Page 1

COMBINATION CAMERA

TK-C675B

RELEASE

LOCK

INSTRUCTIONS

This instruction book is made from 100% recycled paper.

For Customer Use :

Enter below the Serial No. which

is located on the body.

Retain this information for future

reference.

Model No. TK-C675B

Serial No.

Page 2

For USA and CANADA

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION : TO REDUCE THE RISK OF ELECTRIC SHOCK,

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

DO NOT REMOVE COVER (OR BACK).

NO USER SERVICEABLE PARTS INSIDE.

Due to design modifications, data given in this instruction

book are subject to possible change without prior notice.

WARNING:

TO REDUCE THE RISK OF FIRE OR

ELECTRIC SHOCK, DO NOT EXPOSE THIS

APPLIANCE TO RAIN OR MOISTURE.

The lightning flash with arrowhead symbol, within an

equilateral triangle is intended to alert the user to the

presence of uninsulated “dangerous voltage” within the

product's enclosure that may be of sufficient magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle

is intended to alert the user to the presence of important operating and maintenance (servicing) instructions in the literature accompanying the appliance.

Information for USA

This device complies with Part 15 of the FCC Rules.

Changes or modifications not approved by JVC could v oid

the user's authority to operate the equipment.

Thank you for purchasing this product.

CONTENTS

FEATURES ......................................................................... 2

OPERATING PRECAUTIONS............................................. 3

SAFETY PRECAUTIONS ................................................... 3

CONTROLS, CONNECTORS AND INDICATORS.............. 4

INSTALLATION ................................................................... 5

CONNECTIONS.................................................................. 8

HOW TO USE THE FERRITE CORE.................................. 9

MENU SETTINGS............................................................. 10

Menu operations ............................................................... 10

Menu screen flow .............................................................. 11

CAMERA MODE SELECT screen .................................... 12

CAMERA VIDEO ADJUST screen.................................... 13

VIDEO ADJUST FOR POSITION screen ......................... 14

POSITION TEXT screen ................................................... 15

CAMERA TEXT screen ..................................................... 16

AREA TEXT screen .......................................................... 17

ALARM TEXT screen ........................................................ 18

AUTO PAN SET screen..................................................... 19

AUTO PATROL SETUP screen ......................................... 20

FACTORY SETTINGS screen ........................................... 21

TROUBLESHOOTING ...................................................... 22

SPECIFICATIONS............................................................. 23

m Before starting an important recording, be sure to per-

form a test recording in order to confirm that a normal

recording is possible.

m We do not accept liability for the loss of a recording in

the case of it becoming impossible to record due to a

problem in the video camera, VCR or video tape.

m We do not accept liability for any damage to the cam-

era in cases when it is dropped because of incomplete

installation due to not observing the installation instructions correctly. Please be careful when installing the

camera.

AVERTISSEMENT:

POUR EVITER LES RISQUES D'INCENDIE OU

D'ELECTROCUTION, NE PAS EXPOSER

L'APPAREIL A L'HUMIDITE OU A LA PLUIE.

INFORMATION (FOR CANADA)

RENSEIGNEMENT (POUR CANADA)

This Class [B] digital apparatus meets all requirements of

the canadian Interference-Causing Equipment Regulations.

Cet appareil numénque de la classe [B] respecte toutes les

exigences du Réglement sur le matériel brouilleur du Canada.

FEATURES

m Features large aper ture lens with 16x zoom ratio (f=4.5 to

72mm, F1.2, at wide angle).

m Wide coverage angle (Horizontal 3.8° to 56°, Vertical 2.9° to

44°).

m 64 preset positions .

m 360 deg ree endless panning.

m Maxim um 240 deg ree/sec. panning speed.

m Maxim um 2-second z oom speed.

m One-push auto focus capability.

m RS-485 (Maximum Number of Connections: 32) or RS-422A

control signal.

m High-quality pictures by adopting dome cover with optical

distortion compensation and CCD with 380,000 (U: type)

or 440,000 (E: type) effective pixels.

m Adopts large aperture lens, highly sensitiv e CCD.

(Minimum illumination : 2.8 lx, at wide angle)

m Auto panning function.

m Variable panning speed.

The panning speed is varied automatically according to

the zoom ratio of the lens. (The panning speed decreases

when the zoom lens is set near TELE and increases when

it is set near WIDE.)

m Auto flip

When the camera reaches its tilting limit, it automatically

flips itself over by 180 degrees by panning around.

(This makes it possible for the camera to continue tilting

even after it has been tilted straight downward.)

mAuto patrol

Preset positions are activated in sequence.

m Menu screen display

A built-in character generator provides an on-screen menu

display for easy selection and setting of various functions.

m 5-language on-screen display

Names or designations for camera, preset, area and alarm

can be displayed in English, German, F rench, Italian and

Spanish. (E type only)

m Area title indication

The 360˚ panning angle (horizontal rotation) is divided into

16 sectors, allowing you to chec k the title in each area.

When the camera is manually panned, the preset area

designation is shown on the screen.

2

Page 3

Operating precautions

● To save energy, when it is not being used turn the system's

power off.

● This camera has been designed for indoor use. It cannot be

used outdoors.

● This camera has been designed exclusiv ely to be hung from

the ceiling.It may malfunction if it is placed on a surface or if

it is tilted.

● Do not install or use the camera in the following places.

• In a place exposed to rain or moisture.

• In a place with vapor or oil soot, for example in a kitchen.

• In a temperature outside the operating temperature range

(–10°C to 50°C).

• Near a source of radiation, X-rays, strong radio waves or

magnetism.

• In a place subject to vibration.

• In a place with excessive dirt.

● Insufficient head ventilation of the camera ma y cause a malfunction.

Be careful not to block the ventilation to the camera.

● If this camera and the cables connected to this camera are

used where there are strong electromagnetic waves or where

there is magnetism present, for example near a r adio or TV

transmitter, po w er tr ansformer or an electric motor, the picture may produce noise and the colors may be affected.

● This camera incorporates an AGC circuit. As a result, when

it is used under low light conditions, the camera sensitivity

is automatically boosted and the picture may look uneven.

This is not a malfunction however.

● When the AGC is ON in the auto iris mode, varying the iris

with the IRIS control button may not change the picture

brightness due to the gain boost function. In this case, s witch

the AGC OFF or set the iris mode to manual.

● In auto iris mode, the IRIS control buttons may not function

under certain brightness conditions (i.e. when a sufficient

amount of light cannot be obtained). In this case , set the iris

mode to manual.

● The white balance setting when used under a fluorescent

lamp should be A TW (A uto White). If it is set to MANU (Manual), the white balance may not be adjustable.

● When presetting this unit’ s position, turn it on and wait until

it has warmed up sufficiently inside (about 30 minutes). This

is to avoid a change in the lens focus due to a rise in temperature after installation.

● When this camera is used in the AUT O white balance mode,

the recorded colors may be slightly different from the actual

colors due to the operational principles of the auto-tracking

white balance circuit. This is however not a malfunction.

● If a high-intensity object (such as a lamp) is shot, the image

on the screen may hav e vertical lines (smear) or blur (blooming) at its periphery. This is a characteristic of the CCD, and

is not a defect.

● The electronic shutter of this camera has been set to 1/60(1/

50) sec. at the factory. When the camera is used under a

fluorescent lamp or in an area with a local power frequency

of 50/60 Hz, change the shutter speed to 1/100(1/60) on the

remote control unit. (The sensitivity deteriorates slightly with

a shutter speed of less than 1/100(1/60) sec.)

Utype (Etype)

● When the camera is used to monitor the same position continuously for 24 hours or more, the contact resistance of the

horizontal rotary parts may increase after long hours of use,

and the picture may be affected b y noise interference or the

remote control operation may become unstable.

To prevent this, turn the system power off and on at least

once a week (to initialize) and also clean the contacts.

● Do not touch the dome cover of the lens directly with your

hand, contamination of this cover will lead to a deterioration

of the picture quality.

● Observe the following when carrying out camera maintenance.

• Turn the power OFF bef ore proceeding to carry out main-

tenance.

• Clean the dome cover lens using a lens wiper cloth (or a

tissue).

If it is contaminated seriously , clean the contaminated part

with a cloth (or a tissue) which has been soaked in a solution of water and a neutral detergent.

