Jvc SR-HD1500-US, SR-HD1500-KR, SR-HD1500-EU, SR-HD1500-AG, SR-HD1500-AC Service Manual

...Page 1

SERVICE MANUAL

BLU-RAY DISC & HDD RECORDER

YD125<Rev.001>20101SERVICE MANUAL

SR-HD1250US, SR-HD1500US,

SR-HD1500KR, SR-HD1250EU,

SR-HD1500EU, SR-HD1500ER,

SR-HD1500AG, SR-HD1500AC

OPEN/

STANDBY/ON

COPYRIGHT © 2010 Victor Company of Japan, Limited

1 PRECAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1 SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3.1 Removing the top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3.2 Removing the front panel assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3.3 Removing the HDD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3.4 Removing the BD drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3.5 Removing the REG/SD board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3.6 Removing the BE-DIGITAL board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3.7 Removing the D-SUB/BNC board and TERMINAL board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3.8 Removing the DISPLAY board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

5 TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

5.1 DISPLAYING TEST MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

5.2 UPDATING MAIN UNIT FIRMWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

5.3 UPDATING SYSCON FIRMWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

5.4 UPDATING DRIVE FIRMWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

5.5 INITIALIZING TO FACTORY SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

5.6 REPLACING HDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

5.7 Exchanging the fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

5.8 Taking out a disc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

5.9 DISPLAYING MAINTENANCE MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

TABLE OF CONTENTS

CLOSE

STOP REV PLAY PAUSEFWD

REC

REC

INPUT

RESET

MODE

SELECT

COPYRIGHT © 2010 Victor Company of Japan, Limited

ONETOUCH

MIDIA SELECT

HDD

BD/SD

HDV/DVIN

No.YD125<Rev.001>

SDREC CERDDHBD

DUBBING

2010/1

Page 2

SPECIFICATION

SR-HD1250US SR-HD1500US SR-HD1500KR SR-HD1250EU SR-HD1500EU SR-HD1500ER SR-HD1500AG SR-HD1500AC

GENERAL

Power requirement AC 120 V~, 60 Hz AC 220-240V~,

Power consumption Power on: 34 W

Laser specifi-

cation

For DVD Wavelength: 656 to 663 nm

Temperature Operating 5°C to 35°C (41°F to 95°F) 5°C to 35°C

Operating position Horizontal only

Dimensions (WxHxD) 435 mm x 70 mm x 351 mm

Input/Output

Video input 1.0 Vp-p, 75Ω (BNC)

Video output 1.0 Vp-p, 75Ω (BNC)

Audio input Max 2 Vrms / 10 kΩ (pin jack)

Audio output 2 Vrms 10 kΩ terminated (pin jack)

S-video input Y: 1.0 Vp-p, 75Ω

S-video output Y: 1.0 Vp-p, 75 Ω

Remote Input 3.5 mm Jack

Serial Command - D-SUB 9-PIN - D-SUB 9-PIN -

Component video output Y: 1.0 Vp-p, 75 Ω

Digital audio output Optical : PCM, AAC, Dolby Digital and DTS

HDMI output 19-pin type A

USB terminal USB2.0

SD memory card

HDD Deck

Recording

compression

system

BD/DVD Deck

Recording

compression

system

ACCESSORIES

Provided accessories AC power cord,Audio/Video ca-

Power off: 3.0 W

For CD Wavelength: 779 to 789 nm

Output: 13.1 mW (Operating condition)

Output: 9.02 mW (Operating condition)

For BD Wavelength: 400 to 410 nm

Output: 17.3 mW (Operating condition)

Storage -20°C to 60°C (-4°F to 140°F) -20°C to 60°C

(17-1/10" x 2-6/8" x 13-13/16")

Weight 5.0 kg (11.0 lbs) 5.1 kg (11.2 lbs) 5.1 kg 5.0 kg 5.1 kg

C: 0.286 Vp-p, 75 Ω

C: 0.286 Vp-p, 75 Ω

DV 4-pin for HDV/DV IN

CB/CR, PB/PR: 0.7 Vp-p, 75 Ω

Corresponding to copy protection

(Deep Color, x.v.Color, Ver1.3)

SD, SDHC

250GB 500GB 250GB 500GB

Video MPEG2 (VBR)

H.264/AVC

Audio Dolby Digital (2 ch)

Linear PCM (2ch, XP mode only)

Video MPEG2 (CBR/VBR)

H.264/AVC

Audio Dolby Digital (2 ch)

Linear PCM (2ch, XP mode only)

Region

BD : Region A

code

DVD : #1

ble,BNC male to RCA female

adapter,Infrared remote control

unit,”AA” battery x 2,CD-ROM

60Hz

Power on: 34 W

Power off: 3.0 W

435 mm x 70 mm x 351 mm

BD : Region A

DVD : #3

AC power

cord,Audio/Video cable,BNC

male to RCA female adapter,Infrared remote

control unit,”AA”

battery x 2

AC 220-240V~, 50Hz/60Hz

Power on: 34 W

Standby: 0.5 W

BD : Region B

DVD : #2

AC power cord (for continental Europe, etc),AC power cord (for

U.K.),Audio/Video cable,Infrared

remote control unit,”AA” battery x

2,CD-ROM

BD : Region C

DVD : #5

AC power cord,Audio/Video cable,Infrared remote control

unit,”AA” battery x 2,CD-ROM

BD : Region A

DVD : #3

BD : Region C

DVD : #6

AC power

cord,Audio/Video cable,Infrared remote

control unit,”AA”

battery x 2

1-2 (No.YD125<Rev.001>)

Page 3

SECTION 1

r

PRECAUTION

1.1 SAFETY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

• Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

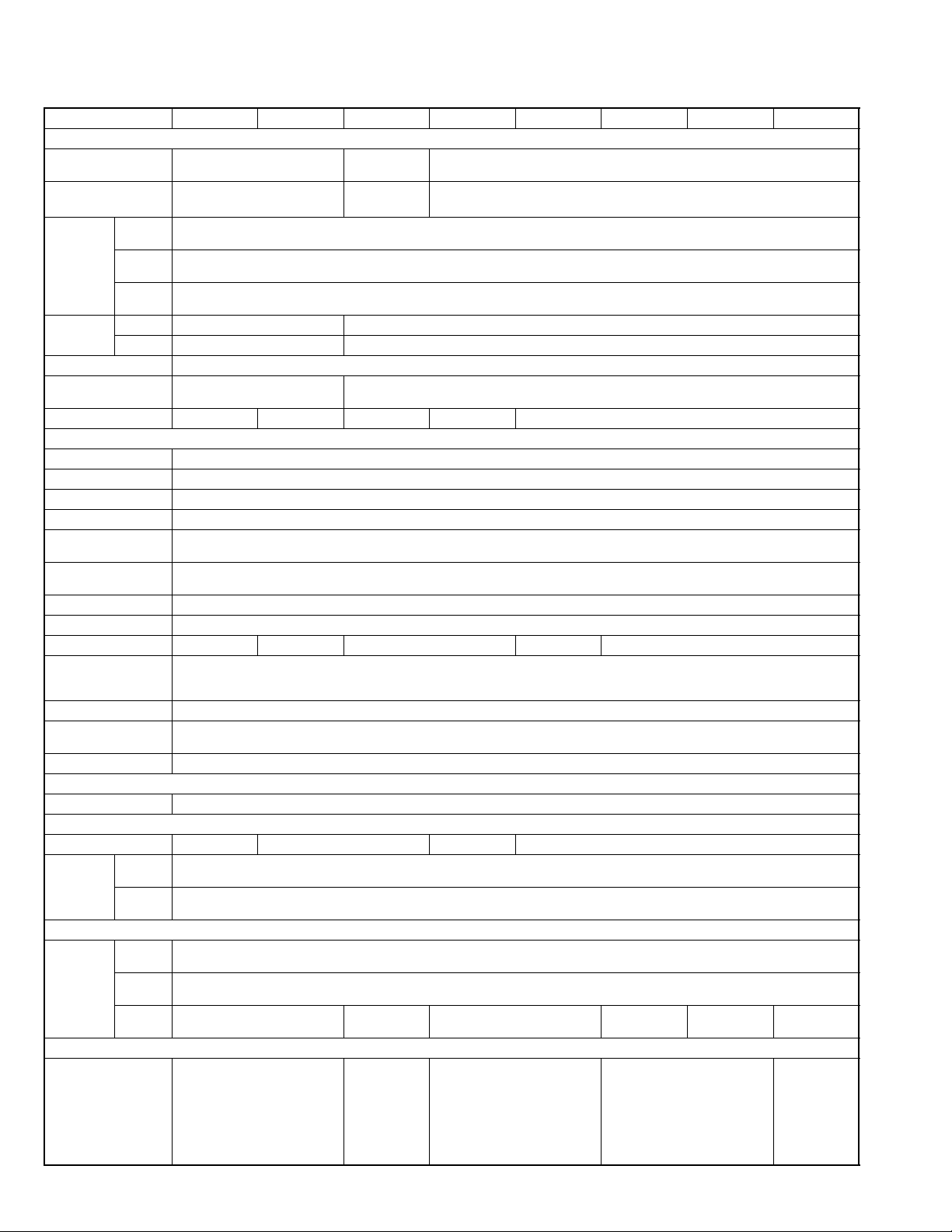

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

cathode ray tubes and other parts with only the specified

parts. Under no circumstances attempt to modify these circuits.Unauthorized modification can increase the high voltage value and cause X-ray emission from the cathode ray

tube.

(12) Crimp type wire connector In such cases as when replac-

ing the power transformer in sets where the connections

between the power cord and power trans former primary

lead wires are performed using crimp type connectors, if

replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according

to the following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected. In-

sert the wires fully into the connector.

Metal sleeve

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to

crimp the metal sleeve at the center position. Be

sure to crimp fully to the complete closure of the

tool.

1

.2

2.0

5.5

5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Crimped at approx. cente

of metal sleeve

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs) In regard to such

products, the cathode ray tubes themselves, the high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the

Conductors extended

Wire insulation recessed

more than 4 mm

Fig.1-1-7

(13) Battery replacement caution notice.

CAUTION RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECTIVE TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE

INSTRUCTIONS.

(No.YD125<Rev.001>)1-3

Page 4

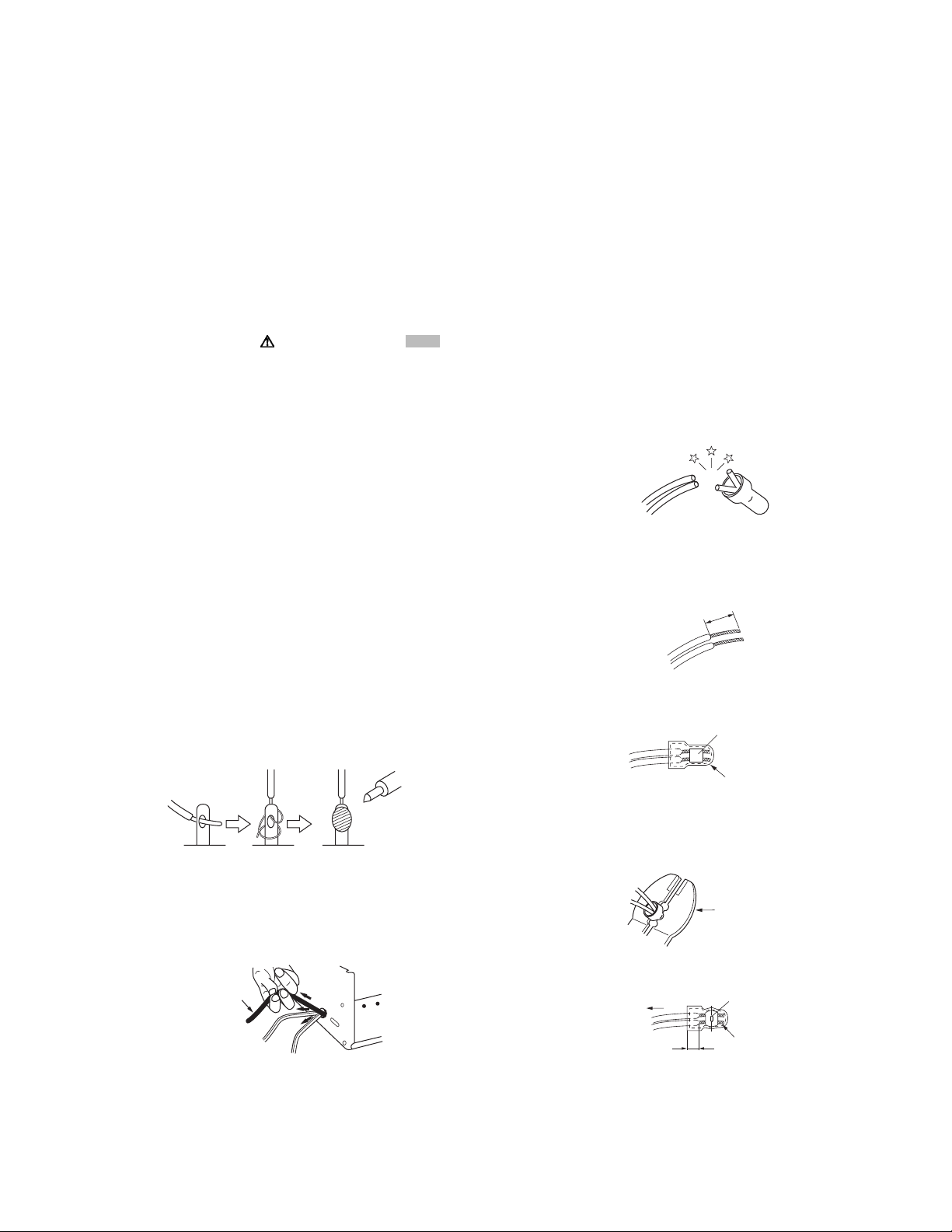

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify compliance with safety standards.

