Page 1

SERVICE MANUAL

POWERED SUBWOOFER

2205620036

SP-DW103

Area suffix

B ------------------------------- U.K.

E ----------- Continental Europe

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.22056

2003/6

Page 2

SPECIFICATION

Type Powered Subwoofer Bass-reflex type, (magnetically shielded type)

Speaker unit 16.0 cm cone (× 1)

Frequency range 30 Hz to 200 Hz

Input impedance 50 kΩ (LOW-LEVEL) 470 Ω (HIGH-LEVEL)

Input terminals INPUT 1 (LOW-LEVEL) INPUT 2 (HIGH-LEVEL)

Power requirements AC 230 V , 50 Hz

Output power of built-in amp 100 W (45 Hz, 4 Ω, 10 % THD)

Power consumption 27 W

Dimensions 210 mm (width) × 392 mm (height) × 348 mm (depth)

Mass 10 kg

Accessories Monaural audio cord (× 1)

1-2 (No.22056)

Page 3

1.1 Safety Precautions

Good earth ground

d

AC VOLTMETER

SECTION 1

PRECAUTION

(1) This design of th is product contains special hardw are and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

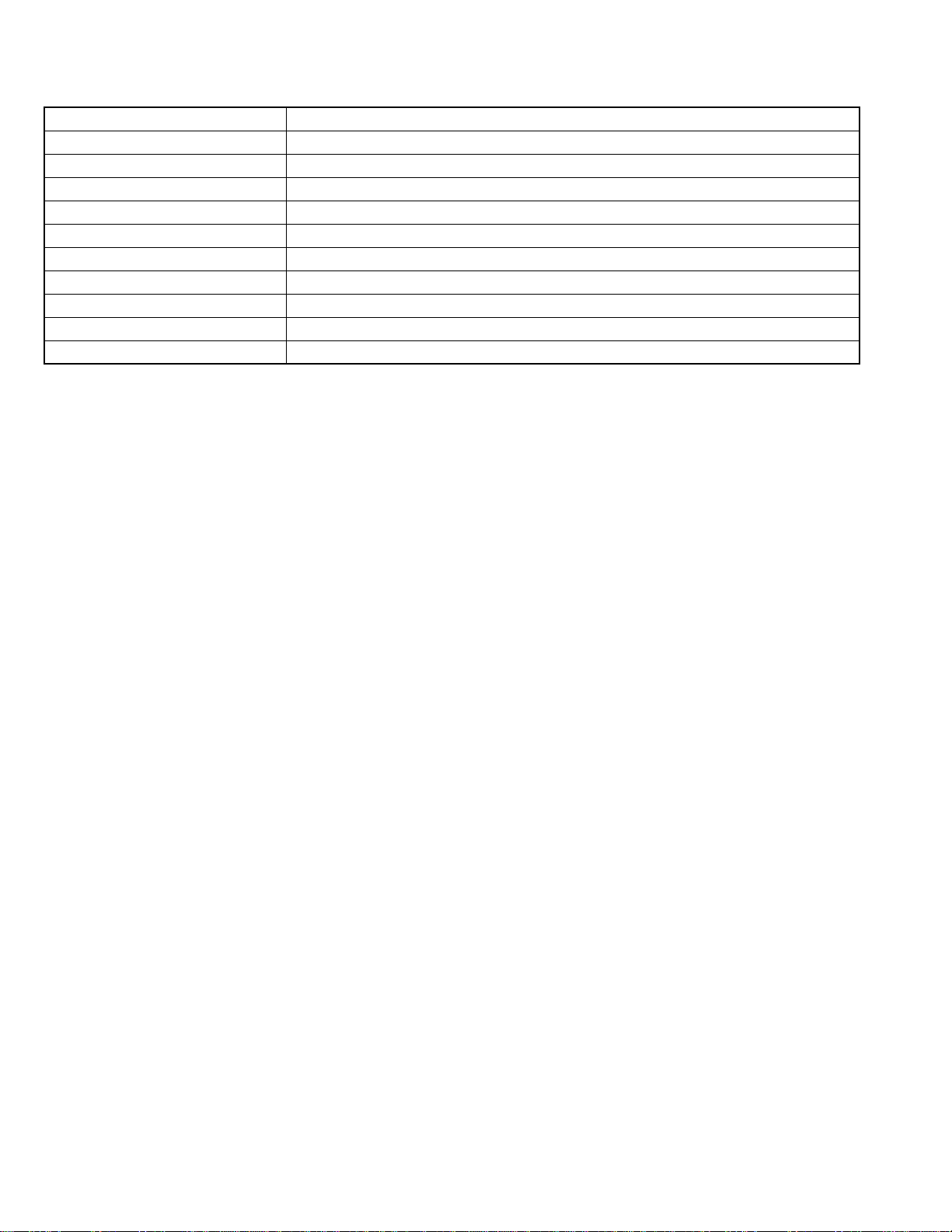

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5µ

mA AC (r.m.s.).

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal resp onsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical compone nts are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each expose

metal part.

(No.22056)1-3

Page 4

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-4 (No.22056)

Page 5

SECTION 3

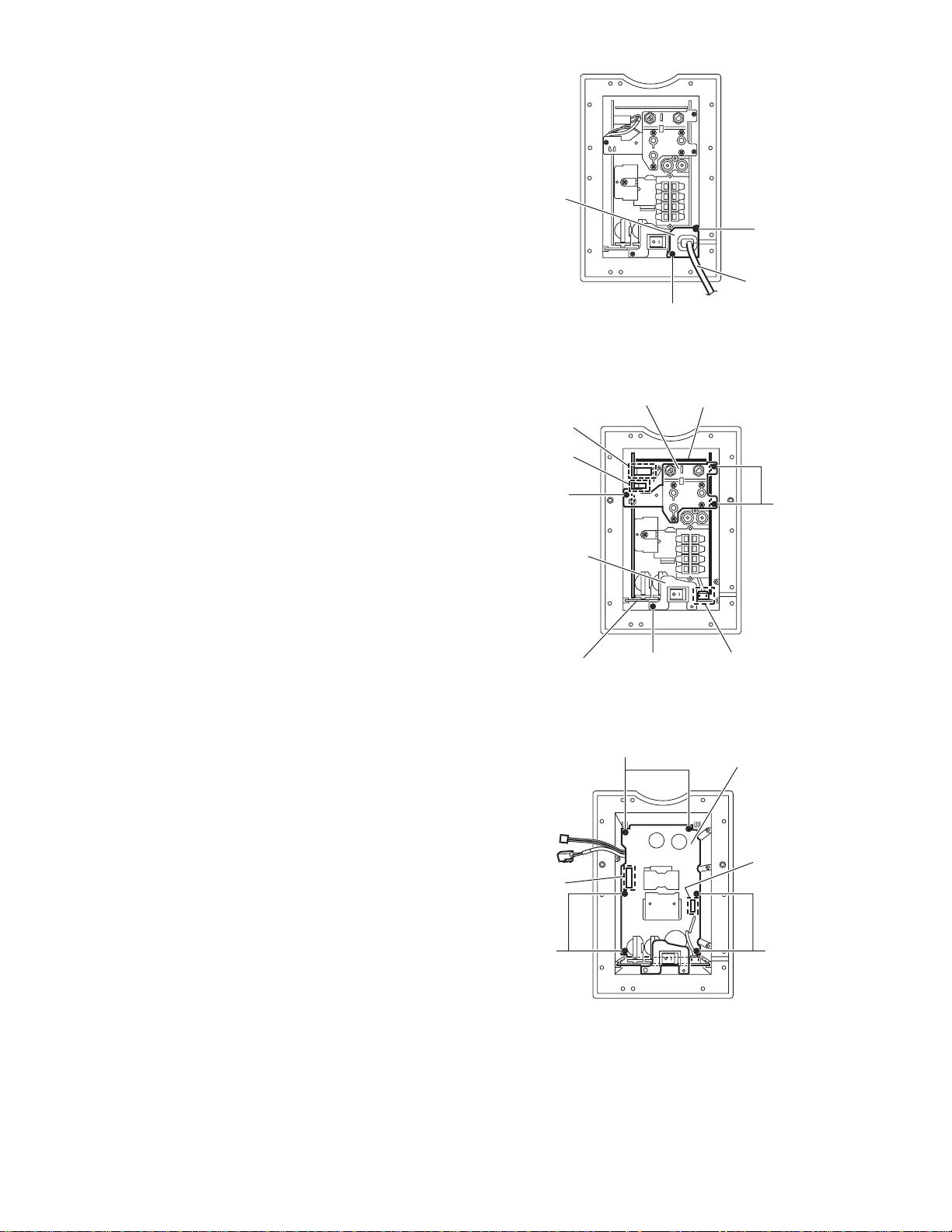

A

A

A

Amplifier assembly

Amplifier assembly Wire connector

al

B

Frequency knobVolume knob

DISASSEMBLY

3.1 Disassembly method

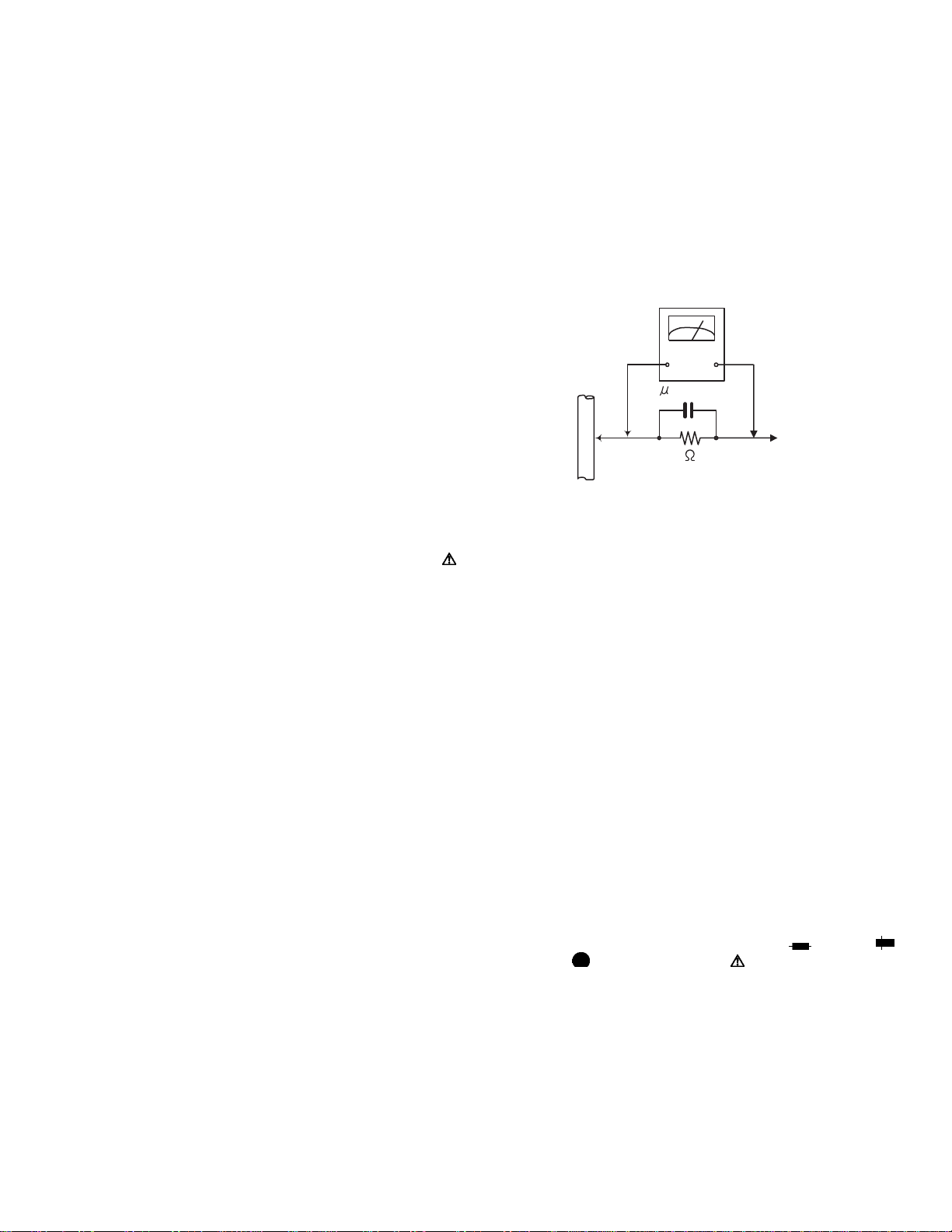

3.1.1 Removing the Amplifier assembly.

(See Fig1 and 2.)

