Page 1

MB141200312

SERVICE MANUAL

DVD DIGITAL THEATER SYSTEM

TH-A25

Area suffix

J ----------------------------- U.S.A.

C -------------------------- Canada

SOUND

VOLUME

STANDBY/ON

STANDBY

DVD DIGITAL CINEMA SYSTEM TH-A25

SOURCE

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.MB141

2003/12

Page 2

SPECIFICATION

Center unit (XV-THA25)

Amplifier Front/Center/Rear 30 W per channel, min. RMS, driven into 6 Ω at 1 kHz, with no more than 10% total harmonic distortion

Subwoofer 55 W, min. RMS, driven into 3 Ω at 100 Hz, with no more than 10% total harmonic distortion

Audio Audio input sensitivity/Impedance (at 1 kHz)

Analog input AUX ("AUDIO IN") 500 mV/47 kΩ

Signal-to-Noise Ratio 68 dB

Digital input* DIGITAL IN (OPTICAL) -24 dBm to -14.5 dBm (700 nm ±50 nm)

* Corresponding to Linear PCM, Dolby Digital, and DTS Digital Surround (with samp ling frequency-32 kHz, 44.1 kHz, 48

kHz)

Video Color System NTSC

Horizontal Resolution 480 lines

Output Level VIDEO OUT (Composite) 1.0 V(p-p)/75 Ω

S-VIDEO (Y):1.0 V(p-p)/75 Ω

(C):0.286 V(p-p)/75 Ω

COMPONENT

VIDEO OUT

Tuner Tuning Range FM 87.50 MHz - 108.00 MHz

Usable Sensitivity FM 8.0 dBf (0.9 µV/75 Ω)

General Readable Discs DVD VIDEO, Video CD, Super Video CD, Audio CD, CD-R/RW (Audio CD,

Power Requirements AC 120 V , 60 Hz

Power Consumption 110 W (at operation) 2 W (in standby mode)

Dimensions (W × H × D) 360 mm × 65 mm × 404 mm (14 3/16 in. × 2 9/16 in. × 15 15/16 in.)

Mass 6.3 kg (13.9 lbs)

Speaker 15 cm (5 15/16 in.) Bass-reflex, magnetically shielded

Power Handling Capacity 55 W

Impedance 3 Ω (min)

Frequency Range 30 Hz to 200 Hz

Dimensions (W × H × D) 210 mm × 382 mm × 338 mm (8 5/16 in. × 15 1/16 in. × 13 5/16 in.)

Mass 6 kg (13.3 lbs)

Speaker 8 cm (3 3/16 in.) Bass-reflex, magnetically shielded

Power Handling Capacity 30 W

Impedance 6 Ω (min)

Frequency Range 80 Hz to 20 kHz

Dimensions (W × H × D) 105 mm × 114 mm × 116 mm (4 3/16 in. × 4 1/2 in. × 4 5/8 in.)

Mass 640 g (1.5 lbs)

Y 1.0 V(p-p)/75 Ω

PB/PR 0.7 V(p-p)/75 Ω

AM 530 kHz - 1 710 kHz

AM loop antenna 650 µV/m

Video CD, Super Video CD, MP3, JPEG), DVD-R/RW (Video format)

Subwoofer (SP-WA25)

Satellite Speakers (SP-XTHA25)

Designs & specifications are subject to change without notice.

1-2 (No.MB141)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of th is product contains special hardw are and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

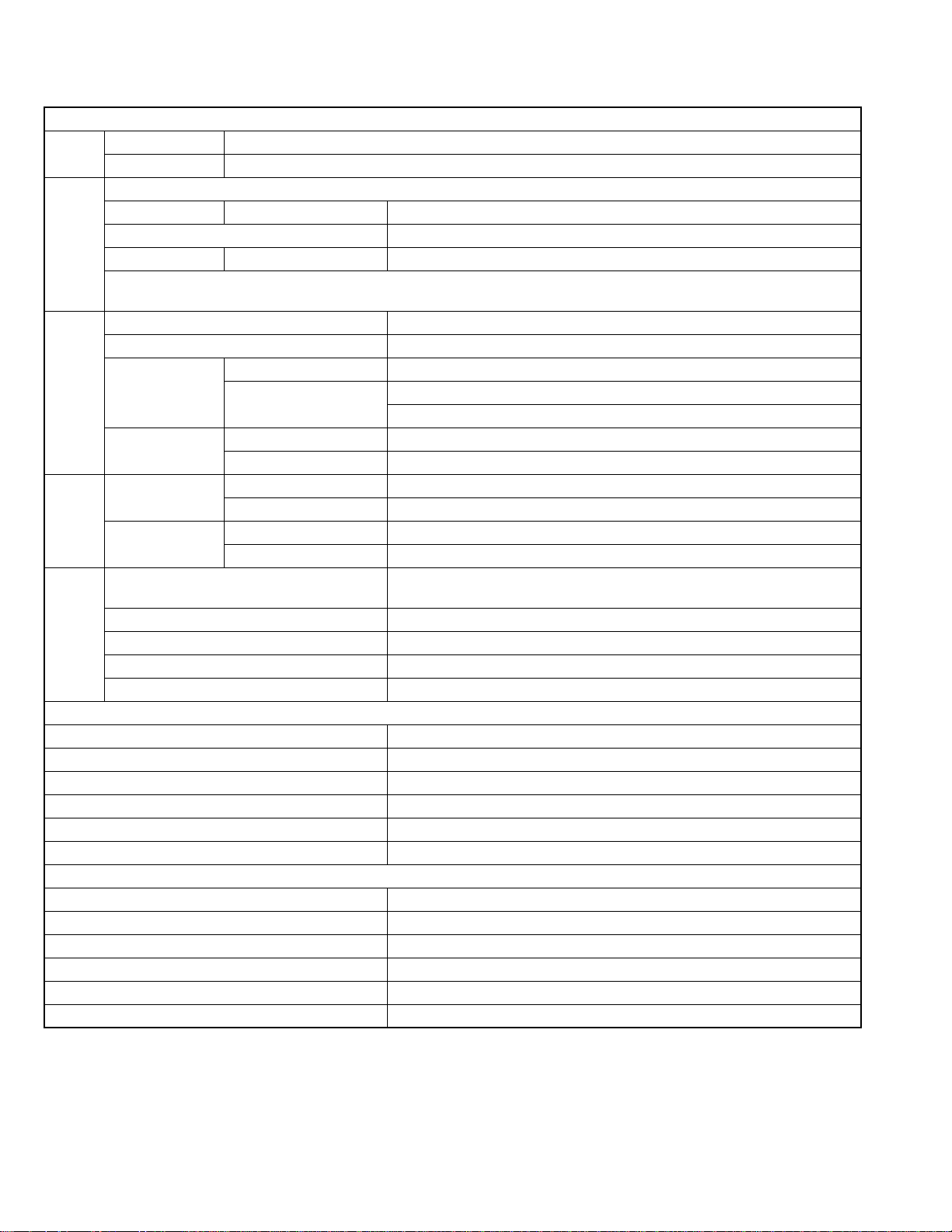

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal resp onsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical compone nts are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB141)1-3

Page 4

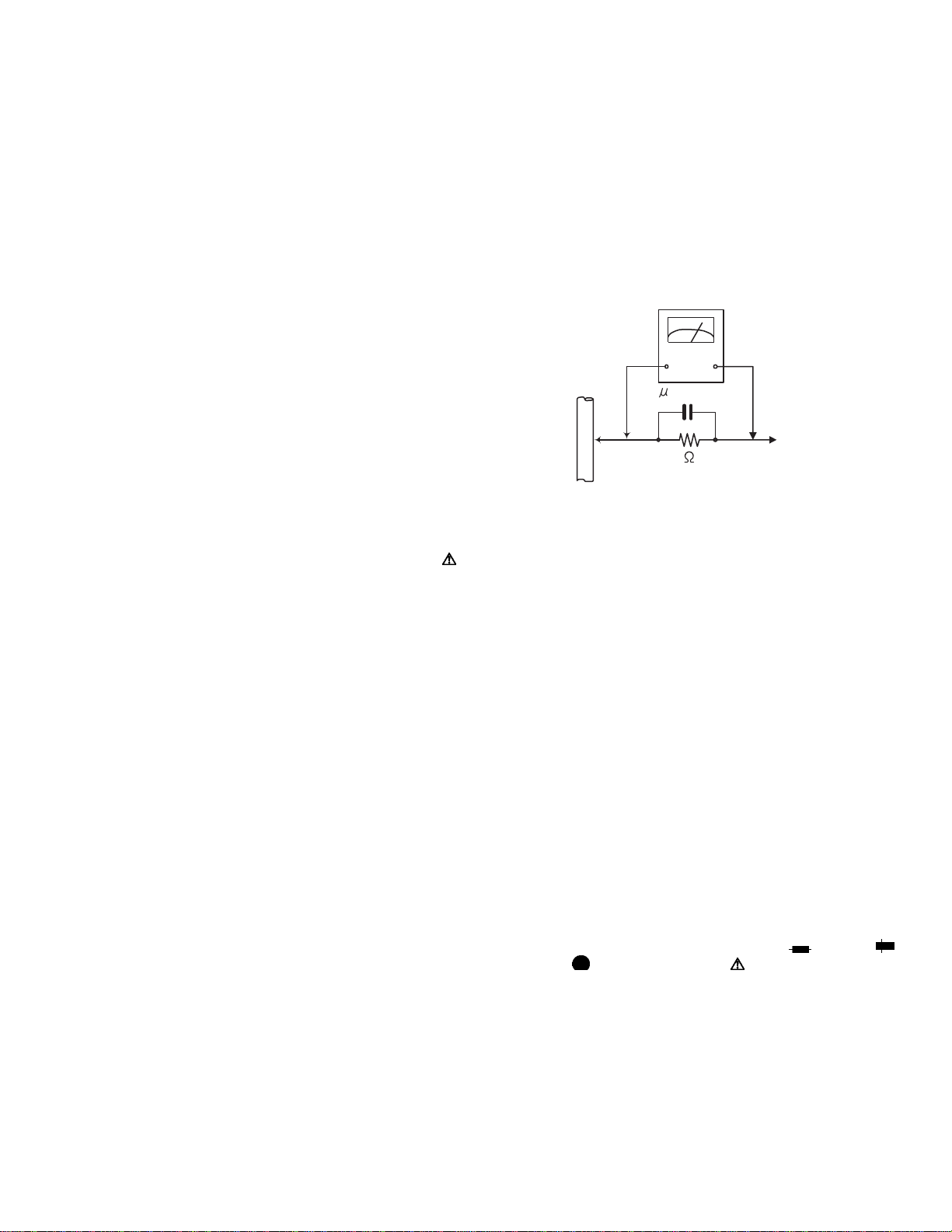

1.5 Preventing static electricity

1.5.1 Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.2 About the earth processing for the destruction prevention by static electricity

Static electricity in the work area can destroy the optical pickup (laser dio de) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sh eet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

1.5.3 Handling the optical pickup

(1) In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical pick-

up are shorted. After replacement, return the shorted parts to their orig inal condition. (Refer to the text.)

(2) Do not use a tester to che ck the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.5.4 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Remove solder of the short lands on the flexible wire after replacing the optical pickup. For specific details, refer to the replace-

ment procedure in the text. Remove the anti-static pin when replacing the traverse unit.

Be careful not to take too long a time when attaching it to the connector.

(3) Handle the flexible wire carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.5.5 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the DVD pickup.

• Apply solder to the short circuit points before the flexible wire is disconnected from the connector on the DVD pickup.

(If the flexible wire is disconnected without applying solder, the DVD pickup may be destroyed by static electri city.)

• In the assembly, be sure to remove solder from the short circuit points after connecting the flexible wire.

1-4 (No.MB141)

Page 5

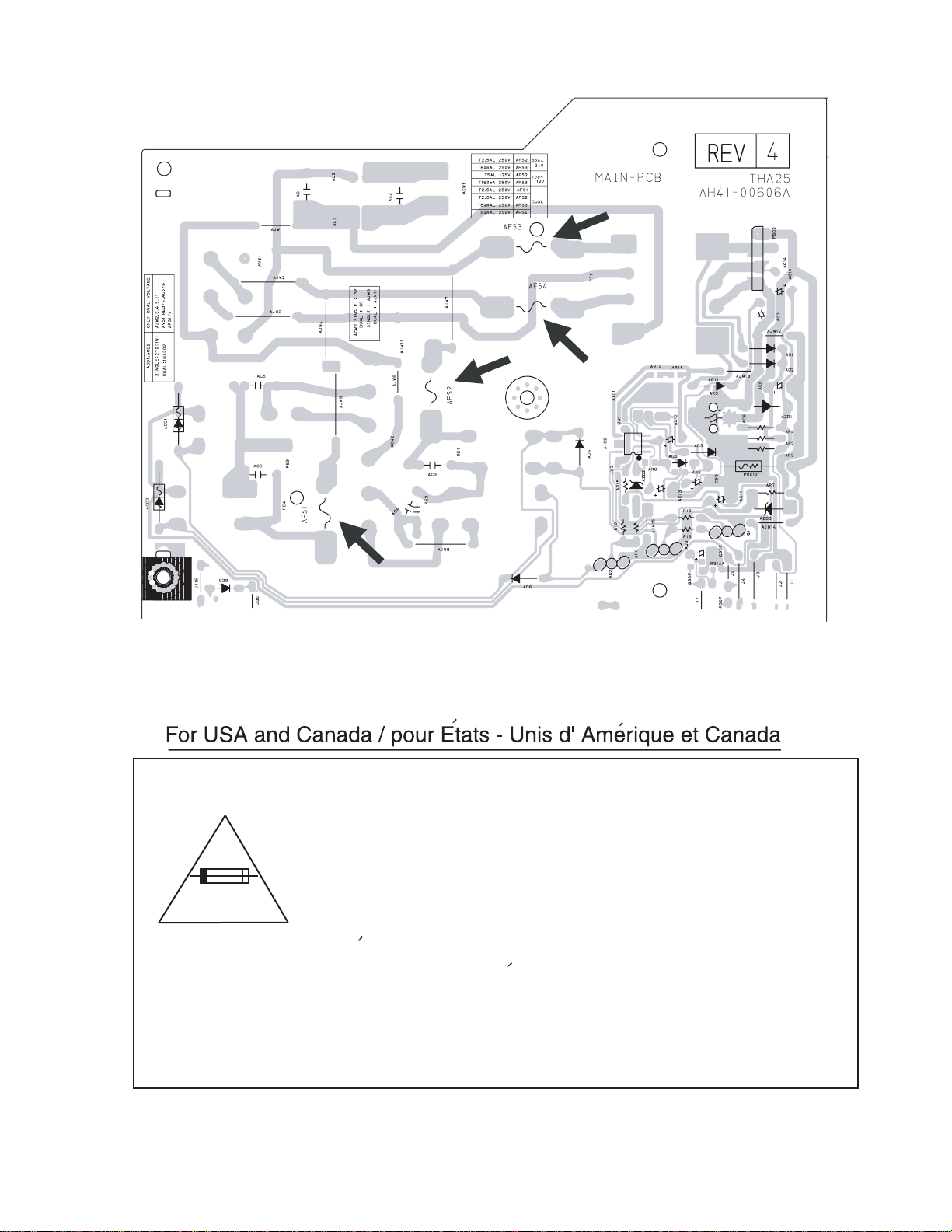

1.6 Importance administering point on the safety

Caution: For continued protection against risk of

fire, replace only with same type T1.25A/250V for

AFS1, T5A/125V for AFS2, T160mA/250V for AFS3

and T80mA/250V for AFS4. This symbol specifies

type of fast operating fuse.

Precaution: Pour eviter risques de feux, remplacez

le fusible de surete de AFS1 comme le meme type

que T1.25A/250V, et T5A/125V pour AFS2, et

T160mA/250V pour AFS3, et T80mA/250V pour AFS4.

Ce sont des fusibles suretes qui functionnes rapide.

