Page 1

SERVICE MANUAL

PORTABLE MINIDISC PLAYER

XM-P55

XM-PJ1

XM-P55

XM-PJ1

Contents

B

E

EE

EN

J

UB

US

UT

UX

UY

5

5

P

-

M

X

OPEN

XM-P55

Area Suffix

(XM-P55 )

U.K. (BU,SL)

Continental Europe (BU,SL)

Russian Federation (BU,SL)

Northern Europe (BU,SL)

U.S.A. (SL)

Hong kong (BU,GN,SL)

Singapore (BU,SL)

Taiwan (SL)

Saudi Arabia (SL)

Argentina (SL)

B

E

EE

EN

J

UB

US

UT

UX

UY

XM-PJ1

Area Suffix

(XM-PJ1 )

U.K. (BU)

Continental Europe (BU)

Russian Federation (BU)

Northern Europe (BU)

U.S.A. (BU)

Hong kong (BU,GD)

Singapore (BU)

Taiwan (BU)

Saudi Arabia (BU)

Argentina (BU)

Safety Precautions

Instructions (For XM-P55&PJ1)

Description of Major ICs

Removal of Main Parts

Maintenance of MD Pickup

Procedures of Changing the MD Pickup

Self-diagnosis Function of MD

1-2

1-3~16

2-1

2-12

2-23

2-23

2-24

COPYRIGHT 1999 VICTOR COMPANY OF JAPAN, LTD.

Block Diagrams

Standard Schematic Diagrams (XM-P55)

Standard Schematic Diagrams (XM-PJ1)

Printed Circuit Boards

Parts List (XM-P55)

Parts List (XM-PJ1)

2-27

2-29

2-36

2-42,43

3-1~15

4-1~15

No.20738

Jan. 1999

Page 2

XM-P55

XM-PJ1

Safety Precaution

CAUTION

CAUTION

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-2 4-15

Page 3

Description of Major ICs

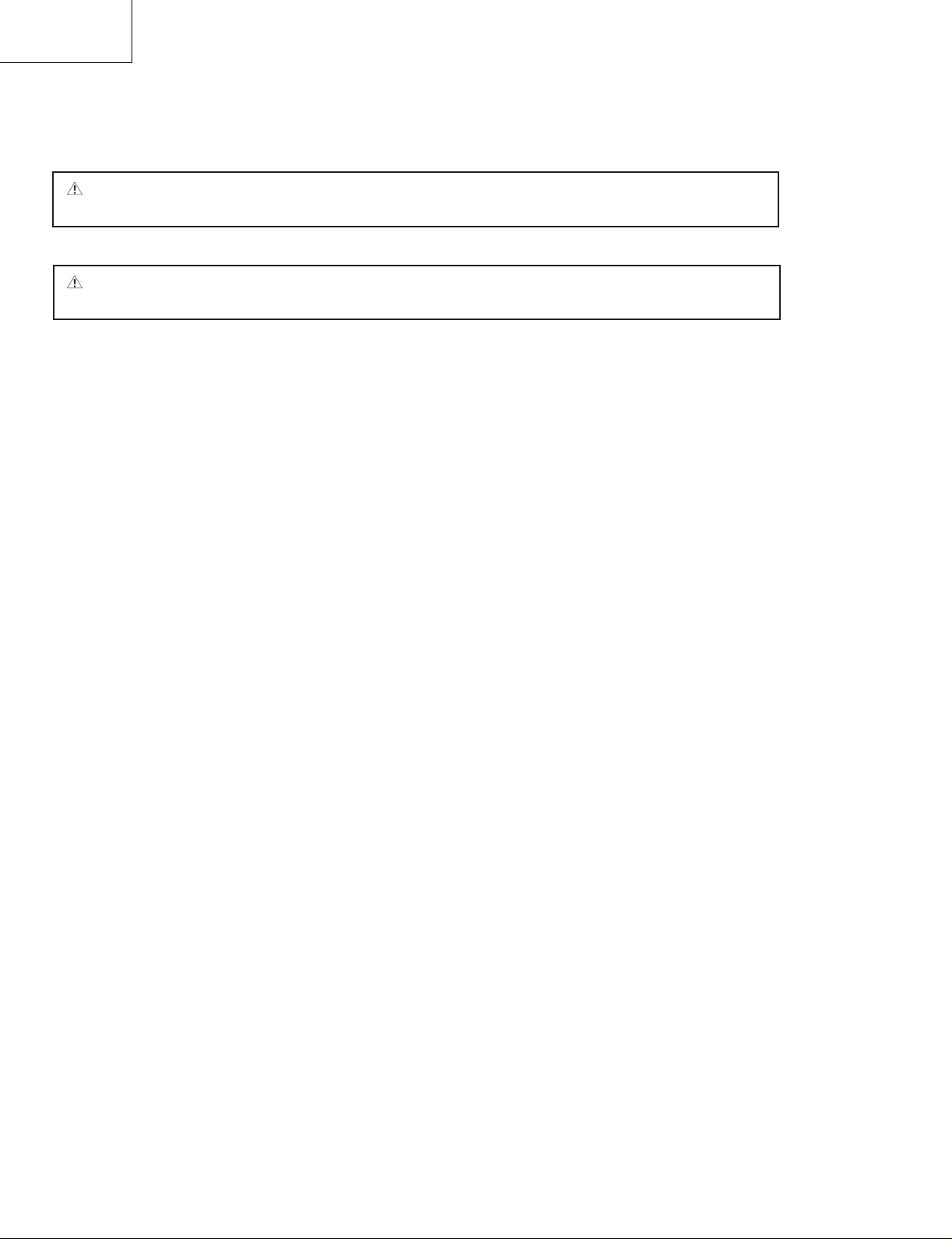

CXA2523AR(IC310):MD RF & Servo

1.Block Diagram

BOTM

ABCD34FE33AUX32ADFG31ADAGC30ADIN29ADFM28SE27CSLED26TE25WBLADJ

36 35

XM-P55

XM-PJ1

37

PEAK

38

RF

39RFAGC

40AGCI

41COMPO

42COMPP

43ADDC

44OPO

45OPN

46RFO

47MORFI

48

MORFO

2.Pin Function

AGC, EQ

Comp

USER

USER

OP Amp

RF Amp

1 2

I

ADIP Amp TE/SE Amp

MUX FE Amp

Peak, Bottom Detector

ABCD Amp

3T Detector

I-V Amp APC

3VC4A5B6C7D8E9F10PD11

J

CPU

Command I/F

TEMP Amp

12

APC

APCREF

24

Vcc

23

3TADJ

22 EQADJ

21 VREF

20 F0CNT

19 XSTBY

18 XLAT

17 SCLK

16 SWDT

15 TEMP R

14 TEMP I

13 GND

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Symbol

I

J

VC

A

B

C

D

E

F

PD

APC

APCREF

GND

TEMPI

TEMP R

SWDT

SCLK

XLAT

XSTBY

F0CNT

I/O

I-V converted RF signal I input.

I

I-V converted RF signal J input.

I

Vcc/2 voltage output.

O

A current input for main beam servo signal.

I

B current input for main beam servo signal.

I

C current input for main beam servo signal.

I

D current input for main beam servo signal.

I

E current input for side beam servo signal.

I

F current input for side beam servo signal.

I

Reflection light quantity monitor signal input.

I

Laser APC output.

O

Reference voltage input for the laser power intensity setting.

I

Connect to GND.

Connects the temperature sensor.

I

Connects the temperature sensor. outputs the reference voltage.

I

Data input for microcomputer serial interface.

I

Shift clock input for microcomputer serial interface.

I

Latch signal input for microcomputer serial interface.Latched when low.

I

Standby setting pin. Normal operation when high Standby when low.

I

Internal current source setting pin.

I

Function

2-1

Page 4

XM-P55

XM-PJ1

Pin No.

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Symbol

VREF

EQADJ

3TADJ

Vcc

WBLADJ

TE

CSLED

SE

ADFM

ADIN

ADAGC

ADFG

AUX

FE

ABCD

BOTM

PEAK

RF

RFAGC

AGCI

COMPO

COMPP

ADDC

OPO

OPN

RFO

MORFI

MORFO

I/O

Reference voltage output.

O

Equalizer center frequency setting pin.

I/O

BPF3T center frequency setting pin.

I/O

Power supply.

BPF22 center frequency setting pin.

I/O

Tracking error signal output.

O

Connects the sled error signal LPF capacitor.

Sled error signal output.

O

ADIP FM signal output.

O

ADIP signal comparator input.

I

Connects the ADIPAGC capacitor.

ADIP2 binary value signal output.

O

13 output / temperature signal output. Switched with serial commands.

O

Focus error signal output.

O

Reflection light quantity signal output for the main beam servo detector.

O

RF/ABCD bottom hold signal output.

O

Peak hold signal output for the RF/ABCD signals.

O

RF equalizer output.

O

Connects the RFAGC capacitor.

RFAGC input.

I

User comparator output.

O

User comparator non-inverted input.

I

Connects the capacitor for ADIP amplifier feedback circuit.

I/O

User operational amplifier output.

O

User operational amplifier inverted input.

I

RF amplifier output. Eye pattern checkpoint.

O

Input of the groove RF signal with AC coupling.

I

Groove RF signal output.

