Page 1

SERVICE MANUAL

MICRO COMPONENT SYSTEM

UX-M5R

Area suffix

B ------------------------------- U.K.

E ----------- Continental Europe

EN ------------ Northern Europe

EV -------------- Eastern Europe

UX-M5R

Contents

Safety precautions

Preventing static electricity

Important for laser products

Disassembly method

Adjustment method

Flow of functional operation

until TOC read

CA-UXM5R SP-UXM5SP-UXM5

1-2

1-3

1-5

1-6

1-15

1-18

Maintenance of laser pickup

Replacement of laser pickup

Trouble shooting

Description of major ICs

Wiring connection

1-19

1-19

1-20

1-21

1-36

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

No.21110

Jul. 2002

Page 2

UX-M5R

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

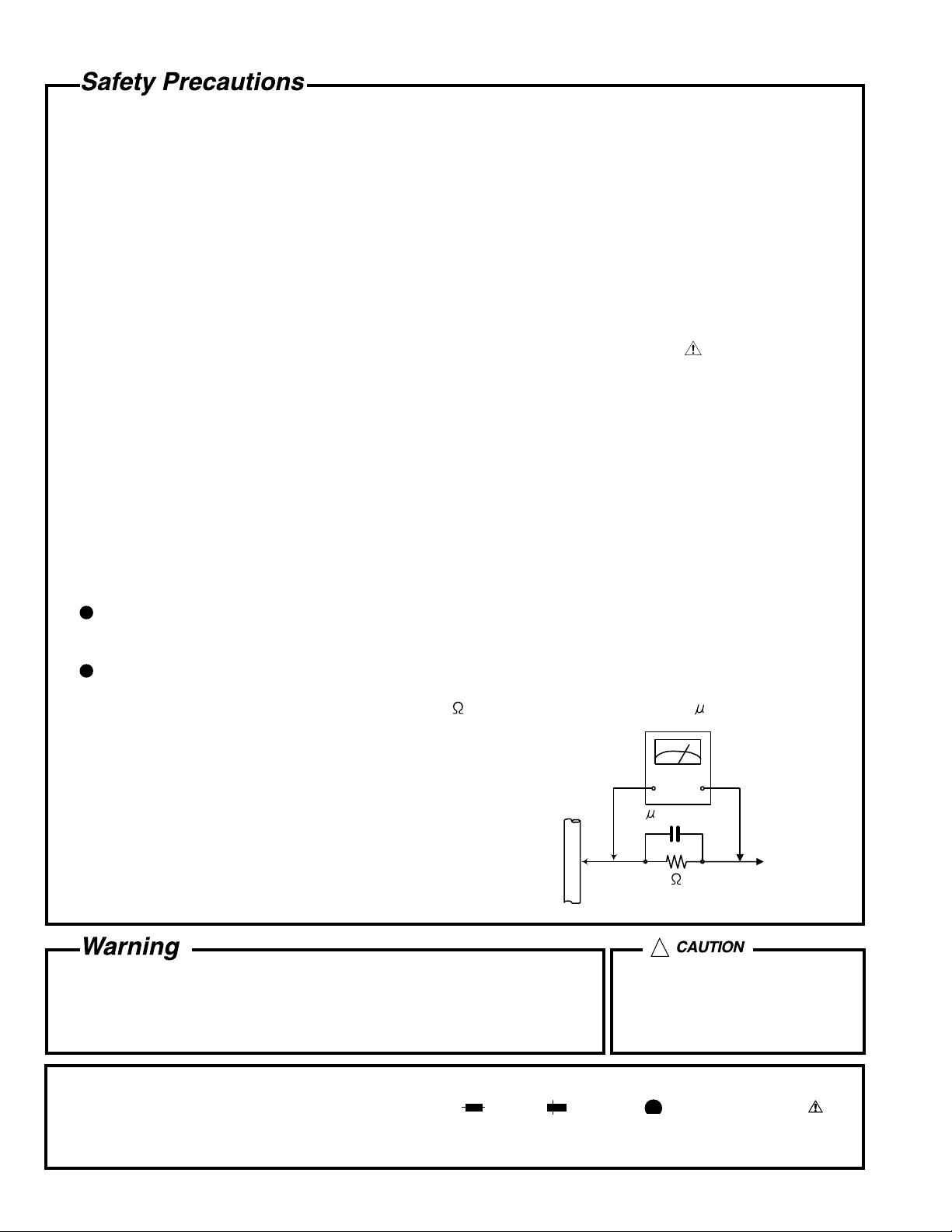

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

1-2

Page 3

UX-M5R

(U.K only)

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer. Replacement parts must be identical to

those used in the original circuits.

2. Any unauthorised design alterations or additions will void the manufacturer's guarantee ; furthermore the

manufacturer cannot accept responsibility for personal injury or property damage resulting therefrom.

3. Essential safety critical components are identified by ( ) on the Parts List and by shading on the

schematics, and must never be replaced by parts other than those listed in the manual. Please note

however that many electrical and mechanical parts in the product have special safety related

characteristics. These characteristics are often not evident from visual inspection. Parts other than

specified by the manufacturer may not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of the Service Manual and may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the original lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

1. Service should be performed by qualified personnel only.

2. This equipment has been designed and manufactured to meet international safety standards.

3. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

4. Repairs must be made in accordance with the relevant safety standards.

5. It is essential that safety critical components are replaced by approved parts.

6. If mains voltage selector is provided, check setting for local voltage.

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-3

Page 4

UX-M5R

Preventing static electricity

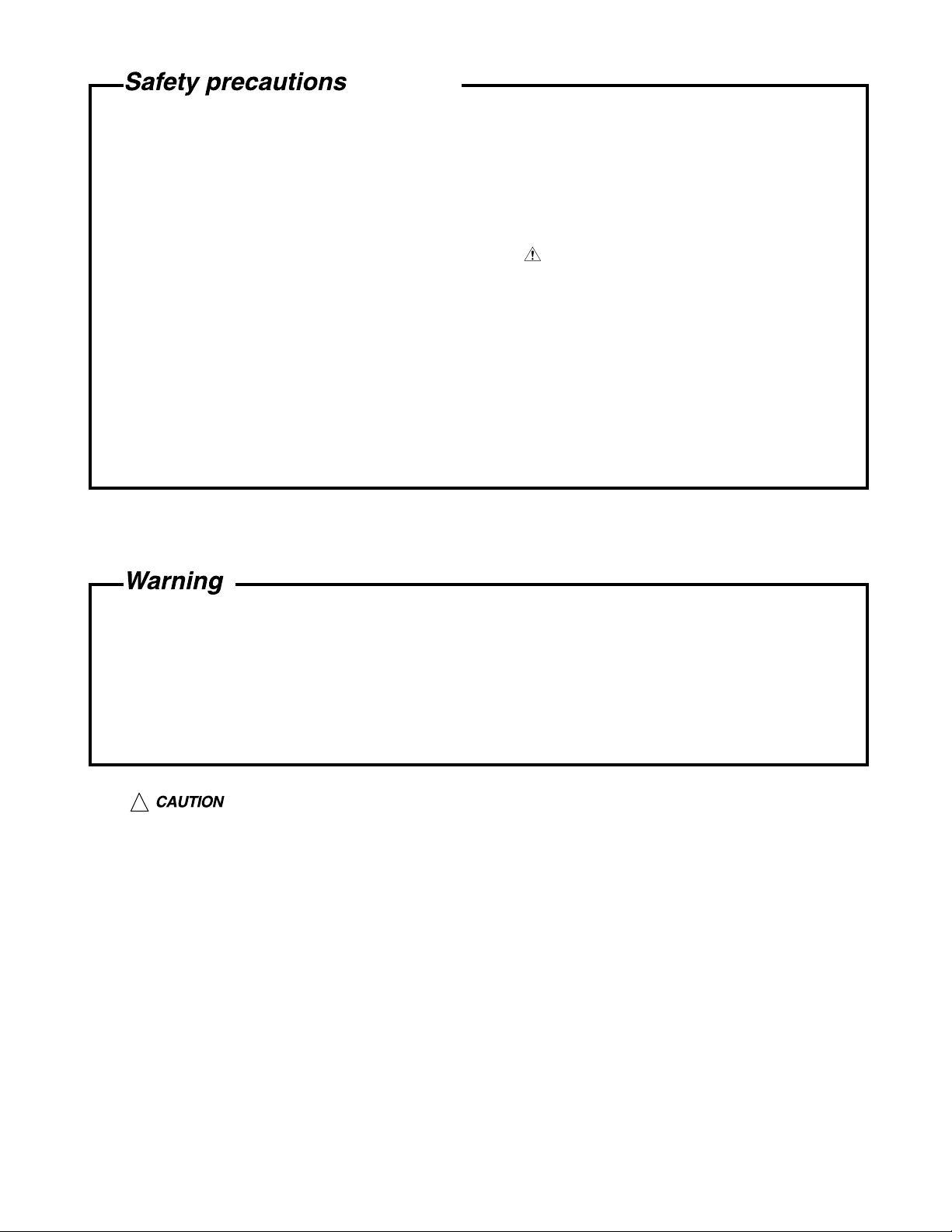

1. Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2. About the earth processing for the destruction prevention by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it

before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

In order to maintain quality during transport and before installation, both sides of the laser diode on the

1.

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

2.

source can easily destroy the laser diode.

4. Handling the traverse unit (optical pickup)

1.

Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2.

Remove solder of the short land on the card wire after replacing the optical pickup. For specific details, refer to

the replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit.

Be careful not to take too long a time when attaching it to the connector.

3.

Handle the card wire carefully as it may break when subjected to strong force.

4.

It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

5. Attention when traverse unit is decomposed

Connector

*Please refer to "Disassembly method" in the text for the CD pickup unit.

Short land

Apply solder to the short land before the card wire is disconnected from

the connector on the CD pickup unit.

(If the card wire is disconnected without applying solder, the CD pickup

may be destroyed by static electricity.)

In the assembly, be sure to remove solder from the short land after

connecting the card wire.

1-4

CD pickup unit

Page 5

Important for laser products

UX-M5R

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

VARNING : Osynlig laserstrålning är denna del är öppnad

och spårren är urkopplad. Betrakta ej strålen.

VARO : Avattaessa ja suojalukitus ohitettaessa olet

alttiina näkymättömälle lasersäteilylle.Älä katso

säteeseen.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

ADVARSEL : Usynlig laserstråling ved åbning , når

sikkerhedsafbrydere er ude af funktion. Undgå

udsættelse for stråling.

ADVARSEL : Usynlig laserstråling ved åpning,når

sikkerhetsbryteren er avslott. unngå utsettelse

for stråling.