^

(No.MB141)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.MB141)

Page 7

SECTION 3

DISASSEMBLY

3.1 Main body section

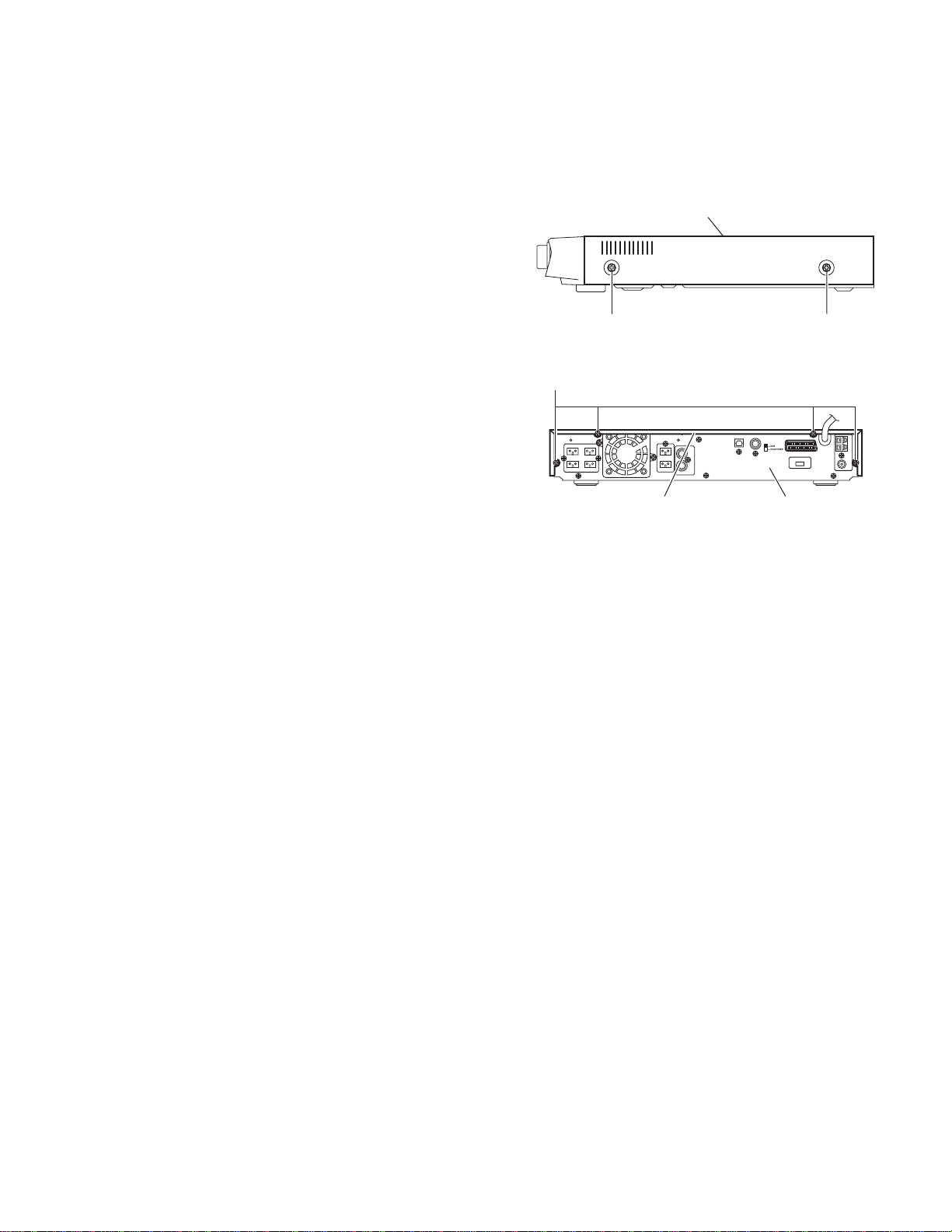

3.1.1 Removing the top cover

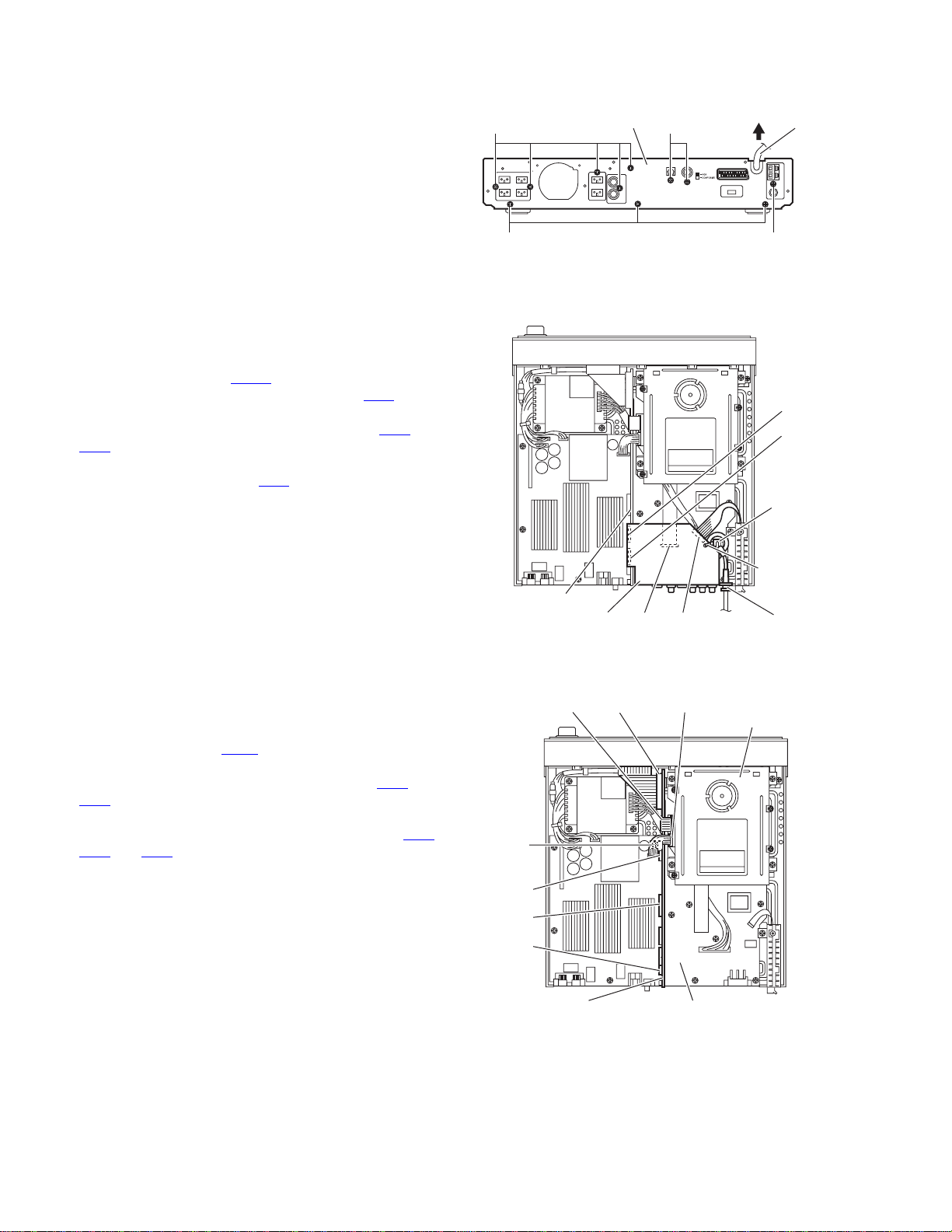

(See Figs.1 and 2)

(1) From the both sides of the main body, remove the four

screws A attaching the top cover. (See Fig.1)

(2) From the back side of the main body, remove the four

screws B attaching the top cover. (See Fig.2)

(3) Take out the to p cover in the upward direction while ex-

tending the lower sections of the top cover in the directi on

of right and left.

Top cover

AA

Fig.1

B

Top cover Rear panel

Fig.2

(No.MB141)1-7

Page 8

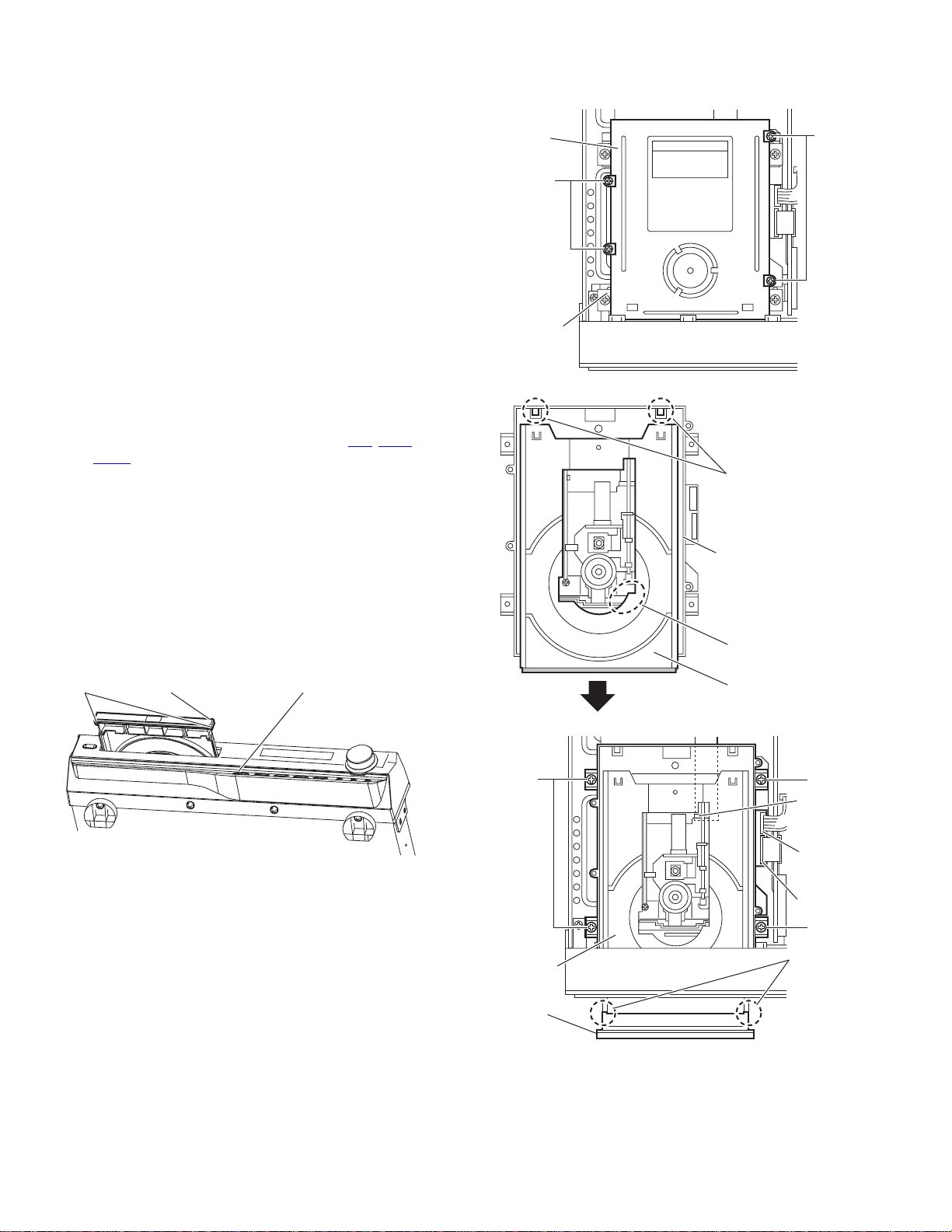

3.1.2 Removing the tray door

(See Figs.3 to 6)

• Prior to performing the following procedures, remove the top

cover.

• The following procedures are performed in the case of power

on.

(1) From the front side of the main body, push the di sk open

bottom and eject the disc tray. (See Fig.3)

(2) Release the joints a in the upward direction and take out

the tray door. (See Fig.3)

NOTE:

The following procedures are performed in th e case of power

off.

(1) From the top side of the main body, remove the four

screws C attaching the DVD top cover. (See Fig.4)

(2) Take out the disc tray in the direction of the arrow w hile

lifting the section b. (See Fig.5)

(3) Release the joints a in an upward direction and take out

the tray door. (See Fig.6)

(4) Remove the four screws D attaching the DVD mecha-

nism assembly. (See Fig.6)

(5) Disconnect the wires from the connectors AJ1

on the DVD mechanism assembly, and take out

PCN1

the DVD mechanism assembly. (See Fig.6)

(6) Push in the disc tray while lifting the section b. (See

Fig.5)

Reference:

• When pushing in the disc tray, push it until the position of the claw c. (See Fig.5)

(7) Attach the DVD top cover with the four screws C to the

DVD mechanism assembly.

Reference:

• Attaching method of the DVD mechanism assembly

refers to the section 3.1.3.

Joints a Disk open buttonTray door

, AJS1 and

DVD

top cover

C

DVD

mechanism

assembly

C

Fig.4

Claws c

DVD mechanism

assembly

Section b

Disk tray

Fig.3

D

DVD

mechanism

assembly

Tray door

Fig.5

D

AJ1

PCN1

AJS1

D

Joints a

Fig.6

1-8 (No.MB141)

Page 9

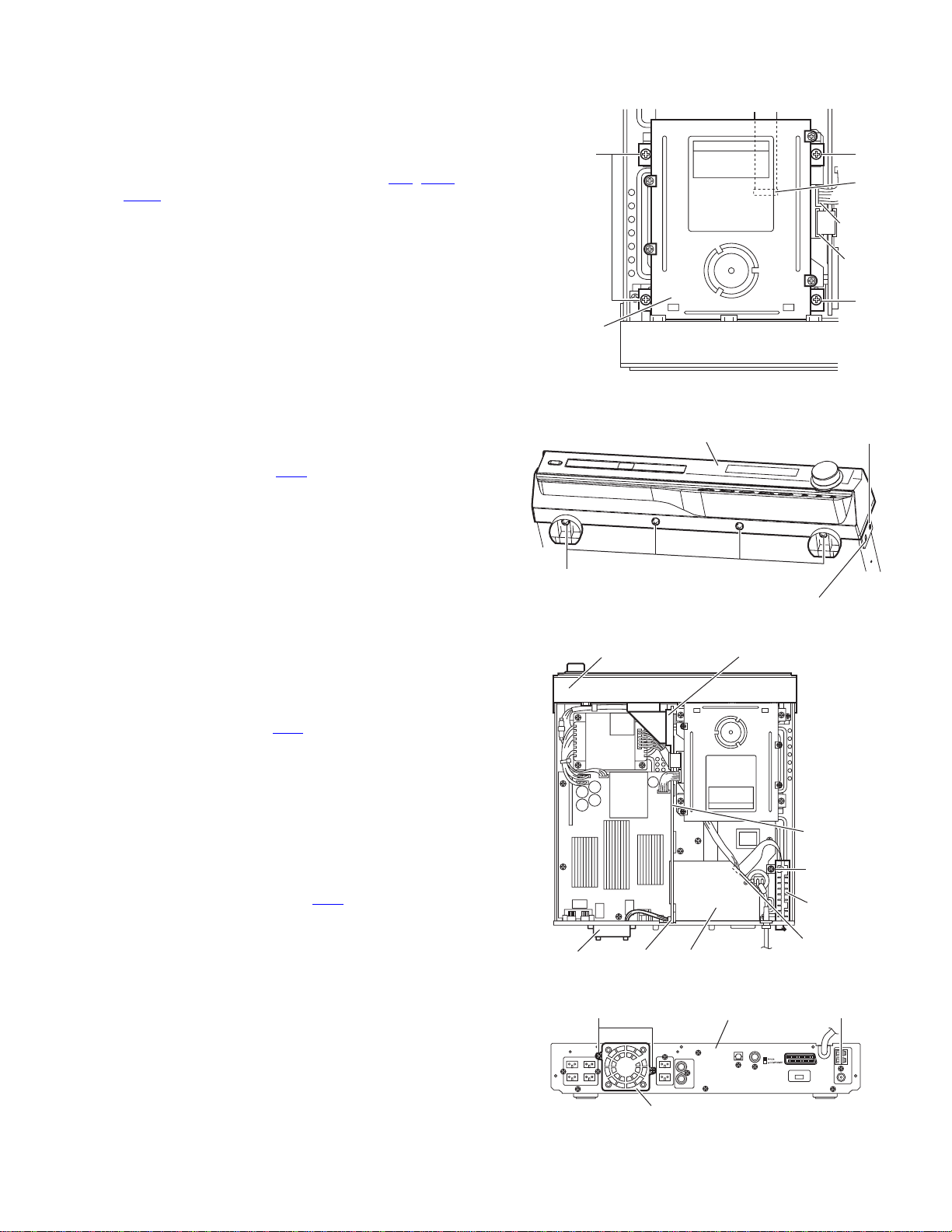

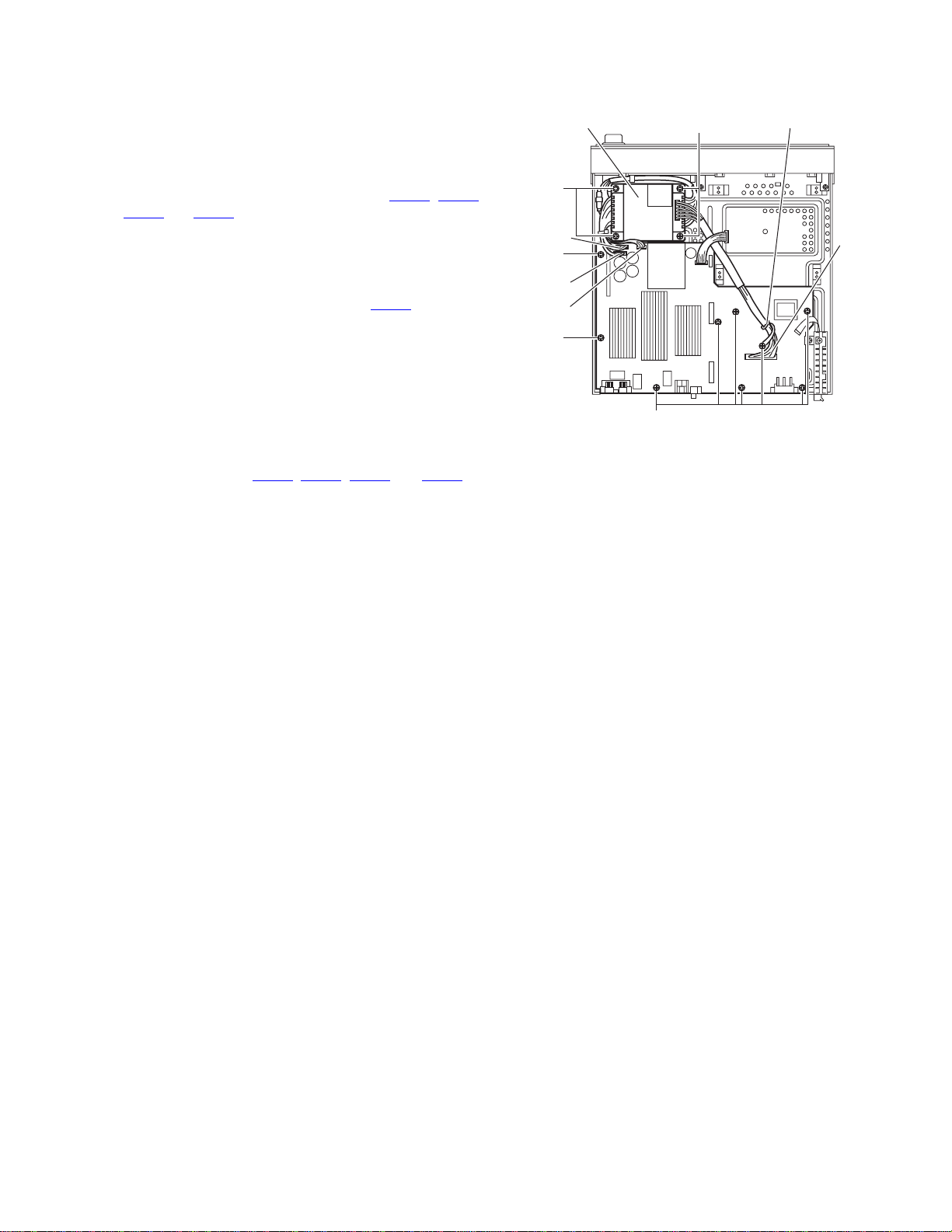

3.1.3 Removing the DVD mechanism assembly

(See Fig.7)

• Prior to performing the following procedures, remove th e top

cover and tray door.