(1) Remove the eleven screws A attaching the amplifier as-

sembly. (See Fig 1.)

(2) Remove the amplifier assembly from the main body.

(3) Disconnect the wire connector from the back side of the

amplifier assembly. (See Fig 2.)

(4) Disconnect the speaker wire from the speaker terminal.

(See Fig 2.)

A

A

Fig.1

3.1.2 Removing the back panel.

(See Fig 3.)

(1) From the back side of the main body pull out the volume

and frequency knobs.

(2) Remove the seven screws B attaching the back panel.

Speaker termin

Fig.2

B

B

Fig.3

(No.22056)1-5

Page 6

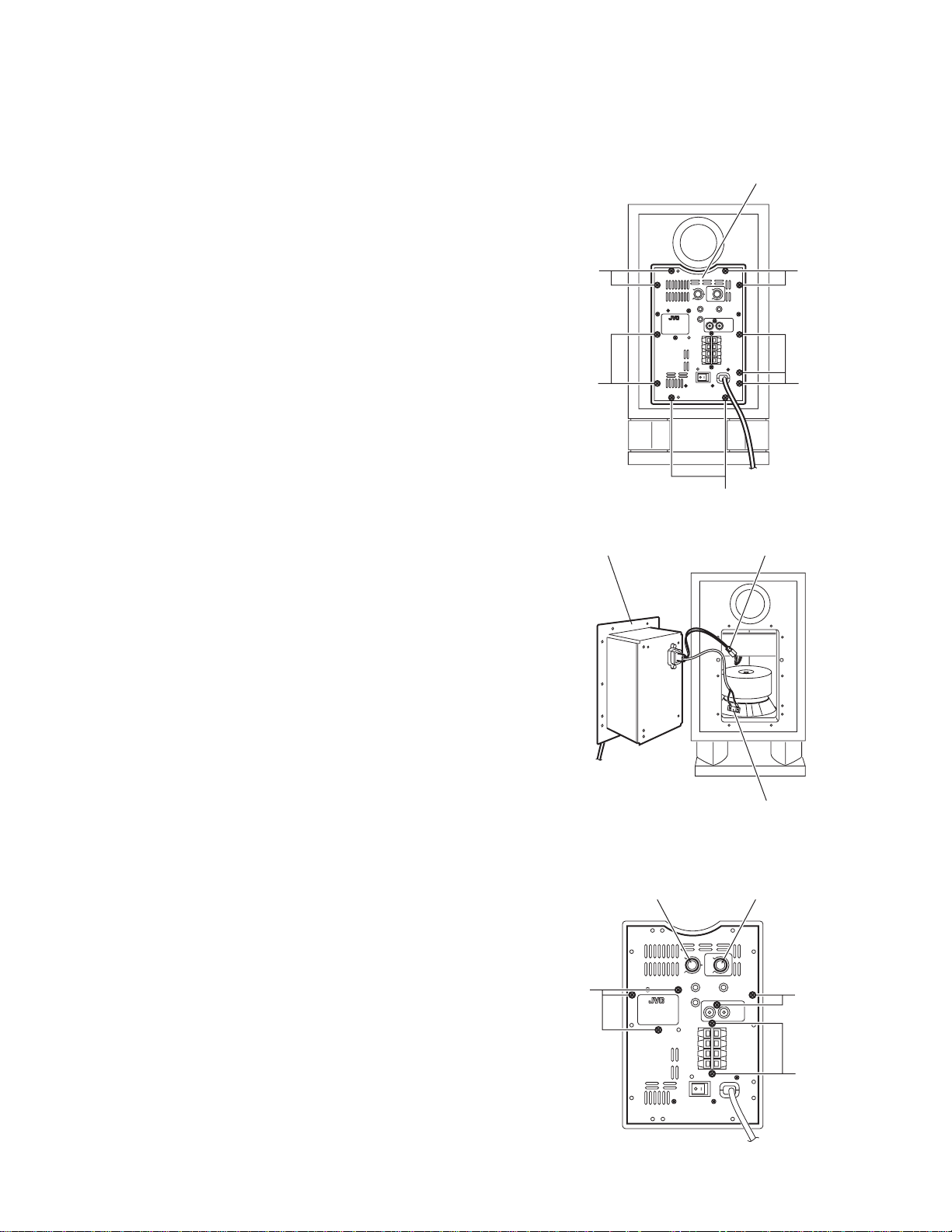

3.1.3 Removing the power cord.

B

rd

Amplifier assembly

B

rd

C

2

(See Fig 4 and 5)

• Prior to performing the following procedures. remove the back

panel.

(1) Remove the two screw C attaching the bracket. (See Fig 4)

(2) Pull out the bracket toward you.

(3) Disconnect the power cord from the connection CN901 on

the power supply assembly.

3.1.4 Removing the amplifier board assembly.

(See Fig 5 and 6)

• Prior to performing the following procedures remove the back

panel and the power cord.

(1) Remove the screw D attaching the bracket b. (See Fig 5.)

(2) Remove the three screws E attaching the bracket c. (See

Fig 5.)

(3) Disconnect the wire from the connection CN102 and

CN103 on the amplifier board assembly. (See Fig 6.)

(4) Remove the amplifier boa rd assembly from the connector

CN951 and Cn952 on the power supply board assembly.

(See Fig 6.)

(5) Pull out the amplifier board assembly toward you.

3.1.5 Removing the power supply board assembly.

(See Fig 6.)

• Prior to performing the following procedures remove the back

panel remove the power cord and amplifier board assembly.

(1) Remove the two screws F and four screws G attaching the

power supply board assembly.

(2) Pull out the power supply board assembly toward you.

racket a

CN503

CN102

racket b

E

Bracket c

C

Power co

C

Fig.4

board

E

CN901

Power supply

assembly boa

CN95

Power supply

assembly board

N951

D

Fig.5

F

GG

Fig.6

1-6 (No.22056)

Page 7

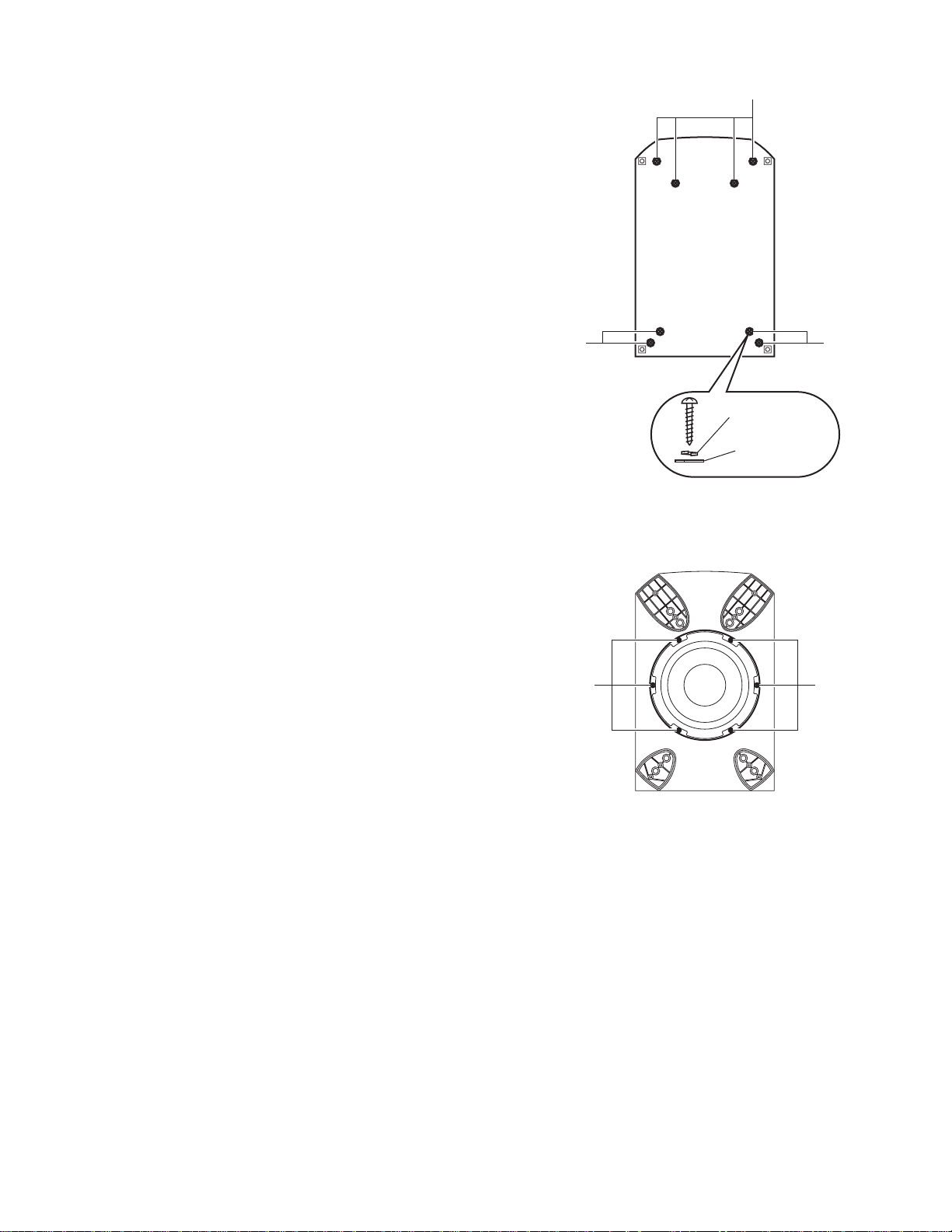

3.1.6 Removing the bottomplate.

HH

JJ

(See Fig 7.)

