Page 1

SERVICE MANUAL

CARD PRINTER

XID8600-DS

No.HD017 <Rev.001>

2014/11

Page 2

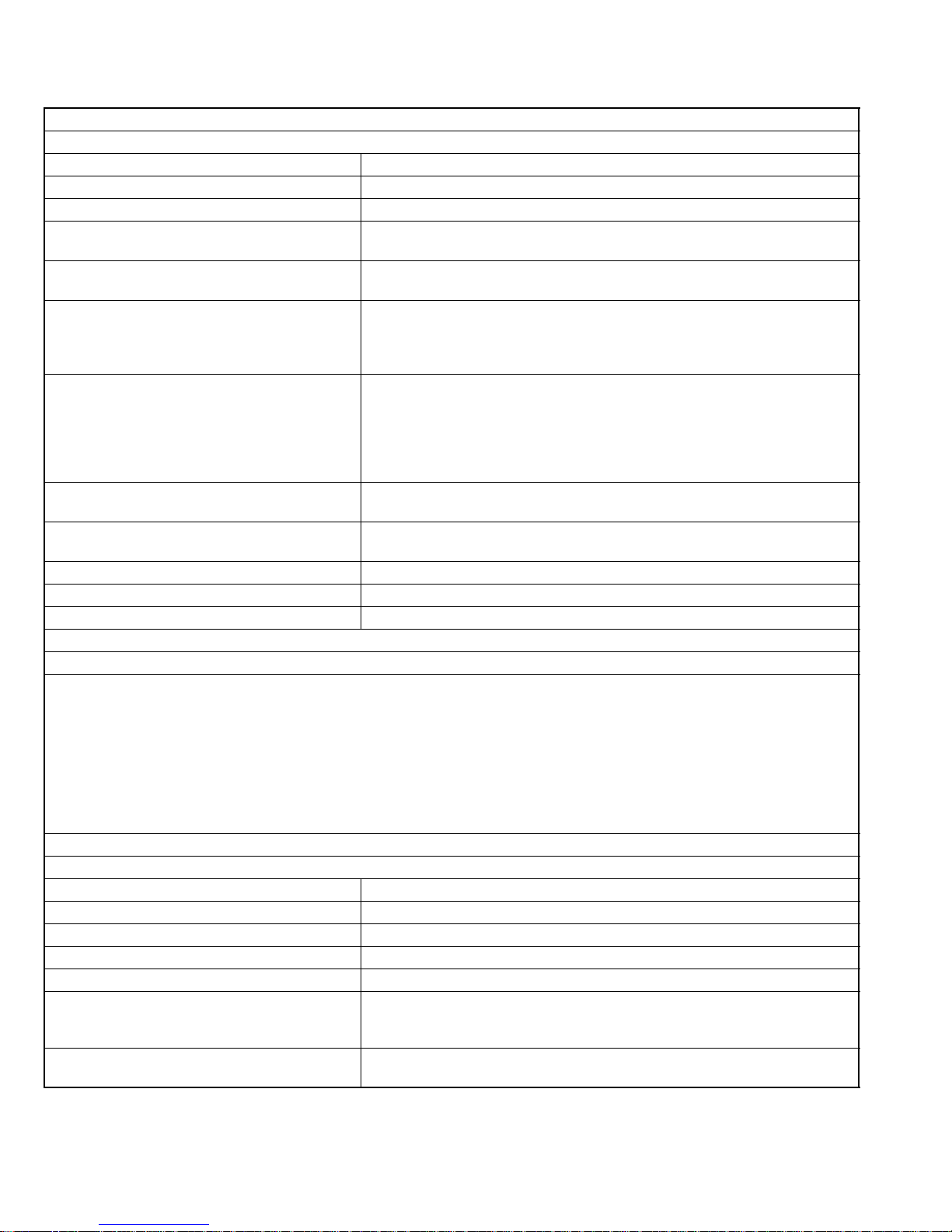

SPECIFICATION

XID8600

Specifications

Recording system Dye sublimation retransfer

Paper feed mode Automatic

Recording density 600 dpi

Reproduction gradation 256 levels each for Y, M and C

2 levels for Resin K

Interface USB 2.0 (Hi-Speed/Full-Speed)

Ethernet (100BASE-TX/10BASE-T)

Operating environment conditions Temperature: 15°C to 30°C

(When peel-off ink, UV ink is used: 17 °C to 28 °C)

Humidity: 35 % to 70 % No condensation

(When peel-off ink, UV ink is used: 35 % to 60 %)

Storage environment co nditions <Printer unit>

Temperature: -15°C to 55°C

Humidity: 20 % to 80 %

<Printing media (retransfer film or ink ribbon) /card>

Temperature: 5 °C to 25 °C

Humidity: 40 % to 60 %

Power supply AC 100 V - 120 V, 50 Hz/60 Hz

AC 220 V - 240 V, 50 Hz/60 Hz

Current consumption 3.5 A (100 V system)

1.6 A (200 V system)

Power consumption 310 W (maximum power when all options are installed)

Mass approx. 14.6 kg (excluding optional built-in items)

Dimensions 343 mm x 360 mm x 322 mm (W x H x D)

Accessories

Please check to ensure that the printer accessories are in place when unpacking the product package.

• CD-ROM× 1

• Getting started guide× 1

• Read Me First × 1

• Power Cord (2 m)× 2

• Cleaning Card× 1

• Card Stacker× 1

• USB 2.0 Cable (2 m) × 1

•Gloves× 1

• Card Pickup× 1

Products Sold Separately

To purchase these items, please consult our authorized dealers.

YMCK (1000 frames/roll) Set Model: DIC10216

YMCK-PO(750 frames/roll) Set Model: DIC10218

Ink Ribbon (YMCKK) 750 frames/roll Model: DIC10217

Ink Ribbon (YMCK-UV) 750 frames/roll Model: DIC10313

Retransfer Film 1000 frames/roll Model: DIC10319

Cleaning Kit Model: DIK10044

Set incl. 10 print head cl eaning swab s, 10 cleaning tissues for rolle rs and 10 special cleaning cards

Magnetic Stripe Encoder Head Cleaning Cards Model: DIC10311

Box of 10 cards

1-2 (No.HD017<Rev.001>)

Page 3

SECTION 1

r

PRECAUTION

1.1 SAFETY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly inspected to conform w ith th e rec og niz ed pro duc t s afe ty and electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions o n the cab inet, chassis and certa in parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identif ied by the symbol and shade d ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specifi ed to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding spurious radiation emission.

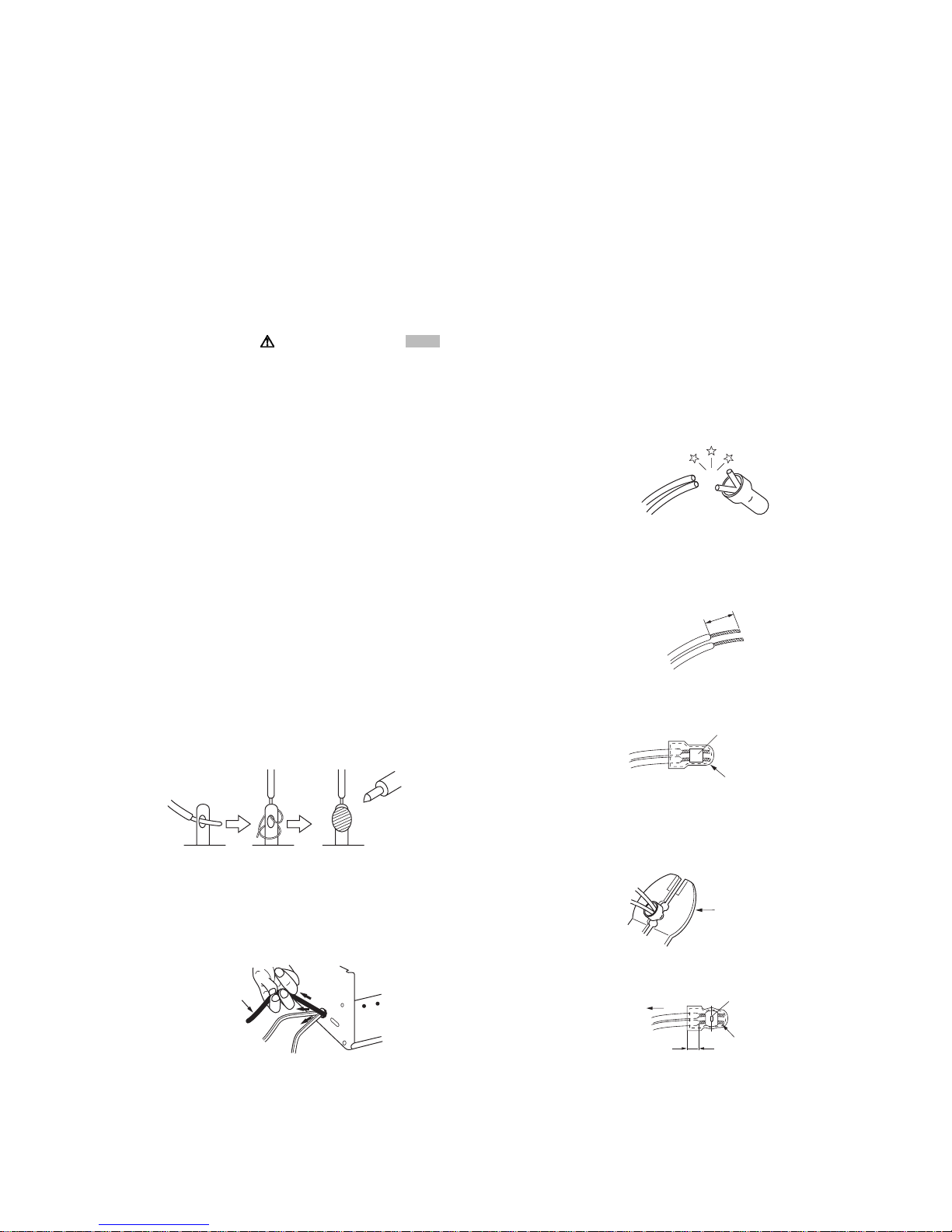

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use sp ec ifie d i n su la ting materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

• Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacito rs, etc.) wrap ends of

wires securely about the terminals before soldering.

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxi de metal film resi stors, fu sible re sistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

cathode ray tubes and other parts with only the specified

parts. Under no circumsta nces atte mpt to m odify these circuits.Unauthorized modification can increase the high voltage value and cause X-ray emission from the cathode ray

tube.

(12) Crimp type wire connector In such cases as when replac-

ing the power transformer in sets where the connections

between the power cord and power trans former primary

lead wires are performed using crimp type connectors, if

replacing the connec tors is unavoidabl e, in order to p revent

safety hazards, perform carefully and precisely according

to the following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insula ted part s.

• Replacement procedure

a) Remove the ol d conn ector b y cutting t he wi res at a

point close to the connector.Important : Do not reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the in sulat ion fr om the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected. In-

sert the wires fully into the connector.

Metal sleeve

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to

crimp the me tal sleeve at t he center posit ion. Be

sure to crimp fully to the complete closure of the

tool.

1.25

2.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Crimped at approx. cente

of metal sleeve

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products us ing cathod e ray tubes (CRTs) In regard to such

products, the cathode ray tubes themselves, the high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the

Conductors extended

Wire insulation recessed

more than 4 mm

Fig.1-1-7

(13) Battery replacement caution notice.

CAUTION RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECTIVE TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE

INSTRUCTIONS.

(No.HD017<Rev.001>)1-3

Page 4

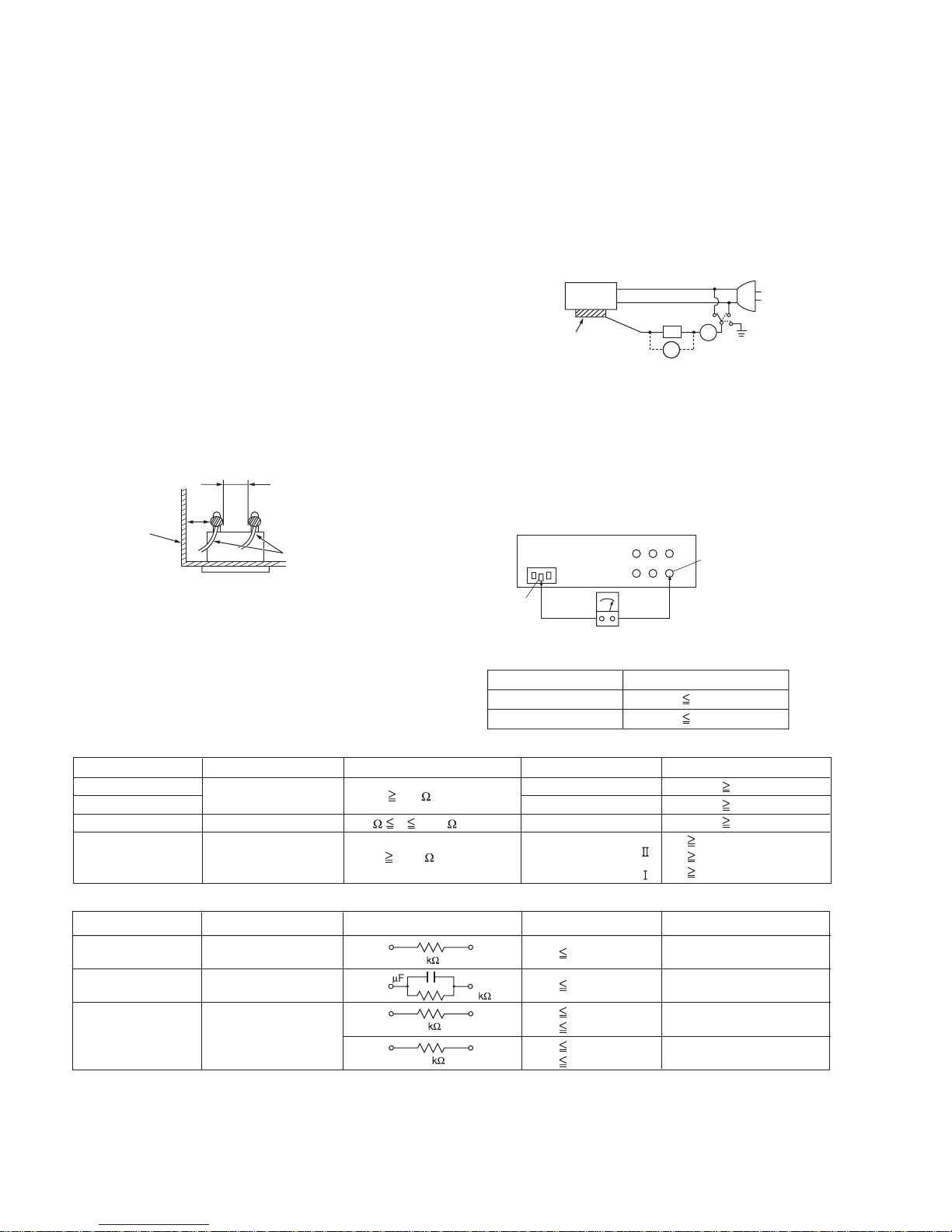

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe th at screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify compliance with safety standards.