(1) From the top side of the main body, remove the four screws

D attaching the DVD mechanism assembly.

(2) Disconnect the wires from the connectors AJ1

PCN1 on the DVD mechanism assembly, and take out the

DVD mechanism assembly.

, AJS1 and

D

D

JS1

PCN1

AJS1

3.1.4 Removing the front panel assembly (See Figs.8 and 9)

• Prior to performing the following procedures, remove th e top

cover and tray door.

(1) From the top side of the main bo dy, disconnect the card

wire from the connector UW4

Fig.8)

(2) From the bottom side of the main body, remo ve the four

screws E attaching the front panel assembly. (See Fig.9)

(3) From the both sides of the main body, remove the two

screws F attaching the front panel assembly. (See Fig.9)

(4) Release the joints d in forward direction and ta ke out the

front panel assembly. (See Fig.9)

3.1.5 Removing the tuner pack

(See Figs.8 and 10)

• Prior to performing the following procedures, remove th e top

cover.

(1) From the top side of the main bo dy, disconnect the card

wire from the connector VW4

(2) Remove the screw G attaching the tuner pack. (See Fig.8)

(3) From the back side of the main body, remove the screw H

attaching the tuner pack. (See Fig.10)

on the function board. (See

on video board. (See Fig.8)

DVD

mechanism

assembly

E

Front panel assembly

Fig.7

Front panel assembly

Fig.8

UW4

D

F

Joint d

3.1.6 Removing the fan motor (See Figs.8 and 10)

• Prior to performing the following procedures, remove th e top

cover.

(1) From the top side of the main body, disconnect the fan

motor wire from the connector UW9

(See Fig.8)

(2) From the back side of the main body, remove two screws J

attaching the fan motor. (See Fig.10)

on the function board.

Fan motor

J H

UW9

Fan motor

Video board

Fig.9

Rear panel

Fig.10

Function

board

G

Tuner

pack

VW4

(No.MB141)1-9

Page 10

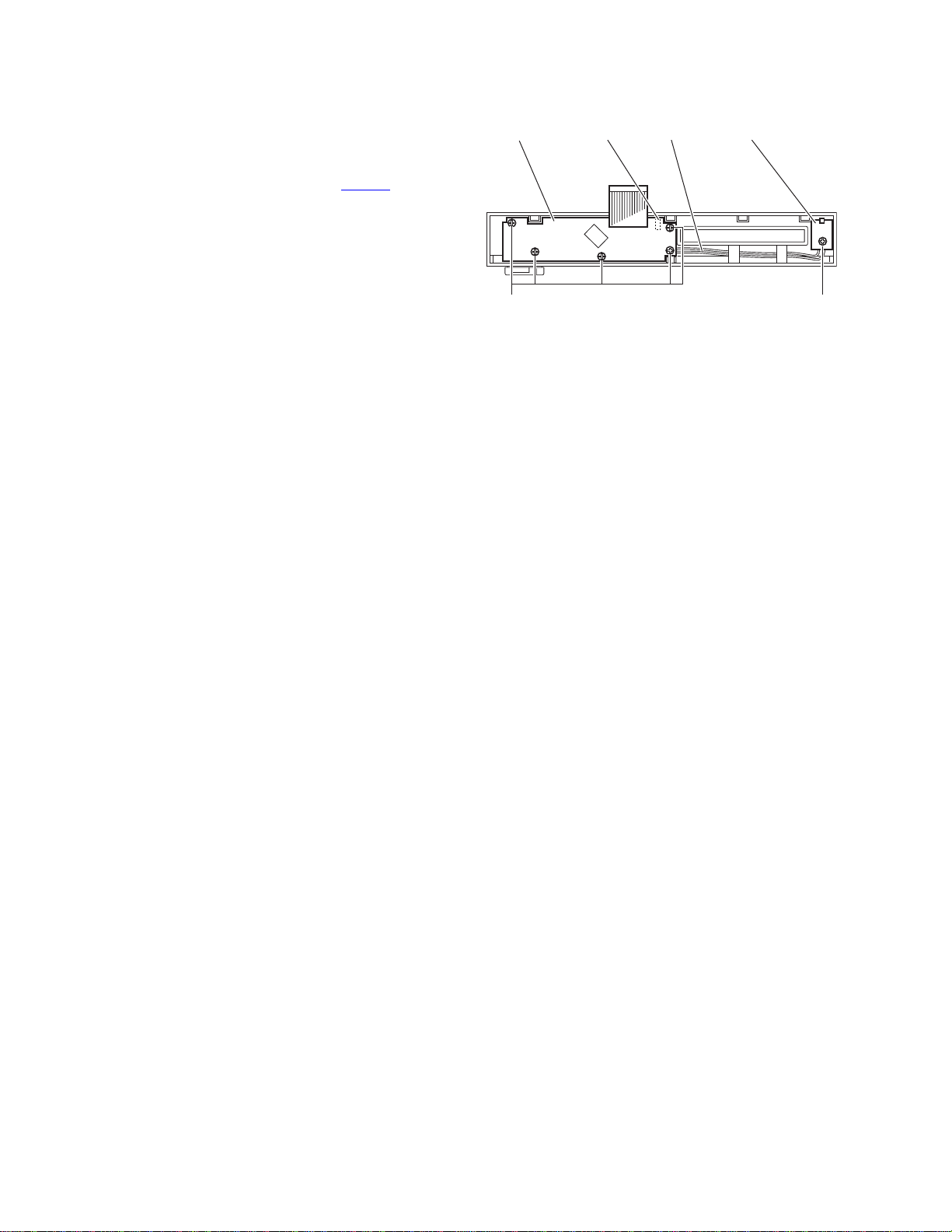

3.1.7 Removing the rear panel

(See Fig.11)

• Prior to performing the following procedures, remove the top

cover and fan motor.

(1) From the back side of the main body, remove the power

cord from the rear panel in the direction of the arrow.

(2) Remove the screw H, two screws K, five screws L three

screws M and attaching the rear panel.

(3) Take out the rear panel.

L

Rear panel

K

Power cord

3.1.8 Removing the video board

(See Fig.12)

• Prior to performing the following procedures, remove the top

cover, fan motor and rear panel.

(1) From the top side of the main body, discon nect the power

cord from the connector ACW1

(2) Disconnect the card wire from the connecto r VW4

video board.

(3) Disconnect the video board from the connector UW7

on the function board, and turn over the video board.

UW8

(4) From the reverse side of th e video board, disconnect the

card wire from the connector VW3

take out the video board.

Reference:

• Remove the tie band as required.

3.1.9 Removing the function board

(See Fig.13)

• Prior to performing the following procedures, remove the top

cover, fan motor, rear panel and video board.

(1) From the top side of the main body, disconnect the wires

from the connector PCN1

assembly.

(2) Disconnect the card wire from the connector UW4

on the function board.

UW6

(3) Remove the screw N attaching the function board.

(4) Disconnect the function board from the connector CW5

and CW7 on the main board.

CW6

on the main board.

on the

and

on the video board, and

on the DVD mechanism

and

M

Fig.11

Function board

Video board

,

VW3 VW4

Fig.12

UW4UW6 DVD mechanism

PCN1

H

UW7

UW8

ACW1

Tie band

Power cord

assembly

N

1-10 (No.MB141)

CW5

CW6

CW7

Main boardFunction board

Fig.13

Page 11

3.1.10 Removing the main board

A

A

A

(See Fig.14)

• Prior to performing the following procedures, remove th e top

cover, tray door, DVD mechanism assembly, fan motor, rear

panel, video board and function board.

(1) From the top side of the main body, remove the nine

screws P attaching the main board.

(2) Disconnect the wires from the connectors ACW2

and ACW5 on the main board and take out the main

ACW4

board.

Reference:

• When attaching the screw P, attach the wire clamp together

with it.

• After connecting the wire to the connector ACW2

wire using the wire clamp.

3.1.11 Removing the power trans

(See Fig.14)

• Prior to performing the following procedures, remove th e top

cover, tray door, DVD mechanism assembly, fan motor, rear

panel, video board and function board.

(1) From the top side of the ma in body, disconnect the wires

from the connectors ACW2

the main board.

(2) Remove the four screws Q attaching the power trans.

, ACW3, ACW4 an d ACW5 on

, ACW3,

, bundle the

Power trans

Q

CW4

P

CW3

CW5

P

P

Q

Fig.14

Wire clamp

ACW2

(No.MB141)1-11

Page 12

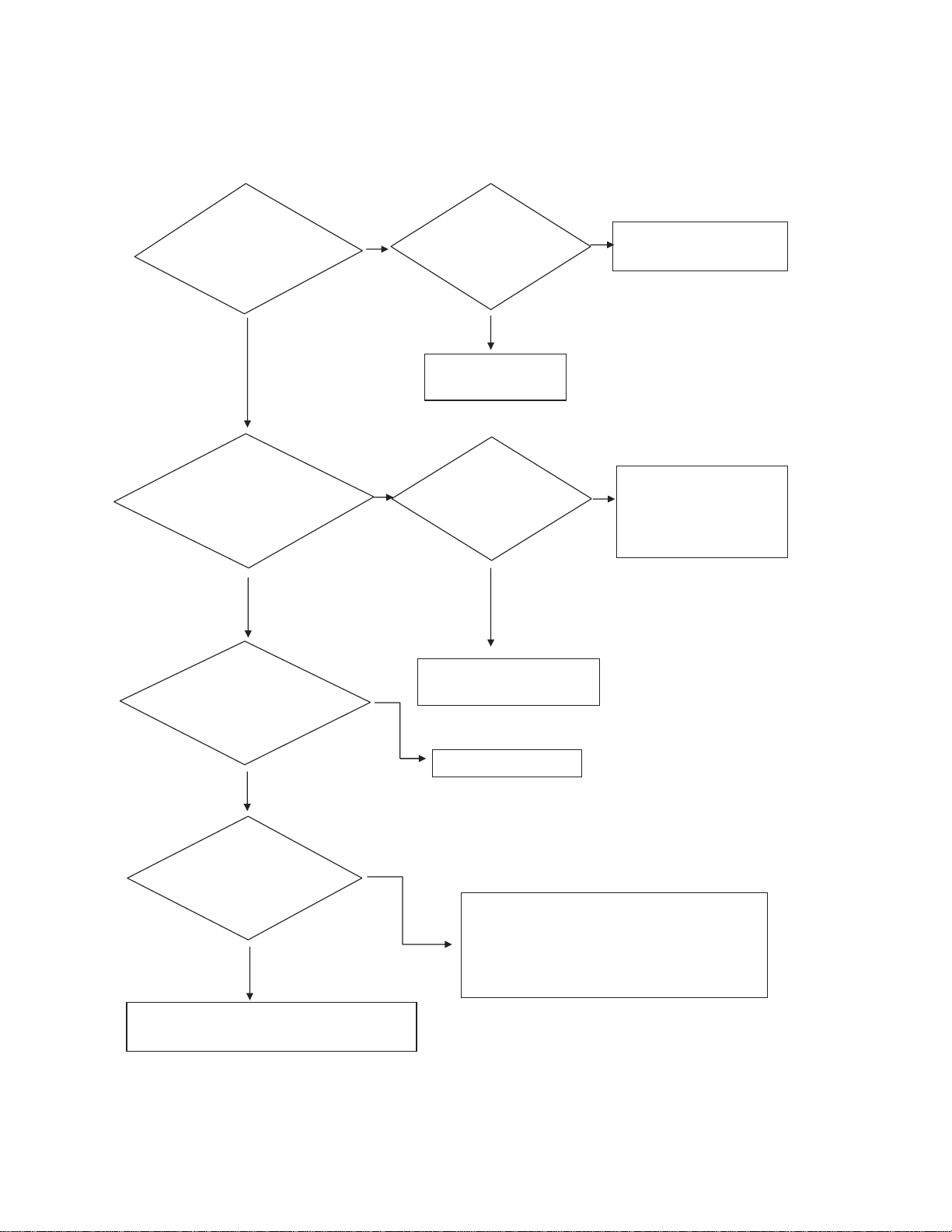

3.2 Front panel assembly section

3.2.1 Removing the front board (See Fig.15)

• Prior to performing the following procedures, remove the top

cover, tray door and front panel assembly.

(1) From the back side of the front panel assembly, remove the

five screws R attaching the FRONT board.

(2) Disconnect the wire from the connector UCW13

front board.

(3) Take out the front board from the fro nt panel assembly.

3.2.2 Removing the power SW board

(See Fig.15)

• Prior to performing the following procedures, remove the top

cover, tray door, front panel assembly and front board.

(1) Remove the screw S attaching the power SW board.

(2) Take out the power SW board from the front panel

assembly.

on the

Front board Power SW boardUCW13

Wire

R S

Fig.15

1-12 (No.MB141)

Page 13

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

(No.MB141)1-13

Page 14

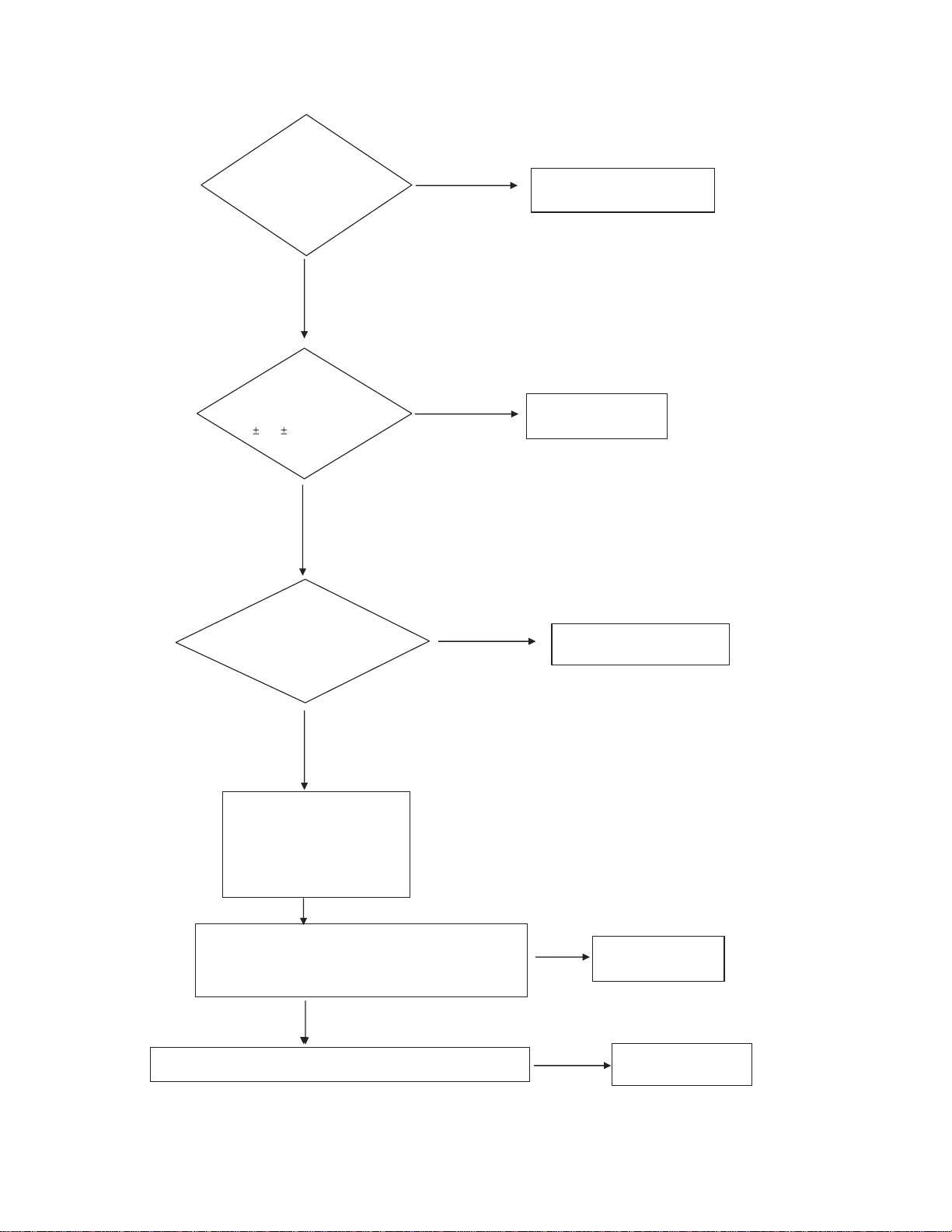

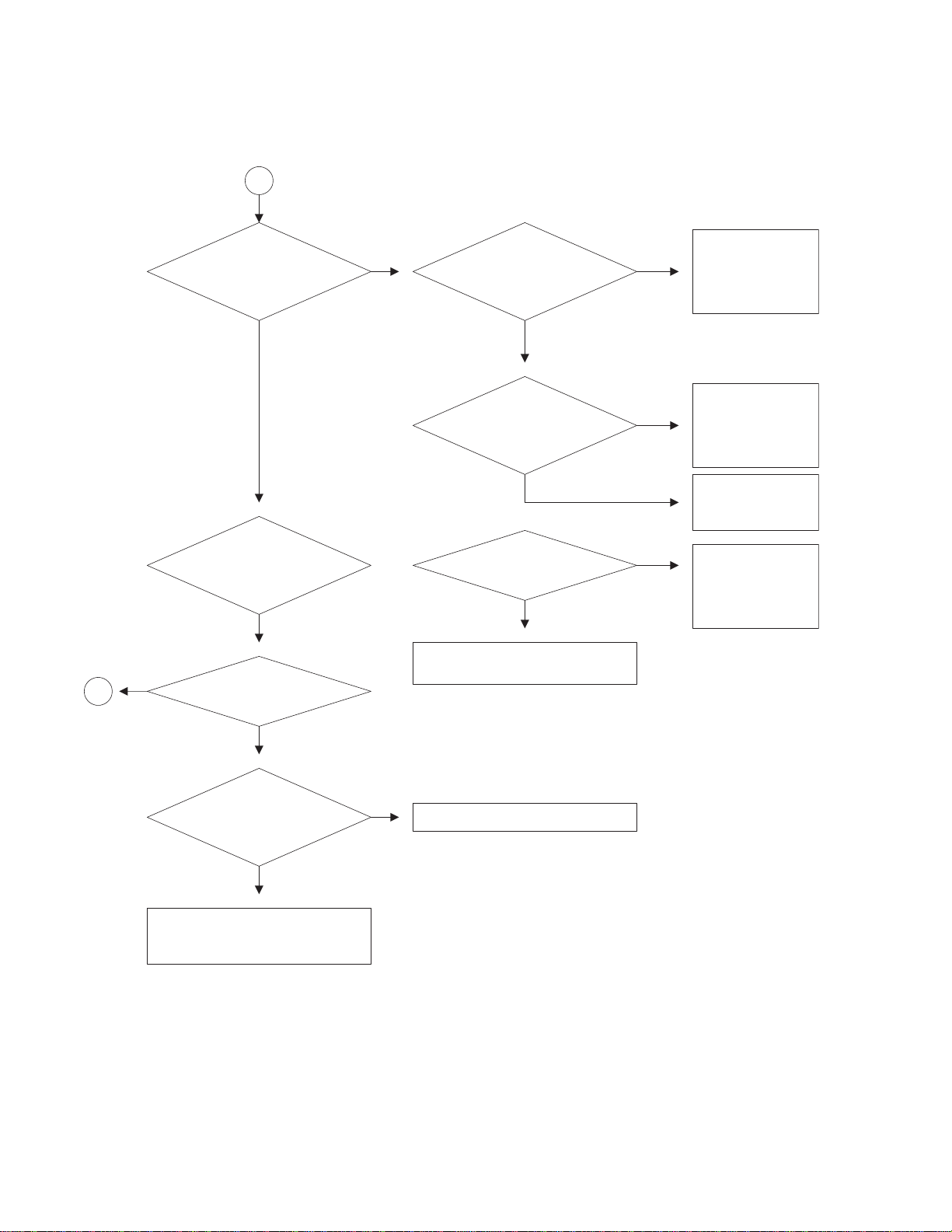

5.1 MAIN

5.1.1 POWER

SECTION 5

TROUBLESHOOTING

Check for VCC(5V)

