Page 1

SERVICE MANUAL

MICRO COMPONENT SYSTEM

MB57420069

UX-QX3WA,UX-QX3AA

SP-UXQX1W

SP-UXQX1A

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

CA-UXQX3W SP-UXQX1W

CA-UXQX3A SP-UXQX1A

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

COPYRIGHT © 2006 Victor Company of Japan, Limited

No.MB574

2006/9

Page 2

SPECIFICATION

CD receiver section (CA-UXQX3W/CA-UXQX3A)

Amplifier Output power 20 W × 2ch (THD 10%/4 Ω)

Input terminal LINE IN × 1 LEVEL1 : 500 mV/47 kΩ

LEVEL2 : 250 mV/47 kΩ

LEVEL3 : 125 mV/47 kΩ

Output terminals Speaker × 2 20 W/4 Ω

Impedance : 4 Ω - 16 Ω

Headphones (× 1) 25 mW/32 Ω

Impedance : 16 Ω - 1 kΩ

LINE OUT × 1 1 V/47 kΩ

Tuner Tuner Frequency FM 87.50 MHz - 108.00 MHz

AM 531 kHz - 1 710 kHz (9 kHz spacing)

530 kHz - 1 710 kHz (10 kHz spacing)

General Power requirement AC 240 V , 50 Hz

Power consumption 55 W (at operation)

8 W (Touch illumination ON/QP Link ON)

1.1 W (Touch illumination OFF/QP Link OFF)

Dimensions 165 mm (W) × 204 mm (H) × 339.5 mm (D)

Mass (approx.) 4.1 kg

CD player Playable discs Audio CDs and MP3

Speaker section (SP-UXQX1W/SP-UXQX1A)

System 2-way bass reflex type

Speakers Woofer 11 cm cone speaker × 1

Tweeter 4 cm cone speaker × 1

Power handling capacity 20 W

Impedance 4 Ω

Frequency range 56 Hz - 40 kHz

Sound pressure level 84 dB/W·m

Dimensions 135 mm (W) × 200.5 mm (H) × 215 mm (D)

Mass (approx.) 1.9 kg each

Micro component system (UX-QX3W/UX-QX3A)

Dimensions 435 mm (W) × 204 mm (H) × 339.5 mm (D)

Mass (approx.) 7.9 kg

Design and specifications are subject to change without notice.

1-2 (No.MB574)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

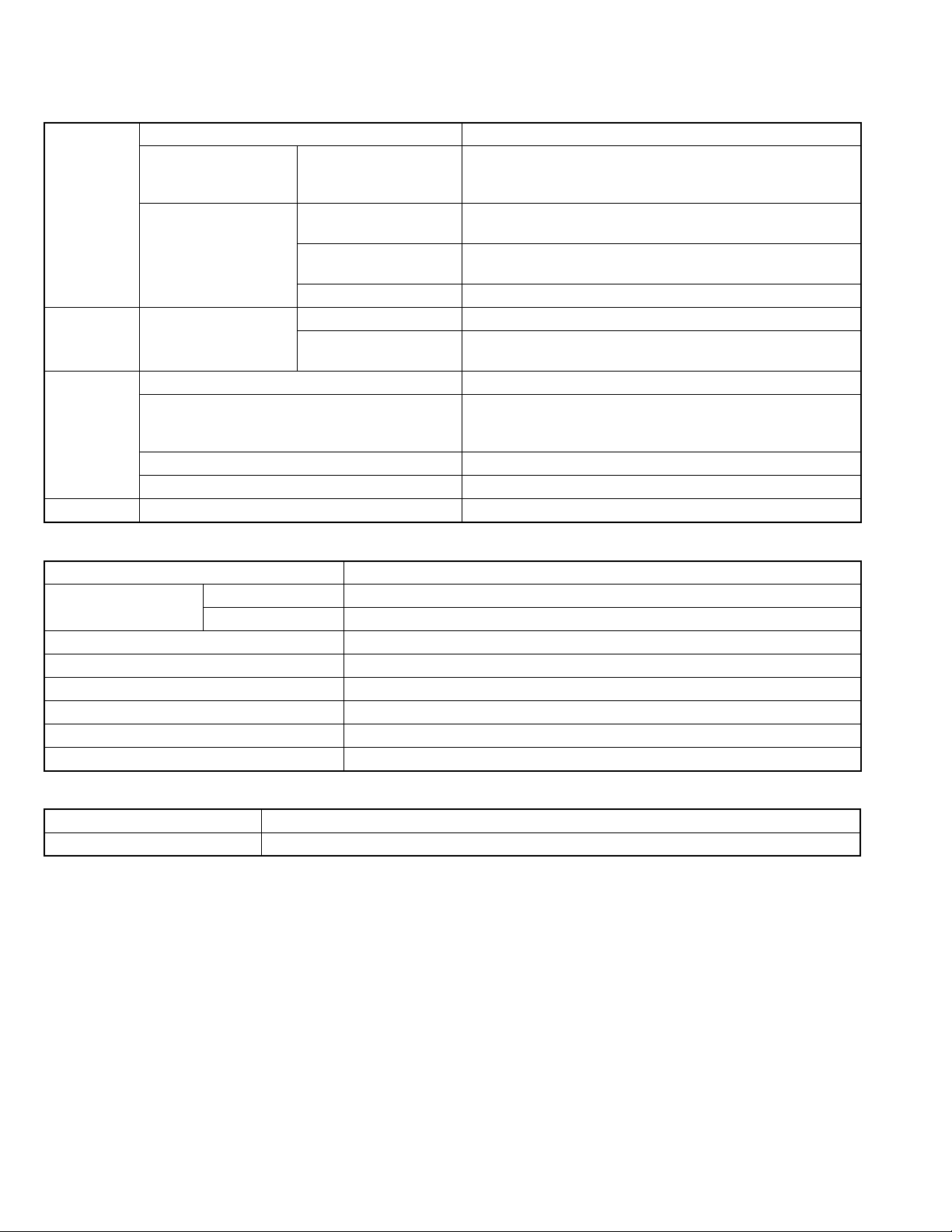

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000

in the following manner. Connect a 1,500

paralleled by a 0.15

exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

Ω per volt or more sensitivity

Ω 10W resistor

µF AC-type capacitor between an

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB574)1-3

Page 4

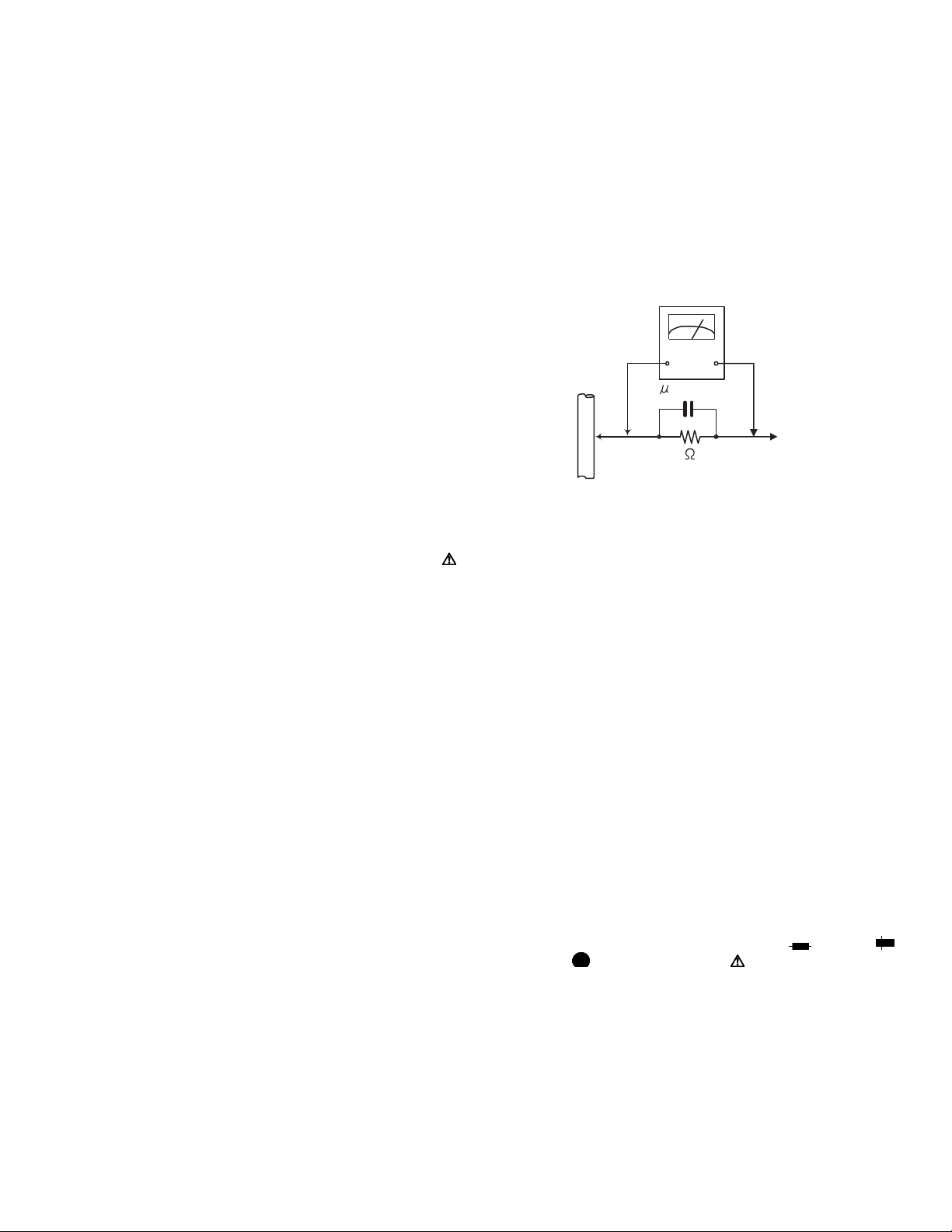

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

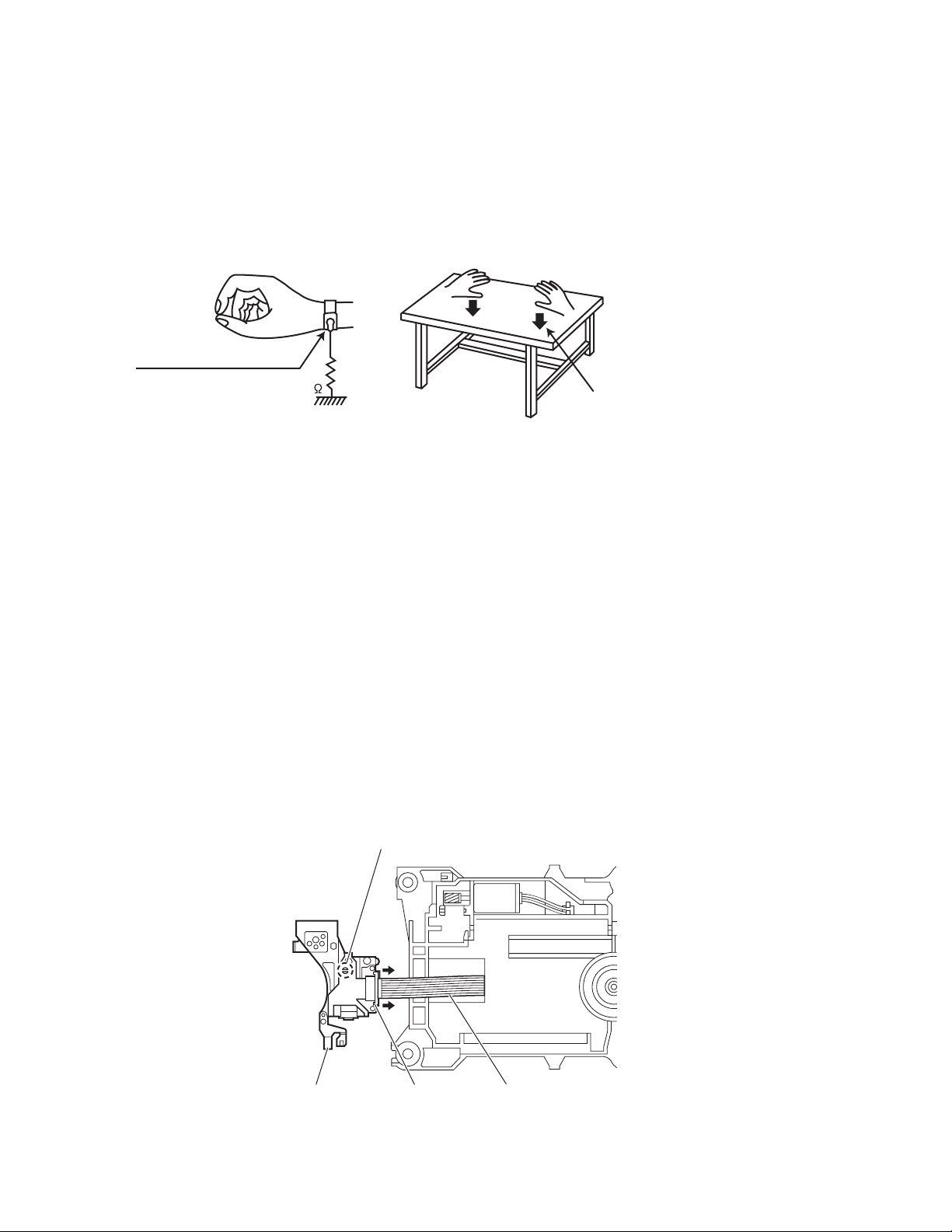

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the card wire is disconnected from the connecto on the servo board. (If the card wire

is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the card wire.

1-4 (No.MB574)

Short land section

Pickup Connector Card wire

Page 5

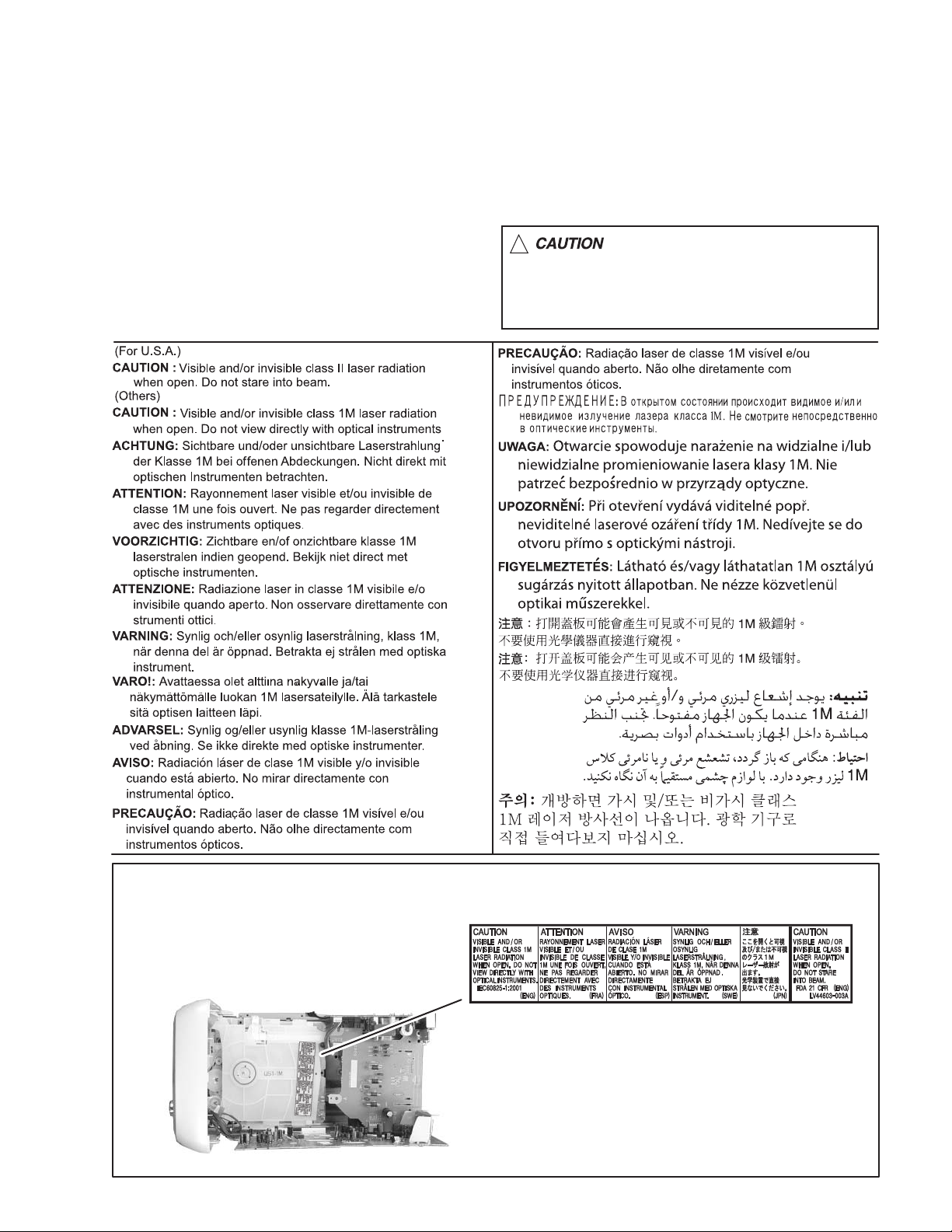

1.8 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

(No.MB574)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.MB574)