(1) Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed accessible parts (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON) Insert load Z between

earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure

across both terminals of load Z. See Fig.1-1-9 and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.YD125<Rev.001>)

Page 5

SECTION 2

Top cover

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

SECTION 3

DISASSEMBLY

Before disassembly, be sure to turn OFF the power and unplug

the power cord.

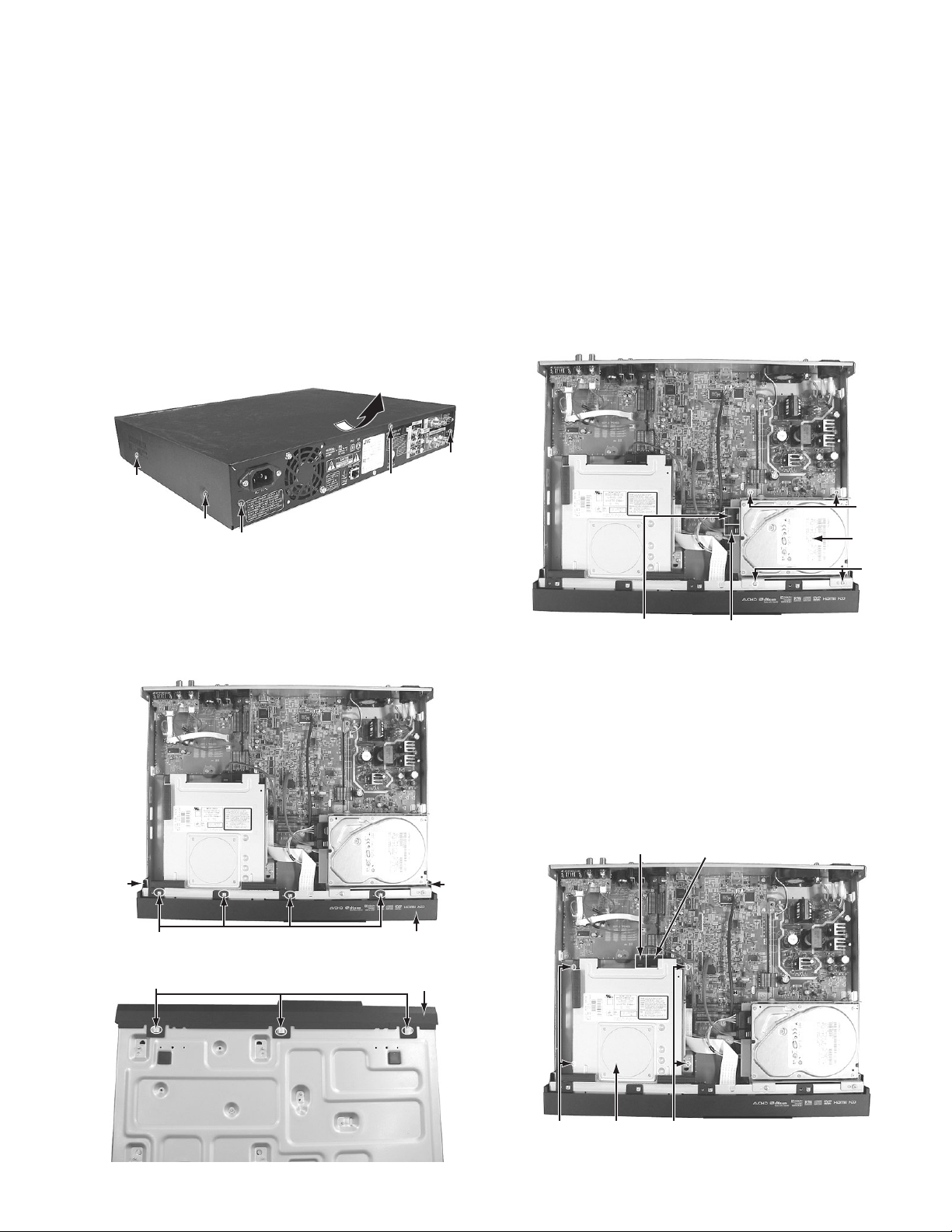

3.1 Removing the top cover (See Figure 1)

(1) Remove the four screws A attaching the top cover from

both sides.

(2) Remove the three screws B attaching the top cover from

the back.

(3) Remove the top cover by sliding it backward.

Top cover

Top cover

B

A x 2

A x 2

B

Fig.1

3.2 Removing the front panel assembly (See Figure 2 and Figure 3)

• Remove the top cover.

(1) Remove the nine tabs on the front panel assembly, and

then remove the front panel assembly.

B

3.3 Removing the HDD (See Figure 4)

• Remove the top cover.

(1) Pull out the SATA cable and the HDD power cable con-

nected to the HDD.

(2) Remove the four screws C attaching the HDD bracket.

(3) HDD is removed from the HDD bracket.

C

HDD

C

HDD Power cable

SATA Cable

Fig.4

Tab

Tab

Tab

Fig.2

Fig.3

Tab

Front panel assembly

Front panel assembly

3.4 Removing the BD drive unit (See Figure 5)

• Remove the top cover.

(1) Pull out the SATA cable and the BD drive power cable con-

nected to the BD drive unit.

(2) Remove the four screws D attaching the drive bracket.

(3) The rear side of the BD drive unit is lifted a little and re-

moved.

(4) Drive bracket is removed from the BD drive unit.

SATA Cable

DD

BD Drive unit

BD Drive power cable

Fig.5

(No.YD125<Rev.001>)1-5

Page 6

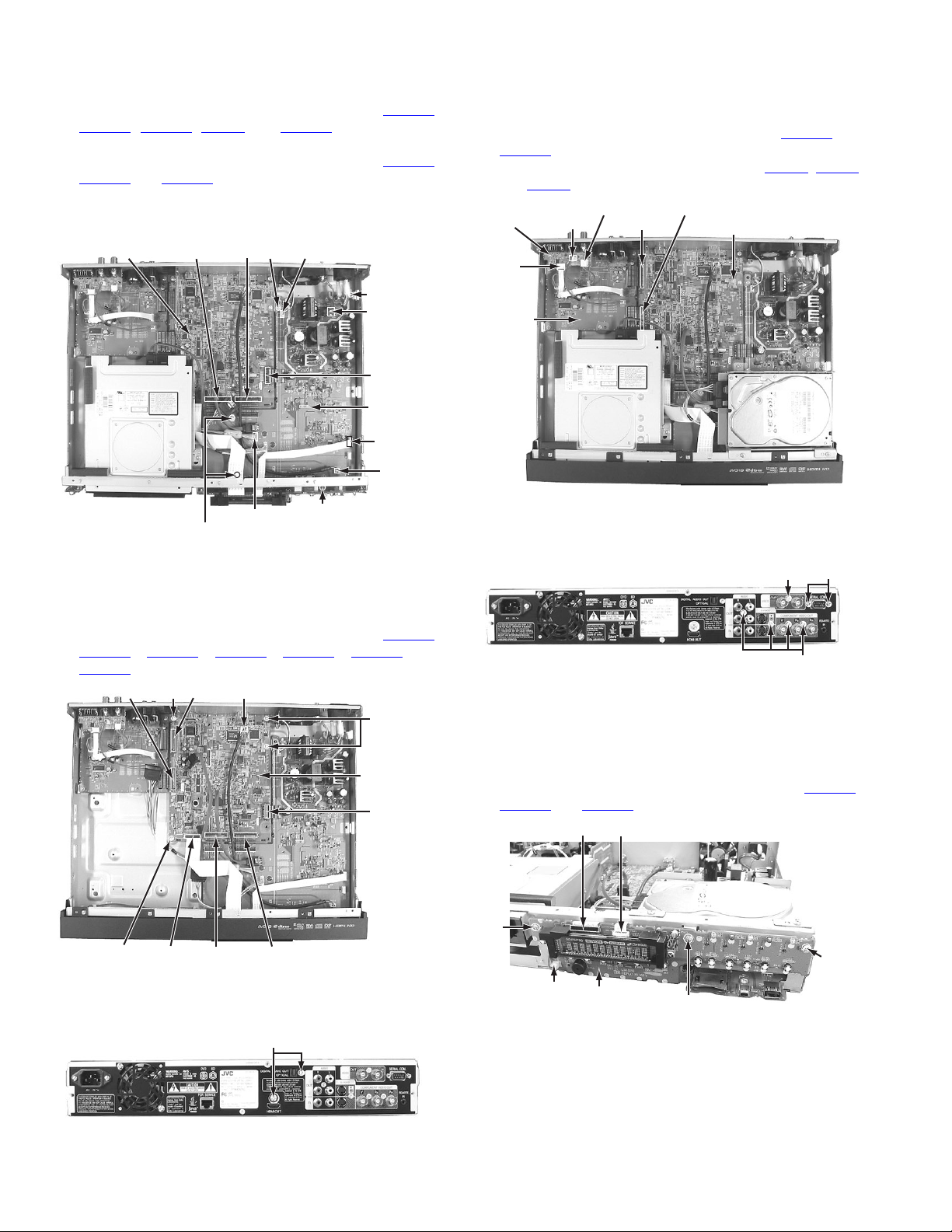

3.5 Removing the REG/SD board (See Figure 6)

• Remove the top cover, front panel assembly and HDD.

(1) Pull out the each wire from the connectors CN5306

CN5001

, CN5303, CN801 and CN5305 on the REG/SD

board.

(2) Pull out the socket wires from the connectors CN2102

CN5501

and CN4002 on the BE-DIGITAL board.

(3) Remove the five screws E attaching the REG/SD board,

and then remove the REG/SD board.

BE-DIGITAL

Board CN5501

CN5305

E

CN5303ECN2102

E

CN5001

CN4002

REG/SD

Board

CN5306

CN801

E

Fig.6

3.6 Removing the BE-DIGITAL board (See Figure 7 and

Figure 8)

• Remove the top cover, HDD and BD drive unit.

(1) Pull out the each wire from the connectors CN1501

CN1502

CN2801

, CN4001, CN2102, CN5501, CN4002 and

on the BE-DIGITAL board.

CN1502 CN1501 CN2801

G

3.7 Removing the D-SUB/BNC board and TERMINAL board (See Figure 9 and Figure 10)

,

• Remove the top cover.

(1) Pull out the socket wires from the connectors CN1501

,

CN1502

(2) Pull out the each wire from the connectors CN401

on the BE-DIGITAL board.

and CN403 on the D-SUB/BNC board.

D-SUB/BNC

Board

CN401

TERMINAL

Board

CN402

CN403

CN1501

CN1502

BE-DIGITAL Board

Fig.9

(3) Remove the five screws H and the two nuts attaching the

each terminal from back of the main unit.

H

,

Fig.10

and

, CN402

Nut

H

G

BE-DIGITAL

Board

CN4002

G

CN4001

CN2102 CN5501

Fig.7

(2) Remove the two screws F attaching the terminal from back

of the main unit.

F

Fig.8

(3) Remove the four screws G attaching the BE-DIGITAL

board.

1-6 (No.YD125<Rev.001>)

3.8 Removing the DISPLAY board (See Figure 11)

• Remove the top cover and front panel assembly.

(1) Remove the three screws J attaching the DISPLAY board.

(2) Pull out the each wire from the connectors CN7401

CN7402

J

and CN7403 on the DISPLAY board.