FRONT PCB

at

;pin #17,46,72,90 of UIC1

YES

Check for power-sense(5V)at FRONT PCB

;pin #77 of UIC1

YES

When power on for FRONT PCB

Check for High Voltage(5V) at"M"com

74 of UIC1

;pin#

NO

NO

Check for Input voltage

POWER PCB

at

;AIC1(7805)

YES

Replace

Check normal Voltage

at

POWER PCB

AZD1 (5.1V, 1/2W)

YES

Check pattern from VCW7

to pin#77 of UIC1

NO

AIC1

NO

Check for circuit at Sub Trans

;PBD2, PT1, AFS3(Fuse)

Replace AZD1

NO

Check resistant from GND

to pin #77 of MICOM(UIC1)

if the short(0 ohm),to replace

Micom(UIC1)

Check for connector from DSP PCB to FRONT PCB

;VCW7

1-14 (No.MB141)

YES

Check low Voltage(0V)

at

EXPAND IC (M66010)

;pin#32 of UIC500

YES

Replace Micom(UIC1)

NO

If High Voltage (5V), check for Circuit protection

Check connector wire Ass'y of power

P/T - MAIN PCB(7P,ACW3)

MAIN PCB (8P,PW3)

Page 15

5.1.2 OUTPUT

Check voltage at Main PCB

; VM, VL

YES

Check Audio channel at CW5

for input:5.1 channel Audio signal

YES

NO

Check Connector PW1

Check ABD2,4

NO

Check Voltage for CW7

; 12V

Check signal for FR/FL/C/W/RL/RR

at MAIN PCB

YES

Check voltage for CW7(SPK Relay)

;High(5V)

Check Q4,Q5

NO

NO

Check circuit for AMP channel

;Out ports of FIC6, IC7, RIC5

Reference to NEXT page

; "A" position

Check circuit for Speak Relay

(No.MB141)1-15

Page 16

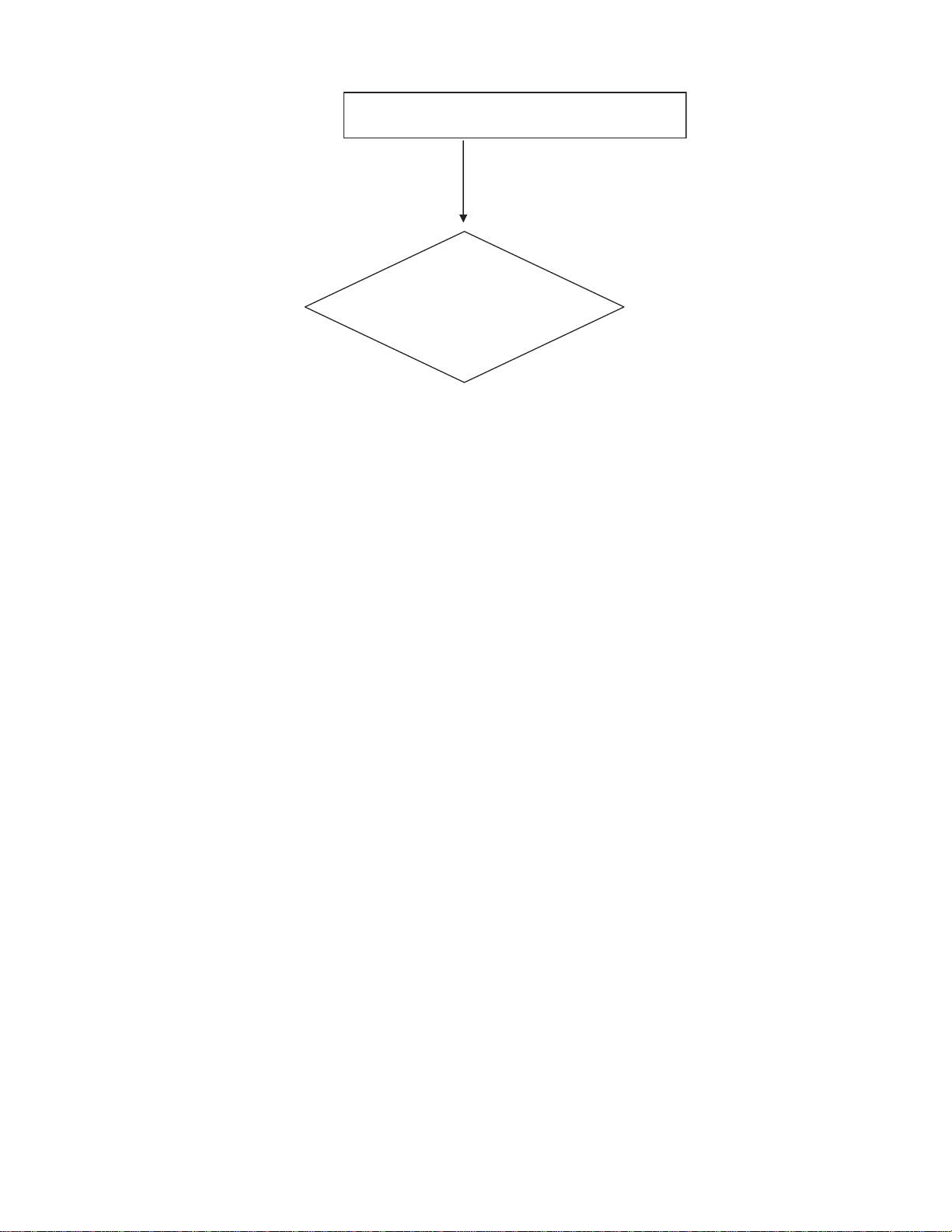

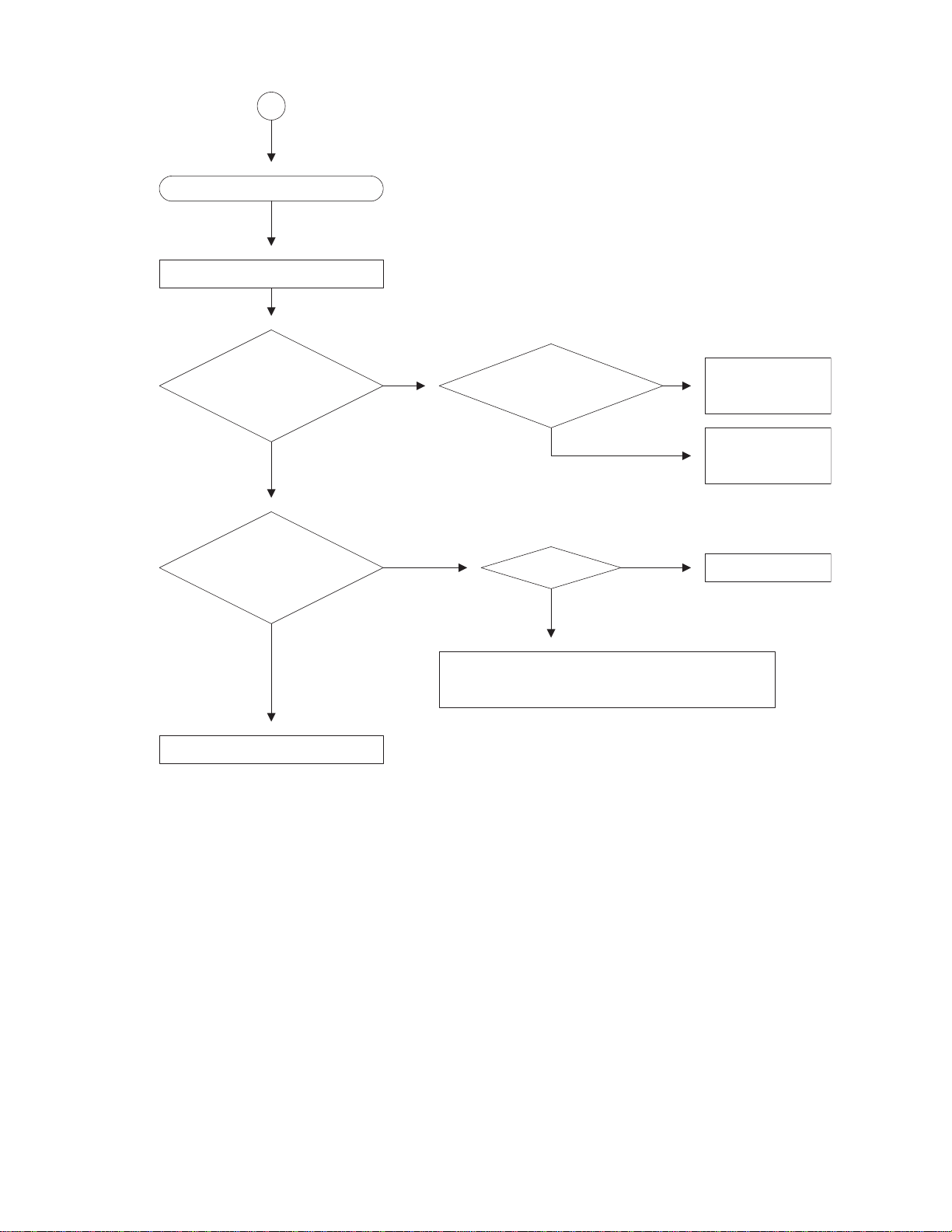

5.1.3 Protection(When High Voltage at Protectiion port)

5.1.3.1 In this case "LOW" for, Base port of Q12(R2003 TR) at MAIN PCB

Check voltage for IC4

-12V

YES

Check Voltage

for Main AMP of Main PCB

VM, VL

YES

"A"

Check DC Voltage for Speaker port

NO

Check circuit for voltage(-12V)

NO

Check ABD2,4

NO

Check circuit for DC Voltage

1-16 (No.MB141)

YES

Check the parts is normal?

;ZD6,ZD5(3.9V)

;R33,R36(27K)

R34,R37 (150 O h m)

YES

Check normal condition for Q15(C945)

;temperature-sense S/W be operated in the Power Trans

is Turn on

YES

Check electric potention for PBD 1, ABD1, PD3 at DVD Power PCB

NO

NO

Replace P/T, Q15

Check circuit for

Diode behind position

Page 17

5.1.3.2 In this case "LOW" for Base of Q13(A733) at Main PCB

Check the Turn on for channel of Q35(C945)

Check circuit for channel(Turn on)

according feedback "A"position of

previous page

5.1.3.3 Check the Connector Wire Ass'y Connectin of each PCB

;DVD MECHA - Main PCB (8P,PW3)

;POWER TRANS - Main PCB (ACW3)

(No.MB141)1-17

Page 18

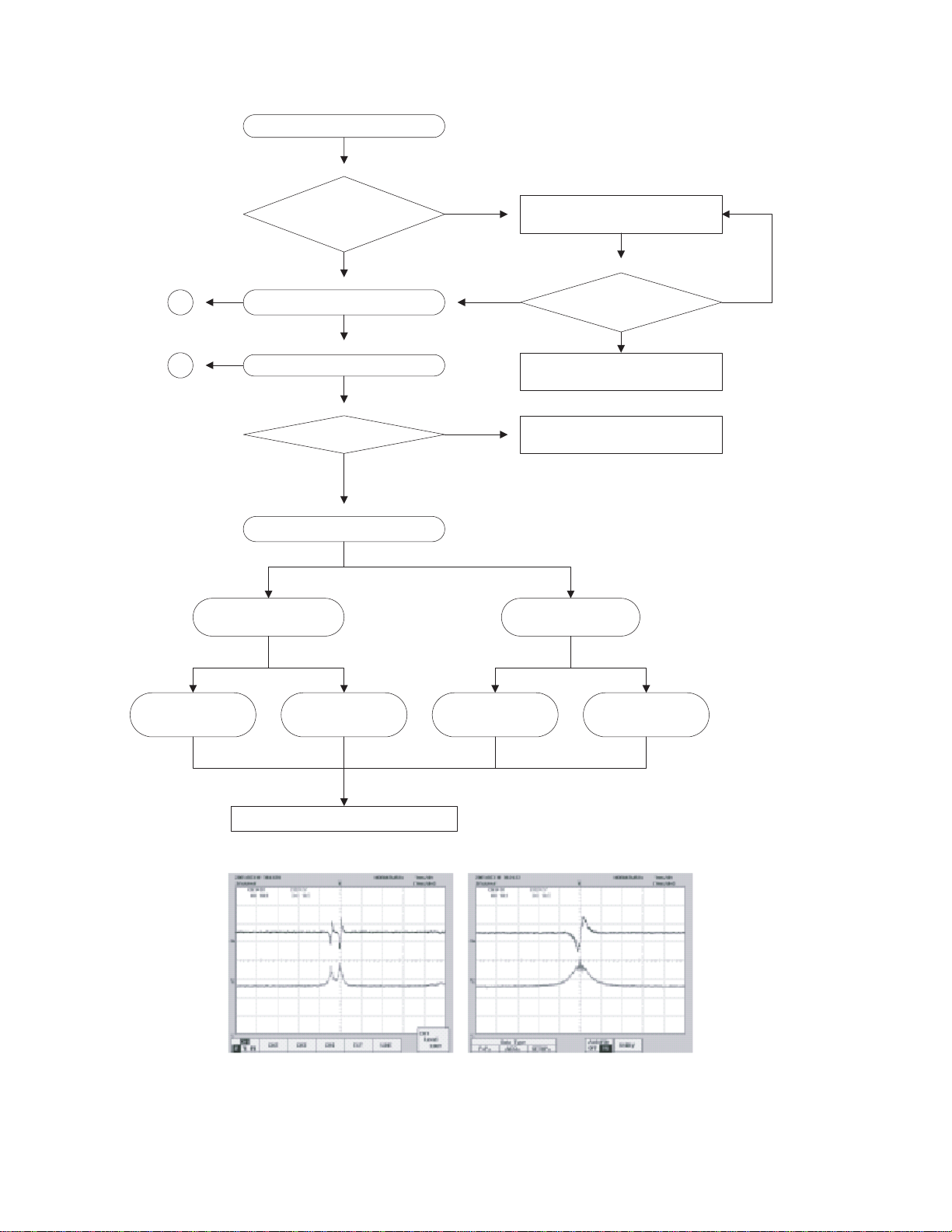

5.2 DVD Servo parts

5.2.1 Initial operation after power ON

POWER ON

3

4

DVD single or

Dual layer judgement

Is Tray closed?

Y

Pick up headinit ial position.

Disc present or not

Disc present

Y

CD or DVD judgement

DVD

N

CD

Tray close operation.

about 3sec.

N

Y

Is Tray closed?

Stop Close operation.

Wait Open Command from MPEG

N

Laser Off

Monitor Display=NO DISC

CD or CDRW

judgement

Single

DVD single

initial setting

Dual

DVD Dual

initial setting

To Each disc playback

(DVD Dual) (DVD single)

CD CDRW

CD

initial setting

CDRW

initial setting

1-18 (No.MB141)

Page 19

5.2.2 Play operation

Play

5

Disc Motor forced accelleration

Repeat

seveal times

Change

Disc Type

Focus Seach

Is focus servo

on?

