Page 1

SERVICE MANUAL

MICRO COMPONENT MD SYSTEM

UX-A70MD

UX-A70MD

UX-A70MD

DEF

ABCMARK

21 3

GHI JKL MNO

54 6

PQRS TUV WXYZ

87

9

0

10

+10

Contents

Safety precautions

Preventing static electricity

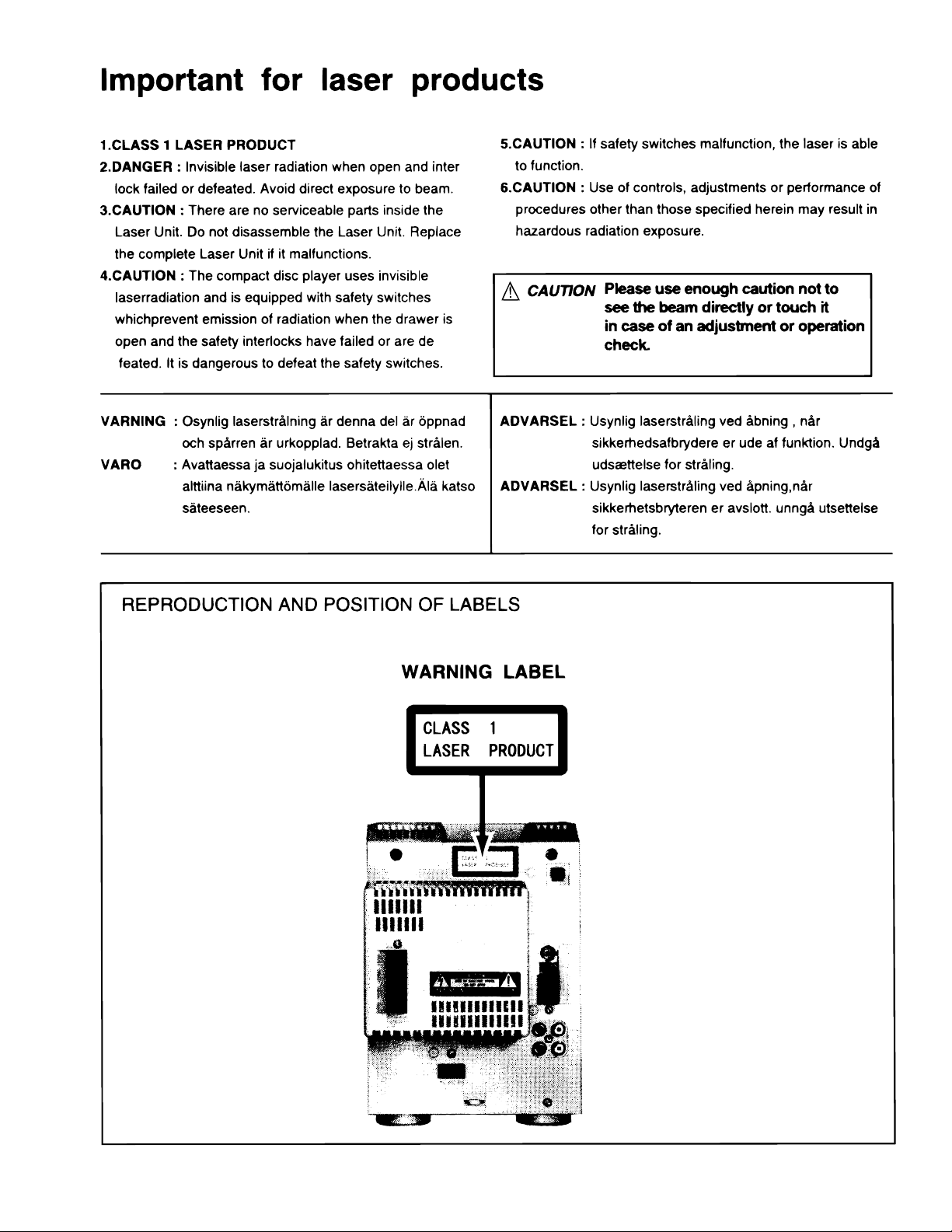

Important for laser products

Disassembly method

Main adjustment

Flow of functional operation

until TOC read (CD)

Flow of functional operation

until TOC read (MD)

1-2

1-3

1-5

1-6

1-28

1-32

1-33

COMPACT

DIGITAL AUDIO

Area Suffix

UB

US

UT

UF

UJ

Maintenance of laser pickup

Replacement of laser pickup

Maintenance of MD pickup

Procedures of changing

the MD pickup

Description of major ICs

Hong Kong

Singapore

Taiwan

China

U.S.Military

1-34

1-34

1-35

1-35

1-36~56

This service manual is printed on 100% recycled paper.

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

No.20901

1-1

Jan. 2001

Page 2

UX-A70MD

Safety Precautions

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original design

unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of

the product should not be made. Any design alterations or additions will void the manufacturer`s

warranty and will further relieve the manufacture of responsibility for personal injury or proper ty

damage resulting therefrom.

3. Many electrical and mechanical par ts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded

by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special safety characteristics are identified in

the Parts List of Service Manual. Electrical components having such features are identified by

shading on the schematics and by ( ) on the Parts List in the Service Manual. The use of a

substitute replacement which does not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of Service Manual may create shock, fire, or other

hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the or iginal lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

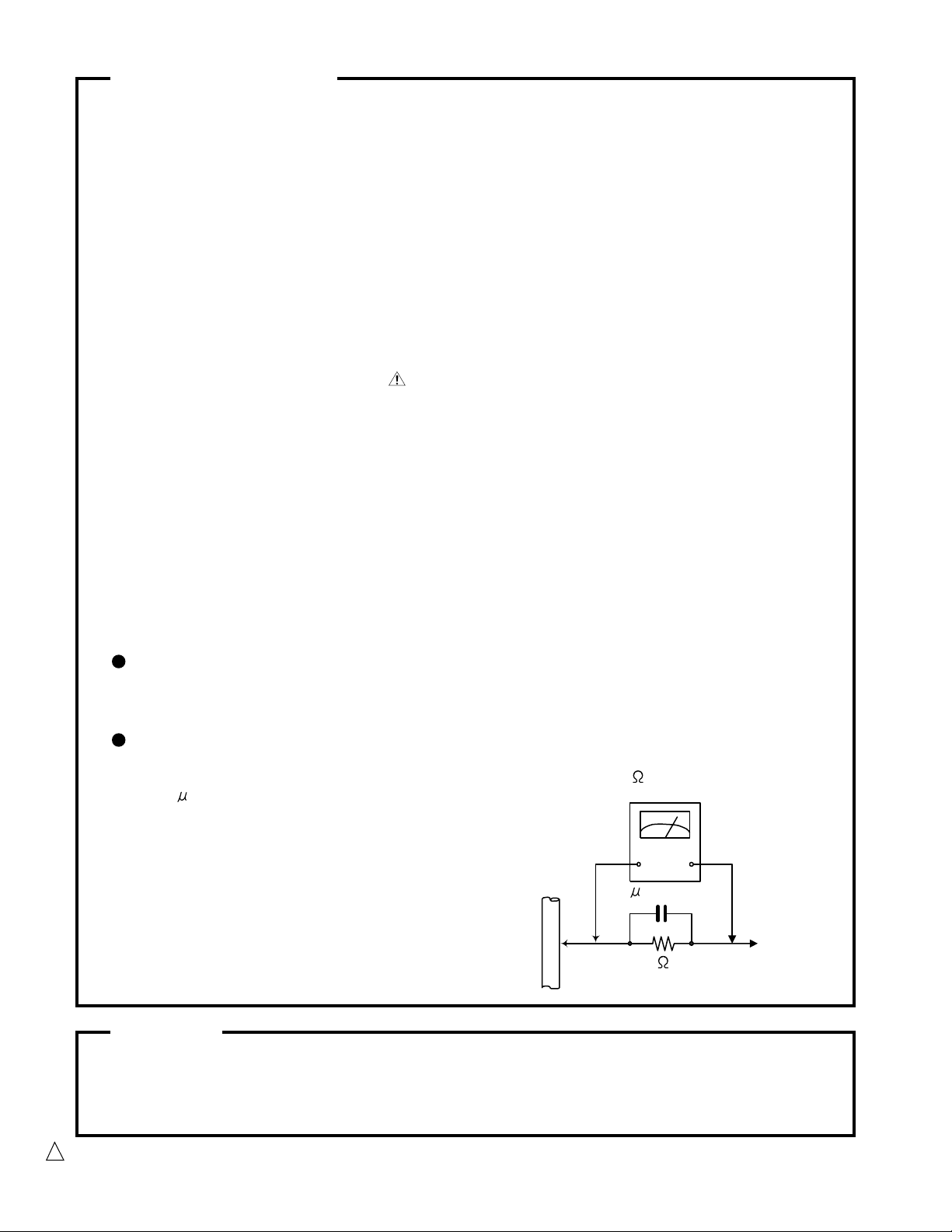

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts

of the product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control

shafts, etc.) to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure

the leakage current from each exposed metal parts of the cabinet , particularly any exposed

metal part having a return path to the chassis, to a known good earth ground. Any leakage

current must not exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms

per volt or more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by

a 0.15 F AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with the

AC voltmeter.

Move the resistor connection to eachexposed metal

part, par ticularly any exposed metal part having a

return path to the chassis, and meausre the AC

voltage across the resistor. Now, reverse the plug in

the AC outlet and repeat each measurement. voltage

measured Any must not exceed 0.75 V AC (r.m.s.).

This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1-2

Warning

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

CAUTION

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Page 3

UX-A70MD

Preventing static electricity

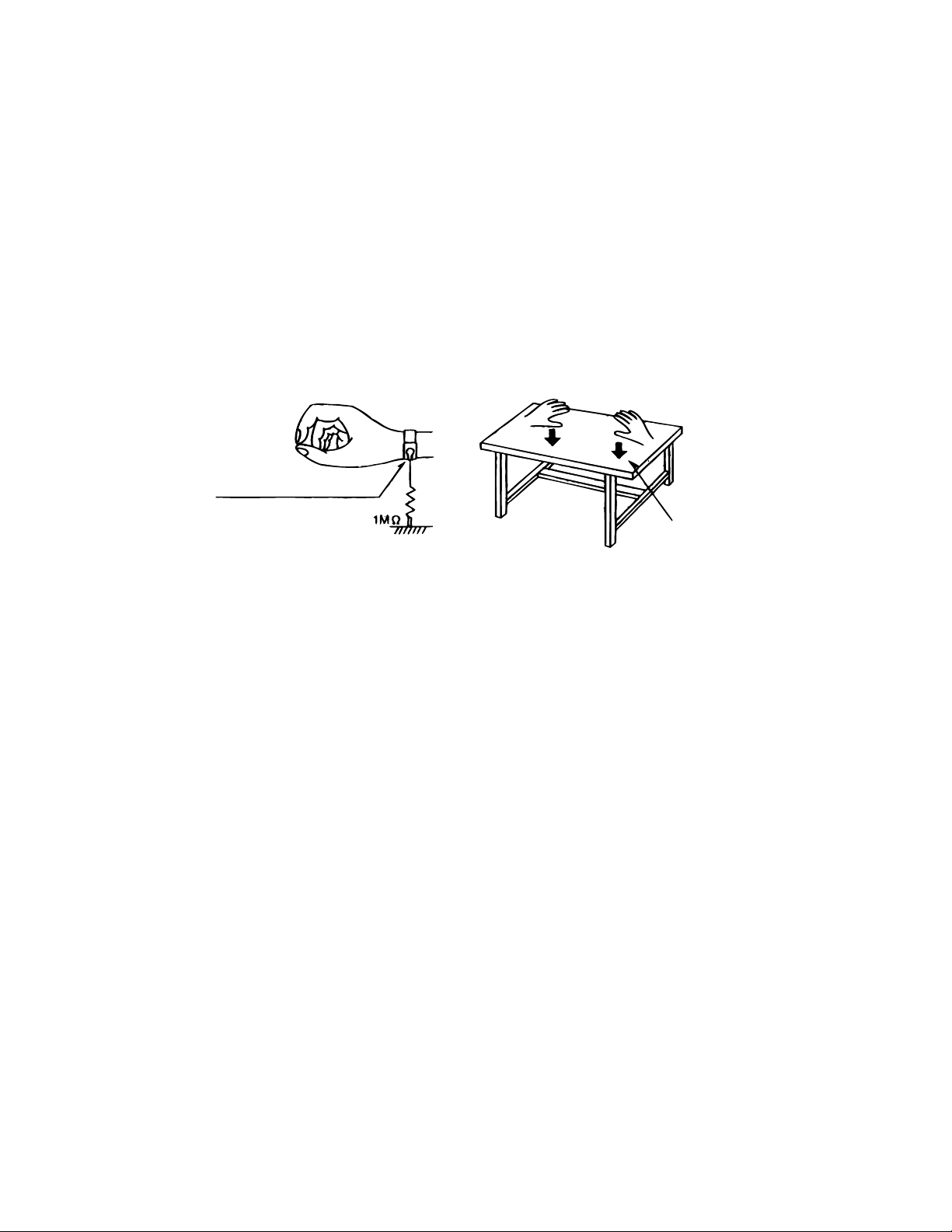

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.1. Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

