Page 1

SERVICE MANUAL

COLOR VIDEO CAMERA

TK-C400U/TK-C400E/TK-C401EG

TK-C400U/E

COPYRIGHT © 1997 VICTOR COMPANY OF JAPAN, LTD.

(Lens is optional)

TK-C401EG

No. 6675

November 1997

Page 2

TABLE OF CONTENTS

Section Title PageSection Title Page

IMPORTANT SAFETY PRECAUTIONS

INSTRUCTIONS

1. SERVICE CAUTIONS AND DISASSEMBLY

1.1 REPLACEMENT OF FUSE ......................................... 1-1

1.2 CARD FIT CABLE .......................................................1-1

1.3 REMOVAL OF CIRCUIT BOARDS ............................. 1-1

REPLACEMENT OF COLOR CCD IMAGE SENSOR ..........

1.4

1.4.1 Removing of CCD image sensor ....................... 1-3

1.4.2 Installing of CCD image sensor ......................... 1-4

2. ELECTRICAL ADJUSTMENTS

2.1 REQUIRED MEASURING INSTRUMENTS FOR

ADJUSTMENTS ......................................................... 2-1

2.1.1 Required measuring instruments for

adjustments ...................................................... 2-1

2.1.2 Applicable lens for adjustments ........................2-1

2.1.3 Required system for adjustments ..................... 2-2

2.1.4 Required instruments for adjustment ............... 2-2

2.2 STANDARD SETUP .................................................... 2-3

2.3 SWITCH SETTING FOR ADJUSTMENT ..................... 2-3

2.4 NOTES ....................................................................... 2-4

2.4.1 Installation ......................................................... 2-4

2.4.2 How to adjusting the EVR .................................2-4

2.4.3 What is “Initial Data” ........................................ 2-4

2.4.4 How to write adjusted data to EEPROM in

camera .............................................................. 2-4

2.5 INITIALIZE ..................................................................2-5

2.6 ADJUSTMENT OF SSG ............................................. 2-5

2.7 ADJUSTMENT OF CCD ............................................. 2-6

2.8 ADJUSTMENT OF VIDEO SIGNAL ............................2-7

2.9 ADJUSTMENT OF WHITE BALANCE ........................ 2-9

2.10 ADJUSTMENT OF CHROMA SIGNAL ..................... 2-12

2.11 WRITE DATA ...........................................................2-12

1-3

4. EXPLODED VIEW AND ASSEMBLY PARTS LIST

4.1 ASSEMBLY ................................................................ 4-1

5. ELECTRICAL PARTS LIST

5.1 CCD BOARD ASSEMBLY PARTS LIST 01 ................ 5-2

5.2 PRO BOARD ASSEMBLY PARTS LIST 02 ................ 5-2

5.3 EE BOARD ASSEMBLY PARTS LIST 03 ................... 5-5

5.4 TERMINAL BOARD ASSEMBLY PARTS LIST 04...... 5-5

5.5 PS BOARD ASSEMBLY PARTS LIST 05 ................... 5-6

5.6 POWER BOARD ASSEMBLY PARTS LIST 06 .......... 5-7

6. PACKING ........................................................................6-1

3. CHARTS AND DIAGRAMS

3.1 BLOCK DIAGRAM ..................................................... 3-2

3.2 CCD BOARD SCHEMATIC DIAGRAM ....................... 3-3

3.3 CCD CIRCUIT BOARD ............................................... 3-3

3.4 PRO BOARD SCHEMATIC DIAGRAM ....................... 3-4

3.5 PRO CIRCUIT BOARD ............................................... 3-5

3.6 EE BOARD SCHEMATIC DIAGRAM .......................... 3-6

3.7 EE CIRCUIT BOARD .................................................. 3-7

3.8 TERMINAL BOARD SCHEMATIC DIAGRAM ............ 3-7

3.9 TERMINAL CIRCUIT BOARD ..................................... 3-7

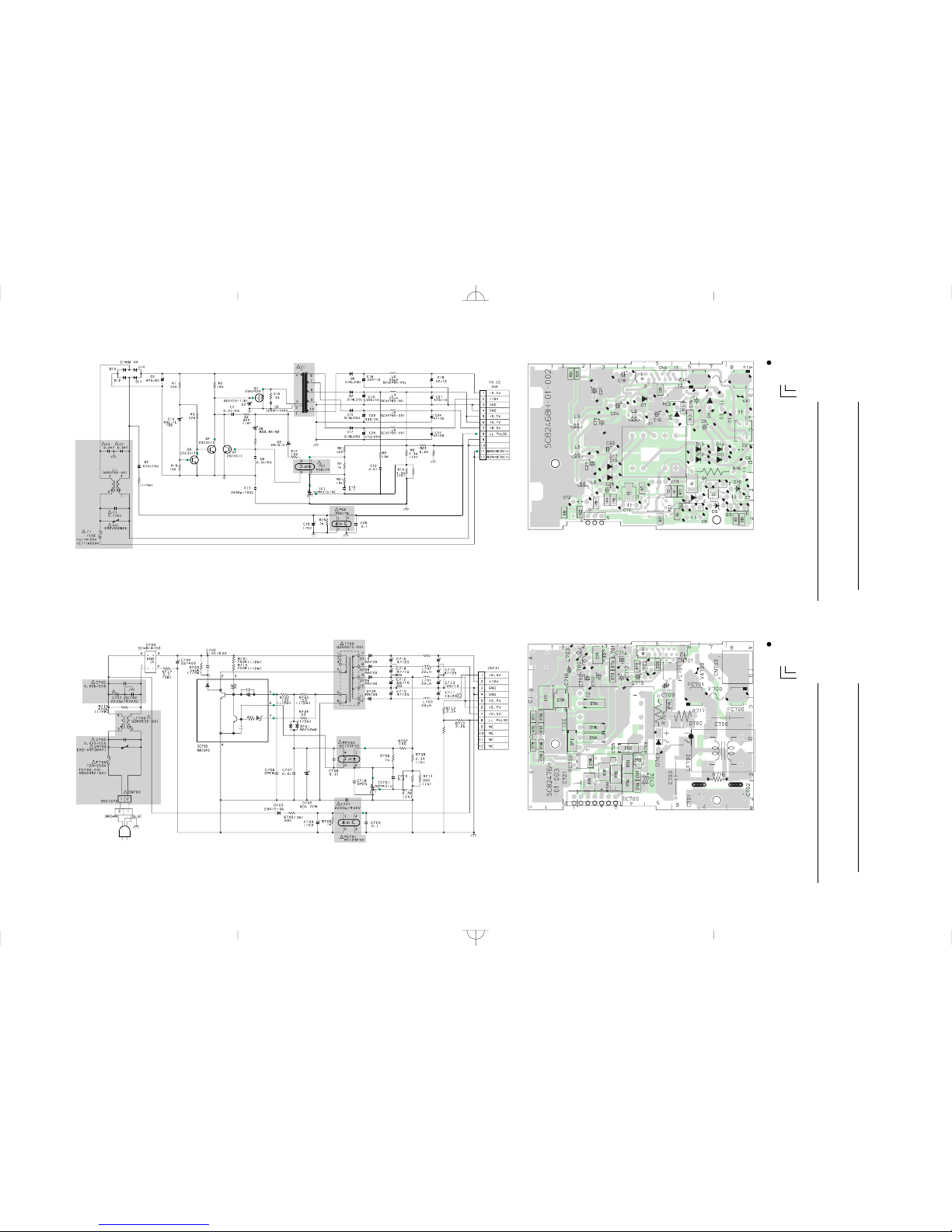

3.10 PS BOARD SCHEMATIC DIAGRAM

(TK-C400U/TK-C400E) ................................................ 3-8

3.11 PS CIRCUIT BOARD (TK-C400U/TK-C400E) .............. 3-8

3.12 POWER BOARD SCHEMATIC DIAGRAM

(TK-C401G) .................................................................3-8

3.13 POWER CIRCUIT BOARD (TK-C401G) ...................... 3-8

3.14 BLOCK DIAGRAM of IC’S

Page 3

Important Safety Precautions

Connector

Metal sleeve

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

symbol and shaded ( ) parts are

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

15 mm

7. Observe that wires do not contact heat producing parts

8. Check that replaced wires do not contact sharp edged or

9. When a power cord has been replaced, check that 10-15 kg of

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

Fig.1

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

pointed parts.

force in any direction will not loosen it.

Power cord

Fig.2

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

Page 4

p

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and

externally exposed parts of the set (RF terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed

accessible parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Chassis

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in,

Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

AC inlet

Earth pin

Exposed accessible part

Grounding Specifications

Region

USA & Canada

Europe & Australia

Externally

exposed

accessible

Grounding Impedance (Z)

d

d'

art

≤

Z 0.1 ohm

≤

Z 0.5 ohm

Power cord,

primary wire

Z

V

Fig. 9

ab

c

A

Milli ohm meter

Fig. 10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Region

Japan R 1 MΩ/500 V DC

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Region Load Z

Japan

USA & Canada

Europe & Australia

Table 2 Leakage current specifications for each region

Insulation Resistance (R)

≤

–

≤

Table 1 Specifications for each region

1 kΩ

0.15 µF

1.5 kΩ

2 kΩ

50 kΩ

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 900 V 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

i 1 mA rms Exposed accessible parts

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

≤

≤

≤

≤

≤

≤

(Class 2)

(Class 1)

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

a, b, cLeakage Current (i)AC Line Voltage

Exposed accessible parts

Antenna earth terminals

Other terminals

2

Page 5

SECTION 1

B

B

2

2

TK-C401TK-C400

SERVICE CAUTIONS AND DISASSEMBLY

1.1 REPLACEMENT OF FUSE

Before replacing the fuse, the reason why it blew should be

investigated to prevent trouble from spreading. The malfunction should be repaired before replacing the fuse.

When replacing the fuse, make sure to disconnect the power

supply from the camera beforehand and to replace it with new

one of the specified part number for safety and protection of

the set.

1) Remove two screws 1, and then open the rear panel A and

escutcheon B.

1

1

2) Then, a fuse F1 on the PS/POWER board is exposed.

PS board

A

Fig. 1-1

F1

1

B

POWER board

1

TK-C401TK-C400

B

1.2 CARD FIT CABLE

Pay careful attention to the connecting side of the card fit cable. When connecting it, insert it so as to contact the copper

leaf on its edge to the connector's conductive surface as shown

in Fig. 1-3.

When disconnecting the card fit cable, pull the cable stoppers

in the direction of the arrows. To secure the connection, push

the cable stoppers in the reverse direction of the arrows after

inserting the cable.

A

Fig. 1-3

1.3 REMOVAL OF CIRCUIT BOARDS

1) Remove three screws 2 and then detach the bottom cover

B.

TK-C400

When replacing a fuse, make sure to use new one of the specified part number for safety and protection of the set.

Symbol

No.

!F1 1A-125V QMF51U1-1R0 TK-C400U

!F1 T1A-250V QMF51E2-1R0 TK-C400E

!F1 T2A-250V QMF51E2-2R0 TK-C401EG

Rating Parts No. Note

TK-C401

Fig. 1-2

Fig. 1-4

1-1

Page 6

2) Remove two screws 3.

5) Disconnect a connector F, then remove the EE board.

3

PRO board

D

C

Fig. 1-5 Removal of PRO board

3) Disconnect the connector C and D, and then remove the

PRO board.

F

Fig. 1-7

6) Remove a screw 5, then remove the TERMINAL board with

rear panel G.

In case of TK-C401, remove a screw 6 and connector H

before removing the TERMINAL board.

4) Remove a screw 4 and disconnect a connector E, then lift

the EE board.