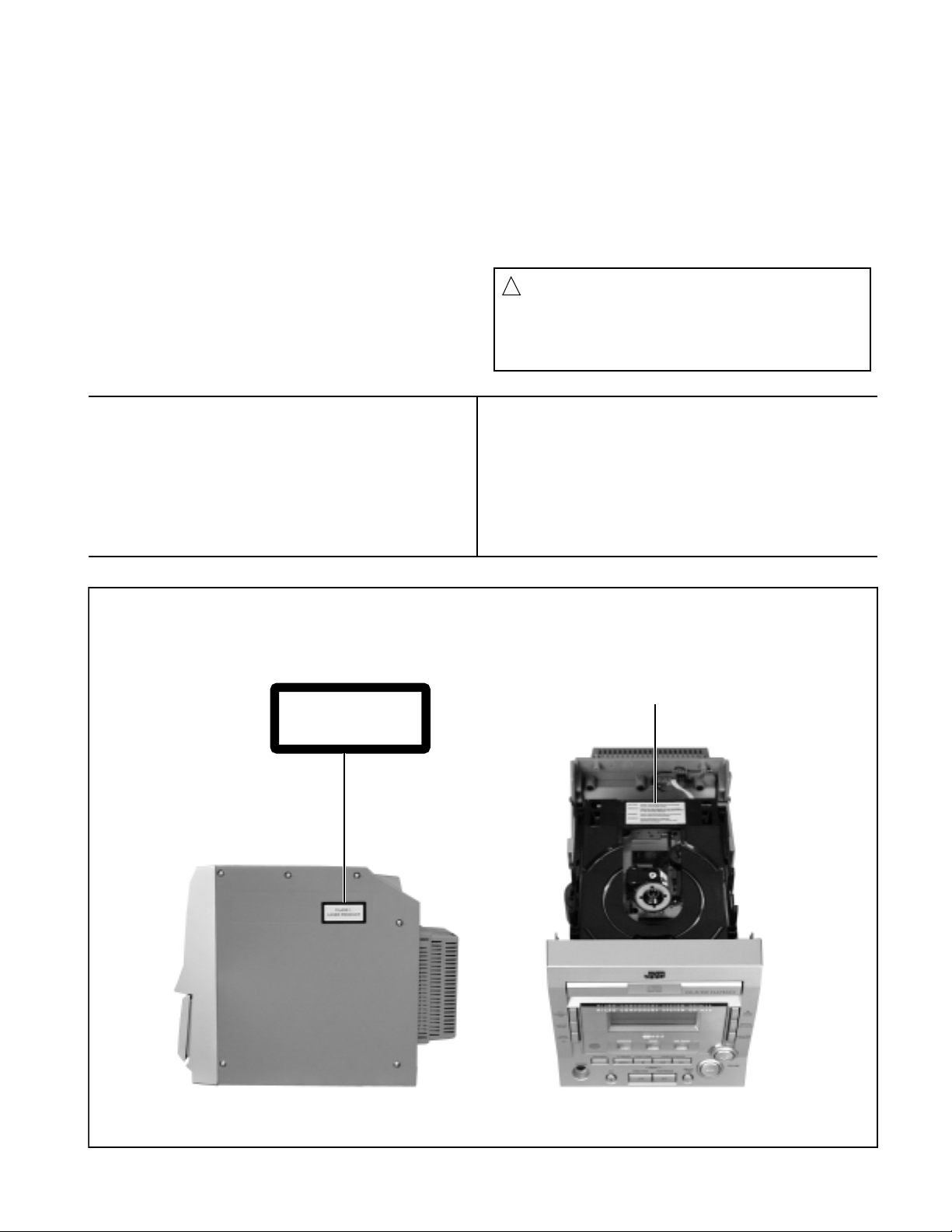

REPRODUCTION AND POSITION OF LABELS

CLASS 1

LASER PRODUCT

WARNING LABEL

1-5

Page 6

UX-M5R

Disassembly method

<Main body section>

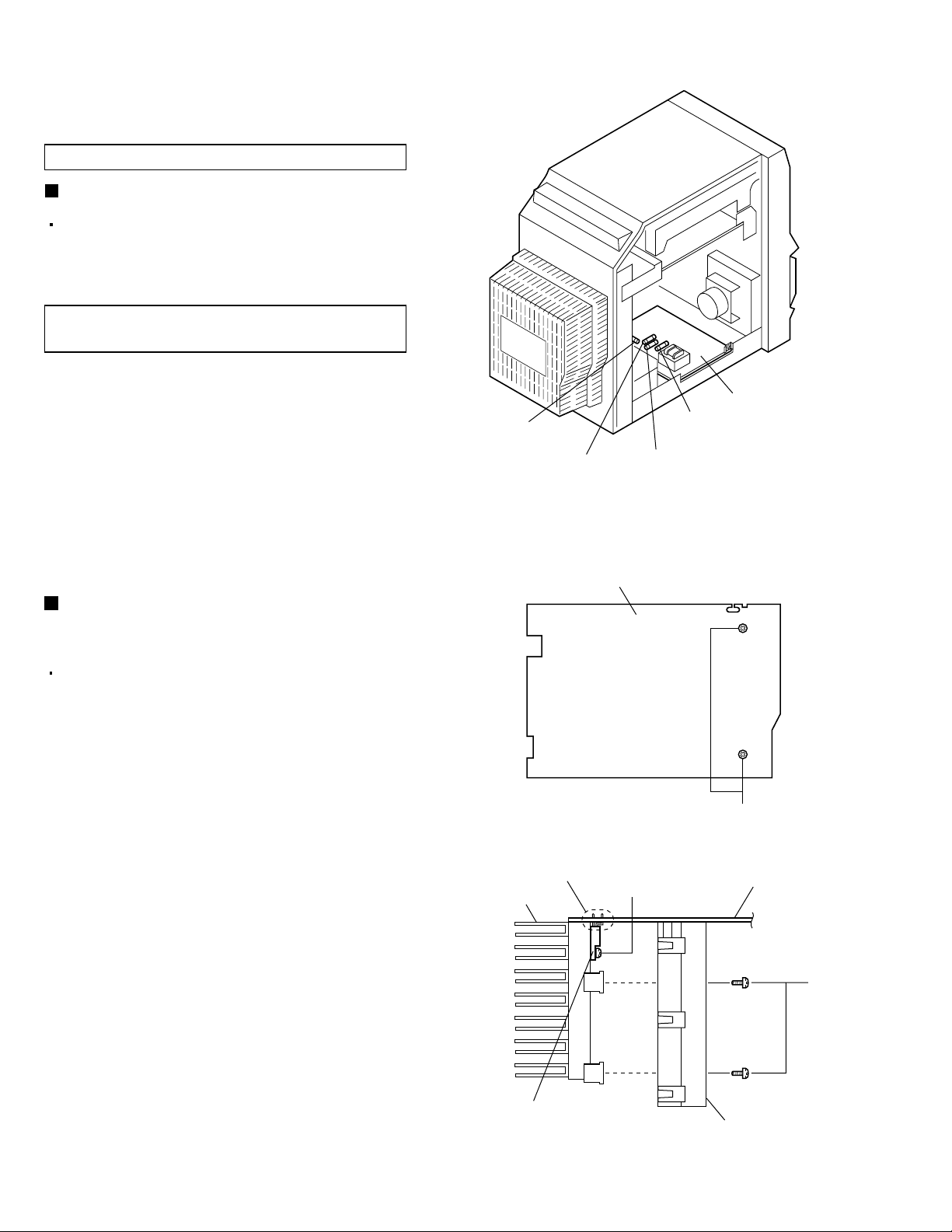

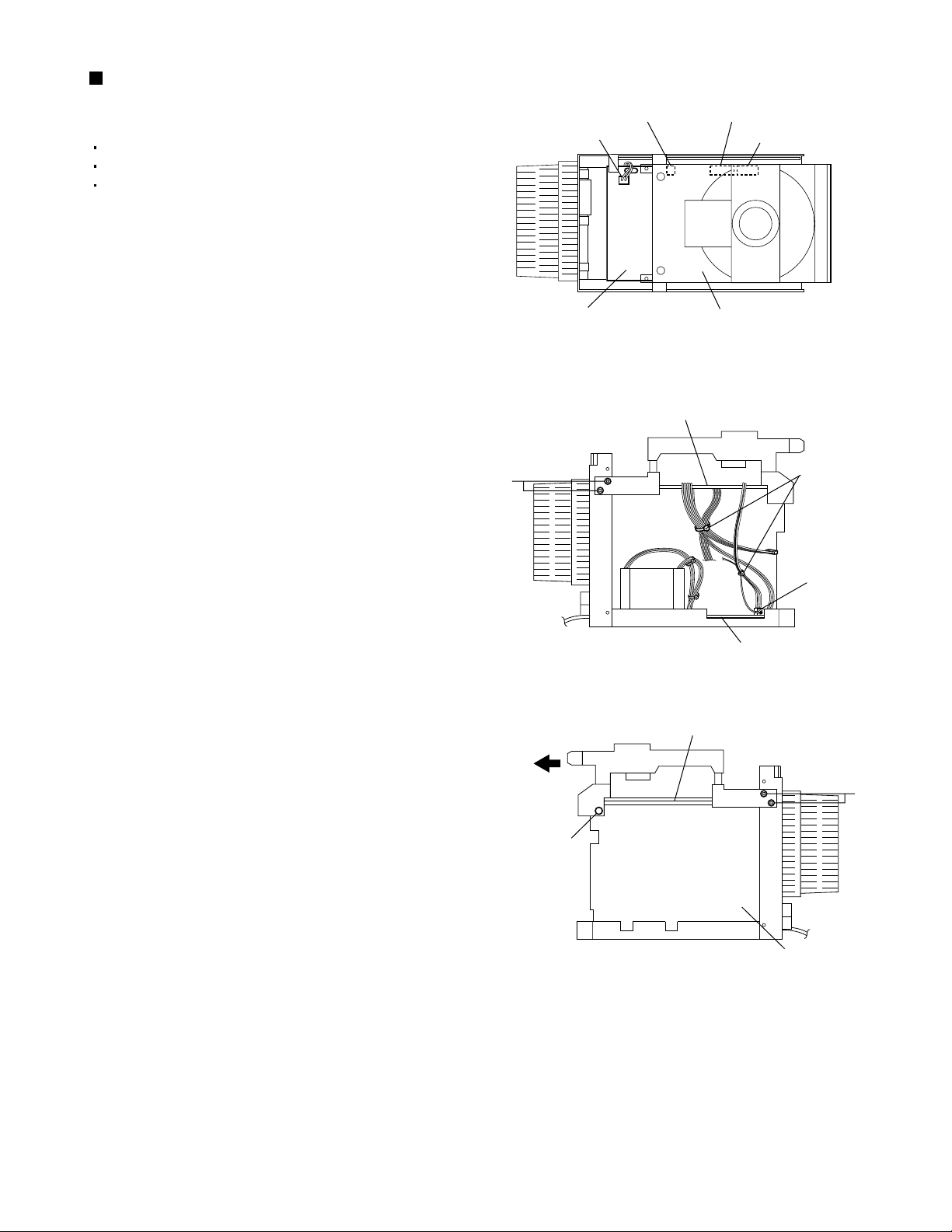

Replacement of the fuses and power amplifier IC

Replacing the fuses (See Fig. 1.)

Remove the left side panel according to its

disassembly method (see Figs. 6 and 7).

Fuses are located inside the left side panel.

[Caution] Be sure to replace the required fuses

with designated ones.

Fuse(F904)

1.6A 250V

Fuse(F903)

2.5A 250V

Power board

Fuse(F901)

1.6A 250V

Fuse(F902)

2.5A 250V

Replacing the power amplifier IC on

the main board (See Fig. 2.)

Remove the main board according to its

disassembly method (see Figs. 18 and 19).

1.

From the reverse side of the main board, remove

the two screws A retaining the bracket.

2.

From the forward side of the main board, remove

the four screws B retaining the bracket.

3.

Remove the screw C attaching the power amplifier

IC onto the heat sink.

4.

In order to replace the power amplifier IC, remove

the solder from soldered part a on the reverse side

of the main board.