(1) Remove the eight screws H attaching the bottom plate.

Referense:

When attaching the screw H. attach the plane and spring

washers with them.

(2) Pull out the bottom plate toward you.

H

Spring washer

Plane washer

Fig.7

3.1.7 Removing the woofer.

(See Fig 8.)

• Prior to performing the following procedures. remove the bot-

tom plate.

(1) Remove the six screws J attaching the woofer.

(2) Pull out the woofer toward you.

Fig.8

(No.22056)1-7

Page 8

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

1-8 (No.22056)

Page 9

SECTION 5

TROUBLE SHOOTING

This service manual does not describe TROUBLE SHOOTING.

(No.22056)1-9

Page 10

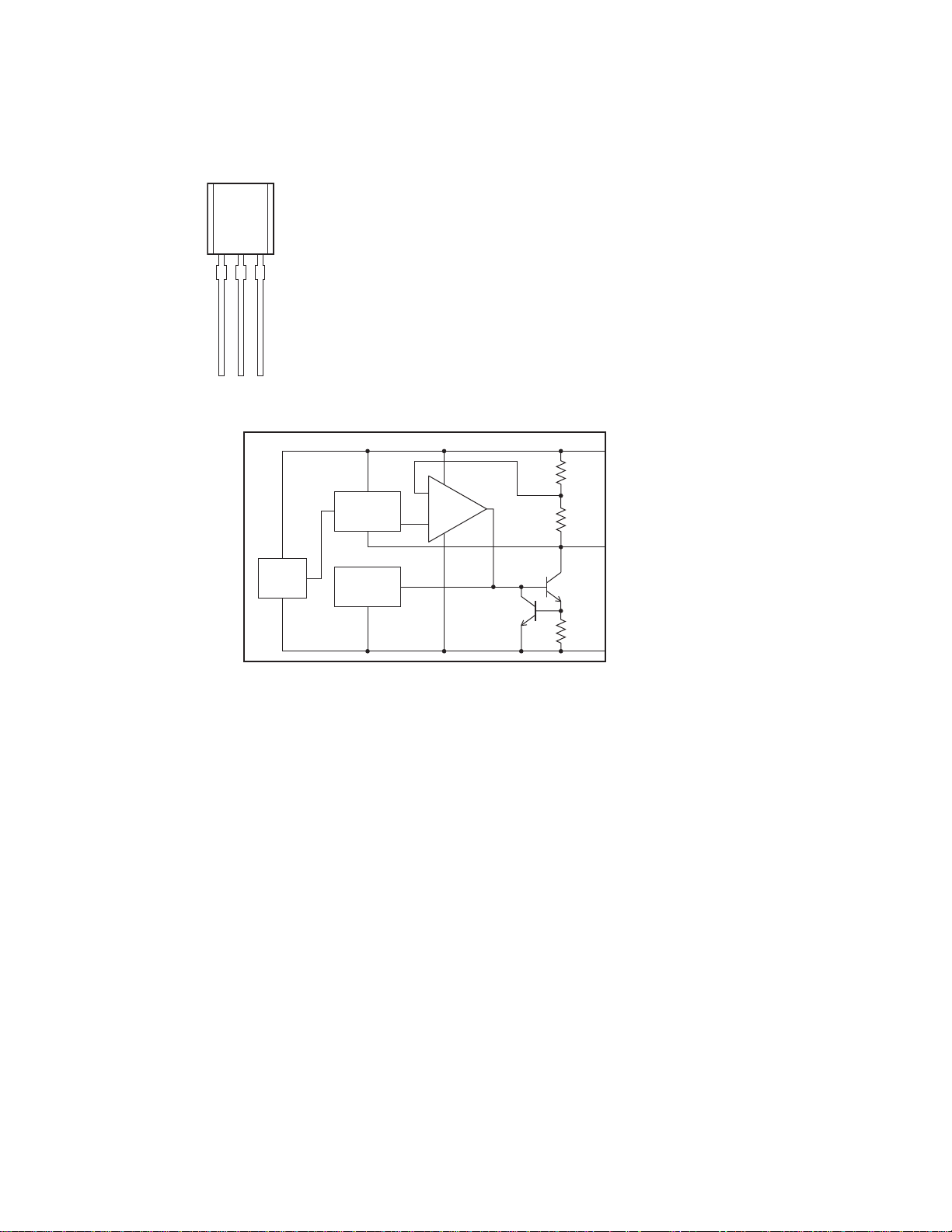

6.1 AN79L05-T (IC592) : Regulator

2

n

(2)

• Pin Layout

3

1

• Block Diagram

Starter

SECTION 6

Description of major ICs

R

1

Voltage

Reference

Terminal

Protection

+

Error Amp.

-

Current

Limiter

R

R

2

Q

SC

1

Pass Tr.

2

1

3

Commo

(1)

Output

(3)

Input

1-10 (No.22056)

Page 11

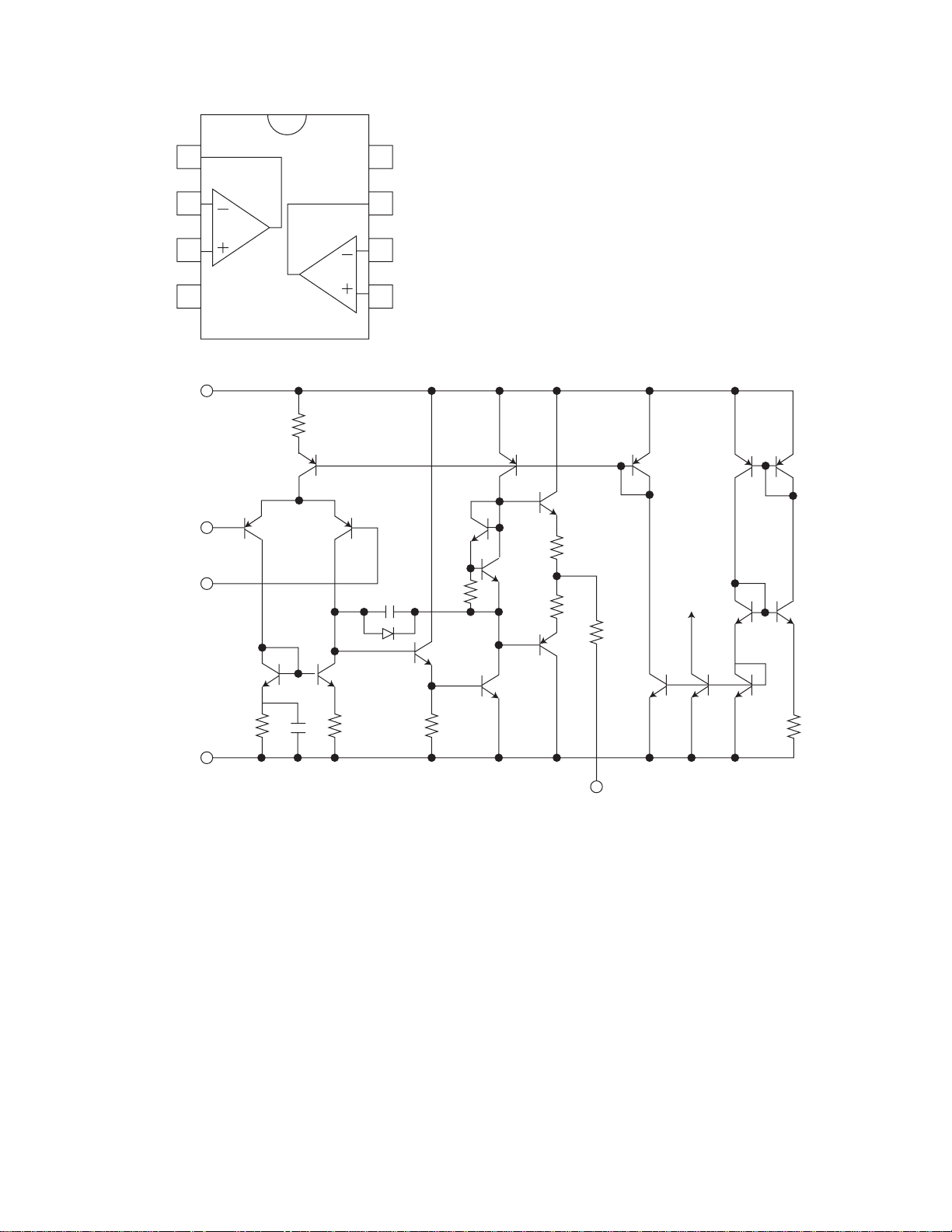

6.2 BA15218F-XE (IC101,IC102,IC103,IC104,IC501) : Dual operation amplifier

•Pin layout

OUT1 1

-IN1 2

+IN1 3

VEE 4

• Block diagram

Vcc

-IN

+IN

1

2

R1

Q5

Q1

Q2

D1

Q3 Q4

8 Vcc

7 OUT2

6 -IN2

5 +IN2

C2

R5

Q6

Q9

Q8

Q10

Q7

R7

Q11

R6

Q12

R8

Q18Q13

OTHER

CH

Q19

Q17Q16

VEE

C1

R3R2

R4

Q14 Q15Q114

R9

OUTPUT

(No.22056)1-11

Page 12

6.3 BU4584BF-X (IC505) : Hex schmitt inverter

I

O1I

O2I

O

Vss

LO COM VCC VS VB

HO

V

H

V

M

• Pin layout & Block diagram

VDD I6 O6 I5 O5 I4 O4

14 13

12

11 10 9 8

2

1

1

2

6.4 IR2113S-X (IC506) : Gate driver

• Pin Layout

VSS LIN SD HIN VDD

16 15

2

1

• Block Diagram

14 13

DD

IN

SD

LIN

ss

12

543

R Q

S

S

R Q

543

3

11 10

6

6

3

7

V

V

7

DD/VCC

LEVEL

SHIFT

DD/VCC

LEVEL

SHIFT

9

8

V

B

UV

PULSE

GEN

HV

LEVEL

SHIFT

DETECT

PULSE

FILTER

UV

DETECT

DELAY

R Q

R

S

HO

V

V

LO

CO

S

CC

1-12 (No.22056)

Page 13

6.5 NJM311M-XE (IC502) : Comparator

+

-

E

T

INPUT

T

• Pin Layout

(TOP VIEW)

1

GND

INPUT

2

3

INPUT

-

V

4

6.6 NJM78L05A-T (IC591) : Regulator

• Pin Layout

1.OUTPU

2.GND

3.INPUT

123

• Block Diagram

8

V

OUTPUT

7

6

BAL/STROB

BAL

5

+

OUTPU

GND

(No.22056)1-13

Page 14

6.7 STR-F6676 (IC951) : Switching regulator

5

B

1A 1B 1Y 2A 2B 2Y GND

1A 1Y 2A 2Y 3A 3Y GND

• Pin Layout • Block Diagram

VIN

4

START

O.V.P

12 3 4

REG.

T.S.D

Iconst

Rconst-Rconst+

R2

6.8 TC74HC00AF-W (IC503) : Quad 2-input NAND gate

• Pin layout & Block diagram

Vcc 4B 4A 4Y 3B 3A 3Y

14 13

12

11 10 9 8

LATCH

O.S. C

Vth(2)

Comp.2

R1C1

DRIVE

Comp.1

R3

Vth(1)

R4

D

3

S

2

O.C.P./F.

