Page 1

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

MX-GT90

Area Suffix

US

UW

UY

Brazil,Mexico,Peru

MX-GT90

Singapore

Argentina

SP-MXGT90

(No MIC jack and MIC LEVEL volume for UY ver.)

Contents

Safety precautions

Important for laser products

Preventing static electricity

Disassembly method

Adjustment method

STANDBY/ON

STANDBY

CD-R/RW PLAYBACK

CA-MXGT90

1-2

1-3

1-4

1-5

1-25

PLAY & EXCHANGE

MX-GT90

SP-MXGT90

Flow of functional operation

until TOC read

Maintenance of laser pickup

Replacement of laser pickup

Description of major ICs

1-29

1-30

1-30

1-31~50

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

No.20996

Jun. 2001

Page 2

MX-GT90

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitr y of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer's warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage current check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and measure the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs m ust be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local v oltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen pr inted side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

When replacing them, be sure to use the parts of the same type and rating as specified by the manufacturer.

(Except the JC version)

1-2

Page 3

Important for laser products

MX-GT90

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible laser

radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

VARNING : Osynlig laserstrålning är denna del är öppnad

och spårren är urkopplad. Betrakta ej strålen.

VARO : Avattaessa ja suojalukitus ohitettaessa olet

alttiina näkymättömälle lasersäteilylle.Älä katso

säteeseen.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

ADVARSEL : Usynlig laserstråling ved åbning , når

sikkerhedsafbrydere er ude af funktion. Undgå

udsættelse for stråling.

ADVARSEL : Usynlig laserstråling ved åpning,når

sikkerhetsbryteren er avslott. unngå utsettelse

for stråling.

POSITION OF LABELS

CLASS 1

LASER PRODUCT

WARNING LABEL

DANGER : Invisibie laser radiation

when open and interlock or

defeated.

AVOID DIRECT EXPOSURE TO

BEAM (e)

VARO : Avattaessa ja suojalukitus

ohitettaessa olet alttiina

näkymättömälle lasersäteilylle.Älä

katso säteeseen. (d)

VARNING : Osynlig laserstrålning

är denna del är öppnad och spårren

är

urkopplad. Betrakta ej strålen.

(s)

ADVARSEL :Usynlig laserstråling

ved åbning , når

sikkerhedsafbrydere er ude af

funktion. Undgå udsættelse for

stråling. (f)

1-3

Page 4

MX-GT90

Preventing static electricity

1. Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2. About the earth processing for the destruction prevention by static electricity

In the equipment which uses optical pick-up (laser diode), optical pick-up is destroyed by the static electricity of

the work environment.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

4. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for pick-up and how to

detach the CD traverse mechanism.

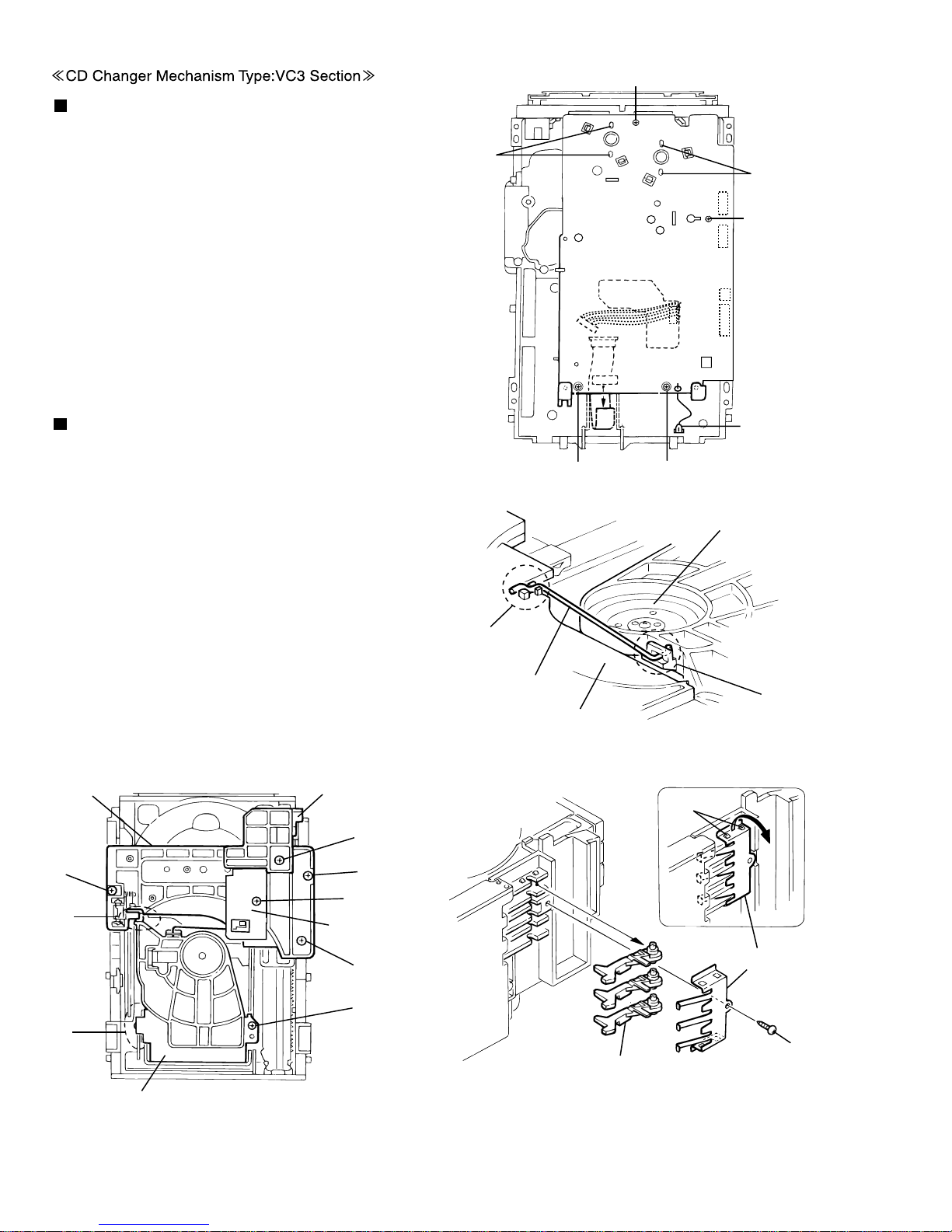

1. Remove the disk stopper and T. bracket on the CD changer mechanism

assembly.

2. Disconnect the harness from connector on the CD motor board.

3. CD traverse unit is put up as shown in Fig.1.

4. Solder is put up before the card wire is removed from connector CN601

on the CD servo control board as shown in Fig. 2.

(When the wire is removed without putting up solder, the CD pick-up

assembly might destroy.)

5. Please remove solder after connecting the card wire with CN601 when

you install picking up in the substrate.

CD changer

mechanism

assembly

CD traverse

unit

Flexible cable

Fig.1

Soldering

Fig.2

1-4

Page 5

MX-GT90

Disassembly method

<Main body>

Removing the metal cover

(See Fig.1 to 3)

1.

Remove the six screws A on the back of the body.

2.

Remove the two screws B on both sides of the

body.

3.

Remove the metal cover from the body by lifting the

rear part of the cover.

CAUTION:

Do not break the front panel tab fitted to

the metal cover.

A

A

Metal cover

Metal cover

A

Fig.1

B

Fig.2

Metal cover

B

Fig.3

1-5

Page 6

MX-GT90

Removing the CD changer mechanism

assembly (See Fig.4 to 6)

Prior to performing the following procedure, remove

the metal cover.

1.

Disconnect the card wire from connector CN561 on

the main board.

2.

Remove the two screws C on the upper side of the

body and the two screws D on the back of the rear

panel.

3.

