Page 1

SERVICE MANUAL

XL-SV205GD

VIDEO CD PLAYER

XL-SV205GD

POWER

ON / OFF

1 – MIC VOLUME – 2 ECHO

MIN MAX MIN MAX MIN MAX

1 — MIC — 2

OPEN/CLOSE

RETURN

1 2 3 4 5

+10 6 7 8 9 10/0

VCD / CD 10 KEY

10/0

1 2

7 8 9

10+

3

654

P/N

IMPORTANT

PLEASE TAKE NOTE BEFORE ORDERING

1. Order all service parts through JVC ASIA PTE LTD.-Customer Satisfaction Dept.

2. Two order are availiable: Initial order and last order (Before End of Line).

3. Minimum order quantity: 100pcs

4. Delivery term: Minimum 2 months upon confirmation of order.

Contents

Safety precautions ------------------------------------------------- 1-2

Preventing static electricity ------------------------------------- 1-3

Disassembly ---------------------------------------------------------- 1-4

Description of major IC ----------------------------------------- 1-5

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN LTD.

No:28206

Jun. 2001

Page 2

XL-SV205GD

Safety precautions

1. This design of this product contains special hardware and many circuits and components specially for

safety purposes. For continued protection, no changes should be made to the original design unless

authorised in writing by the manufacturer. Replacement parts must be identical to those used in the

original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the

product should not be made. Any design alterations or additions will void the manufacturer’s warranty

and will further relieve the manufacture of responsibility for personal injury or property damage resulting

therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded by

them necessarily be obtained by using replacement components rated for higher voltage, the Parts

List of Service Manual. Electrical components having such features are identified by shading on the

schematics and by ( ) on the Parts List in the Service Manual. The use of a substitute replacement

which does not have the same safety characteristics as the recommended replacement parts shown

in the Parts List of Service Manual may create shock, fire, or other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubing’s, barriers and the like to

be separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention

of electric shock and fire hazard. When service is required, the original lead routing and dress should

be observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage current check (Electrical Shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the

product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.)

to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a “Leakage Current Tester”, measure the

leakage current from each exposed metal parts of the cabinet, particularly and exposed metal

part having a return path to the chassis, to a known good earth ground. Any leakage current must

not exceed 0.5mA AC (r.m.s.)

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per

volt or more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a

0.15µF AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor

with the AC voltmeter.

Move the resistor connection to each exposed

metal part, particularly any exposed metal part

having a return path to the chassis, and

measure the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and

repeat each measurement. voltage measured

Any must not exceed 0.75 V AC (r.m.s.). This

corresponds to 0.5 mA AC (r.m.s.).

0.15µF AC TYPE

1500 10W

AC Voltmeter

(Having 1000

ohms/volts,

or more sensitivity

Place this

probe on

each exposed

metal part.

Good earth ground

Warning

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

1-2

Page 3

XL-SV205GD

Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when

performing repairs.

1.1. Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

1.1.1. Ground the workbench

1. Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

1.1.2. Ground yourself

1. Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or

iron plate

1.1.3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original

condition. (Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester’s internal

power source can easily destroy the laser diode.

1.2. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For spe-

cific details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the

traverse unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1-3

Page 4

XL-SV205GD

Disassembly

Procedure of disassembly

No. Description QTY. Action Remark

1 Main part 1 Place

2 Plane tray 1 Remove Turn on VCD, open the plane tray

then take up the CD door.

3 Self screw 1 Loosen screw Loose the screw, remove from the upper cover.

4 ¢4.0 Self screw 4 Loosen screw

5 Upper cover 1 Remove Loose screws then remove the upper cover

from the main part.

6 Self screw 5 Loosen screw

7 Self screw 1 Loosen screw

8 Front panel block 1 Remove Remove the front panel block from the main part.

1-4

Page 5

IC lead identification, internal diagram and description

IC301: HT16512 (VFD DRIVER)

Block diagram

XL-SV205GD

Pin configuration (Top view)

1-5

Page 6

XL-SV205GD

Pin description

Symbol Pin Name Pin No. Description

D

IN Data input 6 Inputs serial data at the rising edge of the shift clock, starting from

the low order bit.

D

OUT Data output 5 Output serial data at the falling edge of the shift clock, starting from

the low order bit. This is the N-ch open-drain output pin.

STB Strobe 9 Initializes the serial interface at the rising or falling edge of the µPD16512.

It then waits for reception of a command. Data input after STB has fallen is

processed as a command. While command data is processed, current

processing is stopped, and the serial interface is initialized. While STB is

high, CLK is ignored.

CLK Clock input 8 Reads serial data at the rising edge, and outputs data at the falling edge.

OSC Oscillator pin 44 Connect a resistor to this pin to determine the oscillation frequency to this

pin.

Seg1/KS1 to High-voltage 15 to 20 Segment output pins (Dual function as key source)

Seg6/KS6 output

Seg7 to seg11 High-voltage 21 to 25 Segment output pins

output (segments)

Grid1 to Grid6 High-voltage 37 to 32 Grid output pins

output (grid)

Seg12/Grid11 to High-voltage 26,28 to 31 These pins are selectable for segment or grid driving.

Seg16/Grid7 output

(segment/grid)

Led to Led Led output 42 to 39 CMOS output. +20 mA max.

Key1 to Key4 Key data input 10 to 13 Data input to these pins is latched at the end of the display cycle.

SW1 to SW4 Switch input 1 to 4 These pins constitute a 4-bit general-purpose input port.

VDD Logic power 14, 38 5V ± 10%

Vss Logic ground 7, 43 Connect this pin to system GND.

V

EE Pull-down level 27 VDD-35 V max.

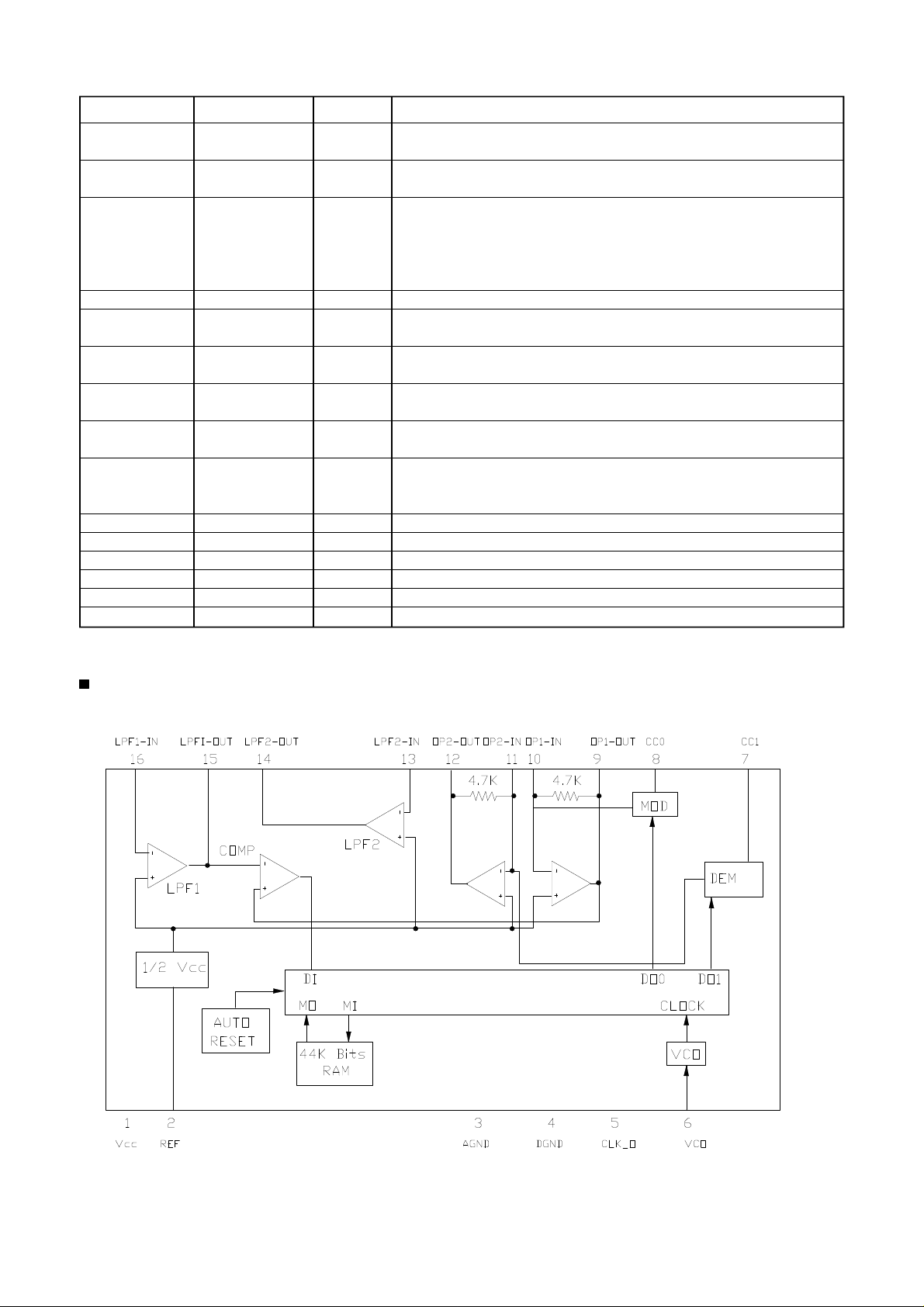

IC203: PT2399 (ECHO PROCESSOR)

Block diagram

1-6

Page 7

Pin configuration

Pin description

Pin No. Pin Name I/O Description

1 VCC - Analog supply voltage input

2 REF - Analog reference voltage (=1/2Vcc)

3 AGND - Analog ground

4 DGND - Digital ground

5 CLK_O O System clock output pin

6 VCO I Frequency adjustment pin

7 CC1 - Current control 1

8 CC0 - Current control 0

9 OP1-OUT O OP amplifier 1 output

This pin can be used as modulated integrator by connecting capacitor.

