Page 1

SERVICE MANUAL

MICRO COMPONENT SYSTEM

MB698<Rev.004>200910SERVICE MANUAL

UX-LP5B, UX-LP5E, UX-LP5EN,

UX-LP5EV, UX-LP5J, UX-LP5C,

UX-LP5A, UX-LP5US, UX-LP5UB,

UX-LP5UP, UX-LP5UT

SP-UXLP5

CA-UXLP5

SP-UXLP5

(for Europe)

COPYRIGHT © 2009 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

COPYRIGHT © 2009 Victor Company of Japan, Limited

No.MB698<Rev.004>

2009/10

Page 2

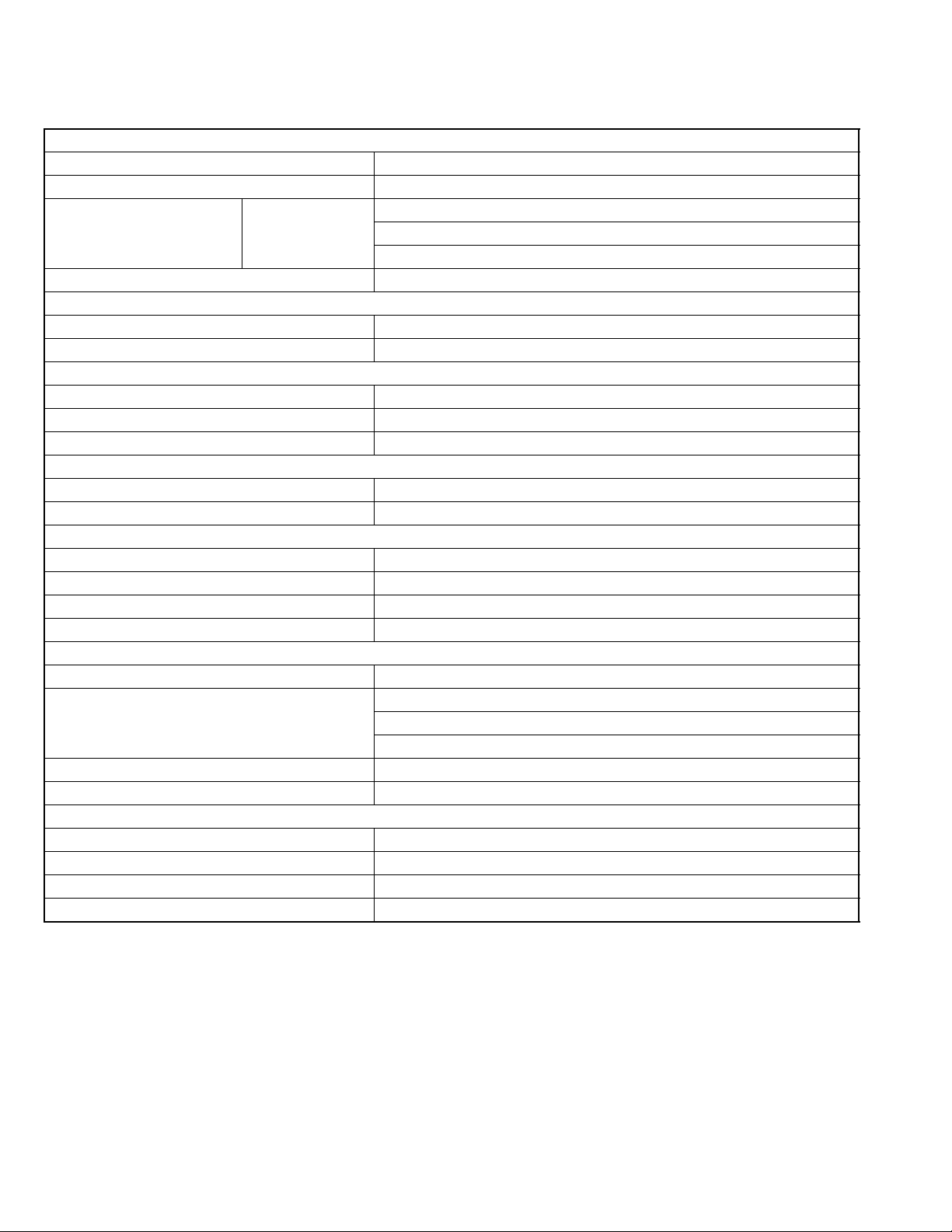

SPECIFICATION

UX-LP5 for Europe

Amplifier section

OUTPUT POWER 60 W (30 W + 30 W) at 6 Ω (10% THD)

Speakers/Impedance 6 Ω - 16 Ω

Audio input AUDIO IN 500 mV/47 kΩ (at “LEVEL 1”)

250 mV/47 kΩ (at “LEVEL 2”)

125 mV/47 kΩ (at “LEVEL 3”)

Digital input USB MEMORY

Tuner section

FM tuning range 87.50 MHz - 108.00 MHz

AM (MW) tuning range 522 kHz - 1 629 kHz

CD player section

Dynamic range 88 dB

Signal-to-noise ratio 85 dB

Wow and flutter Immeasurable

iPod section

iPod output power DC 5 V 500 mA

VIDEO OUT Composite

USB storage

USB specification Compatible with USB 2.0 Full Speed

Compatible device Mass storage class

Compatible file system FAT16, FAT32

Bus power supply DC 5 V 500 mA

General

Power requirements AC 230 V , 50 Hz

Power consumption 35 W (power on)

8 W (standby mode)

1 W or less (Ecology Mode)

Dimensions (approx) 165 mm × 259 mm × 258 mm (W × H × D)

Mass (approx) 1.9 kg

Speakers

Speaker units 10 cm × 1; 1.5 cm × 1

Impedance 6 Ω

Dimensions (approx.) 140 mm × 250 mm × 188 mm (W × H × D)

Mass (approx.) 1.4 kg each

Specifications and appearance are subject to change without prior notice.

1-2 (No.MB698<Rev.004>)

Page 3

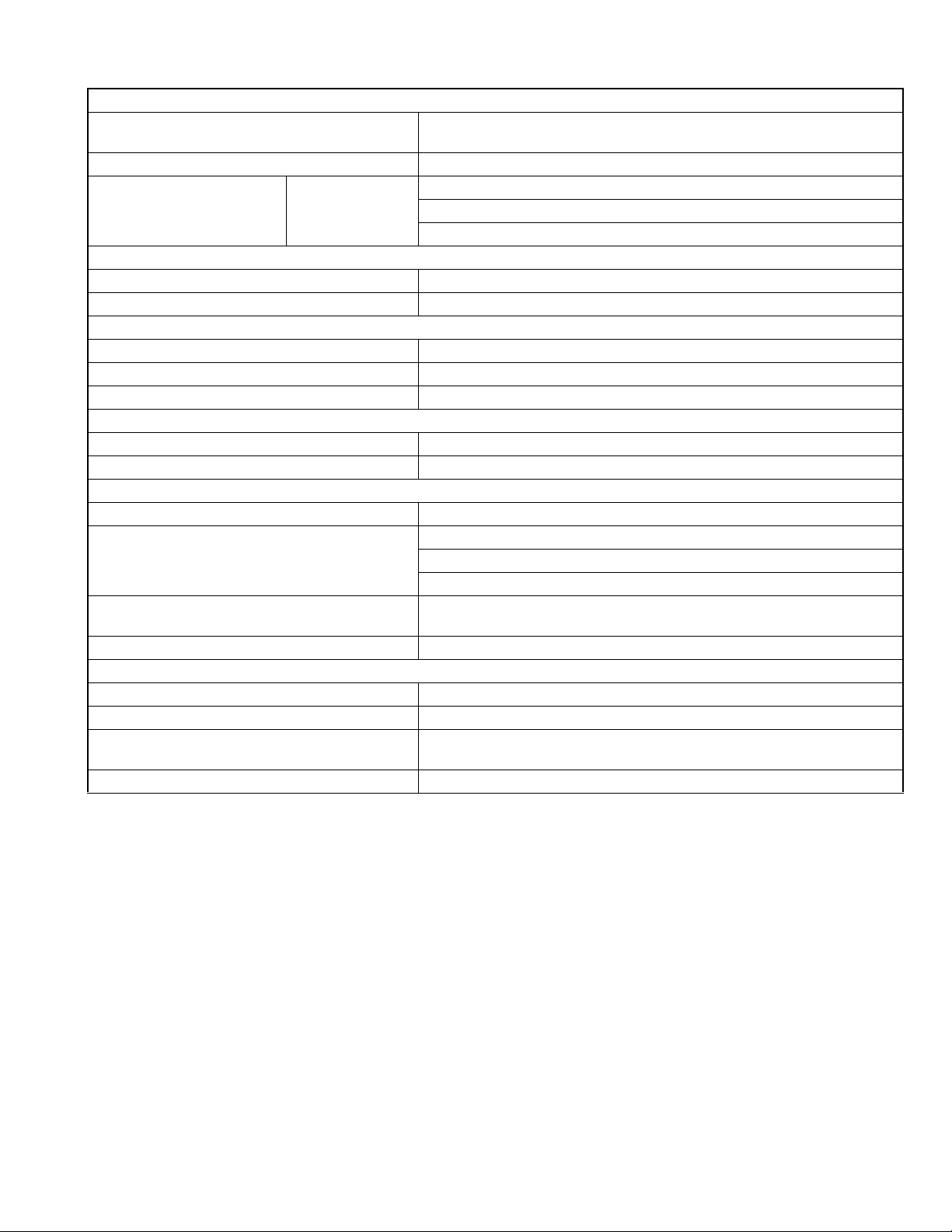

UX-LP5J/C

Amplifier section

OUTPUT POWER 35 W per channel, min. RMS, driven into 4 Ω at 1 kHz with no more than 10%

total harmonic distortion

Speakers/Impedance 6 Ω - 16 Ω

Audio input AUDIO IN 500 mV/47 kΩ (at “LEVEL 1”)

250 mV/47 kΩ (at “LEVEL 2”)

125 mV/47 kΩ (at “LEVEL 3”)

Tuner section

FM tuning range 87.5 MHz - 108.0 MHz

AM tuning range 530 kHz - 1 710 kHz

CD player section

Dynamic range 88 dB

Signal-to-noise ratio 85 dB

Wow and flutter Immeasurable

iPod section

iPod output power DC 5 V 500 mA

VIDEO OUT Composite

General

Power requirements AC 120 V , 60 Hz

Power consumption 35 W (power on)

8 W (standby mode)

1 W or less (Ecology Mode)

Dimensions (approx.) 165 mm × 259 mm × 258 mm

(6-1/2 inches × 10-1/4 inches × 10-3/16 inches) (W × H × D)

Mass (approx.) 1.9 kg (4.2 lbs)

Speakers

Speaker units 10 cm (3-15/16 inches) × 1; 1.5 cm (5/8 inch) × 1

Impedance 6 Ω

Dimensions (approx.) 140 mm × 250 mm × 188 mm

(5-9/16 inches × 9-7/8 inches × 7-7/16 inches) (W × H × D)

Mass (approx.) 1.4 kg (3.1 lbs) each

Specifications and appearance are subject to change without prior notice.

