Page 1

SERVICE MANUAL

RADIO CASSETTE RECORDER

RC-W305

Area Suffix

U ----- Asia

UX ----- Middle East

SERVICE POLICY

No service part is available for this model.

Based on One to One exchange policy.

Contents

Safety Precaution...........................................................................2

Preventing Static Electricity...........................................................3

Disassembly Method......................................................................4

Adjustment Method.........................................................................5

Description Of Major IC................................................................8

Voltage Charts..............................................................................12

Wiring Connection Diagram........................................................13

Schematic Diagram ......................................................................14

Printed Circuit Board...................................................................15

COPYRIGHT © 2005 JVC ASIA PTE LTD

No: 28223

SEP. 2005

Page 2

RC-W305

CAUTION

Safety Precautions

1. This design of this product contains special hardware and many circuits and components specially for

safety purposes. For continued protection, no changes should be made ti the original design unless

authorised in writing by the manufacturer. Replacement parts must be identical to those used in the

original circuits. Services should be performed by qualified personel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the

product should not be made. Any design alterations or additions will void the manufacturer's warranty

and will further relieve the manufacturer of responsibility for personal injury or property damage

resulting therefrom.

3. Many eletrical and mechanical parts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded by

them necessarily be obtain by using replaement components rated for higher voltage, the Parts

List of Service manual. Electrical components having such features ate identified by the shading on the

schematics and by (

repalcement which does not have the same safety characteristics as the recommended replacement

parts shown in the Parts List of Service manual may create shock, fire, or other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubing's, barriers and the like to

be separated from live parts, high temperatures parts, moving parts and/or sharp edges for the

prevention of electric shcok and fire hazard. When service is required, the original leat routing and

dress should be observed, and it should be confirmed that they have been returned to normal, after

re-assembling.

!

