Page 1

SERVICE MANUAL

DVD / HDD & Mini DV VIDEO RECORDER

YD04920054

SR-DVM70AG, SR-DVM70EU

CABLE/SAT

DVD

TV

STANDBY/ON

DVD

TV/CBL/SAT

TV

AV

TV

VIDEO

DV HDD DVD

TV

PR

AUX

CANCEL

MEMO/MARK

PROGRAMME

EDITDUBBING

LIVE

NAVIGATIONTOPME NU

ENTER

RETURN

MENU

NEXTPREVIOUS

SLOWSLOW PLAY/SELECT

CLEAR

PAUSEREC

STOP/

JUMP

RECMODE

DISPLAY

ONSCREEN

REMAIN

VPS/PDC

AUDIO

SUBTITLE

ANGLE

LIVECHECK

SETUP

PROGRESSIVE

OPERATE

EJECTEJECTDISPLAY

DV/HDD/DVD REC MODE INSTANTREPLAY AUDIODUB. INSERT

SAT

SCAN

S-VIDEO

VIDEO(MONO)L - AUDIO - R

INF-1

INPUTSELECT

RECDVDRECHDDRECDV

RECPAUSEPLAY

FFREWSTOP

DVIN / OUT

(AG model)

SR-DVM70AG, SR-DVM70EU [D4MC29]

(EU model)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.YD049

2005/4

Page 2

SPECIFICATION

SR-DVM70AG SR-DVM70EU

GENERAL

Power requirement AC 220 V ~ 240 V, 50 Hz/60 Hz

Power consumption

Power on 45 W

Power off 18 W

Temperature

Operating 5°C to 35°C

Storage -20°C to 60°C

Operating position Horizontal only

Dimensions (W × H × D) 435 mm × 96 mm × 372 mm

Weight 6.2 kg

Input/Output

Video input 0.5 - 2.0 Vp-p, 75 Ω (pin jack)

Video output 1 Vp-p, 75 Ω (BNC)

Audio input -8 dB, 50 kΩ (pin jack), Corresponding to mono (left)

Audio output -8 dB, 1 kΩ (pin jack)

21-pin SCART connectors IN/OUT × 1, IN/DECODER × 1

S-video input Y: 0.8 - 1.2 Vp-p, 75 Ω, C: 0.2 - 0.4 Vp-p, 75 Ω

S-video output Y: 1.0 Vp-p, 75 Ω, C: 0.3 Vp-p, 75 Ω

DV 4-pin for DV IN/OUT

Component video output Y: 1.0 Vp-p, 75 Ω, CB/CR, PB/PR: 0.7 Vp-p, 75 Ω

Remote Input Ø3.5 mm

Digital audio output Optical: -18 dBm, 660 nm, Coaxial: 0.7 Vp-p, 75 Ω,

VIDEO/AUDIO (DVD deck)

Recording time Maximum 8 hours (with 4.7 GB disc)

Audio recording system Dolby Digital (2 ch), Linear PCM (XP mode only)

Video recording compression system MPEG2 (CBR/VBR)

VIDEO/AUDIO (HDD Deck)

Video recording compression system MPEG2 (VBR)

Audio recording system Dolby Digital (2 ch), Linear PCM (XP mode only)

Recording time Maximum 300 hours (with 160 GB HDD)

VIDEO/AUDIO (DV Deck)

Signal system PAL colour signal, 625 lines/50 fields

Recording system Digital Component Recording

Format DV format (SD mode)

Cassette Mini DV Cassette

Maximum recording time

(SP) (SP): 80 min. with M-DV80ME cassette

(LP) (LP): 120 min. with M-DV80ME cassette

Audio recording system PCM 48 kHz, 16 bit (2 ch)/32 kHz, 12 bit (4 ch)

TUNER/TIMER

Tuning system Frequency synthesized tuner

Channel coverage VHF : 47 MHz - 89 MHz/104 MHz - 300 MHz/302 MHz - 470 MHz

Memory backup time Approx. 60 minutes

ACCESSORIES

Provided accessories

RF cable, Input Cable Adapter, Output

Cable Adapter, Audio/Video Cable, Infrared

remote control unit, "R6" battery × 2

Corresponding to Dolby Digital and DTS Digital Surround

Bit stream Selectable in digital audio output setting menu

(XP): Approx. 1 hour, (SP): Approx. 2 hours, (LP): Approx. 4 hours

(EP): Approx. 6 hours, (FR): Approx. 1 hour - 8 hours

(XP): Approx. 34 hours, (SP): Approx. 69 hours, (LP): Approx. 138 hours

• Specifications shown are for SP mode unless otherwise specified.

• E.& O.E. Design and specifications subject to change without notice.

• Manufactured under license from Dolby Laboratories. "Dolby" and the double-D symbol are trademarks of Dolby Laboratories.

• "DTS" and "DTS Digital Out" are trademarks of Digital Theater Systems, Inc.

• Cassettes marked Mini DV can be used with the DV deck of this unit. The DV deck can play back and record only PAL signals.

• SHOWVIEW is a trademark of Gemstar Development Corporation. The SHOWVIEW system is manufactured under licence from Gemstar Development Corporation.(EU MODEL)

• G-CODE is registered trademarks of Gemstar Development Corporation. The G-CODE system is manufactured under license from Gemstar Development Corporation.(AG MODEL)

• (i.Link) refers to the IEEE1394-1995 industry specification and extensions thereof. The logo is used for products compliant with the i.Link standard.

Corresponding to copy protection

(EP): Approx. 209 hours, (FR): Approx. 300 hours

UHF : 470 MHz - 862 MHz

RF cable, 21-pin SCART cable,

SCART/RCA adapter × 2, Infrared remote

control unit, "R6" battery × 2

1-2 (No.YD049)

Page 3

SECTION 1

r

PRECAUTION

1.1 SAFTY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

•Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

Consequently, when servicing these products, replace the

cathode ray tubes and other parts with only the specified

parts. Under no circumstances attempt to modify these circuits.Unauthorized modification can increase the high voltage value and cause X-ray emission from the cathode ray

tube.

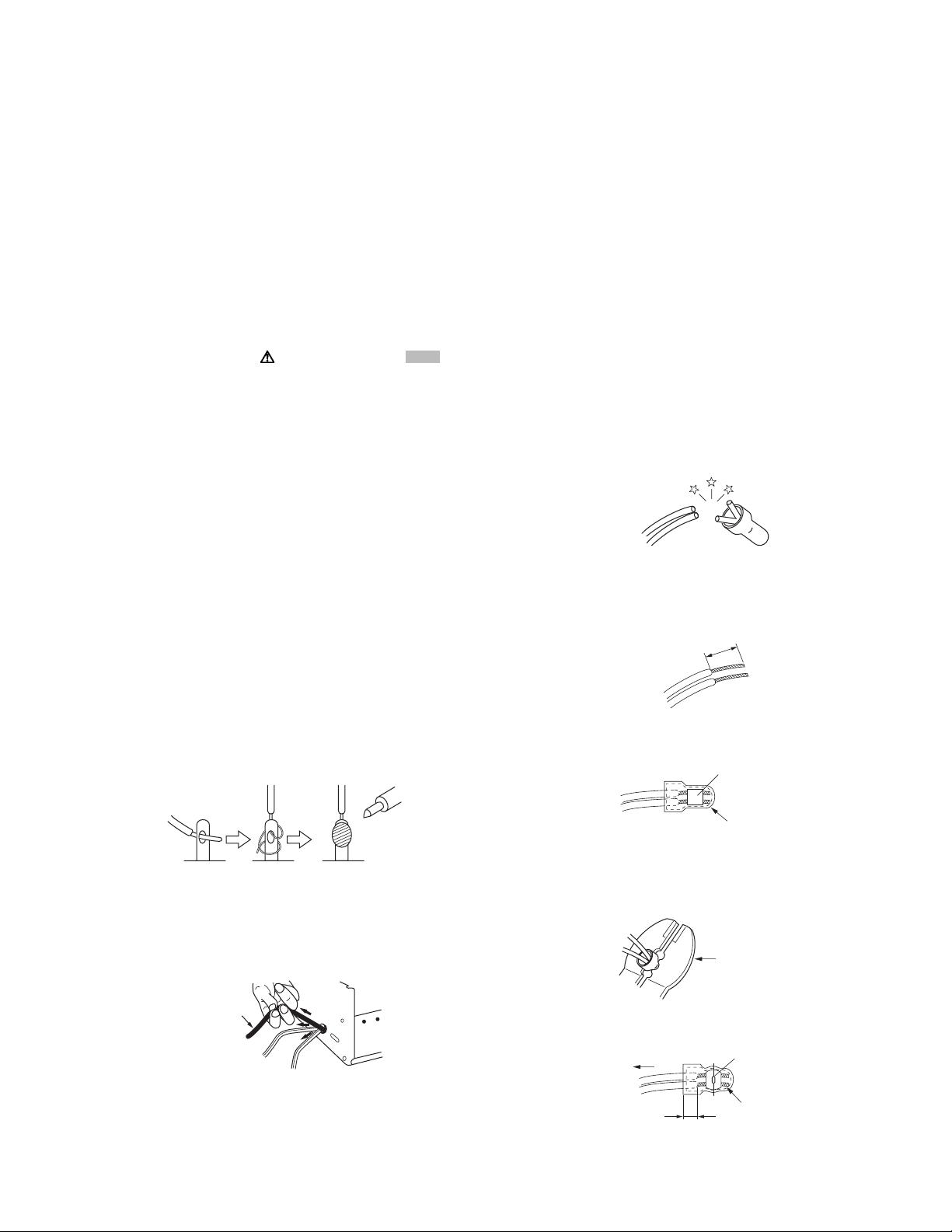

(12) Crimp type wire connectorIn such cases as when replacing

the power transformer in sets where the connections between the power cord and power trans former primary lead

wires are performed using crimp type connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely according to the

following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected. In-

sert the wires fully into the connector.

Metal sleeve

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to

crimp the metal sleeve at the center position. Be

sure to crimp fully to the complete closure of the

tool.

1.2

5

2.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleeve

Conductors extended

Fig.1-1-7

(No.YD049)1-3

Page 4

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify compliance with safety standards.

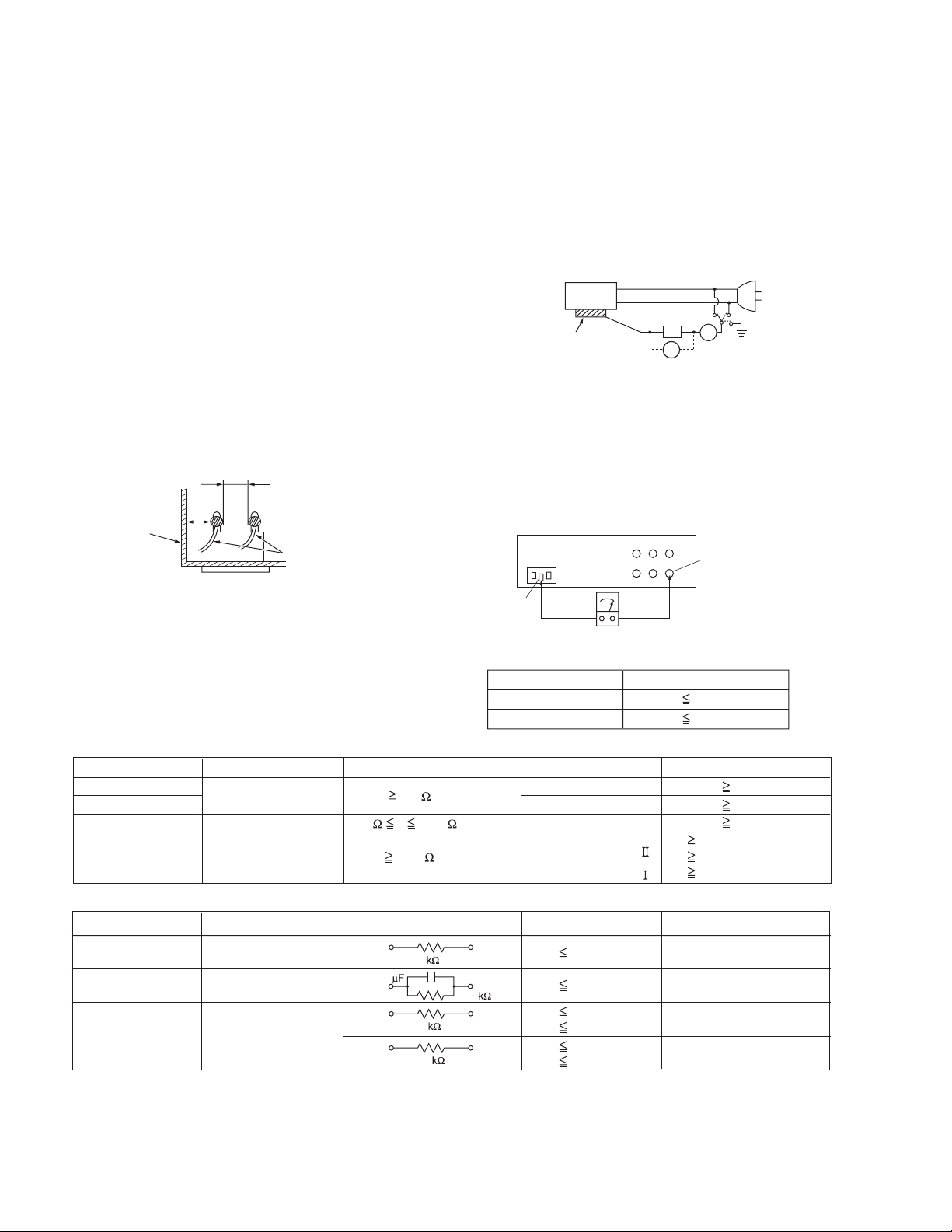

(1) Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed accessible parts (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)Insert load Z between

earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure

across both terminals of load Z. See Fig.1-1-9 and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.YD049)

Page 5

1.2 Hard Disk Drive (HDD) Handling Precautions

The HDD is a precision device for use in reading and writing a large amount of data on or from a disk rotating at a high speed. If it is

not handled carefully, either abnormal operation may result or it may not be possible to read data. The HDD is sensitive to the following

items and special care is required in safeguarding against them when handling an HDD. Also take care in handling a set incorporating

an HDD.

(1) Vibrations and impacts

(2) Static electricity

(3) Rough handling

1.2.1 Handling in transport, etc.

• Be sure to place the HDD in the manufacturer's specified package carton before transport.

• When receiving a package containing an HDD, check that the

package carton is not damaged (such as having holes in the

carton, crushed corners, etc.).

• Do not impact the packaging carton when loading or unloading

HDD

Do not throw or

drop packages.

it.

• It is not permitted to use the inner package carton only for

transporting an HDD.

• Do not stack package cartons one upon another.

Be sure to package and

transport the HDDs correctly.

1.2.2 Handling an HDD in the stand-alone status

• When handling an HDD on a hard workbench, place an antistatic mat (rubber sheet) or similar object on the hard surface

(to prevent any impacts occurring between the HDD and

bench).

• Do not stack the HDDs one upon another.

• Do not knock an HDD with a hard object (such as a screwdriver).

• Do not place an HDD on its side panel without using a support

(do not place an HDD in an unstable position).

1.2.3 Handling the installation of an HDD

• Place antistatic mats or similar sheets on all of the surfaces on which work is conducted or when the HDD is transported.

• Do not permit the HDD to knock against the set's brackets.

• When screwing the brackets, be careful not to knock the HDD. When using a power screwdriver, use a low-shock model and arrange

the tightening torque properly.

• When mounting an HDD in a main body, take care not to apply excessive force to the brackets.

(No.YD049)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 Different table of features

The following table indicates main different points between models SR-DVM70AG and SR-DVM70EU.