(No.MB698<Rev.004>)1-3

Page 4

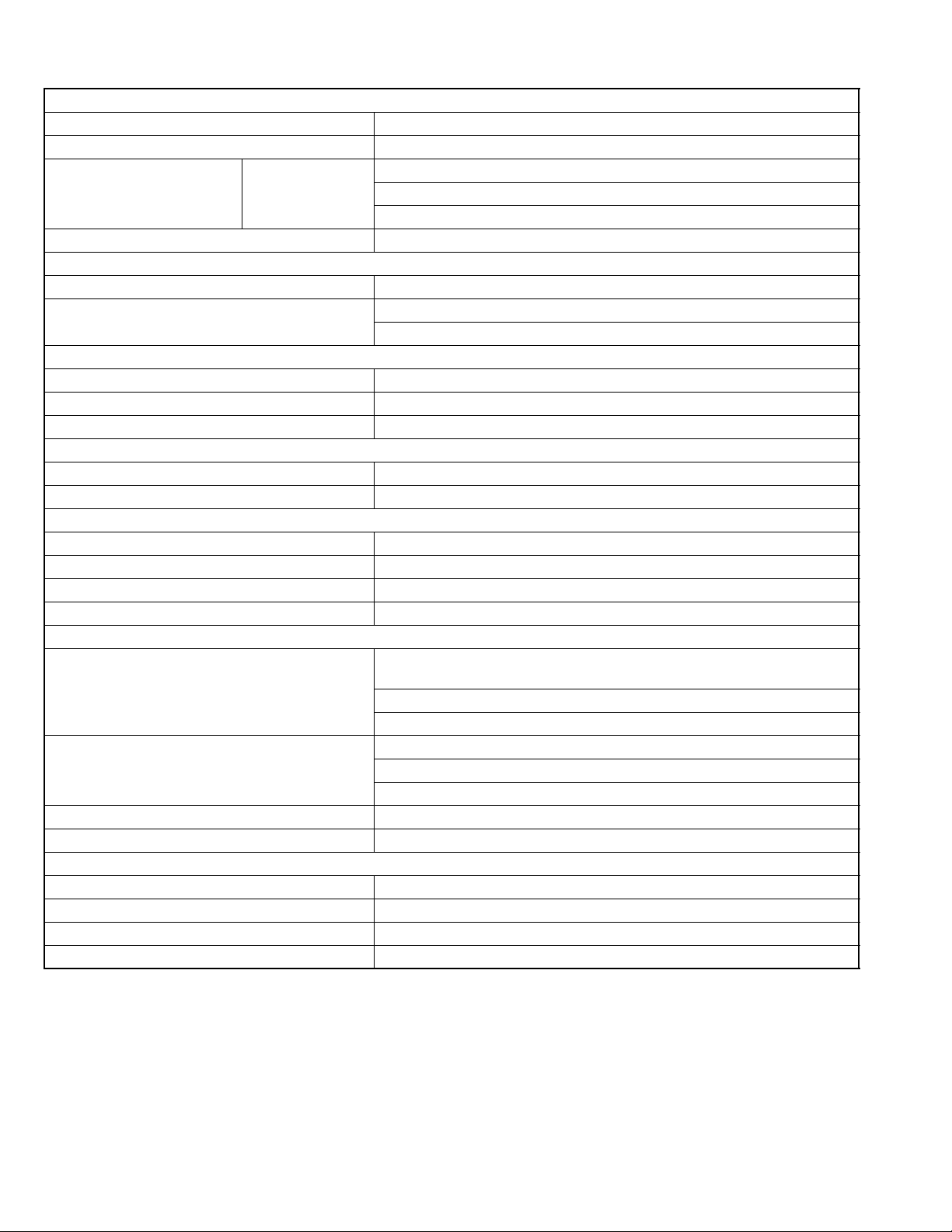

UX-LP5 for Asia, Australia

Amplifier section

OUTPUT POWER 60 W (30 W + 30 W) at 6 Ω (10% THD)

Speakers/Impedance 6 Ω - 16 Ω

Audio input AUDIO IN 500 mV/47 kΩ (at “LEVEL 1”)

250 mV/47 kΩ (at “LEVEL 2”)

125 mV/47 kΩ (at “LEVEL 3”)

Digital input USB MEMORY

Tuner section

FM tuning range 87.50 MHz - 108.00 MHz

AM tuning range 531 kHz - 1 710 kHz (in 9 kHz spacing)

530 kHz - 1 710 kHz (in 10 kHz spacing)

CD player section

Dynamic range 88 dB

Signal-to-noise ratio 85 dB

Wow and flutter Immeasurable

iPod section

iPod output power DC 5 V 500 mA

VIDEO OUT Composite

USB storage

USB specification Compatible with USB 2.0 Full Speed

Compatible device Mass storage class

Compatible file system FAT16, FAT32

Bus power supply DC 5 V 500 mA

General

Power requirements AC 110 V - 127 V/AC 220 V - 240 V (adjustable with the voltage selector),

50 Hz/60 Hz

AC 240 V , 50 Hz (only Australia)

AC 220 V , 50 Hz (only Hong Kong)

Power consumption 35 W (power on)

8 W (standby mode)

1 W or less (Ecology Mode)

Dimensions (approx) 165 mm × 259 mm × 258 mm (W × H × D)

Mass (approx) 1.9 kg

Speakers

Speaker units 10 cm × 1; 1.5 cm × 1

Impedance 6 Ω

Dimensions (approx.) 140 mm × 250 mm × 188 mm (W × H × D)

Mass (approx.) 1.4 kg each

Specifications and appearance are subject to change without prior notice.

1-4 (No.MB698<Rev.004>)