EE board

E

4

Fig. 1-6 Removal of EE board

G

G

55

TK-C400 TK-C401

Fig. 1-8 Removal of TERMINAL board

TERMINAL board

6

G

1-2

H

Fig. 1-9 Removal of TERMINAL board (TK-C401)

Page 7

7) Remove a screw 7, then slide the PS/POWER board in the

direction of arrow to remove it.

7

Fig. 1-10 Removal of PS/POWER board (1)

8) Remove two screws 8, then remove the heat sink J and

chassis K.

1.4 REPLACEMENT OF COLOR CCD IMAGE SENSOR

䡵 The CCD image sensor is not interchangeable with any-

thing other than the specified one.

䡵 Be careful in handling a new image sensor neither to leave

fingerprints on the glass surface nor to make it stained with

grease.

To clean dust and greasy stain, breathe out to mist the glass

surface and gently wipe it with cotton swab, etc. (Do not

use alcohol and the like.)

䡵 After replacement of the CCD image sensor, the camera

needs to undergo electrical adjustment.

䡵 The image sensor has a weak characteristic in electrostatic

destruction. When replacing, make sure of electrostatic

shielding of the CCD image sensor.

䡵 For a while after removing the image sensor, there are elec-

tric charge remaining at the circuit terminals. If a new image sensor is set into the socket in such a condition, it may

damage it in a moment because of stored electric charge.

When replacing the image sensor, wait a few (2 to 3) minutes after removing it before setting new one into the

socket.

PS/POWER board

8

J

K

Fig. 1-11 Removal of PS/POWER board (2)

1.4.1 Removing of CCD image sensor

1) Remove the bottom cover.

(See the subsection 1.3.1))

2) Disconnect the connector L.

L

Fig. 1-12

1-3

Page 8

3) Remove two screws 9, then remove the front frame M.

9

1.4.2 Installing of CCD image sensor

Note:

Before installation, take notes of the code of the CCD

image sensor. It needs to refer to this code for adjustment.

1st. pin Index

V

RGL

code

V

SUB

code

M

Fig. 1-13

4) Remove two screws 10, and then the CCD board has removed with the CCD image sensor.

10

CCD board

Fig. 1-14

5) Detach the CCD image sensor and sensor holder N slowly

in the direction of the arrow.

ICX0**AK-

A

1) When installing the CCD image sensor, pay attention to its

orientation.

2) For installing a new CCD image sensor to the set, perform

reassembling parts in the reverse order of removing.

3) Adjust the V

SUB and VRGL voltage. (See subsection 2.7)

Fig. 1-15

1-4

N

CCD board

Page 9

SECTION 2

ELECTRICAL ADJUSTMENTS

To change the setting of adjustment items, use a computer with the adjustment software to change the set value of the EVR for each

adjustment item as well as to store the changed data into the memory of the camera. If any of the following parts is replaced or the

camera needs to adjust settings of itself such as auto white balance, etc., it requires adjustment of the EVR with a computer.

• CCD board

IC 200 CCD Image sensor ICX 054AK-A: for TK-C400U

ICX 055AK-A: for TK-C400E/TK-C401EG

• PRO board

IC205 EEPROM AK6420AM

2.1 REQUIRED MEASURING INSTRUMENTS FOR ADJUSTMENTS

2.1.1 Required measuring instruments for adjustments

Instrument

Oscilloscope

Frequency counter

2.1.2 Applicable lens for adjustments

• Manual zoom

• Manual iris

• Filter diameter

The infinity adjustment lens (YTU92001B) is provided with five kinds of screw-in adapters that make it attachable to camera

lenses of five different filter sizes (∅=37, 43, 46, 49 and 52 mm, pitch=0.75 mm each). Use a camera lens whose filter size is any

of the above-mentioned diameters. If is desirable to use a zoom lens that covers the focal length of 20-40 mm (for to the 2/3-inch

image size) or so as an intermediate focal length of its zoom ratio.

• Recommended lens (example)

Capable of measuring 100MHz or

higher bands and calibrated.

Readable in 8 or more digits. Constancy

of 0.1 ppm/1 x 10-7 or more at 0°C to

40°C.

Condition

Focal point

Lens

Flange-back

Instrument

Vectorscope

Digital voltmeter

Lens

C mount lens

CS mount lens

Condition

Must be calibrated.

Input impedance of 10 M ohm or more,

and calibrated.

Flange back

17.526 mm

12.5 mm

Dimension L

10 mm or less

5.5 mm or less

MODEL J6 x 11-

Manufacture CANON FUJINON

Focal length 11.5 - 69 mm 12.5 - 75 m

Zoom ratio 6:1 6:1

Zoom operation Manual Manual

Iris range F1.4 to close F1.2 to close

Iris control Manual Manual

Mount C mount C mount

Filter diameter ∅46 mm P = 0.75 mm ∅52 mm P = 0.75 mm

Note: Set the camera’s back focus adjustment ring to the position appropriate for the camera lens to be used. (Refer to the instruc-

tions.)

22

2 (HZ-H8061) H6 x 12.5R

22

2-1

Page 10

2.1.3 Required system for adjustments

Equipments Specifications

Computer 486DX4/100MHz or higher micro processor (Recommended Pentium Processor)

Operating system Windows 95 or Windows NT 3.51

Memory 16M Byte or more

FDD 3.5 inch (1.44 MB) floppy diskette drive

I/O port Serial port

Hard disk unit 1 MB hard disk space

2.1.4 Required instruments for adjustment

Program disk

(For IBM-PC)

PLSC1215

Infinity adjustment lens

YTU92001B

Light box

YTU93072

Lens*

(Ex: HZ-H8061)

Color bar chart

YTU92001-051

Interface cable

(For IBM-PC)

YTU93063

Gray scale chart

YTU92001-052

Color temp. Conversion filter* Waveform monitor (W.F.M.)*

(Example)

KODAK Wratten gelatin filter

• No. 80B + No. 80B (or equivalent)

• No. 80D + No. 82A (or equivalent)

• No. 81A + No. 81D (or equivalent)

Conversion cable

YTU94066

White balance chart

YTU92001-053

Note: Equipments marked with asterisk are not handled by parts department.

2-2

Page 11

2.2 STANDARD SETUP

Supply power

AC 24V/DC 12V

TK-C400

REAR

PANEL

DC output

Interface

terminal

TK-C401EG

REAR

PANEL

75 ohm

terminator

Supply power

AC230V

Vetorscope Waveform

monitor (WFM)

Color monitor

75 ohm

terminator

Oscilloscope

PLSC1215

Computer

Windows 95 or NT

2.3 SWITCH SETTING FOR ADJUSTMENT

REAR PANEL

SW100

• SW100 (TERMINAL BOARD)

PHASE/W.B

LL/INT.

ATW/MANU

BLC ON/OFF

AES ON/OFF

AGC ON/OFF

VR500S500

W.B

INT

ATW

OFF

OFF

ON

2-3

Page 12

2.4 NOTES

2.4.1 Installation

To install the adjustment program, perform the following procedure.

1) If you have any programs currently installed in the serial I/O

port, remove them.

2) Insert the adjustment program diskette into a floppy diskette

drive.

3) From Windows 95, select “Run” from the “Start” button

and type “a:\setup (or b:\setup)” depending on which drive

contains the diskette.

4) Follow the instructions on the screen.

2.4.2 How to adjusting the EVR

Click the “䊱” or “䊲” button to the right of the adjustment

items displayed on the screen to adjust EVR to the required

value.

2.4.3 What is “Initial Data”

The initial data loaded at “2.5 INITIALIZE” consists of preset

adjustment values. Therefore, once the adjustment procedure

is started, all adjustment should be done from beginning to the

end. Otherwise, the preset adjustment values would be written

as the adjustment data.

2.4.4 How to write adjusted data to EEPROM in camera

The adjustment values are written in the EEPROM of the camera when you click “YES” from the “Are you sure to write

EEPROM?” message box which is displayed at the end of the

adjustment.

These buttons

If you abort the adjustment in the middle, the adjustment

values in the camera are not changed (the adjustment values which have been set before the start of the adjustment

remain unchanged).

2-4

Page 13

No.

Item Mode Adjustment procedure

2.5 INITIALIZE

Measuring

instrument &

Input signals

Measuring point (*)

Adjustment parts (-)

Adjustment level (+)

1) Select either “TK-C400U.cor” for TK-C400U

or “TK-C400E.cor” for TK-C400E/401EG to on

Scenario file define adjustment.

2) Selecting either “NEXT” or “BACK” button

to be initialized the camera data.

All EVR are installed the initial data. (See 2.4.3)

2.6 ADJUSTMENT OF SSG

1 fsc

adjustment

Frequency

counter

*

TP207 [PRO]

-

EVRUSR

[CAT: CLAMP, Byte: 5]

+

U-ver. 3.579545MHz

E-ver. 4.43361875MHz

1) Select the “NEXT” button to display “fsc ad-

justment” on the title bar.

2) Adjust the EVRUSR with “䊱” and “䊲” buttons

to obtain the specified level at the measuring

point.

2-5

Page 14

Measuring

No.

Item Mode Adjustment procedure

instrument &

Input signals

2.7 ADJUSTMENT OF CCD

Measuring point (*)

Adjustment parts (-)

Adjustment level (+)

1 VSUB voltage

adjustment

2 Reset voltage

adjustment

Digital voltmeter *

Oscilloscope

(H-rate:10:1)

TP205 [PRO]

-

VSUB [CAT: DCREF,

Byte: 3]

+

Specified voltage on

the back of the CCD.

*

TP214 [PRO]

-

VRGL [CAT: DCREF,

Byte:4]

+

Specified voltage on

the back of the CCD.

1) Select the “NEXT” button to display “VSUB

voltage” on the title bar.

2) Adjust the VSUB with “䊱” and “䊲” buttons to

obtain the specified level at the measuring

point.

Note:

For the specified voltage, check on the VRGL

and VSUB codes shown on the back of the

CCD, and find out the proper value according to the correlation table of the “How to

Find Specified Voltage” as shown below.

1) Select the “NEXT” button to display “Reset

voltage” on the title bar.

2) Adjust the VRGL with “䊱” and “䊲 ” buttons to obtain the specified level at the measuring point.

How to Find Specified Voltage

Note:

For the specified voltage, check on the V

RGL

and VSUB codes shown on the back of the

CCD, and find out the proper value according to the correlation table of the “How to

Find Specified Voltage” appearing in the

lower part of this page.

2-6

Page 15

Measuring

No.

Item Mode Adjustment procedure

instrument &

Input signals

2.8 ADJUSTMENT OF VIDEO SIGNAL

Measuring point (*)

Adjustment parts (-)

Adjustment level (+)

1 White clip

adjustment

2 Contour level

adjustment

Oscilloscope

(H-rate: 10:1) or

W.F.M.

Gray scale chart

(Just scan size)

Oscilloscope

(H-rate: 10:1) or

W.F.M.

Gray scale chart

(Just scan size)

LENS OPEN

*

VIDEO OUT (75 ohm

Termination)

-

DAVREFY

[CAT: DCREF, Byte: 1]

+

U-ver.

0.79 Vp-p (110 IRE)

E-ver.

0.77 Vp-p (110%)

*

VIDEO OUT (75 ohm

Termination)

-

LENS IRIS

+

U-ver.

0.57 Vp-p (80IRE)

E-ver.

0.56 Vp-p (80%)

1) Select the “NEXT” button to display “White

clip” on the title bar.

2) Turn the lens iris so that the wavefrom of

grayscele is saturated as shown left figure.

3) Adjust the DAVREFY with “䊱” and “䊲” buttons to obtain the specified level at the measuring point.

1) Select the “NEXT” button to display “Con-

tour level” on the title bar.

2) Adjust the lens iris to obtain the specified level

at the measuring point.

*

VIDEO OUT (75 ohm

Termination)

-

VHAPGH

[CAT: FIELD, Byte: 3]

+

U-ver.

