Page 1

DOME TYPE CAMERA

TK-C676

INSTRUCTIONS

LWT0003

Page 2

IMPORTANT SAFEGUARDS

1. Read all of these instructions.

2. Save these instructions for later use.

3. All warnings on the product and in the operating instructions should be adhered to.

4. Unplug this appliance system from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use

a damp cloth for cleaning.

5. Do not use attachments not recommended by the appliance manufacturer as they may cause hazards.

6. Do not use this appliance near water – for example, near a bathtub, washbowl, kitchen sink, or laundry tub, in a wet

basement, or near a swimming pool, etc.

7. Do not place this appliance on an unstable cart, stand, or table. The appliance may fall,

causing serious injury to a child or adult, and serious damage to the appliance.

Use only with a cart or stand recommended by the manufacturer, or sold with the appliance.

Wall or shelf mounting should follow the manufacturer’s instructions, and should use a

mounting kit approved by the manufacturer.

An appliance and cart combination should be moved with care. Quick stops, excessive

force, and uneven surfaces may cause the appliance and cart combination to overturn.

8. Slots and openings in the cabinet and the back or bottom are provided for ventilation, and to

insure reliable operation of the appliance and to protect it from overheating, these openings

must not be blocked or covered. The openings should never be blocked by placing the appliance on a bed, sofa, rug,

or other similar surface. This appliance should never be placed near or over a radiator or heat register. This appliance

should not be placed in a built-in installation such as a bookcase unless proper ventilation is provided.

9. This appliance should be operated only from the type of power source indicated on the marking label. If you are not

sure of the type of power supplied to your home, consult your dealer or local power company. For appliance designed

to operate from battery power, refer to the operating instructions.

10. This appliance system is equipped with a 3-wire grounding type plug (a plug having a third (grounding) pin). This plug

will only fit into a grounding-type power outlet. This is a safety feature. If you are unable to insert the plug into the

outlet, contact your electrician to replace your obsolete outlet. Do not defeat the safety purpose of the grounding plug.

11. For added protection for this product during a lightning storm, or when it is left unattended and unused for long

periods of time, unplug it form the wall outlet and disconnect the antenna or cable system. This will prevent damage to

the product due to lightning and power-line surges.

12. Do not allow anything to rest on the power cord. Do not locate this appliance where the cord will be abused by

persons walking on it.

13. Follow all warnings and instructions marked on the appliance.

14. Do not overload wall outlets and extension cords as this can result in fire or electric shock.

15. Never push objects of any kind into this appliance through cabinet slots as they may touch dangerous voltage points

or short out parts that could result in a fire or electric shock. Never spill liquid of any kind on the appliance.

16. Do not attempt to service this appliance yourself as opening or removing covers may expose you to dangerous

voltage or other hazards. Refer all servicing to qualified service personnel.

17. Unplug this appliance from the wall outlet and refer servicing to qualified service personnel under the following conditions:

a. When the power cord or plug is damaged or frayed.

b. If liquid has been spilled into the appliance.

c. If the appliance has been exposed to rain or water.

d. If the appliance does not operate normally by following the operating instructions. Adjust only those controls that

are covered by the operating instructions as improper adjustment of other controls may result in damage and will

often require extensive work by a qualified technician to restore the appliance to normal operation.

e. If the appliance has been dropped or the cabinet has been damaged.

f. When the appliance exhibits a distinct change in performance – this indicates a need for service.

18. When replacement parts are required, be sure the service technician has used replacement parts specified by the

manufacturer that have the same characteristics as the original part. Unauthorized substitutions may result in fire,

electric shock, or other hazards.

19. Upon completion of any service or repairs to this appliance, ask the service technician to perform routine safety

checks to determine that the appliance is in safe operating condition.

PORTABLE CART WARNING

(symbol provided by RETAC)

S3126A

2

Page 3

WARNING:

TO REDUCE THE RISK OF FIRE OR

ELECTRIC SHOCK, DO NOT EXPOSE THIS

APPLIANCE TO RAIN OR MOISTURE.

Thank you for purchsing this product.

(These instructions are for TK-C676E)

Before beginning to operate this unit, please read the instruction manual carefully in order to make sure that the best possible

performance is obtained.

AVERTISSEMENT:

POUR EVITER LES RISQUES D'INCENDIE OU

D'ELECTROCUTION, NE PAS EXPOSER

L'APPAREIL A L'HUMIDITE OU A LA PLUIE.

Contents

Introduction

Features ............................................................................................................................................................................. 4

Provided Accessories ......................................................................................................................................................... 4

Safety Precautions ............................................................................................................................................................. 5

Precautions for Correct Operation ...................................................................................................................................... 5

Controls, Connectors and Indicators .................................................................................................................................. 6

Connections & Installation

A Multi-Drop Communication System ................................................................................................................................ 8

Point-to-Point Communication System ............................................................................................................................. 10

Switch Settings ................................................................................................................................................................. 12

Cable Connections ........................................................................................................................................................... 14

Attaching the Ceiling Mount ............................................................................................................................................. 16

Attaching the Camera....................................................................................................................................................... 16

Setting Up the Camera using an RM-P2580

Setup Procedure .............................................................................................................................................................. 18

Menu Screen Flow............................................................................................................................................................ 19

CAMERA FUNCTION Screen .......................................................................................................................................... 20

CAMERA TITLE/ALARM Screen ...................................................................................................................................... 21

CAMERA VIDEO ADJUSTMENT Screen ........................................................................................................................ 23

CAMERA ALC/ExDR Screen ........................................................................................................................................... 23

HOME MOTION DETECT Screen.................................................................................................................................... 26

AUTO PAN/PATROL/TRACE Screen ................................................................................................................................ 27

POSITION FUNCTION SET Screen ................................................................................................................................ 28

FACTORY SETTINGS Screen .......................................................................................................................................... 28

PRIVATE MASK Setup ..................................................................................................................................................... 29

CAMERA TITLE Setup ..................................................................................................................................................... 30

AREA TITLE Setup ........................................................................................................................................................... 31

ALARM TITLE Setup ........................................................................................................................................................ 32

HOME MOTION DETECT Setup...................................................................................................................................... 33

AUTO PAN Setup ............................................................................................................................................................. 34

AUTO PATROL Setup ....................................................................................................................................................... 35

AUTO TRACE Setup ........................................................................................................................................................ 36

POSITION TITLE Setup ................................................................................................................................................... 37

Other

Attaching a Ceiling Flush Mount Bracket (Optional WB-S575) ......................................................................................... 38

Removing a Ceiling Flush Mount Bracket (Optional WB-S575) ....................................................................................... 40

Troubleshooting ................................................................................................................................................................ 41

Specifications ................................................................................................................................................................... 42

3

Page 4

Introduction

Features

DSP with a wide dynamic range

Even objects that have a large difference in brightness can be monitored clearly.

Day/night surveillance

When the light is low, the camera pictures can be switched automatically to black and white pictures.

The camera is also compatible with IR illumination (wavelength 850 nm to 880 nm).

Private masking facility

When the camera target area contains an area that is required to be hidden the camera can be set accordingly in order to mask it.

Simplified waterproof design

The simplified waterproof design (IEC529) of the camera allows it to be installed in many locations, including under eaves,

provided that it is not subjected to direct water splash. (However, note that the camera cannot be used outdoors.)

Optical + electronic zooming

The 27X optical zoom lens and 10X electronic zoom circuitry allows the camera to be used even in surveillance situations in

which the object is very small.

High-sensitivity CCD and bright zoom lens

The CCD features an improved sensitivity of nearly 70% over the previous model and the zoom lens has a large aperture ratio of

f1.4 (at WIDE end). These features provide the camera with a high sensitivity of 0.5 lx in the color mode (25% output, AGC 20 dB,

WIDE end, electronic sense up x2).

High-speed pan/tilt table

The high-speed rotating table with a horizontal panning speed of 300°/sec. and a vertical tilting speed of 180°/sec. makes it

possible to recall a preset position quickly.

Provided Accessories

DOME TYPE CAMERA

INSTRUCTIONS

TK-C676

LWT0003-001A-H

Instructions Ceiling mount

Screw

(M3 × 12 mm)

For cable plate

Cable plate

4P Alarm cable 6P Alarm cable

Screws (M 4 x 12 mm)

For the ceiling flush

mount bracket

Safety Precautions

WARNING

• Install the unit on a strong and stable surface.

This unit has been designed to revolve at high speed. Due to its weight (about 2.4 kg) and the vibrations it may be subjected to, the

camera must be mounted to a sturdy and stable material. If the ceiling material lacks strength, for example it is made of a decorative

laminated material or plasterboard, then the mount should be reinforced using materials such as veneered plywood. If such reinforcement is inadequate images may fluctuate due to vibration or, in the worst case, the camera may fall and cause a serious accident

should there be anyone below it.

• For installation, use the provided ceiling mount and the optional flush mounted ceiling bracket, which is sold separately.

When installing this device the provided ceiling mount and the optional flush mounted ceiling bracket, which is sold separately

should be used. Also be sure to connect the drop prevention wire and tighten all screws and nuts firmly.

• Power the unit with the rated power voltage.

The power rating for this unit is 24 V AC, 50 Hz/60 Hz. If a power above this rating is supplied, a malfunction will occur or, in the

worst case, smoke or fire may be produced.

• This unit offers a certain degree of protection against any damage either to itself or to its connection cable that might result from

indirect lightning strikes, but it is not capable of preventing all damage by lightning strikes. For example it is not protected against

a direct lightning strike. If lightning damage can be expected in the place where the unit is installed, be sure to take countermeasures by adding an arrester to the connection cable, etc.

