Page 1

SERVICE MANUAL

COMBINATION CAMERA

TK-C675BU/TK-C675BE

RELEASE

K

C

LO

COPYRIGHT © 1998 VICTOR COMPANY OF JAPAN, LTD.

No. 6681

December 1998

Page 2

TABLE OF CONTENTS

Section Title Page Section Title Page

INSTRUCTIONS

1. DISASSEMBLY

1.1 REMOVING THE SIDE AND DOME COVERS ............ 1-1

1.2 REMOVING THE CAMERA ......................................... 1-1

1.3 REPLACING THE CCD IMAGE SENSOR .................... 1-2

1.4 REMOVING MAJOR CIRCUIT BOARDS ..................... 1-3

1.4.1 Removing the PR board ...................................... 1-3

1.4.2 Removing the IF board ........................................ 1-3

1.4.3 Removing the MD board and MD SUB board ..... 1-3

1.4.4 Removing the CN board ...................................... 1-4

1.4.5 Removing the power supply unit ........................ 1-4

1.4.6 Removing the lens assembly .............................. 1-5

1.4.7 Removing the pan/tilt assembly .......................... 1-5

1.5 DIP SWITCHES ........................................................... 1-5

1.6 CONSUMABLE PARTS ............................................... 1-6

1.7 REFFERENCE REPLACEMENT PERIODS OF

PARTS WHITCH REQUIRE MAINTENANCE AND

INSPECTION ............................................................... 1-6

1.8 Replacement of IC ROM (IF board IC27, IC29) ........... 1-6

1.9 Positional adjustments to the sensor plate ................. 1-7

1.10 Care in Transportation .............................................. 1-7

2. ELECTRICAL ADJUSTMENTS

2.1 EQUIPMENT NECESSARY FOR ADJUSTMENT ........ 2-1

2.2 COMPUTER AND PERIPHERAL EQUIPMENT ........... 2-1

2.3 GENERAL SETUP ........................................................ 2-2

2.4 SWITCH SETTING FOR ADJUSTMENTS .................... 2-2

2.5 HOW TO EXECUTE PROGRAM

SOFTWARE (PLSC1209) ............................................. 2-3

2.6 KEYBOARD OPERATION (PLSC1209) ........................ 2-3

2.7 MENUS ....................................................................... 2-3

2.8 CAMERA ADJUSTMENT ............................................ 2-4

2.9 BACK-FOCUS ADJUSTMENT ..................................... 2-4

2.10 EVR ADJUSTMENT ................................................. 2-5

3. DIAGRAMS AND CIRCUIT BOARDS

3.1 CCD/PR BOARD BLOCK DIAGRAMS ......................... 3-2

3.2 IF BOARD BLOCK DIAGRAM ..................................... 3-3

3.3 CCD BOARD SCHEMATIC DIAGRAM ........................ 3-4

3.4 CCD CIRCUIT BOARD ................................................ 3-4

3.5 PR CIRCUIT BOARD ................................................... 3-5

3.6 PR BOARD SCHEMATIC DIAGRAM ........................... 3-6

3.7 IF BOARD SCHEMATIC DIAGRAM ............................ 3-7

3.8 IF BOARD CIRCUIT BOARD ....................................... 3-8

3.9 MD/MD SUB BOARD SCHEMATIC DIAGRAM .......... 3-9

3.10 MD BOARD CIRCUIT BOARD ............................... 3-10

3.11 MD SUB CIRCUIT BOARD .................................... 3-10

3.12 CN BOARD SCHEMATIC DIAGRAM ..................... 3-11

3.13 CN CIRCUIT BOARD ............................................. 3-11

3.14 TM BOARD SCHEMATIC DIAGRAM ..................... 3-11

3.15 TM CIRCUIT BOARD ............................................. 3-11

3.16 OVERALL WIRINGS .............................................. 3-12

3.17 BLOCK DIAGRAMS of IC’s .................................... 3-13

4. EXPLODED VIEW AND PARTS LIST

4.1 EXPLODED VIEW ....................................................... 4-1

5. ELECTRICAL PARTS LIST

5.1 CCD BOARD ASSEMBLY PARTS LIST ....................... 5-2

5.2 PR BOARD ASSEMBLY PARTS LIST .......................... 5-3

5.3 IF BOARD ASSEMBLY PARTS LIST ............................ 5-6

5.4 MD BOARD ASSEMBLY PARTS LIST ......................... 5-8

5.5 MD SUB BOARD ASSEMBLY PARTS LIST ................. 5-9

5.6 CN BOARD ASSEMBLY PARTS LIST .......................... 5-9

5.7 TM BOARD ASSEMBLY PARTS LIST ......................... 5-9

6. PACKING ....................................................................... 6-1

Page 3

SECTION 1

DISASSEMBLY

1.1 REMOVING THE SIDE AND DOME COVERS

(1) Rotate the side cover A in the direction of

it from the main body.

Fig. 1-1

(2) Remove the 3 screws 1 . Slide the dome cover B slightly

in the direction of , and pull it up in the direction of

B

and remove

A

.

1.2 REMOVING THE CAMERA

(1) Remove the covers as described in 1.1.

(2) Unplug the FPC cable C from the IF board.

IF board

C

Fig. 1-3

(3) Remove the 3 screws 2 and remove the camera D .

2

1

Fig. 1-2

CAUTION

When attaching the dome cover, tilt the camera by about

45° so as not to foul the FPC cable.

D

Fig. 1-4

(4) Remove the FPC cable from the section of the wire holder.

E

Fig. 1-5

1-1

Page 4

1.3 REPLACING THE CCD IMAGE SENSOR

F

E

䡵 The image sensor is interchangeable only with a specified

image sensor.

䡵 New image sensors and crystal filters should be handled so

as not to leave fingerprints or grease on their glass surfaces.

To remove attached dirt or grease, blow on the glass surface

until it becomes misted then wipe it gently with a cotton

swab. (Do not use alcohol or other similar substances.)

䡵 After replacement, all of the adjustments should be performed

from the beginning.

䡵 Note that the image sensor is susceptible to static damage.

Be sure to take anti-static measures before replacing it.

䡵 After an image sensor has been removed, an electrical charge

may remain on the terminals of the camera circuit for a certain period of time.

If a new image sensor is inserted into the socket in this condition, the image sensor may be instantly damaged by the

remaining electric charge. To prevent this happening, wait a

while (2 to 3 minutes) after removing an image sensor until

inserting another one in the socket.

䡵 After the CCD board has been removed from the lens as-

sembly, the back-focus adjustment should be performed

again.

(1) Remove the camera as described in 1.2.

(2) Remove the 3 screws 3 , the 3 screws 4 and the 2

screws 5 .

(3) Lightly push the section of the right camera cover F .

(4) Remove the left camera cover E in the direction as indi-

cated by the arrow →.

Fig. 1-8

CAUTION

Be careful not to damage the FPC cable when removing the camera cover.

(5) Remove the 2 screws 6 and take out the CCD board. (The

CCD is inserted into the CCD board.)

CCD board

4

3

6

Fig. 1-6

Fig. 1-9

4

5

Fig. 1-7

1-2

Page 5

1.4 REMOVING MAJOR CIRCUIT BOARDS

MD boad

M

N

9

P

1.4.1 Removing the PR board

(1) Remove the camera cover as described in 1.3.

(2) Remove the 2 screws 7 and remove the PR board.

PR board

1.4.3 Removing the MD board and MD SUB board

(1) Remove the camera as described in 1.2.

(2) Remove the IF board as described in 1.4.2.

(3) Remove the blind mask L .

L

7

Fig. 1-10

1.4.2 Removing the IF board

(1) Remove the side and dome covers as described in 1.1.

(2) Disconnect CN202 G and CN4 H from the IF board.

(3) Remove the 2 screws 8 and pull the IF board in the direc-

tion of the arrow. Now the IF board can be removed together

with the bracket (L) J and bracket (R) K .

G

IF board

H

J

K

Fig. 1-12

(4) Disconnect CN11 M , CN12 N and CN504 P from the MD

board.

(5) Remove the screw 9 and remove the MD board.

Fig. 1-13

Fig. 1-11

8

1-3

Page 6

(6) Remove the 2 spacers R .

(7) Remove the MD. INSULATOR Q and remove the MD SUB

board.

1.4.5 Removing the power supply unit

(1) Remove the screws and disconnect the connectors as de-

scribed in 1.4.4.

(2) Remove the 2 screws 12 .

V

Q

R

Fig. 1-14

1.4.4 Removing the CN board

(1) Remove the 5 screws 10 and pull out the chassis assembly

in the direction of the arrow.

10

(3)

Remove the screw

Fig. 1-17

13

and remove the power supply unit

12

V .

Fig. 1-15

(2) Disconnect CN1 S , CN2 T and CN4 U from the CN

board, remove the 3 screws 11 , and remove the CN board.

U

S

T

CN boad

11

Fig. 1-16

13

Fig. 1-18

1-4

Page 7

1.4.6 Removing the lens assembly

(1) Remove the CCD board as described in 1.3.

(2) Remove the PR board as described in 1.4.1. Now the lens

assembly can be removed.

1.4.7 Removing the pan/tilt assembly

(1) Remove the MD board as described in 1.4.3.

(2) Remove the CN board as described in 1.4.4

(3) Remove the power supply unit as described in 1.4.5. Now

the pan/tilt assembly can be removed.

Board

Symbol No.

MD S1-1

S1-2

S1-3

Function

Not used.

All switches should be set to OFF .

Switches whether “MANUAL” is displayed during manual pan/tilt operation.

ON : Not displayed.

OFF : Displayed.

1.5 DIP SWITCHES

See Table 1-1 for the description of DIP switches on the PC

boards.

Values inside indicate the factory-set values.

Board

Symbol No.

IF S1

Switches the camera (PR board) control.

Function

JIG : Camera is controlled from the

jig connected to CN5 on the IF

board.

IF : Camera is controlled from the

CPU of the IF board.

S2

Switches enable/disable the pan/tilt operation.

INIT : The pan/tilt assembly is initial-

ized at power ON and the pan/

tilt operation from the controller is enabled.

OFF : The pan/tilt assembly is not ini-

tialized at power ON and the

pan/tilt operation from the controller is disabled. (This setting

is used during adjustments.)

S3-1

Switches the maximum rotation speed in

the manual pan/tilt operation.

ON : PAN 240 degree/sec.

TILT 120 degree/sec.

OFF : PAN 80 degree/sec.

TILT 60 degree/sec.

S3-2

Switches the CPU operation mode according to the TV system.

OFF : NTSC

ON : PAL

S1-4

S1-5

S1-6

S2

S3

CN S1

Switches the communication line connection mode. (This also results in switching

the communication protocol.)

ON : Bus connection (multi-drop).

OFF : Star connection (1-to-1 connec

tion).

Switches the communication directions.

ON : Simplex (1-way).

OFF : Duplex (2-way/4-wire).

Switches the internal sync and external

sync (power line lock).

ON : External sync (line lock) mode.

OFF : Internal sync mode.