Page 7

SECTION 3

r

DISASSEMBLY

3.1 Main body

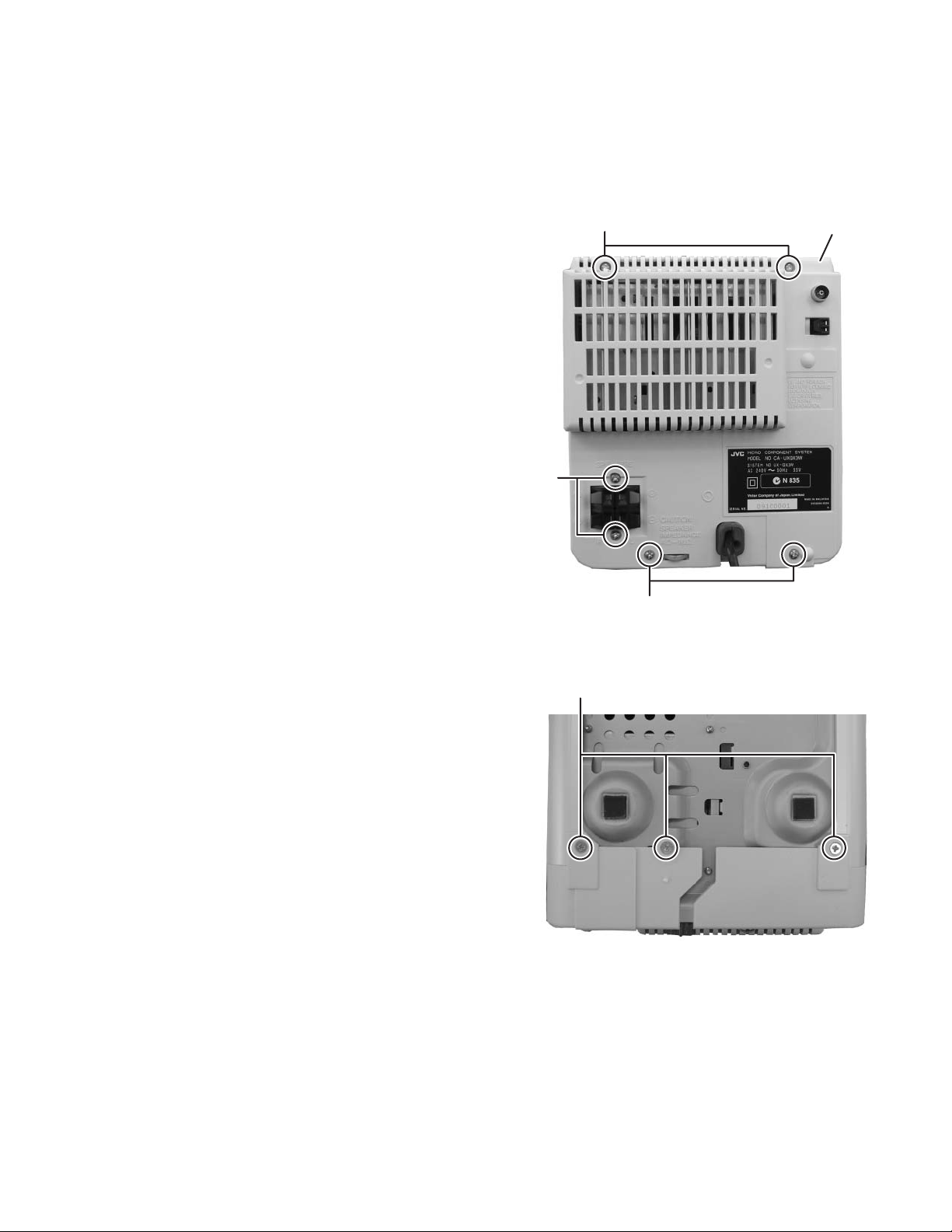

3.1.1 Removing the rear cover

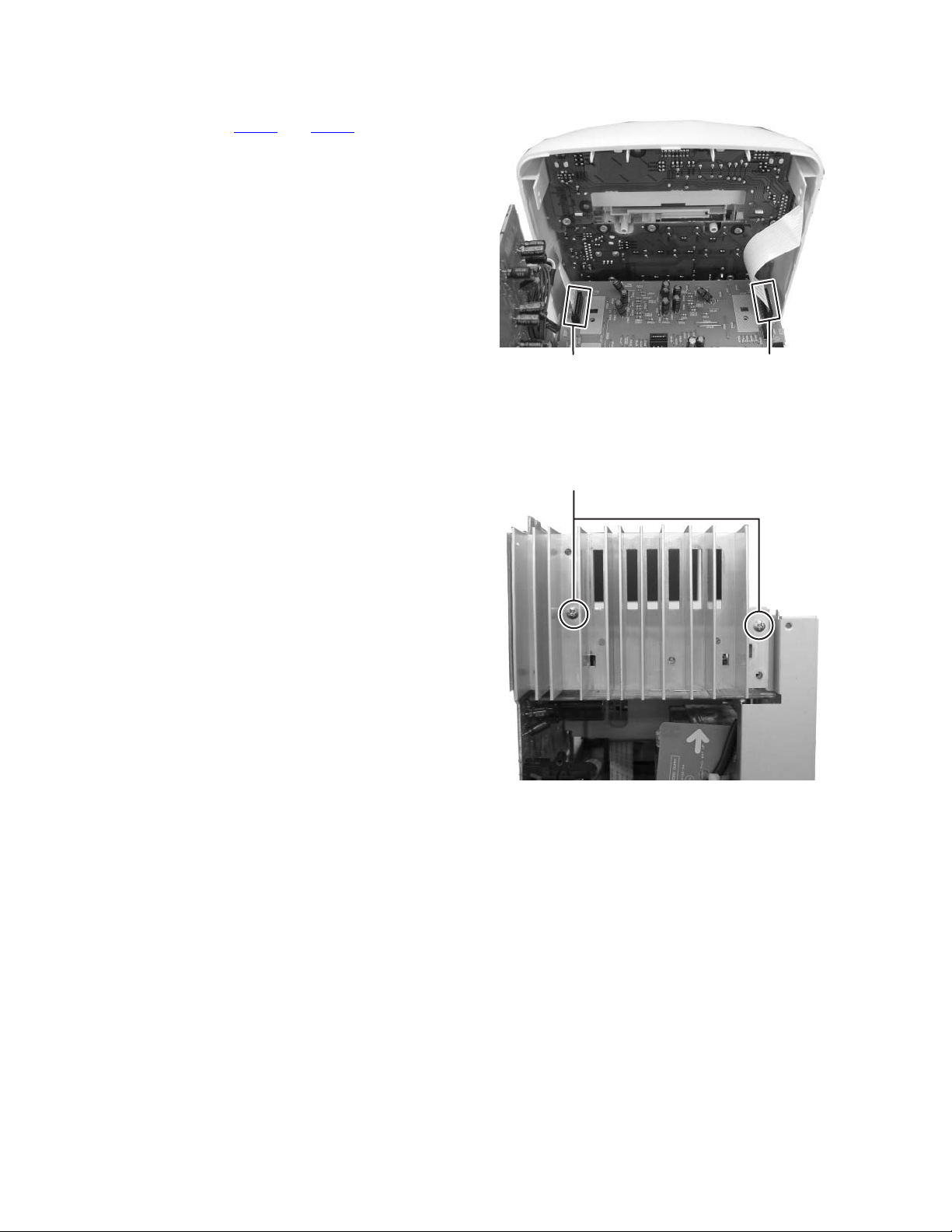

(See Fig. 1, 2)

(1) Remove the six screws A attaching the rear cover. (See

Fig. 1)

(2) Remove the three screws B attaching the rear cover from

bottom side of main body. (See Fig. 2)

A

A

Rear cove

A

Fig.1

B

Fig.2

(No.MB574)1-7

Page 8

3.1.2 Removing the side panel

(See Fig. 3, 4)

(1) Remove the two screws C attaching the both side panels.

(See Fig. 3)

(2) Slide to backward and lift up then remove the both side

panels. (See Fig. 4)

Side panel

C

hook

Fig.3

c

Side panel

Fig.4

1-8 (No.MB574)

Page 9

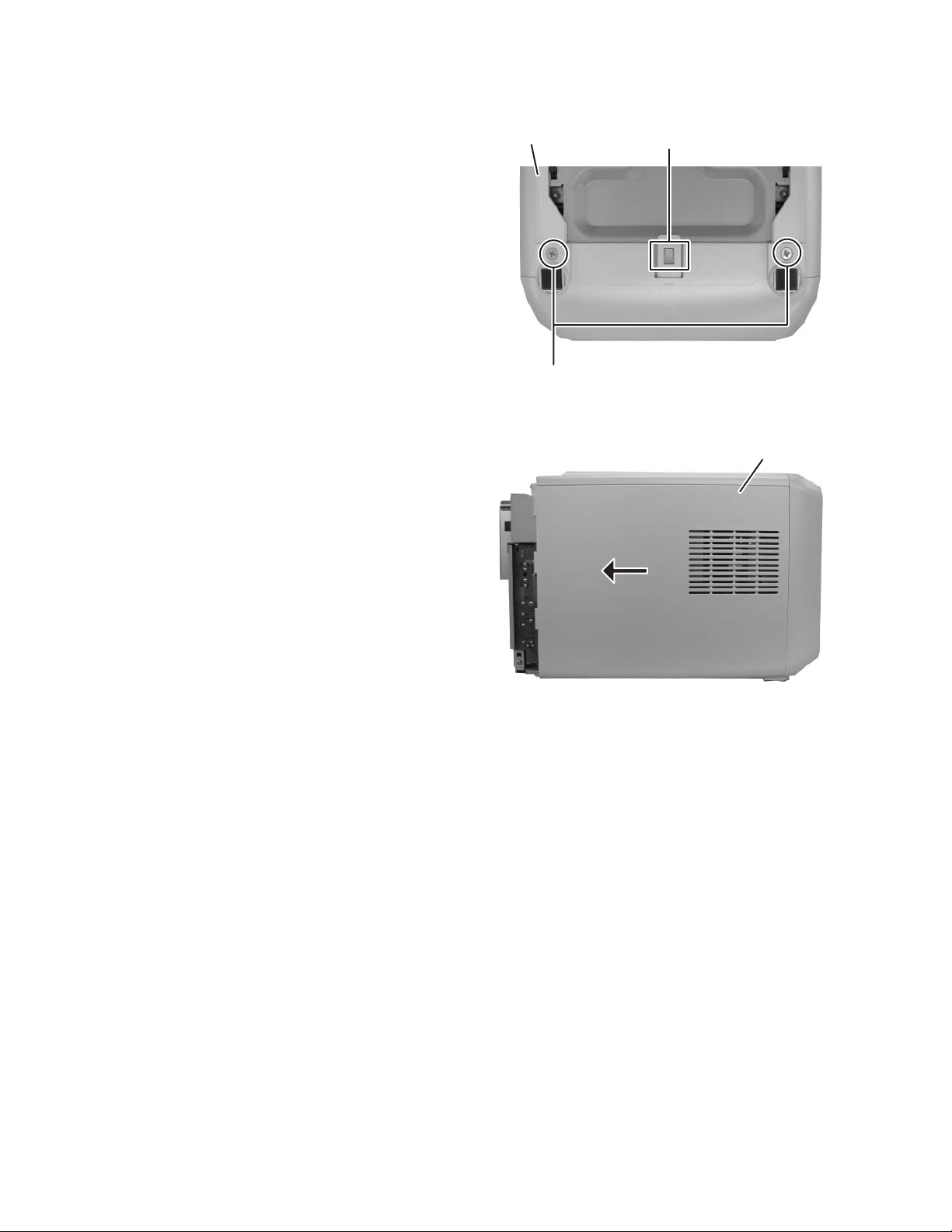

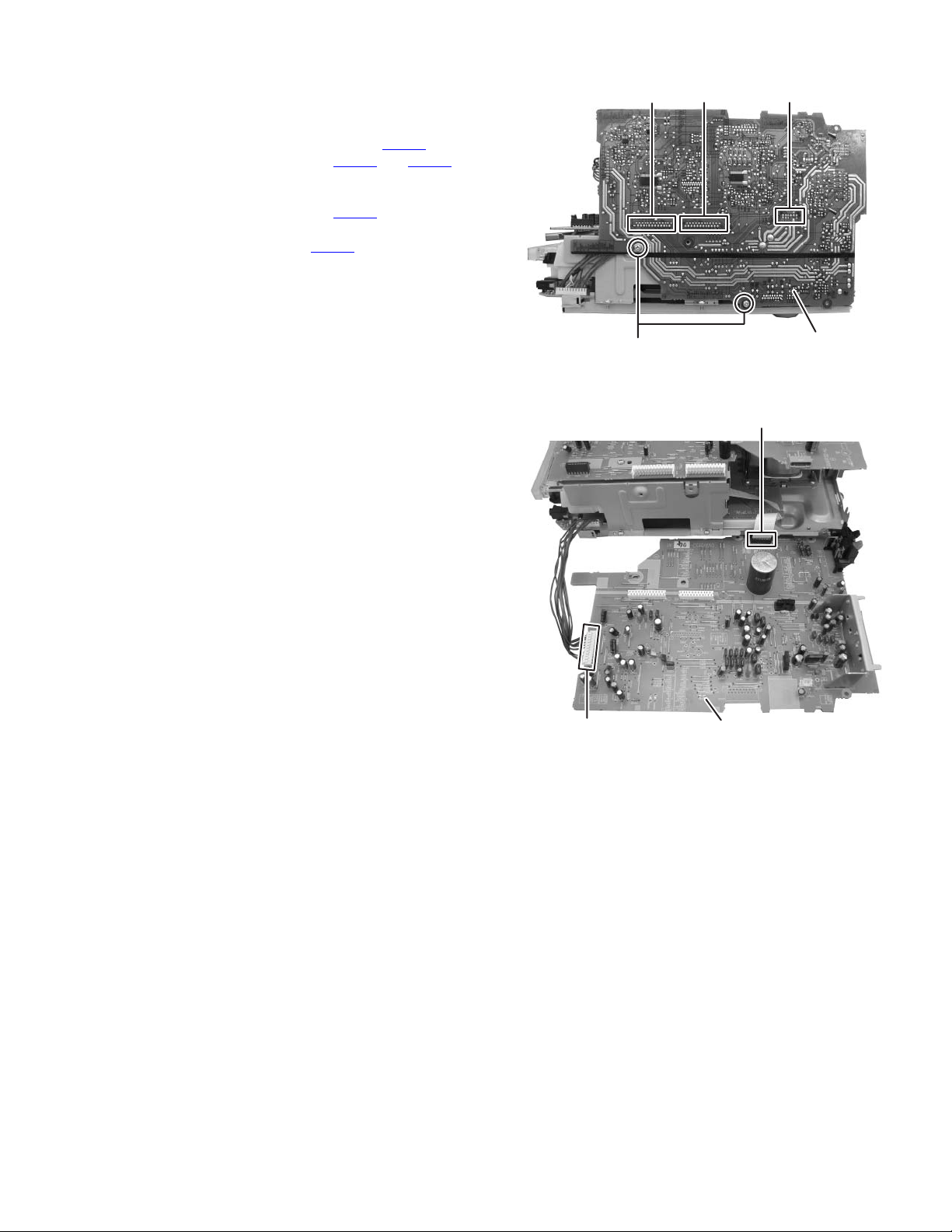

3.1.3 Removing the top cover

(See Fig. 5 to 8)

(1) Remove the one screw D attaching the tuner bracket. (See

Fig. 5)

(2) Disconnect the card wire from tuner pack connected the

connector CN709

(3) Disconnect the card wire from touch illumination board

connected the connector CN711

Fig. 6)

(4) Remove the two screws E attaching the top cover. (See

Fig.6, 7)

(5) Disengage the hook a and b form front panel assembly.