CN7401 CN7402

CN7403

DISPLAY Board

J

Fig.11

,

J

Page 7

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

SECTION 5

TROUBLE SHOOTING

5.1 DISPLAYING TEST MODE

TEST MODE contains the firmware version information of the main unit and the drive unit.

(1) While pressing the [PLAY] button and the [STOP] button, plug in the power cord.

(2) “TEST” flashes in the display window on the main unit. In about one minute, the TEST MODE menu is displayed on the TV

screen.

TEST MODE

MODEL INFORMATION

MODEL NAME SR-HDxxxx

DESTINATION xx

TOTAL Ver. xxxx

APPLI Ver. xxxx

BOOT Ver. xxxx

DRIVE Ver. x.xx

SYSCON ROM CODE xxx

SYSCON Ver. xx.xx

REGION(DRIVE/DVD/BD/NUM) x/x/x/x

Firmware version of main unit.

Firmware version of drive unit.

Firmware version of system controller.

CHANGE MODE

VIDEO ADJ [VIDEO ADJ] KEY

TEST MODE OFF [POWER] KEY

(3) To exit the TEST MODE menu, press the POWER button on the main unit.

5.2 UPDATING MAIN UNIT FIRMWARE

• The firmware update disc supports CD-R.

• When firmware update is needed, information will be available from SMIS in JS-NET.

5.2.1 Creating an Update Disc

Refer to JS-NET for details of creating an update disc.

(1) Download the update file (#########.iso) from SMIS in JS-NET.

(2) Write the update file onto a CD-R in image writing using writing software.

• Be sure to write in “Disc-at-Once”.

• Refer to the instructions of the writing software for image writing settings.

5.2.2 Update Procedures

(1) Place an update disc on the tray and close the tray.

During disc reading, a warning “THERE IS NO PLAYABLE MEDIA INSERTED” is displayed once or twice. Ignore the warning.

CONFIRM

THERE IS NO PLAYABLE MEDIA INSERTED

(No.YD125<Rev.001>)1-7

Page 8

(2) When disc reading is completed, the following displays are repeated in the display window on the main unit. “APPLI FIRM” →

“START [PLAY]” → “CANCEL [FF]”. Press the [PLAY] button on the main unit to start update.

When update starts, the followings are displayed in the display window on the main unit.

“L 10” → “L 20” → *** → “L 100” →

“C 10” → *** → *** → “C 100” → “W 10” → *** → “W 100”

“R 10” → *** → “R 100” → “V 00” → “COMPLETED”

(3) After update disc reading, the tray is ejected. Remove the update disc.

(4) Press the POWER button on the main unit.

The main unit power is turned on, and then turned off. The update is completed.

(5) In the TEST MODE menu, check whether the main unit firmware is correctly updated.

5.3 UPDATING SYSCON FIRMWARE

• The SYSCON firmware update disc supports CD-R.

• When SYSCON firmware update is needed, information will be available from SMIS in JS-NET.

5.3.1 Creating an Update Disc

Refer to JS-NET for details of creating an update disc.

(1) Download the update file (#########.iso) from SMIS in JS-NET.

(2) Write the update file onto a CD-R in image writing using writing software.

• Be sure to write in “Disc-at-Once”.

• Refer to the instructions of the writing software for image writing settings.

5.3.2 Update Procedures

(1) Place an update disc on the tray and close the tray.

During disc reading, a warning “THERE IS NO PLAYABLE MEDIA INSERTED” is displayed once or twice. Ignore the warning.

CONFIRM

THERE IS NO PLAYABLE MEDIA INSERTED

(2) When disc reading is completed, the following displays are repeated in the display window on the main unit. “SYSCON FIRM”

→ “START [PLAY]” → “CANCEL [FF]”.

Press the [PLAY] button on the main unit to start update.

When update starts, “PLEASE WAIT” is displayed in the display window on the main unit.

(3) After update disc reading, the following is displayed on the TV screen and the tray is ejected. Remove the update disc.

SYSCON FIRM UPDATE COMPLETE!!

Take out the disc and turn off power.

(4) Press the POWER button on the main unit.

The main unit power is turned off and update is completed.

(5) In the TEST MODE menu, check whether the SYSCON firmware is correctly updated.

5.4 UPDATING DRIVE FIRMWARE

• The drive firmware update disc supports CD-R.

• When drive firmware update is needed, information will be available from SMIS in JS-NET.

5.4.1 Creating an Update Disc

Refer to JS-NET for details of creating an update disc.

(1) Download the update file (#########.iso) from SMIS in JS-NET.

(2) Write the update file onto a CD-R in image writing using writing software.

• Be sure to write in “Disc-at-Once”.

• Refer to the instructions of the writing software for image writing settings.

1-8 (No.YD125<Rev.001>)

Page 9

5.4.2 Update Procedures

(1) Place an update disc on the tray and close the tray.

During disc reading, a warning “THERE IS NO PLAYABLE MEDIA INSERTED” is displayed once or twice. Ignore the warning.

CONFIRM

THERE IS NO PLAYABLE MEDIA INSERTED

(2) When disc reading is completed, the following displays are repeated in the display window on the main unit. “DRIVE FIRM” →

“START [PLAY]” → “CANCEL [FF]”. Press the [PLAY] button on the main unit to start update.

When update starts, “PLEASE WAIT” is displayed in the display window on the main unit.

(3) After update disc reading, the following is displayed on the TV screen and the tray is ejected. Remove the update disc.

DRIVE FIRM UPDATE COMPLETE!!

Take out the disc and turn off power.

(4) Press the POWER button on the main unit.

The main unit power is turned off and update is completed.

(5) In the TEST MODE menu, check whether the drive firmware is correctly updated.

5.5 INITIALIZING TO FACTORY SETTING

Before starting initialization, always obtain permission from the user as initialization returns all the setting information to the initial settings, and the user content and the related information will all be erased.

(1) Set the main unit to the TEST MODE.

(2) Transmit “##

·6F” using the JIG remote control. (Set “##” as follows according to the main unit remote control code. Code setting

1: Set “##” to “43”. Code setting 2: Set “##” to “53”. Code setting 3: Set “##” to “6F”. Code setting 4: Set ““##” to “7F”).

JIG remote control

JIG remote control

(Part number : PTU94023B)

[Data transmission]

Set the data code,

and then press the

" " button.

3

Custom code

43:A(1) Code

53:B(2) Code

6F:C(3) Code

7F:D(4) Code

Data code

Initial

mode

“COLD SET” flashes in the display window on the main unit. The initialization completes in about 30 seconds and the power is

turned off.

(No.YD125<Rev.001>)1-9

Page 10

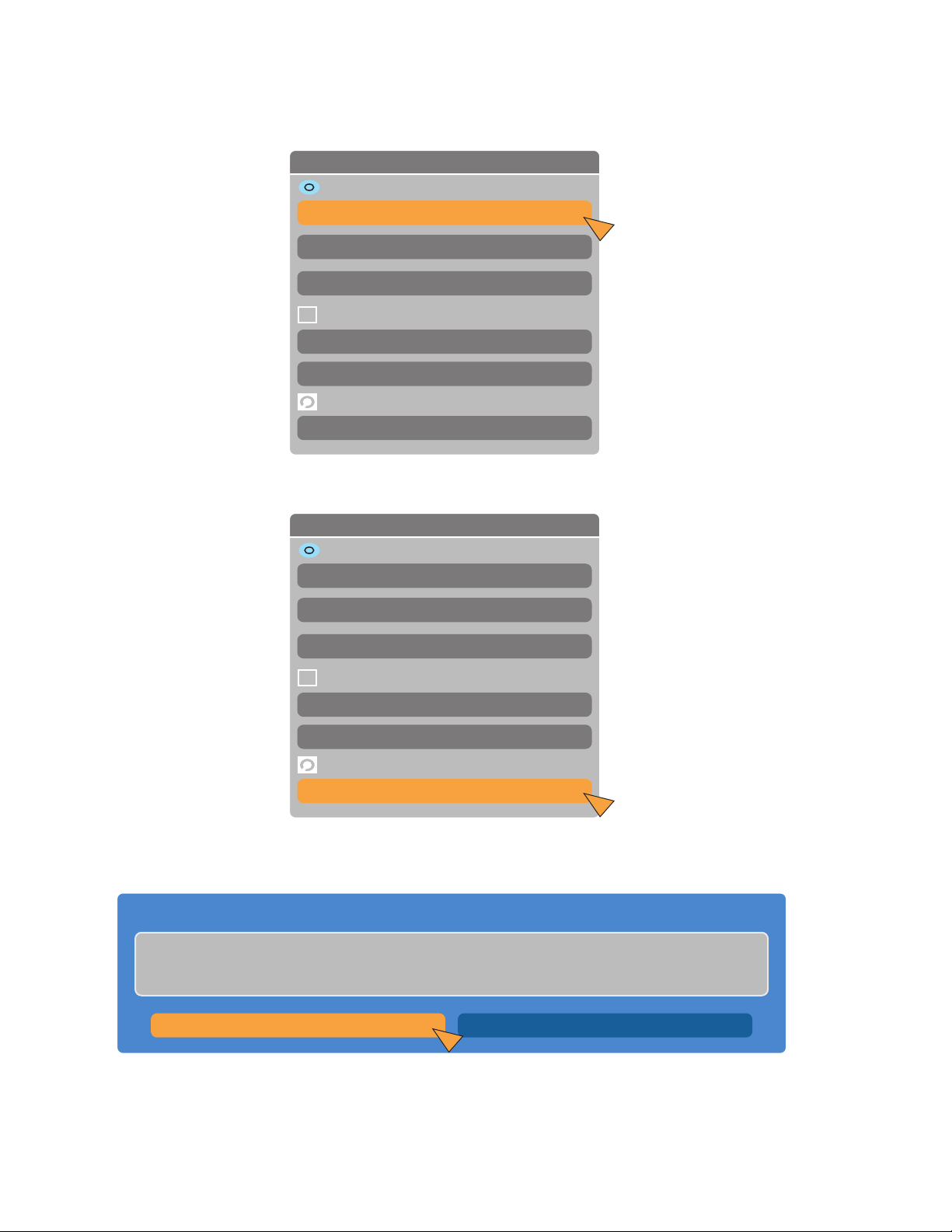

5.6 REPLACING HDD

After HDD replacement, initialize the HDD following the procedure below. (Without HDD initialization, HDD recording is impossible.)

(1) Turn on the power of the main unit.

(2) Press the [MEDIA MANAGE] button on the supplied remote control to display the MEDIA MANAGE menu on the TV screen.

MEDIA MANAGE

BD/DVD

FORMAT

FINALIZE

RENAME DISC

SD CARD

FORMAT

BD-VIDEO DATA ERASE

HDD

FORMAT

(3) Use the [Down] button on the remote control to move the highlight to HDD FORMAT, and then press the [OK] button on the

remote control.

MEDIA MANAGE

BD/DVD

FORMAT

FINALIZE

RENAME DISC

SD CARD

FORMAT

BD-VIDEO DATA ERASE

HDD

FORMAT

(4) The confirmation to execute HDD FORMAT is displayed on the TV screen. Move the highlight to “YES” using the [Left] button,

and then press the [OK] button on the remote control.

CONFIRM

THE HDD WILL BE FORMATTED

ALL RECORDED TITLES WILL BE ERASED

DO YOU WANT TO FORMAT?

YES NO

1-10 (No.YD125<Rev.001>)

Page 11

(5) Once again, the confirmation to execute HDD FORMAT is displayed. Perform the same procedure as step (4).

HDD FORMAT is executed.

CONFIRM

THE HDD WILL BE FORMATTED

ALL RECORDED TITLES WILL BE ERASED

DO YOU WANT TO FORMAT?

FORMAT DO NOT FORMAT

(6) When the HDD FORMAT is completed, the confirmation for the completion of HDD FORMAT is displayed on the TV screen.

Press the [OK] button on the remote control.

