Page 1

SERVICE MANUAL

MICRO COMPONENET SYSTEM

UX-A52R

UX-A52R

UX-A52R

- RDS -

COLOR

DIMMER

CONTROL

STANDBY/ON

CLOCK

SLEEP

FM MODE

/TIMER

1 2 3

DISPLAY

4 5 6

DISPLAY

TA/NEWS

PTY

/INFO

7 8 9

SELECT–+

10

0

+

10

SET

CANCEL

REPEAT

PLAY MODE

REV.MODE

CD

FM/AM

TAPE

AUX/MD

BEEP

SOUND

AHB

VOLUME

MODE

PRO

RM-SUXA52R

Contents

Safety precautions

Preventing static electricity

Important for laser products

Disassembly method

Adjustment Method

PHONES

1-2

1-4

1-5

1-6

1-25

MICRO COMPONENT SYSTEM UX-A52R

COMPACT

DIGITAL AUDIO

STANDBY/ON

B ---------------------------- U.K.

E -------- Continental Europe

EN ----------- Nor them Europe

Flow of functional operation

until TOC read (CD)

Maintenance of laser pickup

Replacement of laser pickup

Description of major ICs

Area Suffix

1-29

1-30

1-30

1-31~49

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

No.21064

Feb. 2002

1-1

Page 2

UX-A52R

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

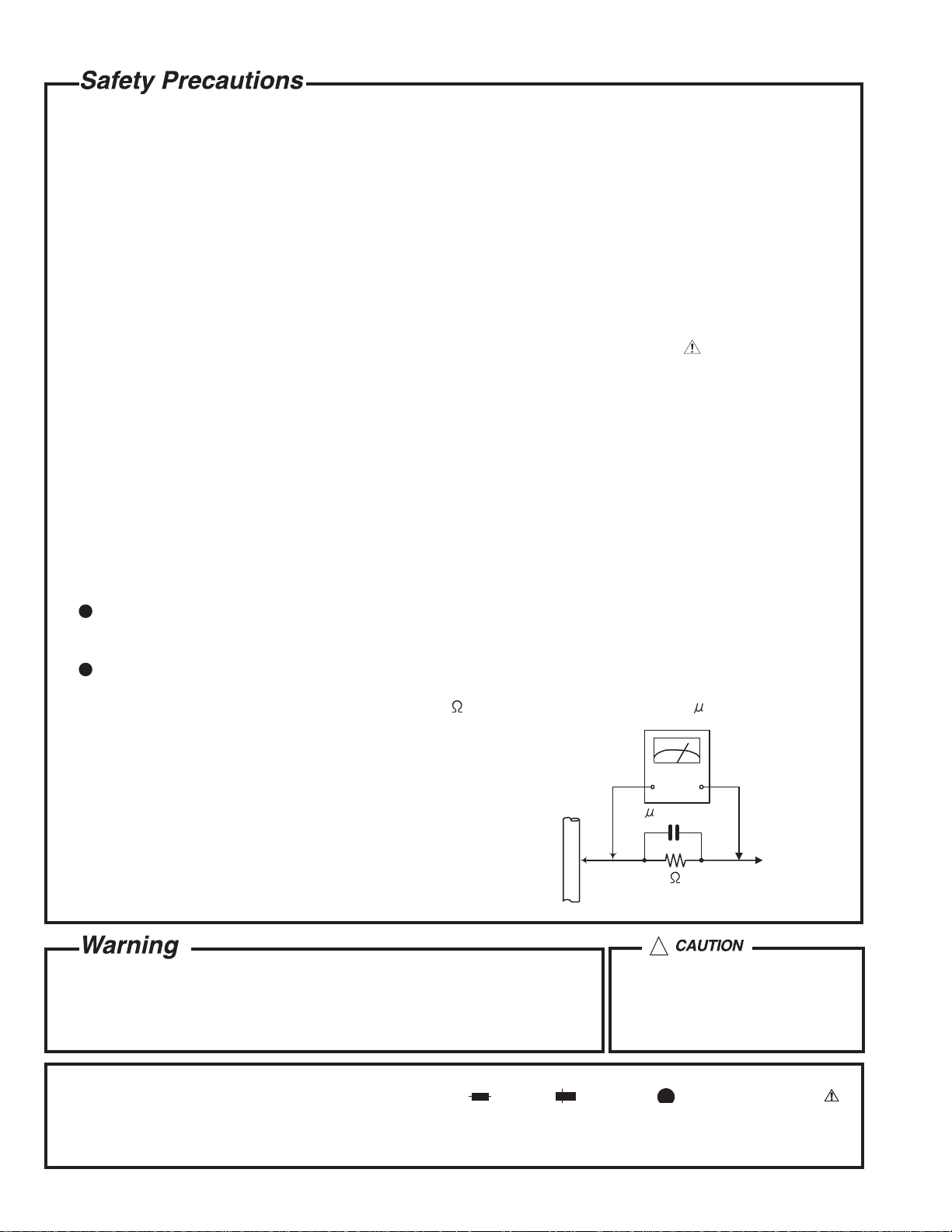

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

1-2

Page 3

UX-A52R

(U.K only)

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer. Replacement parts must be identical to

those used in the original circuits.

2. Any unauthorised design alterations or additions will void the manufacturer's guarantee ; furthermore the

manufacturer cannot accept responsibility for personal injury or property damage resulting therefrom.

3. Essential safety critical components are identified by ( ) on the Parts List and by shading on the

schematics, and must never be replaced by parts other than those listed in the manual. Please note

however that many electrical and mechanical parts in the product have special safety related

characteristics. These characteristics are often not evident from visual inspection. Parts other than

specified by the manufacturer may not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of the Service Manual and may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the original lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

1. Service should be performed by qualified personnel only.

2. This equipment has been designed and manufactured to meet international safety standards.

3. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

4. Repairs must be made in accordance with the relevant safety standards.

5. It is essential that safety critical components are replaced by approved parts.

6. If mains voltage selector is provided, check setting for local voltage.

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-3

Page 4

UX-A52R

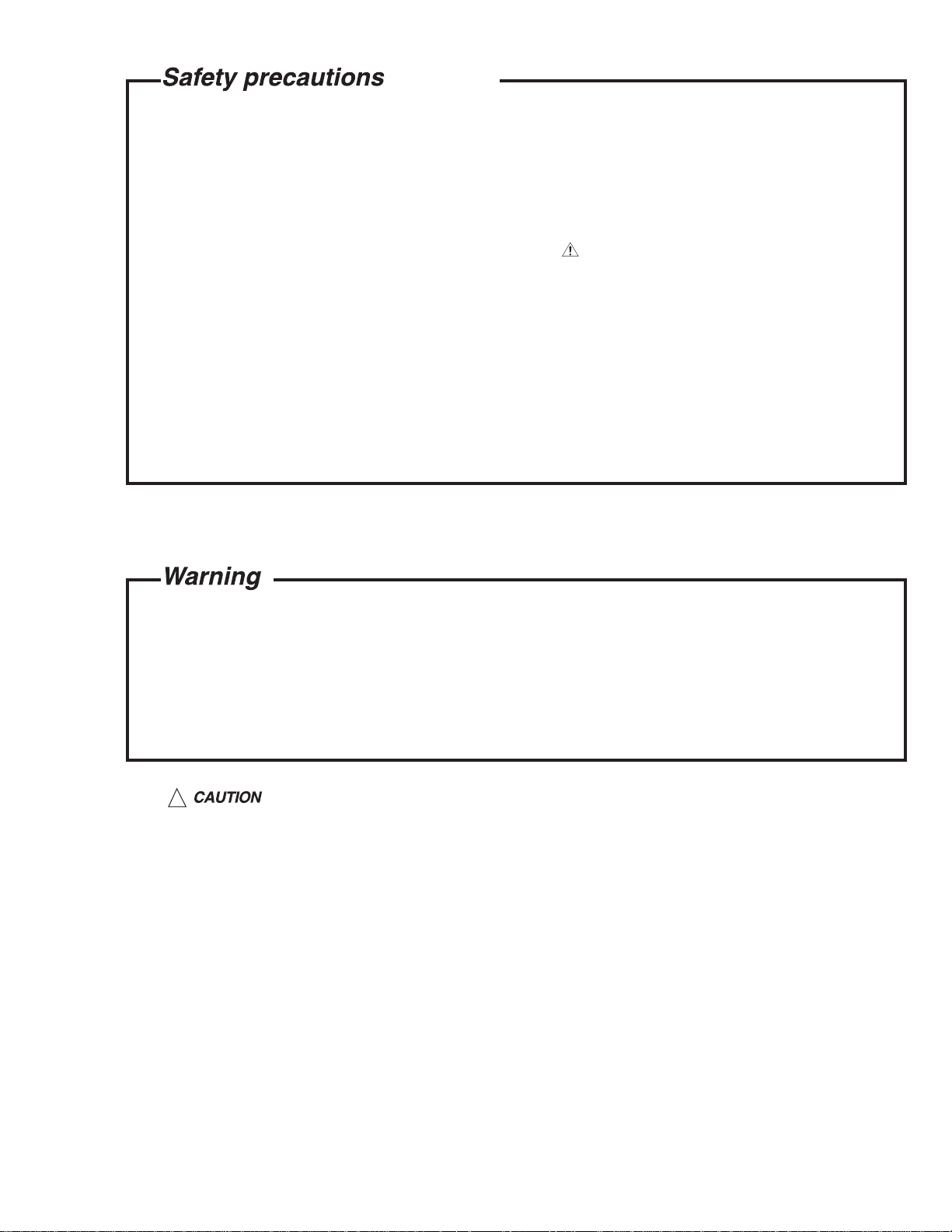

Preventing static electricity

1.Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2.About the earth processing for the destruction prevention by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

4.Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for pick-up and how to

detach the substrate.

Shorting round

1.Solder is put up before the card wire is removed from connector on

the CD substrate as shown in Figure.

(When the wire is removed without putting up solder, the CD pick-up

assembly might destroy.)

2.Please remove solder after connecting the card wire with

when you install picking up in the substrate.

1-4

Flexible wire

Shorting round

CN601 on

mechanism

board

Page 5

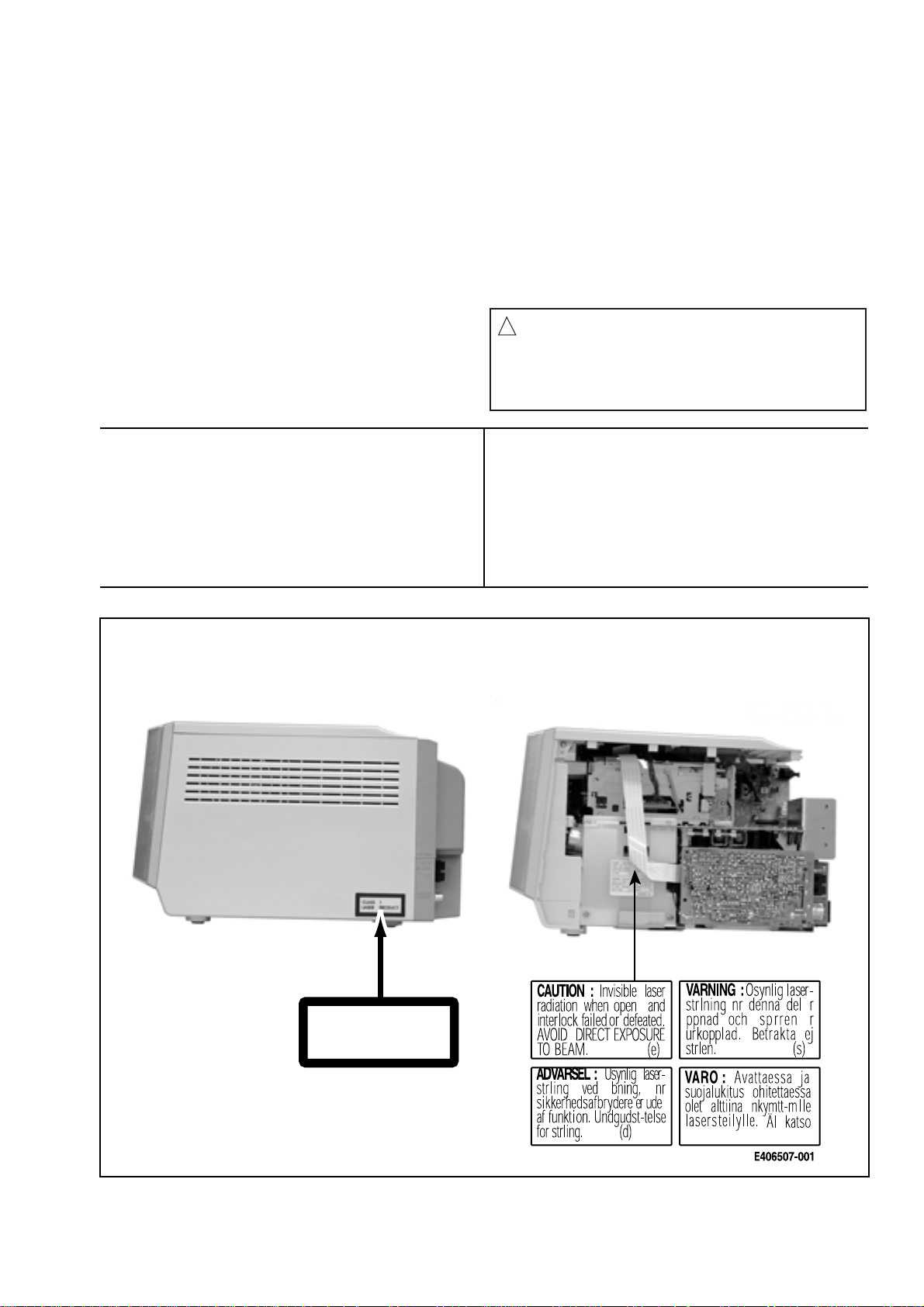

Important for laser products

UX-A52R

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

VARNING : Osynlig laserstrålning är denna del är öppnad

och spårren är urkopplad. Betrakta ej strålen.

VARO : Avattaessa ja suojalukitus ohitettaessa olet

alttiina näkymättömälle lasersäteilylle.Älä katso

säteeseen.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

ADVARSEL : Usynlig laserstråling ved åbning , når

sikkerhedsafbrydere er ude af funktion. Undgå

udsættelse for stråling.

ADVARSEL : Usynlig laserstråling ved åpning,når

sikkerhetsbryteren er avslott. unngå utsettelse

for stråling.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CLASS 1

LASER PRODUCT

1-5

Page 6

UX-A52R

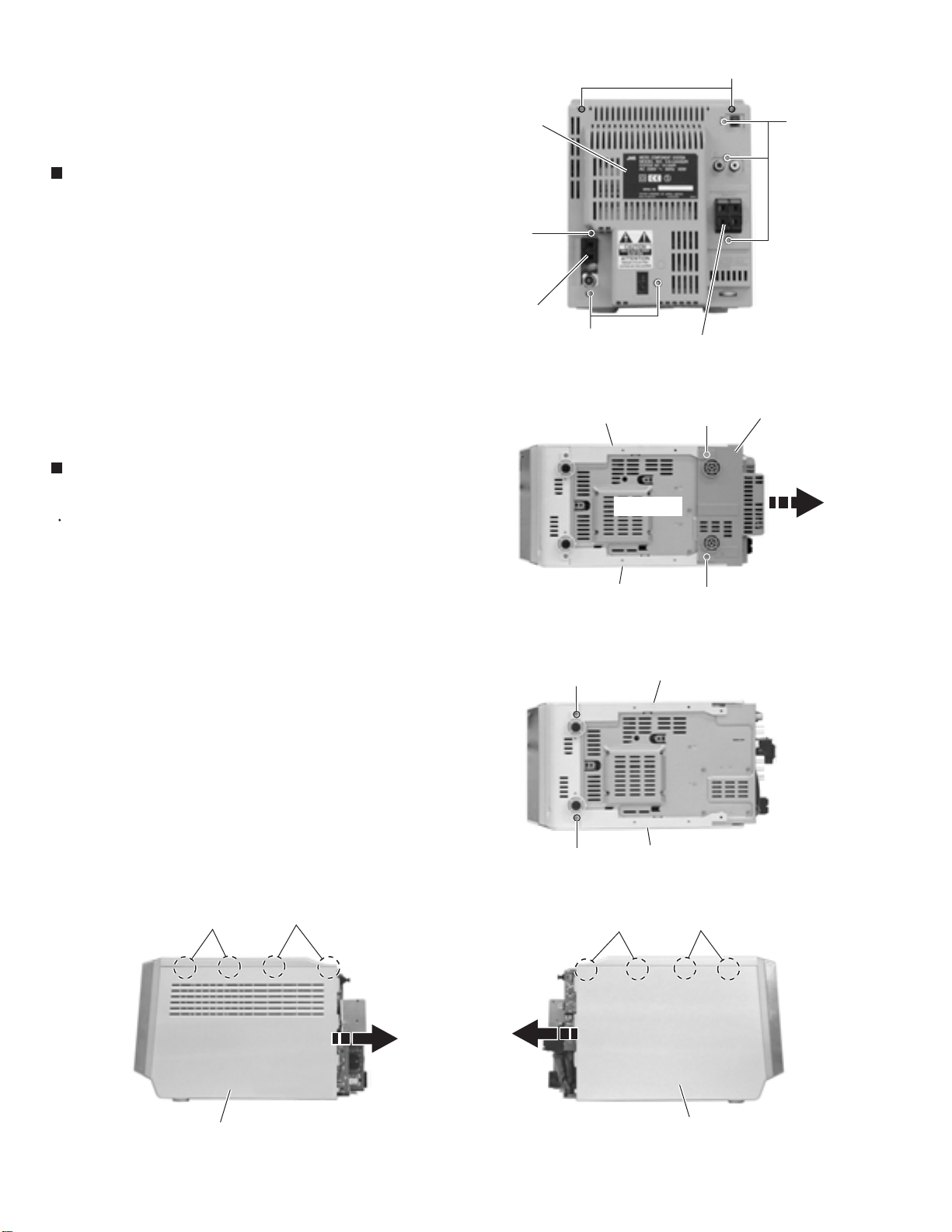

Disassembly method

<Main body>

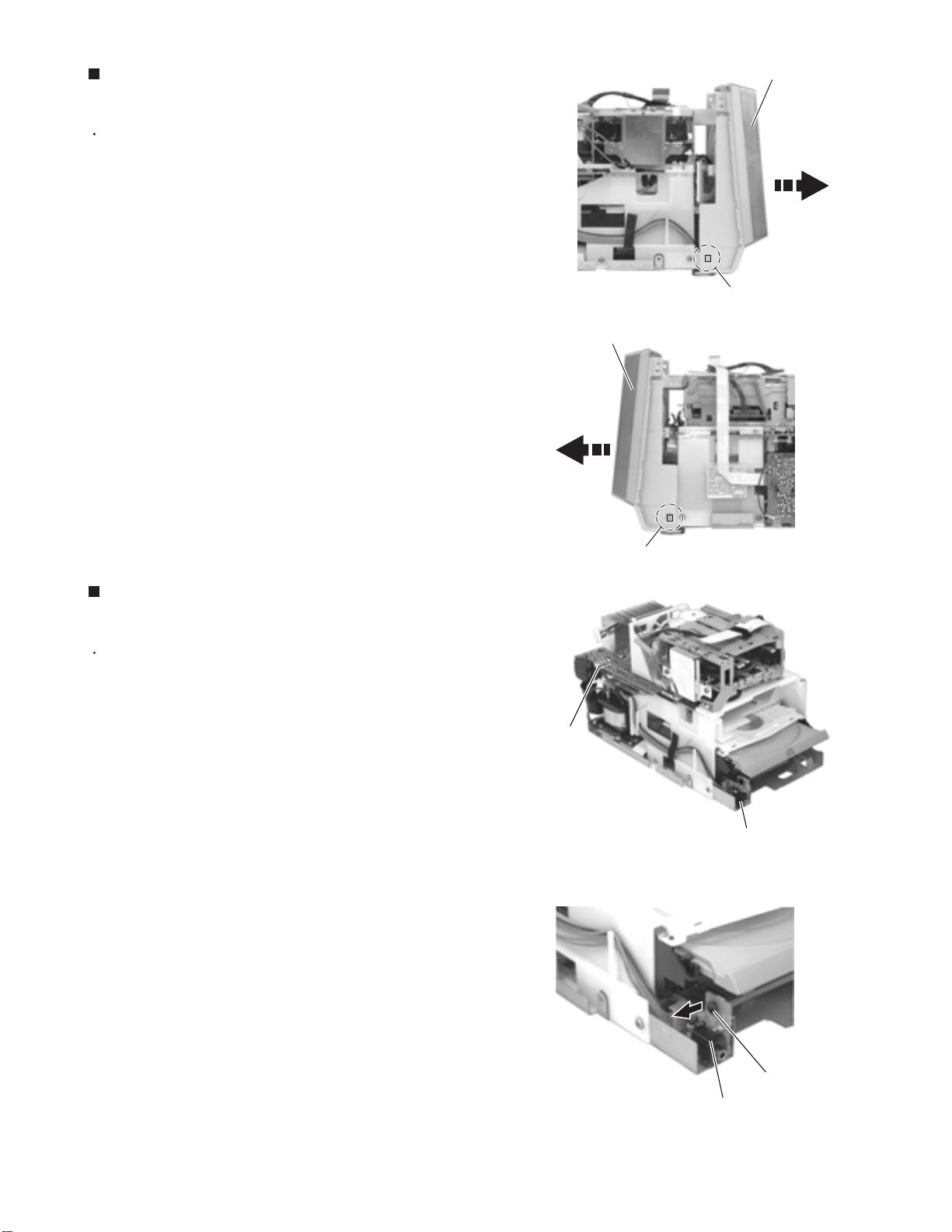

Removing the rear cover

(See Fig.1 and 2)

1.