1

GND

5

2

1

6

543

7

6.9 TC74HC14AF-X (IC504, IC571) : Hex Schmitt inverter

• Pin layout & Block diagram

Vcc 6A 6Y 5A 5Y 4A 4Y

14 13

1

12

11 10 9 8

2

6

543

7

1-14 (No.22056)

Page 15

(No.22056)1-15

Page 16

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.22056)

Printed in Japan

WPC

Page 17

SP-DW103

SCHEMATIC DIAGRAMS

POWERED SUBWOOFER

SP-DW103

CD-ROM No.SML200306

Area suffix

B ------------------------------- U.K.

E ----------- Continental Europe

Contents

Block diagrams

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2003 VICTOR COMPANY OF JAPAN, LTD.

2-1

2-3

2-3 to 5

No.22056SCH

2003/06

Page 18

SP-DW103

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

2-2

Page 19

Block diagram

SP-DW103

5

4

INPUT

(LOW-LEVELL)

L/MONO

IN PUT L / H AMP

& H.P FIL TER

3

AUTO POWER ON / STANDBY SW

ON -- CANCEL

L.P FILTER /

PHASE /

A.H.B

IC101

1/2

PHASE SW

NORMAL-- REVERSE

CN151

W1001

IC102

IC103

1/2

FREQUENCY

VOLUME

VOLUME

AMP

IC103

2/2

CN101

CN501

CN504

POWER AMP

IC501

IC502

IC503

IC504

VR501

Off set

VR502

Carrier Freq.

W9001 to 4

W9001 to 4

POWER-SUPPLY

CIRCUIT

IC951

+B

+B

TRANS

T9501

CN951

CN502

Q5902

Q5904

REGULATOR

Q5903

Q5905

POWER

CN901

MAINS

PLUG

IN

IN PUT L / H AMP

VARIABLE-- FIX

CUT OFF

INPUT

(HIGH-LEVEL)

2

IC101

2/2

FILTER SW

CN505

IC505

MUTE

IC506

OUTPUT

(SPEAKER-OUT)

IC104

AUTO POWER ON

MUTE

IC104

LED CONT.

LED

Q5006

Q5007

IC571

Q5706

RY502

OUT

1

SPEAKER

CN503

CN102

CN861

RED GREEN

INDICATOR

AB CD E F G

2-1

Page 20

SP-DW103

SP-DW103

Standard schematic diagram

CN861

R8601

C1005

68k

BA15218F

C1009

2.2k

C1028

4.7/50

0.01

!

LF901

0.0022

IC101

0.022

6.8k

100/16

0.68

0.68

C1008

R1050

C9503

D8602

100/16

470P

!

47k

R1052

R9504

C9002

220

2.2K

3.3k

C1010

0.1

47

47

BA15218F

R1051

C1029

C9003C9004 C9504

!!

0.1/275

R1015

R1017

IC104

47p

1.5K

1M

D9503

AG01Z

100/35

D9502

AG01Z

0.001/2500.001/250

D8601

SPR325MVW

5

C1003

R1003

56k

4.7/50

470k

R1006

470/1W

R1007

470/1W

150p

R1069

C1001

C1002

150p

C1026

1K

0.001

C1004

4.7/50

0.001

R1002 R1001

470k

K1001

NQR0129-003X

R1008

150k

R1009

150k

R1010

150k

R1011

150k

1K/1/4W

R1071 C1039

R1070

1K/1/4W

J1001

QNN0090-001

4

J1002

QNB0159-002

C1025

3

W9001

W9002

2

1

W9003

W9004

QGA7901F2-02

CN901

!

!

F9001

( D) 3.15A/125V

C9501

!

470/400

R9501

!

S9001

QSW1001-001

!

C9005

0.01/275

R1005

R1004

56k

56k

R1014

C1007

R1013

IC101

BA15218F

0.022

6.8k

C1006

R1012

C1038

R1049

C1027

!

IC951

STR-F6676

C9502

( D) 680P/2K

D9501

AW04

K9501

QQR0779-001Z

R9503

!

680

R9502

0.33/1W

0.33/1W

!! !

LF901 LF902

QQR1360-001 QQR1360-001

C9001

0.22/275

!

R9002

3.3M

!

QQR1353-001

VR101

20KB

C1011

0.1

R1021R1020

5.6K

33K

R1022

Q1002

2SC2412K

C1030

4.7/50

75K/1/4W

R9528

R9529

75K/1/4W

Q9504

2SC2412K

2.2k

R9505

D9505

C9505

470P

D9001

!

TH901

QAD0141-6R0

R1066

D9504

R1023

R1048

R1053

4.7k

47k

R9510

75K/1/4W

MTZJ20B

R9506

MTZT20B

RBV-606

180K

D9506

AG01Z

10k

IC102

BA15218F

C1013

100/16

1k

Q1001

2SC2412K

1SS133

0.01

D1001

C1031

C9506

D9507

R1047

220k

Q1003

2SC2412K

0.01/630

SARS03

R9508

22/1W

R9001

100k/2W

10K

R1034

C1015

R1033

10K

R1030

5.6k

R1028

C1023

!

PC951

PC123Y22

0.22

47

1/50

R1067

R1054

0.12

C1036

R1025

C1012

82K

R1046

56

56

!

QQS0172-001

!

0.0033/250

W9001

W9002

W9003

W9004

S1001

47/1/4W

100/16

T9501

C9515

R1019

4.7K

C1037

0.0033

R1055

Q1004

2SA1037AK

R1056

R9527

R1035

R1036

1.5k

10k

Q1005

2SD2114K

10k

15k

R1057

470/16

C1032

2.2k

R1031

5.6k

R1032

680K

R1037

FML-G22S

0.0047/1K

0.0047/1K

FML-G22S

150K

D9509

C9507

C9508

D9510

C1014

0.056

39k

R1059R1060

220k

0.068

C1017

100k

R1061

1M

IC104

BA15218F

C1034

C9509

0.022/100

C9510

0.022/100

QGA2001C1-08

CN151

W1001

QJB001-080701

IC103

BA15218F

C1035

0.015

IC102

BA15218F

R1038

12k

C1018

0.047

C1033

10/16

R9516

C9511C9512

2200/50

R9517

R9520

2200/50

R9521

R1062

47

10/16

R1064

47

13K

D9511

MTZJ15A

C9513

10k

13K10k

D9512

MTZJ15A

C9514

0.01

S1501

C1016

10/35

Q1007

2SC2412K

Q1006

2SA1037AK

R9518

0.01

R9522

10K

Q9508

2SA1514K

10k

Q9509

2SA1514K

R9524

C1502

3.9k

0.0033

10KB

R1501

VR151

C1501

10/35

47

10/35

R1041

C1019

C1021

15K

R1016

47/16

C1020

0.0022

R1040

68K

IC103

R1044

BA15218F

47

22k

R1039

C1022

47/16

R1065

D1002

1SS133

1K

R1068

D1003

1SS133

1K

QGB2016J1-05

CN103

CN952

QGB2016K1-05

10k

R9519

1k

R9523

Q9510

2SC2412K

4.7k

1k

10k

R9526

R9525

EP951

EP952

CN101

CN501

QGB2016K1-08

CN951

CN502

QGB2510J1-10

QGB2016J1-08

QGB2510K1-10

R5002 R5001

15K

10K

R5006

C5001

100/16

VR501

5K

7.5K

MTZJ16BMTZJ16B

D5907

D5908

R5003

10k

10k

R5004

R5005

10k

R5007

13K

R5008

10k

C5002

100/16

C5003

R5041 R5040

L5903 L5901

NQL114K-471X

C5911

100/25

C5912

100/25

L5904

NQL114K-471X

100/16

5.6k 1k

L5902

R5020

1k

R5042

Q5005

2SA1514K

R5044

3.3K

R5043

D5909

RB160L-40-XRB160L-40-X

D5910

10k

R5009

4.7

C5004

QGB2016J1-11

CN504

CN505

QGB2016K1-11

560

C5016

2SA1037AK

12K12K

R5911

220P220P

C5907

Q5904

2SC2412K

Q5905

2SA1037AK

C5908

R5912

2SC2412K

10k

R5010

IC501

BA15218F

R5012

100/16

D5005

R5045

8.2K

56P

100K100K

R5748R5747

Q5902

R5909

D5911

1SS355

D5912

1SS355

R5910

Q5903

10k

1SS133

1K

1K

R5011

C5005

R5913R5914

10k

100/16

C5017

2SK303/3-4/-X

R5749

100K

C5711

0.22/25

330330

R5905

MTZJ15A

D5903

D5904

MTZJ15A

R5906

4.7

R5019

C5006

IC505

BU4584BF-X

D5006

1SS133

R5046

8.2K

56P

C5025

Q5723

47K

C5909

C5910

47K

R5013

4.7k

R5014

4.7k

D5717

1SS355-X

!

R5915

22/1/4W

100/50

100/50

!

R5916

22/1/4W

100/16

0.1

D5718

R5021

4.7

1K1K

2.2k2.2K/1/4W

R5017R5018

R5015

Q5001

2SA1037AK

Q5002

2SC2412K

R5016

R5022

4.7

15K

R5713R5714

D5704

1SS355-X

1SS355-X

Q5707

2SA1037AK

47k

R5746

100K

TH592

TH591

!

!

NAD0032-330X

NAD0032-330X

KRC104S-X 10k

!

!

TH594

TH593

NAD0032-330X

NAD0032-330X

R5023

Q5716

100

D5007

D5716

R5025

2.7k

R5024

R5048

10k

C5018

MTZJ16B

TH501

Q5708

KRC104S

R5715

Q5715

KRA104S-X

1SS133

4.7

R5028

1k

IC502

NJM311M-XE

Q5003

2SA1037AK

R5027

2.2

0.022

470p

0.1

4.7

C5007

C5008

C5009

R5026

IC506

IR2113S-X

0.22

Q5721

KRC104S-X

!

R5049

22/1/4W

!

R5050

2.2/1/2W

QAD0015-153Z

4.7k

Q5709

2SC2412K

C5703

100k

R5730

R5731

R5732

100K

C5706

3.3/10

Q5717 Q5718

DTC115EKA-X DTC115EKA-X KRC104S-X

6.8k

R5029

Q5004

2SC4452/3-4/-X

C5021

0.68

C5019

R5716

100k

R5717

47/16

D5001D5002

R5030

C5026

0.22/100

C5020

!

220k

Q5710

1SS133

1SS133

6.8k

R5031

R5032

4.7/100

10/35

!