Soldered part a

Heat sink

Fig.1

Main board (Reverse side)

Fig.2

C

A

Main board

1-6

Power amplifier IC

(IC402)

B

Bracket

Fig.3

Page 7

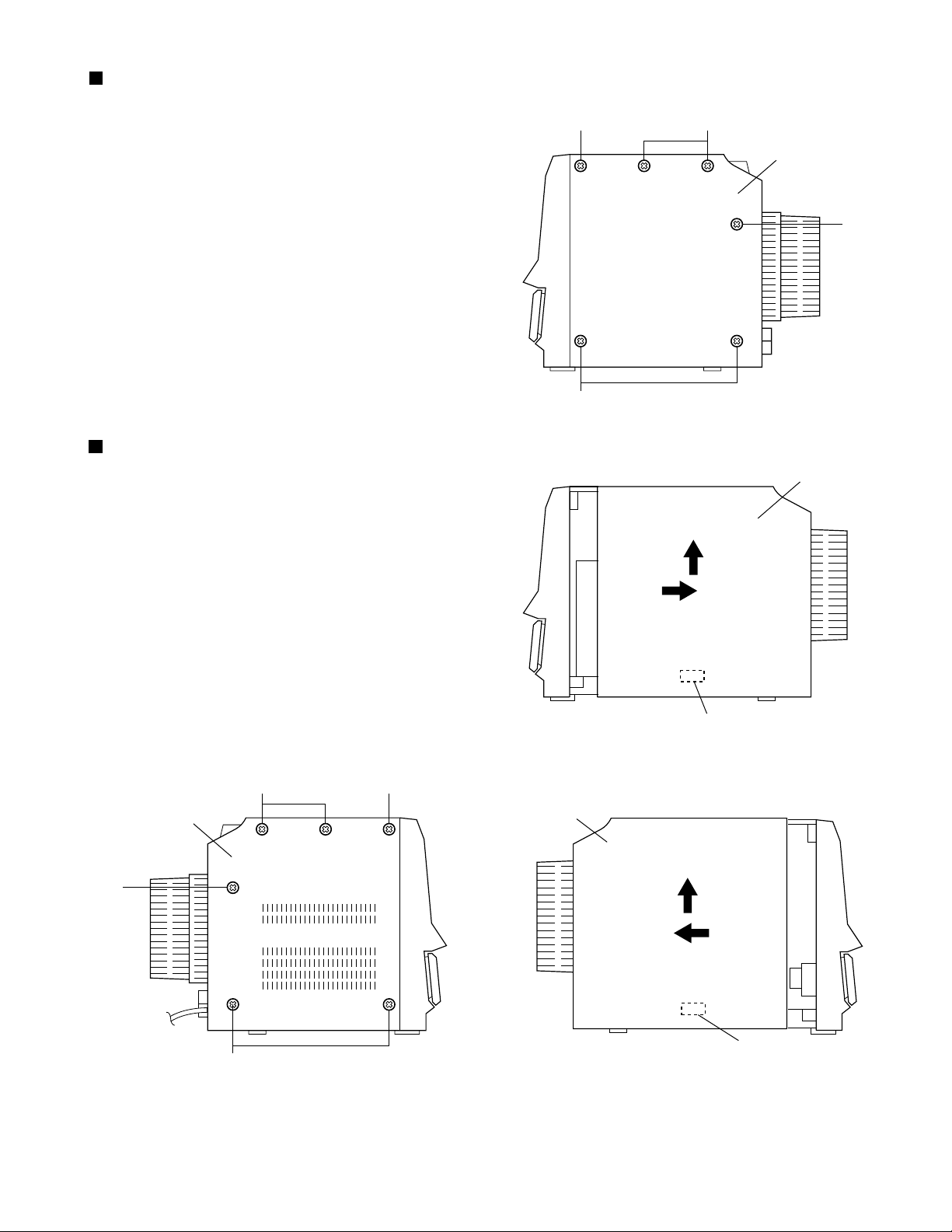

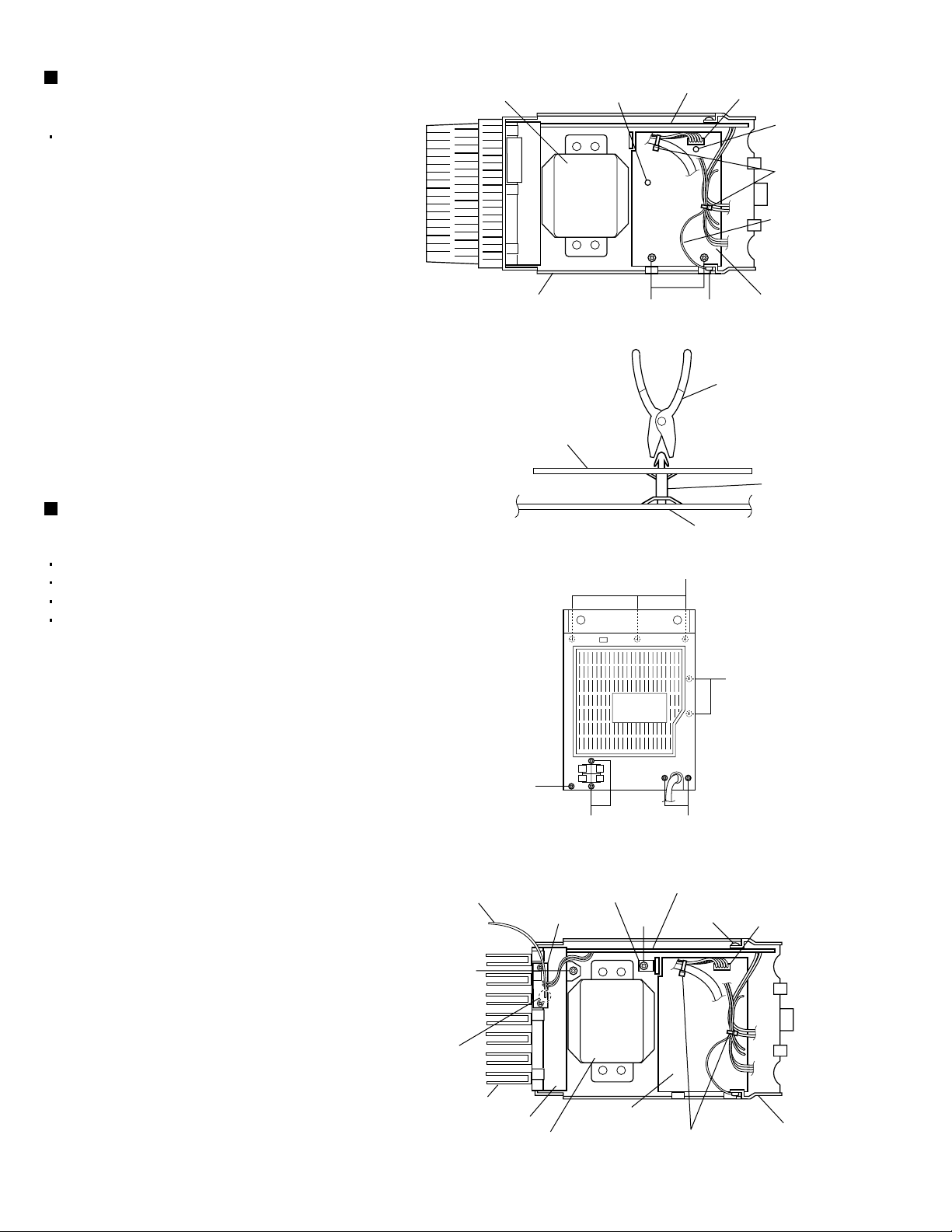

Removing the right side panel

(See Figs. 4 and 5.)

1.2.From the right side of the main body, remove the

three screws D and three screws E retaining the

right side panel.

Slide the right side panel toward the rear (in the

direction of arrow 1) until the claw b at the back of

the panel is hooked by the chassis and then lift the

panel upward (in the direction of arrow 2) to

remove it.

Removing the left side panel

(See Figs. 6 and 7.)

1.2.From the left side of the main body, remove the

three screws D and three screws E retaining the

left side panel.

D

D

UX-M5R

E

Right side

panel

E

Fig.4

Right side

panel

2

Slide the left side panel toward the rear (in the

direction of arrow 3) until the claw c at the back of

the panel is hooked by the chassis, and then lift the

panel upward (in the direction of arrow 4) to

remove it.