1.1.1. Ground the workbench

1. Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

1.1.2. Ground yourself

1. Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

1.1.3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

1.2. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

1-3

Page 4

UX-A70MD

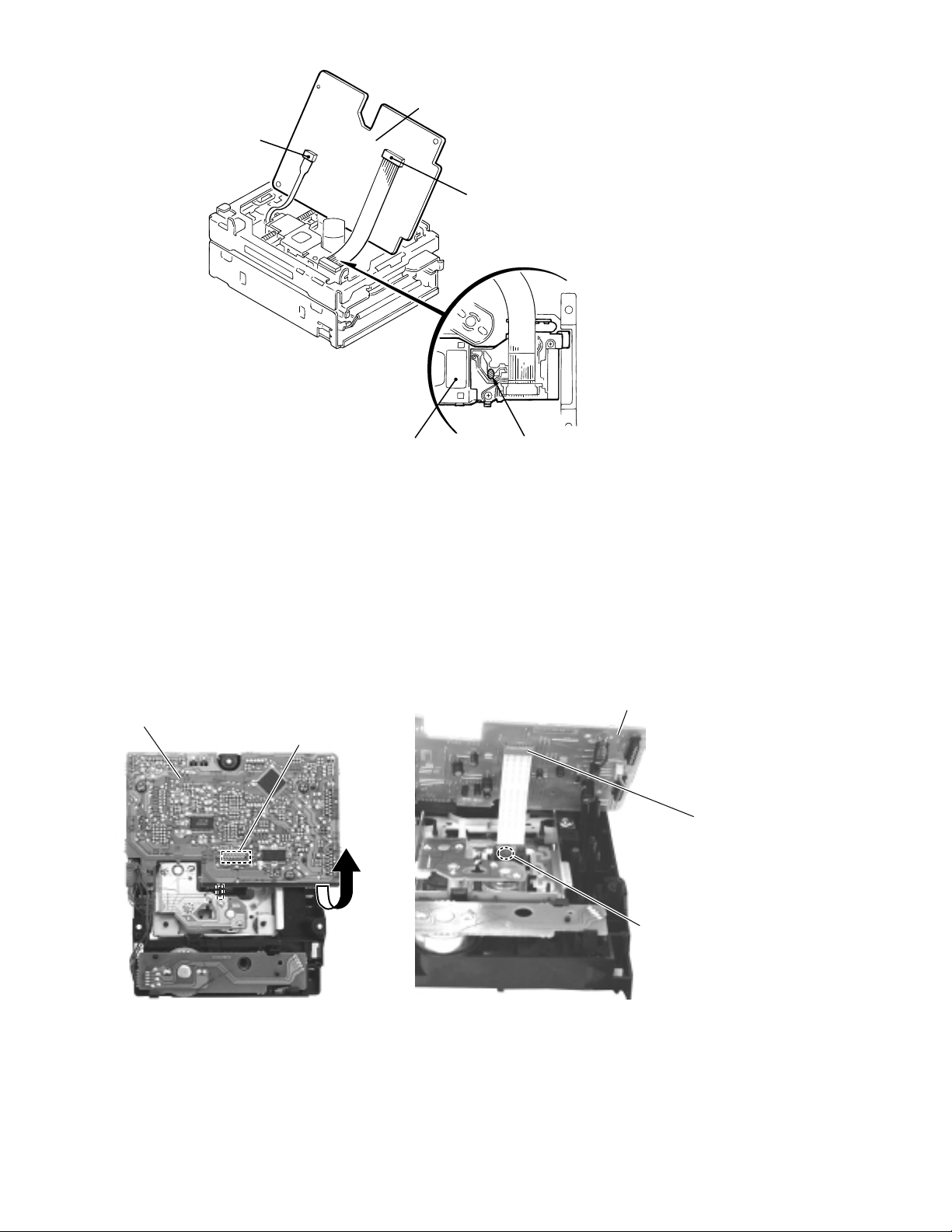

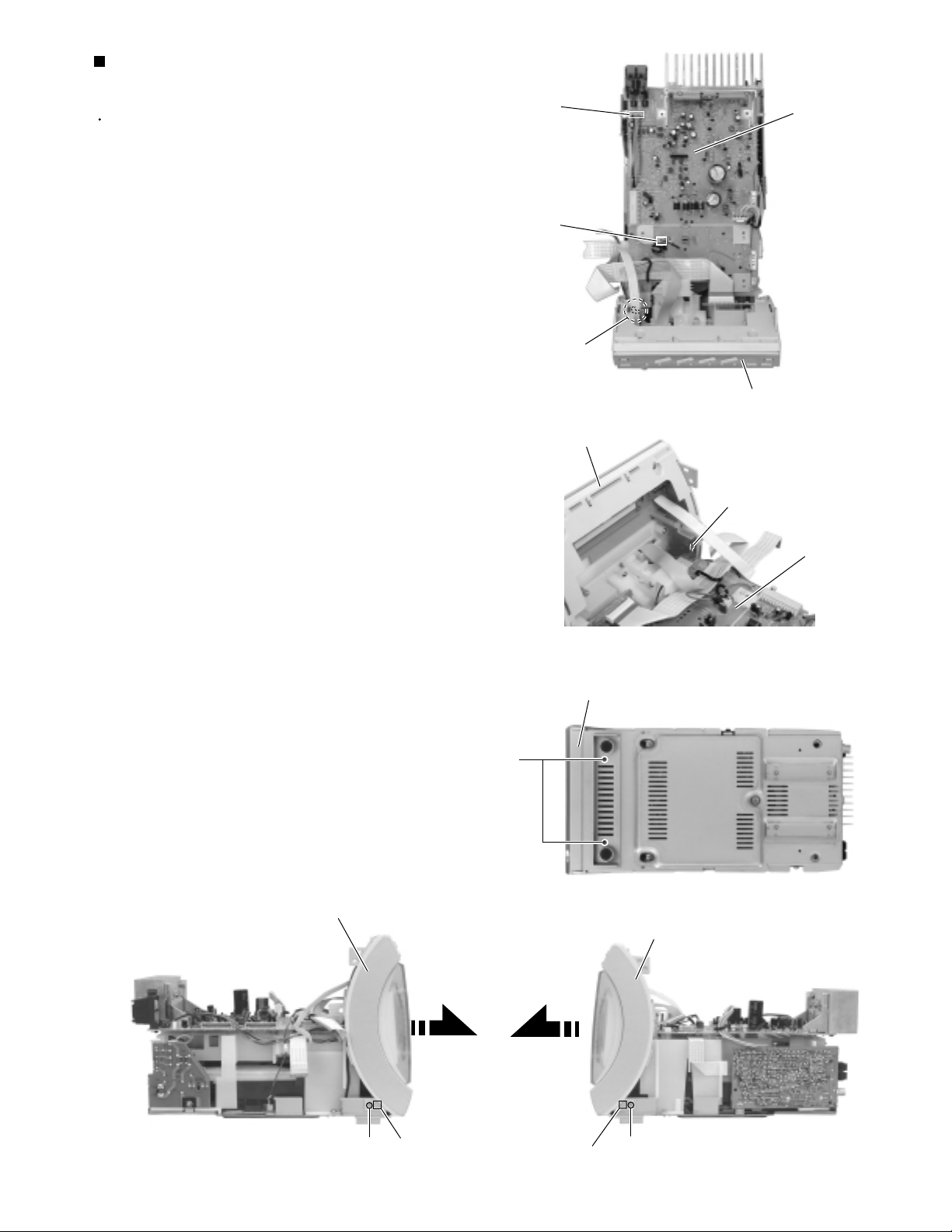

MAIN board

CN451

CN321

CD SERVO board

Pickup

Soldering part b

1.3. Cautions on removing the CD traverse unit

* For removing the CD traverse unit in detail, refer to the "Adjustment Method" section of this manual.

1. Before disconnecting the flexible wire from the connector CN601 on the CD SERVO board, solder the part shown in

the figure below.

(Note:If the flexible wire is disconnected from the CN601 without presoldering, it may cause breakdown of the CD

pickup assembly.)

2. When reassembling the CD traverse unit, be sure to remove the solder from the soldered part after reconnecting the

flexible wire to the CN601.

CD SERVO board

CD SERVO board

CN601

CN601

1-4

Soldering part

Page 5

UX-A70MD

1-5

Page 6

UX-A70MD

Disassembly method

<Main body>

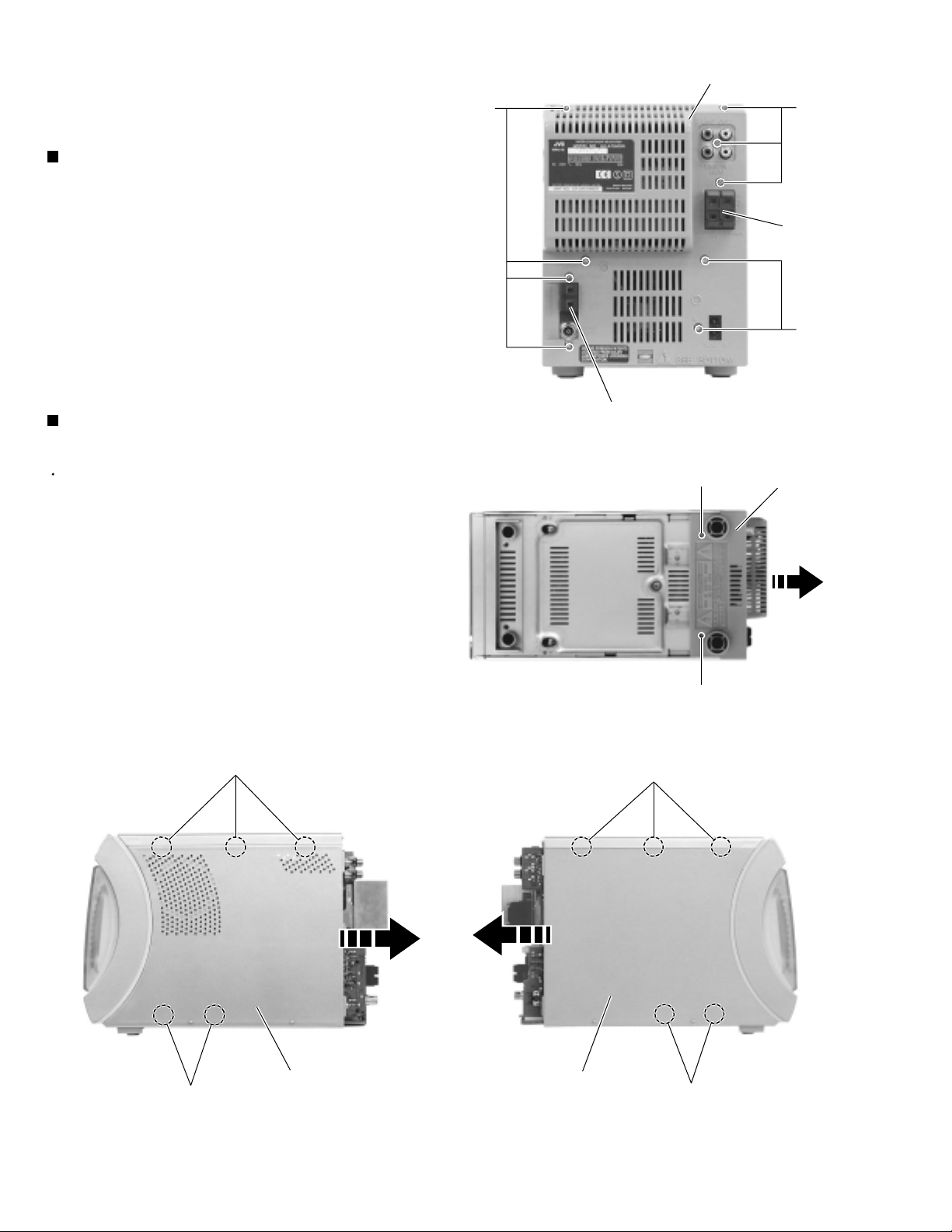

Removing the rear cover

(See Fig.1 and 2)

1.

Remove the nine screws A attaching the rear cover

on the back of the body.

2.

Remove the two screws B attaching the rear cover

on the bottom of the body.

3.

Unlock the speaker terminal and the antenna

terminal, then remove the rear cover backward with

releasing the hooks.

Removing the side panels

(See Fig.3 and 4)

Prior to performing the following procedure, remove

the rear cover.

A

Antenna terminal

Fig.1

Rear cover

B

A

Speaker

terminal

A

Rear cover

1.

Remove each side panel backward while releasing

the joints a.

Joints a

Fig.2

Joints a

B

1-6

Joints a

Side panel (Right)

Fig.4

Side panel (Left)

Joints a

Fig.3

Page 7

UX-A70MD

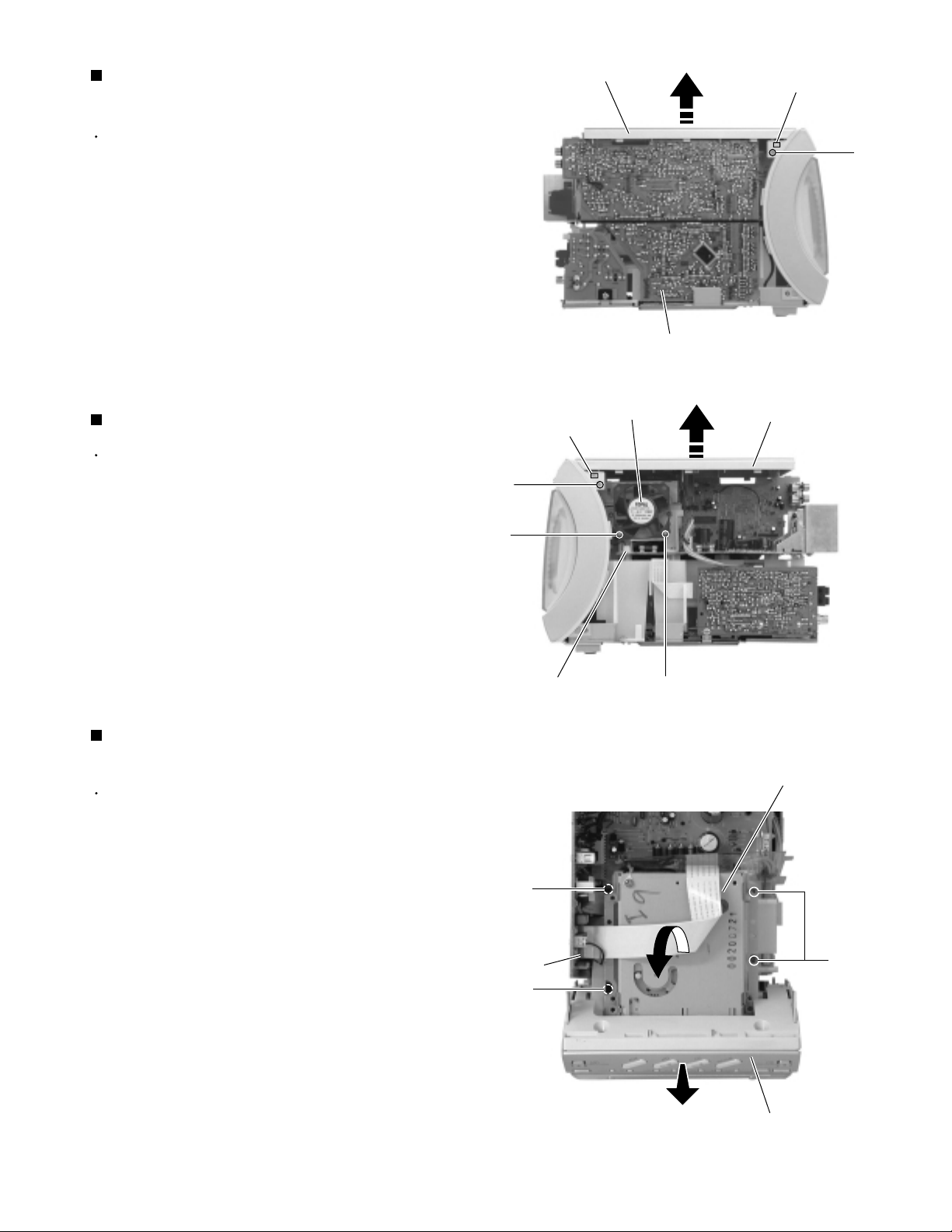

Removing the top cover

(See Fig.5 and 6)

Prior to performing the following procedure, remove

the rear cover and the side panels.