Page 5

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

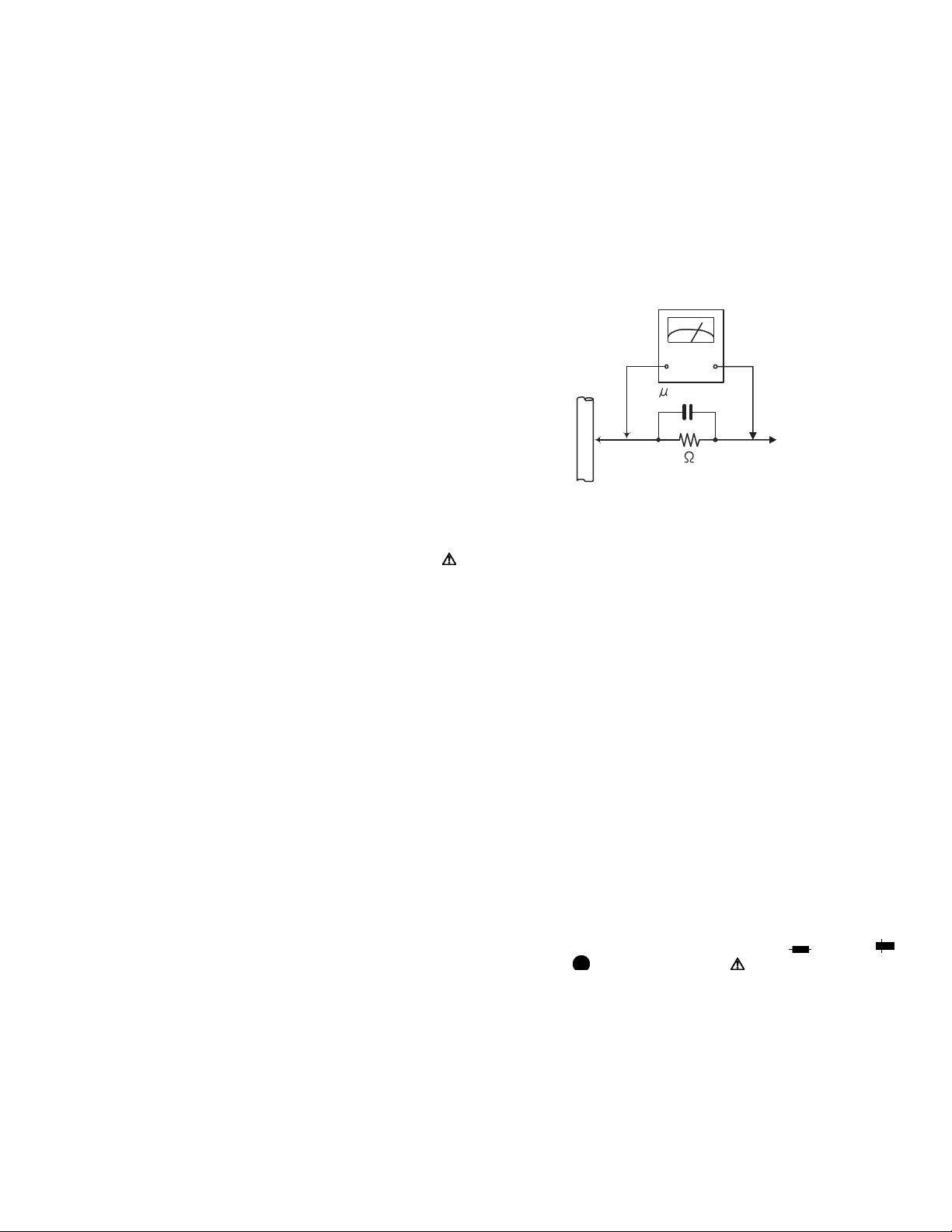

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

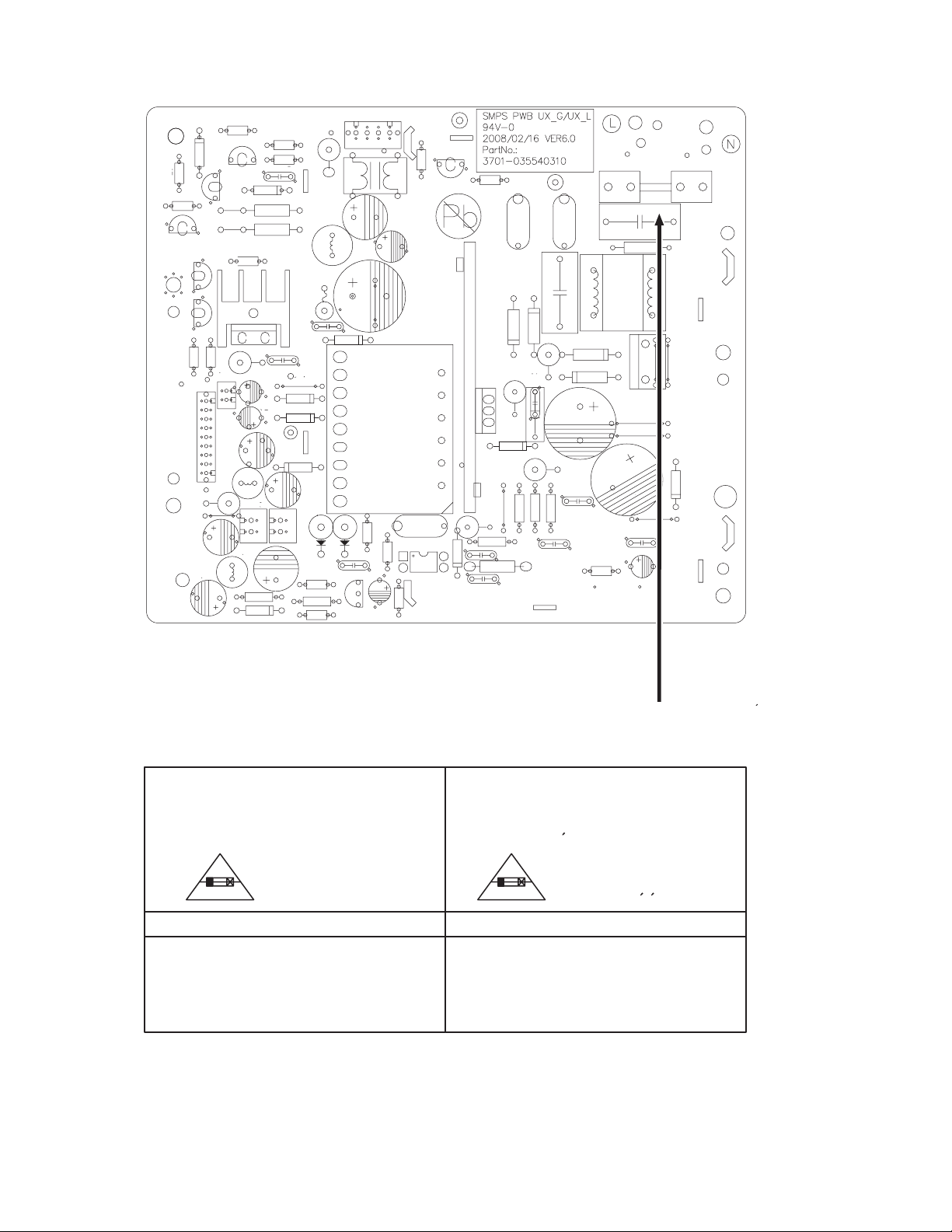

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB698<Rev.004>)1-5

Page 6

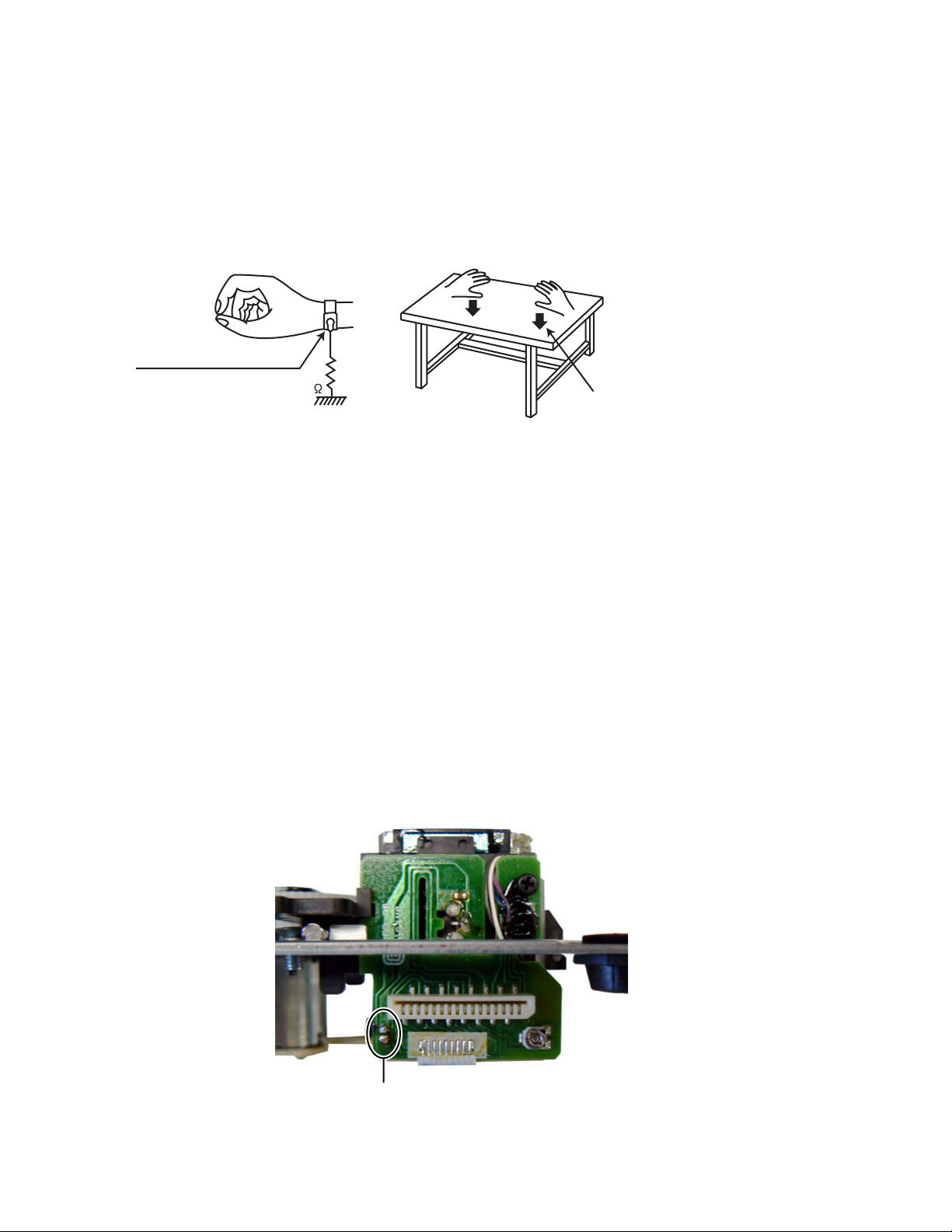

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

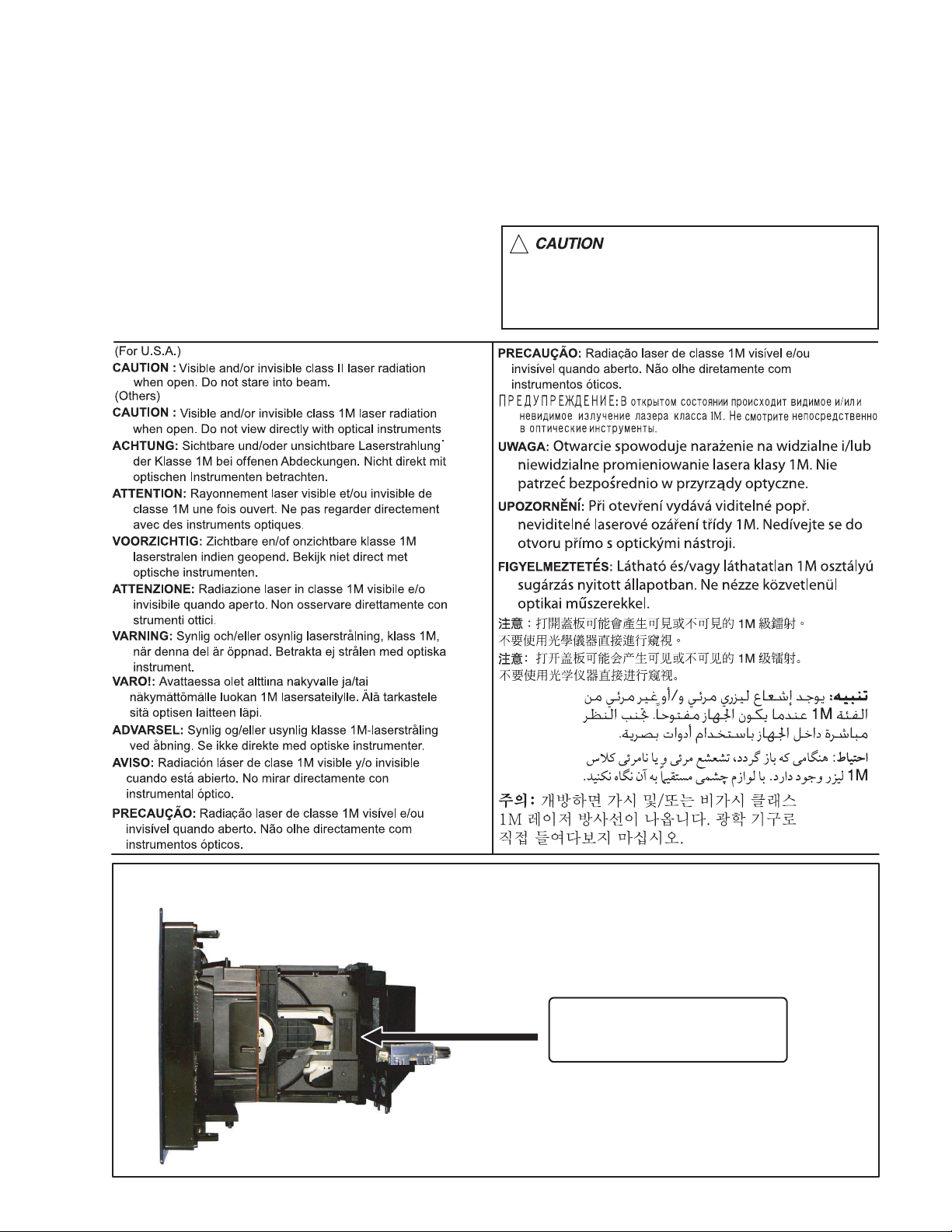

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the card wire is disconnected from the connecto on the servo board. (If the card wire

is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the card wire.

1-6 (No.MB698<Rev.004>)

Solder short part

Page 7

1.8 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION

CAUTION:

DANGER:

INVISIBLE LASER RADIATION WHEN OPEN

DO NOT STARE INTO BEAM

INVISIBLE LASER RADIATION WHEN OPEN

AVOID DIRECT EXPOSER TO THE BEAM

(No.MB698<Rev.004>)1-7

Page 8

1.9 Importance administering point on the safety

R27

R26

U6

D17

R28

V7

R29

V5

V3

V4

R22

R15

CN5

FL+

CN2

-25V

ECO

FL+

5VE

GND

12V

GND

GND

5VD

5VD

L4

R23

JP7

C14

L3

C21

R25

C26

D18

R16

HS1

D9

C11

C25

R10

CN1

5V

GND

JP8

GND3

D10

D19

C27

GND2

C16

D12

CN4

C13

L6

D13

PVCCPVCC

CN3

L7

R13

R30

R31

L5

F2

C31

C15

5V

GND

D16D11

C12

R18

U3

R20

R21

PGND PGND

JP9

D14

R11

R19

C20

GND

R14

F1

V2

C18

C19

C17

T1

R12

HS2

C22

U2

D8

R9

C3

R2R1C6

V1

D6

JP5

R7

R24

C28

C24

GND

C4

C2

D2

D1

R3

C7

R6

R5

C8

R8

L2

R4

T2.5AH250V

C1

R32

L1

D3

D4

JP3

JP4

C5

SW1

JP1

JP2

C23

D5

JP6

C10

C9

Full Fuse Replacement Marking

Graphic symbol mark

(This symbol means slow blow type fuse.)

should be read as follows ;

FUSE CAUTION

FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE

AND RATING OF FUSES ;

F901 : T1.6AH 250V F901 : T1.6AH 250V

slow blow type / type a fusion lent

Marquage Pour Le Remplacement

Complet De Fusible

Le symbole graphique (Ce symbole signifie

fusible de type a fusion lent.)

