Page 1

XL-R5020BK

SERVICE MANUAL

CD/CDR MULTIPLE COMPACT DISC RECORDER

XL-R5020BK

Area Suffix

J ------------- U.S.A.

CD1 CD2 CD3

1

2

5

4

8

7

10

10

PLAY

MODE

REPEAT CD CDR

Y

A

L

P

S

I

D

GROUP

SET

R

E

GROUP

C

S

O

U

R

C

E

CD REC CD EDIT SYNCHRO FADE

REC

PITCH 0

FINALIZE

REC MUTING

RM-SXL001J

REMOTE CONTROL

STANDBY/ON

3

6

9

GROUP

CONTROL

M

E

N

U

L

E

C

N

A

C

MIN MAX

PITCH

XLÐR5020 CD/CDR MULTIPLE COMPACT DISC RECORDER

COMPACT

DIGITAL AUDIO

MP3 PLAYBACK

COMPACT

DIGITAL AUDIO

Recordable

ReWritable

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

No.A0035

Aug. 2002

Page 2

XL-R5020BK

TABLE OF CONTENTS

1 Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Critical parts for safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Preventing static electricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.6 Handling the traverse unit (optical pickup) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.7 Importance admistering point on the safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.8 Precautions for Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Disassembly method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Main body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Changer mechanism assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Confirm method of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Check mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 All release of set content. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Running operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.5 Display of version number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.6 Extension cord for diagnosis of changer mechanism unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5 Description of major ICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 AN22000A-W(IC601):RF & SERVO AMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2 BU4066BCF-X(IC831,IC841,IC861):Source selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 BU4052BCF-X(IC821):Channel switch controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4 LB1641 (IC851,IC852) : DC Motor driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.5 TC74HC00AF(IC301,IC311):Digital I/O selector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.6 BR24C01AFV-W-X (IC201) : EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.7 LA6541-X (IC801) : Focus & Spindle & Feed & Tracking BTL driver . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.8 M66004SP(IC721):FL Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.9 MN35505-X (IC361) : DAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.10 TC9246F-X(IC404):Clock generation for digital audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.11 TC74HCU04AF-W(IC331):Digital input selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.12 74VHC00MTC-X (IC406) : 2-input nand gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.13 74VHC08SJ-X(IC407):2-input AND gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.14 TC94A02F-005(IC401) : MP3 Decoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.15 TC9412AF(IC891) : Rec Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.16 MN662790RSC(IC651):Digital servo & processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.17 UPD780076GK-533(IC251):Unit microcomputer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.18 UPD784215AGF513(IC501):System controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.19 W24L010AJ-12-X (IC402) : SRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2

Page 3

SECTION 1

Important Safety Precautions

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes.

For continued protection, no changes should be made to the

original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will vo id

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by

using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these specia l

safety characteristics are identified in the Parts List of Service

Manual. Electrical components having such features are

identified by shading on the schematics and by ( )

on the Parts List in the Service Manual. The use of a substitute replacement which does not have the same safety

characteristics as the recommended replacement parts

shown in the Parts List of Service Manual may create

shock, fire, or other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

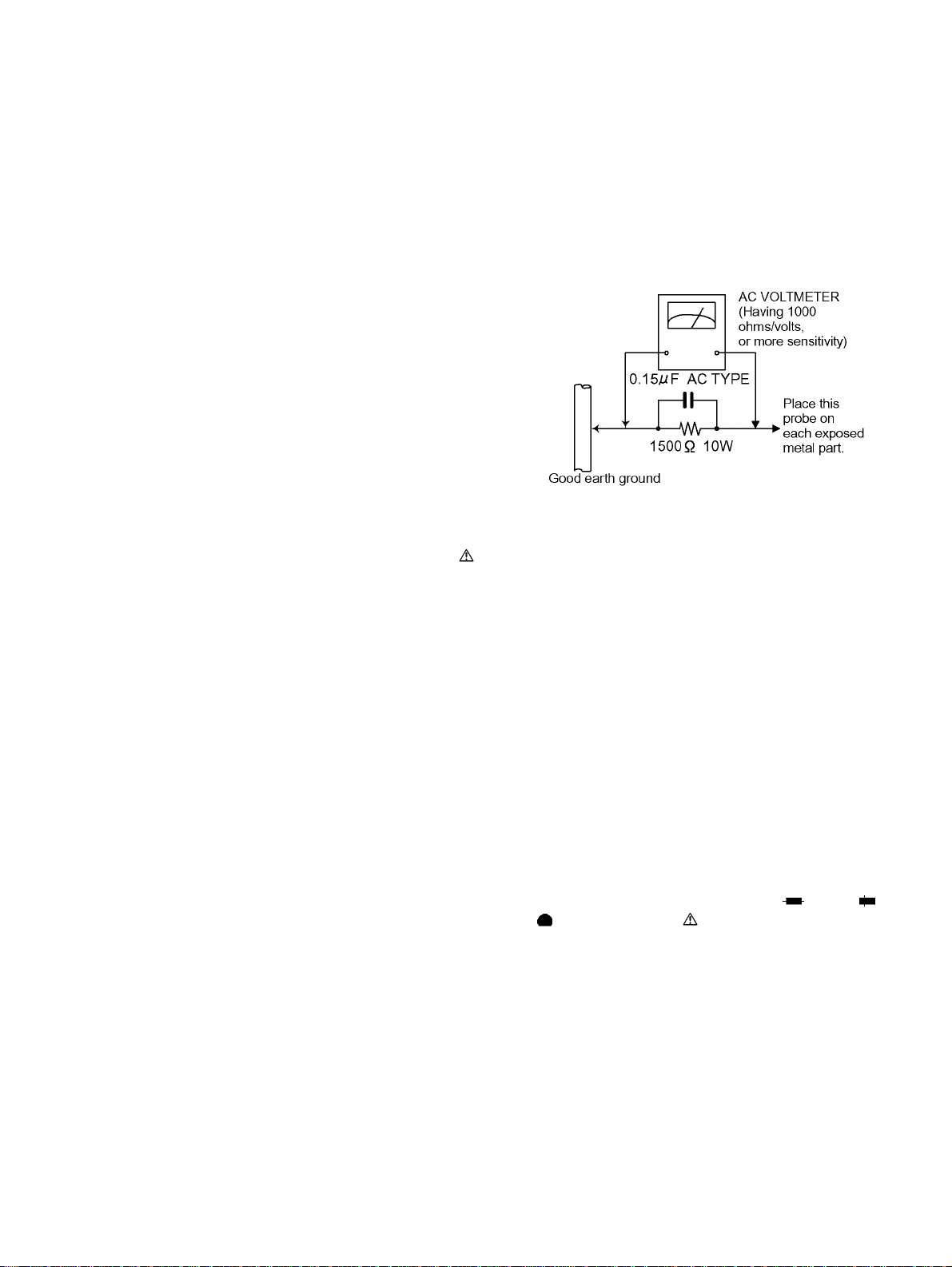

(5) Leakage shock hazard testing)

After reassembling the product, always perform an isolation

check on the exposed metal parts of the product (antenna

terminals, knobs, metal cabinet, screw heads, headphone

jack, control shafts, etc.) to be sure the product is safe to

operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage

current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord direct ly into the AC outle t. Use a n AC

voltmeter having, 1,000 ohms per volt or more sensitivity in

the following manner. Connect a 1,500 ohm 10W resistor

paralleled by a 0.15 µF AC-type capacitor between an

exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

XL-R5020BK

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and repeat

each measurement. Voltage measured any must not

exceed 0.75 V AC (r.m.s.). This corresponds to 0.5 mA AC

(r.m.s.).

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for lo-

cal voltage.

1.3 Caution

Burrs formed during molding may be left over on some

parts of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

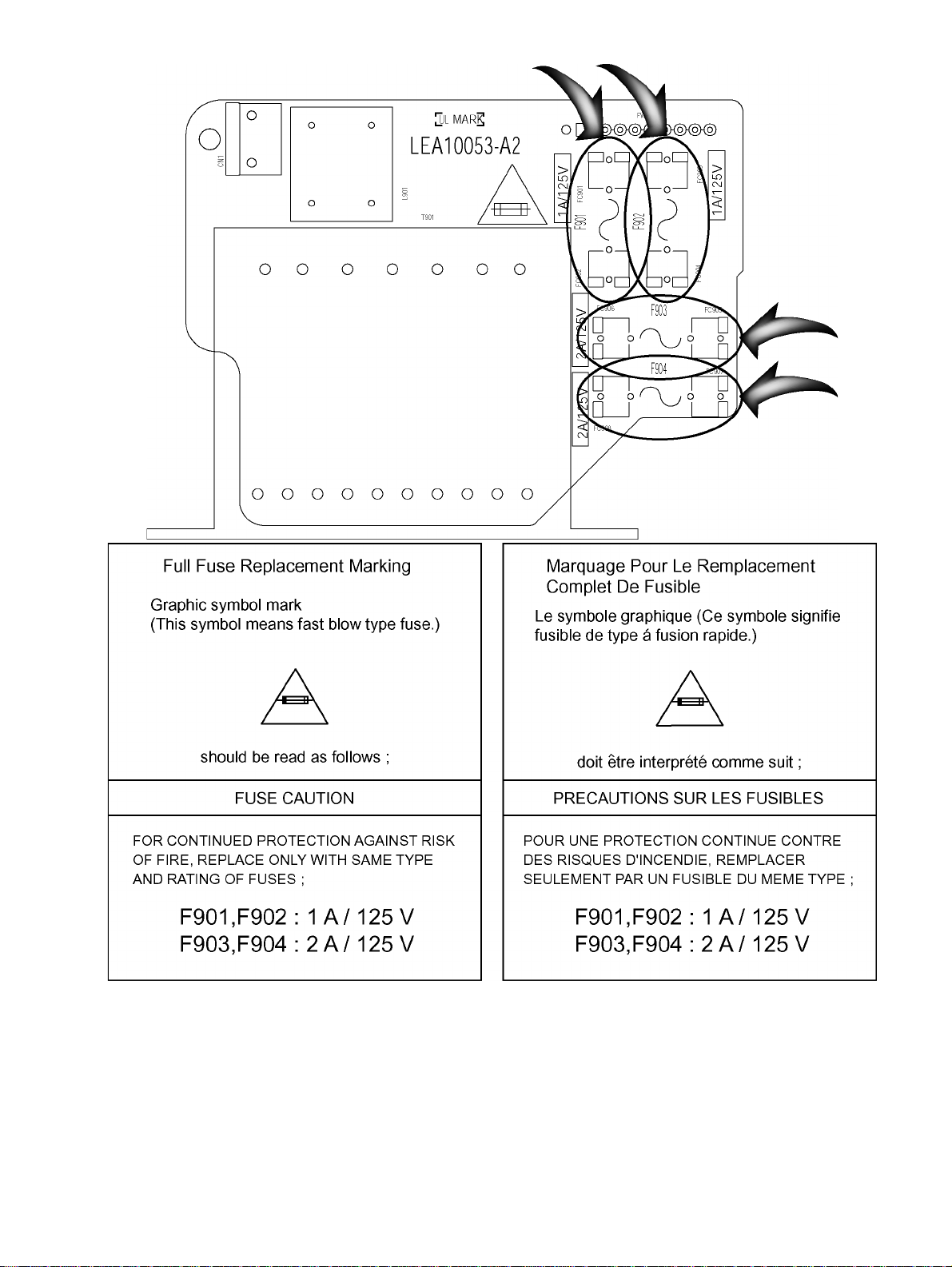

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( ) and

ICP ( ) or identified by the " " ma rk nearby are critical for safety.