1.

Remove the two screws C on each side of the body.

2.

Release the joint b on each side of the body and

remove the top cover backward and upward.

Removing the fan assembly (See Fig.6)

*Prior to performing the following procedure, remove

the rear cover, the right and left side panels.

1.

Remove the two screws D on the right side of the

body and pull out the fan assembly sideward.

D

C

Joint b

Top cover

Tuner & function board

Fan assembly

Joint b

C

Fig.5

Top cover

2.

Disconnect the wire from connector CN807 on the

main board.

Removing the MD mechanism assembly

unit (See Fig.7)

Prior to performing the following procedure, remove

the rear cover, the side panels, the top cover and the

fan assembly.

1.

Disconnect the card wire from connector CN721 on

the tuner & function board.

2.

Remove the four screws D and the MD mechanism

assembly backward and upward while pulling the

front panel assembly forward.

CN807

D

CN721

D

D

Fig.6

MD mechanism assembly

D

Front panel assembly

Fig.7

1-7

Page 8

UX-A70MD

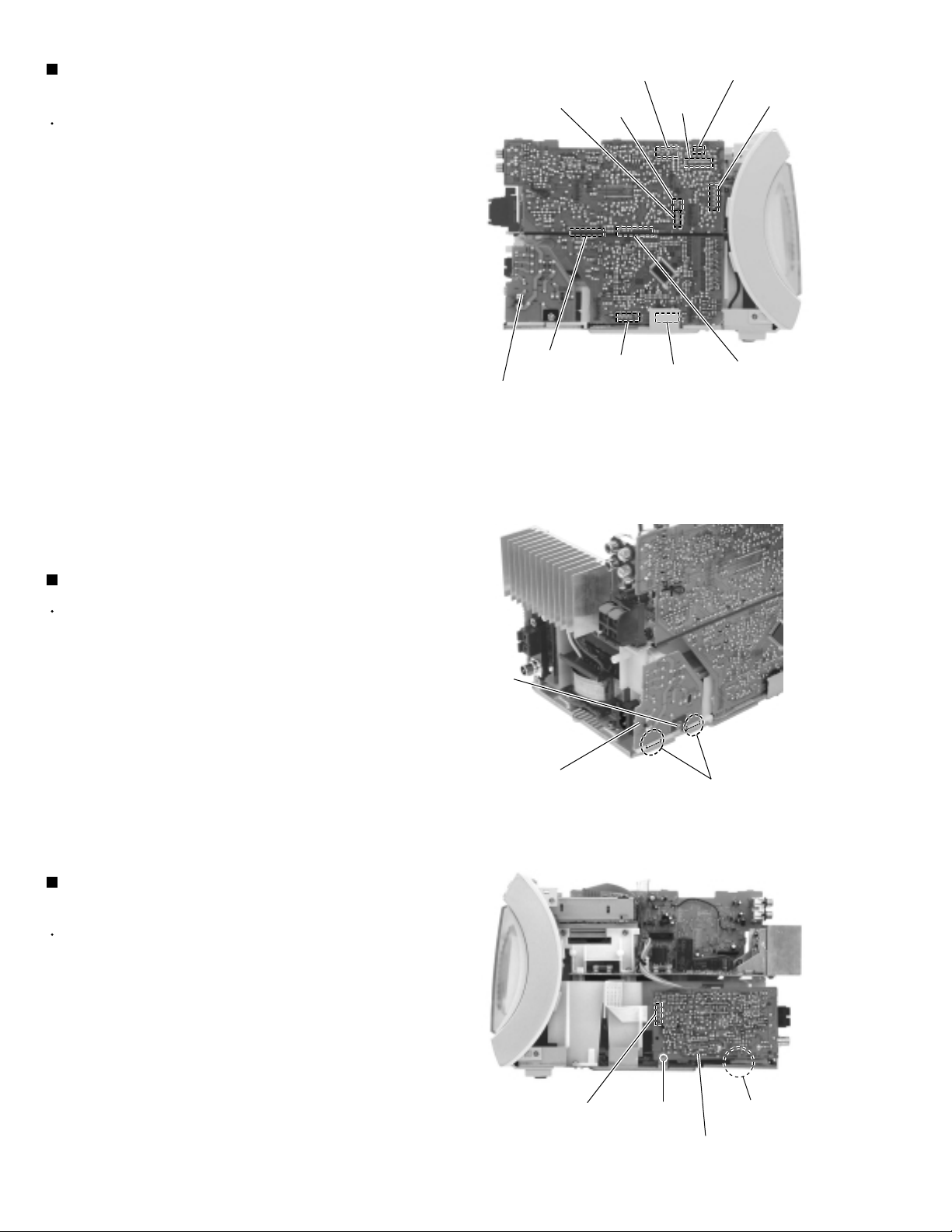

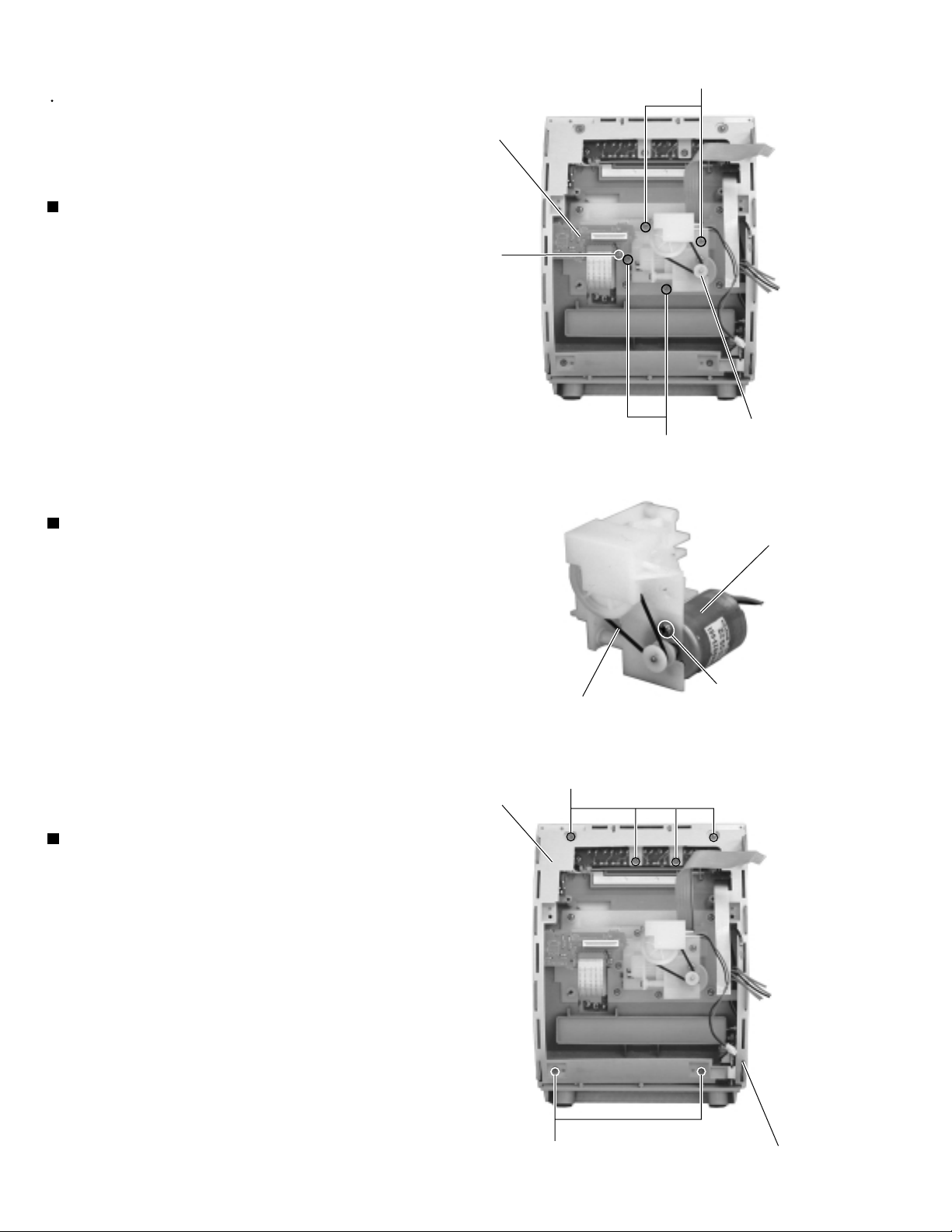

Removing the tuner & function board

(See Fig.8)

Prior to performing the following procedure, remove

the rear cover, the side panels and the top cover.

1.

Disconnect the card wire from connector CN701,

CN705, CN707, CN708 and CN721 on the tuner &

function board on the right side of the body.

Similarly, disconnect the harness from CN706.

CAUTION:

2.

Disconnect connector CN711 and CN712 on the

tuner & function board from CN801 and CN802 on

the main board by pulling them outward.

3.

Disconnect connector CN703 and CN704 on the

tuner & function board from CN603 and CN604 on

the CD servo board by pulling them upward.

For the card wire connected to CN707,

disconnect it after performing the following

procedure 2 and 3.

CN712

AC jack board

CN707

CN701

CN705

CN704

CN703

Fig.8

CN721

CN706

CN708

CN711

Removing the AC jack board (See Fig.9)

Prior to performing the following procedure, remove

the rear cover and the right side panel.

1.

Remove the screw E on the right side of the body

and release the AC jack board from the two joints c.

2.

Disconnect the harness from connector CN805 on

the AC jack board.

Removing the antenna terminal board

(See Fig.10)

Prior to performing the following procedure, remove

the rear cover and the left side panel.

1.

Disconnect the card wire from connector CN1 on the

left side of the body.

E

AC jack board

Fig.9

Joints c

2.

Remove the screw F and release the antenna

terminal board from the joint d upward.

1-8

CN1

F

Antenna terminal board

Fig.10

Joint d

Page 9

Removing the front panel assembly unit

(See Fig.11 to 15)

Prior to performing the following procedure, remove

the rear cover, the side panels, thetop cover, the MD

mechanism assembly and the tuner & function

board.

1.

Disconnect the wire from connector CN804 and

CN806 on the main board. Disconnectthe wire from

W802 pin terminal.

2.

Remove the two screws G on the bottom of the

body.

3.

Remove the lower screw H on each side of the body.

4.

Release the lower joint e on each side of the body.

Pull out the front panel assemblytoward the front.

CN804

CN806

W802

Front panel assembly

UX-A70MD

Main board

Front panel assembly

Fig.11

Front panel assembly

W802

Main board

Fig.12

Front panel assembly

G

Fig.13

Front panel assembly

Fig.15

H

Joint e

Joint e

H

Fig.14

1-9

Page 10

UX-A70MD

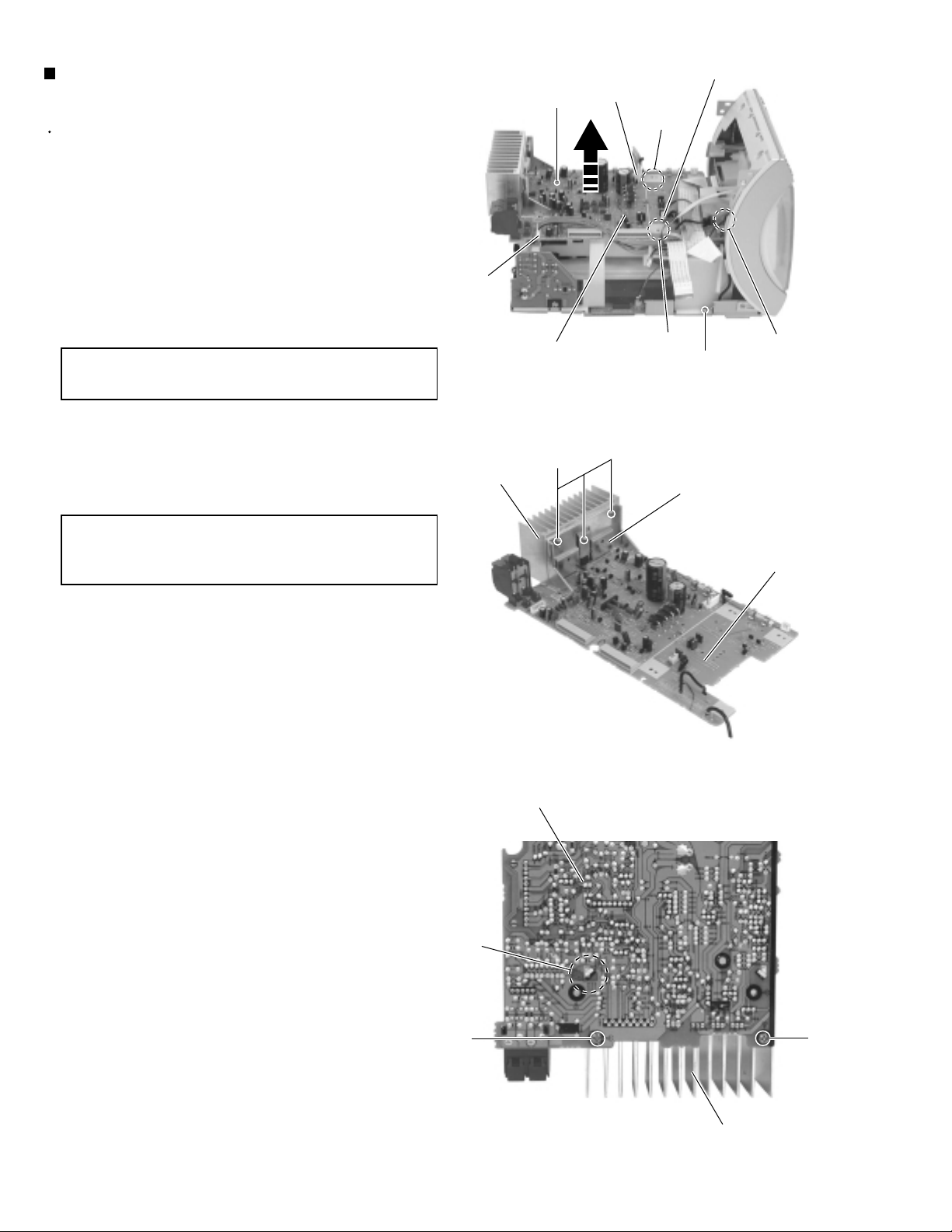

Removing the main board / heat sink

(See Fig.16 to 18)

Prior to performing the following procedure, remove

the rear cover, the side panels, thetop cover, the MD

mechanism assembly and the tuner & function

board.