Track servo ON

CLV servo ON

6

7

8

Automatic Adjustment

Automatic Adjustment is done once

when the disc is replaced

Read TOC

Search Picture appears

(No.MB141)1-19

Page 20

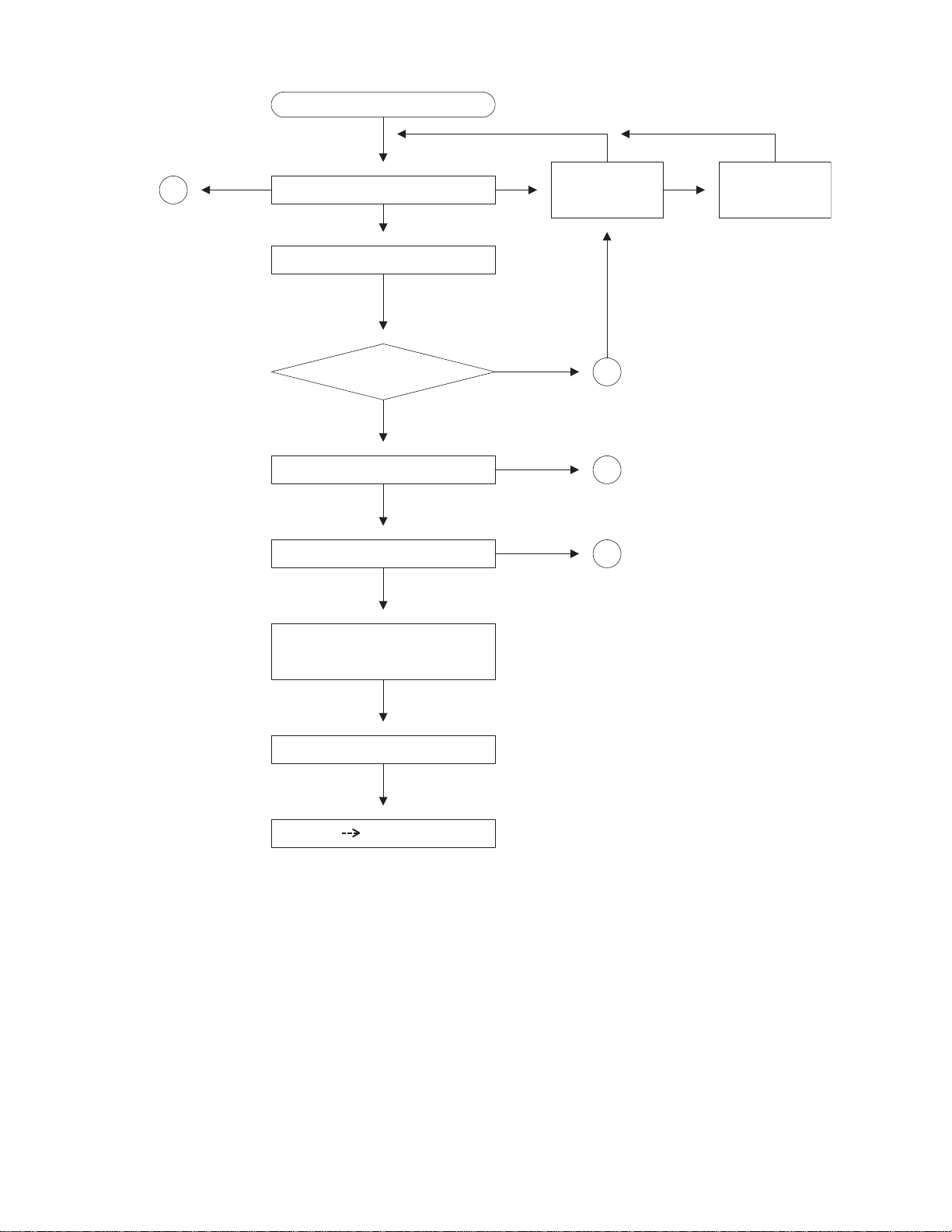

5.2.3 PickUp Head Initial Position

PickUp Head Initial Position

(1) 1. Move Pick Up Head to inner direction until pin5 of MJ4="L"

(2) 2. If pin5 of MJ4="L", then move Pick Up Head to outer direction for a short time.

(3) 3. Turn On the Laser of Pick Up Head to judge that disc is present or not.

3

OK

Does Pick Up

Move to inner

direction?

Y

Does Pick Up

Move to out

direction again?

Y

Does Laser Turn

On?

N

Is pulse of 2.5

Y

+-2.5V developed

at pin3,4 of MJ4?

Check

connection

between PCB

and MECHA

N

Is pulse of 2.5

+-2.5V developed

at pin13 of SIC1

Y

N

Check

peripheral

circuit of SIC1

and DRIC1

Check BUS

line between

SIC1 and MIC1

N

Is pin5 of MJ4 =

N

"L" appeared?

Check

connection

between PCB

Y

Check line between SIC1

and MJ4

and MECHA

N

Check voltage at

pin8 of RCN1 is

about 2.5V?

N

Check BUS line between RIC1 and

SIC1,SIC1 and MIC1

Y

Replace Pick Up Head

1-20 (No.MB141)

Page 21

5.2.4 Disc Presence/Absense Judgment

4

Disc Presence Judgment

Turn On Laser

Does lens move

with UP/DOWN

full stroke in focus

direction?

Y

Check PI

(pin36 of RU1)

signal and FE

(pin42 of RIC1)signal

Normal

Disc is presence

N

Is focus search

voltage developed

at pin 11 of SIC1

N

Check

Y

peripheral

circuit of DRIC1

Check BUS

line between

SIC1 and MIC1

YNo signal

No Disc OK

N

Check connection between RIC1 and RCN1.

Check BUS line RIC1and SIC1.

Check RIC1

(No.MB141)1-21

Page 22

5.2.5 Disc Motor Does Not Rotate

Disc Motor Does Not Rotate

5

Is Voltage of 0V

developed at

pin15 of SIC1

Check peripheral circuit of SIC1.

Check SIC1

5.2.6 Focus Servo does not Work

Focus Servo does not Work

Are FE(pin42 of RIC1)

and PI(pin36 of RIC1)

normal?

Y

Check peripheral circuit of DRIC1

N

6

N

Check peripheral circuit of SIC1 and

RIC1

Y

Check peripheral circuit of SIC1 and

RIC1

Check peripheral circuit of DRIC1

Check Connection between PCB and

MECHA

(CD-RW)

(DVD Dual)(DVD Single)(CD)

1-22 (No.MB141)

Page 23

5.2.7 Tracking Servo Does Not Work

Tracking Servo Does not Work

7

Check Voltage of

PI(pin36 of RIC1) is

normal

Y

Is TE(pin41 of RIC1)

normal?

Y

Check peripheral circuit or RCN1 and

DRIC1

Check connection between PCB

and MECHA

N

Disc Judgment Error

N

Check peripheral circuit or RIC1

Change PickUp or RIC1

Change SIC1

(CD)

(DVD Single) (DVD Dual)

(CD-RW)

(No.MB141)1-23

Page 24

5.2.8 CLV Servo Does Not Work

CLV Servo Does not Work

8

Y

Is XSRFIN(pin2 of SIC1)

normal?

N

Is RF(pin21 of RCN1)

normal?

N

Check connection between PCB

and MECHA

Check peripheral circuit of SIC1

Check peripheral circuit of DRIC1

Y

Check peripheral circuit of RIC1

1-24 (No.MB141)

Page 25

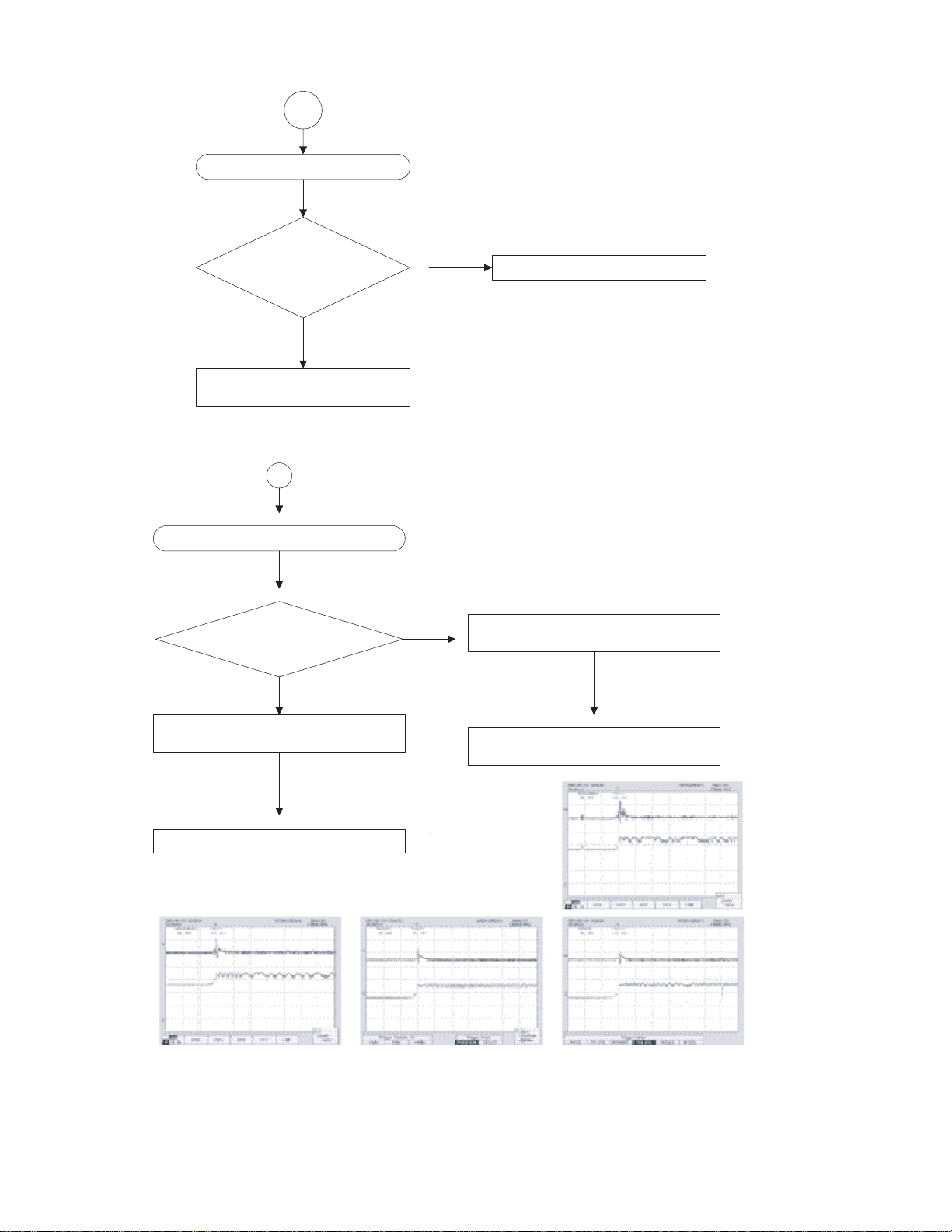

5.3 DVD MPEG Parts

5.3.1 Initial operation after NO

POWER ON

WAIT

N

2

LOGO ON

N

Check Reset Voltage at 24pin of

U13

Y

"NO DISC" DISPLAY

(in time of absence)

N

Check Servo parts and MPEG

ATAPI Line

Y

Loading

(in time of presence)

N

Check Servo spindle motor

parts

Y

Play

Y

Audio out/ in

normal

Y

OK

N

Check

Pick up Lens and Pick up Flat

Cable

N

3

(No.MB141)1-25

Page 26

5.3.2 Logo operation

2

Fig.1

5.3.3 Audio operation

Check 27MHZ crystal

FIg.1

Check 114MHZ(pin 102

of U13)

Video OK

OK

3

Check Voltage

of REG2 2.85V

REG3 3.50V

Y

Y

N

Check Video signal of

VQ1,VQ3,VQ4,VQ5,VQ6

Y

Check Audio Digital signal

at pin 33,36,37 of U13

Y

Audio out

Y

OK

N

Check NEW DSP Parts

N

Check Main AMP parts

1-26 (No.MB141)

Page 27

(No.MB141)1-27

Page 28

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB141)

Printed in Japan

WPC

Page 29

SCHEMATIC DIAGRAMS

DVD DIGITAL THATER SYSTEM

TH-A25

CD-ROM No.SML200312

Area suffix

J ----------------------------- U.S.A.

C -------------------------- Canada

SOUND

DVD DIGITAL CINEMA

SYSTEM TH-A

STANDBY/ON

STANDBY

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

25

SOURCE

VOLUME

2-1

2-3

2-13 to 21

COPYRIGHT 2003 VICTOR COMPANY OF JAPAN, LTD.

No.MB141SCH

2003/12

Page 30

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

Page 31

< MEMO >

Page 32

Block diagram

0

R

0

R

TUNER

DVD PACK

LPF

LPF

LPF

LPF

AUX

TUNER L

AUX L

TUNER R

AUX R

OPTICAL IN

CS8415

DIR

ESS

(MPEG)

FRONT L

FRONT R

REAR L

REAR R

CENTER

STAC9460S

SUB WOOFER

CODEC

CLK

LPF

LPF

LPF

LPF

LPF

FL

RL

C

BA456

(MIXE

2-1

FR

RR

S/W

BA456

(MIXE

Page 33

V F D

X

R

DI1

LC87F67C8A

L

L

R

R

TDA7440

RL IN

RR IN

C IN

S/W IN

CLK

RL

RR

C

S/W

DO1

CE1

CLK

E. VOL

DO1

DI1

CE1

CLK

POWER

AMP

POWER

AMP

POWER

AMP

POWER

AMP

M66010

EXPAND

6 OHM

(30 W)

6 OHM

(30 W)

6 OHM

(30 W)

6 OHM

(30 W)

FRONT L-CH

FRONT R-CH

REAR L-CH

REAR R-CH

BA4560

MIXER)

BA4560

MIXER)

M62446AFP

VOLUME/TONE

RCA JACK

POWER

AMP

POWER

AMP

VIDEO OPTION

6 OHM

(30 W)

3 OHM

(50 W)

Center

SUB WOOFE

2-2

Page 34

(

)

Standard schematic diagrams

Main section

To UW2

(SHEET 2)

2-3

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

To UW1

SHEET 2

Page 35

To PCN1

(SHEET 4)

To UW3

(SHEET 2)

SHEET 1

2-4

Page 36

Function section

To AJS1

(SHEET 5)

To VW1

(SHEET 3)

To UCW7

(SHEET 3)

2-5

Page 37

To VW2

(

)

(SHEET 3)

To CW5

(SHEET 1)

To CW7

SHEET 2

(SHEET 1)

SHEET 1

To CW6

2-6

Page 38

Front display section

To UW4

(SHEET 2)

2-7

Page 39

Video section

To AJ1

(SHEET 5)

To UW8

(SHEET 2)

To UW7

(SHEET 2)

To TUNER

SHEET 3

2-8

Page 40

DVD loader section

To PW3 (SHEET 1)

2-9

Page 41

SHEET 4

2-10

Page 42

DVD MPEG DEC section

2-11

Page 43

To UW6 (SHEET 2)

SHEET 5

To VW3 (SHEET 3)

2-12

Page 44

Printed circuit boards

Main board

2-13

Page 45

2-14

Page 46

Function board

Forward side

Reverse side

2-15

Page 47

side

e side

2-16

Page 48

Front board

(Power SW board)

Forward side

(FL board)

Reverse side

(FL board)

2-17

Page 49

(Power SW board)

2-18

Page 50

DVD servo control board

Forward side

2-19

Page 51

Reverse side

2-20

Page 52

Video board

2-21

Page 53

< MEMO >

Page 54

PARTS LIST

[ TH-A25 ]

* All printed circuit boards and its assemblies are not available as service parts.

Area suffix

J ----------------------------- U.S.A.

C -------------------------- Canada

MB141

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

Electrical parts list (Block No.01~05)

Packing materials and accessories parts list (Block No.M3)

3- 2

3- 5

3-16

3-1

Page 55

Exploded view of general assmbly and parts list

M

o

Block No.

M

52

45

M

1

Tuner pack

M

54

46

Video b

47

DVD pack

DVD board

50

11

51

12

52

51

52

15

Front board

Function board

51

14

46

52

23

9

24

52

52

19

22

21

20

52

3-2

9

49

5

4

3

2

1

48

10

6

7

13

53

50

34

9

8

49

35

Page 56

M

M

33

pack

2

19

52

52

46

Video board

21

52

20

54

Main board

16

22

25

18

17

51

26

49

38

29

54

40

41

42

32

49

54

31

30

28

27

53

34

35

53

9

44

Power trans

3-3

Page 57

General assembly

Block No. [M][1][M][M]

Symbol No.

1 AH64-02580A BADGE-DVD

2 AH64-02575B WINDOW-CD

3 AH64-02569A DOOR-CD

4 AH61-01404A HOLDER-DOOR

5 AH61-01325A SPRING-DOOR (x2)

6 AH64-02574C WINDOW-FRONT

7 AH64-02570A KNOB-VOLUME

8 AH64-02573B DECO-VOLUME

9 AH73-00005A RUBBER-FOOT (x4)

10 AH63-00610A FILTER-VFD

11 AH64-02568C CABINET-FRONT

12 AH64-02572B KNOB-POWER

13 AH64-02571B KNOB-FUNCTION

14 AH61-01406A HOLDER-VFD

15 AH64-02316A CABINET-BOTTOM

16 AH62-00052D HEAT-SINK DIO

17 AH62-00096A HEAT-SINK S

18 AH62-00097A HEAT-SINK L

19 AH62-00098A HEAT-SINK TR

20 AH62-00062C HEAT-SINK TR

21 AH62-00062D HEAT-SINK TR

22 AH61-01140A BRKT-PCB (x2)

23 AH61-01355A BRKT-TUNER

24 AH63-00278H COVER-FUSE

25 AH61-00855A HOLDER-IC

26 AH61-00779A HOLDER-IC (x5)

27 AH64-02648B CABINET-REAR

28 AH63-00384A SHIELD-SPK8

29 AH63-00385A SHIELD-SPK4

30 AH31-00039A MOTOR FAN

31 AH63-00517A COVER-FAN

32 AH64-02315B CABINET-TOP

33 AH39-00258U POWER-CORD

34 AH63-00632B SHIELD-FRONT.L

35 AH63-00632C SHIELD-FRONT.R

38 AH68-01348B LABEL-RATING A25C

38 AH68-01348A LABEL-RATING A25J

40 AH68-00093E LABEL-NO.1

41 AH68-00331C LABEL-FCC

42 AH68-00331D LABEL-HHS A25J

44 AH26-00261B TRANS POWER

45 AH40-00058A TUNER-PACK ASSY

46 3601-000301 FUSE-CARTRIDGE (x2)

47 AH59-01153B DVD MECHA ASSY

48 AJ60-10001A SCREW TAP (x2)

49 AH60-00025A SCREW-TAPTITE (x18)

50 6002-000126 SCREW-TAPPING (x2)

51 6003-000276 SCREW-TAPTITE (x29)

52 6003-000283 SCREW-TAPTITE (x16)

53 AH60-00014A SCREW-TAPTITE (x6)

54 6003-001499 SCREW-TAPTITE (x8)

Part No. Part Name Description Local

3-4

Page 58

Electrical parts list

Main board

Block No. [0][1][0][0]

Symbol No.