When replacing them, be sure to use the parts of the same type

and rating as specified by the manufacturer. (Except the JC version)

3

Page 4

XL-R5020BK

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser dio de) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron pl ate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can

easily destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too

long a time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4)I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

4

Page 5

1.7 Importance admistering point on the safety

XL-R5020BK

5

Page 6

XL-R5020BK

1.8 Precautions for Service

1.8.1 Handling of Traverse Unit and Laser Pickup

(1) Do not touch any peripheral element of the pickup or the actuator.

(2) The traverse unit and the pickup are precision devices and therefore must not be subjected to strong shock.

(3) Do not use a tester to examine the laser diode. (The diode can easily be destroyed by the internal power supply of the tester.)

(4) To replace the traverse unit, pull out the metal short pin for protection from charging.

(5) When replacing the pickup, after mounting a new pickup, remove the solder on the short land which is provided at the center

of the flexible wire to open the circuit.

(6) Half-fixed resistors for laser power adjustment are adjusted in pairs at shipment to match the characteristics of the optical block.

Do not change the setting of these half-fixed resistors for laser power adjustment.

1.8.2 Destruction of Traverse Unit and Laser Pickup by Static Electricity

Laser diodes are easily destroyed by static electricity charged on clothing

or the human body. Before repairing peripheral elements of the traverse unit or pickup, be sure to take the following electrostatic

protection:

(1) Wear an antistatic wrist wrap.

(2) With a conductive sheet or a steel plate on the workbench on wh ich the trave rse unit or the pick up is to be repaired, grou nd

the sheet or the plate.

(3) After removing the flexible wire from the connector (CN101), short-circuit the flexible wire by the metal clip.

(4) Short-circuit the laser diode by soldering the land which is provided at the center of the flexible wire for the pickup.

After completing the repair, remove the solder to open the circuit.

Please refer to "Fig.2-4" of "Disassembly

method" for details.

6

Page 7

SECTION 2

Disassembly method

2.1 Main body

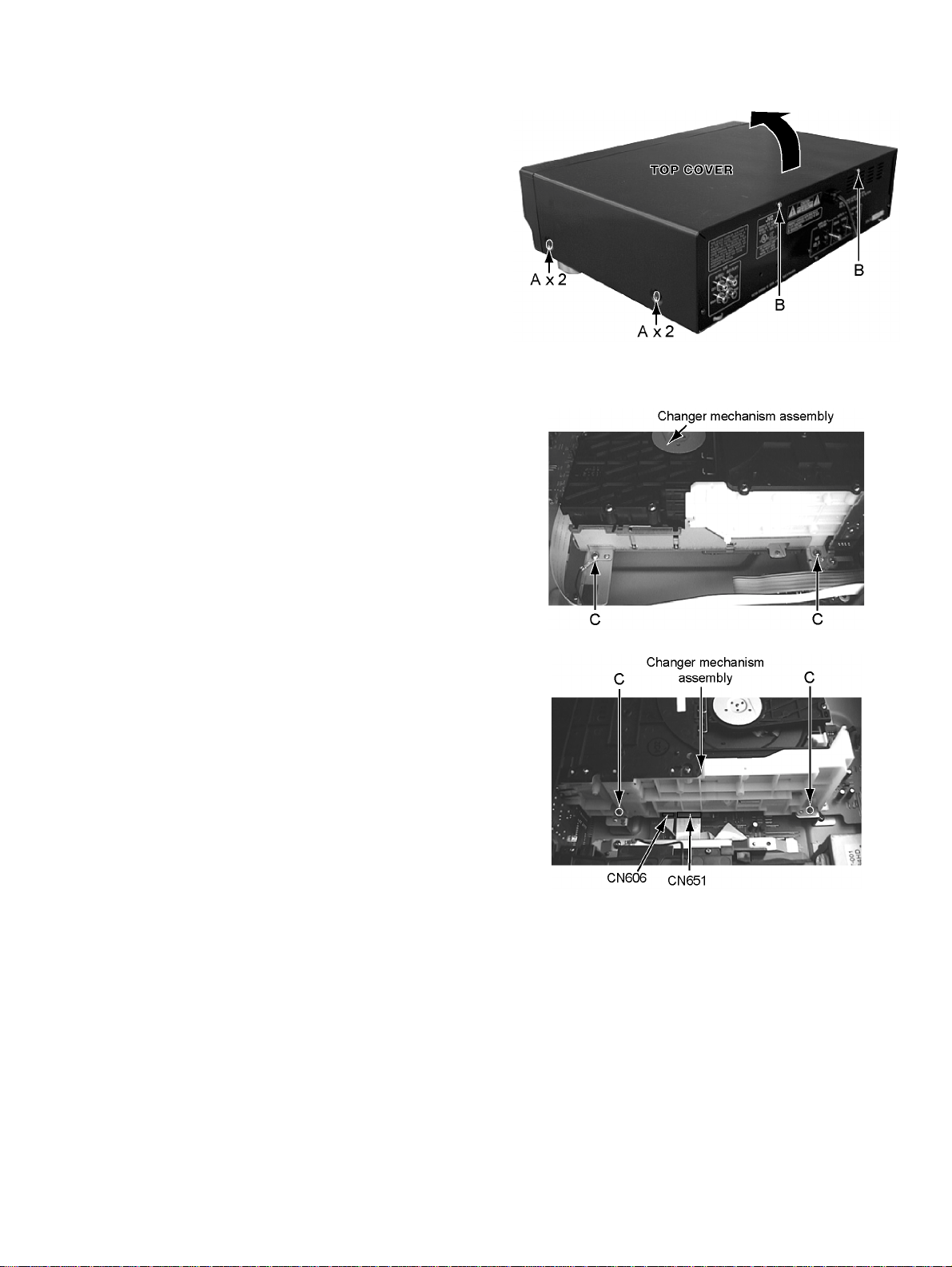

2.1.1 Removing the top cover (see Fig.1)

(1) Remove the four screws A attaching the top cover on both

sides of the body.

(2) Remove the two screws B attaching the top cover on the

back of the body.

(3) Remove the top cover from the body by lifting the rear part

of the top cover.

ATTENTION:

Do not break the front panel tab fitted to the top cover.

2.1.2 Removing the changer mechanism assembly

(see Fig.2~3)

*Prior to performing the following procedure, remove the top

cover.

(1) Remove the four screws C attaching the changer mecha-

nism assembly.

(2) Disconnect the card wire from connector CN606 and

CN651 on the CD servo control board respectively.

(3) Remove the changer mechanism assembly from the body

by lifting the rear part of the changer mechanism asse mbly.