● In order to reduce the generation of unnecessary signals,

be sure to install the provided ferrite cores when connecting the cables. (See “How to use the f errite core” on page 9)

● Some subjects may not be brought into f ocus with the autofocus facility of this unit. Focusing will be made easier by

locating a subject with highly contrasted vertical stripes near

the center of the image.

● Optional controller is required to use the TK-C675B camera. Please contact your local dealer or installer for more

information about this controller.

Caution during continuous use

Continuous use of the preset sequence or auto panning operation may make the service life much shorter than expected.

The guaranteed operation count for the zoom lens of this

camera is around 400,000 times.

(Example)

24 hours of operation per day with single zoom

operation per minute:

400,000 (times)/60 (minutes)/24 (hours) = 278 (da ys)

Safety precautions

• As this unit contains parts which rotate at high speeds, it

should be installed in a place suitable to withstand the possible vibrations and to support the unit weight of 2 kg. If the

ceiling is made of dressed-face plywood, plaster board or

another material which is not strong enough to support the

unit, reinforce the installed surface by using a reinforcing

material (including plywood). If the reinforcement is insufficient, the monitor picture may be blurred due to vibrations

or in the worst case the unit may fall.

• Installation of this unit requires expertise. Please contact

your dealer for details.

• The ceiling to mount the TK-C675B has to be strong enough

to support ten times the weight of this product.

If the ceiling is not strong enough, make sure to apply reinforcement to the ceiling before installation.

• Be sure to tighten the screws and nuts securely, Insufficient

tightening may cause the unit to fall from its mount.

• The unit is to be powered by an AC24V.

Isolated power supply only. (E type)

Class 2 only (U type)

3

Page 4

Controls, connectors and indicators

View when the camera body

cover is removed

11

15

14

16

15

13

12

Camera position

alignment mark

Dome cover lens

Dome cover

17

Ventilation

18

■ Ceiling mount ■ Camera body

10

23 1

9

(Front)

4

5

6

7

8

5

(Back: Camera side)

1

VIDEO OUTPUT terminal

Outputs composite video signals and is to be connected

to a monitor, etc. (Output impedance 75ohm)

2

Control signal terminals

The camera can be controlled by RS-422A or RS-485 signals.

3

AC 24V input terminals

Input the 24 V AC power.

Isolated power only (E type)

Class 2 only (U type)

Drop prevention wire

4

Engage this wire in the drop prevention wire hook

the camera.

Mounting holes (× 4)

5

Use these holes to attach the ceiling mount to the ceiling.

6

Camera connector (male)

Connects with the camera connector 13 on the camera.

7

Lock screw

Use this screw to fasten the camera clamp 14 to fix the

camera.

8

Camera position alignment mark

Align with the mark 17 when mounting the camera onto

the ceiling mount.

9

Safety wire hole

To prevent the camera from dropping accidentally, pass a

12

on

safety wire from the ceiling through these holes.

10

Terminal board cover

Protects the cable connection terminals against dirt, etc.

11

Control signal termination switch (TERM)

This is a termination ON/OFF switch for the input signals

2

to the control signal terminal

. When it is set to ON, the

“RX+” to “RX–” route is terminated via 110Ω resistor.

12

Hook for attaching the drop prevention wire

4

Attach the drop prevention wire

13

Camera connector (female)

Connects with the camera connector

to this hook.

6

on the ceiling

mount.

14

Camera clamp

Fix the camera body to the ceiling mount by fastening the

7

lock screw

15

Camera body cover

to this clamp.

Remove this cover when using the setting switches 16.

16

Setting switches

Set the PROTOCOL, etc.

Ref. “Switch settings” on page 6.

17

Camera positioning alignment mark

When mounting the camera onto the ceiling mount ,align it

with the mark

18

Ventilation

.

8

This is the ventilator for the internal cooling fan.

CAUTION

Make sure that nothing interferes with the v entilator when

installing the camera.

4

Page 5

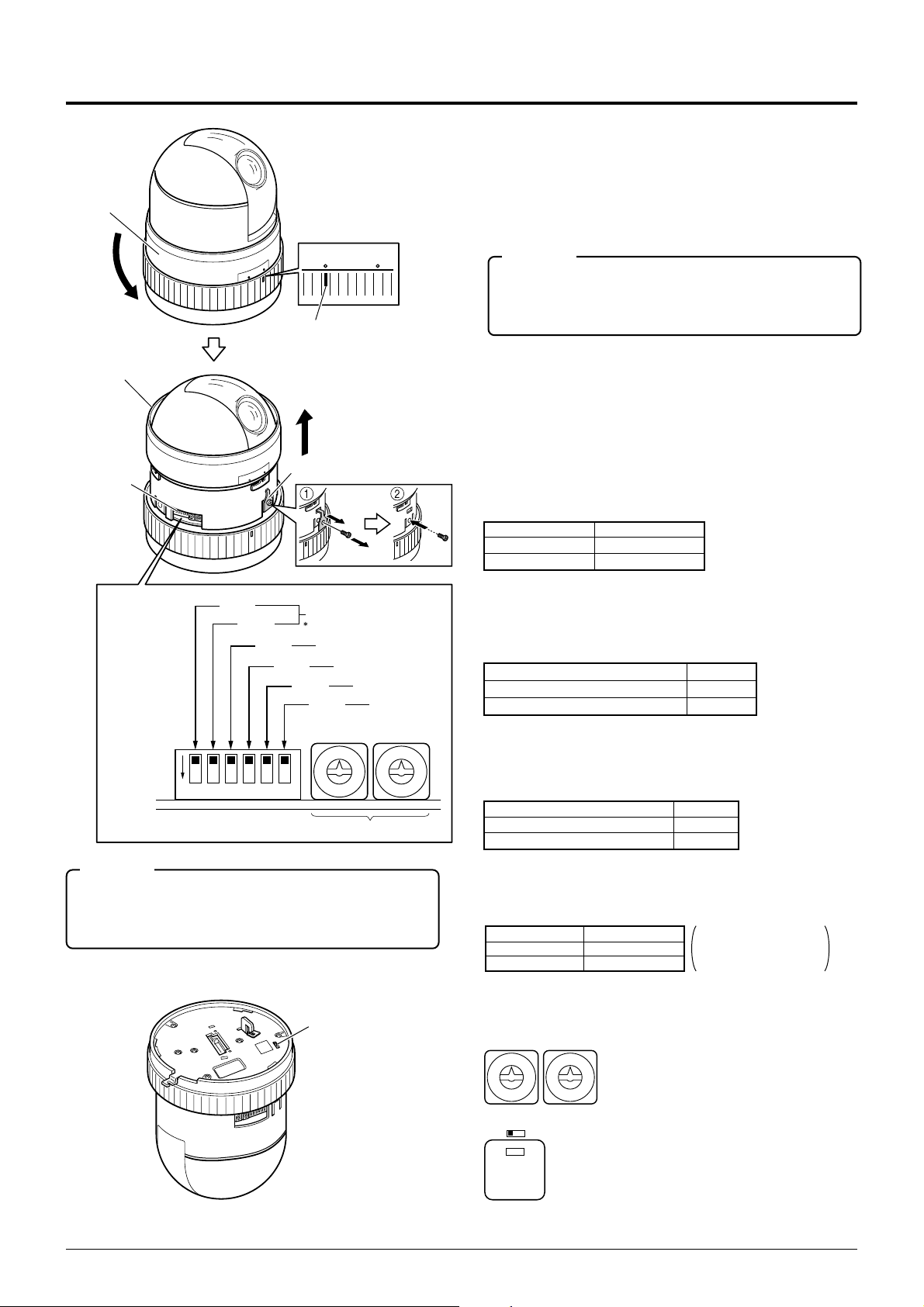

Installation

1.

2.

ø90mm

Remove the terminal board

cover by flipping it up while

pushing its top to the left.

TX+

TX–

VIDEO OUT

RX+

RX–

1.

Make a hole (90 mm dia.) in the ceiling for passing through the

connection cables.

2.

Connect the cables to the terminal board.

Tur n the power of all the connected equipment to OFF before

connecting the cables.