) on the parts List in the Service Manual. The use of a substitute

XL-SV320SL/SV305GD

XL-SV308BU

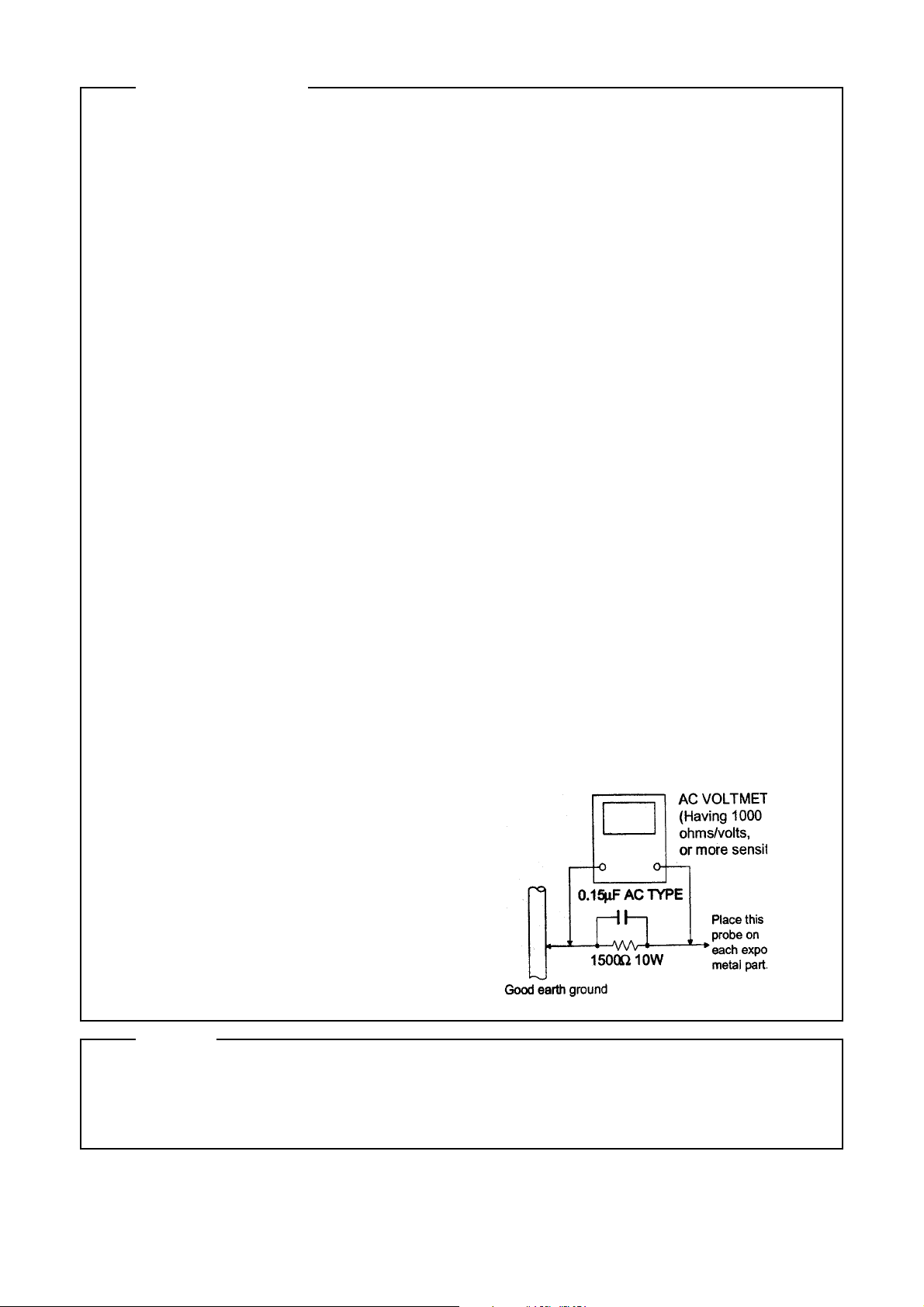

5. Leakage current check (Electrical Shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metap Parts of the

product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.)

to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isloation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the

leakage current from each ecposed metal parts of the cabinet, particularly and exposed metal

part having a return path to the chassis, to a known good earth ground. Any leakage current must

not exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per

volt or more sensitvity in the following manner. Connect a 1,500 ohm 10W resistor paralleled by a

0.15uF AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with

the AC voltmeter.

Move the resistor connection to each exposed

metal part, particularly and exposed metal part

having a return path to te chassis and

measure the AC voltage across the resistor. Now,

reverse the plug in the AC outlet and repeat

each measurement. Voltage measured Any must

not exceed 0.75 V AC (r.m.s.). This corresponds

to 0.5 mA AC (r.m.s.).

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. It mains voltage selector is provided, check setting for local voltage.

Warning

Burrs formed during moulding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of performing repair of this system.