XL-R5020BK

Fig.1

Fig.2

Fig.3

7

Page 8

XL-R5020BK

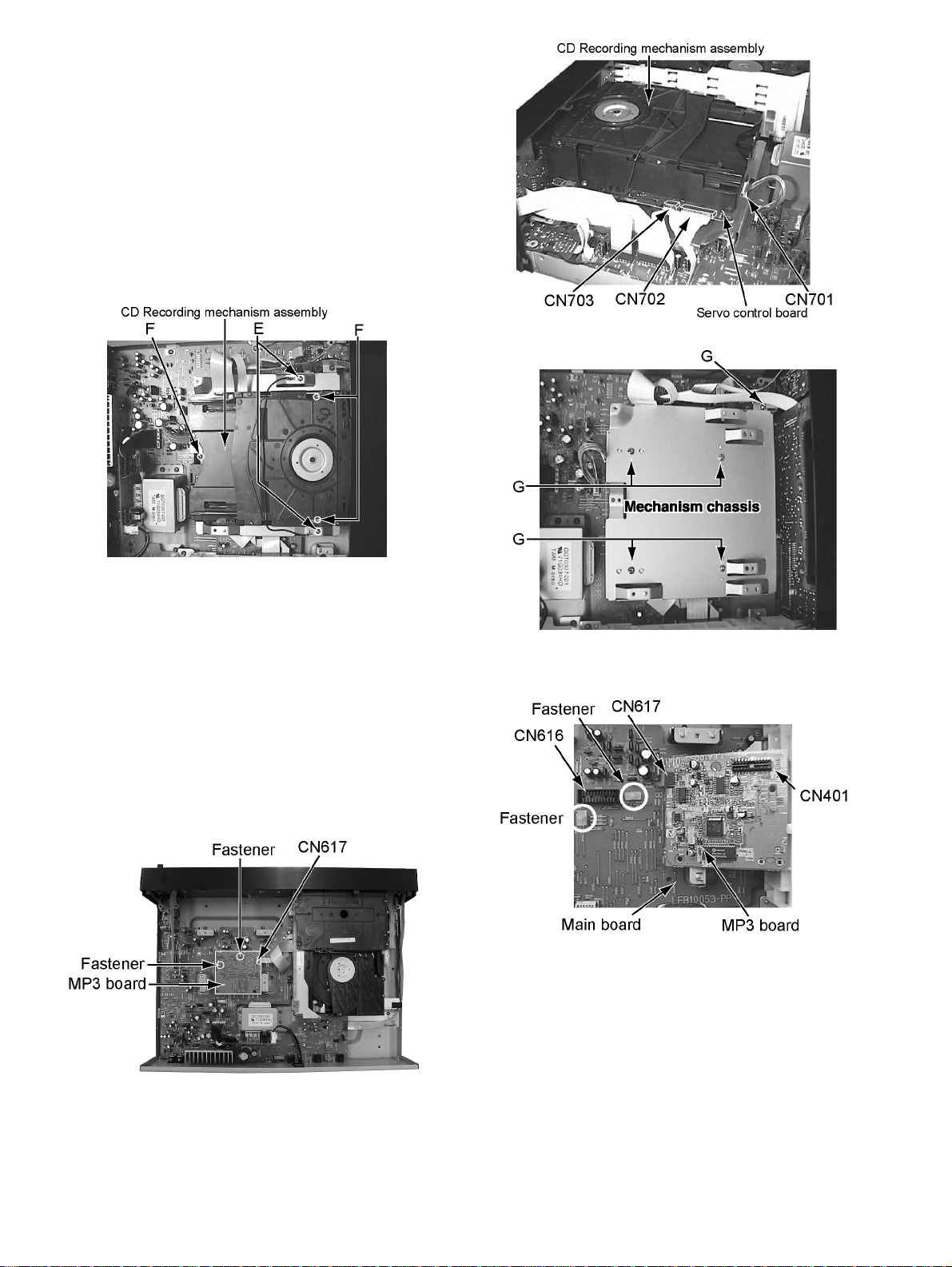

2.1.3 Removing the CD recording mechanism assembly

(see Fig.4~6)

*Prior to performing the following procedure, remove the top

cover.

*There is no need to remove the changer mechanism assembly.

(1) Remove the two screws E attaching the mechanism chas-

sis.

(2) Remove the three screws F attaching the CD recording

mechanism assembly.

(3) Disconnect the card wire from connector CN702 and

CN703 on the servo control board respectively.

(4) Disconnect the connect wire from connector CN701 on the

servo control board.

(5) Remove the five screws G attaching the mechanism chas-

sis

Fig.5

Fig.4

2.1.4 Removing the MP3 board

(see Fig.7,8)

*Prior to performing the following procedure, remove the top

cover, CD recording mechanism assembly.

*There is no need to remove the changer mechanism assembly.

(1) Pull out the MP3 board from the fastener.

At this time, disconnect the connector CN401 of the MP3

board from connector CN616 on the Main board.

(2) Disconnect the card wire from connector CN617 on the

MP3 board.

Fig.6

Fig.8

Fig.7

8

Page 9

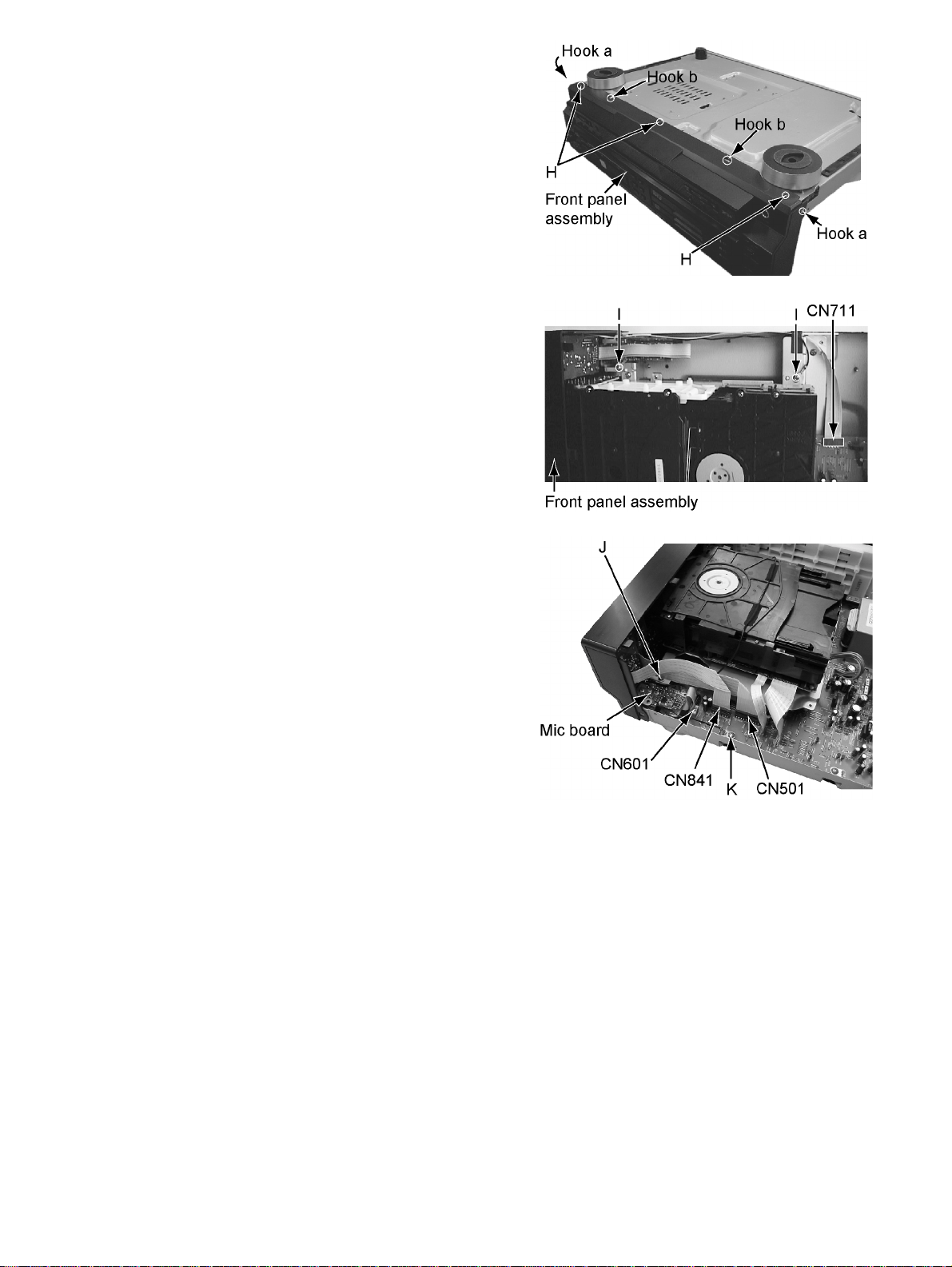

2.1.5 Removing the front panel assembly

(see Fig.9~11)

*Prior to performing the following procedure, remove the top

cover.

*There is no need to remove the changer mechanism assembly

and CD recording mechanism assembly.

(1) Remove the three screws H attaching the front panel as-

sembly on the bottom of the body.

(2) Remove the two screws I attaching the headphone jack

bracket.

(3) Remove the one screw J attaching the mic jack bracket.

(4) Remove the one screw K attaching the main board.

(5) Disconnect the card wire from connector CN711, CN841

and CN501 on the main board respectively.

(6) Disconnect the flat wire from connector CN601 on the

main board from mic board.

(7) Hook a and b are removed respectively, and the front

panel assembly is removed.

XL-R5020BK

Fig.9

Fig.10

Fig.11

9

Page 10

XL-R5020BK

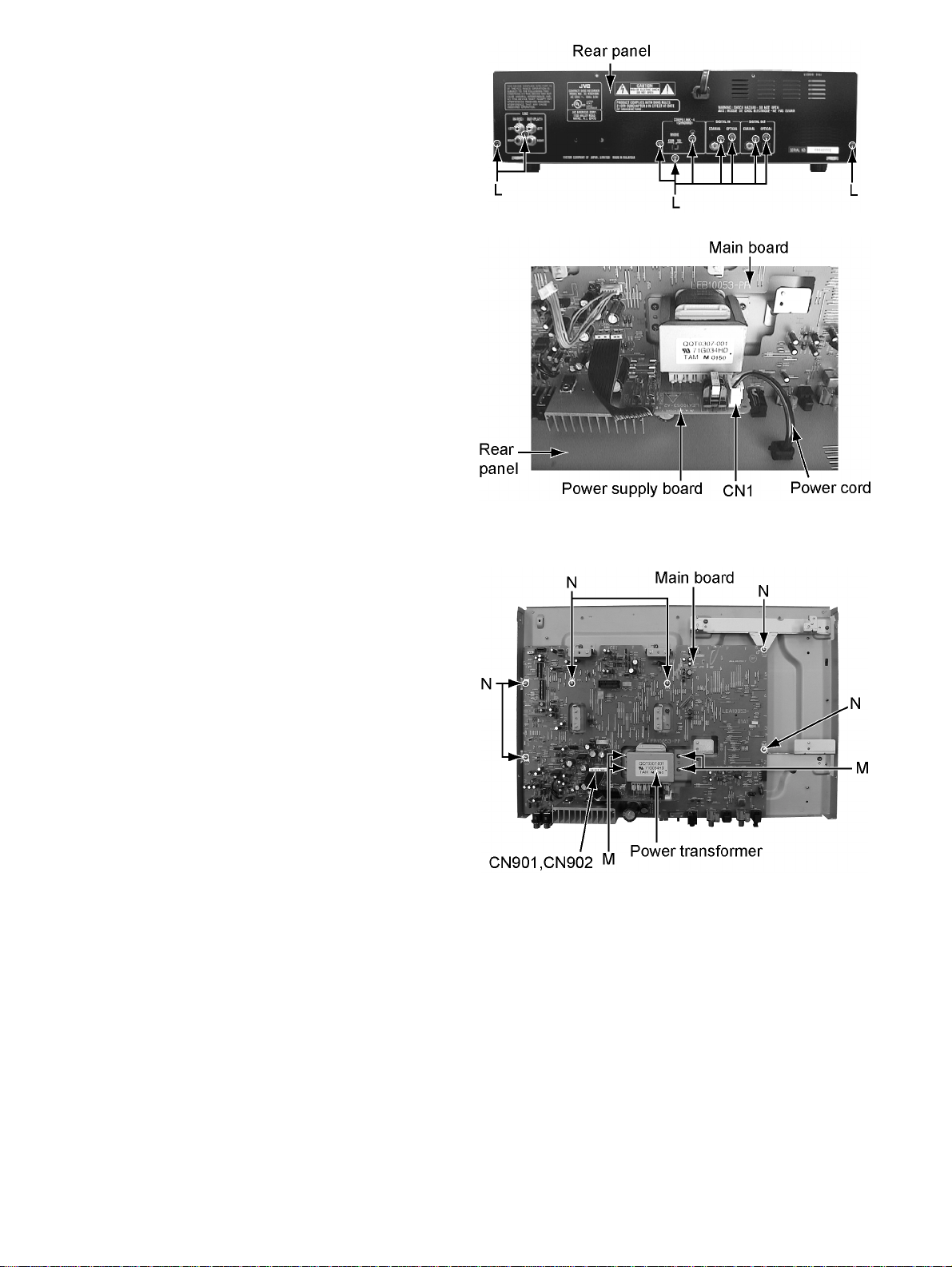

2.1.6 Removing the rear panel

(see Fig.12,13)

*Prior to performing the following procedure, remove the top

cover.