O

Function

2-2

Page 5

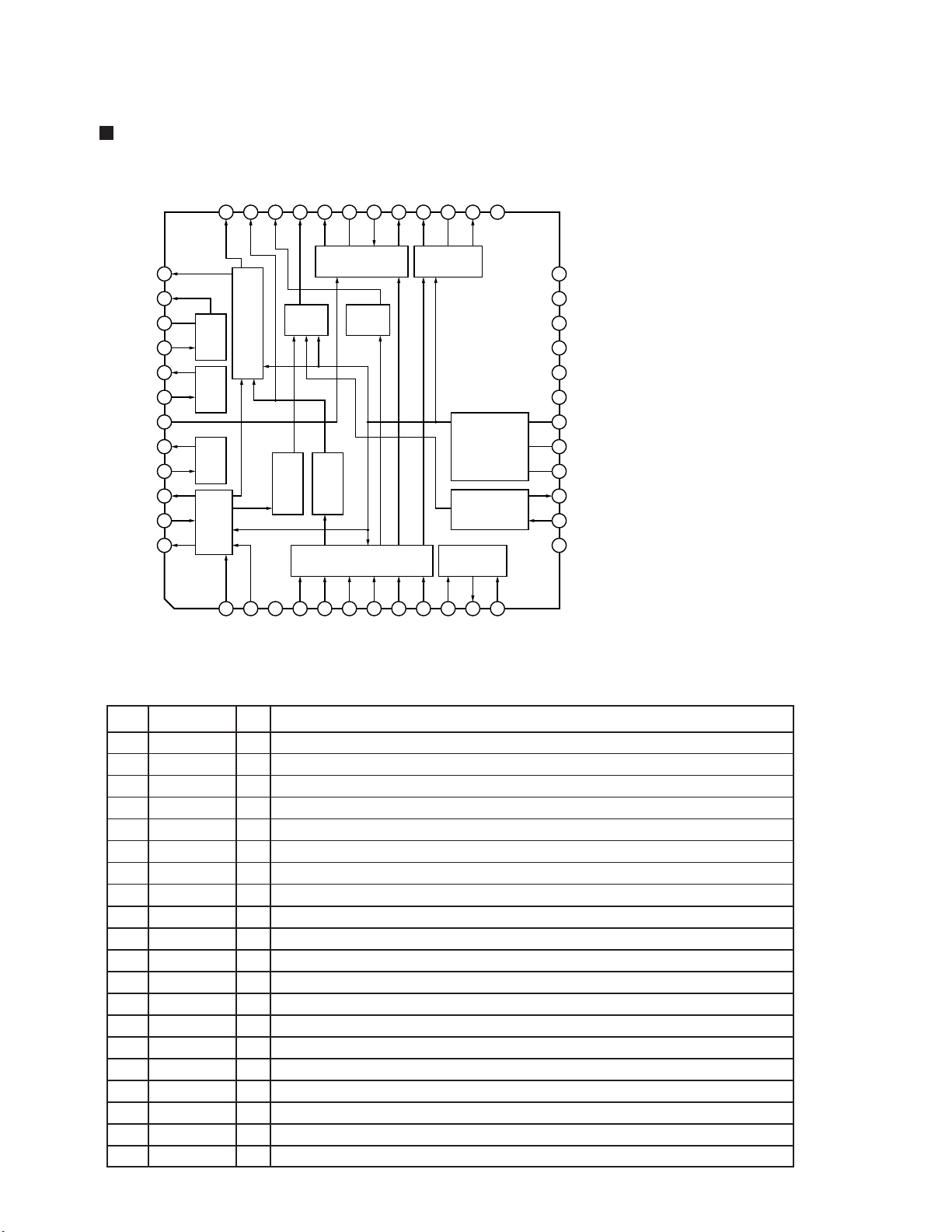

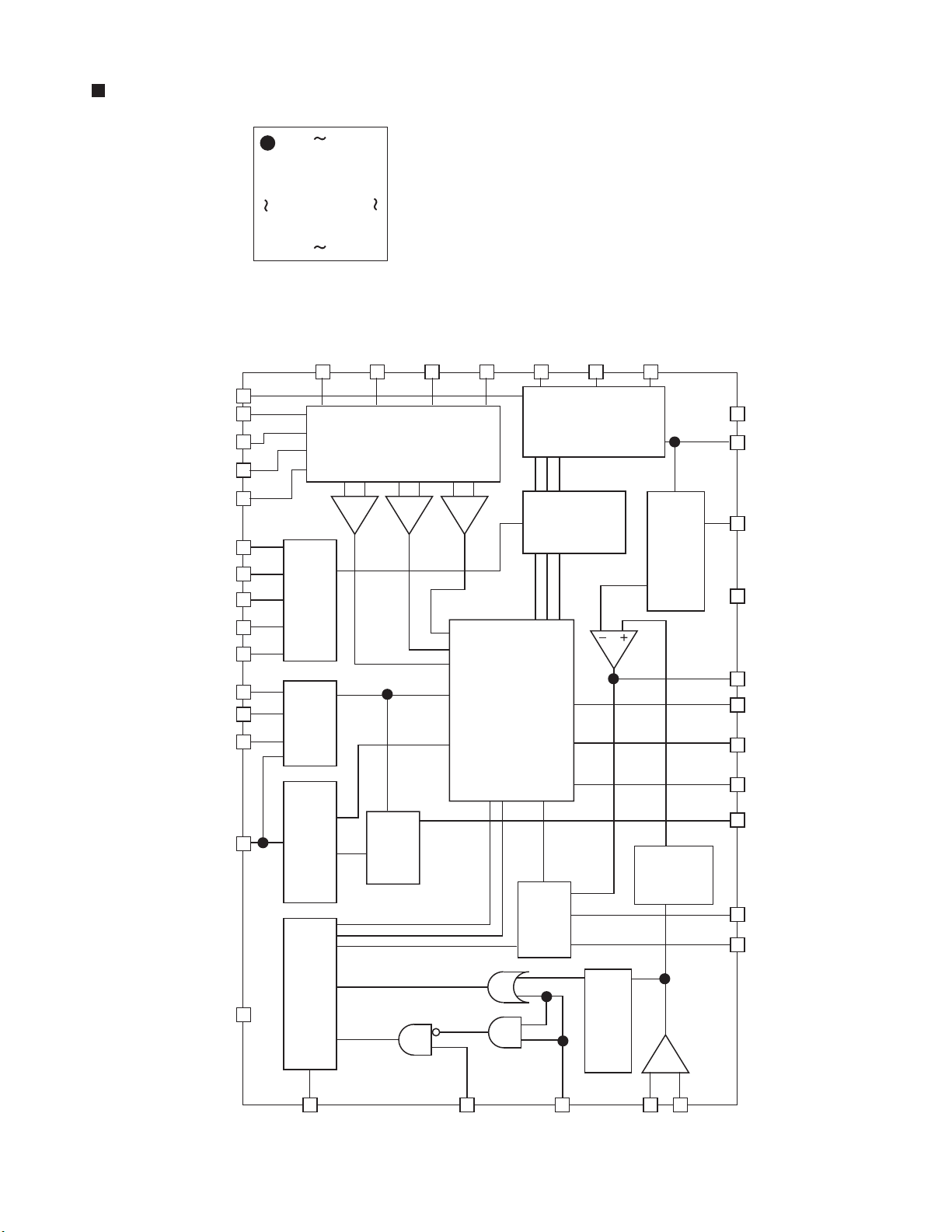

CXA8069M(IC450):Sensorless Motor Driver

1.Pin Layout

48 37

36

XM-P55

XM-PJ1

2.Block Diagram

VS

WF

VF

UF

COMF

CPOUT

CPC2

CP2

CPC1

CP1

VCO

RMAX

RMIN

12 1

13 24

Charge

Pump

VCO

25

UIN

VIN

Voltage Driver

WIN

+ -+ -+ -

Sensorless

Logic

COM

UOUT

Power Stage

Level Shifter

VOUT

WOUT

Sample

and Hold

PGND

RF

CF

GND

FC

FG2

FG

VCOIN

VCC

Phase

Comparator

Timing

Controllor

MCLOCK

1/8

S/S

PWM

F/R

BRAKE

Full Wave

Rectifier

Controllor

+ -

VCONT

RESET

CLOCK

SLOPE

OSC

VCREF

2-3

Page 6

XM-P55

XM-PJ1

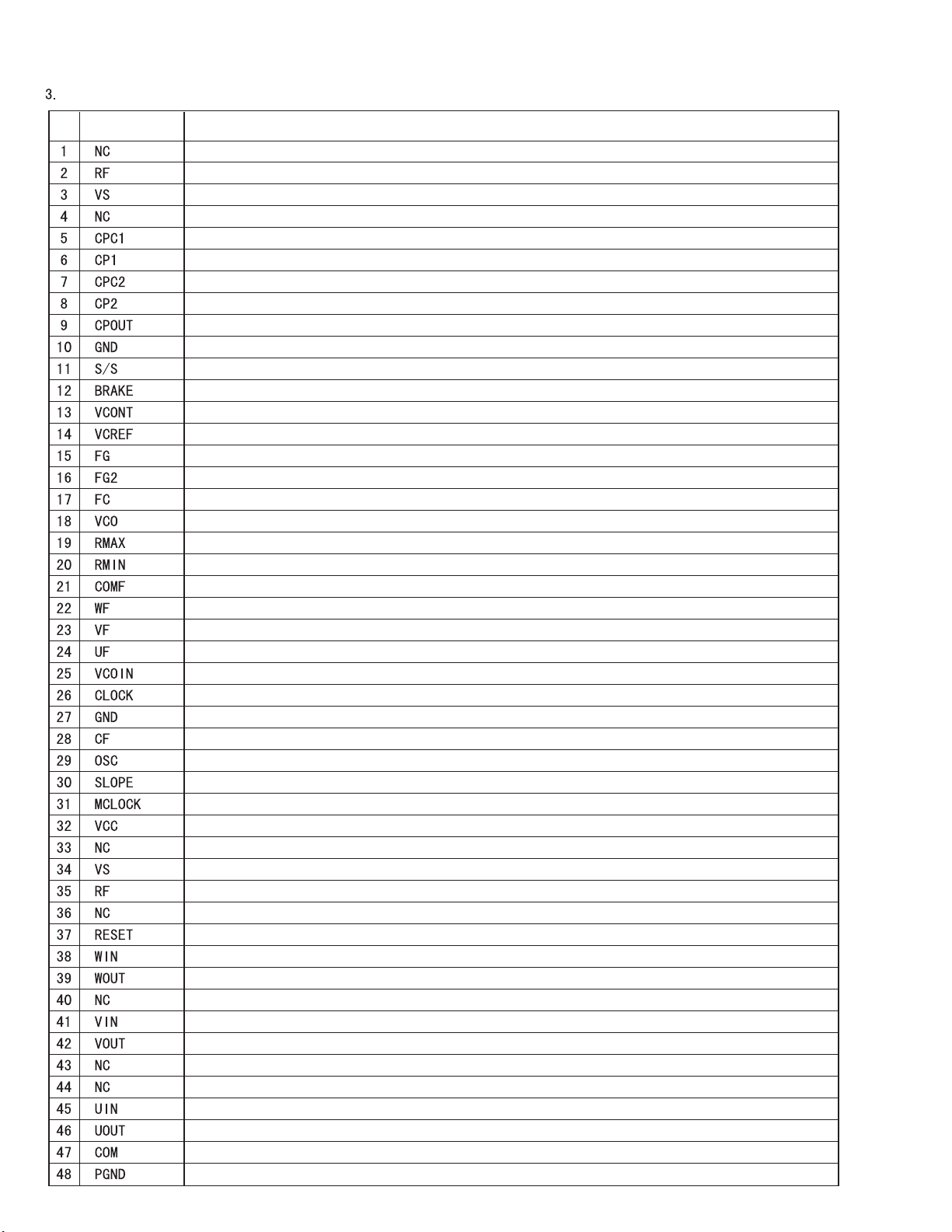

Pin Functions

Pin

Pin Name Functions

No.

2-4

Non connection

Detection of motor current

Motor driven power supply

Non connection

Connect first condenser of charge pump to this terminal.

Connect first condenser of charge pump to this terminal.

Connect second condenser of charge pump to this terminal.

Connect second condenser of charge pump to this terminal.