Remove the eight screws A on the back of the body.

2.

Remove the two screws B on the bottom of the

body.

3.

Unlock the speaker terminal and the antenna

terminal, then remove the rear cover backward with

releasing the hooks.

Removing the side panels

(See Fig.3 to 5)

Prior to performing the following procedure, remove

the rear cover.

Rear cover

A

Antenna terminal

Side panel (R)

A

Speaker terminal

Fig.1

(Bottom)

(Bottom)

B

A

A

Rear cover

1.

Remove the two screws C attaching the side panels

on the bottom of the body.

2.

Remove each side panel backward while releasing

the eight joints a as shown in Fig.4 and 5.

Joint a

Joint a

Side panel (L)

Fig.2

C

C

Side panel (R)

Side panel (L)

Fig.3

Joint a

B

Joint a

1-6

Side panel (R)

Fig.4

Side panel (L)

Fig.5

Page 7

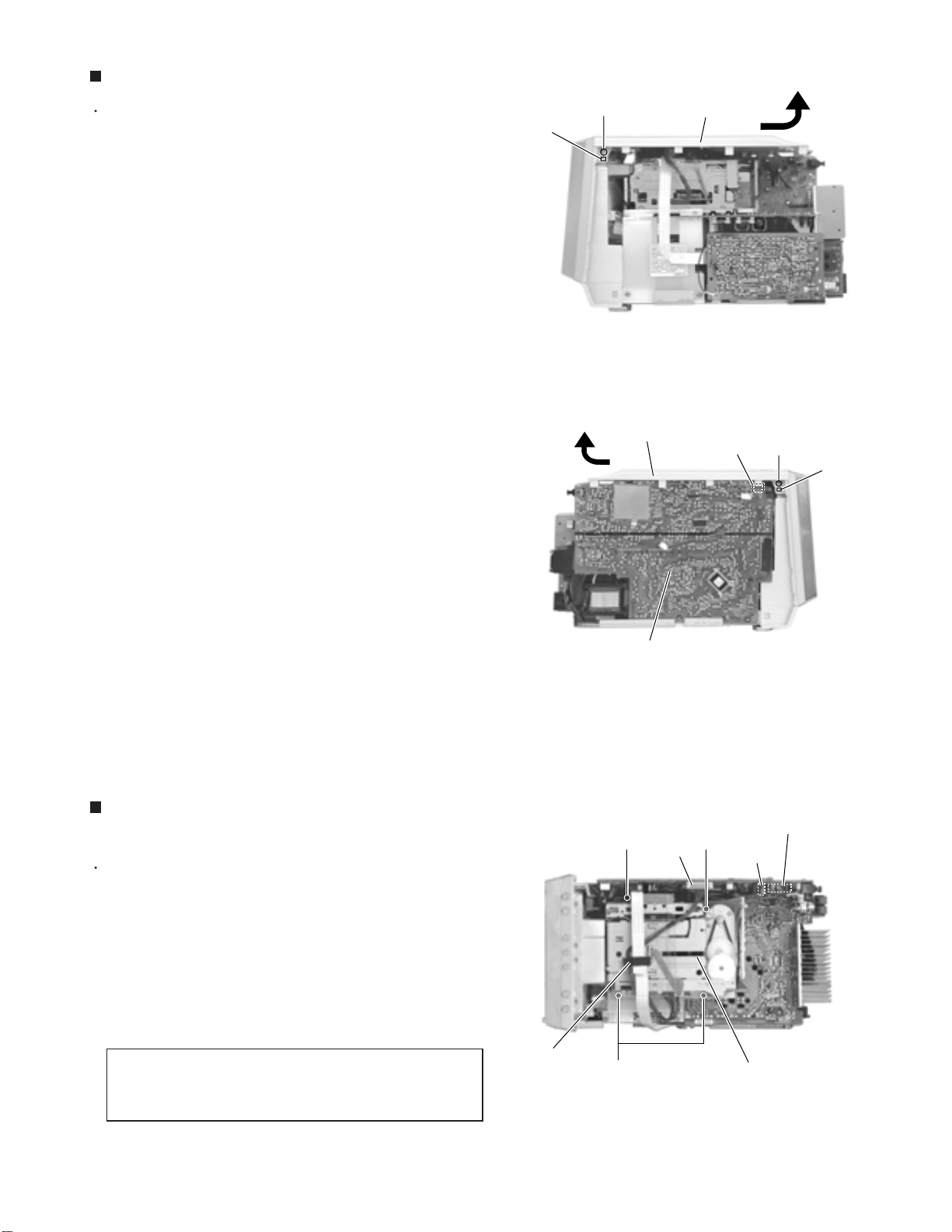

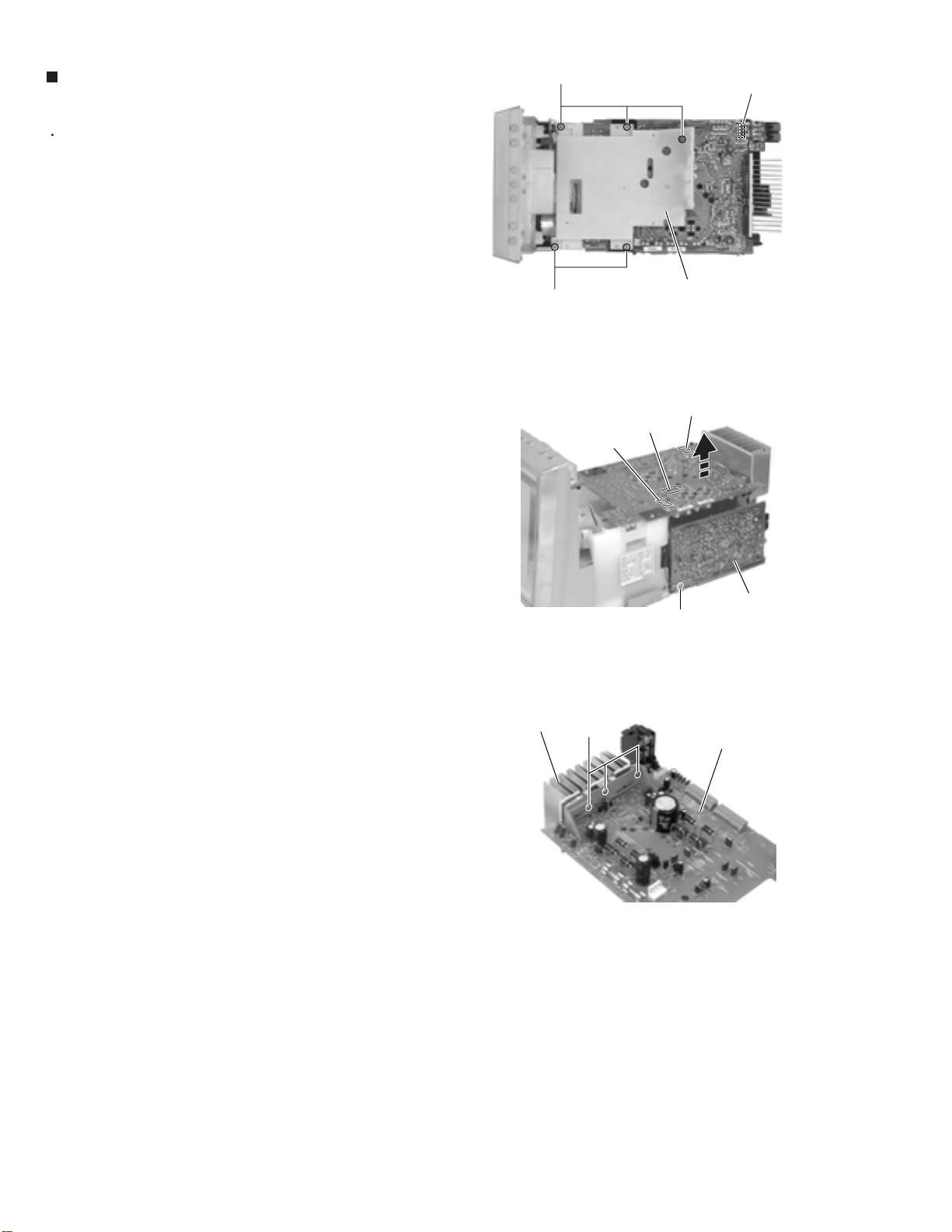

Removing the top panel (See Fig.6 and 7)

UX-A52R

Prior to performing the following procedure, remove

the rear cover and the side panels.

1.

Remove the two screws D on each side of the body.

2.

Release the two joints b on each side of the body

and remove the top panel in the direction of the

arrow.

3.

Disconnect the card wires from connector CN705 on

the system control board on the left side of the body.

Joint b

D

Top panel

Top panel

Fig.6

CN705

D

Joint b

Removing the cassette mechanism

assembly section (See Fig.8)

Prior to performing the following procedure, remove

the rear cover, the side panels and the top panel.

1.

Disconnect each wire from connector CN706, CN715

and CN716 on the system control board on top of the

body.

2.

Remove the four screws E retaining the cassette

mechanism assembly section on top of the body.

REFERENCE:

Reference: If necessary, remove the

spacer marked h and the wire from the

Cassette mechanism assembly section.

h (spacer)

System control board

Fig.7

E E

CN715

E

Cassette mechanism section

Fig.8

System control board

CN706

CN716

1-7

Page 8

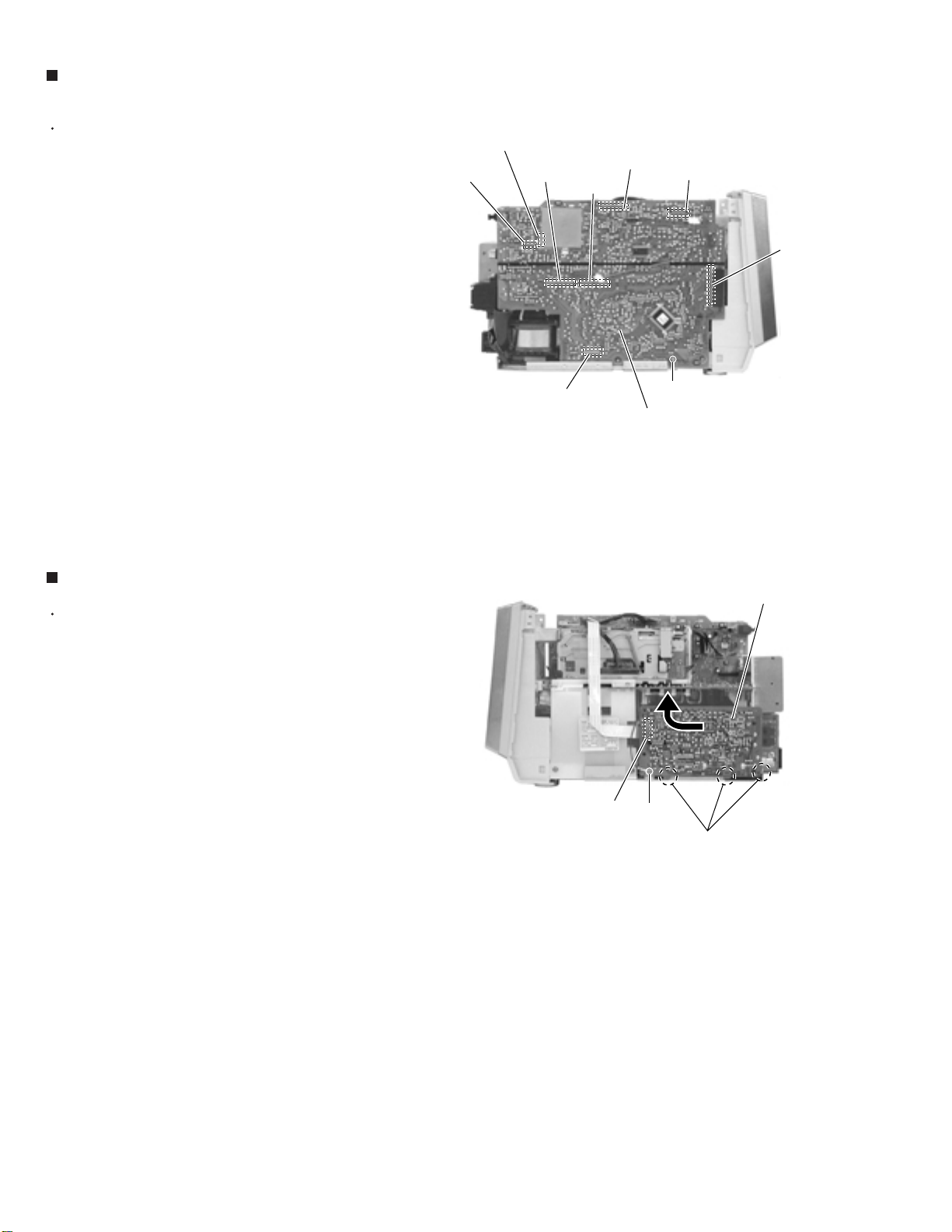

UX-A52R

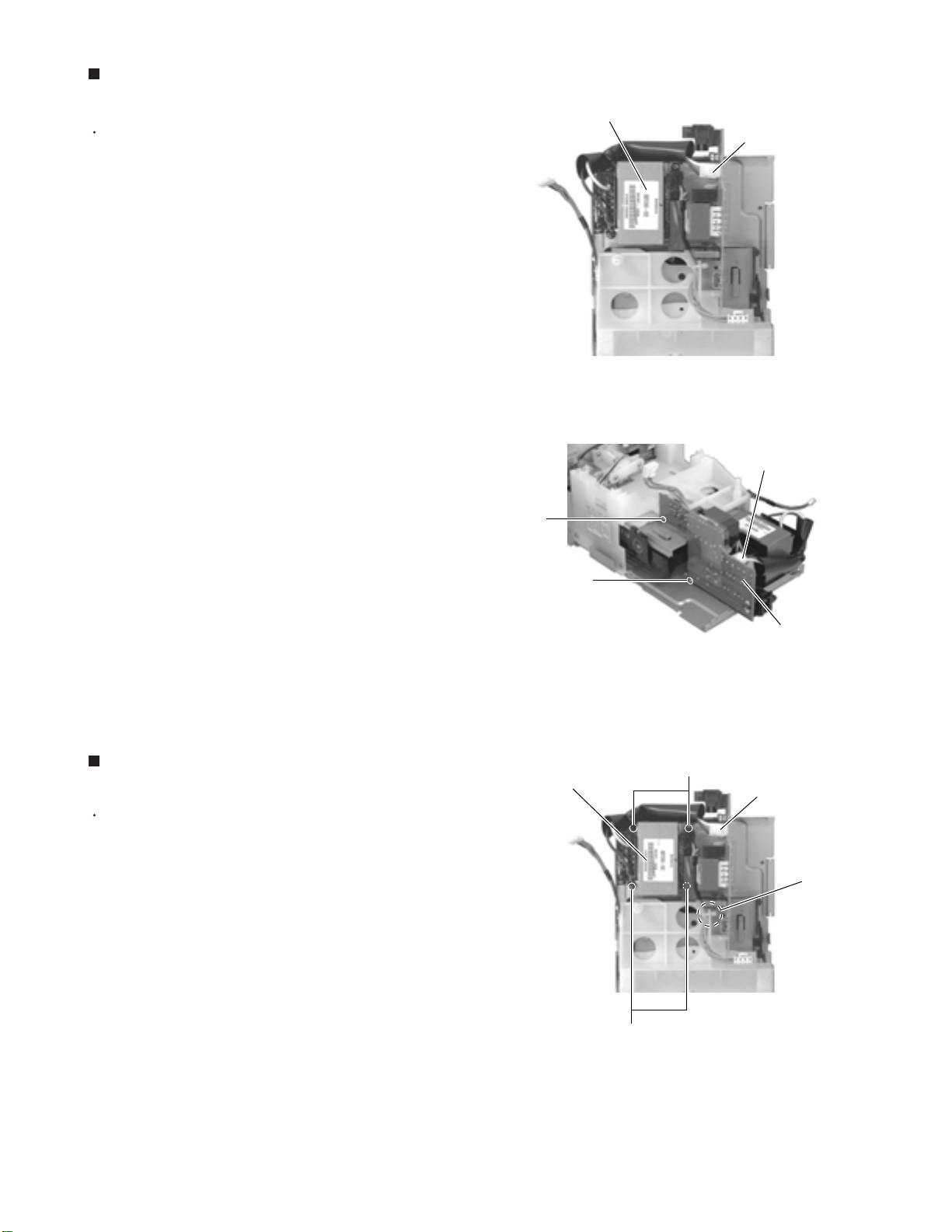

Removing the system control board

(See Fig.9)

Prior to performing the following procedure, remove

the rear cover, the side panels and the top panel.

1.

Disconnect the card wire from connector CN701 and

the wire from connector CN706, CN715, CN716 on

the system control board.

2.

Remove the screw F on the left side of the body.

3.

Disconnect connector CN709, CN711 and CN712 on

the system control board from the body outward.

4.

Disconnect the card wire from connector CN704 on

the underside of the system control board.

Removing the tuner board (See Fig.10)

Prior to performing the following procedure, remove

the rear cover and the right side panel.

CN706

CN716

CN712

CN704

CN715

CN701

CN711

CN709

F

System control board

Fig.9

Tuner board

1.

Disconnect the card wire from connector CN1 on the

tuner board on the right side of the body.

2.

Remove the screw G and remove the tuner board

upward while disengaging the three joints c.

CN1

G

Joints c

Fig.10

1-8

Page 9

UX-A52R

Removing the front panel assembly

(See Fig.11 and 12)

Prior to performing the following procedure, remove

the rear cover, the side panels, the top panel and the

system control board.

1.

Release the two joints d on the lower right and left

sides of the front panel assembly, then remove the

front panel assembly toward the front.

Front panel assembly

Front panel assembly

Fig.11

Joint d

Removing the headphone jack board

(See Fig.13 and 14)

Prior to performing the following procedure, remove

the rear cover, the side panels, the top panel, the

system control board and the front panel assembly

section.

1.

Disconnect the wire from connector CN804 on the

main board.

2.

Remove the plastic rivet fixing the headphone jack

board.