E

Left side

panel

D

E

1

Claw b

Fig.5

Left side

panel

4

3

D

Fig.6

Claw c

Fig.7

1-7

Page 8

UX-M5R

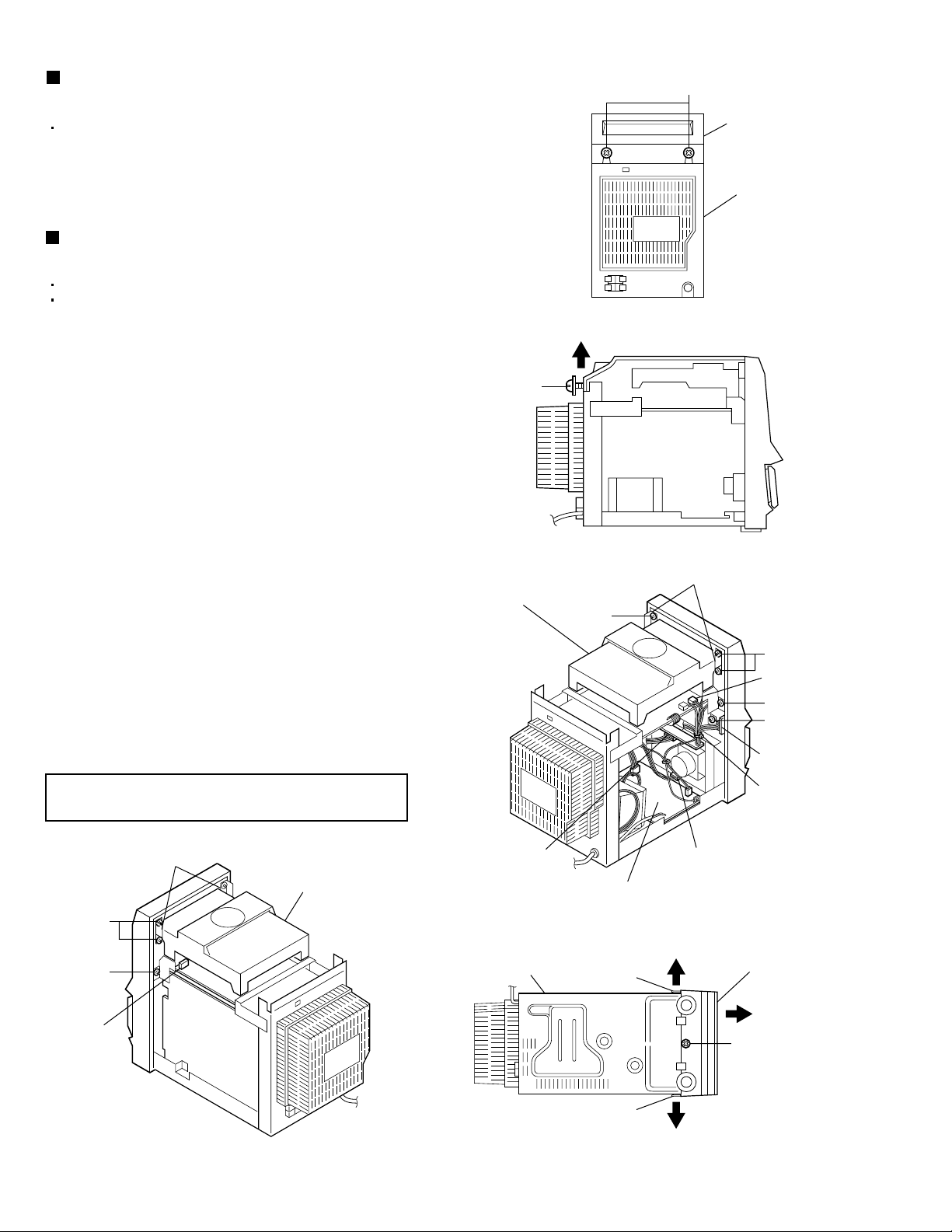

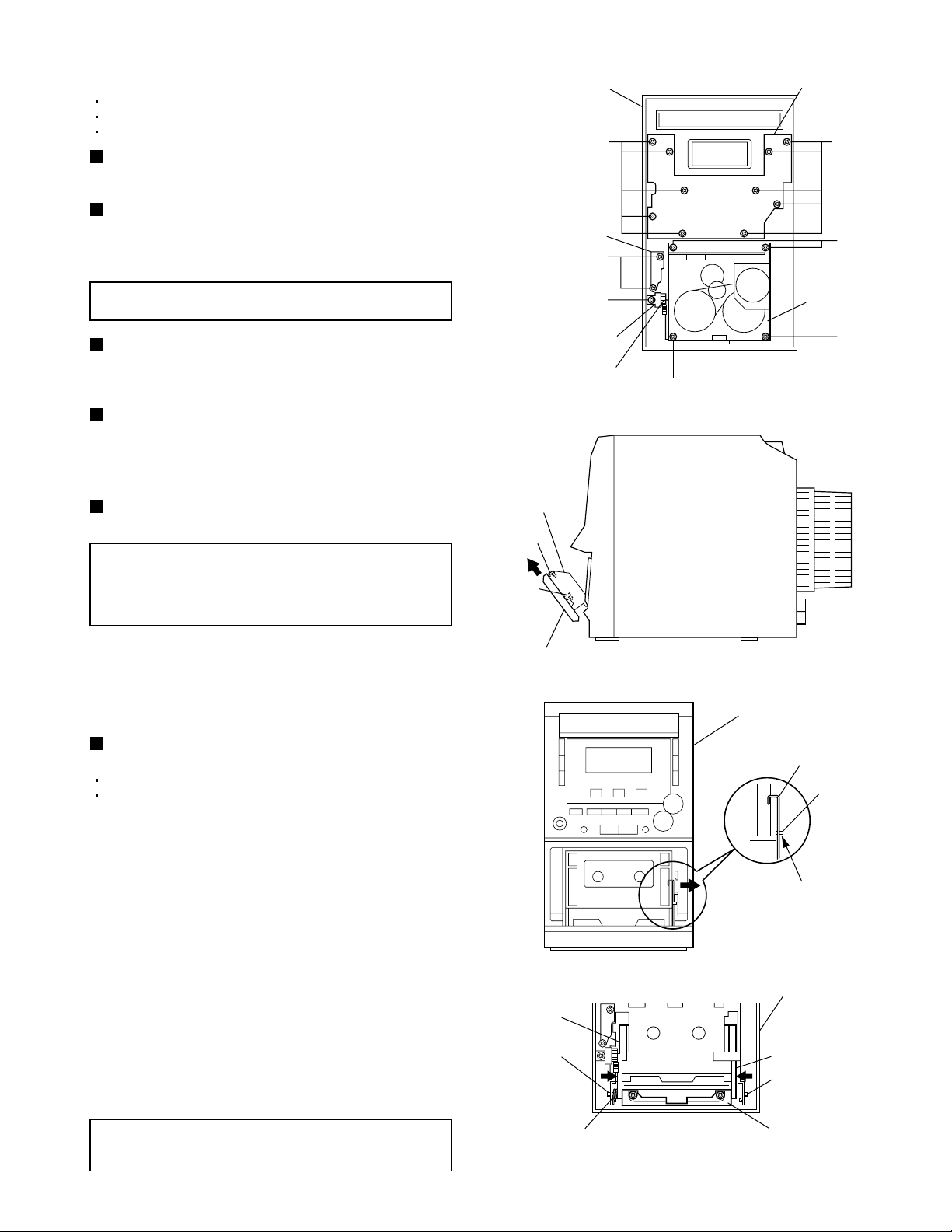

Removing the top cover

(See Figs. 8 and 9.)

Remove the left and right side panels.

1.2.From the back side of the main body, loosen the

two screws F retaining the top cover.

Lift the rear part of the top cover to remove it.

Removing the front panel assembly

(See Figs. 10 to 12.)

Remove the left and right side panels.

Remove the top cover.

1.

Remove the tie band bundling the wires.

2.

Disconnect the wire from the connector on the

cassette switch board.

3.

Remove the screw G retaining the bracket on the

earphone board.

4.

Disconnect the wires from the two connectors

CN607 and CN608 on the CD & MCU board.

5.

Remove the four screws H and the two screws J

retaining the bracket of the CD mechanism

assembly from the left and right.

6.

Remove the screw K retaining the front panel

assembly from the bottom side of the main body.

7.

While opening the hooks d to the left and right of

the lower part of the front panel assembly (in the

direction of arrows 1), slide the front panel

assembly toward the front (in the direction of arrow

2).

8.

Disconnect the wire from the connector on the

PB/REC head board, and then remove the front

panel assembly.

[Note] After assembly, apply a locking agent to

the screws G, H and J.

Lift the rear

part to remove.

F

CD mechanism

assembly

H

Fig.8

Fig.9

(To be loosened)

F

Top cover

Rear panel

Brackets

H

CN608

J

G

Earphone

board

Tie band

1-8

H

CN607

J

Brackets

Fig.11

CD mechanism

assembly

Connector on the

cassette switch

board

Chassis

Power board

Fig.10

Hook d

Hook d

Fig.12

Connector on the

PB/REC head board

1

Front panel assembly

2

K

1

Page 9

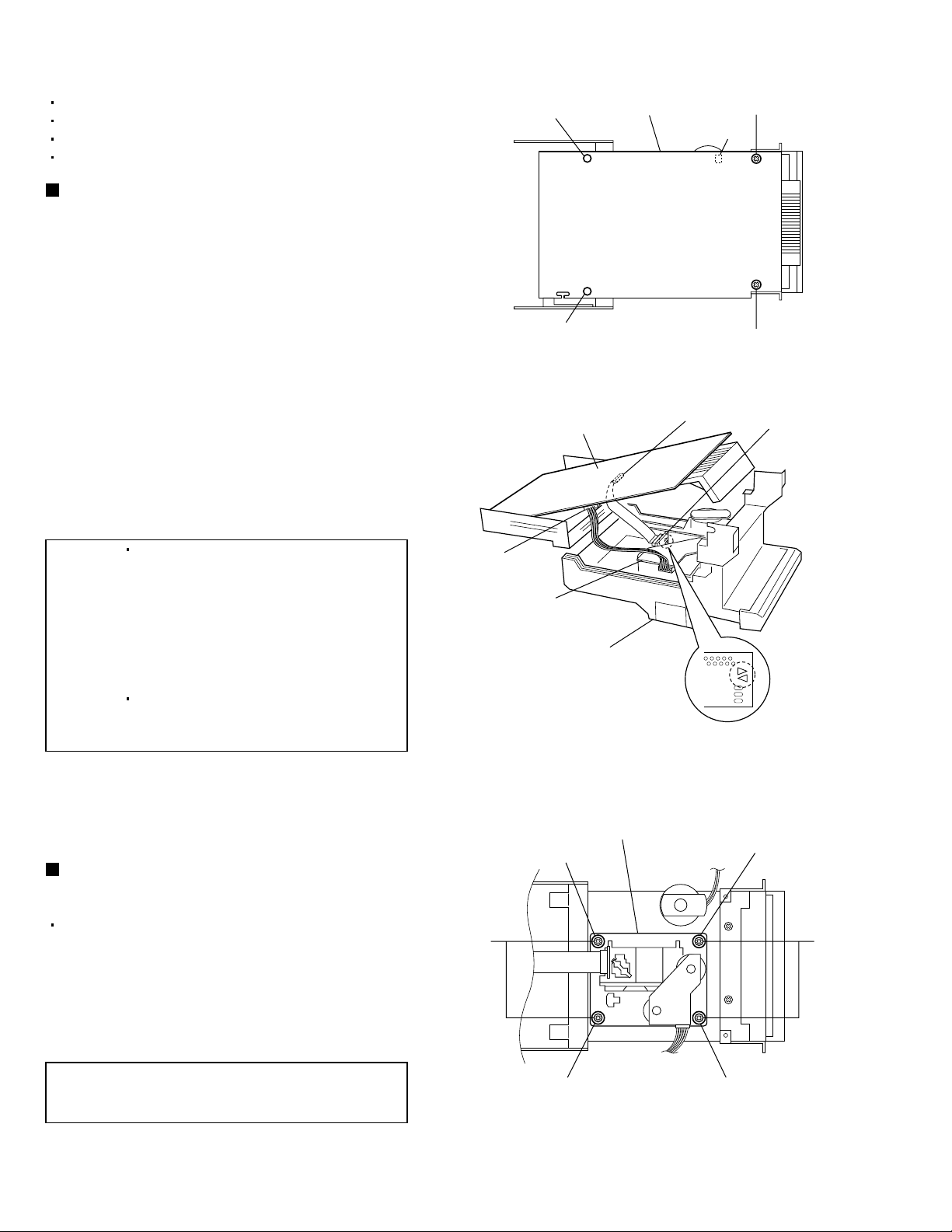

Removing the CD mechanism

assembly (See Figs. 13 to 15.)

Remove the left and right side panels.

Remove the top cover.

Remove the front panel assembly.

1.

Disconnect the wires from the four connectors

CN601, CN602, CN603 and CN701 on the CD &

MCU board.

2.

From the left side of the main body, remove the tie

bands bundling the wires.

3.

Disconnect the wire from the connector CN902 on

the power board.

4.

From the left and right sides of the main body,

remove the four screws L retaining the bracket.

5.

Slide the CD mechanism assembly toward the front

and remove it from the stud of the main board.

CN603

CN701

CD & MCU board CD mechanism assembly

CD & MCU board

CN601

CN602

Fig.13

L

UX-M5R

Tie bands

Stud

CN902

Power board

Fig.14

CD & MCU board

L

Main board

Fig.15

1-9

Page 10

UX-M5R

Removing the power board

(See Figs. 16 and 17.)

Remove the left and right side panels.

1.

Disconnect the wires from the connector CN901 on

the power board.

2.

Remove the tie bands bundling the wires.

3.

Remove the screw M retaining the lug wire.

4.

Remove the two screws N retaining the chassis .

5.

Remove the power board by pinching the two studs

retaining the power board using radio pliers, etc.

Removing the main board

(See Figs. 18 and 19.)

Remove the left and right side panels.

Remove the top cover.

Remove the front panel assembly.

Remove the CD mechanism assembly.

Chassis

Power board

StudPower transformer

Main board

NM

Fig.16

Fig.17

CN901

Stud

Tie bands

Lug wire

Power board

Radio pliers, etc.

Stud

Chassis

P

1.

From the inside of the rear panel, remove the five

screws P retaining the bracket.

2.

Remove the two screws Q retaining the speaker

terminal of the main board.

3.

Remove the solder from the soldered part e that

attaches the FM antenna wire to the antenna

board.

4.

Remove the three screws R retaining the rear

panel, then remove the rear panel.

5.

From the top side of the main body, remove the

screw S retaining the bracket of the main board.

6.

Remove the screw T retaining the regulator

IC(IC302).

7.

Remove the tie bands bundling the wires.

8.

Disconnect the wire from the connector CN901 on

the power board.

9.

Remove the stud on the main board, and then take

out the main board from the chassis.

FM antenna wire

S

Soldered

part e

Heat sink

Bracket

Power transformer

R

QR

Regulator IC

(IC302)

Antenna board

Power board

Fig.18

T

Fig.19

Main board

Stud

Tie bands

P

CN901

Chassis

1-10

Page 11

UX-M5R

<Front panel assembly section>

Remove the left and right side panels.

Remove the top cover.

Remove the front panel assembly.

Removing the key board

(See Fig. 20.)

Remove the ten screws U retaining the key board.

Removing the cassette mechanism

assembly (See Fig. 20.)

Remove the two screws V and the two screws W

retaining the cassette mechanism assembly.

