Page 1

SERVICE MANUAL

CD PORTABLE SYSTEM

RV-B550BU

Supplement

RV-B550BU

TIMER

ON/OFF

CLOCK TIMER

SLEEP

DOWN UP SET

PROGRAM

RANDOM

AUTO

PRESET

REPEAT

TUNER

TAPE

C D

BAND

AUX

FM MODE

REVERSE MODE

FF

REW

MULTI CONTROL

DISPLAY

ACS

SOUND

AHB PRO

VOLUME

RM-RXVB55

REMOTE CONTROL

This service manual adds UY version to the service manual

(RV-B550BU No.20826) previously issued.

Contents

Safety precautions ...................................1-2

Importance administering

point on the safety .............1-3

Important for laser products .................... 1-4

Preventing static electricity ...................... 1-5

Disassembly method ............................... 1-6

Area Suffix

UY ................ Argentina

Adjustment method ................................. 1-15

Flow of functional operation

until TOC read ................. 1-19

Maintenance of laser pickup ....................1-20

Replacement of laser pickup ....................1-20

Description of major ICs .......................... 1-21~29

This service manual is made from 100% recycled paper.

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

No.20826C

Jan. 2001

Page 2

RV-B550BU

Safety precautions

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original design

unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

2. Alter ations of the design or circuitry of the product should not be made. Any design alterations of

the product should not be made. Any design alterations or additions will void the manufacturer`s

warranty and will further relieve the manufacture of responsibility for personal injury or property

damage resulting therefrom.

3. Many electrical and mechanical par ts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded

by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special safety characteristics are identified in

the Parts List of Service Manual. Electrical components having such features are identified by

shading on the schematics and by ( ) on the Parts List in the Service Manual. The use of a

substitute replacement which does not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of Service Manual may create shock, fire, or other

hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the original lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

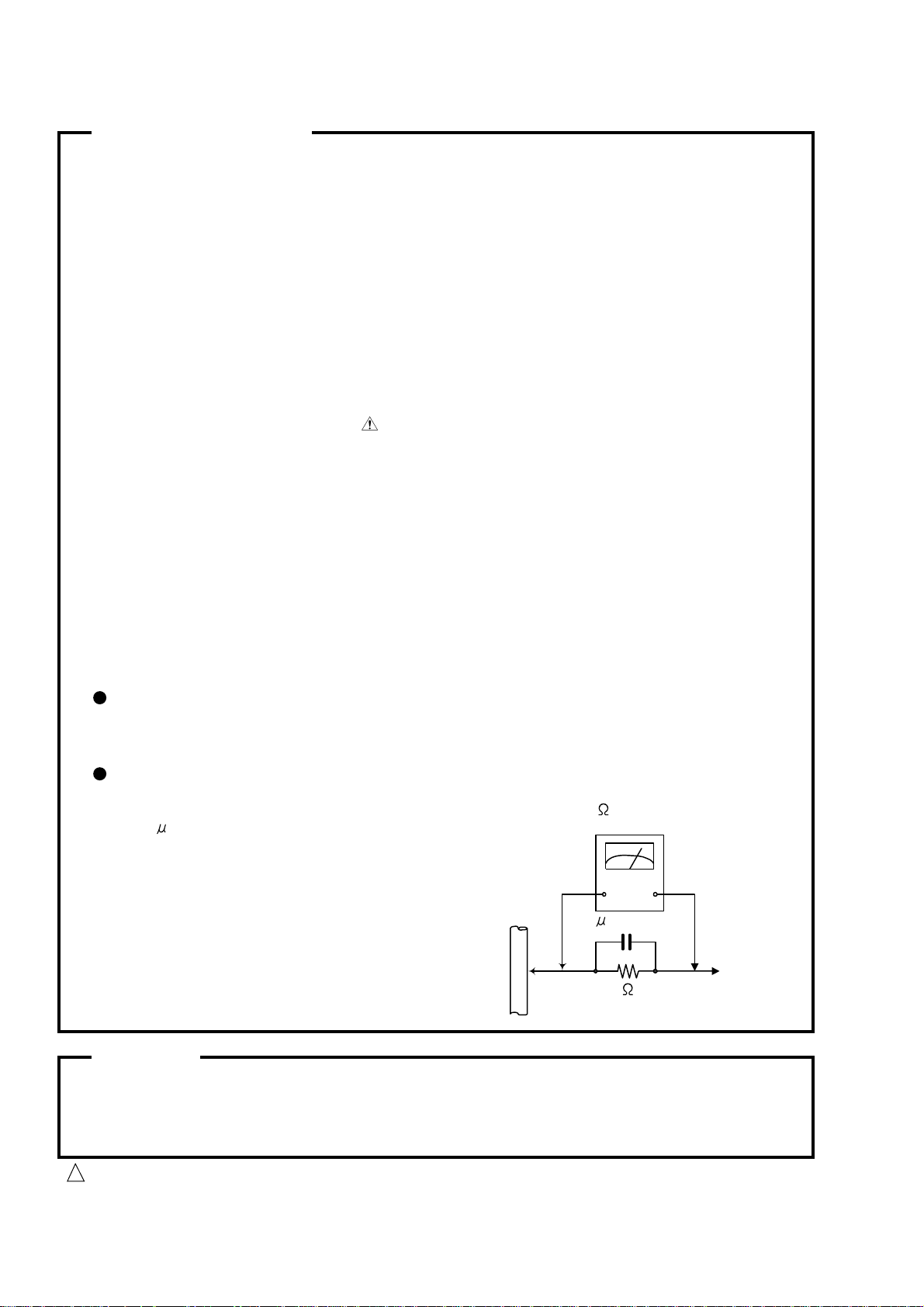

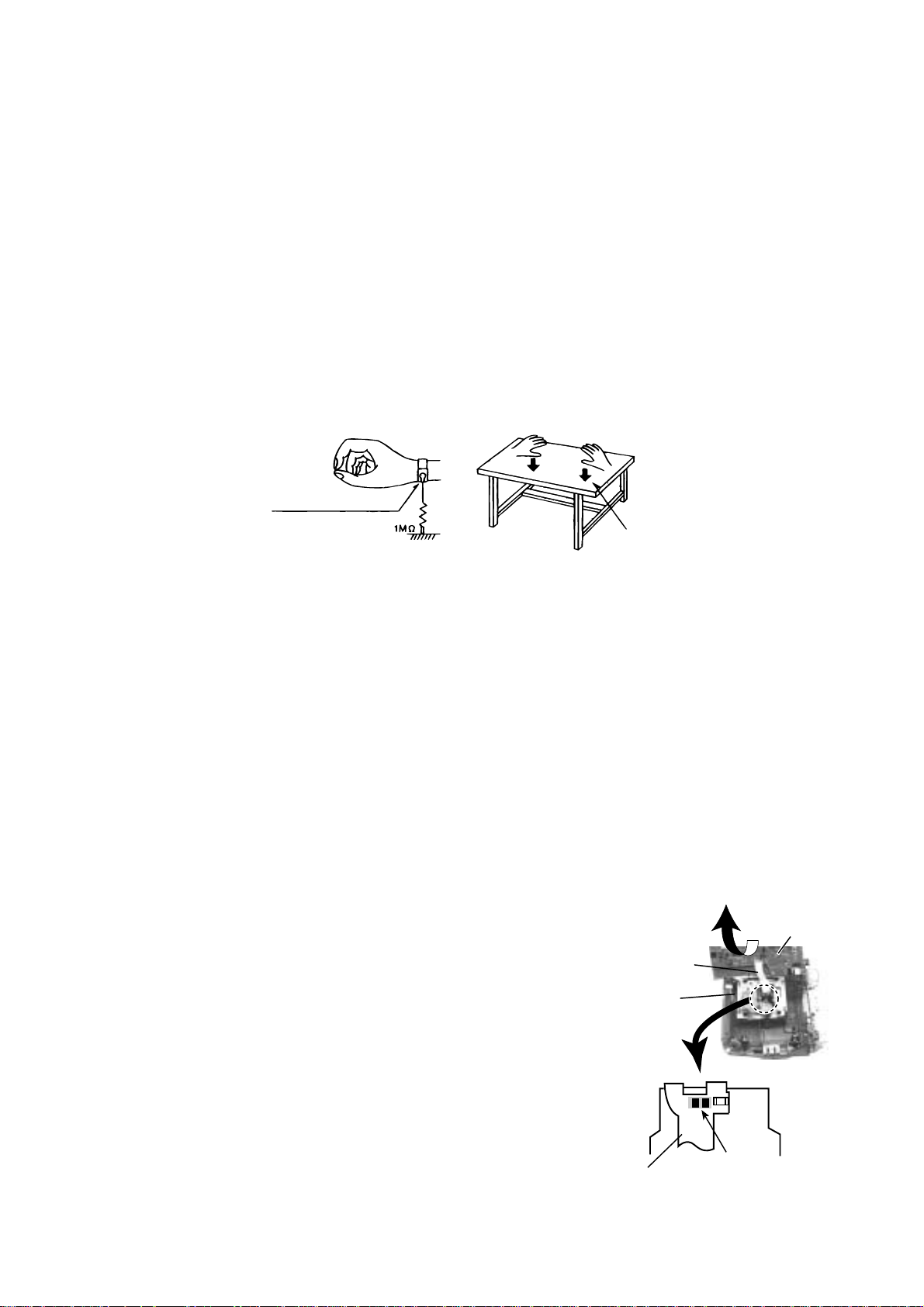

5. Leakage current check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts

of the product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control

shafts, etc.) to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure

the leakage current from each exposed metal parts of the cabinet , particularly any exposed

metal part having a return path to the chassis, to a known good earth ground. Any leakage

current must not exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having 1,000 ohms

per volt or more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by

a 0.15 F AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with the

AC voltmeter.

Move the resistor connection to each exposed metal

part, par ticularly any exposed metal part having a

return path to the chassis, and measure the AC

voltage across the resistor. Now, reverse the plug in

the AC outlet and repeat each measurement. Voltage

measured any must not exceed 0.75 V AC (r.m.s.).

This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

Warning

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

CAUTION

!

Page 3

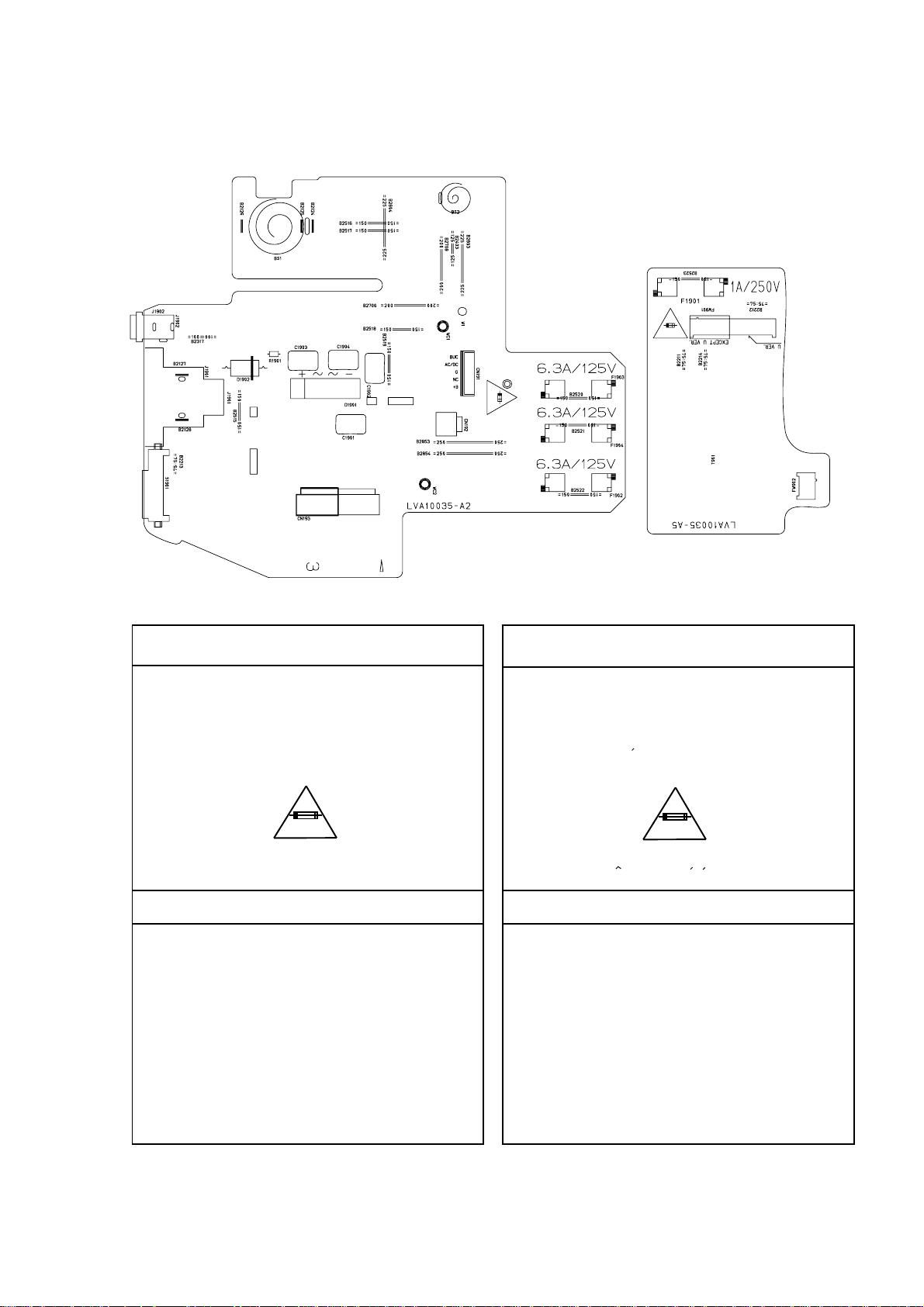

RV-B550BU

I

mportance administering point on the safety

Note : It's means "J" for U.S.A. and Canada market model.

RV-B550J ONLY

Full Fuse Replacement Marking

Graphic symbol mark

(This symbol means fast blow type fuse.)

should be read as follows ;

FUSE CAUTION

FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE

AND RATING OF FUSES ;

F1901 : 1.0-A, 250-V

F1902 : 6.3-A, 125-V

F1903 : 6.3-A, 125-V

F1904 : 6.3-A, 125-V

RV-B550J SEULEMENT

Marquage Pour Le Remplacement

Complet De Fusible

Le symbole graphique (Ce symbole signifie

fusible de type a fusion rapide.)

doit etre interprete comme suit ;

PRECAUTIONS SUR LES FUSIBLES

POUR UNE PROTECTION CONTINUE CONTRE

DES RISQUES D'INCENDIE, REMPLACER

SEULEMENT PAR UN FUSIBLE DU MEME TYPE ;

F1901 : 1.0-A, 250-V

F1902 : 6.3-A, 125-V

F1903 : 6.3-A, 125-V

F1904 : 6.3-A, 125-V

1-3

Page 4

RV-B550BU

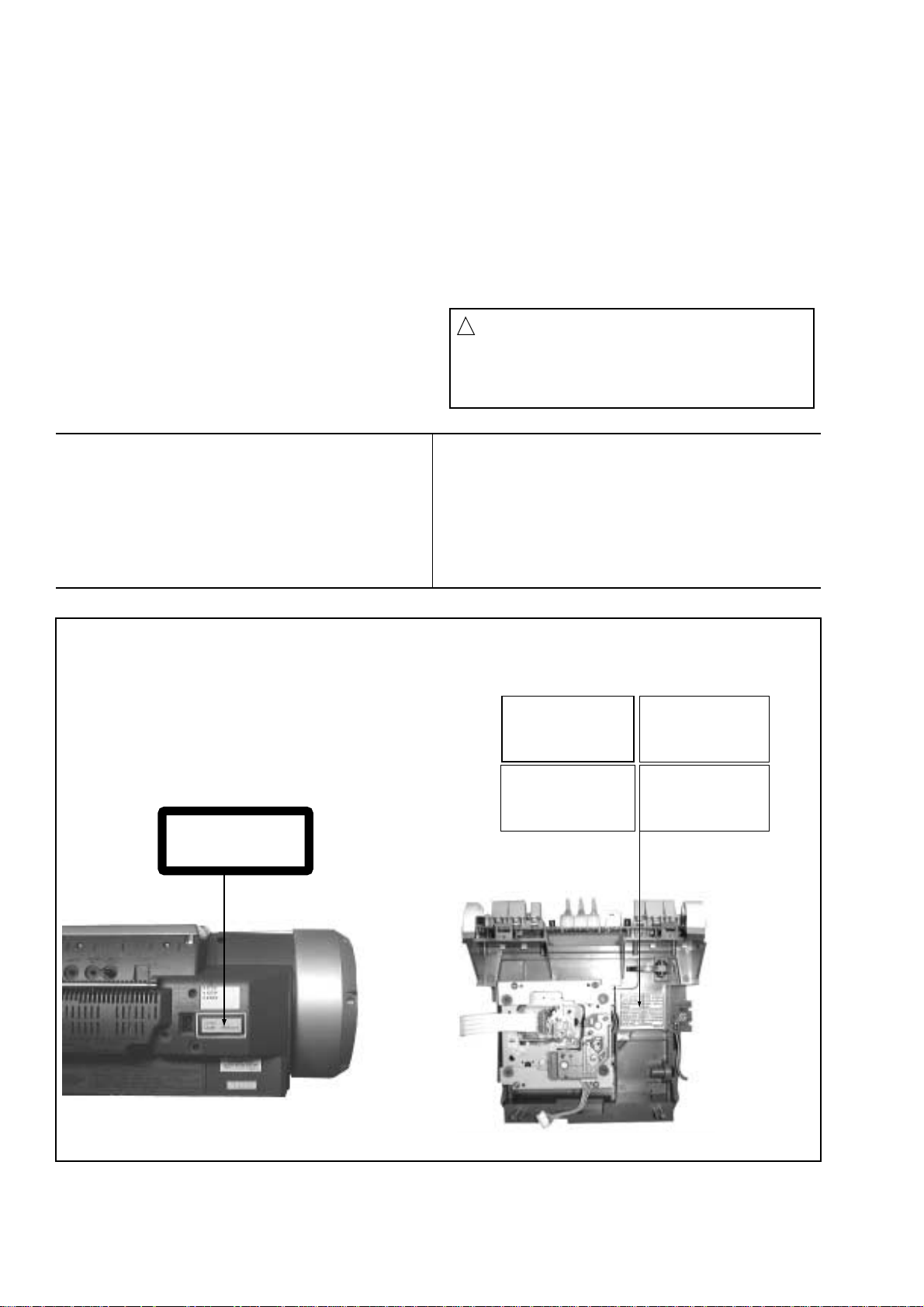

Important for laser products

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

VARNING : Osynlig laserstrålning är denna del är öppnad

och spårren är urkopplad. Betrakta ej strålen.

VARO : Avattaessa ja suojalukitus ohitettaessa olet

alttiina näkymättömälle lasersäteilylle.Älä katso

säteeseen.

REPRODUCTION AND POSITION OF LABELS

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

ADVARSEL : Usynlig laserstråling ved åbning , når

sikkerhedsafbrydere er ude af funktion. Undgå

udsættelse for stråling.

ADVARSEL : Usynlig laserstråling ved åpning,når

sikkerhetsbryteren er avslott. unngå utsettelse

for stråling.

CLASS 1

LASER PRODUCT

WARNING LABEL

DANGER : Invisibie laser radiation

when open and interlock or

defeated.

AVOID DIRECT EXPOSURE TO

BEAM (e)

VARNING : Osynlig laserstrålning är

denna del är öppnad och spårren är

urkopplad. Betrakta ej strålen. (s)

VARO : Avattaessa ja suojalukitus

ohitettaessa olet alttiina

näkymättömälle lasersäteilylle.Älä

katso säteeseen. (d)

ADVARSEL :Usynlig laserstråling

ved åbning , når

sikkerhedsafbrydere er ude af

funktion. Undgå udsættelse for

stråling. (f)

1-4

Page 5

RV-B550BU

Preventing static electricity

1. Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2. About the earth processing for the destruction prevention by static electricity

In the equipment which uses optical pick-up (laser diode), optical pick-up is destroyed by the static electricity of

the work environment.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

4. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

Attention when CD mecanism assembly is decomposed

*Please refer to "Disassembly method" in the text for pick-up and how to

detach the CD mechanism.

1. Remove CD mechanism assembly.

2. Remove the four screws on the microcomputer board.

3. Disconnect the connector CN907 and CN602 on the microcomputer board.

4. The microcomputer board is put up as shown in Fig.1.

5. Solder is put up before the card wire is removed from connector CN601

on the maicroconputer board as shown in Fig. 2.

(When the wire is removed without putting up solder, the CD pick-up

assembly might destroy.)

6. Please remove solder after connecting the card wire with CN601 when

you install picking up in the substrate.