Joint d

Fig.12

Main board

CN804

Headphone jack board

Fig.13

Plastic rivet

Headphone jack board

Fig.14

1-9

Page 10

UX-A52R

Removing the main board / the heat sink

(See Fig.15 to 17)

Prior to performing the following procedure, remove

the rear cover, the side panels, the top panel, the

cassette mechanism assembly section and and the

system control board.

1.

Disconnect the wire from connector CN804 on the

main board.

2.

Remove the five screws H attaching the cassette

mechanism bracket.

3.

Remove the screw G attaching the grounding

terminal extending from the main board.

4.

Disconnect connector CN805 on the main board

from the AC jack board while pulling out it. Remove

the main board in the direction of the arrow and

disconnect the wire from connector CN803 on the

reverse side of the main board.

5.

Remove the three screws I attaching the heat sink

on the reverse side of the main board.

H

H

Main board

CN804

Cassette mechanism bracket

Fig.15

Main board

CN804

CN805

CN803

Heat sink

Tuner board

G

Fig.16

I

Fig.17

Main board

1-10

Page 11

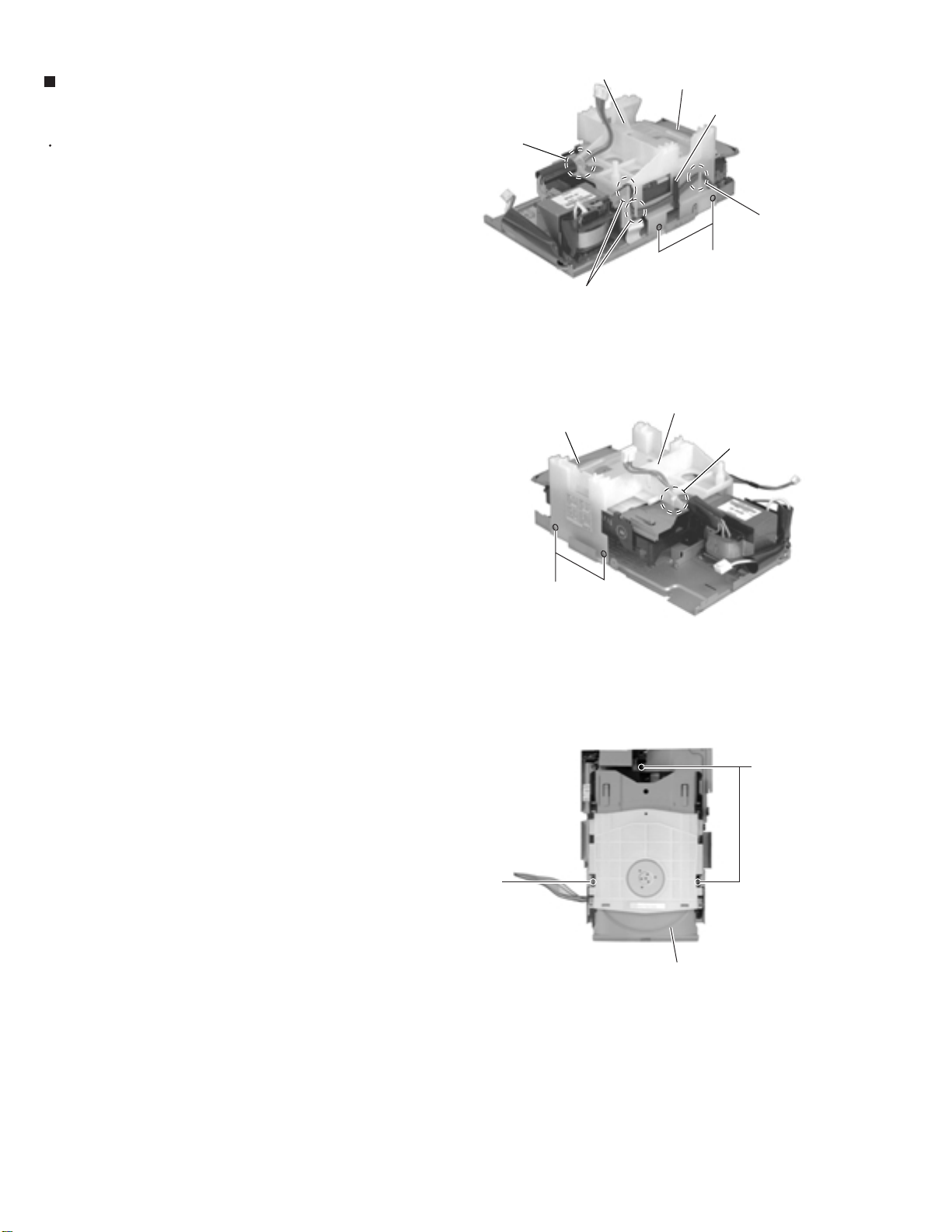

Removing the AC jack board

(See Fig.18 and 19)

Prior to performing the following procedure, remove

the rear cover, the side panels, the top panel, the

cassette mechanism assembly section, the system

control board and the main board / the tuner board.

1.

Disconnect the wire from connector CN809 on the

AC jack board.

2.

Remove the screw J and screw K attaching the AC

jack board.

Power transformer assembly

UX-A52R

AC jack board

CN809

Fig.18

CN809

Removing the power transformer

assembly (See Fig.20)

Prior to performing the following procedure, remove

the rear cover, the side panels, the top panel, the

cassette mechanism assembly section, the system

control board and the main board.

1.

Disconnect the wire from connector CN809 on the

AC jack board.

2.

Cut off the band setting the wire on the CD

mechanism cover.

J

K

Power transformer

assembly

Fig.19

L

AC jack board

AC jack board

CN809

Band

3.

Remove the four screws L attaching the power

transformer assembly.

L

Fig.20

1-11

Page 12

UX-A52R

Removing the CD mechanism assembly

(See Fig.21 to 23)

Prior to performing the following procedure, remove

the rear cover, the side panels, the top panel, the

cassette mechanism assembly section, the system

control board, the front panel assembly section, the

main board / the tuner board and the AC jack board.

1.

Cut off the band setting the wire on the CD

mechanism cover.

2.

Release the wire extending from the headphone jack

board from the spacer and the three notches of the

CD mechanism cover on the left side of the body.

3.

Remove the four screws M on the left and right side

of the CD mechanism cover. Then remove the CD

mechanism cover upward.

4.

Remove the three screws N attaching the CD

mechanism assembly.

CD mechanism cover

Band

Notches

CD mechanism assembly

CD mechanism assembly

Spacer

Notch

M

Fig.21

CD mechanism cover

Band

N

M

Fig.22

N

CD mechanism assembly

Fig.23

1-12

Page 13

UX-A52R

<Front panel assembly section>

Prior to performing the following procedure, remove

the rear cover, the side panels, the top panel, the

system control board and the front panel assembly

section.

Removing the relay board (See Fig. 24)

Disconnect the wire from connector CN906, CN907

1.

and the card wire from CN908 on the relay board

respectively.

Remove the two screws O.

2.

Removing the drive motor assembly

(See Fig.25)

Prior to performing the following procedure, remove

the relay board.

CN907

Drive motor assembly

CN908

Fig.24

O

O

Door switch board

P

Relay board

CN906

1.

Remove the four screws P attaching the drive motor

assembly.

Removing the belt and the drive motor

(See Fig.26)

REFERENCE:

1.

Remove the two screws Q attaching the plate.

2.

Remove the belt from the two pulleys.

3.

Remove the two screws R attaching the drive motor.

REFERENCE:

The belt and the drive motor can be

removed respectively without removing the

drive motor assembly from the front panel

section.

When removing the drive motor only,

remove the belt from the drive motor

pulleys in advance.

P

Fig.25

Belt

Plate

Drive motor

R

Fig.26

Q

1-13

Page 14

UX-A52R

Removing the door switch board

(See Fig.27 and 28)

Prior to performing the following procedure, remove

the relay board.

1.

Loosen the screw S attaching the door switch.

2.

Remove the door switch board while releasing it from

the joint e.

CAUTION:

When reattaching the door switch board,

fit it to the joint e and check the

operating state of the switch before

tightening the screw S.

Removing the LCD section

(See Fig.29 to 31)

Prior to performing the following procedure, remove

the relay board.

Drive motor assembly

Switch section

S

Fig.27

Door switch board

S

Fig.28

Door switch board

Joint e

Joint e

1.

Loosen the two screws T attaching the lock lever.

2.

Push the part f of the lock lever in the direction of

the arrow as shown in Fig.30-1 / 30-2 and disengage

the LCD section from the front panel assembly.

CAUTION:

Because the LCD may come off, hold it

when loosening the screws T.

Lock lever f Lock lever f

Lock lever

T

LCD section

Lock lever

T

Front panel assembly

Fig.29

Front panel assembly

Joint f

1-14

Fig.30-1 Fig.30-2

Joint f

Fig.31

Page 15

UX-A52R

Removing the LCD board assembly

(See Fig.32 to 36)

Prior to performing the following procedure, remove

the relay board and the LCD section.

1.

Remove the four screws U attaching the case cover.

2.

Remove the four screws V attaching the LCD panel

on the back of the LCD section.

3.

Remove the LCD cover.

4.

Release the three joints g and remove the LCD

board assembly in the direction of the arrow.

U

V

U

Case cover

U

U

Fig.32

LCD section

Joint g

V

Fig.33

LCD panel

Fig.34

Joint g

Joint g

LCD cover

LCD board assembly

Fig.35 Fig.36

1-15

Page 16

UX-A52R

<Top panel section>

Prior to performing the following procedure, remove

the rear cover, the side panels and the top panel.

Removing the operation switch board

(See Fig.37)

1.

Remove the seven screws W attaching the

operation switch board on the reverse side of the top

panel.

W

Cassette amplifier board

W

Fig.37

Operation switch board

W

1-16

Page 17

UX-A52R

<CD Mechanism Assembly>

Removing the CL. Base Assembly and Tray

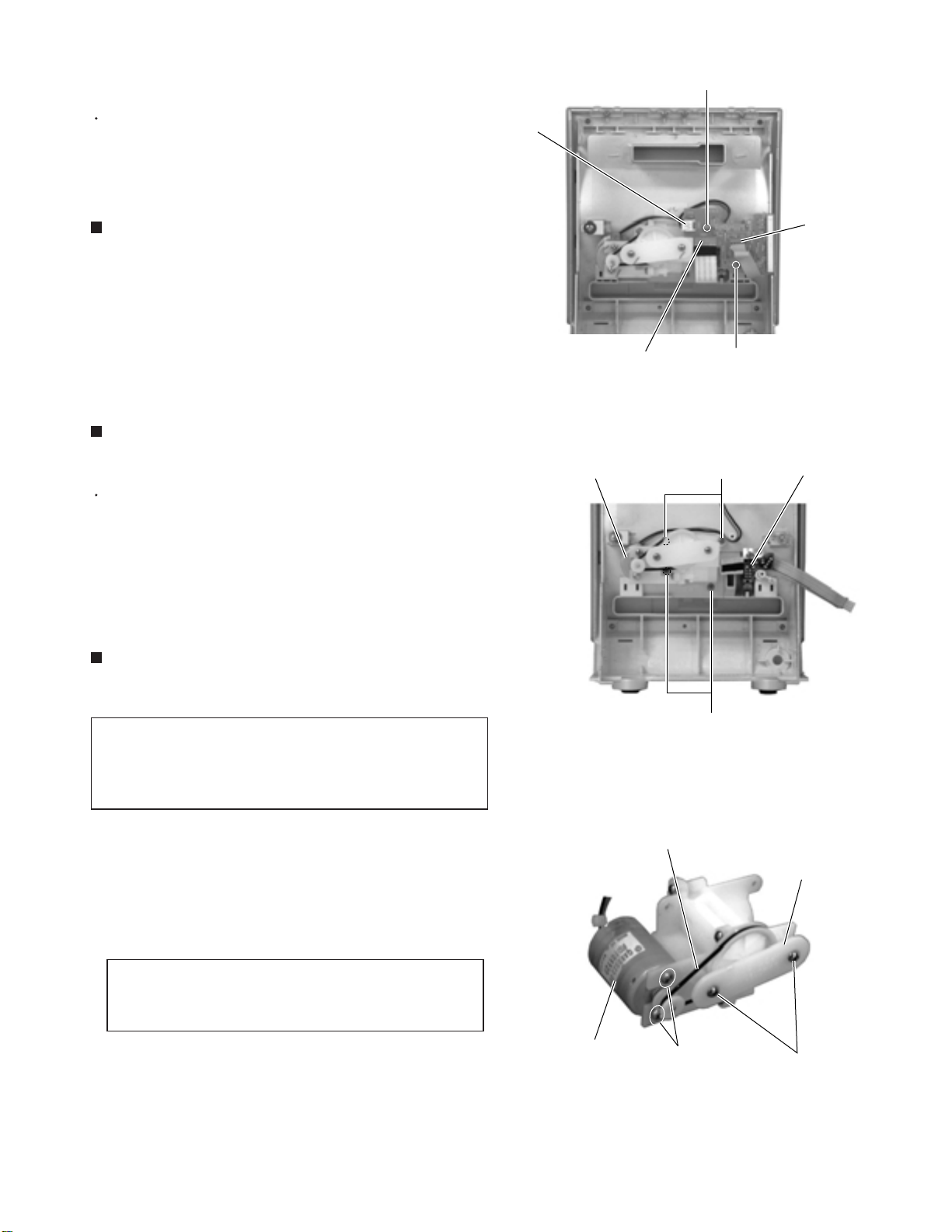

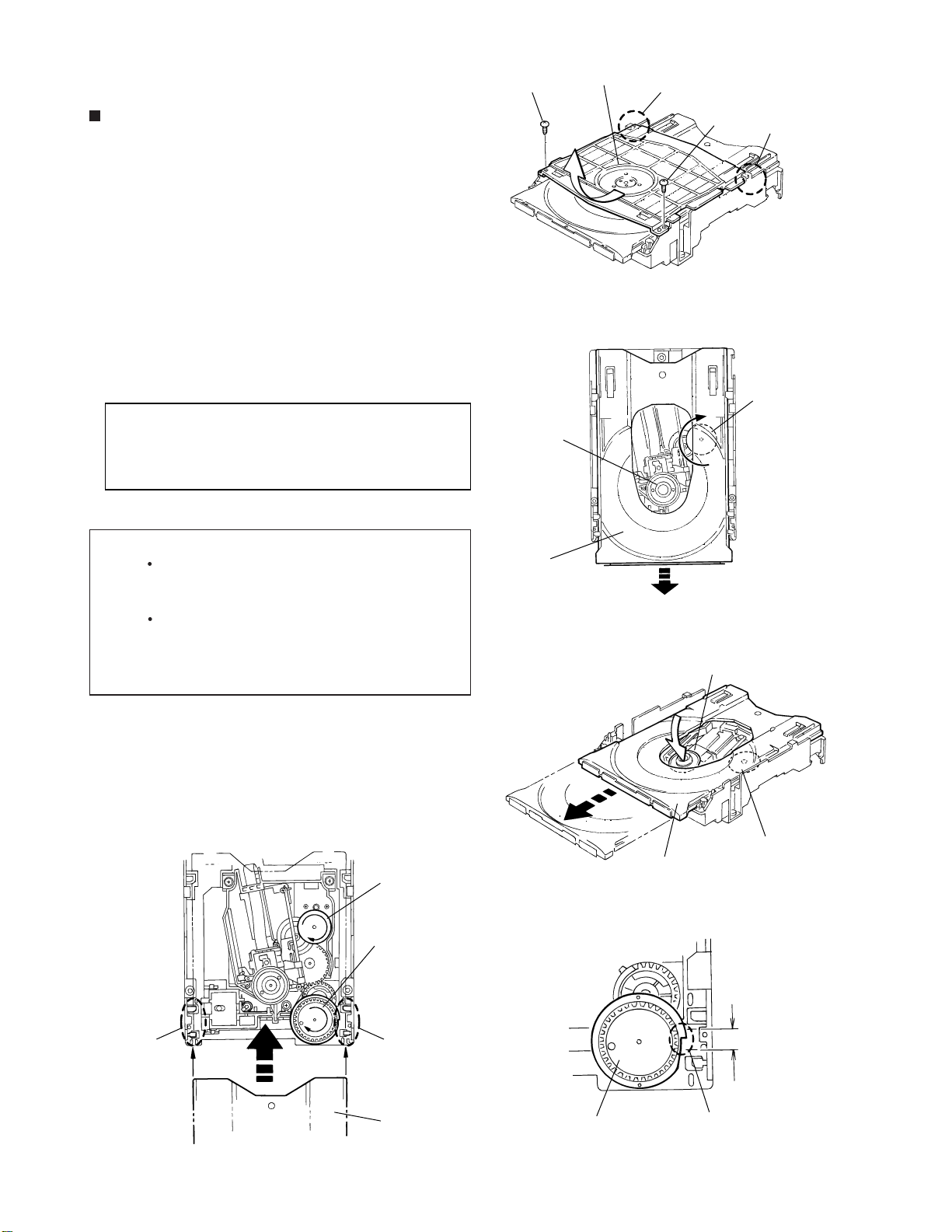

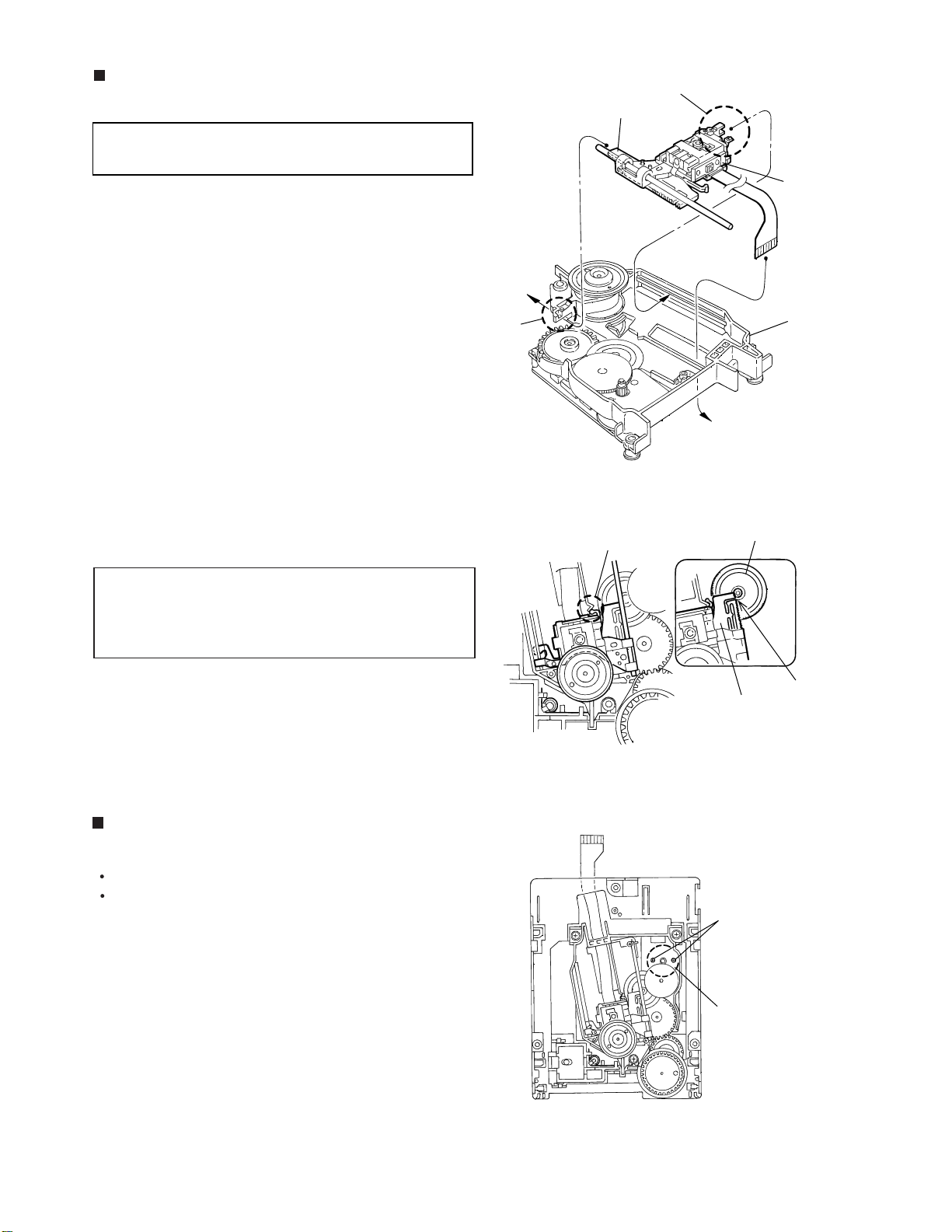

(Refer to Figs. 1 to 5.)