Remove the plastic rivet attaching the main board.

4.

Remove the fan connector CN705.

5.

Pull both the rear panel and the front panel assembly

to the outside, then remove the CD changer

mechanism assembly by lifting the rear part of the

assembly. it is assembly to remove the fan's card

wire.

Front panel assembly

C

Main board

CN561

Fig.4

CD changer mechanism assembly

Main board

CN561

C

CD changer

mechanism assembly

Rear panel

Rear panel

CAUTION:

To prevent damage to the CD fitting, be

sure to pull both the rear panel and the

front panel assembly enough to remove

the CD changer mechanism assembly.

D

Plastic rivet

Front panel assembly

Fig.5

1-6

Page 7

MX-GT90

Removing the front panel assembly

(See Fig.6 to 10)

Prior to performing the following procedure, remove

the metal cover and CD changer mechanism

assembly.

1.

Disconnect the card wires from connector CN870,

CN871 and CN315 on the main board respectively.

2.

Remove the tie band and disconnect the wire from

connector CN703 on the amplifier board.

3.

Disconnect the wire from connector CN220 on the

transformer board.

4.

Remove the four screws E on the bottom of the

body.

5.

Release the two joints a on the lower right and left

sides of the body using a screwdriver, and remove

the front panel assembly toward the front.

Amplifier board

CN703

CN705

Transformer board

CN220

Tie band

Fig.6

Main board

CN870

CN871

CN315

Front panel

assembly

Front panel assembly

Fig.9

Joint a

Front panel assembly

Front panel assembly

Fig.7

Main board

E

(Bottom)

Fig.8

Joint a

Front panel assembly

Fig.10

1-7

Page 8

MX-GT90

Removing the tuner board

(See Fig.11 and 12)

Prior to performing the following procedure, remove

the metal cover and the CD changer mechanism

assembly.

1.

Disconnect the card wire from connector CN1 on the

tuner board on the right side of the body.

2.

Remove the plastic rivet fixing the tuner board.

3.

Remove the two screws F on the back of the body.

Removing the rear cover / rear panel

(See Fig.12 to 15)

Prior to performing the following procedure, remove

the metal cover and the CD changer mechanism

assembly.

F

Joint b

CN1

Plastic rivet

Fig.11

G

Tuner board

Rear panel

Rear panel

Joint b

1.

Remove the screw G attaching the rear cover on the

back of the body.

2.

Push each tab of the four joints b in the direction of

the arrow and release.

3.

Remove the ten screws H and two screws H' (US,

UW only) attaching the rear panel.

4.

Release the joints c on each lower side of the rear

panel using a screwdriver and remove the rear panel

backward.

Note : Remove the tuner board in case of necessity.

(Refer to Fig.22)

F

H

H

Rear cover

Fig.12

Rear panel

(US,UW only)

H'

H

Joint c

1-8

Rear panel

Fig.15

Rear panel

Fig.14

Joint c

Page 9

MX-GT90

Removing the main board

(See Fig.16 and 17)

Prior to performing the following procedure, remove

the metal cover, the CD changer mechanism

assembly, the rear panel and the tuner board.

1.

Disconnect the card wires from connector CN870,

CN871 and CN315 on the main board.

2.

Disconnect the flat wires from connector CN704 and

CN706 on the amplifier board.

3.

Remove the screw I attaching the main board on the

right side of the body.

4.

Disconnect connector CN211 and CN212 on the

main board from the regulator board.

CN871

CN315

Amplifier board

CN704,CN706

Front panel assembly

Main board

CN870

Fig.16

Plastic rivet

Front panel assembly

Main board

Removing the speaker terminal board

(See Fig.18)

Prior to performing the following procedure, remove

the metal cover, the CD changer mechanism

assembly and the rear panel.

REFERENCE:

1.

Disconnect connector CN217 on the speaker

terminal board from the regulator board.

It is not necessary to remove the main

board.

Regulator board

Regulator board

I

Fig.17

Fig.18

CN212

CN211

Speaker terminal board

CN217

1-9

Page 10

MX-GT90

Removing the voltage selector board

(See Fig. 19)

Prior to performing the following procedure, remove

the metal cover, the CD changer mechanism

assembly and the rear panel.

1.

Disconnect the wires from connector CN218, CN219

and CN250 on the voltage selector board

respectively.

2.

Remove the two tie band attaching the wire to the

voltage selector board.

3.

Disconnect connector CN213 on the voltage selector

board from the regulator board.

Removing the amplifier board / voltage

board / heat sink (See Fig.20 and 21)

Prior to performing the following procedure, remove

the metal cover, the CD changer mechanism

assembly and the rear panel.

1.

Remove the two tie band attaching the wire to the

amplifier board and the voltage board.

Voltage selector board

CN213

Amplifier board

CN704

CN706

Voltage

board

Regulator

board

Tie band

Tie band

Fig.19

CN218

CN219

Tie band

CN703

CN215

2.

Disconnect the wires from connector CN703, CN704

and CN706 on the amplifier board respectively.

3.

Disconnect connector CN215 on the amplifier board

and CN216 on the voltage board from the regulator

board (The heat sink and heat sink bracket will be

detached at once).

4.

Pull out the upper and lower heat sink brackets from

the heat sink respectively.

5.

Remove the four screws J attaching the amplifier

board to the heat sink.

6.

Remove the two screws K, the board bracket and

the voltage board.

K

J

Fig.21

Fig.20

J

Amplifier board

CN216

Heat sink

Voltage board

1-10

Page 11

MX-GT90

Removing the power transformer

assembly (See Fig.22 and 23)

Prior to performing the following procedure, remove

the metal cover, the CD changer mechanism

assembly and the rear panel.

1.

Disconnect the wires from connector CN218 and

CN219 on the voltage selector board.

2.

Remove the two tie band from the voltage s

elector

board.

3.

Disconnect the wire from connector CN204 on the

regulator board.

4.

Remove the plastic holder.

5.

Remove the four screws L attaching the transformer

assembly.

Removing the regulator board

(See Fig.23)

Voltage selector

board

Power cord

stopper

Power cord

Base chassis

Regulator board

CN204

Tie band

CN219

CN250

Fig.22

Transformer board CN220

CN218

Power transformer

assembly

L

Transformer

board

Prior to performing the following procedure, remove

metal cover, CD changer mechanism assembly, rear

panel, tuner board, main board, amplifier board,

voltage board, voltage selector board.

1.

Disconnect the wire from connector CN204 on the

regulator board.

2.

Remove the two screws M attaching the regulator

board.

Removing the power cord (See Fig.24)

Prior to performing the following procedure, remove

the metal cover, the CD changer mechanism

assembly and the rear panel.

1.

Disconnect the power cord from connector CN250

on the v

2.

Remove the tie band from the voltage s

3.

Move the power cord stopper upward and pull out it

from the base chassis.

oltage selector board.

elector board.

Plastic

holder

Regulator board

Voltage selector board

CN219

Power cord

stopper

Fig.23

CN218

M

Power transformer assembly

Power

transformer

assembly

L

Power cord

Tie band

Fig.24

CN250

1-11

Page 12

MX-GT90

<Front panel assembly>

Prior to performing the following procedure, remove

the metal cover, the CD changer mechanism

assembly and the front panel assembly.

Removing the cassette mechanism

assembly (See Fig.25)

1.

Disconnect the card wire from connector CN306 on

the head amplifier & mechanism control board.

2.

Remove the four screws M and three screws M'

attaching the cassette mechanism assembly.

Removing the display system control

board (See Fig.26 to 28)

1.

Remove the four screws O attaching the stay

bracket.

2.

Disconnect the card wires from connector CN316 and

CN880 on the display system control board.

Head amplifier

& Mechanism control board

CN306

N

N'

Cassette mechanism

assembly

N

N

N'

N'

Fig.25

O

3.