CONFIRM

THE HDD HAS BEEN FORMATTED

OK

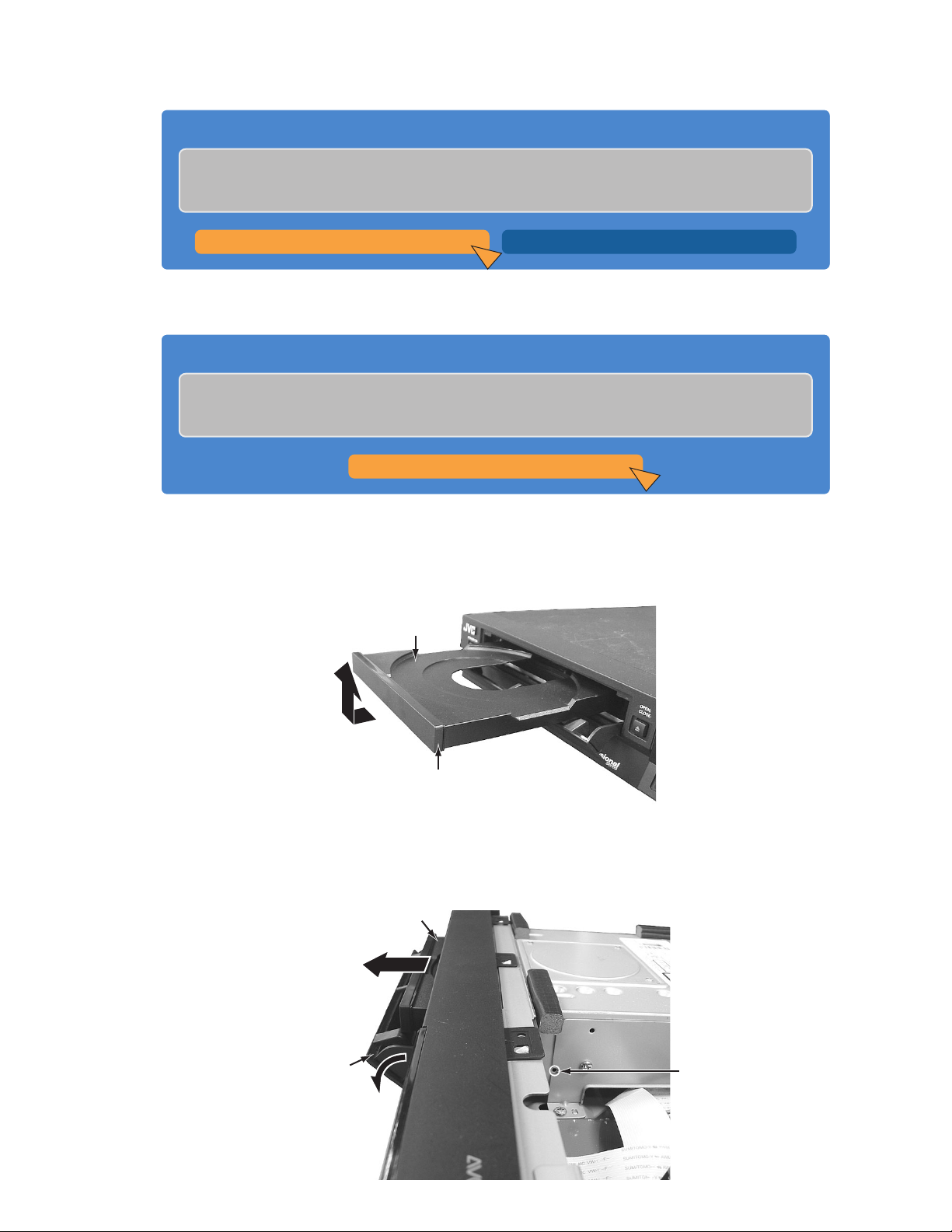

5.7 Exchanging the fitting

As the fitting that comes with the service drive unit cannot be used, make sure to attach a service fitting when the drive unit is exchanged.

The fitting that is removed from the old drive unit can be attached to the new drive unit.

The fitting can be removed by pulling upwards while opening out the lower part of the fitting outwards.

Tray

Fitting

5.8 Taking out a disc

(1) Remove the top cover.

(2) Open the front door of the main unit manually.

(3) Insert a fine wire (e.g. a straightened paper clip) into the hole in the right side part of the drive unit.

(4) As the tray ejects a little, pull out the tray manually.

Tray

Front door

Hole

(No.YD125<Rev.001>)1-11

Page 12

5.9 DISPLAYING MAINTENANCE MODE

MAINTENANCE MODE contains information about the HDD and the drive unit.

(1) Displaying MAINTENANCE Top Menu

a) Turn off the power of the main unit.

b) Press the [REC] button and the [RESET] switch on the main unit at the same time.

c) “SERVICE” is displayed in the display window on the main unit. In about 30 seconds, the MAINTENANCE Top Menu is

displayed on the TV screen.

MAINTENANCE MODE

Press key

[1] key : Product Information

[2] key : Temperature Information

[3] key : Laser Diode Information

[4] key : HDD SMART Information

[5] key : REBOOT COUNT Information

[Power off] : Exit

d) To exit MAINTENANCE MODE, press the POWER button on the main unit.

(2) Displaying Product Information

Product Information contains the firmware version information of the main unit and the drive unit.

a) While the MAINTENANCE Top Menu is displayed, press the [1] button on the supplied remote control to display Product

Information on the TV screen.

MAINTENANCE MODE > Product Information

[Return] : Top Menu, [Power off] : Exit

<<<Reviesion>>>

Middle Ware Version : xxxx

NAND Version : xxxx

Application Version : xxxx

NOR Version : xxxx

Drive Version

ID : xxxx

Farm Version : xxxx

<<<Information>>>

Vendor Name : JVC

Model Name : SR-HDxxxx

1394 Serial Num : xxxxxxxxx

b) To go back to the MAINTENANCE Top Menu, press the [Return] button on the remote control.

To exit MAINTENANCE MODE, press the POWER button on the main unit.

1-12 (No.YD125<Rev.001>)

Page 13

(3) Displaying Temperature Information

Temperature Information records the temperatures around the drive unit measured in the past.

While the power is on, the temperature is recorded every 20 minutes. The temperature is also recorded if it changes drastically.

(Maximum recording: 2000 measurements)

Recording date/time and the elapsed time after the last recording are also recorded.

a) While the MAINTENANCE Top Menu is displayed, press the [2] button on the remote control to display Temperature In-

formation on the TV screen.

MAINTENANCE MODE > Temperature Information [Total Data]13 [Page]1/2

[Left] : Prev, [Right] : Next, [Return] : Top Menu, [Power off] : Exit

[no]xxxx [date]xxxx/ xx/ xx [time]xx:xx:xx [lenght]xxxx [type]xx

[no]xxxx [date]xxxx/ xx/ xx [time]xx:xx:xx [lenght]xxxx [type]xx

[no]xxxx [date]xxxx/ xx/ xx [time]xx:xx:xx [lenght]xxxx [type]xx

[no]xxxx [date]xxxx/ xx/ xx [time]xx:xx:xx [lenght]xxxx [type]xx

[no]xxxx [date]xxxx/ xx/ xx [time]xx:xx:xx [lenght]xxxx [type]xx

[no]xxxx [date]xxxx/ xx/ xx [time]xx:xx:xx [lenght]xxxx [type]xx

b) To display old records, press the [Right] button on the remote control.

To display new records, press the [Left] button on the remote control.

c) To go back to the MAINTENANCE Top Menu, press the [Return] button on the remote control.

To exit MAINTENANCE MODE, press the POWER button on the main unit.

(4) Displaying Laser Diode Information

Laser Diode Information records the past rates of diode current change in the drive unit.

The rate of diode current change in the drive unit at the time of power off is recorded.

(Maximum recording: 2000 measurements)

Recording date/time is recorded at the same time.

a) While the MAINTENANCE Top Menu is displayed, press the [3] button on the remote control to display Laser Diode Infor-

mation on the TV screen.

MAINTENANCE MODE > Laser Diode Information [Total Data]11 [Page]1/2

[Left] : Prev, [Right] : Next, [Return] : Top Menu, [Power off] : Exit

[No]xxxx [Date]xxxx/ xx/ xx [Time]xx:xx:xx [DVD]xxx [BD]xxx [CD]xxx

[No]xxxx [Date]xxxx/ xx/ xx [Time]xx:xx:xx [DVD]xxx [BD]xxx [CD]xxx

[No]xxxx [Date]xxxx/ xx/ xx [Time]xx:xx:xx [DVD]xxx [BD]xxx [CD]xxx

[No]xxxx [Date]xxxx/ xx/ xx [Time]xx:xx:xx [DVD]xxx [BD]xxx [CD]xxx

[No]xxxx [Date]xxxx/ xx/ xx [Time]xx:xx:xx [DVD]xxx [BD]xxx [CD]xxx

[No]xxxx [Date]xxxx/ xx/ xx [Time]xx:xx:xx [DVD]xxx [BD]xxx [CD]xxx

b) To display old records, press the [Right] button on the remote control.

To display new records, press the [Left] button on the remote control.

c) To go back to the MAINTENANCE Top Menu, press the [Return] button on the remote control.

To exit MAINTENANCE MODE, press the POWER button on the main unit.

(No.YD125<Rev.001>)1-13

Page 14

(5) Displaying HDD SMART Information

HDD SMART Information displays the total HDD operating time and SMART information obtained when starting MAINTENANCE

MODE.

a) While the MAINTENANCE Top Menu is displayed, press the [4] button on the remote control to display HDD SMART In-

formation on the TV screen.

First page

MAINTENANCE MODE > HDD SMART Information [Page]1/2

[Left] : Prev, [Right] : Next, [Return] : Top Menu, [Power off] : Exit

HDD total time : xxx hour

-----------------------------------------------------------------------------------Raw Read Error Rate xx xx xx xx xx xx xx xx xx xx xx xx

Throughput Performance xx xx xx xx xx xx xx xx xx xx xx xx

Spin Up Time xx xx xx xx xx xx xx xx xx xx xx xx

Start/Stop Count xx xx xx xx xx xx xx xx xx xx xx xx

Real located Sectors Count xx xx xx xx xx xx xx xx xx xx xx xx

Seek Error Rate xx xx xx xx xx xx xx xx xx xx xx xx

Seek Time Performance xx xx xx xx xx xx xx xx xx xx xx xx

Power-On Hours xx xx xx xx xx xx xx xx xx xx xx xx

Spin Retry Count xx xx xx xx xx xx xx xx xx xx xx xx

Device Power Cycle Count xx xx xx xx xx xx xx xx xx xx xx xx

Second page

MAINTENANCE MODE > HDD SMART Information [Page]2/2

[Left] : Prev, [Right] : Next, [Return] : Top Menu, [Power off] : Exit

Load/Unload Cycle Count xx xx xx xx xx xx xx xx xx xx xx xx

Temperature xx xx xx xx xx xx xx xx xx xx xx xx

Real location Event Count xx xx xx xx xx xx xx xx xx xx xx xx

Current Pending Sector Count xx xx xx xx xx xx xx xx xx xx xx xx

Off-Line Scan Uncorrectable Sector Count xx xx xx xx xx xx xx xx xx xx xx xx

UltraDMA CRC Error Count xx xx xx xx xx xx xx xx xx xx xx xx

b) To go to the next page, press the [Right] button on the remote control.

To go back to the previous page, press the [Left] button on the remote control.

c) To go back to the MAINTENANCE Top Menu, press the [Return] button on the remote control.

To exit MAINTENANCE MODE, press the POWER button on the main unit.

1-14 (No.YD125<Rev.001>)

Page 15

(6) REBOOT COUNT Information

REBOOT COUNT Information displays date/time of reboot occurred due to any reason.

a) While the MAINTENANCE Top Menu is displayed, press the [5] button on the remote control to display REBOOT COUNT

Information on the TV screen.

(Maximum recording: 100 occurrences)

MAINTENANCE MODE > REBOOT COUNT Information [TotalData]xxxx [Page]xxx/xxx

[Left] : Prev, [Right] : Next, [Return] : Top Menu, [Power off] : Exit

[No]xxxx [Date]xxxx/ xx/ xx [Time]xx:xx:xx

[No]xxxx [Date]xxxx/ xx/ xx [Time]xx:xx:xx

[No]xxxx [Date]xxxx/ xx/ xx [Time]xx:xx:xx

b) To display old records, press the [Right] button on the remote control.

To display new records, press the [Left] button on the remote control.

c) To go back to the MAINTENANCE Top Menu, press the [Return] button on the remote control.

To exit MAINTENANCE MODE, press the POWER button on the main unit.

(No.YD125<Rev.001>)1-15

Page 16

Victor Company of Japan, Limited

Business Solution Division

(No.YD125<Rev.001>)

Printed in Japan

VSE

Page 17

PARTS LIST

[SR-HD1250US, SR-HD1500US, SR-HD1500KR,

SR-HD1250EU, SR-HD1500EU, SR-HD1500ER,

SR-HD1500AG, SR-HD1500AC]

* SAFETY PRECAUTION

Parts identified by the symbol are critical for safety. Replace only with

specified part numbers.

* BEWARE OF BOGUS PARTS

Parts that do not meet specifications may cause trouble in regard to safety and

performance. We recommend that genuine JVC parts be used.