(1) Insulation res is tanc e test

Confirm the sp ecified insul ation resistance or greater between power cord plug prongs and externally exposed

parts of the set (RF term inals, antenna termi nals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed accessible parts (RF t erminals, antenna terminals, vi deo and

audio input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON) Insert load Z between

earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure

across both terminals of load Z. See Fig.1-1-9 and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Clas s 1 mode l only )

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Metho d:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 mm

)

d' 8 mm (Power cord

d' 6 mm (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z Leakage Current (i)

1

0.15

1.5

2

50

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.HD017<Rev.001>)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 MODEL NAME

Model name of printers

XID8600-DS : Dual Side Model

Basic Struct ure

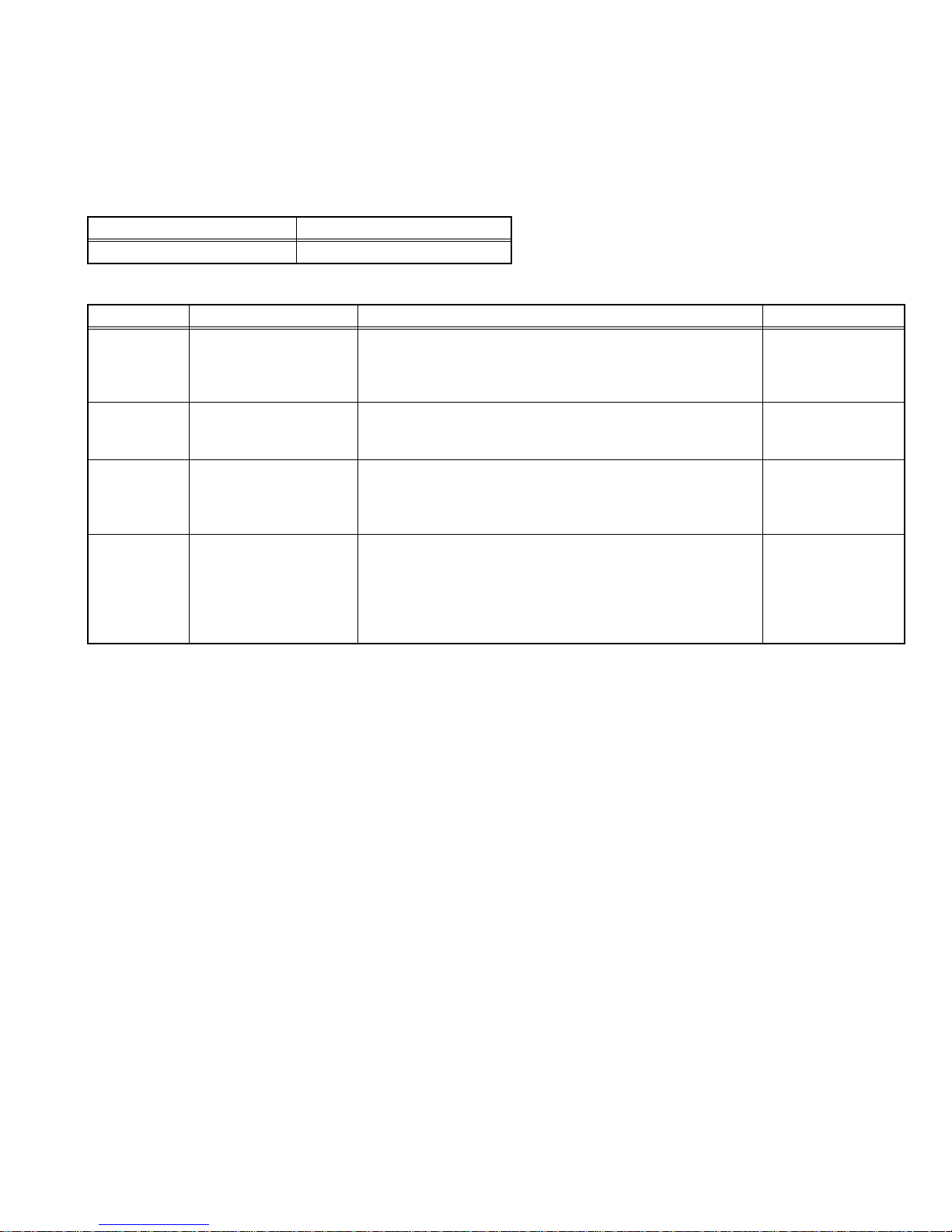

Model Name Convey Unit

XID8600-DS Dual Side

2.2 Model name of built in option units. (Sell separately)

Product name Description Remarks Appended goods

CF-7BR Bend Remedy Unit Remedy the bend of card after retransfer • Pressurized spring

ASSY

•Fixed screw

• Model label

CF-7MGS MG Encoding Unit (ISO) In accordance with ISO7810, 7811/2 MG stripe card

Only for dual side model (built in flip unit)

CF-7CRW Standard Contact IC R/W In accordance with ISO7816 IC card PC/SC, USB connect R/W

When it is installed to the printer, USB or Ethernet is selectable

CF-7CCS ISO Contact IC Case In accordance with ISO7816 IC card Coupled with the ISO MG

encoding unit.

• Connection wire

•Fixed screw

• Model label

• IC contact cable

• USB Cable

•Fixed screw

• Model label

• Option bracket

• GND wire

•Drive board

• Contact label

•Fixed screw

• Model label

2.3 Life time of each p arts

2.3.1 About thermal head

120,000 passes

(Approximately equivalent to 30,000 prints by using 4 colors, YMCK ink ribbon)

The life time of th ermal head is de fined a s the time period when th e heat ing elem ent of the the rmal h ea d is br oken caus ed by wearing

off the surface protective material.

2.3.2 Life time

• Durable parts

1) Heater : 2,000 Hours

2) Thermal Head : 120,000 passes

3) Motor (DC motor ) : 100,000 panels

4) Heat Roller : 100,000 pan els

5) Belt : 100,000 panels

• Consumable parts

Life time to exchange is estimated based on enforcing daily maintenance.

1) Fan Filter : about 1 year

2) Cleaning Roller : about 1 year

• Life time for mechanism

100,000 cards printing for dual side printing with standard maintenance

• MTBF exclude life time parts is more than 12,000 hours

Life time to exchange

Life time to exchange

(No.HD017<Rev.001>)1-5

Page 6

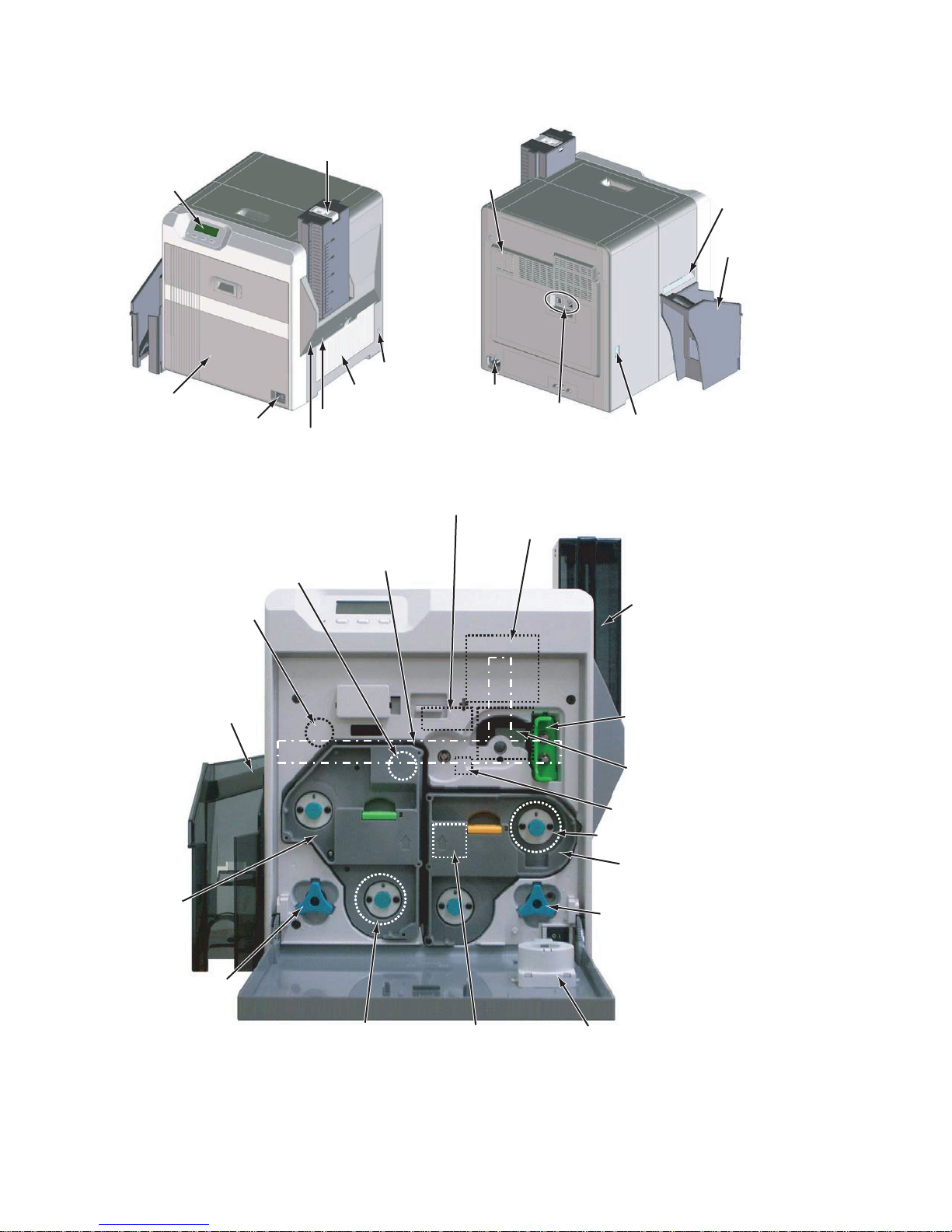

2.4 Name and functions of parts

2.4.1 Exterior

Display Panel

Printer door

Power Switch

2.4.2 Internal mechanism

Retransfer heating roller

Bend Remedy

Heat Roller

Card Hopper

NG Card Exit

Preliminary screw hole

Space for input

out put connectors

Security Slot

Cooling Fan

Contactless IC Encoder install space

Card Convey

Section

AC Inlet

Host Interface

Mag Encoder Unit

Card Exit

Card stacker

Communication Port for Laminator

Card hopper

Card stacker

Re-Transfer

Film Cassette

JOG Dial

Retransfer Film

Thermal head

Cleaning Roller

Card Convey Unit for

Single Sided or Dual Sided

IC Contact

Ink Ribbon

Ink Cassette

JOG Dial

RF-ID Antenna

1-6 (No.HD017<Rev.001>)