Remove the terminal board cover and connect the video signal

cable (coaxial cable),the control signal cables (× 4) and the AC

24 V power cables (× 2).

●AC 24 V power cables

Connect the AC 24 V power supply to the AC 24V terminals on

the terminal board. To prevent connection errors or a cable disconnection, we recommend the use of lug plates for the connections.

The following table shows the connection distances and connection cables provided that 2-conductor VVF cab les (vinyl-insulated

vinyl sheath cables) are used.

Drop prevention wire rail

To controller

Lug plates

To AC24V

To monitor, etc.

RX+ RX–

(TX–)(TX+)

(RX–)

(RX+)

TX+

TX–

To controller

Meshed wire

Polyethylene

Core

conductor

12mm

6mm

Fold the meshed wire back.

CAUTION

In order to reduce the generation of unnecessary signals, be sure to install the provided ferrite cores when

connecting the cables.

3.

Ceiling mount

Maximum extension

(reference)

Conductor diameter

100 m 260 m 410 m 500 m

1.0ømm

and more than

1.6ømm

and more than

2.0ømm

and more than

2.6ømm

and more than

CAUTION

• If thin cables are used(i.e. with a high resistance), a significant

voltage drop will occur when the unit is at its maximum power

consumption (pan, tilt, zoom operated simultaneously). Either use

a thick cable to restrict the voltage drop at the camera side to

below 10%, or place the AC 24V pow er supply near to the camera.

If voltage drop occurs during operation, the performance will be

unstable.

• Attach the cable conductors so that they do not come into contact with the drop prevention wire.

• Be sure to connect the AC 24 V cables correctly. Otherwise the

camera will be damaged.

●Control signal cables

These cables should be connected only when it is required to

control the camera using the RS-422A or RS-485 signals. The

use of 0.65 4-conductor twisted pair cables is recommended. With

these cables, the maximum extension distance is 1,200 m.

●Video signal cables

Connect the coaxial cables to the video signal output terminals.

Treat the tips of the coaxial cables as shown on the left before

connection.

After having connected all of the required cables, again attach the

terminal board cover.

3.

Attach the ceiling mount to the ceiling.

Attach the ceiling mount to the ceiling using 4 screws, while pa ying attention not to foul the connection cables.

Use M4 or No. 8-32 UNC screws and bolts f or attaching the mount.

If using wood screws, use those with a diameter of 4.1 mm.

The screw head height should be no more

than 4 mm.

max.

4 mm

Screws

CAUTION

The ceiling to mount the TK-C675B has to be strong enough to

support ten times the weight of this product.

If the ceiling is not strong enough, make sure to apply reinforcement to the ceiling before installation.

To prevent accidental dropping of the camera, connect the ceiling

plate or channel with the ceiling mount using a safety wire. Thread

the safety wire through the safety wire hole on the ceiling mount.

5

Page 6

Installation (continued)

4.

Camera body

cover

RELEASE

LOCK

RELEASE

LOCK

Mark

Camera body

cover

LOCK

RELEASE

Transportation bracket

Setting

switches

5.

SW1

SW2

SW3

123456

ON

Reserved

This switch must be set OFF.

DISP

SW5

PROTOCOL (1)

PROTOCOL (2)

SW4

SW6

DOUBLE

FIGURES

0

1

9

2

8

3

7

4

6

5

SYNC

SINGLE

FIGURES

0

9

8

7

6

Board

Machine ID

CAUTION

The setting of these switches will be read only once at the

time when the power is turned on. Even if the setting is

changed in a state where the power is on, such a change

will not be reflected.

5.

TERM switch

4.

Tur n the camera body cover to anti clockwise to set the word

“RELEASE” on the camera body cov er ov er the mark, then pull

the camera body cover upward.

Transportation bracket is mounted when it is shipped from the

factory. Make sure to remove it bef ore installation.

<How to remove the transportation bracket>

Remove the screw to remo ve the transportation bracket.

1

Then fasten the dome cov er with the screw which was removed.

2

CAUTION

If the power is supplied without removing the transportation

bracket, initialization won’t be carried out properly , so that the

camera cannot be controlled with a remote control unit.

Make sure that it is removed.

5.

Check the switch settings and the communication protocol.

Read the controller specifications carefully before proceeding

to the switch settings.

■ Switch settings

DISP, PROT OCOL (1), (2), SYNC, Machine ID . Set these switches as required.

●DISP (SW3)

Selects whether “MANUAL” is displayed or not when the camera's preset position is changed by the manual operation of the

remote control unit.

MANUAL SW3

Displayed OFF

Not displayed ON

●PROTOCOL (1) (SW4)

Selects whether a single or multiple cameras are controlled in

the system.

Set PROT OCOL(1) to Multi drop when connecting multiple cameras in series.

Point to point OFF

Multi drop (when using the RM-P2580)

When set to Multi drop, be sure to set the Machine ID of each camera.

1

2

3

4

5

●PROTOCOL (2) (SW5)

Set according to the communication protocol used for controlling the cameras.

PROTOCOL (2)

Duplex (when using the RM-P2580)

Simplex ON

Ref. “Control signal connection” is on page 9.

●SYNC (SW6)

When this switch is set to ON, the vertical sync of the camera is

locked to the AC power line frequency.

SYNC SW6

INT OFF

LL ON

(Initial set: OFF)

• SW1 and SW2 are not in use for the present. Make sure that

they are set to OFF.

●Machine ID

0

1

9

8

7

6

9

2

8

3

7

4

5

6

The machine ID should be set when us-

0

1

2

ing the camera in Multi drop.

3

4

Choose an ID in the 1 to 32 range.

5

(Initial set: 00)

●TERM switch

• When SW4 is set to ON in order to connect more

ON OFF

RX TERM

(110 Ω)

SC46125-002

(Initial set: ON)

than one camera in series, set the TERM switch of

only the terminal camera to ON. The TERM switches of the other cameras should be set to OFF.

See “Connections” on page 8.

• When SW4 is set to OFF, this switch should be set to

ON.

(Initial set: OFF)

SW4PROTOCOL (1)

ON

SW5

OFF

LL mode

U type: 60 Hz area only

E type: 50 Hz area only

(Initial set: OFF)

(Initial set: OFF)

6

Page 7

Camera body cover

6.

Claw

Setting

switches

Cover

7.

Claw

LOCK

RELEASE

RELEASE

Indication

mark

LOCK

RELEASE

Ceiling mount on the ceiling

RELEASE

LOCK

LOCK

Installation (continued)

6.

Attach the camera body cover.

Align "RELEASE on the camera body cover with the indication mark on the camera body , fit the cover onto the camera body, then rotate the cover clockwise until “LOCK” is

indicated.

• Check that the three claws on the cover are locked onto

the camera body and that there is no clearance between

the cover and the camera body.

7.

Attaching the drop prevention wire.

As shown in the illustration, pull out the drop prevention

wire from the ceiling mount and engage it with the drop

prevention wire hook on the back of the camera.

CAUTION

Be sure to connect the drop prevention wire . Otherwise the

camera body may drop from the ceiling.

8.

Mount the camera body.

1) Ensure that the lock screw on the ceiling mount is loose.

2) Align the camera position alignment mark (^) on the ceil-

5

ing mount with the camera position alignment mark (

the camera body and fit the camera body into the mount.

3) Rotate the camera body clockwise until it is checked.

Then, check that the camera body clamp is located on the

lock screw on the ceiling mount.

4) Tighten the lock screw.

) on

Pull

out.

Drop prevention

wire

8.

Lock screw

Ceiling mount

on the ceiling

Hook for attaching

the Drop prevention

wire

Camera position

alignment mark

Camera position

alignment mark

CAUTION

Be sure to tighten the lock screw fully. Otherwise the camera body may vibrate or drop from the ceiling.

For dismounting the camera from the ceiling, perf orm steps

1.

to 8. in the reverse order.

Camera clamp

Lock screw

Camera body Rotate the camera

body clockwise.

Tighten the lock screw.

7

Page 8

Connections

CAUTION

If this camera and the cables connected to this camera is used where there are strong electromagnetic waves or where there

is magnetism present, for example near a radio or TV transmitter, power transformer or an electric motor, the picture may

produce noise and the colors may be affected.

Optional controller is required to use the TK-C675B camera. Please contact your local dealer or installer for more information

about this controller.