CAUTION

• Installation of this unit requires special skills. Please be sure to consult your dealer about installation procedures.

If the mounting screws or nuts are not tightened sufficiently, the camera may fall from its installation location. Be sure to tighten the

mounting nuts firmly to prevent this happening.

• Inspect the unit periodically.

Check periodically for any deterioration of the mount sections or loosening of screws due to vibration and ensure that there is no

likelihood of the unit dropping.

4

Page 5

Precautions for Correct Operation

Note on consumable parts

The following parts are consumable and should be replaced

after a certain number of hours or a count of operations.

The service lives given below are only typical values. They

may vary depending on the operating environment and

conditions.

Note that the replacement of consumable parts is chargeable even when they are replaced before the termination of

the warranty period.

• Zoom lens assembly

Zooming operation : 1 million times

Focusing operation : 4 million times

• Slip rings : 5 million operations

• Cooling fan : Approx. 30,000 hours

• Alarm output 1 relay : 200,000 times of operation

Note on auto focusing

Although this unit incorporates a one-push auto-focusing

system and EASY AF functions, auto-focusing may sometimes be impossible depending on the object and camera

setup. In this case, adjust the focusing manually.

Objects and images with which auto focusing may be difficult:

• When the image brightness is extremely high.

• When the image brightness is extremely low.

• When the image brightness varies continuously (for ex-

ample when the object is a flashing light).

• When the image contrast (difference between bright and

dark) is very poor.

• When the image does not contain a vertical contour

component.

• When vertical stripe patterns recur on the screen.

Camera setups with which auto focusing may be difficult:

• When the AGC is activated and the image is coarse.

• When SENSE UP is activated and the image contains

only little motion.

• When electronic zooming is activated and the image

does not contain a large enough contour component.

● To save energy, turn the system off whenever it is not in use.

● This camera has been designed for indoor use. It cannot be used out-

doors.

● This camera has been designed to be hung from a ceiling, do not install

it in an upright position on a surface or at an angle, as this may cause a

malfunction or a noticeable shortening of its service life.

● Do not install or use the camera in the following locations.

• In a place exposed to rain or water. (The waterproof characteristics of

the camera are equivalent to IEC 529.)

• In a place containing vapor or oil soot, for example in a kitchen.

• In a place outside the operating temperature range (-10°C to 50°C).

• Near a source of strong radio waves or magnetism, radiation or X-rays.

• In a place subject to vibrations.

• In a place with excessive dust.

● Insufficient ventilation of the camera may cause a malfunction. Be careful not to block ventilation to the camera.

This unit radiates heat from the panel surfaces (top panel and side

panels). Do not install it in a place where a heat pool may form, such as

near a wall.

● Do not install the camera in a place exposed to cold air, for example

near to the air outlet of an air conditioner. Otherwise, moisture may

become condensed inside the dome cover.

● Do not point the lens at a strong light source, for example the sun, doing

so may cause the camera to malfunction.

● The camera incorporates an AGC circuit. As a result, when it is used

under low light conditions the camera gain may increase automatically.

This makes the picture appear uneven , however this is not a malfunction

● When equipment that generates strong magnetism such as a transceiver

is used near to the unit while the AGC circuit is ON, beat noise, etc may

interfere with the picture. If a transceiver or similar equipment is used

keep it a distance of at least 3 meters from this unit.

● In auto iris mode, when the AGC circuit is ON, varying the iris with the

iris control button may not change the picture brightness. This is due to

the automatic gain boost by the AGC circuit. In this case, set AGC to

OFF or use the manual iris mode.

● In auto iris mode, the iris control button may not function under certain

brightness conditions (i.e. when a sufficient amount of light cannot be

obtained). In this case, set the iris mode to manual.

● When the camera is used in ATW (Auto White balance) mode, the

colors captured by the camera may differ from the actual colors being

shot due to the mechanics of the auto-tracking operation within the

white balance circuit. However, this is not a malfunction.

● If a very bright object (such as a lamp) is being monitored, the picture

may contain vertical lines (smear) above and below the bright object in

the picture. This is a phenomenon normal to a solid-state image pickup

devices (CCD) and is not a malfunction.

● The electronic shutter speed of the camera has been set to 1/50 second at the factory. If the camera is used under a fluorescent light source

in an area with a local power frequency of 60 Hz, change the shutter

speed to 1/120 second using the remote control unit. (Note that the

sensitivity will deteriorate slightly.)

However, when the ExDR function is ON, the flicker may not disappear.

● When the camera is used to monitor the same position over many

hours ( e.g. continuously for 24 hours a day) the contact resistance of

the panning mechanism may increase. This may cause the picture to

be affected by noise interference or the remote control operation becoming unstable. To prevent this happening, once a week, turn the system off and on in order to initialize the camera and to clean the contacts.

● Do not touch the lens on the dome cover directly by hand. Contamination of the cover will lead to deterioration of the picture quality.

● Since the dome cover has a semispherical shape, the picture is distorted

at the edges of the semisphere. When the camera is pointed for horizontal-direction shooting by tilting, it shoots the edge of the hemisphere, so

that the picture may be distorted or out of focus.

● When an object is located near a light source or contains a large difference in brightness, a ghost may interfere with the picture. This phenomenon is due to the characteristics of the dome cover and the built-in lens

and is not a malfunction.

● Observe the following points when carrying out maintenance of the

camera.

• Turn the system off before proceeding.

• Clean the dome cover using a lens cleaning cloth (or tissue).

The dome cover may become stained in a very short period in certain

operating environments. If the dome cover lens becomes excessively contaminated, clean it with a lens cleaning cloth (or tissue)

moistened with a solution of neutral detergent in water.

Zooming

When zooming is stopped near the TELE end during manual

operation or by selecting a preset position, focusing may deviate

slightly. In addition, the manual zooming operation may not always be smooth.

These phenomena are due to the characteristics of the built-in

lens and are not malfunctions.

Preset positions

• The zooming position of the camera can be set to a total of 100

preset positions, including the home position.

• The electronic zoom can be preset up to x2.

However, if the electronic zoom menu on the screen is set to

OFF even presetting the electronic zooming to x2 , the camera

itself moves to the preset position without the electronic zooming being activated.

• It is not permitted to preset the electronic zoom to a larger ratio

than x2. The message "INVALID POSITION (D.ZOOM)" will

appear on the screen if a larger ratio than x2 is set.

• The TILT position can be set and operated only between 0° to

90° even when the item “FLIP” is set to DIGITAL.

(A TILT position between 91° and 180° cannot be set or oper-

ated. The message "INVALID POSITION (TILT) will appear on

the screen if a larger TILT position than 90° is set. )

→

See page 1-9 “1.11 COUNTER INFROMATION”

5

Page 6

Introduction

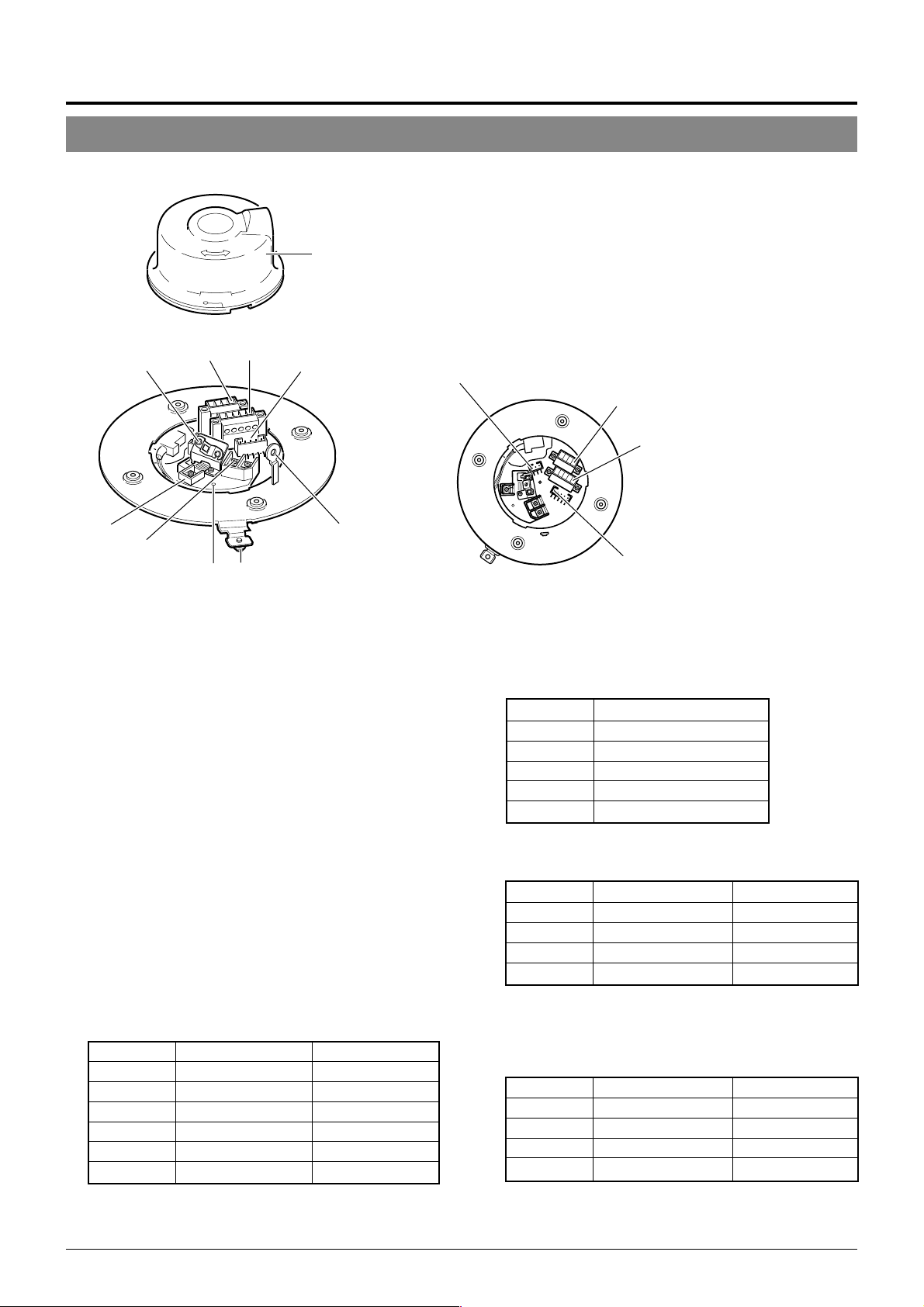

Controls, Connectors and Indicators

Ceiling Mount

0

Cover

96

1

2

87

9

5

43

■ Camera body

Pin 1 of alarm output terminal

(CN24)