Card wire

CD changer

mechanism

assembly

Flexible cable

Soldering

Fig.2

Microcomputer

board

Fig.1

1-5

Page 6

RV-B550BU

Disassembly method

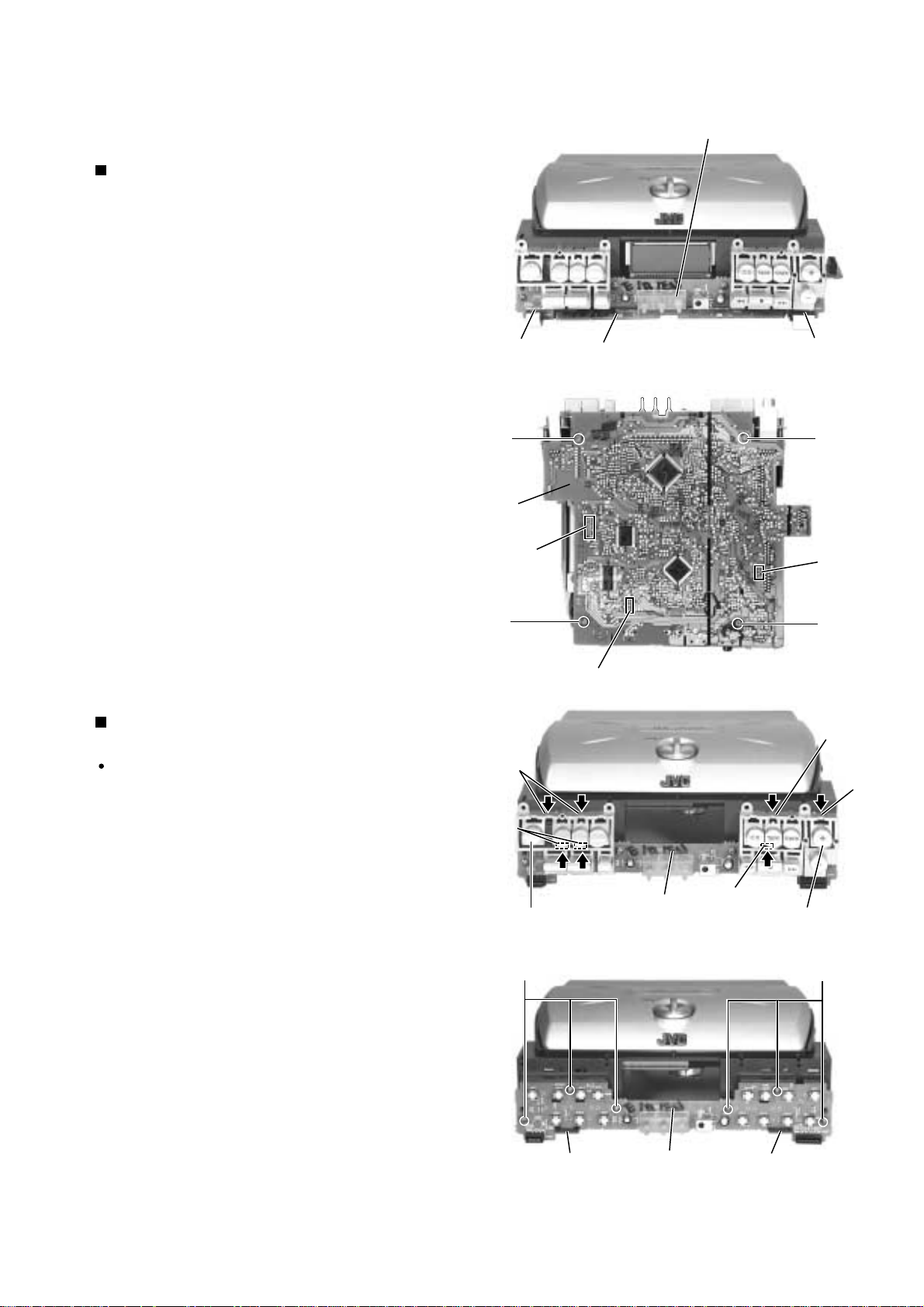

<Main Body>

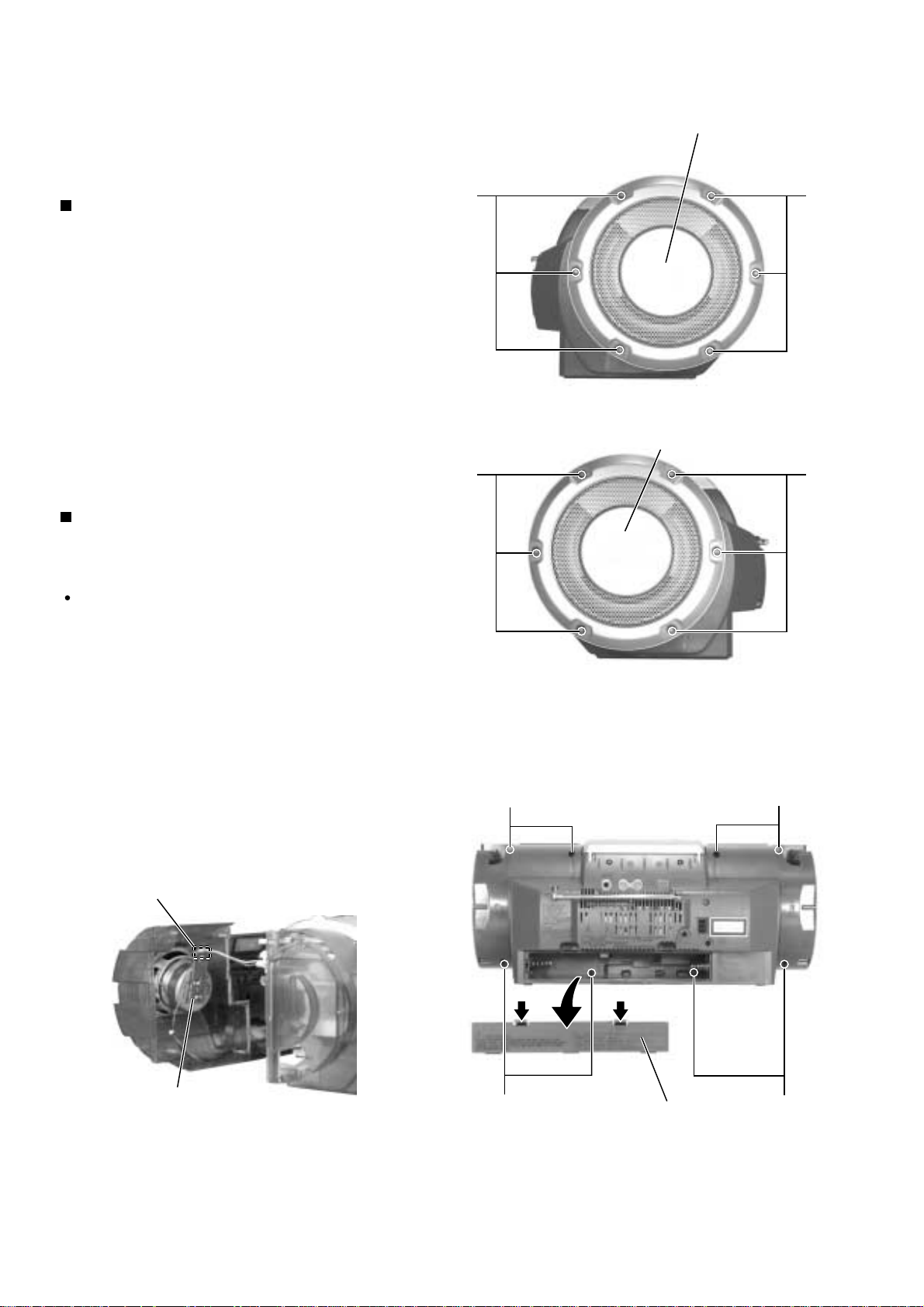

Removing the side grilles

(See Fig.1 and 2)

1.

Remove the six screws A attaching the side grille on

the left side of the body and pull out the side grille

from the body.

2.

Similarly, remove the side grille on the right side.

Removing the front cabinet assembl y and

the rear cabinet assembly (See Fig.3

and 3a)

A

A

Side grille (left)

A

Fig.1

Side grille (right)

A

Prior to performing the following procedure, remove

the right and left side grilles.

1.

Remove the battery cover on the back of the body.

2.

Remove the eight screws B on the back of the body

and detach the front cabinet assembly and the rear

cabinet assembly. Disconnect the connector CN904

on the LED

Attention:

(Illumination) board.

When reassembling, make sure that

connector CN633 on the rear cabinet is

connected to the speaker terminal on the

front cabinet.

CN904

B

Push Push

Fig.2

B

1-6

LED (Illumination) board

Fig.3a

B

Battery cover

Fig.3

B

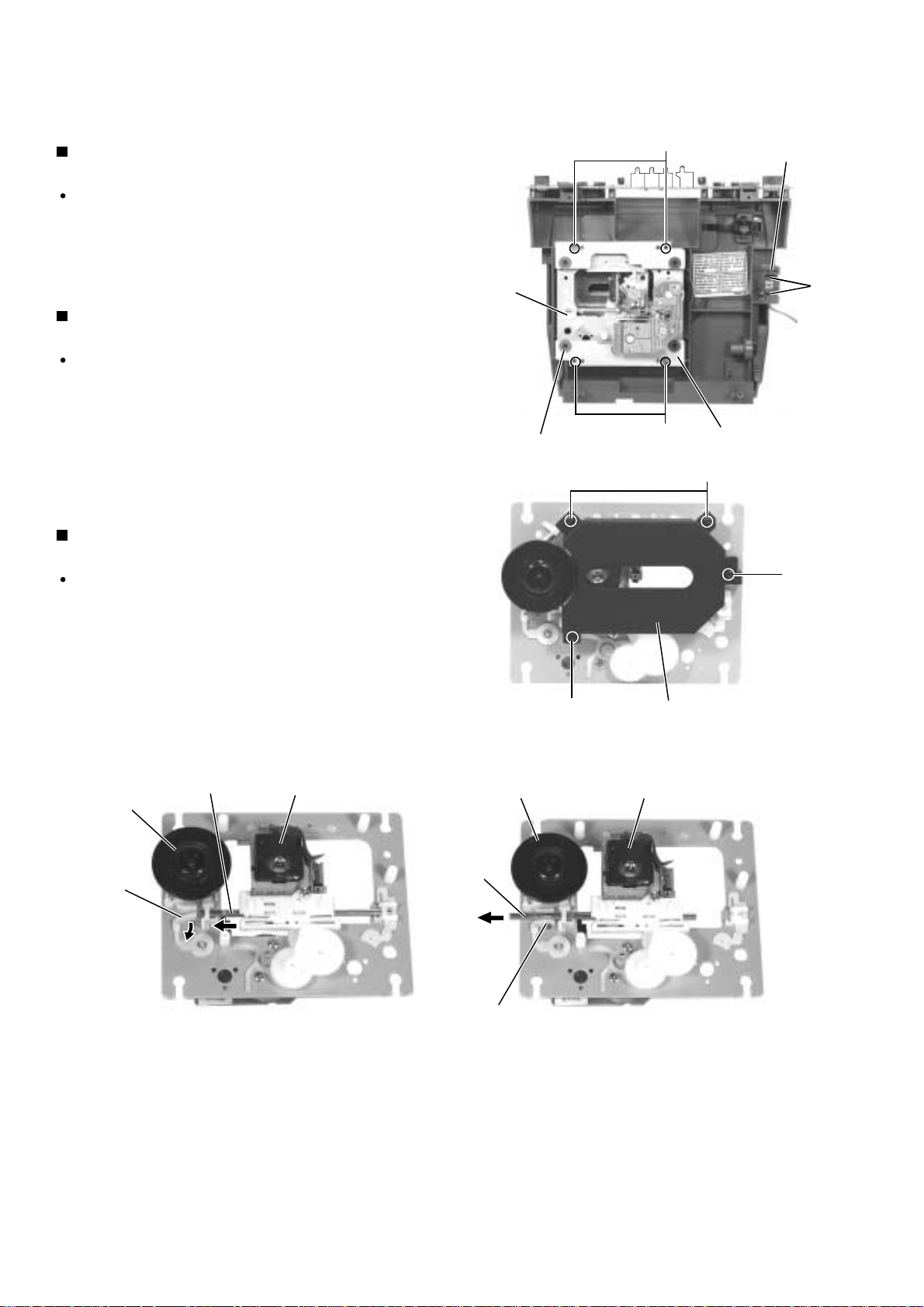

Page 7

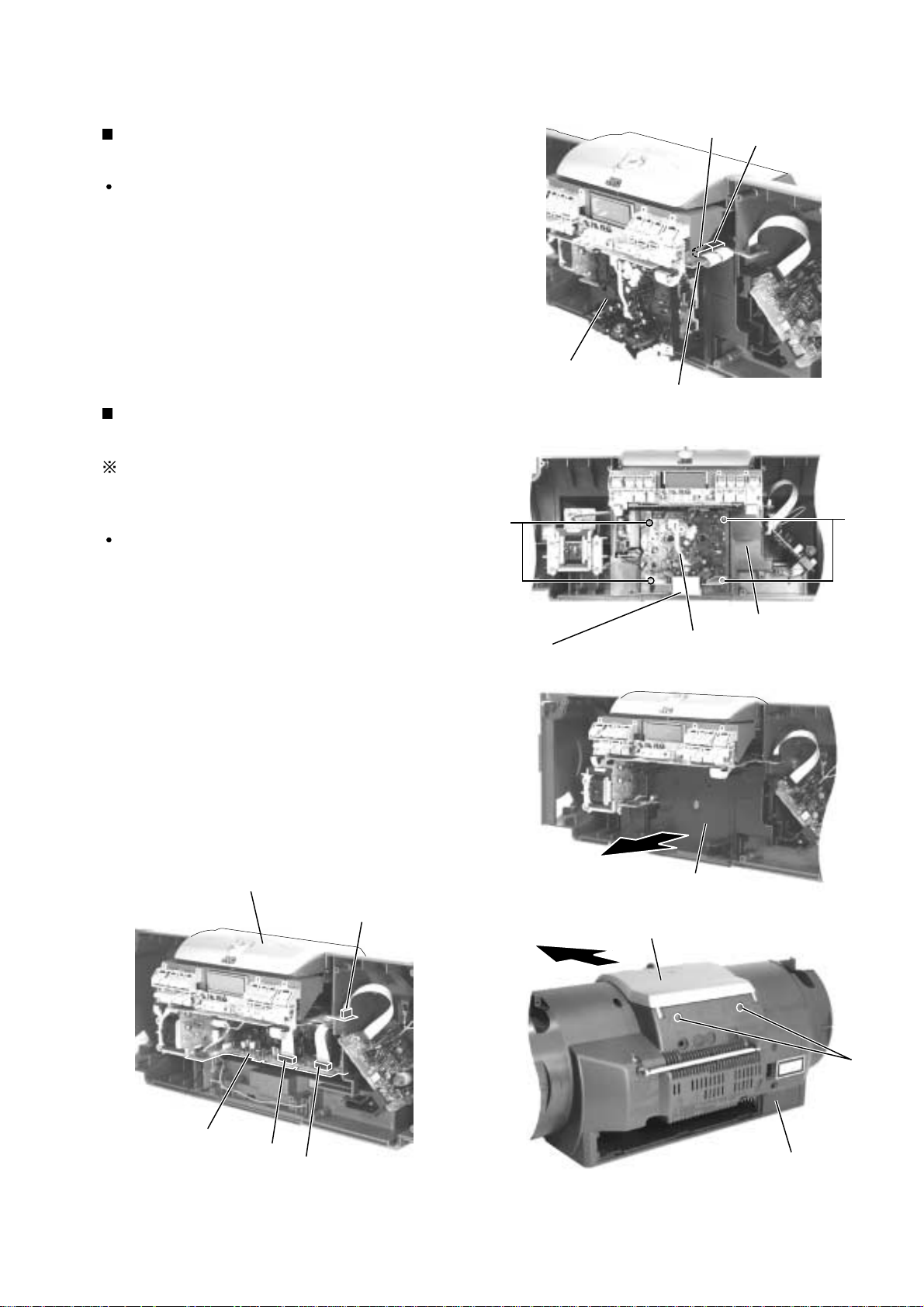

RV-B550BU

The CD unit assembly cannot be removed if the

cassette mechanism assembly has not been

removed.

Prior to performing the following procedure, remove

the right and left side grilles, the front cabinet

assembly and the cassette mechanism assembly.

Remove the cassette chassis (See Fig.6).

Disconnect the card wires from connector CN631

and CN632 on the amplifier board.

Disconnect the card wires from connector CN403 on

the microcomputer board.

Remove the two screws D attaching the CD

mechanism assembly on the back of the rear cabinet

(See Fig.8).

Pull out the CD unit assembly toward the front.

1.

2.

3.

4.

5.

Removing the CD unit assembly

(See Fig.6 to 8)

Prior to performing the following procedure, remove

the right and left side grilles and the front cabinet

assembly.

Disconnect the card wires from connector CN405

and CN406 on the microcomputer board located on

the underside of the CD unit of the rear cabinet

assembly.

Remove the four screws C attaching head shield and

the cassette mechanism assembly.

1.

2.

Removing the cassette mechanism

assembly (See Fig.4 and 5)

Fig.4

Fig.5

CN406

CN405

Microcomputer board

Cassette mechanism

assembly

Cassette chassis

Cassette mechanism assembly

C

C

CD unit assembly

CN403

Microcomputer board

CN632

CN631

amplifier board

Cassette chassis

Rear cabinet

D

CD unit assembly

Fig.6

Fig.8Fig.7

Head shield

1-7

Page 8

RV-B550BU

Removing the tuner board (See Fig.9)

Prior to performing the following procedure, remove

the right and left side grilles, the front cabinet

assembly.

1.

Disconnect the card wire from connector CN403 on

the microcomputer board.

2.

Remove the screw E attaching the tuner board

holder and pull out the tuner board holder together

with the tuner board. Disconnect the antenna wire

from TP1.

Remove the power transformer assemb ly

(See Fig.10)

Prior to performing the following procedure, remove

the right and left side grilles, the front cabinet assembly,

the cassette mechanism assembly and the cassette

chassis.

Microcomputer board

CN403

Tuner board holder

Power supply board

F

Fig.9

Antenna wire

E

Tuner board

CN193

TP1

1.

Disconnect the harness from connector CN192 and

CN193 on the power supply board respectively.

2.

Remove the four screws F attaching the power

transformer assembly.

Remove the amplifier board, the power

supply board and the battery board

(See Fig.11)

Prior to performing the following procedure, remove

the right and left side grilles, the front cabinet

assembly, the cassette mechanism assembly, the

cassette chassis and the CD unit assembly.

1.

Disconnect the 5pin harness from connector CN191

on the power supply board.

2.

Remove the two screws G and the one screw H

attaching the amplifier board.

3.

Disconnect the harness from connector CN192 and

CN193 on the power supply board respectively.

F

Power supply board

CN192

CN191

CN192

Power transformer assembly

Fig.10

CN193

I

G

H

CN631

4.

Remove the two screws I attaching the power supply

board.

5.

Pull out the battery board.

1-8

CN191

Amplifier board

CN631

Fig.11

Battery board

Page 9

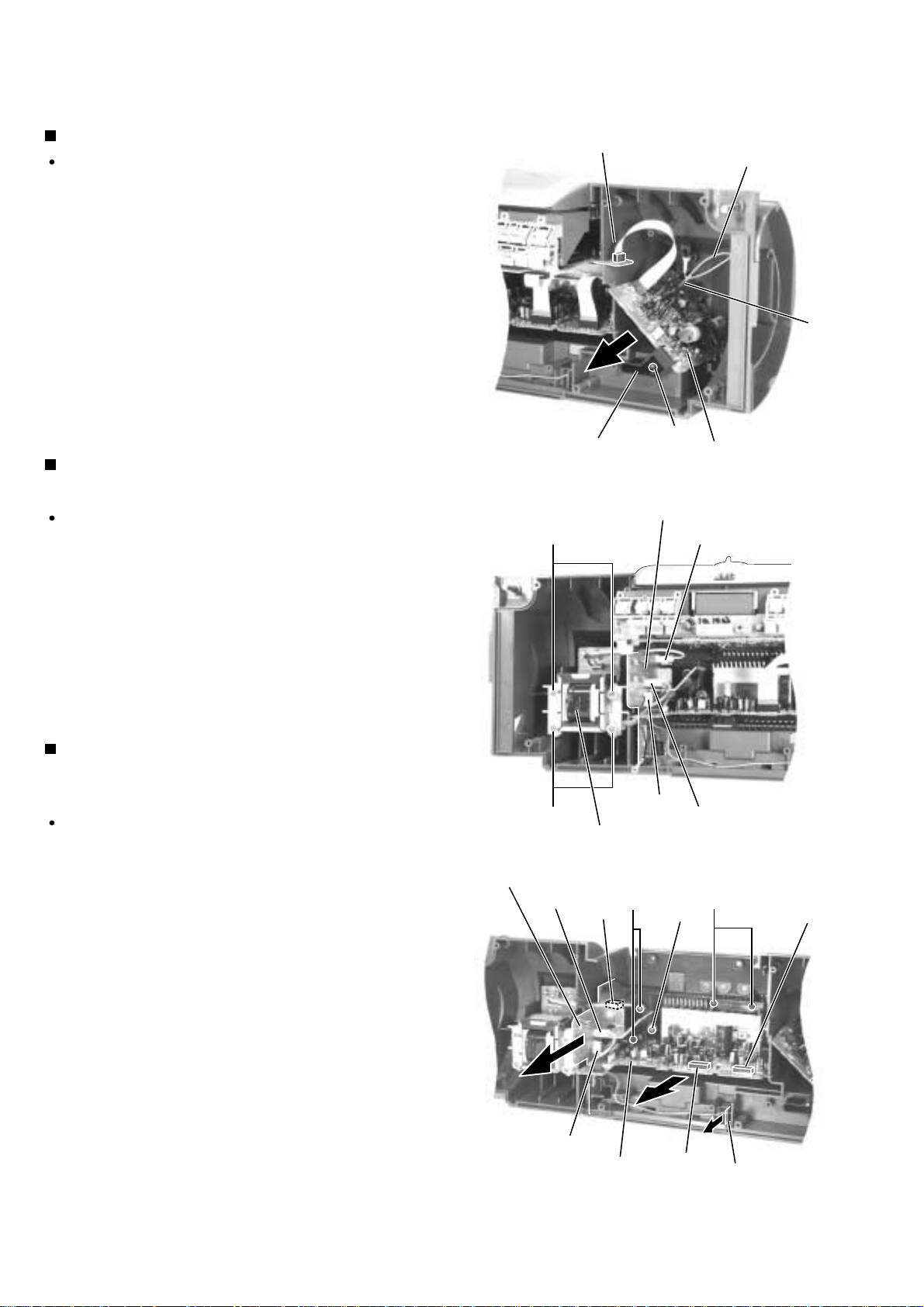

RV-B550BU

Disconnect the card wire from connector CN251 and

CN252 on the key switch board on the front side of

the CD unit assembly.