Connect last condenser of charge pump / VG external input

Ground of circuits except for output section

Start / Stop

Brake

Speed control

Reference voltage of speed control

FG pulse output

FG pulse output when pin15 FG signal goes half round

Correction of frequency characteristic of speed control loop

Setting of VCO oscillation frequency

Setting of VCO maximum oscillation frequency

Setting of VCO minimum oscillation frequency

Forms motor waveform

Forms motor waveform

Forms motor waveform

Forms motor waveform

VCO oscillation frequency control

Monitors CLOCK signal

Ground of circuits except for output section

Sample board for output current detection

Forms saw-tooth wave for PWM wave formation

Forms santooth waveform for soft switching wave formation

Clock input

Power supply except for output section

Non connection

Motor driven power supply

Detection of motor current

Non connection

Reset for operation check

Detection of counter electromotive voltage

Motor source output

Non connection

Detection of counter electromotive voltage

Motor source output

Non connection

Non connection

Detection of counter electromotive voltage

Motor source output

Detection of motor common voltage

Ground for output guard

Page 7

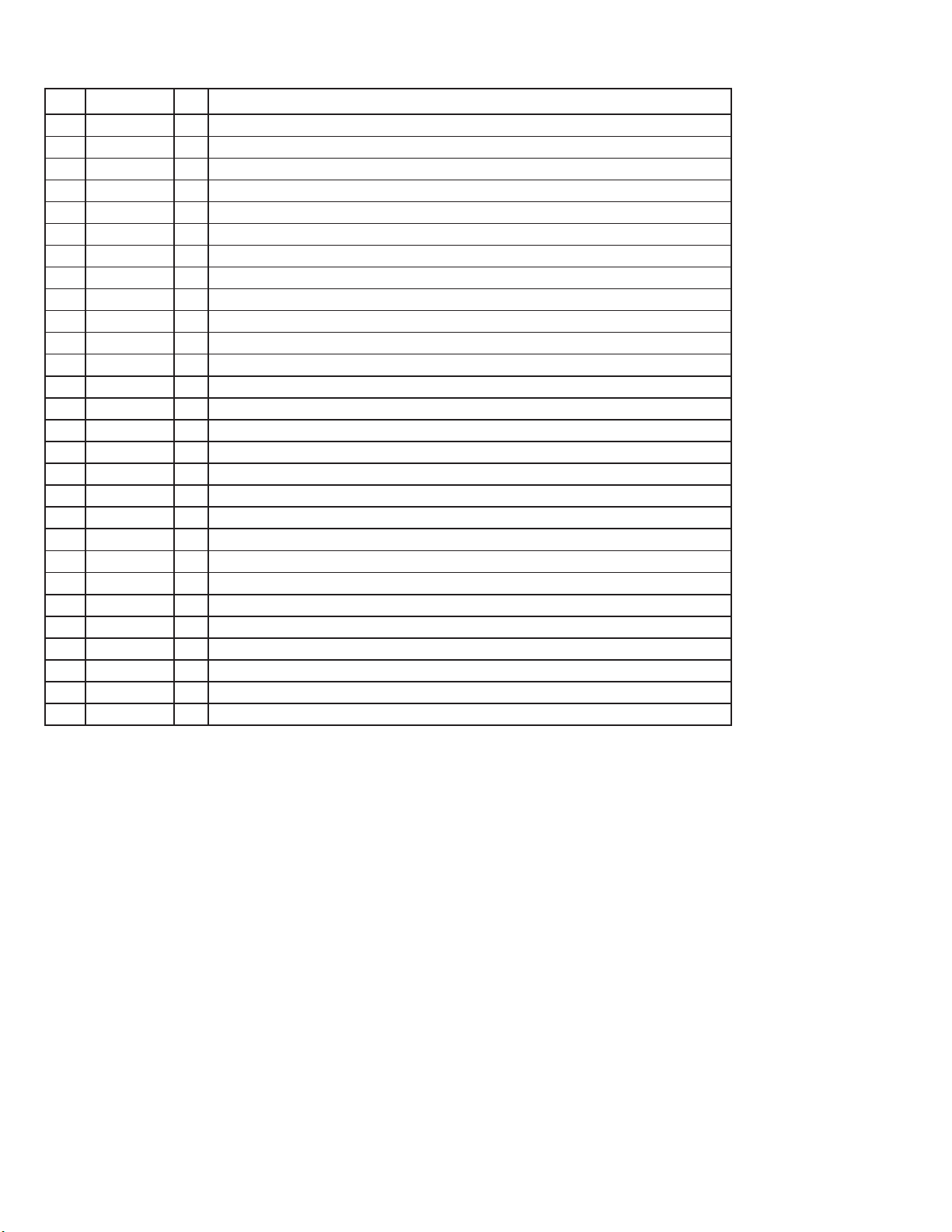

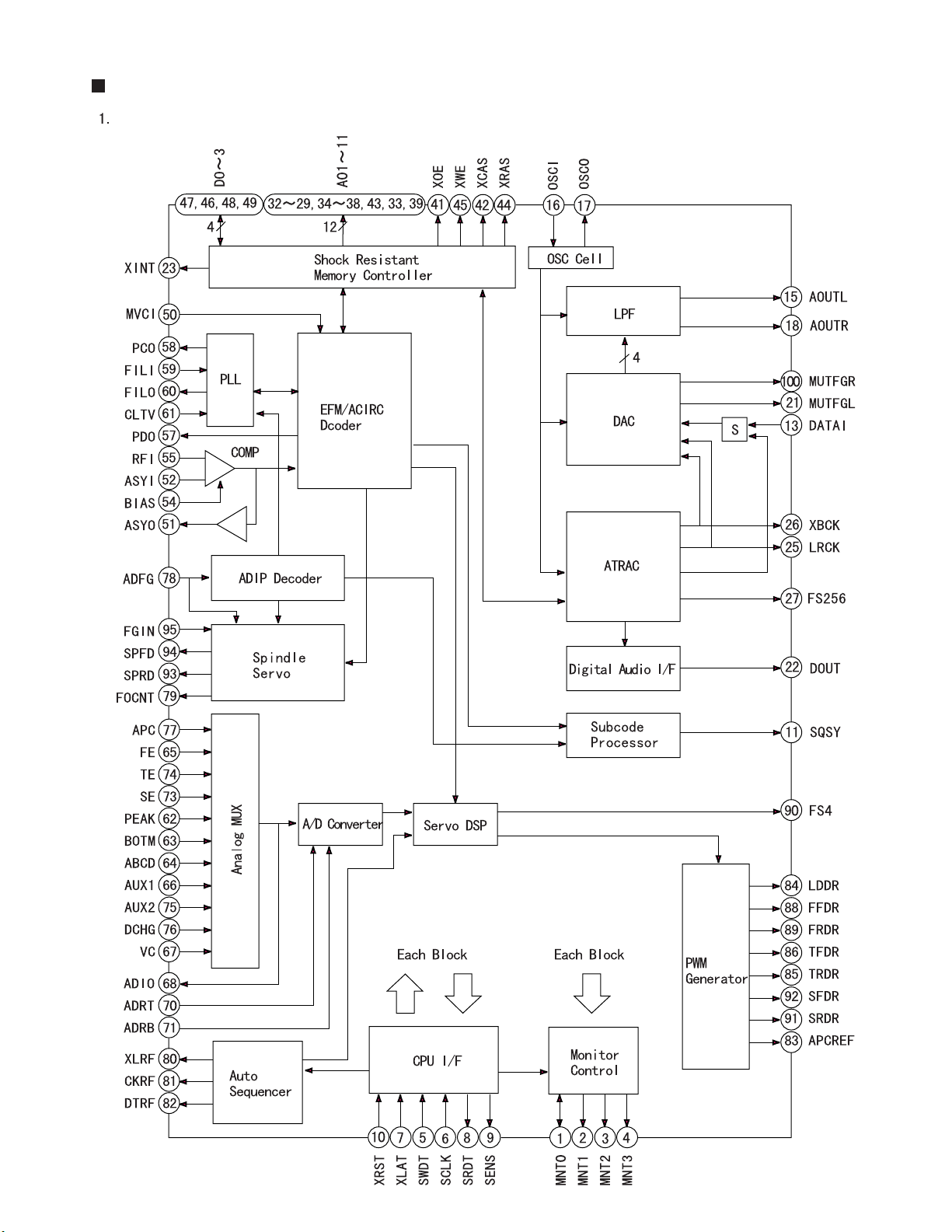

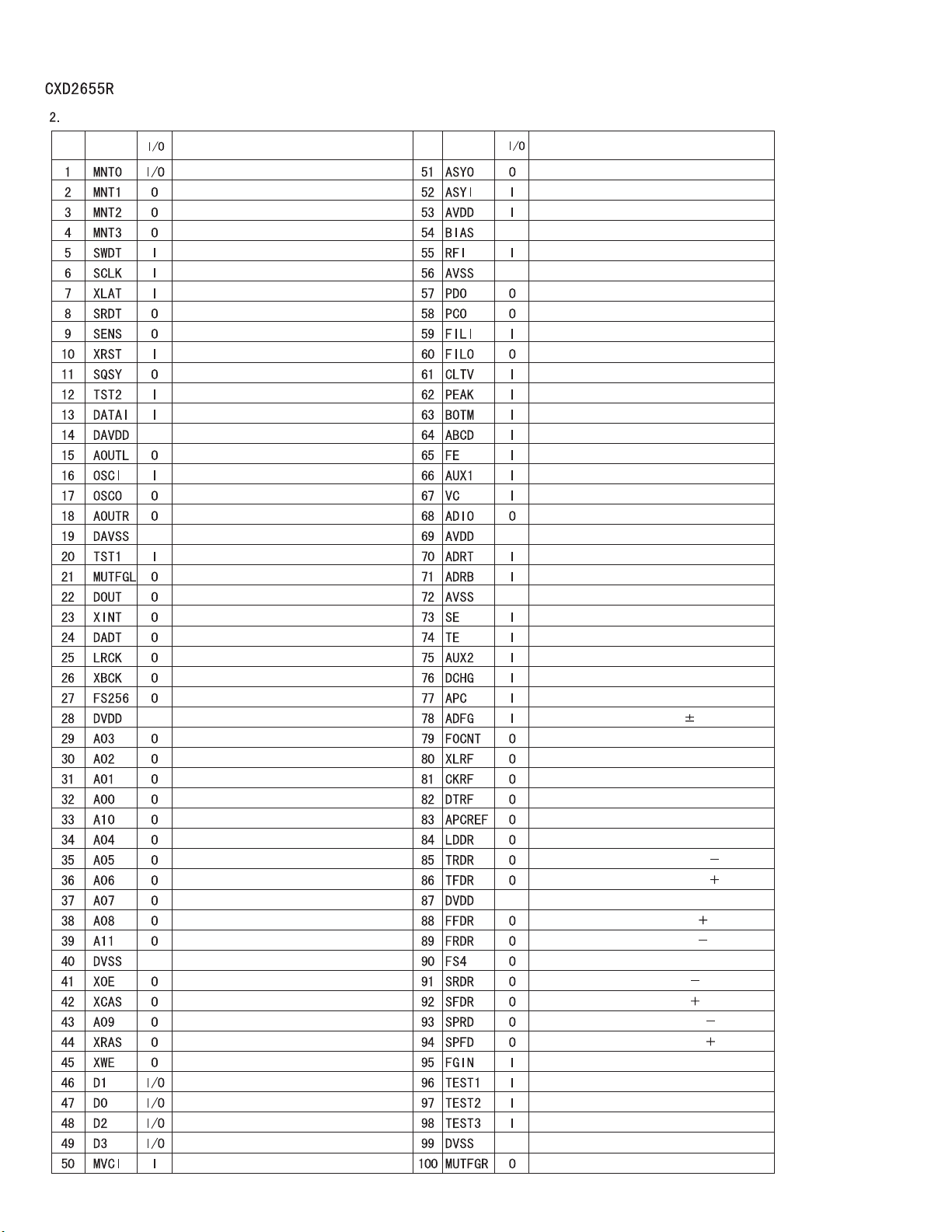

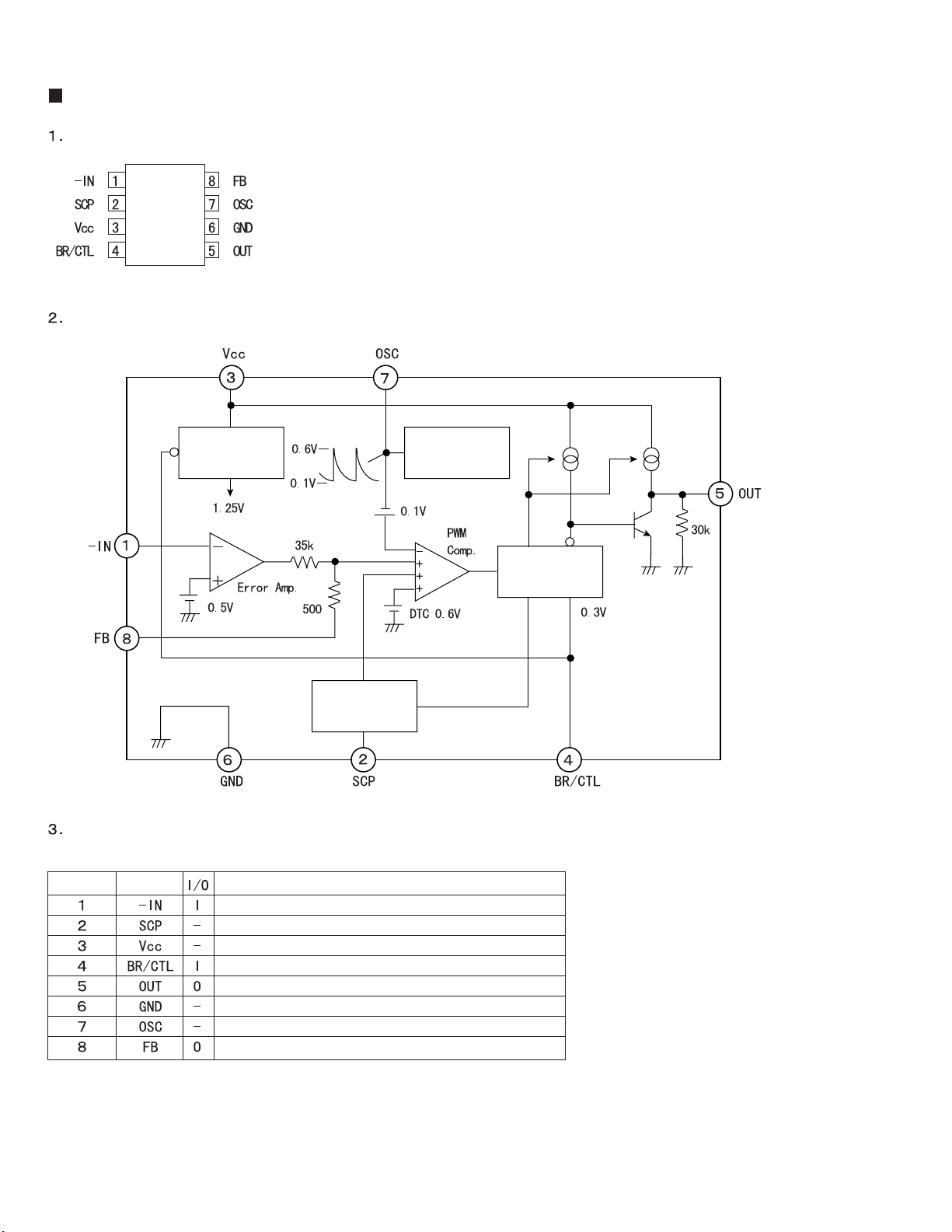

CXD2655R (IC351):Digital Servo Processor

Block Diagram

XM-P55

XM-PJ1

2-5

Page 8

XM-P55

XM-PJ1

Pin Function Description

Pin

Symbol

No.

Functions and Operations

Monitor input and output

Monitor output

Monitor output

Monitor output

Data input of microcomputer serial interface

Shift lock input of microcomputer serial interface

Latch input of microcomputer serial interface/

Latch at the Falling edge

Date output of microcomputer serial interface

Output of internal status corresponding to

microcomputer serial interface address

Reset input L : reset

Disc sub cord Q sync / ADIP sync output

Test pin

Input of external audio data to internal DAC

DAC power supply

Integrated DAC Lch output

Crystal oscillation circuit input (512Fs=22.5792MHz)

Crystal oscillation circuit output (Inverted output of OSCI)

Integrated DAC Rch output

DAC ground

Test pin

Detection of Lch zero data / flag output

Out put of digital audio interface signal

Interrupt request output L: When the interrupt

status occurs.

Output of audio date to external audio block

LRCK to external audio block (44.1kHz)

Output pin (2.8224MHz)

256Fs output (11.2896MHz)

Digital power supply

External DRAM address output

External DRAM address output

External DRAM address output

External DRAM address output

External DRAM address output

External DRAM address output

External DRAM address output

External DRAM address output

External DRAM address output

External DRAM address output

External DRAM address output

Digital ground

External DRAM output enable

External DRAM CAS output

External DRAM address output

External DRAM RAS output

External DRAM write enable

External DRAM date bus

External DRAM date bus

External DRAM date bus

External DRAM date bus

External VCO (784Fs) clock input

Pin

No.

Symbol

Functions and Operations

Playback EFM full-swing output

Playback EFM comparator slice voltage input

Analog power supply

Playback EFM comparator bias current input

Playback EFM RF signal input

Analog ground

Phase comparison output for analog PLL of

EFM decoder

Phase comparison output for master PLL of

playback digital PLL

Filter input for master PLL of playback digital PLL

Filter output for master PLL of playback digital PLL

Internal VCO control voltage input for master PLL of

playback digital PLL

Peak hold signal input for quantity of light

Bottom hold signal input for quantity of light

Signal input for quantity of light

Focus error signal input

Auxiliary input 1

Center voltage input

Monitor output of A/D converter input signal

Analog power supply

Input of upper-limit voltage of the A/D converter

operating range

Input of lower-limit voltage of the A/D converter

operating range

Analog ground

Sled error signal input

Tracking error signal input

Auxiliary input 2

Connect to the low-impeddance power supply

Error signal input for laser digital APC

ADIP binary FM signal (22.05

Output for setting of CXA 2523 current source

Latch output for CXA 2523 control

Shift lock output for CXA 2523 control

Data output for CXA 2523 control

Reference PWM output for laser APC

PWM output for laser digital APC

Tracking servo drive PWM output (

Tracking servo drive PWM output (

Digital power supply

Focus servo drive PWM output (

Focus servo drive PWM output (

4Fs output (176.4kHz)

Sled servo drive PWM output (

Sled servo drive PWM output (

Spindle servo drive PWM output (

Spindle servo drive PWM output (

FG input of spindle CAV servo

Test pin

Test pin

Test pin

Digital ground

Detection of Rch zero date / flag output

1kHz) input

)

)

)

)

)

)

)

)

2-6

Page 9

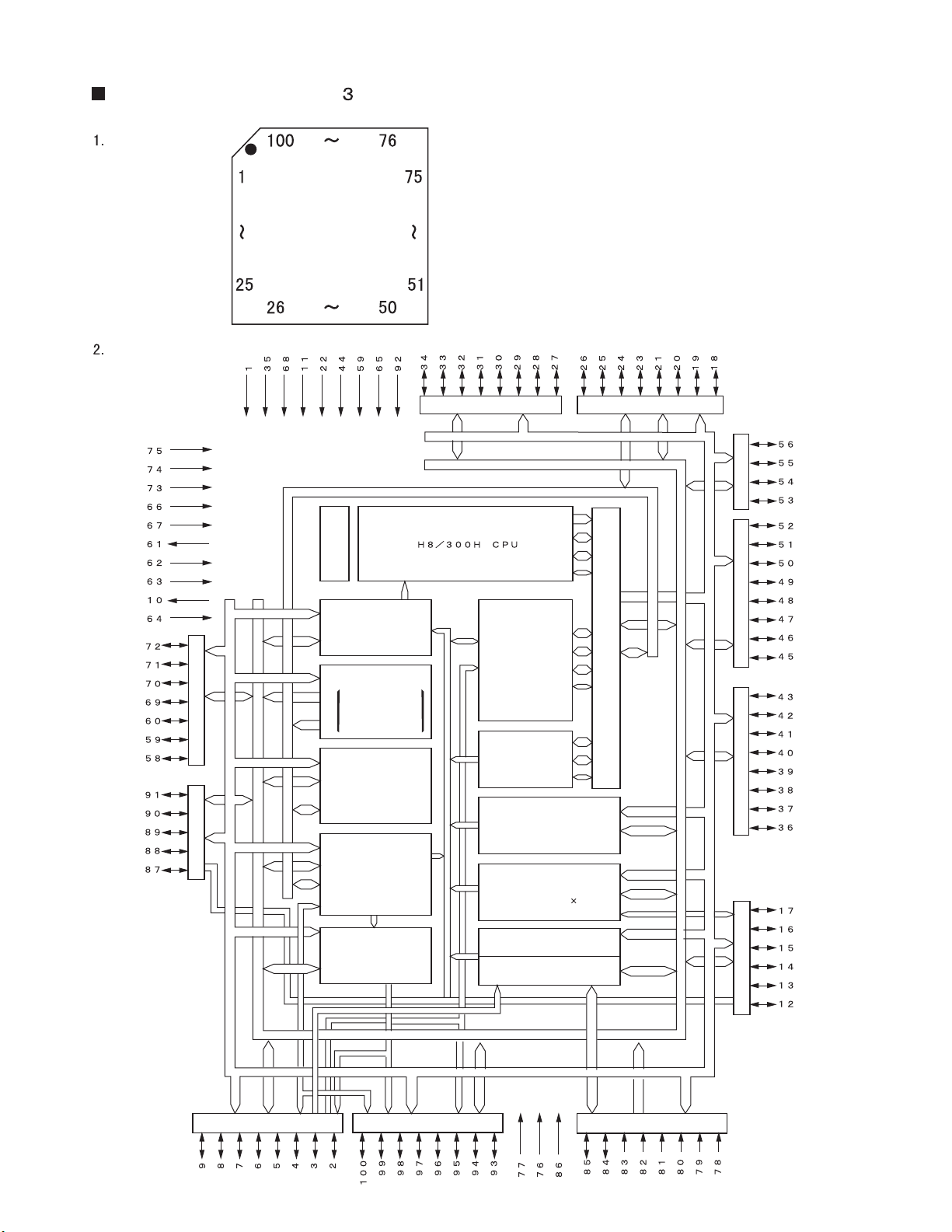

HD6433045SV14X (IC501): Beams Microcomputer

Terminal Layout

Block Diagram

XM-P55

XM-PJ1

Port 3

Address bus

Data bus (upper level)

Data bus (lower level)

Clock generator

Port 4

Port 5Port 2

Interrupt controller

DMA

ROM

Mask ROM

Port 6Port 8

PROM

Flash memory

RAM

16 bits

integrated

timer unit

(ITU)

controller

(DMAC)

Refresh

controller

Watch dog timer

(WDT)

Serial communication

interface (SCI)

2ch

Bus Controller

Port 1Port 9

Programmable

timing pattern

controller (TPC)

A/D converter

D/A converter

Port B Port A Port 7

2-7

Page 10

XM-P55

XM-PJ1

Description

Pin

Symbol

No.