Pin 1 of CONTROL terminal

8

(CN22)

7

Pin 1 of alarm input terminal

6

(CN26)

Pin 1 of ALARM I/O terminal

(CN23)

(Connector side)

[VIDEO OUT] Coaxial Cable Connectors

1

Output connector of a composite video signal (1 V(p-p))

with an output impedance of 75 Ω, to be connected to a

switcher, etc.

[AC ` 24V INPUT] Connector

2

Connect to a 24 V AC power supply.

Cover Position Alignment Mark

3

When attaching the cover, use this mark to align its final

position correctly.

Locking Screw

4

Tighten this screw to fasten the camera clamping bracket

.

*

Safety Wire Hole

5

To prepare for possible dropping of the camera, pass the

wire from the ceiling slab or channel through this hole.

Alarm Input Terminals (CN26)

6

Input terminals for Alarm 2, Alarm 3 and Alarm 4.

Connect the provided cables to these terminals.

P. 1 5

☞

Pin No. Signal Name Color of Cable

1 Alarm input 2 Brown

2 GND Red

3 Alarm input 3 Orange

4 GND Yellow

5 Alarm input 4 Violet

6 GND Gray

(Terminal Pin Layout)

[ALARM I/O] Input/Output Terminals (CN23)

7

Terminals for Alarm input 1 and Alarm output 1.

P. 1 5

☞

Pin No. Signal Name

1 Alarm output 1

2 Alarm output 1 (COM)

3 Alarm output 1

4 Alarm input 1

5 GND

[CONTROL] Terminals (CN22)

8

Connect to a RM-P2580 remote control unit.

Pin No. Signal Name Mark

1 TX + A

2 TX – B

3 RX + C

4 RX – D

Alarm Output Terminals (CN24)

9

Output terminals for Alarm 2 and Alarm 3.

Connect the provided cables to these terminals.

P. 1 5

☞

Pin No. Signal Name Color of Cable

1 Alarm output 2 + Red

2 Alarm output 2 – White

3 Alarm output 3 + Orange

4 Alarm output 3 – Gray

(N.OPEN)

(N.CLOSE)

6

Page 7

#

%

&

^

$

*

⁄

!

#

@

(Setting switch side)

Cover

0

For protection against water drips. Slit the rubber cap on

this cover and pass the cable through the slits.

P. 1 4

☞

Camera Connector (Female)

!

Connect to ^, the Male Connector on the camera.

Drop Prevention Hook

@

Attach the Drop Prevention Wire & to this hook to prevent

the camera from falling.

Clamping Holes (x 4)

#

Attach the camera to a ceiling or to a Ceiling Flush Mount

Bracket (optionally available) using these holes.

[MACHINE ID] Switch

$

When an RS-485 communication system is used, for example when using the camera in a system controlled by

an RM-P2580, set the camera IDs individually for each

camera.

P. 1 3

☞

)

Connector (Male)

^

Connect to !, the Female Camera Connector on the Ceil-

ing Mount.

Drop Prevention Wire

&

Attach this wire to the Drop Prevention Hook @ on the

Ceiling Mount.

Camera Clamping Bracket

*

In order to clamp the camera onto the Ceiling Mount, insert and tighten the Locking Screw

Lens

(

The lens cannot be replaced.

Dome Cover

)

The dome cover is fragile. Take care when handling it.

Camera Body Cover

⁄

Do not remove the camera body cover while the camera is

installed on a ceiling. Doing so will cause the dome cover

to fall down.

(

into this bracket.

4

Setting Switches

%

Use these to set the PROTOCOL, etc.

P. 1 2

☞

7

Page 8

TO CAMERA

DATA I / O

RX

RX

TX

TX

COM

COM

COM

COM

COM

CAMERA

UNIT

ALARM

AUTO

SERIAL-2

SERIAL-1

VIDEO INPUT

VIDEO OUTPUT

ON

POWER

OFF

ON

AC INPUT

Connections & Installation

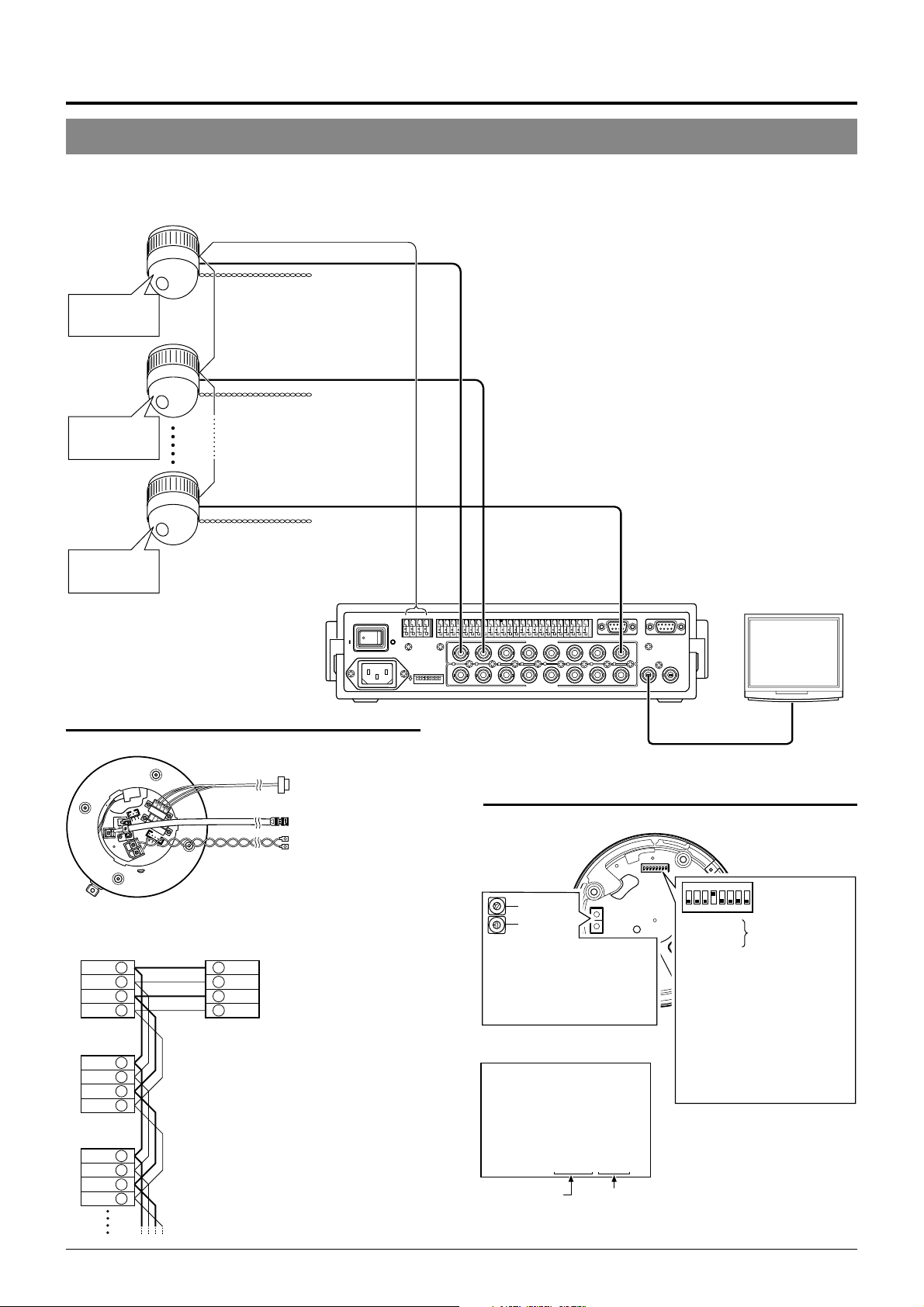

A Multi-Drop Communication System

A system that employs the RM-P2580 as the controller

The following figure shows a system that can accommodate up to eight cameras. (64 positions can be preset per camera.)