Remove the seven screws P attaching the display

system control board.

4.

If necessary, disconnect the wire from connector

CN911 on the front side of the display system control

board and unsolder FW915.

If necessary, remove the CD play board. (Fig. 29)

Removing the CD eject board

(See Fig.28 and 29)

1.

Remove the three screws Q attaching the CD eject

board.

2.

If necessary, unsolder FW915 on the CD eject

board.

CD eject board

FW915

(Soldering)

Q

Q

Display system control board

P

FW915

(Soldering)

P

CN880

P

Stay bracket

Fig.26

CN316

Display system control board

Fig.27

CD eject board

CN911

P

P

FW915

FW915

Fig.29

1-12

Display system control board

Fig.28

Page 13

MX-GT90

Removing the preset / tuning switch

board (See Fig.30 and 31)

Prior to performing the following procedure, remove

the display system control board.

1.

Pull out the preset knob on the front panel.

2.

Remove the five screws R attaching the preset /

tuning switch board.

Removing the operation switch board

(See Fig.31 and 32)

Prior to performing the following procedure, remove

the display system control board and the preset /

tuning switch board.

1.

Pull out the VOLUME knob on the front panel and

remove the nut. Pull out the SOUND MODE knob

and the SUB WOOFER level knob MIC LEVEL

volume knob(Only US, UW) toward the front.

R

PRESET knob

Preset / tuning switch board

R

Fig.30

SOUND MODE knob

SUB WOOFER

level knob

2.

Remove the twelve screws S and the screw S' (Only

US, UW) attaching the operation switch board.

3.

Release the wire clamp.

4.

Remove the screw T attaching the earth terminal

extending from the switch board.

Release each tab of the seven joints g retaining the

operation switch board.

VOLUME knob

Joint g

Joint g

S'

(US,UW only)

S

S

Joints g

Nut

MIC LEVEL

volume knob

(US,UW only)

Fig.31

S

Operation

switch board

Joint g

Wire clamp

S

Joints g

S

Fig.32

S

S

T

1-13

Page 14

MX-GT90

Removing the CD Servo control board

(See Fig.1)

1.Remove the metal cover.

2.Remove the CD changer mechanism assembly.

3.From bottom side the CD changer mechanism assembly,

remove the four screws A retaining the CD servo control

board.

4.Absorb the four soldered positions "a" of the right and

left motors with a soldering absorber.

5.Pull out the earth wire on the CD changer mechanism

assembly.

6.Disconnect the connector CN854 on the CD servo

control board.

7.Disconnect the card wire CN601 and the connector

CN801 on the CD servo control board.

A

a

a

CN854

A

CN651

CD servo control board

CN652

CN801

CN601

CN151

Removing the CD tray assembly

(See Fig.2~4)

Remove the front panel assembly.

1.

Remove the CD changer mechanism assembly.

2.

Remove the CD Servo control board.

3.

Remove the screw B' retaining the lod stopper.

4.

From the T.bracket section "b" and clamper base

5.

section "c" , remove both of the edges fixing the

rod(See Fig.2 and 3).

Remove the screw B retaining the disc stopper

6.

(See Fig.3).

Remove the three screws C retaining the T.bracket

7.

(See Fig.3).

Remove the screw D retaining the clamper assembly

8.

(See Fig.3).

From the left side face of the chassis assembly, remove

9.

the one screw E retaining both of the return spring and

lock lever(See Fig. 4).

10.

By removing the pawl at the section "d" fixing the return

spring, dismount the return spring(See Fig.4).

11.

Remove the three lock levers(See Fig.4).

T.Braket

Disc stopper

b

Rod

A

T.Braket

Fig.1

Fig.2

B

CC

A

Clamper base

d

Earth

wire

c

a

b

Clamper ass'y

1-14

Fig.3

B'

Lod stopper

(C/J version only)

C

D

Return spring

E

Lock lever

Fig.4

Page 15

MX-GT90

11.

Check whether the lifter unit stopper has been caught

into the hole at the section "e" of CD tray assembly as

shown in Fig.5.

Make sure that the driver unit elevator is positioned as

12.

shown in Fig.6 from to the second or fifth hole on the

left side face of the CD changer mechanism assembly.

[Caution]

13.

14.

15.

In case the driver unit elevator is not at above

position, set the elevator to the position as

shown in Fig.7 by manually turning the pulley

gear as shown in Fig.8.

Manually turn the motor pulley in the clockwise

direction until the lifter unit stopper is lowered from the

section "e" of CD tray assembly(See Fig.8).

Pull out all of the three stages of CD tray assembly in

the arrow direction "f" until these stages stop

(See Fig.6).

At the position where the CD tray assembly has

stopped, pull out the CD tray assembly while pressing

the two pawls "g and g' " on the back side of CD tray

assembly(See Fig.9). In this case, it is easy to pull out

the assembly when it is pulled out first from the stage

CD tray assembly.

Stopper

e

CD tray

assembly

Fig.5

Chassis assembly

Refer to Fig.7

Pawl

Fig.6

CD tray assembly

g

CD

CD

CD

f

Drive unit of elevator

Fig.7

3

2

1

CD tray assembly

Pulley gear

Motor pulley

Fig.8

Pawl ,

g

Fig.9

g'

1-15

Page 16

MX-GT90

Removing the CD loading mechanism

assembly(See Fig.10)

1.2.While turning the cams R1 and R2 assembly in the

arrow direction "h" ,align the shaft "i" of the CD loading

mechanism assembly to the position shown in Fig.10.

Remove the four screws F retaining the CD loading

mechanism assembly.

Removing the CD traverse mechanism

(See Fig.11 and 12 )

1.

For dismounting only the CD traverse mechanism

without removing the CD loading mechanism assembly,

align the shaft "j" of the CD loading mechanism

assembly to the position shown Fig.11 while turning the

cam R1 and R2 assembly in the arrow direction "k" .

By raising the CD loading mechanism assembly in the

2.

arrow direction "l", remove the assembly from the lifter

unit

Cam R1, R2 assembly

Arrow

k

Cams R1, R2 assembly

Arrow

h

i

F

F

CD loading mechanism assembly

Fig.10

F

F

CD traverse mechanism

j

Fig.11

Removing the CD pick unit

(See Fig.13 )

1.

Move the cam gear in the arrow direction "m" . Then,

the CD pickup unit will be moved in the arrow direction

"n" .

According to the above step, shift the CD pickup unit to

2.

the center position.

While pressing the stopper retaining the shaft in the

3.

arrow direction "o" , pull out the shaft in the arrow

direction "p".

After dismounting the shaft from the CD pickup unit,

4.

remove the CD pickup unit

Lifter unit

o

Stopper

Shaft

Fig.12

CD Pickup unit

n

m

Shaft

p

Stopper

Fig.13

Arrow

CD loading

mechanism

Shaft

Cam gear

l

1-16

Page 17

MX-GT90

Removing the try select switch board

(See Fig.14)

1.2.Remove the two screws G retaining the tray select

switch board.

Disconnect the tray select switch board from connector

CN804 on the CD servo control board.

Removing the cam unit

(See Fig.15 ~17 )

1.

Remove the CD loading mechanism assembly.

2.

While turning the cam gear "q", align the Paul "r"

position of the drive unit to the notch position(Fig.16) on

the cam gear "q".

Pull out the drive unit and cylinder gear(See Fig.17).

3.

While turning the cam gear "q", align the Paul "s"

4.

position of the select lever to the notch position(Fig.18)

on the cam gear "q".

Remove the four screws H retaining the cam unit(cam

5.

gear "q" and cams R1/R2 assembly)(See Fig.18).