0.714 Vp-p (100IRE)

E-ver.

0.7 Vp-p (100%)

3) Adjust the VHAPGH with “䊱” and “䊲” buttons to obtain the specified level at the measuring point.

2-7

Page 16

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point (*)

Adjustment parts (-)

Adjustment level (+)

3 Setup level

adjustment

4 Burst level

adjustment

Oscilloscope

(H-rate: 10:1) or

W.F.M.

Oscilloscope

(H-rate, 10:1) or

W.F.M.

*

VIDEO OUT

(75 ohm Termination)

-

SETUP

[CAT: Fix, Byte: 3]

50 mVp-p

+

*

VIDEO OUT

(75 ohm Termination)

-

DAVREFC

[CAT: DCREF, Byte: 2]

+

U-ver.

286 mVp-p (40IRE)

E-ver.

300 mVp-p

1) Select the “NEXT” button to display “Setup

level” on the title bar.

2) Turn the lens iris to be closed.

3) Adjust the SETUP with “䊱” and “䊲” buttons to obtain the specified level at the measuring point.

1) Select the “NEXT” button to display “Burst

level” on the title bar.

2) Adjust the DAVREFC with “䊱” and “䊲” buttons to obtain the specified level at the measuring point.

2-8

Page 17

Measuring

No.

Item Mode Adjustment procedure

instrument &

Input signals

2.9 ADJUSTMENT OF WHITE BALANCE

Measuring point (*)

Adjustment parts (-)

Adjustment level (+)

1 White

balance

adjustment(1)

Gray scale chart

Oscilloscope

(H-rate, 10:1) or

W.F.M

Auto-white balance (1)

Oscilloscope or Waveform monitor

*

VIDEO OUT

(75 ohm Termination)

-

LENS IRIS

+

U-ver.

E-ver.

MCRDIP = 1

MCRAE = 1

AWBCNT = &H8229

INTGR = &H4B6151

0.714 Vp-p (100IRE)

0.7 Vp-p (100%)

1) Select the “NEXT” button to display “White

balance (1)” on the title bar.

2) Adjust the lens iris to obtain the specified level

of white chip at the measuring point.

3) Press either “䊱” or “䊲” button of the

“AWBPRER”, then “AWBCNT” and “INTGR”

data are appeared in the “Show Controls”

box.

4) Press the “䊱” or “䊲” button of the

“AWBPRER” to be same data of AWB CNT’s

data. (last 2 digit)

5) Press the “䊱” or “䊲” button of the “WBR”

to be the same data of AWB CNT’s data. (last

2 digit)

6) Press the “䊱” or “䊲” button of the

AWBPREB to be the same data of INTGR’s

data. (last 2 digit)

7) Press the “䊱” or “䊲” button of the WBB to

be same data of INTGR’s data. (last 2 digit)

2 White

balance

adjustment(2)

AWBPRER WBR AWBPREB WBB

&H29 &H51 &H51&H29

*

Gray scale chart

filter

(No. 80B+80B)

VIDEO OUT

(75 ohm Termination)

-

LENS IRIS

Oscilloscope

(H-rate, 10:1) or

W.F.M.

+

U-ver.

E-ver.

0.714 Vp-p (100IRE)

0.7 Vp-p (100%)

1) Select the “NEXT” button to display “White

balance (2)” on the title bar.

2) Adjust the lens iris to obtain the specified level

of white chip at the measuring point.

3) Press the “䊱” or “䊲” button of the PRE2R,

then AWB CNT and INTGR data are appeared

in the Show Controls box.

4) Press the “䊱” or “䊲” button of the PRE2R

to be same data of AWB CNT’s data. (last 2

digit)

5) Press the “䊱” or “䊲” button of the PRE2B

to be same data of INTGR’s data. (last 2 digit)

2-9

Page 18

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point (*)

Adjustment parts (-)

Adjustment level (+)

3 White

balance

adjustment(3)

Gray scale chart

filter

(No. 80D+82A)

Oscilloscope

(H-rate, 10:1) or

W.F.M

*

VIDEO OUT

(75 ohm Termination)

-

LENS IRIS

+

U-ver.

0.714 Vp-p (100IRE)

E-ver.

0.7 Vp-p (100%)

1) Select the “NEXT” button to display “White

balance (3)” on the title bar.

2) Adjust the lens iris to obtain the specified level

of white chip at the measuring point.

3) Press the “䊱” or “ 䊲” button of the

PRESETMWR, then AWBCNT and INTGR

data are appeared in the Show Controls box.

4) Press the “䊱” or “ 䊲” button of the

PRESETMWR to be same data of AWB CNT’s

data. (last 2 digit)

5) Press the “䊱” or “ 䊲” button of the

PRESETMWB to be same data of INTGR’s

data. (last 2 digit).

4 White

balance

adjustment (4)

Gray scale chart

filter

(No. 81A+81D)

*

VIDEO OUT

(75 ohm Termination)

-

LENS IRIS

+

U-ver.

0.714 Vp-p (100IRE)

E-ver.

0.7 Vp-p (100%)

1) Select the “NEXT” button to display “White

balance (4)” on the title bar.

2) Adjust the lens iris to obtain the specified

level of white chip at the measuring point.

3) Press the “䊱” or “䊲” button of the

RLOGAIN, then AWBCNT data are appeared

in the “Show Controls” box.

4) Press the “䊱” or “䊲” button of the

RLOGAIN to be same data of AWBCNT’s

data. (last 2 digit)

2-10

Page 19

No.

Measuring

Item Mode Adjustment procedure

instrument &

Input signals

Measuring point (*)

Adjustment parts (-)

Adjustment level (+)

5 White

balance

adjustment (5)

White balance

chart

filter

(No.80B+80B)

Oscilloscope

(H-rate, 10:1) or

W.F.M.

*

VIDEO OUT

(75 ohm Termination)

-

LENS IRIS

+

Center of carrier

U-ver.

0.357 Vp-p (50IRE)

E-ver.

0.35 Vp-p (50%)

1) Select the “NEXT” button to display “White

balance (5)” on the title bar.

2) Adjust the lens iris to obtain the specified level

of center of carrier at the measuring point.

3) Press the “䊱” or “䊲” button of the PRERBL,

then AWBCNT and INTGR data are appeared

in the “Show Controls” box.

4) Press the “䊱” or “䊲” button of the PRERBL

to be same data of AWBCNT’s data. (last 2

digit)

5) Press the “䊱” or “䊲” button of the PRERBM

to be same data of AWBCNT’s data. (Middle

2 digit)

6) Press the “䊱” or “䊲” button of the

PRERBGL to be same data of INTGR’s data

(last 2 digit)

7) Press the “䊱” or “䊲” button of the

PRERBGM to same data of INTGR’s data. (3rd

and 4th digit from right)

Auto-white balance (5)

Oscilloscope or Waveform monitor

PRERBL PRERBM PRERBGL PRERBGM

&H71 &HA7 &H0A&HE5

AWBCO = 2

AWBCNT = &HE571

INTGR = &H220AA7

2-11

Page 20

Measuring

No.

Item Mode Adjustment procedure

instrument &

Input signals

2.10 ADJUSTMENT OF CHROMA SIGNAL

Measuring point (*)

Adjustment parts (-)

Adjustment level (+)

1 Color level

and hue

adjustment

Yellow

Oscilloscope

(H-rote, 10:1) or

W.F.M.

Color bar chart

Red

Yellow

*

VIDEO OUT

(75 ohm Termination)

-

LENS IRIS

+

U-ver.

0.57 Vp-p (80IRE)

E-ver.

0.56 Vp-p (80%)

-

RY GAIN

[CAT: FIELD, Byte: 8]

-

RYHUE

[CAT: FIELD, Byte: 10]

-

BYGAIN

[CAT: FIELD, Byte: 9]

-

BYHUE

[CAT:FIELD, Byte:11]

Red

1) Select the “NEXT” button to display “Color

level and Hue” on the title bar.

2) Adjust the lens iris to obtain the specified level

of white part at the measuring point.

3) Adjust the RYGAIN, RYHUE, BYGAIN and

BYHUE with “䊱” and “䊲” buttons to obtain

the specified position at the measuring position.

2 Chroma

suppress

adjustment

2.11 WRITE DATA

1 Write data

[NTSC] [PAL]

Oscilloscope

(H-rate, 10:1) or

W.F.M

Gray scale chart

LENS OPEN

*

VIDEO OUT

(75 ohm Termination)

-

CSHLV

[CAT: FIELD, Byte: 4]

+

Minimum carrier

leakage.

1) Select the “NEXT” button to display “chroma

suppress at high light” on the title bar.

2) Turn the lens iris so that the wevefome of

gray scale is saturated as shown left figure.

3) Adjust the CSHLV with “䊱” and “䊲” buttons to minimize carrier leakage on saturated

signal.

1) Select the “NEXT” button to display “Write

data to the EEPROM” on the title bar.

2) Press the “NEXT” button, then message box

are appeared.”Are you sure to write EEPROM?”

3) Select the “YES” button to write all data just

adjusted to memory in camera.