■ When the system is composed of a single camera

24V AC

■ When the system is composed of more than one camera

CAUTION

Be sure to terminate the control signal cable at both ends. The cables (length of stub) connecting to non-terminated equipment

(camera or controller) must be as short as possible. If the length of stub is long, control may not be made correctly.

CONTROL

VIDEO OUT

PROTOCOL(1) SW4 :OFF

TERM : ON

Controller*

Monitor

● When the controller is not located at the end.

CAM1 CAM2 CAM31 CAM32

PROTOCOL(1) : ON

MACHINE ID : 01

TERM : ON

PROTOCOL(1) : ON

MACHINE ID : 02

TERM : OFF

• Set the TERM switches of the cameras at both ends

(CAM1 and CAM32) to ON, and TERM switches of the

other cameras to OFF.

• Do not terminate at the controller.

length of stub

● When the controller is located at the end.

CAM1 CAM2 CAM32

length of stub

CONTROL Cable

length of stub

CONTROLLER*

VIDEO

SWITCHER, etc.

CONTROL Cable

length of stub

PROTOCOL(1) : ON

MACHINE ID : 31

TERM : OFF

length of stub

PROTOCOL(1) : ON

MACHINE ID : 32

TERM : ON

Terminate it

with 110ohm.

CONTROLLER*

PROTOCOL(1) : ON

MACHINE ID : 01

TERM : ON

PROTOCOL(1) : ON

MACHINE ID : 02

TERM : OFF

PROTOCOL(1) : ON

MACHINE ID : 32

TERM : OFF

• Set the TERM switch of CAM1 to ON, and also, terminate at the controller with 110 ohm.

Set the TERM switches of the other cameras to OFF.

8

VIDEO

SWITCHER, etc.

Page 9

■ control signal connection

Wire clamp

Use a twisted-pair cable for the connection.

Connections (continued)

●Duplex

When the camera is controlled with the full duplex protocol, set SW5 to OFF.

Camera Controller

RX+

RX–

TX+

TX–

Four wires must be connected.

●For example (connection with the RM-P2580)

Camera RM-P2580

RX+ C

RX– D

TX+ A

TX– B

TX+

TX–

RX+

RX–

C TX+

D TX–

A RX+

B RX–

●Simplex

When the camera is controlled with the simplex transmission protocol, set SW5 to ON.

Camera Controller

RX+

RX–

Two wires must be connected.

TX+

TX–

How to use the ferrite core

In order to reduce the generation of unnecessary signals, be sure to install the provided ferrite cores when connecting

the cables.

TERMINAL BOARD

AC 24V INPUT

terminals

Large ferrite core

Control signal

terminals

Small ferrite core

VIDEO OUTPUT

terminals

Large ferrite core

Notes

Install the ferrite cores within 100 mm of the camera-side connectors.

(Fasten the ferrite core with the provided wire clamp as the drawing

on the right.)

• For AC 24V INPUT terminals

Pass the AC 24V cable through the ferrite core twice and cconnect it to the camera.

• For Control signal terminals

Pass the Control signal cable through the ferrite core three times and cconnect it to the camera.

• For VIDEO OUTPUT terminals

Pass the VIDEO SIGNAL cable through the ferrite core and cconnect it to the camera.

AC 24V

Controller

Monitor, etc.

9

Page 10

Menu settings

This chapter shows an example of connection to the JVC’s remote control unit RM-P2580. Read it and refer also to the instruction

manual of the RM-P2580.

Menu operations

It is possible to set the menu screen of the remote control unit (RM-P2580).

Item

Cursor

SETUP

MENUMENU SET

CLOSECLOSE

FOCUS

NEAR

WIDEWIDE

SETMENU

buttonbutton

SPEED

IRIS

AF

ZOOM

OPENOPEN

FAR

TELE CLEAR

CAMERACAMERA POSITIONPOSITION

POWERPOWER

ALARM

KEY LOCKKEY LOCK

CAMERA/POSITION

1

2

4

5

7

8

0

/HOME/HOME

SETUP

CAME AR..

CONT ORL U

3

6

9

ENTER

CAMERACAMERA

OPTIONOPTION

SETU

NIT..

OPTIONOPTION

1

AUTO

PAN

PATROLPATROL

P..POSI ITON

PAN/TILT

control lever

REMOTE CONTROL UNIT REMOTE CONTROL UNIT

AUTO F-1 F-2 F-3

POSI-POSI-

TIONTION

2

AUTO

RM-P2580

PAN/TILTLENS

Submenu

to be

followed

1.

Turn the rear power switch of the RM-P2580 to ON.

2.

Pressing the MENU button for approximately 3 seconds

will light the LED and the SETUP screen will be outputted

from the rear MONITOR OUTPUT-1.

3.

Use the pan/tilt control lever to move the cursor (>) and

select CAMERA.

• The cursor will move up when the lever is pressed up

(6).

• The cursor will move down when the lever is pressed

down (7).

4.

Press the SET button to display the SETUP screen of the

camera.

MEMO

Submenu is to follow for items with · · .

5.

Select the item in the same manner as step 3.

SETUP screen (main menu)

CAME ARMO

CAME ARV

VIDEO A JD

SETUP

DE S

DEOI

FOR

.TEXT ED .TI

ET. .AUTO PA SN

LSET..AUTO PA ORT

TTINGS. .FACT ROY ES

SETUP screen of the camera

V.PH SAE

POS. ETXT

AUTO FL PI

AREA T I ELT

DE SELECTCAME ARMO

LOC.

EEDVAR. APN PS

SIZE NORMALALM. TE TX

Sample screen display

Change

mark

V .PH SAE

POS. ETXT

AUTO FL PI

AREA T I ELT

DE SELECTCAME ARMO

LOC.

EEDVAR. APN PS

SIZE NORMALALM. TE TX

ELECT. .

ADJUST . .

POS I . .

127

UP—L

OFF

OFF

OFF

130

UP L

OFF

OFF

OFF

6.

Change the value of the selected item by moving the pan/

tilt control elver right and left.

• The value will become smaller when the lev er is pressed

to the left (8).

• The value will become larger when the lever is pressed

to the right (t).

The change mark ( ) shown in the diagram on the left will

appear when changes have been made.

MEMO

For details concerning submenu settings, see the next

page.

7.

When changes have been made, press the MENU button

to return to the normal screen.

10

Sample screen after change

Page 11

Menu screen flow

The menu screen flow is as follows. For details, see the reference pages.

Normal screen

Menu settings (continued)

Camera SETUP screen

CAME ARMO

CAME ARV

VIDEO A JD

SETUP

DE S

DEOI

FOR

.TEXT ED .TI

ET. .AUTO PA SN

LSET..AUTO PA ORT

TTINGS. .FACT ROY ES

ELECT. .

ADJUST . .

POS I . .

CAMERA MODE SELECT screen

DE SELECTCAME ARMO

V.PH SAE

POS. ETXT

AUTO FL PI

AREA T I ELT

LOC.

127

UP—L

OFF

EEDVAR. APN PS

OFF

OFF

SIZE NORMALALM. TE TX

Z Page 12

VIDEO ADJUST FOR POSITION screen

ST FOR PO ISIDEO ADJVU

POSI ITON

IRIS MOD

BLC OMDE

W.BA ALNEC

RB G IAN

TEXT . .

E

AUTO

OFF

ATW

127

Z Page 14

CAMERA VIDEO ADJUST screen

AGC OMDE

SHUT ETR

ENHA CNE

AV/ P AEK

COLOR LLEVE

DEO AD JUSTCAME ARVI

PEEDS

12dB

1/60

HHIG

8/2

5

Z Page 13

TEXT EDIT screen

TEDITTEX

CAME ARTE

ALARM TE

AREA TE .TX

XT . .

T..X

.

AUTO PAN SET screen

AUTO PAN

STAR T PO

RETU NRSOP

PAN SETUATO

MODE

ITIOS

ITION

RETURN

NSET..

SET . .