Chassis assembly

Drive unit

CN851

CN854

Fig.14

Cam gear q

Tray select

switch board

CN804

G

Drive unit

Cylinder gear

r

Cam gear q

H

s

H

Fig.15

Cams R1, R2 assembly

Cam unit

J

Fig.16

Select lever

Fig.17

1-17

Page 18

MX-GT90

Removing the actuator motor and belt

(See Fig.18~21)

1.

Remove the two screws I retaining the gear bracket

(See Fig.18).

2.

While pressing the pawl "t" fixing the gear bracket in the

arrow direction, remove the gear bracket

(See Fig.18).

From the notch "u section" on the chassis assembly

3.

fixing the edge of gear bracket, remove and take out the

gear bracket(See Fig. 19).

Remove the belts respectively from the right and left

4.

actuator motor pulleys and pulley gears(See Fig. 18).

After turning over the chassis assembly, remove the

5.

actuator motor while spreading the four pawls "v" fixing

the right and left actuator motors in the arrow

direction(See Fig. 20).

[Note]

When the chassis assembly is turned over under

the conditions wherein the gear bracket and belt

have been removed, then the pulley gear as well

as the gear, etc. constituting the gear unit can

possibly be separated to pieces. In such a case,

assemble these parts by referring to the assembly

and configuration diagram in Fig. 21.

Chassis assembly

Pulley gear

Gear bracket

Belt

Motor pulley

I

Fig.18

Actuator motor

Pulley gear

Belt

Motor pulley

I

Pawl

t

u

Gear bracket

Fig.19

Assembly and Configuration Diagram

Pulley gear

Gear B

v

v

Fig.20

Pulley gear

Gear B

Cylinder gear

1-18

Gear C

Select gear

Gross gear L

Fig.21

Gross gear U

Gear C

Page 19

MX-GT90

Removing the cams R1/R2 assembly

and cam gear q(See Fig.22)

Remove the slit washer fixing the cams R1 and R2

1.

assembly.

By removing the two pawls "w" fixing the cam R1,

2.

separate R2 from R1.

Remove the slit washer fixing the cam gear "q".

3.

Pull out the cam gear "q" from the C.G. base assembly.

4.

Removing the C.G. base assembly

(See Fig.22 and 23)

Remove the three screws J retaining the C.G. base

assembly.

[Caution]

To reassemble the cylinder gear, etc.with the

cam unit (cam gear and cans R1/R2 assembly),

gear unit and drive unit, align the position of the

pawl "x" on the drive unit to that of the notch on

the cam gear "q". Then, make sure that the

gear unit is engaged by turning the cam gear

"q" (See Fig. 23).

Slit washer

Cam gear q

J

Slit washer

Cam R2

Pawl

w

Cam R1

Cam switch board

C.G. base assembly

Pawl

w

Notch

Pawl

x

Cylinder

gear

Drive unit

Fig.22

Cam gear q

Cam R1, R2 assembly

Gear unit

Gear bracket

Fig.23

1-19

Page 20

MX-GT90

< Cassette mechanism section >

Removing the playback,recording and eraser

heads (See Fig.1~3)

1. While shifting the trigger arms seen on the right

side of the head mount in the arrow direction,turn

the flywheel R in counterclockwise direction until

the head mount has gone out with a click

(See Fig. 1).

2. When the flywheel R is rotated in counterclockwise

direction, the playback / recording & eraser head will

be turned in counterclockwise direction from the

position in Fig.2 to that in Fig.3.

3. At this position, disconnect the flexible P.C.board

(outgoing from the playback head) from the

connector CN301 on the head amp. and mechanism

control P.C. board.

4. Remove the flexible P.C.board from the chassis

base.

5. Remove the spring "a" from behind the playback /

recording head.

6. Loosen the reversing azimuth screw retaining the

playback head.

7. Take out the playback head from the front of the

head mount.

8. The recording and eraser heads should also be

removed similarly according to Steps 1~7 above.

Flexible

P.C.board

Cassette mechanism

Trigger armHead mount

Fig.1

Playback/Recording &

eraser head

(Mechanism A side)

Flywheel R

Spring "a"

Trigger arm

Reassembling the playback, recording

and eraser heads (See Fig.3)

1. Reassemble the playback head from the front of

the head mount to the position as shown in Fig.3.

2. Fix the reversing azimuth screw.

3. Set the spring a from behind the playback head.

4. Attach the flexible P.C.board to the chassis base

as shown in Fig.3.

5. The recording and eraser heads should also be

reassembled similarly according to Steps 1~4

above.

CN301

Head amplifier & mechanism

control P.C. board

Fig.2

Playback head

Spring "a"

CN302

FPC holder

Fig.3

Flywheel R

(Mechanism A side)

Reversing azimuth

screw

Head

mount

Flexible

P.C.board

Head amplifier &

mechanism control

P.C. board

(Mechanism B side)

1-20

Page 21

Removing the head amp. and mechanism

control board (See Fig. 4)

MX-GT90

1.Remove the cassette mechanism assembly.

2.After turning over the cassette mechanism

assembly,remove the five screws "A" retaining

the head amplifier & mechanism control board.

3.Disconnect the connectors CN303 on the board

and the connectors CN301 and on CN302 both

the right and left side reel pulse boards.

4.When necessary, remove the 4pin parallel

wire soldered to the main motor

Removing the capstan motor assembly

(See Fig.5 to 7)

1.Remove the six screws "B" retaining capstan

motor assembly (See Fig. 5).

2.While raising the capstan motor, remove the

capstan belts A and B respectively from the

motor pulley (See Fig. 6).

Caution 1: Be sure to handle the capstan

belts so carefully that these belts

will not be stained by grease and

other foreign matter. Moreover,

these belts should be hand while

referring to the capstan belt

hanging method.(See Fig.6 and 7)

A

Flexible

board

Head amplifier &

mechanism control board

AA

CN303

CN302 CN301

Flexible

board

Fig.4

BB

Capstan motor

assembly

AA

Capstan

belt A

Fig.7 Fig.6

Capstan

belt B

Capstan

belt A

BBBB

Fig.5

Capstan motor

Capstan

belt B

Motor pulley

1-21

Page 22

MX-GT90

Removing the capstan motor (See Fig. 8)

From the joint bracket, remove the two screws "C"

retaining the capstan motor.

Removing the flywheel (See Fig. 9,10)

1.Remove the head amp. and mechanism control

P.C.Board.

2.Remove the capstan motor assembly.

3.After turning over the cassette mechanism, remove

the two slit washers "a" & "b" fixing the capstan shafts

R and L, and pull out the flywheels R and L respectively

from behind the cassette mechanism.

C

Capstan motor

Joint

bracket

C

Fig.8

Flywheel R Flywheel L

Flywheel R Flywheel L

Fig.10

Removing the reel pulse board and solenoid

(See Fig. 11)

1.Remove the five pawls (c,d,e,f,g) retaining

the reel pulse P.C.Board.

2.From the surface of the reel pulse P.C.Board parts,

remove the two pawls "h" and "i" retaining the solenoid.

hi

Solenoid

c

a

d

Slit

washer "a"

Fig.9

e

f

b

Slit

washer "b"

Reel pulse board

g

1-22

Solenoid

Fig.11

Page 23

Speaker section

Removing the front panel

(See Fig.1 and 2)

1.

Remove the four screws A attaching the front panel

on the front of the body.

2.

Pull out the front panel toward the front and

disconnect the wire from the two speaker terminals

of the speaker (tweeter) on the back of the front

panel.

A

MX-GT90

A

Front panel

Removing the speaker (tweeter)

(See Fig.3)

Prior to performing the following procedures, remove

the front panel.

1.

Remove the two screws B attaching the speaker

(tweeter) on the back of the front panel.

Removing the sub panel (See Fig.4)

Prior to performing the following procedures, remove

the front panel.

1.