(See Fig. 6, 7)

(6) Lift up the top panel and then, disconnect the connector

wire from fan connected to the connector CN108

power amplifier board. (See Fig. 8)

of the micon board. (See Fig. 6)

of the micon board, (See

of the

E

hook

b

Top cover

Fig.5

E

D

hook

e

hook

Fig.7

CN108

a

Micon board

CN709

Fig.6

hook

d

CN711

Power amplifier board

Fig.8

(No.MB574)1-9

Page 10

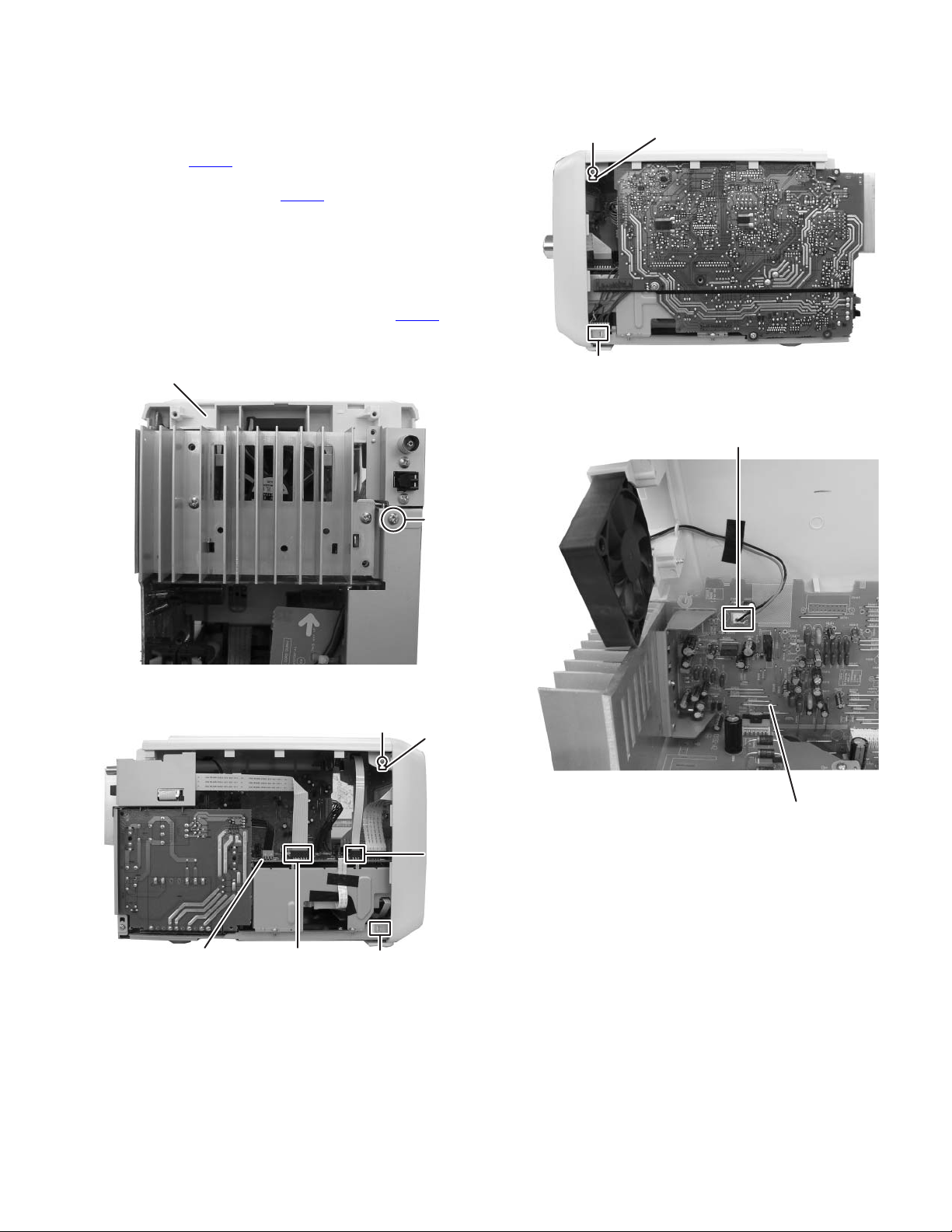

3.1.4 Removing the front panel assembly

(See Fig. 9, 3, 6, 7)

(1) Disconnect the card wires from front panel assembly con-

nected to the connector CN702 and CN710 of the micon

board. (See Fig. 9)

(2) Disengage the hook c, d and e from the bottom chassis.

(See Fig. 3, 6 and 7)

3.1.5 Removing the heat sink

(See Fig. 10)

(1) Remove the two screws F attaching the heat sink.

CN710 CN702

Fig.9

F

1-10 (No.MB574)

Fig.10

Page 11

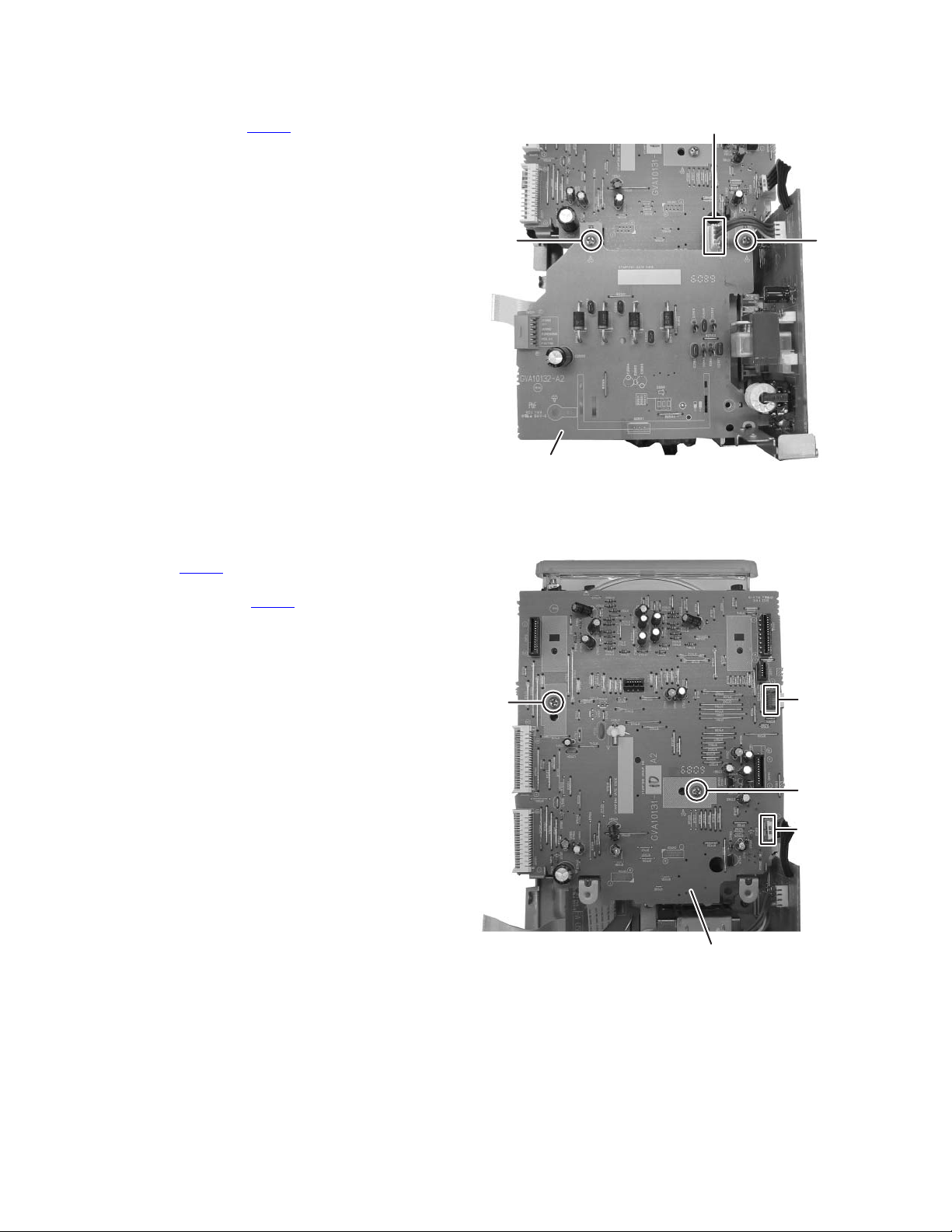

3.1.6 Removing the power amplifier board assembly

(See Fig. 11, 12)

(1) Remove the two screws G attaching the power amplifier

board assembly. (See Fig. 11)

(2) Disconnect the board to board connectors CN101

ed to secondary board assembly, CN102

nected to micon board assembly. (See Fig. 11)

(3) Disconnect the connector wire from head phone board as-

sembly connected to connector CN109

board assembly and disconnect the card wire from CD

board connected to connector CN106

er board. (See Fig. 12)

and CN103 con-

of the amplifier

of the power amplifi-

connect-

CN103 CN102 CN101

CN109

G

Fig.11

Power amplifier board

Fig.12

Power amplifier board

CN106

(No.MB574)1-11

Page 12

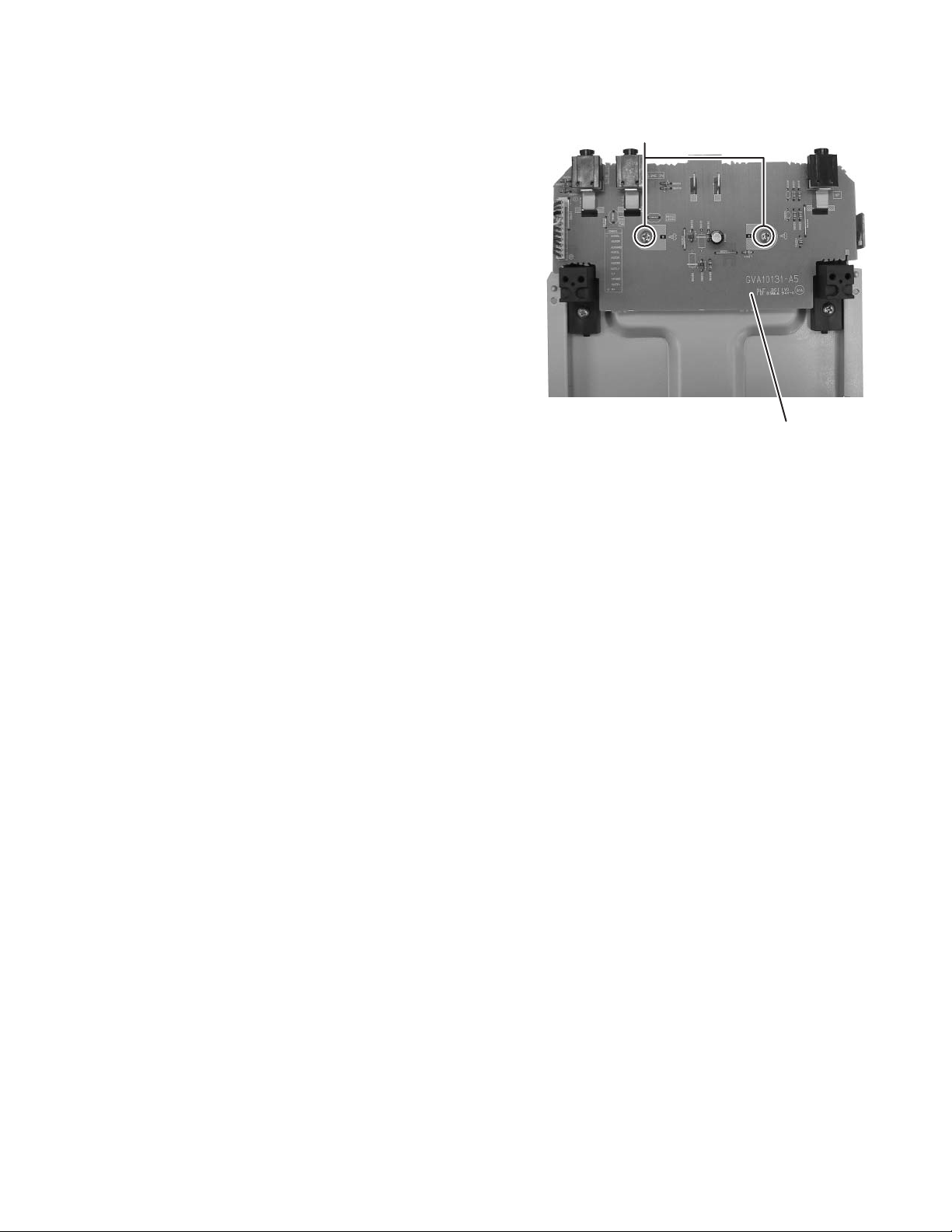

3.1.7 Removing the secondary board assembly

(See Fig. 13)

(1) Disconnect the connector wire from primary board assem-

bly connected to connector CN202 of the secondary board.

(2) Remove the two screws H attaching the secondary board

assembly.

3.1.8 Removing the micon board assembly

(See Fig. 14)

(1) Disconnect the card wire from the CD servo board connect-

ed to connector CN705

(2) Disconnect the connector wire from primary board assem-

bly connected to connector CN713

sembly.

(3) Remove the two screws J attaching the micon board as-

sembly.

of the micon board.

of the micon board as-

CN202

HH

Secondary board

Fig.13

J

CN705

J

CN713

Micon board

Fig.14

1-12 (No.MB574)

Page 13

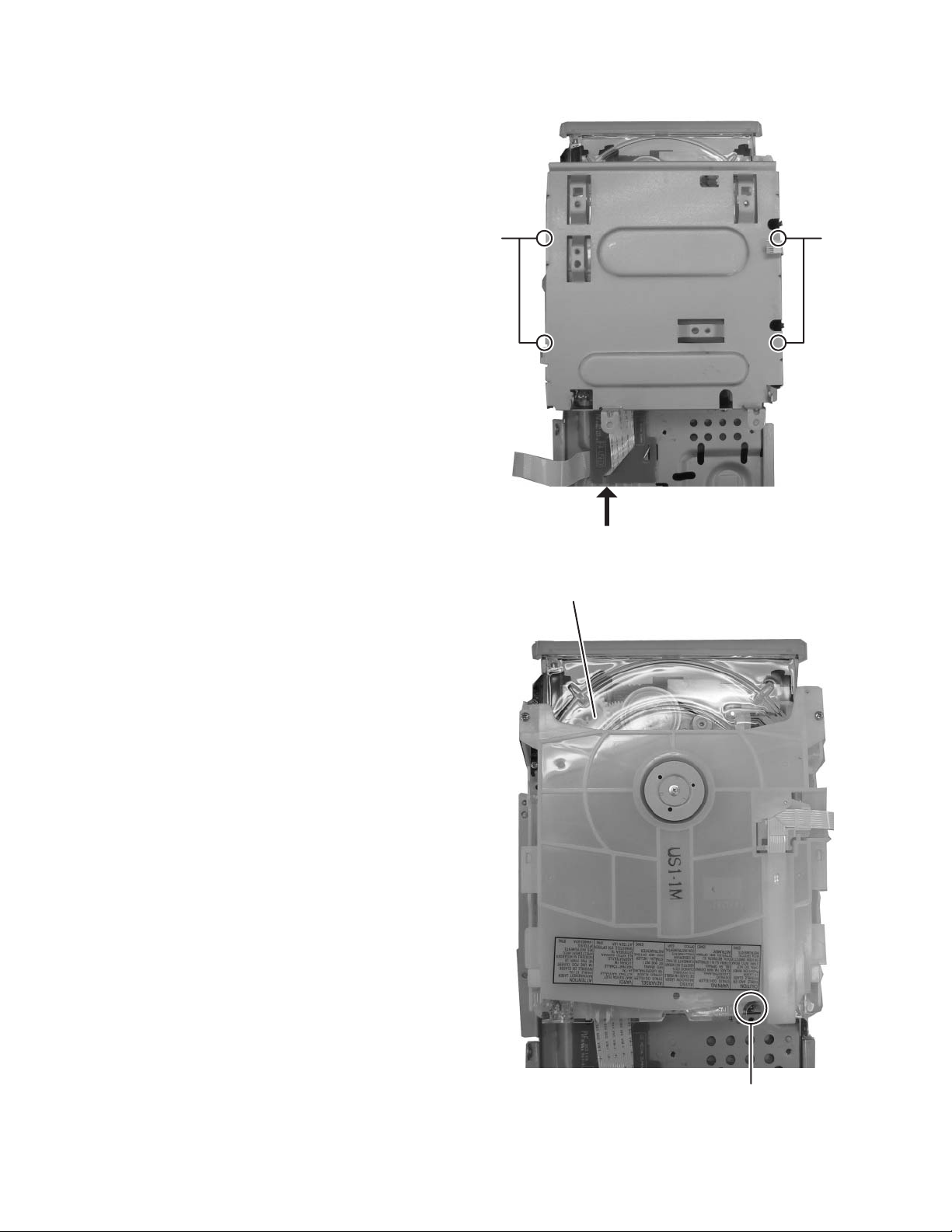

3.1.9 Removing the primary board assembly with power transformer

(See Fig. 15)

(1) Remove the three screws K attaching the primary board

assembly with power transformer.

(2) Slide to direction of the arrow and then take out it.

KK

Fig.15

(No.MB574)1-13

Page 14

3.1.10 Removing the CD mechanism assembly

(See Fig.16, 17)

(1) Remove the four screws L attaching the CD mecha brack-

et. (See Fig. 16)

(2) Disengage the card wire from the CD board assembly en-

gaged to bracket board. (See Fig. 16)

(3) Remove the one screw M attaching the CD mechanism as-

sembly. (See Fig.17)

LL

CD mechanism assembly

Fig.16

1-14 (No.MB574)

M

Fig.17

Page 15

3.1.11 Removing the Headphone board assembly

(See Fig. 18)

(1) Remove the two screws N attaching the headphone jack

board assembly.