10 OP1-IN I OP amplifier 1 input

This pin can be used as demodulated integrator by connecting capacitor.

11 OP2-IN I OP amplifier 2 input

This pin can be used as demodulated integrator by connecting capacitor.

12 OP2-OUT O OP amplifier 2 output

This pin can be used as modulated integrator by connecting capacitor.

13 LPF2-IN I Low pass filter 2 input pin

14 LPF2-OUT O Low pass filter 2 output pin

15 LPF1-OUT O Low pass filter 1 output

16 LPF1-IN I Low pass filter 1 input

XL-SV205GD

IC201/IC202,U5/U6: BA4558 (OP-AMP)

Pin configuration

Pin description

Pin Function

1 A Output

2 A-Input

3 A+Input

4 V5 B+Input

6 B-Input

7 B Output

8 V+

1-7

Page 8

XL-SV205GD

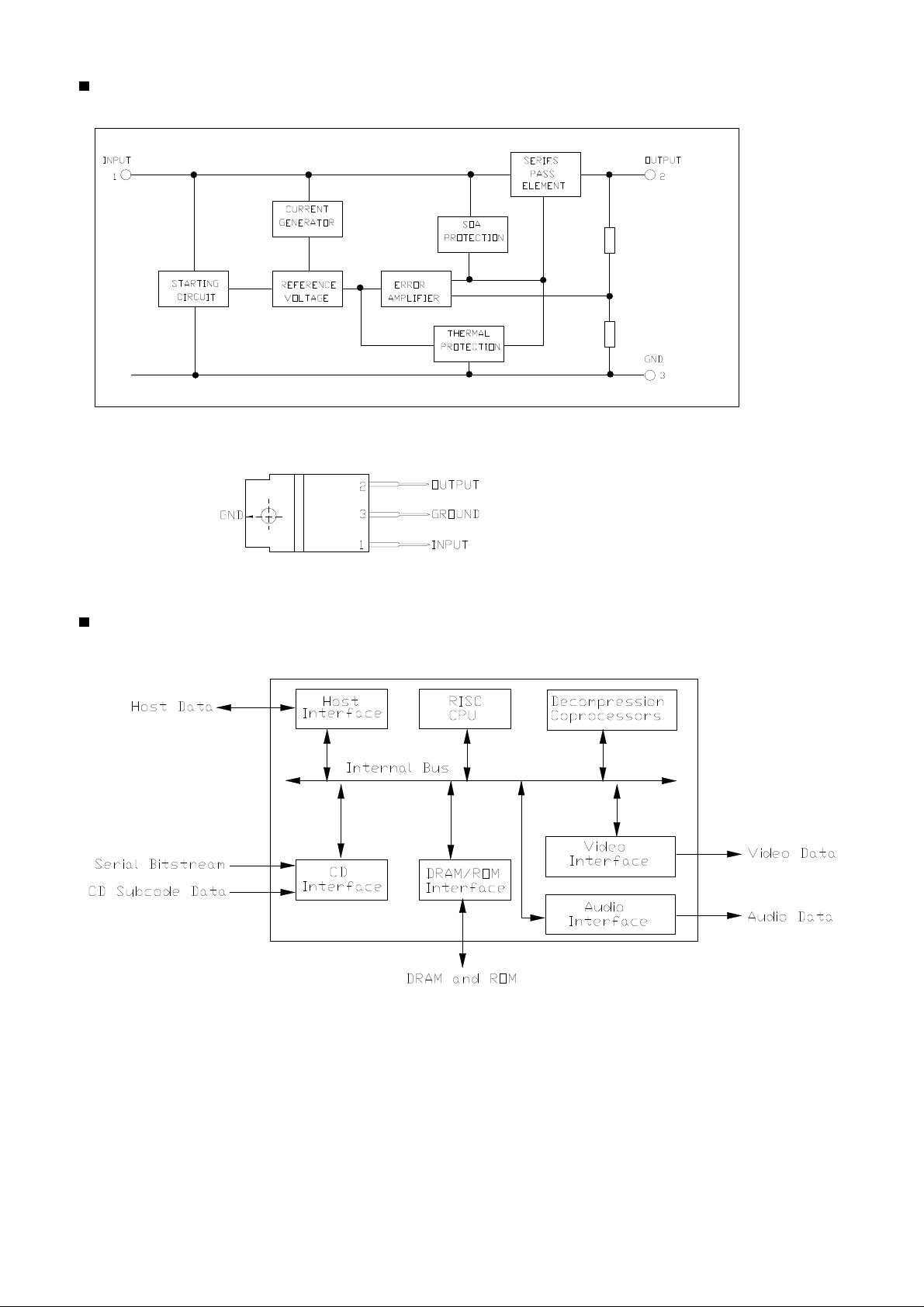

IC101: 7805 (REGULATOR)

Block diagram

Pin configuration

U1: CL680 (MPEG-1 DECODER)

Block diagram

1-8

Page 9

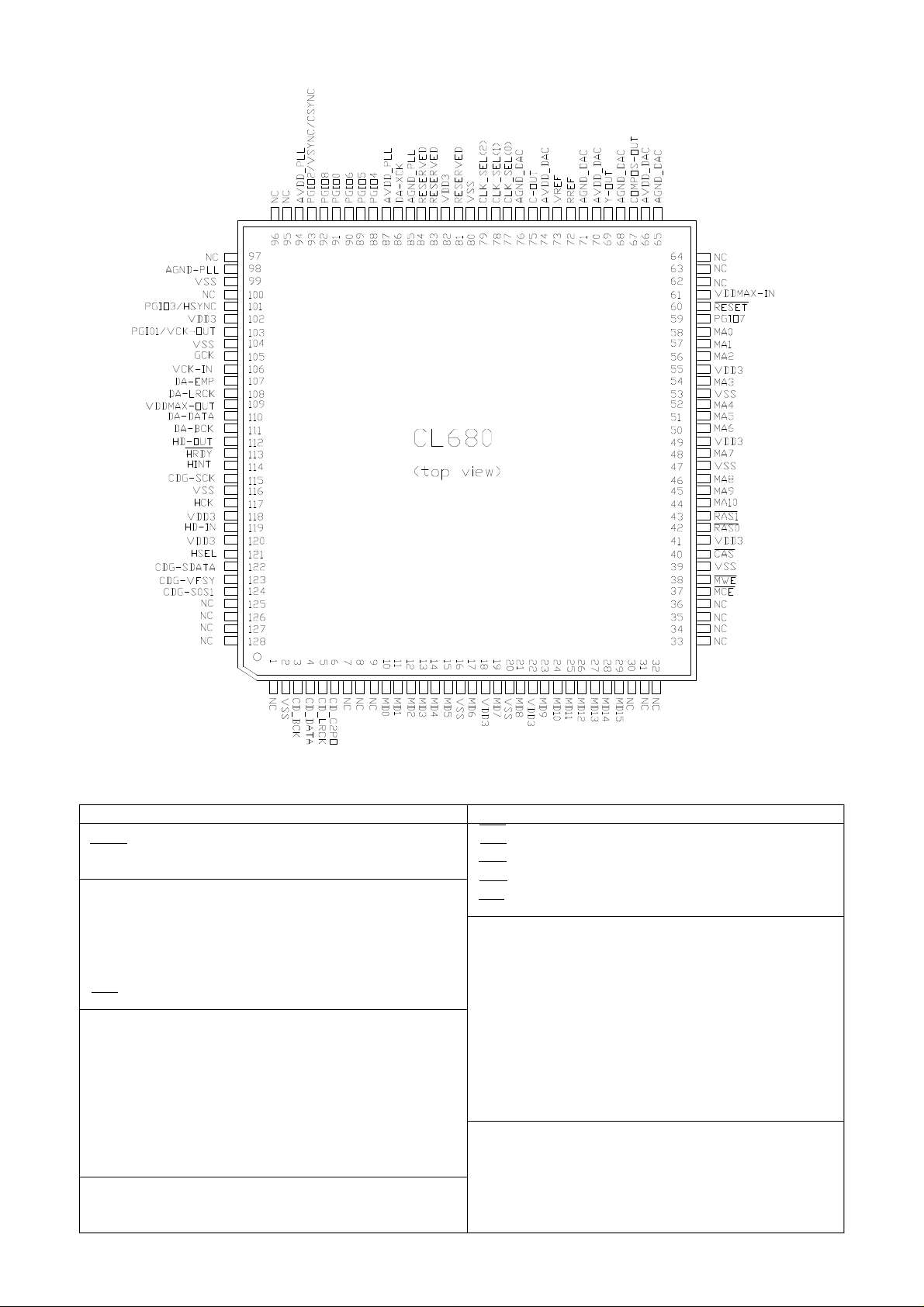

Pin configuration

XL-SV205GD

Pin description (Maximum voltage)