TK-C676

Camera 1

MACHINE ID: 01

Switch 8: OFF

(RX TERM)

TK-C676

Camera 2

MACHINE ID: 02

Switch 8: OFF

(RX TERM)

TK-C676

Camera 8

MACHINE ID: 08

Switch 8: ON

(RX TERM)

Control signal cable

Coaxial cable

Remote control unit

RM-P2580

AC 24 V

power supply

AC 24 V

power supply

AC 24 V

power supply

CAMERA

TO

TO CAMERA

+

RX

RX

ON

-

+

TX

-

TX

431 2 875 6

Observe the following points when connecting components together:

• Turn all the components off before proceeding.

• Read the instruction manuals of all components before pro-

ceeding.

• For the types and lengths of connection cables, see “Cable

Connections” on page 14.

• Do not connect the control signal cables in a loop.

COM

1 2 3 4 5 6 7 8

1

1

DATA I / O

COM

9/1 10/2 11/3 12/4 13/514/6 15/7 16/8

2 3 4 5 6 7

2 3 4 5 6 7

VIDEO INPUT

VIDEO OUTPUT

UNIT

CAMERA

COM

AUTO

SERIAL-1

COM

COM

SW

ALARM

SERIAL-2

8

MONITOR

MONITOR

OUTPUT

OUTPUT

1

2

8

Monitor

Cable connections

☞

P. 1 4

(Terminal side of Ceiling Mount)

Control signal cable

Coaxial cable

Power cable

Connection of the control signal cable

(A twisted pair cable is recommended.)

Camera 1

CONTROL terminals

TX +A

TX –B

RX +C

RX –D

Camera 2

CONTROL

terminals

+

TX

A

TX –B

RX +C

RX –D

Camera 3

CONTROL

terminals

TX +A

TX –B

RX +C

RX –D

RM-P2580

terminal

+

RX

A

–

RX

B

TX +C

TX –D

Each terminal on the camera and the RMP2580 is marked

to facilitate understanding and to avoid

connection mistakes, it is recommended

to connect the terminals carrying the

same marks.

To the TO CAMERA connector of the

RM-P2580 and to the next camera

To the CAMERA INPUT connector

of the RM-P2580

To AC 24V power supply

A

, B, C or D. In order

MONITOR

OUTPUT 1

Switch settings

☞

P. 1 2

(Setting switches are on the side of the Ceiling Mount)

Machine ID

3

2

4

1

5

0

6

9

Figure of 1

7

8

3

2

4

1

5

0

6

Figure of 10

9

7

8

Set it to the same number as the

VIDEO INPUT terminal of the RMP2580.

(Example) Camera 1:

Set the figure of 10 to “0” and

figure of 1 to “1”.

Camera 1 monitor display

at power ON

LPROCESS<<>> I INTIA

:--I--PAN

:--I--TILT

Duplex display ID No. display

(ID check procedure

DUPLEX ID- 01ROT>P COOL

☞

P. 13)

1234678

F

F

O

Switch 1

Switch 2

Switch 4 : ON

Switch 5 : OFF

Switch 7 : Invalid (Set to OFF)

Switch 8 :

5

:

Invalid (Set to OFF.)

:

Set to ON only for the

camera connected at

the end of the control

signal cable.

Set to OFF for all

other cameras.

8

Page 9

VIDEO

SWITCHER, etc.

CONTROLLER*

Length of stub

CONTROL Cable

PROTOCOL(1) : ON

MACHINE ID : 01

RX TERM : ON

PROTOCOL(1) : ON

MACHINE ID : 02

RX TERM : OFF

PROTOCOL(1) : ON

MACHINE ID : 32

RX TERM : OFF

Length of stub

CAM1 CAM2

CAM32

Terminate it

with 110 Ω.

A system that does not employ the RM-P2580 as the controller

MEMO

Be sure to terminate the control signal cable at both ends. The cables (length of stub) connecting pieces of non-terminated

equipment (cameras or controllers) must be as short as possible. If the length of stub is too long, control precision may suffer.

● When the controller is not located at the end of a system.

(An AC 24V power source must be supplied to each camera)

CONTROL Cable

CAM1 CAM2

PROTOCOL(1) : ON

MACHINE ID : 01

RX TERM : ON

PROTOCOL(1) : ON

MACHINE ID : 02

RX TERM : OFF

• Set the TERM switches of the cameras at each end

(CAM1 and CAM32) to ON, and the TERM switches of

Length of stub

CONTROLLER*

VIDEO

SWITCHER, etc.

the other cameras to OFF.

• Do not terminate at the controller.

● When the controller is located at the end of a system.

(An AC 24V power source must be supplied to each camera)

Length of stub

CAM31 CAM32

PROTOCOL(1) : ON

MACHINE ID : 31

RX TERM : OFF

Length of stub

PROTOCOL(1) : ON

MACHINE ID : 32

RX TERM : ON

• Set the TERM switch of CAM1 to ON, and terminate at the controller with a resistance of 110 Ω.

Set the TERM switches of the other cameras to OFF.

9

Page 10

Connections & Installation

Point-to-Point Communication System

The following illustration shows a system in which a remote control unit (or a similar piece of equipment) controls a single camera.

Video out

Control signal cable

AC 24 V

power supply

Monitor

Switch 4 : OFF

(Point to Point)

Switch 8 : ON

(Terminated 110Ω)

Observe the following points when connecting components together:

• Turn all the components off before proceeding.

• Read the instruction manuals of all components before proceeding.

Controller

Cable connections

(Terminal side of the Ceiling Mount)

P. 1 4

☞

Control signal cable

To controller

Coaxial cable

Power cable

To monitor

To the AC 24V power supply

Switch settings

(Setting switches are on the side of the Ceiling Mount)

Setting not

Setting not

required

required

P. 1 2

☞

123

4

678

5

F

F

O

Switch 1 : OFF

Switch 2 : OFF

Switch 4 : OFF

Switch 5 :

accordance with the requirements

of the controller communication

system.

Switch 7 : OFF

Switch 8 : ON

Configure in

MEMO

If this camera or the cables connected to this camera are used in places subject to strong electromagnetic waves or other forms

of magnetism, for example near a radio or TV transmitter, a power transformer or an electric motor, the picture may suffer from

noise and colors may be affected.

An optionally available controller is required to use a TK-C676 camera. Please contact your local dealer or installer for more

information about these controllers.

10

Page 11

Use twisted-pair cables for the connections.

●Duplex

When the camera is controlled using the full duplex protocol, set Switch 5 to OFF.

Camera Controller

RX+

RX–

TX+

TX–

Four wires must be connected.

For example (connection with an RM-P2580)

Camera RM-P2580

RX+ C

RX– D

TX+ A

TX– B

TX+

TX–

RX+

RX–

C TX+

D TX–

A RX+

B RX–

●Simplex

When the camera is controlled using the simplex transmission protocol, set Switch 5 to ON.

Camera Controller

RX+

RX–

Two wires must be connected.

TX+

TX–

11

Page 12

Connections & Installation

Switch Settings

Set the switches on the Ceiling Mount before installing the camera.

Settings vary according to configuration of the system used.

Setting switches

123

O

● Switches 1, 2

These switches must be set to OFF.

● DISP (Switch 3)

This switch selects whether “MANUAL” is displayed in the

screen when a remote control unit is used to move the camera manually (to a position other than those preset.).

Switch 3MANUAL

Displayed

Not displayed

(Initial setting: Displayed)

OFF

ON

● PROTOCOL (1) (Switch 4)

Selects whether a single camera or multiple cameras are controlled in a system.

Set PROTOCOL(1) to Multi drop when connecting multiple

cameras in series.

Switch 4PROTOCOL (1)

Point to point OFF

Multi drop (when using the RM-P2580)

(Initial set: OFF)

ON

When set to Multi drop, be sure to set the Machine ID of each camera.

● PROTOCOL (2) (Switch 5)

Set this switch according to the communication protocol used

when controlling the cameras.

PROTOCOL (2)

Duplex (when using the RM-P2580)

Simplex ON

(Initial set: OFF)

Switch 5

OFF

Switch 1

Switch 2

Reserved

This switch must be set “OFF”

Switch 3 DISP

Switch 4 PROTOCOL(1)

Switch 5 PROTOCOL(2)

Switch 6 SYNC

Switch 7

Reserved

This switch must be set “OFF”

Switch 8 RX TERM

4

678

5

F

F

● SYNC (Switch 6)

When this switch is set to ON, the vertical sync of the camera

becomes locked to the frequency of the AC power line.

SYNC Switch 6

INT OFF

LL ON

(Initial set: OFF)

(LL mode : 50 Hz area only)

● Switch 7

This switch must be set to OFF.

● RX TERM (Switch 8)

This switch sets whether or not the section between control

signal terminals RX + and RX – is to be terminated (with a

resistance of 110 Ω.)

Switch 8RX Termination

Terminated (110 Ω)ON

Open OFF

(Initial setting: Terminated (110 Ω))

When the system in which this camera is used is a multidrop system (RS-485 system), set only the camera located

at the extreme end of the control signal cables to “Termi-

nated” and set the other cameras to “Open”.

→

See page 1-6 “1.8 FUNCTION OF SWITCHES”

12

Page 13

Setting switches

3

2

4

1

5

0

6

7

4

5

6

7

Figure of 1

Figure of 10

9

8

3

2

1

0

9

8

● Machine ID

When using a multi-drop system with a remote control unit

such as a RM-P2580, the machine IDs need to be set for

each camera.

Machine IDs are used to identify each of the multiple cameras connected to the RM-P2580. Set the machine IDs according to the corresponding VIDEO INPUT terminal numbers on the RM-P2580.

(Example)

The machine ID of the camera connected to VIDEO INPUT 1 should be

set to “0” “1” as shown on the right.