2

Page 3

RC-W305

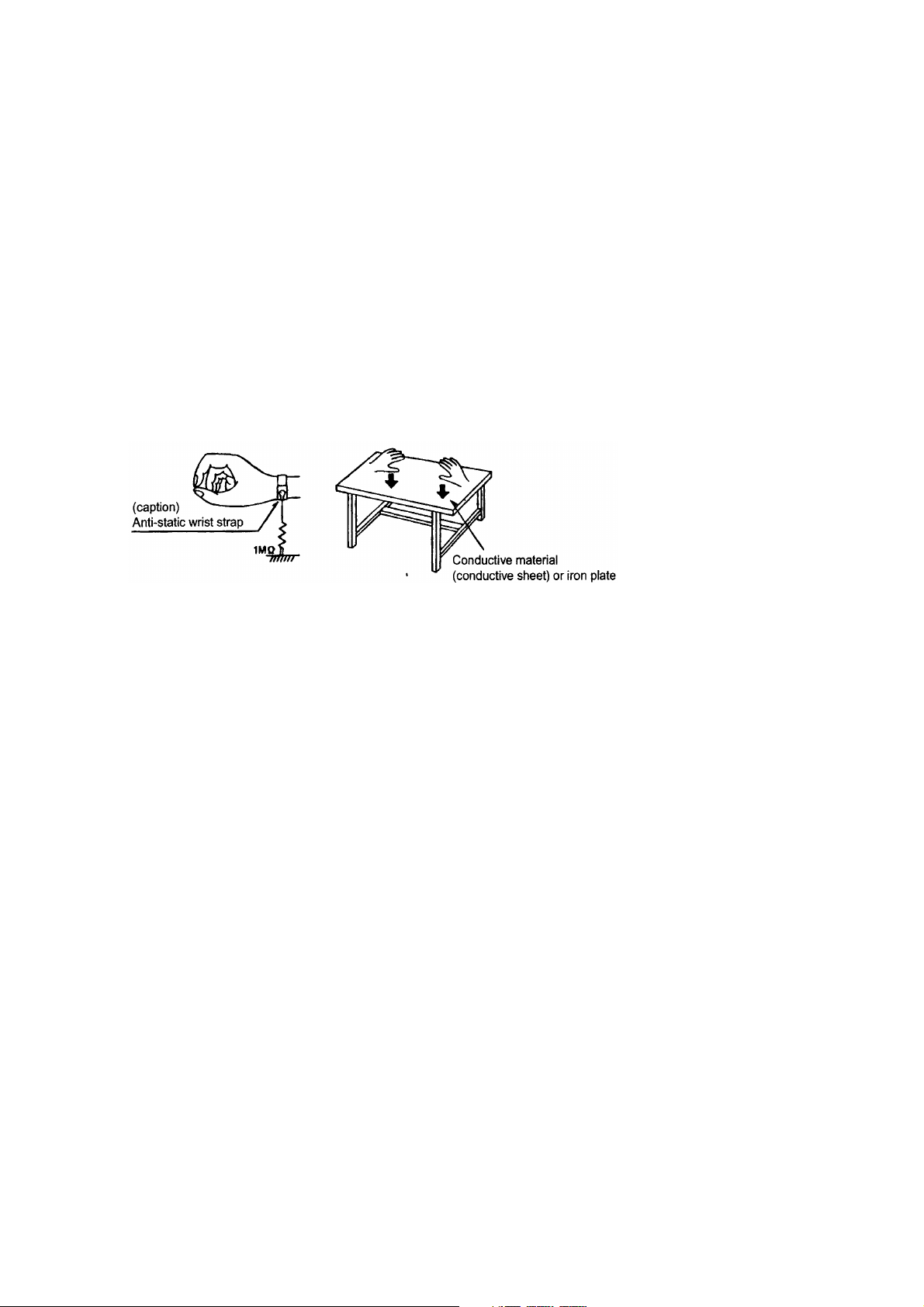

Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pcikup). Take care to prevent this when performing repairs.

1.1. Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup in devicessuch.

Be careful to use proper grounding in the area where repairs are being performed.