Z Page 19

FACTORY SETTINGS screen

SETTINGSFA TCORY

ETT INGS YESFACT ROYS

Z Page 21

Z Page 15

AUTO PATROL SETUP screen

TROL MO E1DAU OTPA

HOME 3 0 SECPAT ORL1

POS1 3 0SECPAT ORL2

POS2 3 0SECPAT ORL3

POS3 3 0SECPAT ORL4

POS4 3 0SECPAT ORL5

POS5 3 0SECPAT ORL6

POS6 3 0SECPAT ORL7

POS7 3 0SECPAT ORL8

M MODE F OCUS/BWFWD D Z O O

Z Page 20

11

Page 12

Menu settings (continued)

CAMERA MODE SELECT screen

Item

V.PHASE

POSITION TEXT

LOCA TION

AUTO FLIP

Function

Set when adjusting the vertical of other cameras operating in

the line lock (LL) mode.

Adjust while viewing the screen.

The value will become smaller when the pan/tilt lev er is pressed

to the left (8).

The value will become larger when the pan/tilt lever is pressed

to the right (t).

Used to set the display position of position titles.

UP: positions the title at the top of the screen.

DOWN: positions the title at the bottom of the screen.

L: positions the title towards the left of the screen.

C: positions the title in the center of the screen.

R: positions the title towards the rigt of the screen.

The camera is flipped over automatically by 180 degree at the

tilting limit.

(This makes it possible for the camer a to continue tilted straight

down ward.)

ON: Auto flip will funtion

OFF: Auto flip will not funtion

Variable

range

0 ~ 255

UP–L, DOWN–L

UP–C, DOWN–C

UP–R, COWN–R

OFF

ON

Factory

setting

127

UP–L

OFF

V AR.PAN SPEED

AREA TITLE

ALM.TEXT SIZE

The panning speed is varied automatically according to the zoom

ratio of the lens.

(The panning speed decreases when the zoom lens is set near

TELE and increases when it is set near WIDE).

ON: Var. pan speed will function

OFF: Var. pan speed will not function

The Area Title function divides the space covered by a camera

into sixteen units, with a 16-character ID allocated to each unit.

(AREA 1 ~ AREA16)

The set AREA TITLE is displayed when manually panning the

camera.

ON: Area title is displayed

OFF: Area title is not displayed

The character size to display during ALARM is set.

ALARM

ALARM

OFF

ON

OFF

ON

NORMAL

DOUBLE

AREA

16

AREA

1

AREA

2

OFF

OFF

AREA

3

DOUBLE

12

NORMAL SIZE DOUBLE SIZE

Page 13

CAMERA VIDEO ADJUST screen

Menu settings (continued)

Item

AGC MODE

SHUTTER

SPEED

Function

The maximum gain of the AGC (Automatic gain control) is set.

This setting value becomes a maximum limit when the gain is

automatically changed according to brightness.

Set this to 20dB when there is little light on the subject.

MEMO

The gain is automatically raised in dark areas when the

AGC is in operation. At this time, the screen may appear

rough; however, this is not a malfunction.

Set the electronic shutter speed for each camera.

To reduce flickering of fluorescent lighting, set the electronic

shutter is speed to 1/100 (1/50) when in areas with commercial

power supply frequency of 50Hz, and 1/60 when in areas of

60Hz, set to 1/60.

MEMO

More of the smearing effect, which is characteristic of CCD ,

will be noticed when the shutter speed is increased.

Variable

range

OFF

12 dB

20 dB

1/60 (1/50), 1/100 (1/60),

1/1000, 1/2000, 1/4000,

1/10000

( ) is version E.

Factory

setting

12 dB

1/60 (1/50)

ENHANCE

AV/PEAK

COLOR LEVEL

This function compensates the edge to enhance the sharpness

of the monitor screen and can be set per camera.

LOW: low edge enhancement

HIGH: high edge enhancement

This setting is effective only during auto iris.

For the exposure detection, the ratio of the average value (AV)

and the peak value (PK) is set for each camera.

Increase the AV (ex. 10/0):

Increase the A V when portions other than the highlighted areas of the screen is dark. Conv enient when there is lighting in

a dark room.

Increase the PK (ex. 5/5):

Increased when there is halation on the highlighted areas of

the screen.

Used when setting the color level of the image signal. The screen

colors will become lighter when small value is set. The colors

will become darker when large value is set.

LOW

HIGH

10/0

9/1

8/2

7/3

6/4

5/5

0 ~ 10

(increments of 1)

HIGH

8/2

5

13

Page 14

Menu settings (continued)

VIDEO ADJUST FOR POSITION screen

Item

POSITION TEXT

IRIS MODE

BLC MODE

Function

It is possible to set up to 16 characters to use as titles for set

positions (max. 63) and home positions (max. 1).

See the next page for details on settings

MEMO

Always register positions before setting titles. Positions

cannot be selected unless they have been registered. For

details on registering positions, see the instruction manual of the used remote control.

Set the iris depending on the brightness.

AUTO: the iris is automatically adjusted to the normal value.

AUT O+: the iris is automatically adjusted brighter than the nor-

mal value

AUTO–: the iris is automatically adjusted darker than the nor-

mal value.

MANU: used when settings the iris manually

With this setting, light measurement areas are selected during

auto iris control.

Set when there is light in the background of the subject.

There are 4 types of settings. Choose depending on the location of the light source.

Light measurement

area

Light

measurement

area

OFF AREA 1 AREA 2 AREA 3 AREA 4

Light measurement

area

Light measurement

area

Light measurement

area

AUTO

AUTO+

AUTO–

MANUAL

OFF

AREA1

AREA2

AREA3

AREA4

Variable

range

Factory

setting

AUTO

OFF

W. BALANCE

RB GAIN

The white balance is adjusted manually or automatically for light

within the range of 2000°k and 7000°k.

ATW: automatic light temperature adjustment mode

MANU: manual adjustment mode

(Adjustment is made in the next item, RB GAIN)

Used when adjusting the white balance manually.

Small value: blue is enhanced

Large value: red is enhanced

MEMO

Value cannot be changed when W. BALANCE is set to

ATW.

ATW

MANUAL

0 ~ 255

(increments of 1)

ATW

127

14

Page 15

Menu settings (continued)

POSITION TEXT screen

It is possible to set titles to positions (max. 63) and home positions (max. 1) using text of 16 characters or less.

MEMO

Always register positions before setting titles. Positions cannot be selected when they are not registered.

To register positions, see the instruction manual of the used remote control unit.

SPACE Character section (blink)

NTEXTPO ISTIO

9ABCDEFGHIJK0123 54678

VWXYZabcdefgNMLOPRQSTU

/–:

Title input section (blink)

POSITION TEXT screen

POSITION TEXT screen

rs tuvwxyz. ,'jkhi l nmopq

TEXT ZOOMSE ELCT

(U version)

NTEXTPO ISTIO

9ABCDEFGHIJK0123 54678

VWXYZabcdefgNMLOPRQSTU

rs tuvwxyz. ,'jkhi l nmopq

ЫЗСдлпцьвкоф/–: ÄÖ ÂÜÊÎÔ

ùçñß¡¿éíûá ó àúèìò

TEXT ZOOMSE ELCT

(E version)

1.

Select the camera using the remote control (See the instruction manual of the used remote control)

The image signal of the home position of the selected camera will be outputted.

Press the MENU button to display the SETUP screen of

the remote control, select CAMERA, then press the SET

button to display the CAMERA SETUP screen.

2.

Select POSITION TEXT item in the VIDEO ADJUST FOR

POSI screens, then press the SET button to display the

POSITION TEXT screen (see left).

3.

To set a home position title, skip to 4.

To set a position title, select the position to title from the

remote control unit. The camera will move to the selected

position.

4.

In the POSITION TEXT screen, the first characters of the

character area and the title input area will flash, allowing

input.

5.

Use the 6, 7, 8 and t of the pan/tilt control lever to

select the character.

NTEXTPO ISTIO

9ABCDEFGHIJK0123 54678

VWXYZabcdefgNMLOPRQSTU

rs tuvwxyz. ,'jkhi l nmopq

ЫЗСдлпцьвкоф/–: ÄÖ ÂÜÊÎÔ

ùçñß¡¿éíûá ó àúèìò

VEDDA ATSA

When selecting the next position

6.

When the first character of the title as been selected, press

the ZOOM (TELE) button to move on to the next character.

At this time, the first character will be confirmed.