1.

Disconnect the wire from connector CN803, CN804

and CN806 on the main boardrespectively.

Disconnect the wire from W802 pin terminal.

2.

Remove the screw I attaching the main board and

the screw J attaching the wireterminal.

CAUTION:

3.

Remove the three screws K on the heat sink bracket.

4.

Remove the two screws L on the back of the main

board.

When reasse mbling, fit the slots of the

main board to the two bosses.

CN804

Heat sink

I

Main board

K

CN803

Fig.16

CN806

Bosse

Bosse

J

Heat sink bracket

W802

CAUTION:

When removing the heat sink bracket,

disengage the two joints d on theback of

the main board.

Main board

Fig.17

Main borad

Joint d

1-10

L

Heat sink

Fig.18

L

Page 11

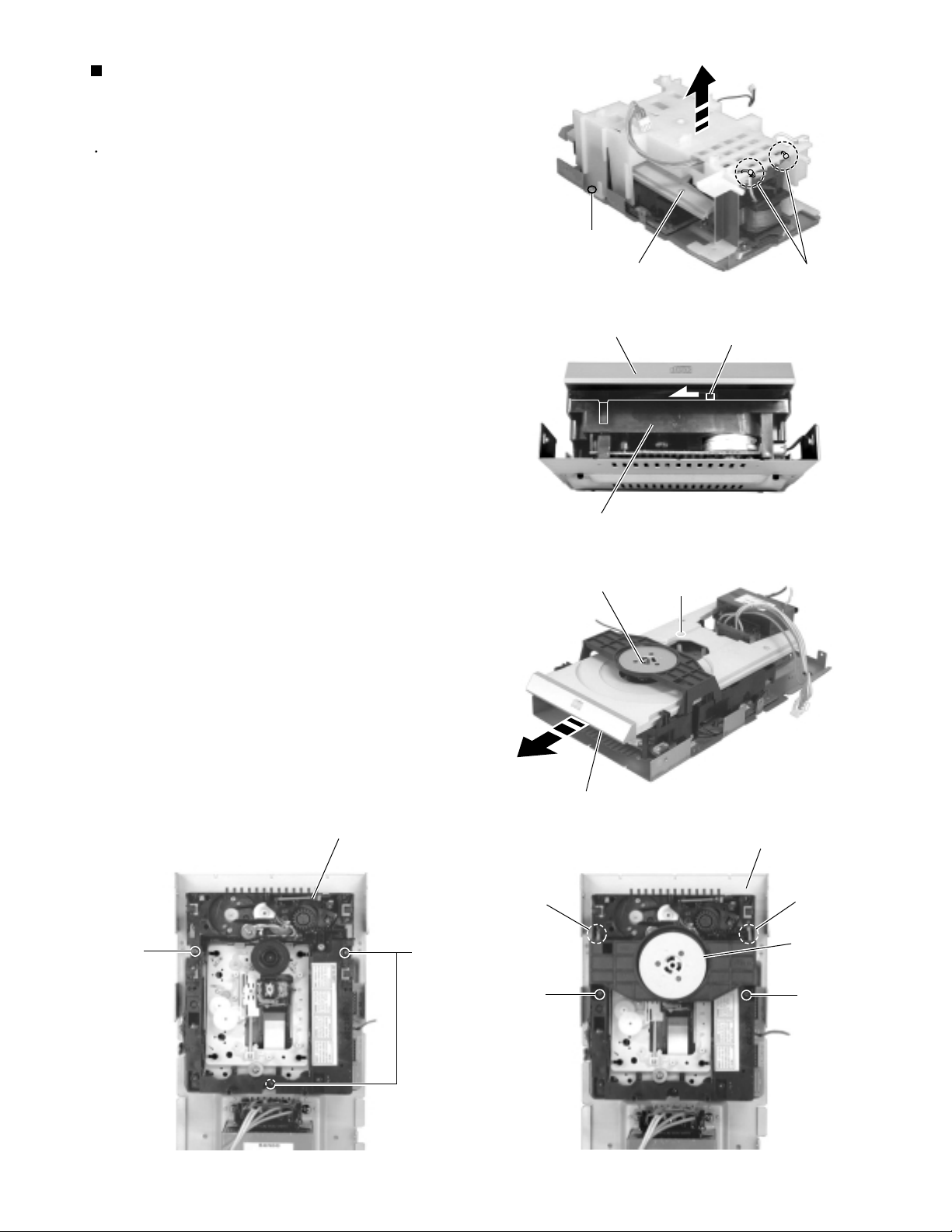

Removing the CD mechanism assembly

and the CD servo board

(See Fig.19 to 24)

Prior to performing the following procedure, remove

the rear cover, the side panels, the top cover, the

MD mechanism assembly, the tuner & function

board, the AC jack board, the antenna terminal

board, the front panel assembly and the main board.

1.

Cut off the two tie band on the back of the CD

mechanism assembly top cover.

2.

Remove the screw M and the top cover.

3.

Move the lever f in the direction of the arrow to draw

the loading tray manually.

4.

Remove the screw N on the CD tray and pull out the

CD tray from the CD mechanism assembly.

5.

Remove the two screws O attaching the clamper

base on top of the CD mechanism assembly.

Release the two joints g with the CD mechanism

assembly and remove the clamper base upward.

6.

Remove the three screws P attaching the CD

mechanism assembly.

M

CD mechanism assembly

Loading tray

CD mechanism assembly

Clamper base

UX-A70MD

Tie band

Fig.19

Lever f

Fig.20

N

7.

Remove the three screws Q attaching the CD servo

board on the back of the CD mechanism assembly.

8.

Disconnect the harness from connector P031 on the

CD mechanism assembly. Disconnect the harness

and the card wire from connector CN602 and CN601

on the CD servo control board respectively.

CD mechanism assembly

P

P

Joint g

O

Loading tray

Fig.21

CD mechanism assembly

Joint g

Clamper base

O

Fig.23

Fig.22

1-11

Page 12

UX-A70MD

CD servo board

Q

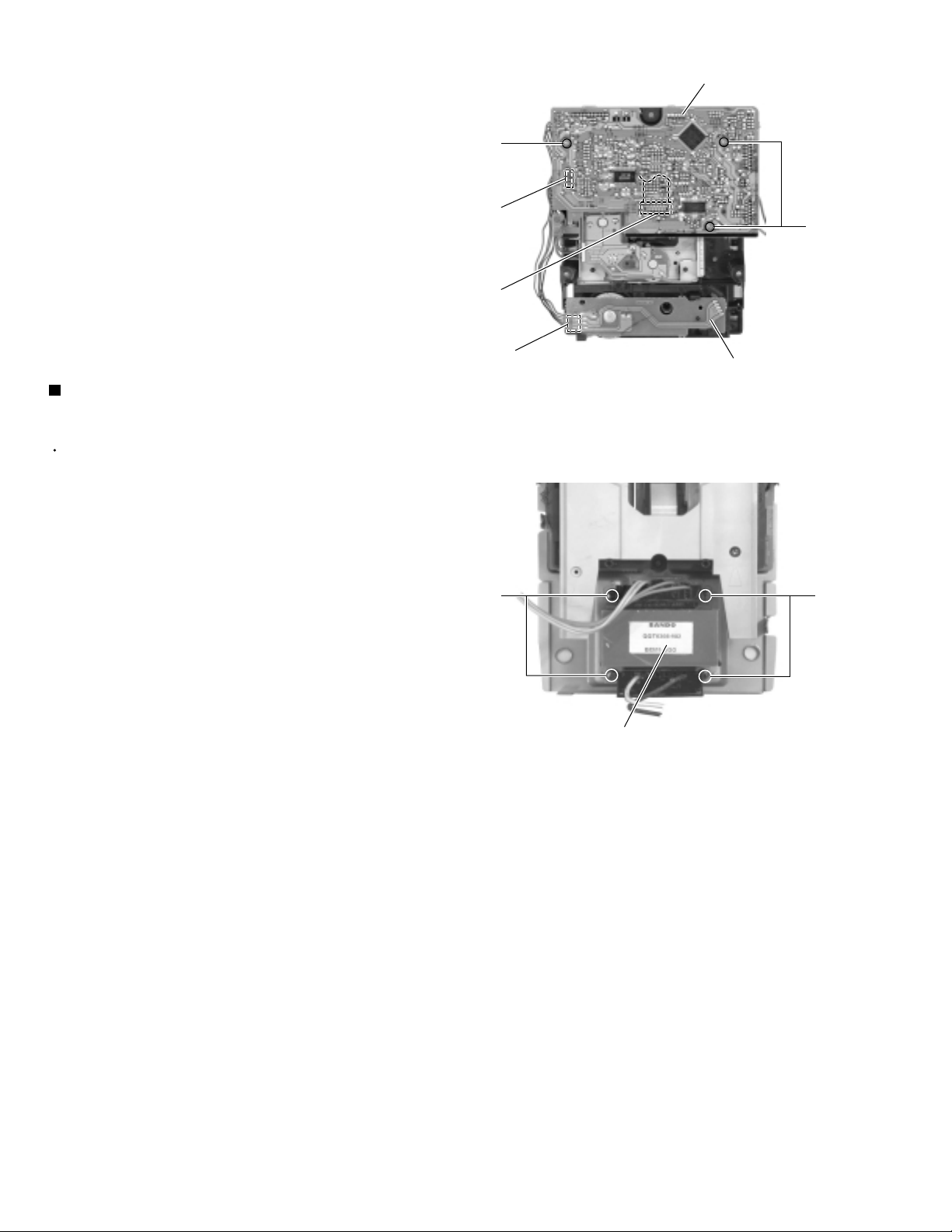

Removing the transformer assembly

(See Fig.19 and 25)

Prior to performing the following procedure, remove

the rear cover, the side panels, the top cover, the

MD mechanism assembly, the tuner & function

board, the AC jack board, the antenna terminal

board, the front panel assembly and the main board.

Cut off the two wire clamp on the back of the CD

1.

mechanism assembly upper cover.

Remove the screw M and the CD mechanism

2.

assembly upper cover.

Remove the four screws R attaching the transformer

3.

assembly.

CN602

CN601

P031

R

Q

CD mechanism board

Fig.24

R

Transformer assembly

Fig.25

1-12

Page 13

UX-A70MD

<MD mechanism assembly unit>

Prior to performing the following procedure, remove

the rear cover, the side panels, the top cover unit

and the MD mechanism assembly unit.

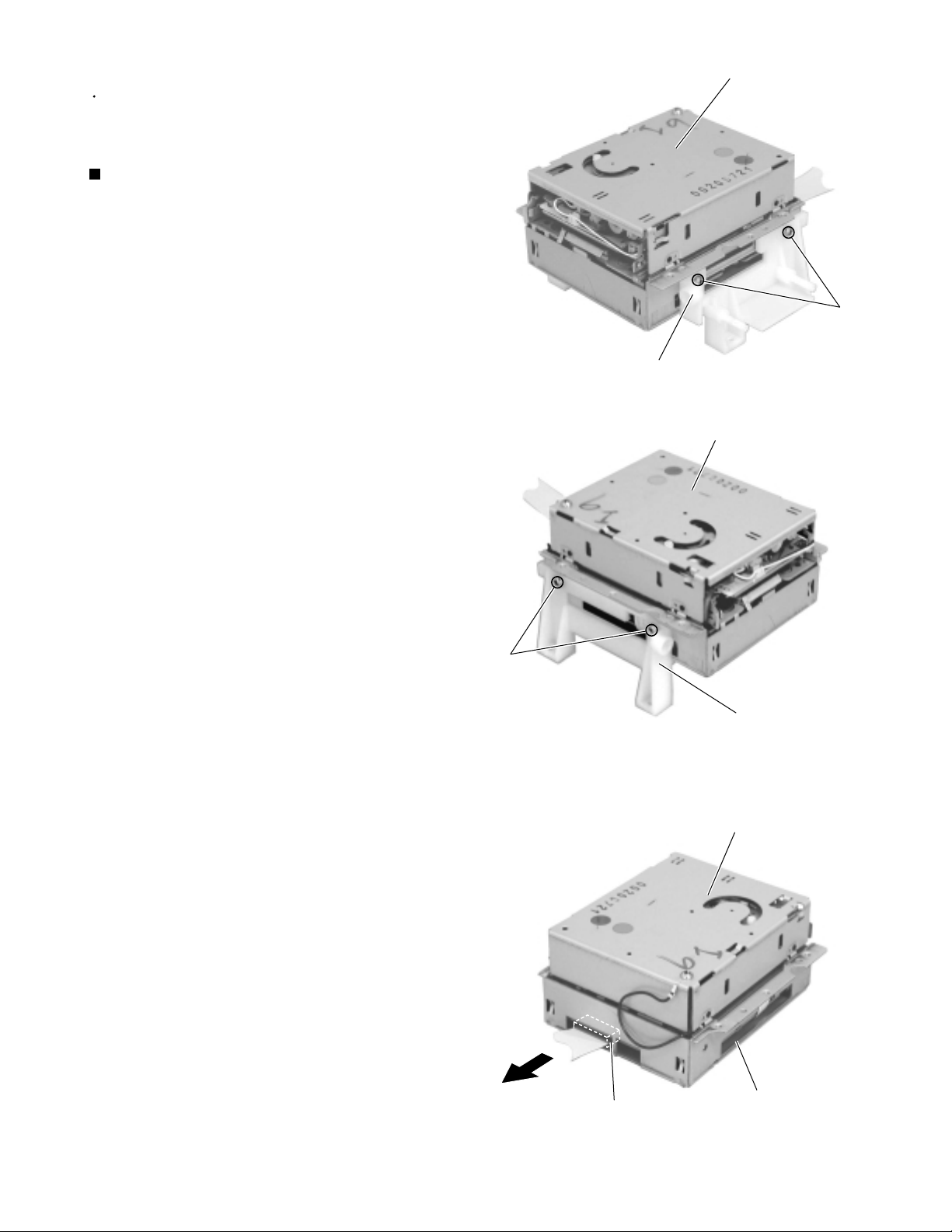

Removing the MD mechanism assembly

(See Fig.26 to 28)

1.

Remove the four screws S attaching the bracket (a)

and (b) on both sides of the MD mechanism

assembly unit.

2.

Disconnect the card wire from connector CN521 on

the MD mechanism board. Remove the MD

mechanism assembly bottom cover downward.