* (x_) in a description column shows the number of the used part.

- Contents -

Exploded view of general assembly and parts list

Electrical parts list

Packing materials and accessories parts list

3-2

3-4

3-8

(No.YD125<Rev.001>)3-1

Page 18

Exploded view of general assembly and parts list

32

6

13

11

4

OPE board assembly<07>

1B

REG/SD

board assembly<01>

29

a

d

25

12

13

5

6

m

WR11

m

1A

3

2

30

28

d

WR4

WR3

c

6

OPT DIGI

board assembly<08>

WR1

WR8

h

6

Terminal

board assembly<06>

6

p

10

31

h

j

Display

6

board assembly<05>

1

WR2

a

3

Block No.M1MM

3

36

6

6

j

WR9

e

e

6

b

WR5

3

27

6

f

D-SUB/BNC

board assembly<09>

6

33

n

WR12

35

19

19

6

f

g

WR7

Green/Yellow

16

13

20

23

19

22

Brown

Blue

18

WR6

26

17

19

WR10

10

k

n

34

k

6

p

WR13

9

21

7

g

15

8

24

c

b

6

15

8

17

16

14

3-2(No.YD125<Rev.001>)

Page 19

General assembly

Block No. [M][1][M][M]

Symbol No. Part No. Part Name Description Local

1 LS10265-005A FRONT PANEL ASSY 1250EU

1 LS10265-002B FRONT PANEL ASSY 1250US

1 LS10265-006A FRONT PANEL ASSY 1500AC

1 LS10265-004A FRONT PANEL ASSY 1500AG,1500ER,1500EU

1 LS10265-001B FRONT PANEL ASSY 1500KR,1500US

1A LS20429-001B DOOR(DVD)

1B LS42002-001A TORSION SPRING

2 LS10267-001B TOP COVER

3 LS31279-003A SPECIAL SCREW (x7)

4 LS20430-001A FITTING(P)

5 LS10268-001A BOTTOM CHASSIS

6 LS31279-001A SPECIAL SCREW (x25)

7 QYSPSP4008ZA SCREW M4 x 8mm

8 LS31280-002A FOOT (x4)

9 LS42015-001A COOLING SHEET

10 QZW0092-005 WIRE CLAMP (x3)

11 LS31281-001A BRACKET(DRIVE)(L)

12 LS31282-001A BRACKET(DRIVE)(R)

13 QYSDST3006NA TAP SCREW M3 x 6mm(x5)

14 LS20431-001A BRACKET(HDD)

15 LS42004-001A DAMPER (x4)

16 LS42005-001A SPRING (x2)

17 LS42006-001A SPECIAL SCREW (x4)

18 LS20432-006A REAR PANEL 1250EU

18 LS20432-002B REAR PANEL 1250US

18 LS20432-007A REAR PANEL 1500AC

18 LS20432-004B REAR PANEL 1500AG,1500KR

18 LS20432-005A REAR PANEL 1500ER,1500EU

18 LS20432-001B REAR PANEL 1500US

19 QYSDSF3008NA TAP SCREW M3 x 8mm(x9)

20 QYSPSPH4025NA SCREW M4 x 25mm(x2)

21 QYNFS4000NA NUT M4(x2)

22 QAR0505-001 FAN MOTOR

23 QNC0116-001 AC INLET

24 QAL1223-001 HDD 1250EU,1250US

24 QAL1222-001 HDD

25 QAL1229-001-1 DRIVE UNIT 1250US,1500US

25 QAL1229-001-2 DRIVE UNIT 1500EU,1250EU

25 QAL1229-001-3 DRIVE UNIT 1500AG,1500KR

25 QAL1229-001-5 DRIVE UNIT 1500ER

25 QAL1229-001-6 DRIVE UNIT 1500AC

26 QZW0001-001 WIRE CLAMP

27 QMF51V2-2R0-S FUSE 2A AC250V

28 QQR0490-001 NOISE FILTER

29 LS31422-001A-H GASKET (x2)

30 LS31422-002A-H GASKET

31 LS31422-003A-H GASKET

32 LS31422-004A-H GASKET

33 QNB0036-001 CONN ACCESSORY (x2)

34 LSU06907-01AEU2 BE DIGI BOARD ASSY 1250EU

34 LSU06907-01AUS2 BE DIGI BOARD ASSY 1250US

34 LSU06907-01AAC5 BE DIGI BOARD ASSY 1500AC

34 LSU06907-01AAG5 BE DIGI BOARD ASSY 1500AG

34 LSU06907-01AER5 BE DIGI BOARD ASSY 1500ER

34 LSU06907-01AEU5 BE DIGI BOARD ASSY 1500EU

34 LSU06907-01AKR5 BE DIGI BOARD ASSY 1500KR

34 LSU06907-01AUS5 BE DIGI BOARD ASSY 1500US

35 QYWAS326505NA WASHER 6.5mm/3.2mm x 0.5mm 1250EU

36 QZW0384-001 WIRE CLAMP

WR 1 QAM1049-002 SATA CABLE BE DIGI J4801-DRIVE UNIT

WR 2 QAM1049-002 SATA CABLE BE DIGI PWB J4901-HDD

WR 3 WJJ1064-001A-E WIRE REG/SD CN5304-HDD

WR 4 WJJ1064-002A-E WIRE REG/SD CN5305-DRIVE UNIT

WR 5 WJW0127-001A-E E-TWISTED ASSY DIGI CN2801-REG/SD CN801

WR 6 WJM0522-001A-E WIRE AC INLET-REG/SD CN5001

WR 7 WJV0146-001A-E E-PRIMARY WIRE AC INLET-BOTTOM CHASSIS

WR 8 QUR310-2122AC-E FFC WIRE BE DIGI CN4001-DISPLAY CN7401

WR 9 QUQ112-0724CG-E FFC WIRE DISPLAY CN7402-REG/SD CN5306

WR10 QUQ112-0516CG-E FFC WIRE D-SUB/BNC CN401-TERMINAL CN203

WR11 QJJ009-022612-E WIRE DISPLAY CN7403-OPE CN7404

WR12 QJJ009-021512-E WIRE D-SUB/BNC CN402-TERMINAL CN204

WR13 QJJ009-031313-E WIRE D-SUB/BNC CN403-TERMINAL CN205

1500AC,1500AG,1500ER,1500EU,1500KR,1500US

1500AC,1500AG,1500ER,1500EU,1500KR,1500US

1250EU,1500AC,1500AG,1500ER,1500EU,1500KR

1250US,1500AC,1500AG,1500ER,1500EU,1500KR,1500US

(No.YD125<Rev.001>)3-3

Page 20

Electrical parts list

REG/SD board

Symbol No.

Part No. Part Name Description Local

Block No. [0][1]

Symbol No.

PW1 LSA10109-01B1H

PW1 LSA10109-01A1H

IC5101 FSQ0565R IC(HYBRID)

IC5301 MM1431AT-T IC

IC5303 AOZ1016AI-X IC

IC5305

IC5306 AOZ1016AI-X IC

Q5303 2SC2412K/QR/-X TRANSISTOR

Q5304 2SB1184/QR/-X POW TRANSISTOR

Q5305 2SA1037AK/R/-X TRANSISTOR

Q5307 2SA1363/EF/-X TRANSISTOR

Q5308 2SC3928A/QR/-X TRANSISTOR

Q5309 ISA1530AC1/QR/X TRANSISTOR

Q5310 ISA1530AC1/QR/X TRANSISTOR

Q5311 RT1N144C-X DIGI TRANSISTOR

Q5312 2SC3928A/QR/-X TRANSISTOR

Q5313 ISA1530AC1/QR/X TRANSISTOR

Q5314 RT1N241C-X DIGI TRANSISTOR

Q5315 ISA1530AC1/QR/X TRANSISTOR

Q5316 2SC3928A/QR/-X TRANSISTOR

Q5317 ISA1530AC1/QR/X TRANSISTOR

Q5318 2SB1184/QR/-X POW TRANSISTOR

Q5319 2SA1947/E/-X TRANSISTOR

Q5320 2SC3928A/QR/-X TRANSISTOR

Q5321 ISA1530AC1/QR/X TRANSISTOR

Q5323 2SC3928A/QR/-X TRANSISTOR

Q5325 ISA1530AC1/QR/X TRANSISTOR

D5001 D3SBA60 BRIDGE DIODE

D5101 SARS01-T FR DIODE

D5102 FR104S-T5 FR DIODE

D5201 FMN-G12S SI DIODE

D5203 FMB-24M SB DIODE

D5205 FR104S-T5 FR DIODE

D5304 RB400VA-50-X SB DIODE

D5306 MA2SD31-X SB DIODE

D5310 MA111-X SI DIODE

D5311 RB160M-30-X SB DIODE

D5312 MA2SD31-X SB DIODE

D5314 SR24-X SB DIODE

D5315 MA2SD31-X SB DIODE

D5318 MA2SD31-X SB DIODE

PC5101 PC123Y22FZ PHOTO COUPLER

C811 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C812 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C813 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C814 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C815 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C5001 QFZ9073-104 MM CAPACITOR 0.1uF AC250V M

C5002 QFZ9067-223 MM CAPACITOR 0.022uF

C5003 QETM2GM-107 E CAPACITOR 100uF 400V M

C5004 QCZ9079-101 C CAPACITOR 100pF AC250V K

C5101 QCZ0213-472 C CAPACITOR 4700pF 1kV K

C5102 NCB31HK-333X C CAPACITOR 0.033uF 50V K

C5103 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C5104 QTMT1HM-476 E CAPACITOR 47uF 50V M

C5105 NCB31HK-331X C CAPACITOR 330pF 50V K

C5107 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C5201 QTM91CM-128 E CAPACITOR 1200uF 16V M

C5202 QTM91AM-338 E CAPACITOR 3300uF 10V M

C5204 QTM91CM-477 E CAPACITOR 470uF 16V M

C5301 QETN1CM-107Z E CAPACITOR 100uF 16V M

C5304 QETN1CM-107Z E CAPACITOR 100uF 16V M

C5306 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C5307 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C5308 QETN1HM-226Z E CAPACITOR 22uF 50V M

C5309 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C5311 NCB41CK-226X C CAPACITOR 22uF 16V K

Part No. Part Name Description Local

PQ6CU12X2APQ-X

REG/SD BOARD ASSY

REG/SD BOARD ASSY

IC

1250EU,1500AC,1500AG,1500ER,1500EU

1250US,1500KR,1500US

C5312 NCB41AK-226X C CAPACITOR 22uF 10V K

C5313 NCB41AK-226X C CAPACITOR 22uF 10V K

C5314 NCB31HK-102X C CAPACITOR 1000pF 50V K

C5315 NCB31CK-103X C CAPACITOR 0.01uF 16V K

C5316 NCB31CK-103X C CAPACITOR 0.01uF 16V K

C5326 NCB30JK-225X C CAPACITOR 2.2uF 6.3V K

C5327 NCB11HK-474X C CAPACITOR 0.47uF 50V K

C5328 NCB11HK-474X C CAPACITOR 0.47uF 50V K

C5329 NCB41AK-226X C CAPACITOR 22uF 10V K

C5330 NCB31CK-103X C CAPACITOR 0.01uF 16V K

C5331 NCB31HK-102X C CAPACITOR 1000pF 50V K

C5332 NCB41AK-226X C CAPACITOR 22uF 10V K

C5333 NCB41AK-226X C CAPACITOR 22uF 10V K

C5334 QETN1CM-107Z E CAPACITOR 100uF 16V M

C5335 QETN0JM-478Z E CAPACITOR 4700uF 6.3V M

C5336 QETN1HM-106Z E CAPACITOR 10uF 50V M

C5337 QCZ9079-102 C CAPACITOR 1000pF AC250V M

C5339 NCB31HK-333X C CAPACITOR 0.033uF 50V K

C5342 QETN1HM-106Z E CAPACITOR 10uF 50V M

C5343 NCB31AK-154X C CAPACITOR 0.15uF 10V K

C5344 NCB31HK-333X C CAPACITOR 0.033uF 50V K

C5348 QETN1CM-477Z E CAPACITOR 470uF 16V M

C5350 NCB21CK-105X C CAPACITOR 1uF 16V K

C5353 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C5354 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C5355 NCB31CK-103X C CAPACITOR 0.01uF 16V K