1. Remove the two screws A fastening the CL. base

assembly from the top of the CD mechanism

assembly.

2. Move the CL. base assembly diagonally upwards

as indicated by the arrow to release it from the two

hooks a.

3. Turn the idle gear in the arrow-marked direction

from the upper side of the CD mechanism

assembly. Accordingly, the TRAMECHA assembly

moves downwards.

Note: When drawing out the tray, shift down the

TRAMECHA assembly to the position where

the tray does not contact the T-T assembly

of the TRAMECHA assembly.

4. Draw out the tray frontwards for removing it.

CL. base assembly

A

TRAMECHA

assembly

Hook a

Fig. 1

A

Hook a

Idle gear

Note: When reinstalling the tray:

Turn the idle gear so that the part b of the

tray gear is positioned in the part c shown in

Fig. 4. (Eject position)

Engage the right and left hooks d and e of

the tray with the right and left grooves of the

TRAMECHA assembly respectively for

retaining the tray.

Idle gear

Tray gear

Tray

Fig. 2

TRAMECHA assembly

Idle gear

Tray

Fig. 3

Hook d

Hook d

Tray

Tray gear

Part c

Part b

Fig. 4Fig. 5

1-17

Page 18

UX-A52R

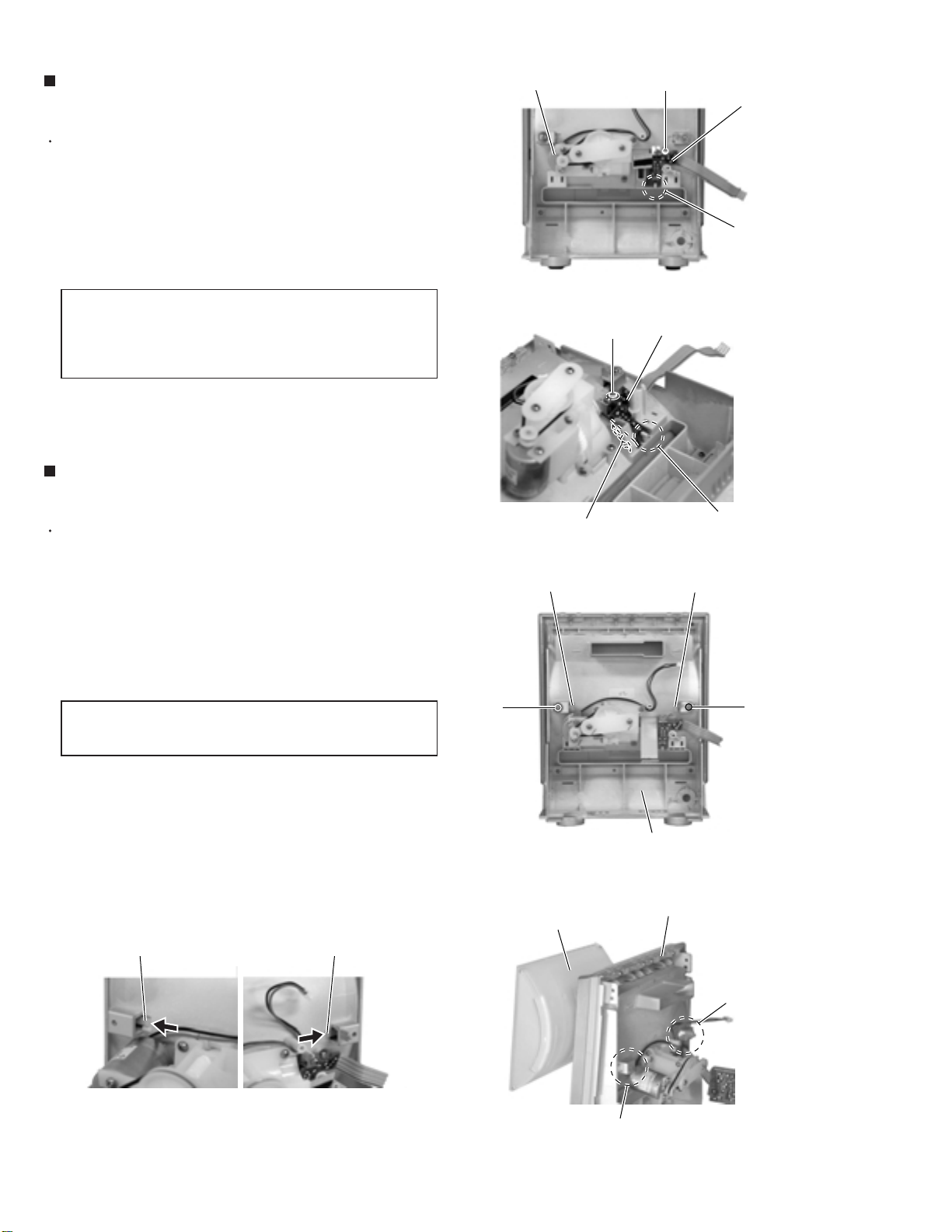

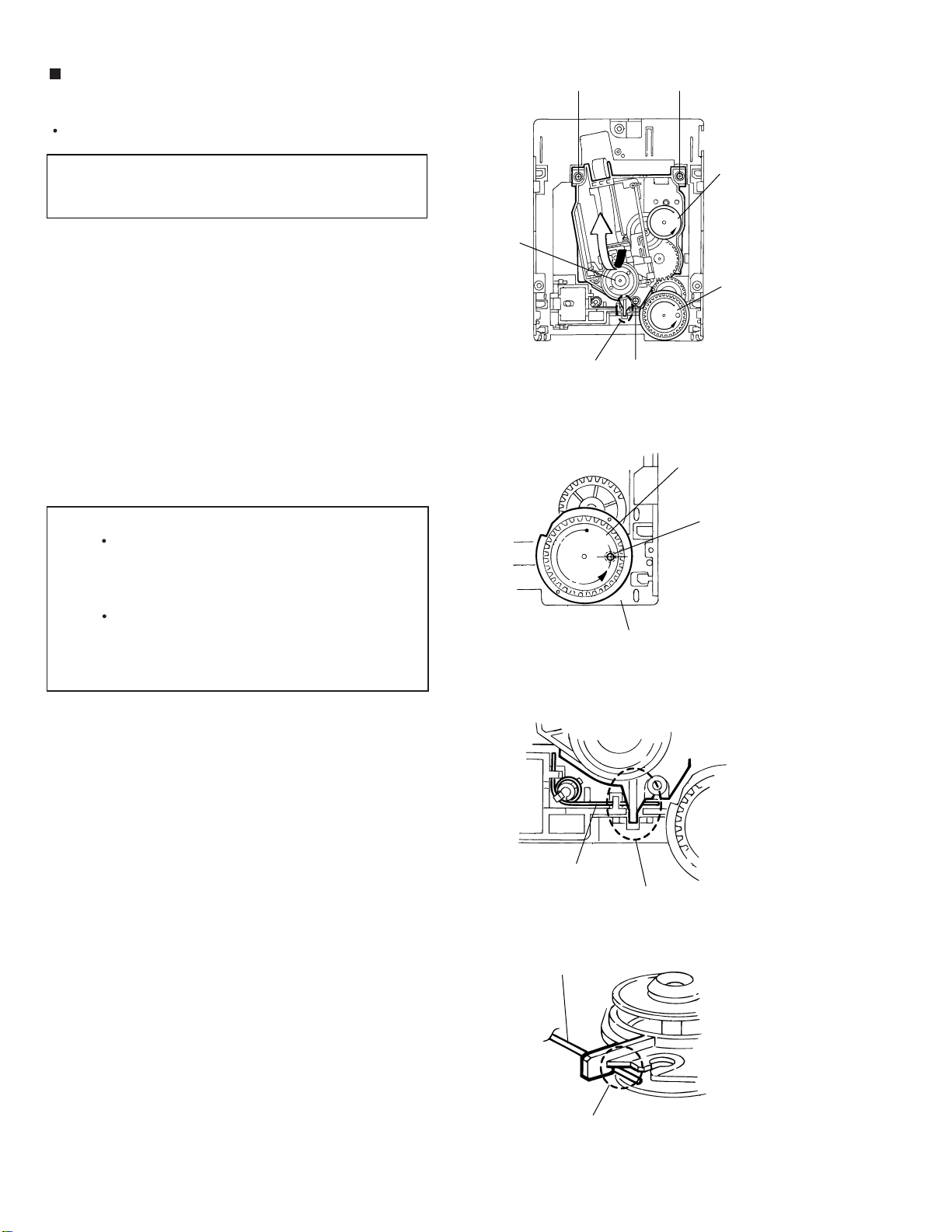

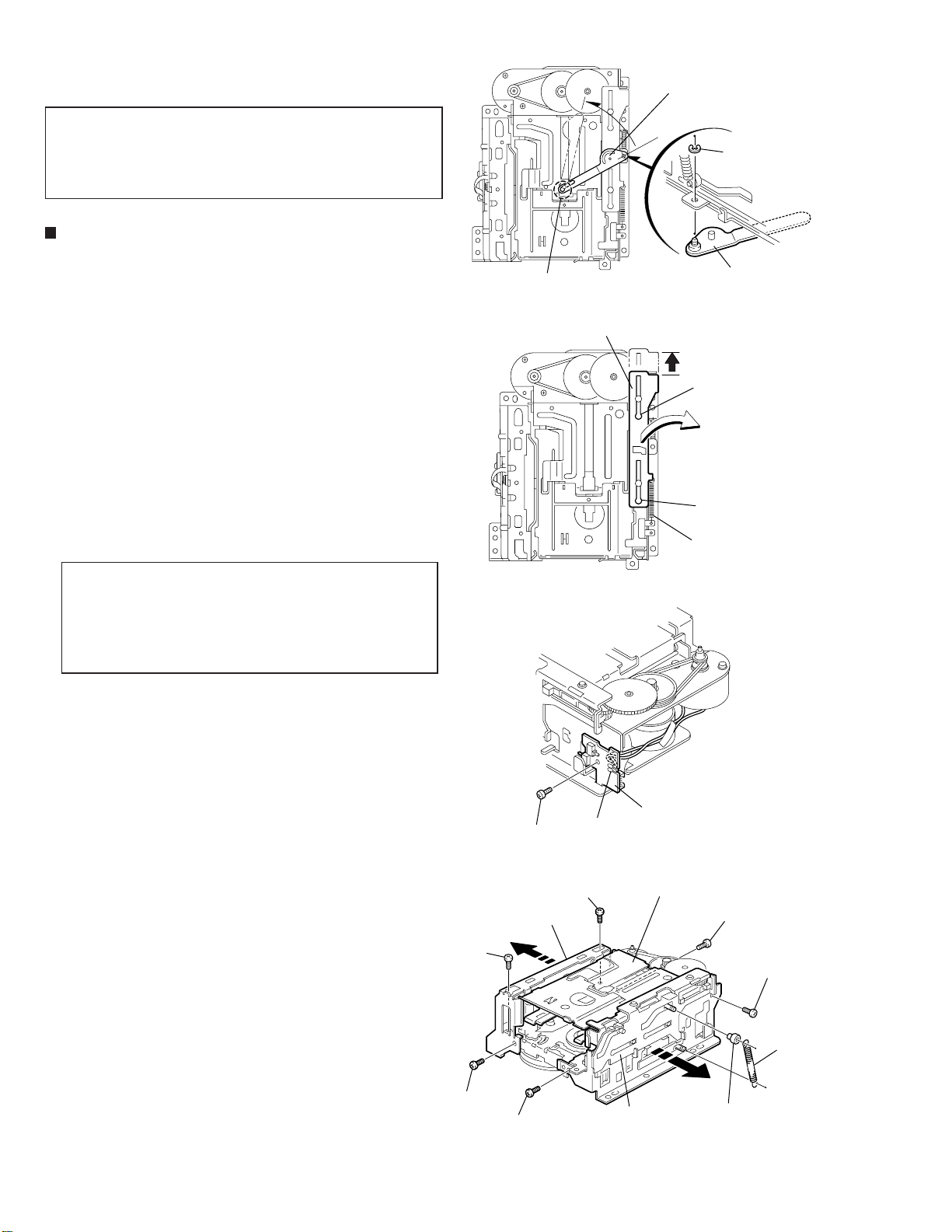

Removing the TRAMECHA Assembly

(Refer to Figs. 6 to 9.)

Remove the CL. base assembly and tray.

Reference: The TRAMECHA assembly can be

removed without removal of the

mechanism board.

1. If the TRAMECHA assembly is lowered and it is

located out of the PLAY position, turn the idle gear

in the arrow-marked direction so that the hole in the

part f of the tray gear meets the hole on the CL.

base assembly. (Set the TRAMECHA assembly at

the PLAY position.)

2. Remove the three screws B fastening the

TRAMECHA assembly and then remove the

TRAMECHA assembly upwards from the front side.

3. At the same time, remove the spring from the groove of

the CH. base assembly in the part g of the TRAMECHA

assembly.

Note: When reinstalling the TRAMECHA assembly:

Check to see if the spring is properly

engaged with groove of the CH. base

assembly in the part g of the TRAMECHA

assembly.

After making sure that the three insulators of

the TRAMECHA assembly are properly set

on the bosses of the L. base assembly's

guide, fasten them with the screws.

