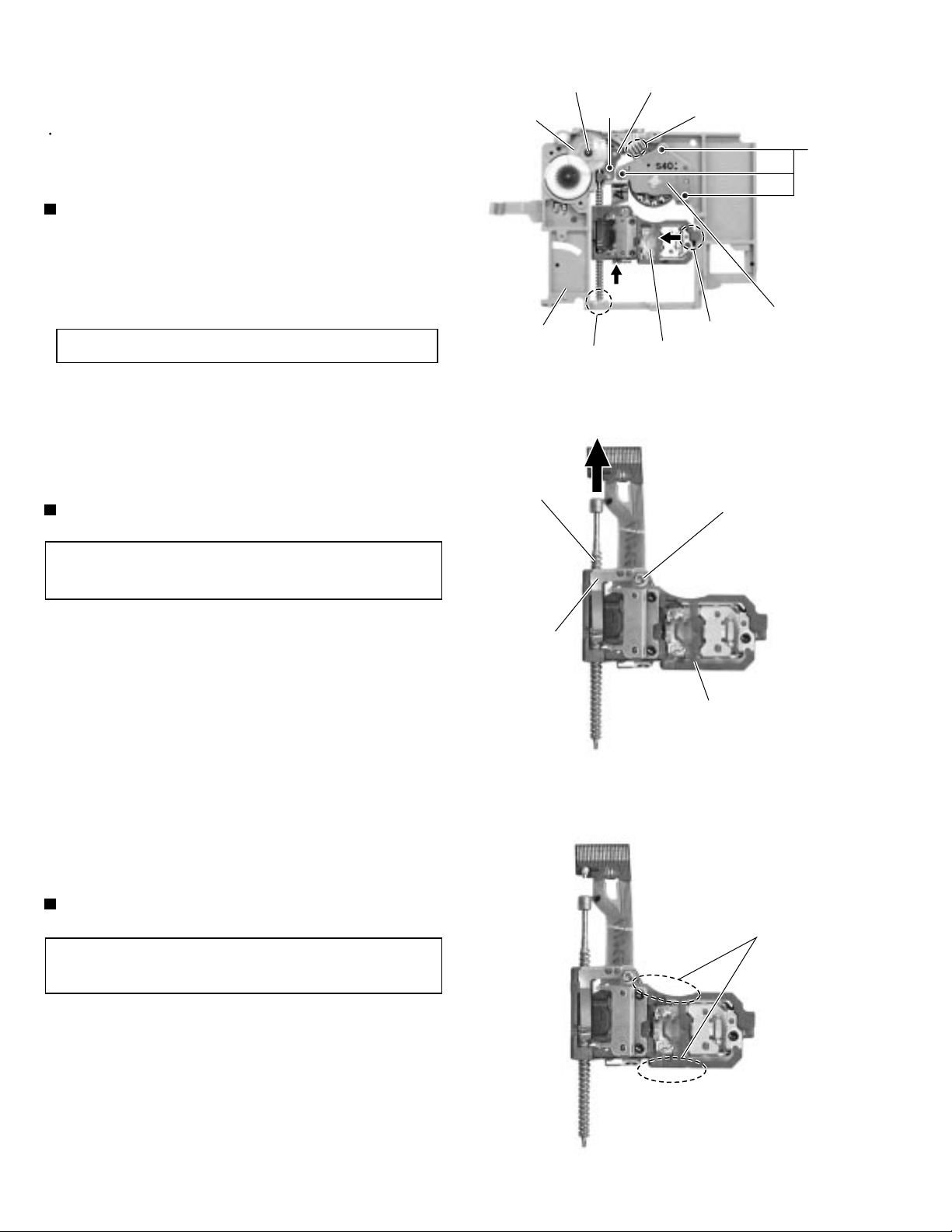

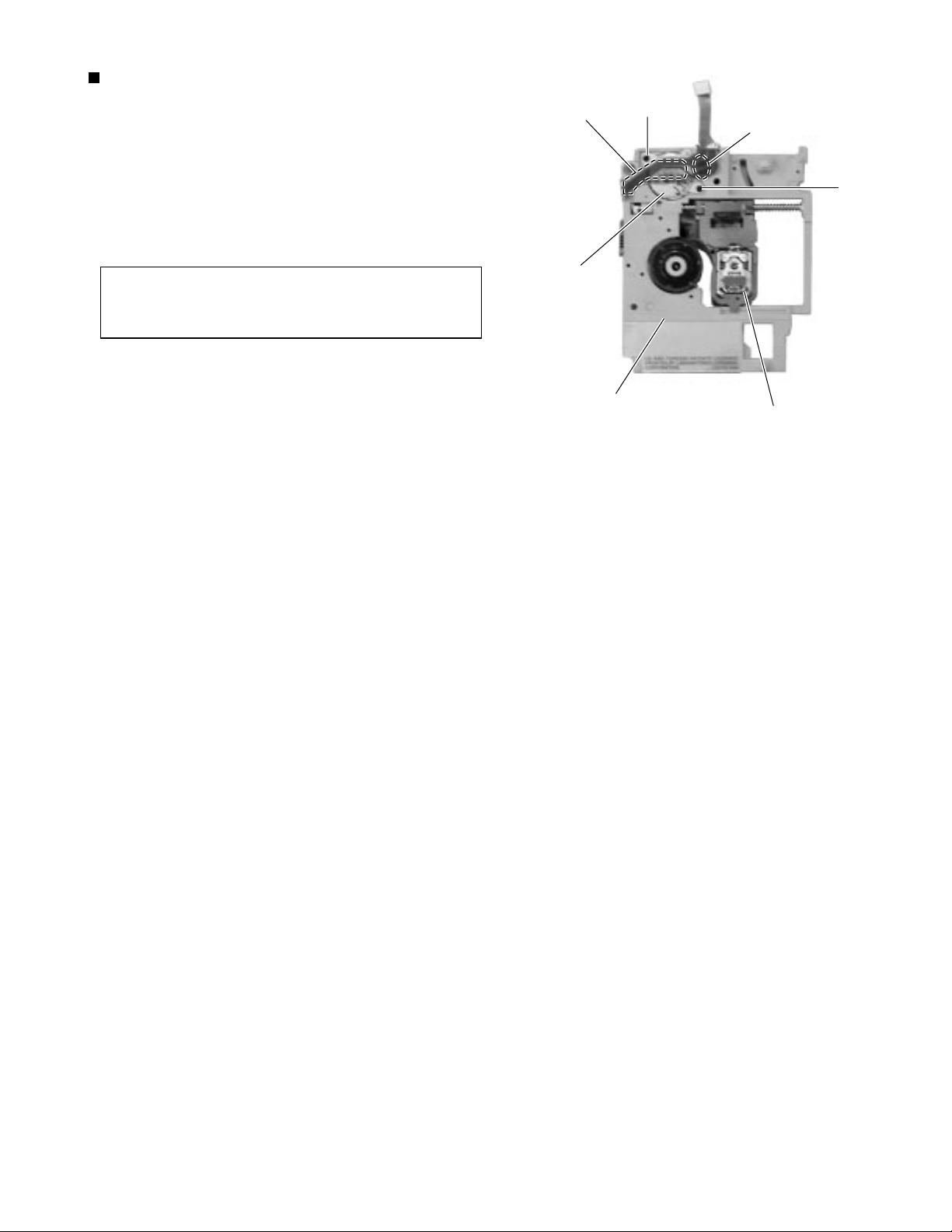

<Removal of the MD

mechanism section>

Prior to performing the following procedures, remove

the MD door assembly, the holder assembly, the

chassis assembly and the main board.

Removing the spindle motor

(See Fig.11)

1.

Unsolder the part g on the flexible wire extending

from the underside of the Chassis assembly to the

spindle motor.

ATTENTION:

2.

Remove the three screws I attaching the spindle

motor.

Removing the pickup unit (See Fig.11)

Do not spill flux on the gear and others.

Slit washer

Worm gear

Chassis assembly

Lead screw

Part i

J

Pickup unit

Shaft holder

Soldering g

I

Spindle motor

Part h

Fig.11

K

ATTENTION:

1.

Remove the slit washer and the worm gear from the

underside of the Chassis assembly.

2.

Remove the screw J attaching the shaft holder and

draw out the shaft (lead screw).

3.

Pull out the Pickup unit and the lead screw while

disengaging the part h and i.

When handling the Pickup unit, touch the

parts marked in Fig.13 only.

Removing the pickup (See Fig.12 and 13)

ATTENTION:

When handling the pickup unit, touch the

parts marked in Fig.13 only.

Lead spring

Pickup

Fig.12

Touch these parts only.

1.

Remove the screw K and the lead spring.

2.

Pull out the shaft from the pickup.

1-8

Fig.13

Page 9

Removing the feed motor (See Fig.14)

XM-PX50WT

1.

Peel off the adhesive tape j on the flexible wire on

the underside of the feed motor.