When the camera is used in a RS-485

multi-drop connection system, set the

camera ID.

S2 : Sets the figure of 10.

S3 : Sets the figure of 1.

(Example: When S2 = 3 and S1

= 5, “35” is set.)

When it is used in a RS-422 system, these

switches should be set as

follows.

S2 : 0

S3 : 0

Sets the termination of the lines connected to RX+ and RX- on the bottom

panel.

ON : 110 ohm termination across

RX+ and RX-.

OFF : No termination.

S3-3

Switches the protocol.

OFF : Sets S1-4 and S1-5 of the MD

board.

ON : Uses the JVC-CAM protocol.

S3-4

S3-5

Not used.

All switches should be set to OFF .

S3-6

S3-7

S3-8

Note:

The settings of other DIP switches than S1 on the CN

board and S1-6 on the MD board are read at the time

the power is turned ON. Therefore, when changing the

position of these DIP switches, it is necessary to turn

the power OFF then ON again.

Table 1-1

1-5

Page 8

1.6 CONSUMABLE PARTS

The pan/tilt assembly and the lens assembly of the TK-C675B

are consumable parts. Therefore, their servicing is charged to

the user even when it occurs within the warranty period.

For the method of checking the operation count, refer

to the instruction manual of the remote control software.

See Table 1-2 for the reference periods for the replacement of

the consumable parts.

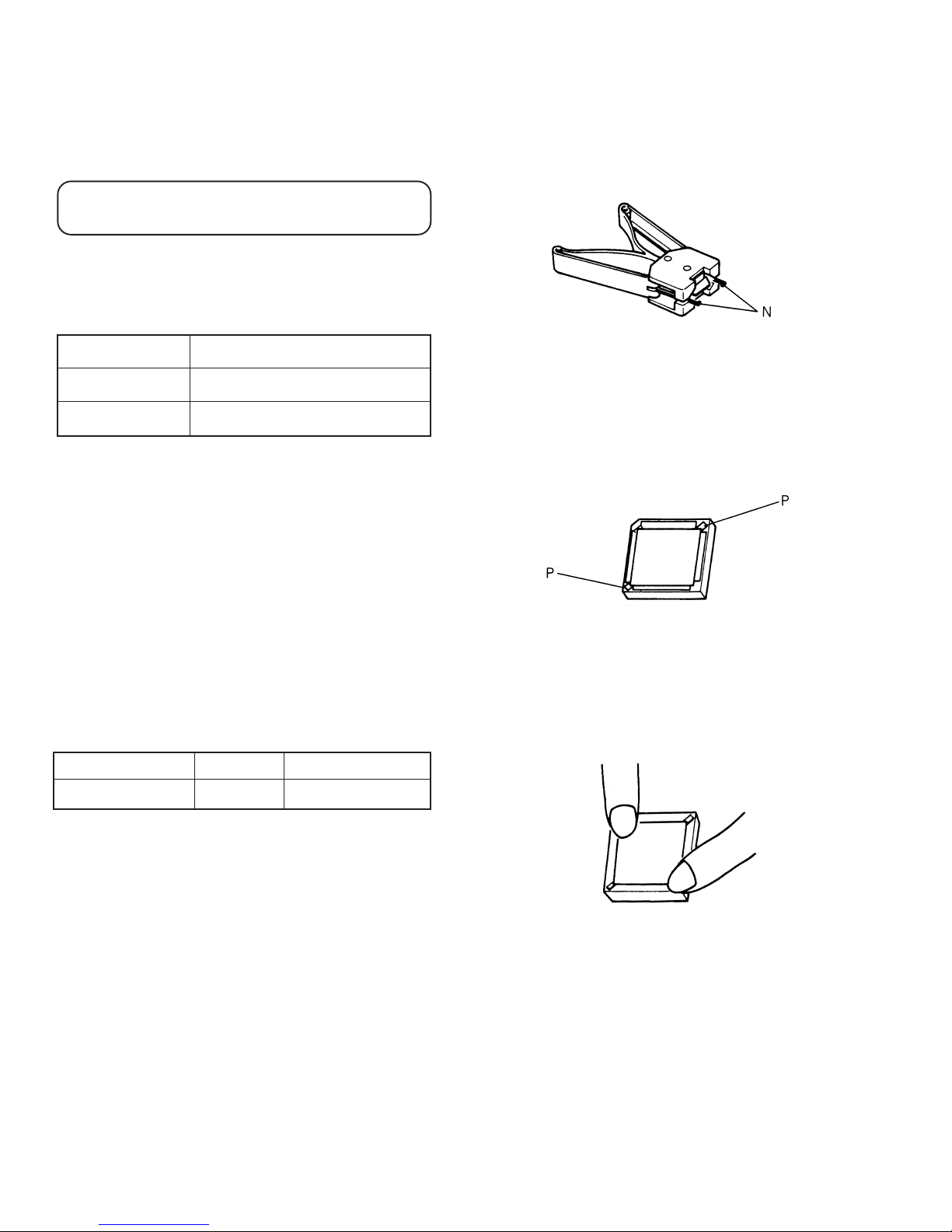

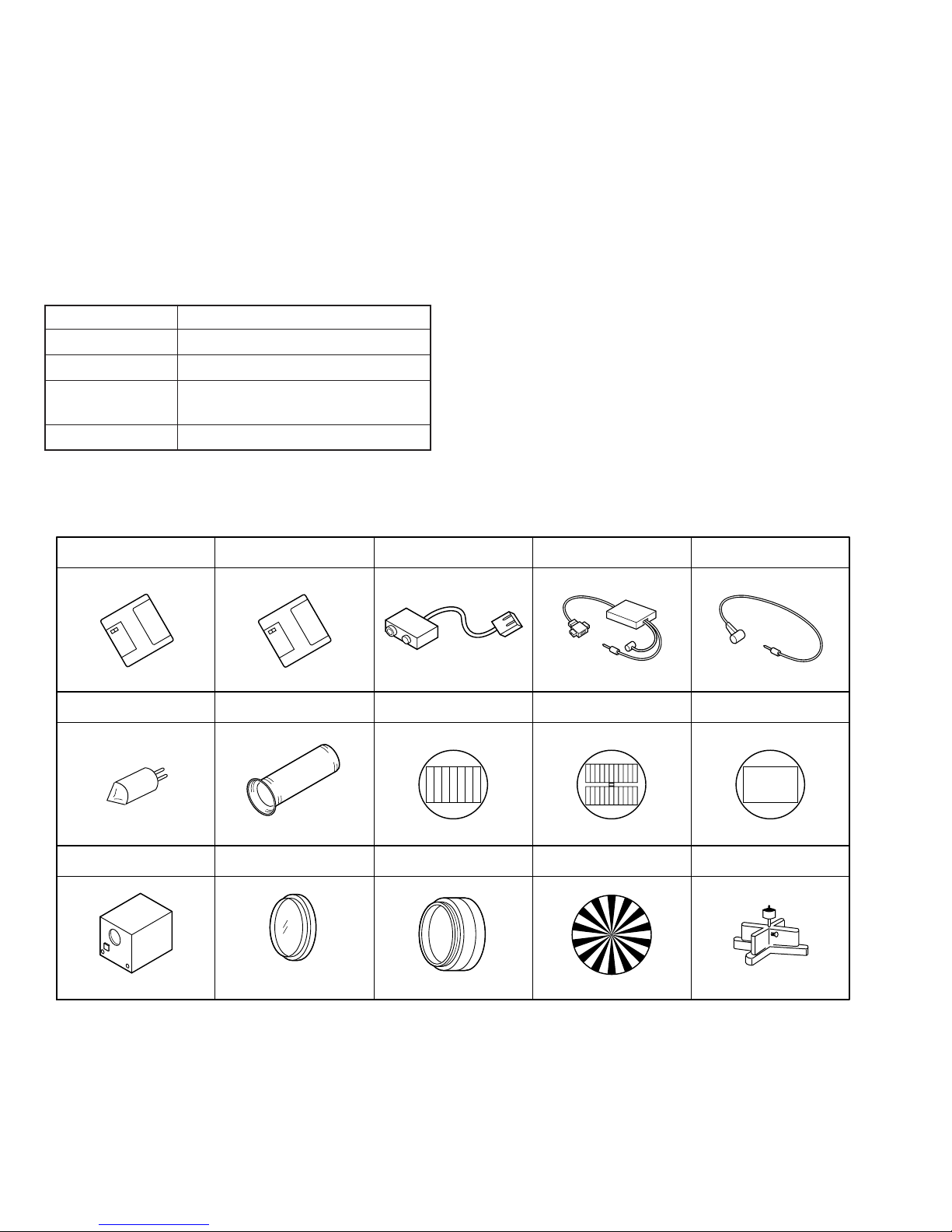

1.8 Replacement of IC ROM (IF board IC27, IC29)

(1) For removing the IC ROM, it is recommended to use a spe-

cial tool, however, two small screwdrivers are substitutable

for it.

Part Name Replacement Period

Pan/tilt assembly 1,000,000 times of operation

Lens assembly 400,000 times of operation

Table 1-2

1.7

REFFERENCE REPLACEMENT PERIODS OF PARTS

WHITCH REQUIRE MAINTENANCE AND INSPECTION

Periodical maintenance and inspection are required to maintain

the initial performance and reliability of the unit. Table 1-3 has

been complied assuming the use of the unit under room temperature, and the periods indicated in the table are greatly variable depending on the operating environment and conditions.

Lack of proper maintenance, inspection and servicing will result

in great reductions of the times indicated in the table and will

cause other effects as well.

Part Name Part No. Reference Period

POWER SUPPLY UNIT

Refer to Sec. 4.1

30,000 hours or 3 years

Fig. 1-19 Example of special tool

(2) Insert the portions N of the special tool into the notches P of

the IC socket to pick up the IC. When using small screwdrivers, insert their tips into the notches P respectively and pick

up the IC with the two screwdrivers.

Fig. 1-20

(3) When in a new IC for replacement, make sure of its orienta-

tion and insert it gently into the IC socket with fingers keeping the IC level with the board surface.

Table 1-3

The figures shown in Table 1-3 are accumulated operating hours

assuming that the unit is operated for 24 hours a day under

room temperature (approx. 25°C). The figures will be reduced

to 15,000 hours or 1.5 years if the unit is accommodated in a

camera housing or used outdoors.