C5356 NCB31CK-103X C CAPACITOR 0.01uF 16V K

C5357 QETN1CM-107Z E CAPACITOR 100uF 16V M

C5358 QETN1CM-107Z E CAPACITOR 100uF 16V M

C5359 QETN1CM-107Z E CAPACITOR 100uF 16V M

Ω

R811 NRSA63J-473X MG RESISTOR 47k

R812 NRSA63J-473X MG RESISTOR 47k

R813 NRSA63J-123X MG RESISTOR 12k

R814 NRSA63J-220X MG RESISTOR 22

R815 NRSA63J-220X MG RESISTOR 22

R816 NRSA63J-220X MG RESISTOR 22

R817 NRSA63J-220X MG RESISTOR 22

R818 NRSA63J-0R0X MG RESISTOR 0

R819 NRSA63J-220X MG RESISTOR 22

R820 NRSA63J-123X MG RESISTOR 12k

R821 NRSA63J-123X MG RESISTOR 12k

R822 NRSA63J-123X MG RESISTOR 12k

R823 NRSA63J-123X MG RESISTOR 12k

R5101 QRL01DJ-683X OMF RESISTOR 68k

R5102 QRZ9005-470X FUSI RESISTOR 47

R5103 QRL01DJ-753X OMF RESISTOR 75kΩ 1W J

R5105 QRJ143J-223X

R5106 QRJ143J-333X

R5107 QRZ9051-4R7X FUSI RESISTOR 4.7

R5109 QRE141J-0R0Y C RESISTOR 0Ω 1/4W J

R5301 NRSA63J-0R0X MG RESISTOR 0

R5302 NRSA63J-683X MG RESISTOR 68k

R5303 NRSA63J-133X MG RESISTOR 13k

R5304 NRSA63J-223X MG RESISTOR 22k

R5309 NRSA63J-102X MG RESISTOR 1k

R5311 NRSA63D-103X MG RESISTOR 10k

R5312 NRSA63D-304X MG RESISTOR 300k

R5313 NRSA63J-124X MG RESISTOR 120k

R5314 NRSA63J-472X MG RESISTOR 4.7k

R5315 NRSA63J-472X MG RESISTOR 4.7k

R5317 NRSA63J-223X MG RESISTOR 22k

R5318 NRSA63J-563X MG RESISTOR 56k

R5319 NRSA63J-153X MG RESISTOR 15k

R5320 QRE141J-181Y C RESISTOR 180

R5321 NRSA63J-0R0X MG RESISTOR 0

R5322 NRSA63J-103X MG RESISTOR 10k

R5323 NRSA63J-102X MG RESISTOR 1k

R5324 QRE141J-331Y C RESISTOR 330

R5325 QRE141J-131Y C RESISTOR 130

R5328 QRE141J-104Y C RESISTOR 100k

R5329 NRSA63J-562X MG RESISTOR 5.6k

R5330 NRSA63J-223X MG RESISTOR 22k

R5331 NRSA63J-222X MG RESISTOR 2.2k

R5332 NRSA63J-102X MG RESISTOR 1k

R5333 NRSA63J-102X MG RESISTOR 1k

UNF C RESISTOR

UNF C RESISTOR

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/10W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1W J

Ω

22kΩ 1/4W J

33kΩ 1/4W J

Ω

Ω

1/10W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W D

Ω

1/16W D

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/4W J

Ω

1/10W J

Ω

1/16W J

Ω

1/16W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

3-4(No.YD125<Rev.001>)

Page 21

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R5334 NRSA63J-0R0X MG RESISTOR 0Ω 1/10W J

R5335 NRSA63D-472X MG RESISTOR 4.7k

R5336 NRSA63J-471X MG RESISTOR 470

R5338 NRSA63J-182X MG RESISTOR 1.8k

R5339 NRSA63J-152X MG RESISTOR 1.5k

R5340 NRSA63J-391X MG RESISTOR 390

R5341 NRSA63D-392X MG RESISTOR 3.9k

R5343 NRSA63J-242X MG RESISTOR 2.4k

R5345 NRSA63J-101X MG RESISTOR 100

R5346 NRSA63J-122X MG RESISTOR 1.2k

R5347 NRSA63J-222X MG RESISTOR 2.2k

R5348 NRSA63J-103X MG RESISTOR 10k

R5349 NRSA63J-562X MG RESISTOR 5.6k

R5350 NRSA63J-242X MG RESISTOR 2.4k

R5351 NRSA63J-222X MG RESISTOR 2.2k

R5352 NRSA63J-222X MG RESISTOR 2.2k

R5354 NRSA63J-102X MG RESISTOR 1k

R5355 NRSA63J-102X MG RESISTOR 1k

R5356 QRL01DJ-561X OMF RESISTOR 560

R5357 NRSA63J-102X MG RESISTOR 1k

R5358 NRSA63J-102X MG RESISTOR 1k

R5360 NRSA63J-103X MG RESISTOR 10k

R5361 NRSA63J-471X MG RESISTOR 470

R5364 NRSA63J-0R0X MG RESISTOR 0

R5365 NRSA63J-102X MG RESISTOR 1k

R5367 NRSA63J-103X MG RESISTOR 10k

R5369 QRZ9051-101X FUSI RESISTOR 100

R5370 QRZ9051-4R7X FUSI RESISTOR 4.7

R5371 NRSA63J-0R0X MG RESISTOR 0Ω 1/10W J

R5374 NRSA63J-562X MG RESISTOR 5.6k

R5375 NRSA63J-472X MG RESISTOR 4.7k

R5376 NRSA63J-102X MG RESISTOR 1k

R5377 NRSA63J-103X MG RESISTOR 10k

R5378 NRSA63J-223X MG RESISTOR 22k

R5379 NRSA63J-821X MG RESISTOR 820

R5380 NRSA63J-391X MG RESISTOR 390

R5381 NRSA63J-821X MG RESISTOR 820

R5382 NRSA63J-221X MG RESISTOR 220

R5383 NRSA63J-102X MG RESISTOR 1k

R5384 NRSA63J-103X MG RESISTOR 10k

R5385 NRSA63J-103X MG RESISTOR 10k

R5386 NRSA63J-103X MG RESISTOR 10k

R5387 NRSA63J-391X MG RESISTOR 390

R5388 NRSA63J-182X MG RESISTOR 1.8k

R5390 QRE141J-102Y C RESISTOR 1k

L5201 QQL26AK-100Z COIL 10uH K

L5202 QQL26AK-100Z COIL 10uH K

L5203 QQL26AK-100Z COIL 10uH K

L5301 NQLG2EN-4R3X COIL 4.3uH N

L5303 NQL52EM-470X COIL 47uH M

L5304 NQLZ018-4R7X COIL 4.7uH

T5001 QQS0452-001 SW TRANSF

CN801 QGA1217C2-05X CONNECTOR W-B (1-5)

CN811 QGB1231M1-23 CONNECTOR B-B (1-23)

CN813 QGF1208C1-05 CONNECTOR FFC/FPC (1-5)

CN5001 QGA7901C1-02 CONNECTOR W-B (1-2)

CN5301 QGB1231M1-23 CONNECTOR B-B (1-23)

CN5302 QGB1231M1-15 CONNECTOR B-B (1-15)

CN5303 QGA2001C1-03 CONNECTOR W-B (1-3)

CN5304 QGA2501C1-04 CONNECTOR W-B (1-4)

CN5305 QGA2501C1-04 CONNECTOR W-B (1-4)

CN5306 QGF1208C1-07 CONNECTOR FFC/FPC (1-7)

F5301

FC5001 QNG0003-001Z FUSE CLIP

FC5002 QNG0003-001Z FUSE CLIP

FL801 NQR0506-002X EMI FILTER

HS5101 QZW0197-002 HEAT SINK

HS5201 QZW0197-002 HEAT SINK

HS5203 QZW0197-002 HEAT SINK

J801 QNZ0851-001 USB CONNECTOR

J811 QNZ0954-001 SD CARD CONNE

J812 QNZ0715-001 D CONNECTOR

K811 NQR0360-004X FERRITE BEADS

K812 NQR0360-004X FERRITE BEADS

K813 NQR0360-004X FERRITE BEADS

QMFZ050-1R25X-E

FUSE 1.25A 125V

Ω

Ω

1/16W J

Ω

Ω

Ω

1/16W J

Ω

Ω

Ω

1/16W J

Ω

Ω

Ω

1/16W J

Ω

Ω

Ω

Ω

Ω

1/16W J

Ω

1/16W J

Ω

1W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/10W J

Ω

1/16W J

Ω

1/16W J

Ω

Ω

Ω

Ω

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

Ω

1/4W J

1/16W D

1/16W J

1/16W J

1/16W D

1/16W J

1/16W J

1/16W J

1/16W J

1/16W J

1/16W J

1/16W J

1/16W J

1/16W J

1/16W J

1250EU,1500AC,1500

AG,1500ER,1500EU

K814 NQR0360-004X FERRITE BEADS

K816 NQR0360-004X FERRITE BEADS

K817 NQR0360-004X FERRITE BEADS

K818 NQR0360-004X FERRITE BEADS

K5101 NQR0499-004X FERRITE BEADS

K5302 NQR0499-004X FERRITE BEADS

K5304 NQR0499-004X FERRITE BEADS

K5305 NQR0499-004X FERRITE BEADS

LF801 NQR0568-005X CHOKE COIL

LF5001 QQR1841-001 LINE FILTER

OT1 QYSDST3008NA TAP SCREW M3 x 8mm(x3)

SG5002 NAF0016-301X

VA5001 QAF0066-471

SURGE ABSORBER

SURGE ABSORBER

300V

470V

Display board

Symbol No.

PW1 LSA10110-01A1H DISPLAY BOARD ASSY

IC7401 GP1UE281RKC1 IR DETECT UNIT

Q7423 RT1N141C-X DIGI TRANSISTOR

Q7424 RT1N141C-X DIGI TRANSISTOR

Q7425 RT1N141C-X DIGI TRANSISTOR

Q7426 RT1N141C-X DIGI TRANSISTOR

Q7427 RT1N141C-X DIGI TRANSISTOR

D7401 MA8024-X Z DIODE

D7411 MA111-X SI DIODE

D7423 SLR-343VC-T LED

D7424 SLR-343VC-T LED

D7425 SLR-343MC-T LED

D7426 SLR-343MC-T LED

D7427 SLR-343MC-T LED

C7401 NEAF0JM-107X E CAPACITOR 100uF 6.3V M

C7402 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C7403 NEAF0JM-476X E CAPACITOR 47uF 6.3V M

C7404 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C7405 NEAF1HM-106X E CAPACITOR 10uF 50V M

C7406 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C7407 NCB31HK-473X C CAPACITOR 0.047uF 50V K

C7408 NCB31HK-473X C CAPACITOR 0.047uF 50V K

C7409 NEAF0JM-476X E CAPACITOR 47uF 6.3V M

C7431 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C7441 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C7451 NCB31HK-103X C CAPACITOR 0.01uF 50V K

R7401 NRSA63J-100X MG RESISTOR 10

R7402 NRSA63J-100X MG RESISTOR 10

R7403 NRSA63J-100X MG RESISTOR 10

R7404 NRSA63J-103X MG RESISTOR 10k

R7406 NRSA63J-101X MG RESISTOR 100

R7407 NRSA63J-101X MG RESISTOR 100

R7408 NRSA63J-222X MG RESISTOR 2.2k

R7409 NRSA63J-222X MG RESISTOR 2.2k

R7410 NRSA63J-183X MG RESISTOR 18k

R7411 NRSA63J-0R0X MG RESISTOR 0

R7416 NRSA63J-0R0X MG RESISTOR 0

R7417 NRSA63J-102X MG RESISTOR 1k

R7423 NRSA63J-181X MG RESISTOR 180

R7424 NRSA63J-181X MG RESISTOR 180

R7425 NRSA63J-181X MG RESISTOR 180

R7426 NRSA63J-181X MG RESISTOR 180

R7427 NRSA63J-181X MG RESISTOR 180

R7431 NRSA63J-103X MG RESISTOR 10k

R7432 NRSA63J-222X MG RESISTOR 2.2k

R7433 NRSA63J-272X MG RESISTOR 2.7k

R7434 NRSA63J-472X MG RESISTOR 4.7k

R7435 NRSA63J-103X MG RESISTOR 10k

R7441 NRSA63J-103X MG RESISTOR 10k

Part No. Part Name Description Local

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/10W J

Ω

1/10W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

1250EU,1500AC,1500A

G,1500ER,1500EU

Block No. [0][5]

(No.YD125<Rev.001>)3-5

Page 22

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R7442 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R7443 NRSA63J-272X MG RESISTOR 2.7k

R7451 NRSA63J-103X MG RESISTOR 10k

R7452 NRSA63J-222X MG RESISTOR 2.2k

R7453 NRSA63J-272X MG RESISTOR 2.7k

R7454 NRSA63J-472X MG RESISTOR 4.7k

R7455 NRSA63J-103X MG RESISTOR 10k

R7456 NRSA63J-333X MG RESISTOR 33k

BZ7401 QAN0023-001Z BUZZER

CN7401 QGF1045F2-21X CONNECTOR FFC/FPC (1-21)

CN7402 QGF1208F1-07 CONNECTOR FFC/FPC (1-7)

CN7403 QGA2001C1-02 CONNECTOR W-B (1-2)

DI7401 QLF0200-001 FL TUBE

HD1 LS31285-001A FL HOLDER(L)

HD2 LS31286-001A FDP HOLDER(R)

S7432 QSW0683-001Z PUSH SWITCH

S7433 QSW0683-001Z PUSH SWITCH

S7434 QSW0683-001Z PUSH SWITCH

S7435 QSW0683-001Z PUSH SWITCH

S7441 QSW0683-001Z PUSH SWITCH

S7442 QSW0683-001Z PUSH SWITCH

S7443 QSW0683-001Z PUSH SWITCH

S7451 QSW0683-001Z PUSH SWITCH

S7452 QSW0683-001Z PUSH SWITCH

S7453 QSW0683-001Z PUSH SWITCH

S7454 QSW0683-001Z PUSH SWITCH

S7455 QSW0683-001Z PUSH SWITCH

S7456 QSW0683-001Z PUSH SWITCH

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Terminal board

Symbol No.