^

doit etre interprete comme suit ;

PRECAUTIONS SUR LES FUSIBLES

POUR UNE PROTECTION CONTINUE CONTRE

DES RISQUES D'INCENDIE, REMPLACER

SEULEMENT PAR UN FUSIBLE DU MEME TYPE ;

1-8 (No.MB698<Rev.004>)

Page 9

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.MB698<Rev.004>)1-9

Page 10

SECTION 3

DISASSEMBLY

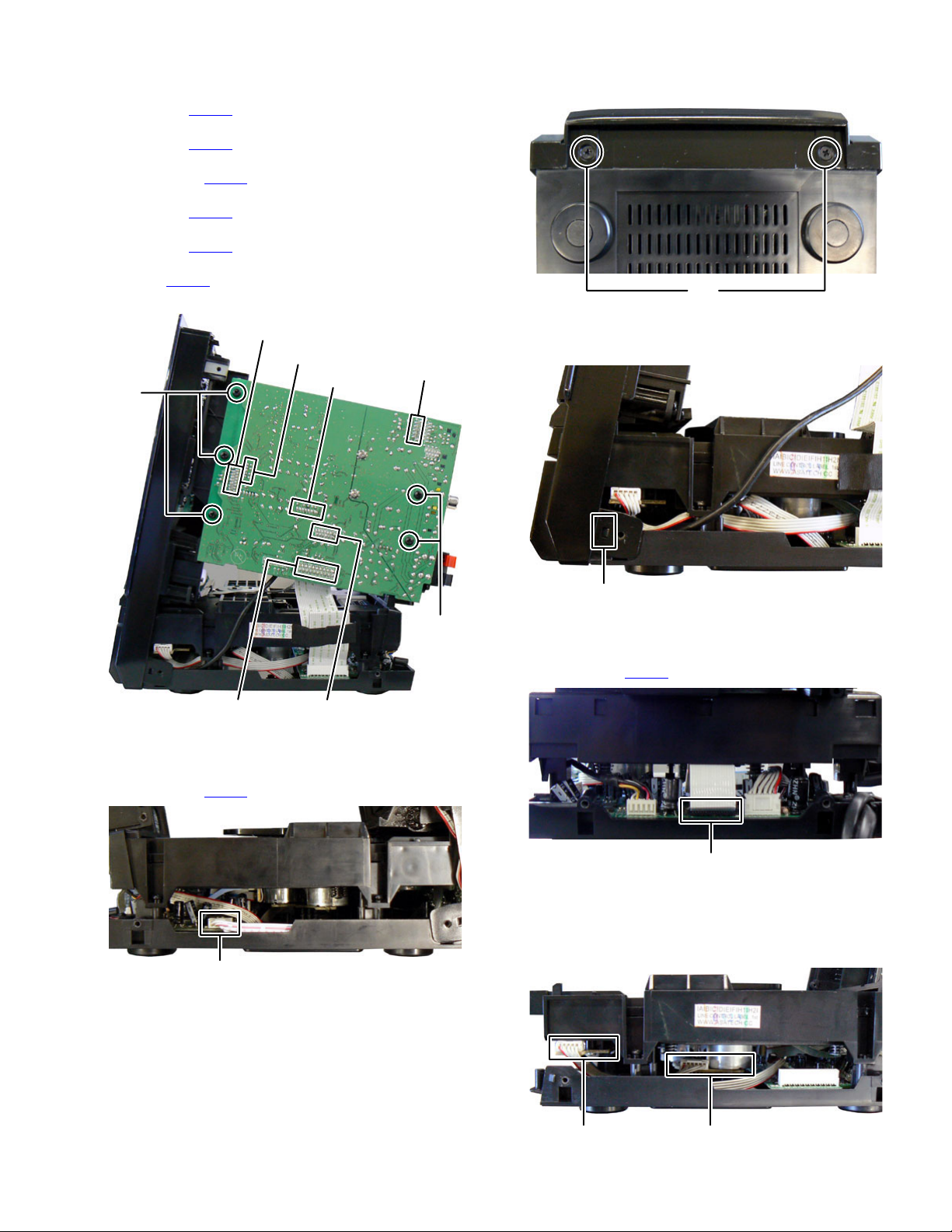

3.1 Main body (Used figure are UX-LP5E)

3.1.1 Removing the Top cabinet (See Fig.1, 2)

(1) Remove the six screws A attaching the both side of the Top

cabinet. (See Fig.1)

A

A

3.1.2 Removing the SMPS board (See Fig.3)

(1) Remove the four screws C attaching the SMPS board.

(2) Disconnect the connector wires from MCU board connect-

ed to connectors CN2

CN2

and CN3 of the SMPS board.

CN3

C

C

Fig.1

(2) Remove the five screws B attaching the Top cabinet. (See

Fig.2)

B

B

Fig.3

1-10 (No.MB698<Rev.004>)

Fig.2

Page 11

3.1.3 Removing the MCU board (See Fig.4)

(1) Disconnect the card wire from Tuner pack connected to

connector CN201

(2) Disconnect the card wire from Display board connected to

connector CN202

(3) Disconnect the connector wire from USB board connected

to connector CN210 of the MCU board.

(4) Disconnect the connector wire from CD board connected to

connector CN208

(5) Disconnect the card wire from iPod board connected to

connector CN206

(6) Disconnect the card wire from CD board connected to con-

nector CN207 of the MCU board.

(7) Remove the five screws D attaching the MCU board.

of the MCU board.

of the MCU board.

of the MCU board.

of the MCU board.

CN202

CN208

CN210

CN201

D

(2) Remove the two screws E attaching the Front cabinet.

(See Fig.6)

E

Fig.6

(3) Disengage two hooks a engaged both side of the Front

cabinet. (See Fig.7)

D

CN207

3.1.4 Removing the Front cabinet (See Fig.5 to 7)

(1) Disconnect the connector wire from USB board connected

to connector CN114

CN114

of the CD board. (See Fig.5)

CN206

Fig.4

Fig.5

hook

a

Fig.7

3.1.5 Removing the CD mechanism (See Fig.8 to 10)

(1) Disconnect the card wire from CD mechanism connected

to connector CN102

(2) Disconnect the connector wire from CD board connected to

connector of the Loader board. (See Fig.9)

(3) Disconnect the connector wire from CD board connected to

connector of Mechanism board. (See Fig.9)

of the CD board. (See Fig.8)

CN102

Fig.8

Loader board Mechanism board

Fig.9

(No.MB698<Rev.004>)1-11

Page 12

(4) Remove the four screws F attaching the CD mechanism.

(See Fig.10)

3.1.7 Removing the CD board (See Fig.12)

(1) Remove the four screws H attaching the CD board.

F

F

Fig.10

3.1.6 Removing the Traverse mechanism (See Fig.11)

(1) Remove the two screws G attaching the Traverse mecha-

nism.

GG

H

H

Fig.12

3.1.8 Removing the LED board (See Fig.13)

(1) Disconnect the connector wire from Display board connect-

ed to connector CN45

(2) Remove the two screws J and one screw K attaching the

Reflector bracket.

of the LED board.

J

Fig.11

K

Fig.13

3.1.9 Removing the Display board (see Fig.14 to 16)

(1) Remove the six screws L attaching the USB board. (See

Fig.14)

(2) Disconnect the connector wire from Display board connect-

ed to connector CN43

of the USB board. (See Fig.14)

CN45

L

L

Fig.14

CN43

1-12 (No.MB698<Rev.004>)

Page 13

(3) Remove the four screws M attaching the PCB bracket.

(See Fig.15)

M

M

3.1.10 Removing the iPod board (See Fig.17, 18)

(1) Remove the iPod door cover.

(2) Remove the Eject spring. (See Fig.17)

(3) Remove the one screw Q and one screw R attaching the

Cassette lid latch. (See Fig.17)

(4) Remove the one screw S attaching the Cassette cam

bracket. (See Fig.17)

(5) Remove the one screw T and one screw U attaching the

iPod door bracket. (See Fig.17)

S

Q

U

R

T

Fig.15

(4) Remove the two screws N and one screw P attaching the

Display board. (See Fig.16)

N

N

P

Fig.16

Eject spring

Fig.17

(6) Remove the four screws V attaching the Cosmetic frame.

(See Fig.18)

(7) It takes both picks off the hook and take off iPod door while

inclining the fulcrum of the door inward. (See Fig.18)

V

Fig.18

(No.MB698<Rev.004>)1-13

Page 14

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

1-14 (No.MB698<Rev.004>)

Page 15

Page 16

Victor Company of Japan, Limited

Audio/Video Systems Division 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB698<Rev.004>)

Printed in Japan

VSE

Page 17

SCHEMATIC DIAGRAMS

MICRO COMPONENT SYSTEM

UX-LP5B, UX-LP5E, UX-LP5EN,

UX-LP5EV, UX-LP5J, UX-LP5C,

UX-LP5A, UX-LP5US, UX-LP5UB,

UX-LP5UP, UX-LP5UT

DVD-ROM No.SML2009S2

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Contents

Block diagrams

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2009 Victor Company of Japan, Limited.

SP-UXLP5

CA-UXLP5

SP-UXLP5

(for Europe)

2-1

2-2

2-10 to 14

No.MB698SCH<Rev.004>

2009/10

Page 18

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

Page 19

Block diagram

r

to iPod

CN51

iPod DOCK & OP section

IC402

OP AMP

IPOD L/R

System control & Audio Amp section

IPOD_ON

SLEEP_DET

CN52

CN206

IPOD

TXD/RXD

IC203

UART

SELECT

X203

32.768K

EEPROM

SCLK

SDA

IC202

IPOD L/R

IC204

E,VOLUME

IC212

POWER AMP

CVBS

OUT

JK203CN212

TO

Speake

CD traverse

mechanism

CD PICKUP

mechanism

TRY SW

M

LOADER

Section

CN104

CN102

CN103

IC104

MOTOR

DRIVER

Q106 to Q109

LOADER DRIVER

D+/-

CN114

CP42

SDRAM

X101

27MHz

IC103

IC101, IC102

1V8,3V3 REG

IC106

MPEG

IC105

FLASH

ROM

SCLK

SDA

AUTHENTIC

CD servo control section

CD R/L

N_RST

IC109

IPOD

CN208

CN106

CN207

CN107

CD

TXD/RXD

CD_ON N_RST

TR+

TROPEN

CLOSE

CN210

CP41

SCLK

SDA

HP_MUTE

IC205

HP AMP

MUTE

HP L/R

TXD/RXD

IC201

MICON

Q201

RESET

IC210,IC211

SUBWOOFER

LFT OUT

CN202

CN41

TU_CLK

TU_DA

TU_RST

TU_DET

JK204

SUB OUT

CD R/L

AUX L/R

POWER ON

Q207

+9V REG

Q205,Q206

A+12V

SWITCH

CN203

CN2

D11,D16

5VD REG

Q217,Q218

AMP_MUTE

AMP_STBY

Q202,Q203

Z201

+5V REG

TU_ON

TUNER L/R

CN211

CN3

D9

+23V REG

CN201

UNIT

TUNER

HP L/R

JK41JK42JK43

AUX L/R

D+/-

USB AUDIO IN HEADPHONE

+5V_USB

CN43

KEY_1

KEY_2

Ornament

Blue LED

SW401-SW413

CP43

CP44

CN45

KEY MATRIX

TACT SW LED section

HP&AUDIO&USB JACK section

LED ON

IPOD_LED

LED MATRIX

WITH DIM

LED1

STANDBY

LED

DIM OFF

STB LED OFF

VFD_DATA

VFD_STB

U501

VFD DRIVER

GR1 to 12

VFD1 DISPLAY

IR_RXVFD_CLK

IR401

REMOCON

LCD section

SG1 to 16

CN5

CN42

CN1

CP45

+12V REG

D13

5VE REG

D19

-25V REG

D10

FL+/- REG

D12

POWER TRANS

SW REG.

CONTROL

T1

SW1

110V/230V

U1

AC IN

AC CORD

D1 to D4

DIODE

BRIDGE

SMPS section

2-1

Page 20

Standard schematic diagrams

Smps section

D2

D1

RL207

RL207

C2

!

0.22uF/275V

!

L1

40mH_0.35mm

C1

0.22uF/275V

!