ITEM SR-DVM70AG SR-DVM70EU

DVD REGIONAL CODE REGION 3 REGION 2

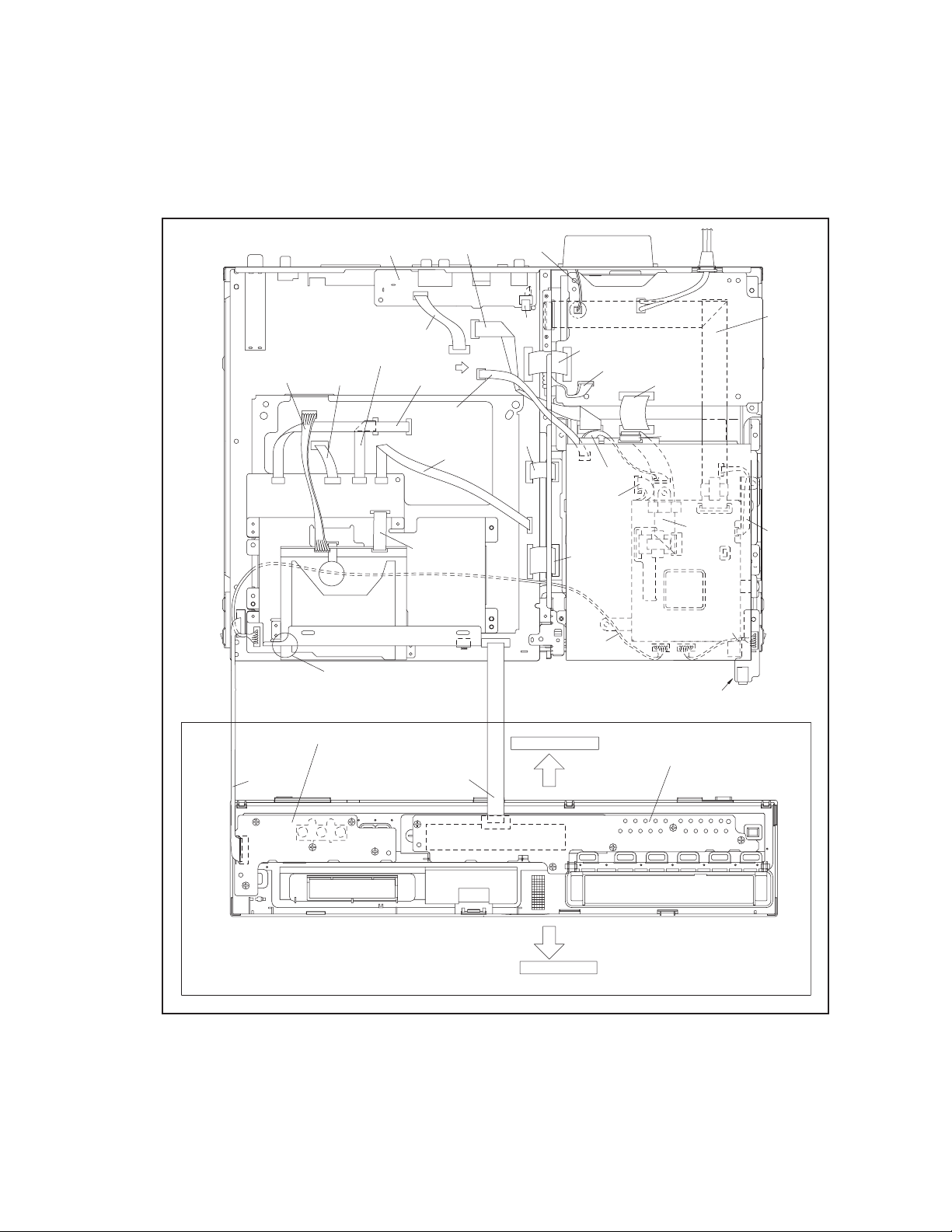

2.2 Service position

This unit has been designed so that the Mechanism and Main

board assemblies can be removed together from the bottom

chassis. Before diagnosing or servicing the circuit boards, take

out the major parts from the bottom chassis.

2.2.1 How to set the "Service position"

(1) Refer to the disassembly procedure and perform the disas-

sembly of the major parts before removing the Mechanism

assembly.

(2) Remove the screws that fix the Mechanism, Main board as-

sembly to the bottom chassis. If any other screws are used

to fix the boards, remove them also.

(3) Remove the combined Mechanism, HDD, DVD unit,

switching regulator, digital, DV jack, junction and Main

board assemblies.

(4) If any other major parts are used, remove them also.

(5) Connect the wires and connectors of the major parts that

have been removed in steps (1) to (4). (Refer to Fig. 2-2a.)

(6) Place the combined Mechanism, Main board and other

board assemblies upside down.

(7) Insert the power cord plug into the power outlet and then

proceed with the diagnostics and servicing of the board as-

sembly.

Notes:

• Before inserting the power cord plug into the power out-

let, make sure that none of the electrical parts are able

to short-circuit between the workbench and the board

assembly.

• For the disassembly procedure of the major parts and

details of the precautions to be taken, see "Removing

the major parts".

• If there are wire connections from the Main board and

Mechanism assemblies to the other major parts, be sure

to remove them (including wires connected to the major

parts) first before performing step (2).

• When carrying out diagnosis and repair of the Main

board assembly in the "Service position", be sure to

ground both the Main board and Mechanism assemblies. If they are improperly grounded, there may be

noise on the playback picture or FDP counter display

may move even when the mechanism is kept in an inoperative status.

• In order to diagnose the playback or recording of the

cassette tape, set the Mechanism assembly to the required mode before placing it upside down. If the mechanism mode is changed (including ejection) while it is in

an upside down position the tape inside may be damaged.

• For some models, the mechanism and board assem-

blies are attached by connectors only. When carrying

out a diagnosis or repair of the boards in the "Service

position", make sure that the connectors are not disconnected.

TP3901

TP3902

TP3906

TP3907

TP3908

TP3903

TP3904

TP3905

SWITCHING

REGULATOR

board assembly

JUNCTION

board assembly

DIGITAL

board

assembly

DV JACK

board

assembly

DVD

UNIT

DISPLAY / SWITCH

board assembly

HDD

Fig.2-2a

REAR JACK

board assembly

MAIN

board

assembly

MDA

board

assembly

DV MAIN

board

assembly

OPERATION / JACK

board assembly

1-6 (No.YD049)

Page 7

2.3 Jig RCU mode

This unit uses the following two modes for receiving remote control codes.

(1) User RCU mode:Ordinary mode for use by the user.

(2) Jig RCU mode: Mode for use in production and servicing.

When using the Jig RCU, it is required to set the unit to the Jig

RCU mode (the mode in which codes from the Jig RCU can be

received). As both of the above two modes are stored in the EEPROM, it is required to set the unit back to the User RCU mode

each time that an adjustment is made or to check that the necessary operations have been completed.These modes can be set

by the operations described below.

Note:

• When the unit is set to Jig RCU mode and when the unit

is under Jig RCU mode, the remote control unit attached

to product operates only in "Remote Control Code 1".

Since the unit is in "Remote Control Code 3" when it is

shipped and just after its batteries are changed, "Remote Control Code 3" needs to be changed to "Remote

Control Code 1."

• Confirm the RCU mode when exchanged parts. Since

some SERVICE PARTS sets the unit to the Jig RCU

mode as initial setting. Therefore please set the unit to

the user RCU mode after replacing the EEPROM.

User RCU mode

Jig RCU mode

2.3.1 Changing Remote Control Code

(1) Slide the TV/CABLE/SAT/DVD switch to DVD.

(2) Press the number key "1" of the remote control unit while

pressing the "SET UP" button of the remote control unit.

Then,press the "ENTER" button, and then release the

"SET UP" button.

(3) Press the "POWER" button on the unit to turn off the unit.

(4) Press the "PLAY" button on the unit for over 5 seconds

while the unit is turned off. The code currently set appears

on the front display panel.

(5) Press the "STOP" button on the remote control to change

the unit’s code. When FDP indicator displays "DVD1," it

means that the Remote Control Code has been changed to

"1."

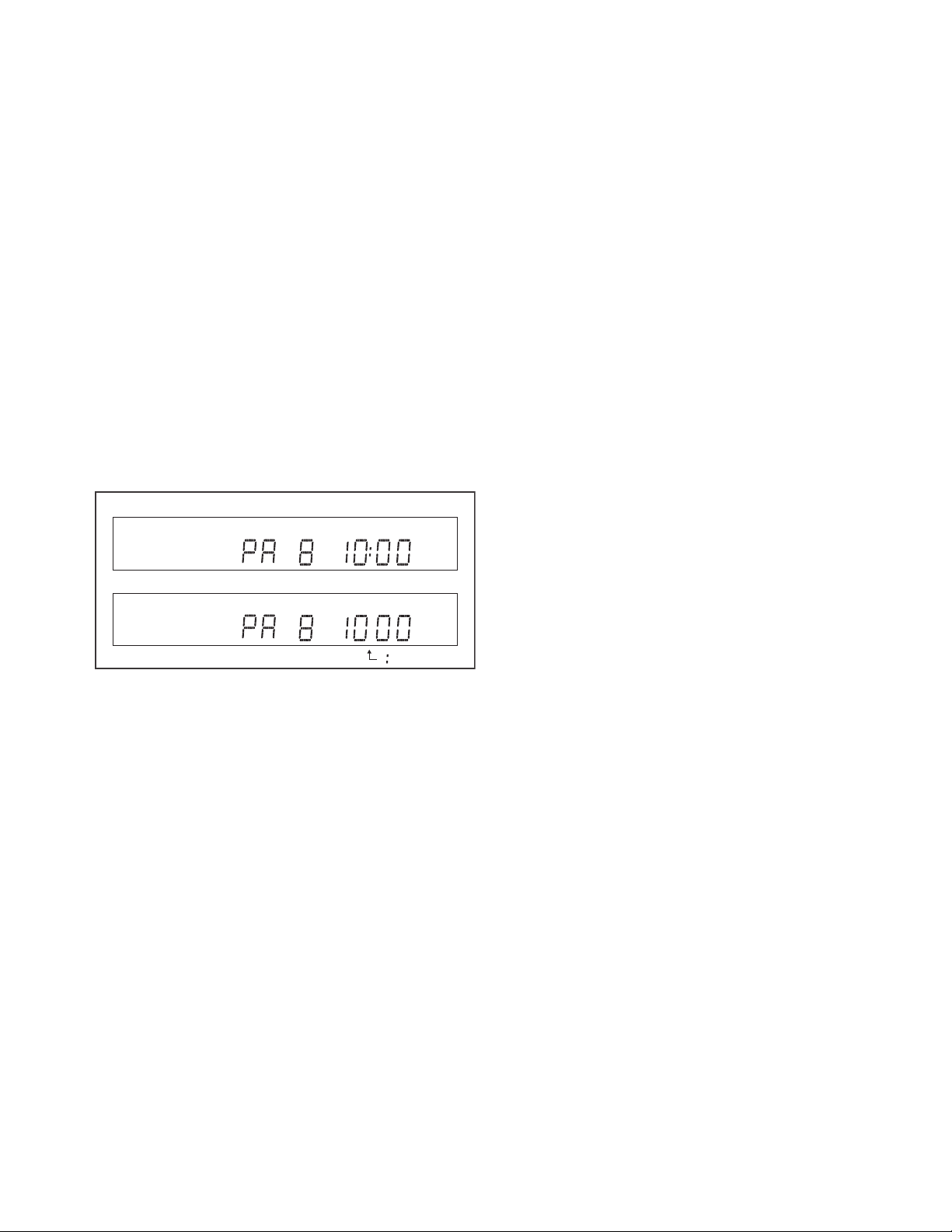

2.3.2 Setting the Jig RCU mode

(1) Turn on the power.

(2) Press the "DV/HDD/DVD" select button repeatedly on the

unit so that the DVD lamp lights up on the unit.

(3) Press the following remocon keys continuously within 2

seconds " SET UP " → " 2 " → " 8 " → " ENTER ".

When the unit is set to the Jig RCU mode, the symbols

( " : " ) in the time display of the FDP are blinked.

(Refer to Fig.2-3a User/Jig RCU mode)

2.3.3 Setting the User RCU mode

(1) Turn off the power.

(2) Press the "REC" and "PAUSE" buttons of the unit simulta-

neously. Alternatively, transmit the code "43-9D" from the

Jig RCU.

Fig.2-3a User/Jig RCU mode

( blinked)