1-6

Fig. 1-21

Page 9

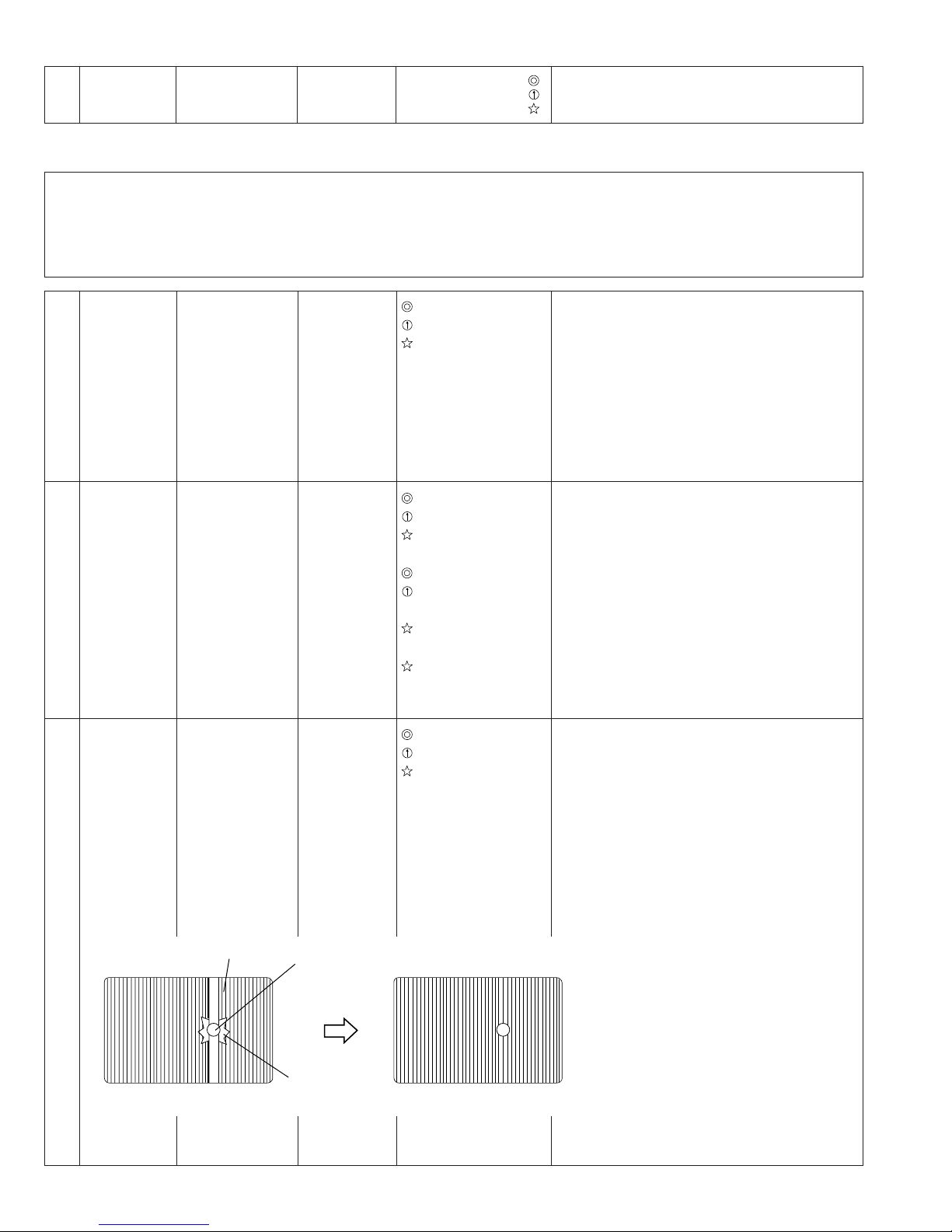

1.9 Positional adjustments to the sensor plate

Whenever the sensor plate has been replaced, carry out the

adjustments listed below.

(1) Loosen screw 1 .

(2) Adjust the sensor plate position so that b is less than half of

a (b

a/2).

(3) Tighten screw 1 .

(4) Make sure that the sensor plate is positioned so that c=d.

a

b

c

d

Camera cover (L)

Sensor plate

1

Photo

Interrupter IF board

Fig. 1-22

1.10 Care in Transportation

In order to prevent damage to the photo interrupter on the IF

board during transportation, a bracket has been added. Be sure

to remove the bracket before installation by referring to the diagram below. Also, be sure to reinstall the bracket at the time of

transportation by reversing the removal procedure.

Don't Forget! Be sure to remove the transportation bracket.

A bracket to reduce shock during transportation is mounted

when this unit is shipped from the factory.

Be sure to remove this bracket before installation.

1.

Turn the camera

body cover in a

counterclockwise

direction to set the

mark to "RELEASE".

RELEASE

LOCK

(5) If the sensor plate is not positioned so that c=d, use pliers

etc. to bend the sensor plate until e becomes equal to f.

e

f

Bend here.

Fig. 1-23

RELEASE

LOCK

Camera body cover

2.

Pull the camera body

cover upward.

Claw

LOCK

R

ELEASE

3.

Remove the

Claw

5.

screw.

Put the screw back

and tighten it.

Camera body

4.

Remove the

transportation bracket

6.

Install the camera body cover in the reverse order of

removing and set the mark to "Lock".

Check that the three claws on the cover are locked onto

the camera body and that there is no clearance

between the cover and the camera body.

.

1-7

Page 10

SECTION 2

ELECTRICAL ADJUSTMENTS

This unit is a camera incorporating an EVR (Electric Variable

Resistor) function. The EVR varies the resistance using a PC

and writes the varied resistance data in the memory of the camera.

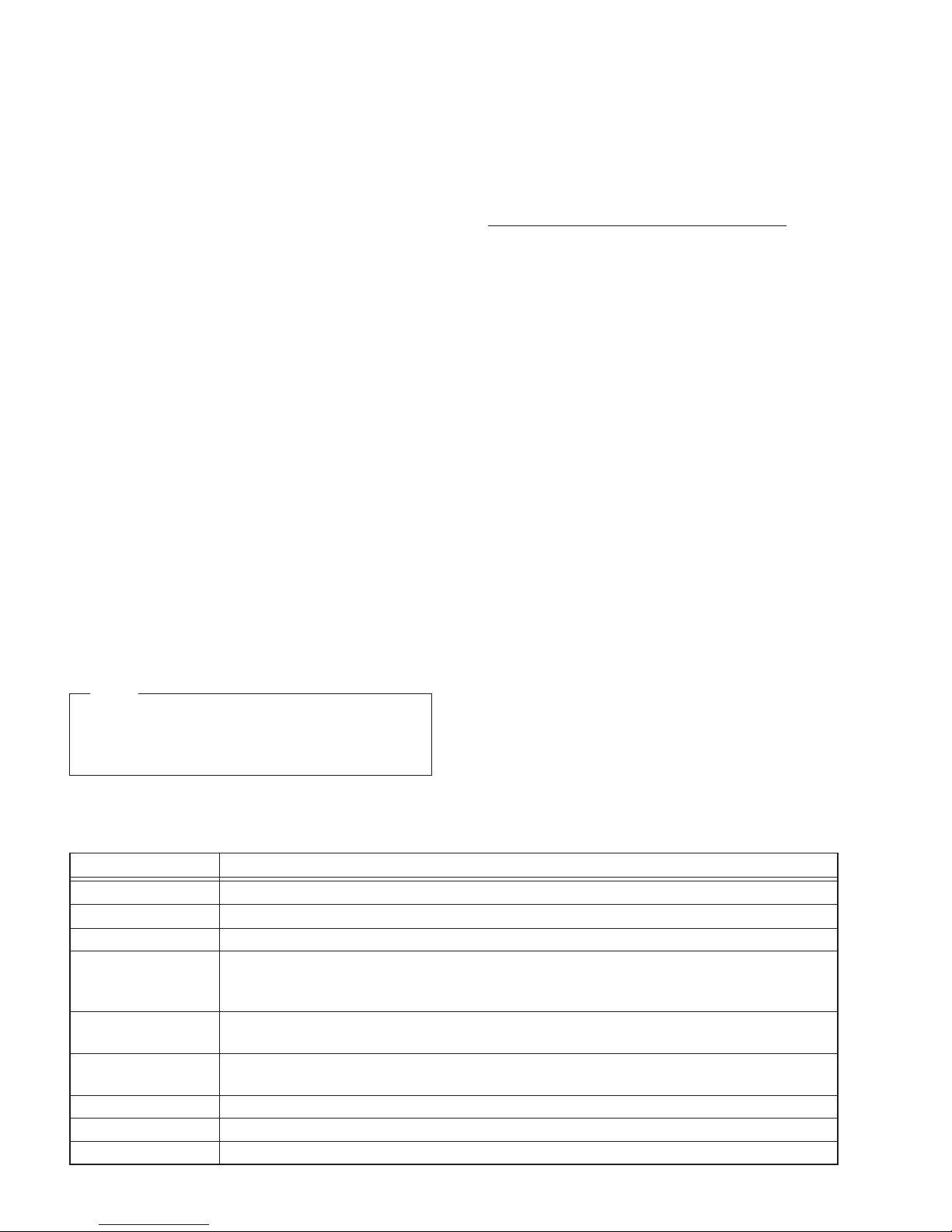

2.1 EQUIPMENT NECESSARY FOR ADJUSTMENT

Instrument

Oscilloscope

Vectorscope

Color video monitor

Digital voltmeter

Program disk

(Software for adjustment)

(IBM-PC) (Windows 95) (For IBM-PC)

Available for 100MHz or higher

A calibrated instrument.

A color type instrument with a 75 ohm

video input.

Input impedance of 10M ohm or higher

(Remote control software)

Condition

Program disk

Conversion cable Interface cable Conversion cable

2.2 COMPUTER AND PERIPHERAL EQUIPMENT

• IBM PC/AT or compatible with MS-DOS operating system (For

Adjustment)

• 3.5inch FDD

• Serial port (RS232C)

• CPU:80386 or higher microprocessor

• VGA monitor (color or monochrome)

• Mouse

• WINDOWS 95 operating system (For Remote Control)

• 3.5inch FDD

• Serial port (RS232C)

• VGA monitor

• Mouse

J

V

C

PLSC1209 * PLSC1210

Light box lamp

YQ20645-001

Light box

YTU93072

Infinity adjustment lens Color bar chart Gray scale chart Test chart (Portrait)

YTU92001B YTU92001-051 YTU92001-052 YTU92001-054

Color temp. Conversion filter

KODAK wratten gelatin filter

No. 80C (or equivalent) SC32125 YTU93079

SC32124 YTU93063 YTU94066

Lens mount tool Focus chart Camera Stand

(Included in Infirity adjustment lens.)

* When used with TK-C675BU/E, it does not display “Camera Model” and “Camera ID”.