10/1/2W

R5051

R5718

47k

2SA1037AK

R5033

4.7k

2.2k

R5053R5054

R5052

D5008

R5719

2.2

0.1

0.1

C5010

C5011

R5055

6.8/1W

1M

D5009

MTZJ18B

R5056

6.8/1W

1M

MTZJ18B

22/1/2W

D5902

M1FL20U

Q5711

2SC2412K

47k

R5742

2.2

Q5719

R5035

0.1

C5013

D5010

VR502

2.2

C5906

MTZJ18B

R5745

20K

C5014

680p

Q5006

IRFI540N

Q5007

IRFI540N

22K

D5705

0.1

C5707

47/25

1SS355-X

D5714

PRE MAIN signal

D5003

1SS133

R5036

D5901

D5706

1SS355-X

D5707

1SS355-X

R5733

10K

10k

C5015

47p

D5011D5012

R5902

MTZJ16B

Q5712

KRA104S

R5721

47k

1SS355-X

Q5713

2SK303/3-4/-X

R5034

2.2

IC503

TC74HC00AF-W

R5037

2.2k 12K

R5038

C5012

IC504

TC74HC14AF-X

10K

R5039

1SS133

D5004

R5059

11k

180k

R5058

C5023

!

( D) QQR1352-001

15

R5061

15

R5063

R5701

1k

R5724

68K

1SS355-X

0.01

10k

R5739

100K

2.2/10

2.2/50

L5001

C5027C5028

C5702

39K

Q5714

DTC115EKA-X

R5725

R5057

270P270P

C5022

R5726

R5729 R5728

D5715

R5740

0.018

0.082

0.018

C5024

15

R5060

15

R5062

D5710

1SS355-X

D5712

0.01

D5708

MA3300/L/

MA3200/H/

D5711

D5709

C5705

MA3200/H/

47k

470k

10k

R5737

R5738

C5710

2.2/10

C5901

M1FL20UM1FL20U

C5902

!

6.8k

2SD2395/EF/

C5905

4.7/25

R5734

C5708

1SS355

0.1/100

C5903

220/50

C5904

0.1/100

R5901

10/1/4W

Q5901

R5720

2.2k

R5723

220k

TC74HC14AF-X

10k

470k

R5735

3.3/10

D5013

C5918

C5917

220/50

C5704

R5722

IC571

R5736

C5709

Parts are safety assurance parts.

When replacing those parts make

0.1

22K

R5744

0.0039/100

220/35

100k

R5727

D5713

68K

1SS355-X

47k

Q5720

KRA104S

C5913

10/16

NJM78L05A

IC591

C5916

10/25

D5905

MTZJ6.8B

Q5722

DTC144TKA

R5743

2.2k

390

K5001

QQR1183-001Z

D5703

1SS133

Q5706

2SC2412K

R5702

10k

100k

MA3300/L/

33K

C5914

10/16

C5915

10/25

D5906

MTZJ6.8B

RY502

QSK0148-001

AN79L05

IC592

QQR1183-001Z

K5002

CN102

QGA2501C1-02

CN503

QGA3901C1-02

sure to use the specified one.

2-2

HAB C DE FG

Page 21

Printed circuit boards

Main board (1/3)

(Terminai board)

SP-DW103

S1001

R1033

Q1005

R1017

R1049

C1033

R1062

C1019

C1027

R1016

C1035

R1032

R1020

C1009

C1014

R1021

R1012

R1066

W1001

R1034

C1006

C1030

CN101

R1022

C1031

C1034

C1015

R1013

R1019

C1017

IC101

C1007

R1053

C1018

C1011

R1014

R1064

C1016

R1060

R1030

R1059

R1031

R1025

R1005

Q1003

R1061

C1012

C1005

C1008

R1015

R1054

D1001

R1067

IC104

IC103

Q1007

R1023

D1003

D1002

IC102

Q1006

C1021 C1022

R1044

C1023

R1040

R1050

R1039

C1020

R1041

R1038

C1013

R1047

Q1004

R1056

R1052

R1036

Q1002

R1048

R1057

R1055

R1051

R1035

R1028

R1046

Q1001

C1024

C1029

R1065

R1037

R1068

CN103

5

VR101

C1036

4

3

J1001

C1001

R1069

C1002

R1001

R1010

R1008

K1001

J1002

R1002

C1004

R1011

C1025

C1010

C1039

R1009

R1007

C1026

C1003

C1038

R1071

R1070

C1028

R1006

C1037

R1003

C1032

R1004

C5010

IC592

TP501 VR501 VR502

D5906

C5914

R5035

R5029

R5037

R5030

D5003

2

1

C5913

C5915

Q5003

R5006

R5032

R5033

C5015

IC591

C5007

Q5004

C5916

D5905

R5027

D5002

R5031

R5036

R5038

C5014

C5009

R5024

D5001

C5008

R5026

C5002

R5025

R5039

D5004

R5023

R5028

C5011

IC504

IC502

CN504

CN501

Q5002

C5013

B5101

IC503

C5006

R5021

R5016

R5019

C5012

C5005

R5014

R5034

R5007

R5018

R5013

R5009

R5015

R5011

Q5001

R5008

R5003

R5017

IC501

R5020

R5010

R5022

R5012

R5004

C5004

R5005

C5003

C5001

R5002

R5001

(Volume board)

AB C

2-3

Page 22

SP-DW103

5

4

3

Main board (2/3)

R5719

D5707

R5723

TH501

CN502

D5709

D5706

R5915

R5715

R5714

R5713

D5704

Q5707

Q5708

C5909

Q5904

D5911

C5910

R5916

R5721 R5722

R5914

Q5713

R5720

Q5709

C5703

Q5710

R5717

D5904

D5912

R5718

Q5711

C5705

D5903

Q5905

Q5903

R5045

C5016

R5745

R5749

R5909

R5906

D5005

D5718

C5704

R5905

R5913

R5910

B8110

C5017

D5006

R5901

R5902

D5705

D5708

Q5902

B8111

Q5005

C5025

R5042

Q5723

D5902

Q5712

L5901

R5046

R5040

R5050

R5725

D5716

R5041

(Amp board)

R5911

D5909

D5910

L5904

L5902

C5908

R5912

IC505

R5049

D5901

C5905

Q5901

B8106

R5727

R5724

Q5714

D5710

D5711

D5712

C5906

R5726

D5713

C5907

L5903

D5907 D5908

R5728

R5729

C5911 C5912

C5020

R5051

C5706

R5730

B8102

R5731

Q5721

R5043

R5044

B8112

R5747

R5702

R5701

Q5715

Q5716

Q5719

Q5717

Q5718

C5711

R5048

D5007

C5902

R5054

C5019

D5008

TH591

TH592

D5703

C5018

B8113

CN505

RY502

Q5706

C5903 C5904

R5056

R5748

C5022

C5901

R5055

R5052

TH593

TH594

D5717

C5702

R5053

IC506

C5024

K5002

C5027

C5021

R5732

R5741

D5013

L5001

R5062

R5733

B8103

R5742

Q5720

C5707

K5001

C5028

C5026

C5709

IC571

C5023

D5009

D5010

R5057

R5744

Q5006

R5734

C5708

R5059

CN102

Q5007

R5735

B8105

R5058

R5743

R5060

R5063

D5714

R5061

D5011

B8104

C5710

B8107

Q5722

C5918

R5736

R5737

R5740

D5715

R5746

C5917

D5012

R5738

CN503

R5739

R5716

2-4

S1501

2

C1501

VR151

R1501

CN151

C1502

(Swich board)

1

AB CD

Page 23

Main board (3/3)

SP-DW103

(Regulator board)

C9510

EP951

5

T9501

C9509

HS953 HS952

C9511 C9512

C9507 C9508

D9509 D9510

R9518

Q9508

R9519

C9513

Q9510

R9516

R9524

R9517

C9514

D9511

R9520

R9526

R9525

EP952

R9521

R9522

Q9509

R9523

CN951

D9512

4

R9527

W9004

CN952

D9504

R9506

C9515

D9506

Q9504

R9508

C9502

HS954

C9506

D9507

IC951

R9503

PC951

R9504

R9510

R9529

R9528

D9001

C9505

D9501

W9001

LF901

D9503

R9501

R9502

C9503

D9502

R9001

C9002

3

W9002

2

W9004

W9002

CN901

1

D9505

Z9001 Z9002

R9002

C9005

S9001

C9501

C9001

C9003

C9004

K9501

C9504

W9001

R9505

W9003

W9003

TH901

LF902

(Power swich board)

AB C

2-5

Page 24

SP-DW103

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY 10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.22056SCH)

Printed in Japan

2003/06

Page 25

PARTS LIST

[ SP-DW103 ]

* All printed circuit boards and its assemblies are not available as service parts.

Area suffix

SP-DW103

B ------------------------------- U.K.

E ----------- Continental Europe

- Contents -

Exploded view of general assembly and parts list(Amp) (Block No.M1)

Exploded view of general assembly and parts list( Speaker) (Block No.M2)

Electrical parts list (Block No.01)

Packing materials and accessories parts list (Block No.M3)

3- 2

3- 4

3- 6

3-10

22056

3-1

Page 26

SP-DW103

Exploded view of general assmbly and parts list

(Amp)

F

Terminal board

Switch board

25

26

21

3

Acessories

8

Block No.

21

24

23

C

25

G

20

10

11

C

23

12

a

4

13

29

46

28

9

28

D

36

32

30

29

Power switch

17

39

22

board

19

16

34

33

19

35

M

37

31

18

M

1

M

40

45

40

1

43

40

43

Regulator board

2

3

44

40

40

a

G

5

47

48

7

F

3

E

6

14

15

Volnme board

27

B

A

A

D

B

42

41

Amp board

3-2

Page 27

Exploded view of general Assembly and parts list (Amp)

Block No. [M][1][M][M]

Symbol

No.

1 LV21341-001A SHIELD

2 LV10709-002A COVER

3 LV30225-044A SPACE R (x4)

4 LV30225-079A SPACE R

5 LV30225-0E4A SPACER

6 LV30225-025A SPACE R

7 LV30225-044A SPACE R

8 QYSBSG3016E TAPPING SCREW 3mm x 16mm(x2)

9 QYSBSF3008Z SCREW 3mm x 8mm(x4)

10 LV43179-002A BKT(SW)

11 LV30225-0H6A SPACER

12 LV30225-0H7A SPACER (x2)

13 QYSBSF2612M TAPPING SCREW 2. 6mm x 12mm

14 LV41148-002A COR D COVER

15 QYSBSF4012Z TAP SCREW 4mm x 12mm(x2)

16 LV43178-001A B KT(CO RD )

17 QZW0033-001 STRAIN RELIEF

18 QMPN160-200-JD POWER CORD(EK) 2m BLACK

18 QMPK190-200-JC POWER CORD(EU) 2m BLACK

19 QYSBSF2612M TAPPING SCREW 2.6mm x 12mm(x2)

20 LV33804-002A B KT(KN OB)

21 QYSBST3006Z TAPPING SCRE W 3mm x 6mm(x4)

22 LV30734-002A KNO B (x2)

23 E407321-002SM PUSH BUTTON (x3)

24 LV30225-0H5A SPACER

25 QYSBSF2612M TAPPING SCREW 2.6mm x 12mm(x3)

26 LV30225-0H5A SPACER

27 LV30225-0E5A SPACER

28 LV30225-0E5A SPACER (x2)

29 LV30225-0A4A SPACER (x2)

30 LV30225-074A S PACER

31 LV21342-008A B ACK PANEL

32 LV30225-0H4A SPACER

33 LV30225-0H5A SPACER

34 QYSBSGY3008E SPECIAL SCREW 3mm x 8mm

35 QYSBSGY3008E SPECIAL SCREW 3mm x 8mm(x2)

36 QYSBSGY3008E SPECIAL SCREW 3mm x 8mm

37 QYSBSGY3008E SPECIAL SCREW 3mm x 8mm

39 QYSBSGY3008E SPECIAL SCREW 3mm x 8mm(x2)

40 QYSDSA4020M TAPPING SCRE W 4mm x 20mm(x11)

41 LV33803-001A HEAT SINK

42 QYSBSG3012Z SCREW 3mm x 12mm

43 LV30225-0G7A SPACER (x2)

44 LV30225-0G4A SPACER

45 LV43211-001A SPACER

46 QMF51E2-2R0-J1 FUSE

47 WJJ0098-001A E-SI C WIRE C-C

48 WJN0095-001A E-SH C WIRE C-C

Part No. Part Name Description Local

DW10

3B

DW10

3E

F 9001 2A

AC250V

SP-DW103

3-3

Page 28

SP-DW103

Exploded view of general assmbly and parts list

(Speaker)

Block No.