Pressing the ZOOM (WIDE) button will move the flashing

position in the title input area to the left. Use when correcting errors to the set title.

7.

To set the next position title, repeat steps 3 through 6.

DAT A SA VED will appear for appro ximately 3 seconds when

selecting the next position.

8.

To set other position title of a camera, repeat steps

through 7.

9.

When all positions have been set, press the MENU button

to return to the normal screen.

1

15

Page 16

Menu settings (continued)

CAMERA TEXT screen

It is possible to set up to 16 characters to use as a title during camera selection.

ZOOM(WIDE)

button

ZOOM(TELE)

button

SETUP

SETU

CAME AR..

CONT ORL U

P..POSI ITON

NIT..

Remote control SETUP screen

SETUP

MENU SET

CLOSE

NEAR

WIDE

SPEED

IRIS

FOCUS

ZOOM

buttonbutton

AF

SETMENU

POWERPOWER

ALARM

KEY LOCKKEY LOCK

OPEN

FAR

TELE CLEAR

CAMERA POSITION

CAMERA/POSITION

1

2

3

4

5

6

7

8

9

0

ENTER

/HOME

PAN/TILT

control lever

REMOTE CONTROL UNIT REMOTE CONTROL UNIT

AUTO F-1 F-2 F-3

RM-P2580

Numeric Key

buttons

CAMERACAMERA

OPTION

AUTOAUTO

POSI-

TION

OPTION

1

AUTOAUTO

PANPAN

PATROLPATROL

PAN/TILTLENS

2

CAMERA

button

ENTER

button

1.

Select the camera to set the camera title (See the instruction manual of the used remote control).

The image signal of the selected camera will be outputted

when pressing CAMERA → Numeric Key → ENTER button.

2.

Press the MENU button to display the SETUP screen of

the remote control.

Use the pan/tilt control lever to select CAMERA, then press

the SET button to display the SETUP screen of the camera.

At this time, the camera will move to the home position.

CAME ARMO

CAME ARV

VIDEO A JD

SETUP

DE S

DEOI

FOR

.TEXT ED .TI

ET. .AUTO PA SN

LSET..AUTO PA ORT

TTINGS. .FACT ROY ES

Camera SETUP screen

TEDITTEX

CAME ARTE

ALARM TE

AREA TE .TX

XT . .

T..X

.

TEXT EDIT screen

ATEXTACMER

9ABCDEFGHIJK0123 54678

VWXYZabcdefgNMLOPRQSTU

rs tuvwxyz. ,'jkhi l nmopq

ЫЗСдлпцьвкоф/–: ÄÖ ÂÜÊÎÔ

ùçñß¡¿éíûá ó àúèìò

TEXT ZOOMSE ELCT

ELECT. .

ADJUST . .

POS I . .

Displayed

only for

E version.

3.

Use the pan/tilt control lever to select TEXT EDT , then press

the SET button to display the TEXT EDUT screen.

4.

Select CAMERA TEXT, then press the SET button to display the CAMERA TEXT screen.

5.

In the CAMERA TEXT screen, the first characters of the

character area and the title area will flash, allowing input.

6.

Use the 6, 7, 8 and t of the pan/tilt control lever to

select the character.

7.

When the first character of the title as been selected, press

the ZOOM (TELE) button to confirm the first character and

to move on to the next character of the title.

Pressing the ZOOM (WIDE) button will move the flashing

position in the title input area to the left. Use when correcting errors to the set title.

1

■ To set the next camera title, repeat steps

8.

When all camera title have been set, press the MENU b ut-

through 7.

ton to return to the normal screen.

16

CAMERA TEXT screen

Page 17

Menu settings (continued)

AREA TEXT screen

The 360° panning angle (horizontal rotation) is divided into 16 sectors, allowing you to check the title in each area. When the

camera is manually panned, the preset area designation is shown on the screen.

It is possible to set titles of 16 characters or less to each area.

To select whether to display the title or not is made in AREA TITLE.

AREA

16

AREA

1

AREA

AREA

CAME AR..

CONT ORL U

3

2

SETUP

SETU

NIT..

Remote control SETUP screen

SETUP

MENUMENU SET

SETMENU

buttonbutton

CAMERACAMERA POSITION

POWERPOWER

ALARMALARM

KEY LOCKKEY LOCK

PAN/TILT

control lever

REMOTE CONTROL UNIT REMOTE CONTROL UNIT

AUTO F-1 F-2 F-3

RM-P2580

Numeric Key

buttons

FOCUS(FAR)

button

FOCUS(NEAR)

button

ZOOM(WIDE)

CAMERA/POSITION

CAMERACAMERA

1

SPEED

IRIS

OPEN

CLOSE

FOCUS

FAR

NEAR

AF

TELE CLEAR

WIDEWIDE

ZOOM

2

4

5

7

8

0

ENTER

/HOME/HOME

POSI-

3

TION

OPTION

OPTION

6

1

AUTOAUTO

AUTOAUTO

9

PANPAN

PATROLPATROL

PAN/TILTLENS

CAMERA

button

2

button

ZOOM(TELE)

button

ENTER

button

1.

Select the camera to set the area title (See the instruction

P..POSI ITON

manual of the used remote control).

The image signal of the selected camera will be outputted

when pressing CAMERA → Numeric Key → ENTER button.

2.

Press the MENU button to display the SETUP screen of

the remote control.

Use the pan/tilt control lever to select CAMERA, then press

the SET button to display the SETUP screen of the camera.

At this time, the camera will move to the home position.

CAME ARMO

CAME ARV

VIDEO A JD

SETUP

DE S

DEOI

FOR

.TEXT ED .TI

ET. .AUTO PA SN

LSET..AUTO PA ORT

TTINGS. .FACT ROY ES

Camera SETUP screen

TEDITTEX

CAME ARTE

ALARM TE

AREA TE .TX

XT . .

T..X

.

TEXT EDIT screen

TEXT 10RAEA

9ABCDEFGHIJK0123 54678

VWXYZabcdefgNMLOPRQSTU

rs tuvwxyz. ,'jkhi l nmopq

ЫЗСдлпцьвкоф/–: ÄÖ ÂÜÊÎÔ

ùçñß¡¿éíûá ó àúèìò

AREA FOCUSEXTTZOOM

ELECT. .

ADJUST . .

POS I . .

Displayed

only for

E version.

3.

Use the pan/tilt control lever to select TEXT EDIT, then

press the SET button to display the TEXT EDIT screen.

4.

Select AREA TEXT, then press the SET button to display

the AREA TEXT 1 screen.

This corresponds to home position area 1.

5.

In the AREA TITLE 1 screen, the first characters of the

character area and the title area will flash, allowing input.

6.

Use the 6, 7, 8 and t of the pan/tilt control lever to

select the character.

7.

When the first character of the title as been selected, press

the ZOOM (TELE) button to confirm the first character and

to move on to the next character of the title.

Pressing the ZOOM (WIDE) button will move the flashing

position in the title input area to the left. Use when correcting errors to the set title.

8.

To set the next area title, press the FOCUS (FAR) button.

The camera will move to the ne xt area and the AREA TEXT

2 screen will appear. In the same manner as AREA TEXT

5

1, repeat steps

9.

When all area title have been set, press the MENU button

through 7 to set the title.

to return to the normal screen.

AREA TEXT screen

17

Page 18

Menu settings (continued)

ALARM TEXT screen

It is possible to set up to 12 characters to use as a title during alarm.

FOCUS(FAR)

button

FOCUS(NEAR)

button

ZOOM(WIDE)

button

ZOOM(TELE)

button

SETUP

SETU

CAME AR..

CONT ORL U

P..POSI ITON

NIT..

Remote control SETUP screen

SETUP

MENU SET

CLOSE

NEAR

WIDE

SPEED

FOCUS

ZOOM

buttonbutton

IRIS

AF

SETMENU

POWER

ALARM

KEY LOCKKEY LOCK

OPEN

FAR

TELE CLEAR

CAMERA POSITION

CAMERA/POSITION

1

2

3

4

5

6

7

8

9

0

ENTER

/HOME

PAN/TILT

control lever

REMOTE CONTROL UNIT REMOTE CONTROL UNIT

AUTO F-1 F-2 F-3

RM-P2580

Numeric Key

buttons

CAMERACAMERA

OPTION

AUTOAUTO

POSI-

TION

OPTION

1

AUTOAUTO

PANPAN

PATROLPATROL

PAN/TILTLENS

2

CAMERA

button

ENTER

button

1.