(Not necessory for adjustment)

2-1

Page 11

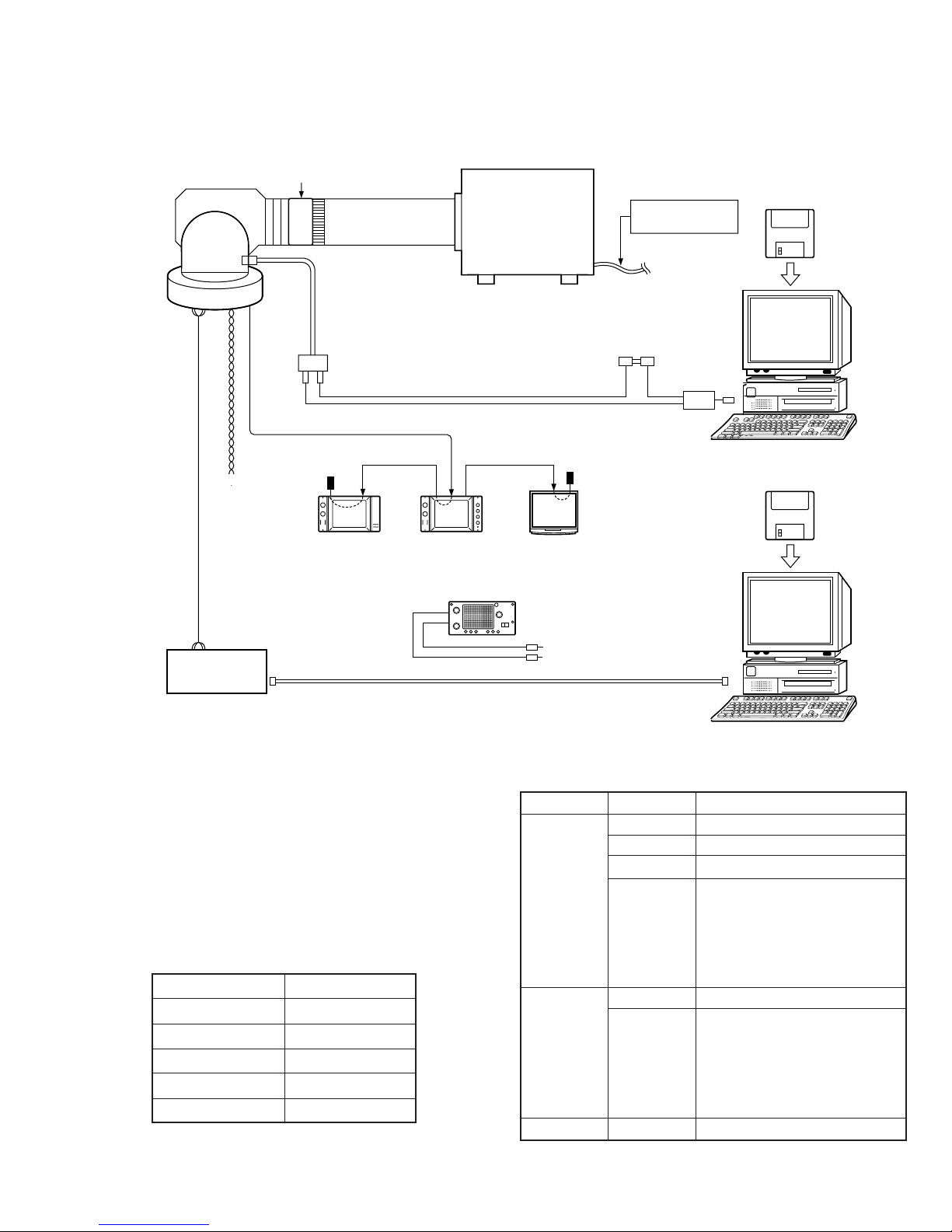

2.3 GENERAL SETUP

Connect the equipment as shown below. The Left camera cover should be removed for adjustments (see 1.1).

Lens mount tool

SC32125

POWER SUPPLY

DC 6V

To RS232C

port

(IBM PC/AT or compatible with MS-DOS)

TK-C675B

To RS422

port

IF board

CN5

AC 24V

Video out

75 Ω

terminator

Infinity adjustment lens

YTU92001B

Conversion cable

SC32124

Connect

Vectorscope

Light box

YTU93072

Connect

Conversion cable YTU94066

Interface cable YTU93063

75 Ω

terminator

Color monitorWaveform monitor

(WFM)

Adjustment

software

Computer

Remote control

software

Oscilloscope

RS422

RS232C

RS232C to RS422 conversion adapter

2.4 SWITCH SETTING FOR ADJUSTMENTS

(1) Set the camera functions by software (PLSC1210) as shown

in Table 2-1. (Note that S1 on the camera’s IF board should

be set to “IF”.)

(2) After the setting above, turn the power OFF, and set the

camera’s internal switches as shown in Table 2-2.

(3) Turn power ON again to start the adjustments.

Item Setting

AGC mode OFF

Shutter NORMAL

BLC mode OFF

Iris mode MANU

White balance ATW

Table 2-1 Function Setting

To RS232C

port

Computer

(Windows 95)

Board Switch Setting

IF S1 JIG

S2 OFF

S3-2 OFF (U Ver.) ON (E Ver.)

S3-1 OFF

S3-3

S3-4

S3-5

S3-6

MD S1-3 ON

S1-1 OFF

S1-2

S1-4

S1-5

S1-6

CN S1 ON

Table 2-2 Internal Switches

2-2

Page 12

2.5

HOW TO EXECUTE PROGRAM SOFTWARE (PLSC1209)

2.6 KEYBOARD OPERATION (PLSC1209)

1) Install the MS-DOS “MOUSE. COM”. (This program can also

be used without Mouse.)

2) At the MS-DOS command line, type as follows.

A>TK-C675 {/N or /P} [/BW] [/COM2] <Enter>

/N or /P Set type of TV system. The program cannot

start without specified.

N : NTSC (U Ver.)

P : PAL (E Ver.)

/BW Set if the monitor is Black & white.

/COM2 Set if a serial mouse is connected to the

COM1 serial port to allow camera data com-

municate via COM2. If not specified, COM1

becomes the main communication port auto-

matically.

3) At the “Welcome” message, click <OK> or press [ENTER]

key.

Follow the message appearing on the display to prepare and

execute each setting.

4) When the main window is displayed, data communication

begins. However, if due to faulty connection or other abnormality, the program stops. Observe the check indication at

the lower right of the screen. If indication is “NG”, check

the cable connections and camera power. When indication

is “OK”, the program operation starts. If communication is

abnormal, press the [Break] key to terminate the program.

5) When the program starts, check the TV system indication of

the main window. If this is incorrect, restart the program

and correct the TV system entry.

To terminate the program, click the EEPROM menu, then

click Quit (or press [Crtl] + [F4] keys).

NOTE

For Remote Control Software (PLSC1210), See instruction manual attached to the software. Not described on

this Service Manual.

Although a mouse is recommended for using this program, it

can also be operated from the keyboard in cases when a mouse

is not available.

The commonly use keys are as follows.

Key Function

[Alt] Menu selection

[Enter] Confirm

[Esc] Cancel

[Up] or [Shift] + [Up] Cursor shift

[Down] or [Shift] + [Down] Cursor shift

[Left] or [Shift] + [Left] Cursor shift

[Right] or [Shift] + [Right] Cursor shift

[Tab] or [Shift] + [Tab] Item select

[Insert] Insert or Overwrite text

[Delete] Delete text

[Back space] Cursor backspace during

text input

Short key operations are indicated on the screen.

2.7 MENUS

1) EEPROM Menu

Menu command Function

Read Readout EEPROM data (256 bytes) from camera.

Backup Backup EEPROM readout data to disk.

Restore Write disk backup data or EEPROM initial data of this disk into camera EEPROM.

Edit After EEPROM data readout, edit the data of a selected address (if using a mouse, double click

the desired address of the data table). Use care since editing rewrites the camera EEPROM

data.

Compare Compare EEPROM readout data with data in disk. Different data's color are change on the

screen.

Difference After comparing the data, data difference of a selected address is displayed.

(Double click the desired address data of the data table.)

Esc compare End comparison

Help Display “README. DOC” file.

Quit Terminate program.

2-3

Page 13

2) BUFF menu

2.8 CAMERA ADJUSTMENT

Menu command Function

Buffer 1

Buffer 2

Buffer 3

3) CAM. ADJ. menu

Menu command

PLL control voltage

Gain

OFD

Y setup

White clip

AGC set

Burst level

Color difference balance (1)

Carrier dot balance

Color difference balance (2)

Carrier balance

Display white balance data on

main window.

Burst phase (E Ver. only)

SC phase (E Ver. only)

Offset data

R-Y/B-Y low

R, B gain

Color difference gain

Color difference matrix

White level

Manual white balance

Auto iris level

Menu command

• Light source and object for adjustment

Use the specified light box and object when adjusting the

camera with this program.

• Adjustment

Prepare the equipment and fixtures required for adjustment

Before adjusting, it is recommended to backup the

EEPROM data. Refer to the screen messages and perform accordingly. Unless otherwise indicated, avoid operating other menus etc. while adjustment is in progress.

Caution

If the camera power supply is cut off during program operation, communication error is produced. The program

stops and operations are not recognized. Communication

and program operation resume when camera power is restored. However, if communication error occurs during

adjustment or EEPROM data editing, first terminate, and

then restart the program again.

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point ( )

Adjustment parts ( )

Adjustment level ( )

2.9 BACK-FOCUS ADJUSTMENT

This unit is shipped from the factory after its back-focus has been adjusted. Therefore, back-focus adjustment is usually unnecessary. It should be performed only when required, for example after replacing the lens assembly.

1 Back-focus

adjustment

Monitor screen,

focusing chart.

The adjustment

software is not

used in this

adjustment.

Monitor screen

1) Attach the focus chart onto the INF adjustment tool.

2) Set the iris to fully open.

3) Adjust the illumination of the light box so that

the signal level is between 0.57 and 0.64 Vpp (80 and 90 IRE).

4) Adjust the back-focus by referring to the instruction manual of the remote control software (PLSC1210).

2-4

Page 14

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point ( )

Adjustment parts ( )

Adjustment level ( )

2.10 EVR ADJUSTMENT

• After replacing the CCD image sensor or EEPROM, execute “Restore” in the EEPROM menu to write the initial value data

“TKC675_N.DAT”(U Ver.) or “TKC675_P.DAT”(E Ver.) in EEPROM before proceeding to the adjustment.

• Set the lens iris using the remote control software (refer to the instruction manual of the remote control software).

• To adjust items which require the adjustment software, select the required menu commands from the CAM. ADJ. menus using

the [Alt] key or mouse.

1 PLL control

voltage

adjustment

2 Gain

adjustment

3 OFD

adjustment

• Oscilloscope

(H-rate 10:1)

• It is not neces

sary to use the

infinity adjust

ment lens for

this adjustment.

• Gray scale chart

(just scan)

• Oscilloscope

(H-rate 10:1)

• It is not necessary to use the

infinity adjustment lens for

this adjustment.

• TV monitor

screen.

• Incandescent

lamp.

Shutter

<U Ver.>

1/100

<E Ver.>

1/60

TP1 (A-2B) [IF]

2Bh (PLL voltage)

2.75V DC

TP201 (B-1C) [PR]

LENS IRIS

0.7Vp-p

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - VIDEO output

36h (Y gain)

<U Ver. >

0.714Vp-p [100 IRE]

<E Ver.>

0.7Vp-p

TV monitor screen

26h (V. sub)

Minimum blooming

1) Set S1-6 on the MD board to ON.

2) Adjust the PLL voltage data so that the voltage at TP1 [IF] is 2.75V DC.

3) Set S1-6 on the MD board to OFF.

1) Set lens iris so that the white level in the

center of the gray scale chart at TP201 [PR] is

0.7Vp-p.

