Page 1

SERVICE MANUAL

SERVICE POLICY

No service parts are available for this model.

Exchange only.

Revised 28/9/2004 Service Policy added

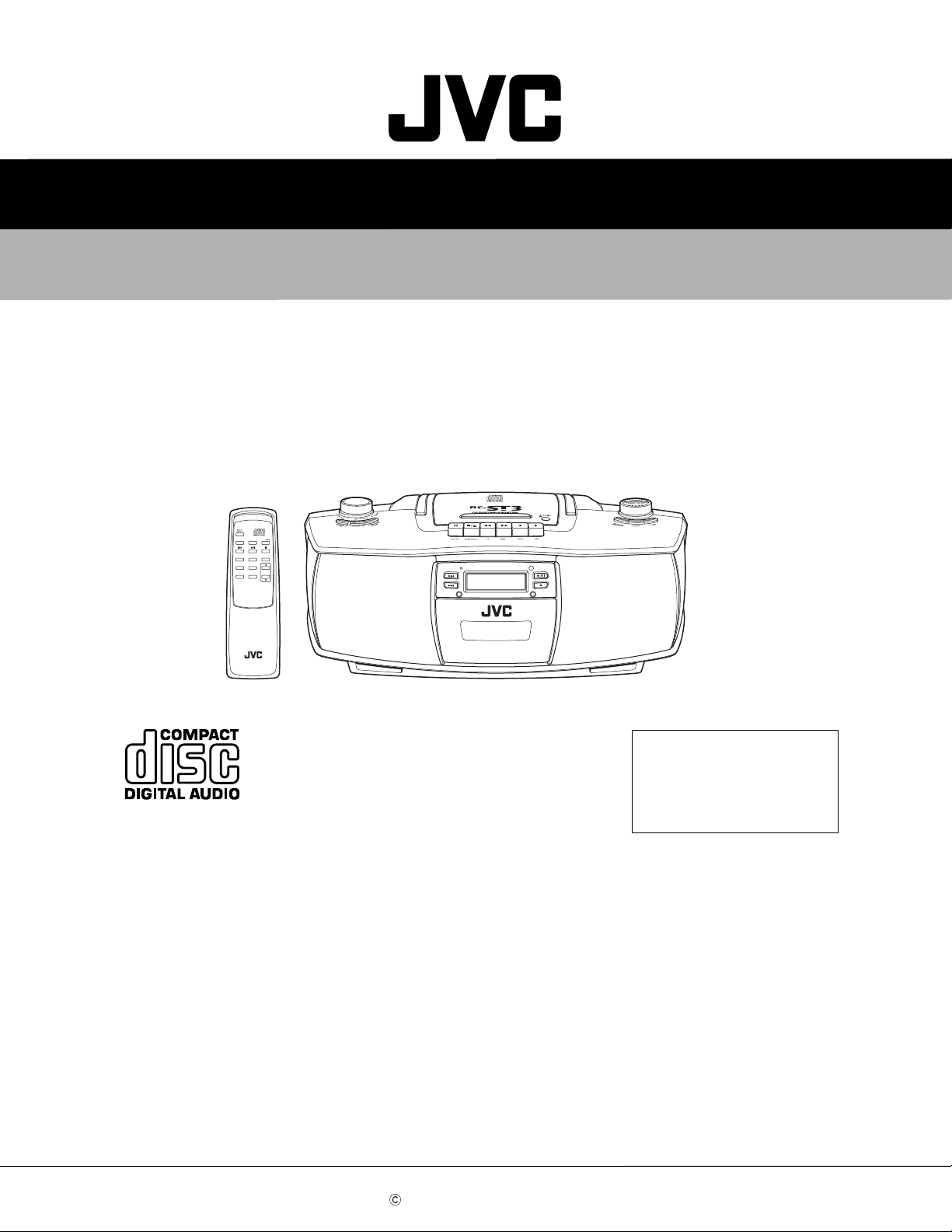

CD PORTABLE SYSTEM

RC-ST3SL

TUNER

TAPE CD

PRESET/

PROGRAM

INTRO

REPEAT

FM MODE

HBS EQ

RANDOM

VOL

STANDBY

SE

A

R

C

H

U

P

SE

A

R

C

H

D

OW

N

RANDOM INTRO

RC-ST3

CD PORTABLE SYSTEM

REMOTE

SENSOR

E

S

U

A

/P

Y

A

PL

P

O

ST

Contents

Specification --------------------------------------------------------------------------------------------1-2

Safety Precautions -----------------------------------------------------------------------------------1-3

Preventing static electricity ------------------------------------------------------------------------ 1-5

Block Diagram ---------------------------------------------------------------------------------------- 1-6

Schematic Diagrams -------------------------------------------------------------------------------- 1-8

COPYRIGHT 2003 VICTOR COMPANY OF JAPAN, LTD.