Page 7

2.5 ATTACHING THE SEPARATELY SOLD PARTS

r

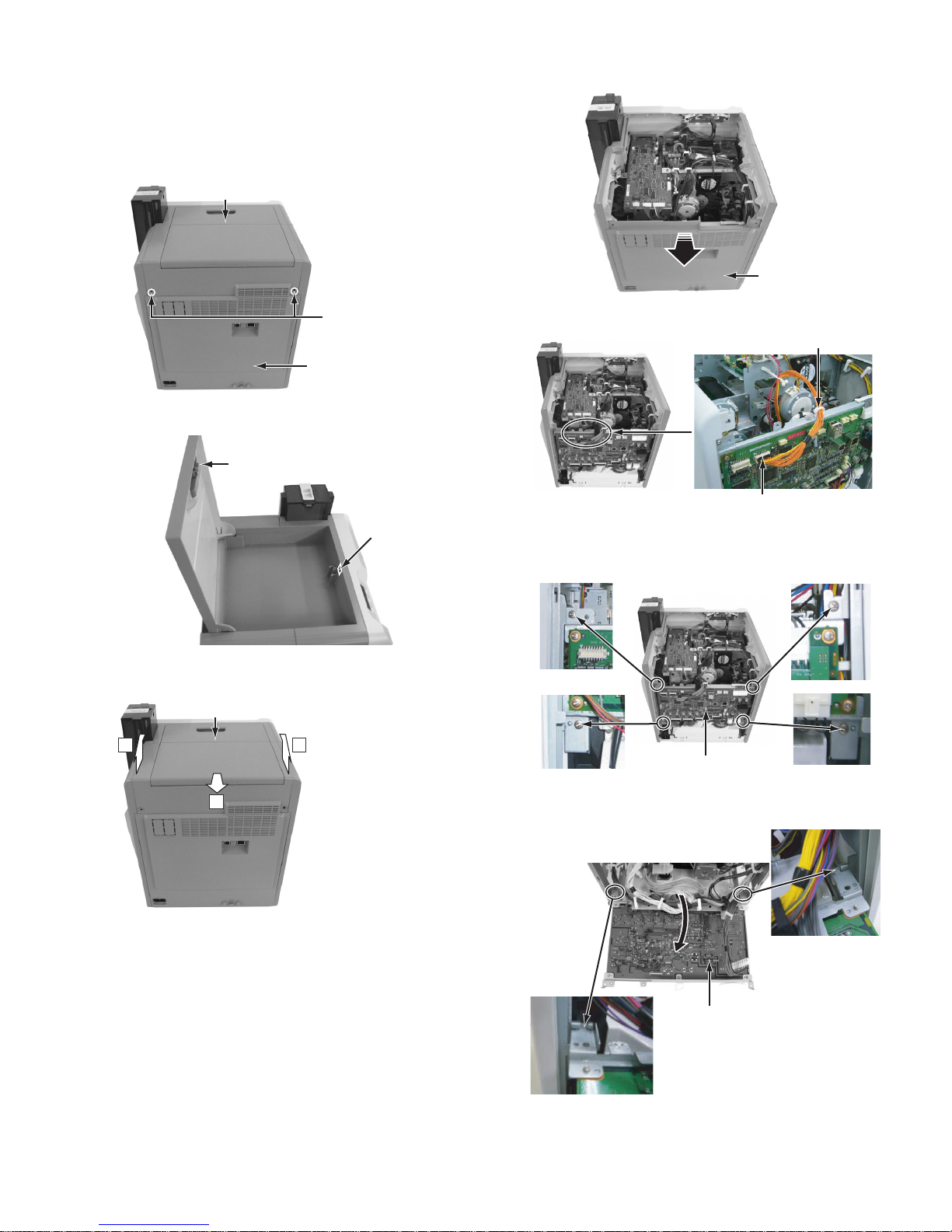

2.5.1 Preparation

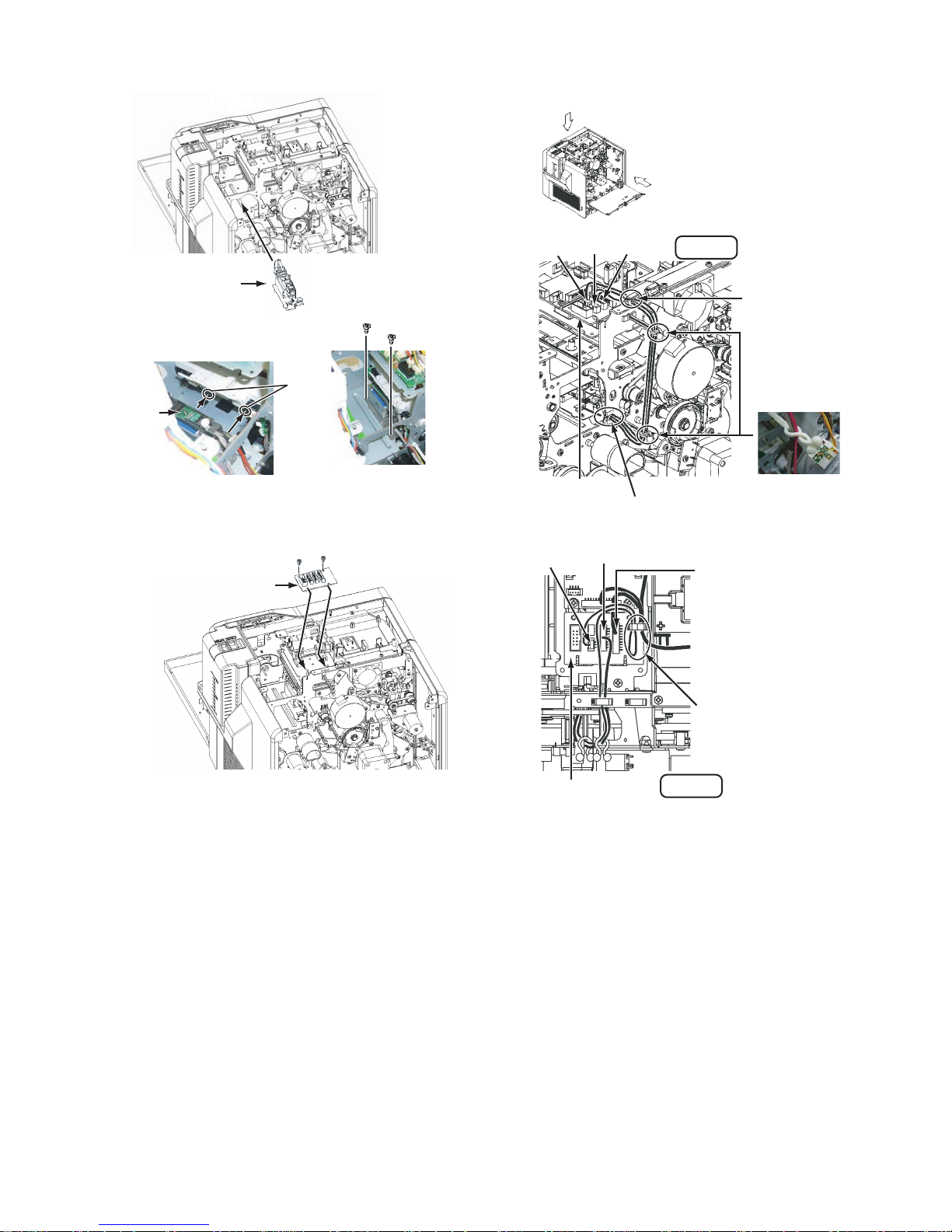

Before connecting the sep arately sol d parts, remove th e top c over unit and the rear cover to pull open the MAIN Board.

(1) Remove the tw o s crews a ttac hi ng f rom the rear side of the

main unit.

Top cover unit

(4) Remove the rear cover by pulling it open to the rear side.

Rear cove

Screw:

QYSDSP4012NA x 2

Rear cover

(2) Open the case cover,then remove the one screw.

Case cover

Screw

(3) Remove th e top cover unit by sliding it to the direction of the

arrow.

Top cover unit

22

(5) Disconnect the wire connected to the MAIN Board.

Release the wires from the wire clamp.

Disconnect the connector from the turn unit.

(Only the models with turn unit)

(6) Remove the four screws attaching the brackets that fix the

MAIN Board.

Screw : QYSDST3006 x 4

MAIN Board

1

Slide the top cover unit

to the rear side about

10 mm, and then pull it up.

(7) Pull open the MAIN Board, and hook the two brackets at

the bottom of the MAIN Board to the f rame of the main unit.

Main board

• Be careful not to catch wires in between.

(No.HD017<Rev.001>)1-7

Page 8

2.5.2 Attaching the reform H unit

r

A

Note:

After mounting the reform H unit, be su re to ch eck th e relevant item referring to "2.6 Check details after mounting

separately sold parts".

(1) Insert the reform H unit, and fix it with a screw.

(2) Fix the bracket with an attaching screw.

Reform H unit

* When attaching the reform H unit,

be careful not to damage the heat

roller with the bracket.

Bracket

2.5.3 Attaching the IC contact unit

Note:

After mounting the IC contact unit, be sure to check the

relevant item referring to "2.6 Check details after mounting separately sold parts".

(1) Remove the screw attaching the turn unit from the front

side of the main unit.

Screw :

QYSDST3006NA

Screw :

QYSDST3006NA

Screw :

QYSDST3006NA

Insert the tip of the

shaft into the front

plate.

(3) Remove the dummy connector connected to the CN3 on

the MAIN Board. (Only when attaching the reform H unit)

MAIN

Board

CN3

Dummy

connecto

(4) Guide the wires from the reform H unit through the wire

clamps as shown in the drawing, and then connect the

wires to the MAIN Board.

(2) Remove the wires , which come fro m the turn unit, fro m the

wire clamp.

Wire clamp

(3) Remove the three screws attaching the turn unit, and then

pull out the turn unit. (Only the models with turn unit)

Turn unit

Screw :

QYSDST3006NA x 3

Wire clamp

MAIN Board

CN2

s the reform H unit moves up and down during operation,

be sure to allow about 1 to 2 cm wire slack.

1-8 (No.HD017<Rev.001>)

CN3

Page 9

(4) Mount the IC contact unit.

(6) Connect the wire from the IC contact unit following the

drawing below.

B

A

IC Contact unit

Screw :

QYSDST2604NA x 2

Slide the IC contact unit into the

hook of the bracket on the main unit.

Hook

IC Contact

unit

Align the screw holes, make sure that

the IC contact unit does not move, and

then fix the IC contact unit with the screws.

(5) Attach the IC CONTACTIFC Board.

Screw : QYSDST3006NA x 2

IC CONTACTIFC Board

Insert the IC CONTACTIFC

Board into the bracket

on the main unit.

CN4 CN1 CN3

IC CONTACTIFC

Board

Run the wires from the IC contact

unit through this wire clamp.

CN4

CN3

View A

Run the wires through

this wire clamp.

Fix the wires with the two

wire clamps. (Tighten the

wire clampsas shown in the

picture below.)

Be careful to prevent wires from

touching nearby rotating objects

such as belts/gears.

CN2

Connect the free PH10-pin

connector of the jump wire.

Jump wire

IC CONTACTIFC Board

Fold back, and then run the

excess of the wire (red),

connected to the CN4, through

the wire clamp as shown in the

drawing.

View B

(No.HD017<Rev.001>)1-9

Page 10

(7) Reattach the turn unit.

A

(c)

fter attaching this screw, attach

another two screws.

Screw : QYSDST3006NA x 3

Turn unit

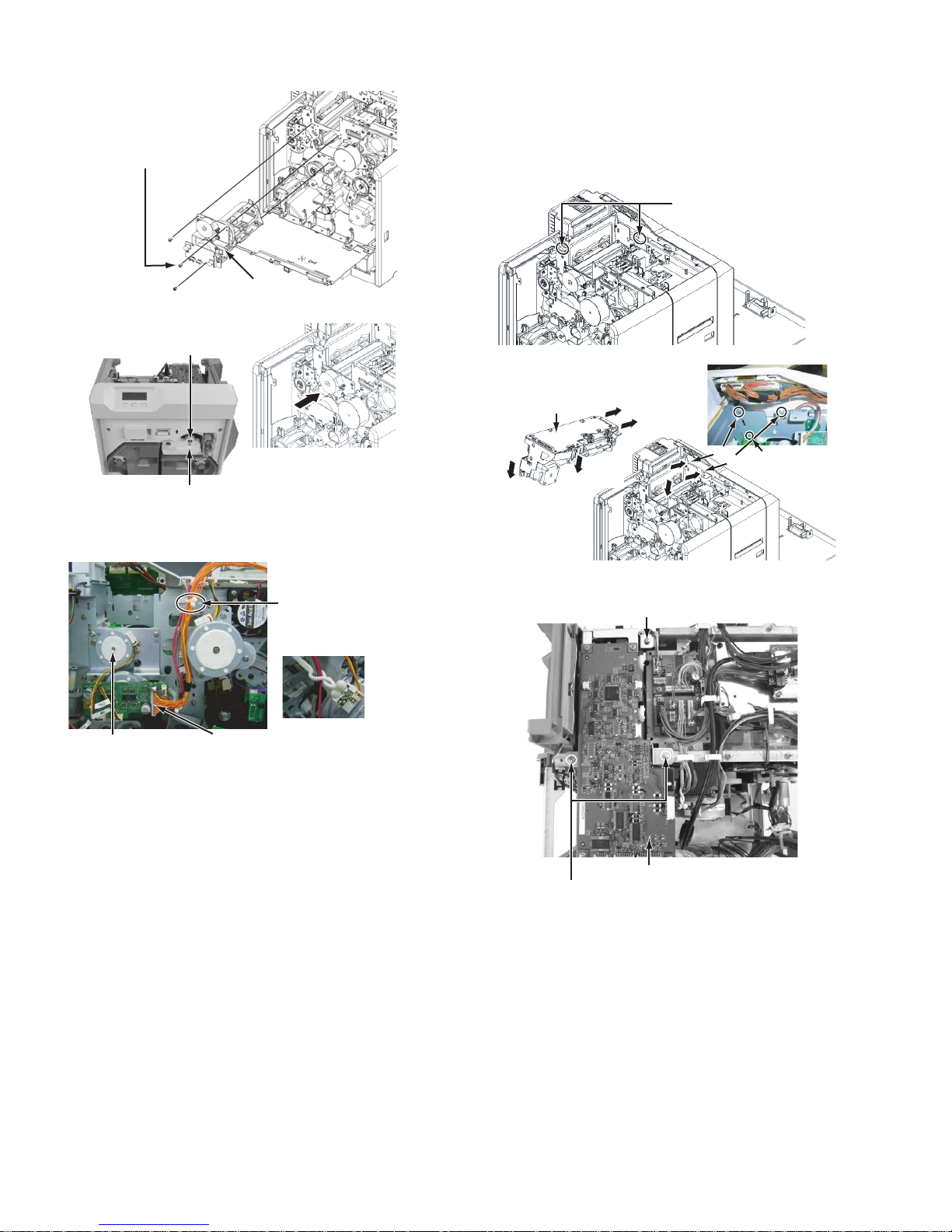

2.5.4 Attaching the MG unit

Note:

After mounting the MG unit, be sure to check the relevant

item referring to "2.6 Check details after mounting separately sold parts".

(1) Mount the MG unit.

Make sure that the wires do not

run over the brackets.

If the wires run over the brackets,

release the wires.

Bearing fitting hole

Make sure that the turn unit bearing

securely fits the hole on the main unit,

and the screw holes align.

Screw : QYSDST3006NA

Push the turn unit from the rear side to

attach the screw.

(8) Connect the wires from the turn unit following the picture

below.

Wire clamp

Be careful to prevent wires from

touching nearby rotating objects

such as belts/gears.