PW3 AH39-00525A LEAD CONNECTOR

IC4 7912 IC 1203-000110

IC7 BA4560 IC 1201-000163

Q1 0504-000118 DIGI TRANSISTOR

Q4 0501-000294 TRANSISTOR

Q5 0501-000398 TRANSISTOR

Q6 0501-000610 TRANSISTOR

Q7 0501-000314 TRANSISTOR

Q8 0501-000341 TRANSISTOR

Q9 0501-000331 TRANSISTOR

Q10 0501-000398 TRANSISTOR

Q11 0501-000398 TRANSISTOR

Q12 0504-001003 DIGI TRANSISTOR

Q13 0501-000303 TRANSISTOR

Q14 0501-000398 TRANSISTOR

Q15 0501-000398 TRANSISTOR

Q16 0501-000303 TRANSISTOR

Q17C 0501-002184 TRANSISTOR

Q17W 0501-002184 TRANSISTOR

Q19C 0501-000398 TRANSISTOR

Q19W 0501-000354 TRANSISTOR

Q20C 0501-000303 TRANSISTOR

Q20W 0501-002188 TRANSISTOR

Q21C 0501-000294 TRANSISTOR

Q21W 0501-002332 TRANSISTOR

Q22C 0501-000010 TRANSISTOR

Q22W 0501-000359 TRANSISTOR

Q23C 0501-000010 TRANSISTOR

Q25C 0501-000010 TRANSISTOR

Q26C 0501-000294 TRANSISTOR

Q28C 0501-000294 TRANSISTOR

Q29C 0502-001048 TRANSISTOR

Q30W 0503-001014 TRANSISTOR

Q31C 0502-001048 TRANSISTOR

Q31W 0503-001014 TRANSISTOR

Q32C 0502-001210 TRANSISTOR

Q32W 0503-001016 TRANSISTOR

Q33W 0503-001016 TRANSISTOR

Q34C 0502-001210 TRANSISTOR

Q35C 0501-000398 TRANSISTOR

Q35W 0501-000331 TRANSISTOR

Q36C 0502-001048 TRANSISTOR

Q36W 0502-001048 TRANSISTOR

Q50C 0504-000156 DIGI TRANSISTOR

Q50F 0504-000156 DIGI TRANSISTOR

Q50R 0504-000156 DIGI TRANSISTOR

Q17FL 0501-002184 TRANSISTOR

Q17FR 0501-002184 TRANSISTOR

Q17RL 0501-002184 TRANSISTOR

Q17RR 0501-002184 TRANSISTOR

Q19FL 0501-000398 TRANSISTOR

Q19FR 0501-000398 TRANSISTOR

Q19RL 0501-000398 TRANSISTOR

Q19RR 0501-000398 TRANSISTOR

Q20FL 0501-000303 TRANSISTOR

Q20FR 0501-000303 TRANSISTOR

Q20RL 0501-000303 TRANSISTOR

Q20RR 0501-000303 TRANSISTOR

Q21FL 0501-000294 TRANSISTOR

Q21FR 0501-000294 TRANSISTOR

Q21RL 0501-000294 TRANSISTOR

Q21RR 0501-000294 TRANSISTOR

Q22FL 0501-000010 TRANSISTOR

Q22FR 0501-000010 TRANSISTOR

Q22RL 0501-000010 TRANSISTOR

Q22RR 0501-000010 TRANSISTOR

Q23FL 0501-000010 TRANSISTOR

Q23FR 0501-000010 TRANSISTOR

Q23RL 0501-000010 TRANSISTOR

Q23RR 0501-000010 TRANSISTOR

Part No. Part Name Description Local

Symbol No.

Q25FL 0501-000010 TRANSISTOR

Q25FR 0501-000010 TRANSISTOR

Q25RL 0501-000010 TRANSISTOR

Q25RR 0501-000010 TRANSISTOR

Q26FL 0501-000294 TRANSISTOR

Q26FR 0501-000294 TRANSISTOR

Q26RL 0501-000294 TRANSISTOR

Q26RR 0501-000294 TRANSISTOR

Q28FL 0501-000294 TRANSISTOR

Q28FR 0501-000294 TRANSISTOR

Q28RL 0501-000294 TRANSISTOR

Q28RR 0501-000294 TRANSISTOR

Q29FL 0502-001048 TRANSISTOR

Q29FR 0502-001048 TRANSISTOR

Q29RL 0502-001048 TRANSISTOR

Q29RR 0502-001048 TRANSISTOR

Q31FL 0502-001048 TRANSISTOR

Q31FR 0502-001048 TRANSISTOR

Q31RL 0502-001048 TRANSISTOR

Q31RR 0502-001048 TRANSISTOR

Q32FL 0502-001210 TRANSISTOR

Q32FR 0502-001210 TRANSISTOR

Q32RL 0502-001210 TRANSISTOR

Q32RR 0502-001210 TRANSISTOR

Q33FR 0501-000398 TRANSISTOR

Q34FL 0502-001210 TRANSISTOR

Q34FR 0502-001210 TRANSISTOR

Q34RL 0502-001210 TRANSISTOR

Q34RR 0502-001210 TRANSISTOR

Q35FL 0501-000398 TRANSISTOR

Q35RL 0501-000398 TRANSISTOR

Q35RR 0501-000398 TRANSISTOR

Q36FL 0502-001048 TRANSISTOR

Q36FR 0502-001048 TRANSISTOR

Q36RL 0502-001048 TRANSISTOR

Q36RR 0502-001048 TRANSISTOR

D12 0401-001090 FR DIODE

D13 0401-001090 FR DIODE

D14 0401-001090 FR DIODE

D15 0401-001090 FR DIODE

D20 0401-001090 FR DIODE

D21 0401-001090 FR DIODE

D22 0402-000127 FR DIODE

D23 0402-000127 FR DIODE

D25 0402-000127 FR DIODE

D28 0401-001090 FR DIODE

D29 0401-000101 FR DIODE

D30 0401-001090 FR DIODE

D31 0401-001090 FR DIODE

D32 0401-001090 FR DIODE

D33 0401-001090 FR DIODE

D34 0401-001090 FR DIODE

D100 0403-000379 Z DIODE

D18C 0401-001090 FR DIODE

D18W 0401-001090 FR DIODE

D19C 0401-001090 FR DIODE

D19W 0401-001090 FR DIODE

D35C 0401-001090 FR DIODE

D36W 0401-001090 FR DIODE

D37W 0401-001090 FR DIODE

D38C 0401-001090 FR DIODE

D39C 0401-001090 FR DIODE

D39W 0401-001090 FR DIODE

D40C 0402-000309 FR DIODE

D40W 0402-001484 FR DIODE

D41C 0402-000309 FR DIODE

D41W 0402-001484 FR DIODE

D18FL 0401-001090 FR DIODE

D18FR 0401-001090 FR DIODE

D18RL 0401-001090 FR DIODE

D18RR 0401-001090 FR DIODE

D19FL 0401-001090 FR DIODE

D19FR 0401-001090 FR DIODE

D19RL 0401-001090 FR DIODE

D19RR 0401-001090 FR DIODE

Part No. Part Name Description Local

3-5

Page 59

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

D33FR 0401-001090 FR DIODE

D35FL 0401-001090 FR DIODE

D35FR 0401-001090 FR DIODE

D35RL 0401-001090 FR DIODE

D35RR 0401-001090 FR DIODE

D38FL 0401-001090 FR DIODE

D38RL 0401-001090 FR DIODE

D38RR 0401-001090 FR DIODE

D39FL 0401-001090 FR DIODE

D39FR 0401-001090 FR DIODE

D39RL 0401-001090 FR DIODE

D39RR 0401-001090 FR DIODE

D40FL 0402-000309 FR DIODE

D40FR 0402-000309 FR DIODE

D40RL 0402-000309 FR DIODE

D40RR 0402-000309 FR DIODE

D41FL 0402-000309 FR DIODE

D41FR 0402-000309 FR DIODE

D41RL 0402-000309 FR DIODE

D41RR 0402-000309 FR DIODE

PC2 2401-001572 E CAPACITOR

PC3 2401-001879 E CAPACITOR

PC4 2401-001879 E CAPACITOR

PC5 2401-001052 E CAPACITOR

PC6 2401-000475 E CAPACITOR

PC7 2401-001893 E CAPACITOR

PC8 2401-001893 E CAPACITOR

PC9 2401-001893 E CAPACITOR

PC11 2401-001893 E CAPACITOR

PC13 2401-000475 E CAPACITOR

PC19 2201-000161 C CAPACITOR

PC20 2201-000161 C CAPACITOR

PC50 2401-003681 E CAPACITOR

C27 2401-000325 E CAPACITOR

C28 2401-000475 E CAPACITOR

C29 2401-000475 E CAPACITOR

C30 2401-001364 E CAPACITOR

C31 2401-001364 E CAPACITOR

C34 2401-000385 E CAPACITOR

C35 2401-001361 E CAPACITOR

C36 2401-001912 E CAPACITOR

C37 2401-001975 E CAPACITOR

C38 2401-001912 E CAPACITOR

C39 2401-001912 E CAPACITOR

C40 2401-000438 E CAPACITOR

C41 2203-001036 CHIP CAPACITOR

C43 2401-000907 E CAPACITOR

C44 2203-000710 CHIP CAPACITOR

C47 2301-000375 M CAPACITOR

C49 2203-000236 CHIP CAPACITOR

C53 2401-000475 E CAPACITOR

C55 2401-001975 E CAPACITOR

C40W 2401-000438 E CAPACITOR

C41W 2203-001036 CHIP CAPACITOR

C43W 2401-000907 E CAPACITOR

C44W 2203-000295 CHIP CAPACITOR

C47W 2301-000375 M CAPACITOR

C49W 2203-000295 CHIP CAPACITOR

C50F 2401-001975 E CAPACITOR

C50R 2401-001975 E CAPACITOR

C202L 2203-000787 CHIP CAPACITOR

C202R 2203-000787 CHIP CAPACITOR

C39-1 2401-001975 E CAPACITOR

C40FL 2401-000438 E CAPACITOR

C40FR 2401-000438 E CAPACITOR

C40RL 2401-000438 E CAPACITOR

C40RR 2401-000438 E CAPACITOR

C41FL 2203-001036 CHIP CAPACITOR

C41FR 2203-001036 CHIP CAPACITOR

C41RL 2203-001036 CHIP CAPACITOR

C41RR 2203-001036 CHIP CAPACITOR

C43FL 2401-000907 E CAPACITOR

C43FR 2401-000907 E CAPACITOR

C43RL 2401-000907 E CAPACITOR

C43RR 2401-000907 E CAPACITOR

C44FL 2203-000710 CHIP CAPACITOR

C44FR 2203-000710 CHIP CAPACITOR

C44RL 2203-000710 CHIP CAPACITOR

C44RR 2203-000710 CHIP CAPACITOR

C47FL 2301-000375 M CAPACITOR

C47FR 2301-000375 M CAPACITOR

C47RL 2301-000375 M CAPACITOR

C47RR 2301-000375 M CAPACITOR

C49FL 2203-000236 CHIP CAPACITOR

C49FR 2203-000236 CHIP CAPACITOR

C49RL 2203-000236 CHIP CAPACITOR

C49RR 2203-000236 CHIP CAPACITOR

R10 2007-000282 CHIP RESISTOR

R12 2007-000586 CHIP RESISTOR

R13 2007-000282 CHIP RESISTOR

R14 2007-000572 CHIP RESISTOR

R16 2007-000518 CHIP RESISTOR

R19 2007-000774 CHIP RESISTOR

R20 2007-000774 CHIP RESISTOR

R21 2007-000586 CHIP RESISTOR

R22 2007-000586 CHIP RESISTOR

R27 2007-000468 CHIP RESISTOR

R28 2007-000300 CHIP RESISTOR

R29 2007-000468 CHIP RESISTOR

R30 2007-000572 CHIP RESISTOR

R31 2007-000941 CHIP RESISTOR

R32 2007-000493 CHIP RESISTOR

R33 2007-000586 CHIP RESISTOR

R34 2007-000401 CHIP RESISTOR

R35 2007-000493 CHIP RESISTOR

R36 2001-000522 C RESISTOR

R37 2007-000401 CHIP RESISTOR

R38 2007-001039 CHIP RESISTOR

R39 2003-000578 METAL RESISTOR

R41 2001-000052 C RESISTOR

R43 2007-000774 CHIP RESISTOR

R44 2003-000616 METAL RESISTOR

R45 2003-000429 R-METAL OXIDE(S

R47 2007-000872 CHIP RESISTOR

R48 2007-000941 CHIP RESISTOR

R49 2007-000941 CHIP RESISTOR

R50 2007-000300 CHIP RESISTOR

R51 2007-000300 CHIP RESISTOR

R52 2007-000735 CHIP RESISTOR

R53 2007-000001 CHIP RESISTOR

R54 2007-000300 CHIP RESISTOR

R55 2007-000586 CHIP RESISTOR

R56 2007-000300 CHIP RESISTOR

R57 2007-000586 CHIP RESISTOR

R58 2007-000300 CHIP RESISTOR

R59 2007-000300 CHIP RESISTOR

R60 2007-001118 CHIP RESISTOR

R61 2007-000774 CHIP RESISTOR

R62 2007-000586 CHIP RESISTOR

R63 2007-000300 CHIP RESISTOR

R64 2007-000355 CHIP RESISTOR

R65 2007-000300 CHIP RESISTOR

R66 2007-000872 CHIP RESISTOR

R67 2007-000586 CHIP RESISTOR

R68 2007-000872 CHIP RESISTOR

R69 2007-000774 CHIP RESISTOR

R70 2007-000774 CHIP RESISTOR

R71 2007-000300 CHIP RESISTOR

R72 2001-000977 C RESISTOR

R73 2007-000710 CHIP RESISTOR

R74 2007-000300 CHIP RESISTOR

R75 2007-000941 CHIP RESISTOR

R76 2007-000468 CHIP RESISTOR

R78 2007-001039 CHIP RESISTOR

R79 2007-000267 CHIP RESISTOR

R80 2007-001039 CHIP RESISTOR

R81 2007-000872 CHIP RESISTOR

R82 2007-000686 CHIP RESISTOR

R83 2007-000686 CHIP RESISTOR

R84 2007-000300 CHIP RESISTOR

R86 2007-000931 CHIP RESISTOR

R87 2007-000981 CHIP RESISTOR

R88 2007-000493 CHIP RESISTOR

3-6

Page 60

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R89 2007-000931 CHIP RESISTOR