[Note] After assembly, apply a locking agent

to the screws V and W.

Removing the cassette door damper

(See Fig. 20.)

Remove the screw X retaining the damper bracket

and take out the cassette door damper.

Removing the cassette door stopper

(See Fig. 20.)

Remove the two screws Y retaining the cassette

door stopper and remove the cassette door

stopper.

Removing the cassette door cover

(See Fig. 21.)

[Note] Use the following procedure to remove

only the cassette door cover.

This procedure does not require the

removal of exterior parts such as the

side panels.

1.2.Open the cassette door.

Slide the cassette door cover in the direction of the

arrow and disengage the two claws f and the two

claws g on the left and right of the cassette door

cover from the cassette door.

Front panel assembly

U

Cassette door

stopper

Y

X

Damper bracket

Cassette door

damper

Cassette door

Claw f

Claw g

Cassette door cover

Key board

U

V

Cassette

mechanism

assembly

W

W

Fig.20

Fig.21

Front panel assembly

Removing the cassette door

(See Figs. 22 and 23.)

Remove the cassette mechanism assembly.

Remove the cassette door cover.

1.

Open the cassette door, disengage the spring

hooked across the front of the front panel assembly

and the cassette door in the outward direction, and

remove it from the claw h.

2.

From the back side of the front panel assembly,

remove the two screws Z retaining the bracket.

3.

While pushing the arm section i of the cassette

door in the direction of the arrow, remove the shaft

section j of the cassette door from the front panel

assembly.

4.

While pushing the cassette door arm section k in

the direction of the arrow, remove the shaft section

m of the cassette door from the front panel

assembly.

5.

Take out the cassette door from the back side of

the front panel assembly.

[Caution] In the assembly, be sure to put the

spring around the shaft j before

attaching the cassette door.

Arm section i

Shaft section j

Spring

Spring

Claw h

Disengage the spring so

that it comes to the front

of the claw h.

Fig.22

Front panel assembly

Arm section k

Shaft section m

Bracket

Z

Fig.23

1-11

Page 12

UX-M5R

<CD mechanism section>

Remove the left and right side panels.

Remove the top cover.

Remove the front panel assembly.

Remove the CD mechanism assembly.

Removing the CD & MCU board

(See Figs. 1 and 2.)

1.

From the back side of the CD mechanism

assembly, remove the two screws A retaining the

CD & MCU board.

2.

Disengage the two studs retaining the CD & MCU

board.

3.

Disconnect the wires from the two connectors

CN702 and CN703 on the CD & MCU board.

4.

Lift the CD & MCU board and attach solder to the

short land part a on the CD pickup assembly.

Stud

Stud

CD & MCU board

CD & MCU board

Fig.1

CN704

A

CN702

A

CD pickup unit

5.

Disconnect the card wire from the connector

CN704 on the CD & MCU board, and take out the

CD & MCU board.

[Caution] Be sure to solder the short land

part a on the CD pickup unit before

disconnecting the card wire from the

CD pickup assembly (see Fig. 2).

If the card wire is disconnected

without attaching solder, the CD

pickup may be destroyed by static

electricity.

In the assembly, be sure to remove

solder from the short land part a

after connecting the card wire.

Removing the CD pickup assembly

(See Fig. 3.)

Remove the CD & MCU board.

1.

From the back side of the CD mechanism

assembly, remove the four screws B retaining the

CD pickup assembly.

CN703

CD pickup

assembly

CD mechanism assembly

CD pickup assembly

Damper(Gray)

B

Short land part a

Fig.2

Damper(Blue)

B

2.

Take out the CD pickup assembly.

[Note] When removing or replacing the

dampers, note their colors and be sure

to attach them in their correct positions.

1-12

Damper(Blue)Damper(Gray)

Fig.3

Page 13

UX-M5R

Removing the tray motor

(See Figs. 4 to 7.)

Remove the CD & MCU board.

1.

On the top of the CD mechanism assembly, open

up the claws b and c at the left and right of the

clamper assembly and lift the assembly to remove

it.

2.

On the top of the CD mechanism assembly, push

the section d of the elevator in the direction of the

arrow and lower the CD pickup assembly.

3.

Pull out the tray.

4.

While opening up the claws e at the left and right of

the tray in the directions of the arrows, remove the

tray.

5.

While pushing the claw f on the CD mechanism

assembly downwards, slide the elevator fully in the

direction of the arrow.

6.

Remove the transparent cover.

CD mechanism assembly

Claw b

Claw c

Fig.4

Clamper assembly

Claw c

Tray

7.

Remove the belt from the tray motor pulley.

8.

Remove the two screws C retaining the tray motor

and remove it.

[Note] Take care not to attach grease on the

belt.

After attaching the tray motor in the

assembly, apply a locking agent to the

screws C.

Fig.5

d section

TrayClaw e

Claw e

Fig.6

CD mechanism assembly

Claw f

Tray motor pulley

Fig.7

C

Transparent

Belt

cover

1-13

Page 14

UX-M5R

Replacing the CD pickup unit

(See Figs. 8 to 11.)

[Note] Use the following procedure to replace

only the CD pickup unit.

1.

Remove the left and right side panels (see Figs.4

to 7 of "Main body section" on page 1-7).

2.

Remove the top cover (see Figs.8 and 9 "Main

body section" on page 1-8).

3.

On the top of the main body, open up the claws b

and c on the left and right of the clamper assembly

in the direction of the arrows and lift the assembly

to remove it.

4.

On the top of the main body, push section d on the

elevator of the CD mechanism assembly and lower

the CD pickup assembly.

5.

Pull out the tray.

6.

Remove the slit washer retaining the feed middle

gear, and take out the feed middle gear.

Clamper assembly

Claw c

Claw b

Front panel assembly

Claw c

Fig.8

Front panel assembly

7.

Remove the two screws D retaining the shaft.

8.

Turn the CD pickup unit upside down and apply

solder to the short land part a.

9.

Disconnect the card wire from the CD pickup unit

and replace the unit.

[Caution] Be sure to solder the short land

part a on the CD pickup unit before

disconnecting the card wire from the

CD pickup unit (see Fig. 11).

If the card wire is disconnected

without attaching solder, the CD

pickup may be destroyed by static

electricity.

In the assembly, be sure to remove

solder from the short land part a

after connecting the card wire.

[Note] Removing the CD pickup unit

involves the removal of the sliding

spring. In the assembly, be sure to

attach the spring in the correct

orientation before attaching the CD

pickup unit (see Fig. 11).

D

Feed middle gear

Sliding spring

Fig.9

CD pickup assembly

D

Fig.10

Card wire

d section

TraySlit washer

1-14

Short land part a

Fig.11

Page 15

Adjustment method

UX-M5R

Measuring instructions required for

adjustment

1. AM signal generator

2. FM signal generator

3. Inter mediate frequency sweep generator

4. FM stereo signal generator

5. Low-frequency oscillator

(oscillation frequency 50Hz-20kHz, 0dB output

with 600 ohm impedance)

6. Attenuator (600 ohm impedance)

7. Electronic voltmeter

8. Distortion meter

9. Torque gauge (cassette for CTG-N)

10. Wow & flutter meter

11. Frequency counter meter

12. Test tape

VT712 : For tape speed and wow flutter

VT724 : For reference level

VT702 : For playback frequency

VT702 : For head azimuth adjustment

13. Blank tape

TAPE : AC-225

Measuring instruments

Radio section

FM 1kHz, 22.5kHz deviation

FM STEREO : 1kHz, 67.5kHz deviation

pilot signal 7.5kHz

AM : 1kHz, 30% modulation

Reference output :

H.phone output -10dBs(0.245V) 32 ohm

Speaker output 0dBs(2.8V) 8 ohm

Cassette amplifier section

Reference output :

H.phone output -10dBs(0.245V) 32 ohm

Speaker output 0dBs(2.8V) 8 ohm

Standard mode of function knob :

Press TAPE knob of select TAPE mode

CD section

CD test disc : CTS-1000

Measurement conditions

Power supply voltage

AC230V/50Hz

1-15

Page 16

UX-M5R

Cassette amplifier section

Item Measuring condition Check and adjustment procedure Standard value Adjusting part

Head azimuth

adjustment

Tape speed and

wow/flutter check

and adjustment

PB frequency

response check

Bias frequency

check

REC and PB

frequency

response

adjustment

Test tape:

VT702 (8kHz)

Signal output terminal:

H.phone out

(with 32 ohm load)

Test tape:

VT712 (3kHz)

Signal output terminal:

H.phone out

(with 32 ohm load)

Test tape: VT702

Signal output terminal:

H.phone out

(with 32 ohm load)

Tape: Normal

Signal output terminal:

Cassette REC./PLAY

HEAD

Test tape: AC225

Signal input:

SG 1kHz -20dBs

with emphasis

Signal output terminal:

H.phone out

(with 32 ohm load)

Play back the test tape VT702 (8kHz).

1.

Adjust the head azimuth adjusting screw so that the

2.

phase difference between the R and L channels is

minimized at an output level that is within 2dB of the

maximum output level. After this adjustment, lock the

head azimuth adjusting screw with screw sealant to

cover more than a half of the screw head.

When the head azimuth is maladjusted, correct it with

3.

the head azimuth adjusting screw.

Play back the test tape VT712 (3kHz) by the end

1.

portion.

Connect a frequency counter and check that it reads

2.

between 2940 and 3090Hz. If not, adjust the frequency

with the motor semifixed resistor.

Check that the wow/flutter is within 0.38%

3.

(unweighted).

Play back the test tape VT702 while con-firming that

deviation between the 1kHz signal and 8kHz signal

should be (0+3dB-6dB).

Set the TUNER or CD function and with TAPE to

record. Check to see if the frequency at the measuring

point P201 is 67kHz 1kHz if not adjust L203 until the

frequency counter indicates 67 kHz 1kHz.

At TUNER, set the BAND to the FM position, and

record the reference 1kHz signal and 8kHz signal

alternately repeatedly. While playing back the recorded

signal of the 1kHz signal differ from that of the 8kHz

signal by within (0+3dB-6dB).

Output level:

Within 2dB of

maximum output

level

Phase difference R

and L channels:

Minimum

2940 to 3090Hz

Within 0.38%

(unweighted)

Deviation between

1kHz and 8kHz:

(0+3dB-6dB)

Level difference for

1kHz singnal: Within

(0+3dB-6dB)

Head azimuth

adjusting screw

(To be used only

after head

replacement)

See Fig.1 on

page 1-17.

Tape speed:

Motor semifixed

resistor

See Fig.2 on

page 1-17.

Check only

L203, P201

See Fig.3 on

page 1-17.

Tuner section

Item Measuring condition Check and adjustment procedure Standard value Adjusting part

AM IF adjustment 1.

AM tracking

adjustment

FM tracking

adjustment

Signal input:

Loop antenna

Signal output:

IC101 pin19

Signal input:

Loop antenna

Signal output:

H.phone out

(with 32 ohm load)

Signal input:

Dummy antenna

FM ANT

FM GND

Signal output:

H.phone out

(with 32 ohm load)

Set the intermediate frequency sweep generator to AM

450kHz.

Adjust T101 for maximum and center output.

2. T101

See Fig.3 on

page 1-17.

Set the TUNER at 522kHz adjust L101 until the test

1.

point P107 voltage at 1.1V 0.1V.

Set the TUNER at 1629kHz, check the test point P107

2.

voltage at 7.0V 0.3V.

Set the TUNER and S/G at 603kHz, adjust L102 for

3.

maximum output.

Set the TUNER and S/G at 1404kHz, adjust the TC101

4.

for maximum output.

Repeat the above steps 3 and 4.

5.