N

Head phone board

Fig.18

(No.MB574)1-15

Page 16

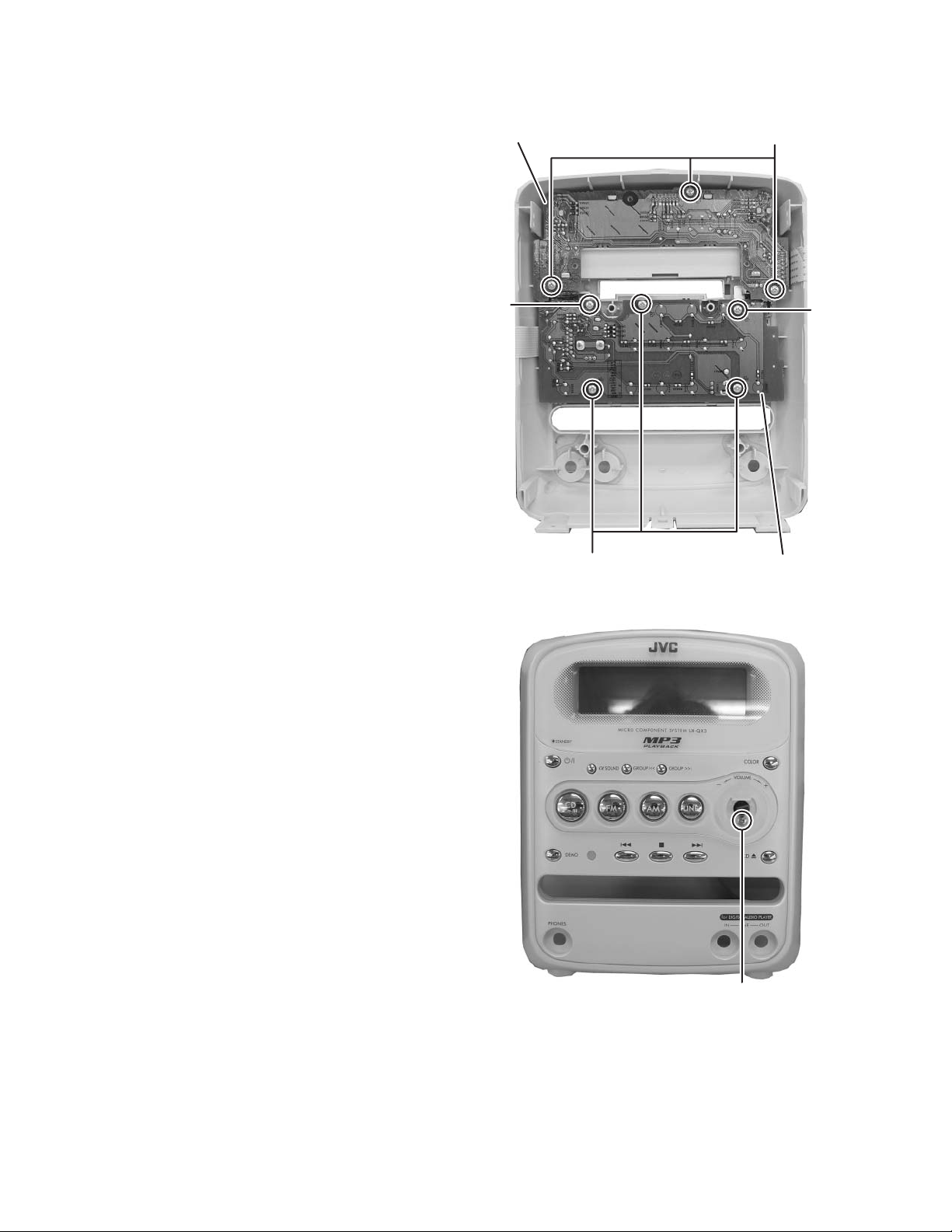

3.1.12 Removing the LCD board assembly

(See Fig. 19)

(1) Remove the three screws P attaching the LCD board as-

sembly.

3.1.13 Removing the key function board assembly

(See Fig. 19, 20)

(1) Remove the volume knob from front panel assembly.

(2) Remove the one screw Q attaching the key function board

assembly from front side. (See Fig. 20)

(3) Remove the five screws R attaching the key function board

assembly. (See Fig. 19)

LCD board

P

R

R

R

Key function board

Fig.19

1-16 (No.MB574)

Q

Fig.20

Page 17

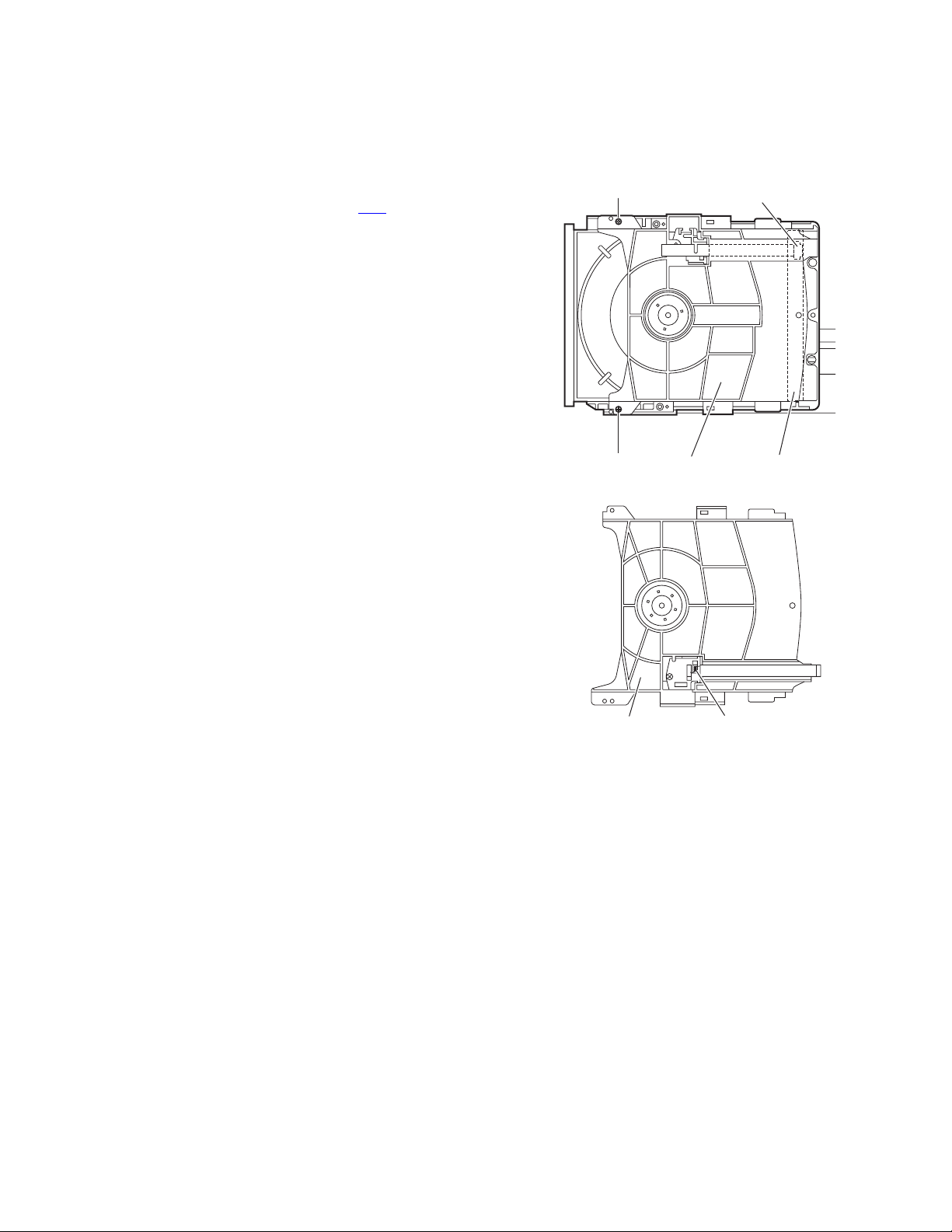

3.2 CD mechanism assembly

• Remove the CD mechanism assembly from main body.

(Refer to "Disassembly method")

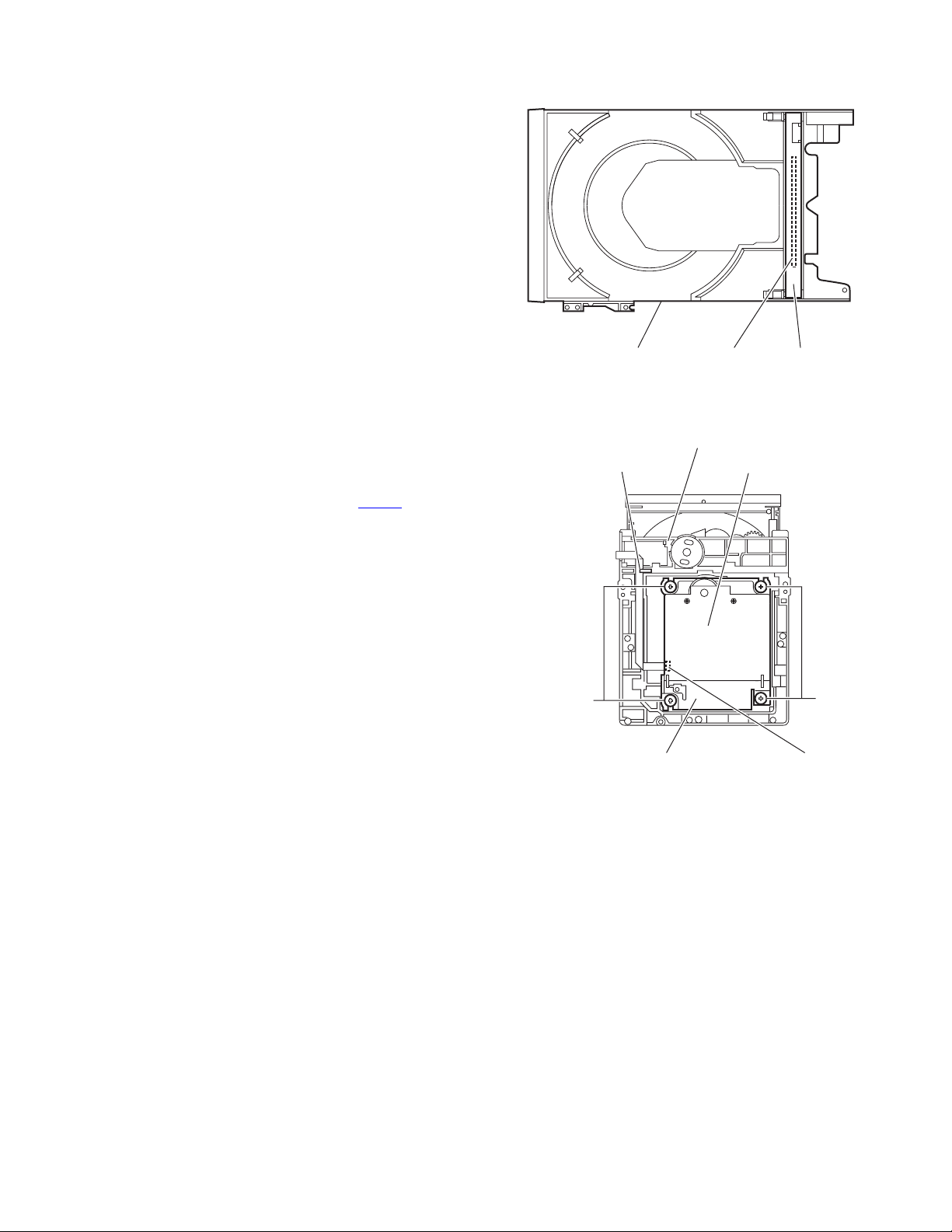

3.2.1 Removing the CD cover

(See fig.1 and 2)

(1) Remove the two screws A attaching the CD cover from top

side of CD mechanism assembly. (See fig.1)

(2) Remove the card wire from connector CN4

sembly. (See fig.1)

(3) Take out the CD cover.

Caution:

The spring which presses down a card wire is attached to CD

cover.

Please do not lose a spring. (See fig.2)

on the LED as-

A

CN4

A

CD cover

CD cover

Fig.1

Spring

Fig.2

LED assembly

(No.MB574)1-17

Page 18

3.2.2 Removing the tray assembly

(See fig.3 and 4)

• Remove the CD cover.

(1) From the right-hand side of CD mechanism assembly, a

slide cam is pushed and a tray assembly is pulled out in the

direction of an arrow. (See fig.3)

(2) Remove the two screws B attaching the tray assembly

from top side of CD mechanism. (See fig.4)

(3) Remove the bushing of tray assembly from hook a of CD

mechanism assembly, and then take out the tray assembly. (See fig.4)

Tray assembly CD mechanism assembly

Slide cam

Fig.3

B

Hook a Hook a

Tray assembly

Fig.4

1-18 (No.MB574)

Page 19

3.2.3 Removing the LED assembly

(See fig.5)

• Remove the CD cover and tray assembly.

(1) Remove the double face tape attaching the LED assembly

from top side of tray assembly, and then take out the LED

assembly.

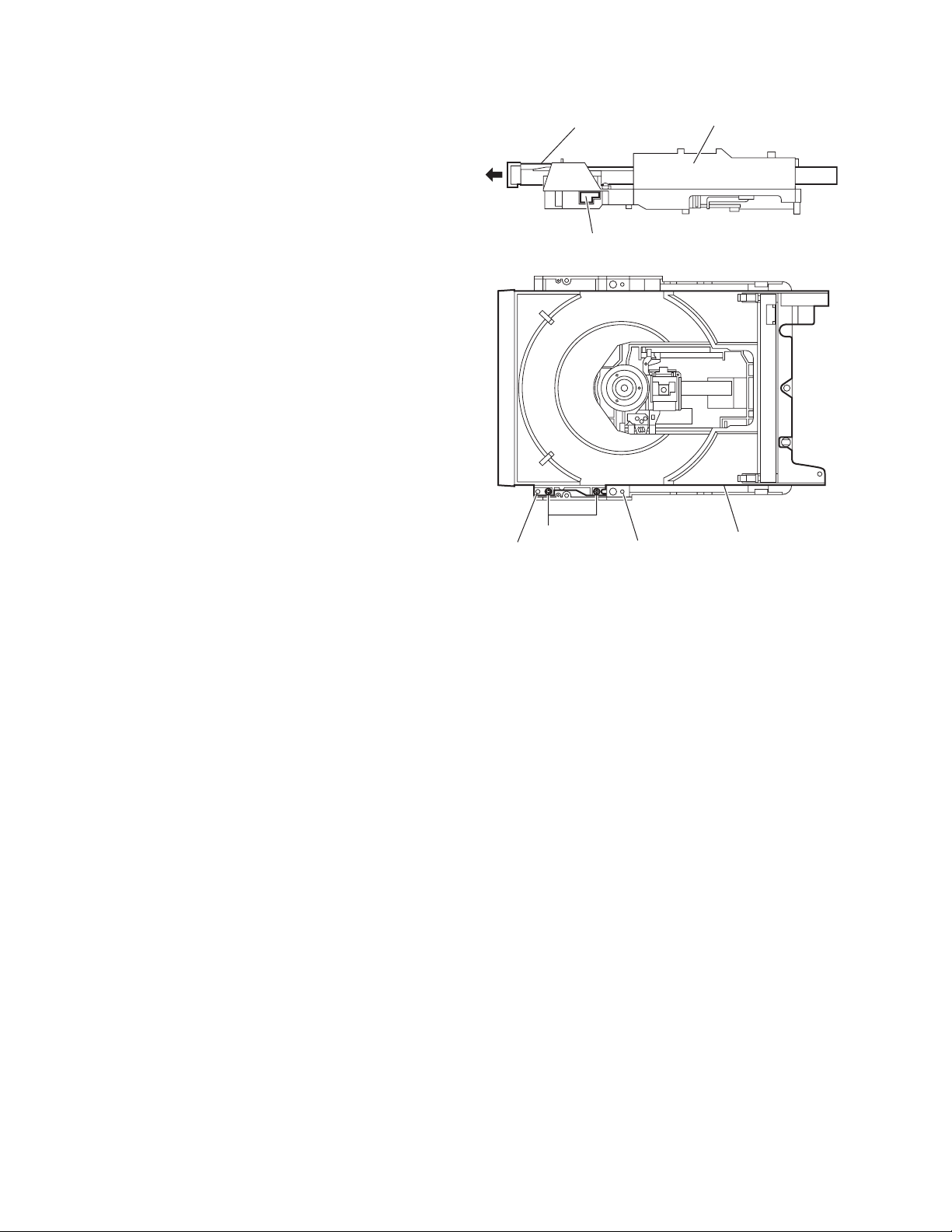

3.2.4 Removing the traverse mechanism assembly

(See fig.6)

• Remove the CD cover.

(1) Remove the four screws C attaching the traverse mecha-

nism assembly from bottom side of CD mechanism assembly.

(2) Remove the card wire from connector CN602

board, and then take out the traverse mechanism assembly and CD servo board together.

Reference:

When attach the traverse mechanism assembly, the wire

should through part b.

on CD servo

Tray assembly LED assemlbyDouble face tape

Fig.5

CD mechanism assembly

Slot b

CD servo board

C

Traverse mechanism assembly

Fig.6

C

CN602

(No.MB574)1-19

Page 20

3.2.5 Removing the CD servo board

(See fig.7 and 8)

• Remove the CD cover and traverse mechanism assembly.