MD mechanism assembly

S

Bracket (a)

Fig.26

MD mechanism assembly

S

CN521

Bracket (b)

Fig.27

MD mechanism assembly

MD mechanism assembly

bottom cover

Fig.28

1-13

Page 14

UX-A70MD

<Front panel assembly unit>

Prior to performing the following procedure,remove

the rear cover,the side panels, the top cover, the MD

mechanism assembly unit,the tuner & function board

and the front panel assembly unit.

Removing the relay board (See Fig.29)

1.

Disconnect the card wire from connector CN908 on

the relay board respectively.

2.

Remove the screw T attaching the relay board.

Removing the drive motor assembly

(See Fig.29 and 30)

U

Relay board

T

Drive motor assembly

U

Fig.29

Drive motor

1.

Remove the four screws U attaching the drive motor

assembly.

2.

Remove the belt and the screw V attaching the drive

motor.

Removing the headphone jack board

(See Fig.31)

1.

Remove the six screws W attaching the bracket (c),

and detach the headphone jack board.

Bracket (c)

Belt

W

V

Fig.30

1-14

W

Headphone jack board

Fig.31

Page 15

UX-A70MD

Removing the key switch board / (d)

board (See Fig.32 and 33)

Prior to performing the following procedure, remove

the bracket (c).

1.

Remove the three screws X attaching the key switch

board.

2.

Remove the spring g and the screw Y attaching the

(d) board.

(d) board

Y

Relay board

X

CN908

(d) board

Key switch board

Fig.32

Spring g

X

Y

Fig.33

1-15

Page 16

UX-A70MD

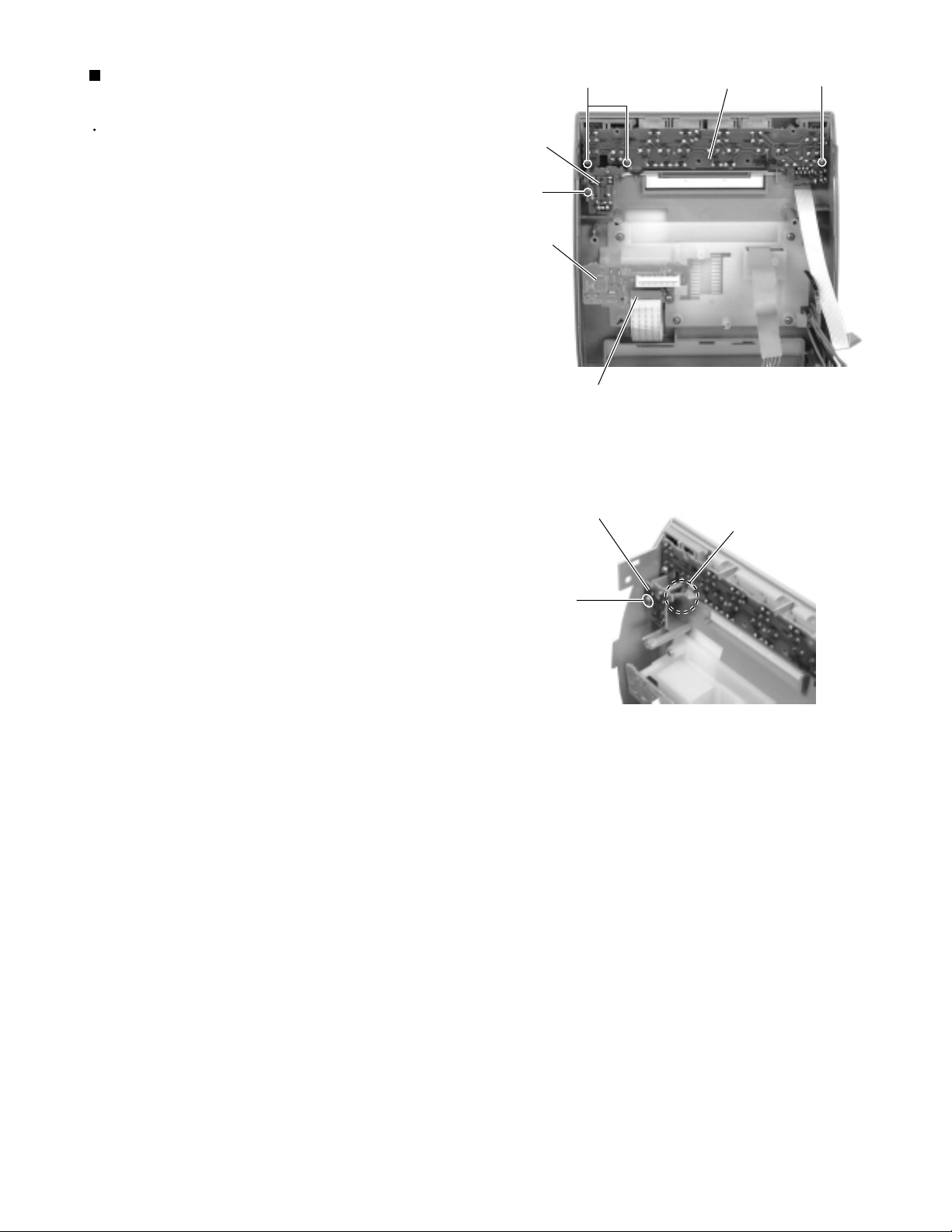

Removing the LCD board / sub board

(See Fig.32 and 34 to 37)

1.

Disconnect the card wire from connector CN908 on

the relay board on the back of thefront panel

assembly.

2.

Remove the four screws A’ attaching the CD / MD

door cover on the front side of the frontpanel

assembly. Remove the CD / MD door cover, then the

LCD board unit.

3.

Pull out the LCD lens from the four bosses on the

LCD board unit.

4.

Remove the LCD board and the lens cover in the

direction of the arrow (The lens cover isattached with

a double-sided tape).

5.

Disconnect the sub board from connector CN913 on

the LCD board.

CD / MD door cover

LCD board unit

A'

A'

Fig.34

Slot h

Lens cover

Fig.35

LCD lens

Slot h

Slot h

LCD board

Fig.36

Sub board

1-16

Fig.37

CN913

LCD board

Page 17

UX-A70MD

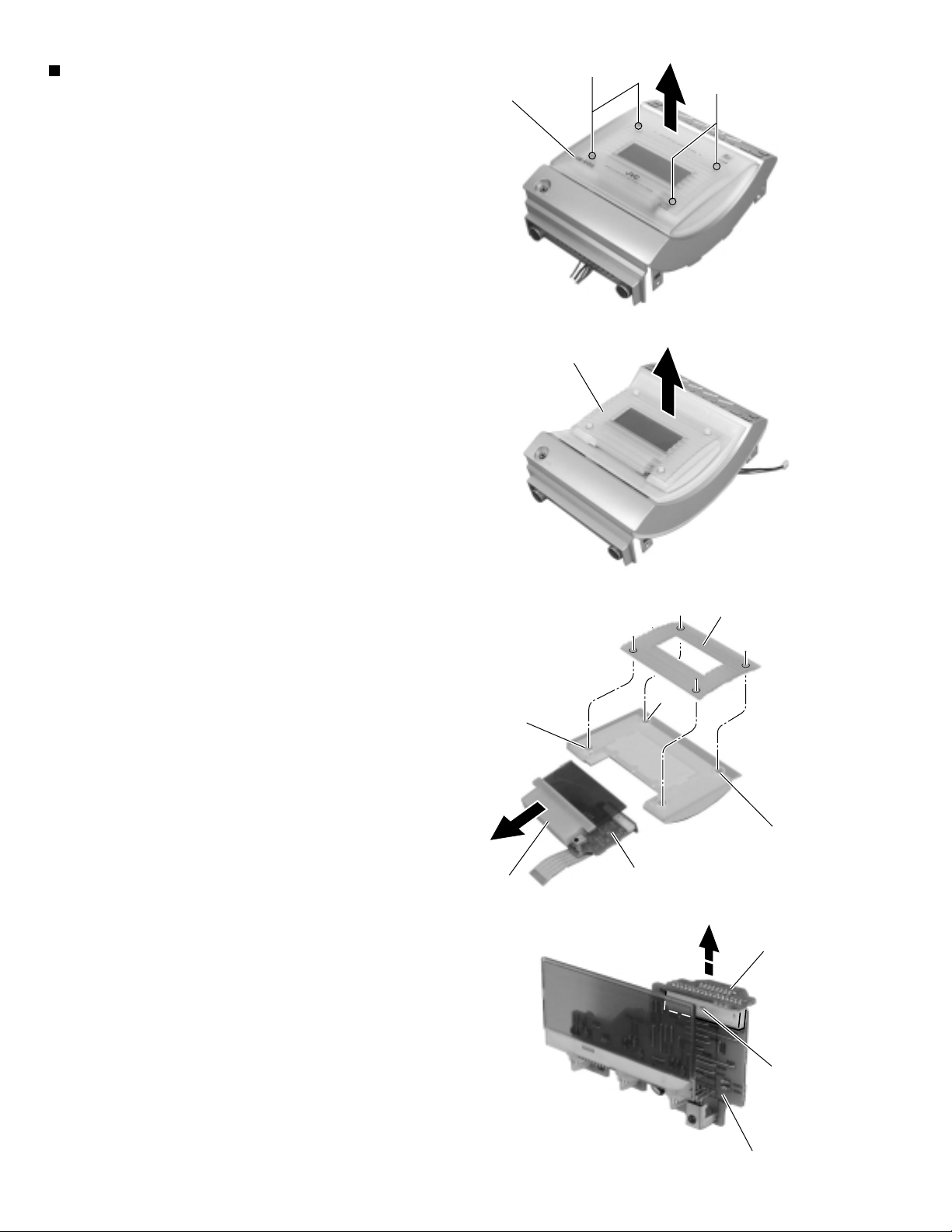

Removing the CD / MD door board

(See Fig.38 and 39)

Prior to performing the following procedure,remove

the LCD board unit.

1.

Remove the four screws B' attaching the two

brackets (e). Remove the CD / MD door base and

the two brackets (e).

2.

Remove the screw C' attaching the CD / MD door

board.

CD / MD door base

B'

B'

Brackets (e)

Fig.38

C'

CD / MD door board

Fig.39

1-17

Page 18

UX-A70MD

Disassembly method

<Main body>

Removing the main board

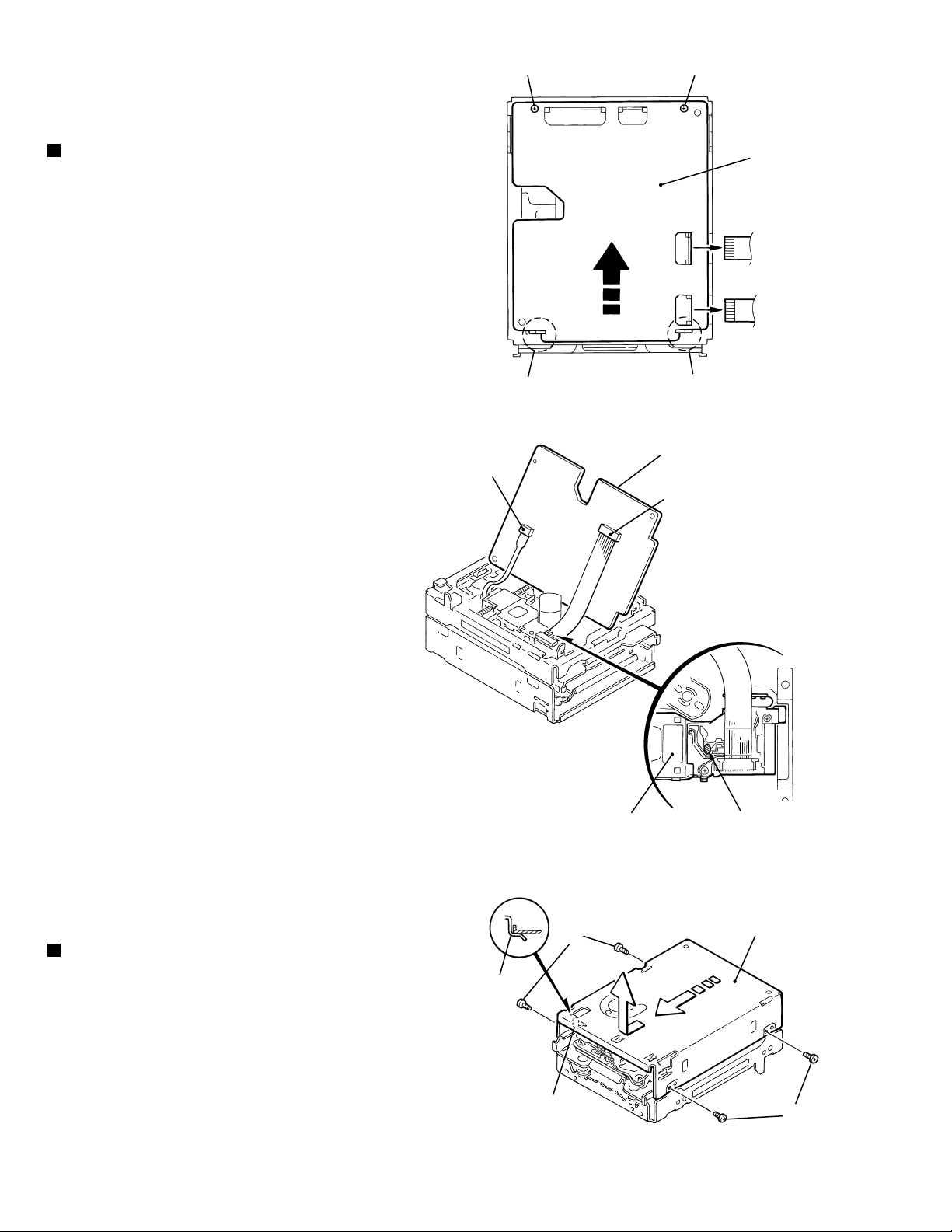

(See Fig.1 and 2)

1.

Turn over the body and disconnect the card wire

from connector CN408 and the flexible wire from

CN407 on the main board.

2.

Remove the two screws A attaching the main board.

Slide the main board in the direction of the arrow to

release the two joints a with the single flame.

3.

Solder part b on the pickup in the body. Disconnect

the flexible harness from connector CN321 and

CN451 on the underside of the main board. Then

remove the main board.

AA

(Bottom)

Main board

CN408

CN407

Joint b Joint b

Fig.1

Main board

CN451

CN321

Removing the mechanism cover

(See Fig.3)

1.

Remove the four screws B on both sides of the

body.

2.

Move the mechanism cover toward the front to

disengage the front hook of the mechanism cover

from the internal loading assembly (Joint c). Then

remove the mechanism cover upward.