Remove the f our screws J attaching the microcomputer

board on the underside of the CD unit assembly.

Disconnect the card wire or the harness from

connector CN601, CN602 and CN907 on the

microcomputer board respectively.

1.

2.

3.

Removing the microcomputer board

(See Fig.12 and 13)

Prior to performing the following procedure, remove

the microcomputer board.

Release the four tabs a fixing the right and left

function buttons and the three tabs b by the key

switch board.

Push tabs a and b in the directions of the arrows

carefully not to damage the function buttons

Remove the six screws K attaching the key switch

board.

Pull out the key switch board from two tabs c.

1.

2.

3.

Removing the key switch board

(See Fig.14 and 15)

<CD unit assembly>

Fig.15

Fig.14

Fig.12

PushPush

CN252

CN251

Microcomputer board

Microcomputer board

J

J

J

J

CN602

CN601

CN907

Push

PushPushPush

PushPushPush

Push

a

b

a

b

Key switch board

Function switch buttons

(power)

Function switch buttons

(volume)

Key switch board

c

c

KK

a

Key switch board

PushPushPush

Fig.13

1-9

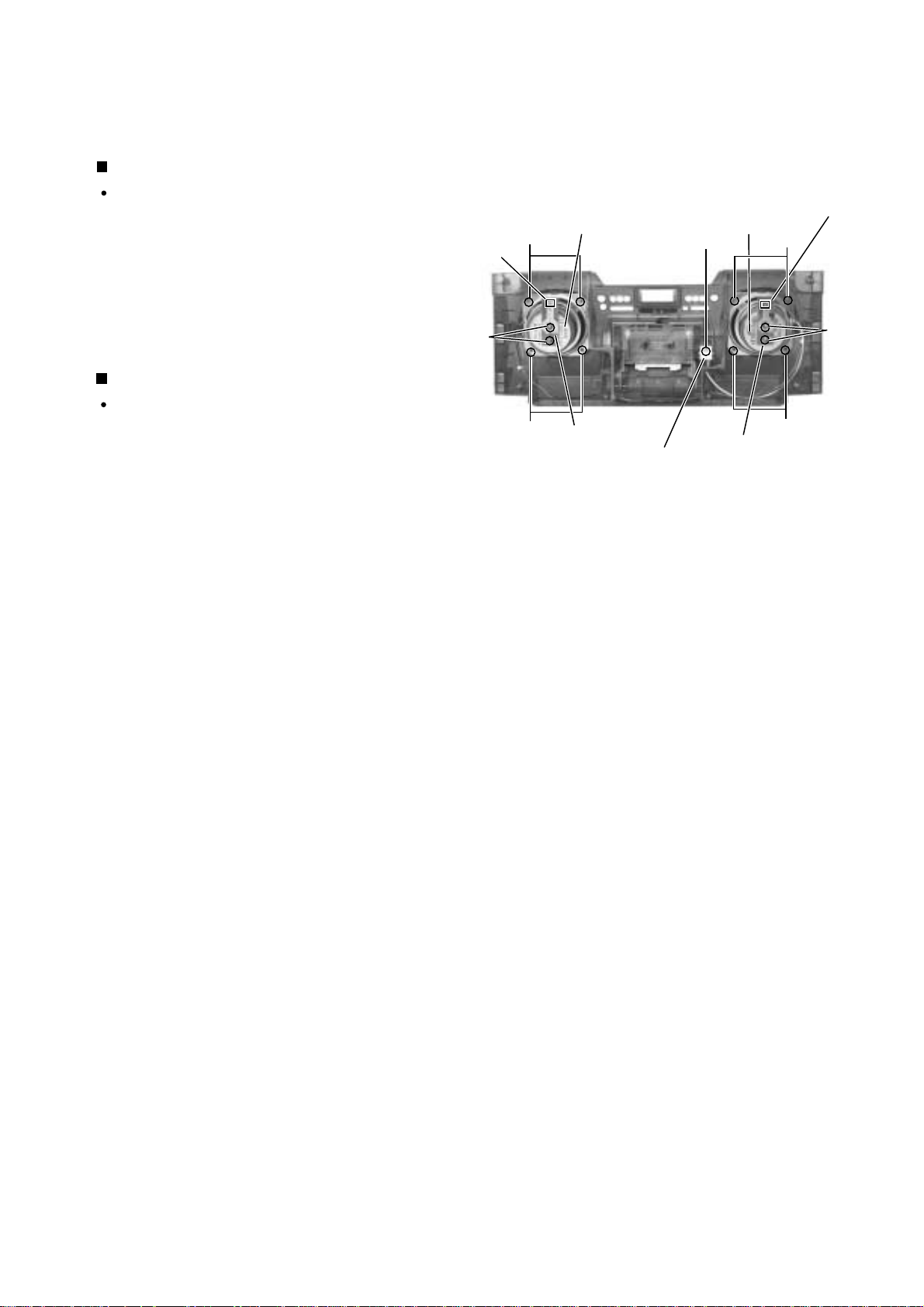

Page 10

RV-B550BU

Removing the CD door switch board

(See Fig.16)

Prior to performing the following procedure, remove

the microcomputer board.

1.

Release the two tabs d fixing the CD door switch

board on the back of the CD unit assembly.

Removing the CD mechanism assembly

(See Fig.16)

Prior to performing the following procedure, remove

the microcomputer board.

1.

Remove the f our scre ws L attaching the CD mechanism

holder on the back of the CD unit assembly.

2.

Remove the CD mechanism holder, the CD cushion

and the CD mechanism assembly respectively.

Removing the pickup assembly

(See Fig.17 to 19)

Prior to performing the following procedure, remove

the CD mechanism assembly.

CD mechanism

Assembly

CD cushion

L

L

CD door switch

board

CD mechanism holder

M

d

Fig.16

M

1.

Remove the f our screws M attaching the pickup cover.

2.

Push the shaft stopper by the turn table in the direction

of the arrow and pull out the shaft. The pickup assembly

comes off.

Turn table

Shaft

Shaft stopper

Pickup assembly

Fig.18

Turn table

Shaft

Shaft stopper

M

Pickup assembly

Pickup cover

Fig.17

Fig.19

1-10

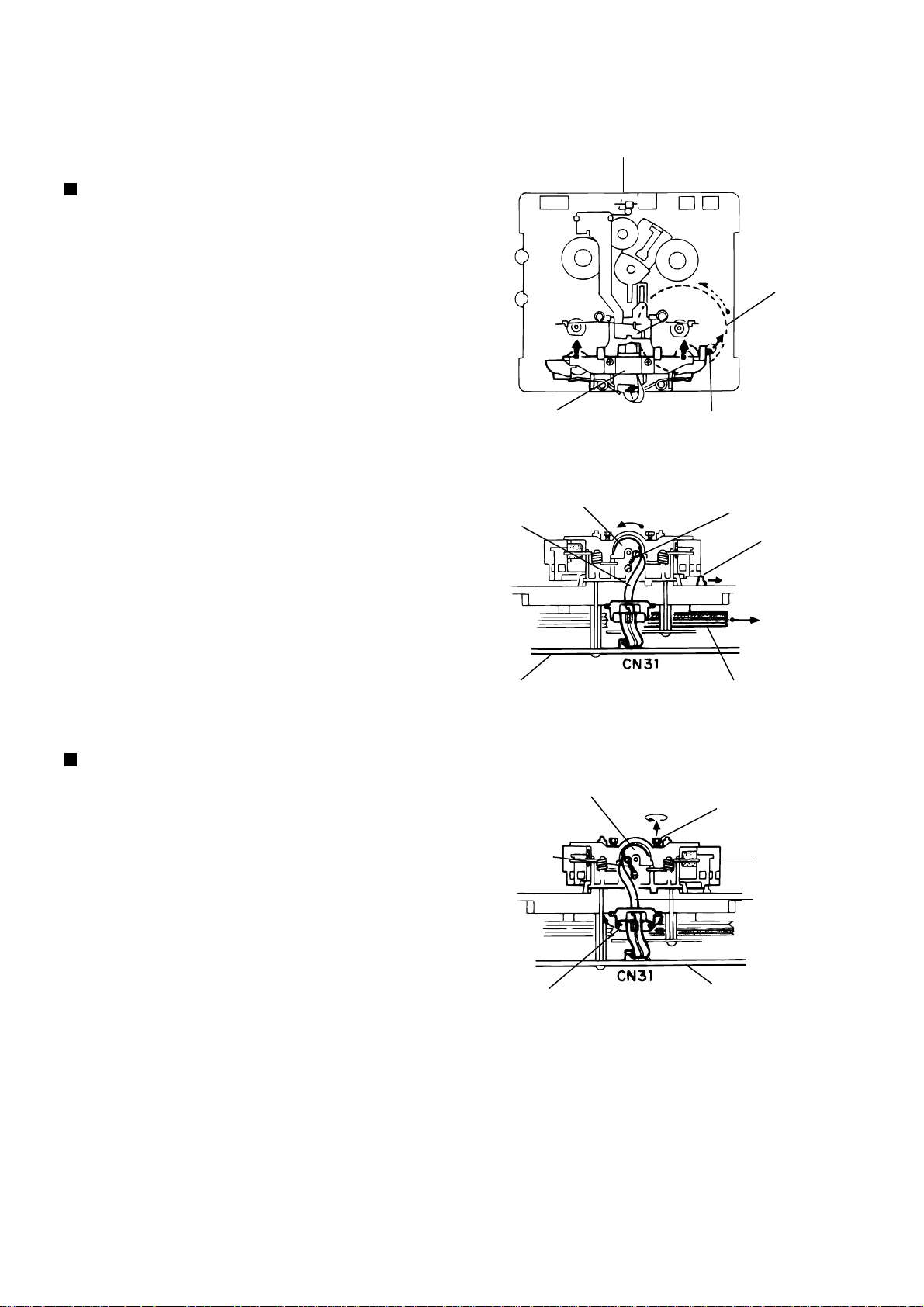

Page 11

RV-B550BU

Prior to performing the following procedure, remove

the front cabinet assembly and the rear cabinet

assembly.

Remove the eight screws P attaching the right and

left speakers on the inside of the front cabinet assembly.

Remove the screw Q attaching the speaker terminal.

1.

2.

Removing the speakers (See Fig.20)

<Front Cabinet Assembly>

Prior to performing the following procedure, remove

the front cabinet assembly and the rear cabinet

assembly.

Remove the two screws N and two screws O

attaching the LED boards on the speaker .

Disconnect the harness from connector FW251 and

FW261.

1.

2.

Removing the LED boards (See Fig.20)

Fig.20

P

P

P

Q

Speaker terminal

Speaker Speaker

LED board

LED board

O

N

P

FW261

FW251

1-11

Page 12

RV-B550BU

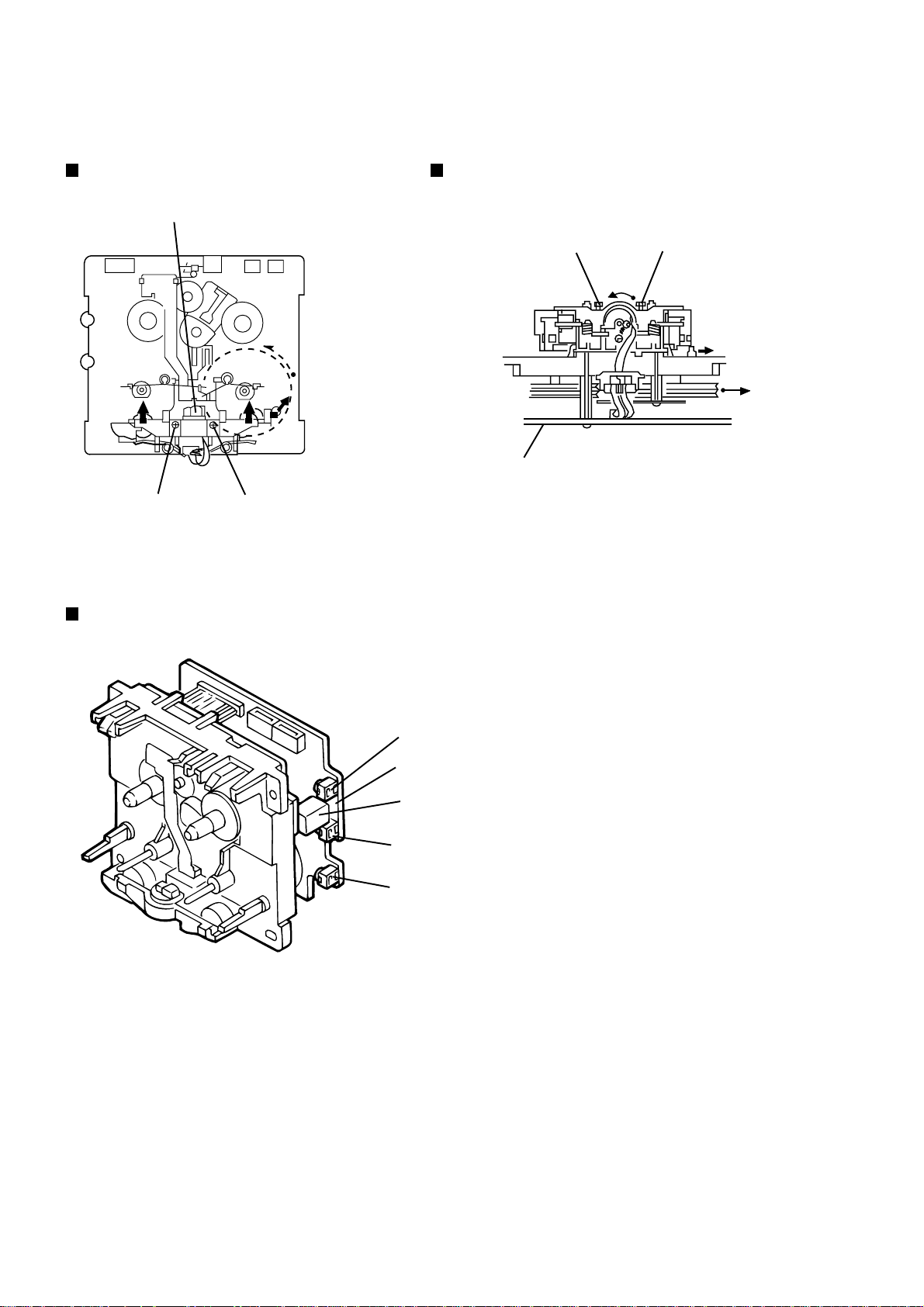

<<Cassette mechanism section>>

Removing the playback/recording & eraser

head ( See Figs. 1 and 2 )

1. While shifting the trigger arms seen on the right

side of the head mount in the arrow direction,

turn the flywheel R in counterclockwise direction

until the head mount has gone out with a click

(See Fig. 1).

2. When the flywheel R is rotated in counterclockwise

direction, the playback/recording & eraser head

will be turned in counterclockwise direction from the

position in Fig. 2 to that in Fig. 3.

3. At this position, disconnect the flexible P.C. board

(outgoing from the playback/recording & eraser head)

from the connector CN31 on the head amplifier &

mechanism control P.C. board.

4. After dismounting the FPC holder, remove the flexible

P.C. board.

5. Remove the flexible P.C. board from the chassis base.

6. Remove the spring a from behind the playback/recording

& eraser head.

7. Loosen the reversing azimuth screw retaining the playback

/recording & eraser head.

8. Take out the playback/recording & eraser head from the

front of the head mount.

9. The playback/recoring & eraser head should also be

removed similarly according to Steps 1 ~ 8 above.

Cassette mechanism

Fig. 1

Playback/recording &

eraser head

Frexible

board

Head amplifier & mechanism

control P.C. board

Flywheel R

Trigger armHead mount

Spring a

Trigger arm

Flywheel R

Reassembling the playback/recording

& eraser head

1. Reassemble the playback head from the front of the head

mount to the position as shown in Fig. 3.

2. Fix the reversing azimuth screw.

3. Set the spring a from behind the Playback/Recording &

Eraser head.

4. Attach the flexible P.C. board to the chassis base, and fix

it with the FPC holder as shown in Fig. 3.

5. The playback/recording & eraser head should also be

reassembled similarly to Step 1 ~ 4 above.

Playback/recording &

eraser head

Spring "a"

FPC holder

Fig. 2

Reversing azimuth

screw

Head

mount

Frexible

board

Head amplifier &

mechanis control

P.C. board

Fig. 3

1-12

Page 13

RV-B550BU

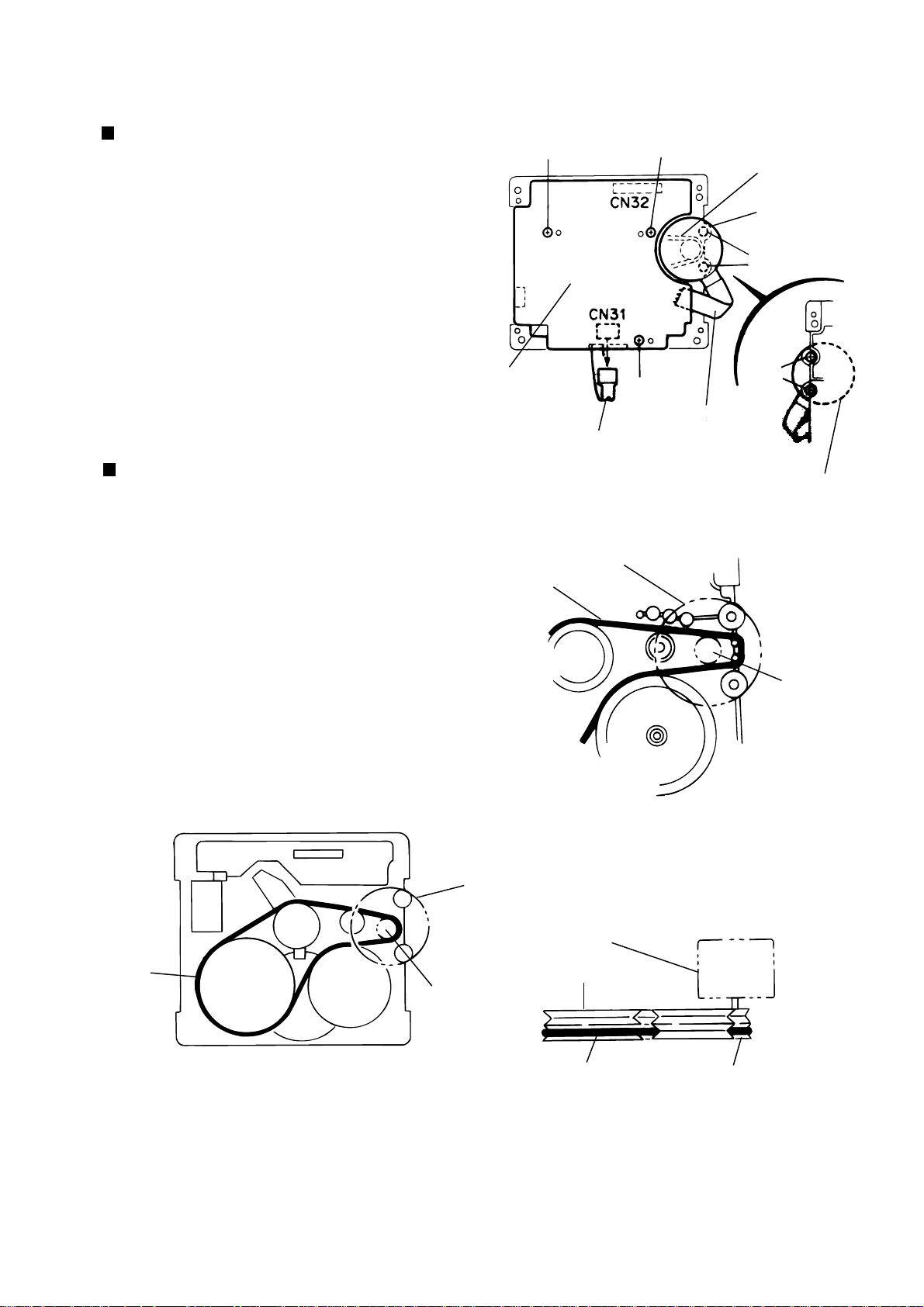

Removing the head amplifier & mechanism

control P.C. board (See Fig. 4)

1. Remove the cassette mechanism assembly.

2. After turning over th cassette mechanism assembly,

remove the three screws A retaining the head

amplifier & mechanism control P.C. board.