Function and Operation

Power supply

Communications line terminals to CXA2523AR,

connect to XSTB terminal

Communications line terminals to CXA2523AR,

connect to SWDT terminal

Communications line terminals to CXA2523AR,

connect to SCLK terminal

Communications line terminals to CXA2523AR,

connect to XLAT terminal

Non connection

Non connection

Connect to XRST terminal of CXD2655R

Connect to XLAT terminal of CXD2655R

Supplies +12V when flash memory is writing.

Ground

Remote control UART output

Connect to SWDT terminal of CXD2655R

Remote control URAT input

Connect to SRDT terminal of CXD2655R

Non connection

Connect to SCLK terminal of CXD2655R

RF source pre-charge output

Laser ON / OFF output

RF source OFF output

Sled driven voltage ON/OFF

Ground

Clear signal of power supply circuit flip-flop

MUTE output for audio circuit

Starting control output

Debug / test mode

Parallel mode monitor

Parallel mode monitor

Parallel mode monitor

Parallel mode monitor

Debug / test mode

Debug / test mode

Debug / test mode

Sleep function enable input

Power supply

Non connection

Non connection

Non connection

Non connection

Non connection

Non connection

Non connection

Non connection

Ground

Non connection

Ground

Non connection

Non connection

LSI source down detective input

ALL tracks repeat key input

Pin

No.

Symbol

Function and Operation

Connect to MPC17A39 power save terminal

Connect to CXA8069 start / stop terminal

CXD2655R monitor output selection

CXD2655R monitor output selection

CXD2655R monitor output selection

CXD2655R monitor output selection

Ground

PLAY key input

Starting signal output for power supply circuit

Remote control power OFF

Non connection

Power supply

Microcomputer reset input

Power supply

Ground

Connect to Crystal NAX0275-001X

Connect to Crystal NAX0275-001X

Power supply

EEPROM2 chip select terminal output

EEPROM communication serial clock output

EEPROM communication serial DATA output

EEPROM chip select terminal output

Power supply

Power supply

Power supply

Power supply

Power supply

Key input (analog)

Non connection

Non connection

Battery voltage input (analog)

Non connection

Connect to temperature-detective thermistor

Remote control PLAY key input

Disc detective switch input

Ground

Connect to XINT terminal of CXD2655R

Connect to SQSY terminal of CXD2655R

Non connection

Non connection

Non connection

Ground

Connect to MINT0 terminal of CXD2655R

Non connection

Connect to BEEP of audio circuit

Connect to MINT3 terminal of CXD2655R

Connect to SENS terminal of CXD2655R

EEPROM communication serial data input

Non connection

ACTIVE CLEAR BASS circuit ON / OFF output

2-8

Page 11

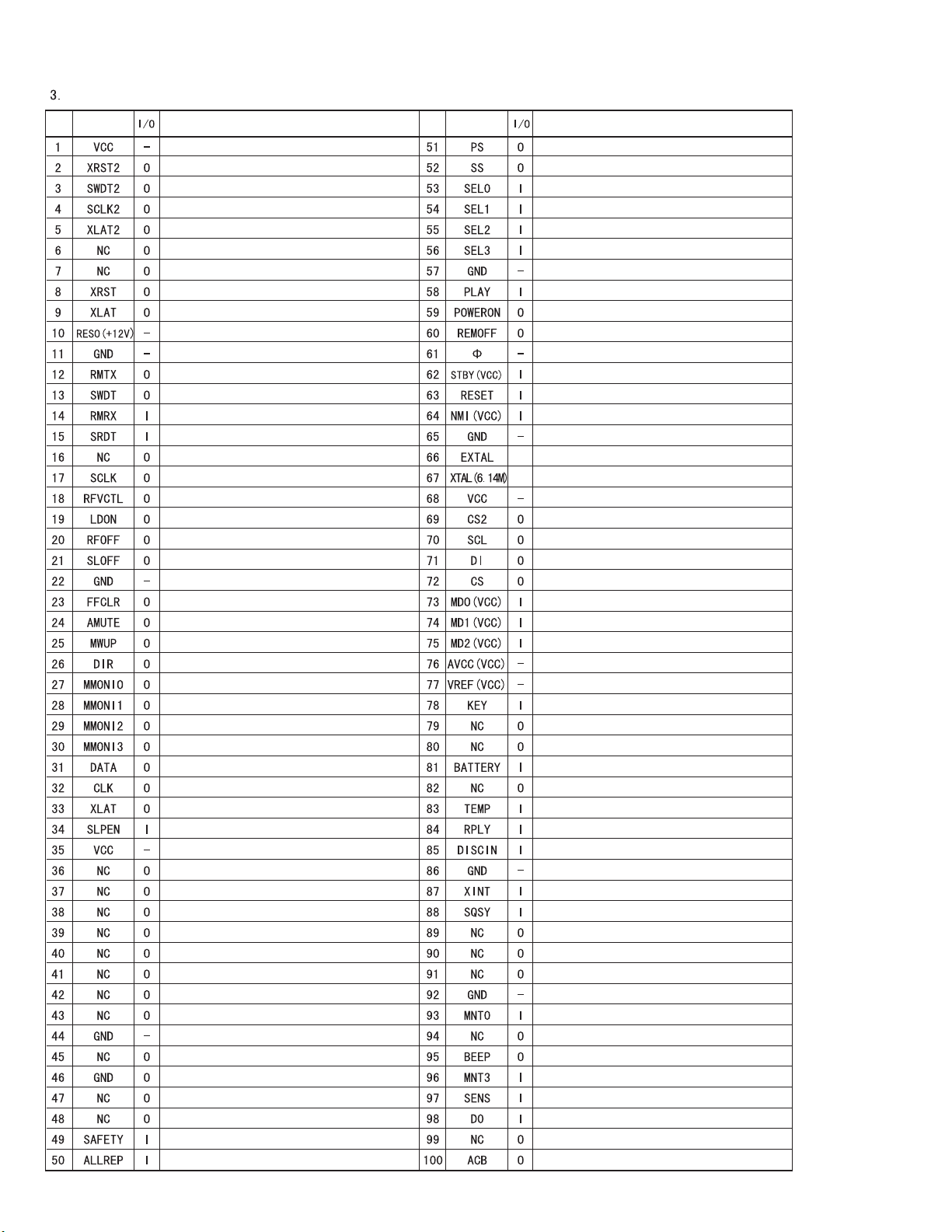

MPC17A39DTB-X (IC400):4Channel Bridge Driver

XM-P55

XM-PJ1

Terminal Layout

Block Diagram

Pin Function Description

Pin

No.

Symbol

Functions and Operations

DC / DC Converter circuit ground

External CLOCK input connection

Standby mode control

Output enable

Driver power supply

Driver output

Power ground

Driver output

Driver power supply

Driver power supply

Driver output

Power ground

Driver output

Driver power supply

CH 1 control signal input

CH 1 control signal input

CH 2 control signal input

CH 2 control signal input

Pin

No.

Symbol

Functions and Operations

CH 4 control signal input

CH 4 control signal input

CH 3 control signal input

CH 3 control signal input

Driver output

Driver output

Power ground

Power ground

Driver power supply

Driver power supply

Driver output

Power ground

Driver output

Driver power supply

Control circuit ground

DC / DC Converter boosting inductance, diode ground

Control circuit power supply

Pre-driver circuit power supply

2-9

Page 12

XM-P55

XM-PJ1

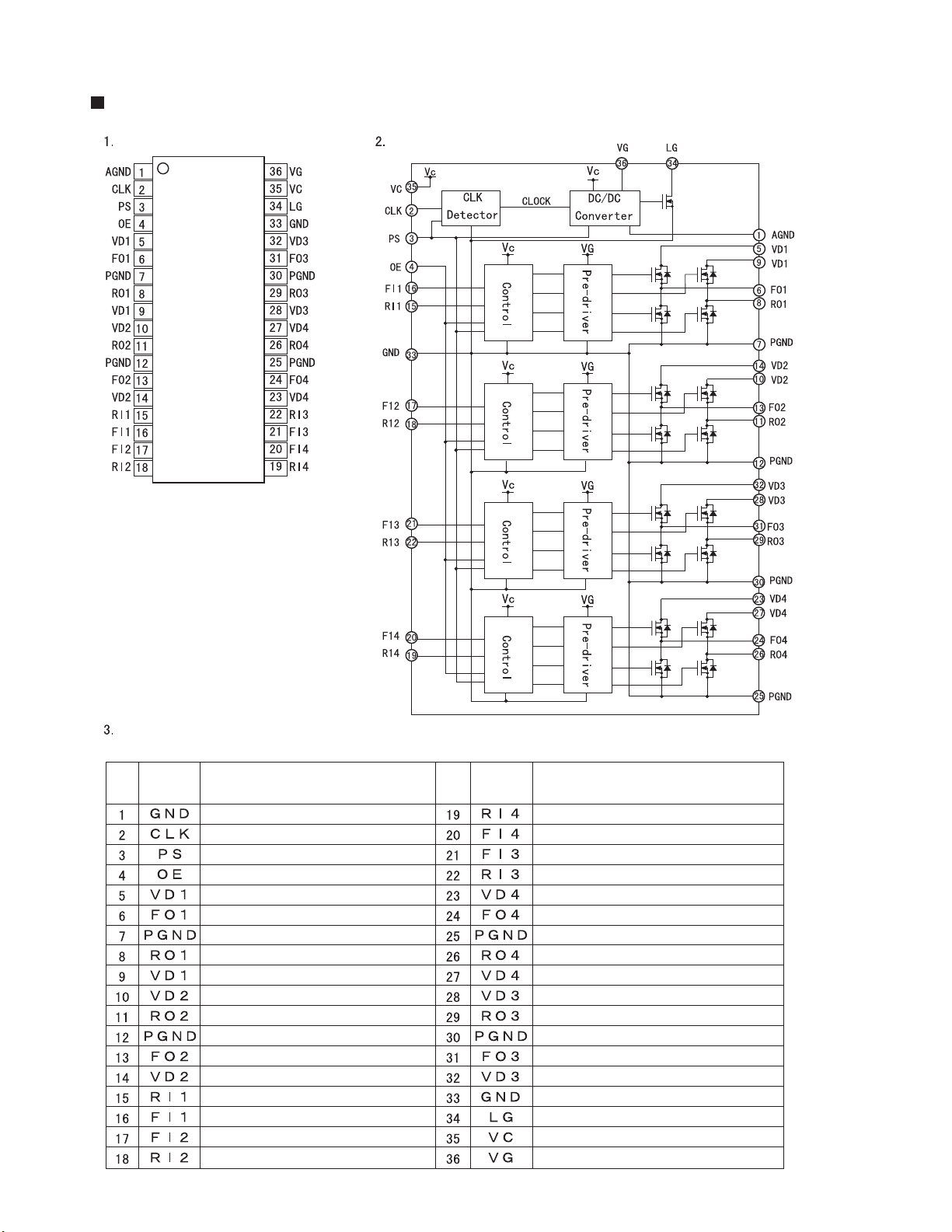

MB3800PFV-W(IC931):Switching Regulator Controller

Terminal Layout

Block Diagram

Reference

voltage

Soft start

S.C.P

Pin Function Description

Pin No. Symbol Functions and operations

Error amplifier inversion input

Soft start, capacity for SCP setting connection

Power supply

Output current setting, control

Totem-pole output

Ground

Capacity for oscillation frequency setting, resistant connection

Error amplifier output

Santooth

wave generator

Output drive

control circuit

2-10

Page 13

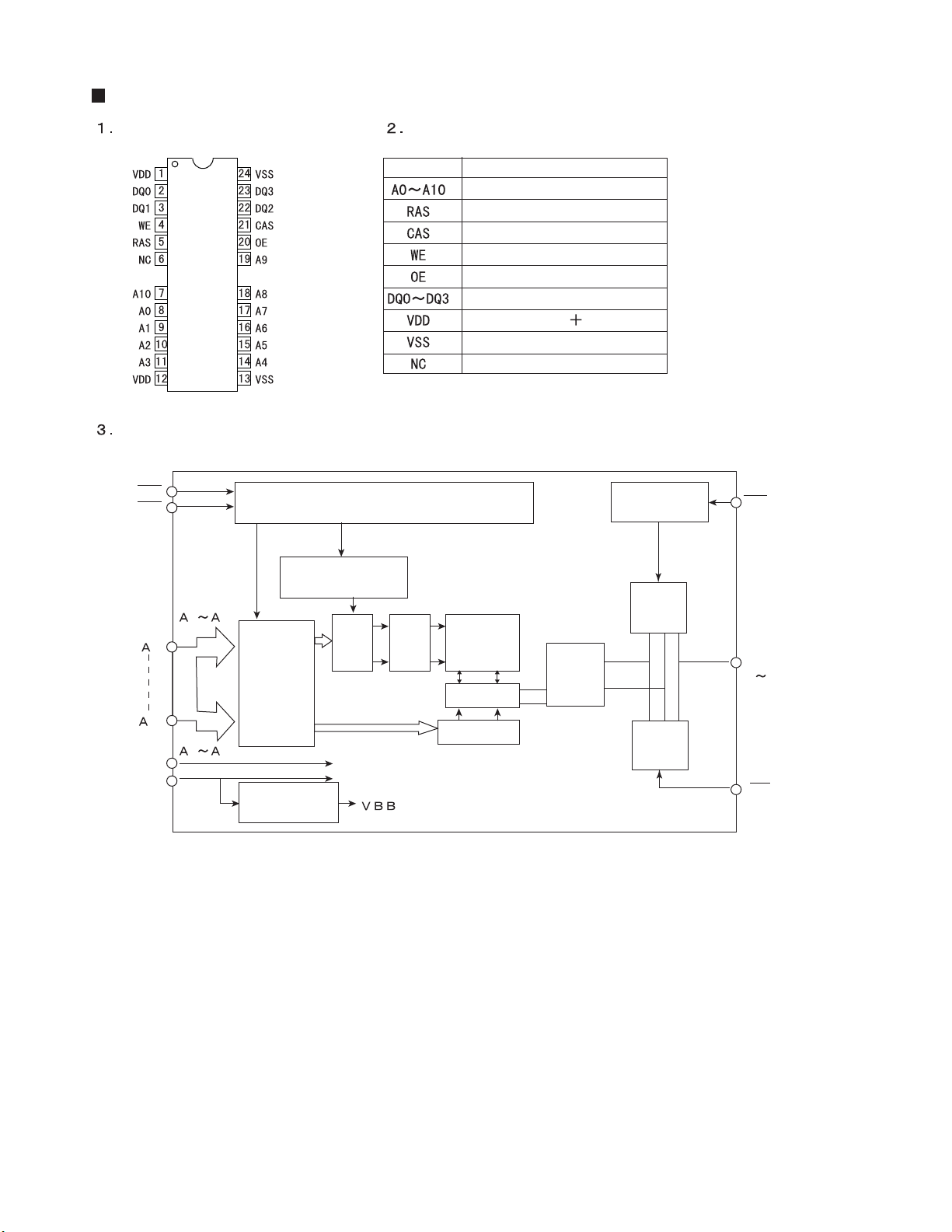

MN41X17400CTT10X(IC391):DRAM

XM-P55

XM-PJ1

Terminal Layout

Block Diagram

RAS

CAS

0 10

0

10

VSS

VDD

0 10

Row

Address

Buffer

Column

Address

Buffer

On Chip

VBB

Generator

Clock Generator

CBR Refresh

Counter

Row

Decoder

Pin Functions

Symbol

Word

Driver

Function

Address input

Row address / strove

Column address / strove

Write enabling input.