(1) Remove the two screws D attaching the CD servo board

from bottom side of traverse mechanism assembly. (See

fig.7)

(2) Remove the solder from soldered section c of CD servo

board. (See fig.7)

(3) Remove the yellow wire and white wire from soldered sec-

tion d of CD servo board. (See fig.7)

(4) CD servo board is removed upward, hook e is removed in

the direction 1 of an arrow, and CD servo board is turned

over. (See fig.7)

(5) Solder the short land section f of pickup. (See fig.8)

(6) The lock of the connector CN601

moved in the direction 2 of an arrow, and a card wire is re-

moved. (See fig.8)

Caution:

• Please solder the short land section f of a pickup before re-

moving a card wire from the connector CN601

board. If a card wire is removed without soldering, a pickup

may be destroyed by static electricity. (See fig.8)

• At the time of CD servo board attachment, please remove

the solder of the short land section f of a pickup after attaching a card wire in a connector CN601

of CD servo board is re-

of CD servo

. (See fig.8)

CN601

Hook e

Soldered section c

Wire(yellow)

DD

Wire(white)

Soldered

section d

11

Hook e

Travers mechanism assemblyCD servo board

Fig.7

CD servo board

Pickup

Short land section f

CN601

22

Traverse mechanism assembly

Fig.8

1-20 (No.MB574)

Page 21

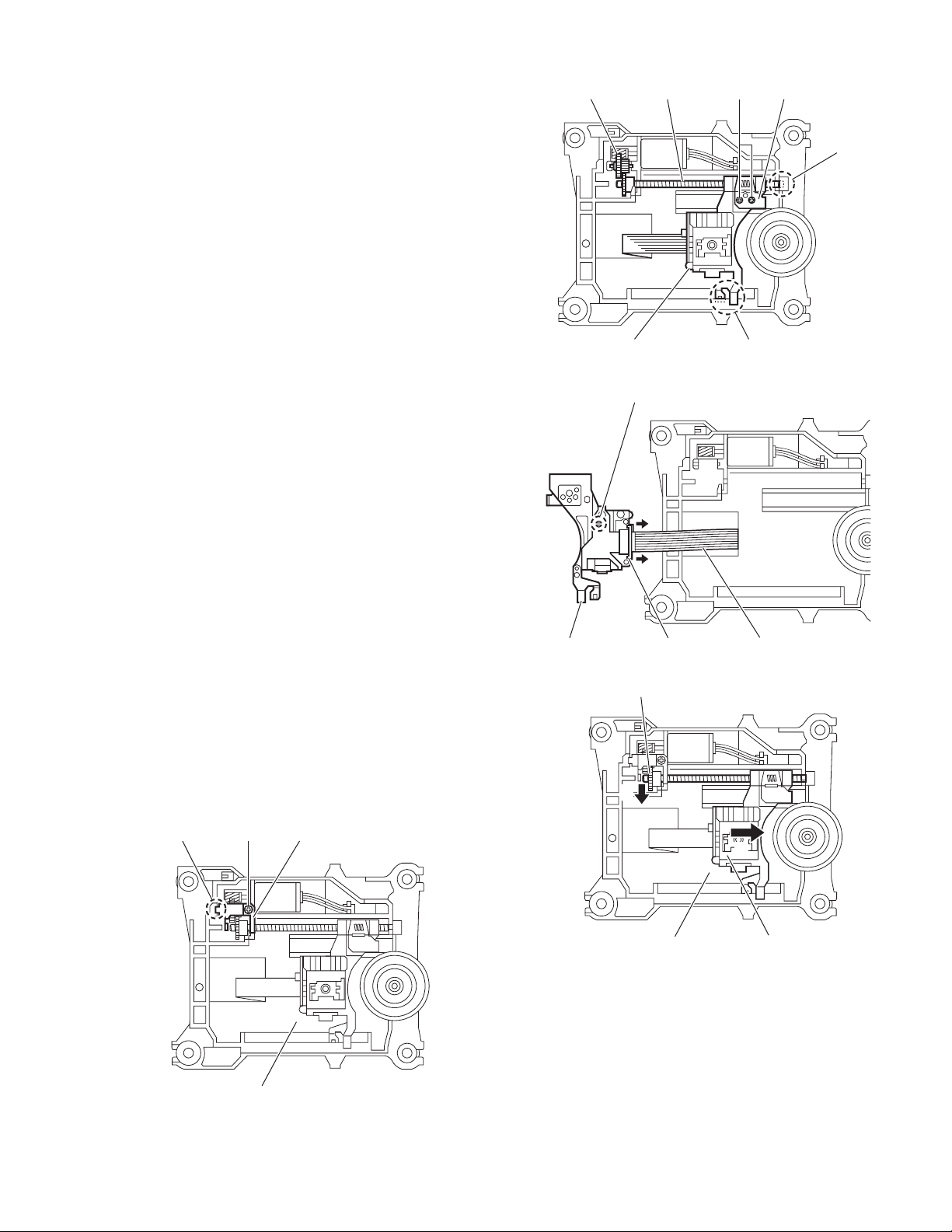

3.2.6 Removing the pickup

(See fig.9 to 11)

• Remove the CD cover and traverse mechanism assembly.

(1) Remove the screw E attaching the plate from top side of

traverse mechanism assembly. (See fig.9)

(2) Remove the plate from fixing part g, and then take out the

plate. (See fig.9)

(3) Remove the two screws F attaching the LAED spring. (See

fig.10)

(4) Take out the feed gear, and then remove the shaft of pick-

up from part h of traverse mechanism assembly. (See

fig.10)

(5) Remove the pickup from the part j of traverse mechanism

assembly, and then take out the pickup and shaft together.

(See fig.10)

(6) Draws out the shaft from pickup. (See fig.10)

(7) Solder the short land section k of pickup. (See fig.11)

(8) The lock of the connector of pickup is remover in the direc-

tion of an arrow, and a card wire is removed. (See fig.11)

Caution:

• Please solder the short land section of a pickup before re-

moving a card wire from the connector of pickup. If a card

wire is removed without soldering, a pickup may be destroyed by static electricity. (See fig.11)

• At the time of pickup attachment, please remove the solder

of the short land section k of a pickup after attaching a card

wire in a connector. (See fig.11)

Feed gear Shaft LEAD spring

Pickup

Short land section

F

j part

Fig.10

k

h part

3.2.7 Attaching the pickup

(See fig.9 to 12)

• Refer "Removing the pickup"

(1) After attaching a card wire in the connector of a pickup, the

solder of the short land section k of a pickup is removed.

(See fig.11)

(2) Attach the shaft to pickup. (See fig.10)

(3) A pickup is united with the part j of a traverse mechanism

assembly, and the end of the shaft of a pickup is attached

in the part h. (See fig.10)

(4) Attach the LEAD spring and feed gear. (See fig.10)

(5) Attach the plate. (See fig.9)

(6) A LEAD gear is turned in the direction 1 of an arrow, and

until full movement of the pickup is made to carry out in the

direction 2 of an arrow. (See fig 12)

Plate

EFixing point g

Pickup Connector Card wire

Fig.11

LEAD gear

1

2

Traverse mechanism assembly

Fig.12

Pickup

Traverse mechanism assembly

Fig.9

(No.MB574)1-21

Page 22

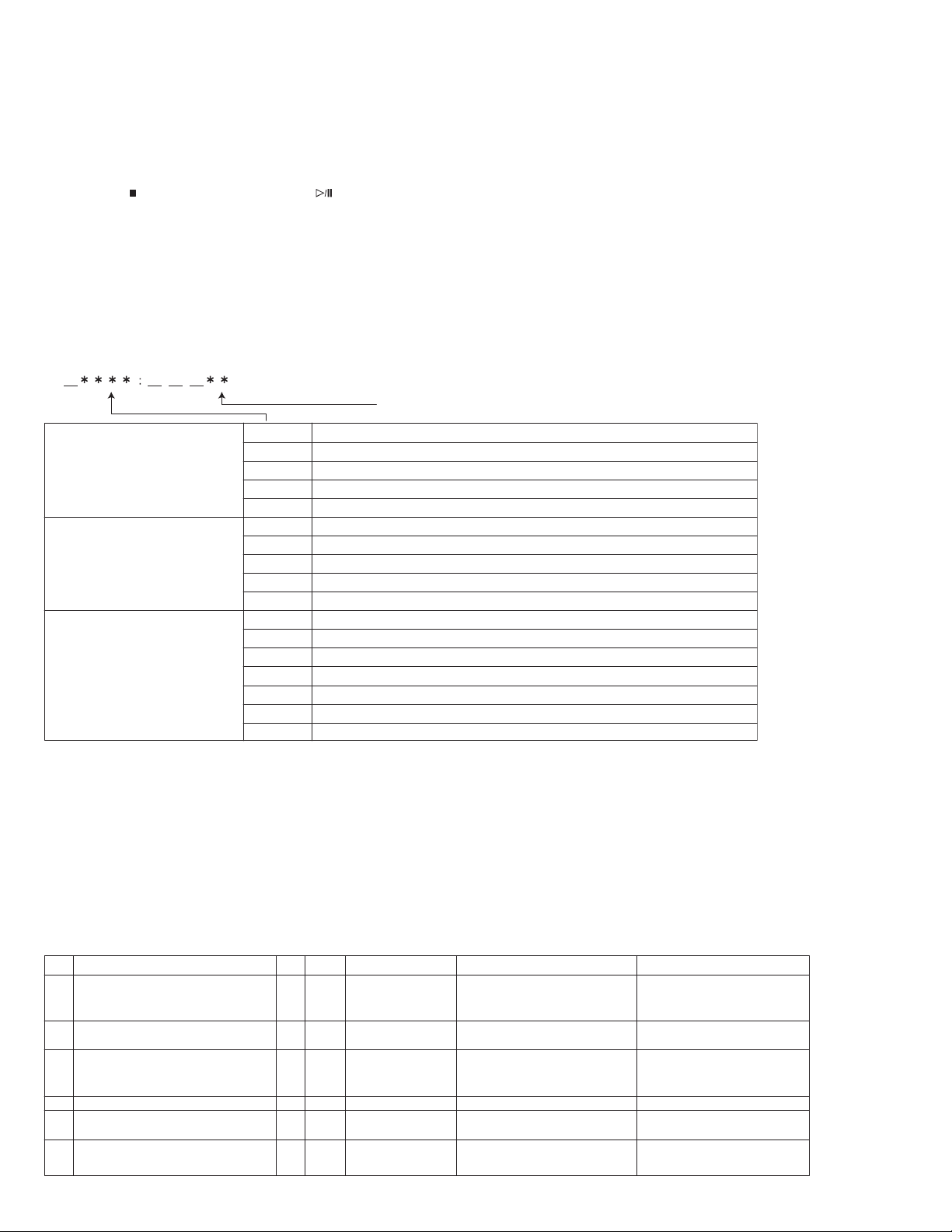

3.2.8 Removing the feed motor

(See fig.13 to 15)

• Remove the CD cover and traverse mechanism assembly.

(1) Remove the yellow wire and white wire from soldered sec-

tion m of the CD servo board at bottom side of traverse

mechanism assembly. (See fig.13)

(2) Remove the screw G attaching the plate, and the take out

the feed gear. (See fig.14 and 15)

(3) Remove the screw H attaching the feed motor, and then

take out the feed motor. (See fig.15)

Reference:

A time of feed motor attachment, the wire should through part

n of spindle base. (See fig.15)

G

Wire(yellow)

Wire(white)

Soldered

section m

Traverse mechanism assemblyCD servo board

Fig.13

Plate

Traverse mechanism assembly

Fig.14

H

Feed gear Feed motor

Traverse mechanism assembly

Fig.15

n part

1-22 (No.MB574)

Page 23

3.2.9 Removing the switch board

(See fig.6 and 16)

• Remove the CD cover.

(1) Remove the card wire from connector CN602

board from bottom side of CD mechanism assembly. (See

fig.6)

(2) Remove the wire from soldered section p of switch board.

(3) A switch board is raised pushing the hook q of CD mecha-

nism assembly in the direction of an arrow, and it removes

from the part r.

Reference:

• The wire should hook to part s after attached switch board

to CD mechanism assembly.

• Hook q of CD mechanism assembly should lock by glue.

3.2.10 Removing the motor

(See fig.16 and 17)

• Remove the CD cover and tray assembly.

(1) Remove the wire from soldered section p of switch board

from bottom side of CD mechanism assembly. (See fig.16)

(2) Remove the belt from motor pulley from top side of CD

mechanism assembly. (See fig.17)

Caution:

Be careful not to make grease adhere to a belt.

(3) Remove the two screws J attaching the motor to CD mech-

anism assembly, and then take out from bottom side of CD

mechanism assembly. (See fig.17)

Reference:

The wire should hook to part s after attached the motor to CD

mechanism. (See fig.16)

of switch

Switch board Wire

Soldered

section p

r part

s part

CD mechanism assembly

Hook q

CD mechanism assembly

Fig.16

BeltMotor pulley

J

Fig.17

(No.MB574)1-23

Page 24

SECTION 4

ADJUSTMENT

4.1 CD TEST MODE

4.1.1 Set the CD TEST MODE

Press STOP [ ] button and CD play/pause [ ] button together and keep then connect AC power cord.

LCD indication [ __CD_TEST_1].

Complete the setting TEST MODE.

4.1.2 Set the CD TEST MODE 2 (Indication auto adjustment value)

At LCD indication [ __CD_TEST_1] condition, press [SET] key of the remote controller more than 3 sec.

LCD indication change to [ __CD_TEST_2].

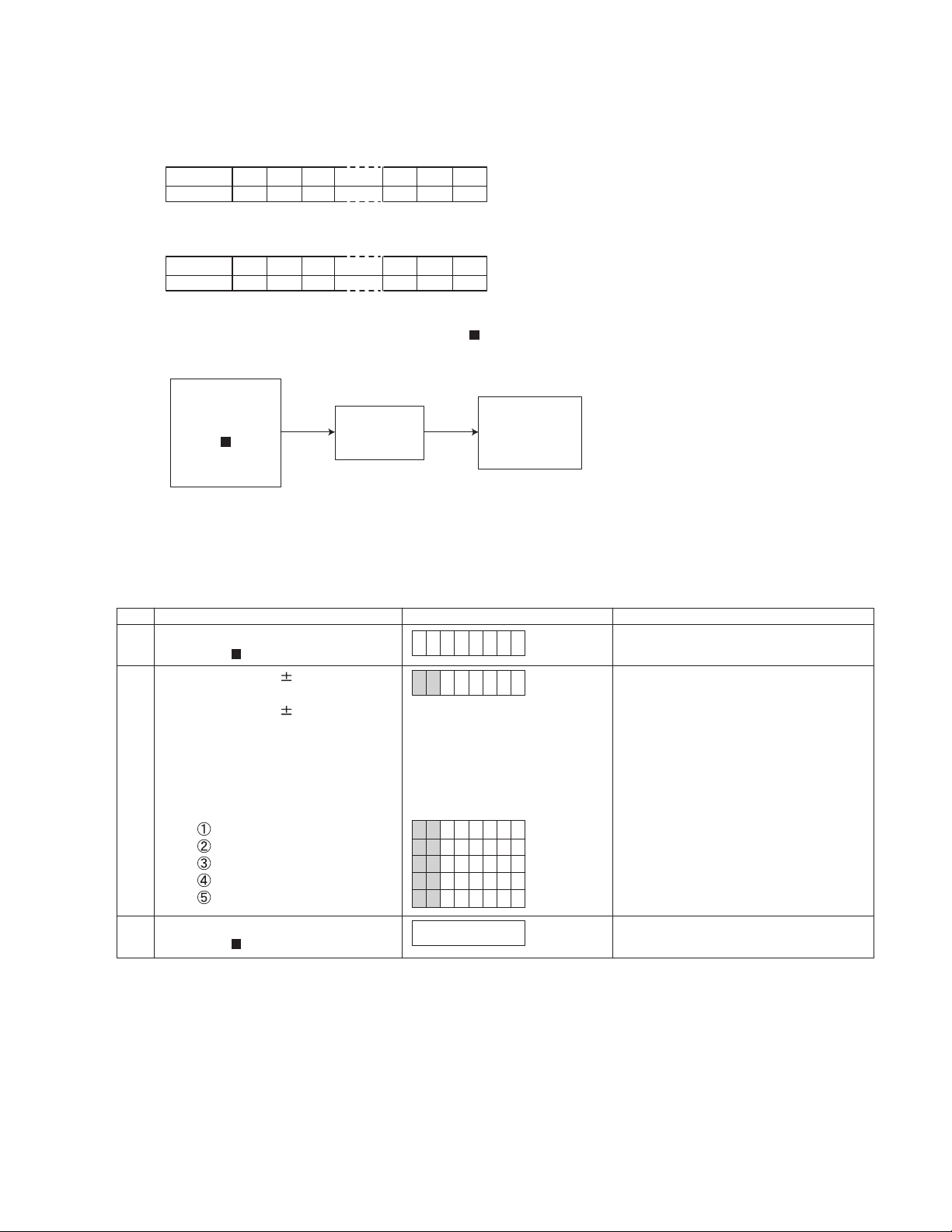

Assumes after the TOC reading to be effective, and (E1 ~ E3) is transmittend in order in the table at each SET

reception of remote control.

The E1 status : the adjustment value (ten kinds) based on status with [1:OK,0:NG] of bit like the HEX data.

As follows at each reception

[ ] and the toggle are displayed.

Adjust value

Focus gain mantissa

Focus gain index part

Focus balance adjustment value

Focus offset adjustment value

Turbulence amplitude when focus gain is adjusted

Tracking gain mantissa

Tracking gain constant index part

Tracking balance adjustment value

Tracking offset adjustment value

Turbulence amplitude when tracking gain is adjusted

Tracking energy gain (Only ST1 :. )

Focus energy gain

Tracking balance

Focus balance

Tracking rough gain

Focus rough gain

Focus offset

E2 status

(FOCUS system self

adjustment information)

E3 status

(TRACKING system self

adjustment information)

E1 status

(self adjustment information)

FG_ _

FEXP

FBAL

FOFS

FES_

TG_ _

TEXP

TBAL

TOFS

TES_

TAGC

FAGC

ABC2

ABC1

AGC2

AGC1

AOC1

"CD test mode 2" is released by CANCEL key to remote control.