Signal Input Output

Global Interface VDDMAX-IN

RESET CLK_SEL(0:2) VDDMAX-IN

Host Interface

HCK VDDMAX-IN HD-IN VDDMAX-IN HD-OUT VDDMAX-IN

HRDY - VDDMAX-OUT

HSEL VDDMAX-IN HINT VDDMAX-IN

CD Interface Signals

CD-BCK VDDMAX-IN CD-DATA VDDMAX-IN CD-LRCK VDDMAX-IN CD-C2PO VDDMAX-IN CDG-SCK VDDMAX-IN VDDMAX-OUT

CDG-SDATA VDDMAX-IN CDG-VFSY VDDMAX-IN CDG-SOS1 VDDMAX-IN DRAM Interface

MD(15: 0) VDDMAX-IN VDD3

MA(10: 0) - VDD3

1

2

VDDMAX-OUT

VDDMAX-OUT

Signal Input Output

RAS(0) - VDD3

RAS(1) - VDD3

CAS - VDD3

MWE - VDD3

MCE - VDD3

Video Interface

PGIO0 VDDMAX-IN VDD3

PGIO1 VDDMAX-IN VDD3

PGIO2 VDDMAX-IN VDD3

PGIO3 VDDMAX-IN VDD3

VCK-IN VDDMAX-IN VREF Analog RREF Analog Y-OUT - AVDD

C-OUT - AVDD

COMPOS-OUT - AVDD

Audio Interface

DA-DATA VDDMAX-OUT

DA-LRCK VDDMAX-OUT

DA-BCK VDDMAX-OUT

DA-XCK VDDMAX-IN DA-EMP - VDDMAX-OUT

1-9

Page 10

XL-SV205GD

U2: C16256 (4MB DRAM)

Block diagram

Pin configuration

Pin description

Pin No. Pin Name Type Description

16~19,22~26 A0-A8 Input Address input

14 RAS Input Row address

strobe

28 CASH Input Column address

strobe/Upper

byte control

29 CASL Input Column address

strobe/lower

byte control

13 WE Input Write enable

27 OE Input Output enable

2~5,6~10, I/O1 - I/O16 Input/Output Data input/

31~34,36~39 output

1,6,20 Vcc Supply Power, 5V

21, 35, 40 Vss Ground Ground

11,12,15,30 NC - No connect

1-10

Page 11

U3: 27C010 (1MB EEPROM)

Block diagram

XL-SV205GD

Pin configuration

U4: CS4338 (AUDIO DAC)

Block diagram

Pin description

I/O Pin Name Pin No. Description

- Vpp 1 Voltage input for program erase

operations

I A16,A15,A12 2,3,4 Address input pins

I A7-A0 5-12 Address input pins

I/O D0-D2 13-15 Input/Output pins

- GND 16 Ground

I/O D3-D7 17-21 Input/Output pins

I CE 22 Chip enable (Active low)

I A10 23 Address input pins

I OE 24 Output enable (Active low)

I A11,A9,A8 25,26,27 Address input pins

I A13,A14,A17 28,29,30 Address input pins

I WE 31 Write enable bar (Active low)

- VCC 32 Power supply for device

operation (5V ± 10%)

1-11

Page 12

XL-SV205GD

Pin description

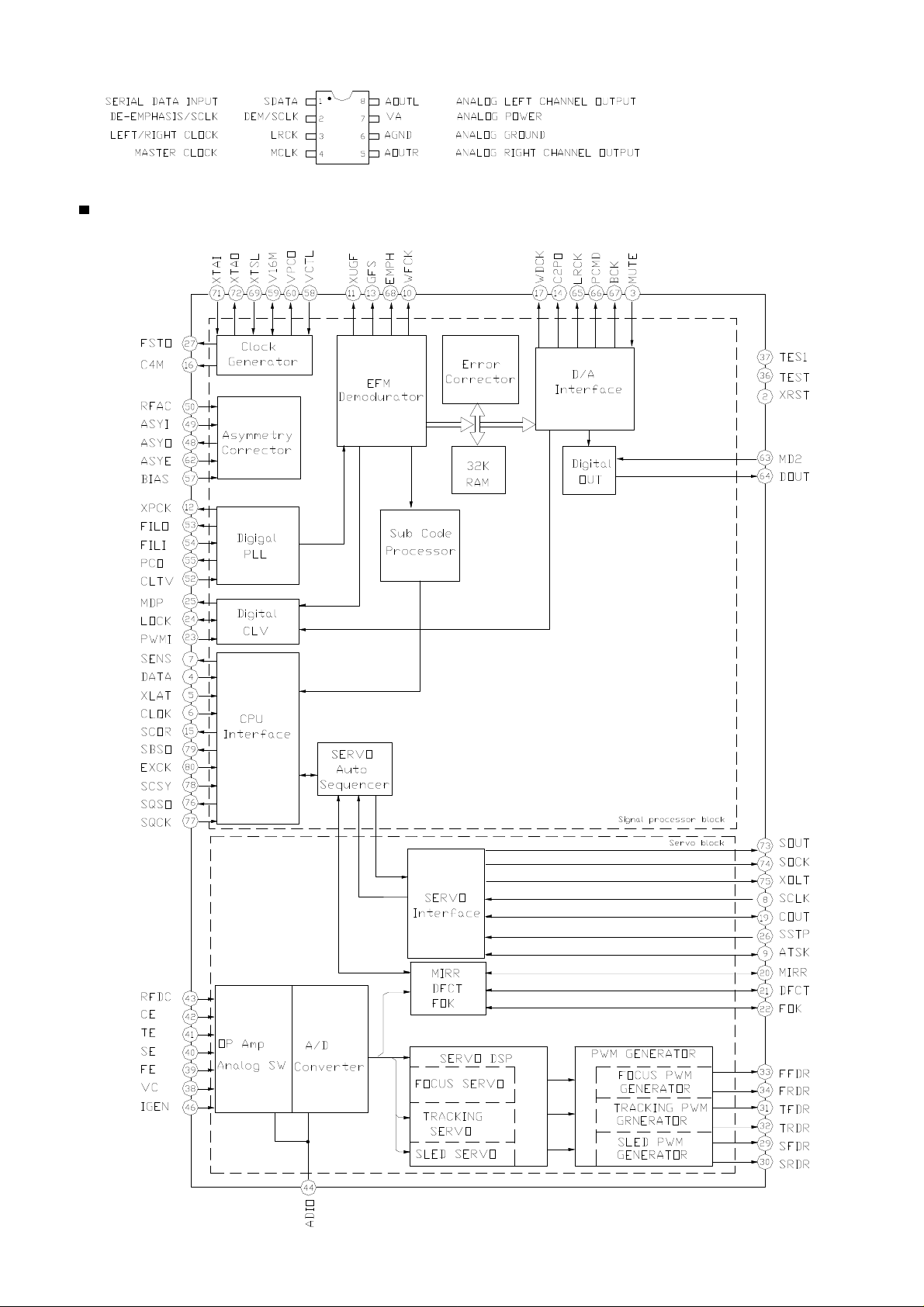

U7: CXD3068Q (CD DSP)

Block diagram

1-12

Page 13

Pin configuration

XL-SV205GD

Pin description

Pin No. Pin Name I/O Description

1 DVDD0 - Digital power supply

2 XRST I System reset. Reset when low.

3 MUTE I Mute input (Low: off, high : on)

4 DATA I Serial data input from CPU

5 XLAT I Latch input from CPU. Serial data is latched at the falling edge.

6 CLOK I Serial data transfer clock input from CPU.

7 SENS O 1,0 SENS output to CPU.

8 SCLK I SENS serial data readout clock input.

9 ATSK I/O 1,0 Anti-shock input/output

10 WFCK O 1,0 WFCK output

11 XUGF O 1,0 XUGF output. MNT0 or RFCK is output by switching with the command.

12 XPCK O 1,0 XPCK output. MNT1 is output by switching with the command.

13 GFS O 1,0 GFS output. MNT2 or XROF is output by switching with the command.

14 C2PO O 1,0 G2PO output. MNT3 or GTOP is output by switching with the command.

15 SCOR O 1,0 Outputs a high signal when either subcode sync S0 or S1 is detected.

16 C4M O 1,0 4.2336MHz output. 1/4 frequency division output for V16M in CAV-W mode or variable

pitch mode.

17 WDCK O 1,0 Word clock output. f=2Fs. GRSCOR is output by the command switching.

18 DVss0 - - Digital GND.

19 COUT I/O 1,0 Track count signal I/O

20 MIRR I/O 1,0 Mirror signal I/O

21 DFCT I/O 1,0 Detect signal I/O

22 FOK I/O 1,0 Focus OK signal I/O

23 PWMI I Spindle motor external control input.

24 LOCK I/O 1,0 GFS is sampled at 460Hz; when GFC is high, this pin outputs a high signal. If GFS is low

eight consecutive samples, this pin outputs low. Input when LKIN=1.