TRAMECHA

assembly

B

Part g

L. base assembly

B

Fig. 6

Fig. 7

B

Idle gear

Tray gear

Tray gear

Part f

1-18

Spring

Part g

Fig. 8

Spring

Groove of CH. base assembly

Fig. 9

Page 19

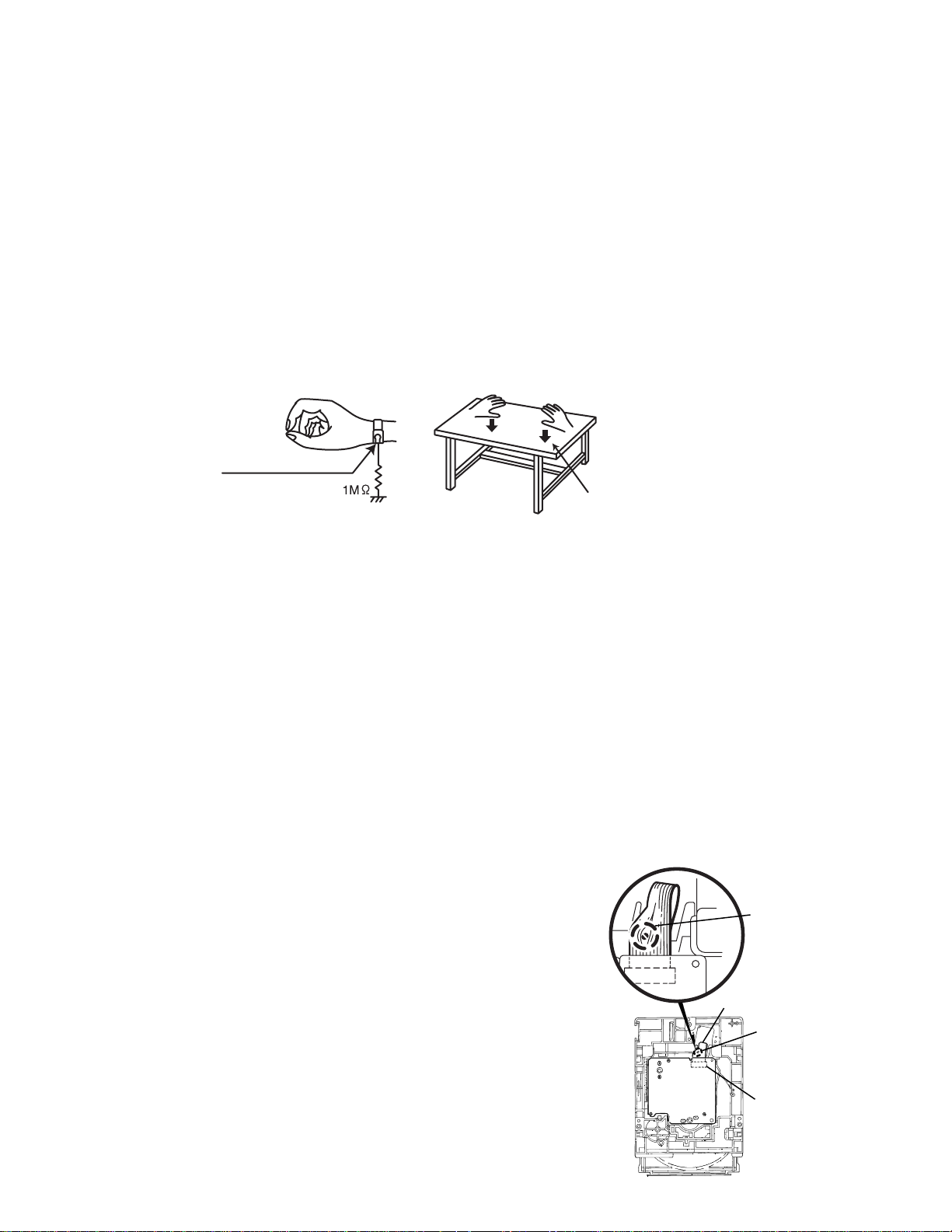

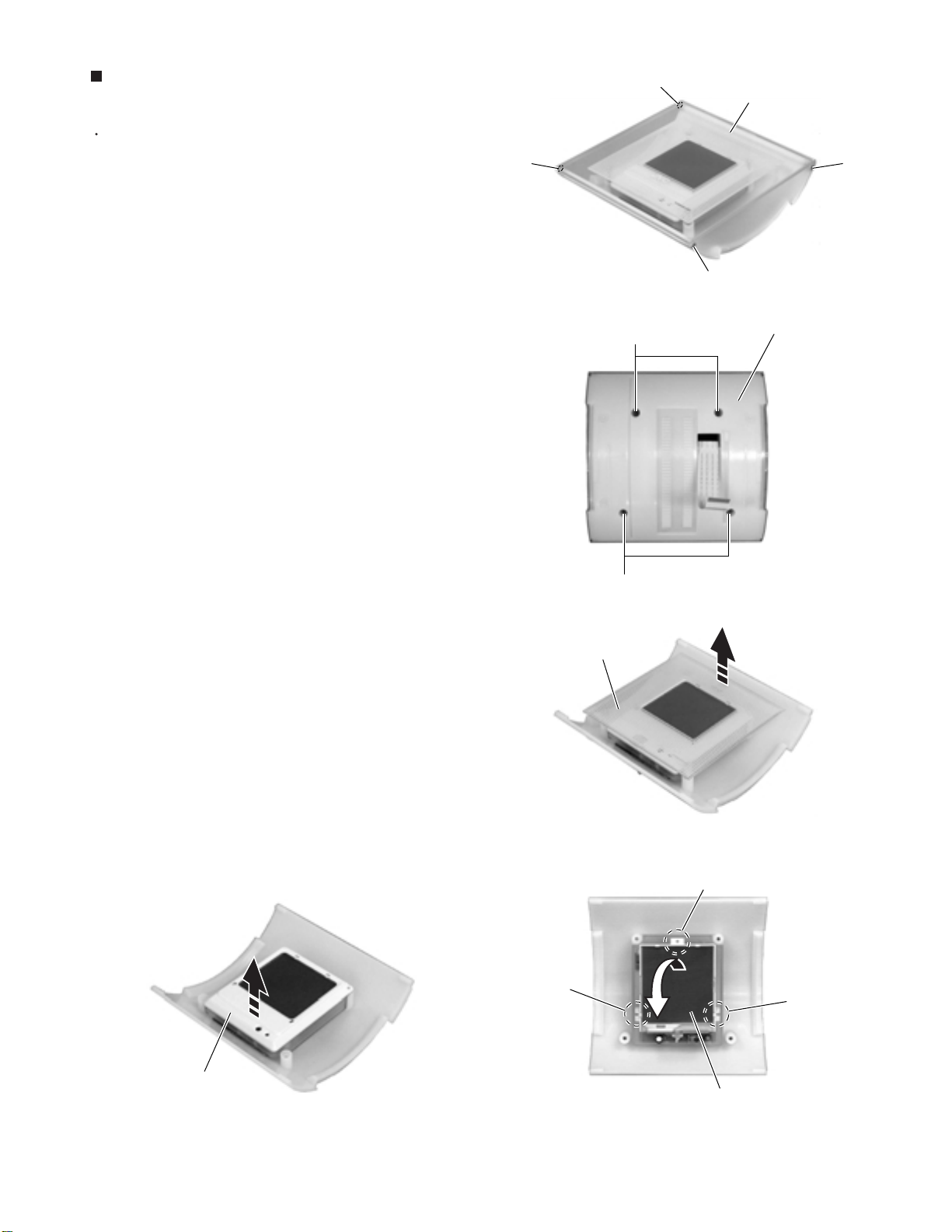

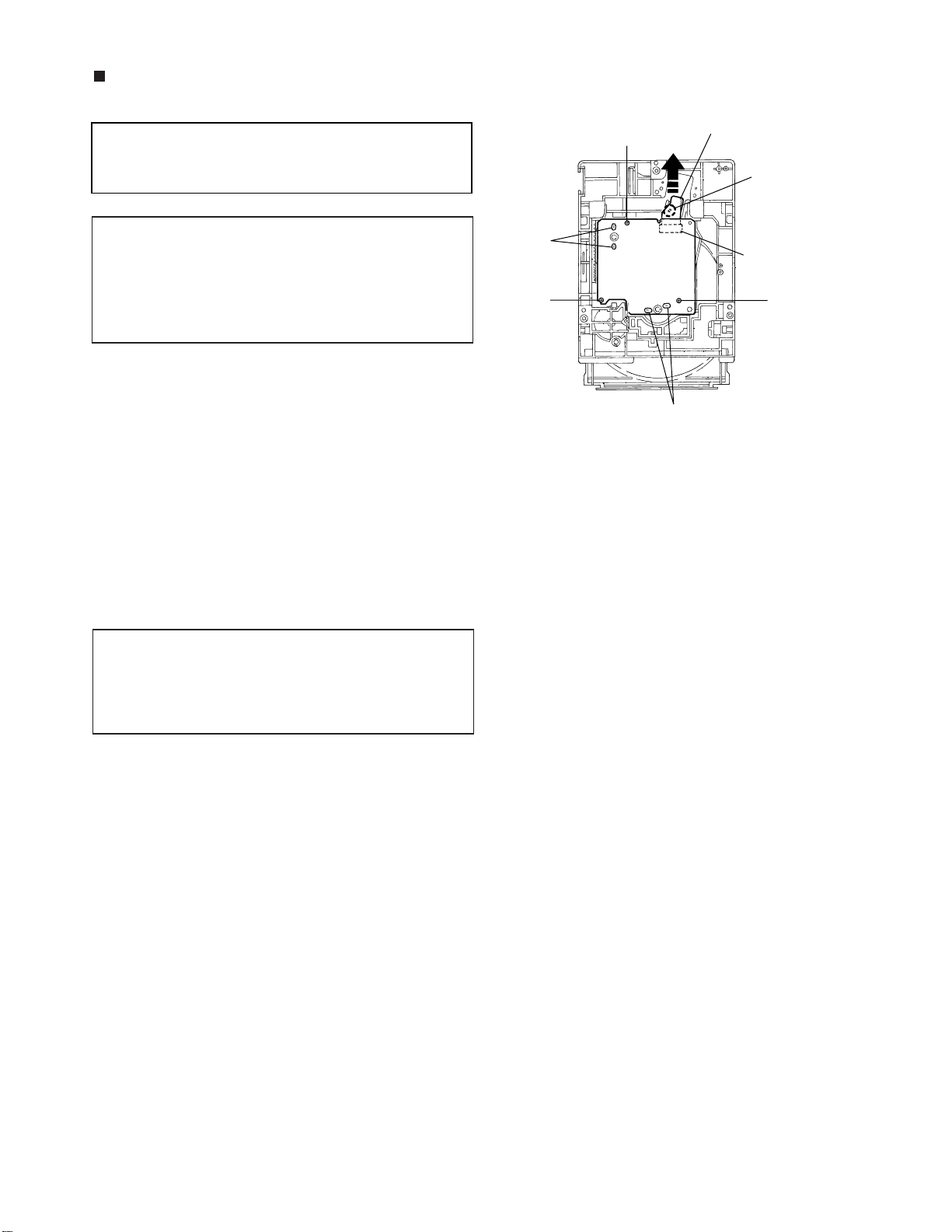

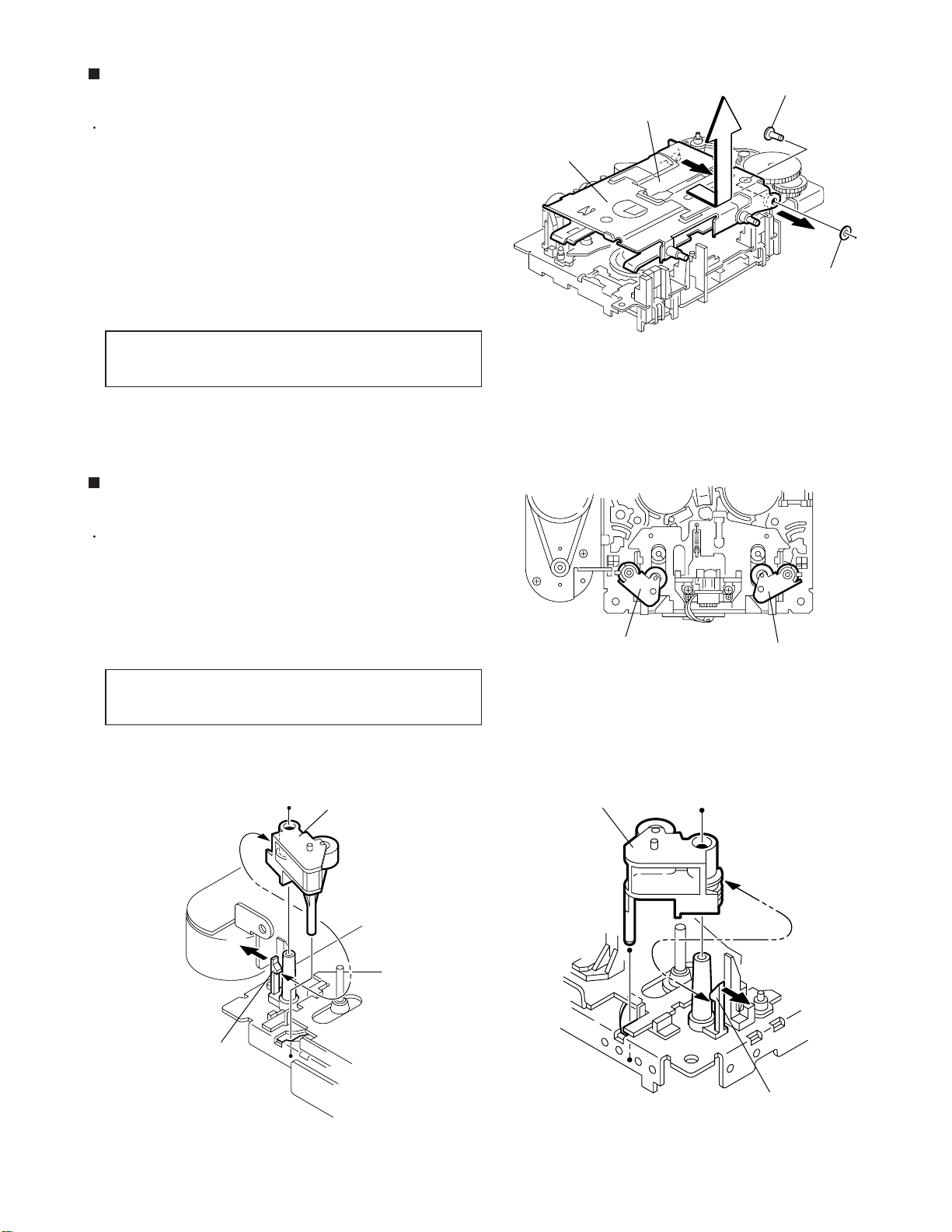

Removing the Mechanism Board

(Refer to Fig 10.)

Reference:The mechanism board can be removed

without removal of the TRAMECHA

assembly.

UX-A52R

Flexible wire

C

Shorting round

Note: Before disconnecting the flexible wire coming

from the pickup from the connector, be sure to

solder its shorting round.

If the flexible wire is connected without

soldering, it may cause breakdown of the

pickup.

1. Solder the shorting round of the flexible wire

connected with the mechanism board from the back

of the mechanism assembly.

2. Disconnect the flexible wire from the connector

CN601 on the mechanism board.

3. Remove the three screws C fastening the

mechanism board.

4. Unsolder the two points of the part h and one point

of the part i of the mechanism board. Then, remove

the mechanism board upwards.

Note: When reinstalling the mechanism board,

connect the flexible wire coming from the

pickup to the connector first and then remove

the solder from the shorting round of the

flexible cable.

Soldered

part h

C

CN601 on

mechanism

board

C

Soldered part i

Fig. 10

1-19

Page 20

UX-A52R

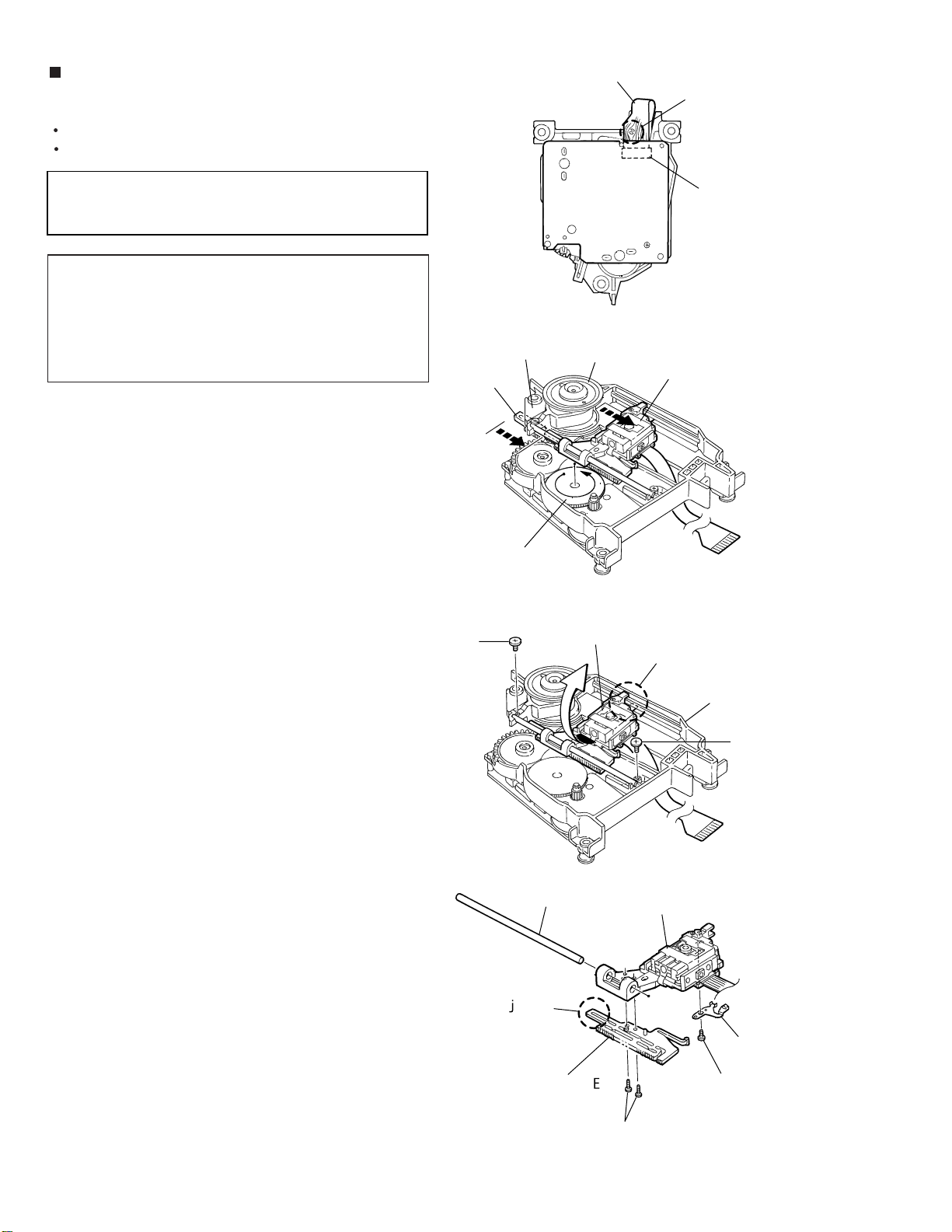

Removing the Pickup

(Refer to Figs. 11 to 14.)

Remove the CL. base assembly and tray.

Remove the TRAMECHA assembly.

Reference: The pickup can be removed without

removal of the mechanism board.

Note: Before disconnecting the flexible wire coming

from the pickup from the connector, be sure to

solder its shorting round.

If the flexible wire is connected without

soldering, it may cause breakdown of the

pickup.

1. Solder the shorting round of the flexible wire

connected with the mechanism board from the back

of the TRAMECHA assembly.

2. Disconnect the flexible wire from the connector

CN601 on the mechanism board.

Part j of

rack plate

CH. base

assembly

Flexible wire

Shorting round

CN601 on

mechanism

board

Fig. 11

T-T assembly

Pickup assembly

3. Turn the idle gear in the arrow-marked direction from

the top of the TRAMECHA assembly so that the

pickup assembly is shifted to the reverse side of the

T-T assembly.

Move the pickup assembly until the part j of the rack

plate in the lower part of the pickup assembly comes

out of the CH. base assembly.

4. Remove the two screws D retaining the shaft of the

pickup assembly. Next, disengage the hook k from

the CH. base assembly and then remove the pickup

assembly together with the shaft.

5. Pull the shaft out of the pickup.

6. Remove the two screws E fastening the rack plate

from the pickup.

7. Remove the screw F retaining the P.S. spring from

the pickup.

D

Idle gear

Shaft

Fig. 12

Pickup assembly

Part k

CH. base

assembly

D

Fig. 13

Pickup

1-20

Part j

Rack plate

P.S. spring

F

E

Fig. 14

Page 21

UX-A52R

Reinstalling the Pickup Assembly

(Refer to Figs. 15 and 16.)

Reference: Refer to the explanation of "Removing

the Pickup" on the preceding page.

1. Fit the P.S. spring and rack plate to the pickup.

2. Insert the shaft into the pickup.

3. Engage the hook k of the pickup assembly with the

CH. base assembly first, and set the part j of the

rack plate in the opening I next. Then, reinstall the

pickup assembly while shifting it to the T-T side

(inward) so that the part m of the rack plate is

positioned as shown in Fig. 16.

4. Move the pickup assembly to the center position

and fasten the shaft with the two screws D. (Make

sure that the part n of the rack plate is correctly

engaged with the middle gear.)

5. After passing the flexible wire coming from the

pickup through the opening of the CH. base

assembly, connect it to the connector CN601.

Part I

Part j

Part m

Part k

Pickup

assembly

CH. base

assembly

Fig. 15

Middle gear

Note: When reinstalling the pickup assembly,

remove the solder from the shorting round

after connecting the flexible wire coming from

the pick to the connector CN601.

Removing the Feed Motor Assembly

(Refer to Fig. 17.)

Remove the CL. base assembly and tray.

Remove the mechanism board.

Remove the two screws E fastening the feed motor

assembly from the top of the mechanism assembly.

Rack plate

Part n

Fig. 16

E

Feed motor assembly

Fig. 17

1-21

Page 22

UX-A52R

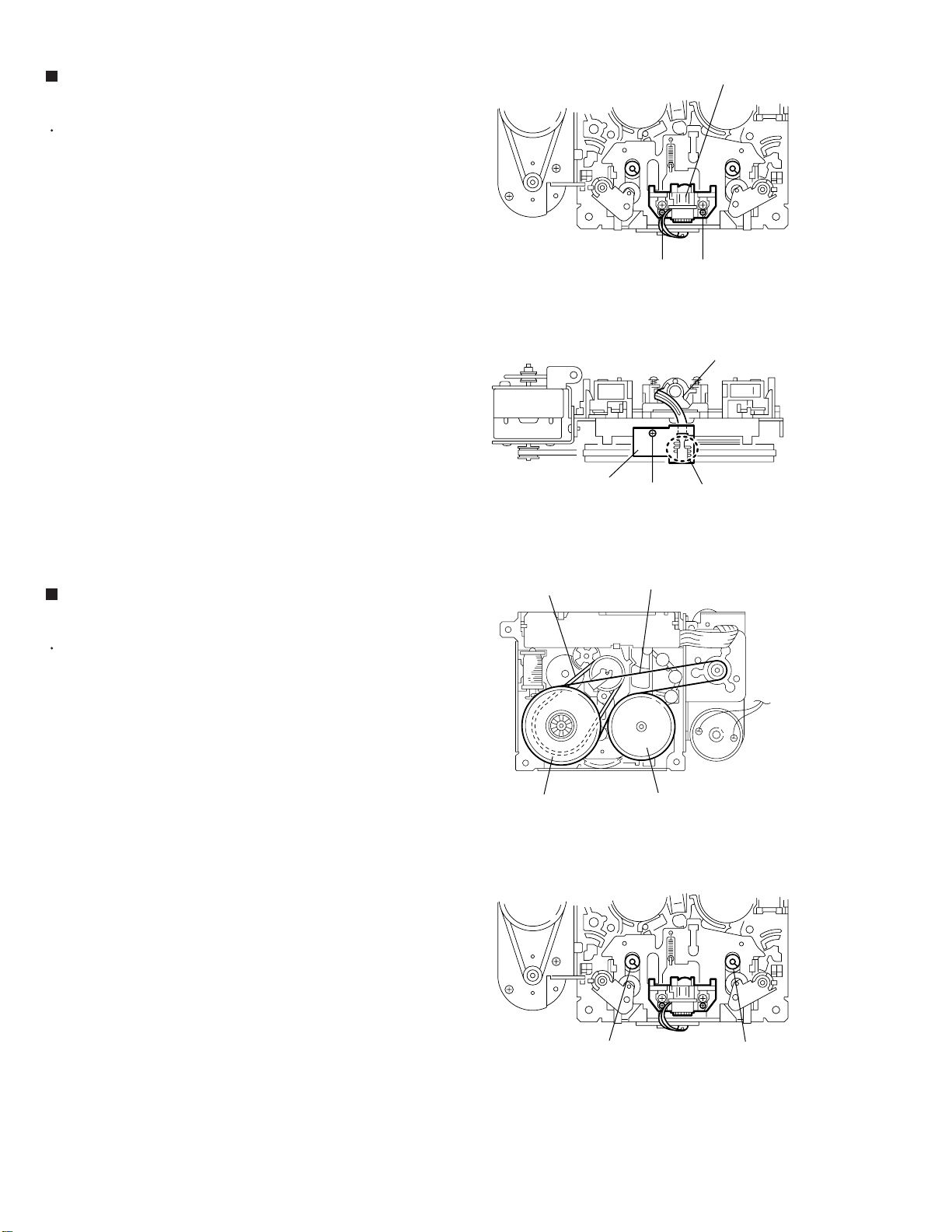

<Cassette mechanism section>

CAUTION:

Removing the side bracket (L) and (R) /

load board (See Fig.1 to 4)

1.