Set the TUNER at 87.5MHz adjust the L104 until the

1.

test point P105 voltage at 2.3V 0.1V.

Set the TUNER at 108MHz, check the test point P105

2.

voltage at 6.5V 0.3V.

Set the TUNER and S/G at 90.1MHz, adjust L103 for

3.

maximum output.

Set the TUNER and S/G at 106.1MHz, adjust the

4.

TC102 for maximum output.

Repeat the above steps 3 and 4.

5.

L101, P107

L102

TC101

See Fig.3 on

page 1-17.

L104, P105

L103

TC102

See Fig.3 on

page 1-17.

1-16

Page 17

Location of adjusting parts

Cassette mechanism section

UX-M5R

CASSETTE MOTOR

Tape Speed Adj.

Fig.1 Head azimuth adjustment

Main board (Forward side)

Note: Measuring points (P105, P107 and P201) are located on the reverse side.

P105

(FM VT)

L104

(FM OSC)

TC101

(AM RF)

L101

L102

(AM RF)

TC102

(FM RF)

L103

(FM RF)

P107

(AM VT)

IC101

-

+

Fig.2

T101

(AM IF)

Fig.3

P201

(BIAS FREQUENCY)

L203

(BIAS FREQUENCY ADJ.)

1-17

Page 18

UX-M5R

Flow of functional operation until TOC read

Power ON

Slider turns REST

SW ON.

Laser ON

Focus start

FOK

Turn on focus

servo

Confirm that the voltage at the pin5 of CN703 is

"H"/"L"/"H"

Check that the voltage at the pin10(LD) of

CN704 is +1.35V.

Caution

Before connecting a measuring instrument to

the measuring point, turn the power of the

main unit to OFF.

After performing a measurement and before

disconnecting the measuring instrument,

again turn the power of the main unit to OFF.

(If a measuring instrument is disconnected

while an electric current is being output to the

main unit, the pick up of the main unit will be

damaged.)

Disc spinning

Radial_error

scaling

PLL Lock

Turn on radial

servo

Read TOC

Check that the voltage at the pin1 and pin2 of

CN703 is +0.65V.

Confirm the eye-pattern at the pin25 (RFGO) of IC704

on the CD & MCU board.

1-18

Page 19

UX-M5R

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode

When the life of the laser diode has expired,

the following symptoms will appear.

The level of RF output (EFM output:ampli tude of eye pattern) will below.

Is the level of

RF OUT under

1.25V 0.22Vp-p?

YES

O.K

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the AC OUTLET.

Replace the pickup with a normal one.(Refer

to "Removing the CD pickup" on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3 seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at the pin25 (RFGO)

of IC704 on the CD & MUC board.

Finish.

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board which is attached to the pickup is used to adjust the laser

power.

Since this adjustment should be performed to match the characteristics of the whole optical block, do not touch the

semi-fixed resistor.

If the laser power is lower than the specified value,the laser diode is almost worn out, and the laser pickup should

be replaced.

If the semi-fixed resistor would be adjusted when the pickup operates normally,the laser pickup may be damaged

due to excessive current.

1-19

Page 20

UX-M5R

Trouble shooting

Circuit Symptom Cause

No soundGeneral

AM

FM Connect the built-in or external antenna.

No sound, weak sound

(Low sensitivity)

No sound, weak sound

(Low sensitivity)

Speakers are not connected.

Wrong function is selected.

Defective volume control

Defective earphone jack

Defect in IC402

Defect in IC301

Improper location of unit

Defect in IF T101

Defect AM antenna coil L102 or oscilloscope

coil L101

Intermediate frequency tuning faulty

RF tracking faulty

Defective IC101

Defective IC102

Poor contact in antenna circuit

FM antenna not connected

Defective band selector switch

Check the speaker connection.

Set switch to the proper position.

Set the volume control to a proper sound

level.

Replace the earphone jack.

Check voltages. Replace if necessary.

Check voltages. Replace if necessary.

Rotate or reposition the unit.

Check resistance, voltage, and current.

Replace as needed.

Replace if necessary.

Readjust (see "Adjustment method").

Readjust (see "Adjustment method").

Check voltages. Replace if necessary.

Check voltages. Replace if necessary.

Check resistance and resolder.

Replace or repair the switch.

Remedy

Defective IC101

Defective IC102

Intermediate frequency tuning faulty

Poor contact in FM antenna circuit

Tape Clean the capstan or head with alcohol.

CD Insert disc correctly.

No sound/recording,

unsteady tape sound,

weak sound

Cannot read the table

of content.

No sound

Dirty capstan or head

Irregular cassette tape winding

Defective IC201

Defective IC202

Cassette erasure prevention tabs broken out

Disc is inserted upside down.

Disc is dirty.

Disc is scratched.

Disc is seriously warped.

A non-standard disc has been inserted.

Moisture has formed inside the CD deck.

Defective IC701

Defective IC704

Check voltages. Replace if necessary.

Check voltages. Replace if necessary.

Readjust (see "Adjustment method").

Resolder or repair as required.

Replace tape.

Check voltages. Replace if necessary.

Check voltages. Replace if necessary.

Replace tape or cover tab openings with

adhesive tape.

Wipe clean with a soft cloth.

Use a new disc.

Use a new disc.

Use only a brand name disc.

Wait about 20 to 30 minutes.

Check voltages. Replace if necessary.

Check voltages. Replace if necessary.

1-20

Defective IC703

Defect in the CD pickup mechanism

Check voltages. Replace if necessary.

Replace as required.

Page 21

Description of major ICs

TC9462F (IC701) : Digital servo single chip processor

1. Terminal layout

80 51

UX-M5R

100 81

1 30

2. Pin function

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

TEST0

HSO

UHSO

EMPH

LRCK

VSS1

BCK

AOUT

DOUT

MBOV

IPF

SBOK

CLCK

VDD1

VSS2

DATA

SFSY

SBSY

SPCK

SPDA

COFS

MONIT

VDD2

TESIO0

P2VREF

HSSW

ZDET

PDO

I

O

O

O

O

O

O

O

O

O

O

I/O

-

O

O

O

O

O

O

O

-

I

O

O

O

31 50

Test mode terminal. Normally, keep at open.

Playback speed mode flag output terminal.

UHSO

H

H

L

L

Subcode Q data emphasis flag output terminal. Emphasis ON at "H" level and

OFF at "L" level. The output polarity can invert by command.

Channel clock output terminal. (44.1kHz) L-ch at "L" level and R-ch at "H" level.

The output polarity can invert by command.

Digital ground terminal.

Bit clock output terminal. (1.4112MHz)

Audio data output terminal.

Digital data output terminal.

Buffer memory over signal output terminal. Over at "H" level.

Correction flag output terminal. At "H" level, AOUT output is made to correction

impossibility by C

Subcode Q data CRCC check adjusting result output terminal. The adjusting

result is OK at "H" level.

Subcode P W data readout clock input/output terminal. This terminal can select

by command bit.

Digital power supply voltage terminal.

Digital ground terminal.

Subcode P W data output terminal.

Playback frame sync signal output terminal.

Subcode block sync signal output terminal.

Processor status signal readout clock output terminal.

Processor status signal output terminal.

Correction frame clock output terminal. (7.35kHz)

Internal signal (DSP internal flag and PLL clock) output terminal. Selected by

command. This terminal output the text data with serial by command.

Digital power supply voltage terminal.

Test input/output terminal. Normally, keep at "L" level. The terminal that inputted

the clock for read of text data by command.

PLL double reference voltage supply terminal.

2/4 times speed at "VREF" voltage.

1 bit DA converter zero detect flag output terminal.

Phase difference signal output terminal of EFM signal and PLCK signal.

HSO

PLAYBACK SPEED

H

L

H

L

2

correction processing.

Normal

2 times

4 times

-

1-21

Page 22

UX-M5R

Pin No. Symbol I/O

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

TMAXS

TMAX

LPFN

LPFO

PVREF

VCOREF

VCOF

AVSS1

SLCO

RFI

AVDD1

RFCT

RFZI

RFRP

FEI

SBAD

TSIN

TEI

TEZI

FOO

TRO

VREF

RFGC

TEBC

FMO

FVO

DMO

2VREF

SEL

FLGA

FLGB

FLGC

FLGD

VDD3

VSS3

IO0

IO1

IO2

IO3

O

O

I

O

I

O

-

O

I

I

I

I

I

I

I

I

I

O

O

O

O

O

O

O

O

O

O

O

O

-

-

I/O

I/O

I/O

I/O

Function

TMAX detection result output terminal. Selected by command bit (TMPS).

TMAX detection result output terminal. Selected by command bit (TMPS).

DIFFERENCE RESULT TMAX OUTPUT

Longer than fixed freq.

Shorter than fixed freq.

Within the fixed freq.

LPF amplifier inverting input terminal for PLL.

LPF amplifier output terminal for PLL.

PLL reference voltage supply terminal.

VCO center frequency reference level terminal. Normally, keep at "PVREF" level.

VCO filter terminal.

Analog ground terminal.

Data slice level output terminal.

RF signal input terminal.

Analog power supply voltage terminal.

RFRP signal center level input terminal.

RFRP zero cross input terminal.

RF ripple signal input terminal.

Focus error signal input terminal.

Sub-beam adder signal input terminal.

Test input terminal. Normally, keep at "VREF" level.

Tracking error signal input terminal. Take in at tracking servo on.

Tracking error zero cross input terminal.

Focus servo equalizer output terminal.

Tracking servo equalizer output terminal.

Analog reference voltage supply terminal.

RF amplitude adjustment control signal output terminal.

Tracking balance control signal output terminal.

Feed equalizer output terminal.

Speed error signal or feed search equalizer output terminal.

Disk equalizer output terminal.

(PWM carrier=88.2kHz for DSP, Synchronize to PXO)

Analog double reference voltage supply terminal.

APC circuit ON/OFF indication signal output terminal.

At the laser on time, UHF = L at "HiZ" level and UHF = H at "H" level.

External flag output terminal for internal signal.

Can select signal from TEZC, FOON, FOK and RFZC by command.

External flag output terminal for internal signal.

Can select signal from DFCT, FOON, FMON and RFZC by command.

External flag output terminal for internal signal.

Can select signal from TRON, TRSR, FOK and SRCH by command.

External flag output terminal for internal signal.

Can select signal from TRON, DMON, HYS and SHC by command.

Digital power supply voltage terminal.

Digital ground terminal.

General I/O terminal. Can change over input port or output port by command.

At the input mode time can readout a state of terminal (H/L) by read command.

At the output mode time can control a state of terminal (H/L/HiZ) by command.

"P2VREF"

"Vss"

"HiZ"

1-22

Page 23

UX-M5R

Pin No. Symbol I/O

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

DMOUT

CKSE

DACT

TESIN

TESIO1

VSS4

PXI

PXO

VDD4

XVSS

XI

XO

XVDD

DVSR

RO

DVDD

DVR

LO

DVSL

TEST1

TEST2

TEST3

BUS0

BUS1

BUS2

BUS3

VDD5

VSS5

BUCK

CCE

TEST4

TSMOD

RST

I

I

I

I

I

I

O

-

I

O

-

-

O

-

-

O

I

I

I

I/O

I/O

I/O

I/O

-

-

I

I

I

I

I

Function

This terminal controls IO0 IO3 terminal. At "L" level time, IO0, 1 out feed

equalizer signal of 2-state PWM, IO2,3 out disk equalizer signal of 2-state PWM.

Normally, keep at open.

DAC test mode terminal. Normally, keep at open.

Test input terminal. Normally, keep at "L" level.

Test input/output terminal. Normally, keep at "L" level.

Digital ground terminal.

Crystal oscillator connecting input terminal for DSP. Normally, keep at "L" level.

Crystal oscillator connecting output terminal for DSP.