(Tighten the wire clamp

as shown in the picture

above.)

Turn unit

CN1

Align the front end of the

MG unit to the grooves

(a) and (b) of the front

MG Unit

While aligning the

grooves of the MG unit

bracket and the main unit

bracket, lower the back

end of the MG unit.

bracket.

(c)

(a)

(b)

(a)

(c)

(c)

(2) Fix the MG unit with the three screws.

Screw : QYSDST3006NA

Attention of there is

(b)

groove also under (a).

1-10 (No.HD017<Rev.001>)

MG unit

Screw : QYSDST3006NA x 2

Page 11

(3) Close back the MAIN Board to its original position, and fix

r

MAIN Board

the MAIN Board with the four screws.

Securely hook the two brackets, fixing the

MAIN Board, to the frame of the main unit.

(4) Connect the wires from the MG unit an d the turn unit follow-

ing the drawing below.

Connect the MG unit and the board bracket, and fix them with screws.

Wire : QUB030-05HMHM-E

Screw : QYSDST3006NA x 2

Wire from the turn unit CN1

View A

MAIN Board

Coaxial connector

Make sure that the coaxial

connector is not loose.

Allow about 5 mm slack to

enable the cable to move.

A

B

The cam gear and the wire should be parted.

MG UNIT

Run the wires from the turn

unit and the MG unit togethe

through this wire clamp, and

fix them.

CN19

CN15

MAIN Board

MG Unit

MG unit accessories

Wire from the

turn unit CN1

Wire clamp

MAIN Board

MAIN Board

CN19CN15

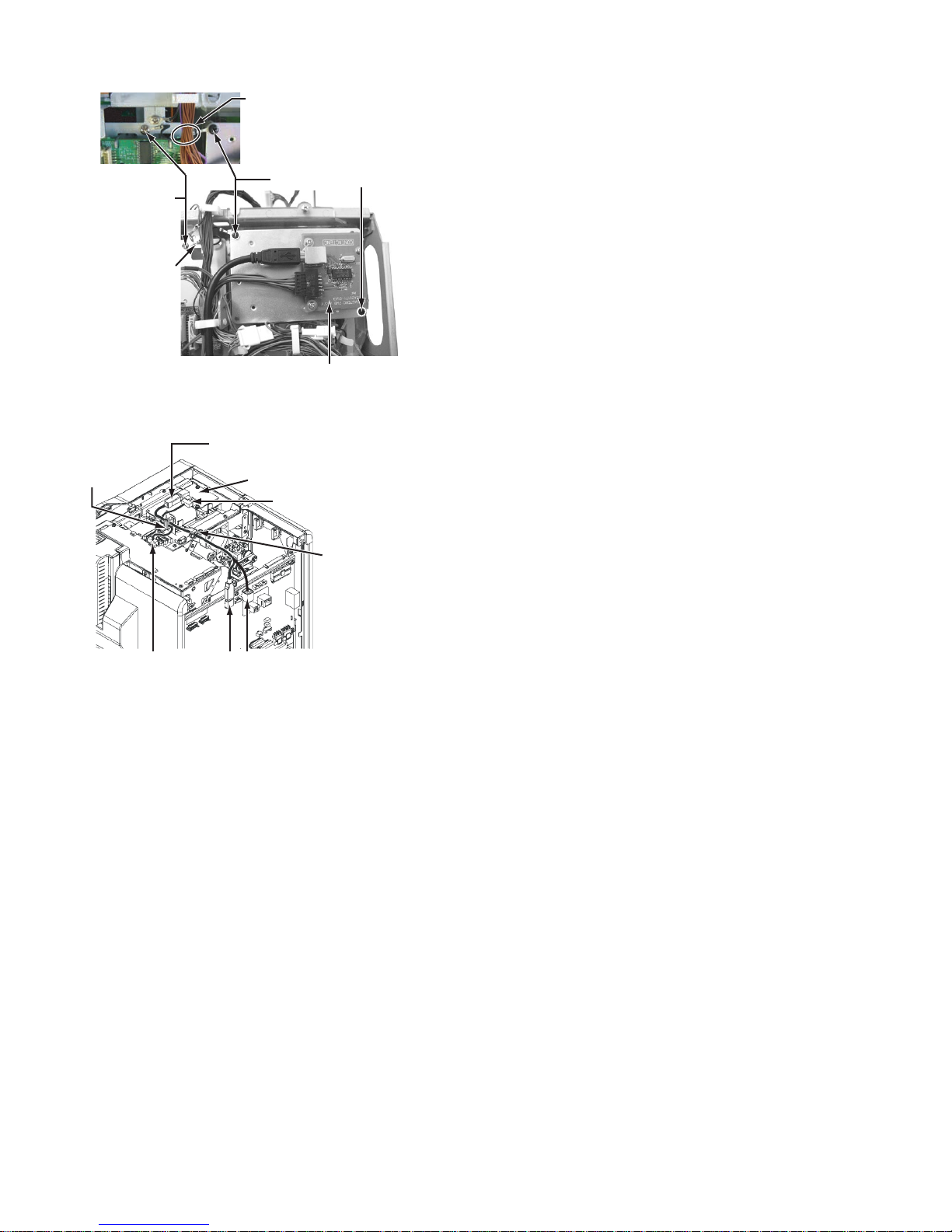

2.5.5 Attaching the IC R/W unit

Note:

After mounting the IC R/W unit, be sure to check the relevant item referring to "2.6 Check details after mounting

separately sold parts".

(1) Attach the IC R/W unit to the plate.

QYSPSPH3006NA x 3

Organize the head wire so that it does not

touch the rotating parts such as belts/gears,

and then fix the head wire with the wire clamp.

Make sure that the wires do not touch the encoder.

View B

Opened MAIN Board

IC R/W Unit

QZW0326-002 x 3

(No.HD017<Rev.001>)1-11

Page 12

(2) Mount the IC R/W unit.

Run the earth wire under

the wires from the FRONT Board.

Screw :

Screw :

QYSDST3006NA

Wire :

QUB340-07DMDM-E

QYSDSF3008NA x 2

IC R/W Unit

(3) Connect th e wires f rom the IC R/W un it foll owin g the dra w-

ing below.

Connect the supplied USB cable

and the connector J1 on the MAIN Board.

Wire clamp

IC R/W Unit

Connect the supplied wire (10-pin)

to the connector CN5 on the

IC CONTACTIFC Board.

Wire clamp

CN5 J1

J3

For direct connectio n of the IC R/ W unit and a PC, conn ect

to J3, not to J1.

Note that the IC R/W unit c annot be recogn ized o n the sta tus monitor in the J3 connection.

2.5.6 Attaching the top cover and the rear cover

(1) Attach the to p cover a nd the rear c over in th e reverse r pro-

cedure of disassembly.

1-12 (No.HD017<Rev.001>)

Page 13

2.6 Check details after mounting separately sold parts

Item Check details Required tools

1 Reform H unit The warpage of the printed card should be within the specs (1.5

mm).

2 IC Contact unit Check the IC contact position mark using a blank card and a

contact label.

• Service mode > Offline Test > Test the IC (Contact).

• If the position is out of sp ecs, Ma inte nance > Off setConta ct to

adjust the positi on. (See 2.6.1 IC contac t position adjustmen t)

The card written with an a pplic ation s hould b e read by the reader.

(Check in the USB and Ethernet connections)

3 MG Unit Service mode > Offline Test > test the MG.

• The test should be finished normally.

The card written with an a pplic ation s hould b e read by the reader.

• There is no adjustm ent for an MG un it after mounti ng because

MG units are shipp ed after being position adjust ed. C hec k for

normal operation only.

4 Running after mounting the

separately sold parts

Test for normal printing on about 10 cards

• Service mode > Offline Test > print

(For all separately sold parts)

Item Item Conditions & specs Test point

5 Safety test (for

all separately

sold parts)

Withstand

voltage test

Insulation resistance test

Grounding

continuity test

Timer Leak current Test voltage (With the POWER SW: ON)

2 to 3 sec. 30mA AC1600±50V

Test voltage Insulation resistance value

DC 500V 100MΩ and over

Timer Test current Spec value (With the POWER SW: ON)

3 to 4 sec. AC25A 0.1Ω or under

(Without power cord)

Blank card

Blank card, Contact label

Contact IC card

Contact IC reader

MG card

MG reader

Evaluation card

GND C on the AC inlet in the

drawing below

|

Bipolar B on the po wer cor d in

the drawing below

Screw A on the top left of the

rear panel in the drawing belo w

|

GND C on the AC inlet in the

drawing below

A

C

B

(No.HD017<Rev.001>)1-13

Page 14

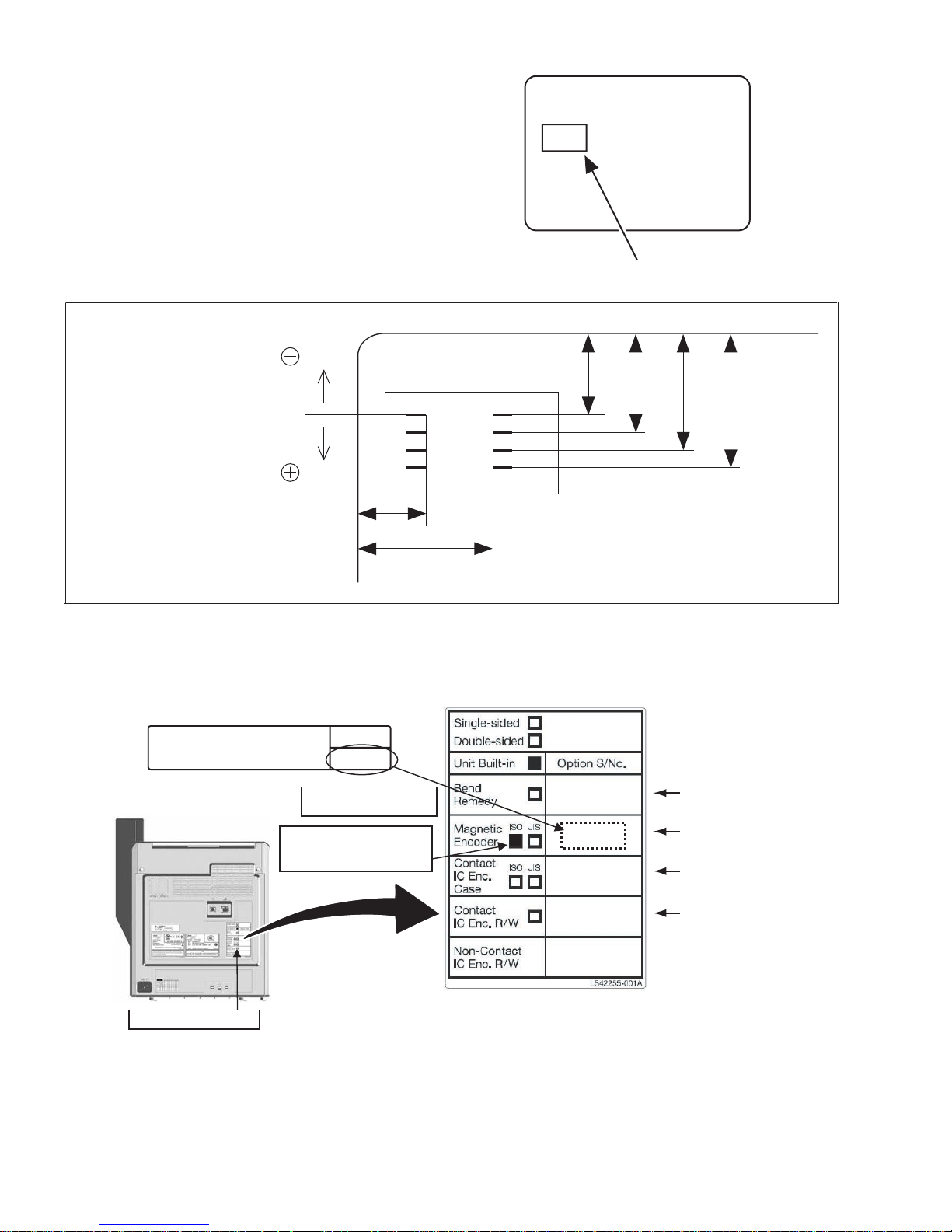

2.6.1 IC contact position adjustment

Apply a contact label (part number: KXL46372-001) on the IC

chip of a contact IC card.

Select the IC contact test from “off line test” in the service mode

to perform the test.

After the test, measure the IC contact position mark on the contact label using a vernier caliper to check if the position stays

within the specs.

If the position does not stay wi thin the spec s, correct the po sition

in the “OffsetContact” mode in the service mode.

When the position is corrected, turn off the power and turn it on

again before testing the IC contact.

(Specs)

direction

IC contact

position specs

direction

a

b

Contact label

(part number:KXL46372-001)

c

d e f

a : 10.25 ~ 12.25 mm

b : 17.87 ~ 19.87 mm

c : 19.23 ~ 20.93 mm

d : 21.77 ~ 23.47 mm

e : 24.31 ~ 26.01 mm

f : 26.85 ~ 28.55 mm

2.6.2 Optional installed label

When installing opt ional unit after ship ping from JVC, mark c orresponding col umn of option built- in label and stick model label attac hed

with optional unit to secure traceability.

Model label attached with option

Optional installed label

(ex. CF-7MGS)

NOTE)This option must be installed, following procedures

in the Service Manual , by a trained and skilled installer in

a facility. Stick the small label on the printer rear after

installation of this option unit.

CF-7MGS

Magnetic Encoder (ISO)

Rear side

Mark corresponding

CF-7MGS

xxxxxxxx

CF-7MGS

xxxxxxxx

Stick model label

For CF-7BR

For CF-7MGS

column

For CF-7CCS

For CF-7CRW

Installed option label

1-14 (No.HD017<Rev.001>)

Page 15

SECTION 3

DISASSEMBLY

Before disassembly, be sure to turn OFF the power and unplug

the power cord.