2) Adjust the Y gain data so that the white level

in the center of the gray scale chart at VIDEO

output is 0.714 Vp-p [100 IRE] (U Ver.) or 0.7

Vp-p (E Ver.).

1) Set the shutter to “1/100” (U Ver.) or 1/60(E

Ver.).

2) Shoot an incandescent lamp and set the iris

to a position at which blooming becomes

most clear.

3) While observing the monitor screen, adjust

the V. sub data so that blooming disappears.

4) Set the shutter to “NORMAL”.

Smear

Incandescent lamp

Blooming

Monitor

2-5

Monitor

Page 15

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point ( )

Adjustment parts ( )

Adjustment level ( )

4 Y setup

adjustment

5 White clip

adjustment

0.785 Vp-p

(U Ver.)

0.77 Vp-p

(E Ver.)

• Oscilloscope

(H-rate, 10:1)

• Gray scale chart

(Just scan)

• Oscilloscope

(H-rate, 10:1)

VIDEO output

22h (Y setup level)

30mVp-p

30 mVp-p

VIDEO output

37h (White clip level)

<U Ver.>

0.785Vp-p

<E Ver.>

0.77Vp-p

1) Close the lens iris.

2) Adjust the Y set up level data so that setup

level is 30mVp-p. (From the pedestal level)

1) Attach the infinity adjustment lens with gray

scale chart to the lens.

2) Open the lens iris.

3) Adjust the white clip level data so that the

white peak of gray scale chart is following

specified level at VIDEO output.

NOTE

When the carrier level of the white clip exceeds 100mVp-p, use the menu command

[Edit] after completing white clip adjustment

in order to move the 26(Vsub) data and bring

the carrier level to a minimum.

6 AGC set

adjustment

• Gray scale chart

(Just scan)

• Oscilloscope

(H-rate, 10:1)

0.678 Vp-p

(U Ver.)

0.665 Vp-p

(E Ver.)

VIDEO output

LENS IRIS

<U Ver.>

0.643Vp-p [90 IRE]

<E Ver.>

1) Set lens iris so that the white level in the

center of the gray scale chart at VIDEO output is 0.643Vp-p [90 IRE] or 0.63Vp-p (E Ver.).

2) Click “OK”. The camera’s AGC mode is

switched automatically to 20 dB.

0.63Vp-p

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - VIDEO output

39h (AGC normal

reference)

<U Ver.>

0.678Vp-p [95 IRE]

<E Ver.>

3) Adjust the AGC normal reference data so that

the white level in the center of the gray scale

chart at VIDEO output is 0.678Vp-p [95 IRE]

(U Ver.) or 0.665Vp-p (E Ver.). (After this adjustment, the AGC mode is switched automatically to OFF.)

0.665Vp-p

NOTE

As the output has hysteresis, decrease the

white level to below -95 IRE before starting

the adjustments.

2-6

Page 16

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point ( )

Adjustment parts ( )

Adjustment level ( )

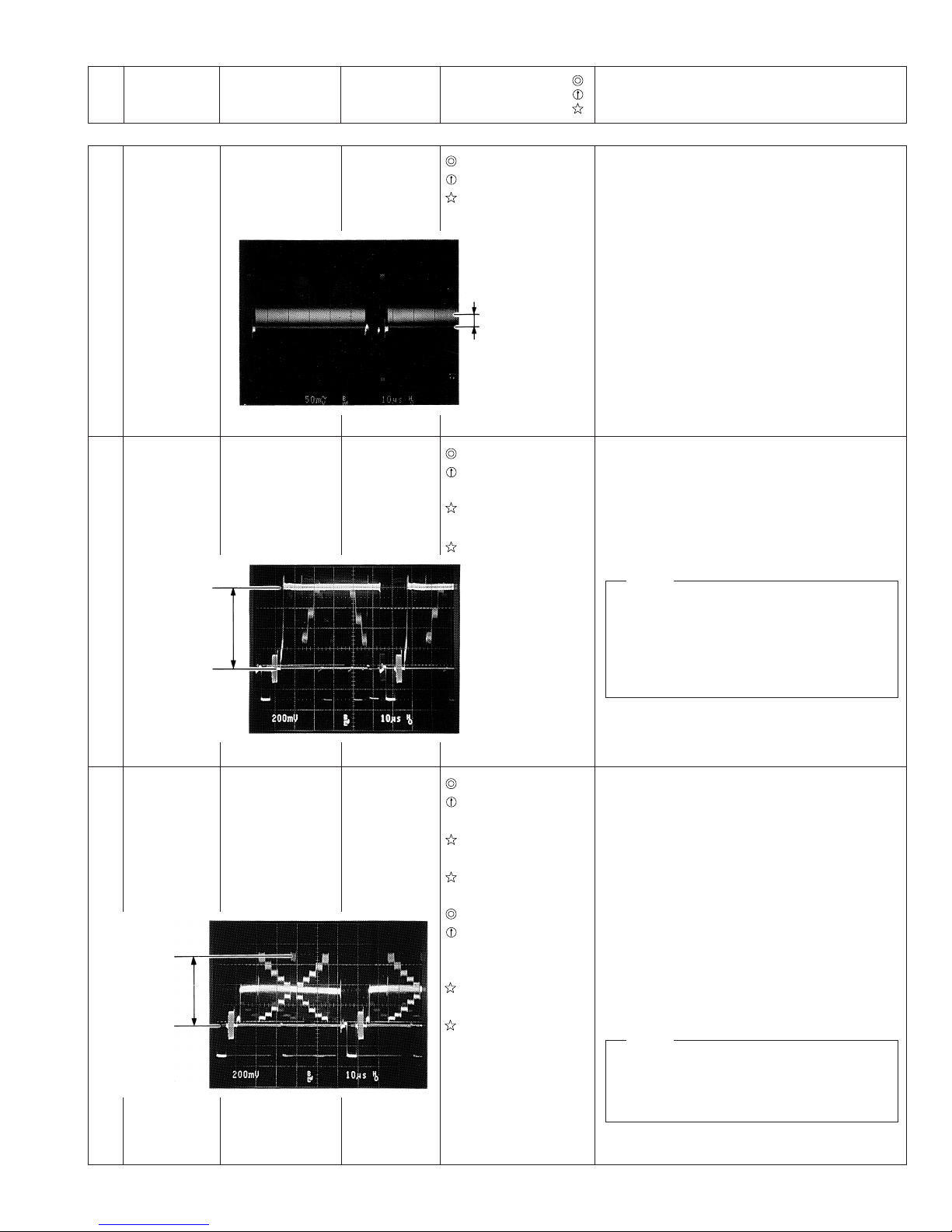

7 Burst level

adjustment

8 Color

difference

balance(1)

adjustment

• Oscilloscope

(H-rate, 10:1)

• It is not necessary the infinity

adjustment lens

for this adjustment.

• Color bar chart

(Just scan)

•Oscilloscope

(H-rate, 10:1)

• Vectorscope

VIDEO output

25h (Burst level)

<U ver.>

0.286Vp-p [40 IRE]

1) Adjust the Burst level data so that the level

of the burst signal at the VIDEO output is

0.286 Vp-p [40 IRE] (U Ver.) or 0.300 Vp-p (E

Ver.).

<E ver.>

0.300Vp-p

VIDEO output

LENS IRIS

0.65Vp-p

1) Attach the infinity adjustment lens with color

bar chart to the lens.

2) Set lens iris so that white level of color bars

is 0.65Vp-p at VIDEO output.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - TP202 (B-1C) [PR]

30h [1H delay gain

(Yellow)]

3) Adjust the 1H delay gain (Yellow) data so that

the levels of the adjacent 1H signals at TP202

[PR] are identical.

Identical

0.65 Vp-p

9 Carrier dot

balance

adjustment

• Vectorscope

• It is not neces-

sary the infinity

adjustment lens

for this adjustment.

VIDEO output

34h (Carrier balance

dot adjustment)

Two dots are overlapped.

1) Close the lens iris.

2) Adjust the Carrier balance dot adjustment data

so that the two dots on the vectorscope are

overlapped.

(It is recommended to be easier to see that

the gain of vectorscope is boosted.)

2-7

Page 17

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point ( )

Adjustment parts ( )

Adjustment level ( )

10 Color

difference

balance(2)

adjustment

0.65 Vp-p

11 Carrier

balance

adjustment

• Color bar chart

(just scan)

• Oscilloscope

(H-rate, 10:1)

• Vectorscope

• Vectorscope

• It is not neces-

sary the infinity

adjustment lens

for this adjustment.

VIDEO output

LENS IRIS

1) Set lens iris so that the white level of the color

bar chart is 0.65Vp-p.

0.65Vp-p

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - VIDEO output

31h (1H delay gain

(Cyan))

2) Adjust the 1H delay gain (Cyan) data so that

the dots of different colors are superimposed

on the vectorscope.

Chroma (colored) dots

should be superimposed.

VIDEO output

27h

(Blue carrier balance)

28h

(Red carrier balance)

1) Close the lens iris.

2) Adjust the Blue carrier balance and Red carrier balance data alternately so that the dot

on the vectorscope is center.

(It is recommended to be easier to see that

the gain of vectorscope is boosted.)

12 Burst phase

adjustment

(E Ver. only)

R-Y

• Vectorscope

B-Y

R-Y

R-Y

B-Y

VIDEO output

2Ah (Burst phase)

Angle of burst phase

is 90 degrees.

B-Y

1) Close the lens iris.

2) Adjust the Burst phase data so that the angle

of burst phase is 90 degrees on the

vectorscope.

90°90°

2-8

Page 18

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point ( )

Adjustment parts ( )

Adjustment level ( )

13 SC phase

adjustment

(E Ver. only)

14 Offset data

adjustment

• Color bar chart

(just scan)

• Oscilloscope

(H-rate, 10:1)

• Vectorscope

• It is not neces-

sary the infinity

adjustment lens

for this adjustment.

VIDEO output

LENS IRIS

0.65Vp-p

1) Attach the infinity adjustment lens with color

bar chart to the lens.

2) Set lens iris so that white level of color bar

chart is 0.65Vp-p at VIDEO output.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - VIDEO output

29h (SC phase)

3) Adjust the SC phase data so that the red dots

are superimposed on the vectorscope.

Red dots should be

superimposed.

66h (2R-G offset)

67h (2B-G offset)

6Ah (Y low offset)

1) Close the lens iris.

2) Press Enter key. The adjustment is preformed

automatically.

15 R-Y low, B-Y

low (indoor/

outdoor)

adjustment

(INDOOR)

• Color bar chart

(just scan)

•Oscilloscope

(H-rate, 10:1)

(OUTDOOR)

• Color bar chart

(just scan)

• Filter (80C+80C)

• Oscilloscope

(H-rate, 10:1)

VIDEO output

LENS IRIS

0.65Vp-p

1) Attach the infinity adjustment lens with color

bar chart to the lens.