Remove the E-washer attaching the load arm on the

right side of the body.

2.

Turn the load arm in the direction of the arrow to

release from the cassette hook at the joint a.

3.

Remove the spring (1) attaching the trig lever.

4.

Move the trig lever in the direction of the arrow and

release it from the two holes b.

5.

Remove the screw A attaching the load board on

the right side of the body and unsolder the wire

extending from the sub motor.

Prior to performing the following

procedures, turn the mode gear in the

direction of the arrow to move each section

to the eject position.

Joint a

Slide bracket

Load arm

E-washer

Load arm

Fig.1

Hole b

Hole b

Spring (1)

REFERENCE:

6.

Remove the spring (2) and the holder collar on the

right side of the body.

7.

Remove the two screws B attaching the side

bracket unit (R) in the direction of the arrow.

8.

Remove the four screws C attaching the side

bracket (L) in the direction of the arrow.

The side bracket unit (R) can be

removed even if the load board is

attached. In such case, make sure to

unsolder the wire extending from the

sub motor.

A

Side bracket unit (L)

C

Fig.2

Load board

Soldering

Fig.3

Cassette hanger assembly

C

C

B

1-22

C

Side bracket unit (R)

B

Spring (2)

Holder collar

Fig.4

Page 23

UX-A52R

Removing the cassette hanger assembly

/ cassette holder (See Fig.5)

Prior to performing the following procedure, remove

the side bracket (L) and (R).

1.

Remove the slit washer attaching the cassette

hanger assembly and pull out the pin.

2.

Move the cassette hanger assembly in the direction

of the arrow to release the boss of the joint c on the

left rear side and detach the cassette hanger

assembly upward.

REFERENCE:

The cassette hanger assembly is

detached with the cassette holder.

Removing the pinch roller (F) and (R)

(See Fig.6 to 8)

Pin

Cassette hanger assembly

Cassette holder

E-washer

Fig.5

Prior to performing the following procedure, remove

the side bracket (L), (R), cassette hanger assembly /

cassette holder.

1.

Release the tab d in the direction of the arrow and

pull out the pinch roller upward.

REFERENCE:

The above method is for removing the

pinch roller (F) and (R).

Pinch roller (F)

Pinch roller (F)

Pinch roller (R)

Pinch roller (R)

Fig.6

Tab d

Tab d

Fig.8Fig.7

1-23

Page 24

UX-A52R

Removing the head assembly / head

board (See Fig.9 and 10)

Prior to performing the following procedure, remove

the side bracket (L), (R), cassette hanger assembly /

cassette holder.

1.

Remove the spring on the lower side of the head

assembly.

2.

Remove the two screws D and remove the head

assembly upward.

3.

Remove the screw E attaching the head board.

Unsolder the flexible wire extending from the head

assembly if necessary.

Head board

Fig.9

Head assembly

DD

Head assembly

Soldering

E

Removing the flywheel assembly (F) and

(R) (See Fig.11 and 12)

Prior to performing the following procedure, remove

the side bracket (L), (R), cassette hanger assembly /

cassette holder.

1.

Remove the belt and sub belt on the bottom of the

body.

2.

Remove the polywasher from the flywheel (F) and

(R) on top of the body.

3.

Pull out the flywheel (F) and (R).

Sub belt

Flywheel assembly (R)

Fig.10

Belt

Flywheel assembly (F)

Fig.11

1-24

Polywasher

Fig.12

Polywasher

Page 25

Adjustment Method

1. Jigs and test instruments

Test disc (CTS-1000)

Test tape (VT712)

Test tape (VT703)

Test tape (AC225)

2. Adjustment and check items

1) Indications in the modes that all LCD's are on

2) CD section

(1) Indication of the C1 error

(2) Cancel of the C1 error indication

3. Adjustment and check method

1) CD section

(1) Indication of the C1 error

While pressing both the POWER key

and BACK SKIP key on the main unit,

turn on the primary power supply.

UX-A52R

FL indication

CRC = 0

Press the CD OPEN/CLOSE key

and insert the test disk.

Press the CD PLAY key. The set starts

counting and the number of error correction

times is indicated every 10 seconds.

FL indication

CRC = ***

(2) Cancel of the C1 error indication

To cancel the C1 error indication, cut off the power supply.

200 Hz or less

1-25

Page 26

UX-A52R

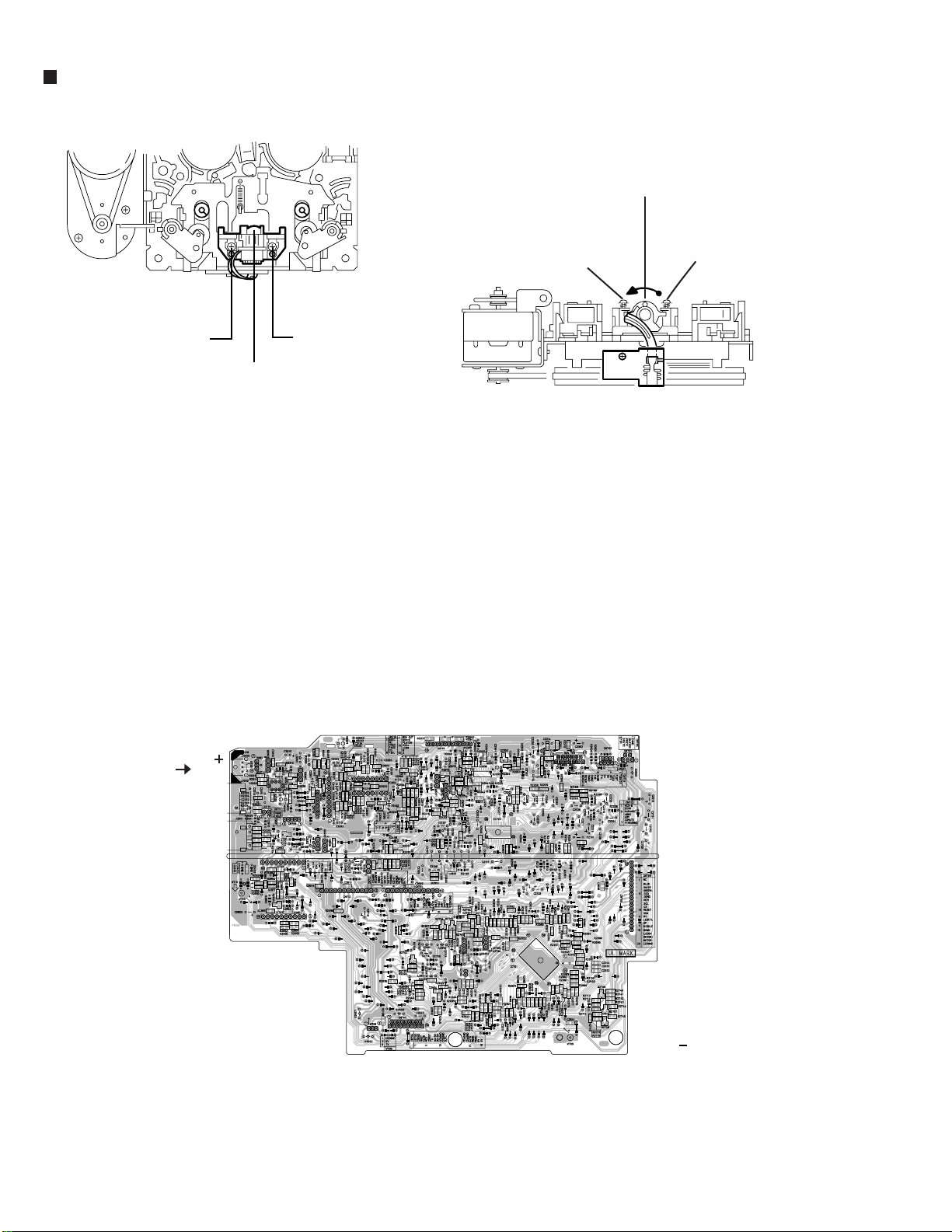

Cassette section

Playback/Recording &

eraser head

Head azimuth

adjusting screw

(Forward side)

Head azimuth

adjusting screw

(Forward side)

Playback/Recording &

eraser head

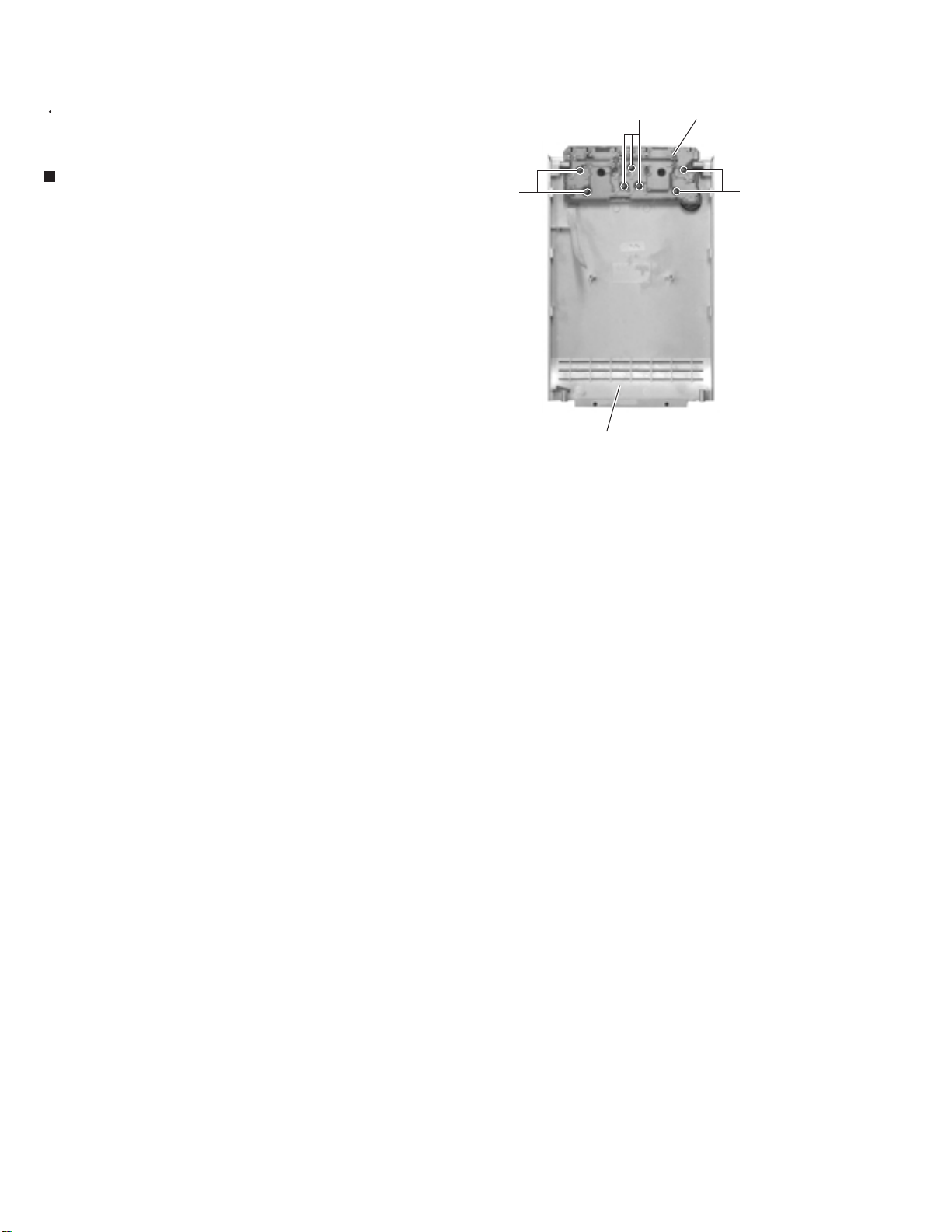

Removing the Cassette Mechanism Assembly

1. Remove the rear cover.

2. Remove the side panels (right and left).

3. Remove the cassette mechanism assembly.

4. Remove the four screws S fastening the cassette mechanism assembly from the back

of the cassette mechanism.

5. Press the EJECT button on the front side of the cassette mechanism assembly to open

the cassette door, and then remove the cassette mechanism assembly.

Head azimuth

adjusting screw

(Reverse side)

Head azimuth

adjusting screw

(Reverse side)

BIAS TEST POINT

1-26

GND

PCB FMB

Page 27

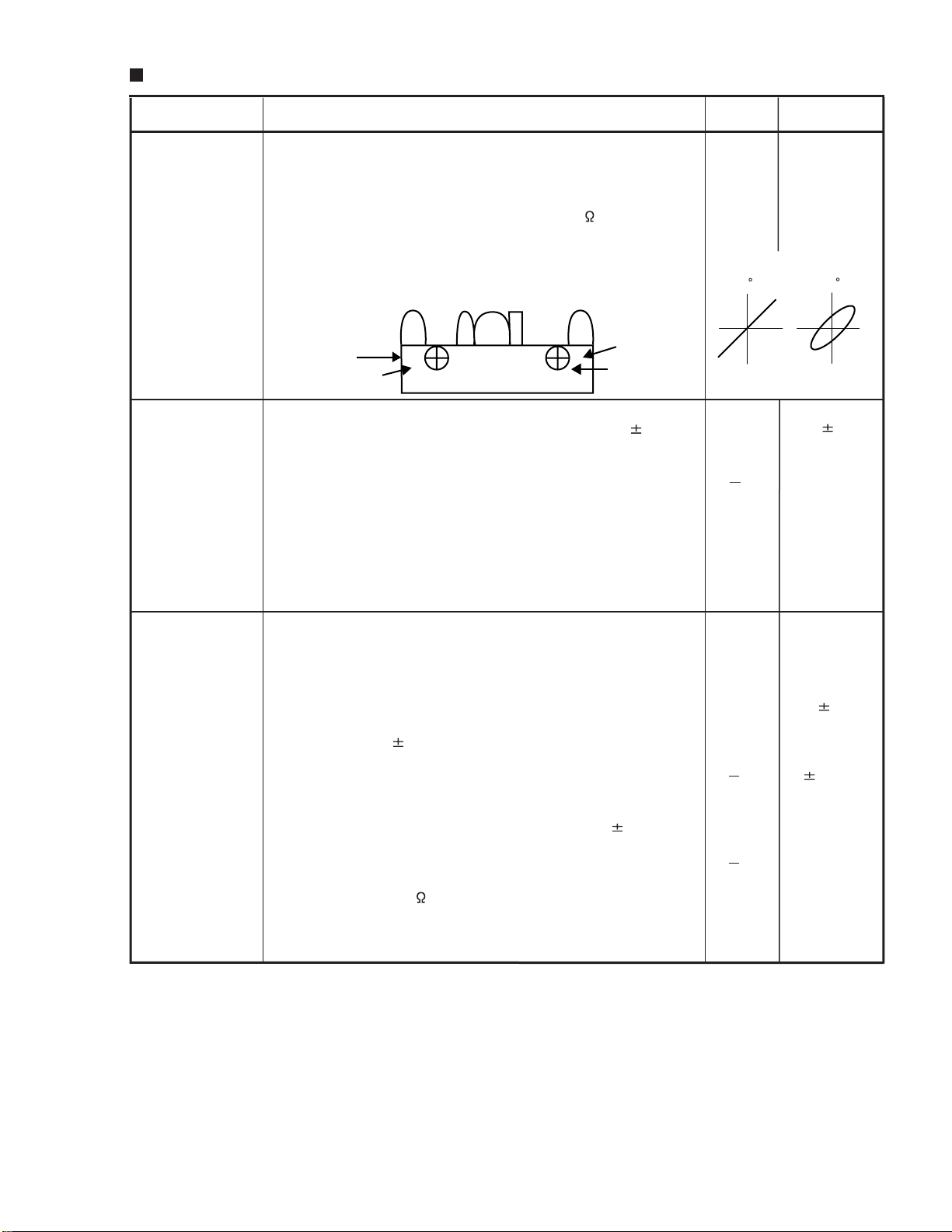

Check and adjustment of the Head amplifier section

UX-A52R

Item

1. Head azimuth

adjustment

2. Tape speed

adjustment

(Reference value)

Speed difference

between the

normal and

reverse directions

Check/Adjustment Method

1) Play back the end part of the test tape VT703 (10 kHz).

2) Adjust the head azimuth screws so that the output becomes

maximum in both the normal and reverse directions. After

adjustment, lock the screws with screw bond without fail.

Measuring output terminal: Speaker terminal, 4 load resistance

Difference between L-ch and R-ch: Within 3 dB

Difference between FWD and REV directions: Within 4 dB

Adjust max level in FWD and REV. After adjusting, should be

Applied bond (THREEBOND 1401 A/C) to screw.

Azimuth screw

Screw for

REV

Neji Lock

1) Play back the end part of the test tape VT712 (3 kHz).

2) Adjust VR37 so that the frequency counter reads 3000 15 Hz

in playback in the normal direction.

Measuring output terminal: Speaker terminal

Make sure that speed difference between the normal and

reverse directions is 60 Hz or less by reading of the frequency

counter. (With the beginning part of the test tape)

Azimuth

for FWD

Neji Lock

Adjusting

Point

Head

azimuth

screw

phase

(0 ) (45 )

VR37

Standard

Value

Maximum

output

3000 15Hz

60 Hz or less

Wow and flutter

3. Recording /

playback

frequency

characteristic

adjustment

(Reference value)

Recording bias

frequency

(Reference value)

Erasing current

Play back the end part of the test tape VT712 (3 kHz).

Make sure that the wow and flutter meter reads 0.25 % (WRMS)

or less.

1) Set a blank cassette tape (Type I: AC225) and enter the set into

the recording pause mode.

2) Cancel the pause mode and start recording. Repeat to input the

1 kHz and 10 kHz reference signals alternately from the CD test

disk to record the signals on the blank tape.

3) While playing back the repeatedly input 1 kHz and 10 kHz

reference signals, adjust VR31 so that output level of 10 kHz

signals is +2 dB 1 dB of 1 kHz.

1) Set a blank cassette tape (Type I: AC225) and enter the set into

the recording pause mode.

2) Make sure that the bias frequency at the bias test point (Refer on

1-26 board drowing) on the head amplifier board is 70 9 kHz.

1) Set a blank cassette tape (Type I: AC225) and enter the set into

the recording pause mode.

2) After connecting a 1 resistor to the erasing head in series,

cancel the pause mode and start recording. Connect the

electronic voltmeter to both the terminals and measure the

erasing current.