1.1.1. Gound the workbench

1. Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

1.1.2. Ground yourself

1. Use an anti-static wrist starp to release and static electricity built up in your body.

3

Page 4

RC-W305

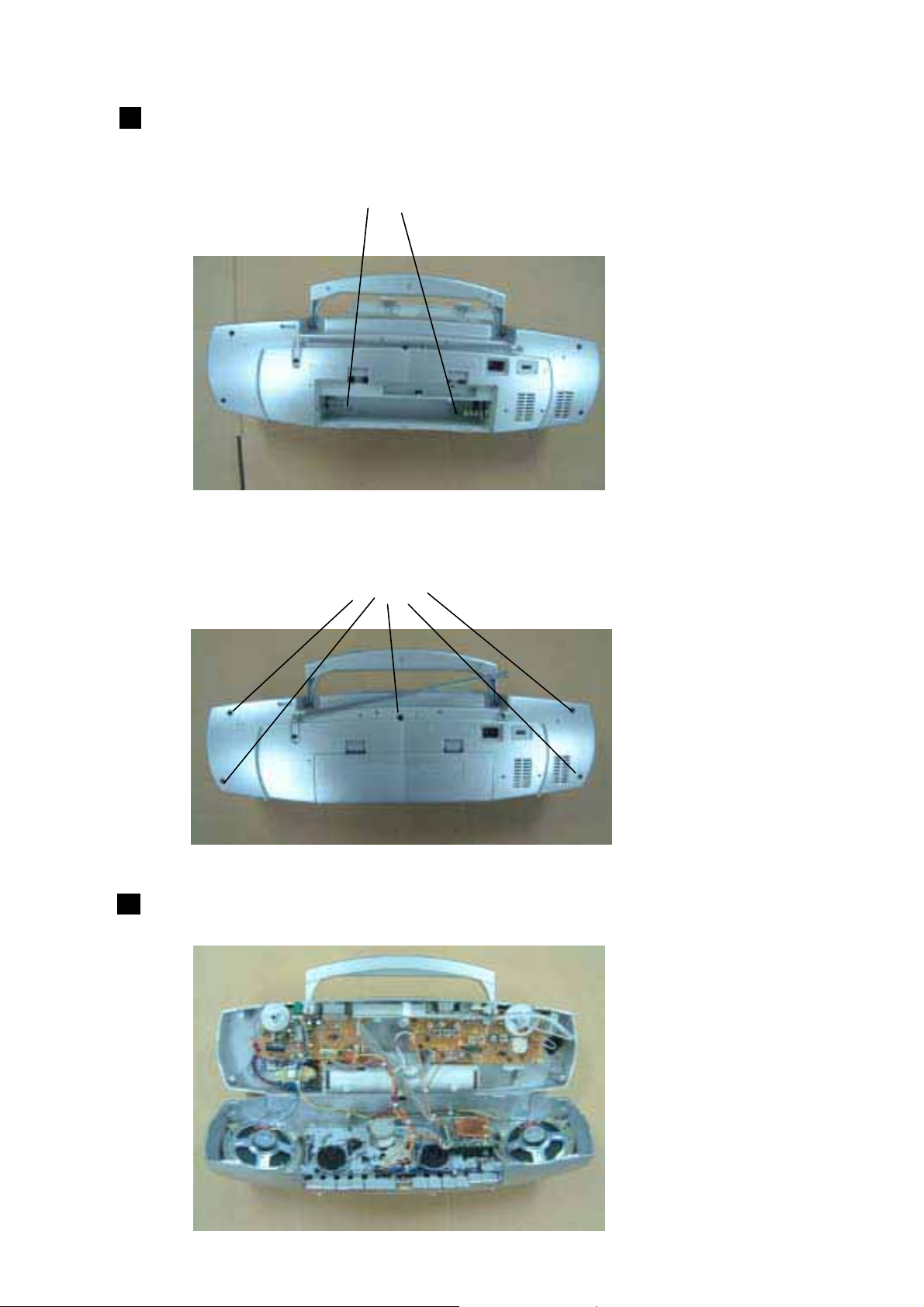

Disassembly Method

Remove the back cabinet

1, Open the battery cover and remove 2 screws inside it. (Screw A)

XL-SV320SL/SV305GD

XL-SV308BU

Screw A

2, Remove 5 screws on back side. (Screw B)

Screw B

Then the unit would be disassembled.

4

Page 5

Adjustment Method

Instrument required Precautions for alignment

1 Direct connect to the IF sweeper output

1 Low frequency oscillator side and 1 UF and 22 Kohm connect to the

This oscillator should have a capacity to output sweeper input side . Same as FIG1 .

0dB to 600Ө at an oscillation frequency of

50Hz-20KHz IC101

PIN18

2 Electronic voltmeter

3 Distortion meter

4 Frequency counter

5 Wow & flutter meter

6 Test tape 2 The IF sweeper output level should be made as

TCC-112 : Tape speed and running unevenness (3KHz) low as possible within the adjustable range .

TCC-140 : Reference level (1KHz) 3 Since the IF sweeper is a fixed device , there is no

TCC-182A : Head angle (8KHz) , playback frequency need to adjust this sweeper .

characteristics (1KHz) and dubbing frequency 4 Since a ceramic oscillator is used , there is no need

characteristics (125Hz and 8KHz) to perform any MIX adjustment .

5 Since a fixed coil is used , there is no need to

7 Blank tape adjust the FM tracking .

TYPE I : TDK-D60 6 The input and output earth systems are separated .

In case of simultaneously measuring the voltage in

8 Torque gauge : For play and back tension both of the input and output systems with an

FWD(CT-120m) , and FF/REW(CT-F) electronic voltmeter for two channels , therefore , the

earth should be connected particularly carefully .

General conditions

Power supply voltage ------------- RC-S2055( U ) AC 110V/220V 60Hz/50 8 Whenever any mixed tape is used , use the band

Reference output -------------- Speaker : 0.63V/8Ө

Headphone : 0.245V/32Ө

7 For connecting a dummy resistor when measuring

the output , use the wire with a greater code size .

pass filter (DV-12V)

RC-W305

playback characteristics

Measurement output terminal ---------- Speaker CN301

* Load resistance -------------------------------------- 8Ө

Tuner conditions

AM frequency -------------------------------- 400Hz

AM modulation ---------------------------------- 30%

FM frequency --------------------------------- 1 KHz

FM frequency deviation ------------------ 22.5KHz

Reference measurement ----- 26.1mV(0.63V/8Ө)

output

Input positions ----- AM : Standard loop antenna

FM : TP2 (hot) and TP3 (GND)