F1

T2.5AH250V

LN

AC_plug

R1

NC

1M/0.5W

L

T5AL250V

C11

2/1KV_M

D10

FR104

R33 2 2

C12

103

L6

R27

2K2

C19 47UF/50V

F2

C27

22UF/50V

D17

4.3V

U6

AZ431

R9

18K

+

L5

10UH

+

C17

2200UF/35V

R34 22

C15

330UF/16V

+

+

+

R14

4K7

+

L4

10UH

C13

1000UF/16V

L 3 10UH

5VE

C21

330UF/16V

KTA1275A

+

C18

470UF/35V

-25 V

C16

330UF/16V

C14

330UF/16V

R22

4K7

R28

330

V7

S8050

D18

1N4148

V2

AGND

12V

R16

1K

+

+

33/2W

R29

2K2

L7

33UH

FL-

+

100UF/16V

FL+

DGND

R23

4.7K/0.5W

C25

1N4148

5VD

S8050C

PVCC

R13

PGND

D15

V5

S 8 550

V3

EC O

R17

1K

R30

22/2W

V4

S8050C

R15

1K

R31

22/2W

D14 FR104

+

C5

120uF/200V

!

T1

P

NC

DAIN

EMI

VCC

5VD

R24

10/1W

1

23

U3

AZ431

DGND

2

2302- 285000500

R18

100

R19

1K

C20

1UF/50V

CN4

1

NC

+

+

C23

!

CN1

CN2-2.0

5VD

5VD

9

120uF/200V

1

2

3

4 5

0

12V

DGND

DGND

AGN D

4

5

6

7

8

R6

10K

U1

ADJ

FB

CS

GND DRV

NCP1216D65G2

C7

471

C8

471

R8

22

EC O

-25 V

5VE

2

3

8

HV

7

NC

6

VCC

C9

47UF/25V

+

C10

104

VD1

24V

PVC C

PGN D

PGN D

2

3

1

4

D3

RL207

R32

N

D4

RL207

SW1

NC

1N4007

D5

!

C3

102/250V_Y1

CN2.0-9

CN2

FL-

FL+

2

C4

102/250V_Y1

1

PVC C

1

R2

47K/2W

R7

1K

1000UH(0410)

C24

102

CN2.5-4

CN3

D7

1N4148

R4

47

R5

3K3

L2

FQPF5N60C

!

4

C22

!

NC

5VD

!

6

C6

472/1KV_M

5

D6

FR107

4

V1

3

R3

0R47/2W

2

Hot_GND

1 15

D8

FR104

472K/100V

C28

U2

EL817C

DGND

CN1

1

2

NC

Parts are safety assurance parts.

!

When replacing those parts make

R20

3K3 1%

STB

21V

PGND

-25V

FL-

FL+

12V

GND

5V

D13

1N5819

R21

3K6 1%

R12

100K

7

8

9

11

10

12

13

14

R11

10

R26

180 K

C26

104

D9

UF802

R10

33/2W

47

D19

FR104

D12

FR104

C29 102/100V

D11

1N5822

1N5822

PVCC 5VD

R25

24K

C32 102

D16

10UH(0307)

sure to use the specified one.

2-2

Page 21

Main section 1

T81

CN202

16-PINS FFC HEADER.1.0MM

1

2

3

4

5

6

7

8

9

10

11

12

TO DISPLAY BOARD

13

14

15

16

T29

CN203

9-PINS HEADER.2.0MM

1

2

3

4

5

6

7

8

FROM_SMPS BOARD

9

IPOD_CVBS

T87

TUNER_DAB_L

TUNER_DAB_R

T82

T83

T84

T88

T89

T90

D+5V

FB07

T25

T26

T27

+5V_TUNER

D+5V

100U/16V(LP5)

R20

75R(LP5)

T91

T23

T24

T28

T22

T16

T13

T14

T15

T17

T18

T85

T93

R23

OPEN

0R(LP5)

C12

CHGND

T86

R304

R303 0R

SYSTEM_ON

C8B

OEN

R22

CHGND

TO TUNER MODULE

TUNED

CN213

1 3 5 7 9

OPEN

0R

T92

T94

T95

+12V ST+5V -25V

0R

C8A

0.1U

OPEN

R16

75R(LP5)

+

R17

75R(LP5)

R7

OPEN

R21

OR(LP5)

855OC,TO-92(LP5)

ST_IND

SDA

2 4 6

R301

1K5

R302

1K5

VFD_DATA

VFD_CLK

VFD_STB

IR_RX

LED_ON

SYSTEM_ON

IPOD_LED_ON

KEY_2

KEY_1

VOL+

VOL-

C8

0.1U

75R(LP5)

C13

100P(LP5)

Q2

SCL

PORT_SEL

C7

R18

75R(LP5)

R19

L_OUT

TU_GND

R_out

VCC

RDS_CLK

8

10

T20 T21

-25V +12V_VFD

R327

4K7

R328

487K

C7B

C7A

OPEN

OPEN

C15

10P(LP5)

L4

1U(LP5)

RDS DATA

11

ST+5V

+3V6

R321

4K7

R326

10k

Q206

8050C

C14

100P(LP5)

TO TUNER MODULE(SI47XX SERIES)

L_CH

GND

R_CH

T19

1

2

3

4

Q204

8050C

C305

OPEN

Q205

AP2301N

S

G

R329

CVBS_OUT

AT24C02

A0

A1

A2

GND

R325

47K

C301

0.1U

1M

2 4 6

1 3 5 7 9

IC202

8

VCC

7

WP

6

SCL

5

SDA

MCU_SCL

MCU_SDA

AMP_STB

ECO_STBY

LED_ON

VFD_STB

VFD_DATA

VFD_CLK

VOL+

VOL-

ST+5V

R324

10K

R323

1K

A+12V

100UH,AXIAL

D

+

C302

100U/16V,SHORT TYPE

L213

C303

0.1U

VCC

C307

0.1U

ECO_STBY

SCLK

SDIO

SEN/

RDS DATA

8

OR

OPENOROR

FB03

FB05

FB04

R320

22K

+12V_VFD

+

100U/16V,SHORT TYPE

ST+5V

D203 D202

LL4148 LL4148

CN201

10-PINS FFC HEADER, 1.25MM

RST/

RDS_CLK

10

11

T69

R26 100R

OPEMOROPEN

OPEN

FB10

FB06

FB09

FB02

FB01

R322

22K

C306

0.1U

7-PINS HEADER,2.0MM(SOFTWARE UPGRADE)

MCU_UPGRADE

C304

+3V6

A

R305

100R

4K7

R306

100R

R310

100R

R311

1K

R312

1K

R313

1K

R314

1K

R315

1K

R316

1K

R317

1K

R13

1K

R14

1K

R15

1K

R318

IPOD_LED_ON

AMP_MUTE

SLEEP_DET

CN204

7

6

5

4

3

2

1

+3V6

GND AGND

C309

4.7U/16V

+

100UH,AXIAL

4K7

4K7

R307

R308

A

+3V6

+3V6

L212

R395

4K7

R393

12K

R394

D201

6K8

LL4148

STB+5V

+

315

100U/16V

4K7

R309

1

P60/SCL0

2

P61/SDA0

3

P62/EXSCL0

4

P63

5

P33/TI51/TO51/INTP4

6

P75

7

P74

8

P73/KR3

9

P72/KR2

10

P71K/KE1

11

P70K/KE0

12

P32/INTP3

R300 1K

R330

1K

R256

1K

IPOD_ON/OFF(SCLK)

FMLDO

RESET

D6

LL4148

D7

LL4148

C16

0.01U

C17

0.01U

C18

0.01U

C19

0.01U

R392

22K

Q201

8050C

C316

48

VDD

P31/INP2

13

C310

0.1U

0.1U

C317

47

VSS

P30/INTP1

14

R445

10K

RESET

C311

C312

24P

24P

X203

32.768K

R397

T97

OPEN

0.1U

R433

0R

46

45

44

43

42

41

REGC

FLMDO

P123/XT1

P121/X1/OCDOA

P124/XT2/EXCLKS

P122/X2/EXCLK/OCDOA

IC201

UPD78F0514GA(T)-8EU-A

P17/TI50/I050

P16/TOH1/INTP5

P15/TOH0

P14/RXD6

P13/TXD6

R347

16

R8

OPEN

17

22R

R331

47K(LP5)

18

R350

19

22R

R332

R348

4K7(LP5)

P12/SO10

20

RXD

15

4K7(LP5)

C3

0.01U

R396

10K

C1

0.01U

40 3938

P40

RESET

P11/SI10/RXD0

P10/SCK10/TXD0

21

22

22R

22R

R334

R335

TXD

R349

10K(LP5)

C313

0.1U

37

P41

P120/NT

P140/PCL/INTP6

P00/TI000

P01/TI010/T000

P130

P20/ANI0

ANI1/P21

ANI2/P22

ANI3/P23

ANI4/P24

ANI5/P25

ANI6/P26

ANI7/P27

AV-REF

AVSS

23

24

C319

0.1U

74HC4052(LP5)

1

2Y0

2

2Y2

3

2Z

4

2Y3

5

2Y1

6

E

7

VEE

GND

8

R351

47K(LP5)

+5V_TUNER

L211

100UH,AXIAL

++

C314

100U/16V

C318

100P

+3V6

R375

36

35

34

33

32

31

30

29

28

27

26

25

R383

OR

3K9(G355,LP5),8K2(L5V)

IC203

UART_SEL2

UART_SEL1

10K

10K

10K

R387

R388

R389

R390

3K9(G355,LP5),8K2(L5V)

16

VCC

15

1Y2

14

1Y1

13

1Z

12

1Y0

11

1Y3

10

S0

S1

9

R25

OPEN (AXIAL)

R24

OPEN (AXIAL)

R358

120R,1/2W (AXIAL)

R443

OR

C340

OPEN

R367

10K

1K

R366

10K

R446

1K(UX-G355/UX-LP5),OR(UX_L)

1K(UX-G355/UX-LP5),OR(UX_L)

10K

10K

10K

R391

R385

R384

C320

0.1U

R333 22R

R338 0R(G355 0R L5V)

0R(G355 0R L5V)

R339

R340 1K(LP5)

R342 1K(LP5)

R343 1K(LP5)

R344 1K(LP5)

R346

10K(LP5)

UART_SEL1

UART_SEL2

Z201

5V1,AXIAL

10K

R368

+3V6

+

T96

Q202

8550C,TO-92

Q203

8050C

R363 1K

R434 22R

R364 1K

R365 1K

R431 1K

R370

10K

22K

R369

R380

10K

R371

R372

R373

1K(G355 OR LP5)

R374

R376

R377 1K

R378 1K

R382 1K

R337 1K

R336

C308

100U/16V,SHORT TYPE

ST+5V

CD

IPOD DAB

10011

R360

4K7

C337

0.1U(LP5)

1

A+12V

R359

22K

R361

4K7

R362

10K

1K(L5V)

1K(L5V)

1K

1K

R379

R381

1K

DAB_TUNER_ON

AM_HOP

IPOD_ON/OFF(SCLK)

FMLDO

LINE_MUTE

STB+5V

HP_MUTE

IR_RX

IPOD_SEL1

IPOD_SEL2

NREST

IPOD_DET

DAB_TUNER_ON

CD_ON

CLOSE_SW

OPEN_SW

TRAY-

TRAY+

HP_DET

KEY_1

KEY_2

DVD_STB

RXD/DVD/_DAT

TXD/DVD_CLK

UR_FROM_IPOD

UR_TO_IPOD

9-PINS FFC HEADER,1.0MM(L5V)

FROM DVD BOARD

CN205

SPDF_OUT

SPDF+5V

CVBS_OUT

Y_OUT

PB_OUT

PR_OUT

VGND

CVBS_OUT

IPOD_CVBS

T48

1

2

3

4

5

6

7

8

9

SLEEP_DET

IPOD_DET

UR_TO_IPOD

UR_FROM_IPOD

D+5V

IPOD_ON/OFF(SCLK)