25 MDP O 1,Z,0 Spindle motor servo control output.

26 SSTP I Disc innermost track detection signal input.

27 FSTO O 1,0 2/3 frequency division output for XTAI pin.

28 DVDD1 - - Digital power supply.

29 SFDR O 1,0 Sled drive output.

30 SRDR O 1,0 Sled drive output.

31 TFDR O 1,0 Tracking drive output.

32 TRDR O 1,0 Tracking drive output.

33 FFDR O 1,0 Focus drive output.

1-13

Page 14

XL-SV205GD

Pin No. Pin Name I/O Description

34 FRDR O 1,0 Focus drive output.

35 DVss1 - - Digital GND.

36 TEST I Test normally, GND

37 TES1 I Test normally, GND

38 VC I Center voltage input

39 FE I Focus error signal input

40 SE I Sled error signal input

41 TE I Tracking error signal input

42 CE I Center servo analog input

43 RFDC I RF signal input

44 ADIO O Analog Test No. connected

45 AVss0 - - Analog GND

46 IGEN I Constant current input for operational amplifier

47 AVDD0 - - Analog power supply

48 ASYO O 1,0 EFM full-swing output. (low=Vss, high=VDD)

49 ASYI I Asymmetry comparator voltage input

50 RFAC I EFM signal input

51 AVss1 - - Analog GND

52 CLTV I Multiplier VCO1 control voltage input

53 FILO O Analog Master PLL filter output (slave=digital PLL)

54 FILI I Master PLL filter input

55 PCO O 1,Z,0 Master PLL charge pump output

56 AVDD1 - - Analog power supply

57 BIAS I Asymmetry circuit constant current input

58 VCTL I Wide-band EFM PLL VCO2 control voltage input

59 V16M I/O 1,0 Wide-band EFM PLL VCO2 oscillation output. Serves as wide-band EFM PLL clock

input by switching with the command.

60 VPCO O 1,Z,0 Wide-band EFM PLL change pump output

61 DVDD2 - - Digital power supply

62 ASYE I Asymmetry circuit on/off (low=off, high=on)

63 MD2 I Digital Out on/off control (low=off, high=on)

64 DOUT O 1,0 Digital Out output

65 LRCK O 1,0 D/A interface. LR clock output. f=Fs

66 PCMD O 1,0 D/A interface. Serial data output (two’s complement, MSB first)

67 BCK O 1,0 D/A interface. Bit clock output

68 EMPH O 1,0 Outputs a high signal when the playback disc has emphasis, and a low signal when

there is no emphasis.

69 XTSL I Crystal selection input. Low when the crystal is 16.9344MHz; high when it is

33.8688MHz.

70 DVss2 - - Digital GND

71 XTAI I Crystal oscillation circuit input. When the master clock is input externally, input it from

this pin.

72 XTAO O Crystal oscillation circuit output.

73 SOUT O 1,0 Serial data output in servo block.

74 SOCK O 1,0 Serial data readout clock output in servo block.

75 XOLT O 1,0 Serial data latch output in servo block.

76 SQCO O 1,0 Sub-Q 80-bit, PCM peak or level data outputs. CD TEXT data output.

77 SQCK I SQCO readout clock input.

78 SCSY I GRSCOR resynchronization input.

79 SBSO O 1,0 Sub-Q P to W serial output.

80 EXCK I SBSO readout clock input.

1-14

Page 15

U8: CXA2550N (RF AMPLIFIER)

Block diagram

XL-SV205GD

Pin configuration

Pin description

Pin No. Pin Name I/O Description

1 AGCVTH - Reference level variable pin for RF level control. The reference level can be varied by the

external resistor.

2 LD O APC amplifier output pin.

3 PD I APC amplifier input pin.

4 PD1 I Inversion input pin for RF I-V amplifiers.

5 PD2 I Connect these pins to the photodiodes A + C and B + D respectively. The current is supplied.

6 VEE - //VEE pin

7 F I Inversion input pin for F and E I-V amplifiers

8 E I Connect these pins to the photodiodes F and E respectively. The current is supplied.

9 EI - Gain adjustment pin for I-V amplifier.

10 VC O DC voltage output pin of (Vcc + V

smoothing capacitor for single +3.5V Power supply.

11 TE O Tracking error amplifier output pin. E-F signal is output.

12 FE_BIAS I Bias adjustment pin for inverted side of focus error amplifier.

13 FE O Focus error amplifier output pin.

14 FRM I RF amplifier inverted side input pin. RF amplifier gain is determined by the resistor connected

between this pin and RFO pin.

15 RF O O RF amplifier output pin.

16 RF I I The RF amplifier output RFO is input with its capacitance coupled.

17 RFTC - External time-constant pin for RF level control.

18 AGCCONT I RF level control ON (limit level of 50%/30%)/OFF switching pin. OFF for Vcc, 30% for open or Vc

and 50% for VEE.

19 LD_ON I APC amplifier ON/OFF switching pin. OFF for Vcc and ON for VEE.

20 Vcc Vcc pin

EE)/2. Connect to GND for ±1.75 power supply; connect a

1-15

Page 16

XL-SV205GD

U9: BA5983FM (BTL DRIVER)

Block diagram

Pin description

Pin No. Pin Name Description

1 BIAS IN Input for Bias-amplifier

2 OPIN1(+) Non inverting input for CH1 OP-AMP

3 OPIN1(-) Inverting input for CH1 OP-AMP

4 OPOUT1 Output for CH1 OP-AMP

5 OPIN2(+) Non inverting input for CH2 OP-AMP

6 OPIN1(-) Non inverting input for CH2 OP-AMP

7 OPOUT2 inverting input for CH2 OP-AMP

8 GND Substrate ground

9 STBY1 Input for CH1/2/3 stand by control

10 PowVcc1 Vcc for CH1/2 power block

11 VO2(-) Inverted output of CH2

12 VO2(+) Non inverted output of CH2

13 VO1(-) Inverted output of CH1

14 VO1(+) Non inverted output of CH1

15 VO4(+) Non inverted output of CH4

16 VO4(-) Inverted output of CH4

17 VO3(+) Non inverted output of CH3

18 VO3(-) Inverted output of CH3

19 PowVcc2 Vcc for CH3/4 power block

20 STBY2 Input for CH4 stand by control

21 GND Substrate ground

22 OPOUT3 Output for CH3 OP-AMP

23 OPIN3(-) Inverting input for CH3 OP-AMP

24 OPIN3(+) Non inverting input for CH3 OP-AMP

25 OPOUT4 Output for CH4 OP-AMP

26 OPOUT4(-) Inverting input for CH4 OP-AMP

27 OPOUT4(+) Non inverting input for CH4 OP-AMP

28 PreVcc Vcc for pre block

U10: 74HCU04 (HEX INVERTER)

Pin configuration

1-16

Page 17

XL-SV205GD

JVC Asia Pte Ltd

101 Thomson Road, #28-04 United Squares, Singapore 307591

No (28206)

Printed in Japan

200102(L)

Page 18

XL-SV205GD

PARTS LIST

[XL-SV205GD]

IMPORTANT

PLEASE TAKE NOTE BEFORE ORDERING

1. Order all service parts through JVC ASIA PTE LTD.-Customer Satisfaction Dept.

2. Two order are availiable: Initial order and last order (Before End of Line).

3. Minimum order quantity: 100pcs

4. Delivery term: Minimum 2 months upon confirmation of order.

3-1

- ContentsExploded view diagram --------------------------------------- 3-2

Mechanical parts list ------------------------------------------- 3-3

Electrical parts list ----------------------------------------------

3-4

Packing list --------------------------------------------------------- 3-8

Parts ordering form ---------------------------------------------

3-9

Page 19

Exploded view diagram

Main unit exploded view diagram

XL-SV205GD

3-2

Page 20

XL-SV205GD

Mechanical parts list

Ref. Parts Number Description QTY.