Reference measurement ----- 26.1mV(0.63V/8Ө)

output

Input positions ----- AM : Standard loop antenna

FM : TP2 (hot) and TP3 (GND)

5

Page 6

RC-W305

t

t

p

p

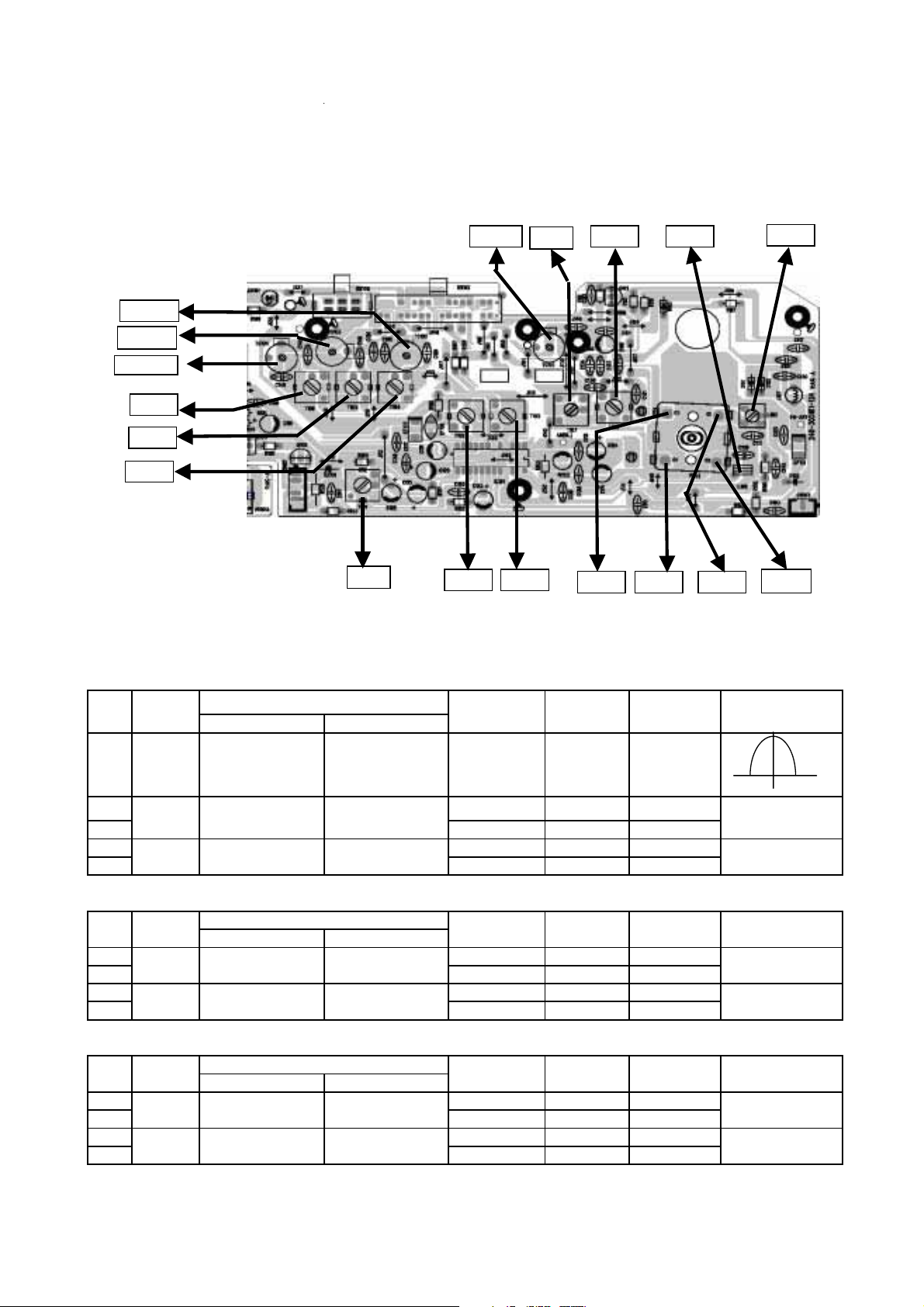

TUNER ADJUSTMENTS

Use a plastic screw driver for adjustments.

Adjust the intermediate frequency of AM and FM to th

Set of unit

Supply voltage : DC 9.0V

Speaker impedance :8 ohms

Standard output : 50 mW

Function switch : RADIO

a. Parts Location

TC102

TC103

TC104

T106

T105

T104

e frequency of ceramic filter.