2.

Unsolder soldering k connecting the flexible wire to

the feed motor.

3.

Remove the two screws L attaching the feed motor.

ATTENTION:

When reassembling, reattach the

flexible wire with an adhesive tape and

solder.

j

Feed motor

Chassis assembly

L

Soldering k

L

Pickup unit

Fig.14

1-9

Page 10

XM-PX50WT

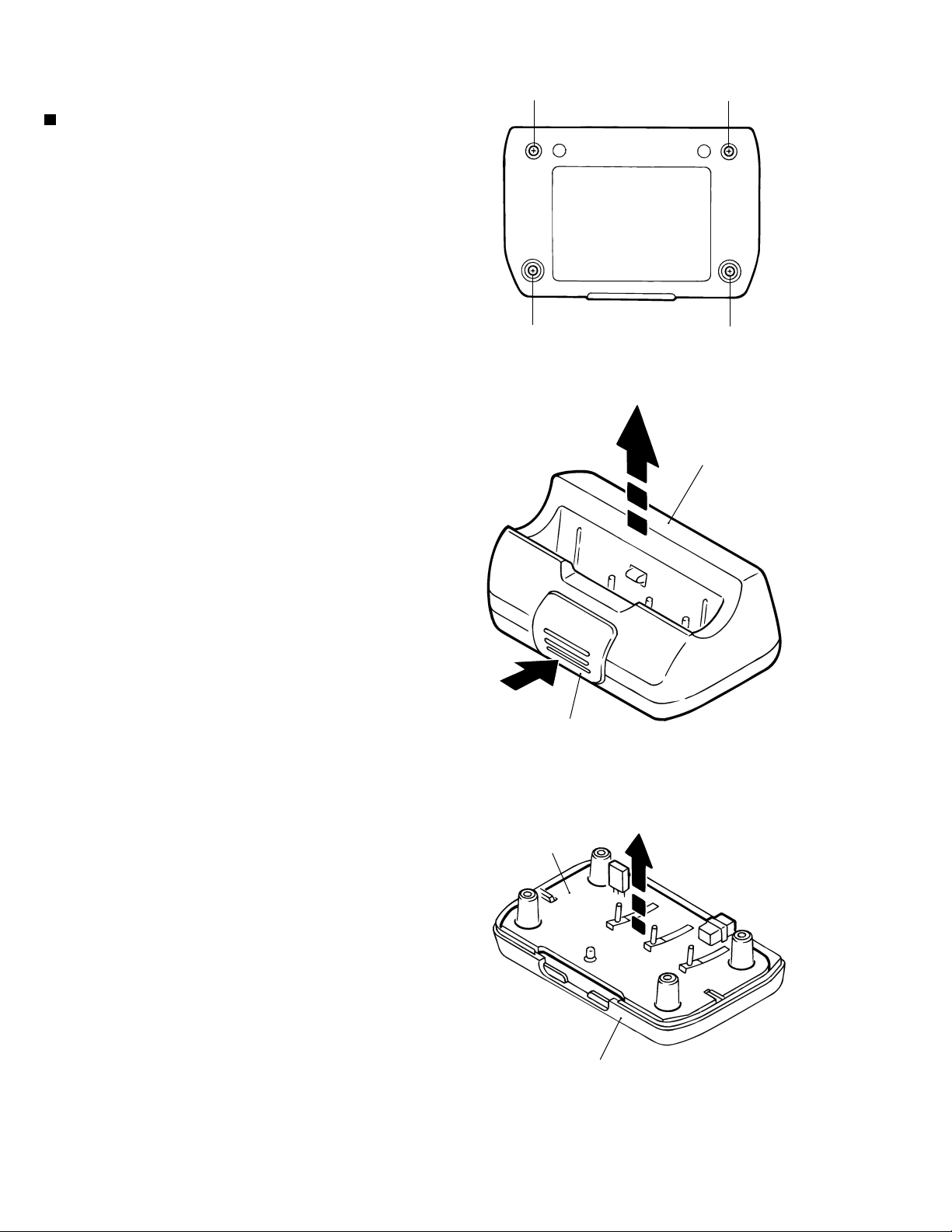

<Charge stand>

Removing the charge board

(See Fig.1 to 3)

1.

Remove the four screws A on the bottom of the

body.

2.

Remove the top cover upward while pushing the

front part a. Pull out the charge board from the

bottom cover.

AA

A

Fig.1

A

Top cover

Push

Charge board

Part a

Fig.2

Bottom cover

Fig.3

1-10

Page 11

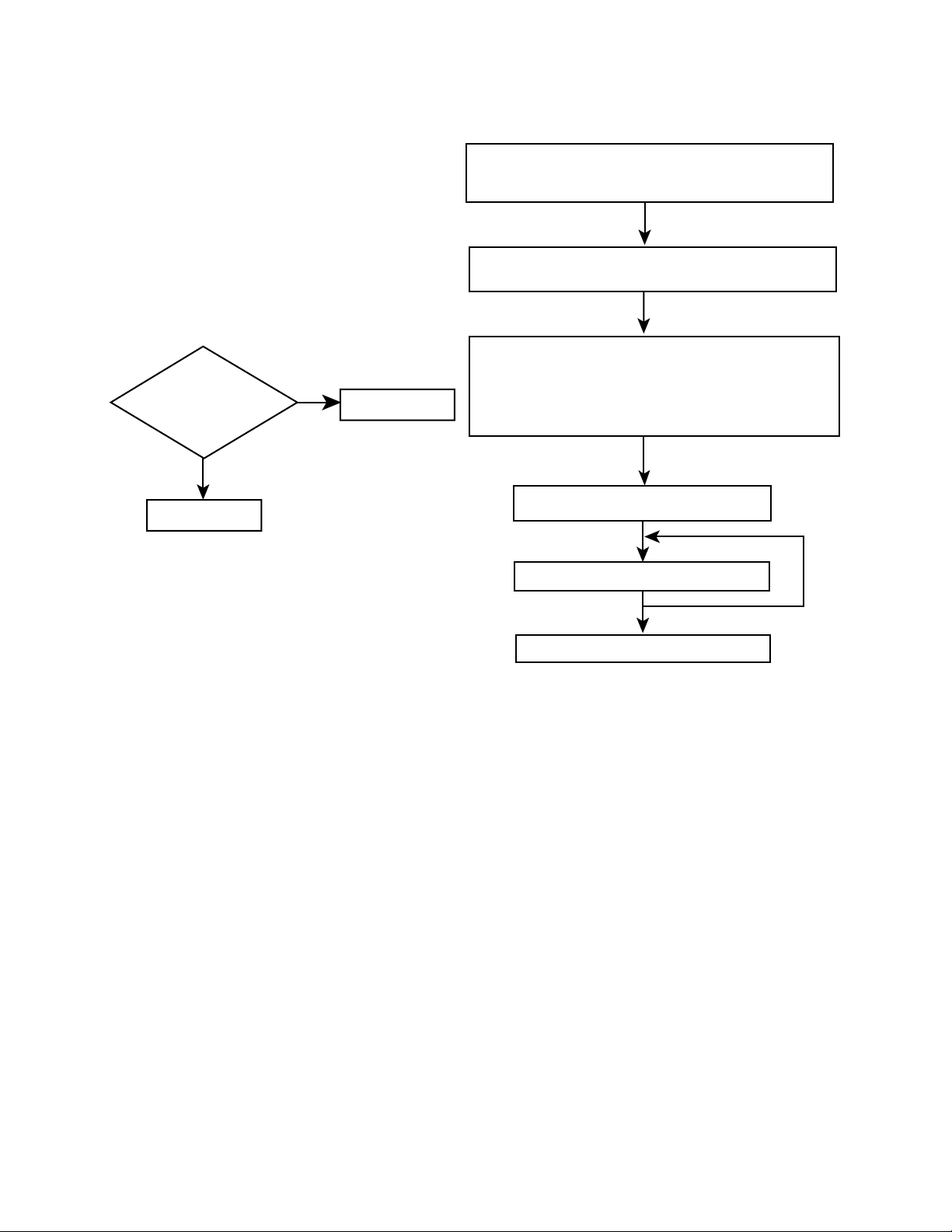

Adjustment method

This model is auto adjustment by Remote Controller.

Please adjust the attached remote controller.

Equipments----- 1. Remote controller 2. DC power supply

3. Laser power meter 4. MO disc (AU-1)

5. Pre master disc (TGYS 1)

<Test mode setting method>

Press < PLAY MODE + DISPLAY + BASS > and < PLAY >key together more than 3sec. at power off condition.

< VOL > next item .< VOL+ >before item.

LCD indication

0. TMD-V2

Test mode setting OK. Indicate at 2sec.

When LCD indicate [NG] at another item,

Return back this item by press (STOP) key

Resume initialize

LCD Indication change :

* Initializing

*

Servo initialize

LCD Indication change : [ ]

PLAY LASER Insert the laser power meter.