(1) Remove the ten screws L attaching the rear panel.

(2) Disconnect the power cord from connector CN1 on the

power supply board.

Fig.12

2.1.7 Removing the main board and power supply board

(see Fig.14)

*Prior to performing the following procedure, remove the top

cover, front panel assembly, changer mechanism assembly, CD

recording mechanism assembly and rear panel.

(1) Remove the four screws M attaching the power transform-

er.

(2) Disconnect the flat wire from connector CN901 and

CN902 on the main board.

(3) Remove the six screws N attaching the main board.

Fig.13

Fig.14

10

Page 11

SECTION 3

MECHANISM

3.1 Changer mechanism assembly

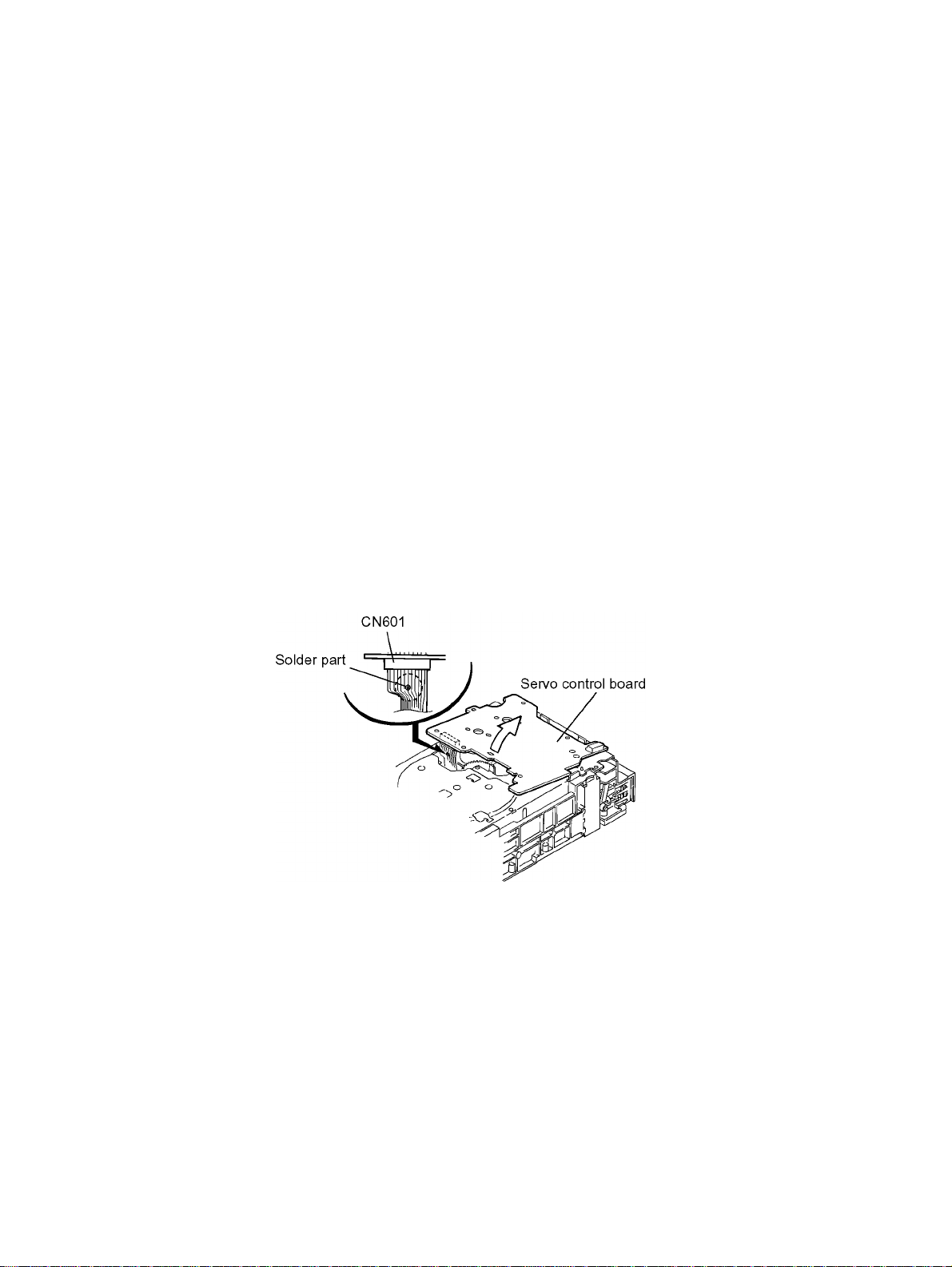

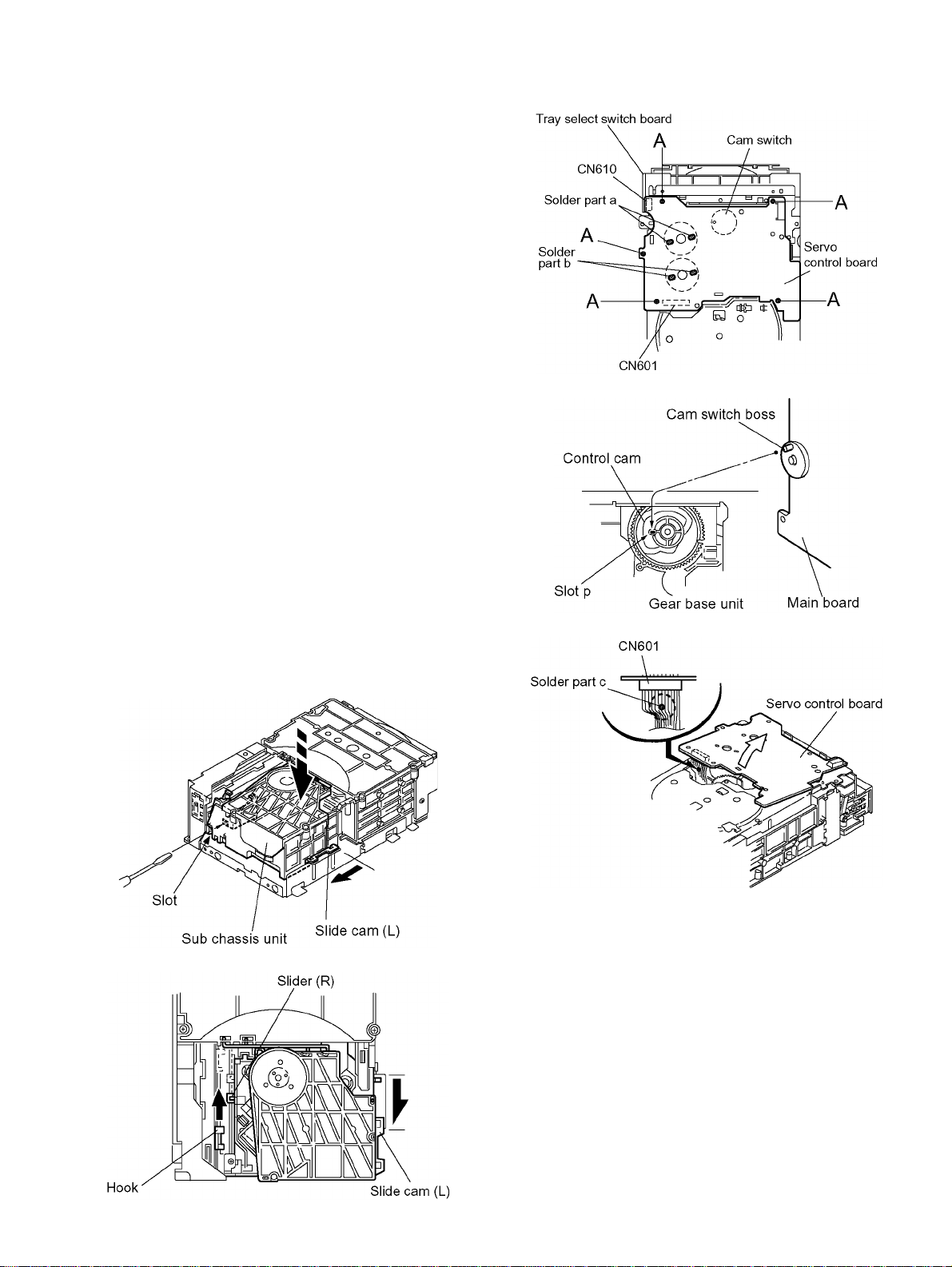

3.1.1 Removing the servo control board

(See Fig.1 to 5)

ATTENTION:

Make sure the sub chassis unit is locating at the lowest position. If not,perform the following procedure from 1 to 3.

(1) Insert a screwdriver into the sub chassis slot on the back

of the body and push the slider (R) toward the front.

(2) From the top of the body, slide the hook and the slider (R)

forward until they stop.