2) Set lens iris so that white level of color bar

chart is 0.65Vp-p at VIDEO output.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 62h (B/Y

63h (R/Y

L indoor data)

L indoor data)

VIDEO output

LENS IRIS

0.46Vp-p

3) Press Enter key. The adjustment is preformed

automatically.

1) Put the filters (80C+80C) to the lens.

2) Set lens iris so that white level of color bar

chart is 0.46Vp-p at VIDEO output.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 64h

(B/YL outdoor data)

3) Press Enter key. The adjustment is preformed

automatically.

65h

(R/YL outdoor data)

2-9

Page 19

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point ( )

Adjustment parts ( )

Adjustment level ( )

16 R, B gain

(indoor/

putdoor)

adjustment

(INDOOR)

• Color bar chart

(just scan)

• Oscilloscope

(H-rate, 10:1)

• Vectorscope

VIDEO output

LENS IRIS

1) Set lens iris so that white level of color bar

chart is 0.65Vp-p at VIDEO output.

0.65Vp-p

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

VIDEO output

A0h [R gain (indoor)]

A1h [B gain (indoor)]

A white signal

2) Adjust the R gain (indoor) and B gain (indoor)

data alternately so that the dot of the white

signal component appears in the center of the

vectorscope.

component dot should

appear in the center of

the vectorscope.

(OUTDOOR)

• Color bar chart

(just scan)

• Filter (80C+80C)

• Oscilloscope

(H-rate, 10:1)

• Vectorscope

VIDEO output

LENS IRIS

0.46Vp-p

1) Put the filters (80C+80C) to the lens.

2) Set lens iris so that white level of color bar

chart is 0.46Vp-p at VIDEO output.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - VIDEO output

A4h [R gain (outdoor)]

A5h [B gain (outdoor)]

A white signal

3) Adjust the R gain (outdoor) and B gain (outdoor) data alternately so that the dot of the

white signal component appears in the center

of the vectorscope.

component dot should

appear in the center of

the vectorscope.

2-10

Page 20

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point ( )

Adjustment parts ( )

Adjustment level ( )

17 Color differ-

ence gain

(indoor/

outdoor)

adjustment

(INDOOR)

• Color bar chart

(just scan)

• Oscilloscope

(H-rate, 10:1)

VIDEO output

LENS IRIS

1) Set lens iris so that the white level of color

bar chart is 0.65Vp-p at VIDEO output.

0.65Vp-p

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - VIDEO output

A2h [R-Y gain(indoor)]

A3h [B-Y gain (indoor)]

Red signal level:

2) Adjust the R-Y gain (indoor) data so that the

Red signal level is 0.46Vp-p at video output.

3) Adjust the B-Y gain (indoor) data so that the

Blue signal level is 0.36Vp-p at video output.

0.46Vp-p

Blue signal level:

0.36Vp-p

Red

Blue

(OUTDOOR)

• Color bar chart

(just scan)

• Filter

(80C +80C)

• Oscilloscope (Hrate)

VIDEO output

LENS IRIS

0.46Vp-p

1) Attach the filters (80C + 80C) to the lens.

2) Set lens iris so that the white level of the color

bar chart at the output is 0.46Vp-p.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - VIDEO output

A6h [R-Y gain(outdoor)]

A7h [B-Y gain (outdoor)]

Red signal level:

0.32Vp-p

Blue signal level:

3) Adjust the R-Y gain(outdoor) data so that the

Red signal level in the color bar signal is

0.32Vp-p.

4) Adjust the B-Y gain(outdoor) data so that the

Blue signal level in the color bar signal is

0.23Vp-p.

0.23Vp-p

2-11

Page 21

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point ( )

Adjustment parts ( )

Adjustment level ( )

18 Color differ-

ence matrix

(indoor/

outdoor)

adjustment

(INDOOR)

• Color bar chart

(just scan)

• Oscilloscope

(H-rate, 10:1)

• Vectorscope

Red signal dot: 105˚

VIDEO output

LENS IRIS

0.65Vp-p

VIDEO output

24h [B-Y matrix

(indoor)]

23h [R-Y matrix

(indoor)]

Red signal dot:

105 degrees

Blue signal dot:

350 degrees

Blue signal dot:

350˚

1) Adjust lens iris so that white level of color bar

chart is 0.65Vp-p at VIDEO output.

2) Adjust the SC phase data so that the red signal dot of the color bar signal appears in the

105 degrees position on the vectorscope.

3) Adjust the R-Y matrix data so that the blue

signal dot of the color bar signal appears in

the 350 degrees position on the vectorscope.

19 White level

adjustment

(OUTDOOR)

• Color bar chart

(just scan)

• Filter

(80C + 80C)

• Oscilloscope (Hrate)

• Vectorscope

• Gray scale chart

(just scan)

• Oscilloscope

(H-rate, 10:1)

VIDEO output

LENS IRIS

0.46Vp-p

1) Attach the filters (80C + 80C) to the lens.

2) Set lens iris so that the white level of the color

bar chart at VIDEO output is 0.46Vp-p.

3) Adjust the B-Y matrix data so that the red sig-

VIDEO output

6Dh [B-Y matrix

(outdoor)]

6Ch [R-Y matrix

(outdoor)]

nal dot of the color bar signal appears in the

105 degrees position on the vectorscope.

4) Adjust the R-Y matrix data so that the blue

signal dot of the color bar signal appears in

the 350 degrees position on the vectorscope.

Red signal dot:

105 degrees

Blue signal dot:

350 degrees

VIDEO output

LENS IRIS

<U Ver.>

0.714Vp-p [100 IRE]

<E Ver.>

1) Attach the infinity adjustment lens with gray

scale chart to the lens.

2) Set lens iris so that the white level of the gray

scale chart at VIDEO output is 0.714Vp-p (U

Ver.) or 0.7Vp-p (E Ver.).

0.7Vp-p

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60h (B-Y offset)

61h (R-Y offset)

3) Press Enter key. The adjustment is performed

automatically.

2-12

Page 22

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point ( )

Adjustment parts ( )

Adjustment level ( )

20 Manual

WHT. BAL

adjustment

• Gray scale chart

(just scan)

• Oscilloscope

(H-rate)

• Vectorscope

W.BAL is set

automatically

to

“MANUAL”.

VIDEO output

LENS IRIS

<U Ver.>

0.714Vp-p[100 IRE]

<E Ver.>

1) Attach the infinity adjustment lens with gray

scale chart to the lens.

2) Set lens iris so that the white level of the gray

scale chart at VIDEO output is 0.714Vp-p[100

IRE] (U Ver.) or 0.7Vp-p (E Ver.).

0.7Vp-p

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - VIDEO output

DAh (MWB R gain)

DBh (MWB B gain)

3) Adjust the two data alternately so that the

dot of the VIDEO output appears in the center

of the vectorscope.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

• Filter(80C)

VIDEO output

LENS IRIS

<U Ver.>

0.714Vp-p[100 IRE]

4) Attach the filter (80C) to the lens.

5) Set lens iris so that the white level of the gray

scale chart at VIDEO output is 0.714Vp-p[100

IRE] (U Ver.) or 0.7Vp-p (E Ver.).

<E Ver.>

0.7Vp-p

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - VIDEO output

DCh (C8 MWB R gain)

DDh (C8 MWB B gain)

6) Adjust the two data alternately so that the

dot of the VIDEO output appears in the center

of the vectorscope.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

• Filter(80C+80C)

VIDEO output

LENS IRIS

<U Ver.>

0.714Vp-p[100 IRE]

7) Attach the filters (80C + 80C) to the lens.

8) Set lens iris so that the white level of the gray

scale chart at VIDEO output is 0.714Vp-p[100

IRE] (U Ver.) or 0.7Vp-p (E Ver.).

<E Ver.>

0.7Vp-p

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - VIDEO output

DEh(C16 MWB R gain)

DFh(C16 MWB B gain)

9) Adjust the two data alternately so that the

dot of the VIDEO output appears in the center

of the vectorscope.

2-13

Page 23

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point ( )

Adjustment parts ( )

Adjustment level ( )

21 Auto iris level

adjustment

• Gray scale chart

(just scan)

• Oscilloscope

(H-rate)

LENS IRIS:

AUTO

VIDEO output

35h (Auto iris level)

<U Ver.>

0.714Vp-p[100 IRE]

<E Ver.>

0.7Vp-p

1) Set the iris to “AUTO”.

2) Adjustment the Auto Iris level data so that

the white level at the center of the gray scale

chart at VIDEO output is 0.714Vp-p[100 IRE]

(U Ver.) or 0.7Vp-p (E Ver.).

2-14

Page 24

VICTOR COMPANY OF JAPAN, LIMITED

Printed in Japan

Page 25

TK-C675B COMBINATION CAMERA

VICTOR COMPANY OF JAPAN, LIMITED

Printed in Japan

SC96837-001

© 1998 VICTOR COMPANY OF JAPAN, LIMITED

is a registered Trademark owned by VICTOR COMPANY OF JAPAN, LTD.

is a registered Trademark in JAPAN, the U.S.A., the U.K. and many other countries.

TK-C675B

COMBINATION CAMERA

INSTRUCTIONS

For Customer Use :

Enter below the Serial No. which

is located on the body.

Retain this information for future

reference.

Model No. TK-C675B

Serial No.

L

O

C

K

R

E

LE

A

S

E

Page 26

2

For USA and CANADA

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION : TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK).

NO USER SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important operating and maintenance (servicing) instructions in the literature accompanying the appliance.

The lightning flash with arrowhead symbol, within an

equilateral triangle is intended to alert the user to the

presence of uninsulated “dangerous voltage” within the

product's enclosure that may be of sufficient magnitude to constitute a risk of electric shock to persons.

Information for USA

This device complies with Part 15 of the FCC Rules.

Changes or modifications not approved by JVC could void

the user's authority to operate the equipment.

WARNING:

TO REDUCE THE RISK OF FIRE OR

ELECTRIC SHOCK, DO NOT EXPOSE THIS

APPLIANCE TO RAIN OR MOISTURE.

AVERTISSEMENT:

POUR EVITER LES RISQUES D'INCENDIE OU

D'ELECTROCUTION, NE PAS EXPOSER

L'APPAREIL A L'HUMIDITE OU A LA PLUIE.

FEATURES ...........................................................................2

OPERATING PRECAUTIONS ...............................................3

SAFETY PRECAUTIONS .....................................................3

CONTROLS, CONNECTORS AND INDICATORS................ 4

INSTALLATION ..................................................................... 5

CONNECTIONS.................................................................... 8

HOW TO USE THE FERRITE CORE ....................................9

TROUBLESHOOTING ........................................................10

SPECIFICATIONS...............................................................11

Due to design modifications, data given in this instruction

book are subject to possible change without prior notice.

CAUTION

INFORMATION (FOR CANADA)

RENSEIGNEMENT (POUR CANADA)

Cet appareil numénque de la classe [B] respecte toutes les

exigences du Réglement sur le mat

ér

iel brouilleur du Canada.

This Class [B] digital apparatus meets all requirements of

the canadian Interference-Causing Equipment Regulations.