“0”“1”

0

1

9

8

7

6

5

Figure of 10 Figure of 1

9

2

8

3

7

4

MEMO

In a system using an RM-P2580, multiple cameras are connected

by a single set of control cables. An error in the switch setting of

even a single camera will make the entire system inoperable.

<Camera ID check procedure>

1.

0

1

2

3

4

6

5

Set the picture being monitored to that of the camera to

be checked.

2.

Turn the AC 24V power source of the camera OFF and

then ON again.

3.

The camera now performs the initialization operation and

the following display appears:

PROCESSIN TIIAL

I--PNA:-I--TI TL:--

UPLEX I D- 10PROT OCLD

“DUPLEX” should be displayed. “ID-□□” is displayed.

4.

Ensure that “DUPLEX” and “ID-□□” are displayed and

Ensure that the number

□□

is correct.

that the ID number is identical to the VIDEO INPUT terminal number on the RM-P2580.

5.

If the ID number is incorrect, reset it accordingly.

13

Page 14

Maximum cable length

100 m 260 m 410 m 500 m

Wire diameter (mm) 1.0 or more 1.6 or more 2.0 or more 2.6 or more

Connections & Installation

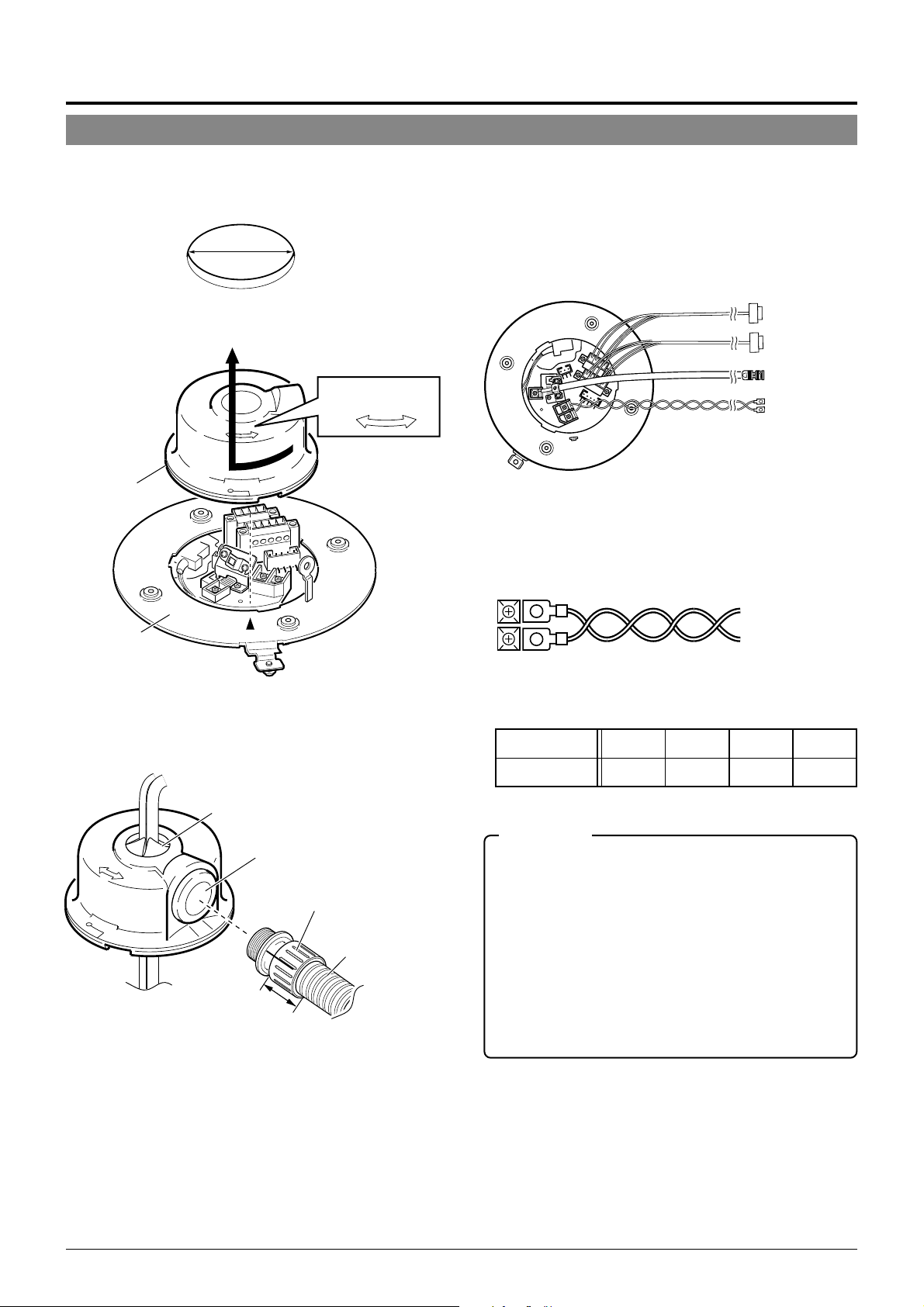

Cable Connections

Connect cables to the Ceiling Mount as described below.

1.

Make a 90 mm diameter hole in the ceiling.

Diameter 90 mm

2.

Remove the cover from the Ceiling Mount.

RELEASE LOCK

Cover

4.

Connect the cables.

Connect the cables to the terminals on the Ceiling Mount.

The four connection cables should consist of a AC 24V

power cable, a coaxial cable, a control signal cable and

an alarm signal cable.

Control signal cable

Alarm signal cable

Coaxial cable

Power cable

To a remote controller

such as RM-P2580

To a device with

alarm input

To the monitor, etc.

To the AC 24 V

power supply

AC 24V power cable

This cable connects the AC 24V power supply to the AC

24V input connector. To prevent connection errors and

disconnections, the use of lug plate for connections to the

AC 24 V INPUT connector is recommended.

Ceiling mount

3.

Pass the cables through the cover.

Make slits in the rubber cap on the cover as shown in the

diagram below. Pull the cables through the hole in the

ceiling and pass the cables through the slits.

Cap (Top)

Cap (Side)

Connector

Maximum diameter 31 mm

Tube

Maximum diameter

22 mm

33 mm or less

Drip-proof pipe

The diameter of the cover hole without the cap is 20.5 mm.

When the camera is installed in a place where it may sometimes be exposed to water splashes, for example under

eaves, enclose cables in a drip-proof pipe.

(Be sure to use a water-drip pipe that complies with the

IP52. standard. The maximum diameter of the pipe connector is 31 mm.)

When distributing the cable from the side, use the WBS573 ceiling direct-mount bracket. In this case, the length

of the connector should be 33 mm or less, and the maximum diameter of the tube should be 22 mm or less.

14

When a 2-conductor VVF (Vinyl-insulated vinyl-sheath cable) is used, the maximum connection length is as shown

below. (These are merely the standard reference values.)

CAUTIONS

● When a thin cables are used the cable resistance increases.

As a result, when the power consumption of the unit is at its

maximum level (during the simultaneous operation of panning

and tilting) the effective voltage will drop.

If the voltage does drop while the camera is in use, performance can become unstable and preset positions may not be

reproduced accurately.

To prevent problems, use thicker cables that have a lower resistance or decrease the cable length by installing the power

supply unit close to the camera. Attempt to reduce drops in

voltage to less than 10% while the rated current level of the

camera is flowing through the cable.

● Do not connect an AC 24V cable directly to an AC 230 V outlet.

This will damage the unit.

Page 15

Coaxial cable

Connecting a RG-59 coaxial cable.

If a RG-11 coaxial cable is used it cannot be connected directly to the terminal board. To use such a

cable, connect a RG-59 cable to the camera and then

connect the RG-11 cable to the RG-59 cable.

Treat the extremity of the coaxial cable as shown below

before connecting it.

Fold back the mesh wires and secure them with insulation tape in order

to prevent them from becoming loose and thus causing a short circuit.

Mesh wiresPolyethylene

Conductor

wire

7

(5)

Insulation tape

The figures inside the brackets ( ) are the dimensions

when the coaxial cable is distributed from the side of the cover.

(Unit : mm)

17

(12)

If the cable is extended, the signal attenuation is increased,

the resolution drops and the noise increases. Should it be

required to extend the cable, use a thicker cable or a cable length compensator.

To lead the coaxial cable through the cap on the side of

the cover, change the positioning of the cable plate as

shown below.

Provided screw

Screw removed in the

Provided cable

plate

figure on the left

Control signal cables

RM-P2580 units allow the connection of up to eight cameras to a single set of control signal cables. The overall

maximum permissible length of these control signal cables

is 1200 meters.

Alarm signal cables

P. 6

☞

Alarm output terminals (CN24)

Connect the provided 4P Alarm cable

to these terminals.

Alarm input/output terminals

(CN23)

Alarm input terminals (CN26)

Connect the provided 6P Alarm cable

to these terminals.

Electrical Specification of the Alarm Output Terminals

N. OPEN

COM.

N. CLOSE

ALARM2+

or

ALARM3+

22 Ω

ALARM2–

or

ALARM3–

• The ALARM 1 terminal outputs a

contact signal. In the alarm status,

the section between N.OPEN and

COM is shorted (makes an electrical contact) and the section between N.CLOSE and COM is

opened (breaks contact).

Rating

Maximum applied voltage: 30 V

DC or 24 V AC

Maximum applied current: 2 A

Contact life: 200,000 times of

operation

• The ALARM 2 and ALARM 3 terminals output open-collector signals insulated by photocouplers.