(3) From the right side of the body, slide the slide cam (L)

backward until it stops. The sub chassis unit will move to

the lowest position.

(4) From the bottom of the body, unsolder each soldered part

a and b of the motors on the servo control board.

(5) Remove the five screws A attaching the servo control

board.

(6) Disconnect connector CN610 on the servo control board

from the tray select switch board to suspend the servo

control board tentatively. Solder the part c of the flexible

wire connected to connector CN601 on the underside of

the servo control board.

(7) Disconnect the flexible wire from connect or CN601 and

remove the servo control board from the body.

ATTENTION:

In case of disconnecting the flexible wire without soldering, the CD pick up may be damaged.

ATTENTION:

When reassembling, make sure the cam switch boss of

the servo control board is fitted to the slot p of the control cam on the bottom of the body

(Refer to Fig.3).

XL-R5020BK

Fig.3

Fig.4

Fig.1

Fig.2

Fig.5

11

Page 12

XL-R5020BK

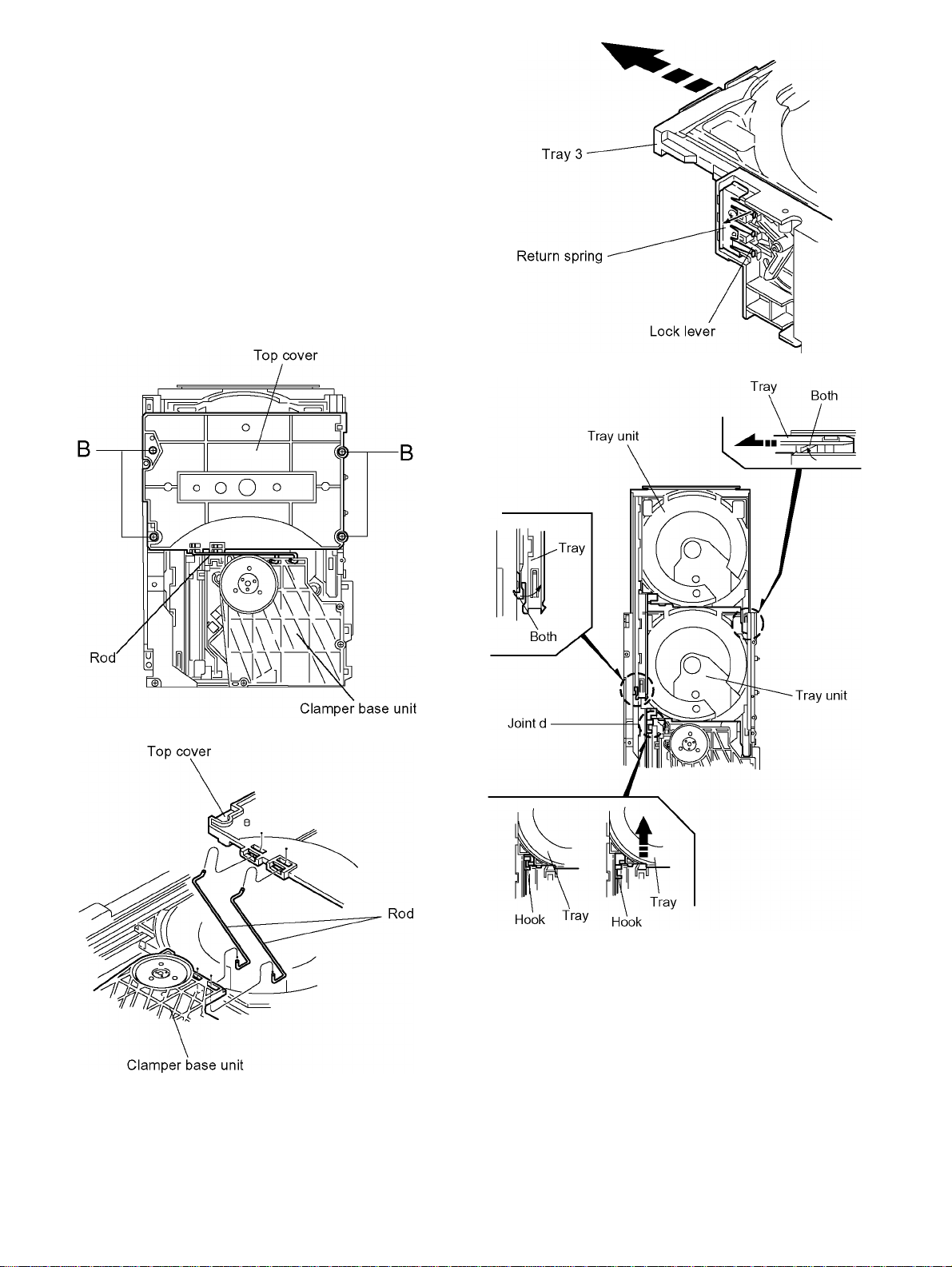

3.1.2 Removing the tray unit

(See Fig.6 to 9)

*The tray unit can be removed despite the position of the sub

chassis unit, but the lowest position is recommended to expedite

the work.

(1) Remove the four screws B attaching the top cover on the

top of the body.

(2) Remove the top cover with the two rods attached to the top

cover and the clamper base unit.

(3) Pull the lock lever of the return spring on the right si de of

the body to eject the tray unit.

(4) From the top of the body, release the tray from the joi nt

hook marked d (Push the tray toward the front).

(5) Release the stoppers on both sides in the direction of the

arrow and pull out the tray unit from the body.

ATTENTION:

Pull out the tray unit from the top tray 3 in sequence.

Fig.8

Fig.6

Fig.7

Fig.9

12

Page 13

3.1.3 Removing the side unit (L) and (R)

(See Fig.10 to 14)

*Prior to performing the following procedures, remove the servo

control board, the top cover and the tray unit.

(1) Remove the two screws C attaching the side unit (L).

(2) Slide and remove the side unit (L) toward the fro nt while

releasing the two joints e and the joint f with the chassis

unit.

(3) Slide the slide cam (L) toward the front until it stops to

place the sub chassis unit at the top position.

ATTENTION:

The side unit (R) can be removed when the sub chassis

unit is located at the top position.

(4) Turn the hook gear counterclockwise to move th e slide

hook and the slider (R) backward until they stop.

(5) Remove the three screws D attaching the side unit (R).

Raise the side unit (R) upward and release the joint g with

the chassis unit and the boss from the select arm marked

h. Then remove the side unit (R) from the body.

ATTENTION:

When reassembling, make sure the boss is fitted to the

select arm marked h.

XL-R5020BK

Fig.12

Fig.10

Fig.11

Fig.13

Fig.14

13

Page 14

XL-R5020BK

3.1.4 Removing the sub chassis unit

(See Fig.15 to 17)

*Prior to performing the following procedures, remove the servo

control board, the top cover, the tray unit,the side unit (L) and

the side unit (R).

(1) Turn the hook gear counterclockwise to move the slide

hook and the slider (R) backward until they stop.

(2) Slide the slide cam (L) and the slide cam (R) in the direction

of the arrow until they stop.

(The notches of each slide cam are fitted to the pins on

both sides of the sub chassis unit.)

(3) Detach the sub chassis unit upward.

ATTENTION:

When reassembling, turn the hook gear of the chassis

unit counterclockwise until it stops and slide the slide

hook and the slider (R) of the sub chassis unit backward

until they stop.

Fig.15

Fig.16

Fig.17

14

Page 15

3.1.5 Removing the flap base unit and the gear ba se unit

(See Fig.18 and 19)

*Prior to performing the following procedures, remove the servo

control board, the top cover, the tray unit,the side unit (L) and

the side unit (R).

(1) Remove the screw E attaching the flap base unit. Release

the joint tabs i and j, then remove the flap base unit from

the body.

(2) Remove the belts from the two pulleys on the gear base

unit.

(3) Remove the three screws F and remove the gear base unit

from the body.

XL-R5020BK

Fig.18

3.1.6 Removing the motors

(See Fig.20)

*Prior to performing the following procedure, remove the main

board.

(1) Remove the belts from the two pulleys.

(2) Remove the four screws G and detach each motor from

the body.

Fig.19

Fig.20

15

Page 16

XL-R5020BK

3.1.7 Removing the pickup

(See Fig.21 to 25)

(1) From the top of the body, remove the three screws H

attaching the clamper base unit.

(2) Remove the clamper base unit with the two rods attached

to the clamper base unit and the top cover.

(3) Turn the screw shaft gear marked k in the direction of the

arrow to move the pickup unit.

(4) Remove the screw I attaching the shaft holder.

(5) Move the screw shaft in the direction of the arrow and

release it from the joint l. Then release it from the joint m

with the pickup holder. Detach the pickup with the screw

shaft.

(6) Solder the part n of the flexible board on the underside of

the pickup. After soldering, disconnect the flexible wire

connected to the pickup (In case of disconnecting the

flexible wire without soldering, it may cause damage to the

CD pickup).

(7) Remove the two screws J attaching the rack arm to the

pickup unit.

(8) Pull out the screw shaft from the pickup.

Fig.23

Fig.21

Fig.24

Fig.25

16

Fig.22

Page 17

3.1.8 Removing the traverse mechanism assemb ly

(See Fig.26)

*Prior to performing the following procedure, remove the servo

control board and the clamper base unit.

(1) Remove the three screws K attaching the traverse

mechanism assembly.

(2) Detach the rear part of the traverse mechanism assembly

upward to release the joint o with the sub chassis unit.

Then remove the assembly from the body.

3.1.9 Removing the feed motor

(See Fig.27)

*Prior to performing the following procedure,remove the

traverse mechanism assembly.

(1) Remove the screw L attaching the feed motor.

XL-R5020BK

Fig.26

Fig.27

17

Page 18

XL-R5020BK

3.1.10 Removing the tray select switch board

(See Fig.6,7 and 28)

(1) Remove the four screws B attaching the top cover on the

top of the body.

(2) Remove the top cover with the two rods attached to the top

cover and the clamper base unit.

(3) Remove the screw M on the right side of the body.