1 620-300606-70 S-TAP.SCREW P-B 3X6 A BZN +H 29

2 620-300610-70 S-TAP.SCREW P-B 3X10 A BZN +H 2

3 E4101-023001 SWITCH POW KDC-A09 1

4 322-SV2001-01Y CUSHION FOOT FRONT 2

5 207-323911-01R CABINET FOOT FRONT SV20 R 2

6 E3701-00L010C PCB AC SW 1

7 612-300212-10 S-TAP.SCREW WHR 3X12 A NIP +H 2

8 E3701-00L020-1 PCB MIC AMP SV205GD 65X50 HB 1

9 273-SV2001-01S KNOB ECHO 3

10 E3701-00L010A PCB POWER SUPPL Y 168X68 V0 1

11 E2301-237001 IC L7805CV 1

12 E5102-114001 TRANSFORMER POW T57-0123008-10 EI57 1

13 620-400606-70 S-TAP SCREW P-B 4X6 8

14 459-SV2001-01 HOLDER MECH(1) 1

15 E4103-020001 SWITCH SLIDE LZ1-22A2 4410206199 1

16 459-SV2002-01 HOLDER MECH(2) 1

17 E7701-005001 MECHANISM VCD KSS-213V 1

18 211-SV2001-02S PANEL TRAY W/SILK SV20 S 1

19 402-SV2001-01 PANEL REAR 1

20 E7801-006001 PCB ASSY HY-24AVER1.6 1

21 322-SV2002-01Y CUSHION FOOT BACK 2

22 403-SV2001-01 CHASSIS BOTTOM 1

23 610-260108-00 S-TAP.SCREW RND 2.6X8 B BZN +H 12

24 620-400605-90 S-TAP SCREW P-B 4X5 4

25 372-SV2001-01Y SPACER FLD 10X10X4 2

26 E6201-019001 DISPLA Y FLD 20U391 18BAN 1

27 279-SV2002-01S BUTTON SP A TIALIZER 1

28 279-SV2003-01S BUTTON PLA Y 1

29 260-SV2001-01K WINDOW LEN FLD 1

30 200-SV2001-01R PANEL FRONT 1

31 286-SV2001-01S NAME PLA TE 1

32 279-SV2001-01S BUTTON POWER 1

33 603-305005-00 MACH.SCREW TRS 3X5 BZN +H 2

3-3

Page 21

Electrical parts list

Electrical parts list (Remote board)

Ref. Parts Number Description QTY.

090-385610-03 PCB HANSET 119X46 HB 1

C002 E1321-001053 CAPACITO R CE V T C SL221 J 50DC T05 7 2

C003 E1321-001053 CAPACITO R CE V T C SL221 J 50DC T05 7 2

R001 E1501-002007 RESISTOR CBF H 1/4W 1R0J T52 1

JP001 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0001

C001 E1301-004030 CAPACITO R EC V S A T05 470M 16DC 5 1

CF001 E4302-044001 OSCILLATOR CE XZT455E 455K 1

Q001 E2103-109001 TRANSISTOR 3DA8050(8050) C T05 1

IC001 E2351-033001 IC HT-6222-24 1

LED001 E2509-029001 DIODE LED TSAL6200 INFRARED 1

D001 E2501-010001 DIODE SILICON H 1N4148-T72 T52 4

D002 E2501-010001 DIODE SILICON H 1N4148-T72 T52 4

D003 E2501-010001 DIODE SILICON H 1N4148-T72 T52 4

D004 E2501-010001 DIODE SILICON H 1N4148-T72 T52 4

Electrical parts list (Power board)

Ref. Parts Number Description QTY.

EY1 437-015030-02 EYELET 1.5X3 N+T 4B 2

EY2 437-015030-02 EYELET 1.5X3 N+T 4B 2

EY3 437-020030-02 EYELET 2X3 N+T 4B 6

EY4 437-020030-02 EYELET 2X3 N+T 4B 6

EY5 437-020030-02 EYELET 2X3 N+T 4B 6

EY6 437-020030-02 EYELET 2X3 N+T 4B 6

EY7 437-020030-02 EYELET 2X3 N+T 4B 6

EY8 437-020030-02 EYELET 2X3 N+T 4B 6

F101 456-701201-01 FUSE HOLDER 7012 2

C109 E1301-004002 CAPACITO R EC V SA T05 1R0M 50DC 1

C132 E1301-004019 CAPACITO R E C V S A 221M 35DC 1

C121 E1301-041008 CAPACITOR EC V SAII T05 471M 16DC 1

C128 E1301-041012 CAPACITO R EC V SAII 102M 16DC 1

C127 E1301-041013 CAPACITO R EC V SAII 222M 16DC 1

C108 E1301-041025 CAPACITO R EC V A SAII 332M 16DC 13X25 1

C104 E1321-002002 CAPACITO R CE V HIK F 103Z 50DC T05 8 8

C105 E1321-002002 CAPACITO R CE V HIK F 103Z 50DC T05 8 8

C106 E1321-002002 CAPACITO R CE V HIK F 103Z 50DC T05 8 8

C107 E1321-002002 CAPACITO R CE V HIK F 103Z 50DC T05 8 8

C123 E1321-002002 CAPACITO R CE V HIK F 103Z 50DC T05 8 8

C124 E1321-002002 CAPACITO R CE V HIK F 103Z 50DC T05 8 8

C125 E1321-002002 CAPACITO R CE V HIK F 103Z 50DC T05 8 8

C126 E1321-002002 CAPACITO R CE V HIK F 103Z 50DC T05 8 8

C120 E1321-011006 CAP ACITOR CE V SC F 104Z 5 0DC T0 5 7 5

C129 E1321-011006 CAP ACITOR CE V SC F 104Z 5 0DC T0 5 7 5

C130 E1321-011006 CAP ACITOR CE V SC F 104Z 5 0DC T0 5 7 5

C131 E1321-011006 CAP ACITOR CE V SC F 104Z 5 0DC T0 5 7 5

C133 E1321-011006 CAP ACITOR CE V SC F 104Z 5 0DC T0 5 7 5

C101 E1325-012002 CAPACITO R CE V CT81-4 E 222M 250AC 13 1

C102 E1333-009002 CAPACITOR SPP MPX-X2 CUT 473K 275AC 2

C134 E1333-009002 CAPACITOR SPP MPX-X2 CUT 473K 275AC 2

R108 E1501-002035 RESISTOR CBF H 1/4W 223J T52 1

R106 E1501-002066 RESISTOR CBF H 1/4W 471J T52 2

R107 E1501-002066 RESISTOR CBF H 1/4W 471J T52 2

R105 E1501-002082 RESISTOR CBF H 1/4W 681J T52 1

R101 E1509-005013 RESISTOR FUSE H 1/2W R22J F10 1

R109 E1509-011019 RESISTOR FUSE H 1/4W R22J F10 1

IC101 E2301-237001 IC L7805CV 1

D11 2 E2501-010001 DIODE SILICON H 1N4148-T72 T52 2

D11 3 E2501-010001 DIODE SILICON H 1N4148-T72 T52 2

XL-SV205GD

3-4

Page 22

XL-SV205GD

Electrical parts list (Power board)

Ref. Parts Number Description QTY.

D101 E2501-055001 DIODE SILICON H 1N4004 1A400V T52 D0-41 10

D102 E2501-055001 DIODE SILICON H 1N4004 1A400V T52 D0-41 10

D103 E2501-055001 DIODE SILICON H 1N4004 1A400V T52 D0-41 10

D104 E2501-055001 DIODE SILICON H 1N4004 1A400V T52 D0-41 10

D105 E2501-055001 DIODE SILICON H 1N4004 1A400V T52 D0-41 10

D106 E2501-055001 DIODE SILICON H 1N4004 1A400V T52 D0-41 10

D107 E2501-055001 DIODE SILICON H 1N4004 1A400V T52 D0-41 10

D108 E2501-055001 DIODE SILICON H 1N4004 1A400V T52 D0-41 10

D1 10 E2501-055001 DIODE SILICON H 1N4004 1A400V T52 D0-41 10

D1 1 1 E2501-055001 DIODE SILICON H 1N4004 1A400V T52 D0-41 10

ZD102 E2504-003006 DIODE ZENER H TZX20V-B 1/2W T52 20V 1

ZD101 E2504-003017 DIODE ZENER H TZX6V8-B 1/2W T52 6.8V 1

P102 E3101-065001 PLUG STV8-2W 2P 1

CN102 E3101-094006 PLUG EH-7A 7P 1

P101 E3101-172001 PLUG V VH-3A P4.0 2P 1

CN103 E3101-175004 PLUG V HX2503-5A P2.5 5P WHI 1

JP101 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0004

JP102 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0004

JP103 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0004

L102 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0004

R102 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0004

R103 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0004

R111 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0004

R112 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0004

CN106 E3421-798001 WIRE ASSY 1H8.0-2TKN5 2- L367 CG 2P 1

CN101 TO MPEG E3421-799001 WIRE ASSY 1H2.5-2T2.5 9- L361 GG 10P 1

A1-A2 E3451-000078 WIRE WD CG-2N-0140-D0A-D0A 1

B1-B2 E3451-000079 WIRE WD CG-3N-0140-D0A-D0A 1

C1-C2 E3451-000215 WIRE WD CG-4N-0140-DOA-DOA 1

E3701-00L010A PCB POWER SUPPLY 168X68 V0 1

E3701-00L010B PCB AC SELEC V0 1

E3701-00L010C PCB AC SW V0 1

SW102 E4101-023001 SWITCH POW KDC-A09 1

SW101 E4103-020001 SWITCH SLIDE LZ1-22A2 4410206199 1

L101 E4405-021001 FILTER LINE LCL-2002WH 1

Electrical parts list (MIC board)

Ref. Parts Number Description QTY.