Digital power supply voltage terminal.

Oscillator ground terminal for system clock.

Crystal oscillator connecting input terminal for system clock.

Crystal oscillator connecting output terminal for system clock.

Oscillator power supply voltage terminal for system clock.

Analog ground terminal for DA converter.(R-ch)

R channel data forward output terminal.

Analog supply voltage terminal for DA converter.

Reference voltage terminal for DA converter.

L channel data forward output terminal.

Analog ground terminal for DA converter.(L-ch)

Test mode terminal. Normal, keep at open.

Test mode terminal. Normal, keep at open.

Test mode terminal. Normal, keep at open.

Micon interface data input/output terminal.

Digital power supply voltage terminal.

Digital ground terminal.

Micon interface clock input terminal.

Command and data sending/receiving chip enable signal input terminal.

The bus line becomes active at "L" level.

Test mode terminal. Normal, keep at open.

Local test mode selection terminal.

Reset signal input terminal. Reset at "L" level.

1-23

Page 24

UX-M5R

TMP87EP26F (IC601) : MCU

1. Terminal layout

80 51

81

50

(Top view)

100

130

31

2.Pin function

Pin No. Symbol I/O Function

GND (0V)

VSS

1

XOUT

2

XIN

3

RESET

4

XTOUT(P22)

5

XTIN(P21)

6

TEST

7

SHIFT FREQ

8

REMOTE

9

MUTE

10

PLAY MUTE

11

REC MUTE

12

PLAY/REC

13

NC(SCK2)

14

NC(SI2)

15

NC(SO2)

16

REC SW (RVS)/(WAIT)

17

Resonator connecting pins for high clock(4-8MHz).

O

For inputting external clock, XIN is used and XOUT is opened.

I

Reset signal input or watchdog timer output/address-trap-reset output

I/O

Resonator connecting pins for slow clock(32.768kHz)

I/O

or general purpose I/O.

I/O

Test pin for out-going test. Always fixed to low.

I

Shift the crystal oscillation frequency to reduce tuner noise.

O

Remote control signal input

I

Audio mute output

O

Muting output during play

O

Muting output during recording

O

Play or recording output, low for recording.

O

Not connect

Not connect

Not connect

Deck reverse record protection input. Low means can record on

I

reverse side.

Deck forward record protection input. Low means can record on

REC SW (FWD)

18

I

forward side.

Solenoid output for deck B.

B-SOL+

19

B-MODE SW

20

VOL STB

21

POWER

22

B-HALF SW

23

JOG-B/VOL DATA

24

JOG-A/VOL CLK

25

RDS CLK

26

V MOTOR

27

B-PHOTO OUT

28

CD-RW

29

RES

30

O

Mode switch input of deck B. Low means the head is up.

I

TC9422F volume STB output

O

Power output control

O

Half switch input of deck B. Low means deck B have tape.

I

Jog dial input and TC9422F volume data output

I/O

Jog dial input and TC9422F volume clock output

I/O

BU1923F(RDS demodulator) interface CLK input

I

Motor output

O

Reel pulse input of deck B. Have pulse input means the tape is rotating.

I

CD-RW control output

O

CD servo reset output

O

1-24

Page 25

Pin No. Symbol I/O Function

Servo DSP chip enable output

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52 91

92 95

96

97

98

99

100

CCE

BUCK

BUS0

BUS1

BUS2

BUS3

SLOUT

SLIN

SLT

SLEND

NC

RDS DATA

STEREO

POWER DETECT

AD K3

AD K2

AD K1

VAREF

BOOT

VSS

VDD

SEG39 0

COM3 0

VLC

PLL DATA

PLL CLK

PLL PERIOD

VDD

O

Servo DSP clock output

O

Servo DSP command and data I/O

I/O

Servo DSP command and data I/O

I/O

Servo DSP command and data I/O

I/O

Servo DSP command and data I/O

I/O

Tray open/close outputs for current sensor drawer type mechanism.

O

O

CD pick up position input: L if pick up is in inner side.

I

Current sensor input

I

Not connected

BU1923F(RDS demodulator) interface data input

I

Stereo input pin for tuner stereo indication

I

Power down detection

I

Panel key analog input

I

Panel key analog input

I

Panel key analog input

I

Analog reference voltage input

Control input for writing MCU program area via ICU interface.

I

GND (0V)

VDD (+5V)

LCD segment outputs

O

LCD common outputs

O

LCD drive power supply

TC9257P (PLL) interface

I/O

TC9257P (PLL) interface

O

TC9257P (PLL) interface

O

VDD (+5V)

-

UX-M5R

1-25

Page 26

UX-M5R

AN7312 (IC202) : Dual recording/Playback pre-amplifier circuit with ALC

1. Terminal layout

14 8

~

2. Block diagram

Vcc

14 13 12 11 10

8

9

Ripple Filter

17

~

1 2 3 4 5 6

GND

ALC

3. Pin function

Pin No. Symbol Function

1

GND

2

ALC time constant

3

ALC input Ch.1

4

Output Ch.1

5

Phase compensation Ch.1

6

N.F.B. Ch.1

7

Input Ch.1

8

Input Ch.2

9

N.F.B. Ch.2

10

Phase compensation Ch.2

11

Output Ch.2

12

ALC input Ch.2

13

Ripple filter

14

Vcc

I/O

GND

ALC time constant by resistance and capacitor

Right channel ALC input

I

Right channel output

O

No connect

Right channel negative feed back input

I

Right channel signal input

I

Left channel signal input

I

Left channel negative feed back input

I

No connect

Left channel output

O

Left channel ALC input

I

Ripple filter

Power supply

-

Amp.

Ch2

Amp.

Ch1

7

BA4558N (IC401,IC403) : Dual operational amplifier

1. Terminal layout & Block diagram

1ch 2ch

2

34

EE

5678

+IN2 -IN2 OUT2 Vcc

1

OUT1 -IN1 +IN1 V

2. Pin function

Pin No. Symbol I/O Function

1

OUT1

2

3

4

5

6

OUT2

7

8

-IN1

+IN1

EE

V

+IN2

-IN2

CC

V

O

I

I

I

I

O

-

A output

A -input

A +input

VB +input

B -input

B output

V+

1-26

Page 27

LM1876TF (IC402) : Overture audio power amplifier series

1. Terminal layout

LM1876TF

1

23456 7891011 1213 14 15

2. Pin function

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

OUT B

VCC A

OUT A

-Vcc

GND A

MUTE A

-IN A

+IN A

Standby A

GND B

MUTE B

-IN B

+IN B

Standby B

VCC B

O

B output

-

A V+

O

A output

-

V-

-

Power terminal

-

Control

I

A -input

I

A +input

-

Control

-

Power terminal

-

Control

I

B -input

I

B +input

-

Control

-

B V+

3. Block diagram

+IN A

-IN A

+IN B

-IN B

8

7

13

12

5

AMP A

AMP B

10

Standby A

VCC AGND A

2

15 14

Standby B

MUTE A

96

11

MUTE BVCC BGND B

3

4

1

UX-M5R

OUT A

-VCC

OUT B

NJM7812A (IC302) : Regulator

1. Terminal layout

1.INPUT

2.OUTPUT (+12V)

3.GND

1 2 3

2. Block diagram

1

INPUT

THERMAL SHUTDOWN

BANDGAP REFERENCE

OVER VOLTAGE PROTECTION

SOA PROTECTION

SHORT CIRCUIT

PROTECTION

3

GND

2

R1

R2

OUTPUT

1-27

Page 28

UX-M5R

TA2092N (IC703) : Power driver

1.Terminal Layout & Block Diagram

PW GND1

OUT(-)1

PW VCC1

OUT(+)1

VIN1

VRI

VCI

VIN2

OUT(+)2

PW VCC2

OUT(-)2

PW GND2

1

2

3

4

5

6

7

8

9

10

11

12

PW GND4

24

OUT(-)4

23

PW VCC4

22

OUT(+)4

21

VIN4

20

SVCC1

19

18

SGND

17

VIN3

16

OUT(+)3

15

PW VCC3

14

OUT(-)3

13

PW GND3

2. Pin function

Pin No. Symbol I/O Function

PW GND1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

OUT(-)1

PW VCC1

OUT(+)1

VIN1

VRI

VCI

VIN2

OUT(+)2

PW VCC2

OUT(-)2

PW GND2

PW GND3

OUT(-)3

PW VCC3

OUT(+)3

VIN3

SGND

SVCC1

VIN4

OUT(+)4

PW VCC4

OUT(-)4

PW GND4

Power GND

Inverted output for CH1

O

Supply terminal of output stage for CH1

Non-inverted output for CH1

O

Input for CH1

I

Input reference voltage

I

Output reference voltage

O

Input for CH2

I

Non-inverted output for CH2

O

Supply terminal of output stage for CH2

Inverted output for CH2

O

Power GND

Power GND

Inverted output for CH3

O

Supply terminal of output stage for CH3

Non-inverted output for CH3

O

Input for CH3

I

Supply terminal of small signal GND

Small signal GND

Input for CH4

I

Non-inverted output for CH4

O

Supply terminal of output stage for CH4

Inverted output for CH4

O

Power GND

-

UPC1330 (IC201) : REC/PB audio head switch

1. Terminal layout

19

3. Pin function

Pin No. Symbol I/O Function

SWR1

1

GND

2

SWP1

3

CONT

4

GND

5

VCC

6

SWP2

7

GND

8

SWR2

9

Record SW (Left channel)

GND

Play SW (Left channel)

Record/play control pin

GND

Power supply

Play SW (Right channel)

GND

Record SW (Right channel)

-

2. Block diagram

123456 789

INVERTER

COMPARATOR

1-28

Page 29

TA2104BN (IC101) : 1chip AM/FM, MPX tuner system

1. Terminal layout 2. Pin function

UX-M5R

RFGND

FMRF IN

AM LOW CUT

MIX OUT

VCC

AMIF IN

FMIF IN

GND

AGC

QUAD

R OUT

L OUT

10

11

12

1

2

3

4

5

6

7

8

9

24

FMRF OUT

23

RF VCC

22

AMRF IN

21

FM OSC

20

AM OSC

19

OSC OUT

18

ST LED

17

IF REQ

16

DET OUT

15

MPX IN

14

LPF1

13

LPF2

Pin No. Symbol I/O Function

RFGND

1

FMRF IN

2

AM LOW CUT

3

MIX OUT

4

VCC

5

AMIF IN

6

FMIF IN

7

GND

8

AGC

9

QUAD

10

R OUT

11

L OUT

12

LPF2

13

LPF1

14

MPX IN

15

DET OUT

16

IF REQ

17

ST LED

18

OSC OUT

19

AM OSC

20

FM OSC

21

AMRF IN

22

RF VCC

23

FMRF OUT

24

Ground terminal for RF

Input of FMRF signal

I

AM low frequency cut

I

Output of FM/AM RF mix

O

Power supply terminal

Input of AMIF signal

I

Input of FMIF signal

I

Ground terminal

AGC voltage input terminal

I

OSC terminal for FM DET.