(No.YD049)1-7

Page 8

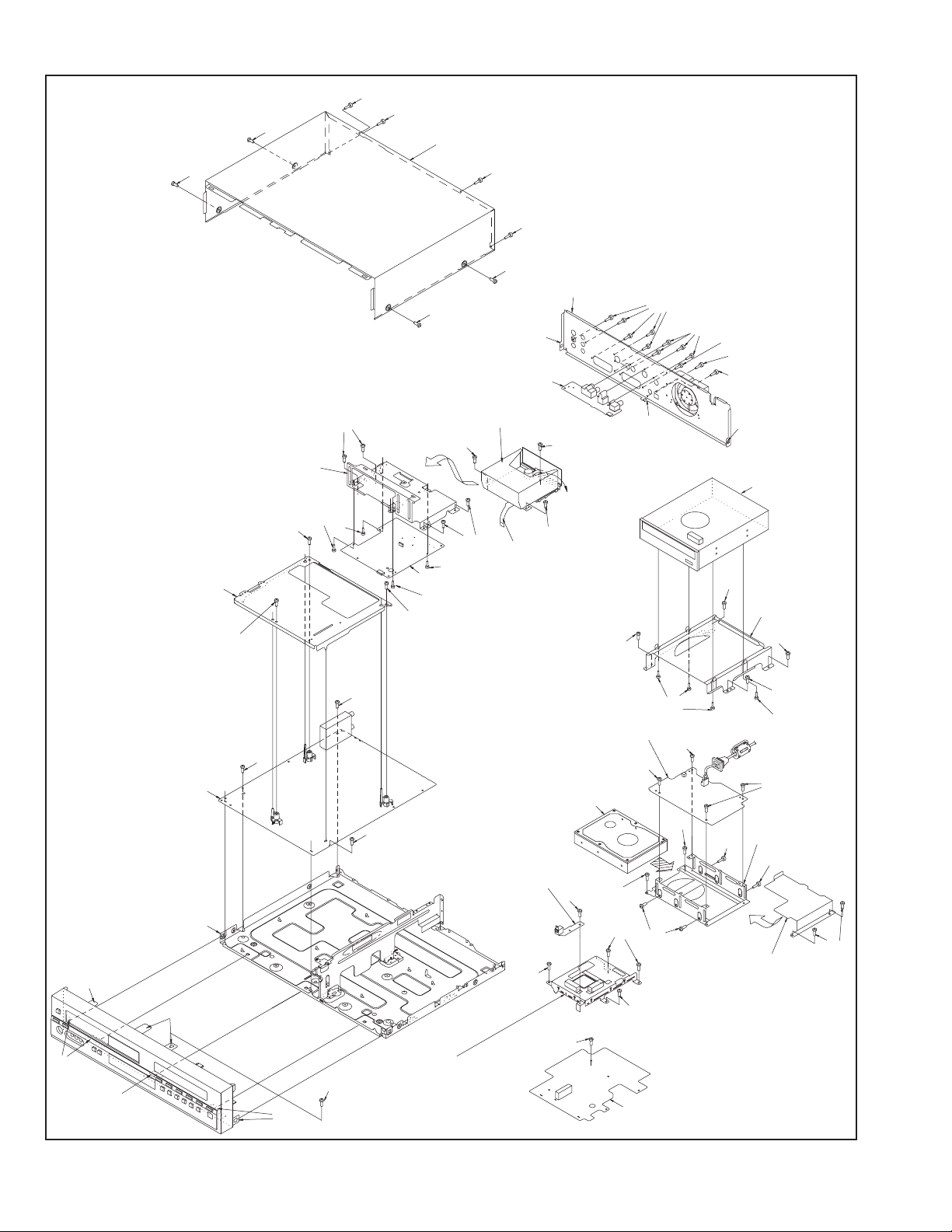

DISASSEMBLY

3.1 Removing the major parts

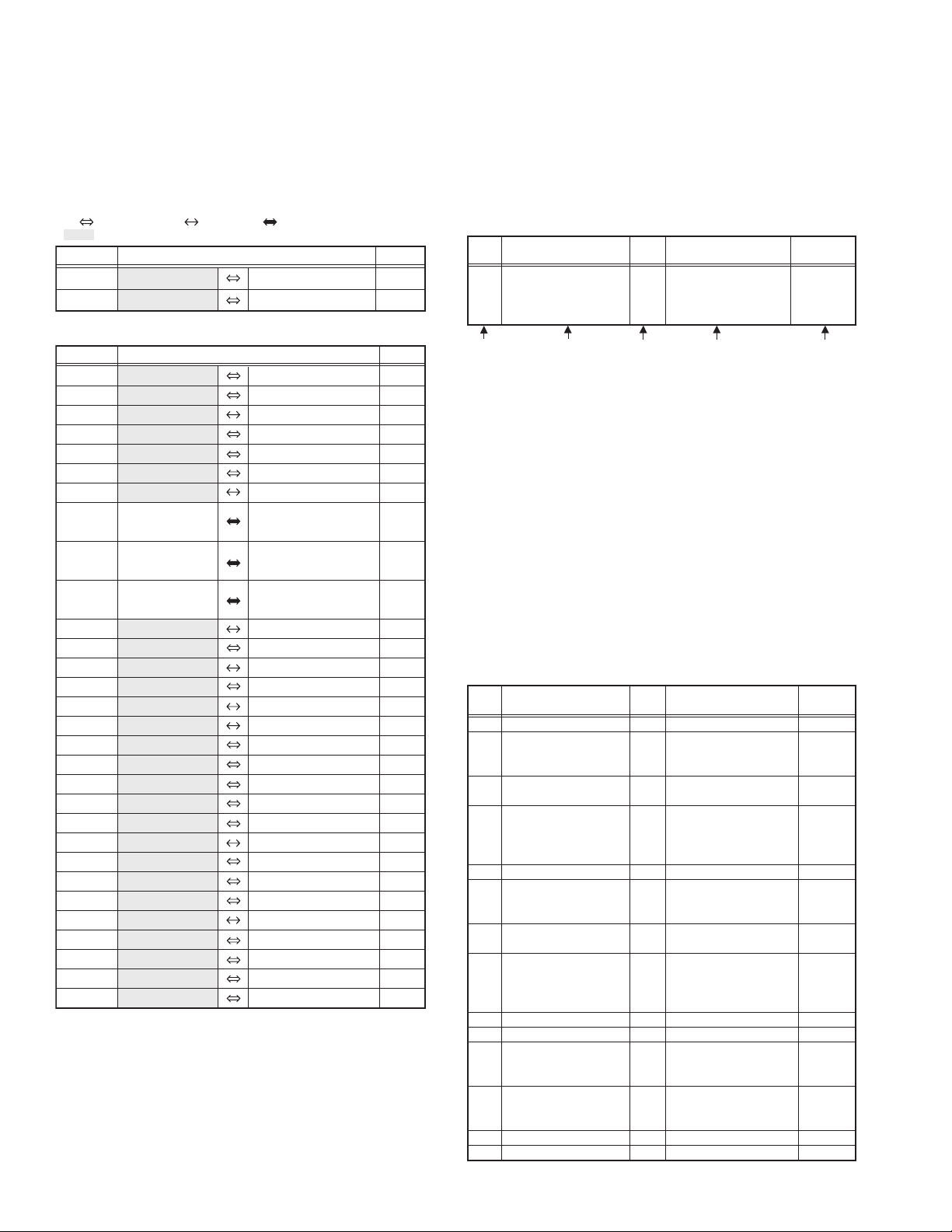

3.1.1 Destination of connectors

Two kinds of double-arrows in connection tables respectively

show kinds of connector/wires.

: The connector of the side to remove

CONN. No. PIN No.CONNECTOR

WR2a

WR2b

Main CN101

Main CN103

Destination of connectors

CONN. No. PIN No.CONNECTOR

WR2a

WR2b

WR3a

WR3b

WR4a

WR4b

WR4c

CN7108

(CN1001)

CN7109

(CN1002)

CN7121

(CN1802)

WR5a

WR6a

WR6b

WR6c

WR6d

WR8a

WR8b

WR8c

WR8d

WR8e

WR9a

WR9b

WR11a

WR11b

WR11c

WR11d

WR12a

WR12b

WR12c

WR12d

Main

Main

Junction

Digital

Digital

Digital

Junction

Junction

Junction

Junction

Junction

SW. REG

SW. REG

SW. REG

SW. REG

Junction

Main

Main

Main

Main

Rear jack

Rear jack

DV Main

DV Main

DV Main

DV Main

Main

Main

Main

Main

: Wire: Flat wire : Board to board (B-B)

Digital CN761

Digital CN762

CN3104

CN3102

CN5504

CN2201

CN2101

CN1405

CN5502

CN7108

CN7109

CN7121

CN7126

CN5304

CN5303

CN5301

CN5302

CN7127

CN3103

CN2602

CN701

CN901

CN951

CN952

CN1502

CN4001

CN1501

CN5501

CN5404

CN2601

CN501

CN3104

Operation/jack

Display/switch

DVD unit

DVD unit

HDD

Junction

Digital

Digital

Digital

Digital

DV jack

Junction

HDD

Main

Fun motor

DV Main

Junction

Junction

Junction

Junction

Main

Main

DV mechanism sensor

DV drum motor

DV MDA

Main

DV Main

DV Main

DV Main

DV Main

CN7201

CN7001

CN1406

CN1003

CN1001

CN1002

CN1802

CN4104

CN5501

CN5402

CN2002

CN7102

CN8001

CN7123

CN7107

CN902

FW851

CN5506

CN5403

CN1001

CN3701

CN3501

CN1503

SECTION 3

3.1.2 How to read the procedure table

This table shows the steps for disassembly of the externally furnished parts and board assemblies. Reverse these steps when

re-assembling them.

Step/

Loc No.

40

10

15

15

4

40

40

4

6

28

20

14

6

19

4

19

2

6

19

11

4

9

8

3

15

8

20

5

8

8

7

7

[1] Top cover 3-1a

(1) (2) (3) (4) (5)

(1) Order of steps in Procedure

(2) Part name to be removed or installed.

(3) Fig. No. showing procedure or part location.

(4) Identification of part to be removed, unhooked, unlocked,

(5) Adjustment information for installation

3.1.3 Disassembly procedure

Step/

Loc No.

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

Part Name

Bracket 2(S1c)

Fig.

No.

----------------------------------------

Point Note

4(S1a),(S1b),3(L1a), <Note 1a>

2(SD1a),(P1a),(W1a),

CN1(WR1a),

When reassembling, perform the step(s) in the reverse order.

These numbers are also used as the identification (location) No. of parts Figures.

released, unplugged, unclamped or unsoldered.

P= Spring, W= Washer, S= Screw, L= Locking tab, SD=

Solder, CN**(WR**)= Remove the wire (WR**) from the

connector (CN**).

Note:

• The bracketed ( ) WR of the connector symbol are

assigned nos. in priority order and do not correspond to those on the spare parts list.

Part Name

Top cover

Front panel assembly

(Operation jack board assembly)

(Display/switch display board assembly)

DVD unit

(Bracket)

Digital board assembly

DV jack board assembly

Switching regulator board assembly

HDD

(Bracket),(Sheet)

Junction board assembly

Rear jack board assembly

Rear cover

DV mechanism assembly

DV main board assembly

(Bracket)

Bracket(DV MAIN)

Main board assembly

Fig.

No.

3-1b

3-1a

3-1b

3-1a

3-1b

3-1a

3-1b

3-1a,3-1b

3-1a

3-1b

3-1a

3-1b

3-1a

3-1b

3-1b

3-1b

3-1a

3-1b

3-1a

3-1b

3-1b

3-1a,3-1b

Point Note

8(S1a)

(S2a),3(L2a),5(L2b)

CN3104(WR2a),CN3102(WR2b

4(S3a),4(S3b)

CN5504(WR3a),CN2201(WR3b)

4(S4a),CN2101(WR4a)

CN1405(WR4b),CN5502(WR4c),

CN7108(CN1001),CN7109(CN1002)

CN7121(CN1802)

(S5a),CN7126(WR5a)

4(S8a)

CN5304(WR6a),CN5303(WR6b),

CN5301(WR6c),CN5302(WR6d)

4(S7a),4(S7b)

(S8a),CN7127(WR8a),

CN3103(WR8b),

CN2602(WR8c),

CN701(WR8d),CN901(WR8e)

3(S9a),CN951(WR9a),CN952(WR9b)

7(S10a),(S10b),3(L10a)

3(S11a),CN1502(WR11a),

CN4001(WR11b),

CN1501(WR11c),CN5501(WR11d)

4(S12a),4(S12b),CN5404(WR12a),

CN2601(WR12b),CN501(WR12c),

CN3104(WR12d)

3(S13a)

3(S14a)

<Note2a>

<Note2b>

)

<Note2a>

<Note2a>

<Note2a>

<Note2a>

<Note2a>

<Note3a>

<Note3b>

1-8 (No.YD049)

Page 9

<Note 2a>

• Be careful not to damage the connector and wire etc. during

connection and disconnection.

• When connecting the flat wire to the connector, be careful with

the flat wire direction.

<Note 2b>

• When attaching the Front panel assembly, make sure that the

door opener of DV deck is in the down position.

<Note 3a>

• When reattaching the bracket(DV MAIN), secure the screws

(S13a) in the order of 1,2,3.

<Note 3b>

• When reattaching the Main board assembly, secure the

screws (S14a) in the order of 1,2,3.

REAR JACK

BOARD ASSY

MAIN BOARD ASSY

(WR12a)

(WR11d)

<Note2a>

CN5403

CN5404

CN3501

CN1001

CN3701

DV MAIN BOARD ASSY

CN4001

CN5501

CN3104

CN2002

<Note2b>

(WR12b)

<Note2a>

CN2601

CN1503

CN1501

CN5506

CN951

(WR9a)

<Note2a>

(WR12c)

<Note2a>

(WR8d)

CN501

<Note2a>

(WR11c)

<Note2a>

(WR8e)

<Note2a>

CN901

CN902

CN701

D

(WR12d)

<Note2a>

CN3102

(WR6d)

FW851

CN852

(WR9b)

CN5402

(WR8c)

CN2602

CN3014

CN3103

CN5302

(WR6c)

CN5301

<Note2a>

CN7107

CN7123

(WR3a)

CN8001

(WR4c)

CN7102

(WR8b)

DRIVE UNIT

(WR8a)

FAN

CN5001

SWITCHING REGLATOR

BOARD ASSY

(WR6b)

CN5303

(WR6a)

<Note2a>

CN5304

CN5501

JUNCTION BOARD ASSY

CN5502

CN5504

CN1003

(WR3b)

<Note2a>

CN2201

DIGITAL

BOARD ASSY

CN7127

DV JACK BOARD ASSY

CN7106

CN2101

(WR5a)

CN7126

(WR4a)

<Note2a>

CN1405

(WR4b)

<Note2a>

CN4104

Operation/jack board assembly

(WR2a)

<Note2a>

CN7201

NOTE) INSERT FFC WIRE

TO THE CONNECTOR BEFORE

ATTACHING TO FRONT PANEL.

(WR2b)

<Note2a>

CN7001

Fig.3-1a

BOTTOM SIDE

TOP SIDE

Display/switch board assembly

NOTE) WHEN YOU FIX ANY PWB

WITH THE SCREW,

PUT IT ON THE JIGS.

(No.YD049)1-9

Page 10

(S1a)

(S1a)

(S1a)

[1]Top cover

(S1a)

[13]Bracket(DV MAIN)

(S13a)

[12]Bracket

(S13a)

1

3

(S12a)

(S12b)

(S1a)

(S1a)

[9]Rear jack board assembly

[11]DV mechanism assembly

(S11a)

u

j

CN4001

CN1502

[12]DV main board assembly

2

(S12b)

(S12b)

(S12a)

<Note2a>

(S13a)

(S1a)

(S1a)

[10]Rear cover

(L10a)

(S11a)

(WR11a)

(S11a)

(WR11b)

<Note2a>

(S3a)

(S10a)

(L10a)

(S9a)

(S10a)

(S10b)

(S10a)

(L10a)

[3]DVD unit

(S3a)

[3]Bracket

(S3a)

[14]Main board assembly

Bottom chassis

(L2a)

(L2b)

(L2b)

(L2a)

(S14a)

1

(L2b)

j

3

(S2a)

(S14a)

2

(S14a)

[5]DV jack board assembly

c

[4]Digital board assembly

[6]Switching regulator

board assembly

[7]HDD

(S5a)

(S4a)

(S8a)

(S3b)

(S6a)

(S6a)

CN5302

CN5001

(S7a)

(S7b)

(S7a)

(S4a)

(S7b)

(S4a)

[8]Junction board assemly

(S3a)

(S3b)

(S6a)

[7]Bracket(HDD)

(S7b)

(S7a)

[7]SHEET

1-10 (No.YD049)

Fig.3-1b

Page 11

SECTION 4

ADJUSTMENT

4.1 Before adjustment

4.1.1 Precautions

(1) Observe the specified screw tightening torque when

attaching parts. The torque should be 0.04 Nm (0.4 kgfcm)

unless otherwise specified.

(2) Always disconnect the power supply unit before proceed-

ing to solder or attach parts.

(3) When plugging or unplugging a wire, be careful not to

damage the connector.

(4) When replacing a part, be careful not to damage other

parts or to mistakenly attach parts.