3. Disconnect the connector CN32 on the P.C. board

including the connector CN 1 on the reel pulse P.C.

board.

4. When necessary, remove the 4 pin parallel wire

soldered to the main motor.

Head amplifier &

mechanism control

P.C. board

Removing the main motor assembly

(See Fig. 4~6)

1. Remove the two screws B retaining the main

motor assembly (See Fig. 4, 4a).

2. While raising the main motor, remove the capstan

belt from the motor pulley (See Fig. 4a).

Caution 1: Be sure to handle the capstan belt so

carefully that this belt will not be

stained by grease and other foreign

matter. Moreover, this belt should be

hanged while referring to the capstan

belt hanging method in Fig. 5, 6.

A

Flexible P.C. board

Capstan belt

A

Fig. 4

Main motor

assembly

A

Belt

Main motor

assembly

B

B

4pin parallel wire

Main

moteor

assembly

Motor

pulley

Capstan

belt

Fig. 5

Mechanism motor

assembly

Motor

pulley

Fig. 4a

Main motor

assembly

Flywheel

Motor pulleyCapstan belt

Fig. 6

1-13

Page 14

RV-B550BU

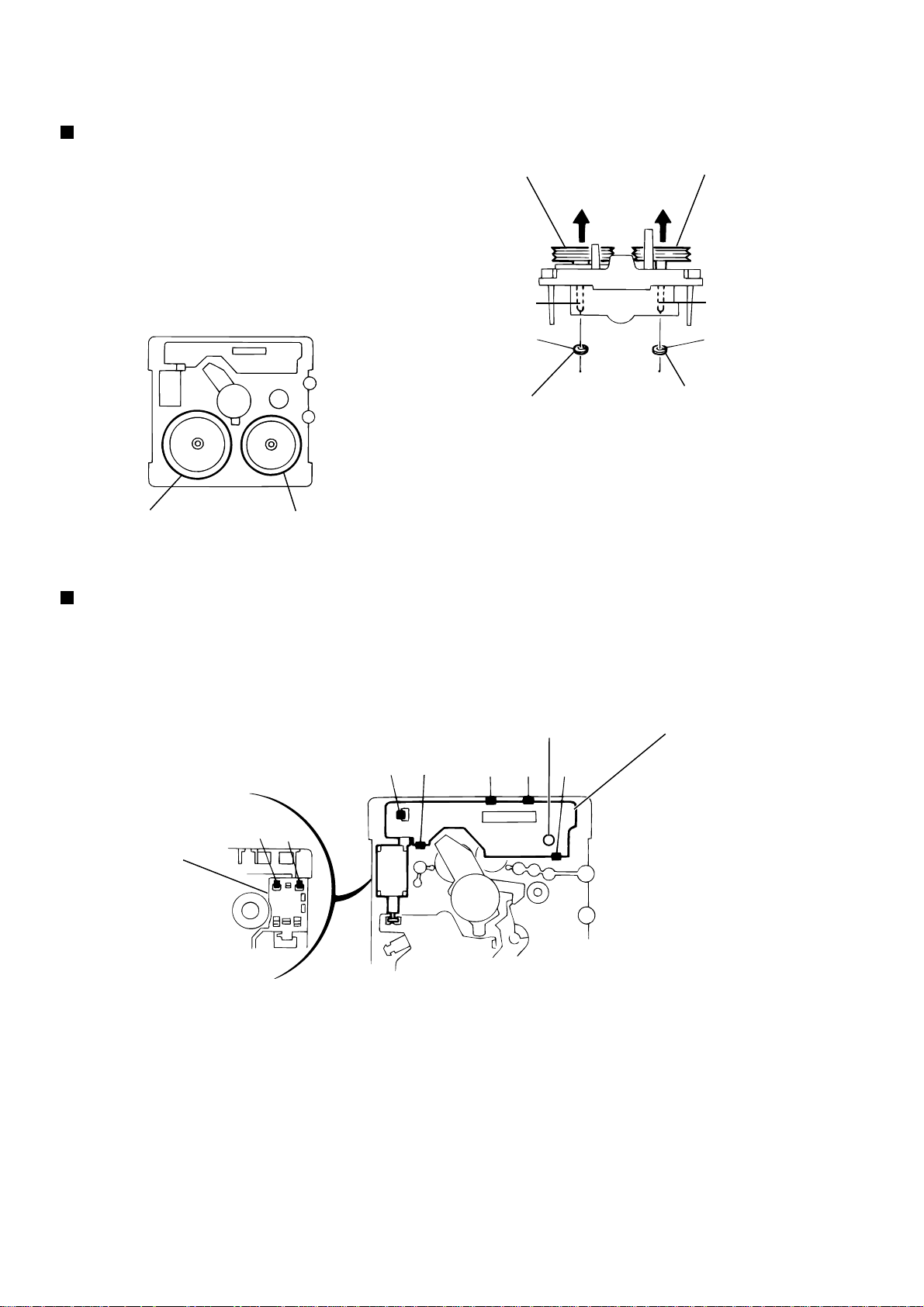

Removing the flywheel

(See Figs. 7 and 8)

1. Remove the head amplifier & mechanism control

P.C. board.

2. Remove the main motor assembly.

3. After turning over the cassette mechanism,

remove the slit washers b and c fixing the capstan

shafts R and L, and pull out the flywheel R and L

respectively from behind the cassette mechanism.

Flywheel R Flywheel L

Capstan shaft R Capstan shaft L

Flywheel R Flywheel L

Fig. 8

Removing the reel pulse P.C. board and solenoid

(See Fig. 9)

1. Remove the five pawls d~h and screw C reataining the reel pulse

P.C. board.

2. From the surface of the reel pulse P.C. board parts, remove

the two pawls i and j retaining the solenoid.

hd

e

C

Slit

washer

f

b

Slit

washer

Fig.7

C

g

Reel pulse P.C. board

1-14

Solenoid

j

i

Fig. 9

Page 15

Adjustment method

RV-B550BU

Measuring devices necessary for adjustment

1. Low-frequency oscillator

It must have the ability to output 600ohm from 0 dBs

at an oscillation frequency of 20 Hz 50 Hz.

2.Attenuator impedance: 600ohm

3.Electronic voltmeter

Tuner section

Voltage input to the tuner .......................... +B: DC 5.7 V

VT: DC 12 V

Standard measuring output ...... 26.1 mV (0.28 V) /3ohm

Input locations ..................... AM: standard loop antenna

FM: TP1 (hot) and TP2 (GND)

Standard settings for measuring volume

4.Distortion meter

5.Frequency counter

6.Wow and flutter meter

7.Test tapes

VT-712: tape speed and rotational distortion (3 kHz)

VT-724: standard level (1 kHz)

VT-703: head angle adjustment (10 kHz),

or use VT-73

VT-739: reproduction of frequency characteristics

(1 kHz, 63 Hz, 10 kHz)

8.Blank tape

Type I : AC-225 (TDK-AD)

Type II : AC-514 (TDK-SA)

9.Torque gauge: Tension gauge for playback,

fast-forward and rewind.

FWD (TW211A), REW (TW212A)

and FF/REW (TW2231A)

Sound ..................................................................... OFF

Effective hyper bass ............................................... OFF

Volume adjustment ........................................... VOL. 23

Precautions for measuring

1.Input 30 pF and 33 kohm to the IF sweeper output

2.Lower the output level of the IF sweeper as much as

3.The IF sweeper needs no adjustment as it is a fixed

4.It is not necessary to perform any kind of adjustment

and 0.082 F and 100 kohm to the sweeper input,

respectively.

possible in the adjustable range.

component.

on the MPX, as a ceramic oscillator is used for

measuring.

Specifications for measurement

Power supply voltage ................... AC 100 V (50/60 Hz)

Standard output ........................ Speaker: 0.775V/4ohm

Headphone:0.245V/32ohm

Standard frequency and input level

................... 1 kHz: AUX: -8 dBs

Input level for reproduction of recording characteristics

................... AUX: -28 dBs

Measuring output terminal ................... Speaker: CN633

Load resistance .................................................... 4ohm

Radio input signal

AM frequency ..................................................... 400 Hz

Degree of modulation in AM band .......................... 30%

FM frequency ...................................................... 400 Hz

Frequency deviation in FM band ..................... 22.5 kHz

5.FM tracking adjustment is not necessary as a fixed

coil is used.

6.The grounding circuit is separate from the input and

output. Therefore, be sure to connect to ground

carefully when measuring both the input and output

voltages simultaneously using 2 channels of the

electronic voltmeter.

7.The speaker's minus terminal cannot be connected to

ground when using a BTL format amplifier. Therefore,

do not connect any type of ground wire to this

terminal. The OTL format is used with this system.

8.Use a large wire to connect to the dummy impedance

generator when measuring the output.

9.Be sure to use a band pass filter (DV-12) when using

mixed tape.

1-15

Page 16

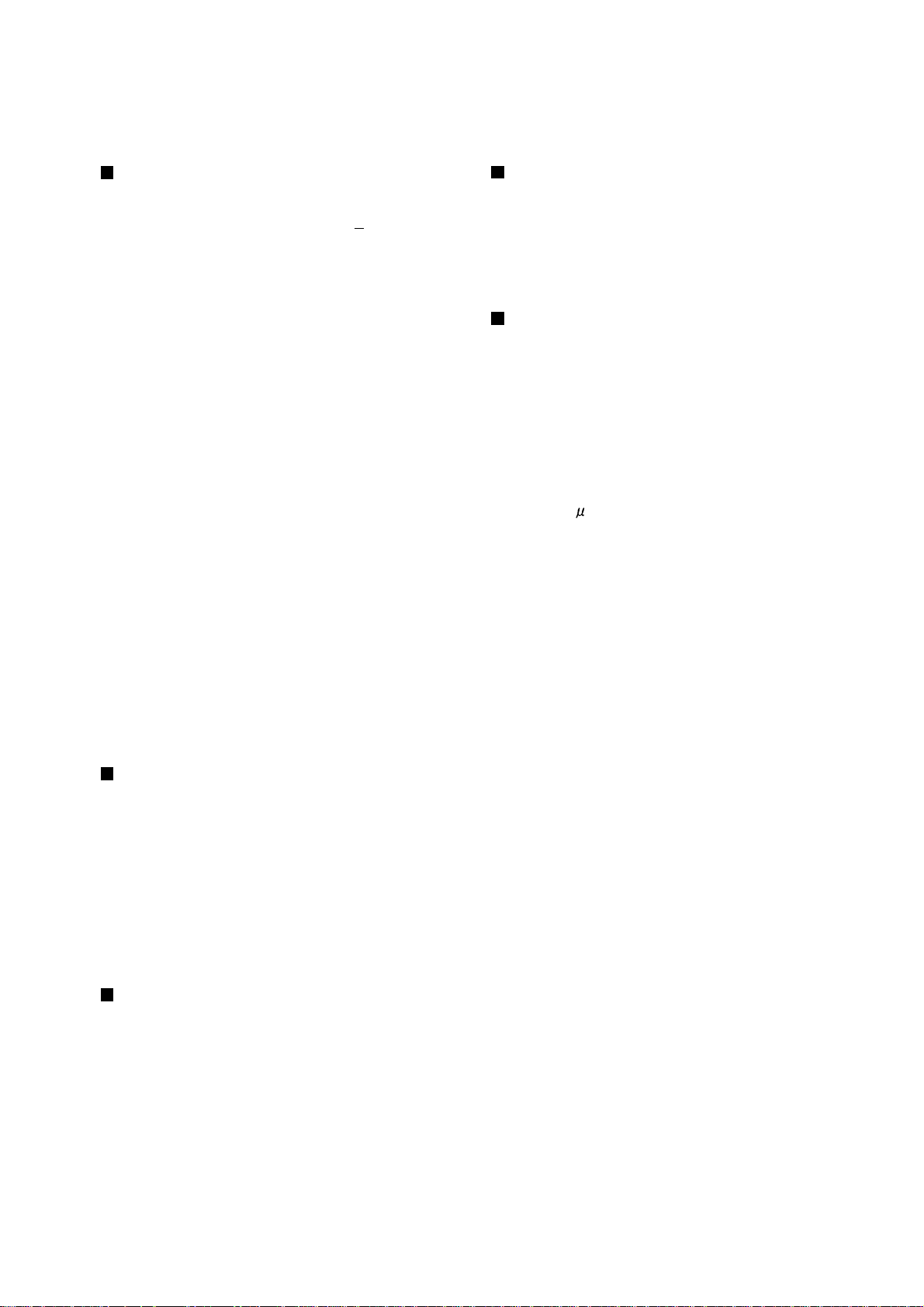

RV-B550BU

Location of parts to be adjusted

Cassette handling mechanism Cassette handling mechanism (reverse side)

Head for recording, playing

and erasing the tape

Head azimuth adjusting

screw (fast-forward)

CN31

Head azimuth adjusting

screw (rewind)

Head azimuth adjusting

adjusting screw (fast-forward)

Head azimuth

screw (rewind)

Location of parts to be adjusted

Head for recording,

playing and erasing the tape

VR37

Motor speed

TP

Bias oscillation frequency (wide pattern)

L301

Bias oscillation frequency

VR31

Lch recording frequency (bias adjustment)

VR32

Rch recording frequency (bias adjustment)

1-16

Page 17

Adjustment of cassette handling mechanism

RV-B550BU

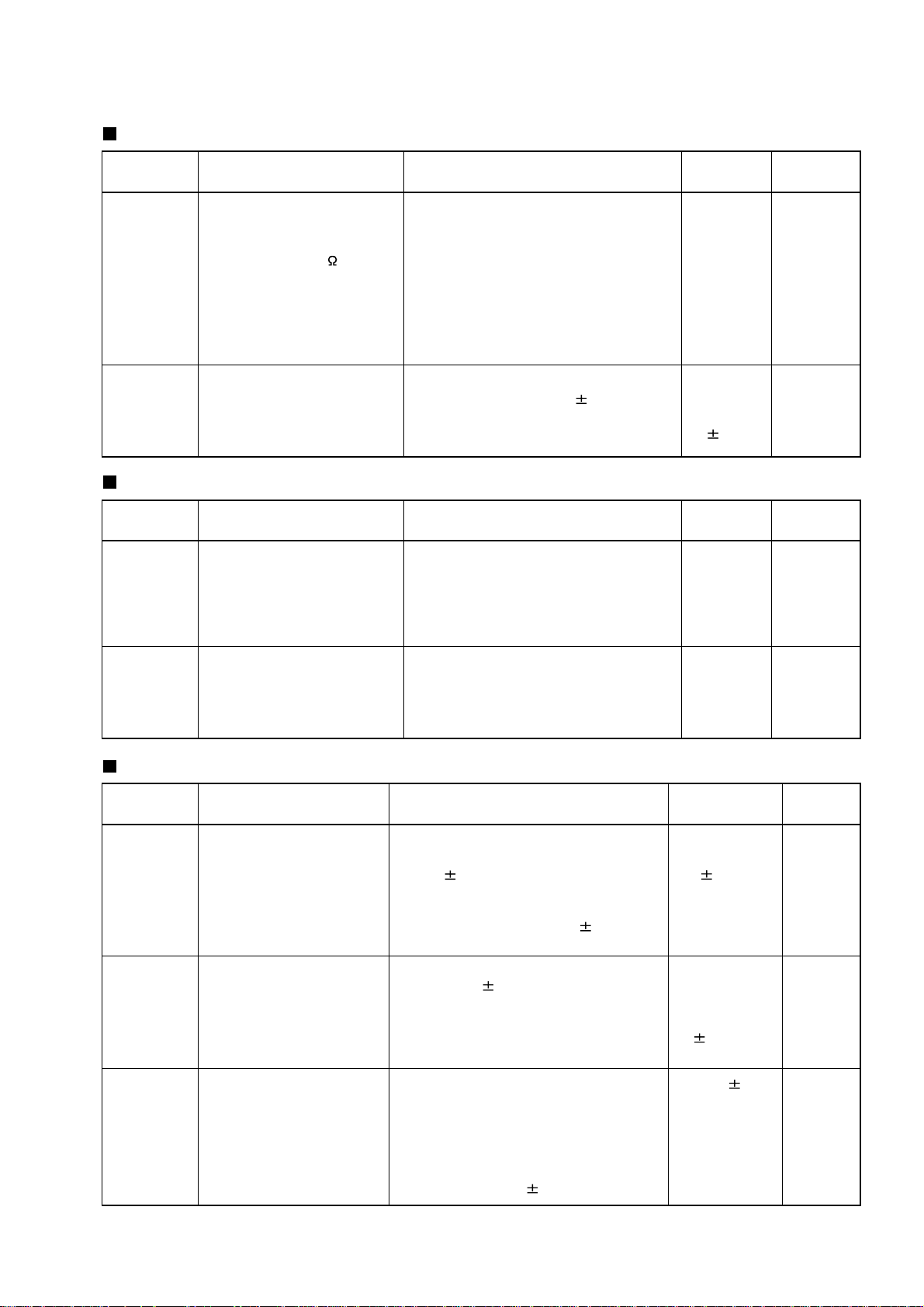

Items Condition Method for adjustment

Confirmation

of head angle

Confirmation

of tape speed

Test tape: VT-703 (10 kHz)

Measuring output terminal:

Speaker terminal, speaker (R)

(Load resistance: 4 ),

headphone terminal

Test tape: VT-712 (3 kHz)

Measuring output terminal:

Headphone terminal

(1) Play back the VT-703 test tape.

(2) Adjust the head azimuth screws so

that the tape playback mechanism

records the maximum output level in

both the fast-forward and rewind

direction.

(3) In all cases, both the fast-forward and

rewind direction should be adjusted

using head azimuth screws.

Adjust VR37 so that the frequency

counter records 3,015 Hz 15 Hz when

playing back the end of the VT-712 test

tape (3 kHz) in the fast-forward direction.

and confirmation

Items to be confirmed and standard values

Items Condition Method for adjustment

Difference in

speed

between fastforward and

rewind

Test tape: VT-712 (3 kHz)

Measuring output terminal:

Speaker terminal, speaker (R)

(Load resistance: 4 ),

headphone terminal

The difference between fast-forward and

rewind should be less than 60 Hz on the

frequency counter when playing back the

beginning of the VT-712 test tape (3 kHz)

in both directions.

and confirmation

Standard

value

Maximum

output

Tape speed

of cassette

deck: 3,015

Hz 15 Hz

Standard

value

Less than 60 HzShould be

Parts to be

adjusted

Adjust the

head

azimuth

screws

when

changing

the head.

VR37

Parts to be

adjusted

confirmed

when

changing

the motor.

Wow and

flutter

Test tape: VT-712 (3 kHz)

Measuring output terminal:

Headphone terminal

Wow and flutter should be recorded at

less than 0.25% (WRMS) when playing

back the VT-712 test tape (3 kHz) in the

fast-forward direction.

Electronic performance

Items Condition Method for adjustment

Confirmation

of output

Confirmation

of

reproduction

of frequency

characteristics

Recording

bias

frequency

Measuring output terminal:

CN34-5 or 7-terminal

preamp base

Test tape: VT-724

Measuring output terminal:

Headphone terminal

Test tape: VT-739

Fast-forward or rewind

direction:

Test tape: TYPE II (AC-

514)

Measuring terminal: Bias

TP on the base

Confirm that the output from the CN34-5

or 7-terminal preamp base connector is 25 dBs 3 dB when playing back the VT724 test tape.

Reference value: The output from the

headphone terminal is -7 dB 4 dB.

Confirm that the 10 kHz reproduction

level is -1 dB 5 dB compared to the 1

kHz reproduction level when playing back

the VT-739 test tape.

Switch the bias (beat cut switch) between

1 and 2 to confirm that the frequency

changes. Load the test tape (AC-514 for

TYPE II) into the mechanism and preset

it to the record-pause mode.