Fig.6

18

Fig.7

Fig.28

Page 19

SECTION 4

Confirm method of operation

XL-R5020BK

4.1 Chec k mod e

All lighting FL display and reducing time operation of clock

(1) Setting method of all lighting FL display

"STANDBY/ON" key is pushed while pushing "REC/REC

MUTING" key by the stand-by state.

(2) Setting method of reducing time operation of clock

FL display is put into the state of all lighting by the method of the

above-mentioned, and "STANDBY/ON" key is pushed afterwards.

The clock display comes to advance during one minute a

second in actual time when changing to this mode.

Because other operation can do the normal operation,

Uses for the confirmation of the operation of the timer

function etc.

(3) Release method

"STANDBY/ON" key is pushed while pushing "REC/REC

MUTING" key.

4.2 All release of set content

All content of the item in the following set is returned to initial

state. (State of factory shipment)

(1) Setting method

"STANDBY/ON" key is pushed while pushing "REC

SOURCE SELECTOR" key by the stand-by state.

[Set items]

• Deletion of time setting

• The setting of the timer is deleted.

• The program of the program play is deleted.

• The content of the registration of the listen ing editing

and the program editing is deleted.

The repeat setting is turned off.

• Release of disc lock

• The unit of busy is adjusted to the changer mechanism side.

• The play mode of changer mechanism is made a normal mode.

• The pitch control setting is turned off.

• The selection of the recording source is made DIGITAL of CD.

• DUB-SPEED setting is made HIGH.

• AUTO TRACK setting is turned ON.

• TRACK SPACE setting is turned ON.

• CONVERTER setting is turned ON.

• D-IN SYNCHRO setting is START

• FINALISE setting is ON

4.3 Service menu

There is an item displayed besides "SYSTEM_AGING" and

"READ_VERSION" in the service menu.

However, because the effective item is only "SYSTEM_AGING" and

"READ_VERSION", the function does not actually use other items.

The running operation and the version of the firmware can be

confirmed by the undermentioned method.

(1) Setting method of service menu

a) "STANDBY/ON" key is pushed while pushing "FI-

NALIZE" key by the stand-by state.

b) When the blinking display of the disk distinction

ends, "MENU" key is pushed.

The menu display changes if "MULTI JOG" knob of

the main body is turned.

c) The execution of the each item is completed or either

"CANCEL"key, "CD-RW STOP"key or "MENU"key

is pushed when going out of the menu mode.

(2) Release method

a) If "STANDBY/ON" key is pushed, and the power

supply is turned off once, becomes a normal menu.

4.4 Running operation

When this mode is executed, the operation of the recording and

the playback is repeated.

Please use to confirm operation.

It is necessary to put the recorded disk or CD-DA in tray 1

of changer mechanism beforehand to execute this item,

and put CD-RW of the blank disk in recording mechanism.

(1) Setting method of running operation

a) "Service menu" is made to be displayed on the FL

display referring to the above-mentioned.

b) "SYSTEM_AGING" is made to turn "MULTI JOG"

knob, and to be displayed on the FL display.

c) The undermentioned operation starts when "SET"

key is pushed.

The undermentioned control becomes possible according to the

content of the disk turned on to tray 1 of changer mechanism.

* The time required of operation of running once

* Movement frequency of pick-up

F L display becomes " ", and the frequency to which the

running operation is done is displayed by the figure when

"STOP" key is pushed to the running working or interrupted because of the error etc.

4.5 Display of versio n n umber

When this item is executed, version number "system controller",

"CD recording unit", and "3CD changer unit" respectively is displayed in FL display for five seconds.

When five seconds pass, this mode is automatically made clear.

Setting method of display of version number

(1) "Service menu" is made to be displayed on the FL dis-

play referring to the previous page.

(2) "READ_VERSION" is made to turn "MULTI JOG" knob,

and to be displayed on the FL display.

(3) The undermentioned operation starts when "SET " key is pushed.

It is displayed instead of version number when failing in reading

version number, "000".

4.6 Extension cord for diagnosis of changer mechanism unit

There is an extension cord to diagnose chan ger mechanism unit.

The undermentioned connector is connected, and used mutually.

19

Page 20

XL-R5020BK

SECTION 5

Description of major ICs

5.1 AN22000A-W(IC601):RF & SERVO AMP

• Pin layout

• Pin function

Pin

Symbol Description

No.

1 PD APC Amp. Input terminal 16 GND Connect to ground

2 LD APC Amp.Output terminal 17 VREF VREF output terminal

3 VCC Power supply terminal 18 VDET VDET output terminal

4 RFN RF addition Amp.Reversing input terminal 19 TEBPF VDET input terminal

5 RF OUT RF addition Amp.Output terminal 20 TEOUT TE Amp. output terminal

6 RF IN AGC input terminal 21 TEN TE Amp. reversing input terminal

7 C.AGC Terminal of connection of capacity of AGC loop

filter.

8 ARF AGC output terminal 24 GCTRL Terminal GCTL & APC

9 CEA Capacity connection terminal for HPF-Amp. 25 FBAL FBAL control terminal

10 3TOUT 3TENV output terminal 26 TBAL TBAL control terminal

11 CBDO Capacity connection terminal for RF shade side

envelope detection

12 BDO BDO output terminal 29 D Focus signal input terminal 4

13 COFTR Capacity connection terminal for RF discernment

side envelope detection

14 OFTR OFTR output terminal 32 A Focus signal input terminal 1

15 RFDET

RFDET output terminal

Pin

Symbol Description

No.

22 FEN FE Amp. reversing input terminal

23 FEOUT FE Amp. output terminal

27 PDE Tracking signal input terminal 1

28 PDF Tracking signal input terminal 2

30 B Focus signal input terminal 2

31 C Focus signal input terminal 3

5.2 BU4066BCF-X(IC831,IC841,IC861):Source selector

• Pin layout & block diagram • Truth table

Control Switch

HON

LOFF

20

Page 21

5.3 BU4052BCF-X(IC821):Channel switch controller

• Pin layout

• Truth table

INHIBIT A B ON SWITCH

LLLX0Y0

LHLX1Y1

LLHX2Y2

LHHX3Y3

HXX NONE

X : Don't Care

5.4 LB1641 (IC851,IC852) : DC Motor driver

• Pin layout • Truth table

Input Output

IN1 IN2 OUT1 OUT2

0000 Brake

1010 CLOCKWISE

0 1 0 1 COUNTER-CLOCKWISE

1100 Brake

XL-R5020BK

Mode

5.5 TC74HC00AF(IC301,IC311):Digital I/O selector

• Pin layout & block diagram

21

Page 22

XL-R5020BK

5.6 BR24C01AFV-W-X (IC201) : EEPROM

• Pin layout

• Block diagram

• Pin function

Pin name I/O Description

Vcc - Power supply

GND - Ground (0v)

A0A1A2 IN Slave address set

SCL IN Serial clock input

SDA IN / OUT Slave and word address,seri al data input serial data output *1

WP IN Write protect in pu t

*1 An open drain output requires a pull-up resister.

22

Page 23

5.7 LA6541-X (IC801) : Focus & Spindle & Feed & Tracking BTL driver

• Pin layout & Block diagram

• Pin function

XL-R5020BK

Pin No. Symbol Description

1 Vcc Power supply (Shorted to pin 24)

2 Mute All BTL amplifier outputs ON/OFF

3 Vin1 BTL AMP 1 input pin

4 Vg1 BTL AMP 1 input pin (For gain adjustment)

5 Vo1 BTL AMP 1 input pin (Non inverting side)

6 Vo2 BTL AMP 1 input pin (Inverting side)

7 Vo3 BTL AMP 2 input pin (Inverting side)

8 Vo4 BTL AMP 2 input pin (Non inverting side)

9 Vg2 BTL AMP 2 input pin (For gain adjustment)

10 Vin2 BTL AMP 2 input pin

11 Reg Out External transistor collector (PNP) connection. 5V power supply output

12 Reg In External transistor (PNP) base connection

13 Res

14 Cd Reset output delay time setting (Capacitor connected externally)

15 Vin3 BTL AMP 3 input pin

16 Vg3 BTL AMP 3 input pin (For gain adjustment)

17 Vo5 BTL AMP 3 output pin (Non inverting side)

18 Vo6 BTL AMP 3 output pin (Inverting side)

19 Vo7 BTL AMP 4 output pin (Inverting side)

20 Vo8 BTL AMP 4 output pin (Non inverting side)

21 Vg4 BTL AMP 4 output pin (For gain adjustment)

22 Vin4 BTL AMP 4 output pin

23 Vref Level shift circuit's reference voltage application

24 Vcc Power supply (Shorted to pin 1)

Reset output

23

Page 24

XL-R5020BK

5.8 M66004SP(IC721):FL Driver

• Block diagram

• Pin function

Pin.No. Symbol I/O Description

1~12 12G~1G O FL grid control signal output.

13 SRST I Reset signal input

14 FLCS I Chip select signal input.

15 FLCLK I Shift clock signal input.

16 FLDATA I Serial data input.

17 P1 O Outp ut port (static operation)

18 P0 O Outp ut port (static operation)

19 VCC1 - Power supply for internal logic.

20 XOUT O Clock signal output.

21 XIN I Clock signal input.

22 VSS - Connect to ground.

23~31 P36~P28 O FL Segment control signal output.

32 VP - Power supply.

33~59 P27~P01 O FL Segment control signal output.

60 VCC2 - Power supply for grid output and segment output.

61~64 16G~13G O FL grid control signal output.

24

Page 25

5.9 MN35505-X (IC361) : DAC

• Terminal layout

• Pin function

XL-R5020BK

Pin No.

1 M5 I Control signal for DAC

2 DIN I Digital data input

3 LRCK I L and R clock for DAC

4 BCK I Bit clock for DAC

5 M3 I Control signal for DAC

6 DVDD2 - Power supply terminal

7 CKO - Non connect

8 DVSS2 - Connect to ground

9 M2 I Control signal for DAC

10 M1 I Control signal for DAC

11 OUT1C O Analog output 1

12 AVDD1 - Power supply terminal

13 OUT1D O Analog output 1

14 AVSS1 - Connect to ground

15 AVSS2 - Connect to ground

16 OUT2D O Analog output 2

17 AVDD2 - Power supply terminal

18 OUT2C O Analog output 2

19 M9 - Non connect

20 DVSS1 - Connect to ground

21 XOUT - Non connect

22 XIN - Non connect

23 VCOF I VCO Frequency

24 DVDD1 - Power supply D+5V

25 M7 I System clock rate selection

26 M8 I System clock rate selection

27 M4 I Control signal for DAC

28 M6 - Connect to ground

Symbol I/O Description

25

Page 26

XL-R5020BK

5.10 TC9246F-X(IC404):Clock generation for digital audio

• Pin layout

• Pin function

Pin No.