1-18

Fook

Joint c

Joint c

B

Pickup

Fig.2

Fig.3

Solder part b

Mechanism cover

B

Page 19

Removing the head lifter (See Fig.4 to 6)

1.

Move the head lifter on top of the body in the

direction of the arrow and turn around.

2.

Detach the spring from the hook of the body.

Remove the head lifter with the spring.

3.

If necessary, remove the spring from the head lifter.

Head lifter

Fig.5

UX-A70MD

Head lifter

Fig.4

Spring

Removing the head assembly (See Fig.7)

1.

Remove the screw C on the upper side of the body.

Remove the head assembly while pulling the flexible

harness from the body.

Head lifter

Spring

Fig.6

Head assembly

Fig.7

C

1-19

Page 20

UX-A70MD

Removing the Loading assembly

(See Fig.8 and 9)

Ref:

The loading assembly, the traverse mechanism

assembly and the single flame will be

removable after removing the loading assembly

from the body.

D

D

Prior to performing the following procedure, remove

the main board, the mechanism cover, the head lifter

and the head assembly.

1.

Remove the three screws D on the upper side of the

body.

2.

Move the loading assembly forward to disengage it

from the traverse mechanism assembly (Joint d).

Then remove it upward.

3.

Remove the traverse mechanism assembly from the

single flame.

Joint d

Loading assembly

D

Fig.8

Loading assembly

1-20

Traverse mechanism

assembly

Single flame

Fig.9

Page 21

<Loading assembly>

Slide base (R)

UX-A70MD

E'

Removing the slide base (L) / (R)

(See Fig.10)

1.

Remove the two screws E on the upper side of the

loading assembly.

2.

Remove the slide base (L) outward. (Release it from

the joint bosses E.)

3.

Remove the slide base (R) outward.

Removing the loading mechanism

assembly (See Fig.11)

1.

Detach the loading mechanism assembly upward to

release the four pins on both sides from the loading

motor, paying attention to the part e of the loading

mechanism base.

E

Slide base (L)

E

E'

Fig.10

Part e

Loading mechanism assembly

Removing the loading motor

(See Fig.12 and 13)

1.

Disconnect the harnesses from the wire holder and

from connector CN612 on the cam switch board.

2.

Remove the screw F attaching the loading motor

and release the joint f.

3.

Remove the belt from the loading motor assembly.

4.

Remove the two screws G attaching the loading

motor.

Removing the cam gear and the cam

switch board (See Fig.12)

Loading mechanism

assembly

Loading motor assembly

Joint f

CN612

F

Loading mechanism base

Fig.11

Wire holder

H

Cam switch board

Slit washer

H

Cam gear

Fig.12

Loading motor

1.

Remove the slit washer attaching the cam gear and

pull out the cam gear.

2.

Disconnect the harness from the wire holder and

from connector CN612 on the cam switch board.

3.

Remove the two screws H and the clamp. Remove

the cam switch board.

G

Belt

Fig.13

1-21

Page 22

UX-A70MD

Removing the cartridge holder assembly

(See Fig.14 and 15)

1.

Remove the two screws I on the upper side of the

loading assembly.

I

I

Removing the slide bar and the eject bar

(See Fig.14 and 15)

Prior to performing the following procedure, remove

the cartridge holder assembly.

Slide bar

Cartridge holder assembly

Eject bar

Eject bar

Part g

Fig.14

I

1.

Remove the slide bar upward.

2.

Move the eject bar outward until it stops as shown in

Fig.14. Push the convex part g on the bottom of the

body and remove the eject bar from the chassis.

Slide bar

k

Eject bar

UD base

1-22

Cartridge holder assembly

Fig.15

Page 23

<Traverse mechanism assembly>

UX-A70MD

Removing the Insulators (See Fig.16)

1.

Disengage the four insulators from the notches of the

traverse mechanism chassis.

Removing the pickup unit (See Fig.17)

1.

Turn over the traverse mechanism assembly and

remove the screw J attaching the shaft holder (F).

2.

Move the shaft inward and remove it from the shaft

holder (R).

Pickup unit

Insulators

Traverse machanism chassis

Fig.16

Joint h

Pickup guide

Pickup unit

Insulators

3.

Detach the shaft side of the pickup unit upward and

release the joint h with the pickup guide. Then

remove the pickup unit with the shaft.

Removing the pickup (See Fig.18)

1.

Draw out the shaft from the pickup.

2.

Remove the two screws K attaching the rack spring.

Shaft holder (F)

Rack spring

Shaft holder (R)

J

Fig.17

K

Pickup

Fig.18

Shaft

1-23

Page 24

UX-A70MD

Removing the feed motor assembly

(See Fig.19-1, 19-2)

It is not necessary to remove the pickup unit.

1.

For the white and black harnesses extending from

the feed motor assembly, unsolder the soldering i on

the traverse mechanism board.

Traberse mechanism board Soldering j

M

2.

Remove the two screws L attaching the feed motor

assembly.

3.

Remove the two screws N attaching the feed motor

bracket.

Removing the traverse mechanism

board (See Fig.19-1)

Prior to performing procedure, remove the feed

motor assembly.

1.

For the red and black harnesses extending from the

spindle motor, unsolder the soldering j on the

traverse mechanism board.

Soldering i

Feed motor assembly

L

Fig.19-1

Feed motor

Feed motor bracket

N

2.

Remove the screw M attaching the traverse

mechanism board.

Fig.19-2

1-24

Page 25

<Reattaching the loading assembly>

1.

Reattach the eject bar to the UD base.

(Fig.15 and 20)

2.

Reattach the slide bar to the loading mechanism

chassis while fitting the boss marked k to the eject

bar slot. (Fig.20)

3.

Slide the slide bar and the eject bar in the direction

of the arrow in Fig.20 and reattach the cartridge

holder assembly using the two screws I.

(Fig.20 and 21)

UX-A70MD

ATTENTION:

Make sure the pin of the eject lever

marked l is fitted to the slot of the eject

bar marked m at the bottom of the

loading mechanism chassis after

moving the eject lever and the loading

slider of the cartridge holder assembly

in the direction of the arrow.

(Refer to Fig.21)

Slide bar

I

I

Cam switch board

H

Point marked

H

Cam switch boss

Ditch

UD base

Eject bar

Fig.20

Ditch m

UD base (Bottom)

Cartridge holder assembly

Loading slider

Eject lever

l

Fig.21

1-25

Page 26

UX-A70MD

4.

Reattach the wire holder to the UD base while

engaging the UD base hook marked u to the wire

holder slot marked t (At the same time, the boss on

the reverse side of the wire holder is fitted to the UD

base round hole).

5.

Reattach the cam switch board using the two screws

H. (Fig.22)

6.

Turn the cam switch to bring the boss to the point

marked on the cam switch board. Reattach the

cam gear using a slit washer while fitting the cam

gear slot to the cam switch boss. (Fig.22)

ATTENTION:

When reattaching the cam gear, the

cam switch boss should be fitted to the

cam gear slot, and the triangle mark of

the cam gear should be aligned to the

hole of the eject bar as shown in

Fig.22.

7.

Reattach the loading motor assembly, using the

screw F. Connect the harness extending from the

loading motor to connector CN612 on the switch

board and fix it with the wire holder. (Fig.22)

Slide bar CN612

Loading motor assembly

Point marked

Boss

Cam switch

Cam switch board

1-26

F

Eject lever

Fig.22

Cam gear

n

Cam gear

(Triangle mark)

Eject lever

Page 27

UX-A70MD

8.

Reattach the UD base while engaging the four pins

on both sides of the UD base to the notches of the

loading mechanism base and placing the edge

(marked e’) of the cartridge holder assembly under

the hook e of the loading mechanism base. (Fig.23)

9.

Reattach the slide base (R) while fitting the two pins

on another side of the UD base to the slots of the

slide base (R). (Fig.24)

ATTENTION:

10.

Reattach the slide base (L) on the slide base (R)

while fitting the two pins on another side of the UD

base to the slots of the slide base (L) (Fig.25). Make

sure the two slots of the slide base (L) are fitted to

the two bosses marked E’ and tighten the two

screws E. (Fig.26)

Ref:

To expedite the work, bring up the UD base

slightly when fitting each pin to the appropriate

notch.

Fit the part v of the slide base (R) to

the part w on the inward side of the

cam gear rib. (Fig.25)

Hook e

Hook e'

Hook e'

Pin

Loading mechanism base

Fig.23

Slide base (R)

Part v

Pin

E

E'

Pin

Slide base (L)

Pin

Part w

Fig.24

Slide base (L)Slide base (R)

Slide base (R)

Cam gear

E

Part v

Part w

E'

Fig.25Fig.26

1-27

Page 28

UX-A70MD

Adjustment Method (CD/MD section)

1. Jigs and test instruments

Laser power meter

Laser power meter sensor (or disk sensor)

Premastered disk (MRG-1018 or TGYS1)

Recordable disk (MDW-74/AU1)

2. Adjustment and check items

1) Indications in the modes that all LCD's are on

2) CD section

(1) Indication of the C1 error

(2) Cancel of the C1 error indication

3) MD section

(1) Setup of the TEST MODE 1

(2) Initialization of the EEPROM

(3) Adjustment of the laser power

(4) Adjustment of the disk

(5) Setup of the TEST MODE 2

(6) Indication of variation in the pickup adjustment value

(7) Indication of the C1 error

(8) Cancel of the TEST MODE

3. Adjustment and check method

1) CD section

(1) Indication of the C1 error

While pressing both the POWER key

and BACK SKIP key on the main unit,

turn on the primary power supply.

FL indication

CRC = 0

Press the CD OPEN/CLOSE key

and insert the test disk.

Press the CD PLAY key. The set starts

counting and the number of error correction

times is indicated every 10 seconds.

FL indication

CRC = ***

200 Hz or less

1-28

(2) Cancel of the C1 error indication

To cancel the C1 error indication, cut off the power supply.

Page 29

2) MD section

UX-A70MD

(1) Setup of the TEST MODE 1

While pressing both the POWER

key and FORWARD SKIP key, turn

on the primary power supply.

FL indication

MD TEST MODE 1

Setup is complete.

(3) Adjustment of the playback laser power

Set up the MD TEST MODE 1.

(2) Initialization of the EEPROM

(The EEPROM can be initialized on the precondition that the

setup of the TEST MODE 1 is complete. After setup of the

TEST MODE 1, proceed to the following operations with the

remote controller*.)

* For EJECT operation, use the EJECT key on the main unit.

Initialization of the EEPROM

Press the PLAY MODE key

on the remote controller.

FL indication MD

TEST MODE 1

Setup is complete.

(4) Adjustment of the recording laser power

Set up the MD TEST MODE 1.

Insert the laser power

meter sensor.

Press the "2" key on

the remote controller.

Set up the playback

laser power.

Increase the laser

power with the F.

SKIP key on the

remote controller.

Adjust the power to be 0.68 mW or

more. If the value exceeds 0.68 mW,

approximate it to 0.68 mW as

accurately as possible.

Press the MD EJECT

key on the main unit.

Decrease the laser

power with the B.

SKIP key on the

remote controller.

Insert the laser power

meter sensor.

Press the "4" key on

the remote controller.

Set up the recording

laser power.

Increase the laser

power with the F.

SKIP key on the

remote controller.

Adjust the power to be 6.23 mW or

more. If the value exceeds 6.23 mW,

approximate it to 0.68 mW as

accurately as possible.

Press the MD EJECT

key on the main unit.

Decrease the laser

power with the B.

SKIP key on the

remote controller.

Setup of the MD laser

power is complete.

Setup of the MD laser

power is complete.

1-29

Page 30

UX-A70MD

(5) Adjustment of the disk

Set up the MD TEST MODE 1.

Insert the

premastered disk.

Reading of TOC ends.

Press the MD PLAY

key on the remote

controller.

FL indication

ON TUNING

Automatic adjustment starts.

Adjustment OK?

YES

FL indication

OK TUNING

Press the STOP key on

the remote controller.

Press the EJECT key

on the main unit.

Insert a recordable

disk.

Press the MD PLAY key

on the remote controller.

FL indication

ON TUNING

Automatic adjustment starts.

Adjustment OK?

YES

NO

NO

* If an error indication of "ERR:07"

appears at the first adjustment, try

to make a fresh start of the same

adjustment.

FL indication

NG ERR: XX

XX: Refer to the NG judgment code table.

NG Judgment Code Table

Code

00 Automatic adjustment is incomplete.

01 Rest switch detection

02 Focus-on

03 EF balance, tracking offset adjustment (Pit area)

04 ABCD level (I-V resistance) adjustment (Pit area)

05 Focus servo AGC (Pit area)

06 Tracking servo AGC (Pit area)

07 Focus bias adjustment (Pit area)

08 EF balance, tracking offset adjustment (GRV area)

09 ABCD level (I-V resistance) adjustment (GRV area)

0A Focus servo AGC (GRV area)

0B Tracking servo AGC (GRV area)

0C Focus bias adjustment (GRV area)

0D Room temperature measurement

0E Write in EEPROM

10 (Focus, TRK, SLED) AGC data read time-out

20 Pit area spindle lock

30 Groove area spindle lock

XX Automatic adjustment is complete.

NG item in adjustment

FL indication

ON TUNING

Press the STOP key on

the remote controller.

Press the MD EJECT

key on the main unit.

1-30

FL indication

NG ERR: XX

Refer to the NG judgment code table.

Automatic adjustment

ends.

Press the POWER key on the

main unit or remote controller.

Cut off the power supply after

cancelling the TEST MODE.

Page 31

UX-A70MD

For investigating the mode in which an error

occurred during the disk adjustment, freeze the

set in the mode by pressing the proper key

(refer to the table on the right) on the remote

controller before cancelling the TEST MODE 1.

(6) Setup of the TEST MODE 2

While pressing both the POWER key and

FORWARD STOP key on the main unit,

turn on the primary power supply.

FL indication MD

TEST MODE 1

While pressing the STOP key on the main

unit, press the FM/AM key on the main

unit double. The TEST MODE 2 is set up.

Key to press Mode

SLEEP key (Remote controller)

"6" key (Remote controller)

"7" key (Remote controller)

"8" key (Remote controller)

"9" key (Remote controller)

STOP key (Remote controller)

EJECT key (Main unit)

FOCUS SEARCH

PIT ROUGH SERVO

GROOVE ROUGH SERVO

TRACKING ON

TRACKING OFF

STOP

EJECT

FL indication MD

TEST MODE 2

Setup is complete.

(7) Indication of variation in the pickup adjustment value

Set up the TEST MODE 2.

Press the MD OPEN/CLOSE key

and insert the MD test disk.

Press the "6" key on the

remote controller.

Press the "8" key on the remote controller. Counting of

number of C1 errors starts and it continues until it

counts up the maximum number of C1 errors with

indication (maximum number of error indication is 432).