Remove the six screws C attaching the sub panel

on the back of the front panel.

2.

Pull out the sub panel toward the front.

A

Front panel

Speaker terminals

A

Fig.1

Speaker (tweeter)

Fig.2

C

Front panel

Fig.4

C

Speaker (tweeter)

C

Sub panel

Front panel

B

Speaker (tweeter)

Fig.3

1-23

Page 24

MX-GT90

Removing the speaker (squawker)

(See Fig.5)

Prior to performing the following procedures, remove

the front panel.

1.

Remove the four screws E attaching the speaker

(squawker) on the front of the body.

2.

Disconnect the wire from the two speaker terminals

of the speaker (squawker).

Removing the speaker (woofer)

(See Fig.6 and 7)

Prior to performing the following procedures, remove

the front panel.

1.

Remove the eight screws D attaching the punch

panel on the front of the body.

Speaker (squawker)

E

E

Fig.5

2.

Remove the six screws F attaching the speaker

(woofer) on the front of the body.

3.

Remove the speaker (woofer) toward the front and

disconnect the wire from the two speaker terminals.

Removing the duct (See Fig.8)

1.

Remove the four screws G attaching the duct on the

upper side of the body.

2.

Move the duct upwards and pull out backward.

Caution :

When servicing SP-MXGT90 speaker system, never

push or pull the speaker system on the table or floor.

It will damage the leg cushions attached on the

bottom of speaker system.

Leg cushion is important to prevent vibration and

protect speaker system not to slip down from the

shelf or table.

Duct

G

Front panel

G

D

Speaker (squawker)

D

Punch panel

Fig.6

Speaker (woofer)

F

F

Fig.8

1-24

Fig.7

Page 25

Adjustment method

Measurement instruments required

for adjustment

1. Low frequency oscillator,

This oscillator should have a capacity to output 0dBs

to 600ohm at an oscillation frequency of 50Hz-20kHz.

2. Attenuator impedance : 600ohm

3. Electronic voltmeter

4. Frequency counter

5. Wow flutter meter

6. Test tape

VTT712 : For Tape speed and wow flutter ( 3kHz)

VTT724 : For Reference level (1kHz)

TMT7036 : For Head angle(10kHz),Play back frequency

characteristics(1kHz),and dubbing frequency

characteristics(63,1,10kHz)

Because of frequency-mixed tape with 63,1k,10k and

14kHz(250nWb/m -24dB).

Use this tape together with a filter.

7. Blank tape

TAPE : AC-225,

8. Torque gauge : For play and back tension

Forward ; TW2111A, Reverse ; TW2121A

Fast Forward and Rewind ; TW2231A

9. Test disc

: CTS-1000(12cm),GRG-1211(8cm)

10. Jitter meter

Measurement conditions

Power supply voltage

AC220V(50Hz) : UY model

AC110/127/230-240V(50Hz) : US,UW model

Measurement

output terminal : Speaker out

:TP101(Mesuring for TUNER/DECK/CD)

:Dummy load 6ohm

MX-GT90

Radio input signal

AM modulation frequency : 400Hz

Modulation factor : 30%

FM modulation frequency : 400Hz

Frequency displacement : 22.5kHz

Frequency Range

AM 531kHz~1710kHz

FM 87.5MHz~108MHz

Standard measurement positions of volume

and switch

Power : Standby (Light STANDBY Indicator)

Sub woofer VOL. : Minimum

Sound mode : OFF

Main VOL. : 0 Minimum

Traverse mecha set position : Disc 1

Mic MIX VOL : MAX (Only US,UW)

ECHO : OFF

Precautions for measurement

1. Apply 30pF and 33kohm to the IF sweeper output

side and 0.082 F and 100kohm in series to

the sweeper input side.

2. The IF sweeper output level should be made as

low as possible within the adjustable range.

3. Since the IF sweeper is a fixed device, there is

no need to adjust this sweeper.

4. Since a ceramic oscillator is used, there is no need

to perform any MPX adjustment.

5. Since a fixed coil is used, there is no need to adjust

the FM tracking.

6. The input and output earth systems are separated.

In case of simultaneously measuring the voltage

in both of the input and output systems with an

electronic voltmeter for two channels, therefore,

the earth should be connected particularly.

7. In the case of BTL connection amplifier, the minus

terminal of speaker is not for earthing. Therefore,

be sure not to connect any other earth terminal

to this terminal. This system is of an OTL system.

1-25

Page 26

MX-GT90

Arrangement of adjusting positions

Cassette mechanism section (Mechanism A section)

Head azimuth

adjusting screw

(Forward side)

Playback

head

Head azimuth

adjusting screw

(Reverse side)

Cassette mechanism section (Back side)

Head azimuth

adjusting screw

(Forward side)

Playback, recording and eraser

heads or playback head

Head azimuth

adjusting screw

(Reverse side)

Cassette Mechanism Unit Section

Tape speed ADJ

Bias ADJ L

Bias ADJ R

1-26

Page 27

Tape recorder section

MX-GT90

Items Measurement

conditions

Confirmation

of head angle

Test tape

:TMT7036(10kHz)

Measurement

output terminal

:Speaker terminal

Speaker R

(Load resistor:6 )

:Headphone terminal

1.Playback the test tape TMT7036(10kHz).

2.With the playback mechanism or recording &

playback mechanism, adjust the head azimuth

screw so that the forward and reverse output

levels become maximum.After adjustment,lock

the head azimuth at least by half a turn.

3.In either case,this adjustment should be

performed in both the forward and reverse

directions with the head azimuth screw.

Confirmation

of tape speed

Test tape

:VTT712(3kHz) or

TMT7036(3kHz)

Measurement

output terminal

:Headphone terminal

<Constant speed>

Adjust VR301 so that the frequency counter reading

becomes 3,000Hz 60Hz when playing back the

test tape VTT712(3kHz)with the playback mechanism

or playback and recording mechanism after ending

forward winding of the tape.

Reference values for confirmation items

Items Measurement

Double tape

speed

conditions

Test tape

:TMT7036(10kHz)

Measurement

output terminal

:Speaker terminal

Speaker R

(Load resistance:6 )

measurement

output terminal

:Headphone terminal

After setting to the double speed motor, confirm

that the frequency counter reading becomes

4,800+400/-300Hz when the test tape VTT712

(3kHz) has been play back with the playback

mechanism.

Measurement method

Measurement method

Standard

values

Maximum

output

Tape speed

of decks

(A and B)

:3,000Hz

60Hz

Standard

values

4,800+400/

-300Hz

Adjusting

positions

Adjust the head

azimuth screw

only when the

head has been

changed.

VR301

Adjusting

positions

Playback

mechanism side

Difference

between the

forward and

reverse speed.

P.mecha and

R/P mecha

speed

Wow & flutter

Test tape

:TMT7036(10kHz)

Measurement

output terminal

:Headphone terminal

When the test tape VTT712(3kHz) has been played

back with the playback mechanism or recording and

playback mechanism at the beginning of forward

winding, the frequency counter reading of the

difference between both of the mechanisms should

be 6.0Hz or less.

When the test tape VTT712(3kHz) has been played

back with the playback mechanism or recording and

playback mechanism at the beginning of forward

winding the frequency counter reading of wow &

flutter should be 0.25% or less(WRMS).

60Hz or

less

with in

0.25%

JIS(WTD)

Both the playback

and recording &

playback

mechanism

Both the playback

and recording &

playback

mechanism

1-27

Page 28

MX-GT90

Electrical performance

Items Measurement

Adjustment of

recording bias

current

(Reference

value)

conditions

*Mode : Forward or

reverse mode

*Recording mode

*Test tape

: AC-225

Measurement output

terminal

:Both recording and

headphone terminals

Measurement method

1.With the recording and playback mechanism,

load the test tapes(AC-225 to TYP ),and set the

mechanism to the recording and

pausing conditions in advance.