Confirm that the bias TP frequency on

the base is 100 kHz 6 kHz.

and confirmation

Less than

0.25%

(WRMS)

Standard

value

Output of CN345 terminal: -25

dBs 3 dB

Difference

between Lch

and Rch: within

3 dB

Difference

between 10

kHz and 1 kHz

should be -1

dB 5 dB.

100 kHz 6 kHz

Parts to be

adjusted

1-17

Page 18

RV-B550BU

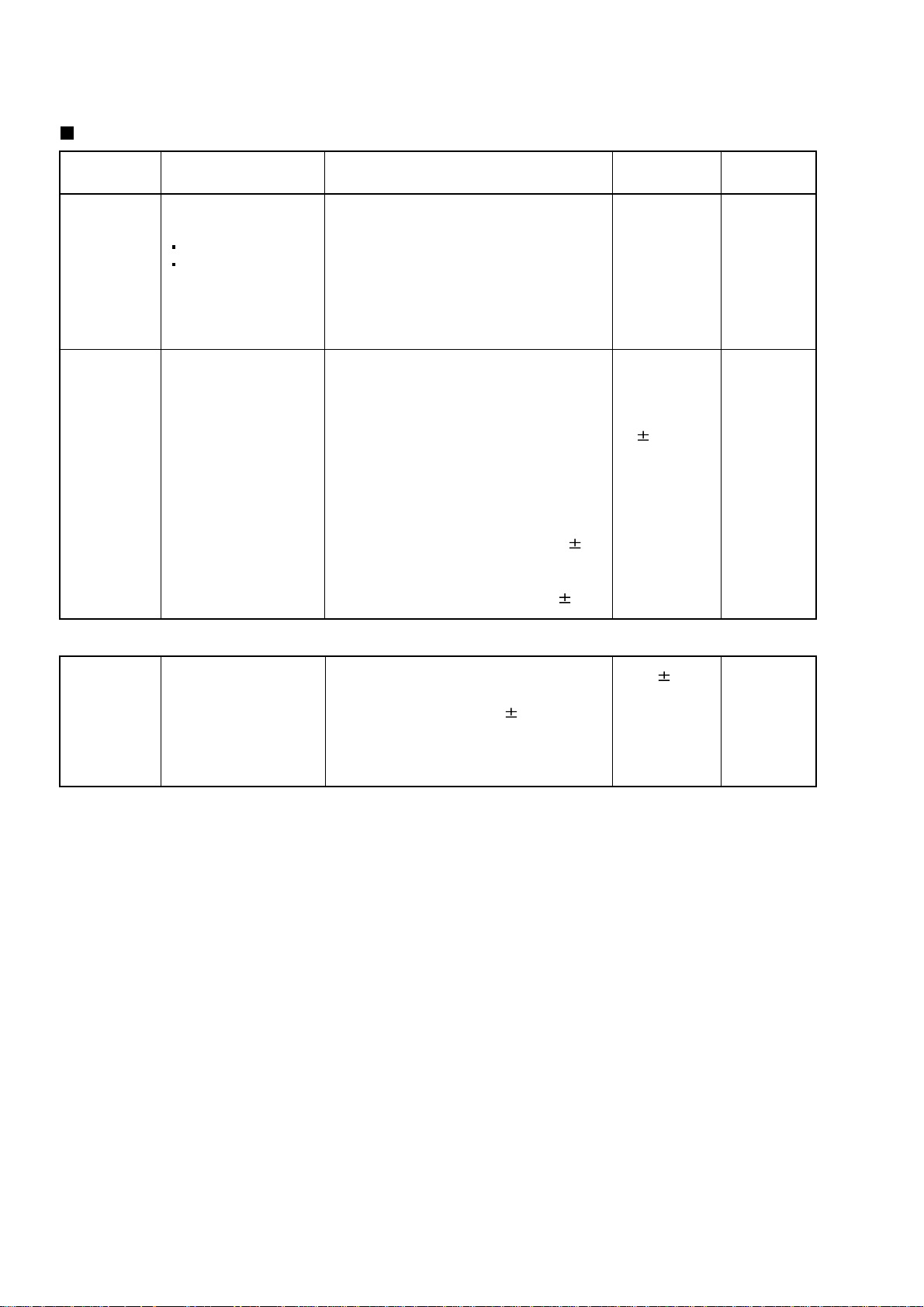

Standard values for confirmation of electronic performance

Items Condition Method for adjustment

Erasing

current

(standard

and

reference

value)

Adjustment of

reproduction

of frequency

characteristics

Fast-forward and

rewind direction:

Recording mode

AC-514 for TYPE II,

AC-225 for TYPE I

Measuring terminal:

Both erase head ter

minals

Standard frequencies:

1 kHz and 10 kHz

(REF: -20 dB)

Test tape: TYPE II:

AC-514

Measuring input

terminal: OSC IN

Load the test tape (AC-514 for TYPE II,

AC-225 for TYPE I) into the tape

playback mechanism and preset it to the

record-pause mode.

After setting it to the recording mode,

send 1 M in series to the erase head and

measure the erasing current from both

erase head terminals.

Load the test tape (AC-514 for TYPE II,

AC-225 for TYPE I) into the tape

playback mechanism and preset it to the

record-pause mode.

Input the standard value of -20 dB and

the standard frequencies of 1 kHz and 10

kHz repeatedly to the microphone input

from the transmitter in the recording

mode. Adjust VR31 for Lch and VR32 for

Rch so that the difference in level

between 10 kHz and 1 kHz is -1 dB 5

dB.

Repeat the above for TYPE I and confirm

that the difference in level is -XdB dB.

and confirmation

Standard

value

TYPE II: 110

mA

TYPE I: 75 mA

Difference in

output

between 1 kHz

and 10 kHz: -1

dB 5 dB

Parts to be

adjusted

Lch: VR31

Rch: VR32

(U version only)

Sensitivity of

reproduction

of

microphone

mixing

Microphone input

terminal: 1 kHz, -65 dB

Test tape: VT-724

Based on the reproduction level of the

VT-724 test tape, confirm that the

microphone level is 0 dBs 3 dB when a

1 kHz, 65 dBs signal is input.

(The mixing volume and sound volume

should be at maximum.)

0 dBs 3 dB

(Based on the

reproduction

level of the

VT-724)

1-18

Page 19

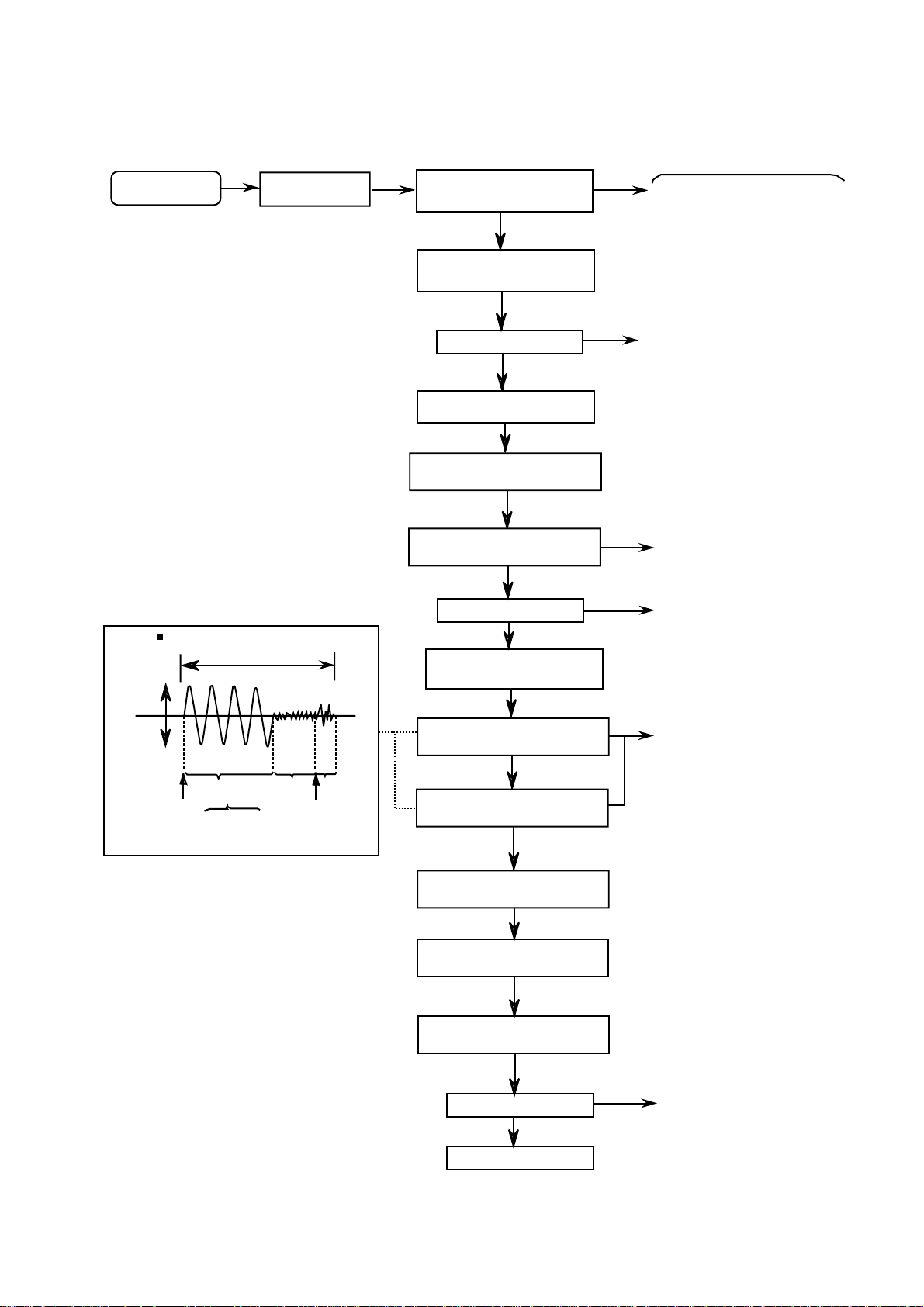

Flow of functional operation until TOC read

Slider turns REST

SW ON.

Automatic tuning

of TE offset

Laser ON

Detection of disc

Automatic measurement of

Focus A-curve amplitude

Automatic tuning of

Foucus offset

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic tuning of

Tracking error balance

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Focus error balance

Disc to be

braked to stop

Tracking

servo

on statas

Tracking

servo

off statas

Disc statas

to rotate

TOC reading

finishes

Automatic measurement

of TE amplitude and

automatic tuning of

TE balance

500mv/div

2ms/div

Fig.1

Approx.3sec

pin 25 of

IC601(TE)

Approx

1.8V

VREF

Tracking error waveform at TOC reading

Power ON

Power Key

Confirm that the Focus error

S-cuve siganl at the pin27 of

IC601 is approx.2Vp-p

Confirm that the siganl from

pin24 IC603 is 0V as a

accelerated pulse during

approx.400ms.

Confirm the waveform of

the Tracking error signal

at the pin25 of IC601 (R612)

(See fig-1)

Automatic tuning of

Focus error gain

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the eys-pattern

at the lead of TP602

Check that the voltage at the pin 5

of CN602 (or pin 5 of IC901)

is 0V (a moment)?

Check Point

Check that the voltage at the

pin3 of IC601 + side is + 5V?

RV-B550BU

1-19

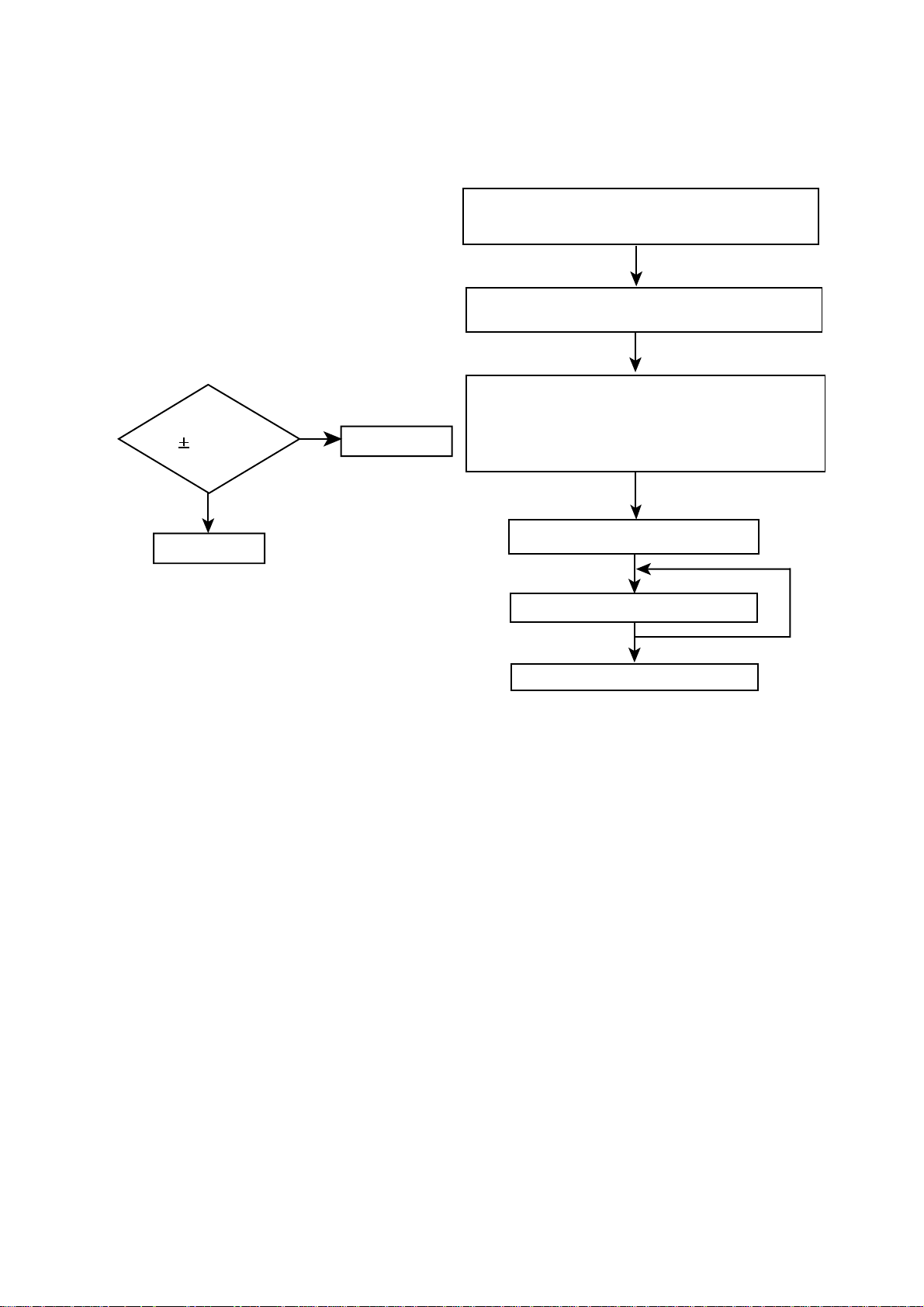

Page 20

RV-B550BU

Maintenance of laser pickup

(1) Cleaning the pick up lens

Befor you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode (Fig.1)

When the life of the laser diode has expired,

the following symptoms wil appear.

(1) The level of RF output (EFM output:ampli

tude of eye pattern) will below.

Is RF output

1.1 0.15Vp-p?

YES

O.K

NO

Replace it.

(Fig.1)

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to " Pickup Removal " on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at TP1.

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed

circuit board which is attached to the pickup

is used to adjust the laser power.Since this

adjustment should be performed to match the

characteristics of the whole optical block,

do not touch the semi-fixed resistor.

If the laser power is lower than the specified

value,the laser diode is almost worn out, and

the laser pickup should be replaced.

If the semi-fixed resistor is adjusted while

the pickup is functioning normally,the laser

pickup may be damaged due to excessive current.

Finish.