2-12

Page 21

TK-C400U/TK-C400E/TK-C401EG

VICTOR COMPANY OF JAPAN, LIMITED

No. 6675

Printed in Japan

(S) T. A

Page 22

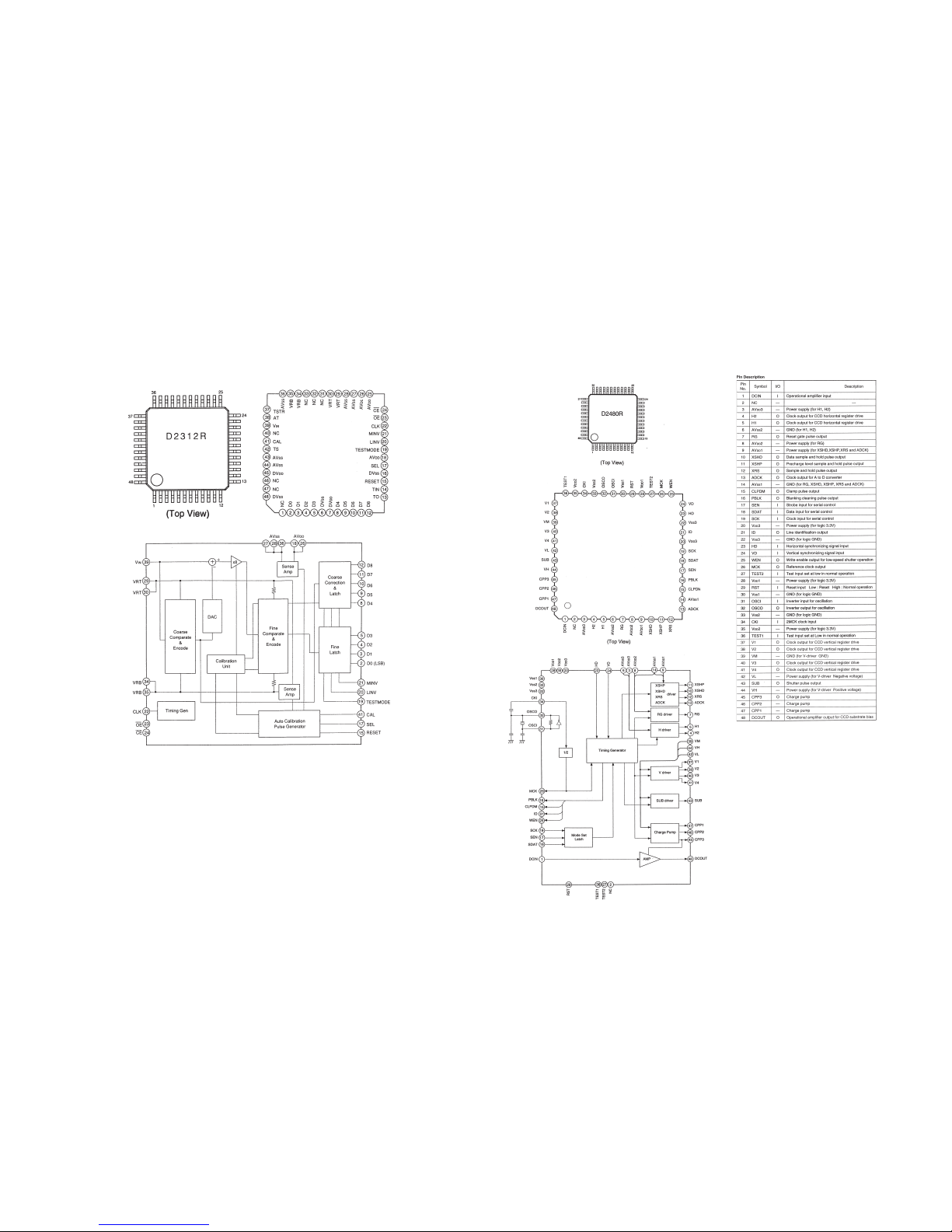

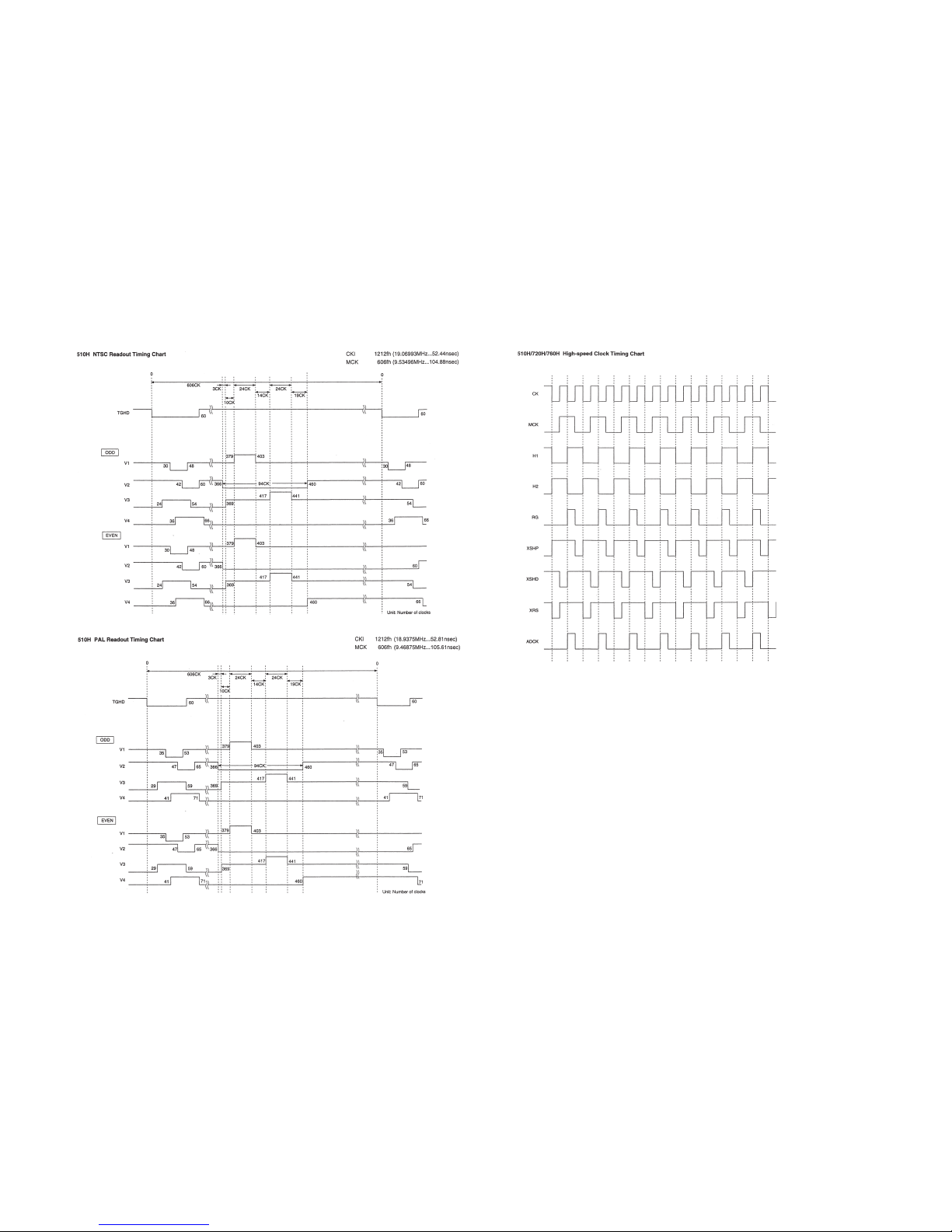

SECTION 3

CHARTS AND DIAGRAMS

䡵 REPLACING SUBMINIATURE “CHIP” PARTS

• Some resistors, shorting jumpers (0 ohm resistance), ceramic

capacitors, transistors, and diodes are chip parts. These chip

parts cannot be reused after they are once removed.

• Chip resistors used in some circuits are of high precision

type having little error in resistance.

To demonstrate the full capacity of this camera head, place

an order for proper parts referring to the diagrams and parts

lists in the sections 5.

• Soldering cautions:

1) Do not apply heat for more than 3 seconds.

2) Avoid using a rubbing stroke when soldering.

3) Discard removed chips; do not reuse them.

4) Supplementary cementing is not required.

5) Use care not to scratch or otherwise damage the chips.

• Definistion of the (A) and the (B) or circuit boards diagrams

(A) : Side on which discrete parts are assembled.

(B) : Side on which only chip parts are assembled.

• Transistors are:

䡵 SCHEMATIC DIAGRAM NOTES

• Schematic safety precaution

! Parts are safety related parts.

When replacing them, be sure to use the specified parts.

• Voltage and waveform measurements.

Voltage: Measured with digital voltmeter in DC range;

iris closed.

• Waveform: Color bars illuminated more than 4000lux at

3200K lighting.

• Terminal logic

Top bar of terminal name show input or output logic.

Top bar shows, the control circuit become active at negative (low) logic input for example.

B

C

E

2SA1576A

MSB1218A

B

C

E

2SC4681

MSD1819A

C

B

E

1

2

3

1

2

3

6

5

4

6

5

4

E

E

B

E

E

E

E

B

B

C

B

B

C

C

C

C

B

C

XP6401

XP6534

3-1

3-1

Page 23

BLC SW10

V11

V22

V33

V44

H25

H16

RG7

Vsub8

V1 16

V2 15

V3 14

V4 13

H2 12

H1 11

RG 10

Vsub 9

VIDEO IRIS11

DC IRIS16

VBS OUT7

Rxd4

Txd2

LL SW6

IC217

IC217

CP

15

10

9

4

P. BLK

SYNC

Drive

IC215

LPF

Q215/Q216

+

AMP

3

1

8

IC213

Y-Process

DL1

DL02

MCRCON

FSC

PRE

C-Process

VSPRS/HLSPRS

OPD

AE

Y-AE

C-WB

SYNC

SG

SCS

SW-IF

AWB

DOUT

D/AGAINGAM

1HDL

A/D

PG

1HDL

BLK

DADJ

APAC

GAIN

HLAPAC

GAIN

HL

APAC

VH

APAC

Y-INTG

(

5wind

)

HIST-CNT

HIST-INTG

(

2ch

)

RGB-CNT

RGB-INTG

LPF

CLMP

OB

DET

SYNC

GEN

SYNC

SEP

MASTER

HD GEN

REF

GATE

LPF

CLMP

LN

MTX

RGB

MTX

WB GAM

DOUT

ENC D/A

SYS

MAN

DIP

SW

EXT-SIF

・RS232C

・IICOM

DO

IC205

DI

DI

IC206

CAM-SIF

・TG・EVR

・EEPROM

YC

SPRS

INIT SG

AWBAE

CLMP

VH

PHASE

COMP

EXT

SYNC

DET

FSC

PHASE

COMP

WIND

GEN

+

INTERNAL BUS

10

XSHO

11

XSHP

30

Vss1

33

Vss2

22

Vss3

34

32

OSCO

31

26

MCK

16

PBLK

15

CLPDM

21

ID

25

WEN

19

SCK

17

SEN

18

SDAT

1

DCIN

12

XRS

13

ADCK

38

V2

37

V1

40

V3

44

VH

39

VM

42

VL

41

V4

7

RG

5

H1

4

H2

43

SUB

47

CPP1

48

CPP2

45

CPP3

48

DCOUT

983

VD

24

HD

23203528

RST

29

TEST1

36 27NC2

AMPAMP

XSHP

XSHD

XRS

ADCK

driver

RG driver

H driver

V driver

Timing Generator

1/2

SUB driver

Change

Pump

Mode Set

Latch

146

25

PIN

26

DIN

27

Vcc2

28

N.C.

29

LIN/CH

30

GND2

31

RFCONT

32

PBRFC

CAM/VIDEO

1

PB/REC

2

CH/CL

3PS4

VSHP

5

GND3

6

LOUTCLP

7DR8

16

AGCCLP

15

CLPOB

14

XRS

13

PBLK

12

OFFSET

11

VRT

10

VRB

9

Vcc3

CLPDM24GND123SHO22SHP21Vcc120CCDLEVEL19AGCCONT18Vcc4

17

SH1 SH2

SH3

COSCLP1

COSCLP2

LIN CLP

LIN/CH SW

V1 SW

C/V SW

OFFSET

SW

CENTER BIAS

CENTER BIAS

VISH

GCA

AMP

AGC LPF CAMSH

AGCCLP

BLK

DRV

CH/CL

DC

REF

BOTTOM

REF

TOP

MODE SWITCHING LOUTCLP

Fine

Comparate

&

Encode

Coarse

Correction

&

Latch

Calibration

Unit

Auto Calibration

Pulse Generator

Sense

Amp

Fine

Latch

Coarse

Comparate

&

Encode

DAC

Timing Gen

12

D8

11

D7

10

D6

9

D5

8

D4

5

D3

4

D2

3

D1

2

D0(LSB

)

21

MINV

20

LINV

19

TESTMODE

41

CAL

17

SEL

15

RESET

AVss AV

DD

362827

Sense

Amp

1826

39

V

IN

29

VRT

30

VRT

34

VRB

35

VRB

22

CLK

23

OE

24

CE

+

x8

Y

C

VCO

EVR

Vref Y/Vref C

<AGC CONT/OFFSET>

<V Sub>

14

12

IC208

LPF

LPF

CN200

IC200

CCD

Drive pulse

Vsub

Q201

1CCD OUT6

Vref C

Vref Y

IO C

IO Y

5

1

6

7

Sampling pulse

85 93

63

20

15

21

26

72

73

14

3

Voo1

Voo2

Voo3

AVss3

AVoo3

AVoo2

AVoo1

AVss1

Buffer

CCD BOARD

11

PRO BOARD

CN200

CK1

TEST2

OSCI

IC202

Shutter

Pulse

3

5

I

O

Buffer

1

2

I

O

Buffer

ON/OFF

Buffer

Filter

IC203

DRVOUT

IC204

O

I

IC207

4

EEPROM

INT/LL

+

-

+

PHASE-/WBR

PHASE+/WBB

BLOCK DIAGRAM3.1

3-2 3-2

Page 24

8.5

15.0

9.2

12.5

-7.9

5.0

2.62.6

2.3

0000

CCD

3-3 3-3

CCD BOARD SCHEMATIC DIAGRAM

CCD CIRCUIT BOARD

. SIDE A .

. SIDE B .

Note : The parts in ( ) are not mounted on the board.