0.25 %

(WRMS) or

less

VR31

-1dB 1dB

70 9kHz

Erasing

current: 60

mA (Type I

tape)

1-27

Page 28

UX-A52R

Extension code connecting method

Cassette mechanism assembly

System control board

(CN706, CN715, CN716)

QUQ110-1940BJ

CD mechanism assembly

CD servo control board

(CN651)

Extension wire

System control board

(CN704)

1-28

Page 29

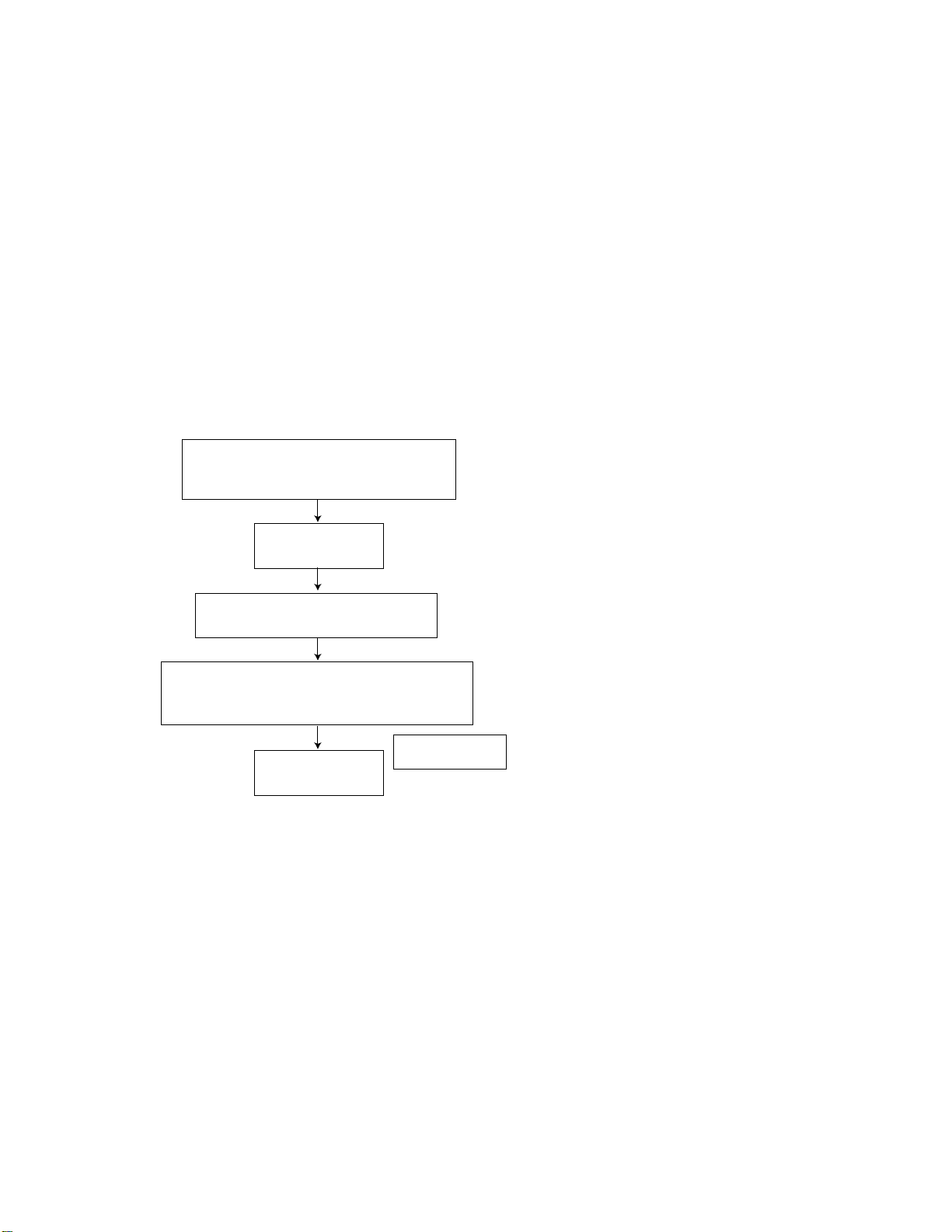

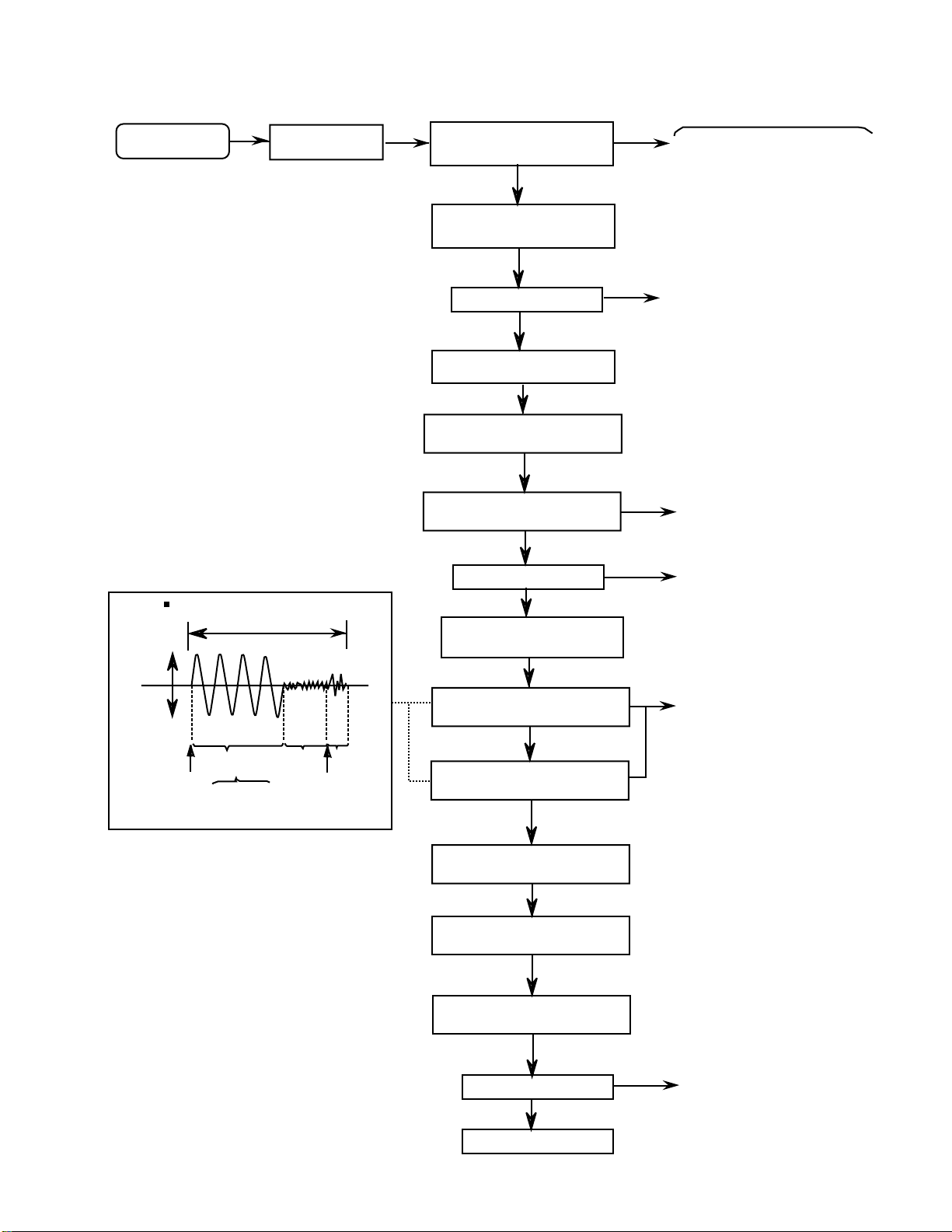

Flow of functional operation until TOC read (CD)

Power ON

Power Key

Slider turns REST

SW ON.

Automatic tuning

of TE offset

Check to see if the voltage at the

pin 72 of IC701 or pin 5 of CN602

becomes 0 V for an instant. (The

moment the switch is turned on,

the voltage becomes 0 V.)

UX-A52R

Check Point

VREF

Tracking error waveform at TOC reading

pin 25 of

IC601(TE)

Approx

1.8V

Tracking

servo

Disc statas

to rotate

off statas

Automatic measurement

of TE amplitude and

automatic tuning of

TE balance

Approx.3sec

Tracking

servo

on statas

Disc to be

braked to stop

TOC reading

finishes

500mv/div

2ms/div

Fig.1

Laser ON

Detection of disc

Automatic tuning of

Foucus offset

Automatic measurement of

Focus A-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Tracking error balance

Make sure of the H level at

the pin 40 of IC603.

Confirm that the Focus error

S-curve siganl at the pin28 of

IC603 is approx.2Vp-p

Confirm that the siganl from

pin24 IC603 (R645) is 0V as

a accelerated pulse during

approx.400ms.

Make sure that the TE

signal (1.8 Vp-p approx.)

indicating the tracking

servo off status is output

from the pin 25 (one side

of R609) of IC601.

Automatic tuning of

Focus error balance

Automatic tuning of

Focus error gain

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the eys-pattern

at the lead of TP602

1-29

Page 30

UX-A52R

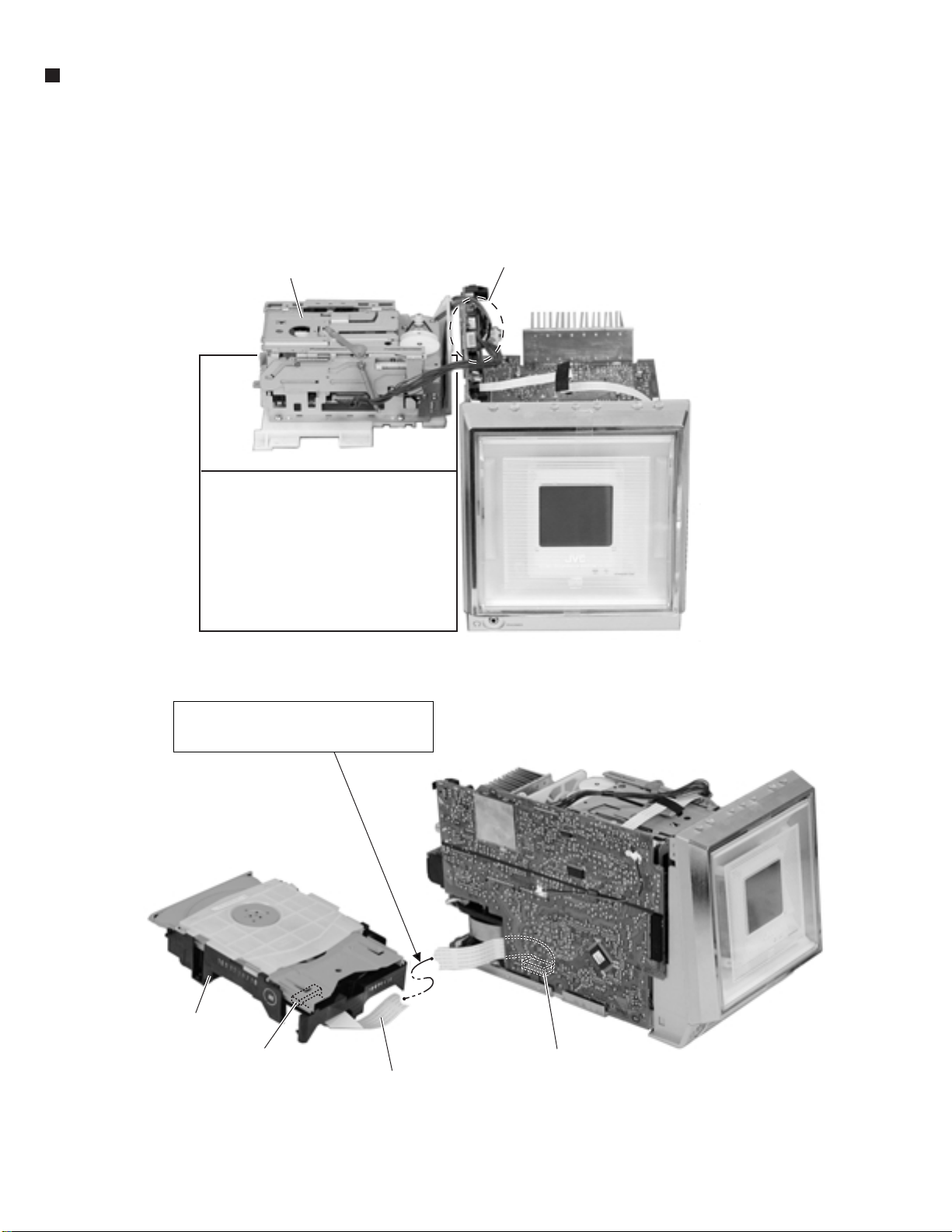

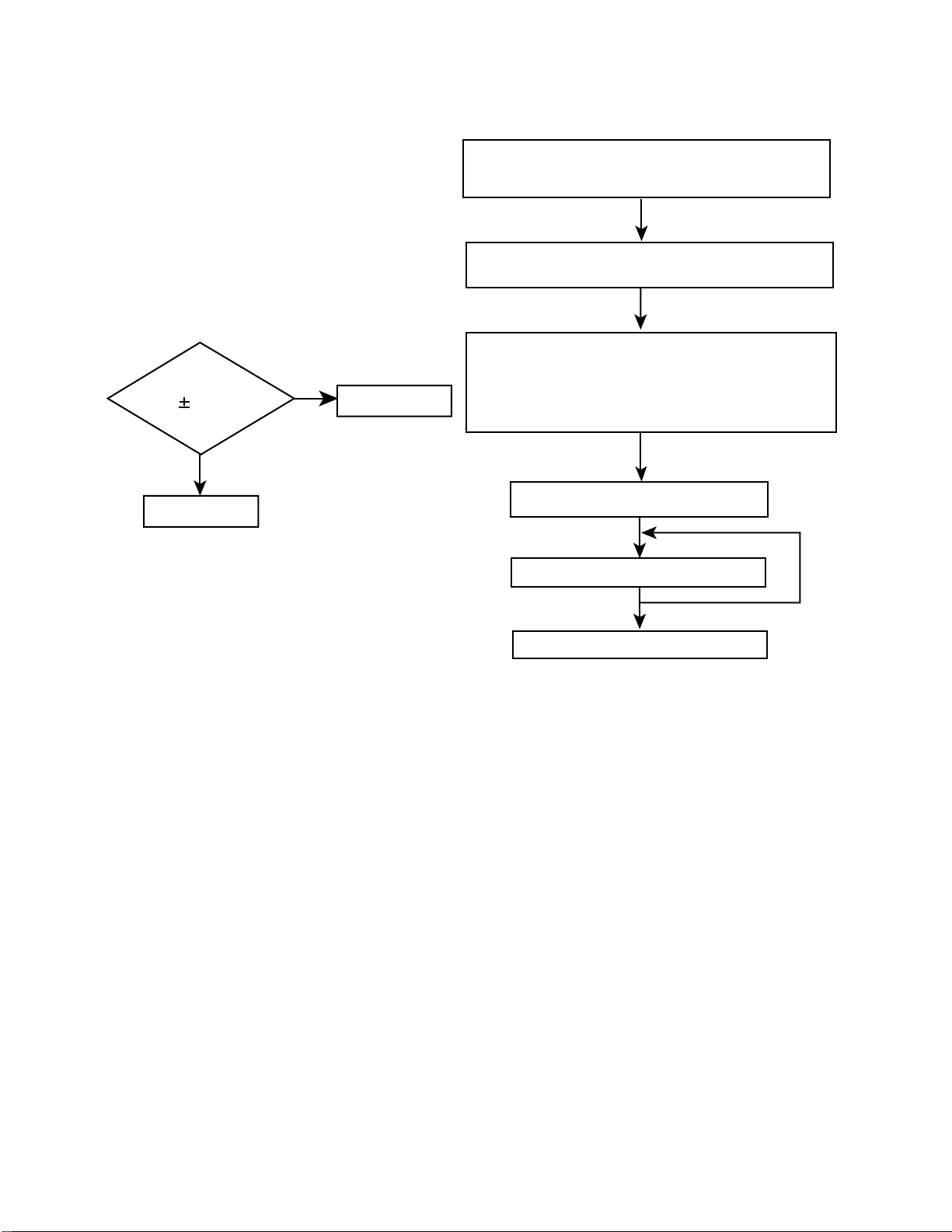

Maintenance of laser pickup

(1) Cleaning the pick up lens

Befor you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode (Fig.1)

When the life of the laser diode has expired,

the following symptoms wil appear.

(1) The level of RF output (EFM output:ampli

tude of eye pattern) will below.

Is RF output

1.25 0.22Vp-p?

YES

O.K

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

(Fig.1)

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed

circuit board which is attached to the pickup

is used to adjust the laser power.Since this

adjustment should be performed to match the

characteristics of the whole optical block,

do not touch the semi-fixed resistor.

If the laser power is lower than the specified

value,the laser diode is almost worn out, and

the laser pickup should be replaced.

If the semi-fixed resistor is adjusted while

the pickup is functioning normally,the laser

pickup may be damaged due to excessive current.

Check the eye-pattern at TP602.

Finish.

1-30

Page 31

Description of major ICs

UPD784216AGF (IC701) : System micon

1. Pin layout

1

100

76

75

UX-A52R

2. Block diagram

INTP2/NMI

INTP0.INTP1.

INTP3-INTP6

TI00

TI01

TO0

TI1

TO1

TI2

TO2

TI5/TO5

TI6/TO6

TI7/TO7

TI8/TO8

RTP0-RTP7

ANO0

ANO1

REF1

AV

AV

SS

ANI0-ANI7

REF0

AV

AV

D0

AV

SS

P03/INTP3

PCL

BUZ

25

26

PROGRAMMABLE

INTERRUPT

CONTROLLER

TIMER/EVENT

COUNTER

(16BITS)

TIMER/EVENT

COUNTER1

(8BITS)

TIMER/EVENT

COUNTER2

(8BITS)

TIMER/EVENT

COUNTER5

(8BITS)

TIMER/EVENT

COUNTER6

(8BITS)

TIMER/EVENT

COUNTER7

(8BITS)

TIMER/EVENT

COUNTER8

(8BITS)

WATCH TIMER

WATCHDOG TIMER

REAL-TIME

OUTPUT PORT

D/A

CONVERTER

A/D

CONVERTER

CLOCK OUTPUT

CONTROL

BUZZER OUTPUT

50

51

78K/1V

CPU CORE

RAM

8192BITS

ROM

128K BITS

UART/IOE1

BAUD-RATE

GENERATOR

UART/IOE2

BAUD-RATE

GENERATOR

CLOCKED

SERIAL

INTERFACE

BUS I/F

PORT0

PORT1

PORT2

PORT3

PORT4

PORT5

PORT6

PORT7

PORT8

PORT9

PORT10

PORT12

PORT13

SYSTEM CONTROL

RxD1/SI1

TxD1/SO1

ASCK1/SCK1

RxD2/SI2

TxD2/SO2

ASCK2/SCK2

SI0

SO0

SCK0

AD0-AD7

A0-A7

A8-A15

A16-A19

RD

WR

WAIT

ASTB

P00-P06

P10-P17

P20-P27

P30-P37

P40-P47

P50-P57

P60-P67

P70-P72

P80-P87

P90-P95

P100-P103

P120-P127

P130.P131

RESET

X1

X2

XT1

XT2

V

DD

V

SS

TEST

1-31

Page 32

UX-A52R

3. Pin function (1/2)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Symbol

FAUX2

NC

RDSDATA

MPX

TUST

NC

FTUNER

FCD

VDD

NC

PBMUTE

NC

PIN

LEDCTL

BUZER

MDPOUT

MDRESET

SMUTE

NC

NC

POUT

VPP

UP

RMT0

RMT1

MIDDLE

DOWN

RMSPEED

VOLCK

VOLCE

VOLDA

AHB

BUB

BTCL

NC

XKILL

VDD

X1

X2

VSS

XT2

XT1

RESET

REM

RDSCK

NC

PHOTO

SAFTEY4

NC

NC

I/O

Not connected

-

Not connected

-

Not connected

-

Stereo detection

I

Stereo indicator detection

I

Not connected

O

Tuner switch output

O

CD switch output

O

Connected with VDD

-

Not connected

-

PB mute output

O

Not connected

-

Power key input

I

LED control output

O

Buzzer output

O

MD PB output

O

MD reset output

O

System mute output

O

Not connected

-

Not connected

-

Power-on control output

O

GND

I

Door position detection - UP

I

Door open/shut motor control output

O

Door open/shut motor control output

O

Door position detection - MIDDLE

I

Door position detection - DOWN

I

Door open/shut motor speed control output

O

Volume control clock

O

Volume control chip enable

O

Volume control data

O

Active hyper bus control

O

Backup detection

I

Battery control

O

Not connected

O

Power-off clock oscillator control

I/O

Power supply

I

Master clock

I

Master clock

O

GND

I

Clock for timer

O

Clock for timer

I

Power-on reset

I

Remote control sensor

I

Not connected

-

Not connected

-

Reel pulse detection

I

Current detection

I

-

Not connected

Not connected

-

Description

1-32

Page 33

UX-A52R

3. Pin function (2/2)

Pin No.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Symbol

AVREF

AVREF0

SEFTY2

SEFTY3

LDCK

FKEY1

VERSION

FKEY2

KEY1

SEFTY1

VSS

RCDL

BCDL

AVREF1

RXD

TXD

NC

CDRXD

CDTXD

CDRST

GCDL

NC

TUDATA

TUDATA

TUCK

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

SCL

CS

RESET

SDA

NC

RS

NC

NC

S DATA

SCK

STTA

PLAY

VSS

UPD784216AGF(2/2)

I/O

Reference power supply +5 V

I

Reference power supply +5 V

I

Current detection

I

Current detection

I

Description

I/O

Function switch key input

I

Destination switch input

I

Function switch key input

I

Cassette key input

I

Current detection

I

GND

I

LED color display control

O

LED color display control

O

Reference power supply +5 V

I

Digital input

I

Digital output

O

Not connected

-

CD digital input

I

CD digital output

O

CD reset

O

LED color display control

O

Not connected

-

1

Tuner data

I

Tuner data

O

Tuner clock

O

Not connected

-

Not connected

-

Not connected

-

Not connected

-

Not connected

-

Not connected

-

Not connected

-

Not connected

-

Not connected

-

Not connected

-

Not connected

-

Not connected

-

LCD clock

O

LCD power supply

O

LCD reset

O

LCD serial data

I/O

Not connected

-

LCD start

I

Not connected

-

Not connected

-

Cassette control serial data

I/O

Cassette control serial clock

I/O

Cassette control status signal

I/O

Cassette PB switch detection

O

I

GND

1-33

Page 34

UX-A52R

UPD780024AGKB21 (IC251) : Unit micon

1. Pin layout

64 ~ 49

1

48

~

16

17 ~ 32

2. Pin function (1/2)

Pin

No.