IPOD_L

IPOD_R

A+12V

TRAY+

TRAY-

OPEN_SW

CLOSE_SW

DVD_STB

RXD/DVD_DAT

TXD/DVD_CLK

CD_ON

MCU_SCL

MCU_SDA

NREST

IR_RX

IPOD_SEL1

IPOD_SEL2

CD/DVD_LIN

CD/DVD_RIN

T49

R357

33R(L5V)

T50

T51

T52

T53

T54

T55

T56

R1

0R(UX-G355,UX-LP5),OPEN(UX-L5V)

0R(UX-G355,UX-LP5),OPEN(UX-L5V)

F201

JK60-075(LP5)

T57

T58

T59

T32

T33

T34

T35

T36

T37

R356

0R(CD)

R355

0R(CD)

T60

T62

T38

T39

T42

47U/16V(L5V)

C321

0.1U(L5V)

R2

SUB_OUT

C338

1000P(SUBWOOFER)

T63

T64

T65

T74

T73

T40

T41

T43

T44

T45

T71

C322

+

Z202

5V1(L5V)

Z203

5V1(L5V)

T61

T30

C339

0.1U

T31

T72

T107

T105

T108

Z204

Z208

5V1(L5V)

5V1(L5V)

Z207

Z205

5V1(L5V)

5V1(L5V)

Z211

5V1(L5V)

Z212

5V1(L5V)

+5V_IPOD

D+5V

1

3

5

7

9

10

11

12

13

14

15

16

17

18

19

20

CHGND

CN208

3-PINS HEADER,2.0MM

T111

T110

T109

GND

1

VCC

2

IN

3

T106

1

2

3

4

5

6

Z210

5V1(LP5 0R L5V)

1

2

Z209

5V1(LP5 0R L5V)

T104

T103

1

2

T167

T102

A+12V

T168

16-PINS FFC HEADER 1.0MM(LP5)

JK202

YPBPR RCA JACK(L5V)

JK203

CVBS RCA JACK(LP5 0R L5V)

JK204

SUB RCA JACK(L5V)

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CN206

TO iPod BOARD (CD MODELS)

2

4

CN207

6

20-PINS FFC HEADER,1.25MM

8

TO CD BOARD OR DVD BOARD

1

2

3

4

FROM CD BOARD OR DVD BOARD

5

6

7

JK201

GP1FA553TZ(L5V)

2-3

Page 22

Main section 2

IPOD_L

R220

6K8

(LP5)

C280

R215

1U

2K4

CD/DVD_LIN

CD/DVD_RIN

4.7U/16V

4.7U/16V

R9

(L5V)

56K

C328

(REVERSE INSERT)

R10

(L5V)

56K

C327

(REVERSE INSERT)

A+12V

R11

33K

(L5V)

R12

33K

(L5V)

R436

3K3

R255

3K3

R223

3K9

R257

3K9

TO HEADPHONE BOARD

C4

(L5V)

100U/16V

C332

1U

C325

1000P

C336

1U

C325

1000P

CN210

7-PINS HEADER, 2.0MM

1

2

3

4

5

6

7

TUNER_DAB_R

TUNER_DAB_L

T75

T76

IPOD_R

AUX_R

AUX_L

CD/DVD_L

CD/DVD_R

CD/DVD_L

CD/DVD_R

T77

T78

HP_L_OUT

T79

T80

HP_R_OUT

R247

R248

R213

R224

(LP5)

6K8

A+12V

C270

0.1U

MCU_SDA

MCU_SCL

R430

470R

1K8

1K8

R229

5K6

R201

5K6

Q207

C271

100U/16V

R250 R251

5K6 5K6

C283

22U/16V

TO-928050C,

Z214

9V1, AXIAL

AUX_L

AUX_R

HP_DET

R437

C284

1000P

C268

1U

C269

1U

IC204

ET2314

C256

0.1U

C279

1U

1U

1U

DGND

OUT_L

TREB_R

RIN

2700P MYLAR

C274

C276

2U2/16V

2K4

2K4

2K4

2K4

C266

220U/16V

C257

220U/16V

IC205

BH4453F

C258

220U/16V

R214

R216

OUT_T

100U/16V

2K4

R227

5K6

0.1U MYLAR

C291

BOUT_R

ROUT

LOUD_R

0.1U MYLAR

C275

VDD

OUT1

C2

2K4

2K4

0.1U MYLAR

0.1U MYLAR

C292

C293

BIN_R

BOUT_L

RIN4

RIN3

8

OUT2

MUTE

1

0 = MUTE

0.1U MYLAR

C294

1011121314

R203

5K6

C278

C286

R202

C285

5K6

1000P

100RR200

100R

28272625242322212019181716

CLK

REF

DATA

VDD

AGND

TREB_L

123456789

2700P MYLAR

C273

C272

47U/16V

R210

R212

R217

R218

R228

5K6

C295

2U2/16V

LIN

LOUT

BIN_L

RIN2

RIN1

LOUD_L

0.1U MYLAR

C277

R231 R230

560R

R232

47K

657

IN2

BIAS

IN1

GND

342

C260

0.1U

LIN1

LIN4

15

R233

100K

LIN2

LIN3

D206

LL4148

R242

47K

560R

C265

47U/16V

R234

10K

Q219

8050C

C267

47U/16V

C264

C262

Q212

8050C, TO-92

1U

1U

R235

10K

C5

1000P

C6

1000P

Z218

5V6, AXIAL

R236

10K

R241

820R

R239

OPEN

C281 C282

10U/16V 10U/16V

A+12V

R237

OPEN

R240

47K

R238

SUB_L

SUB_R

R244

2K2

R243

10K

R245

2K2

R246

10K

47K

HP_MUTE

PRE_L

PRE_R

HPR

HPL

Headphone amplifier section

2-4

Page 23

Main section 3

AM_HOP

For AM TUNER

4-PINS HEADER, 2.5MM

FROM SMPS BOARD

A+12V

4K7

R3

R424

0R (AM)

C201

1000P (AM)

C202

0R (AM)

C211

1

+25V

2

3

4

T46 T47

+25V

D1

LL4148

R5

10K

R4

Q1

8550C

ZD1

11V ZENER

R421

C203

OPEN

R423

OPEN

OPEN

R422

OPEN

EC1

10U/16V

SCREW2SCREW1

R425

0R (AM)

0.47U/63V, BOX

UNPLUG_MUTE

R419

1K (AM)

R420

C9

1

2

3

4

5

6

7

OPEN

C207

OPEN

AGND

1A

1Y

2A

2Y

3A

3Y

GND

C210

0.1U

IC214

OPEN

R426

OPEN

220K (AXIAL)

OPEN

+25V

VCC

6A

6Y

5A

5Y

4A

4Y

X201

Q213

2SK3018 (AM)

X202

R286

1M

Z217

OPEN (AXIAL)

C204

14

0R (L5V)

13

12

11

10

9

8

C206

OPEN

Q214

0R (E-C)

C208

0R (AM)

SUB_L

SUB_R

A+12V

R283

560R (L5V)

R284

10K (L5V)

R285

10K (L5V)

OPEN (1206)

R428

3K9

(L5V)

R440

OPEN

AMP_STB

ECO_STBY

UNPLUG_MUTE

AMP_MUTE

2

3

8

6

5

220U/16V (L5V)

C214

100U/16V (L5V)

IC210-B

4

C215

1

IC210-A

AZ4558 (L5V)

AZ4558 (L5V)

7

+12VV

+12VV

R281

2K2 (L5V)

R282

2K2 (L5V)

C216

0.1U (L5V)

VREF

D3

LL4148

D2

LL4148

VREF

C209

OPEN

R429

OPEN

C213

10U/16V (L5V)

OPEN (L5V)

R287

A+12V

R402

22K

R401

22K

R288

2K2 (L5V)

R406

2K2

Z215

3V3, AXIAL

R405

2K2

Z216

3V3, AXIAL

R403

51K

3

2

+12VV

1K (L5V)

R289

8

T98

PRE_L

PRE_R

C222

0.1U

C221

0.1U

Q217

8050C

C220

0.1U

IC211-A

AZ4558 (L5V)

1

R441

OPEN

R290

100K (L5V)

R404

51K

SYNCLK

C237

0.47U

C238

0.47U

R291

100K (L5V)

4700P (L5V)

Q218

8050C

C217

R407

33K

R408

33K

ST+5V

C10

1U

0.01U (L5V)

C223

C219

1U

C225

2U2/16V

C224

1U

1K (L5V)

R6

R410

1M

R409

C226

0.1U

IC211-B

AZ4558 (L5V)

5

6

4

LINE_MUTE

19

VDDPW

PGND

22R

STBY

OUTPA

C229

1500U_35V

T1

R450

10K (L5V)

R413

39K

C241

1000P

1M

R411

C240

0.47U

R412

C239

0.1U

R435

100K

INPA

INNA

VDDS

MUTE

OUTPA

R417

22R

SGND

ROSC

SYNCLK

OUTNA

OUTNA

PVCCA

PVCCA

PGNDA

PGNDA

101112131415161718

C227 C228

0.1U

C296

330P

T3

T2

C218

10U/16V (L5V)

7

R296

47K (L5V)

Q215

8550C (L5V)

R299

47K (L5V)

C242

1000P

1M

SVR

R415

SVR

DIAG

GAIN0

PVCCB

OUTNB

OUTNB

R418

22R

R295

1K (L5V)

Q222

8050C (L5V)

C244

0.1U

C243

0.47U

1M

R414

0R

0R

R416

0.1U

C11

3635343332313029282726252423222120

VSS

INPB

INNB

VREF

SVCC

GAIN1

SUB_GND

OUTPB

OUTPB

PGNDB

PGNDB

PVCCB

123456789

0.1U

C230

330P

T4

0.47U/63V, BOX

L206

22UH CHOKE

L207

22UH CHOKE

0.47U/63V, BOX

L208

22UH CHOKE

FB11

0R (L5V)

Q216

8050C, TO-92 (L5V) + 10U (0805 B-E)

C245

1U

C246

1U

C247

0.1U

IC212

TDA7492

L205

22UH CHOKE

C231

C234

SUB_OUT

L1

FERRITE BEAD, AXIAL

C232

0.22U

C233

0.22U

C235

0.22U

C236

0.22U

Gain

R415

R416

20dB 26dB 30dB 32dB

NC NC

NC NC

0R 0R

L3

30UH COMMON MODE CHOKE

1

3

4

2

1

3

4

2

L2

30UH COMMON MODE CHOKE

0R0R

CN212

2X2 SPEAKER JACK

4

L+

3

L-

6 OHM 35WX2

2

R+

1

R-

T66

T99

T101

T100

T10

T5

T11

T6

T7

T12

T8

T9

SUBWOOFER PRE-OUT (DVD MODELS)

2-5

Page 24

Front section

2

1

CN42

TO SMPS BOARD

TP11

TP12

TP13

CN41

FFC-16P/1.00

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

TO MCU BOARD

TP14

FB404

FB100R

TO USB BOARD

GND_KEY

KEY_1

TP15

TP16

TP17

TP18

TP19

TP20

TP21

100RFB100R 1206

GND

+5V_VFD

IR_RX

GND_KEY

LED_ON

IPOD_LED_ON

KEY_2

KEY_1

VOL+

VOL-

TP32

TP33

OPTION:NOT FOR G355

CP43

3P/2.0MM

1

2

3

TP10

JW13

JW12

CK402

FB401

1000P

FB100R

TP30

VFD1

QV503

CV501

0.1U

CV514

0R

STOP

FR

FF

VOL-

VOL+

(REC)