Shifts to "CD test mode 1" (The display is returned to "__CD_TEST_1").

Clearness of test mode

All the CD test modes are made clear by the thing that the POWER key is pushed.

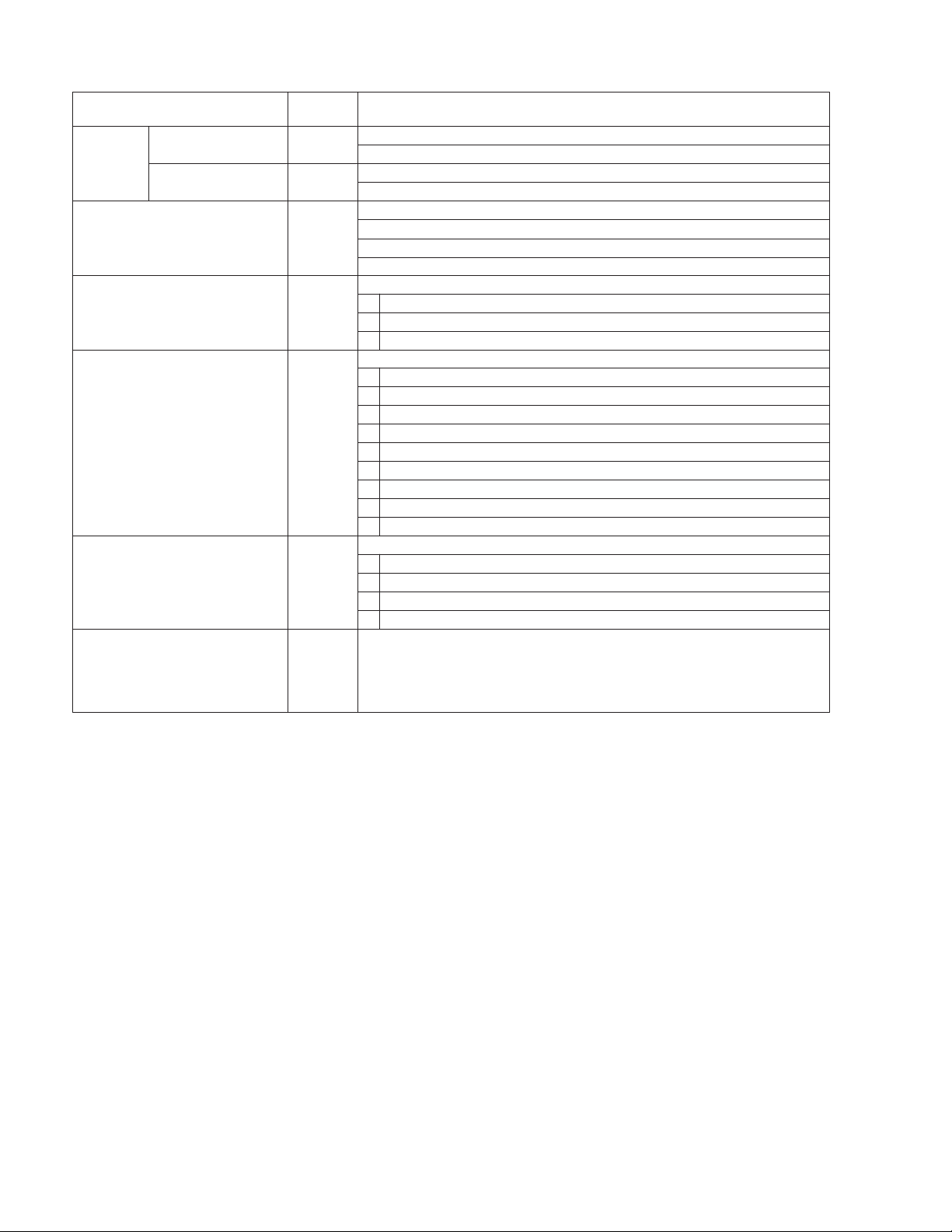

4.2 ERROR HISTORY

4.2.1 Outline

EEPROM use 256byte, when an abnormal state is generated, the factor is written in EEPROM.

Worth of a history is left for each item 16 times.

ERROR HISTORY.

4.2.2 EEPROM writing

(1) EEPROM information

ITEM EEP address byte Count Value of writing Writing condition Guessed factor

No.

1

SAFETY Number

AD value

2

Timer playback start NG

factor

3

P.OFF timeout factor

4

CD

5

P.OFF factor

6

Other

0x100

0x110

0x120

0x150

0x160

0x1A0

0x1B0~

1

1

1

1

1

1

Safety abnormal

16

No. & AD value

16

Factor of failure

16

Factor of failure

16

Factor of failure

16

Factor of power off

16

When detectiong of SAFETY

error, writing SAFETY number

and AD value

Timer playback is not starting

Time out of power OFF process

Error with CD

When starting of power OFF

process

Power circuit failure.

Damege of card wire.

Missing key operation.

User operation.

Mechanical and module failure.

Damege of card wire.

Missing key operation.

Mechanical and pickup failure.

User operation.

1-24 (No.MB574)

Page 25

(2) EEPROM writing timing

When abnormality occurs respectively, the value of the generated item is rewritten.

at the following.

The writing method does the batch writing 16 bytes with PAGE WRITE.

exp.) The data taking to EEPROM

address

data

120 01121 02122

03

12D 0D12E 0E12F

0F

After it shifts in the direction of the subordinate position by one byte, "20" is written at head byte when ERROR

information new "20" is written. The data of final byte is thrown away.

address

data

(3) EEPROM clear condition

120 20121 01122

02

12D 0C12E 0D12F

0E

When COLD SET is fixed by remote control code [ 0 ]+[ ]+[STANDBY/ON] receive, the ERROR HISTORY part is

cleared (ALL0x00).

RECEIVE

[ 0 ]

+

[ ]

+

EEPROM

E.HISTORY

CLEAR

COLD SET

INDICATION

/

PROCESSING

[STANDBY/ON]

Do not clear EEPROM when COLD SET processing at power to ON.

In case of clear EEPROM, so that the ERROR HISTORY data may disappear when the set returned from the user.

4.2.3 Reading the ERROR HISTORY

Reading ERROR HISTORY is assumed to be able to read set both POWER ON and turning off.

The reading method is done by the following ways.

No.

Operation Indication System micon processing

1 Receive the remocon code.

[COLOR]+[ ]+STANDBY/ON]

2 Address change to 0x01 by |<<, >>|

(skip) key of remote controller.

Address change to 0x10 by G|<<,

ERR I NFO

00 : 01

address data

Read out the ERROR HISTORY

information from EEPROM.

Indicate the read out value by key

operation.

G>>| (GROUP SKIP) key of remote

controller.

Indication is start address to 00 then

indicate staep by 1 byte.

operation exp.) address 00 indicating

Press >>| key

Press G>>| key

Press |<< key

Press G|<< key

Press G|<< key

3 Cancel the mode by remocon code.

01 : 05

10 : 21

0F: 11

00 : 01

F0 : 00

Return to normal function indication.

[COLOR]+[ ]+STANDBY/ON]

(No.MB574)1-25

Page 26

4.2.4 ERROR details

Item

SAFETY

Number

AD value

Timer playback start NG factor

P.OFF timeout factor 50

CD 60

P. O F F

OTHER

To p

address

00

10

20

A0

Low address and contents

SAFETY number at SAFETY occur.

1~5 (SAFETY watch umber difference by model)

AD value at SAFETY occur

00~FF

Factor that was not able to be playbacked at timer start of the playback.

10 CD NO DISC

11 CD OPEN

90 OTHER

Factor that was not able to be power off.

10 CD TIMEOUT

70 MECHA CLOSE TIMEOUT

90 OTHER

Abnormal factor concerning CD

31 SLED IN TIMEOUT SLED inside track shift timeout

32 SLED OUT TIMEOUT SLED outside track shift timeout

34 Q CODE 3s TIMEOUT Q code input 3sec timeout

35 TOC READ TIMEOUT TOC read timeout

36 SEARCH TIMEOUT Search timeout

3B FOCUS TIMEOUT Focus out ->[/FLOCK=H] detection

3C PLAY Q CODE ERROR Q Code continuous Error in Play

70 MECHA CLOSE TIMEOUT

71 MECHA OPEN TIMEOUT

Factor that was power off

10 NORMAL

20 AUTO STANDBY

30 SLEEP

40 TIMER

1-26 (No.MB574)

Page 27

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.MB574)1-27

Page 28

Victor Company of Japan, Limited

Audio/Video Systems Category 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB574)

Printed in Japan

VPT

Page 29

SCHEMATIC DIAGRAMS

MICRO COMPONENT SYSTEM

UX-QX3WA,UX-QX3AA

CD-ROM No.SML200609

SP-UXQX1W

SP-UXQX1A

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Contents

Block diagrams

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2006 Victor Company of Japan, Limited.

CA-UXQX3W SP-UXQX1W

CA-UXQX3A SP-UXQX1A

2-1

2-2

2-7 to 9

No.MB574SCH

2006/9

Page 30

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

Page 31

Block diagram

PICKUP

FOCUSING

COIL

TRACKING

COIL

LOADING

MOTOR

S1

TRAY

SWITCH

SW601

REST

SWITCH

FEED

MOTOR

M601

SPINDLE

MOTOR

CD servo control section

A+C, B+D, E, F

CN601 CN602

CN001

CN1

MD, LD

T+/-, F+/-

LD+/-

OPEN, CLOSE

REST

FM+/-

SM+/-

RF & SERVO

IC801

FOCUS, SPINDLE

FEED, TRACKING

LOADING BTL

DRIVER

IC601

AMP

TBAL, FBAL, FE, TE

GCTL, RFENV, OFT

BDO, ARF, /RFDET

TRD

FOD

FEED

SPINDLE

FWD

REV

DRMUTE

MON,

XTCK

TXTD

DQSY

/RST_DSP

STAT

BLKCK

MLD

MDATA

MCLK

FLAG

P.ON

IC251

UNIT

MICON

IC651

DSP

E2PSDA

E2PSCL

TXDO

RXDO

/RESET

X651

33.8688MHz

/DCAS

/DRAS

IC682

CASCNT

RASCNT

IC681

/DWE

WECNT

IC201

EEPROM

X251

8.38MHz

CD mecha LED section

LCDR, LCDG, LCDB

RCDR, RCDG, RCDB

D1,D2

LED

OUTL

OUTR

AD0 to AD10

D0 to D3

IC671

DRAM

/CAS

/RAS

/WE

CN4

CN651

System control section

CN705

QA781 to QA785

Q7801 to Q785

LCDR

LCDG

LDE DRIVER

LCDB

RCDR

RCDG

RCDB

IC741

E2CLK

E2DATA

EEPROM

Q7301,Q7311

BUP,RESET

IC401

Q4301 to Q4306

DETECTOR AMP.

BUP

RESET

Main amplifier section

CDCMD

CN106

CDSTAT

CDRESET

CDL/R

Q6151,Q6251

AHB

IC601

ALPHA SOUND

LOUT, ROUT

IC311

FUNCTION VOL.

CD5V

IC250

CD5V REG.

SW10V

IC240

SW10V REG.

S1+

CD8V

IC280

CD8V REG.

POUTSW10V

CLEDR

CLEDG

CLEDB

LLEDR

LLEDG

LLEDB

RLEDR

RLEDG

RLEDB

CN711

CN401

SENSOR1

AHB

PS1, PS2

MIXLEVEL

EXCTL

SOUNDCTL

OUTL2/R2

VOLCE

VOLCK

VOLDATA

TUL/R

LSELO, RSELO

AUXIL/R

FCD

VOLCE

VOLCK

VOLDATA

AHB

PS1

PS2

MIXLEVEL

EXCTL

SOUNDCTL

CN707

CN102

LLCR, LLCG, LLCB

RLCR, RLCG, RLCB

X7002

32.768kHz

IC701

X7001

MICON

CDCMD

CDSTAT

CDRESET

QPLINK

SMUTE

AUXMUTE

POUTAMP

POUTSW10

FCD

PROTECT

AUXSW

FANON

CN706 CN713

CN103

8MHz

REM, KEYP, FKEY1, FKEY2, JOGL/R

US6V

Q7901

to Q7903

US6V REG.

SUBTRDC

FTU

Q7351

to Q7353

TU9V REG.

SW10V

TU9V

Trans & Diode bridge section

CN101

CN201

FAN_ON

SMUTE

Q1103,Q1203

SYSTEM MUTE

Q3037

Q3038

FAN

DRIVE

Q1302

S1+

D2901

to D2904

DIODE

BRIDGE

CN108

FAN

MOTOR

POUTAMP

INL

INR

AUXMUTE

AUXOL/R

QPLINK

S1A

S1B

PROTECT

POWER

to Q3382

AUX MUTE

IC391,IC392

QP LINK

LCDSO, LCDSCL

LCDCSB, LCDRS

LCDXRESET

STANDBYLED

CVOR

CVOG

CVOB

TUCE

TUCLK

TUDATAI

TUDATAO

TUL/R

POUTRELAY

WR902

CN202

SUBTRDC

to D9005

BRIDGE

Q1101,Q1102

Q1201,Q1202

PROTECTOR

IC101

AMP.

Q3380

Q3190

D9002

DIODE

Q1301

+OUTL/R

AUXOL/R

AUXIN-L/R

LCD & LED section

CN702

CN531

STANDBYLED

LCDSO

LCDSCL

LCDCSB

LCDRS

LCDXRESET

LLCR, LLCG

LLCB, RLCR

RLCG, RLCB

Key & LED section

CN710

CN501

FKEY1

FKEY2

KEYP

CVOR

CVOG

CVOB

REM

JOGL/R

CN709

TUNER

UNIT

FW903

US6V

POUTRELAY

RY901

Q9001

RELAY

T9002

POWER

TRANS.

J1001

-OUTL/R

L+

SPEAKER

R+

WR601

CN109

AUXSW

Q5300,D5300

STANDBY LED

DI531

LCD DISPLAY

D5341,D5351

ILLUMI.

S5001 to S5013

KEY MATRIX

S5014

POWER SW

D5033

VOL ILLUMI.

IC501

REMOCON

JS501

VOLUME

S1A

S1B

T9001

POWER

TRANS.

CN901

L+, R+

+OUTL/R

AUXOL/R

AUXIL/R

AUXSW

J6000

J6001

J6030

AC IN

HEAD

PHONE

AUX

OUT

AUX

IN

2-1

Page 32

Standard schematic diagrams

Transformer and Rectifiers section

GVA10132-B2

S1GND

1

S1+

2

S2GND

S2REGGND

MD5.4VREG

POUTMD

of CN101

3

4

5

6

3.5V

TO GVA10132-B1

QGB2510K2-06

0V

19.8V

0V

0V

5V

CN201

MD5.4V REG.

Q2601

GVA10131-B1

C2906 1000/25

!

!

D2911

1N4003S-T5

D2912

1N4003S-T5

D2903

1N5402M-20

D2904

1N5402M-20

0.01/50

C2907

C2901

0.01/50

D2902

1N5402M-20

D2901

1N5402M-20

D2913

!

!

D2910

1N4003S-T5

1N4003S-T5

NI

NI

C2902

C2903

C2904

C2905

0.1/50

0.1/50

NI

NI

!

of CN201

of WR902

TO GVA10131-B1

1

9.2V

2

!

3

4

CN202

QGA2536C1-04

9.3V

6.5V

6.5V

TO GVA10132-B2

S1A

1

S1B

2

S2A

3

4

S2B

WR902

QJK008-040504-E

FT932

F9002

FT931

NI

1SS133-T2

NI

D9001

NI

NI

US6V

POUTRELAY

DG

SUBTRDC

CN713

FW903

QUM154-06DGZ4-E

5.8V

1

0.7V

2

0V

3

10.6V

4

0.7V

0.1V

0V

Q9001

KTC3875/YG/-X

C9002

330/25

1N4003S-T5

1N4003S-T5

1N4003S-T5

1N4003S-T5

D9005

D9002

C9003

D9004

0.01

D9003

61

7

8

9

11

13

14

QSK0124-001

12

T9002

*1

!

QQT0253-001

T9001

RY901

!

*1

7

B9004

6

5

4

2

!

34

4

B9005

100V

*1

*1

!

C9001

0.0047/250

!

B9902

41

LF901

QQR1321-001

B9901

!

NI

3

2

NI

F9001

FT911

CN901

QGA7901C1-02

!

*1

1

2

FT912

!

MAINS

PLUG

NIC2604

D2602

R2610

NI

R2606

R2603

D2601

NI

C2601

R2607

NI

NI

NI

R2605

NI

R2604

NI

C2603

NI

C2602

NI

R2608

NI

NI

0.6V

0.5V

0V

Q2604

NI

R2602

NI

Q2602

NI

NI

NI

NI

R2611

R2601

Q2603

NI

NI

R2612

TO GVA10132-A1 of

*1

A

UP

1,VOLTAGES ARE DC-MEASURED WITH A DIGITAL VOLT METER

NOTES

OR OSCILLOSCOPE WITHOUT INPUT SIGNAL.

CONDITION: CD STOP MODE/LED:RAINBOW/NO TAPE/AHB:ON/ALPHA SOUND:OFF

2.UNLESS OTHERWISE SPECIDIED.