2

1

2

5

2

2

10

9

11

10

9

M

12

11

M

2

M

9

10

11

10

12

10

9

11

12

3

2

9

10

6

2

9

4

7

10

8

11

3-4

Page 29

Exploded view of general Assembly and parts list (Speaker)

Block No. [M][P][M][M]

Symbol

No.

1 CR160063-01 SPEAKER

2 7005942502 SCREW (x14)

3 9000008701 FOOT(FRONT/R)

4 9000008711 FOOT(FRONT/L)

5 9000008801 FOOT (x2)

6 2810006601 SPACER(R)

7 2810006611 SPACER(L)

8 9916011201 BAFFLE ASSY

9 6903540001 PLANE WASHER (x8)

10 6903640001 SPRING WASHER (x8)

11 7001542501 SCREW (x8)

12 5600006901 RUBBER FOOT (x4)

Part No. Part Name Description Local

SP-DW103

3-5

Page 30

SP-DW103

Electrical parts list

Main board

Symbol

No.

IC101 BA15218F-XE IC

IC102 BA15218F-XE IC

IC103 BA15218F-XE IC

IC104 BA15218F-XE IC

IC501 BA15218F-XE IC

IC502 NJM311M-XE IC

IC503 TC74HC00AF-W IC

IC504 TC74HC14AF-X IC

IC505 BU4584BF-X IC

IC506 IR2113S-X GATE DRIVER

IC571 TC74HC14AF-X IC

IC591 NJM78L05A-T IC

IC592 AN79L05-T IC

IC951 STR-F6676 IC

Q1001 2SC2412K/RS/-X TRANSISTOR

Q1002 2SC2412K/RS/-X TRANSISTOR

Q1003 2SC2412K/RS/-X TRANSISTOR

Q1004 2SA1037AK/RS/-X TRANSISTOR

Q1005 2SD2114K/VW/-X TRANSISTOR

Q1006 2SA1037AK/RS/-X TRANSISTOR

Q1007 2SC2412K/RS/-X TRANSISTOR

Q5001 2SA1037AK/RS/-X TRANSISTOR

Q5002 2SC2412K/RS/-X TRANSISTOR

Q5003 2SA1037AK/RS/-X TRANSISTOR

Q5004 2SC4452/3-4/-X TRANSISTOR

Q5005 2SA1514K/RS/-X TRANSISTOR

Q5006 IRFI540N FET

Q5007 IRFI540N FET

Q5706 2SC2412K/RS/-X TRANSISTOR

Q5707 2SA1037AK/RS/-X TRANSISTOR

Q5708 KRC104S-X TRANSISTOR

Q5709 2SC2412K/RS/-X TRANSISTOR

Q5710 2SA1037AK/RS/-X TRANSISTOR

Q5711 2SC2412K/RS/-X TRANSISTOR

Q5712 KRA104S-X DIGI TRANSISTOR

Q5713 2SK303/3-4/-X FET

Q5714 DTC115EKA-X DIGI TRANSISTOR

Q5715 KRA104S-X DIGI TRANSISTOR

Q5716 KRC104S-X DIGI TRANSISTOR

Q5717 DTC115EKA-X DIGI TRANSISTOR

Q5718 DTC115EKA-X DIGI TRANSISTOR

Q5719 KRC104S-X DIGI TRANSISTOR

Q5720 KRA104S-X DIGI TRANSISTOR

Q5721 KRC104S-X TRANSISTOR

Q5722 DTC144TKA-X TRANSISTOR

Q5723 2SK303/3-4/-X FET

Q5901 2SD2395/EF/ TRANSISTOR

Q5902 2SA1037AK/RS/-X TRANSISTOR

Q5903 2SC2412K/RS/-X TRANSISTOR

Q5904 2SC2412K/RS/-X TRANSISTOR

Q5905 2SA1037AK/RS/-X TRANSISTOR

Q9504 2SC2412K/RS/-X TRANSISTOR

Q9508 2SA1514K/RS/-X TRANSISTOR

Q9509 2SA1514K/RS/-X TRANSISTOR

Q9510 2SC2412K/RS/-X TRANSISTOR

D1001 1SS133-T2 SI DIODE

D1002 1SS133-T2 SI DIODE

D1003 1SS133-T2 SI DIODE

D5001 1SS133-T2 SI DIODE

D5002 1SS133-T2 SI DIODE

D5003 1SS133-T2 SI DIODE

D5004 1SS133-T2 SI DIODE

D5005 1SS133-T2 SI DIODE

D5006 1SS133-T2 SI DIODE

D5007 MTZJ16B-T2 Z DIODE

Part No. Part Name Description Local

Block No. [0][1][0][0]

Dual operational

amplifier

Dual operational

amplifier

Dual operational

amplifier

Dual operational

amplifier

Dual operational

amplifier

Symbol

No.

D5008 M1FL20U-X FR DIODE

D5009 MTZJ18B-T2 Z DIODE

D5010 MTZJ18B-T2 Z DIODE

D5011 M1FL20U-X FR DIODE

D5012 M1FL20U-X FR DIODE

D5013 1SS355-X SI DIODE

D5703 1SS133-T2 SI DIODE

D5704 1SS355-X SI DIODE

D5705 1SS355-X SI DIODE

D5706 1SS355-X SI DIODE

D5707 1SS355-X SI DIODE

D5708 MA3200/H/-X Z DIODE

D5709 MA3200/H/-X Z DIODE

D5710 1SS355-X SI DIODE

D5711 1SS355-X SI DIODE

D5712 MA3300/L/-X Z DIODE

D5713 MA3300/L/-X Z DIODE

D5714 1SS355-X SI DIODE

D5715 1SS355-X SI DIODE

D5716 1SS133-T2 SI DIODE

D5717 1SS355-X SI DIODE

D5718 1SS355-X SI DIODE

D5901 MTZJ16B-T2 Z DIODE

D5902 MTZJ18B-T2 Z DIODE

D5903 MTZJ15A-T2 Z DIODE

D5904 MTZJ15A-T2 Z DIODE

D5905 MTZJ6.8B-T2 Z DIODE

D5906 MTZJ6.8B-T2 Z DIODE

D5907 MTZJ16B-T2 Z DIODE

D5908 MTZJ16B-T2 Z DIODE

D5909 RB160L-40-X SB DIODE

D5910 RB160L-40-X SB DIODE

D5911 1SS355-X SI DIODE

D5912 1SS355-X SI DIODE

D9001 RBV-606 BRIDGE DIODE

D9501 AW04-T2 SB DIODE

D9502 AG01Z-T2 DIODE

D9503 AG01Z-T2 DIODE

D9504 MTZJ20B-T2 Z DIODE

D9505 MTZJ20B-T2 Z DIODE

D9506 AG01Z-T2 DIODE

D9507 SARS03 SI DIODE

D9509 FML-G22S SI DIODE

D9510 FML-G22S SI DIODE

D9511 MTZJ15A-T2 Z DIODE

D9512 MTZJ15A-T2 Z DIODE

PC951 PC123Y22 PHOTO COUPLER

C1001 NCB31HK-102X C CAPACITOR 1000pF 50V K

C1002 NCB31HK-102X C CAPACITOR 1000pF 50V K

C1003 QTE1H06-475Z E CAPACITOR 4.7uF 50V

C1004 QTE1H06-475Z E CAPACITOR 4.7uF 50V

C1005 NCB31HK-222X C CAPACITOR 2200pF 50V K

C1006 NCB31HK-223X C CAPAC ITOR 0.022uF 50V K

C1007 NCB31HK-223X C CAPAC ITOR 0.022uF 50V K

C1008 QERF1CM-107Z E CAPACITOR 100uF 16V M

C1009 QERF1CM-107Z E CAPACITOR 100uF 16V M

C1010 QFN31HJ-104Z M CAPACITOR 0.1uF 50V J

C1011 QFN31HJ-104Z M CAPACITOR 0.1uF 50V J

C1012 QEKC1CM-107Z E CAPACITOR 100uF 16V M

C1013 QEKC1CM-107Z E CAPACITOR 100uF 16V M

C1014 QFN31HJ-563Z M CAPACITOR 0.056uF 50V J

C1015 QFVJ1HJ-224Z MF CAPA CITOR 0.22uF 50V J

C1016 QTE1V06-106Z E CAPACITOR 10uF 35V

C1017 QFN31HJ-683Z M CAPACITOR 0.068uF 50V J

C1018 QFN31HJ-473Z M CAPACITOR 0.047uF 50V J

C1019 QTE1V06-106Z E CAPACITOR 10uF 35V

C1020 NCB31HK-332X C CAPACITOR 3300pF 50V K

C1021 QTE1C06-476Z E CAPACITOR 47uF 16V

C1022 QTE1C06-476Z E CAPACITOR 47uF 16V

C1023 QERF1HM-105Z E CAPACITOR 1uF 50V M

C1025 NCS31HJ-151X C CAPACITOR 150pF 50V J

C1026 NCS31HJ-151X C CAPACITOR 150pF 50V J

C1027 NCB31HK-103X C CAPAC ITOR 0.01uF 50V K

Part No. Part Name Description Local

3-6

Page 31

SP-DW103

Symbol

No.