C222 E1301-004002 CAPACITO R EC V SA T05 1R0M 50DC 5 2

C223 E1301-004002 CAPACITO R EC V SA T05 1R0M 50DC 5 2

C205 E1301-004003 CAPACITO R EC V S A T05 100M 16DC 5 5

C206 E1301-004003 CAPACITO R EC V S A T05 100M 16DC 5 5

C207 E1301-004003 CAPACITO R EC V S A T05 100M 16DC 5 5

C215 E1301-004003 CAPACITO R EC V S A T05 100M 16DC 5 5

C224 E1301-004003 CAPACITO R EC V S A T05 100M 16DC 5 5

C216 E1301-004007 CAPACITO R EC V S A T05 101M 16DC 7 1

C201 E1301-004026 CAPACITO R EC V SA T05 R47M 50DC 5 2

C211 E1301-004026 CAPACITOR EC V SA T05 R47M 50DC 5 2

C208 E1301-004030 CAPACITO R EC V S A T05 470M 16DC 5 3

C218 E1301-004030 CAPACITO R EC V S A T05 470M 16DC 5 3

C232 E1301-004030 CAPACITO R EC V S A T05 470M 16DC 5 3

C204 E1321-001012 CAPACITO R CE V T C SL151K 50DC T05 6 2

C213 E1321-001012 CAPACITO R CE V T C SL151K 50DC T05 6 2

C203 E1321-001016 CAPACITO R CE V T C SL221K 50DC T05 7 3

C212 E1321-001016 CAPACITO R CE V T C SL221K 50DC T05 7 3

C231 E1321-001016 CAPACITO R CE V T C SL221K 50DC T05 7 3

C221 E1321-001102 CAPACITOR C E V TC S L561J 5 0DC T0 5 9 2

C225 E1321-001102 CAPACITOR C E V TC S L561J 5 0DC T0 5 9 2

C202 E1321-002002 CAPACITO R CE V HIK F 103Z 50DC T05 8 4

C210 E1321-002002 CAPACITO R CE V HIK F 103Z 50DC T05 8 4

3-5

Page 23

Electrical parts list (MIC board)

Ref. Parts Number Description QTY.

C217 E1321-002002 CAPACITO R CE V HIK F 103Z 50DC T05 8 4

C226 E1321-002002 CAPACIT OR CE V HIK F 103Z 50DC T05 8 4

C214 E1321-002023 CAPACIT OR CE V HIK B 331K 50DC T05 5 1

C209 E1321-011006 CAP ACITOR CE V SC F 104Z 50DC T0 5 7 4

C219 E1321-011006 CAP ACITOR CE V SC F 104Z 50DC T0 5 7 4

C227 E1321-011006 CAP ACITOR CE V SC F 104Z 50DC T0 5 7 4

C233 E1321-011006 CAP ACITOR CE V SC F 104Z 50DC T0 5 7 4

C220 E1331-001003 CAPACIT OR MY V W 104K 100DC T05 2

C229 E1331-001003 CAPACIT OR MY V W 104K 100DC T05 2

C228 E1331-001029 CAPACIT OR MY V W 562J 100DC T05 2

C230 E1331-001029 CAPACIT OR MY V W 562J 100DC T05 2

R206 E1501-001002 RESISTOR CBF H 1/6W 101J T52 2

R215 E1501-001002 RESISTOR CBF H 1/6W 101J T52 2

R201 E1501-001003 RESISTOR CBF H 1/6W 102J T52 2

R21 1 E1501-001003 RESISTOR CBF H 1/6W 102J T52 2

R219 E1501-001004 RESISTOR CBF H 1/6W 103J T52 5

R220 E1501-001004 RESISTOR CBF H 1/6W 103J T52 5

R224 E1501-001004 RESISTOR CBF H 1/6W 103J T52 5

R227 E1501-001004 RESISTOR CBF H 1/6W 103J T52 5

R229 E1501-001004 RESISTOR CBF H 1/6W 103J T52 5

R203 E1501-001005 RESISTOR CBF H 1/6W 104J T52 2

R213 E1501-001005 RESISTOR CBF H 1/6W 104J T52 2

R218 E1501-001019 RESISTOR CBF H 1/6W 153J T52 3

R223 E1501-001019 RESISTOR CBF H 1/6W 153J T52 3

R225 E1501-001019 RESISTOR CBF H 1/6W 153J T52 3

R208 E1501-001028 RESISTOR CBF H 1/6W 203J T52 1

R207 E1501-001033 RESISTOR CBF H 1/6W 223J T52 2

R216 E1501-001033 RESISTOR CBF H 1/6W 223J T52 2

R202 E1501-001050 RESISTOR CBF H 1/6W 303J T52 2

R212 E1501-001050 RESISTOR CBF H 1/6W 303J T52 2

R221 E1501-001067 RESISTOR CBF H 1/6W 472J T52 3

R233 E1501-001067 RESISTOR CBF H 1/6W 472J T52 3

R234 E1501-001067 RESISTOR CBF H 1/6W 472J T52 3

R230 E1501-001068 RESISTOR CBF H 1/6W 473J T52 1

R232 E1501-001076 RESISTOR CBF H 1/6W 561J T52 1

R228 E1501-001077 RESISTOR CBF H 1/6W 562J T52 1

R222 E1501-001086 RESISTOR CBF H 1/6W 682J T52 1

R226 E1501-001091 RESISTOR CBF H 1/6W 752J T52 1

R205 E1501-001095 RESISTOR CBF H 1/6W 822J T52 2

R214 E1501-001095 RESISTOR CBF H 1/6W 822J T52 2

R209 E1501-002002 RESISTOR CBF H 1/4W 101J T52 2

R210 E1501-002002 RESISTOR CBF H 1/4W 101J T52 2

R217 E1501-002072 RESISTOR CBF H 1/4W 4R7J T52 1

Q201 E2103-110001 TRANSISTOR 3DG9014(9014) C 1

IC201 E2301-145001 IC BA4558 2

IC202 E2301-145001 IC BA4558 2

IC203 E2301-460001 IC PT2399 1

CN201 E3101-094006 PLUG EH-7A 7P 1

M1 E3202-031001 MIC JACK CK3-6.35-31 2

M2 E3202-031001 MIC JACK CK3-6.35-31 2

JP201 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0006

JP202 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0006

JP203 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0006

JP204 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0006

JP205 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0006

JP206 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0006

JP207 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0006

JP208 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0006

JP209 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0006

CN202 E3421-718001 WIRE ASSY 1H2.5-2T2.5 96- L111 GG 7P 1

E3701-00L020-1 PCB MIC AMP SV205GD 65X50 HB 1

XL-SV205GD

3-6

Page 24

XL-SV205GD

Electrical parts list (Key board)

Ref. Parts Number Description QTY.