Symbol I/O Description

P50/A8

1

P59/A9

2

MCS

3

MRDY

4

CDINDEX

5

CDEMP

6

CDTNO

7

CDCOPY

8

VSS0

9

VDD0

10

P30

11

P31

12

P32

13

MUTE

14

SUBQ

15

P35/SO31

16

SQCK

17

KCMND

18

M STAT

19

MCLK

20

RXDO

21

TXDO

22

P25/SCK0

23

VDD1

24

AVSS

25

KEY1

26

KEY2

27

PCHK

28

P14/AN14

29

P13/AN13

30

/OPEN

31

/REST

32

~

33

Connected to GND

Not used

Pull-up +B

Not used

Not used

CD emphasis detection

I

CD track No. detection

I

CD copy detection

I

GND

Power supply

Not used

Not used

Not used

Mute output

O

Sub-code Q data input from IC651

I

Not used

Sub-code Q register clock output to IC651

O

Kick command data

O

CD control status output to IC801

O

CD control command clock input from IC801

I

Digital data input

I

Digital data output

O

Connected to GND

Power supply

GND

Key input 1

I

Key input 2

I

Parity check

I

Connected to GND

Connected to GND

Open switch input

I

Rest switch input

I

1-34

Page 35

2. Pin function (2/2)

UX-A52R

Pin

No.

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

Symbol I/O

P10/AN10

AVREF

AVDD

/RESET

XT2

XT1

IC

X2

X1

VSS1

FLAG

BLKCK

/RFDET

EQx2

EQx4

VCOx4

OPEN

/CLOSE

IREFx4

P75/BUZ

/RESET

S TAT

/DMUTE

/P.ON

MLD

M DATA

MCLK

CLKSW

JIG

JIG

JIG

JIG

Function

-

Connected to GND

-

Analog circuit reference voltage. Connected with analog circuit power supply

-

Analog circuit power supply

I

CD control reset input from IC801

-

Not used

-

Connected with power supply

O

Flash memory control

-

Connected with external crystal oscillator

-

Connected with external crystal oscillator

-

GND

I

Flag signal input from IC651

I

Sub-code block clock signal input from IC651

I

RF signal amplitude detection input

O

2 equalizer switch output

O

4 equalizer switch output

-

Not used

I

Open door detection

I

Closed door detection

O

4 DSP current switch output

-

Not used

O

Reset signal output to IC651 (L: Reset)

I

Status signal input from IC651

O

Muting output to IC651

O

Power on/off switch signal output to IC291

O

Microcomputer command load signal output to IC651

O

Microcomputer command data output to IC651

O

Microcomputer command clock signal output to IC651

-

Not used

-

Not used

-

Not used

-

Not used

-

Connected to GND

1-35

Page 36

UX-A52R

LC75345M-X (IC702) : E.volume

1. Pin layout

CL

VDD

ROPOUT

RINM

36 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21 20 19

DI

CE

VSS

LOPOUT

RINP

LINM

ROOUT

RSB

LINP

RBASS2

LOUT

LSB

RBASS1

RTRE

LBASS2

LBASS1

RVRIN

RSELOR5R4

LTRE

LVRIN

L5

LSELO

R3

L4

R2

L3

R1

L2

Vref

181716151413121110987654321

L1

2. Block diagram

14

L5

15

L4

16

L3

17 18

L2

L1

19

Vref

20

R1

21

R2

22 23

R3

R4

24

R5

LSELO

13

LVRIN

12

LTRE

11

LVref

RVref

CONTROL

CIRCUIT

LOGIC

CIRCUIT

CONTROL

CIRCUIT

LBASS1

10

LBASS2

9

LSB

8

CCB

INTERFACE

LOUT

7

6

5

34

2

1

36

35

34

33

32

LINP

LINM

LOPOUT

VSS

CE

DI

CL

VDD

ROPOUT

RINM

RINP

1-36

25

RESLO

26

RVRIN

27

RTRE

28

RBASS1

29

RBASS2

30

RSB

31

ROUT

Page 37

3. Pin function

UX-A52R

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Symbol

DI

CE

VSS

LOPOUT

LINM

LINP

LOUT

LSB

LBASS2

LBASS1

LTRE

LVRIN

LSELO

L5

L4

L3

L2

L1

Vref

R1

R2

R3

R4

R5

RSELO

RVRIN

RTRE

RBASS1

RBASS2

RSB

ROUT

RINP

RINM

ROPOUT

VDD

CL

Function

Serial data and clock input pin for control.

Chip enable pin.

Ground pin.

Output pin of general-purpose operation amplifier.

Non-inverted input pin of general-purpuse operation amplifier.

Non-inverted input pin of general-purpuse operation amplifier.

ATT + equalizer output pin.

Capacitor and resistor connection pin comprising filters for bass and super-bass band.

Capacitor and resistor connection pin comprising filters for bass and super-bass band.

Capacitor and resistor connection pin comprising filters for bass and super-bass band.

Capacitor and resistor connection pin comprising treble band filter.

Volume input pin.

Input selector output pin.

Input signal pin.

Input signal pin.

Input signal pin.

Input signal pin.

Input signal pin.

0.5 x VDD voltage generation block for analog ground.

Input signal pin.

Input signal pin.

Input signal pin.

Input signal pin.

Input signal pin.

Input selector output pin.

Volume input pin.

Capacitor connection pin comprising treble band filter.

Capacitor and resistor connection pin comprising filter for bass and super-bass band.

Capacitor and resistor connection pin comprising filter for bass and super-bass band.

Capacitor and resistor connection pin comprising filter for bass and super-bass band.

ATT + equalizer output pin.

Non inverted input pin of general-purpose operation amplifier.

Non inverted input pin of general purpose operation amplifier.

Output pin of general-purpose operation amplifier.

Supply pin.

Serial data and clock input pin for control.

1-37

Page 38

UX-A52R

MN662790RSC (IC651) : Digital servo & processor

1.Pin layout

60 41

61

40

80

21

1 20

2.Pin function

Pin No. Symbol I/O

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

BCLK

LRCK

SRDATA

DVDD1

DVSS1

TX

MCLK

M DATA

MLD

SENSE

FLOCK

TLOCK

BLKCK

SQCK

SUBQ

DMUTE

S TAT

LSI_RST

SMCK

CSEL

TEST2

TVD

PC

ECM

ECS

VDETMON

TRD

FOD

VREF

FBAL

TBAL

FE

TE

RFENV

TEST3

OFT

TRCRS

RFDET

BDO

LDON

O

O

O

-

-

O

I

I

I

-

-

-

O

I

O

I

O

I

O

I

-

O

O

O

O

O

O

O

I

I

I

I

I

I

I

I

-

MN662790RSC (1/2)

Description

Bit clock output for SRDATA

Identifying signal output of L,R

Serial data output

Power supply for digital circuit

Connect to ground for digital circuit

Digital audio interface output signal

Micom command clock signal input

Micom command data signal input

Micom command load signal input L:load

Non connect

Non connect

Non connect

Sub code block clock signal

Export clock signal input for sub code Q resister

Sub code Q data output

Muting input H:muting

Status signal output

Reset signal input L:reset

Clock signal output MSEL is H : 8.4672 MHz MSEL is L : 4.2336 MHz

Oscillation frequency specification terminal H:33.8688 MHz L:16.9344 MHz

TEST2 terminal usually : open

Traverse drive output

Non connect

Spindle motor drive signal output (Compulsion mode output)

Spindle motor drive signal output (Servo error signal output)

Non connect

Tracking drive signal output

Focus drive signal output

Reference voltage for DA output section

Focus balance adjust signal output

Tracking balance adjust signal output

Focus error signal input (analog input)

Tracking error signal input (analog input)

RF Envelope signal input (analog input)

TEST3 Terminal usually : Fixation L

Off track signal input H : off track

Track cross signal input (analog input)

RF detection signal input L : detection

Dropout signal input H : dropout

Non connect

(Command execution : CD-TEXT data readout enabling signal (DQSY) output)

1-38

Page 39

UX-A52R

2.Pin function

Pin No. Symbol I/O

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

PLLF2

DSLBDA

WVEL

ARF

IREF

DRF

DSLF

PLLF

VCOF

AVDD2

AVSS2

EFM

DSLB

VCOF2

SUBC

SBCK

VSS

X1

X2

VDD

BYTCK

LDON

GCTRL

IPFLAG

FLAG

CLVS

CRC

DEMPH

RESY

IOSEL

TEST

AVDD1

OUTL

AVSS1

OUTR

DQSY

VCC5V

PSEL

MSEL

SSEL

I/O

-

-

I/O

I/O

I/O

-

-

-

O

I/O

O

-

O

-

O

O

O

-

O

-

O

O

O

O

O

MN662790RSC (2/2)

Functions

Terminal for loop filter characteristic switch for PLL

Non connect

Non connect

I

RF Signal output

I

Standard electric current input terminal

I

Bias terminal for DSL

Loop filter terminal for DSL

Loop filter terminal for PLL

Loop filter terminal for VCO

Power supply terminal for analog circuit

Connect to ground terminal for analog circuit

Non connect

PLL extraction clock output

Loop filter terminal for VCO

Sub code serial output

I

Clock signal input for sub code serial output

Connect to ground terminal for oscillation circuit

I

Oscillation circuit input terminal f=16.9344 MHz, 33.8688 MHz

Oscillation circuit output terminal f=16.9344 MHz, 33.8688 MHz

Power supply terminal for oscillation circuit

Non connect

Laser ON signal output H : ON

General I/O port

Non connect

Flag signal output

Non connect

Non connect

De-emphasis detection signal output

Non connect

I

Mode switch terminal

I

TEST terminal usually : H

Power supply terminal for analog circuit (for audio output section)

Lch audio output

Connect to ground terminal for analog circuit (for audio output section)

Rch audio output

RF signal polarity specification terminal

I

Power supply terminal (5V)

IOSEL=H TEST terminal IOSEL=L SRDATA input

IOSEL=H SMCK terminal output (frequency switch terminal) IOSEL=L LRCK input

IOSEL=H SUBQ terminal output mode switch terminal IOSEL=L BCLK input

1-39

Page 40

UX-A52R

LA6541-X (IC801) : Servo driver

1. Pin layout & Block diagram

Vcc Vref Vin4 Vg4 Vo8 Vo7

24 23

11k

ohm

22

20

21

19

Vcc

Gnd

Vo6 Vo5 Vg3 Vin3 Cd Res

18

17 16

- +

- +

Level

shift

Level

shift

11k

ohm

1

2

3456

Vcc Mute Vin1 Vg1 Vo1 Vo2 Vo3 Vo4 Vg2 Vin2 Reg

B T L

driver

B T L

driver

Gnd

B T L

driver

B T L

driver

7 8 9101112

Level

shift

Level

shift

2. Pin function

Pin

Symbol Function

No.

1

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

2

3

4

5

6

7

8

9

Vcc

Mute

Vin1

Vg1

Vo1

Vo2

Vo3

Vo4

Vg2

Vin2

Reg Out

Reg In

Res

Cd

Vin3

Vg3

Vo5

Vo6

Vo7

Vo8

Vg4

Vin4

Vref

Vcc

Power supply (Shorted to pin 24)

All BTL amplifier outputs ON/OFF

BTL AMP 1 input pin

BTL AMP 1 input pin (For gain adjustment)

BTL AMP 1 input pin (Non inverting side)

BTL AMP 1 input pin (Inverting side)

BTL AMP 2 input pin (Inverting side)

BTL AMP 2 input pin (Non inverting side)

BTL AMP 2 input pin (For gain adjustment)

BTL AMP 2 input pin

External transistor collector (PNP) connection. 5V power supply output

External transistor (PNP) base connection

Reset output

Reset output delay time setting (Capacitor connected externally)

BTL AMP 3 input pin

BTL AMP 3 input pin (For gain adjustment)

BTL AMP 3 output pin (Non inverting side)

BTL AMP 3 output pin (Inverting side)

BTL AMP 4 output pin (Inverting side)

BTL AMP 4 output pin (Non inverting side)

BTL AMP 4 output pin (For gain adjustment)

BTL AMP 4 output pin

Level shift circuit's reference voltage application

Power supply (Shorted to pin 1)

15

11k

ohm

14

13

RESET

Regulator

11k

ohm

out

Reg

In

1-40

Page 41

LA1838 (IC1) : FM AM IF amp & Detector, FM MPX decoder

1. Block diagram

UX-A52R

30

ALC

BUFF

FM

S-METER

FM IF

1

2. Pin function

Pin

Symbol

No.

FM IN

1

AM MIX

2

3

FM IF

AM IF

4

GND

5

6

TUNED

STEREO

7

8

VCC

9

FM DET

10

AM SD

FM VSM

11

AM VSM

12

13

MUTE

14

FM/AM

MONO/ST O

15

29

28

AM

OSC

SD

COMP

S-CLRVE

PM

DET

2

I/O

I

This is an input terminal of FM IF

REG

AM

MIX

AM/FM

IF-BUFF

3

27

FM

RF.AMP

AM IF

4

26

AGC

AM

S-METER

GND

Function

DET

5

signal.

This is an out put terminal for AM

O

mixer.

I

Bypass of FM IF

Input of AM IF Signal.

I

I

This is the device ground terminal.

When the set is tunning,this terminal

O

becomes "L".

O

Stereo indicator output. Stereo "L",

Mono: "H"

III

This is the power supply terminal.

I

FM detect transformer.

I

This is a terminal of AM ceramic filter.

O

Adjust FM SD sensitivity.

O

Adjust AM SD sensitivity.

I/O

When the signal of IF REQ of IC121(

LC72131) appear, the signal of FM/AM

IF output. //Muting control input.

Change over the FM/AM input.

I

"H" :FM, "L" : AM

Stereo : "H", Mono: "L"

25

TUNING

DRIVE

6

24

STEREO

DRIVE

7

22

23

P-DET

VCC

89

Pin

Symbol

No.

16

L OUT

17

R OUT

18

19

20

21

22

23

24

25

26

27

28

29

30

L IN

R IN

RO

LO

MPX IN

FM OUT

AM DET

AM AGC

AFC

AM RF

REG

AM OSC

OSC BUFFER

21

DECODER

ANIT-BIRDIE

VCO

384KHz

10

20

STEREO

5N

SW

FF

38k

11

I/O

O

Left channel signal output.

O

Right channel signal output.

Input terminal of the Left channel post

I

18

19

MUTE

FF

/

19k

2

12 13

FF

19k

/

LS

Function

17 16

PILOT

DET

14

AMP.

Input terminal of the Right channel

I

post AMP.

Mpx Right channel signal output.

O

O

Mpx Left channel signal output.

I

Mpx input terminal

FM detection output.

O

AM detection output.

O

This is an AGC voltage input terminal

I

for AM

I

This is an output terminal of voltage

for FM-AFC.

AM RF signal input.

I

Register value between pin 26 and pin28

O

besides the frequency width of the

input signal.

I

This is a terminal of AM Local

oscillation circuit.

AM Local oscillation Signal output.

O

15

1-41

Page 42

UX-A52R

LC72136N (IC2) : PLL frequency synthesizer

1. Pin layout

FM/AM

CLOCK

FM/ST/VCO

AM/FM

2. Block diagram

XT

CE

DI

DO

SDIN

1

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

XT

GND

LPFOUT

LPFIN

PD

VCC

FMIN

AMIN

IFCONT

IFIN

1

22

16

15

3

4

5

6

17

21

3. Pin function

Pin

Symbol

No.

1

2

3

4

5

6

7

8

9

10

11

XT

FM/AM

CE

DI

CLOCK

DO

FM/ST/VCO

AM/FM

LW

MW

SDIN

Reference

Driver

Swallow Counter

1/2

C

2

B

I/F

Powe r

on

Reset

Function

I/O

X'tal oscillator connect (75kHz)

I

LOW:FM mode

O

When data output/input for 4pin(input) and

I

Swallow Counter

1/16,1/17 4bit

1/16,1/17 4bit

12bit

Programmable

DriverS

Data Shift Register & Latch

7821113

6pin(output): H

Input for receive the serial data from

I

controller

Sync signal input use

I

Data output for Controller

O

Output port

"Low": MW mode

O

Open state after the power on reset

O

Input/output port

I/O

Input/output port

I/O

Data input/output

I/O

Phase

Detector

Charge Pump

Unlock

Detector

Universal

Counter

Pin

No.

12

IFCONT

13

14

15

16

17

18

19

LPFOUT

20

21

22

Symbol

IFIN

AMIN

FMIN

VCC

PD

LPFIN

GND

XT

18

19

20

12

I/O

Function

IF counter signal input

I

IF signal output

O

Not use

-

AM Local OSC signal output

I

FM Local OSC signal input

I

Power suplly(VDD=4.5-5.5V)

-

When power ON:Reset circuit move

PLL charge pump output(H: Local OSC

O

frequency Height than Reference frequency.

L: Low Agreement: Height impedance)

Input for active lowpassfilter of PLL

I

Output for active lowpassfilter of PLL

O

Connected to GND

-

X'tal oscillator(75KHz)

I

1-42

Page 43

LA72723 (IC3) : RDS demodulation

1. Pin layout

UX-A52R

VREF

MPXIN

Vdda

Vssa

FLOUT

CIN

TES

XOUT

2. Block Diagram

+5V

Vdda

Vssa

MPXIN

TEST

1

2

3

4

5

6

7

8

REFERENCE

VOLTAGE

ANTI ALIASING

FILTER

TEST

RDS-ID/READY

16

RDCL

15

RDDA

14

RST

13

MODE

12

Vddd

11

Vssd

10

XIN

9

VREF

57kHz

BPF

(SCF)

FLOUT

SMOOTHING

FILTER

CLK(4.332MHz)

OSC

VREF

CIN

+

PLL

(57kHz)

-

CLOCK

RECOVERY

(1187.5Hz)

DATA

DECODER

RAM

(128-bits)

RDS-ID

DETECT

Vddd

Vssd

RDDA

RDCL

MODE

RST

RDS-ID/

READY

+5V

3. Pin functions

Pin

Symbol

No.

1

VREF

2

MPXIN

Vdda

3

4

Vssa

5

FLOUT

6

CIN

TEST

7

8

XOUT

9

XIN

10

Vssd

11

Vddd

12

MODE

13

RST

14

RDDA