FL indication*

XXXXX - XXXX

*Each time the

"6" key on the

remote

controller is

pressed, the

indication

changes from

ASG to TRG,

from TRG to

TRB, and so

on as shown

in the figure.

ASG

TRG

TRB

FOB

FGR

FEXP

FGC

FG

TGR

TEXP

TGC

TG

-1

-2

:

-128

127

126

:

1

0

(8) Indication of the C1 error

Set up the TEST MODE 2.

Press the MD OPEN/CLOSE key

and insert the MD test disk.

FL indication*

200 Hz or less

X X Y Y Z Z

(9) Cancel of the TEST MODE

(The cancel operation is common to the TEST

MODE 1 and 2.)

Cut off the primary power supply to cancel the

TEST MODE.

1-31

Page 32

UX-A70MD

Flow of functional operation until TOC read (CD)

Power ON

Power Key

Slider turns REST

SW ON.

Automatic tuning

of TE offset

Check that the voltage at the pin17

of CN604 is 0V (a moment)?

Check Point

VREF

Tracking error waveform at TOC reading

pin 25 of

IC601(TE)

Approx

1.8V

Tracking

servo

Disc statas

to rotate

off statas

Automatic measurement

of TE amplitude and

automatic tuning of

TE balance

Approx.3sec

Tracking

servo

on statas

Disc to be

braked to stop

TOC reading

finishes

500mv/div

2ms/div

Fig.1

Laser ON

Detection of disc

Automatic tuning of

Foucus offset

Automatic measurement of

Focus A-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Tracking error balance

Check that the voltage at the

pin3 of IC601 + side is + 5V?

Confirm that the Focus error

S-cuve siganl at the pin27 of

IC601 is approx.2Vp-p

Confirm that the siganl from

pin24 IC603 is 0V as a

accelerated pulse during

approx.400ms.

Confirm the waveform of

the Tracking error signal

at the pin25 of IC601 (R612)

(See fig-1)

1-32

Automatic tuning of

Focus error balance

Automatic tuning of

Focus error gain

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the eys-pattern

at the lead of TP1

Page 33

Flow of functional operation until TOC read (MD)

Power ON

MD play key

Check Point

Slider turns REST

Switch ON.

Confirm that the voltage

at the pin 4 of CN406 are 0V

UX-A70MD

Mechanism Operation ON

Laser ON

Detection of Disc

Automatic tuning of

Focus S-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic tuning of

Focus error gain

Confirm that the voltage

at the pin 19 of IC500 are 4V

Confirm that the Focus error

S-cuve signal at the pin34 of

IC310 is approx.2Vpp

It is confirmed that pin7 of CN408

become 0V from VREF as an acceleration

pulse between about 400ms.

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm that the eye-pattern

at the pin38 of IC310

1-33

Page 34

UX-A70MD

Maintenance of laser pickup

(1) Cleaning the pick up lens

Befor you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode (Fig.1)

When the life of the laser diode has expired,

the following symptoms wil appear.

(1) The level of RF output (EFM output:ampli

tude of eye pattern) will below.

Is RF output

1.1 0.15Vp-p?

YES

O.K

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

(Fig.1)

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed

circuit board which is attached to the pickup

is used to adjust the laser power.Since this

adjustment should be performed to match the

characteristics of the whole optical block,

do not touch the semi-fixed resistor.

If the laser power is lower than the specified

value,the laser diode is almost worn out, and

the laser pickup should be replaced.

If the semi-fixed resistor is adjusted while

the pickup is functioning normally,the laser

pickup may be damaged due to excessive current.

Check the eye-pattern at TP1.

Finish.

1-34

Page 35

UX-A70MD

Maintenance of MD pickup

1. Cleaning of pickup lens

(1) Prior to changing the pickup, clean the pickup lens.

(2) For cleaning the lens, use the following cotton swab after

mearsing it in alcohol.

Product No. JCB-B4; Manufacturer;Nippon Cotton Swab

2. Confirmation of the service life of laser

diode when the service life of the laser

diode has been exhausted, the following

symptoms will appear.

(1) Recording will become impossible.

(2) The RF output (EFM output and eye pattern amplitude)

will become lower.

(3) The drive current required for light emitting of laser diode

will be increased.

Confirm the service life according to the following flow chart:

Procedures of changing the MD pickup

Change the MD pickup by referring

to "Removing the MD pickup" in the

Disassembly Method.

Set the pickup to [TEST] mode according

to the procedures described in the

Adjustment Method.

Adjust the laser power.

Completion the disc.

Is the recording power

(6.23mV) output with the

laser power under

test mode?

YES

Is the drive current

of laser diode

120mA or less?

YES

NO

Change the pickup

NO

Change the pickup

OK.

3. Method of measuring the drive current of

laser diode

When the voltage measured at TP ILCC (Q301 emitter)

and +5V (Q303 emitter) of the MD servo P.C. board

(ENX-0223) have become 600mV or over, the service life

of the laser diode is judged to have been exhausted.

[Caution] When TP ILCC (Q301 collector) and

+5V (Q303 emitter have been is short

circuit on such an occasion, then the

laser diode will be broken. Therefore,

take utmost care in handling the MD

pickup.

Completion of changing the MD pickup.

Since this system is designed to perform magnetic

recording, the laser power ten times or over of the

conventional MD player will be output. Therefore, be

sure to perform not only adjustment and operation

of this system so carefully as not to directly look at the

laser beam or touch on the body.

4. Semi-solid state resistors on

the APC P.C. board

The semi-solid state resistor on the APC P.C.board

attached to the pickup is used for adjusting the laser

power. Since these resistor should be adjusted in

pair according to the characteristics of the optical

block, be sure not to touch on the resistors.

Since the service life of the laser diode will be

exhausted when the laser power is low, it is

necessary to change the pickup. Meanwhile, do not

pickup. Otherwise, the pickup will be damaged due

to over current.

1-35

Page 36

UX-A70MD

Description of major ICs

AK4519VF-X (IC480) : A / D D / A converter

1.Pin layout

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

2.Block diagram

AINL

VCML

AINR

VCMR

VRAD

ARDV

VCOM

AOUTL

AOUTR

3.Pin Function

Pin

Symbol I/O Function

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

VRDA

VRAD

AINR

VCMR

VCML

AINL

PWAD

PWDA

MCLK

LRCK

SCLK

SDTO

DGND

VD

SDTI

CMODE

DEM1

DEM0

AOUTL

AOUTR

VCOM

AGND

VB

VA

Voltage Reference Input Pin for DAC, VA

I

Voltage Reference Input Pin for ADC, VA

I

RCH Analog Input Pin

I

Rch Common Voltage Output Pin, 0.45xVA

O

Lch Common Voltage Output Pin, 0.45xVA

O

Lch Analog Input Pin

I

ADC Power-Down Mode Pin "L":Power Down

I

DAC Power-Down Mode Pin "L":Power Down

I

Master Clock Input Pin

I

Input/Output Channel Clock Pin

I

Audio Serial Data Clock Pin

I

Audio Serial Data Output Pin

O

Digital Ground Pin

Digital Power Supply Pin

Audio Serial Data Input Pin

I

Master Clock Select Pin

I

De-emphasis Frequency Select Pin

I

De-emphasis Frequensy Select Pin

I

Lch Analog Output Pin

O

Rch Analog Output Pin

O

Common Voltage Output Pin, 0.45xVA

O

Analog Ground Pin

Substrate Pin

Analog Power Supply Pin

-

VA AGND VB VD DGND

Decimation

Modulator

Filter

Decimation

Modulator

Filter

Common V oltage

LPF

LPF

Modulator

Modulator

PWAD PWDA

8x

Interpolator

8x

Interpolator

Clock

Divider

Serial I/O

Interface

MCLK

CMODE

LRCK

SCLK

SDTO

SDTI

1-36

Page 37

AK93C65AF-X (IC590) : EEPROM

1.Pin layout

UX-A70MD

PE

VCC

CS

SK

2.Block diagram

DI

CS

INSTRUCTION

1

2

3

4

8 PIN SOP

REGISTER

8

7

6

5

INSTRUCTION

GENERATION

NC

GND

DO

DI

DECODE,

CONTROL

AND

CLOCK

DATA

REGISTER

ADD.

BUFFERS

16

R/W AMPS

AND

AUTO ERASE

DECODER

DO

16

EEPROM

4096bit

256 x 16

SK

PE

3.Pin function

Pin no. Symbol

1 PE

2 VCC

3 CS

4 SK

5 DI

6 DO

7 GND

8 NC

Function

Program enable (With built-in pull-up resistor)

Power supply

Chip selection

Cereal clock input

Cereal data input

Cereal data output

Ground

No connection

NOTE : The pull-up resistor of the PE pin is about 2.5M (VCC=5V)

VREF

VPP SW

VPP

GENERATOR

1-37

Page 38

UX-A70MD

AN8806SB-W (IC601) : RF&Servo AMP

1.Pin layout

PD

LD

LDON

LDP

VCC

RF-

RF OUT

RF IN

C.AGC

ARF

C.ENV

C.EA

CS BDO

BDO

CS BRT

OFTR

/NRFDET

GND

2.Block diagram

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

PDAC

PDBD

PDF

PDE

PDER

PDFR

TBAL

FBAL

EF EF OUT

TE TE OUT

CROSS

TE BPF

VDET

LD OFF

VREF

ENV

6

-+

36

-+

35

--

+

31

34

--

+

VCBA

--

+

VCBA

--

--

VCBA

+

29

728

--

+

-+

27

-+

910 17

8

AGC

EQ

OFTR

BDO

RF

DET

11

12 19

ENV CURCUIT

13

14

15

16

-+

20

+

+

32

33

-+

--

VCBA

+

+

--

-+

--

--

+

+

--

21

2

+

--

1-38

24 25

30

23

26

22

14

3

Page 39

3. Pin function

UX-A70MD

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Symbol

PD

LD

LD ON

LDP

VCC

RF-

RF OUT

RF IN

C.AGC

ARF

C.ENV

C.EA

CS BDO

BDO

CS BRT

OFTR

/NRFDET

GND

ENV

VREF

LD OFF

VDET

TE BPF

CROSS

TE OUT

TE-

FE OUT

FEFBAL

TBAL

PDFR

PDER

PDF

PDE

PD BD

PD AC

I/O

I

APC amp input terminal

APC amp output terminal

O

APC ON/OFF control terminal

I

--

Connect to ground

Power supply

-Inverse input pin for RF amp

I

RFamp output

O

RF input

I

Connecting pin of AGC loop filter

I/O

RF output

O

I/O

A capacitor is connected to this terminal to detect the envelope of RF signal

I/O

A capacitor is connected to this terminal to detect the envelope of RF signal

A capacitor is connected to detect the lower envelope of RF signal

I/O

BDO output pin

O

A capacitor is connected to detect the lower envelope of RF signal

I/O

O

Of-track status signal output

RF detection signal output

O

--

Ground

O

Envelope output

Reference voltage output

O

--

Connect to ground

O

Vibration detection signal output

I

Input pin of tracking error through BPF

O

Tracking error cross output

O

Tracking error signal output

Inverse input pin for tracking error amp

I

O

Output pin of focus error

Inverse input pin for focus error amp

I

I

Focus balance control

I

Tracking balance control

F I-V amp gain control

I/O

E I-V amp gain control

I/O

I

I-V amp input

I-V amp input

I

I

I-V amp input

Function

I I-V amp input

1-39

Page 40

UX-A70MD

BA15218N (IC32 / IC35) : Dual Ope. Amp.

+

+

1

-

1 2 3 4 5 6 7 8

OUT1 +IN1 +IN1

+IN2 -IN2 OUT2

GND

2

-

Vcc

BA3126N(IC31) : R/P Switch

S W

R E C

G

123456789

P / B

S W

C O N T .

BU4094B(IC811):Serial to parallel port extension

1.Pin layout

STROBE

DATA

CLOCK

Q1

Q2

Q3

Q4

Vss

1

2

3

4

5

6

7

8

16

Vdd

15

OUTPUT ENABLE

14

Q5

13

Q6

12

Q7

11

Q8

10

Q's

9

Qs

CLOCK

STROBE

2.Block diagram

DATA

2

3

1

S W

V c c

P / B

G N D

8-STAGE

SHIFT REGISTER

8-BIT

LATHES

G

R E C

10

9

S W

Q's

Qs

SERIAL

OUTPUT

1-40

OUTPUT

ENABLE

15

3-STATE

OUTPUTS

Q1

PARALLEL OUTPUT

Q8

Page 41

BD7910FV-X (IC450) : Pre driver

1.Block diagram

20 19 18 17 16 15 14 13 12 11

UX-A70MD

- +

Vregin

1 2 3 4 5 6 7 8 9 10

- +

VG

SVcc

Pre driver

EFM

2.Pin function

Pin

Symbol Symbol

No.

1

Vreg IN

I/O I/O

Regulator input and regulator

I

power supply

2

3

4

5

6

7

8

9

10

Reg GN

NC

VG

SVCC

PDGND

EFM

MUTE

NC

NC

Regulator GND

Non connect

Voltage input for power MOS drive

I

EFM high level output voltage

O

Pre-driver GND

EFM signal input

I

Mute control (Low active)

I

Non conncet

O

Non connect

O

Function Function

Pin

No.

11

12

13

14

15

16

17

18

19

20

Mute

NC

VOD2

VSS

VOD1

VOS1

VDD

VOS2

Reg DRV

Reg OUT

Reg NF

-

Non connect

O

Sync.output (Lower power MOS,drain)

-

"H"bridge GND (Lower power MOS,source)

O

Sync.output (Lower power MOS,drain)

O

Source output (Upper power MOS,source)

-

"H" bridge power supply terminal

(Upper power MOS,source)

O

Source output (Upper power MOS,source)

O

External PNP drive output for regulator

O

Reglator output (Emitter follower output)

-

Regulator feedbaack terminal

1-41

Page 42

UX-A70MD

CXA2523AR (IC310) : MD servo

1.Block diagram

BOTM

ABCD34FE33AUX32ADFG31ADAGC30ADIN29ADFM28SE27CSLED26TE25WBLADJ

36 35

PEAK

37

38

RF

39RFAGC

40AGCI

41COMPO

42COMPP

43ADDC

44OPO

45OPN

46RFO

47MORFI

48

MORFO

2.Pin function

Pin No.