Executes by < BASS > LCD Indication change :[XX:YY]

Up by < VOL+> .Down by <VOL > LCD Indication change :[VW.YY]

Setting by <STOP> LCD Indication change :[ OK ]

Laser power adjust 560 adjust

Adjust power-supply voltage 1.5v 20mv before the laser power is adjusted and stops.

Resume

Initializing

Servo

PLAY LASER

XM-PX50WT

5. M o T G

7.

FEED

Executes by < BASS >

<VOL+> :Pickup is go to outside

Press < STOP >

MO TG Insert the Recordable disc.

Executes by < BASS >

LCD Indication change : [ ]

MO DISC ADJUST

Executes by < BASS >

LCD Indication change : [ ]

Press < STOP >

LCD Indication change : [OK

Pre TG Insert the Pre master disc.

Executes by < BASS >

LCD Indication change : [ ]

Pre DISC ADJUST

Executes by < BASS >

LCD Indication change : [

Press < STOP >

RESET

Executes by < BASS >

LCD Indication :

*

*

Left out the test mode ,power off ,and END.

LCD Indication change :[FwdBwd]

< VOL-> :Pickup is go to inside

LCD Indication change :[OK ]

*

*

*

Adjusting

]

Adjusting

XXYYZZ

Adjusting

*

Adjusting

MO DISC ADJUST

FEED

]

1-11

Page 12

XM-PX50WT

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode

When the life of the laser diode has expired,

the following symptoms will appear.

1. The level of RF output (EFM output:ampli

tude of eye pattern) will below.

Is the level of

RFOUT under

0.35Vp-p?

YES

O.K

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at TP1.

Finish.

(3) Semi-fixed resistor on the APC PC board The semi-fixed resistor on the APC printed circuit board which is

attached to the pickup is used to adjust the laser power.Since this adjustment should be performed to match the

characteristics of the whole optical block, do not touch the semi-fixed resistor.

If the laser power is lower than the specified value,the laser diode is almost worn out, and the laser pickup should

be replaced.

If the semi-fixed resistor is adjusted while the pickup is functioning normally,the laser pickup may be damaged

due to excessive current.

1-12

Page 13

Description of major ICs

JCV8002-W (IC601) : Head phone amp

1. Pin layout

24 ~ 19

1

XM-PX50WT

18

2. Block diagram

3. Pin function

Pin

Symbol

no.

CC2

1

V

2

OUT

3

PWR GND

4

OUT

5

DET

6

AGC IN

7

BST OUT

8

BST NF

9

LPF

10

BST NF

11

ADD IN

12

V

ref

13

V IN

ref

14

GND

15

BEEP IN

16

BST SW

17

MT SW

18

PW SW

19

MT TC

20

V

CC1 CC

21

IN

22

IN

BEEP OUT

23

BEEP OUT

24

V

Power amplifier output

A

GND in power amplifier output steps

Power amplifier output

B

Smoothness of level detection of boost

BST amplifier input signal level variable control by input lever to boost AGC input terminal

Output terminal of BST amplifier2

2

Terminal NF of BST amplifier2

Output BST amplifier1

2

NF of BST amplifier1

1

ADD amplifier input

Standard potential circuit

Standard potential circuit

Power part input steps GND

Beep input terminal

Beep output terminal

Mute switch

Power On/OFF switch

Mute smoothing Power mute switch

Main parts V

Power amplifier input

B

Power amplifier input

A

Beep output terminal

B

Beep output terminal

A

~

6

7 ~ 12

PW

SW

18

MT

TC

PW

19

SW

V

CC1

20

IN

B

21

IN

A

22

BEEP

OUT

B

23

BEEP

OUT

A

24

V

CC2

1

FUNCTION

(+B) in power amplifier output steps

CC2

CUT

MT

SW

~

13

BST2

BST

AGC

Vref

IN

AGC

IN

13

Vref

6

Vref

ADD

IN

BST

OUT

10

12

11

BST

NF1

9

LPF

2

8

BST

NF

2

7

BST

SW

PWR

GND

16

BST

SW

3

BEEP

IN

PW

B

OUT

BEEP

B

15

4

GND

DET

14

BST1

5

17

MT

SW

PW

A

A

2

AGC

1-13

Page 14

XM-PX50WT

CXA8059Q (IC450) : Motor driver

1. Pin layout

36

37

~

25

24

2. Block diagram

~

48

CPC3

1

VSWFVFUFCOMFCPOUT

CP3

~

13

~

UIN

12

VIN

Voltage

Driver

WIN

COM

UOUT

VOUT

WOUT

Sample

and Hard

GNDPGNDFG2FGSLOPE

CPC2

CPC1

RMAX

CP2

CP1VCO

RMINVCOINVCC

Charge Pump

VCO

Phase

Comparator

Timing

controllor

MCLOCK

1/8

CLKSEL

S/S

Sensoeless Logic

PWM

F/R

Controllor

BRAKE

Full Wave

Rectifilter

VCREF

VCONT

OSC CLOCK RESET FC CF RF

1-14

Page 15

3.

Pin function

Pin

Symbol Function

no.

1

PGND

2

3

4

CPOUT

5

6

7

8

9

10

11

12

13

BRAKE

14

VCONT

15

VCREF

16

17

18

19

20

21

RMAX

22

23

VCOIN

24

CLKSEL

25

26

SLOPE

27

CLOCK

28

29

30

31

32

COMF

33

34

MCLOCK

35

36

RESET

37

38

39

40

41

WOUT

42

43

44

45

UOUT

46

47

48

COM

VS

CPC3

CP3

CPC2

CP2

CPC1

CP1

GND

S/S

FC

CF

FG

FG2

VCO

RMIN

OSC

GND

WF

VF

UF

VCC

VS

RF

NC

NC

WIN

VIN

VOUT

UIN

NC

NC

RF

XM-PX50WT

The GND to guard the power stage.

The terminal to detect the voltage.

The terminal to supply the voltage for the power stage.

The terminal to connect the capacitor in the final charge pump.

The terminal to connect the capacitor in the third charge pump.

The terminal to connect the capacitor in the third charge pump.

The terminal to connect the capacitor in the second charge pump.

The terminal to connect the capacitor in the second charge pump.

The terminal to connect the capacitor in the first charge pump.

The terminal to connect the capacitor in the first charge pump.

The GND for the part except the power section.

The terminal for start and stop.

The terminal for braking.

The terminal for controlling velocity.

The terminal as referable voltage of controlling velocity.

The terminal to compensate the frequency characteristics of the loop controlling velocity.

The terminal of sampling and holding for detecting motor current.

The terminal to output FG pulse.

The terminal to output FG pulse divided Pin15 signal by 2.

The terminal to set oscillation frequency of VCO.

The terminal to set maximum oscillation frequency of VCO.

The terminal to set minimum oscillation frequency of VCO.

The terminal to control oscillation frequency of VCO.

The terminal to select inside and outside clock.

The terminal to oscillation sawtooth for PWM signal.

The terminal to oscillation sawtooth for soft-switching signal.

The terminal to monitor CLOCK signal.

The GND for the part except the power section.

The terminal to shape waveform of motor voltage.

The terminal to shape waveform of motor voltage.

The terminal to shape waveform of motor voltage.

The terminal to shape waveform of motor voltage.

The terminal to supply the voltage except the power section.

The terminal to input clock.

The terminal to supply the voltage for the power stage.

The terminal to reset a register for checking the movement.

The terminal to monitor current.

Non connect

Non connect

The terminal to sense the back electro magnetic force of coils.

The terminal to supply the motor current.

The terminal to sense the back electro magnetic force of coils.

The terminal to supply the motor current.

The terminal to sense the back electro magnetic force of coils.

The terminal to supply the motor current.

Non connect

Non connect

The terminal to monitor current.

1-15

Page 16

XM-PX50WT

CXD2672GA(IC351):DSP

1.Pin layout

17

16

TFDR TRDR

15

FRDR FFDR VDC4

14

VSC4

13

12

11

10

9

8

7

SRDR

SPFD SPRD

TEST1 FGIN

TEST2

TST2 EFM0

VSI03

SPCU SPDW SPDV

TST4 SPCW SPCV

LDDR

DTRF VSI02 ADFG ADRB AVS2 ADI0 FE PEAK FILI

APCR CKRF FOCN APC SE ADRT VC ABCD

XLRF VDI02 DCHG TE AVD2 AUX1

FS4

SFDR

TEST3

TST3

VDI03

TOP

VIEW

CLTV

PCO BIAS ASYO XWE TST6

BOTH

FILO RFI AVD1 MVCI

AVS1

ASYI

DVSS1

PD0

DVDD1

VDC3

D1

A09

A07

DVI01

A05 A01

A03

A11

XOE

D3

VSC3

D2

D0

XCAS IXWE

IXOE

XRAS

A08

A10

A00

VSI01

A06

A02

A04

VSC5 SLDW SLDV

6

SLCV SLCU VDC5

5

BYPS TST5

4

MNT1

3

MNT0

2

1

SLCW

VDC0

MNT2 SWDT

MNT3

SCLK

SENS XRST

SRDT

SQSY XINT OSCI

VSCO DQSY TX

XLAT

RPWR

VDI

OSC

DVDD0

DVSS0

OSCO

DA

VDDLDAVDDR

AOUTL VREFL

DA

VSI

VSSLDAVSSR

OSC

VREFR TST1

AOUTR XTSL DOUT

VSC1 DIN1

F256

XBCK

DADT LRCK

VDC2

VDI00

TST8

VDC1 TST0 DATAI TST7

MT

MT

FLGR

FLGL

VSI00

DA

PWMLP

ABCDEFG JH KLMNPRTU

2.Pin function (1)

Pin

Symbol

No.