ALL RESISTANCE VALUES ARE IN OHM(

T9001 B9005B9004Versions T9002AC(V) FREQ(Hz)

110

240

220

50

60

QQT0451-002 QQT0253-001

60

QQT0451-003

QQT0451-003

QQT0253-002 USE

QQT0253-003

NIUT

NI

NI

F9001 F9002

QMF51W2-1R6-J8USE

QMF51W2-R80-J8

QMF51W2-R80-J8

NI

NI

NIUSE

).

ALL CAPACITORS ARE CERAMIC CAPACITOR OR MYLAR CAPACITOR.

ALL CAPACITANCE VALUES ARE IN

ALL INDUCTANCE CALUES ARE IN

ALL E.CAPACITORS ARE SHOWN IN THE FORM

CAPACITANCE (

F)/RATED VOLTAGE (V).

3.NI MEANS NO INSERT

F(P=pF).

H(m=mH).

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

2-2

Page 33

Amplifier and Jack section

GVA10132-B1

CN107

FAN-ON

NI

1.4V

21

0V

20

C3161

1.4V

19

4.8V

18

C3266

1.6V

17

NI

5V

16

1.6V

15

0V

14

0V

13

0V

12

5V

11

0V

10

4.9V

9

4.7V

8

3V

7

6

4.4V

5

4.4V

4

4.4V

3

1.6V

2

4.4V

1

4.4V

1

0V

2

0V

3

0V

4

12V

5

0V

6

0V

7

0V

8

8.4V

9

4.9V

10

0V

11

0V

12

4.9V

13

0V

14

0V

15

0V

16

5V

17

0V

1

2.7V

2

4.3V

3

4

4.9V

5

1.6V

6

4.8V

7

4.8V

8

0V

9

0V

10

1.5V

11

0V

12

0V

13

1.5V

14

0V

15

0V

16

7.8V

17

7.8V

QGA2501C1-02

CN108

1

MGND

2

R3364

CN105

QGF1205F2-17

CN106

QGF1036C2-17

C3200

100/10

LEDGND

NI

C3166

L3363

NI

R3362

R3365

NI

100R3251

100R3151

PBMUTE

RECB

RECMUTE

A/B

SOL1

MOTOR

KEY

ENDSW1

L3321

(B1505)

BUS

K3321

(B1501)

BUS

K3324

(B1502)

BUS

K3323

(B1504)

TUL

DGND

AGND

TUR

0V

ACM-S2-1M CN100

TO CD MECHA

*

PART A VERSION

1. C3104, C3204

2. TAPE SECTION NO INSERT INSERT

4. D2700, D2701

C2701

FIGURE 1 (EMC C/M)

PART UP VERSION

1. C1110, C1210

2. C1111, C1211

3. C6006, C6008

4. C6012, C6014

5. PP300

0.033 u

0.033 u

0.01 u

680p

QNZ0104-001

RIN

AGND

LIN

A5V

ROUT

D5V

LOUT

DG

DOUT

DIN0

M5V

MGND

RESET

COMMAND

STATUS

COMCLK

STSRDY

DOUTOFF

DIN1

UART

MODESEL

RECR

MG

RECL

MB12V

PBR

AG

PBL

SW8V

PBMUTE

RECB

RMUTE

TO TAPE

A/B

SOL1

MOTOR

ACMSAFETY

KEY

ENDSW1

TXD0

RXD0

NC

/RESET

TX

3.3V

3.3V

DGND

DGND

OUTL

AGND

FMU-US1-1M

AGND

OUTR

MGND

MGND

+8V

+8V

TO FAN MOTOR

OTHERS

INSERTNO INSERT

INSERTNO INSERT3. IC270

INSERTNO INSERT

OTHERS

NO INSERT

NO INSERT

NO INSERT

NO INSERT

NO INSERT

AHB

C6322

D6301

100/16

MTZJ4.7C-T2

1k

R6306

68k

R6354

C6353

D6353

NI

R6019

C6014

FIGURE 1

C6004

27K

27K

300

300

300

0.01/50

1SS133-T2

J1001

QNB0181-002

1

2

3

4

5

300

1/4W

1/4W

1/4W

C6003

0.01/50

FIGURE 1

R6031

R6033

R+

L+

R-

L-

GND

1/4W

D6006

27K

27K

FIGURE 1

C6012

1SS133-T2

1SS133-T2

C6351

C6006

D6030

1SS133-T2

68k

R6352

1/50

TO SPEAKER

2

6

1

3

7

4

5

C6008

2

FIGURE 1

6

1

3

7

4

5

D6007

1SS133-T2

2

6

1

3

7

4

5

C6032

0.0022/50

HEAD PHONE

J6000

QNS0266-001

AUX OUT

J6001

QNS0266-001

TO CHASSIS GND

AUX IN

QNS0266-001

J6030

R6351

120k

R6353

NI

NI

C6352

NI

9.5V

9.5V

9.5V

9.5V

C1110

FIGURE 1

R6021

R6020

R6022

470

1/4W

470

1/4W

R6010

R6009

L6000

47

100/16

R6030

1K

C6031

100p

R6032

C6030

100p

R6034

D6031

0.0022

0.0039

C6311

C6309

4.4V

IC601 AN17140A-W

1.8V

R6302

0.47/50

R3384

5.2V

5.3V

R3385

C3380

22/50

CONNECT

TO SHIELD

R1102

C1103

10/25

9.6V

Q1102

KRA109S-X

0V

C6312 0.0015

4.4V

2.1V

47k

2.2K

2.2K

10k

9.6V

PS1

C6323

47/25

4.4V0V4.7V

0V

C6317 0.47/50

R3382

10K

R3383

10K

0V

0.7V

0V

0V

0.7V

0V

R1202

10k

R1101

9.6V

Q1202

KRA109S-X

1.8V

1.5k

R6251

R6259

9.6V

10k

C1203

10/25

9.6V

0V

MIXLEVEL

22

MIXLVL

C6251

NI

R6252

R3380

R3381

9.6V

KRA109S-X

9.6V

S2REGGND

MD5.4V

R6159 NI

C6151

1.5k

R6151

5.0V

C6256

0.47/50

2.7k

KTC3875/YG/-X

4.7K

4.7K

Q3380

2SC5938A/B/-X

Q3381

2SC5938A/B/-X

R1201

Q1201

S1GND

S1+

S2GND

Q6151

KTC3875/YG/-X

0V

0V

2.7k

0V

47k

12K

R6152

R6154

R6157

2k

2.2K

R6155

0.47/50

R6156

C6153

0.082

0.082

C6154

C6156

0.015

21

20

18

+INL19-INL

5.0V

4.7V

4.7V

OUTL1

4.7V

0.015

C6253

2.2K

R6255

R6254

0V

9.6V

9.6V

0V

9.6V

9.6V

0.5V

0V

0V

0V

0V

0V

10k

4.8V

OUTL2

4.4V

4.7V

4.8V

C6254

0.082

0.082

R6256

2K

12K

47k

R6257

C6316

100/25

0V

0V

Q6251

11

R+

11

+OUTR

10

10

HPGND

9

9

L+

8

8

+OUTL

7

7

AUXSW

6

6

AUXIR

5

5

4

4

3

3

AUXOR

2

2

1

1

CN109

WR601

QGA2536F1-11

WJP0084-002A-E

1

2

EP102

QNZ0136-001Z

3

1

W2

NI

0V

CN101

QGB2510J1-06

1

2

3

4

5

6

CN201

AUXIL

TO GVA10132-B2

IN GND OUT

20.5V

IC270

KIA7812API

123

0V

11.9V

C2701

47/25

AUXIR

GVA10131-B5

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

C6315

AUXIL

AUXGND

AUXOL

AUXSW

R6158

10k

330/10

R6301

100

C6155

10/50

R6153

200k

17

VCC

8.6V

0V

GND15VREF14OUTR213INR12+INR11OUTR110LFO39EXTCTL8LFO27LFO16PSC257IN46IN35OUT2OUTR1INR

16

R6253

200k

C6255

10/50

(B1506)

D6351

BUS

D6352

R6258

10k

C1111

C1210

C1211

FIGURE 1

FIGURE 1

FIGURE 1

NI

NI

11EQS03L-T4

11EQS03L-T4

D6003

D6001

D6002

D6000

C6001

B6031

QUY150-050Y

L6031

NI

L6030

NI

B6030

QUY150-050Y

PS2

0V

2.2

R1208

1/4W

C1206

SW10V REG.

KIA278R10PI-U/P

IN OUT GND CTRL

1234

9.6V

0V

2.2

0.1/50

IC240

10.1V

F)/RATED VOLTAGE(V).

EXCTL

0V

C6313

22/50

SOUNDCTL

R6304

Q6301

KTC3875/YG/-X

10k

0V

0V

0.001

R3106

1k

32

INL

3.8V

0.0056

C6305

C6302 0.027

C6307 0.0039

C6301

C6303 0.0033

31

OUTL301IN1292IN1282IN2273IN1263IN2253IN3244IN123PSC1

4.4V

4.4V

4.4V

4.4V

4.4V

SOUND IC

4.3V

4.0V

4.4V

3.7V

4.4V

3.8V

R3206

1k

10k

R6308

R6309

0V

0V

D1101

9.6V

20.6V

VCC13-OUTR12GND11+OUTR10GND9-OUTL8+OUTL7POP6INL5PP4STB3SG2RF1INR

14

36k

R1105

4.7/50

2.2

C1104

R1207

1/4W

7.5k

R1106

0.056/16C1105

0.1/50

C1207

!

C1303

8200/25

POUTSW10V

0V

5.2V

C2401

220/35R2402

10k

0V

Q6304

KTC3875/YG/-X

1SS133-T2

R1205

C1204

0.056/16C1205

!

C6320

0.0068

R6303

11k

C6321

C6319

0.012

10/50

D1201

1SS133-T2

36k

4.7/50

0.47/50C1305

7.5k

R1206

PROTECTOR

Q1301

KRC109S-X

NID1102

PROTECT

NIC1301

NID1202

*

D2701

C6318

KTA1504/YG/-X

Q3382

4.6V

R3386

5.6K

AUXMUTE

AUXSW

AUXIN-R

AUXIN-L

PP300

FIGURE 1

C1311

0.01

9.6V

0V

Q1101

KRA109S-X

POUTMD

A VERSION NI ONLY

TAPE 12V

D2700

1SS133-T2

MTZJ15B-T2

QPLINK

2.2/50

C3191

C3194

R3194

4.7K

4.6V

9.1V

4.6V

4.6V

8765

4.7K

R3191

+VCC

OUT2

-IN2

+IN2

IC391

KIA4558F-X

4.7K

R3291

OUT1

+IN1

-IN1

-VCC

4321

R3154

R3153

101112131415161718192021222324

5.2V

POUTPAMP

NIL3361

SAFETY

R3369

NIL3362

8.2k

12K

R3368

5.1K

10K

AUXMUTE

4.8V

4.6V

4.6V

4.6V

4.6V

NI

NI

C3163

C3263

8.2k

R3254

R3256

Q3300

KRC111S-X

C3037

FCD

POUTSW10V

POUTMD

3.7V

5.2V

5.2V

TO MICON BOARD

0V

R3294

4.7K

NI

C3362

NI

NI

FAN

PROTECT

0V

C3193

47/25

NI

1/4W

R3374

NIC3261

NI

NIR3363

NI

BUS

BUS

NI

R3262

R3162

NI

NI

W1

NI

8.2K

R3152

R3370

5.1K

10K

R3371

L3322

(B1503)

SW10V

CDRESET

SW10V

CDCMD

QPLINK

US5.4V

5.3V0V3.8V0V3.8V

SAFETYREG1

CDSTATO

10V

10V

5.1V

4.5V

2.8V

5.2V

CN103

QGB1218J1-24

FAN

CN706

2.2/50

1.3V

4.5V

9.1V

8765

100K

R3193

R3293

R3297

NI

D3392

3.3kR3255

3.3kR3155

NI

R3156

KRC111S-X

Q3301

1SS133-T2

D3037

AUXSW

SMUTE

123456789

0V

0.5V

4.5V

100K

B3017

100K

C3291

2.2/50

D3391

NI

Q3037

KTA1504/YG/-X

R3037

LEVELDET

0V

KEY

5.2V

C3297

10/50

NI

10K

Q3038

KRC102S-X

ENDSW1

KIA4558F-X

3.9V

D3297

R3295

1N4003S-T5

R3366

R3367

R3038

FAN DRIVE

SAFETY

MOTOR

0V0V0V

5.2V

+VCC

IC392

OUT1

R3264

R3164

1SS133-T2

10K

47K

SOL1

OUT2

-IN1

4.6V

220K

C3294

2.2/50

D3352

*

10K

A/B

+IN2

-IN2

+IN1

-VCC

4321

0V

4.6V

NI

NI

TAPE SECTION :

A VERSION NI ONLY

RECMUTE

5.1V

CN707

3.5V

R3263

NI

R3163

NI

1N4003S-T5

RECB

PBMUTE

QGB1218J1-22

QPLINK

Q3190

KRC109S-X

AUXIL

R3199

10K

R3195

10K

R3196

R3299

0

D3351

SIGN001400

EXCTL

SOUNDCTL

PS2

10111213141516171819202122

0V0V0V

0V0V0V

5V

CN102

R3197

100

0

C3199

47/25

NI

R3198

NI

R3298

AUXIR

MDR

MDL

MDRESET

MDCMD

MDSTAT

TAPER

TAPEL

DGND

D3393

1SS133-T2

CDL

CDR

VOLCE

VOLDATA

VOLCK

MIXLEVEL

PS1

AHB

MDRESET

MDCMD

MDSTAT

123456789

5.2V0V5.1V

3V

4.6V

KRC111S-X 10K

4.7V0V5.2V

AUXIN-R

AUXIN-L

47/25

C3500

R3500

R3400

4.7K

4.7K

22K

R3501

D3500

KDS4148U-X

C3401

47/25

R3402

120K

D3401

UDZW5.1B-X

VOLCK

VOLCE

VOLDATA

C3302

R3306

1/4W

330/10

R3302

2.2k

34

35

36

VDD

7.6V

5.2V

-

VOLCK

LOPOUT

FUNCTION VOL IC

VOLDATA2VOLCE3Vss4ROPOUT5RINM6RINP7ROUT8RSB9RBASS210RBASS111RTRE12RVRIN13RSELO14CDR15TAPER16MDR17TUNERR18AUXR

5.2V

0V

0.6V

1

R3303

2.2k

R3301

2.2k

B3010

R6951

NI

R1211

47/25

C3400

22K

R3401

D3400

KDS4148U-X

4.7k

R1111

4.7k

10KR1110

7.5k

R3105

R3104

180PC3113

180PC3112

-

BUS

Q6951

NI

C6952

NI

KTC2876-T

0.1

C3111

30

31

LSB

LOUT32LINP33LINM

3.8V

3.8V

IC311

LC75345M-X

3.8V

180PC3212

180PC3213

7.5k

R3205

RIPPLE FILTER

NI

0V

R1209

Q1203

0.8V

0V

KTC2876-T

0V

R1109

0.8V

1k

0V

100

-

-

C6951

10KR1210

Q1103

18k

7.5k

R3103

R3102

9.1k

0.1

0.0022

4.7/50C3108

C3109

C3110

C3107

0.0047

25

27

28

LTRE

3.8V-3.8V

3.8V

3.8V

LBASS129LBASS2

3.8V

3.8V

3.8V

3.8V

0.1C3210

0.0022

0.1C3211

C3209

R3203

7.5k

R3204

!

IC101

LA4628

C1209

10/50

C1109

10/50

Q1302

KTA1504/YG/-X

5.3V

5.1V

1k

4.6V

C1310

R1302

22/50

FAN CONTROL

!

IC250

KIA78R33API-U/P

IN

OUT

GND

CTRL

1234

7.9V

3.3V

5.2V

0V

C2502

D2500

1SS133-T2

LEVELDET

Q2403

0.6V

KRC102S-X

R1

R1

5.2V

10K

R2403

NI

0V

R1

R2

R1 R2

KRC102S-X 10K 10K

KRC109S-X 47K 22K

KRA109S-X 47K 22K

220/10

MTZJ5.1B-T2

D2501

SMUTE

FCD

NOTES

R1

R2

R1 R2

1.VOLTAGES ARE DC-MEASURED WITH A DIGITAL VOLT METER

2.UNLESS OTHERWISE SPECIFIED.

3.NI MEANS NO INSERT

MDL

CDL

TUL

TAPEL

AUXIL

10/50

C3105

470

4.7/50C3104

R3110

*

21

22

23

24

MDL

CDL

3.8V

3.8V

3.8V

3.8V

TAPEL

LSELO26LVRIN

3.8V

3.8V

3.8V

3.8V

470R3210

0.0047

C3207

4.7/50C3208

4.7/50C3204

R3202

C3205

10/50

*

9.1k

18k

4.7/50

MDR

C3206

CDR

TAPER

TUNERL

C3106

4.7/50

4.7/50

100/10

C3101

C3301

19

Vref20AUXL

3.8V

3.8V

3.8V

3.8V-3.8V 3.8V

4.7/50C3201

TUR

AUXIR

POWER AMP IC

0V

1.7V

9.4V

C1108

C1208

330P

330P

5.6k

C1309

100/25

1.7V

9.6V

3.3V

2.5V

NI

R1301

R1303 10k

NI

33/50

C1307

D1302

9.6V

2.1V

2.2

R1108

1/4W

R11071/4W

0.47/50C1306

C1107

C1106

0.1/50

0.1/50

CD8V REG.CD3.3V REG.