Symbol

1

2

3

4

5

6

7

8

9

10

11

12

APCREF

13

14

15

16

17

18

19

20

GND

TEMPI

TEMP R

SWDT

SCLK

XLAT

XSTBY

F0CNT

I

J

VC

A

B

C

D

E

F

PD

APC

AGC, EQ

Comp

USER

USER

OP Amp

RF Amp

1 2

I

ADIP Amp TE/SE Amp

MUX FE Amp

Peak, Bottom Detector

CPU

Command I/F

ABCD Amp

3T Detector

I-V Amp APC

3VC4A5B6C7D8E9F10PD11

J

I/O

I-V converted RF signal I input.

I

I-V converted RF signal J input.

I

Vcc/2 voltage output.

O

A current input for main beam servo signal.

I

B current input for main beam servo signal.

I

C current input for main beam servo signal.

I

D current input for main beam servo signal.

I

E current input for side beam servo signal.

I

F current input for side beam servo signal.

I

Reflection light quantity monitor signal input.

I

Laser APC output.

O

Reference voltage input for the laser power intensity setting.

I

Connect to GND.

Connects the temperature sensor.

I

Connects the temperature sensor. outputs the reference voltage.

I

Data input for microcomputer serial interface.

I

Shift clock input for microcomputer serial interface.

I

Latch signal input for microcomputer serial interface.Latched when low.

I

Standby setting pin. Normal operation when high Standby when low.

I

Internal current source setting pin.

I

TEMP Amp

12

APC

APCREF

Function

Vcc

24

23

3TADJ

22 EQADJ

21 VREF

20 F0CNT

19 XSTBY

18 XLAT

17 SCLK

16 SWDT

15 TEMP R

14 TEMP I

13 GND

1-42

Page 43

UX-A70MD

Pin No.

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Symbol

VREF

EQADJ

3TADJ

Vcc

WBLADJ

TE

CSLED

SE

ADFM

ADIN

ADAGC

ADFG

AUX

FE

ABCD

BOTM

PEAK

RF

RFAGC

AGCI

COMPO

COMPP

ADDC

OPO

OPN

RFO

MORFI

MORFO

I/O

Reference voltage output.

O

Equalizer center frequency setting pin.

I/O

BPF3T center frequency setting pin.

I/O

Power supply.

BPF22 center frequency setting pin.

I/O

Tracking error signal output.

O

Connects the sled error signal LPF capacitor.

Sled error signal output.

O

ADIP FM signal output.

O

ADIP signal comparator input.

I

Connects the ADIPAGC capacitor.

ADIP2 binary value signal output.

O

13 output / temperature signal output. Switched with serial commands.

O

Focus error signal output.

O

Reflection light quantity signal output for the main beam servo detector.

O

RF/ABCD bottom hold signal output.

O

Peak hold signal output for the RF/ABCD signals.

O

RF equalizer output.

O

Connects the RFAGC capacitor.

RFAGC input.

I

User comparator output.

O

User comparator non-inverted input.

I

Connects the capacitor for ADIP amplifier feedback circuit.

I/O

User operational amplifier output.

O

User operational amplifier inverted input.

I

RF amplifier output. Eye pattern checkpoint.

O

Input of the groove RF signal with AC coupling.

I

Groove RF signal output.

O

Function

1-43

Page 44

UX-A70MD

CXD2662R (IC350) : DSP

1.Pin layout

2.Block diagram

59

PCO

60

FILI

61

FILO

62

CLTV

100

EFM

57

RFI

54

ASYI

BIAS

56

75 ~ 51

76

~~

100

1 ~ 25

PLL

COMP

50

26

ACIRC

EFM

ENCODER DECODER

OSCI

OSCO

XTSL

FS256

LRCK

16 17 18 29

ONE OFF EACH BLOCK

27 28

CLOCK

GENERATOR

SHOCK RESISTANT

MEMORY CONTROLLER

XBCK

FS4

90 52

MDDT1

12

XRAS

46

XCAS

44

XWE

4

4

47

43

14

15

XOE

A00

D0 D3

XINT

TX

A11

ASYO

ADFG

FGIN

SPFD

SPRD

F0CNT

APC

FE

TE

SE

PEAK

BOTM

ABCD

AUX1

DCHG

VC

ADIO

ADRT

ADRB

DTRF

CKRF

XLRF

53

78

95

94

93

79

77

66

75

74

63

64

65

67

76

68

69

71

72

82

81

80

ADIP DECODER

SPINDLE

SERVO

A/D

CONVERTER

ANALOG MUX

AUTO

SEQUENCER

SERVO

DSP

ONE OFF EACH BLOCK

CPU I/F

ATRAC/ATRAC3

ENCODER/DECODER

SAMPLING

RATE

CONVERTER

ONE OFF

EACH BLOCK

MONITOR

CONTROL

DIGITAL

AUDIO

I/F

SUBCODE

PROCESSOR

PWM

GENERATOR

DADT

26

ADDT

25

XBCKI

4

24

LRCKI

23

DATAI

22

2

21

12

11

84

88

89

86

85

92

91

83

DIN1

DIN

DOUT

DQSY

SQSY

LDDR

FFDR

FRDR

TFDR

TRDR

SFDR

SRDR

APCREF

1-44

10 7

XRST

5689 1234 13

XLAT

SCLK

SWDT

SRDT

SENS

MNT0

MNT1

MNT2

MNT3

RECP

Page 45

3.Pin function

UX-A70MD

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

Symbol

MNT0

MNT1

MNT2

MNT3

SWDT

SCLK

XLAT

SRDT

SENS

XRST

SQSY

DQSY

RECP

XINT

TX

OSCI

OSCO

XTSL

DIN0

DIN1

DOUT

DA TAI

LRCKI

XBCKI

ADDT

DADT

LRCK

XBCK

FS256

DVDD

A03

A02

A01

A00

A10

A04

A05

A06

A07

A08

A11

DVSS

XOE

I/O

I/O

Monitor output.

O

Monitor output.

O

Monitor output.

O

Monitor output.

I

Data input for microcomputer serial interface.

I

Shift clook input for microcomputer serial interface.

I

Latch input for microcomputer serial interface.Latched at the falling edge.

O

Data output for microcomputer serial interface.

Outputs the internal status corresponding to the microcomputer serial

O

interface address.

I

Reset input. Low : reset

O

Disc subcode Q sync / ADIP sync output.

Subcode Q sync output in U-bit CD or MD format when the Digital In

O

source is CD or MD.

Laser power switching input.

I

High : recording power ; low ; playback power

Interruption request output. Low when the interruption status occurs.

O

Enable signal input for recoding data output. High : enabled

I

Crystal oscillation circuit input.

I

Crystal oscillation circuit output. (inverted output ofthe OSCI pin)

O

Function

OSCI input frequency switching.

XTSL1(command) = low and XTSL = high : 512Fs (22.5792MHz)

I

XTSL1(command) = low and XTSL = low : 1024Fs (45.1584MHz)

XTSL1(command) = high : 2048Fs (90.3168MHz)

Digital audio interface signal input 1.

I

Digital audio interface signal input 2.

I

Digital audio interface signal output.

O

Test pin. Connect to GND.

I

Test pin. Connect to GND.

I

Test pin. Connect to GND.

I

Data input from A / D converter.

I

REC monitor output / decoded audio data output.

O

LA clock (44.1kHz) output to the external audio block.

O

Bit clock (2.8224kHz) output to the external audio block.

O

256Fs output.

O

Digital power supply.

External DRAM address output.

O

External DRAM address output.

O

O

External DRAM address output.

O

External DRAM address output.

O

External DRAM address output.

O

External DRAM address output.

O

External DRAM address output.

O

External DRAM address output.

O

External DRAM address output.

O

External DRAM address output.

O

External DRAM address output.

-

Digital ground.

O

External DRAM output enable.

1-45

Page 46

UX-A70MD

Pin No.

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

Symbol

XCAS

A09

XRAS

XWE

D1

D0

D2

D3

MDDTI

ASYO

ASYI

AVDD

BIAS

RFI

AVSS

PCO

FILI

FILO

CLTV

PEAK

BOTM

ABCD

FE

AUXI

VC

ADIO

AVDD

ADRT

ADRB

AVSS

SE

TE

DCHG

APC

ADFG

F0CNT

XLRF

CKRF

DTRF

APCREF

LDDR

TRDR

TFDR

DVDD

FFDR

FRDR

FS4

I/O

O

External DRAM CAS output.

O

External DRAM address output.

O

External DRAM RAS output.

O

External DRAM write enable.

External DRAM data bus.

I/O

External DRAM data bus.

I/O

External DRAM data bus.

I/O

External DRAM data bus.

I/O

MD-DATA mode 1 switching input. (Low : normal mode ; high : MD-DATA mode 1)

I

Playback EFM full-swing input. (Low : vss ; jigh : Vdd)

O

Playback EFM comparator slice voltage input.

I

Analog power supply.

Playback EFM comparator bias current input.

I

Playback EFM RE signal input.

I

Analog ground.

Phase comparison output for master PLL of playback digital PLL and recording

O

EFM PLL.

I

Filter input for master PLL of playback digital PLL and recording EFM PLL.

O

Filter output for master PLL of playback digital PLL and recording EFM PLL.

Internal VCO control voltage input for master PLL of playback digital EFM PLL and

I

recording EFM PLL.

I

Peak hold signal input for quantity of light.

I

Bottom hold signal input for quantity of light.

I

Signal input for quantity of light.

I

Focus error signal input.

I

Auxillary input 1.

I

Center voltage input.

I

Monitor output for A / D converter input signal.

-

Analog power supply.

I

Voltage input for the upper limit of the A / D converter operating range.

Voltage input for the lower limit of the A / D converter operating range.

I

Analog ground.

Sled error signal input.

I

Tracking error signal input.

I

Connect to he low-inpedance power supply.

I

Error signal input for laser digital APC.

I

ADIP binary FM signal (22.05 1kHz) input.

I

O

CXA2523 current source setting output.

O

CXA2523 control latch output. Latched at the falling edge.

O

CXA2523 control shift clook output.

O

CXA2523 control data output.

O

Referevce PWM output for laser APC.

O

PWM output for laser digital APC.

O

Tracking servo drive PWM output. ( )

O

Tracking servo drive PWM output. (+)

-

Digital power supply.

O

Focus servo drive PWM output. (+)

O

Focus servo drive PWM output. ( )

O

4Fs output. (176.4kHz)

Function

1-46

Page 47

UX-A70MD

Pin No.

91

92

93

94

95

96

97

98

99

100

Symbol

SRDR

SFDR

SPRD

SPFD

FGIN

TEST1

TEST2

TEST3

DVSS

EFMO

I/O

O

Sled servo drive PWM output. ( )

O

Sled servo drive PWM output. (+)

O

Spindle servo drive output. (PWM ( ) or polarty)

O

Spindle servo drive output. (PWM (+) or PWM absolute value)

I

Spindle CAV servo FG input.

I

Test pin. Connect to GND.

I

Test pin. Connect to GND.

I

Test pin. Connect to GND.

-

Digital ground.

O

Low when playback ; EFM (encoded data) output when recording.

GP1U271X (IC701) : Receiver for remote

+

–

Amp.

Limiter Integrator Comparator

B.P.F

Function

Demodulator

GND

VCC Vout

1-47

Page 48

UX-A70MD

HY51V17400CT-60 (IC390) : DRAM

1.Pin layout

Vcc

DQ0

DQ1

WE

RAS

A11

A10

A0

A1

A2

A3

Vcc

3.Block diagram

Vss

DQ3

DQ2

CAS

OE

A9

A8

A7

A6

A5

A4

Vss

2.Pin function

Pin Name Parameter

/RAS

/CAS

/WE

/OE

A0~A11

A0~A10

DQ0~DQ3

Vcc

Vss

NC

Row Address Strobe

Column Address Strobe

Write Enable

Output Enable

Address Input (4K Refresh Product)

Address Input (2K Refresh Product)

Data In/Out

Power (3.3V)

Ground

No Connection

DQ0 DQ1 DQ2 DQ3

4

4

WE

CAS

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

*(A11)

CAS Clock

Generator

Cloumn Predecoder

(11/12)*

Refresh Counter

Refresh Counter

Address Buffer

Row Presecoder

(11/12)*

Data Input Buffer

DQ0~3 DQ0~3

44

(11/10)*

Decoder

(11/12)*

Row

Data Output Buffer

Column Decoder

Sense Amp

I/O Gate

Memory Array

4,194,304 x 4

OE

1-48

RAS

RAS Clock

Generator

X16 Parallel

Test

Substrate Bias

Generator

Vcc

Vss

Page 49

LA1838(IC1): FM AM IF AMP&detector, FM MPX decoder

1. Block Diagram

UX-A70MD

30

ALC

BUFF

FM

S-METER

FM IF

1

2. Pin Function

Pin

Symbol

No.

FM IN

1

AM MIX

2

3

FM IF

AM IF

4

GND

5

6

TUNED

STEREO

7

8

VCC

9

FM DET

10

AM SD

FM VSM

11

AM VSM

12

13

MUTE

14

FM/AM

MONO/ST O

15

29

AM

OSC

SD

COMP

S-CLRVE

PM

DET

2

I/O

I

This is an input terminal of FM IF

28

REG

AM

MIX

AM/FM

IF-BUFF

3

27

FM

RF.AMP

AM IF

4

26

AGC

AM

S-METER

Function

GND

5

DET

TUNING

DRIVE

signal.

This is an out put terminal for AM

O

mixer.

I

Bypass of FM IF

Input of AM IF Signal.

I

I

This is the device ground terminal.

When the set is tuning, this terminal

O

becomes "L".

O

Stereo indicator output. Stereo "L",

Mono: "H"

III

This is the power supply terminal.

I

FM detect transformer.

I

This is a terminal of AM ceramic filter.

O

Adjust FM SD sensitivity.

O

Adjust AM SD sensitivity.

I/O

When the signal of IF REQ of IC121(

LC72131) appear, the signal of FM/AM

IF output. //Muting control input.

Change over the FM/AM input.

I

"H" :FM, "L" : AM

Stereo : "H", Mono: "L"

25

6

24

STEREO

DRIVE

7

22

23

P-DET

VCC

89

Pin

Symbol

No.

16

L OUT

17

R OUT

18

19

20

21

22

23

24

25

26

27

28

29

30

L IN

R IN

RO

LO

IF IN

FM OUT

AM DET

AM AGC

AFC

AM RF

REG

AM OSC

OSC BUFFER

21

DECODER

ANIT-BIRDIE

VCO

384KHz

10

20

STEREO

5N

SW

FF

38k

11

I/O

O

Left channel signal output.

O

Right channel signal output.

Input terminal of the left channel post

I

18

19

MUTE

FF

/

19k

2

12 13

FF

19k

/

LS

Function

17 16

PILOT

DET

14

AMP.

Input terminal of the right channel

I

post AMP.

Mpx Right channel signal output.

O

O

Mpx Left channel signal output.

I

Mpx input terminal