Area Suffix

B -------------------------- U.K.

E -------Contnental Europe

EN ------- Northern Europe

EV --------- Eastern Europe

No.MB063

2003/11

Page 2

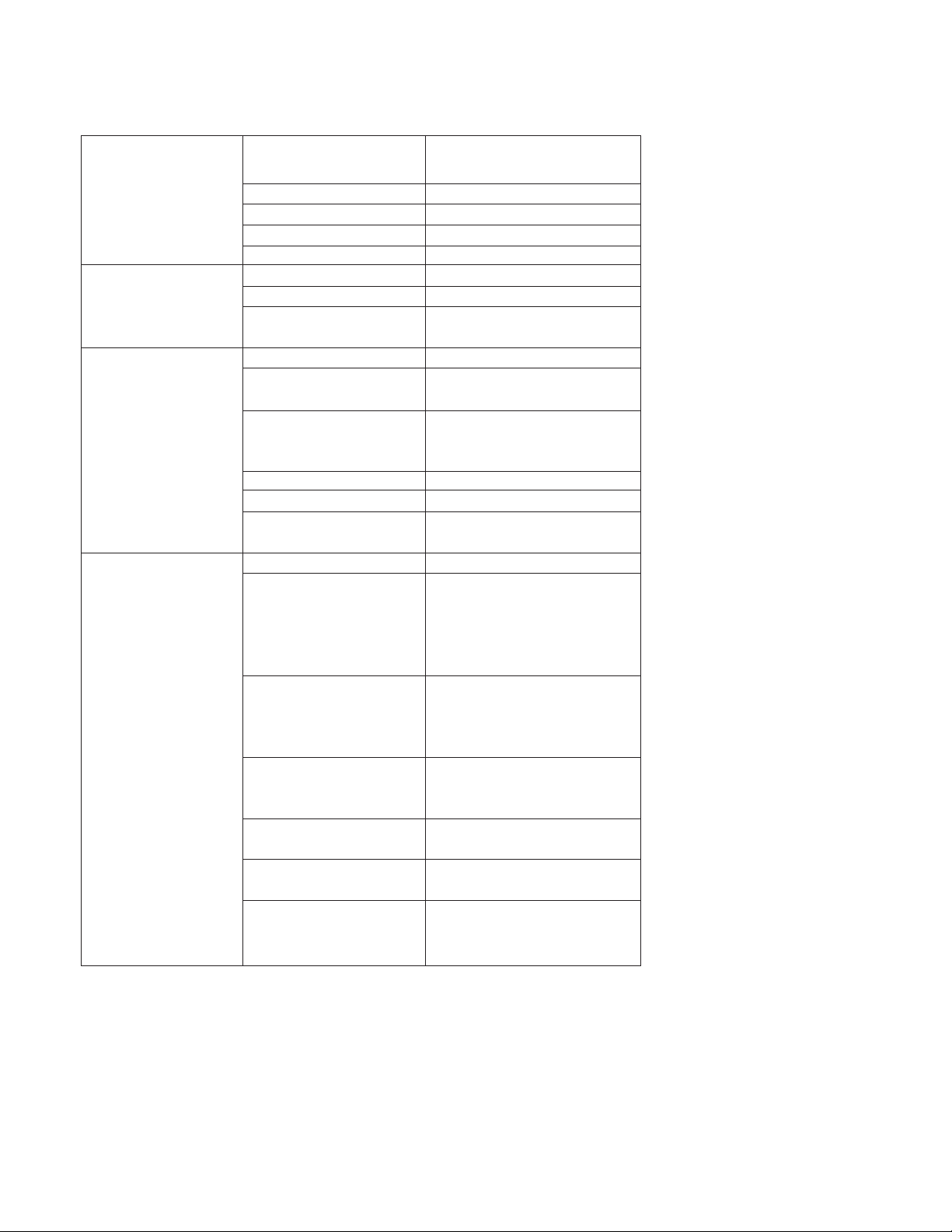

Specification

Compact disc player Signal detection system Non-contact op tical pickup

Tuner FM frequency range 87.50 MHz - 108.00 MHz

Cassette deck Track system 4-track 2-channel stereo

General Speakers 10 cm × 2

(semiconductor laser)