3.2

3.3

TP200

200mV/DIV, 10U/DIV

216

115

1

16

9

8

(

CN201

)

Page 25

-8.6

0

-7.9

19.2

15.1

0

0

0

0

0

-7.9

-7.9

15.2

22.3

14.0

21.0

12.6

2.9

4.9

0

2.3

0.7

4.9

4.9

3.9

3.3

3.2

0

3.3

1.4

0

1.7

1.5

0

3.3

3.3

0

0.7

3.2

2.9

0

1.6

3.3

2.7

3.2

0.6

3.1

0

3.0

2.9

0

3.0

3.3

0

2.1

3.3

3.4

3.4

2.9

2.8

3.1

3.2

2.7

1.2

4.1

2.0

4.9

4.9

0

0

0

0.9

0

1.5

1.1

1.4

1.5

0

2.1

2.3

1.7

3.0

2.4

0.6

0

0.1

1.1

1.1

1.7

1.7

1.4

1.1

7.9

2.1

0.4

0.4

0

0

0

0

3.3

0

0

2.4

2.3

1.8

2.9

2.5

1.2

4.9

0

0

0

1.3

3.3

1.5

1.5

3.2

0.3

1.0

1.1

8.5

10.2

0

0

0.8

0

0

0

3.3

0.402.9

2.9

0

00000

0

2.3

4.9

4.9

0.3

1.4

4.9

2.8

1.8

0

3.3

3.3

0

0

3.3

0

0

1.4

0

4.5

0

1.4

4.9

3.3

1.6

1.6

0

1.3

2.5

1.2

3.3

3.3

1.0

0

3.3

3.3

0

0.4

1.8

5.0

5.6

5.0

5.6

5.6

3.3

1.3

2.0

1.4

2.0

2.7

2.5

2.1

5.0

1.0

3.2

3.8

3.4

2.8

3.1

2.4

3.1

2.5

2.5

3.3

2.5

TG/V-DRV

CDS/AGC

A/D CONVERTER

D/A

DSP

1/2

V

DRIVER

TIMING

DRIVER

DRIVER

DRIVER

DRIVER

CHARGE

PUMP

LATCH

MODE

SET

CDS

CDS

LPF

S&H BLK

AGC

CLP

DAC

X8

FINE

LATCH

COMPARATE

ENCODE

&

LATCH

CORRECTION

COARSE

&

COMPARATE

&

FINE

ENCODE

DET

1H

DL

LPF

CLMP

SYNC

SEP

VH

PHASE

COMP

SYNC

GEN

HD

GEN

RGB

MTX

WB

GAIN

BLK

D/A

LN

MTX

ENC

D/A

1HDLLPF

CLMP

EEPROM

GENERATOR

XRS

+

-

OB

R

R

8.2

0

3.1

COARSE

3.4

3-4 3-4

U

E/EG

C327

33p

18p

L211

15u

8.2u

C333

33p

33p

FL200

NAX0147-001X

NAX0147-001X

R245

OPEN

33k

R246

33k

OPEN

R287

OPEN

OPEN

R288

33k

33k

X200

SCV2219-001W

CE42275-001Y

C221

56p

56p

C223

33p

33p

C225

56p

56p

L203

5.6u

5.6u

R311

OPEN

OPEN

R342

470

470

R219

47

47

R220

47

47

R221

47

47

C238

OPEN

OPEN

C248

OPEN

OPEN

SET

IC217.3

11

12

14

13

6

7

16

8

PRO BOARD SCHEMATIC DIAGRAM

TO CCD

TO EE

R233

2.7k

R240

330

D212

D211

0.33

0.22

to TP205

R314

R315

2.2M

2.2M

R295

OPEN

R297

33k

R372

560

R374

12k

C337

OPEN

The details of components marked by astarisk are shown below.

Note : The parts in ( ) are not mounted on the board.

Q201-204, 206

Page 26

D212

D212

PRO CIRCUIT BOARD3.5

3-5 3-5

. SIDE A .

. SIDE B .

IC200 B-2A

IC201 B-1A

IC202 B-2C

IC203 B-1D

IC204 B-2E

IC205 B-4C

IC206 B-4D

IC207 A-6C

IC208 B-6A

IC209 B-3A

IC210 B-4B

IC211 B-4B

IC212 B-3B

IC213 B-7D

IC214 B-6B

IC215 B-7A

IC216 B-5B

IC217 B-4E

IC218 B-5C

Q200 B-3B

Q201 B-3E

Q202 B-3D

Q203 B-3E

Q204 A-3B

Q205 A-3B

Q206 B-4D

Q207 B-6A

Q208 A-7B

Q209 B-7E

Q210 A-6A

Q211 B-5C

Q212 B-7F

Q213 B-7F

Q214 B-7F

Q215 B-7B

Q216 B-6B

Q217 B-3E

Q218 A-4A

Q219 A-4C

Q220 B-5D

D200 B-1B

D201 B-1B

D202 A-1E

D203 B-1B

D204 A-2F

D205 A-3C

D206 A-3C

D207 A-2A

D208 B-6C

D209 B-5C

D210 B-6D

R200 B-2A

R201 B-2A

R202 A-4A

R204 A-4A

R206 B-3E

R207 B-1B

R208 A-3E

R209 A-3E

R210 B-3B

R211 A-3C

R212 A-2C

R213 A-3D

R214 B-2D

R215 B-3C

R216 A-3D

R217 B-3C

R219 A-2E

R220 A-2D

R221 B-2B

R222 B-3A

R224 A-2D

R225 B-2E

R226 B-2D

R228 A-2A

R232 B-3D

R233 B-3E

R234 B-3D

R235 B-3D

R236 B-3E

R237 A-3B

R238 A-3B

R239 A-3B

R240 A-3B

R241 A-3B

R242 B-3E

R243 A-3C

R244 A-4C

R245 A-7B

R246 B-6E

R247 B-4D

R252 A-3D

R253 A-3D

R254 A-4D

R255 A-4C

R280 B-5C

R281 A-5D

R282 B-6B

R283 A-6D

R284 A-6D

R285 B-5D

R286 B-6C

R287 B-7D

R288 B-7D

R289 B-6E

R290 A-6D

R291 A-4B

R292 B-7D

R293 A-5A

R294 B-5E

R295 B-5F

R296 B-6E

R297 B-6F

R298 B-5E

R299 B-5F

R300 B-5D

R301 B-5E

R302 B-5E

R303 B-5E

R304 B-5E

R305 B-5F

R306 B-5D

R307 B-5E

R308 B-5E

R309 B-5E

R310 B-5B

R311 B-5F

R312 B-5C

R313 B-5C

R314 B-6E

R315 B-5E

R316 A-5D

R317 A-6E

R318 A-6E

R319 A-5F

R320 A-6F

R321 B-5A

R322 B-5A

R323 B-6A

R324 B-6B

R325 B-6B

R326 B-5C

R327 B-6D

R328 B-6D

R329 B-5D

R330 A-5D

R331 A-5D

R332 A-5E

R333 A-5E

R334 A-7D

R335 A-7D

R336 A-7D

R337 B-6D

R338 B-6E

R339 B-6B

R340 B-5A

R341 B-5A

R342 B-5A

R343 A-7A

R344 B-7E

R345 B-7E

R346 B-7E

R347 B-7E

R348 B-7E

R349 B-7D

R350 B-7D

R351 A-5D

R352 B-6F

R353 B-7F

R354 A-6A

R355 A-6A

R356 B-7E

R357 B-6F

R358 A-4D

R359 B-7F

R360 B-7F

R361 B-7F

R362 A-7A

R363 B-7F

R364 B-7F

R365 B-7F

R366 B-7F

R367 B-7F

R368 B-7E

R369 B-7B

R370 B-7B

R371 B-7B

R372 B-7B

R373 A-7E

R374 B-7B

R375 A-6E

R376 B-6C

R377 A-6E

R378 B-6A

R379 B-6A

R380 B-7B

R381 A-7F

R382 B-2D

R383 A-1B

R384 A-6A

R385 A-6A

R386 B-6E

R387 B-6E

R388 B-6F

R389 A-7B

R390 A-1B

R391 A-1B

R392 A-7D

R393 B-7C

R394 B-5E

R395 A-3A

R396 B-5C

R397 A-7C

R398 A-4C

R399 A-3E

C200 A-2F

C201 B-2A

C202 A-2F

C203 A-1E

C204 B-2A

C205 A-1F

C206 A-2E

C207 B-2B

C212 B-1B

C213 B-1C

C214 A-1E

C215 A-2E

C216 B-1C

C217 B-2B

C218 B-2B

C219 B-3B

C220 B-3B

C221 A-2D

C222 A-2C

C223 B-3C

C224 A-3C

C225 A-3C

C226 A-3D

C227 A-2D

C228 B-2C

C229 A-2D

C230 A-3D

C231 A-3E

C232 A-2D

C233 B-2B

C234 A-2E

C235 A-2D

C236 A-2D

C237 B-2B

C238 B-3A

C239 A-2E

C240 A-2E

C241 B-1E

C242 A-1C

C243 B-2E

C244 B-1E

C245 B-1E

C246 B-1E

C247 B-1E

C248 B-2E

C249 B-2D

C250 A-1C

C251 B-2D

C252 B-2C

C253 A-1C

C254 A-1D

C255 B-1E

C256 A-2A

C257 A-4C

C258 A-3A

C259 A-3C

C260 A-3B

C261 A-3C

C262 A-3B

C263 A-3A

C264 A-3B

C265 A-4D

C266 B-7C

C267 B-7C

C268 A-4C

C271 B-4B

C272 B-4C

C273 B-4B

C274 B-5D

C275 B-6F

C276 A-6A

C282 B-6C

C283 B-6C

C284 B-5D

C285 A-6D

C286 A-6E

C287 B-4B

C288 A-4D

C289 B-7E

C290 A-5A

C291 A-6A

C292 B-6E

C293 A-6A

C294 B-6F

C295 B-6E

C296 B-6E

C297 B-7E

C298 A-7B

C299 A-6F

C300 A-6E

C301 A-6F

C302 A-6F

C303 B-5A

C304 B-6B

C305 B-5A

C306 A-5F

C307 A-5E

C308 B-6C

C309 B-6C

C310 B-6D

C311 B-6D

C312 A-5E

C313 A-3F

C314 B-3A

C315 A-3F

C316 A-5E

C317 B-4B

C318 A-5E

C319 A-4E

C320 B-4B

C321 A-4E

C322 A-3E

C323 B-3B

C324 A-3E

C325 A-7A

C326 B-7E

C327 A-7B

C328 B-7E

C329 A-7C

C330 A-7C

C331 A-7B

C332 B-6F

C333 A-6A

C334 B-7C

C335 A-7D

C336 A-6E

C337 B-6B

C338 B-6B

C339 A-6E

C340 B-7A

C341 B-6A

C342 B-6C

C343 B-7A

C344 A-7E

C345 B-7B

C346 B-2D

C347 A-2B

C348 A-3B

C349 A-1C

C350 A-2A

C351 B-3F

C352 B-3E

C353 B-1D

C354 A-4A

C355 B-4E

C356 B-5E

L203 B-3D

L205 B-1E

L211 A-7B

L212 A-7C

L213 A-3A

DL200 A-7A

TP200 B-1A

TP201 B-3A

TP202 B-1E

TP203 B-1C

TP204 B-3E

TP205 B-6C

TP206 B-5D

TP207 B-7D

TP208 B-6E

TP209 B-7E

TP210 B-7D

TP211 B-6F

TP212 B-4A

TP213 B-4A

TP214 B-2B

TP215 B-1B

TP216 B-3B

TP217 B-3C

TP218 B-6A

TP219 B-5B

CN200 A-2C

CN201 A-4F

CN202 A-1B

X200 B-6D

TC200 B-3D

FL200 A-6A

Each address may have an address error by one interval.