Output enabling input.

Data input

Power supply (

3.3V)

Power supply (0V)

Non connection

Memory

Cell

Sense.

Amp

Column

Decoder

I/O

Selector

Write

Clock

Generator

Data

Input

Buffer

Data

Output

Buffer

WE

DQ0

DQ3

OE

2-11

Page 14

XM-P55

XM-PJ1

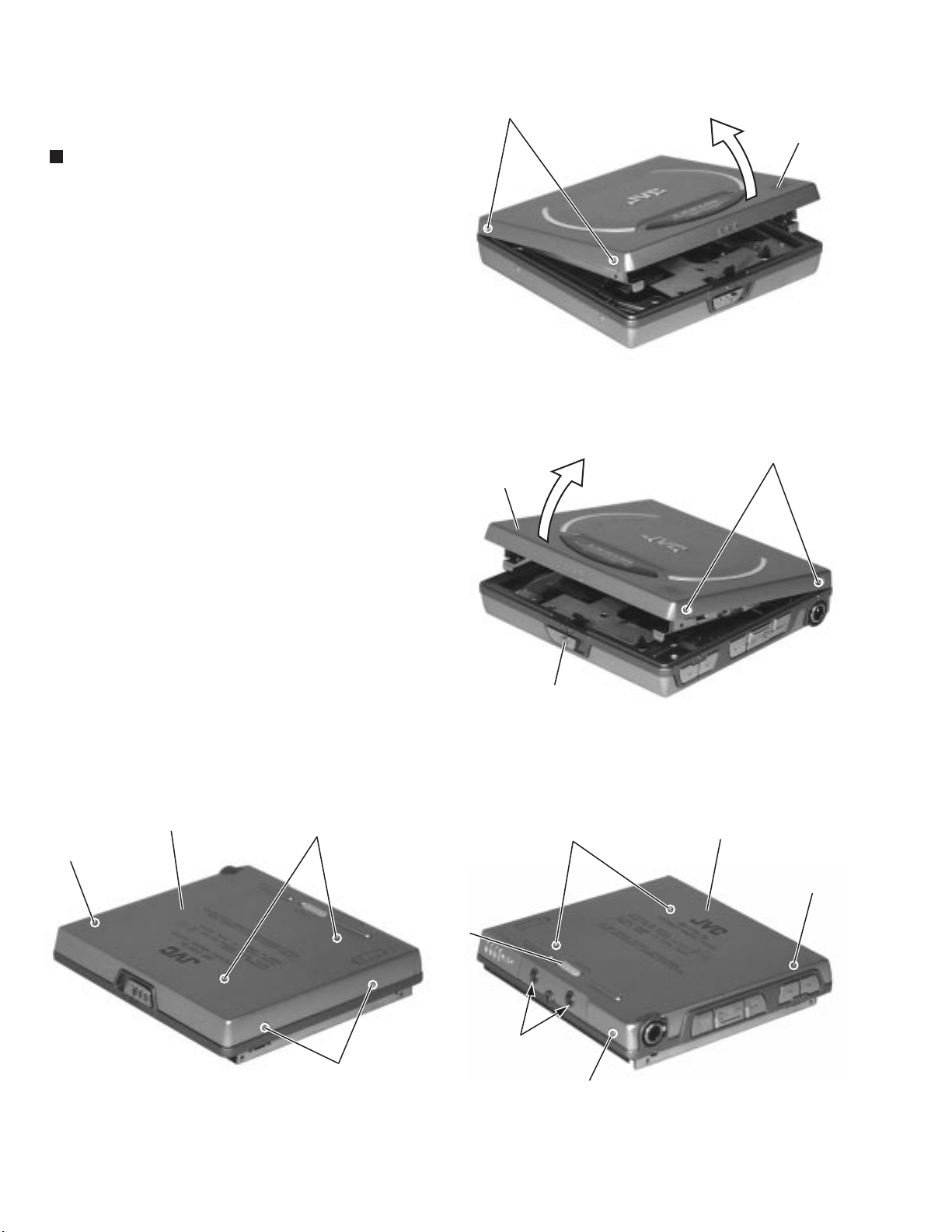

Removal of Main Parts

<XM-P55 Section>

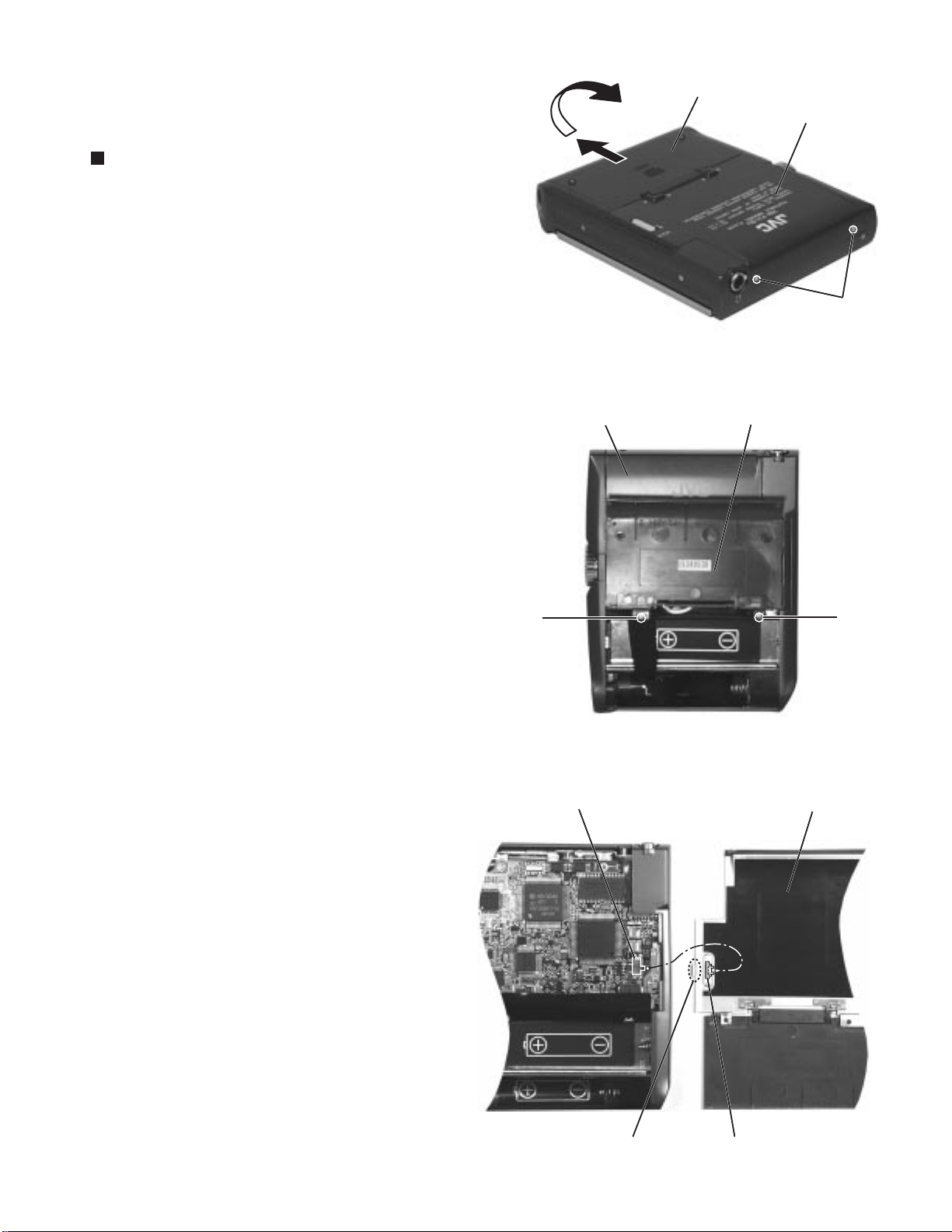

Removing the MD Door Assembly and

the Bottom Cover (See Fig.1 to 4)

1.

Move the door lever and open the door.

2.

Remove the four A screws attaching the MD door

assembly and remove the MD door assembly from the

body.

Reverse the body and remove the six B screws attaching

3.

the bottom cover.

Release the joint a outside and remove the bottom cover

4.

from the body.

CAUTION: When reassembling the bottom cover, fit the

part b of the hold knob slot to the hold

switch on the main board (See Fig.4, 5).

A

MD door assembly

MD door

assembly

Fig.1

A

B

Bottom cover

B

B

Part b

Part a

Door lever

B

Fig.2

Bottom cover

B

B

Fig.4Fig.3

2-12

Page 15

XM-P55

XM-PJ1

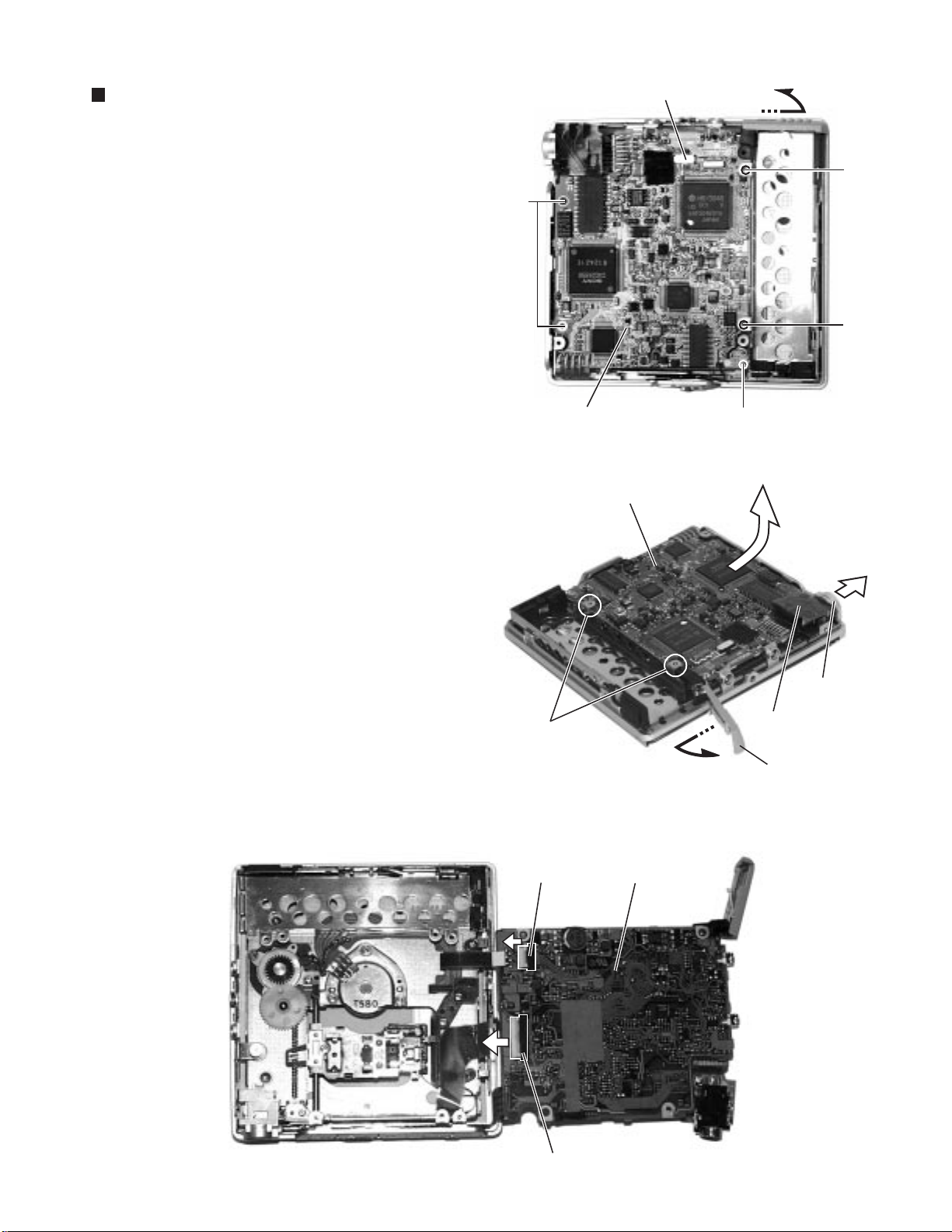

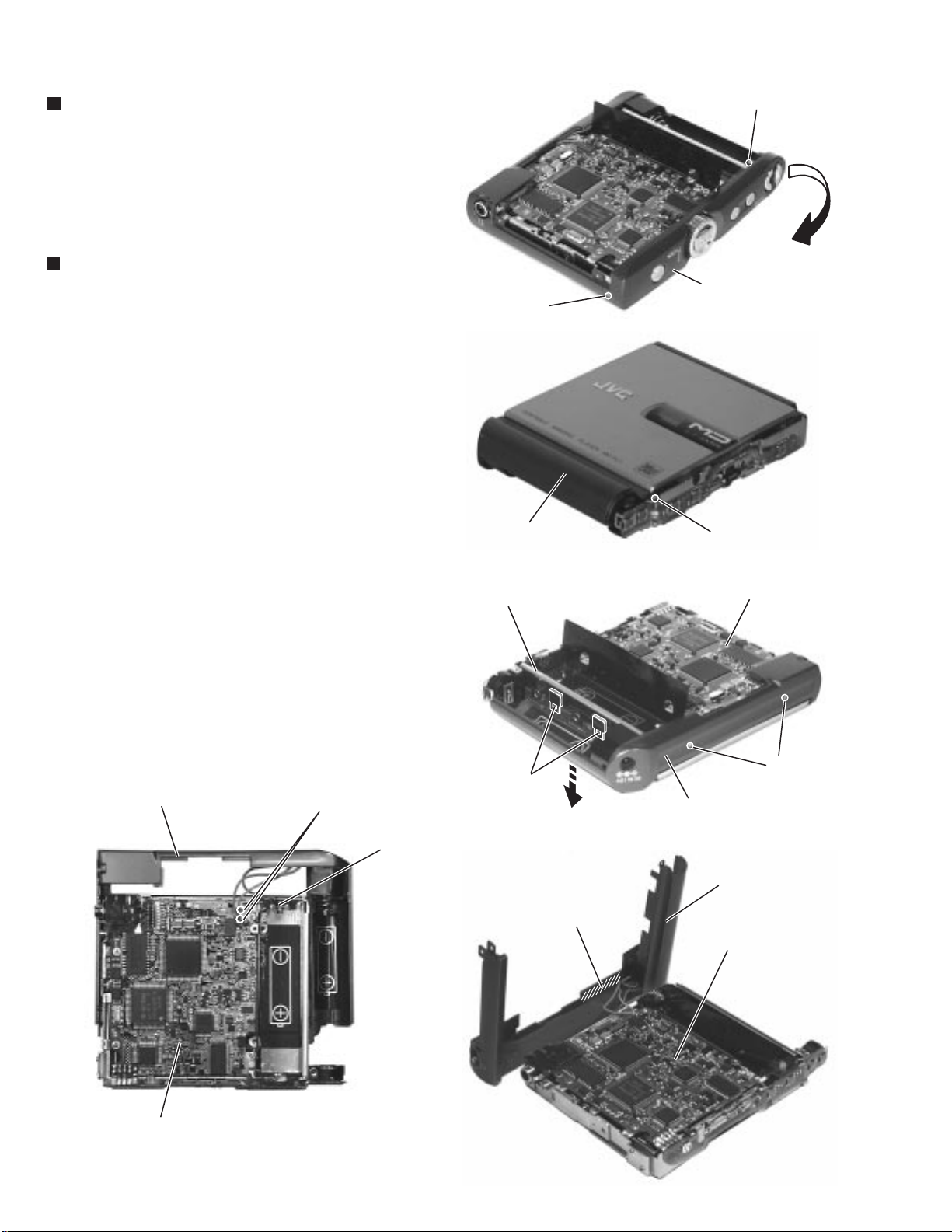

Removing the Main Board

(See Fig.5 to 7)

1.