2.After connecting 100 in series to the recorder

head,measure the bias current with a valve

voltmeter at both of the terminals.

3.After resetting the [PAUSE] mode,start recording.

At this time,adjust VR101 for LcH and VR201 for

RcH so that the recording bias current values

become 4.0 A (TYP ).

Standard

values

AC-225

:4.20 A

Adjusting

positions

LcH

:VR101

RcH

:VR201

Adjustment of

recording and

playback

frequency

characteristics

Reference frequency

:1kHz and 10kHz

(REF:-20dB)

Test tape

:TYP AC-225

Measurement input

terminal

:OSC IN

1.With the recording and playback mechanism,load

the test tape(AC-225 to TYP ),and set the

mechanism to the recording and pausing condition

in advance.

2.While repetitively inputting the reference frequency

signal of 1kHz and 10kHz from OSC IN, record and

playback the test tape.

3.While recording and playing back the test tape in

TYP ,adjust VR101 for LcH and VR201 for RcH

so that the output deviation between 1kHz and

10kHz becomes -1dB 2dB.

Reference values for electrical function confirmation items

Items Measurement

Recording

bias frequency

conditions

*Recording and

playback side forward

or reverse

*Test tape

:TYP AC-225

*Measurement

terminal BIAS TP on

P.C.board

1.While changing over to and from BIAS 1 and 2,

confirm that the frequency is changed.

2.With the recording and playback mechanism.

load the test tape (AC-225 to TYP ),and set the

mechanism to the recording and pausing

conditions in advance.

3.Confirm that the BIAS TP frequency on the

P.C.board is 100kHz 6kHz.

Measurement method

Output

deviation

between

1kHz and

10kH

:-1dB 2dB

Standard

values

100kHz

+9kHz

-7kHz

LcH

:VR101

RcH

:VR201

Adjusting

positions

Eraser current

(Reference

value)

*Recording and

playback side forward

or reverse

*Recording mode

*Test tape

:AC-225

Measurement terminal

Both of the eraser

head

1.With the recording and playback mechanism,

load the test tapes(AC-225 to TYP ),and set the

mechanism to the recording and pausing condition

in advance.

2.After setting to the recording conditions,connect

1M in series to the eraser head on the recording

and playback mechanism side,and measure the

eraser current from both of the eraser terminal.

1-28

TYP

:75mA

Page 29

Flow of functional operation until TOC read

Power ON

Play Key

Slider turns REST

SW ON.

Automatic tuning

of TE offset

Confirm that the voltage at the pin5

of CN801 is "H"\"L"\"H".

MX-GT90

Check Point

Tracking error waveform at TOC reading

Approx.3sec

Tracking

servo

off states

Automatic measurement

of TE amplitude and

automatic tuning of

TE balance

VREF

pin 25 of

IC601(TE)

Approx

1.8V

Disc states

to rotate

Tracking

servo

on states

Disc to be

braked to stop

TOC reading

finishes

500mv/div

2ms/div

Fig.1

Laser ON

Detection of disc

Automatic tuning of

Focus offset

Automatic measurement of

Focus S-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Tracking error balance

Check that the voltage at the

pin40 of IC651 is + 5V?

Confirm that the Focus error

S-cuve signal at the pin28 of

IC651 is approx.2Vp-p

Confirm that the signal from

pin24 IC651 is 0V as a

accelerated pulse during

approx.400ms.

Confirm the waveform of

the Tracking error signal.

at the pin 25 of IC601 (R604)

(See fig-1)

Automatic tuning of

Focus error balance

Automatic tuning of

Focus error gain

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the eys-pattern

at the lead of TP1

1-29

Page 30

MX-GT90

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode

When the life of the laser diode has expired,

the following symptoms will appear.

1. The level of RF output (EFM output : ampli

tude of eye pattern) will below.

Is the level of

RFOUT under

1.25V 0.22Vp-p?

YES

O.K

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and, disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in, and turn the power on.

At this time, check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at TP1.

Finish.

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board which is attached to the pickup is used to adjust the laser

power. Since this adjustment should be performed to match the characteristics of the whole optical block, do not

touch the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup should

be replaced.

If the semi-fixed resistor is adjusted while the pickup is functioning normally, the laser pickup may be damaged

due to excessive current.

1-30

Page 31

Description of major ICs

AN7345(IC302) : PB/REC amp.

1. Block diagram

MX-GT90

L1

24

1

R1

2. Pin Function

Pin

Symbol

No.

1

R1

2

R2

L2

NF1

OUT1

22

23

Pre

AMP

Pre

AMP

2

3

R2

I/O

I

Playback amplifier input

Playback amplifier input

I

NF2

OUT2

4

EQ1

2021

EQ

CTRL

5

EQ2

Function

CTL1

Pre

Source

CTRL

6

CTL2

RIN1

RNF1

1819

17

78

RIN2

RNF2

ROUT1

ALC

AMP

ALC

AMP

ROUT2

Pin

No.

13

14

9

Vcc

RF

EQ

CTL

10 11

LC

Symbol

141516

ALC

LPF GND

RF

REPPLE

REJ

I/O

I

I

Ripple filter

VCC

13

12

Function

Power supply

3

NF2

4

OUT2 Playback amplifier output

EQ2 I

5

CTL2 I Pre Amplifier input switching time

6

RIN2 I

7

RNF2 I Recording amplifier negative feedback

8

ROUT2

9

LC I

10

11

LPF

GND I

12

I

Playback amplifier negative feedback

O

Equalizer

constant

Recording amplifier input

Recording amplifier output

O

ALC low cut

ALC low pass filter

I

EQCTL EQ control

15

16

ROUT1

17

RNF1 Recording amplifier negative feedback

RIN1

18

CTL1

19

20

EQ1 Equalizer

21

OUT1

NF1

22

L2 I

23

24

L1

I

O

Recording amplifier output

I

I Recording amplifier input

Pre amplifier input switching control

I

I

Playback amplifier output

O

Playback amplifier negative feedback

I

Playback amplifier input

Playback amplifier input

I

1-31

Page 32

MX-GT90

BA15218F-XE (IC652) / BA15218N (IC481,501,502,526,571) : Dual op. amp.

1. Pin layout

OUT1 1

-IN1 2

+IN1 3

VEE 4

2. Block diagram

Vcc

-IN

+IN

1

2

R1

Q5

Q1

Q2

D1

Q3 Q4

8 Vcc

7 OUT2

6 -IN2

5 +IN2

C2

Q9

R5

Q6

Q8

Q10

Q7

R7

Q11

R6

Q12

R8

Q18Q13

OTHER

CH

Q19

Q17Q16

VEE

C1

R3R2

R4

OUTPUT

Q14 Q15Q114

R9

1-32

Page 33

BA3126N(IC301) : R/P switch

MX-GT90

S W

R E C

G

123456789

P / B

S W

C O N T .

G N D

V c c

P / B

S W

G

BU4094B(IC303):Serial to parallel port extension

1.Pin layout

STROBE

DATA

CLOCK

Q1

Q2

Q3

Q4

Vss

1

2

3

4

5

6

7

8

16

Vdd

15

OUTPUT ENABLE

14

Q5

13

Q6

12

Q7

11

Q8

10

Q's

9

Qs

CLOCK

STROBE

2.Block diagram

DATA

2

3

1

S W

R E C

8-STAGE

SHIFT REGISTER

8-BIT

LATHES

10

9

Q's

Qs

SERIAL

OUTPUT

OUTPUT

ENABLE

KIA7019AP (IC830) : Voltage detector

1. Pin layout

1 2 3

15

Q1

2. Pin function

Pin No.