I

Output R-channel

O

Output L-channel

O

FM/AM switch

I

Stereo/monoral switch

I

Multiplex signal input

I

AM/FM detection output

O

IF out/REQ out

O

Stereo indicator output

O

PLL data bus for FM or AM

O

AM local oscillation circuit

FM local oscillation circuit

Input of AMRF signal

I

Power supply terminal for RF

Output of FMRF signal

O

3. Block diagram

FMRF

OUTRFVCC

RF

GND

AMRFINFM

OSCAMOSC

2324 2122 1920 1718 1516 1314

FM

OSC

AM

MIX

LOW

CUT

FM

MIX

MIX

OUT

FMRF

21 43 65 87 109 1211

FMRFINAM

OSC

OUTSTLEDIFREQ

AM

OSC

FMRF

FMRF

VCC AMIFINFMIFINGND AGC R OUT L OUTQUAD

ST SW

BUFF

LEVEL

1/8

DET

AMIF FMIF

IF

IF

REQ

AM

DET

DET

OUT

AF

BUFF

AGC

FM

DET

AF

MPX

IN

LPF1 LPF2

VCD

DIVIDE

ST/MO

FM/AM

MUTE

DECODE

1-29

Page 30

UX-M5R

TA2153FN (IC704) : RF amplifier for digital servo

1. Terminal layout 2. Block diagram

VCC

RFGC

GMAD

FNI

FPI

TPI

TNI

MDI

LDO

SEL

TEB

2VRO

TEN

TEO

SBAD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

RFN2

GND

RFO

AGCIN

GVSW

RFGO

RFRPIN

PKC

RFCT

BTC

RFRP

VRO

SEB

FEN

FEO

RFN229GND28RFO27AGCIN26GVSW25RFGO24RFRPIN23PKC22RFCT21BTC20RFRP19VRO18SEB17FEN16FEO

30

+

1

VCC

2

RFGC

3

GMAD

AGC Amp.

+

-

+

4

FNI

+

-

5

FPI6TPI

-

I-I

PEAK

BOTTOM

+

-

I-I

7

8

TNI

-

MDI

3. Pin function

Pin No. Symbol I/O Function

1

VCC

2

RFGC

Power supply input terminal

RF amplitude adjustment control signal input terminal. Controlled by 3-PWM

I

signals. (PWM carrier = 88.2kHz)

3

4

5

6

7

8

9

10

GMAD

FNI

FPI

TPI

TNI

MDI

LDO

SEL

Open loop gain adjustment terminal for AGC amplifier

I

Main beam I-V amplifier input terminal

I

Main beam I-V amplifier input terminal

I

Sub beam I-V amplifier input terminal

I

Sub beam I-V amplifier input terminal

I

Monitor photo diode amplifier input terminal

I

Laser diode amplifier input terminal

O

Laser diode control signal input terminal and APC circuit ON/OFF control signal

I

terminal

SEL level APC circuit LDO Detect frequency

GND OFF Connected to Vcc through Low

resistor (1kohm)

Hiz ON Control signal output Low

Vcc ON Control signal output High

+

+

SW3

9

-

-

+

LDO

+

-

10

+

SW2

SW1

11

SEL

+

-

-

-

+

-

+

3 STATE DET.

12

13

14

TEB

TEN

2VRO

+

-

+

TEO

+

15

SBAD

-

1-30

11

12

13

14

15

16

17

TEB

2VRO

TEN

TEO

SBAD

FEO

FEN

Tracking error balance adjustment signal input terminal. Controlled by 3-PWM

I

signals. (PWM carrier = 88.2kHz)

Reference voltage (2VRO) output terminal 2RVO = 4.2V when Vcc = 5V

O

TE amplifier negative input terminal

I

TE error signal output terminal

O

Sub beam adder signal output terminal

O

Focus error signal output terminal

O

FE amplifier negative input terminal

I

Page 31

Pin No. Symbol I/O Function

18

SEB

RFRP output circuit switching terminal

I

SEL level Bottom detection Peak detection

GND ON ON

Vcc OFF ON

19

20

21

22

23

24

25

26

VRO

RFRP

BTC

RFCT

PKC

RFRPIN

RFGO

GVSW

Reference signal (VRO) output terminal

O

Track count signal output terminal

O

Time constant adjustment terminal for bottom detection

I

RFRP signal center level output terminal

O

Time constant adjustment terminal for peak detection

I

Input terminal for track count signal output amplifier

I

Output terminal for RF signal amplitude adjustment amplifier

O

Amplifier (AGC, FE, TE) gain switching terminal

I

GVSW Mode

GND CD-RW

Hiz Normal

Vcc Normal

27

28

29

30

AGCIN

RFO

GND

RFN2

Input terminal for RF signal amplitude adjustment amplifier

I

Output terminal RF signal amplifier

O

Ground terminal

Input terminal for RF signal amplifier

I

UX-M5R

TA7291S (IC702) : Bridge driver

1.Terminal Layout

123456789

Vs

NC

Vcc

IN2(M+)

OUT2

3.Block diagram

Vcc Vref

28

GND

PROTECTOR

CIRCUIT

(TSD)

OUT1

REG

Vref

IN1(M+)

2.Pin function

Pin No. Symbol I/O Function

IN2(M-)

1

2

3

4

5

6

7

8

9

Vcc

OUT2

NC

GND

Vs

OUT1

Vref

IN1(M+)

Input terminal

I

Supply voltage terminal for logic

Output terminal

O

Not connect

Ground terminal

Supply voltage terminal for motor driver

Output terminal

O

Supply voltage terminal for control

Input terminal

I

6

Vs

OUT1

7

OUT2

3

91

IN1 IN2

5

GND

1-31

Page 32

UX-M5R

TC9422F (IC301) : System electronic volume

1.Terminal Layout

VDD

GND

L-IN1

L-IN2

L-IN3

L-IN4

L-SW-OUT

L-VR-IN

L-B1

L-B2

L-B3

L-TONE-OUT

L-T1

Vref

CK

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

R-IN1

27

R-IN2

26

R-IN3

25

R-IN4

24

R-SW-OUT

23

R-VR-IN

22

R-B1

21

R-B2

20

R-B3

19

R-TONE-OUT

18

R-T1

17

STB

16

DATA

15

2.Block Diagram

L-IN1

L-IN2

L-IN3

L-IN4

L-SW-OUT

L-VR-IN

L-B1

L-B2

L-B3

L-TONE-OUT

L-T1

INPUT SELECTOR

2

3

4

5

6

7

8

9

1k

10

CAPACITOR FOR

OSCILLATION

11

500

12

750

100k

GAIN CONTROL

MAIN VR

50k /64STEP

50k

13k

0,6,12,18dB

13k

BASS VR

50k /16STEP

TREBLE VR

50k /16STEP

GND VDD

281

LATCH

DECODER

CIRCUIT

100k

GAIN CONTROL

0,6,12,18dB

MAIN VR

50k /64STEP

BASS VR

50k /16STEP

TREBLE VR

50k /16STEP

INPUT SELECTOR

50k

CAPACITOR FOR

OSCILLATION

13k

13k

500

750

27

26

25

24

23

22

21

20

1k

19

18

17

R-IN1

R-IN2

R-IN3

R-IN4

R-SW-OUT

R-VR-IN

R-B1

R-B2

R-B3

R-Tone-OUT

R-T1

1-32

32BIT SR

50k

50k

Vref CK DATA STB

1613 14 15

Page 33

3.Pin Function

Pin No. Symbol I/O Function

GND

1

L-IN1

2

L-IN2

3

L-IN3

4

L-IN4

5

L-SW-OUT

6

L-VR-IN

7

L-B1

8

L-B2

9

L-B3

10

L-TONE-OUT

11

L-T1

12

Vref

13

CK

14

DATA

15

STB

16

R-T1

17

R-TONE-OUT

18

R-B3

19

R-B2

20

R-B1

21

R-VR-IN

22

R-SW-OUT

23

R-IN4

24

R-IN3

25

R-IN2

26

R-IN1

27

VDD

28

Ground pin

Audio signal input pin (L-ch)

I

Audio signal input pin (L-ch)

I

Audio signal input pin (L-ch)

I

Audio signal input pin (L-ch)

I

Audio signal output pin (L-ch)

O

Main volume input pin (L-ch)

I

Tone control tap pin 1 for bus

I

Tone control tap pin 2 for bus

I

Tone control tap pin 3 for bus

I

Tone control output pin (L-ch)

O

Tone control tap pin for treble (L-ch)

I

Reference voltage input pin

I

Clock input pin

I

Data input pin

I

Strobe input pin

I

Tone control tap pin for treble (R-ch)

I

Tone control output pin (R-ch)

O

Tone control tap pin 3 for bus

I

Tone control tap pin 2 for bus

I

Tone control tap pin 1 for bus

I

Main volume input pin (R-ch)

I

Audio signal output pin (R-ch)

O

Audio signal input pin (R-ch)

I

Audio signal input pin (R-ch)

I

Audio signal input pin (R-ch)

I

Audio signal input pin (R-ch)

I

Power supply voltage pin

-

UX-M5R

1-33

Page 34

UX-M5R

TC9257F (IC102) : PLL frequency synthesizer

1. Terminal layout

1

XT

2

XT

3

PRD

4

CLK

5

DATA

6

MUTE

CD

AUX

7

8

9

10

TUNER

ST MONO

2. Block diagram

FM OSC

14

AM OSC

13

XT

2

XT

1

DATA

5

CLK

4

PRD

3

AMP

20

19

18

17

16

15

14

13

12

11

FM VT

AM VT

B1

B0

IF

GND

FM OSC

AM OSC

VDD

EE

FM

L

1/2

FMHHF

OSC

CIRCUIT

2 MODULUS

PRESCALER

FM MODE LF

OSC

1ms

ADDRESS

DECODER

OUTPUT PORT

MUTE

TUNER

PSC

4bit SWALLOW

COUNTER

12bit PROGRAMMABLE COUNTER

4

REFERENCE COUNTER

24bit REGISTER

24bit SHIFT REGISTER

4

TEST

24bit REGISTER

4 4

20bit BINARY COUNTER

UNIVERSAL COUNTER CONTROL

OT-4

9876

CD

AUX

12

24 22

XT

POWER ON

15

10

1ms

VDD

12

RESET

MAX

5

4

RESET

PHASE

COMPARATOR

UNLOCK

5

GATE

GND

15

TRI-STATE

BUFFER

TRI-STATE

BUFFER

OT4

I/O PORT

AMP

AMP

AM VT

19

FM VT

20

ST MONO

10

EE

11

IF

16

B0

17

B1

18

3. Pin function

Pin No. Symbol I/O Function

XT

1

2

3

4

5

6

7

8

9

10

XT

PRD

CLK

DATA

MUTE

TUNER

CD

AUX

ST MONO

Crystal oscillator pins

I

Crystal oscillator pins

O

Period signal input

I

Clock signal input

I

Serial data input/output

I/O

General-purpose output port

O

General-purpose output port

O

General-purpose output port

O

General-purpose output port

O

General-purpose I/O port

I/O

1-34

Pin No. Symbol I/O Function

EE

11

12

13

14

15

16

17

18

19

20

VDD

AM OSC

FM OSC

GND

IF

B0

B1

AM VT

FM VT

General-purpose I/O port

I/O

Power supply pin

Programmable counter input

I

Programmable counter input

I

Ground pin

General-purpose I/O port

I/O

General-purpose I/O port

I/O

General-purpose I/O port

I/O

Phase comparator output

O

Phase comparator output

O

Page 35

BU1923F (IC602) : RDS decoder

1. Terminal layout 2. Block diagram

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

MUX

REF

V

V

DD1

V

SS1

100k

4

120k

3

5

Analog

power supply

6

100k

+

anti-aliasing

filter

8th Switched

capacitor filter

CMPVSS3

87

comparator

16

1

UX-M5R

RCLK

QUAL

12

V

DD2

V

SS2

Digital

power supply

11

3. Pin function

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

QUAL

R DATA

VREF

MUX

VDD1

VSS1

VSS3

CMP

T1

T2

VSS2

VDD2

XI

XO

NC

RCLK

O

Demodulator quality good: HI

O

Demodulator data

-

1/2 VDD1 see application

-

Composite see application

-

Analog power supply

-

Analog power supply

-

Analog power supply

-

See application

-

H: Internal clock stop L: operation

-

Testing (do not use)

-

Digital power supply