1-20

Page 21

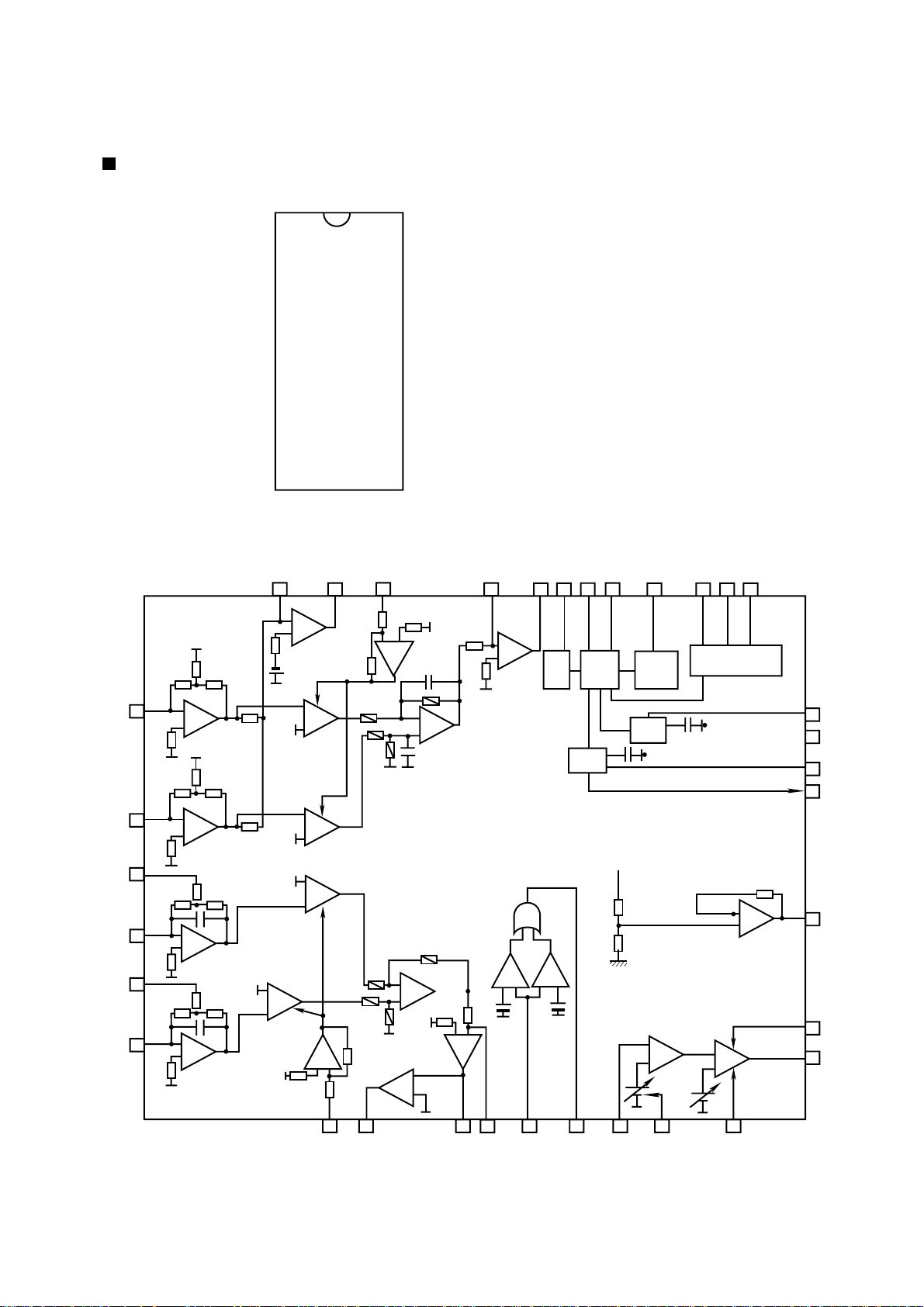

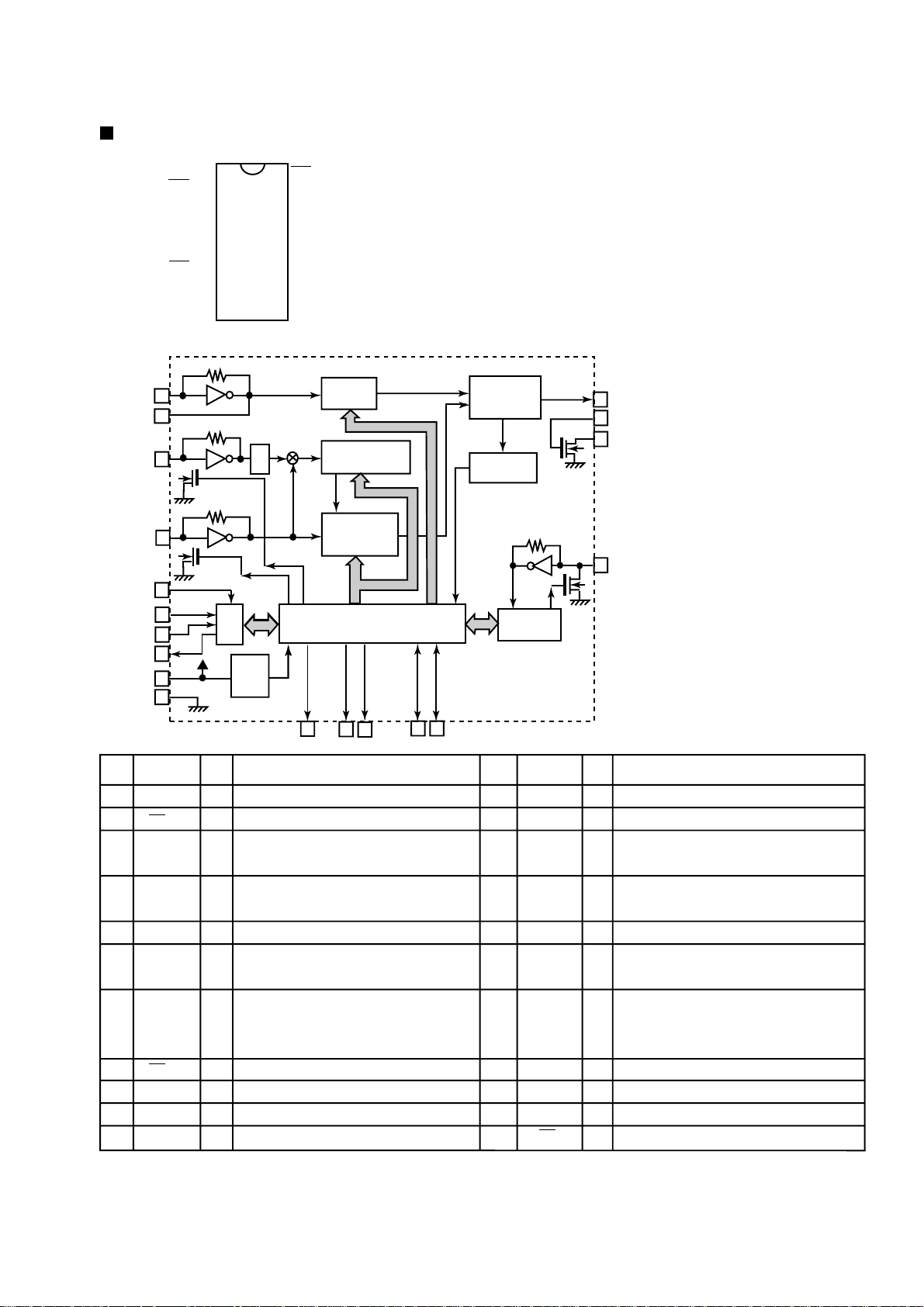

Description of major ICs

AN8806SB (IC601) : RF&Servo AMP

1.Terminal Layout

36

PD

LD

LDON

LDP

VCC

RF-

RF OUT

RF IN

C.AGC

ARF

C.ENV

C.EA

CS BDO

BDO

CS BRT

OFTR

/NRFDET

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

PDAC

PDBD

PDF

PDE

PDER

PDFR

TBAL

FBAL

EF EF OUT

TE TE OUT

CROSS

TE BPF

VDET

LD OFF

VREF

ENV

RV-B550BU

2.Block Diagram

36

-+

35

-+

31

34

-+

32

33

-+

6

--

VCBA

+

29

728

-+

--

+

+

VCBA

--

+

VCBA

--

--

VCBA

+

+

--

-+

-+

+

--

27

-+

--

EQ

+

+

--

+

--

910 17

8

AGC

OFTR

BDO

RF

DET

11

12 19

ENV CURCUIT

13

14

15

16

-+

20

21

2

24 25

30

14

23

26

22

3

1-21

Page 22

RV-B550BU

3. Functions

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Symbol

PD

LD

LD ON

LDP

VCC

RF-

RF OUT

RF IN

C.AGC

ARF

C.ENV

C.EA

CS BDO

BDO

CS BRT

OFTR

/NRFDET

GND

ENV

VREF

LD OFF

VDET

TE BPF

CROSS

TE OUT

TE-

FE OUT

FEFBAL

TBAL

PDFR

PDER

PDF

PDE

PD BD

PD AC

I/O

I

APC amp input terminal

APC amp output terminal

O

APC ON/OFF control terminal

I

--

Connect to ground

Power supply

-Inverse input pin for RF amp

I

RFamp output

O

RF input

I

Connecting pin of AGC loop filter

I/O

RF output

O

I/O

A capacitor is connected to this terminal to detect the envelope of RF signal

I/O

A capacitor is connected to this terminal to detect the envelope of RF signal

A capacitor is connected to detect the lower envelope of RF signal

I/O

BDO output pin

O

A capacitor is connected to detect the lower envelope of RF signal

I/O

O

Of-track status signal output

RF detection signal output

O

--

Ground

O

Envelope output

Reference voltage output

O

--

Connect to ground

O

Vibration detection signal output

I

Input pin of tracking error through BPF

O

Tracking error cross output

O

Tracking error signal output

Inverse input pin for tracking error amp

I

O

Output pin of focus error

Inverse input pin for focus error amp

I

I

Focus balance control

I

Tracking balance control

F I-V amp gain control

I/O

E I-V amp gain control

I/O

I

I-V amp input

I-V amp input

I

I

I-V amp input

Functions and operations

I I-V amp input

1-22

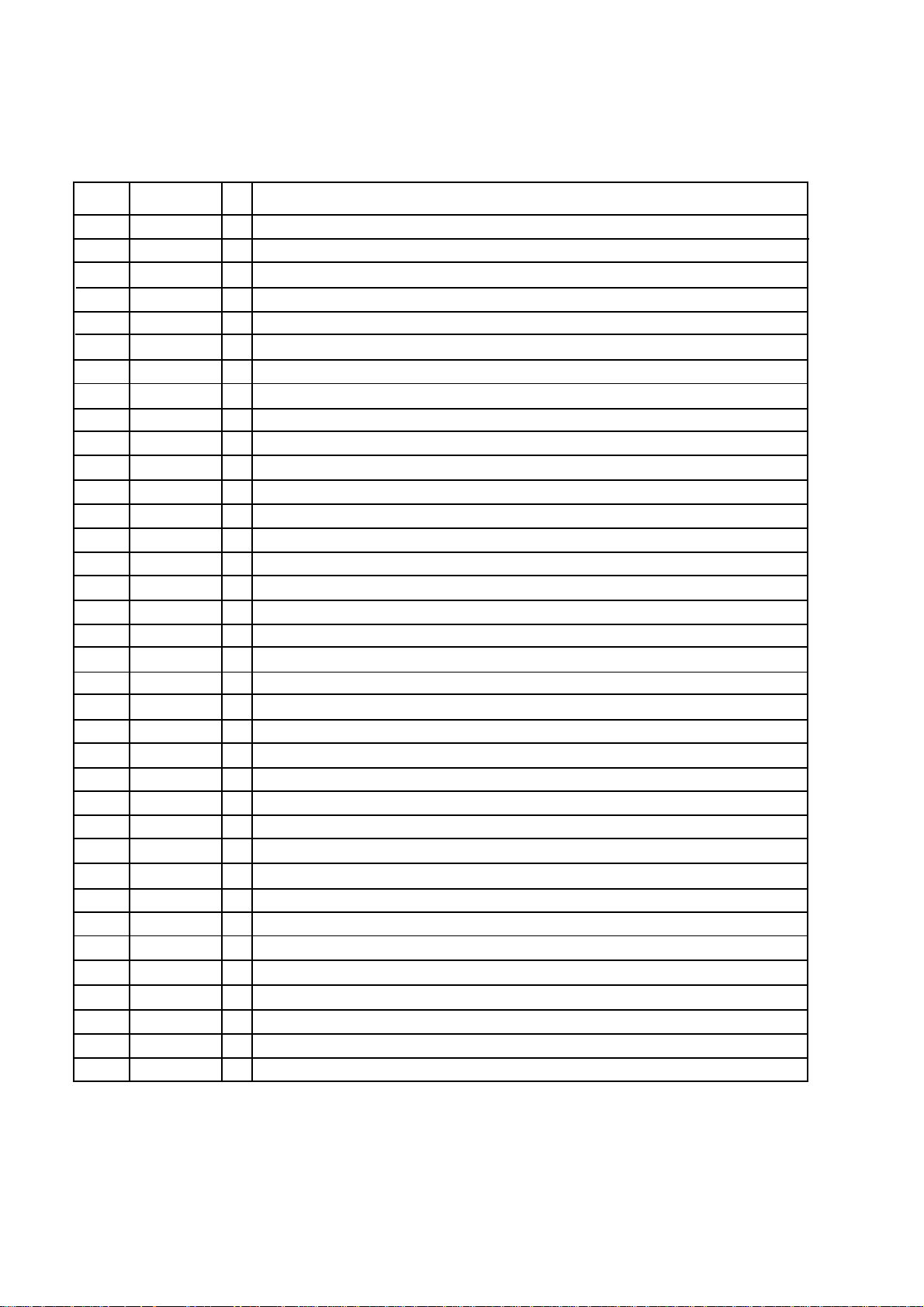

Page 23

RV-B550BU

1

2

3

4

5

6

7

- +

Level

shift

-+

+ Level

shift

+-

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

Level

shift

- +

Level

shift

+ -

-+

-+

D.BUF

D.BUF

DRIVER

MUTE

D.BUF

D.BUF

D.BUF

T.S.D

D.BUF

D.BUF

D.BUF

GND

CH4-OUTA

CH4-OUTB

CH4-INA

CH4-INB

BIAS IN

Vcc

CH1-OUTA

CH1-OUTB

CH1-INA

CH1-INB

TEST1

TEST2

MUTE

Vcc

CH3-INB

CH3-INA

CH3-OUTB

CH3-OUTA

OP IN(+)

OP IN(-)

CH2-INB

CH2-INA

CH2-OUTB

CH2-OUTA

GND

OP-OUT

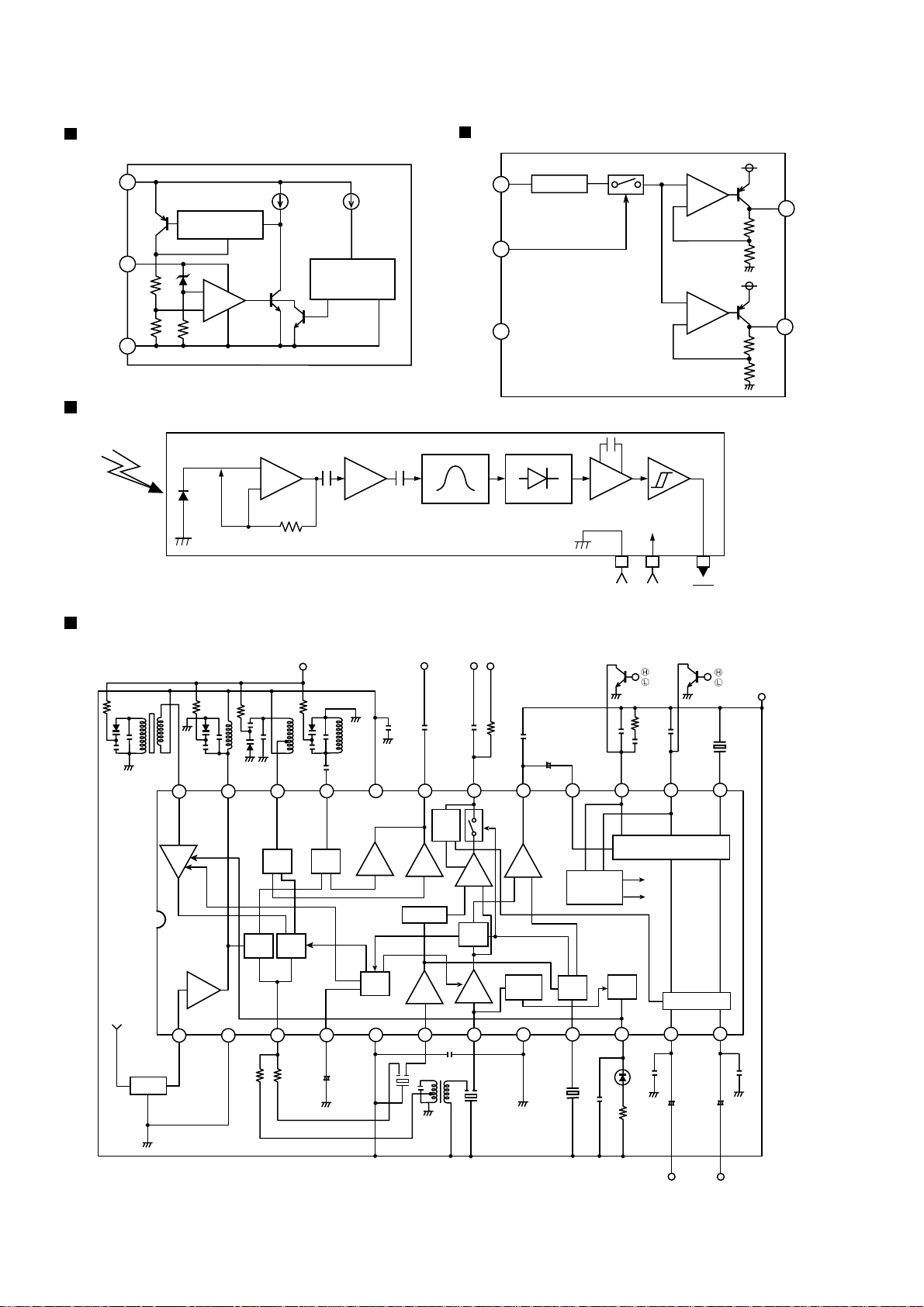

BA6897FP-W (IC602)

: 4channel driver

-+

+-

6

8 9 10 11

12

13

14

15

16

17

2

5

4

7

1813

RIPPLE

FILTER

BIAS

CIRCUIT

STANDBY

SW

IN

IN

POP NOISE

PREVENTION

CIRCUIT

PREDRIVER

PREDRIVER

PREDRIVER

PREDRIVER

POWER

POWER

POWER

POWER

LOAD SHORT

PROTECTOR

LOAD SHORT

PROTECTOR

THERMEL

SHUTDOWN

OVER VOLT AGE/

SURGE PROTECTOR

OUTPUT PIN TO Vcc

SHORT PROTECTOR

OUTPUT PIN TO Vcc

SHORT PROTECTOR

OUTPUT PIN TO GND

SHORT PROTECTOR

OUTPUT PIN TO GND

SHORT PROTECTOR

Vcc

POWER

GND1

POWER

GND2

Vcc2NCNC

GND

NC Vcc1

LA4705N

123456789101112131415161718

LA4705NA (IC631) : power amplifier

1

2

+

-

+

-

1

2

34

5

67

8

OUT1 -IN1

+IN1

VEE

+IN2 -IN2

OUT2

Vcc

BA15218N

BA15218N (IC801/IC831)

: Dual op amplifier

1-23

Page 24

RV-B550BU

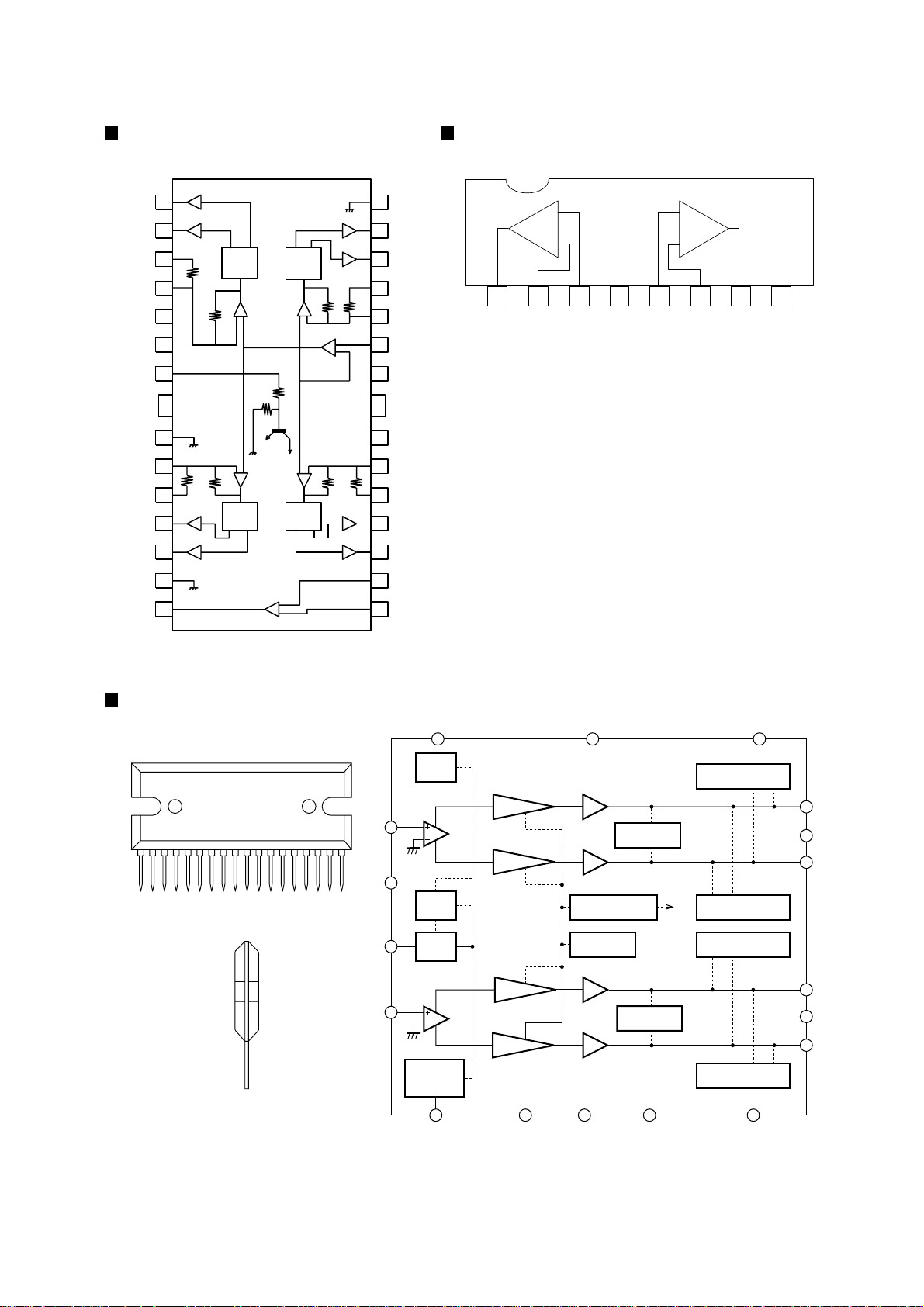

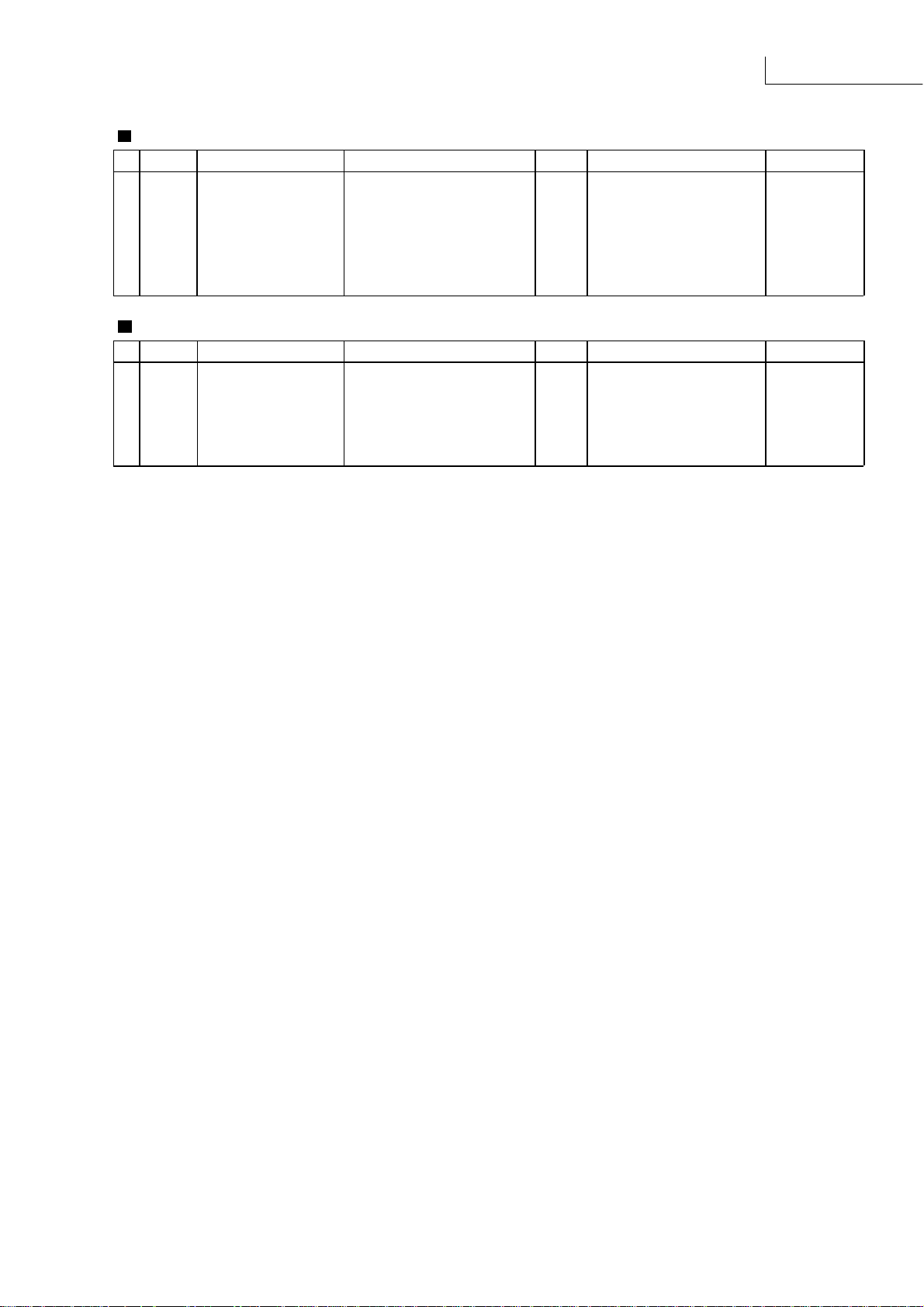

BH3852S (IC501) : E.Volume

1.Block diagram

FILTER

IN2

24 23 22 21 20 19 18 17 16 15 14 13

Vcc

20k

20k

1 2 3 4 5 6 7 8 9 10 11 12

GND

NF2

+

(BASS) (TREBLE)

TONE CONTROL

IN1

NF1

BVN2

BIN2

BVO2

TIN2

2k

(BASS) (TREBLE)

TONE CONTROL

20k

+

47k

47k

BVN1

+

-

20k

BIN1

VOLUMEVOLUME

MATRIX SURROUND SOUND

2k

TIN1

BVO1

TVO2

CONTROL

TVO1

OUT2VCTC

10M

10M 10M

-

+

VOLUMEVOLUME

-

+

Vcc

Vcc

OUT1

BC

Ref.Voltage

10M

SC

VREF

2.Pin function

1

Pin name

GND

Pin No.