1

2

3

3-STATE

OUTPUTS

Q8

PARALLEL OUTPUT

Function

Vcc

Ground

OUT

1-33

Page 34

MX-GT90

LB1641 (IC851,IC852) : DC motor driver

1. Pin layout

1 2 3 4 5 6 7 8 9

GNDOUT1 P1

VZ IN1 IN2

VCC1

VCC2 P2

2. Pin function

Input Output

IN1 IN2 OUT1 OUT2

0 0 0 0

1 0 1 0

0 1 0 1

1 1 0 0

NJM4580L (IC901) : Mic amplifier

10

OUT2

Mode

Brake

CLOCKWISE

COUNTER-CLOCKWISE

Brake

1. A OUTPUT

2. A-INPUT

3. A+INPUT

-

4. V

5. B+INPUT

6. B-INPUT

1

2

34

5

6

7

8

7. B OUTPUT

1-34

Page 35

BA3835S (IC812) : SPI B.P.F.

1.Block Diagrams

MX-GT90

BIASC

VREFC

RREF

DIFOUT

N.C.

N.C.

CIN

AIN

VCC

1

2

3

4

5

6

7

8

9

2.Pin Function

No. Symbol

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

BIASC

VREFC

RPEF

NC

NC

NC

CIN

AIN

VCC

SPI-A

SPI-B

SPI-C

SPICSB

NC

NC

TEST

AOUT

GND

A-C

DIF

105Hz

BPF

340Hz

BPF

1kHz

BPF

3.4kHz

BPF

10.5kHz

BPF

REFERENCE

CURRENT

PEAK

HOLD

PEAK

HOLD

PEAK

HOLD

PEAK

HOLD

PEAK

HOLD

I/O

-

-

-

-

-

-

I

O

O

O

O

-

-

O

-

BIAS

VREF

RES

RES

MPX

RES

RES

RES

DEC

18

17

16

15

14

13

12

11

10

GND

AOUT

TEST

N.C.

N.C.

SEL

C

B

A

Function

Decoupling condenser connection terminal.

Decoupling condenser connection terminal.

Reference resistance connection terminal.

Non connect.

Non connect.

Non connect.

Connected to GND of audio system through a condenser.

Inputs the audio signal through a condenser.

Power supply terminal.

Output selection control terminal.

Output selection control terminal.

Output selection control terminal.

Output selection control terminal.

Non connect.

Non connect.

Connected to GND upon normal use.

Multi-plexor output terminal.

Connect to GND.

1-35

Page 36

MX-GT90

BA3837(IC466):MIC mixer

1.Block diagram

C

16

B

15

14

A

ROUT

13

LP

12

LP

11

LP

10

RIN

9

1

VCC

2.Pin function

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

LOGIC

+

-

2

MIC

Symbol

VCC

MIC IN

LOUT

FK

TK

LIN

BIAS

GND

RIN

LPF1

LPF2

LPF3

ROUT

CONTA

CONTB

CONTC

-

+

3

LOUT

+

-

SW2 SW1

4

FK

I/O

Power supply

Microphone mixing input

I

O

O

O

O

O

Channel L output

Non connect

Non connect

Channel L input

I

Signal bias

I

Connect to GND

Channel R input

I

Connects to LPF time constant element

Connects to LPF time constant element

LPF outpout

Channel R output

Mode select input A

I

Mode select input B

I

Mode select input C

I

5

TK

-

+

R

L+R

-

+

L-R

L

+

-

6

LIN

Description

7

BIAS

-

+

+

8

GND

1-36

Page 37

BU9253AS(IC902) : LPF&ECHO MIX.

1.Pin layout & block diagram

1

GND

ECHO VR

BIAS

DAINT IN

2

3

4

5

OSC

COUNTER

18

17

16

15

14

MX-GT90

CR

MUTE

VCC

ADINT IN

DAINT OUT

DALPF IN

DALPF OUT

MIX OUT

2.Pin function

Pin No. Symbol

1

2

ECHO VR

3

4

5

6

7

8

9

DAINT IN

DAINT OUT

DALPF IN

DALPF OUT

MIX OUT

10

11

12

13

14

ADLPF IN

ADLPF OUT

ADINT OUT

ADINT IN

15

16

17

18

6

7

- +

8

9

GND

BIAS

MIX IN

VCC

NC2

MUTE

CR

D/A

MIX

SRAM

I/O

I

-

I

O

I

O

O

I

I

O

O

I

-

-

I

-

A/D

13

ADINT OUT

12

ADLPF OUT

- +

11

ADLPF IN

10

MIX IN

Descriptions

Connect GND

Echo level control

Non connect

Analog part DC bias

DA side integrator input

DA side integrator output

DA side LPF input

DAside LPF output

Mix AMP output for original tone& echo tone

Mix AMP input pin for original tone

AD side LPF input

AD side LPF output

AD side integrator output

AD side integrator input

Power supply

Non connect

Mute control signal input

CR pin for oscillator

1-37

Page 38

MX-GT90

LA1838(IC1): FM AM IF AMP&detector, FM MPX decoder

1. Block Diagram

30

ALC

BUFF

FM

S-METER

FM IF

1

2. Pin Function

Pin

Symbol

No.

FM IN

1

AM MIX

2

3

FM IF

AM IF

4

GND

5

6

TUNED

STEREO

7

8

VCC

9

FM DET

10

AM SD

FM VSM

11

AM VSM

12

13

MUTE

14

FM/AM

MONO/ST O

15

29

28

AM

OSC

SD

COMP

S-CLRVE

PM

DET

2

I/O

I

This is an input terminal of FM IF

REG

AM

MIX

AM/FM

IF-BUFF

3

27

FM

RF.AMP

AM IF

4

26

AGC

AM

S-METER

GND

Function

DET

TUNING

DRIVE

5

signal.

This is an out put terminal for AM

O

mixer.

I

Bypass of FM IF

Input of AM IF Signal.

I

I

This is the device ground terminal.

When the set is tuning, this terminal

O

becomes "L".

O

Stereo indicator output. Stereo "L",

Mono: "H"

III

This is the power supply terminal.

I

FM detect transformer.

I

This is a terminal of AM ceramic filter.

O

Adjust FM SD sensitivity.

O

Adjust AM SD sensitivity.

I/O

When the signal of IF REQ of IC121(

LC72131) appear, the signal of FM/AM

IF output. //Muting control input.

Change over the FM/AM input.

I

"H" :FM, "L" : AM

Stereo : "H", Mono: "L"

25

21

DECODER

ANIT-BIRDIE

STEREO

5N

SW

10

I/O

O

O

I

20

FF

38k

11

Left channel signal output.

Right channel signal output.

Input terminal of the left channel post

24

STEREO

DRIVE

6

7

22

23

P-DET

VCC

89

Pin

Symbol

No.

16

L OUT

17

R OUT

18

L IN

VCO

384KHz

18

19

MUTE

FF

/

19k

2

12 13

FF

19k

/

LS

Function

17 16

PILOT

DET

15

14

AMP.

Input terminal of the right channel

19

R IN

I

post AMP.

Mpx Right channel signal output.

20

24

21

22

23

25

RO

LO

IF IN

FM OUT

AM DET

AM AGC

O

O

Mpx Left channel signal output.

I

Mpx input terminal

FM detection output.

O

AM detection output.

O

This is an AGC voltage input terminal

I

for AM

I

26

AFC

This is an output terminal of voltage

for FM-AFC.

27

28

AM RF

REG

AM RF signal input.

I

Register value between pin 26 and pin28

O

desides the frequency width of the

input signal.

29

AM OSC

I

This is a terminal of AM Local

oscillation circuit.

30

OSC BUFFER

AM Local oscillation Signal output.