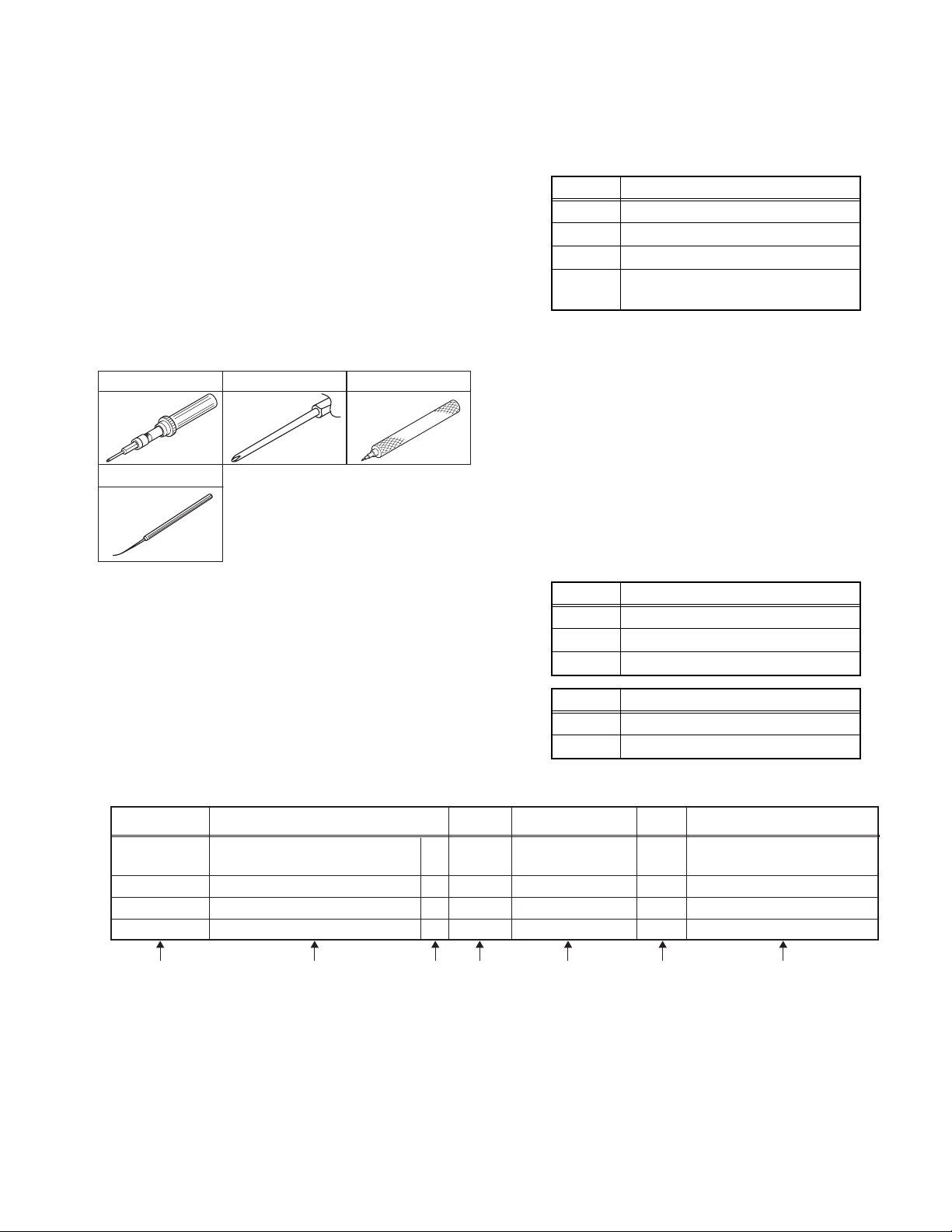

4.1.2 Tools required for adjustments

TORQUE DRIVER

12

YTU94088

Tool for replacing tip IC

4

PTS40844-2

BIT

YTU94088-003

Tool for installing slit washer

3

YTU94121A

Table 4-1-1

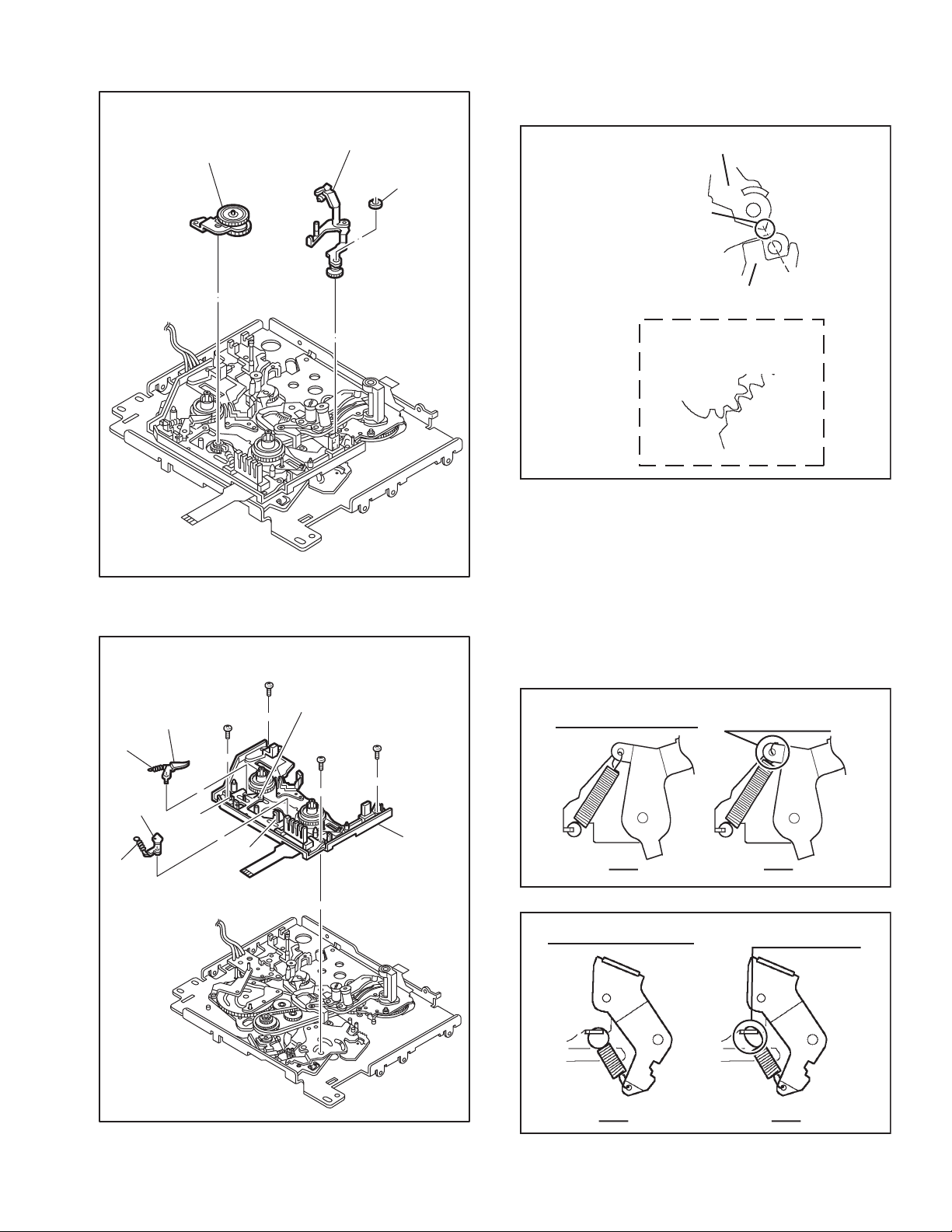

4.1.3 Disassembly and assembly procedures

The following table shows the steps for assembling or disassembling the mechanism parts. Read the following descriptions carefully before actual assembly/disassembly operations.

(1) : Order of disassembly steps. Reverse this order when as-

sembling.

(2) : Name of the disassembled/assembled part.

Surface where the disassembled/assembled part is

(3) :

mounted. T = Top. B: Bottom.

(4) : Number of disassembly drawing.

(5) : Parts to be removed in disassembly/assembly, such as

screws, washers and springs, and the points.

Symbol Name & Point

SScrew

W Washer

PSpring

* Connector, lock(L), soldering(SD),

shield, etc.

[Example] • (W1) = Remove the washer W1.

• (P1) = Remove the spring P1.

(6) : Notes for disassembly/assembly.

(7) : For the phase alignment in disassembly/assembly and

the parts which require phase adjustments after assembly,

see "4.7 Mechanism phase check/adjustment".

4.1.4 Screws and washers used in disassembly/assembly

of the mechanism assembly

Table 4-1-2 shows the symbols and part numbers of the screws

and washers used in the mechanism assembly.

When disassembling or assembling the mechanism assembly,be sure to attach screws and washers correctly by referring

to the following table.

Symbol Part number

(S1) QYSDSP2005ZA

(S2) YQ43893

(S3) YQ43893-7

Symbol Part number

(W1) YQ44246

(W2) YQ44246-3

Table 4-1-2

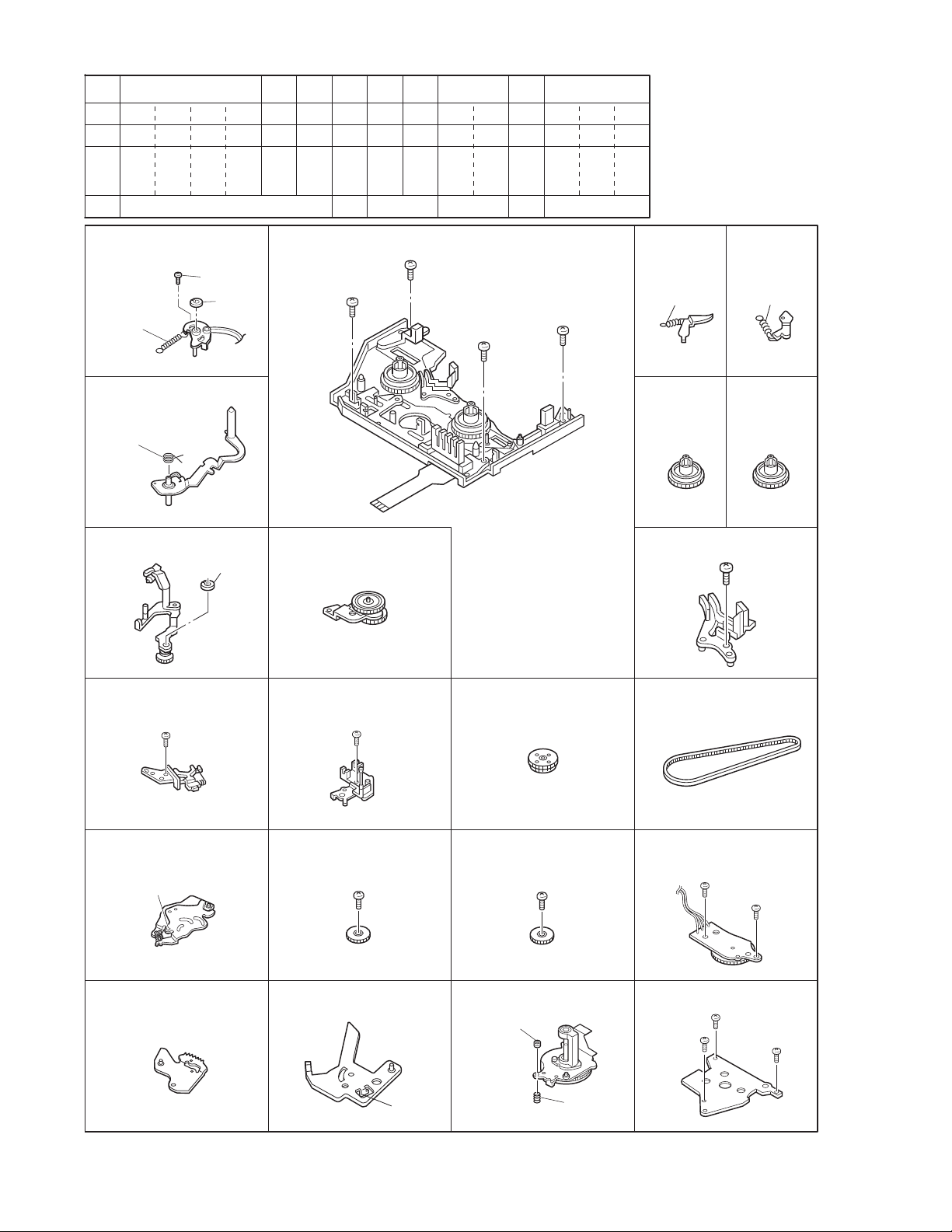

Step/Loc No. Fig. No. Point Note Discription

1

2

3

4

[A] Cassette housing assembly/

[B] Mechanism assembly

[1]Drum assembly

[2]Motor bracket assembly

[3]Middle catcher assembly

Part Name

1

2

2

3

2(S1),(L1) (L5)

3(S2)

4(S2)

3(S2)

T

T

T

T

1

2,3

2,4

(1) (2) (3) (4) (5) (6) (7)

(No.YD049)1-11

Page 12

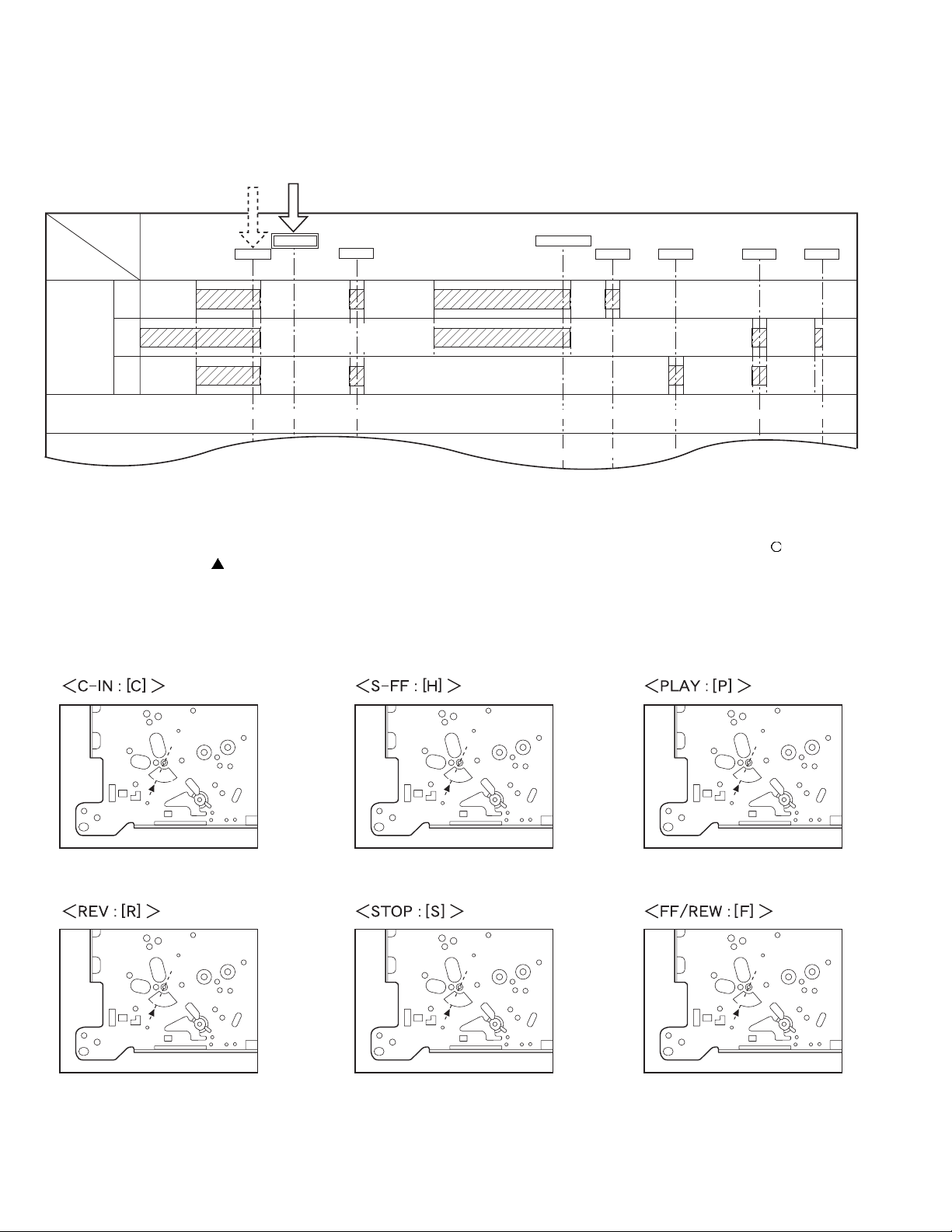

4.2 Disassembly/assembly of the mechanism assembly

4.2.1 Introduction

The disassembly and assembly of the mechanism assembly should usually be performed in the ASSEMBLY mode.(Table 4-2-1)

Note that the mechanism is in the cassette in (C-IN) mode when the mechanism assembly is taken out of the set and that the C-IN

mode should be switched to the ASSEMBLY mode in this case.

To set the ASSEMBLY mode, apply 3 V DC to the electrodes on the upper part of the loading motor as shown in Fig. 4-2-7.

MODE

PARTS

[1]

ROTARY

ENCORDER

R. ENC -20

MAIN CAM GEAR 0

[2]

[3]

36

C-IN

ASSEMBLY

17

S. FF

30.33

36.33

87

0

15

33.33

40

LOADING END

169.66

166.66

140

PLAY REV STOP FF/REW

270.33

276.33

223.66

226.66

185

229.66

273.33

220

303.66

306.66

245

190.33

193.33

160

196.33

Table 4-2-1

4.2.2 Mechanism modes

The mechanism has 6 modes as shown in Table 4-3-1. The current mode can be confirmed by the positioning of the " " marking on

the sub-cam gear and the " " marking on the mechanism. See the following figures (Figs. 4-2-1 to -6) for details.

Note:

• This mechanism assembly has another ASSEMBLY mode. However, this mode cannot be identified from the markings because

it corresponds to an intermediate position between the C-IN ( C ) mode and S-FF ( H ) mode. This mode can be confirmed by the

rotary encoder phase. See Fig. 4-2-7.

1. Checking the mechanism mode

Fig.4-2-1

Fig.4-2-4

1-12 (No.YD049)

[H]

[H][C]

Fig.4-2-2

Fig.4-2-5

[P]

Fig.4-2-3

[F][S][R]

Fig.4-2-6

Page 13

2. Setting/checking the ASSEMBLY mode

Wire (Brown)

DC 3 V

Motor bracket assembly (Loading Motor)

Marking

(Colored red)

Rotary encoder

< ASSEMBLY >

Wire (Red)

[C]

[H]

Fig.4-2-7

(No.YD049)1-13

Page 14

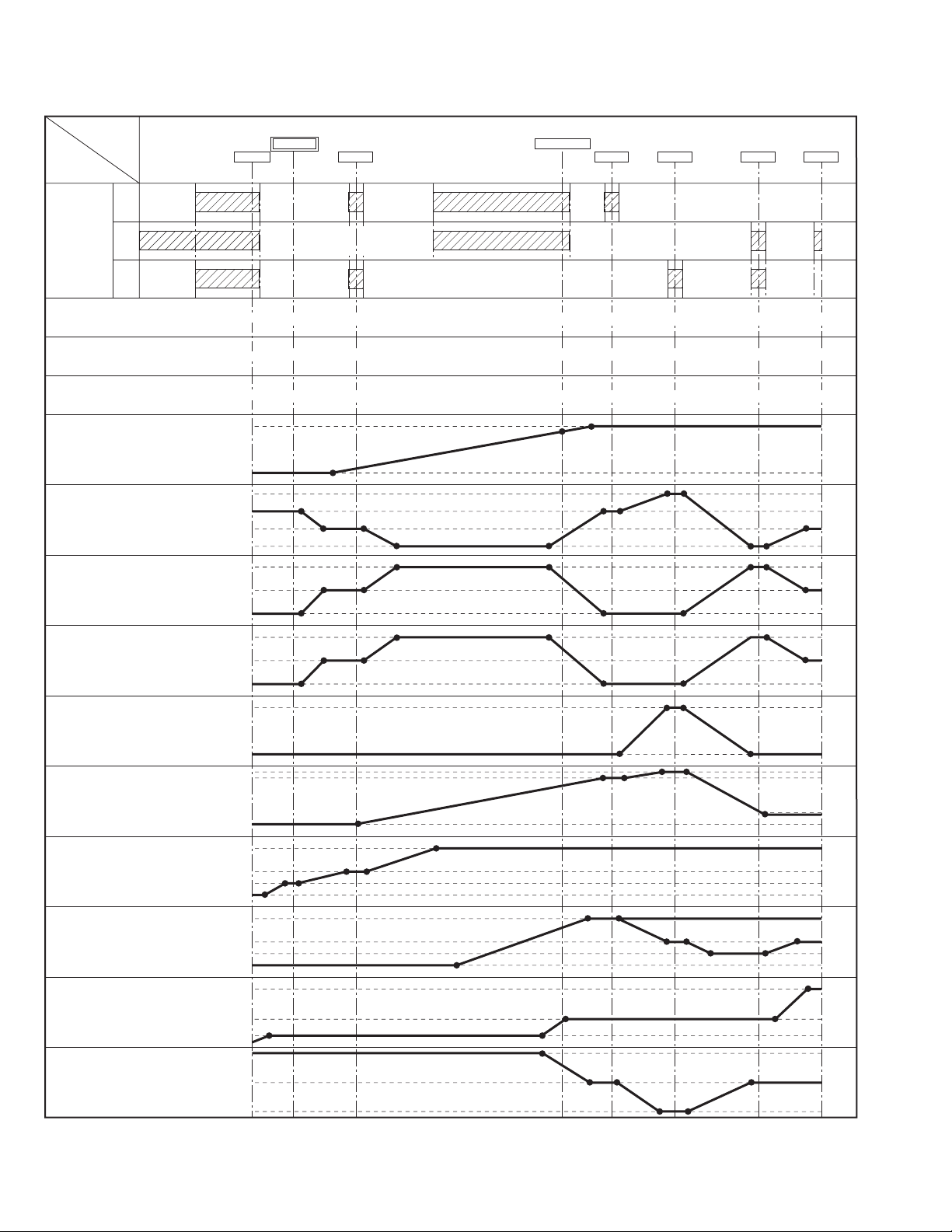

4.3 Mechanism timing chart

See following table (Table 4-3-1).