2

3

NF1

4 6

7.8

9

10

11

12

BASS1

TRE1

OUT1

VCC

LIVE

VREF

IN1

I/O

Grand terminal

Terminal for 1ch volume input

I

Terminal for gain adjustment of

I

Function Function

input step amp.

Terminal for connection of 1ch

low-frequency filter

Terminal for connection of 1ch

High frequency filter

Terminal for 1ch volume output

O

Terminal for power supply

Terminal for surround control

Terminal for reference voltage

O

output

Pin No.

13

14

15

16

17.18

19 21

22

23

24

Pin name

BASS

TRE

VOL

OUT2

TRE2

BASS2

NF2

IN2

VSET

I/O

Terminal for bass control

I

Terminal for treble control

I

Terminal for volume control

I

Terminal for 2ch volume output

O

Terminal for connection of 2ch

high-frequency filter

Terminal for connection of 2ch

low-frequency filter

Terminal for gain adjustment of

I

input step amp.

Terminal for 2ch volume output

I

Terminal for filter

-

1-24

Page 25

1. Layout

1

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

XT

FM/AM

CE

DI

CLOCK

DO

FM/ST/VCO

AM/FM

SDIN

XT

GND

LPFOUT

LPFIN

PD

VCC

FMIN

AMIN

IFCONT

IFIN

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

Pin

No.

12

13

14

15

16

17

18

19

20

21

22

Symbol

XT

FM/AM

CE

DI

CLOCK

DO

FM/ST/VCO

AM/FM

SDIN

Symbol

IFIN

IFCONT

AMIN

FMIN

VCC

PD

LPFIN

LPFOUT

GND

XT

Function

X'tal oscillator connect (75kHz)

LOW:FM mode

When data output/input for 4pin(input) and

6pin(output): H

Input for receive the sirisl data from

controller

Sync signal input use

Data output for Controller

Output port

"Low": MW mode

Not use

Not use

Input/output port

Data input/output

Function

IF counter signal input

IF signal output

Not use

AM Local OSC signal output

FM Local OSC signal input

Power suplly(VDD=4.5-5.5V)

When power ON:Reset circuit move

PLL charge pump output(H: Local OSC

frequency Height than Reference frequency.

L: Low Agreement: Height impedance)

Input for active lowpassfilter of PLL

Output for active lowpassfilter of PLL

Connected to GND

X'tal oscillator(75KHz)

I/O

I

O

I

I

I

O

O

O

-

-

I/O

I/O

I

O

-

I

I

-

O

I

O

I

Reference

Driver

Phase

Detector

Charge Pump

Unlock

Detector

Universal

Counter

Swallow Counter

1/16,1/17 4bit

12bit

Programmable

DriverS

Swallow Counter

1/16,1/17 4bit

Data Shift Register & Latch

Power

on

Reset

C

2B

I/F

1/2

7821113

21

17

6

5

4

3

15

16

22

1

18

19

20

12

2. Block

3. Function

LC72136N(IC2):PLL Frequency synthesizer

RV-B550BU

1-25

Page 26

RV-B550BU

TA78DL06S(IC390) : Regulator

1

INPUT

SHORT

PROTECTION

GND

2

–

OVER VOLTAGE/

THERMAL SHUT

DOWN PROTECTION

+

3

+

–

Limiter Integrator Comparator

Amp.

OUTPUT

GP1U281X(IC903) : Remocon sensor

BA44W12ST-V5/Z1(IC310):Regulator

2

B.P.F

VCC

CTL

GND

5

3

Demodulator

+

–

+

–

4

1

OUT1

OUT2

TA2008AN (IC 1): FM/AM,IF/DET

FM

AM

OSC

AM

MIX

OUT

VT

FM

OSC

FM

OSC

AGC

+-

Block diagram

AM

ANTENNA

FM

ANTENNA

24 23 22 21 20 19 18 17 16 15 14 13

AM

RF

123456789101112

BPF

AM

RF IN

FM

RF

FM

RF IN

FM

RF OUTAMOSC

MIX

GND 1 MIX

OSC Buff OUT

V

CC1

Buff

AGC

V

CC2

Buff

1/8 DIV

FM

IF

OSC

0UT

AM

REQ

SW

FM IF

IF OUT

Buff

AM

DET

AM

IF OUT

/REQ

IF

IF

AM IF

IF REQ

+-

DET OUT

AF

Buff

LEVEL

DET

GND 2 FM

MPX IN

AM/FM

ST/MONO

SW

FM

DET

DET

GND

ST

LED

LPF 1

ST

IIND

VCC Vout

AM

FM

LPF 2

FM MPX

MUTE

L OUT

+-

MONO

SY

VCO

R OUT

+-

V

CC

1-26

L OUT

R OUT

Page 27

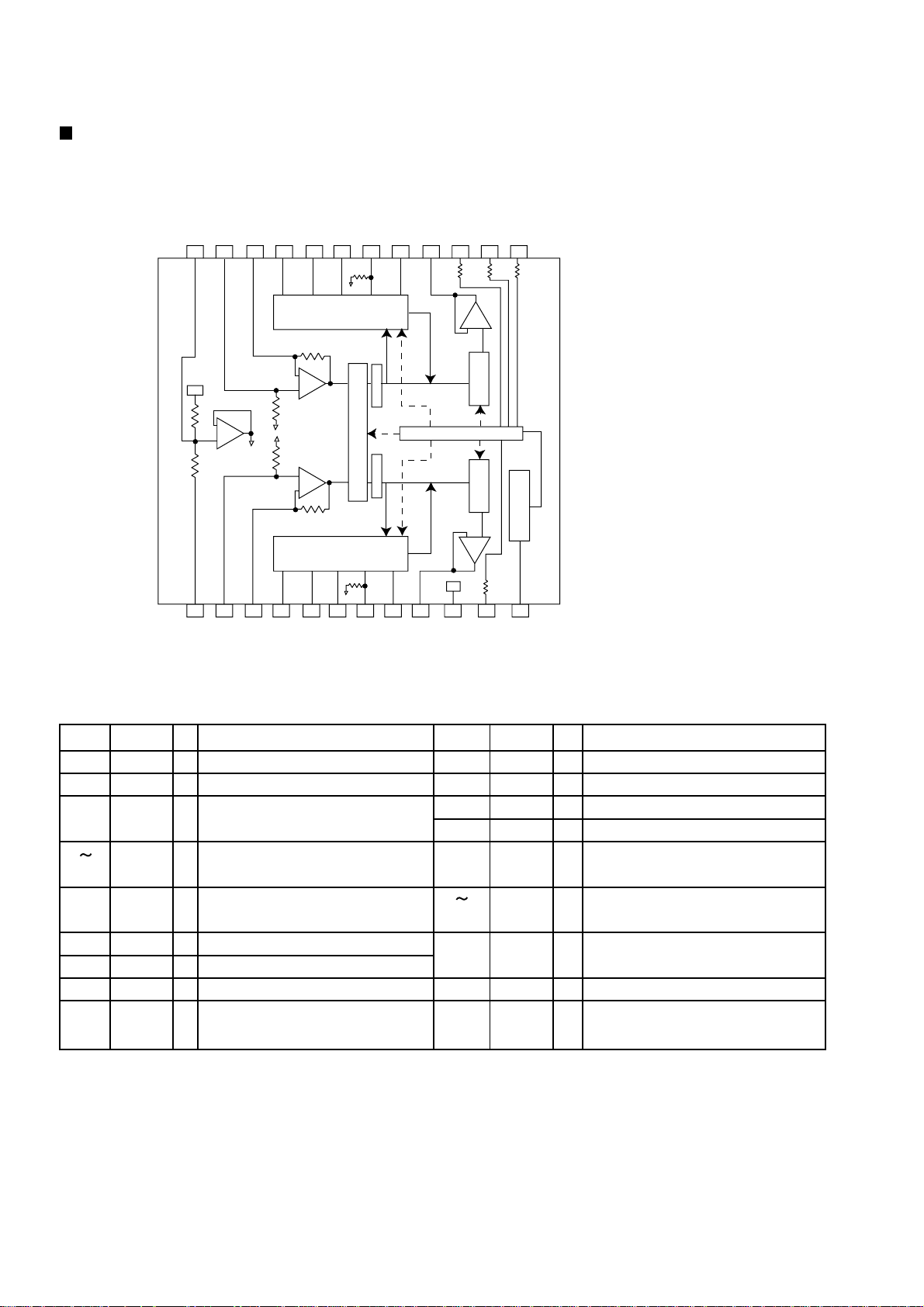

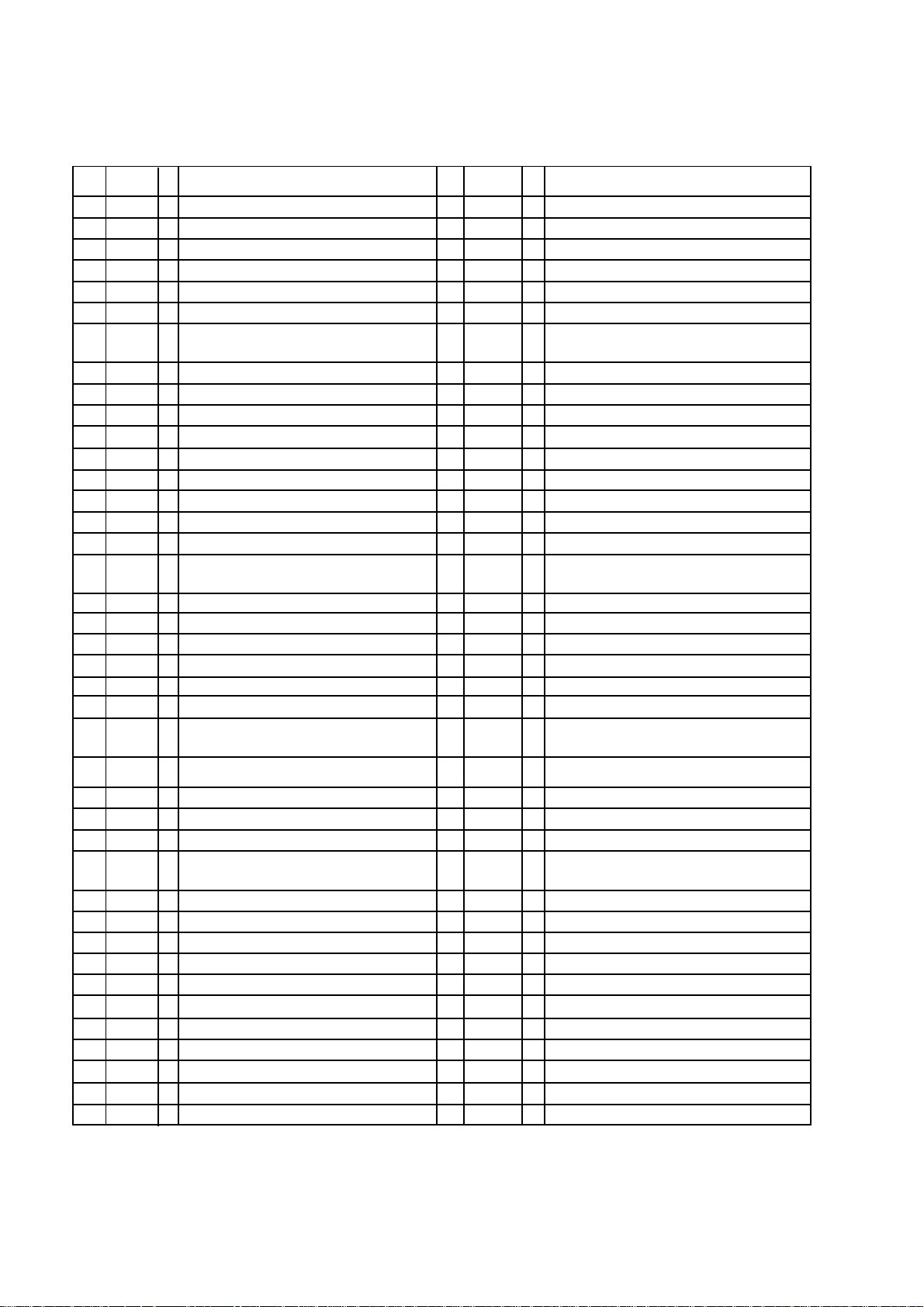

MN35510(IC603):DIGITAL SERVO&DIGITAL SIGNAL PROCESSER

RV-B550BU

1. Terminal Layout

2.Block Diagram

LRCKIN(MSEL)

BCLK(SSEL)

SRDATAIN

(PSEL)

IOSEL

CLVS

CRC

BLKCK

CLDCK

SBCK

SUBC

DEMPH

RESY

FLAG6(RESY)

SSEL

SQCK

SUBQ

AVDD2

AVDD2

PCK

EFM

PLLF

DSLF

IREF

DRF

ARF

RSEL

PSEL

MLD

MCLK

MDATA

CK384(EFM)

VCOF

BYTCK

SMCK

FCLK

CSEL

MSEL

X2

X1

ÊSTAT

DIGITAL

DEEMPHSIS

SUB

CODE

BUFFER

DSL.

PLL

VCO

VCO

ITUNING

GENERATION

PITCH

CONTROL

20 ~ 1

21

~

40

41 ~ 60

8TIMES

OVER SAMPUNC

DIGITAL FILTER

EFM

DEMODULATION

SYNC

INTERPOLATION

SUBCODE

DEMODULATION

MICRO

COMPUTER

INTERFACE

COVERTER

A/D

80

~

61

CIRC

ERROR

CORRECTION

DEINTERLEVE

CLV

SERVO

1BIT

DAC

LOGIC

S

16k

SRAM

INPUT

PEM

(R)

PEM

(L)

D/A

CONVERTER

OUTPUT

DIGITAL

AUDIO

INTERFASE

DIGITAL

AUDIO

INTERFASE

INTER POLATION

SOFT MUTING DIGITAL

ATTENUATION

PEAK DETECTIVE

AUTO CUE

PORT

SERVO

TIMING GENERATOR

AVSS1

AVDD1

OUTR

OUTL

FLAG

IPFLAG

TX

ECM

PC

LRCK

SRDATA

BCLK

DMUTE

TRKV

KICK

VREF

TRVSTR

ECS

TVD

TRD

FOD

TBAL

FBAL

TOFS

TES

/TLOCK

/FLOCK

PLAY

LDON

WVEL

SENSE

D

/

D

V

V

V

R

V

S

D

D

S

S

S

D

D

T

S

1

1

F

/

E

T

E

S

T

R

T

F

E

E

N

V

T

R

C

R

S

B

V

D

D

O

E

T

/

R

F

D

E

O

F

T

1-27

Page 28

RV-B550BU

3. Description

Pin

symbol

No.

BCLK

1

2

LRCK

SRDATA

3

4

DVDD1

DVSS1

5

TX

6

7

MCLK

MDATA

8

MLD

9

10

SENSE

11

FLOCK

12

TLOCK

13

BLKCK

14

SQCK

15

SUBQ

16

DMUTE

STATUS

17

18

RST

19

SMCK

20

PMCK

21

TRV

22

TVD

23

PC

24

ECM

25

ECS

26

KICK

27

TRD

28

FOD

29

VREF

30

FBAL

31

TBAL

FE

32

TE

33

34

RF ENV

35

VDET

OFT

36

37

TRCRS

38

RFDET

BDO

39

LDON

40

I/O

O

Not used

Not used

O

O

Not used

I

Power supply (Digital)

I

Connected to GND

Digital audio interface output

O

Micom command clock signal input

I

(Data is latched at signal's rising point)

Micom command data input

I

I

Micom command load signal input

Sence signal output

O

O

Focus lock signal output Active :Low

O

Tracking lock signal output Active :Low

sub-code - block - clock signal output

O

I

Outside clock for sub-code Q resister input

Sub-code Q -code output

O

I

Connected to GND

Status signal

O

(CRC,CUE,CLVS,TTSTOP,ECLV,SQOK)

Reset signal input (L:Reset)

I

I

Not used

I

Not used

O

Traverse enforced output

O

Traverse drive output

I

Not used

Spindle motor drive signal (Enforced

O

mode output) 3-State

Spindle motor drive signal (Servo error

O

signal output)

Kick pulse output

O

Tracking drive output

O

O

Focus drive output

Reference voltage input pin for D/A

I

output block (TVD,FOD,FBA,TBAL)

Focus Balance adjust signal output

O

O

Tracking Balance adjust signal output

Focus error signal input(Analog input)

I

Tracking error signal input(Analog input)

I

I

RF envelope signal input(Analog input)

Vibration detect signal input(H:detect)

I

Off track signal input(H:off track)

I

Track cross signal input

I

RF detect signal input(L:detect)

I

BDO input pin(L:detect)

I

Laser ON signal output(H:on)

O

Description

Pin

No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

symbol

TES

PLAY

WVEL

ARF

IREF

DRF

DSLF

PLLF

VCOF

AVDD2

AVSS2

EFM

PCK

PDO

SUBC

SBCK

VSS

XI

X2

VDD

BYTCK

CLDCK

FLAG

IPPLAG

FLAG

CLVS

CRC

DEMPH

RESY

IOSEL

TEST

AVDD1

OUT L

AVSS1

OUT R

RSEL

CSEL

PSEL

MSEL

SSEL

I/O

Tracking error shunt signal output(H:shunt)

O

I

Not used

I

Not used

I

RF signal input

I

Reference current input pin

Bias pin for DSL

I

I/O

Loop filter pin for DSL

Loop filter pin for PLL

I/O

I

Not used

I

Power supply(Analog)

Connected to GND(Analog)

Not used

III

Not used

I

Not used

I

Not used

I

Not used

Connected to GND(for X'tal oscillation

I

circuit)

Input of 16.9344MHz X'tal oscillation circuit

I

Output of X'tal oscillation circuit

O

I

Power supply(for X'tal cscillation circuit)

I

Not used

I

Not used

I

Not used

I

Not used

I

Not used

I

Not used

I

Not used

Not used

I

Not used

III

pull up

pull up

Power supply(Digital)

Lch audio output

O

I

Connected to GND

Rch audio output

O

II

pull up

Connected to GND

I

Connected to GND

I

Connected to GND

I

Pull up

Description

1-28

Page 29

BA15218F-XE(IC401/751):OP AMP.

RV-B550BU

EE

1OUT1

2-IN1

1

3+IN1

+

4

-

2

+

8

7

6

5V

VCC

OUT2

-IN2

+IN2

1-29

Page 30

RV-B550BU

VICTOR COMPANY OF JAPAN, LIMITED

AUDIO DIVISION,10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.20826C)

Printed in Japan

200101 (V )

Page 31

PARTS LIST

[ RV-B550BU ]

* All printed circuit boards and its assemblies are not available as service parts.

RV-B550BU

- Contents -

Exploded view of general assembly and parts list

CD mechanism assembly and parts list

Cassette mechanism assembly and parts list

Electrical parts list

Packing materials and accessories parts list

Area suffix

UY ---------------------- Argentina

3- 2

3- 7

3- 8

3-13

3-24

3-1

Page 32

RV-B550BU

Exploded view of general assembly and parts list

Block No.