Remove the three C screws and the screw D attaching

the main board.

2.

Unsolder the part c of the battery terminal.

3.

Open the battery lid and remove it from the flame

assembly.

Remove the headphone jack assembly while pulling the

4.

cabinet assembly of the headphone jack outwards.

Move the main board in the direction of the arrow in Fig.6

5.

and remove it upward from the two parts d of the

bending on the flame assembly.

Disconnect the flexible harnesses from connector CN300

6.

and CN401 on the reverse side of the main board.

C

Main board

Main board

Hold switch

D

C

Part c : unsoldering

Fig.5

Parts d

CN401

Flame assembly

Headphone jack assembly

Battery lid

Fig.6

Main board

Fig.7

CN300

2-13

Page 16

XM-P55

XM-PJ1

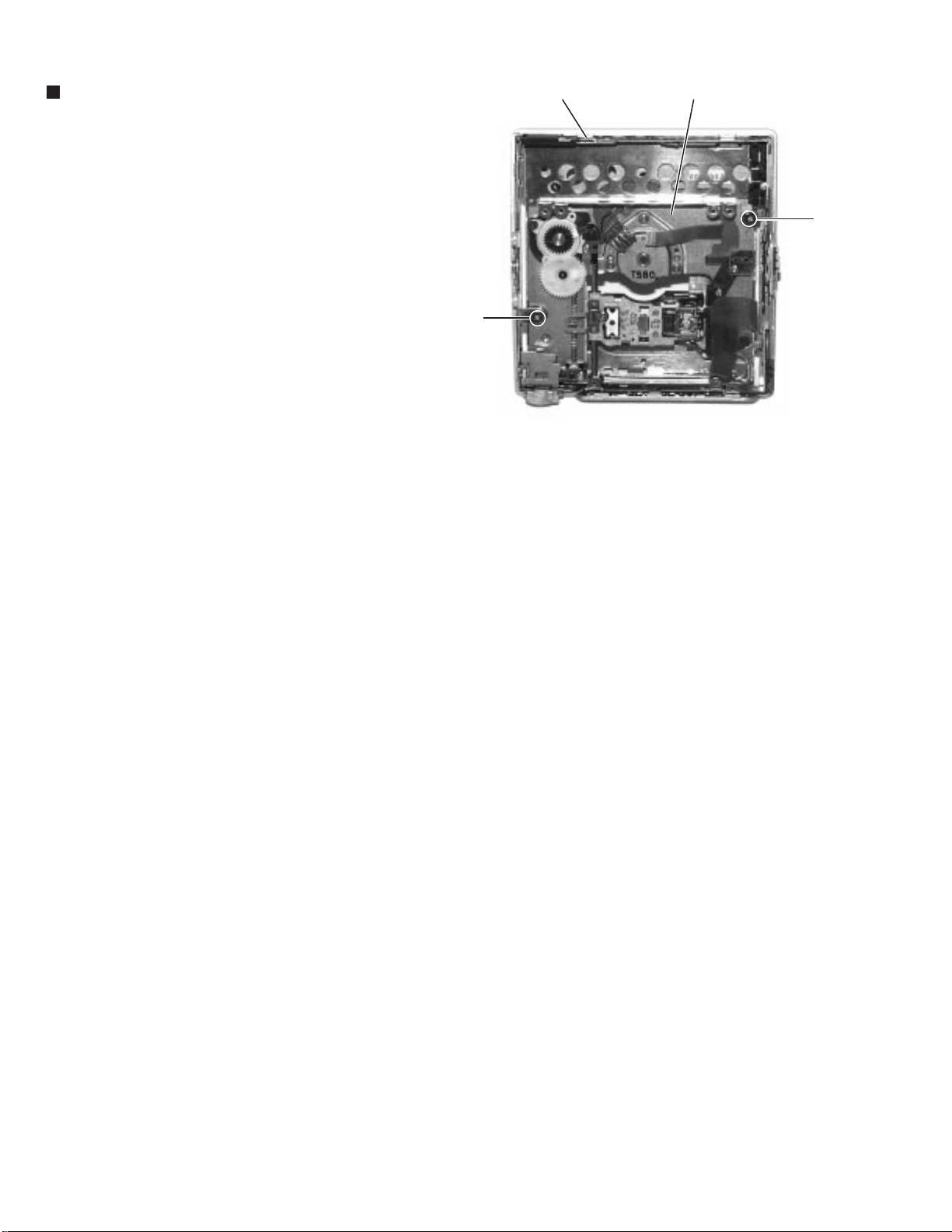

Removing the Mechanism Assembly

(See Fig.8)

1. Remove the two E screws attaching the mechanism

assembly and remove the mechanism assembly from the

flame assembly.

Flame assembly

E

Mechanism assembly

E

Fig.8

2-14

Page 17

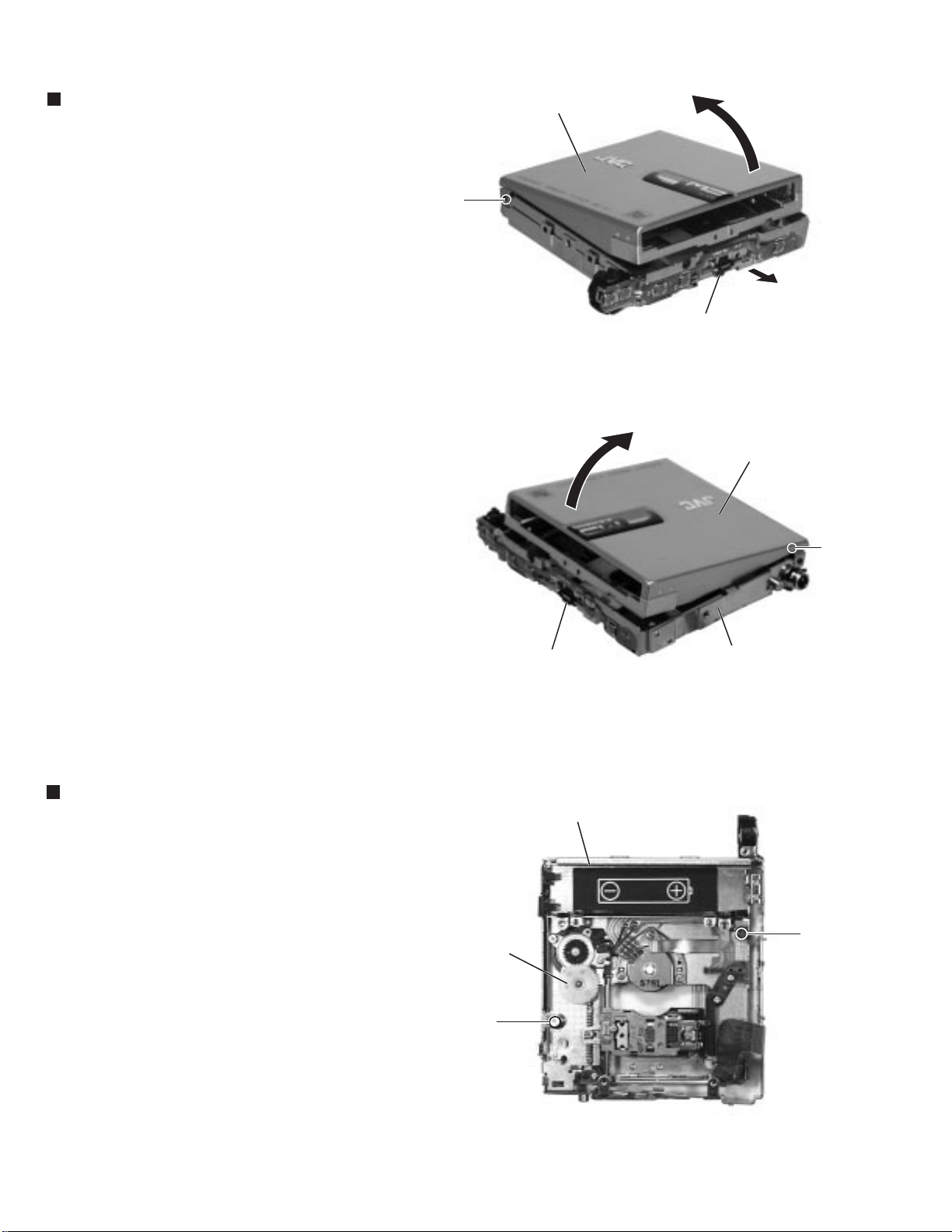

Removal of Main Parts

<XM-PJ1 Section>

Removing the Bottom Cover

(See Fig.1 to 3)

1.

1.

Move and remove the battery lid of the bottom cover

assembly on the side of the body in the direction of the

arrow.

2.

2.

Remove the two A screws attaching the bottom cover on

the bottom of the body.

3.

Remove the two B screws attaching the bottom cover on

3.

the side of the body.

Remove the bottom cover from the body while releasing

4.

4.

the tab a of the bottom cover on the side of the hold

switch to the inside.

CAUTION: When reassembling, make sure that the

convexity of the hold switch is fitted to the

concave of the switch knob before inserting

the tab a of the bottom cover assembly.

Bottom cover assembly

XM-P55

XM-PJ1

Battery lid

Bottom cover assembly

B

Fig. 1

Battery lid

A

Hold switch

A

Fig. 2

Bottom cover assembly

Fig. 3

Switch knobJoint a

2-15

Page 18

XM-P55

XM-PJ1

Removing the Front Cover Assembly

(See Fig.4)

1.

Remove the bottom cover assembly.

2.

Remove the two C screws attaching the front cover

assembly, and remove the front cover assembly while

turning it in the direction of the arrow in the Fig.4.

Removing the Cabinet (See Fig.5 to 8)

1.

Remove the bottom cover assembly.

2.

Remove the front cover assembly.

3.

Remove the screw D attaching the cabinet on the upper

side of the body.

4.

Reverse the body and remove the two E screws attaching

the cabinet on the back of the body.

Release the two joints b on the flame assembly side of

5.

the battery case in the direction of the arrow, and remove

the cabinet from the flame assembly.

Unsolder the two harnesses (one is orange, the other is

6.

gray) connected to the main board. Disconnect the

battery connector B with the brown harness by pulling

upward.

CAUTION: When reassembling, attach the harnesses

with a double-sided tape to the part c on the

inside of the cabinet (See Fig.8).

C

Cabinet

Flame assembly

C

Front cover assembly

Fig. 4

D

Main board

Fig. 5

2-16

Cabinet

Main board

Fig. 7

Unsoldering

Battery connector B

Joints b

Part c

Cabinet

E

Fig. 6

Cabinet

Main board

Fig. 8

Page 19

Removing the Main Board

(See Fig.9 to 11)

1.

Remove the four F screws attaching the main board.

2.

Remove the headphone jack fixed with a double-sided

tape upward.

3.

Unsolder the part d of the main board.

4.

Remove the flexible harness 1 fixed to the front side of

the flame assembly with a double-sided tape.

5.

Move the battery terminal e from the flame assembly

upward.

Move the main board to the inside, and remove it upward

6.

while releasing it from the two hinges f on the bending of

the flame assembly.

Disconnect the flexible harnesses from connector CN300

7.

and CN401 on the reverse side of the main board.

CAUTION: When reattaching the flexible harness 1,

position it to the six g points and fix it with a

double-sided tape (See Fig.10).

Headphone jack

F

Main board

Main board

F

Fig. 9

F

Joints f

Part d

F

XM-P55

XM-PJ1

Battery

terminal e

F

Positioning

points g

F

Positioning points g

Positioning points g

Fig. 10

Main board

CN401

CN300

Fig. 11

2-17

Page 20

XM-P55

XM-PJ1

Removing the Door Cover

(See Fig.12, 13)

Remove the bottom cover.

1.

Remove the front cover.

2.

Remove the cabinet.

3.

Push the lower part of the door lock lever outside on the

4.

lower front side of the body, and open the door.

Remove the two G screws attaching the door cover on

5.

both sides of the body, and remove the door cover.

CAUTION: When reattaching the flexible harness 1,

position it to the six g points and fix it with a

double-sided tape (See Fig.10).

Door cover

G

Door lock lever

Fig. 12

Door cover

G

Removing the Mechanism Assembly

(See Fig.14)

1.

Remove the bottom cover.

2.

Remove the front cover.

3.

Remove the cabinet.

4.

Remove the main board.

5.

Remove the two H screws attaching the mechanism

assembly and remove the mechanism assembly from the

flame assembly.