Side Y axis

X axis

A-1C

TP202 TP211 TP209 TP218

200mV/DIV,10U/DIV 500mV/DIV,10U/DIV 200mV/DIV,10U/DIV 200mV/DIV,10U/DIV

ADDRESS TABEL OF PRO BOARD PARTS

TP215

10V/DIV,5ms/DIV

SHUTTER ON

(

AGC ON, AES ON

)

C

115

13

31

14

85

85

41

41

85

169

18

112

13 24

25 36

37 48

37 48

3625

112

2413

81

169

8

5

41

216

13

3

3

1

1

Page 27

1.5

2.2

2.2

1.6

9.0

1.6

0.2

0

5.7

1.4

0

0

0

1.5

0

2.1

0

0

3.3

0

0

2.2

0

3.3

LEVEL

VIDEO/DC

3.6

3-6 3-6

R507

27K

C521

22/10

(

R522

)

C520

1/25

C500

0.047

MA152WK

C515

0.01

GND(PRIMARY

)

GND(PRIMARY

)

PHASE/W.B

+8.5V

Vref

VIDEO IRIS

+5.7V

ATW/MANU

DC IRIS

PHASE-/WB R

+5.7V

LL PULSE

EE BOARD SCHEMATIC DIAGRAM

C509

0.01

C522

22/10

LL SW

PHASE+/WB B

MA152WK

TO POWER (TK-C401EG

)

TO PS (TK-C400U/E

)

Note : The parts in ( ) are not mounted on the board.

D500-D503 : MA3240(M)-W

Page 28

0

0

0

3.3

3.3

3.3

3.3

3.3

3.3

0

0

EE CIRCUIT BOARD TERMINAL BOARD SCHEMATIC DIAGRAM

TERMINAL CIRCUIT BOARD

3.7 3.8

3.9

3-7 3-7

. SIDE A .

. SIDE B .

.. SIDE B

+5.7V

TK-C400U/E only

TK-C400E only

IC501 B-3A

IC502 B-1A

Q500 B-1A

Q501 A-3A

Q502 A-3A

Q503 B-2A

D500 B-3B

D501 B-2B

D502 B-3B

D503 B-3B

D504 B-1B

D505 B-1A

R500 B-3A

R501 B-2A

R502 B-2B

R503 B-2B

R504 B-2B

R505 B-1A

R506 B-1B

R507 B-1B

R508 A-3A

R509 A-3A

R510 A-3A

R511 B-3A

R512 A-3A

R514 B-3A

R515 A-3A

R516 B-3A

R517 B-3A

R518 B-3A

R519 B-3A

R520 B-2A

R521 B-2A

R522 B-3A

R530 B-1B

R531 B-1B

R533 B-1A

R534 B-1A

VR500 A-3B

C500 B-1A

C501 A-1B

C502 B-1B

C503 B-1A

C504 A-3A

C505 B-2B

C506 B-2B

C507 B-2B

C508 B-3A

C509 B-3A

C511 B-1B

C513 B-2A

C514 A-1A

C515 B-1A

C517 A-3A

C518 A-3A

C519 A-3A

C520 B-3B

C521 B-3A

C522 A-2A

CN500 A-1A

CN501 A-2B

CN502 A-2A

S500 A-2B

TB500 A-3B

Each address may have an address error by one interval.

Side Y axis

X axis

A-1C

ADDRESS TABEL OF EE BOARD PARTS

123

A

B

B

A

213

TB100

AC24V/DC12V

VBS

out

RS232C

5V

D104-107

MA3270-M

TK-C400U and

S101-103

Page 29

2.5

4.3

5.4

-0.8

-0.6

0

2.2

0.7

0

2.8

-0.2

2.8

11.6

5.4

4.4

2.5

3.4

12.4

3.10 3.11

3.12 3.13

3-8 3-8

TO EE

GND(PRIMARY

)

GND(PRIMARY

)

R22

12K

R5

1K

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

R12

3.9k

R24

5.6K

L703

0

C717

OPEN

R714

5.6k

PS BOARD SCHEMATIC DIAGRAM (TK-C400U/TK-C400E

)

POWER BOARD SCHEMATIC DIAGRAM (TK-C401EG

)

PS CIRCUIT BOARD (TK-C400U/TK-C400E

)

POWER CIRCUIT BOARD (TK-C401EG

)

ADDRESS TABEL OF PS BOARD PARTS

Each address may have an address error

by one interval.

IC1 4E

Q1 3F

Q2 7F

Q3 8F

Q4 7E

D2 7E

D3 7F

D4 7B

D5 6B

D7 5B

D9 7F

D10 8E

D11 8D

D12 7D

D13 7D

D14 8D

D15 4E

D17 4D

R1 6E

R2 6E

R3 8F

R4 6E

R5 6F

R6 4F

R7 5E

R8 3F

R9 3F

R10 2F

R12 6C

R15 6B

R16 8E

R17 6E

R18 8F

R21 5F

R22 2F

R23 2A

R24 2A

C1 8B

C2 8D

C3 7B

C5 7C

C6 8D

C7 8E

C8 6F

C10 4F

C12 2F

C13 5E

C15 7B

C16 5B

C18 4A

C19 3C

C21 3A

C22 4D

C24 4B

C25 4E

C27 3D

C28 5B

L1 8C

L2 4B

L3 2C

L5 2D

L6 2E

CN4 5A

FC1 7A

FC2 7A

PC1 5F

PC2 6B

T1 6D

VA1 8B

by one interval.

Each address may have an address error

X axis

Y axis

IC700 2F

IC701 2C

D700 6D

D701 4E

D702 4D

D703 5D

D704 3C

D706 3D

D708 3D

D710 2D

R700 3F

R701 3E

R702 4E

R703 4E

R704 4F

R705 5D

R706 6C

R707 1D

R708 1D

R709 1C

R710 1D

R711 1C

R712 4A

R713 4B

R714 4A

R715 3F

R716 8F

R717 6C

C700 7C

C701 6F

C702 8F

C703 6F

C704 5E

C705 4E

C706 4F

C707 4E

C708 3E

C709 6B

C710 3B

C711 3A

C712 3B

C713 4B

C714 4A

C715 5B

C716 2A

C717 1C

C718 1E

C719 1D

C720 5A

C721 3F

L700 3A

L701 3A

L702 5B

L703 2A

CN700 7A

CN701 5A

FC700 7C

FC701 7C

LF700 8E

PC700 2E

PC701 6B

T700 5B

VA700 7B

1C

X axis

Y axis

1C

ADDRESS TABEL OF POWER BOARD PARTS

Page 30

5-15-1

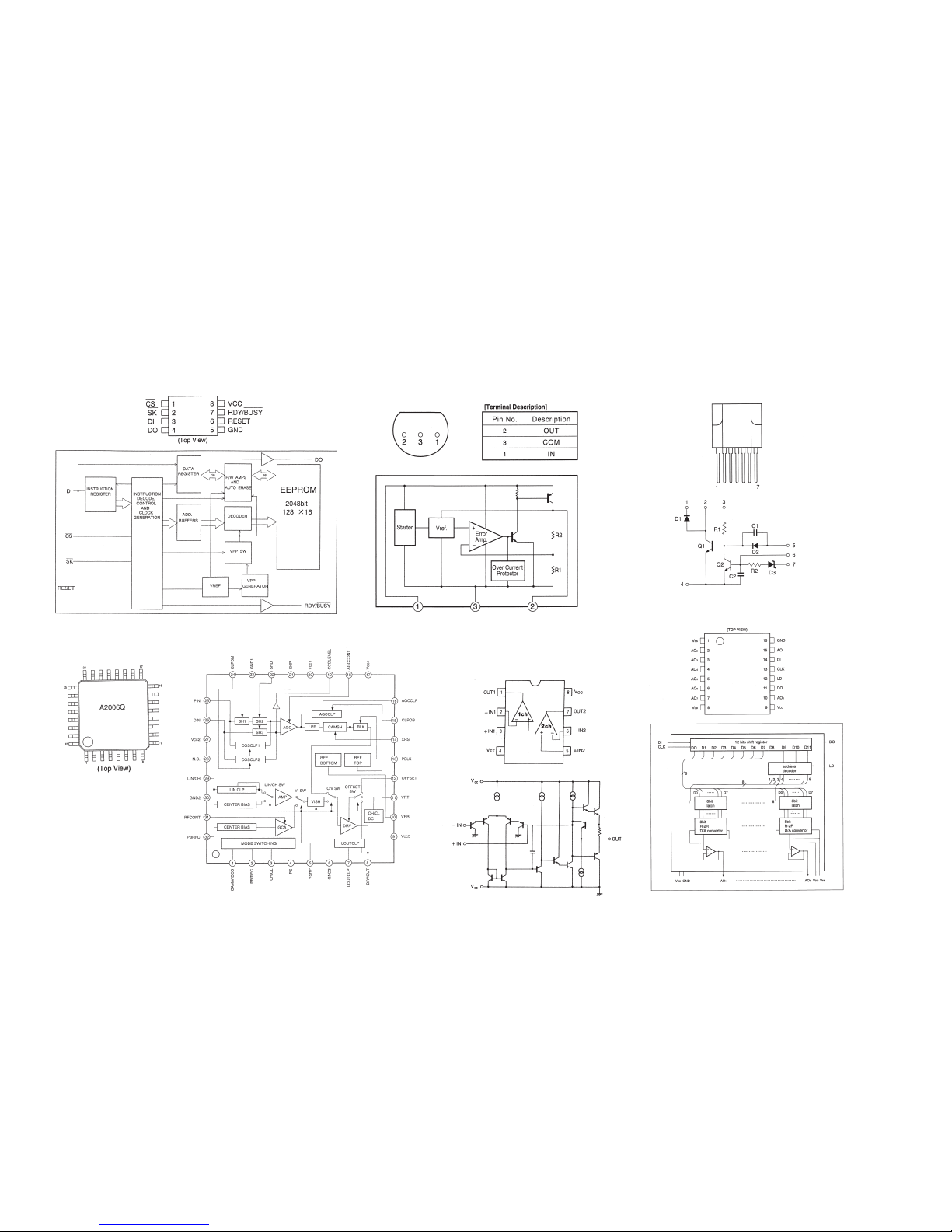

䡵 AN8085M-X [MATSUSHITA]

(REG Servo)

䡵 AK6420AM-W [ASAHIKASEI]

(2048 bits (128 Words X 16 bits) EEPROM)

䡵 CXA2006Q [SONY]

(CDS and AGC)

䡵 BA10358F-E2 [ROHM]

(Dual Ground Sense Op.Amp.)