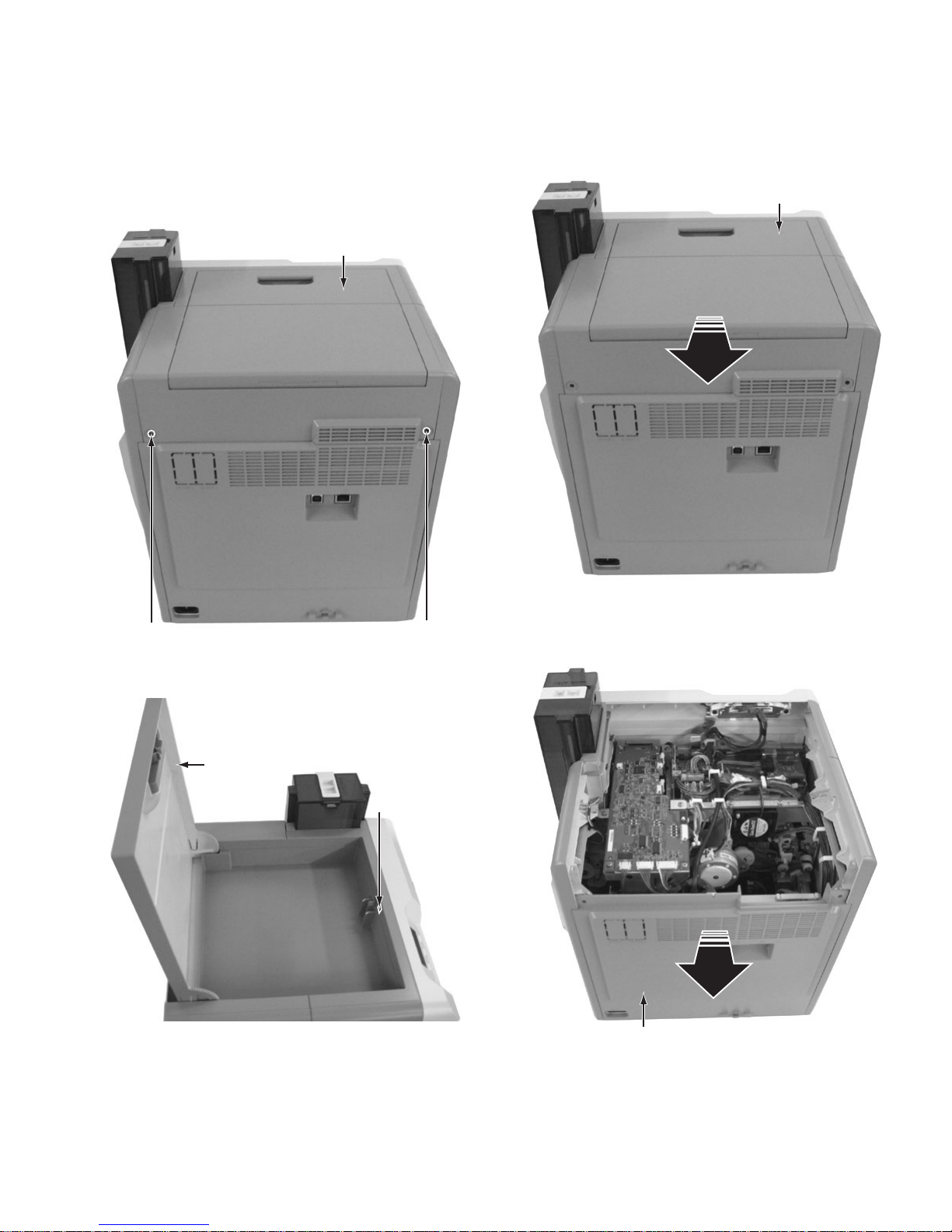

3.1 Removing the covers (See figure 1 to figure 5)

(1) Remove the two screws A attaching the top cover unit.

Top cover unit

(3) Slide the top cover unit to the rear side, then remove the

top cover unit.

Top cover unit

A

Fig.1

(2) Open the case cover, then remove the one screw B.

Case cover

B

Fig.2

A

Fig.3

(4) Pull the rear cover unit open to the rear side, then remove

the rear c over unit.

Rear cover unit

Fig.4

(No.HD017<Rev.001>)1-15

Page 16

(5) Remove the two screws C attaching the side cover U-R

and side cover U-L, then remove the side cover U-R and

side cover U-L.

(2) Remove the two screws D attaching the cover, then re-

move the cover.

C

Side cover U-R

Side cover U-L

C

Fig.5

3.2 Removing the front panel unit (See figure 6 to figure

13)

(1) Remove the Media F CA un it, the Ink F CA u nit, and the CL

Roller unit.

CL Roller unit

D

Cover

Head unit

Fig.7

(3) Remove the four screws E attaching the front panel unit.

• Be careful not to break the cable.

E

Front panel unit

E

Media F CA unit

Ink F CA unit

Fig.6

1-16 (No.HD017<Rev.001>)

E

Cable

E

Fig.8

Page 17

(4) Disconne ct the two c ables fro m the con nectors o n the front

Tab

Tab

board, then remove the one screw F.

F

Connectors

(6) Front panel unit with the co ver removed.

Front panel unit

Fig.9

(5) Press the two tabs, pull up the cover at the point marked

with an arrow, and then remove the cover.

Tab

Tab Tab

Tab

Cover

Fig.11

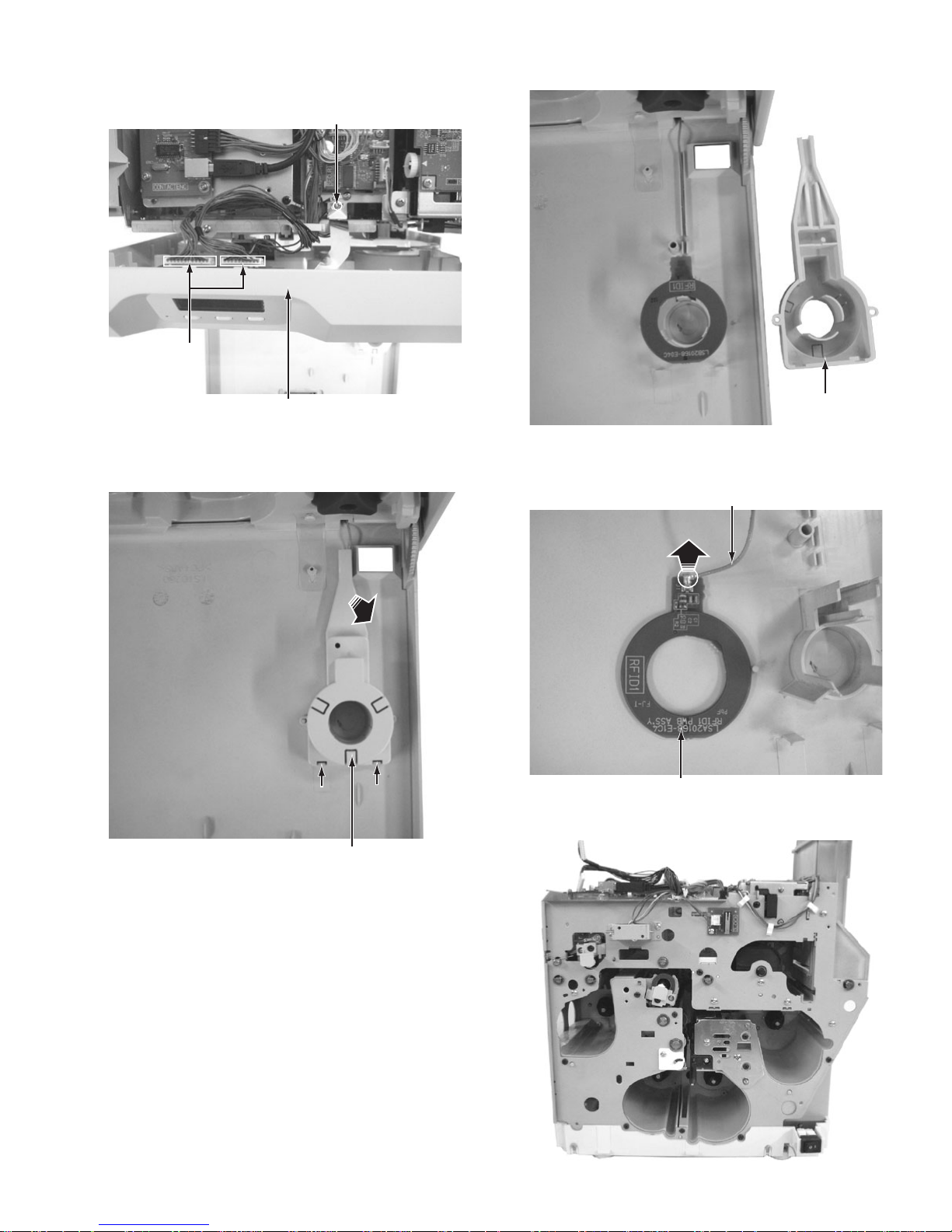

(7) Disconnecting the cable from the RFID1 board detaches

the front panel unit from the main unit.

Cable

RFID1 board

Fig.12

(8) Main unit with the front panel unit removed.

Fig.10

Cover

Fig.13

(No.HD017<Rev.001>)1-17

Page 18

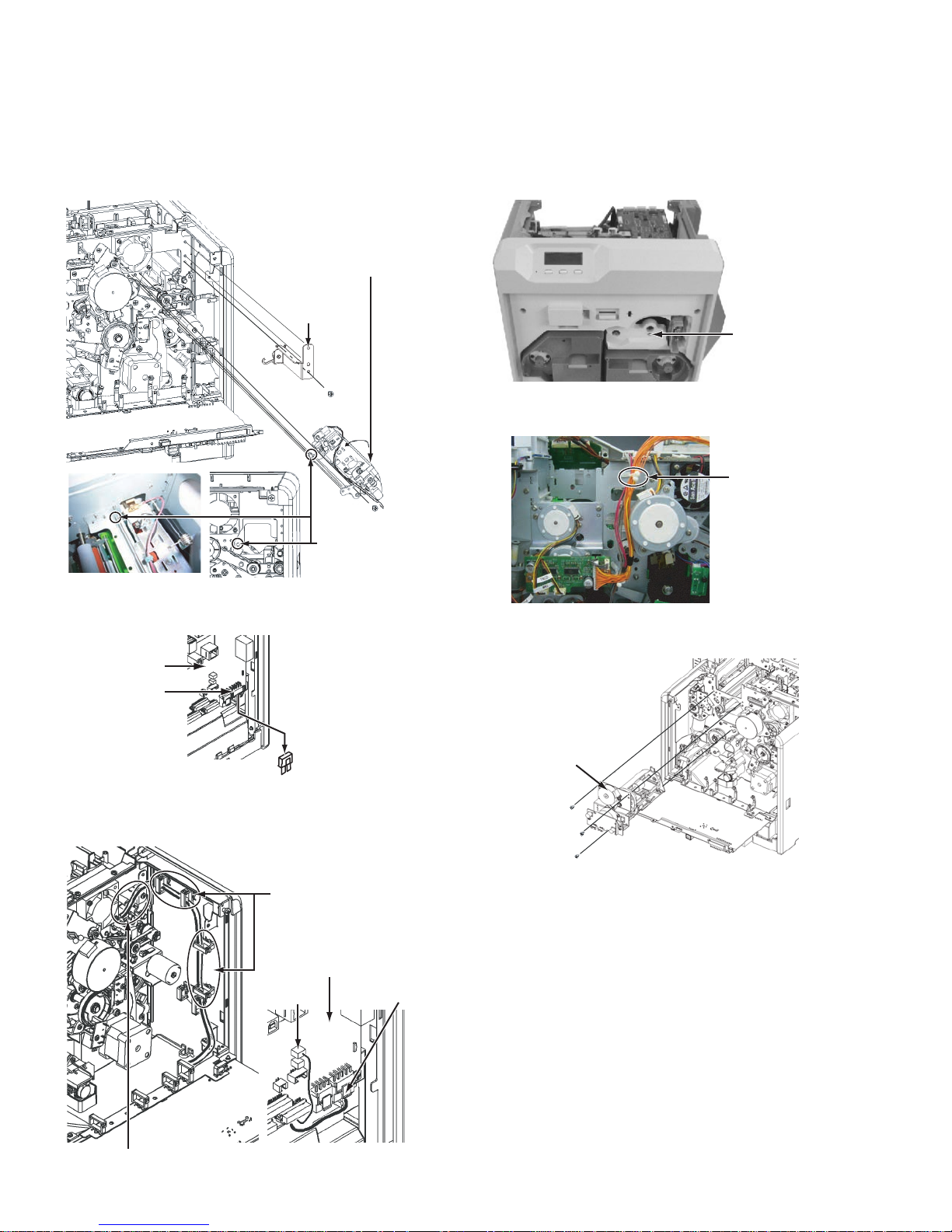

3.3 Removing the major boards and major units (See figure 14 to figure 34)

(1) Disconnect the four cables from the connectors on the

main board.

(2) Remove the four screws G attaching the main board.

(4) Hanging the left and right brackets on the mai n board to the

hooks on the chassis prev ents the main board fr om falling.

Hook

G

G

Main board

Connectors

Fig.14

(3) Pull the main board open to the rear side.

G

Fig.16

Hook

G

Main board

Fig.15

Fig.17

(5) Remove the three screws H attaching the MG encoding

unit, then remove the unit.

H

MG encoding unit

H

Fig.18

1-18 (No.HD017<Rev.001>)

Page 19

(6) Removed MG encoding unit.

Fig.19

(7) The KEY LOCK UNIT consists of a SECURITY PWB ASSY

and two solenoids.

SECURITY PWB ASSYSolenoid

(9) Remove the four screws K to release the SECURITY PWB

ASSY and the solenoid on the front side.