Door lock lever

Mechanism assembly

H

Flame assembly

Fig. 13

Flame assembly

H

2-18

Fig. 14

Page 21

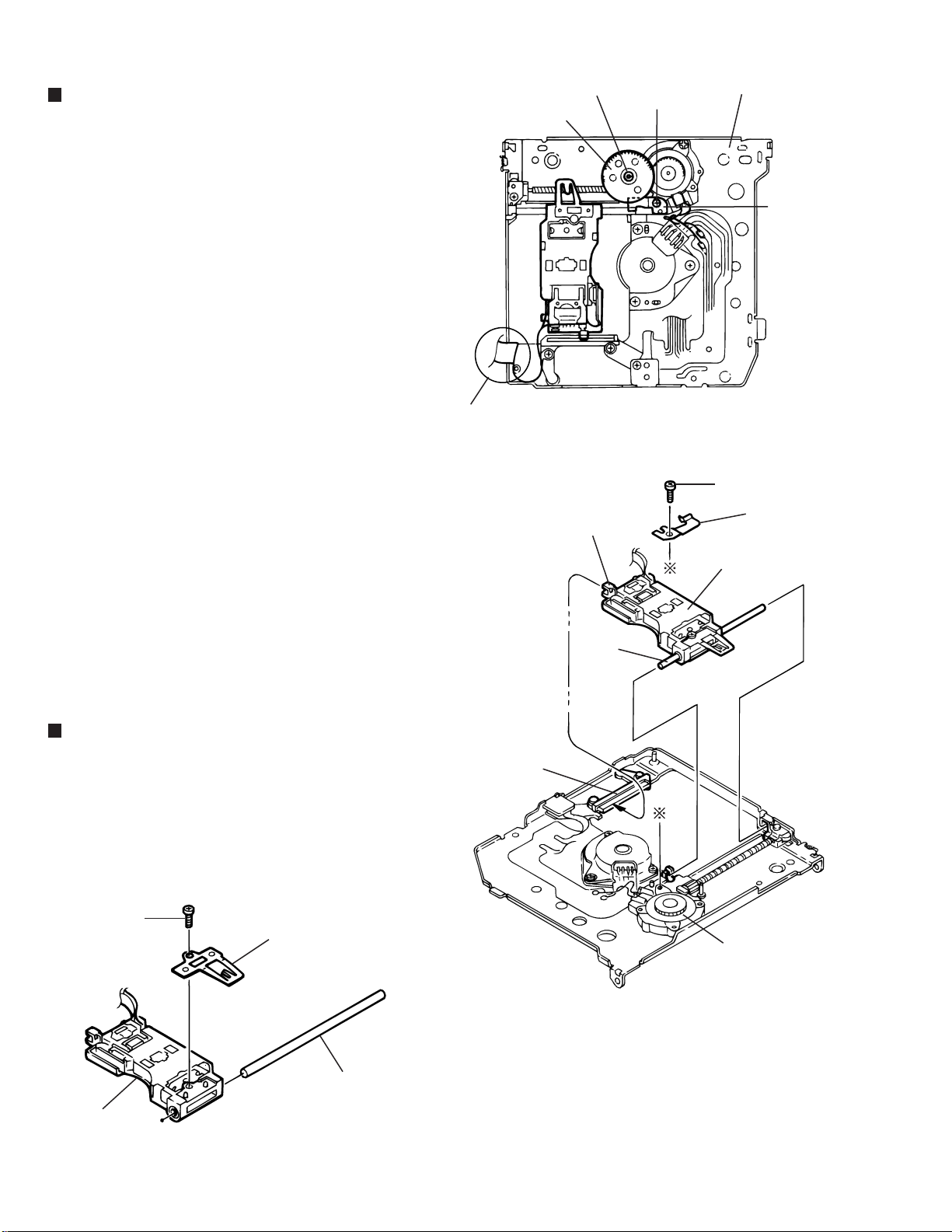

<Removal of MD Mechanism Assembly>

Removing the Holder Assembly

(See Fig.1, 2)

Turn the holder assembly as shown in Fig.1.

1.

Push the stopper of the holder assembly to release its

2.

tab, and turn the holder assembly as shown in Fig.2.

Move the part a of the holder assembly in the direction of

the arrow and release its U-shaped notch from the shaft

of the chassis assembly.

Push the part b of the holder assembly and pull out the

3.

holder assembly from the shaft of the chassis assembly.

CAUTION: When reassembling, first attach the part (b)

of the holder assembly to the shaft of the

chassis assembly. Next, attach the U-shaped

notch to the shaft.

XM-P55

XM-PJ1

Holder Assembly

Stopper

Push inside

Fig.1

Holder assembly

Shaft

U-shaped notch

Removing the Spindle Motor

(See Fig.3)

1.2.Unsolder the part c of the flexible harness connected to

the spindle motor.

Remove the three A screws attaching the spindle motor

and remove the spindle motor from the chassis assembly.

Chassis assembly

A

Part a

Fig.2

Chassis assembly

Part b

Chassis assembly

Part c : unsoldering

A

Fig.4

Fig.3

Spindle motor

2-19

Page 22

XM-P55

XM-PJ1

Removing the Pickup Unit

(See Fig.4, 5)

1.

Remove the slit washer on the reverse side of the MD

mechanism and remove the worm gear.

2.

Remove the screw B and the hold spring.

Detach the shaft of the pickup unit on the feed motor

3.

side, and the other side.

Remove the spacer of the flexible harness extending from

4.

the pickup unit (marked d), and remove the pickup unit

from the chassis assembly.

Slit washer

Worm gear

B

B

Chassis assembly

Hold spring

Removing the Pickup (See Fig.5, 6)

1.2.Remove the screw C from the pickup unit and the lead

spring.

Pull out the main shaft from the pickup.

d

Guide base

Fig.4

B

Hold spring

Part e

Pickup unit

Shaft

2-20

Pickup

C

Lead spring

Feed motor

Fig.5

Main shaft

Fig.6

Page 23

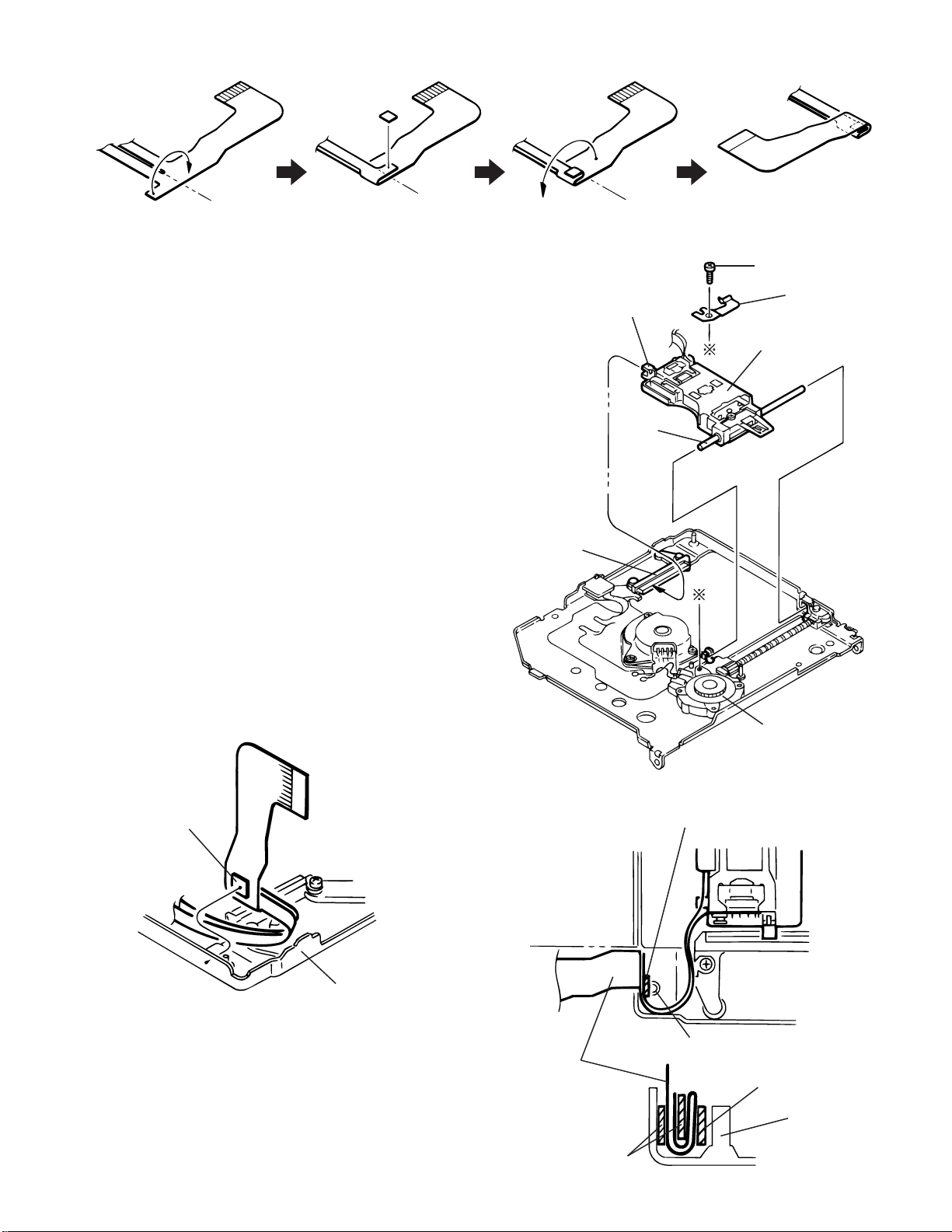

(Fold fast.) (Attach a spacer.) (Fix fast not to unfold.) (Fold fast.)

<Reassembling the Pickup Unit>

1.

Prior to performing the following procedures, fold the

flexible harness of the pickup unit (see Fig.7,8 and 9). Fix

the flexible harness with a spacer not to unfold.

2.

Attach the U-shaped slot of the pickup marked ’e’ to the

guide base.

For the shaft, firstly attach its shaft base side and next

3.

attach its feed motor base side.

XM-P55

XM-PJ1

Fig.7

B

Hold spring

Part e

Pickup unit

Shaft

Attach a spacer to the folded flexible harness and fix the

4.

flexible harness to the chassis assembly (see Fig.7, 8).

Attach a spacer between the chassis boss and the

5.

flexible harness (see Fig.9).

Make sure that the flexible harness is folded fast and

6.

fixed to the right position.

Attach a spacer

Guide base

Feed motor

Fig.5

Attach a spacer

Attach this position

Fig.8

Chassis assembly

Flexible harness

Spacer

Chassis boss

Spacer

Chassis boss

Fig.9

2-21

Page 24

XM-P55

XM-PJ1

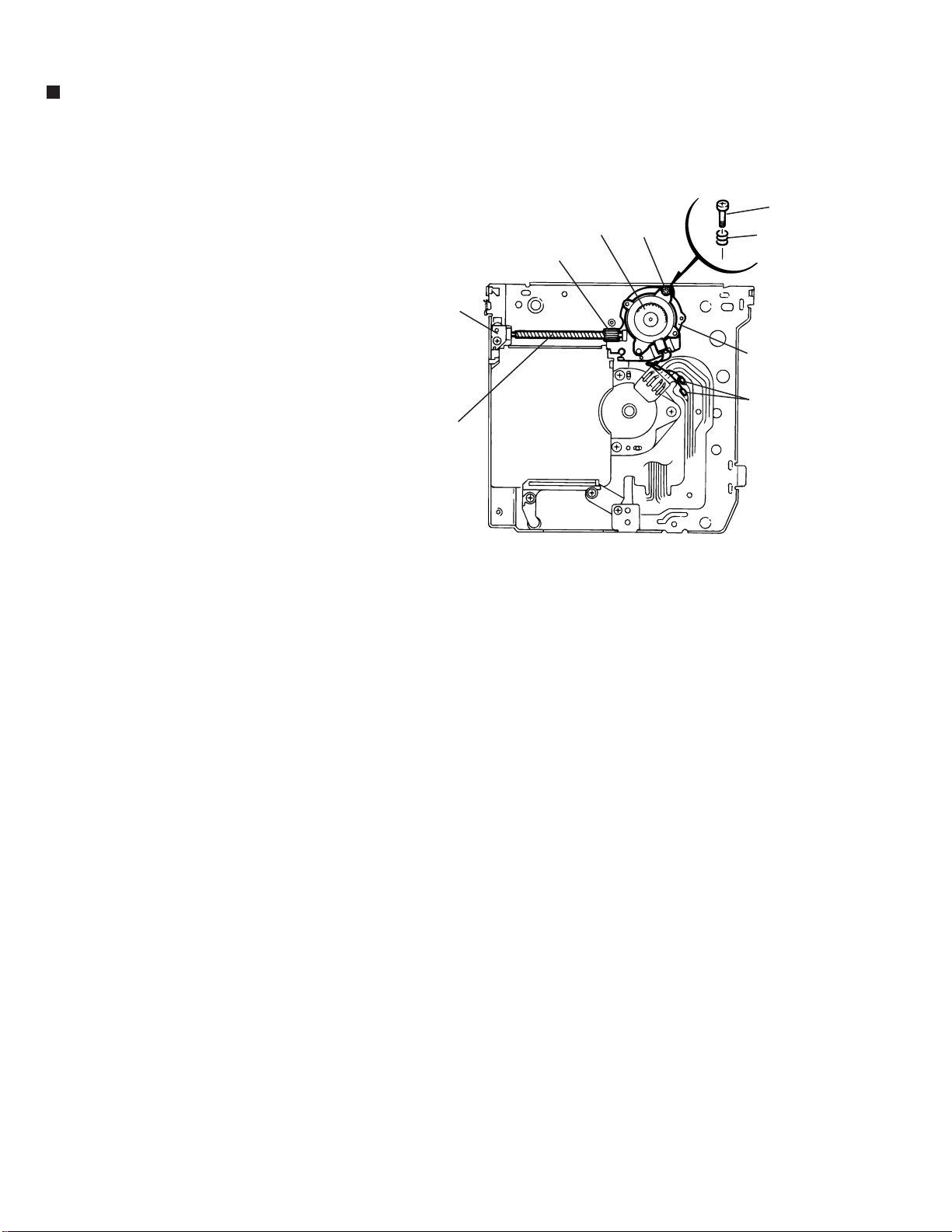

Removing the Feed Motor/ Screw

Shaft Assembly and Wheel Gear

1.

Unsolder the two harnesses extending from the feed

motor.

2.

Remove the screw D attaching the feed motor, then the

spring. Remove the feed motor from the feed motor base.

Lift the feed motor base and pull out the screw shaft

3.

assembly.

Screw shaft gear

Shaft base

Feed motor

Wheel gear

D

D

Spring

Feed motor base

Soldering

Fig.10

2-22

Page 25

XM-P55

XM-PJ1

Maintenance of MD Pickup

1. Cleaning of pickup lens

(1) Prior to changing the pickup, clean the pickup lens.

(2) For cleaning the lens, use the following cotton swab after

mearsing it in alcohol.

Product No. JCB-B4; Manufacturer;Nippon Cotton Swab

2. Confirmation of the service life of laser

diode when the service life of the laser

diode has been exhausted, the following

symptoms will appear.

(1) Recording will become impossible.

(2) The RF output (EFM output and eye pattern amplitude)

will become lower.

(3) The drive current required for light emitting of laser diode

will be increased.