A-1

A-2

A-3

B-1

B-2

B-3

C-1

C-2

C-3

D-1

D-2

D-3

NC

NC

MNT1

NC

NC

MNT0

MNT3

MNT2

NC

SCLK

SWDT

VDC0

I/O Function

-

Open

-

Open

O

Monitor output

-

Open

-

Open

I/O

Monitor in/output

O

Monitor output

O

Monitor output

-

Open

I

Micon serial bus clock input

I

Micon serial bus data write input

-

Internal logic VDD(1.8V)

VSC2

ADDT

DA

PWMRP

DA

PWMLN

1-16

Page 17

2.Pin function(2)

Pin No.

E-1

E-2

E-3

F-1

F-2

F-3

G-1

G-2

G-3

H-1

H-2

H-3

K-1

K-2

K-3

L-1

L-2

L-3

M-1

M-2

M-3

N-1

N-2

N-3

P-1

P-2

P-3

U-1

R-1

U-2

R-2

U-3

R-3

U-4

R-4

U-5

R-5

U-6

R-6

U-7

R-7

U-8

R-8

Symbol I/O Function

XLAT

SRDT

SENS

VSC0

SQSY

XRST

DQSY

XINT

RPWR

TX

OSCI

VDIOSC

J-1

J-2

J-3

T- 1

T- 2

T- 3

T- 4

T- 5

T- 6

T- 7

T- 8

OSCO

DVSS0

DVDD0

VSIOSC

AOUTL

DAVDDL

DAVSSL

VREFL

DAVDDR

DAVSSR

AOUTR

VREFR

VSC1

XTSL

TST1

DIN1

DOUT

VDC1

DAPWMLN

DAPWMLP

VSIO0

DAPWMRP

MTFLGR

MTFLGL

TST7

DATA I

TST0

ADDT

TST8

VDIO0

LRCK

DADT

VDC2

VSC2

XBCK

F256

A02

A04

A03

A06

A01

A05

I

Micon serial bus latch input

O

Micon serial bus data read out output

O

Internal output of micon serial bus address

-

Internal logic GND

O

PTGR=0 ADIPsink output / PTGR=1 DISC SUB-Q sink output

I

Reset input L:reset

O

Ubit SUB-Q sink output from digital audio input from MD or CD

O

Request status output L:request status

I

Laser power select input (H=rec power / L=playback power)

I

Output permit input of recorded data

I

X'tal osc circuit input

-

OSC sel VDD (2.5V)

O

X'tal osc circuit output

-

Internal 16bit DRAM GND

-

Internal 16bit DRAM GND

-

OSC sel GND

O

Internal DAC Lch output

-

Internal DAC VDD (Lch,2.5V)

-

Internal DAC GND

O

Internal DAC GND VREF(Lch)

-

Internal DAC VDD (Rch,2.5V)

-

Internal DAC GND (Rch)

O

Internal DAC Rch output

O

Internal DAC VREF (Rch)

-

Internal logic GND

I

X'tal frequency select (L=45.1584MHz/H=22.5792MHz)

I

Test terminal Connect to GND

I

Digital audio input Outer I/F mode EXRQ input

O

Digital audio output

-

Internal logic VDD (1.8V)

O

Internal DAC PWM output L-

O

Internal DAC PWM output L+

-

2.5V I/O VSS

O

Internal DAC PWM output R+

O

Internal DAC zero detect flag (Rch)

O

Internal DAC zero detect flag (Lch)

I

Test terminal Connect to GND

I

Serial data input

O

Open

I

Data input from A/D converter

I

Test terminal Connect to GND

-

2.5V I/O VDD

O

LR clock(44.1kHz) for A/D, internal DAC

O

Data output for internal DAC / Internal DAC PWM output R-

-

Internal logic VDD (1.8V)

-

Internal logic GND

O

A/D, internal DAC bit clock (2.8224MHz)

O

11.2896MHz clock output (X'tal)

O

External DRAM address output

O

External DRAM address output

O

External DRAM address output

O

External DRAM address output

O

External DRAM address output

O

External DRAM address output

XM-PX50WT

1-17

Page 18

XM-PX50WT

2.Pin function (3)

Pin No.

U-9

R-9

U-10

T-10

R-10

U-11

T-11

R-11

U-12

T-12

R-12

U-13

T-13

R-13

U-14

T-14

R-14

U-17

U-16

U-15

T-17

T-16

T-15

R-17

R-16

R-15

P-17

P-16

P-15

N-17

N-16

N-15

M-17

M-16

M-15

L-17

L-16

L-15

K-17

K-16

K-15

J-17

J-16

J-15

H-17

H-16

H-15

G-17

G-16

G-15

F-17

F-16

F-15

T- 9

Symbol

VSIO1

A00

ADIO1

A08

A10

A07

IXOE

XRAS

A09

IXWE

XCAS

VDC3

VSC3

DVDD1

NC

NC

XOE

NC

TST6

A11

DVSS1

XWE

PDO

ASYI

ASYO

MVCI

AVS1

BIAS

AVD1

FILI

PCO

RFI

PEAK

CLTV

FILO

ABCD

BOTOM

ADIO

AUX1

AVS2

ADRT

AVD2

ADRB

ADFG

APC

DCHG

D1

D2

D0

D3

FE

VC

SE

TE

I/O

-

2.5V I/O sel Vss

O

External DRAM address output

-

2.5V I/O sel VDD

O

External DRAM address output

O

External DRAM address output

O

External DRAM address output

O

Open

O

External DRAM RAS output

O

External DRAM address output

O

Open

O

External DRAM CAS output

I/O

External DRAM data input/output

I/O

External DRAM data input/output

I/O

External DRAM data input/output

-

Internal logic VDD

-

Internal logic GND

I/O

External DRAM data input/output

-

Internal 16Mbit DRAM VDD

-

Open

-

Open

O

External DRAM output chip enable output

-

Open

O

Open

O

Open

-

Internal 16Mbit DRAM GND

O

External DRAM write enable output

O

Analog PLL phase compare output

I

Playback EFM comparator slice level input

O

Playback EFM binarization signal output

I

Clock input from external VCO

-

Analog GND

I

Playback EFM comparator bias current input

O

Analog power supply (2.5V)

I

Filter input for playback EFM system mastering PLL

I

Phase comparison output for playback EFM system mastering PLL

I

Playback EFM RF signal input

O

Peak holding input optical amount signal

I

Internal VCO control voltage input for playback EFM system mastering PLL

I

Filter output for playback EFN system mastering PLL

I

Focus error signal input

O

Optical amount signal input

I

Bottom holding input of optical amount signal

I

Open

-

Middle point voltage input

I

Assistance A/D input

-

Analog GND

I

A/D converter operation range upper bound voltage input

-

Analog power supply (2.5V)

I

A/D converter operation range lower bound voltage input

I

Sled error input

I

Tracking error input

I

ADIP binary-coded FM signal input

I

Error signal input for laser digital APC

I

Connects with an analog power supply of low impedance

Function

1-18

Page 19

2.Pin function (4)

XM-PX50WT

Pin No.