FEATURES

䡵 Features large aperture lens with 16x zoom ratio (f=4.5 to

72mm, F1.2, at wide angle).

䡵 Wide coverage angle (Horizontal 3.8° to 56°, Vertical 2.9° to

44°).

䡵 64 preset positions.

䡵 360 degree endless panning.

䡵 Maximum 240 degree/sec. panning speed.

䡵 Maximum 2-second zoom speed.

䡵 One-push auto focus capability.

䡵 RS-485 (Maximum Number of Connections: 32) or RS-422A

control signal.

䡵 High-quality pictures by adopting dome cover with optical

distortion compensation and CCD with 380,000 (U: type)

or 440,000 (E: type) effective pixels.

䡵 Adopts large aperture lens, highly sensitive CCD.

(Minimum illumination : 2.8 lx, at wide angle)

䡵 Auto panning function.

䡵 Variable panning speed.

The panning speed is varied automatically according to

the zoom ratio of the lens. (The panning speed decreases

when the zoom lens is set near TELE and increases when

it is set near WIDE.)

䡵 Auto flip

When the camera reaches its tilting limit, it automatically

flips itself over by 180 degrees by panning around.

(This makes it possible for the camera to continue tilting

even after it has been tilted straight downward.)

䡵Auto patrol

Preset positions are activated in sequence.

䡵 Menu screen display

A built-in character generator provides an on-screen menu

display for easy selection and setting of various functions.

䡵 5-language on-screen display

Names or designations for camera, preset, area and alarm

can be displayed in English, German, French, Italian and

Spanish. (E type only)

䡵 Area title indication

The 360˚ panning angle (horizontal rotation) is divided into

16 sectors, allowing you to check the title in each area.

When the camera is manually panned, the preset area

designation is shown on the screen.

CONTENTS

Thank you for purchasing this product.

Caution during continuous use

Continuous use of the preset sequence or auto panning operation may make the service life much shorter than expected.

The guaranteed operation count for the zoom lens of this

camera is around 400,000 times.

(Example)

24 hours of operation per day with single zoom

operation per minute:

400,000 (times)/60 (minutes)/24 (hours) = 278 (days)

䡵 Before starting an important recording, be sure to per-

form a test recording in order to confirm that a normal

recording is possible.

䡵 We do not accept liability for the loss of a recording in

the case of it becoming impossible to record due to a

problem in the video camera, VCR or video tape.

䡵 We do not accept liability for any damage to the camera

in cases when it is dropped because of incomplete installation due to not observing the installation instructions correctly. Please be careful when installing the

camera.

3

Operating precautions

● To save energy, when it is not being used turn the system's

power off.

● This camera has been designed for indoor use. It cannot be

used outdoors.

● This camera has been designed exclusively to be hung from

the ceiling.It may malfunction if it is placed on a surface or if

it is tilted.

● Do not install or use the camera in the following places.

• In a place exposed to rain or moisture.

• In a place with vapor or oil soot, for example in a kitchen.

• In a temperature outside the operating temperature range

(-10°C to 50°C).

• Near a source of radiation, X-rays, strong radio waves or

magnetism.

• In a place subject to vibration.

• In a place with excessive dirt.

● Insufficient head ventilation of the camera may cause a malfunction.

Be careful not to block the ventilation to the camera.

● If this camera and the cables connected to this camera are

used where there are strong electromagnetic waves or where

there is magnetism present, for example near a radio or TV

transmitter, power transformer or an electric motor, the picture may produce noise and the colors may be affected.

● This camera incorporates an AGC circuit. As a result, when

it is used under low light conditions, the camera sensitivity

is automatically boosted and the picture may look uneven.

This is not a malfunction however.

● When the AGC is ON in the auto iris mode, varying the iris

with the IRIS control button may not change the picture

brightness due to the gain boost function. In this case, switch

the AGC OFF or set the iris mode to manual.

● In auto iris mode, the IRIS control buttons may not function

under certain brightness conditions (i.e. when a sufficient

amount of light cannot be obtained). In this case, set the iris

mode to manual.

● The white balance setting when used under a fluorescent

lamp should be ATW (Auto White). If it is set to MANU (Manual), the white balance may not be adjustable.

● When presetting this unit

’ s position, turn it on and wait until

it has warmed up sufficiently inside (about 30 minutes). This

is to avoid a change in the lens focus due to a rise in

temperature after installation.

● When this camera is used in the AUTO white balance mode,

the recorded colors may be slightly different from the actual

colors due to the operational principles of the auto-tracking

white balance circuit. This is however not a malfunction.

● If a high-intensity object (such as a lamp) is shot, the image

on the screen may have vertical lines (smear) or blur (blooming) at its periphery. This is a characteristic of the CCD, and

is not a defect.

● The electronic shutter of this camera has been set to 1/60(1/

50) sec. at the factory. When the camera is used under a

fluorescent lamp or in an area with a local power frequency

of 50/60 Hz, change the shutter speed to 1/100(1/60) on the

remote control unit. (The sensitivity deteriorates slightly with

a shutter speed of less than 1/100(1/60) sec.)

Utype (Etype)

● When the camera is used to monitor the same position continuously for 24 hours or more, the contact resistance of the

horizontal rotary parts may increase after long hours of use,

and the picture may be affected by noise interference or the

remote control operation may become unstable.

To prevent this, turn the system power off and on at least

once a week (to initialize) and also clean the contacts.

● Do not touch the dome cover of the lens directly with your

hand, contamination of this cover will lead to a deterioration

of the picture quality.

● Observe the following when carrying out camera maintenance.

• Turn the power OFF before proceeding to carry out main-

tenance.

• Clean the dome cover lens using a lens wiper cloth (or a

tissue).

If it is contaminated seriously, clean the contaminated part

with a cloth (or a tissue) which has been soaked in a solution of water and a neutral detergent.

● In order to reduce the generation of unnecessary signals,

be sure to install the provided ferrite cores when connecting the cables. (See

“How to use the ferrite core

” on page 9)

● Some subjects may not be brought into focus with the autofocus facility of this unit. Focusing will be made easier by

locating a subject with highly contrasted vertical stripes near

the center of the image.

● Optional controller is required to use the TK-C675B camera.

Please contact your local dealer or installer for more information about this controller.

Safety precautions

• As this unit contains parts which rotate at high speeds, it

should be installed in a place suitable to withstand the possible vibrations and to support the unit weight of 2 kg. If the

ceiling is made of dressed-face plywood, plaster board or

another material which is not strong enough to support the

unit, reinforce the installed surface by using a reinforcing

material (including plywood). If the reinforcement is insufficient, the monitor picture may be blurred due to vibrations

or in the worst case the unit may fall.

• Installation of this unit requires expertise. Please contact

your dealer for details.

• The ceiling to mount the TK-C675B has to be strong enough

to support ten times the weight of this product.

If the ceiling is not strong enough, make sure to apply reinforcement to the ceiling before installation.

• Be sure to tighten the screws and nuts securely, Insufficient

tightening may cause the unit to fall from its mount.

• The unit is to be powered by an AC24V.

Isolated power supply only. (E type)

Class 2 only (U type)

Page 27

4

Controls, connectors and indicators

■ Ceiling mount ■ Camera body

View when the camera body

cover is removed

11

15

14

16

15

13

12

Camera position

alignment mark

Dome cover lens

Dome cover

17

Ventilation

18

1

VIDEO OUTPUT terminal

Outputs composite video signals and is to be connected

to a monitor, etc. (Output impedance 75ohm)

2

Control signal terminals

The camera can be controlled by RS-422A or RS-485 signals.

3

AC 24V input terminals

Input the 24 V AC power.

Isolated power only (E type)

Class 2 only (U type)

4

Drop prevention wire

Engage this wire in the drop prevention wire hook

12

on

the camera.

5

Mounting holes (× 4)

Use these holes to attach the ceiling mount to the ceiling.

6

Camera connector (male)

Connects with the camera connector

13

on the camera.

7

Lock screw

Use this screw to fasten the camera clamp

14

to fix the

camera.

8

Camera position alignment mark

Align with the mark

17

when mounting the camera onto

the ceiling mount.

9

Safety wire hole

To prevent the camera from dropping accidentally, pass a

safety wire from the ceiling through these holes.

10

Terminal board cover

Protects the cable connection terminals against dirt, etc.

11

Control signal termination switch (TERM)

This is a termination ON/OFF switch for the input signals

to the control signal terminal

2

. When it is set to ON, the

“RX+” to “RX–” route is terminated.

12

Hook for attaching the drop prevention wire

Attach the drop prevention wire

4

to this hook.

13

Camera connector (female)

Connects with the camera connector

6

on the ceiling

mount.

14

Camera clamp

Fix the camera body to the ceiling mount by fastening the

lock screw

7

to this clamp.

15

Camera body cover

Remove this cover when using the setting switches

16

.

16

Setting switches

Set the PROTOCOL, etc.

Ref. “Switch settings” on page 6.

17

Camera positioning alignment mark

When mounting the camera onto the ceiling mount ,align it

with the mark

8

.

18

Ventilation

This is the ventilator for the internal cooling fan.

2

3

1

9

(Front)

(Back: Camera side)

4

5

6

5

7

8

10

Make sure that nothing interferes with the ventilator when

installing the camera.

CAUTION

5

1.

Make a hole (90 mm dia.) in the ceiling for passing through the

connection cables.

2.

Connect the cables to the terminal board.

Turn the power of all the connected equipment to OFF before

connecting the cables.

Remove the terminal board cover and connect the video signal

cable (coaxial cable),the control signal cables (x 4) and the 24 V

AC power cables (x 2).

●24 V AC power cables

Connect the 24 V AC power supply to the AC 24V terminals on

the terminal board. To prevent connection errors or a cable disconnection, we recommend the use of lug plates for the connections.

The following table shows the connection distances and connection cables provided that 2-conductor VVF cables (vinyl-insulated

vinyl sheath cables) are used.

Installation

●Control signal cables

These cables should be connected only when it is required to

control the camera using the RS-422A or RS-485 signals. The

use of 0.65 4-conductor twisted pair cables is recommended. With

these cables, the maximum extension distance is 1,200 m.

●Video signal cables

Connect the coaxial cables to the video signal output terminals.

Treat the tips of the coaxial cables as shown on the left before

connection.

After having connected all of the required cables, again attach

the terminal board cover.

3.

Attach the ceiling mount to the ceiling.

Attach the ceiling mount to the ceiling using 4 screws, while paying attention not to foul the connection cables.

Use M4 or No. 8-32 UNC screws and bolts for attaching the mount.

If using wood screws, use those with a diameter of 4.1 mm.

The screw head height should be no more

than 4 mm.

• If thin cables are used(i.e. with a high resistance), a significant

voltage drop will occur when the unit is at its maximum power

consumption (pan, tilt, zoom operated simultaneously). Either use

a thick cable to restrict the voltage drop at the camera side to

below 10%, or place the AC24V power supply near to the camera.

If voltage drop occurs during operation, the performance will be

unstable.

• Attach the cable conductors so that they do not come into contact with the drop prevention wire.