T107

T108TC101

XL-SV320SL/SV305GD

XL-SV308BU

L102

L103

T101

T103T102

C4C3

b. MW Adjustment Band switch : MW

Step Adjustment

c. SW Adjustmen

Ste

Adjusting Connections

Circuit lnput Output

1 IF generator to IC101 455KHz Low T102

2

3

4

5

Connect AM sweep

generator to loop

ANT.

Tuning Connect AM SG to Connect VTVM to 515 KHz Low end T104

coverage loop ANT speaker terminals. 1640 KHz High end TC102

Tracking

Connect AM SG to Connect VTVM to 600 KHz 600 KHz MW ANT COIL

loop ANT speaker terminals 1400 KHz 1400 KHz PVC101-C3

Connect sweep

(18)PIN(A)

Band switch : SW1

Adjusting Connections

Circuit lnput Output

1 Tuning Connect AM SG to Connect VTVM to 5.8 MHz Low end T105

2 coverage FM ANT & D105(-) speaker terminals. 15.4 MHz High end TC103

3 Connect AM SG to Connect VTVM to 7.0 MHz 7.0 MHz T107

Tracking

4 FM ANT &D105(-) speaker terminals. 12.0 MHz 16.0 MHz TC101

SG

Frequency

SW Dummy antenna : 75 ohms unbalance

SG

Frequency

Position of VTVM

Tuning dial Oscilloscope

Position of VTVM

Tuning dial Os

C1

C2

Max.

Max.

cilloscope

Max.

Max.

d. SW Adjustmen

Ste

Adjusting Connections

Circuit lnput Output

1 Tuning Connect AM SG to Connect VTVM to 14.8 MHz Low end T106

2 coverage FM ANT & D105(-) speaker terminals. 22.4 MHz High end TC104

3 Connect AM SG to Connect VTVM to 15.0 MHz 15.0 MHz T108

Tracking

4 FM ANT &D105(-) speaker terminals. 22.0 MHz 22.0 MHz PVC101-C4

Band switch : SW2

SW Dummy antenna : 75 ohms unbalance

SG

Frequency

Position of VTVM

Tuning dial Os

cilloscope

Max.

Max.

6

Page 7

e. FM Adjustment Band switch : FM FM Dummy antenna : 75 ohms unbalance

Adjusting Connection position o f VTVM

Step SG Frequen cy

Circuit Input Output tuning dia l Oscillosc

Connect sweep

1 IF generator to IC101 10.7 MHz Low

2 Tuning Connect FM SG to Connect VTVM to 87.4 MHz Low end L103

3 coverage FM ANT & D105(-) speaker terminals. 108.4 MHz High end PVC101-C1

4 Connect FM SG to Connect VTVM to 90.0 MHz 90.0 MHz

Tracking

5 FM ANT &D105(-) speaker terminals. 106.0 MHz 106.0 MHz PVC101-C2

generator to

IC101(24)pin (B)

Connect sweep

(18)PIN(A)

Adjustment

T101~T103

L102

偩.TAPE DECK ADJUSTMENTS

1. HEAD REPLACEMENT

After replacement, demagnetize. the heads by using a degausser.

Be sure to clean the head before attempting to make any adjustments.

All wiring should be returned to the original position after work is completed.

2. HEAD AZIMUTH ADJUSTMENT

(1) Load the test tape(VTT-703, etc., 10 KHZ) for azimuth

adjustment.

(2) Press the PLAY button.

(3) Use a cross-tip screwdriver to turn the screw for azimuth

adjustment so that the left and right output are maximized

(4) Press the STOP button.

(5) After completion of the adjustment, use thread lock(TB-1401B)

to secure the azimuth-adjustment screw.

RC-W305

ope

Max.

Max.

3. MOTOR SPEED ADJUSTMENT

(1) Insert the test tape(MTT-111N, etc., 3,000 HZ)

(2) Press the PLAY button.

(3) Use a flat-tip screwdriver to turn the SVR(located inside the

rear of the motor) to adjust SVR so that the frequency counter

become 3,000 HZ

4. CHECKING THE MECHANISM TORQUSE AND TENSION

Clean the head, capstan and pinch roller making any measurement.