IC280

!

KIA78R08API

IN

OUT

GND

CTRL

1234

10.1V

0V

5.2V

7.9V

D2800

D2801

C2801

C2800

MTZJ9.1A-T2

100/16

NI

20.5V

C2400

100/35

D2401

D2400

MTZJ15B-T2

1SS133-T2

).

F(P=pF).

H(m=mH).

1SS133-T2

POUTPAMP

OR OSCILLOSCOPE WITHOUT INPUT SIGNAL.

CONDITION- CD STOP MODE/LED:RAINBOW/NO TAPE/AHB:ON/ALPHA SOUND:OFF

ALL RESISTANCE VALUES ARE IN OHM(

ALL CAPACITORS ARE CERAMIC CAPACITOR OR MYLAR CAPACITOR.

ALL CAPACITANCE VALUES ARE IN

ALL INDUCTANCE VALUES ARE IN

ALL E.CAPACITORS ARE SHOWN IN THE FORM OF CAPACITANCE(

2-3

Page 34

Micon, Key, Touch illumination and LCD section

RLCG

LCDG

LCDB

RCDB

LCDR

RCDR

LCDCSB

LCDRS

LCDSO

REM

JOGL

JOGR

KEYP

RLCR

RLCG

RLCB

LLCR

LLCG

LLCB

CVOR

CVOG

CVOB

R4309

470K

R4310

R4304

2.2M

15P

C4305

IC401

NJM4565M-WE

R4315

1M

2P

C4301

R7836

180

CVOB

R7843

180

CVOG

R7833

180

RLCB

R7808

180

R7829

180

LLCG

LLCB

CVOR

RLCR

LCDR

LLCR

22K

C4308

2P

4321

0V

GND

3.7V

-

+

+

-

4.8V

4.9V

R4316

220K

R4314

100K

680P

33P

C4307

C4311

C4304

R4311

2.2M

4.9V

GVA10131-B4

GVA10131-B3

39K

R5016

R5025

12K

6.8K

R5024

3.9K

R5023

2.7K

R5022

3.3K

R5021

VOL ILLUMI.

NSTM515AS

D5034

NI

D5036

NI

NI

D5035

KRC102S-X

KRC104S-X

KRA102S-X

KRA104S-X

KRC111S-X 10K

FKEY1

D5033

R1

D5341

R1

NSTM515AS

R1

1

3

LLCR

1C5307 /10

12

S5007

QSW0683-001Z

[COLOR/DEMO]

12

S5013

QSW0683-001Z

[ALPHA SOUND]

12

S5012

QSW0683-001Z

[MD REC]

/[G,BSKIP]

12

S5011

QSW0683-001Z

[TAPE REC]

/[G.FSKIP]

12

S5010

QSW0683-001Z

[BSKIP]

12

S5009

QSW0683-001Z

[STOP]

12

S5008

QSW0683-001Z

[FSKIP]

1

CVOR

R2

R1

10K

R2

10K 10K

47K 47K

R1

2

4

LLCB

LLCG

DI531

QLD0418-001

VSS

VDD

VO

1234567

4.5V

5.3V

2.7K

R5301

/10

1

C5306

2

4

3

CVOG

CVOB

R2

10K

47K47K

R2R1

NI

LCDSO

47P C5305

QSW0683-001Z

QSW0683-001Z

[MD EJECT]

QSW0683-001Z

[TU/AUX]/[AUX]

QSW0683-001Z

[TAPE]/[TU]

QSW0683-001Z

[MD]/[TAPE]

QSW0683-001Z

JOGL

D5343NID5342NID5344

LCDSCL

5.0V-0V

47P C5304

12

S5006

[CD OP/CL]

12

S5005

/[TAPE REC]

12

S5004

12

S5003

12

S5002

12

S5001

[CD]

JOGR

QSW0975-001

LCDCSB

JS501

JS501

100P C5303

LCDRS

4.9V

132

5.3V

0.4V

100P C5302

4

D5351

NSTM515AS21

LCDXRESET

8

5.3V

100P C5301

FKEY2

5

0V

0V

RLCR

D5300

R5015

R5014

R5013

R5012

R5011

3

RLCB

SLR-343VC-T

12K

6.8K

3.9K

2.7K

3.3K

REM

4

RLCG

R5300

1/10W

680

Q5300

KRC111S-X

S5014

QSW0683-001Z

12

[POWER]

IC501

GP1UM271XKVF

GP1UM271XKVF

IC501

123

5.3V

C5032

0.001

5.3V

D5354NID5353NID5352

KEYP

4

5

0V

C5031

NI

RLCR

RLCG

RLCB

LLCR

LLCG

LLCB

LCDCSB

LCDRS

SW10V

DGND

STANDYLED

US5.4V

LCDXRESET

LCDSO

LCDSCL

CN501

QGF1205F2-13

47/16

GVA10132-B3

II

TP401

TP501

LCDR

LCDB

LCDG

SW10V

RCDR

RCDB

RCDG

FMU-US1-1M

TO CD MECHA

CN531

QGF1205C2-15

15

14

13

12

11

10

9

LCDCSB

8

LCDRS

7

6

5

STANDBYLED

4

3

LCDXRESET

2

LCDSO

1

LCDSCL

REM

13

JOGL

12

JOGR

11

KEYP

10

FKEY1

FKEY1

9

FKEY2

FKEY2

8

SW10V

SW10V

7

DGND

6

5

US5.4V

US5.4V

4

CVOR

3

CVOG

2

CVOB

1

WR501

NI

DETECTOR

BUFFER AMP

OSCILLATOR

CIRCUIT

R7838

0

1

8.2V

2

7.1V

3

7.2V

4

10V

5

8.2V

6

7V

7

7.2V

CN705

QGF1036F2-07

for LED

QGF1205C2-15

TO LCD

CN702

8V

RLCR

15

7.8V

RLCG

14

6.8V

RLCB

13

8V

LLCR

12

7.8V

LLCG

11

6.9V

LLCB

10

5V

9

0.2V

SW10V

8

10V

SW10V

7

0V

6DGND

STANDBYLED

0V

5

US5.4V

5.3V

4US5.4V

LCDXRESET

5.2V

3

2.8V

2

LCDSCL

5.1V

1

CN710

TO KEY

QGF1205C2-13

5.2V

13REM

5.2V

JOGL

12

5.2V

JOGR

11

5.2V

10KEYP

FKEY1

5.2V

9

FKEY2

5.2V

8

SW10V

10V

7

0V

6DGND

0V

5

5.3V

4

8.5V

CVOR

3

7.7V

CVOG

2

6.6V

CVOB

1

22K

R4312

4.3V

18K

R4317

C4309

2.2/50

100K

R4301

R4302

100K

RT3CLLM/EF/-X

123

RT3CLLM/EF/-X

123

RT3CLLM/EF/-X

123

RT3CLLM/EF/-X

123

2SC3928A/QR/-X

CLEDR

2SC3928A/QR/-X

RLEDR

2SC3928A/QR/-X

RLEDR

2SC3928A/QR/-X

LLEDR

2SC3928A/QR/-X

LLEDR

2P

4.5V

Vcc

8765

C4302

QA781

RLEDG

RLEDG

QA782

CLEDB

CLEDG

QA783

LLEDG

RLEDB

QA784

LLEDB

RLEDB

QA785

RT3CLLM/EF/-X

LLEDB

123

Q7802

Q7801

Q7805

Q7803

Q7804

D4301

1SS133-T2

4.3V

9.7V

10/50

LLEDG

R7850

R7851

R7858

R7859

R7854

R7855

R7856

R7857

R7101 R7102

OPEN

68K

10K

10K

10K

1/4W

R7804

456

180

R7841

456

180

456

R7824

456

180

R7828

456

180

R7852

220

R7853

220

220

220

220

220

220

220

220

220

10K

10K

16K

30K

OPEN

R4303

100

4.4V

R4313

0.047

C4306

R7837

Q4301

180

FIGURE 1

C7801

C7803

DGNDDGND

0V

10K

C7805

C7812

C7814

220/10

C7807

220/10

C7811

220/10

C7809

220/10

C7813

220/10

220/10

220/10

VERSIONRESISTOR VALUE

UX-QX3

UX-QX3WA

UX-QX3AA

UX-QX3-PUT/-PUP

UX-QX3AUT

UX-QX3-WUP/-WUT

R4305

10

4.8V

2SA1530A/QR/-X

CN704

QGF1036C2-08

NI

8NC

7 CDTN0

6 CDCOPY

5 CDLRCK

4 CDEMP

3 CDDATA

2 GND

1 CDBCK

R7815

RLEDG

100

NI

R7834

220/10

R7847

CLEDG

100

NI

220/10

R7844

R7849

CLEDB

100

NI

R7846

R7816

RLEDB

100

NI

R7835

R7818

LLEDB

100

NI

R7806

R7817

LLEDG

100

NI

R7810

R7848

CLEDR

100

NI

R7845

R7813

RLEDR

100

NI

R7811

R7814

100

NI

R7802

US5.4V

Q4303

2SA1530A/QR/-X

10.1V

9.5V

100K

R4306

4.7/50

C4312

1SS133-T2

1/50C4303

10.0V

4.8V

Q4302

2SC3928/QR/-X

D4304

4.3V

D4302

10K

1SS133-T2

R4307

1K

R4318

4.3V

1M

R4308

C4310

100/16

D4303

1SS133-T2

Q4304

KRC104S-X

10.1V

9.5V

10.0V

47K

R4321

4.7M

C4313

R4319

10/50

0.1V

0V

RESISTOR

R7037

R7038

R7052

R7053

R7054

R7055

R7056

R7057

R7058

R7114

ROM CORRECTION & HISTORY

0V

1

0V

2

0V

3

0V

L7001

QUY150-050Y

K7001

NI

QUY150-050Y

Q4305

KTA1504/YG/-X

Q4306

33K

R4323

0V

7.5V

0V

100K

R4322

FIGURE 2

A VERSION UT/UP

IC741

BR24L02F-W-X

2KBYTES

Vcc

A0

A1

SCL

A2

SDA4GND

1C7402

NIC7401

0V

10V

10V

0V

0V

CN401

KTA1504/YG/-X

NI INSERT

5.3V

8

0V

7

WP

0V

6

5.2V

5

C7002

C7001

1/50

SENSOR1

5

SW10V

4

3

SW10V

DGND

2

DGND

1

QGF1205F2-05

2.2K

R7114

FIGURE 2

C7003

100K

NOTES

5

4

3

2

1

R7121

0.1/25

CN711

QGF1205C2-05

NI

R7125

10K

R7118

10K

L7024

QUY150-050Y

1.VOLTAGES ARE DC-MEASURED WITH A DIGITAL VOLT METER

OR OSCILLOSCOPE WITHOUT INPUT SIGNAL.

CONDITION- CD STOP MODE/LED:RAINBOW/NO TAPE/AHB:ON/ALPHA SOUND:OFF

2.UNLESS OTHERWISE SPECIFIED.

ALL RESISTANCE VALUES ARE IN OHM(

ALL CAPACITORS ARE CERAMIC CAPACITOR OR MYLAR CAPACITOR.

ALL CAPACITANCE VALUES ARE IN

ALL INDUCTANCE VALUES ARE IN

ALL E.CAPACITORS ARE SHOWN IN THE FORM OF CAPACITANCE(

3.NI MEANS NO INSERT

ENDSW1

E2CLK

E2DATA

SMUTE

+BCTL

FTU

FCD

FANON

BUFFER

AUXSW

BUP

PROTECT

POUTRELAY

POUTSW10

POUTAMP

POUTMD

AUXMUTE

8 MBCK

7 GND

6 MDATA

Q7035

KRA102S-X

+BCTL

RESET

BUP

R7058 FIGURE 2

R7062

R7065

R7074

R7076

F(P=pF).

H(m=mH).

5 MEMP

4 MLRCK

3 MCOPY

2MTN0

1NC

CN703

QGF1036C2-08

NI

D7301

1SS133-T2

330

R7321

D7321

10K

100K

R7312

R7303

RESET

SW5.4V

Q7311

KRC102S-X

5.3V

0V

0V

C7312

2.2/50

2.2KR7059

22KR7060

22KR7061

2.2K

39KR7063

1KR7064

10K

2.2KR7066

NIR7067

2.2KR7068

1KR7069

2.2KR7070

10KR7072

2.2KR7073

2.2K

2.2KR7075

22K

C7311

1SS133-T2

4.7/50

BUP

C7321

Q7301

2200/6.3

10K

R7311

D7311

1SS133-T2

MOTOR

ACMSAFETY

FIGURE 2

FIGURE 2

R7056

73

74

75

NC

ACMSAFETY

76 ENDSW1

77 E2CLK

78 E2DATA

79 SMUTE

80 BCTL

81 FTU

82 FCD

83 CBTEST

84 FANON

85 BUFFER

86 AUXSW

87 BUP

88 PROTECT

89 NC

90 POUTRELAY

91 POUTSW10

92 POUTAMP

93 POUTAMP

94 AUXMUTE

95 DAVSS

96 NC

97 NC

98 NC

99 NC

100

DAVDD

VREF-2VERSION3ACMKEY4FKEY15FKEY26SAFETYREG7QPLINK8NC9LEVELDET10VREF+11VDD12X213X1I14VSS15XI16XO17MMOD18MDCMD19MDSTAT20MDRESET21VOLDATA22VOLCE23VOLCK24AHB25NC

1

2.2KR7001

FIGURE 2

R7057

10KR7119

FIGURE 1

FIGURE 1

R7102

R7101

CLOCK SHIFTER

D7303

D7903

1SS133-T2

MTZJ5.1C-T2

C7901

100/16

D7901

33K

1.8KR7051

RECMUTE

2.2KR7005

SAFETYREG

10kR7106

R7632

C7635

LLEDB

1.8KR7050

QPLINK

NI

0V

NI

LLEDR

LLEDG

1.8KR7048

1.8KR7049

2.2KR7077

LEVELDET

C7634

0V

0V

MTZJ5.6B-T2

R7904

1K

0.6V

1K

R7903

RLEDR

RLEDG

RLEDB

1.8KR7045

1.8KR7046

1.8KR7047

63

64

RLEDR65RLEDG66RLEDB67LLEDR68LLEDG69LLEDB

IC701

MN101C49GFJ

(FLASH:MN101CF49KYD)

VREF+

C7024 0.01

QAX0667-001Z

NI

NI

C7633

Q7631

NI

NI

R7634

R7301

47K

R7302

A/B

SOL1

RECMUTE

FIGURE 2

FIGURE 2

R7052 FIGURE 2

R7053

R7054

R7055

70

71

72

A/B

SOL1

MOTOR

2.2KR7002

2.2KR7003

2.2KR7004

FKEY2

FKEY1

ACMKEY

10KR7105

10KR7103

10K

R7104

STANDBYLED

X7001

).

F)/RATED VOLTAGE(V).

0.8V

0V

CLEDB

STANDBYLED

1.8KR7044

1.8KR7042

for PRI.

CN713

QGD2504C1-04Z

US6V REG.

Q7901

KTA1273/Y/-T

6.1V 9.5V

R7901

10K

0.8V

0.2V

Q7903

KTC3875/YG/-X

CLEDG

CLEDR

1.8KR7041

R7039

58

59NC60

CLEDR61CLEDG62CLEDB

NIR7006

MDCMD

8MHz

TO PRIMARY

GVB10131-B1

US6V

1/4W

R7905

8.9V

8.9V

Q7902

KTC3875/YG/-X

1K

R7902

10K

R7116

SOUNDCTL

RECB

EXCTL

PBMUTE

15KR7035

4.7KR7036

FIGURE 2

FIGURE 2

R7037

R7038

54

55

56

57

RECB

PBMUTE

SENSOR1

SOUNDCTL

NIR7007

NIR7008

2.2KR7009

2.2KR7010

VOLCE

MDSTAT

MDRESET

VOLDATA

NIC7632

NI

C7631

0V

NI

Q7632

0V

0V

NI

R7633

123

POUTRELAY

2.2

0.1/25C7903

10KR7034

EXCTL

2.2KR7011

VOLCK

R7631

C7636

MIXLEVEL

BEATCUT

NI

NI

10KR7033

52

2.2KR7012

AHB

4

SUBTRDC

1N4003S-T5

PS2

2.2KR7032

51

PS2

MIXLEV153MIXLEV2

D7902

POUTRELAY

C7353

FTU

22PC7651

22PC7652

TO TUNER MODULE

CN709

QGF1205C2-11

15

NININI

NI

TUG

TU9V REG.

D7351

1SS133-T2

D7352

C7351

4.7/50

MTZJ10B-T2

NI

50PS1

49LCDRS

48LCDCSB

47LCDSO

46LCDXRESET

45LCDSCL

44CDRESET

43CDSTAT

42CDCMD

41VPP

40TUCE

39TUDATAI

38TUDATAO

37TUCLK

36BEATCUT

35NC

34NC

33RESET

32VDD2

31MODEL

30JOGR

29JOGL

28KEYP

27REM

26NC

FOR MASK MICON

B7129

QUY158-100Y

FOR FLASH ONLY

X7002

32.768KHz

QAX0401-001

UP VERSION

QGF1205C1-15

1011121314

NI

NI

SIGR

TU9V

C7360

0.047

C7359

0.047

Q7353

KTC3199/GL/-T

1/4W

R7352

220

47/25

C7358

R7353

R7018

C7081