O

1-38

Page 39

LA6541-X (IC801) : Servo driver

1. Pin Layout & block diagram

MX-GT90

Vcc Vref Vin4 Vg4 Vo8 Vo7

24 23

11k

ohm

22

20

21

19

Vcc

Gnd

Vo6 Vo5 Vg3 Vin3 Cd Res

18

17 16

- +

- +

Level

shift

Level

shift

11k

ohm

1

2

3456

Vcc Mute Vin1 Vg1 Vo1 Vo2 Vo3 Vo4 Vg2 Vin2 Reg

B T L

driver

B T L

driver

Gnd

B T L

driver

B T L

driver

7 8 9101112

Level

shift

Level

shift

2. Pin function

Pin

Symbol Function

No.

1

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

2

3

4

5

6

7

8

9

Vcc

Mute

Vin1

Vg1

Vo1

Vo2

Vo3

Vo4

Vg2

Vin2

Reg Out

Reg In

Res

Cd

Vin3

Vg3

Vo5

Vo6

Vo7

Vo8

Vg4

Vin4

Vref

Vcc

Power supply (Shorted to pin 24)

All BTL amplifier outputs ON/OFF

BTL AMP 1 input pin

BTL AMP 1 input pin (For gain adjustment)

BTL AMP 1 input pin (Non inverting side)

BTL AMP 1 input pin (Inverting side)

BTL AMP 2 input pin (Inverting side)

BTL AMP 2 input pin (Non inverting side)

BTL AMP 2 input pin (For gain adjustment)

BTL AMP 2 input pin

External transistor collector (PNP) connection. 5V power supply output

External transistor (PNP) base connection

Reset output

Reset output delay time setting (Capacitor connected externally)

BTL AMP 3 input pin

BTL AMP 3 input pin (For gain adjustment)

BTL AMP 3 output pin (Non inverting side)

BTL AMP 3 output pin (Inverting side)

BTL AMP 4 output pin (Inverting side)

BTL AMP 4 output pin (Non inverting side)

BTL AMP 4 output pin (For gain adjustment)

BTL AMP 4 output pin

Level shift circuit's reference voltage application

Power supply (Shorted to pin 1)

15

11k

ohm

14

13

RESET

Regulator

11k

ohm

out

Reg

In

1-39

Page 40

MX-GT90

MN101C35DEC3 (IC810) : System controller

Pin function (1/2)

Pin No.

1

2

3

4

5

6

7

8

9,10

11

12,13

14

15

16C19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47~63

Symbol

KCMND

MSTAT

KCLK

DATAOUT

DA TAIN

CK

NC

VDD

OSC2,1

VSS

NC

MMOD

VREF-

KEY1~4

SLCKEY1

SLCKEY2

NC

SPIDTI

VREF+

MRDY

RESET

BASS VOL+

BASS VOLAUX MUTE

RDSDATA/KARA

SPI A

SPI B

REMIN

PHOTOA

PHOTOB

SOUNDMODE+

RDS_CLK

PRT

TAPE LED

ECON

POUT

VOLDA/EXT

VOLCK/EXT

EXTCE

SLCCE

VC3 RESET

G17~1

I/O

O

I

O

O

I

O

-

-

I/O

-

-

-

-

I

I

I

-

I

-

I

I

I

I

O

I

O

O

I

I

I

I

I

I

O

O

O

O

O

O

O

O

O

Function

VC3 Serial data output

VC3 status input

VC3 Serial clock

SLC/TUNER data output

TUNER data input

SLC/TUNER clock

Not used

Power supply +5V

Oscillation terminal (8MHz)

Connect to GND

Not used

Connect to GND

Connect to GND

Key matrix input 1~4

SLC Key input 1

SLC Key input 2

Not used

SPI Analog data input

AD +5V

VC3 Ready

Micon reset

Bass volume +

Bass volume AUX muting

RDS Data / Karaoke

SPI A data

SPI B data

Remote control signal input

SLC Photo-A

SLC Photo-B

Soundmode reverse

RDS Clock

Protector input

Tape LED

Economy ON

Power ON

Volume / EXT IC Data

Volume / EXT IC CLK

EXT IC Chip select

SLC Chip enable

VC3 Reset

FL Display grid

1-40

Page 41

Pin function (2/2)

MX-GT90

Pin No.

64~85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Symbol

P22~P1

TUCE

SMUTE

SEARCH LE

CD1 LED

CD2 LED

CD3 LED

R SEARCH

MSI

MPX

INH

F SEARCH

VOL -

VOL +

SOUNDMODE

VPP

I/O

O

O

O

O

O

O

O

I

I

I

I

I

I

I

I

-

Function

FL segment control signal output

Tuner chip enable

System mute

Skip LED

LED Control signal output (CD1)

LED Control signal output (CD2)

LED Control signal output (CD3)

Reverse skip

Music scan input

Tuner stereo indicator

Backup mode detect

Forward skip

Rotary encoder VOLRotary encoder VOL+

Soundmode foeward

-B for FL

1-41

Page 42

MX-GT90

MN662748RPM (IC651) : Digital servo & digital signal processer

1. Pin layout

2.Block diagram

LRCKIN(MSEL)

BCLK(SSEL)

SRDATAIN

(PSEL)

IOSEL

CLVS

CRC

BLKCK

CLDCK

SBCK

SUBC

DEMPH

RESY

FLAG6(RESY)

SSEL

SQCK

SUBQ

AVDD2

AVDD2

PCK

EFM

PLLF

DSLF

IREF

DRF

ARF

RSEL

PSEL

MLD

MCLK

MDATA

CK384(EFM)

VCOF

BYTCK

SMCK

FCLK

CSEL

MSEL

X2

X1

ÊSTAT

DIGITAL

DEEMPHSIS

SUB

CODE

BUFFER

DSL.

PLL

VCO

VCO

ITUNING

GENERATION

PITCH

CONTROL

20 ~ 1

21

~

40

41 ~ 60

8TIMES

OVER SAMPUNC

DIGITAL FILTER

EFM

DEMODULATION

SYNC

INTERPOLATION

SUBCODE

DEMODULATION

MICRO

COMPUTER

INTERFACE

COVERTER

A/D

80

~

61

CIRC

ERROR

CORRECTION

DEINTERLEVE

CLV

SERVO

1BIT

DAC

LOGIC

S

16k

SRAM

INPUT

PEM

(R)

PEM

(L)

D/A

CONVERTER

OUTPUT

DIGITAL

AUDIO

INTERFASE

DIGITAL

AUDIO

INTERFASE

INTER POLATION

SOFT MUTING DIGITAL

ATTENUATION

PEAK DETECTIVE

AUTO CUE

PORT

SERVO

TIMING GENERATOR

AVSS1

AVDD1

OUTR

OUTL

FLAG

IPFLAG

TX

ECM

PC

LRCK

SRDATA

BCLK

DMUTE

TRKV

KICK

VREF

TRVSTR

ECS

TVD

TRD

FOD

TBAL

FBAL

TOFS

TES

/TLOCK

/FLOCK

PLAY

LDON

WVEL

SENSE

D

/

D

V

V

V

S

D

D

S

D

D

1

/

R

V

T

S

S

E

T

S

S

1

T

F

E

1-42

R

T

F

E

E

N

V

T

R

C

R

S

B

V

D

D

O

E

T

/

R

F

D

E

O

F

T

Page 43

3. Pin function

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Dymbol

BCLK

LRCK

SRDATA

DVDD1

DVSS1

TX

MCLK

MDATA

MLD

SENSE

FLOCK

TLOCK

BLKCK

SQCK

SUBQ

DMUTE

STATUS

RST

SMCK

PMCK

TRV

TVD

PC

ECM

ECS

KICK

TRD

FOD

VREF

FBAL

TBAL

FE

TE

RF ENV

VDET

OFT

TRCRS

RFDET

BDO

LDON

I/O

O

O

O

O

I

I

I

O