C1028 QETN1HM-475Z E CAPACITOR 4.7uF 50V M

C1029 NCS31HJ-470X C CAPACITOR 47pF 50V J

C1030 QEKC1HM-475Z E CAPACITOR 4.7uF 50V M

C1031 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C1032 QETN1CM-477Z E CAPACITOR 470uF 16V M

C1033 QEKC1CM-106Z E CAPACITOR 10uF 16V M

C1034 QEKC1CM-106Z E CAPACITOR 10uF 16V M

C1035 QFN31HJ-153Z M CAPACITOR 0.015uF 50V J

C1036 QFVJ1HJ-124Z MF CAPACITOR 0.12uF 50V J

C1037 NCB31HK-332X C CAPACITOR 3300pF 50V K

C1038 QFVJ1HJ-684Z MF CAPACITOR 0.68uF 50V J

C1039 QFVJ1HJ-684Z MF CAPACITOR 0.68uF 50V J

C1501 QTE1V06-106Z E CAPACITOR 10uF 35V

C1502 QFN31HJ-332Z M CAPACITOR 3300pF 50V J

C5001 QERF1CM-107Z E CAPACITOR 100uF 16V M

C5002 QERF1CM-107Z E CAPACITOR 100uF 16V M

C5003 QERF1CM-107Z E CAPACITOR 100uF 16V M

C5004 QERF1CM-107Z E CAPACITOR 100uF 16V M

C5005 QERF1CM-107Z E CAPACITOR 100uF 16V M

C5006 QERF1CM-107Z E CAPACITOR 100uF 16V M

C5007 NCS31HJ-471X C CAPACITOR 470pF 50V J

C5008 NCB31HK-223X C CAPACITOR 0.022uF 50V K

C5009 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C5010 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C5011 QCBB1HK-104Y C CAPACITOR 0.1uF 50V K

C5012 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C5013 QCBB1HK-104Y C CAPACITOR 0. 1uF 50V K

C5014 NCS31HJ-681X C CAPACITOR 680pF 50V J

C5015 NCS31HJ-470X C CAPACITOR 47pF 50V J

C5016 NCS31HJ-560X C CAPACITOR 56pF 50V J

C5017 NCS31HJ-560X C CAPACITOR 56pF 50V J

C5018 NCB11EK-224X C CAPACITOR 0.22uF 25V K

C5019 NCB11EK-684X C CAPACITOR 0.68uF 25V K

C5020 QTE1V06-106Z E CAPACITOR 10uF 35V

C5021 QFV72AJ-224Z MF CAPACITOR 0.22uF 100V J

C5022 QFG32AJ-392Z PP CAPACITOR 3900pF 100V J

C5023 QENC1HM-225Z BP E CAPACITOR 2.2uF 50V M

C5024 NCB31CK-823X C CAPACITOR 0.082uF 16V K

C5025 NCF21HZ-104X C CAPACITOR 0.1uF 50V Z

C5026 QETN2AM-475Z E CAPACITOR 4.7uF 100V M

C5702 QETN1VM-227Z E CAPACITOR 220uF 35V M

C5703 QER61CM-476Z E CAPACITOR 47uF 16V M

C5704 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C5705 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C5706 NCB11AK-335X C CAPACITOR 3.3uF 10V K

C5707 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C5708 NCB11AK-335X C CAPACITOR 3.3uF 10V K

C5709 NCB21AK-225X C CAPACITOR 2.2uF 10V K

C5710 NCB21AK-225X C CAPACITOR 2.2uF 10V K

C5711 NCB11EK-224X C CAPACITOR 0.22uF 25V K

C5901 QFV72AJ-104Z MF CAPACITOR 0.1uF 100V J

C5902 QFV72AJ-104Z MF CAPACITOR 0.1uF 100V J

C5903 QEHR1HM-227Z E CAPACITOR 220uF 50V M

C5904 QEHR1HM-227Z E CAPACITOR 220uF 50V M

C5905 QER61EM-475Z E CAPACITOR 4.7uF 25V M

C5906 QER61EM-476Z E CAPACITOR 47uF 25V M

C5907 NCS31HJ-221X C CAPACITOR 220pF 50V J

C5908 NCS31HJ-221X C CAPACITOR 220pF 50V J

C5909 QEHR1HM-107Z E CAPACITOR 100uF 50V M

C5910 QEHR1HM-107Z E CAPACITOR 100uF 50V M

C5911 QEHR1EM-107Z E CAPACITOR 100uF 25V M

C5912 QEHR1EM-107Z E CAPACITOR 100uF 25V M

C5913 QERF1CM-106Z E CAPACITOR 10uF 16V M

C5914 QERF1CM-106Z E CAPACITOR 10uF 16V M

C5915 QTE1E51-106Z E CAPACITOR 10uF 25V

C5916 QTE1E51-106Z E CAPACITOR 10uF 25V

C5917 NCB31HK-183X C CAPACITOR 0.018uF 50V K

C5918 NCB31HK-183X C CAPACITOR 0.018uF 50V K

C9001 QFZ9075-224 MPP CAPACITOR 0.22uF AC275V M

C9002 QFZ9075-104 MPP CAPACITOR 0.1uF AC275V M

C9003 QCZ9079-102 C CAPACITOR 1000pF AC250V M

C9004 QCZ9079-102 C CAPACITOR 1000pF AC250V M

C9005 QFZ9075-103 MPP CAPACITOR 0.01uF AC275V M

C9501 QEZ0603-227 E CAPACITOR 220uF

C9502 QCZ0366-102 C CAPACITOR 1000pF

C9503 NCB31HK-471X C CAPACITOR 470pF 50V K

C9504 QETN1VM-107Z E CAPACITOR 100uF 35V M

Part No. Part Name Description Local

Symbol

No.

C9505 NCB31HK-471X C CAPACITOR 470pF 50V K

C9506 QFKB2JK-103 MM CAPACITOR 0.01uF 630V K

C9507 QCZ0213-472 C CAPACITOR 4700pF 1kV K

C9508 QCZ0213-472 C CAPACITOR 4700pF 1kV K

C9509 QFG32AJ-223Z PP CAPACITOR 0.022uF 100V J

C9510 QFG32AJ-223Z PP CAPACITOR 0.022uF 100V J

C9511 QEHQ1HM-228 E CAPACITOR 2200uF 50V M

C9512 QEHQ1HM-228 E CAPACITOR 2200uF 50V M

C9513 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C9514 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C9515 QCZ9079-332 C CAPACITOR 3300pF AC250V M

R1001 NRSA63J-474X MG RESISTOR 470kΩ 1/16W J

R1002 NRSA63J-474X MG RESISTOR 470kΩ 1/16W J

R1003 NRSA63J-563X MG RESISTOR 56kΩ 1/16W J

R1004 NRSA63J-563X MG RESISTOR 56kΩ 1/16W J

R1005 NRSA63J-683X MG RESISTOR 68kΩ 1/16W J

R1006 QRL01DJ-471X OMF RESISTOR 470Ω 1W J

R1007 QRL01DJ-471X OMF RESISTOR 470Ω 1W J

R1008 NRSA63J-154X MG RESISTOR 150kΩ 1/16W J

R1009 NRSA63J-154X MG RESISTOR 150k

R1010 NRSA63J-154X MG RESISTOR 150k

R1011 NRSA63J-154X MG RESISTOR 150kΩ 1/16W J

R1012 NRSA63J-682X MG RESISTOR 6.8kΩ 1/16W J

R1013 NRSA63J-682X MG RESISTOR 6.8kΩ 1/16W J

R1014 NRSA63J-563X MG RESISTOR 56kΩ 1/16W J

R1015 QRE141J-470Y C RESISTOR 47Ω 1/4W J

R1016 NRSA63J-153X MG RESISTOR 15kΩ 1/16W J

R1017 QRE141J-470Y C RESISTOR 47Ω 1/4W J

R1019 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R1020 NRSA63J-152X MG RESISTOR 1.5kΩ 1/16W J

R1021 NRSA63J-562X MG RESISTOR 5.6kΩ 1/16W J

R1022 NRSA63J-333X MG RESISTOR 33kΩ 1/16W J

R1023 NRSA63J-184X MG RESISTOR 180kΩ 1/16W J

R1025 QRE141J-470Y C RESISTOR 47Ω 1/4W J

R1028 QRE141J-470Y C RESISTOR 47Ω 1/4W J

R1030 NRSA63J-562X MG RESISTOR 5.6kΩ 1/16W J

R1031 NRSA63J-562X MG RESISTOR 5.6kΩ 1/16W J

R1032 NRSA63J-684X MG RESISTOR 680kΩ 1/16W J

R1033 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1034 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1035 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1036 NRSA63J-153X MG RESISTOR 15kΩ 1/16W J

R1037 NRSA63J-393X MG RESISTOR 39kΩ 1/16W J

R1038 NRSA63J-123X MG RESISTOR 12kΩ 1/16W J

R1039 NRSA63J-223X MG RESISTOR 22kΩ 1/16W J

R1040 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R1041 QRE141J-470Y C RESISTOR 47

R1044 QRE141J-470Y C RESISTOR 47

R1046 NRSA63J-823X MG RESISTOR 82k

R1047 NRSA63J-224X MG RESISTOR 220kΩ 1/16W J

R1048 NRSA63J-102X MG RESISTOR 1k

R1049 NRSA63J-222X MG RESISTOR 2.2k

R1050 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R1051 NRSA63J-105X MG RESISTOR 1M

R1052 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R1053 NRSA63J-472X MG RESISTOR 4.7k

R1054 NRSA63J-560X MG RESISTOR 56

R1055 NRSA63J-152X MG RESISTOR 1.5kΩ 1/16W J

R1056 NRSA63J-103X MG RESISTOR 10k

R1057 NRSA63J-154X MG RESISTOR 150k

R1059 NRSA63J-104X MG RESISTOR 100kΩ 1/16W J

R1060 NRSA63J-224X MG RESISTOR 220k

R1061 NRSA63J-105X MG RESISTOR 1M

R1062 QRE141J-470Y C RESISTOR 47Ω 1/4W J

R1064 QRE141J-470Y C RESISTOR 47

R1065 QRE141J-102Y C RESISTOR 1k

R1066 NRSA63J-473X MG RESISTOR 47k

R1067 NRSA63J-560X MG RESISTOR 56

R1068 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R1069 NRSA63J-102X MG RESISTOR 1k

R1070 QRE141J-102Y C RESISTOR 1k

R1071 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R1501 NRSA63J-392X MG RESISTOR 3.9k

R5001 NRSA63J-153X MG RESISTOR 15k

R5002 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R5003 NRSA63J-103X MG RESISTOR 10k

Part No. Part Name Description Local

Ω

1/16W J

Ω

1/16W J

Ω

1/4W J

Ω

1/4W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/4W J

Ω

1/4W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/4W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

3-7

Page 32

SP-DW103

Symbol

No.