The terminal is ON in the alarm status.

As these terminals are provided

with polarity, make sure that the

voltage at the + terminal is higher

than that at the – terminal.

Do not apply inverse voltage to prevent damage of these terminals.

Rating

Maximum applied voltage: 20 V DC

Maximum drive current: 25 mA

Cable

Flat-blade

screwdriver

Cables with a thickness between 16 AWG and 26 AWG can be used.

Connect the control signal cables so that the TX+ and TX- signals

form a pair and the RX+ and RX- signals form another pair.

4 mm

The connector can be released by

loosening the screws on the two sides as

shown in the figure.

Flat-blade screwdriver

Strip the coating of each cable by about 4

mm before inserting it. After connecting all

of the cables, turn the screws on the side

to fasten the connectors.

It is recommended to use a 4-core (a pair)

twisted pair cable (0.65) or a twisted pair

cable of category 3 or higher which is

used for a Ethernet.

Electrical Specifications of Alarm Input Terminals

ALARM1

GND

• Use the appropriate menu to select whether the alarm is

identified by shorting (making contact) or by opening (breaking contact).

• Apply an alarm signal for at least 200 ms. If it is shorter, it is

not guaranteed that the signal will be recognized as an alarm

signal.

5.

Attach the cover.

Attach the cover to the ceiling mount by reversing the

operations in step

• To prevent penetration of noise in

the internal circuitry, apply a nonvoltage contact signal to the

ALARM input terminal

Never apply a voltage.

2

.

15

Page 16

Connections & Installation

Attaching the Ceiling Mount

To a ceiling slab or channel

Safety wire hole

Ceiling mount

Rubber packings

(Four on each side)

1.

Attaching a safety wire.

Attach a safety wire to the ceiling mount and to the ceiling slab or channel to prevent the unit from dropping.

First attach the safety wire to the ceiling mount by passing the wire through the safety wire hole (see the diagram on the left).

MEMO

● Connect the wire so that it can be insulated from the ceiling struc-

ture. If the ceiling structure is made of a metallic material, improper insulation with the camera may produce noise in the video.

● Use a wire and ceiling attachment having sufficient length and

strength to prevent danger in case the camera drops.

● A safety wire is not provided. Please select an appropriate com-

mercially available wire.

2.

Attaching the ceiling mount to the ceiling.

While taking care not to catch the connection cables, attach the ceiling mount to the ceiling using four screws

(as shown in the diagram). Use M4-sized screws or bolts.

If woodscrews are used, use those with a diameter of 4.1

mm.

Screws

Attaching the Camera

Attach Drop

Prevention Wire

to this hook.

Drop Prevention

Wire

MEMO

● Be sure to use four screws and attach them firmly. If the screws

are not tightened firmly, dust and moisture may penetrate through

the screw holes.

● The rubber packings attached to the ceiling mount screw holes of

the ceiling mount play the role of insulation in case the ceiling

structure is made of a metallic material as well as the role of drip

proofing. If the ceiling structure is made of a metallic material,

improper insulation with the camera may produce noise in the

video. To prevent this occurring, be sure to ensure correct insulation of the installation.

1.

Attach the drop prevention wire.

As shown in the diagram, take the drop prevention wire

from the camera and attach it to the hook on the ceiling

mount.

Be sure to connect the drop prevention wire. Otherwise,

the camera will not fit properly to the ceiling mount. If

they are engaged forcibly, they may be damaged.

CAUTION

Be sure to attach the drop prevention wire. Otherwise, the camera is in danger of falling.

16

Page 17

Ceiling Mount

Camera

Camera clamping bracket

Lock screw

Camera clamping

bracket

2.

Ensure that the lock screw is loose.

The camera cannot be attached properly if the lock screw

of the Ceiling Mount is too tight.

3.

Fit the camera.

Check the position of the camera clamping bracket and

that of the lock screw, and fit the camera onto the ceiling

mount.

Lock screw

Rotate the camera

clockwise.

4.

Rotate the camera.

Make sure that the camera is horizontal, then turn the

camera clockwise until it stops. Ensure that the cameraclamping bracket is in line with the lock screw of the Ceiling Mount.

5.

Tighten the lock screw.

Tighten the lock screw using a Phillips screwdriver.

CAUTION

If the lock screw is not tightened firmly, the camera may rattle or

fall down. Be sure to tighten the lock screw firmly.

* To remove of the camera from the ceiling

1

mount, reverse the steps

to 5.

Tighten the lock screw.

17

Page 18

Setting Up the Camera Using an RM-P2580

Setup Procedure

In systems using an RM-P2580 remote control unit, the menus for use during camera setup can be displayed on the remote control

unit. (Please refer to the instructions for RM-P2580.)

<Setting the camera menus from an RM-P2580>

1.

MENU button

SET button

SETUP

POWER

ALARM

MENU SET

KEY LOCK

POWER lamp

CAMERA POSITION

Power switch

(Rear panel)

REMOTE CONTROL UNIT

RM-P2580

AUTO F-1 F-2 F-3

Set the Power switch on the rear panel of the RMP2580 to ON.

The POWER lamp lights up.

CAMERA/POSITION

SPEED

IRIS

OPEN

CLOSE

FOCUS

FAR

NEAR

AF

TELE CLEAR

WIDE

ZOOM

CAMERA

1

2

3

OPTION1OPTION

4

5

6

AUTO

7

8

9

PAN

0

ENTER

/HOME

PAN/TILTLENS

POSITION

2

AUTO

PATROL

cursor

POSITION SETUP..

CAMER A . .

CONTROL UN I T . .

SETUP

SETUP menu of the remote control unit

CAM . FUNC T I ON . .

CAM. T I T L E / ALARM. .

CAM. V I DEO ADJUST. .

CAM. ALC / Ex DR . .

HOME MOT I ON DET EC T . .

AUTO PAN / PATROL / TRACE. .

POS I . FUNCT I ON SET . .

FACTORY SETT INGS. .

–––M E N U –––

SETUP menu of the camera

Change mark

PAN/TILT

lever

Indication of

presence of

submenus

2.

Press and hold the MENU button for 3 seconds.

• The LED of the MENU button lights up.

• The SETUP menu of the remote control unit is displayed on the

monitor connected to MONITOR OUTPUT-1.

3.

Move the PAN/TILT lever downward to move the

cursor (>) to “CAMERA” in the menu.

• Tilting the lever upward () moves the cursor upward.

• Tilting the lever downward (

4.

Press the SET button.

) moves the cursor downward.

• The MENU screen for the camera is displayed.

• Items followed by “..” have further submenus.

5.

Tilt the PAN/TILT lever up or down to select an item.

6.

Tilt the PAN/TILT lever to the left or right to change

the value of the item.

• Tilting the lever toward the left ( ) decreases the value.

• Tilting the lever toward the right (

) increases the value.

–––CAMERA FUNC T I ON –––

POS.TITLE LOC. UP-L

FLIP DIGITAL

VAR. P / T SPEED ON

EASY AF OFF

D.ZOOM MAX X2

PRI VATE MASK. .

Example of a submenu

18

7.

Press the MENU button.

After completing the setup of the menu items, press the MENU button to return to the previous menu screen.

Page 19

Menu Screen Flow

The menu screens are arranged in a hierarchical structure as shown below. Refer to the respective reference pages for the details of each

menu.

Normal screen

P.20

☞

POS I T ION SE TUP . .

CAMERA. .

CONTROL UN I T . .

SETUP

SETUP screen of the remote control unit

––– M E N U – ––

CAM. FUNCT I ON. .

CAM. T ITLE/ALARM. .

CAM. V I DEO AD JUST . .

CAM. ALC / E xDR . .

HOME MOT I ON DET EC T . .

AUTO PAN / PA TROL / TRACE . .

POS I . FUNCT I ON SET . .

FACTORY SETT INGS. .

c

MENU screen

• Menus for setting up the function of

each camera:

CAM. FUNCTION

CAM. TITLE/ALARM

CAM. VIDEO ADJUST

CAM. ALC/ExDR

AUTO PAN/PATROL/TRACE

• Menu for setting up the home position only:

HOME MOTION DETECT

• Menu for setting up the function of

each preset position:

POSI. FUNCTION SET

––CAMERA F UNCT I ON – –

V.PHASE 0

POS . T I T L E LOC . UP - L

FLIP DIGITAL

VAR. P / T SPEED ON

EASY AF OFF

D.ZOOM MAX X2

PRIVATE MASK. .

CAMERA FUNCTION screen

P.23

☞

–––CAMERA V I DEO ADJUST –––

COL OUR L EV E L NORMAL

ENHANCE LE VE L NORMA L

PEDESTAL LEVE L NORMAL

AUTO B LK . CTL . OF F

CAMERA VIDEO ADJUSTMENT screen

P.26

☞

–––HOME MOT I ON DE T EC T – ––

MOD E OF F

LEV EL NORMAL

AREA ED I T . .

ALARM DI SPLAY 5s

DEMONSTRAT I ON . .

HOME MOTION DETECT screen

P.28

☞

––POSITION FUNCTION SET – –

POS I T ION T I TL E . .

IRIS MODE AUTO

BLC OFF

W.BALANCE ATW

R-B GAIN –––

M-G GAIN –––

P.21

☞

–––CAMERA T I TL E / ALARM

CAM. T I TL E ED I T . .

AREA T I TL E OFF

AREA T I TL E ED I T . .

ALM.T I TLE S I ZE DOUBLE

ALM.T I TLE COLOUR WHI TE

AL ARM T I T L E ED I T . .