MODE

PARTS

36

[1]

ROTARY

ENCODER

[2]

[3]

ROTARY ENCODER

MAIN CAM 0

SUB CAM

POLE BASE

CTL PLATE

FF/REW

MAIN BRAKE(SUP)

MAIN BRAKE(TU)

SUB BRAKE

ON(REV MODE PRESS UP)

ON(PLAY MODE)

PINCH ROLLER

EXIT GUIDE ARM

HALF LOADING

TENSION ARM

BAND ARM PLATE

CLUTCH LOCK

SUP CENTRRING

OFF

S/REV

PLAY

ON 1

ON 2

OFF

ON 1

ON 2

OFF

OFF

OFF

ASSY

OFF

OFF 1

OFF 2

OFF

OFF 1

OFF 2

ASSEMBLY

C-IN

17

-20

0

15

0

ON

ON

ON

ON

ON

S. FF

30.33

33.33

40

4015

36.33

87

LOADING END

169.66

166.66

140

140

PLAY REV STOP FF/REW

270.33

276.33

223.66

226.66

185

185

229.66

273.33

220

220

303.66

306.66

245

245

190.33

193.33

160

160

196.33

CENTERRING ARM

1-14 (No.YD049)

S/REV

Table 4-3-1

Page 15

4.4 Mechanism assembly/disassembly procedure table

Step/Loc

No.

1 [A] Cassette housing assembly/ [B] Mechanism assembly T 4-5-1 2(S1),(L1) (L5) 1

2 [1] Drum assembly T 4-5-2 3(S2) 2,3

3 [2] Motor bracket assembly T 4-5-2 4(S2) 2,4

4 [3] Middle catcher assembly T 4-5-3 3(S2)

5 [4] Reel cover assembly T 4-5-3 (S2), 2(L6) 5

6 [5] Pinch roller arm assembly T 4-5-4 (W1), (L7) 6

7 [6] Sub brake assembly T 4-5-4 (P1), (W1), (L8)

8 [7] Band arm plate sub assembly T 4-5-4 (S3), (L9), (P2), (W2) 7,8

9 [8] Tension arm sub assembly T 4-5-4 (P3) 8

10 [9] EXIT guide arm assembly T 4-5-5 (W1)

11 [10] Swing arm assembly T 4-5-5 Position alignment

12 [11] Sub deck assembly T 4-5-6 4(S2) 9 Position alignment

13 [12] Main brake (Supply) assembly T 4-5-6 (P4), (L10)

14 [13] Main brake (Take up) assembly T 4-5-6 (P5), (L11)

15 [14] Reel disk assembly (Supply) T 4-5-7

16 [15] Reel disk assembly (Take up) T 4-5-7

17 [16] Prism T 4-5-7 (S2)

18 [17] Control plate T 4-5-7 2(L12)

19 [18] Guide rail (Take up) assembly T 4-5-8 4(S2) 10 Position alignment

20 [19] Guide rail (Supply) assembly T 4-5-8 (S2), 2(L13) 10 Position alignment

21 [20] Base plate assembly T 4-5-8 (S2), 2(L14)

22 [21] Ent. guide base assembly T 4-5-9 (S2)

23 [22] Worm wheel 2 T 4-5-9 11 Phase alignment

24 [23] Timing belt T 4-5-9

25 [24] Center gear assembly T 4-5-9

26 [25] Reel drive pulley assembly T 4-5-10 (W1)

27 [26] Push plate T 4-5-10 (W1)

28 [27] Clutch lock gear (2) T 4-5-10

29 [28] Clutch lock gear (1) T 4-5-10 (P6)

30 [29] Tension control arm assembly T 4-5-11 (L15) 12 Position alignment

31 [30] Brake control arm assembly T 4-5-11 (W1), (L16) 12 Position alignment

32 [31] Charge arm assembly T 4-5-11 (L17) 13 Position alignment

33 [32] Connect gear 2 T 4-5-12 (S2) (Phase alignment)

34 [33] Connect gear 2 T 4-5-12 (S2) (Phase alignment)

35 [34] Rotary encoder assembly T 4-5-13 2(S2) 14 Phase alignment

36 [35] Main cam T 4-5-13 (W1) 15 Phase alignment

37 [36] Arm gear 1 assembly T 4-5-13 Collar 15,16 Position alignment

38 [37] Centering arm assembly T 4-5-13 (L18) 15 Position alignment

39 [38] Sub cam T 4-5-14 (S2) 17 Phase alignment

40 [39] Arm gear 2 assembly T 4-5-14 17 Position alignment

41 [40] Clutch lock lever assembly T 4-5-14 (L19) 17,18 Position alignment

42 [41] Capstan motor T 4-5-15 (P7), Adjust nut Vertical adjustment

43 [42] Drum base deck T 4-5-15 3(S2)

Part Name Fig. No.

Point Note Discription

(No.YD049)1-15

Page 16

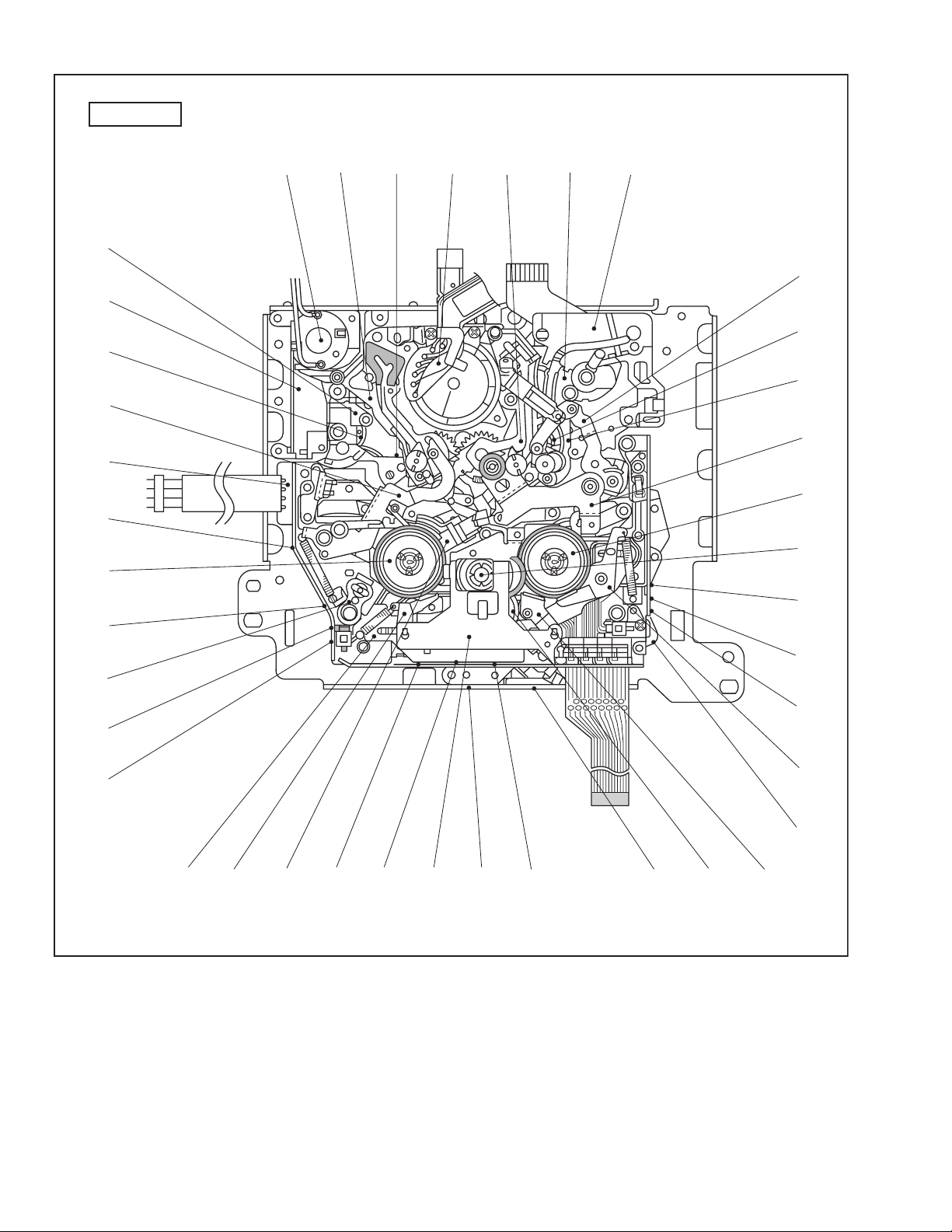

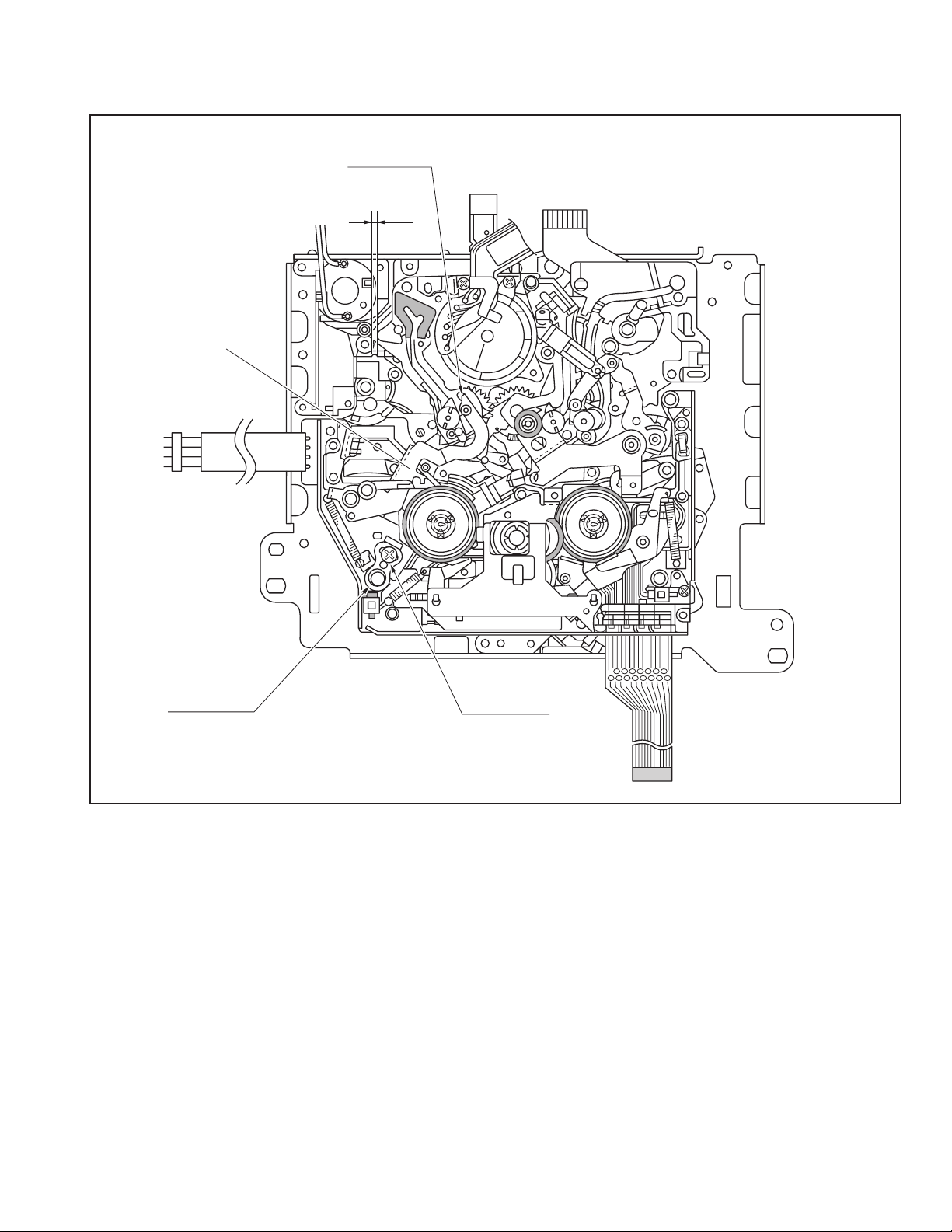

TOP VIEW

[21]

[11]

[22]

[8]

[34]

[35]

[14]

[37]

[2]

[19]

[42]

[1]

[18]

[41]

[3]

[9]

[23]

[25]

[5]

[15]

[10]

[38]

[7]

[29]

[30]

[17][12][16]

[36]

[20][4][32][26]

Fig.4-4-1

[39]

[31]

[6]

[40]

–

[33]

[24]

[13][28]

1-16 (No.YD049)