K

K

Solenoid

SECURITY PWB ASSY

Fig.22

(10) Removed KEY LOCK UNIT SET. (LS31237-201A)

Solenoid

Fig.20

(8) Remove the one screw J to release the solenoid on the

card stocker side.

J

Solenoid

Fig.21

Fig.23

(11) Remove the two screws L, then remove the bra cket with IC

R/W UNIT.

L

IC R/W UNIT

(CF-7CRW)

Fig.24

(No.HD017<Rev.001>)1-19

L

Page 20

(12) Removed IC R/W UNIT.

This bracket is an accessory of

the IC contact unit.

(14) Remove the two screws N attaching the cover, then re-

move the cover.

N

Fig.25

(13) Remove th e on e sc rew M attaching the bracket with CON-

TACTIFC board, then slide the CONTACTIFC board forward to remove.

CONTACTIFC board

M

Fig.26

Cover

N

Fig.28

(15) Before removing the IC contact unit, the turn unit needs to

be removed first.

IC contact unit

Fig.29

• To attach the CONTACTIFC board, insert the part a into

the slit on the front side.

Part a

Fig.27

1-20 (No.HD017<Rev.001>)

Page 21

(16) Remove the four screws P attaching the turn unit from the

front side and the rear side.

Turn unit

(18) Remove the two screws Q attaching the IC contact unit,

then remove the unit.

IC contact unit

P

(17) Removed turn unit.

Fig.30

Turn unit

Fig.31

P

Q

Fig.33

P

(19) Removed IC contact unit.

ISO: CF-7CCS

P

This bracket is an accessory of

the card printer unit.

Fig.34

Fig.32

(No.HD017<Rev.001>)1-21

Page 22

3.4 Replacing the head unit (See figure 35 and figure 36)

(1) Remove the one screw R attaching the head unit.

R

3.5 Removing the reform H unit (See figure 37 and figure

38)

(1) Remove the one scr ew S attaching the reform H unit, then

pull out the reform H unit.

(2) To replace the heater only, remove the one screw T.

Head unit

Fig.35

(2) Pull out the head unit paying attention to the cable, then

disconnect the two connectors.

Connectors

Note:

* Do not cut the cable lock. This cable lock is removable.

* Press to loosen the lock in the direction of the arrow.

The cable lock can be removed.

Fig.36

T

S

Fig.37

(3) Removed reform H unit.

Heater

Fig.38

3.6 Replacing the heater on the heat unit (See figure 39

and figure 40)

(1) Remove the one screw U attaching the cover from the front

side.

1-22 (No.HD017<Rev.001>)

U

Fig.39

Page 23

(2) Pulled out heater.

r

(3) Remove the five screws V attaching the motor base unit,

then remove the motor base unit.

V

Heater

Fig.40

3.7 Removing the motor base unit (See figure 41 to figure

44)

(1) Push two tabs on the PS cover, then remove the PS cov er.

PS cover

Fig.41

(2) Main unit with the PS cover removed

Motor base unitCable for head unit

V

Fig.43

(4) Main unit with the motor base unit removed.

Motor base unit

Power supply unit

Fig.42

When the gear is detached, the position of a triangula

sign and a round sign is matched and installed.

Fig.44

(No.HD017<Rev.001>)1-23

Page 24

SECTION 4

r

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

SECTION 5

TROUBLE SHOOTING

5.1 When an error message is display

When the error occurs, the error code and the e rror code number

are displayed in the operation panel.

Solve the error referring to the following when the error occurs.

XXXXXXXXX XX

Error code Error code numbe

5.1.1 No Card

No Card

• Cards have run out.

Replenish the cards.

• The card hopper is not installed.

Install the card hopper.

Memo:

• The operation panel display appears blinking when the

cards have run out o r when the c ard hop per is not installe d.

• Replenish the cards.

• The card hopper is able to store up to about 100 cards with a

thickness of 0.76 mm.

Cautions:

• Get ready cards that a re designat ed by the authoriz ed dealer.

• If the security lock is on, deactivate it. After work is complete,activate the security lock again.

• Do not touc h the printing su rface of the car d. Touching it

may cause printing e rrors. Pu t on th e sup plied gl oves when

handling the cards.

• To prevent card jams from occurring, limit the number of

cards stored in the card hopper at any time to about 100

pieces regardless of the card thickness.

• When using new card s, set them after m aking sure that th ey

are not adhered to each other due to static.

• Align the cards before setting them in the printer. Otherwise, the card hopper cover may not close properly, and

this may damage the printer.

• Printing th e card on the si de with the magn etic st ripe may

cause printing errors or damage to the card’s functions. If

you want to do so, plea se c on sult our authorized dealers in

advance.

• To set cards with both functions (magnetic stripe and contact IC),follow the procedure for se tting the co ntact IC card.

(1) Set the card hopper knob to [OPEN].

(2) Lift to remove the card hopper cover.

(3) Align the orientation of the cards, and set them in the

printer.

• Magnetic stripe cards

- Set the card with the magnetic stripe facing upward

and toward the printer, or facin g downward and toward

you.

• ISO contact IC cards

- Set the card with the Contact IC terminal facing upward and toward the rear of the printer, or downward

and toward the rear of the printer.

- For single-sided printers, set the cards with the IC terminal facing down and toward the rear of the printer.

(4) Install the card hopper cover, and set the card hopper

knob to [LOCK]

1-24 (No.HD017<Rev.001>)

Page 25

5.1.2 Jam(Hopper) 90

Jam (Hopper) 90

• Card jam near the card hopper and cleaning roller.

Remove the jammed card.

Note:

• Do not apply excessive force on the card hopper. Doing so

may damage it.

• Do not touch the printing surface of the card. Touching it

may cause printing errors. Put on the supplied gloves when

handling the cards.

(1) Detach the card hopper cover, and remove the unused

cards.

• The card is discharged from the NG card outlet.

5.1.2.2 If the card cannot be discharged

(1) Turn off the power.

(2) Open the printer door, and check the position of the

jammed card.

(3) Attach the jog dial to the cleaning roller shaft.

(2) Remove the jammed card with a hand.

(3) Return the unused cards to their original position.

(4) Install the card hopper cover.

5.1.2.1 If the card cannot be removed by hand.

(1) Press [RESET] → to reset the printer.

(4) Turn the cleaning roller shaft in the clockwise direction,

while checking the position of the card.

(5) Remove the card after it is discharged from the card load

slot.

(6) Restore the jog dial to its original position, and close the

printer door.

(7) Turn on the power.

(No.HD017<Rev.001>)1-25

Page 26

5.1.3 Jam(TurnOver) 91

Jam (Turn Over) 91

• Card jam near the card turn over unit.

Remove the jammed card.

(1) Turn off the power.

(2) Remove the card hopper.

(6) Install the cleaning unit.

(7) Attach the jog d ial to the card t urn over un it s haf t, an d set

the card turn over unit to “Home Pos.”

• “Home Pos.” is the position where the slit on the jog dial

points to the righ t and the card turn over unit is h orizontal.

(3) Detach the card load slot cover.

(4) Open the printer door, and remove the cleaning unit.

(8) Restore the jog dial to its original position.

(9) Install the card load slot cover and card hopper, and close

the printer door.

(10) Turn on the power.

Cautions:

• When a Jam(TurnOver) error occurs, the [Jam(TurnOver)]

message will not d isappear after re moving the jam med card

until the card turn over unit is set to “Home Pos.”.

• If the printer door is opened when a Jam(TurnOver) error

occurs, a [Please Adjust Turn Unit Pos!] message will be

displayed. Remove the jammed card, and set the card turn

over unit to “Home Pos.”.

5.1.3.1 If the card cannot be removed

(1) Install the cleaning unit.

(2) Attach the jo g di al to t he c le ani ng roll er s ha ft an d c ard turn

over unit shaft.

(5) Remove t he jammed card i n the card turn o ver unit from the

card load slot.

1-26 (No.HD017<Rev.001>)

Page 27

(3) Set the card turn over unit to “Home Pos.”

• “Home Pos.” is the position where the slit on the jog dial

points to the righ t and the card t urn over unit is horizontal.

• If the card protrudes fr om the card turn over u nit, turn the

cleaning roller shaft to move the card into the unit.

• Turning the card turn over un it moves the c ard inside the

unit outward. Turn the card turn over unit while turning

the cleaning roller s haft so that th e card is reta ined inside

the card turn over unit, and set to “Home Pos.”.

5.1.4 Jam(MG) 92

Jam (MG) 92

• Card jam in the magnetic encoder unit.

Remove the jammed card.

(1) Press [RESET] → to reset the printer.

• The card is discharged from the NG card outlet.

Cautions:

• Do not turn the ca r d t urn ov er un it fo rc i bl y if the r e i s a ca rd

inside the unit.

Doing so may jam the card and damage the printer.

(4) Turn the cleaning roller shaft in the clockwise direction.

(5) Remove the card after it is discharged from the card load

slot.

Go to step 8 of 5.1.3.

5.1.5 Jam(Transfer) 93

Jam (Transfer) 93

• Card jam in the card feed roller.

Remove the jammed card.

(1) Press [RESET] → to reset the printer.

(No.HD017<Rev.001>)1-27

Page 28

• The card is discharged from the NG card outlet.

5.1.5.1 If the card cannot be discharged

(1) Turn off the power, and detach the card hopper.

(2) Open the printer door, and check the position of the

jammed card.

(3) Attach the jo g dial to the car d feed roller sh aft and clean ing

roller shaft.

5.1.6 Jam(Discharge) 94

Jam (Discharge) 94

• Card jam near the card outlet.

Remove the jammed card.

(1) Press [RESET] → to reset the printer.

• The card is discharged from the card outlet.

.

(4) Turn the card feed roller shaft and cleaning roller shaft in

the clockwise direction, while checking the position of the

card.

• Remove the card a fter it is discha rged from t he card l oad

slot.

(For single-sided printers, the card is discharged from

the NG card outlet.)

(5) Restore the jog dial to its original position.

(6) Install the card hopper, and close the printer door.

(7) Turn on the power.

5.1.6.1 If the card cannot be discharged

(1) Turn off the power, and open the printer door.

(2) Pull out the retransfe r film c assette, an d chec k the po sition

of the card.

(3) Attach the jog dial to the card feed roller shaft.

1-28 (No.HD017<Rev.001>)

Page 29

(4) Turn the card feed roller shaft in the anti-clockwise direc-

tion, while checking the position of the card.

• The card is discharged from the card outlet.

(5) Restore the jog dial to its original position, and install the re-

transfer film cassette.

(6) Close the printer door, and turn on the power.

5.1.7 Jam(Retran.) 95

Jam(Retran.) 95

• Card jam near the retransfer heating roller.

Remove the jammed card.

(1) Open the printer door.

• A [Please Remove Jam Card!] or [Please Close Door]

message appears.

(2) Pull out the retransfer film cassette.

(5) Press [RESET] .

• A [Jam Card Removed?] message appears.

(6) Press [Yes] .

Cautions:

• Initializing the printer without first removing the card will

cause the printer to m alfunction. Be sure to remove the card

then press [Yes].

• An [Initializing..] message appears, and initialization of

the printer starts.

Cautions:

• The card may be adhered to the retrans fer film. Pu ll out the

retransfer film while taking care not to jam it.

• If a [Please Close Door] me ssage is di splayed , the retransfer film is stuck and the retransfer film cassette cannot be

removed.

In this case, close the print er door before pullin g out the retransfer film cassette.

(3) Remove the jammed card.

There is an explanation in each sympt om.

• If the card is adhered to the retransfer film.

• If the card is inside the printer unit.

• If the card is caught in the card feed roller to the right of

the retransfer heating roller.

• If the card is caught in the card fee d roller to the left of the

retransfer heating roller.

(4) Install the retransfer film cassette, and close the printer

door.

5.1.7.1 If the card is adhered to the retransfer film

• Remove the jammed card with a hand.

Cautions:

• The card may be very h ot. Be carefu l not to burn yo ur fingers when removing the card.

Go to step 4 of 5.1.7.

(No.HD017<Rev.001>)1-29

Page 30

5.1.7.2 If the card is inside the printer unit

• If the card is n ot drawn in to the card feed roller a nd is left i nside

the printer, use the tweezers (supplied) to remove the card.

(1) Turn off the power.

(2) Check the positi on of the card that is left inside the printer.

(3) Pick up the card us ing the tip of th e card Pickup . (supplied )

• Be careful not to drop the card inside the printer.

(4) Pull out the card slowly.

5.1.7.3 If the card is caught in the card feed roller to the

right of the retransfer heating roller

(1) Turn off the power, and detach the card hopper.

(2) Check the position of the card.

(3) Attach the jo g dial to the car d feed roll er shaft and cl eaning

roller shaft.

Cautions:

• The card may be very hot. Be careful not to burn your fingers when removing the card.

Memo:

Example of how to pick up the card

• Pick up the card by following the diagram above.

(5) Install the retransfer film cassette, and close the printer

door.

(4) Turn the card feed roller shaft and cleaning roller shaft in

the clockwise direction, while checking the position of the

card.

• Remove the card a fter it is discha rged from t he card l oad

slot.

(For single-sided printers, the card is discharged from

the NG card outlet.)

(5) Restore the jog dial to its original position, and install the

card hopper.

(6) Install the retransfer film cassette, and close the printer

door.

(7) Turn on the power.

Go to step 5 of 5.1.7.

(6) Turn on the power.

Go to step 5 of 5.1.7.

1-30 (No.HD017<Rev.001>)

Page 31

5.1.7.4 If the card is caught in the card feed roller to the

left of the retransfer heating roller

(1) Turn off the power.

(2) Check the position of the card.

(3) Attach the jog dial to the card feed roller shaft.

(4) Turn the card feed roller shaft in the anti-clockwise direc-

tion, while checking the position of the card.

• The card is discharged from the card outlet.

(5) Restore the jog dial to its original position.

(6) Install the retransfer film cassette, and close the printer

door.

(7) Turn on the power.

Go to step 5 of 5.1.7.