E-17

E-16

E-15

D-17

D-16

D-15

A-17

B-17

C-17

A-16

B-16

C-16

A-15

B-15

C-15

A-14

B-14

C-14

A-13

B-13

C-13

A-12

B-12

C-12

A-11

B-11

C-11

A-10

B-10

C-10

A-9

B-9

C-9

A-8

B-8

C-8

A-7

B-7

C-7

A-6

B-6

C-6

A-5

B-5

C-5

A-4

B-4

C-4

Symbol I/O Function

VSIO2

F0CN

VDIO2

DTRF

CKRF

XLRF

NC

NC

LDDR

NC

NC

APCR

TFDR

TRDR

NC

FRDR

FFDR

VDC4

VSC4

SRDR

FS4

SPFD

SPRD

SFRD

TEST2

TEST1

FGIN

TST2

EFMO

TEST3

VSIO3

TST3

VDIO3

SPCU

SPDW

SPDV

TST4

SPCW

SPCV

VSC5

SLDW

SLDV

SLCV

SLCU

VDC5

BYPS

TST5

SLCW

-

2.5V I/O Vss

O

Filter cutoff control output

-

2.5V I/O VDD

O

Controller data output

O

Controller clock output

O

Controller latch output

-

Open

-

Open

O

Laser digital APC PWM output

-

Open

-

Open

O

Laser APC reference PWM output

O

Tracking servo drive PWM output (+)

O

Tracking servo drive PWM output (-)

-

Open

O

Focus servo drive PWM output (-)

O

Focus servo drive PWM output (+)

-

Internal logic VDD (1.8V)

-

Internal logic GND

O

Sled servo drive PWM output (-)

O

176.4kHz clock output (X'tal system)

O

Spindle servo drive output

O

Spindle servo drive output

O

Sled servo drive PWM output (+)

I

Test terminal Connect to GND

I

Test terminal Connect to GND

I

Spindle CAV servo FG input

O

Test terminal Open

O

EFM output at recording

I

Test terminal Connect to GND

-

2.5V I/O Vss

O

Test terminal Open

-

2.5V I/O VDD

I

Blush less spindle motor drive comparate input (U)

O

Blush less spindle motor 3 phase drive truth output (W)

O

Blush less spindle motor 3 phase drive truth output (V)

O

Test terminal Open

I

Blush less spindle motor drive comparete input (W)

I

Blush less spindle motor drive comparate input (V)

-

Internal logic GND

O

Blush less sled motor 3 phase drive truth output (W)

O

Blush less sled motor 3 phase drive truth output (V)

I

Blush less sled motor 3 phase drive comparate input (V)

I

Blush less sled motor 3 phase drive comparate input (U)

-

Internal logic VDD (1.8V)

O

Open

O

Test terminal Open

I/O

Blush less sled motor 3 phase drive comparate input

1-19

Page 20

XM-PX50WT

AK93C55BH-W (IC502) : EEPROM

1. Pin layout

CS

SK

DI

DO

1

2

3

4

3. Block diagram

DI

INSTRUCTION

REGISTER

8

7

6

5

INSTRUCTION

DECODE,

CONTROL

AND

CLOCK

GENERATION

VCC

NC

PE

GND

DATA

REGISTER

ADD.

BUFFER

2.Pin function

Pin name

CS

SK

DI

DO

PE

VCC

GND

NC

16

R/W AMPS

AUTO ERASE

DECODER

Fnction

Chip select

Serial data clock

Serial data input

Serial data output

Program enable

Ground

Power supply

Not connected

DO

16

AND

EEPROM

2048bit

128 X 16

CS

SK

PE

TC75S51F-X(IC505):Ope amp

1.Pin layout/Block diagram

VDD OUT

54

123

IN(+) Vss IN(-)

VREF

VPP SW

VPP

GENERATOR

1-20

Page 21

CXA2588R (IC300) : RF amp.

1. Pin layout & block diagram

36 35 34 33 32 29 28 26

BOTM

ABCDFEAUX

ADFG

ADAGC

ADIN

ADFMSECSLEDTEWBLADJ

31 30 27 25

XM-PX50WT

PEAK 37

RF 38

RFAGC 39

AGCI 40

NC 41

NC 42

ADDC 43

NC 44

TEGC 45

RFO 46

MORFI 47

MORFO 48

2.Pin function

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Symbol

APCREF

OPOUT

OPIN

SWDT

SCLK

XSTBY

F0CNT

VREF

EQADJ

3TADJ

I

J

VC

A

B

C

D

E

F

PD

APC

GND

XLAT

Vcc

I/O

O

O

O

O

I/O

I/O

AGC,EQ

Peak,Bottom Detector

0/-2dB

3T Detector

RF Amp

123456789101112

I

J

VC

Function

I-V converted RF signal I input

I

I-V converted RF signal J input

I

Vcc/2 voltage output

A current input for main beam servo signal

I

B current input for main beam servo signal

I

C current input for main beam servo signal

I

D current input for main beam servo signal

I

E current input for side beam servo signal

I

F current input for side beam servo signal

I

Reflection light q'ty monitor signal input

I

Laser APC output

Ref. voltage input for laser power intensity setting

I

Ground

-

Ope. amp output terminal

21dB ope. amp input terminal

I

Serial data input terminal

I

Shift clock input terminal

I

Latch input terminal

I

Stand by setting terminal

I

F0 count setting terminal

I

Reference voltage output terminal

EQ IF setting terminal

BPF3T IF setting terminal

Power supply

-

ADIP Amp

TE/SE Amp

FE Amp

ABCD Amp

TE

SE

AUX

FE

RF

NC

NC

NC

RFO

I-V

Amp

F

E

D

I/O

I/O

O

O

O

I

O

O

O

O

O

O

O

-

I

-

-

I/O

-

I

O

I

O

PD

Function

BPF3T IF setting terminal

Tracking error signal output terminal

Sled error signal LPF capacitor connect terminal

Sled error signal output terminal

ADIP FM signal output terminal

ADIP signal completer input terminal

ADIP AGC capacitor connect terminal

ADIP binary signal output

I3 output/temp.signal output

Focus error signal output

Reflection light q'ty signal output for main beam servo detector

RF/ABCD bottom-hold signal output

RF/ABCD peak-hold signal output

RF equalizer output

RFAGC capacitor connection

RFAGC input

Non connect

Non connect

ADIP amp. feedback circuit capacitor connection

Non connection

TE amp. gain switching

RF amp. output

Groove RF signal AC-coupled input

Groove RF signal output

I-V Amp APC

A

B

C

Pin

Symbol

No.

25

WBLADJ

26

27

CSLED

28

29

ADFM

30

ADIN

31

ADAGC

32

ADFG

33

34

35

ABCD

36

BOTM

37

PEAK

38

39

RFAGC

40

AGCI

41

42

43

ADDC

44

45

TEGC

46

47

MORFI

48

MORFO

CPU

Command

I/F

OP

Amp

APC

APCREF

24 Vcc

23 3TADJ

22 EQADJ

21 VREF

20 F0CNT

19 XSTBY

18 XLAT

17 SCLK

16 SWDT

15 OP IN

14 OP OUT

13 GND

1-21

Page 22

XM-PX50WT

IC-PST3421U-X(IC504):System reset

1.Pin layout 2.Pin function

VOUT 1

VDD 2

3.Block diagram

2

VDD

Vref

4

VSS

4 VSS

3 NC

Pin

No.

1

2

3

4

VOUT

VDD

NC

VSS

FunctionSymbol

Reset signal output terminal

Power supply terminal

Non connect

VSS terminal

1

VOUT

TK11223BMC-X (IC961) : Regulator

1. Pin layout

VIN VOUT

GND

6 5 4

1 2 3

CONT NOISE BYPASSGND

2. Block diagram

VIN

CONT.

BANDGAP

REFERENCE

VOUT

THERMAL

SENSOR

Cnp

GND

1-22

Page 23

MPC17A139MTB-X (IC400) : 4ch bridge driver

1.Pin layout 2.Pin function

Driver section

VGVCLG

3635343332313029282726252423222120

GND

VD3

FO3

PGND

RO3

VD3

VD4

RO4

PGND

FO4

VD4

RI3

FI3

FI4

RI4

19

PS,OE INPUT OUTPUT 1~4

PS

H

H

H

H

H

123456789

PS

OE

AGND

CLK

VD1

FO1

RO1

PGND

101112131415161718

VD1

VD2

RO2

PGND

FO2

VD2

RI1

FI1

FI2

RI2

L

X:Don't Care

Z:High Impedance

OE

L

L

L

L

H

X

FI

L

L

H

H

X

X

RI

L

H

L

H

X

X

FO

L

L

H

L

L

Z

RO

L

H

L

L

L

Z

Clock detector section

CLK PS OSC circuit

X

H

H

X

L

XM-PX50WT

Auto

Syncro

Stop

3.Block diagram

G

L

G

36 34

V

Vc

DC/DC

CLOCK

CLK

Vc

2

35

Vc

Converter

Detector

CLK

D1VD1

V

AGND

159

G

V

Vc

3

PS

Pre-driver

Control

4

16

FI1

OE

FO1R

6

O1

8

15

RI1

GND

R

7

33

GND

VD2VD2FO2R

14

G

V

Vc

10

Pre-driver

13

Control

17

FI2

O2

11

18

RI2

GNDVD3VD3

P

12

32

G

V

Vc

28

Pre-driver

O3

FO3R

31

29

Control

22

21

FI3

RI3

GNDVD4VD4

P

30

23

G

V

Vc

27

Pre-driver

O4

FO4R

24

26

Control

20

19

FI4

RI4

GND

P

25

1-23

Page 24

XM-PX50WT

UPD784225GK-617C(IC501):CPU

1.Pin layout

1 ~ 20

2.Pin function

Pin

Symbol

No.