Select the camera to set the alarm title (See the instruction manual of the used remote control).

The image signal of the selected camera will be outputted

when pressing CAMERA → Numeric Key → ENTER button.

2.

Press the MENU button to display the SETUP screen of

the remote control.

Use the pan/tilt control lever to select CAMERA, then press

the SET button to display the SETUP screen of the camera.

At this time, the camera will move to the home position.

CAME ARMO

CAME ARV

VIDEO A JD

SETUP

DE S

DEOI

FOR

.TEXT ED .TI

ET. .AUTO PA SN

LSET..AUTO PA ORT

TTINGS. .FACT ROY ES

Camera SETUP screen

TEDITTEX

CAME ARTE

ALARM TE

AREA TE .TX

XT . .

T..X

.

TEXT EDIT screen

TEXT 1AALRM

9ABCDEFGHIJK0123 54678

VWXYZabcdefgNMLOPRQSTU

rs tuvwxyz. ,'jkhi l nmopq

ЫЗСдлпцьвкоф/–: ÄÖ ÂÜÊÎÔ

ùçñß¡¿éíûá ó àúèìò

A L ARM F OCUSETXTZOOM

ELECT. .

ADJUST . .

POS I . .

Displayed

only for

E version.

3.

Use the pan/tilt control lever to select TEXT EDIT, then

press the SET button to display the TEXT EDIT screen.

4.

Select ALARM TEXT, then press the SET button to display

the ALARM TEXT 1 screen.

5.

In the ALARM TITLE 1 screen, the first characters of the

character area and the title area will flash, allowing input.

6.

Use the 6, 7, 8 and t of the pan/tilt control lever to

select the character.

7.

When the first character of the title as been selected, press

the ZOOM (TELE) button to confirm the first character and

to move on to the next character of the title.

Pressing the ZOOM (WIDE) button will move the flashing

position in the title input area to the left. Use when correcting errors to the set title.

8.

T o set the ne xt alarm title, press the FOCUS (FAR) button.

The ALARM TEXT 2 screen will appear . In the same man-

5

ner as ALARM TEXT 1, repeat steps

through 7 to set

the title.

9.

When all alarm title have been set, press the MENU button to return to the normal screen.

18

ALARM TEXT screen

Page 19

Menu settings (continued)

FOCUS

button

ZOOM

button

IRIS

button

buttonbutton

PAN/TILT

SETMENU

control lever

SETUP

MENU SET

SPEED

IRIS

AF

FOCUS

ZOOM

OPEN

FAR

TELE CLEAR

/HOME

7

4

1

8

0

5

2

9

6

3

ENTER

AUTOAUTO

PANPAN

OPTION

1

OPTION

2

CAMERACAMERA

POSI-

TION

AUTOAUTO

PATROLPATROL

CLOSE

NEAR

WIDE

AUTO F-1 F-2 F-3

PAN/TILTLENS

CAMERA/POSITION

CAMERA POSITION

REMOTE CONTROL UNIT REMOTE CONTROL UNIT

RM-P2580

ALARM

POWERPOWER

KEY LOCKKEY LOCK

button

CAMERA

button

ENTER

buttons

Numeric Key

AUTO PAN SET screen

Auto pan is a feature which allows the camera to slowly move sideways automatically and is set per each camera.

There are 3 AUTO PAN modes: RETURN that goes back and forth between two points,

RIGHT that makes a right rotation and LEFT that makes a left rotation.

Picture at the

start position

Example:

Action of Retun mode

Remote control SETUP screen

CAME ARMO

CAME ARV

VIDEO A JD

AUTO PAN

STAR T PO

RETU NRSOP

START POSITION SET screen

RETURN POSITION SET screen

Slow speed

SETUP

SETU

FOR

.TEXT ED .TI

ET. .AUTO PA SN

LSET..AUTO PA ORT

TTINGS. .FACT ROY ES

NIT..

P..POSI ITON

ELECT. .

ADJUST . .

POS I . .

CAME AR..

CONT ORL U

SETUP

DE S

DEOI

Camera SETUP screen

PAN SETUATO

MODE

ITIOS

SITION SETSTA TRPO

NSET..

ITION

RETURN

SET . .

SITION SETRETU NRPO

Picture at the

stop position

1.

Select the camera to set (See the instruction manual of the used

remote control).

Press CAMERA → Numeric Key → ENTER button to output the image signal to the selected camera.

2.

Press the MENU button to display the SETUP screen of the remote

control.

Use the pan/tilt control lever to select CAMERA, then press the SET

button to display the SETUP screen of the camera.

At this time, the camera will move to the home position.

3.

Use the pan/tilt control lever to AUTO PAN SET, then press the SET

button to display the AUTO PAN SET screen.

4.

In the AUTO PAN SET screen, select AUTO PAN MODE.

Select the auto pan mode from RETURN, RIGHT and LEFT using

the pan/tilt control lever.

5.

Next, select START POSITION SET, then press the SET button to

display the START POSITION SET screen.

Adjust the angle of view at the start position using the pan/tilt control

lever, IRIS, focus and zoom button.

6.

Pressing the MENU button will display the AUTO PAN SET screen

and the set angle of view at the start position will be registered. At

this time, DATA SAVED will appear on the screen.

■ When selecting the mode to RETURN, set RETURN POSITION SET .

7.

Select RETURN POSITION SET, then press the SET button to display the RETURN POSITION SET screen.

Adjust the angle of view at the stop position, then press the MENU button. DATA SAVED will appear and the stop position will be registered.

MEMO

• Shifting in the direction of the tilt and lens operations cannot be

made at the stop position. To mak e field of view changes and lens

operations, press the SET button and set the stop position after

setting the field of view and making lens operations in the START

POSITION SETUP screen.

• Correct data will not be written when pressing the MENU button or

SET button while the camera is in motion. Always check to make

sure that the camera is still before pressing the MENU or SET button.

8.

When the start and stop positions have been set, press the MENU

button to return to the normal screen.

19

Page 20

Menu settings (continued)

AUTO PATROL SETUP screen

The auto patrol is a feature to mov e the camera to m ultiple positions at high speed in a set sequence and time and is set per each

camera.

SETMENU

buttonbutton

PAN/TILT

control lever

High speed

POSITION

POSITION

High speed

SETUP

CAME AR..

CONT ORL U

SETU

Remote control SETUP screen

CAME ARMO

CAME ARV

VIDEO A JD

SETUP

DE S

DEOI

FOR

.TEXT ED .TI

ET. .AUTO PA SN

LSET..AUTO PA ORT

TTINGS. .FACT ROY ES

POSITION

High speedHigh speed

POSITION

P..POSI ITON

NIT..

ELECT. .

ADJUST . .

POS I . .

FOCUS

button

SETUP

MENU SET

POWER

ALARM

KEY LOCKKEY LOCK

CAMERA POSITION

REMOTE CONTROL UNIT REMOTE CONTROL UNIT

AUTO F-1 F-2 F-3

RM-P2580

Numeric Key

buttons

CAMERA/POSITION

CAMERACAMERA

1

SPEED

IRIS

OPEN

CLOSE

FOCUS

FAR

NEAR

AF

TELE CLEAR

WIDE

ZOOM

2

4

5

7

8

0

ENTER

/HOME

POSI-

3

TION

OPTION

OPTION

6

1

AUTOAUTO

AUTOAUTO

9

PANPAN

PATROLPATROL

PAN/TILTLENS

CAMERA

button

2

ENTER

button

1.

Select the camera to set for auto patrol (See the instruction manual of the used remote control)

Press CAMERA → Numeric Key → ENTER button to output the image of the selected camera.

2.

Press the MENU button to display the SETUP screen of

the remote control.

Use the pan/tilt control lever to select the camera, then

press the SET button to display the SETUP screen of the

camera.

At this time, the camera will move to the home position.

3.

Select AUTO PATROL SET using the the pan/tilt control

lever, then press te SET button to display the AUTO PATROL MODE 1 screen.