M

M

1

M

5

Front Cabinet

86

86

3

2

3

a

3

13

4

4

b

5

4

86

12

14

86

84

108

3

6

3

2

3

3

10

1

20

20

15

21

85

86

2

23

17

22

19

24

27

25

16

18

26

86

86

1

3-2

ABCD

Page 33

Exploded view of general assembly and parts list

Block No.

Rear Cabinet

53

5

48

47

91

40

58

68

69

Back light board

RV-B550BU

M

M

1

M

62

34

51

50

61

Key switch board

9

9

38

88

64

66

59

43

8

70

66

7

9

35

37

T

ra

n

s

97

bo

87

a

rd

78

36

99

80

80

Main

board

9

11

37

39

76

88

Battery

board

75

74

65

109

CD door

switch board

88

63

Cassette sw

28

42

93

102

41

44

92

42

90

89

45

Tuner board

32

itch board

106

101

72

105

77

88

Micon

board

42

107

46

42

103

104

82

71

88

83

88

87

73

31

56

55

57

54

4

38

78

49

52

35

100

36

33

39

98

3

79

94

79

Power supply

2

board

95

96

110

67

29

60

32

Head amp. & mecha. control board

1

30

29

ABC

29

3-3

Page 34

RV-B550BU

)

)

Parts list(General assembly)

Item Parts number Parts name Area

A

1 LV10160-012A FRONT CABI ASSY 1 H.F.WELDING

2 LE10010-012A SPEAKER 2 L/R

3 QYSBSF3010Z SCREW 8 FOR SPK.

4 QYSBST3006Z T.SCREW 4 SPK+LED PWB

5 LV41752-001A SPK.LED HOLDER 2

6 VJK4520-081 LCD LENS 1 AS SILK X 1

7 LV20331-001A POWER BUTTON 1

8 LV20332-001A VOLUME BUTTON 1

9 QYSBSF2610Z SCREW 6 BUTTON + SW PWB

10 LV40715-002A LENS 1 AS PAD X 1

11 LV40716-002A LED HOLDER 1 ABS

12 LV40750-001A PACKING SHEET L 1 PEFU(FRONT CABI

13 LV40751-001A PACKING SHEET R 1 PEFU(FRONT CABI

14 QYSBSFG3010Z TAP SCREW 1 SPK.CON+FRONT

15 LV20298-003A CASSETTE HOLDER 1 MIPS

16 VKZ4794-002 SPECIAL SCREW 3 EJECT SAFTY

17 LV20299-005A DOOR COVER 1

18 LV30844-001A EJECT SAFTY 1 CASS HOLDER

19 LV40717-003A DOOR LENS 1 PC SILK X 2

20 VKY4180-001 CASSETTE SPRING 2 SUS

21 VYH5601-001 GEAR 1 POM

22 LV40718-001A EJECT KNOB 1 ABS

23 LV40719-001A CAM(CASS

24 LV40749-001A TENSION SPRING 1 CAM + DOOR COVE

25 QYSDSF2614Z SCREW 1 E.KNOB + CAM

26 LV40721-001A DOOR SPRING 1 SUS T1.0

27 LV40720-002A COLLAR (CASS

28 ------------ SLC MECHA ASS'Y 1

29 QYSBSF3014Z SCREW 4 FOR SLC

30 LV30845-001A HEAD SHIELD 1 SPTE T 0.4

31 LV10192-001A CASS CHASSIS 1 MIPS

32 VYSA1R6-080 SPACER 2 FOR CASS CHASSI

33 ------------ EXL-M6MAYPM 1

34 VJD5410-205 PICK COVER 1

35 QYSDSF2006M SCREW 4

36 VKZ4791-001 INSULATOR 2

37 VKZ4791-001 INSULATOR 2

38 LV40723-001A CD MECHA HOLDER 2 EGC T1.0

39 QYSBSF3010Z SCREW 4 FOR HOLDER

40 LV10162-009A CD CASE 1 MIPS

41 LV31305-001A SHIELD 1 FOR CD CASE

42 QYSBSF3010Z SCREW 4 FOR MICON PWB

43 LV40726-001A LOCK LEVER 1 POM

44 VYH4769-002SS GEAR 1 FOR CD CASE

45 VXL4442-001 VOLUME KNOB 1 MIC VOLUME

46 VYSA1R6-080 SPACER 2 FOR MICON PWB

47 LV10163-008A CD DOOR 1

48 PQ45130-7 JVC MARK 1 FOR CD DOOR

Q'ty Description

1 POM

1 SLIDER + D.COVE

Block No. M1MM

3-4

Page 35

RV-B550BU

)

)

)

)

)

)

)

Parts list(General assembly)

Item Parts number Parts name Area

A

49 VYH3644-201 CLAMPER 1 FOR OPTIMA-6

50 VYH7313-003 MAGNET 1

51 VYH7314-001 YOKE 1

52 VYH7315-005 PAD 1

53 LV40718-001A EJECT KNOB 1 ABS

54 QYSBSF2610Z SCREW 1 E.KNOB + SLIDER

55 LV30846-001A SLIDER(CD

56 LV40725-001A TORSION SPRING 1 FOR SLIDER

57 LV40728-002A COLLAR(CD

58 LV40729-002A CD DOOR SPRING 1 SUS

59 LV30847-001A HEAT SINK(A

60 QYSBSF3012Z SCREW 2 HEAT SINK(A)+PW

61 LV30848-001A HEAT SINK(B

62 E65923-003 TAPPING SCREW 2 FOR AC

63 QYSBSF3012Z SCREW 3 FOR POWER IC

64 QYSBSF3012Z SCREW 2 H.SINK(A)+BKT.

65 LV40730-001A HEAT SINK BKT 1 FOR HEAT SINK

66 QYSBSF3010Z SCREW 2 REAR + H.BKT.

67 VYSA1R6-080 SPACER 1 FOR AMP PWB

68 LV30849-001A LCD HOLDER 1 SPTE T0.4

69 VYH8193-002 SHEET 1 LCD + LCD HOLDE

70 LV10164-030A REAR CABINET 1 MIPS

71 VND4118-004 CAUTION LABEL 1 FOR REAR

72 FMJA3001-00A(D

73 VYH5012-006 TERMINAL LUG 1 SPTE T0.4

74 QYSBSF3012Z SCREW 1 TUNER HOLDER+RE

75 LV41032-001A TUNER HOLDER 1

76 E65923-003 TAPPING SCREW 1 FOR H.PHONES

77 QYSDSP3012N SCREW 1 FOR ROD ANT

78 VYH8101-001 TRANS SUPPORT 2 POM

79 QYSBSF3030Z SCREW 4 FOR TRANS

80 LV30225-021A SPACER 2 TRANS WIRE

82 VJC2016-341 BATTERY COVER 1 MIPS

83 VYH5657-001 BATTERY SPRING 1

84 LV10165-005A SIDE PROT.ASY L 1

85 LV10166-005A SIDE PROT.ASY R 1

86 QYSBSF3012N SCREW 12 FOR SIDE PROTEC

87 VKH3012-073 SHAFT(E

88 QYSBSF3040Z SCREW 8 FRONT+REAR

89 QYSBSF3010Z SCREW 2 CD CASE + REAR

90 LV31998-004A NAME PLATE

A

91 LV40231-001A CAUTION LABEL 1

92 QLD0024-002 L.C.DISPL.PANEL 1

93 E70306-001 HEAT SINK 1

94 QQT0247-004 POWER TRANS

A

95 QMF51E2-4R0-J1 FUSE

A

96 QMF51E2-6R3-J1 FUSE

A

97 LV41029-001A HEAT SINK 1

ROD ANT ASS'Y 1

Q'ty Description

1 POM

1

1 AL T2.0

1

2 REAR(S.BELT

1

1

1 F1902

1 F1904

Block No. M1MM

3-5

Page 36

RV-B550BU

Parts list(General assembly)

Item Parts number Parts name Area

A

98 QMF51E2-R80-J1 FUSE 1

99 QJJ010-060606 SIN CR C-C WIRE 1

100 QUQ610-1508AJ FFC WIRE 1

101 QUQC12-0806CJ FFC WIRE 1

102 QUQC12-1006CJ FFC WIRE 1

103 QUQ412-1313CJ FFC WIRE 1

104 QUQ412-1415CJ FFC WIRE 1

105 QUQ412-1012DJ FFC WIRE 1

106 QUQ412-0914DJ FFC WIRE 1

107 QUQ412-0912CJ FFC WIRE 1

108 WJJ0034-010A E-SI C WIRE C-C 1

109 QYSBSSF3010Z SCREW 1

110 QYSBSF3014Z SCREW 1

Q'ty Description

F1901

Block No. M1MM

3-6

Page 37

CD mechanism assembly and parts list

Grease Point

FG-87HS

(Grease to apply have to be a little for the exchange.)

3

FG-87HS

FG-87HS

Block No.

RV-B550BU

2

M

M

M

2

0.1mm

+

-

19.4

FG-87HS

12

1

EXL-M7TMB

Turn table hight

EXL-M7MB

ABC

Parts list ( CD mechanism )

A

Item

1 E102731-221SM MECHA BASE 1

2 OPTIMA-7B OPTICAL PICK UP 1

3 E406777-002SM CD SHAFT 1

4 LV31002-001A CD RACK 1

5 E307745-441SM MECHA GEAR 1

6 QYSDSP2003N SCREW 4

7 E406750-442SM PINION GEAR 1

8 EPB-001PK TURN TABLE 1 SINGLE CD

9 E406784-001 FEED MOTOR 1

10 QAR0130-001 SPPINDLE MOTOR 1

11 EMW10190-441 P.C.BOARD 1

12 QGA2001F1-06 6P PLUG ASSY 1

13 QSW0506-001 LEAF SWITCH 1

14 E75832-221SS SPECIAL SCREW 1

Parts number Parts name

EPB309173PKA TURN TABLE 1 CHANGER CD

Q'ty

Block No. M2MM

Description

Area

3-7

Page 38

RV-B550BU

Cassette mechanism assembly and parts list

SLC-S1YPM

5

4

Block No.

M

3

M

M

C

C

3

63

Cassette switch board

2

Head amplifier &

mechanism control board

mm

1

3-8

0.1

0.15

+

-

8.7

Motor pulley hight

ABCD

Page 39

RV-B550BU

)

)

)

)

)

)

Parts list(Cassette mechanism)

Item Parts number Parts name Area

A

1 VKS1165-00G CHASSIS B.ASS'Y 1

4 VKS2274-002 REEL GEAR 2

5 VKW5286-002 B.T. SPRING 2

6 VKS5559-001 PLAY IDLE GEAR 1

7 VKS5597-00A BUND ASS'Y 1

8 VKW5296-001 EARTH SPRING 1

9 VKR4749-003 IDLE PULLEY 1

10 VKH5786-003 SHAFT 1

11 VKS2275-00E HEAD MOUNT ASSY 1

12 VKS1167-003 HEAD MOUNT BASE 1

14 LV41089-001A R/P&E HEAD 1 VKS2275-00B

18 VKW5302-001 HEAD SPRING 1

19 VKZ4730-001 SPECIAL SCREW 2

20 VKS2277-005 DIRECTION LEVER 1

21 VKP4233-00A PINCH ROL. ASSY 2

24 VKW5299-002 PIN ROL.SP.(R

25 VKW5300-002 PIN ROL.SP.(L

26 VKW5285-001 RETURN SPRING 1

27 VKY3149-002 CASSETTE SP. 1

28 VKM3906-002 PLAY SW LEVER 1

29 VKS1166-003 CONTROL CAM 1

30 VKW5279-001 HEAD BASE SP(R

31 VKW5280-001 HEAD BASE SP(L

32 VKS5603-00D MAIN PULLEY ASY 1

33 VKS3785-001MM FR ARM 1

34 VKW5284-002 SWING SPRING 1

35 VKS2278-003 TRIGGER ARM 1

36 VKW5301-001 FR SPRING 1

37 VKW5266-001 ELEVATOR SPRING 1

38 WDL214025 WASHER 1

39 VKS3786-00G CLUTCH ASS'Y 1

45 VKF3205-00B F.WHEEL ASSY(R

48 WDL183425 SLIT WASHER 1

49 VKF3207-00B F.WHEEL ASSY(L

52 WDL173525-6 SLIT WASHER 1

53 VKZ3174-00A DC SOLENOID 1

56 VKB3000-181 CAPSTAN BELT 1

57 MSI-5U2LWA D.C.MOTOR ASS'Y 1

58 VKR4761-001 MOTOR PULLEY 1

59 QYSPSP2604Z SCREW 2

61 QYSBSF2608Z T.SCREW 3 FOR P.W.B.

63 QYSBSF2006Z SCREW 1

Q'ty Description

1

1

1

1

1

1

Block No. M3MM

3-9

Page 40

RV-B550BU

Grease point 1/3

Grease

*

5

EM-30L

UD-24

LEN-320M

*

EM-30L

*

Fig.2

EM-30L

Fig.1

*

EM-30L

Fig.2

4

Fig.1

Fig.3

*

EM-30L

3

Fig.3

2

1

3-10

Fig.4

EM-30L

*

EM-30L

*

EM-30L

*

(Remove the Head mount Ass'y on the Chasis Base)

Fig.4

ABCD

*

EM-30L

Page 41

RV-B550BU

Grease point

EM-30L

*

2/3

*

EM-30L

5

Fig.1

Fig.5

4

Fig.5

Fig.1

EM-30L

3

Fig.2

Fig.4

2

EM-30L

Fig.3

LEN-320M

Note: It is a putting up of the control

cam to UD-24H(Hanarl) and

LEN-320M(Grease)dipping on the

Control cam

*

Fig.2

1

Fig.4

Fig.3

ABC

3-11

Page 42

RV-B550BU

Grease point 3/3

*

EM-30L

*

EM-30L

*

EM-30L

*

EM-30L

5

Fig.1

Fig.2

Fig.2

4

Fig.1

Fig.3

3

Fig.5

Fig.4

2

Fig.3

UD-24

*

EM-30L

EM-30L

*

Fig.6

UD-24

Fig.4

1

3-12

Fig.5

Fig.6

ABCD

Page 43

)

)

Electrical parts list

Electrical parts list(Micon board)

Item

A

C 604 QEKC1AM-107Z E CAPACITOR 100MF 20% 10V

C 605 QETN1HM-106Z E CAPACITOR 10MF 20% 50V

C 606 NCB21HK-102X C CAPACITOR

C 607 NCB21HK-102X C CAPACITOR

C 608 QETN1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 609 NCS21HJ-101X C CAPACITOR

C 610 QFLM1HJ-273Z M CAPACITOR .027MF 5% 50V

C 611 NCB21HK-472X C CAPACITOR

C 612 NCB21HK-103X C CAPACITOR

C 613 NCS21HJ-331X C CAPACITOR

C 614 QFVF1HJ-104Z TF CAPACITOR .10MF 5% 50V

C 615 NCB21HK-223X C CAPACITOR

C 616 NCB21HK-223X C CAPACITOR

C 617 NCB21HK-223X C CAPACITOR

C 618 NCB21HK-222X C CAPACITOR

C 619 NCS21HJ-271X C CAPACITOR

C 620 NCS21HJ-181X C CAPACITOR

C 622 QETN1EM-476Z E CAPACITOR 47MF 20% 25V

C 623 QFVF1HJ-104Z TF CAPACITOR .10MF 5% 50V

C 628 QDX31EM-473Z C CAPACITOR

C 629 QETN1AM-107Z E CAPACITOR 100MF 20% 10V

C 631 QETN1AM-477Z E CAPACITOR 470MF 20% 10V

C 632 QEKC1AM-107Z E CAPACITOR 100MF 20% 10V

C 640 NCB21HK-822X C CAPACITOR

C 641 NCB21HK-223X C CAPACITOR

C 651 NCS21HJ-270X C CAPACITOR

C 652 NCS21HJ-270X C CAPACITOR

C 653 NCB21HK-223X C CAPACITOR

C 655 QDX31EM-473Z C CAPACITOR

C 661 NCS21HJ-471X C CAPACITOR

C 662 NCB21HK-223X C CAPACITOR

C 663 QFLM1HJ-223Z M CAPACITOR .022MF 5% 50V

C 664 NCB21HK-223X C CAPACITOR

C 665 QFVF1HJ-104Z TF CAPACITOR .10MF 5% 50V

C 671 NCB21HK-222X C CAPACITOR

C 672 NCB21HK-222X C CAPACITOR

C 673 QTE1A28-227Z E CAPACITOR

C 674 NCB21HK-223X C CAPACITOR

C 675 NCB21HK-102X C CAPACITOR AG-DG

C 691 NCS21HJ-151X C CAPACITOR DENGEN NOISE

C 692 NCS21HJ-151X C CAPACITOR DENGEN NOISE

C 693 NCS21HJ-151X C CAPACITOR DENGEN NOISE

C 694 NCS21HJ-151X C CAPACITOR DENGEN NOISE

C 696 NCS21HJ-101X C CAPACITOR

C 697 NCS21HJ-101X C CAPACITOR

C 698 NCS21HJ-101X C CAPACITOR

C 699 NCS21HJ-101X C CAPACITOR

CN251 QGF1205C1-10 CONNECTOR

CN252 QGF1205C1-08 CONNECTOR

CN403 QGF1205C1-09 CONNECTOR

CN405 QGF1205F1-10 CONNECTOR

CN406 QGF1205F1-09 CONNECTOR

CN407 QGF1205F1-13 CONNECTOR

CN408 QGF1205F1-14 CONNECTOR

CN601 QGF1008F1-15 21-41 CONNECTOR TO RF

CN602 QGA2001C1-06 6P PLUG ASSY

CN901 QGF1205F1-10 CONNECTOR

CN902 QGF1205F1-08 CONNECTOR

CN904 QGA2501F1-02 CONNECTOR

CN907 QGA2501C1-02 2P CONNECTOR

C2501 QER61AM-226Z E CAPACITOR 22MF 20% 10V

C2502 QER41CM-476 E CAPACITOR 47MF 20% 16V

C3361 QER41AM-107 E CAPACITOR 100MF 20% 10V

Parts number Parts name Area

Block No. 01

Remarks

RV-B550BU

Item

Parts number Parts name Area

C3362 QER61EM-475Z E CAPACITOR 4.7MF 20% 25V

C3571 QER41CM-476 E CAPACITOR 47MF 20% 16V

C4142 NCS21HJ-100X C CAPACITOR

C4143 QER61EM-475Z E CAPACITOR 4.7MF 20% 25V

C4144 QER61EM-475Z E CAPACITOR 4.7MF 20% 25V

C4145 QTE1V06-106Z E CAPACITOR

C4151 NCB21HK-681X C CAPACITOR

C4242 NCS21HJ-100X C CAPACITOR

C4243 QER61EM-475Z E CAPACITOR 4.7MF 20% 25V

C4244 QER61EM-475Z E CAPACITOR 4.7MF 20% 25V

C4245 QTE1V06-106Z E CAPACITOR

C4251 NCB21HK-681X C CAPACITOR

C4341 QER41CM-476 E CAPACITOR 47MF 20% 16V

C4342 QER61CM-107Z E CAPACITOR 100MF 20% 16V

C4343 NCS21HJ-151X C CAPACITOR

C4344 QER61EM-475Z E CAPACITOR 4.7MF 20% 25V

C7351 QET N1 HM-226Z E CAPACITOR 22MF 20% 50V

C7352 QET N1 HM-226Z E CAPACITOR 22MF 20% 50V

C7353 NCS21HJ-390X C CAPACITOR

C7354 QET N1 HM-335Z E CAPACITOR 3.3MF 20% 50V

C7355 QER61HM-474Z E CAPACITOR .47MF 20% 50V

C7356 QET N1 HM-336Z E CAPACITOR 33MF 20% 50V

C7357 QET N1 HM-335Z E CAPACITOR 3.3MF 20% 50V

C7358 QET N1 HM-475Z E CAPACITOR 4.7MF 20% 50V

C9001 NCS21HJ-220X C CAPACITOR SUB CLOCK

C9002 NCS21HJ-220X C CAPACITOR SUB CLOCK

C9003 NCS21HJ-151X C CAPACITOR BEAT

C9004 NCS21HJ-471X C CAPACITOR

C9005 NCS21HJ-240X C CAPACITOR MAIN CLOCK

C9006 NCS21HJ-240X C CAPACITOR MAIN CLOCK

C9007 NCS21HJ-360X C CAPACITOR MAIN CLOCK

C9008 NCS21HJ-360X C CAPACITOR MAIN CLOCK

C9009 NCB21HK-103X C CAPACITOR VDD

C9011 NCB21HK-103X C CAPACITOR RESET

C9012 QER61HM-226Z E.CAPACITOR 22MF 20% 50V

C9013 NCS21HJ-151X C CAPACITOR

C9015 NCS21HJ-151X C CAPACITOR

C9016 NCS21HJ-151X C CAPACITOR

C9017 NCS21HJ-151X C CAPACITOR

C9018 QER41AM-107 E CAPACITOR 100MF 20% 10V

C9019 QER61HM-106Z E CAPACITOR BASS

C9020 QER61HM-106Z E CAPACITOR TRE