1

ANI5

2

ANI6

3

SPSEL

4

AVSS

5

-

6

VADJ

7

AVREF1

8

RMRX

9

RMTX

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

-

SRDT

SWDT

SCLK

-

BEEP

PSW

MONDATA

MONCLK

XRST2

TG

ACB

TRAIN

XRST

XLAT

LVCTL

LDON

RFOFF

SLOFF

-

MUTE

-

DIR

VSS1

PS

SS

MON1

MON2

MONXLAT

-

-

80 ~ 61

60 ~ 41

21 ~ 40

Function

GND

GND

Non connect

GND

Non connect

Voltage adjust

Analog reference voltage

Remocon data input terminal

Remocon data output terminal

Non connect

Serial data read input terminal

Serial data write input terminal

Serial bus clock output terminal

Non connect

BEEP output terminal

Power ON/OFF output terminal

Test terminal

Test terminal

Standby setting output terminal

Tracking gain setting terminal

Non connect

Non connect

Reset signal output terminal

Serial bus latch output terminal

LSI power supply control signal output

Laser diode ON signal output terminal

RF OFF signal input terminal

Sled OFF signal output terminal

Non connect

Mute signal output terminal

Mon connect

Test terminal

GND

Standby mode output terminal

Start/Stop output terminal

Test terminal

Test terminal

Test terminal

Non connect

Non connect

Pin

No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Symbol

-

-

-

-

DPON

-

RFVCTL

PSAVE

RPON

DPON

REMOFF

CS2

SCL

DI

CS1

MNT0

MNT3

SENS

DO

RESET

XINT

SQSY

-

RPLY

DOOR

PLAYKEY

VSS0

VDD1

X2

X1

VPP

XT2

XT1

VDD0

AVD0

KEY

BATTERY

TEMP

ANI3

ANI4

Function

Non connect

Non connect

Non connect

Test terminal

Test terminal

Non connect

Test terminal

Non connect

RP ON signal input terminal

DP ON signal input terminal

Remocon OFF signal output terminal

Chip select 2

Serial clock signal output terminal

Data output terminal

Chip select 1

Monitor 0 input terminal

Monitor 3 input terminal

DSP internal status input terminal

Data input terminal

Reset signal input terminal

Interrupt status data input terminal

Sink input terminal

Non connect

Remocon PLAY detect terminal

Door open/close detect terminal

PLAY key detect terminal

GND

Reference voltage terminal

Connect to X'tal osc

Connect to X'tal osc

Test terminal

Non connect

GND

GND

Reference voltage terminal

Remocon STOP key detect terminal

Battery voltage detect terminal

Connect to temp. detect

GND

GND

1-24

Page 25

XC6367A251M-X(IC901):Regulator

1.Pin layout

54

123

3.Block diagram

2.Pin function

Pin

Symbol Function

No.

1

VOUT

2

VDD

3

CE

4

GND

5

EXT

XM-PX50WT

Output voltage det.

Power supply

Chip enable

GND

Ext. Tr connect

VOUT

CE

Vref with

Soft Start,

GE

Error Amp.