Page 17

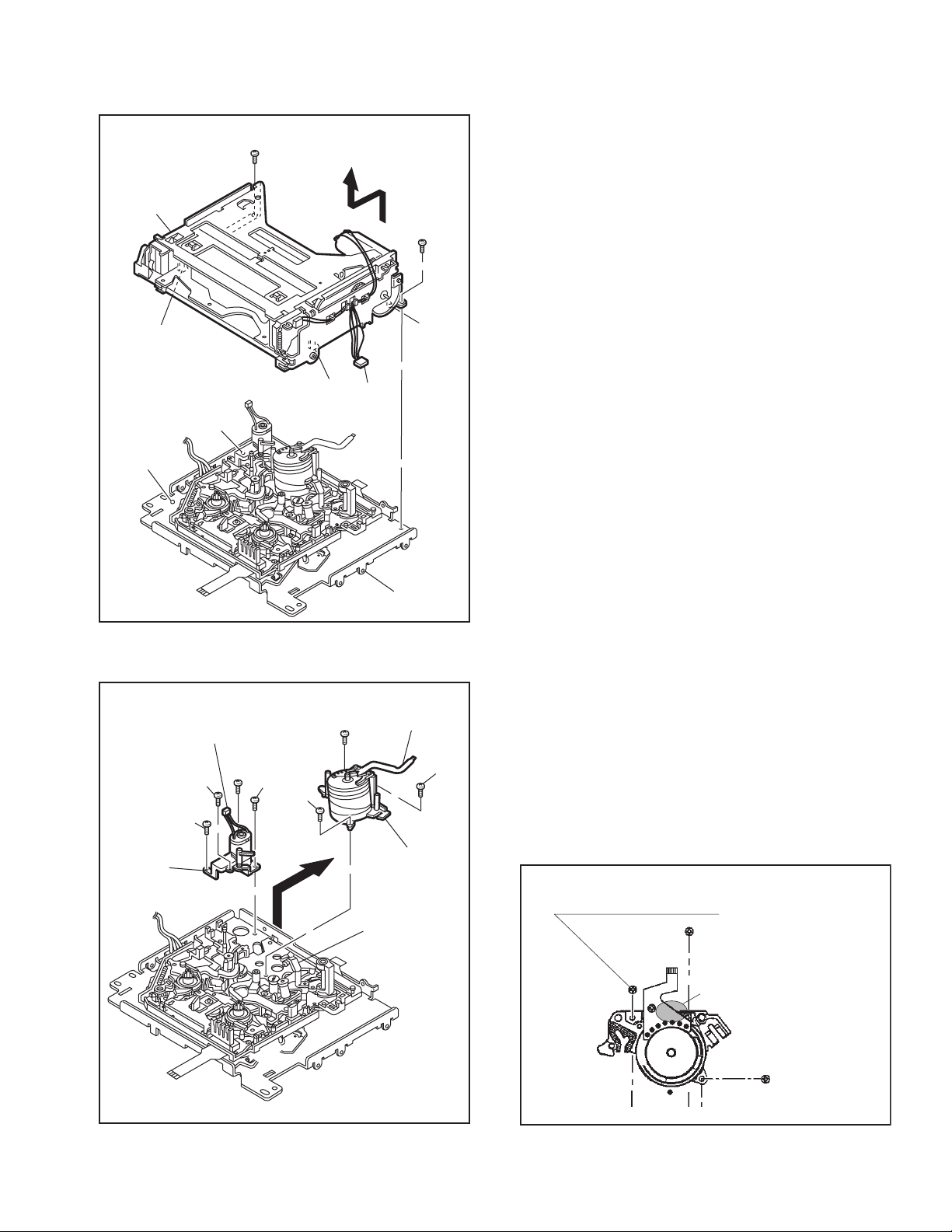

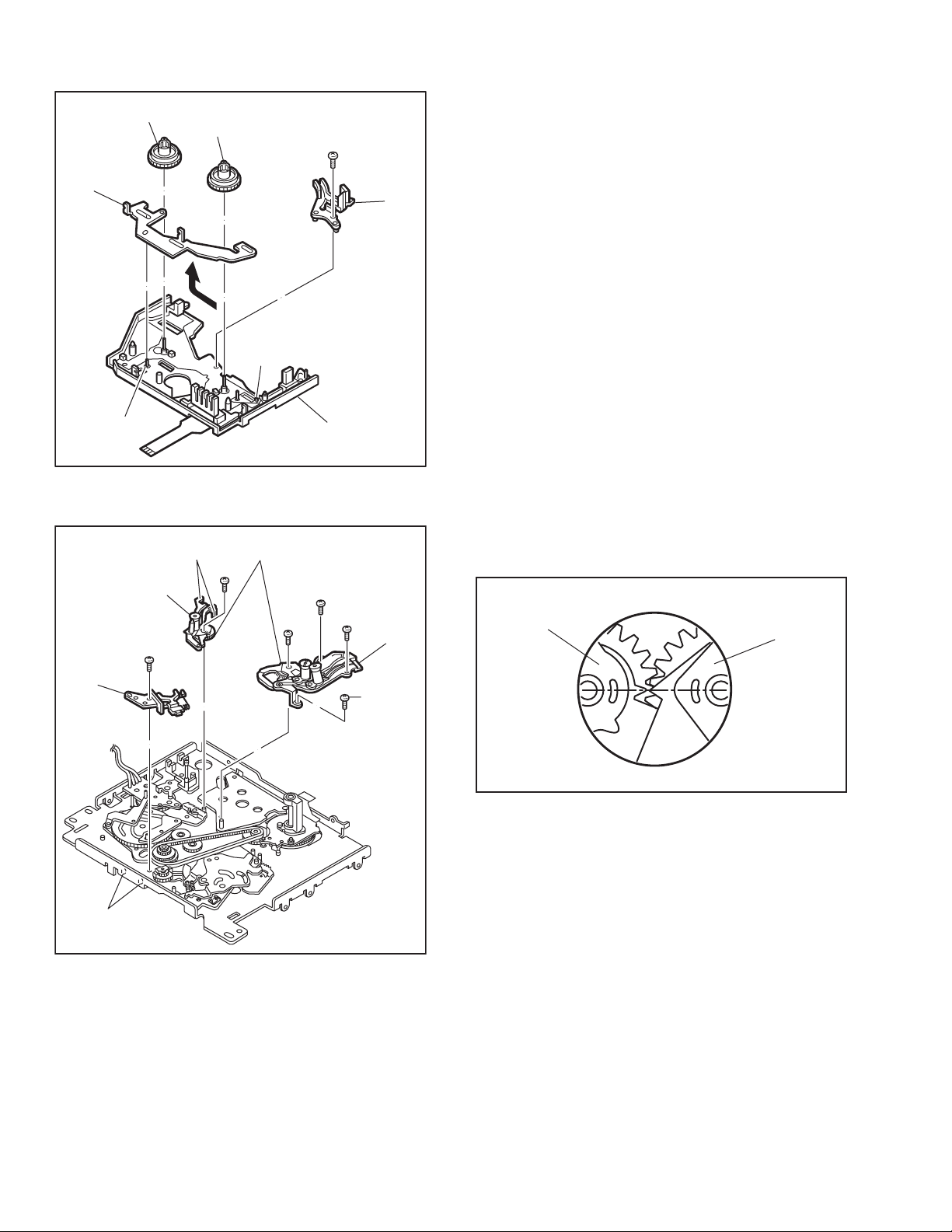

4.5 Disassembly/assembly

1. [A] Cassette housing assembly/ [B] Mechanism assembly

1

(S1)

<Note 1a>:

If the wires for the cassette housing motor are connected to

the circuit board, remove them before disassembly.

[A]

(L3)

(L4)

(L1)

Fig.4-5-1

(L5)

<Note1a>

[B]

2

(S1)

(L2)

2. [1] Drum assembly / [2] Motor bracket assembly

3

<Note2a>

(S2)

8

(S2)

(S2)

6

(S2)

9

7

(S2)

(S2)

<Note2c>

4

<Note2a>

[2]

<Note2b>

[1]

5

(S2)

<Note 2a>:

If wires are connected to the circuit board, remove them before disassembly.

<Note 2b>:

Be careful not to damage the drum assembly when removing it.

<Note 2c>:

The bracket (DV) may come in the way of removal of screw

(7). Be sure to remove the bracket before proceeding to the

screw removal.

NOTE: Fasten screw in order

of .

[a] [b]

[a]

[c]

[c]

When Handling hold this part.

[b]

Fig.4-5-2

Fig.4-5-2a

(No.YD049)1-17

Page 18

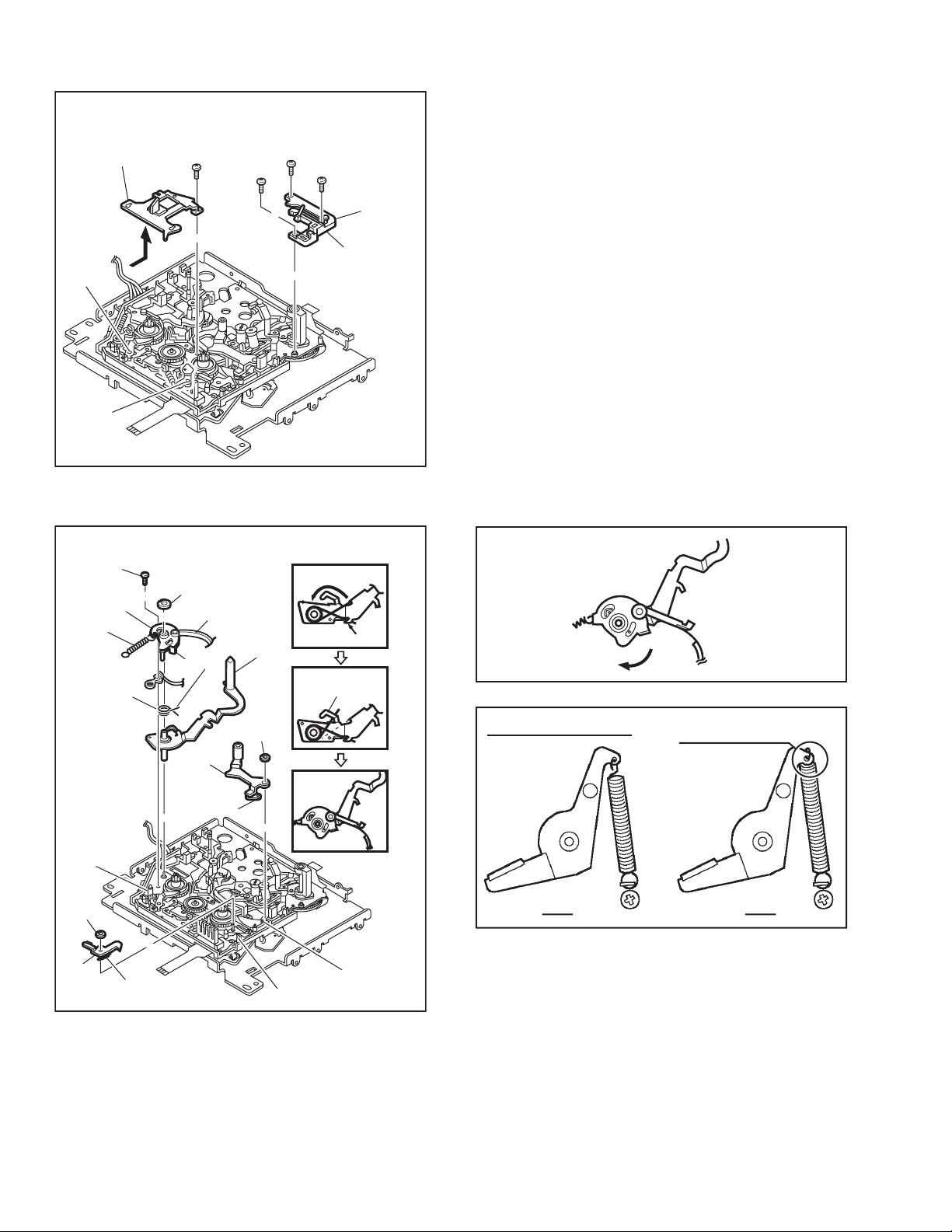

3. [3] Middle catcher assembly/ [4] Reel cover assembly

(b)

[4]

13

(S2)

(c)

12

<Note3b>

(S2)

<Note3b>

10

(S2)

(a)

11

(S2)

<Note3b>

Apply grease

<Note 3a>:

Once the reel cover assembly has been removed, the parts

located below it tend to slip out easily: Be careful.

<Note 3b>:

When attaching these screws, screwing order (a),(b),( c)

<Note3a>

[3]

(L6)

(L6)

Fig.4-5-3

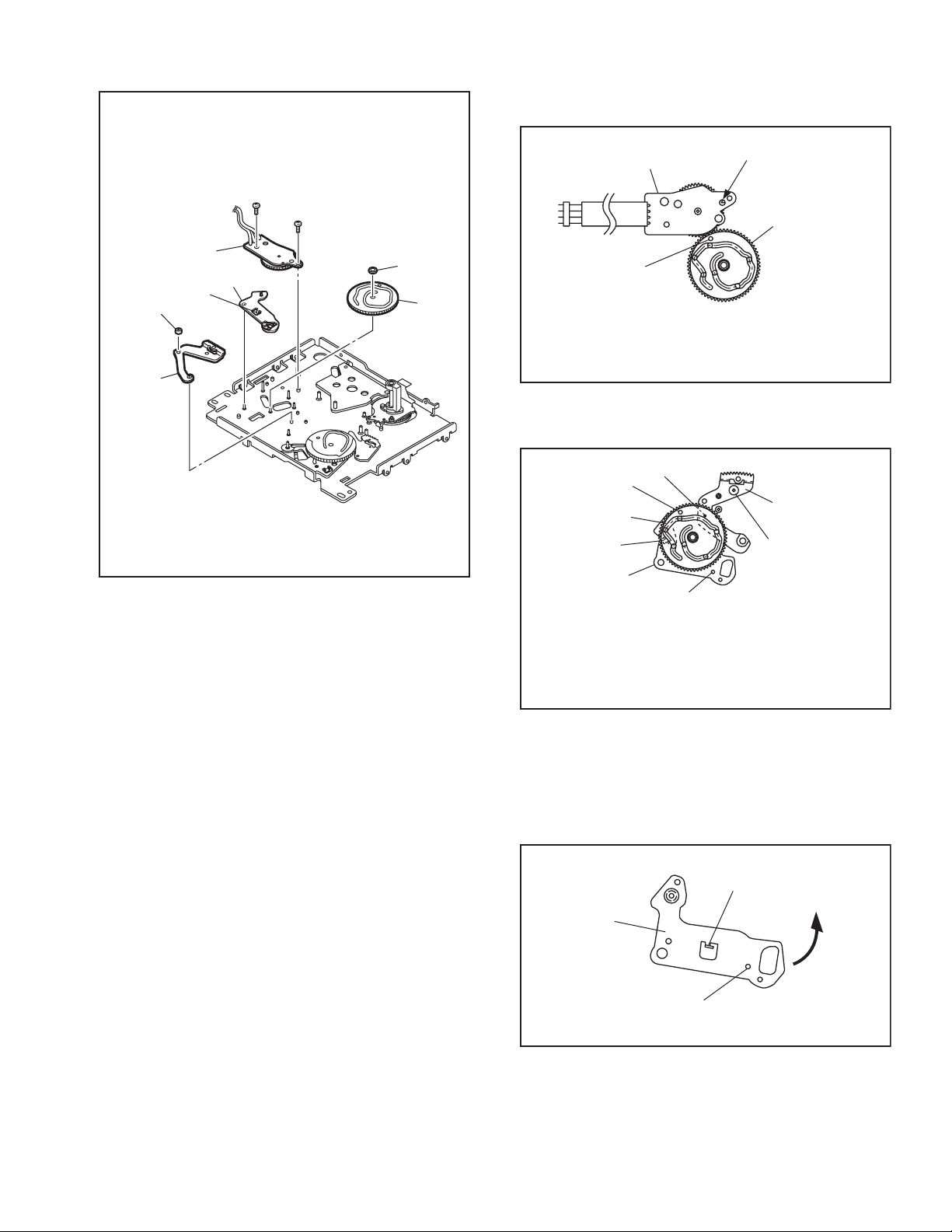

4. [5] Pinch roller arm assembly/[6] Sub brake assembly/[7] Band arm plate sub assembly/ [8] Tension arm sub assembly

<Note 4c>:

How to install the spring

Step 1

Hook [a]

[8]

Step 2

Hook [b]

Fig.4-5-4a

(P2)

14

(S3)

(P3)

[7]

(W2)

<Note4b>

NOTE4c

(L9)

(W1)

[6]

(P1)

[5]

<Note4a>

Fig.4-5-4

(W1)

(L8)

Step 3

(L7)

sub brake (Take up)

spring hooked

reverse-side

OK NG

Fig.4-5-4b

<Note 4a>:

When attaching this part, fit it in the boss (L7) on the charge

arm assembly.

<Note 4b>:

When attaching or removing this part, take care of the handling of the band section.

<Note 4c>:

After fitting the spring on the shaft, engage it with hook [a]

first then with hook [b] .

After attaching it, set it to the positioning shown in "Step 3"

and confirm that band arm plate sub assembly [7] can be rotated in the direction of the arrow as shown below.

1-18 (No.YD049)

Page 19

5. [9] Exit guide arm assembly/ [10] Swing arm assembly

[9]

[10]

<Note5a>

(W1)

<Note 5a>:

Exit guide arm assembly phase alignment.

Exit guide arm assembly

This protrusion is

combined to

the dent of Charge

arm assembly.

Charge arm assembly

Gear alignment

Exit guide arm

assembly

Arm gear 2

assembly

Fig.4-5-5a

Fig.4-5-5

6. [11] Sub deck assembly/ [12] Main brake (Supply) assembly/[13] Main brake (Take up) assembly

<Note 6a>:

When attaching the sub deck assembly, make sure to adjust

the phase of the control plate.