PW1 LSA10109-01A2H TERMINAL BOARD ASSY

IC301 MM1757FH-X IC

Q301 RT1N44HC-X DIGI TRANSISTOR

Q302 RT1N44HC-X DIGI TRANSISTOR

Q1101

Q1102

Q1103 RT1P44HC-X DIGI TRANSISTOR

Q1104

Q1105

C201 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C301 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C302 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C303 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C304 NCB31AK-105X C CAPACITOR 1uF 10V K

C305 NCB31AK-105X C CAPACITOR 1uF 10V K

C306 NCB31AK-105X C CAPACITOR 1uF 10V K

C307 NCB31AK-105X C CAPACITOR 1uF 10V K

C308 NEHM0JM-107X E CAPACITOR 100uF 6.3V M

C309 QETN1AM-477Z E CAPACITOR 470uF 10V M

C310 QETN1AM-477Z E CAPACITOR 470uF 10V M

C312 QETN0JM-108Z E CAPACITOR 1000uF 6.3V M

C313 QETN0JM-108Z E CAPACITOR 1000uF 6.3V M

C315 QETN0JM-108Z E CAPACITOR 1000uF 6.3V M

C317 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C318 NEHM0JM-226X E CAPACITOR 22uF 6.3V M

C322 NCB31AK-105X C CAPACITOR 1uF 10V K

C1111 NEHM1CM-226X E CAPACITOR 22uF 16V M

C1112 NEHM1CM-226X E CAPACITOR 22uF 16V M

C1113 NCB31HK-102X C CAPACITOR 1000pF 50V K

C1114 NCB31HK-102X C CAPACITOR 1000pF 50V K

C1117 NEHM1CM-226X E CAPACITOR 22uF 16V M

C1118 NEHM1CM-226X E CAPACITOR 22uF 16V M

C1119 NCB31HK-102X C CAPACITOR 1000pF 50V K

C1120 NCB31HK-102X C CAPACITOR 1000pF 50V K

C1123 NEHM1CM-106X E CAPACITOR 10uF 16V M

Part No. Part Name Description Local

2SC2412K/QRS/-X

2SC2412K/QRS/-X

2SC2412K/QRS/-X

2SC2412K/QRS/-X

TRANSISTOR

TRANSISTOR

TRANSISTOR

TRANSISTOR

Block No. [0][6]

C1124 NEHM1CM-106X E CAPACITOR 10uF 16V M

C1127 NCB31HK-103X C CAPACITOR 0.01uF 50V K

Ω

R201 NRSA63J-750X MG RESISTOR 75

R202 NRSA63J-750X MG RESISTOR 75

R205 NRSA63J-0R0X MG RESISTOR 0

R301 NRSA63D-750X MG RESISTOR 75

R302 NRSA63D-750X MG RESISTOR 75

R303 NRSA63J-122X MG RESISTOR 1.2k

R307 NRSA63J-0R0X MG RESISTOR 0

R308 NRSA63J-0R0X MG RESISTOR 0

R309 NRSA63J-0R0X MG RESISTOR 0

R314 NRSA63J-0R0X MG RESISTOR 0

R315 NRSA63J-103X MG RESISTOR 10k

R316 NRSA63J-103X MG RESISTOR 10k

R317 NRSA63J-101X MG RESISTOR 100

R318 NRSA63J-101X MG RESISTOR 100

R319 NRSA63J-0R0X MG RESISTOR 0

R320 NRSA63J-0R0X MG RESISTOR 0

R321 NRSA63D-750X MG RESISTOR 75

R322 NRSA63D-750X MG RESISTOR 75

R323 NRSA63D-750X MG RESISTOR 75

R324 NRSA63J-0R0X MG RESISTOR 0

R325 NRSA63D-472X MG RESISTOR 4.7k

R326 NRSA63D-472X MG RESISTOR 4.7k

R327 NRSA63D-512X MG RESISTOR 5.1k

R328 NRSA63D-512X MG RESISTOR 5.1k

R1125 NRSA63J-473X MG RESISTOR 47k

R1126 NRSA63J-473X MG RESISTOR 47k

R1127 NRSA63J-471X MG RESISTOR 470

R1128 NRSA63J-273X MG RESISTOR 27k

R1129 NRSA63J-273X MG RESISTOR 27k

R1130 NRSA63J-471X MG RESISTOR 470

R1131 NRSA63J-103X MG RESISTOR 10k

R1132 NRSA63J-103X MG RESISTOR 10k

R1133 NRSA63J-101X MG RESISTOR 100

R1134 NRSA63J-101X MG RESISTOR 100

R1137 NRSA63J-471X MG RESISTOR 470

R1138 NRSA63J-273X MG RESISTOR 27k

R1139 NRSA63J-273X MG RESISTOR 27k

R1140 NRSA63J-471X MG RESISTOR 470

R1141 NRSA63J-103X MG RESISTOR 10k

R1142 NRSA63J-103X MG RESISTOR 10k

R1143 NRSA63J-101X MG RESISTOR 100

R1144 NRSA63J-101X MG RESISTOR 100

R1145 NRSA63J-101X MG RESISTOR 100

R1146 NRSA63J-101X MG RESISTOR 100

R1147 NRSA63J-101X MG RESISTOR 100

L301 QQL342J-4R7Z COIL 4.7uH J

CN201 QGB1231M1-23 CONNECTOR B-B (1-23)

CN202 QGB1231M1-23 CONNECTOR B-B (1-23)

CN203 QGF1208C1-05 CONNECTOR FFC/FPC (1-5)

CN204 QGA2001C1-02 CONNECTOR W-B (1-2)

CN205 QGA2001C1-03 CONNECTOR W-B (1-3)

J302 QND0159-001 S JACK

J303 QNZ0154-001 BNC CONNECTOR

J304 QNS0258-001 3.5 JACK

J1101 QNN0854-001 PIN JACK

1/16W J

Ω

1/16W J

Ω

1/10W J

Ω

1/16W D

Ω

1/16W D

Ω

1/16W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/10W J

Ω

1/10W J

Ω

1/16W D

Ω

1/16W D

Ω

1/16W D

Ω

1/10W J

Ω

1/16W D

Ω

1/16W D

Ω

1/16W D

Ω

1/16W D

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

OPE board

Symbol No.

PW1 LSA10110-01A2H OPE BOARD ASSY

CN7404 QGA2001C1-02 CONNECTOR W-B (1-2)

S7431 QSW0683-001Z PUSH SWITCH

Part No. Part Name Description Local

Block No. [0][7]

3-6(No.YD125<Rev.001>)

Page 23

OPT DIGI board

Symbol No.

PW1 LSA10110-01A3H OPT DIGI BOARD ASSY

IC701 GP1FAV31TK0F OPT TRANSMITTER

C701 NEHM0JM-226X E CAPACITOR 22uF 6.3V M

C702 NCB31HK-104X C CAPACITOR 0.1uF 50V K

R701 NRSA63J-4R7X MG RESISTOR 4.7

R702 NRSA63J-0R0X MG RESISTOR 0

CN701 QGB1238J1-11 CONNECTOR B-B (1-11)

Part No. Part Name Description Local

Ω

Ω

1/10W J

D-SUB/BNC board

Symbol No.

Part No. Part Name Description Local

Block No. [0][8]

1/16W J

Block No. [0][9]

PW1 LSA10110-02A4H D-SUB/BNC BOARD ASSY 1250EU,1250US

PW1 LSA10110-01A4H D-SUB/BNC BOARD ASSY

IC401 MAX3221CAE-E-X IC

D401 MA8120-X Z DIODE

D402 MA8120-X Z DIODE

D403 MA8120-X Z DIODE

D404 MA8120-X Z DIODE

C401 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C402 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C403 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C404 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C405 NCB31EK-104X C CAPACITOR 0.1uF 25V K

R401 NRSA63J-0R0X MG RESISTOR 0Ω 1/10W J

R402 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R403 NRSA63J-0R0X MG RESISTOR 0Ω 1/10W J

R404 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R405 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R406 NRSA63J-750X MG RESISTOR 75Ω 1/16W J

R407 NRSA63D-750X MG RESISTOR 75

R408 NRSA63J-0R0X MG RESISTOR 0

Ω

1/16W D

Ω

1/10W J

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

CN401 QGF1208F1-05 CONNECTOR FFC/FPC (1-5)

CN402 QGA2001C1-02 CONNECTOR W-B (1-2)

CN403 QGA2001F1-03 CONNECTOR W-B (1-3)

J401 QNZ0560-002 D CONNECTOR

J402 QNZ0540-001 BNC CONNECTOR

K401 NQR0499-001X FERRITE BEADS

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

1500AC,1500AG,1500ER,

1500EU,1500KR,1500US

(No.YD125<Rev.001>)3-7

Page 24

Packing materials and accessories parts list

4

5

8

7

9

6

Block No.M2MM

12

ADHESIVE TAPE

2

GENERAL ASSY<M1>

11

13

3

2

10

14

3-8(No.YD125<Rev.001>)

1

Page 25

Packing and accessories

Symbol No. Part No. Part Name Description Local

Block No. [M][2][M][M]

1 LS31283-002A PACKING CASE

1 LS31283-001A PACKING CASE 1250US,1500US

2 LS31284-001B CUSHION ASSY

3 LS31458-001A POLY BAG

4 ------------ BATTERY R6 TYPE(x2)

5 QAM0498-001 A/V CABLE

6 QAM0259-001 ADAPTOR PLUG

7 QMPP170-200-JC POWER CORD UK TYPE 2m BLACK 1250EU,1500AG,1500EU

7 QMPE470-200-JC POWER CORD(US/CA) 2m BLACK 1250US,1500US

7 QMPS210-200-JC POWER CORD 2m BLACK 1500AC

7 QMPS370-200-JC POWER CORD 2m BLACK 1500KR

8 QMPL040-200-JC POWER CORD EU TYPE 2m BLACK 1250EU,1500ER,1500EU

9 QPA01002503 POLY BAG 10cm x 25cm

10 LST0948-001A-H INST.BOOK (ENGLISH) 1250US,1500US

10 LST0964-001A-H INST.BOOK (KOREAN) 1500KR

10 LST0965-001A-H INST.BOOK (ENGLISH) 1500KR

11 QAM1273-001 CD ROM 1250US,1500US

12 ------------ WARRANTY CARD BT-51047-1H 1250US,1500US

12 ------------ WARRANTY CARD BT-59034-1 1500AC

13 QPA02503505PB POLY BAG 25cm x 35cm(x2) 1250EU,1500EU

13 QPA02503505PB POLY BAG 25cm x 35cm

13 QPA02503505PD POLY BAG 25cm x 35cm SR-HD1500AC

14 RM-SSR009E REMOTE CONTROL UNIT

14 RM-SSR008U REMOTE CONTROL UNIT 1250US,1500KR,1500US

1250EU,1500AC,1500AG,1500ER,1500EU,1500KR

1250US,1500AG,1500ER,1500KR,1500US

1250EU,1500AC,1500AG,1500ER,1500EU

(No.YD125<Rev.001>)3-9

Page 26

CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM

Safety precautions

The Components indentified by the symbol are

critical for safety. For continued safety, replace safety

critical components only with manufacturer's recommended parts.

1. Units of components on the schematic diagram

Unless otherwise specified.