AL ARM I NPUT . .

ALARM OUTPUT. .

–––

CAMERA TITLE ALARM screen

P.23

☞

–––CAMERA A LC / Ex DR

AVERAGE : PEAK 8 : 2

SHUTTER 1 / 5 0

AGC MODE 1 0 d B

SENSE UP OFF

PR I OR I TY MOT I ON

Ex DR MODE OFF

ExDR LEVEL –––

B&W / COLOUR MODE. .

–––

CAMERA ALC/ExDR screen

P.27

☞

––AUTO PAN / PATROL / TRACE

AUTO PAN MODE RETURN

AUTO PAN SPEED NORMAL

A.PAN START POS.SET. .

A.PAN RETURN POS.SET. .

AUTO PA TROL SET . .

AUTO TRACE SET . .

RM.A.PAN KEY A.PAN

RM.A.PATROL KEY A.PATROL

––

AUTO PAN/PATROL/TRACE screen

P.28

☞

POSITION FUNCTION SET screen

––FACTORY SETT I NGS – –

CANCEL

CLEAR(W/ O POS I . TI TLE )

CLEAR( AL L )

FACTORY SETTINGS screen

19

Page 20

Setting Up the Camera Using an RM-P2580

CAMERA FUNCTION Screen

This screen sets up the functions of the camera itself.

Item

V. PHASE

POS. TITLE LOC.

FLIP

VAR. P/T SPEED

EASY AF

Function & Setting

This adjusts the vertical synchronization to those of other cameras when a selector

switch for the synchronizing system on the Ceilling Mount is at LL. (50 Hz power

region only.)

When it is not set to LL, “---” will appear, disabling change the set value.

Setting values : –156 to 0 to 156

Sets the location of the position title and area title in the monitor.

UP : At the top of the screen.

DOWN : At the bottom of the screen.

L : In the left half of the screen.

C : In the center of the screen.

R : In the right half of the screen

Setting values : UP-L, UP-C, UP-R, DOWN-L, DOWN-C, DOWN-R

When a tilting operation is started while this item is OFF, the camera will stop at the

position where it is pointing straight downwards. When an object moves directly

below the camera, the camera makes three movements

ward

The FLIP function makes it possible to reduce these operations. Use this function

when monitoring an object passing directly below the camera.

OFF : Turns the FLIP function off.

DIGITAL : Once the camera reaches a tilt of 135 degrees from horizontal after

AUTO : When the camera reaches a position facing directly downwards, it pans

Under this function, the panning and tilting speeds are adjusted automatically relative to the zoom ratio of the lens. Setting the zoom lens towards TELE decreases

the pan and tilting speeds.

Setting the zoom lens towards WIDE end increases the pan and tilting speeds.

Use this function when monitoring objects at differing zoom ratios.

OFF : Turns this function off.

ON : Turns this function on.

When this item is set to ON, the auto focusing (AF) is activated automatically during manual pan/tilt and zoom operations.

This function is convenient when frequent manual operations are expected as it

eliminates the need to focus manually after every manual operation.

OFF : Turns this function off.

ON : Turns this function on.

pans 180° 3 points upwards.

2

passing a position facing directly downwards, a picture is inverted both

vertically and horizontally.

by 180° then stops.

points the straight down-

1

MEMO

Auto focusing may sometimes be incapable of bringing certain objects into accurate focus.

(

P. 4 )

☞

In this case, use the manual focusing facility.

Initial Value

0

UP-L

DIGITAL

ON

OFF

D. ZOOM MAX

PRIVATE MASK..

20

When the zoom lens is set toward TELE, optical zooming is activated first and

electronic zooming second. This function sets the maximum zoom ratio of the

electronic zooming.

Setting values : x1, x2, x4, x6, x8, x10.

MEMO

● Note Picture quality deteriorates under electronic zooming as it is accompanied by digital

image processing.

● An increase in the electronic zooming ratio may deviate the center of the image slightly

toward the top left. This is due to the camera properties and is not a malfunction.

● Continuous operation from optical zooming to electronic zooming is not available. When

optical zooming reaches the TELE end, press the TELE button again.

This function grays out sections that are not to be displayed in the monitored picture area.

The grayed out section moves accordingly when the camera is panned, tilted or

when the zoom is adjusted.

P.29, “PRIVATE MASK Setup”

☞

x2

–

Page 21

CAMERA TITLE/ALARM Screen

This screen sets items related to titles and alarms.

Item

CAM. TITLE EDIT

AREA TITLE

AREA TITLE EDIT

ALM. TITLE SIZE

ALM. TITLE COLOUR

ALARM TITLE EDIT

ALARM INPUT

Function & Setting

..

This sets the title which is displayed permanently at the bottom left of the picture.

This title can be up to 16 characters in length.

P. 30, “CAMERA TITLE Setup”

☞

The 360° panning range can be divided into 16 areas and a title, of up to 16character in length, can be set for each area. As the camera is panned manually

these area titles are displayed. This function determines whether area titles are

displayed or not.

ON : Display area titles.

OFF : Do not display area titles.

..

Sets the area titles.

P. 31, “AREA TITLE Setup”

☞

Sets the size of the characters in the alarm title. (Displayed when an alarm is activated.)

NORMAL : Same size as the characters used in the menu screen.

DOUBLE : Double the size, both horizontally and vertically, of the characters used

Sets the color of the alarm titles.

Setting values: WHITE, YELLOW, CYAN, GREEN

..

Sets the alarm titles.

P. 32, “ALARM TITLE Setup”

☞

..

Sets the configuration of the alarm input terminals on the Ceiling Mount.

The picture can be turned black-and-white mode when an alarm signal is input.

P. 25, Item “B&W”

☞

in the menu screen.

MEMO

● When the item “B&W” is set to ALARM 1 to 4, [B&W] will be displayed at the correspond-

ing ALARM IN 1 to 4 items and the setting cannot be varied.

● When ALARM IN 1 to 4 are set to positions between POS 64 and POS 99, switching to

the preset position does not occur even when an alarm signal is input.

Initial Value

–

OFF

–

DOUBLE

WHITE

–

–

ALARM IN1

ALARM IN2

ALARM IN3

ALARM IN4

Sets the camera position for alarm 1. When an alarm signal is input to the Alarm 1

input terminal, the camera moves to this set position.

HOME means the home position and POS1 means position 1.

Setting values: OFF, HOME, POS1 to POS99.

Sets the camera position for alarm 2. When an alarm signal is input to the Alarm 2

input terminal, the camera moves to this set position.

HOME means the home position and POS1 means position 1.

Setting values: OFF, HOME, POS1 to POS99.

Sets the camera position for alarm 3. When an alarm signal is input to the Alarm 3

input terminal, the camera moves to this set position.

HOME means the home position and POS1 means position 1.

Setting values: OFF, HOME, POS1 to POS99.

Sets the camera position for alarm 4. When an alarm signal is input to the Alarm 4

input terminal, the camera moves to this set position.

HOME means the home position and POS1 means position 1.

Setting values: OFF, HOME, POS1 to POS99.

OFF

OFF

OFF

OFF

21

Page 22

Setting Up the Camera Using an RM-P2580

CAMERA TITLE/ALARM Screen (Continued)

Item

ALARM INPUT

POLARITY

DURATION

PRIORITY

Function & Setting

..

(Continued)

Sets the polarity of the alarm signal inputs.

MAKE : Alarm signals are transmitted when point of contact is made.

BREAK : Alarm signals are transmitted when contact is broken.

MEMO

When an item for the B&W is set to the ALARM 1 to 4, it is set to the MAKE mode even if

“BREAK” is displayed.

Sets the length of an alarm operation once an alarm signal has been transmitted.

(Unit:second)

Setting values : 5s, 6s, 7s, 8s, 9s, 10s, 15s, 20s, 30s or 60s

CAUTION

This item is invalid with the system using the RM-P2580. When using the RM-P2580, use

item “ALARM TIME” instead.

Sets whether or not manual operation is accepted in case an alarm input is recognized during manual operation of the camera.

ALARM : Manual operation is not accepted when there is an alarm input.

MANUAL : Manual operation is accepted even when there is an alarm input.

(Priority on alarm)

(Priority on manual)

CAUTION

This item is invalid with a system using the RM-P2580. With this system, the ALARM input

is permanently given the priority.

Initial Value

MAKE

5s

ALARM

ALARM OUTPUT

ALARM OUT1

ALARM OUT2

ALARM OUT3

..

Sets the configuration of the alarm output terminals on the Ceiling Mount.

Sets the configuration of the Alarm output 1 terminal.

OFF : Does not output an alarm signal.

ALARM : Alarm signal is output upon input of motion detection or an alarm signal.

B&W : Alarm signal is output when the camera enters the B&W mode.

PRESET : Alarm signal is output when a camera moves to a preset position.

AUX1 to 3 : Alarm signal is output when a corresponding AUX signal is input. (This

is variable depending on the remote control unit in use.)

MEMO

● Since the ALARM OUT 1 terminal employs a mechanical relay, its operating sound may

seem noisy in a quiet environment. In this case, use the ALARM OUT 2 or 3 terminal

instead.

● Sine the ALARM OUT 1 terminal employs a mechanical relay, the service life of the relay

may be shortened if signals causing an alarm (motion detect signal, etc.) are applied frequently. The service life of a relay is 200,000 times of operation. The relay is a consumable

part and a replacement is chargeable even before the termination of the warranty period.

Sets the configuration of the Alarm output 2 terminal.

OFF : Does not output an alarm signal.