0.1U

JR04

8550, TO-92

RV518

EC501

EC514

GND

STBLED_ON

KEY_2

0R

RK435

RK434

RK433

RK432

RK431

150R

ZD507

100U/16V

8050C, TO-92

RV514

220U/16V

IR_RX

-25V

3K9

3K3

2K7

470R

RV520

1K

QV504

ZD508

470R

4V7

220R

RV519

+5V_VFD

5V1

LED_ON

F-

FILAMENT

F+

FILAMENT

JW08

CV502

0.1U

NOTE

SW403

SW404

SW405

SW408

JW16

JW15

+5V_LED

JW04

USB

TUNER

AUX

REC

CK411

RK420

2K2

0.1U

CP44

8050C

QK401

RK407

1

2

10K

F-

F+

-25V

+5V_VFD

VFD_STB

VFD_CLK

VFD_DATA

UX-L5VUX-G355

USB

REC

TUNER

AUX

VOL+

RK439

150R

LED9

BLUE

STBLED_ON

RK438

LED8

150R

BLUE

iPod

TUNER

AUX

USB

VOL+

RK437

150R

BLUE

LED7

RK421

2K2

21

ZD502

5V6

0.1U

CV503

EC505

47U/35V

ZD501

27V

UX-LP5

+5V_VFD

CN45

1

2

RK402

QK402

8050C

10K

RK410

RV509

FB502

FB100R

NO USBWITH USB

RV507

RV508

470R

12K

iPod

AUX

TUNER

VOL+

2K2

LED1

RED

F-F-NCP1P2P3P4P5P6P7P8P9P10

3534333231302928272625242322212019

P1P2P3P4P5P6P7P8P9

P[1:16]

BLUE

LED3

RK423

2K2

SS0520

150R

RK404

22

21

20

19

18

17

16

15

14

13

12

JR06

0R

RK424

S/K_10

S/K_9

S/K_8

S/K_7

S/K_6

S/K_5

S/K_4

S/K_3

S/K_2

S/K_1

VDD1

VSS1

RV501

10K

EC504

470R

10U/50V

0.1U

CK401

P9

P8

P7

P6

P5

P4

P3

P2

P1

OPEN

0.1U

CV506

IPOD_LED_ON

CV504

DV501

RK403

BLUE

LED2

150R

FB513

FB100R

FB512

FB100R

+12V_VFD

FB402

FB100R

JW09

TP24

CK403

+12V_VFD

RV502FB511

NOTE

SW405

NOTE

SW404

NOTE

SW403

CD

SW402

STBY

SW401

VFD_DATA

VFD_CLK

VFD_STB

-25V

7K5

RK416

3K9

RK415

3K3

RK414

2K7

RK413

1K8 1K8

RK412

470R

RK411

GND_KEY

KEY_2

1000P

JR02

FB501

FB100R

JW10

JW11

0R

SW413

SW412

SW411

SW409

SW408

JW01

JW02

JR03

JW19

JW17

SW409 NOT FOR G355

SW410 ONLY FOR G355

SW406 SW407 ONLY FOR G355

JVC VFD 35P PH=2.54

P17

P18

P19

P11

P12

P13

P14

P15

18

P10

P11

P12

P13

P14

P15

P16

P10

P11

P12

P13

P14

P15

P16

2324252627282930313233

S/K_11

S/K_12

S/K_13

S/K_14

S/K_15

U501

ET16315

KEY2

KEY1

STB

CLK

DIN

220R

RV504

FB504

FB100R

LED+

GND_KEY

220R

RV505

FB100R

FB505

DOUT

FB100R

ZD505

ZD504

987654321

11

10

220R

RV503

10K

FB503

FOR iPod

QK403

8050C

P20NC1G2G3G4G5G6G7G8GNCF+F+

P16

1716151413

G1G2G3G4G5G6G7G8G9

G1G2G3

VEE

S/K_16

S17/G12

S18G11

LED2

OSC

LED4

LED3

RV506

20K

220P

CV527

220P

CV526

220P

CV525

ZD503

5V1

5V1

5V1

5V1

ZD506

IR_RX

+5V_VFD

GND_KEY

121110

S19/G10

S20/G9

S21/G8

S22/G7

S23/G6

S24/G5

VDD2

VSS2

LED1

QK405

8550

G4

G3

G1

G1

JW03

FB403

FB100R

98765

34

35

36

37

34

39

40

41

42

43

44

JW20

DK401

GND_KEY

G10

G11

G[1:12]

EC503

10U/50V

G4

G5

G6

G7

G8

G9

G10

G11

G12

EC502

100U/16V

STBLED_ON

JW07

JW18

RK401

220R

ZD405

SM4001

10K

RK417

G12

3.9V

RK425

2K2

432

0.1U

CV505

DV502

JW

RK422

OPEN

QK404

8050C

1

CV507

OPEN

JW14

IR401

ARM-3837BW

VCC

0.1U

100U/16V

EC412

CK404

+5V_LED

JW06

JW05

GND

RK418

123

RK419

10K

STBLED_ON

JR01

0R

ROUT

DIM_OFF

2K2

2-6

Page 25

Front jack section

AUDIO_IN

TP2

TP1

5

4

2

3

6

7

1

TC38-103

JK42

CH06

ESD

TP3

CH05

ESD

LH03

10uH

LH04

10uH

SW416

SW415

ECO

EJECT

OPTION:NOT FOR G355

CN43

CON3P/2.0

1

2

3

TO DIASPLAY BOARD

USB

JK43

USB-4P

HEADPHONE

JK41

TC38-103

VCC

D-

D+

GND

6

1

2

3

4

5

5

4

2

3

1

CK406

TP25

TP4

NC

TP22

TP31

CH08

FB42

0R

GND_USB

TP6

ZD43

ZD44

TP23TP5

ESD

ESD

CH07

TP7

5V15V1

LH01

0R

LH02

0R

CH04

1000P

ZD41

5V1

5V1

ZD42

TP8

CH03

1000P

TP9

CH10

PTC01

JK60-075F

NC

CH09

FB45

NC

NC

CK405

FB46

0.1U

NC

510R

RH01

FB43

FB44

510R

RH02

0R

0R

CP45

2P/2.5MM

1

2

CP42

3P/2.0MM

1

2

3

CP41

7P/2.0MM

1

LINE_LIN

2

LINE_GND

3

LINE_RIN

4

HP_DET

5

HP_LOUT

6

HP_GND

7

HP_ROUT

+5V_USB

GND_ESD

USB_DM

USB_DP

GND_USB

TO SMPS BOARD

TO MPEG BOARD

TO MCU BOARD

CK407

NC

FB41

0R

GND_USB

CH02

100P

CH01

100P

2-7

Page 26

ipod section

+5V

+12V

RA26

RA27

OPEN

560R

APPLE 30-PINS CONNECTOR

iPod Dock

RA25

RA19

CN51

56K

56K

AGND

5

6

C2

47U/16V

TP26

TP27

IC402-B

LM324

RA32

7

373533

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

363432

OPEN

31

CA13

2U2

TP21

TP20

TP19

TP18

TP12

TP9

TP7

TP5

TP3

TP17

TP16

TP15

TP1

CA3

2U2

CA4

CA11

RA10

549K

2U2

2U2

1%

RA33

49K9 1%

49K9 1%

RA36

RA31

49K9 1%

RA30

49K9 1%

RA34

49K9 1%

RA24

0R

RA13

RA17

RA20

10K

1%

75K

1%

49.9K

13

12

RA29

10

RA23

OPEN

RA22

RA21

1%

49K9

9

1%

75K

1%

49.9K

CA09

11

GND

4

VCC

LM324

IC402-D

IC402-C

LM324

49K9

RA38

0.1U

49K9 1%

RA37

14

8

1%

R2

R1

CA10

0R

OPEN

47U/16V

OPEN

CA5

0R

C3

RA08

0R

RA09

0R

RA14

RA281K0R

RA11

RA12

OPENOPEN

RA15

OPEN

RA07

OPEN

+12V

CA08

OPEN

TP28

TP29

16-PINS FFC HEADER, 1.25MM

IPOD_OFF

VGND

+5V

UR_FROM_IPOD

UR_TO_IPOD

IPOD_DET

SLEEP_DET

IPOD_CVBS

IPOD_R

IPOD_L

AGND

VGND

RA18

OPEN (1812P075TF)

RA16

0R

RA03

4K7

CN52

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

RA04

4K7

CD

QA01

AP2305

S

RA01

10K

10K

RA06

QA03

8050C

DVD

G

RA05

1K

NOTE:

13PIN TO MCU BOARD

16PIN TO DVD BOARD

D

RA02

10K

+5V_IPOD

QA02

8050C

2-8

Page 27

CD section

TRAY_IN

1

2

MGND

TRAY_OUT

3

4

MOTOR-

5

MOTOR+

CN103

5-PINS HEADER, 2.0MM

TP37

TP38

CN104

6-PINS HEADER, 2.0MM

TP41

1

2

3

4

5

6

OPEN_SW

CLOSE_SW

SP+

SP-

SLED+

SLED-

HOME

TP36

MGND

R161

R169

C103

0.1U

R116

OPEN

C122

10U/16V

TP6

2R2, 0.5W

(AXIAL)

D101

IN4001, AXIAL

LM1117-ADJ

MGND

C124

100U/16V

0.1U

C123

TP16

12S_IN

OR

(close to CN107)

MGND

R164

C101

0.1U

IC102

R103

51R,1%

OPEN

MD0

MD1

MD2

MD3

MD4

MD5

MD6

MD7

R117

R170

OR

MGND

R101

OR

2

Out

In

ADJ

1

120R,1%

F118

OR

600R/100MHZ

R113

OPEN

CHGND

RFGND

LM1117-3V3

2

ADJ

3

R104

F107

1

2

3

4

RN101

33RX4

RN102

1

2

3

4

33RX4

IC101

3

Out

In

1

VVCC1V8

C104

220U/16V

(Close to CN107)

100U/16V,SHORT

8

7

6

5

8

7

6

5

R102

OPEN

C186

0.1U

C118

C105

0.1U

MGND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

VCC3

C100

0.1U

C102

220U/16V

CHGND

C119

0.1U

SDRAM 16M-BITS

VCC

DQ0

DQ1

VSSQ

DQ2

DQ3

VCCQ

DQ4

DQ5

VSSQ

DQ6

DQ7

VCCQ

DQML

WE

CAS

RAS

CS

BA/A11

A10

A0

A1

A2

A3

VCC

+5V

R2

(LP5)

82R

MGND

(LP5)

3V3

3-WAYS SHIELD CABLE,2.0MM

TP64

CD_L

CD_R

CD_R

AGND

CD_L

C120

0.1U

IC103

DQ15

DQ14

VSSQ

DQ13

DQ12

VCCQ

DQ10

VSSQ

VCCQ

DQMH

Z13

1

TP62

C121

0.1U

VSS

DQ11

DQ9

DQ8

NC

CLK

CKE

NC

A9

A8

A7

A6

A5

A4

VSS

Q105

2

R167

47K

TV_AVDD

M_CLK

C111

R165

47K

MGND

VCC3

TV_AVSS

VDD_33

TP16

100U/16V

1

R168

680R

3

Q104

1

8050C

2

R122

1K

TP15

TV_DAC0

TV_AVDD

GPIO35/I2S_LRCK

GPIO29/SPDIF_IN

GPIO28/SPDIF_OUT

M_A9

M_A11/GPIO25

0.1U

C112

3

AP2301GN

3-PINS HEADER, 2.0MM, 90 DEGREE (USB)