5.1.8 Film Search A1

Film Serch A1

• Retransfer film is broken.

Repair the retransfer film.

Cautions:

• If the security lock is on, deactivate it. After work is complete, activate the security lock again.

• Stand the cass ette on a f lat surface as illustrated in the di agram.

Avoid doing so on the floor as dust atta ched to it may ca use

printing errors.

• Do not touch the retransfer face (the side that faces outward

when installed) with your hand . Touching it may cau se printing errors. Put on the suppl ied g loves when handl ing th e retransfer film.

• The cassette i s hea vy wh en the retran sfer fi lm i s loa ded. T o

prevent the cassette from dropping during handling, make

sure to hold it with both hands.

• When installing a used re transfer fil m, align the unused s ide

of the film with the arrow indicated on the label of the cassette. Improper alignment may result in errors, or the print

may turn out light.

• Do not perform any work on the printer door. Do not place

heavy objects or apply load on the printer. Doing so may

damage it.

• During replacement, clean the four bobbin holders on the

printer. If burrs produced by friction with the bobbins are attached to the bobbin hold ers, they m ay fall onto the card, ink

ribbon, or retransfer film, causing printing errors.

(1) Open the printer door.

(2) Press and hold down the cassette button, and remove

the retransfer film cassette. (on the left)

(3) Cut away the broken portion, an d attach the unus ed portion

at the supply sid e to the other end at the take-up s ide usi ng

an adhesive tape, while making sure that the joint surface

is even.

Cautions:

• Do not discard the used retransfer film at the take-up side.

(No.HD017<Rev.001>)1-31

Page 32

(4) Turn the take-u p side using your hand until the brok en por-

tion can no longer be seen.

5.1.9 MG Test Err A8

MG Test Err A8

• A writing error has occurred during magnetic encoder self-diagnosis.

Press [RESET] → to reset the printer.

• Align the film side of the unused portion with the arrow indicated on the label of the cassette.

(5) Remove any slack in the film.

(6) Insert the ca ssette all the way in along the guide rail un til

a “click” sound is heard, followed by closing the printer

door.

(7) Press [RESET] → to reset the printer.

5.1.10 Ink Error B0

Ink Error B0

• An incorrect ink ribbon is installed.

Install a correct ink ribbon.

5.1.11 Ink Search B1

Ink Serch B1

• Ink ribbon is broken.

Repair the ink ribbon.

Cautions:

• If the security lock is on, deactivate it. After work is complete, activate the security lock again.

• Stand the cassette on a flat surface as illustrated in the diagram. Avoid doing so on the floor as dust attached to it

may cause printing errors.

Memo:

• To avoid printi ng errors , it is recommende d that you forward

by one or two images after inst allin g the ink rib bon casse tte

or retransfer film cassette.

• Do not touch the inked s urface (the side that fac es outward

when installed) with your hand. Touching it may cause

printing errors. Put on the supplied gloves when handling

the ink ribbon.

• The cassette is heavy when the ink ribbon is loaded. To

prevent the cassette from dropping during handling, make

sure to hold it with both hands.

• When installing a used ink ribbon, align the yellow side of

the unused ribbon with the arrow indicated on the label of

the cassette. If the posi tion of the yellow side is not properly

aligned, the print may turn out light.

• Do not perform any work on the printer door. Do not place

heavy objects or apply load on the printer. Doing so may

damage it.

• During replacement, clean the four bobbin holders on the

printer. If burrs prod uced by frictio n wi th the b obbin s are a ttached to the bobbin holders, they may fall onto the card,

ink ribbon, or retransfer film, causing printing errors.

(1) Open the printer door.

1-32 (No.HD017<Rev.001>)

Page 33

(2) Press and hold down the cassette button, and remove

the ink rib bon cassette. (on the right)

(3) Cut away the broken portion, an d attach the unus ed portion

at the supply sid e to the other end at the take-up s ide usi ng

an adhesive tape, while making sure that the joint surface

is even.

Cautions:

• Do not discard the used ribbon at the take-up side.

(4) Turn the take-up sid e using your hand unt il the broken por-

tion can no longer be seen.

(7) Press [RESET] → to reset the printer.

Memo:

• To avoid printing errors, it is rec ommended that y ou forward

by one or two image s after ins talling t he ink rib bon ca ssette

or retransfer film cassette.

5.1.12 Door Open D1

Door Open D1

• Align the yellow sid e of the unused po rtion with the arrow

indicated on the label of the cassette.

(5) Remove any slack in the ink ribbon.

(6) Insert the cass ette all the w ay in along the gui de rail until

a “click” sound is heard, followed by closing the printer

door.

• The printer door is open.

Close the printer door, and Press [RESET] → to reset the

printer.

• Cleaning unit is not installed.

Install the cleaning unit, close the printer door, and press

[RESET] → to reset the printer.

Memo:

• The operation pane l display appears blin king when the print er door is open or when the cleaning unit is not installed.

5.1.13 Film Run Out A2

Film Run Out A2

• Retransfer film has run out.

Replace with a new one.

5.1.14 Ink Run Out B2

Ink Run Out B2

• Ink ribbon has run out.

Replace with a new one.

5.1.15 Hardware 44

.

Hard ware 44

• A hardware failure has occurred on the printer.

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

(No.HD017<Rev.001>)1-33

Page 34

5.1.16 MG Mechanical AB

5.1.23 TR Thermister F2

MG Mechanical AB

• An error has occurred in the mechanical component of the

magnetic encoder.

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

5.1.17 MG Hardware AC

MG Hardware AC

• A hardware failure has occurred on the magnetic encoder.

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

5.1.18 Cam Error C1

Cam Error C1

• A heating roller operation error has occurred .

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

5.1.19 HR Overheat C2

HR Overheat C2

TR Thermister F2

• The retransfer heating roller thermistor is faulty.

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

5.1.24 RR Overheat F3

RR Overheat F3

• The temperature o f the bend remedy heating ro lle r i s too high.

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

5.1.25 RR Heater F4

RR Heater F4

• The bend remedy unit is faulty.

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

5.1.26 RR Thermister F5

RR Thermister F5

• The temperature of the bend remedy heating roller or retransfer heating roller is too high.

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

5.1.20 Hardware D8

Hardware D8

• A hardware error has occurred during initialization.

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

5.1.21 TR Overheat F0

TR Overheat F0

• The temperature of the retransfer heating roller is too high.

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

5.1.22 TR Heater F1

TR heater F1

• The bend remedy heating roller thermistor is faulty.

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

5.1.27 Overcool F6

Overcool F6

• The operating ambient temperature of the printer is too low.

Check the te mp e rat u re. I f th e s am e pro bl e m re cu r s wit hin t h e

range of operating ambient temperatu re, turn off th e power and

consult our authorized dealers.

5.1.28 Head Overheat F8

Head Overheat F8

• The temperature of the thermal head is too high.

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

5.1.29 Power Intrpt C3

Power Intrpt C3

• The retransfer heating roller is faulty.

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

1-34 (No.HD017<Rev.001>)

• An instantaneous interruption is detected.

Turn off and on the power again. If the same problem recurs,

turn off the power and consult our authorized dealers.

Page 35

5.2 Use of service mode

Besides "User mode" that is for setting this unit depending on the printing media or card used by the user, there is a "Service mode"

for status checking and changing setting of this unit during service. The checking and adjustment of the following items can be performed in service mode:

(1) Fine adjustment of the printing position

(2) Printing of built-in test pattern

(3) Operation checking of various motors and sensors

(4) Information display of printer

(5) Saving of setting data

(6) Setting change of user mode

For user mode, only the items that can be changed in this mode are described.

For details of other items, please refer to the instruction manual.

5.2.1 Entry into service mode

In ready condition, in preheating condition, or in error condition, press the buttons [MENU] and [Center button] simultaneously.

When the button [MENU] is released first, the printer will enter into the following service mode.

>Maintenance> >>Offset Prt Y

[NEXT]

[ENTER]

[EXIT]

>>Offset Prt X

>>Offset Trf X

>>Offset Card X

>>Ink Snsr Lvl

>>Film Snsr Lvl

>>IC ContactType

>>OffsetContact

>>ISO Hico Type

>>JIS Loco Type

>>IC Antenna

>>Vth Gain

>>Ink Eco Mode

>>B.RemedySpeed

[ENTER]

>User Mode>

[NEXT]

[EXIT]

>>Media

>>Print

1 1

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

Setting of the printing position Y

[-15(Front) ~ -1(Front),0,+1(Back) ~ +15(Back)]

Select with [ ] and save with [ ].

Setting of the printing position X

[-7(Left) ~ -1(Left),0,+1(Right) ~ +7(Right)]

Select with [ ] and save with [ ].

Setting of the retransfer position X

[-14(Left) ~ -1(Left),0,+1(Right) ~ +14(Right)]

Select with [ ] and save with [ ].

Setting of the card stop position X

[-7(Left) ~ -1(Left),0,+1(Right) ~ +7(Right)]

Select with [ ] and save with [ ].

Adjust the threshold level of the Ink-Sensor

[0 ~ 254]

Select with [ ] and save with [ ].

Adjust the threshold level of the Film-Sensor

[0 ~ 254]

Select with [ ] and save with [ ].

Select IC Contact Type

[ISO/JIS]

Select with [ ] and save with [ ].

Setting of the Offset Contact

[-15 ~ -1, 0, 1 ~ +15]

Select with [ ] and save with [ ].

Select ISO Hico Type

[Standard, Super]

Select with [ ] and save with [ ].

Select JIS Loco Type

[Standard, Overlay]

Select with [ ] and save with [ ].

Setting of IC Antenna

[None, Installed]

Select with [ ] and save with [ ].

Vth Gain Adjustment

[0 ~15]

Select with [ ] and save with [ ].

Ink Eco Mode Setting

[On,Off]

Select with [ ] and save with [ ].

Transporting Speed Setting

[Standard,Fast]

Select with [ ] and save with [ ].

[ENTER]

[EXIT]

[ENTER]

[EXIT]

>>>Film Type

[NEXT]

>>>Card Thickness

>>>YMC Level

[NEXT]

>>>Black Level

[NEXT]

>>>Black Mode

[NEXT]

>>>UV Level

[NEXT]

>>>PO Level

Select the re-transfer film

[1000 ~ 750]

Select with [ ] and save with [ ].

Select the card thickness

[Standard, Thin]

Select with [ ] and save with [ ].

Setting of the YMC level

[-3 ~ -1, 0, +1 ~ +3]

Select with [ ] and save with [ ].

Setting of the black level

[-3 ~ -1, 0, +1 ~ +3]

Select with [ ] and save with [ ].

Select the black mode

[Standard, Fine]

Select with [ ] and save with [ ].

Setting of the UV ink level

[-3 ~ -1, 0, +1 ~ +3]

Select with [ ] and save with [ ].

Setting of the peel off ink level

[-3 ~ -1, 0, +1 ~ +3]

Select with [ ] and save with [ ].

(No.HD017<Rev.001>)1-35

Page 36

1 1

>>Retransfer >>>Temp Level

>>Bend Remedy

>>Heat Roller

>>Setting

>>MG

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[ENTER]

[EXIT]

[ENTER]

[EXIT]

[ENTER]

[EXIT]

[ENTER]

[EXIT]

[ENTER]

[EXIT]

[NEXT]

>>>Speed (Front)

[NEXT]

>>>Speed (F-UV)

[NEXT]

>>>Speed (Back)

[NEXT]

>>>Speed (B-UV)

[NEXT]

>>>MG Peel Mode

[NEXT]

>>>Standby Mode

[NEXT]

>>>Backside Cool

>>>Temp Level

[NEXT]

>>>Speed

>>>Power Saving

[NEXT]

>>>HR Control

>>>Display

[NEXT]

>>>Buzzer

[NEXT]

>>>Unit No.

>>>ISO Type

[NEXT]

>>>Retry Count

Setting of the retransfer heating roller temperature

[-2, -1, 0, +1, +2]

Select with [ ] and save with [ ].

Setting of the front side retransfer speed

[-3 ~ -1, 0, +1, +2]

Select with [ ] and save with [ ].

Setting of the retransfer speed of the second panel on the front side

during UV ink printing of retransfer films in two panels

[-3 ~ -1, 0, +1, +2]

Select with [ ] and save with [ ].

Setting of the back side retransfer speed

[-3 ~ -1, 0, +1, +2]

Select with [ ] and save with [ ].

Setting of the retransfer speed of the second panel on the back side

during UV ink printing of retransfer films in two panels

[-3 ~ -1, 0, +1, +2]

Select with [ ] and save with [ ].

Select method for peeling the retransfer film

[Standard, MG Stripe]

Select with [ ] and save with [ ].

Select whether to standby using the front or back side

[Front wait, Back wait]

Select with [ ] and save with [ ].

Select time interval for cooling the card

[On, Off]

Select with [ ] and save with [ ].

Setting of the bend remedy heating roller temperature

[-5 ~ -1, 0, Off]

Select with [ ] and save with [ ].

Setting of the bend remedy speed

[-2, -1, 0, +1, +2]

Select with [ ] and save with [ ].

Setting of the time for the Power Saving mode

[5, 10, 15, 20, 25, 30, 45, 60, Off]

Select with [ ] and save with [ ].

Select whether to standby the printer

[Off, On]

Select with [ ] and save with [ ].

[ENTER]

[EXIT]

>>>>Mode

[NEXT]

>>>>Counter

[NEXT]

>>>>Contrast

Select buzzer

[On, Off]

Select with [ ] and save with [ ].

Setting of the unit number

[No.1 ~ No.10]

Select with [ ] and save with [ ].

Select antimagnetic force when writing data

[Loco, Hico]

Select with [ ] and save with [ ].

Setting of the maximum number of retries

[0 ~ 3]

Select with [ ] and save with [ ].

Select display mode

[Counter, Laminator State]

Select with [ ] and save with [ ].