1 REF I Standard signal input terminal

2 PD O Phase difference signal output terminal

3 VDDA - Power supply voltage terminal for analog circuit

4 AMPI I AMP input terminal for LPF or oscillator 1

5 AMPO O AMP output terminal for LPF or oscillator 1

6 VSSA - Connect to ground for analog circuit

7 XI I AMP input terminal for oscillator 3

8 XO O AMP output terminal for oscillator 3

9 VSS - Connect to ground for digital circuit

10 CKO O Oscillation clock output terminal

11 M1 I Mode select terminal

12 M2 I Mode select terminal

13 S1 I Parallel mode : Dividing frequency selection terminal

14 S2 I Parallel mode : Dividing frequency selection terminal

15 LOCK O Lock detect signal output terminal

16 VDD - Power supply voltage terminal for digital circuit

5.11 TC74HCU04AF-W(IC331):Digital input selector

• Pin layout & block diagram • Truth table

Symbol I/O Description

Serial mode : Microcomputer data input terminal

Serial mode : Shift clock input terminal

AY

LH

HL

26

Page 27

5.1274VHC00MTC-X (IC406) : 2-input nand gate

• Pin layout

5.1374VHC08SJ-X(IC407):2-input AND gate

• Pin layout

XL-R5020BK

• Truth table

ABY

LLH

LHH

HLH

HHL

L : High impedance

• Truth table

GYA

LZL

LZH

HZL

HLH

27

Page 28

XL-R5020BK

5.14TC94A02F-005(IC401) : MP3 Decoder

• Block diagram

28

Page 29

• Pin function

Pin No.

1 /RESET I Hard reset input terminal(H:Normal operation L: Reset)

2 MiMD I Micon I/F mode select input terminal

3 AD0 O External SRAM address output 0 terminal

4 AD1 O External SRAM address output 1 terminal

5 MiDio I/O Micon I/F data input/output terminal

6 /MiCK I Micon I/F clock input terminal

7 AD2 O External SRAM address output 2 terminal

8 VDDT - Digital power supply (3.3V)

9 SDo O Data output terminal

10 AD3 O External SRAM address output 3 terminal

11 AD4 O External SRAM address output 4 terminal

12 SDi0 I Data input terminal 0

13 BCKiA I Bit clock input terminal A

14 LRCKiA I LR clock input terminal A

15 AD5 O External SRAM address output 5 terminal

16 CE O External SRAM chip enable terminal

17 OE O External SRAM output enable terminal

18 VDD - Digital power supply (2.5V)

19 STANBY I Standby mode control terminal

20 VSS - Digital GND

21 VSSL - DAC Lch GND

22 VRAL - DAC Lch reference voltage terminal

23 LO O DAC Lch output terminal

24 VDAL - DAC Rch power supply terminal(2.5V)

25 VDAR - DAC Lch power supply terminal(2.5V)

26 RO O DAC Rch output terminal

27 VRAR - DAC Rch reference voltage terminal

28 VSSR - DAC Rch GND

29 TESTP I Test terminal

30 CKS I VCO select terminal

31 AD12 O External SRAM address output 12 te rminal

32 AD11 O External SRAM address output 11 te rminal

33 AD10 O External SRAM address output 10 te rminal

34 AD9 O External SRAM address output 9 terminal

35 VDDT - Digital power supply terminal (3.3V)

36 AD8 O External SRAM address output 8 terminal

37 AD7 O External SRAM address output 7 terminal

38 AD6 O External SRAM address output 6 terminal

39 REQ O Squeeze request terminal to host

40 VSS - Digital GND

41 AD13 O External SRAM address output 13 te rminal

42 AD14 O External SRAM address output 14 te rminal

43 WR O External SRAM write signal

44 AD16 O External SRAM address output 16 te rminal

45 AD15 O External SRAM address output 15 te rminal

46 io0 I/O External SRAM data input/output 0 terminal

47 io1 I/O External SRAM data input/output 1 terminal

Symbol I/O Description

XL-R5020BK

29

Page 30

XL-R5020BK

Pin No.

48 VSS - Digital GND

49 io2 I/O External SRAM data input/output 2 terminal

50 io3 I/O External SRAM data input/output 3 terminal

51 io4 I/O External SRAM data input/output 4 terminal

52 VDD - Digital power supply (2.5V) terminal

53 io5 I/O External SRAM data input/output 5 terminal

54 io6 I/O External SRAM data input/output 6 terminal

55 io7 I/O External SRAM data input/output 7 terminal

56 VSSP - VCO GND

57 Pdo O PLL phase error detection signal output terminal

58 Vcoi I VCO control voltage input terminal

59 VDDP - VCO power supply

60 Cko O 16.934 MHz clock output terminal

61 VDDX - Power supply (2.5V) terminal for oscillator

62 Xi I Connection terminal for oscillator (input)

63 Xo O Connection terminal for oscillator (output)

64 VSSX - GND for oscillator

Symbol I/O Description

30

Page 31

5.15 TC9412AF(IC891) : Rec Level

• Pin layout

• Block diagram

XL-R5020BK

• Pin functions

Pin No. Symbol Description Pin No. Symbol Description

1 VSS Negative power supply temrinal 13 DATA Volume setup serial data input terminal

2 NC Non connect 14 STB Data write strobe input terminal

3 L-OUT L-ch Volume output terminal 15 NC Non connect

4 L-IN L-ch Volume input terminal 16 CS2 Chip select terminal

5 LD1 L-ch Loudness ta p output terminal 17 NC Non connect

6 LD2 L-ch Loudness ta p output terminal 18 A-GND R-ch Analog ground

7 A-GND L-ch Analog ground 19 LD2 R-ch Loudness tap output terminal

8 NC Non connect 20 LD1 R-ch Loudness tap output terminal

9 CS1 Chip select input terminal 21 R-IN R-ch Volume input terminal

10 NC Non connect 22 R-OUT R-ch Volume output terminal

11 GND Digital ground 23 NC Non connect

12 CK Data transfer clock input terminal 24 VDD Positive power supply terminal

31

Page 32

XL-R5020BK

5.16MN662790RSC(IC651):Digital servo & processor

• Pin layout

• Pin function

MN662790RSC (1/2)

Pin No. Symbol I/O Description

1 BCLK O Bit clock output for SRDATA

2 LRCK O Identifying signal output of LR

3 SRDATA O Serial data ou tput

4 DVDD1 - Power supply for digital circuit

5 DVSS1 - Connect to ground for digital circuit

6 TX O Digital audio interface output signal

7 MCLK I Micom command clock signal input

8 MDATA I Micom command data signal input

9 MLD I Micom command load signal input L:load

10 SENSE - Non connect

11 FLOCK - Non connect

12 TLOCK - Non connect

13 BLKCK O Sub code block clock signal (Command execution : CD-TEXT data readout enabling signal (DQSY) output)

14 SQCK I Export clock signal input for sub code Q resister

15 SUBQ O Sub code Q data output

16 DMUTE I Muting input H:muting

17 STAT O Status signal output

18 LSI_RST I Reset signal input L:reset

19 SMCK O Clock signal output MSEL is H : 8.4672 MHz MSEL is L : 4.2336 MHz

20 CSEL I Oscillation frequency specification terminal H:33.8688 MHz L:16.9344 MHz

21 TEST2 - TEST2 terminal usually : open

22 TVD O Traverse drive output

23 PC - Non connect

24 ECM O Spindle motor drive signal output (Compulsion mode ou tput)

25 ECS O Spindle motor drive signal output (Servo error signal output)

26 VDETMON - Non connect

27 TRD O Tracking drive signal output

28 FOD O Focus drive signal output

29 VREF - Reference voltage for DA output section

30 FBAL O Focus balance adjust signal output

31 TBAL O Tracking balance adjust signal output

32 FE I Focus error signal input (an alog input)

33 TE I Tracking error signal input (analog input)

34 RFENV I RF Envelope signal input (analog input)

35 TEST3 I TEST3 Terminal usually : Fixation L

36 OFT I Off track signal input H : off track

37 TRCRS I Track cross signal input (analog input)

38 RFDET I RF detection signal input L : detection

39 BDO I Dropout signal input H : dropout

40 LDON - Non connect

32

Page 33

Pin No. Symbol I/O Functions

41 PLLF2 I/O Terminal for loop filter characteristic switch for PLL

42 DSLBDA - Non connect

43 WVEL - Non connect

44 ARF I RF Signal output

45 IREF I Standard electric current input terminal

46 DRF I Bias terminal for DSL

47 DSLF I/O Loop filter terminal for DSL

48 PLLF I/O Loop filter terminal for PLL

49 VCOF I/O Loop filter terminal for VCO

50 AVDD2 - Power supply terminal for analog circuit

51 AVSS2 - Connect to ground terminal for analog circuit

52 EFM - Non connect

53 DSLB O PLL extraction clock output

54 VCOF2 I/O Loop filter terminal for VCO

55 SUBC O Sub code serial output

56 SBCK I Clock signal input for sub code serial output

57 VSS - Connect to ground terminal for oscillation circuit

58 X1 I Oscillation circuit input terminal f=16.9344 MHz 33.8688 MHz

59 X2 O Oscillation circuit output terminal f=16.9344 MHz 33.8688 MHz

60 VDD - Power supply terminal for oscillation circuit

61 BYTCK - Non connect

62 LDON O Laser ON signal output H : ON

63 GCTRL O General I/O port

64 IPFLAG - Non connect

65 FLAG O Flag signal outp ut

66 CLVS - Non connect

67 CRC - Non connect

68 DEMPH O De -emphasis detection signal output

69 RESY - Non connect

70 IOSEL I Mode switch terminal

71 TEST I TEST terminal usually : H

72 AVDD1 - Power supply terminal for analog circuit (for audio output section)

73 OUTL O Lch audio output

74 AVSS1 - Connect to ground terminal for analog circuit (for audio output section)

75 OUTR O Rch audio output

76 DQSY I RF signal polarity specification termin al

77 VCC5V - Power supply terminal (5V)

78 PSEL O IOSEL=H TEST terminal IOSEL=L SRDATA input

79 MSEL O IOSEL=H SMCK terminal output (frequency switch terminal) IOSEL=L LRCK input

80 SSEL O IOSEL=H SUBQ terminal output mode switch terminal IOSEL=L BCLK input

XL-R5020BK

MN662790RSC (2/2)