TP58

R171

22R (USB)

R135

15K (USB)

C130

C131

OPEN

0.1U

VGND

1U

C129

65

ADAC_AVSS

64

ADAC_AVDD

63

V_FSADJ

AOUT_FL

AOUT_FR

V_COMOP

62

VREF

61

GPIO38

60

GPIO37/I2S_XCK

59

GPIO36/I2S_BCK

58

57

GPIO34/I2S_D0

56

GPIO33/I2S_D1

55

GPIO32/I2S_D2

54

GPIO31/I2S_DIN

53

GPIO30

52

51

50

M_A3

49

M_A2

48

M_A1

47

M_A0

46

M_A10

45

M_BA1/GPIO27

44

M_BA0

43

M_RAS

42

M_CAS

41

M_WE

40

M_DQM0

M_A4

39

M_A5

M_A6

M_A7

M_A8

3837363534333231302928272625242322212019181716151413121110

CN114

5

2

3

1

4

+5VV

TP59

TP60

TP61

R10

R11

OR

OPEN

CHGND

R172

22R (USB)

R153

15K (USB)

R100

F119

OPEN

C132

0.1U

MS

R111

47K

OR

VCC3

R114

OR

R115

OR

TP1

TP5

MAIN_CLK

BCLK

L/R_CLK

TP14

TP15

R112

10K

TP23

TP3

PLL_VSS

M_D15

MD15

DQ2

DQ0

100P

MD14

4

3

2

1

USB_AVSS

M_D14

L102

1UH

USB_DM

M_D13

MD13

CD_ON

C137

0.1U

USB_DP

M_D12

MD12

N7

N6

N5

USB_AVDD

M_D11

MD11

+5V

C136

0.1U

C134

100U/16V

C135

1000P

L101

1UH

VDD_18

M_D10

MD10

VCC1.8V

TP12

TV_AVSS

M_D9

MD9

R166

10K

C133

0.1U

TP13

TV_DAC3

M_D8

MD8

F120

600R/100MHZ

0.1U

C187

TP14

TV_DAC1

TV_DAC2

M_DQM1

VSS

MDVRLD

MGND

MGND

T-

T+

F+

F-

123456789

VCC3

TP47

R118

OR

C160

0.1U

C161

100U/16V

TP44

R120

4K7

D103

LL4148

TP42

TP43

+5VV

C159

0.1U

RFGND

TR-_CD

TR+_CD

TP46

C162

0.1U

MGND

TP45

IC104

AM5888

28

27

26

25

24

23

22

21

20

19

18

17

16

15

30

MGND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

29

MGND

R145

TP48

C163

47U/16V

LL4148

OR

TP49

VCC3

F124

600R/100MHZ

C155

0.01U

C164

0.1U

D104

B

F

10

TP51

TP50

F125

600R/100MHZ

RFGND

C156

0.01U

RFGND

RFGND

C167

0.1U

R119

VCC3

C165

1500P

4K7

C174

0.1U

11

TP52

MGND

C157

0.01U

M+5V

TP39

R157

TP40

R3

4R7,0.5W(AXIAL)

N2

N3

TP82

TP83

F110

OR

5

6

7

8

EN25T40,SOP

R162

OPEN

DQ1

SCK

DQ3

VDD

IC105

+5VV

C127

470U/16V

MGND

GND

DQ2

DQ0

CE_B

LOAD-

LOAD+

F127

(close to CN103)

0R

F128

0R

(close to CN103)

N1

R163

10K

C171

0.1U

N7

4

3

2

1

F104

OPEN

C172

10U/16V

R154

N6

N5

F102

600R/100MHZ

VCC3

0R

R155

10U/16V

R105

10K

C170

C169

0.1U

0.1U

MGND

OR

R160

OR

R156

10K

N4

C168

470U/16V

R159

R158

1R

OR

TP35

OR

TP34

TP33

TP32

TP19

D

12

TP53

C152

0.1U

2SB1132R

1000P

OPEN

R151

0R

R183

2K2

R181

R180

C196

0.1U

C106

VC(ref)

C

E

CN102

16-PINS FFC HEADER, 1.0MM, 90 DEGREE

16

131415

C149

0.1U

TP56

TP55

TP54

C151

47U/16V

5R1

R144

2

1

Q102

3

R143

OR

C158

100U/16V

C166

R148

39K

R147

10K

R149

2K2

R150

2K2

TP21

TP22

I2C_DA

RFGND

I2C_CLK

TP20

TP81

5K6

R4

R5

R6

5K6

R1

C1

VCC3

0.01U

OPEN

R152

C3

0.01U

R182

2K2

2K2

2K2

R107

22R

R106

100R

3

1

D102

2

LL4148

TP7

RFGND

C147

1U

C148

RFIS

RFSUM

VDD_18

M_DQ2/HSYNC

100R

100R

R7

R8

0.1U

UR_TO_CD

C193

0.1U

C194

0.1U

C140

TP26

C146

0.1U

0.1U

AGCCAP

AD_AVSS

AD_AVDD

M_D1

M_D0

M_DQ3/HSYNC

MDO

MD1

MD2

UR_FROM_CD

51P

RF3.3V

R142

TRAY-

HOME/GPIO39

M_D3

M_D2

MD3

C139

51P

R123

4K7

X101

27MHZ

PLLVCC1.8

4K7

CLKIN

VDD_18

CLKOUT

IC106

SPHE8104TW-128

M_D6

M_D5

M_D4

MD4

MD5

MD6

N2

N1

N3

N4

OPEN (EN25T40, DIP)

5

6

7

8

PLLVCC3

TP31

PLL_VDD

M_D7

MD7

DQ1

SCK

DQ3

VDD

CE_B

IC107

C138

GND

TP4

TP57

C195

C150

47U/16V

AGND

C192

0.1U

0.1U

MGND

RFGND

RF3.3V

RFGND

APC_AVSS

102

101

10099989796959493929190898887868584838281807978777675747372717069686766

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

1K

124

125

1K

126

127

128

R199

4K7

600R/100MHZ

CDLDO

CDMDI

SRV_AVDD

V21

V165

DA_AVSS

DA_TEO

DA_FEO

DA_AVDD

SPDC_OUT

SC_OUT

TRAY+

DMEA/GPIO3

GPIO4/SD_D1

GPIO5/SD_D0

GPIO6/SD_CLK

VSS

GPIO7/SD_CMD

GPIO8/SD_D3

GPIO9/SD_D2

TRAYIN

SPI_D0

SPI_CE

SPI_CLK

SPI_D1

TRAYOUT

GPIO16

TP8

CDF

CDB

CDA

OPVIN

GPIO17

TP10TP9

OPVIP

GPIO18

CDE

VDD_33

C173

0.1U

RESET_B

R9

0R

VSS

TP25

CDC

GPIO20

IR/GPIO19

TP2

CDD

GPIO21

987654321

TP11

VCC1.8V

F105

C109

100U/16V

C110

VVCC1V8

F103

600R/100MHZ

R108

47R

R109

100R

Q101

8050C

C107

C108

1U

0.1U

VCC

A

GND

2

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

CN106

3

AGND

TP63

C189

2

1

0.1U

(LP5)

0

2

9

1

AUTHENTICATION IC

8

1

7

1

6

1

15

141312

(LP5)

10K

R174

R173

(LP5)

10K

(LP5)

10K

R146

C2

R129

(LP5)

0.1U

220R

(LP5)

4

5

6

7

SEL_L

SEL_R

TP66

TP65

TP27

TP28

TP29

TP84

TP85

TP30

8

7

6

5

RN103

33RX4

8

7

6

5

RN104

33RX4

1

2

3

4

1

2

3

4

MAIN_CLK

L/R_CLK

600R/100MHZ

MD15

MD14

MD13

MD12

MD11

MD10

MD9

MD8

BCLK

12S_IN

F106

TP80

R110

33R

C113

10P

MD[0:30]

3

IC109

APPLE

(LP5)

(LP5)

220R

R124

NREST

VCC3

VCC3

SDA

OPEN

4

C145

5

11

R131

220R

SCK

F114

OPEN

TR+

TR-

0.1U

C114

C115

C190

100U/16V, SHORT(LP5)

6

7

8

9

10

MGND

(LP5)

OPEN_SW

CLOSE_SW

C142

OPEN

C188

OPEN

OPEN

R126

OPEN

R136

OPEN

R140

OPEN

R141

D110

LL4148

TR+_CD

D111

LL4148

TR-_CD

0.1U

C116

0.1U

0.1U

C117

CN107

20-PINS FFC HEADER, 1.25MM

1

3

7

9

2

5

4

6

F121

+5V

OR

TP17

F123

OR

TP79

TP77

F108

TR+

OR

F109

TR-

OR

F117

OR

F122

OR

F115

OPEN

C144

C143

OPEN

OPEN

1

14

Vref

Vref

VinR

13

2

AGND

AGND

VinL

12

3

Vcc

Vcc

MS

4

11

MC

Vdd

Vdd

10

5

DGND

DGND

MD

6

9

DOUT

SCK1

SCK1

7

8

LRCK

LRCK

BCK

OPEN

IC108

SEL_R

SEL_L

TP76

C175

C154

C185

8

TP75

C184

OPEN

OPEN

TP74

10

TP73

11

121314

TP18

TP68

TP67

+5VV

MS

F111

OPEN

C176

OPEN

OPEN

R134

OPEN

OPEN(REC)

OPEN(REC)

R139

OPEN

TP69

15

R137

R138

161718

TP70

OPEN

TP71

TP72

19

OPEN

C182

20

F113

OR

F112

OR

OPEN

C181

CHGND

NREST

SDA

SCK

CD_ON

UR_FROM_CD

UR_TO_CD

C141

OPEN

C153

OPEN

+5V

F101

C178

1

1

1

Q103

8050C

3

2

C179

0.1U

2

Q108

8550C,TO-92

3

Q107

8050C,TO-92

8050C,TO-92

OR

MGND

8550C,TO-92

C180

0.1U

R127

2R2,0.25W

(AXIAL)

Q109

Q106

47U/16V

2

1

3

R130

2K2

LOADLOAD+

3

1

R132

2

100R

R125

10K

R133

100R

C177

47U/16V

R128

2K2

MGND

3

2

MGND

2-9

Page 28

Printed circuit boards

Smps board ( forward side )

( Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade) )

GND

GND

D13

R21

R12

C20

R20

GND

5VD

JP7

C14

C21

L3

GND

R18

U3

C12

R19

5V

C13

GND

5V

D16D11

R11

U2

L6

5VD

R23

L4

CN1

CN4

C16

D12

C15

12V

GND2

5VE

FL+

ECO

C27

D19

-25V

D10

CN2

CN5

FL+

R10

C25

GND3

C11

JP8

R22

R15

V4

D9

C31

D14

T1

HS1

F2

JP9

C17

R16

Smps board ( reverse side )

( Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade) )

R28

C19

R30

C18

R29

V7

D18

C26

R25

R13

D17

R27

U6

R26

L7

CN3

PVCC PVCC

PGND PGND

PVCC

D15

R17

R35

EC0

FL+

C32

R34

FL-

C30

-25V

AGND

R33

PGND

R14

GND

D5V

12V

DGND

C29

5VE

V5

V3

L5

R31

C24

C22

D8

R24

C28

L2

R4

C9

JP5

R3

C23

D6

JP2

JP1

R7

R8

R5

R6

C8

C7

C10

JP6

D5

C5

SW1

V1

R2

R1

C6