Select counter

[Total Cnt, Head Cnt, Free Cnt, Cleaning Cnt, Error Cnt]

Select with [ ] and save with [ ].

Setting of the contrast

[-3 ~ -1, 0, +1 ~ +3]

Select with [ ] and save with [ ].

2 2

1-36 (No.HD017<Rev.001>)

Page 37

2

>>Network

2

[ENTER]

[EXIT]

>>>Host IF

[NEXT]

>>>IPv4

[NEXT]

>>>IPv6

[NEXT]

>>>Session Time Out

[NEXT]

>>>IPSec Mode

Select interface

[LAN, USB]

Select with [ ] and save with [ ].

[ENTER]

[EXIT]

[ENTER]

[EXIT]

Setting of the session timeout interval.

[Off, 10min, 20min, 30min, 60min]

Select with [ ] and save with [ ].

Select availability of IPSec

[Off, On]

Select with [ ] and save with [ ].

>>>DHCP

>>>Adrs Config

Switching DHCP

[On, Off]

Select with [ ] and save with [ ].

Setting of the IPv6

[Auto, Manual]

Select with [ ] and save with [ ].

>Parameter Print

[NEXT]

>Offline Test> >>Pattern

[NEXT]

Select printer or laminator

[ENTER]

[EXIT]

>>Side

>>Times

>>Test

>Diag Test> >>Actuator>

[NEXT]

[ENTER]

[EXIT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

Test pattern setting

[Step, Registration, Address, Color, Vth, Gray, Black, Normal, Adjust, All]

Select with [ ] and save with [ ].

Switching between printing single side and both sides

[Single, Both]

Select with [ ] and save with [ ].

Setting of the number of times for testing

[1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 20, 30, 40, 50, 100, 200, 300, 400, 500, Free]

Select with [ ] and save with [ ].

Setting the test type

[Print, Feed, IC(Contact), IC(Antenna), MG]

Select with [ ] and save with [ ].

[ENTER]

[EXIT]

>>>Ink TUP Enc

[NEXT]

>>>Ink TUP Mo

[NEXT]

>>>Ink SPY Mo

[NEXT]

>>>Film TUP Mo

[NEXT]

>>>Film SPY Mo

[NEXT]

>>>Card Feed Mo

[NEXT]

>>>Turn Over Mo

[NEXT]

>>>Turn Feed Mo

[NEXT]

>>>Card Load Mo

[NEXT]

>>>Cam Mo-Platen

[NEXT]

>>>Cam Mo-HR

Ink take-up encoder

Ink take-up motor

Ink supply motor

Film take-up motor

Film supply motor

Card feed motor

Turnover motor

Turnover card feed motor

Card load motor

Cam motor-Platen

Cam motor-Heater

33

(No.HD017<Rev.001>)1-37

Page 38

33

>>Sensor

0010010001100100

[NEXT]

>>Memory

[NEXT]

>>Display

In case of an error, the buzzer sounds and the LED lights.

When there is no error, the indication just returns to the initial indication.

[ ]

>Information>

[NEXT]

[ENTER]

[EXIT]

[NEXT]

>>Back Color

[NEXT]

>>Register>

>>Firmware Ver

[NEXT]

>>Config Ver

[NEXT]

>>Table Ver

[NEXT]

>>Thermal Head

[NEXT]

>>Assistance

[NEXT]

>>HR POT>

[NEXT]

Display for 1 sec Display for 1 sec

[ENTER]

[EXIT]

Display for 1 sec Display for 1 sec Display for 1 sec

>>>ADPORT0

[NEXT]

>>>ADPORT1

Firmware version

Configure version

Table version

Information of Thermal Head

[ENTER]

[EXIT]

>>>Retransfer

[NEXT]

>>>Bend Remedy

Value obtained by A/D conversion of

the thermistor value of the heater or head.

>Push

[NEXT]

>Pop

[NEXT]

>Error Log Clear

[NEXT]

4

>>HR POT Reset>

[ENTER]

[EXIT]

>>>Retransfer

>>>Bend Remedy

Parameter settings save in the head EEP-ROM.

* The buzzer beeps in case of an error.

Loading the parameter settings from the head EEP-ROM.

* If the correct data is not stored by the head EEP-ROM,

"No Data" is displayed and the buzzer beeps.

Cleared the error log

Cleared the total lighting time of the heat roller

[NEXT]

1-38 (No.HD017<Rev.001>)

Page 39

>Laminator>

4

[ENTER]

[EXIT]

>>User Mode>

[NEXT]

[ENTER]

[EXIT]

>>>Mode

[NEXT]

>>>Film-T

[NEXT]

>>>Film-B

[NEXT]

>>>Film-T Pos

[NEXT]

>>>Film-B Pos

[NEXT]

>>>HR-T Temp

[NEXT]

>>>HR-B Temp

[NEXT]

>>>Speed

[NEXT]

>>>Cooling Time

Select operational mode

[Laminate, Pass]

Select with [ ] and save with [ ].

Select film used with upper cassette

[Patch, Overlay]

Select with [ ] and save with [ ].

Select film used with lower cassette

[Patch, Overlay]

Select with [ ] and save with [ ].

Patch position setting of film traveling direction

[-7 ~ -1,0,+1 ~ +7]

Select with [ ] and save with [ ].

Patch position setting of film traveling direction

[-7 ~ -1,0,+1 ~ +7]

Select with [ ] and save with [ ].

Setting of the heating roller temperature

O

C] (Different according to the version of the firmware.)

[90 ~ 180

Select with [ ] and save with [ ].

Setting of the heating roller temperature

O

C] (Different according to the version of the firmware.)

[90 ~ 180

Select with [ ] and save with [ ].

Setting of the card transportation speed at lamination

[3 ~ 12 mm/s]

Select with [ ] and save with [ ].

Setting of card cooling standby time before lamination

[0, 5, 7, 10, 15, 20, 30 sec]

Select with [ ] and save with [ ].

>>Maintenance>

[NEXT]

[ENTER]

[EXIT]

>>>Card Pos

>>>PM Snsr-T Lvl

>>>PM Snsr-B Lvl

>>>EM Snsr-T Lvl

>>>EM Snsr-B Lvl

>>Information> >>>Firmware

[ENTER]

[EXIT]

>>>Total Count

>>>HR-T Temp

>>>HR-B Temp

>>>HR-T POT

>>>HR-B POT

>>>HR-T POT Rst

>>>HR-B POT Rst

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

[NEXT]

Setting of the card stop position X

[-7(Left) ~ -1(Left),0,+1(Right) ~ +7(Right)]

Select with [ ] and save with [ ].

Adjust the threshold level of the Marker Sensor T

[1 ~ 10]

Select with [ ] and save with [ ].

Adjust the threshold level of the Marker Sensor B

[1 ~ 10]

Select with [ ] and save with [ ].

Adjust the threshold level of the End Sensor T

[1 ~ 10]

Select with [ ] and save with [ ].

Adjust the threshold level of the End Sensor B

[1 ~ 10]

Select with [ ] and save with [ ].

Laminator Firmware version

Laminator Total Counter

Laminator Heater-T Temperature

Laminator Heater-B Temperature

Laminator Heater-T Power on time

Laminator Heater-B Power on time

Laminator Heater-T Power on time Reset

Laminator Heater-B Power on time Reset

(No.HD017<Rev.001>)1-39

Page 40

5.3 Explanation of the Various Modes

5.3.1 Maintenance

Set to this mode if a constant setting that is different from the

standard setting of this unit is to be used.

In addition, the printing position is adjusted using the following 4

items. Do not change "Offset Card X" as it is the reference of X

direction (card transport direction). Follow 5.3.1.2 and 5.3.1.3 to

perform adjustment.

• Item for changing the position of longer side of the card:

(1) Item 5.3.1.1: Offset Prt Y --- Adjust the start position

used for printing within the thermal head heat source.

• Item for changing the position of shorter side of the card:

(1) Item 5.3.1.2: Offset Prt X --- Adjus t the feed amount from

the black marker of re-transfer film to the start position of

printing. (adjust the printing position on the re-tr ansfer

film)

(2) Item 5.3.1.3: Offset Trf X --- Adjust the feed amount up

to the start position of re-transfer film. (adjust the retransfer position for the card)

(3) Item 5.3.1.4: Offset Card X --- Adjust the feed amount

from the card edge sensor to the card. (adjust the card

position for starting re-transfer)

5.3.1.1 Offset Prt Y Setting

(1) Determine s the displace ment amount ac cording to the p rint

results (those owned by the us er). Every st ep co rrespo nds

to a displacement of about 0.17 mm. The step can be v ar-

ied in the range between -15 and +15.

(2) Press [ ] to save the setting.

(3) Print and check the result.

(4) To adjust to the standard setting:

In the service mode, print color patterns on single sides of

4 to 5 cards.

Adjust so that the distance from the card edge to the box

enclosing the line (A) is a bout 2 .15 mm . (Ch eck the thir d to

fifth cards.)

B=2.07mm

X

A=2.15mm

BACK

LEFT RIGHT

R

G

Y

(3) Print and check the result.

(4) To adjust to the standard setting:

In the service mode, print color patterns on single sides of

4 to 5 cards. And then remove the film cassette.

Adjust so that the distance from the black marker on the

film to the remaining vertical line (P) is about 8.5 mm.

(Check the third to fifth cards.)

P

Take-up side

Supply side

5.3.1.3 Offset Trf X Setting

(1) 1) Determine the displacement amount according to the

print results (those owned by the user). Every step corresponds to a displacemen t of about 0.085 mm. The ste p can

be varied in the range between -14 and +14.

(2) Press [ ] to save the setting.

(3) Print and check the result.

(4) To adjust to the standard setting:

In the service mode, print color patterns on single sides of

4 to 5 cards.

Adjust so that the distance from the card edge to the box

enclosing the line (B) is a bout 2 .07 mm. ( Check the thi rd to

fifth cards.)

5.3.1.4 Offset Card X Setting

This adjustment adj usts the st op positio n of the card and change

the re-transfer start po sition. If this adjustm ent is perfo rmed while

using standard card, the card position against the heat roller will

shift causing card jam or retransfe r error. Do not chan ge the se tting value for normal case.

5.3.1.5 Setting of the ink-sensor level

Set the threshold level of the ink sensor so tha t the ink sensor defect the ink color "yellow" and "magenta" as transmission, and

"cyan" and "Bk" as interrup tion. Se lect th reshol d val ue by usi ng [

] buttons, and press the [ ] button to save the select

Value.

5.3.1.6 Setting of the film Sensor level

The threshold leve l of the film senso r is set. The setti ng value can

be changed with the [ ] button and set with the [ ] button. Adjust the value with transparent film area as transmission,

and with the black marker area as interruption.

B

FRONT

Printing startCard shifting direction

5.3.1.2 Offset Prt X Setting

(1) Determine the displacement amount according to the print

results (those owned by the us er). Every st ep co rrespo nds

to a displacement of about 0.085 mm. The step can be varied in the range between -7 and +7.

(2) Press [ ] to save the setting.

1-40 (No.HD017<Rev.001>)

5.3.1.7 IC Contact Type Selection

Select the type of IC contact to be mounted.

5.3.1.8 Offset Contact Setting

To be used for adjus ting t he posit ion of the att ache d IC cont act

unit. Refer to "IC Contact Adj Setting" for adjusting method.

5.3.1.9 ISO Hi-co Type Selection

When the ISO type Mag. Encoder is built in, and Hi-co is selected, the following two types of Hi-co mode can be selected:

• Standard : Use the standard Hi-co card. Antimagnetic force

2750 Oe

• Super : Use the super Hi-co card. Ant imagn etic for ce 4000 Oe

5.3.1.10 IC Antenna Setting

When a contact less IC R/W is mounted, select Installed.

Page 41

5.3.1.11 Vth Gain Adjustment

Set the Vth Gain level to reduce Vth lines. (Normal Value : 12)

5.3.1.12 Ink Eco Mode Setting

When this setting is On, Ink ribbon is used in 1 group of panels

with follows pattern.

• YMCKUV Ink : YMCUV+K

• YMCKPO Ink : YMCPO+K

5.3.1.13 Transporting Speed Setting

When the Bend remedy unit is installed, this mode will be activated.

• Standard : Normal speed (Default)

• Fast : Transporting Speed is set '+3' when Bend re medy Te mp

Level is 'OFF'.

Note :

Printing speed will be faster, but it's required to tes t pr inti ng

with no problem.

5.3.2 Off-line Test

This is used to print the built-in tes t patt ern of this printe r and for

execution of an MG self-test.

5.3.2.1 Pattern setting

This printer has nine types of built-in printing patterns. Select a

pattern and press the [ ] button to store it. Return to the initial pattern is made when the power is cut.

(1) Step

This is for confirmation of uniform gradation.

(2) Registration

This is used to confirm that each color overlaps correctly.

(3) Address

The head has 1036 heater elements for printing. This is

used to confirm the u niformity of the de nsity for each heater

element.

(4) Color

This is a pattern for overall evaluation.

(5) Vth

A and B are printed w ith the same data values . This is used

to confirm that the power supply voltage compensation

(Vth) has been done correctly (same density).

(6) Gray

For checki ng of feed irregul arities caused by mechanical

trouble etc.

(7) Black

For checking of black ink blurring, drop-outs, etc.

(8) Normal

This is a pattern for overall evaluation.

(9) Adjust

This is a pattern for overall evaluation.

(10) ALL

The above patterns (1) to (9) are printed in sequence.

(Each pattern is printed on separate card.)

A

B

Step Vth Registration

Address Color Black

Gray Normal Adjust

5.3.2.2 Side

Selection whether test printing is to be done on one side or both

sides.

5.3.2.3 Times

The number of cards for the test contents selected by "Test select" of the following item is selected.

5.3.2.4 Test

The test to be executed is selected.

(1) Print

Select this for printing and press [ ] twice to start.

(2) Feed

Select this to test only the card feed.

(3) IC (Contact)

The cards are fed and the contact for clip card is lowered.

There is no data communication.