Measurement Take-up torqe Back tension Tape tension

Drive-power cassette

Cassette ofr PLAY:TW-211A PLAY: TW-2111A

measurement F.FWD/REW:TW-2231 TW-2412

PLAY 30-60 gr.cm 2.0 - 4.5 gr. cm 60 gr or more

F.FWD 55-120 gr.cm ------ ------

REW 55-120 gr.cm ------ ------

7

Page 8

RC-W305

Description of Major IC

XL-SV320SL/SV305GD

XL-SV308BU

LA1824 Block Diagram

8

Page 9

BA3308 Block Diagram

RC-W305

9

Page 10

RC-W305

Block Diagram

XL-SV320SL/SV305GD

XL-SV308BU

BA3416BL

10

Page 11

RC-W305

11

Page 12

RC-W305

Voltage Charts

IC No.

Item

DC9V

Item

DC9V

IC No.

Item

DC9V

Item

DC9V

IC No.

Item

DC9V

Item

DC9V

IC No.

Item

DC9V

Item

DC9V

IC No.

Item

DC9V

IC No.

Item

DC9V 9.30 4.77 8.47 1.20 0.00 9.32 0.00 0.00 1.20 8.49 4.70 9.32

IC No.

Item

DC9V

IC No.

Item

DC9V

IC No.

Item

DC9V

IC No.

Item

DC9V

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

0.04 1.31 3.04 4.37 4.37 0.00 4.37 0.10 2.84 1.30 1.30 0.17 4.37 3.65 3.66 1.22 1.22 1.26 1.3

21 22 23 24

4.34 4.34 0.00 0.29

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

1.29 1.29 4.61 4.62 4.62 0.00 4.62 1.25 3.38 1.29 1.29 0.69 4.62 3.01 0.00 1.26 1.25 1.26 0.48

21 22 23 24

4.62 4.62 0.00 0.00

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

1.29 1.29 4.59 4.61 4.61 0.00 4.61 1.23 3.35 1.29 1.29 0.55 4.61 3.00 0.00 1.26 1.25 1.26 0.40

21 22 23 24

4.61 4.61 0.00 0.00

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

1.29 1.29 4.61 4.63 4.63 0.00 4.63 1.21 3.38 1.29 1.29 0.57 4.63 3.02 0.0 1.26 1.25 1.26 0.41

21 22 23 24

4.63 4.63 0.00 0.00

1 2 3 4 5 6 7 8 9 10 11 12

10.03 5.12 9.20 1.19 0.00 10.03 0.00 0.00 1.19 9.18 5.13 10.16

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

0.99 0.00 0.00 0.00 2.16 2.14 5.50 1.87 5.13 1.07 0.00 1.31 0.59 0.59 0.00 0.00 0.00 0.00

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

0.06 0.00 0.00 0.00 2.16 2.15 5.50 0.67 5.14 1.07 0.00 1.31 0.59 0.59 0.00 0.00 0.00 0.00

1 2 345 6 789

0.95 0.00 0.92 0.46 0.00 0.00 0.90 0.00 0.89

1 2 345 6 789

1.80 0.00 1.80 5.06 0.00 0.00 1.79 0.00 1.78

IC101 LA-1824 TUNER FM

IC101 LA-1824 TUNER AM

IC101 LA-1824 TUNER SW1

IC101 LA-1824 TUNER SW2

IC303 LA-4227 TUNER

IC303 LA-4227 CASS PLAY

IC301 BA3416 A CASS PLAY

IC301 BA3416 B CASS PLAY

IC302 BA3308 CASS PLAY

IC302 BA3308 CASS REC

XL-SV320SL/SV305GD

XL-SV308BU

9

Transistor No.

Item

Votage(v)

Q401 (CASS PLAY)

EBCEBC

6.10 6.80 9.35 6.10 6.80 9.05

Q401 (TUNER)

12

Page 13

Wiring Connections Diagram

RC-W305

13

Page 14

RC-W305

Schematic Diagram

XL-SV320SL/SV305GD

XL-SV308BU

14

Page 15

Printed Circuit Board

RC-W305

15

Page 16

RC-W305

XL-SV320SL/SV305GD

XL-SV308BU

16

Page 17

RC-W305

17

Page 18

JVC Asia Pte Ltd

101 Thomson Road, #28-04 United Squares, Singapore 307591

(No: 28223)

Printed in Singapore

200505(L)

Loading...

Loading...