ALARM : Alarm signal is output upon input of motion detection or an alarm signal.

B&W : Alarm signal is output when the camera enters the B&W mode.

PRESET : Alarm signal is output when a camera moves to a preset position.

AUX1 to 3 : Alarm signal is output when a corresponding AUX signal is input. (This

Sets the configuration of the Alarm output 3 terminal.

OFF : Does not output an alarm signal.

ALARM : Alarm signal is output upon input of motion detection or an alarm signal.

B&W : Alarm signal is output when the camera enters the B&W mode.

PRESET : Alarm signal is output when a camera moves to a preset position.

AUX1 to 3 : Alarm signal is output when a corresponding AUX signal is input. (This

is variable depending on the remote control unit in use.)

is variable depending on the remote control unit in use.)

–

ALARM

ALARM

ALARM

22

Page 23

CAMERA VIDEO ADJUSTMENT Screen

This menu sets the picture signal of the camera, such as the color level and contour enhancement.

Item

COLOUR LEVEL

ENHANCE LEVEL

PEDESTAL LEVEL

AUTO BLK. CTL

Sets the color level of the picture signal.

To increase : Set a smaller value.

To decrease : Set a larger value.

Setting values : –5 to NORMAL to 5.

Sets the contour enhancement which controls the sharpness of the monitor picture.

To soften the picture : Set a smaller value.

To sharpen the picture : Set a larger value.

Setting values : –5 to NORMAL to 5.

Sets the pedestal level (black level) of the video signal.

To darken the picture : Set a smaller value.

To brighten the picture : Set a larger value.

Setting values : –5 to NORMAL to 5.

Use this function when darker parts of a picture are unclear even after the gain has

been increased using the AGC (Auto Gain Control).

ON : When the black level of the video signal is low, the pedestal level is in-

creased automatically in order to improve the clarity of the darker parts.

OFF : Turns this function off.

Function & Setting

CAMERA ALC/ExDR screen

This screen adjusts the settings of automated functions relating to picture brightness.

Initial Value

NORMAL

NORMAL

NORMAL

OFF

Item

AVERAGE : PEAK

SHUTTER

Function & Setting

Sets the method of exposure detection to the ratio between the average and peak

values.

Large Average value

Large Peak value : Use this setting when highlighted areas appear as halation.

Setting values : 10:0, 9:1, 8:2, 7:3, 6:4, 5:5

Sets the electronic shutter speed.

When the item “SENSE UP” is set to “x2” or higher, the, available settings for the

SHUTTER are limited to 1/50 and 1/120.

When the item “ExDR MODE” is set to “ON”, the available settings for the SHUT-

TER are limited to 1/50 and 1/120.

Setting values : 1/50, 1/120, 1/250, 1/500, 1/1000, 1/2000, 1/4000, 1/10000

: Use this setting when areas other than the highlighted ar-

eas are filled with dark. (Example: 10:0)

(Example: 5:5)

MEMO

● To reduce the flickering which occurs under fluorescent lighting, set the shutter speed

to 1/50 if your local power supply frequency is 50 Hz and to 1/120 if it is 60 Hz.

● When a high shutter speeds are used, white stripes may be observed above and

below bright objects. This is called the smear phenomenon and is usual to CCD

cameras.

Initial Value

8:2

1/50

23

Page 24

Setting Up the Camera Using an RM-P2580

CAMERA ALC/ExDR Screen (Continued)

Item

AGC MODE

SENSE UP

Function & Setting

Sets the maximum gain of the AGC (Auto Gain Control), which electronically increases the gain when the object is under low light conditions.

OFF : Turns the AGC off.

10 dB : According to the brightness of the object, gain is increased by up to 10 dB

20 dB : According to the brightness of the object, gain is increased by up to 20 dB

SUPER : Use this setting when brightness is still insufficient under the “20 dB”

setting.

MEMO

When the item “B&W” is set to “AUTO”, [SUPER] is displayed when the item “AGC MODE”

●

is set to “SUPER”, and [20 dB] is displayed for other settings. Increase the gain up to the

value displayed.

● Note that increasing gain affects picture quality.

● When the “SUPER” setting is used, the AGC operation may take a while to adjust to

sudden drastic changes in the brightness level.

This function is used to increase the sensitivity by extending the exposure time.

When the object is dark, this function sets how high the level of sensitivity will

automatically increase to. “x32” means that the sensitivity will be increased continuously up to 32 times the normal level.

Increasing this value slows the shutter speed and motion may appear unnatural.

When the item “SHUTTER” is set to “1/250” or more, the SENSE UP item does not

work and “---“ is displayed as the item name in the CAMERA ALC/ExDR Screen.

Setting values: OFF, x2, x4, x8, x16, x24, x32

MEMO

● As the setting of the “SENSE UP” function is increased, the picture may become rough

and whitish, and subject to white blemishes. This is not a malfunction.

● When the setting of the “SENSE UP” function is not OFF, flicker may appear on the

screen under fluorescent light or mercury lamps. This is due to the principles of the

SENSE UP, and is not a malfunction.

● There may be cases where flicker can not be reduced even under the following condi-

tions: 1) Shutter speed is set at 1/120 in areas where the commercial electric current

frequency is 50 Hz. 2) The shutter speed is set at 1/50 in areas where the commercial

electric current frequency is 60 Hz.

Initial Value

10 dB

OFF

PRIORITY

ExDR MODE

When an object is dark, this functions sets whether priority during monitoring is

placed on maintaining the motion of the camera or on picture quality.

MOTION : Motion of the camera is given priority. When an object is dark, the

AGC function is prioritized. This setting is suitable when objects are

characterized by quick motion.

PICTURE : Picture quality is given priority. When an object is dark, the SENSE UP

function is prioritized. This setting is suitable when picture quality is

important.

MEMO

● When the “AGC MODE” and “SENSE UP” functions are both set to “OFF”, this function

does not work and “---” is displayed as the item name in the CAMERA ALC/ExDR Screen.

● When item “B&W” is set to AUTO, item “PRIORITY” is set to the MOTION priority mode

and “---” is displayed.

The ExDR function synthesizes pictures captured at a shutter speed of 1/100 and

those captured at higher shutter speeds to help monitor objects having large differences in brightness levels.

When the “SHUTTER” function is set to “1/250” or a higher, this function does not

work and “---” is displayed as the item name in the CAMERA ALC/ExDR Screen.

OFF : Turns the ExDR function off.

ON : Turns the ExDR function on.

MEMO

● When the ExDR function is on, flicker may appear on the screen under fluorescent light

or mercury lamps. This is due to the principles of the ExDR, and is not a malfunction.

● There may be cases where flicker cannot be reduced even under the following condi-

tions: 1) Shutter speed is set at 1/120 in areas where the commercial electric current

frequency is 50 Hz. 2) The shutter speed is set at 1/50 in areas where the commercial

electric current frequency is 60 Hz.

MOTION

OFF

24

Page 25

Item

Function & Setting

Initial Value

ExDR LEVEL

B&W/COLOUR

..

MODE

B&W

LEVEL

This function sets which section of the object is to be displayed in the easiest-toview brightness level in the ExDR mode.

To make a low-light section of the object easy to view: Increase the level.

To make a highlighted section of the object easy to view: Decrease the level.

Setting values: –5 to NORMAL to 5

MEMO

● When the difference in brightness between objects is large, the picture may not change

even when the ExDR LEVEL is varied. This is due to the characteristics of the camera

and is not a malfunction.

● When the item “SHUTTER” is set to 1/250 or higher, “---“ is displayed and the settings to

the item “ExDR LEVEL” cannot be carried out.

● When the item “ExDR MODE” is set to OFF, the settings for the item “ExDR LEVEL”

cannot be varied.

This function sets the color modes to color or B&W.

When switching the mode between “color” and “B&W” is carried out, the focus may

be dislocated. In such a case adjust the focus again.

Switches the mode from color to B&W and vice-versa.

OFF : Turns the B&W mode switching function off.

ON : Sets the camera permanently to B&W mode.

AUTO : The camera automatically switches to Color mode when the ob-

ject is bright and to B&W mode when it is dark.

ALARM IN 1 to 4

: The camera switches to B&W mode when there is an alarm

input from terminals Alarm 1 to Alarm 4.

The B&W mode is set to ON when the contact is shorted (makes

contact) and OFF when the contact is opened (breaks contact).

MEMO

● To ensure switching between the color and B&W modes:

Setting item “B&W” to AUTO allows the color and B&W modes to be switched according

to the brightness of the object. However, this switching may sometimes not occur depending on the lighting condition and viewing angle.

To ensure the switching, it is recommended to connect the signal from an external sensor (to be purchased separately by the user) to one of the ALARM input terminals of the

camera and perform switching according to the sensor signal.

● In order to prevent hunting do not set the item “B&W” to AUTO when using an infrared

lamp.

When the “B&W” function is set to “AUTO”, this function sets the signal level of the

object at which the camera will automatically switch to B&W mode.

LOW : The camera switches to B&W mode when the signal level of the object

is low.

NORMAL : The camera switches to B&W mode when the signal level of the object

is normal.

HIGH : The camera switches to B&W mode when the signal level of the object

is high.

MEMO

When the item “B/W” is set to other than AUTO, “---“ is displayed and the settings to the item

“LEVEL” cannot be varied.

NORMAL

OFF

NORMAL

LIGHT TYPE

Use this function to set the type of light illuminating the object in the B&W mode.

NORMAL : Setting for normal lighting.

IR : Setting for using IR lighting.

MEMO