+

-

Phase

Compensation

PWM/PFM

Controller

PWM

Comparator

+

-

Ramp Wave

Generator,

OSC

Buffer,

Driver

VDD

EXT

GND

1-25

Page 26

XM-PX50WT

Block diagram

J101

CN601

Lch,Rch

IC601

HP AMP

AOUTL

AOUTR

DSP

IC351

AOUTL

AOUTR

RF

IC300

MUTE

BEEP

PSW

FS4

RMDATA

SLCK

SWDT

FFDR

FRDR

SRAT

SQSY

TFDR

TRDR

XRST2

XINT

SENS

SFDR

SRDR

LDON

MNT3

MNT0

SLOFF

XLAT

XRST

IC502

CSI

CPU

IC501

PS

IC400

DRIVER

EEPROM

CSL

DO,DI

2-2

RFI,VC,PEAK,BOTM,ABCD,FE

AUX1,ADFG,SE,T,E,F0CNT

APCREF,DTRF,CKRF,XLRF

CN301

PICKUP

SPFD,SPRD

SPFG,XBCK

TRK

FCS

IC450

DRIVER

SPINDLE

SS

W,V,U,COM

CN401

W,V,U

COM

FEED

MOTOR

SLD

SLD

MOTOR

SPINDLE

Page 27

Standard schematic diagrams

ANALOG SIGNAL

L901

D901

IC501

C352

IC351

R463

R402

D921

L501

TP518

BT3

R376

R377

BT4

R366

Q921

C376

IC921

C356

R372

TH501

C355

IC300

TP902

R510

C316

R905

IC400

D400

L400

L404

L402

L403

L405

C406

C407

C408

C409

C404

C402

R326

Q61

C358

R325

R324

R323

C311

C373

Q906

Q901

C401

TP513

C310

R322

TP512

R321

C4

C309

CN601

TP509

TP510

R921

C922

TP511

TP353

TP352

TP354

TP351

TP514

L902

R302

Q944

L921

L941

C603

R527

R339

R317 R318

IC901

C450

D941

BT1

TP901

R948

BT2

S60

IC941

Q965

Q925

TP326

TP457

K605

IC504

K606

K607

C203

C103

R63

R462

Q301

Q943

TP325

C300

Q63

R62

Q904

Q300

D942

R301

R904

R369

C360

C403

Q945

R947

R607

R605

C630

R201

C631

R101

TP504

C353

C325

Q966

TP505

TP506

R967

TP507

R902

R941

C942

R903

R308

R311

C357

R945

R946

C65

R310

R517

Q964

R530

C508

TP305

Q926

CN301

R329

R345

R942

C319

C464

C462

C453

X500

C452

R466

C320

C351

IC502

R509

C500

C318

C503

C504

L301

C324

C590

R320

IC2

R2R3

C3 C2

R502 R503

R504

R400

S501

CN401

TP307

TP306

K602

K201

K101

C112

R454

R451

R450

K601

K603

C457

C456

C455

C454

C212

IC503

R528

C323

C113

C213

IC601

C613

R601

R603

R604

C614

C602

K604

R613

IC450

TP323

R335

R336

R337

TP324

R338

R354

X300

C903

C923

R353

R944

R508

R378R379

R380

C377

C374

R367

C372

C371

R385

R465

C315

R386

R371

C314

C313

C943

Q941

R373

C317

R328

R364

R901

C902

R965

R316

R315

R314

C904

C308

C312

R305

R387

R388

C359

R306

R352

C302

C301

C901

R925

R511

R512

R351

R513

C906

R966

R922

R926

R514

R307

C506

R943

C507

Q64

R61

R64

TP502

TP503

R907

R908

R909

R304

R340

R341

R924

C905

C921

C941

TP519

Q60

R519

C924

R928

R929

C945

TP515

C451

R518

C463

R516

C604

C321

R507

R303

TP458

C354

C62

C63

C64

R501

S502

S503

R455

C461

C460

R461

R460

R459

C459

C458

R113R213

C111

R506

R103

R203

C211

R211 R111

C102

C202

R112R212

L602

R60

22

F1J2E-X

UPD784225GK-607

CXD2661GA-1

NI

1

CRS01-W

10

3.3K

1K

220

SSM3K01F-X

0.47

XC6367B101M-X

22P

100K

27P

CXA2588R

10K

0.1

2.2K

MPC17A139MTB-X

F02J4L-X

470

10

10

10

10

3.3/6.3

3.3/6.3

3.3/6.3

3.3/6.3

1

3.3/16

330

DTC144EE-X

1/16

330

1K

330

1

1

SSM3K01F-X

FMMT617-X

10/6.3

0.0047

330

330

0.1

1

QGF0515F4-09X

0

NI

1

NI

SI2305DS-X

22

100

1

470k

10

100K 10K

XC6367B101M-X

0.047

CRS01-W

15k

NSW0108-001X

XC6367B101M-X

DTC144EE-X

DTC144EE-X

S-80821ANNP-W

1

1

NI

NI

DTA144EE-X

DTC144EE-X

0.01

2SC4081/QR/-X

470K

DTA124XUA-X

2SB1219/RS/-X

NI

0.22

680k

1K

0.1

1

NI

NI

100

100

330P

22k

330P

22k

10/6.3

0.1

DTA143TE-X

22

100K

0

NI

68K

1.2K

10K

1/16

120K

150K

0.01

NI

1K

SSM3J01F-X

0

SSM3J01F-X

QGF0515F3-20X

NI

NI

470k

10/6.3

0.22

0.22

0.22

NAX0410-001X

1

1

0.01

10/6.3

AK93C55BH-W

100K

1

0.001

0.1

10/6.3

10

22/4

0.001

56K

TC7S08FU-X

2.2k2.2k

0.022 0.022

15K 18K

47k

470k

NSW0117-001X

QGF0515F3-07X

0.22

470k

22K

22K

0.001

0.0022

0.1

1

0.22

NI

NI

10/6.3

150/4

150/4

JCV8002-W

10/6.3

470k

470k

470k

4.7/4

1/16

4.7

CXA8095Q

1K

1K

1K

1K

10/6.3

100K

NAX0315-001X

22/4

47/6.3

1

470K

2.2K

1M

1K

150

0.015

470P

1M

0.47

0.01

10K

NI

0.022

10K

10K

0.01

0.22

10/6.3

SSM3K01F-X

680K

0.0068

100

100

5.6K

220P

470K

24K

13K

100K

47/6.3

0.0068

0.033

1.2K

10K

10K

0.1

120K

1

0.082

0.027

4.7

470K

470K

470K

1

470K

0.1

4.7K

470k

4.7K

470K

100K

0.1

4.7K

0.1

2SC4081/QR/-X

470K

470K

NI

0

120K

1

0

5.6K

8.2K

150P

4.7

1

2SA2018-X

NI

150P

100K

68K

NI

NI

NI

10/6.3

47K

1

0.1

27K

120K

10/6.3

0.001

0.001

0.001

47k

NSW0114-001X

NSW0114-001X

1

0.047

0.0068

47K

680k

1M

2.2

0.047

10k10k

0.22

3.9K

3.9K

0.22

10 10

390P

390P

3.9k3.9k

10

4.7K

RFI

APCREF

F0CNT

FCS-

D

I

LDON

MNT3

TE

DIR

XBCK

DPON

ADFG

MNT2

MONXLAT

XRST2

MUTE

LDON

MNT0

MVCC2

SFDR

PLAYKEY

MNT1

TRDR

TFDR

BATTERY

FFDR

FRDR

FS4

RPLY

SRDR

XLRF

MON2

MON1

SFDR

SPRD

TEMP

SS

PS

SPFD

RMDATA

SPFG

RFOFF

CS2

SCL

FCS-

CKRF

BYPS

DOOR

RFOFF

FCS+

LVCTL

DI

B

LVCTL

SLD+

LVCTL

COM

FS4

XLAT

DO

DTRF

W

F

SRDR

V

RPON

XRST

CS1

DPON

TRK-

C

FRDR

FFDR

TFDR

TRDR

J

XRST

SLD-

VC

E

U

KEYGND

TRK+

A

FCS+

SWDT

SCLK

XLAT

SRDT

TRK+

INB

SENS

TRK-

SCL

DI

INA

SQSY

PLAYKEY

DO

FE

APCREF

F0CNT

XINT

TE

SE

AUX1

KEY

FE

ABCD

BOTM

VC

PEAK

XINT

SQSY

PSW

VADJ

DPON2

BEEP

NTCT

BEEPA

SLD+

PD

BOTM

SLD-

COM

U

V

W

BEEPB

ABCD

AUX1

ADFG

SE

APC

SPFG

DTRF

PSW

CKRF

MONCLK

XLRF

REMOFF

VADJ

RPON

BYPS

RMDATA

SPRD

DPON2

SRDT

RESET

MONDATA

SWDT

SCLK

XRST2

AVDD

KEYGND

MNT0

DO

SPFD

MNT3

SENS

DVDD

XBCK

CS1

SCL

CS2

MUTE

DPON

BEEP

COREVDD

KEY

TG

DAVDD

PEAK

RFI

PS

TG

SS

OUTA

VREFIN

PGND

VCC2

OUTB

DI

Standard schematic diagrams

Main amp section

Main amp section

6

5

4

3

2

1

BC

DE

XM-PX50WT

F

G

HA

I

2-3

Page 28

Charger section

XM-PX50WT XM-PX50WT

1M

Q6

SSM3J01F-X

R18

J1

QNA0025-001

100k

P1

6

5

4

LV32351-001A

P2

LV32351-001A

P3

LV32351-001A

R34

R4R5

6.8k10k

C2R1

4.7/10

R36

C14

10k

0.068/16

C3

220P

R6

R8R9

270k82k

10k

47k

IC1

BA10324AF-W

R7

470

Q4

C4

1/16

Q1

KTB772/Y/

Q7

R31

R2

100k

C9

0.01

R21

220k

R22

10k

IC1

BA10324AF-W

Q3

D2

MTZJ3.9B-T2

R11

1k

R10

120

560

R17

C1

220/16

R14

1k

D1

TLSU126-T

R12

82

Q5

R16 R15

43k 100k

IC1

C11

R28

BA10324AF-W

82k

0.01

IC1

BA10324AF-W

3

0.22

R27

10k

2

1

BC

DE

2-4

F

G

HA

I

Page 29

Printed circuit boards

Printed circuit boards

XM-PX50WT

6

5

4

3

R466

Main board (Forward side)

R66

R62

R61

R921

Q921

C62

R67

R357

L901

C356

R356

D901

R907

C65

R967

R908

C359

Q63

X300

R355

R358

C358

C357

R909

R388

R64

C355

Q966

C906

Q64

R387

R366

R201

C202

L902

C903

Q904

R367

R101

R103

R203

C506

C102

IC504

C103

C904

C203

R460

R514

C507

R512

R511

C63

C211

R211

R111

C111

D400

C456

C457

R461

R465

C460

L400

C401

R459

C461

C458

C213

C113

R402

C459

R213

K201

K601

K101

R113

R400

C631

C630

CN601

C404

C403

IC400

S60

S504

S503

C309

R503

C311

R323

S502

R504

R324

R326

R311

C310

R321

R325

R322

IC961

C408

C412

L404

C325

R338

R316

R320

S501

C300

Q301

R315

IC300

R328

C313

C962

R962

C963

C409

L405

R303

R337

C314

C317

R516

R961

C961

Q961

C411

R335

R336

C315

C318

R339

R501

C64

R523

Q501

C406

L402

R307

Q300

R305

R341

C301

C316

C323

R530

X500

TH501

R525

L403

R306

C320

R310

R308

R513

R510

R506

C508

C512

R526

C321

R301

C319

R3

K603

C407

C3

R2

C513

C590

Q61

R522

R613

K602

R65

C402

R463

C452

CN301

C2

R508

R63

R60

K604

C4

R601

R603

C453

C462

C464

R317

IC2

IC501

R507

Q60

C614

R604

C454

R454

R318

R314

C308

C613

R455

C312

R529

IC601

C603

C602

CN401

IC450

IC502

R527

R517

R528

R212

R112

C212

C500

R509

C112

R385

C504

L602

C604

R386

L501

R369

C354

Q965

Q502

C509

IC505

R519

R518

C511

C463

C450

C360

R353

C351

R520

Main board (Reverse side)

R451

R450

R364

R354

R351

R965

R966

IC351

Q964

IC901

R521

C377

C376

R304

R923

R901

C902

C510

R380

R378

R377

R379

Q901

R373

C374

R376

C353

R922

C372

R372

R371

C921

R524

D501

Q906

C352

C924

IC921

C901

C371

C923

C373

R352

Charger board (Forward side)

2

D1

B3

B6

B1

P3

R34

1

P2

J1

P1

C8

C1

Q1

B4

B2

D2

B5

BC

Charger board (Reverse side)

R13

R7

R35

C4

C5

B7

Q1

IC1

R19

C1

R24

R28

C10

P1

C11

R29

R21

R4

R17

C8

R22

C9

D1

R14

B6

R5

C2

R18

C12

R27

R1

Q6

R12

B3

B1

P2

R16

Q5

R15

R8R9

D3

R34

P3

J1

C13

R11

R10

C14

R32

R33

D2

B5

B2

Q4

R36

C3

Q3

R25

R31

B4

B8

C7

R6

Q7

R2

DE

F

G

HA

I

2-5

Page 30

XM-PX50WT XM-PX50WT

< MEMO >

6

5

4

3

2

1

BC

DE

2-6

F

G

HA

I

Page 31

PARTS LIST

[ XM-PX50WT ]

* All printed circuit boards and its assemblies are not available as service parts.

XM-PX50WT

- Contents -

Exploded view of general assembly and parts list

Charger assembly and parts list

MD mechanism assembly and parts list

Electrical parts list

Packing materials and accessories parts list

Area suffix

UB -------------------- Hong Kong

3-2

3-4

3-5

3-6

3-9

3-1

Page 32

XM-PX50WT

Exploded view of general assembly and parts list

Block No.