20

Camera SETUP screen

TROL MO E1DAU OTPA

HOME 3 0 SECPAT ORL1

POS1 3 0SECPAT ORL2

POS2 3 0SECPAT ORL3

POS3 3 0SECPAT ORL4

POS4 3 0SECPAT ORL5

POS5 3 0SECPAT ORL6

POS6 3 0SECPAT ORL7

POS7 3 0SECPAT ORL8

M MODE F OCUS/BWFWD D Z O O

AUTO PATROL MODE 1 screen

4.

Use the pan/tilt control lever to set the auto patrol positions and time.

The time can be selected from 30 sec., 45 sec., 1 min.,

2 min., 3 min., 6 min. and SKIP.

If the selection of auto patrol position is not necessary ,

set to SKIP.

The factory setting for auto patrol will move the camera from HOME to POS63 at 30 seconds.

5.

The setting of the next mode is made using the FOCUS

(FAR) and FOCUS (NEAR) button.

6.

When all settings have been made, press the MENU button. At this time, DATA SAVED will appear on the screen.

Page 21

FACTORY SETTINGS screen

It is possible to return all camera settings to the factory settings.

Menu settings (continued)

MENU SET

CLOSE

NEAR

WIDE

SETUP

SETU

CAME AR..

CONT ORL U

P..POSI ITON

NIT..

Remote control SETUP screen

SETUP

SPEED

FOCUS

ZOOM

IRIS

AF

SETMENU

buttonbutton

OPEN

FAR

TELE CLEAR

POWERPOWER

ALARM

KEY LOCKKEY LOCK

CAMERA POSITION

CAMERA/POSITION

1

2

3

4

5

6

7

8

9

0

ENTER

/HOME

PAN/TILT

control lever

REMOTE CONTROL UNIT REMOTE CONTROL UNIT

AUTO F-1 F-2 F-3

RM-P2580

Numeric Key

buttons

CAMERACAMERA

OPTION

AUTOAUTO

PAN/TILTLENS

POSI-

TION

OPTION

1

2

AUTOAUTO

PANPAN

PATROLPATROL

CAMERA

button

ENTER

button

1.

Select the camera to initialize settings (See the instruction

manual of the used remote control).

Press CAMERA → Numeric Key → ENTER b utton to output the image signal of the selected camera.

2.

Press the MENU button to display the SETUP screen of

the remote control. Use the pan/tilt control lever to select

CAMERA, then press the SET button to display the SETUP screen of the camera.

At this time, the camera will move to the home position.

CAME ARMO

CAME ARV

VIDEO A JD

SETUP

DE S

DEOI

FOR

.TEXT ED .TI

ET. .AUTO PA SN

LSET..AUTO PA ORT

TTINGS. .FACT ROY ES

ELECT. .

ADJUST . .

POS I . .

Camera SETUP screen

SETTINGSFA TCORY

ETT INGS YESFACT ROYS

FACTORY SETTINGS screen

3.

Use the pan/tilt control lever to select FACTORY SETTINGS, then press the SET button to display the FACTORY SETTINGS screen.

4.

Use 8 and t of the pan/tilt control lever to select the

FACTORY SETTINGS item to YES.

5.

Pressing the SET button will initialize settings in approximately 3 seconds and DATA SAVED will appear.

6.

Press the MENU button to return to the normal screen.

CAUTION

If this setting operation is performed, various settings

memorized in the camera will all return to the state of factory shipment.

Especially , all the preset positions will be cleared. Therefore, exercise utmost caution!

21

Page 22

Troubleshooting

Symptom

Video is not

output.

Power cannot be

turned on.

The camera

moves from the

preset position.

Power can be

turned on, but it

later turns off

when the pan/tilt

unit is operated.

Cause (Information)

• Is there a problem in the power cables con-necting the camera to the power supply unit.

(If the power cables are too long or are of the wrong

size, the correct voltage ma y not be supplied due

to an increase in resistance.)

• Are cables connected properly to the ter minal

board on the ceiling mount?

• Was the AC 24 V power supply switched ON and

OFF repeatedly?

(The protection circuit may be activated when the

power is switched ON → OFF → ON within 5 sec.)

• Has the panning been rotated manually for cleaning, etc., while the power was on?

(The camera controls the panning position based

on the initial operation at the time the power is

turned on. If the camera position is changed manually after the initial operation. the preset camera

position is displaced.)

• Is there a problem with the power cables con-necting the camera to the power supply unit.

(If the power cables are too long or are of the wrong

size, the voltage may drop due to an increase in

resistance during the panning operation.)

Remedy

• Connect low resistance cables.

• Place the AC 24V power supply near to the camera.

(Check that the voltage supplied to the terminal

board is as rated when the camera is operating,

that is, when the rated current flows through it.)

• Connect cables properly.

• Once the AC 24 V po wer is switched OFF, it should

be switched ON again only after a lapse of more

than 5 seconds.

• Switch the camera power supply OFF then ON

again.

• Change the power cables to ones of a lower resistance

(i.e. thicker or shorter) cables.

• Place the AC 24V power supply near to the camera.

The remote

control unit does

not function.

Operation is

abnormally slow

when controlling

the unit with the

RM-P2580.

• Is the cable connected correctly?

• Are the dip switches set correctly?

• Is the cable (particularly the line connecting to TX+

and TX– of the camera) correctly connected to

the RM-P2580?

• The PROTOCOL (2) switch is set on the “Simplex” side b y mistake . Is it not? (Ref er to P age 6)

• Connect the cable correctly according to the instructions given in Page 9.

• Set the dip switches correctly according to the instructions given in Page 6, and turn the power on

again.

• Connect the cable correctly according to the instructions given in Page 9.

• Set the PROT OCOL (2) switch to the “Duple x” side.

22

Page 23

Specifications

■ CAMERA

Signal system : U type Based on NTSC standard

E type Based on PAL standard

Image device : 1/3"IT CCD

Effective picture:U type 380,000 pixels, 771 (H) × 492 (V)

E type

element

440,000 pixels, 753 (H) × 582 (V)

Sync system : Line lock/Internal

Video S/N : 48dB (Typ.)

Horizontal : 470 TV lines (Typ.)

resolution

Minimum : 3 lx (Typ. at F1.2)

illumination

Camera ID : 16 letters

White balance : ATW/Manual

■ LENS

Zoom ratio : ×16, f4.5 to f72mm

Iris range : F1.2 to F170 (suitable)

Zooming speed : Approx. 2 sec. (MAX)

Focus speed : Approx. 1 sec. (MAX)

■ External dimensions [Unit : mm]

■ MOVING MECHANISM

Panning : 360 degree endless

Tilting :0 to 90 degrees

Panning speed : 240 degree/sec, 80 degree/sec,

60 degree/sec, 40 degree/sec,

20 degree/sec, 12 degree/sec,

6 degree/sec, 4 degree/sec,

2 degree/sec

Tilting speed :

120 degree/sec, 60 degree/sec,

40 degree/sec, 30 degree/sec,

20 degree/sec, 10 degree/sec,

6 degree/sec, 2 degree/sec, 1 degree/sec,

■ GENERAL

Remote control input :RS-422A or RS-485 (non-isolated)

terminal

Power requirement : AC24V`, 50/60Hz

Power consumption :U type Approx. 23W

E type Approx. 1.4A

Operation temperature

range

Dimensions :Approx. 154mm diameter × 185mm

Mass :Approx. 2.0kg (with Ceiling mount)

Accessories :INSTRUCTIONS × 1

:–10°C to 50°C

(recommendation : 0°C to 40°C)

Ferrite core × 3

Ceiling mount × 1

87

ø154

1

ø152

ø143

ø152

)

T

L

I

T

(

˚

0

9

29

85

116

185

ø88

ø143

Ceiling

Ceiling mount hole

Screw

positions

Mounting hole ø90

113

113

Screw

positions

23

Page 24

TK-C675B COMBINATION CAMERA

is a registered Trademark owned by VICTOR COMPANY OF JAPAN, LTD.

is a registered Trademark in JAPAN, the U.S.A., the U.K. and many other countries.

© 1999 VICTOR COMPANY OF JAPAN, LIMITED

VICTOR COMPANY OF JAPAN, LIMITED

Printed in Japan

SC96898-001

Loading...

Loading...