1) All resistance values are in ohm. 1/6 W, 1/8 W (refer to

parts list).

Chip resistors are 1/16 W.

K: K (1000 ), M: M (1000K )

2) All capacitance values are in µF, (P: PF).

3) All inductance values are in µH, (m: mH).

4) All diodes are 1SS133, MA165 or 1N4148M (refer to parts

list).

Note: The Parts Number, value and rated voltage etc. in

the Schematic Diagram are for references only.

When replacing the parts, refer to the Parts List.

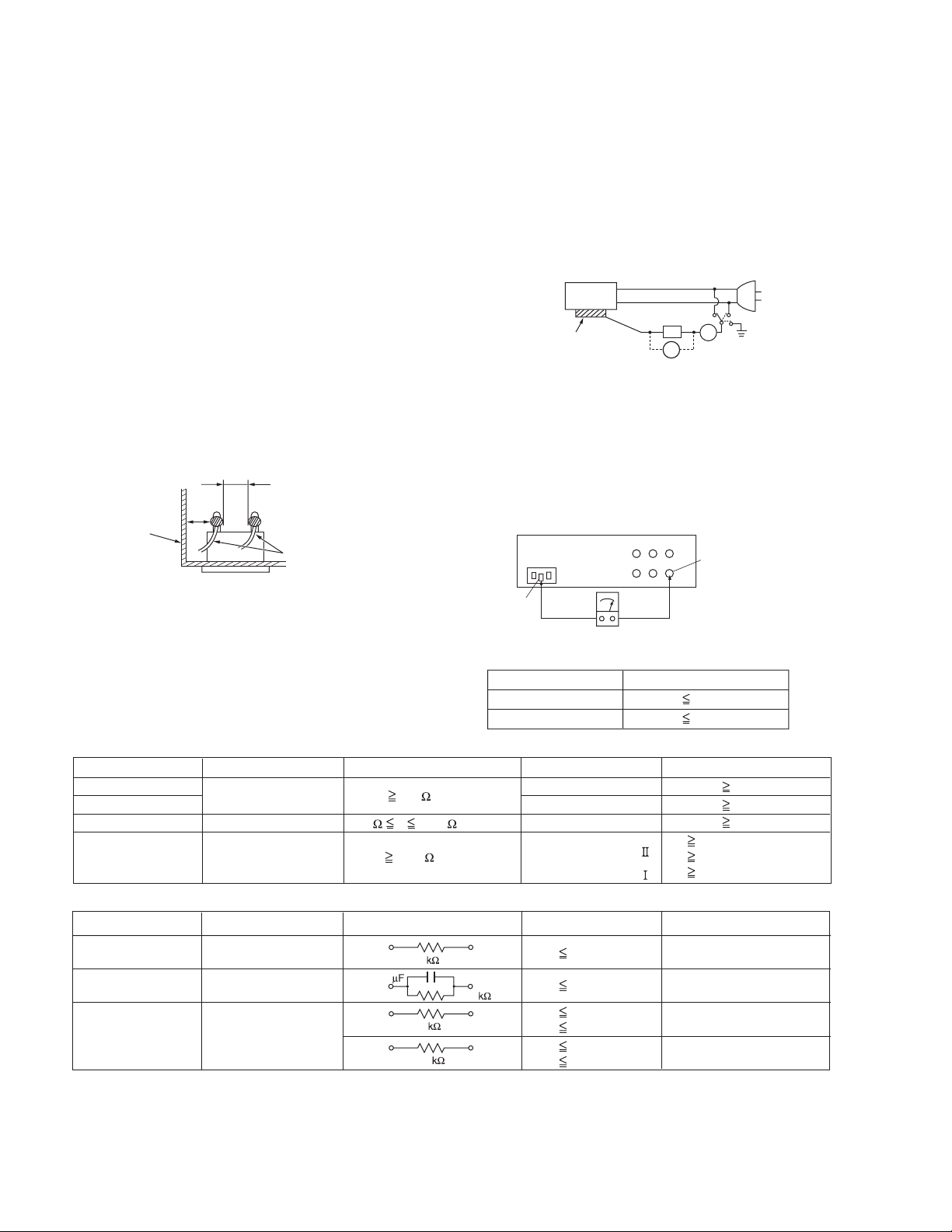

2. Indications of control voltage

AUX : Active at high.

AUX or AUX(L) : Active at low.

!

4. Voltage measurement

1) Regulator (DC/DC CONV) circuits

REC : Colour bar signal.

PB : Alignment tape (Colour bar).

— : Unmeasurable or unnecessary to measure.

2) Indication on schematic diagram

Voltage indications for REC and PB mode on the schematic diagram are as shown below.

REC mode

12 3

2.5

(5.0)

PB mode

1.8

PB and REC modes

(Voltage of PB and REC modes

are the same)

Note: If the voltages are not indicated on the schematic

diagram, refer to the voltage charts.

6. Indication of the parts for adjustments

The parts for the adjustments are surrounded with the circle

as shown below.

3. Interpreting Connector indications

1

2

Removable connector

3

1

2

Wire soldered directly on board

3

1

Non-removable Board connector

2

3

1

2

4

Board to Board

3

Connected pattern on board

The arrows indicate signal path

7. Indication of the parts not mounted on the circuit board

“OPEN” is indicated by the parts not mounted on the circuit

board.

R216

OPEN

(No.YD125<Rev.001>) 2-1 2-1 (No.YD125<Rev.001>)

Page 27

Wiring diagram

5

CN203

4

(

3

2

1

0 9 D-SUB/BNC

/VIDEO

CN401

QGF1208F1-05

QGF1208C1-05

0

5 GND

1GND

6

4 RS232C_RX

2RS232C_RX

1 GND

2 SYS3.3V

3 RS232C_TX

3RS232C_TX

4SYS3.3V

5GND

TERMINAL

VIDEO I/O,

AUDIO I/O,

TERMINAL

)

CN402

QGA2001C1-02

1 V_IN

1V_IN

CN204

QGA2001C1-02

2 GND

2GND

0

)RS232C(

CN403

QGA2001F1-03

1 GND

1GND

CN205

QGA2001C1-03

QGB1231M1-23

QGB1231M1-23

7

2 V_OUT

3 GND

2V_OUT

3GND

CN201

2AGND

4AGND

6AGND

8AGND

10AUDIO_PD_CTL

12I2C_SDA

14SW-9V

16AGND

18A5V

20AGND

22AGND

CN202

2GND

4Y_IN

6S_DET1

8GND

10R1_S1_DET

12SD_C_OUT

14SD_Y_OUT

16GND

18GND

20HD_Pr_OUT

22HD_V_MUTE_L

OPE

CN7404

QGA2001C1-02

POWER KEY

1AUDIO_OUT_R

3AUDIO_OUT_L

5AUDIO_R_IN

7AUDIO_L_IN

9AUDIO_MUTE

11I2C_SCL

13AGND

15SW+9V

17A5V

19TUNER_AUDIO_R

21TUNER_AUDIO_L

23TUNER_VIDEO

1V_IN

3S_DET2

5GND

7C_IN

9R2_S1_DET

11GND

13GND

15SD_V_MUTE_L

17HD_Y_OUT

19HD_Pb_OUT

21GND

23REMOTE_CTL

1 AUDIO_OUT[R]

3 AUDIO_OUT[L]

5 AUDIO_R_IN

7 AUDIO_L_IN

9 AUDIO_MUTE

11 I2C_SCL

13 AGND

15 SW+10V

17 A5V

19 TUNER_AUDIO_R

21 TUNER_AUDIO_L

23 TUNER_VIDEO

1 V_IN

3 S_DET2

5 GND

7 C_IN

9 F1_S1_DET

11 GND

13 GND

15 SD_VMUTE_L

17 HD_Y_OUT

19 HD_Pb_OUT

21 GND

23 D_PLUG_DET

1

2GND

CN1501

QGB1231L2-23W

2AGND

4AGND

6AGND

8AGND

10 AUDIO_PD_CTL

12 I2C_SDA

14 SW-10V

16 AGND

18 A5V

20 AGND

22 AGND

CN1502

QGB1231L2-23W

2 GND

4 Y_IN

6 S_DET1

8 GND

10 R1_S1_DET

12 SD_C_OUT

14 SD_Y_OUT

16 GND

18 GND

20 HD_Pr_OUT

22 HD_VMUTE_L

QGF1045F2-21X

CN7401

QGF1045F2-21X

CN7403

QGA2001C1-02

1 POWER KEY

2 GND

CN4001

1 FLRESET

21FLRESET

2 FLCS

20FLCS

0

2

BE DIGITAL

12 LED6

10LED6

25V

13 LED5

9LED5

5

3 GND

14 LED4

15 LED3

7LED3

8LED4

DISPLAY

4 GND

5 FL-

SYSCON,

16 LED2

17 LED1

18 BUZZER

19 IR_IN

3IR_IN

4BUZZER

5LED1

6LED2

6 -30V

7 FL+

BACKEND,

()

3 FLCLK

4 FLDATA

5 PGND

6 PGND

7 KEY3

8 KEY2

9 KEY1

10 DGND

11 LED7

11LED7

12DGND

13KEY1

14KEY2

15KEY3

16PGND

17PGND

18FLDATA

19FLCLK

0

CN7402

QGF1208F1-07

1 FL3.3V

##

CN4801

QGF0566C1-40X

20 DGND

21 SYS3.3V

1SYS3.3V

2DGND

10INTRQ

11GND

12DMACK

13CAB_SEL

14IORDY

15GND

16DIOR

17GND

18DIOW

19GND

20DMARQ

21

22GND

23DD[15]

24DD[0]

25DD[14]

26DD[1]

27DD[13]

28DD[2]

29DD[12]

30DD[3]

31DD[11]

32DD[4]

33DD[10]

34DD[5]

35DD[9]

36DD[6]

37DD[8]

38DD[7]

39GND

40RESET

1GND

2DASP

3CS1

4CS0

5DA2

6DA0

7PDIAG

8DA1

9

BD_DRIVE

TO REG

MGND

1 BD12V

2

3 MGND

GND

TXP

TXN

GND

RXN

RXP

GND

4 BD5V

M

FAN MOTOR

123

1FAN_VCC

2GND

3FAN_LOCK

CN5303

QGA2001C1-03

CN5001

CN3501

1 GND

2 /RESET

3 SYS_3.3V

4 TOOL_DATA

5 MMOD

6 TOOL_CLK

TO TOOL

5 SM_DET_N

6 SM_VCC

7 GND

5SM_DET_N

4SM_VCC

3GND

QGB1238K1-17

1 TU_VIDEO

2 A_GND

3 TU_L

4 A_GND

5 TU_R

6 A_GND

7 D1.8V

8 DGND

9 AL3.8V

10 DGND

11 AL5.6V

12 AGND

13 BT

14 AGND

15 15V_BS

16 AGND

17 TERR.ATT

CN3502

QGB1238K1-19

1 DTU_P.CTL

2 BS_LNB_SHORT

3 BS_ANT_SW

4 DGND

5 DTU2_SDO

6 DTU2_SCK

7 DTU2_PCK

8 DTU2_DEN

9 DGND

10 DTU1_SDO

11 DTU1_SCK

12 DTU1_PCK

13 DTU1_DEN

14 INTA

15 INTB

16 I2C_DATA

17 I2C_CLK

18 DGND

19 DTU1_RST

8 AL5.6V

9 TU_P.CTL

2AL5.6V

1TU_P.CTL

CN2103

QGA1201C2-05X

1 GND

2 RXD

3 TXD

4 VCC

5 GND

TO JIG

OPT DIGITAL

0

8

HDD12V

1

2 MGND

CN2901

QGB1238K1-11

1SPDIF

1 SPDIF

2D3.3V

2 D3.3V

3GND

3 GND

4MODEM_C2A

4 MODEM_C2A

5MODEM_C1A

5 MODEM_C1A

6GND

6 GND

71394_TPB0-

7 1394_TPB0-

81394_TPB0+

8 1394_TPB0+

9GND

9 GND

101394_TPA0-

10 1394_TPA0-

111394_TPA0+

11 1394_TPA0+

3 MGND

4 HDD5V

CN701

1394

(

/MODEM

/D-AUDIO

J4801

NNZ0209-001

1

2

3

4

5

6

7

1

GND

2

TXP

3

TXN

4

GND

5

RXN

6

RXP

7

GND

J4901

NNZ0209-001

HDD

QGB1238J1-11

)

GND2TXP3TXN4GND5RXN6RXP7GND

1

1

GND2TXP3TXN4GND5RXN6RXP7GND

##

CN2003

QGF1016F8-09W

##

0

4

D.TUNER

1 GND

9GND

CN3601