• Be sure to connect the 24 V AC cables correctly. Otherwise the

camera will be damaged.

CAUTION

The ceiling to mount the TK-C675B has to be strong enough to

support ten times the weight of this product.

If the ceiling is not strong enough, make sure to apply reinforcement to the ceiling before installation.

To prevent accidental dropping of the camera, connect the ceiling

plate or channel with the ceiling mount using a safety wire. Thread

the safety wire through the safety wire hole on the ceiling mount.

CAUTION

ø90mm

1.

VIDEO OUT

TX–

RX–

TX+

RX+

Drop prevention wire rail

2.

Remove the terminal board

cover by flipping it up while

pushing its top to the left.

(TX–)

(TX+)

(RX–)

(RX+)

6mm

12mm

To AC24Vg

RX+ RX–

To monitor, etc.

TX+

To controller

To controller

Meshed wire

TX–

Polyethylene

Fold the meshed wire back.

Lug plates

Core

conductor

3.

Screws

Ceiling mount

max.

4 mm

In order to reduce the generation of unnecessary signals, be sure to install the provided ferrite cores when

connecting the cables.

CAUTION

Maximum extension

100 m 260 m 410 m 500 m

Conductor diameter

1.0ømm

and more than

1.6ømm

and more than

2.0ømm

and more than

2.6ømm

and more than

(reference)

Page 28

6

Installation (continued)

4.

Turn the camera body cover to anti clockwise to set the word

"RELEASE" on the camera body cover over the mark, then pull

the camera body cover upward.

Transportation bracket is mounted when it is shipped from the

factory. Make sure to remove it before installation.

<How to remove the transportation bracket>

1

Remove the screw to remove the transportation bracket.

2

Then fasten the dome cover with the screw which was removed.

MANUAL SW3

Displayed OFF

Not displayed ON

(Initial set: OFF)

SW4PROTOCOL (1)

Point to point OFF

Multi drop ON

(Initial set: OFF)

PROTOCOL (2) SW5

Duplex OFF

Simplex ON

(Initial set: OFF)

SYNC SW6

INT OFF

LL ON

(Initial set: OFF)

LL mode

U type: 60 Hz area only

E type: 50 Hz area only

LO

C

K

R

E

L

E

A

S

E

LO

C

K

R

E

L

E

A

S

E

LOCK

RELEASE

Camera body

cover

Camera body

cover

Mark

Setting

switches

Board

4.

ON

123456

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

SW1

Reserved

*This switch must be set OFF.

DOUBLE

FIGURES

SINGLE

FIGURES

DISP

Machine ID

SW2

SW3

SW4

SW5

SW6

PROTOCOL (1)

PROTOCOL (2)

SYNC

5.

Transportation bracket

12

TERM switch

5.

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

(Initial set: 00)

ON OFF

RX TERM

(110 Ω)

SC46125-002

(Initial set: ON)

Ref. "Control signal connection" is on page 9.

●TERM switch

• When SW4 is set to ON in order to connect more

than one camera in series, set the TERM switch of

only the terminal camera to ON. The TERM switches of the other cameras should be set to OFF.

See “Connections” on page 8.

• When SW4 is set to OFF, this switch should be set to

ON.

●Machine ID

The machine ID should be set when using the camera in Multi drop.

Choose an ID in the 1 to 32 range.

●SYNC (SW6)

When this switch is set to ON, the vertical sync of the camera is

locked to the AC power line frequency.

• SW1 and SW2 are not in use for the present. Make sure that

they are set to OFF.

●PROTOCOL (2) (SW5)

Set according to the communication protocol used for controlling the cameras.

When set to Multi drop, be sure to set the Machine ID of each camera.

●PROTOCOL (1) (SW4)

Selects whether a single or multiple cameras are controlled in

the system.

Set PROTOCOL(1) to Multi drop when connecting multiple cameras in series.

If the power is supplied without removing the transportation

bracket, initialization won't be carried out properly, so that the

camera cannot be controlled with a remote control unit.

Make sure that it is removed.

CAUTION

5.

Check the switch settings and the communication protocol.

Read the controller specifications carefully before proceeding

to the switch settings.

■ Switch settings

DISP, PROTOCOL (1), (2), SYNC, Machine ID. Set these

switches as required.

●DISP (SW3)

Selects whether "MANUAL" is displayed or not when the camera's preset position is changed by the manual operation of the

remote control unit.

7

6.

Attach the camera body cover.

Align "RELEASE on the camera body cover with the indication mark on the camera body, fit the cover onto the camera body, then rotate the cover clockwise until "LOCK" is

indicated.

• Check that the three claws on the cover are locked onto

the camera body and that there is no clearance between

the cover and the camera body.

7.

Attaching the drop prevention wire.

As shown in the illustration, pull out the drop prevention

wire from the ceiling mount and engage it with the drop

prevention wire hook on the back of the camera.

Installation (continued)

Be sure to connect the drop prevention wire. Otherwise the

camera body may drop from the ceiling.

CAUTION

8.

Mount the camera body.

1) Ensure that the lock screw on the ceiling mount is loose.

2) Align the camera position alignment mark (^) on the ceiling mount with the camera position alignment mark (

q

) on

the camera body and fit the camera body into the mount.

3) Rotate the camera body clockwise until it is checked.

Then, check that the camera body clamp is located on the

lock screw on the ceiling mount.

4) Tighten the lock screw.

Be sure to tighten the lock screw fully. Otherwise the camera body may vibrate or drop from the ceiling.

CAUTION

For dismounting the camera from the ceiling, perform steps

1.

to

8.

in the reverse order.

L

O

C

K

RELEASE

LO

C

K

RELEASE

Cover

Camera body cover

Setting

switches

Claw

Claw

6.

Indication

mark

LOCK

RELEASE

LOCK

RELEASE

7.

Ceiling mount on the ceiling

Drop prevention

wire

Pull

out.

Hook for attaching

the Drop prevention

wire

8.

Ceiling mount

on the ceiling

Camera position

alignment mark

Camera position

alignment mark

Lock screw

Camera body Rotate the camera

body clockwise.

Tighten the lock screw.

Lock screw

Camera clamp

Page 29

8

Connections

■ When the system is composed of a single camera

■ When the system is composed of more than one camera

Controller*

Monitor

VIDEO OUT

CONTROL

PROTOCOL(1) SW4 :OFF

TERM : ON

24V AC

VIDEO

SWITCHER, etc.

CONTROLLER*

length of stub

length of stub

CONTROL Cable

CAM1 CAM2 CAM31 CAM32

PROTOCOL(1) : ON

MACHINE ID : 01

TERM : ON

PROTOCOL(1) : ON

MACHINE ID : 02

TERM : OFF

PROTOCOL(1) : ON

MACHINE ID : 31

TERM : OFF

PROTOCOL(1) : ON

MACHINE ID : 32

TERM : ON

length of stub

VIDEO

SWITCHER, etc.

CONTROLLER*

length of stub

CONTROL Cable

PROTOCOL(1) : ON

MACHINE ID : 01

TERM : ON

PROTOCOL(1) : ON

MACHINE ID : 02

TERM : OFF

PROTOCOL(1) : ON

MACHINE ID : 32

TERM : OFF

length of stub

CAM1 CAM2 CAM32

Terminate it

with 110ohm.

If this camera and the cables connected to this camera is used where there are strong electromagnetic waves or where there

is magnetism present, for example near a radio or TV transmitter, power transformer or an electric motor, the picture may

produce noise and the colors may be affected.

Optional controller is required to use the TK-C675 camera. Please contact your local dealer or installer for more information

about this controller.

CAUTION

Be sure to terminate the control signal cable at both ends. The cables (length of stub) connecting to non-terminated equipment

(camera or controller) must be as short as possible. If the length of stub is long, control may not be made correctly.

CAUTION

• Set the TERM switches of the cameras at both ends

(CAM1 and CAM32) to ON, and TERM switches of the

other cameras to OFF.

• Do not terminate at the controller.

• Set the TERM switch of CAM1 to ON, and also, terminate at the controller with 110 ohm.

Set the TERM switches of the other cameras to OFF.

● When the controller is located at the end.

● When the controller is not located at the end.

9

Connections (continued)

■ control signal connection

Use a twisted-pair cable for the connection.

●Duplex

When the camera is controlled with the full duplex protocol, set SW5 to OFF.

●Simplex

When the camera is controlled with the simplex transmission protocol, set SW5 to ON.

Camera Controller

RX+

RX–

TX+

TX–

TX+

TX–

RX+

RX–

Camera Controller

RX+

RX–

TX+

TX–

Four wires must be connected.

Two wires must be connected.

AC 24V`

AC 24V INPUT

terminals

Large ferrite core

Small ferrite core

Large ferrite core

TERMINAL BOARD

Control signal

terminals

VIDEO OUTPUT

terminals

Controller

Monitor, etc.

How to use the ferrite core

In order to reduce the generation of unnecessary signals, be sure to install the provided ferrite cores when connecting

the cables.

Install the ferrite cores within 100 mm of the camera-side connectors.

(Fasten the ferrite core with the provided wire clamp as the drawing

on the right.)

• For AC 24V INPUT terminals

Pass the AC 24V cable through the ferrite core twice and cconnect it to the camera.

• For Control signal terminals

Pass the Control signal cable through the ferrite core three times and cconnect it to the camera.

• For VIDEO OUTPUT terminals

Pass the VIDEO SIGNAL cable through the ferrite core and cconnect it to the camera.

Notes

Wire clamp

Page 30

10

Troubleshooting

Symptom Cause (Information) Remedy

Video is not

output.

• Is there a problem in the power cables connecting the camera to the power supply unit.

(If the power cables are too long or are of the

wrong size, the correct voltage may not be

supplied due to an increase in resistance.)

• Connect low resistance cables.

• Place the AC24V power supply near to the

camera.

(Check that the voltage supplied to the terminal

board is as rated when the camera is operating,

that is, when the rated current flows through it.)

Power cannot be

turned on.

• Are cables connected properly to the terminal

board on the ceiling mount?

• Was the 24 V AC power supply switched ON

and OFF repeatedly?

(The protection circuit may be activated when

the power is switched ON OFF ON within 5

sec.)

• Connect cables properly.

• Once the 24 V AC power is switched OFF, it

should be switched ON again only after a

lapse of more than 5 seconds.

The camera

moves from the

preset position.

• Has the panning been rotated manually for

cleaning, etc., while the power was on?

(The camera controls the panning position

based on the initial operation at the time the

power is turned on. If the camera position is

changed manually after the initial operation.

the preset camera position is displaced.)

• Switch the camera power supply OFF then ON

again.

Power can be

turned on, but it

later turns off

when the pan/tilt

unit is operated.

• Is there a problem with the power cables connecting the camera to the power supply unit.

(If the power cables are too long or are of the

wrong size, the voltage may drop due to an

increase in resistance during the panning

operation.)

• Change the power cables to ones of a lower

resistance

(i.e. thicker or shorter) cables.

• Place the AC24V power supply near to the

camera.

11

Specifications