Confirm the service life according to the following flow chart:

Procedures of Changing

the MD pickup

Change the MD pickup by referring

to "Removing the MD pickup" in the

Disassembly Method.

Set the pickup to [TEST] mode according

to the procedures described in the

Adjustment Method.

Adjust the laser power 75 .

Adjust the disc.

How to operation

Return to feed .

Can the laser power

adjust under test mode?

Is the power output

750

Is the drive current

of laser diode

45mA or less?

YES

YES

NO

Change the pickup

NO

Change the pickup

OK.

3. Method of measuring the drive current of

laser diode

When the voltage measured at the both side of carbon resistor

R301 on the MD servo P.C. board (VMW2424A) have become

45mV or over, the service life of the laser diode is judged to have

been exhausted.

Adjust the Pre D

have been become OK

Return to feed .

Adjust the Mo D

have been become OK

Completion of changing the MD pickup.

Since this system is designed to perform magnetic

recording, the laser power ten times or over of the

conventional MD player will be output. Therefore, be

sure to perform not only adjustment and operation

of this system so carefully as not to directly look at the

laser beam or touch on the body.

4. Semi-solid state resistors on

the APC P.C. board

The semi-solid state resistor on the APC P.C.board

attached to the pickup is used for adjusting the laser

power. Since these resistor should be adjusted in

pair according to the characteristics of the optical

block, be sure not to touch on the resistors.

Since the service life of the laser diode will be

exhausted when the laser power is low, it is

necessary to change the pickup. Meanwhile, do not

pickup. Otherwise, the pickup will be damaged due

to over current.

2-23

Page 26

XM-P55

XM-PJ1

Self diagnosis Function of MD

Power Supply ------------- Use to a battery charger by more than 1.3volt

Establishment ------------ Set up the horizontal

1. The method of changing to the self-diagnosis mode turns off

the power supply of the main body first.

2. The power supply of the main body is turned on while pushing

"PLAYMODE +DISPLAY+A.B.BASS "of the remote control unit at the same time.

3. It changes into the self-diagnosis mode, and the self-diagnosis starts.

Test 's Command for the self-diagnosis mode

Command data1 data2 data3 data4 data5 data6 data7

Ope.mode State PLY P REC P EEP R EEP S

[Indicators on the display

of the remote control]

Play Mode button

A.C.BASS

=00: Wait to Test command

=DD: Going to Resume's EEPROM initialize

=DE: Going to servo's EEPROM initialize

=E2: Turn on the leaser of PLAY

=D3: Turn up the laser

=D4: Turn down the laser

=D1: Turn off the laser

=D5: Rewind to the FEED

=D6: Adjust to the PRE DISC

=D7: Adjust to the MO DISC

=92: Break out the trouble

DISPLAY button

VOL

The following are displayed

and it stops at the NG generation.

The KEY input afterwards

is disregarded.

FAV

Repeat

Battery

2-24

A.C.BASS

(Active Clear Bass) button

JOG

MODE

Disc

mark

BASS

Random

MONO

Page 27

Self-diagnosis Fllow Chart

XM-P55

XM-PJ1

Rewind to the FEED

by PLAY

Turn on the laser

Recieve time out

at 200ms

Except to

recieve DF:E2.

Issue to

Push to "BASS"

E2

Recieve time out

at 200ms

Except to

DF

Issue to

recieve DF:00.

Recieve DF:00

Recieve time out

at 200ms

Except to

recieve DF:D1.

Issue to

Issue to

Push to "VOL -" Push to "SHIFT"

Issue to

Push to "VOL +"

Recieve DF:D1

"D1"

Recieve DF:00

"D4:01"

Except above it

Recieve DF:00:XX:YY

"D3:01"

Recieve time out

at 200ms

Recieve DF:00

DF

Issue to

(Lock to display at 2sec)

Recieve time out at 200ms

Recievable above it.

START

DB

Issue to

Recieve DF:00

Recieve time out

at 200ms

Except to

Recieve time out

at 200ms

Except to

recieve DF:DD.

Recieve DF:00

DE

Issue to

Push to "BASS"

Recieve time out

at 200ms

Except to

recieve DF:DD.

Recieve DF:00

DE

Issue to

Initial to resume Initial to the servo

Push to "BASS"

Recieve time out

Processer Processer

recieve DF:DD.

at 200ms

Except to

recieve DF:DD.

DE

Issue to

DE

Issue to

Recieve DF:00:XX:YY

Recieve DF:00

(Lock to display at 2sec)

Recieve DF:00

(Lock to display at 2sec)

2-25

Page 28

XM-P55

XM-PJ1

Recieve time out

at 200ms

Except to

recieve DF:D7

Recieve time out

at 200ms

Except to

recieve DF:00

Adjust t MO-D

Push to "BASS"

Recieve time out

at 200ms

Except to

recieve DF:D6

Receive DF:D7

D7

Issue to

Receive DF:D6

D6

Issue to

Recieve time out

at 200ms

Except to

DF

Issue to

recieve DF:00

DF

Issue to

Receive DF:00

Receive DF:00

(Lock to display at 2sec)

OK

(Lock to display at 2sec)

Rewind to FEED Adjust PRE -D

Rewind to FEED

Recieve time out

at 200ms

Except to

Push to "BASS" Push to "BASS"

recieve DF:D5

D5

Issue to

Receive DF:D5

Recieve time out

at 200ms

Processor Processor Processor

Except to

recieve DF:00

DF

Issue to

Receive DF:00

(Lock to display at 2sec)

OK OK

2-26

Page 29

Block Diagrams

XM-P55

XM-PJ1

PICKUP

SLED

SPINDLE

FCS, TRK

RF IC DSP

Servo

DRIVER

DRIVER

Each Block

POWER

SUPPLY

Micro

computer

CNT

16M D RAM

ACB BEEP

MUTE

REMOTE

CONTROL

Audio

HP JACK

LEVEL DIAGRAM

ACB Circuit

Headphone AMP

2-27

Page 30

XM-P55

XM-PJ1

-MEMO-

2-28

Page 31

Standard Schematic Diagrams

XM-P55 (Except to U.S.A.)

XM-P55

XM-PJ1

BLOCK B

BLOCK D

5

4

3

2

1

BLOCK A

BLOCK C

ABCD

2-29

Page 32

XM-P55

XM-PJ1

BLOCK A

XM-P55 (Except to U.S.A.)

To BLOCK B

5

4

3

To BLOCK C

2

1

2-30

Digital signal

ABCD

Page 33

XM-P55 (Except to U.S.A.)

XM-P55

XM-PJ1

5

BLOCK B

4

3

To BLOCK D

2

1

To BLOCK A

Digital signal

Analogue signal

ABCD

2-31

Page 34

XM-P55

XM-PJ1

5

4

BLOCK C

XM-P55 (Except to U.S.A.)

To BLOCK D

To BLOCK A

3

2

1

2-32

ABCD

Page 35

XM-P55

XM-PJ1

5

4

BLOCK D

XM-P55 (Except to U.S.A.)

To BLOCK B

3

2

1

To BLOCK C

ABCD

2-33

Page 36

XM-P55

XM-PJ1

-MEMO-

2-34

Page 37

XM-P55

XM-PJ1

XM-P55J ONLY

5

4

3

2

1

ABCD E F G

2-35

Page 38

XM-PJ1 (Except to U.S.A.)

Digital signal

BLOCK A

To BLOCK B

To BLOCK C

XM-PJ1(Except to U.S.A.)

XM-P55

XM-PJ1

5

4

B BLOCK

D BLOCK

3

2

1

A BLOCK

C BLOCK

2-36

HABC DEFG

Page 39

XM-P55

XM-PJ1

5

4

BLOCK B

XM-PJ1(Except to U.S.A.)

3

2

1

Digital signal

To BLOCK A

ABCD

Anologue signal

To BLOCK C

2-37

Page 40

XM-P55

XM-PJ1

5

4

BLOCK C

XM-PJ1(Except to U.S.A.)

To BLOCK D

3

To BLOCK A

2

1

2-38

ABCD

Page 41

BLOCK D

XM-PJ1(Except to U.S.A.)

5

4

XM-P55

XM-PJ1

3

To BLOCK B

2

1

To BLOCK C

ABCD

2-39

Page 42

XM-P55

XM-PJ1

-MEMO-

2-40

Page 43

XM-P55

XM-PJ1

XM-PJ1 J ONLY

5

4

3

2

1

ABCD E F G

2-41

Page 44

Printed Circuit Boards

XM-P55

XM-PJ1

Main board

5

Block No.

XM-P55 ONLY

(Parts side)

: chip parts

(Solder side)

4

3

2

1

2-42

HABC DEFG

Page 45

XM-P55

XM-PJ1

Switch Board

Block No.

5

4

Block No. Headphone Jack Board

3

2

1

ABCD

2-43

Page 46

XM-P55

XM-PJ1

-MEMO-

2-44

Page 47

PARTS LIST

[ XM-P55 ]

* All printed circuit boards and its assemblies are not available as service parts.

XM-P55

XM-PJ1

Area Suffix

B

E

EE

EN

J

UB

US

UT

UX

UY

U.K. (BU,SL)

Continental Europe (BU,SL)

Russian Federation (BU,SL)

Northern Europe (BU,SL)

U.S.A. (SL)

Hong kong (BU,GN,SL)

Singapore (BU,SL)

Taiwan (SL)

Saudi Arabia (SL)

Argentina (SL)

- Contents -

Exploded View of General Assembly and Parts List ..............................................3-2

MD Mechanism Ass'y and Parts List .....................................................................3-4

Electrical Parts List ................................................................................................3-6

Packing Materials and Accessories Parts List (J) .................................................3-10

Packing Materials and Accessories Parts List (E/EE/EN) .................................... 3-12

Packing Materials and Accessories Parts List (B/UB/US/UT/UX/UY) .................. 3-14

3-1

Page 48

XM-P55

XM-PJ1

General Exploded View and Parts List

Block No

5

4

3

(MODEL:XM-P55)

2

44

1

3-2

ABCD

Page 49

XM-P55

XM-PJ1

3-3

Page 50

XM-P55

XM-PJ1

MD Mechanism Ass’y and Parts List

(MODEL:PPM)

5

4

Block No.

3

2

1

3-4

ABCD

Page 51

XM-P55

XM-PJ1

3-5

Page 52

XM-P55

XM-PJ1

Electrical Parts List

¡¡

¡¡

¡ Main board

3-6

Page 53

XM-P55

XM-PJ1

3-7

Page 54

XM-P55

XM-PJ1

3-8

Page 55

XM-P55

XM-PJ1

¡¡

¡¡

¡ Headphone Jack board

¡¡

¡¡

¡ Switch board

3-9

Page 56

XM-P55

XM-PJ1

Packing Materials and Accessories Parts List

J Ver sion Section

5

4

Block No.

Block No.

3

2

turn up

turn down

1

3-10

ABCD

Page 57

¡¡

¡ Packing Parts list

¡¡

¡¡

¡ Accessories Parts list

¡¡

XM-P55

XM-PJ1

3-11

Page 58

XM-P55

XM-PJ1

Packing Materials and Accessories Parts List

E/EE/EN/ Ver sion Section

Block No.

Block No.

5

4

3

2

turn up

turn down

1

3-12

ABCD

Page 59

¡¡

¡ Packing Parts list

¡¡

¡¡

¡ Accessories Parts list

¡¡

XM-P55

XM-PJ1

3-13

Page 60

XM-P55

XM-PJ1

Packing Materials and Accessories Parts List

B/UB/US/UT/UX/UY/ Ver sion Section

Block No.

Block No.

5

4

3

2

1

3-14

turn up

turn down

ABCD

Page 61

¡¡

¡ Packing Parts list

¡¡

¡¡

¡ Accessories Parts list

¡¡

XM-P55

XM-PJ1

3-15

Page 62

XM-P55

XM-PJ1

-MEMO-

3-16

Page 63

PARTS LIST

* All printed circuit boards and its assemblies are not available as service parts.

[ XM-PJ1 ]

B

E

EE

EN

J

UB

US

UT

UX

UY

Area Suffix

U.K. (BU)

Continental Europe (BU)

Russian Federation (BU)

Northern Europe (BU)

U.S.A. (BU)

Hong kong (BU,GD)

Singapore (BU)

Taiwan (BU)

Saudi Arabia (BU)

Argentina (BU)

- Contents -

Exploded View of General Assembly and Parts List ............................................. 4-2

MD Mechanism Ass'y and Parts List .....................................................................4-4

Electrical Parts List ................................................................................................4-5

Packing Materials and Accessories Parts List (J) .................................................4-10

Packing Materials and Accessories Parts List (E/EE/EN) .................................... 4-12

Packing Materials and Accessories Parts List (B/UB/US/UT/UX/UY) .................. 4-14

XM-P55

XM-PJ1

4-1

Page 64

XM-P55

XM-PJ1

General Exploded View and Parts List

(MODEL:XM-PJ1)

5

4

Block No.

C991

J991

3

2

1

4-2

ABCD

Page 65

XM-P55

XM-PJ1

4-3

Page 66

XM-P55

XM-PJ1

MD Mechanism Exploded View and Parts List

MD Mechanism as same as XM-P55.

Please refer of the page 3-4 and 3-5.

Block No.

4-4

Page 67

Electrical Parts List

XM-P55

XM-PJ1

¡¡

¡¡

¡ Main board

4-5

Page 68

XM-P55

XM-PJ1

4-6

Page 69

XM-P55

XM-PJ1

4-7

Page 70

XM-P55

XM-PJ1

4-8

Page 71

XM-P55

XM-PJ1

¡¡

¡¡

¡ Headphone Jack board

¡¡

¡¡

¡ Switch board

4-9

Page 72

XM-P55

XM-PJ1

Packing Materials and Accessories Parts List

J Ver sion Section

Block No.

Block No.

5

4

3

2

1

4-10

turn up

turn down

ABCD

Page 73

¡¡

¡ Packing Parts list

¡¡

¡¡

¡ Accessories Parts list

¡¡

XM-P55

XM-PJ1

4-11

Page 74

XM-P55

XM-PJ1

Packing Materials and Accessories Parts List

E/EE/EN/ Ver sion Section

Block No.

Block No.

5

4

3

2

1

4-12

turn up

turn down

ABCD

Page 75

¡¡

¡ Packing Parts list

¡¡

¡¡

¡ Accessories Parts list

¡¡

XM-P55

XM-PJ1

4-13

Page 76

XM-P55

XM-PJ1

Packing Materials and Accessories Parts List

B/UB/US/UT/UX/UY/ Ver sion Section

A1 A4

5

4

Block No.

Block No.

3

2

1

4-14

turn up

turn down

ABCD

Page 77

Packing Parts List

Accessories Parts List

XM-P55

XM-PJ1

Page 78

XM-P55

XM-PJ1

VICTOR COMPANY OF JAPAN, LIMITED

AUDIO DIVISION,10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.20738)

Printed in Japan

9901 (V )

Loading...

Loading...