3.14 BLOCK DIAGRAMS of IC'S

3-9

3-9

䡵 MA1040P(4100) [SHINDENGEN]

(Power Modul)

䡵 MB88347PFV [FUJITSU]

(D/A Convertor)

Page 31

4-2 4-2

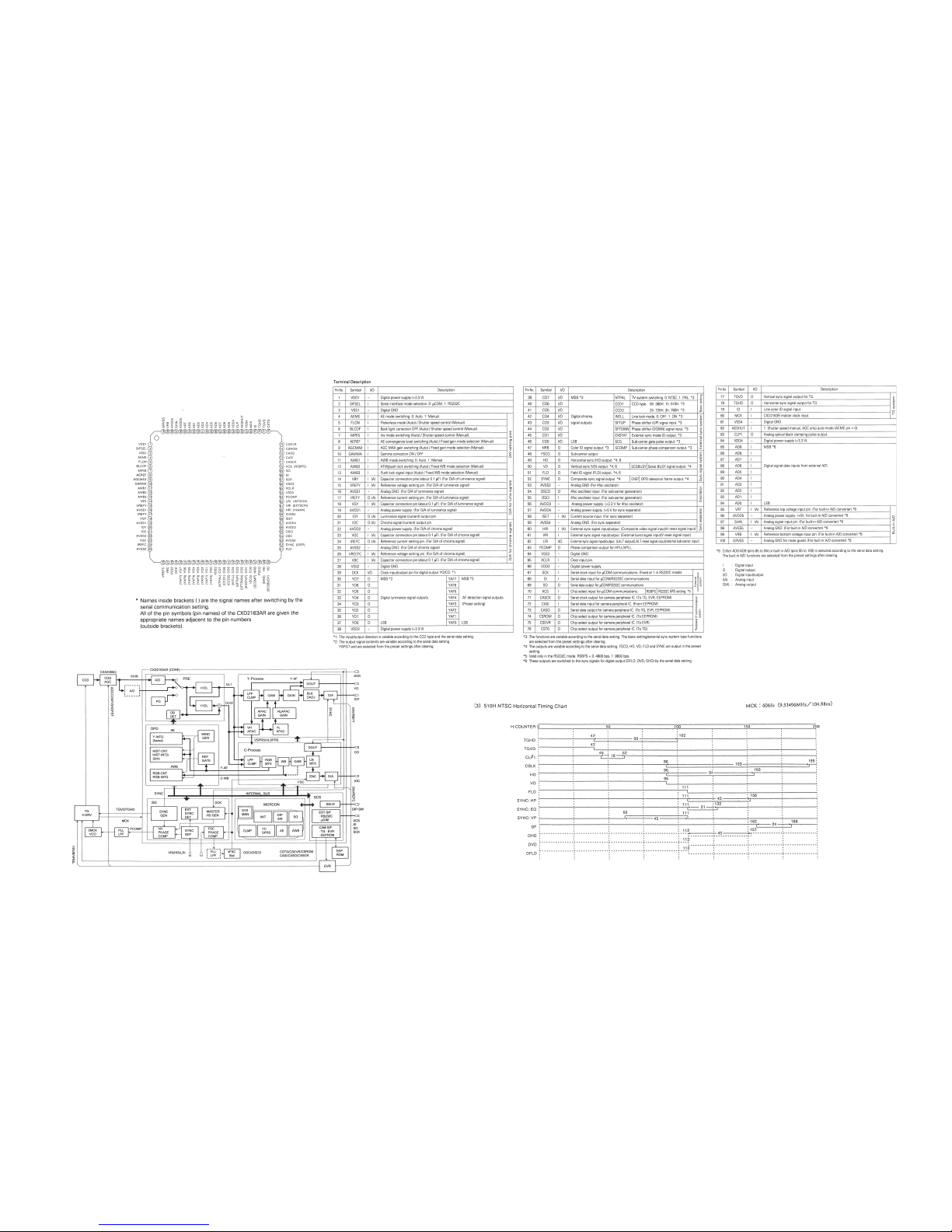

䡵 CXD2163AR [SONY]

(Digital signal processor for single chip CCD color video camera)

3-10

3-10

Page 32

5-35-3

3-113-11

Page 33

4-4 4-4

3-12

3-12

䡵 CXD2312R [SONY]

(9 bit 20 MSPS Video A/D Converter)

䡵 CXD2480R [SONY]

(Timing Control with CCD Drivers)

Page 34

5-55-5

3-13

3-13

Page 35

4-6 4-6

3-14

3-14

Page 36

5-75-7

3-15

3-15

䡵 ICX054AK-A [SONY]

(1/3 inch CCD image sensor for NTSC color camera)

Page 37

4-8 4-8

3-16

3-16

䡵 ICX055AK-A [SONY]

(1/3 inch CCD image sensor for PAL color camera)

Page 38

5-95-9

3-17

3-17

䡵 NJM2509V-W [JRC]

(Super Imposer including Y/C MIX Circuit)

䡵 NJM2267V-W [JRC]

(Dual 6dB Video Amplifier including 75OHM Driver)

䡵 NJM431U-X [JRC]

(Adjustable Precision Shunt Regulator)

䡵 NJM431U-XE [JRC]

(Refer to NJM431U-X.)

䡵 NJM79L08UA-X [JRC]

(3-Terminal Negative Voltage Regulator (-8V))

䡵 NJM78L15UA-X [JRC]

(3-Terminal Positive Voltage Regulator (+15V))

Page 39

4-10 4-10

3-18

3-18

䡵 TC74HC08AF-X [TOSHIBA]

(Quad 2-Input AND Gates)

䡵 TC4W53F-X [TOSHIBA]

(2-Channel Multiplexer)

䡵 UPC358G2-X [NEC]

(Refer to UPC358G2-W.)

䡵 UPC358G2-W [NEC]

(Dual Op.Amp.)

䡵 TK11333BMC-X [TOKO]

(Regulator)

䡵 TC7W02F-X [TOSHIBA]

(2 Input Dual NOR Gate)

䡵 TC7S08F-X [TOSHIBA]

(2 Input Single AND Gate)

䡵 PST9120N-X [MITSUMI]

(System Reset(+2V))

䡵 TC4053BF-X [TOSHIBA]

(Triple 2 Channel Analog Multiplexers/Demultiplexers)

Page 40

5-115-113-19

3-19

䡵 TK11650U-X [TOKO]

(3-Terminal Positive Voltage Regulator)

䡵 UPD5556G-W [NEC]

(CMOS Dual Timer)

Page 41

4-12 4-12

4-1

4-1

SECTION 4

EXPLODED VIEW AND ASSEMBLY PARTS LIST

4.1 ASSEMBLY

M1

䢇 SAFETY PRECATION

Parts identified by the ! symbol are critical for safety.

Replace only with specified parts numbers.

䢇 NOTE

Parts not denoted by parts numbers are not supplied by JVC.

25

24

for EG-Ver.

PRO BOARD

PS/POWER

BOARD

EE BOARD

FUSE

See SECTION1.

CCD BOARD

for E and EG-Ver.

TERMINAL

BOARD

for U and E-Ver.

for EG-Ver.

TERMINAL BOARD

for U-Ver.

Page 42

ASSEMBLY PARTS LIST

Symbol

No.

1 SC32036H-001 CAP

2 SC40286H-001 SHEET

3 SC20489H-002 FRONT FRAME

4 SC45590H-001 SPRING

5 SC20553H-001 SENSOR BASE

6 SC31647H-001 ADJ.RING

7 SC45335-002 LEAF SPRING

8 SC46173H-001 HOLDER PLATE

9 SCV2511-001 OP L.P.F. for TK-C400U/TK-C400E/TK-C401EG

10 SC45592H-001 SENSOR MASK

11 ICX054AK-A CCD SONY for TK-C400U

11 ICX055AK-A CCD SONY for TK-C400E/TK-C401EG

12 SC31797H-001 SENSOR HOLDER

! 13 SCV2337-1605BD FFC CABLE (1) CCD to PRO

! 14 SCV1902H-1805K FFC CABLE (2) TERMINAL to EE

! 15 SCV1902H-1206K FFC CABLE (3) PS/POWER to EE

16 SC46170H-001 HEAT SINK

17 SC32127H-00A CHASSIS for U and E-Ver.

17 SC32127H-00B CHASSIS for EG-Ver.

18 SC45456H-001 F. CAUTION LABEL for U-Ver.

19 SC45396H-002 UL LABEL for U-Ver.

20 SC46066H-001 CAUTION LABEL for U-Ver.

20 SC46171H-001 WARNING LABEL for EG-Ver.

21 SC32129H-001 UPPER COVER

22 SC32128H-001 BOTTOM COVER

23 SC20601H-00A TRIPOD BASE

24 SC31650H-002 ESCUTCHEON

25 SC32130H-001 REAR PANEL for U and E-Ver.

25 SC32130H-002 REAR PANEL for EG-Ver.

! 26 QMPK068-250-K POWER CORD for EG-Ver.

27 QHS6374-162 STRAIN RELIEF for EG-Ver.

28 QXT3820-035 UL TUBE for EG-Ver.

29 SCV1731-003 VH HOUSING for EG-Ver.

S1 SPSP2611N SCREW M2.6x11

S2 SDSF2008M SCREW M2x8, x2

S3 SPSK2040R SCREW M2x4, x12

S4 SPSP2605N SCREW M2.6x5, x7

S5 SDSF2606M SCREW M2.6x6, x2

S6 DPSP4006Z SCREW M4x6, for EG-Ver.

M1

M1MM````

DescriptionPart No. Part Name

4-2

Page 43

SECTION 6

PACKING

Instructions SC96795H (TK-C400U/E)

(English, French, Spanish)

Instructions SC96796H (TK-C400E only)

(Germany, Italian, Chinese)

4P Plug SCV2859-001

Instructions SC96795H

(English, French, Spanish)

Instructions SC96796H

(Germany, Italian, Chinese)

Power Cord

Carton

Carton

Carton

TK-C401EG only

Carton Box

6-1

Page 44

SECTION 5

ELECTRICAL PARTS LIST

SAFETY PRECAUTION:

Parts identified by the ! symbol are criticaI for safety. Replace only with specified parts numbers.

For maximum reliability and performance, all other replacement parts should be identical to those specified.

NOTE:

● Parts not denoted by parts numbers are not supplied by JVC.

● Abbreviations in this list are as follows:

RESISTORS

In the “Description” column:

All resistance values are in ohms (Ω).

k expresses kilo-ohm (1 000 ohms, kΩ).

M expresses mega-ohm (10

6

ohms, MΩ).

CAPACITORS

In the “Description” column:

All capacitance values are in microfarad (

otherwise indicated.

p expresses picofarad (10

–12

farad,pF).

µ

F) unless

In the “Parts Name”column:

CAR.RESISTOR : Carbon Resistor

C.M.F.RESISTOR : Constant Metalized Film Resistor

COMP.RESISTOR : Composition Resistor

FUSI.RESISTOR : Fusible Resistor

M.F.RESISTOR : Metal Film Resistor

M.G.RESISTOR : Metal Graze Resistor

M.P.RESISTOR : Metal Plate Resistor

O.M.F.RESISTOR : Oxide Metalized Film Resistor

TRIM.RESISTOR : Trimerer Resistor

U.F.RESISTOR : Non-inflammable Resistor

VAL.RESISTOR : Valiable Resistor

W.W.RESISTOR : Wire Wound Resistor

ln the “Description” column of the parts list, (U) means the parts for the U version while

Note:

(E) is for the E version.

Symbol

No.

Part No. Part Name Description

In the “Parts Name” column:

CER.CAPACITOR : Ceramic Capacitor

E.CAPACITOR : Electrolytic Capacitor

FILM CAPACITOR : Film Capacitor

M.F.CAPACITOR : Metalized Film Capacitor

MICA CAPACITOR : Mica Capacitor

MPP CAPACITOR : Metalized PolyPropylene Capacitor

MPPS CAPACITOR : Metalized PolyPhenylene Sulfied film

Capacitor

M.M.CAPACITOR : Metalized Mylar Capacitor

MYLAR CAPACITOR

: Mylar Capacitor

N.P.CAPACITOR : Non-Poler electrolytic Capacitor

P.P.CAPACITOR : PolyPropylene Capacitor

PPS CAPACITOR : PolyPhenylene Sulfied film Capacitor

P.S.CAPACITOR : PolyStyrene Capacitor

TAN.CAPACITOR : Tantal Capacitor

TRIM.CAPACITOR : Trimer Capacitor

VAL.CAPACITOR : Valiable Capacitor

JVCIC1 SCV1585-064 I.C.(M) (U)

JVCSCV1585-067 I.C.(M) (E)

for U version

for E version

5-1

Page 45

5.1 CCD BOARD ASSEMBLY PARTS LIST

01

SCK2467-01-N0A (TK-C400U)

SCK2467-01-P0A (TK-C400E/401EG)

Symbol

No.