372-SV2001-01Y SPACER FLD 10X10X4 2

C305 E1301-004006 CAPACITO R E C V S A T05 101M 10DC 5 1

C306 E1301-004015 CAPACITO R E C V S A T05 220M 16DC 5 1

C301 E1321-001016 CAPACITO R CE V T C SL221K 50DC T05 7 3

C302 E1321-001016 CAPACITO R CE V T C SL221K 50DC T05 7 3

C303 E1321-001016 CAPACITO R CE V T C SL221K 50DC T05 7 3

C307 E1321-002002 CAPACITO R CE V HIK F 103Z 50DC T05 8 1

C304 E1321-011006 CAPACIT OR CE V SC F 104Z 5 0DC T0 5 7 1

R314 E1501-001001 RESISTOR CBF H 1/6W 100J T52 1

R309 E1501-001004 RESISTOR CBF H 1/6W 103J T52 3

R310 E1501-001004 RESISTOR CBF H 1/6W 103J T52 3

R31 1 E1501-001004 RESISTOR CBF H 1/6W 103J T52 3

R301 E1501-001054 RESISTOR CBF H 1/6W 333J T52 9

R302 E1501-001054 RESISTOR CBF H 1/6W 333J T52 9

R303 E1501-001054 RESISTOR CBF H 1/6W 333J T52 9

R304 E1501-001054 RESISTOR CBF H 1/6W 333J T52 9

R305 E1501-001054 RESISTOR CBF H 1/6W 333J T52 9

R306 E1501-001054 RESISTOR CBF H 1/6W 333J T52 9

R307 E1501-001054 RESISTOR CBF H 1/6W 333J T52 9

R308 E1501-001054 RESISTOR CBF H 1/6W 333J T52 9

R312 E1501-001054 RESISTOR CBF H 1/6W 333J T52 9

R313 E1501-001073 RESISTOR CBF H 1/6W 512J T52 1

VR301 E1701-048001 VAR RESISTOR ROT R0903N1PF L15.0 A103X1 3

VR302 E1701-048001 VAR RESISTOR ROT R0903N1PF L15.0 A103X1 3

VR303 E1701-048001 VAR RESISTOR ROT R0903N1PF L15.0 A103X1 3

IC301 E2351-077001 IC HT16512 1

D301 E2501-010001 DIODE SILICON H 1N4148-T72 T52 5

D302 E2501-010001 DIODE SILICON H 1N4148-T72 T52 5

D303 E2501-010001 DIODE SILICON H 1N4148-T72 T52 5

D304 E2501-010001 DIODE SILICON H 1N4148-T72 T52 5

D305 E2501-010001 DIODE SILICON H 1N4148-T72 T52 5

OP301 E2701-017002 DETECTOR IR SPS-440-1-E 1

JP301-JP325 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0005

JP326 E3409-001001 WIRE JUMPER 0.6MM 1KG=375M 0.0005

CN303 E3421-718001 WIRE ASSY 1H2.5-2T2.5 96- L111 GG 7P 1

CN301 E3421-792001 WIRE ASSY 1H2.5-2T2.5 08- L231 AF 5P 1

CN302 E3421-793001 WIRE ASSY 1H2.5-2T2.5 92- L230 GE 5P 1

E3701-00L030 PCB KEY AND FLD DISPLAY HB 1

K301 E4102-028001 SWITCH T ACT HCT-1 141A 19

K302 E4102-028001 SWITCH T ACT HCT-1 141A 19

K303 E4102-028001 SWITCH T ACT HCT-1 141A 19

K304 E4102-028001 SWITCH T ACT HCT-1 141A 19

K305 E4102-028001 SWITCH T ACT HCT-1 141A 19

K306 E4102-028001 SWITCH T ACT HCT-1 141A 19

K307 E4102-028001 SWITCH T ACT HCT-1 141A 19

K308 E4102-028001 SWITCH T ACT HCT-1 141A 19

K309 E4102-028001 SWITCH T ACT HCT-1 141A 19

K310 E4102-028001 SWITCH T ACT HCT-1 141A 19

K311 E4102-028001 SWITCH T ACT HCT-1141A 19

K312 E4102-028001 SWITCH T ACT HCT-1 141A 19

K313 E4102-028001 SWITCH T ACT HCT-1 141A 19

K314 E4102-028001 SWITCH T ACT HCT-1 141A 19

K315 E4102-028001 SWITCH T ACT HCT-1 141A 19

K316 E4102-028001 SWITCH T ACT HCT-1 141A 19

K317 E4102-028001 SWITCH T ACT HCT-1 141A 19

K318 E4102-028001 SWITCH T ACT HCT-1 141A 19

K319 E4102-028001 SWITCH T ACT HCT-1 141A 19

FLD301 E6201-019001 DISPLAY FLD 20U39118BAN 1

3-7

Page 25

Packing

XL-SV205GD

Ref. Parts No. Description QTY.

1 790-010115-02 Remote 47 Keys XLSV20 1

2 310-051004-03V Polybag 1

3 300-SV2001-01C Polyfoam L 1

4 XL-SV205GD Main Part 1

5 310-222406-04V Polybag 1

6 580-SV2001-025 INST . Booklet E/C/A 1

7 310-101504-02T Polybag 1

8 510-SV2001-01A Gift Box 1

9 300-SV2002-01C Polyfoam R 1

10 310-051004-03V Polybag 2

11 E3402-008001 AV Line 1

12 579-SV2001-03 Bar Code Label 1

13 E3103-003001 Conversion (Flat to Round)/UX 1

14 E3103-004001 Conversion (Round to Flat)/U 1

3-8

Page 26

TO: Customer Satisfaction Dept.

FAX: (65) 2543284

PARTS-ORDERING FORM

PAGE ______OF_____

Buyer’s Name Date Of Order Buyer’s Signature /Chop

Destination Ship Via AIR AIR MAIL DHL-MAIL

SEA SEA MAIL SEA&AIR

Account Code Destination Code Purchase Order No.

Item No. Model No. Parts No. Parts Name Qty Remarks

★

Please do not forget to describe Model No with Tail code.

3-9

Page 27

SERVICE MANUAL

XL-SV205GD

VIDEO CD PLAYER

XL-SV205GD

POWER

ON / OFF

1 – MIC VOLUME – 2 ECHO

MIN MAX MIN MAX MIN MAX

1 — MIC — 2

OPEN/CLOSE

RETURN

1 2 3 4 5

+10 6 7 8 9 10/0

VCD / CD 10 KEY

10/0

1 2

7 8 9

10+

3

654

P/N

IMPORTANT

PLEASE TAKE NOTE BEFORE ORDERING

1. Order all service parts through JVC ASIA PTE LTD.-Customer Satisfaction Dept.

2. Two order are availiable: Initial order and last order (Before End of Line).

3. Minimum order quantity: 100pcs

4. Delivery term: Minimum 2 months upon confirmation of order.

Contents

Wiring diagram ------------------------------------------------ 2-1

Block diagram ------------------------------------------------- 2-2

Schematic circuit board ----------------------------------- 2-3

Printed circuit board ---------------------------------------- 2-6

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN LTD.

No:28206sch

Jun. 2001

Page 28

Wiring diagram

XL-SV205GD

2-1

Page 29

Block diagram

XL-SV205GD

2-2

Page 30

Schematic Diagrams

!

MIC AMP, Power, Key & FLD Circuit

XL-SV205GD

2-3

Page 31

2-4

§ MPEG Circuit

XL-SV205GD

16M9

RST-3068

RST-3068

AGC

14

U10A

VCC

GND

74U04

7

R102

100E

SQCK

LDON

AGC

XLAT

CLOK

MIC-MUTE

JP5

6

5

VFD-STB-1

4

3

2

1

CON6

74U04

U10C

U10B

3 4

74U04

R101

2K7

27MHZ

X1

C102

20P

VFD-STB

56

C103

20P

CD-BCK

CD-DATA

CD-LRCK

VFD-DATA

R30

DA-LRCK

DA-DATA

DA-BCK

IR

10K

CD-BCK

CD-DATA

CD-LRCK

VFD-CLK

+5VM

DA-LRCK

DA-DATA

DA-BCK

C105

104

SQCK

LDON

XLAT

CLOK SCOR

MIC-MUTE

OPEN

CLOSE

SENS

SQSO

TRAY-SW

2DATA

VFD-CLK

+5VM

C101

104

+5VM

+5VM

1 2

R103

1K

R106

D3

1N4001

MIC-DET

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

97

98

99

2.2

D4

R107

2.2

C109

47U

NC16

AGND-PLL1

VSS7

NC17

PIO12

VDD36

PIO15

VSS8

PIO16

VCK-IN

PIO14

DA-LCK

VDDMAX-OUT

DA-DATA

DA-BCK

HD-OUT

HRDY

PIO13

CDG-SCK

VSS9

HCK

VDD37

HD-IN

VDD38

HSEL

CDG-SDATA

CDG-VFSY

CDG-SISO

NC18

NC19

NC20

NC21

96

1N4001

IR

94

NC1495NC15

AVDD-PLL1

3V3

C110

104

CLOK

OPEN

CLOSE

SENS

MIC-MUTE

93

87

91

PIO688PIO789PIO890PIO9

PIO1092PIO11

AVDD-PLL0

R109

10K

16M9

86

85

DA-XCK

AGND-PLL0

XLAT

84

SCOR

PIO483PIO5

680-D1

R108

10K

82

VDD35

U1

AGC

81

PIO3

R110

R111

10K

10K

R112

10K

R11310K

R115

2.2K

LDON

RST-3068

SQCK

76

80

75

79

PIO077PIO178PIO2

VSS6

C-OUT

AGND-DAC3

NC01VSS02CD-BCK3CD-DATA4CD-LRCK5CD-C2PO6NC17NC28NC39MD010MD111MD212MD313MD414MD515VSS116MD617VDD3018MD719VSS220MD821VDD3122MD923MD1024MD1125MD1226MD1327MD1428MD1529NC430NC531NC6

D1D2D3D4D5D6D7D8D9

D0

1.235V

73

74

RREF72VREF

AVDD-DAC2

D10

D11

71

69

70

Y-OUT

AVDD-DAC1

AGND-DAC2

D12

D13

D14

R114

2K

R116

1K

68

66

67

AVDD-DAC0

AGND-DAC1

COMPOS-OUT

VDDMAX-IN

D15

3V3 DAC

C111

104

65

NC13

AGND-DAC0

NC12

NC11

RESET

PIO18

VDD34

VSS5

VDD33

VSS4

MA10

RAS1

RAS0

VDD32

VSS3

MWE

MCE

NC10

32

C125

103

Y-OUT

C-OUT

R117

75E

L4

C114

XUH

104

+5VM

C115

104

R119

75E

RST-680

C116

104

U3

D3

17

Q3

D4

18

Q4

D5

19

Q5

D6

20

Q6

D7

21

Q7

22

A10

D8

A9

A8

A0

A1

A2

A3

R30

10K

A4

A5

A6

A7

A8

A9

A10

CE

23

A10

24

OE

25

A11

26

A9

27

A8

D10

28

A13

D11

29

A14

D14

30

NC

31

PGM

VCC32VPP

27C010

U2

1

VCC1

VSS3

2

D0

IO1

IO16

3

D1

IO2

IO15

4

D2

IO3

IO14

5

D3

IO4

IO13

6

VCC2

VSS2

7

D4

IO5

IO12

8

D5

IO6

IO11

9

D6

IO7

+5VM

IO8

NC1

NC2

WE

RAS

NC3

A0

A1

A2

A3

VCC320VSS1

814260

C120

104

C121

103

IO10

LCAS

UCAS

IO9

NC4

10

D7 D8

11

12

13

WE

14

RAS

15

16

A0

17

A1

18

A2

19

A3 A4

C113

47U

C112

47U

64

63

62

61

60

59

58

MA0

57

MA1

56

MA2

55

54

MA3

53

52

MA4

51

MA5

50

MA6

49

48

MA7

47

46

MA8

45

MA9

44

43

42

41

40

CAS

39

38

37

36

35

NC9

34

NC8

33

NC7

C123

C124

C122

103

103

103

+5VM

16M9

MIC-DET

L3

3V3 PLL

XUH

C107

47U

2DATA

C106

R105

10K

SQSO

VFD-STB

TRAY-SW

27MHz

VFD-CLK

4K7

R104

104

JP6

S-VIDEO

1

2

3

4

R118

75E

CE

GND

A8

A7

A6

A5

A4

5

+5VM

D5

1N4148

D6

1N4148

A[0..10]