40

41

31

27

29

42

38

34

M

M

1

M

41

17

14

25

16

18

19

15

13

Main board

20

28

1

21

23

3

26

30

22

25

37

41

33

36

39

35

24

32

3-2

4

9

Jack board

A

8

10

6

2

11

12

A

5

7

Page 33

XM-PX50WT

(General assembly)

Parts list

Item

A

1 -----------2 LV10439-004A

3 LV41969-001A

4 LV32205-001A

5 LV41215-006A

6 LV32198-001A

7 LV32200-001A

8 LV32199-001A

9 LV32211-002A

10 LV41215-006A

11 LV32210-001A

12 LV41215-006A

13 LV20899-001A

14 LV31334-003A

15 LV31332-003A

16 LV31333-005A

17 LV32352-001A

18 LV42142-002A

19 LV32242-001A

20 LV32201-002A

21 VKZ4616-008

22 LV42222-001A

23 LV40242-001A

24 LV30225-0A6A

25 QYSPSGU1425M

26 LV40241-004A

27 LV31339-004A

28 LV32202-001A

29 QYSPSGU1425M

30 LV31294-001A-S

31 QYSPSFT1425M

32 LV20881-003A

33 LV10424-002A

34 LV20873-004A

35 LV41967-001A

36 VKZ4616-008

37 LV42158-001A

38 LV42147-004A

39 LV41968-002A

40 LV32197-002A

41 LV41215-006A

42 LV30225-0A1A

Parts number Parts name Area

FLM-FPM

BOTTOM CASE

SHIELD SHEET

EJECT ASSY

MINI SCREW

OPEN KNOB

SLIDE KNOB

PUSH BUTTON

ARM ASSY(L)

MINI SCREW

ARM ASSY(R)

MINI SCREW

BATT HOLDER

BATT CONTACT(-)

CHG CONTACT (+)

CHG CONTACT (-)

CHG CONTACT(S)

SHEET

B.CONTACT ASSY

BATTERY LID

SCREW

PROTECTOR

MINI SCREW

SPACER

TAP SCREW

SPECIAL SCREW

CAUTION LABEL

H.P JACK COVER

TAP SCREW

EJECT UNIT

MINI SCREW

HOLDER ASS'Y

MD DOOR BASE

MD DOOR COVER

HOOK

SCREW

D.F TAPE

SHEET

OPEN LABEL

LENS

MINI SCREW

SPACER

Q'ty

1

1

1

1

2

FOR EJECT ASSY

1

1

VOL/SKIP/HOLD

1

1

1

FOR ARM ASSY(L)

1

1

FOR ARM ASSY(R)

1

1

1

1

1

1

1

1

1

B.CONTACT ASSY

1

FOR PCB

1

FOR PCB-MECHA

1

FOR MECHA(F)-PC

2

FOR PCB

1

FOR MECHA

1

1

1

1

2

(M1.4 PX2.5,B)

1

1

1

1

1

1

FOR MD DOOR

1

FOR LENS

1

1

4

FOR MD DOOR

1

FOR SHEET

Block No. M1MM

Description

3-3

Page 34

XM-PX50WT

Charger assembly and parts list

6

2

Block No.

4

7

8

M

M

M

5

Charger board

1

3

2

3

3

2

3-4

Parts list

Item

A

(Charger)

Parts number Parts name Area

1 LV20897-005A

2 LV40243-001A

3 QYSDSF2006Z

4 LV10451-001A

5 LV20898-001A

6 LV32349-002A

7 LV32350-001A

8 QYSDSF2006Z

BOTTOM CASE

FOOT

SCREW

TOP COVER

INNER CABI

LENS

HOOK

SCREW

Q'ty

1

2

4

1

1

1

1

1

Block No. M2MM

Description

PC CLEAR

FOR BOTTOM

BOTTOM+TOP

PC

PC

PMMA

POM

FOR HOOK

Page 35

XM-PX50WT

MD mechanism assembly and parts list

FLM-FPM

Grease

= FL-7750

= CFD-4007HY2

= FG-87HS

= 948P

15

16

1

2

Both side

10

3

9

8

11

Block No.

8

2

M

10

9

2.1 0.1mm

M

M

+

-

Parts list

Item

A

1 LV20882-001A

2 QAR0113-001

3 QYSPSFT1425M

5 QAL0237-001

6 LV32031-001A

7 QYSPSGT1425N

8 LV32114-001A

9 LV41132-001A

10 LV41133-001A

11 LV41134-003A

12 QYSPSFT1425M

13 QAR0112-001

14 QYSPSFT1425M

15 LV41141-002A

16 WDM082520

17 LVB10188-001A

12

13

17

5

6

14

(MD mechanism)

Parts number Parts name Area

CHASSIS ASS'Y

FEED MOTOR

MINI SCREW

PICK UP

LEAD SPRING

MINI SCREW

LEAD SCREW

METAL

WHEEL GEAR

SHAFT HOLDER

MINI SCREW

SPINDLE MOTOR

MINI SCREW

WORM GEAR

SLIT WASHER

MECHA FPC

14

Q'ty

1

1

2

1

1

1

1

1

1

1

1

1

3

1

1

1

7

Block No. M3MM

Description

(M1.4 PX2.5,B)

(M1.4 BX2.5,N)

(M1.4 PX2.5,B)

(M1.4 PX2.5,B)

3-5

Page 36

XM-PX50WT

Q

Q

Q

Q

Q

Q

Q

Electrical parts list

Item

A

C 62 NCB31HK-102X C CAPACITOR

C 63 NCB31HK-102X C CAPACITOR

C 64 NCB31HK-102X C CAPACITOR

C 65 NCB31HK-103X C CAPACITOR

C 102 NCS31HJ-391X C CAPACITOR

C 103 NCB21AK-105X C CAPACITOR

C 111 NCB21CK-224X C CAPACITOR

C 112 NCB31AK-224X C CAPACITOR

C 113 NBFA0GM-157X TS E CAPACITOR

C 202 NCS31HJ-391X C CAPACITOR

C 203 NCB21AK-105X C CAPACITOR

C 211 NCB21CK-224X C CAPACITOR

C 212 NCB31AK-224X C CAPACITOR

C 213 NBFA0GM-157X TS E CAPACITOR

C 300 NCB31HK-103X C CAPACITOR

C 301 NCB31CK-273X C CAPACITOR

C 302 NCB31CK-823X C CAPACITOR

C 308 NCB31HK-682X C CAPACITOR

C 309 NCB30JK-105X C CAPACITOR

C 310 NCB31HK-472X C CAPACITOR

C 311 NCB30JK-105X C CAPACITOR

C 312 NCB31CK-333X C CAPACITOR

C 313 NCB31AK-224X C CAPACITOR

C 314 NCB31HK-103X C CAPACITOR

C 315 NCB31EK-223X C CAPACITOR

C 316 NCB31CK-104X C CAPACITOR

C 317 NCB31HK-682X C CAPACITOR

C 318 NCB31HK-102X C CAPACITOR

C 319 NBE90JM-106X TS E CAPACITOR

C 320 NCB31HK-103X C CAPACITOR

C 321 NCB21CK-474X C CAPACITOR

C 323 NCB21AK-105X C CAPACITOR

C 325 NCB31CK-104X C CAPACITOR

C 351 NBE20JM-106X TA E CAPACITOR

C 352 NBE20JM-106X TA E CAPACITOR

C 353 NBE20JM-106X TA E CAPACITOR

C 354 NBE20JM-106X TA E CAPACITOR

C 355 NCS31HJ-7R0X C CAPACITOR

C 356 NCS31HJ-7R0X C CAPACITOR

C 357 NCB21AK-105X C CAPACITOR

C 358 NCB21AK-105X C CAPACITOR

C 359 NCB30JK-105X C CAPACITOR

C 360 NCB31CK-104X C CAPACITOR

C 371 NCB31HK-103X C CAPACITOR

C 372 NCB21CK-474X C CAPACITOR

C 373 NCB21AK-105X C CAPACITOR

C 374 NCS31HJ-471X C CAPACITOR

C 376 NCB21CK-474X C CAPACITOR

C 377 NCB31HK-153X C CAPACITOR

C 401 NCB21AK-105X C CAPACITOR

C 402 NBE21CM-335X TS E CAPACITOR

C 403 NCB30JK-105X C CAPACITOR

C 404 NCB30JK-105X C CAPACITOR

C 450 NCB31CK-473X C CAPACITOR

C 454 NCB21AK-105X C CAPACITOR

C 456 NCB31HK-222X C CAPACITOR

C 457 NCB31HK-102X C CAPACITOR

C 458 NCB31CK-473X C CAPACITOR

C 459 NCB21AK-105X C CAPACITOR

C 460 NCB31HK-682X C CAPACITOR

C 461 NCB31CK-473X C CAPACITOR

C 463 NCB21AK-105X C CAPACITOR

C 500 NCB21AK-105X C CAPACITOR

Parts number Parts name Area

(Main board)

Block No. 01

Remarks

Item

A

C 503 NCB31CK-104X C CAPACITOR

C 504 NCB21AK-105X C CAPACITOR

C 506 NCB31CK-104X C CAPACITOR

C 507 NCB31CK-104X C CAPACITOR

C 509 NCB31CK-104X C CAPACITOR

C 510 NCB31HK-102X C CAPACITOR

C 512 NCB31CK-104X C CAPACITOR

C 513 NCB31HK-102X C CAPACITOR

C 590 NCB31HK-102X C CAPACITOR

C 602 NCB30JK-105X C CAPACITOR