R91 2007-000766 CHIP RESISTOR

R93 2007-000766 CHIP RESISTOR

R94 2007-000766 CHIP RESISTOR

R96 2007-000766 CHIP RESISTOR

R97 2007-008317 CHIP RESISTOR

R98 2007-008317 CHIP RESISTOR

R99 2001-000019 C RESISTOR

R100 2003-000473 METAL RESISTOR

R101 2001-001178 C RESISTOR

R135 2007-000941 CHIP RESISTOR

R142 2007-000586 CHIP RESISTOR

R143 2007-000300 CHIP RESISTOR

R14C 2007-000572 CHIP RESISTOR

R14F 2001-000515 C RESISTOR

R14L 2001-000515 C RESISTOR

R14W 2001-000515 C RESISTOR

R200 2007-000686 CHIP RESISTOR

R201 2007-000774 CHIP RESISTOR

R27C 2007-000468 CHIP RESISTOR

R27F 2007-000468 CHIP RESISTOR

R27L 2007-000300 CHIP RESISTOR

R27L 2007-000468 CHIP RESISTOR

R27W 2007-000493 CHIP RESISTOR

R28C 2007-000300 CHIP RESISTOR

R28F 2007-000300 CHIP RESISTOR

R28W 2007-000300 CHIP RESISTOR

R29C 2007-000468 CHIP RESISTOR

R29F 2007-000468 CHIP RESISTOR

R29L 2007-000468 CHIP RESISTOR

R29W 2007-000468 CHIP RESISTOR

R30C 2001-000515 C RESISTOR

R30F 2001-000515 C RESISTOR

R31C 2007-000941 CHIP RESISTOR

R31F 2007-000941 CHIP RESISTOR

R32C 2007-000493 CHIP RESISTOR

R32F 2007-000493 CHIP RESISTOR

R32L 2007-000493 CHIP RESISTOR

R32W 2007-000241 CHIP RESISTOR

R33C 2007-000586 CHIP RESISTOR

R33F 2007-000586 CHIP RESISTOR

R33L 2007-000586 CHIP RESISTOR

R33W 2007-000653 CHIP RESISTOR

R34C 2007-000401 CHIP RESISTOR

R34F 2007-000401 CHIP RESISTOR

R34L 2007-000401 CHIP RESISTOR

R34W 2007-000401 CHIP RESISTOR

R35C 2007-000493 CHIP RESISTOR

R35F 2007-000493 CHIP RESISTOR

R35L 2007-000493 CHIP RESISTOR

R35W 2007-000241 CHIP RESISTOR

R36C 2001-000522 C RESISTOR

R36F 2001-000522 C RESISTOR

R36L 2007-000586 CHIP RESISTOR

R36W 2007-000653 CHIP RESISTOR

R37C 2007-000401 CHIP RESISTOR

R37F 2007-000401 CHIP RESISTOR

R37L 2007-000401 CHIP RESISTOR

R37W 2007-000401 CHIP RESISTOR

R38C 2007-001039 CHIP RESISTOR

R38F 2007-001039 CHIP RESISTOR

R38L 2007-001039 CHIP RESISTOR

R38W 2007-001039 CHIP RESISTOR

R39F 2007-000941 CHIP RESISTOR

R75C 2007-000941 CHIP RESISTOR

R75F 2007-000941 CHIP RESISTOR

R75L 2007-000941 CHIP RESISTOR

R75W 2007-000941 CHIP RESISTOR

R76C 2007-000468 CHIP RESISTOR

R76F 2007-000468 CHIP RESISTOR

R76L 2007-000468 CHIP RESISTOR

R76W 2007-000468 CHIP RESISTOR

R78C 2007-001039 CHIP RESISTOR

R78F 2007-001039 CHIP RESISTOR

R78L 2007-001039 CHIP RESISTOR

R78W 2007-001039 CHIP RESISTOR

R79C 2007-000267 CHIP RESISTOR

R79F 2007-000267 CHIP RESISTOR

R79L 2007-000267 CHIP RESISTOR

R79W 2007-000267 CHIP RESISTOR

R80C 2007-001039 CHIP RESISTOR

R80F 2007-001039 CHIP RESISTOR

R80L 2007-001039 CHIP RESISTOR

R80W 2007-001039 CHIP RESISTOR

R81C 2007-000872 CHIP RESISTOR

R81F 2007-000872 CHIP RESISTOR

R81L 2007-000872 CHIP RESISTOR

R81W 2007-000300 CHIP RESISTOR

R82C 2007-000686 CHIP RESISTOR

R82F 2007-000686 CHIP RESISTOR

R82L 2007-000686 CHIP RESISTOR

R82W 2007-000686 CHIP RESISTOR

R83C 2007-000686 CHIP RESISTOR

R83F 2007-000686 CHIP RESISTOR

R83L 2007-000686 CHIP RESISTOR

R83W 2007-000686 CHIP RESISTOR

R84C 2007-000300 CHIP RESISTOR

R84F 2007-000300 CHIP RESISTOR

R84L 2007-000300 CHIP RESISTOR

R84W 2007-000941 CHIP RESISTOR

R85W 2001-000515 C RESISTOR

R86C 2007-000931 CHIP RESISTOR

R86F 2007-000931 CHIP RESISTOR

R86L 2007-000931 CHIP RESISTOR

R86W 2001-000780 C RESISTOR

R87C 2007-000981 CHIP RESISTOR

R87F 2007-000981 CHIP RESISTOR

R87L 2007-000981 CHIP RESISTOR

R87W 2007-000981 CHIP RESISTOR

R88C 2007-000493 CHIP RESISTOR

R88F 2007-000493 CHIP RESISTOR

R88L 2007-000493 CHIP RESISTOR

R88W 2007-000493 CHIP RESISTOR

R89C 2007-000931 CHIP RESISTOR

R89F 2007-000931 CHIP RESISTOR

R89L 2007-000931 CHIP RESISTOR

R89W 2001-000780 C RESISTOR

R90W 2001-000515 C RESISTOR

R91C 2007-000766 CHIP RESISTOR

R91F 2007-000766 CHIP RESISTOR

R91L 2007-000766 CHIP RESISTOR

R93C 2007-000766 CHIP RESISTOR

R93F 2007-000766 CHIP RESISTOR

R93L 2007-000766 CHIP RESISTOR

R94C 2007-000766 CHIP RESISTOR

R94F 2007-000766 CHIP RESISTOR

R94L 2007-000766 CHIP RESISTOR

R96C 2007-000766 CHIP RESISTOR

R96F 2007-000766 CHIP RESISTOR

R96L 2007-000766 CHIP RESISTOR

R97C 2007-008317 CHIP RESISTOR

R97F 2007-008317 CHIP RESISTOR

R97L 2007-008317 CHIP RESISTOR

R97W 2009-000018 M ETAL RESISTOR

R98C 2007-008317 CHIP RESISTOR

R98F 2007-008317 CHIP RESISTOR

R98L 2007-008317 CHIP RESISTOR

R98W 2009-000018 M ETAL RESISTOR

R99C 2001-000019 C RESISTOR

R99F 2001-000019 C RESISTOR

R99L 2001-000019 C RESISTOR

R99W 2003-000471 M ETAL RESISTOR

R14FL 2001-000515 C RESISTOR

R200L 2007-000686 CHIP RESISTOR

R201L 2007-000774 CHIP RESISTOR

R27FL 2007-000468 CHIP RESISTOR

R28FL 2007-000300 CHIP RESISTOR

R29FL 2007-000468 CHIP RESISTOR

R32FL 2007-000493 CHIP RESISTOR

R33FL 2007-000586 CHIP RESISTOR

R34FL 2007-000401 CHIP RESISTOR

R35FL 2007-000493 CHIP RESISTOR

R36FL 2007-000586 CHIP RESISTOR

R37FL 2007-000401 CHIP RESISTOR

R38FL 2007-001039 CHIP RESISTOR

R39FL 2007-000941 CHIP RESISTOR

3-7

Page 61

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R75FL 2007-000941 CHIP RESISTOR

R76FL 2001-000429 C RESISTOR

R78FL 2007-001039 CHIP RESISTOR

R79FL 2007-000267 CHIP RESISTOR

R80FL 2007-001039 CHIP RESISTOR

R81FL 2007-000872 CHIP RESISTOR

R82FL 2007-000686 CHIP RESISTOR

R83FL 2007-000686 CHIP RESISTOR

R84FL 2007-000300 CHIP RESISTOR

R86FL 2007-000931 CHIP RESISTOR

R87FL 2007-000981 CHIP RESISTOR

R88FL 2007-000493 CHIP RESISTOR

R89FL 2007-000931 CHIP RESISTOR

R91FL 2007-000766 CHIP RESISTOR

R93FL 2007-000766 CHIP RESISTOR

R94FL 2007-000766 CHIP RESISTOR

R96FL 2007-000766 CHIP RESISTOR

R97FL 2007-008317 CHIP RESISTOR

R98FL 2007-008317 CHIP RESISTOR

R99FL 2001-000019 C RESISTOR

ABD1 0402-001408 FR DIODE

ABD2 0402-001258 FR DIODE

ABD4 0402-001258 FR DIODE

AC1 2201-002128 C CAPACITOR

AC2 2201-002128 C CAPACITOR

AC3 2201-002128 C CAPACITOR

AC4 2201-002128 C CAPACITOR

AC5 2201-002128 C CAPACITOR

AC6 2201-002128 C CAPACITOR

AC7 2401-001538 E CAPACITOR

AC8 2401-000475 E CAPACITOR

AC9 2401-001413 E CAPACITOR

AC10 2401-001912 E CAPACITOR

AC11 2401-002183 E CAPACITOR

AC12 2401-001954 E CAPACITOR

AC13 2401-001912 E CAPACITOR

AC14 2201-000161 C CAPACITOR

AC15 2201-000161 C CAPACITOR

AC16 2201-000161 C CAPACITOR

AC18 2401-001879 E CAPACITOR

AC19 2401-003116 E CAPACITOR

AC20 2401-003116 E CAPACITOR

AC21 2401-001879 E CAPACITOR

AC22 2401-001959 E CAPACITOR

AC23 2401-001959 E CAPACITOR

ACD1 2003-000603 METAL RESISTOR

ACD1 0402-000127 FR DIODE

ACD2 2003-000603 METAL RESISTOR

ACD2 0402-000127 FR DIODE

ACW1 3711-000190 CONNECTOR

ACW2 3711-004848 CONNECTOR

ACW3 3711-001098 CONNECTOR

ACW4 3711-000963 CONNECTOR

ACW5 3711-000963 CONNECTOR

AD1 0402-000127 FR DIODE

AD2 0402-000127 FR DIODE

AD3 0402-000127 FR DIODE

AD4 0402-000127 FR DIODE

AD6 0402-000127 FR DIODE

AD8 0401-000101 FR DIODE

AD11 0402-000127 FR DIODE

AFS1 3601-000216 FUSE

AFS1 3602-000147 FUSE-CLIP

AFS2 3601-000216 FUSE

AFS2 3601-001248 FUSE

AFS2 3602-000147 FUSE-CLIP

AFS3 3601-000319 FUSE

AFS3 3601-000184 FUSE

AFS3 3602-000147 FUSE-CLIP

AFS4 3601-000319 FUSE

AFS4 3602-000147 FUSE-CLIP

AIC1 NJM7805 IC 1203-002560

AIC2 BA4560 IC 1201-000163

AL1 AH27-10001F CHOKE COIL

AL2 AH27-10001F CHOKE COIL

AL3C AH27-90001A COIL

AL3W AH27-90001A COIL

AL3FL AH27-90001A COIL

AL3FR AH27-90001A COIL

AL3RL AH27-90001A COIL

AL3RR AH27-90001A COIL

AQ2 0501-000010 TRANSISTOR

AQ3 0501-000010 TRANSISTOR

AR2 2001-000890 C RESISTOR

AR3 2001-000449 C RESISTOR

AR4 2001-000052 C RESISTOR

AR5 2007-000300 CHIP RESISTOR

AR6 2007-000941 CHIP RESISTOR

AR7 2001-001045 C RESISTOR

AR8 2007-001195 CHIP RESISTOR

AR9 2001-000591 C RESISTOR

AR11 2007-000941 CHIP RESISTOR

AR12 2007-000686 CHIP RESISTOR

AR15 2001-000702 C RESISTOR

AUX1 3722-002042 PIN JACK

AVS1 3408-000177 SWITCH

AZD1 0403-000354 Z DIODE

AZD2 0403-000352 Z DIODE

AZD3 0403-000379 Z DIODE

CE2C 2203-001537 CHIP CAPACITOR

CE2W 2203-001537 CHIP CAPACITOR

CE4W 2203-001537 CHIP CAPACITOR

CE5C 2203-000892 CHIP CAPACITOR

CE5W 2203-000892 CHIP CAPACITOR

CE2FL 2203-001537 CHIP CAPACITOR

CE2FR 2203-001537 CHIP CAPACITOR

CE2RL 2203-001537 CHIP CAPACITOR

CE2RR 2203-001537 CHIP CAPACITOR

CE4FL 2203-001537 CHIP CAPACITOR

CE4FR 2203-001537 CHIP CAPACITOR

CE4RL 2203-001537 CHIP CAPACITOR

CE4RR 2203-001537 CHIP CAPACITOR

CE5FL 2203-000892 CHIP CAPACITOR

CE5FR 2203-000892 CHIP CAPACITOR

CE5RL 2203-000892 CHIP CAPACITOR

CE6RL 2203-000892 CHIP CAPACITOR

CE6RR 2203-000892 CHIP CAPACITOR

CW5 3711-004110 CONNECTOR

CW6 3711-005184 CONNECTOR

CW7 3711-004110 CONNECTOR

FIC6 BA4560 IC 1201-000163

J115 3811-000389 WIRE-NO SHEATH

PBD1 0402-001258 FR DIODE

PBD2 0402-001077 FR DIODE

PD1 0402-000127 FR DIODE

PD2 0401-000101 FR DIODE

PD3 0401-000101 FR DIODE

PIC3 7812 IC 1203-000242

PIC4 7812 IC 1203-000242

PL1 AC27-12001N CHOKE COIL

PQ1 NJM7805 IC 1203-002560

PQ2 278R05 IC 1203-001589

PQ5 0503-001014 TRANSISTOR

PQ6 KIA7808API IC 1203-003096

PQ7 0502-000303 TRANSISTOR

PR1 2003-000603 METAL RESISTOR

PR6 2007-000586 CHIP RESISTOR

PR7 2007-000653 CHIP RESISTOR

PR8 2007-000409 CHIP RESISTOR

PR9 2007-000586 CHIP RESISTOR

PR10 2007-000781 CHIP RESISTOR

PR010 2003-000468 METAL RESISTOR

PR012 2003-000710 METAL RESISTOR

PSD1 0404-000156 FR DIODE

PT1 AH26-00143C TRANSISTOR

PZ1 0403-000570 Z DIODE

PZD1 0403-000564 Z DIODE

PZD2 0403-000564 Z DIODE

RE1 3501-001008 RELAY

RE2 3501-001214 RELAY

RE3 3501-001214 RELAY

RE4 3501-001008 RELAY

RE5 3501-001197 RELAY

RE6 3501-001197 RELAY

RE7 3501-001197 RELAY

3-8

Page 62

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

RIC5 BA4560 IC 1201-000163

SPK1 3716-001179 TERMINAL

SPK2 3716-001205 TERMINAL

UD100 0401-001090 FR DIODE

UD101 0401-001090 FR DIODE

UD102 0401-001090 FR DIODE

UD103 0401-001090 FR DIODE

UR27 2007-000449 CHIP RESISTOR

ZD5C 0403-001079 Z DIODE

ZD5W 0403-001079 Z DIODE

ZD6C 0403-001079 Z DIODE

ZD6W 0403-001079 Z DIODE

ZD7C 0403-001376 Z DIODE

ZD7W 0403-001062 Z DIODE

ZD8C 0403-001376 Z DIODE

ZD8W 0403-001062 Z DIODE

ZD5FL 0403-001079 Z DIODE

ZD5FR 0403-001079 Z DIODE

ZD5RL 0403-001079 Z DIODE

ZD5RR 0403-001079 Z DIODE

ZD6FL 0403-001079 Z DIODE

ZD6FR 0403-001079 Z DIODE

ZD6RL 0403-001079 Z DIODE

ZD6RR 0403-001079 Z DIODE

ZD7FL 0403-001376 Z DIODE

ZD7FR 0403-001376 Z DIODE

ZD7RL 0403-001376 Z DIODE

ZD7RR 0403-001376 Z DIODE

ZD8FL 0403-001376 Z DIODE

ZD8FR 0403-001376 Z DIODE

ZD8RL 0403-001376 Z DIODE

ZD8RR 0403-001376 Z DIODE

Front board

Block No. [0][2][0][0]

Symbol No.

E-VR 3406-001047 ROTARY SWITCH

LED1 0601-001238 LED

REYE AC59-60060A MODULE REMOCON

SW2 3404-000165 TACT SWITCH

SW3 3404-000165 TACT SWITCH

SW4 3404-000165 TACT SWITCH

SW5 3404-000165 TACT SWITCH

SW6 3404-000165 TACT SWITCH

SW7 3404-000165 TACT SWITCH

SW9 3404-000165 TACT SWITCH

UC1 2203-000203 CHIP CAPACITOR

UC2 2203-000203 CHIP CAPACITOR

UC3 2401-000485 E CAPACITOR

UC8 2401-000752 E CAPACITOR

UC9 2409-000123 C-EDL

UC10 2203-000979 CHIP CAPACITOR

UC12 2203-000979 CHIP CAPACITOR

UC13 2401-000485 E CAPACITOR

UC14 2401-000243 E CAPACITOR

UC15 2203-000979 CHIP CAPACITOR

UC16 2401-000243 E CAPACITOR

UC20 2401-003336 E CAPACITOR

UC21 2203-000979 CHIP CAPACITOR

UC77 2203-000203 CHIP CAPACITOR

UCW3 3708-000448 CONNECTOR

UCW7 3708-001043 CONNECTOR

UCW12 AH39-00477A LEAD CONNECTOR

UCW13 3711-000907 CONNECTOR

UD1 0401-001090 FR DIODE

UD2 0401-001090 FR DIODE

UD4 0401-001090 FR DIODE

UD5 0401-001090 FR DIODE

UD6 0401-001090 FR DIODE

UD7 0402-000309 FR DIODE

UD8 0401-000101 FR DIODE

UD8 0401-001090 FR DIODE

Part No. Part Name Description Local

UD10 0401-001090 FR DIODE

UD11 0401-001090 FR DIODE

UD12 0401-000101 FR DIODE

UD77 0401-001090 FR DIODE

UIC1 AH11-00106A MASK ROM

UQ3 0504-000156 DIGI TRANSISTOR

UQ4 0501-000398 TRANSISTOR

UR1 2001-000023 C RESISTOR

UR2 2001-000023 C RESISTOR

UR10 2007-000300 CHIP RESISTOR

UR11 2007-000822 CHIP RESISTOR

UR12 2007-000822 CHIP RESISTOR

UR13 2007-000872 CHIP RESISTOR

UR14 2007-000682 CHIP RESISTOR

UR15 2007-000493 CHIP RESISTOR

UR16 2007-000267 CHIP RESISTOR

UR17 2007-000241 CHIP RESISTOR

UR18 2007-000468 CHIP RESISTOR

UR20 2007-000493 CHIP RESISTOR

UR21 2007-000872 CHIP RESISTOR

UR22 2007-000565 CHIP RESISTOR

UR23 2007-000572 CHIP RESISTOR

UR24 2007-000300 CHIP RESISTOR

UR25 2007-000300 CHIP RESISTOR

UR29 2007-000300 CHIP RESISTOR

UR31 2007-000941 CHIP RESISTOR

UR32 2007-000300 CHIP RESISTOR

UR34 2007-000468 CHIP RESISTOR

UR48 2007-000941 CHIP RESISTOR

UR49 2007-000941 CHIP RESISTOR

UR50 2007-000941 CHIP RESISTOR

UR51 2007-000941 CHIP RESISTOR

UR52 2007-000941 CHIP RESISTOR

UR53 2007-000941 CHIP RESISTOR

UR54 2007-000941 CHIP RESISTOR

UR55 2007-000941 CHIP RESISTOR

UR56 2007-000941 CHIP RESISTOR

UR57 2007-000941 CHIP RESISTOR

UR58 2007-000941 CHIP RESISTOR

UR59 2007-000941 CHIP RESISTOR

UR60 2007-000941 CHIP RESISTOR

UR61 2007-000941 CHIP RESISTOR

UR62 2007-000941 CHIP RESISTOR

UR63 2007-000941 CHIP RESISTOR

UR64 2007-000941 CHIP RESISTOR

UR65 2007-000941 CHIP RESISTOR

UR66 2007-000300 CHIP RESISTOR

UR70 2007-000941 CHIP RESISTOR

UR71 2007-000941 CHIP RESISTOR

UR72 2007-000941 CHIP RESISTOR

UR73 2007-000941 CHIP RESISTOR

UR74 2007-000941 CHIP RESISTOR

UR75 2007-000941 CHIP RESISTOR

UR76 2007-000941 CHIP RESISTOR

UR77 2007-000941 CHIP RESISTOR

UR78 2007-000941 CHIP RESISTOR

UR79 2007-000941 CHIP RESISTOR

UR80 2007-000941 CHIP RESISTOR

UR81 2007-000941 CHIP RESISTOR

UR82 2007-000941 CHIP RESISTOR

UR83 2007-000941 CHIP RESISTOR

UR84 2007-000941 CHIP RESISTOR

UR86 2007-000300 CHIP RESISTOR

UR90 2007-000300 CHIP RESISTOR

UR100 2007-000300 CHIP RESISTOR

UR101 2007-000300 CHIP RESISTOR

UR102 2007-000300 CHIP RESISTOR

UR103 2007-000468 CHIP RESISTOR

UX1 2802-001174 RESONATOR

UZD1 0403-000367 Z DIODE

VFD AH07-00110A VF DISPLAY

XR01 2007-000477 CHIP RESISTOR

3-9

Page 63

Function board

Block No. [0][3][0][0]

Symbol No.