D[0..15]

16

15

Q2

14

Q1

13

Q0

A0

12

A0

A1

11

A1

A2

10

A2

A3

9

A3

A4

8

A4

A5

7

A5

A6

6

A6

A7

5

A7

4

A12

3

A15

2

A16

1

40

39

D15

38

D14

37

D13

36

D12

35

34

D11

33

D10

32

D9

31

30

29

28

27

26

A8

25

A7

24

A6

23

A5

22

21

CAS

SHENZHEN HONGYU CL680 SCHEMATIC

4

VIDEO

23

1

5

VIDEO

RST-680

D2

D1

D0

+5VM

C119

D[0..15]

A[0..10]

104

1.0

1/3

ZOUBB

D9

D12

D13

Page 32

2-5

§ Servo Circuit

AGC

AGC

LDON

LDON

R571KR56

1M

C73

100U

C80

104

C79

104

XL-SV205GD

VDD

R88

10k

SW

C69

+8V

104

220U

C68

28

SP-

27

GND2

SP+

26

OUT4-

25

OUT4+

OUT4

MDP

24

IN4-

OUT1+1OUT1-2OUT13IN1-4IN1+5VREFIN6VCC/27GND08IN2+9IN2-10OUT211OUT2+12OUT2-13GND1

F-

F+

FRDR

FFDR

C72

RFTC

1U

VDD

L8

XUH

100U

R65

C78

10E

Q10

C76

100U

C77

102

8550

17

18

19

20

VCC

RFTC

LD_ON

AGCCOUT

AGCVTH1LD2PD3PD14PD25VEE6F7E8EI9VC

R66 120K

F-T-T+F+PDLDFCBADEVC

VR

VEE

10111213141516

JP2

CON16

SFDR

SL+

SL-

SRDR

15

16

17

18

19

20

21

22

23

29

IN3-

IN3+

IN4+

VCC1

GND3

VCC0

OUT3

OUT3-

OUT3+

MUTE

U9

BA6392AFP

GND4

4E7

R55

10K

14

R85

OPEN

VCC

R58

2K

R59

3K

RFM

TFDR

14

T-

T+

TRDR

47P

C75

R60

150

10K

R61

FE

15K

R62

TE

15K

R63

SE

R64

100K

11

12FE13

TE

CXA2550

U8

FE_BIAS

10

VC

C82

C81

10U

104

R86

OPEN

SP-

SP+

123456789

12345

JP3

CON6

30

C70

334

C71104

RF

C74

103

R79

15

16

RF1

RFO

R71 120K

R70 56K

R69 56K

R68 56K

R67 56K

MDP

150K

R54

VC

R75

680E

BC328-40

BC338-40

R73

1K2

SL+

SL-

SW

TRAY-

TRAY+

VDD

6

12345

JP4

CON5

+5VS

Q11

Q9

TRAY-SW

MDP

TFDR

TRDR

RF

FE

SE

R43

270

R42

1K

+5VM

SFDR

SRDR

FFDR

FRDR

VC

TE

Q7

8050

R77

4E7

Q12

BC328-40

Q8

C44

47U/16V

C42

683

BC338-40

CLOP

10K

R72

VDD

C43

C45

220U

R40

15K

R41

10K

VDD

104

1

2

3

4

5

6

7

9

10

12

13

15

16

17

18

19

20

GFS

C4M

MIRR

C2PO14SCOR

COUT

DVSS0

21

DFCT

22

FOK

23

PWMI

24

LOCK

25

MDP

26

SW

SSTP

27

FSTO

28

DVDD1

29

SFDR

30

SRDR

31

TFDR

32

TRDR

33

FFDR

34

FRDR

35

DVSS1

36

TEST

37

TES1

38

VC

39

FE

40

SE

C47

C46

104

471

WDCK

CXD3068Q

TE41CE42RFDC43ADIO44AVSS045IGEN46AVDD047ASYO48ASYI49RFAC50AVSS151CLTV52FILO53FILI54PCO55AVDD156BIAS57VCTL58V16M59VPCO

SENS

XRST

XLAT

SCLK8ATSK

DATA

MUTE

CLOK

XUGF11XPCK

WFCK

U7

DVDD0

60

AVDD0

104

C56

104

C55

CLOSE

OPEN

104

C54

R81 3K3

R84 0E

C58

100U

100U

C53

R80

1K8

R82

OPEN

VC

104

C52

R44

152

33K

C48

R45

R83

10K

C59

104

OPEN

R46

100K

471

103

C51

474

C49

C50

R49

R51

180K

10K

R47

224

474

C88

C61

470K

R50

R48

1M

1K

104

C60

R76

680E

VDD

L7

R74

1K2

XUH

10U

C57

D10

D4148

C41

10u/16v

SCOR

SENS

CLOK

XLAT

2DATA

80

EXCK

79

SBSO

78

SCSY

77

SQCK

76

SQSO

75

XOLT

74

SOCK

73

SOUT

72

XTAO

71

XTAI

70

DVSS2

69

XTSL

68

EMPH

67

BCK

66

PCMD

65

LRCK

64

DOUT

63

MD2

62

ASYE

61

CLTV

DVDD2

101

C62

820K

R52

C64

104

C63

470P

SONY 3068 SCHEMATIC

SQCK

SQSO

RST-3068

C40

104

C67

102

C65

20P

SCOR

SENS

CLOK

XLAT

2DATA

SQCK

SQSO

R53

100E

CD-BCK

CD-DATA

CD-LRCK

R78

6K8

16M9

CLOSE

OPEN

TRAY-SW

16M9

X2

C66

20P

Page 33

2-6

§ Output Circuit

JP1

10PIN

MDET

10

9

8

7

6

5

4

3

2

1

DA-DATA

DA-BCK

DA-LRCK

16M9

MIC-DET

MIC

-12V

+12V

D2

1N4001

+5VS

+5VM

C1

100U/16VC2100U/16VC3100U/16C447U/16VC547U/16V

C6

104

1

2

3

C7

104C8104C9104

SDATA

SCLK

LRCK

MCLK4AOUTR

XL-SV205GD

U10D

9 8

74U04

U10E

11 10

74U04

+8V

VFD-STB

C10

104

R6

8K2

U4

4338

AOUTL

AGND

+5VM

VA

L1

XUH

C14

A-R0

4U7

AUD5V

C12

100U

8

7

6

5

AOUTL

AOUTR

C13

104

C15

A-L0

4U7

R5

R4

10K

5K1

C17

102

C18

102

R9

R8

10K

5K1

R11

8K2

U10F

13 12

74U04

C20

101

2

3

5

6

C19

101

-12V

+12V

VFD-STB1

RST-680

C25

C24

100U

104

U5A

4558

8 4

U5B

4558

C21

1

C34

C23

47U

7

R23

47K

4U7

104

C22

R24

4U7

47K

RST680

Q1

8050

+5VM

R1

10K

R2

1K

R3

10K

C16

4U7

R22

47K

-12V

R25

C32

47K

82P

R7

33K

R10

33K

C33

82P

U6A

2

3

4558

8 4

+12V

U6B

5

6

4558

R26

47K

Q2

1

7

C11

10U/50V

C1815

D1

1N4148

MIC-MUTE

R21

MIC

1K

R20

C29

104

R13

1K

R12

1K

4K7

C26

472

R14

4K7

R15

4K7

472

C27

+5VM

+5VM

C30

47U

Q3

KTD1302

Q4

KTD1302

R16

10K

C31

104

RF-V

A-R1

A-L1

R17 22K

Q6 8550

R18

7.5K

A-L1

A-R1

VIDEO

Y-OUT

C-OUT

+5VM

R27

10K

+12V

R19

470

Z1

5.1V

R28

1K

VIDEO

JP9

8PIN

1

2

3

4

5

6

7

8

JP8

1

2

3

4

4PIN

VIDEO

JP7

1

2

3

4

5

6

7

8

9

A/V

Q5

8550

C28

100U/16V

Page 34

2-7

Printed Circuit Boards

§ Power supply, AC selector & AC switch board (Top view)

XL-SV205GD

Page 35

2-8

§ MPEG, Servo & Output Board

XL-SV205GD

Fig 1

Page 36

2-9

§ MPEG, Servo & Output Board

XL-SV205GD

Fig 2 Fig 3

Page 37

XL-SV205GD

JVC Asia Pte Ltd

101 Thomson Road, #28-04 United Squares, Singapore 307591

No (28206)

Printed in Japan

200102(L)

Loading...

Loading...