Main brake (Supply)

OK NG

Fig.4-5-6a

(P4)

(P5)

[13]

[12]

(

L10

15

(S2)

16

(S2)

)

(

)

L11

<Note6a>

18

(S2)

17

(S2)

[11]

Main brake (Take up)

spring hooked

reverse-side

Twisted spring

Fig.4-5-6

OK NG

Fig.4-5-6b

(No.YD049)1-19

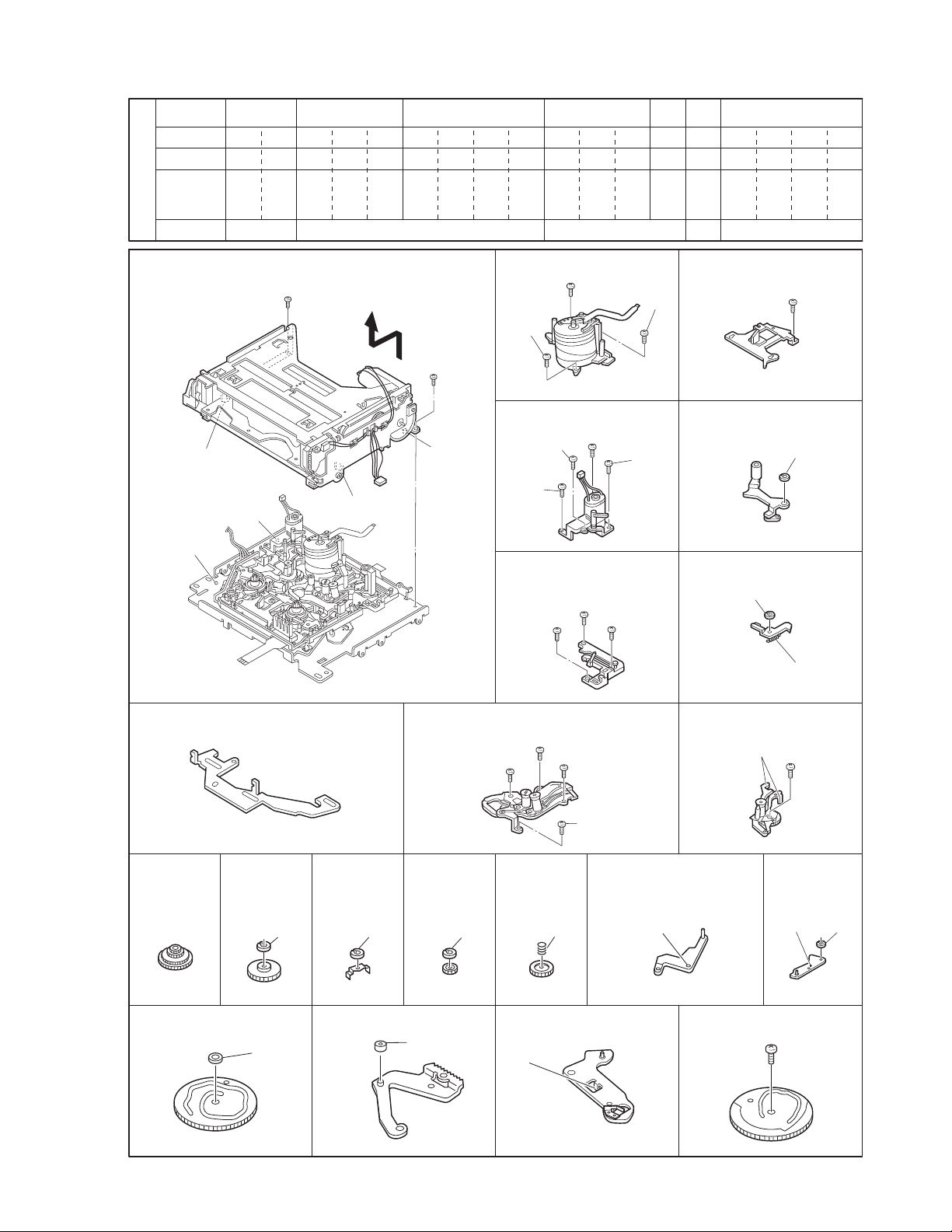

Page 20

7. [14] Reel disk assembly (Supply) / [15] Reel disk assembly (Take up) / [16] Prism / [17] Control plate

[14]

21

(S2)

[11]

20

(S2)

19

22

(S2)

[16]

<Note 8a>:

When attaching, set the alignment markings of the two gears

so that the markings face opposite to each other.

[19]

[18]

[15]

[17]

(

)

L12

(

)

L12

Fig.4-5-7

8. [18] Guide rail (Take up) assembly / [19] Guide rail (Supply) assembly / [20] Base plate assembly

(

)

L13

24

<Note8a>

(S2)

[19]

25

(S2)

(S2)

[18]

[20]

(

L14

23

(S2)

Fig.4-5-8a

)

Fig.4-5-8

1-20 (No.YD049)

Page 21

9. [21] Ent. guide base assembly / [22] Worm wheel 2 / [23] Timing belt / [24] Center gear assembly

<Note 9a>:

26

(S2)

How to attach the worm wheel 2 [22] .

[23]

[22]

[21]

[34]

<Note9a>

[22]

Fig.4-5-9

10. [25] Reel drive pulley assembly / [26] Push plate/ [27] Clutch lock gear (2) / [28] Clutch lock gear (1)

Detail "A"

<Note10b>

(P6)

Flange

[28]

[24]

[23]

Align the phase of the rotary encoder assembly [34],

then attach it by aligning the phase hole of the

mechanism assembly.

Fig.4-5-9a

<Note 10a>:

After attaching (W1), confirm that pushes [26] from the top

and hit to MAIN DECK. If there are a rattling or inclination in

[26] , reconfirm the attachment of (P6). (Take care to the oblique insertion of (P6).)

<Note 10b>:

Attach (P6) straight for it which does not get on on the flange

of [28]

Phase alignment

Mark (Red)

[26]

<Note10a>

[27]

[28]

(W1)

(P6)

"A"

Fig.4-5-10

(W1)

[25]

(No.YD049)1-21

Page 22

11. [29] Tension control arm assembly/ [30] Brake control arm assembly / [31] Charge arm assembly

(

L16

)

(W1)

<Note 11a>:

How to attach the tension control arm assembly [29] / Brake

control arm assembly [30] .

[30]

34

(

<Note11a>

(

)

L15

L17

)

[31]

<Note11b>

30

[29]

Boss

29

(Phase alignment)

35

Align the phase of the main cam [35], then attach it by

fitting the bosses into the cam slot.

Fig.4-5-11a

<Note 11b>:

How to attach the charge arm assembly [31]

[31]

Fig.4-5-11

[38]

12. [32] Connect gear 2 / [33] Connect gear 2

[39]

[32]

27

(S2)

28

(S2)

[33]

Phase alignment

Boss

(Phase alignment)

Align the phase of the sub cam [38], then attach it by

fitting the boss into the cam slot.

Fig.4-5-11b

1-22 (No.YD049)

Fig.4-5-12

Page 23

13. [34] Rotary encoder assembly / [35] Main cam / [36] Arm gear 1 assembly / [37] Centering arm assembly

<Note 13a>:

How to attach the rotary encoder assembly [34].

Collar

<Note13b>

[36]

<Note13a>

[34]

[37]

(

)

L18

<Note13c>

29

(S2)

(S2)

<Note13b>

Fig.4-5-13

[34]

30

Mark (colored : red)

[35]

(W1)

[35]

<Note13b>

Phase alignment

Align the phase of the main cam [35],then attach it by

placing the (red) coloured markings (on 2 gear teeth)

within the encircled area.

Fig.4-5-13a

<Note 13b>:

How to attach the main cam [35] .

Boss

Phase alignment

[35]

Boss

[36]

Phase alignment

[37]

Phase alignment

Align the phases of the arm gear 1 assembly [36] and

centering arm assembly [37],then attach the arm gear 1

assembly [36]/centering arm assembly [37] by fitting the

bosses into the lower cam slot,and fit the slit washer.

Fig.4-5-13b

<Note 13c>:

How to remove the centering arm assembly[37] The center

arm assembly is located behind the mechanism assembly

when the phase is aligned correctly. The center arm assembly can be removed by displacing it in the direction of the arrow.

L18

[37]

Phase alignment

Fig.4-5-13c

(No.YD049)1-23

Page 24

14. [38] Sub cam / [39] Arm gear 2 assembly / [40] Clutch lock lever assembly

<Note 14a>:

How to attach the sub cam [38].

31

(S2)

<Note14a>

<Note14a>

[38]

[40]

Phase alignment

[38]

Boss

[39]

Phase alignment

[40]

<Note14b>

(

)

L19

Fig.4-5-14

15. [41] Capstan motor / [42] Drum base deck

32

(S2)

33

(S2)

34

(S2)

[42]

<Note14a>

[39]

Phase alignment

Align the phases of the arm gear 2 assembly [39] and

clutch lock lever assembly [40],then attach them by fitting

the boss into the lower cam slot and tighiten the screws.

Fig.4-5-14a

<Note 14b>:

How to remove the clutch lock lever assembly [40] L19 is located behind the mechanism assembly when the phase is

aligned correctly. The clutch lock lever assembly can be removed by displacing it in the direction of the arrow.

Phase alignment

[40]

L19

Fig.4-5-14b

1-24 (No.YD049)

Adjust nut

[41]

(P7)

Fig.4-5-15

Page 25

4.6 List of procedures or disassembly

[24]

[23]

[17]

29

(S2)

[34]

[7]

(P3)

[12]

[29]

(W2)

[21]

30

(S2)

25

(S2)

[20]

Collar

14(S3)

[8]

26

(S2)

(W1)

[27]

[13]

[28]

[35]

[37]

[26]

(P6)

16

(S2)

[14]

(W1)

[32]

(S2)

[30]

[22]

15

[11]

33

(S2)

(W1)

[15]

27

(S2)

32

(S2)

ADJ.

NUT

(P7)

28

(S2)

[33]

19

(S2)

[16]

34

(S2)

(W1)

[6]

17

(S2)

(S2)

[42]

[18]

18

(W1)

[25]

21

(S2)

31(S2)

[19]

[41]

[38]

[10]

20

(S2)

[4]

22

(S2)

23

(S2)

12

(S2)

(S2)

[31]

24

8(S2)

[5]

9(S2)

(S2)

10

4

(S2)

(W1)

13

(S2)

6(S2)

11

(S2)

[3]

[9]

7(S2)

[2]

3

(S2)

5

(S2)

[1]

(W1)

[40]

[36]

[B]

Fig.4-6-1

[39]

(No.YD049)1-25

Page 26

4.7 Mechanism phase check/adjustment

See Fig 4-7-1.

[22]

[34]

Rotary encoder assembly

See Figs. 4-5-9a and

4-5-13a.

Worm wheel 2

See Fig. 4-5-9a.

[36]

Arm gear 1 assembly

See Fig. 4-5-13b.

[39]

Arm gear 2 assembly

See Fig. 4-5-14a.

[38]

Sub cam

See Fig. 4-5-14a.

[35]

Main cam

See Figs. 4-5-13a and 4-5-13b.

[37]

Centering arm assembly

See Fig. 4-5-13b.

Fig.4-7-1

[40]

Clutch lock lever assembly

See Fig. 4-5-14a.

1-26 (No.YD049)

Page 27

4.8 Mechanism disassembly/assembly sheet

Fig. No.

No.

Type

[A][

1 18234567891011121314151617

S1

Attachin

Ref. Fig.

Screw Management Table

4-5-1 4-5-2 4-5-3

[A] Cassette housing assembly

1

(S1)

(L4)

(L1)

(L3)

][

1

][

2

[1] Drum assembly

4

(S2)

2

(S1)

S2×3

[2] Motor bracket assembly

(L2)

(L5)

9

(S2)

8

(S2)

S2×4

[3] Middle catcher assembly

12

(S2)

][

3

3

(S2)

10

(S2)

6

(S2)

(S2)

7

(S2)

11

(S2)

][7][

4

11

]

S2 S2 S2

4-5-4

4-5-6

[4] Reel cover assembly

5

(S2)

S2, L6×2

[5]

Pinch roller arm assembly

(W1)

W1, L7

[6] Sub brake assembly

(W1)

S2S1 S2 S2 S2 S2 S2 S2 S2 S2 S2 S2 S2 S3

13

(P1)

S1×2, L1-L5

S2×3

P1, W1, L8

[17] Control plate [18] Guide rail (Take up) assembly [19] Guide rail (Supply)

assembly

(

)

L13

24

(S2)

21

(S2)

20

(S2)

22

(S2)

23

(S2)

L12×2 S2×4 S2, L13×2

[24] Center

gear

assembly

[25] Reel drive

pulley

assembly

(W1)

[26] Push

plate

(W1)

[27] Clutch

lock gear

(2)

(W3)

[28] Clutch

lock

gear (1)

(P6)

[29] Tension control arm

assembly

(

)

L15

[30]

Brake

control arm

assembly

(

) (W1)

L16

W1 W1 W3 P6 L15 W1, L16

[35] Main cam [36] Arm gear 1 assembly

(W1)

Collar

[37]

Centering arm assembly

(

)

L18

[38] Sub cam

31

(S2)

W1 COLLAR L18 S2

Fig.4-8-1a

(No.YD049)1-27

Page 28

[16][

][

18

][20][21][32][33][34][38][

19

42

]

19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34

S2 S2 S2 S2 S2 S2 S2 S2 S2

S2 S2 S2 S2 S2 S2 S2

4-5-7 4-5-9

[7] Band arm plate sub

assembly

(P2)

14

(S3)

(W2)

[11] Sub deck assembly

S3, P2, L9, W2

[8] Tension arm sub

assembly

(P3)

P3

[9]

EXIT guide arm assembly

(W1)

S2×4

[10] Swing arm assembly

16

(S2)

18

(S2)

4-5-14

17

(S2)

[12]

Main

Brake(Supply)

assembly

(P4)

[13]

Main

Brake(Take up)

assembly

(P5)

4-5-12 4-5-13 4-5-154-5-8

15

(S2)

P4, L10 P5, L11

[14]

Reel disk

assembly

(Supply)

[15]

Reel disk

assembly

(Take up)

[16] Prism

19

(S2)

W1

[20] Base plate assembly

[21] Ent. guide base

[22] Worm wheel 2 [23] Timing belt

S2

assembly

25

(S2)

26

(S2)

S2, L14×2 S2

[31] Charge arm assembly [32] Connect gear 2 [33] Connect gear 2 [34] Rotaly encoder

assembly

33

(S2)

29

(S2)

(S2)

32

(S2)

(

L17

)

27

(S2)

L17 S2 S2

[39] Arm gear 2 assembly [40] Clutch lock lever

[41] Capstan motor [42] Drum base deck

assembly

(

)

L19

28

(S2)

S2×2

Adjust nut

(P7)

L19 S2×3Adjust nut, P7

Fig.4-8-1b

30

34

(S2)

1-28 (No.YD049)

Page 29

4.9 Positioning the tension pole

See Fig.4-9-1.

Tension arm sub

assembly

[B] section

[C]

[D] section

4.9.1 Adjustment Method

Note:

• Remove the cassette housing assembly in advance.

(1) Set the mechanism mode to the PLAY mode. (See 4.2.2

Mechanism modes)

(2) Loosen a screw [A].

(3) Check the location of the tip (section [B]) of the tension

arm assembly to make sure that it is within area [C]. If it

is located outside, turn part D to bring it within the spec-

ified area.

(4) Tighten the screw [A].

Note :

Tightening torque for the screw [A] : 0.06 N.m (0.6kgf.cm)

screw [A]

Fig.4-9-1

(No.YD049)1-29

Page 30

4.10 Compatibility and error rate adjustment

4.10.1 Preparation

Before disassembly and adjustment, back up the data stored in

the EEPROM (IC1504 on the DV MAIN board) using the Service

Support System Software (SSS software).

Table 4-13-1 shows the important service points for the compatibility and error rate adjustments.

Drum

replacement

Transport part

replacement

Transport part

(drum) repair

IC4001(PRE/REC

amp on DV MAIN

board) replacement

IC2001(PB. EQ on

DV MAIN board)

replacement

DV MAIN board

replacement

Note 2

Linearity

adjustment

Required

Note 1

Required

Note 1

Required

Note 1

PB Switching

point

adjustment

Required Required

Not Check

Not Check

Not Not Check

Not Not Required

Not Required Required

Error rate

adjustmenmt

Table 4-13-1

Note 1 :

• The linearity adjustment is required only after servicing or replacing the drum or the take up/supply guide rail.

Note 2 :

• After replacing the DV MAIN board, write the original data in

the EEPROM of the new board. If write communication is not

possible, mount the original EEPROM on the new board.

When adjustments of more than one item are required, use the

following order for the adjustments.