R5004 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R5005 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R5006 NRSA63J-752X MG RESISTOR 7.5kΩ 1/16W J

R5007 NRSA63J-133X MG RESISTOR 13kΩ 1/16W J

R5008 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R5009 NRSA63J-103X MG RESISTOR 10k

R5010 NRSA63J-103X MG RESISTOR 10k

R5011 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R5012 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R5013 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R5014 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R5015 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R5016 QRE141J-222Y C RESIS TOR 2.2kΩ 1/4W J

R5017 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R5018 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R5019 NRSA63J-4R7X MG RESISTOR 4.7Ω 1/16W J

R5020 NRSA63J-4R7X MG RESISTOR 4.7Ω 1/16W J

R5021 NRSA63J-4R7X MG RESISTOR 4.7Ω 1/16W J

R5022 NRSA63J-4R7X MG RESISTOR 4.7Ω 1/16W J

R5023 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R5024 NRSA63J-272X MG RESISTOR 2.7k

R5025 NRSA63J-4R7X MG RESISTOR 4.7

R5026 NRSA63J-4R7X MG RESISTOR 4.7Ω 1/16W J

R5027 NRSA63J-2R2X MG RESISTOR 2.2Ω 1/16W J

R5028 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R5029 NRSA63J-682X MG RESISTOR 6.8kΩ 1/16W J

R5030 NRSA63J-682X MG RESISTOR 6.8kΩ 1/16W J

R5031 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R5032 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R5033 NRSA63J-2R2X MG RESISTOR 2.2Ω 1/16W J

R5034 NRSA63J-2R2X MG RESISTOR 2.2Ω 1/16W J

R5035 NRSA63J-2R2X MG RESISTOR 2.2Ω 1/16W J

R5036 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R5037 NRSA63J-123X MG RESISTOR 12kΩ 1/16W J

R5038 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R5039 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R5040 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R5041 NRSA63J-562X MG RESISTOR 5.6kΩ 1/16W J

R5042 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R5043 NRSA63J-332X MG RESISTOR 3.3kΩ 1/16W J

R5044 NRSA63J-561X MG RESISTOR 560Ω 1/16W J

R5045 NRSA63J-822X MG RESISTOR 8.2kΩ 1/16W J

R5046 NRSA63J-822X MG RESISTOR 8.2kΩ 1/16W J

R5048 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R5049 QRZ9038-220X FUSI RES ISTOR 22

R5050 QRZ9015-2R2X FUSI RESISTOR 2.2

R5051 QRZ9015-100X FUSI RES ISTOR 10

R5052 QRZ9015-220X FUSI RES ISTOR 22

R5053 NRSA63J-105X MG RESISTOR 1MΩ 1/16W J

R5054 NRSA63J-105X MG RESISTOR 1M

R5055 QRT01DJ-6R8X MF RESISTOR 6.8Ω 1W J

R5056 QRT01DJ-6R8X MF RESISTOR 6.8

R5057 NRSA63J-223X MG RESISTOR 22k

R5058 NRSA63J-184X MG RESISTOR 180kΩ 1/16W J

R5059 NRSA63J-113X MG RESISTOR 11k

R5701 QRE141J-102Y C RESIS TOR 1kΩ 1/4W J

R5702 NRSA63J-103X MG RESISTOR 10k

R5713 NRSA63J-153X MG RESISTOR 15k

R5714 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R5715 NRSA63J-472X MG RESISTOR 4.7k

R5716 NRSA63J-224X MG RESISTOR 220k

R5717 NRSA63J-104X MG RESISTOR 100kΩ 1/16W J

R5718 NRSA63J-473X MG RESISTOR 47k

R5719 NRSA63J-473X MG RESISTOR 47k

R5720 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R5721 NRSA63J-473X MG RESISTOR 47k

R5722 NRSA63J-473X MG RESISTOR 47k

R5723 NRSA63J-224X MG RESISTOR 220k

R5724 NRSA63J-393X MG RESISTOR 39k

R5725 NRSA63J-683X MG RESISTOR 68kΩ 1/16W J

R5726 NRSA63J-104X MG RESISTOR 100k

R5727 NRSA63J-104X MG RESISTOR 100k

R5728 NRSA63J-333X MG RESISTOR 33kΩ 1/16W J

R5729 NRSA63J-683X MG RESISTOR 68k

R5730 NRSA63J-104X MG RESISTOR 100k

R5731 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R5732 NRSA63J-104X MG RESISTOR 100k

Part No. Part Name Description Local

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

Ω

Ω

Ω

Ω

1/16W J

Ω

1W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Symbol

No.

R5733 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R5734 NRSA63J-474X MG RESISTOR 470kΩ 1/16W J

R5735 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R5736 NRSA63J-474X MG RESISTOR 470kΩ 1/16W J

R5737 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R5738 NRSA63J-104X MG RESISTOR 100k

R5739 NRSA63J-103X MG RESISTOR 10k

R5740 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R5741 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R5742 NRSA63J-2R2X MG RESISTOR 2.2Ω 1/16W J

R5743 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R5744 NRSA63J-391X MG RESISTOR 390Ω 1/16W J

R5745 NRSA63J-223X MG RESISTOR 22kΩ 1/16W J

R5746 NRSA63J-104X MG RESISTOR 100kΩ 1/16W J

R5747 NRSA63J-104X MG RESISTOR 100kΩ 1/16W J

R5748 NRSA63J-104X MG RESISTOR 100kΩ 1/16W J

R5749 NRSA63J-104X MG RESISTOR 100kΩ 1/16W J

R5901 QRZ9005-100X FUSI RESISTOR 10

R5902 NRSA63J-682X MG RESISTOR 6.8kΩ 1/16W J

R5905 NRSA63J-473X MG RESISTOR 47kΩ 1/16W J

R5906 NRSA63J-473X MG RESISTOR 47k

R5909 QRE141J-102Y C RESISTOR 1k

R5910 QRE141J-102Y C RESISTOR 1kΩ 1/4W J

R5911 NRSA63J-123X MG RESISTOR 12kΩ 1/16W J

R5912 NRSA63J-123X MG RESISTOR 12kΩ 1/16W J

R5913 NRSA63J-331X MG RESISTOR 330Ω 1/16W J

R5914 NRSA63J-331X MG RESISTOR 330Ω 1/16W J

R5915 QRZ9038-220X FUSI RESISTOR 22

R5916 QRZ9038-220X FUSI RESISTOR 22

R9001 QRL027J-104 OMF RESISTOR 100kΩ 2W J

R9002 QRZ9037-335 COMP RESISTOR 3.3MΩ 1/2W K

R9501 QRT017J-R33 MF RESISTOR 0.33Ω 1W J

R9502 QRT017J-R33 MF RESISTOR 0.33Ω 1W J

R9503 QRZ9005-681X FUSI RESISTOR 680

R9504 NRSA63J-332X MG RESISTOR 3.3kΩ 1/16W J

R9505 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R9506 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R9508 QRL01DJ-220X OMF RESISTOR 22Ω 1W J

R9510 QRE141J-753Y C RESISTOR 75kΩ 1/4W J

R9516 NRSA63J-133X MG RESISTOR 13kΩ 1/16W J

R9517 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R9518 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R9519 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R9520 NRSA63J-133X MG RESISTOR 13kΩ 1/16W J

R9521 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R9522 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R9523 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R9524 NRSA63J-472X MG RESISTOR 4.7k

R9525 NRSA63J-102X MG RESISTOR 1k

R9526 NRSA63J-103X MG RESISTOR 10k

R9527 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R9528 QRE141J-753Y C RESISTOR 75k

R9529 QRE141J-753Y C RESISTOR 75k

VR101 QVQ0300-B24 V RESISTOR

VR151 QVQ0021-B14 V RESISTOR

VR501 QVP0008-502Z TRIM RESISTOR 5k

VR502 QVP0008-203Z TRIM RESISTOR 20k

L5001 QQR1361-001 TOROIDAL COIL

L5901 NQL114K-471X COIL 470uH K

L5902 NQL114K-471X COIL 470uH K

L5903 NQL114K-471X COIL 470uH K

L5904 NQL114K-471X COIL 470uH K

T9501 QQS0172-001 SW TRANSF

BK501 LV33818-001A BKT(FET)

CN101 QGB2016K1-08 CONNECTOR B-B (1-8)

CN102 QGA2501C1-02 CONNECTOR W-B (1-2)

CN103 QGB2016J1-05 CONNECTOR B-B (1-5)

CN151 QGA2001C1-08 CONNECTOR W-B (1-8)

CN501 QGB2016J1-08 CONNECTOR B-B (1-8)

CN502 QGB2510K1-10 CONNECTOR B-B (1-10)

CN503 QGA3901C1-02 CONNECTOR W-B (1-2)

CN504 QGB2016J1-11 CONNECTOR B-B (1-11)

CN505 QGB2016K1-11 CONNECTOR B-B (1-11)

CN901 QGA7901F2-02 CONNECTOR W-B (1-2)

CN951 QGB2510J1-10 CONNECTOR B-B (1-10)

Part No. Part Name Description Local

Ω

1/16W J

Ω

1/16W J

Ω

Ω

1/16W J

Ω

1/4W J

Ω

Ω

Ω

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/4W J

Ω

1/4W J

Ω

Ω

3-8

Page 33

Symbol

No.

CN952 QGB2016K1-05 CONNECTOR B-B (1-5)

EP951 QNZ0136-001Z EARTH PLATE

EP952 QNZ0136-001Z EARTH PLATE

HS951 L V33 802-001A HEAT SINK1

HS952 E70306-001 HEAT SINK

HS953 E70306-001 HEAT SINK

HS954 E70306-001 HEAT SINK

J1001 QNN0090-001 PIN JACK

J1002 QNB0159-002 SPK.TERMINAL

K1001 NQR0129-003X FERRITE BESDS

K5001 QQR1183-001Z FERRITE BEADS

K5002 QQR1183-001Z FERRITE BEADS

K9501 QQR0779-001Z COIL

LF901 QQR1360-001 LINE FILTER

LF902 QQR1360-001 LINE FILTER

RY502 QSK0148-001 RELAY

S1001 QSW1002-001 PUSH SW

S1501 QSW0999-001 PUSH SW

S9001 QSW1001-001 POWER SW

TH501 QAD0015-153Z THERMISTOR 15k

TH591 NAD0032-330X P THERMISTOR 33

TH592 NAD0032-330X P THERMISTOR 33

TH593 NAD0032-330X P THERMISTOR 33

TH594 NAD0032-330X P THERMISTOR 33

TH901 QAD0141-6R0 THERMISTOR 6

W1001 QJB001-080706 SIN ID C-B WIR

W9001 QUB192-07PPPP SIN TWIST WIRE

W9002 QUB199-09PPPP SIN TWIST WIRE

W9003 QUB191-07PPPP SIN TWIST WIRE

W9004 QUB190-09PPPP SIN TWIST WIRE

Z9001 QNG0003-001Z FUSE CLIP

Z9002 QNG0003-001Z FUSE CLIP

Part No. Part Name Description Local

SP-DW103

Ω

Ω

Ω

Ω

Ω

Ω

3-9

Page 34

SP-DW103

Packing materials and accessories parts list

P3

Block No.

M

3

M

M

P2

P4

1/2

P1

P4

P6

1/2

P7

A1A2

A3

3-10

P5

Page 35

Packing&accessories

Symbol

No.

Part No. Part Name Description Local

SP-DW103

Block No. [M][3][M][M]

A 1 LVT1030-003A INST BOOK

A 2 BT-54008-4 WARRANTY CARD

A 3 QAM0199-001 PIN CABLE

A 4 LV43479-002A CAUTION SHEET

A 5 VNA3000-204 REGIST.CARD

P 1 8500047091 MIRROR MAT

P 2 QPA07007505P POLY BAG 70cm x 75cm

P 3 8000051301 CUSHION(TOP)

P 4 8000051311 CUSHION(BTM)

P 5 LV31492-031A CARTON

P 6 LV33489-007A CARTON SHEET

P 7 QPA02503503P POLY BAG 25cm x 35cm

ENG GER FRE

SPA ITA DUT

DW10

3B

3-11

Loading...

Loading...