SK200 SCV2154-001 IC SOCKET 16PIN

Q201 2SC4618(PQ)-X TRANSISTOR ROHM

R200 NRSA63J-184X M.G.RESISTOR 180k 1/16W

R202 NRSA63J-101X M.G.RESISTOR 100 1/16W

R203 NRSA63J-273X M.G.RESISTOR 27k 1/16W

R204 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R206 NRSA63J-472X M.G.RESISTOR 4.7k 1/16W

R207 NRSA63J-681X M.G.RESISTOR 680 1/16W

R208 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R209 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R210 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R211 NRSA63J-105X M.G.RESISTOR 1M 1/16W

C200 NEH91EM-106X E.CAPACITOR 10 25V

C201 NBH21CM-105X TAN.CAPACITOR 1 16V

C202 NEH90JM-476X E.CAPACITOR 47 6.3V

C205 NCF31EZ-104X CER.CAPACITOR 0.1 25V

C207 NCF31EZ-104X CER.CAPACITOR 0.1 25V

C211 NEH91HM-335X E.CAPACITOR 3.3 50V

C212 NCB31HK-152X CER.CAPACITOR 1500p 50V

C213 NEH91HM-335X E.CAPACITOR 3.3 50V

CN200 SCV2477-016 CONNECTOR 16PIN

TP SSV1096-001 TEST POINT TP200-TP201

Part No. Part Name Description

5.2 PRO BOARD ASSEMBLY PARTS LIST

01``````

02

SCK2467-02-N0A (TK-C400U)

SCK2467-02-P0A (TK-C400E/401EG)

Symbol

No.

IC200 NJM79L08UA-X I.C.(M) JRC

IC201 NJM78L15UA-X I.C.(M) JRC

IC202 CXD2480R I.C.(M) SONY

IC203 CXA2006Q I.C.(M) SONY

IC204 CXD2312R I.C.(M) SONY

IC205 AK6420AM-W I.C.(M) ASAHIKASEI

IC206 MB88347PFV-X I.C.(M) FUJITSU

IC207 CXD2163AR I.C.(M) SONY

IC208 TC4W53F-X I.C.(M) TOSHIBA

IC209 AN8085M-X I.C.(M) MATSUSHITA

IC210 TK11650U-X I.C.(M) TOKO DENSHI

IC211 TK11650U-X I.C.(M) TOKO DENSHI

IC212 TK11333BMC-X I.C.(M) TOKO DENSHI

IC213 NJM2509V-W I.C.(M) JRC

IC214 TC7S08F-X I.C.(M) TOSHIBA

IC215 NJM2267V-W I.C.(M) JRC

IC216 BA10358F-E2 I.C.(M) ROHM

IC217 TC4053BF-X I.C.(M) TOSHIBA

IC218 PST9120N-X I.C.(M)

Q200 MSB1218A/R/-X TRANSISTOR MOTOROLA

Q201 MSD1819A/R/-X TRANSISTOR MOTOROLA

Q202 MSD1819A/R/-X TRANSISTOR MOTOROLA

Q203 MSD1819A/R/-X TRANSISTOR MOTOROLA

Q204 MSD1819A/R/-X TRANSISTOR MOTOROLA

Q205 XP6401-W TRANSISTOR MATSUSHITA

Q206 MSD1819A/R/-X TRANSISTOR MOTOROLA

Q207 MSD1819A/R/-X TRANSISTOR MOTOROLA

Q208 MSB1218A/R/-X TRANSISTOR MOTOROLA

Q209 MSB1218A/R/-X TRANSISTOR MOTOROLA

Q210 MSB1218A/R/-X TRANSISTOR MOTOROLA

Q211 MSD1819A/R/-X TRANSISTOR MOTOROLA

Part No. Part Name Description

02``````

Symbol

No.

Q214 MSB1218A/R/-X TRANSISTOR MOTOROLA

Q215 XP6401-W TRANSISTOR MATSUSHITA

Q216 XP6534-W TRANSISTOR MATSUSHITA

Q217 MSB1218A/R/-X TRANSISTOR MOTOROLA

Q218 MSD1819A/R/-X TRANSISTOR MOTOROLA

Q219 MSB1218A/R/-X TRANSISTOR MOTOROLA

Q220 MSD1819A/R/-X TRANSISTOR MOTOROLA

D200 1SS357-X DIODE TOSHIBA

D201 1SS357-X DIODE TOSHIBA

D202 1SS357-X DIODE TOSHIBA

D203 1SS357-X DIODE TOSHIBA

D204 1SS357-X DIODE TOSHIBA

D205 HVU306A5-W V.C.DIODE HITACHI

D206 HVU306A5-W V.C.DIODE HITACHI

D207 1SS357-X DIODE TOSHIBA

D209 HVU306A5-W V.C.DIODE HITACHI

D210 HVU306A5-W V.C.DIODE HITACHI

D211 MA165 DIODE MATSUSHITA

D212 MA165 DIODE MATSUSHITA

R200 NRSA63F-822X-T M.G.RESISTOR 8.2k 1/16W

R201 NRSA63F-820X-T M.G.RESISTOR 82 1/16W

R202 NRSA63J-682X M.G.RESISTOR 6.8k 1/16W

R204 NRSA63J-472X M.G.RESISTOR 4.7k 1/16W

R206 NRSA63J-332X M.G.RESISTOR 3.3k 1/16W

R207 NRSA63J-104X M.G.RESISTOR 100k 1/16W

R208 NRSA63J-104X M.G.RESISTOR 100k 1/16W

R209 NRSA63J-472X M.G.RESISTOR 4.7k 1/16W

R210 NRSA63J-473X M.G.RESISTOR 47k 1/16W

R213 NRSA63J-104X M.G.RESISTOR 100k 1/16W

R214 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R215 NRSA63J-105X M.G.RESISTOR 1M 1/16W

R216 NRSA63J-104X M.G.RESISTOR 100k 1/16W

R217 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R219 NRSA63J-470X M.G.RESISTOR 47 1/16W

R220 NRSA63J-470X M.G.RESISTOR 47 1/16W

R221 NRSA63J-470X M.G.RESISTOR 47 1/16W

R222 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R224 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R225 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R226 NRSA63J-100X M.G.RESISTOR 10 1/16W

R228 NRSA63J-104X M.G.RESISTOR 100k 1/16W

R232 NRSA63J-222X M.G.RESISTOR 2.2k 1/16W

R233 NRSA63J-272X M.G.RESISTOR 2.7k 1/16W

R234 NRSA63J-122X M.G.RESISTOR 1.2k 1/16W

R235 NRSA63J-272X M.G.RESISTOR 2.7k 1/16W

R236 NRSA63J-103X M.G.RESISTOR 10k 1/16W

R237 NRSA63J-821X M.G.RESISTOR 820 1/16W

R238 NRSA63J-221X M.G.RESISTOR 220 1/16W

R239 NRSA63J-332X M.G.RESISTOR 3.3k 1/16W

R240 NRSA63J-331X M.G.RESISTOR 330 1/16W

R241 NRSA63J-102X M.G.RESISTOR 1k 1/16W

R242 NRSA63J-222X M.G.RESISTOR 2.2k 1/16W

R243 NRSA63J-331X M.G.RESISTOR 330 1/16W

R244 NRSA63J-331X M.G.RESISTOR 330 1/16W

R245 NRSA63J-333X M.G.RESISTOR 33k 1/16W (E)

R246 NRSA63J-333X M.G.RESISTOR 33k 1/16W (U)

R247 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R252 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R253 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R254 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R255 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R280 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R281 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R282 NRSA63J-472X M.G.RESISTOR 4.7k 1/16W

R283 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R284 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R285 NRSA63J-122X M.G.RESISTOR 1.2k 1/16W

R286 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R288 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R290 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

Part No. Part Name Description

5-2

Page 46

[PRO BOARD]

Symbol

No.

R292 NRSA63J-472X M.G.RESISTOR 4.7k 1/16W

R293 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R296 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R297 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R298 NRSA63J-332X M.G.RESISTOR 3.3k 1/16W

R301 NRSA63J-332X M.G.RESISTOR 3.3k 1/16W

R304 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R305 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R306 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R307 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R308 QEJ61VM-334 TAN.CAPACITOR 0.33u 35V

R309 NCF31CZ-224 CER.CAPACITOR 0.22u

R310 NRSA63J-471X M.G.RESISTOR 470 1/16W

R312 NRSA63J-332X M.G.RESISTOR 3.3k 1/16W

R313 NRSA63J-471X M.G.RESISTOR 470 1/16W

R314 NRSA63J-225X M.G.RESISTOR 2.2M 1/16W

R315 NRSA63J-225X M.G.RESISTOR 2.2M 1/16W

R316 NRSA63J-823X M.G.RESISTOR 82k 1/16W

R317 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R318 NRSA63J-105X M.G.RESISTOR 1M 1/16W

R320 NRSA63J-105X M.G.RESISTOR 1M 1/16W

R321 NRSA63J-822X M.G.RESISTOR 8.2k 1/16W

R322 NRSA63J-182X M.G.RESISTOR 1.8k 1/16W

R323 NRSA63J-332X M.G.RESISTOR 3.3k 1/16W

R324 NRSA63J-392X M.G.RESISTOR 3.9k 1/16W

R325 NRSA63J-182X M.G.RESISTOR 1.8k 1/16W

R326 NRSA63J-104X M.G.RESISTOR 100k 1/16W

R327 NRSA63J-105X M.G.RESISTOR 1M 1/16W

R328 NRSA63J-221X M.G.RESISTOR 220 1/16W

R329 NRSA63J-104X M.G.RESISTOR 100k 1/16W

R332 NRSA63J-331X M.G.RESISTOR 330 1/16W

R333 NRSA63J-331X M.G.RESISTOR 330 1/16W

R334 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R335 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R336 NRSA63J-102X M.G.RESISTOR 1k 1/16W

R339 NRSA63J-333X M.G.RESISTOR 33k 1/16W

R340 NRSA63J-471X M.G.RESISTOR 470 1/16W

R341 NRSA63J-471X M.G.RESISTOR 470 1/16W

R342 NRSA63J-471X M.G.RESISTOR 470 1/16W

R343 NRSA63J-201X M.G.RESISTOR 200 1/16W

R344 NRSA63J-392X M.G.RESISTOR 3.9k 1/16W

R345 NRSA63J-102X M.G.RESISTOR 1k 1/16W

R346 NRSA63J-392X M.G.RESISTOR 3.9k 1/16W

R347 NRSA63J-152X M.G.RESISTOR 1.5k 1/16W

R349 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R350 NRSA63J-272X M.G.RESISTOR 2.7k 1/16W

R351 NRSA63J-393X M.G.RESISTOR 39k 1/16W

R352 NRSA63J-201X M.G.RESISTOR 200 1/16W

R353 NRSA63J-392X M.G.RESISTOR 3.9k 1/16W

R354 NRSA63J-222X M.G.RESISTOR 2.2k 1/16W

R355 NRSA63J-102X M.G.RESISTOR 1k 1/16W

R356 NRSA63J-102X M.G.RESISTOR 1k 1/16W

R358 NRSA63J-393X M.G.RESISTOR 39k 1/16W

R363 NRSA63J-0R0X M.G.RESISTOR 0 1/16W

R367 NRSA63J-122X M.G.RESISTOR 1.2k 1/16W

R368 NRSA63J-102X M.G.RESISTOR 1k 1/16W

R369 NRSA63J-182X M.G.RESISTOR 1.8k 1/16W

R370 NRSA63J-222X M.G.RESISTOR 2.2k 1/16W

R371 NRSA63J-105X M.G.RESISTOR 1M 1/16W

R372 NRSA63J-561X M.G.RESISTOR 560 1/16W