4.10.3 Linearity adjustment

4.10.4 PB switching point adjustment

4.10.5 Error rate adjustment

4.10.2.2 Procedure

(1) Take out the 6 screws, then remove the top cover. (See

SECTION 3 DISASSEMBLY)

(2) Connect the jig connector cable to CN2001 on the DV

MAIN board.

Jig Connector Cable

PTU94018B

CN1503

CN2001

B

CN3701

DV

MAIN PW

CN1501

Fig.4-10-2

4.10.2.3 Setup for computer adjustment

-Setup by extending the jig connector-

Connect the Jig Connector Cable and setup the SSS software. It

automatically becomes the TCCS mode and "TCCS" is displayed

on the FDP.

To cancel the TCCS mode, press the CANCEL button of the remote

control unit.

The "TCCS" display on the FDP disappears.

Service Support Software

RS-232C Port

PC Cable

JVC

MENU

Personal Computer

4.10.2 Adjustment

The actual adjustment requires the following preparation.

4.10.2.1 Tools required for adjustment

Alignment tape

US : MC-1

PAL : MC-2

SSS software

PTU94016-5

Guide driver

YTU94085

PC cable

US : QAM0099-002

PAL : QAM0099-005

Jig connector cable

PTU94018B

Jig RCU

PTU94023B

Fig.4-10-1

1-30 (No.YD049)

N

C

D

3701

MAIN PWB

V

<JLIP>

N1503

C

2001

N

C

1501

CN

Fig.4-10-3

Page 31

4.10.3 Linearity adjustment

The following flowchart shows the linearity check/adjustment

procedure.

4.10.4 PB switching point adjustment

The following flowchart shows the PB switching point adjustment

procedure.

Connect an oscilloscope (CH: + Slope) and, while

triggering it with the HID signal, observe the ENV OUT

Play the alignment tape, then set “ATF” (Auto Tracking

Find) in “Deck Controller” of the SSS Software to ON.

(Note 3)

Ensure that the ENV OUT waveform is linear and parallel,

without a noticeable drop or variation in the overall level. If

the waveform linearity is poor or there is a noticeable drop

in level, adjust the guide roller by turning it with the roller

driver.

Set “ATF” (Auto Tracking Find) to OFF using “Deck

Controller” of the SSS Software (Note 4). Observe the ENV

OUT waveform to confirm that the overall waveform

balance and linearity levels vary in accordance with the

tracking variation as shown in Fig. 4-10-4.

Repeat above steps

as required.

No

Is the PB ENV waveform ideally

stable and does it vary ideally

according to the tracking variation?

Load the alignment tape.

The “PB Switching Point” in the Adjustment Utility of

the SSS software is adjusted automatically.

4.10.5 Error rate adjustment

The following flowchart shows the error rate adjustment procedure.

Record for about 5 minutes. (Note 6)

While playing the recorded signal, adjust “

” or “

Frequency (ME SP)

“Deck Section” of the Adjustment Utility.

To adjust VCO Center Frequency (ME SP) : Set Viterbi OFF.

To adjust VCO Center Frequency (ME LP) : Set Viterbi ON.

No

Is the obtained error rate minimum

(almost the typical value)?

VCO Center Frequency (ME LP)

VCO Center

” in

Yes

The linearity adjustment is complete if the PB ENV

waveform is ideally stable and varies ideally according to

the tracking variation. To close, play a prerecorded tape

and check the audio and video.

HID waveform

PB ENV

waveform

CH1

CH2

Adjust variation

in the parallelism

Fig.4-10-4

Note 3 :

• If ATF is turned off, the DV section performs tracking only of

the speed system. Therefore, as time passes, the servo will

be lost and the linearity adjustment will become difficult.

Note 4 :

• Since the speed servo function is active when ATF is off,

there will be no problem even if the DVC ATF function is off,

provided that it is for a few minutes.

Yes

The error rate adjustment is complete when the minimum

error rate which is no higher than the typical value is

obtained. (Note 5)

Note 5 :

• The "typical value" refers to the following:CH1 or CH2: < 498

; with Viterbi OFF. Inter-channel difference: < 10 times between CH1 and CH2.

Note 6 :

• It is desirable to use a brand-new tape or an unused section

of tape. This is to assure the adjustment reliability because

using a damaged tape increases the error rate.

4.10.6 Error rate measuring method

It is not necessary to use the error rate jig (YTU93083) or a frequency counter. The Service Support System Software displays

the error rates of video CH1, CH2 and totals. When measuring

the error rate of a channel, be sure to total the values of the video

and the audio errors.

(No.YD049)1-31

Page 32

4.11 Electrical adjustment (DV SECTION)

4.11.1 Precautions

(1) The DV section of this model is based on a special adjust-

ment method using a PC. However, ordinary adjustment is

required only when the part listed below has been replaced. In this case, the adjustment should be performed

by a service center equipped with the required facilities.

• E2 PROM (IC1504 on DV main board)

In case of trouble with the electrical circuitry, First identify

the faulty position with a measuring tool as described below. Proceed to repair, replacement and/or adjustment only

after the troubleshooting.

(2) When observing a chip TP, use an IC clip or similar tool to

protect the chip against stress. When replacing a chip part

(IC, particularly), remove solder completely before replacing. (This is to prevent separation of the pattern.)

(3) The connectors are fragile. Be careful when plugging or un-

plugging a wire.

4.11.2 Equipment required for adjustment

• Personal computer (Windows compatible)

• Color monitor

• Oscilloscope (2-CH, 100 MHz or more)

• Frequency counter

4.11.4 Setup

1. Setup for computer adjustment

- Setup by extending the jig connector -

-Setup by extending the jig connector-

Connect the Jig Connector Cable and setup the SSS software. It

automatically becomes the TCCS mode and "TCCS" is displayed on

the FDP.

To cancel the TCCS mode, press the CANCEL button of the remote

control unit.

The "TCCS" display on the FDP disappears.

Service Support Software

RS-232C Port

PC Cable

<JLIP>

JVC

MENU

Personal Computer

4.11.3 Tools required for adjustments

Alignment tape

US : MC-1

PAL : MC-2

SSS software

PTU94016-5

Guide driver

YTU94085

PC cable

US : QAM0099-002

PAL : QAM0099-005

Fig.4-11-1

Jig connector cable

PTU94018B

Jig RCU

PTU94023B

CN3701

DV M

AI

CN1503

N PW

B

CN2001

CN1501

Fig.4-11-2

1-32 (No.YD049)

Page 33

4.12 Electrical adjustment (DVD SECTION)

Note:

The following adjustment procedures are not only necessary

after replacement of consumable mechanical parts or board

assemblies, but are also provided as references to be referred

to when servicing the electrical circuitry.

In case of trouble with the electrical circuitry, always begin a

service by identifying the defective points by using the measuring instruments as described in the following electrical adjustment procedures. After this, proceed to the repair,

replacement and/or adjustment. If the required measuring instruments are not available in the field, do not change the adjustment parts (variable resistor, etc.) carelessly.

4.12.1 DVD Video circuit

Note

• When perform these adjustments, set the unit to DVD

mode.(DVD lamp lights up)

4.12.1.1 EE Composite Y level

Signal (A) • Internal colour bar

Mode (B) • EE

Equipment (C) • Oscilloscope

Measuring point (D) • L-1 connector pin19

EVR mode

EVR address

Specified value (G) • 1.00 ± 0.02 Vp-p (terminated)

Adjustment tool (H) • Jig RCU [PTU94023B]

(F1)

• Jig code “43-95”

(F2)

• "ADJUST01 : **"

(F3)

• Jig code “43-21”

(F4)

• Jig code “43-18” or “43-19” (Channel +/-)

(F5)

• Jig code “43-3C”

(1) Observe the V OUT waveform at the measuring point (D).

(2) Set the VCR to the EVR mode by transmitting the code (F1)

from the Jig RCU.

(3) Set the EVR address to (F2) by transmitting the code (F3)

from the Jig RCU.

(4) Transmit the code (F4) from the Jig RCU to adjust so that

the Y level of the V OUT waveform becomes the specified

value (G).

(5) Release the EVR mode of the VCR by transmitting the

code (F5) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

Specified

value (G)

H. rate

Fig.4-12-1 EE composite Y level

4.12.1.2 EE Y level

Signal (A1)

Mode (B) • EE

Equipment (C) • Oscilloscope

Measuring point (D) • L-1 connector pin19

EVR mode

EVR address

Specified value (G) • 1.00 ± 0.02 Vp-p (terminated)

Adjustment tool (H) • Jig RCU [PTU94023B]

• Ext. input

(A2)

• Color (colour) bar signal

• Jig code “43-95”

(F1)

• "ADJUST02 : **"

(F2)

• Jig code “43-22”

(F3)

• Jig code “43-18” or “43-19” (Channel +/-)

(F4)

• Jig code “43-3C”

(F5)

(1) Observe the V OUT waveform at the measuring point (D).

(2) Set the VCR to the EVR mode by transmitting the code (F1)

from the Jig RCU.

(3) Set the EVR address to (F2) by transmitting the code (F3)

from the Jig RCU.

(4) Transmit the code (F4) from the Jig RCU to adjust so that

the Y level of the V OUT waveform becomes the specified

value (G).

(5) Release the EVR mode of the VCR by transmitting the

code (F5) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

Specified

value (G)

H. rate

Fig.4-12-2 EE Y level

4.12.1.3 EE composite burst level

Signal (A) • Internal colour bar

Mode (B) • EE

Equipment (C) • Oscilloscope

Measuring point (D) • L-1 connector pin19

EVR mode

EVR address

Specified value (G) • 0.30 ± 0.01 Vp-p (terminated)

Adjustment tool (H) • Jig RCU [PTU94023B]

• Jig code “43-95”

(F1)

• "ADJUST00 : **"

(F2)

• Jig code “43-20”

(F3)

• Jig code “43-18” or “43-19” (Channel +/-)

(F4)

• Jig code “43-3C”

(F5)

(1) Observe the V OUT waveform at the measuring point (D).

(2) Set the VCR to the EVR mode by transmitting the code (F1)

from the Jig RCU.

(3) Set the EVR address to (F2) by transmitting the code (F3)

from the Jig RCU.

(4) Transmit the code (F4) from the Jig RCU to adjust so that

the burst level of the V OUT waveform becomes the specified value (G).

(5) Release the EVR mode of the VCR by transmitting the

code (F5) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

(No.YD049)1-33

Page 34

Specified

value (G)

Fig.4-12-3 EE composite burst level

4.12.1.4 EE R/G/B level

Signal (A) • Internal colour bar

Mode (B) • EE

Equipment (C) • Oscilloscope

Measuring point (D1)

EVR mode

EVR address

Specified value (G) • 0.70 ± 0.02 Vp-p (terminated)

Adjustment tool (H) • Jig RCU [PTU94023B]

• L-1 connector pin15(R)

• L-1 connector pin11(G)

(D2)

• L-1 connector pin7(B)

(D3)

• Jig code “43-95”

(F1)

• "ADJUST05 : **"

(F2)

• Jig code “43-25”

(F3)

• Jig code “43-18” or “43-19” (Channel +/-)

(F4)

• Jig code “43-3C”

(F5)

(1) Observe the R OUT waveform at the measuring point (D1).

(2) Set the VCR to the EVR mode by transmitting the code (F1)

from the Jig RCU.

(3) Set the EVR address to (F2) by transmitting the code (F3)

from the Jig RCU.

(4) Transmit the code (F4) from the Jig RCU to adjust so that

the R level of the R OUT waveform becomes the specified

value (G).

(5) Release the EVR mode of the VCR by transmitting the

code (F5) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

(6) Observe the G OUT waveform at the measuring point (D2).

(7) Repeat steps (2) to (5) above.

(8) Observe the B OUT waveform at the measuring point (D3).

(9) Repeat steps (2) to (5) above.

Fig.4-12-4 EE R/G/B level

4.12.1.5 EE COMPONENT PB/CB level

Signal (A) • Internal colour bar

Mode (B) • EE

Equipment (C) • Oscilloscope

Measuring point (D) • COMPONENT PB/CB terminal

EVR mode

EVR address

Specified value (G) • 0.70 ± 0.02 Vp-p (terminated)

Adjustment tool (H) • Jig RCU [PTU94023B]

• Jig code “43-95”

(F1)

• "ADJUST06 : **"

(F2)

• Jig code “43-26”

(F3)

• Jig code “43-18” or “43-19” (Channel +/-)

(F4)

(F5)

• Jig code “43-3C”

(1) Observe the CB OUT waveform at the measuring point (D).

(2) Set the VCR to the EVR mode by transmitting the code (F1)

from the Jig RCU.

(3) Set the EVR address to (F2) by transmitting the code (F3)

from the Jig RCU.

(4) Transmit the code (F4) from the Jig RCU to adjust so that

the CB level of the CB OUT waveform becomes the specified value (G).

(5) Release the EVR mode of the VCR by transmitting the

code (F5) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

PB/CB level

Fig.4-12-5 EE component PB/CB level

4.12.2 Syscon circuit

4.12.2.1 Timer clock

Signal (A) • No signal

Mode (B) • EE

Equipment (C) • Frequency counter

Measuring point (D1)

Adjustment part (F) • C3025 (TIMER CLOCK)

Specified value (G) • 1024.008 ± 0.01 Hz

• IC3001 pin 61

• IC3001 pin 17

(D2)

• C3026 + and -

(D3)

(976.5549 ± 0.0010 usec)

(1) Connect the frequency counter to the measuring point

(D1).

(2) Connect the short wire between the short point (D2) and

Vcc (5V).

(3) Short the leads of capacitor (D3) once in order to reset

the microprocessor of the Syscon.

(4) Disconnect the short wire between the short point (D2)

and Vcc then connect it again.

(5) Adjust the Adjustment part (F) so that the output frequency

becomes the specified value (G).

1-34 (No.YD049)

Page 35

SECTION 5

TROUBLESHOOTING

5.1 Manually removing the cassette tape

If a loaded cassette tape cannot be ejected due to a failure in the

electrical circuitry, take the cassette tape out using the following

procedure. However, this method consists of a forced driving of

the loading motor. Therefore, the following description assumes

that there is no trouble in the mechanism operations.

(1) Unplug the power plug from the power outlet, then remove

the top cover.

(2) Apply 3 V DC to the electrodes (Red wire: + pole. Brown

wire: - pole) on the upper part of the loading motor to perform the unloading operation so that the pole base assemblies are returned on the inner side of the tape. At this time,

the exit guide arm assembly should return toward the drum

assembly and the mechanism should enter the C-IN mode.

As the tape is left without winding, be careful not to damage

the tape or leave grease on it.

–

DC 3 V

+

Motor bracket assembly (Loading motor)

(3) If the tape is slack, wind it up by turning the shaft on the top-

side of the capstan motor in the direction of the arrow using

a pointed tool (chip IC replacement jig).This operation may

be difficult because the shaft is located below the housing

motor of the cassette housing assembly. Be careful not to

damage parts during it.

(4) After confirming that the tape is fully wound up, take out the

cassette tape by turning the gear of the cassette housing

assembly in the direction of the arrow.

Note :

• After ejecting the tape, check that grease or similar foreign

material is not attached to the wound tape. Also perform similar checking for the mechanism assembly, particularly the

tape transport system.

Wire (Brown)

Wire (Red)

Pole base assembly (Supply)

Rotary encoder assembly

[3] Tape winding [4] Tape ejection

[A]

Capstan motor Cassette housing assembly, side view

Exit guide arm assembly

Cassette housing motor

[A]

Pole base assembly (Take up)

[B]

Cassette housing assembly

[B]

Chip IC replacement jig

Shaft

Capstan motor

Gear

Ejection direction

Fig.5-1a

(No.YD049)1-35

Page 36

5.2 Manually removing the disk(DVD/CD)

If you cannot remove the disk which is loaded because of any

electrical or mechanical failures, manually remove it by taking the

following steps.

5.2.1 Method 1

(1) AC Plug is pulled out at once and inserted again.

(2) It is displayed on FDP as "LOADING", and while it blinks,

pushing the OPEN/CLOSE button is continued.

(3) After a while, a tray opens (About 20 seconds).

(4) After removed a disk, press the OPEN/CLOSE button

again to close the tray.

(5) The "LOADING" blink display of FDP disappears and it will

be in a standby mode.

(6) If the POWER button is pushed, it will usually be operating.

5.2.2 Method 2

(1) Unplug the ACpower cord from the AC outlet.

(2) Remove the top cover and front panel assembly.

(Refer to the disassembly procedure and perform the dis-

assembly of the major parts before removing)

(3) Pass a thin wire through a hole in the DVD unit.