Number of channels 2 channels (stereo)

Frequency response 20 Hz - 20 000 Hz

Signal-to-noise ratio 90 dB

Wow and flutter Less than measurable level

AM frequency range 522 kHz - 1 629 kHz

Antennas Telescopic antenna for FM

Ferrite core antenna for AM

Motor Electronic governor DC

motor for caps tan

Heads Hard Permalloy head for

recording/playback

Magnetic head for erasure

Frequency response 80 Hz - 12 500 Hz

Wow and flutter 0.15% (WRMS)

Fast-winding time Approx. 120 sec.

(C-60 cassette)

Power output 2 W per channel, min. RMS,

driven into 8 &! at 1 kHz,

with no more than 10% total

harmonic distortion

(IEC 268-3 )

Output terminal PHONES × 1, output level

0 mW - 20 mW/32 ohm,

matching impedance: 16ohm

32 ohm

Power supply AC 230 V , 50 Hz

DC 12 V (ba tteries R2 0P

(SUM-1)/D (13F) × 8)

Power consumption 19 W (operation mode)

3.2 W (standby mode)

Dimensions 440 mm (W) × 168 mm (H)

× 241 mm (D)

Mass Approx. 3.1 kg

(without batteries)

1-2

Page 3

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

Good earth ground

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs m ust be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen pr inted side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

1-3

Page 4

(U.K only)

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer. Replacement parts must be identical to

those used in the original circuits.

2. Any unauthorised design alterations or additions will void the manufacturer's guarantee ; furthermore the

manufacturer cannot accept responsibility f or personal injury or property damage resulting therefrom.

3. Essential safety critical components are identified by ( ) on the Parts List and by shading on the

schematics, and must never be replaced by parts other than those listed in the manual. Please note

however that many electrical and mechanical parts in the product have special safety related

characteristics. These characteristics are often not evident from visual inspection. Parts other than

specified by the manufacturer may not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of the Service Manual and may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the original lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

1. Service should be performed by qualified personnel only.

2. This equipment has been designed and manufactured to meet international safety standards.

3. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

4. Repairs must be made in accordance with the relevant safety standards.

5. It is essential that safety critical components are replaced by approved parts.

6. If mains voltage selector is provided, check setting for local voltage.

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-4

Page 5

Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as mechanism unit.

Be careful to use proper grounding in the area where repairs are being performed.

1. Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2. Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

1-5

Page 6

Block Diagram

FM ANT

R/P HEAD

FM RF

BPF FM F/E , IF/DET/MPX

AM ANT

VD103

TU L&R CH.

R/P SW.

FM OSC.

IC101 LA1823

AM RF/IF/DET.

AM OSC.

REC L&R CH.

IC102 LC72131

PLL

TU-5V

REG.

ERASE HEAD

R/P SW.

TAPE L&R CH.

IC501 LC75342

SIGNAL SLECT SW.

EQ./E. VOL.

IC201 TA8142AP

R/P PRE.AMP.

P/B L&R CH.

R/P SW.

CD L&R CH.

LCD

REC L&R CH.

CD SW.

TU SW.

1-6

Page 7

DISC

PICKUP

SPINDLE

M

M

SLED

MOTOR

IC701

LC587008

(u-COM.)

MOTOR

IC901

LA9242M

(ASP.)

IC903 LA6541D

MOTOR/ACTUATOR

DRIVER

KEY

IC902

LC78622E

(DSP.)

Q907

CD DOOR

LEAF SW.

Q704

LAMP

5V REG.

IC401

8V REG.

P-CON.

L&R CH.

DC SUP.

SW.

CASS.DECK

LEAF SW.

M

DECK

MOTOR

BASS CUT

JOG.VOL.

IC301 TA8227P

POWER AMP.

RECTIFIER

L. SPEAKER

R. SPEAKER

AC INPUT

1-7

Page 8

Schematic Diagrams

1-8

Page 9

1-9

Page 10

1-10

Page 11

1-11

Page 12

JVC Euorpe Limited

JVC House

JVC Budiness Park 12 Priestley Way, London NW2 7BA United Kingdom

(No.MB063)

2003/11

Loading...

Loading...