C1 2401-000407 E CAPACITOR

C2 2401-000407 E CAPACITOR

C3 2203-000592 CHIP CAPACITOR

C4 2203-000592 CHIP CAPACITOR

CC7 2203-000531 CHIP CAPACITOR

CC8 2401-000213 E CAPACITOR

CC11 2203-000531 CHIP CAPACITOR

CC12 2203-000783 CHIP CAPACITOR

CC13 2401-000213 E CAPACITOR

CC19 2203-000236 CHIP CAPACITOR

CC23 2401-000213 E CAPACITOR

CIC2 BA4560 IC 1201-000163

CJ1 2007-000070 CHIP RESISTOR

CQ1 0501-000341 TRANSISTOR

CR6 2007-000078 CHIP RESISTOR

CR10 2007-000078 CHIP RESISTOR

CR12 2007-000124 CHIP RESISTOR

CR13 2007-000084 CHIP RESISTOR

CR21 2007-000094 CHIP RESISTOR

CR25 2007-000092 CHIP RESISTOR

FC19 2401-000407 E CAPACITOR

FC20 2401-001502 E CAPACITOR

FC30 2401-001502 E CAPACITOR

FC31 2401-001502 E CAPACITOR

FC32 2401-001502 E CAPACITOR

FC35 2203-000888 CHIP CAPACITOR

FC36 2203-001103 CHIP CAPACITOR

FC37 2401-000588 E CAPACITOR

FC38 2401-000588 E CAPACITOR

FC39 2203-001103 CHIP CAPACITOR

FC40 2203-000888 CHIP CAPACITOR

FC41 2401-002186 E CAPACITOR

FC42 2401-002186 E CAPACITOR

FC51 2401-000407 E CAPACITOR

FC52 2401-000407 E CAPACITOR

FC53 2401-000407 E CAPACITOR

FC54 2401-000407 E CAPACITOR

FC55 2401-000407 E CAPACITOR

FC56 2401-000407 E CAPACITOR

FC57 2401-001502 E CAPACITOR

FC58 2401-003336 E CAPACITOR

FC60 2401-001502 E CAPACITOR

FC9L 2401-001238 E CAPACITOR

FC9R 2401-001238 E CAPACITOR

FC10L 2203-000236 CHIP CAPACITOR

FC10R 2203-000236 CHIP CAPACITOR

FC11L 2203-000531 CHIP CAPACITOR

FC11R 2203-000531 CHIP CAPACITOR

FC12L 2401-000650 E CAPACITOR

FC12R 2401-000650 E CAPACITOR

FC14L 2401-000650 E CAPACITOR

FC14R 2401-000650 E CAPACITOR

FC15L 2401-000650 E CAPACITOR

FC15R 2401-000650 E CAPACITOR

FC16L 2401-000213 E CAPACITOR

FC16R 2401-000213 E CAPACITOR

FC17L 2203-001034 CHIP CAPACITOR

FC17R 2203-001034 CHIP CAPACITOR

FC18L 2203-000648 CHIP CAPACITOR

FC18R 2203-000648 CHIP CAPACITOR

FC19L 2203-001064 CHIP CAPACITOR

FC19R 2203-001064 CHIP CAPACITOR

FC23L 2401-000213 E CAPACITOR

FC23R 2401-000213 E CAPACITOR

FC24L 2203-000531 CHIP CAPACITOR

FC24R 2203-000531 CHIP CAPACITOR

FC25L 2203-000783 CHIP CAPACITOR

FC25R 2203-000783 CHIP CAPACITOR

FC26L 2401-000213 E CAPACITOR

FC26R 2401-000213 E CAPACITOR

FC43L 2401-000588 E CAPACITOR

FC43R 2401-000588 E CAPACITOR

FC44L 2401-000588 E CAPACITOR

Part No. Part Name Description Local

Symbol No.

FC44R 2401-000588 E CAPACITOR

FD5 0401-001090 FR DIODE

FIC2 BA4560 IC 1201-000163

FIC3 TDA7440D IC 1204-001465

FIC4 BA4560 IC 1201-000163

FIC5 M62446AFP IC 1201-000163

FIC6 BA4560 IC 1201-000163

FIC9 BA4560 IC 1201-000163

FJ1 2007-000070 CHIP RESISTOR

FJ2 2007-000070 CHIP RESISTOR

FQ3 0501-000341 TRANSISTOR

FQ4 0501-000341 TRANSISTOR

FR7 2007-000094 CHIP RESISTOR

FR8 2007-000094 CHIP RESISTOR

FR9 2007-000124 CHIP RESISTOR

FR10 2007-000124 CHIP RESISTOR

FR13 2007-000074 CHIP RESISTOR

FR14 2007-000074 CHIP RESISTOR

FR15 2007-000090 CHIP RESISTOR

FR16 2007-000077 CHIP RESISTOR

FR17 2007-000074 CHIP RESISTOR

FR18 2007-000074 CHIP RESISTOR

FR29 2007-000074 CHIP RESISTOR

FR30 2007-007347 CHIP RESISTOR

FR31 2007-007347 CHIP RESISTOR

FR32 2007-000078 CHIP RESISTOR

FR33 2007-000078 CHIP RESISTOR

FR35 2007-000078 CHIP RESISTOR

FR36 2007-000078 CHIP RESISTOR

FR37 2007-000078 CHIP RESISTOR

FR38 2007-000078 CHIP RESISTOR

FR39 2007-000078 CHIP RESISTOR

FR40 2007-000078 CHIP RESISTOR

FR41 2007-000078 CHIP RESISTOR

FR42 2007-000090 CHIP RESISTOR

FR43 2007-000090 CHIP RESISTOR

FR44 2007-000090 CHIP RESISTOR

FR56 2007-000077 CHIP RESISTOR

FR57 2007-000090 CHIP RESISTOR

FR58 2007-000090 CHIP RESISTOR

FR59 2007-000090 CHIP RESISTOR

FR60 2007-000078 CHIP RESISTOR

FR10L 2007-000084 CHIP RESISTOR

FR10R 2007-000084 CHIP RESISTOR

FR11L 2007-000081 CHIP RESISTOR

FR11R 2007-000081 CHIP RESISTOR

FR12L 2007-000078 CHIP RESISTOR

FR12R 2007-000078 CHIP RESISTOR

FR17L 2007-000078 CHIP RESISTOR

FR17R 2007-000078 CHIP RESISTOR

FR18L 2007-000092 CHIP RESISTOR

FR18R 2007-000092 CHIP RESISTOR

FR19L 2007-000124 CHIP RESISTOR

FR19R 2007-000124 CHIP RESISTOR

FR20L 2007-000084 CHIP RESISTOR

FR20R 2007-000084 CHIP RESISTOR

FR23L 2007-000086 CHIP RESISTOR

FR23R 2007-000086 CHIP RESISTOR

FR42L 2007-000086 CHIP RESISTOR

FR42R 2007-000086 CHIP RESISTOR

FR43L 2007-000077 CHIP RESISTOR

FR43R 2007-000077 CHIP RESISTOR

FR44L 2007-000097 CHIP RESISTOR

FR44R 2007-000097 CHIP RESISTOR

FR47L 2007-000097 CHIP RESISTOR

FR47R 2007-000097 CHIP RESISTOR

FR57L 2007-000090 CHIP RESISTOR

FR57R 2007-000090 CHIP RESISTOR

FR58L 2007-000090 CHIP RESISTOR

FR58R 2007-000090 CHIP RESISTOR

FR59L 2007-000092 CHIP RESISTOR

FR59R 2007-000092 CHIP RESISTOR

FR60L 2007-000094 CHIP RESISTOR

FR60R 2007-000094 CHIP RESISTOR

FR61L 2007-000090 CHIP RESISTOR

FR61R 2007-000090 CHIP RESISTOR

FR62L 2007-000090 CHIP RESISTOR

FR62R 2007-000090 CHIP RESISTOR

Part No. Part Name Description Local

3-10

Page 64

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

FR63L 2007-000134 CHIP RESISTOR

FR63R 2007-000134 CHIP RESISTOR

FR64L 2007-000092 CHIP RESISTOR

FR64R 2007-000092 CHIP RESISTOR

FR65L 2007-000082 CHIP RESISTOR

FR65R 2007-000082 CHIP RESISTOR

FZD1 0403-001409 Z DIODE

FZD5 0403-000621 Z DIODE

FZD6 0403-000621 Z DIODE

RC8L 2401-000213 E CAPACITOR

RC8R 2401-000213 E CAPACITOR

RC9L 2203-000236 CHIP CAPACITOR

RC9R 2203-000236 CHIP CAPACITOR

RC12L 2203-000531 CHIP CAPACITOR

RC12R 2203-000531 CHIP CAPACITOR

RC13L 2203-000783 CHIP CAPACITOR

RC13R 2203-000783 CHIP CAPACITOR

RC14L 2401-000213 E CAPACITOR

RC14R 2401-000213 E CAPACITOR

RIC2 BA4560 IC 1201-000163

RJ1 2007-000070 CHIP RESISTOR

RJ2 2007-000070 CHIP RESISTOR

RQ1 0501-000341 TRANSISTOR

RR7 2007-000094 CHIP RESISTOR

RR10L 2007-000078 CHIP RESISTOR

RR10R 2007-000078 CHIP RESISTOR

RR12L 2007-000124 CHIP RESISTOR

RR12R 2007-000124 CHIP RESISTOR

RR13L 2007-000084 CHIP RESISTOR

RR13R 2007-000084 CHIP RESISTOR

SC8 2401-001238 E CAPACITOR

SC11 2203-001140 CHIP CAPACITOR

SC12 2203-005221 CHIP CAPACITOR

SC13 2401-001324 E CAPACITOR

SC19 2203-000783 CHIP CAPACITOR

SC20 2401-000752 E CAPACITOR

SC25 2203-000604 CHIP CAPACITOR

SIC1 BA4560 IC 1201-000163

SJ1 2007-000070 CHIP RESISTOR

SR6 2007-000101 CHIP RESISTOR

SR10 2007-000101 CHIP RESISTOR

SR11 2007-000098 CHIP RESISTOR

SR12 2007-000129 CHIP RESISTOR

SR13 2007-000098 CHIP RESISTOR

SR14 2007-000075 CHIP RESISTOR

SR18 2007-000075 CHIP RESISTOR

SR20 2007-000119 CHIP RESISTOR

SR21 2007-000084 CHIP RESISTOR

SR29 2007-000094 CHIP RESISTOR

UC500 2203-005005 CHIP CAPACITOR

UC510 2203-000604 CHIP CAPACITOR

UD500 0401-001090 FR DIODE

UIC50 M66010 IC 0904-001316

UR500 2007-000090 CHIP RESISTOR

UR501 2007-000090 CHIP RESISTOR

UR503 2007-000124 CHIP RESISTOR

UR504 2007-000124 CHIP RESISTOR

UR505 2007-000090 CHIP RESISTOR

UR506 2007-000090 CHIP RESISTOR

UR507 2007-000090 CHIP RESISTOR

UR508 2007-000082 CHIP RESISTOR

UR509 2007-000082 CHIP RESISTOR

UR510 2007-000082 CHIP RESISTOR

UR511 2007-000082 CHIP RESISTOR

UR512 2007-000082 CHIP RESISTOR

UR513 2007-000090 CHIP RESISTOR

UR514 2007-000090 CHIP RESISTOR

UR517 2007-000124 CHIP RESISTOR

UR518 2007-000090 CHIP RESISTOR

UR519 2007-000090 CHIP RESISTOR

UR520 2007-000124 CHIP RESISTOR

UR521 2007-000090 CHIP RESISTOR

UR522 2007-000090 CHIP RESISTOR

UR524 2007-000090 CHIP RESISTOR

UR525 2007-000078 CHIP RESISTOR

UW1 3710-001422 CONNECTOR

UW2 3710-001422 CONNECTOR

UW3 3710-001868 CONNECTOR

UW4 3708-000266 CONNECTOR

UW6 3708-001574 CONNECTOR

UW7 3710-001422 CONNECTOR

UW8 3710-001422 CONNECTOR

UW9 3711-000820 CONNECTOR

Jack board

Block No. [0][4][0][0]

Symbol No.

VC2 2401-001092 E CAPACITOR

VC6 2401-001092 E CAPACITOR

VC10 2401-001092 E CAPACITOR

VC14 2202-000781 C CAPACITOR

VC15 2401-001975 E CAPACITOR

VC16 2201-000783 C CAPACITOR

VC17 2202-000781 C CAPACITOR

VC18 2201-000783 C CAPACITOR

VC19 2401-001912 E CAPACITOR

VC20 2401-001893 E CAPACITOR

VC21 2401-001938 E CAPACITOR

VC22 2401-001893 E CAPACITOR

VC23 2401-001938 E CAPACITOR

VC24 2201-000783 C CAPACITOR

VC32 2201-000783 C CAPACITOR

VC35 2202-000797 C CAPACITOR

VR4 2001-000969 C RESISTOR

VR12 2001-000969 C RESISTOR

VR20 2001-000969 C RESISTOR

VR28 2001-000429 C RESISTOR

VR29 2001-000969 C RESISTOR

VR30 2001-000969 C RESISTOR

VR31 2001-000429 C RESISTOR

VR32 2001-000429 C RESISTOR

VR35 2001-000429 C RESISTOR

VR43 2001-000938 C RESISTOR

OC1 2202-000780 C CAPACITOR

OJ1 0603-001126 OP TRANSMITTER

SVJ5 3722-001894 JACK-DIN

VIC4 BA7665FS IC 1201-001922

VJ1 3722-001693 PIN JACK

VJK3 AH37-00005A RCA JACK

VL1 2701-000116 INDUCTOR-AXIAL

VL2 2701-000116 INDUCTOR-AXIAL

VW1 3711-004110 CONNECTOR

VW2 3711-004110 CONNECTOR

VW3 3708-001760 CONNECTOR

VW4 3708-001051 CONNECTOR

Part No. Part Name Description Local

DVD pack board

Block No. [0][5][0][0]

Symbol No.

Q1 0504-000128 DIGI TRANSISTOR

D2 0401-001090 FR DIODE

PC1 2203-005005 CHIP CAPACITOR

PC2 2402-001042 E.CAPACITOR SMD

PC3 2402-001059 E.CAPACITOR SMD

PC4 2203-005005 CHIP CAPACITOR

PC8 2203-005005 CHIP CAPACITOR

PC9 2203-005005 CHIP CAPACITOR

PC10 2402-000107 E.CAPACITOR SMD

PC11 2402-000009 E CAPACITOR

PC12 2203-005005 CHIP CAPACITOR

Part No. Part Name Description Local

3-11

Page 65

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

PC13 2402-000107 E.CAPACITOR SMD

PC14 2203-005005 CHIP CAPACITOR

C11 2402-000176 E.CAPACITOR SMD

C38 2402-000009 E CAPACITOR

C39 2203-005005 CHIP CAPACITOR

C40 2402-000009 E CAPACITOR

C43 2203-005065 CHIP CAPACITOR

C48 2203-005065 CHIP CAPACITOR

C51 2203-000681 CHIP CAPACITOR

C52 2203-000681 CHIP CAPACITOR

C53 2203-000681 CHIP CAPACITOR

C54 2203-000681 CHIP CAPACITOR

C55 2203-000681 CHIP CAPACITOR

C56 2203-005005 CHIP CAPACITOR

C57 2203-000257 CHIP CAPACITOR

C58 2203-005005 CHIP CAPACITOR

C59 2203-000888 CHIP CAPACITOR

C60 2203-005005 CHIP CAPACITOR

C61 2203-005005 CHIP CAPACITOR

C62 2203-005005 CHIP CAPACITOR

C63 2203-005005 CHIP CAPACITOR

C64 2203-005005 CHIP CAPACITOR

C65 2203-005005 CHIP CAPACITOR

C66 2402-000009 E CAPACITOR

C67 2203-005005 CHIP CAPACITOR

C68 2203-005005 CHIP CAPACITOR

C69 2402-000009 E CAPACITOR

C70 2402-000009 E CAPACITOR

C71 2203-005005 CHIP CAPACITOR

C72 2203-005005 CHIP CAPACITOR

C73 2402-000009 E CAPACITOR

C74 2402-000176 E.CAPACITOR SMD

C75 2203-005005 CHIP CAPACITOR

C76 2203-005005 CHIP CAPACITOR

C77 2203-005005 CHIP CAPACITOR

C78 2203-005005 CHIP CAPACITOR

C81 2203-005005 CHIP CAPACITOR

C82 2203-005005 CHIP CAPACITOR

C83 2203-005005 CHIP CAPACITOR

C84 2203-005005 CHIP CAPACITOR

C85 2203-005005 CHIP CAPACITOR

C86 2203-000384 CHIP CAPACITOR

C87 2203-005005 CHIP CAPACITOR

C88 2402-000009 E CAPACITOR

C89 2203-005005 CHIP CAPACITOR

C90 2402-000009 E CAPACITOR

C93 2007-000084 CHIP RESISTOR

C95 2203-005005 CHIP CAPACITOR

C96 2203-005005 CHIP CAPACITOR

C98 2203-005005 CHIP CAPACITOR

C99 2203-005005 CHIP CAPACITOR

C100 2203-005005 CHIP CAPACITOR

C101 2203-000998 CHIP CAPACITOR

C102 2203-005005 CHIP CAPACITOR