33

Page 34

XL-R5020BK

5.17UPD780076GK-533(IC251):Unit microcomputer

• Pin layout

• Pin layout

UPD780076GK-533 1/2

Pin No. Symbol I/O Description

1 E2SCK O Serial clock output to IC201

2 E2SDL I/O Serial data input/output with IC201

3 MCS I Communication method selection input from system microcomputer

L : Synchronization H : Asynchronous

4 MRDY O Signal output to system microcomputer by which command can be received

L H : Status output enable H L : command can be received

5 ITRVP3 I Play position switch (SW3) detection input

6 ITRVP2 I Play position switch (SW2) detection input

7 ITRVP1 I Play position switch (SW1) detection input

8 ITRYSoc I Sub tray open/close detection switch input

9 VSS0 - Connect to ground

10 VDD0 - Power supply terminal (+)

11 RESET I REST switch detection input (traverse mechanism)

12,13 - Non connect

14 ICAMP1 I Cam switch position 1 input

15 KCMND/TXD I/O Command input from system microcomputer (synchronization) or status output (asynchronous)

16 MSTAT/RXD I/O Status output to system microcomputer (synchronization) or command input (asynchronous)

17 KCLK I System microcomputer data/serial/clock input

18 SUBQ I Sub code Q data in put

19 CDCOPY O Right or wrong of CD copy signal output

20 SQCK O Clock output for sub code Q register

21 CDINDEX O CD index information

22 CDTNO O CD track information

23 ICAMP2 I Cam switch position 2 input

24 VDD1 - Power supply terminal (+)

25 AVSS - Connect to ground for A/D converter

26 VDET_LEVEL I Input for vibration detecting changeable level

27 KEY2 I Output voltage monitor of regulator (IC291)

28 TRY3CLOSE I Main tray 3 close switch detection input

29 TRY3OPEN I Main tray 3 open switch detection input

30 TRY2CLOSE I Main tray 2 close switch detection input

31 TRY2OPEN I Main tray 2 open switch detection input

32 TRY1OPEN I Main tray 1 open switch detection input

33 TRY1CLOSE I Main tray 1 close switch detection input

34 AVREF - Standard voltage of A/D converter and analog power supply

35 CAM_CW O Cam motor drive signal output (clockwise)

36 RESET I System reset input

34

Page 35

Pin No. Symbol I/O Description

37 XT2 - Non connect

38 XT1 I Sub system clock oscillation terminal

39 IC I Connect to ground

40 X2 O Main system clock output

41 X1 I Main system clock input

42 VSS1 - Connect to ground

43 FLAG I Flag (C1 error) signal input

44 BLKCK I Sub code/block/clock signal input

45 RFDET I RF signal detection input

46 CAM_CCW O Cam motor drive signal output (counterclockwise)

47 ACT_CCW O Actuator motor drive signal output (counterclockwise)

48 ACT_CW O Actuator motor drive signal output (clockwise)

49 - Non connect

50 EQX2 O Equalizer switch output (H:one time velocity L:double-speed/four time velocity)

51 ICAMP3 I Cam switch position 3 input

52 ICAMP4 I Cam switch position 4 input

53 RESET O Reset output to IC651

54 STAT I Status signal input from IC651

55 D MUTE O Muting output to IC651 H : muting

56 P.ON O Control signal output of 3.5V regulator (IC291)

57 MLD O Command load signal output to IC651

58 MDATA O Command data signal output to IC651

59 MCLK O Command clock signal output to IC651

60 CL KSW O Clock output control terminal to the outside

61 EQX4 I Equalizer switch output (H:one time velocity/double-speed L:four time velocity)

62,63 - Non connect

64 DR_MUTE O Driver IC muting output H : muting

XL-R5020BK

UPD780076GK-533 2/2

35

Page 36

XL-R5020BK

5.18UPD784215AGF513(IC501):System controller

• Pin layout

• Pin function

Pin No. Symbol I/O Description

1 CKSL2 - Not use

2 CKSL1 - Not use

3IDFS2-Not use

4 TEST- I Test mode input terminal L : Test mode

5 VR_STB O Strobe signal output to IC891

6 V R_DATA O Data output to IC891

7 VR_CK O Clock signal output to IC891

8 NC - Non connect

9 VDD - Power supply terminal +5V

10,11 CS1/CS2 I Chip select terminal

12,13 JOGA/JOGB I Multi jog dial A/B input

14 FLDAT O Serial data output to FL driver

15 FLCLK O Shift clock signal output to FL driver

16 FLCS O Chip select signal output to FL driver L : data output

17,18 NC - Non connect

19 PLL LOOK I PLL LOCK detect signal from IC404

20 DIN_COA - When digital input is coaxial for output H

21 NC - Non connect

22 VPP - Connect to ground

23 DIG_LED O Digital LED control signal output L : Lighting

24 CD_LED O 3CD LED control signal output L : Lighting

25 LIN_LED O Line IN LED control signal output L : Lighting

26 MIC_LED O MIC LED control signal output L : Lighting

27 CC LED - Non use

28 MIXBL I Mix balance volume level input

29 DIN_OPT O When digital input is optical for output H

30 SMUTE O System muting signal output

31 DACMUTE O DAC muting signal output

32 CD_DRT O It is a power output to the direct conne c ti o n of an al o g re cording

source 3CD to the A/D input of CD-RW as for L

33 SCD O Analog recording source 3CD select control output

L : selected 3CD

34,35 SLIN1/SLIN2 O Analog recording source select control output

36 SMIC O Analo g recording source MIC select control output

L : selected MIC

37 VDD - Power supply terminal +5V

(connects with the backup capacitor at power supply off. )

38 X2 O Main system clock output terminal 10MHz

39 X1 I Main system clock input terminal 10MHz

40 VSS - Connect to ground

41 XT2 O Sub clock output terminal 32.768KHz

42 XT1 I Sub clock input terminal 32.768KHz

43 RESET I Reset signal input

UPD784215AGF513 1/2

36

Page 37

Pin No. Symbol I/O Description

44 REM I Remote control signal input

45 NC - Non connect

46 ACON I The AC power supply existence detection terminal

L : No AC power supply (backup mode)

H : AC power supply having (normal mode : Backup mode Release)

47 CDR_RREQ I Request demand input from CD-RW unit

48 MP3REQ I Request demand input from MP3 decoder

49 DOCD O Output select control H : selected 3CD L : selected CD-RW

50 SLCDR O Output select control H : selected CD-RW L : selected 3CD

51 AVDD - Power supply terminal +5V

(connects with the backup capacitor at power supply off.)

52 AVREF0 - 3CD Analog signal level reference voltage

53~56 KEY1~4 I Operation switch input terminal 1~4

57 NC - Non use

58 3CDINR I 3CD analog signal level input (for Rch level meter)

59 3CDINL I 3CD analog signal level input (for Lch level meter)

60 MODE I DCS mode setting switch input

61 AVSS - Connect to ground

62 DCSI I DCS command input

63 DCSO O DCS command output

64 AVREF1 - Power supply terminal +5V

65 NC - Non connect

66 NC - Non connect

67 NC - Non connect

68 STAT I 3CD status input

69 COMD O 3CD command output

70 ASCK1 I Connect to ground

71 SRST O System reset signal output L : active

72 POWER O System power supply control terminal / standby LED control

H : power OFF / LED turning off L : power ON / LED lighting

73 CDR_DTI I Serial data input from CD-RW unit

74 CDR_DTO O Serial data output to CD-RW unit

75 CDR_ACLK I Clock signal input from CD-RW unit

76 CDR_SREQ O Request sign al output to CD-RW unit L : active

77 SYS_RDY O System ready output to CD-RW unit L : active

78 NC - Non connect

79 DACPD O DAC power down control output

80 SLCD O Output select control H : 3CD L : CD-RW

81 3CD_RES O Reset signal output to 3CD unit micom (IC251)

82 NC - Non connect

83 DOCDR O Digital output select control H : selected CD-RW L : selected 3CD

84~88 NC - Non connect

89 MP3BYPAS O Bypas signal outpct to IC406 L : MP3 decoder is bypassed

90 MP3LED O MP3LED control signal output L : Lighting

91,92 NC - Non connect

93 MP3RST O Reset signal output to MP3 decoder(IC401) L : Reset

94 DIFENA O M P3 Board(LEB10055) enable/disable control signal output H : operable

95 MP3SDA I/O MP3 Decoder I/F data input/output teminal

96 MP3SCL O MP3 Decoder I/F clock output terminal

97 NC - Non connect

98 CDRRST O Reset signal output to CD-RW unit L : reset ON

99 STBY_LED O Standby LED control signal output L : lighting

100 VSS - Connect to ground

XL-R5020BK

UPD784215AGF513 2/2

37

Page 38

XL-R5020BK

5.19W24L010AJ-12-X (IC402) : SRAM

• Pin layout

• Pin functions

Symbol Description

A0-A16 Address inputs

I/O1-I/O8 Data inputs/outputs

CS1,CS2 Chip select input

WE Write enable input

OE Output enable input

VDD Power supply

VSS Ground

NC No connection

• Block diagram

38

Page 39

XL-R5020BK

39

Page 40

XL-R5020BK

VICTOR COMPANY OF JAPAN, LIMITED

PERSONAL & MOBILE NETWORK BUSINESS UNIT

1644, Shimotsuruma, Yamato, Kanagawa 242-8514, Japan

No.A0035

200208

Loading...

Loading...